Patents

Literature

2873 results about "Stamping press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stamping press is a metalworking machine tool used to shape or cut metal by deforming it with a die. In simple terms, a stamping press is the modern day equivalent of a hammer and anvil. The difference is that a stamping press uses precision-made male and female dies to dictate the shape of the final product.

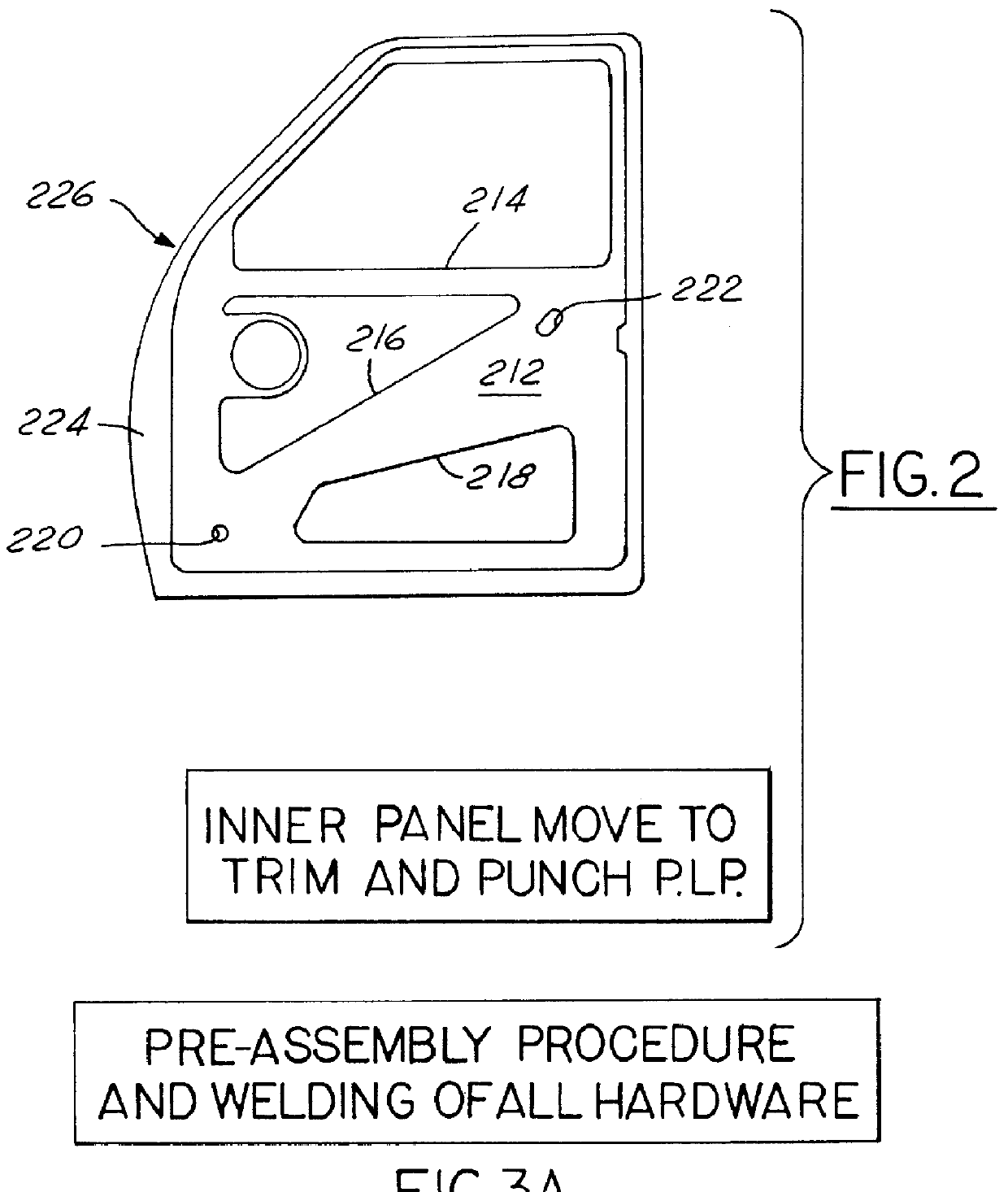

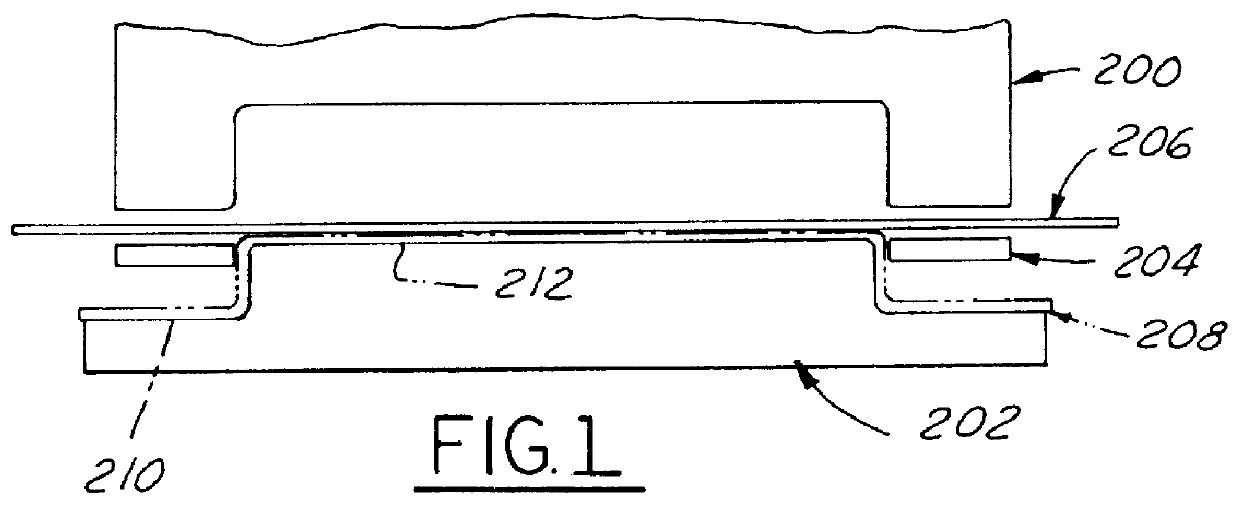

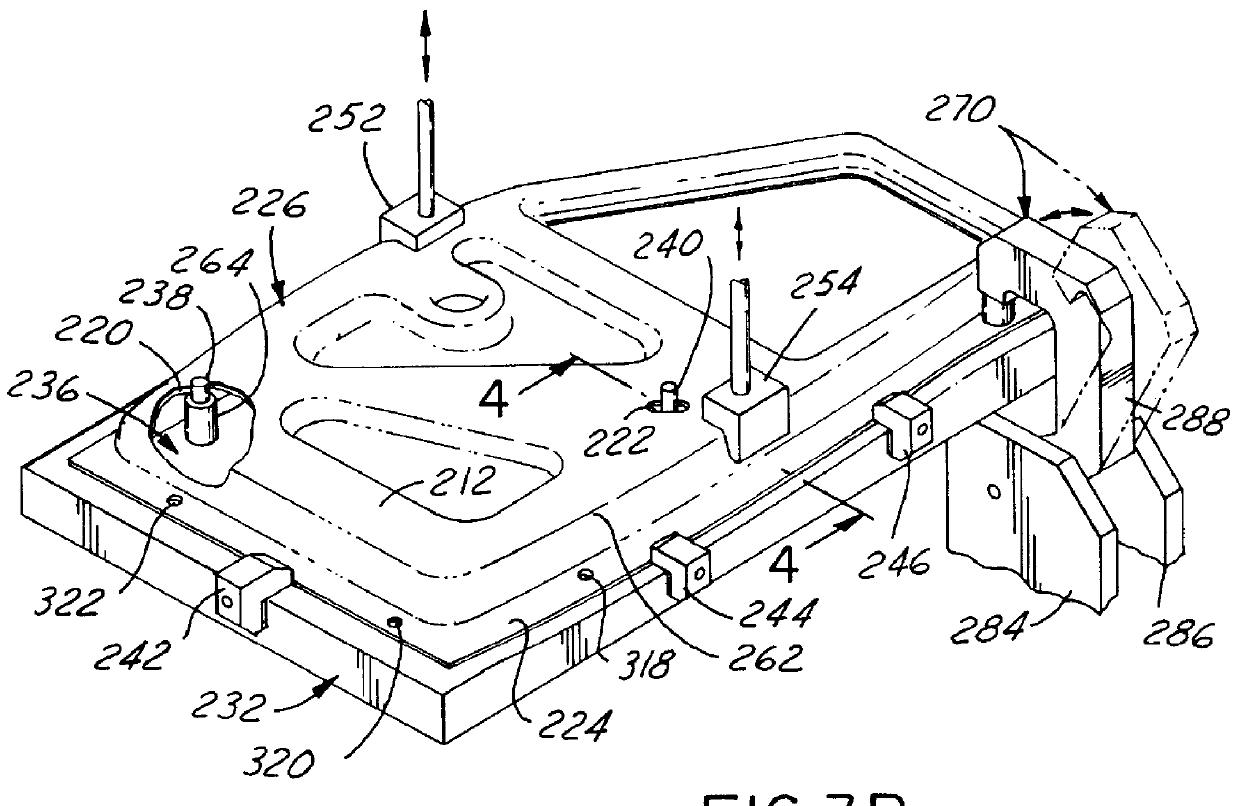

Hemming method and apparatus

InactiveUS6029334AImprove appearance qualityEliminate the problemForging hammersAssembly machinesEmbedmentRead through

Improved method and apparatus for interlocking hemmed together edges of inner and outer vehicle body panels with an improved interlock joint. The inner panel blank is draw stamped and provided with PLP holes in a stamping press. A plurality of conventional hardware components are then welded to the inner panel. Then interlock holes are formed by a piercing tool moving through the inner panel border from its outboard to its inboard side while the inner panel is held by clamps and PLP pins. The hole piercing punch thus leaves cold worked upset material slightly raised inboard, rather than outboard, around the pierced interlock hole margin. Then the inner panel subassembly is married to the outer panel and transferred to a hemming station and again precisely clamped and positioned by PLP pins, whereupon hemming press gates are operable for hemming the flange lip of the outer panel over the inner panel border. The final hemming steel of each gate carries staking punches that individually strike a precision registered portion of such hemmed lip to deform it into locking engagement with the associated interlock hole. The upset material is thus flattened and accurately worked into embedment into the interior surface of the hemmed flange lip, rather than into the interior surface of the outer panel, thereby avoiding creating read through problems on the outer panel.

