Patents

Literature

428 results about "Evaluation testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Test and Evaluation. Definition: Test & Evaluation (T&E) is the process by which a system or components are compared against requirements and specifications through testing. The results are evaluated to assess progress of design, performance, supportability, etc.

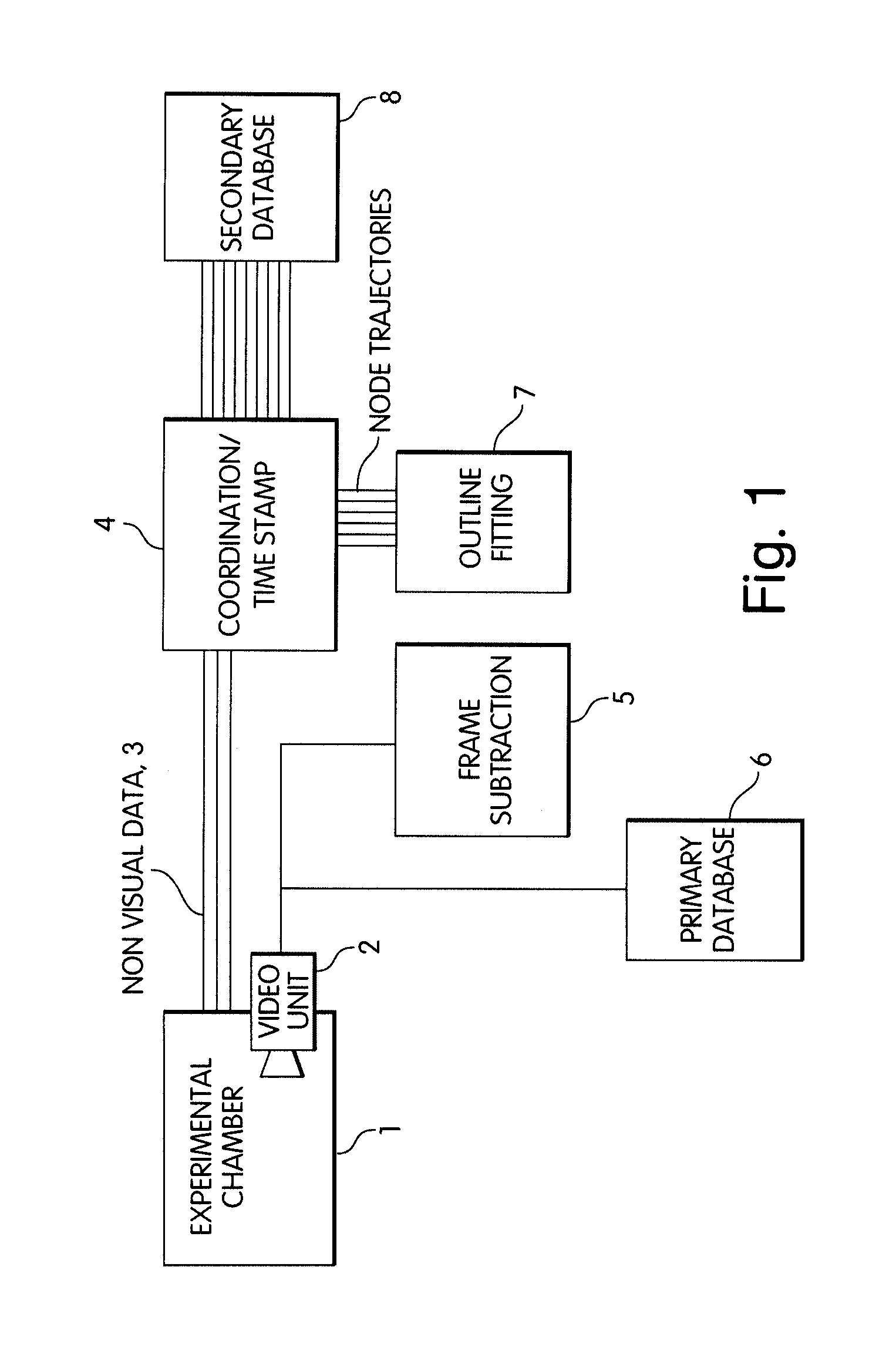

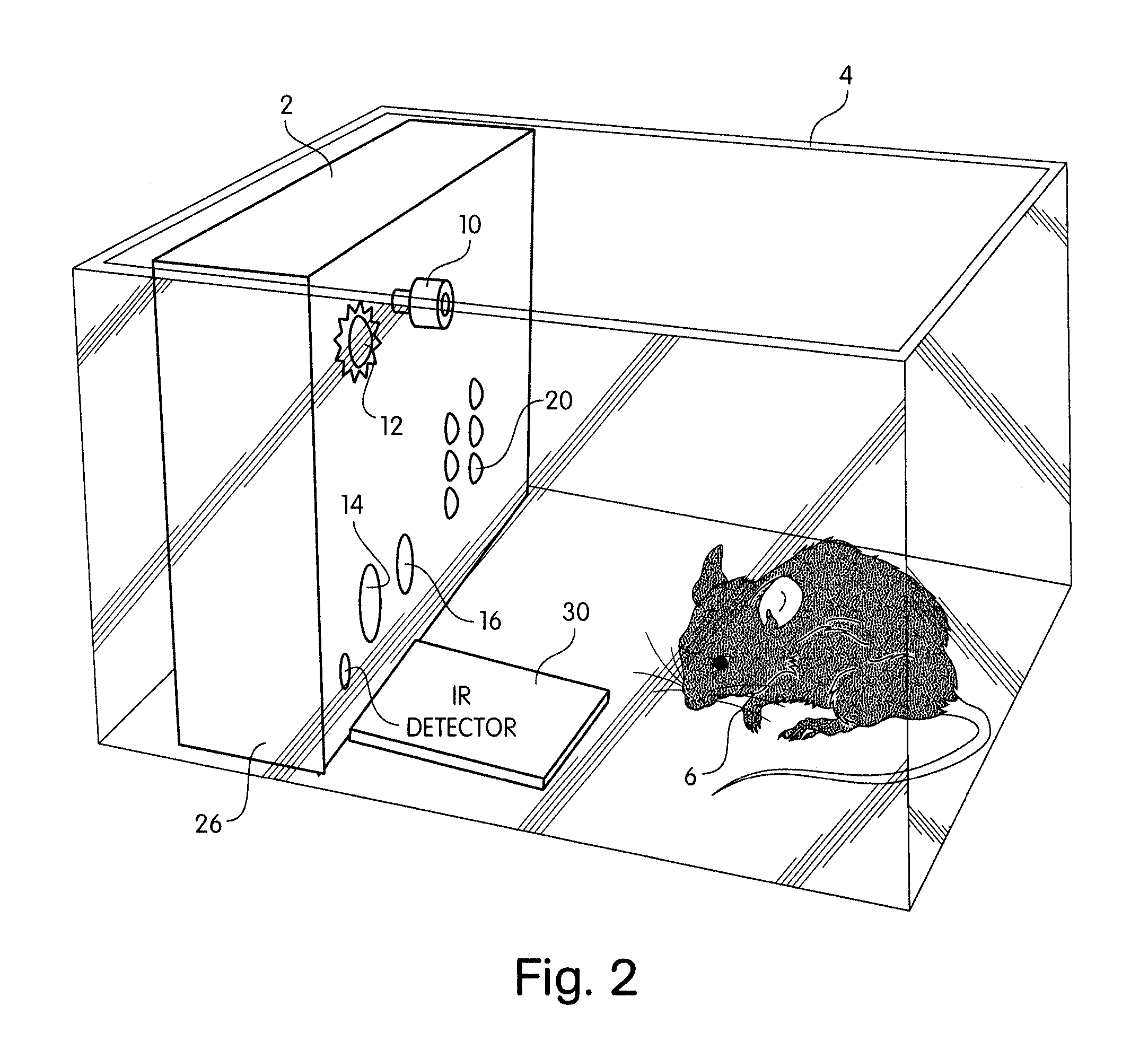

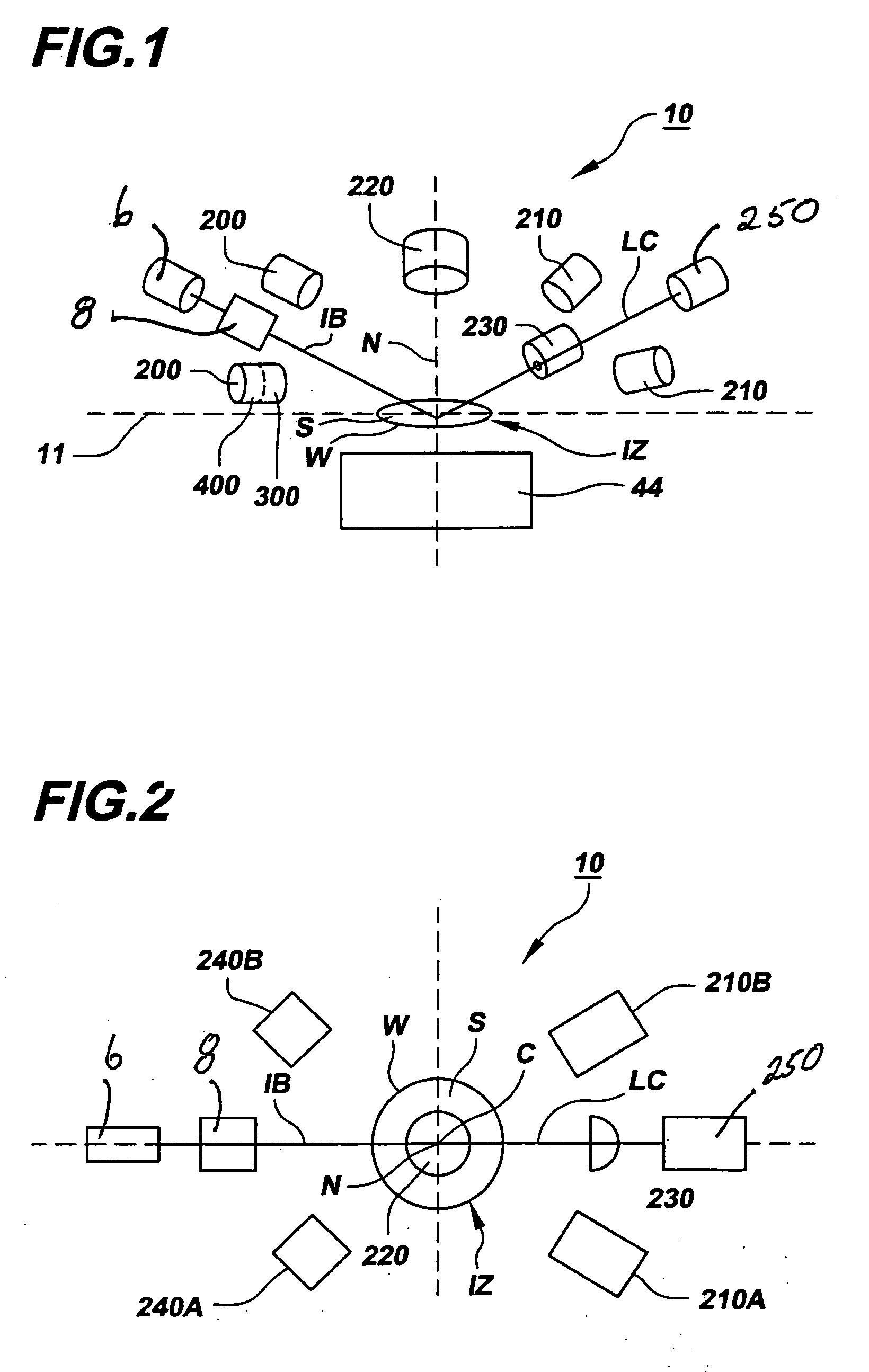

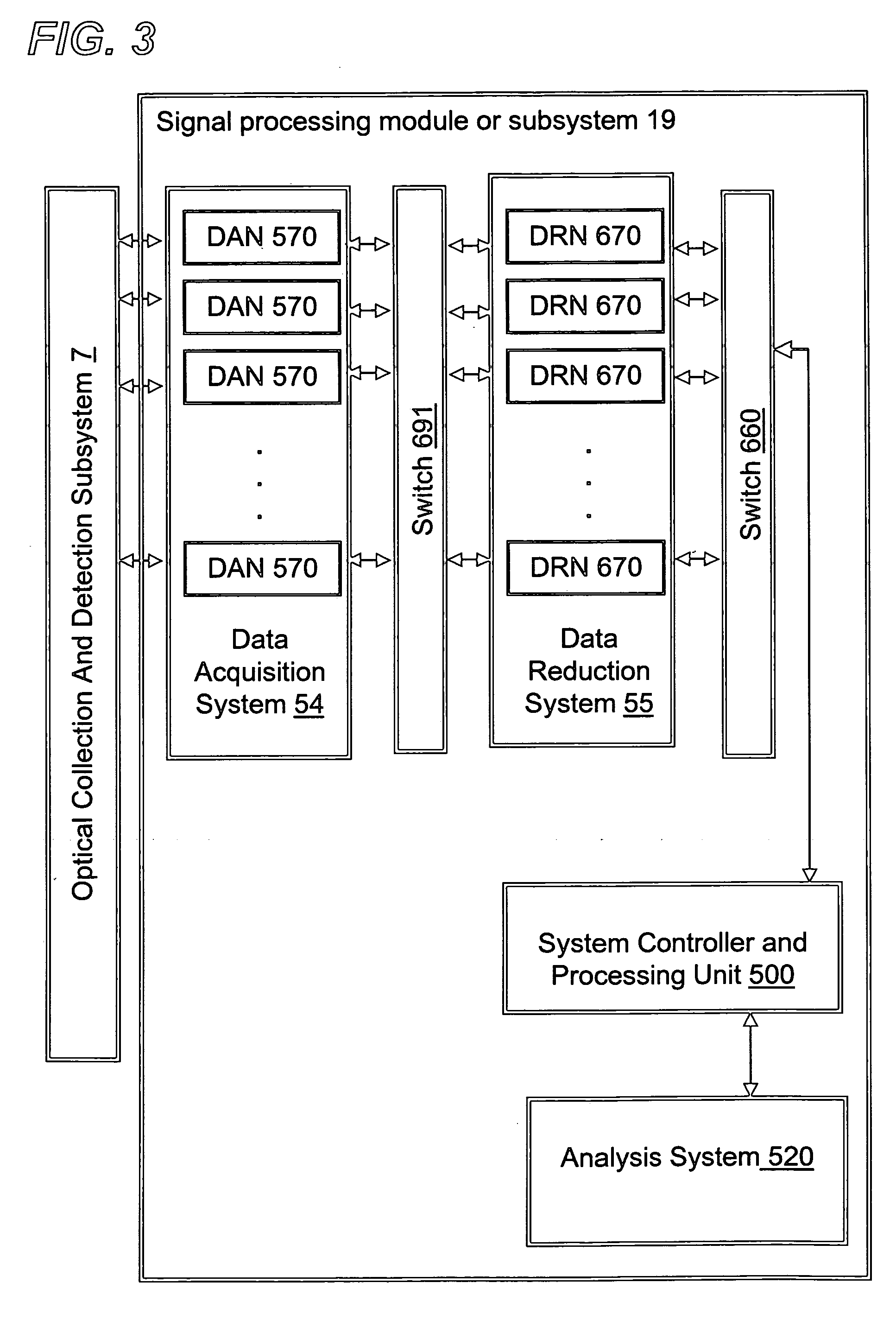

Systems and methods for monitoring behavior informatics

InactiveUS20030100998A2Improve statistics performanceExpand selectionDrug and medicationsBiostatisticsMulti dimensionalOrganism

Abstract of Disclosure A system and method used to assess animal behavior includes a module having sensors that collects a variety of physical and biological data from a test subject. Interpretation of the data is provided to assess the test subject's behavior, neurology, biochemistry and physiology. The module is useful in observing the effects of a drug on the test animal and providing information on the drug's signature. Another advantage is module's portability that allows it to be used in standard laboratory cages. This portability allows the animal to be tested in its own habitat, that can reduce any erroneous data due to stressing the animal when removed to a test cage. Additionally, the module's design allows for parallel data collection and interpretation from several laboratory animals undergoing different experiments. Multi-dimensional modeling of the test subject based the system's interpretation of the data allows pattern recognition of the drug signature, and predictive drug analysis.

