Patents

Literature

2522results about How to "Less consumables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

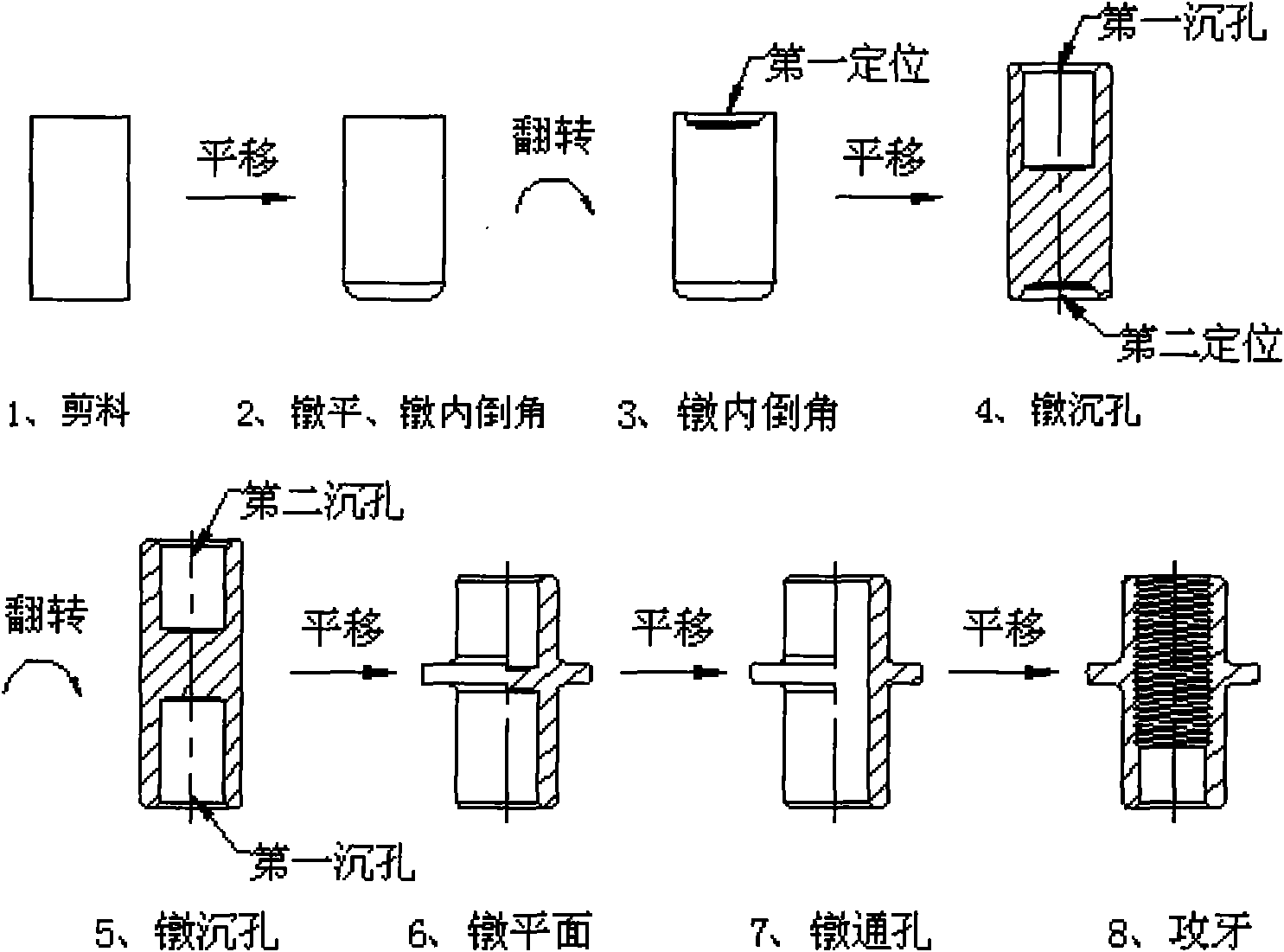

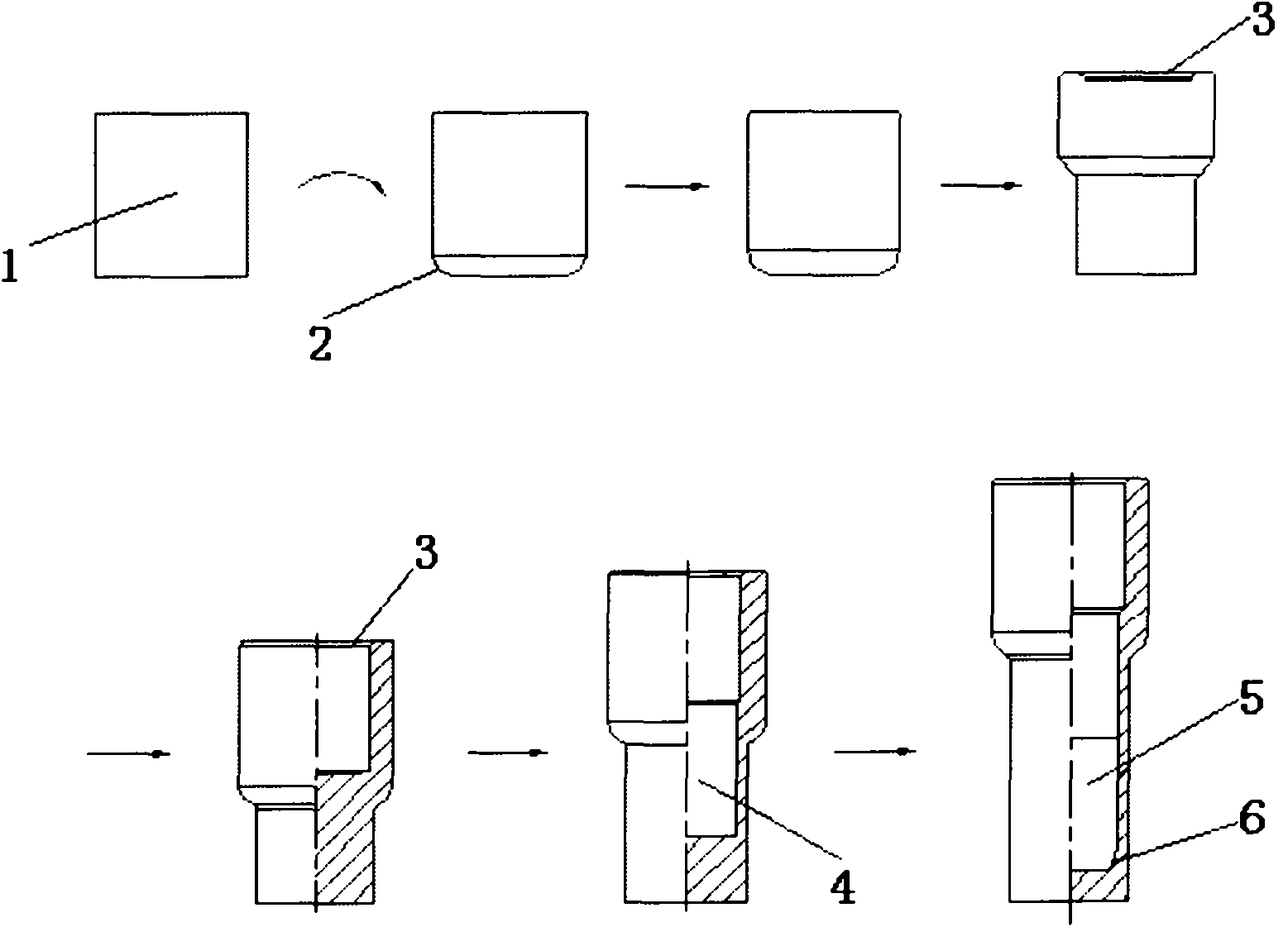

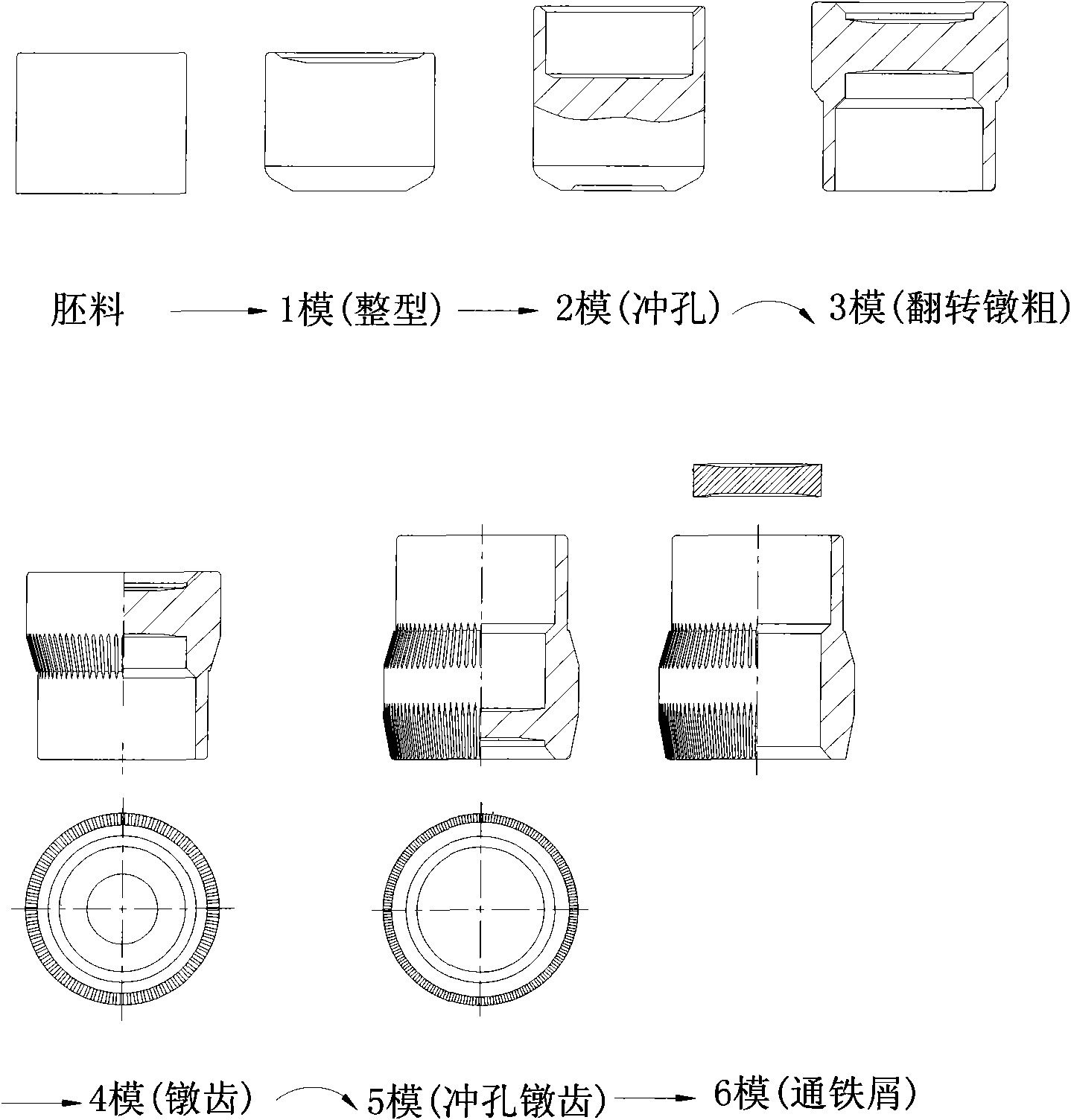

Manufacturing process of adjusting nut

InactiveCN101618498ALess consumablesCompact structureNutsMetal-working apparatusWire rodMolding machine

The invention discloses a manufacturing process of an adjusting nut. The steel billet raw materials are manufactured into wire rod materials, surface treatment is performed on the wire rod materials by using phosphate, spheroidizing annealing, phosphating and fine-drawing and sizing treatment are respectively performed on the wire rod materials after roughing, and finally, the molding working procedure of the adjusting nut is carried out in a cold-heading molding machine; the molding working procedure of the adjusting nut comprises the following steps: material fracturing; material shaping and upsetting, upsetting an inner chamfer at the upper end; material turning, shaping and upsetting a positioning hole at the upper end and an inner chamfer at the lower end; material translating, upsetting a counterbore at the front end and a positioning hole at the rear end; material turning, upsetting a counterbore at the other end; material translating, upsetting a plane in the middle by using the PKO male die technology; discharging the residual scrap iron at a middle hole out and manufacturing a through hole product; and performing tapping to an inner hole of a blank of the adjusting nut. The invention is molded at one time by adopting a cold heading machine, thereby improving the production efficiency and the product quality of the adjusting nut, saving the raw material and reducing the manufacturing cost.

Owner:NINGBO ANCHOR FASTENERS INDAL

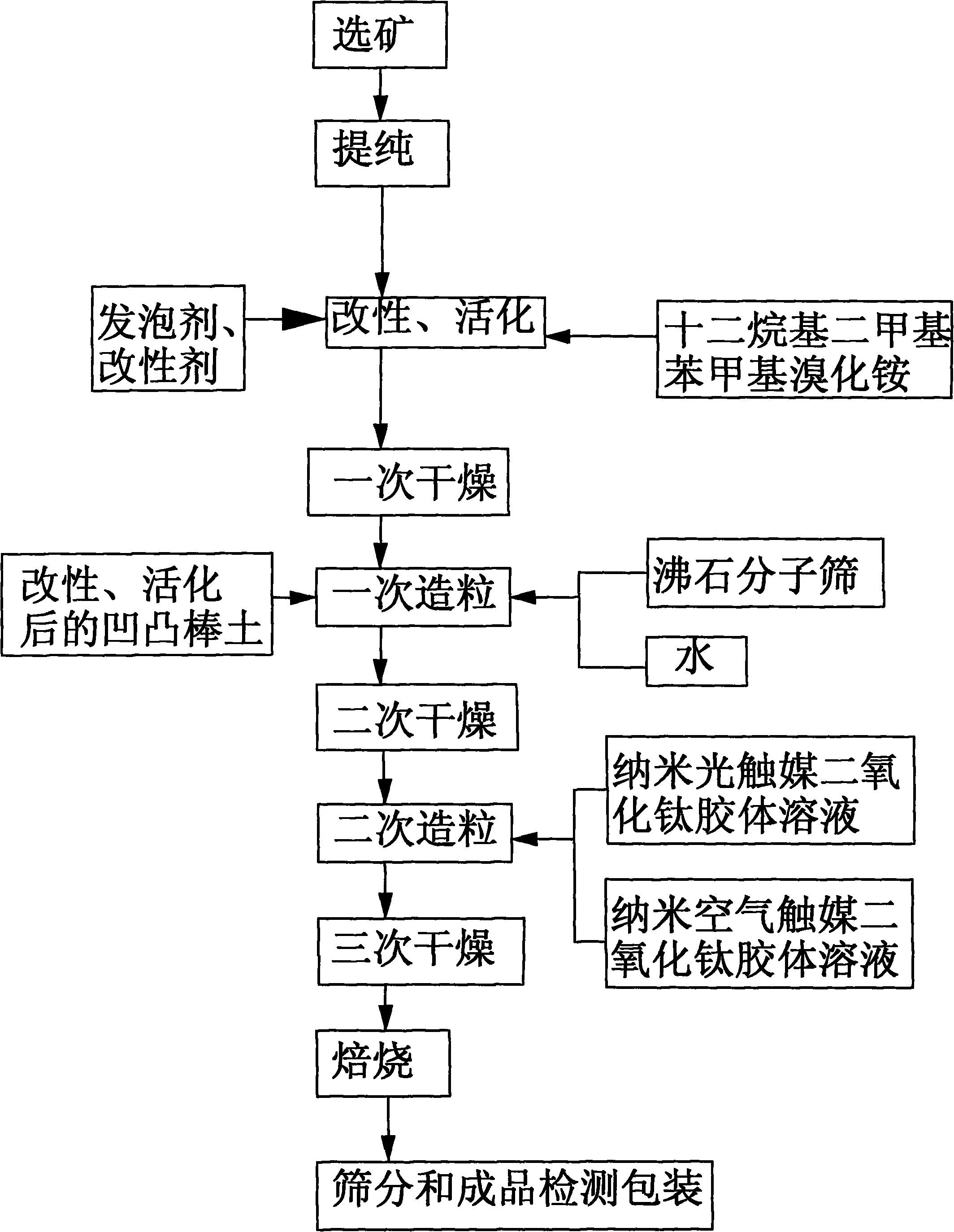

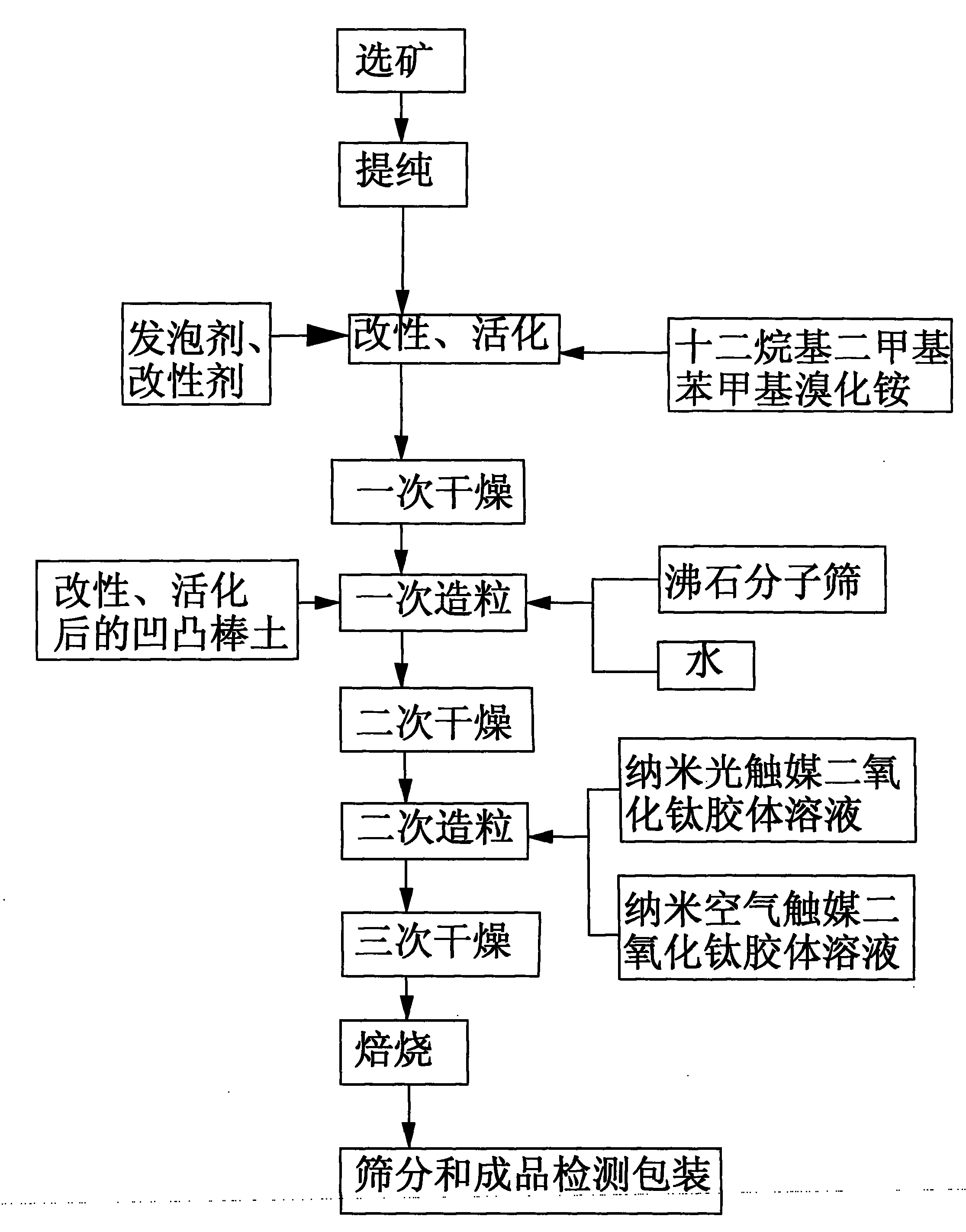

Composite air purificant containing nanometer mineral matters and preparation method thereof

ActiveCN101780288AWill not polluteProcess environmental protectionPhysical/chemical process catalystsDispersed particle separationSodium bicarbonateDecomposition

The invention provides a composite air purificant containing nanometer mineral matters, which contains 47wt% to 78wt% of attapulgite as a natural mineral, 20wt% to 50wt% of synthetic zeolite molecular sieve as a molecular sieve, 0.5wt% to 5wt% of sodium carbonate or sodium chloride or sodium fluoride or sodium hydrogensulfite as a modifier, 0.5wt% to 5wt% of ammonium bicarbonate or sodium bicarbonate or aluminum sulfate as a foaming agent, 0.5wt% to 2wt% of dodecyldimethylbenzylammonium chloride as a surface active agent, 0.2wt% to 2wt% of nanometer photocatalyst titanium dioxide colloidal solution as a photocatalyst and 0.1wt% to 1wt% of nanometer aircatalyst titanium dioxide colloidal solution as photochemical catalysts. The composite air purificant is prepared by first drying, first pelleting, second drying, second pelleting, third drying, baking and finish product detection and package. The invention has high alternative adsorbability and high decomposition efficiency for organic pollutants in the air.