Owner:UNOVA IP

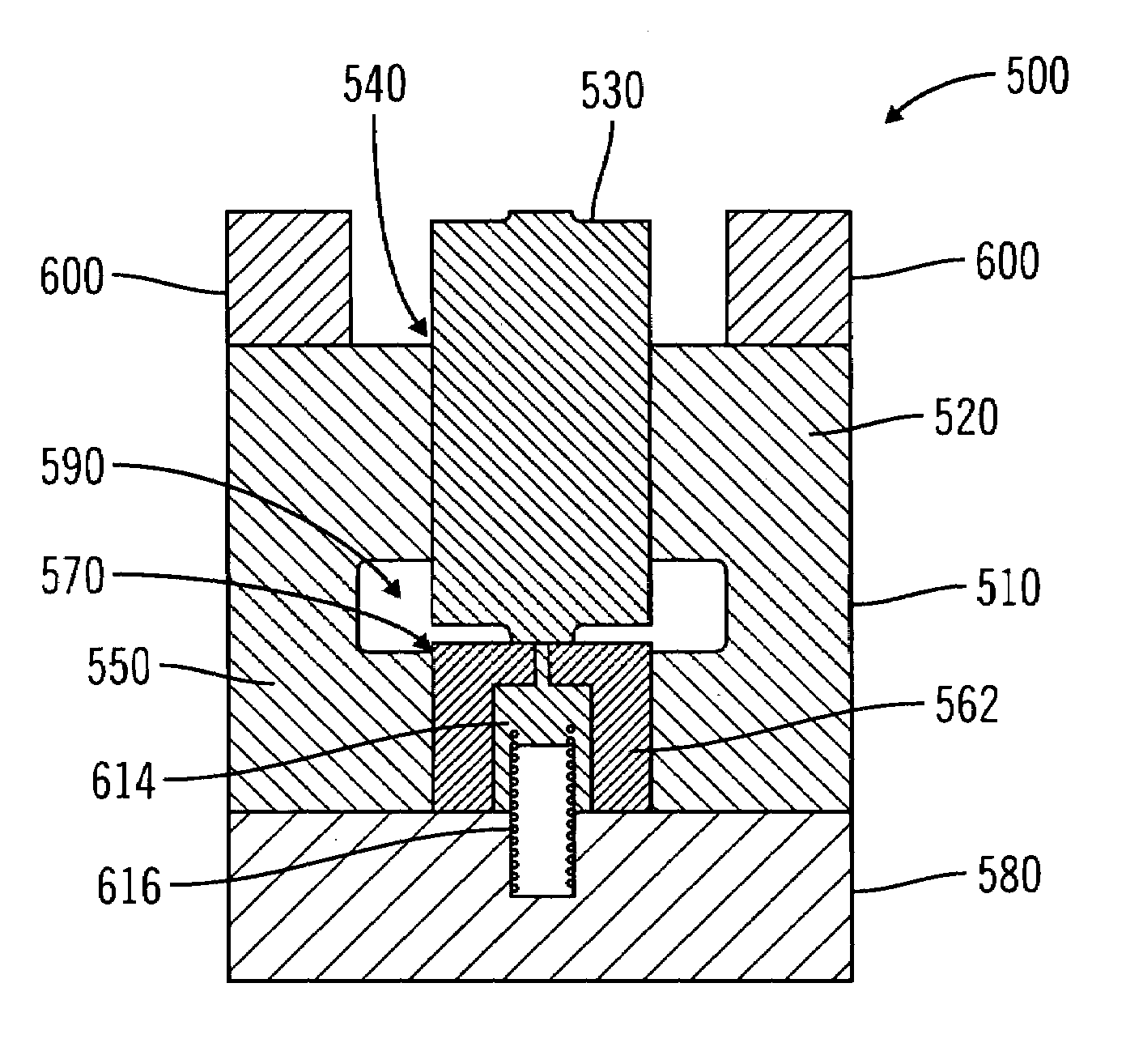

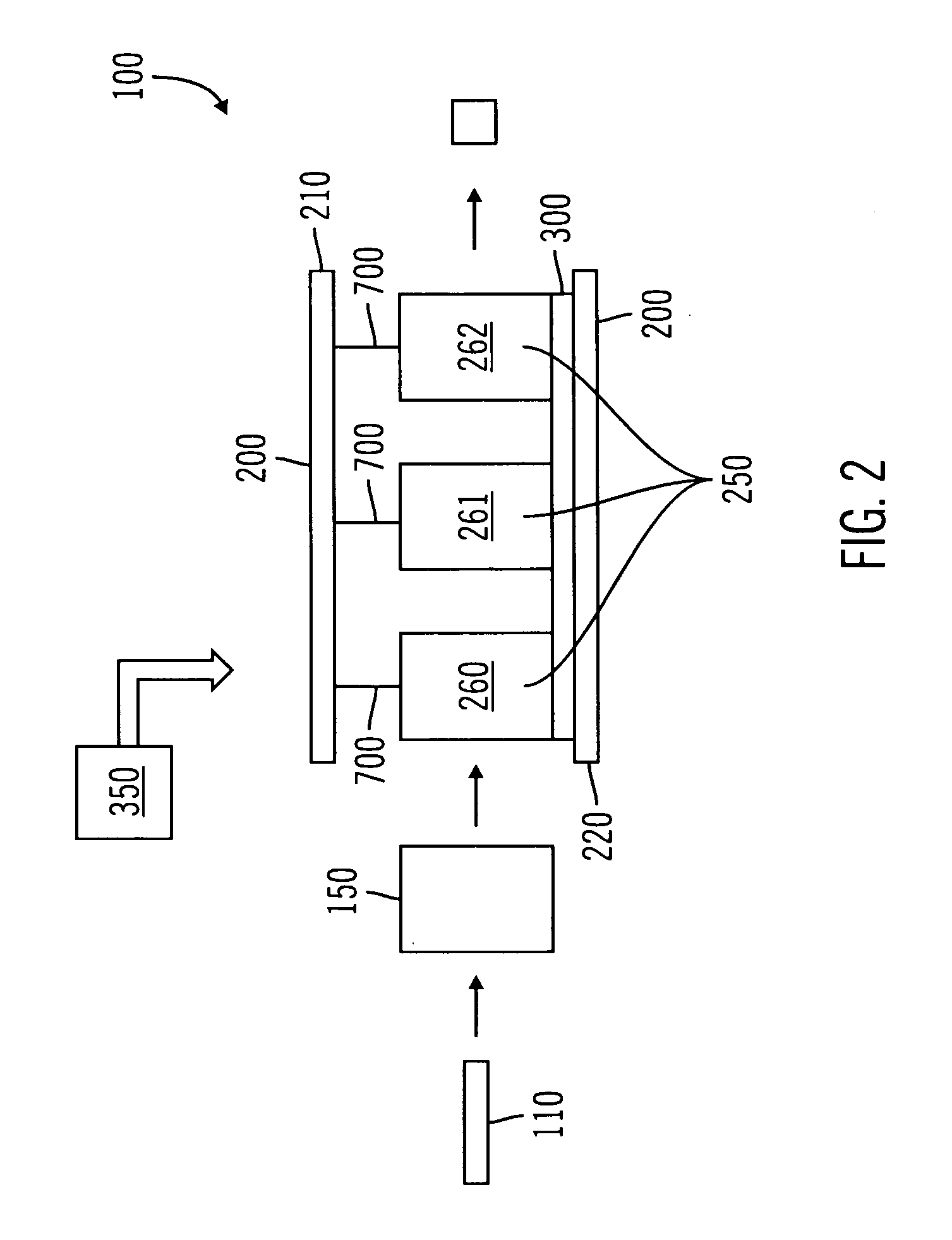

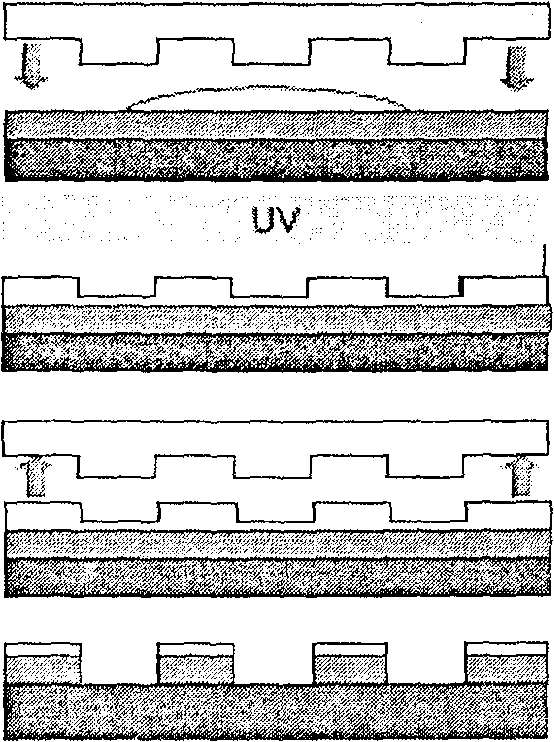

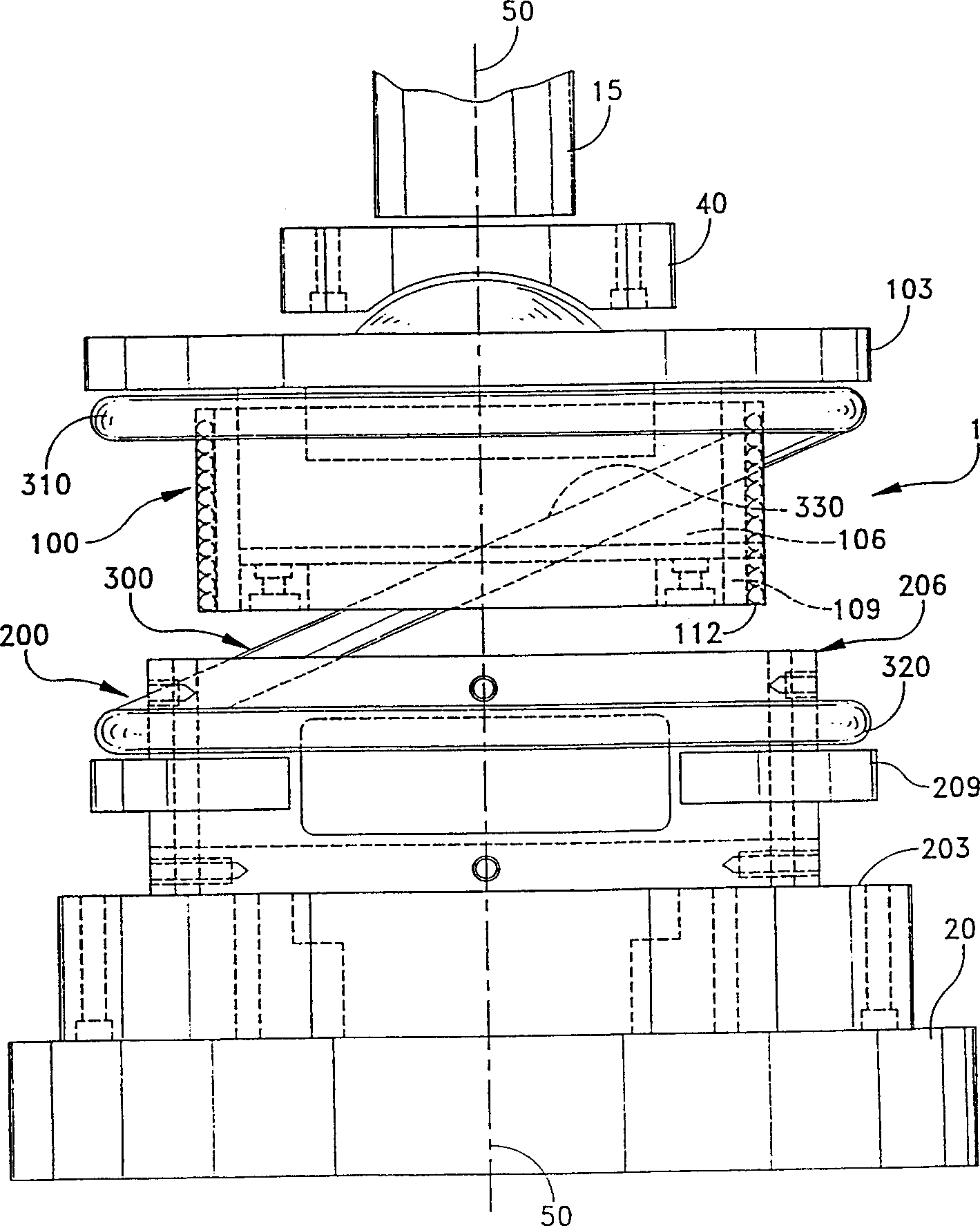

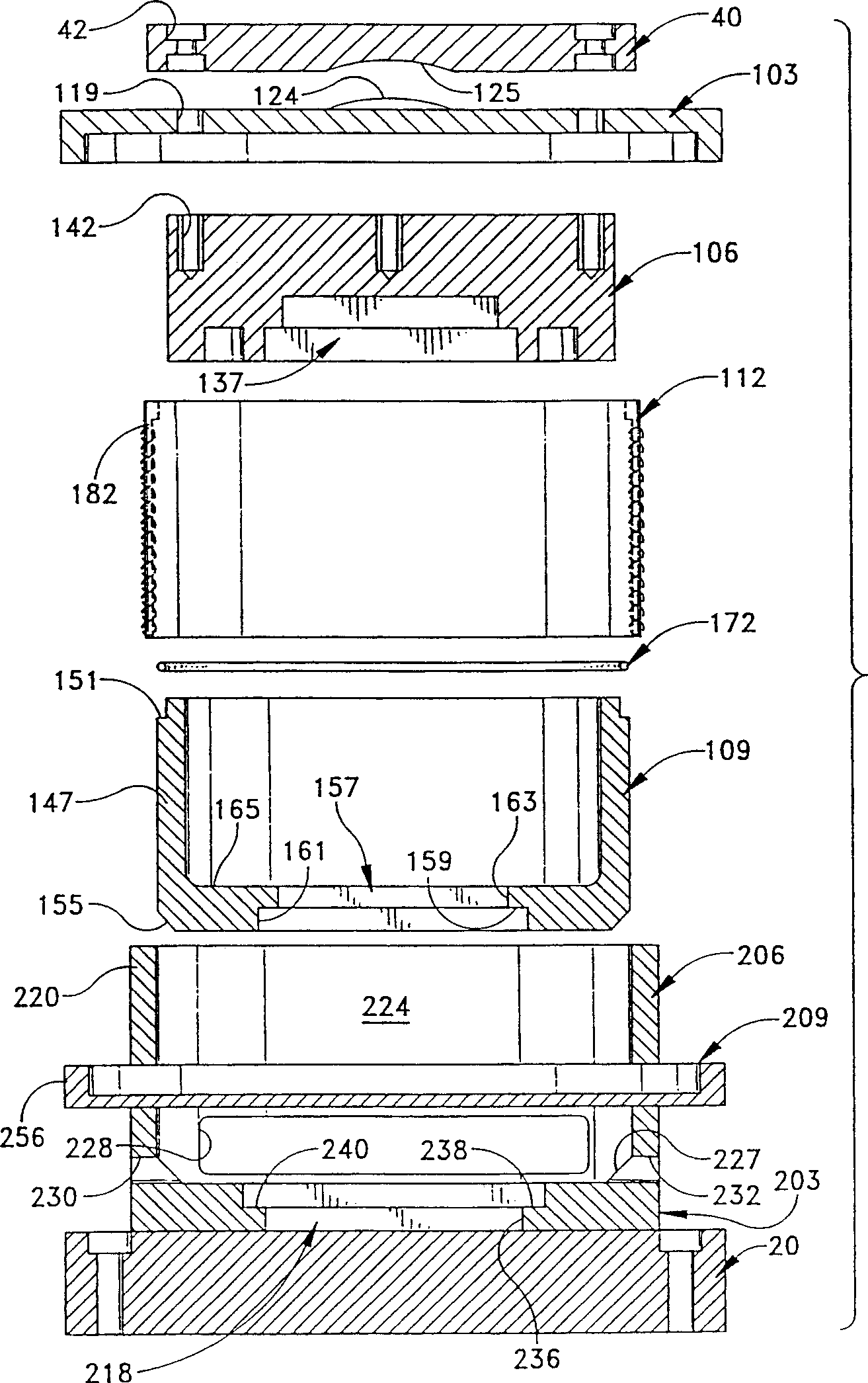

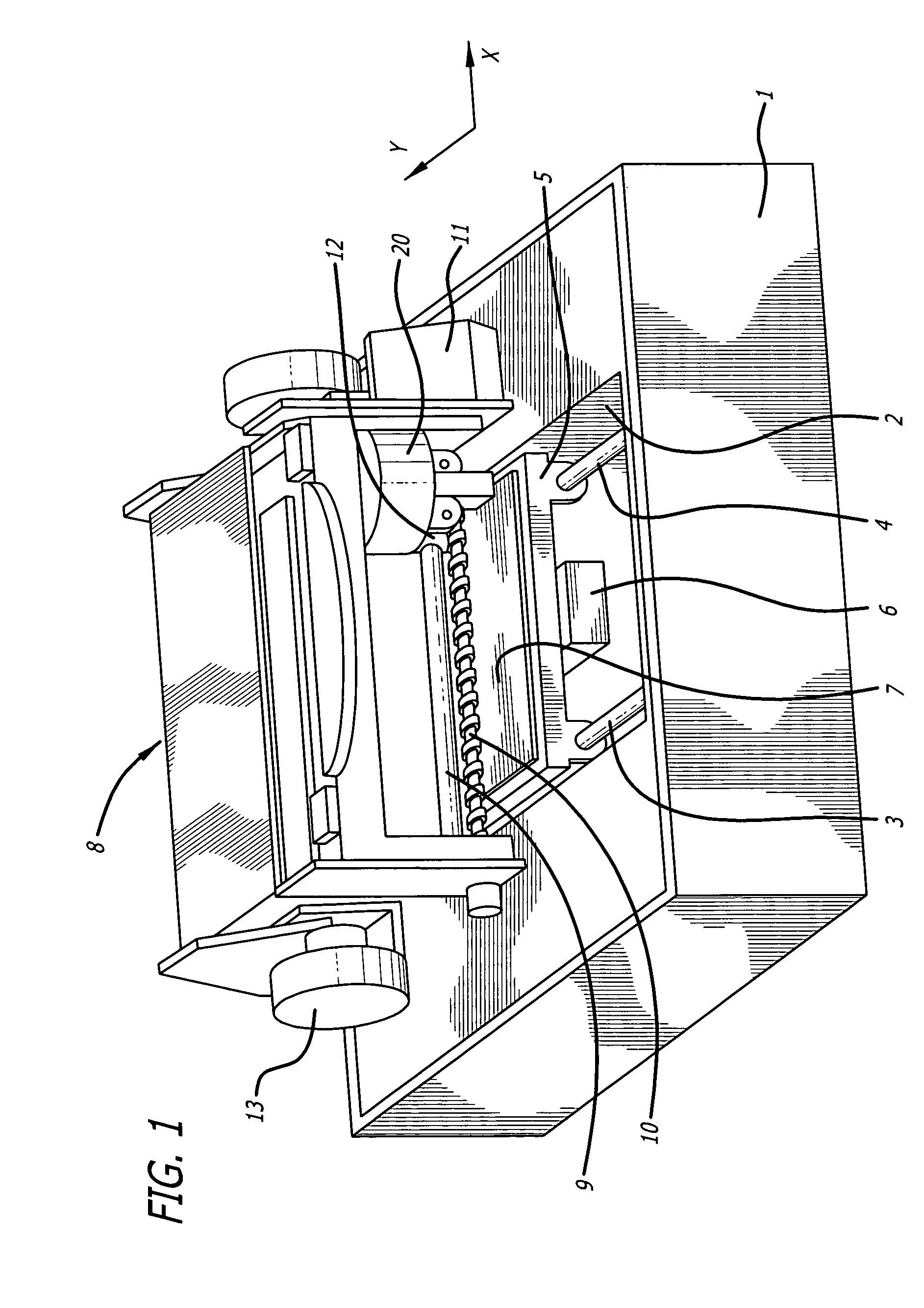

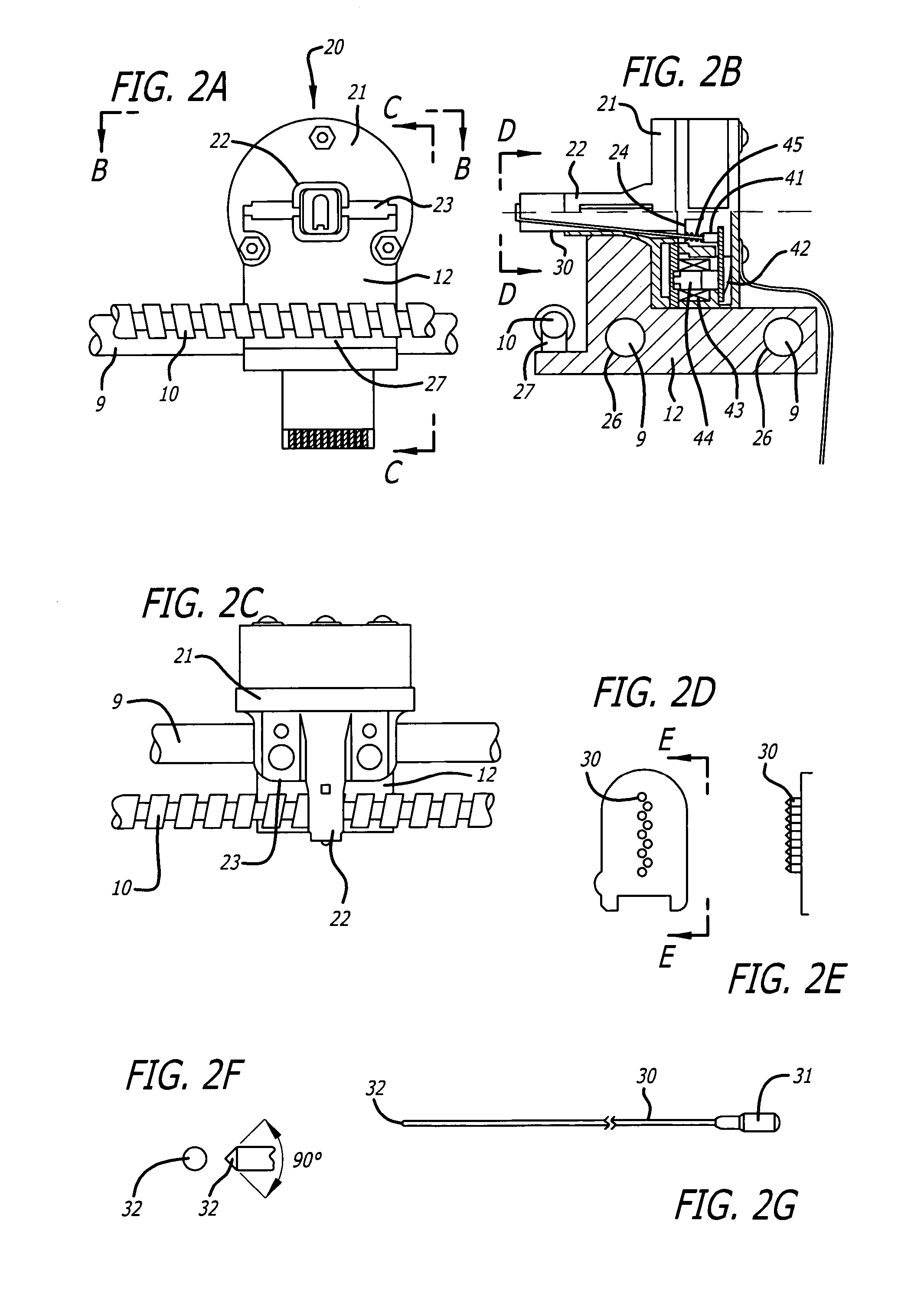

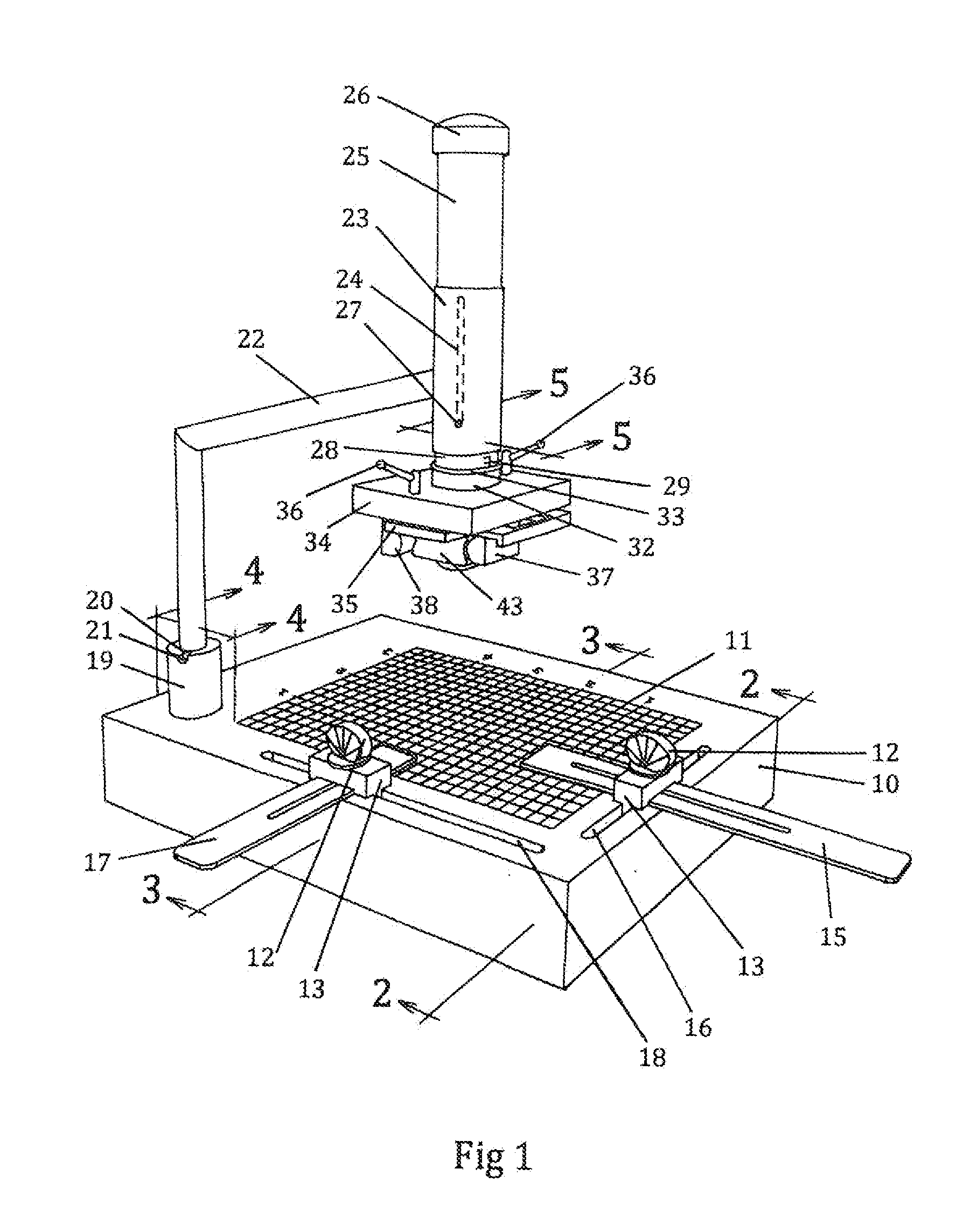

Stamping system for manufacturing high tolerance parts

ActiveUS7343770B2Minimize the numberTight toleranceShaping toolsPerforating toolsMachine pressStamping press

A system and process for stamping parts having tolerances below 1000 nanometers. The inventive system and process is particularly suited for producing optoelectronic parts. The system includes a stamping press and one or a progression of stamping stations for supporting a punch and die. The stamping stations are designed to maintain substantial alignment of the punch and die with minimal moving components. The stamping station includes a shaft for rigidly guiding the punch to the die. The stamping press is capable of providing the punch with the necessary force to perform the stamping operations. The system includes an interface system for interfacing the force of the press with the punch, while simultaneously structurally decoupling the press from the punch. The system also includes a locating sub-plate, for locating the stamping station in alignment relative to each other, and means for in-line machine stock material before entry into the stamping stations.