Owner:CARNEGIE MELLON UNIV +1

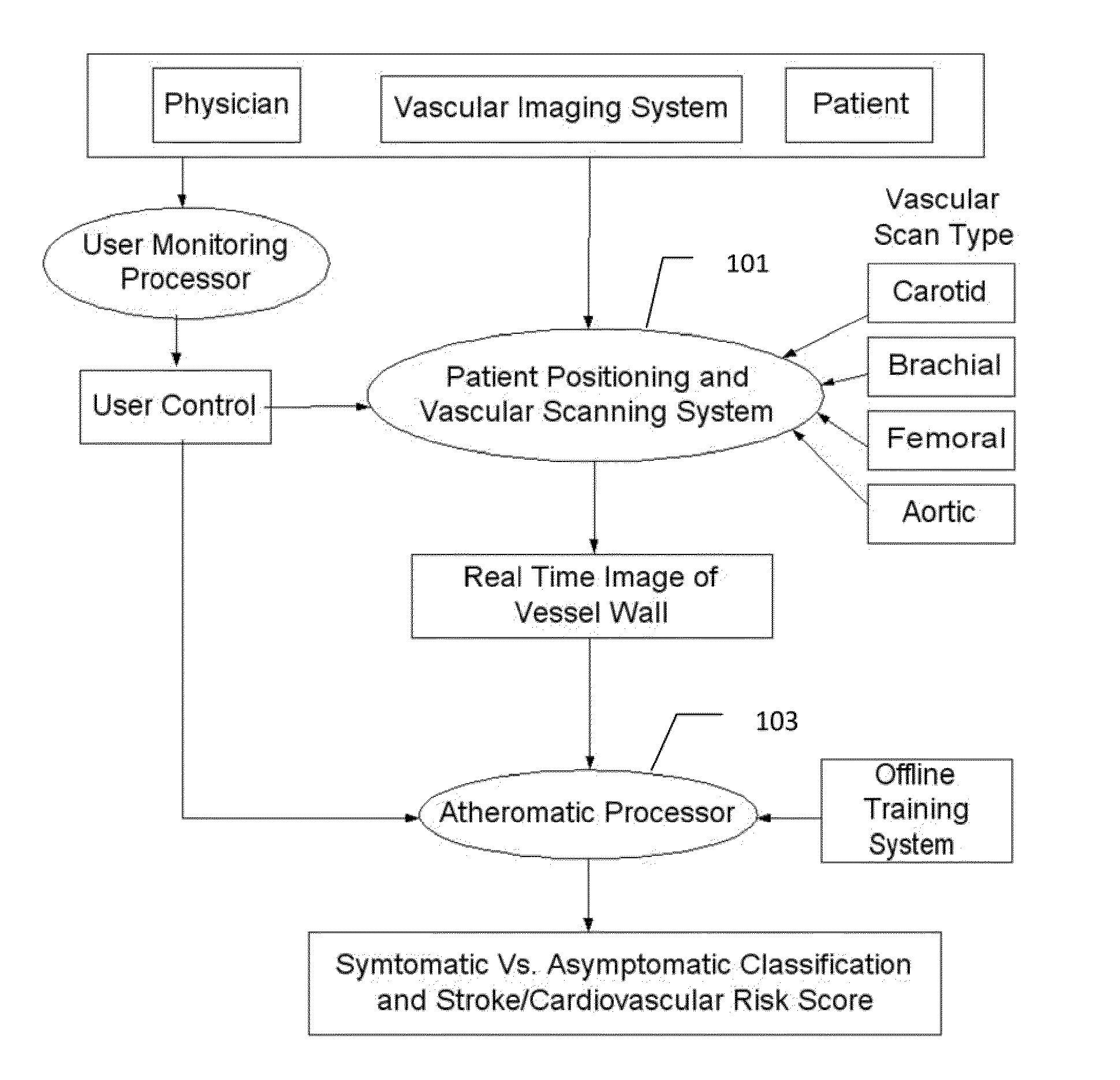

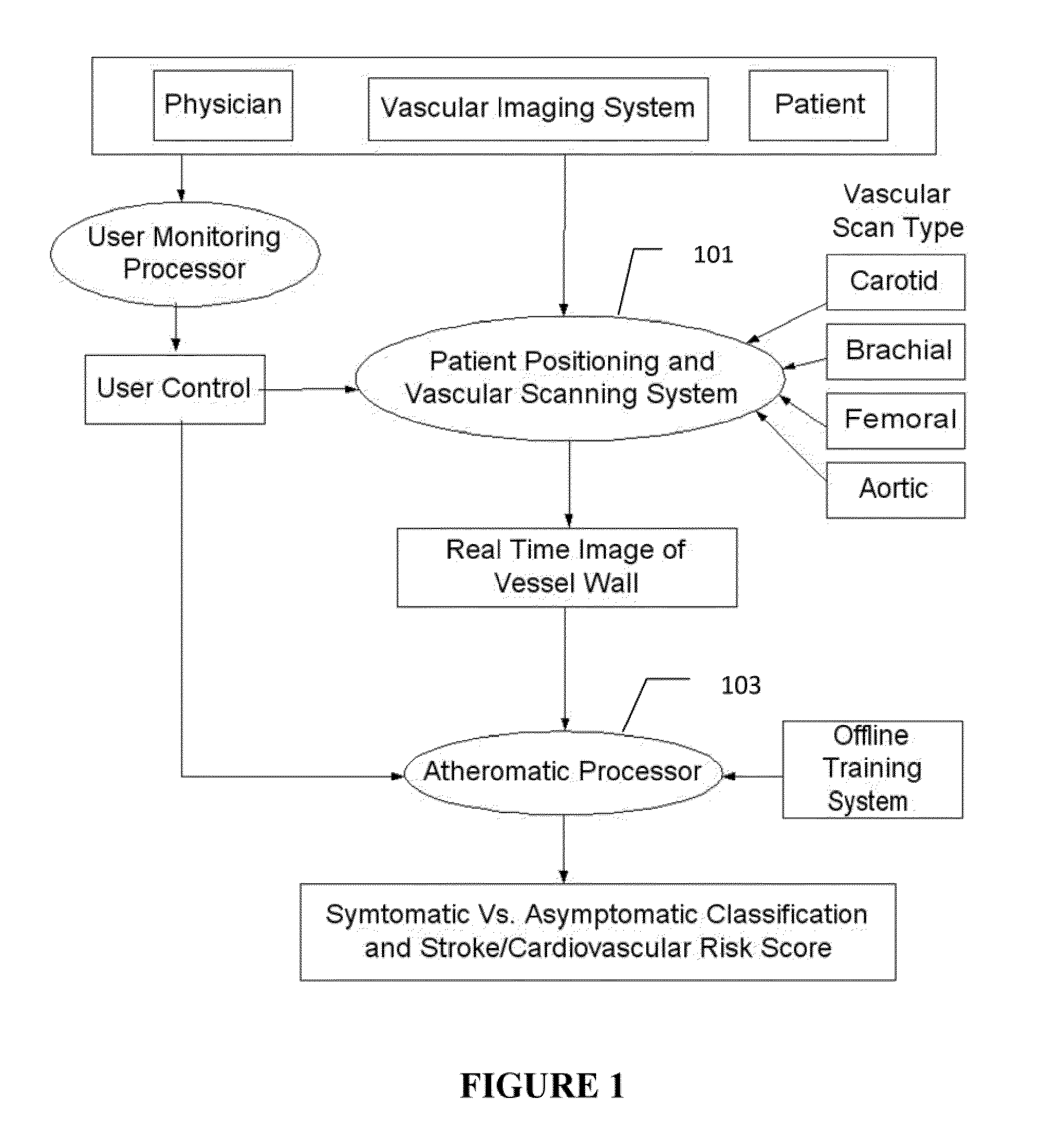

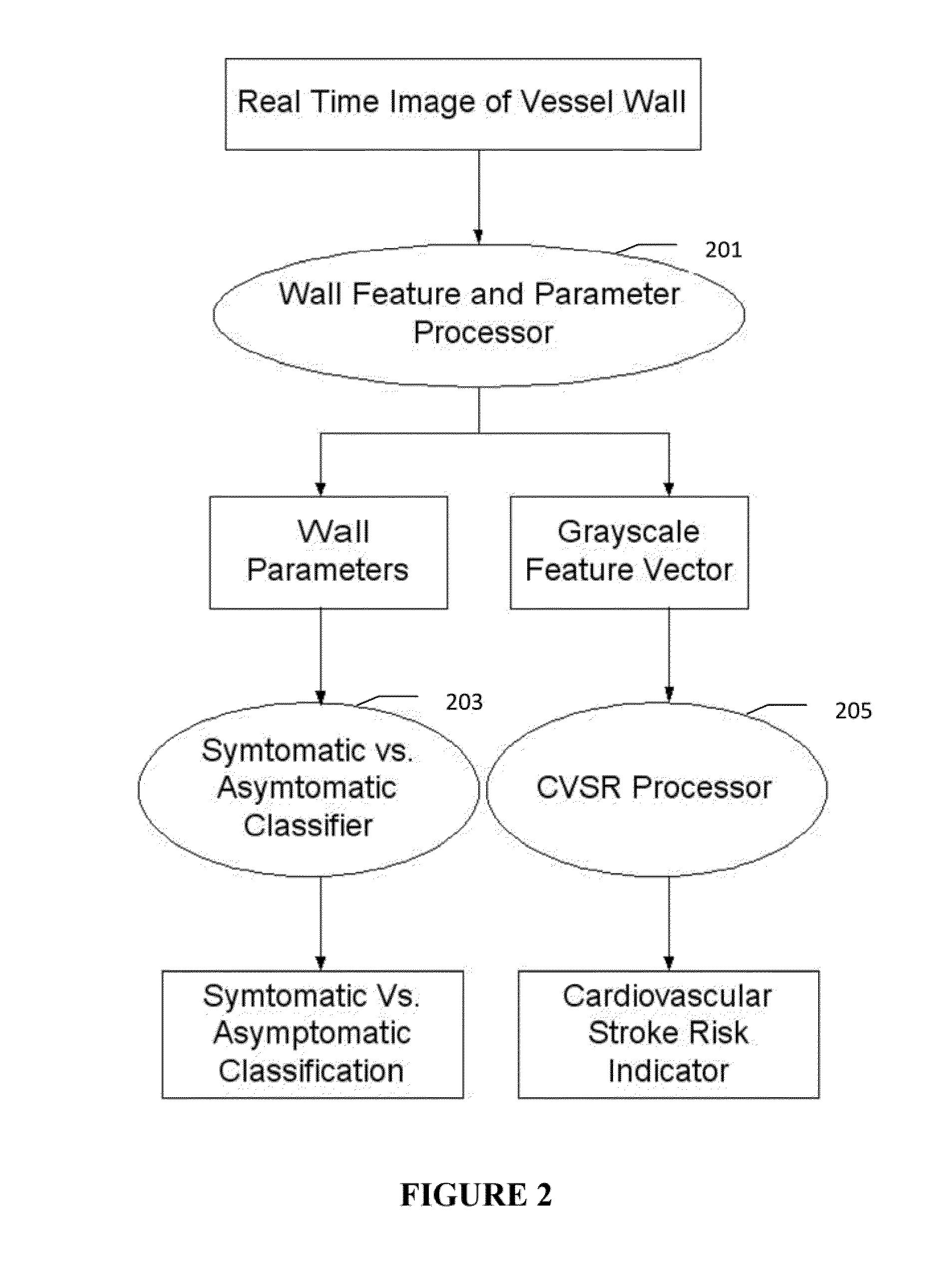

Imaging based symptomatic classification and cardiovascular stroke risk score estimation

InactiveUS20110257545A1Improve accuracyMaximum accuracyUltrasonic/sonic/infrasonic diagnosticsImage enhancementGround truthCross modality

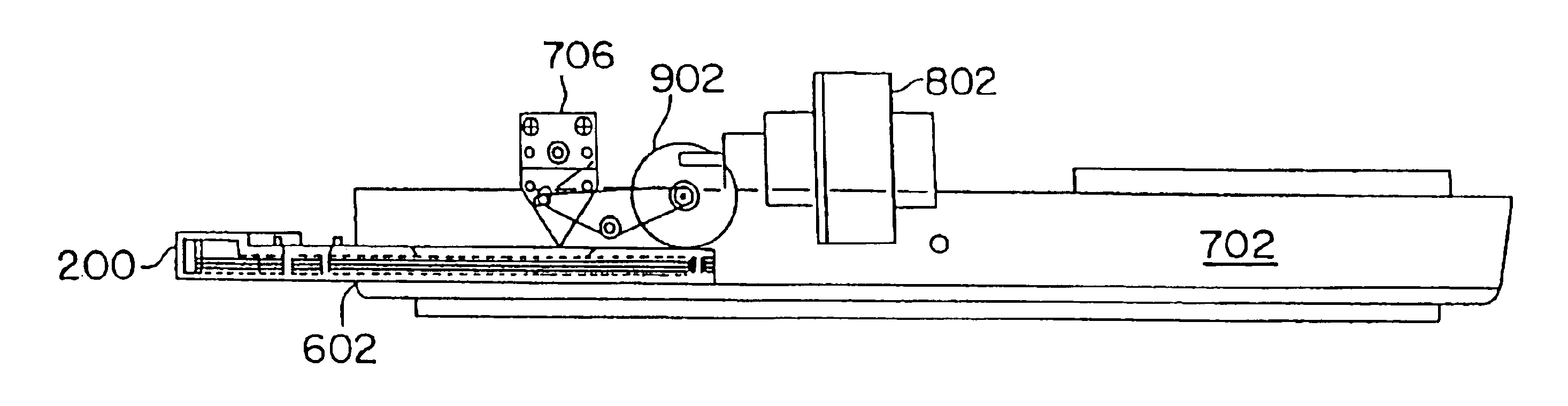

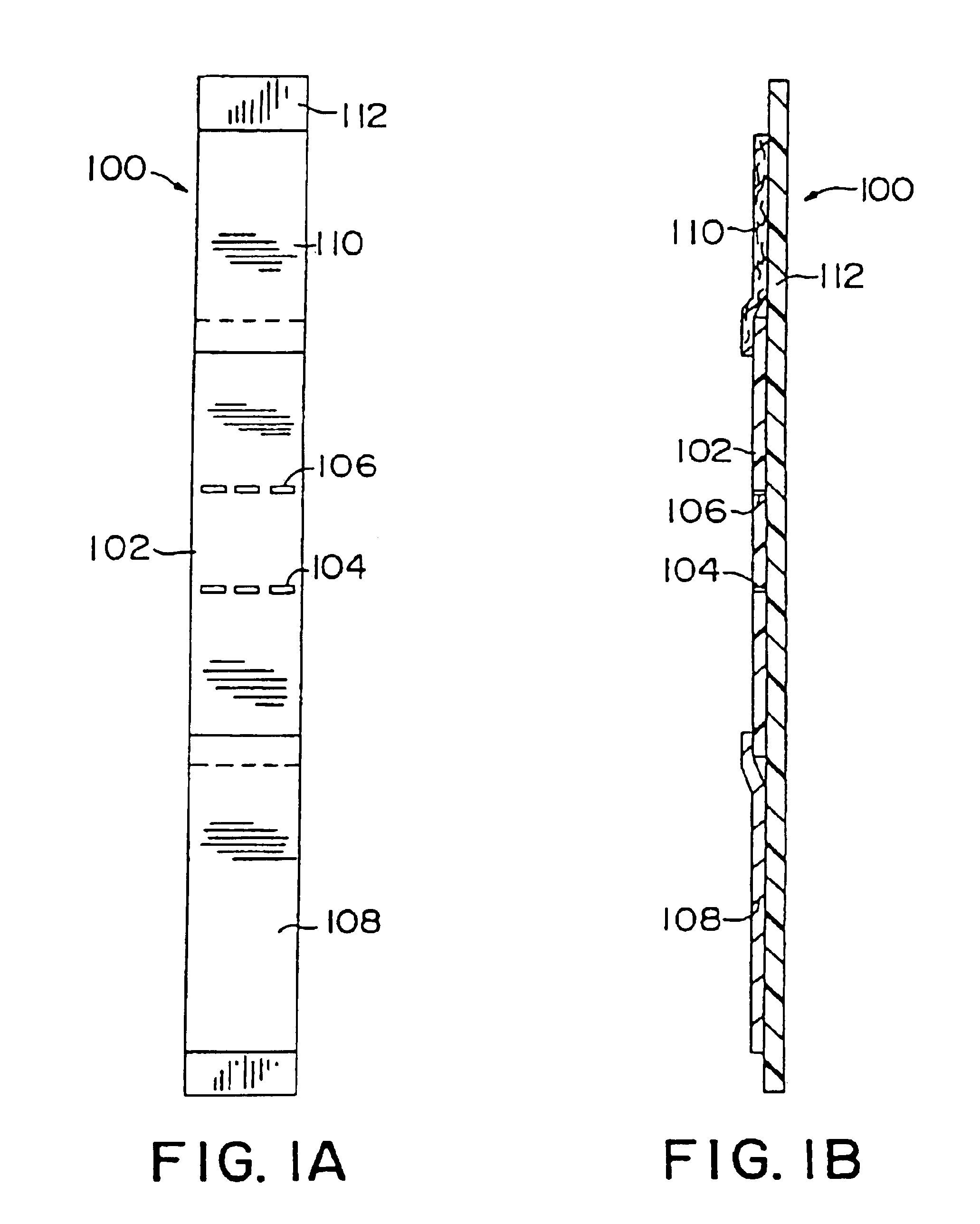

Characterization of carotid atherosclerosis and classification of plaque into symptomatic or asymptomatic along with the risk score estimation are key steps necessary for allowing the vascular surgeons to decide if the patient has to definitely undergo risky treatment procedures that are needed to unblock the stenosis. This application describes a statistical (a) Computer Aided Diagnostic (CAD) technique for symptomatic versus asymptomatic plaque automated classification of carotid ultrasound images and (b) presents a cardiovascular stroke risk score computation. We demonstrate this for longitudinal Ultrasound, CT, MR modalities and extendable to 3D carotid Ultrasound. The on-line system consists of Atherosclerotic Wall Region estimation using AtheroEdge™ for longitudinal Ultrasound or Athero-CTView™ for CT or Athero-MRView from MR. This greyscale Wall Region is then fed to a feature extraction processor which computes: (a) Higher Order Spectra; (b) Discrete Wavelet Transform (DWT); (c) Texture and (d) Wall Variability. The output of the Feature Processor is fed to the Classifier which is trained off-line from the Database of similar Atherosclerotic Wall Region images. The off-line Classifier is trained from the significant features from (a) Higher Order Spectra; (b) Discrete Wavelet Transform (DWT); (c) Texture and (d) Wall Variability, selected using t-test. Symptomatic ground truth information about the training patients is drawn from cross modality imaging such as CT or MR or 3D ultrasound in the form of 0 or 1. Support Vector Machine (SVM) supervised classifier of varying kernel functions is used off-line for training. The Atheromatic™ system is also demonstrated for Radial Basis Probabilistic Neural Network (RBPNN), or Nearest Neighbor (KNN) classifier or Decision Trees (DT) Classifier for symptomatic versus asymptomatic plaque automated classification. The obtained training parameters are then used to evaluate the test set. The system also yields the cardiovascular stroke risk score value on the basis of the four set of wall features.