Owner:宁波市沧海新材料开发有限公司

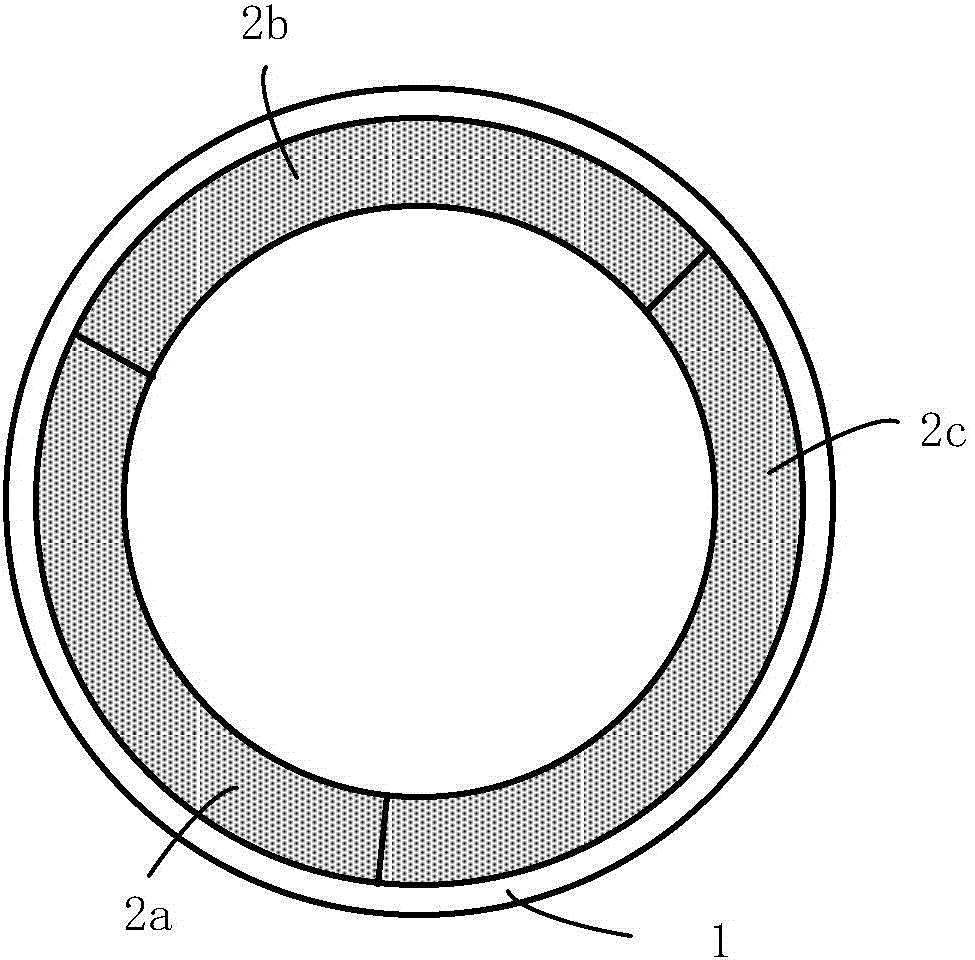

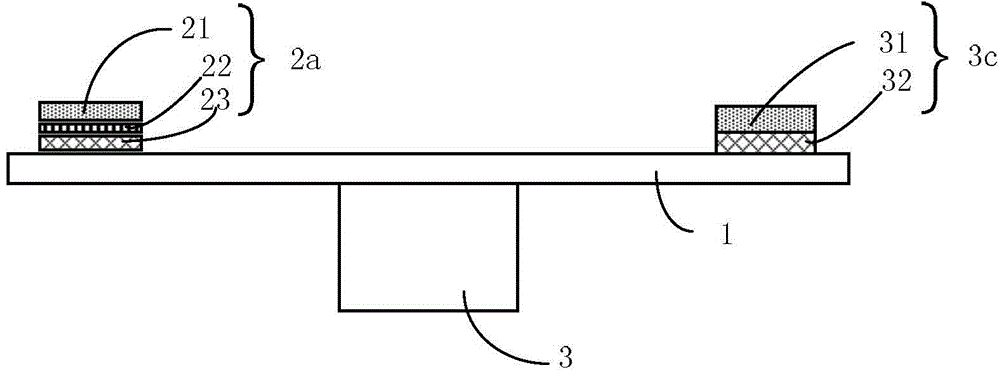

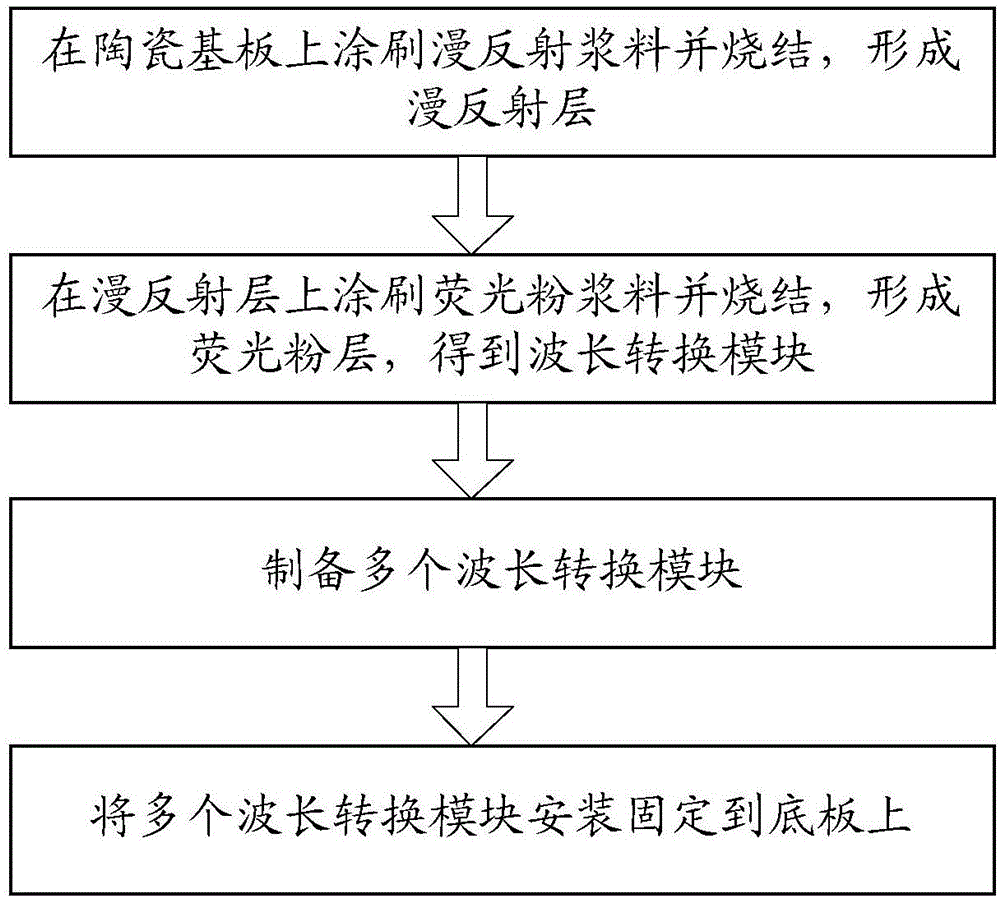

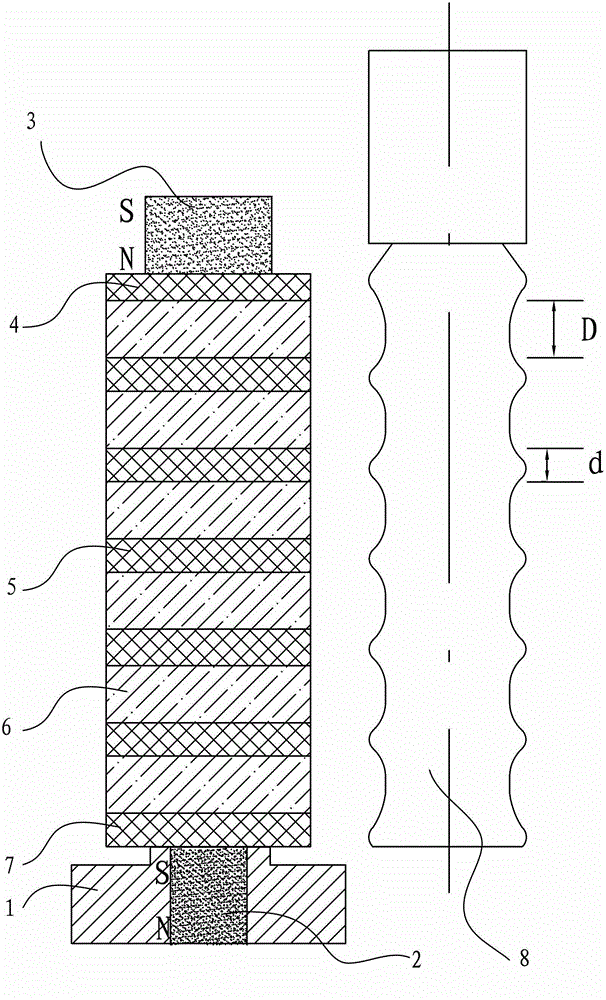

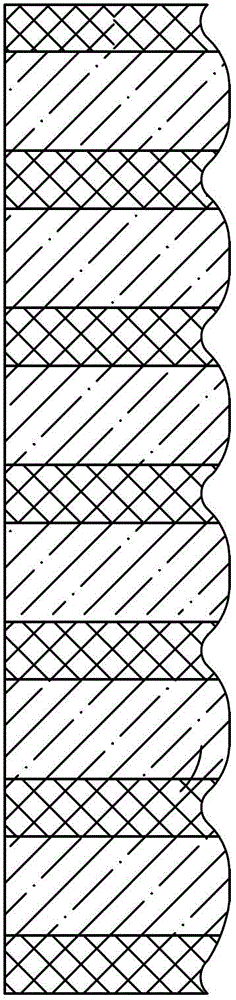

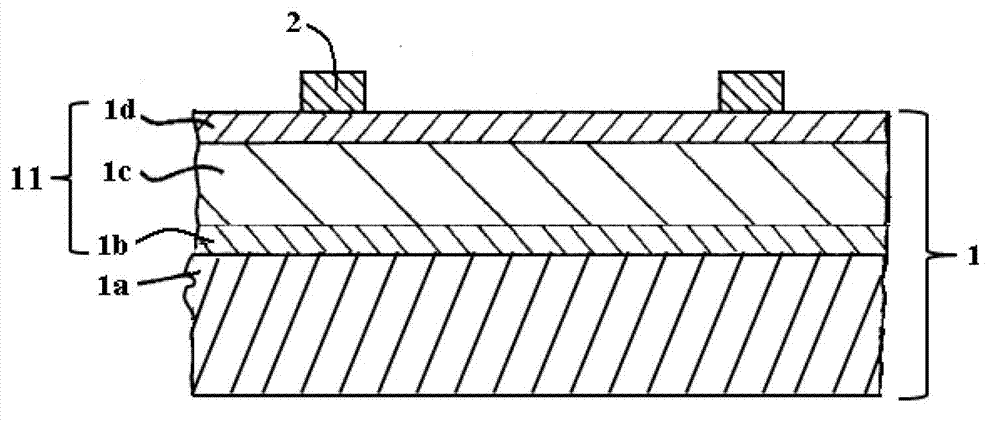

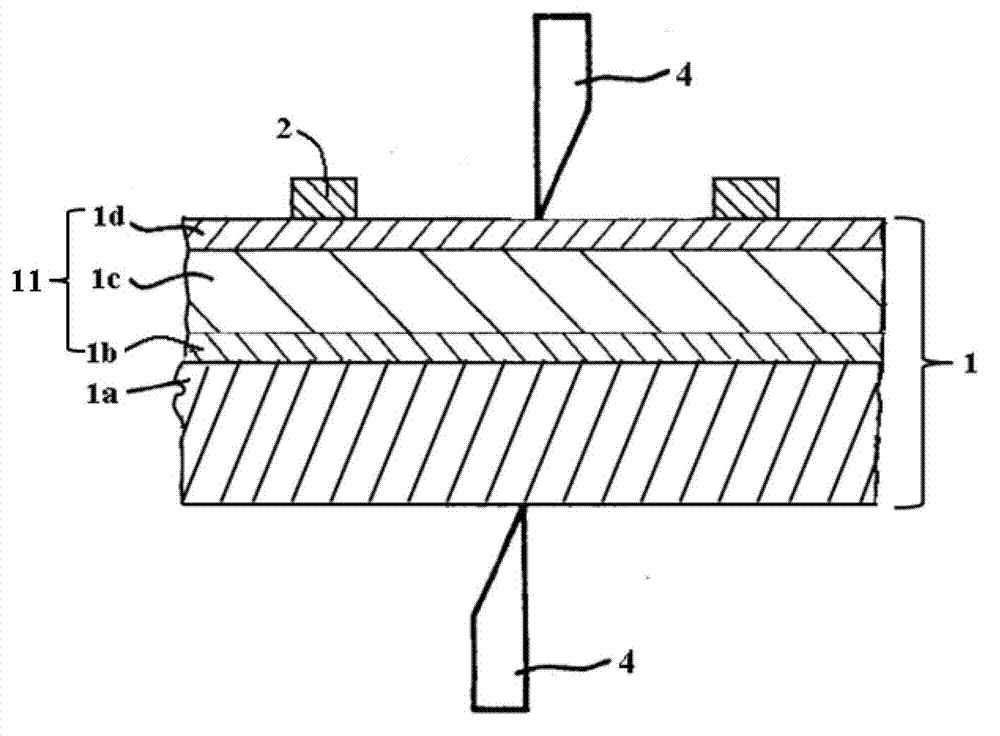

Manufacturing method of wavelength conversion device

ActiveCN104566229ALower interface thermal resistanceNot difficult to attachElectrical apparatusElectroluminescent light sourcesWavelength conversionCeramic substrate

Disclosed is a manufacturing method for a wavelength conversion device, comprising: preparing a plurality of wavelength conversion modules (2a, 2b, 2c), each wavelength conversion module (2a, 2b, 2c) comprising a ceramic substrate (23), a reflecting layer (22) and a fluorescent powder layer (21), said layers being stacked sequentially and formed into one piece; installing and fixing the plurality of wavelength conversion modules (2a, 2b, 2c) on one surface of a base substrate. By arranging different fluorescent powders respectively on the different wavelength conversion modules (2a, 2b, 2c), a plurality of wavelength conversion modules (2a, 2b, 2c) can be produced separately at the same time, thereby significantly shortening the production cycle. Each such module is produced independently and is thus not subject to the restrictions of the characteristics of other fluorescent powders. This is beneficial for the optimization of the various processes, and a wavelength conversion device having optimal performance is thereby obtained.

Owner:APPOTRONICS CORP LTD

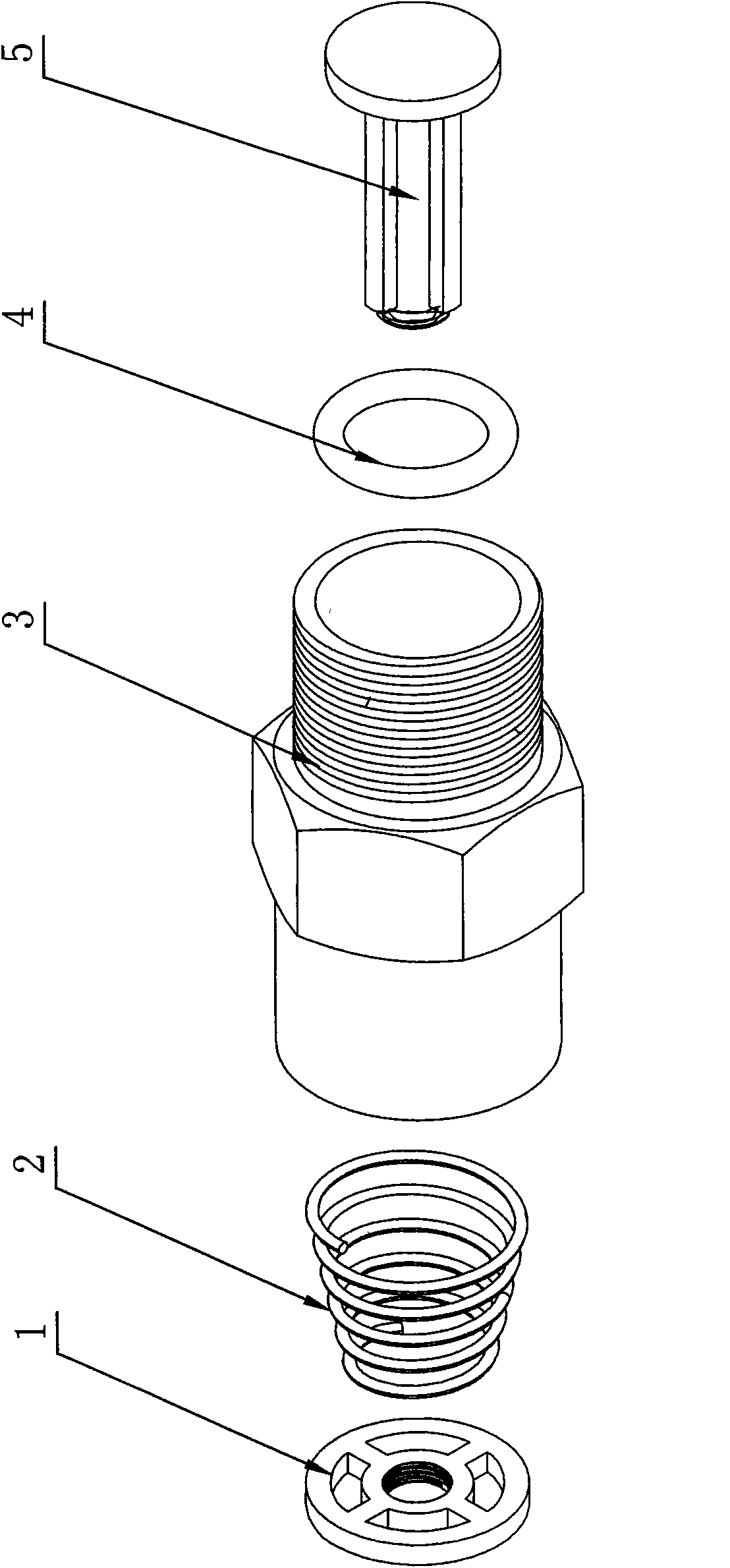

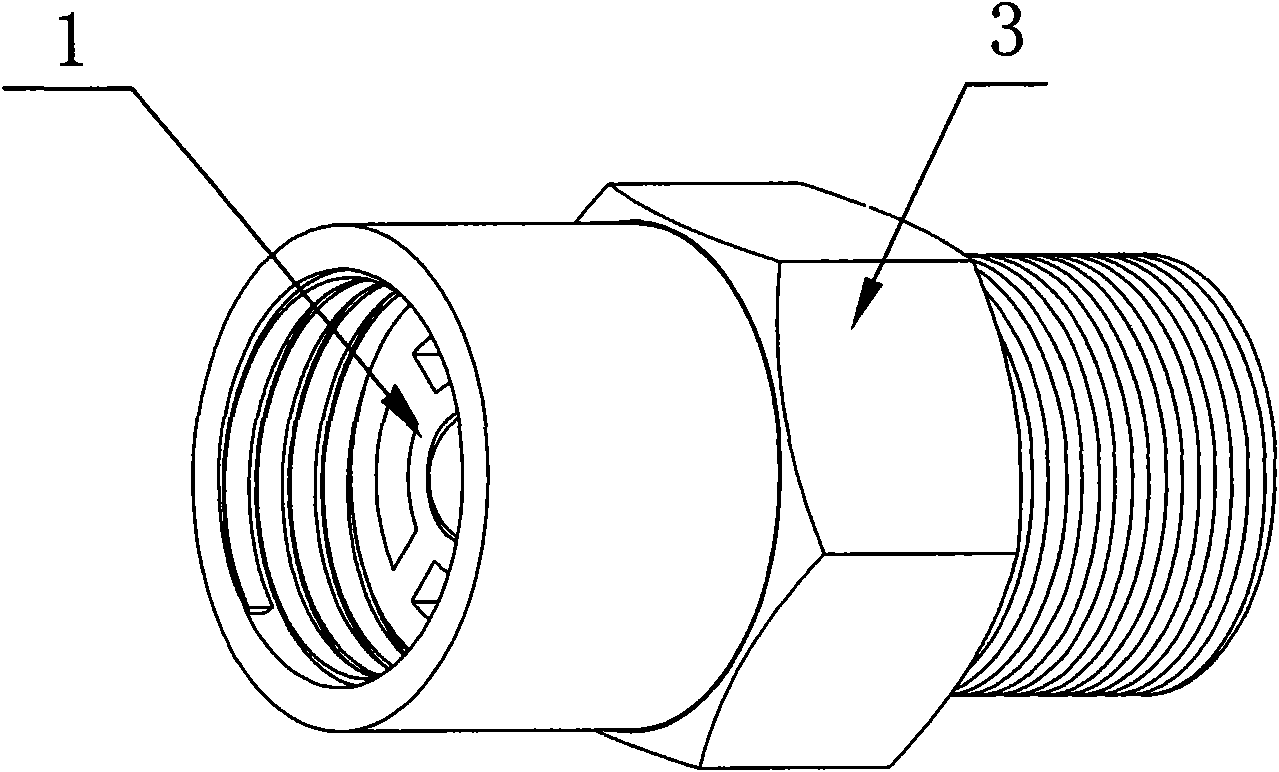

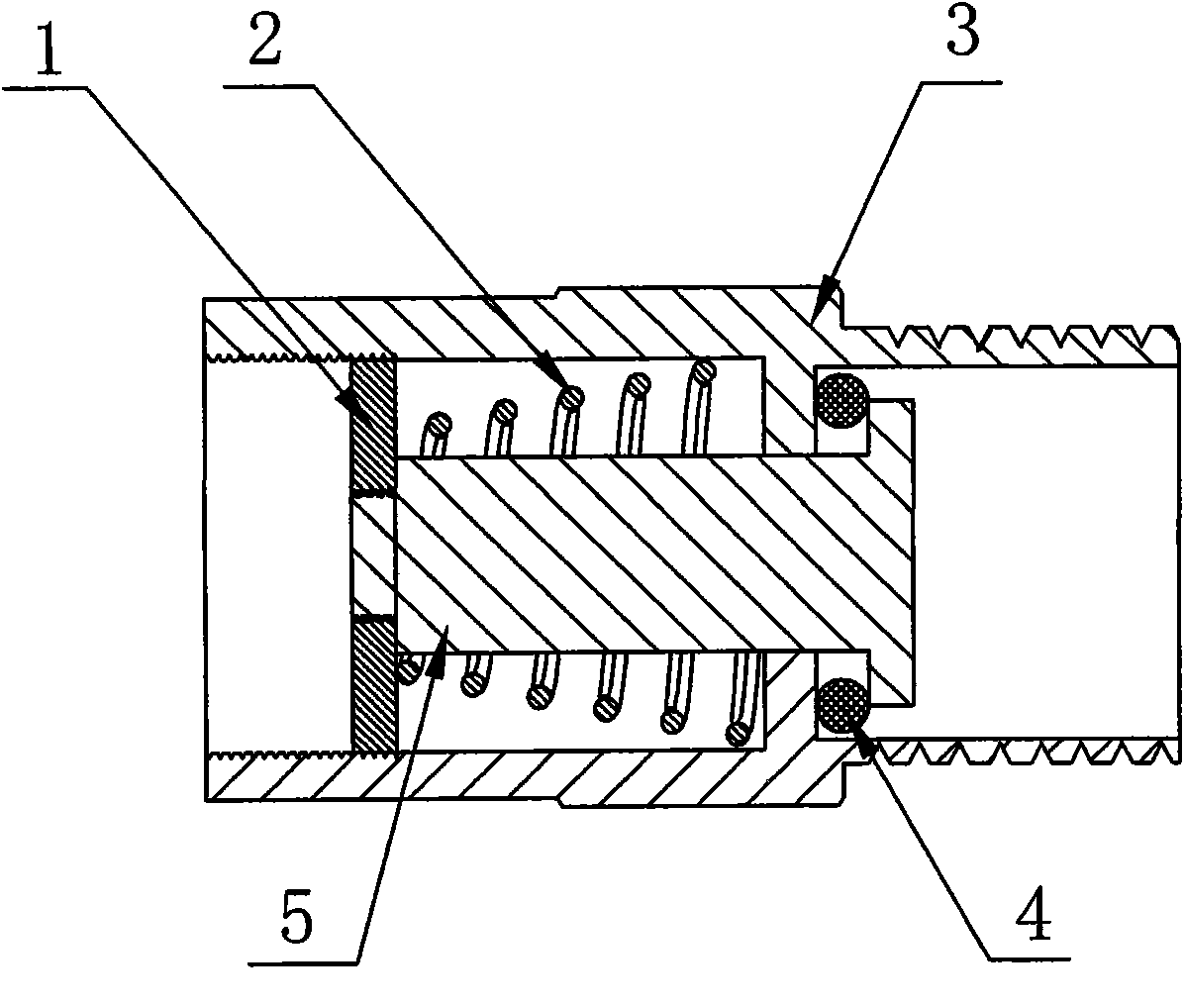

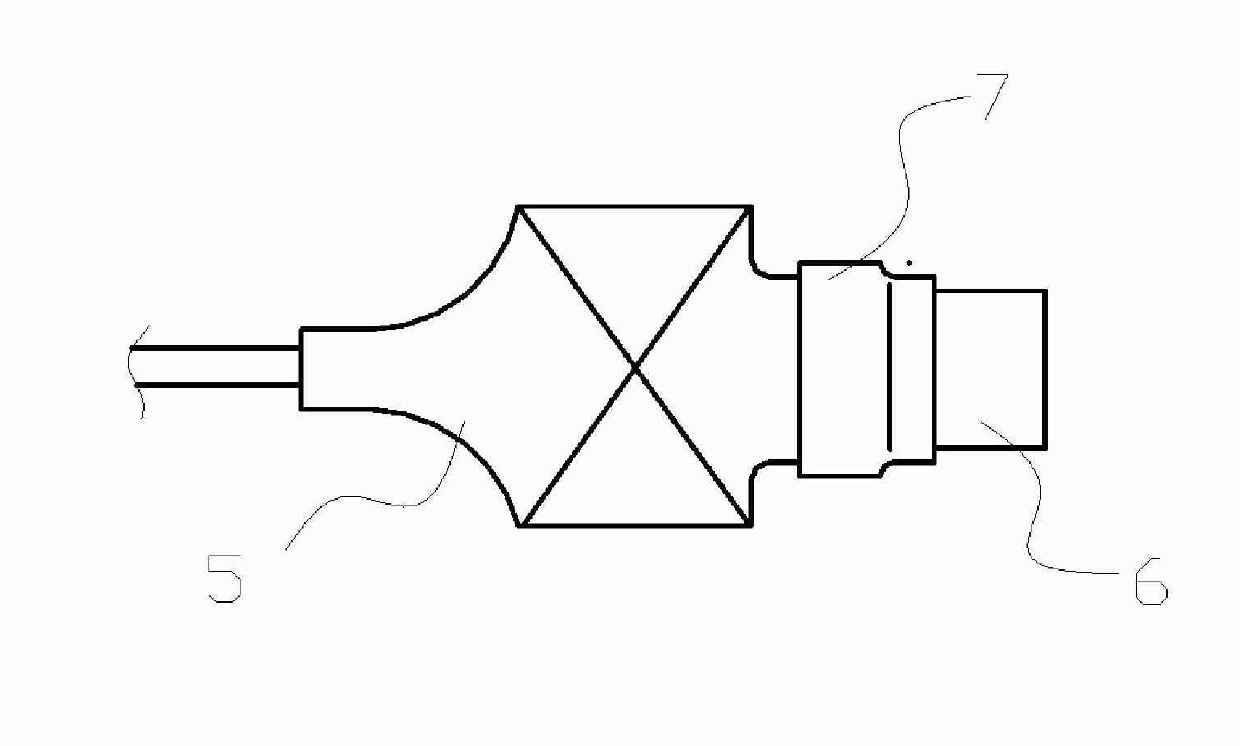

Water-saving type pipe joint and opening or closing method

InactiveCN101561065ALess consumablesGood water saving effectPipe elementsPipe-jointsMaterial consumptionRadial surface

The invention relates to a water-saving type pipe joint; the water-saving type pipe joint has the following design key points that: a through hole of a pipe body is provided with a clapboard with the same matrix; the clapboard is provided with a limber hole for a valve core to penetrate; the valve core has a T shape; a joint part of vertical section and transverse section of the T shape is provided with a sealing ring; the vertical section of the T shape valve core penetrates the limber hole; the sealing ring seals the joint part of the vertical section and the transverse section of the T shape valve core of the limber hole of the clapboard; the vertical section of the T shape valve core penetrates out one section of the limber hole and is sleeved with a spring; the external thread of the section is connected with a screw hole in the central part of a valve sheet; and the radial surface of the valve sheet is provided with a valve hole so that water can flow in. The method is feasible and solves the technical problems that the prior similar product has poor water conservation and unreasonable structural design. A manufactured product has little material consumption, obvious water-saving effect and dual functions of the pipe joint and the valve.

