Patents

Literature

138 results about "Glass disc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

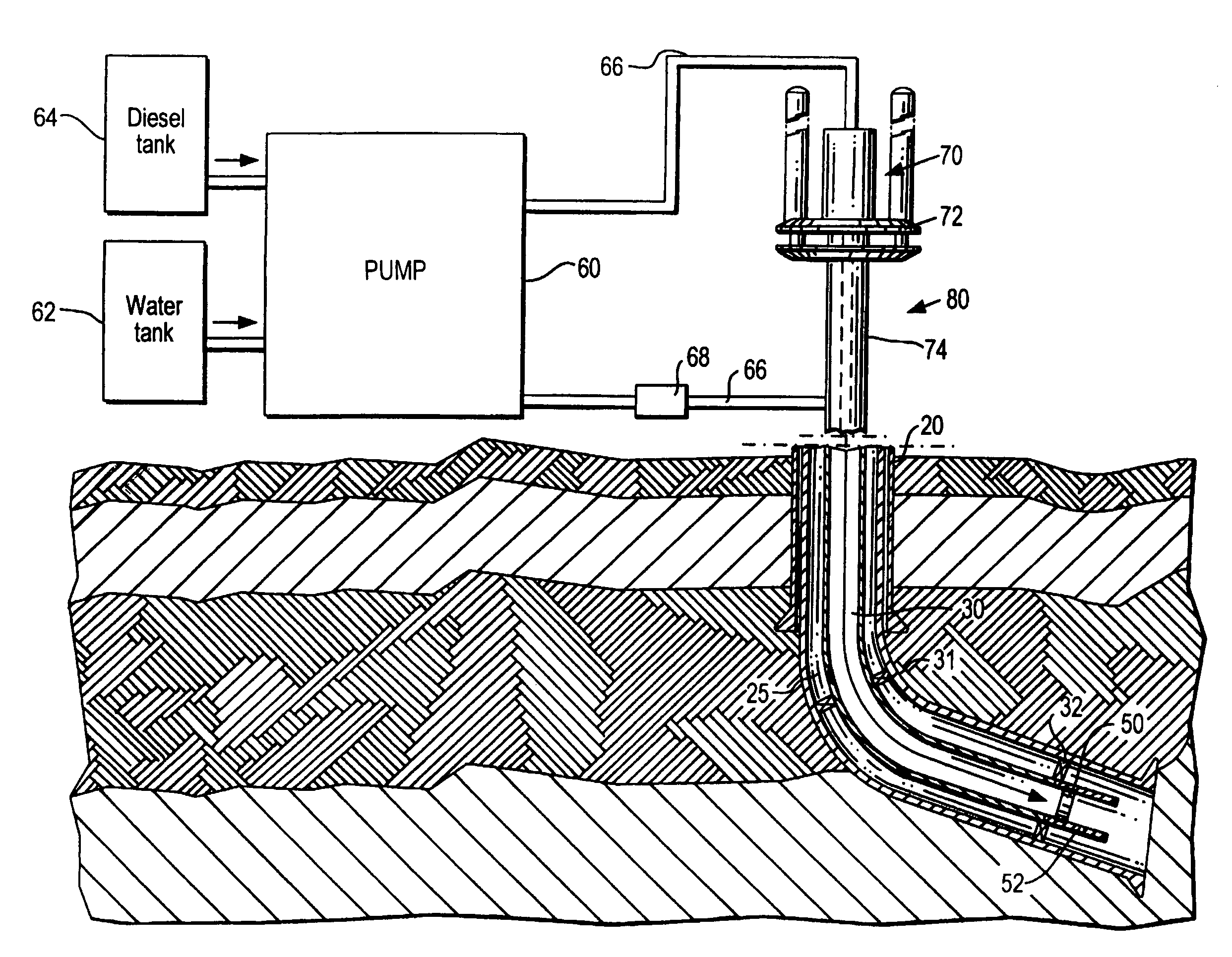

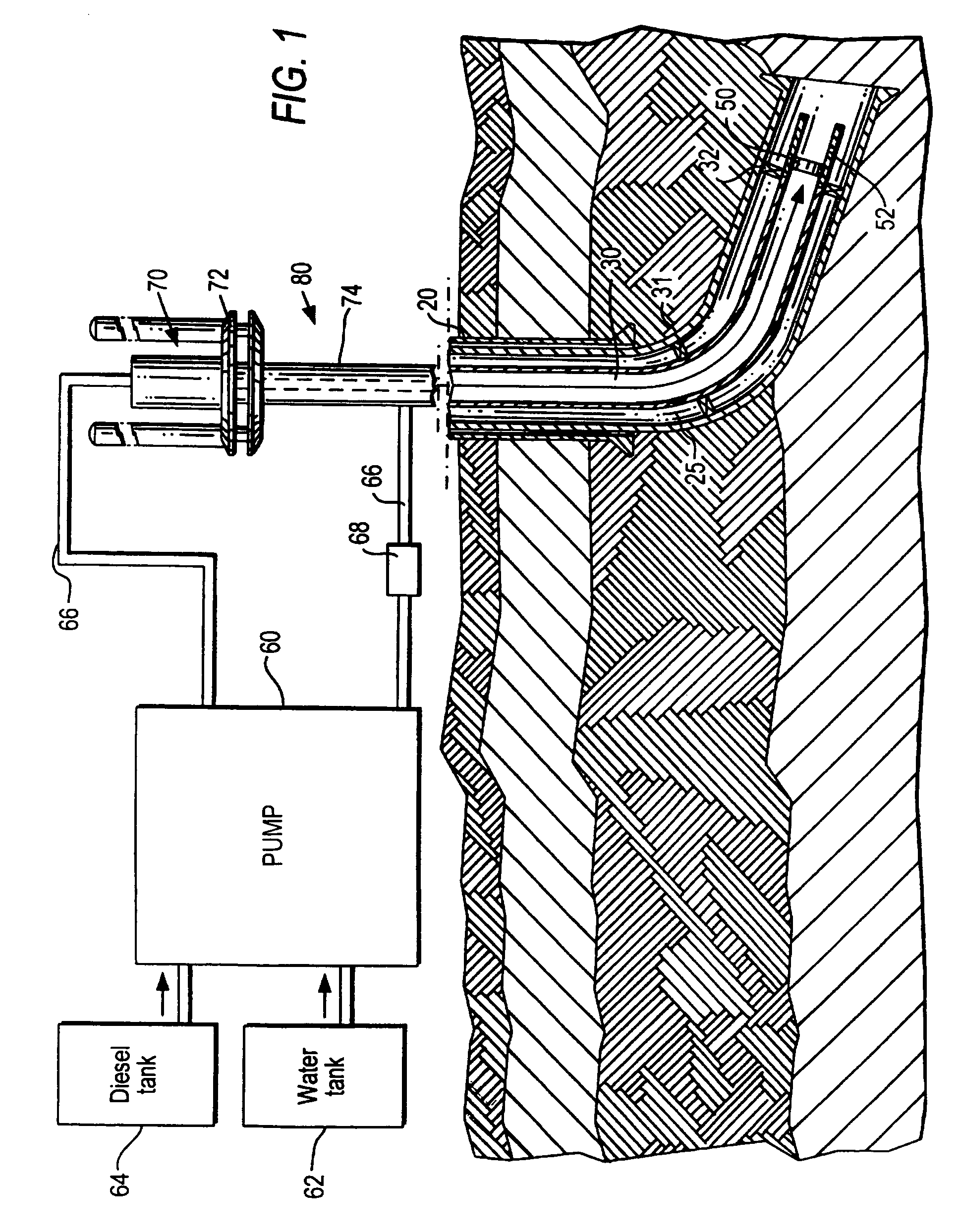

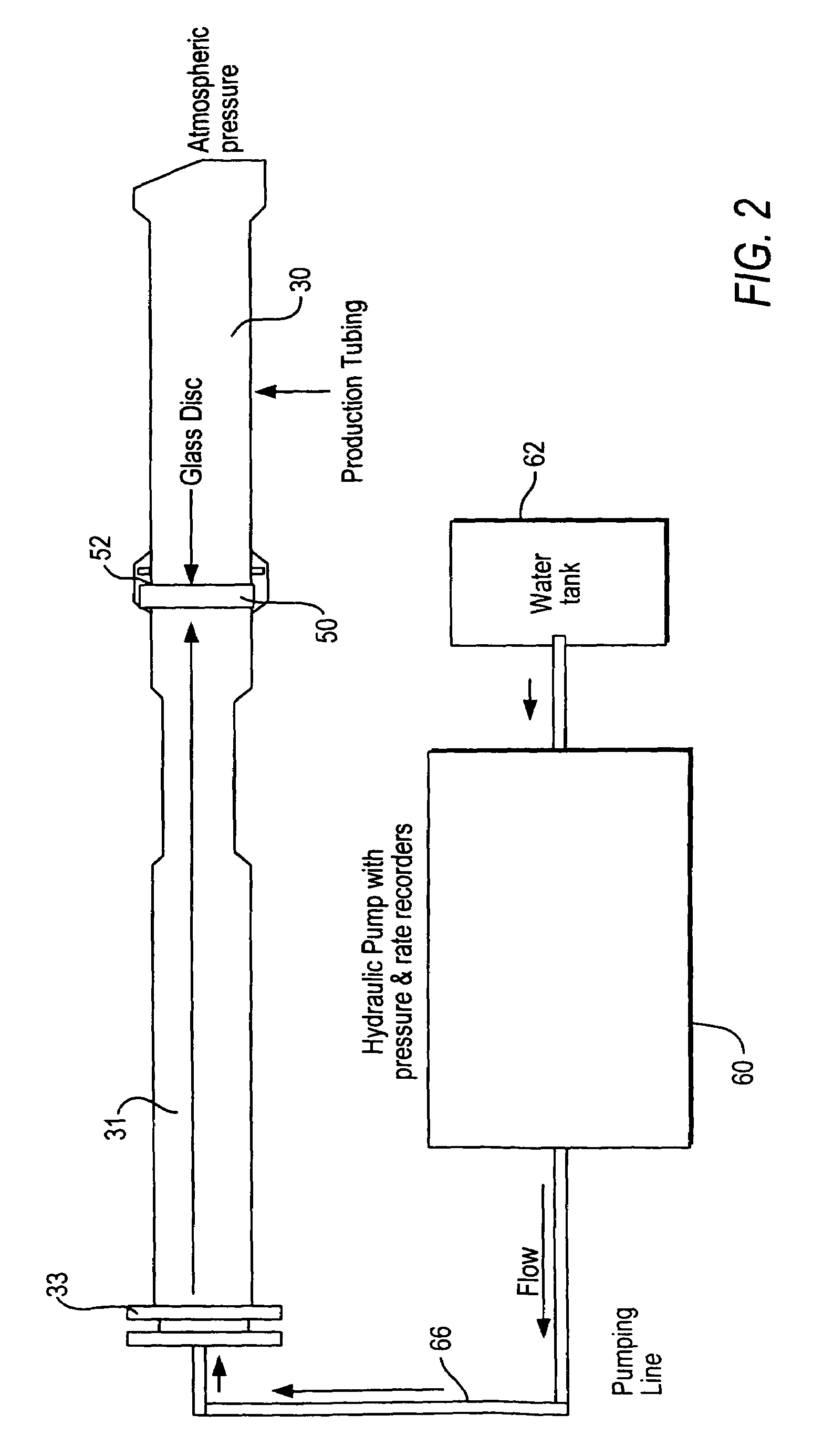

Method for hydraulic rupturing of downhole glass disc

A method for rupturing a glass disc in a well completion tool located downhole in a section of production tubing includes providing a wellhead isolation tool, or tree saver, to isolate the wellhead Christmas tree, adding a pressurized fluid to the tubing / casing annulus and pumping a disc rupturing fluid into the production tubing via the tree saver until the disc is ruptured. Following rupture, the pump can be rapidly stopped, or slowed, and started to create a water hammer effect that removes any glass shards remaining in the disc holder.

Owner:SAUDI ARABIAN OIL CO

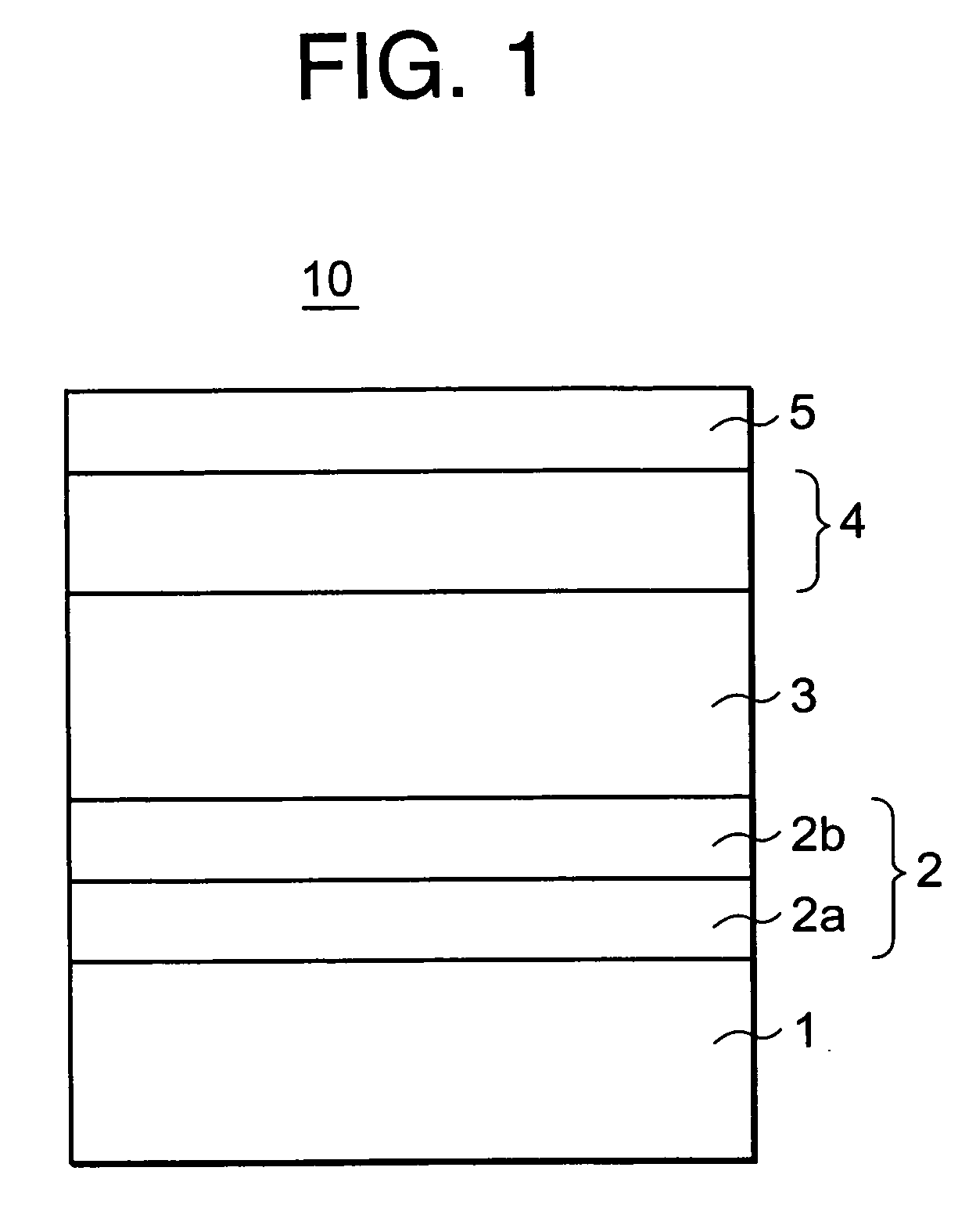

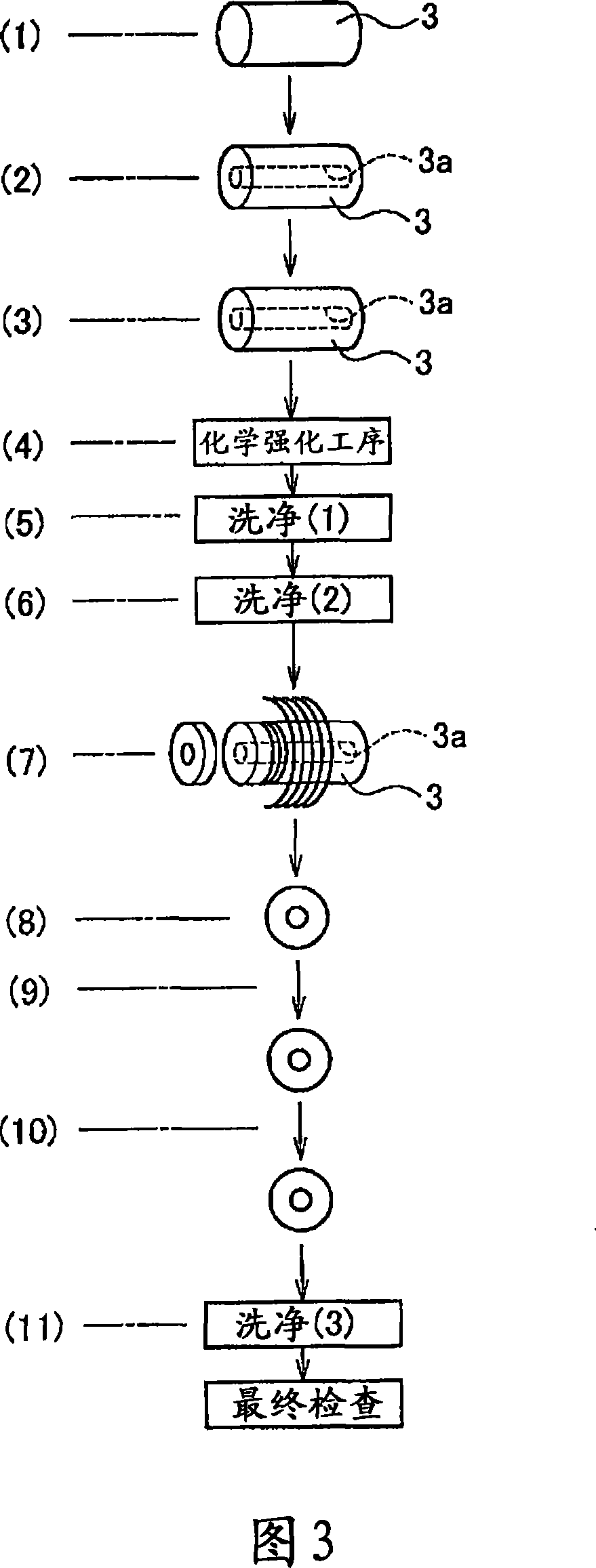

Chemical strengthening treatment method of magnetic disk glass substrate

InactiveUS20070039353A1Low priceLiquid surface applicatorsBase layers for recording layersCompound (substance)Materials science

Chemical strengthening treatment is performed by first providing a granular chemical strengthening salt so as to prevent spread in atmosphere at the time of introduction of chemical strengthening salt in a treating vessel, introducing the chemical strengthening salt in a treating vessel, melting the chemical strengthening salt into molten chemical strengthening salt and bringing a glass disc into contact with the molten chemical strengthening salt. The granular chemical strengthening salt is, for example, one obtained by forming of a powdery chemical strengthening salt material into grains. A chemically strengthened glass substrate for magnetic disk can be obtained through the process of carrying out chemical strengthening treatment of magnetic disk glass substrates. A magnetic disk can be obtained by forming at least a magnetic layer on the chemically strengthened glass substrate for magnetic disk.

