Patents

Literature

146results about How to "Will not affect product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

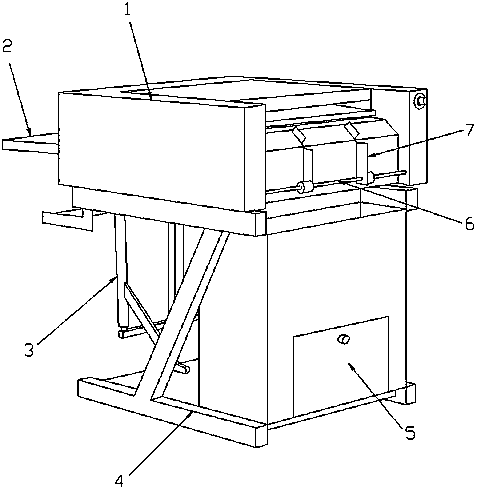

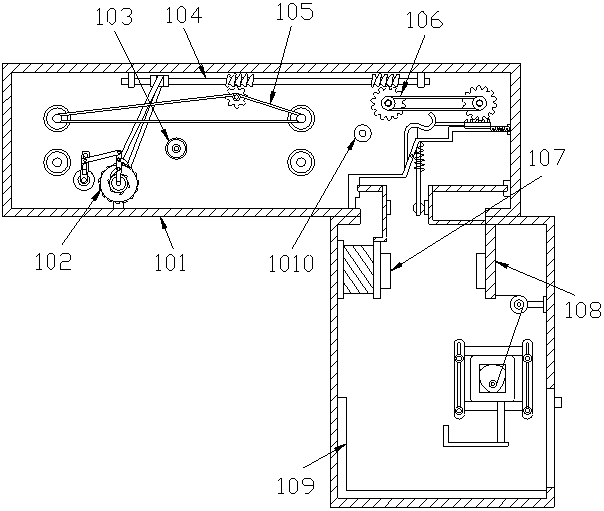

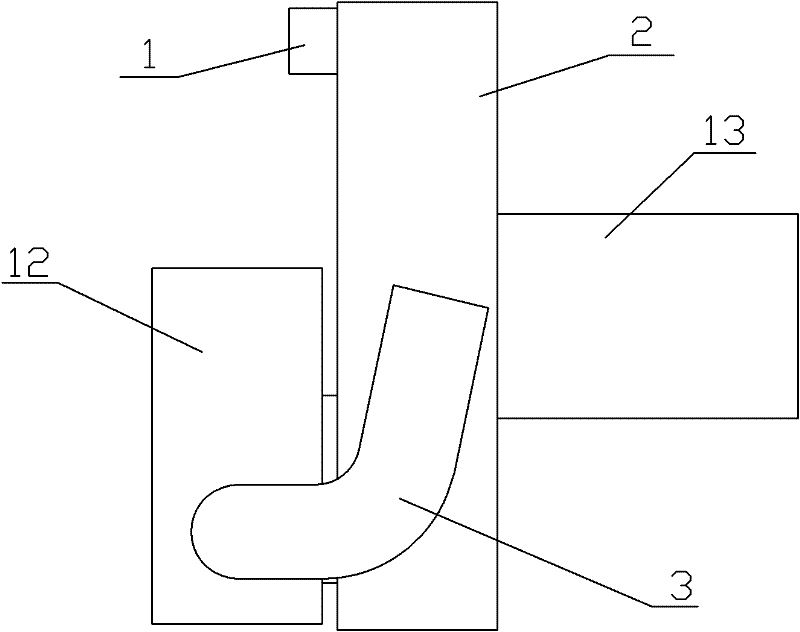

Boxing device for soft-drawn tissues

ActiveCN103057732AWill not affect product qualityWill not affect the overall effectIndividual articlesBiochemical engineeringToilet paper

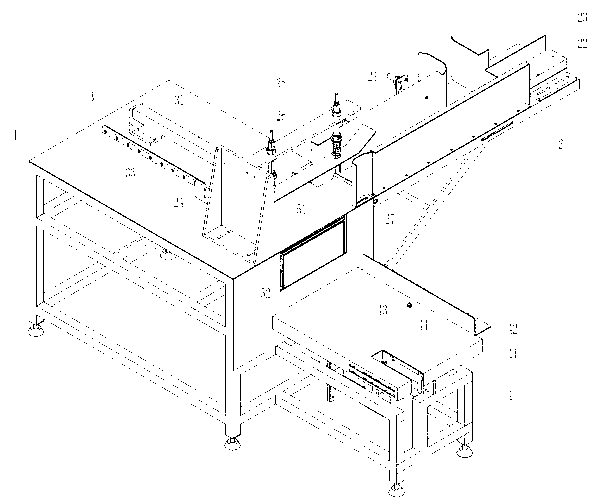

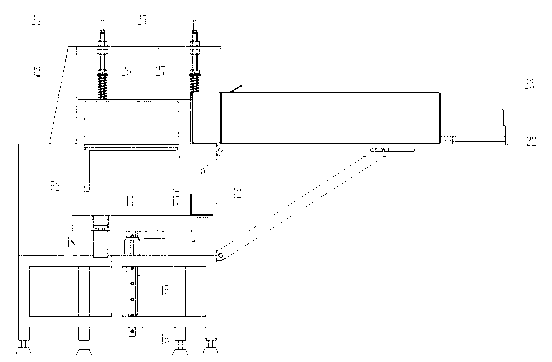

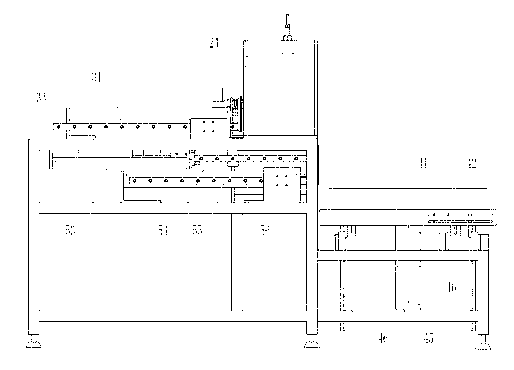

The invention discloses a boxing device for soft-drawn tissues and belongs to the technical field of boxing equipment of toilet paper and tissues. The boxing device comprises an operation platform, a sorting device, a sub-packaging push-rod device and a boxing platform. The sorting device mainly comprises a sorting trough, a sorting push-rod device and a fixed baffle plate, the sorting trough is arranged on the lateral portion of the operation platform, the sorting push-rod device is arranged at a feed end of the sorting trough, the fixed baffle plate is arranged on the surface of the operation platform, a pressure plate arranged horizontally is further arranged on the upper portion of the fixed baffle plate, the sub-packaging push-rod device is arranged on the operation platform, and the boxing platform comprises a boxing lifting platform, a boxing lifting device and a box fixing device. The boxing device for the soft-drawn tissues is reasonable in design, simple to operate, reliable in performance, and can be applied in boxing work of the soft-drawn tissues, and accordingly boxing labor intensity of operators is relieved, production efficiency is increased, production cost is lowered, and due to large operating space, the boxing device is applicable to boxing of tissue paper of multiple specifications and different boxing specifications.

Owner:维达纸业(四川)有限公司

Anhydrous zero-discharge disperse dye dyeing method

InactiveCN103938462AReduce solubilityWill not affect product qualityDyeing processSynthetic fiberOligomer

The invention relates to an anhydrous zero-discharge disperse dye dyeing method, comprising the following steps: adding a disperse dye to an organic solvent, and dissolving to obtain a dye bath; immersing synthetic fiber fabric into the dye bath to dye, wherein the dyeing temperature is 80-150 DEG C and the dyeing time is 0.5-8 hours; cleaning and drying to obtain dyed fabric. An organic solvent is utilized to replace water as dyeing medium, so that use of a dispersant is reduced, dyeing raffinate and cleanout fluid can be recycled by simple treatment, printing and dyeing to reduce emission are facilitated, the problem of a low polymer can be effectively solved by adopting the anhydrous zero-discharge disperse dye dyeing method, and the product quality is improved.

Owner:DONGHUA UNIV

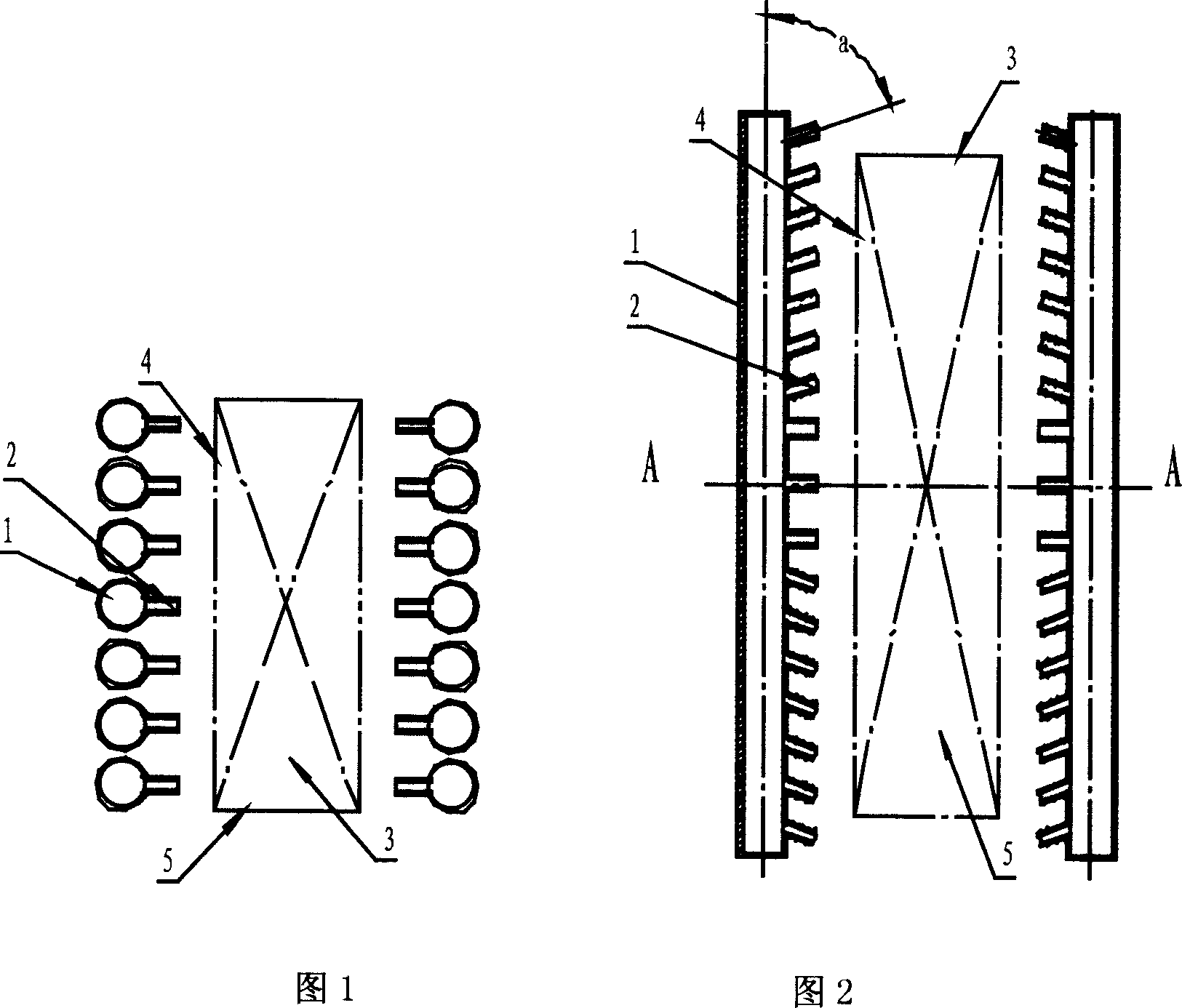

Method for preventing end-face spray quenching cracking of quenching piece by changing spray angle

InactiveCN101012491AReduce cooling intensityIncrease cooling intensityFurnace typesHeat treatment process controlDielectricQuenching

The invention discloses an end-face spray quenching crack-preventing method of quenching piece through changing spraying angle in the heat disposal domain of metal material, which is characterized by the following: placing quenching piece in the quenching equipment with pipe; making quenching piece with lateral and end faces; setting lateral face as rapid freezing face only; paralleling lateral face and pipe; setting the end face of quenching piece perpendicular to pipe; flowing quenching dielectric through pipe; displaying angle a (0-90 deg) for pipe and lateral face of quenching piece; fitting for cooling lateral face of quenching piece; avoiding crack effectively.