Owner:苗玉光

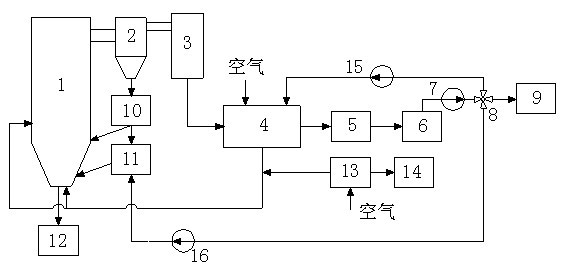

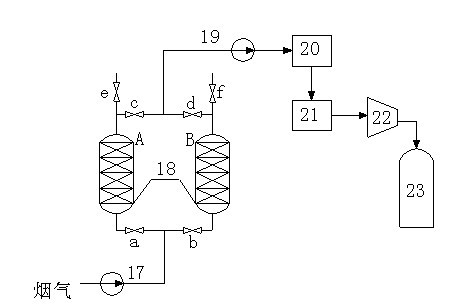

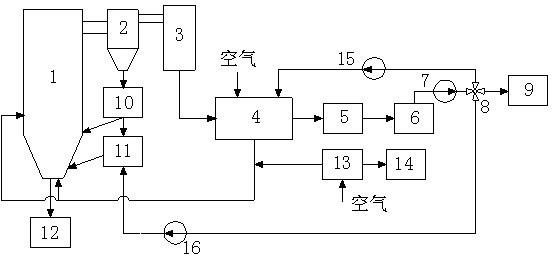

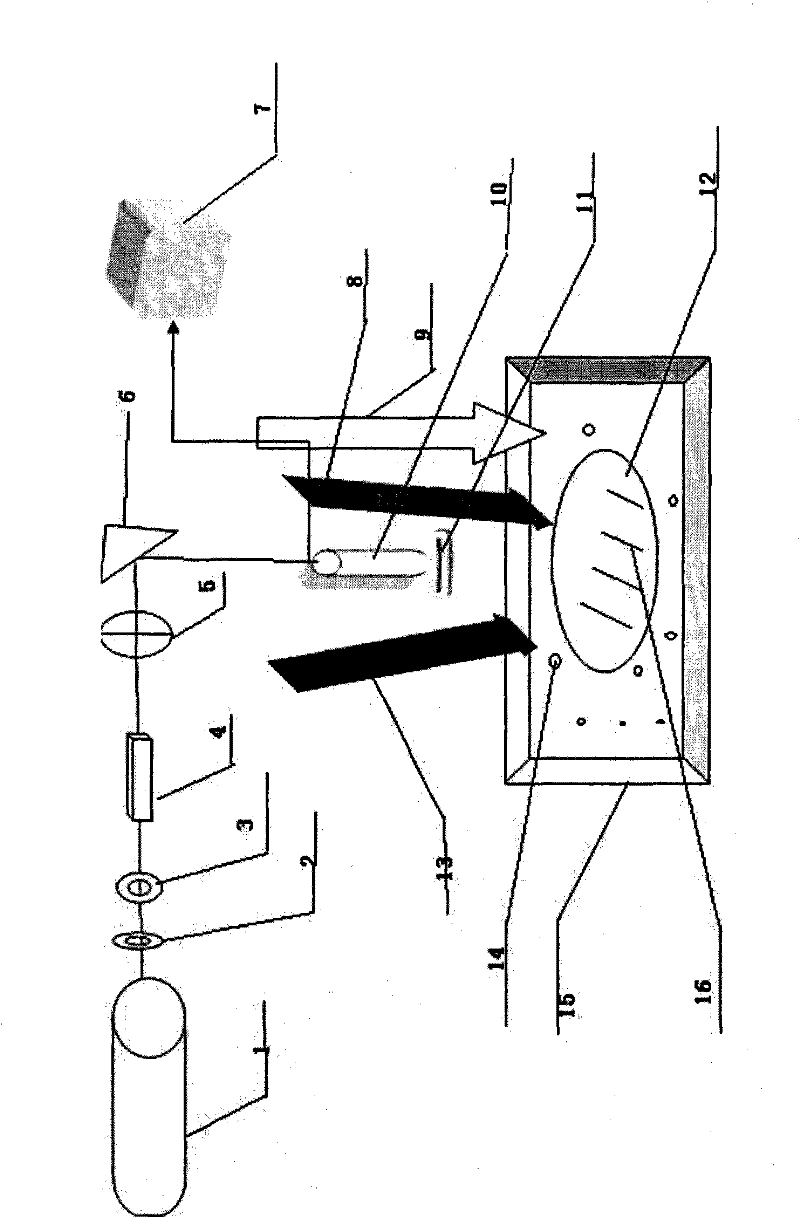

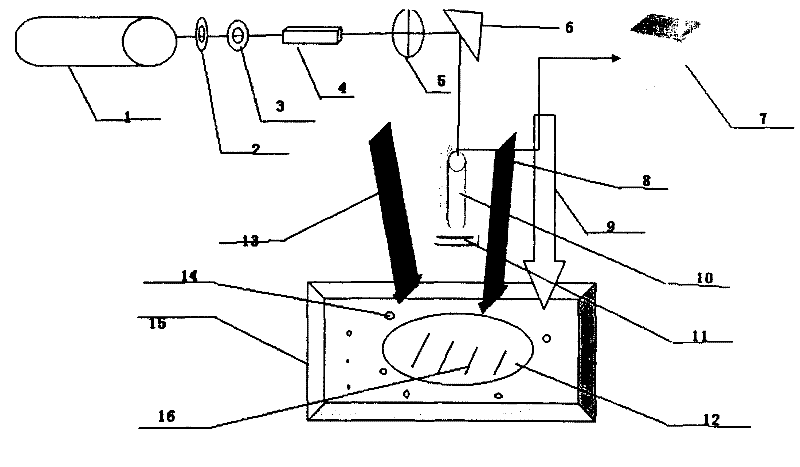

Coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and system

InactiveCN102425789ALow costZero pollution dischargeSolidificationFluidized bed combustionProcess engineeringPollution

The invention discloses a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction system for solving the problem of low-cost CO2 emission reduction of an industrialized coal-fired boiler. A micro oxygen rich combustion mode using mixed gas of air, oxygen and recycled smoke as a combustion aid is adopted, wherein the mixed gas contains about 25 percent of oxygen, 30 to 40 percent of recycled smoke and the balance of air; and in the micro oxygen rich combustion mode, the concentration of the CO2 gas in the generated smoke is 30 to 40 percent, and the CO2 in the smoke is removed by adopting a physical adsorption technology. The invention also provides a system device for implementing the method. By considering oxygen making cost, energy consumption and optimal comprehensive effect of separating CO2 by physical adsorption and combining the micro oxygen rich concept and the circulating fluidized bed combustion technology, desulfuration, denitration, decarburization and zero pollution emission at lower cost can be realized. The invention has the advantages of good economic efficiency, simple process, low energy consumption, high automation degree in operation process and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

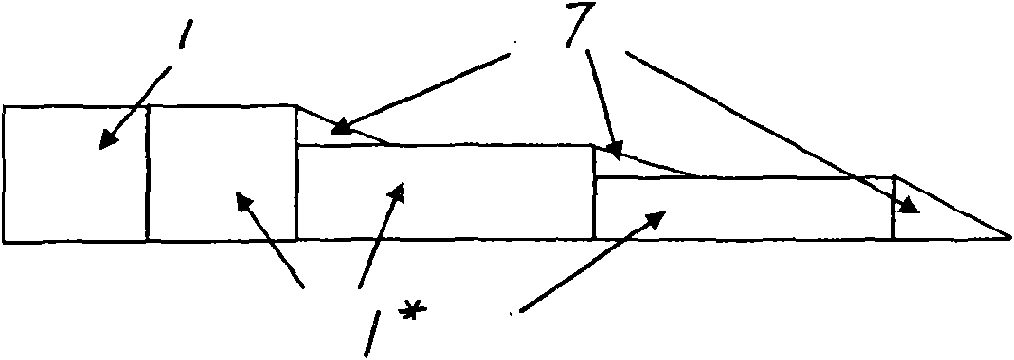

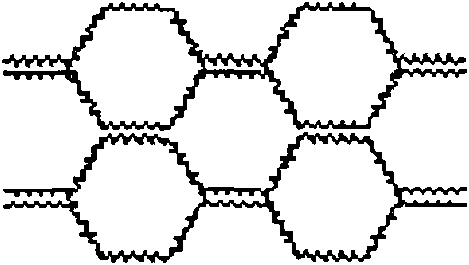

Wind turbine blade structure, processing and forming method and applications thereof

InactiveCN101666290AEasy to placeEvenly wrappedFinal product manufactureMachines/enginesFiberTurbine blade

The invention relates to a wind turbine blade structure, a processing and forming method and applications thereof. The blade consists of a root segment, a main beam and a covering that wraps the rootsegment and the external side of the main beam; the blade is fixed with a wind wheel by a connecting piece that is arranged at the root segment, thus forming a spatial cantilever beam structure; at the main beam area and the root segment, one or more solid or hollow wedge-shaped columns are arranged between a top paving layer and a bottom paving layer; the wedge-shaped column at the internal-mostside of the root end is solid and is internally provided with the connecting piece, wherein the fiber cloth is arranged at least among the adjacent wedge-shaped columns at the internal-most side of the root segment and continuously intersects and enwinds the wedge-shaped columns in a horizontal S-shaped, thus forming an interlayer; and the top paving layer, the bottom paving layer and the fiber cloth interlayer are dipped and solidified to form a framework with a honeycomb-shaped section. The structure and the method have the advantages of: leading the once pouring of resin and once solidifying and forming for the large blade and the realizing of the pre-embedding of the connecting piece of the root part to be possible, dispersing the synergistic effect and solidifying shrinkage quantity of solidified heating of the bottom paving layer and the top paving layer by the wedge-shaped columns, and leading the unsaturated resin used as a substrate material to be possible.

Owner:黄争鸣

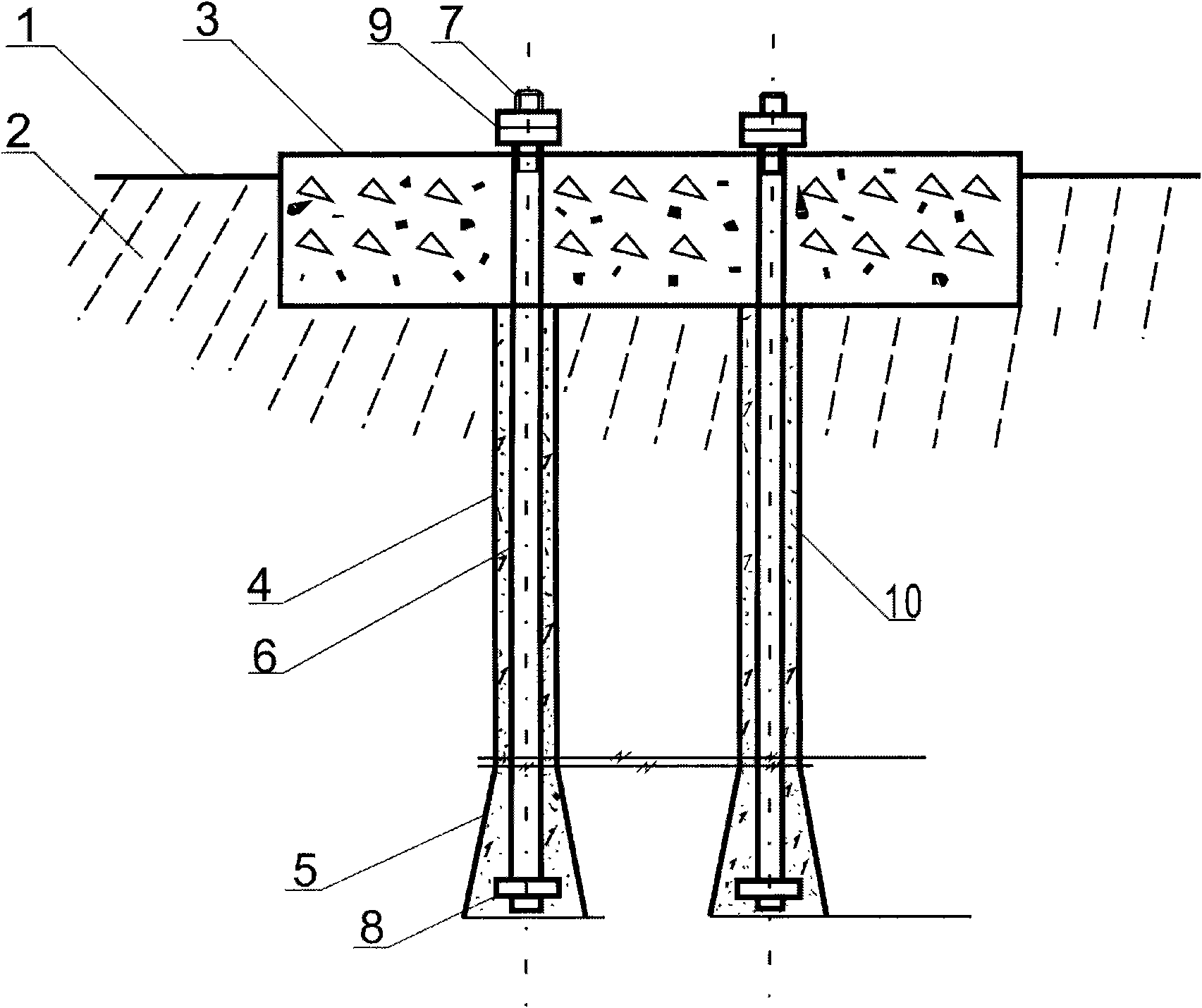

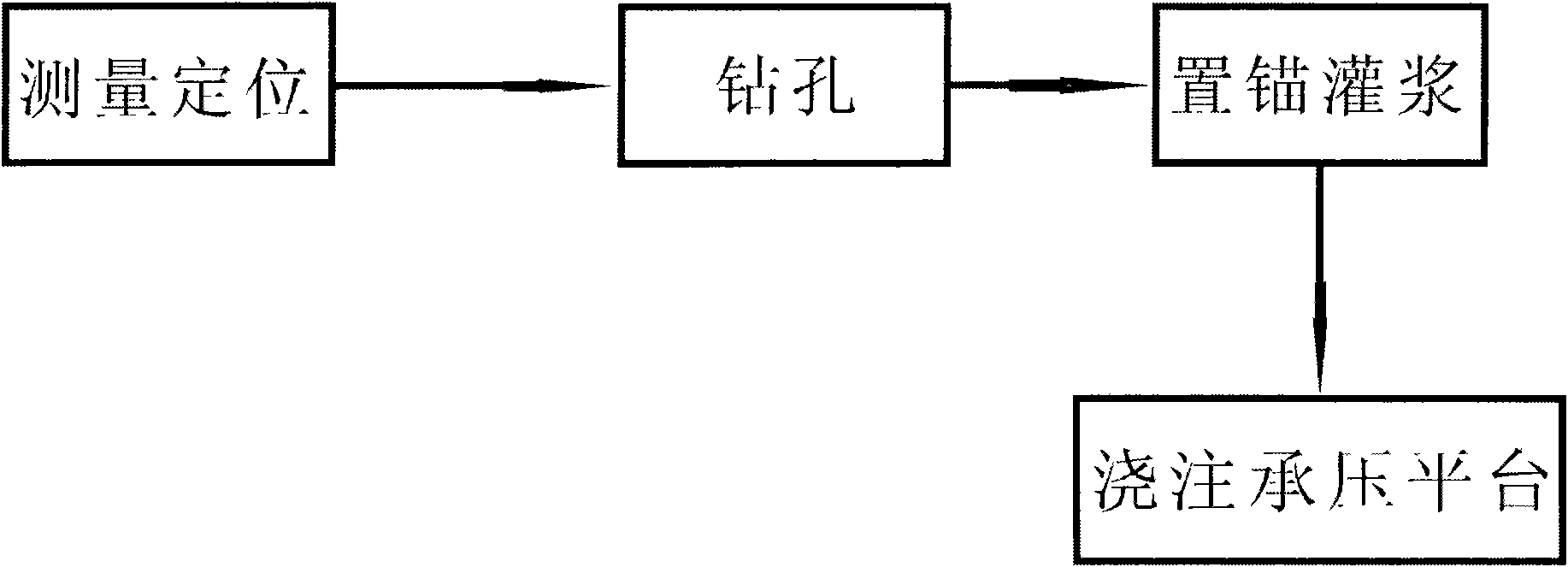

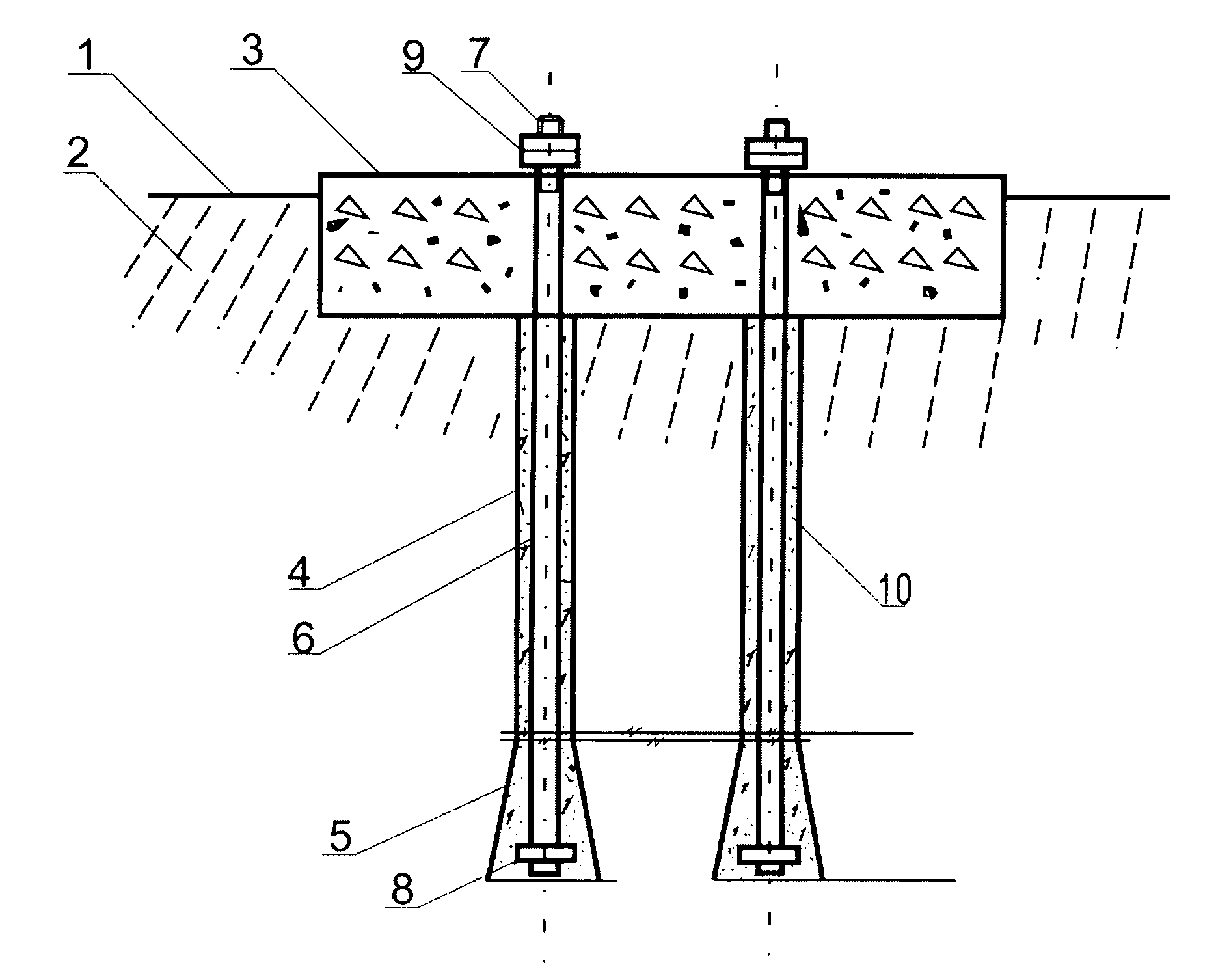

Construction process for rock enlarged toe anchor pile foundation of overhead power transmission line

The invention discloses a construction process for a rock enlarged toe anchor pile foundation of an overhead power transmission line. The construction process comprises the following steps of: (1) measuring and positioning, namely measuring a tower foot position and removing a rock surface to determine a foundation bolt base point; (2) drilling, namely drilling a straight hole at the base point by using a tubular drill until the drilling is finished, and enlarging the bottom of the straight hole by replacing a deviation bit to form a taper hole, wherein the aperture and the depth of the straight hole are determined according to the external diameter and the length of an anchor rod; the taper angle is controlled by controlling the drill bit sinking and the deviation speed; the lower bottom surface of the taper hole is coincided with the bottom of the straight hole; the taper height is determined according to the actual demand; the taper hole is coaxial with the straight hole; the upper bottom of the taper hole is the section of the straight hole; the diameter of the straight hole is 8 to 10cm more than the external diameter of the anchor rod; and the taper angle is 30 to 40 degrees; (3) placing an anchor and grouting, namely placing the anchor rod into the hole to insert a foundation nut and a part of rod body into the taper hole and grouting a CGM30 grout into the hole until the grout reaches the rim of the hole, wherein the anchor rod and the straight hole are coaxial; and (4) pouring a bearing platform, namely pouring the anchor rod which is exposed out of the straight hole into the bearing platform by using high-standard cement, wherein the foundation nut and a foundation bolt are protruded out of the surface of the bearing platform.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY

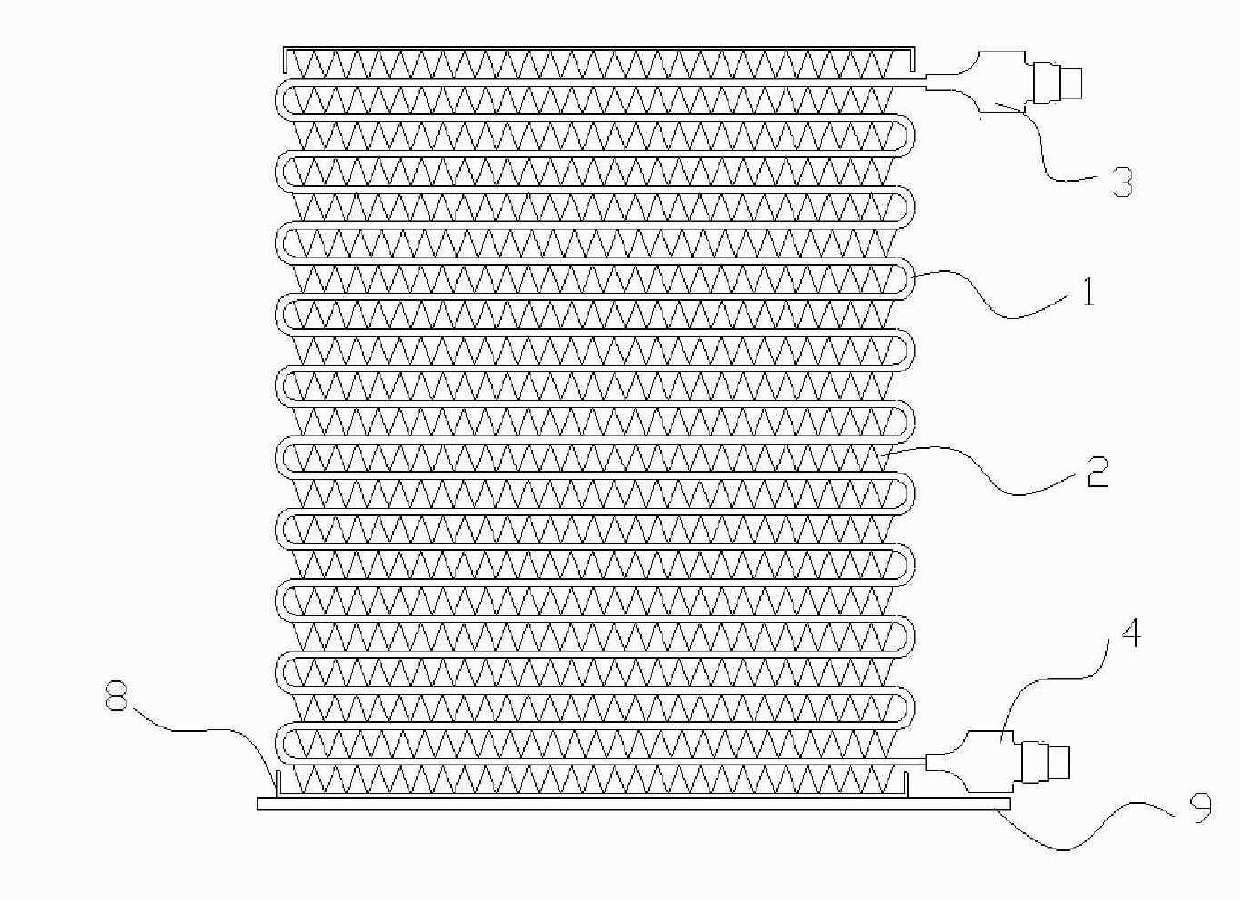

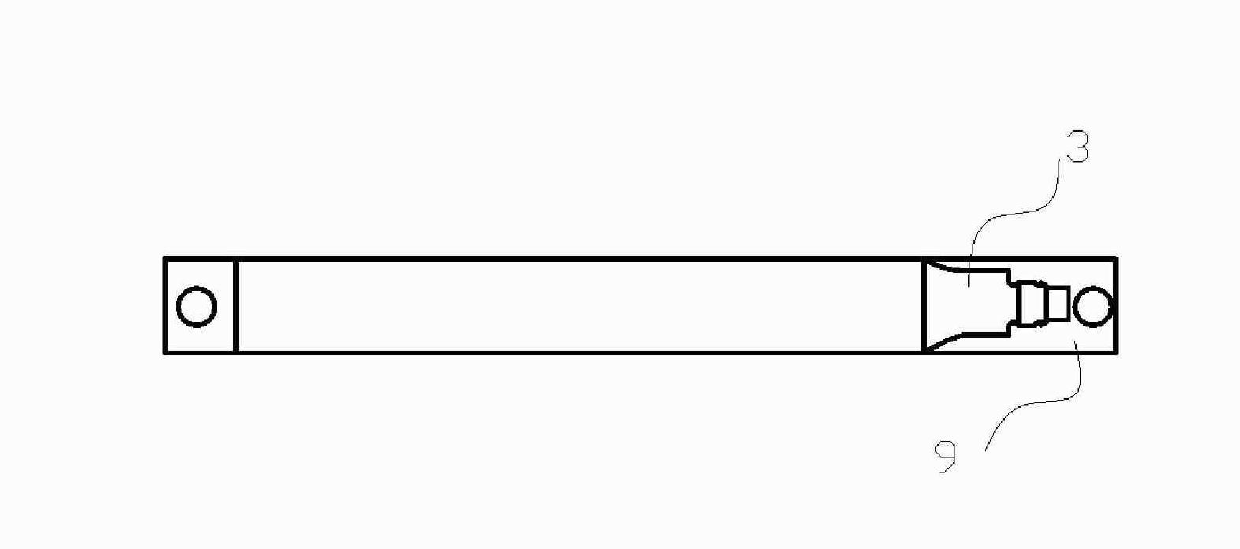

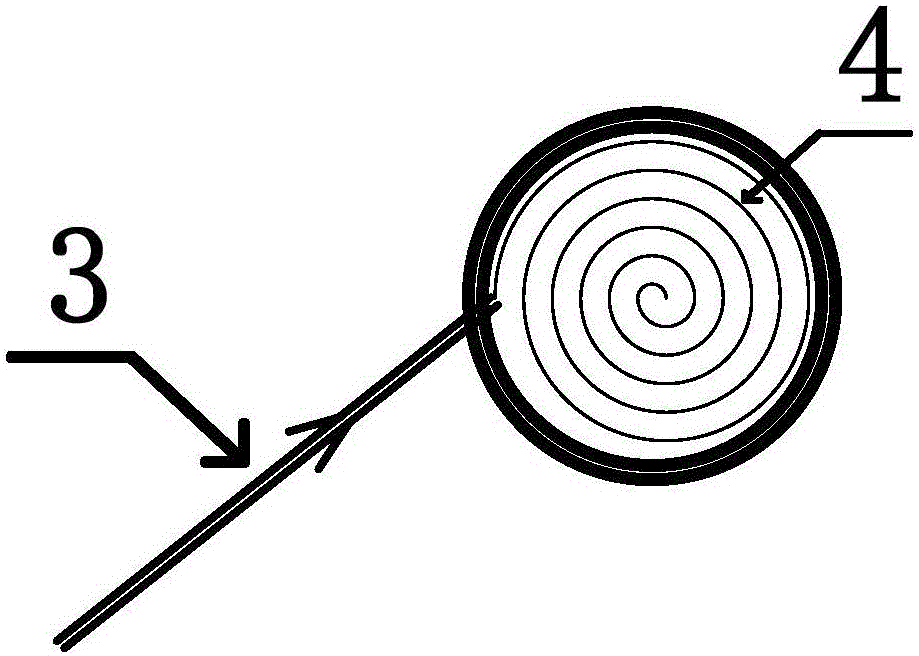

Coiled parallel flow condenser for refrigerator

InactiveCN101769656AReduce chargeCompact structureEvaporators/condensersMaterial consumptionEngineering

The invention relates to the technical field of refrigerating components, in particular to a coiled parallel flow condenser for a refrigerator, which is bent into a multi-layer coiled shape by using aluminum flat pipe at a certain radius of arc. The condenser comprises a flat pipe, fins, an inlet pipe assembly and an outlet pipe assembly, and is characterized in that the flat pipe in a coiled shape is formed by multiple bending arcs and straight lines; radiation sheets are equipped between adjacent coiled flat pipes; radiation sheets on outer side on both ends are equipped with side plates; inlet and outlet ends of the flat pipe are connected with the inlet pipe assembly and the outlet pipe assembly, respectively; the inside of the flat pipe is equipped with multiple micro-passages through which refrigerant passes. The condenser is compact in structure, high in heat exchange performance in unit volume, small in flow resistance, less in material consumption, less in cold medium filling quantity.

Owner:ZHEJIANG KANGSHENG CO LTD

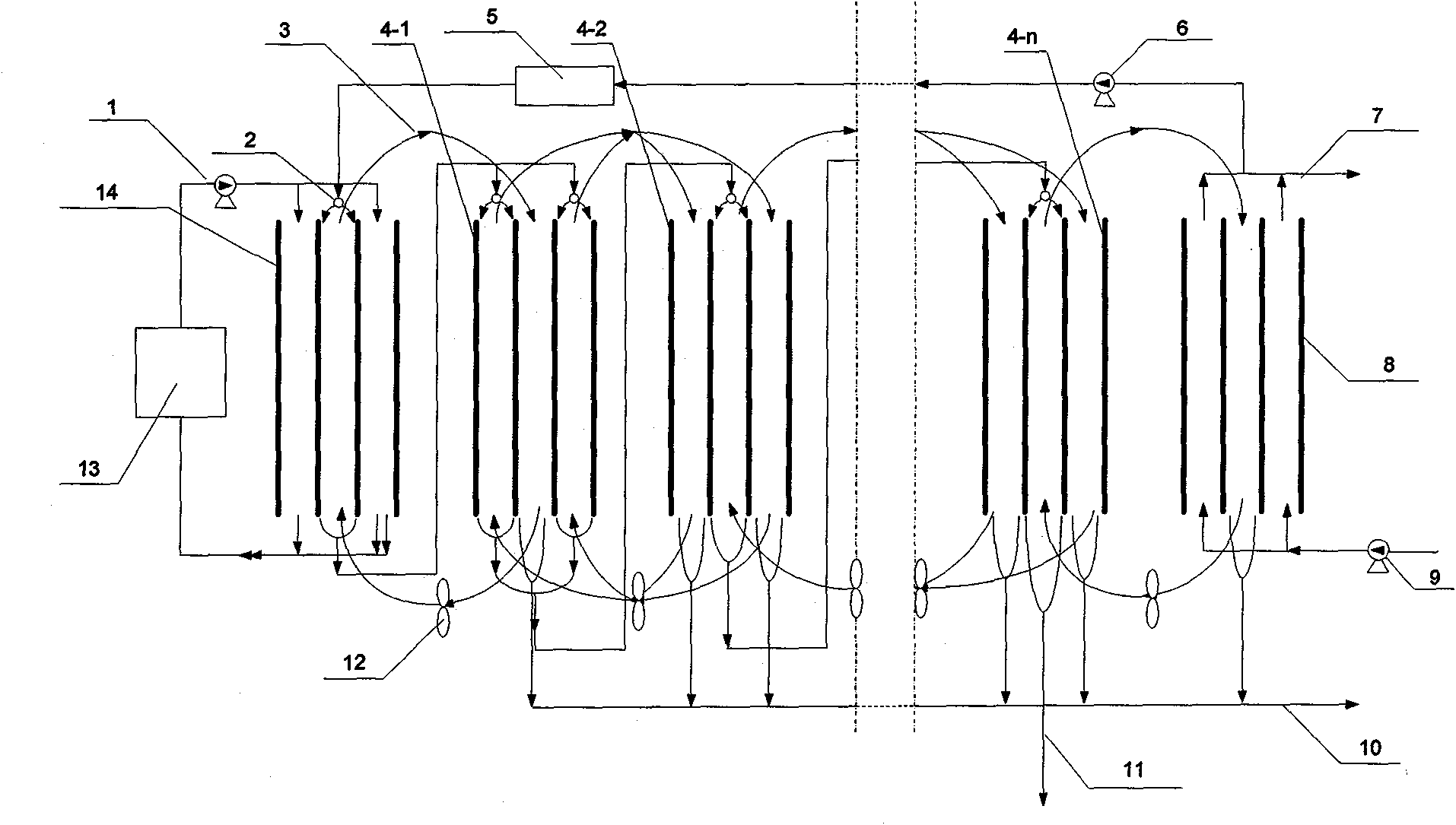

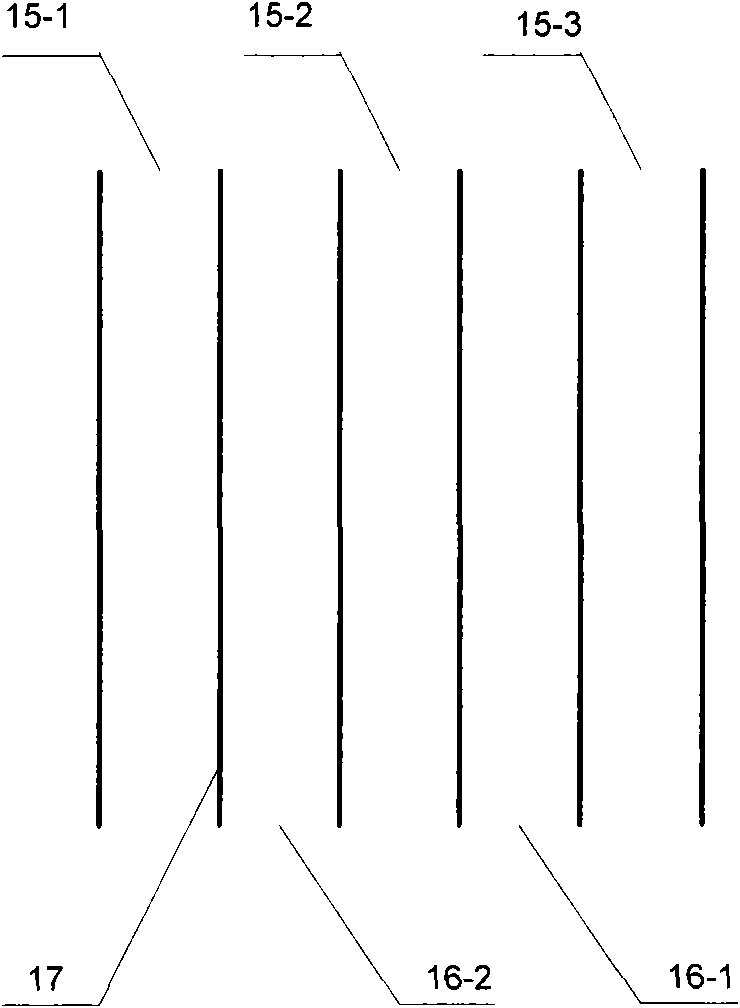

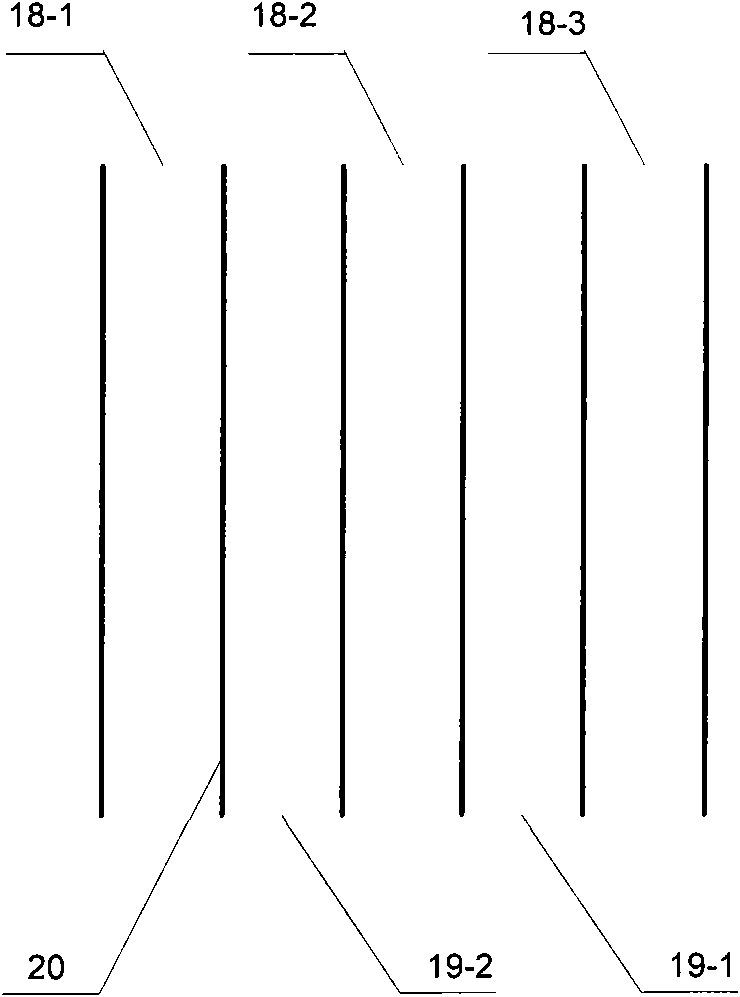

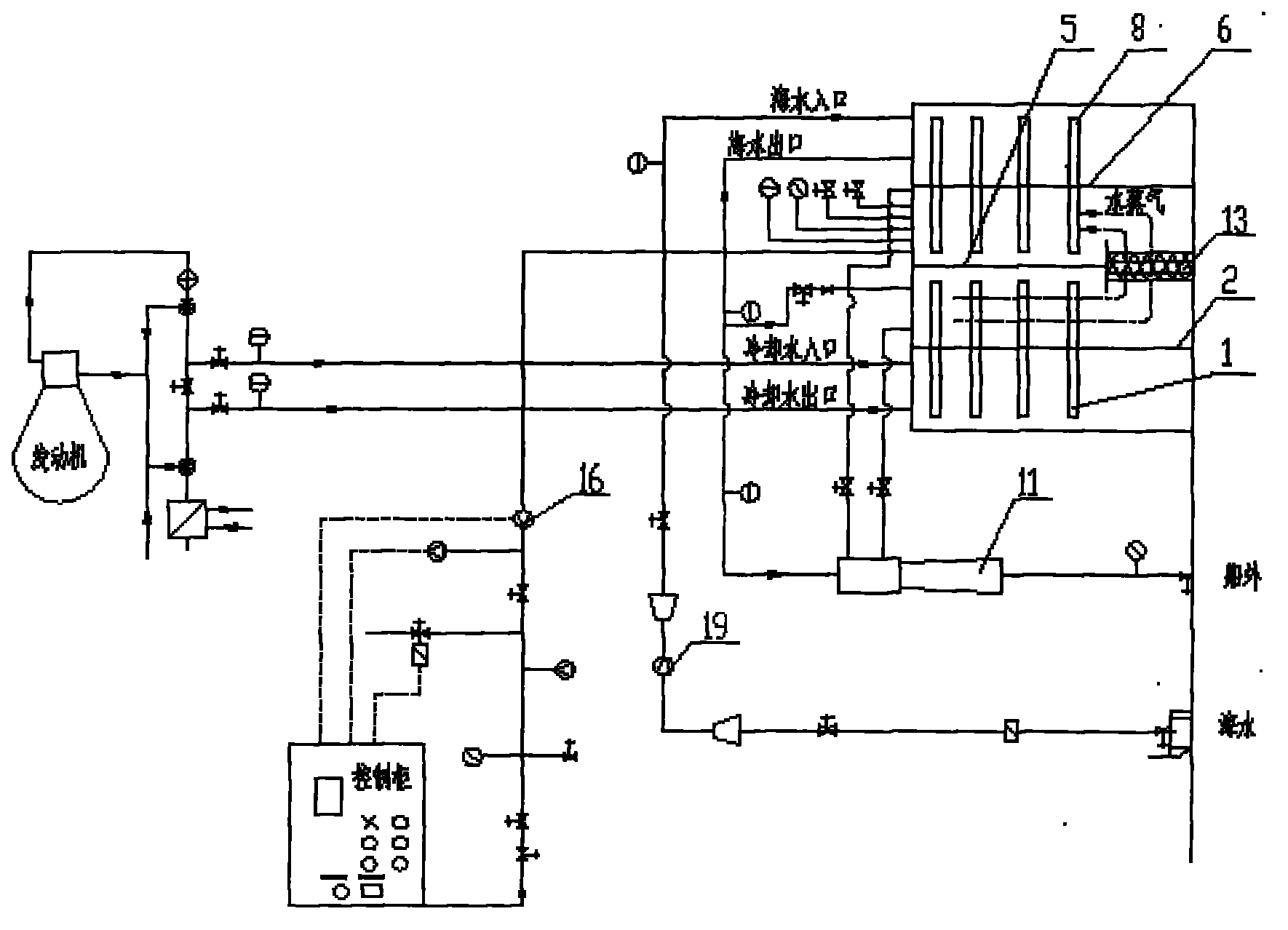

Constant-pressure multiple-effect evaporation condensation sea water desalination device with air medium

InactiveCN101921036AReduce consumptionImprove performanceSeawater treatmentMultistage water/sewage treatmentWater desalinationEnergy recovery

The invention discloses a constant-pressure multiple-effect evaporation condensation sea water desalination device with an air medium, which mainly comprises a low-and-medium temperature heat source (13), a first-stage heating evaporator (14), an evaporation condenser (4) and a last-stage condenser (8). The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser (8) are installed in sequence closely, and the low-and-medium heat source (13) and the first-stage heating evaporator (14) are connected together. The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser are all formed by combining a plurality of heat exchange plates which are arranged from left to right in sequence, and a gap is reserved between every two adjacent heat exchanging plates to form a flow channel for heat exchange fluid. By adopting the plate-type heat exchange principle, the sea water desalination device realizes multiple-effect air humidification and dehumidification evaporation and condensation for sea water desalination under constant pressure. Heat and moisture transfer is performed between sprayed sea water and overflowing air, and the condensation latent heat of fore effect heat and moisture air can be absorbed at the same time, and therefore, energy recovery is realized and the fore effect heat and moisture air can be condensed to obtain fresh water.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

High-speed precision crystal silicon laser etching apparatus and method

InactiveCN102201493AEasy to controlNo pollution in the processLaser beam welding apparatusSemiconductor devicesHeat-affected zoneAutomatic control

The invention provides a high-speed precision crystal silicon laser etching apparatus and method. The method comprises the following steps: (A) placing a single crystal silicon wafer or a polycrystalline silicon wafer on a four-dimensional precision moving platform for laser processing by using a specific manipulator, with the aid of an observation and monitoring CCD system; (B) precisely focusing a laser beam on the surface of the silicon wafer, scanning the surface of the silicon wafer at a high speed by using a three-dimensional dynamic focusing vibration mirror in cooperation with a specific telecentric field lens, rising the surface etching temperature of the silicon wafer, and feeding phosphorous paste or phosphoric acid to a high-speed laser etching line at the same time; and (C) removing the manipulator for the silicon wafer and fixing next silicon wafer at the same time, and repeating the above drilling mode at. The method has the following advantages: laser has the characteristics of non-contact, no environment pollution and easy controllability, and can achieve the automatic control; since the laser focusing spot is in a micrometer size or smaller, thereby achieving high silicon wafer etching accuracy, small heat affected zone at the edge, and little damage to the substrate; and the power generation efficiency of the crystal silicon is further improved, and the production cost is further reduced.

Owner:周明

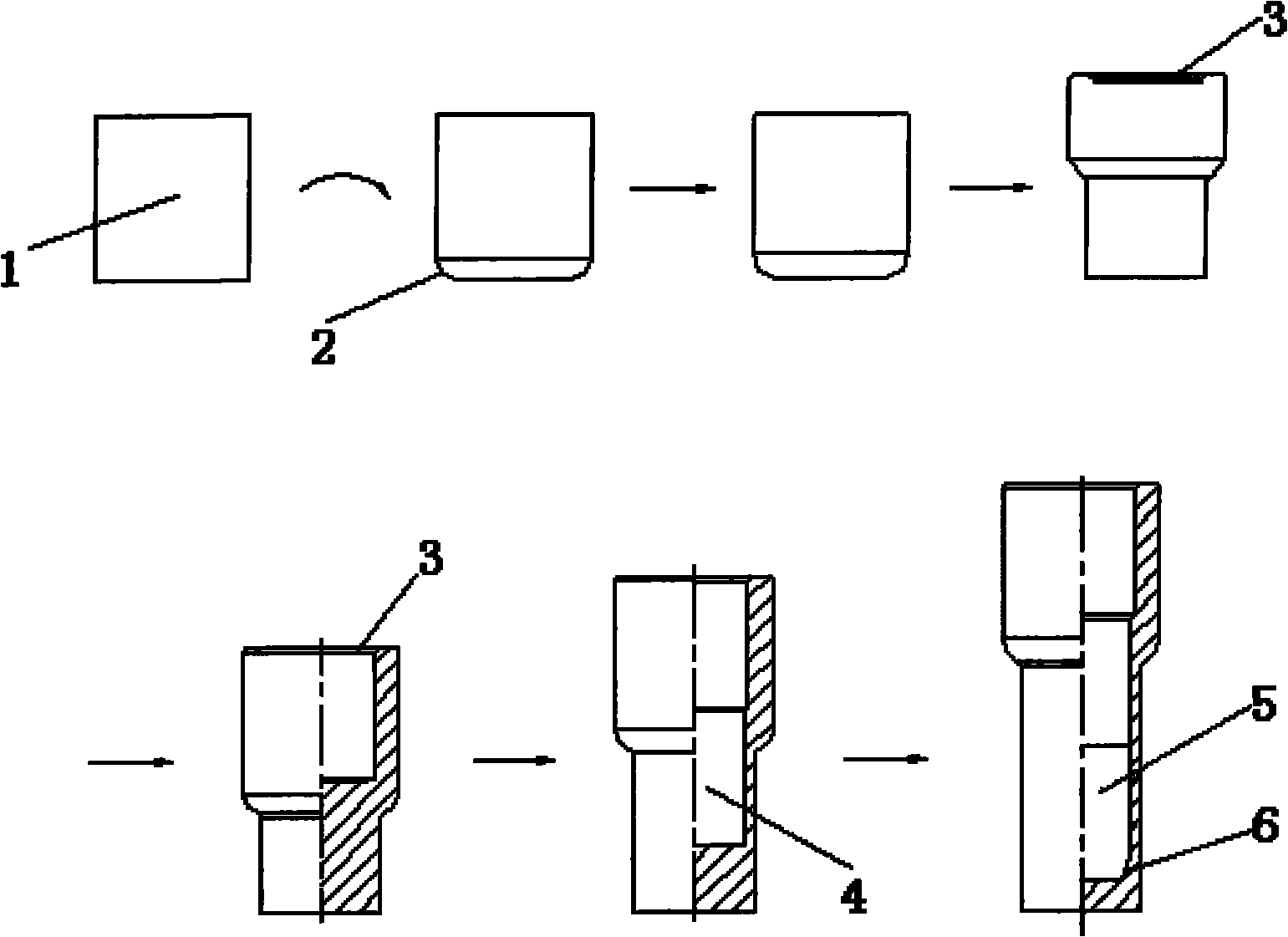

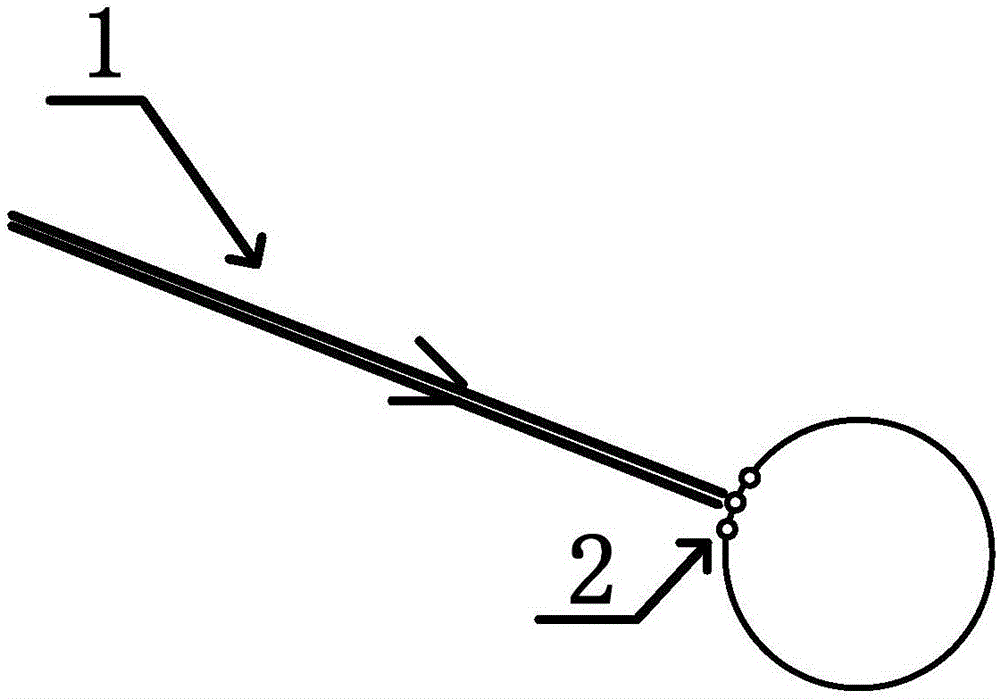

Process for manufacturing outer sleeve blanks

InactiveCN102152061ALess consumablesTight material structureMetal-working apparatusMaterials scienceRaw material

The invention discloses a process for manufacturing outer sleeve blanks, which is characterized by comprising the following steps: preparing billet raw materials into wire rod materials; then carrying out phosphate surface treatment on the wire rod materials; respectively carrying out shpheroidizing annealing, phosphating, fashioning and sizing processing on the wire rod materials subjected to roughing; and finally, completing the process of forming outer sleeve blanks in a cold heading forming machine. The process disclosed by the invention has the advantages that because the outer sleeve blanks are formed at one step by using a cold heading machine, the production efficiency and product quality of the outer sleeve blank are improved, the raw materials are saved, and the production cost is reduced.