Owner:HOYA CORP

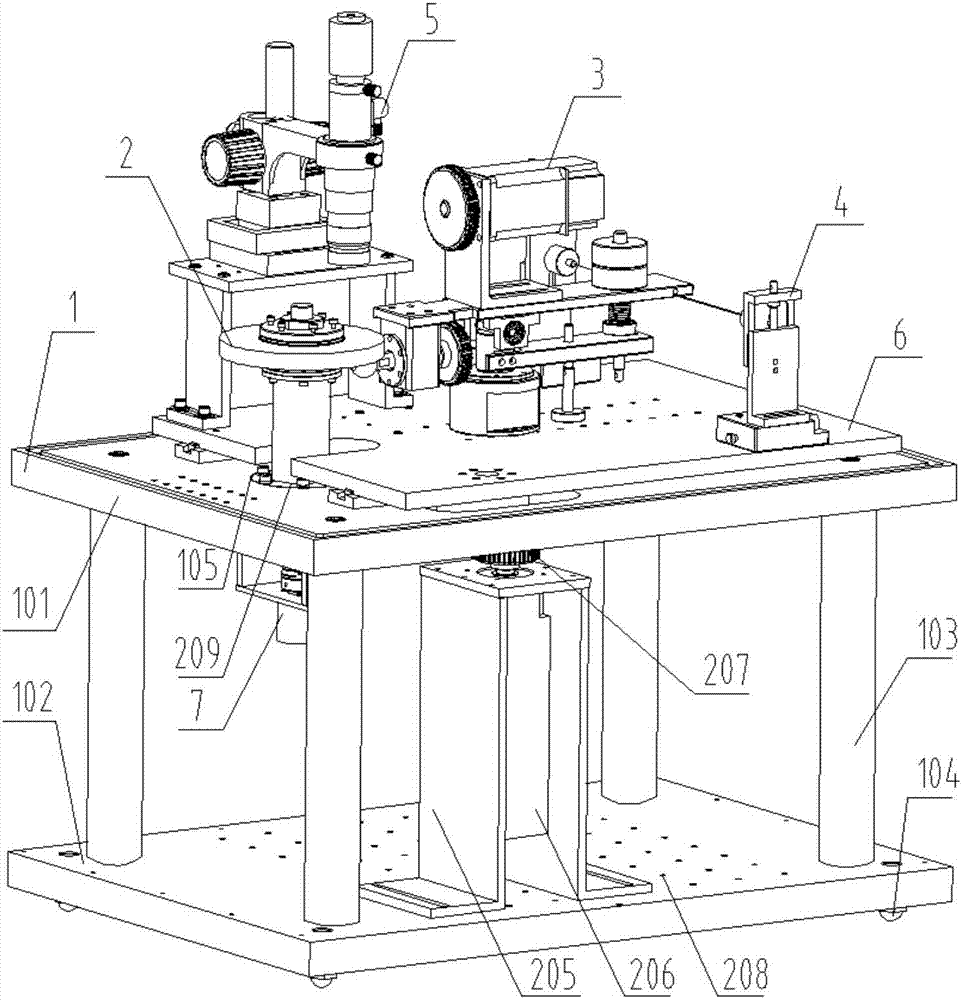

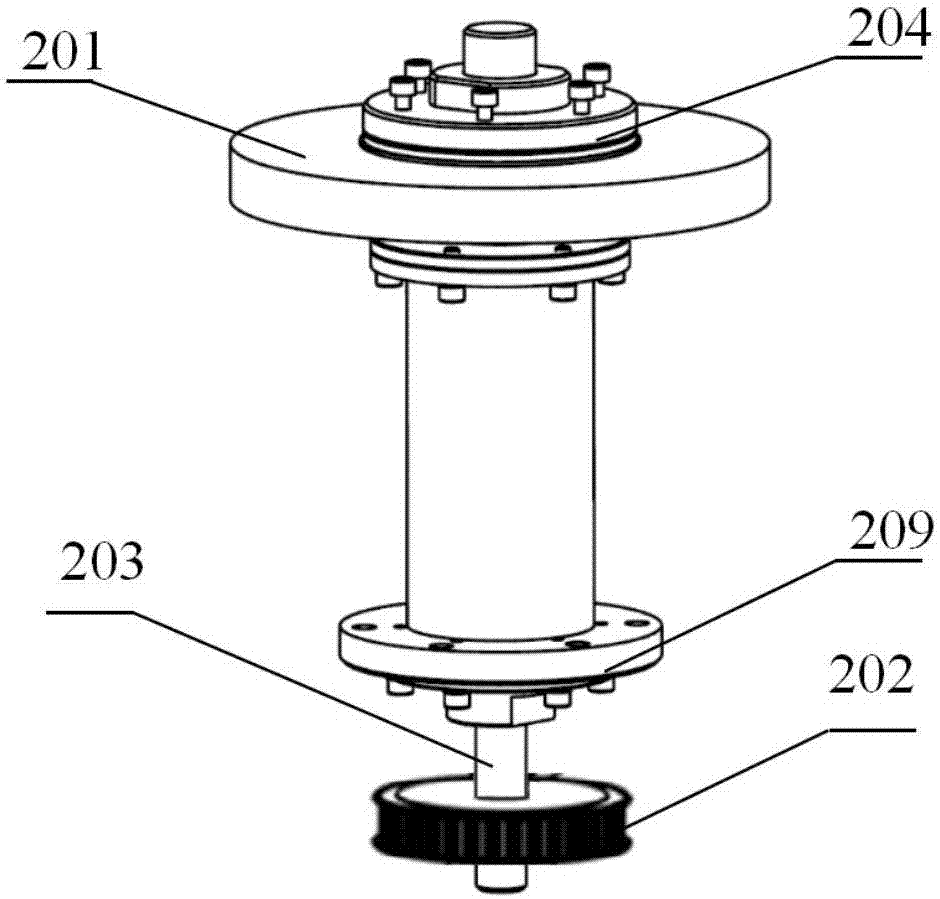

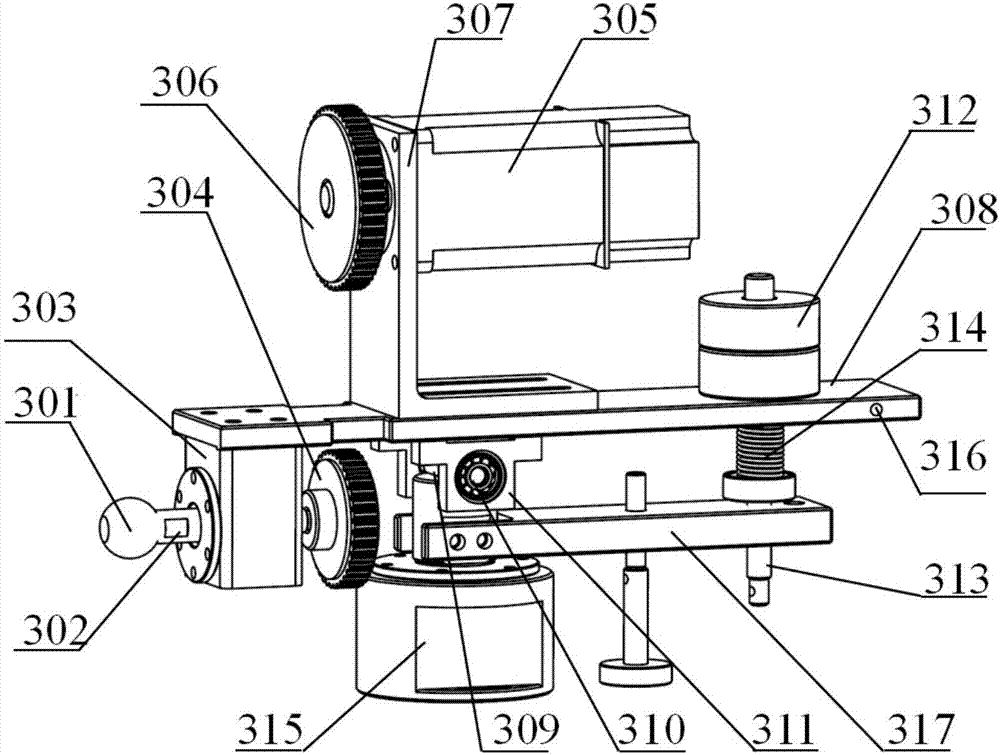

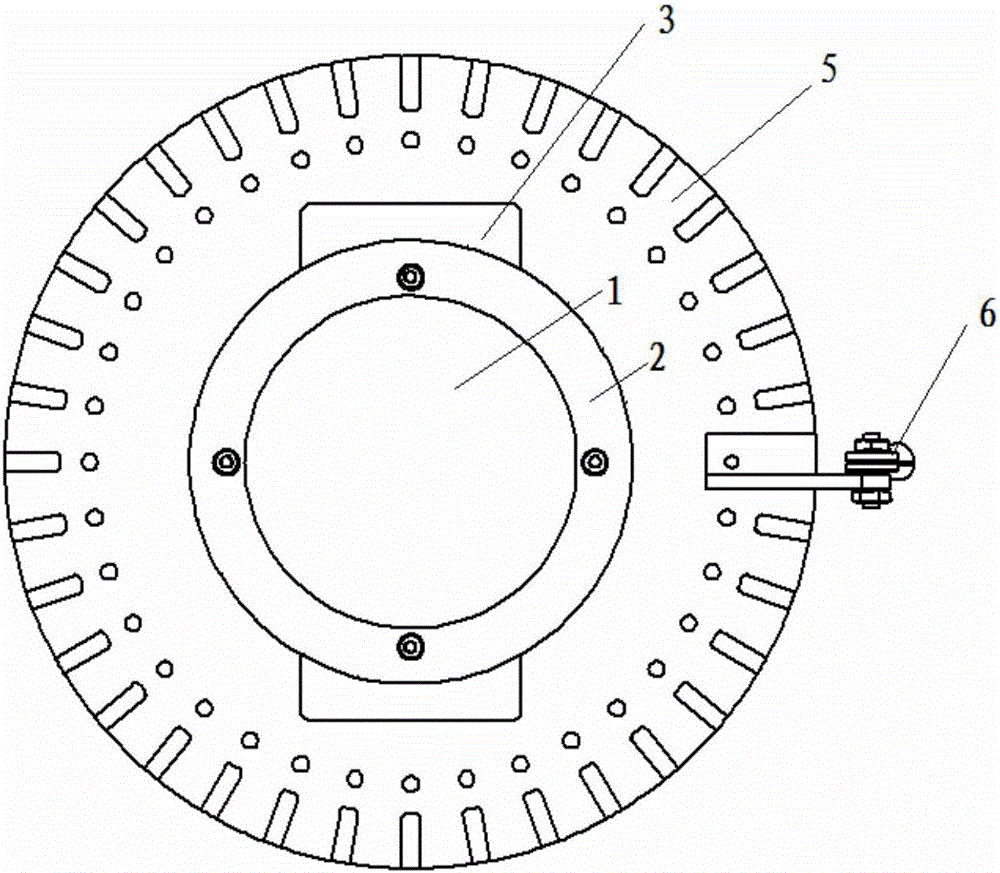

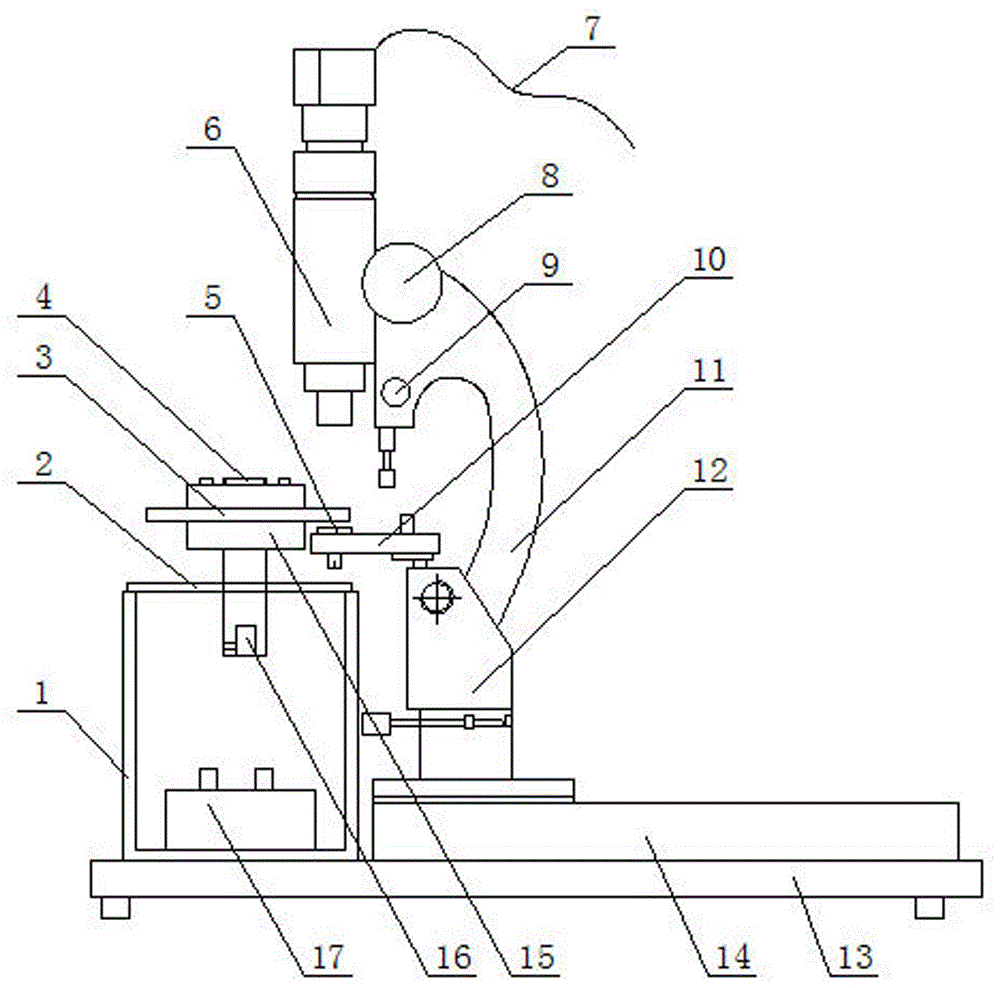

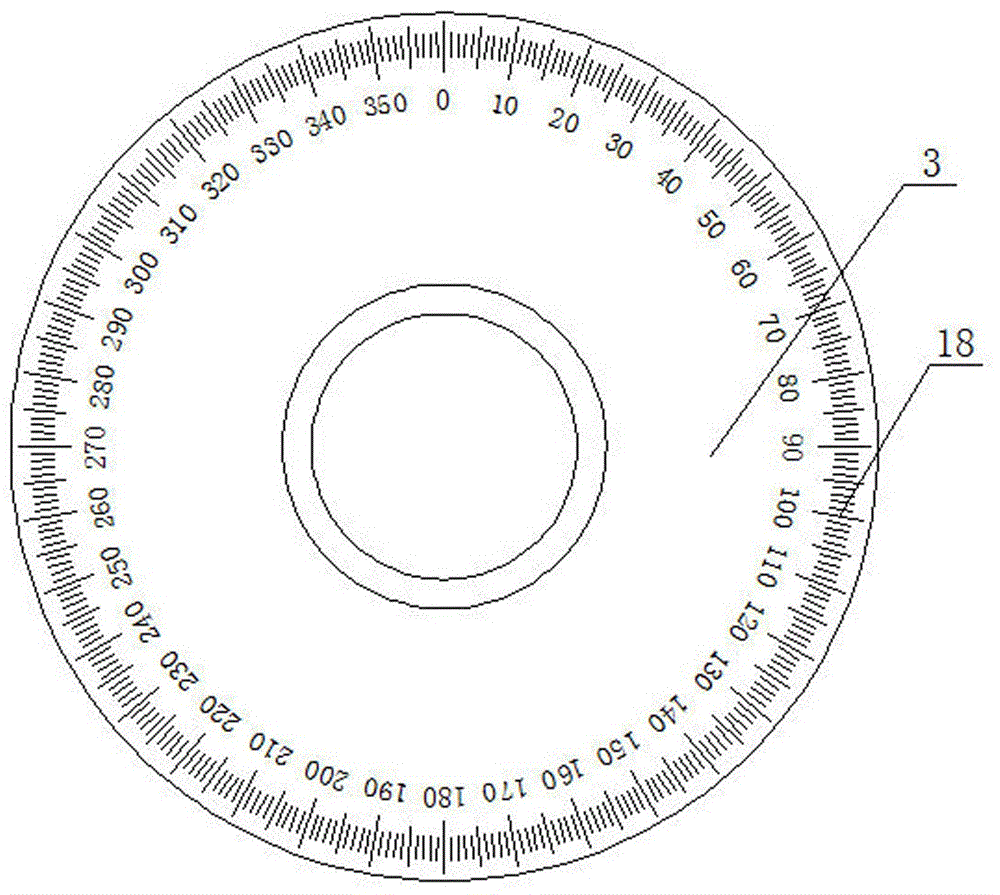

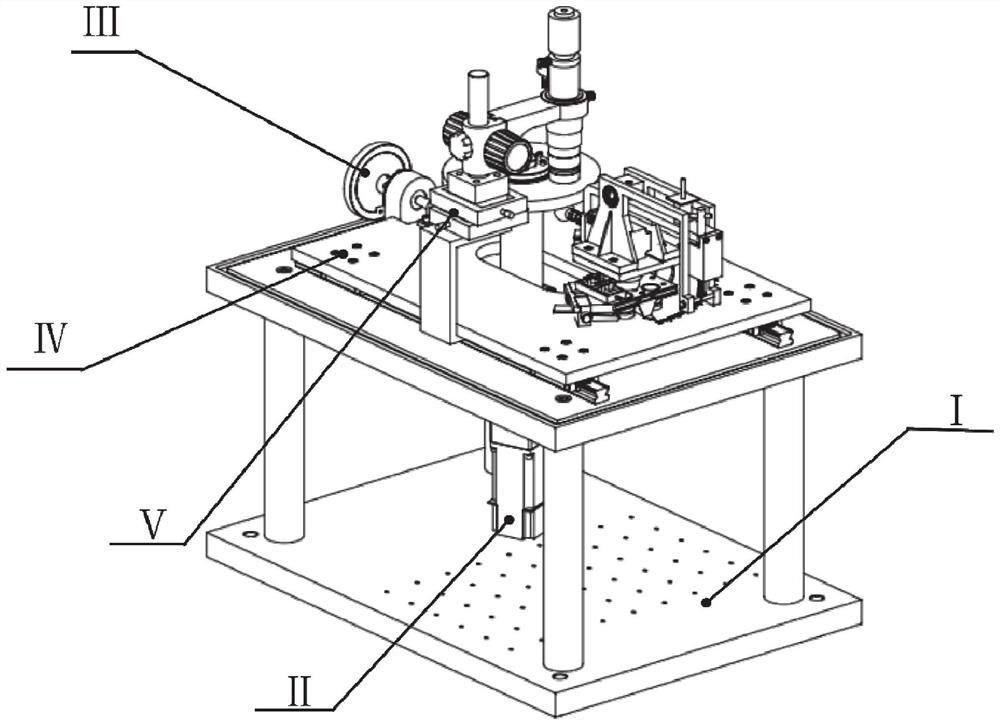

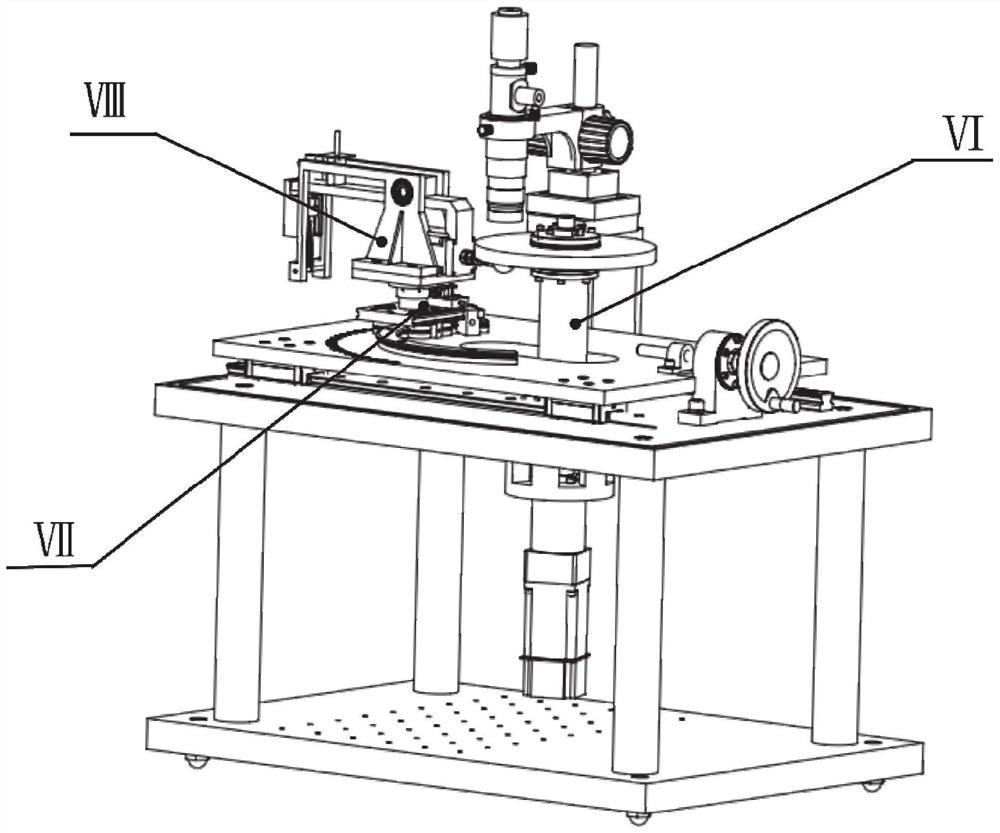

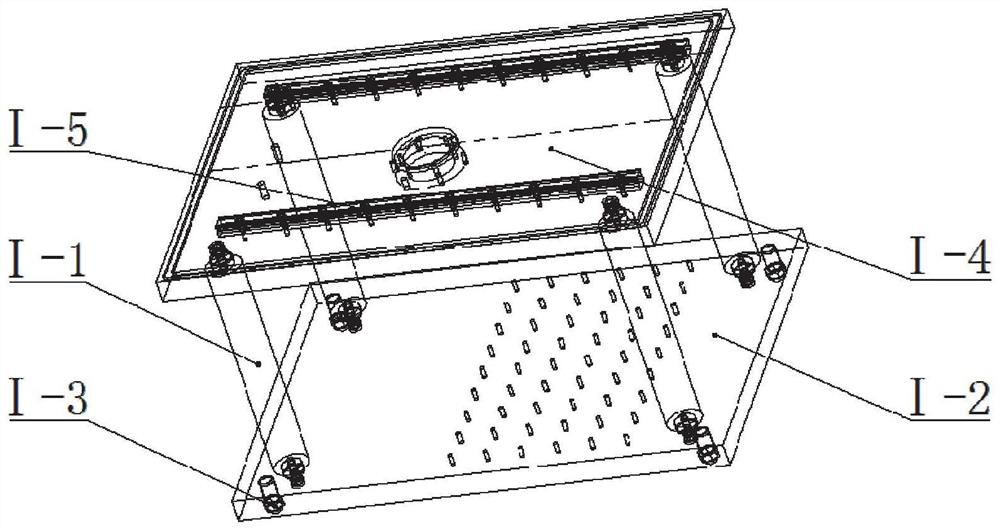

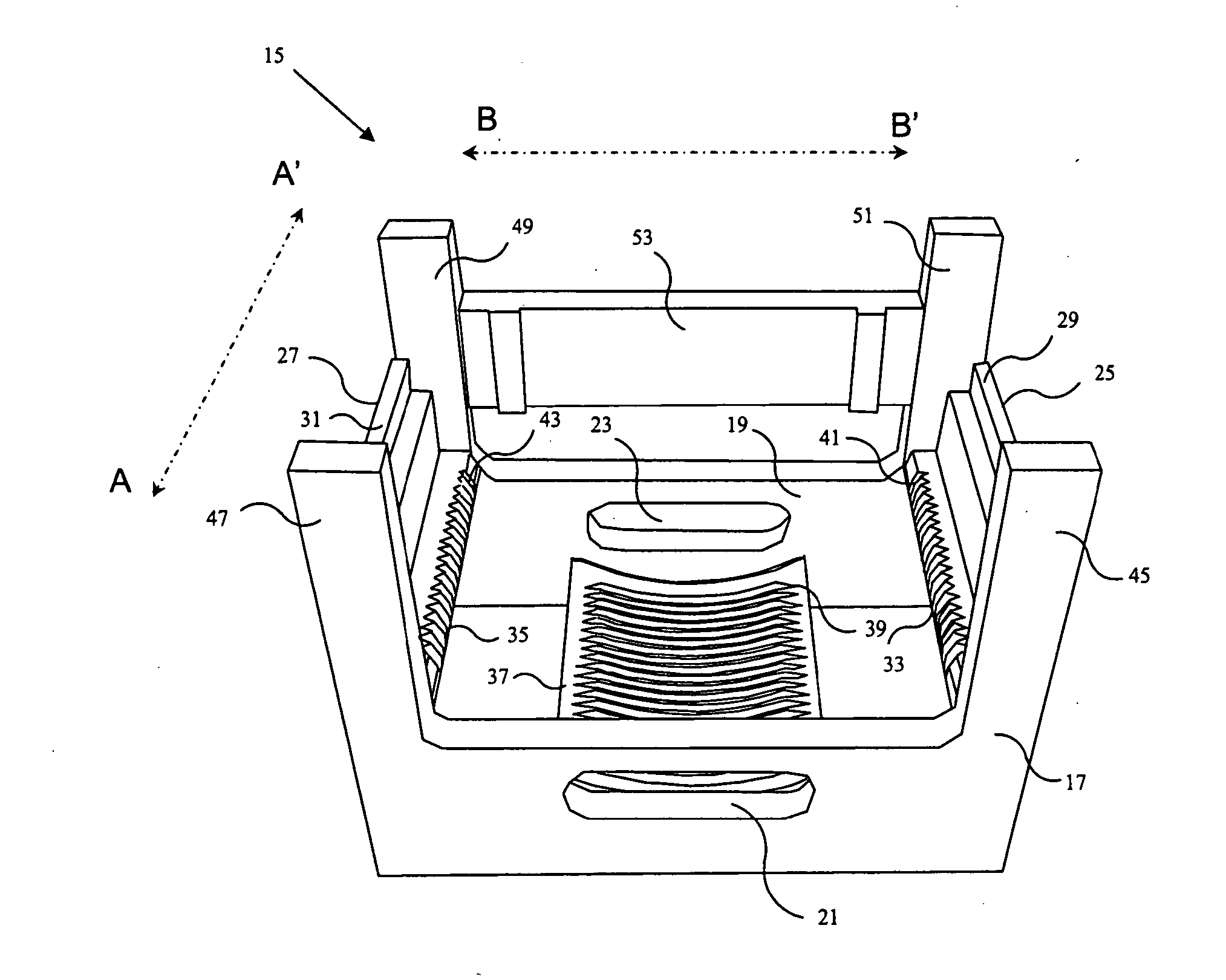

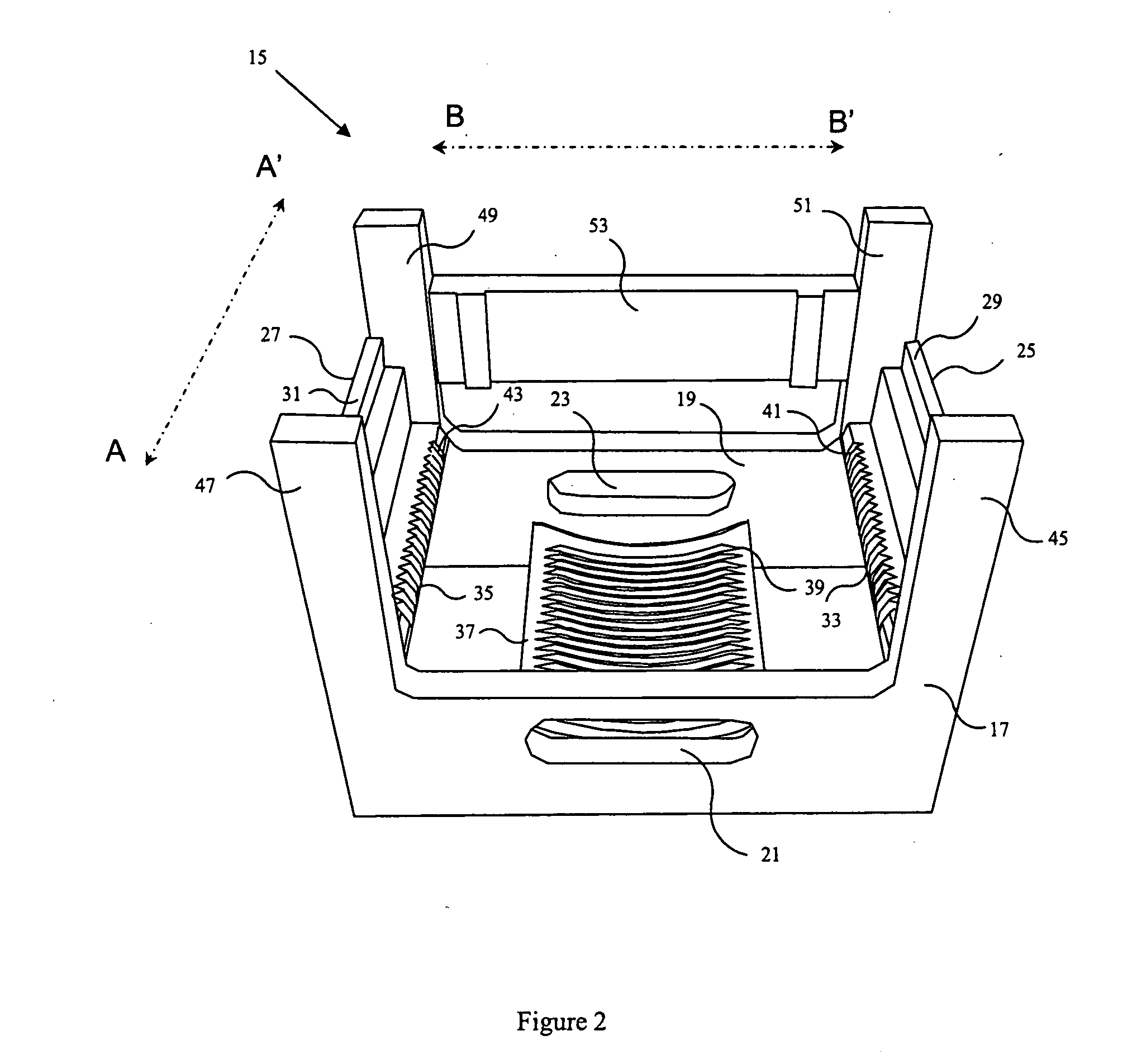

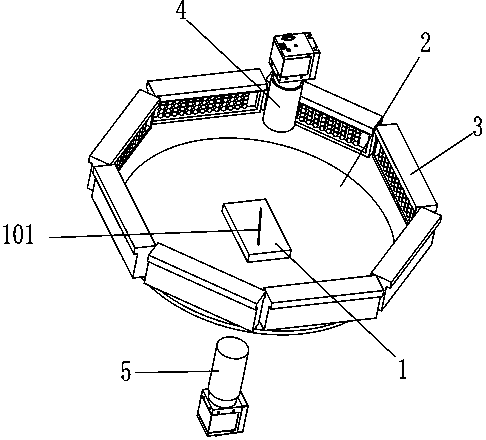

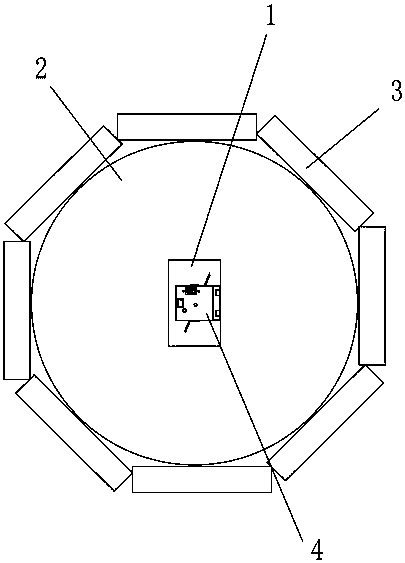

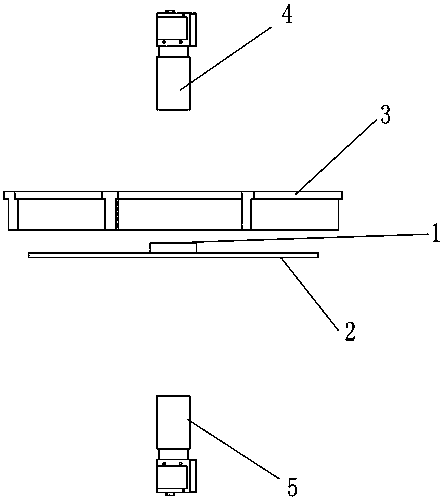

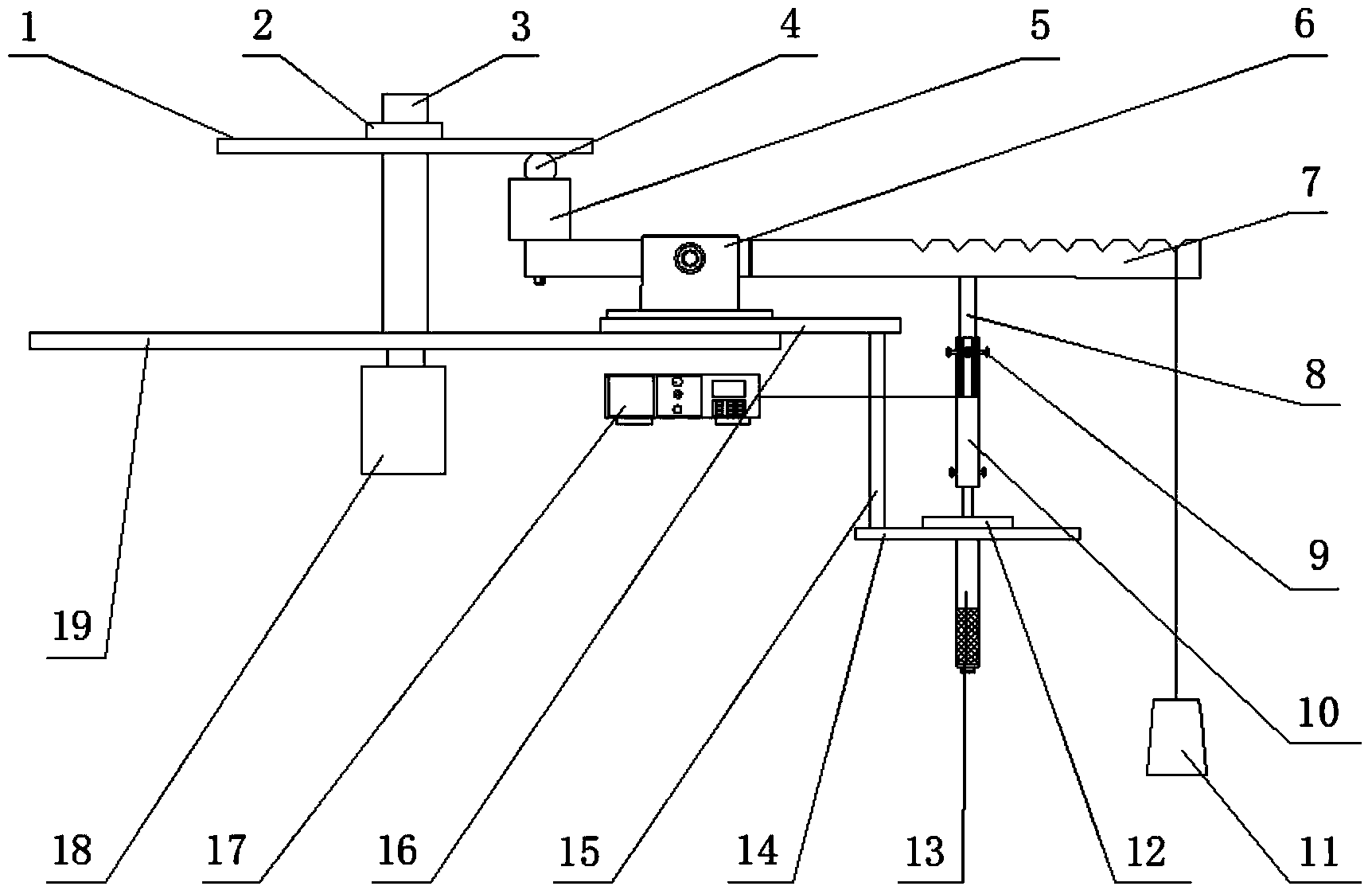

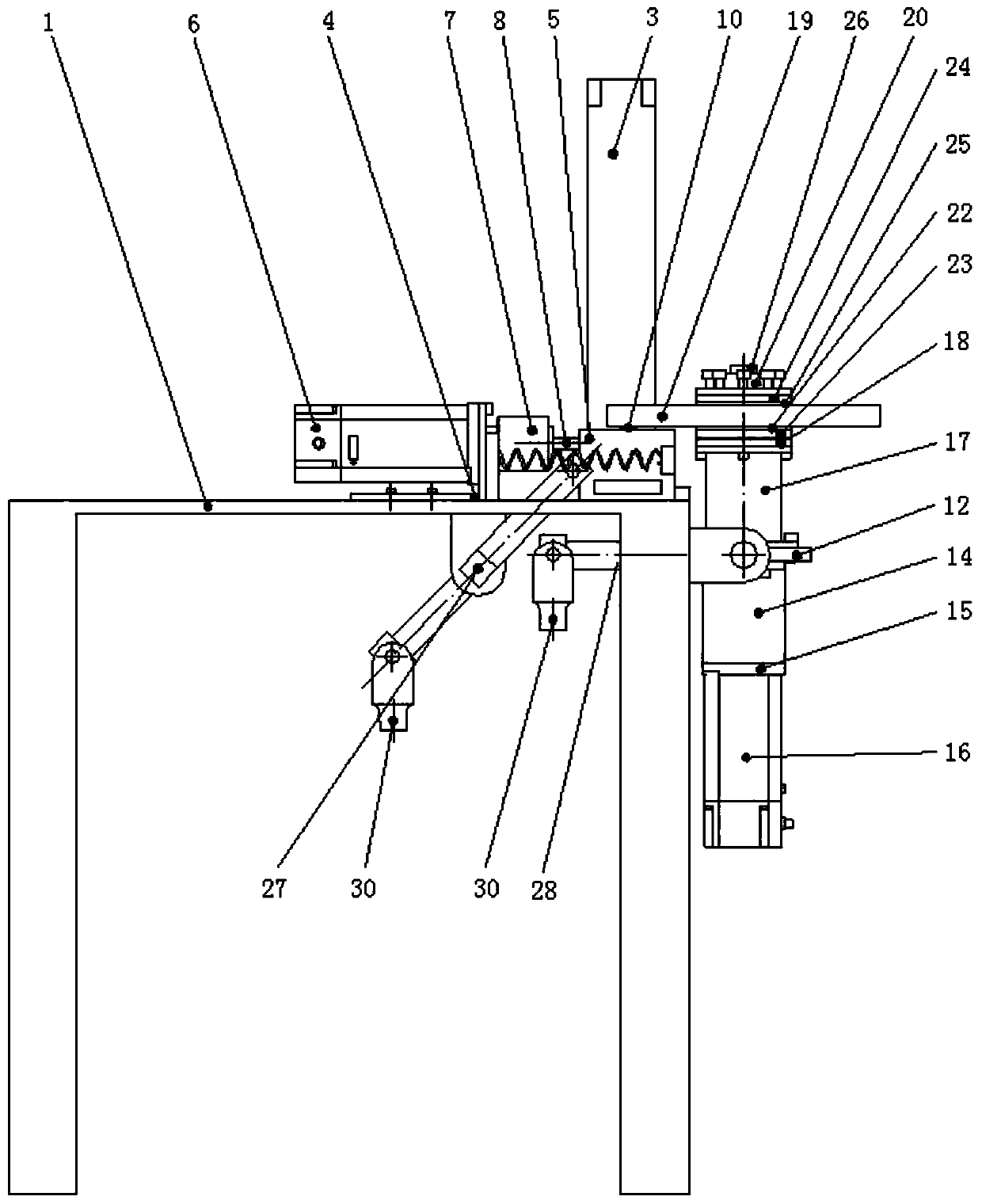

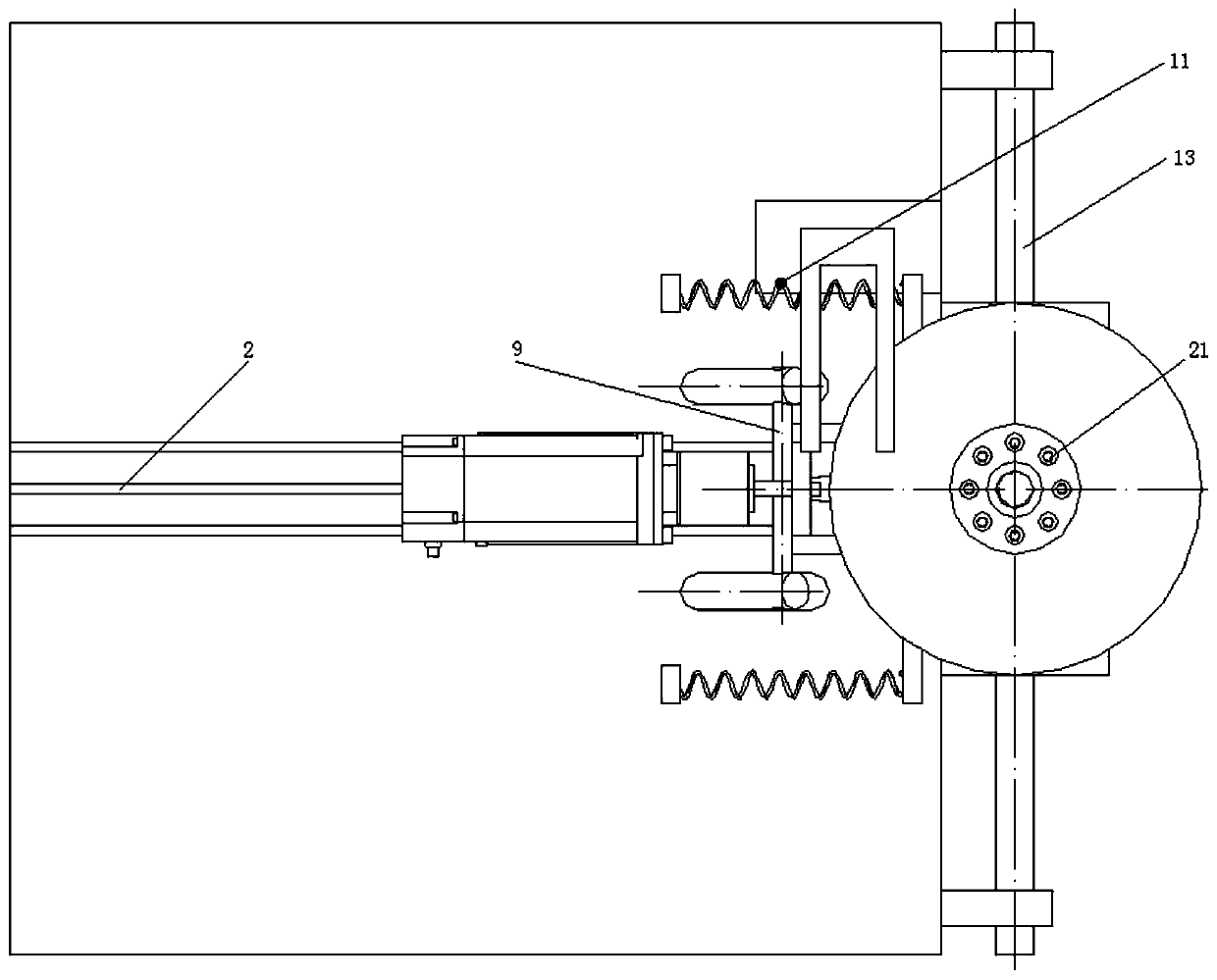

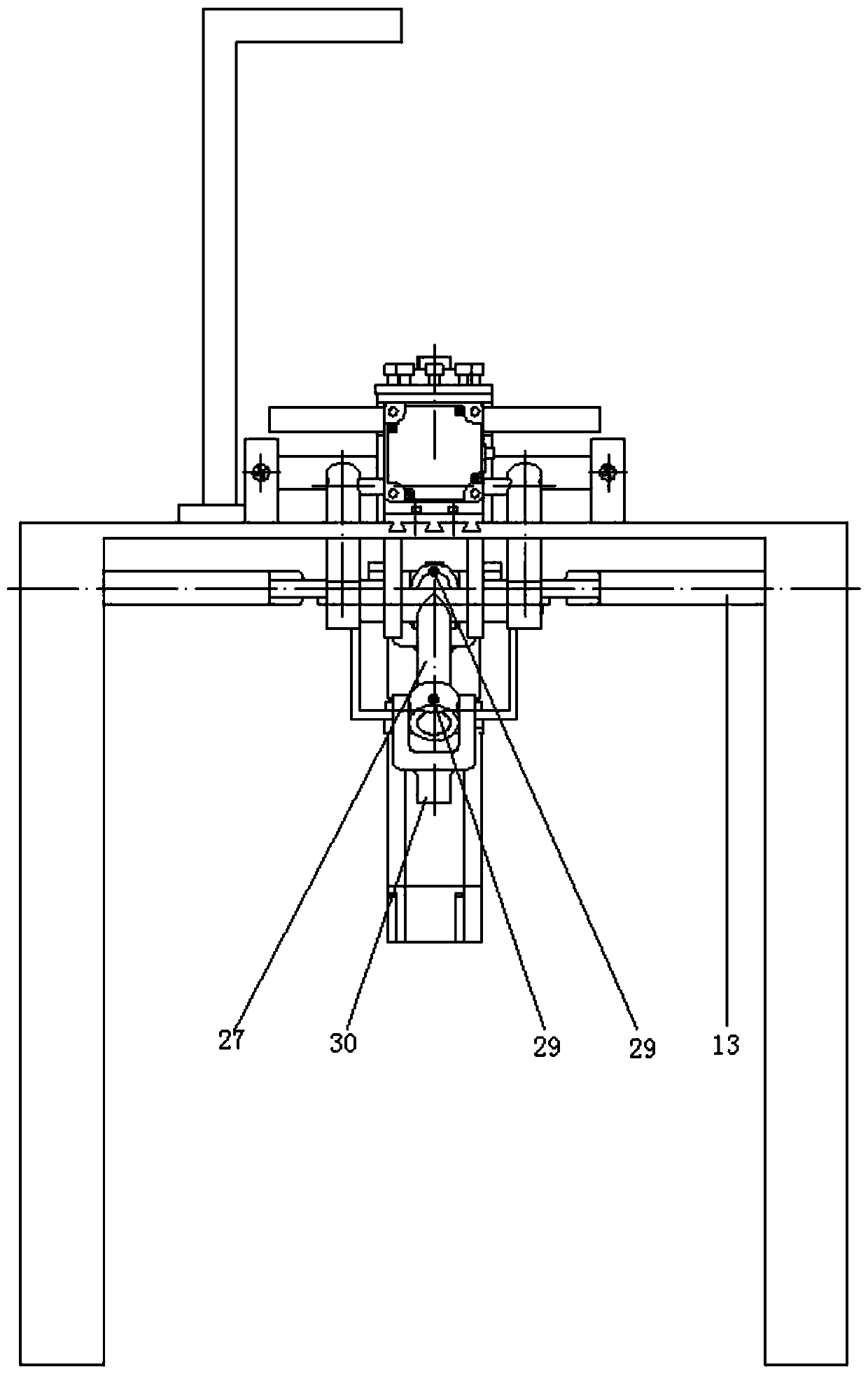

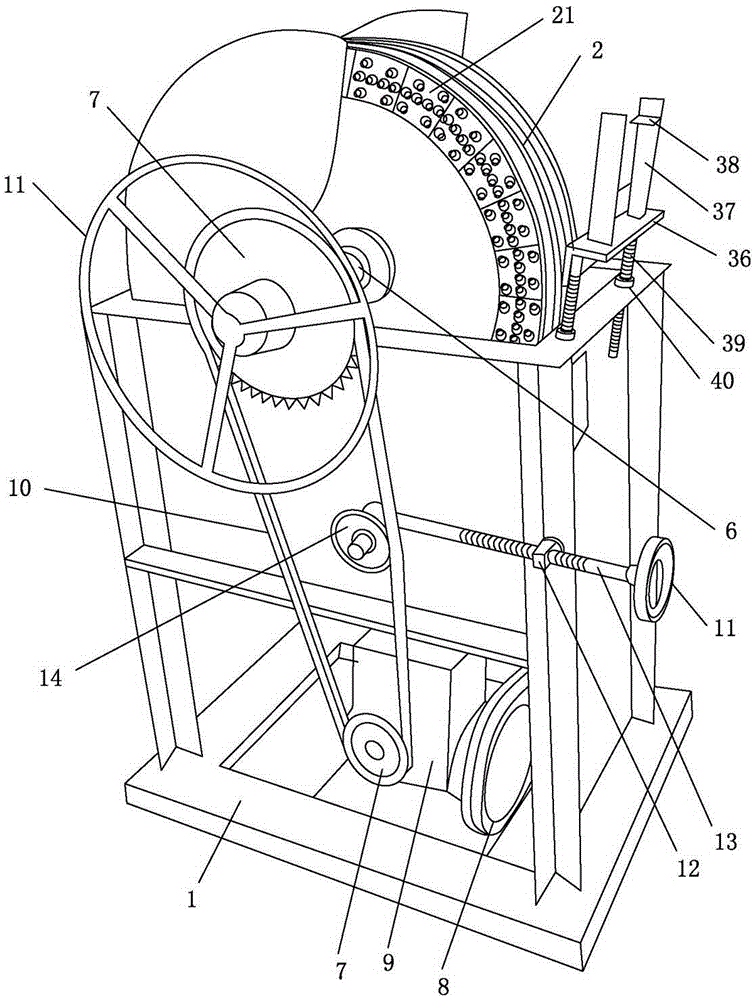

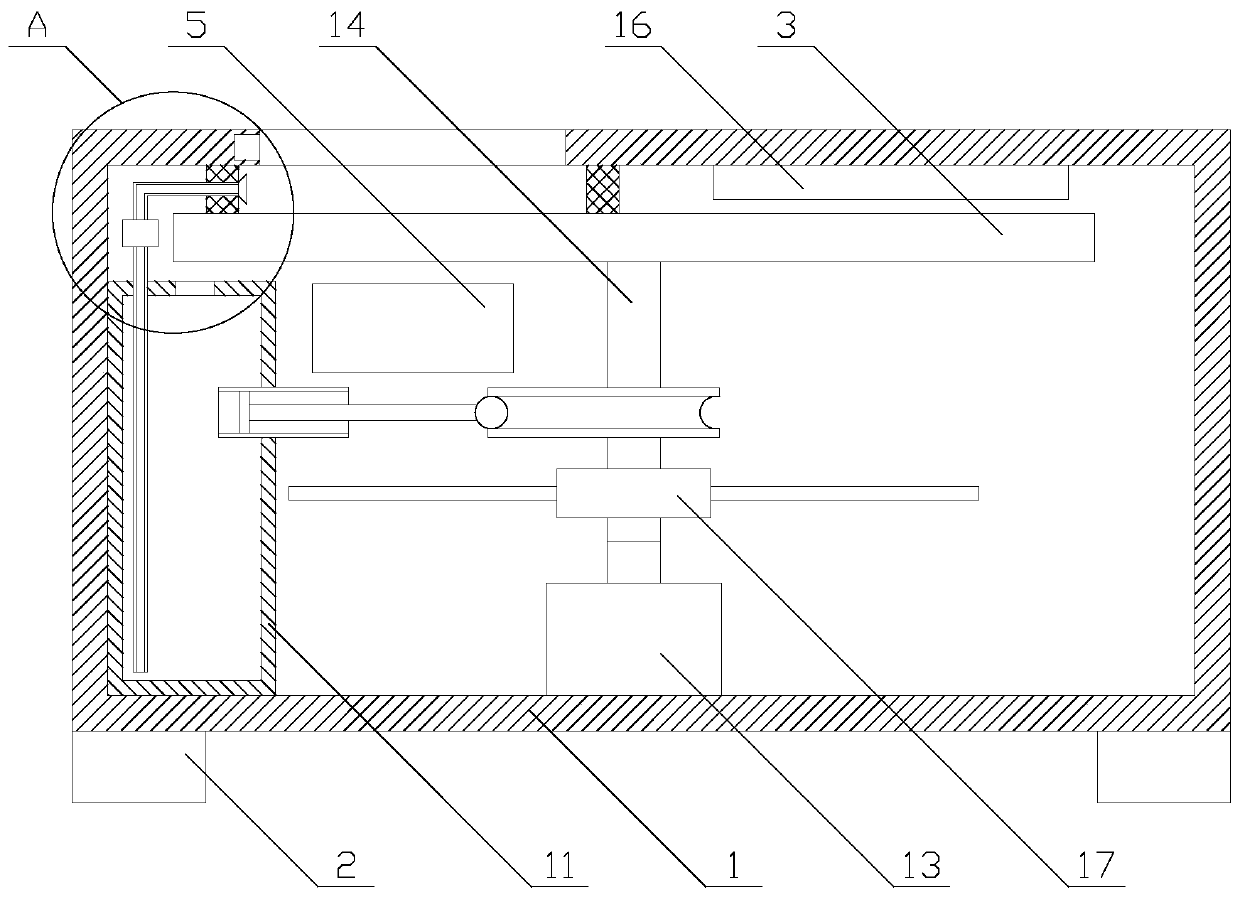

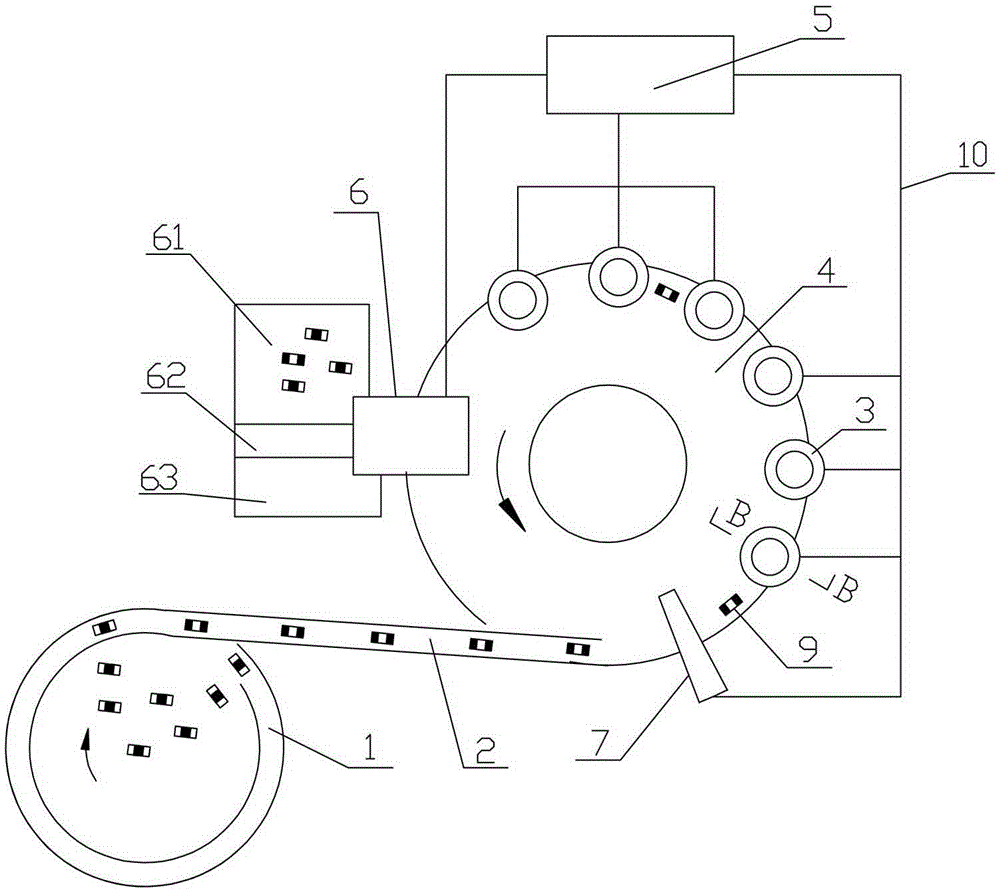

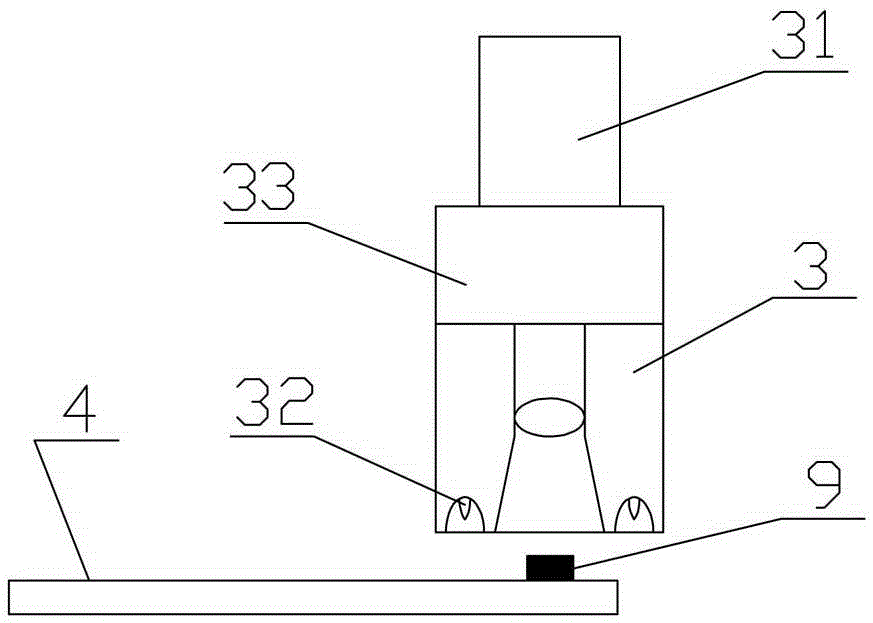

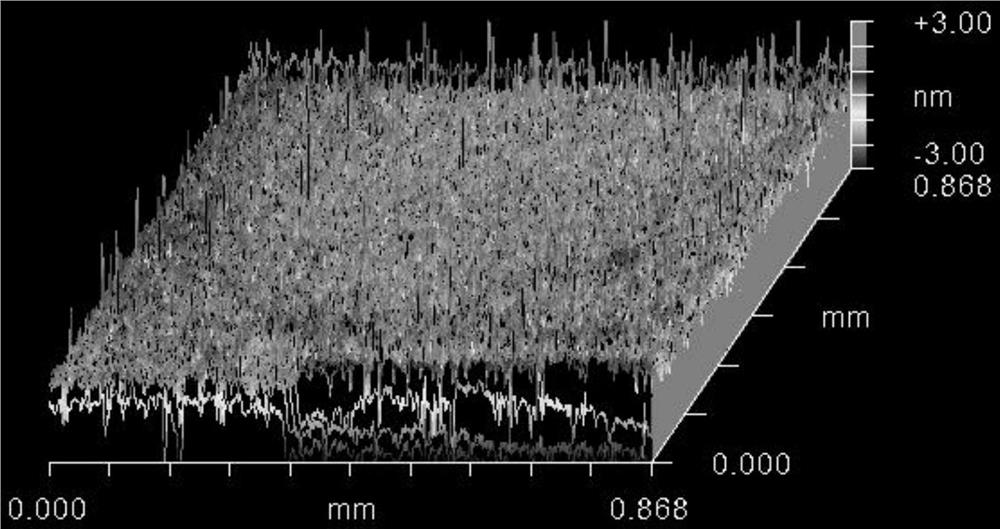

Higher-pair contact variable sliding-rolling ratio oil film thickness and friction simultaneous measurement simulation device

ActiveCN107228629AImprove accuracyGood repeatabilitySustainable transportationUsing mechanical meansCircular discElectric machinery

The invention belongs to the higher-pair point / line contact elastohydrodynamic oil film thickness and friction measurement field and relates to a high-stress contact variable sliding-rolling ratio oil film thickness and friction and simultaneous measurement simulation device. The main body structure of the device includes a supporting platform, a disc driving device, a ball driving, loading and rotating device, sensor fixing and adjustment devices, an image acquisition device, a translation device and a speed measuring device; the upper side of the supporting platform is provided with the disc driving device near the left edge of the supporting platform; the disc driving device is used for driving a glass disc to rotate through a disc