Owner:SURI JASJIT S

Point of care diagnostic systems

InactiveUS6936476B1Accurate concentrationAccurately presenceScattering properties measurementsComputer-assisted medical data acquisitionPoint of careDiagnostic test

Systems and methods for medical diagnosis or risk assessment for a patient are provided. These systems and methods are designed to be employed at the point of care, such as in emergency rooms and operating rooms, or in any situation in which a rapid and accurate result is desired. The systems and methods process patient data, particularly data from point of care diagnostic tests or assays, including immunoassays, electrocardiograms, X-rays and other such tests, and provide an indication of a medical condition or risk or absence thereof. The systems include an instrument for reading or evaluating the test data and software for converting the data into diagnostic or risk assessment information.

Owner:CYTYC CORP

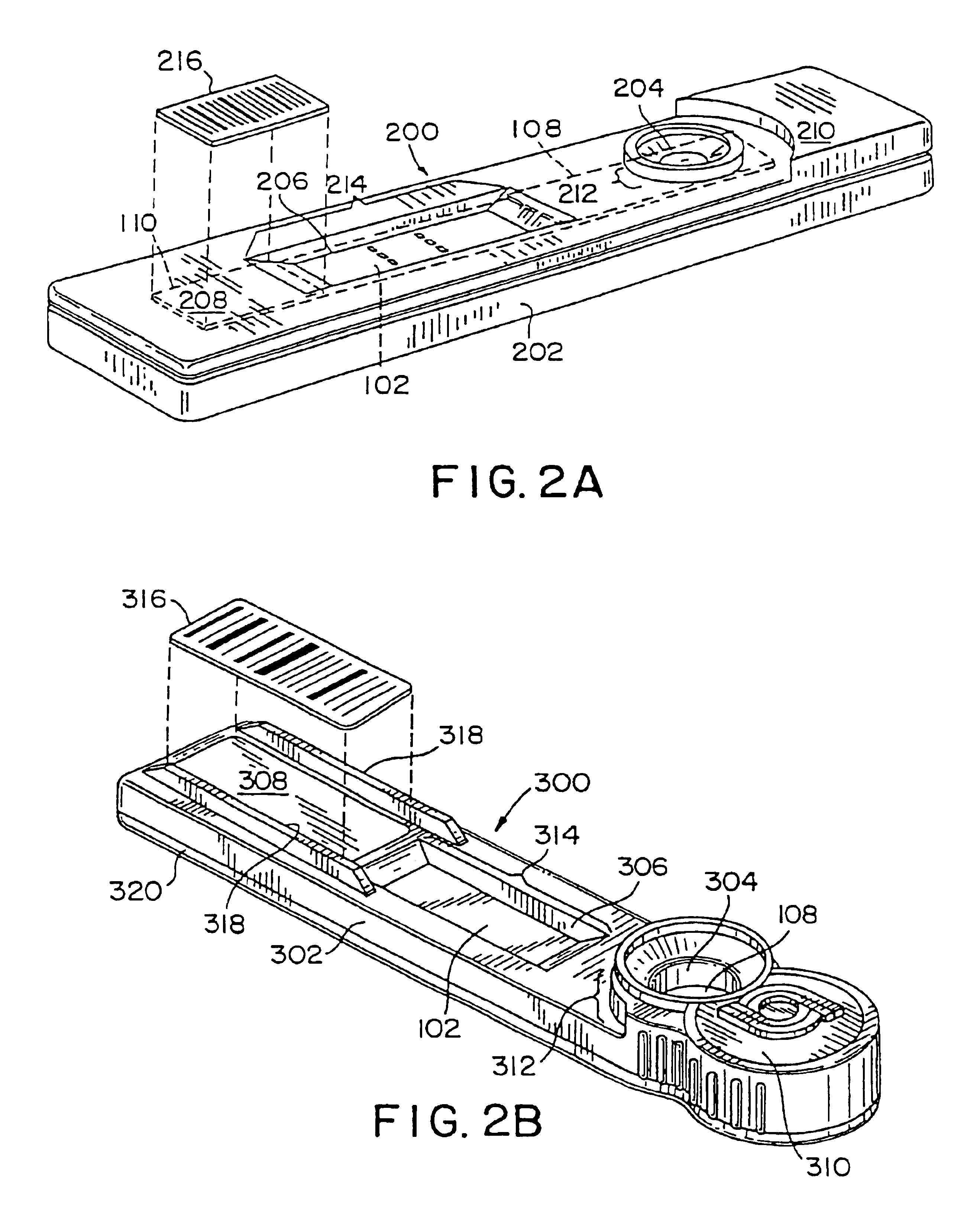

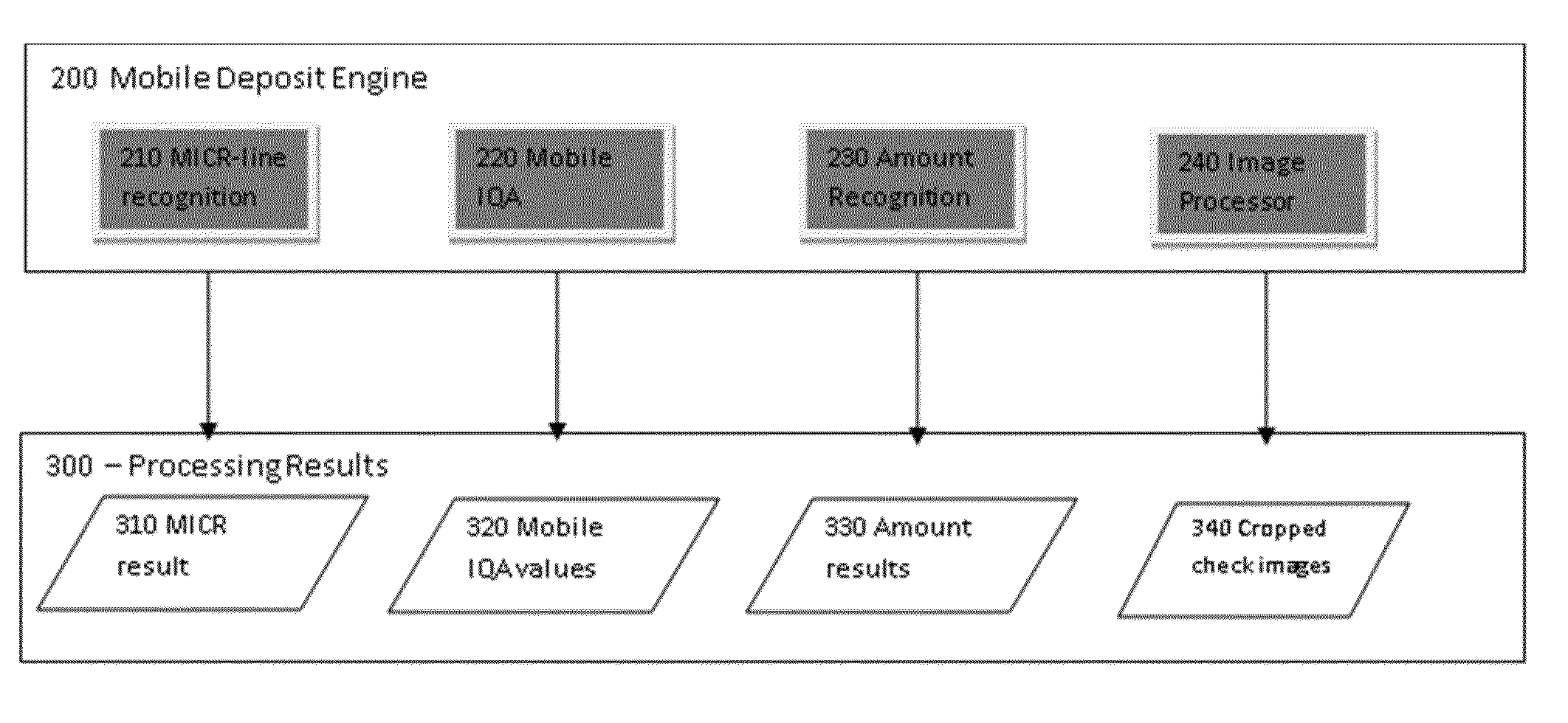

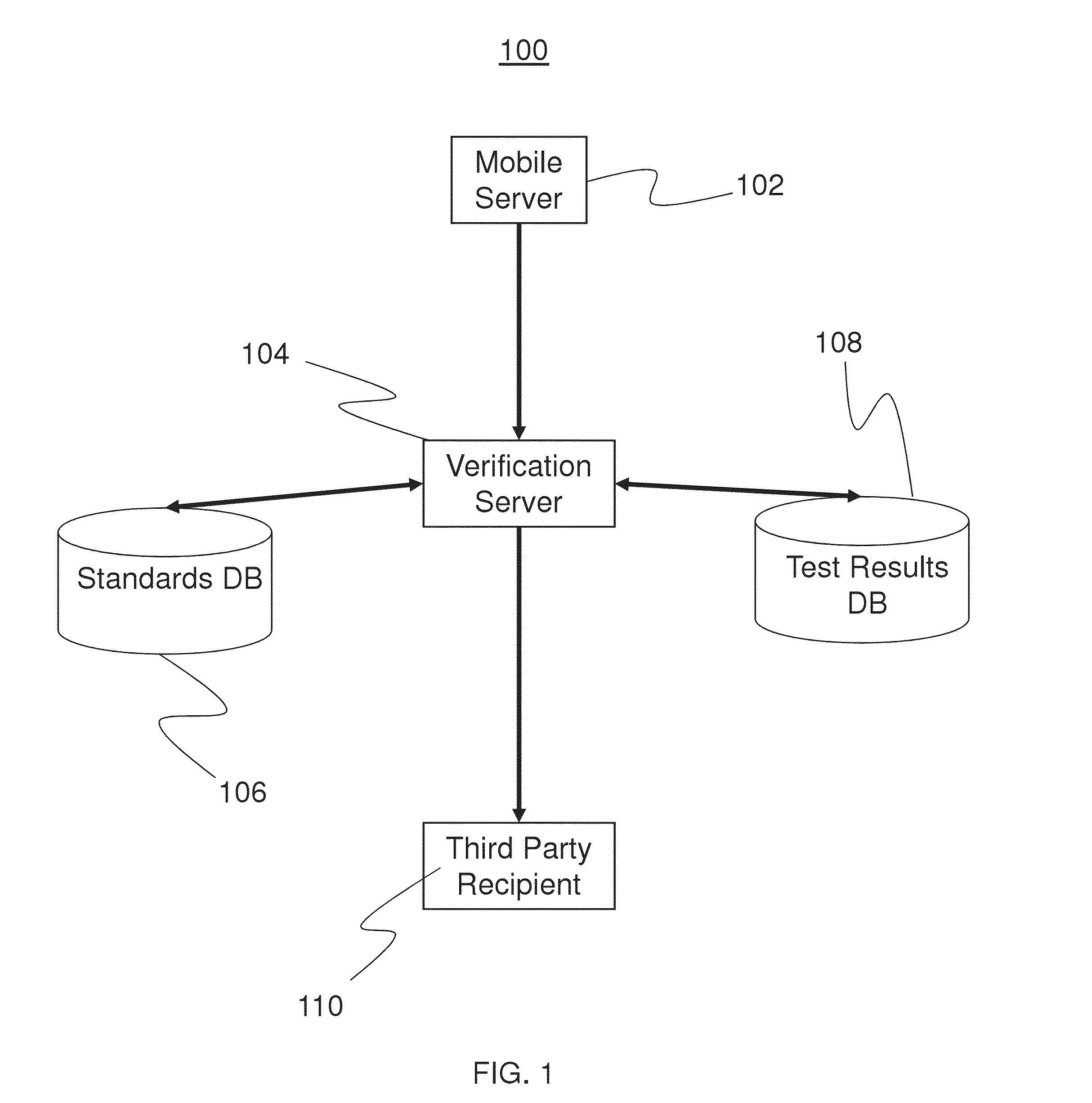

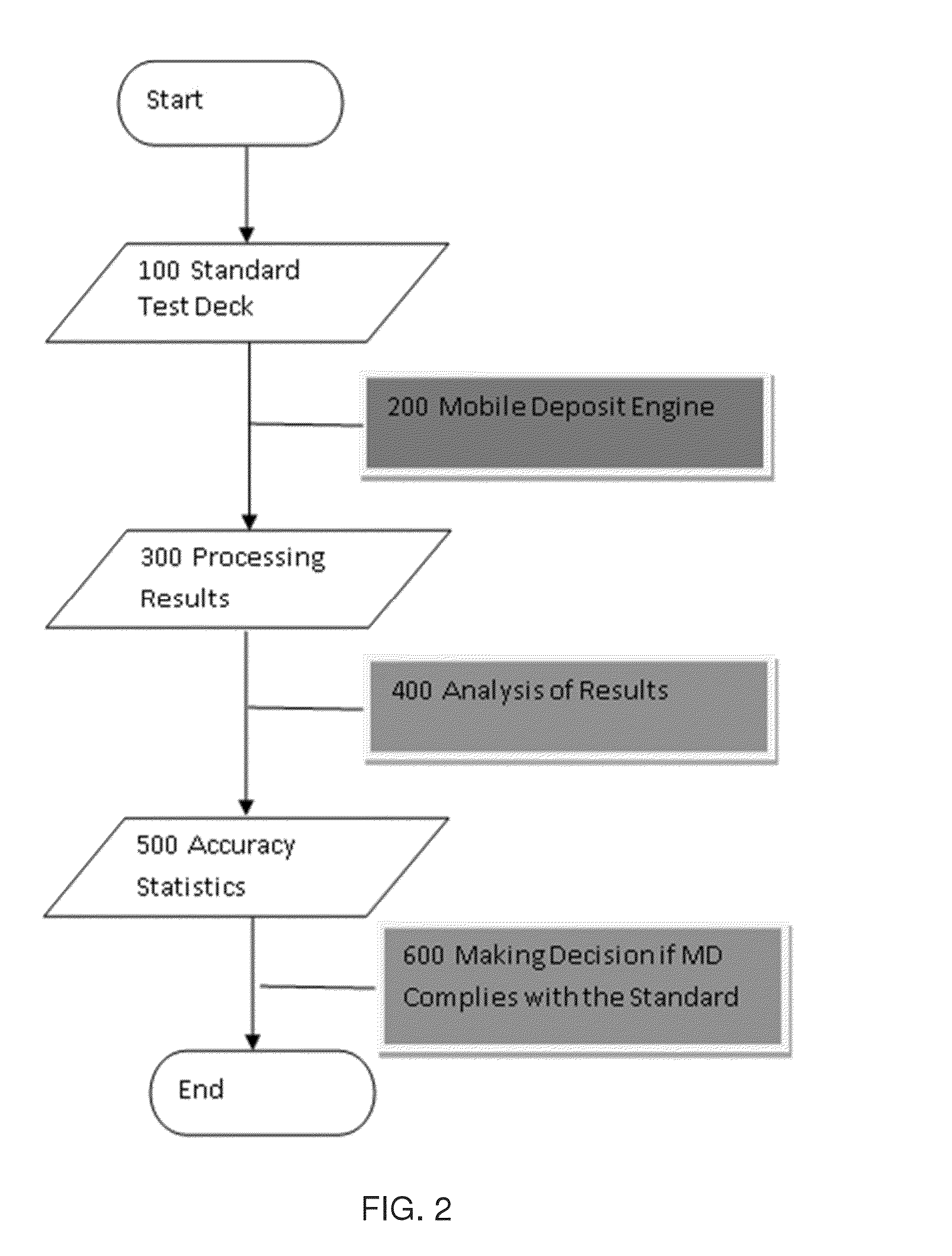

Systems and methods for developing and verifying image processing standards for moble deposit

ActiveUS20130223721A1Improve image qualityConfidence level can be determinedCharacter and pattern recognitionImaging processingImaging quality

Systems and methods are provided for assessing whether mobile deposit processing engines meet specified standards for mobile deposit of financial documents. A mobile deposit processing engine (MDE) is evaluated to determine if it can perform technical capabilities for improving the quality of and extracting content from an image of a financial document. A verification process then begins, where the MDE performs the image quality enhancements and text extraction steps on sets of images from a test deck. The results of the processing of the test deck are then evaluated by comparing confidence levels with thresholds to determine if each set of images should be accepted or rejected. Further analysis determines whether any of the sets of images were falsely accepted or rejected in error. An overall error rate is then compared with minimum accuracy criteria, and if the criteria are met, the MDE meets the standard for mobile deposit.