Owner:SHANGHAI JIAO TONG UNIV

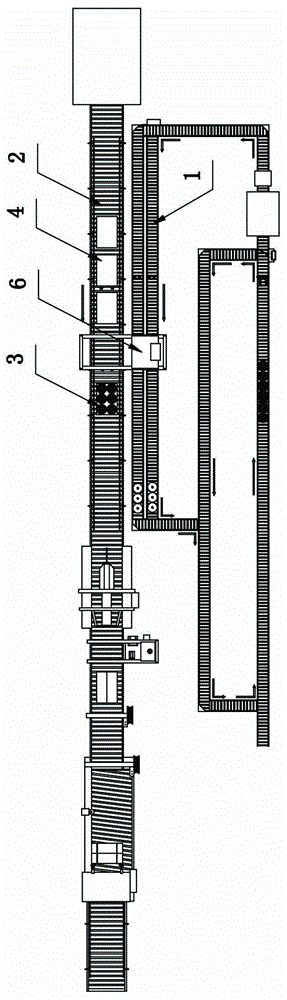

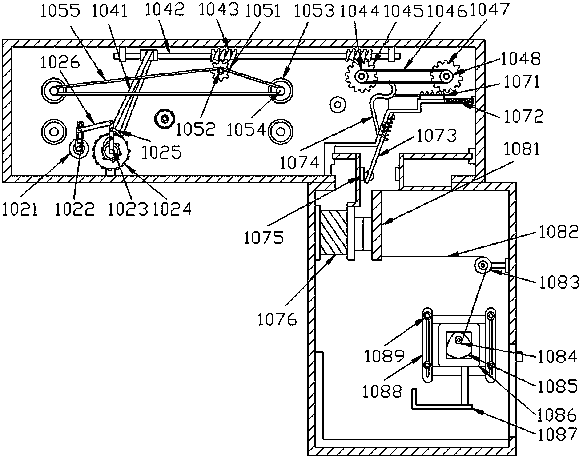

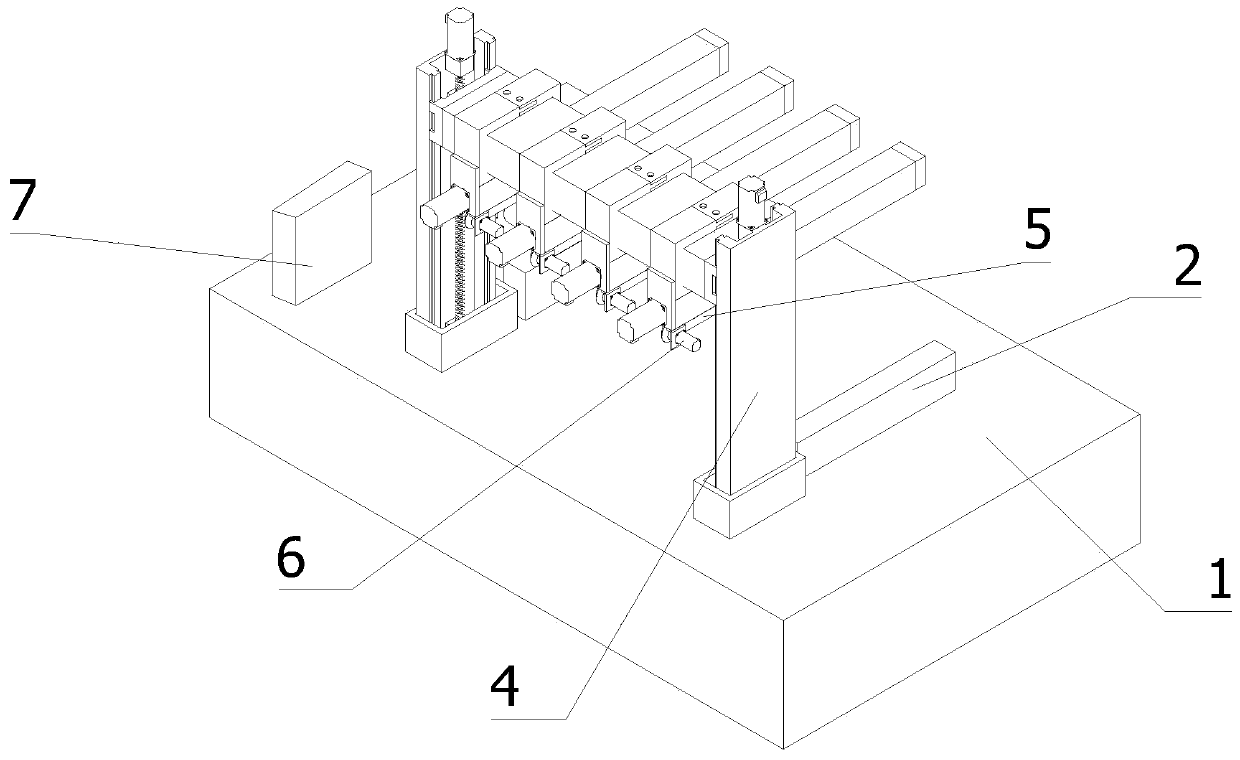

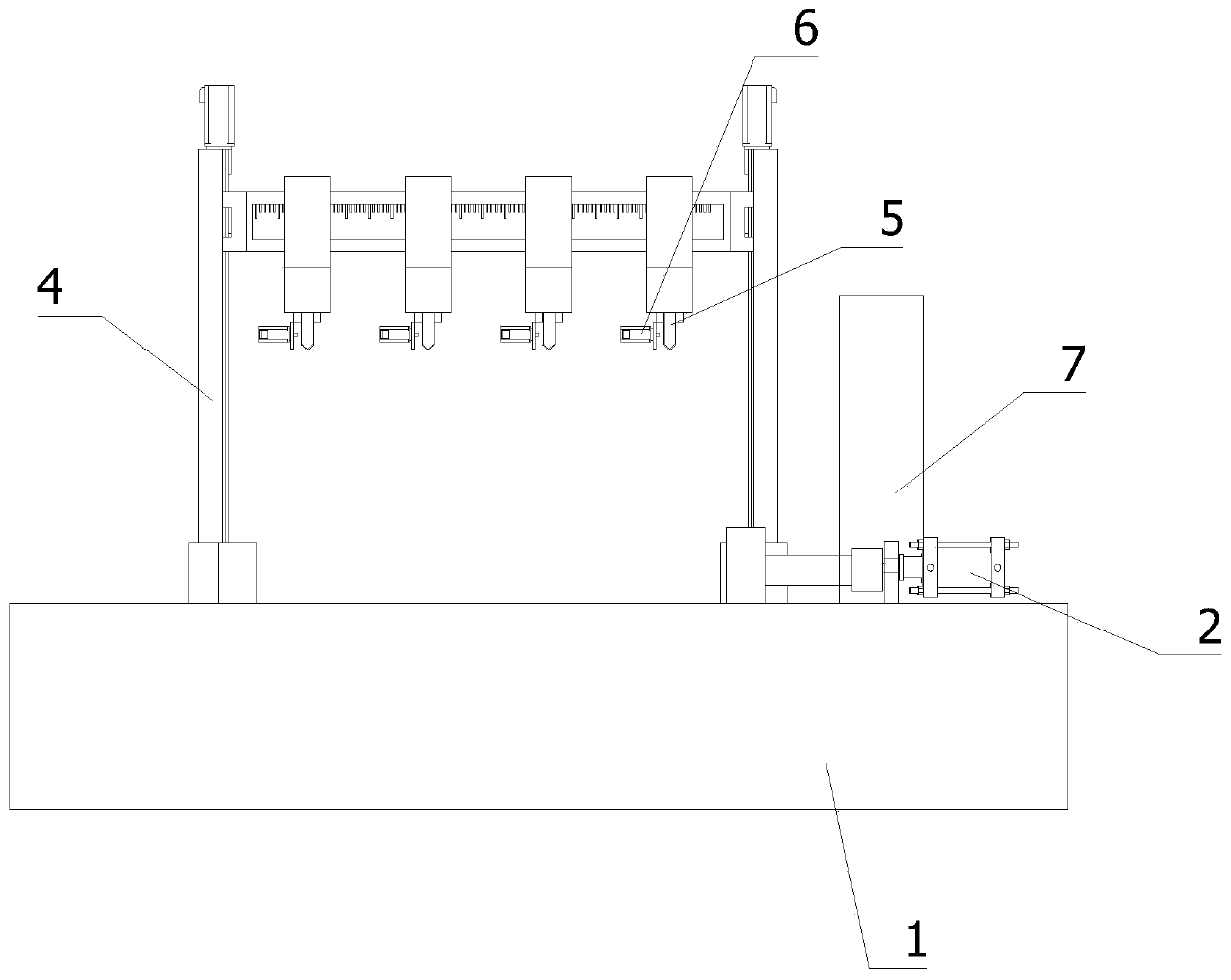

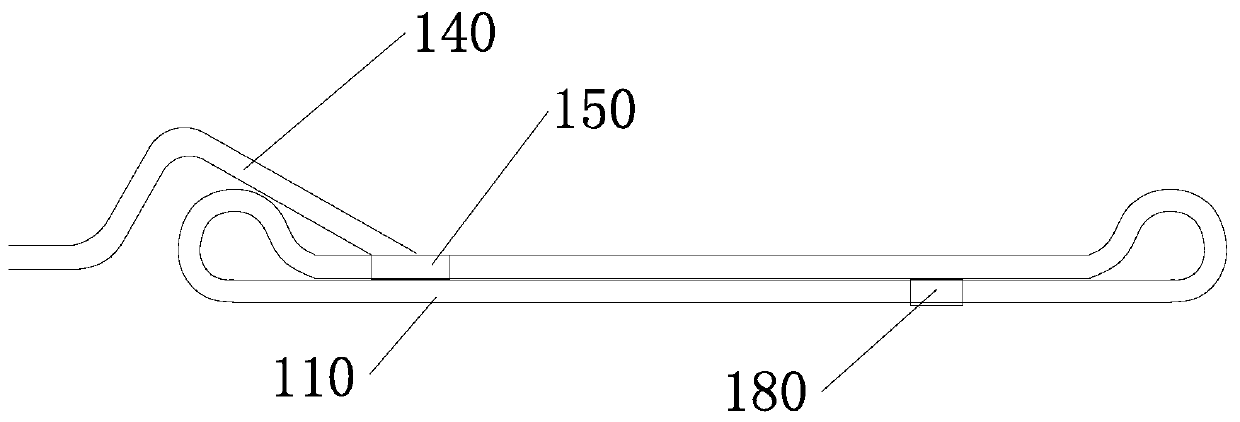

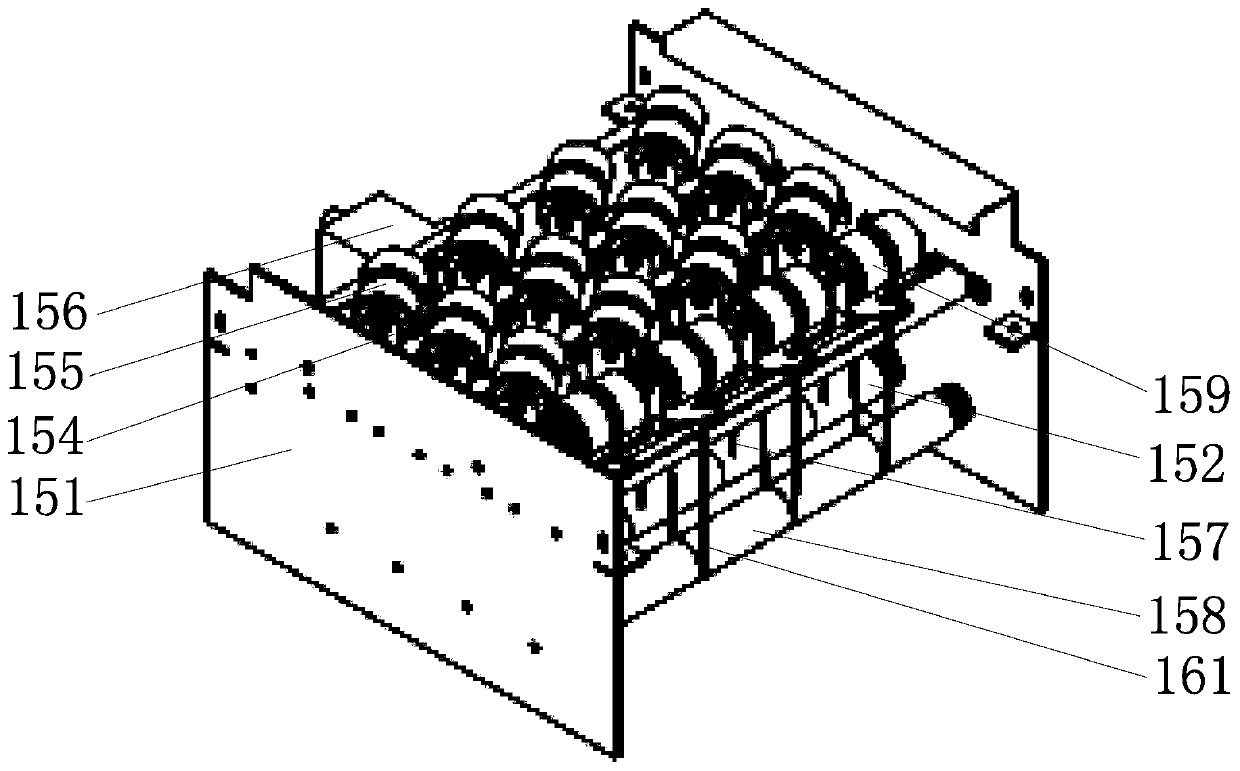

Automatic packing device on cheese packaging conveying equipment

The invention discloses an automatic packing device on cheese packaging conveying equipment. The automatic packing device is arranged above two first packing conveyor belts and a second packing conveyor belt and comprises a cylinder claw opening mechanism and a transmission unit. Cheese on the first packing conveyor belts can be grabbed by the cylinder claw opening mechanism, the cylinder claw opening mechanism comprises a horizontal connecting frame, a first pneumatic manipulator assembly and a second pneumatic manipulator assembly, the horizontal connecting frame is connected with the lower side of the transmission unit, and the first pneumatic manipulator assembly and the second pneumatic manipulator assembly are arranged on the lower side of the horizontal connecting frame and can horizontally move towards each other in the direction perpendicular to conveying directions of the first packing conveyor belts. The automatic packing device has the advantages that two cheese groups which are respectively positioned on the first pneumatic manipulator assembly and the second pneumatic manipulator assembly can approach each other and accordingly can be stably arranged in cartons, and vibration due to excessively large spaces between the two cheese groups and influence on the quality of products can be prevented.

Owner:SHISHI JULING MACHINERY TECH CO LTD

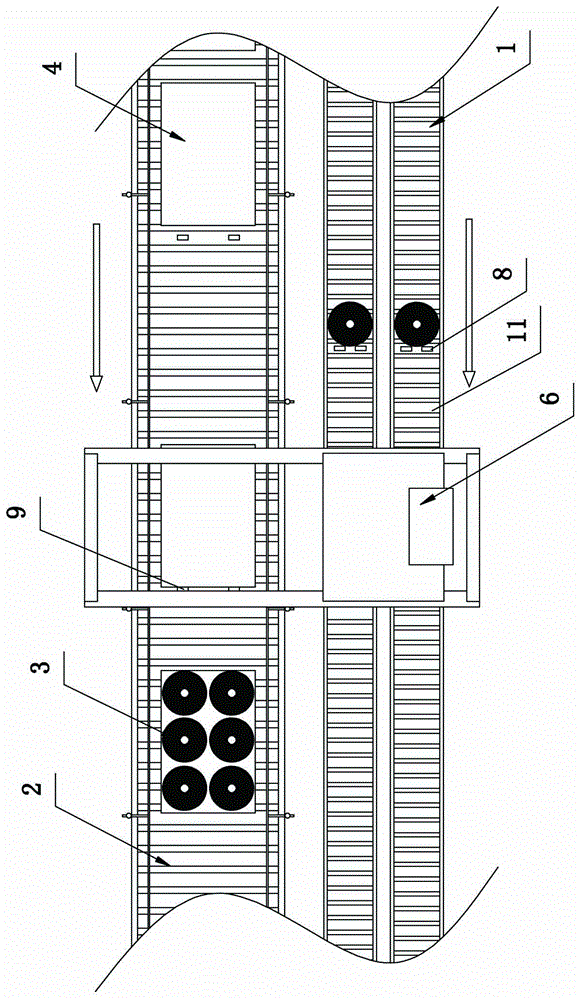

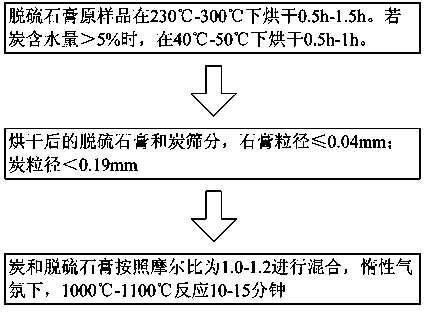

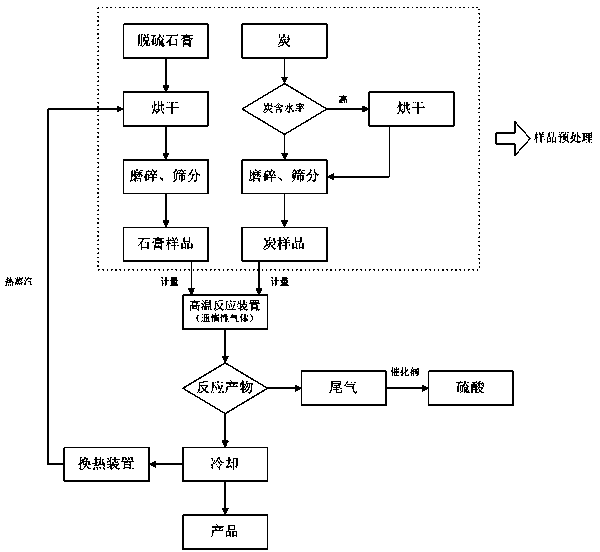

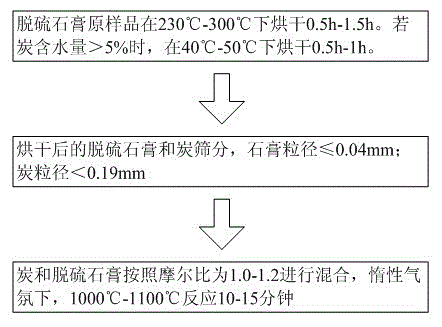

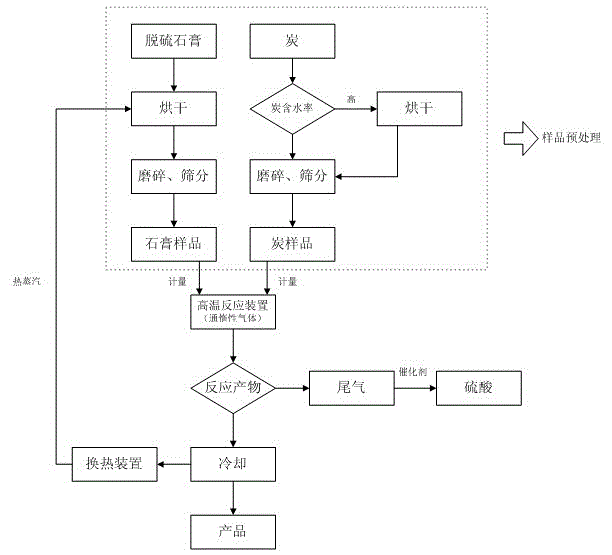

Production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum

ActiveCN103482584AAvoid secondary pollutionReduce miningSulfur compoundsCalcium/strontium/barium oxides/hydroxidesNitrogen gasAtmospheric pollution

