Patents

Literature

1564results about How to "Large operating space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

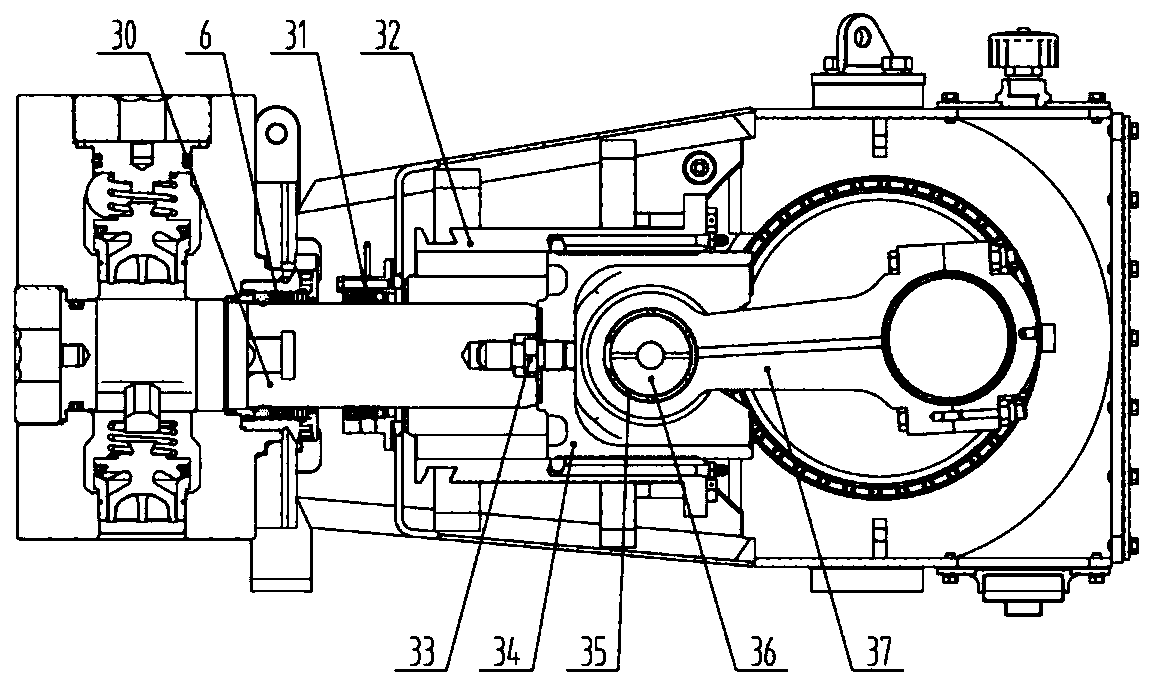

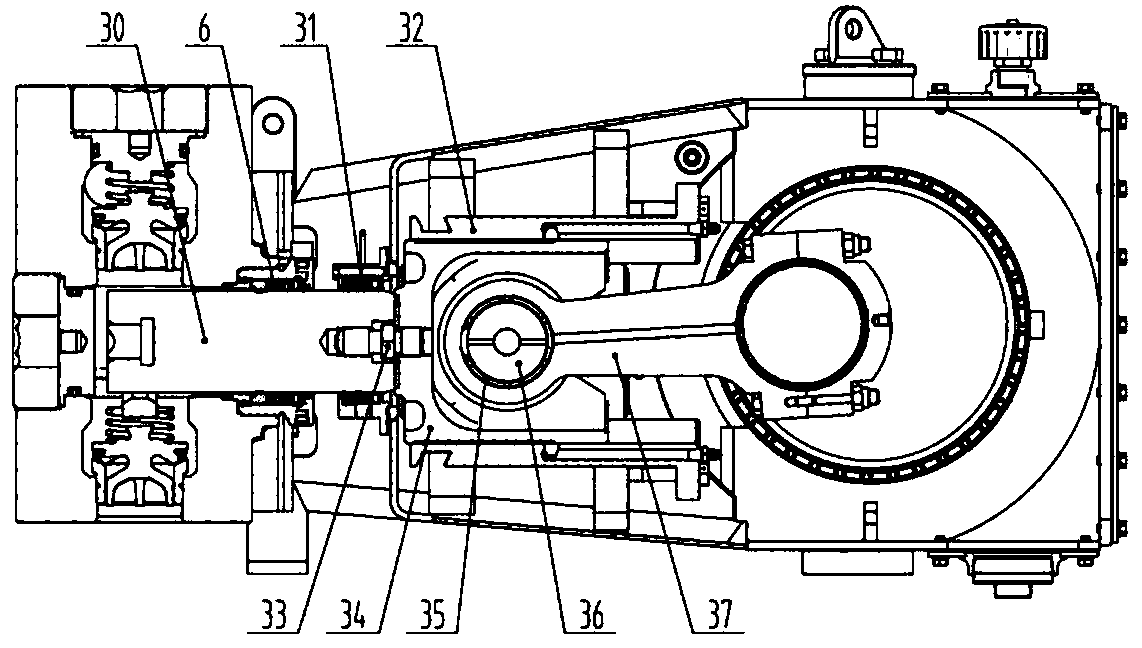

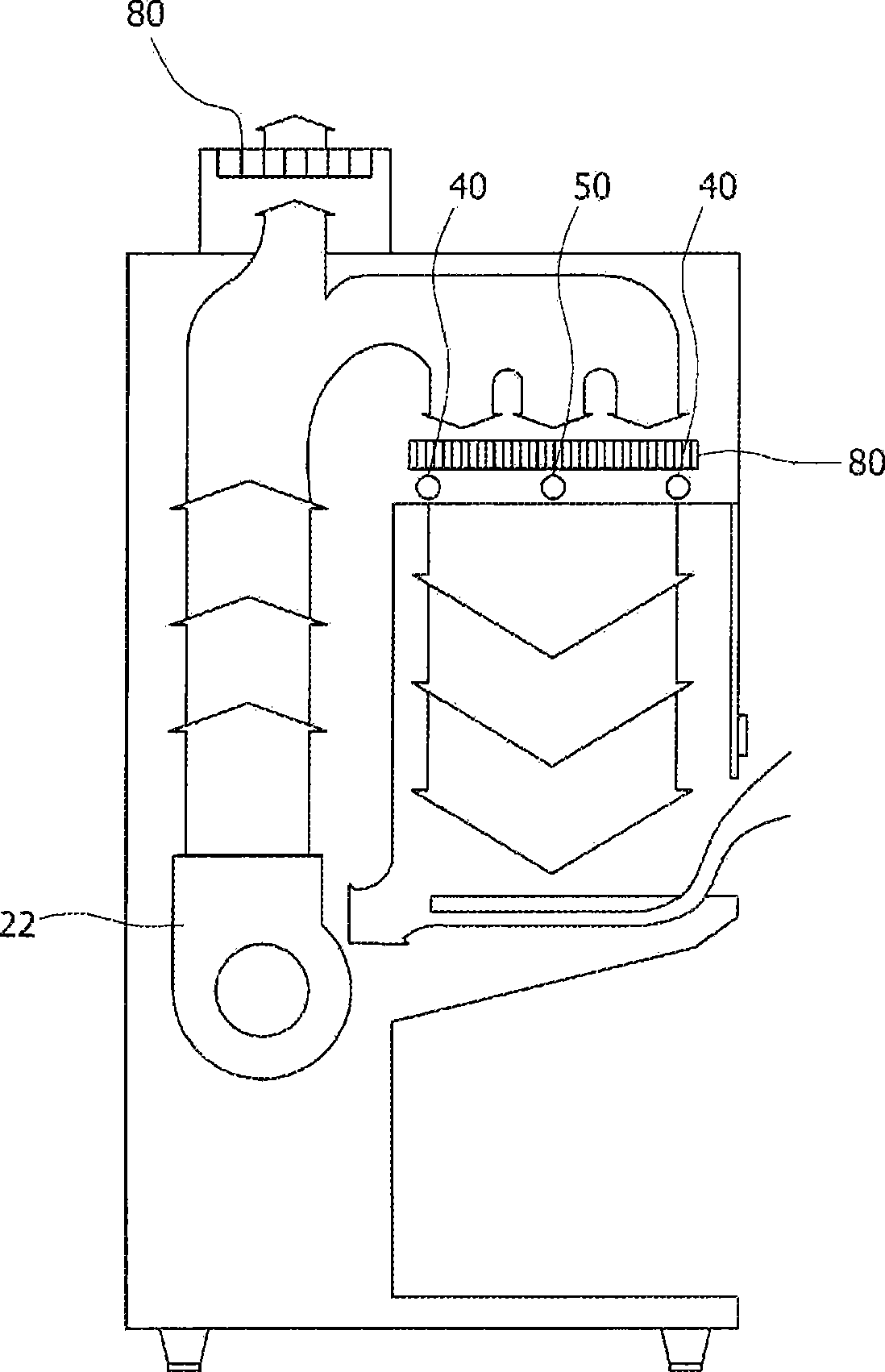

Reciprocating type three-cylinder plunger pump for oil and gas field

PendingCN109882372AExtend your lifeFully lubricatedPositive displacement pump componentsPositive-displacement liquid enginesEngineeringLubrication

The invention provides a reciprocating type three-cylinder plunger pump for an oil and gas field. The reciprocating type three-cylinder plunger pump comprises a gear box assembly, a power end assemblyand a hydraulic end assembly which are transmitted in sequence; and the hydraulic end assembly comprises a disc root and a plunger, the power end assembly comprises a crankshaft, a connecting rod, asliding rail and a crosshead, power is transmitted from the crosshead to the plunger, a pull rod and a fender are arranged between the plunger and the crosshead, the pull rod is fixed on the cross head, the plunger is fixed to the pull rod, the fender is located between the pull rod and the plunger and fixed with the plunger, and the outer diameter of the fender is larger than that of the plungerand the pull rod. The reciprocating type three-cylinder plunger pump can solve the problems that a working medium in a hydraulic end assembly in the prior art is poured into a power end assembly alongthe plunger, a packing is inconvenient to replace, and a connecting rod large-head bearing bush is insufficient in lubrication and the like.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

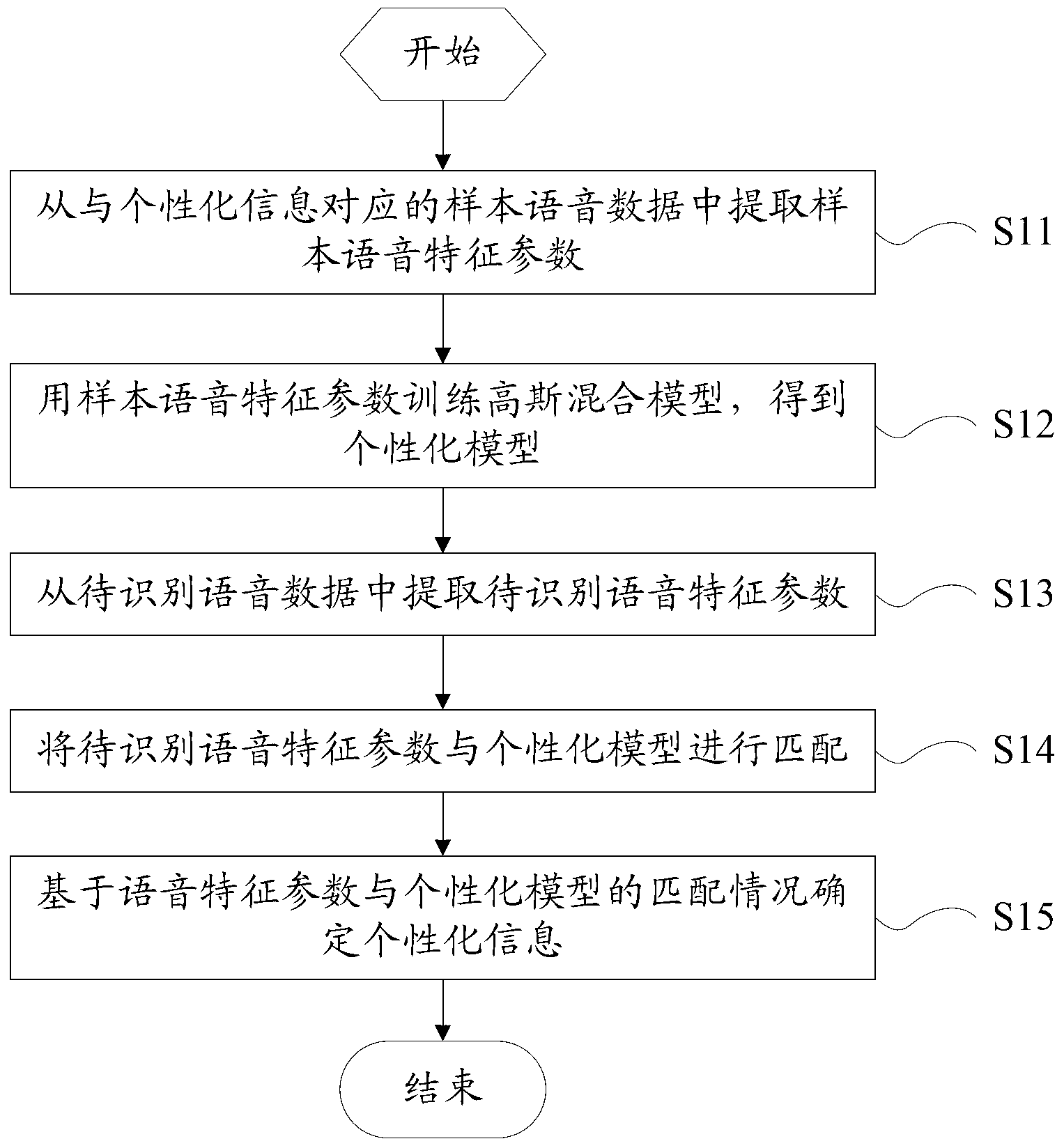

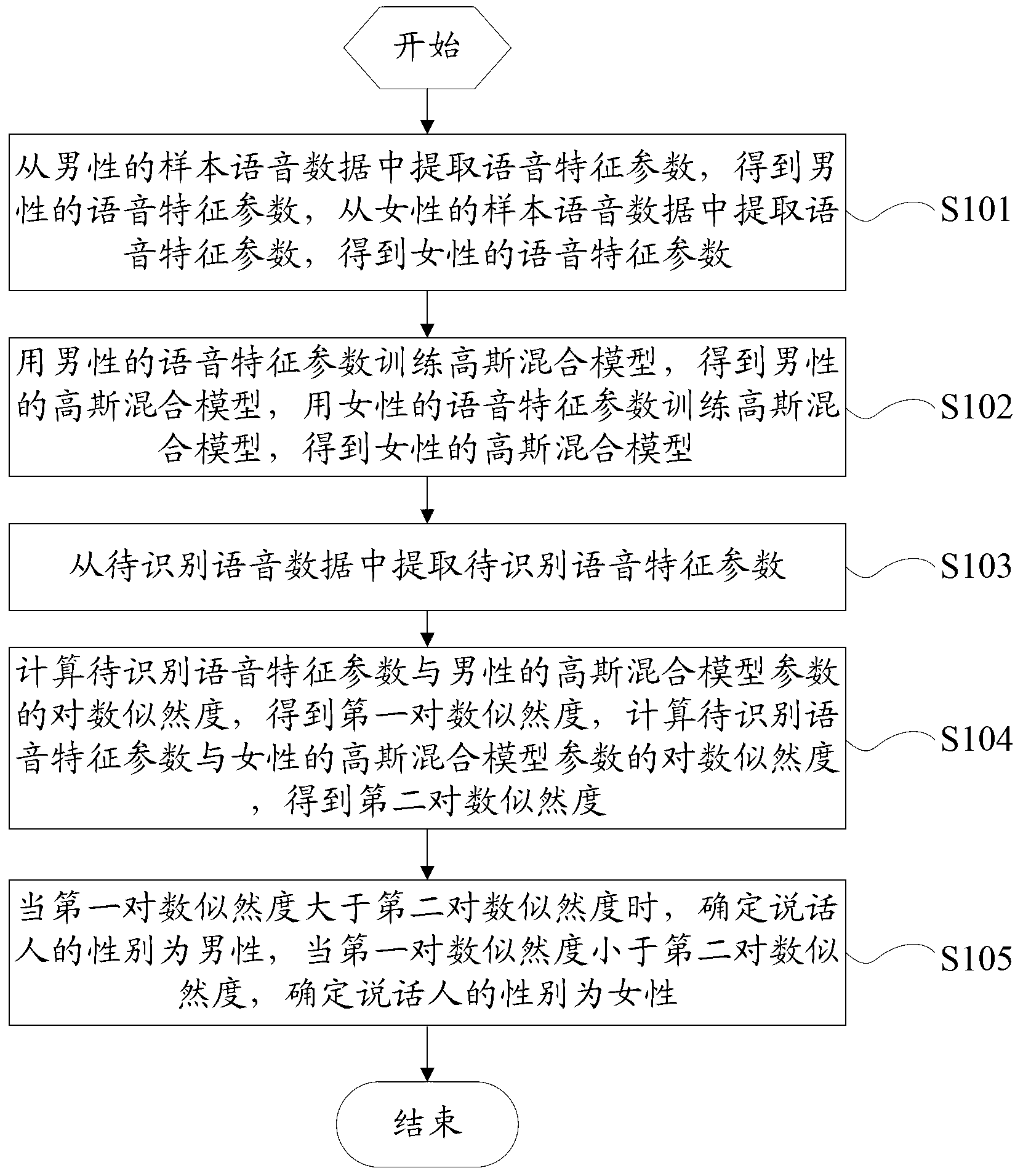

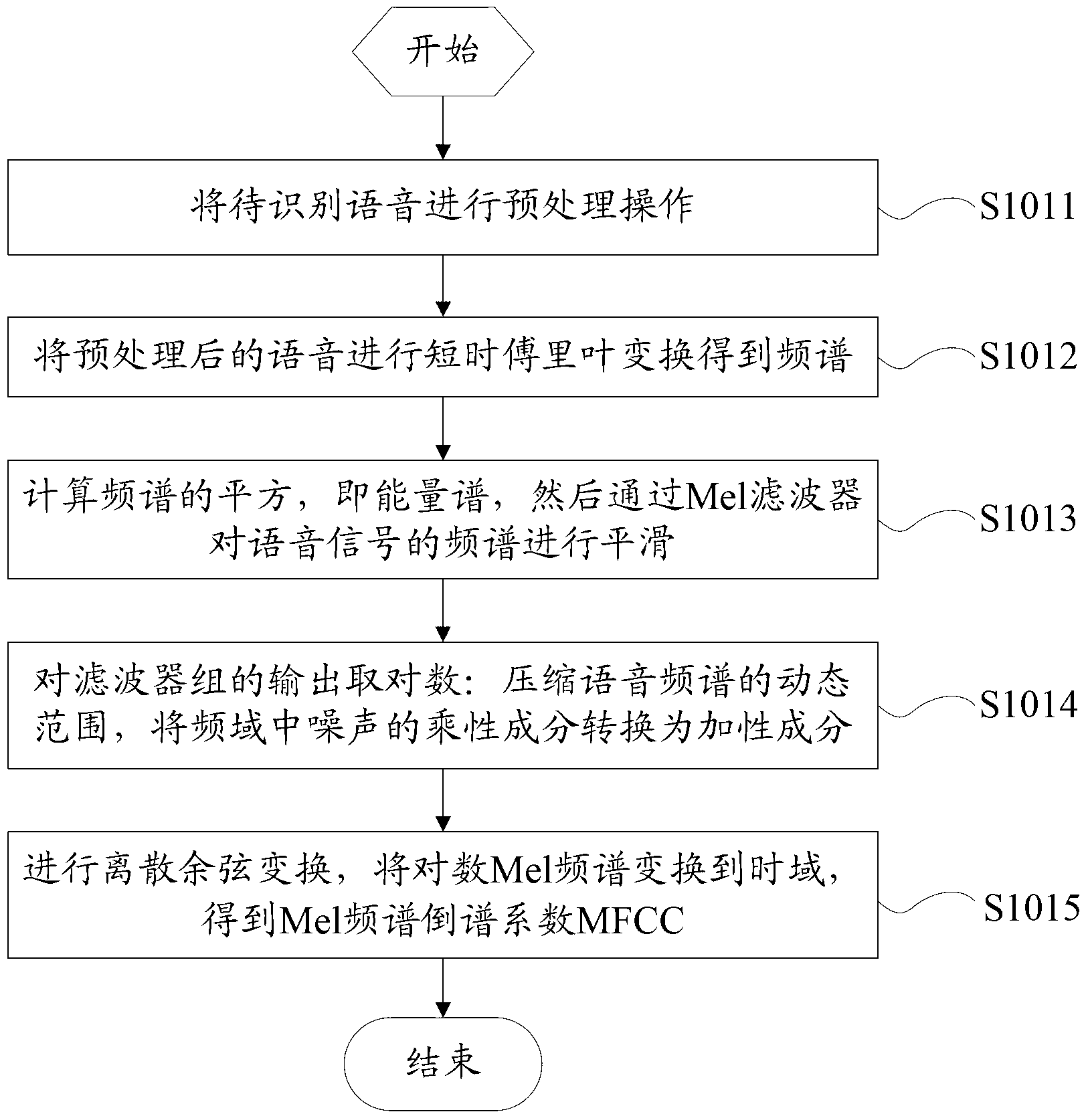

Voice information identification method and system

ActiveCN103310788ASmall recognition speed impactLarge operating spaceSpeech recognitionPersonalizationFeature parameter

The invention provides a voice information identification method and system. The identification method comprises the steps of extracting sample voice feature parameters from sample voice data corresponding to personalized information, using the sample voice feature parameters to train a Gaussian mixed model to obtain a personalized model, extracting to-be-identified voice feature parameters from to-be-identified voice data, matching the to-be-identified voice feature parameters with the personalized model, and determining the personalized information on the basis of the to-be-identified voice feature parameters and the personalized model. The voice information identification method and system can identify the personalized information such as gender and age of a talker from the to-be-identified voice data, and the identified personalized information leaves larger operable space for the subsequent operations such as voice assistant and voice dialogue; in addition, the voice information identification method and system can also identify text information, the personalized information identification and the text information identification share one set of voice feature parameters, and the personalized information identification is smaller than the text information identification in computing amount, so the effect on the identification speed of the text information is smaller.

Owner:BEIJING UNISOUND INFORMATION TECH +1

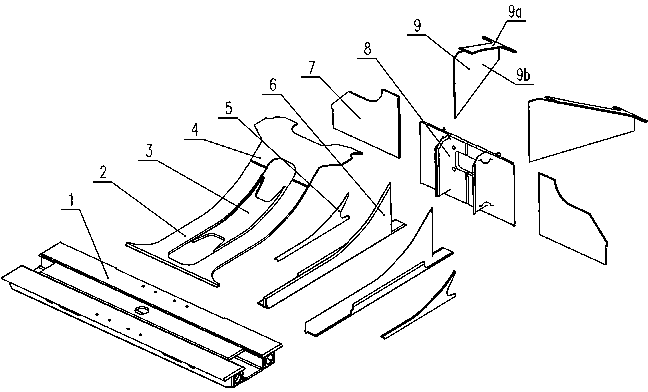

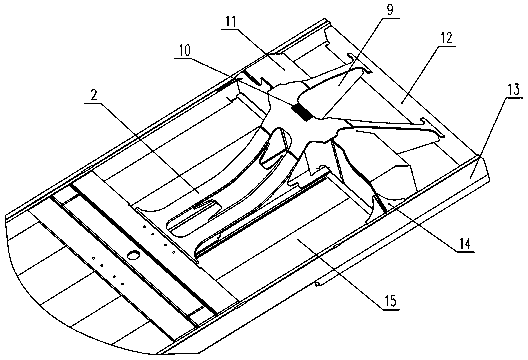

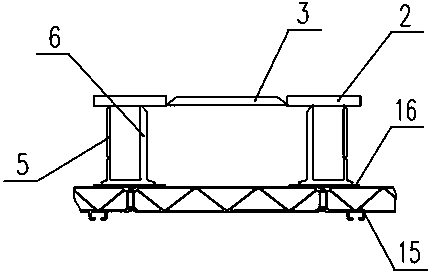

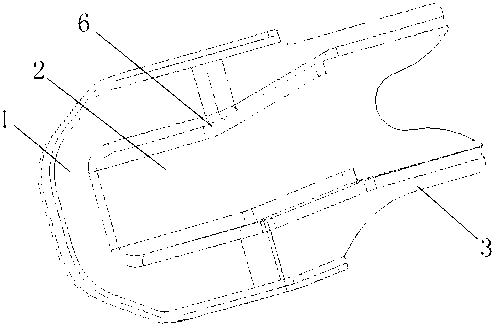

Railway vehicle body chassis structure

The invention discloses a railway vehicle body chassis structure. The railway vehicle body chassis structure soles the problems that the giant torque force is caused due to the fact that a front-arrangement type vehicle hook mounting hole is formed in the side face of a vertical plate of a traction beam, and no operation space exists for mounting a steering frame traction base. The railway vehicle body chassis structure comprises two chassis edge beams, a chassis end beam and a sleeper beam arranged between the two chassis edge beams, a traction beam, a vehicle hook mounting sectional material and a traction guide beam are arranged between the sleeper beam and the chassis end beam, the traction beam is fixed between the sleeper beam and the vehicle hook mounting sectional material, and the traction guide beam is fixed between the vehicle hook mounting sectional material and the chassis end beam. Traction wing plates are fixedly arranged on the two sides of the vehicle hook mounting sectional material, the traction wing plates are fixedly connected with the chassis edge beams on the corresponding sides, and a jumper box is arranged between the traction wing plates and the traction guide beam. The problems are completely solved by optimizing the structures of vehicle hook mounting sectional material, the traction beam and other components, and the high-intensity performance that a vehicle body can bear 1000 kN of compression loads is kept.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

