Glass disk forming machine

A molding machine and wafer technology, applied in glass molding, glass production, glass manufacturing equipment, etc., can solve problems such as complex structure, and achieve the effect of simple overall structure, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

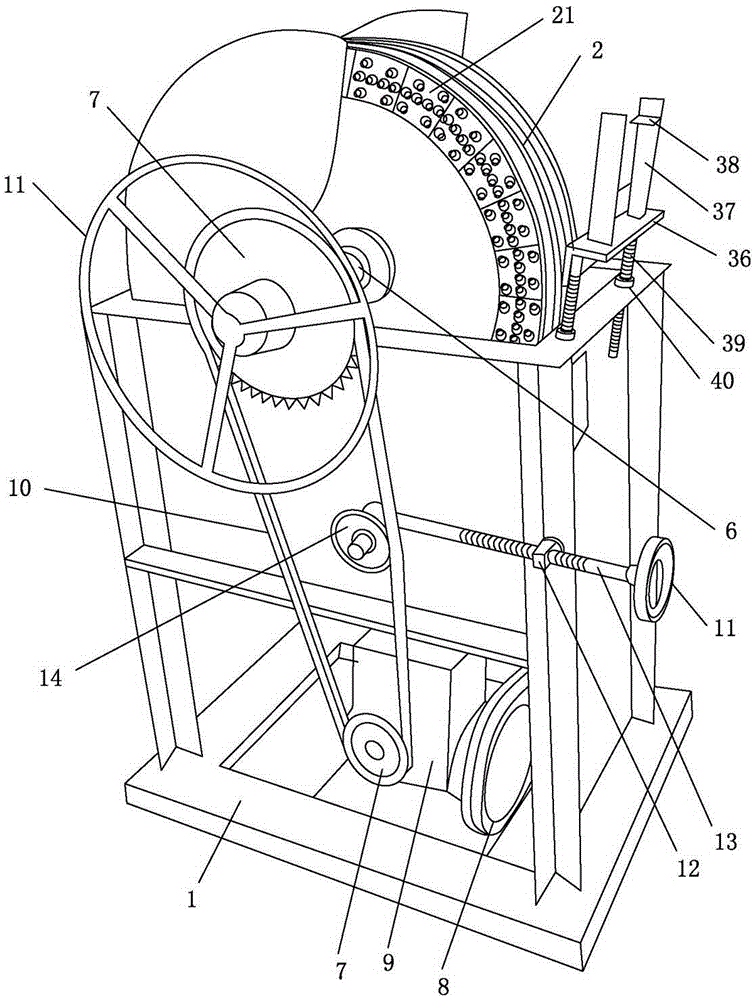

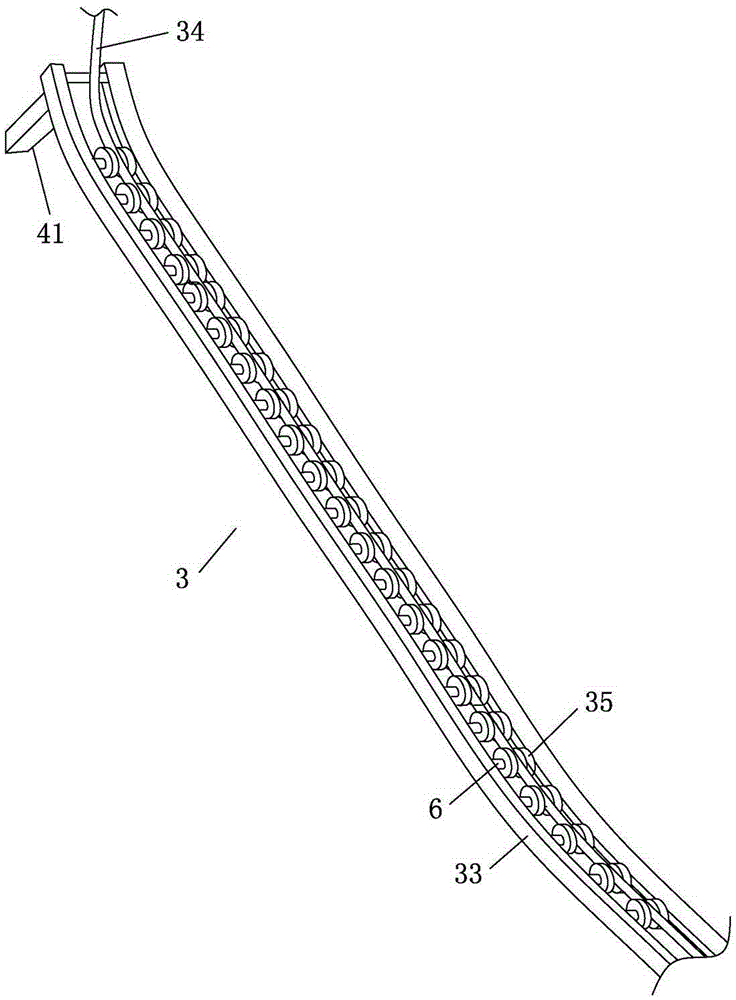

[0028] Glass wafer forming machines, such as Figure 1 to Figure 9 As shown, it includes a base 1, a disc 2 is rotatably connected to the base 1, a feed delivery device 3 for transporting semi-condensed glass melt 34, a scraper device 4 for scraping off residual glass, The lower part of the base 1 is located below the disc 2 and is provided with a sloping plate 52 through which the formed glass wafer can enter the next process.