Owner:MITEK SYST

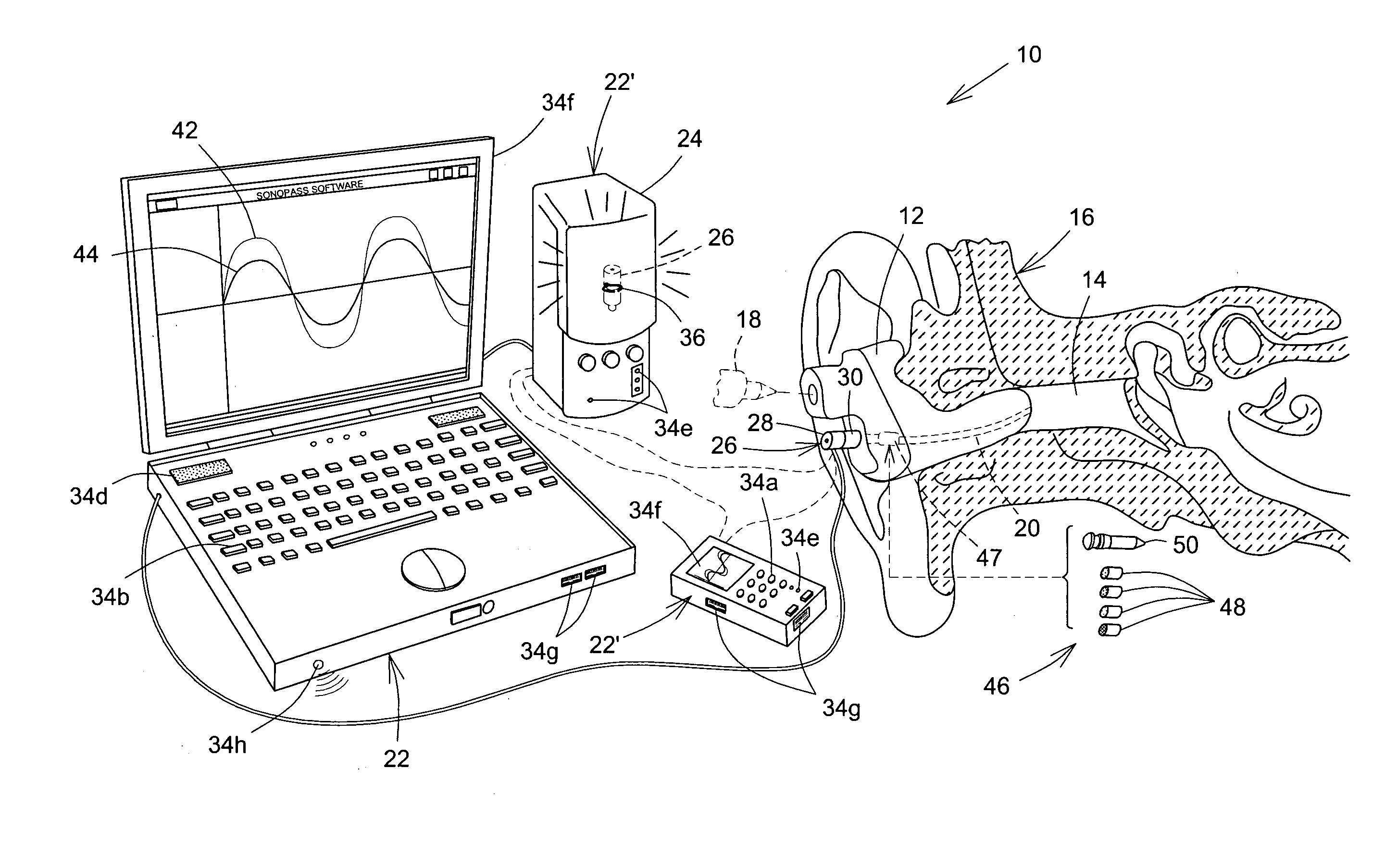

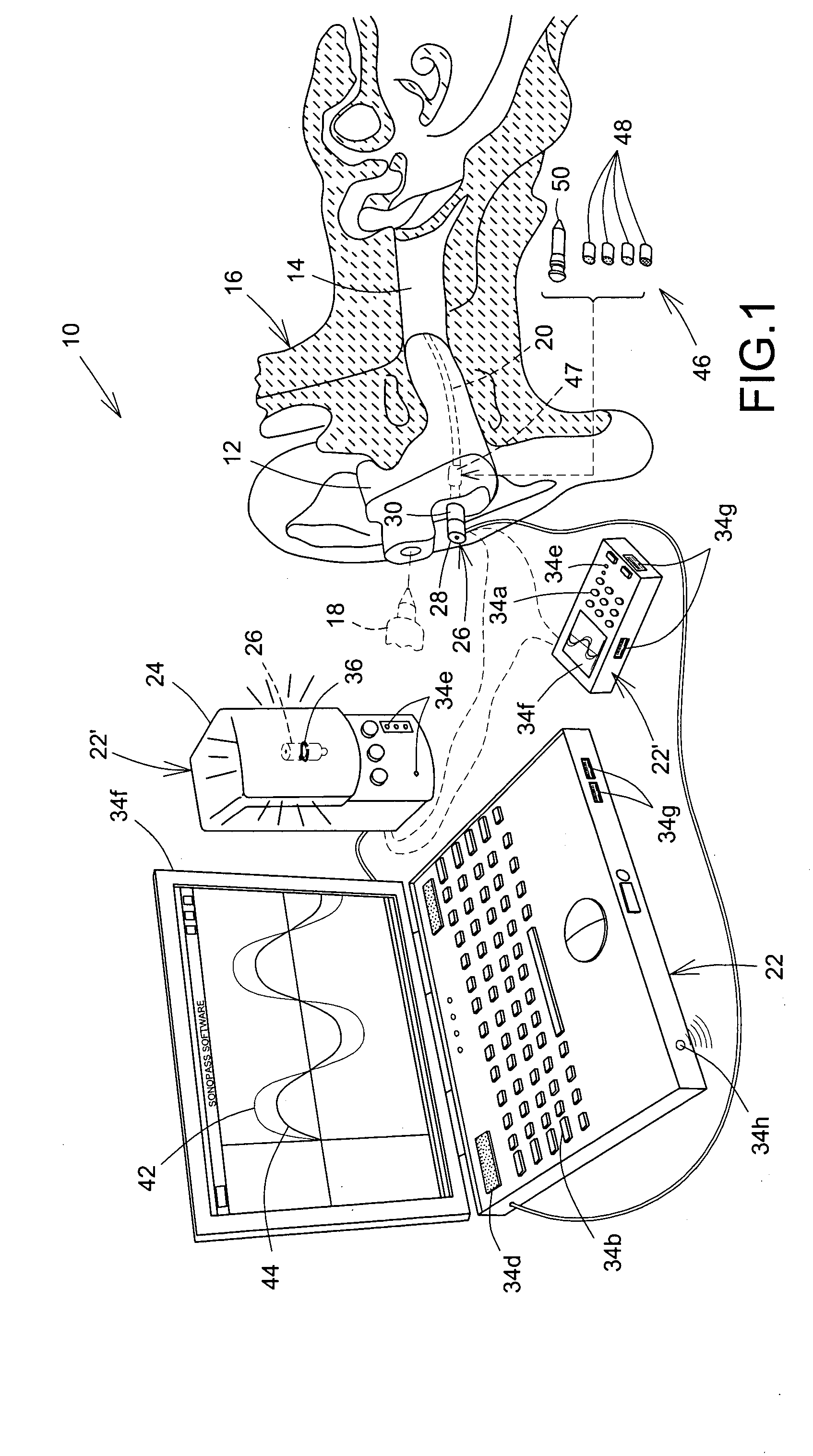

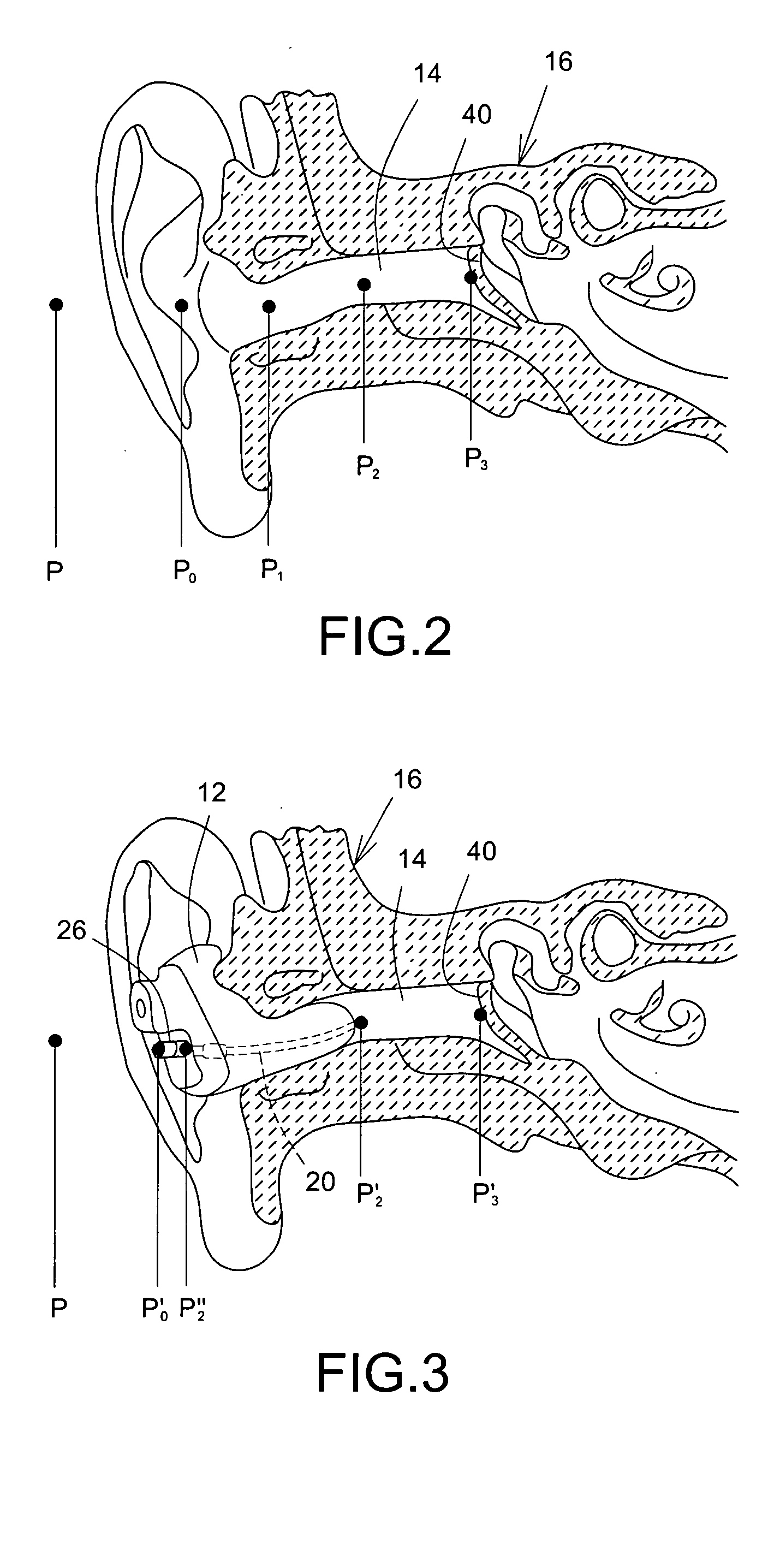

Method and apparatus for objective assessment of in-ear device acoustical performance

ActiveUS20050123146A1Simple reliability (stability) checkEasy to checkEar moulds/tips acoustic sealsHearing aids testing/monitoringSubject specificEvaluation testing

A method and apparatus for objectively assessing acoustical performance of an in-ear device having a passageway extending there through use a dual microphone probe that removably engages the passageway. The acoustical performance of the in-ear device is performed with the in-ear device inserted into the ear canal of the user and a reference sound source. A clip holding the probe in an acoustic near field of the sound source permits real time calibration thereof. The method and apparatus allow on-site and in-situ measurement of a predicted personal attenuation rating of the device, a subject-fit re-insertion test, an acoustic seal test, a rating test, a stability and reliability test, as well as a protection test of the device with an assessment of a filtered predicted exposure level at the ear for a specific noise exposure level. The apparatus may be simply housed along with the sound source for in-field evaluation tests.

Owner:3M INNOVATIVE PROPERTIES CO +1

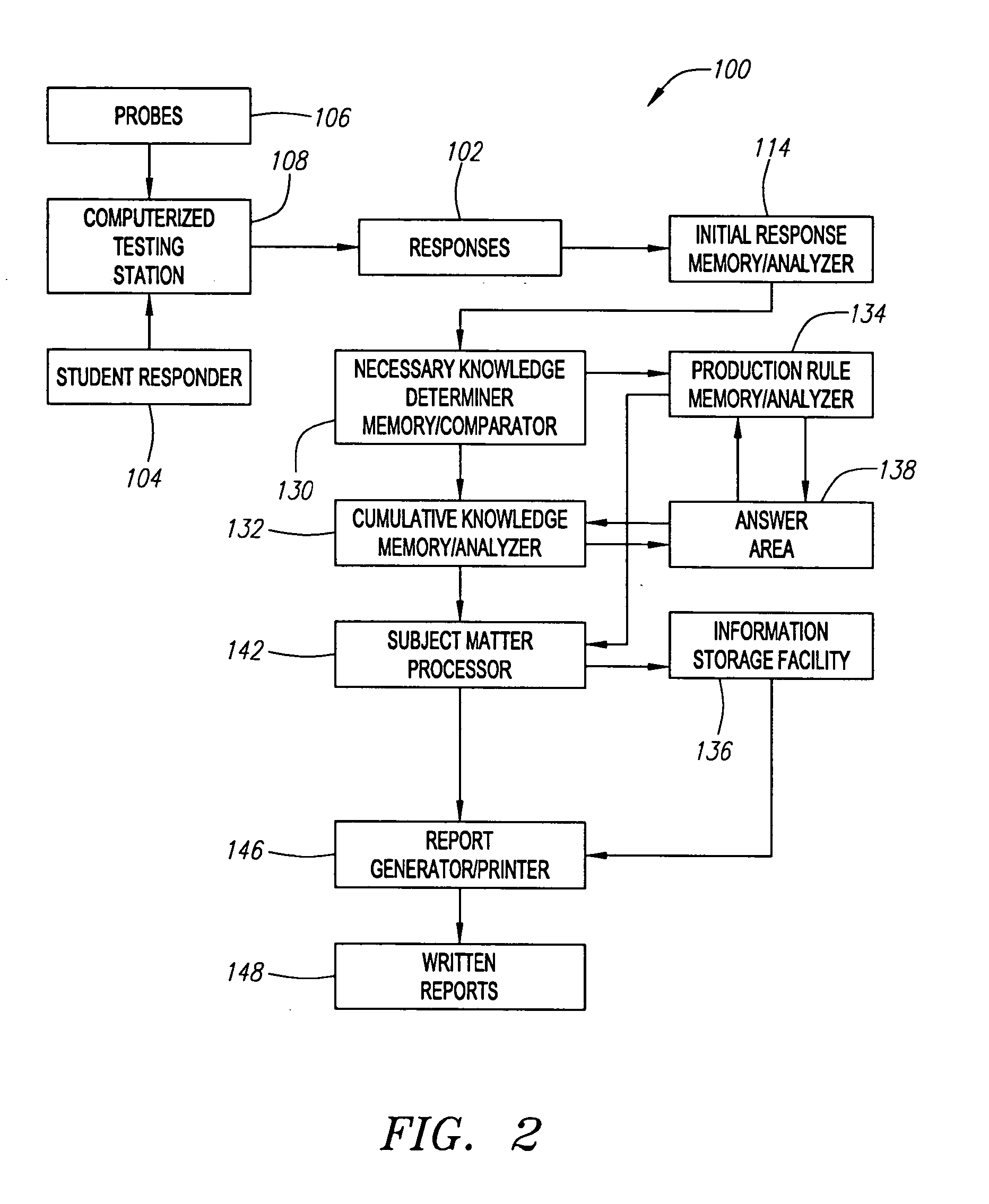

System and method for diagnosing deficiencies and assessing knowledge in test responses

A system and method for diagnosing deficiencies and assessing knowledge in test responses comprises a computerized testing station for presenting a question to a responder. An initial response analyzer communicates with the testing station for determining the correctness of an initial response by the responder to the question. A necessary knowledge determiner is disposed to analyze an incorrect initial response from the initial response analyzer for detecting responder's deficiencies in past cumulative knowledge and in new subject matter knowledge. A cumulative knowledge analyzer is provided for analyzing the incorrect initial response for identifying specific deficiencies in past cumulative knowledge. A production rule analyzer is provided for analyzing the incorrect initial response for identifying specific deficiencies in new subject matter knowledge. Finally, a report generator communicates with the cumulative knowledge analyzer and the production rule analyzer for generating a written deficiency report.

