Method for measuring retention period of tobacco material

A technology of residence time and tobacco materials, which is applied in the field of tobacco processing, can solve the problems of poor test simplicity, manpower consumption, material waste, etc., and achieve the effect of effective marking and easy identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 50 kg of tobacco powder, grind it (fine tobacco powder does not need to be crushed), mix it with 10 kg of defiberized tobacco stem sticks, 20 kg of raw green tea, and 10 kg of fresh lotus leaves, and then add the feed solution (water: phosphoric acid: maltose = 50:1 : 2) 50kg kilograms, and each 80 grams of amylase and protease, fermented at 40~45 ℃ for 3 hours after mixing, after fermentation, material was sent into beater, through beating, dry operation, slitting to get green tobacco flakes. Thin slices cut into 0.8-1.2mm filaments are flakes.

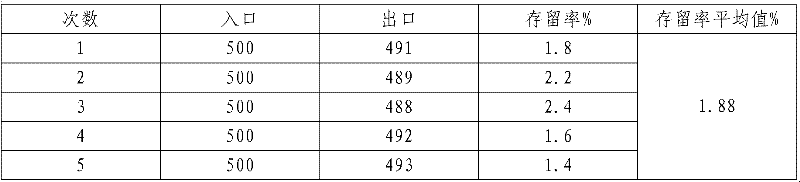

[0017] During the loosening and rehydration stage of Yunyan (Purple) brand cigarette sheets in Kunming Cigarette Factory, the C-line DCRB type Comas loose rehydration equipment has the following normal operation record parameters: material flow rate is 5000kg / h, cylinder speed is 9rpm, return air temperature is 68 ℃, put 500g green tobacco flakes into the equipment inlet (feed port) and start timing in seconds, use the si...

Embodiment 2

[0026] Take 50 kg of tobacco powder, grind it (fine tobacco powder does not need to be crushed), mix it with 10 kg of defibrated tobacco stem sticks, 20 kg of Pu'er tea, 3 kg of fresh bayberry juice, and 3 kg of fresh watermelon juice, then add the feed liquid (water: phosphoric acid: Maltose = 50:1:2) 40kg kg, and 80g each of amylase and protease, after mixing, let it soak for 3 hours at 40-45°C. Get red tobacco flakes. Thin slices cut into 0.8-1.2mm filaments are flakes.

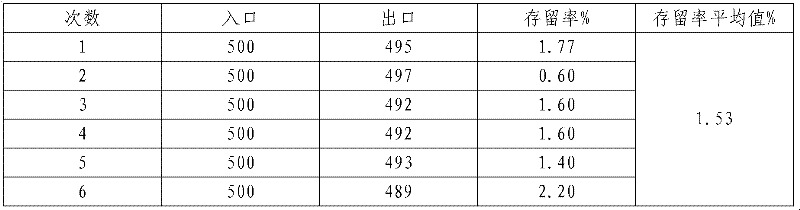

[0027] In the drying stage of Yunyan (soft treasure) brand cigarette leaves in Kunming Cigarette Factory, the KLD-2Z two-stage shredded leaf drying equipment of Hauni Company on Line B has the following normal operation record parameters: material flow rate 5000kg / h, cylinder rotation speed 12rpm , the hot air temperature is 120°C, the cylinder wall temperature in the first zone is 125°C, and the cylinder wall temperature in the second zone is 145°C. Put 500g of red tobacco flakes at the inlet end (feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com