Higher-pair contact variable sliding-rolling ratio oil film thickness and friction simultaneous measurement simulation device

A technology for simulating device and slip-to-roll ratio, applied in measuring device, force/torque/work measuring instrument, mechanical device, etc., can solve personnel error, increase manpower, material and financial resources, and inaccurate performance of lubricating oil in reducing friction and anti-wear Advanced problems, to achieve good practicability, improve accuracy and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

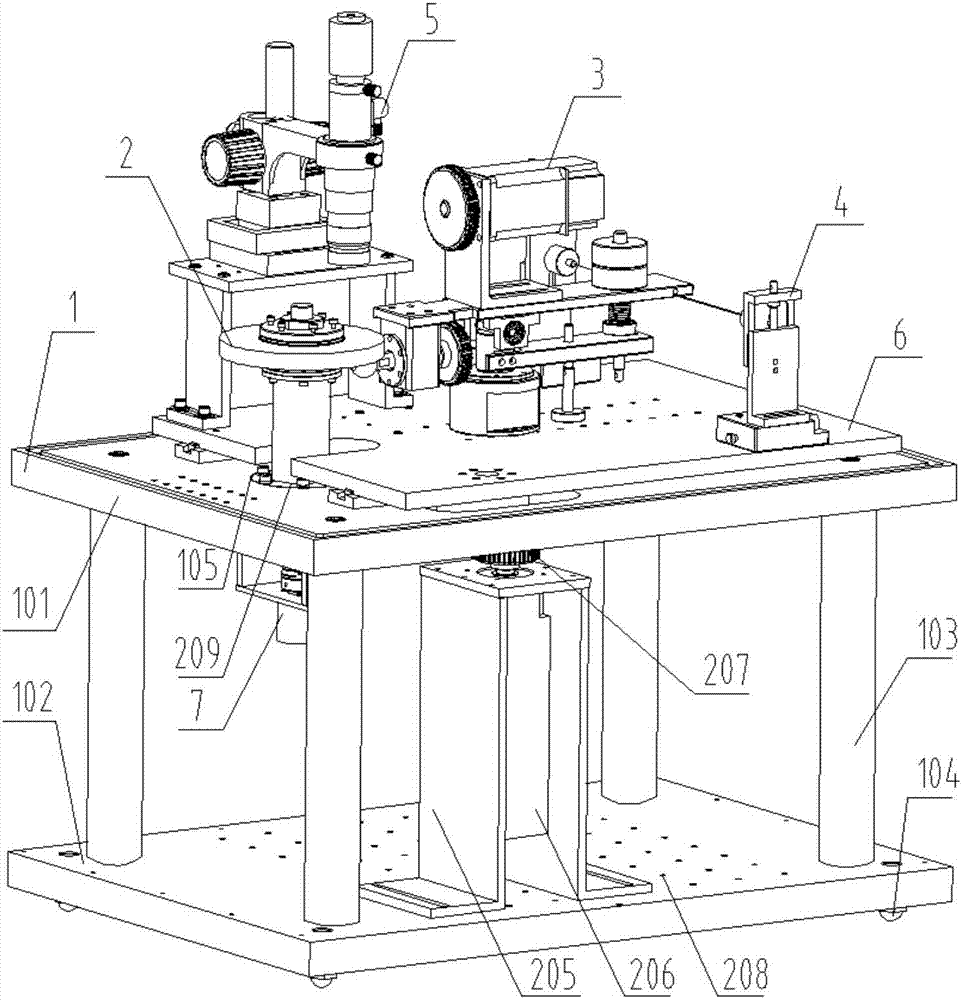

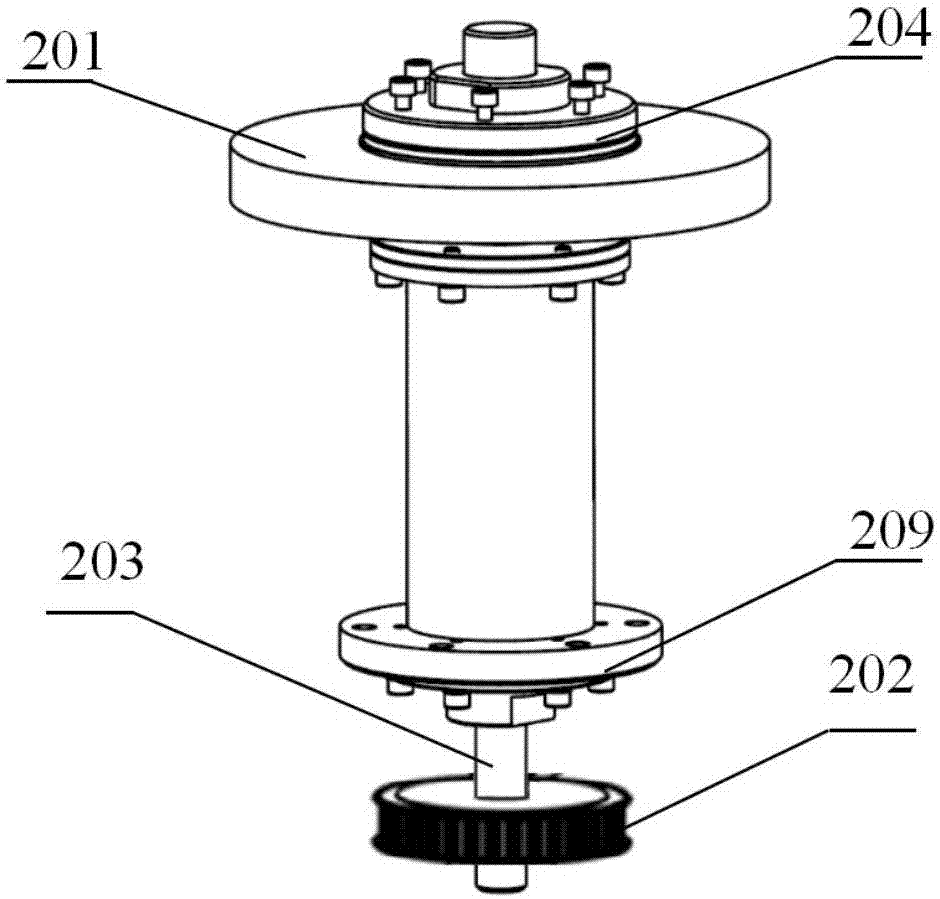

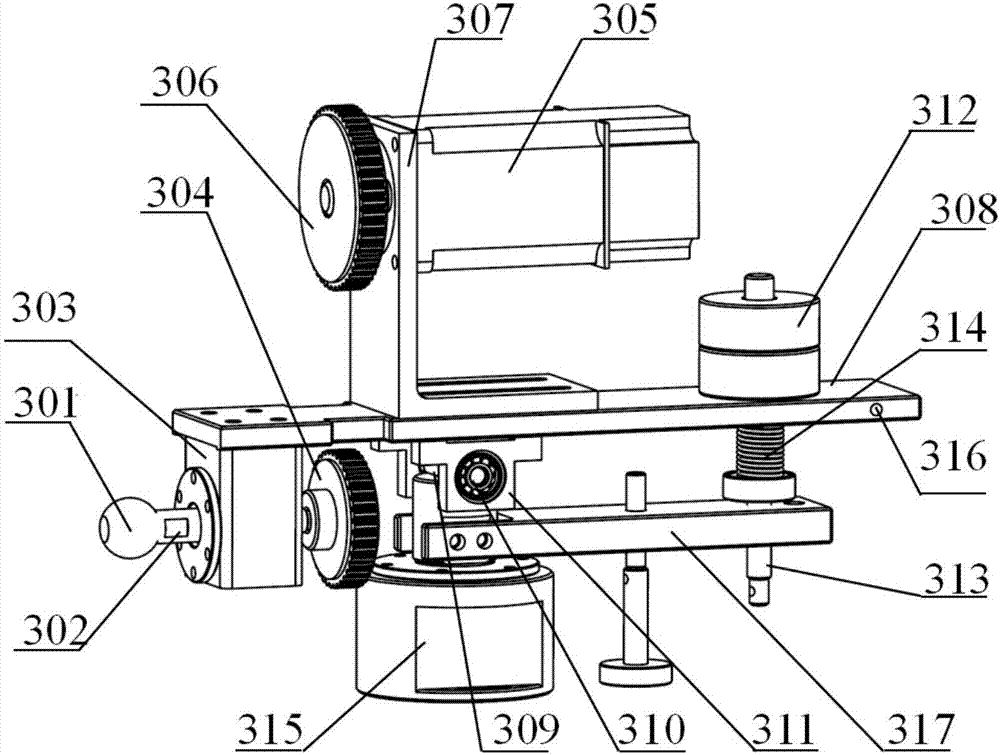

[0040] The main structure of the high-stress contact variable slip-to-roll ratio oil film friction and film thickness measurement simulation device involved in this embodiment includes: a support platform 1, a disk drive device 2, a ball drive loading and turning device 3, a sensor fixing adjustment device 4, an image Acquisition device 5, translation device 6 and velocity measuring device 7, the main structure of described support platform 1 comprises upper platform 101, lower platform 102, support column 103, support foot 104 and through hole 105, described upper platform 11 and lower platform 12 All are metal structures with a square structure, and the length and width of the upper platform 11 and the lower platform 12 are equal, and the upper platform 11 and the lower platform 12 are connected by cylindrical metal support columns 13 at the four corners. The lower side is fixed with support feet 14 for supporting the base, so as to prevent the lower platform 12 from contacti...