driving motor; the ball driving, loading and rotating device is located behind the disc driving device; the sensor fixing and adjustment devices are fixedly arranged at the front end and rear end of the right edge of the translation device; and the image acquisition device is fixedly arranged near the rear part of the left edge of the translation device and is used for acquiring the movement information of the glass disc and a steel ball. The device of the invention has the advantages of simple main structure, ingenious design, accurate measurement result, simple and convenient operation, scientific principles, convenient and flexible use, high practicability, good application environment and bright market prospect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

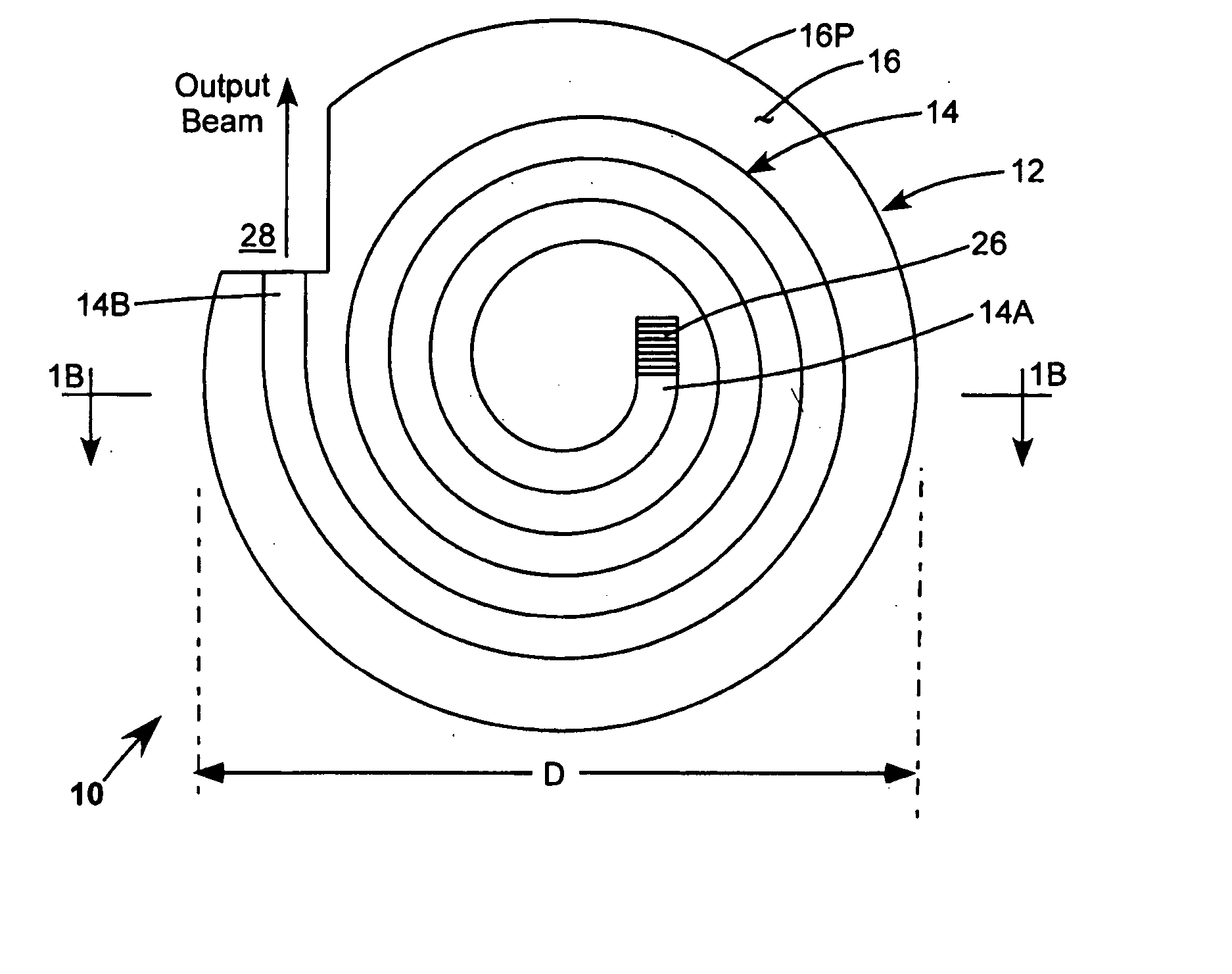

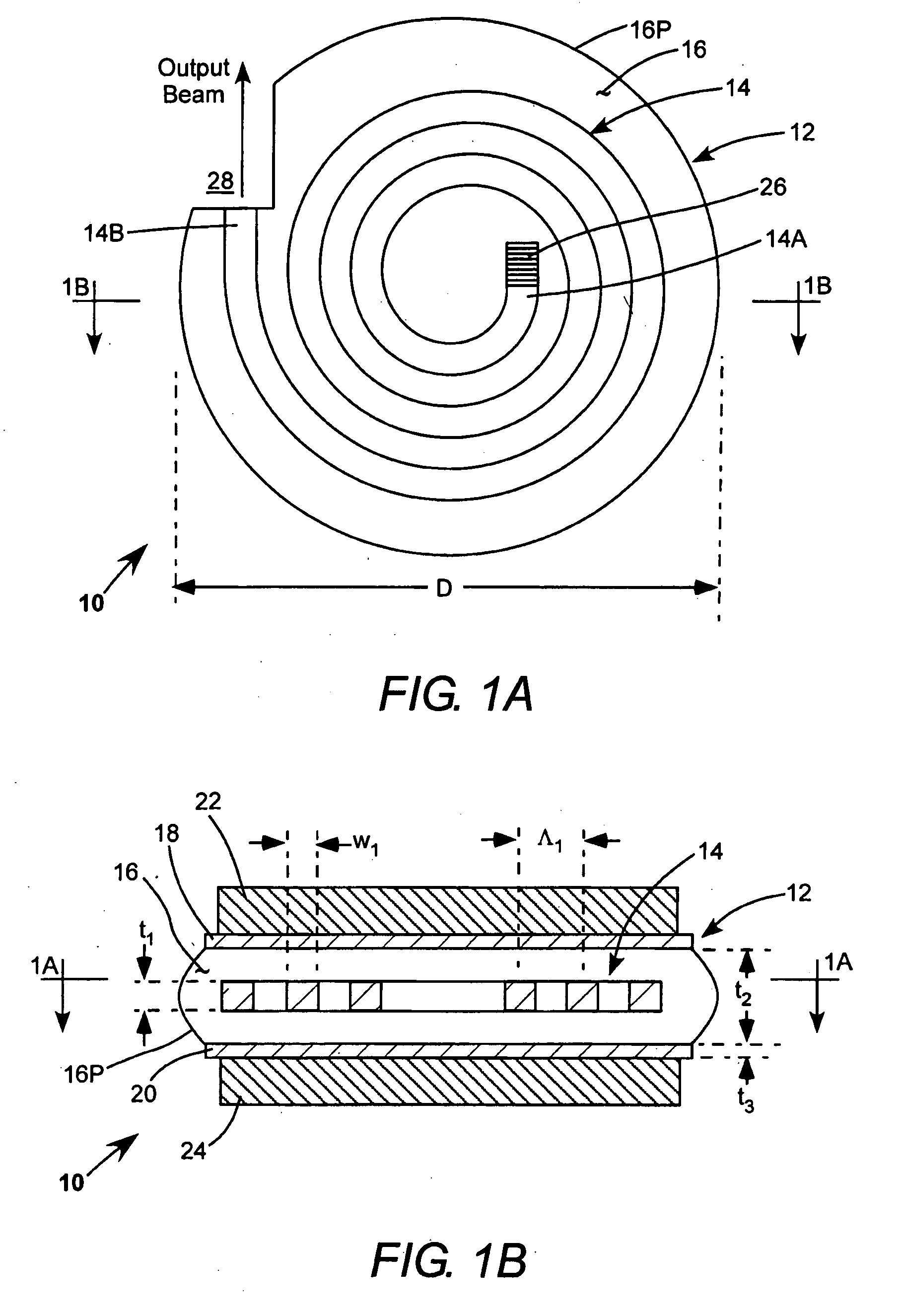

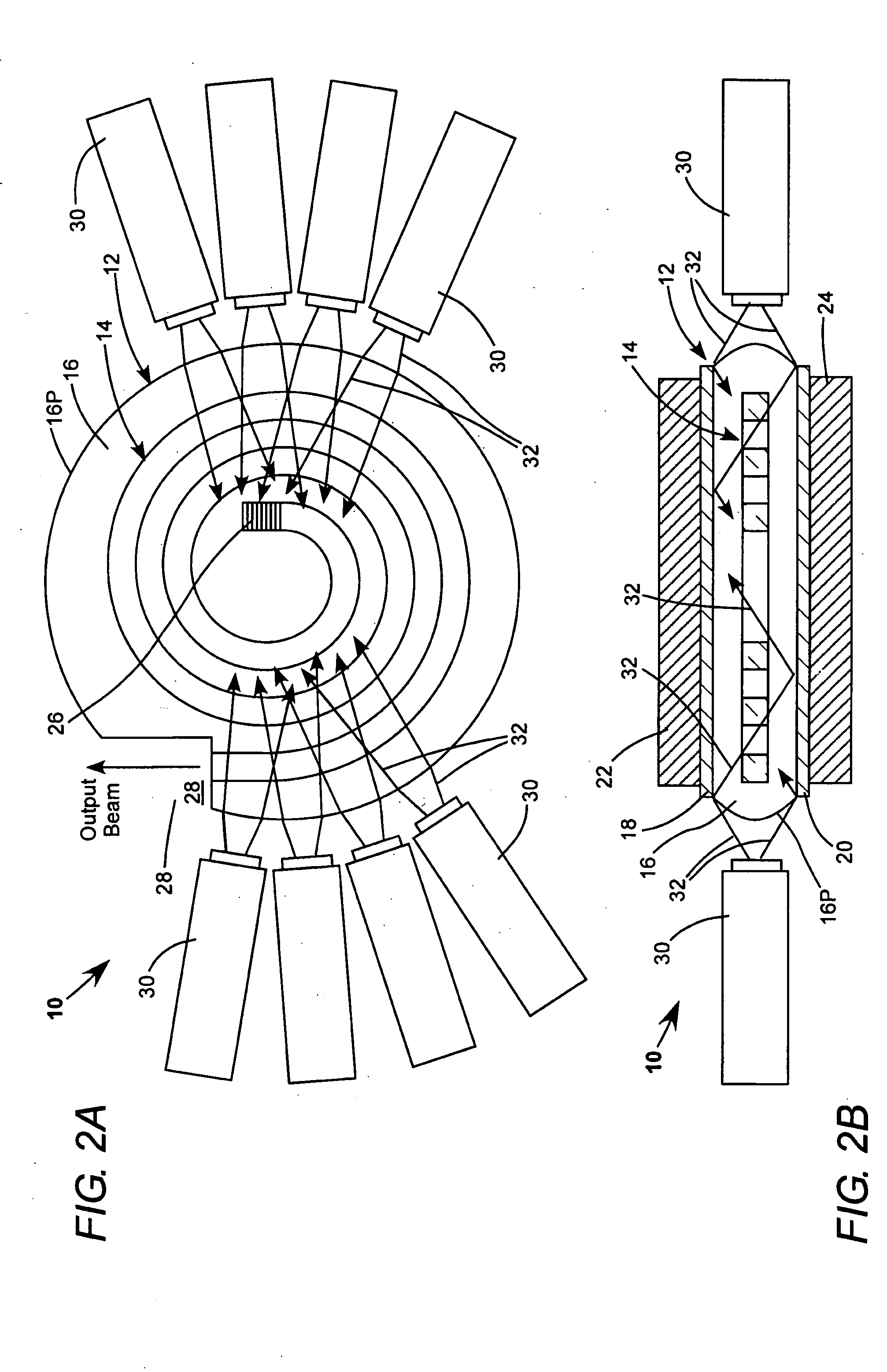

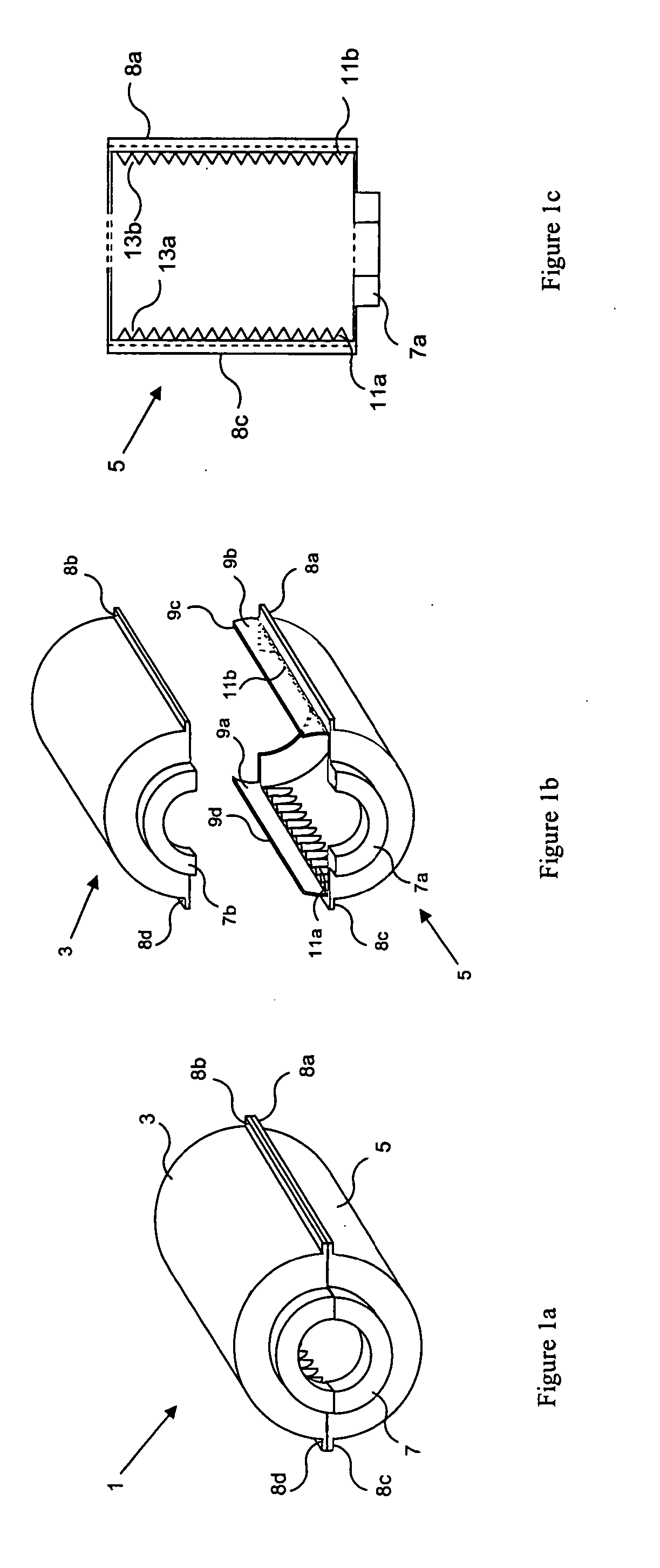

Monolithic wafer-scale waveguide-laser

InactiveUS20050169339A1Enhanced couplingActive medium materialActive medium shape and constructionRare-earth elementCoupling

A waveguide laser is formed by starting with a glass disc doped with a rare earth element to define a lasant material. The disc is etched or machined to define an elongated waveguide channel having a spiral configuration. The open area between the walls of the waveguide channel is filled with a cladding material. An end reflector is formed on the radial inner end of the spiral waveguide. First cladding layers are formed on both sides of the spiral waveguide. A second cladding layer is deposited on at least one of the first cladding layers. A heat sink is connected to the second cladding layer. A plurality of optical pump sources are positioned about the side walls of the structure to excite the lasant material and generate a laser beam. In one preferred embodiment, the side walls of the structure are provided with a convex configuration to enhance pump coupling.