Owner:SENKO ADVANCED COMPONENTS

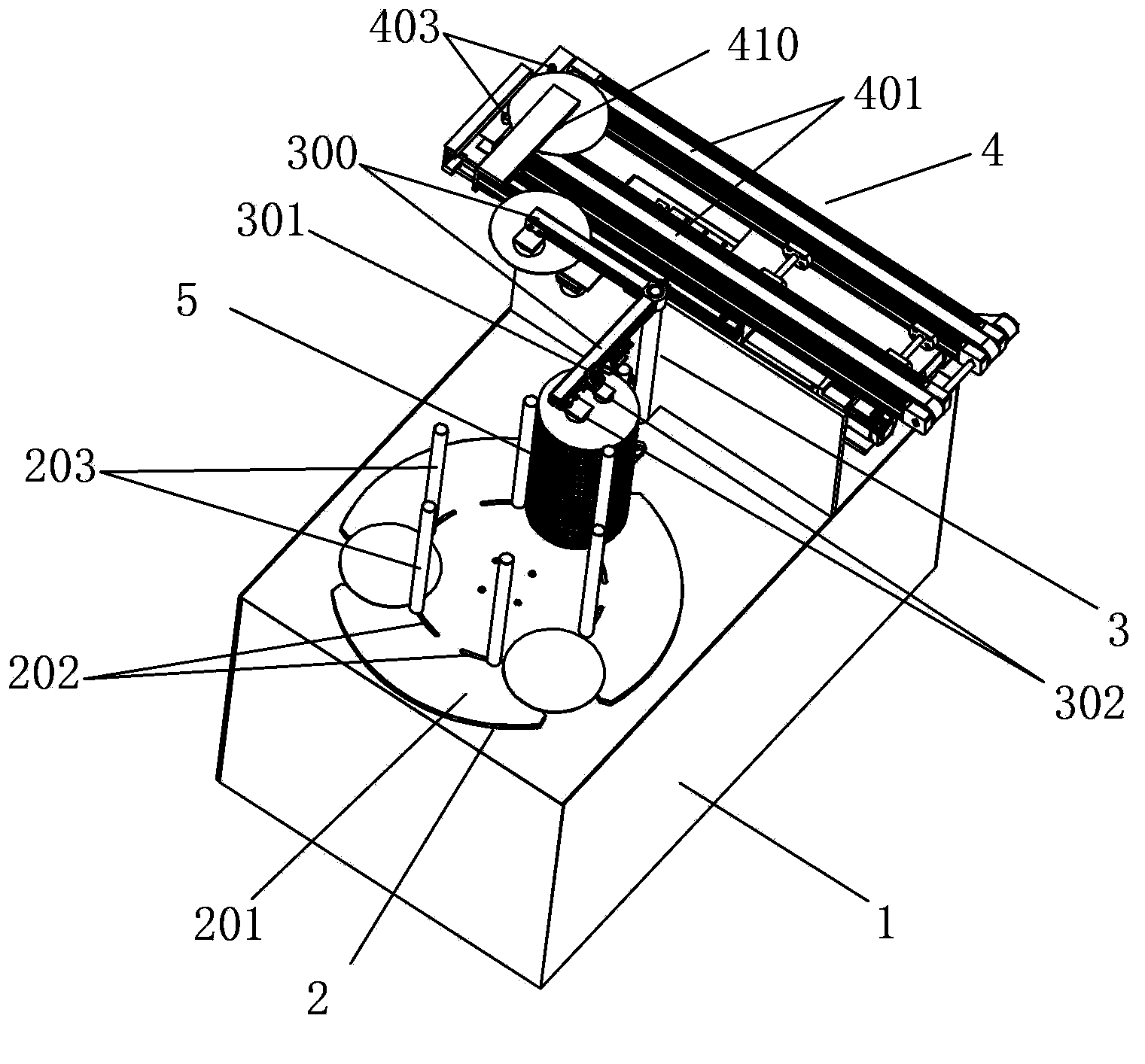

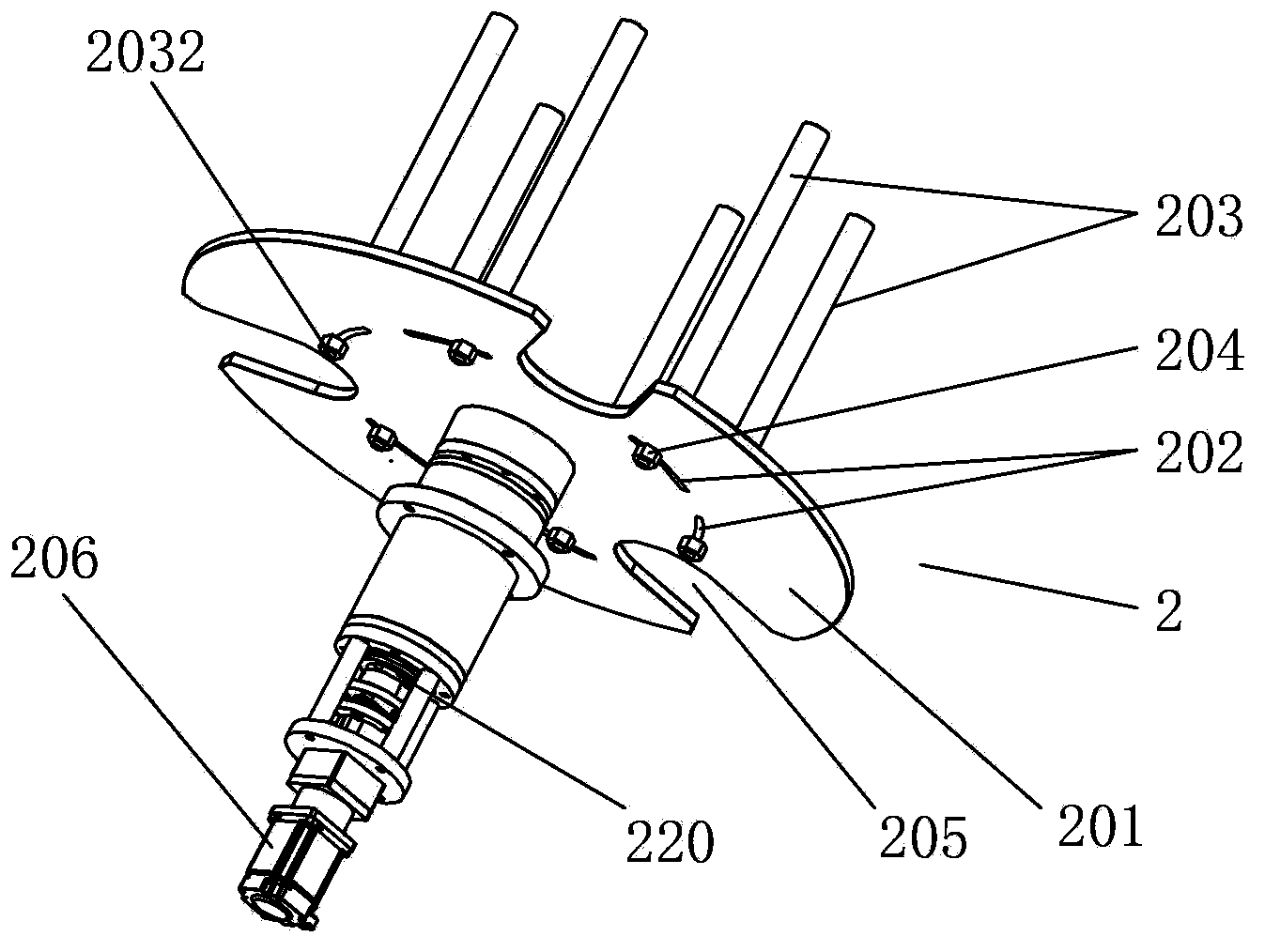

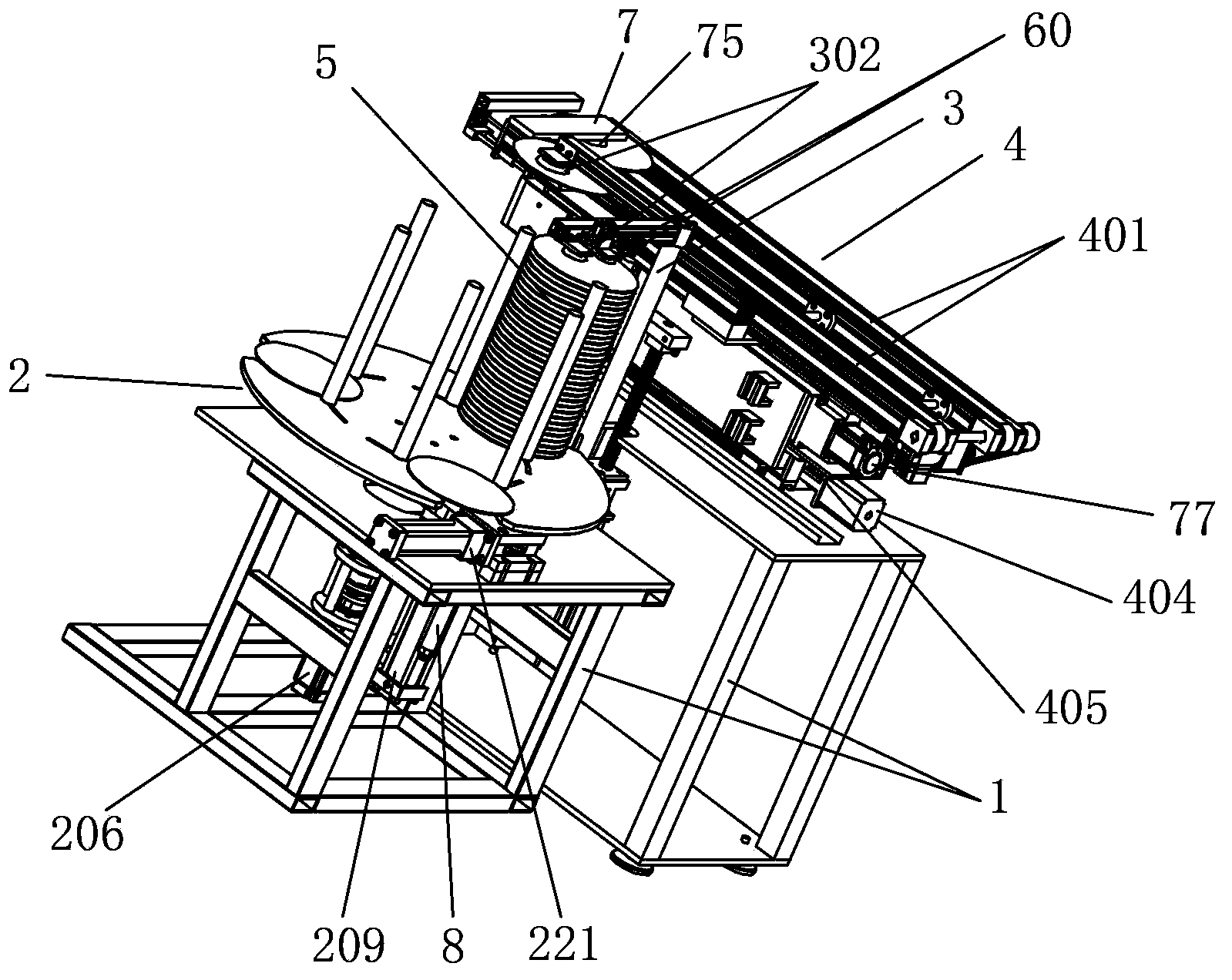

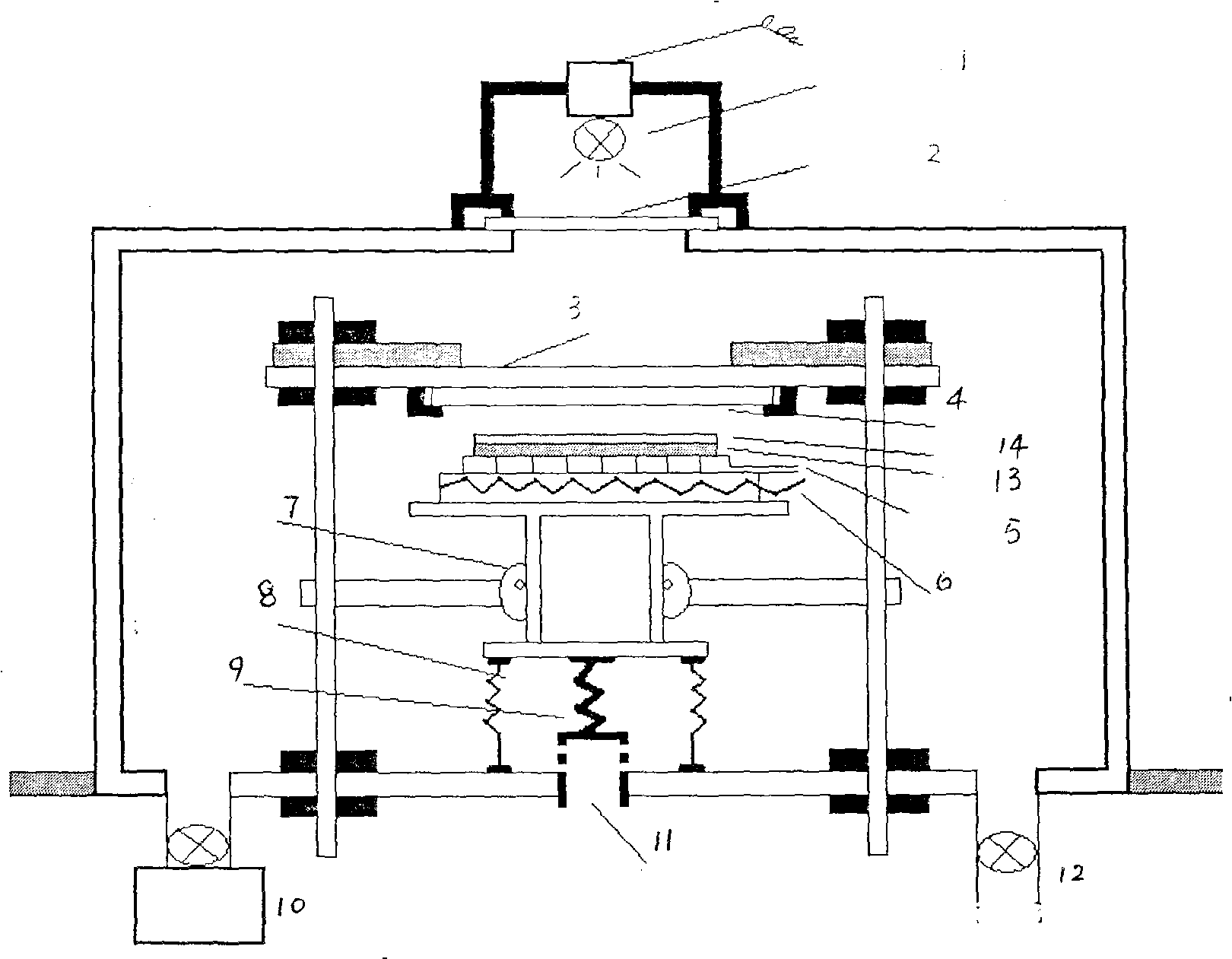

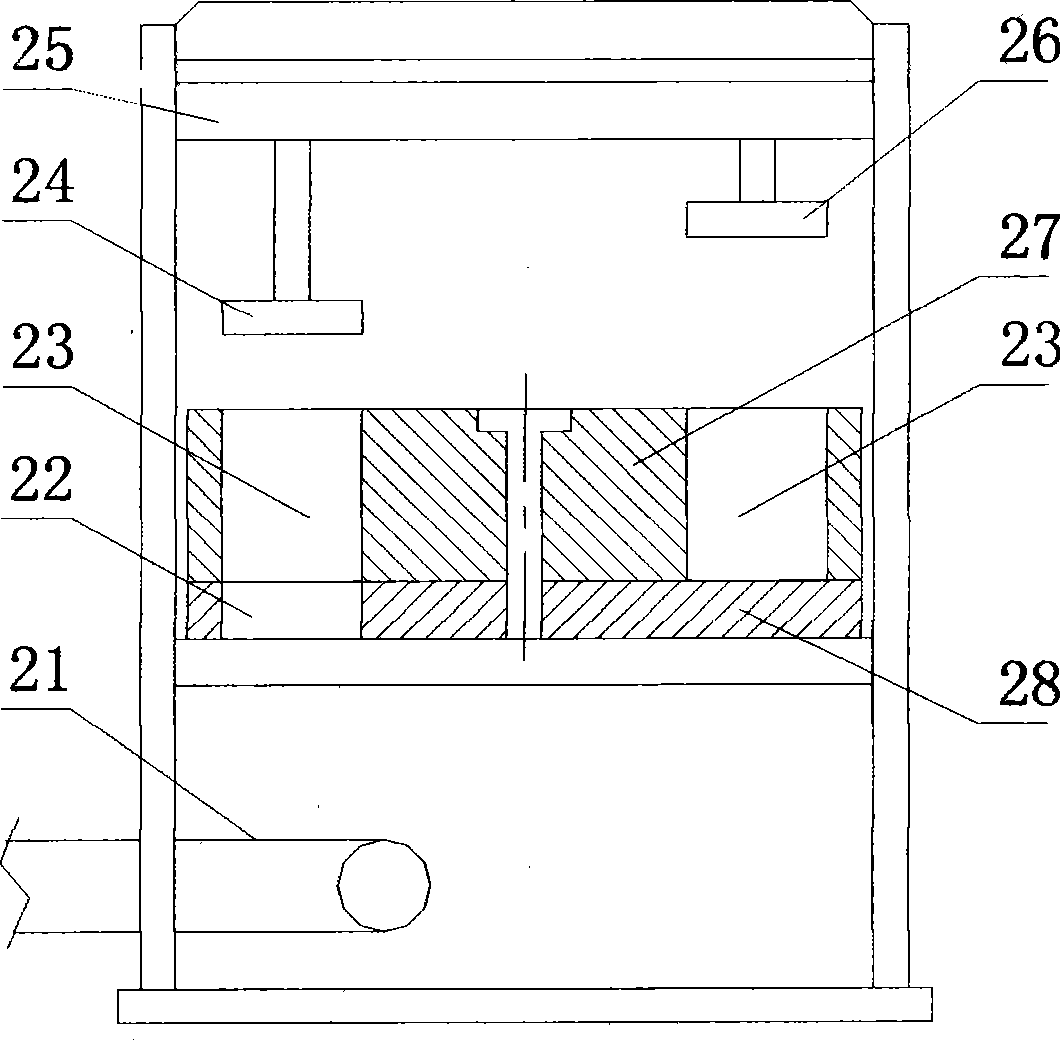

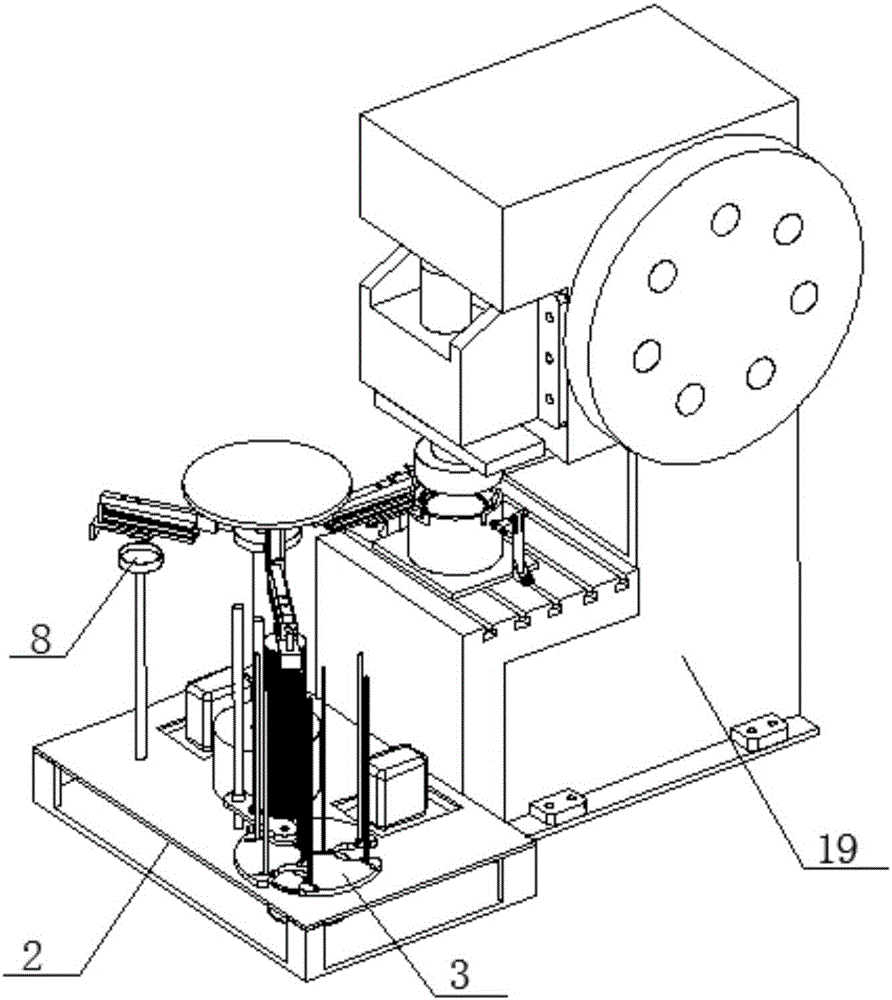

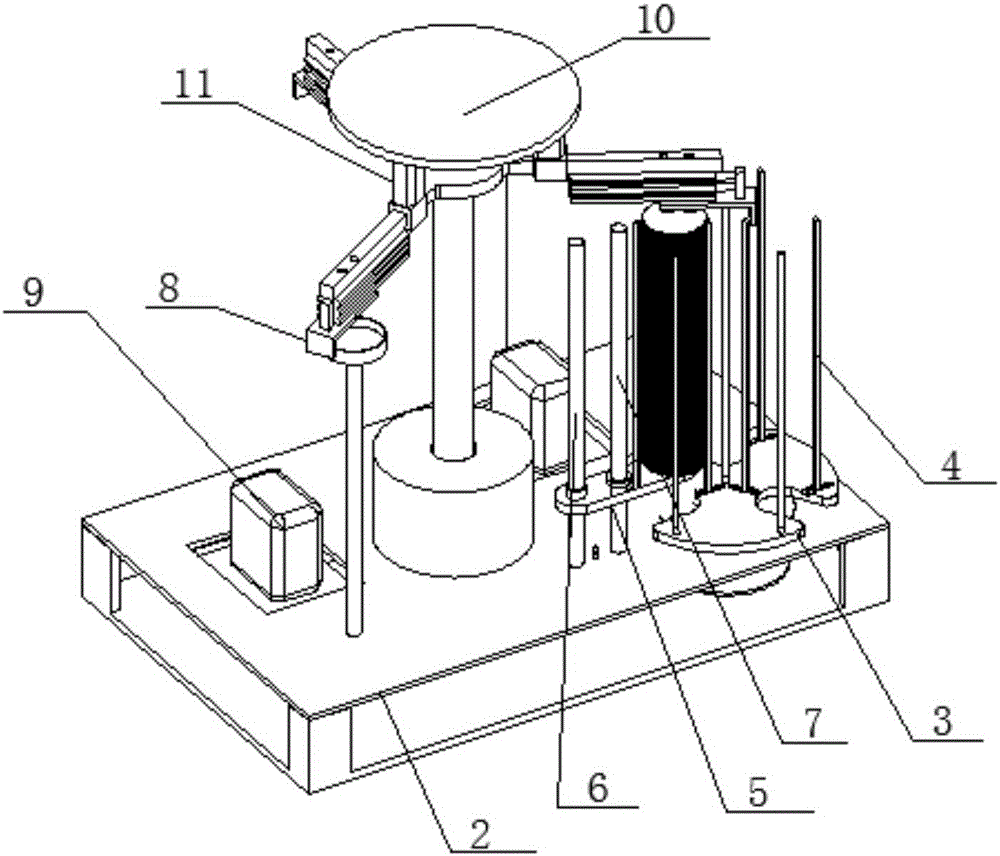

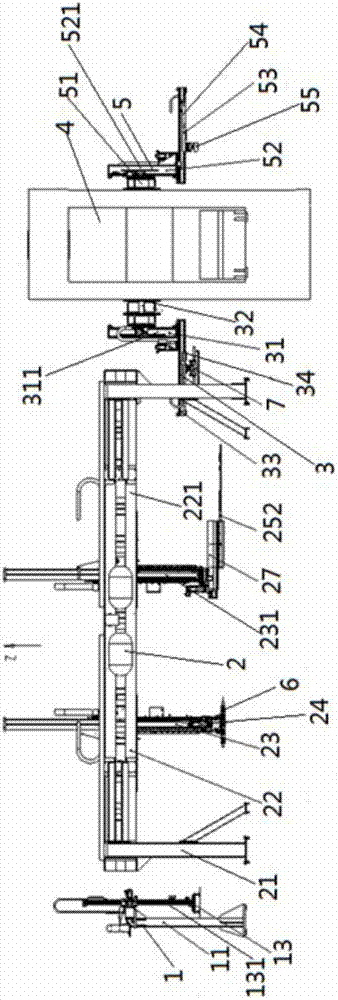

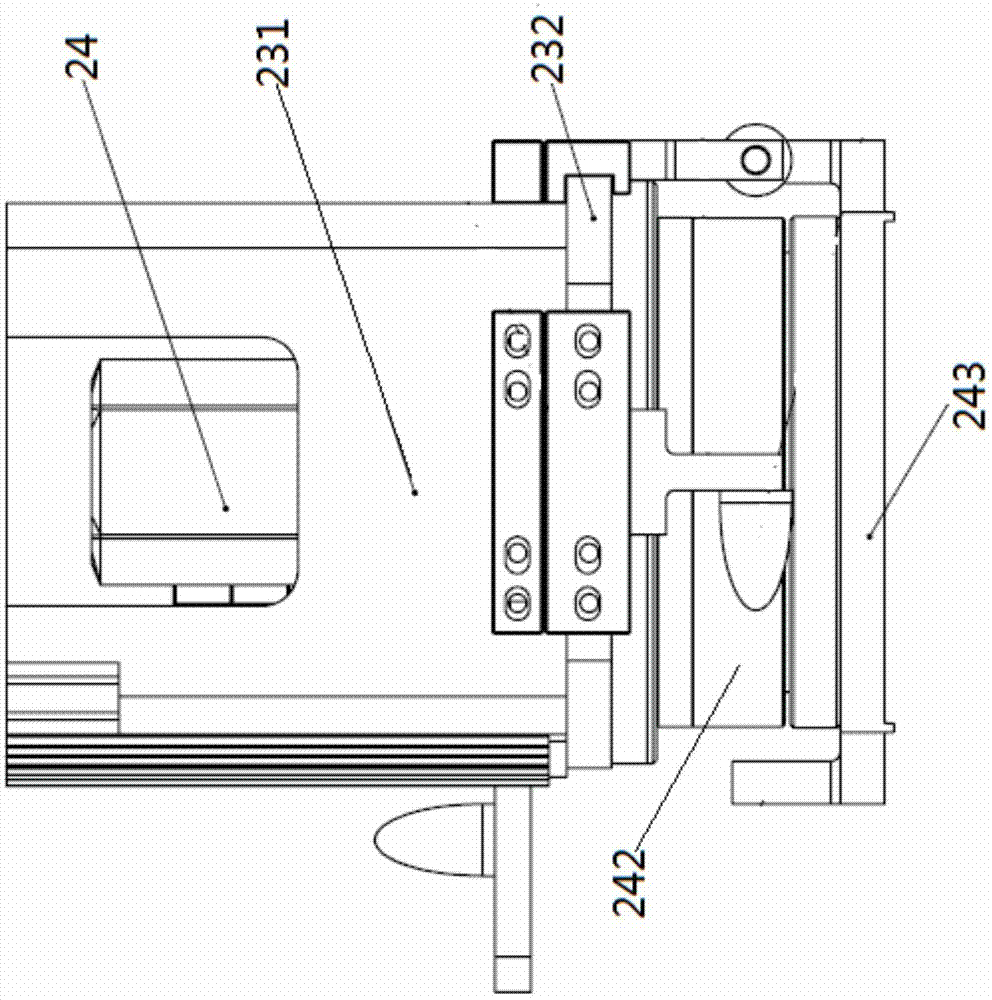

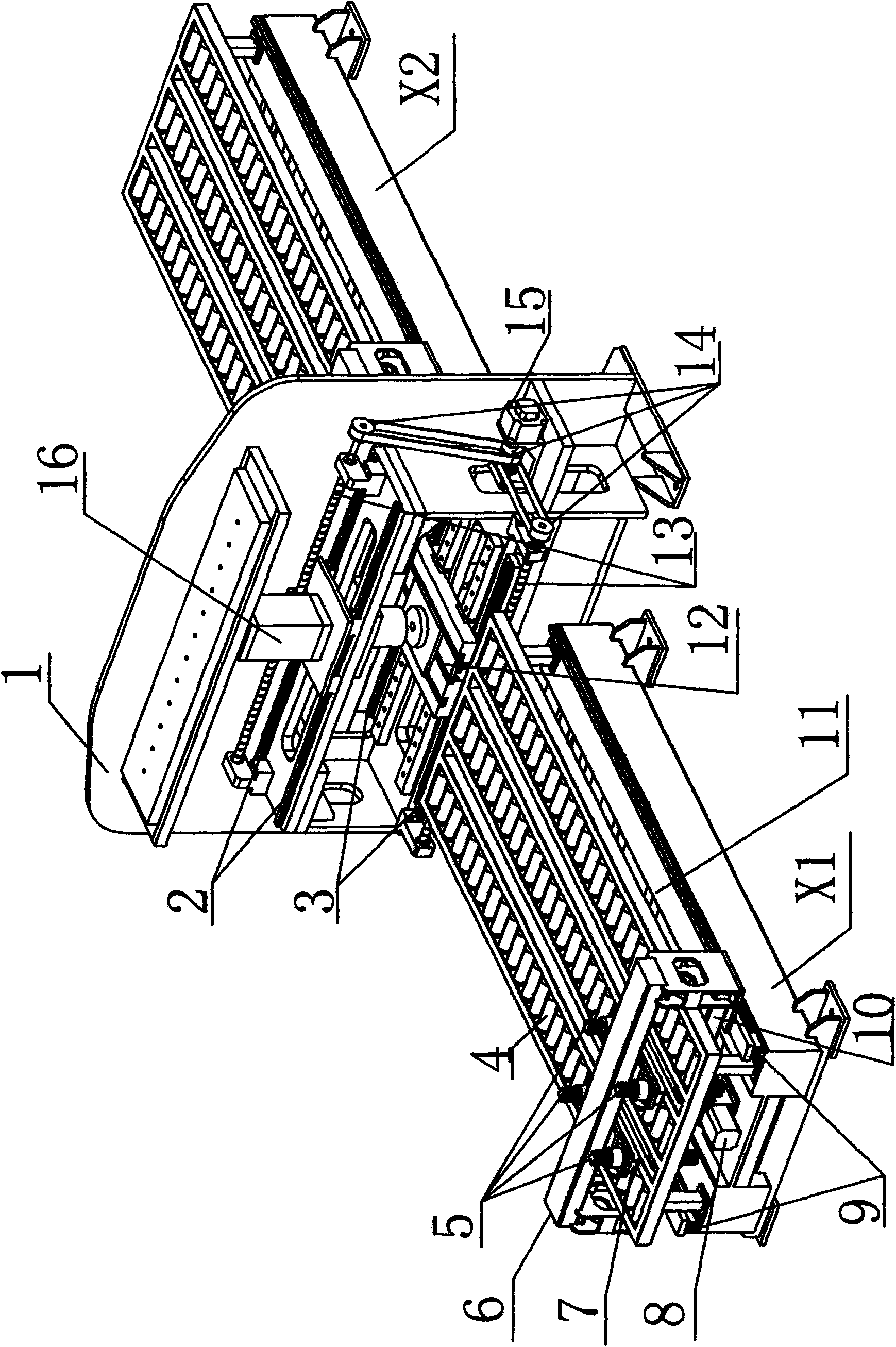

Full-automatic feeding device of punching machine

ActiveCN103394606AImprove intelligenceHigh degree of automationMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention belongs to the technical field of punching machines, and relates to a full-automatic feeding device of a punching machine. The full-automatic feeding device comprises a loading table and a feeding mechanism, wherein the loading table and the feeding mechanism are controlled by a controller to act. The loading table is specifically and structurally characterized in that a rotary table is fixed on a rotating shaft which is driven by a power unit and arranged on a rack; more than two positioning groove sets are evenly distributed in the same circles in the rotary table, wherein the radii of the circles are the same, and the circles are drawn around the same center; each positioning groove set is formed by two arc grooves which are arranged in a spaced mode; a positioning rod is arranged in each arc groove; a positioning rod positioning device is arranged on the lower side of the rotary table; a material position is formed between the two positioning rods of each arc groove set; a hole or groove used for an ejector bar to penetrate through is formed in each material position; the ejector bar driven by the power unit to act is arranged on the lower side of the hole or groove. The full-automatic feeding device of the punching machine has the advantages that materials are convenient to pile, take and feed, the degree of automation is high, and the full-automatic feeding device is applicable to the punching machine.

Owner:林爱福

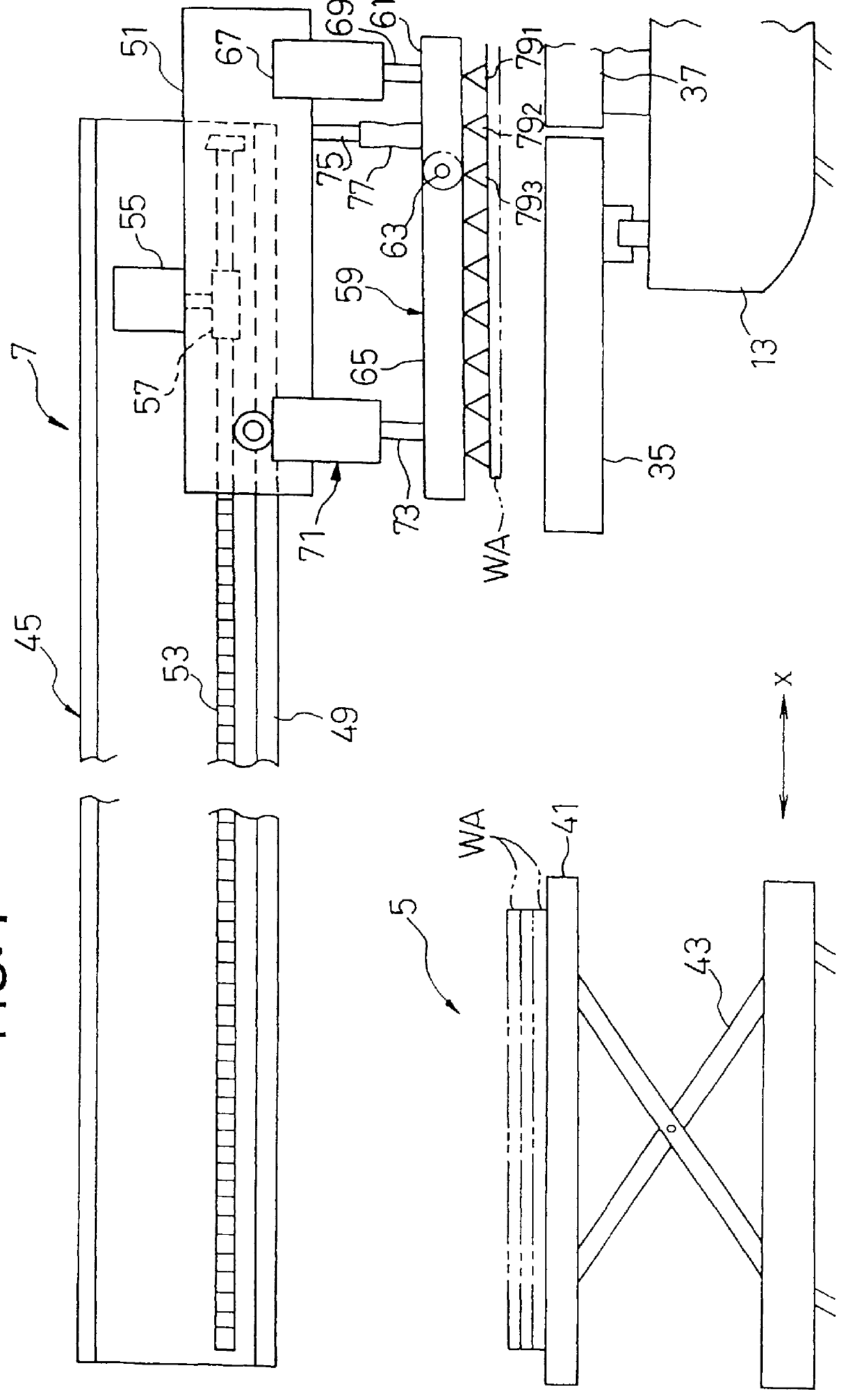

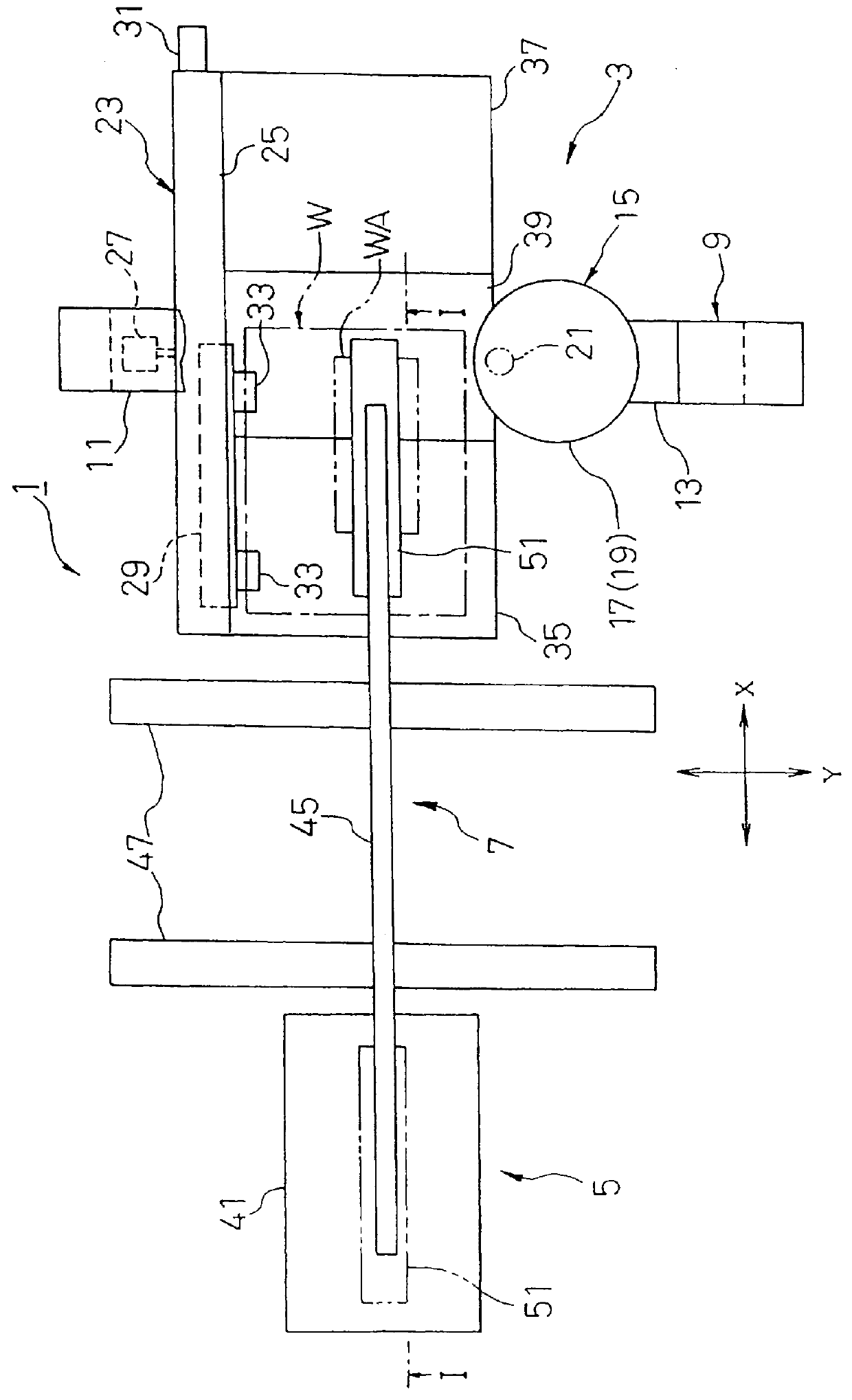

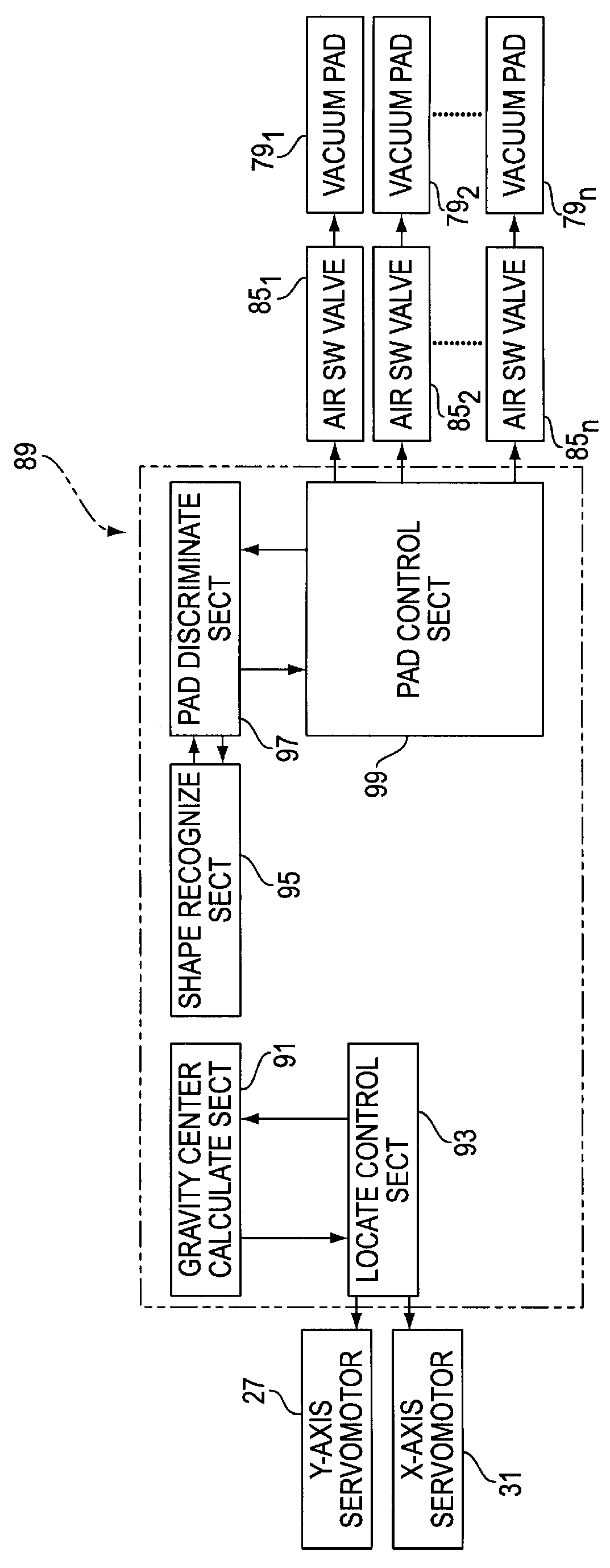

Punched plate material carrying-out system

InactiveUS6055895AReduce in quantitySmall sizeAutomatic control devicesMetal-working feeding devicesPunch pressManufacturing data

A slider of the punch carry out unit is moved in the X-axis direction adjacent a punching section of the punch press machine before or after a plate material is punched into a punched product by a punch press machine. At the same time, a gravity center and a shape of the punched product are calculated and recognized on the basis of the manufacturing data. On the basis of the obtained gravity center and the shape of the punched product, the gravity center of the punched product is moved under the lift arm by the X- and Y-axis locating mechanism. Vacuum pads located just over the punched product are selected or discriminated. Then, the lift arm is lowered and the punched product is held by actuating only the discriminated vacuum pads. During this lift motion, it is preferable to bend one end of the punched product slightly upward to easily separate the punched product from the remaining flat plate material. After the punched product has been lifted, the punched product is moved horizontally away from the punch press, and is then lowered on the punched product supporting unit by releasing only the actuated vacuum pads. Since only the vicinity of the gravity center of the punched product is held by a minimum possible number of the vacuum pads, irrespective of the size and shape of the punched products, the number of the vacuum pads can be reduced.

Owner:U S AMADA

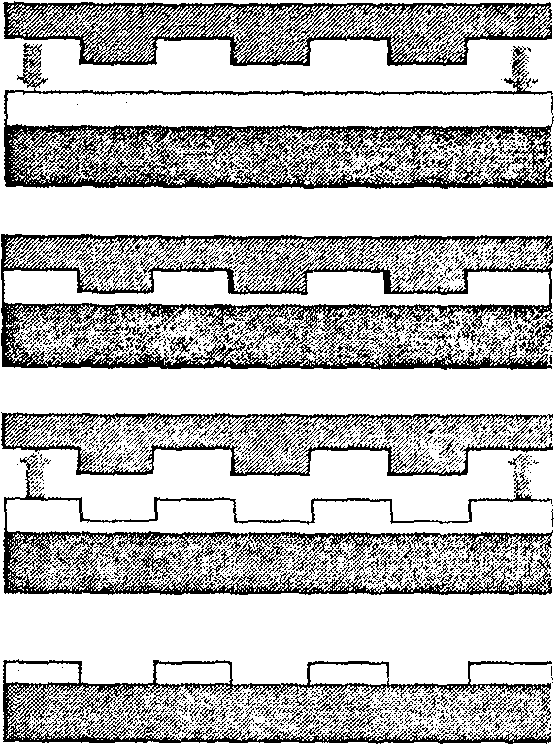

Ultraviolet/hot pressing curing type nano-printing method and stamping press

InactiveCN101403855AAchieve soft soft touchExact transfer replicationPhotomechanical apparatusTemperature controlEngineering

The invention provides an UV / hot-pressing curing type nano-imprint method in which the imprint process is carried out in vacuum environment, the imprint driving force is controllable and steady high pressure gas, and adjustment and matching are carried out by combining the positive-negative pressure. When a bearing substrate and an imprint platform of an imprint template contact an imprint reference surface for imprinting, the imprint process is realized by an automatic leveling mechanism. The two means of the UV exposure curing as well as the heating and quick cooling curing are integrated, that is, the imprint reference surface is a UV-pervious quartz flat plate, and the imprint platform integrates a vacuum absorption sheet and a temperature-control electric heating furnace with a quick water cooling device and the like. The nano-imprint device obtained by the method has the advantages of reasonable and simple structure, simple operation, reliable and stable performance, high-efficiency and cheap preparation process, and high automation degree.

Owner:NANJING UNIV

Punch press tool for stamping successive multicharacter impressions into a workpiece

ActiveUS20080314220A1Addressing machinesMechanical working/deformationPunch pressReciprocating motion

A punch press tool for stamping successive multicharacter impressions into a workpiece such as a piece of steel, sheet metal, or other workpiece, includes a guide body in which a stamp driver is slidably mounted for being driven downwardly toward the workpiece by a punch press ram which is a standard part of a high speed commercial punch press. A multicharacter marking stamp is supported at the lower end of the stamp driver for reciprocal movement therewith. The marking stamp includes multicharacter wheels that are rotated automatically during operation for advancing characters in sequence responsive to the movement of a character advancing arm. At least one character stamp operating lever is operatively associated with the punch press tool for articulation responsive to motion imparted to the tool by the ram. The lever has an operating element that is operatively associated with the character advancing arm of the multicharacter stamp for indexing the arm to enable successive characters thereof to be placed in an operating position responsive to a stroke of the punch press ram.

Owner:MATE PRECISION TOOLING

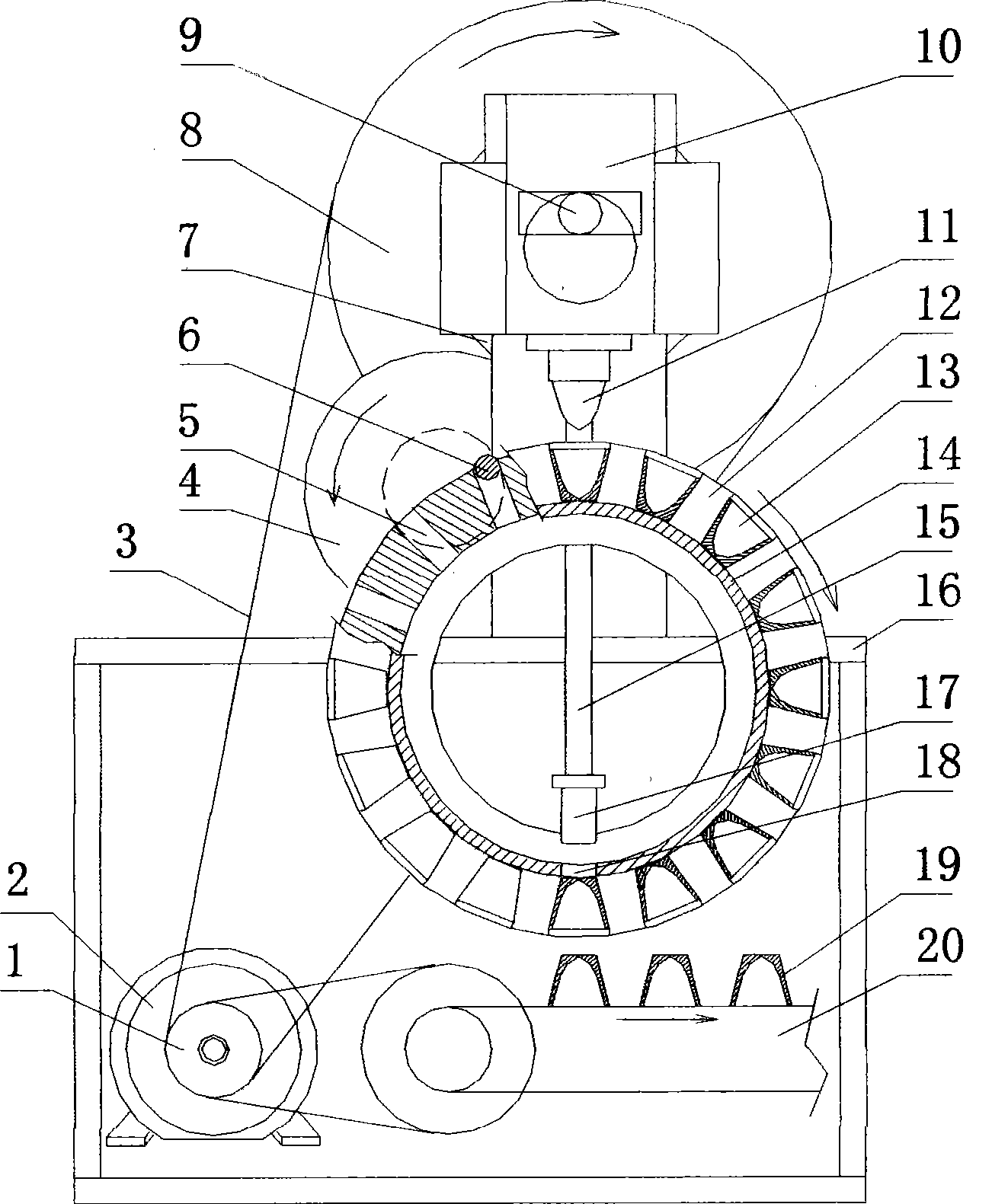

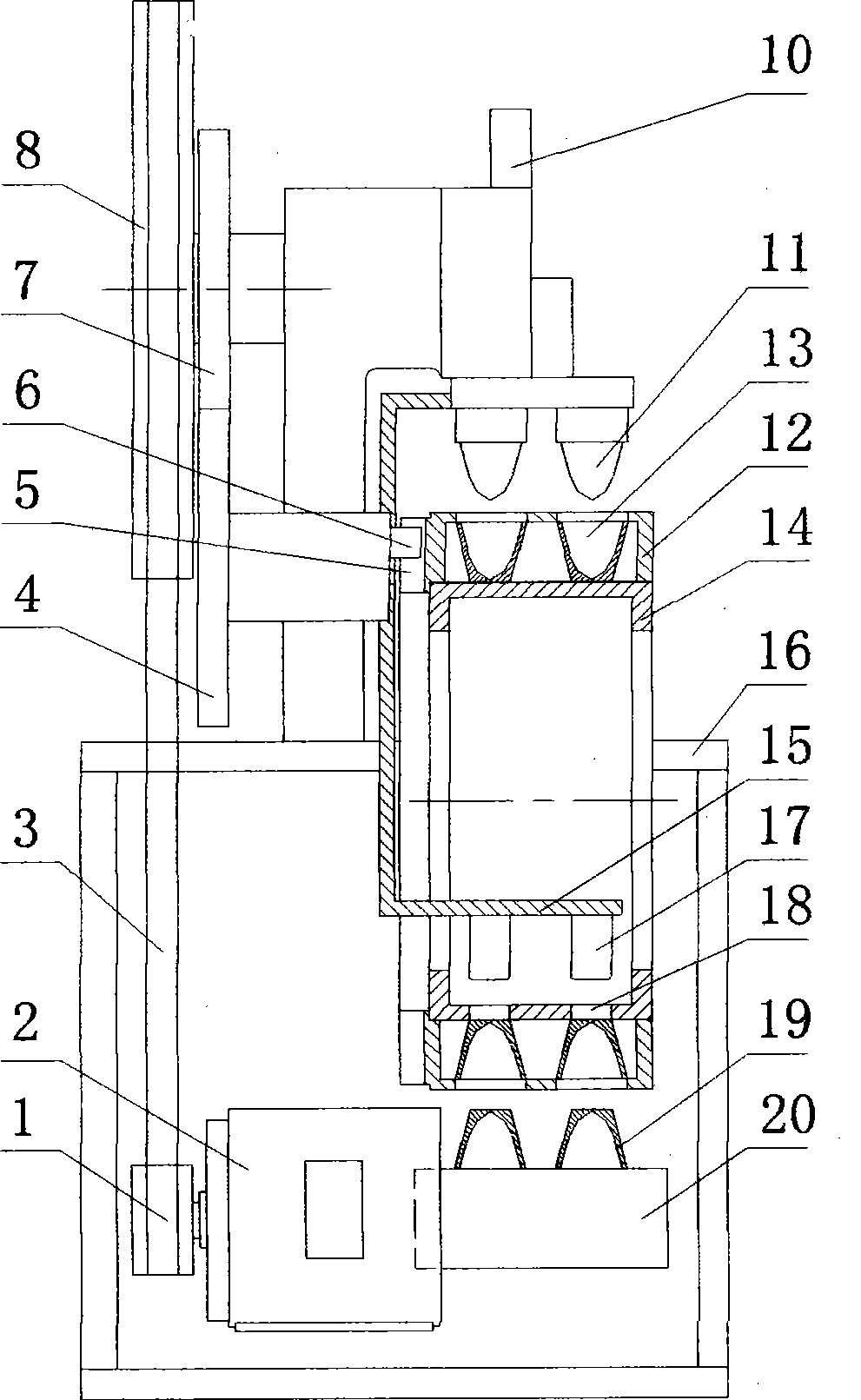

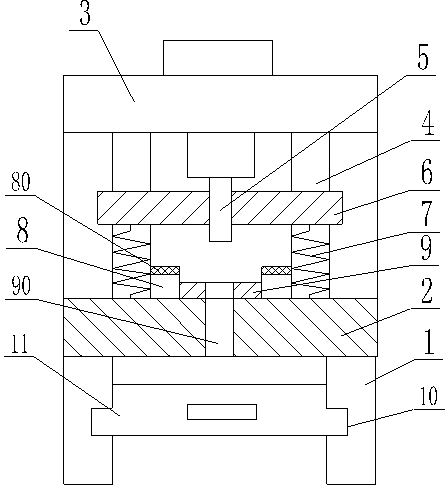

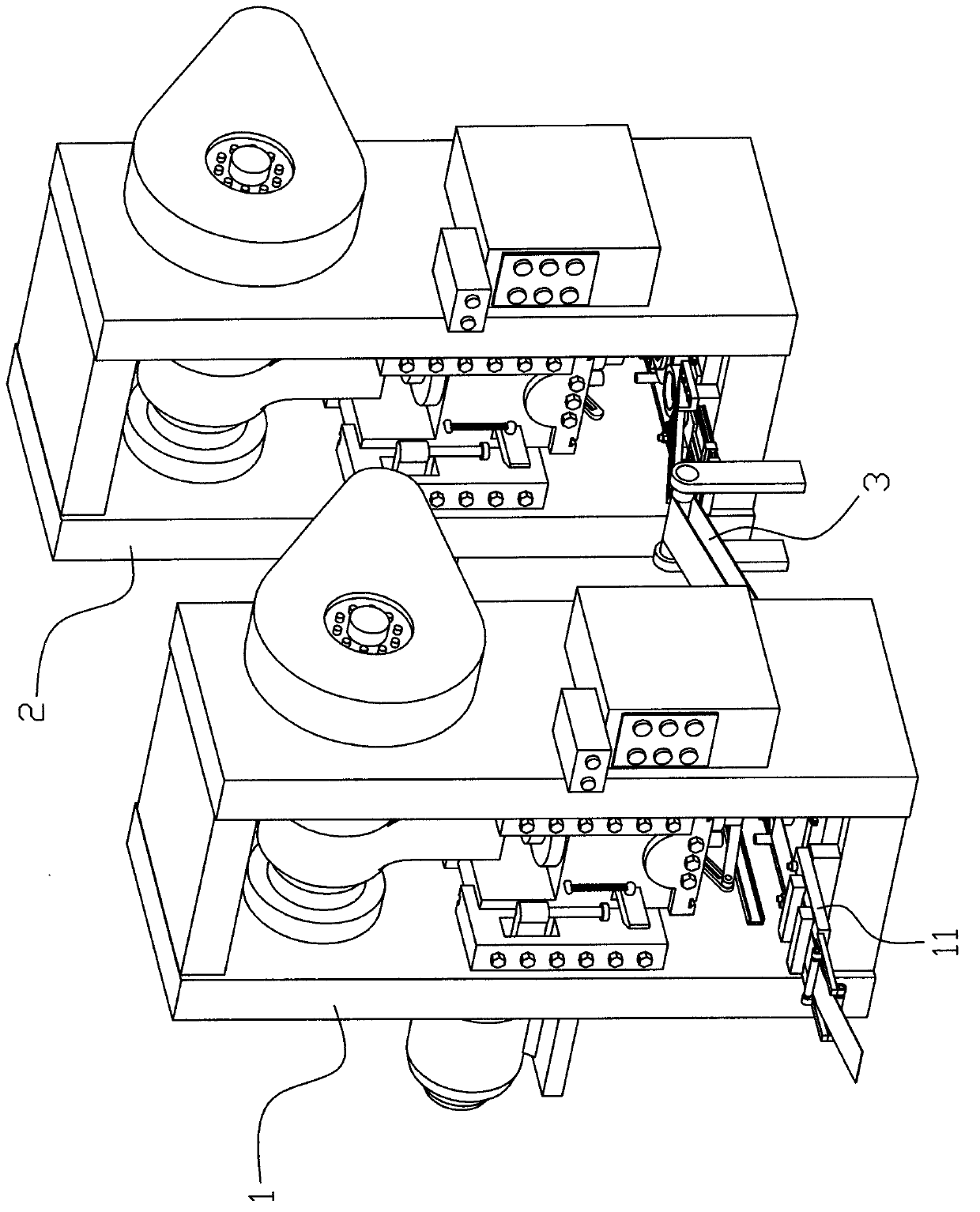

Automatic feeding unit of stamping press

InactiveCN101367276AOptimize layoutEasy to arrange side by sideCeramic shaping apparatusShaping pressCompression moldingPunching

The invention relates to an automatic feeding device for punches, in particular to an automatic feeding device for compression-molding bowl-shaped products. The feeding device adopts a vertical turntable-type worktable rotating intermittently, and a plurality of circles of mold cavities are arranged on the circumference surface of the worktable in the radial direction. A punching slider which does up-down reciprocating motion is arranged above the worktable, and the motion direction of the punching slider is perpendicular to a rotating shaft line of the worktable. A mold release push rod is arranged in an inner cavity of the worktable downwards, and the push rod does reciprocating motion synchronously with the punching slider. A conveyer belt is arranged below the worktable. When a mold cavity follows the worktable to rotate to a punching position, punching process is carried out by a punching mechanism arranged above, and when the mold cavity follows the worktable to rotate 180 degrees to a downward mold release position, the mold cavity realizes natural overturning, so as to push a product onto the conveyer belt below from the bottom of the mold cavity through the mold release push rod arranged in an inner ring of the worktable.