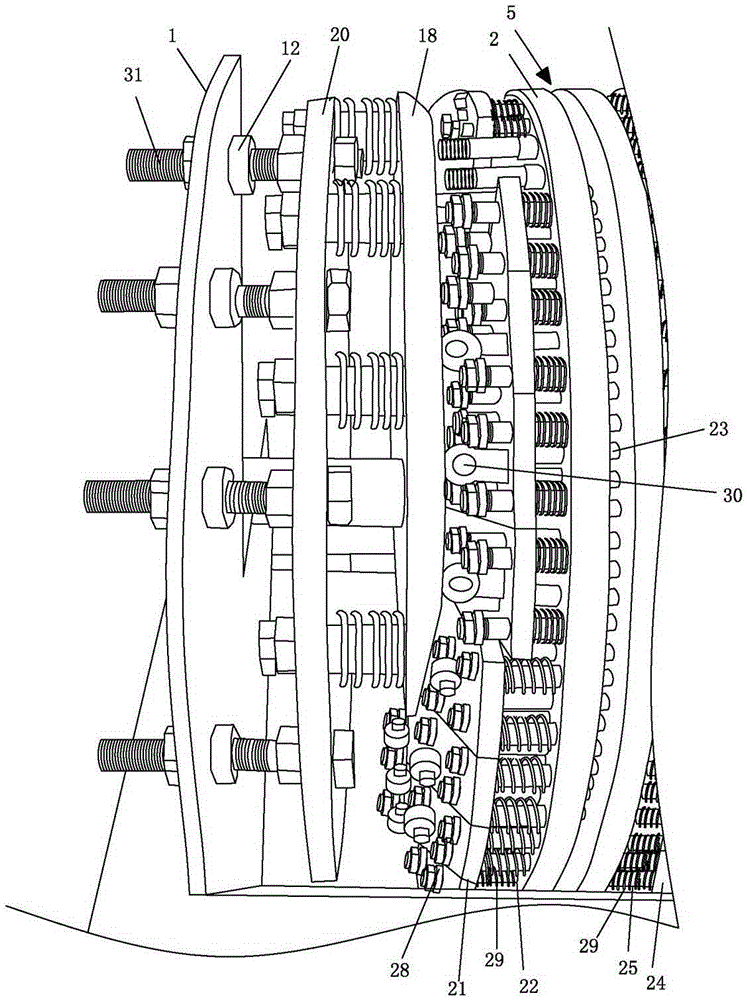

[0029] The circumferential surface of the disk 2 is provided with an annular trough 5, and the outer side of the disk 2 is provided with a plurality of mold units arranged in a ring; The thimble 26 on the other side of the disc 2, the die 15 that is arranged on the side wall of the annular trough 5; one end of the punch 23 stretches out from the disc 2, and the other end of the punch 23 is aligned with the die 15; one end of the thimble 26 extends Out of the disc 2, the other end of the thimble 26 extends into the die 15; the base 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com