Owner:COHERENT INC

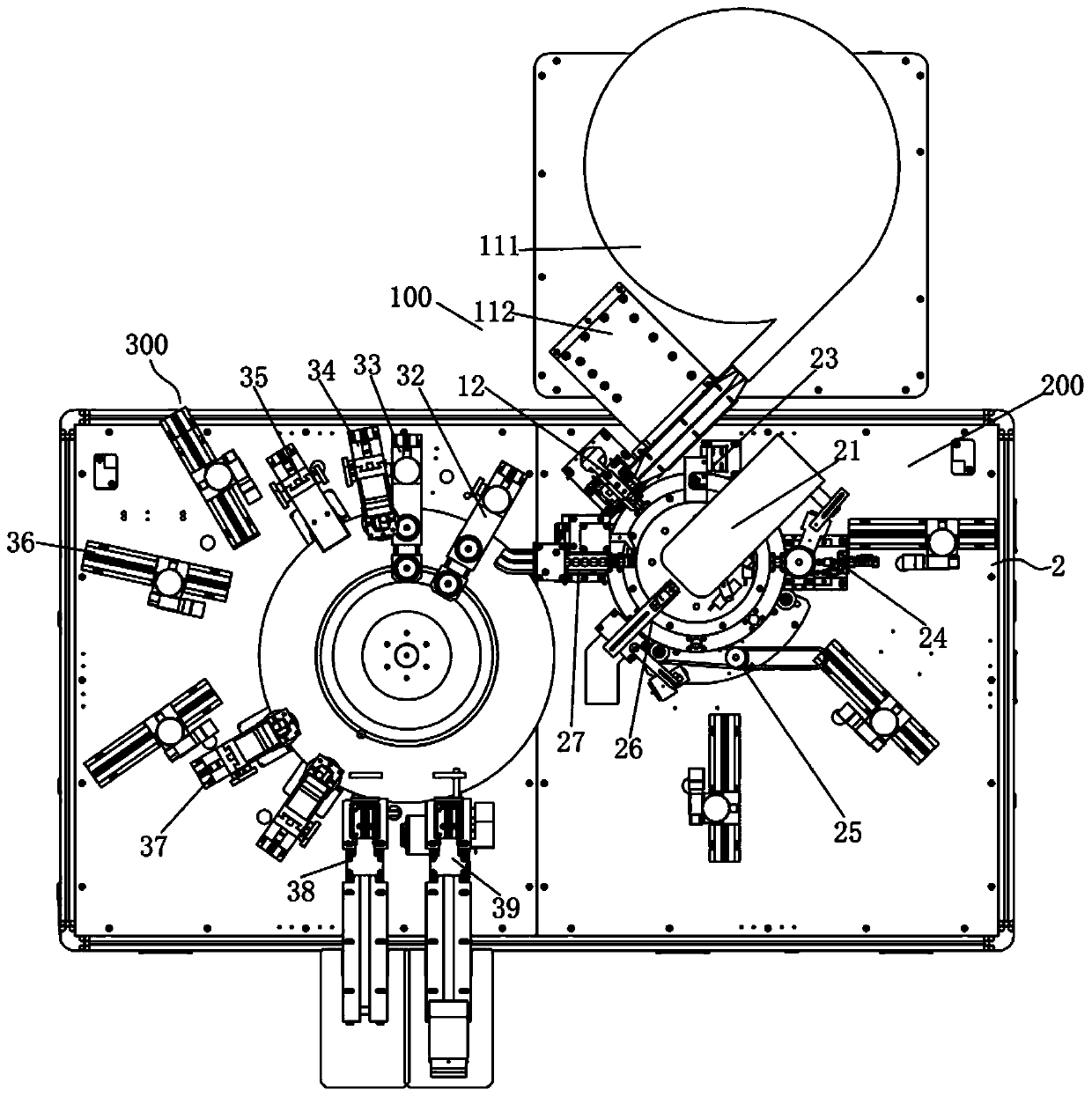

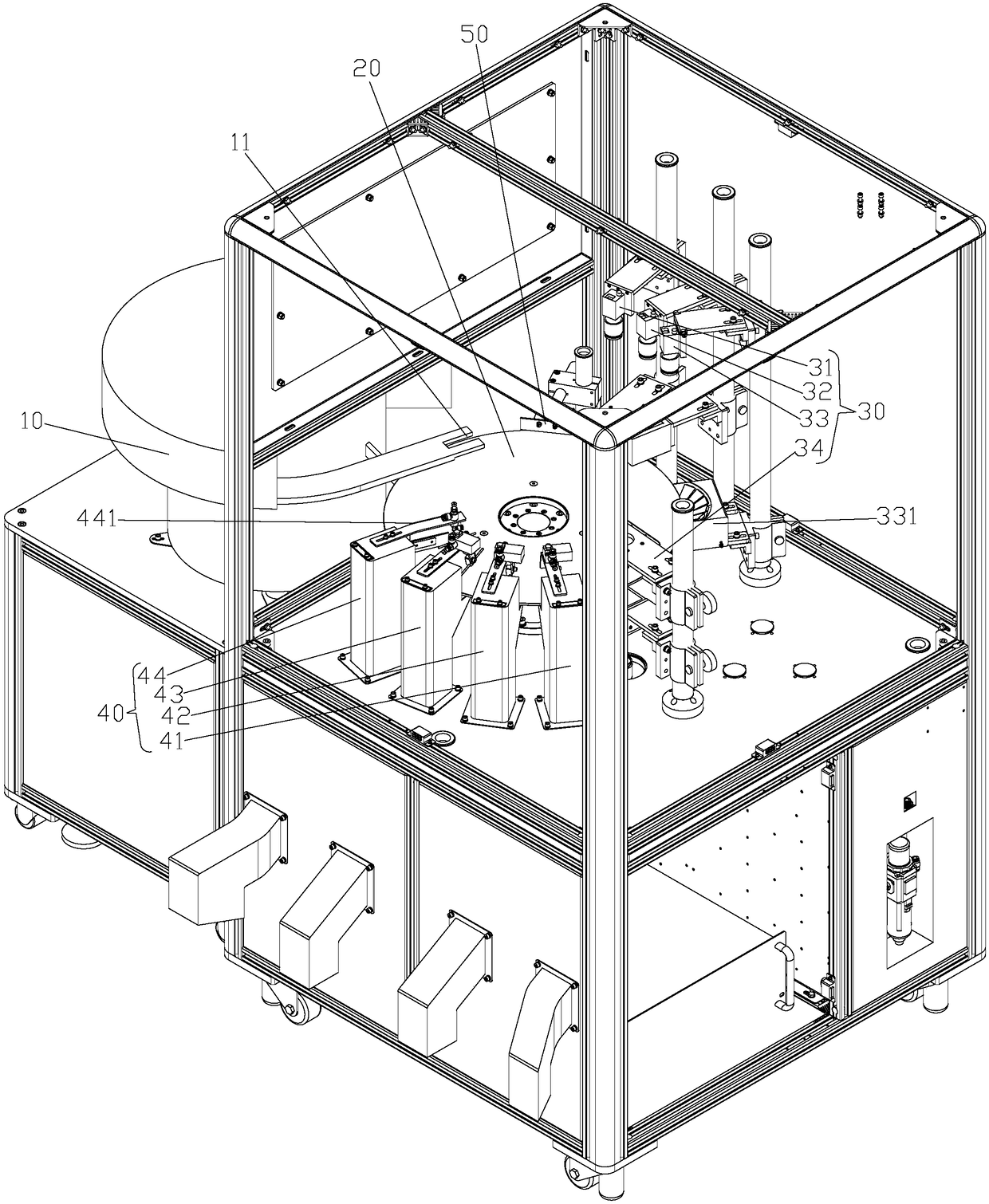

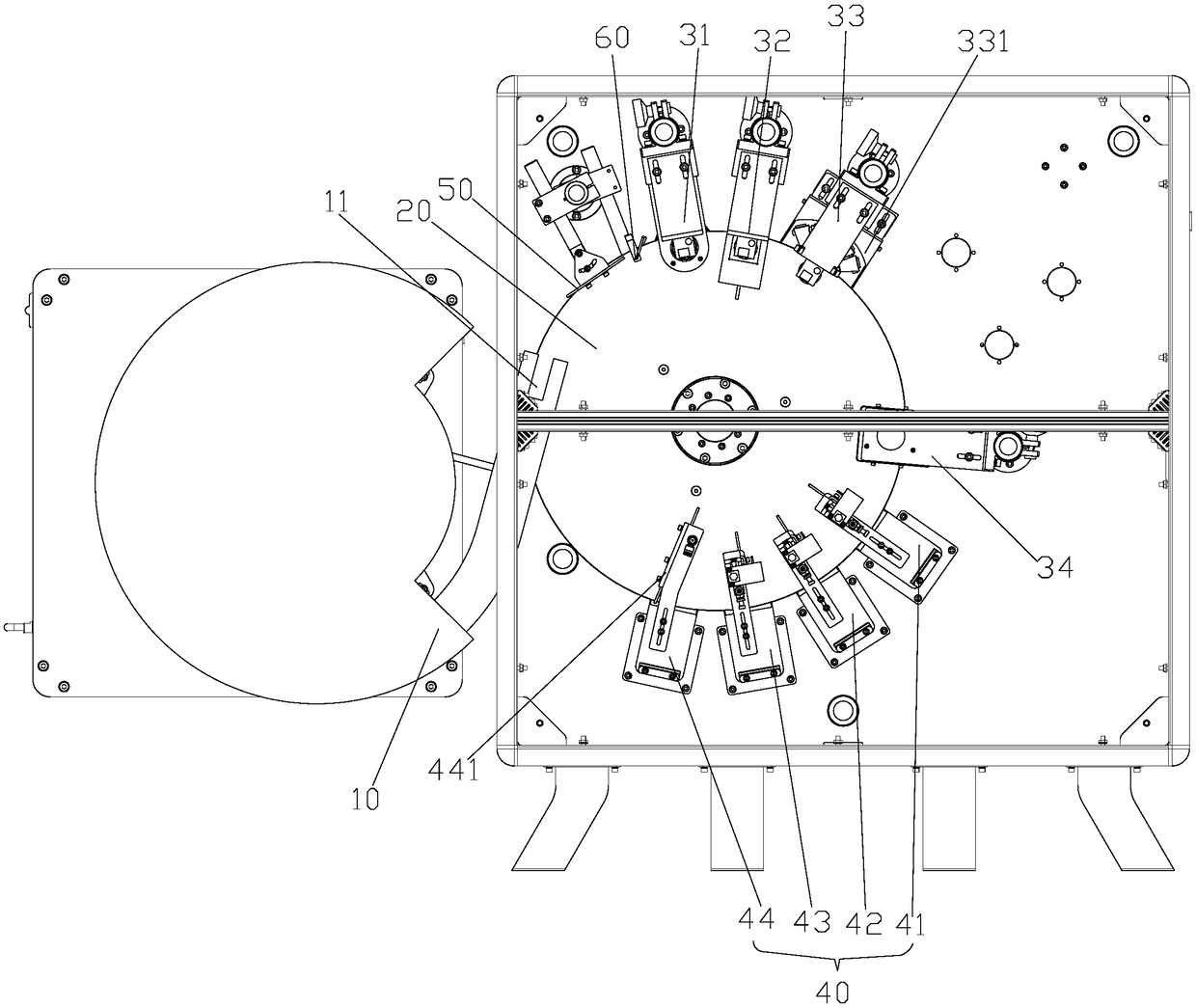

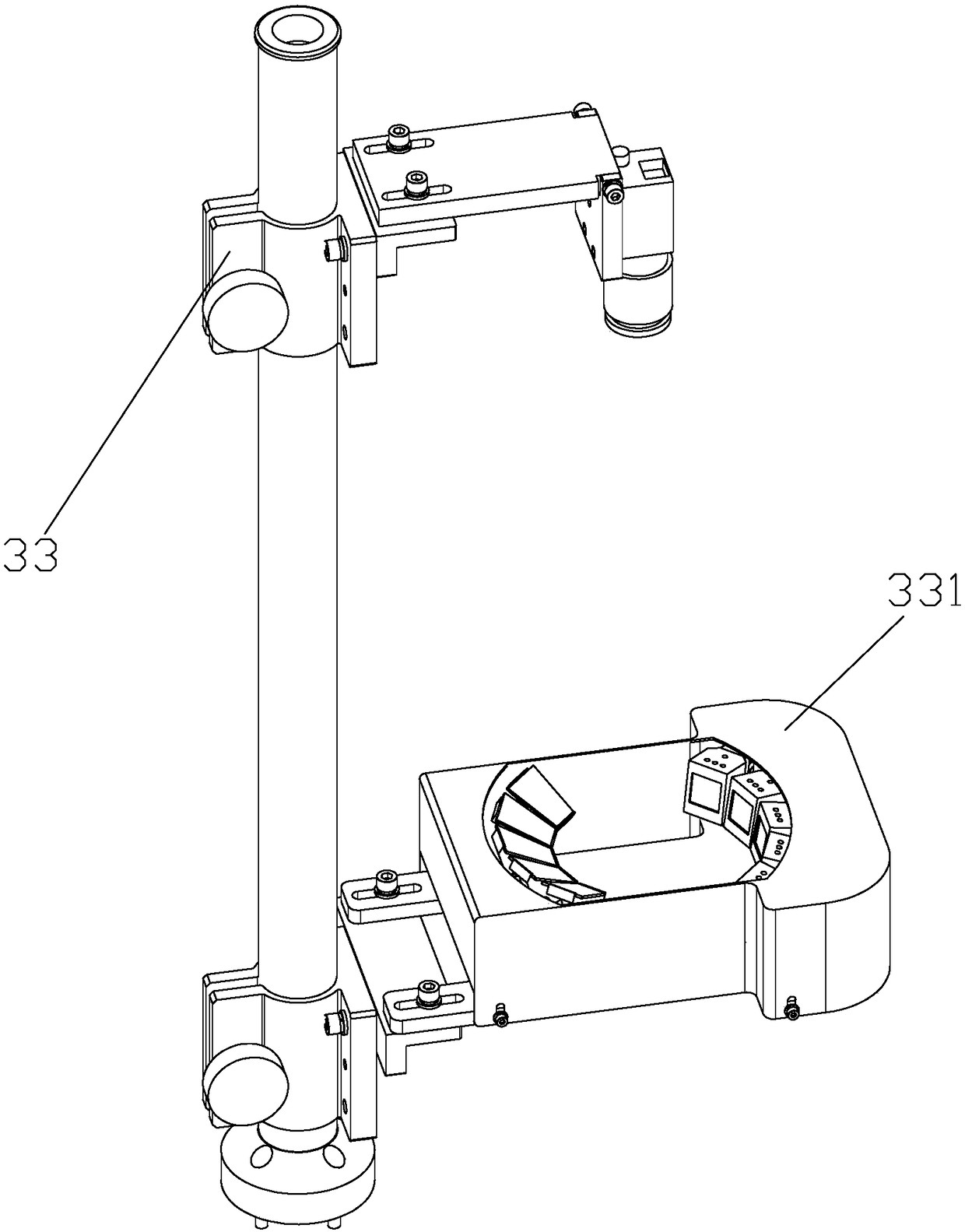

Automatic capacitance detector

PendingCN110261398AReduce defective rateEasy to detectOptically investigating flaws/contaminationCapacitanceButt joint

The invention discloses an automatic capacitance detector. The automatic capacitance detector comprises a feeding mechanism comprising a feeding component and a distributing component which are in butt joint, wherein the distributing component can convey the capacitors conveyed by the feeding component to a first detection mechanism one by one; the first detection mechanism comprising a rotary table component which is provided with a plurality of jig shafts capable of absorbing the capacitors and performing autogiration, wherein the rotary table component can drive the jig shafts to be sequentially butted joint with the distributing component, and a center positioning component, a welding leg positioning detection component, a rotation detection component, a defective product removing component and a material moving component which are sequentially arranged around the rotary table component; and a re-inspection mechanism comprising a glass disc component, and a first radial positioning component, a second radial positioning component, a downward inspection component, an upward inspection component, a plurality of side inspection components, a plurality of first downward inspection components, a first defective product removing components and a blanking components which are sequentially arranged around the glass disc component.

Owner:东莞市瑞科智能科技有限公司

Glass-ceramic discs for use in pigments

InactiveCN102046551AHigh softening temperatureImproved shape stabilityGlass making apparatusPigment preparation by wet methodsPrinting inkGlass-ceramic

Owner:MERCK PATENT GMBH

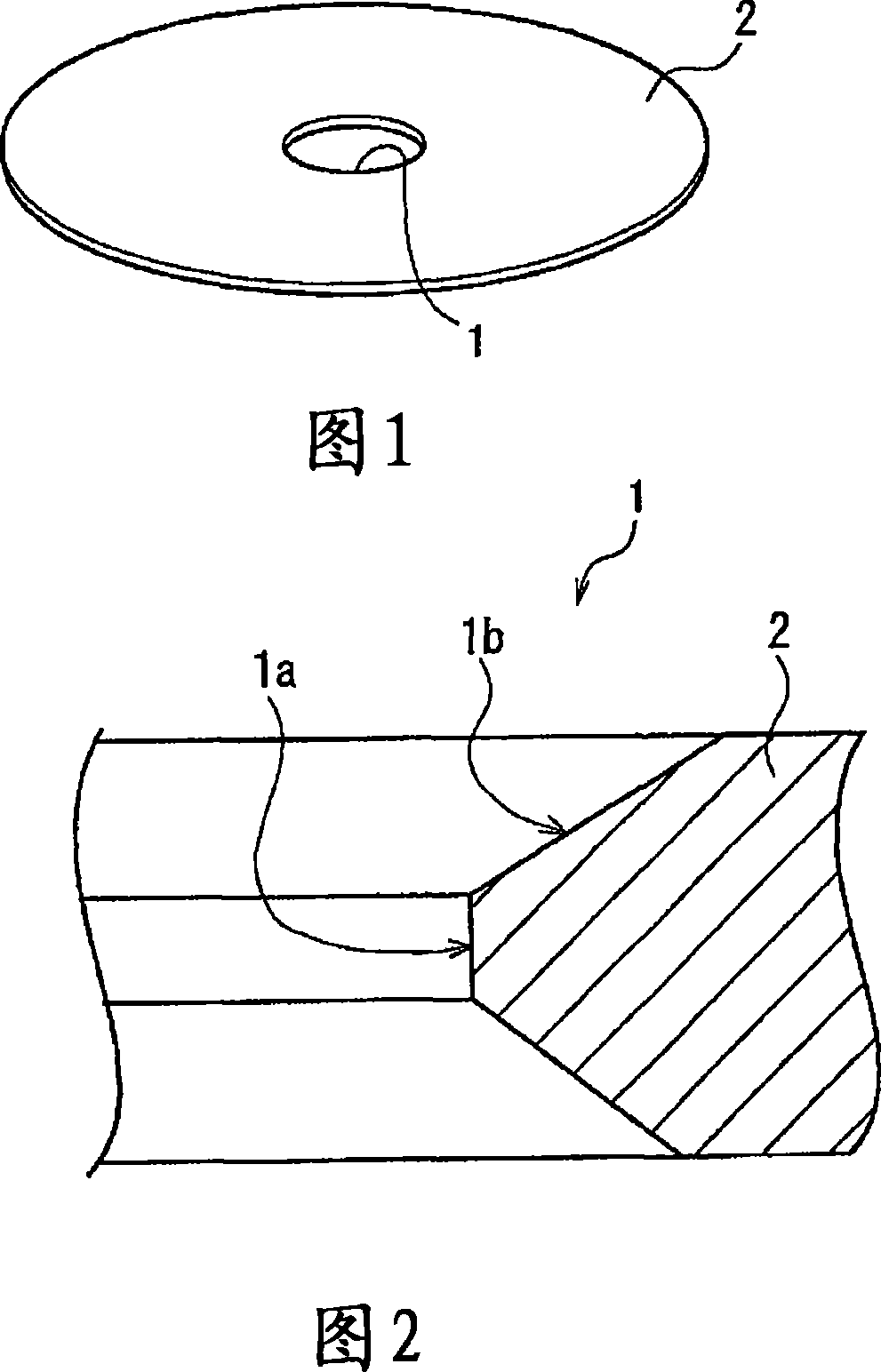

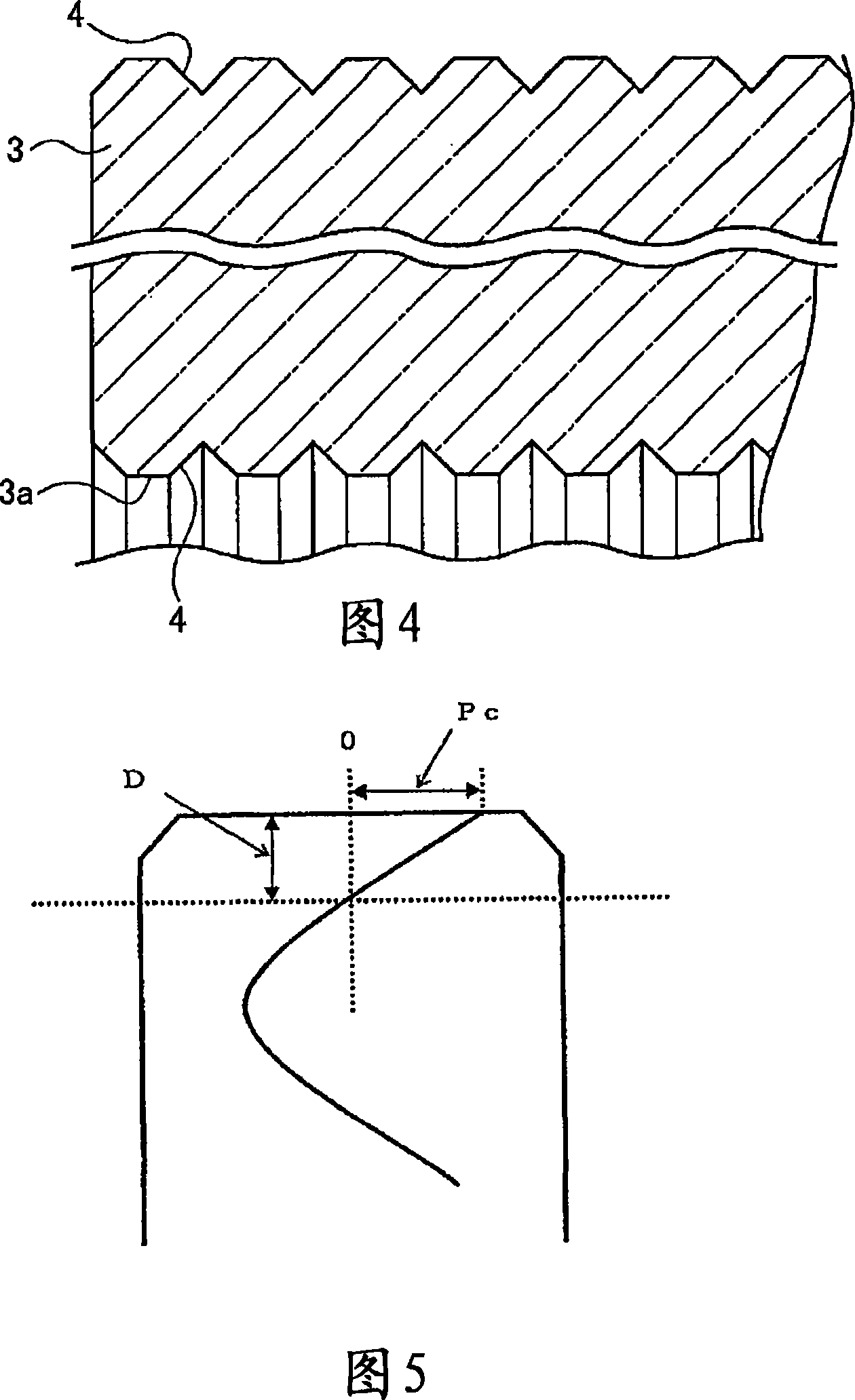

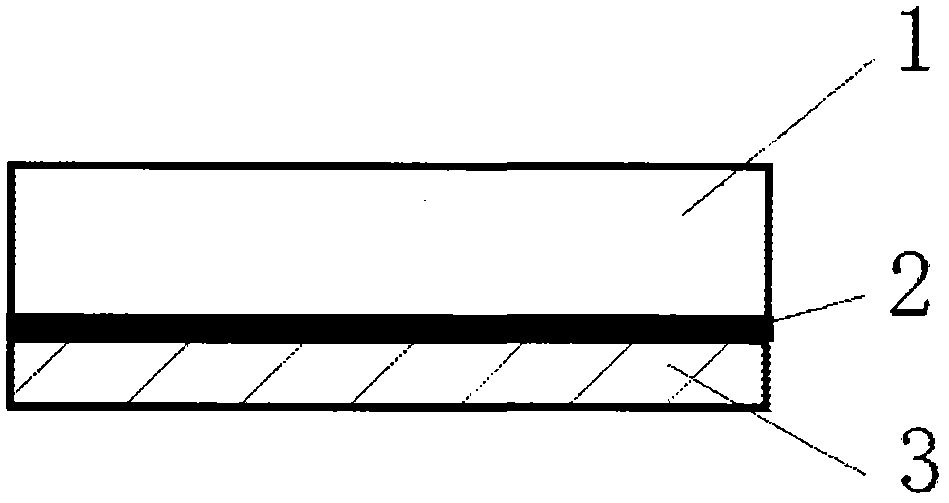

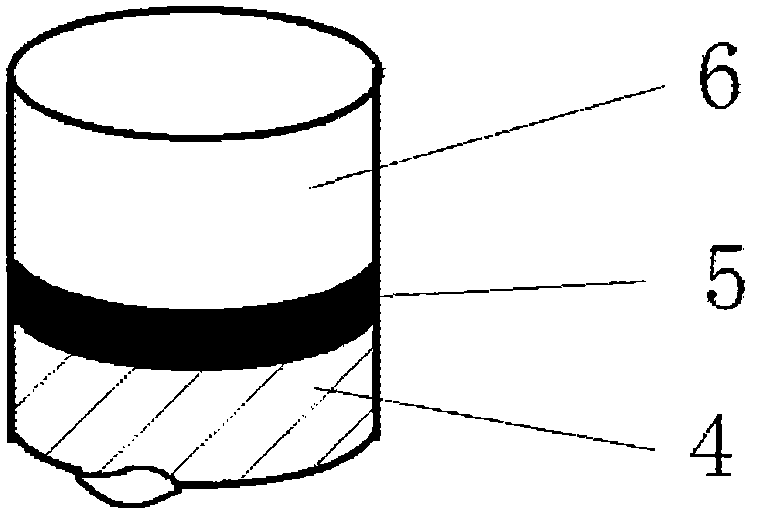

Glass substrate for magnetic disc, method for manufacturing such glass substrate, magnetic disc and method for manufacturing such magnetic disc

InactiveCN101147193APrevent adhesionEasy to GrindBase layers for recording layersBase layer manufactureMetallurgyMaterials science

A method for manufacturing a glass substrate for magnetic disc includes a step of manufacturing a glass disc by cutting a columnar glass base material (3) vertical to the center axis of the glass base material (3). In the method, a side plane of the glass base material (3) is polished or mirror-polished, chemical reinforcing treatment is performed to the side plane of the glass base material (3), and then the glass base material is cut.