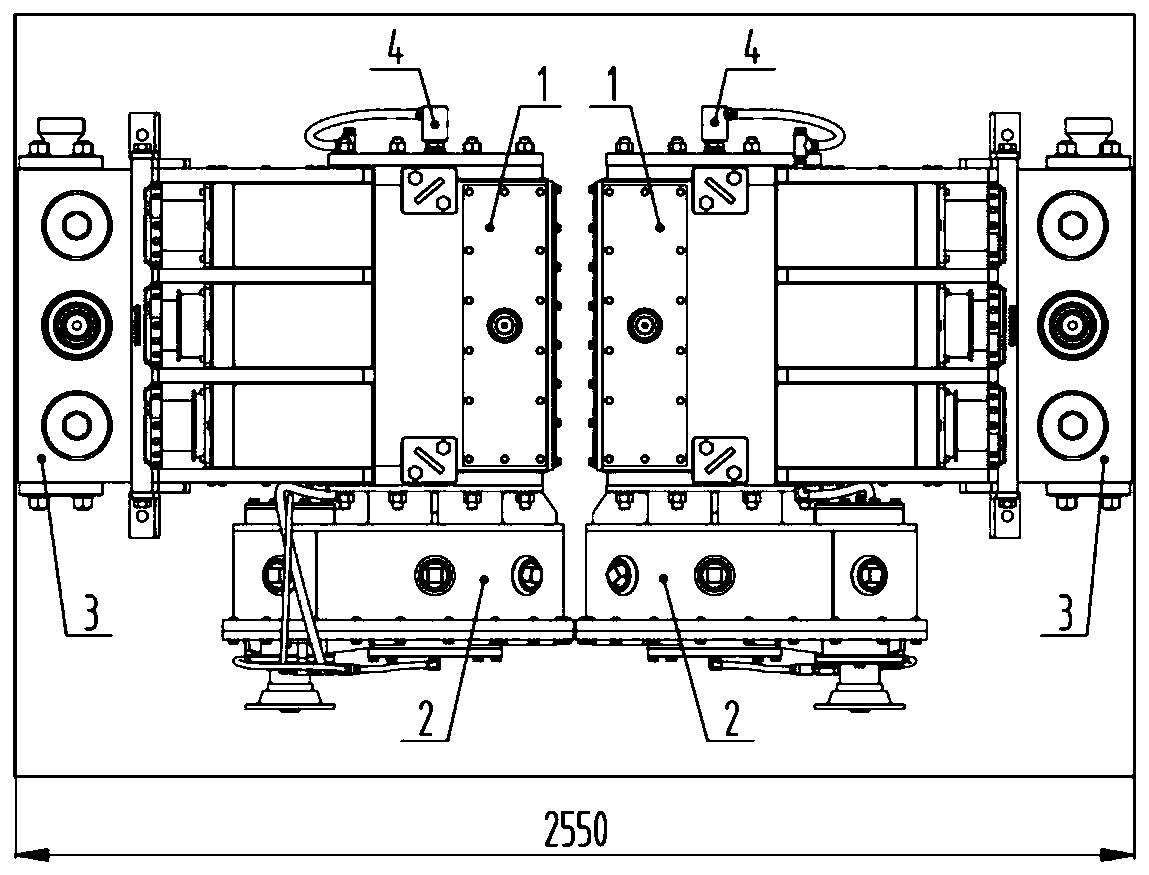

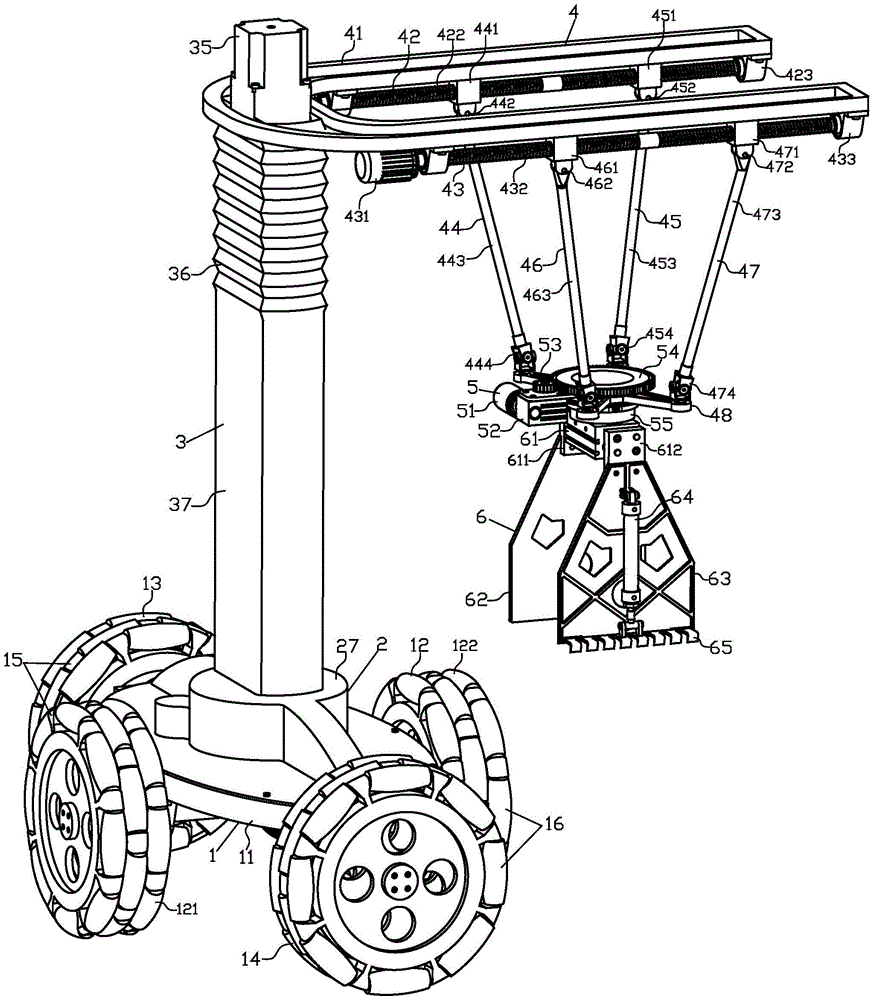

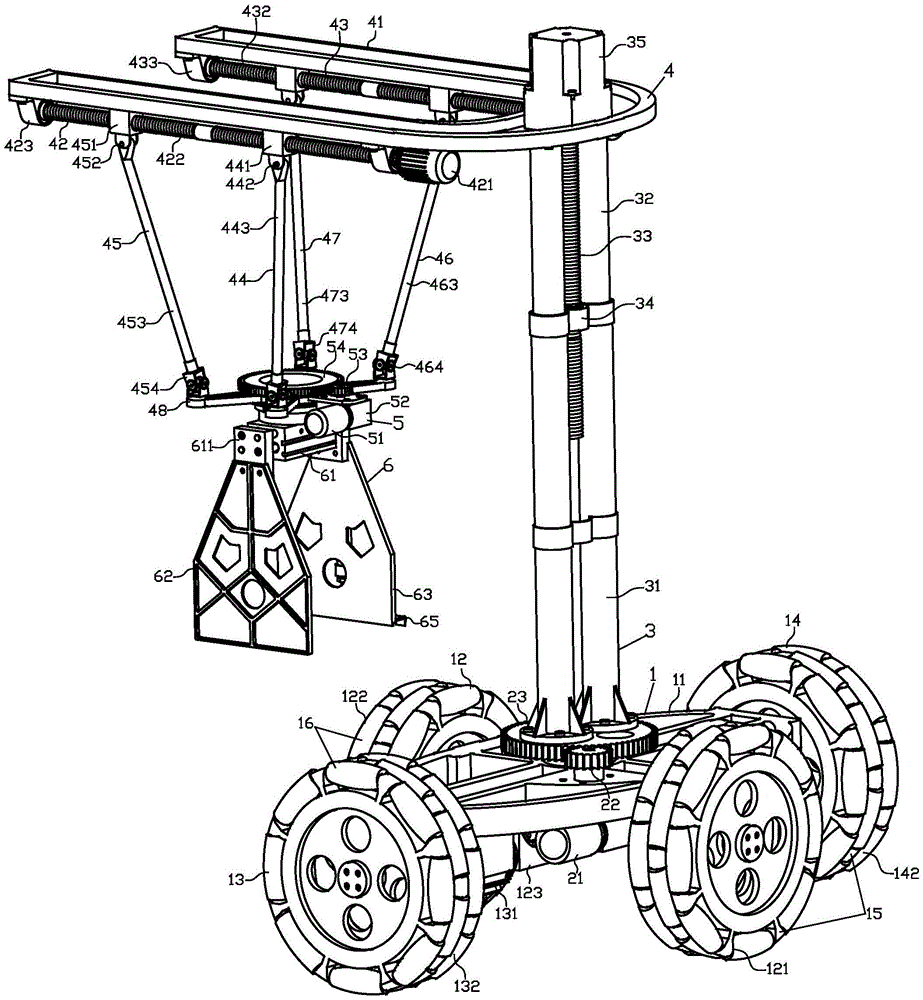

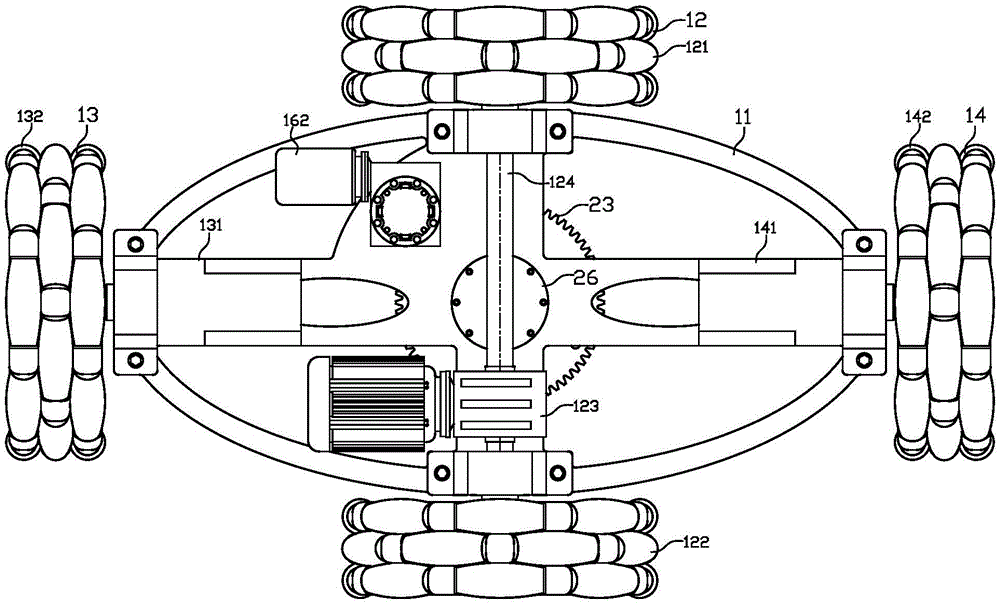

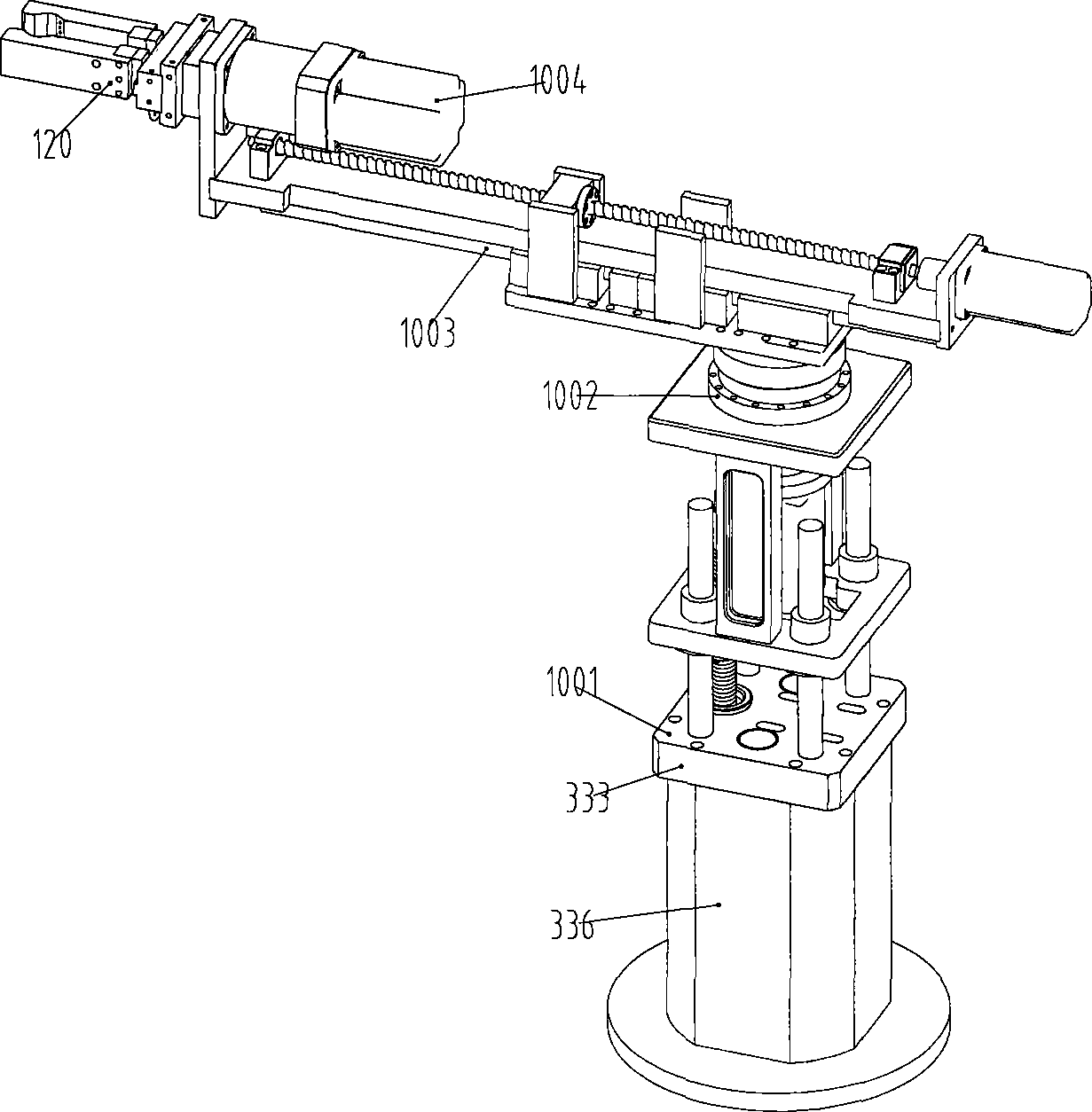

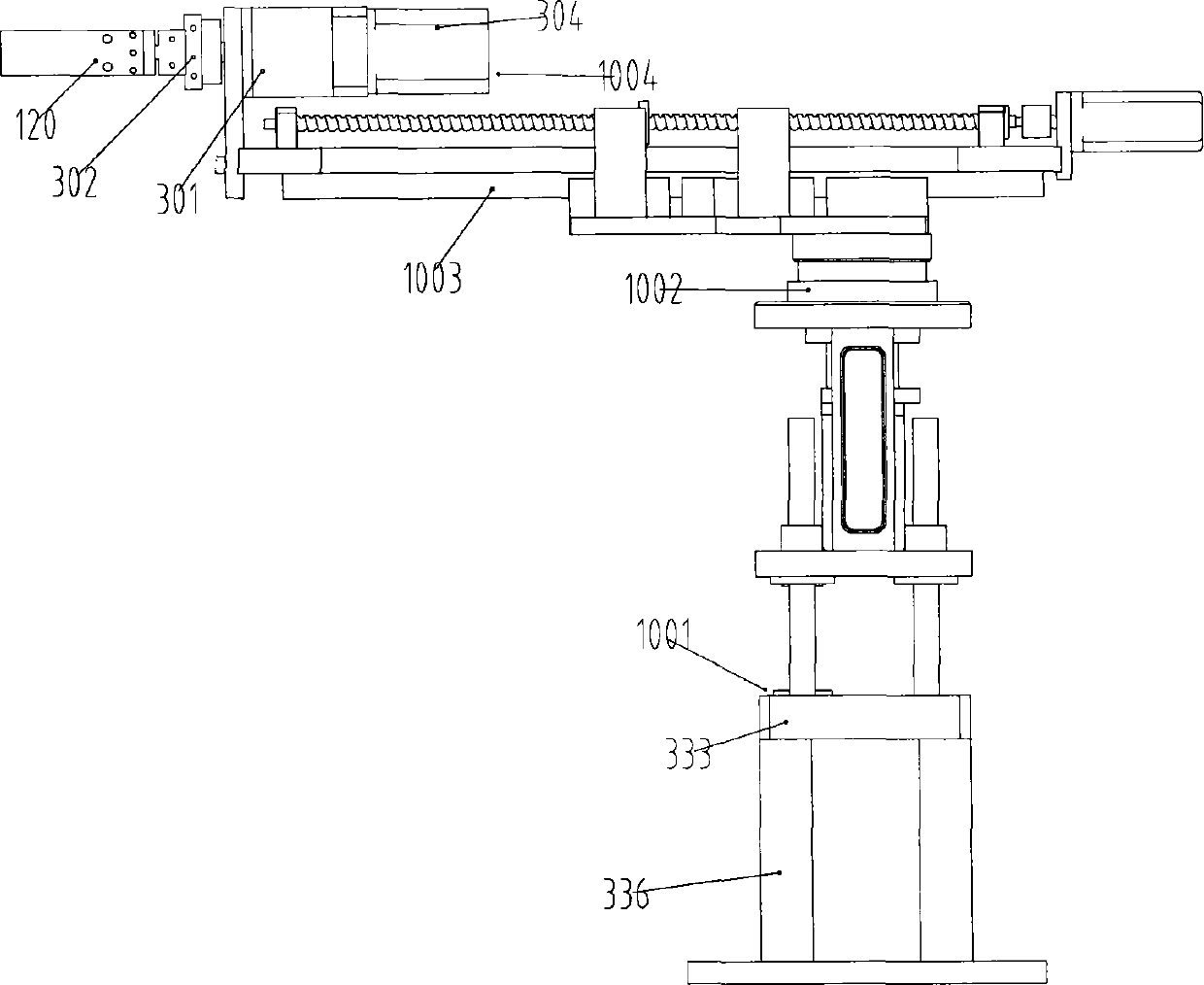

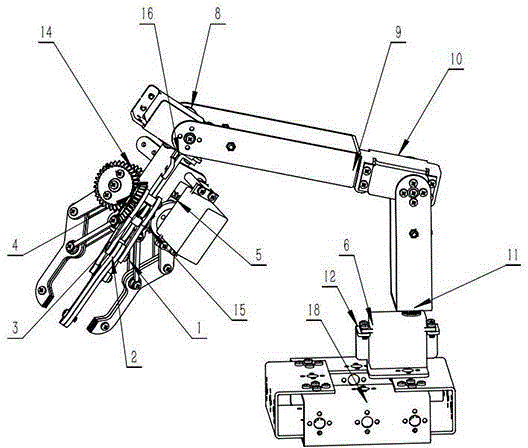

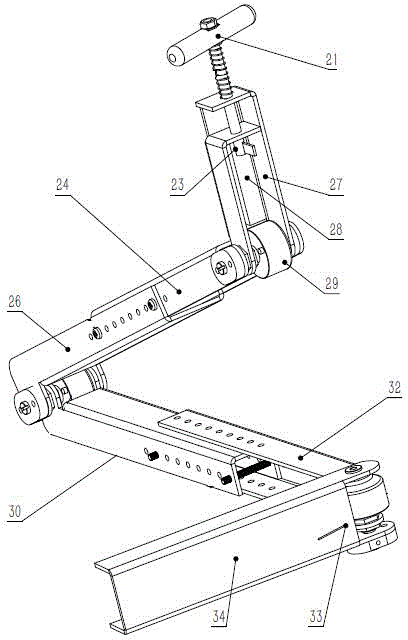

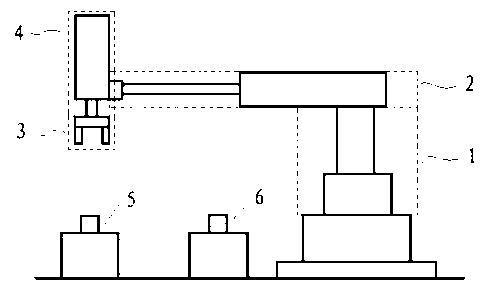

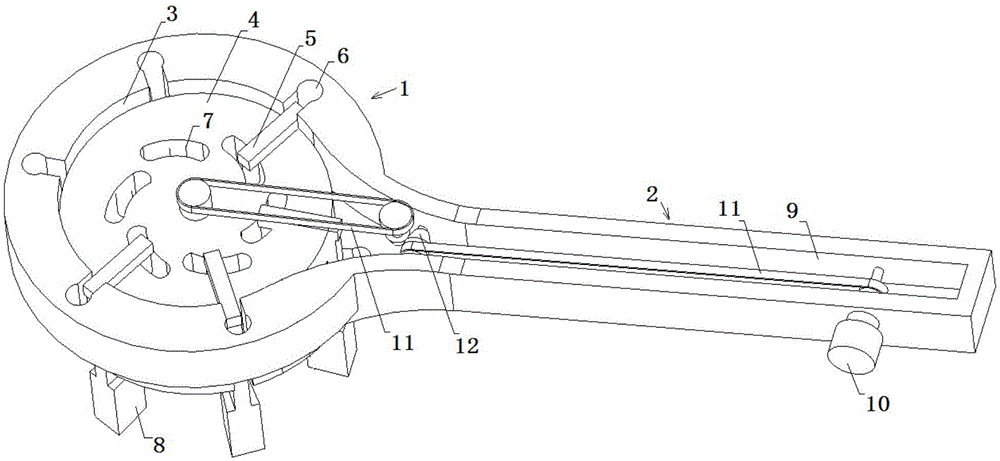

Three-freedom-degree series-parallel omni-directional mobile transfer robot

ActiveCN105459095AIncrease stiffnessImprove carrying capacityProgramme-controlled manipulatorGripping headsIndependent motionCarrying capacity

The invention discloses a three-freedom-degree series-parallel omni-directional mobile transfer robot. The transfer robot comprises an omni-directional mobile chassis, a main slewing gear, a lifting device, parallel working arms, a tail end slewing gear and a clamp holder. The omni-directional mobile chassis is used for executing walking and steering tasks, the lifting device is connected with the omni-directional mobile chassis through the main slewing gear, the parallel working arms installed at the top of the lifting device are connected with the clamp holder through the tail end slewing gear and are used for adjusting the operation posture of the clamp holder. A series-parallel is adopted in a robot body, and the omni-directional mobile transfer robot has the advantages of being high in rigidity, large in carrying capacity, high in motion precision, large in operation space and the like; the clamp holder has six motion ranges and three independent motion freedom degrees and is high in motion flexibility; the tri-drive omni-directional mobile chassis can realize walking tasks of moving forward, or moving backward, or turning left or turning right, and is reasonable in structural design, and high in anti-overturning ability. In addition, the omni-directional mobile transfer robot has the advantages of being convenient to manipulate, and high in adaptability to road conditions.

Owner:ANHUI UNIV OF SCI & TECH

Four-degree-of-freedom servo manipulator

InactiveCN103802095AReduce volumeControl DimensionsProgramme-controlled manipulatorDegrees of freedomEngineering

The invention relates to industrial automation equipment, in particular to an automated manipulator. A four-degree-of-freedom servo manipulator comprises a lifting arm, a rotary arm, a telescopic boom, a torsional arm, a base and a gripper, wherein the lifting arm is fixedly connected to the base, and fixed on the ground; the gripper is fixedly connected to the output end of the torsional arm; the fixing plate of the telescopic boom is fixedly connected to a rotary cover plate; one end of the telescopic boom is fixedly connected to a vertical flange plate, and the torsional arm is fixedly connected to the vertical flange plate. The four-degree-of-freedom servo manipulator provided by the invention is applicable to machine manufacturing processes and achieves material transportation and transmission, the frictional resistance is small, the running is stable, the accuracy is high, the service life is long, the four-degree-of-freedom servo manipulator provided by the invention can be used for picking up workpieces, through the compact structure distribution of the four-degree-of-freedom servo manipulator, the external dimension can be effectively controlled, and a maximal running space can be obtained.

Owner:东莞智得电子制品有限公司

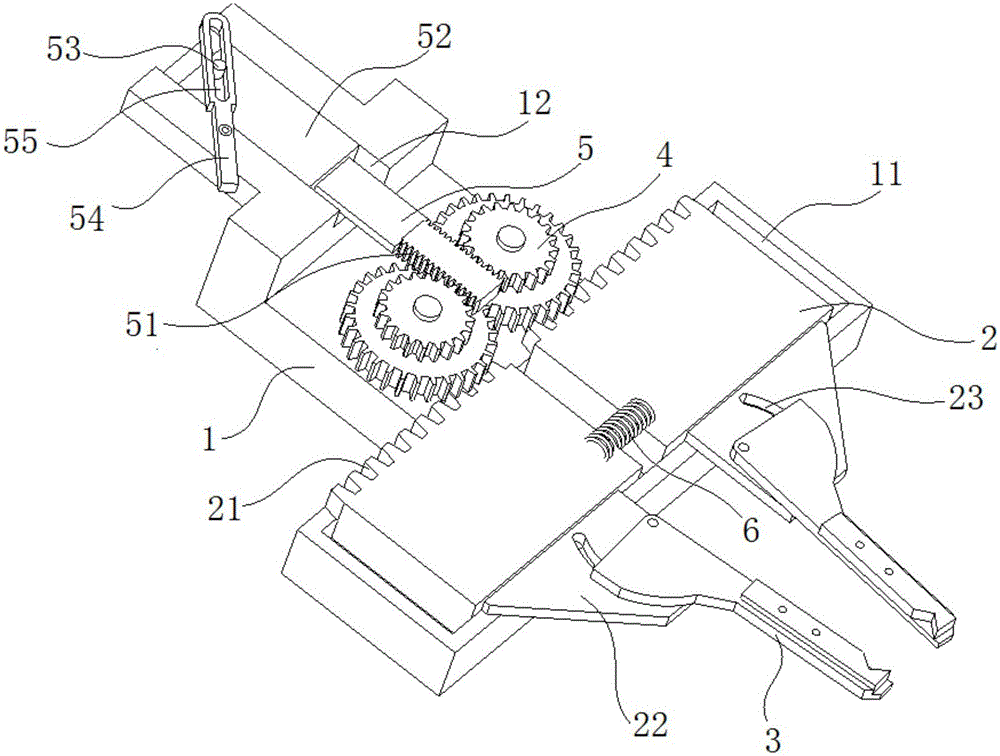

Clamping type manipulator device

The invention discloses a clamping type manipulator device. The clamping type manipulator device comprises a rack, two sliding tables, two clamping jaws, two dual gears, a sliding rod and a driving mechanism, wherein a longitudinal sliding groove is formed in the rear portion of the rack, and a transverse sliding groove is formed in the front portion of the rack; the two sliding tables are arranged in the transverse sliding groove in a left and right slidable mode and each provided with a first rack portion; the rear ends of the two clamping jaws are arranged on the corresponding sliding tables; the two dual gears are arranged on the rack, and lower gears of the two dual gears are each connected with the first rack portion of the corresponding sliding table in an engaged mode; the sliding rod is arranged in the longitudinal sliding groove in a front and back sliding mode, the left side and the right side of the sliding rod are each provided with a second rack portion, and each second rack portion is in engaged connection with an upper gear of the corresponding dual gear; the driving mechanism is used for driving the sliding rod to slide. The clamping type manipulator device is simple and compact in structure, large in operation space, accurate in positioning and high in reliability.