Embodiment 2

[0048] In this embodiment, when measuring the friction force and film thickness of lubricating oil film with high secondary contact variable slip-to-roll ratio, the specific measurement steps are as follows:

[0049] (1) Adjustment of turning radius and loading force:

[0050] First translate the front and rear positions of the plate 603 to adjust the radius of gyration of the steel ball 301 on the glass disc 201, then adjust the spring seat 313 and spring 314 to zero the contact load, and place the weight 312 on the loading plate 308 to the required level for the experiment. load;

[0051] (2) Adjustment of the position of the pull pressure sensor:

[0052] First adjust the support screw 403 to adjust the height of the sensor connecting plate 404, so that the tension and pressure sensor 405 reaches the required height, fix the support screw 403 after the adjustment, and then move the one-dimensional translation platform 401 to adjust the required tension , fix the one-dimen...

Embodiment 3

[0066] This embodiment adopts the device described in embodiment 1 to measure PAO100 lubricating oil under the load condition of 16N, under different slip-to-roll ratios, the oil film thickness and friction coefficient are measured simultaneously, and the measurement results are as follows Figure 9 As shown, the friction coefficient gradually increases with the increase of the slip-to-roll ratio. While measuring the friction coefficient, the real-time lubricating oil film interference image is acquired by the image acquisition device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com