The invention discloses a production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum. The technology comprises the following steps: drying desulfurized gypsum at 230-300DEG C for 0.5-1.5h, wherein drying pretreatment is carried out at 40-50DEG C for 0.5-1h if the water content of carbon is above 5%; screening the desulfurized gypsum and the carbon for controlling the gypsum particle size below 40mum and the carbon particle size below 187.5mum; and mixing the screened carbon and the screened desulfurized gypsum according to a carbon-to-calcium sulfate mole ratio of 1:1-1.2:1 to obtain a mixed sample, putting the mixed sample in a high temperature reaction device, and reacting at 1000-1100DEG C under the protection of nitrogen or an inert gas under a gas flow velocity of 4-10m / s for 10-15min. The technology has the advantages of high reaction efficiency, fast reaction speed, less carbon consumption, high finally-obtained product quality, and no atmospheric pollution.

Owner:NANJING UNIV OF SCI & TECH

Polymer carrier Ziegler-Natta catalyst for olefin hydrocarbon polymerization and its preparation method

This invention relates to a Z-N catalyst that uses polymer as carrying agent is utilized for aethylenum homopolymerization / alpha- alkenes copolymerization and its preparation. The expression of this catalyst is P-S .Mgx MClY(nTHF),in the expression M is titanium or Vanadium; X=1-40,Y=5-96,n=5-10;P-S is benzene vinyl copolymer carrying agent containing Lewis base functional group-OH,-COOH,-COOR, -CONH2, ixo-equal molecular weight is 10000-40000.Its preparation: First stated copolymer carrying agent that contains Lewis base functional group is dissolved in polar solvent and agretopes with magnesic chloride, second generating emboliform catalyst by the method that it is resolved with chloride of metal titanium or Vanadium and THF by nonpolar solvent or drying spray. This catalyst has very high catalytic activity to aethylenum polymerization, Applied to gas and slurry polymerization process, its products don't have inorganic ash content contained in common inorganic carrying agent.

Owner:吉林市朋力科技开发有限公司

Process for preparing methyl sodiosul foaliphatate

InactiveCN101054354AReduce dosageImprove securityTransportation and packagingSulfonic acids salts preparationSulfonateAlcohol

The present invention disclosed a method for preparing sodium fatty acid methyl ester sulfonate, which takes fatty acid methyl ester sulphonic acid as raw material and reacted in pump type recycle mixing device with cooler, including re-esterification, prebleaching, neutralisation and quadric albefaction, in which disodium salt content of prepared product <=5.0%, color (5%a.m) <=50 Klett, neutralisation system MES content >=70%. The present invention rationally combines prebleaching with quadric albefaction through adding modifying agent and strictly controlling pH and using lesser methylic alcohol dosage, therefore the safety, operability and controllability of producing is capable of being greatly enhanced.

Owner:ZANYU TECH GRP CO LTD

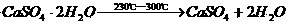

Strip flattening machine

InactiveCN102248330AWon't clogImprove cooling effectWelding/cutting media/materialsSoldering mediaTransformerEngineering

The invention relates to a strip flattening machine, belonging to forming equipment for solder brazing materials. The strip flattening machine consists of a front straightening roller electrode device, a flattening roller, a wire feeding wheel, a cutting-off device, a rear straightening roller electrode device and a transformer, wherein the front straightening roller electrode device and the rear straightening roller electrode device which are used for heating and straightening, the flattening roller for rolling an alloy wire to be flatten, the wire feeding wheel and the cutting-off device for cutting the flattened alloy wire are sequentially arranged on an advancing path of the alloy wire; and the front straightening roller electrode device and the rear straightening roller electrode device are connected with a heating electrode and the transformer. The invention has the advantages of reasonable structural design, high production efficiency, stable quality of products, easiness for control and durability.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

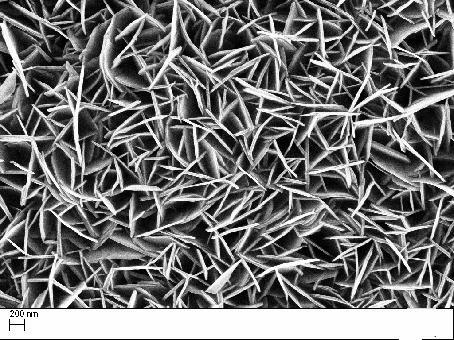

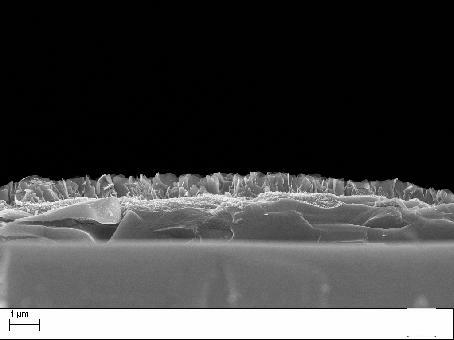

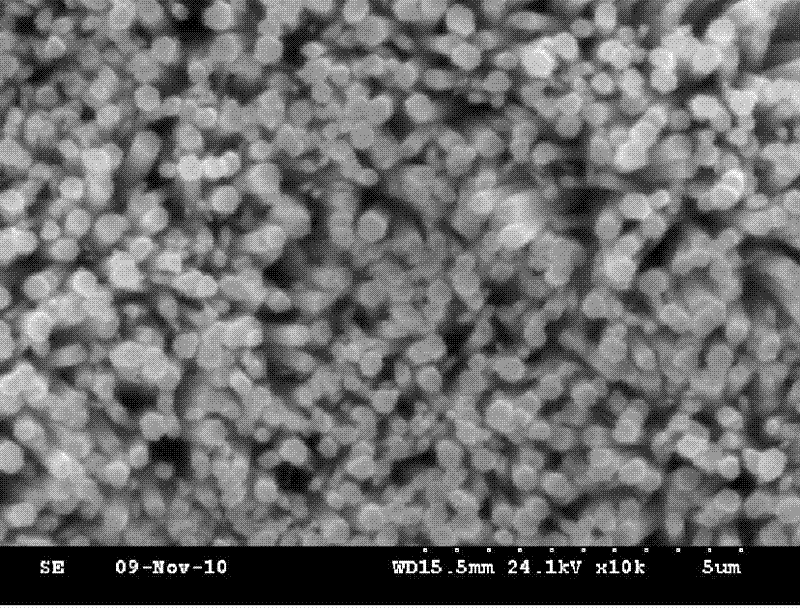

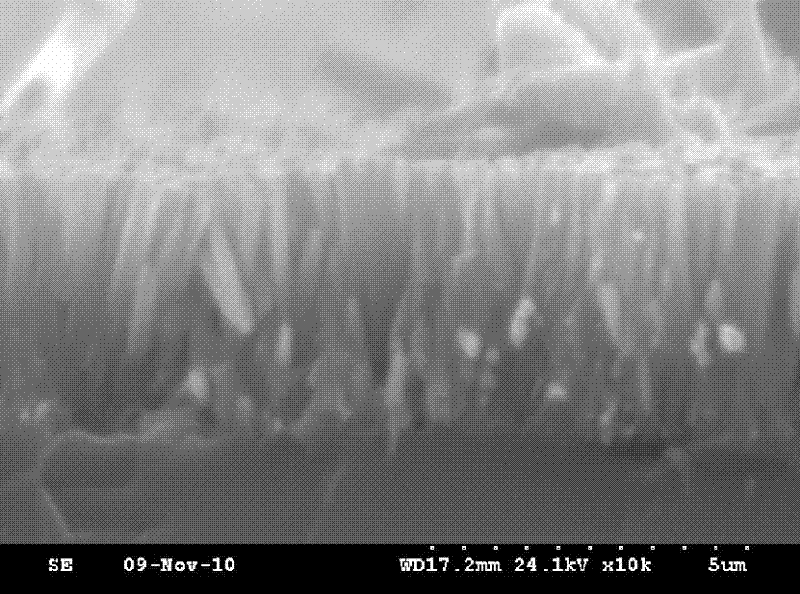

Method for preparing Al mixed with ZnO nanosheet array by adopting pulsed electromagnetic field

InactiveCN102693844ALower resistanceReduced band gapLight-sensitive devicesPhotovoltaic energy generationZinc nitrateZinc Acetate Dihydrate

The invention relates to a method for preparing Al mixed with ZnO nanosheet array by adopting a pulsed electromagnetic field, which is as follows: an FTO conductive sheet glass is placed in an ultrasonic cleaner for cleaning; the mixed solution I of zinc acetate, ethanol amine and ethylene glycol monomethyl ether is dripped on the conductive sheet glass, and is uniformly coated through a spin coater and heat treated to form a ZnO film thereon; the FTO conductive sheet glass coated with the ZnO film is put into a reaction kettle, the mixed solution II formed by aluminium nitrate, zinc nitrate and hexamethylene tetramine as well as deionized water is filled into the reaction kettle, the pulsed electromagnetic field treatment is applied to the reaction system in the reaction kettle, the kettle is moved to a constant temperature oven for hydrothermal reaction after the treatment, and the sediment on the surface of the glass is washed and dried after the hydrothermal reaction, so as to obtain the Al mixed with ZnO nanosheet array. The method is simple to operate, has low energy consumption, enables the orientation of the nanosheets to be identical, has higher verticality, enables the nanosheets to be neatly arrayed, has big specific surface area, facilitates electron transport when serving as the photoanode, and improves the efficiency of the dye sensitized solar cell.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

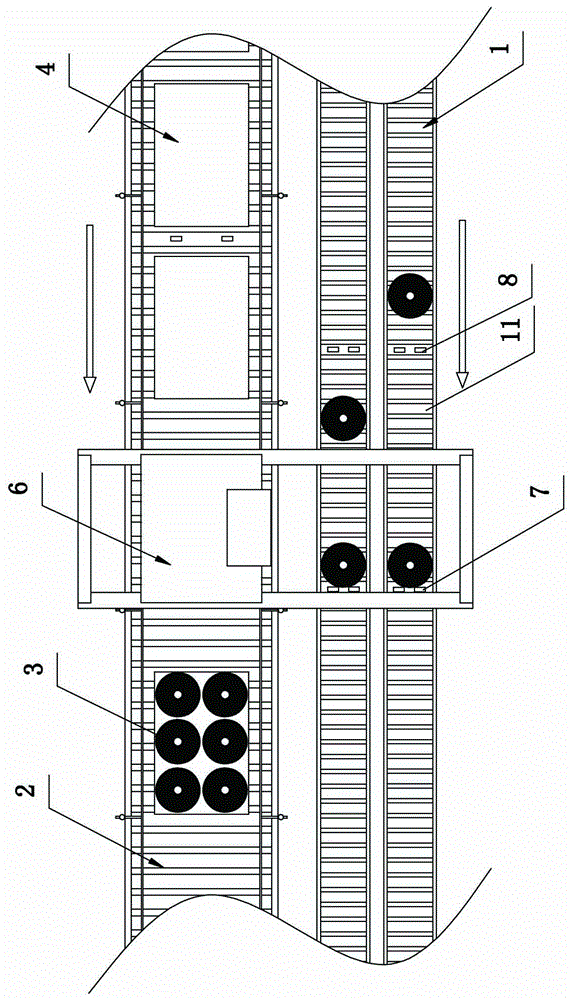

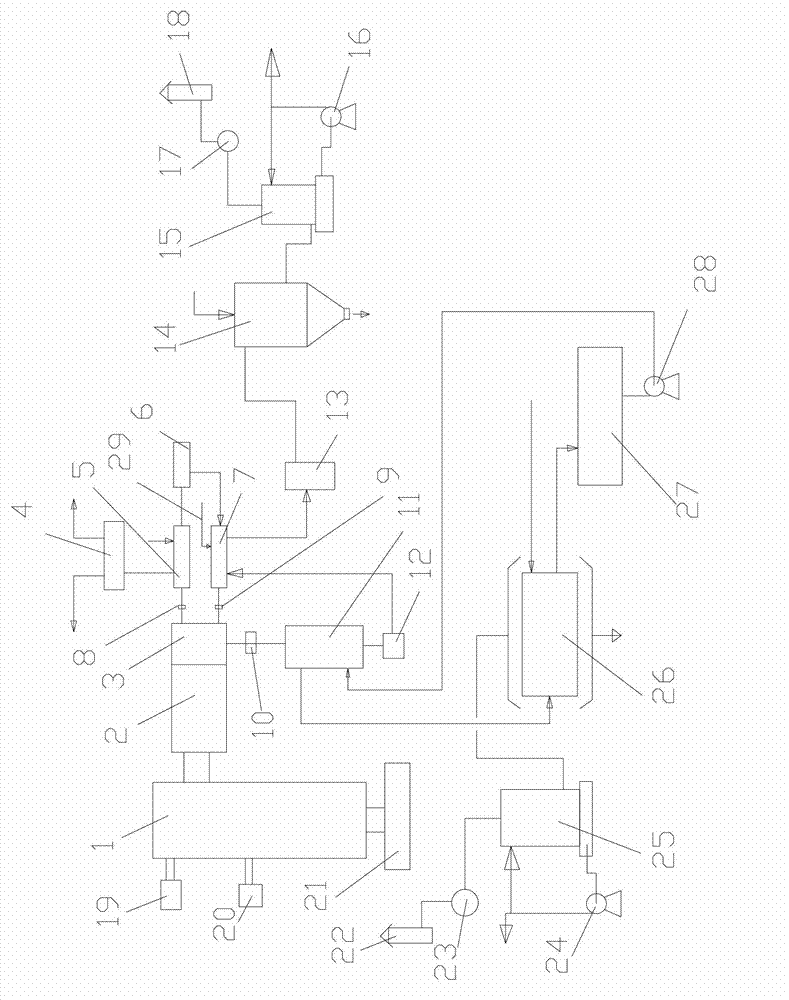

Method and device capable of simultaneously providing various clean heat sources to prepare polyaluminum chloride

ActiveCN102849769AAvoid wastingImprove heat transfer efficiencyChemical industryAluminium chloridesProcess engineeringVapor generator

The invention discloses a method and a device capable of simultaneously providing various clean heat sources to prepare a polyaluminum chloride. The method includes preparing clean high temperature hot wind, performing heat supply by a conduction oil heat exchanger, performing heat supply by a vapor generator, performing heat supply by a spray dryer, performing hot wind purification by the spray dryer and performing tail gas treatment. The method and the device capable of simultaneously providing various clean heat sources to prepare the polyaluminum chloride have the advantages that heat supply systems are centralized, the heat supply efficiency is high, and polyaluminum chloride product production is low in energy consumption, small in pollution and low in operating cost.