Owner:NINGBO ANCHOR FASTENERS INDAL

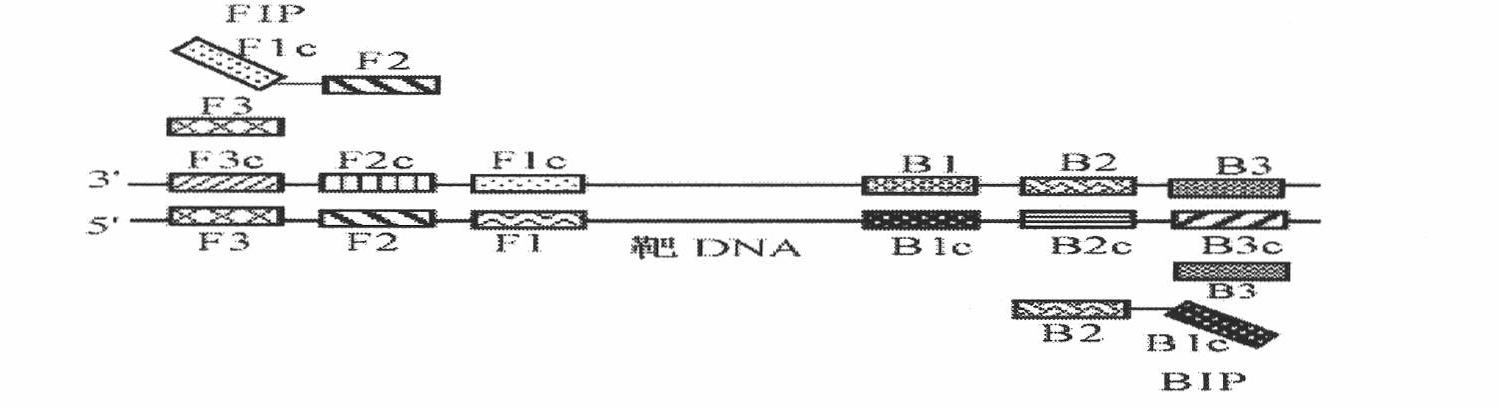

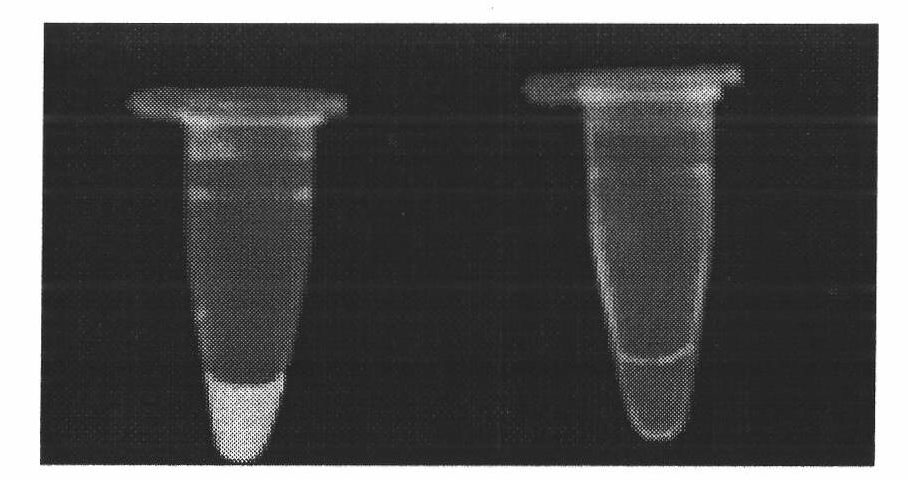

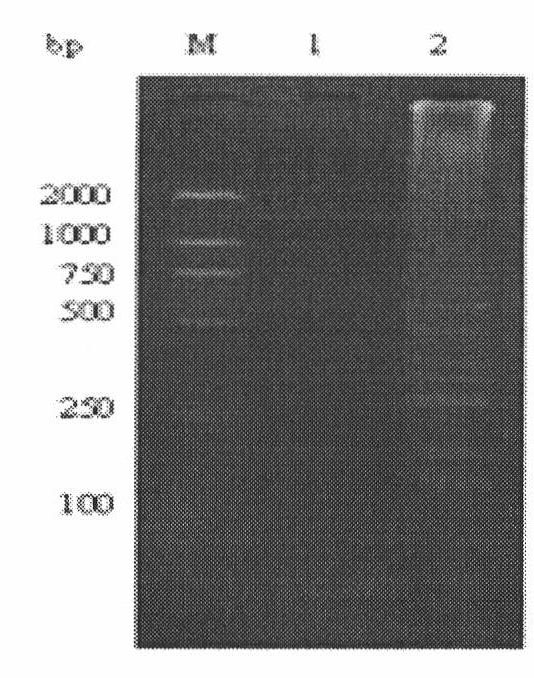

Loop-mediated isothermal amplification (LAMP) primer pair of bacillus cereus and detection method

InactiveCN101831493AStrong specificityImprove featuresMicrobiological testing/measurementMicroorganism based processesLoop-mediated isothermal amplificationToxin

The invention relates to a primer pair and a method required by loop-mediated isothermal amplification (LAMP) detection of bacillus cereus causing vomit food poisoning. The primer pair can be used for preparing an LAMP detection kit which can be used for the rapid detection of the bacillus cereus expressing vomitoxin. The specific solution scheme comprises the step of designing a plurality of groups of LAMP inside and outside primer pairs including the whole target sequence by using a cesA / B gene with plasmid pCERP, carried by the vomit bacillus cereus as a target sequence. The invention comprises a vomit bacillus cereus cesA / B gene specificity LAMP primer pair, optimized reaction conditions, LAMP, minimum detection limit measurement and positive result identification. The LAMP method adopted by the vomit bacillus cereus has the advantages of high efficiency and rapid operation, high sensitivity and specificity, convenience, practicability and the like.

Owner:WUHAN POLYTECHNIC UNIVERSITY

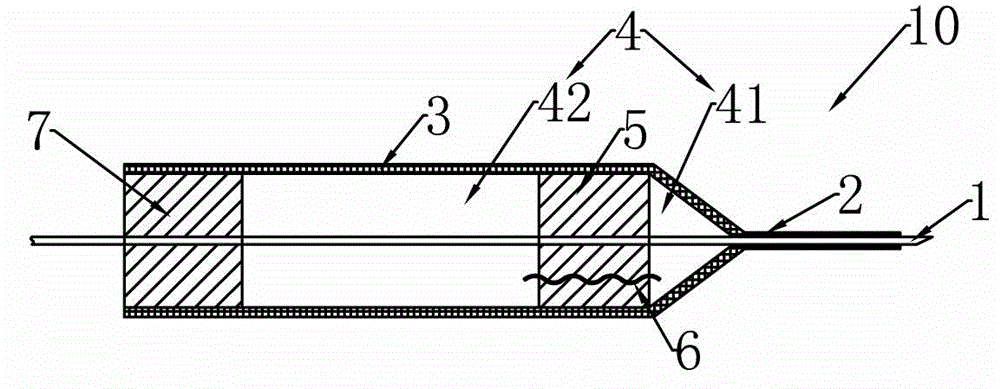

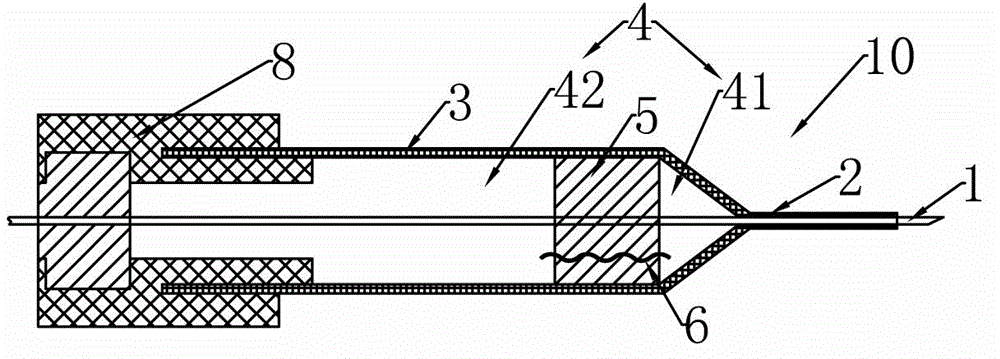

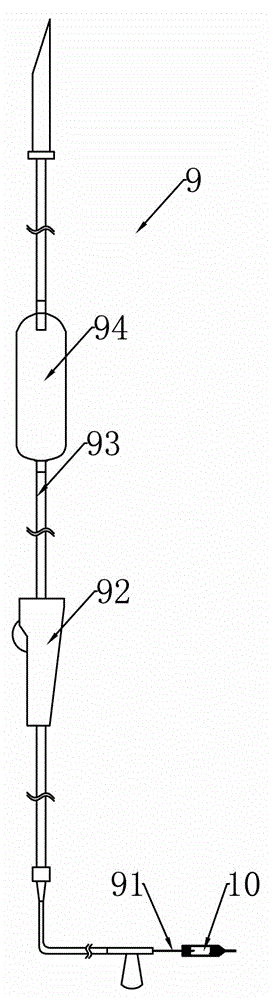

Automatically-sealed thrombus-prevented venous indwelling needle and use method thereof

The invention discloses an automatically-sealed thrombus-prevented venous indwelling needle and a use method thereof. The automatically-sealed thrombus-prevented venous indwelling needle comprises a needle base, a catheter and a puncture needle core, wherein the catheter is arranged at the front end of the needle base, and the puncture needle core axially penetrates through the needle base and the catheter; the internal cavity of the needle base is separated into a positive-pressure chamber and a transfusion chamber by a separation portion, the transfusion chamber is communicated with the catheter, and the separation portion is made from a medical sealing material; and the separation portion is provided with a seepage passage, so that liquid in the positive-pressure chamber can automatically and slowly flow into the transfusion chamber through the seepage passage when the positive-pressure chamber and the transfusion chamber have pressure difference. The automatically-sealed thrombus-prevented venous indwelling needle and the use method of the automatically-sealed thrombus-prevented venous indwelling needle have the beneficial technical effects that the catheter is sealed automatically when transfusion is suspended according to conventional operations, and the liquid in the positive-pressure chamber slowly flows into the transfusion chamber through the seepage passage; and the seepage speed is slowed down along with the reducing of the pressure difference between the positive-pressure chamber and the transfusion chamber, so that the positive-pressure chamber can maintain positive pressure for a long time.

Owner:浙江汉禾医疗器械有限公司

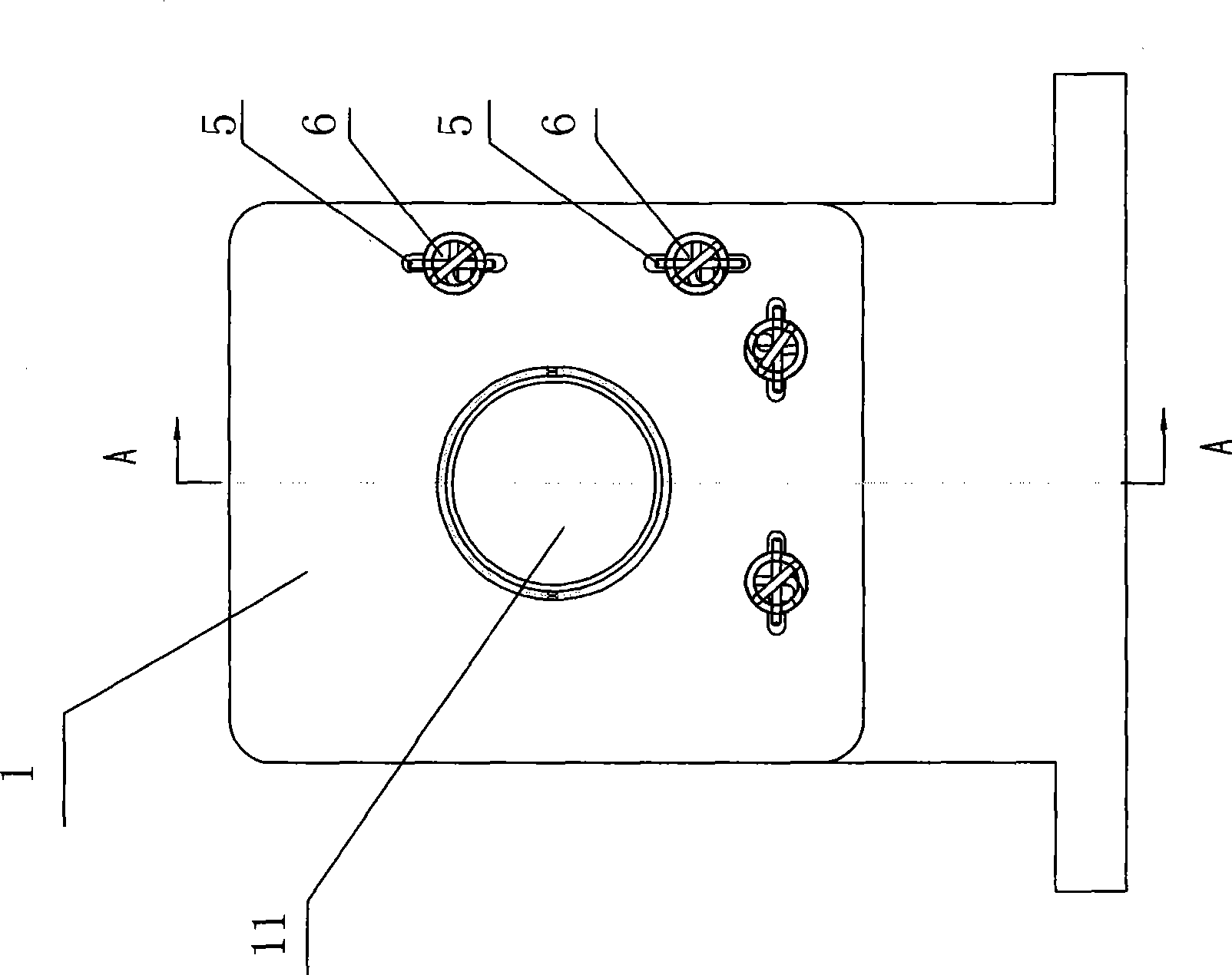

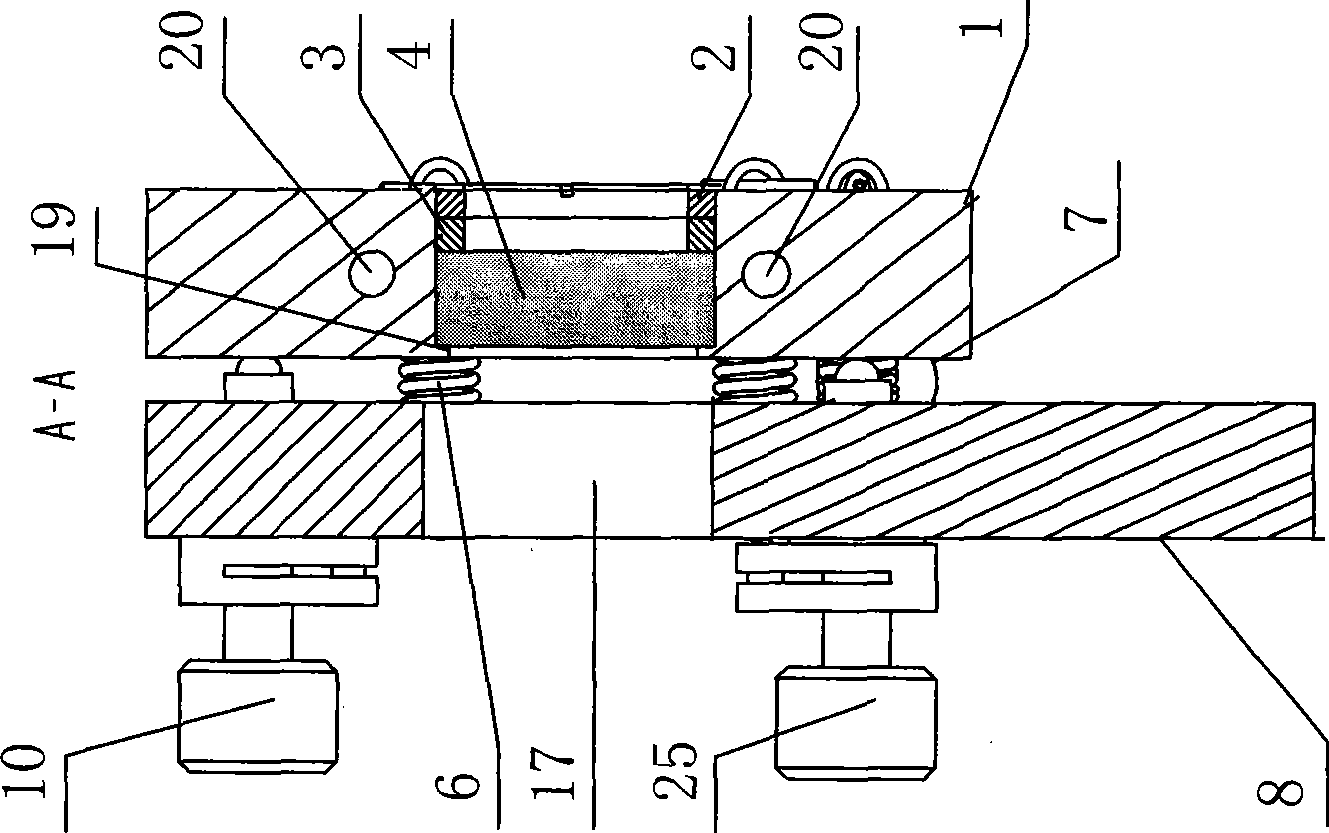

Optical regulation lens frame suitable for mobile process full-solid state high power laser

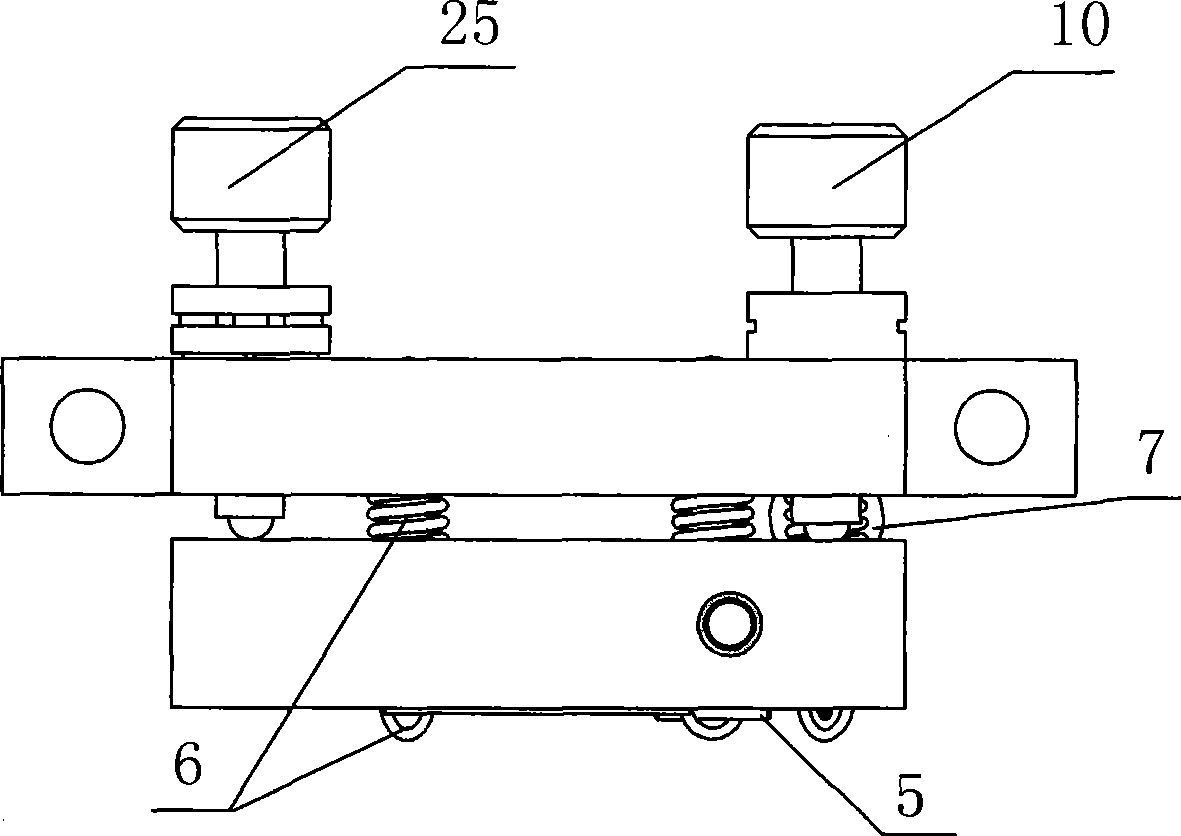

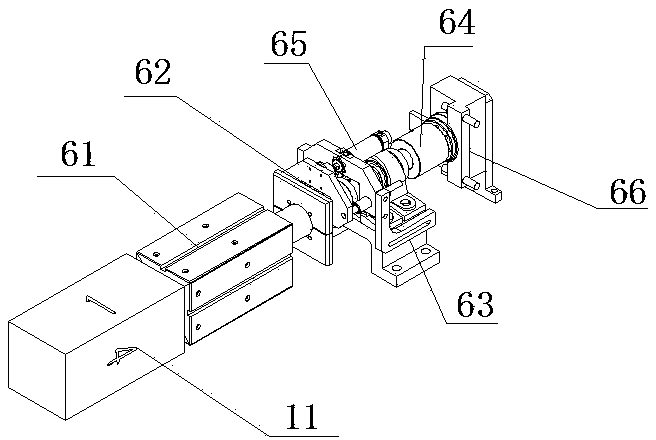

InactiveCN101470236AEasy to change the anglePrecise positioningLaser constructional detailsMountingsAll solid stateCamera lens

An optical adjusting mount capable of movably processing all-solid-state high power lasers comprises a frame, a support and a fine adjustment screw pair, wherein a lens hole of the frame is internally equipped with a baffle ring, a retainer ring is disposed on the front of the baffle ring, four tension spring holes are positioned on the frame, the back face of the frame is equipped with a V-type groove, a concave groove and a ball tapered-groove, the side face of the frame is equipped with a cooling water inlet and an outlet, the support is equipped with four tension spring holes, two holes for the fine adjustment screw pair and a ball tapered-groove which correspond to the frame, the frame and the support are connected through tension springs, each of the ball tapered-grooves of the frame and the support are inlaid with a ball, the fine adjustment screw pair is respectively mounted in the two holes for the fine adjustment screw pair of the support, the front ends of the fine adjustment screw pair are respectively located in the V-type groove and the groove. The optical adjusting mount has the advantages of scientific reasonable design, compact structure, low material consumption and low cost, further utilizes the baffle ring made of low-hardness fine heat conductivity red copper to press the lens on the end face, thereby effectively reducing the lens temperature, and utilizes the V-type groove and the ball for positioning, thereby realizing stable and reliable groove limiting.