Owner:WEINSTEIN PINI A

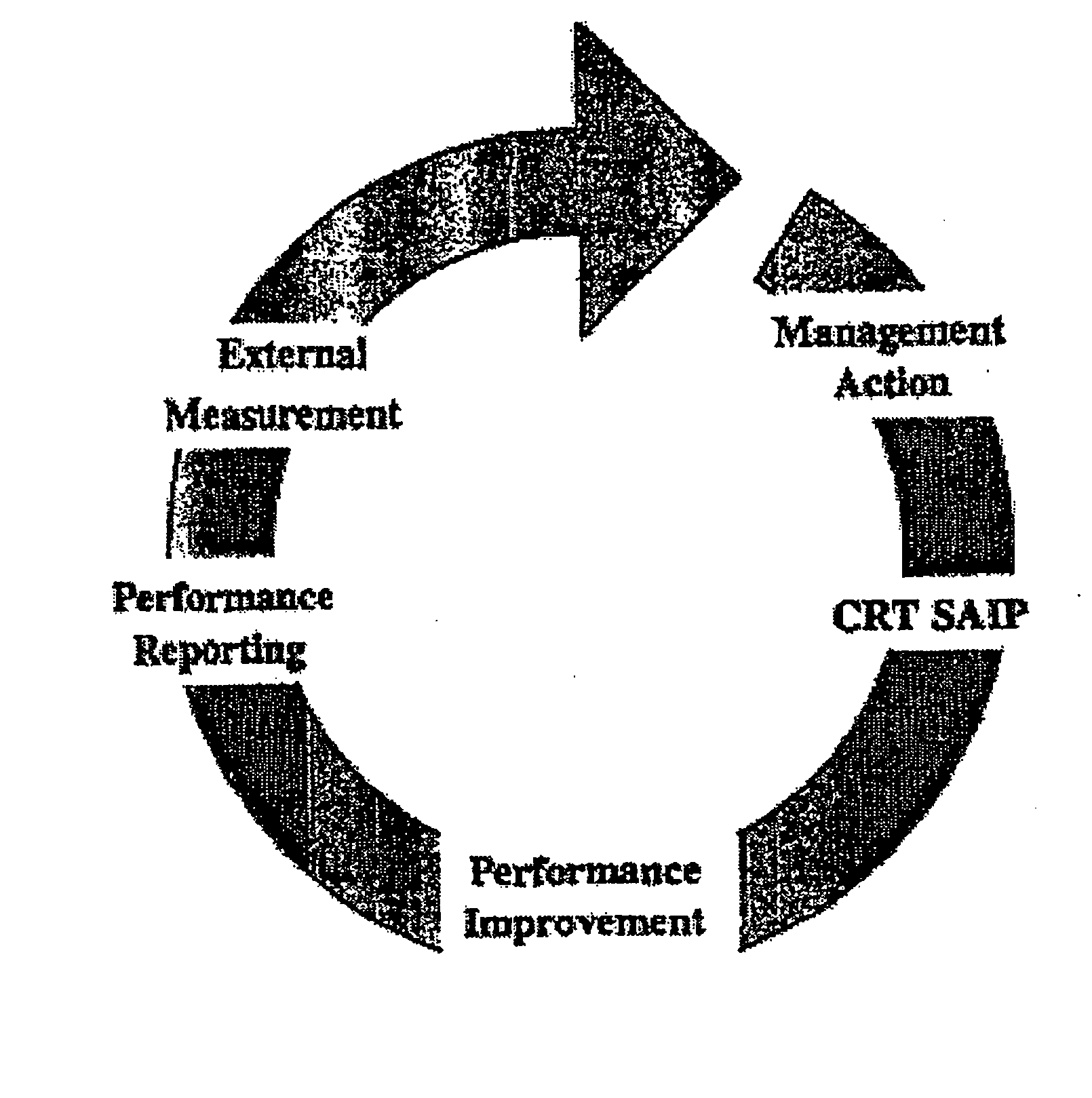

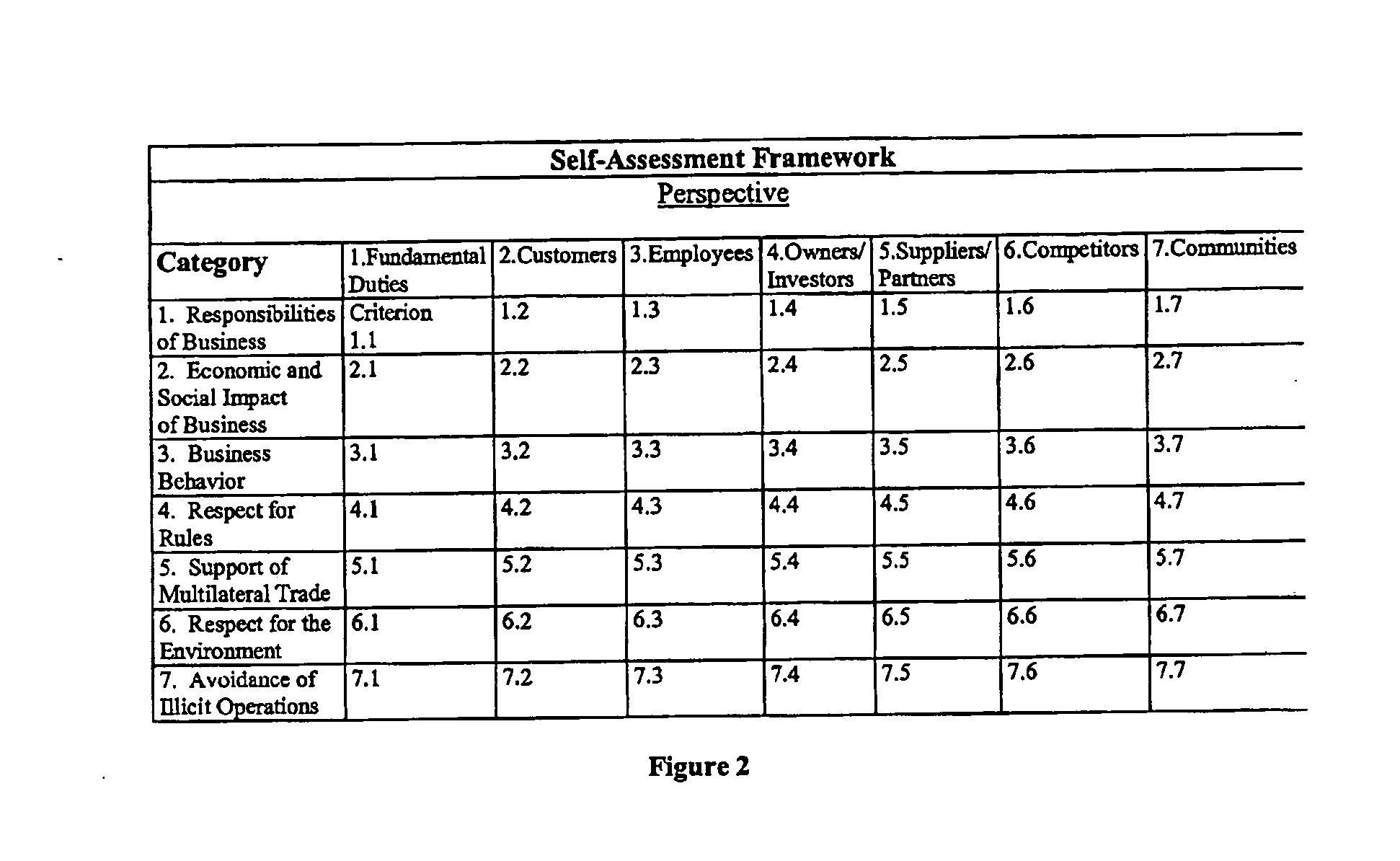

System for assessing and improving social responsibility of a business

InactiveUS20060100897A1Enhancement of social performanceImprove performanceMarket predictionsDiscounts/incentivesComputer scienceExternal validation

The invention pertains to a system for assessing the level of social responsibility of a business and for monitoring improvements using the assessed level as a baseline. The system includes a self-assessment testing method which establishes a score or “grade” indicative of the level of social responsibility of the business which can be used for comparative purposes internally or externally. In terms of a business entity, the invention provides for a self-assessment process to objectively determine the level of social responsibility of the company in a manner subject to outside verification. The process isolates components of social responsibility. The results permit precise decision making implementing change and reevaluation. The process results in a score or grade that is subject to verification or auditing by an outside agency in order that it will be a meaningful assessment outside of the confines of the company and in a broader community. It may be used for comparison to industry standards, universal standards, past performance, or the like. In broader terms, the invention provides a vehicle for a sponsoring agency or a collaboration of entities (“sponsor”) to provide the business community with a means of verifiable self-assessment of the level of social responsibility of businesses. This permits the sponsor to adopt standards for the purpose of comparison of one business to another, to an industry group, to other industries, or to past performance.

