Crucible overturning device and vacuum induction furnace using same

A technology of vacuum induction furnace and turning device, which is applied in the direction of crucible furnace, furnace, furnace type, etc., which can solve the problems of inconvenient maintenance, affecting the service cycle, and damage of seals, etc., so as to achieve convenient maintenance, increase service life, and reduce heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

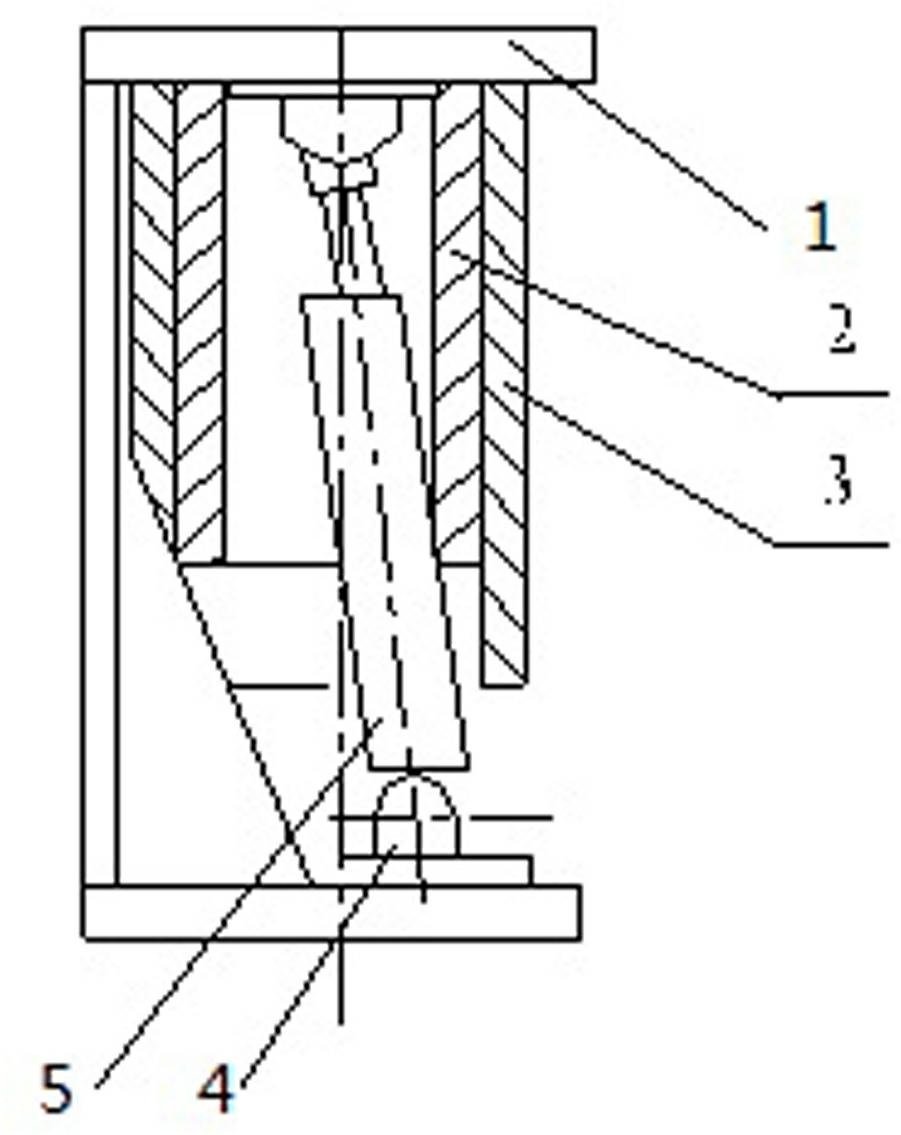

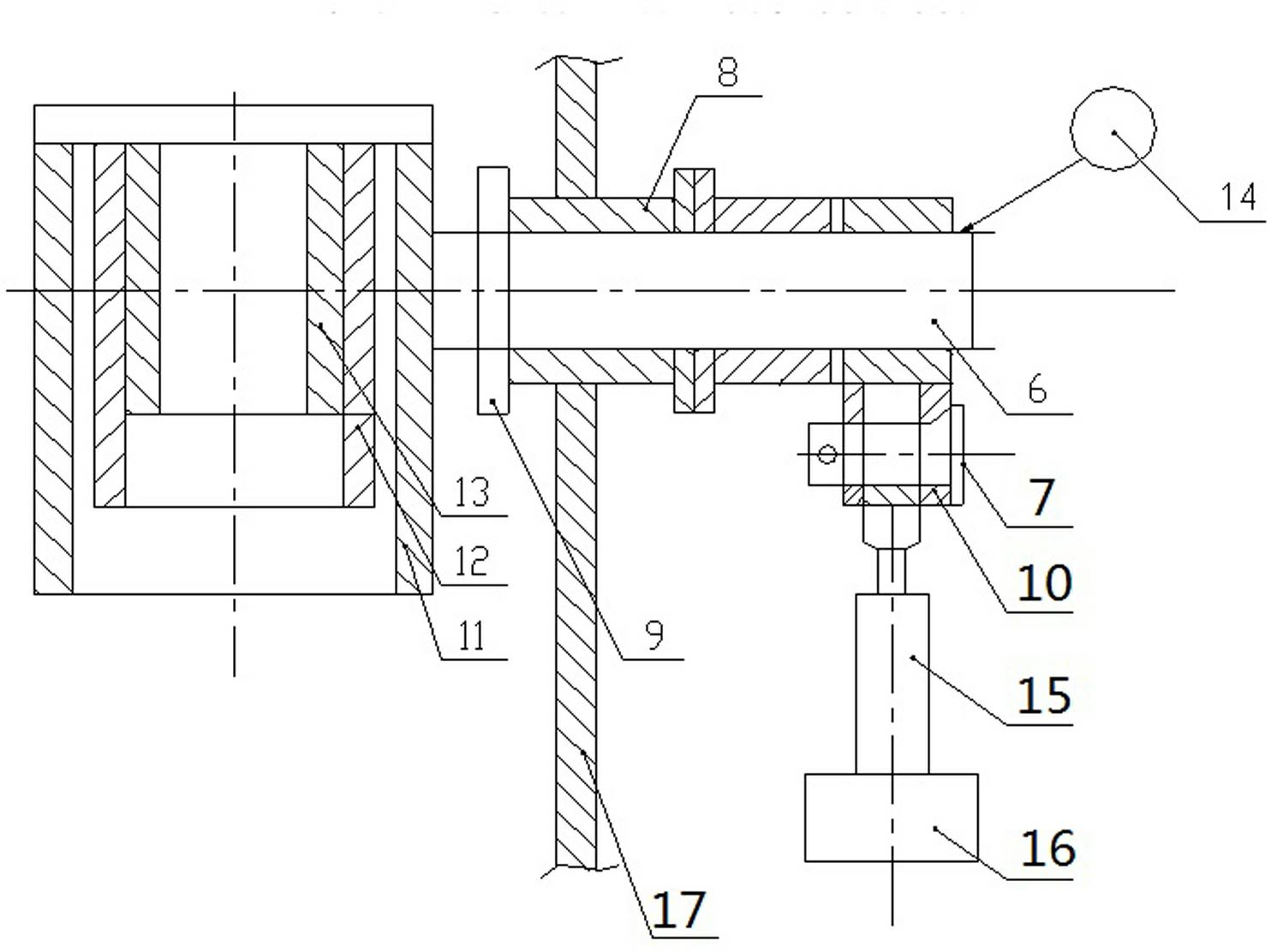

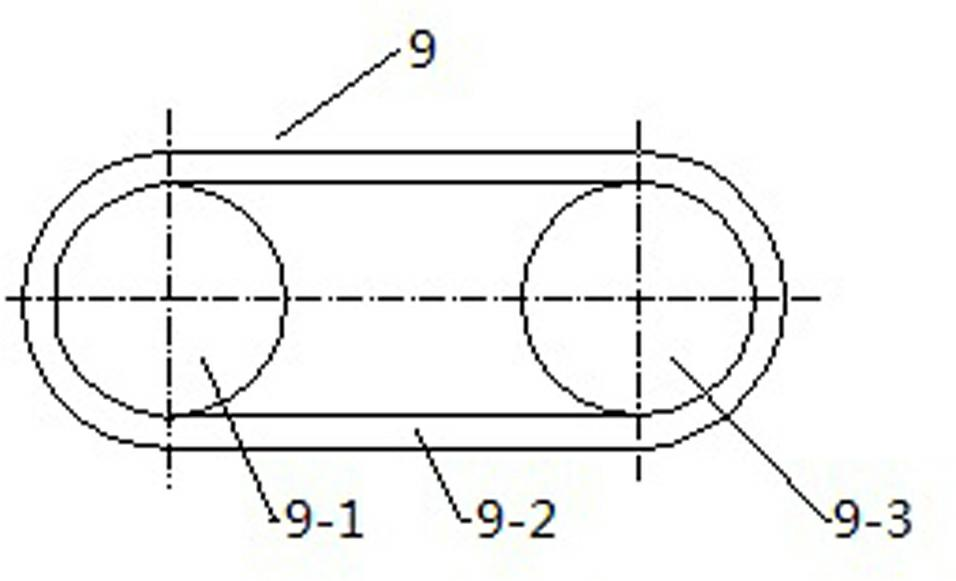

[0025] Examples of vacuum induction furnaces are Figure 2~5 As shown: it includes a furnace body 17, a crucible 13 arranged in the furnace body 17, an intermediate frequency induction coil 12 wound around the periphery of the crucible, and a crucible turning frame 11 fixedly connected to the crucible 13. The vacuum induction furnace also includes a transmission with the crucible turning frame 11. Connected crucible turning device. The crucible turning device includes a transmission shaft 6 mounted on the furnace body 17 through a shaft sleeve 8 that is hermetically sealed and rotated. The extension direction of the rotation axis of the transmission shaft 6 is consistent with the radial direction of the crucible 13. The power output end; the other end is the power input end extending to the outside of the furnace body 17. The crucible turning device also includes a hydraulic cylinder 15 arranged outside the furnace body 17 and connected to the power input end of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com