Owner:DALU AUTOMATION TECH SHENYANG

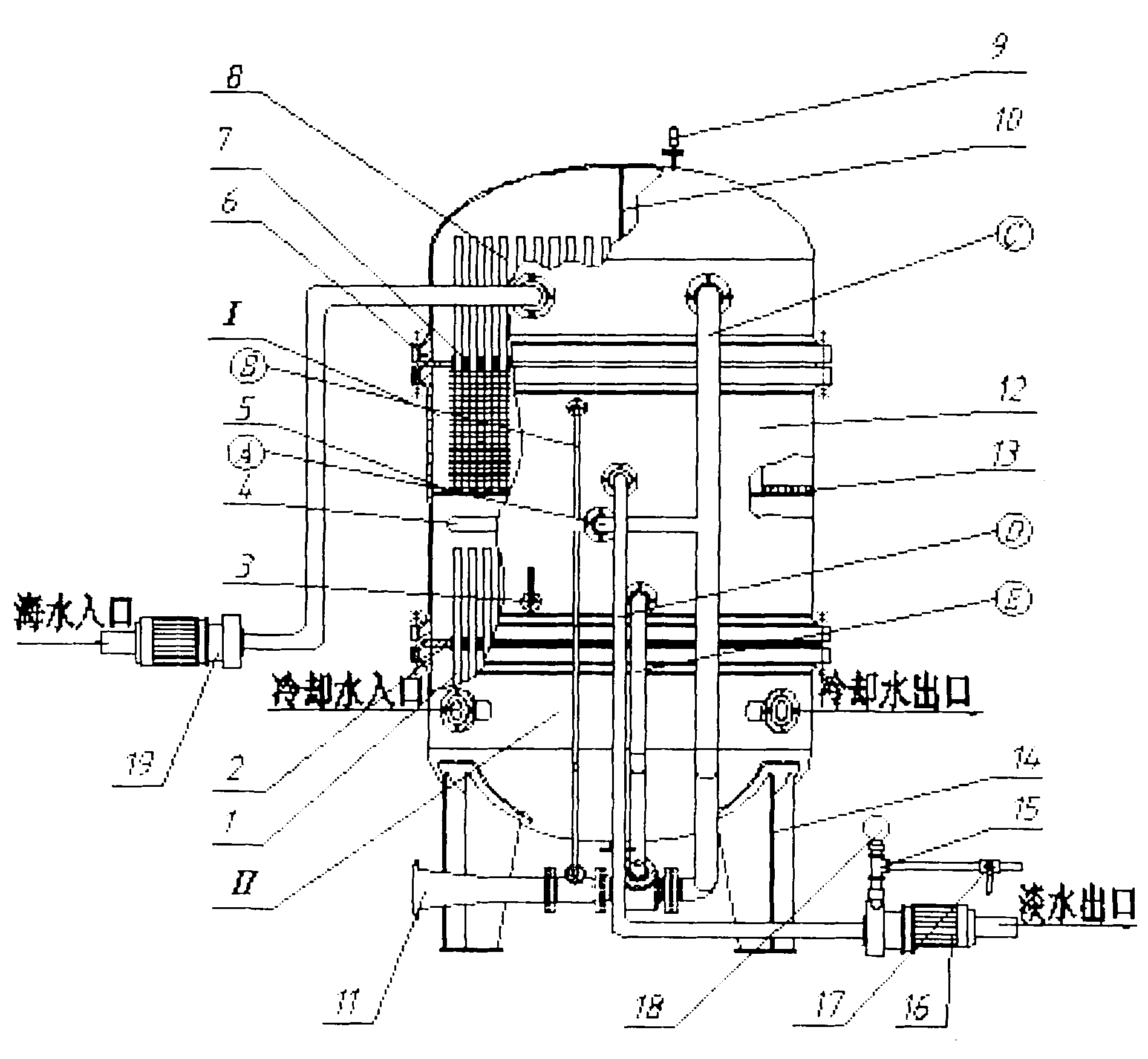

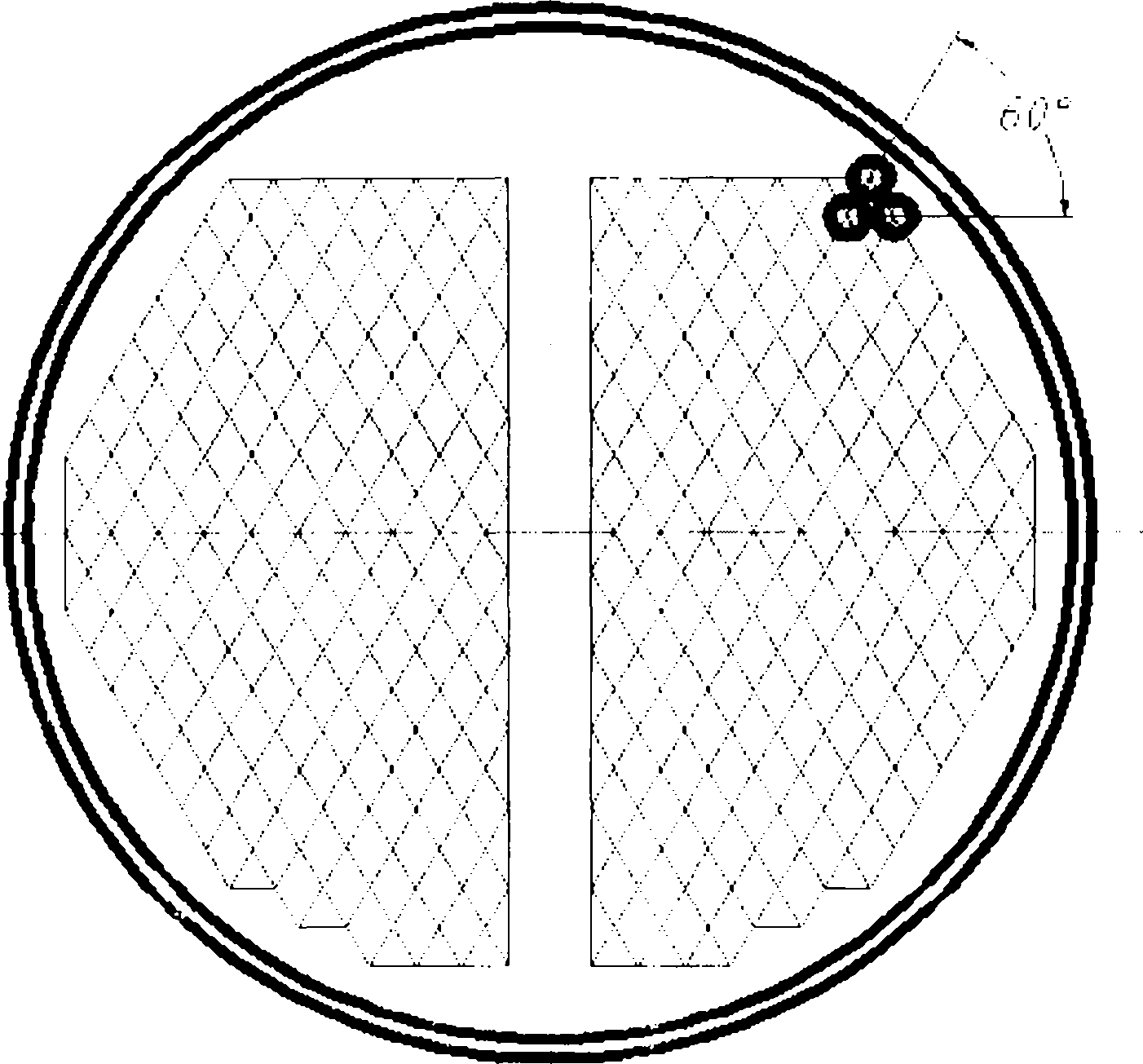

Marine heat pipe type seawater desalination device

InactiveCN103449548AImprove cooling effectIncrease profitGeneral water supply conservationSeawater treatmentBoiling pointWater cycling

The invention belongs to the field of seawater desalination, and particularly relates to a marine heat pipe type seawater desalination device. The marine heat pipe type seawater desalination device is composed of a pressure gage, a liquidometer, heat pipes, a liquid distributor, a baffling plate, a snuffle valve, a cylinder body, a support, a one-way valve, a fresh water pump, a jet flow vacuum pump, a seawater pump, a partition plate, a demister and connecting pipelines. The marine heat pipe type seawater desalination device provided by the invention fully utilizes the advantage that the heat conductivity coefficient of a gravity heat pipe is high, adopts the heat of the cooling water of a ship engine as a heat source, and can greatly reduce the seawater boiling point under the vacuum environment created by the jet flow vacuum pump driven by a centrifugal pump; the seawater is distilled under the lower boiling point, thus the seawater desalination device provided by the invention has the advantages that the manufacture is simple, the structure is compact, the material consumption is less, the dual purposes that the cooling water of the ship engine is recycled and fresh water of a ship body is autarkical are achieved, the maintenance is convenient, the cost is low, the service life is long, and the installation space is small.

Owner:QINGDAO UNIV OF SCI & TECH

Special organic nutrient solution for cultivating edible mushroom and the prepn. and application thereof

The composition of special-purpose organic nutrient liquor for raising yield of edible mushroom is composed of (wt%) 10-20% of rice-washed water, 15-50% of ash solution, 20-50% of fresh animal manureprepared liquor or domestic fowl excrements liquor, 5-15% or carrot juice, 5-15% of soybean milk or soy sprouts juice and 5-20% of spinach juice. The above-mentioned raw materials are mixed and can be made into the invented nutrient liquor, and its application method incldues the modes of spraying, perfusion and soaking. It is safe and has no side effect.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Impact-resistant and fireproof glass fiber reinforced phenolic aldehyde board and preparation method thereof

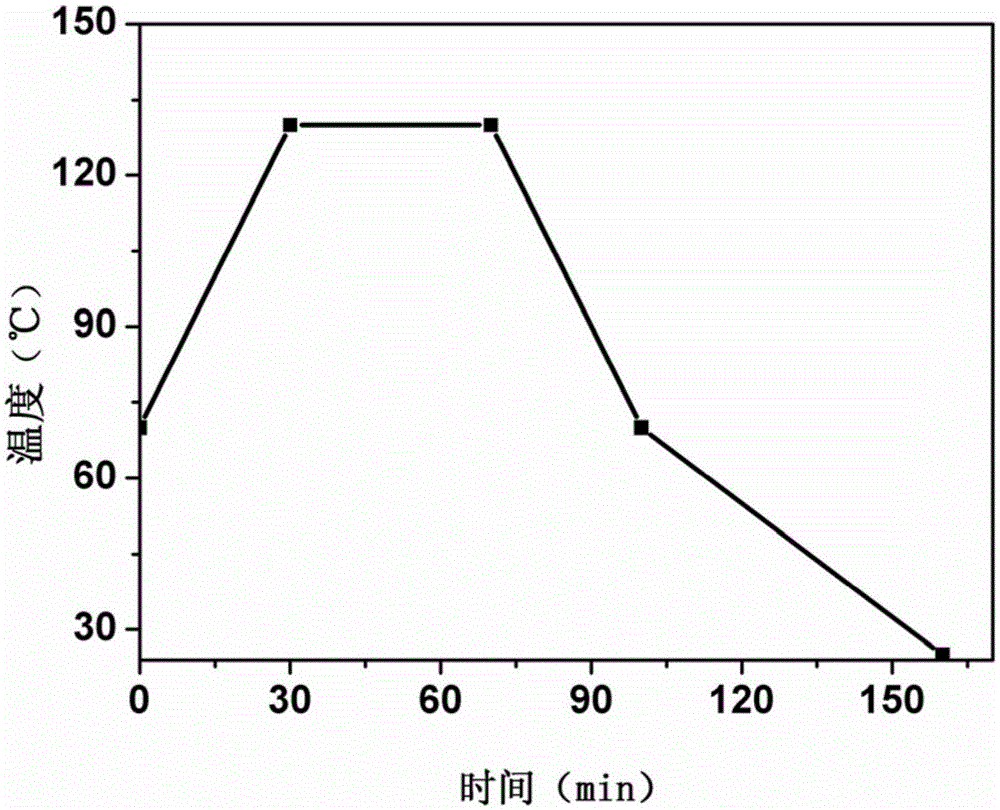

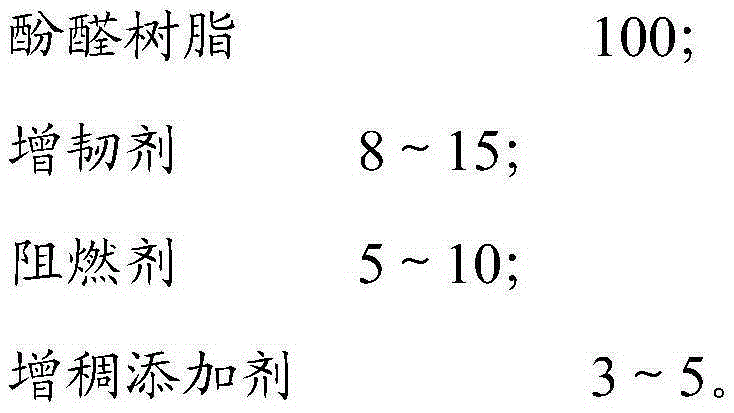

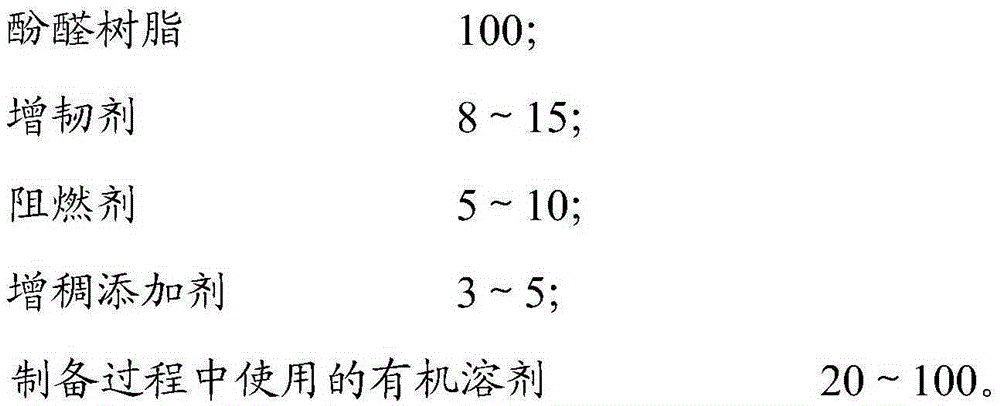

ActiveCN105255101AImprove toughnessImprove high temperature thixotropic propertiesSynthetic resin layered productsMetal layered productsResin matrixResin-Based Composite

The invention relates to an impact-resistant and fireproof glass fiber reinforced phenolic aldehyde board and a preparation method thereof. The board adopts a laminating structure and is formed through hot pressing of multiple layers of prepregs according to the thickness of the board, wherein each prepreg comprises components in percentage by mass as follows: 65%-75% of fiber reinforced materials and 25%-35% of phenolic resin matrix; the phenolic resin matrix comprises components in parts by mass as follows: 100 parts of phenolic resin, 8-15 parts of a toughening agent, 5-10 parts of a fire retardant and 3-5 parts of a thickening additive. The impact resistance of the glass fiber reinforced phenolic aldehyde board is improved by more than 50% while compared with that of conventional phenolic resin based composite, the flame retardant property meets the requirements of CCAR25 and FAR25, particularly, the density of smoke produced after the board is burnt for 4 min is lower than 10, a preparation process is simple, the processing manufacturability and the economical efficiency are good, and the impact-resistant and fireproof glass fiber reinforced phenolic aldehyde board is particularly suitable for being used as a decorative liner plate to be mounted in cargo compartments of an airplane, a ship and a high-speed rail train.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

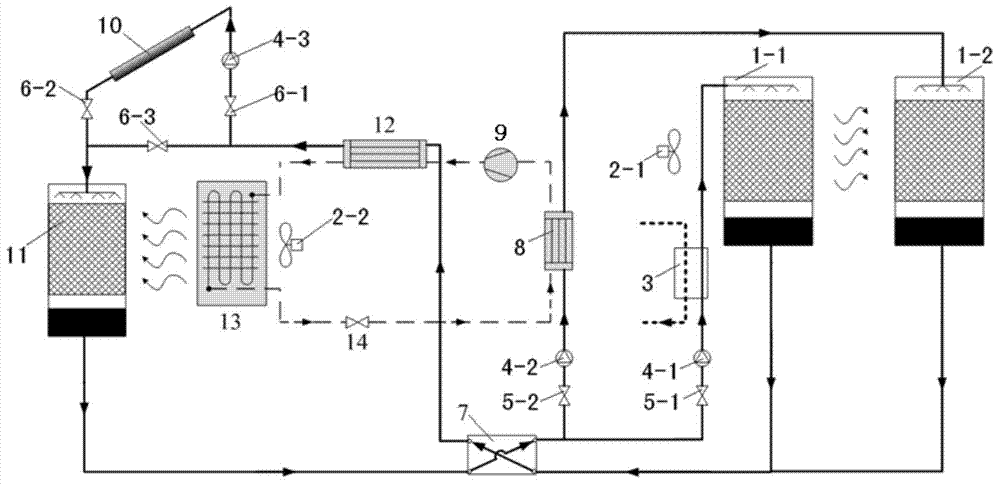

Low-grade heat source drive solution temperature changing two-stage solution dehumidification air conditioner

InactiveCN103791576AEasy to achieve dynamic matchingEasy to transportLighting and heating apparatusAir conditioning systemsEngineeringLoad following power plant

A low-grade heat source drive solution temperature changing two-stage solution dehumidification air conditioner comprises two fans, a solution cooler, an air condenser, a heat pump system, two dehumidifiers, a heat exchanger, a solar thermal collector and a regenerator. The heat pump system comprises an evaporator, a compressor, a solution condenser, the air condenser and a throttling device, wherein the evaporator, the compressor, the solution condenser, the air condenser and the throttling device are sequentially connected through a refrigerant pipeline, the two-stage temperature area dividing and humidification area dividing mode is adopted, a temperature changing dehumidification solution is utilized for treated heat and humid loads of fresh air, condensation heat of the heat pump and solar energy are utilized by the dehumidified dilute solution for regenerating, the solar thermal collector is utilized for achieving effective utilization of solar energy according to the weather condition, and energy consumption of the whole fresh air treating process is obviously reduced. Heat dynamic matching of the components is achieved more easily, meanwhile, the problem that low-grade energy is hard to transport is solved, the system stability is high, only one set of heat pump system and one regenerator are adopted, and the structure is simple.

Owner:SOUTHEAST UNIV

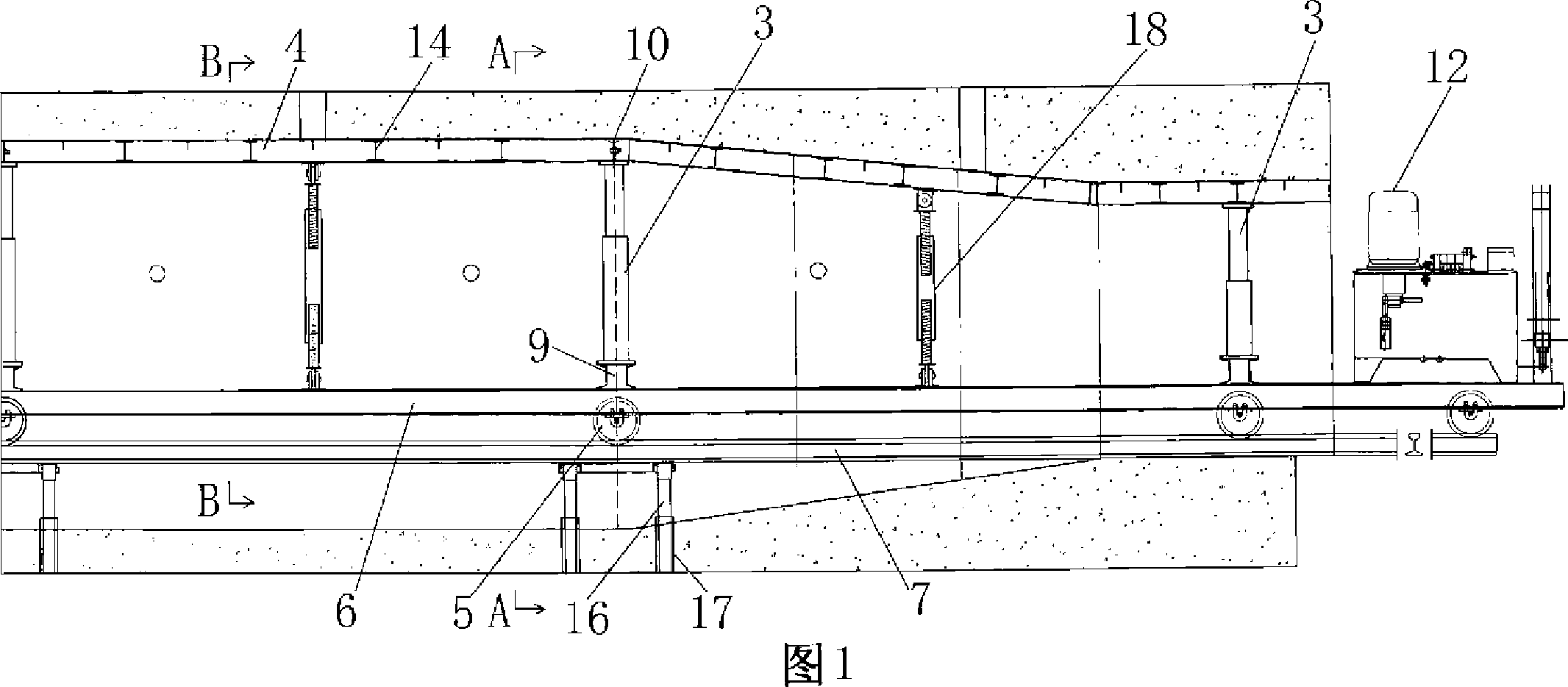

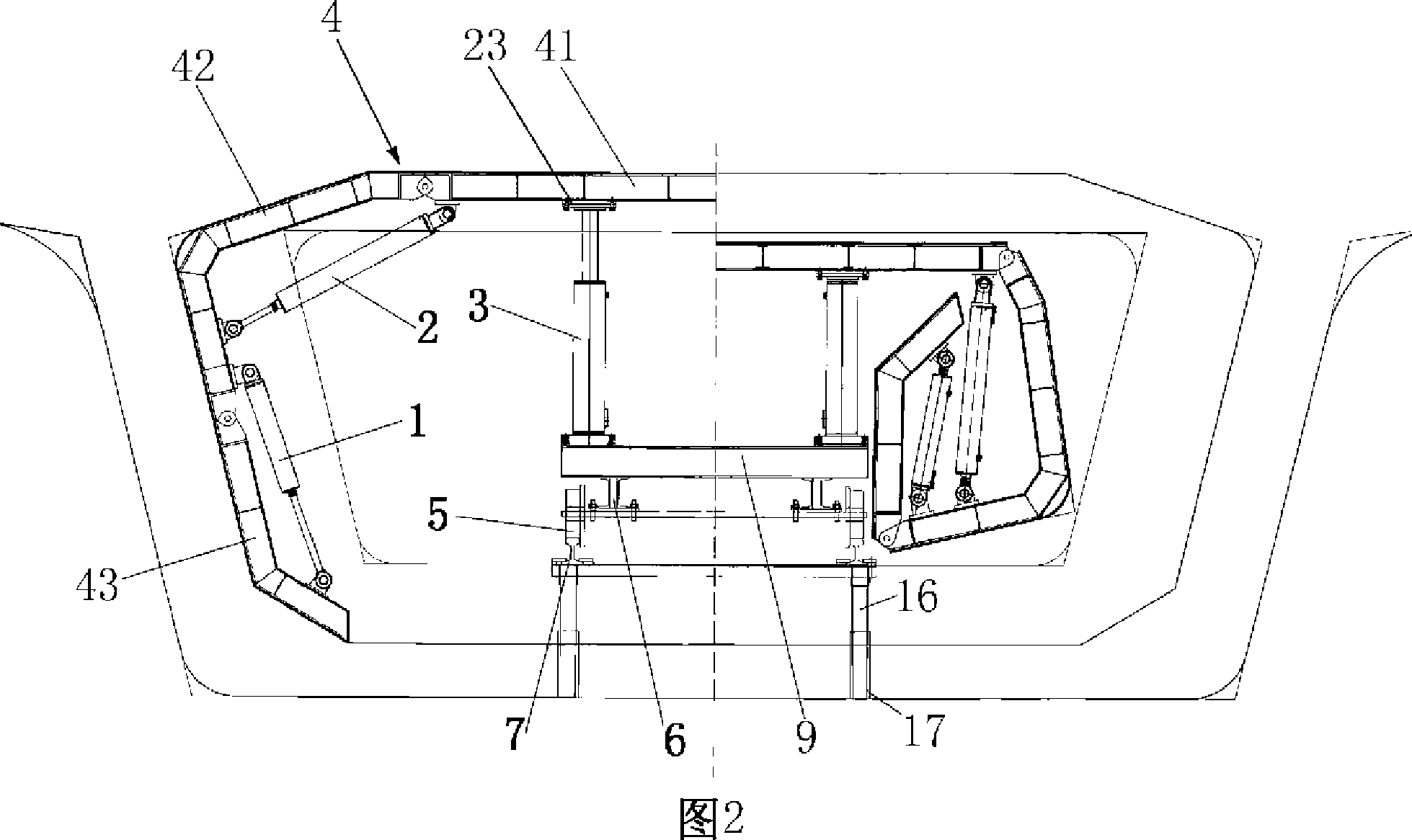

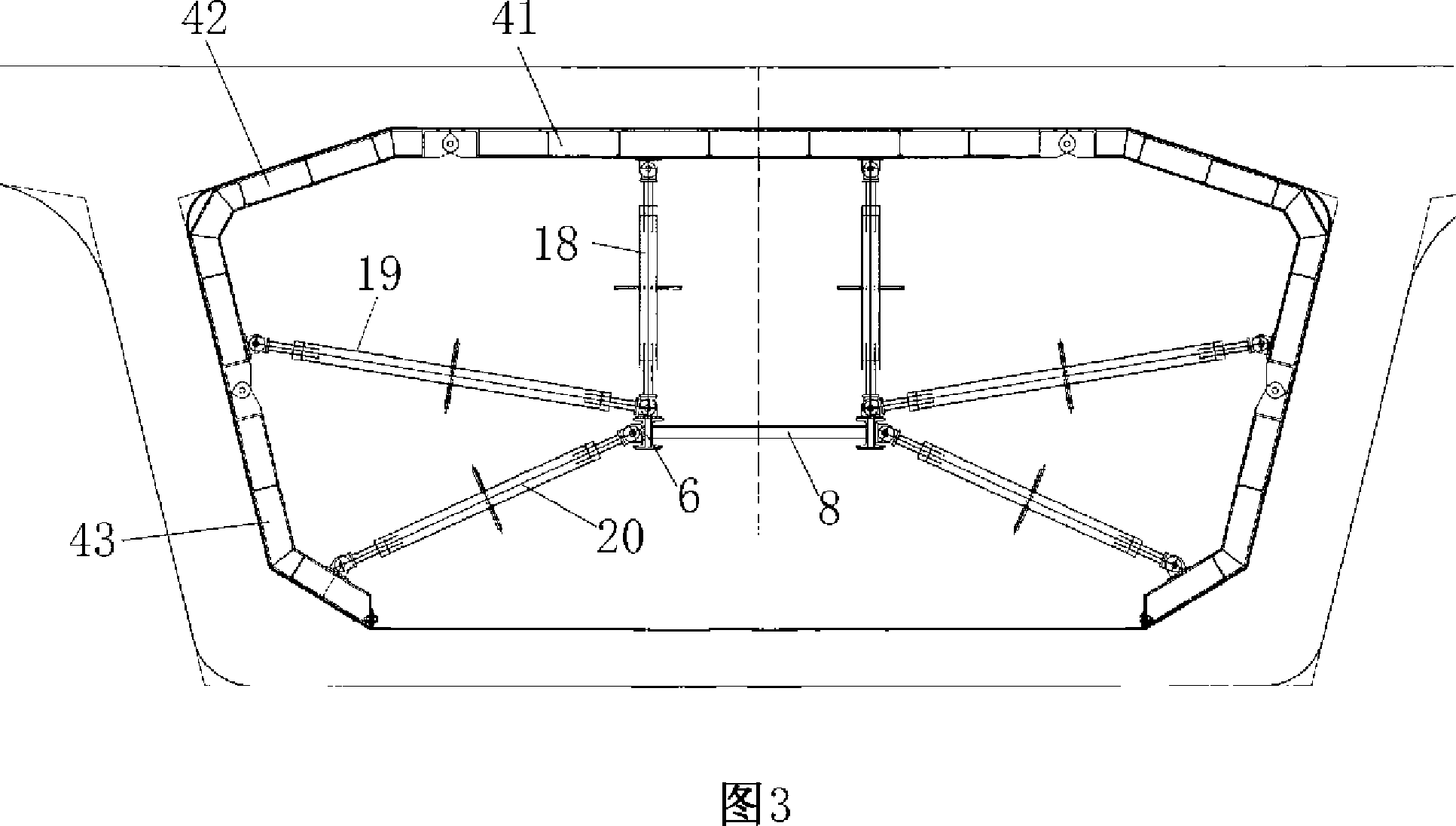

Full-automatic hydraulic prefabricated box girder inner formwork system

InactiveCN1970264ASimple structureLess consumablesMouldsCeramic shaping mandrelsInterior spaceVehicle frame