Owner:HALLORAN HARRY R JR +6

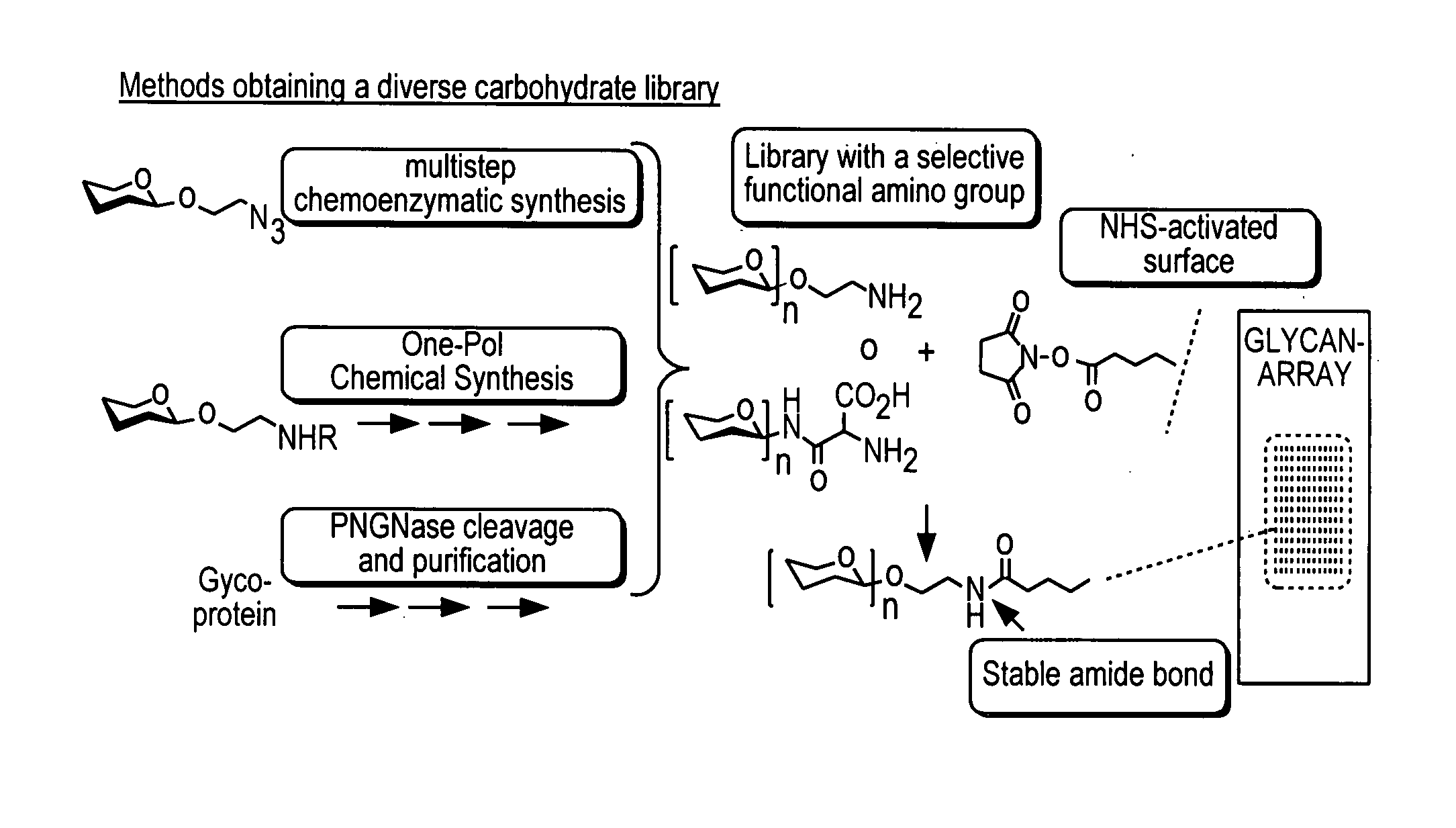

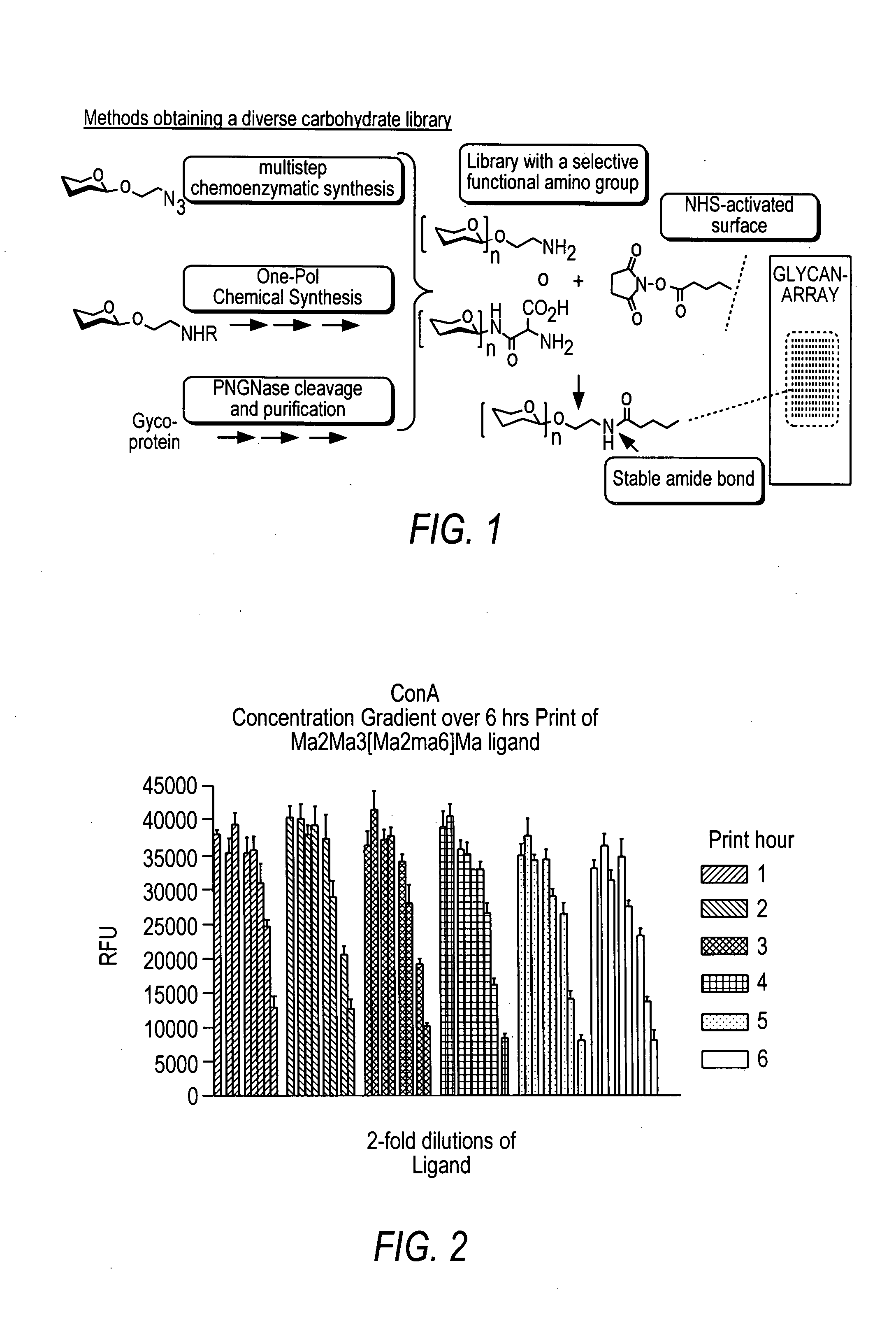

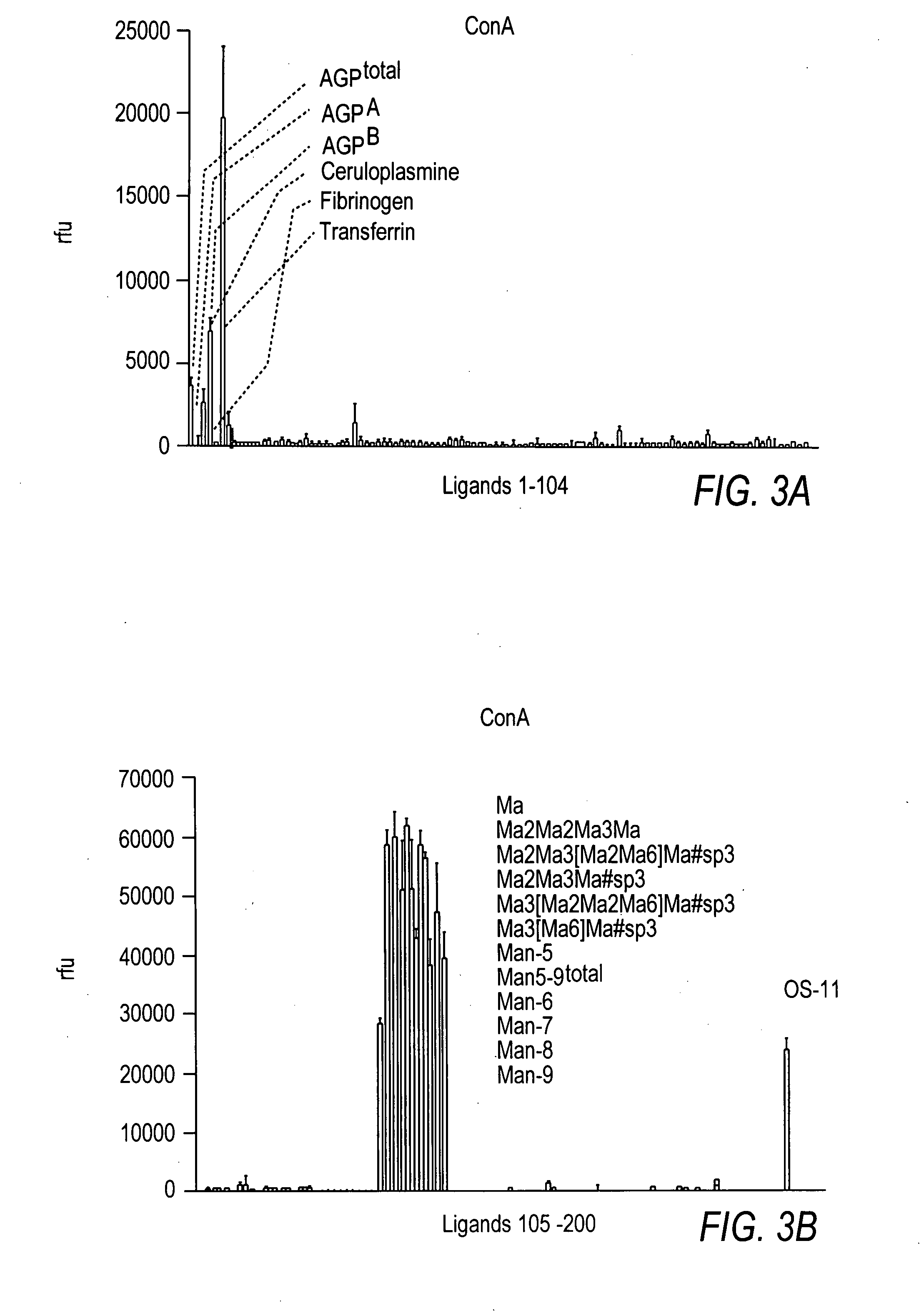

Arrays with cleavable linkers

InactiveUS20070213278A1Treating and preventing HIV infectionAntibacterial agentsBiocideGlycanTest sample

Owner:THE SCRIPPS RES INST

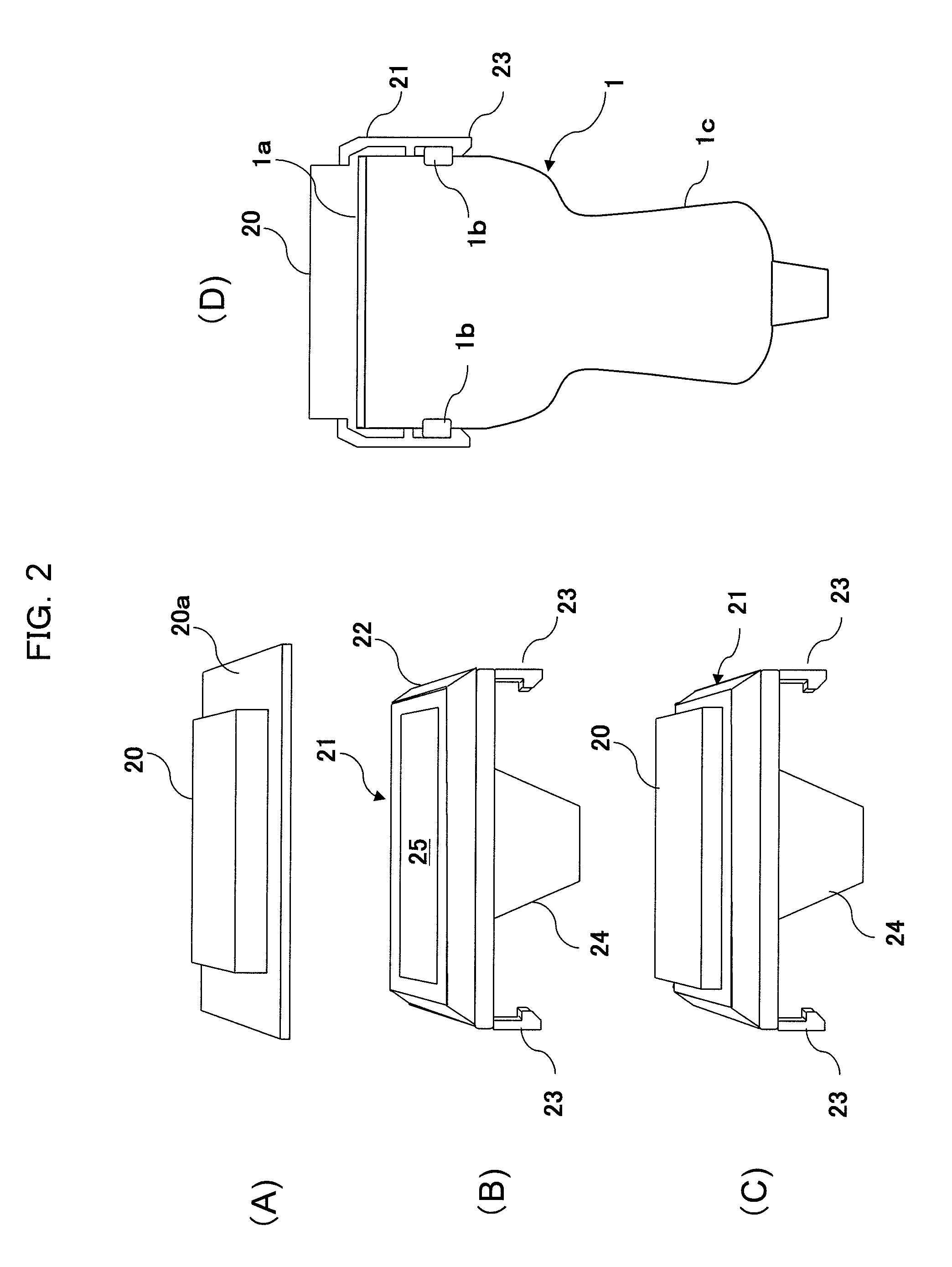

Connection box, system, and method for evaluating a DUT board

InactiveUS6873167B2Good reproducibilityReduce testingCoupling device connectionsLine/current collector detailsProbe cardEngineering

An evaluation device and method for DUT boards and probe cards which increase the reproducibility of the measured values and decrease the abrasion of pads in evaluation tests. A connection box is provided with contact pins, mounting mechanisms used to mount the DUT boards, and a plurality of connectors which feed signals from the contact pins to the outside.

Owner:AGILENT TECH INC

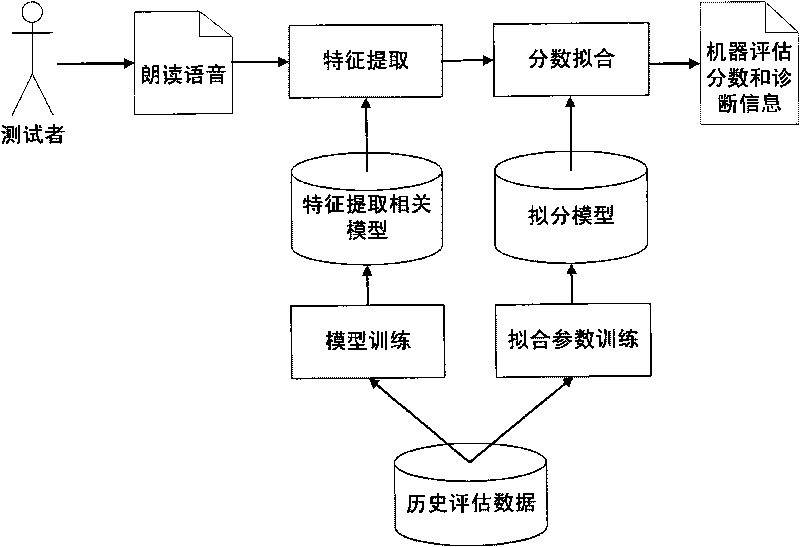

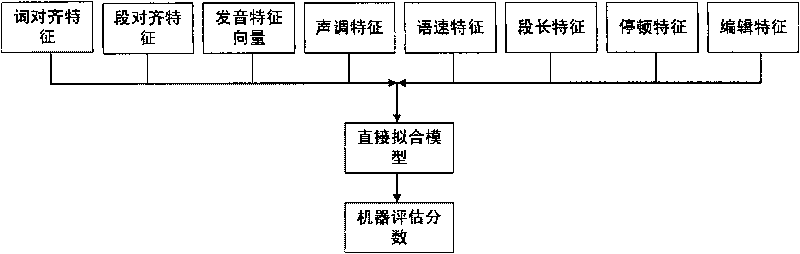

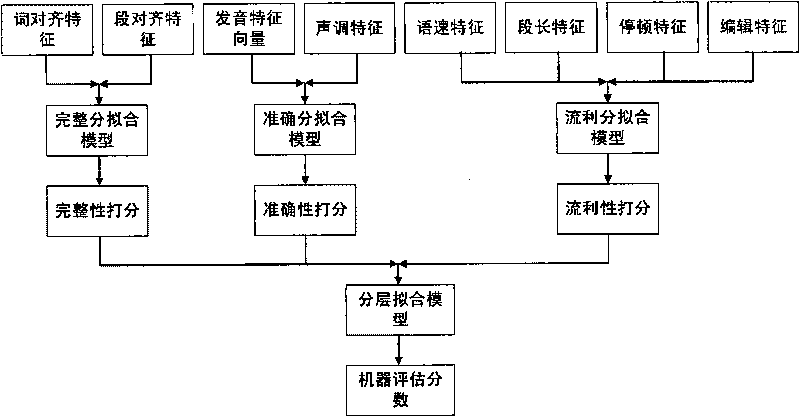

Automatic evaluation and diagnosis method of text reading level for oral test

ActiveCN101739868AOvercome randomnessOvercome subjectivityElectrical appliancesTeaching apparatusReading levelSpoken language