Owner:GUANGXI UNIV

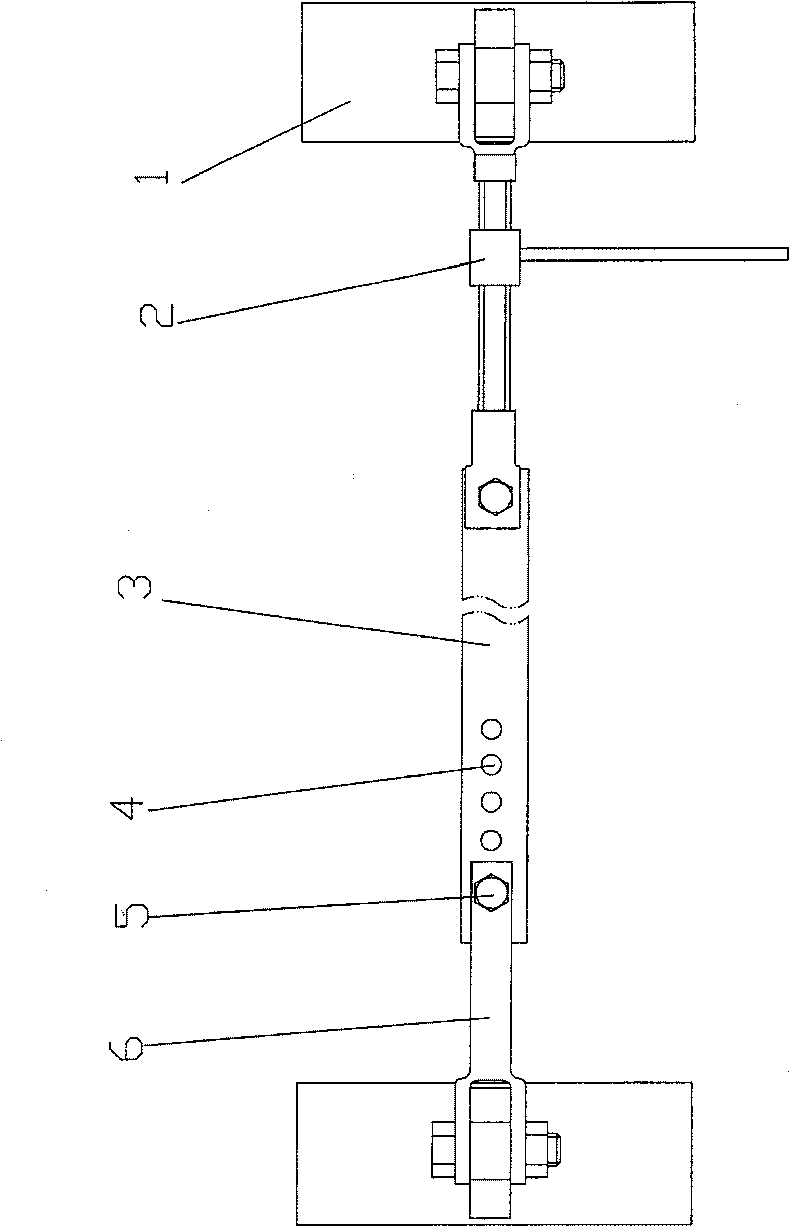

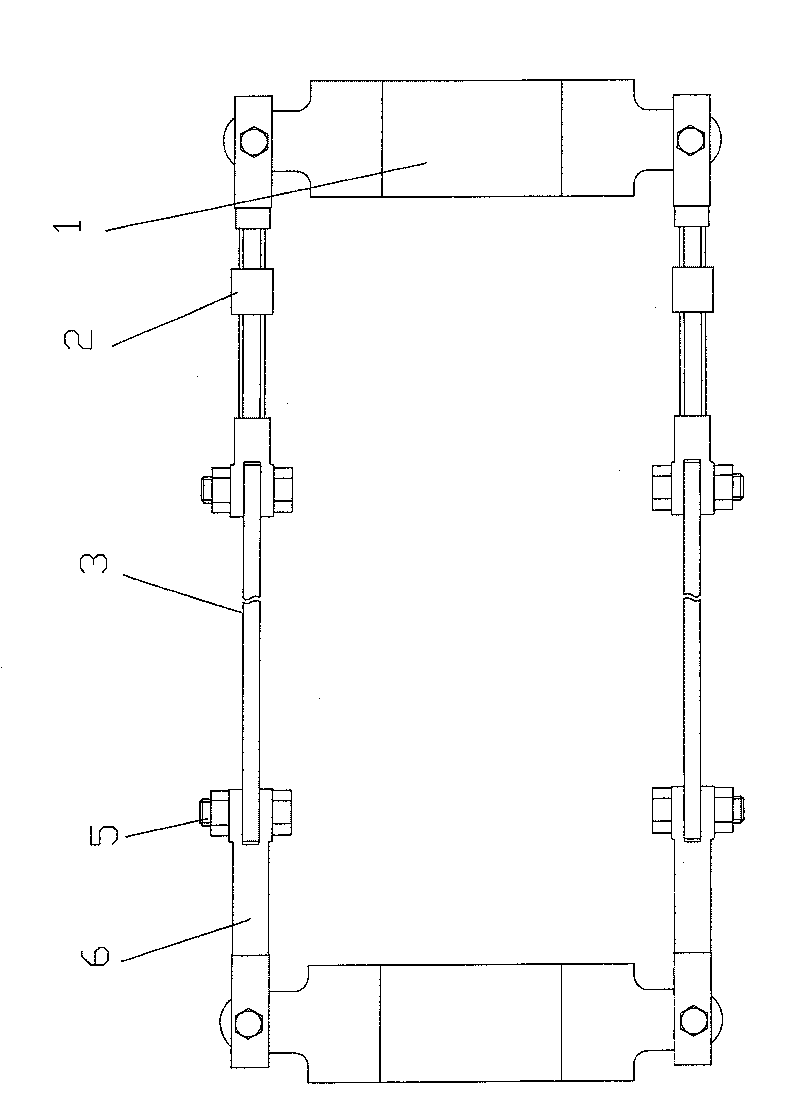

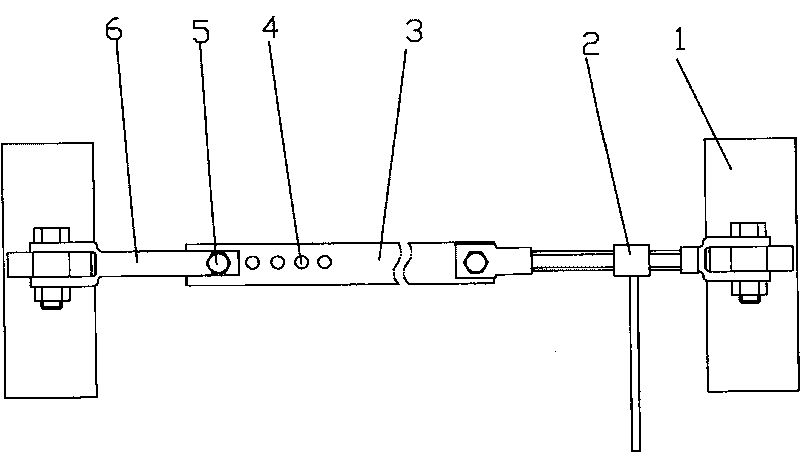

High-voltage power line tension insulator string forward spin live-wire altering method

ActiveCN101174761BAccurate placementLarge operating spaceSuspension/strain insulatorsApparatus for overhead lines/cablesEngineeringTraveling block

The present invention discloses a spinning electricity replacing method and a double yoke-plate device of high-tension transmission line strain insulator. A wing-shaped card and an insulation drawplate and other special tools on the end are used to firstly loose the stain insulator; a pulley block and a lead screw on the sides of a cross arm and a lead wire are used to complete break away the twoends of the strain insulator; finally the pulley block arranged on a ground bracket is used to rotate a porcelain insulator from a horizontal state to a vertical state, thus changing the complicated operation to the simple operation, greatly shortening the equipotential operation time and ensuring the safe operation of the line. The double yoke-plate device of high-tension transmission line strain insulator includes two wing-shaped cards and two lead screws as well as two insulation drawplates; one end of the two insulation drawplates is respectively connected with the two wings of the two wings of the wing-shaped card and the other end is respectively connected with the lead screw; the other end of the two lead screws is respectively connected with the two wings of the other wing-shaped card. The present invention has the advantages of simple structure, easy operation and low cost.

Owner:MAINTENANCE BRANCH OF STATE GRID CHONGQING ELECTRIC POWER +1

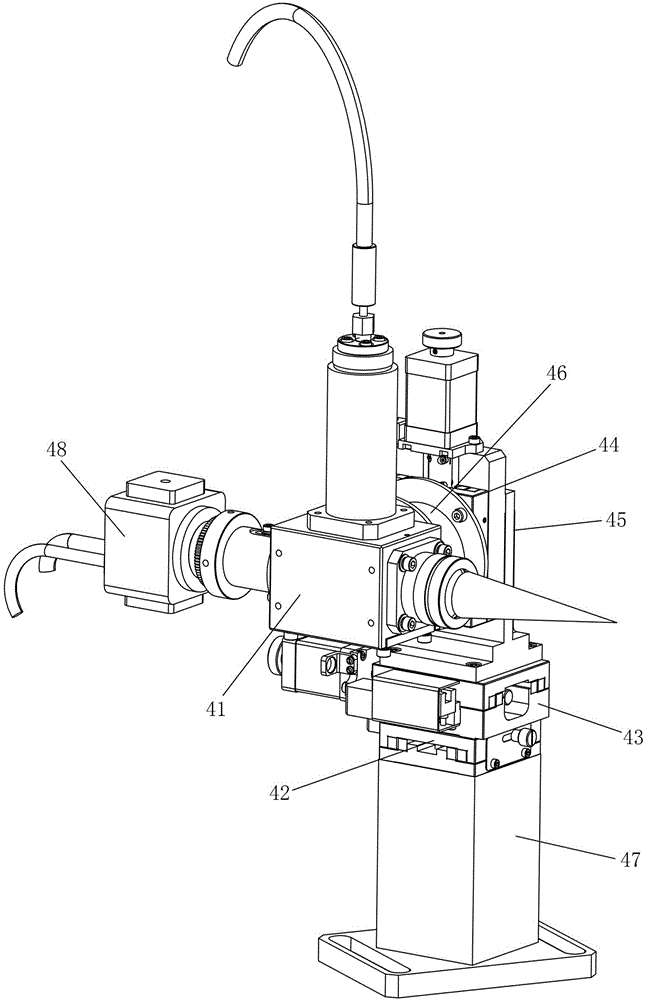

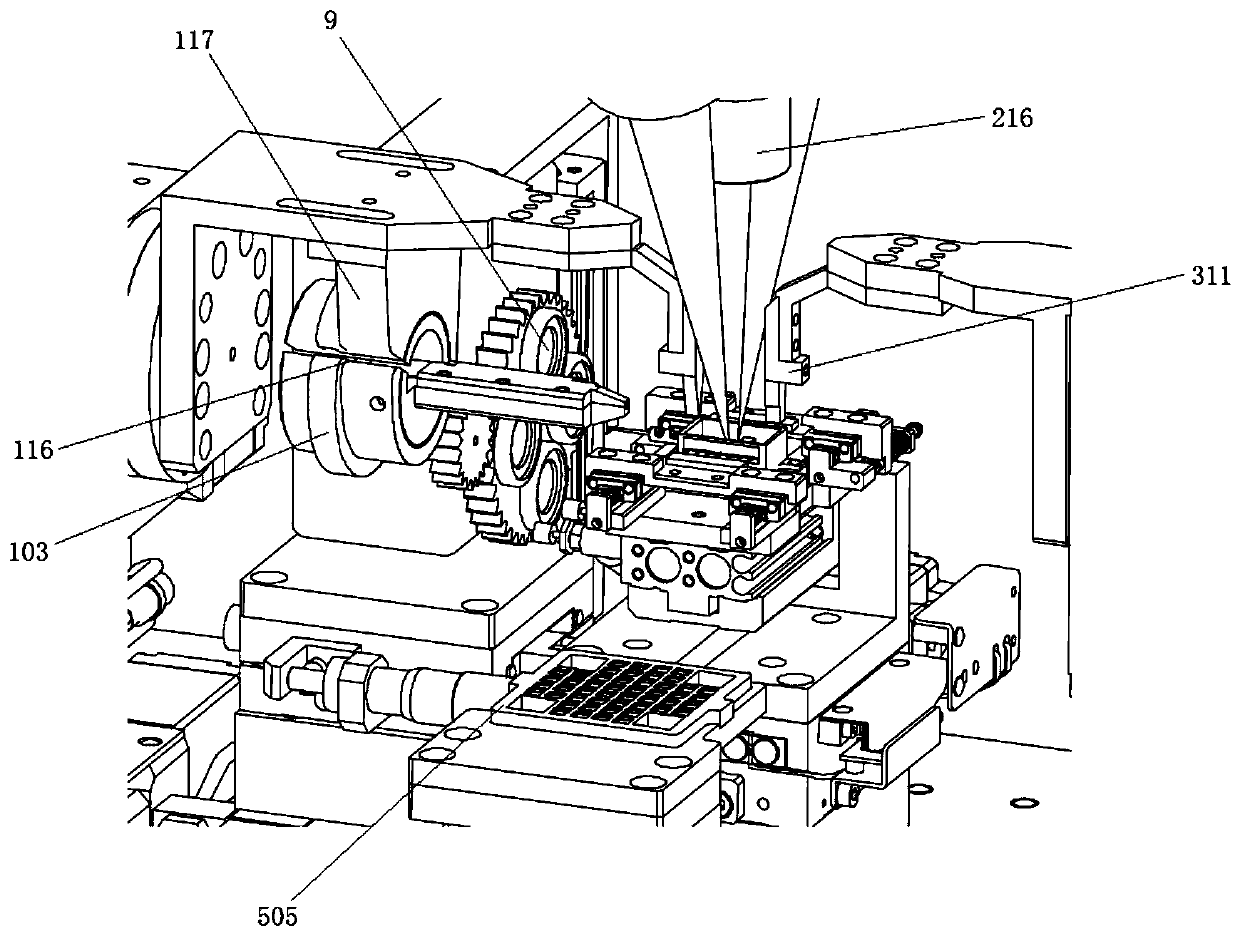

Butterfly-shaped semiconductor laser automatic coupling packaging device

ActiveCN109521536AHigh degree of automationIncrease productivityCoupling light guidesProduction lineCoupling

The invention discloses a butterfly-shaped semiconductor laser automatic coupling packaging device and relates to the automatic coupling packing field of an electronic device. The automatic coupling packaging device includes a column, a cross beam, and a fiber clamp, a lens clamp mechanism, a lower clamp device and a material disc mechanism arranged on a base, and a laser power meter, wherein thefiber clamp, the lens clamp mechanism and a fiber automatic angle adjusting welding device can be adjusted in position to realize accurate coupling and packaging of a butterfly-shaped semiconductor laser. The device is advantaged in that the structure design is reasonable, the whole subsequent operation from coupling, alignment and packaging can be automatically completed, compared with a traditional hand-operated production line, advantages of high automatic degree, simple and convenient operation, high production efficiency, low production cost and stable product quality are achieved.

Owner:CENT SOUTH UNIV

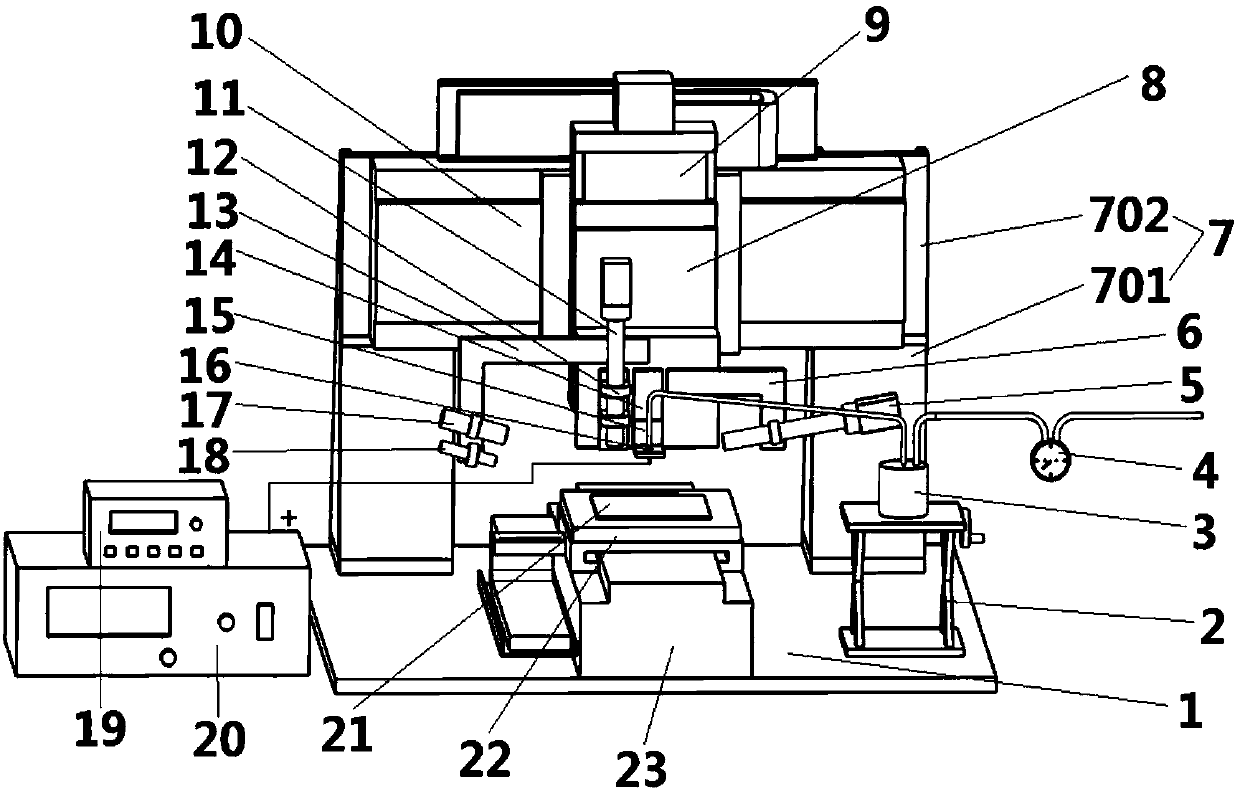

High-precision electric field driven spray deposition 3D printer and working method thereof

PendingCN107932894AHigh frequencyContinuous and stable feedingAdditive manufacturing apparatus3D object support structuresComputer printingImage resolution

The invention discloses a high-precision electric field driven spray deposition 3D printer and a working method thereof, and solves the problems of a traditional 3D printer on multiple aspects of resolution, stability and controllability; high-precision printing of multilayer structures can be realized; the printing process is observed and monitored in real time; and high-precision pattern printing is performed on insulation substrates through electric conducting materials. The high-precision electric field driven spray deposition 3D printer comprises a mounting baseplate; a Y-axle worktable is arranged on the mounting baseplate; a vacuum absorption platform is fixed on the Y-axle worktable; a printing substrate is absorbed on the vacuum absorption platform; a printing nozzle and a vertical observation camera are correspondingly arranged above the printing substrate, and are connected to a Z-axle worktable; the Z-axle worktable is fixed on an X-axle worktable; a squint observation camera is correspondingly arranged on one side of the printing nozzle; an LED light source and a far infrared curing light source are correspondingly arranged on the other side of the printing nozzle; theprinting nozzle communicates with a storage bottle; and the storage bottle is arranged on a lifting table.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

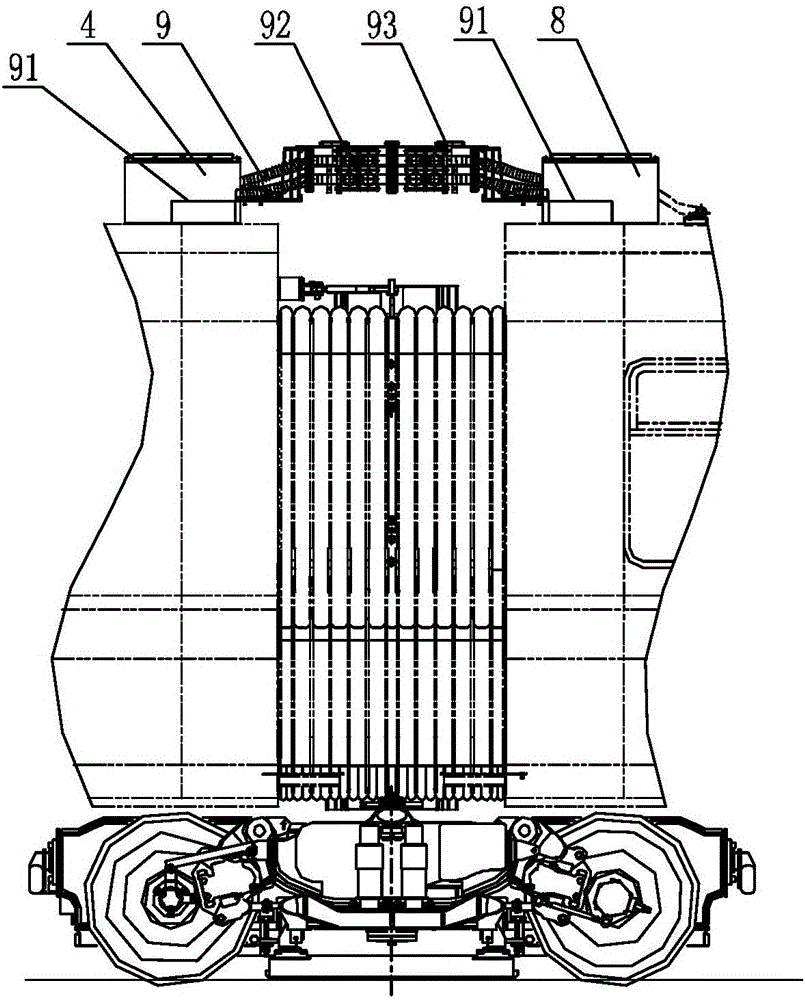

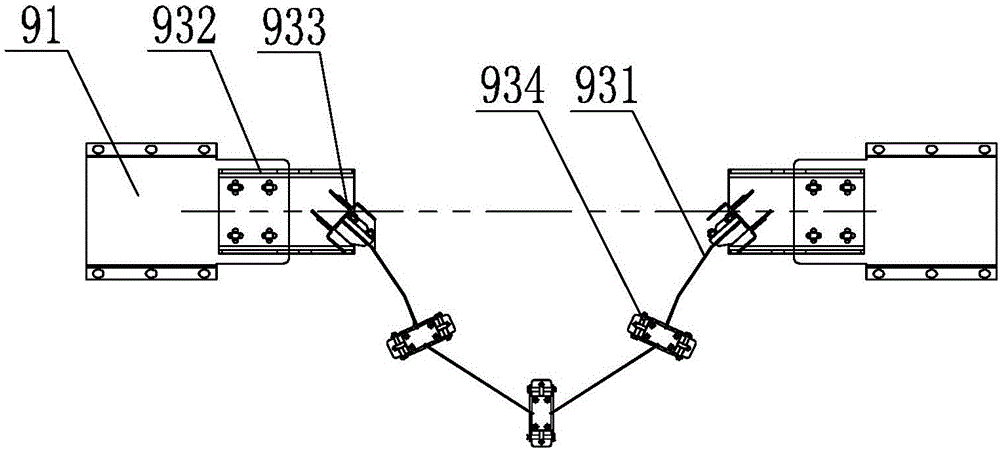

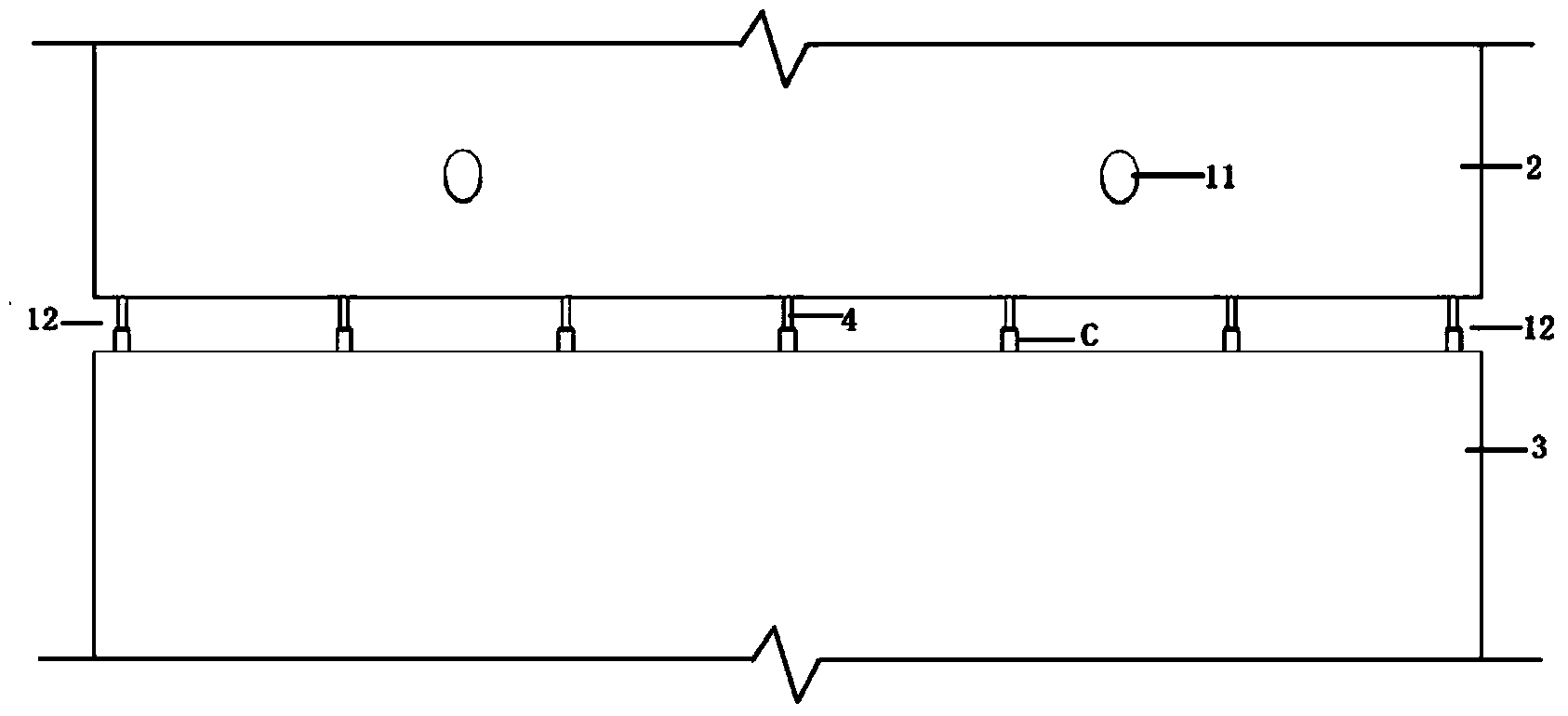

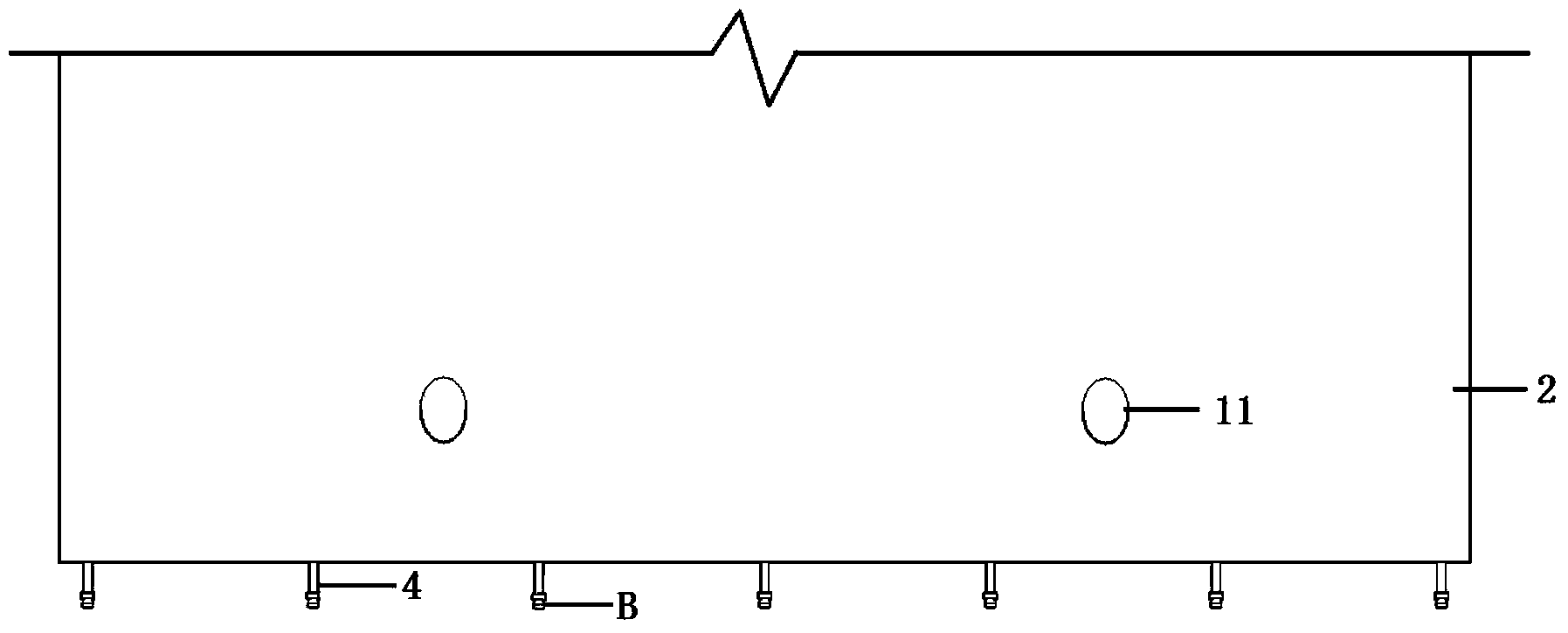

Installation structure of train roof jumper cable of urban rail

ActiveCN106374398ALarge operating spaceSimple installation environmentArrangements using spring-loaded loopArrangements using gravity-loaded loopLow voltageHigh pressure

The invention discloses an installation structure of a train roof jumper cable of the urban rail. A first high-voltage connector casing, a first high / low voltage connector, a second high / low voltage connector and a first low-voltage connector casing are positioned in the top of a first compartment; a second high-voltage connector casing, a third high / low voltage connector, a fourth high / low voltage connector and a second low-voltage connector casing are positioned in the top of a second compartment; the first high / low voltage connector on the first high-voltage connector casing is connected to the third high / low voltage connector on the second high-voltage connector casing via the jumper cable; and the second high / low voltage connector on the first low-voltage connector casing is connected with the fourth high / low voltage connector on the second low-voltage connector casing via the jumper cable. The installation structure has the advantages that the operation space is large, the installation environment is simple, and the structure is safer and more reliable; the service life is longer; the cable path is shorter, and the cost is reduced greatly; the sealing performance is higher; the whole installation structure can be dismounted rapidly, the occupation space is small, and the structure is beautiful and tidy; and it is not required to reconstruct end wall and channel structures, the workload is low, and the cost is lower.