The automatic hydraulic premade box beam inner formwork system has the inner mold hinging with a pair of up corner mold and a lower corner mold, oil tank slanting upward connected between the top mold and the up corner mold, oil tank slanting downward connected between the top corner mold and the lower corner mold, bracket barricaded along the box beam at the center of the cavity bottom surrounded by inner molds supporting up steel track that has translation cart along it with the cart composed of walking wheel, frame, supporting base beam fastened on the frame, frame of the cart extending outside of the inner mold plate with hydraulic pump station and operation platform. It is simple, steel consumption effective, low in cost, improving inner space 25% than the traditional one.

Owner:杨秋利

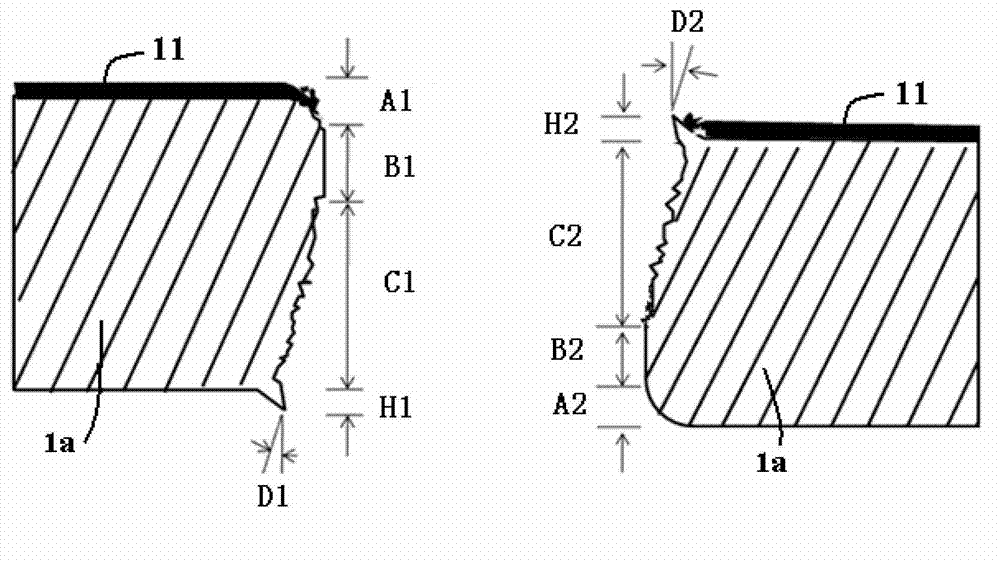

Laminated glass corner processing method and special worktable device

InactiveCN102717316ALess consumablesImprove processing efficiencyEdge grinding machinesGlass severing apparatusMaterial consumptionEngineering

The invention belongs to the technical field of glass processing, and in particular relates to a laminated glass corner processing method and a special worktable device. The processing method comprises the following steps of: preparing materials, and arranging a spacing layer between every two adjacent single glass pieces to form laminated glass; placing the whole laminated glass on the magnetic area of a worktable; and pressing a strong permanent magnet II on the protection layer of the whole laminated glass, wherein the magnet applies clamping force on the whole laminated glass, and thus the laminated glass is fixed to the magnetic area of the worktable. The laminated glass corner processing method provided in the invention is capable of avoiding a bonding step in the conventional method and a plurality of steps such as cleaning for removing a binder caused by the binding step, thereby reducing the problem of environmental pollution caused by cleaning the binder. The magnetic force is taken as clamping force, so that the material consumption is reduced, the processing efficiency is obviously improved, and the production cost is reduced; and therefore, the laminated glass corner processing method is especially suitable for corner processing of ultra-thin glass in electronic products.

Owner:ZHEJIANG XINGXING TECH CO LTD

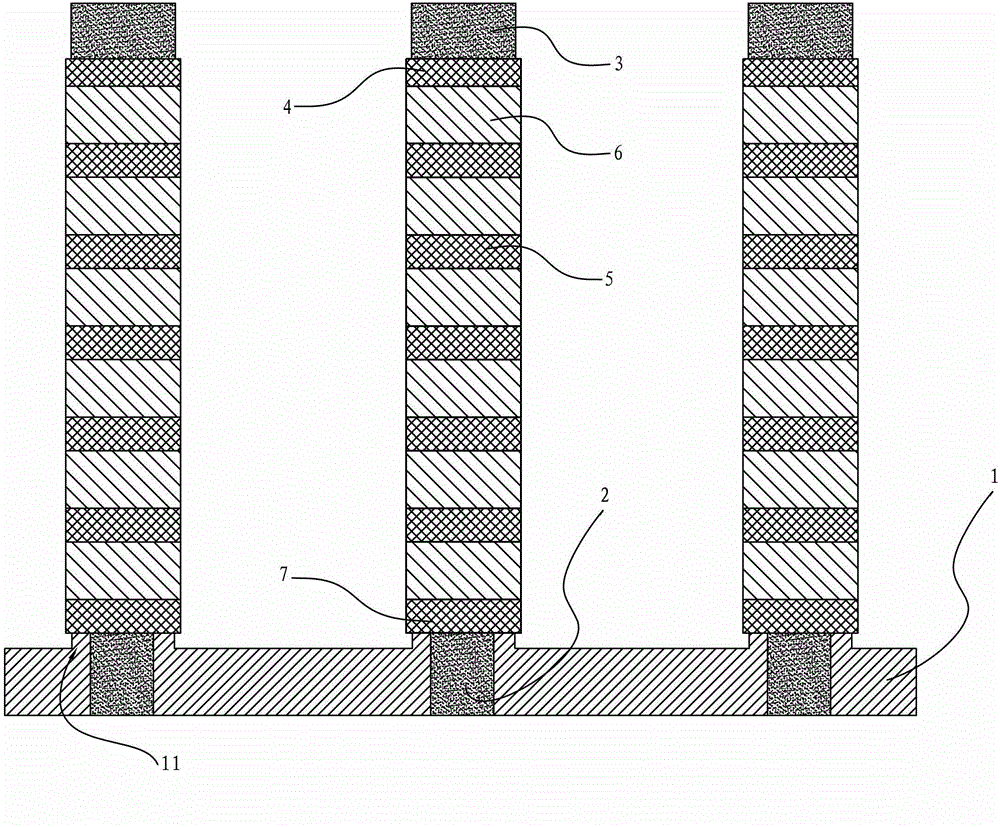

Free curved surface product reverse engineering modeling prototyping method based on three-dimensional optical scanning

InactiveCN107818590ALight and dark effects are smallHigh speed3D modellingPoint cloudOptical scanners

The invention discloses a free curved surface product reverse engineering modeling prototyping method based on three-dimensional optical scanning. The free curved surface product reverse engineering modeling prototyping method based on three-dimensional optical scanning includes over-scanning, reverse modeling, quality analysis, rapid prototyping, and printing of the final three-dimensional model,and is characterized by pasting mark points on the front and back surfaces of a free curved surface product and setting a rotating disk at the same time, realizing integrity and accuracy of scanningby means of auxiliary paste points on the rotating disk, utilizing a non-contact three-dimensional optical scanner to easily scan the full view of a multi-curved-surface product at higher speed, afterreverse modeling, utilizing Geomagic Qualify software to perform 3D comparison of the sampling point on the obtained reverse model and the point cloud data in the step (2), and according to the analysis and comparison situation, continuously correcting and scanning the point cloud data or the reverse three-dimensional model, so that the free curved surface product reverse engineering modeling prototyping method based on three-dimensional optical scanning has the advantages of guaranteeing the quality of the output product, improving the work efficiency, being low in the product quality reworkrate and saving printing of consumables.

Owner:童和平 +1

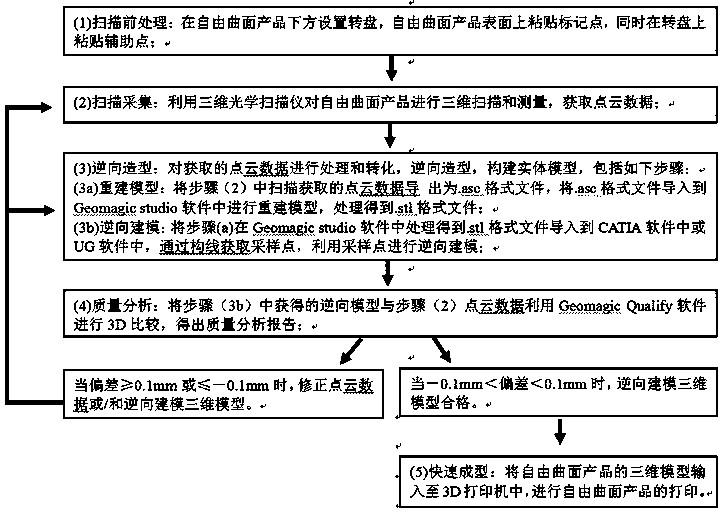

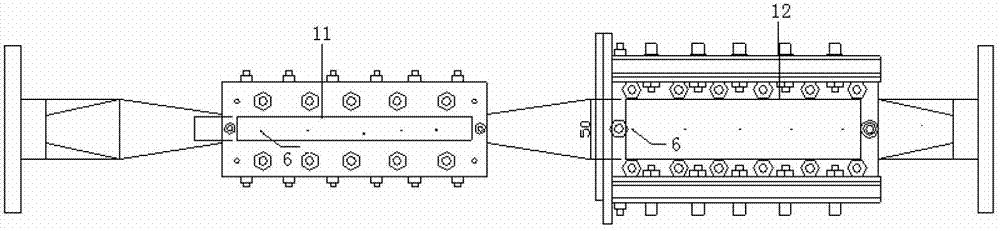

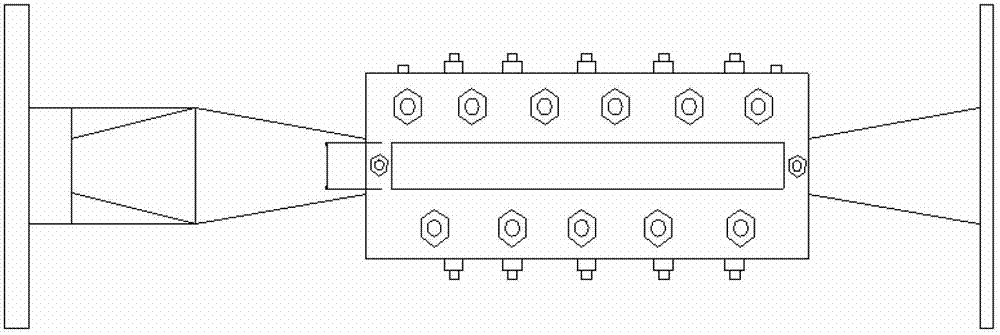

Venturi pipe and perforated plate combined-type hydrodynamic cavitation reaction chamber

InactiveCN103193310APromote degradationSimple structureWater/sewage treatment by oxidationGeneration processSquare cross section

The invention discloses a venturi pipe and perforated plate combined-type hydrodynamic cavitation reaction chamber, including a venturi pipe and a scoop-type porous plate device, wherein the venturi pipe is connected with the scoop-type porous plate device, the venturi pipe is composed of a contraction section, a throat straight pipe section, and a diffusion section which are in sequential connection; the inlet section and the outlet section of the venturi pipe and the throat straight pipe are all of square cross-section, two sides and top of the throat straight pipe are provided with first organic glass which is easy for observation, the bottom of the throat straight pipe section is provided with a first movable steel plate, the first movable steel plate is provided with a plurality of pressure detection holes which are convenient for collecting pressure at each measuring point in a real time manner. According to the invention, a scoop-type porous plate is stretched into the observation section to facilitate an experimenter to observe a cavitation generation process and acquire images; a matrix type and interlacing type distribution is used for the arrangement of porous plate holes to enhance the effects of hydrodynamic cavitation; and the positions of the venture pipe and the porous plate can be exchanged to degrade refractory contaminants of different nature.

Owner:ZHEJIANG UNIV OF TECH

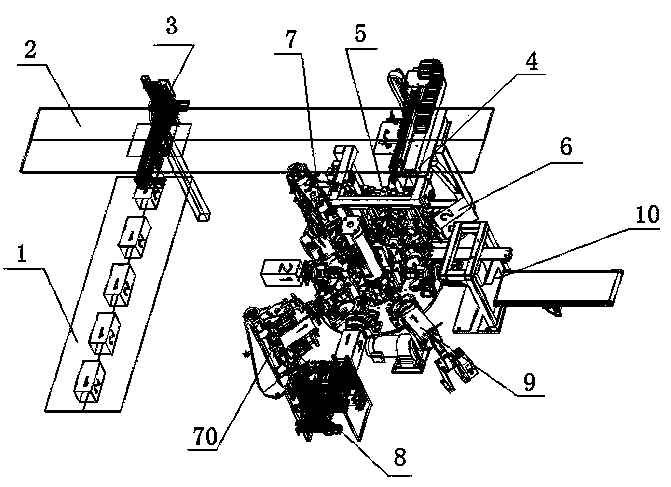

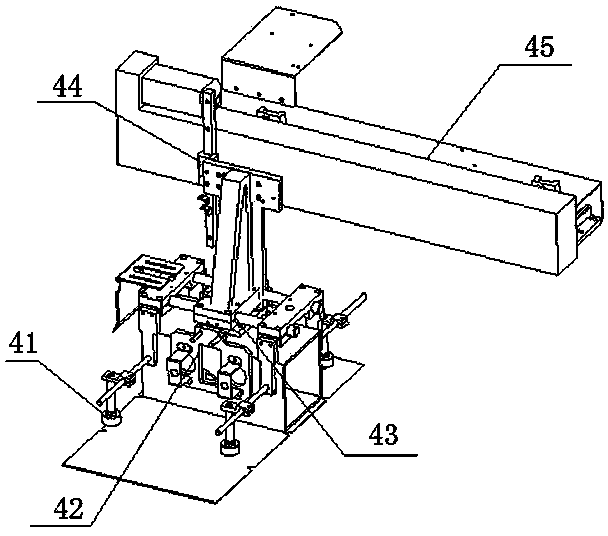

Wine box forming machine

ActiveCN104070705AImprove qualityGood effectBox making operationsPaper-makingPulp and paper industry

The invention discloses a wine box forming machine, and the forming machine comprises an ash box conveying belt, a surface paper conveying belt, an ash box transmitting and positioning mechanism, an ash box feed mechanism, an ash box periphery paper laminating mechanism, a paper box bearing and rotating mechanism, a first blank pressing mechanism, a second blank pressing mechanism, a surface paper cementing and laminating mechanism, an ash box bottom paper pressing mechanism and a box unloading mechanism. The forming machine can precisely position the surface paper and the ash box during lamination, when the ash box and the surface paper are laminated, the periphery of the ash box is firstly laminated, and then the bottom of the ash box is laminated so that they only have a jointed seam after lamination, whole forming paper box has the smooth outer surface, high quality and excellent effect, during the process, the surface paper is saved, according to production demands, the laminated width, height and length between the surface paper and the ash box can be automatically adjusted, thus the forming machine is suitable for formation of different-size paper boxes and has high intelligence, besides the paper box grabbing mechanism can precisely unload the finished paper box, and the wine box forming machine is high in yield and convenient to use.

Owner:广东力顺源智能自动化有限公司

Cutting equipment and cutting method of flexible thin film solar cell

InactiveCN103050578AEliminate short circuitImprove compatibilityFinal product manufactureSemiconductor devicesControl systemMaterial consumption

The invention discloses cutting equipment of a flexible thin film solar cell. The cutting equipment comprises an uncoiling mechanism, a conveying mechanism, a scoring mechanism, a cutting mechanism, a finished product coiling mechanism, a leftover coiling mechanism and a control system, wherein the control system is used for controlling the respective work of the uncoiling mechanism, the conveying mechanism, the scoring mechanism, the cutting mechanism, the finished product coiling mechanism and the leftover coiling mechanism. The invention also discloses a method for cutting the flexible thin film solar cell by the cutting equipment. The method comprises the following steps of uncoiling a cell to be cut, receiving and conveying the cell to be cut by the conveying mechanism, sequentially scoring and cutting the cell to be cut, coiling the obtained finished product by the finished product coiling mechanism, and coiling the cut leftovers by the leftover coiling mechanism. The cutting equipment and the cutting method have the advantages that the short-circuiting of the thin film solar cell caused by cutting can be thoroughly avoided by the cutting method; the automation degree is high, and the qualified rate of the flexible thin film solar cell and the production efficiency are improved; the material consumption amount is little, and the production cost is low; and the splitting process is simple, the equipment is simple, and the operation is convenient.

Owner:普尼太阳能(杭州)有限公司

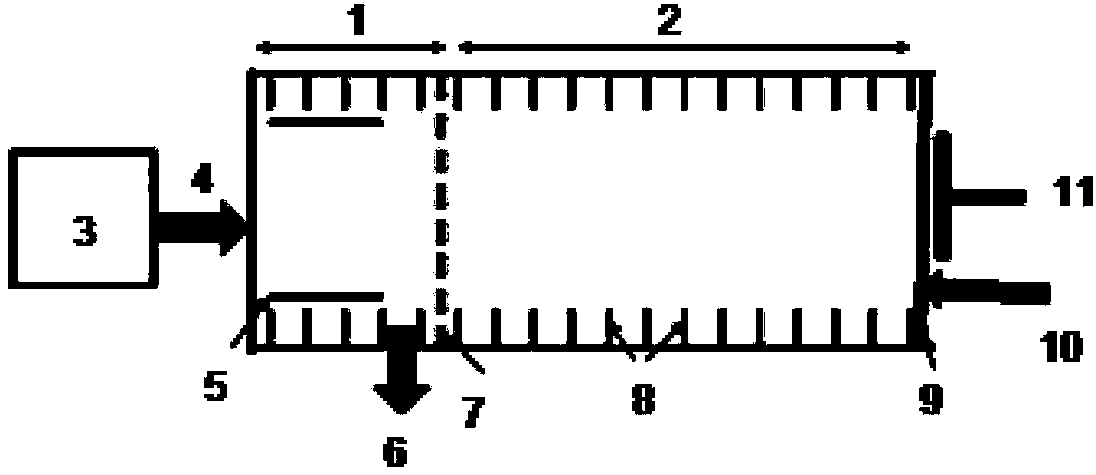

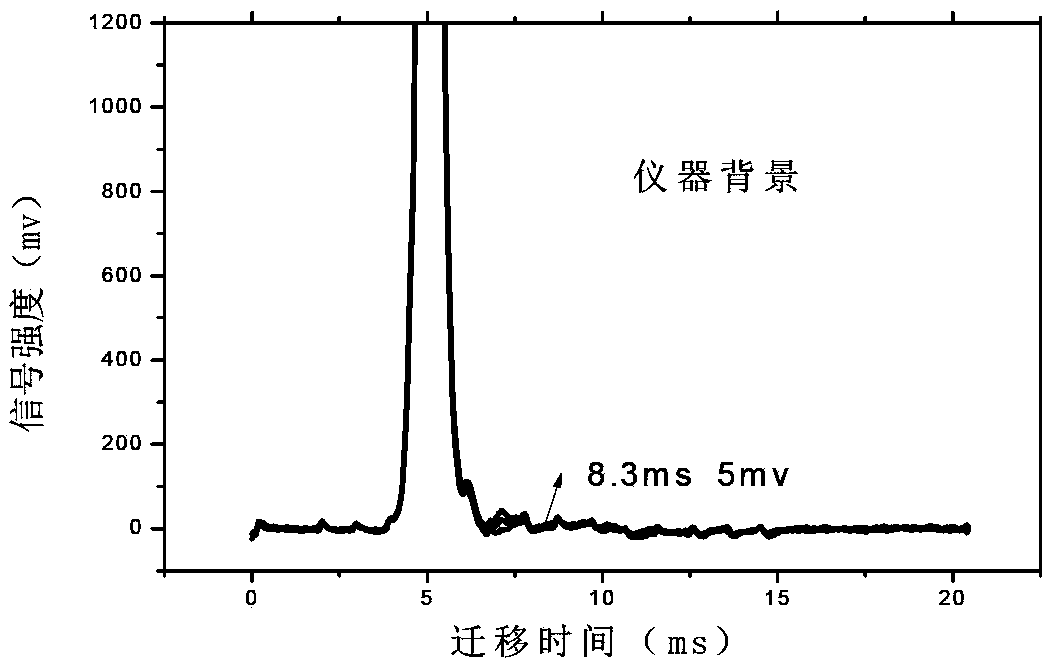

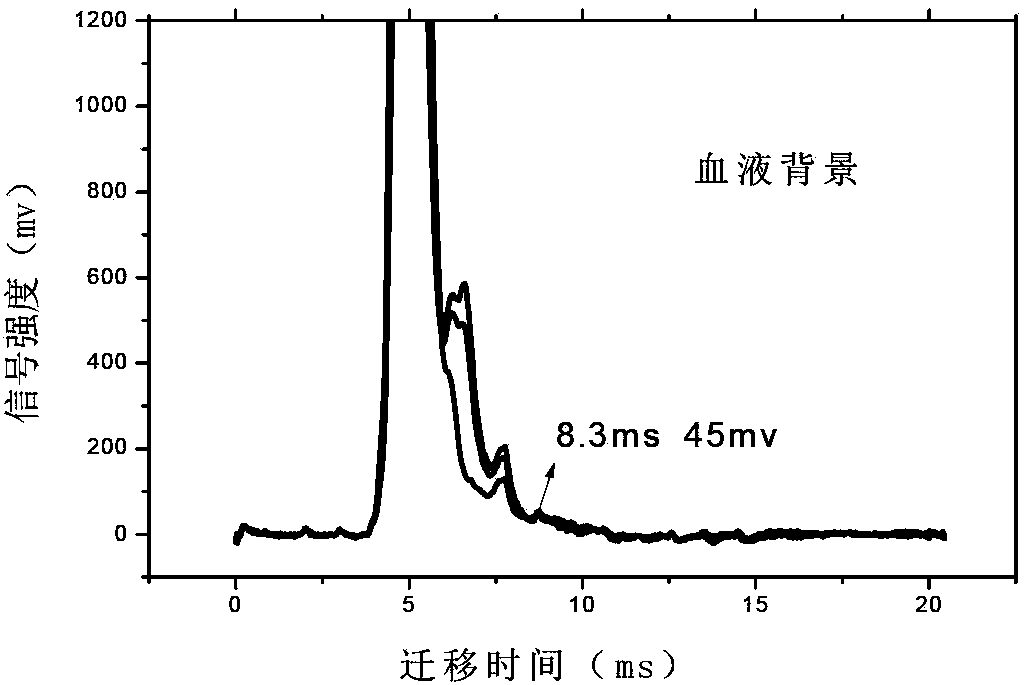

Accurate method for detecting propofol anesthetic in blood

InactiveCN103884771AShorten test timeEasy to carryMaterial analysis by electric/magnetic meansMedicineIon-mobility spectrometry