Owner:王斌

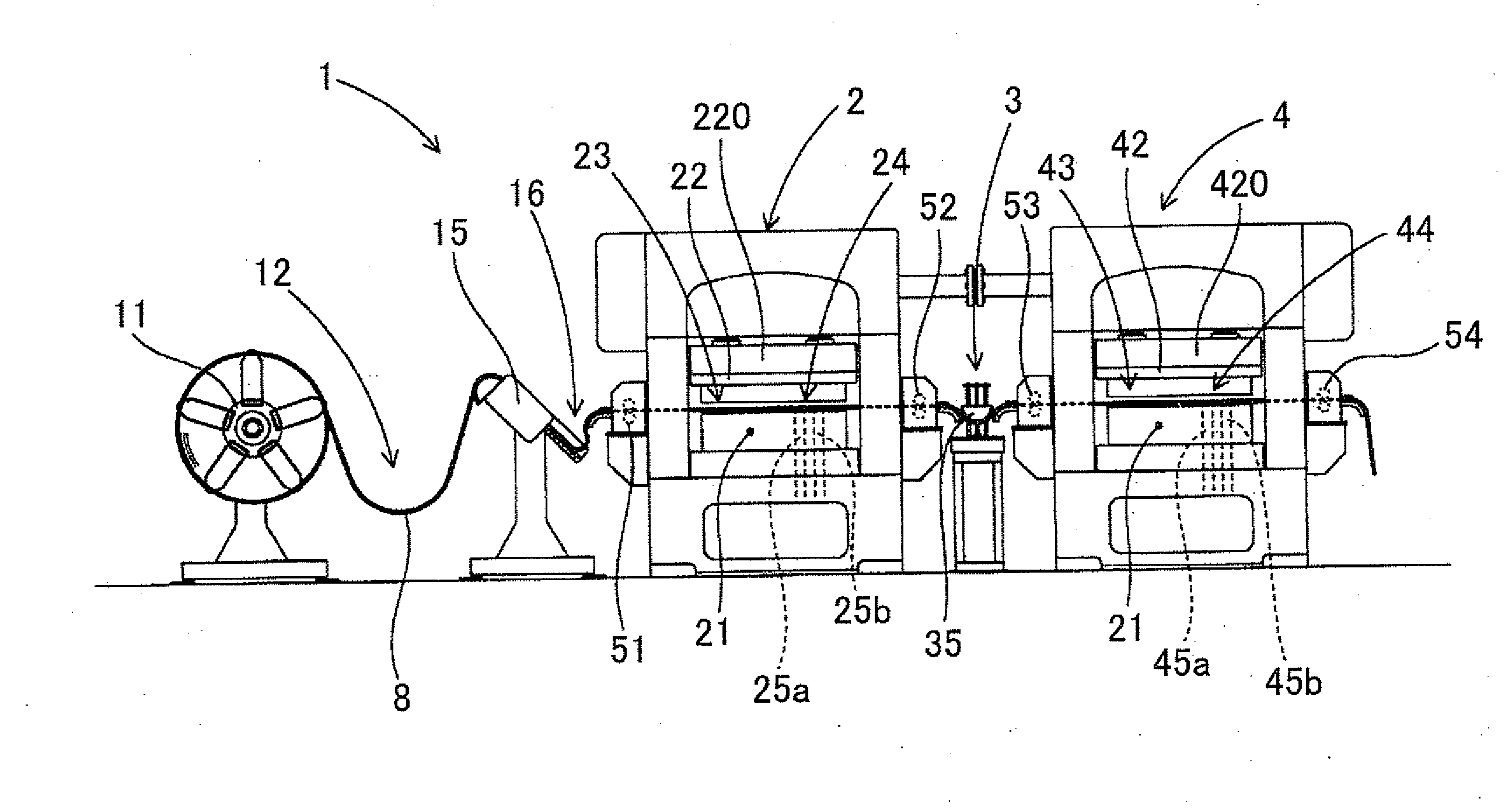

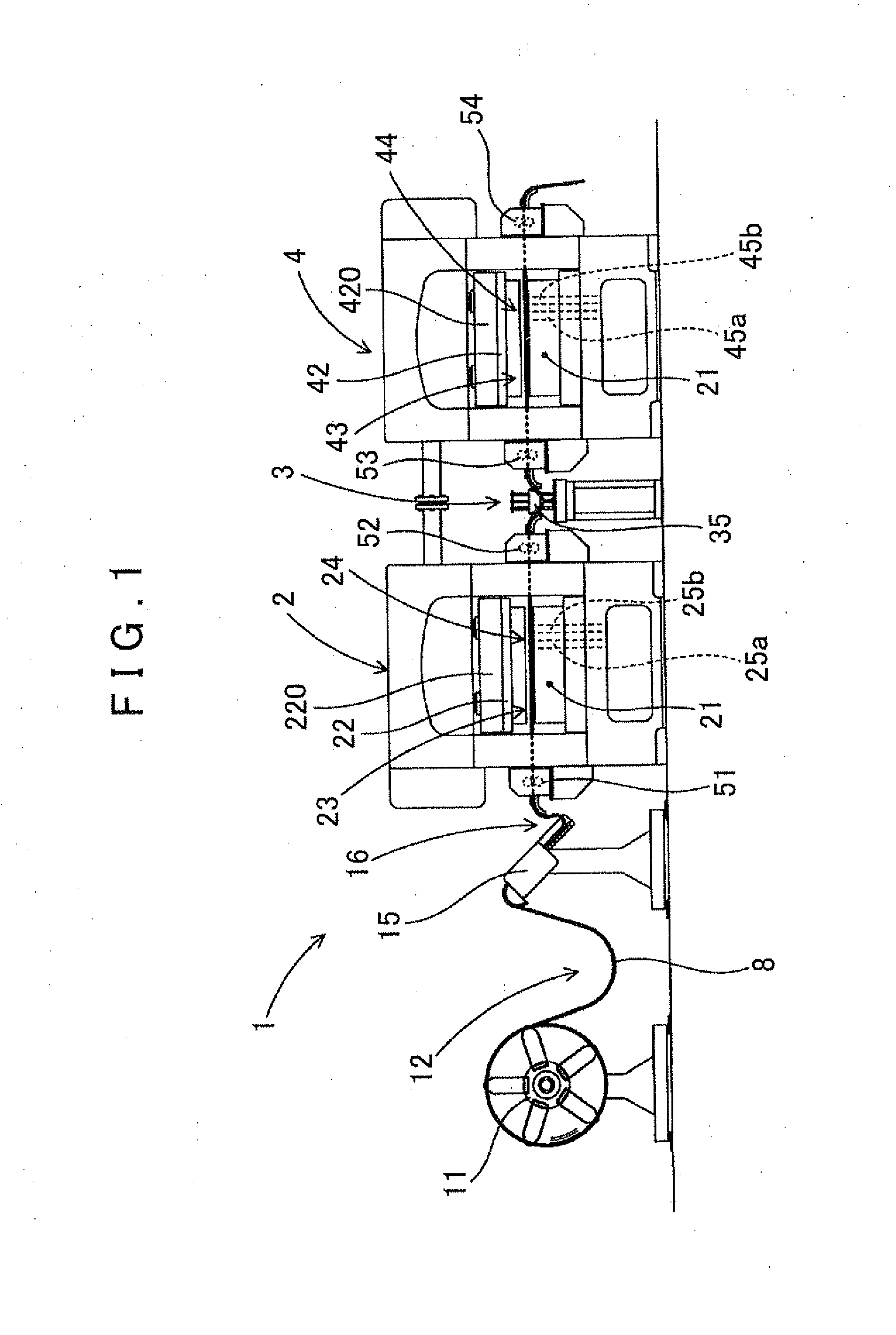

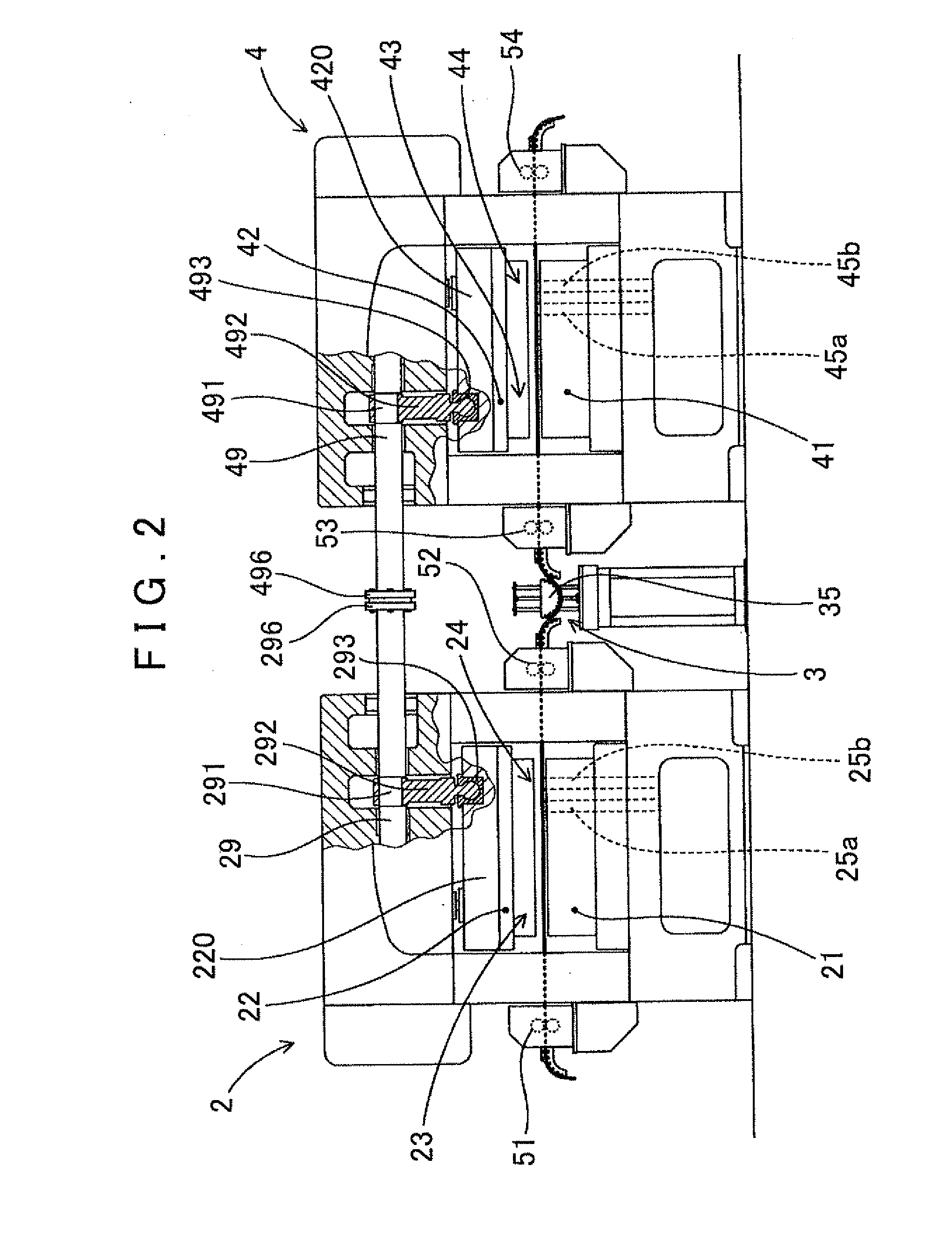

Laminated core punching apparatus

ActiveUS20110232076A1The relative position is appropriateRemarkable effectAssembly machinesOther manufacturing equipments/toolsSheet steelPunch press

A laminated core punching apparatus, configured such that a stator-punching press machine that has a molding die performing a partial punching gradually approaches the shape of the stator core piece. There is a punching die to punching out the stator core piece from a strip-form steel plate, and two stator lamination stations. A rotor-punching press machine and a stator-punching press machine are constructed to operate synchronously. An intermediate loop portion capable of causing a strip-form steel plate to hang down in a loop is provided in order to adjust a length of the strip-form steel plate between the two press machines, and a loop guide portion that guides a loop locus of the strip-form steel plate from above so that the strip-form steel plate does not invert is disposed above the intermediate loop portion to be capable of ascending and descending.

Owner:NORITSU KIKAI SEISAKUSHO

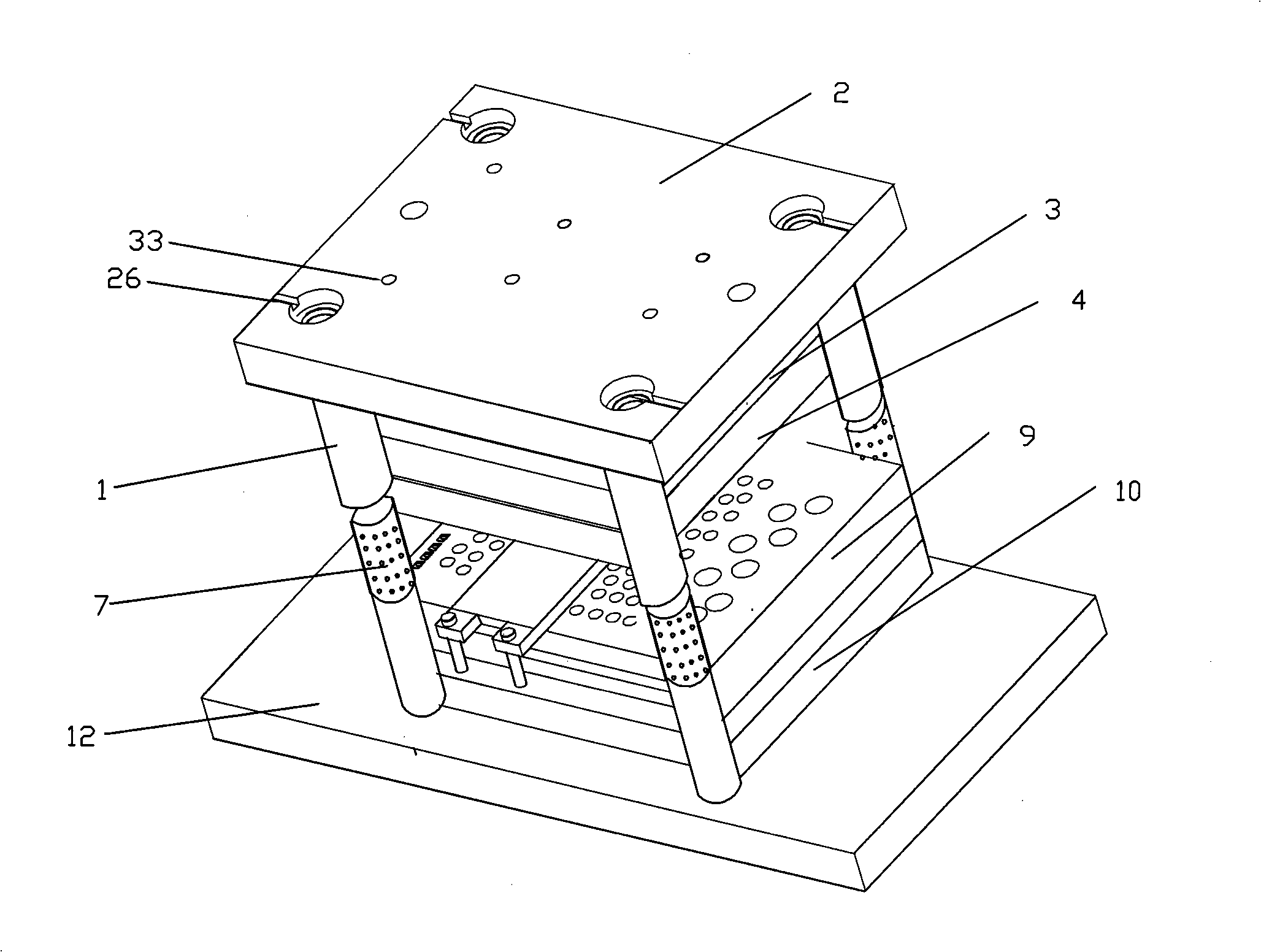

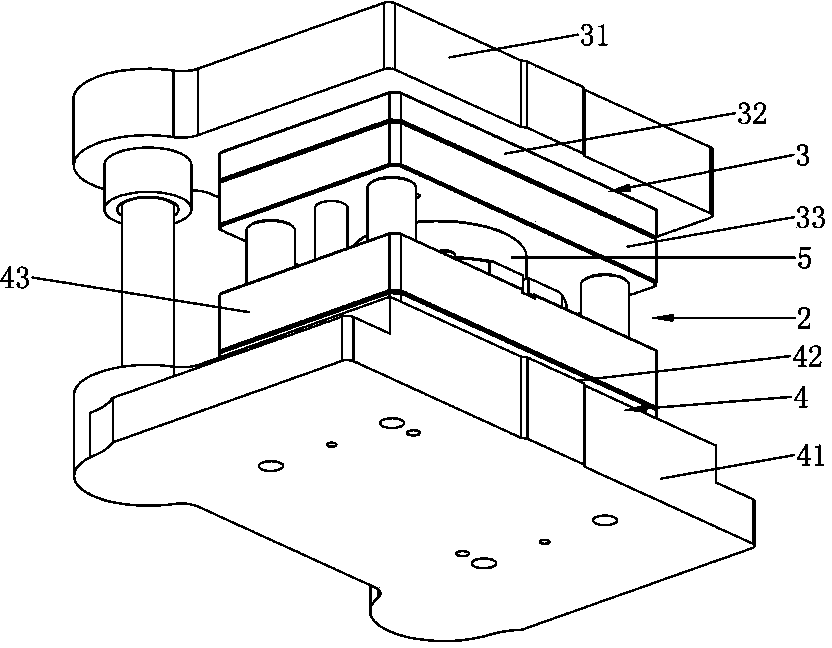

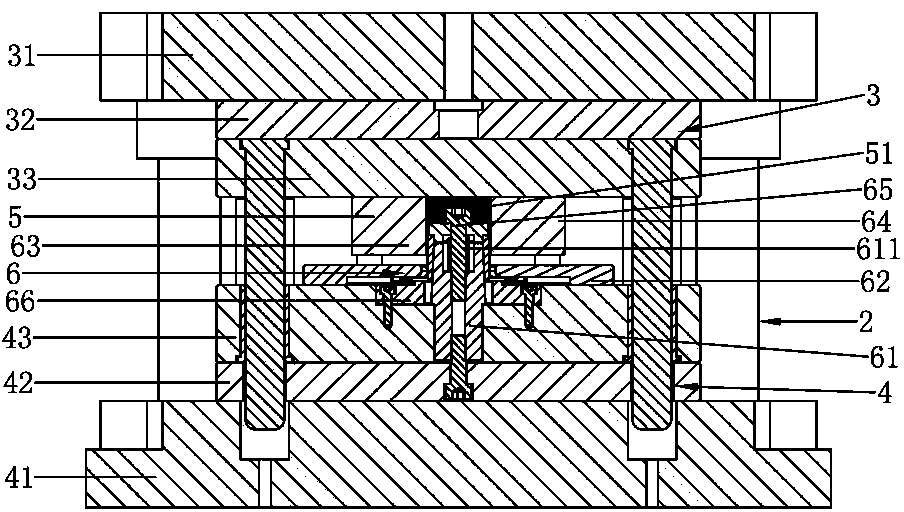

Punching machine mold of metal button and method for processing metal button using the mold

InactiveCN101406918AQuality assuranceReduce product differentiationShaping toolsButtonsPunch pressEngineering

The invention discloses a punching mould for machining a metal button and a method for machining the metal button by utilizing the mould. In the mould, a guide sleeve and a liquid bead sleeve which are arranged on a top slab and a soleplate are matched with each other in order that the positions of an upper mould and a lower mould keep relative fixing; simultaneously, a small guide column of the upper mould and a small guide column of the lower mould are matched with each other in order that the a side blade, a stretching pin, a printing mould and the like keep relative fixing with the position of a mould hole of the lower mould respectively; a stamping machine is utilized to carry out blocking stamping, further stamping, pattern printing, feed dropping and other machining sequentially on the button, thereby realizing the automation of button machining, greatly improving production efficiency and eliminating potential safety hazards.

