Large volume tank container

A tank container, large-volume technology, applied in the direction of large containers, containers, packaging, etc., can solve the problems of increasing the operating space on the top of the tank, complex structure of the reinforcement ring, small and inconvenient top space, etc., to achieve simple structure and less consumables , to solve the effect of inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

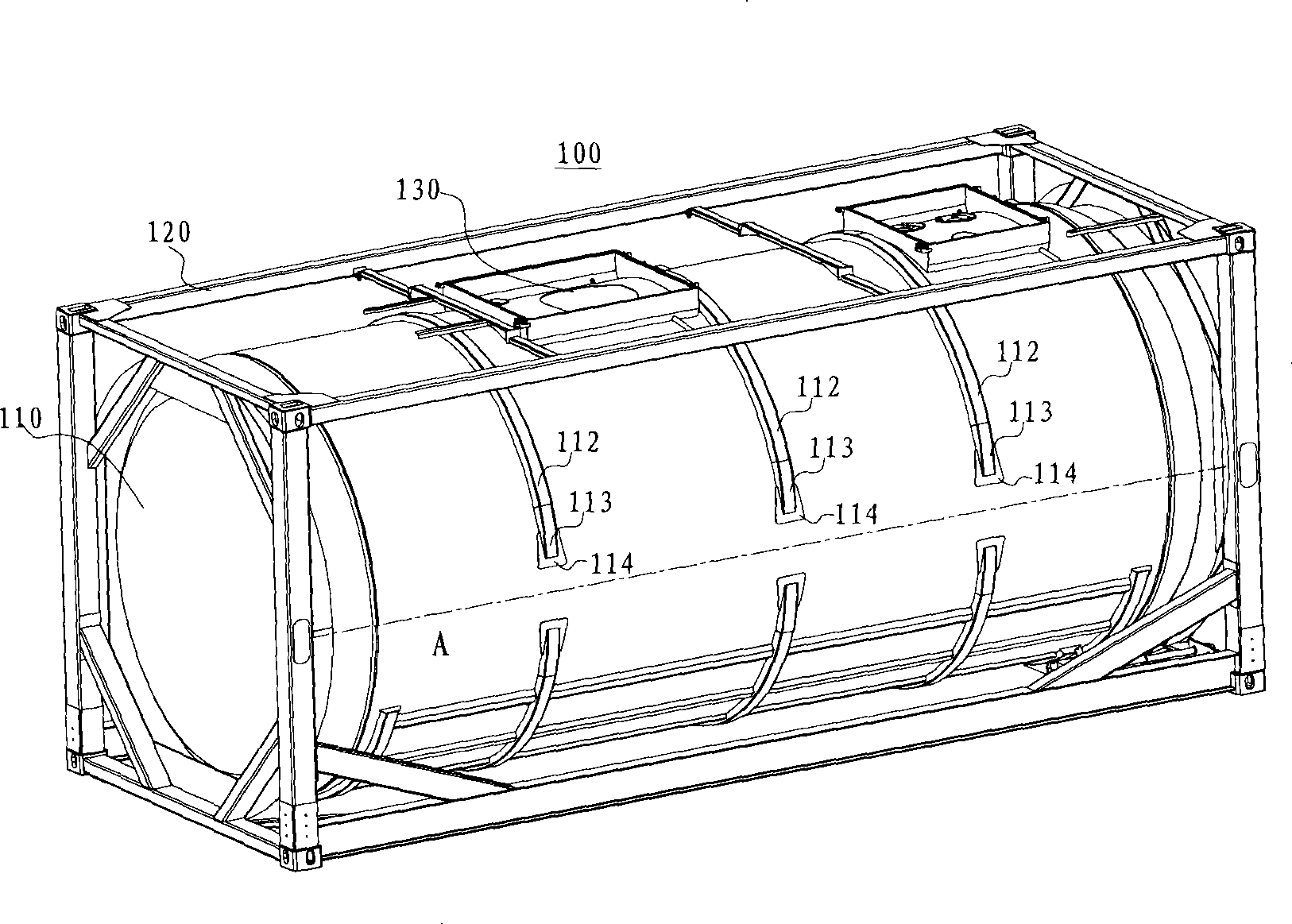

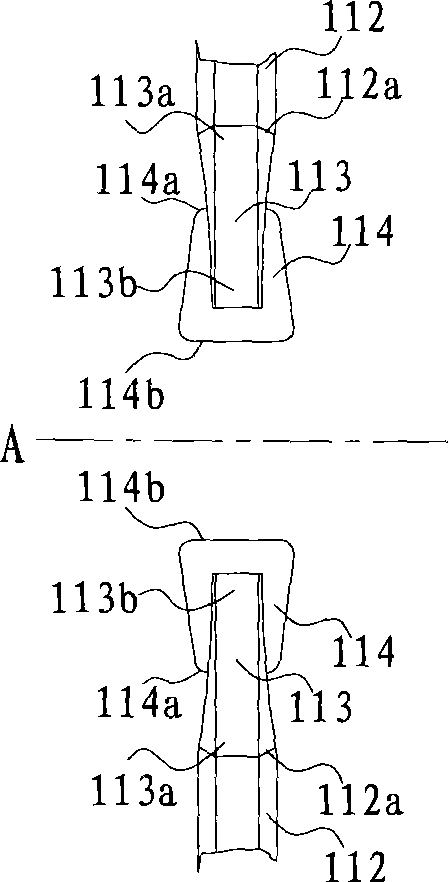

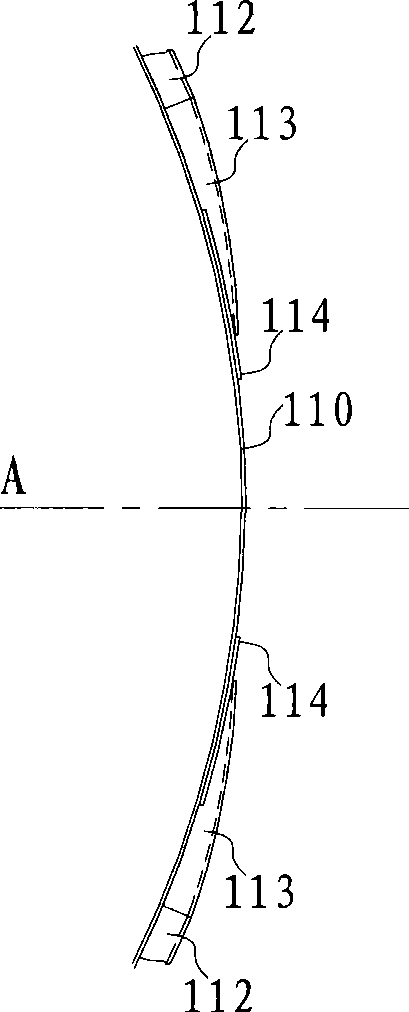

[0026] Such as figure 1 As shown, the large volume tank container 100 of the present invention includes: a tank body 110 and a frame 120 , and the tank body 110 is fixed in the frame 120 . Wherein the top of the tank body 110 is provided with a valve member 130, and a discharge system 111 is installed through a discharge port 140 on the bottom side of one end (see Figure 4 with Image 6 ): Moreover, on the outer circumference of the tank body 110, three reinforcing rings 112 are dispersedly arranged along the length direction of the tank body 110 for strengthening the strength of the tank body 110 to better resist external pressure. It should be understood that the number of the reinforcing rings 112 may be less than three or greater than three, and here only three reinforcing rings 112 are provided as an example for illustration. In particular, the reinforcing ring 112 is disconnected at the side centerline A of the tank body 110, and the end 112a at which the reinforcing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com