Owner:长沙天水环保科技有限公司

Plasma electrode and manufacturing method thereof

ActiveCN105252160ASmall impact on structureShorten brazing timePlasma welding apparatusWelding/cutting media/materialsOptoelectronicsTransmitter

The invention discloses a plasma electrode and a manufacturing method of the plasma electrode. The plasma electrode comprises an electrode body and a brazing type inner core. A cooling hole is formed in the electrode body. An inner core hole communicated with the cooling hole is formed in the head of the electrode body. The brazing type inner core is welded in the inner core hole of the electrode body. The brazing type inner core comprises an electrode body inner core and an electrode transmitter. A brazing hole is formed in the electrode body inner core. The electrode transmitter is welded in the brazing hole in the electrode body inner core. The plasma electrode and the brazing type inner core of the plasma electrode are of split structures, and the electrode body inner core is connected with the transmitter in a brazing manner and is then assembled with the electrode body. The influences of the high temperature on the overall structure of the electrode are small during welding, even if the electrode body inner core deforms due to the high temperature in the brazing process, no influence is caused on the overall shape of the product, and the overall product quality cannot be influenced.

Owner:常州特尔玛科技股份有限公司

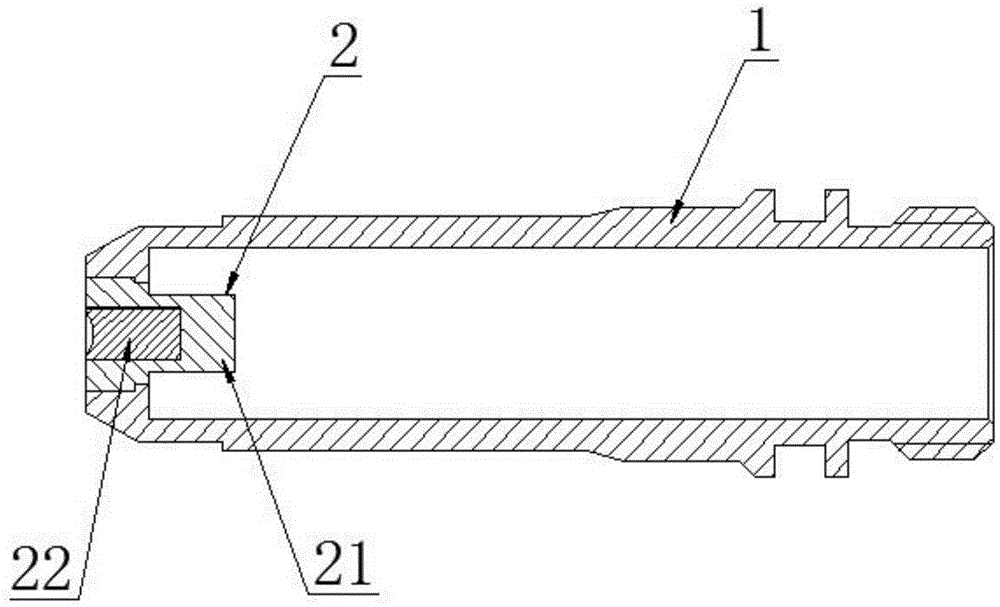

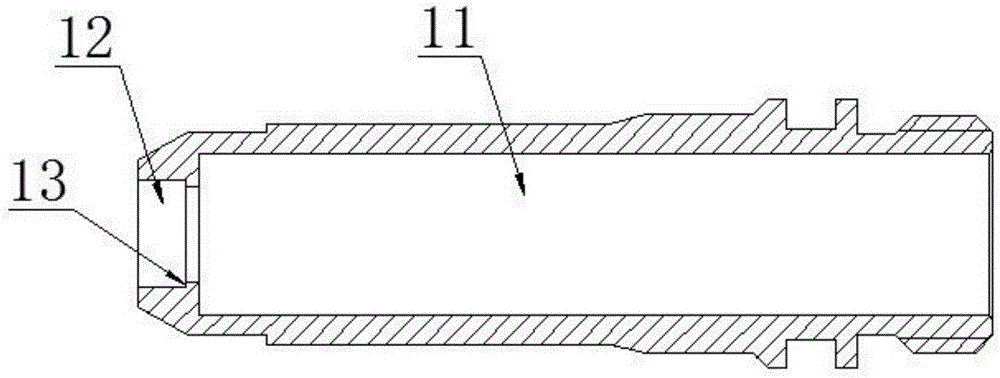

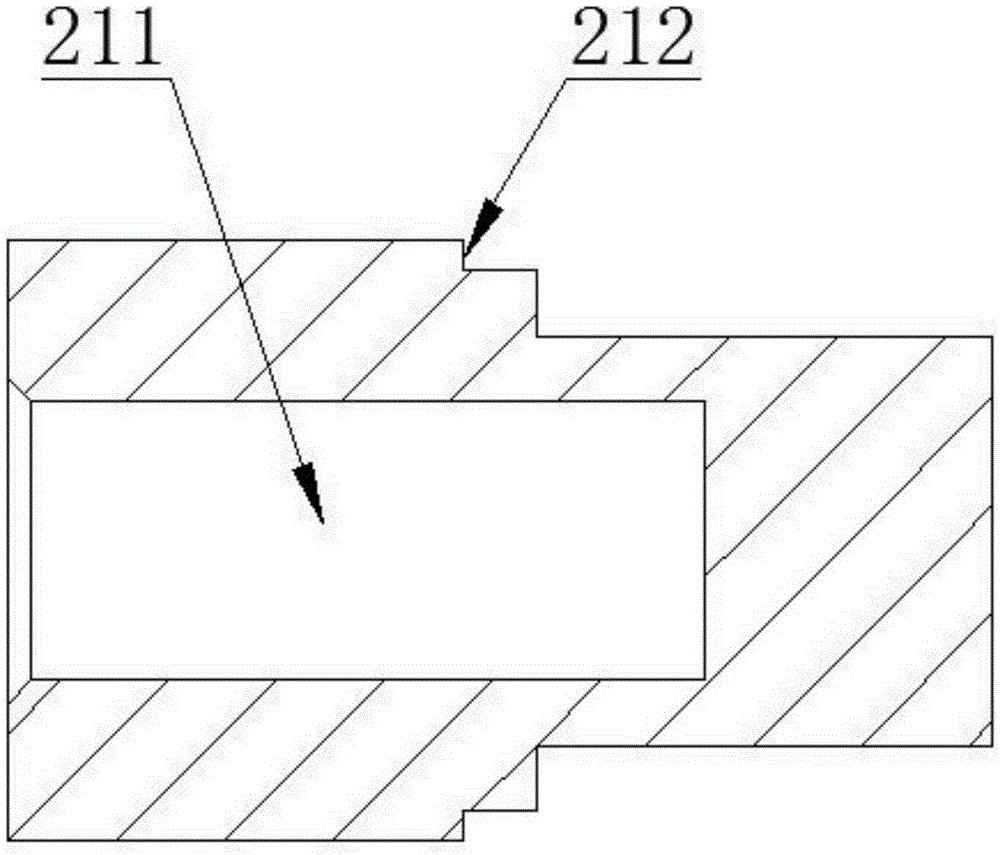

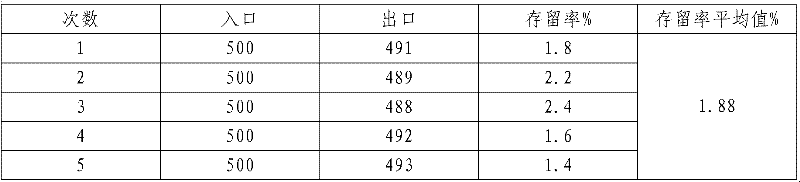

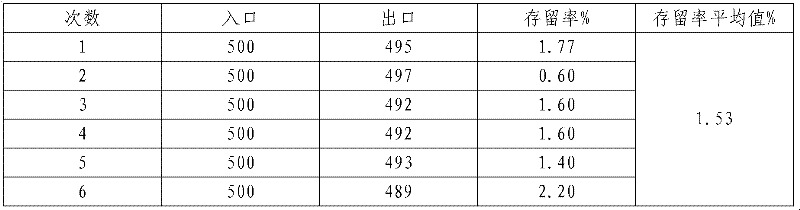

Method for measuring retention period of tobacco material

InactiveCN102564950AWill not affect product qualityEasy to identifyTobacco preparationPreparing sample for investigationEpigallo-catechin gallateEngineering

The invention discloses a method for measuring a retention period of a tobacco material. The method comprises the following steps of: mixing green tea, lotus leaves, Pu'er black tea, carrots, tomatoes, red bayberries or watermelons and tobacco stalks and powder to obtain color tobacco sheets; and under the normal operating condition of equipment, putting the color tobacco sheets or cut sheets through an inlet of a procedure, finding out markers at an outlet of the procedure by using the marked difference of colors, and recording the average time of the markers from the inlet to the outlet, namely the retention period of the tobacco material. The markers are a common substance in tobacco processing, and even if a small number of markers cannot be detected, the product quality is not influenced; and the color sheets are easily identified from the material at the outlet and can effectively mark.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

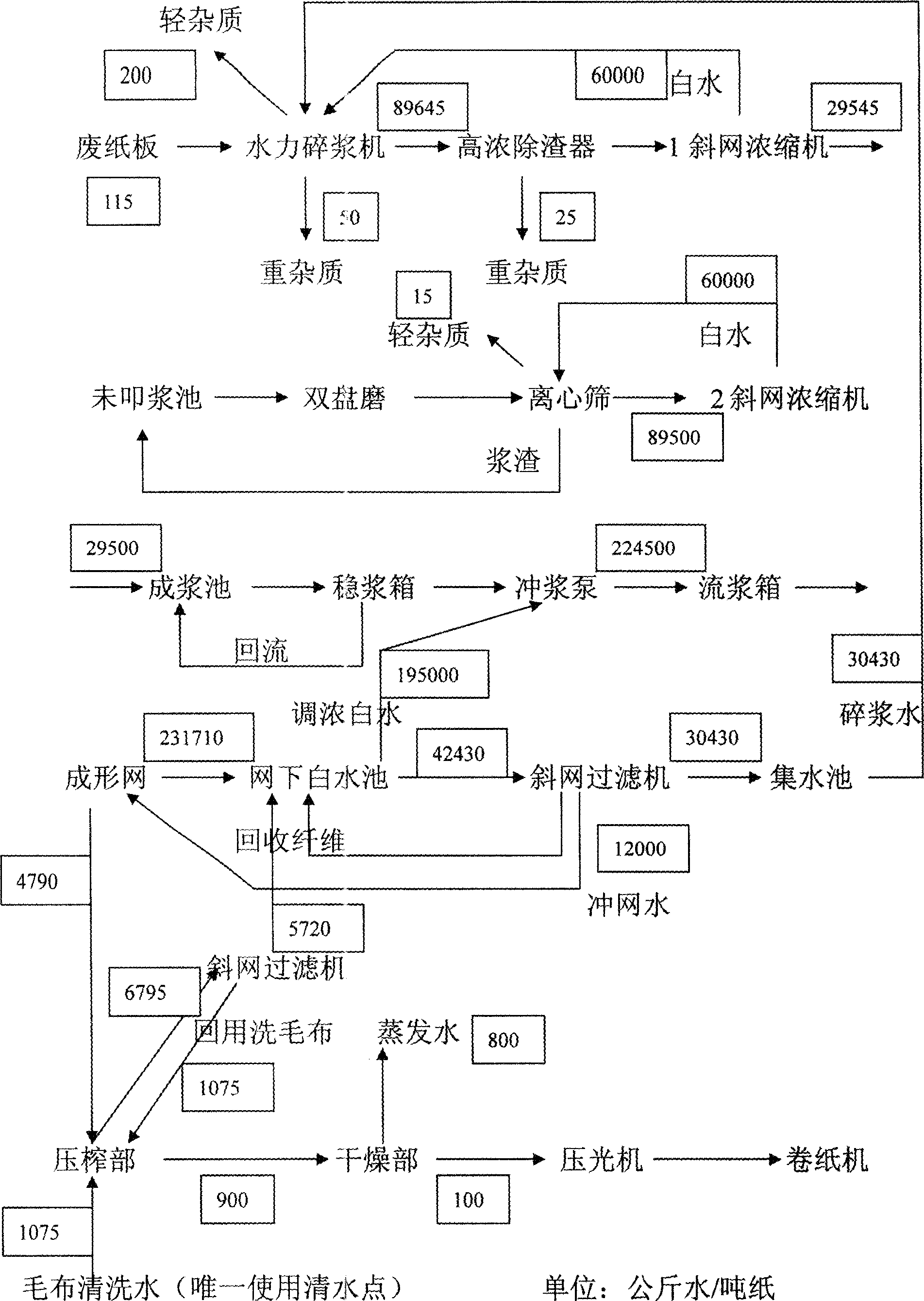

Non-process sealing circulation technology for wastewater from pulp and paper making by non-delignify reaction

InactiveCN101153471AIncrease concentrationReduce water consumption per ton of paperPulp liquor regenerationImpurityUntreated wastewater

The invention provides a closed circulation technology of untreated wastewater of non-delignification reaction pulp and paper and mainly adjusts and reforms a pulp and paper system of the non-delignification reaction to adapt a segment short process closed circulation reuse which is processed to discharge wastewater without chemical, biochemical treatment in a production process of pulp and paper, and to control added quantity of clear water which is the same as the demanded water consumption of the pulp and paper process (namely a sum of evaporated water of a dryer section of paper machine and carried water in impurities which is separated when the paper machine pulps); therefore, wastewater can not be discharged outward, and water consumption per ton production during the production process of pulp and paper is greatly reduced.