Owner:讯飞南亚东南亚信息科技(云南)有限公司

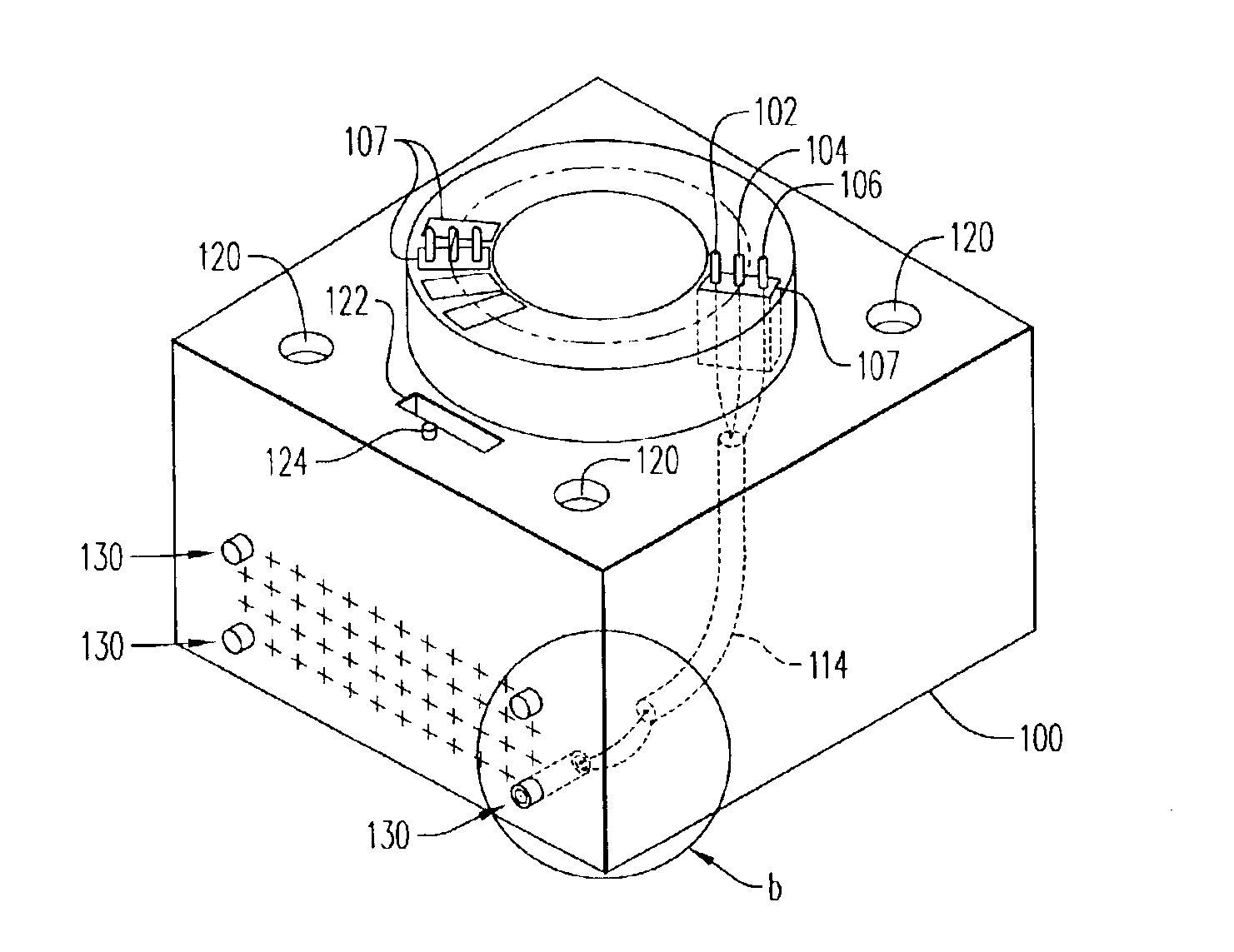

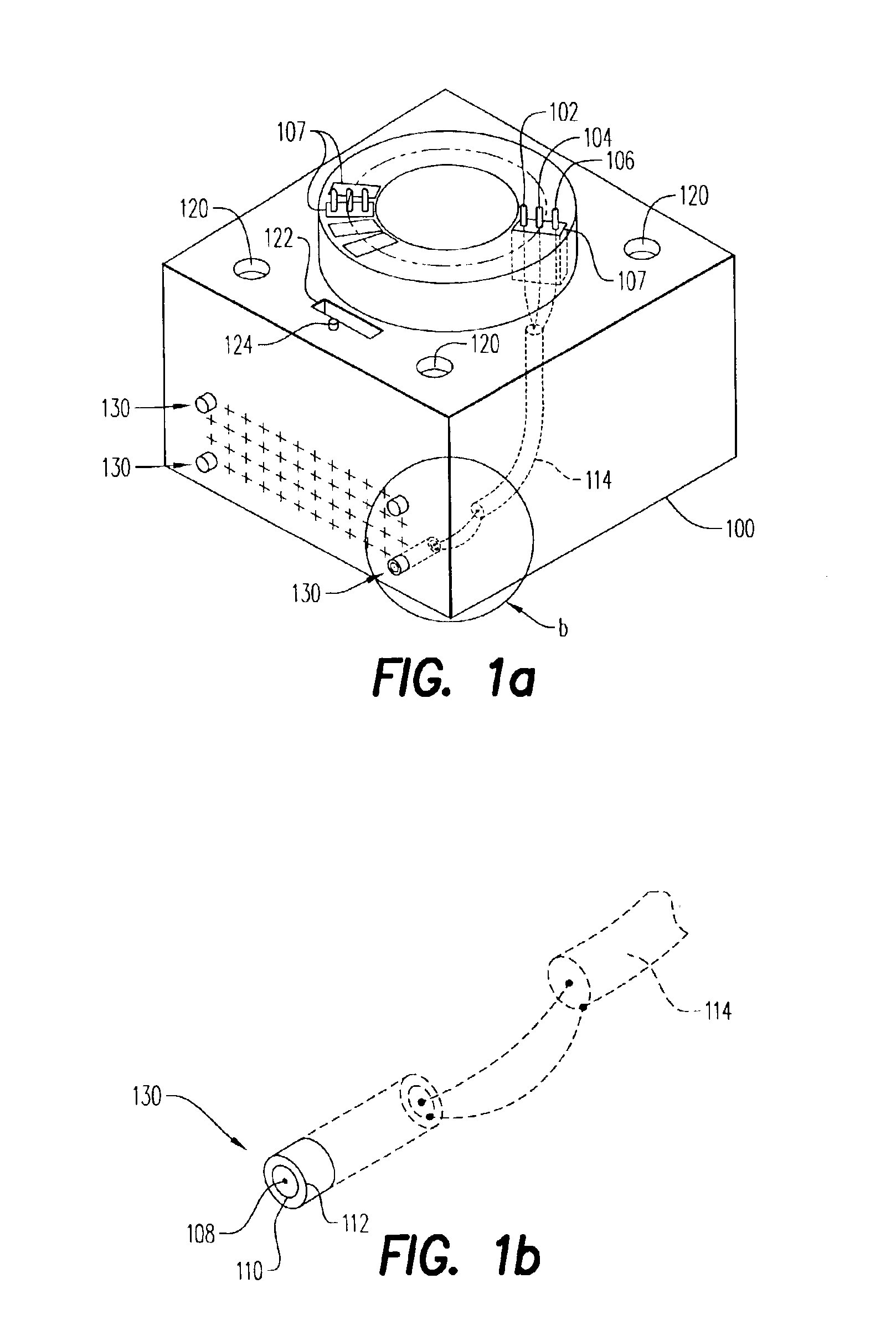

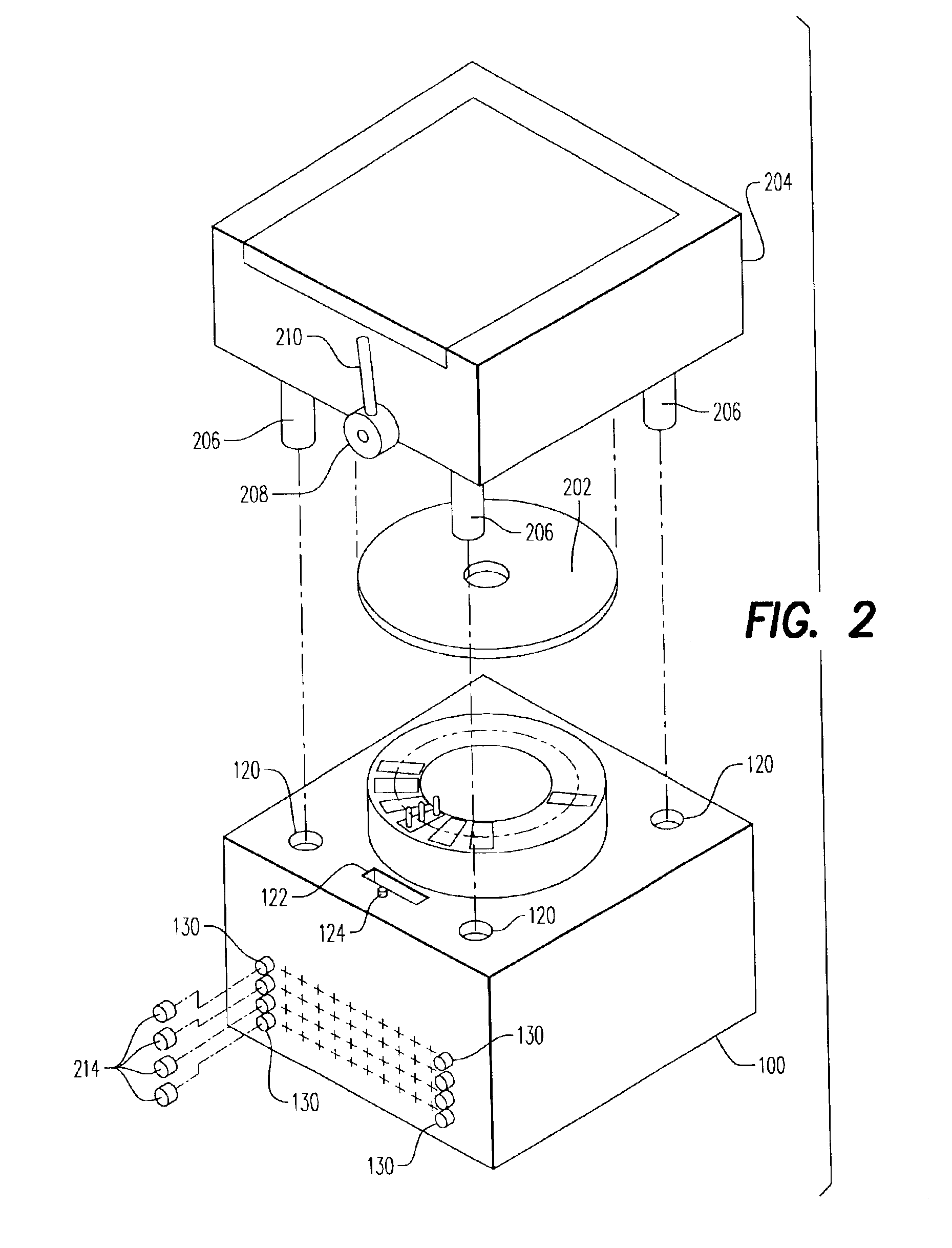

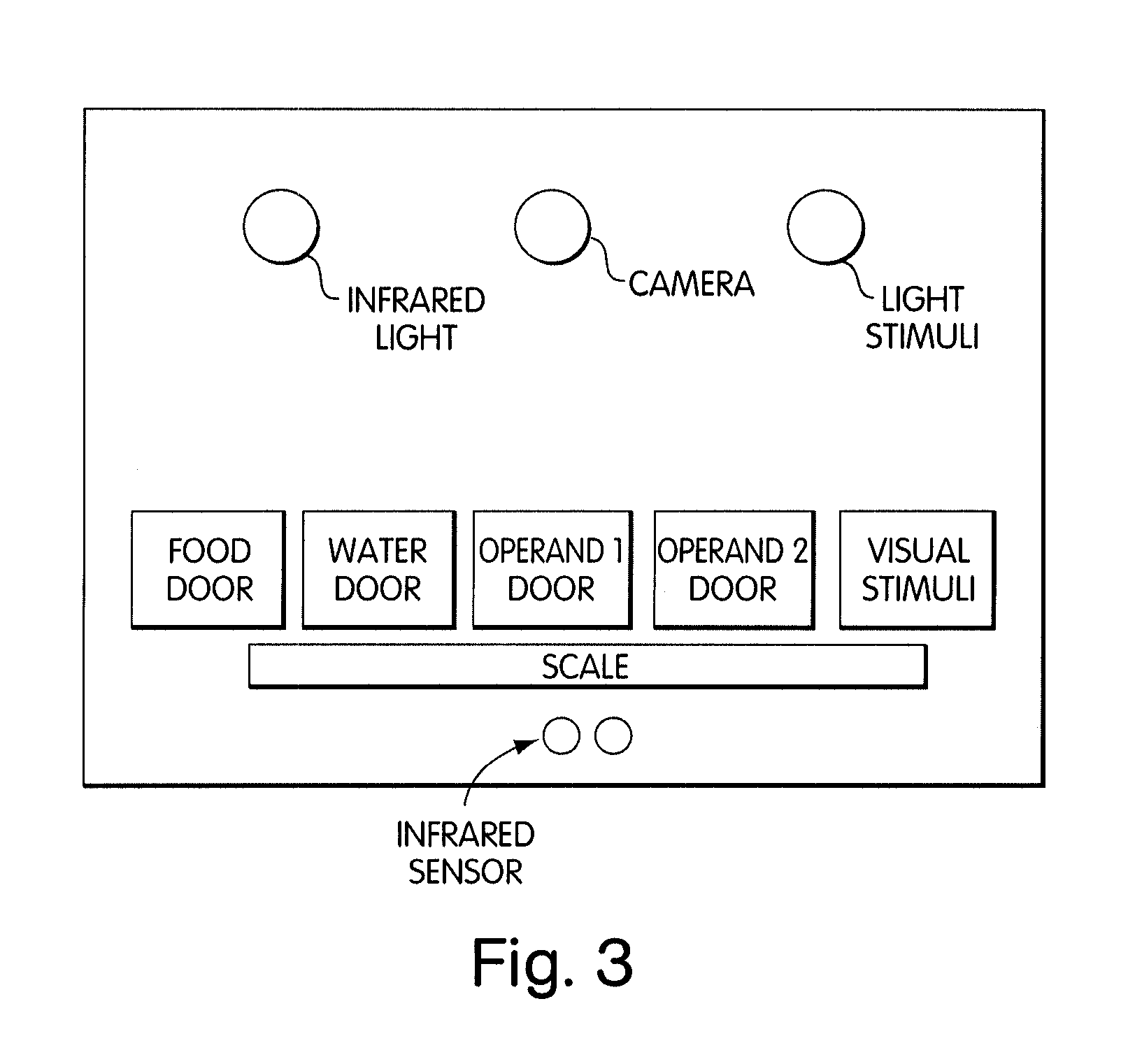

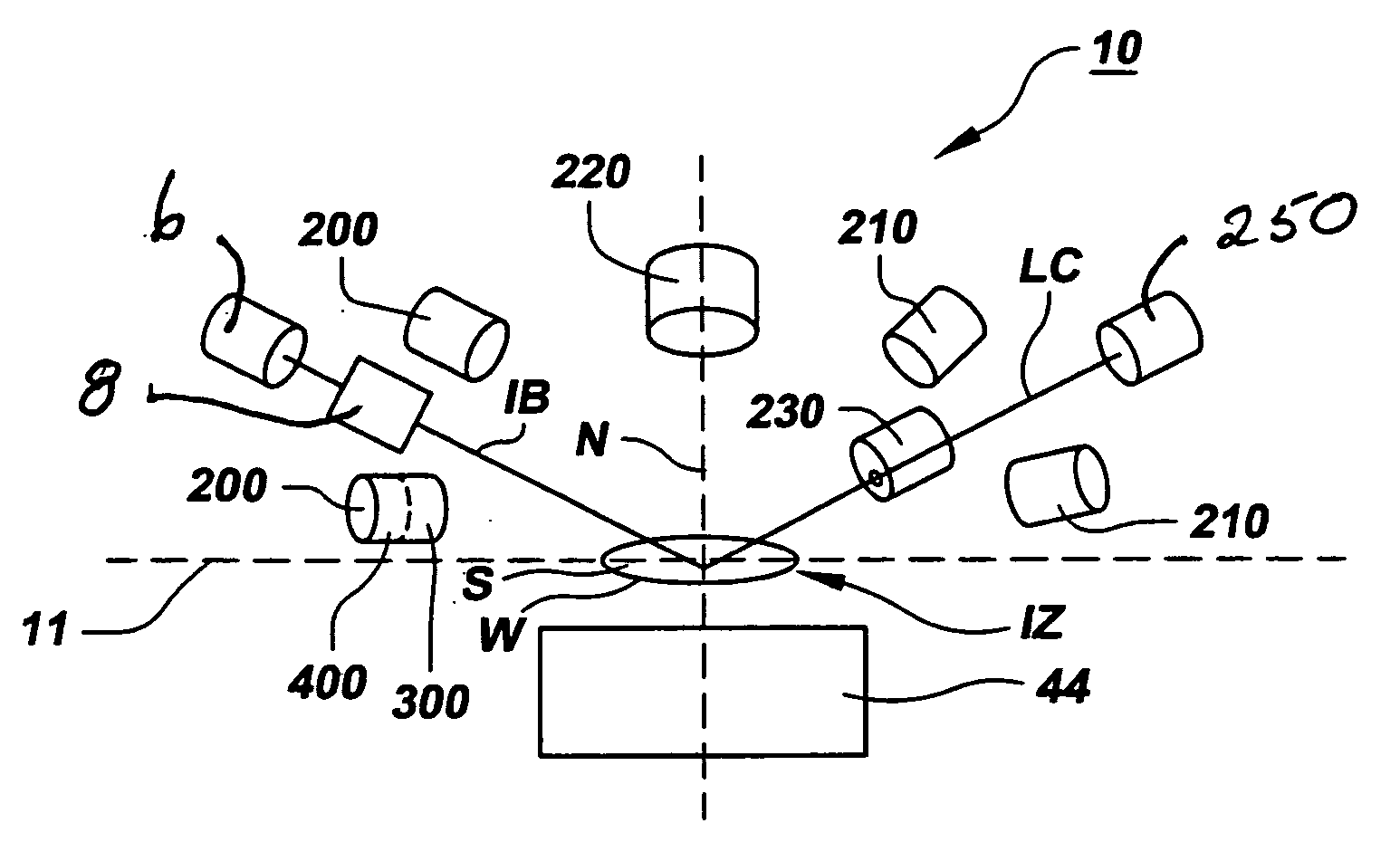

Systems and methods for monitoring behavior informatics

InactiveUS20030083822A2Improve statistics performanceExpand selectionComputer-assisted medical data acquisitionAnimal housingTest objectOrganism

Abstract of Disclosure A system and method used to assess animal behavior includes a module having sensors that collects a variety of physical and biological data from a test subject. Interpretation of the data is provided to assess the test subject's behavior, neurology, biochemistry and physiology. The module is useful in observing the effects of a drug on the test animal and providing information on the drug's signature. Another advantage is module's portability that allows it to be used in standard laboratory cages. This portability allows the animal to be tested in its own habitat, that can reduce any erroneous data due to stressing the animal when removed to a test cage. Additionally, the module's design allows for parallel data collection and interpretation from several laboratory animals undergoing different experiments. Multi-dimensional modeling of the test subject based the system's interpretation of the data allows pattern recognition of the drug signature, and predictive drug analysis.