Owner:深圳市联星服装辅料有限公司

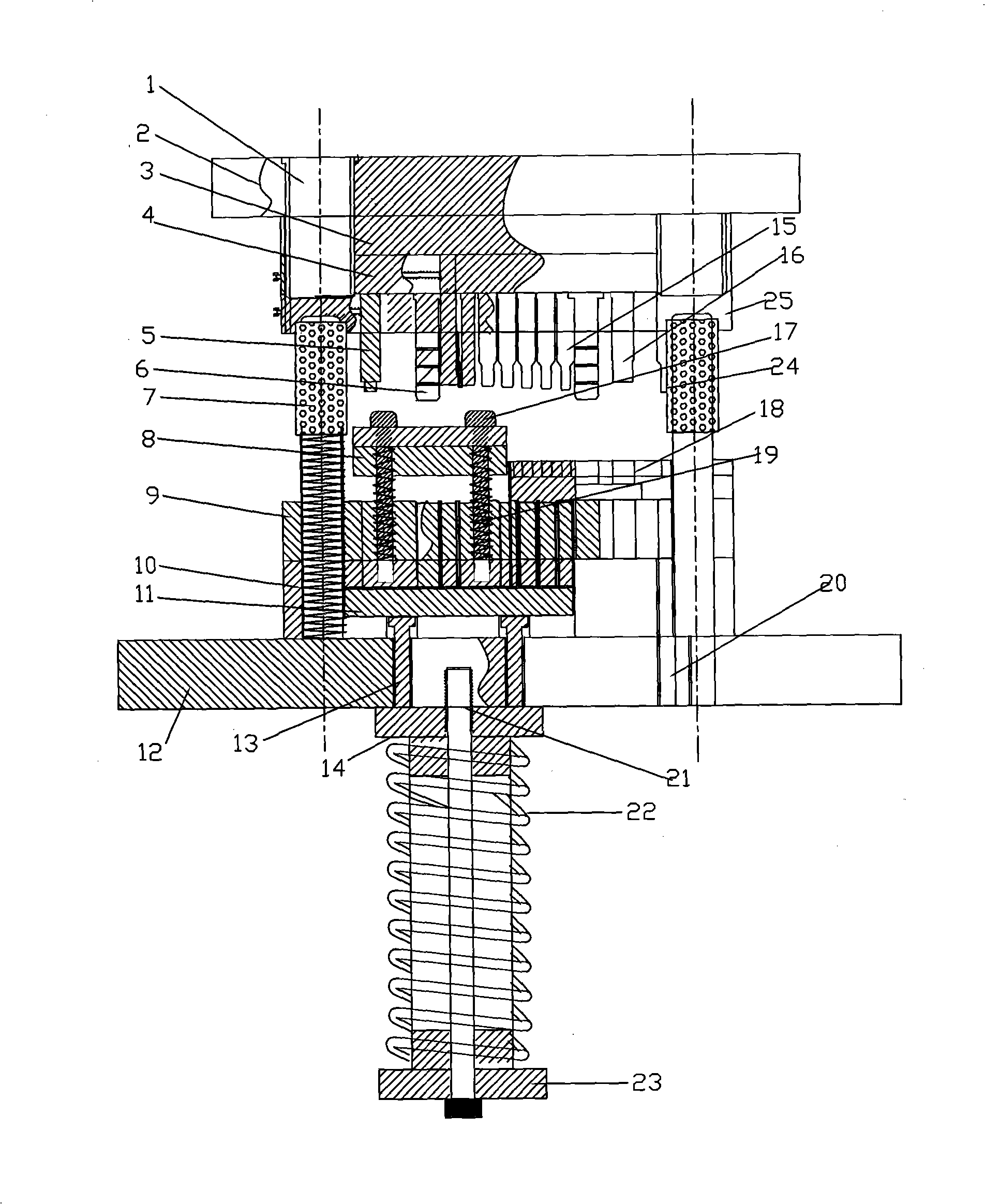

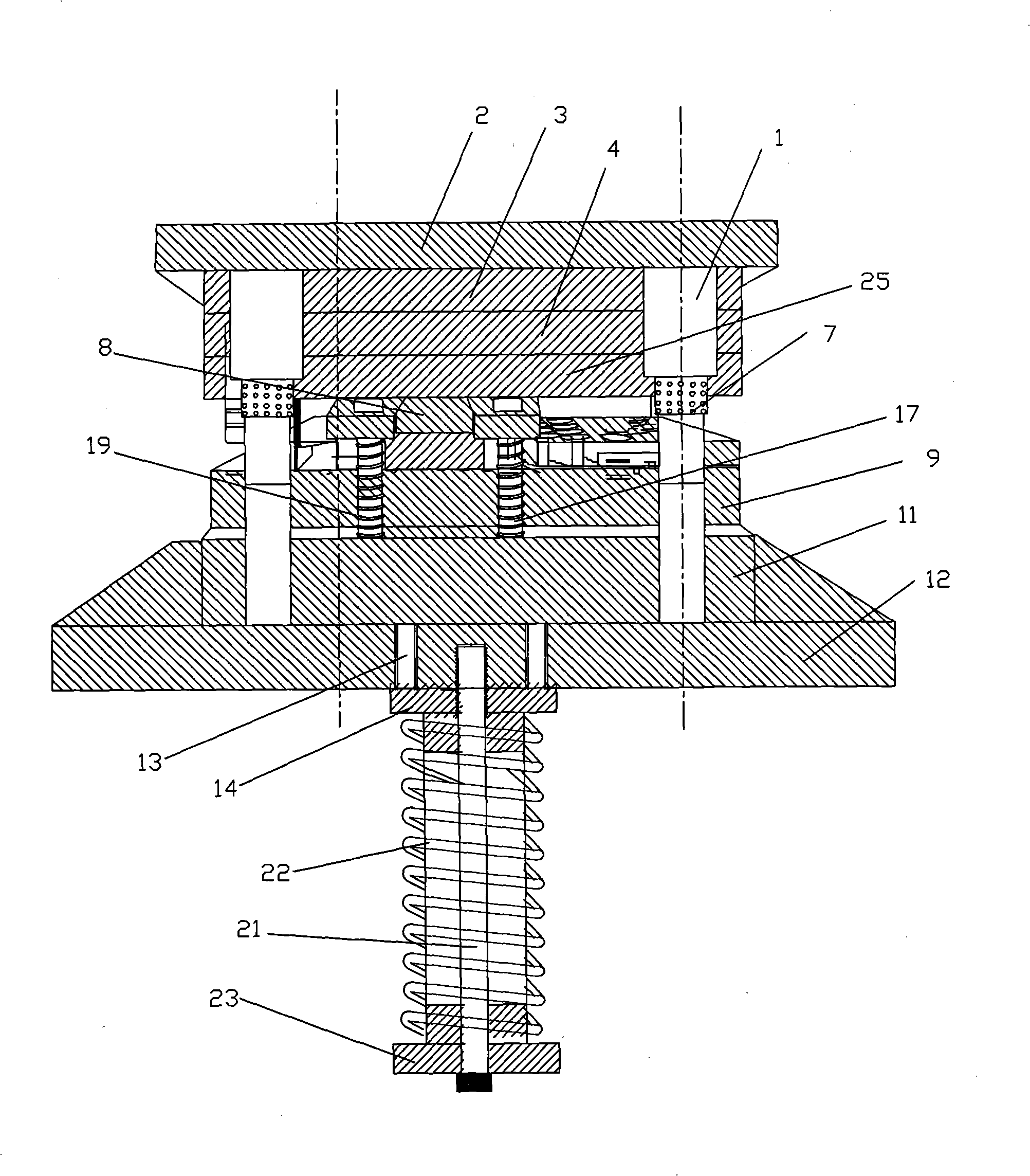

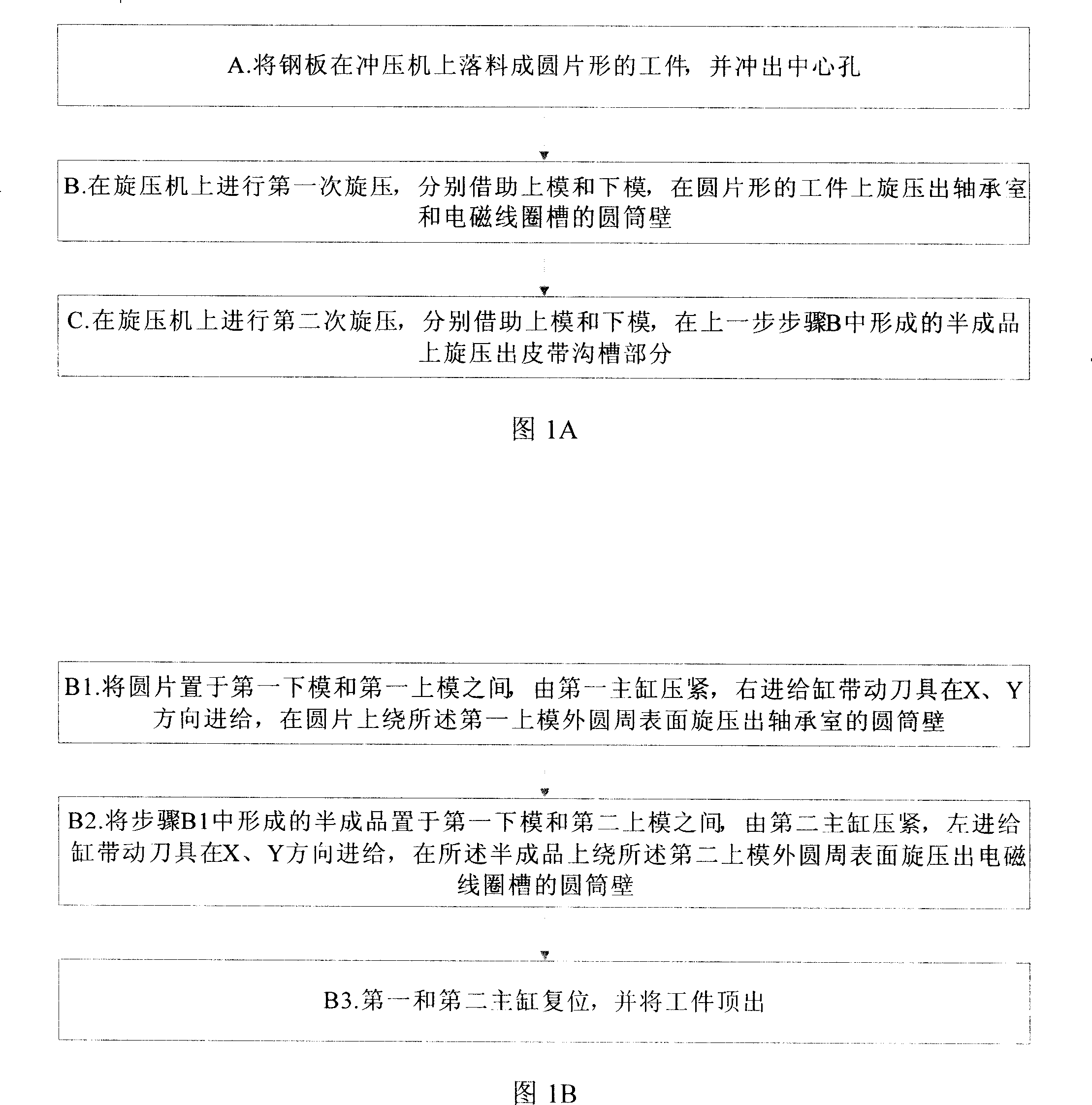

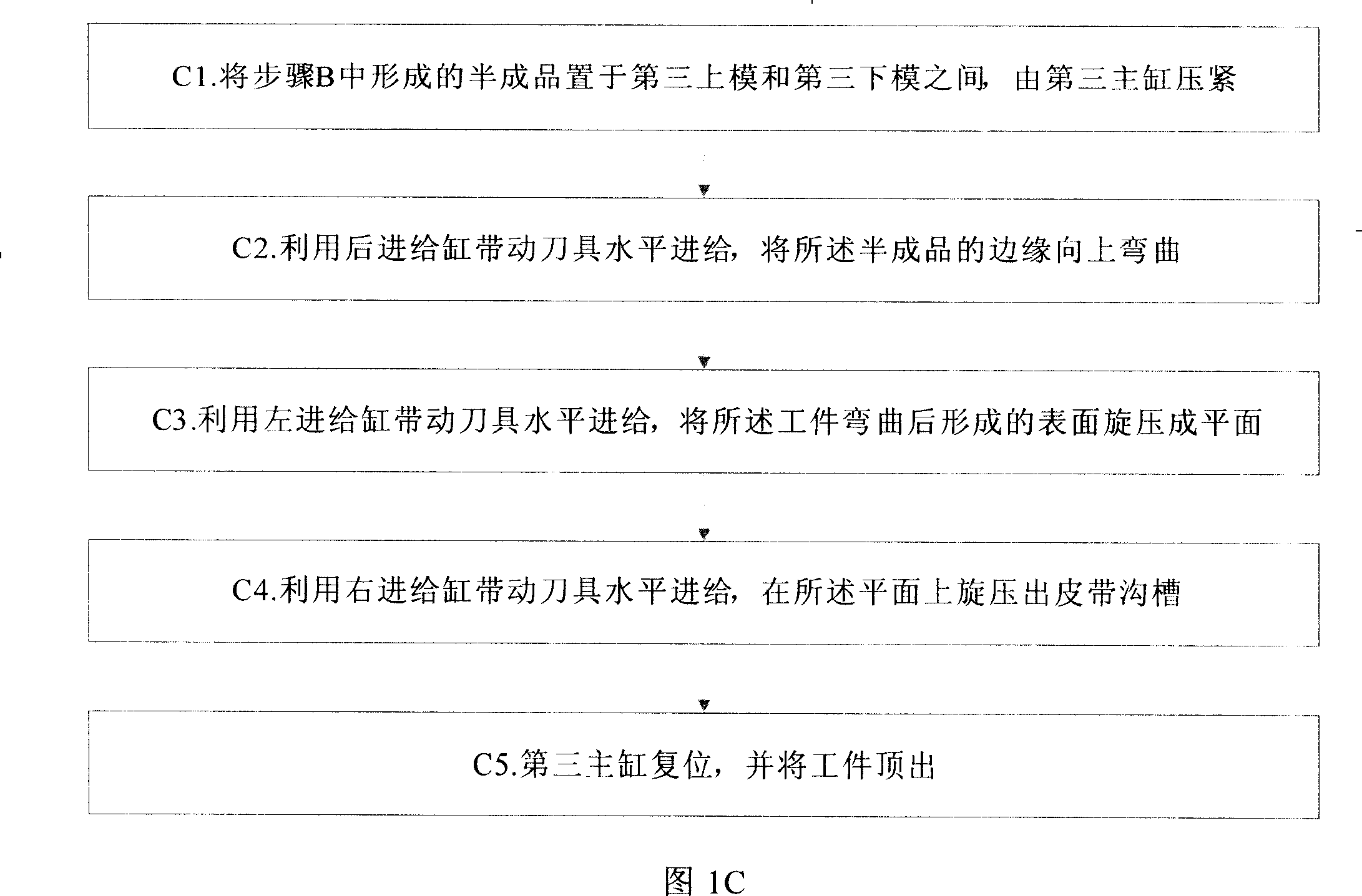

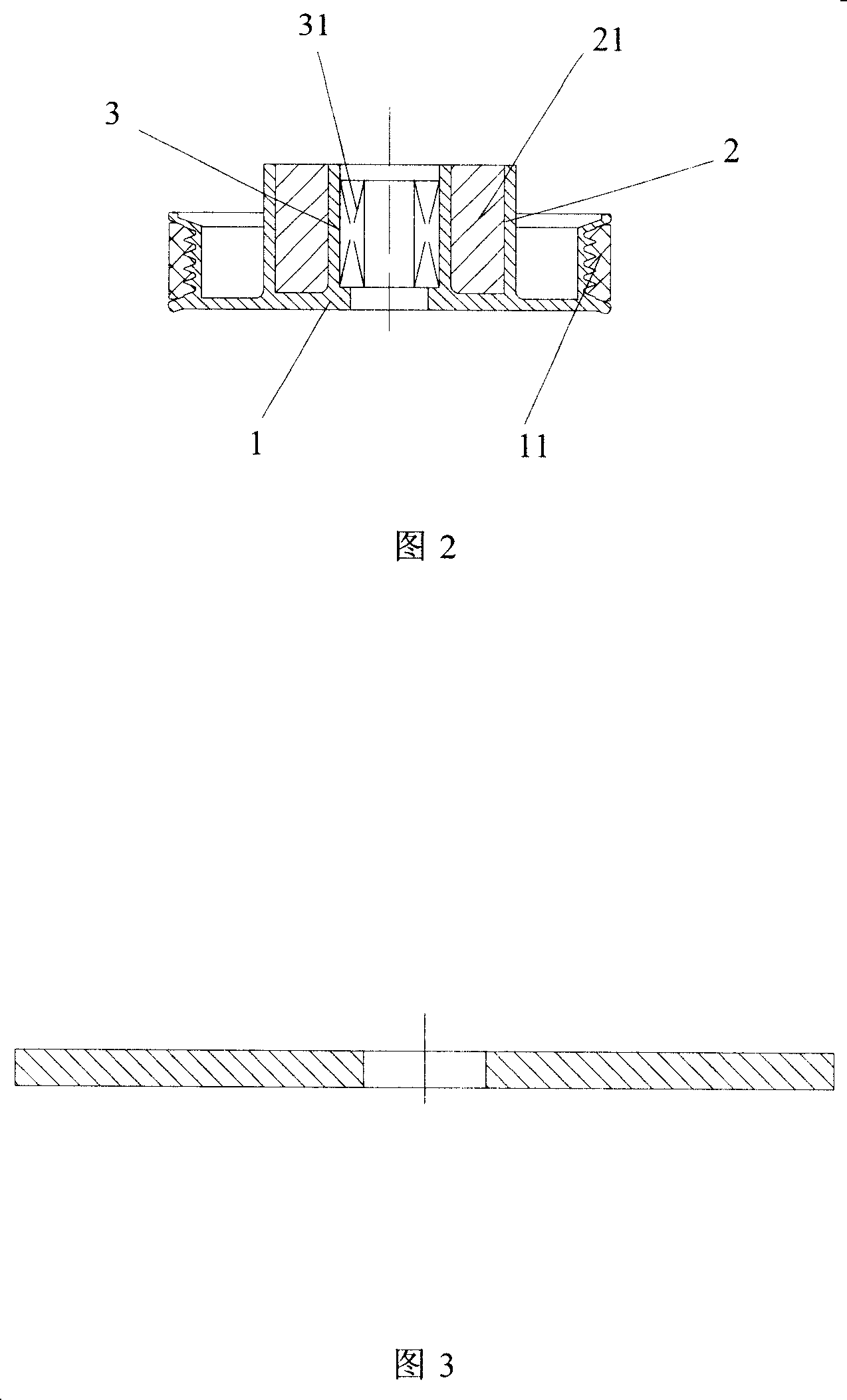

Process of machining belt wheel for electromagnetic clutch

InactiveCN101088655AProduct quality is lightUniform material distributionShaping toolsPortable liftingPunchingElectromagnetic clutch

The present invention relates to process of machining belt wheel for electromagnetic clutch. The belt wheel includes one casing, one bearing chamber, and one electromagnetic coil holder between the casing and the bearing chamber. The process of machining belt wheel includes the following steps: 1. punching steel plate material in a punch to form circular workpiece with central hole; 2. the first spinning in a spinning lathe with upper mold and lower mold to form the bearing chamber and the cylinder of the electromagnetic coil holder; and 3. the second spinning in the spinning lathe to form the belt slot in the casing. The process has environment friendship, high production efficiency and low production cost.

Owner:吴诗

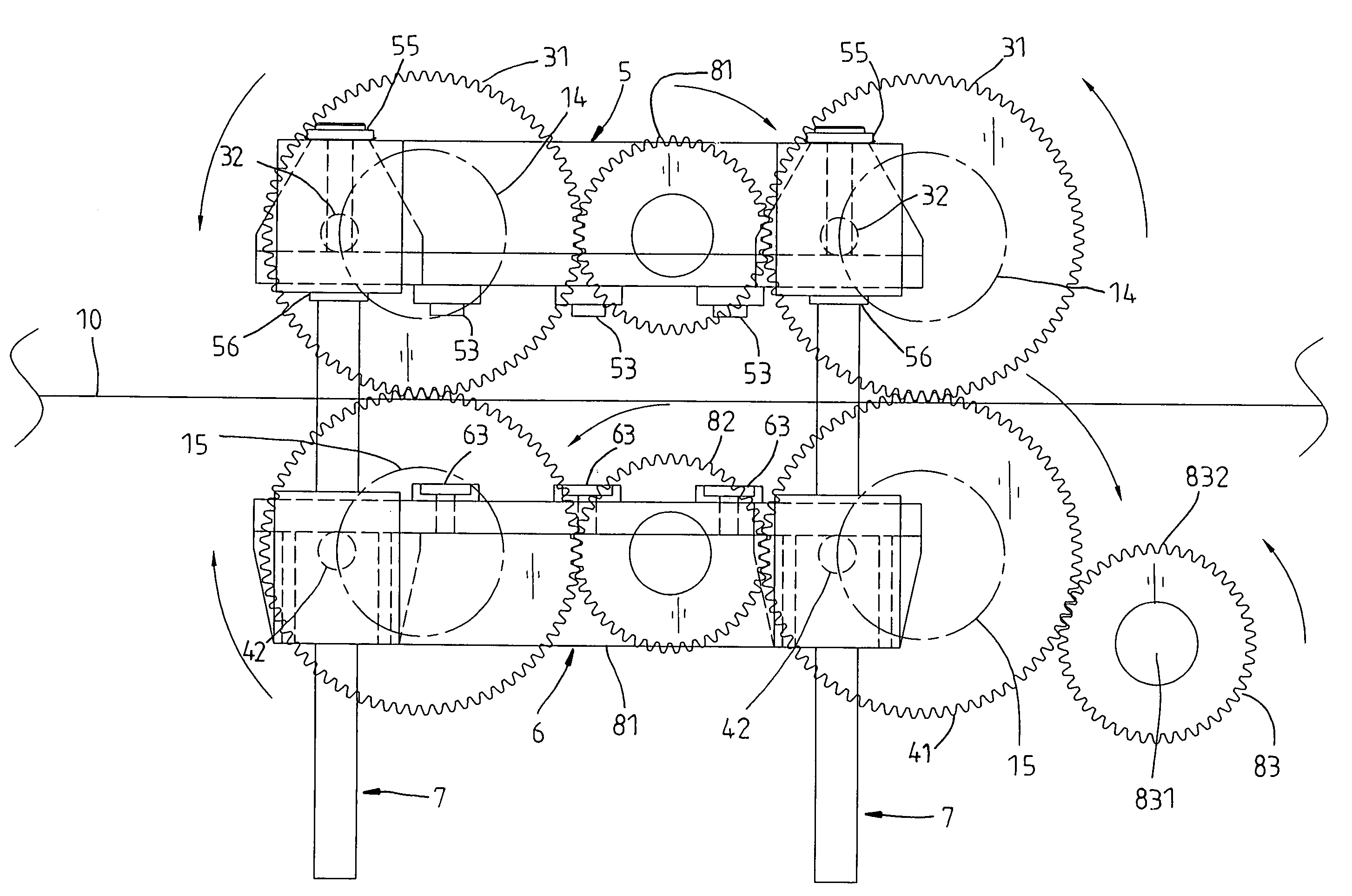

Roll forming and punching machine for metal sheet material

InactiveUS7340931B1Shorten speedMetal-working feeding devicesStock shearing machinesPunchingMetal machining

A punching machine installed in the machine base of a roller shape forming machine in a metal working system and controlled to punch holes on a metal sheet material being delivered through the roller shape forming machine during operation of the roller shape forming machine. The punching action, i.e., the cycling of the closing and opening actions of the punch mold of the punching machine is set to match with the delivering speed of the metal sheet material in the roller shape forming machine so that the punching operation of the punching machine is continued during processing operation of the roller shape forming machine.

Owner:CHUANG SEN JUNG

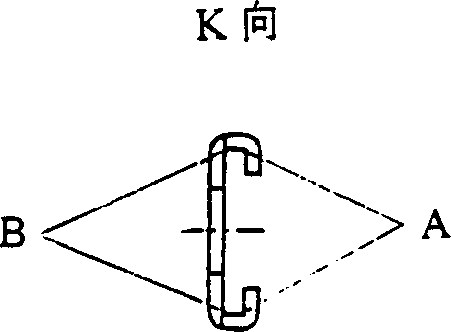

Method for producing C-shaped hardwares of plastic steel door window

InactiveCN1504281AEnsure that the groove gap is greater than or equal to the requirement of 0.9mmMake sure that it is greater than or equal to the requirement of 0.9mmPunchingEngineering

The invention discloses a process for making C-shaped member in the metallic members of the plastic-steel door and window, wherein the C-shaped member manufacturing process of uninterrupted manufacture comprises the steps of, uncoiling the coiled steel on the decoiler, controlling by a first buffer storing device, feeding the belt steel into the progressive forming machine to form a C-shaped cross-section, controlling by a second buffer storing device, sending by the self-feeding machine into punching machine for gap punching, perforating, cutting-off and bending.

Owner:BEI JING NEW BUILDING MATERIALGRP

Method for manufacturing aluminum alloy hub

The invention discloses a method for manufacturing an aluminum alloy hub. The method comprises the following steps: first, manufacturing an aluminum alloy hot rolled plate into a round-sheet-shaped blank; second, stretching the round-sheet-shaped blank into a disc-shaped blank through a spinning machine or punch press; third, extruding the spoke central part of the disc-shaped blank; fourth, punching and trimming the extruded blank; fifth, arranging the punched and trimmed blank into the spinning machine and spinning the blank into a hollow rotating body hub blank with high strength; sixth, conducting stabilizing treatment or solid solution aging hot treatment on the hollow rotating body hub blank formed in a spinning mode; seventh, conducting machining and surface treatment. According to the method for manufacturing the aluminum alloy hub, a material and manufacturing process used by the aluminum alloy hub are improved, Al-Mg-Si aluminum alloy bars in a cast state are adopted as a raw material so that the aim of simplifying the process can be achieved, and the process of upsetting, forging and prefabricating the disc-shaped blank and the like are not needed before spinning forming.

Owner:ZHEJIANG GKO IND CO LTD

Punching machine

InactiveCN103736805AReduce shockQuick collectionShaping toolsStripping-off devicesPunchingEngineering

The invention relates to a punching machine which comprises a supporting leg, wherein a lower die seat is arranged at the upper end of the supporting leg, guide rods are arranged between the lower die seat and an upper die seat, a guide plate is arranged between the guide rods, a punching head is arranged in the middle of the guide plate, stoppage blocks are arranged on the inner sides of the guide rods, a concave die is arranged between the two stoppage blocks, a discharging hole is formed in the concave die and the lower die seat, grooves are formed in the inner side of a supporting seat, a containing box is arranged between the grooves, return springs are arranged in the guide rods and positioned between the guide plate and the lower die seat, and damping layers are arranged at upper ends of the stoppage blocks. The punching machine is simple in structure and reasonable in design. The return springs are arranged between the guide plate and the lower die seat, so that the guide plate can return to the original place automatically after the punching machine punches plates, and electric energy is saved. Furthermore, due to the fact that the damping layers are arranged on the stoppage blocks, impact force to the guide plate and the stoppage blocks is effectively retarded, and the guide plate is protected.

Owner:KUNSHAN HUAKUI MACHINERY ELECTRONICS

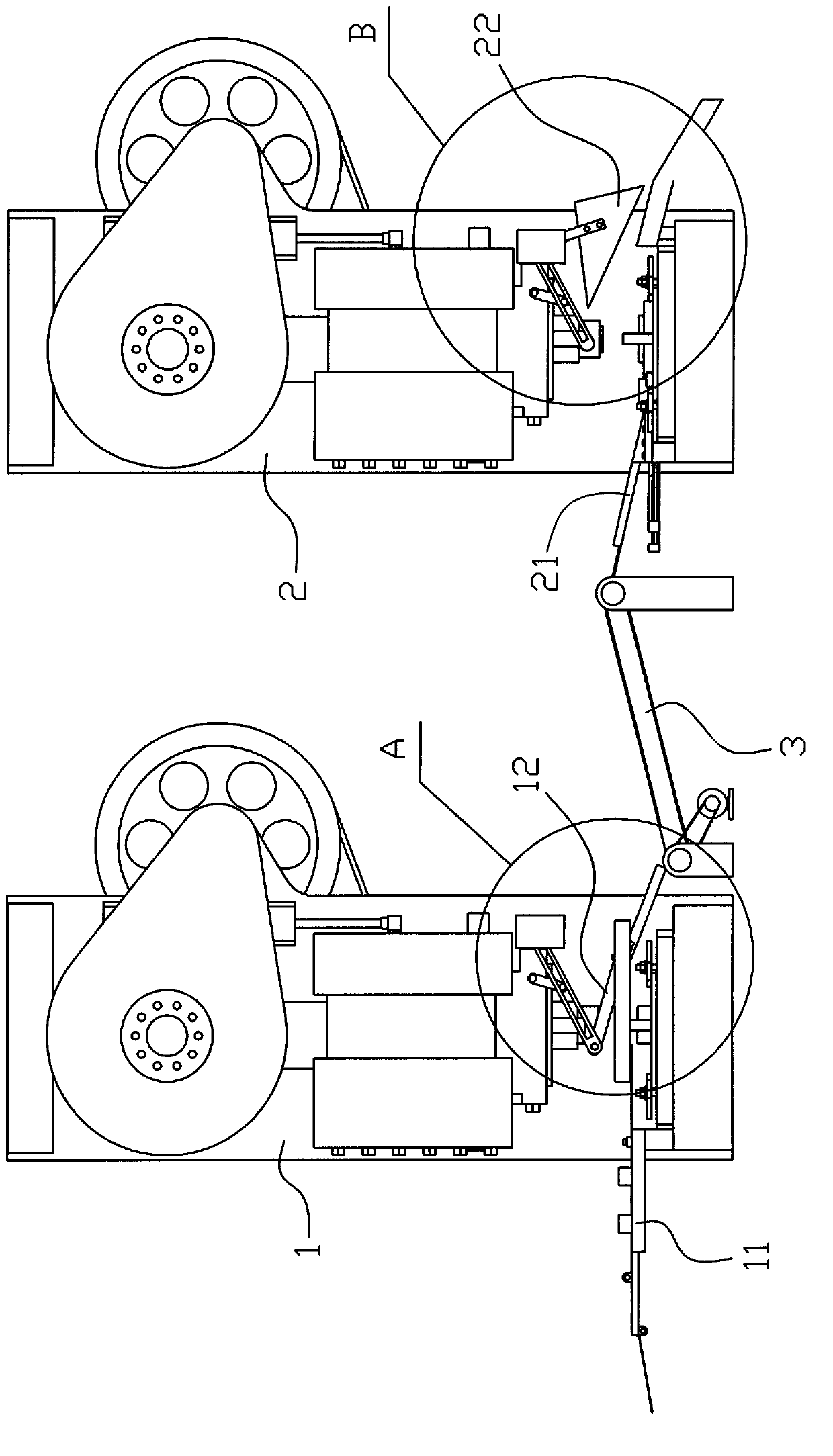

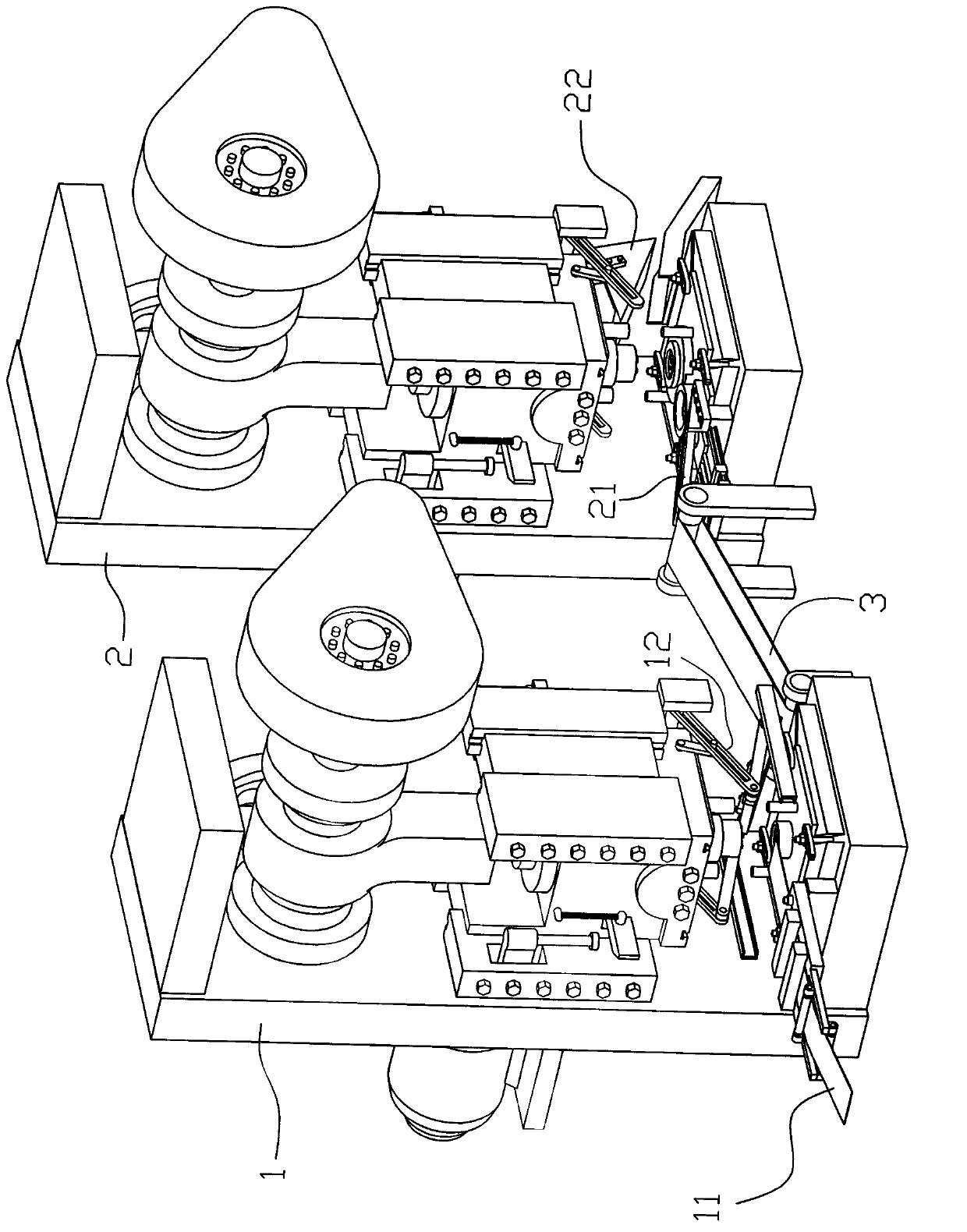

Punching machine

ActiveCN103341541AIngenious design structureRealize continuous processingMetal-working feeding devicesStripping-off devicesPunchingEngineering

Disclosed is a punching machine. The punching machine comprises a first punching machine (1) and a second punching machine (2), and further comprises a steel strip feeding device (11), a first discharging device (12), a workpiece feeding device (21), a second discharging device (22) and a conveying device (3). The steel strip feeding device and the first discharging device are horizontally installed on the first punching machine and synchronously work with the first punching machine in a coordinated mode; the workpiece feeding device (21) and the second discharging device (22) are horizontally installed on the second punching machine (2) and synchronously work with the second punching machine (2) in a coordinated mode; the conveying device (3) is arranged between the steel strip feeding device (11) arranged on the first punching machine (1) and the workpiece feeding device (21) arranged on the second punching machine (2). The punching machine has the advantages of being ingenious in structural design because two punching machines are integrated through an automatic conveying device, and therefore the purpose of continuously machining workpieces is achieved, reducing labor intensity, substantially improving production efficiency of product machining, and effectively reducing production cost of labor force.

Owner:舟山神鹰滤清器制造有限公司

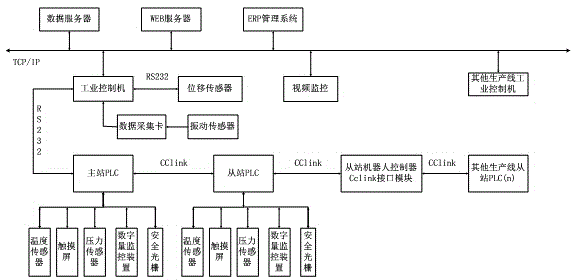

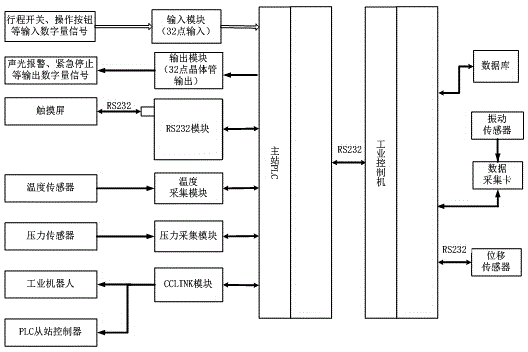

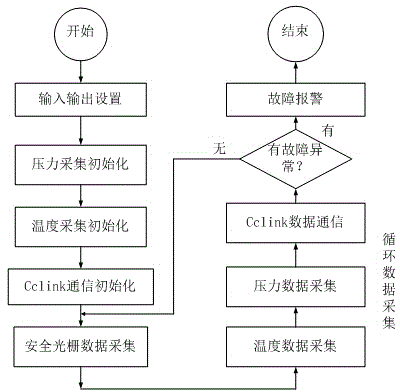

Real-time monitoring system for full-automatic stamping production line

InactiveCN104646565ARealize real-time monitoringAchieve recordShaping safety devicesTotal factory controlCommunication interfaceProduction line

The invention provides a real-time monitoring system for a full-automatic stamping production line. The real-time monitoring system comprises an industrial control machine and a main station PLC for controlling a stamping machine on the stamping production line to work, wherein the signal input end of the main station PLC is connected with a temperature sensor and a pressure sensor which are arranged on the stamping production line and are used for detecting the operation of the stamping machine; the signal output end of the main station PLC is connected with the industrial control machine through a communication interface. Under a high-speed stamping environment, the real-time monitoring system can ensure synchronism and coordination between all units on the production line and a controller to guarantee reliable and safe production of the stamping machine production line. According to the real-time monitoring system, the production efficiency can be improved, and the energy consumption can be reduced.