Owner:HOYA CORP

Pedestal for furnace

ActiveUS20070199659A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingQuality processEngineering

A pedestal is provided for supporting wafer boats in a process chamber during semiconductor fabrication. The pedestal contains hollow spaces, such as within porous insulating plugs, and gases inside the pedestal may expand during semiconductor processing. The pedestal has an opening for exhausting gases out of its interior and into the process chamber. The opening is provided with a filter, in the form of a sintered ceramic or glass disc sealed within a tube covering the opening, to prevent the passage of particles which may be present inside the pedestal. By filtering the particles, the filter removes a source of contamination, thereby allowing for high quality process results on wafers processed in the process chamber.

Owner:ASM INTERNATIONAL

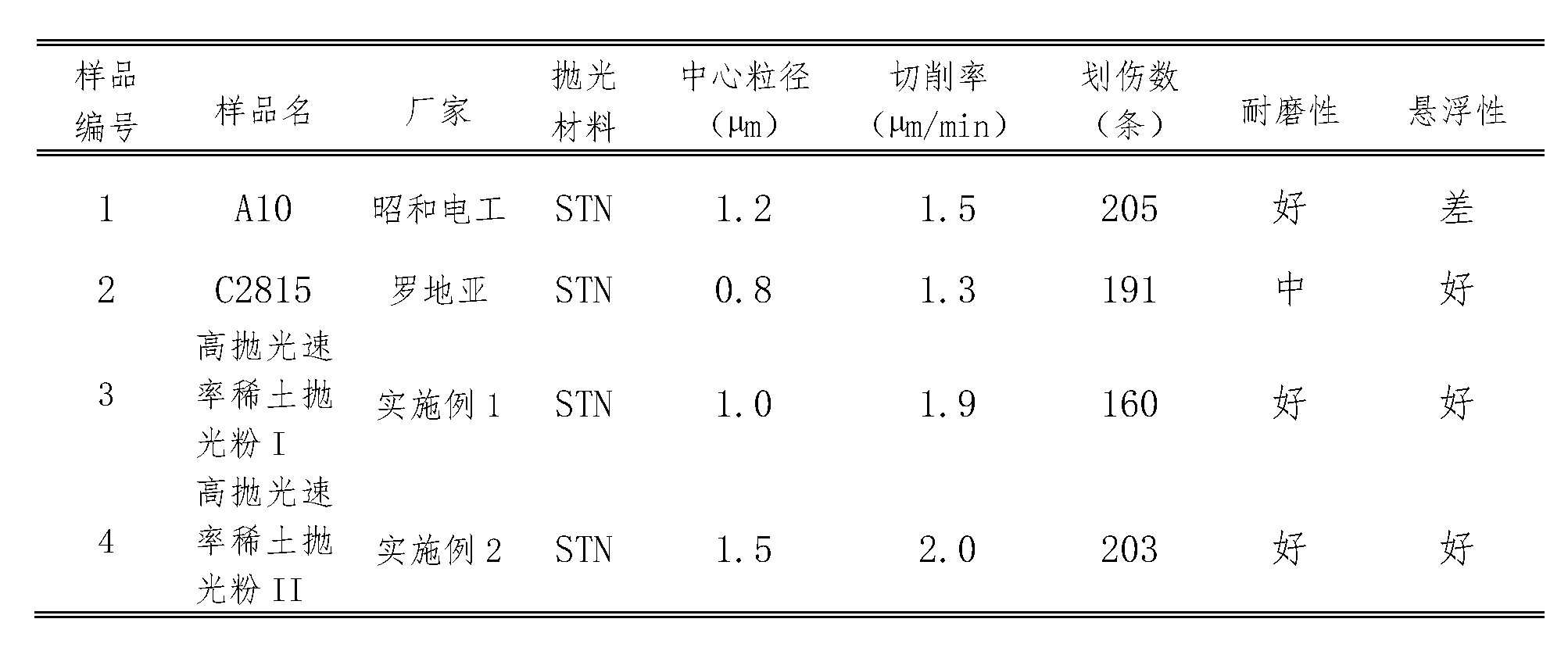

Preparation method of high-polishing-rate rare-earth polishing powder

InactiveCN103059737AGood polishing rateGood suspensionPolishing compositions with abrasivesMaterials preparationSemi solid

The invention discloses a preparation method high-polishing-rate rare-earth polishing powder, relating to the technical field of rare-earth polishing material preparation. The preparation method comprises the following steps: proportioning, preparing a water dispersion solution, carrying out semi-solid-phase synthesis, calcining, pulverizing and mixing. The preparation method has the characteristics of simple process, low cost, low energy consumption and the like. The rare-earth polishing powder prepared by the method has the characteristics of higher polishing rate, favorable suspensibility, favorable wear resistance, favorable fluidity, environmental protection and the like, and can be widely used for polishing mobile phone cover plates, high-precision optical lenses, optical filters, glass disc substrates, liquid crystal glass and other objects.

Owner:湖南皓志新材料股份有限公司

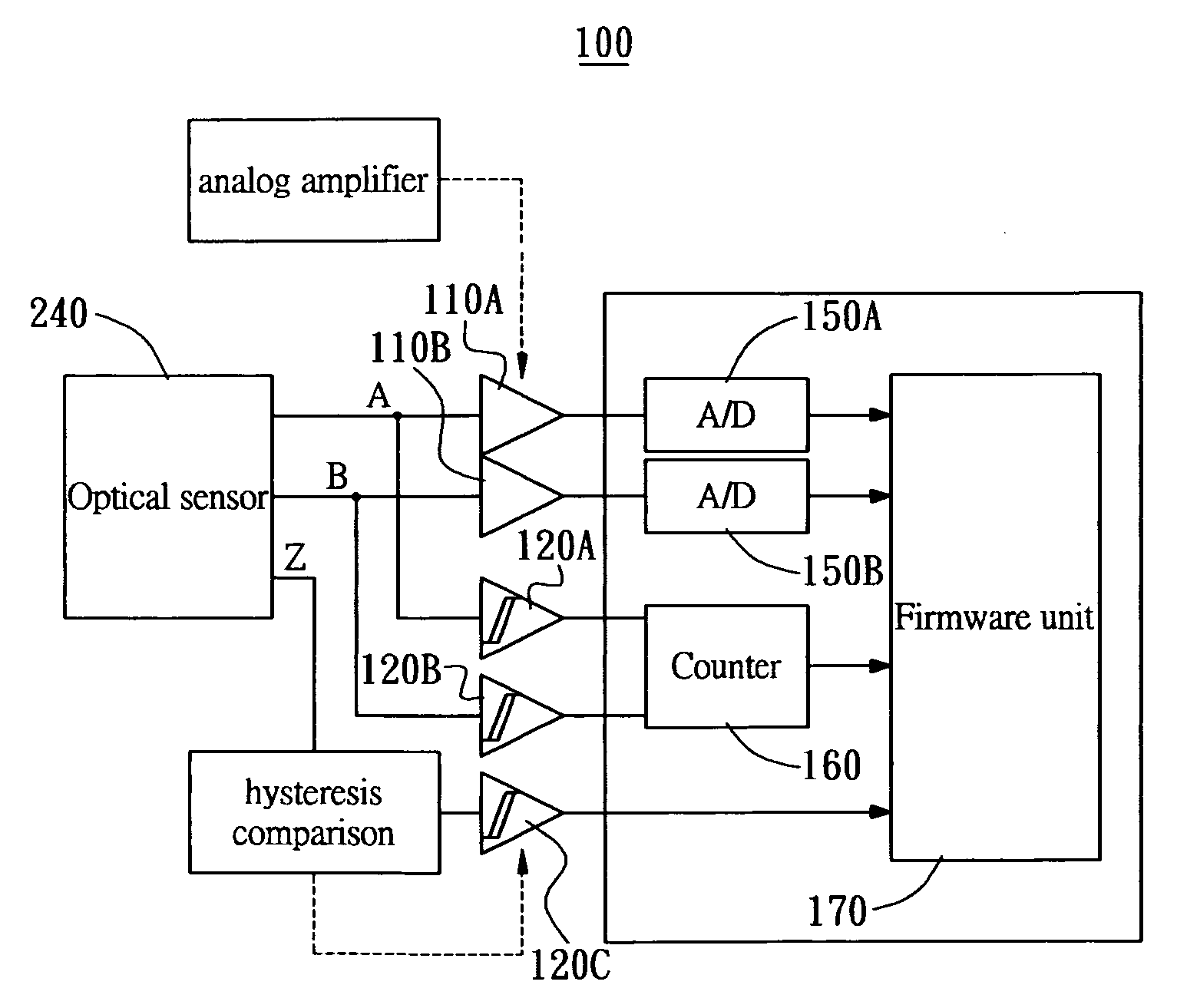

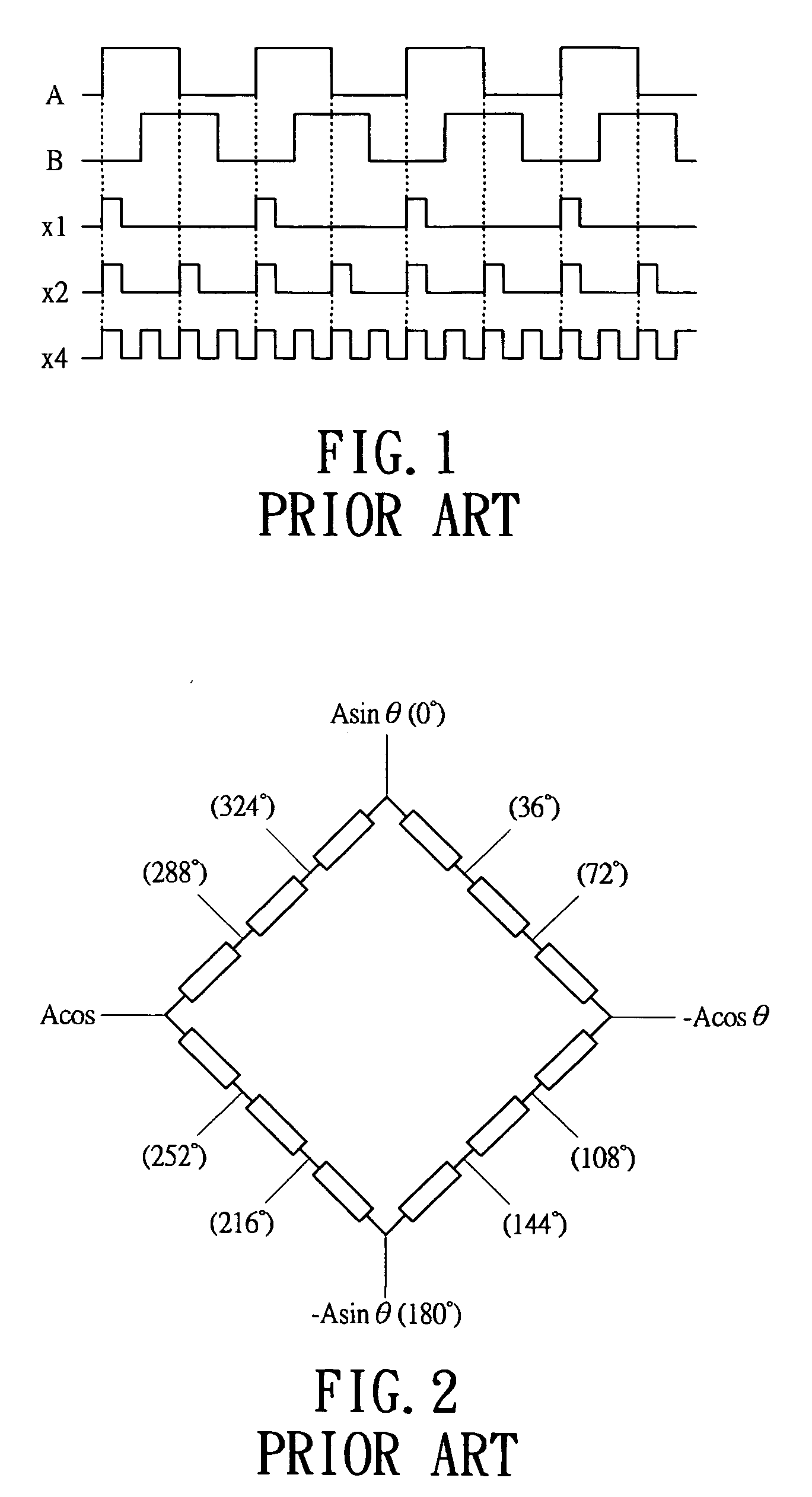

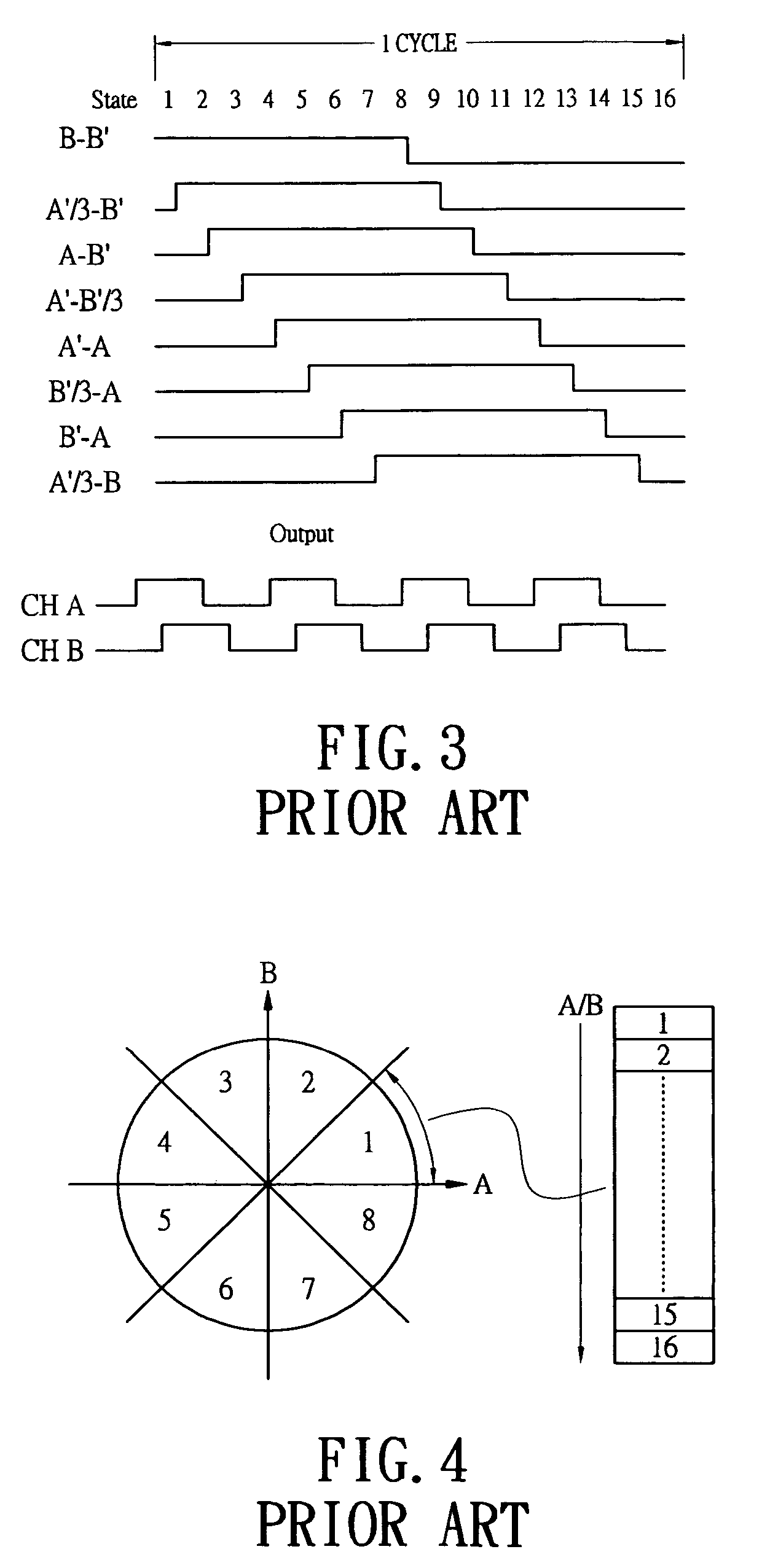

Optical encoder and controller for the same

InactiveUS20070045525A1High resolutionAnalogue/digital conversionMaterial analysis by optical meansHysteresisElectricity

An optical encoder includes a controller electrically connected to an optical sensor to discriminate displacement information of a glass disc. The controller comprises a pair of analog amplifiers for amplifying quadrature periodical output signals of the optical sensor, a pair of A / D converters electrically connected to the analog amplifiers for digitalizing the output of the analog amplifiers, a pair of hysteresis comparators electrically connected to the optical sensor for performing hysteresis comparison for the output of the optical sensor, an up / down counter electrically connected to the pair of hysteresis comparators for up / down counting the output of the hysteresis comparators and a firmware unit electrically connected to the pair of A / D converters and the up / down counter for performing interpolation for the quadrature periodical output signals and counting for the hysteresis compared signals. Therefore, optical encoded result of higher resolution can be achieved.