Owner:吴解生

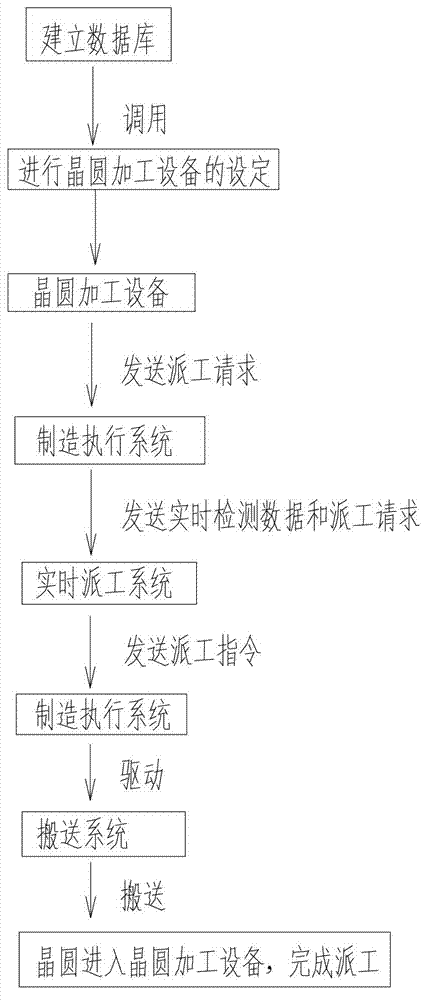

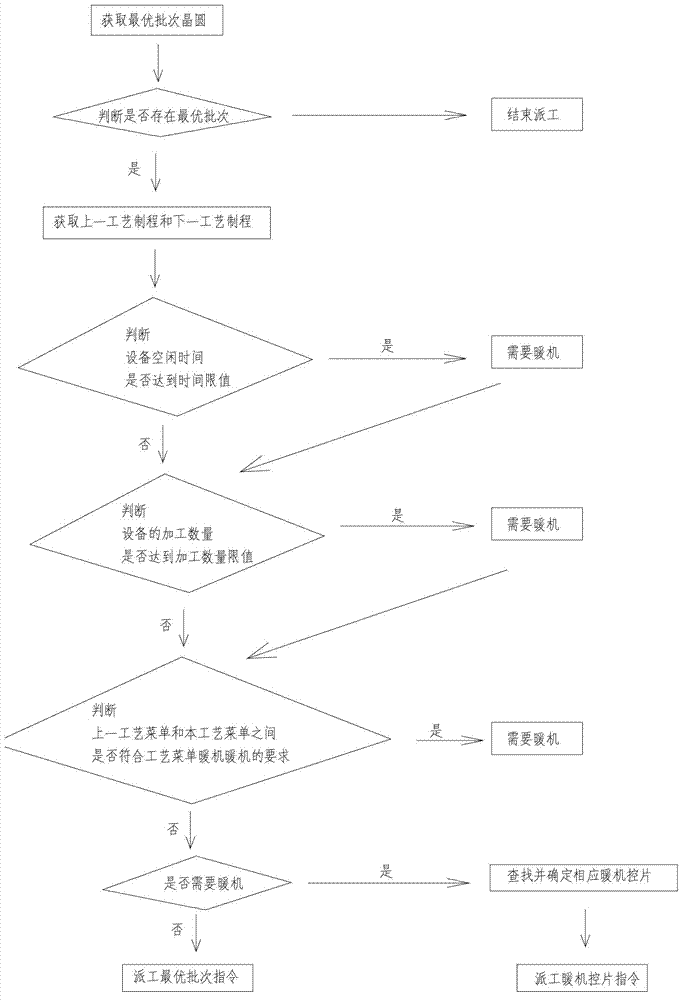

Seasoning control method

ActiveCN103199040ASave human effortImprove equipment utilizationSemiconductor/solid-state device manufacturingNo detectionData information

The invention relates to a seasoning control method. The method comprises the steps of setting at least one season type of wafer machining equipment according to requirements of technological operation before the wafer machining equipment is used for technological operation of a wafer, and setting a season condition and a season lot type corresponding to each season type at the same time; acquiring detection data information of the wafer machining equipment in real time; comparing detection data with each season condition to judge the season type needed by season operation of the wafer machining equipment, dispatching a corresponding season lot to the wafer machining equipment according to a season lot type corresponding to the season type, and continuing to use the wafer machining equipment to perform the technological operation on the wafer after the season operation is carried out on the wafer machining equipment; and carrying out the technological operation on the wafer directly with the wafer machining equipment if no detection data meet the season conditions. By means of the seasoning control method, human intervention is not needed in the whole seasoning process, and the utilizing rate of equipment is effectively improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

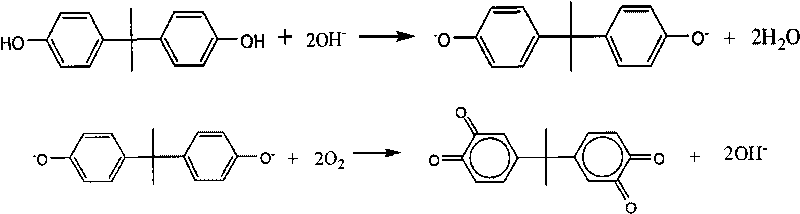

Method for preparing stable bisphenol sodium salt solution

InactiveCN101735022AOvercome the problem that the anti-oxidation effect is not good at higher temperatureAvoid invalid decompositionOrganic chemistryOrganic compound preparationOrganic solventAntioxidant

The invention provides a method for preparing a stable bisphenol sodium salt solution. The method comprises the following steps of: adding the deionized water of an inertia organic solvent or the technical backwater containing dichloromethane, preparing the mixture and the solid sodium hydroxide into alkaline liquor, adding compound antioxidant into the alkaline liquor while stirring under a condition free from oxygen, adding bisphenol into the mixture, stirring and dissolving so as to form the stable bisphenol sodium salt solution. The method of the invention has the advantages of simple operation, mild condition and small oxidation damage and is applied to producing intermittence and continuous makrolon. The stable bisphenol sodium salt solution prepared with the method of the inventionhas high thermal endurance, excellent colour and luster and the color of the makrolon is not damaged.

Owner:CHINA NAT BLUESTAR GRP CO LTD

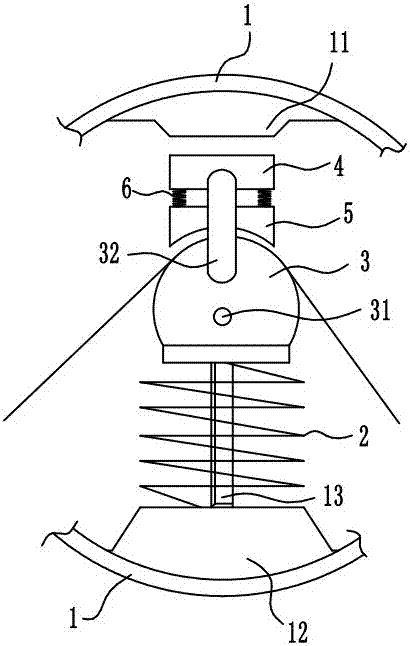

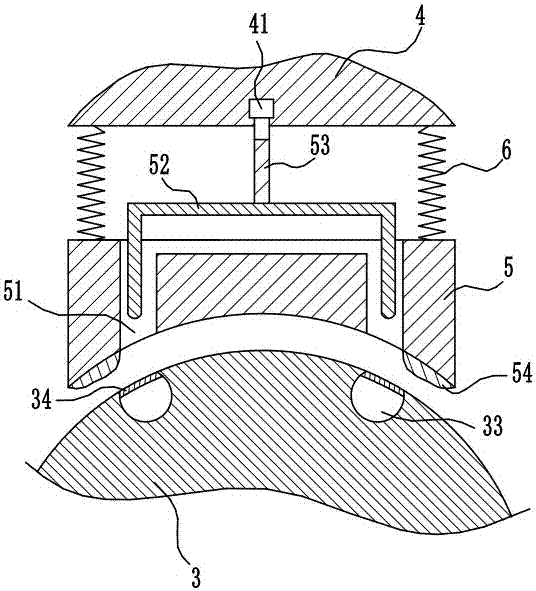

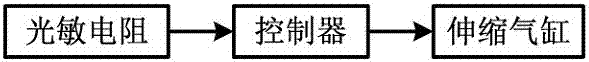

Broken thread connecting device for cotton thread twister

ActiveCN107447313AGood product qualityLarge resistancePiercing arrangementsTelescopic cylinderCotton thread

The invention relates to the field of processing equipment of cotton industry, particularly to a broken thread connecting device for a cotton thread twister. The support piece of a thread guiding unit is fixedly provided with a first press block, the top of the first press block is provided with a photo-resistor, and the first press block is fixedly provided with an abutting block above a frame; a second press block is arranged between the first press block and the thread guiding unit and connected to the bottom of first press block through a tension spring; the thread guiding unit is provided with a groove; the bottom of the second press block is fixedly provided with a rubber block which can press spun yarns; the outer circumference of the thread guiding unit is provided with cavities for containing instant adhesives; the inside of the second press block is provided with a pressing hole, an concave inserting rod which can be inserted into the cavities is matched inside the pressing hole, both ends of the inserting rod are matched in pair with the cavities, and the inserting rod is fixedly provided with a connecting rod; a controller is used for controlling a telescopic cylinder to start according to signals of the photo-resistor. The broken thread connecting device for the cotton thread twister can bond broken yarns without waiting for workers to repair, and meanwhile, save downtime restoration and avoid affecting the production schedule.

Owner:ZUNYI TIANYUN TEXTILE CO LTD

Method for preparing olefins via light alkane dehydrogenation

ActiveCN102910999AWill not affect product qualityHigh selectivityHydrocarbonsHydrocarbon preparationAlkaneSimple Organic Compounds

The present invention discloses a method for preparing olefins via light alkane dehydrogenation. Under dehydrogenation process conditions of light alkanes, light alkanes raw materials in a gas phase contact with a solid catalyst for dehydrogenation reaction; and simultaneously nitrogen-containing organic compounds are added into the reactor continuously or intermittently, wherein the added nitrogen-containing organic compounds have a carbon atom number of 1 to 18, and the adding amount of the nitrogen-containing organic compounds enables the content of the nitrogen-containing organic compounds to be from 10 to 10000 [mu]g / g in the light alkanes. According to the method of the present invention, the reaction process is controlled to raise selectivity of desired products, and the method is simple to realize, high in purity of obtained hydrogen gas, and suitable for industrial applications.

Owner:CHINA PETROLEUM & CHEM CORP +1

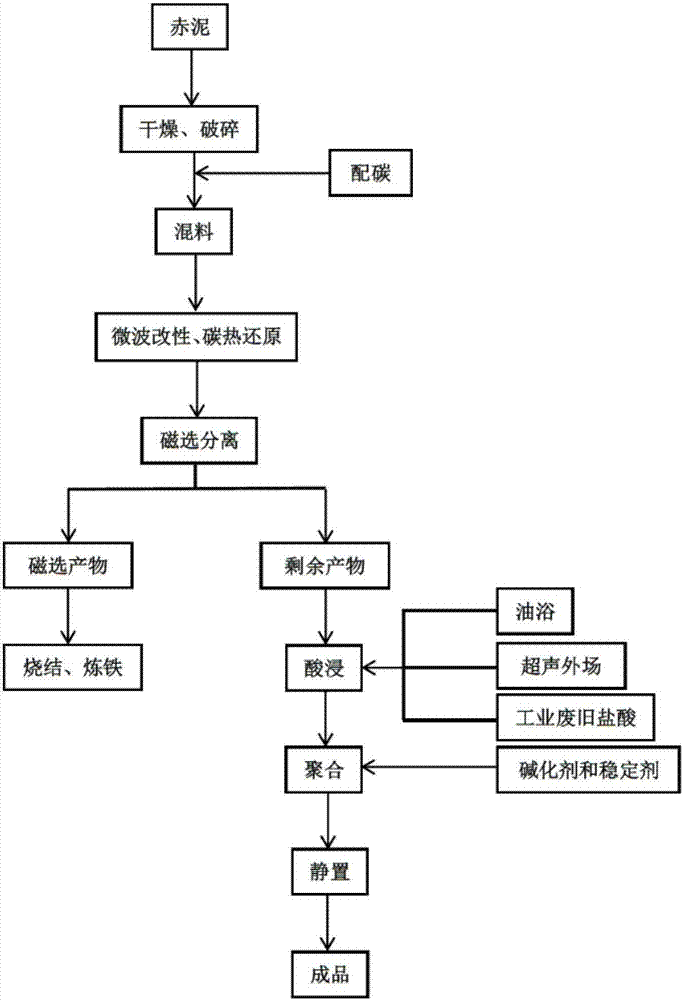

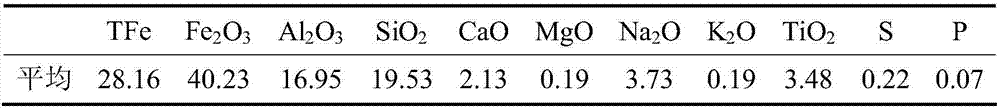

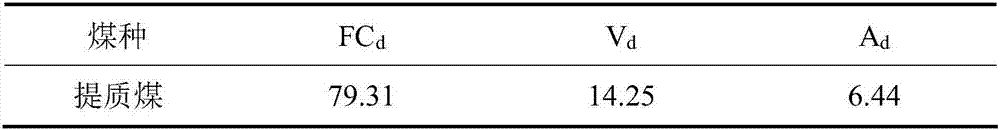

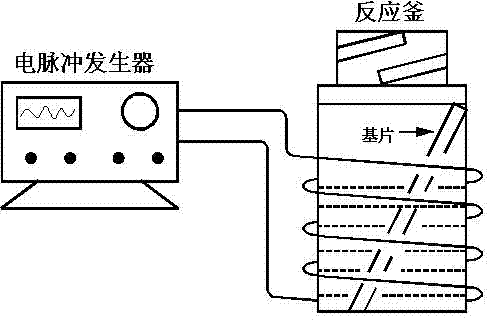

Method of preparing iron and aluminum flocculant by treating red mud by using coupling external field

InactiveCN107140718AEasy to operateAdaptableWater/sewage treatment by flocculation/precipitationRed mudDissolution

The invention provides a method of preparing an iron and aluminum flocculant by treating red mud by using a coupling external field. Red mud is treated by means of a two-step method, so that industrial waste hydrochloric acid is used for acid leaching to prepare the iron and aluminum flocculant. The red mud is treated in an early stage by microwave carbon thermal reduction, so that excessive iron in the red mud can be effectively extracted from a carbon thermal reduction-magnetic separation process, and the enriched iron oxide can be also used as iron ore concentrate which enters an iron-making step for smelting pig iron. As the iron content in the residual red mud is reduced, the dissolution rate of aluminum is favorably increased; in the acid leaching process, ultrasonic external field treatment is adopted, so that the iron and aluminum dissolution rate and the reaction effect of the red mud are further enhanced.

Owner:UNIV OF SCI & TECH LIAONING

Aromatic hydrocarbon modified C5 petroleum resin and synthesis method thereof

The invention discloses an aromatic hydrocarbon modified C5 petroleum resin and a synthesis method thereof. The synthesis method specifically comprises: using the mixing component using C10, C15 and C20 as main components as a raw material, using an aromatic hydrocarbon compound as a modifier, mixing the raw material and the modifier, adding to a reactor, adding a catalyst accounting for 0.3-2.5% of the weight of the mixing component, carrying out a reaction for 4-10 h at a temperature of 100-140 DEG C under a pressure of 0-8 Mpa, heating to a temperature of 150-190 DEG C, continuously carrying out the reaction for 4-10 h under a pressure of 0-8 MPa to obtain a crude resin, adding a solvent to the crude resin, and carrying out dilution, water washing, sedimentation, and pressure reducing distillation to obtain the petroleum resin. According to the present invention, the synthesized aromatic hydrocarbon modified petroleum resin has good compatibility with SIS, SEBS and SBS, improves the initial viscosity between the hot melt adhesive and other sanitary materials, improves the bonding strength of the hot melt adhesive, and can be used in the hot melt adhesives and other adhesive product industry and the health material product field.