Owner:GUANGDONG UNIV OF TECH

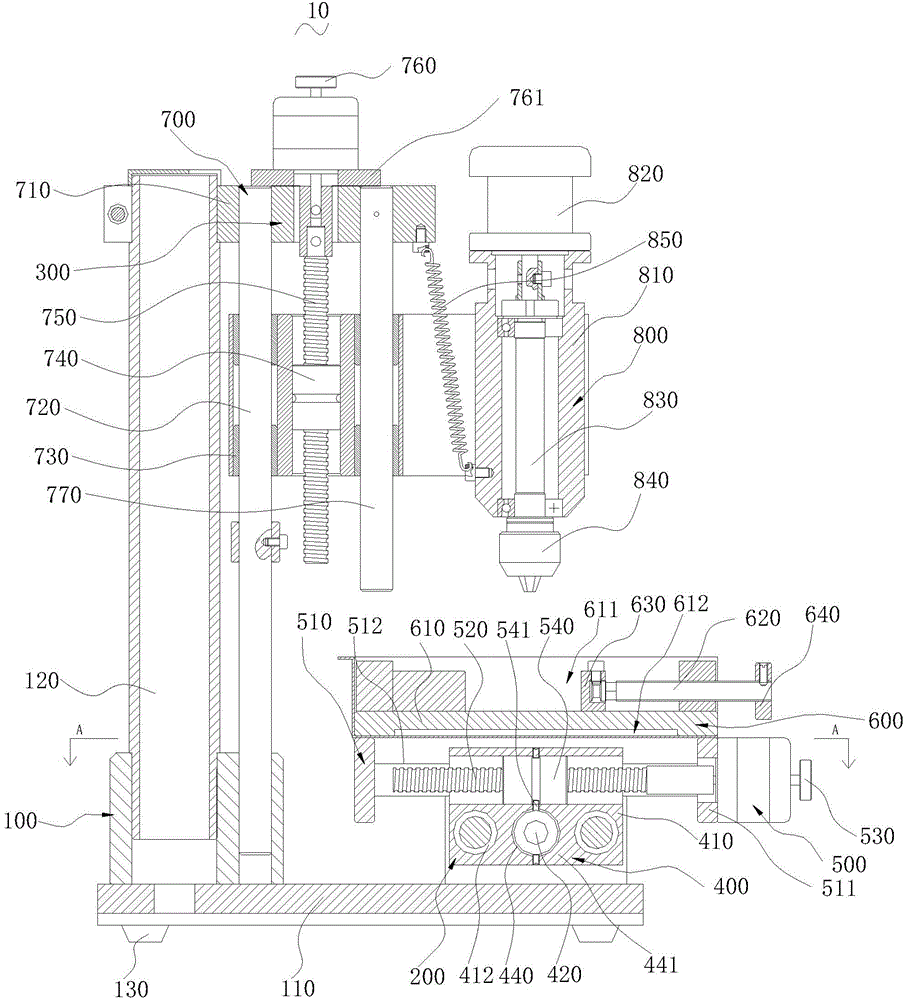

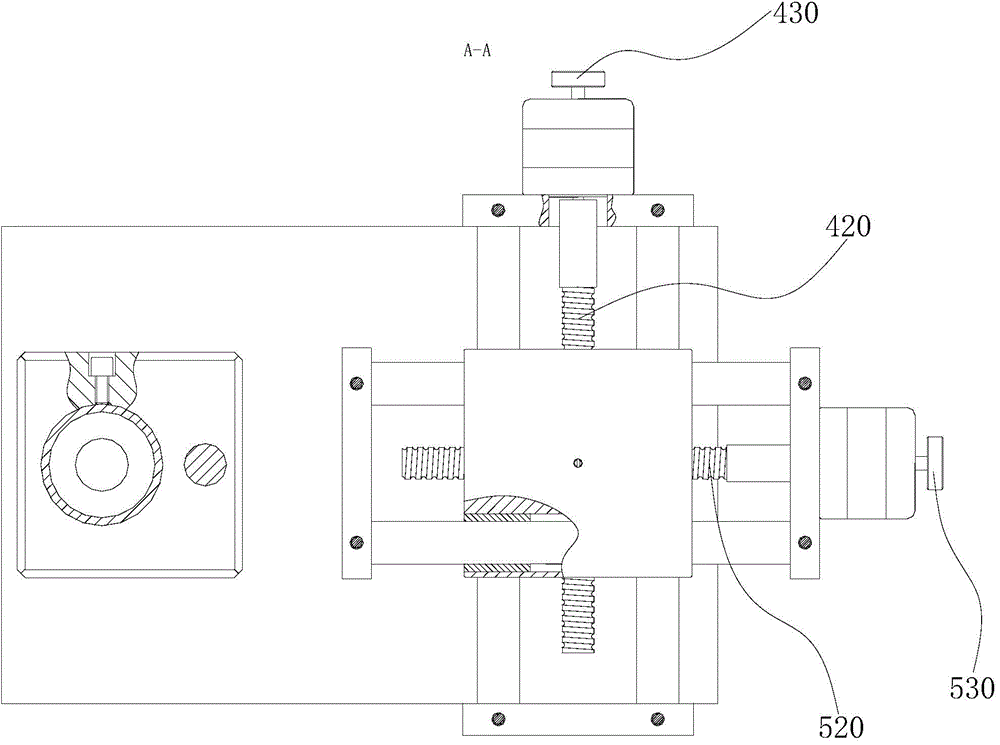

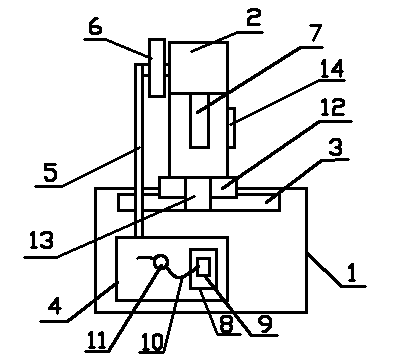

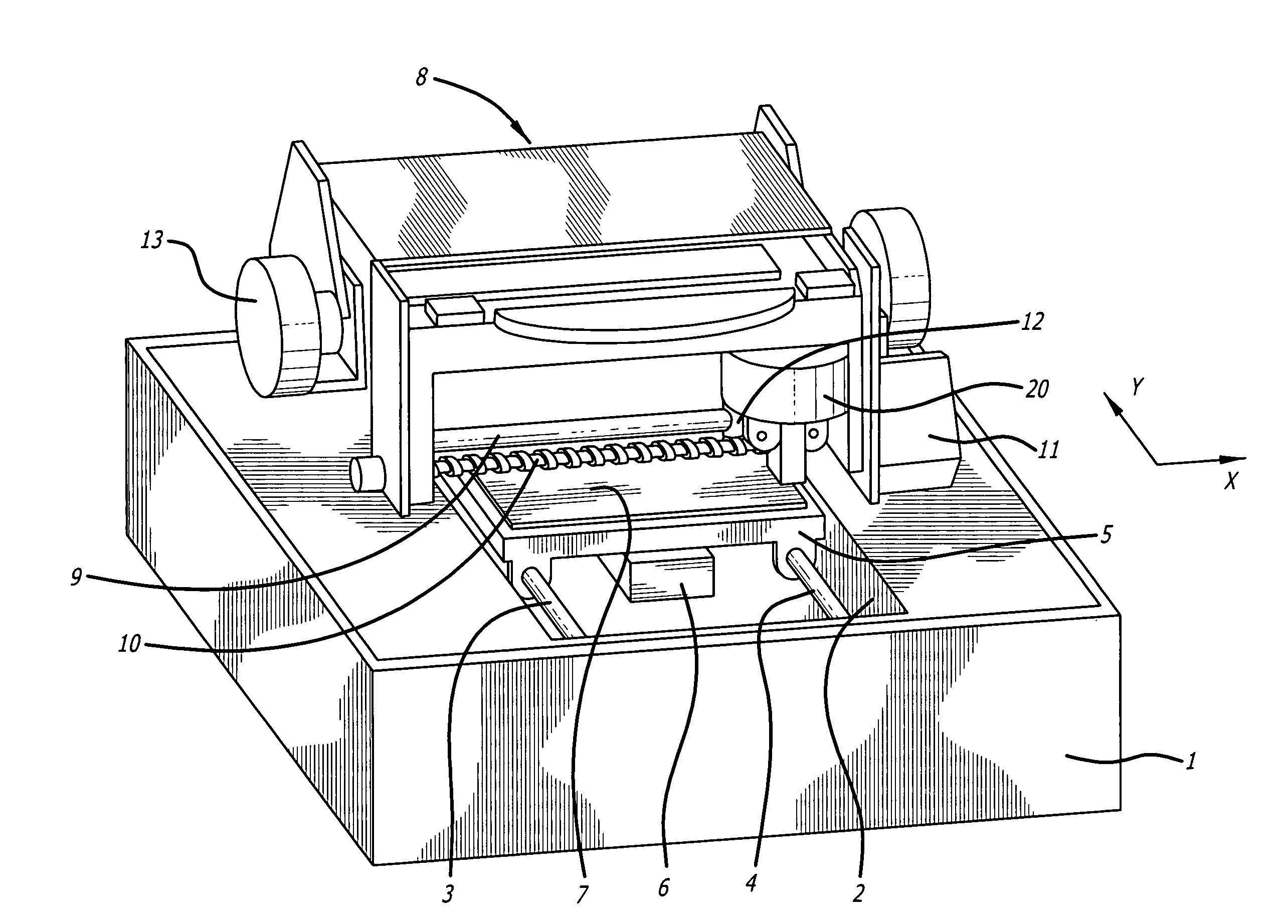

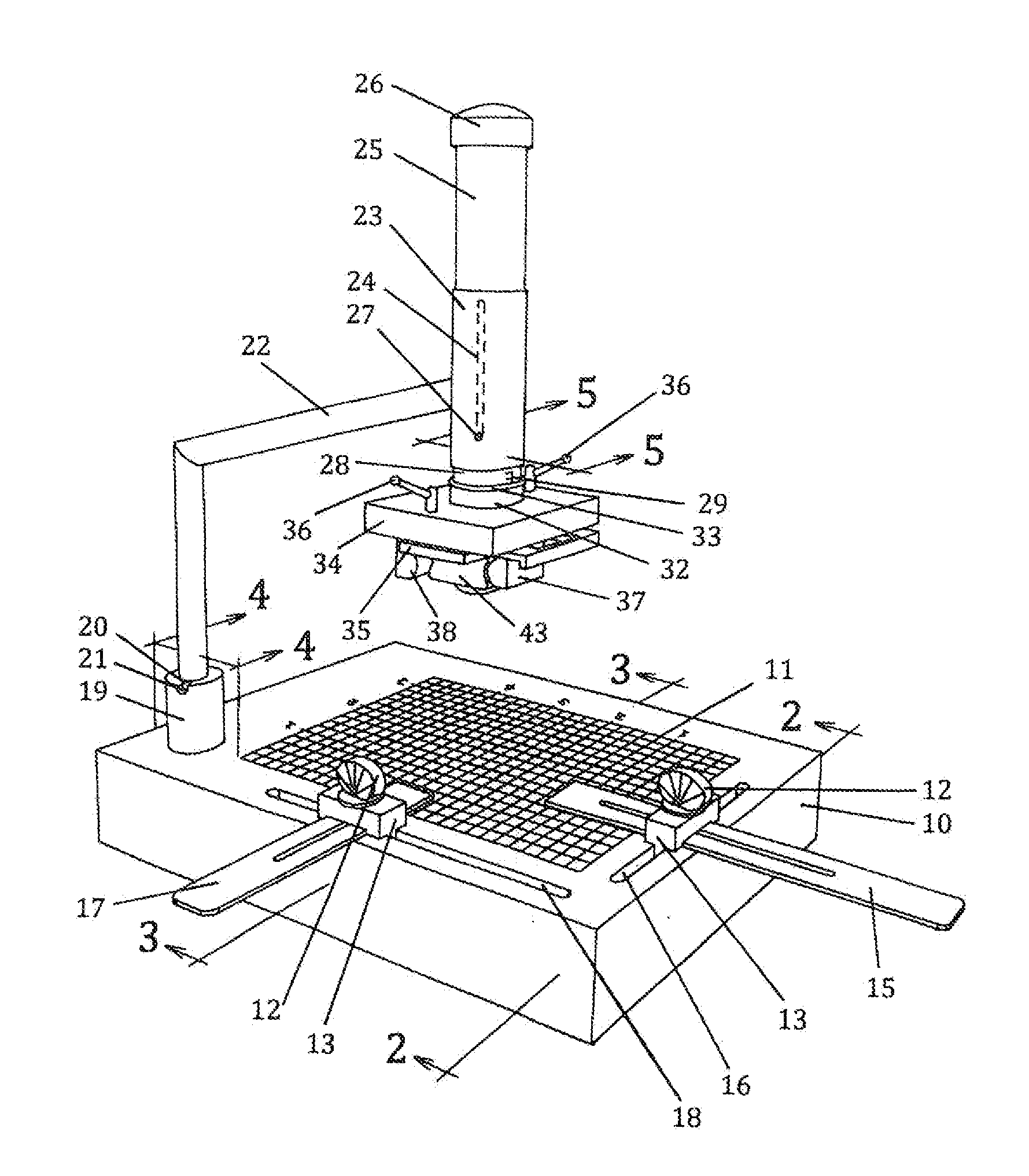

Punching machine

A punching machine comprises a base, a displacement device and a punching device. The displacement device comprises a Y-axis displacement mechanism, an X-axis displacement mechanism and a material placing piece. The Y-axis displacement mechanism comprises a Y-axis support, a Y-axis lead screw, a Y-axis adjusting rotating knob and a Y-axis screwing piece. The X-axis displacement mechanism comprises an X-axis support, an X-axis lead screw, an X-axis adjusting rotating knob and an X-axis screwing piece. The punching device comprises a Z-axis displacement mechanism and a punching mechanism connected with the Z-axis displacement mechanism. The Z-axis displacement mechanism comprises a Z-axis support, a Z-axis guiding column, a Z-axis lifting table, a Z-axis screwing piece, a Z-axis lead screw and a Z-axis adjusting rotating knob. The punching mechanism comprises a punching shaft sleeve, a punching air cylinder, a punching shaft and a punching head. According to the punching machine, by matching of the Y-axis displacement mechanism, the X-axis displacement mechanism and the Z-axis displacement mechanism, the punching mechanism can be driven to move in three freedom degrees, and accordingly a plurality of punching holes which are distributed irregularly can be punched by the punching machine.

Owner:河北林腾电力设备有限公司

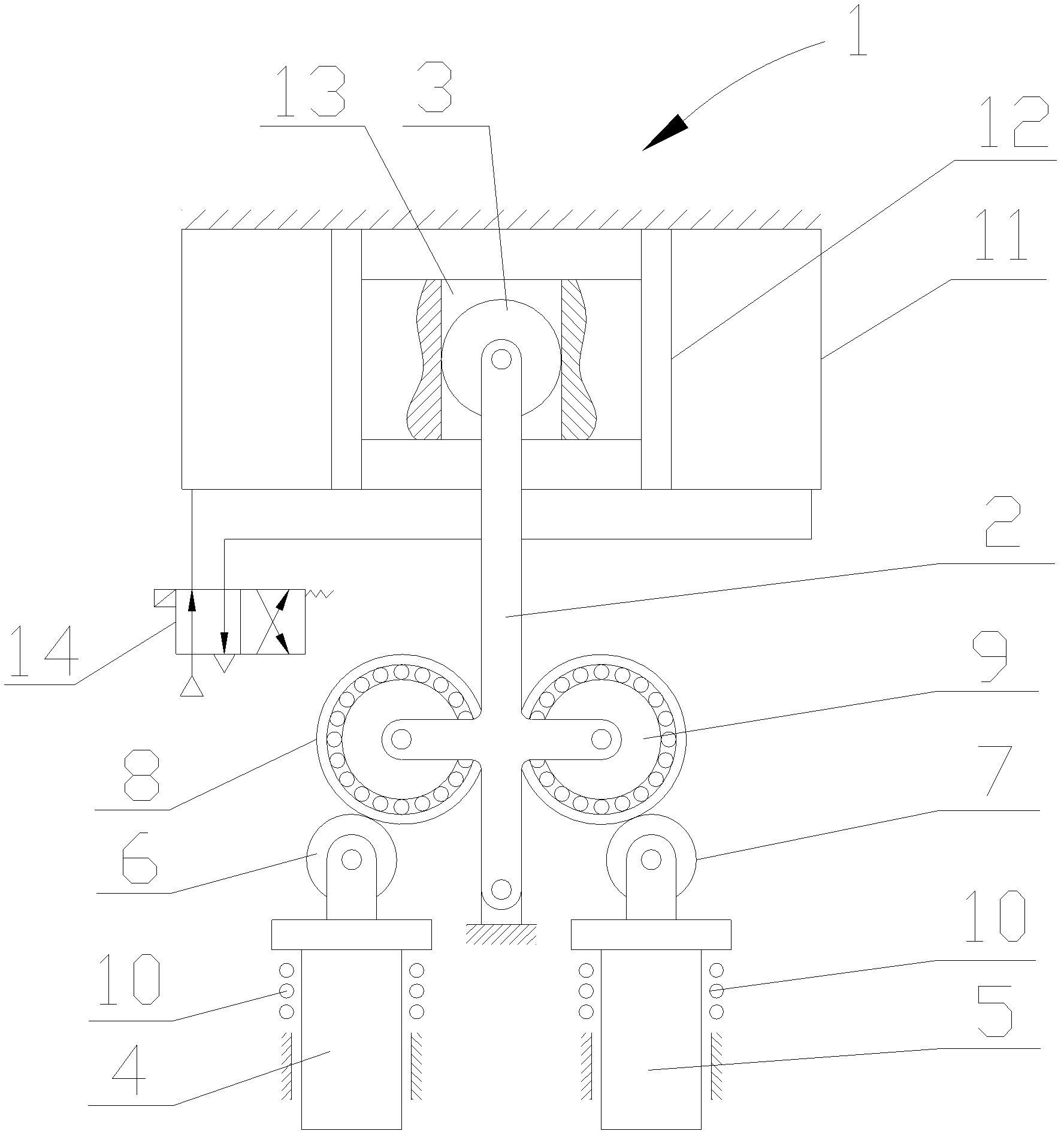

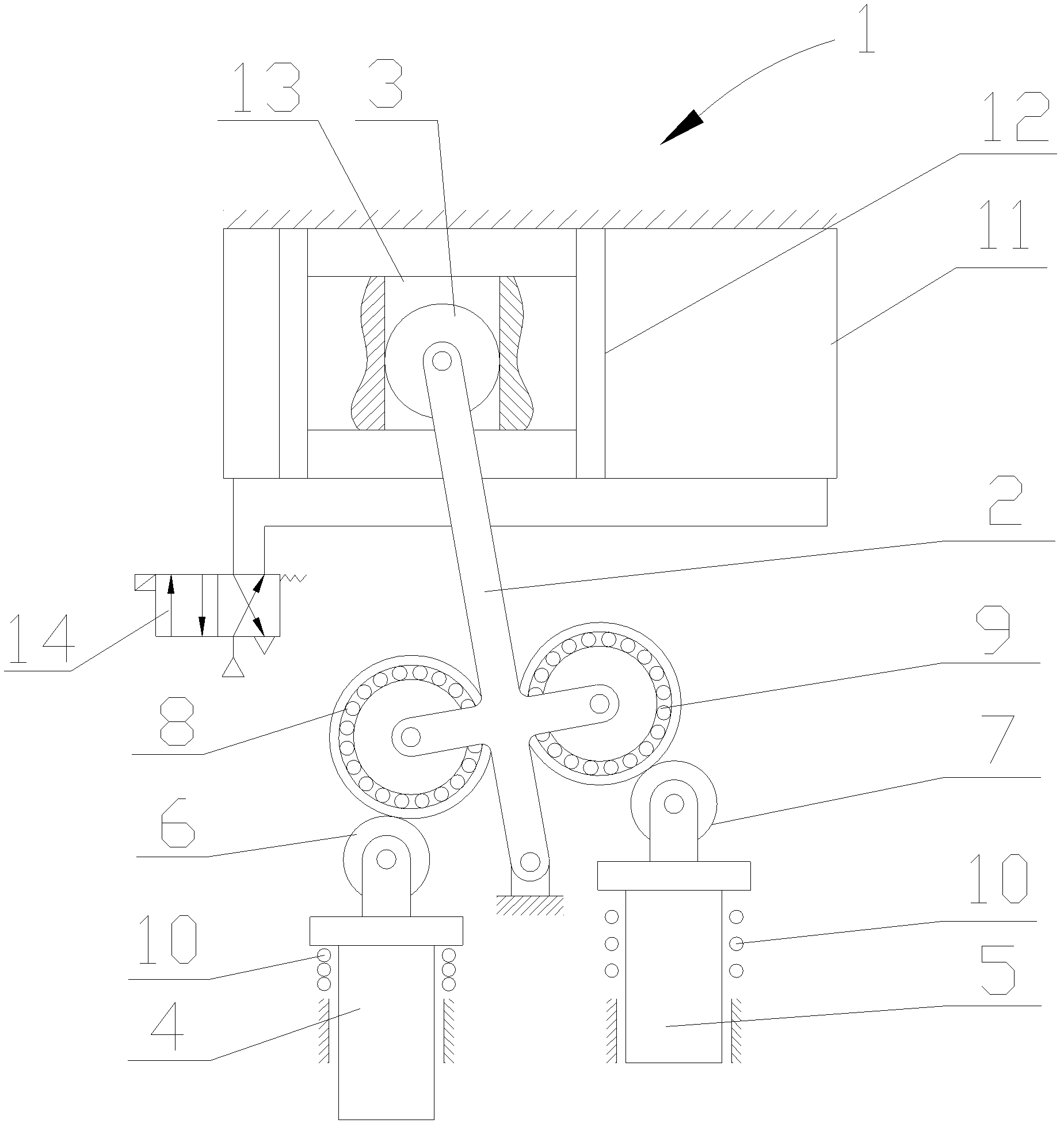

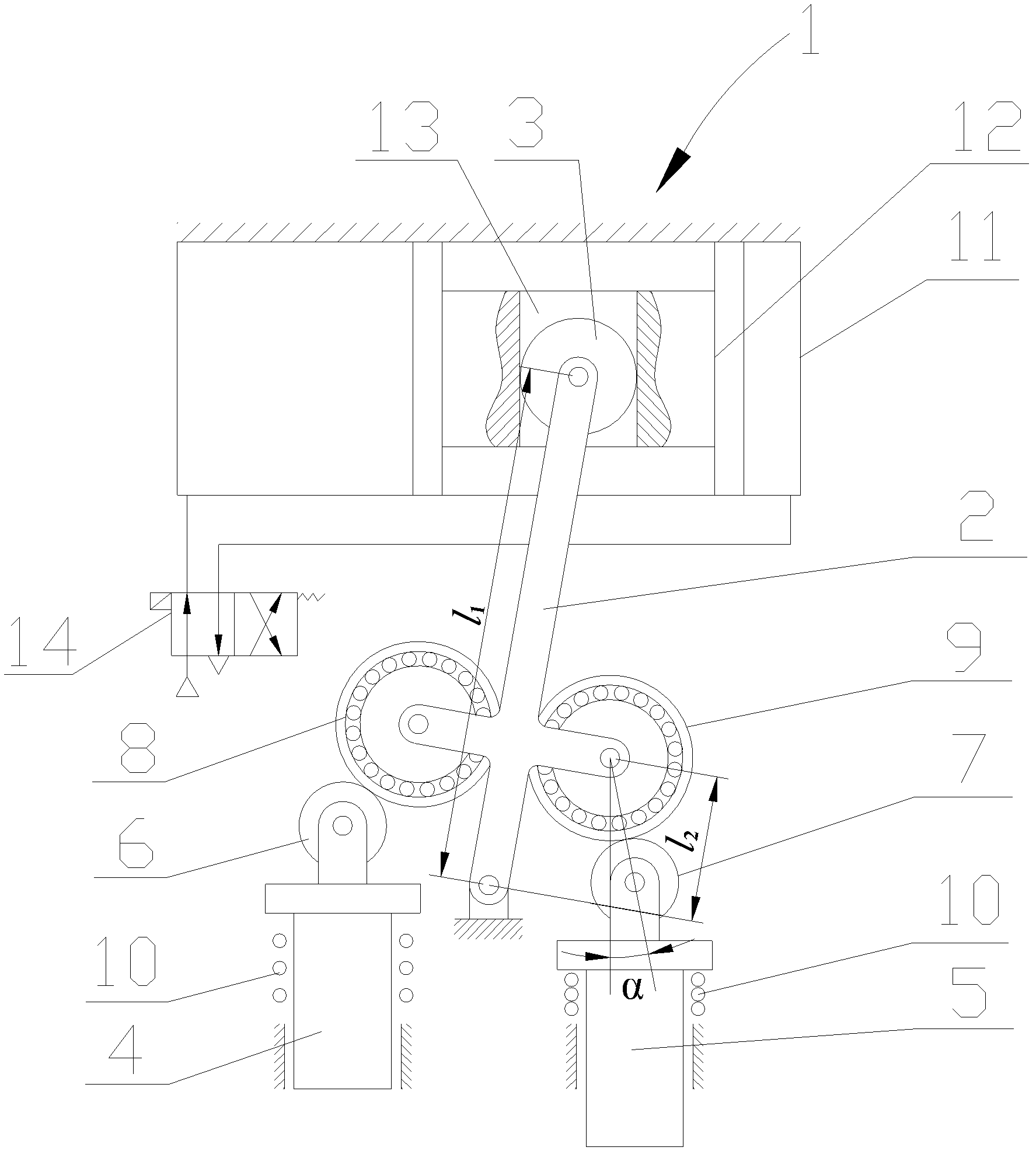

Dual-station pneumatic stamping machine

The invention discloses a dual-station pneumatic stamping machine, which is provided with a double-acting cylinder serving as a power source. A lever capable of swinging along with movement of a piston of the double-acting cylinder is disposed on a frame, and a roller which is capable of matching with upper rollers on stamping heads in transmission is disposed on the lever. When the double-acting cylinder is in operation, the piston continuously moves side by side inside a cylinder barrel, so that the first stamping head on the left of the lever and the second stamping head on the right of the lever are alternately operated in stamping. Idle stroke is absent in operation of the dual-station pneumatic stamping machine, stamping output force is approximately as large as acting force outputted by a piston rod of a medium-pressure hydraulic transmission system, the stamping efficiency is high, and the energy utilization rate is high. In addition, the dual-station pneumatic stamping machine is simple and compact in structure, convenient in operation and highly economical. Pneumatic transmission is used as the power source, so that operation of the machine is pollution-free, and the dual-station pneumatic stamping machine is widely applicable to stamping.

Owner:SUZHOU UNIV

Rotary, continuous and automatic feeding mechanism of punching machine

ActiveCN105710246ASimple and reliable controlSimplify organizationMetal-working feeding devicesMetal working apparatusPunchingEngineering

The invention discloses a rotary, continuous and automatic feeding mechanism of a punching machine. The feeding mechanism comprises a frame, a loading mechanism, a taking mechanism, a punching machine and a main controller, and is characterized by further comprising a detecting disc and a blank detection positioning mechanism; the loading mechanism, the taking mechanism and the detecting disc are all fixed on the frame; the loading mechanism, the detecting disc and the punching machine are fixed around the taking mechanism at intervals in sequence in the clockwise direction; and the distances of the loading mechanism, the detecting disc and the punching machine from the taking mechanism are equal. The mechanism performs two times of positioning for blanks to be machined through a positioning block above the loading mechanism and a mold cover out of a mold so as to guarantee precise placement of the blanks in a machining position, and prevents the mold damage caused by once sucking of multiple blanks by the taking mechanism through the detecting number of the detecting disc. In addition, when the blanks are put in the mold, a photoelectric detector on the punching machine can detect if the blanks are placed precisely, so that such problems as mold damage and punching safety are further guaranteed.

Owner:ZHEJIANG UNIV OF TECH

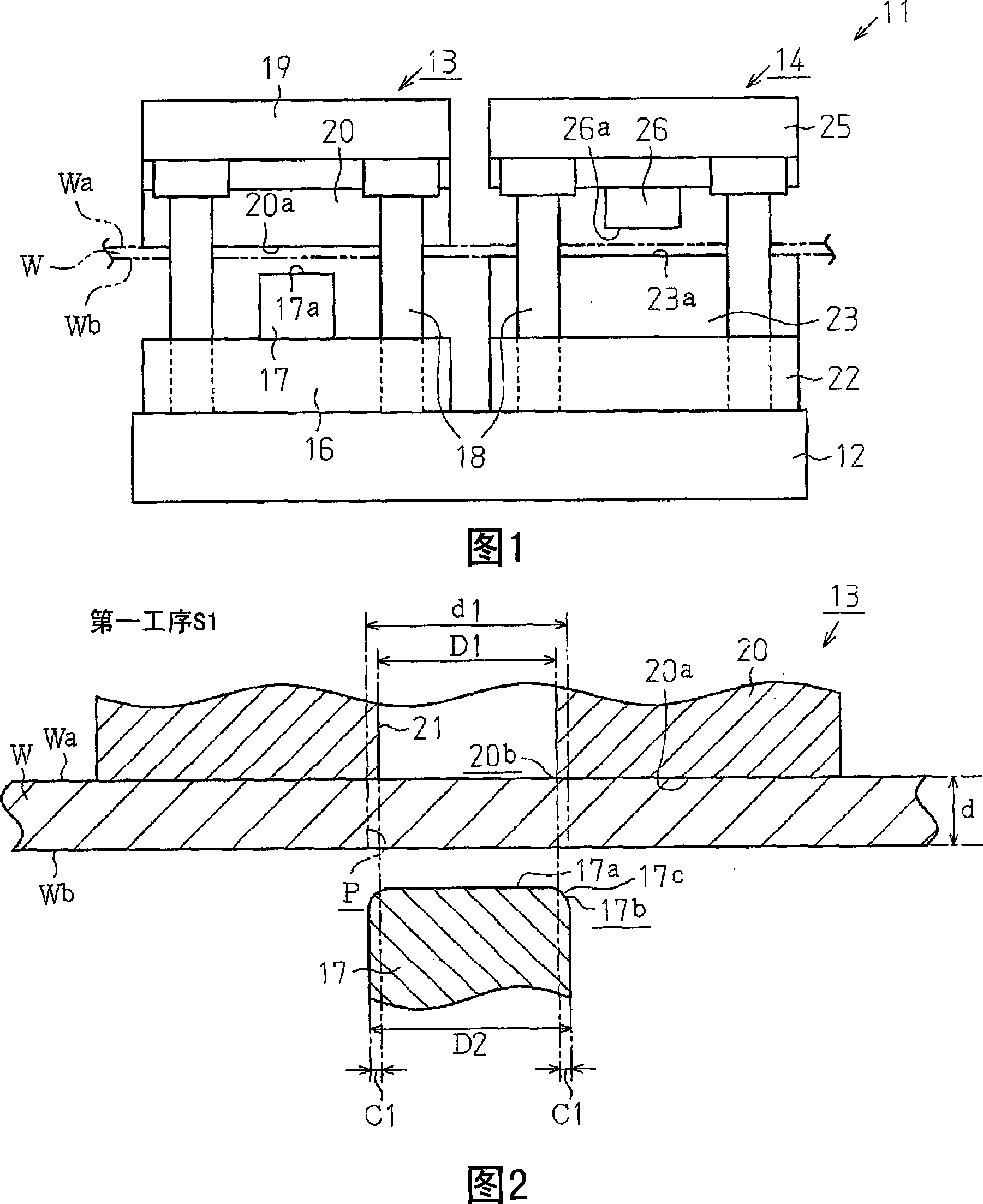

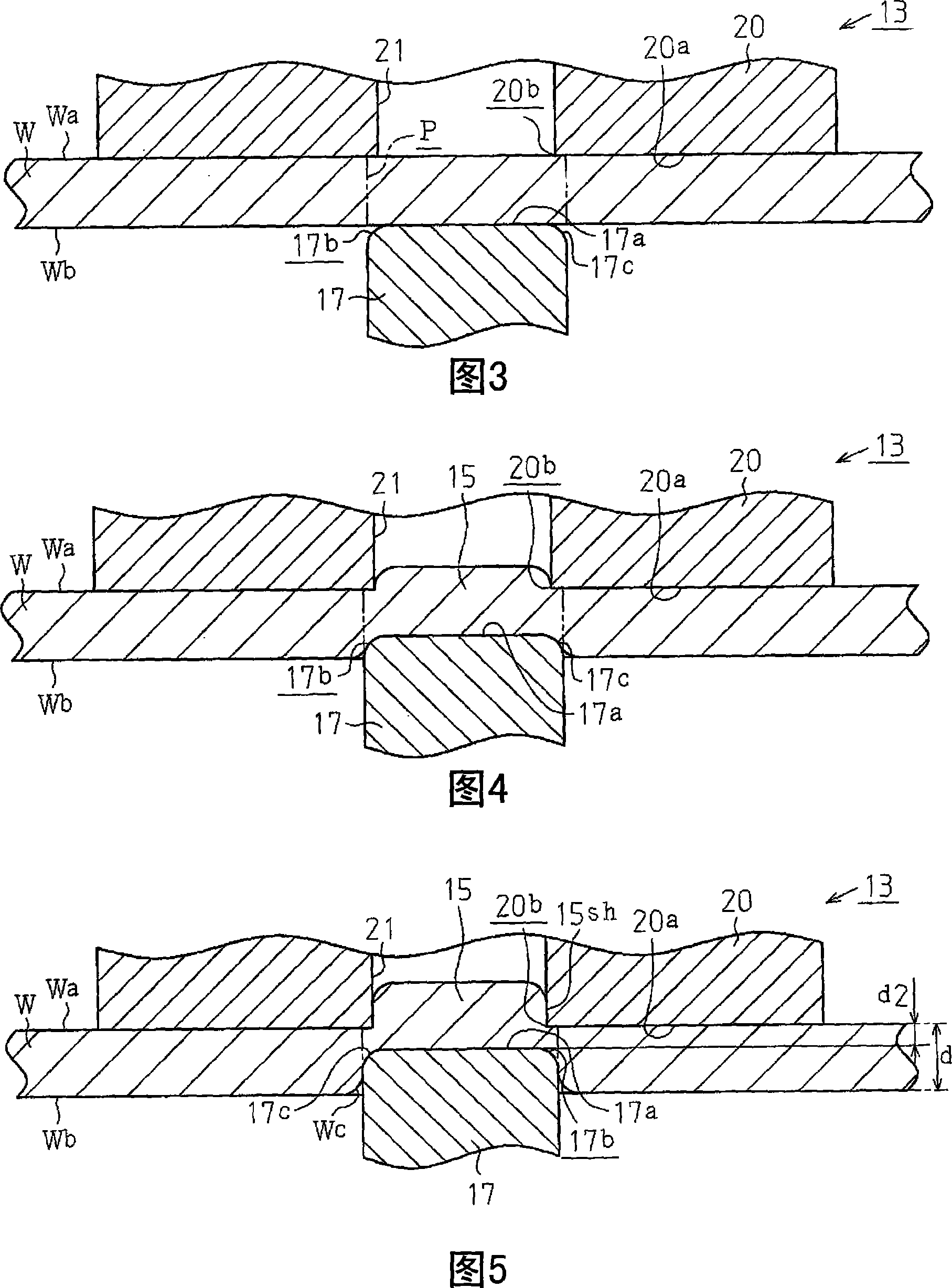

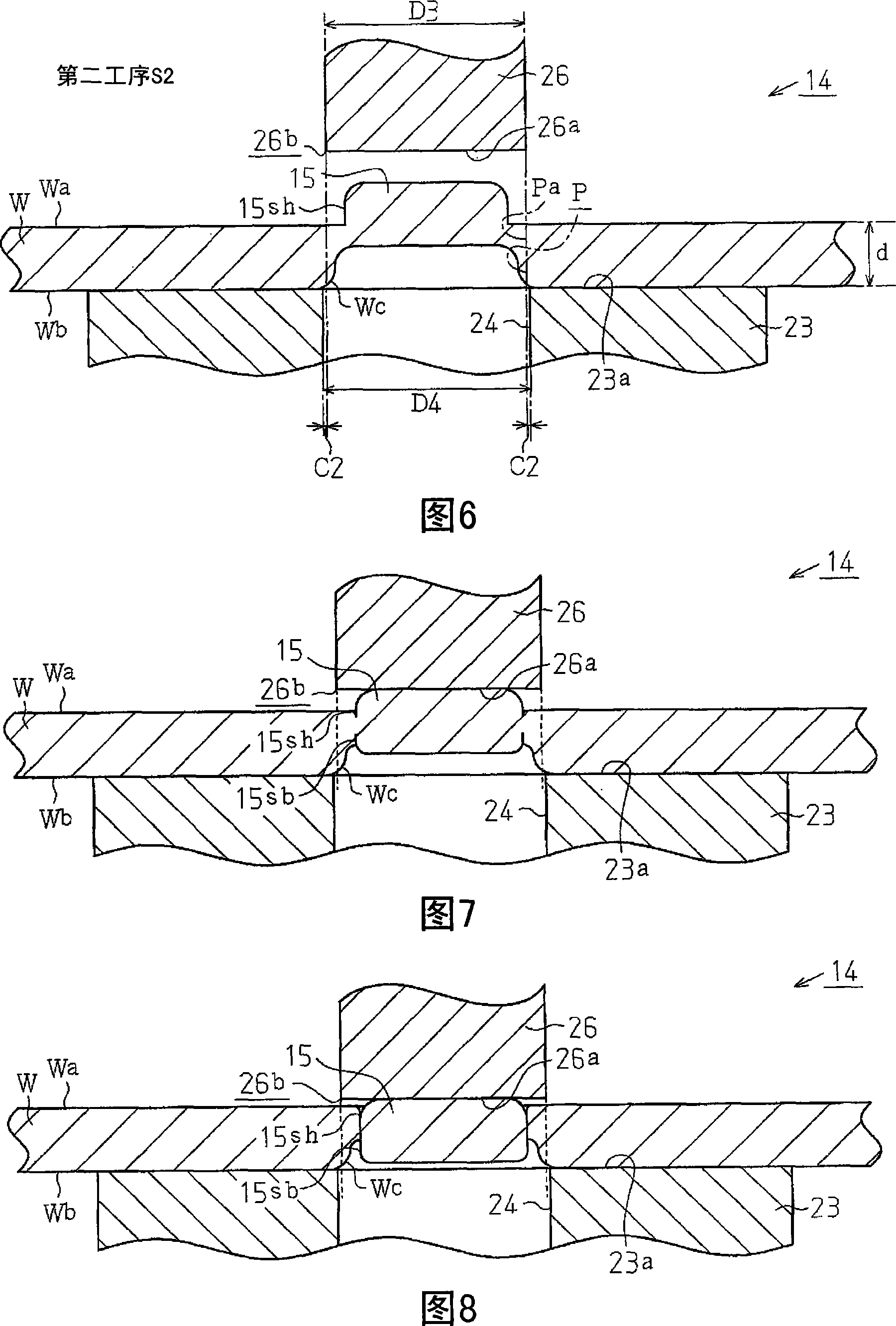

Pressing mechine, pressing method, and punched article

A pressing machine, a pressing method and a punched article in which the punching surface along the punching direction can be formed like a sheared surface at a part where a body to be punched is punched while suppressing increase in size of the machine itself and in the number of punching steps, and generation of burrs in a plate material can be suppressed. The press is provided with a first press unit (13) and a second press unit (14) wherein the first press unit (13) performs a first step for forming a protruding half die cutting portion (15) at a part of the plate material W where a through hole P is formed. The second press unit (14) performs a second step (S2) for punching the half die cutting portion (15) from the plate material W by means of a second punch (26) and a second die (23). When the body to be punched is punched from the plate material W in the second step (S2), side wall face Pa at a part of the plate material W where the body to be punched is punched is subjected to shaving.