Owner:CRRC DALIAN CO LTD

Boxing device for soft-drawn tissues

ActiveCN103057732AWill not affect product qualityWill not affect the overall effectIndividual articlesBiochemical engineeringToilet paper

The invention discloses a boxing device for soft-drawn tissues and belongs to the technical field of boxing equipment of toilet paper and tissues. The boxing device comprises an operation platform, a sorting device, a sub-packaging push-rod device and a boxing platform. The sorting device mainly comprises a sorting trough, a sorting push-rod device and a fixed baffle plate, the sorting trough is arranged on the lateral portion of the operation platform, the sorting push-rod device is arranged at a feed end of the sorting trough, the fixed baffle plate is arranged on the surface of the operation platform, a pressure plate arranged horizontally is further arranged on the upper portion of the fixed baffle plate, the sub-packaging push-rod device is arranged on the operation platform, and the boxing platform comprises a boxing lifting platform, a boxing lifting device and a box fixing device. The boxing device for the soft-drawn tissues is reasonable in design, simple to operate, reliable in performance, and can be applied in boxing work of the soft-drawn tissues, and accordingly boxing labor intensity of operators is relieved, production efficiency is increased, production cost is lowered, and due to large operating space, the boxing device is applicable to boxing of tissue paper of multiple specifications and different boxing specifications.