Owner:PETROCHINA CO LTD

Production method of mellow rapeseed oil on basis of wood pressing device

InactiveCN107267278AUniform ripeningLight colorFatty-oils/fats refiningFatty-oils/fats productionTemperature controlEngineering

A production method of mellow rapeseed oil on the basis of a wood pressing device comprises the following specific steps: a, rapeseeds are cleaned through screening, air separation and proportional stone removal; b, the seed stir-frying temperature is controlled at 100-105 DEG C, the seed stir-frying time is determined on the basis of the seed grain wetness degree, the seed stir-frying time for each pot is selected from the range of 40-50 min, and the well stir-fried seeds are ground to serve as a standby steaming blank; c, steamed seed powder is instantly poured into a tension band where sterilized glutinous rice straw is spread in advance and then is beaten with a wooden hammer to be solid into a cake; d, raw materials forming the cake in the tension band are fed into the wood pressing device timely, and a wooden wedge is added in time and tightly propped in a groove of the wood pressing device; the wooden wedge is impacted, and oil in the rapeseed cake is extruded out; the mellow rapeseed oil is obtained with a conventional processing procedure of the rapeseed oil. Infrared electromagnetic temperature-controlled seed stir-frying is performed, the mature degree of the rapeseeds is uniform and consistent, and the oil is mellow; the oil is light in color, gold, transparent and high in quality; the quality is stable and the safety is high; the aroma is unique, and the oil is strongly mellow.

Owner:罗平成天油脂有限公司

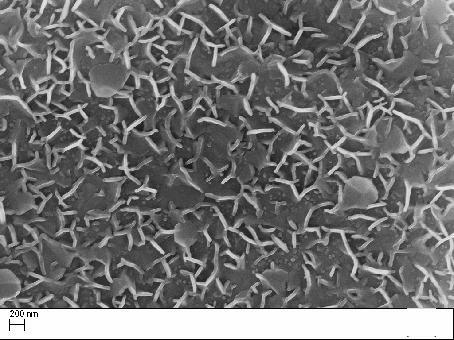

Method for preparing ZnO nano-rod array by pulse electromagnetic field

InactiveCN102515248AIncrease energy densityEasy to separateZinc oxides/hydroxidesNanotechnologyZinc Acetate DihydrateTubing types

The invention discloses a method for preparing a ZnO nano-rod array by a pulse electromagnetic field. The method provided by the invention solves the problem that the existing ZnO nano-rod array has a small length-diameter ratio and low verticality. The method provided by the invention comprises the following steps of putting fluorine-doped tin oxide (FTO) electrically-conductive glass into a supersonic wave washer, carrying out cleaning, dropwisely adding a mixed solution of zinc acetate, ethanolamine and ethylene glycol monomethyl ether on the cleaned FTO electrically-conductive glass, uniformly spreading the mixed solution on the cleaned FTO electrically-conductive glass by a spin coater, putting the cleaned FTO electrically-conductive glass coated with the mixed solution into a tube-type heating furnace, carrying out heating to obtain a ZnO film, dissolving zinc chloride into deionized water to obtain a precursor solution, adjusting a pH value of the precursor solution by ammonia water, putting the FTO electrically-conductive glass coated with the ZnO film into a reactor, pouring the precursor solution into the reactor, carrying out pulse electromagnetic field treatment on thereaction system in the reactor by a pulse electromagnetic field generation device, then transferring the reactor into an incubator, carrying out a hydro-thermal reaction process, washing off white precipitates on the surface of the FTO electrically-conductive glass by deionized water, putting the FTO electrically-conductive glass obtained by the previous step into a constant-temperature dry box and carrying out drying to obtain the ZnO nano-rod array. The method provided by the invention does not adopt a surfactant, and has simple processes, low energy consumption and no pollution.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Output collecting device of printing paper production equipment

InactiveCN108529300AWill not affect product qualityAvoid affecting product qualityPile receiversArticle deliveryPaper productionPulp and paper industry

The invention discloses an output collecting device of printing paper production equipment. The output collecting device structurally comprises a printing paper production collecting machine, an object receiving plate, a folding bracket, a supporting frame, a cover plate, a guide rod and limiting plates. The printing paper production collecting machine is constituted by a machine body, a driving mechanism, a positioning guide roller, a rotating mechanism, a paper conveying mechanism, a cutting mechanism, an electromagnet mechanism, a paper pressing mechanism, a collecting frame and a guide roller. The driving mechanism is adopted to drive the rotating mechanism to operate, the rotating mechanism is utilized to convey printing paper into the next working procedure through the paper conveying mechanism, the printing paper is cut through the cutting mechanism, the rotating mechanism drives the electromagnet mechanism to drive the paper pressing mechanism to manage, press and collect the cut printing paper, thus irregularity of the volumed printing paper is avoided, and the situation that the protruded printing paper is prone to being damaged, and consequently the product quality is affected is avoided.

Owner:马卫东 +3

Production technology of calcium oxide and sulfur dioxide by desulfurization gypsum

ActiveCN103482584BAvoid secondary pollutionReduce miningSulfur compoundsCalcium/strontium/barium oxides/hydroxidesShielding gasNitrogen gas

The invention discloses a production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum. The technology comprises the following steps: drying desulfurized gypsum at 230-300DEG C for 0.5-1.5h, wherein drying pretreatment is carried out at 40-50DEG C for 0.5-1h if the water content of carbon is above 5%; screening the desulfurized gypsum and the carbon for controlling the gypsum particle size below 40mum and the carbon particle size below 187.5mum; and mixing the screened carbon and the screened desulfurized gypsum according to a carbon-to-calcium sulfate mole ratio of 1:1-1.2:1 to obtain a mixed sample, putting the mixed sample in a high temperature reaction device, and reacting at 1000-1100DEG C under the protection of nitrogen or an inert gas under a gas flow velocity of 4-10m / s for 10-15min. The technology has the advantages of high reaction efficiency, fast reaction speed, less carbon consumption, high finally-obtained product quality, and no atmospheric pollution.

Owner:NANJING UNIV OF SCI & TECH

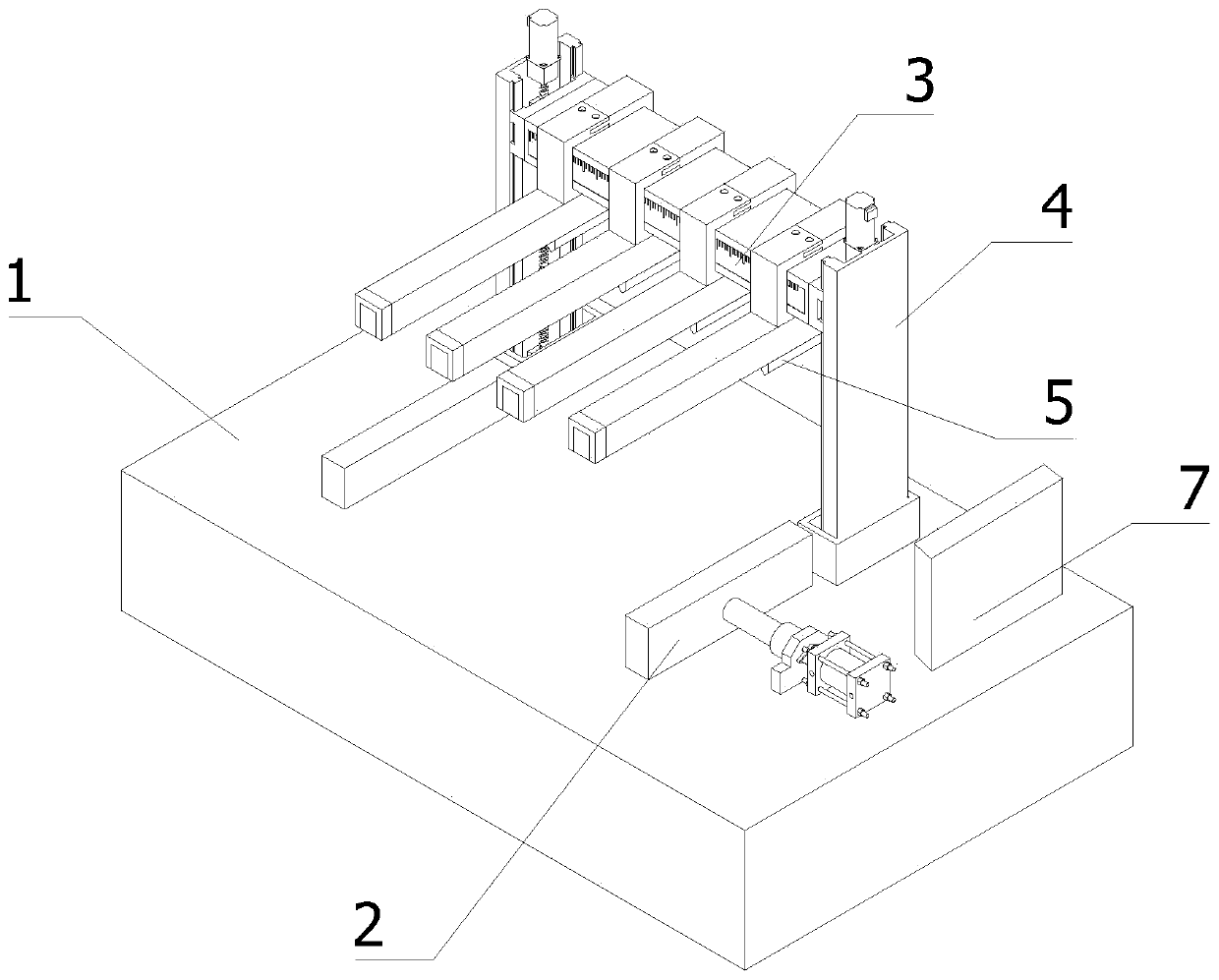

Cutting forming equipment for high-thermal-conductivity aluminum substrate

ActiveCN110682105AWill not affect product qualityReduce workloadWork clamping meansFeeding apparatusEngineeringAluminum substrate

The invention relates to the field of aluminum substrate machining, and particularly relates to cutting forming equipment for a high-thermal-conductivity aluminum substrate. The cutting forming equipment comprises a workbench, a clamping assembly, a scale plate, a lifting assembly, a V-shaped cutting assembly, a polishing assembly and an industrial computer, wherein the clamping assembly is fixedly mounted at the top of the workbench, the lifting assembly is vertically and fixedly mounted on one side of the top of the workbench, the scale plate is horizontally mounted on the side, close to theclamping assembly, of the lifting assembly, the V-shaped cutting assembly is horizontally mounted on the lifting assembly, and the polishing assembly is fixedly mounted at the end, away from the scale plate, of the V-shaped cutting assembly; and the V-shaped cutting assembly comprises a cutting tool capable of cutting transversely, the tool point of the cutting tool is provided with a V-shaped opening, the length direction of the cutting tool is consistent with the working direction of the workbench. According to the cutting forming equipment for the aluminum substrate, the whole aluminum substrate is cut off from the transverse position, half-V-cutting is carried out on the two sides, the two sides of a finished product broken off are smooth and flat without burrs, only a few burrs existat the two ends, and deburring treatment is carried out without needing special labor, so that the workload is reduced, and the machining efficiency is improved.