Owner:DELTA ELECTRONICS INC

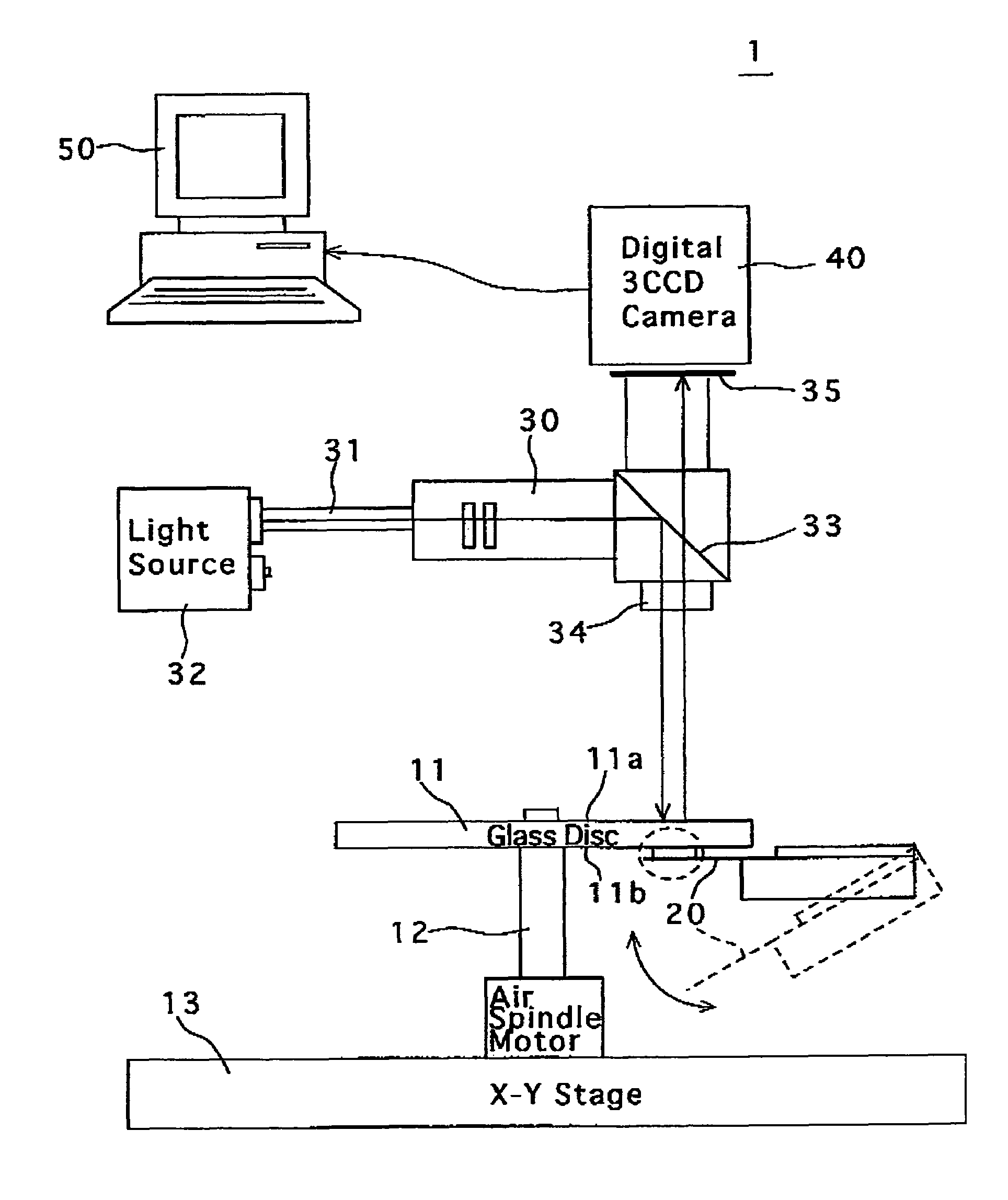

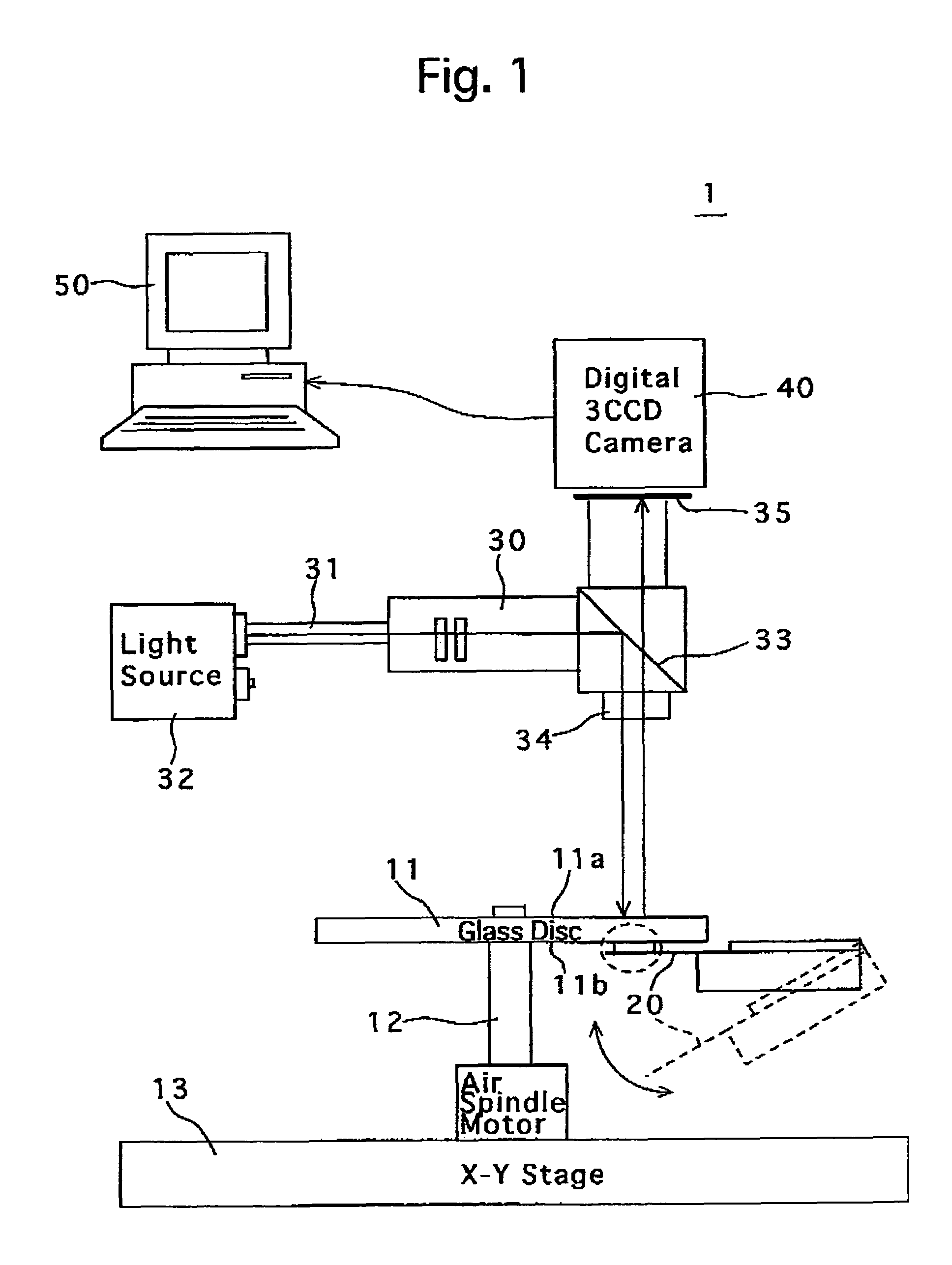

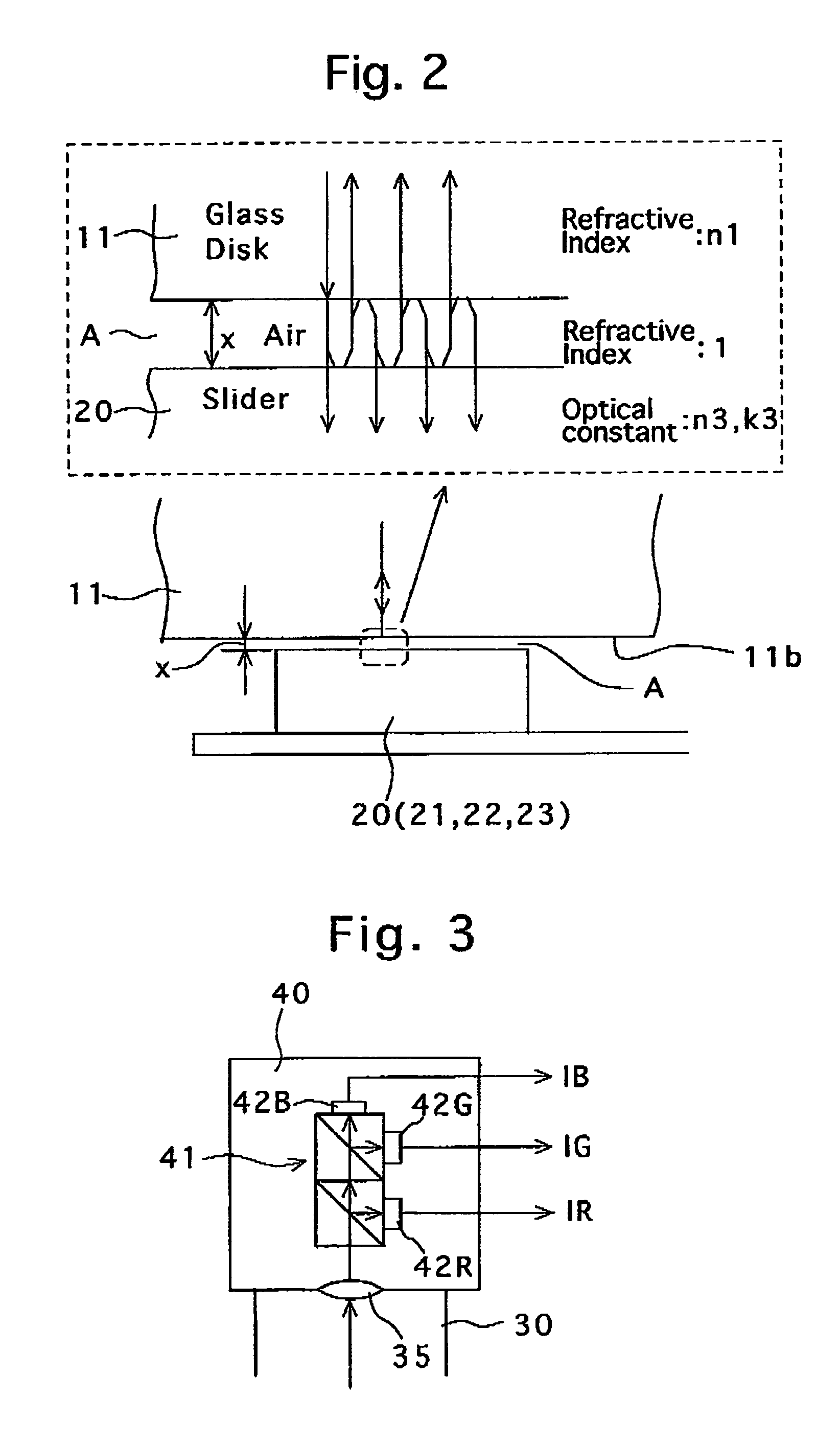

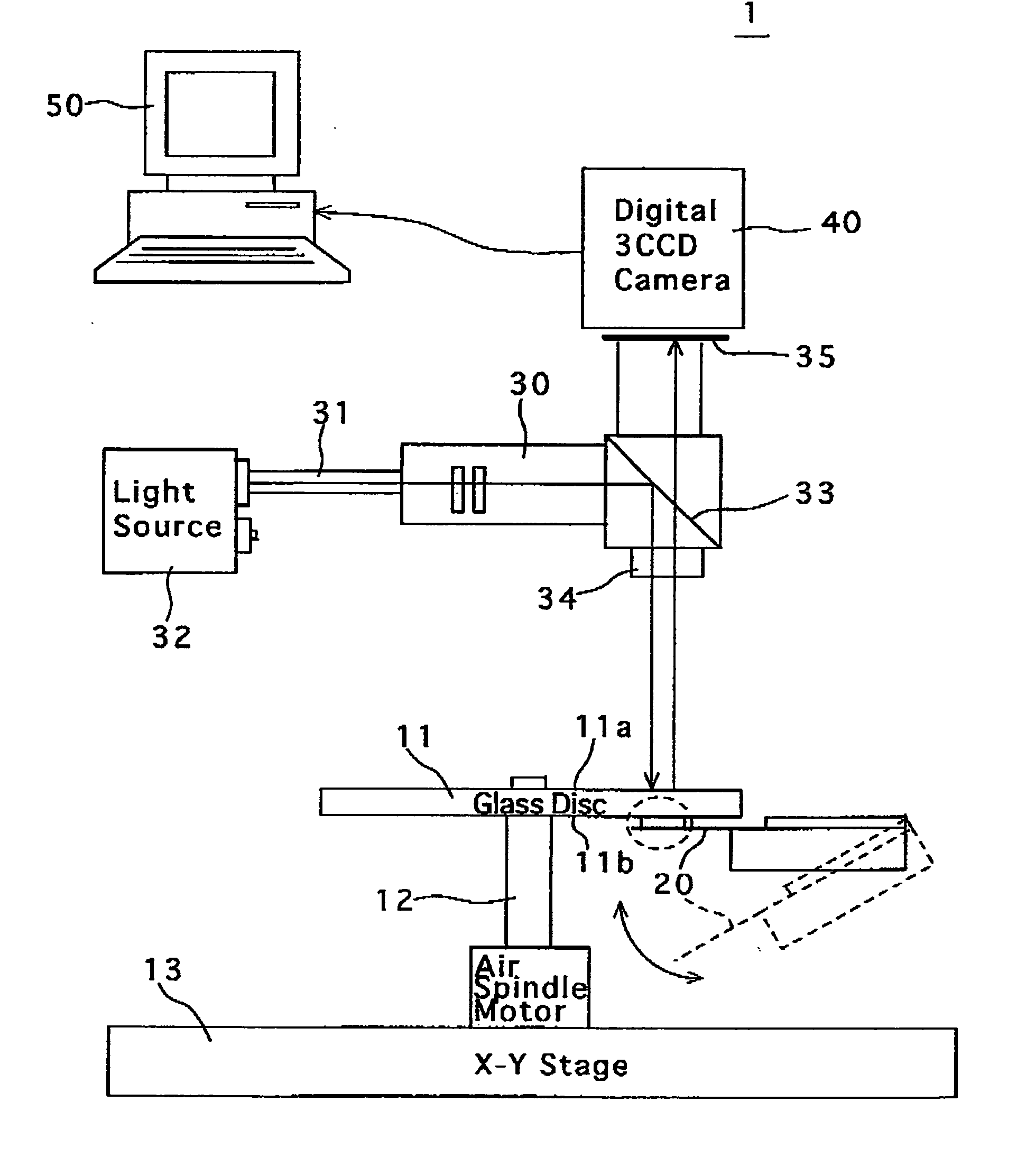

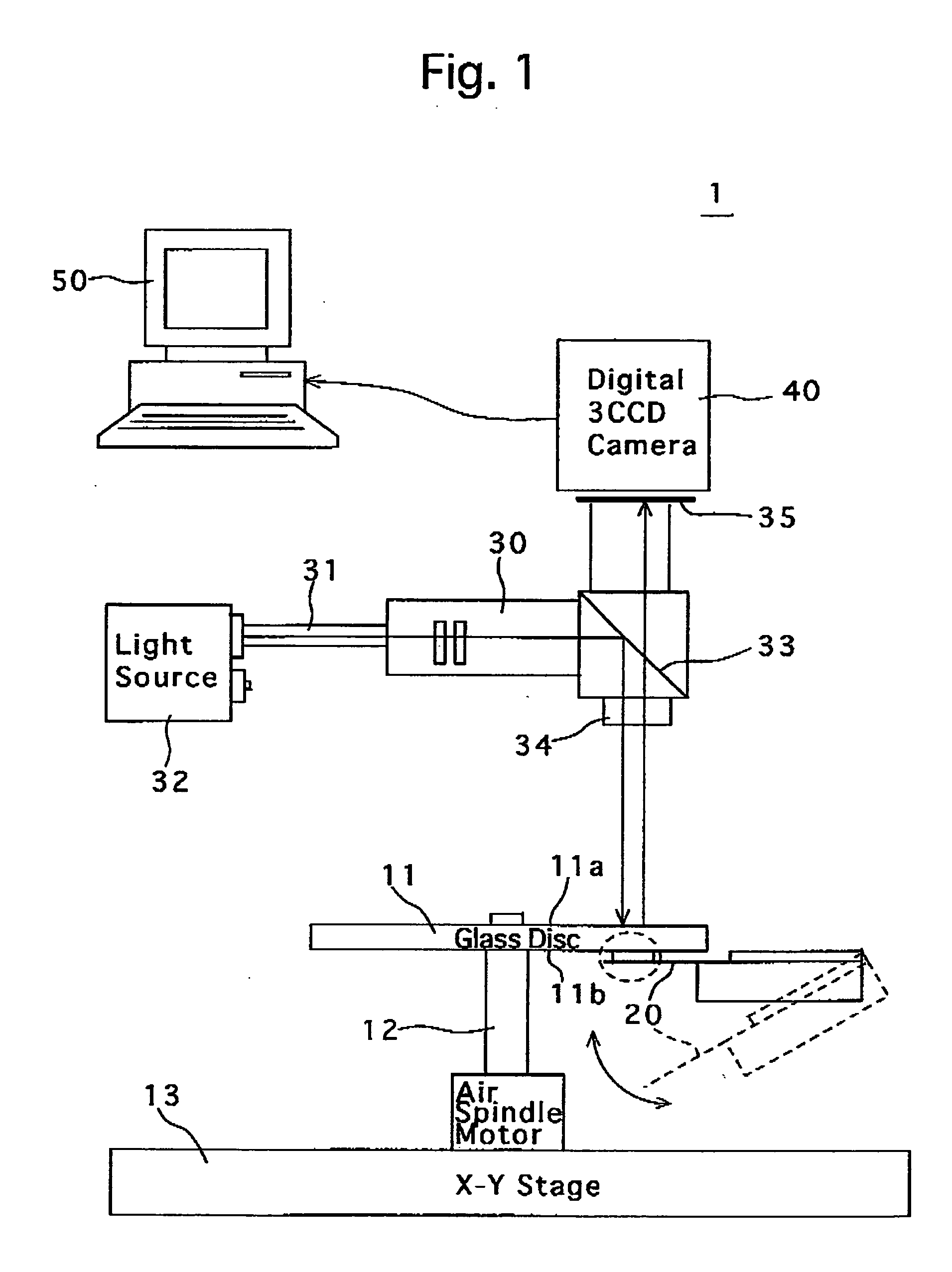

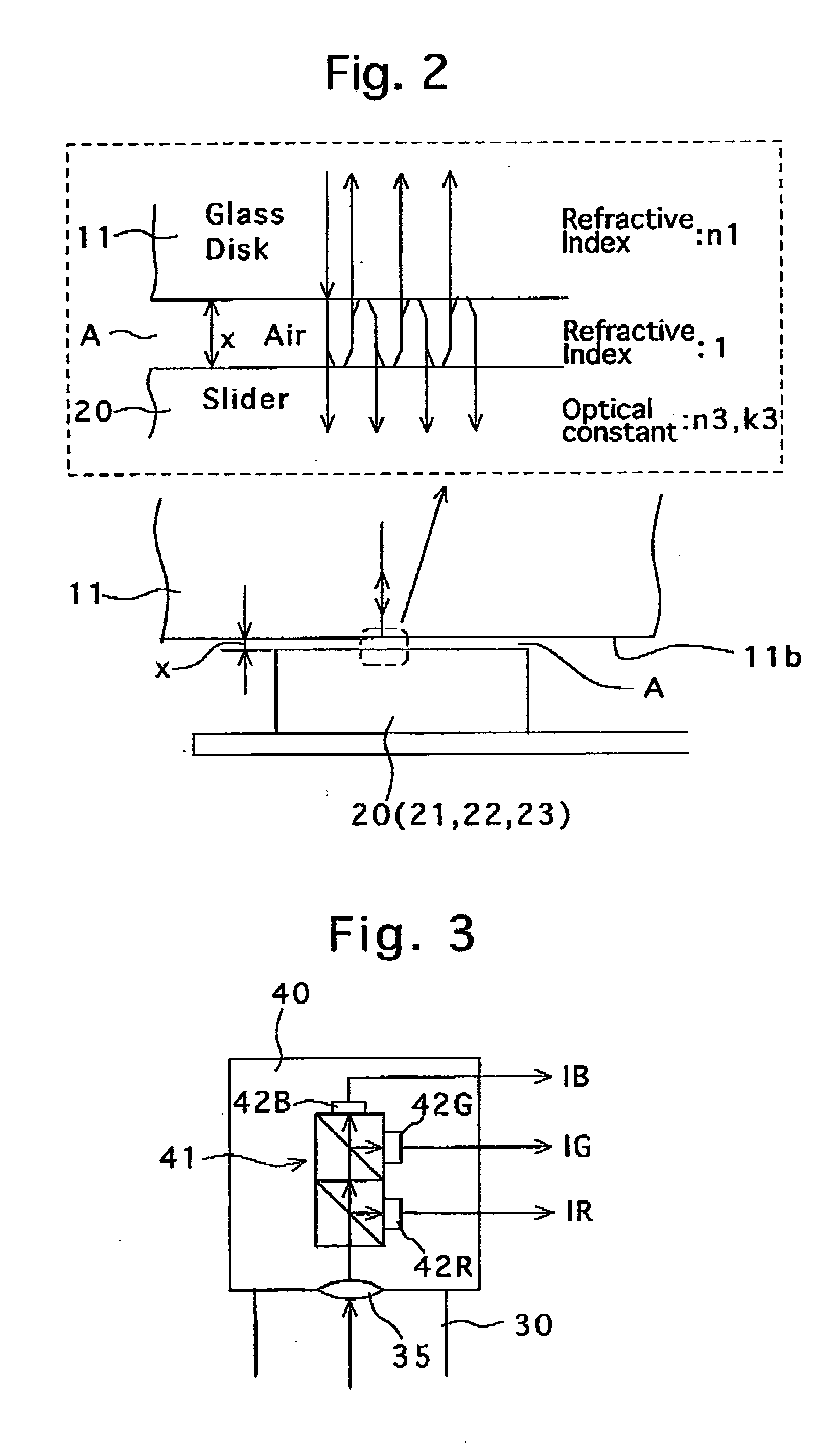

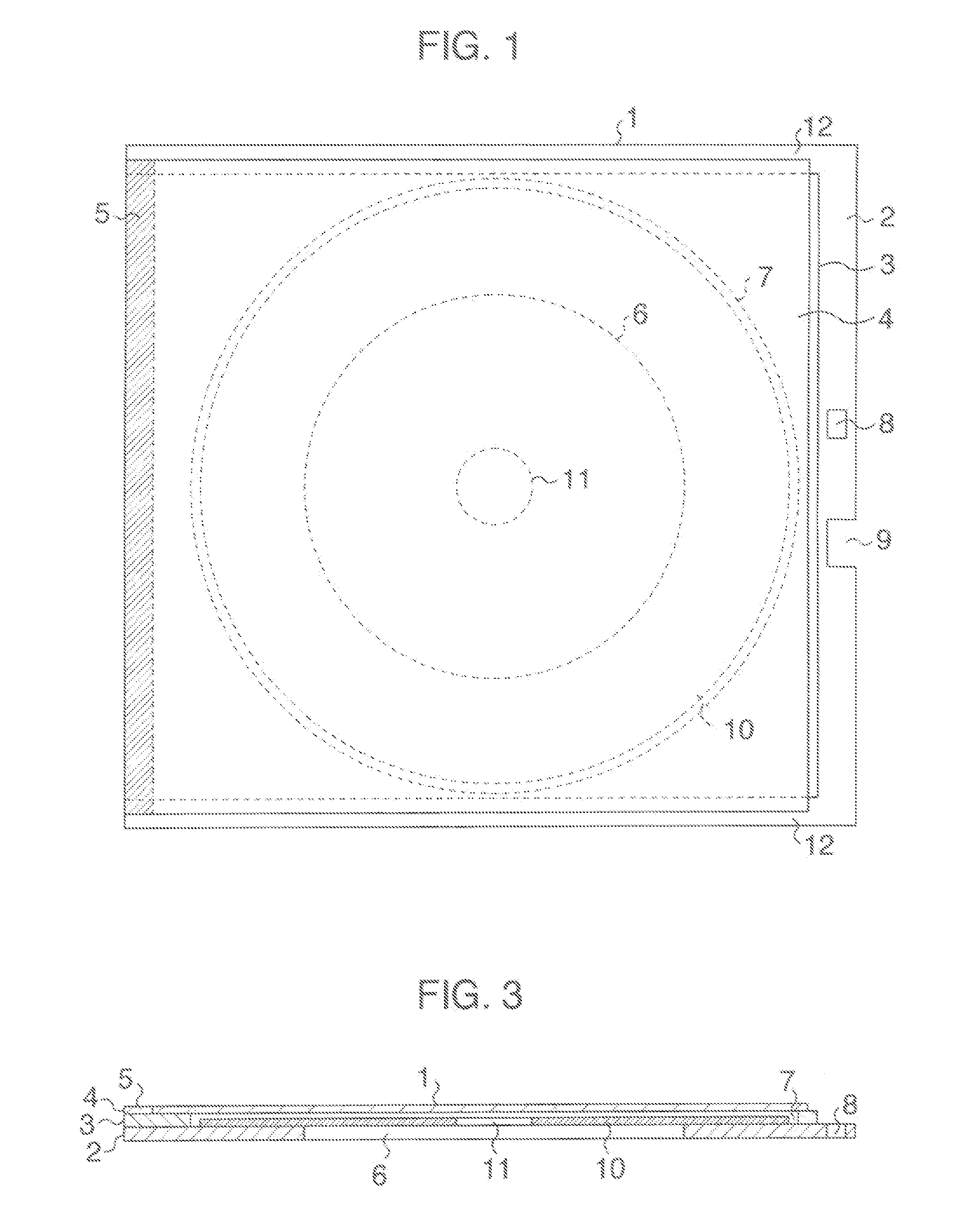

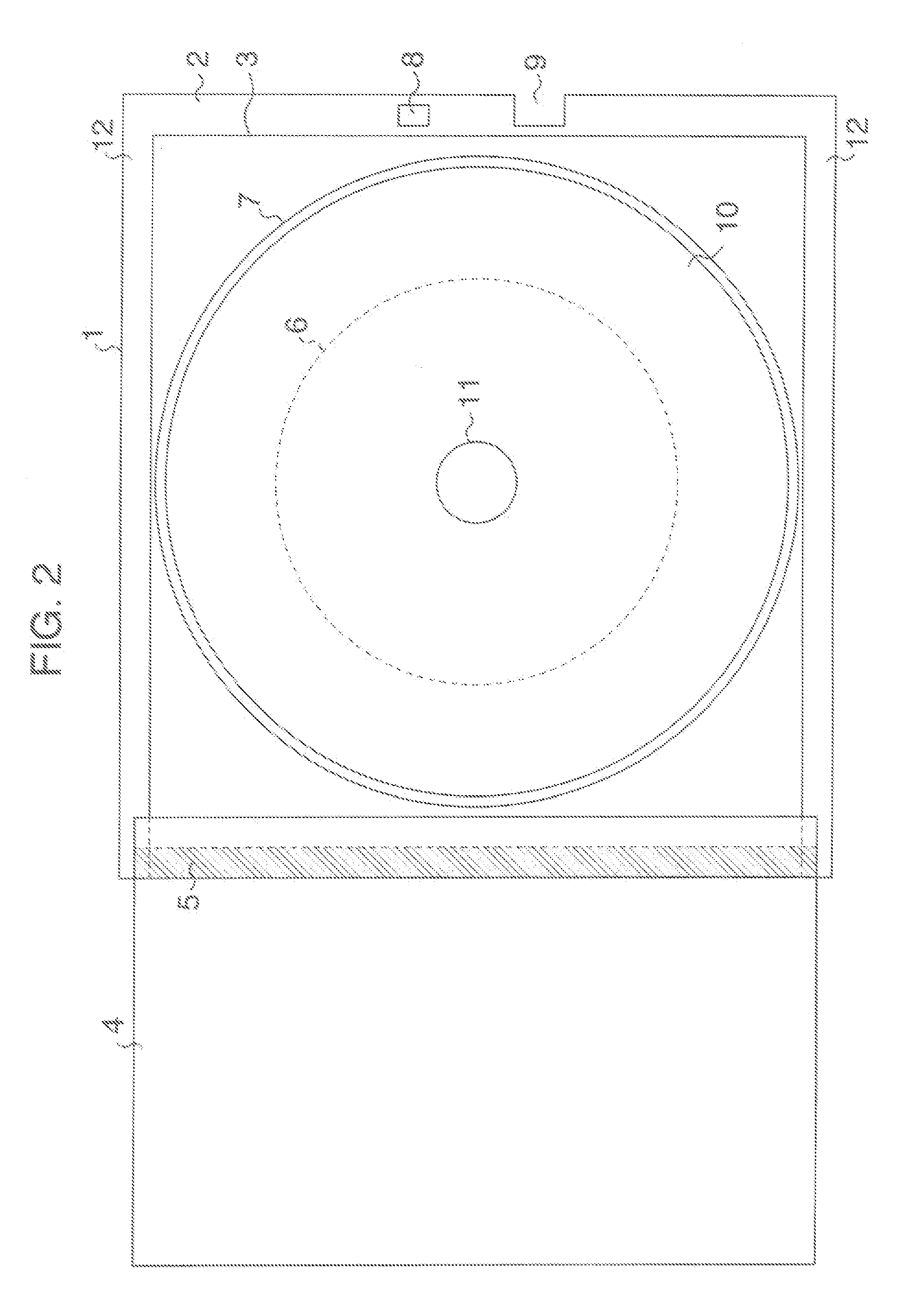

Flying height tester and flying height test method

InactiveUS7206077B2High precisionImprove processing speedRecord information storageFluid-dynamic spacing of headsTester deviceFlying height

A flying height tester includes a glass disc facing a magnetic head slider under test; an optical system for guiding light to the glass disc so that multiple reflections of light occur between the glass disc and the magnetic head slider; a light sensor receiving reflection light from the glass disc to output light intensity data; and a processor which calculates back the flying height based on an output function of the light sensor. The processor calibrates intensity gain data and intensity offset data of the output function using the data obtained in a pseudo-zero state of the flying height. This pseudo-zero state is obtained by applying an index matching liquid between a first-calibration magnetic head slider, having the same optical constants as the magnetic head slider under test, and the glass disc, the index matching liquid having a refractive index identical to the glass disc.

Owner:INT MFG & ENG SERVICES

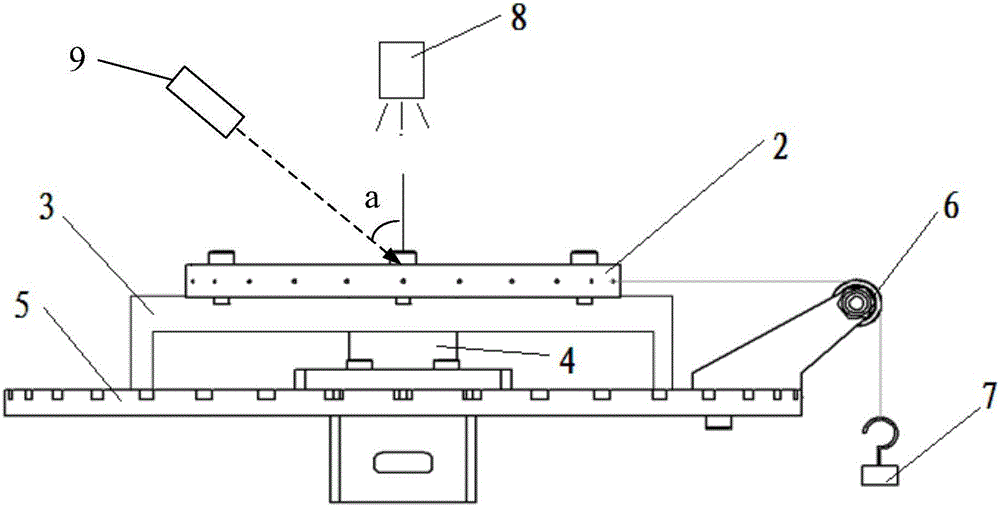

Frictional resistance calibrating device aiming at liquid crystal coating

ActiveCN106644226AEasy to getImprove economySustainable transportationForce measurement by measuring optical property variationCircular discEngineering

The invention discloses a frictional resistance calibrating device aiming at liquid crystal coating, and relates to a model surface friction measurement field of a wind tunnel test. The frictional resistance calibrating device comprises a glass disc, an outer cover, a tray, a measuring bench, a base, a fixed pulley, and a weight. The base is a disc mechanism, and is horizontally disposed on the lowest end. The measuring bench is fixedly disposed on the upper surface of the base, and the tray is fixedly disposed on the upper surface of the base. The glass disc is fixedly disposed on the upper surface of the tray, and the outer cover is fixedly disposed on the upper surface of the tray. The outer edge of the glass disc is fixedly by the outer cover in a limited way, and the fixed pulley is fixedly disposed on the edge part of the base. The weight is fixedly connected with the outer cover side edge by an inelastic rope, which is disposed on the fixed pulley. By using the frictional resistance calibrating device, results are acquired directly without help of other sensors, and the measurement results are not affected by the precision of the sensors, and then loading is easy to adjust and control, and the calibration precision is improved. The frictional resistance calibrating device has advantages of small device size, simple structure, high maintenance performance, economy, and practicability.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Portable attack angle sensor calibrating device

ActiveCN106197479AHigh measurement accuracyImprove acquisition resolutionMeasurement devicesEngineeringTransducer calibration

Owner:HENAN PROVINCE INST OF METROLOGY

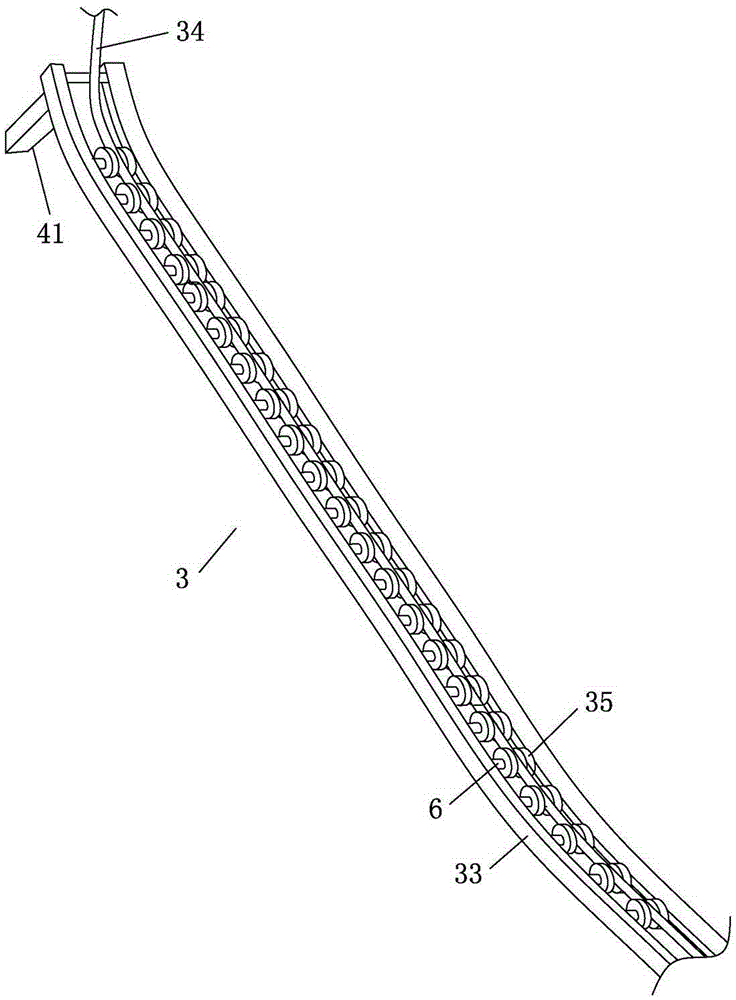

Device for measuring friction force and film thickness of lubricating oil film under different surface speeds

InactiveCN111780972AIncrease positive pressureIncrease the maximum frictionMachine bearings testingUsing optical meansRotational axisEngineering

The invention discloses a device for measuring friction force and film thickness of a lubricating oil film under different surface speeds, and the device comprises an experiment bench which is provided with a translation platform, and the translation platform can move linearly under the drive of a drive device. A main shaft system is arranged on the experiment bench, a glass disc is arranged on the main shaft system, and the glass disc can rotate. An arc-shaped guide rail is arranged on the translation platform. The rotating base is installed on the arc-shaped guide rail and can move along thearc-shaped guide rail, the loading system is installed on the rotating base, a steel ball of the loading system and the glass disc move relatively, and a rotating bearing in the rotating base converts friction force generated by relative movement into pressure which can be collected by a pressure sensor on the rotating base.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Flying height tester and flying height test method

InactiveUS20050117166A1High precisionImprove processing speedFluid-dynamic spacing of headsRecord information storageTester deviceFlying height

A flying height tester includes a glass disc facing a magnetic head slider under test; an optical system for guiding light to the glass disc so that multiple reflections of light occur between the glass disc and the magnetic head slider; a light sensor receiving reflection light from the glass disc to output light intensity data; and a processor which calculates back the flying height based on an output function of the light sensor. The processor calibrates intensity gain data and intensity offset data of the output function using the data obtained in a pseudo-zero state of the flying height. This pseudo-zero state is obtained by applying an index matching liquid between a first-calibration magnetic head slider, having the same optical constants as the magnetic head slider under test, and the glass disc, the index matching liquid having a refractive index identical to the glass disc.