Owner:维达纸业(四川)有限公司

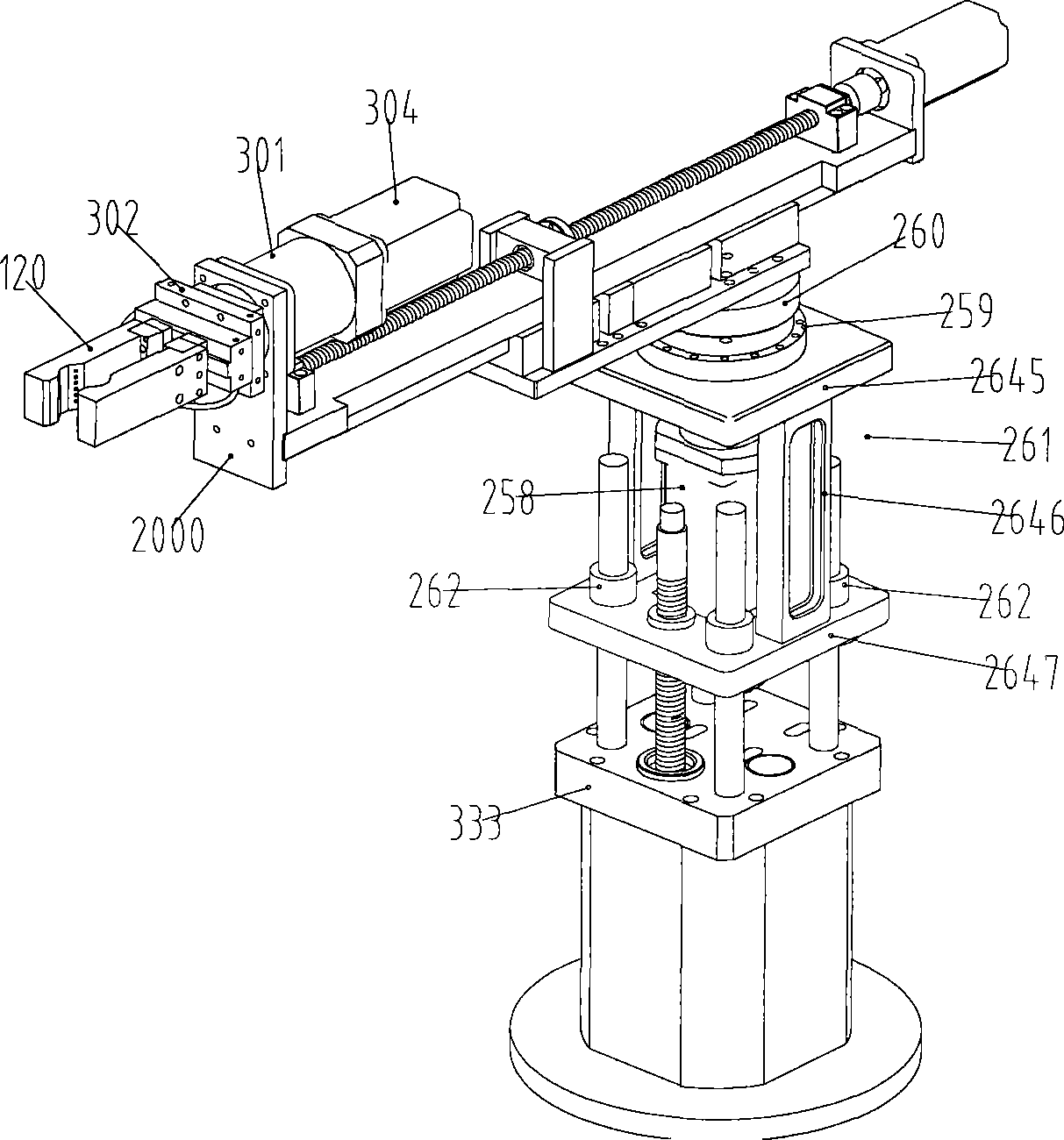

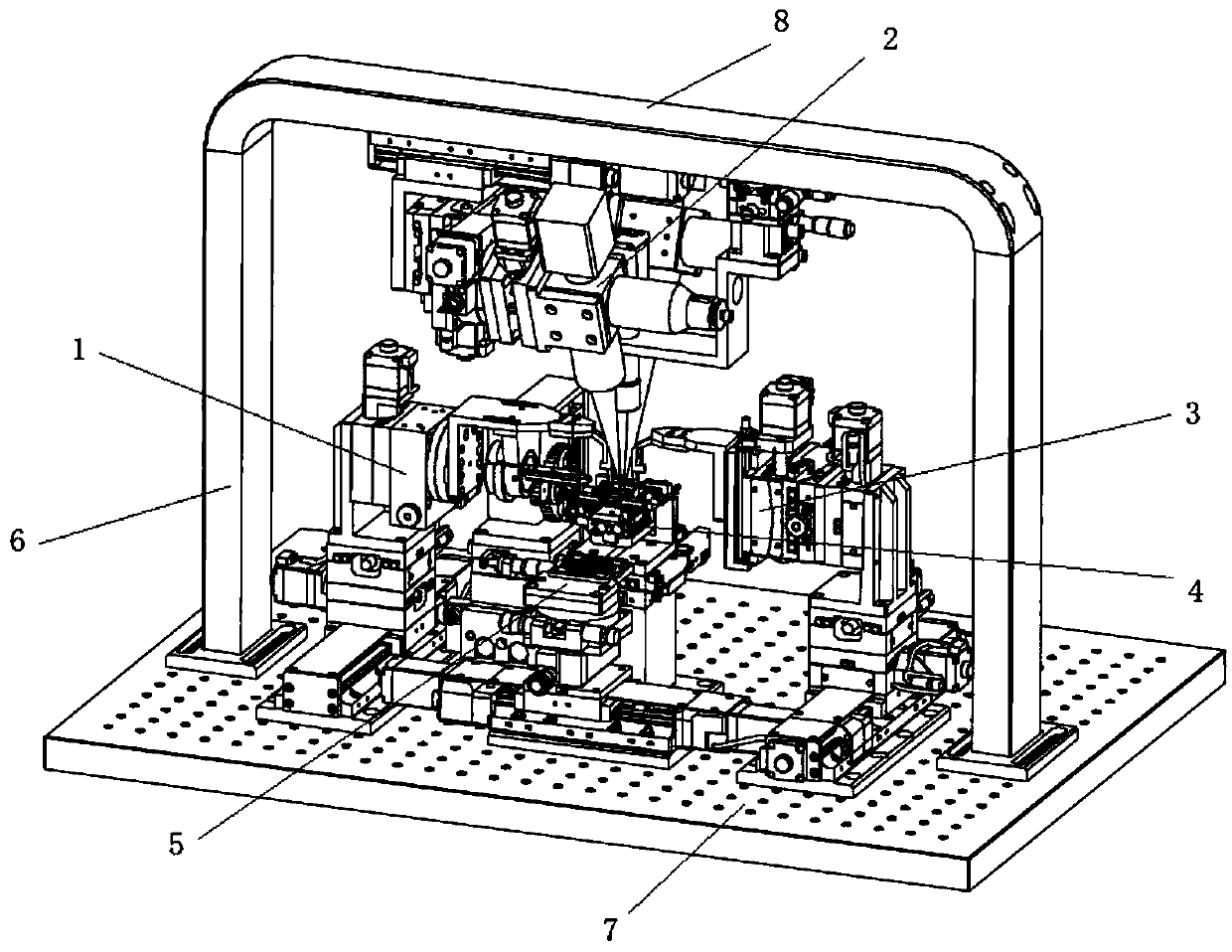

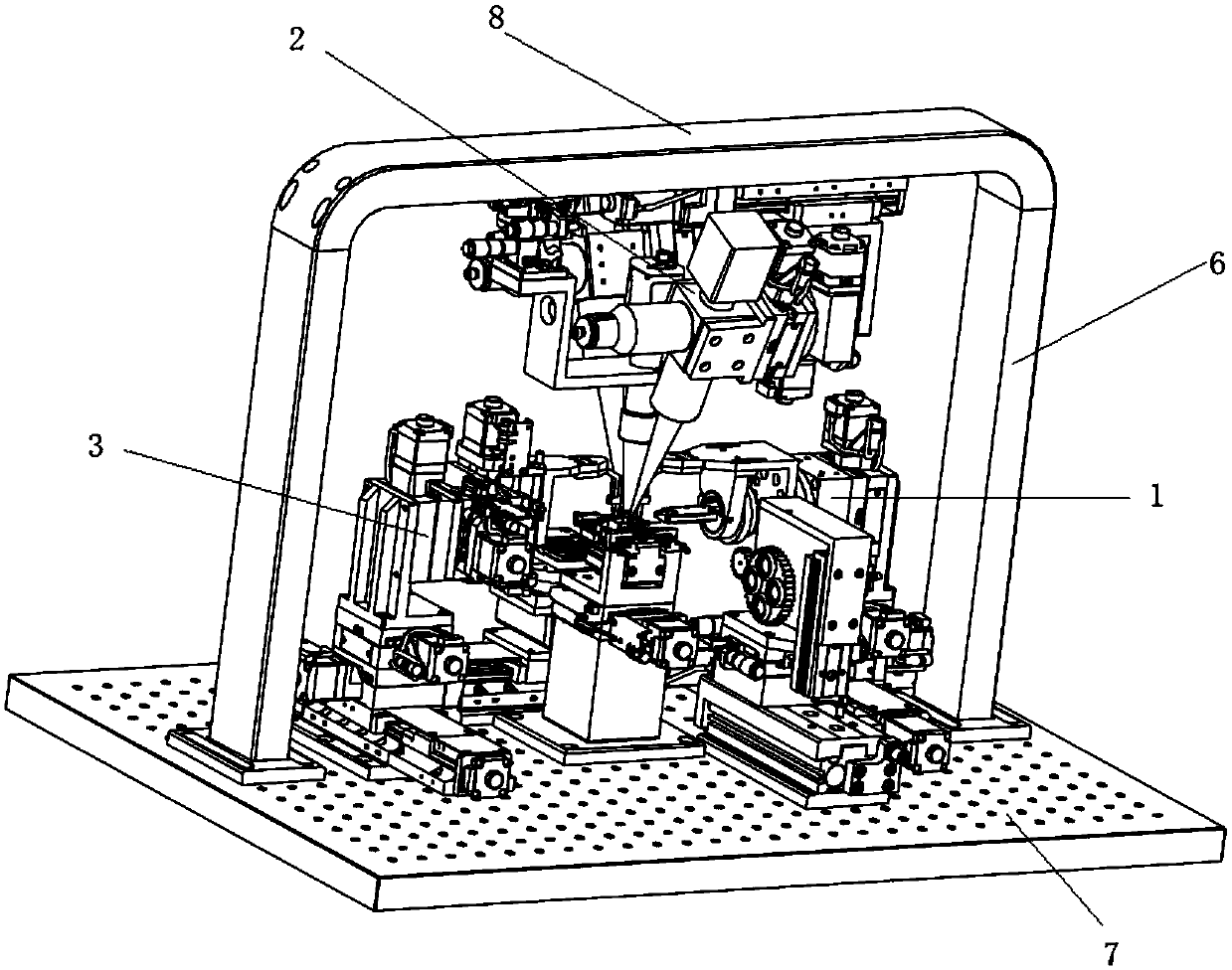

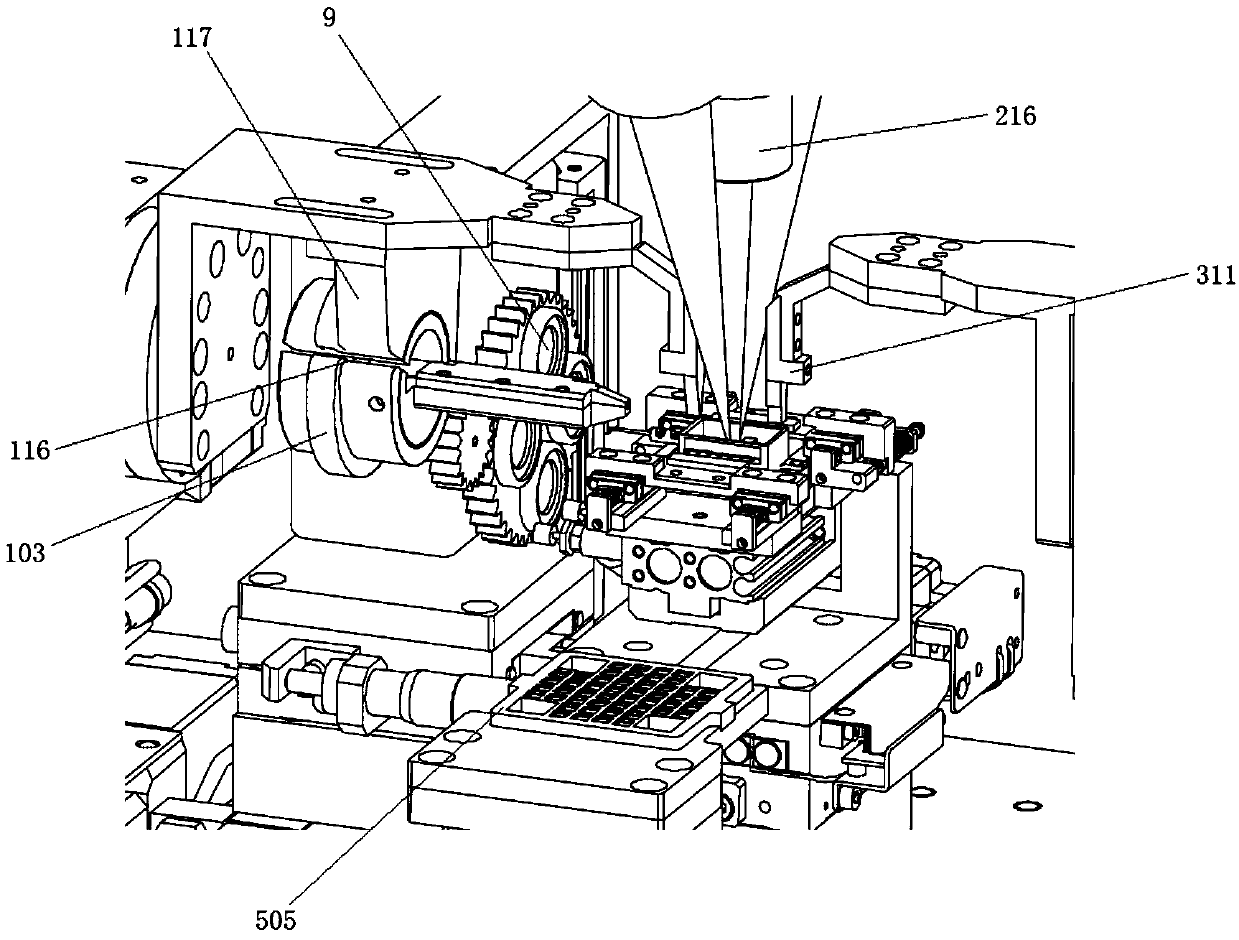

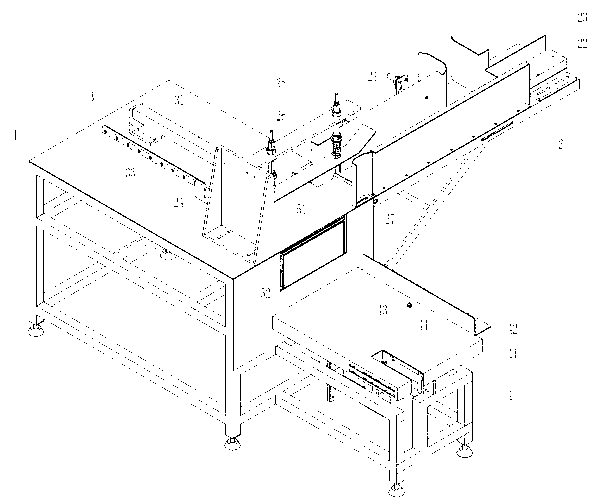

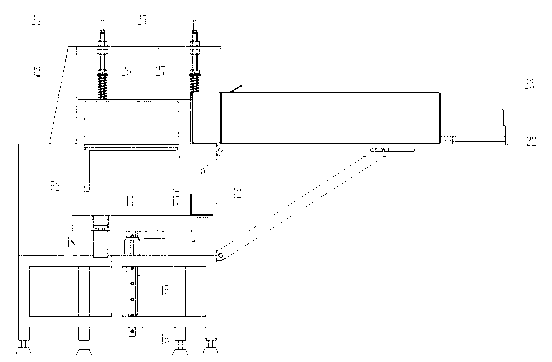

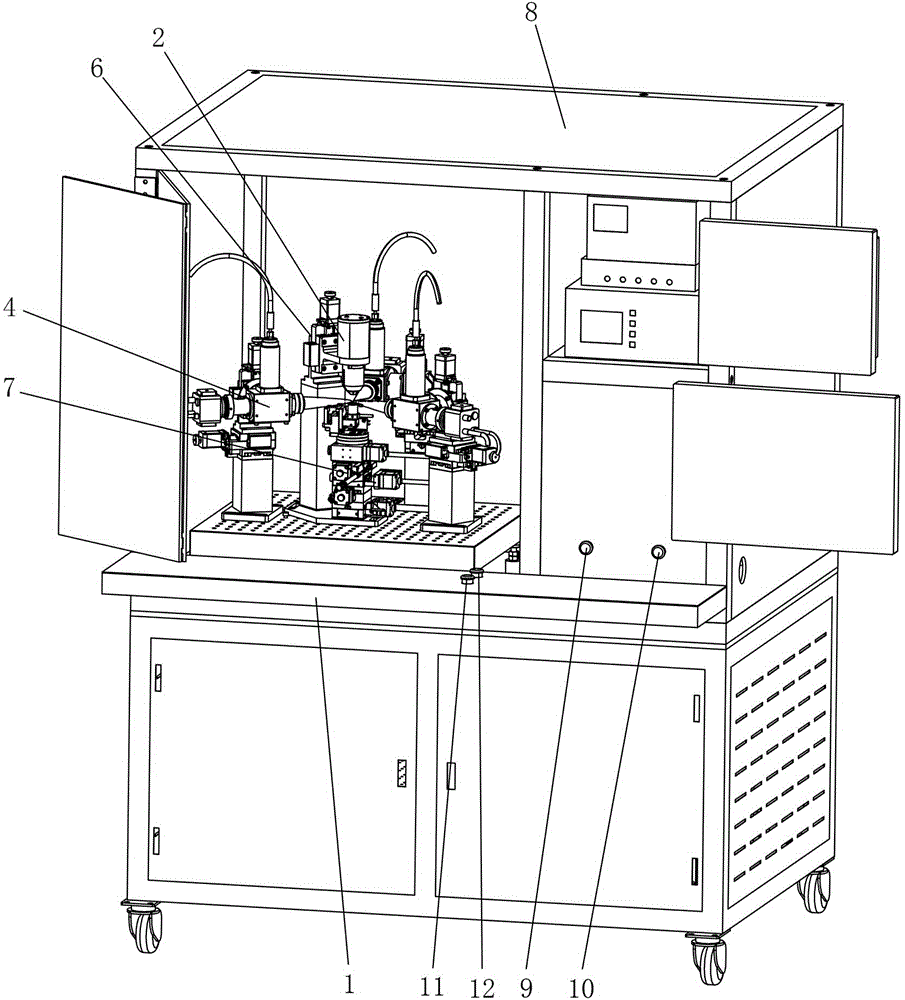

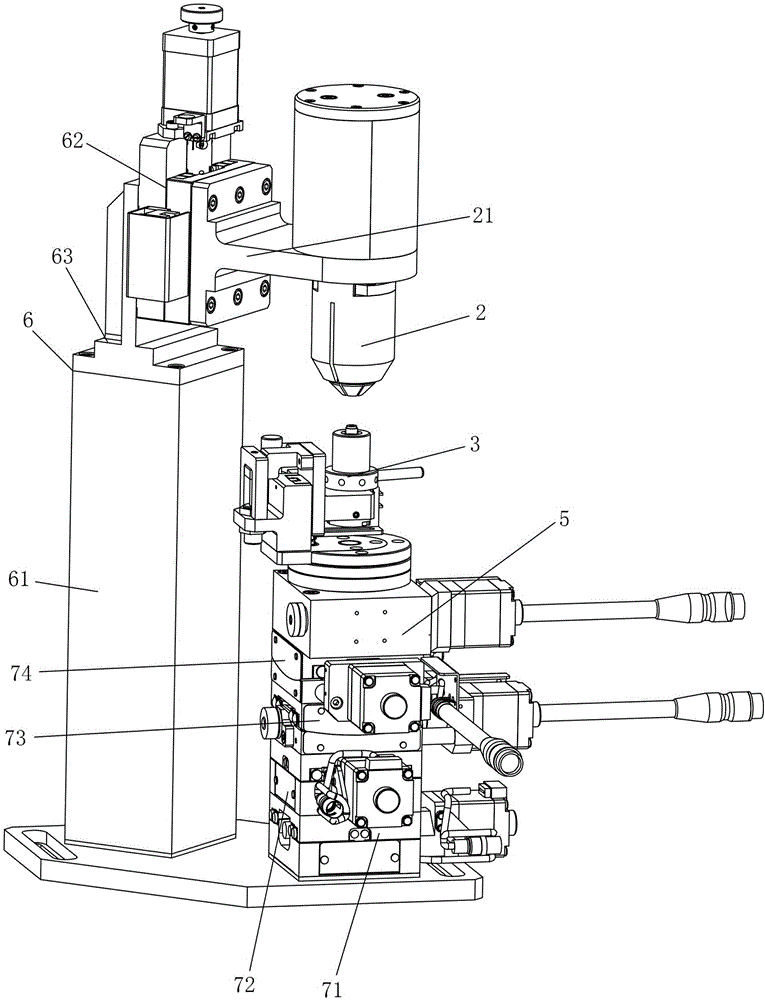

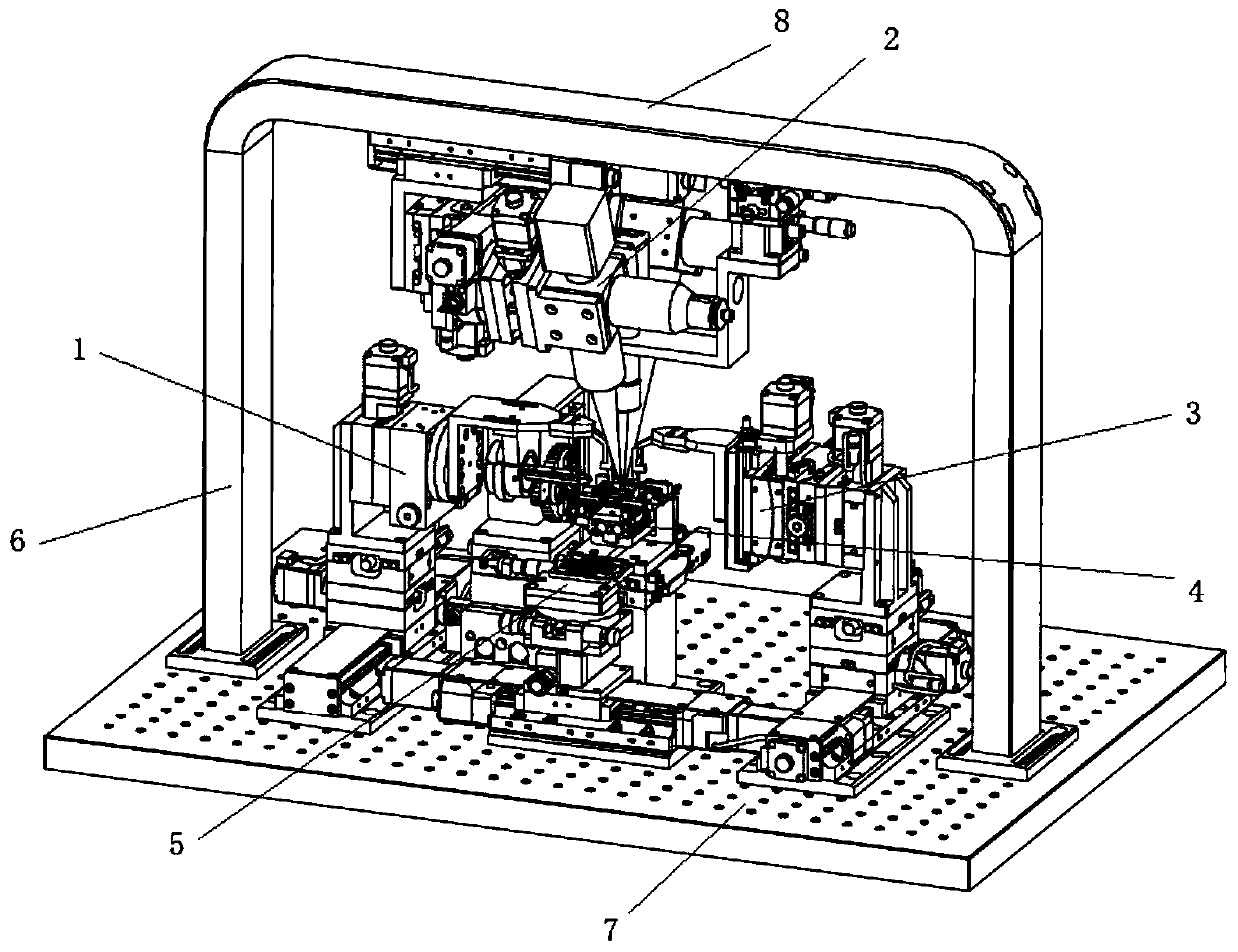

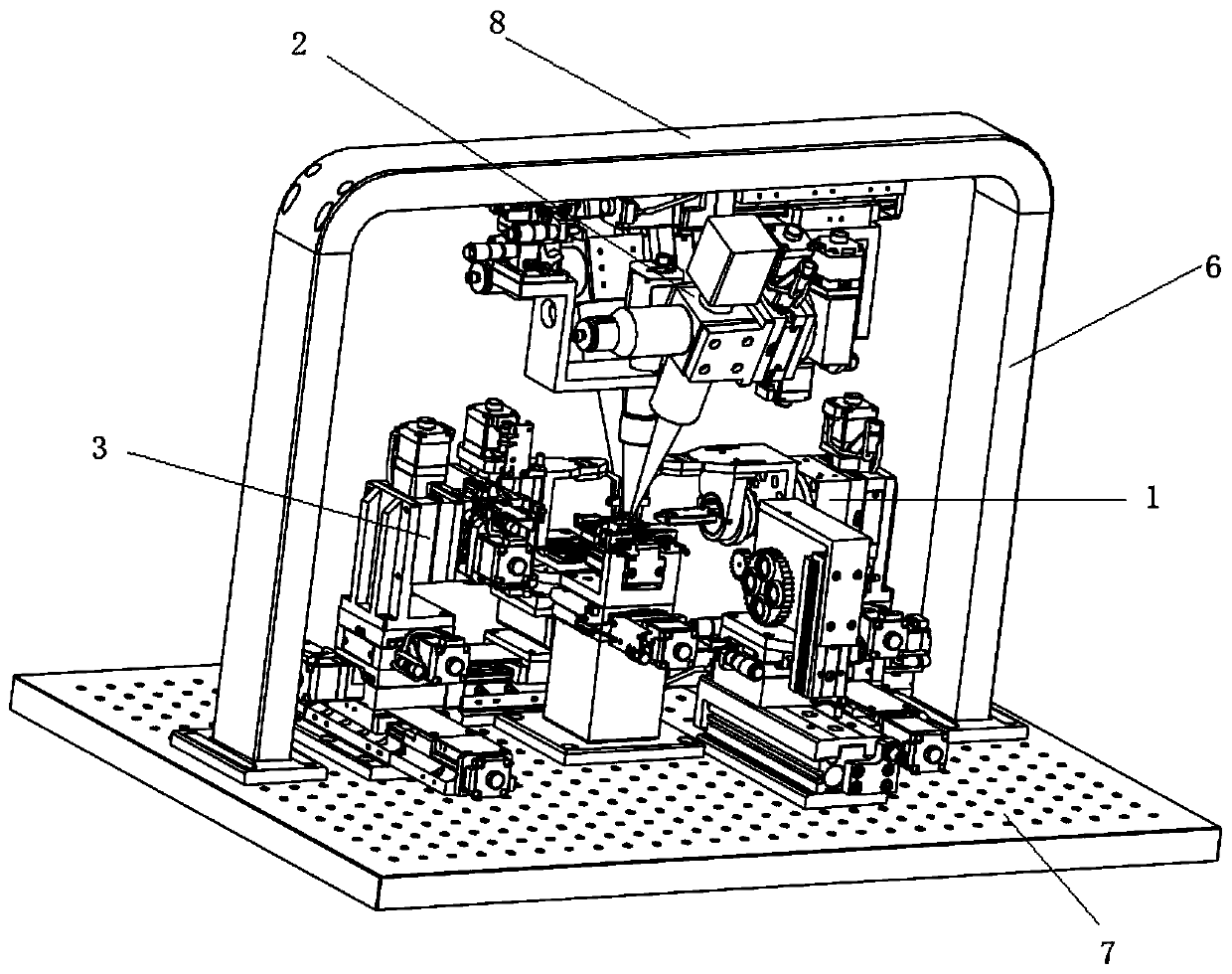

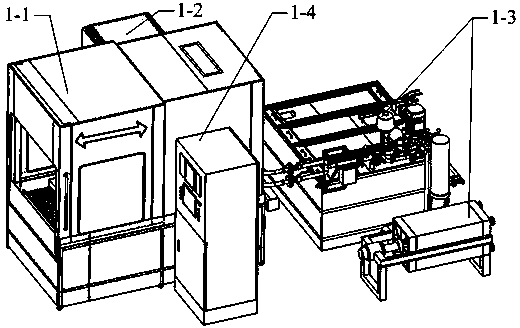

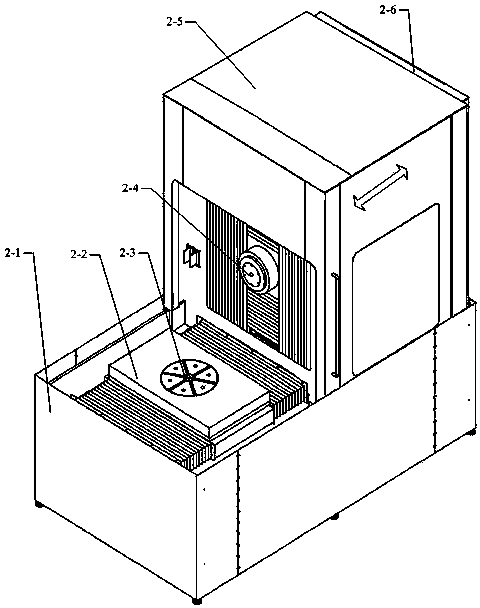

Compactly-structured automatic coupling and welding equipment for coaxial optoelectronic device

ActiveCN104096969AHigh degree of automationIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesCouplingElectron

The invention discloses compactly-structured automatic coupling and welding equipment for a coaxial optoelectronic device. The compactly-structured automatic coupling and welding equipment comprises a frame, an upper clamp, a lower clamp and a plurality of welding devices mounted on the frame, the upper clamp is mounted on the frame via a lifting device and can be driven to move up and down along a Z axis by the lifting device, and the lower clamp is mounted on the frame via an aligning device and can be driven to move along an X axis and a Y axis, swing around the X axis and the Y axis and rotate around the Z axis by the aligning device. The compactly-structured automatic coupling and welding equipment for the coaxial optoelectronic device has the advantages of reasonable and ingenious structure design, strong expandability, small space, high automation degree, simplicity and convenience in operation, short working time, high production efficiency, low production cost, stable product quality, applicability to multiple types of coaxial optoelectronic devices and the like.

Owner:湖南中南鸿思自动化科技有限公司

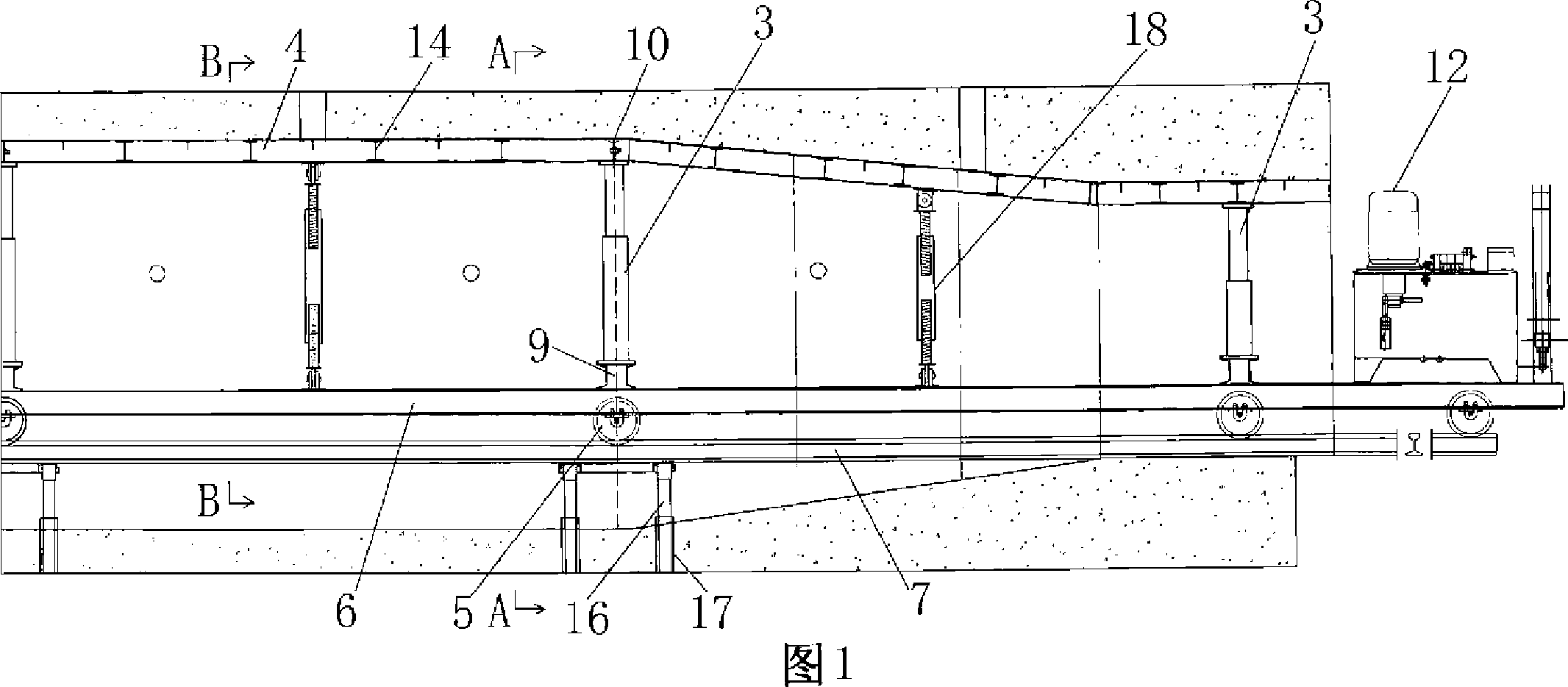

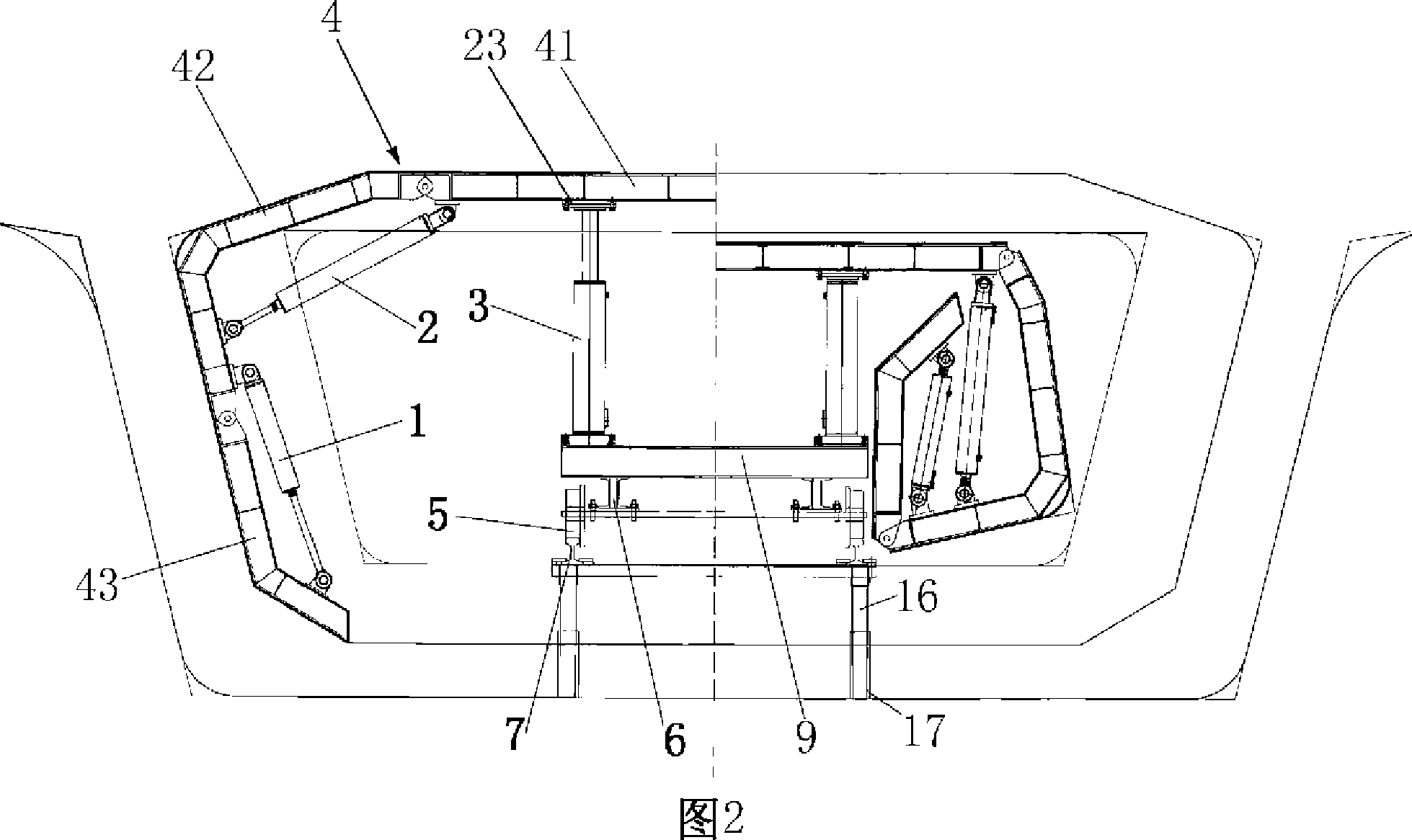

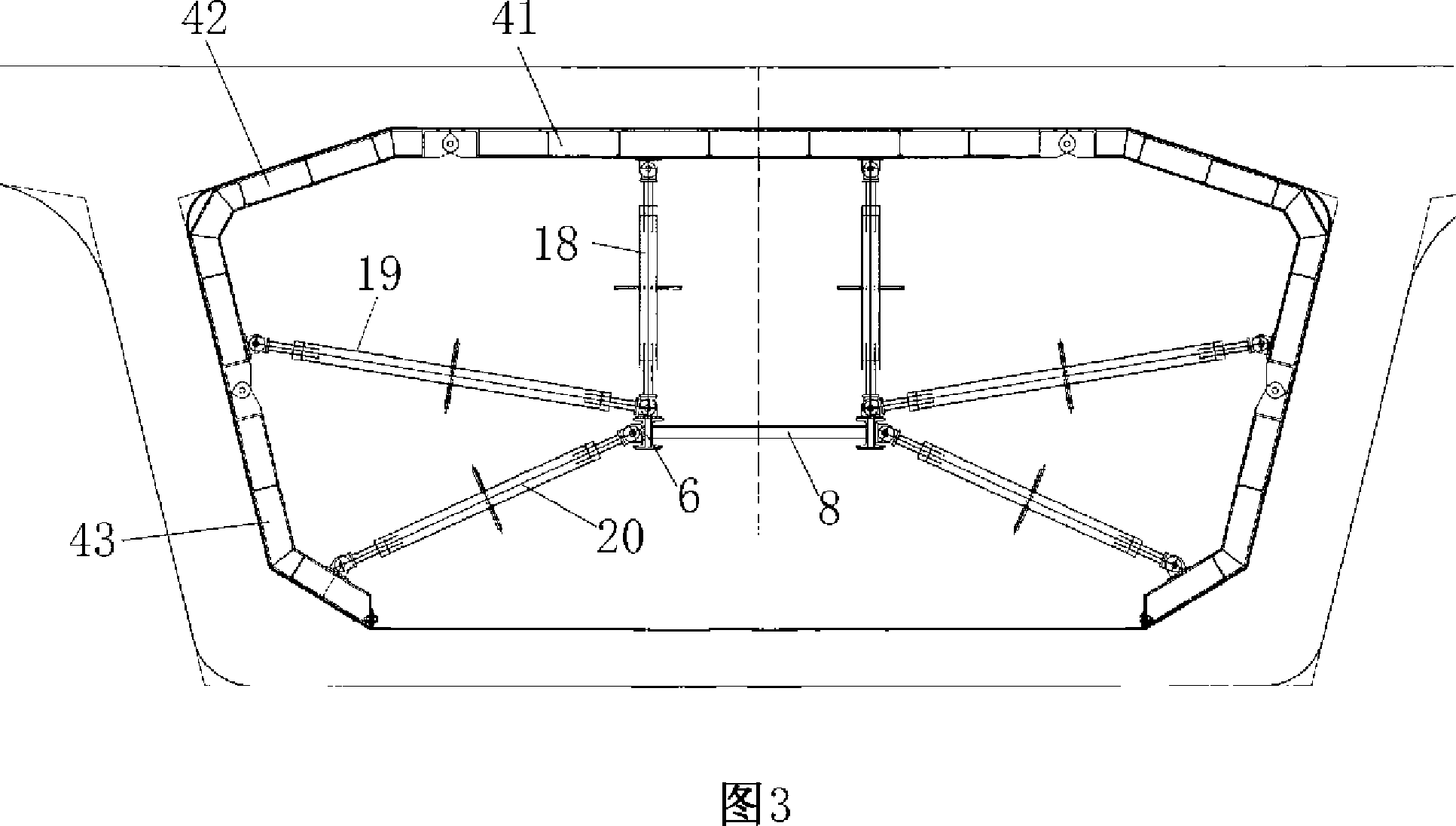

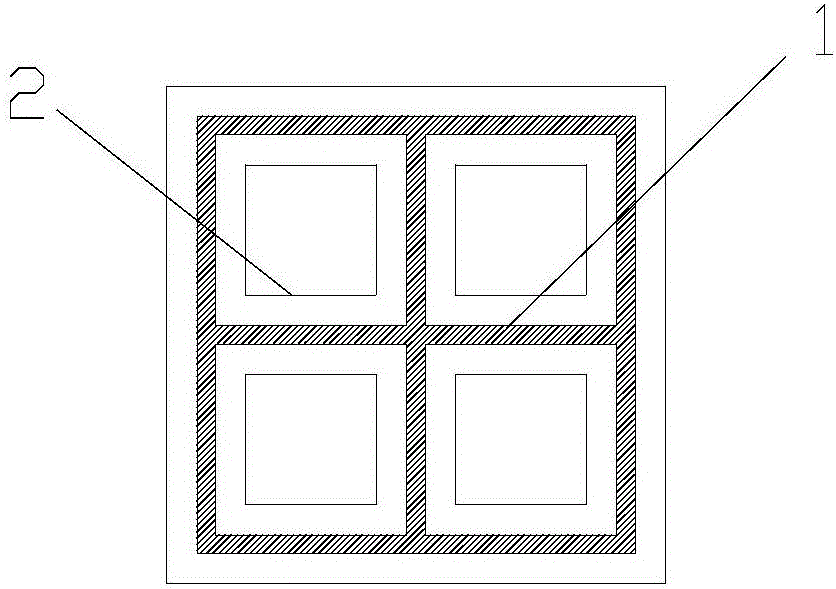

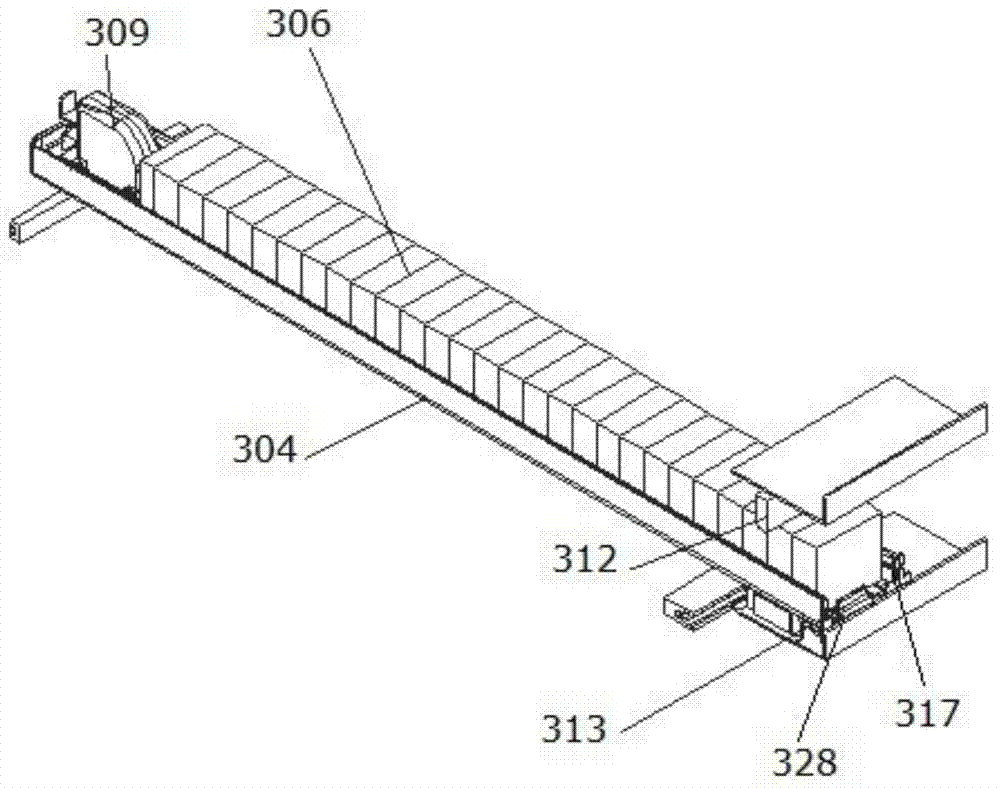

Full-automatic hydraulic prefabricated box girder inner formwork system

InactiveCN1970264ASimple structureLess consumablesMouldsCeramic shaping mandrelsInterior spaceVehicle frame

The automatic hydraulic premade box beam inner formwork system has the inner mold hinging with a pair of up corner mold and a lower corner mold, oil tank slanting upward connected between the top mold and the up corner mold, oil tank slanting downward connected between the top corner mold and the lower corner mold, bracket barricaded along the box beam at the center of the cavity bottom surrounded by inner molds supporting up steel track that has translation cart along it with the cart composed of walking wheel, frame, supporting base beam fastened on the frame, frame of the cart extending outside of the inner mold plate with hydraulic pump station and operation platform. It is simple, steel consumption effective, low in cost, improving inner space 25% than the traditional one.

Owner:杨秋利

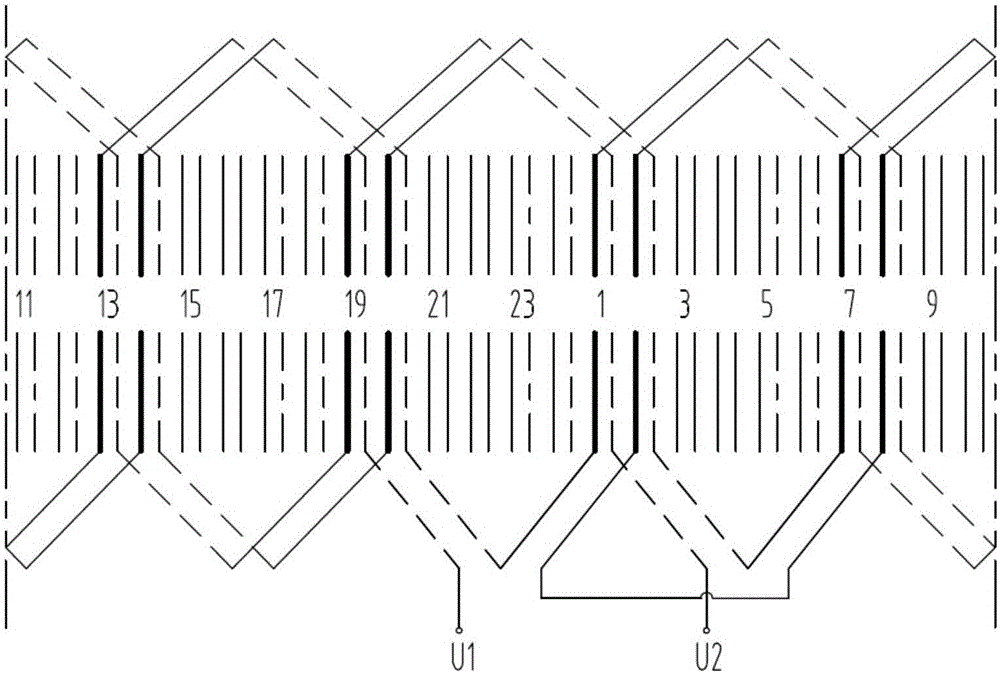

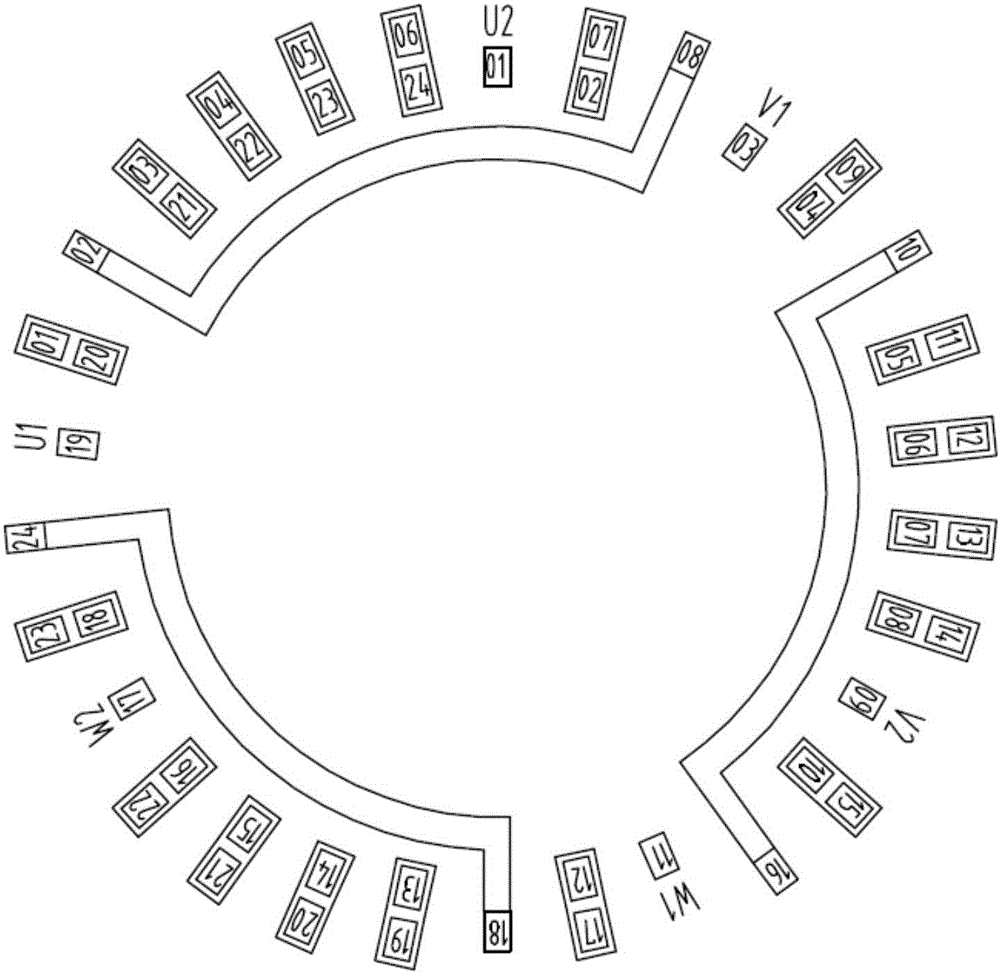

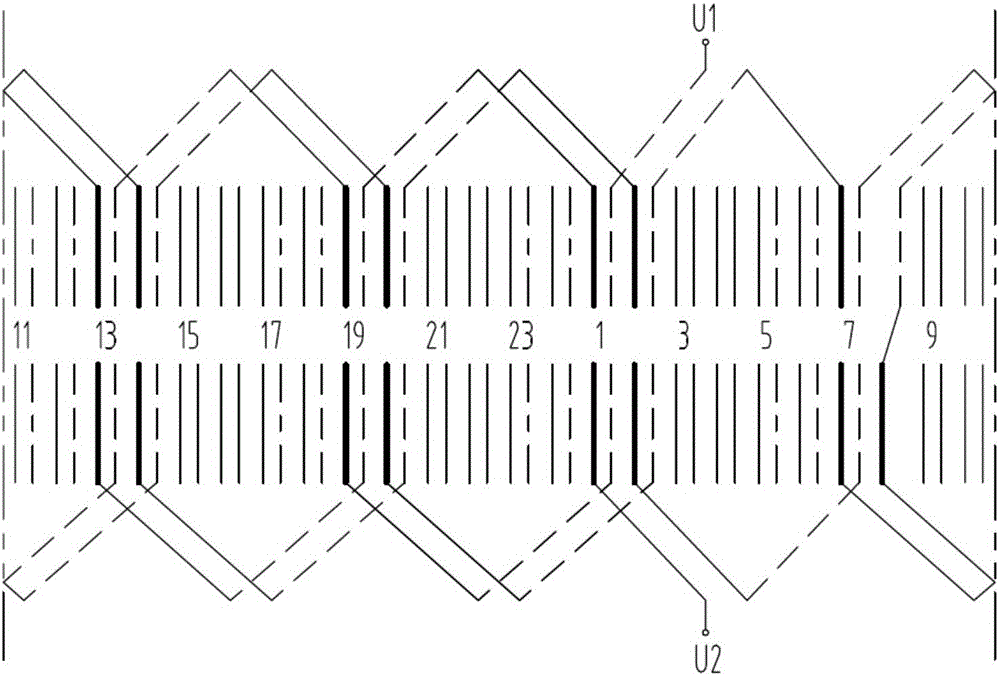

Novel double-layer wave winding method capable of saving wiring space of outlet terminal

ActiveCN106787337AAlleviate the problem of tight wiring spaceLarge operating spaceWindings conductor shape/form/constructionMultiple methodsElectrical and Electronics engineering

The invention discloses a novel double-layer wave winding method capable of saving wiring space of an outlet terminal. The novel double-layer wave winding method capable of saving the wiring space of the outlet terminal adopts multiple methods such as a full pitch one route connection method of a 4-pole 24-slot rotator, and the connection method includes: from the beginning of connection performed by using U1 as a leading wire, first connecting for 1-8 long pitches, then connecting for 3 whole pitches, next connecting for 2-7 short pitches, finally connecting for 3 whole pitches, completing connection of coils belonging to the same phase under U phase N pole, connecting coils under U phase S pole through steps as same as above steps, and finally connecting the coils of the two large groups in series according to the current direction in a slot, and then forming a phase of winding. The novel double-layer wave winding method capable of saving the wiring space of the outlet terminal has advantages of evenly distributing line outgoing heads of the same quantity as rotor slots at a line outgoing terminal by changing a connection mode of the double layer wave winding, alleviating the problem that wiring space is limited at the end of the line outgoing terminal to obtain the maximum distance between each two adjacent line outgoing heads and the maximum operation space of uniform head welding, facilitating uniform head welding operation to the utmost, placing head and tail connection lines of both the phases at one end, and connecting outgoing lines through a Y connecting method and a delta connection method.