Owner:赣州逸豪新材料股份有限公司

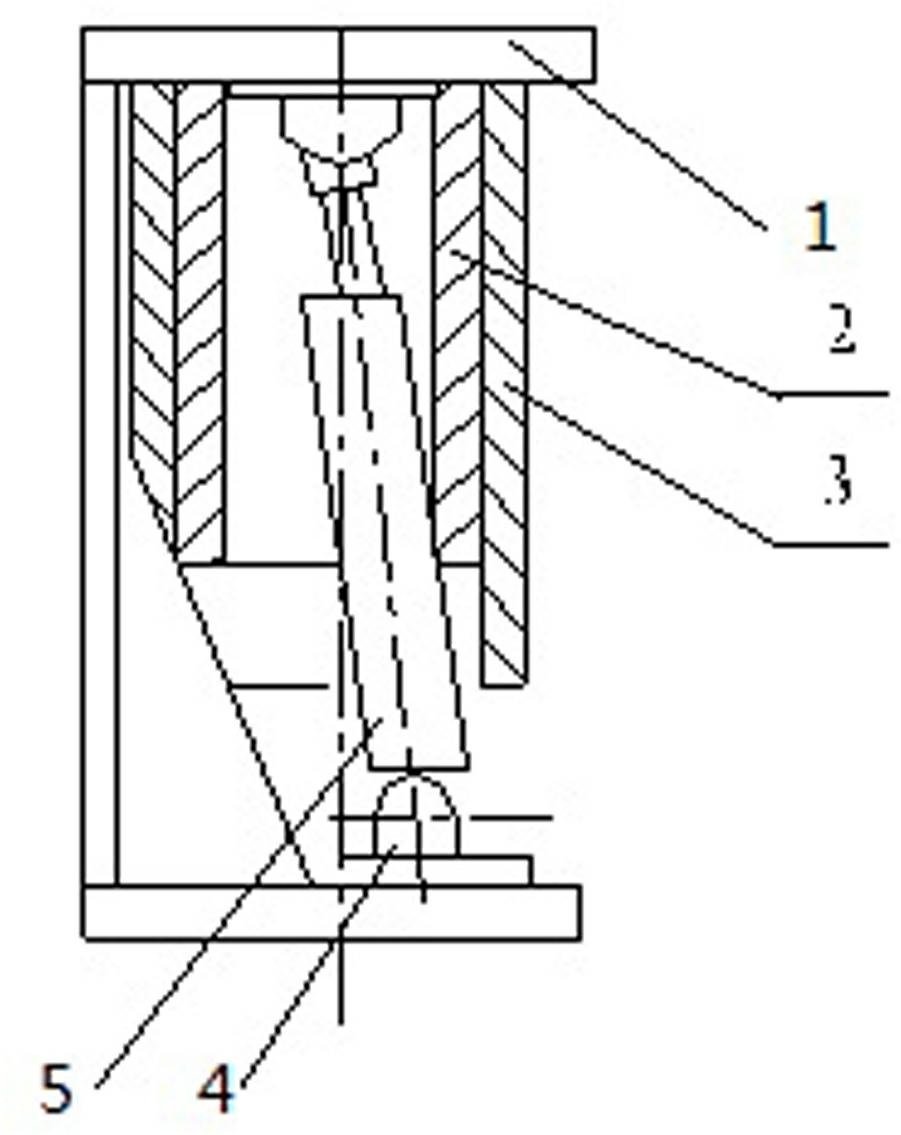

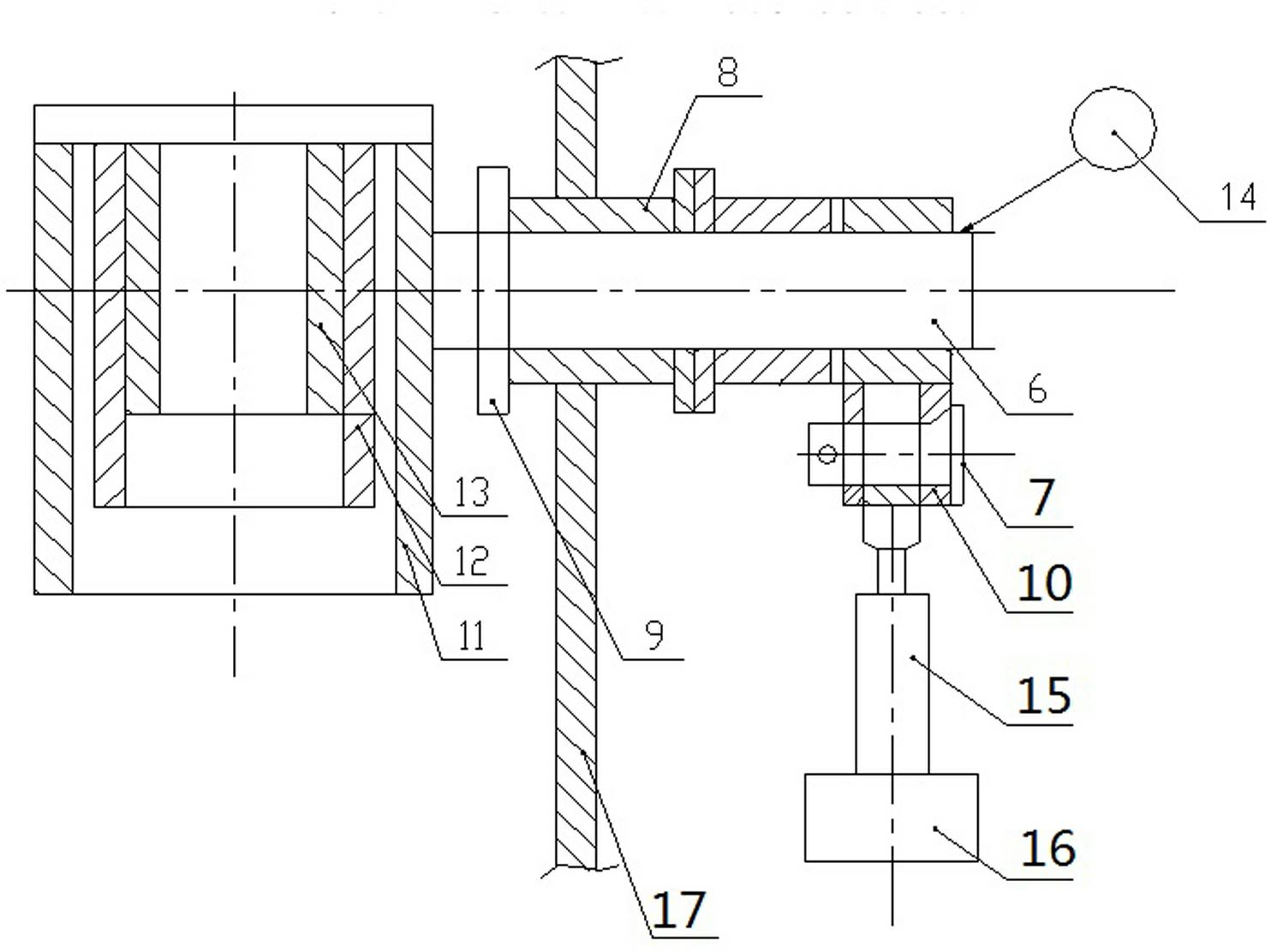

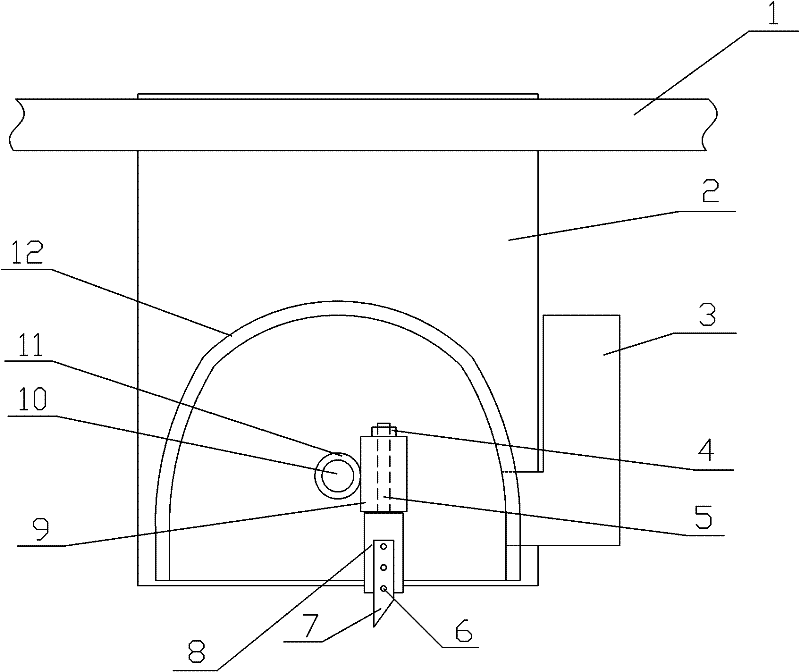

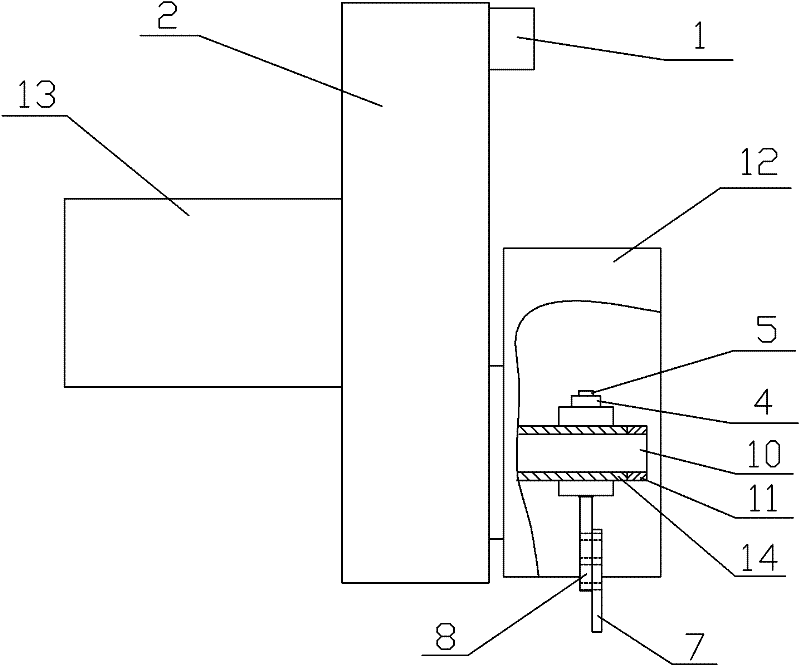

Crucible overturning device and vacuum induction furnace using same

The invention relates to a crucible overturning device, which comprises a transmission shaft. The transmission shaft is rotatably assembled on the corresponding body of the vacuum induction furnace in an air sealing mode during use, one end of the transmission shaft is provided with a power output end which extends into the corresponding furnace body, and the other end of the transmission shaft is provided with a power input end which extends out of the corresponding furnace body. The crucible overturning device also comprises a hydraulic cylinder which is in transmission connection with the power input end of the transmission shaft through an external transmission mechanism so as to drive the transmission shaft to rotate around the rotating axis of the hydraulic cylinder in a reciprocating manner, and the power input end of the transmission shaft is provided with a connecting section which is used for being directly fixedly connected with the corresponding crucible overturning rack or connected with the corresponding crucible overturning rack through an internal transmission mechanism so as to drive the crucible overturning rack to overturn. The hydraulic cylinder is arranged outside the vacuum induction furnace, so that the heated area of the hydraulic cylinder is greatly reduced, sealing parts in the hydraulic cylinder are not easily damaged, the product quality of molten iron cannot be affected by leakage of hydraulic oil, and the hydraulic cylinder can be repaired quite conveniently.

Owner:HENAN UNIV OF SCI & TECH

Erosion-resistant acid-resistant crack-resistant zero-expansion silicon brick and preparation method thereof

InactiveCN109650860AImprove corrosion resistanceImprove creep resistanceCarboxymethyl celluloseBrick

The invention discloses an erosion-resistant acid-resistant crack-resistant zero-expansion silicon brick and a preparation method thereof. The preparation method comprises the following steps of: S1,selecting raw materials: selecting 80-90% of fused quartz, 10-20% of silicon powder, 0.1-3% of carboxymethyl cellulose and 1-5% of silica sol; S2, mixing raw materials, namely mixing the selected rawmaterials, adding SiO2, Al2O3, Fe2O3 and CaO into a stirrer to stir and mix after mixing, and obtaining a mixture after trapping materials; S3, pressing and forming: putting the mixture into a press machine, and pressing and forming by one-way pressure to prepare a cylindrical sample; S4, drying: naturally drying the prepared cylindrical sample at room temperature, placing the cylindrical sample in a drying box to heat, and drying to obtain a dried sample; S5, sintering, namely putting the dried sample into a calcining furnace to heat, preserving heat and calcining to obtain a thermal shock resistant silicon brick. Compared with other preparation methods, the method has the advantages of low technical cost, mature process, easy realization and strong practicability, and greatly improves the using quality of the silicon brick.

Owner:河北炫坤耐火材料科技发展有限公司

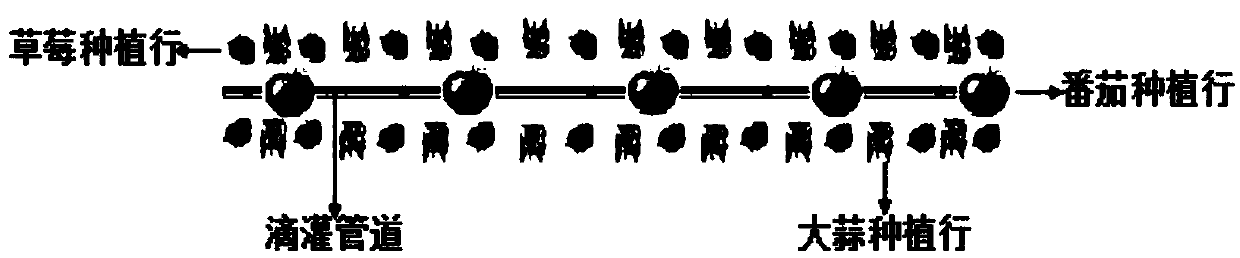

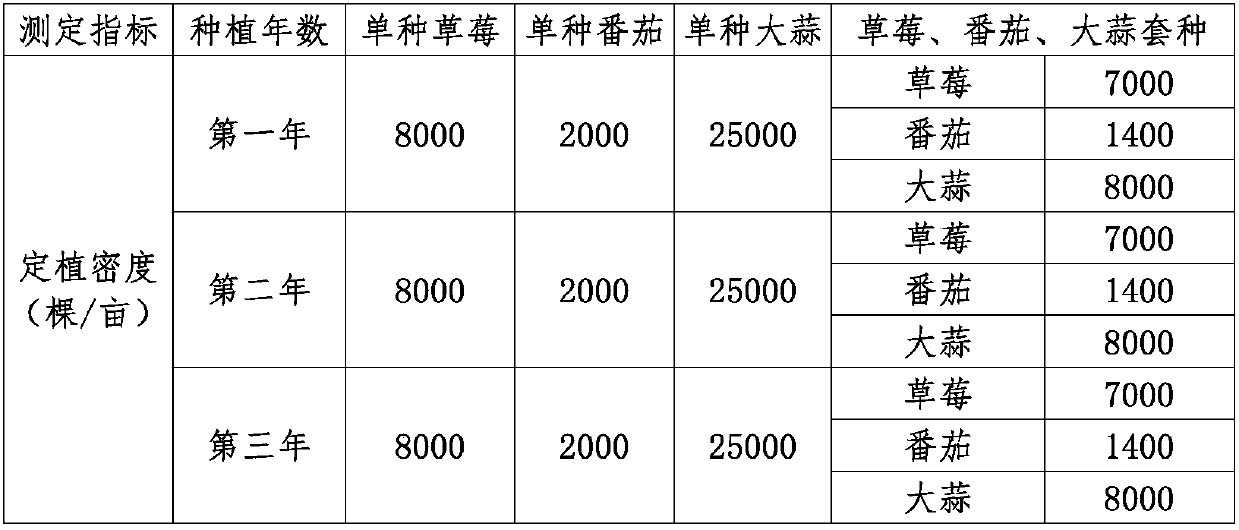

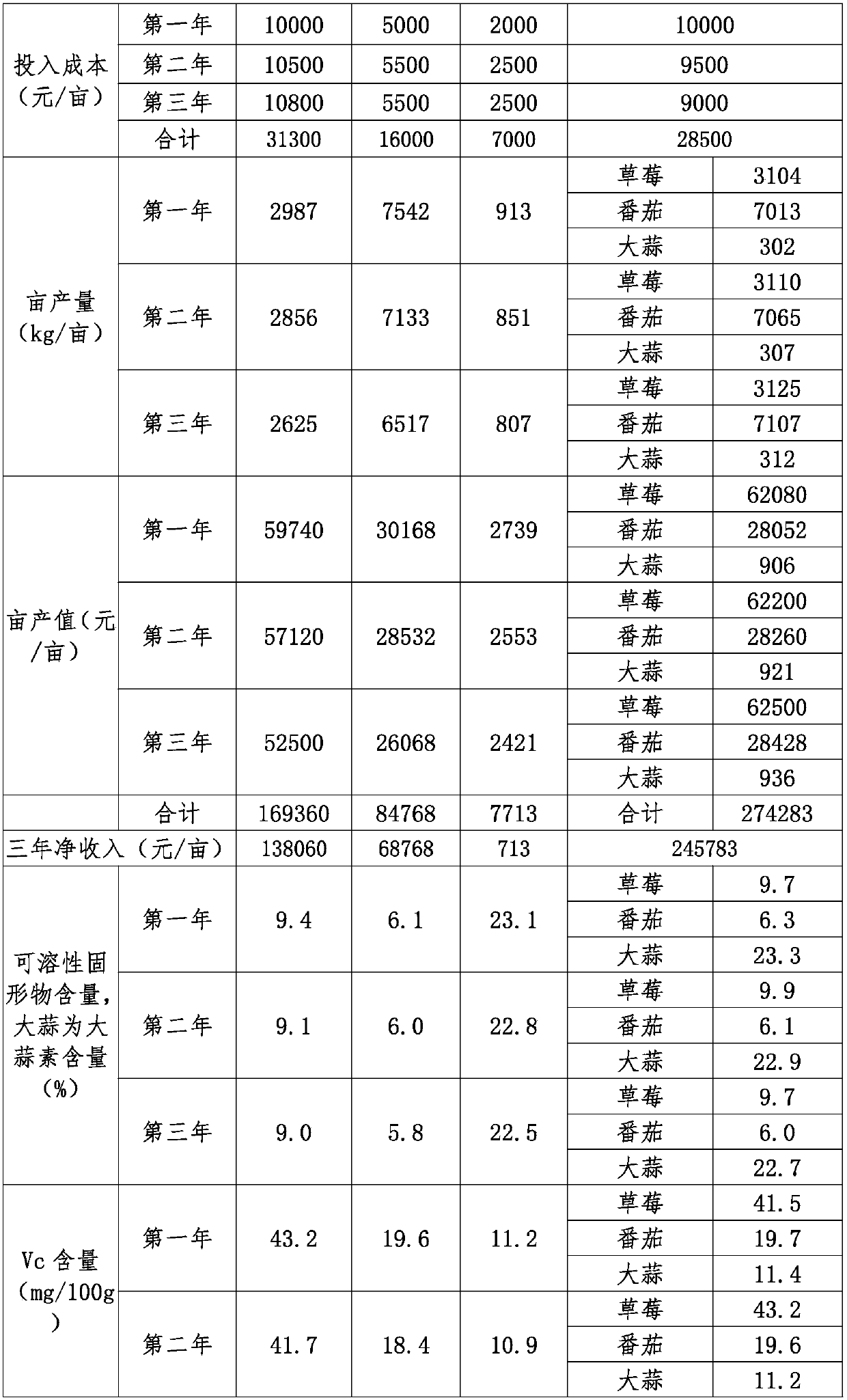

Strawberry, tomato and garlic intercropping planting method suitable for integrated management of water and fertilizer

PendingCN109566296AIncrease moistureImprove efficiencyBulb cultivationPressurised distribution of liquid fertiliserFertilizerNutrient

The invention discloses a strawberry, tomato and garlic intercropping plating method suitable for integrated management of water and fertilizer, which comprises the steps of seedling cultivation, landpreparation and ridging, seedling planting, irrigation and fertilization, plant adjustment and the like, wherein strawberry and tomato planting is taken as an agricultural production main body, garlic planting is taken as an auxiliary material, by adopting a water-fertilizer integrated irrigation and fertilization technology, the water and nutrient utilization efficiency of strawberries, tomatoesand garlics is improved, and meanwhile, the yield of the strawberries and tomatoes and the flavor quality of the garlic are obviously improved. Compared with single specie or intercropping with two species, the method not only improves the output value per mu, but also reduces the annual investment cost and increases the net income. The intercropping of the three components does not influence thecommodity quality of strawberries, tomatoes and garlics, and the indexes of soluble solid content, Vc content and the like are slightly improved; and in addition, the intercropping of the three components can effectively reduce the incidence rate of field plants.