Owner:AISIN AW CO LTD

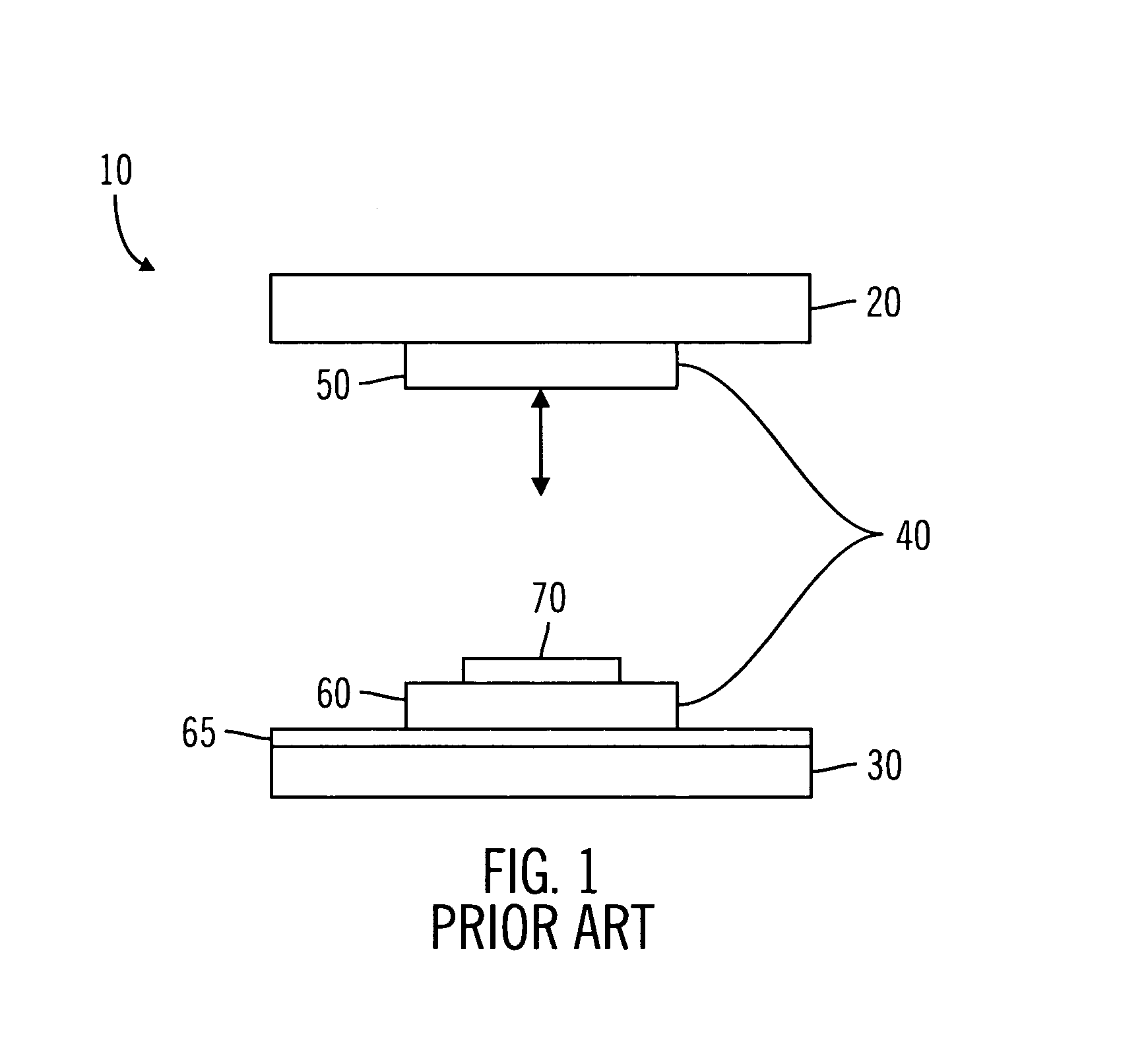

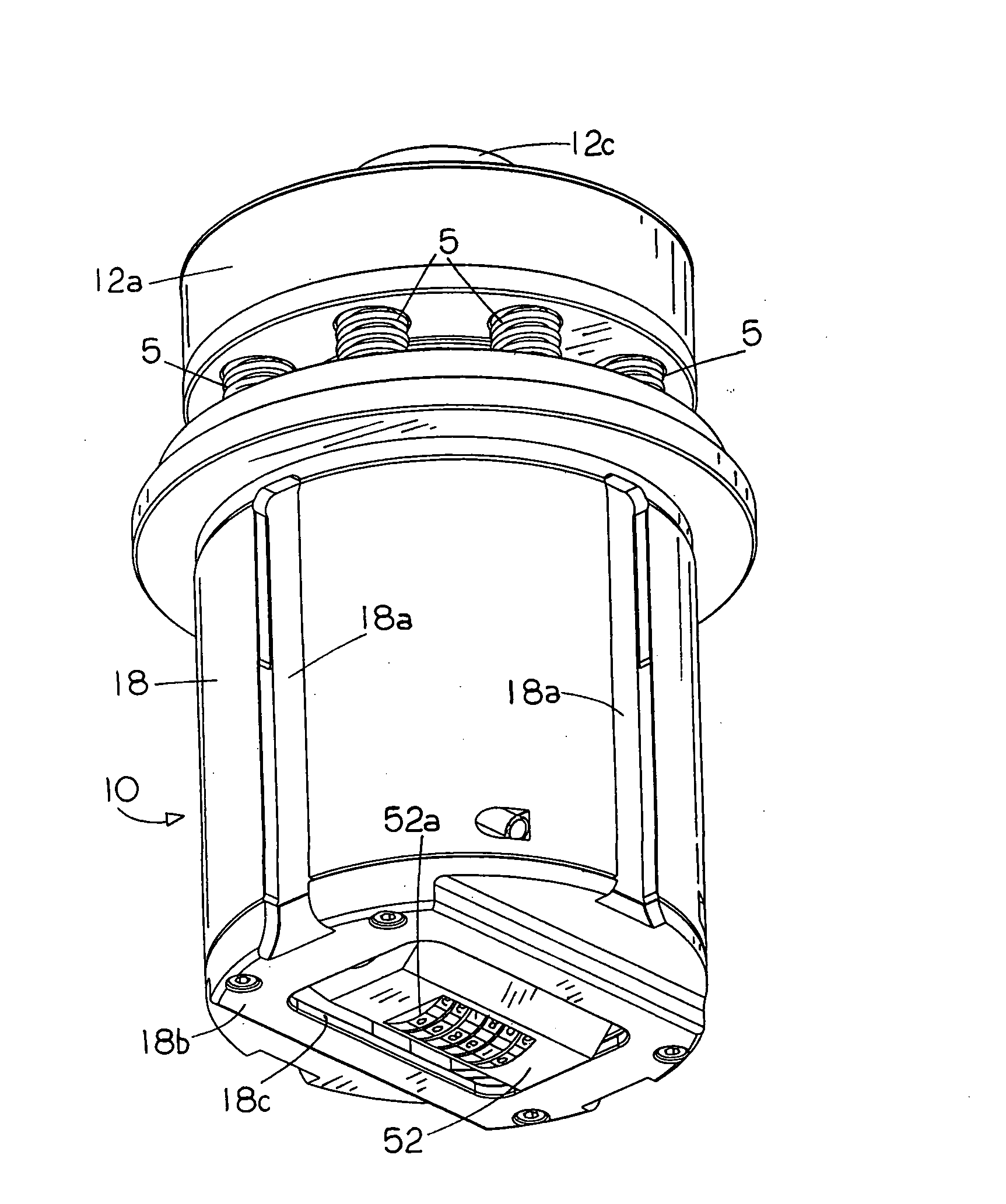

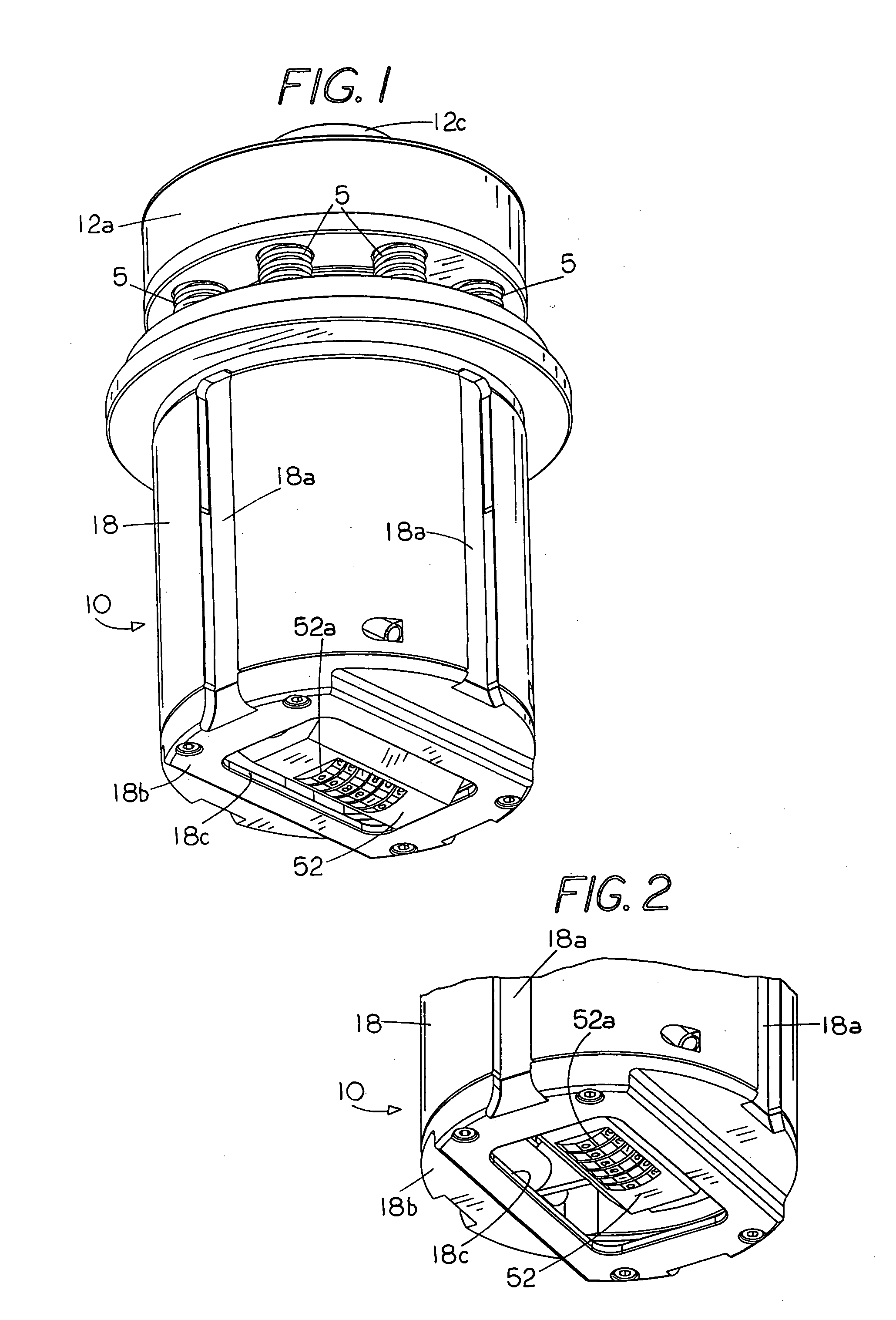

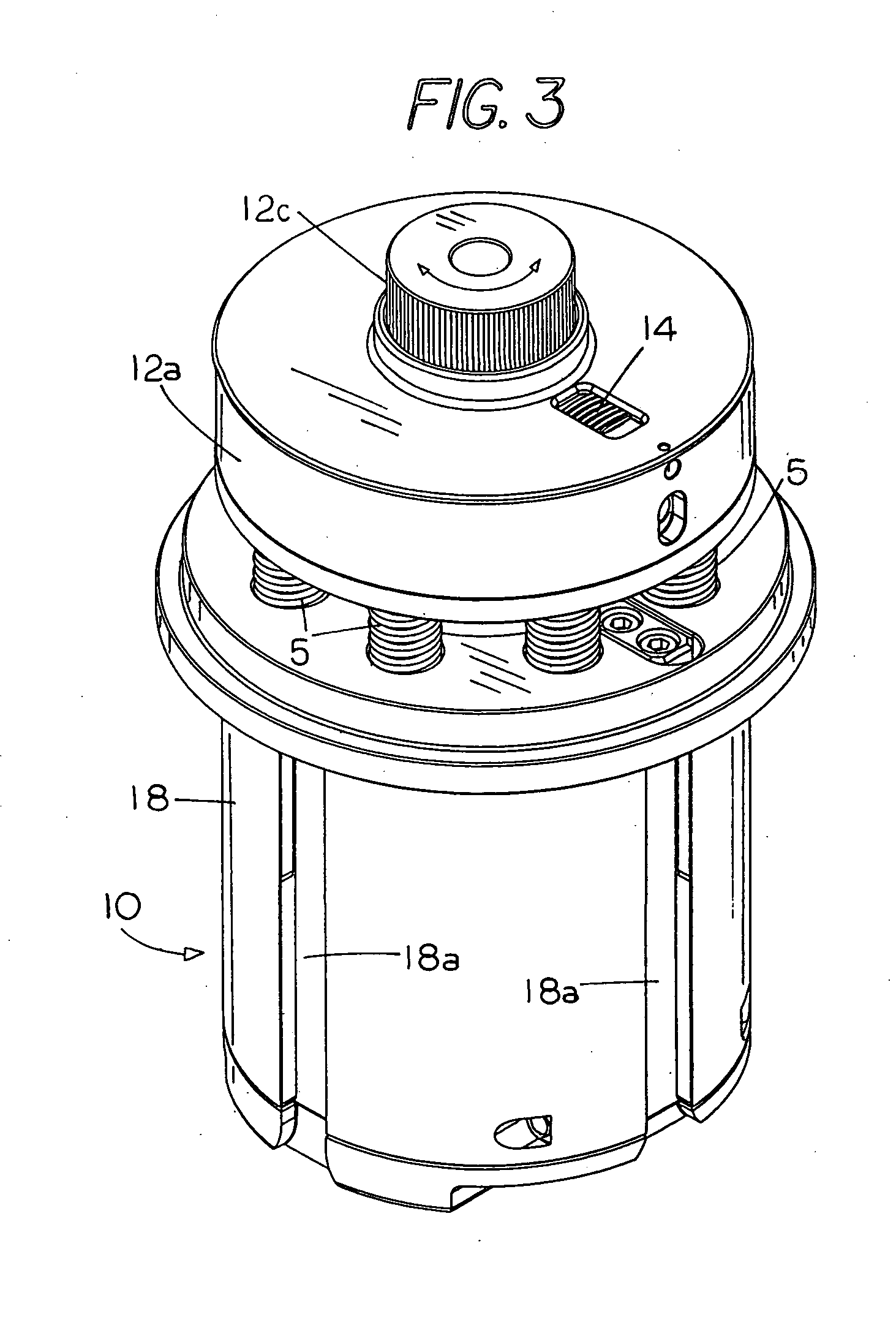

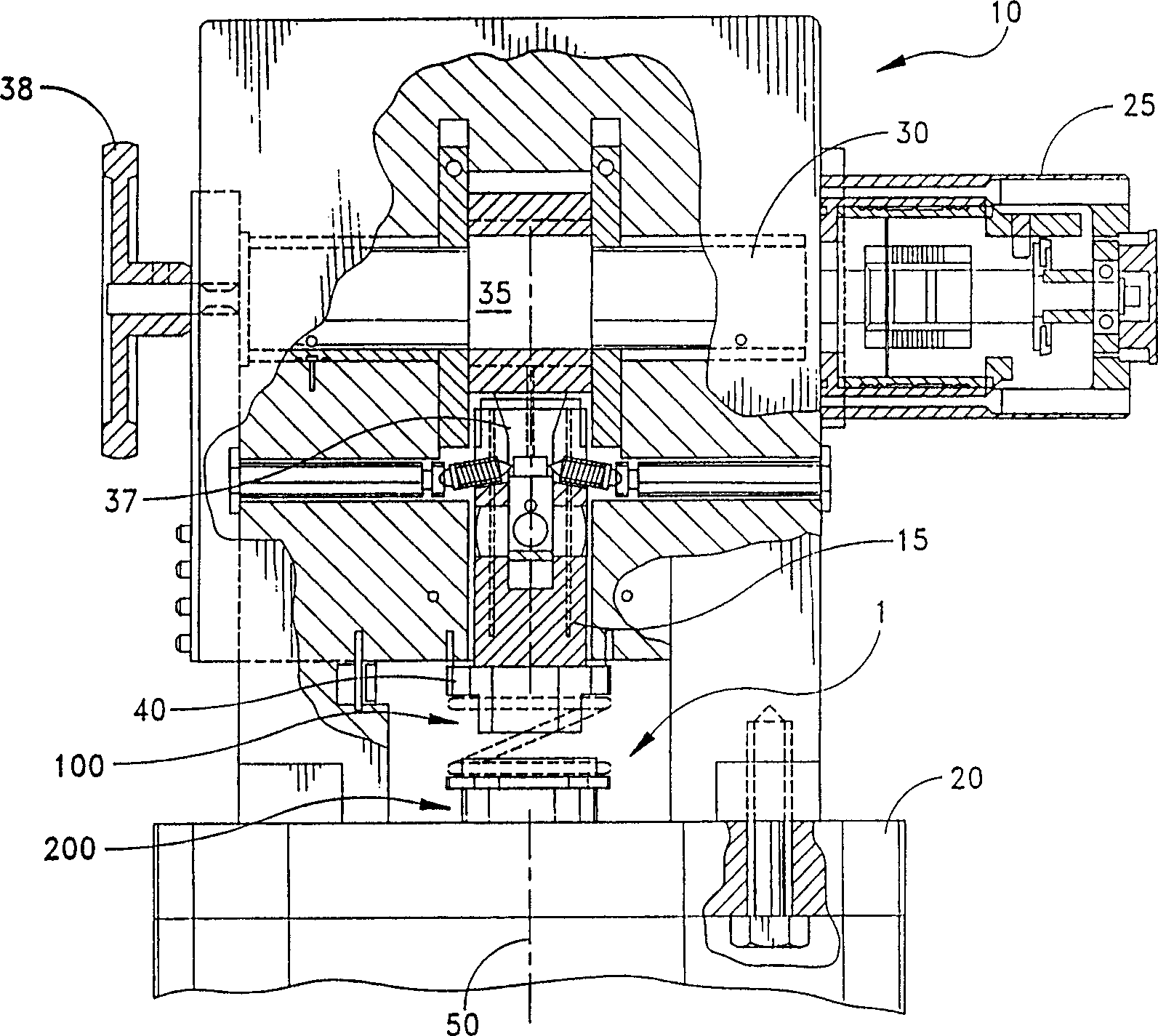

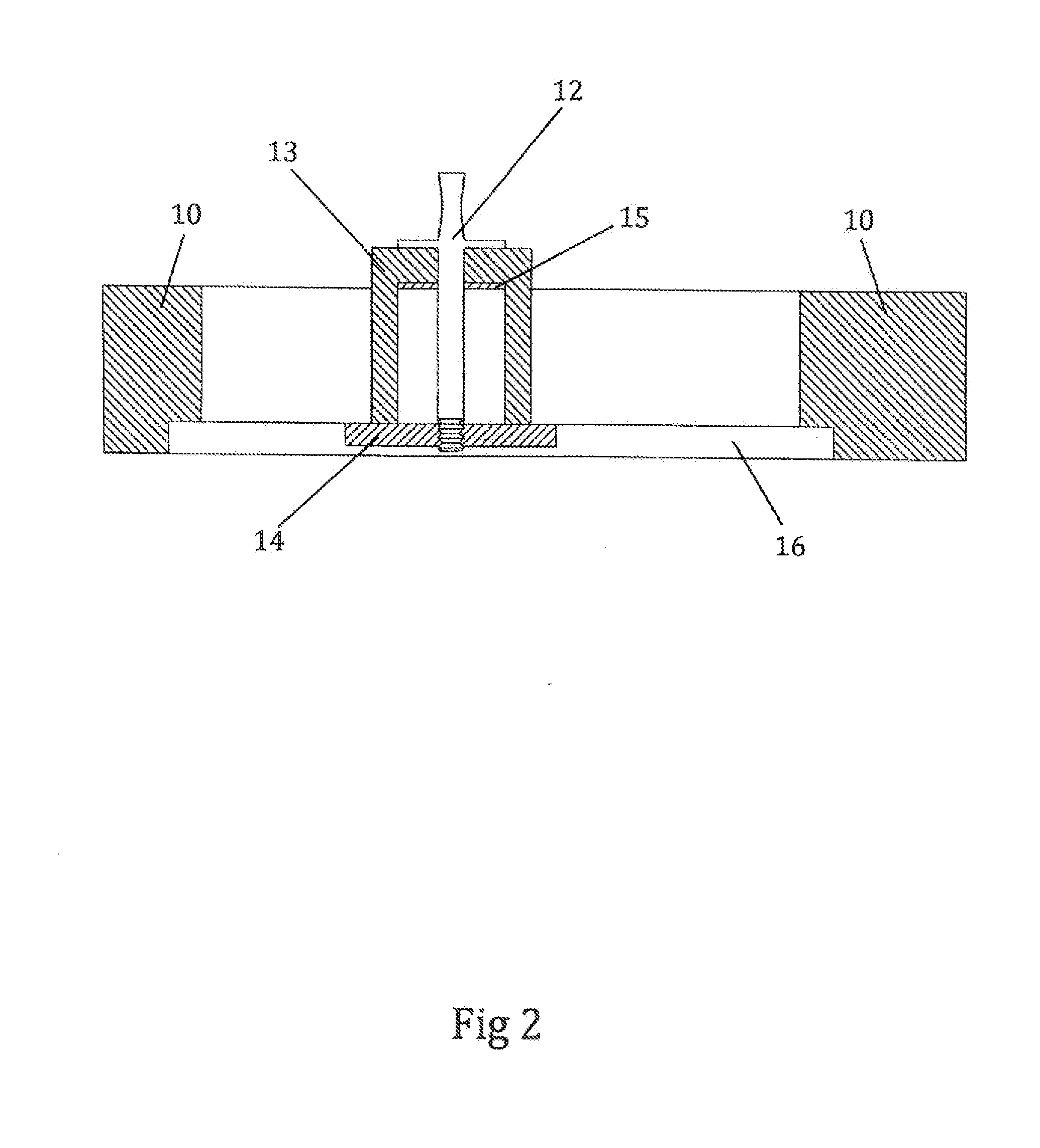

Self-guiding punch and die set

A punch and die set is provided for use in a stamping press having a punch assembly and a die assembly reciprocated by a driving mechanism. The punch and die assemblies are aligned to a common center and are structured to slidably engage one another for positive guidance of the punch and die tools without the need for other guidance by shafts, bars or the like. One of the punch assembly and die assembly can be non-fixedly carried by the drive mechanism, allowing the guidance of the engaged punch and die assemblies to define the relative positions of the tools. This arrangement eliminates any stack-up of tolerances between the assemblies and substantially reduces misalignment during stamping, including any misalignment that may be introduced by the press driving mechanism.