Owner:江西江特电机有限公司 +1

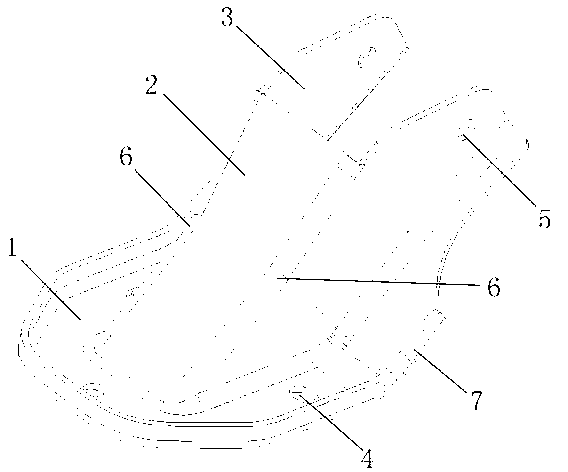

Controllable three-finger manipulator and control method thereof

InactiveCN104972478AStable clampingLarge operating spaceProgramme-controlled manipulatorGripping headsGear wheelEngineering

The invention relates to a controllable three-finger manipulator. The controllable three-finger manipulator comprises a mechanical part and a control frame, wherein the mechanical part comprises a hand part, a wrist and an arm; the hand part consists of fingers and a force transfer mechanism; each finger consists of two pieces of mechanical fingers; the force transfer mechanism consists of six support rods, six gear pieces and four bevel gears; the arm comprises a small arm connecting frame and a large arm connecting frame; steering engines are respectively mounted on swing pairs in the connected place between the hand part and the small arm connecting frame, the connected place between the small arm connecting frame and the large arm connecting frame and the connected place between the large arm connecting frame and a base; the control frame is mounted on an arm of an operator, and comprises potentiometers; and the potentiometers can obtain rotating angles of the arm and the fingers of the operator. The invention further relates to a control method of the controllable three-finger manipulator. The controllable three-finger manipulator and the control method thereof have the beneficial effects of improving the finger sensitivity and the grabbing and releasing speed, realizing the human-computer synchronization motion and becoming more humanized.

Owner:SOUTHEAST UNIV

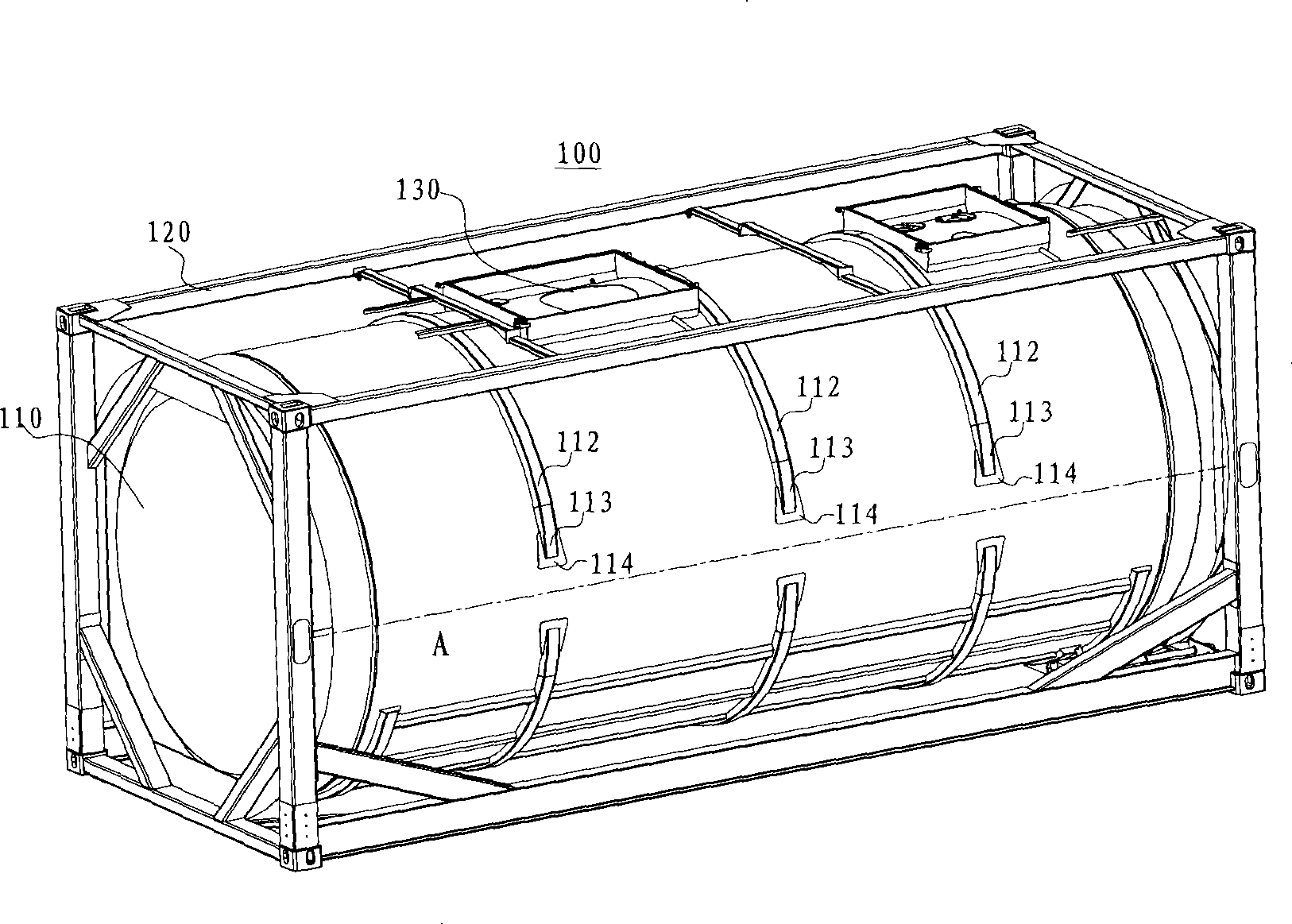

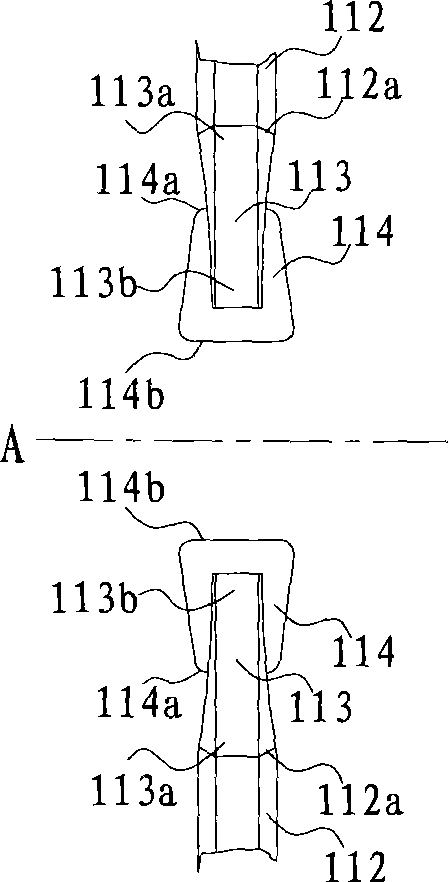

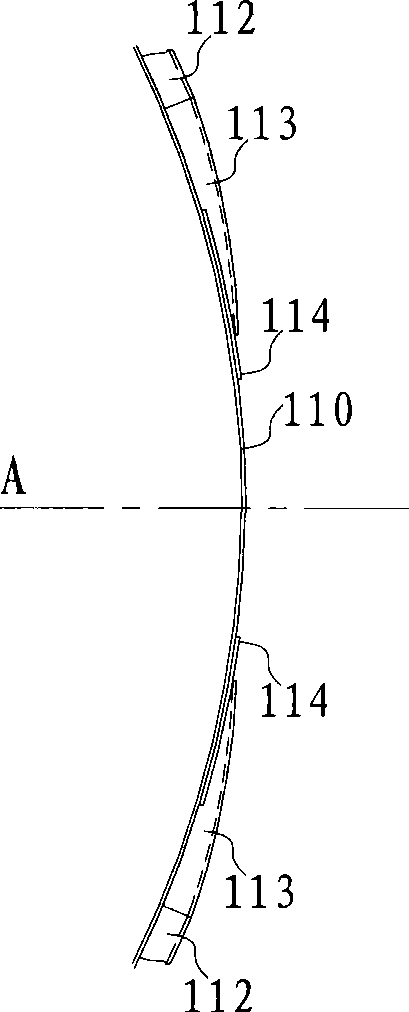

Large volume tank container

ActiveCN101362543ALose weightGuaranteed StrengthLarge containersBiochemical engineeringTank container

The invention relates to a high volume tank container, which comprises a framework, a tank body arranged in the framework, at least one reinforcing ring arranged on the periphery of the tank body and used for reinforcing the intensity of the tank body to better resist the external pressure; wherein, the reinforcing ring is broken in the position closed to the central line on the side of the tank body, and a wedge-shaped reinforcing ring is arranged at the broken end part of the reinforcing ring and connected with the tank on the both sides of the central line on the side of the tank body. A discharging system is installed at the bottom part at the rear end of the tank body, the lower beam corresponding to the position of the discharging system is disconnected into two sections, and a discharging bottom board is connected at the lower end of each lower beam in the disconnecting position. Simultaneously, the central line of the tank body is arranged lower than that of the framework, therefore, not only the dimension of the side surface of the high volume tank container is ensured to be within the ISO dimension, but also a larger operating space exists in the discharging positions at the top part and the bottom part, thus being convenient for the operation.

Owner:NANTONG CIMC TANK EQUIP CO LTD

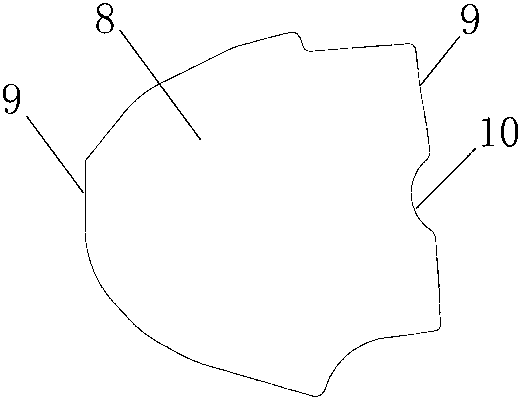

Precast concrete member connected by straight thread and pier head lock anchor grouting sleeve, and method for assembling same

The invention relates to a precast concrete member connected by a straight thread and a pier head lock anchor grouting sleeve, and a method for assembling the precast concrete member, belonging to the technical field of constructional engineering assembly concrete structures. The method of connecting by the straight thread and the pier head lock anchor grouting sleeve is adopted; one end of a reinforcing steel bar is processed into the straight thread (6), and the other end of the reinforcing steel bar is processed into a pier head (5); the inner wall of the end with smaller diameter of a connecting sleeve is processed into a thread (9) which is connected with the reinforcing steel by the straight thread (6) and is used for transmitting force; the inner wall of the end with larger diameter of the connecting sleeve is processed into a thread (16) which is connected with a matched plug ring (10) by an external thread (17); after grouting is carried out through a grouting hole, the original way that the tensile force of the reinforcing steel bar of a prefabricated part connected by grouting is transmitted mainly by bonding is changed by the reinforcing steel bar through lock anchor extrusion and bonding force transmission among the pier head of the reinforcing steel bar, the plug ring, grouting material and the sleeve. The safety and economical efficiency of the connection of the novel precast concrete member are improved.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

Conveying manipulator system

InactiveCN102848387ABroad application prospectsLarge operating spaceProgramme-controlled manipulatorTelescopic cylinderEngineering

The invention discloses a conveying manipulator system which comprises a rotary air cylinder, a telescopic air cylinder, a lifting air cylinder and a clamping air cylinder, wherein the four air cylinders are connected in sequence; the clamping air cylinder is provided with a paw; the four air cylinders are controlled by corresponding electromagnetic valves; the rotary air cylinder, the telescopic air cylinder and the clamping air cylinder are respectively controlled by three two-position five-way double-electromagnetic valves; and the lifting air cylinder is controlled by a two-position three-way single-electromagnetic valve. According to the structure of the conveying manipulator system, a manipulator has large operation space and high motion redundancy and has motion and operation functions at the same time, so that the manipulator is prior to the traditional manipulators and has wide application prospect in the industries such as hazardous operation, manufacturing industry and service industry.

Owner:SUZHOU INST OF TRADE & COMMERCE

Automatic coupling package method of butterfly-shaped semiconductor laser

ActiveCN109752805AHigh degree of automationIncrease productivityCoupling light guidesProduction lineCoupling

The invention discloses an automatic coupling package method of a butterfly-shaped semiconductor laser, and relates to the field of automatic coupling package of electronic devices. The automatic coupling package method comprises the steps of feeding-onto-machine of accessories, coupling alignment, welding and the like. An automatic coupling package device realizing the automatic coupling packagemethod comprises vertical columns, a transverse beam, an optical fiber clamp, a lens clamp mechanism, a lower clamp device, a material disc mechanism, a laser power meter and the like, wherein the optical fiber clamp, the lens clamp mechanism, the lower clamp device, the material disc mechanism and the laser power meter are arranged on a base; and the positions of the optical fiber clamp, the lensclamp mechanism and an optical fiber automatic angle-adjusting welding device can be adjusted so as to realize accurate coupling package of the butterfly-shaped semiconductor laser. The automatic coupling package method is high in automation degree and high in package efficiency; the coupling package device adopted by the automatic coupling package method is reasonable in structural design, the complete subsequent procedures from coupling alignment to package can be automatically completed, and compared with a traditional manual production line, the automatic coupling package device has the advantages of being easy and convenient to operate, low in production cost, stable in product quality and the like.

Owner:CENT SOUTH UNIV

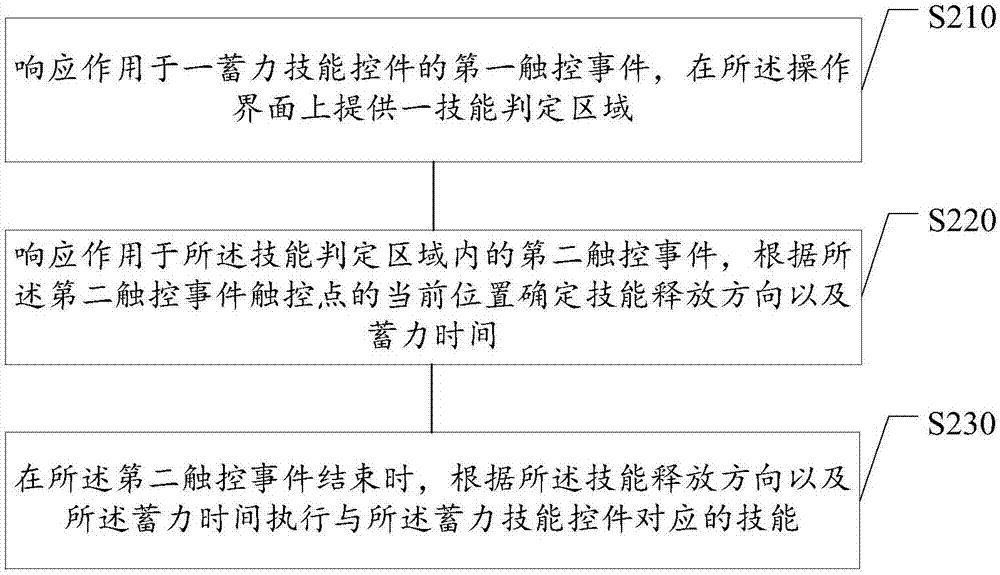

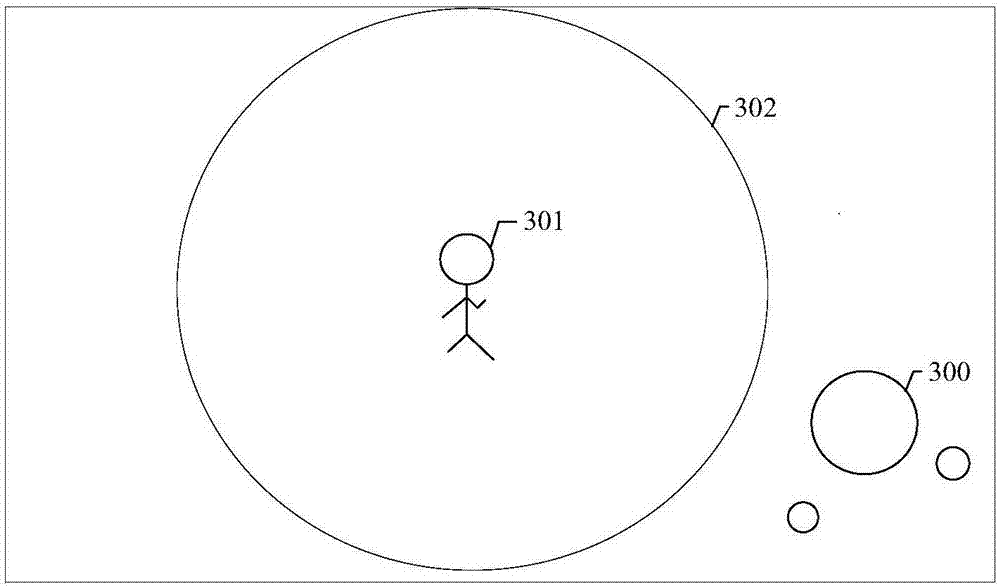

Skill control method and device, electronic equipment and storage medium

ActiveCN107992251AImprove fluencyImprove efficiencySubstation equipmentInput/output processes for data processingHuman–computer interactionElectronic equipment

The invention discloses a skill control method and device, electronic equipment and a readable storage medium of a computer, and relates to the technical field of human-computer interaction. The method includes the following steps that in response to a first touch control event acting on a power storage skill control, a skill determination region is provided on an operating interface; in responseto a second touch control event acting on the skill determination region, according to the current position of a touch control point of the second touch control event, the skill release direction andthe power storage time are determined; when the second touch control event is over, the skill corresponding to the power storage skill control is executed according to the skill release direction andthe power storage time. The method can improve the precision of skill release.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

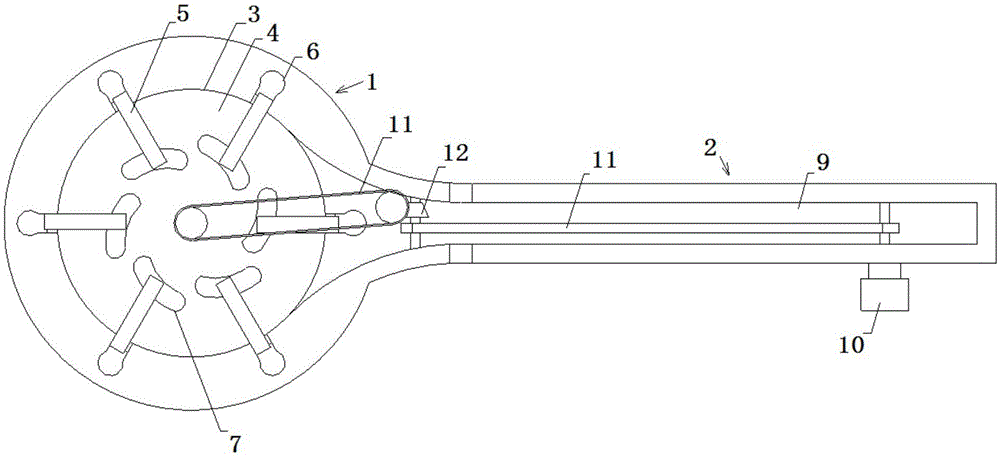

Caliber-adjustable wrench

ActiveCN105108689AAdjustment caliberGood real-time adjustment effectSpannersWrenchesEngineeringWrench

The invention discloses a caliber-adjustable wrench. The wrench comprises a rack, wrench clamping jaws, a round groove, a rotary ring, a plurality of push rods and an adjusting device, wherein the rack comprises a handle area and a wrench area; the wrench clamping jaws are distributed on one end face of the wrench area in an annular shape and can slide back and forth in the radial direction of the annular shape; the round groove is formed in the other end face of the wrench area, and a plurality of first sliding grooves protruding in the radial direction and corresponding to the wrench clamping jaws in a one-to-one mode are formed in the periphery of the round groove; the rotary ring is arranged in the round groove in a rotary mode, a plurality of second sliding grooves corresponding to the first sliding grooves are formed in the end face of the rotary ring, and the second sliding grooves are obliquely formed; one end of each push rod is located in the corresponding first sliding groove and is correspondingly connected with one wrench clamping jaw, and the other end of each push rod is located in the corresponding second sliding groove; the adjusting device is connected with the rotary ring to drive the rotary ring to rotate forwards or reversely. The wrench can overcome the defect that an existing special tool can not change in-pair wrench holes in different gaps.

Owner:GUANGXI UNIV

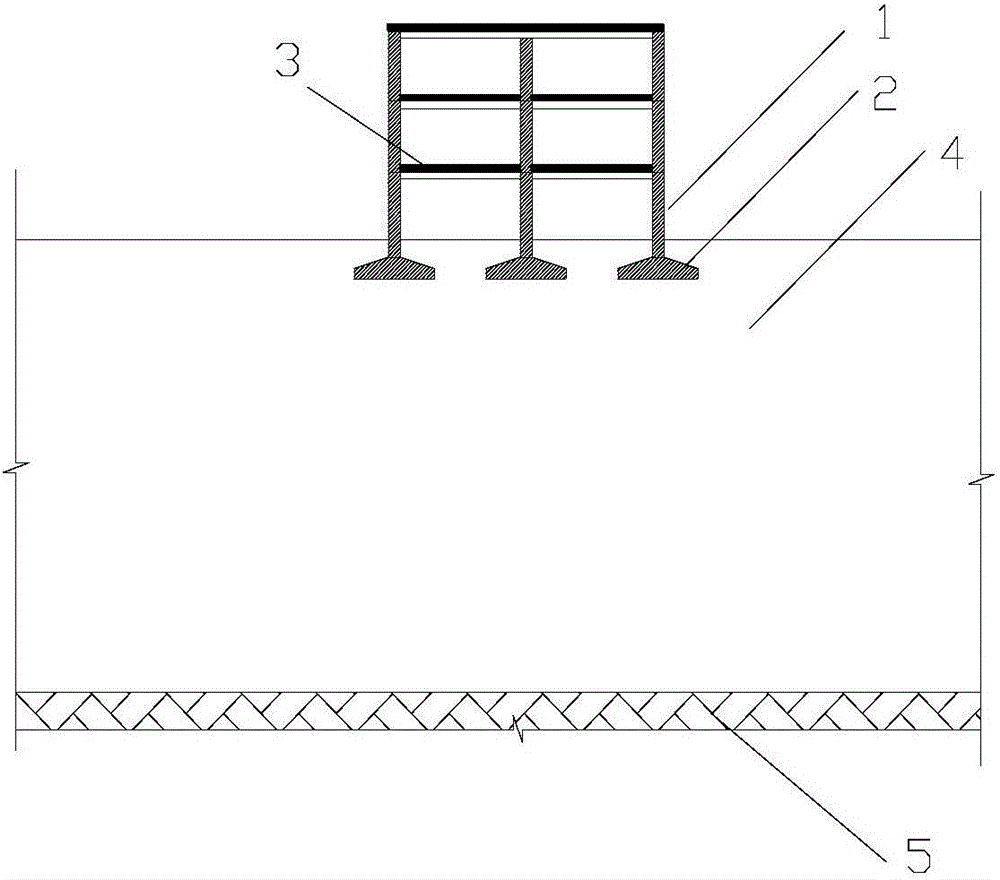

Method suitable for underground storey addition of brick-concrete structure building and building

The invention relates to a method suitable for underground storey addition of a brick-concrete structure building and a building, belonging to the technical field related to constructional engineering. The method mainly comprises the following steps: (A) excavating the part above the strip foundations of the brick-concrete structure building and the earthwork of a planned underground garage area until the foundation of the building is totally exposed; (B) constructing multiple concrete underpinned piles between the strip foundations and on the outer side of the strip foundations; (C) fixedly connecting the pile top of each concrete underpinned pile with a horizontal underpinned beam, wherein the horizontal underpinned beam penetrates through the building wall; (D) arranging concrete jacketed wall beams on the two sides of the building wall, and fixedly connecting the concrete jacketed wall beams with the building wall; (E) removing original strip foundations of the building; (G) excavating the foundation soil below the building till reaching the floor elevation of the planned basement and garage; (H) constructing the floor, the floor slab of each storey and the roof from bottom to top; (I) pouring a new concrete outer wall around the garage and building a partition wall below the building; and (J) backfilling the earthwork till reaching the natural ground.