Owner:INT MFG & ENG SERVICES

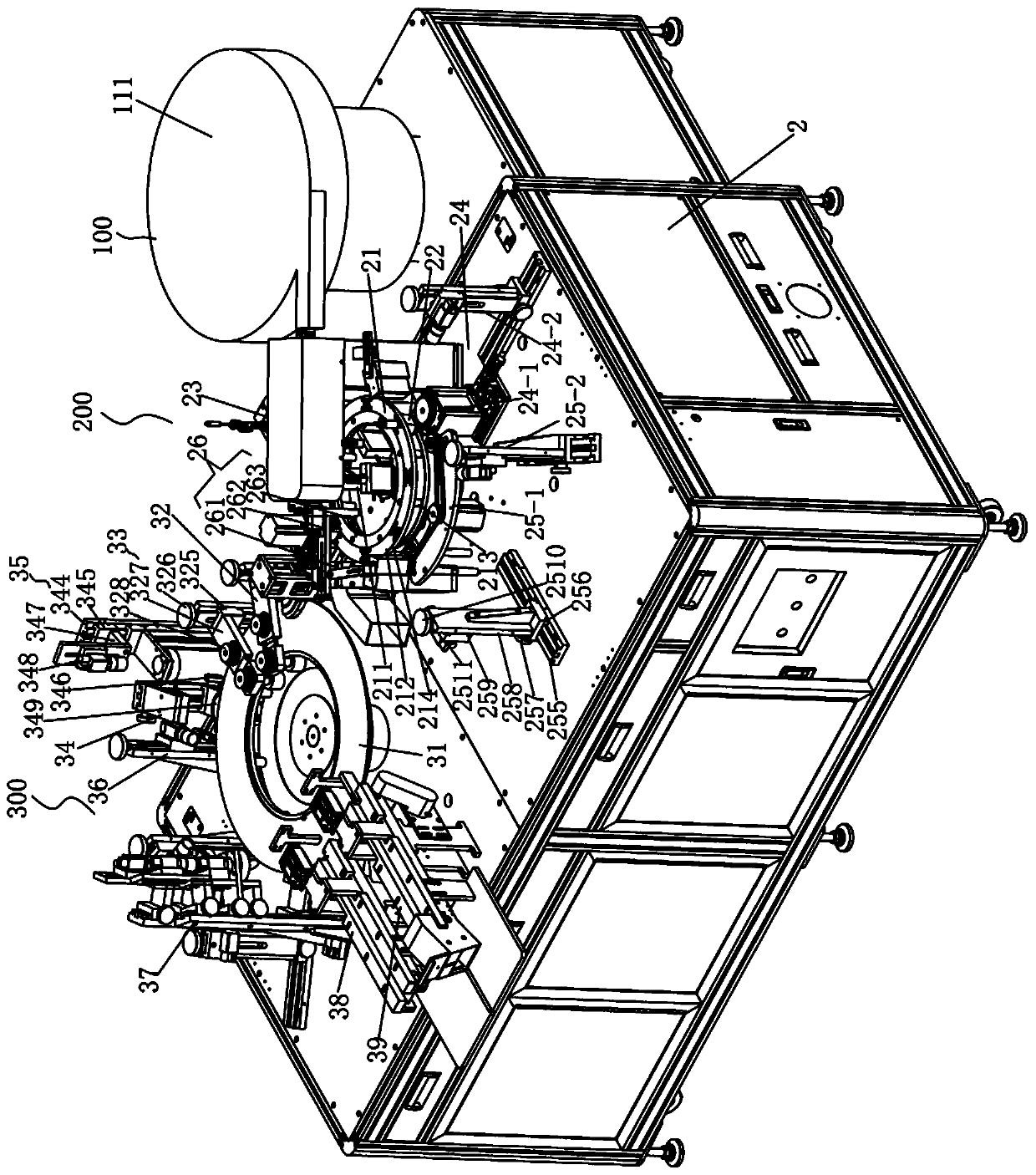

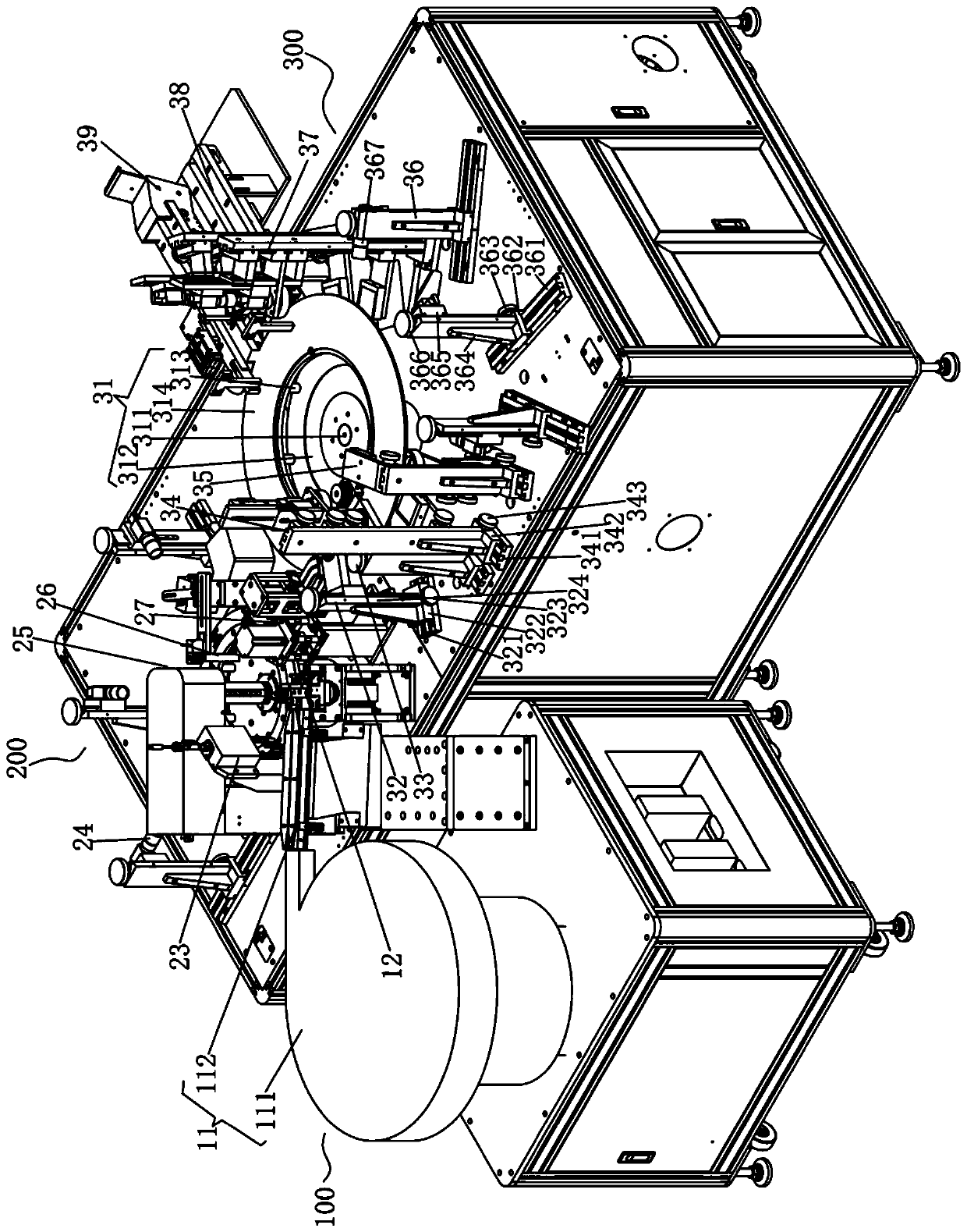

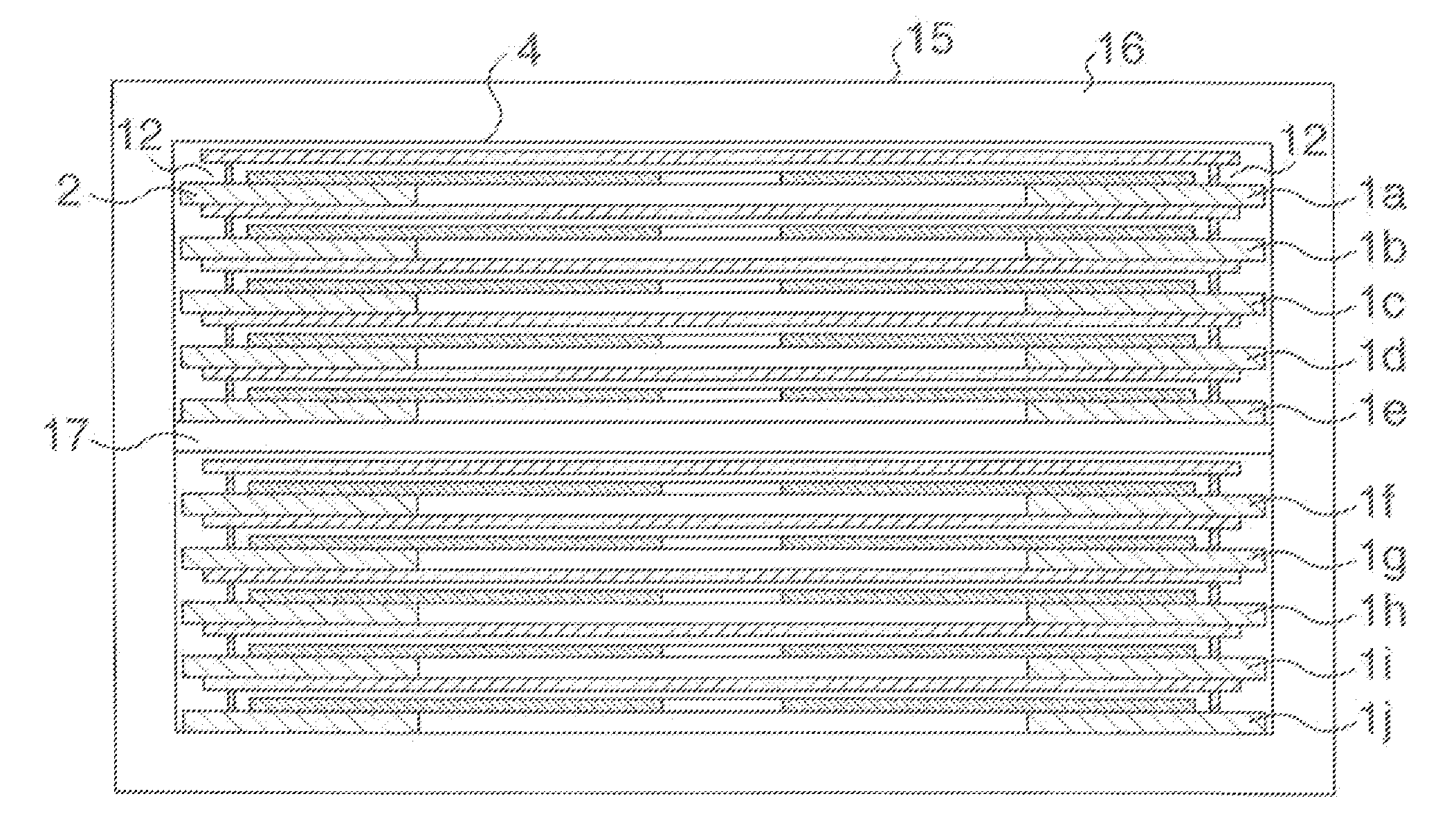

New energy battery cap full inspection machine

The invention relates to a new energy battery cap full inspection machine. The new-energy battery cap full inspection machine comprises a vibration feeder, a glass disc, a full inspection mechanism and a screening rejecting mechanism arranged in turn. The full inspection mechanism comprises a cap inner hole detection mechanism. The cap inner hole detection mechanism comprises a third adjustment fulcrum bar, and a camera assembly is arranged on the third adjustment fulcrum bar above the glass disc, and an auxiliary sampling assembly is arranged on the third adjustment fulcrum bar below the glass disc. The auxiliary sampling assembly is located directly below the camera assembly. The auxiliary sampling assembly comprises a plurality of reflectors arranged in an annular and the plurality of light sources arranged in an annular arrangement on the opposite side of the reflectors. One-to-one corresponding connection lines of the plurality of reflectors and the same plurality of light sourcesintersect at a point. The mirror surfaces of the reflectors are tilted toward the camera assembly. The lighting surfaces of the light sources are directed toward the middle of the corresponding reflectors. The mirror surface angle of each reflector is adjustable, and a lighting surface angle of each light source is adjustable. A protective clamping shell is located outside the reflectors and thelight sources.

Owner:合肥市雅视智能科技有限公司

Optical disc cartridge and recording and reproducing apparatus

InactiveUS20070211581A1Free from damageSo as not to damageRecord information storageOptical recording/reproducingEngineeringSmall hole

An object of the invention is to provide a cartridge storing a plurality of sheet-shaped optical discs in a laminated manner in a state of being accommodated in trays, and a recording and reproducing apparatus of the optical disc. A cartridge stores a lot of trays in a laminated manner. The tray is formed by adhering a flat plate and a flat plate respectively having a smaller hole and a larger hole than a sheet-shaped optical disc, adhering a cover which can be opened and closed to the flat plate, and putting the optical disc in the large hole so as to be covered by the cover. The cartridge is moved up and down by a moving table, and the tray is taken out by being hooked by a hook mechanism. At this time, the cover is peeled out by a peeling claw. The optical disc is fixed to a spindle motor to which a glass disc is attached. The optical disc is rotated while being sucked to the glass disc by a fluid force, and is recorded and reproduced by a recording and reproducing portion. The recording and reproducing apparatus is structured such that the optical disc is turned back to the tray and is compressed to the cartridge by the hook mechanism while being covered by the cover.

Owner:HITACHI-LG DATA STORAGE

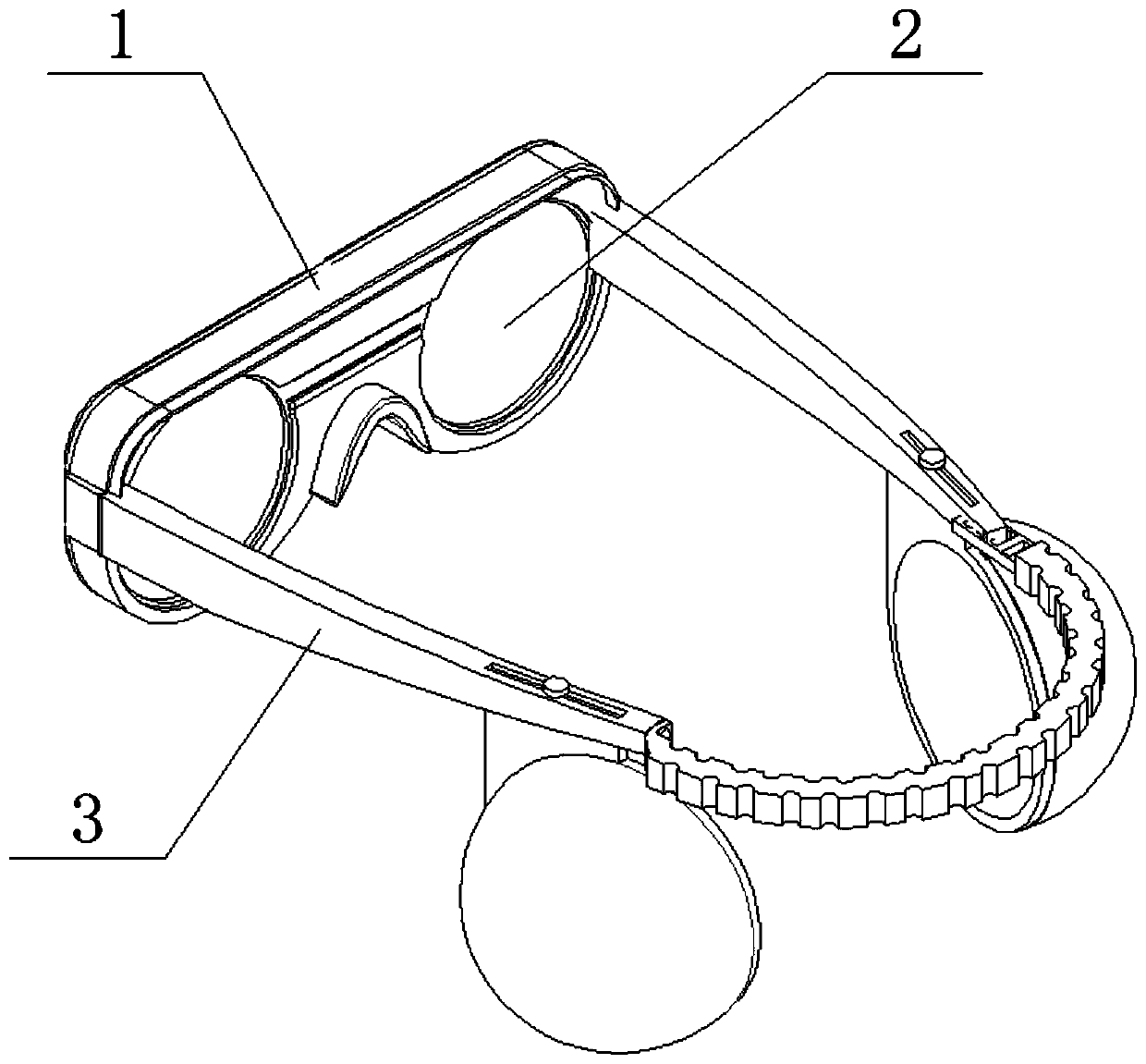

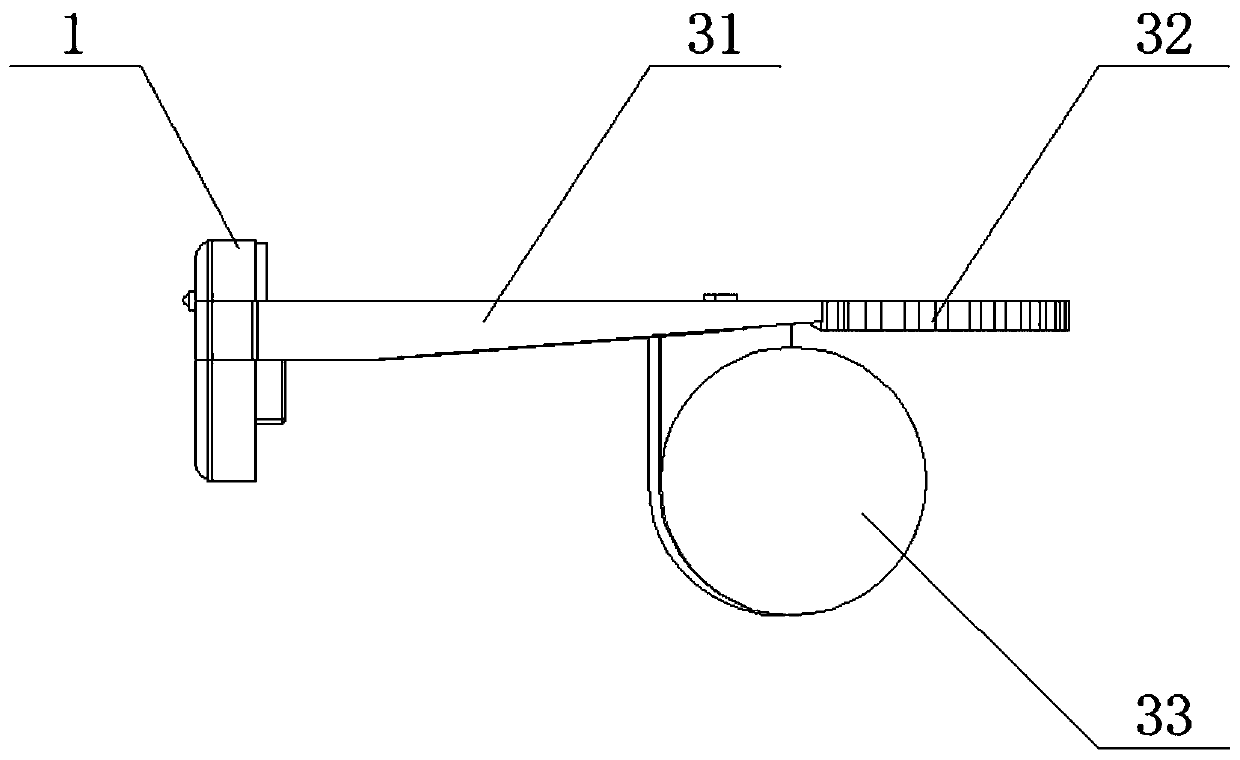

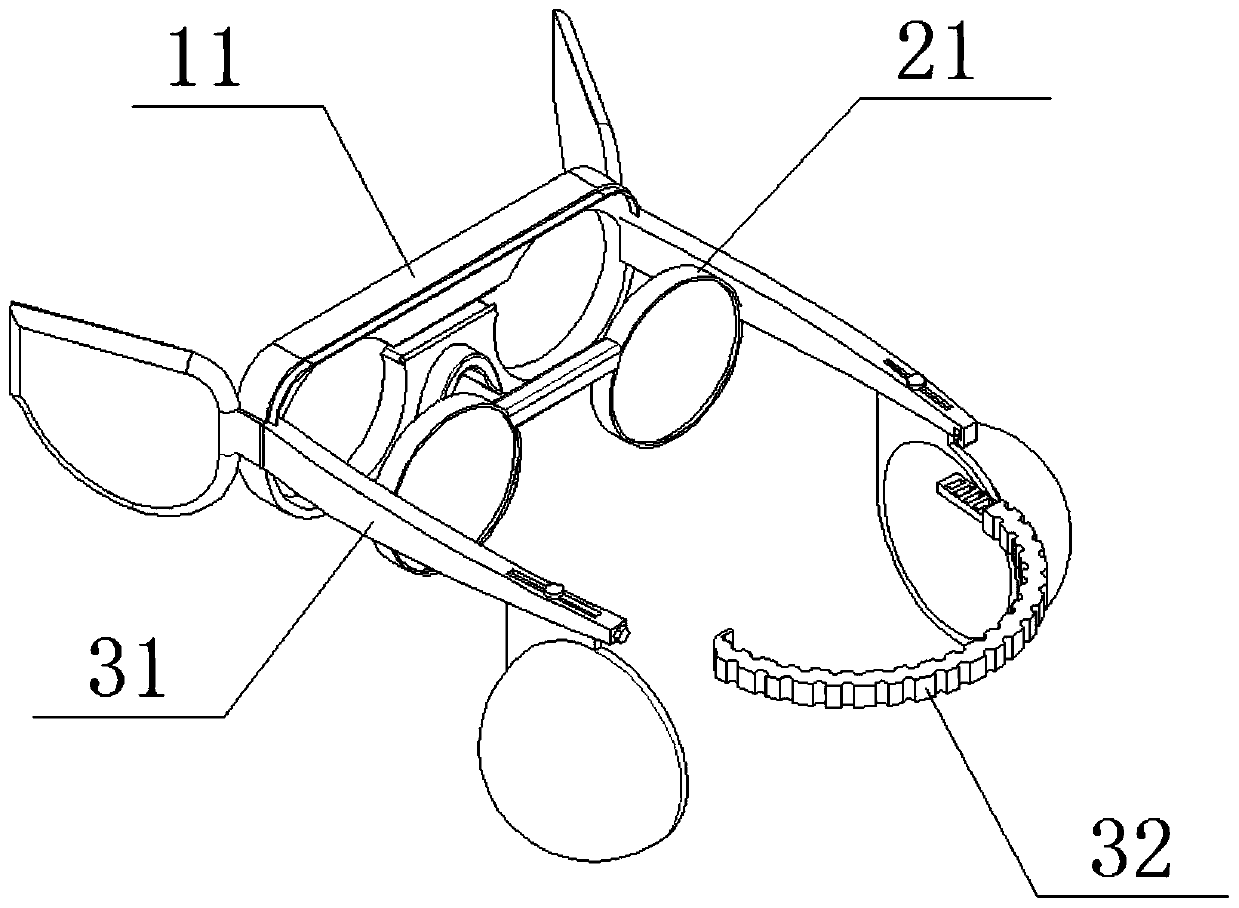

Multi-layer protective outdoor glasses

The invention discloses a pair of multi-layer protective outdoor glasses. The pair of the multi-layer protective outdoor glasses comprises a glasses frame, glasses discs and fixing frames, wherein theglasses frame comprises an auxiliary frame, a transparent baffle and a mounting table; and the transparent baffle is installed in the middle of the inner side face of the matching frame. The transparent baffle plate is fixedly connected with the matching frame. A user can conveniently select proper spectacle lenses to adapt to the outdoor environment according to the use environment and conditions, and the user does not need to carry a plurality of glasses outdoors; through the arrangement of a multi-layer structure, the user can conveniently switch and use the multi-layer structure; the anti-falling performance can be effectively improved; the spectacle frame is simple in structure and convenient to use, normal use of a user is prevented from being affected by damage caused by careless collision when the spectacle frame is used outdoors, and the structural arrangement of the spectacle disc ensures that the user can stably replace the spectacle disc provided with the inner lenses withdifferent colors and functions in the spectacle frame to meet the use requirements in different use environments.

Owner:温州明澈眼镜科技有限公司

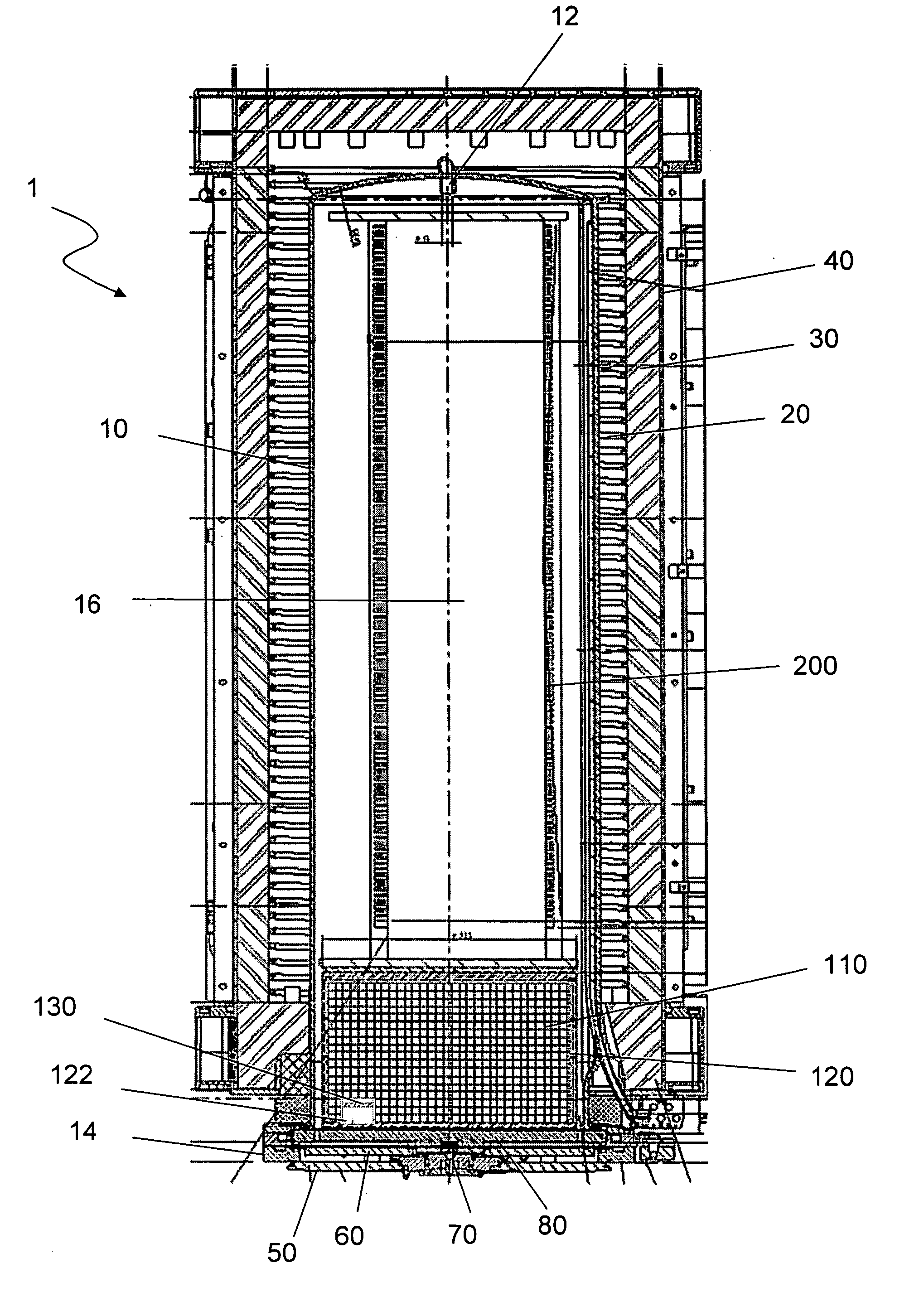

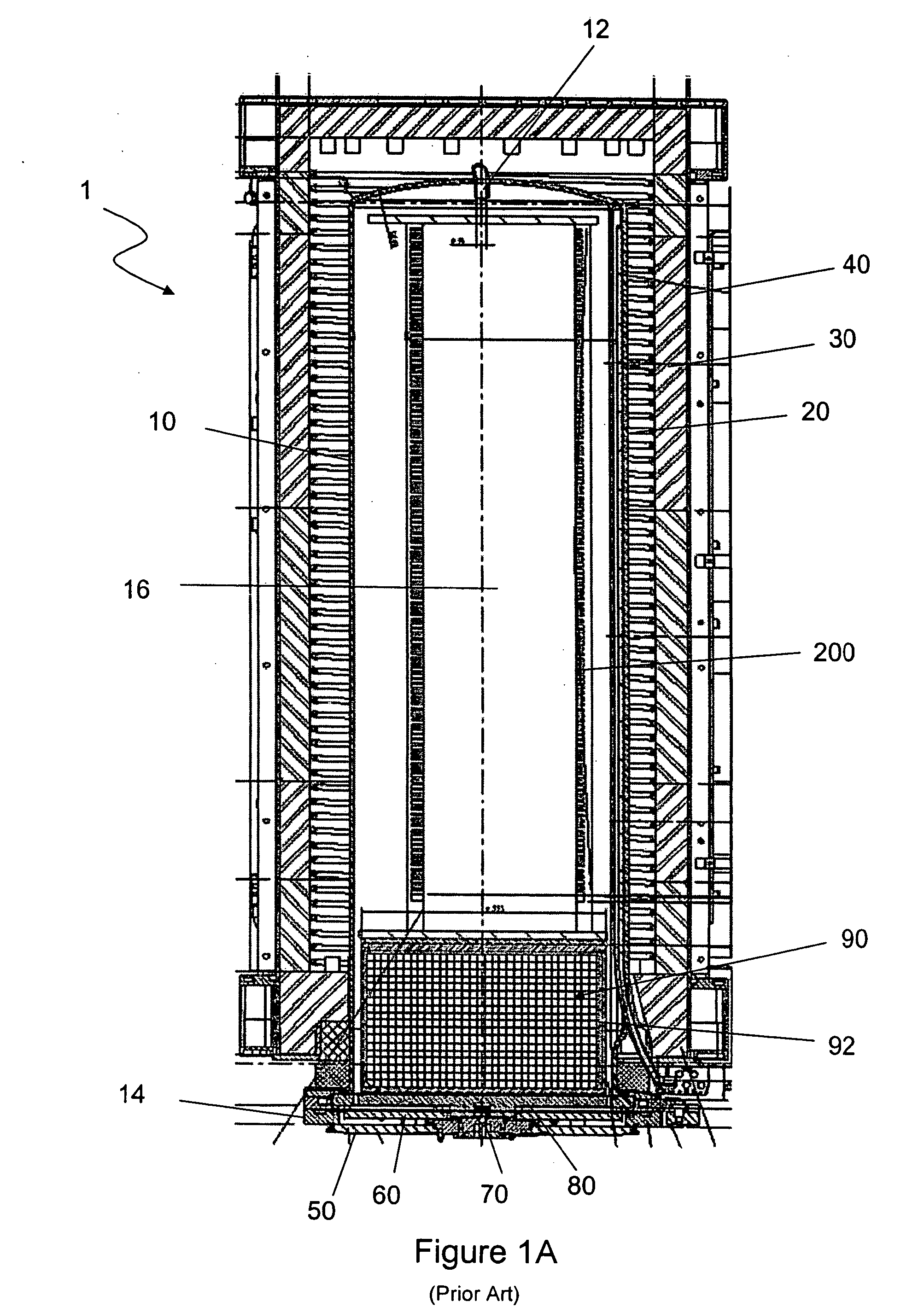

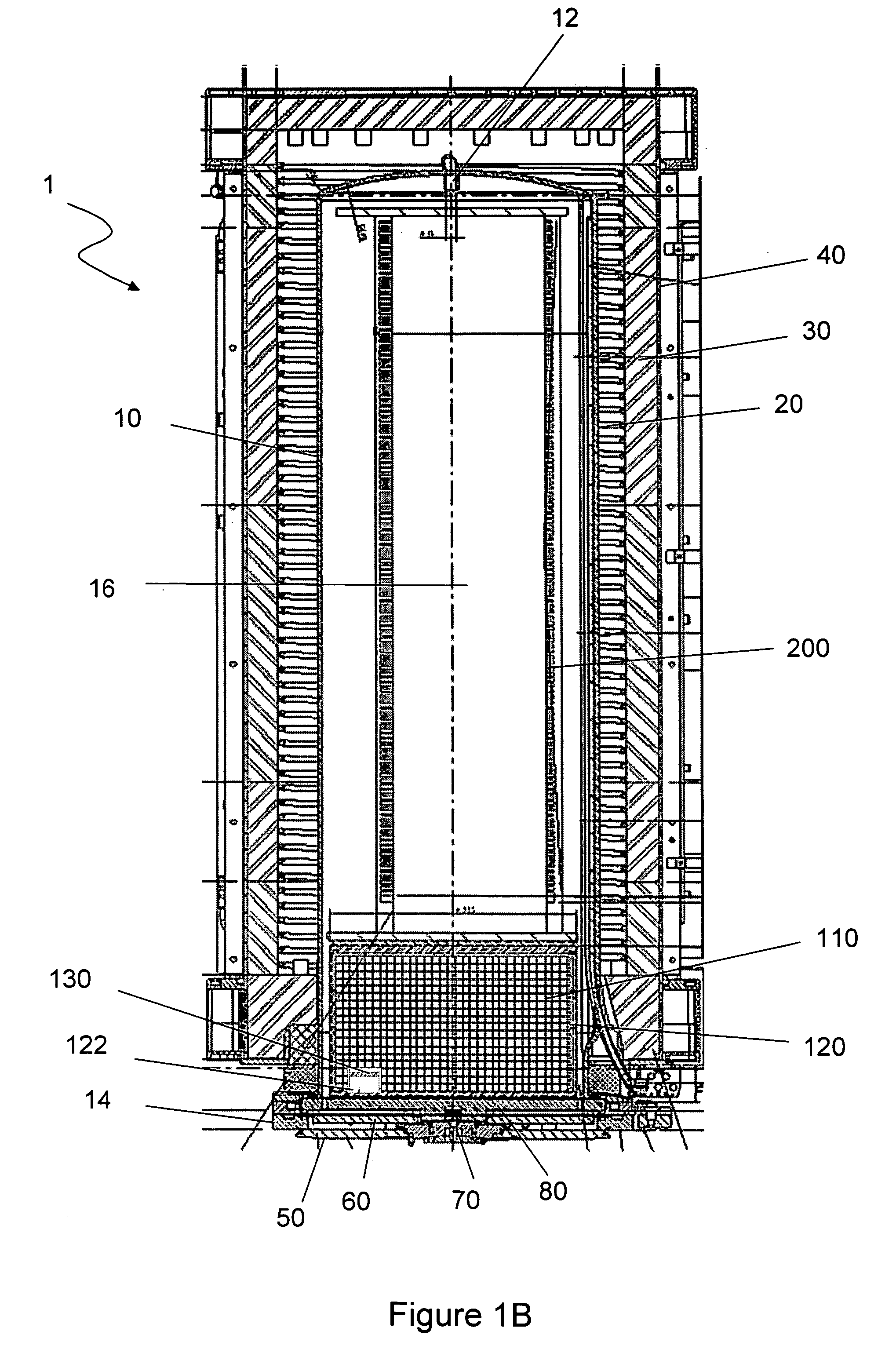

Rack

InactiveUS20080053927A1Easy to insertEasy transferRecord information storagePlatesCompact discMechanical engineering

Glass disc turnover racks for simplifying the insertion of glass discs into a Laser Beam Recorder cartridge are described. The discs are first inserted into the turnover rack and subsequently transferred into the cartridge. The construction of the turnover rack makes it easier to insert the discs in the cartridge. Turnover racks according to the invention comprise a plurality of slots wherein one of the slots has a length that is less than the diameter of the glass disc. Methods of inserting glass discs into the cartridge and use of a glass disc turnover rack to insert glass discs into the cartridge are described.