Owner:HUMDINGER

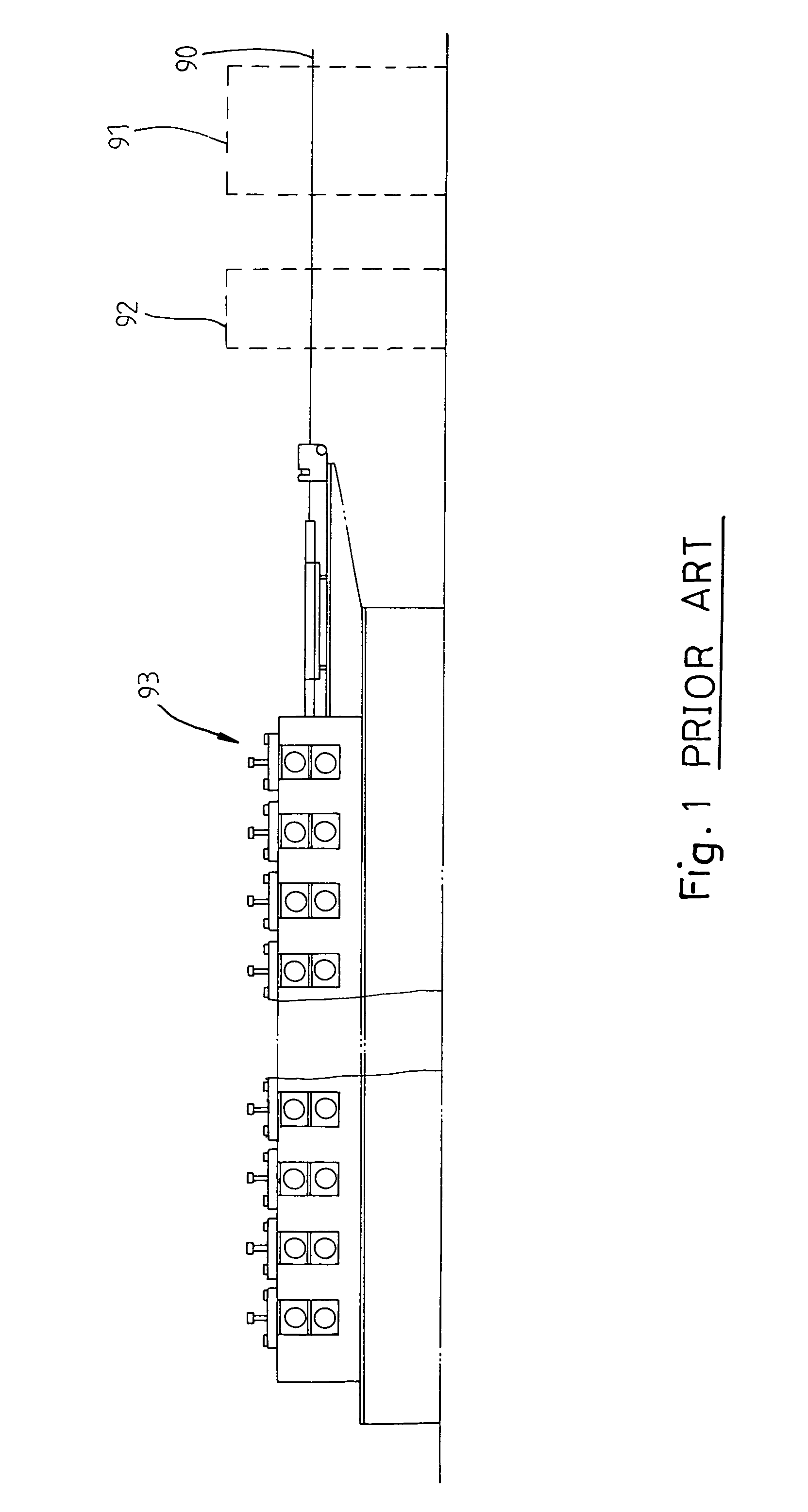

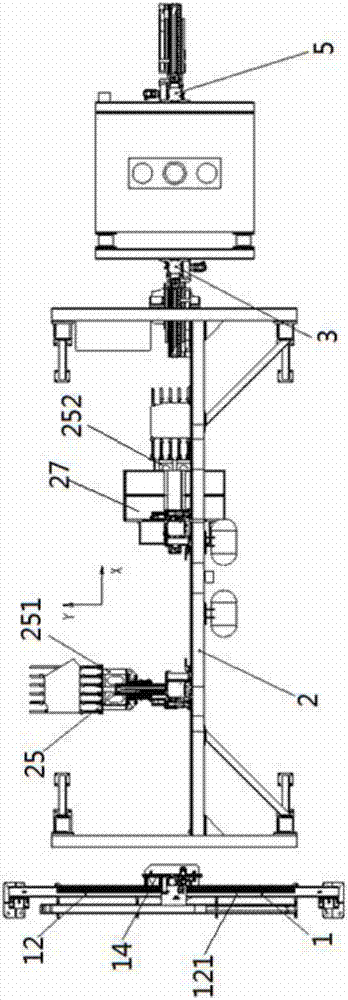

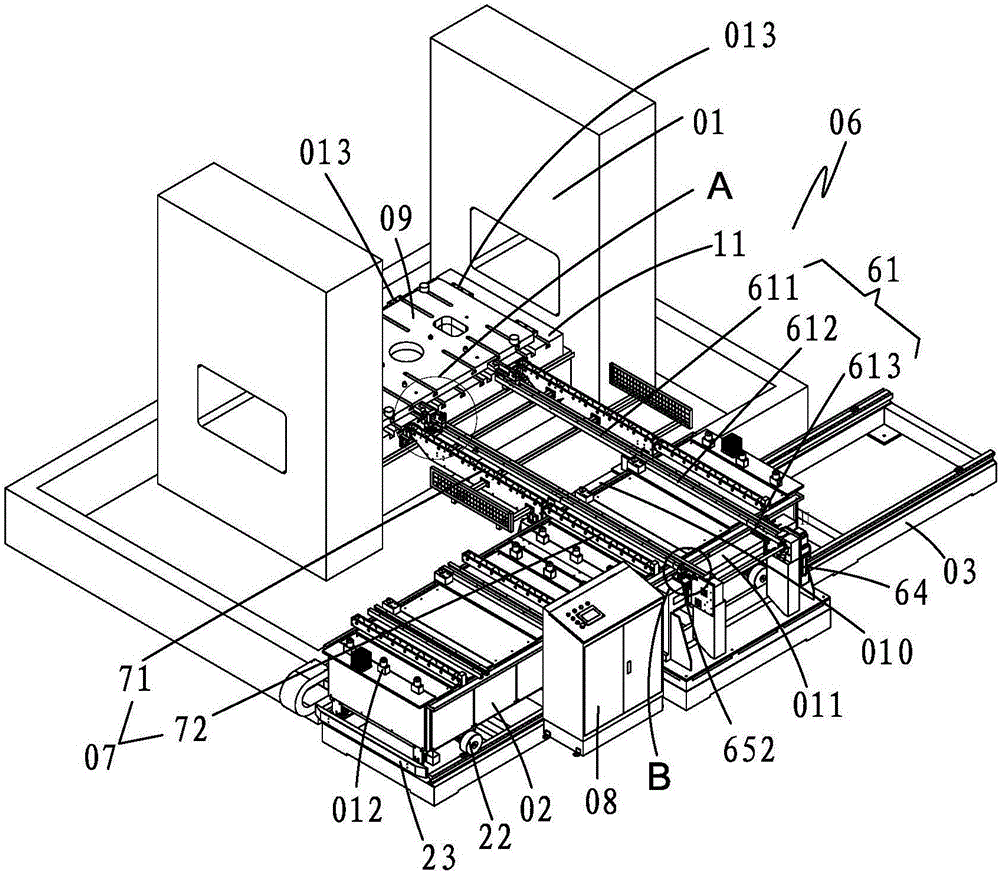

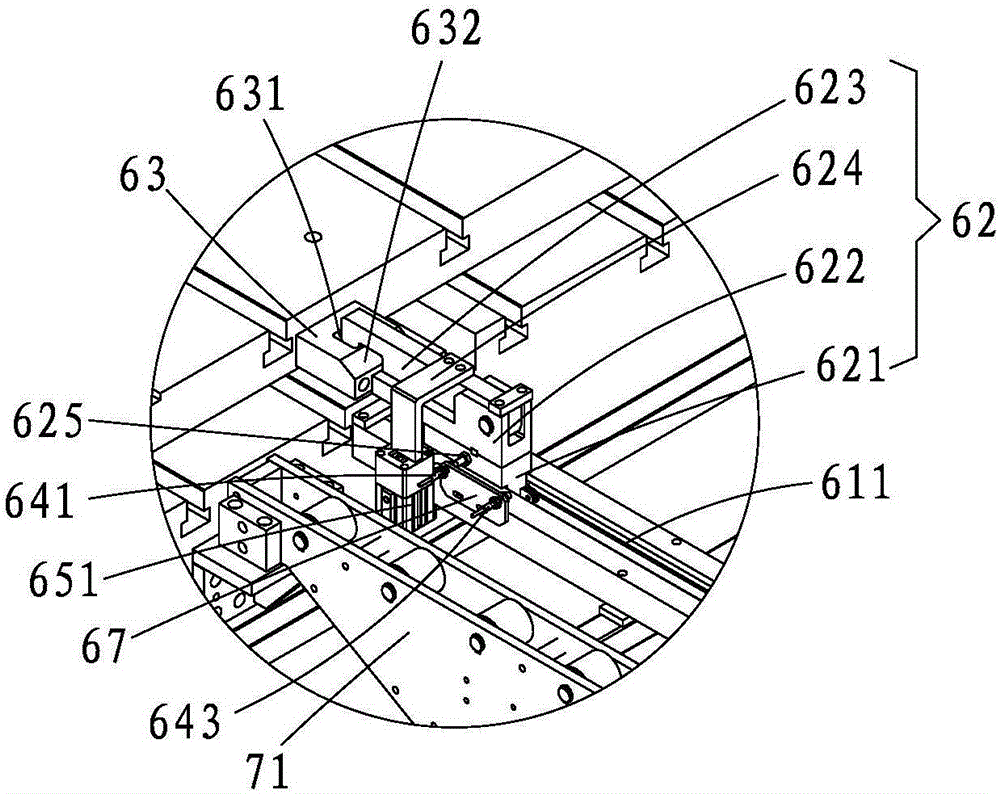

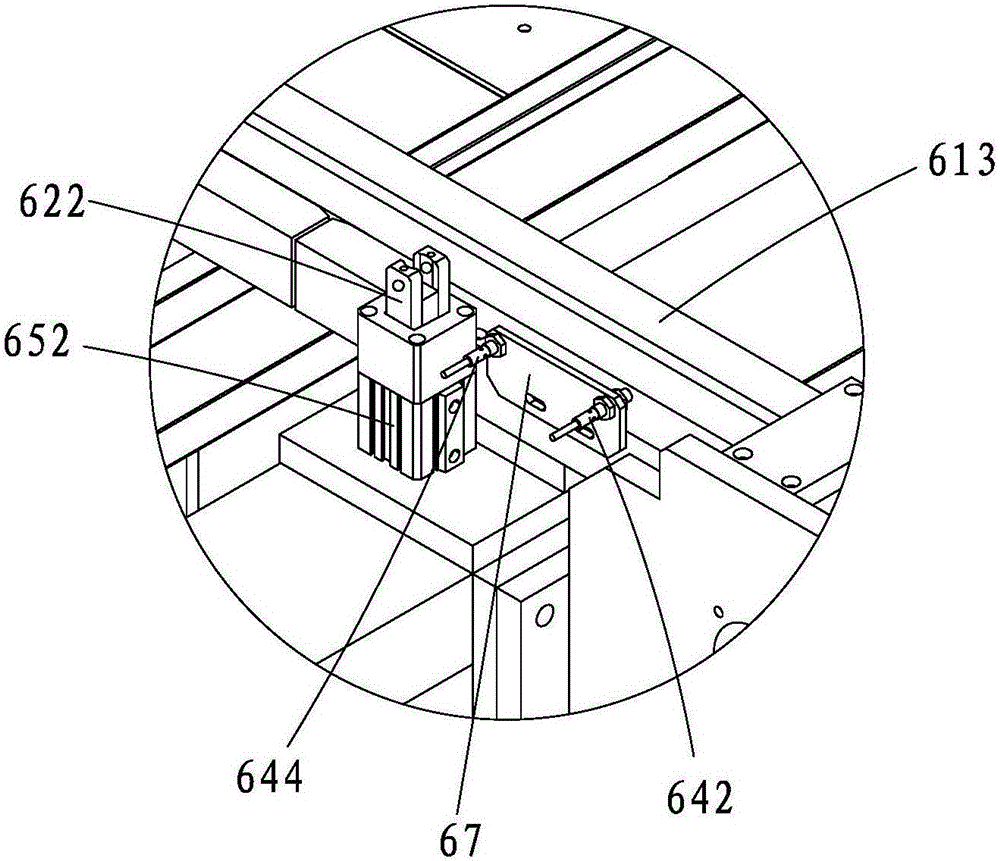

Automated hot-stamping production line

ActiveCN103920780ALow costGuaranteed uptimeMetal-working feeding devicesPositioning devicesProduction lineHot stamping

The invention discloses an automated hot-stamping production line. An unstacking device is arranged on the production line and used for being docked with a heating feeding manipulator in a heating furnace feeding and discharging device after metal plates are separated, transferring the plates onto the heating furnace feeding manipulator and supporting the plates into a heating furnace, a heating furnace discharging manipulator in the heating furnace feeding and discharging device is docked with a press feeding manipulator in a press feeding device after supporting high-temperature plates out of the heating furnace and transfers the high-temperature plates onto a stamping machine to realize forming of the high-temperature plates through stamping, and finally the high-temperature plates are picked out by a press discharging manipulator in a press discharging mechanical device, so that the automated hot-stamping production line is reliable and stable in performance and high in production efficiency.

Owner:SHENYANG ZHONGTUO ROBOT EQUIP

Punch press

The invention discloses a punch press which comprises a base, a stand column and a working platform, wherein the stand column is arranged on the base, the working platform is arranged on the base, a hydraulic power device is arranged in the base, the hydraulic power device is externally connected with an articulated juncture mechanism, the top of the stand column is provided with a flywheel mechanism, one end of the articulated juncture mechanism is connected to the flywheel mechanism on the stand column, and the lower end of the flywheel mechanism is connected with a punching device; oil is transported to the flywheel mechanism through an oil pipe and a hydraulic cylinder so as to make power; and the adjustment on oil amount can be realized through a flow valve, and in the process of punching, a lighting device can achieve a lighting effect on the working platform, thereby ensuring the safety in the process of punching operation.

Owner:苏州天盛电线电缆有限公司

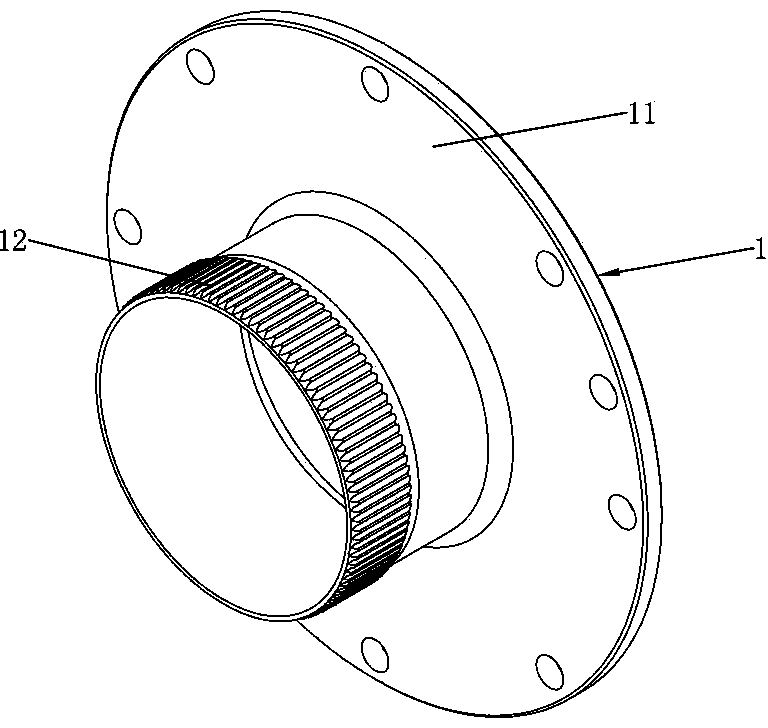

Method for processing harmonic reducer flexible wheel

The invention discloses a method for processing a harmonic reducer flexible wheel. The method sequentially includes processes of blanking, forging and shaping, normalizing for heat treating, spinning, turning in a CNC (computer numerical control) lathe, gear-shaping in a CNC milling machine and punching and shaping. The process of punching and shaping is performed through matching of a punching machine and a punching and shaping die, an upper die base, an upper padding plate, an upper fixing plate, a lower die base, a lower padding plate, a lower fixing plate, an upper shaping die, a positioning column, a pressing plate, a tightening ring, a tightening-ring pressing plate and a locking screw are arranged on the punching and shaping die, and an inner shaping gear hole is formed in a core portion of the upper shaping die. The pressing plate clamps and fixes a fixed portion of the semi-finished flexible wheel, the positioning column, the tightening ring, the tightening-ring pressing plate and the locking screw cooperatively fix a center hole of the semi-finished flexible wheel, and the inner shaping gear hole performs shaping upon a profile of an outer gear portion. Therefore, flexible-wheel processing can be completed through a universal machine tool, financial burden of manufacturers can be reduced on one hand, and on the other hand, processing precision of the flexible wheel can be guaranteed.

Owner:DONGGUAN XINTUO INTELLIGENT MACHINERY TECH

Stamping machine

Owner:ROLAND DG CORP

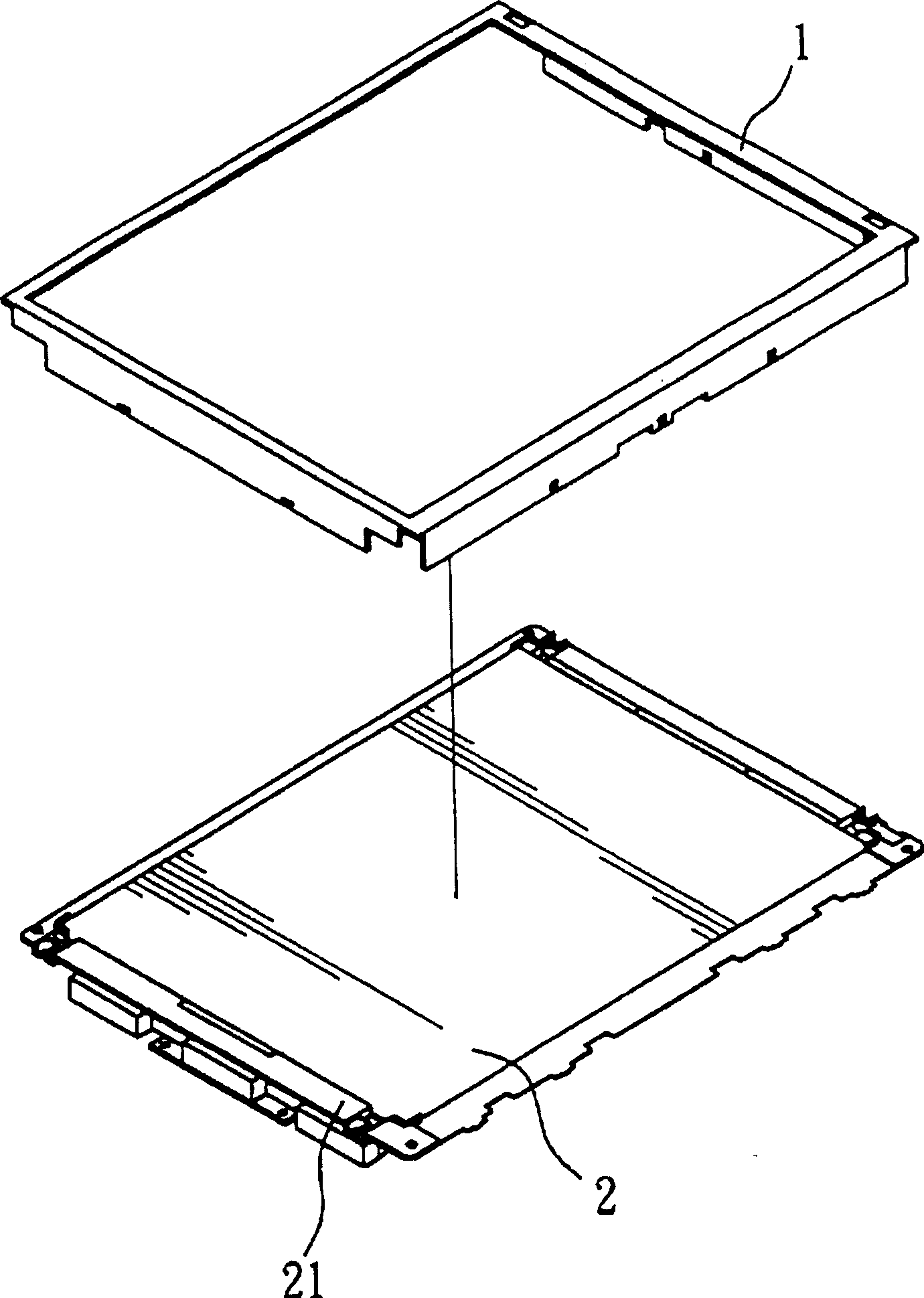

Method for manufacturing metal outer frame for panel display

The invention relates to the metal shell facture used for the plane display, which is to process the outer frame of the metal shell in punching method, use soldering or other methods to joint the brims into the metal outer frame. The mould needed is small and simple, and the punching machine is small, therefore, the cost is lowered.

Owner:CHI LIN TECH CO LTD

Automatic die changing system for punching machine

InactiveCN106040879AShorten the timeImprove mold change efficiencyShaping toolsPunch pressEngineering

The invention provides an automatic mold changing system for a stamping machine, which includes a punching machine, a mold changing trolley, a trolley track matched with the mold changing trolley, and a trolley track for fixing the mold changing trolley on the trolley track. The trolley positioning device, a mold change fixture, two mold transfer arms for transferring molds, and a control cabinet. The table of the punch press is provided with an exchange base plate for placing molds. The mold change trolley slides It is equipped with the trolley track, the trolley positioning device is arranged on the side of the trolley track, and the two mold transfer arms are located on both sides of the mold changing fixture. The invention can automatically replace the stamping die, which not only greatly shortens the time spent on changing the die, thereby improving the efficiency of die changing, but also solves the safety hazards of manual operation.

Owner:无锡明芳汽车部件工业有限公司

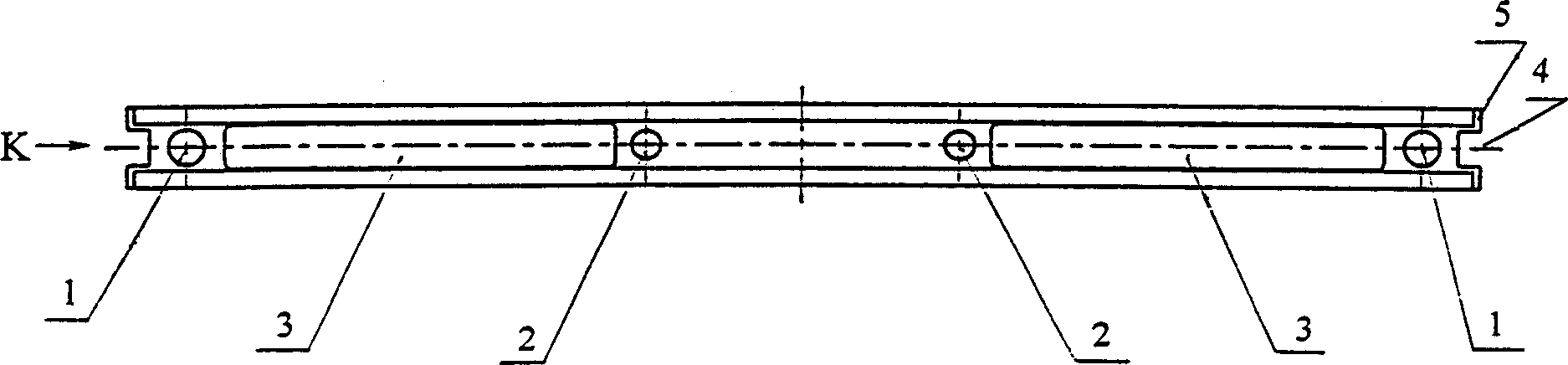

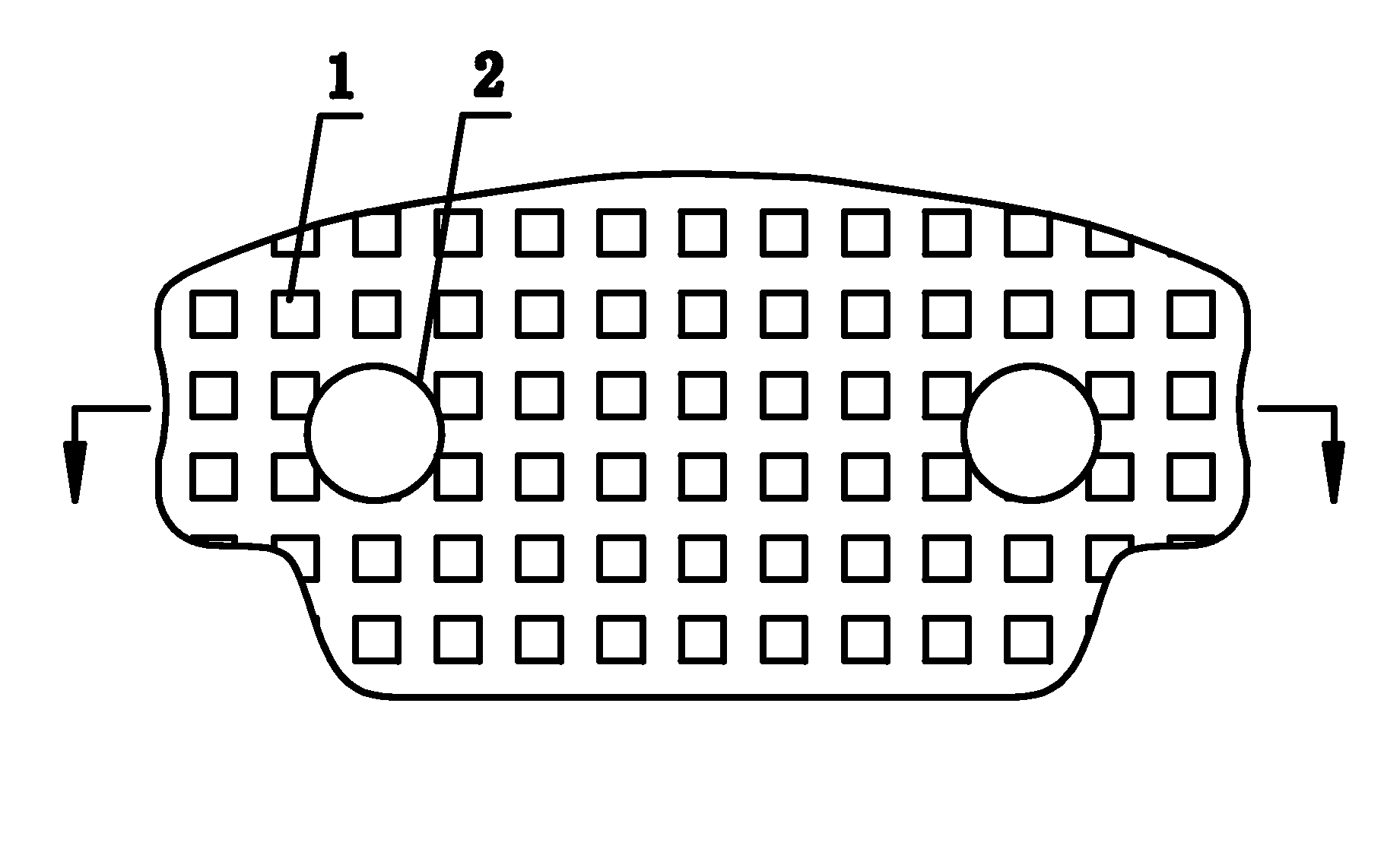

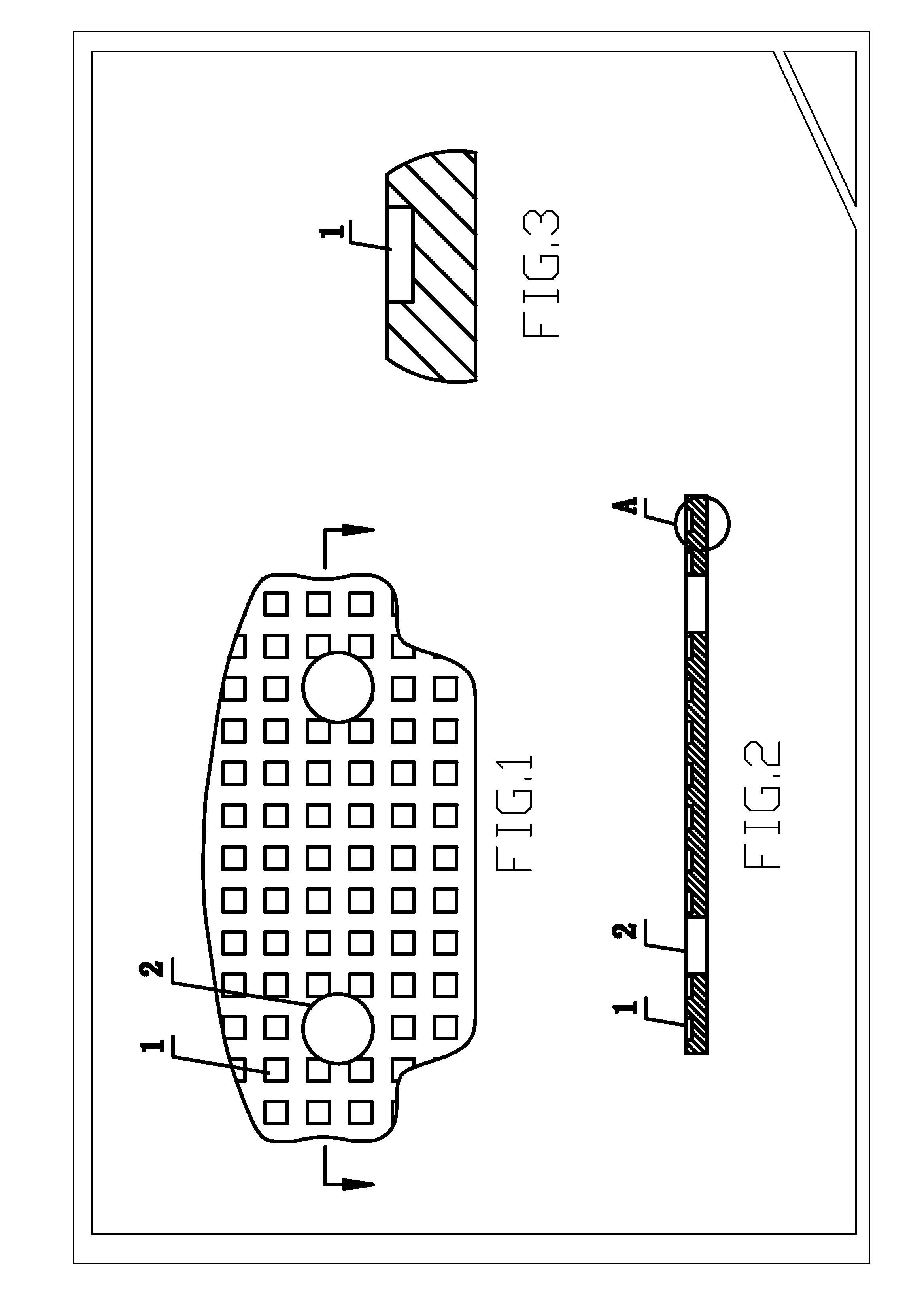

Disc brake backing plate and methods of manufacturing the same

InactiveUS20110220441A1Improve adhesionIncreased shear strengthBraking membersFriction liningMechanical engineeringDisc brake

A disc brake pad is composed of a backing plate and a friction material. The adhesion of the backing plate and the friction material is enhanced in the present invention by multiple recesses on the surface of the backing plate that is attached to the friction material. One of the advantages of the present invention is the ease of manufacturing. In one of the preferred methods of manufacturing, a matrix of recesses (2) is first impressed onto the steel sheet by a stamping press. The existing method of producing a traditional backing plate, i.e., stamping out the backing plate profile and the bores, may then be applied.

Owner:ZHANG JIM ZEWEI

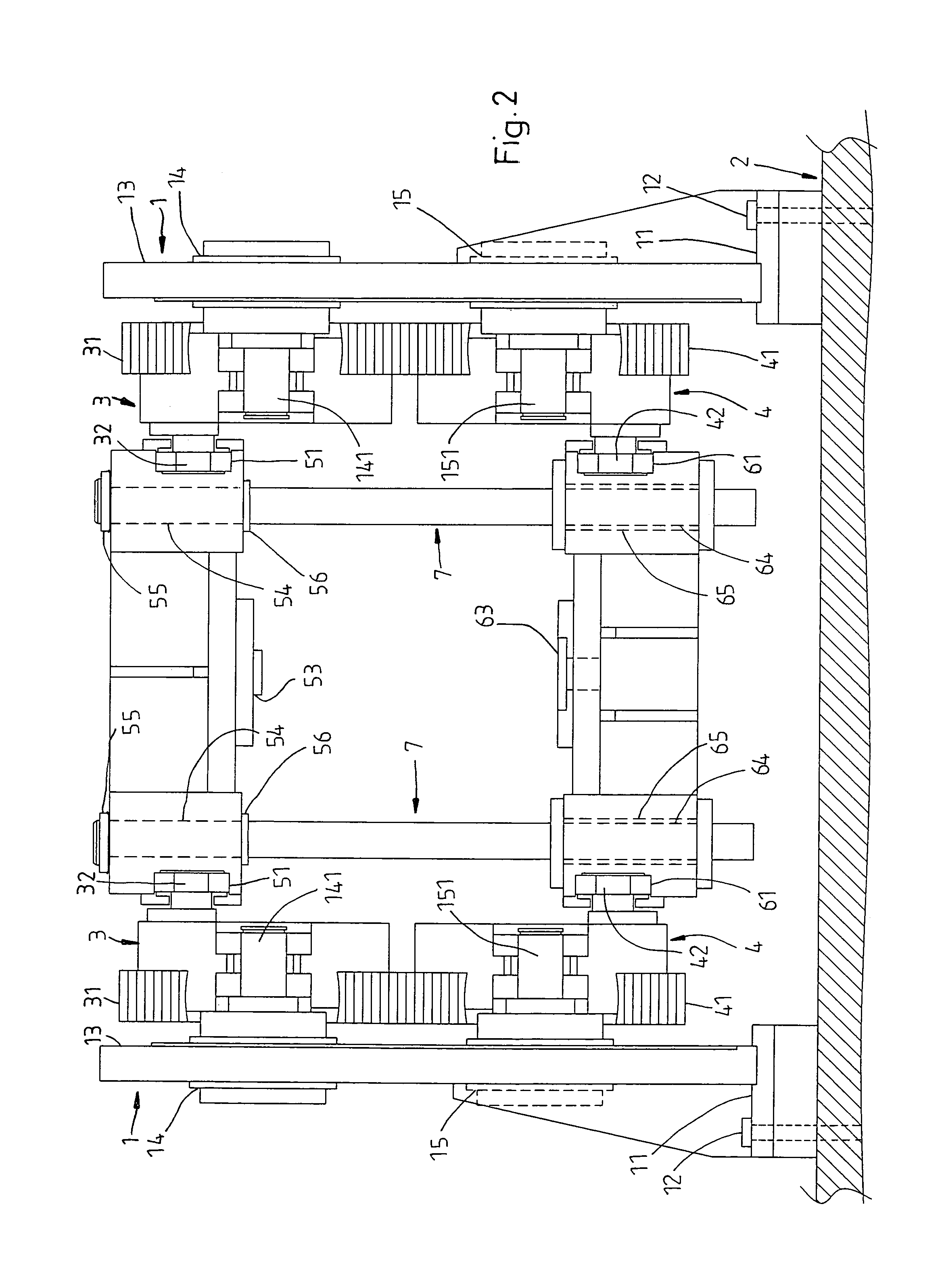

Movable-die type gantry numerical control press

InactiveCN101633016AImprove processing qualitySuitable for stampingMetal-working feeding devicesPositioning devicesNumerical controlEngineering

The invention relates to a movable-die type gantry numerical control press comprising a press body and feeders, wherein the number of the feeders are two; the two feeders are arranged in the X-axis directions of the press body, one of the feeders is arranged at the left side of the press body and the other one is arranged at the right side of the press body; the press body is provided with an upper group of lead rails and a lower group of lead rails and is provided with corresponding actuating units; and the actuating units drive a die of the press body to move along the Y-axis direction via a guide screw and a screw. The invention has the advantages that a gantry oil pressure press is adopted in the Y-axis direction, the die can move in the Y-axis direction, no dead area is caused during the processing, and the whole press body in X-axis direction is disassembled to form two relatively separately operating small press bodies in the X-axis direction, thereby reducing the processing difficult, being beneficial to reducing the production cost and being particularly suitable for pressing and processing of over-long materials.

Owner:QINGDAO DONGHE TECH

Stamp press

This apparatus is small, compact, and light-weight, relatively inexpensive in terms of manufacturing cost, and will substantially improve the quality of a stamped image, also used for repetitive printing on individual sheets of card stock or any flat printable surface, in the same pre-determined location, set be the user, which provides maximum flexibility in arrangement and adjustment to permit the apparatus to be used with various sizes of stamps, and various types of card stock and to be used to make a consistent inked impression at virtually any location on selected card stock.

Owner:KONIK HENRY STEPHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com