Punch press

A punching machine and base technology, applied in the field of punching machines, can solve the problems of being unsuitable for stamping and forging of small parts, large energy consumption of small parts, and bulky punching machine, so as to achieve less use of materials and energy, protection of resources, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

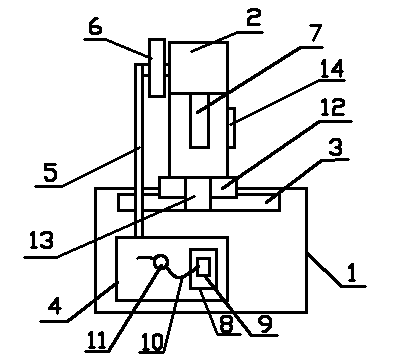

[0010] In this example, refer to figure 1 As shown, a stamping machine of the present invention includes a machine base 1, a column 2 arranged on the machine base 1, and a working platform 3 arranged on the machine base 1, and a hydraulic power device is arranged in the machine base 1 4. The hydraulic power unit 4 is externally connected with a hinge connection mechanism 5, and a flywheel mechanism 6 is provided on the top of the pole 2, and one end of the hinge connection mechanism 6 is connected to the flywheel mechanism 6 on the pole 2, and the flywheel A stamping device 7 is connected to the lower end of the mechanism 6 .

[0011] The hydraulic power unit 4 includes a fuel tank 8, a hydraulic cylinder 9, an oil pipe 10 and a flow valve 11, the hydraulic cylinder 9 is arranged in the fuel tank 8, the oil pipe 10 is connected to the hydraulic cylinder 9, and through the oil pipe 10 and the hydraulic cylinder 9 The oil is transported to the flywheel mechanism 6 to generate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com