The invention discloses a rapid sensitive method for detecting a propofol anesthetic in blood. By adopting the ion-mobility spectrometry technology as a basic detection technology and adopting an anion mode, a rapid qualitative and quantitative analysis method for detecting the propofol anesthetic in the blood by ion-mobility spectrometry is established. The limit of detection can reach smaller than 1 ng (a concentration smaller than 0.1 ppm). The range of quantitative analysis concentrations is 0.5-20 ppm, thus meeting the human blood dose concentration analysis range. The analysis time of each sample is shorter than 30 s. No pretreatment technology is needed. The method is simple, rapid, efficient and high in reliability, and can be widely used for clinical-administration deep analysis and used for guiding the medication by a doctor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

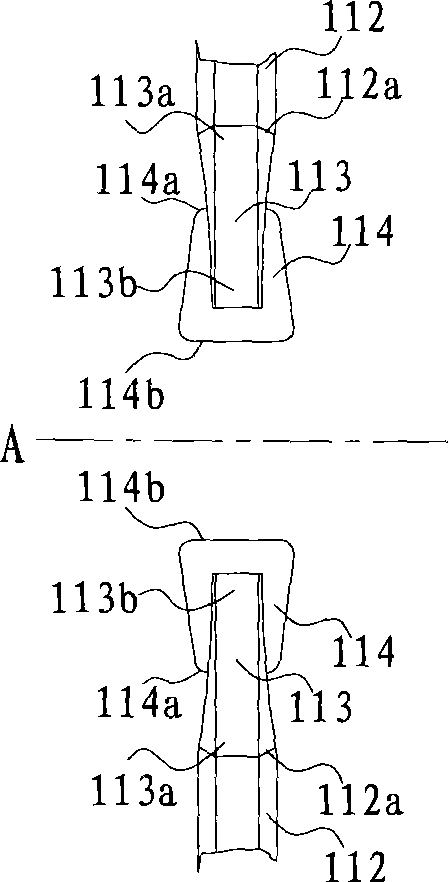

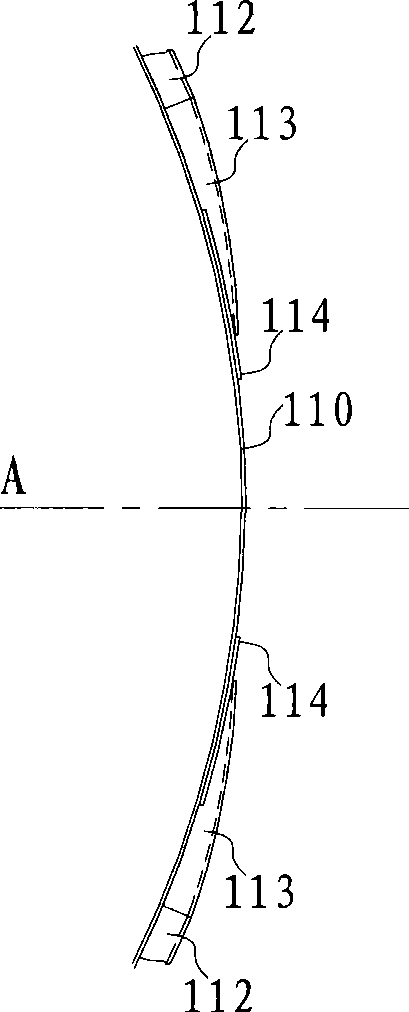

Multi-station cold-heading molding method of clutch conical blank

The invention discloses a multi-station cold-heading molding method of a clutch conical blank. The steel billets are manufactured into wire rod materials, the wire rod materials are cut by using an automatic material cutting system after going through spheroidizing annealing, acid pickling and wire-drawing to form single clutch cone blanks, and the clutch cone molding working procedure is carried out in a cold-extrusion die. The invention greatly promotes the production efficiency and the product quality of the clutch cone, effectively saves the raw material and reduces the manufacturing cost.

Owner:NINGBO ANCHOR FASTENERS INDAL

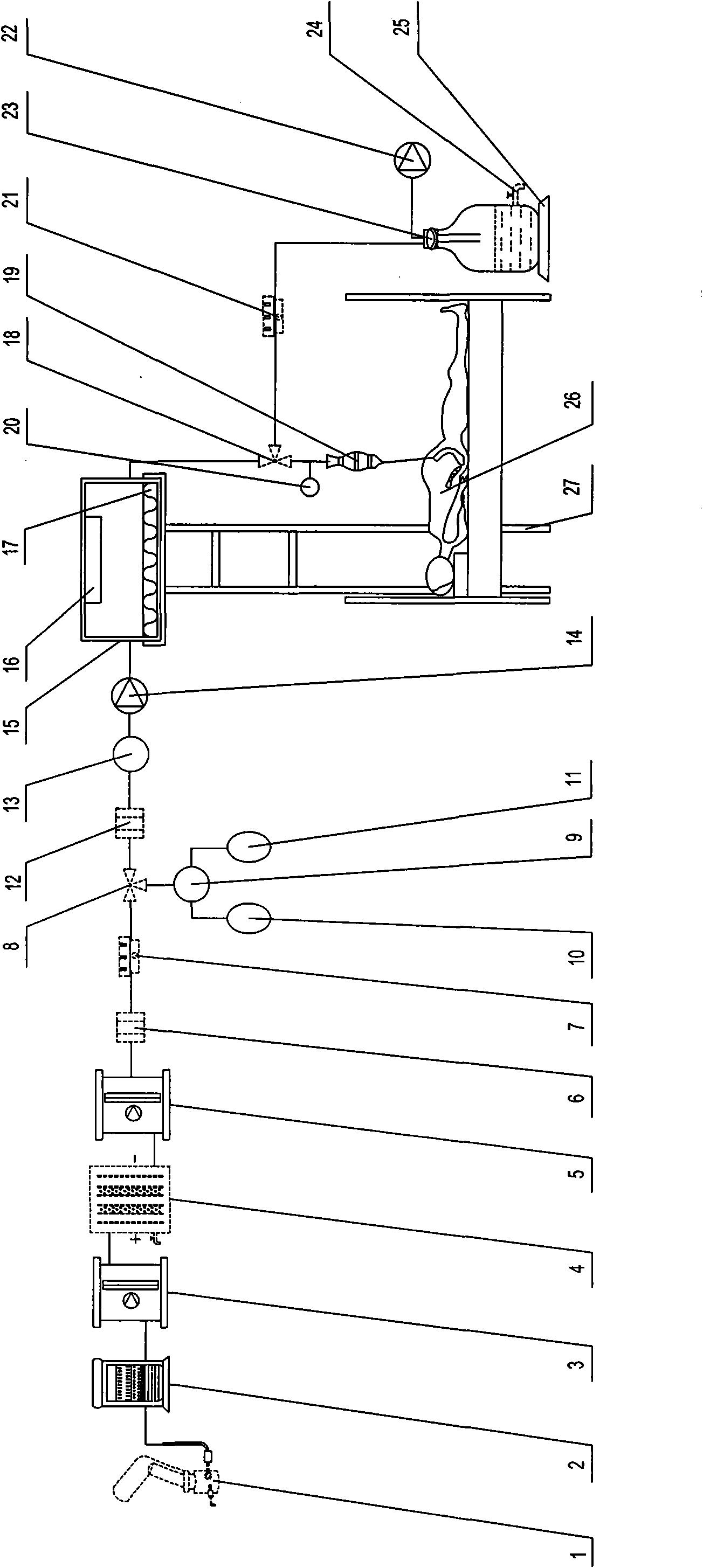

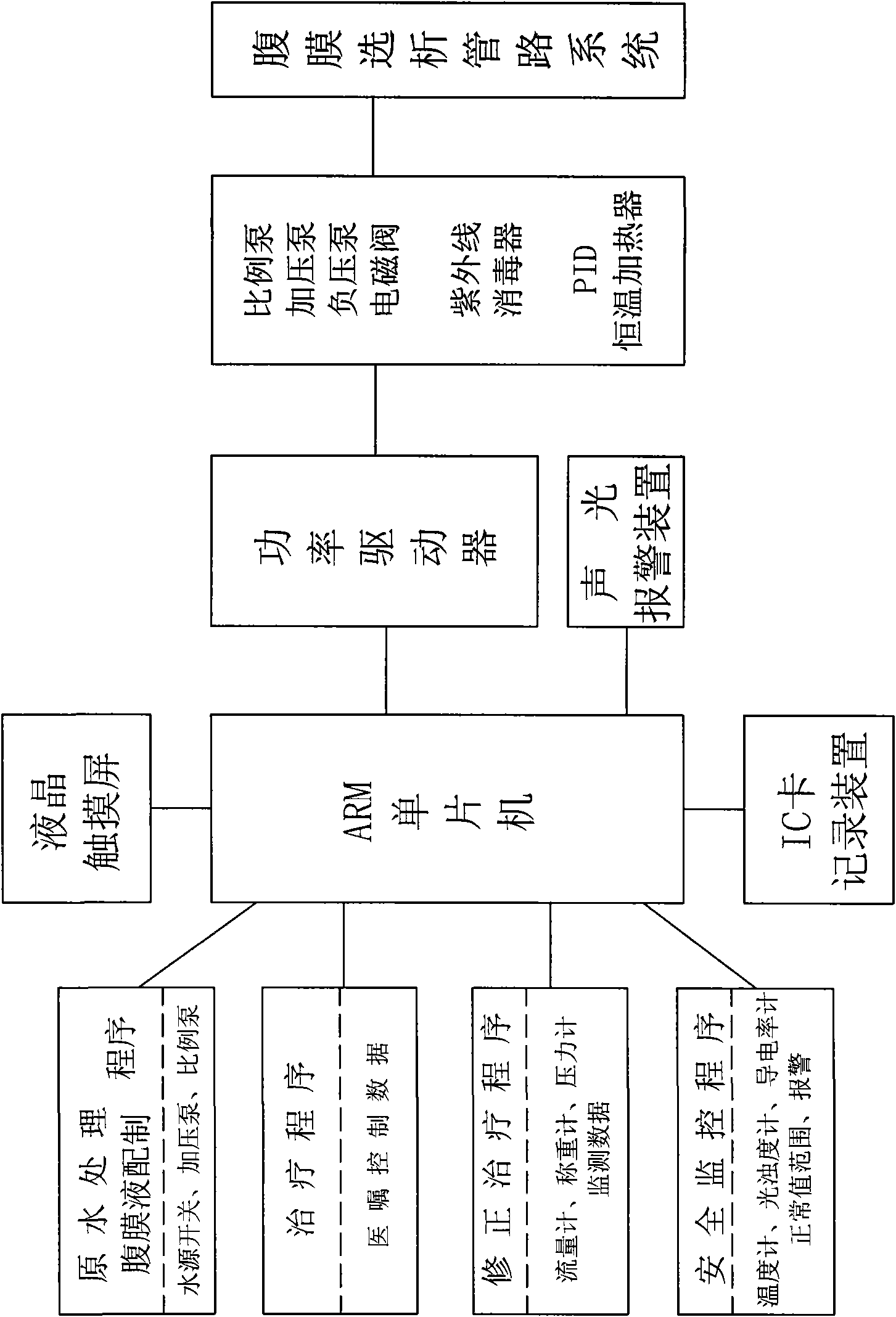

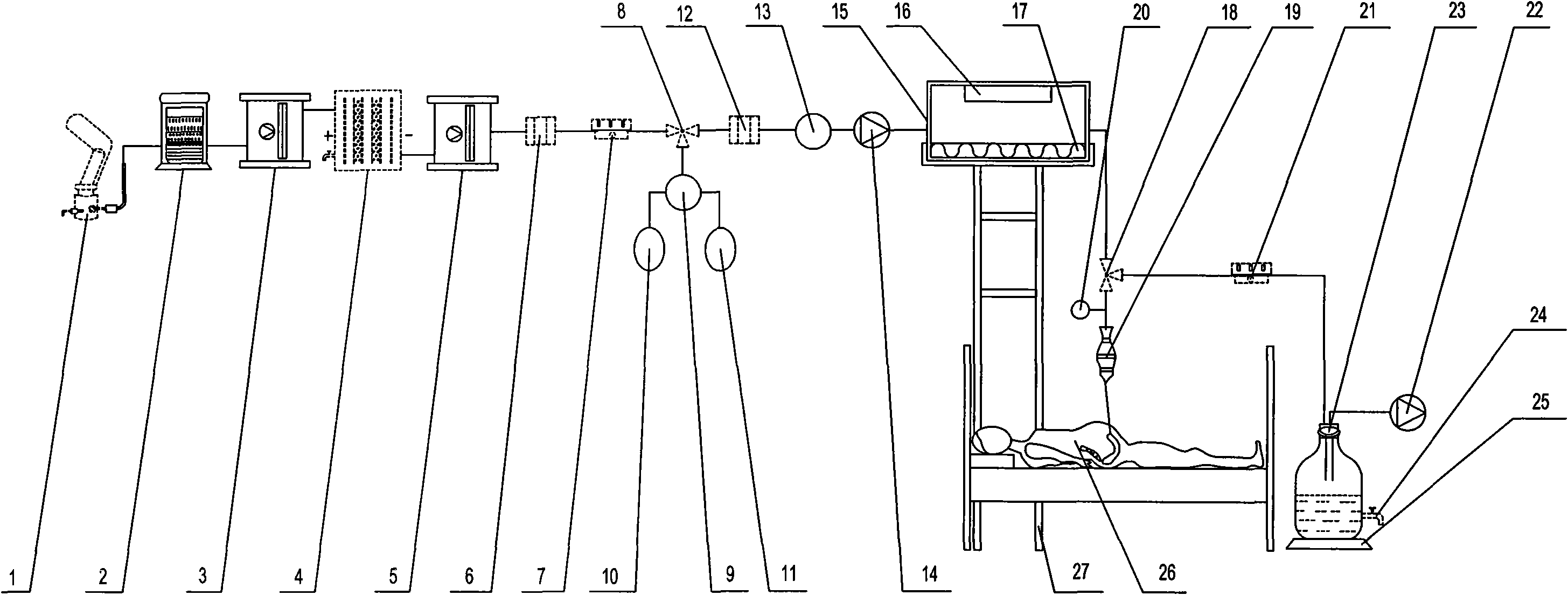

Simple automatic peritoneal dialysis equipment

InactiveCN101862481ARealize fully enclosed one-machine treatmentReduce the chance of infectionPeritoneal dialysisAutomatic controlPeritoneal membrane

The invention relates to medical equipment, in particular to simple automatic peritoneal dialysis equipment. The equipment comprises a raw water filter, an EDI electric deionizater and a raw water processing device composed of I and II class reverse osmosis units, a peritoneal dialysis liquid confecting device composed of a dual-cavity proportioning pump, a peritoneal dialysis liquid confecting three-way solenoid valve and a peritoneal dialysis liquid container, a peritoneal dialysis treating device composed of a peritoneal dialysis treating three-way solenoid valve, an abdominal cavity inner guide coupling, a waste liquid container and a negative pressure pump as well as an automatic control system composed of an ARM singlechip which carries out finishing and programming on the collected signal; wherein the signal input interface of the ARM singlechip is respectively connected with the raw water processing program module, a treating program module, a correction treating program module and a safe monitoring program module, and the signal output interface thereof is connected with a power driver which controls the external parts under the instruction of the ARM singlechip. The invention integrates water treatment, peritoneal dialysis liquid confecting and automatic peritoneal dialysis treatment, totally closed type one machine treatment is realized, and treating expense can be greatly reduced.

Owner:董大泉

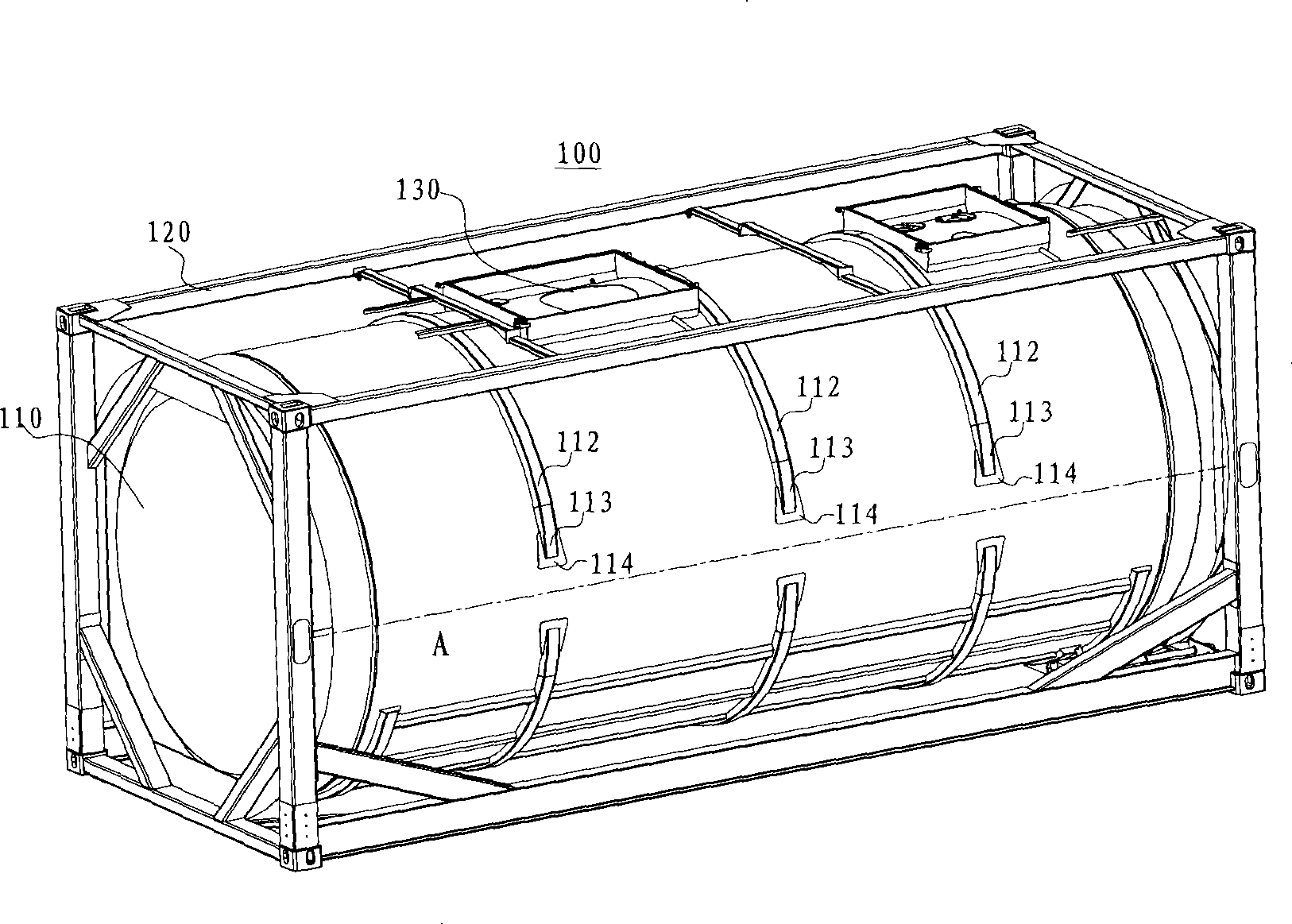

Large volume tank container

ActiveCN101362543ALose weightGuaranteed StrengthLarge containersBiochemical engineeringTank container

The invention relates to a high volume tank container, which comprises a framework, a tank body arranged in the framework, at least one reinforcing ring arranged on the periphery of the tank body and used for reinforcing the intensity of the tank body to better resist the external pressure; wherein, the reinforcing ring is broken in the position closed to the central line on the side of the tank body, and a wedge-shaped reinforcing ring is arranged at the broken end part of the reinforcing ring and connected with the tank on the both sides of the central line on the side of the tank body. A discharging system is installed at the bottom part at the rear end of the tank body, the lower beam corresponding to the position of the discharging system is disconnected into two sections, and a discharging bottom board is connected at the lower end of each lower beam in the disconnecting position. Simultaneously, the central line of the tank body is arranged lower than that of the framework, therefore, not only the dimension of the side surface of the high volume tank container is ensured to be within the ISO dimension, but also a larger operating space exists in the discharging positions at the top part and the bottom part, thus being convenient for the operation.

Owner:NANTONG CIMC TANK EQUIP CO LTD

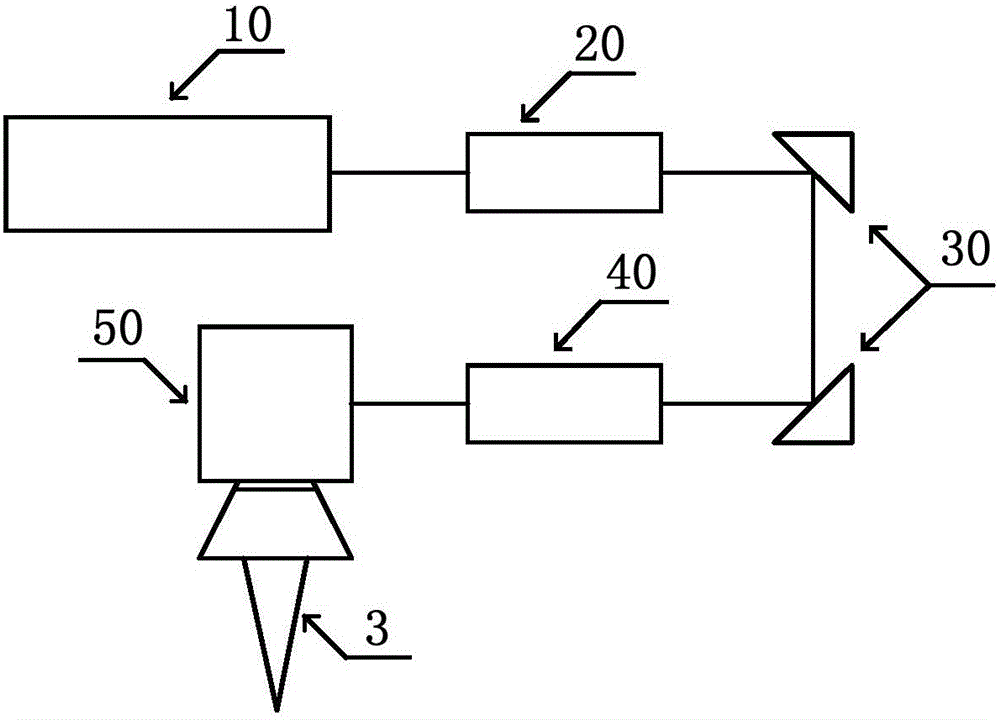

Reconstruction method for hearth three-dimensional temperature field

InactiveCN102393027ADesign scienceCompact structureChamber safety arrangementReconstruction methodHearth

The invention relates to a reconstruction method for a hearth three-dimensional temperature field. The method comprises the following steps that: a burning flame colorized image can be obtained through a CCD (Charge Coupled Device) image pickup system and a computer processing system, based on R,G and B pixels of a flame image, two-dimensional temperature of a burning flame image can be obtained through a neural network BP algorithm, an inverse solution of a radiative transfer equation can be combined, and three-dimensional temperature distribution of a burning flame in a hearth can be further obtained. The reconstruction method has the advantages of scientific design and creativeness, three-dimensional characteristic of coal dust in a large-scale boiler can be fully embodied, and the reconstruction method is significant to safety, economic benefit, clean operation and the like of the boiler. The system disclosed by the invention has the advantages of compact structure, less material consumption, long service life, stable and reliable performance, convenient for maintenance and high measurement precision of three-dimensional temperature, and flame combustion condition in the boiler can be controlled in time.

Owner:SHENYANG LIGONG UNIV

Processing method and device for inner hole of tempered glass

ActiveCN105081564AImprove yield rateHigh speedLaser beam welding apparatusNanosecond laserControl system

The invention discloses a processing method for an inner hole of tempered glass. The processing method comprises the following steps that laser is used for processing the contour of the inner hole in a substrate of the tempered glass firstly, the glass in the hole is separated from the substrate completely at the time, but the glass in the hole does not fall off the substrate; and laser is then used for removing the glass in the inner hole. The invention further discloses a processing device adopting the method. The processing device comprises a workbench, a moving unit, a positioning unit, a laser system and a control system. According to the processing method and device, a processing mode with ultrashort pulse laser and nanosecond laser combined is used, and the processing method and device are applicable to processing of high-intensity tempered glass and inner holes of any shape and size. The processing method and device have the characteristics of being high in speed, good in effect, high in yield, few in consumable, low in cost and the like.

Owner:深圳市大族半导体装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com