Owner:LUDONG UNIVERSITY

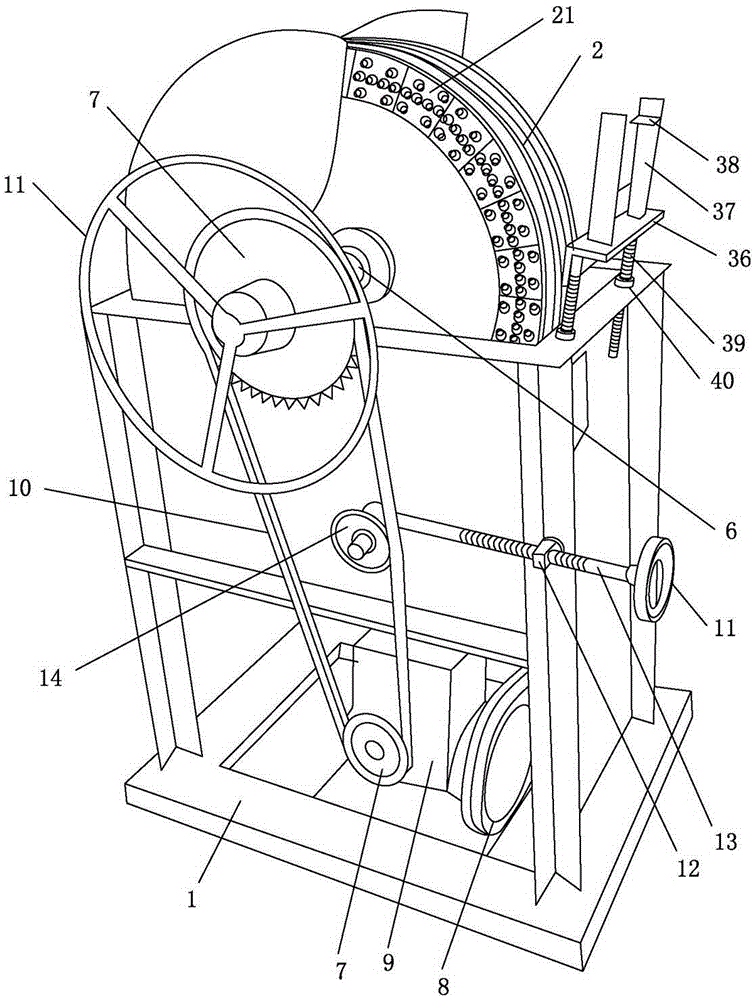

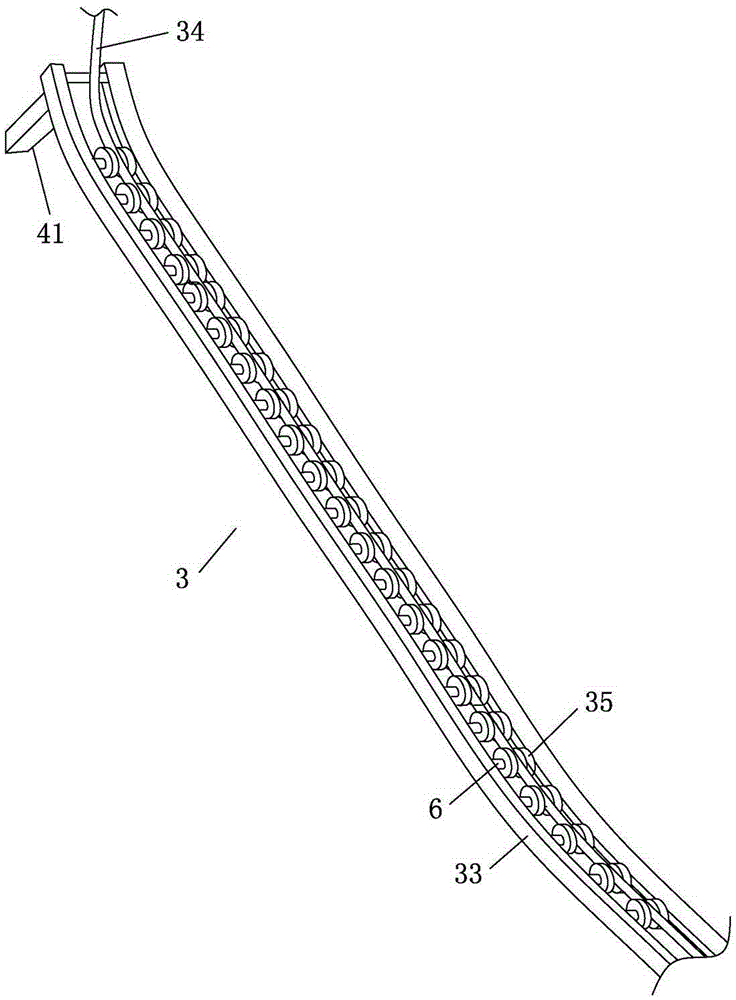

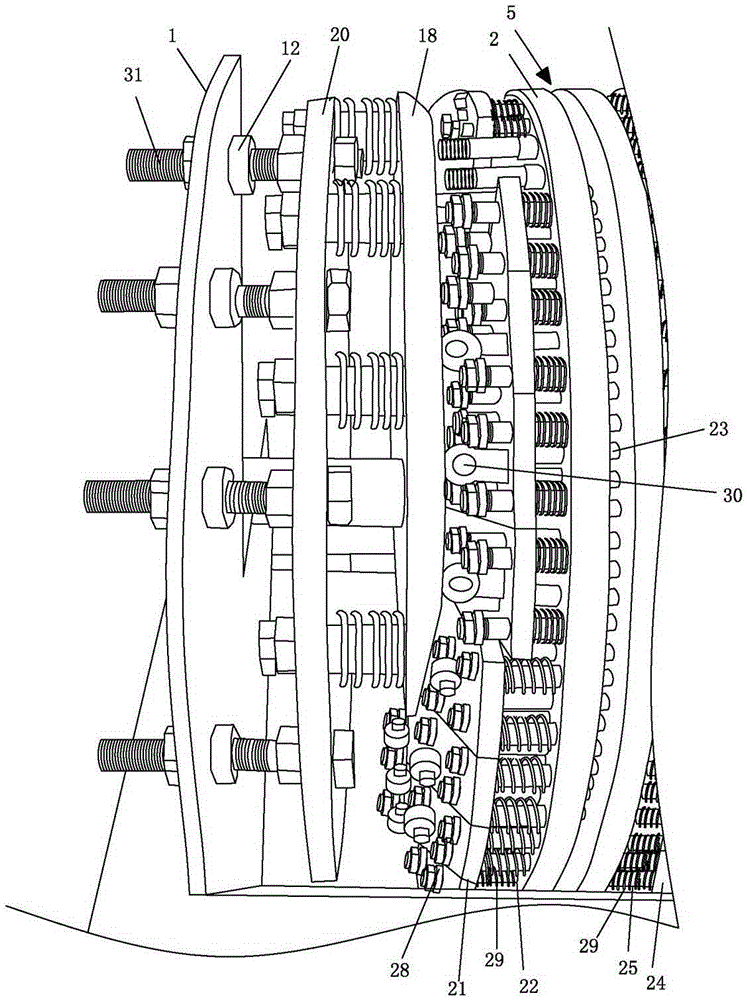

Glass disk forming machine

InactiveCN105347658AGood removal effectGood technical effectGlass shaping apparatusGlass productionPunchingSemi solid

The invention relates to a glass forming machine and discloses a glass disk forming machine. The glass disk forming machine comprises a base, a disc is rotatingly connected to the base, the circumferential surface of the disc is provided with an annular material groove, the outer side of the disc is provided with a plurality of mold units arranged in an annular way, the mold unit comprises a punching pin slidingly sleeved by one side of the disc, an ejector pin slidingly sleeved by the other side of the disc and a female mold arranged at the side wall of the annular material groove, one end of the punching pin stretches out of the disc, the other end of the punching pin aligns at the female mold, one end of the ejector pin stretches out of the disc, the other end of the ejector pin stretches into the female mold, the base corresponding to the punching pin is provided with a first guide plate capable of extruding the punching pin, and the base corresponding to the ejector pin is provided with a second guide plate capable of extruding the ejector pin. The glass disk forming machine has a simple structure. The punching pin is guided by the first guide plate to be inserted into the female mold, simultaneously, semi-solid glass melt in the annular material groove is poured into the female mold, and after the glass disc is molded and cooled, the ejector pin is guided by the second guide plate to go through the female mold so that the molded glass disc is pushed out of the female mold by the ejector pin.

Owner:YONGDING YIXIN MACHINERY MFG

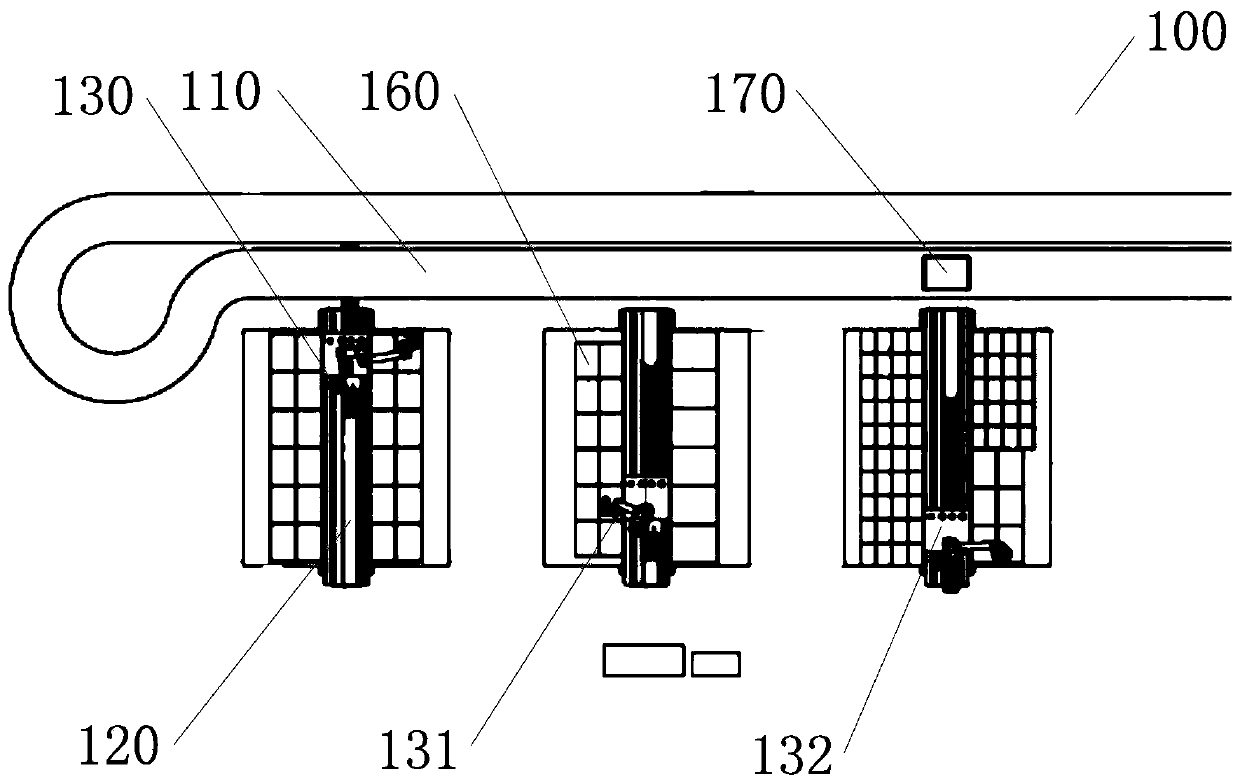

Socks production line and production method

ActiveCN111074418AIncrease productivityAvoid entanglementMechanical cleaningPressure cleaningProcess engineeringManufacturing line

The invention provides a socks production line. The socks production line comprises a weaving area, a batching area, a shaping area, a turnover area, a package area, and a control module; the weavingarea is provided with a feeding conveying line and a plurality of sock knitting machines integrating sock knitting, toe sewing and sock turning; a shaping conveying line and more than two branch conveying lines connected beside the shaping conveying line in parallel; a circulation conveying line is arranged at the turnover area; more than two package conveying lines connected with the shaping machines one by one are arranged on the package area; and the control module is used for controlling the working time sequence of each area. When the specification of the socks flowing into the circulation conveying line from the feeding conveying line is the same with the specification of the socks being shaped by the shaping equipment, the socks are sent to the shaping conveying line through a turnover steering device, otherwise, the socks are remained to flow on the circulating conveying line, the socks processed on the socks machines and the shaping machines on the same production line can bedifferent, and the production efficiency is greatly improved.

Owner:ZHEJIANG HUAER TEXTILE TECH

Dustless cutting device for PVC (polyvinyl chloride) plates

InactiveCN102248553AAvoid scratchesNot easy to slideMetal working apparatusPolyvinyl chlorideElectric machinery

The invention discloses a dustless cutting device for PVC (polyvinyl chloride) plates, and belongs to a cutting device. The device is characterized by comprising a motor, a transmission device and a rotating shaft, wherein the motor and the rotating shaft are connected by virtue of the transmission device; a rotating shaft lock nut is arranged on the rotating shaft; the transmission device is arranged on a slide rail; a sleeve is arranged on the rotating shaft; a protective cover is fixed outside the sleeve; a dust removal cylinder is arranged on one side of the protective cover, and communicated with the cavity of the protective cover; and a blade is connected with the sleeve in the protective cover by virtue of a connecting device. Compared with the prior art, the dustless cutting device for PVC plates has the characteristics that, since dust generated after cutting is discharged through the protective cover and the dust removal cylinder, noise is reduced, the dust is prevented from scratching PVC plates, and the product quality cannot be influenced; the cut PVC plates hardly slide after being stacked, so that potential safety hazard is prevented. Therefore, the device has great popularization and application values.

Owner:JINAN HAIFU PLASTIC & RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com