Owner:PILKINGTON GROUP LTD

Polishing-caused quartz crystal wafer surface shallow scratch visual detection method

InactiveCN107945180AGuarantee the quality of inspectionImage analysisImaging processingOptoelectronics

The invention discloses a polishing-caused quartz crystal wafer surface shallow scratch visual detection method. The method comprises the following steps: 1) placing a quartz crystal wafer onto a glass disc; 2) adopting upper and lower two industrial cameras to focus on the upper and lower surfaces of the quartz crystal wafer respectively; 3) arranging eight 0-angle light sources around the quartzcrystal wafer uniformly with the quartz crystal wafer being the center of a circle; 4) controlling the eight 0-angle light sources to lighten up in sequence, and each time one 0-angle light source islightened up, triggering the upper and lower two industrial cameras to collect a frame of image simultaneously, and enabling the upper and lower two industrial cameras to collect eight frames of images respectively; 5) carrying out processing on the 16 frames of images through an mage processing algorithm, and in the image processing result, if detecting a scratch on one frame of image, judging that the quartz crystal wafer has the scratch, or otherwise, judging that the quartz crystal wafer has no scratch. The method can ensure the detection quality.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

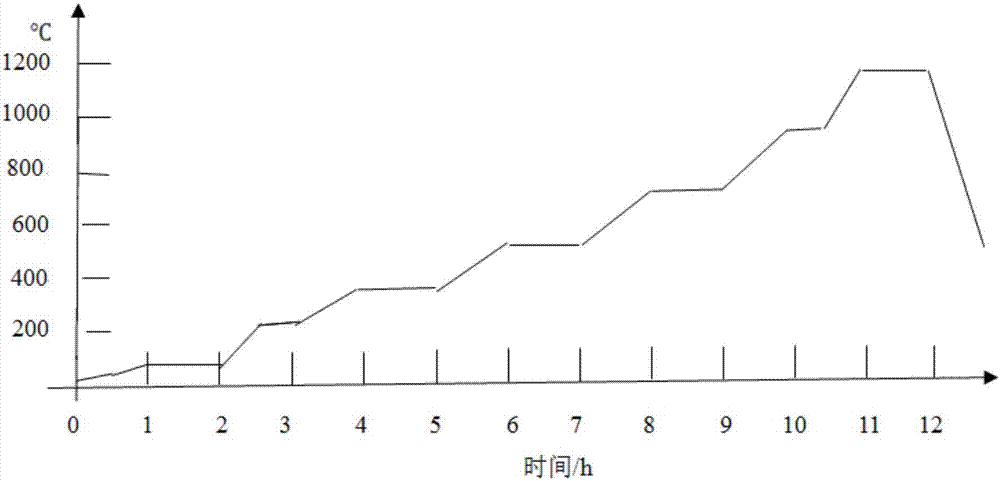

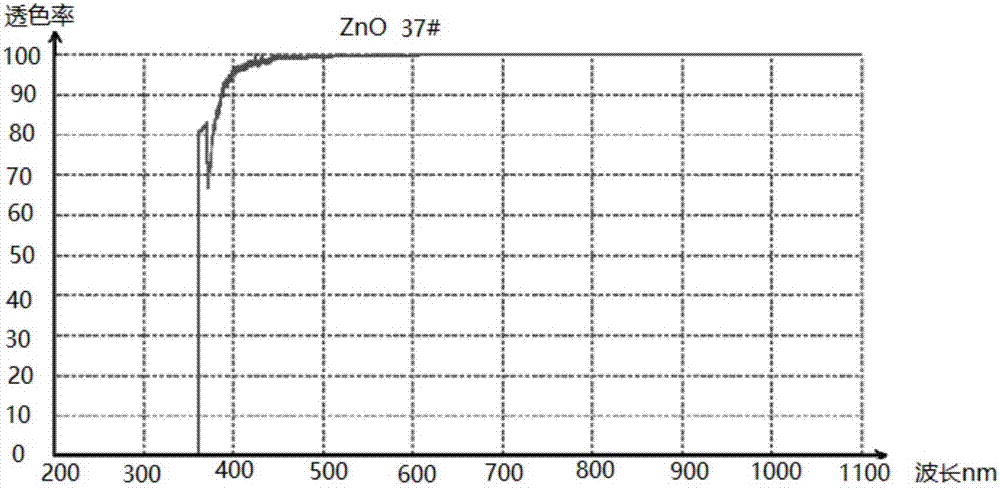

Electron beam evaporation technology based preparation method for ZnO high-transmittance and high-conductivity film

InactiveCN107267929AImprove stabilityHigh light transmittanceVacuum evaporation coatingSputtering coatingNitrogen gasBell jar

The invention discloses an electron beam evaporation technology based preparation method for a ZnO high-transmittance and high-conductivity film. The method comprises the following steps that zinc oxide particles are put in a mold to be pressurized, after the zinc oxide particles are pressed into a compact block, the compact block is taken out and put in a corundum box, the corundum box is put in a sintering furnace after 24 h, and a target is obtained through sinter molding at a certain temperature; and a machine is started to put the target in a copper crucible, quartz glass obtained after cleaning and drying is clamped into a slide glass disc, a bell jar of an electron beam evaporation table is vacuumized, the bell jar is filled with hydrogen or nitrogen to be cleaned, a quartz glass piece is heated, the target is bombarded through electron beams, and the evaporation rate is controlled. The film obtained through the method has high stability, light transmittance and conductivity, the price of adopted raw materials is extremely low, and the basic requirements for the high light transmittance, the high conductivity and the low price of the transparent conductive film are met.

Owner:张治国

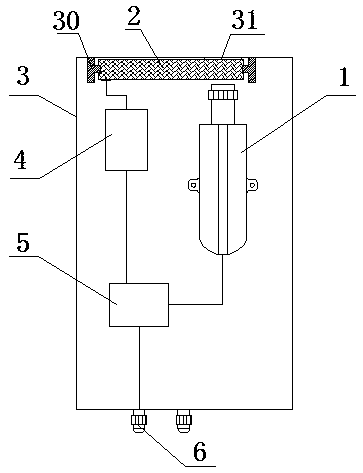

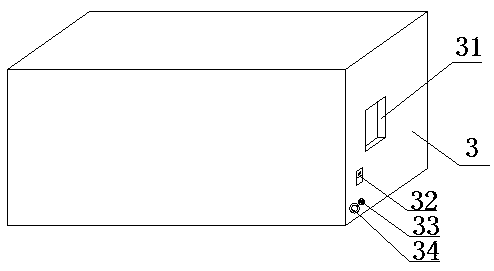

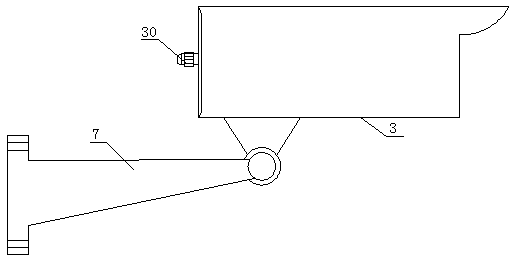

Coal mine intrinsic safety type camera device capable of automatically cleaning camera window

PendingCN111147728AEasy to disassembleGuaranteed clean as newTelevision system detailsColor television detailsCamera lensElectric machinery

The invention relates to a coal mine intrinsic safety type camera device capable of automatically cleaning a camera window. A camera and an automatic cleaning mechanism are integrated in a protectivecover, and the automatic cleaning mechanism is arranged between a camera lens of the camera and a camera port of the protective cover; the automatic cleaning mechanism is integrated in a flat box typeshell, the shell is provided with the camera window, and the camera window is right opposite to the camera lens and the camera port of the protective cover; a circular glass disc is arranged in the shell of the automatic cleaning mechanism and connected with an output shaft of a driving motor, and the driving motor is electrically connected with a control mainboard and a power module in the protective cover. One side of the glass disc shields the camera window, the other side of the glass disc is provided with a cleaning cotton group, the two inner surfaces of the shell are respectively and fixedly provided with the cleaning cotton group, and the cleaning cotton group clamps the glass disc; and a light-transmitting sensor is arranged at the camera shooting window and is electrically connected with the control mainboard. The glass disc replaces a traditional sight glass, the automatic cleaning mechanism can guarantee that the mirror surface of the glass disc is smooth and clean as new,and the light transmitting effect of the camera window is guaranteed.

Owner:KAILUAN GRP

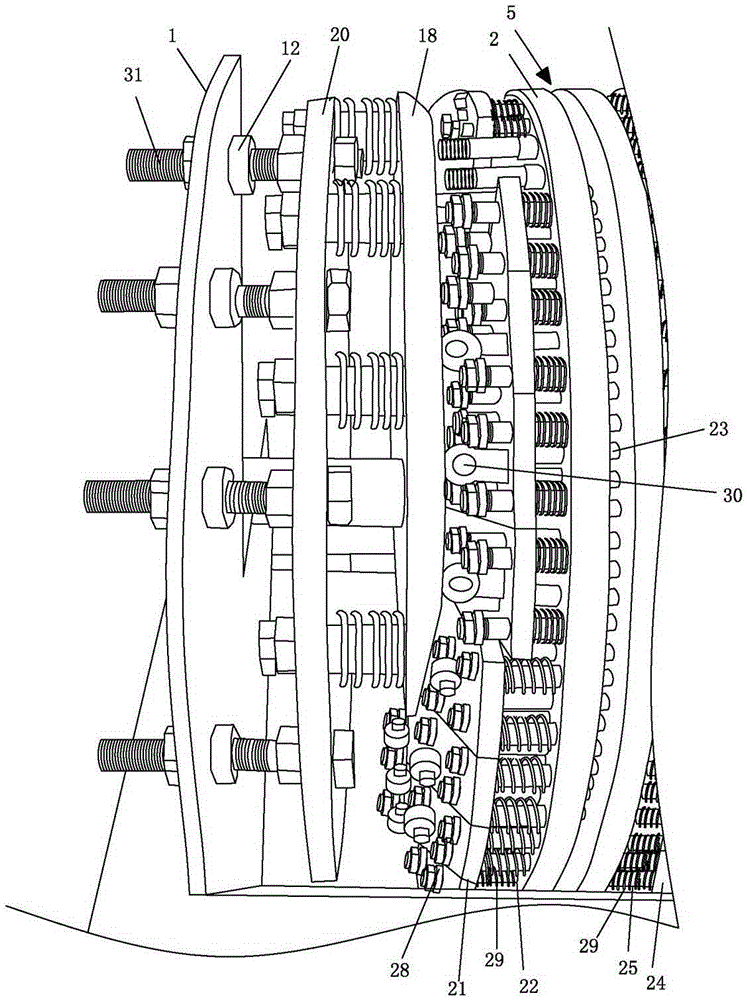

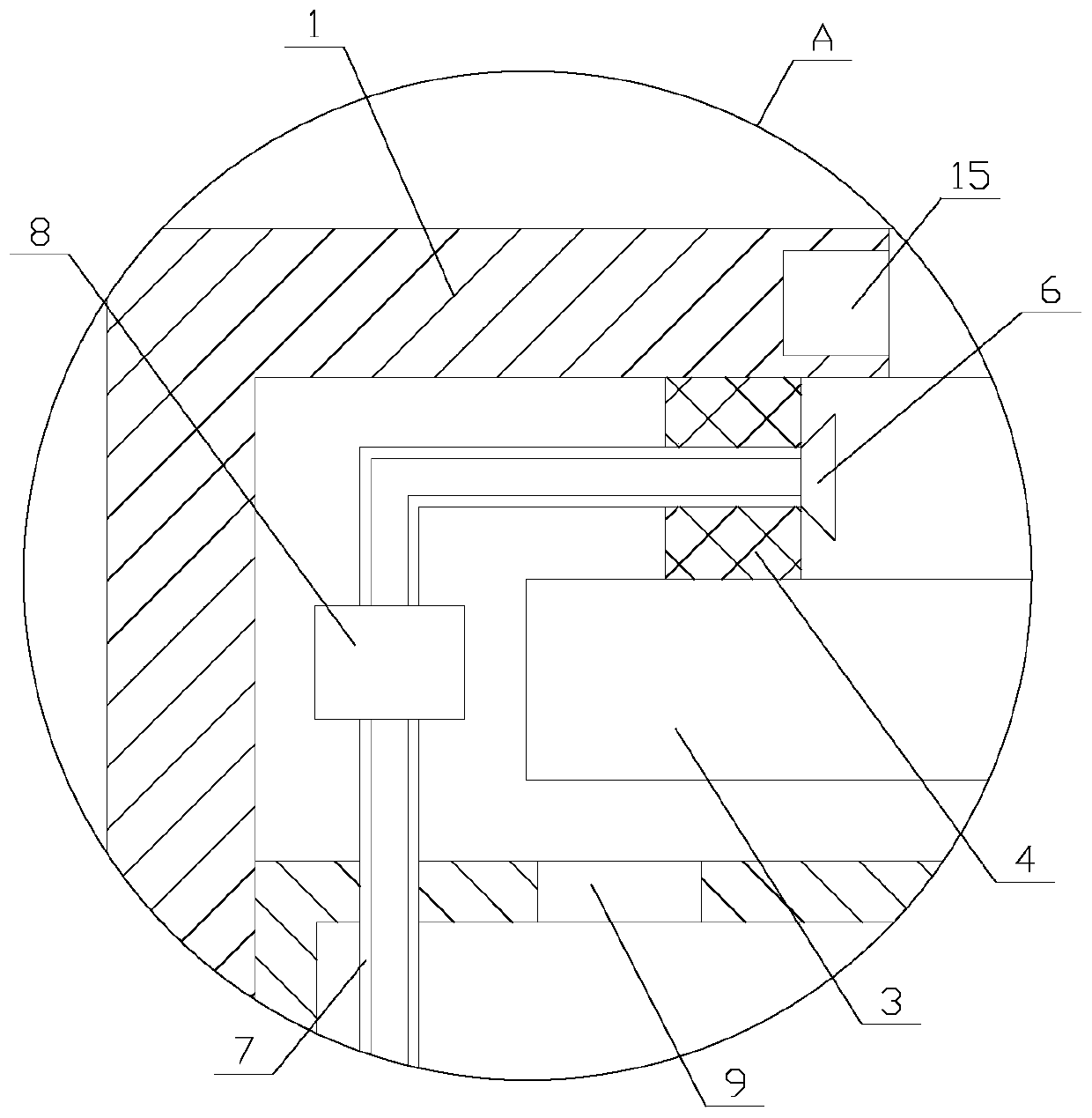

Friction experiment table for initiatively regulating and controlling thickness of lubricating film between friction pair

The invention relates to a friction experiment table for initiatively regulating and controlling the thickness of a lubricating film between a friction pair, belonging to the technical field of mechanical friction. In the experiment table, a glass disc is fixed at the upper end part of a rotating shaft by a fixing screw and is connected with the rotating shaft; a hinge is arranged on a lubricating experiment table and a lever penetrates through the hinge; an oil cup is arranged at one end of the lever and a weight is hung at the other end of the lever; a steel ball is arranged between the upper surface of the oil cup and the lower surface of the lubricating experiment table; the lower part of a piezoelectric ceramic rod is fixed on a piezoelectric ceramic bracket by fastening screws; a fine tuning spiral rod is arranged at the lower part of the piezoelectric ceramic bracket; and the lower end part of the piezoelectric ceramic rod is connected with a piezoelectric ceramic controller by a signal wire. According to the friction experiment table, the gap between the steel ball and a glass disc point contact pair can be roughly adjusted; and the displacement generated by piezoelectric ceramic is further reduced at the near end of the lever by a lever principle, so that the gap between the ball and the disc point contact pair is accurately controlled.

Owner:TSINGHUA UNIV

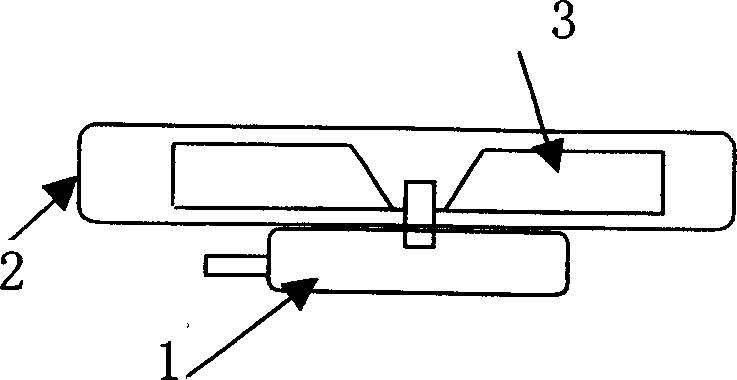

Two-way speed point contact photoelastic flow test bed

InactiveCN110274547AReasonable structureImprove test accuracyUsing optical meansSteel ballVibration exciter

The invention belongs to the technical field of optical interference test equipment and relates to a two-way speed point contact photoelastic flow test bed. The main body structure of the two-way speed point contact photoelastic flow test bed includes a guide rail, a ball box, servo motors, couplings, a small ball connecting rod, a ball support, a steel ball, a tension spring, a glass disc, a threaded pressing plate, a bearing, a main shaft, vibration exciter connecting rods, a vibration exciter shaft sleeve and a vibration exciter threaded support. When the two-way speed point contact photoelastic flow test bed is to be used, the two-way speed point contact photoelastic flow test bed is connected with a camera, a microscope, a signal generator, a computer and two vibration exciters; the vibration exciters drive the steel ball to perform reciprocating motion and the glass disc to rotate; the microscope and the camera arranged on a support are used for recording the oil film image of the contact area of the steel ball and the glass disc in a test process and storing the oil film image into the computer; the No. 1 servo motor controls the rotation speed of the steel ball; the No. 2 servo motor controls the rotation speed of the glass disc; the vibration exciters control the axial reciprocating motion distance of the steel ball; the signal generator controls the frequency of the axial reciprocating motion of the steel ball; and the computer controls the magnitude of the initial load of the vibration exciters in the test process.

Owner:DONGHUA UNIV

Glass disk forming machine

InactiveCN105347658AGood removal effectGood technical effectGlass shaping apparatusGlass productionPunchingSemi solid

The invention relates to a glass forming machine and discloses a glass disk forming machine. The glass disk forming machine comprises a base, a disc is rotatingly connected to the base, the circumferential surface of the disc is provided with an annular material groove, the outer side of the disc is provided with a plurality of mold units arranged in an annular way, the mold unit comprises a punching pin slidingly sleeved by one side of the disc, an ejector pin slidingly sleeved by the other side of the disc and a female mold arranged at the side wall of the annular material groove, one end of the punching pin stretches out of the disc, the other end of the punching pin aligns at the female mold, one end of the ejector pin stretches out of the disc, the other end of the ejector pin stretches into the female mold, the base corresponding to the punching pin is provided with a first guide plate capable of extruding the punching pin, and the base corresponding to the ejector pin is provided with a second guide plate capable of extruding the ejector pin. The glass disk forming machine has a simple structure. The punching pin is guided by the first guide plate to be inserted into the female mold, simultaneously, semi-solid glass melt in the annular material groove is poured into the female mold, and after the glass disc is molded and cooled, the ejector pin is guided by the second guide plate to go through the female mold so that the molded glass disc is pushed out of the female mold by the ejector pin.

Owner:YONGDING YIXIN MACHINERY MFG

Fingerprint identification system with sterilization function for community security and protection

InactiveCN110503016AWith the function of removing fingerprintsImprove securityRegistering/indicating time of eventsIndividual entry/exit registersEngineeringIdentification device

The invention relates to a fingerprint identification system with a sterilization function for community security and protection. The system comprises a fingerprint identification device which comprises a main body and four support legs, wherein the main body is rectangular; the support legs are uniformly arranged at the bottom of the main body; an identification mechanism and an auxiliary mechanism are arranged in the main body; the recognition mechanism comprises a glass disc, a cleaning ring, a recognizer and a rotating assembly. The auxiliary mechanism comprises a nozzle, a connecting pipe, a first one-way valve, a second one-way valve, a fixed pipe, a fixed box, a movable disc and a pushing assembly. According to the fingerprint recognition system with the sterilization function for community security and protection, the fingerprint recognition function is achieved through the recognition mechanism, and in addition, the sterilization and disinfection effect is achieved through theauxiliary mechanism.

Owner:GUANGZHOU JIAJIANPAI ELECTRONICS TECH CO LTD

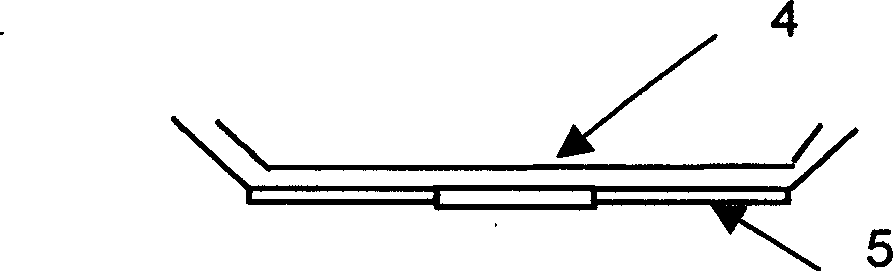

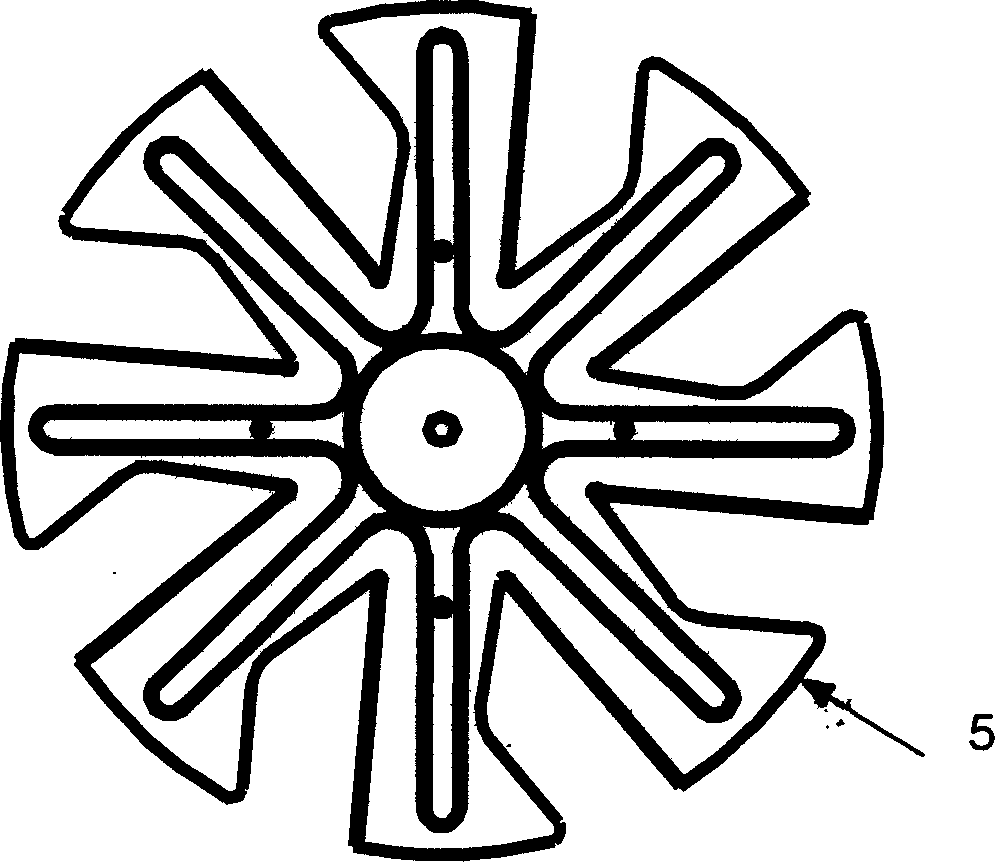

Microwave oven with improved heating uniformity structure

InactiveCN1782504ACooking effect changesImprove uniformityDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

The microwave oven with improved heating uniformity structure includes a microwave oven heating chamber, a driving motor set in the bottom to drive the glass disc to rotate, and a wave disturbing fan set between the driving motor and the glass disc. The wave disturbing fan consists of fan vanes fixed on the wheel shaft and a circular casing with a central hole for fixing onto the driving motor shaft. The fan vanes have diameter not smaller than that of the glass disc. Owing to the large wave disturbing fan vanes to disturb microwave in the bottom, the microwave oven of the present invention has obviously improved cooking effect, especially obviously raised cooking uniformity.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Glass disc cutting method

The present invention provides a glass disc cutting method. The method is characterized in that flat glass is bonded to a liner of whom the strength and material is similar to those of the plat glass by an adhesive before cutting. For example, when flat glass is used as the liner, upper glass and lower glass is bonded together, so that during a process of the upper layer glass being cut by a lip of a hollow drill, when the upper glass left only about 1 mm, as the strength of the lower layer glass is the same as that of the upper layer glass, during the drill lip pushing, downward bending deformation of the glass under the drill lip is effectively limited due to the support of the lower glass, thereby avoiding crack edges.

Owner:黄家军

Appearance detector for electronic chip element

InactiveCN105352962AHigh speed detectionSimple structureMaterial analysis by optical meansLocation detectionCircular disc

The invention relates to the technical field of electronic element and relates to an appearance detector for electronic chip element. The appearance detector comprises a feeding mechanism, a transparent rotary disc convey mechanism, detection mechanisms, a sorting mechanism and a control system. The feeding mechanism is composed of a disc material-conveying device and a straight material-conveying device. The transparent rotary disc convey mechanism comprises a glass disc; each of the detection mechanisms comprises a position detection unit, a CCD camera unit, a LED illumination unit, and a focusing adjusting unit; the six sets of detection mechanisms are separately arranged at upper part, lower part and edge part of the transparent glass disc; the sorting mechanism comprises a high speed solenoid valve, a qualified cabin, unqualified cabin and a redetection cabin. The glass disc is employed to implement high speed detection for the six sides of the electronic element; one sorting mechanism is employed and the structure is simple and is easily maintained ; the detection mechanisms can directly capture images and transmit information about six sides of the electronic element, and adapt to high speed detection and replaces the manual operation; the detection quality is stable and the detector has a low cost.

Owner:肇庆市宏华电子科技有限公司

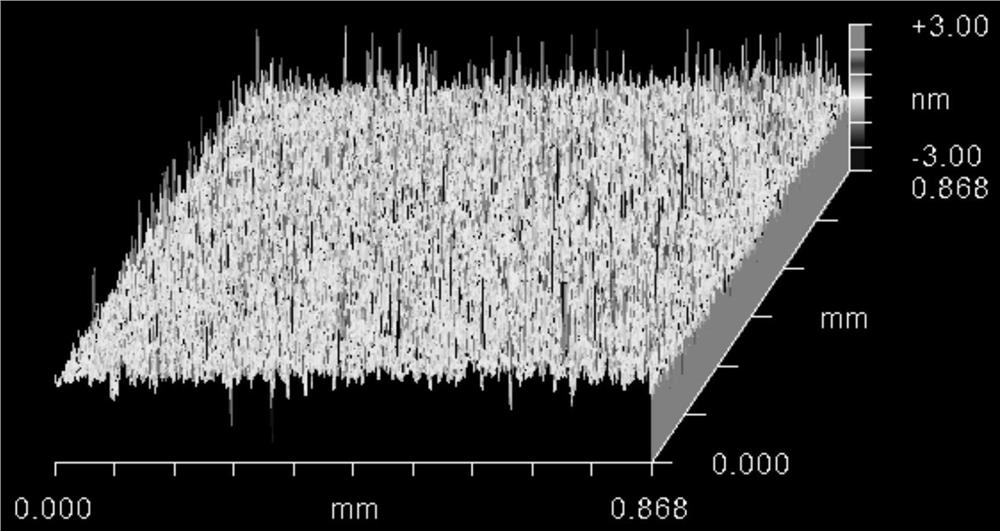

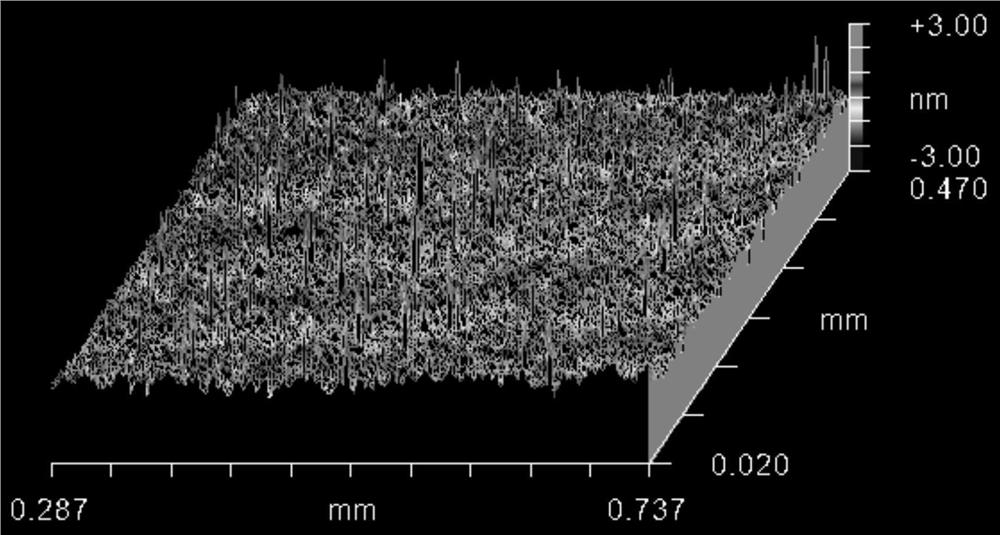

Visible light assisted diamond chemical mechanical polishing solution and polishing method

ActiveCN113831845AReduce surface roughnessFast polishing rateLapping toolsPolishing compositions with abrasivesUltraviolet lightsSurface roughness

The invention provides a visible light assisted diamond chemical mechanical polishing method, and belongs to the field of ultra-precision machining of ultra-hard materials. The polishing solution is composed of a grinding material, an oxidizing agent, a visible light photocatalyst and deionized water. According to the invention, under irradiation of a visible light source, a polishing solution is used for conducting chemical mechanical polishing on diamond, wherein the visible light source is arranged at the position 10-20 cm right above a polishing disc, the polishing disc (pad) is a glass disc or a polyurethane polishing pad, the rotating speed of the polishing disc (pad) is 50-70 r / min, the polishing pressure is 1-2 MPa, the flow of the polishing solution is 10-20 ml / min, and the surface roughness of the polished diamond can reach 0.250 to 0.354 nm; high-efficiency ultra-smooth chemical mechanical polishing of the diamond is realized; compared with a traditional polishing method, the crystal surface roughness is reduced, and the polishing efficiency is improved; and compared with an ultraviolet light-assisted chemical mechanical method, used equipment is simple in structure and high in practicability.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com