Owner:SHANDONG JIANZHU UNIV

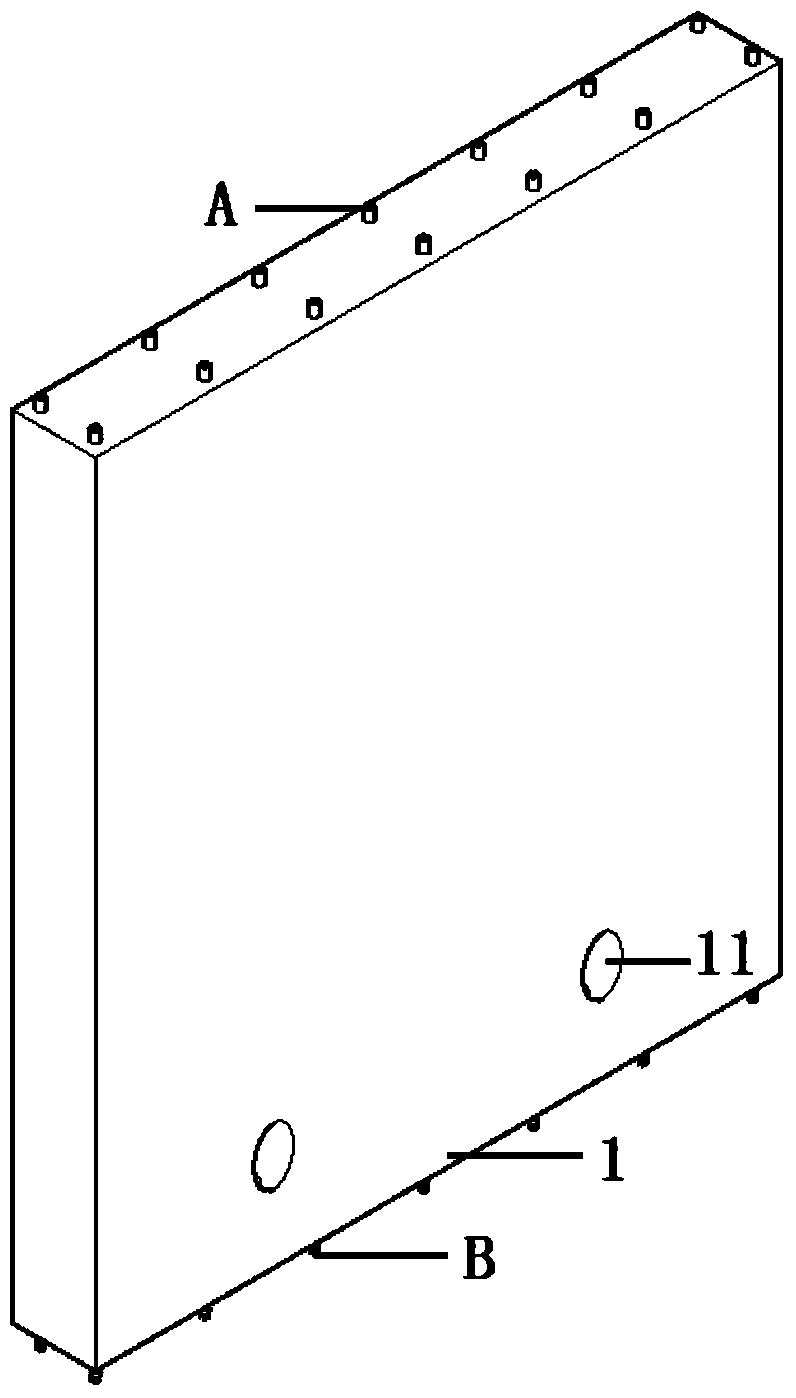

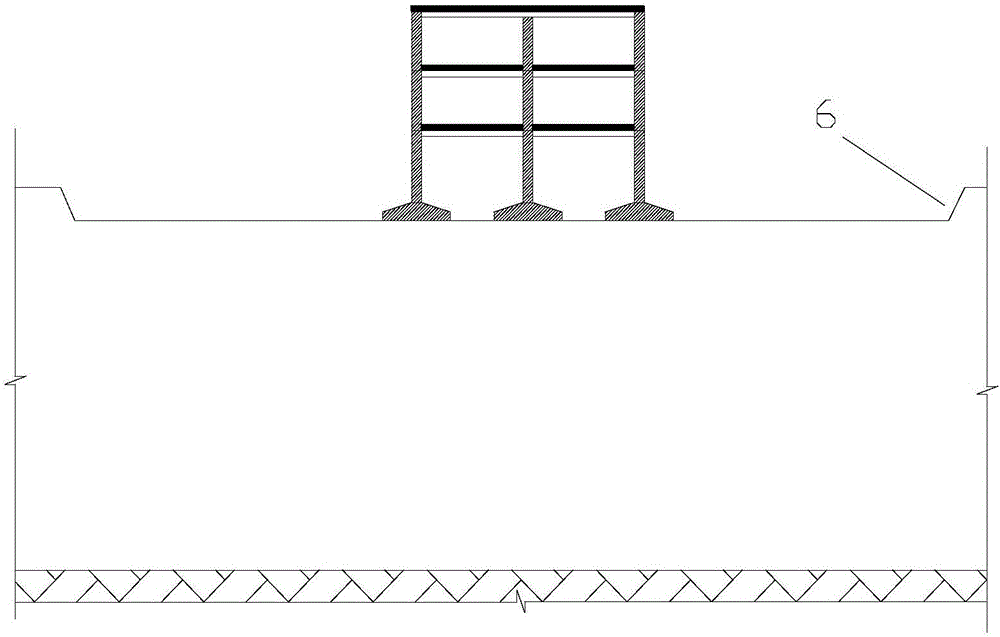

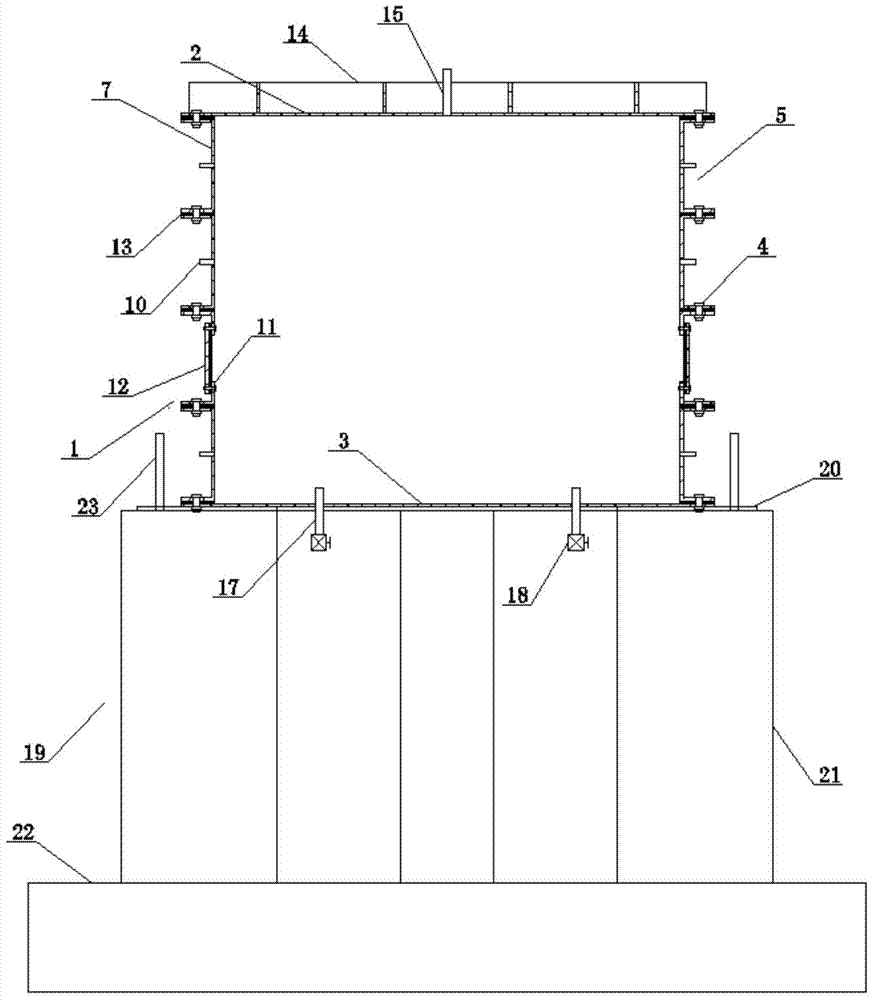

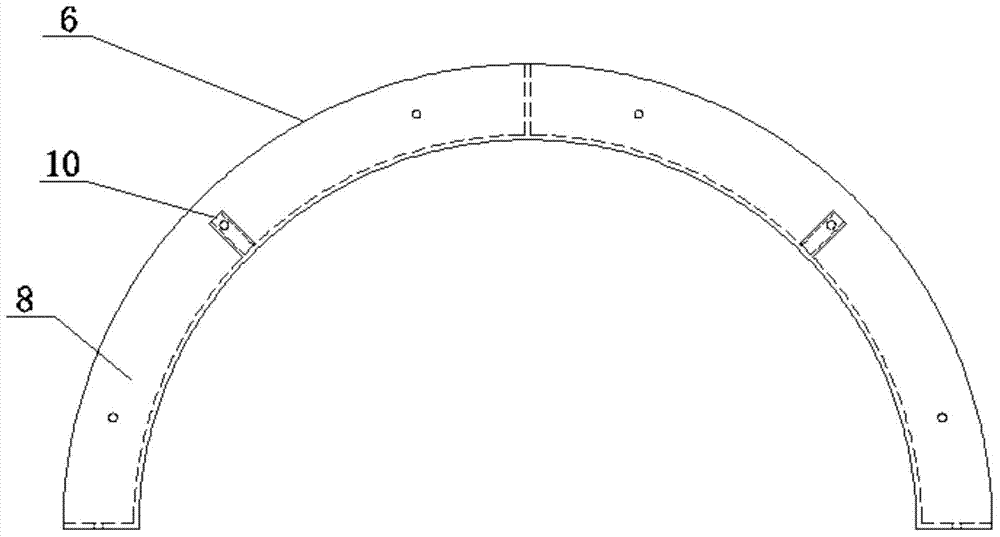

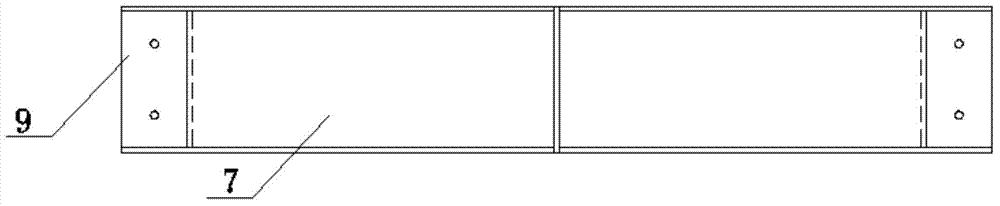

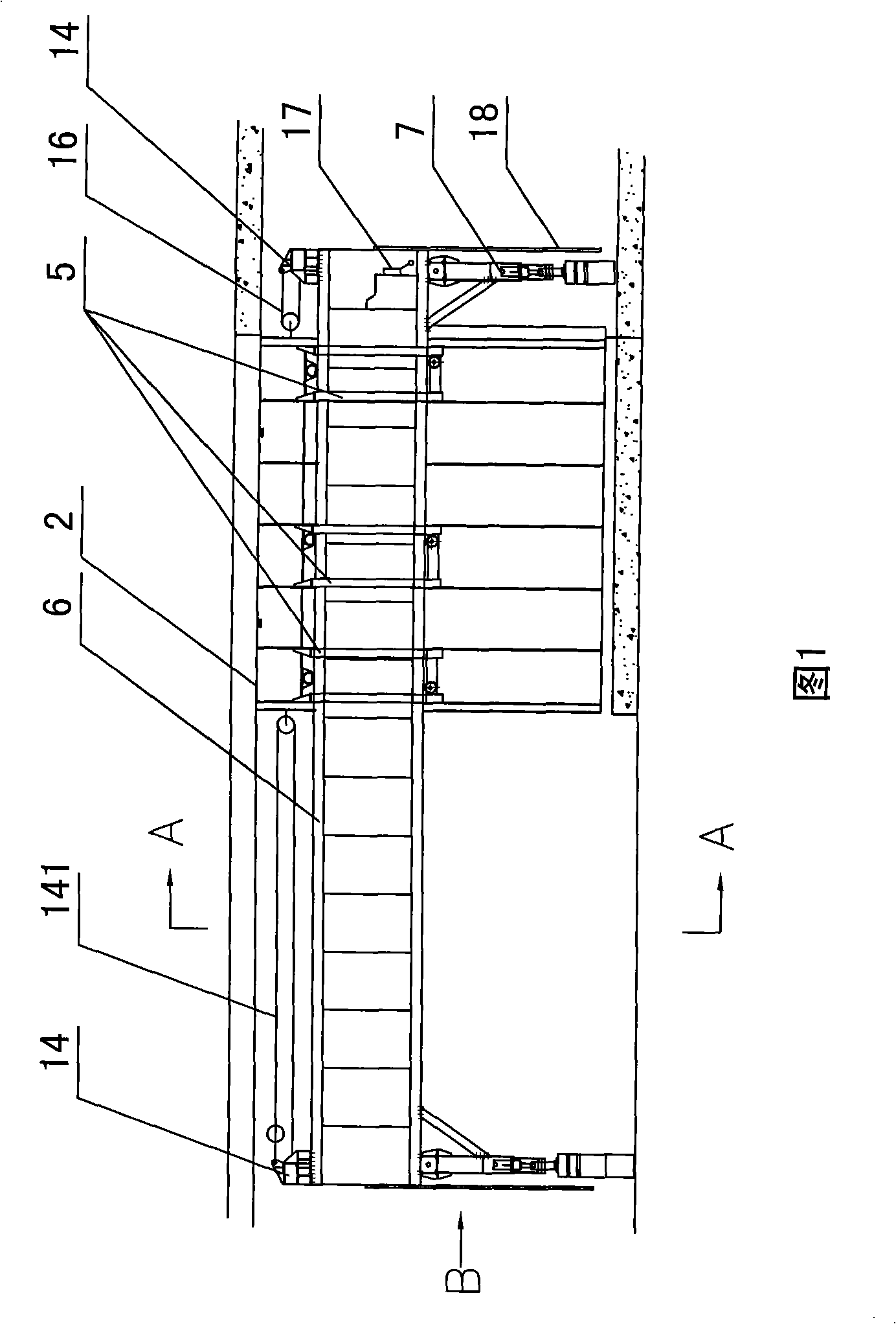

Test bed device for tunnel excavating and grouting model and application method of device

InactiveCN103940968AGuaranteed StrengthGuaranteed stiffnessMaterial analysisReinforced concreteRebar

The invention discloses a test bed device for a tunnel excavating and grouting model and an application method of the device. The test bed device comprises a lateral wall, a head cover for providing and loading a crustal stress platform, and a bottom plate arranged at the top of a reinforced concrete support rack, wherein the lateral wall vertically stands on the bottom plate and is connected with the bottom plate; the head cover is arranged at the top of the lateral wall and connected with the lateral wall; the lateral wall is formed by a plurality of model ring units which are stacked together in the vertical direction and sequentially connected; two round holes are formed in tunnel design positions in the diameter directions corresponding to the model ring units; the round holes are plugged by using arc sealing steel plates which are the same as the lateral wall in radian before tunnel excavation; holes are formed in the positions at four corners of the arc sealing steel plates; the arc sealing steel plates are connected with the lateral wall. By adopting the device, the geological disaster generation process and the later grouting reinforcing process in the tunnel excavation process can be continuously and systematically simulated, and the device has the advantages of being high in strength, and convenient to assemble and dismantle by adopting a modular assembling mode.

Owner:SHANDONG UNIV

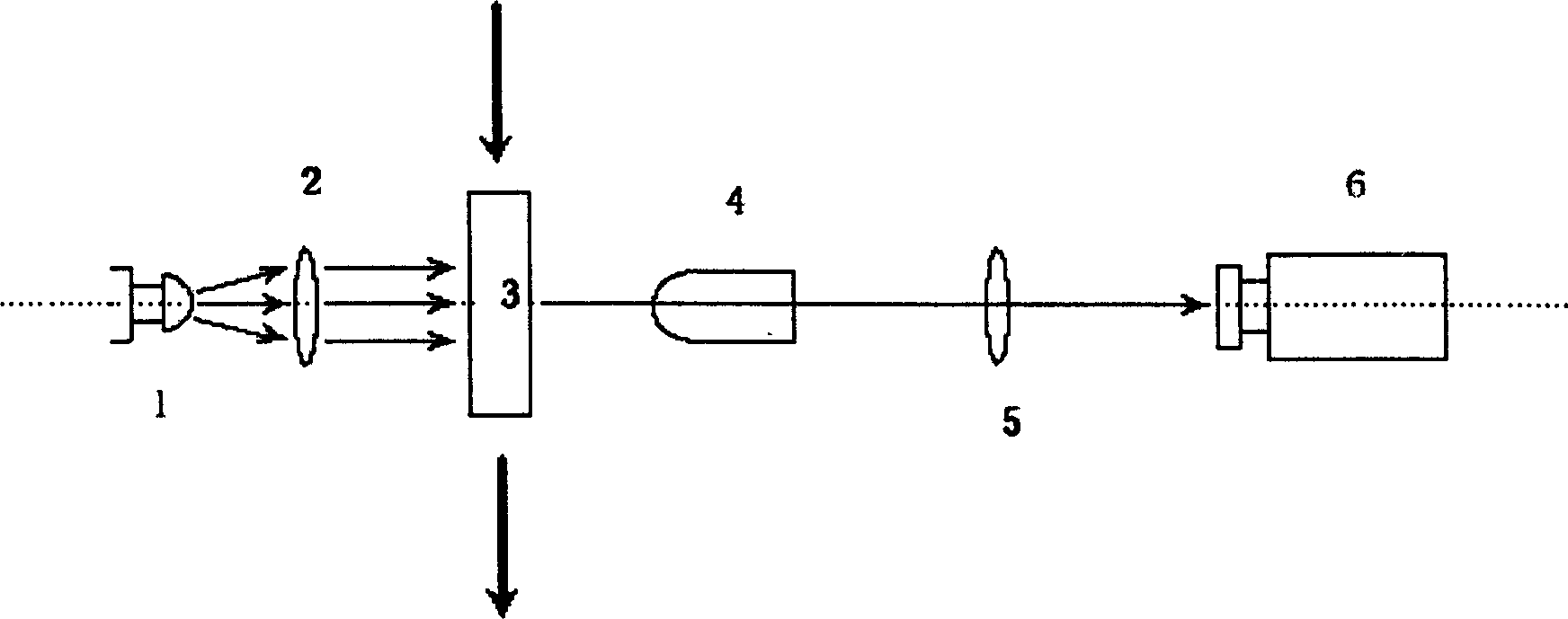

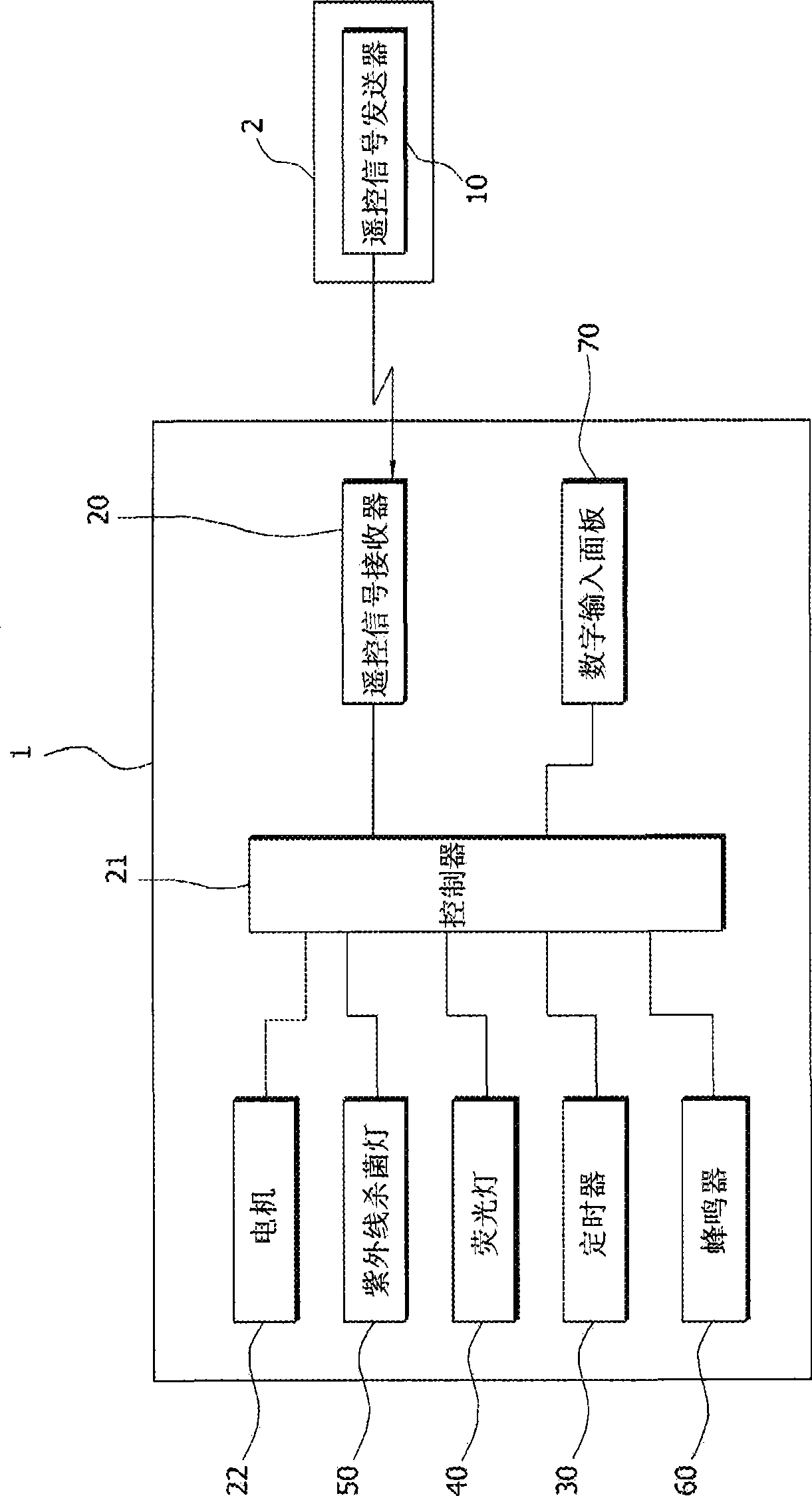

Red tide biological picture automatic identification device and identification method

InactiveCN1556497AGet good resultsUniform background lightCharacter and pattern recognitionImaging FeatureImage segmentation

The invention relates to a red-tide living thing image automatic identifying device and method, provided with a LED, a light source lens, a mobile room, an objective, a depth of focus lens and a camera; the LED is at the focus of the light source lens, the mobile room is between the light source and the objective, and the depth of focus lens is between the objective and the camera. The identifying method: obtaining image, preprocessing, detecting object, separating image, obtaining image feature, classifying and identifying object, and outputting result. It adopts a far-focus objective, adds an operating space between the mobile room and the objective, giving a development space to the mobile room, and increases the application range of the apparatus. It can automatically analyze images, heightening automation degree of the apparatus, and meets the request for field monitoring red-tide living things, hopeful to implement real-time monitoring the generating and disappearing course of the red tide, and on this basis, provides a precaution to the danger degree of the red tide.

Owner:XIAMEN UNIV

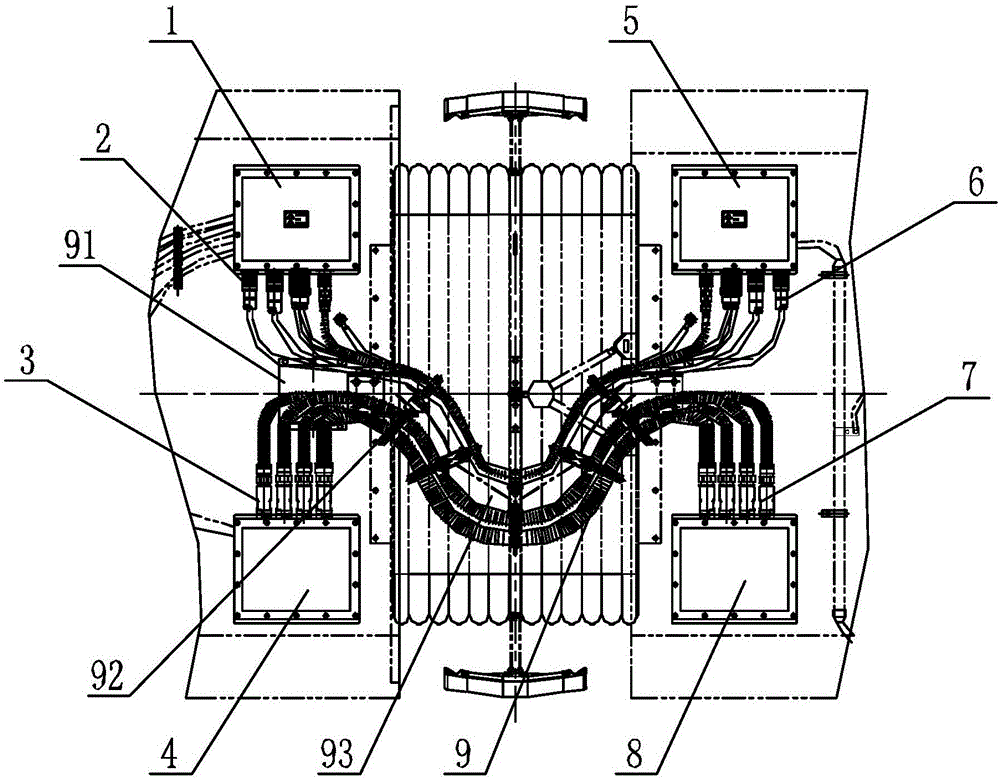

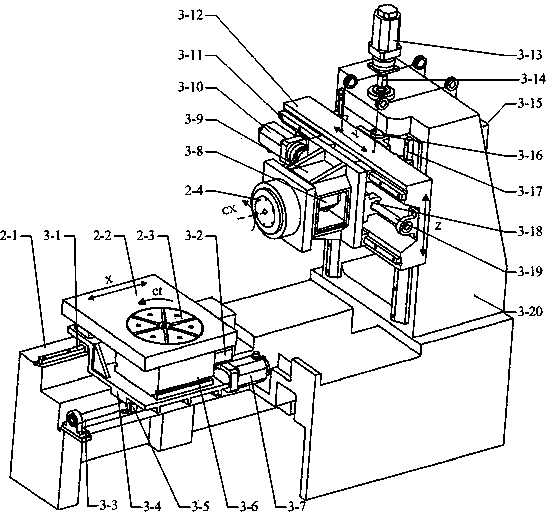

Large-size multi-axis-linkage electrolytic machine tool

ActiveCN103464845ALarge operating spaceEasy to install and adjustMachining working media supply/regenerationElectric circuitsMachine toolPulse power supply

The invention discloses a large-size multi-axis-linkage electrolytic machine tool which comprises a machine tool body, an electrolytic machining pulse power source, an electrolyte circulating and filtering system and an integrated control system. The integrated control system can realize integrated control on machine tool motion parameters, electrolyte parameters and pulse power source parameters; the electrolyte circulating and filtering system adopts parallelly-connected double loops to filter an electrolyte, so that the electrolyte input into a machining area is high in cleanliness, and the electrolyte circulating and filtering system has a function of automatically adjusting the electrolyte parameters ( temperature, concentration and pH value); the machine tool body comprises a bed body, a horizontal workbench, a turnplate, a spindle, a working box and a machine tool cover, and the machine tool can realize five-axis linkage; a numerical-control rotary table is arranged below the turnplate, a sliding device is arranged below the working box, and when a large-size workpiece and a cathode are mounted and adjusted, the working box can move to above the machine tool cover through the sliding device; a protecting device is arranged below the horizontal workbench and the turntable, so that the electrolyte can be effectively isolated from the numerical-control rotary table and a transmission mechanism.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Automobile engine mounting bracket and manufacture method thereof

ActiveCN103009985ASuspension assembly is stableLarge operating spaceJet propulsion mountingInternal combustion mountingAutomobile designThinning

The invention aims at providing an automobile engine mounting bracket and a manufacture method thereof. The automobile engine mounting bracket comprises a base, a support plate, a bracket, an installing hole and a suspending hole, wherein a bending part is arranged on the support plate. According to the automobile engine mounting bracket, the special bending part is adopted, and thus parts structures in an automobile can be avoided, larger operation space is provided for automobile design, especially for a compact automobile, a better design flexibility is achieved; and meanwhile, the shape and the structure ensure enough support strength, and thus the stability of an automobile engine mounting assembly is ensured. The invention also provides a manufacture method of the mounting bracket. By using a specially designed discharging block, the stability in a machining process is ensured; and due to the arrangement of a locating hole and a locating edge, a corresponding locating module is arranged on a matched forming mould, the machining precision can be well ensured, and excessive thinning and cracking on the thickness of parts materials during machining are avoided, and better practicability is achieved.

Owner:LIUZHOU JINYUAN MACHINERY MFG

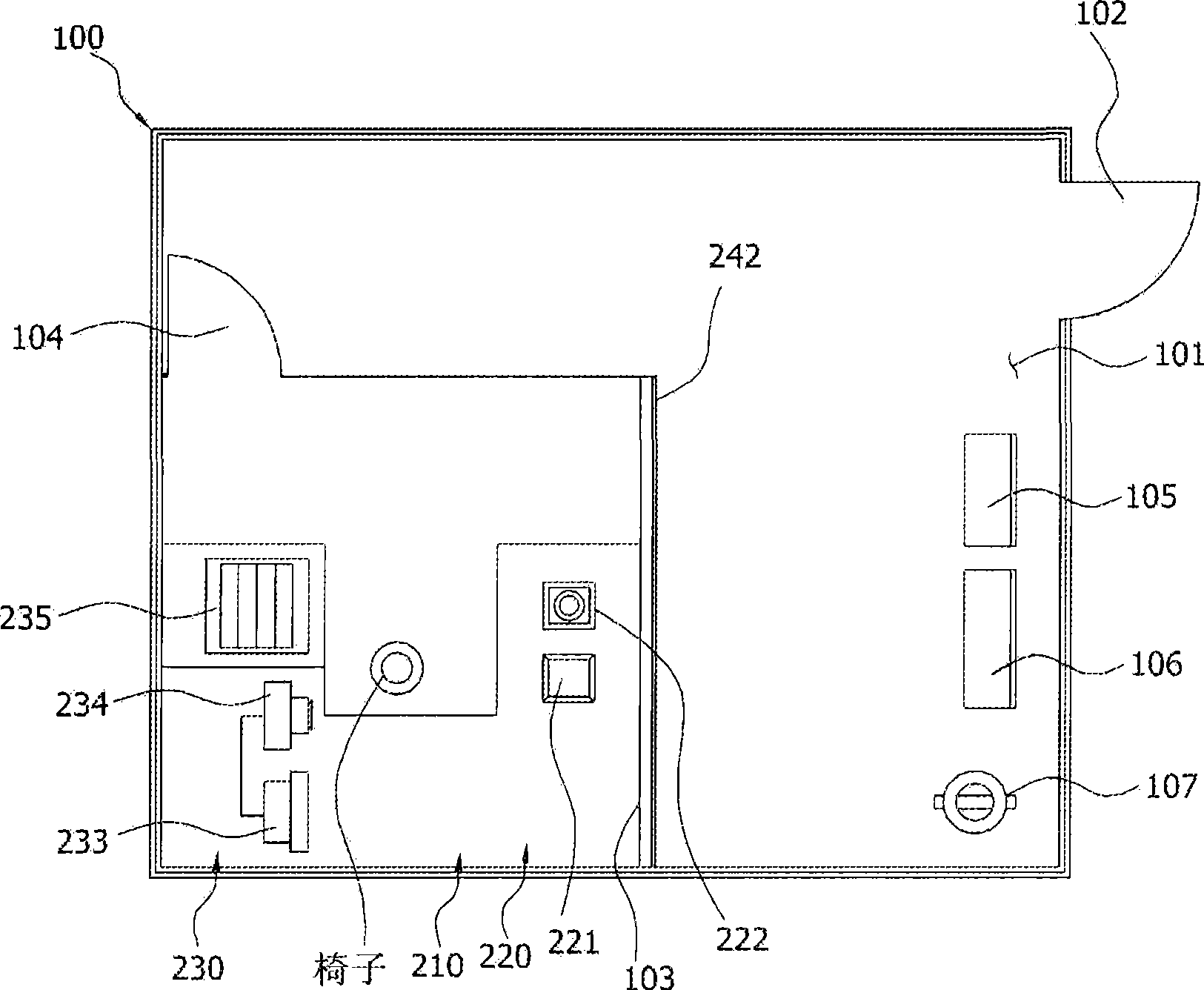

Cell manipulation and cultivation equipments for the production of cell therapy products

ActiveCN101501180ASimple structureAvoid pollutionBioreactor/fermenter combinationsMechanical apparatusInterior spaceEngineering

Disclosed is cell manipulation and cultivation equipment for the production of cell therapy products, for preventing contamination of cells and improving the utility of a space. The equipment includes a room for the production and testing of cell therapy products, the room having an inner space enclosed in all sides and an outer entrance / exit door provided at any one side thereof, an L-shaped partition installed in a position of the room for the production and testing of cell therapy products, the partition having an inner entrance / exit door provided at any one side thereof, and a clean bench device placed inside the partition, the clean bench device including first, second, and third clean benches for preventing contamination of cells and increasing the utility of a space to the maximum extent. The cell manipulation and cultivation equipment can provide the advantages of a remarkably improved clean operating room or clean bench, enhanced space utility, agreeable operating environment, and convenience of use via additional convenience facilities, thereby preventing contamination of equipment for the cultivation and production of cell therapy products, and achieving a great improvement in the quality and reliability of cell therapy products, so as to give a good image to consumers.

Owner:SEWON CELLONTECH CO LTD

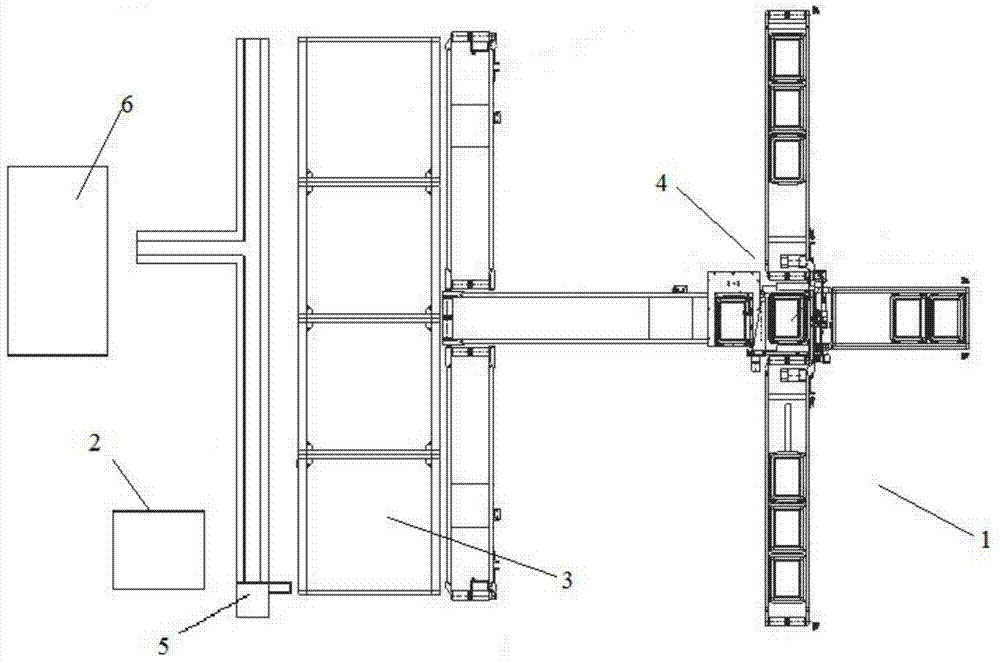

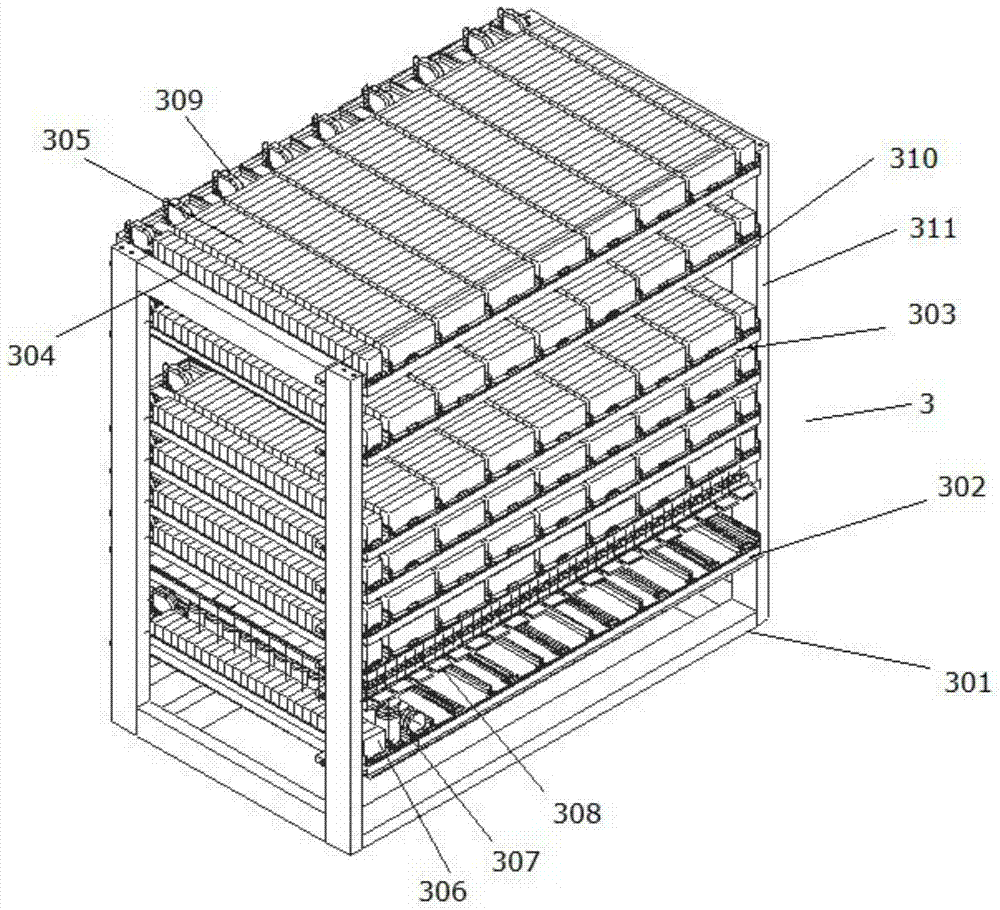

Building block type assembled dispensing system for packaged medicine

Owner:JIANGSU XUNJIE HARNESS TECH

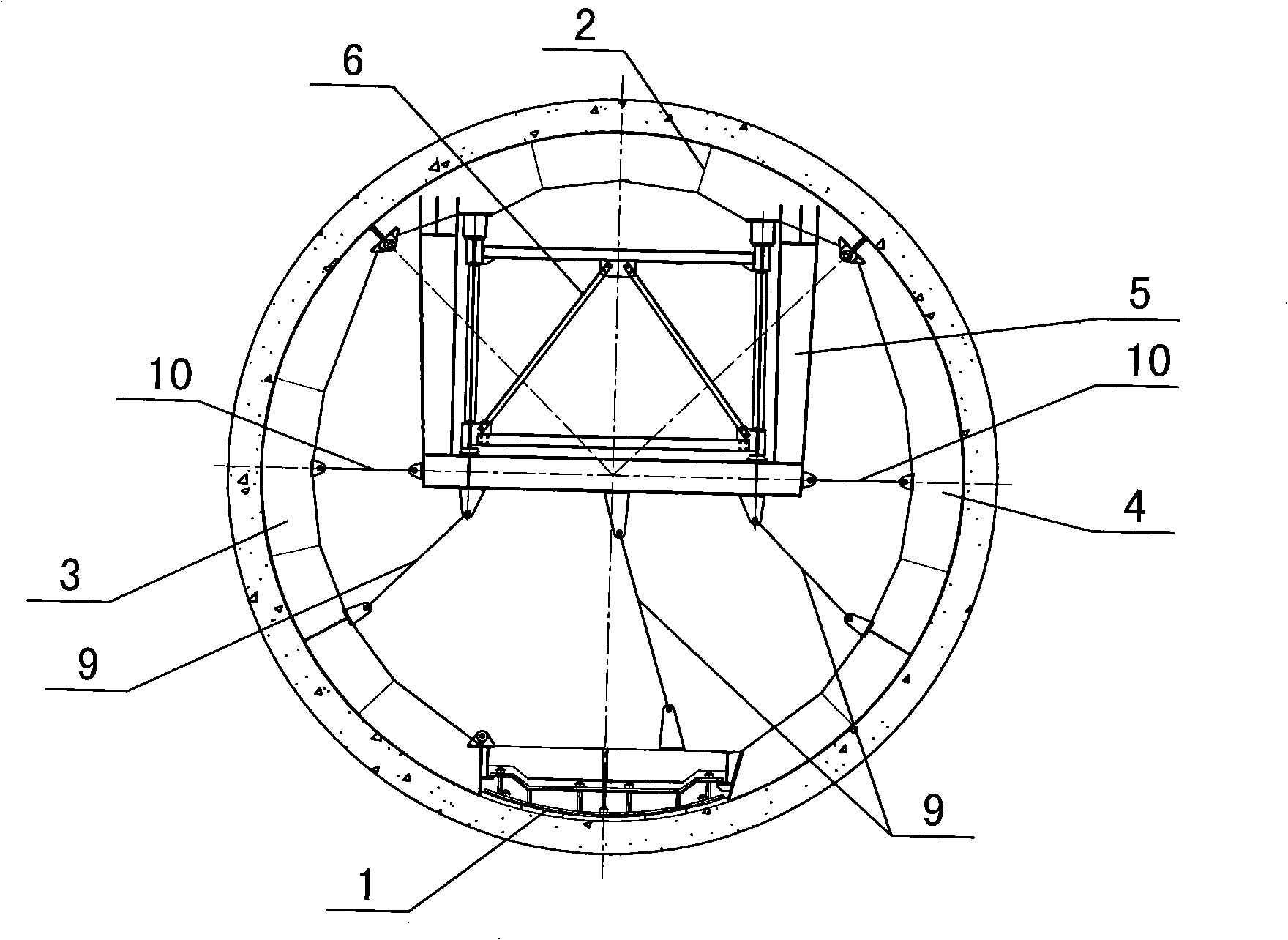

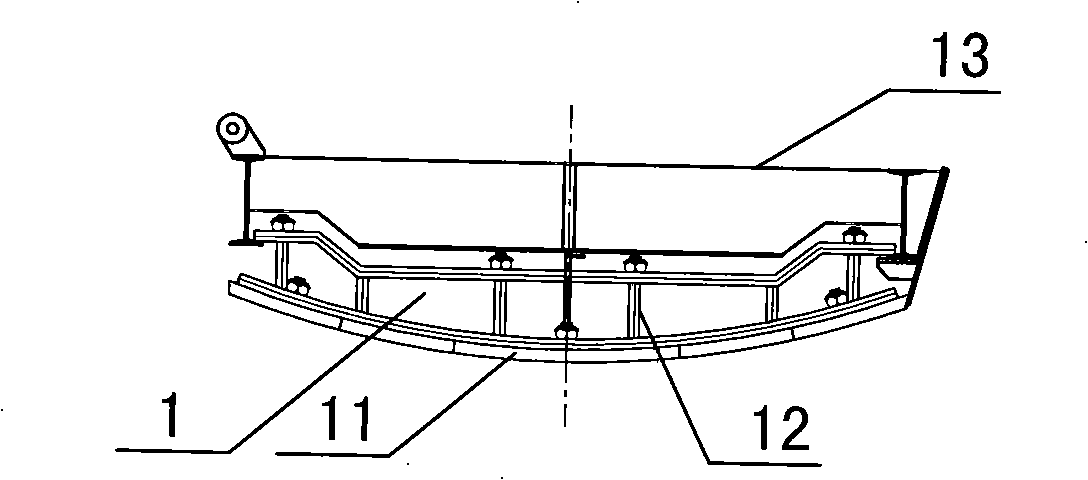

Tunnel concrete lining formwork apparatus

InactiveCN101298839AGood tunnel forming qualityImprove pouring qualityUnderground chambersTunnel liningEngineeringSliding contact

The present invention discloses a tunnel concrete lining template device comprising a template system and needle beam system for bearing; the template system comprises template assembly and template pylon; the template assembly comprises arced left die, right die, top die and bottom die; the left die, right die, top die and bottom die are correspondingly connected to form template assembly with round section; the template pylon is hung on the top die; and bottom of the template pylon is respectively installed with left die, right die and telescopic standing demoulding device connected by the bottom die; the needle beam system comprises bearing needle beam placed in the upper part of the tunnel and pre and post supporting leg device for supporting the bearing needle beam; upper end face of the bearing needle beam is in slide contact with the top die and the needle beam is placed on the template pylon; and the bottom die is in the detachable structure; the bottom die in the detachable structure is installed with opening part which is able to execute trowel-finishing on the surface of the tunnel bottom arch concrete after detaching or turning over when the concrete is initially set. The template device effectively removes the problem of foam of the traditional whole section template bottom arc foam and improves the internal appearance molding quality of the bottom arc concrete.

Owner:SINOHYDRO BUREAU 14 CO LTD

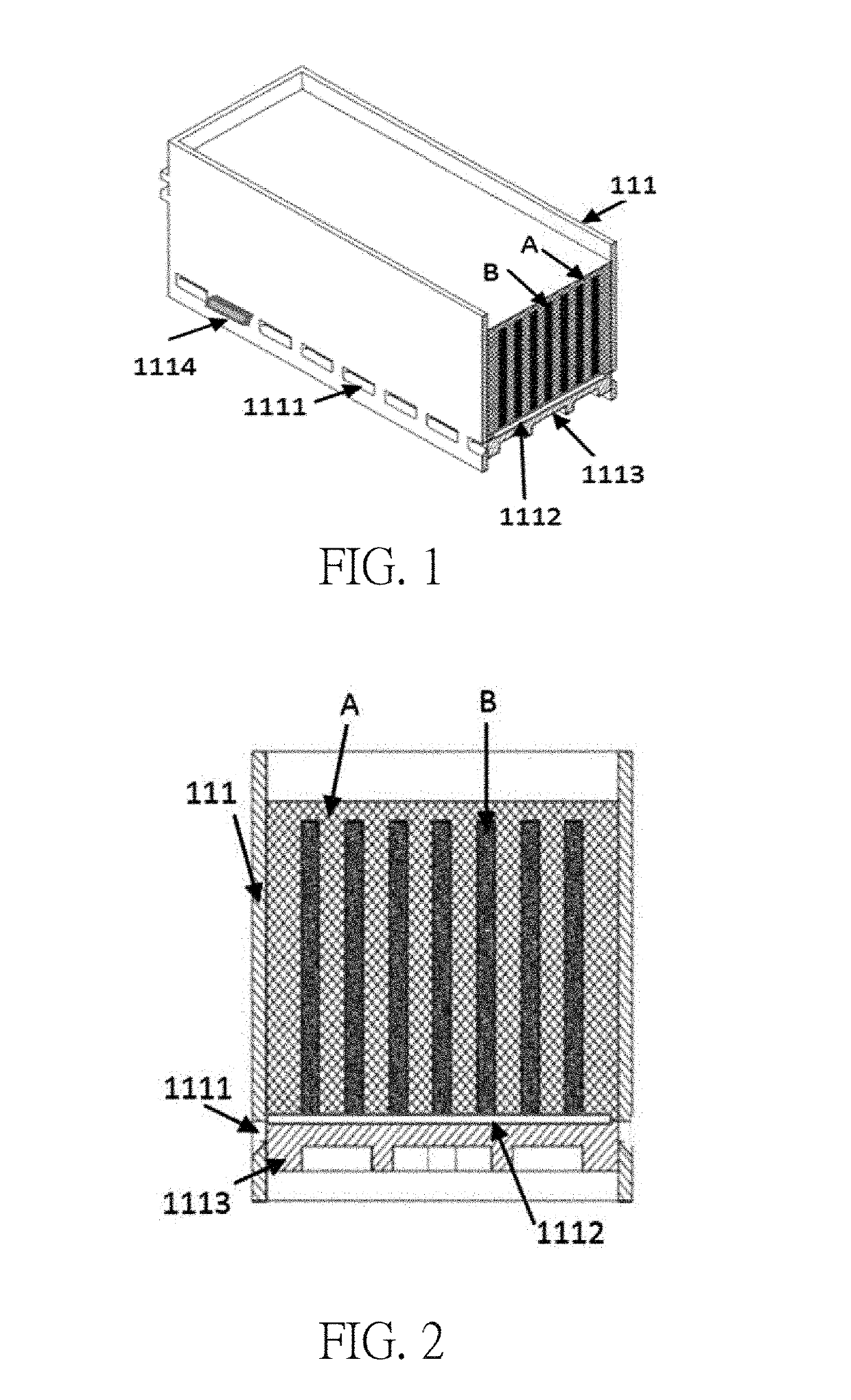

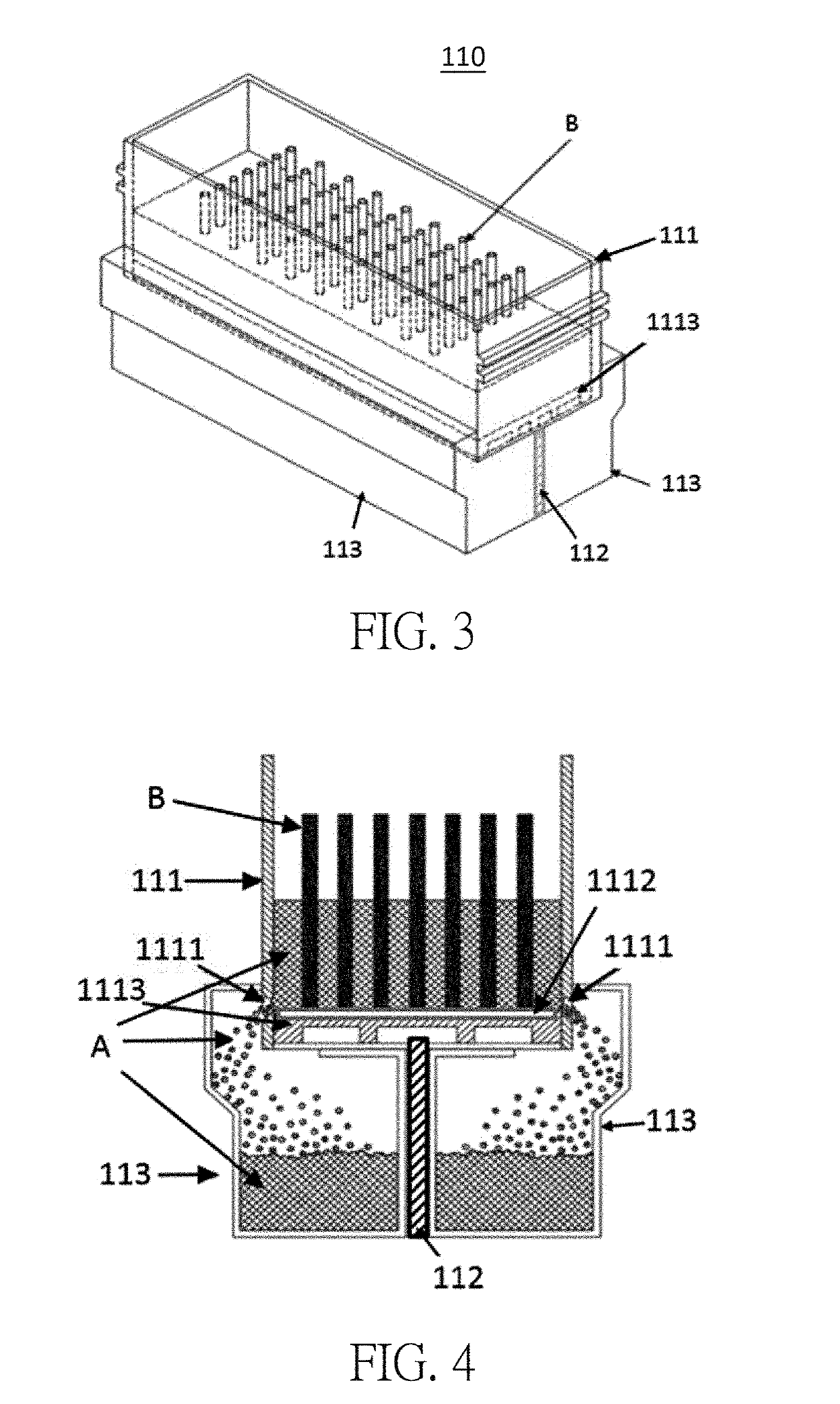

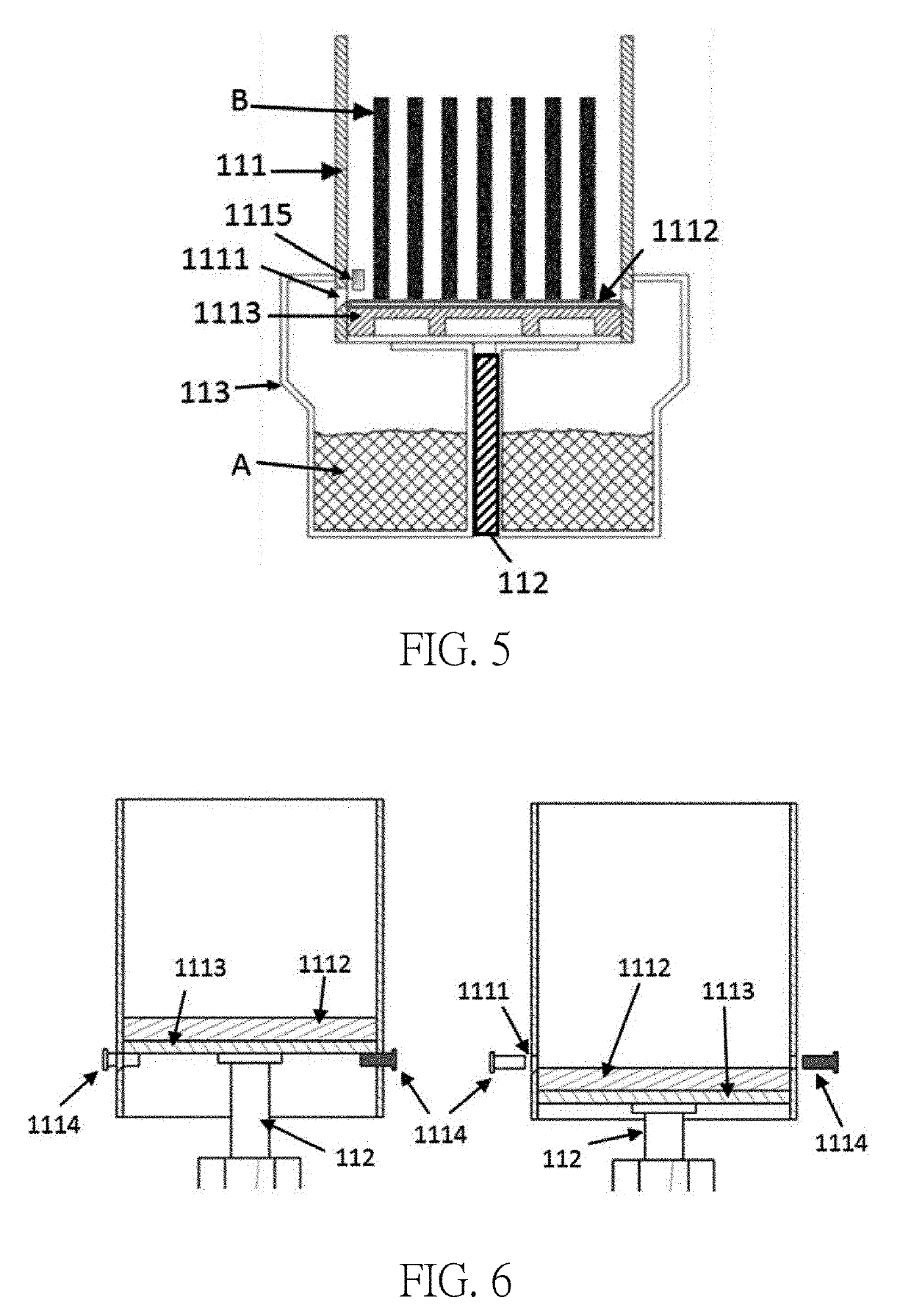

Additive manufacturing chamber, additive manufacturing module and additive manufacturing apparatus therewith

ActiveUS20190143597A1Efficient dischargeConsumes energy excessivelyManufacturing platforms/substratesIncreasing energy efficiencyDelivery systemAdditive layer manufacturing

The present application discloses an additive manufacturing chamber, an additive manufacturing module and an additive manufacturing apparatus therewith. Powder discharging openings are formed at a lower portion of the additive manufacturing chamber, and the powders in the additive manufacturing chamber are discharged down via gravitation. The present application further includes a vibrational unit for vibrating the powders so as to accelerate downward powder discharging via vibration of the vibrational unit. The additive manufacturing apparatus can include a main system and a cleaning transportation system separated from the main system. The present application solves the conventional problems of excessive consumed energy, large required installation and operational space, inconvenience of powder removing and swirled raised powder haze in the environment.

Owner:NAT CHUNG SHAN INST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com