Owner:PSYCHOGENICS

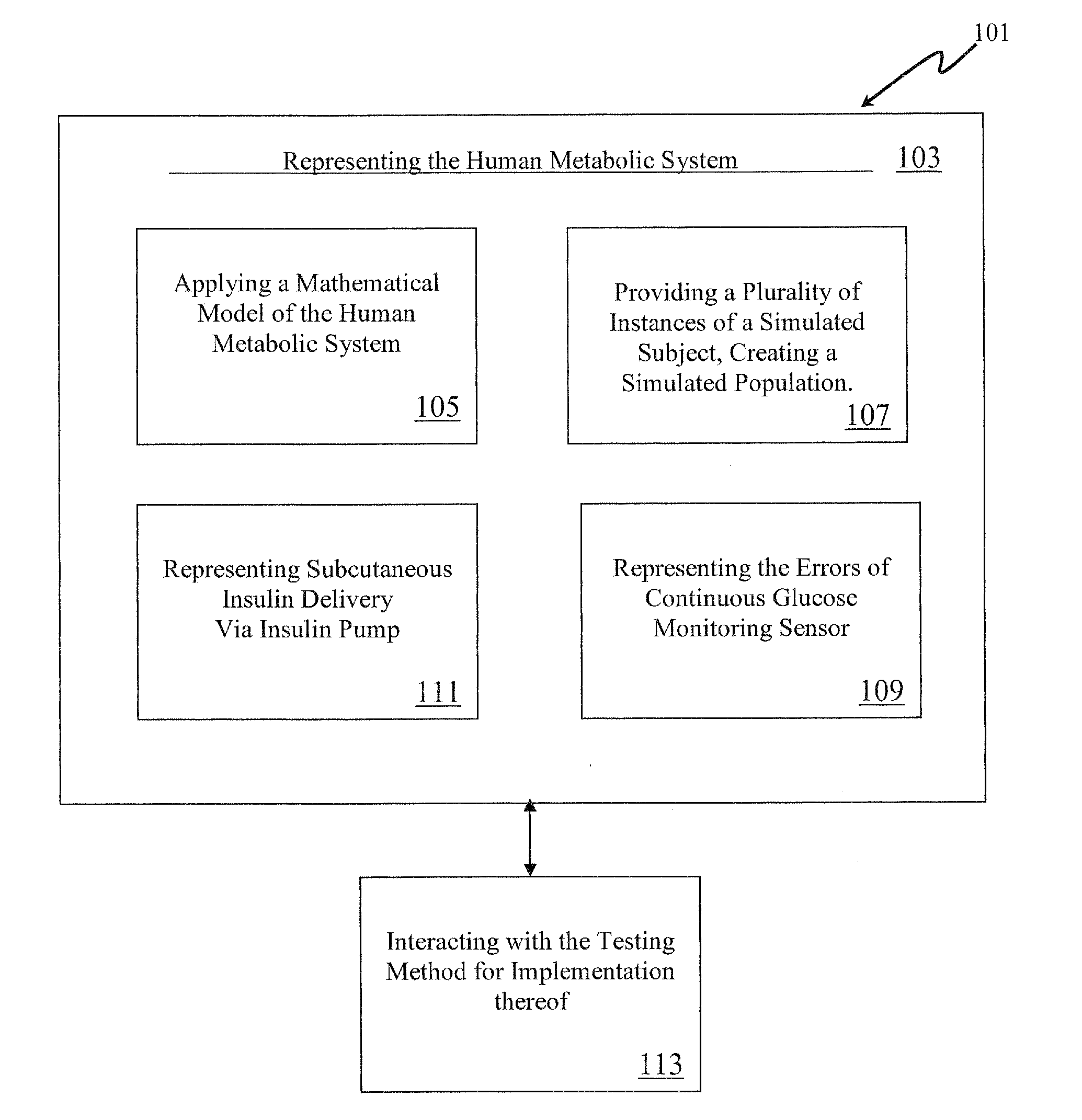

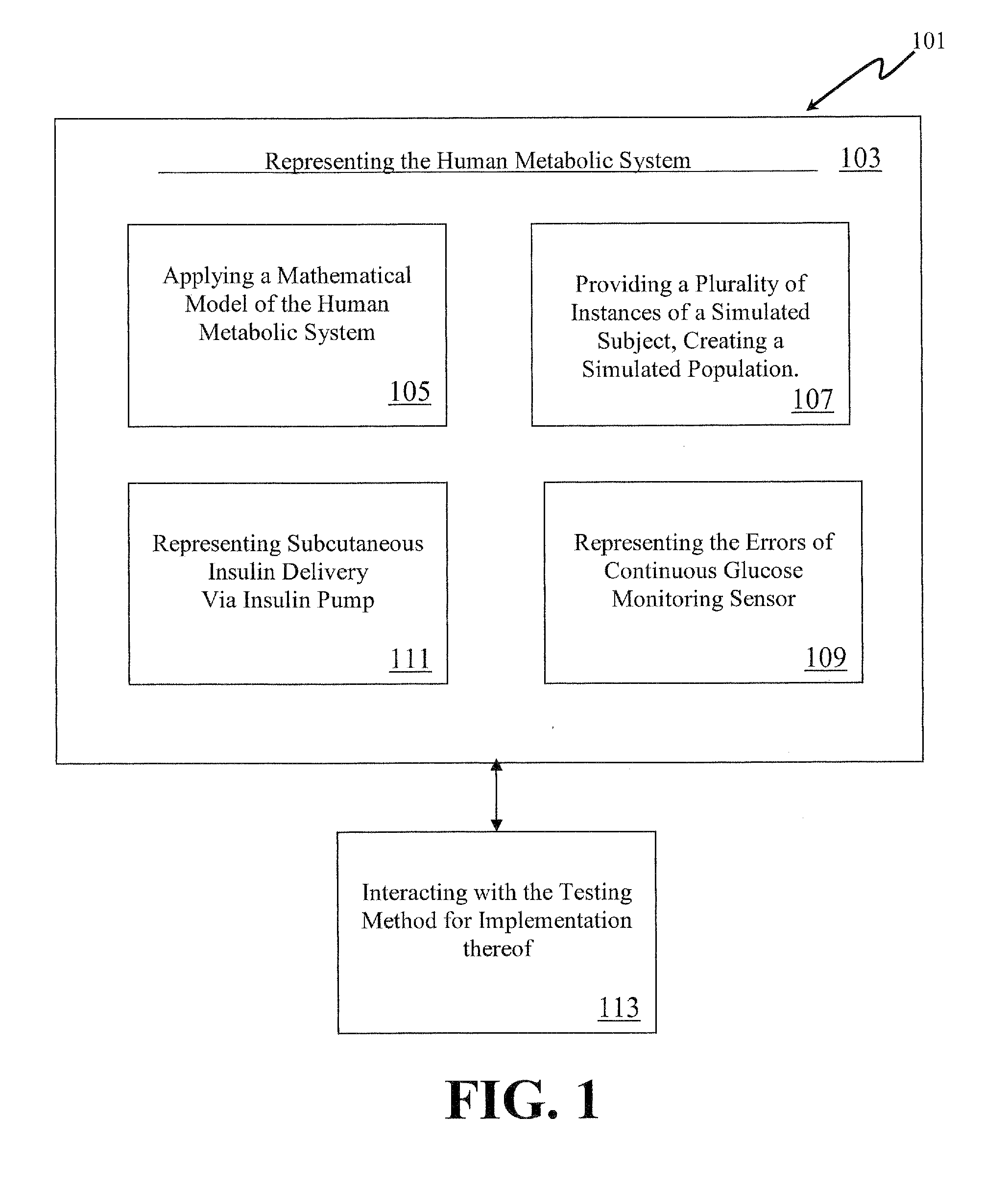

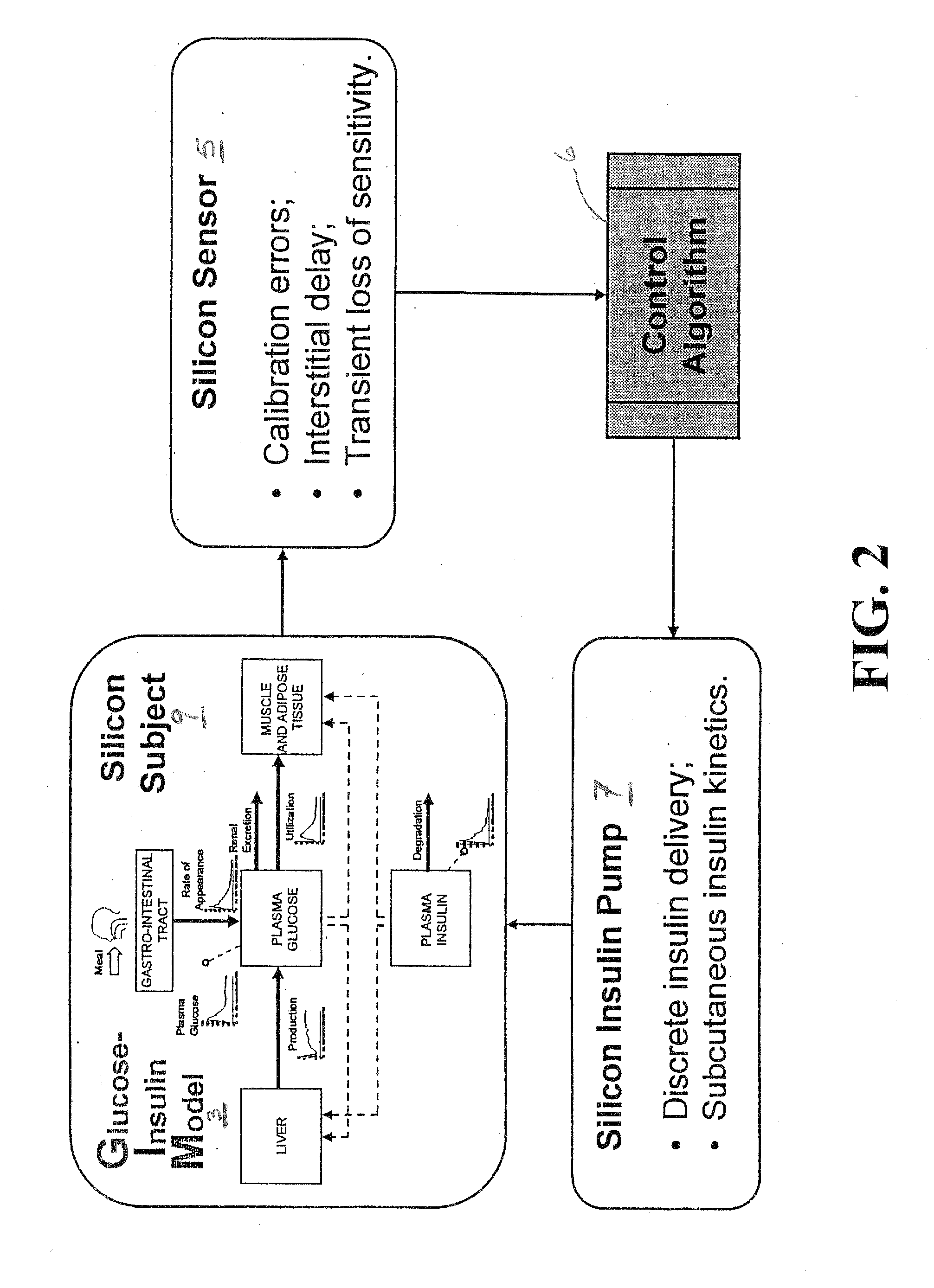

Method, System and Computer Simulation Environment for Testing of Monitoring and Control Strategies in Diabetes

A simulation environment for in silico testing of monitoring methods, open-loop and closed-loop treatment strategies in type 1 diabetes. Some exemplary principal components of the simulation environment comprise, but not limited thereto, the following: 1) a “population” of in silico “subjects” with type 1 diabetes in three age groups; 2) a simulator of CGM sensor errors; 3) a simulator of insulin pumps and discrete insulin delivery; 4) an interface allowing the input of user-specified treatment scenarios; and 5) a set of standardized outcome measures and graphs evaluating the quality of the tested treatment strategies. These components can be used separately or in combination for the preclinical evaluation of open-loop or closed-loop control treatments of diabetes.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

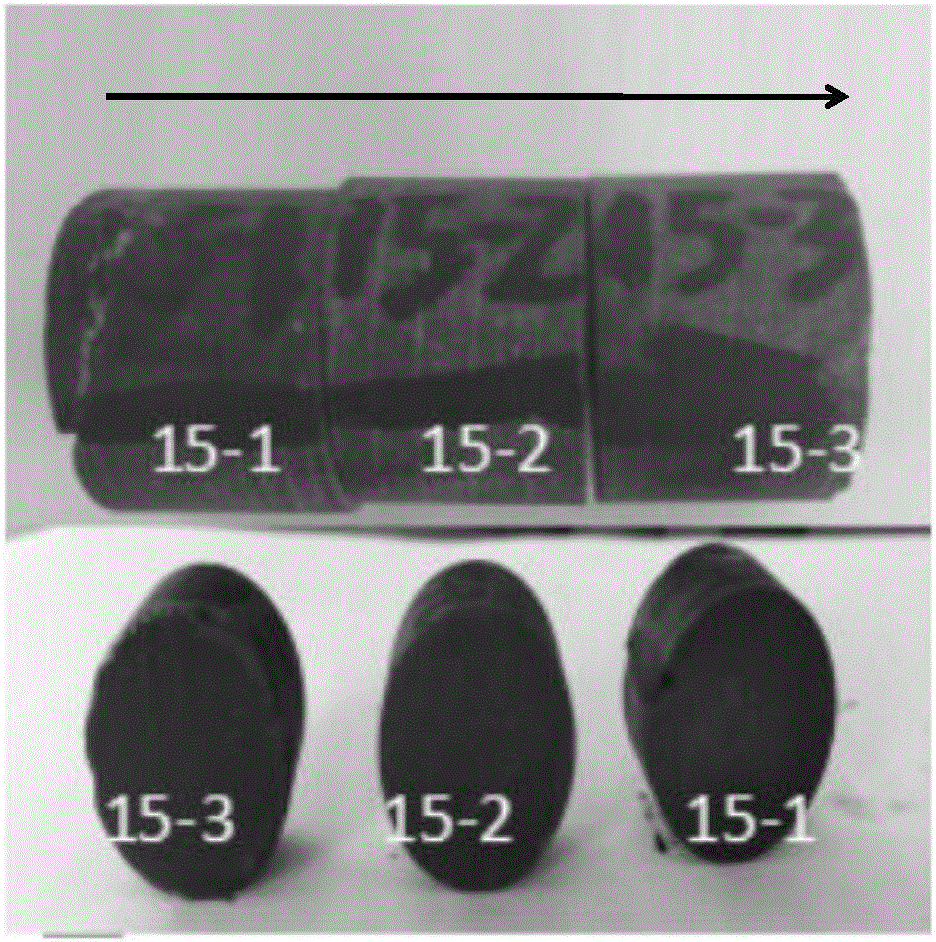

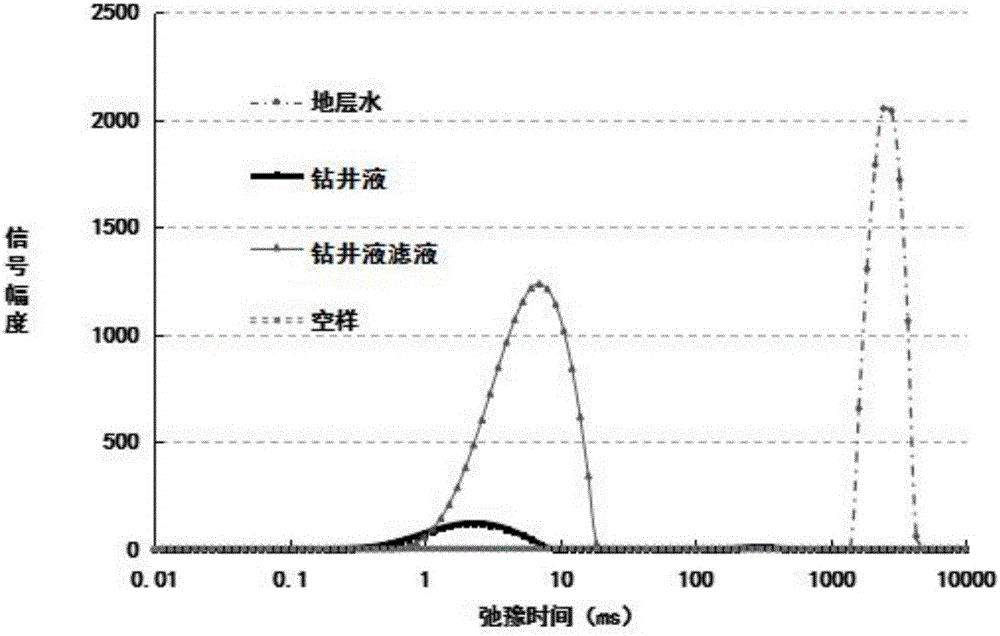

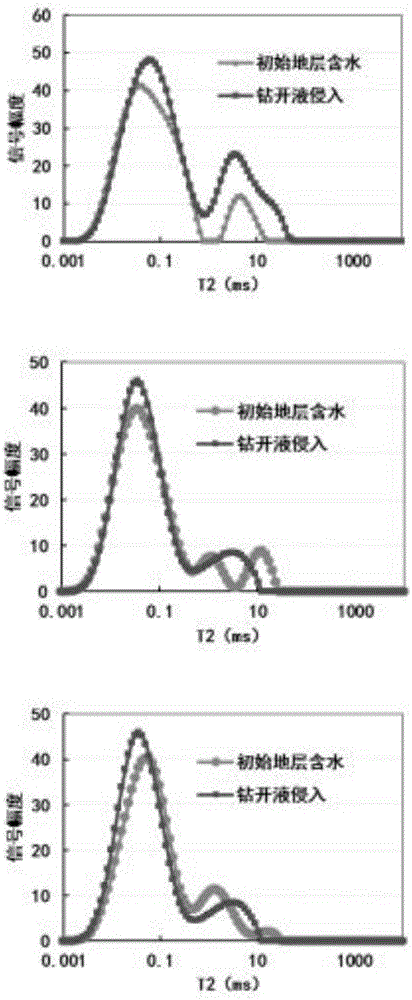

Evaluation testing method for damage of drilling fluid to compact gas reservoir

InactiveCN106093299ASlicing ImprovementsEfficient and accurate damage evaluation indicatorsEarth material testingAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceEvaluation testing

A disclosed evaluation testing method for damage of a drilling fluid to a compact gas reservoir comprises the following steps: drying a core sample, marking, performing uniform segmenting and slicing, and measuring the weight and other parameters of the dry core sample; putting the core segments into a fluid for infiltration and saturation; performing reverse centrifugation operation on the core segments, and acquiring the original water saturation Swi of the small core segment samples; measuring the nuclear magnetic resonance T2 spectrums of simulated stratum water and a filtrate of the drilling fluid and determining the difference; performing NMR imaging measurement on the fluid distribution state in the core; and putting the core segments into a core clamper of a drilling-fluid circulating instrument for measurement after the drilling fluid is circulated and calculating the water saturation Swi and the gas permeability K2 of the core segments, calculating the permeability damaging rate after infiltration of the drilling fluid by using the measurement results through comparison, so as to evaluate the damage degree caused by infiltration of the drilling fluid at different depths. The novel evaluation testing method for damage of a drilling fluid to compact and super compact gas reservoirs is established by improving an original slice method.

Owner:SOUTHWEST PETROLEUM UNIV

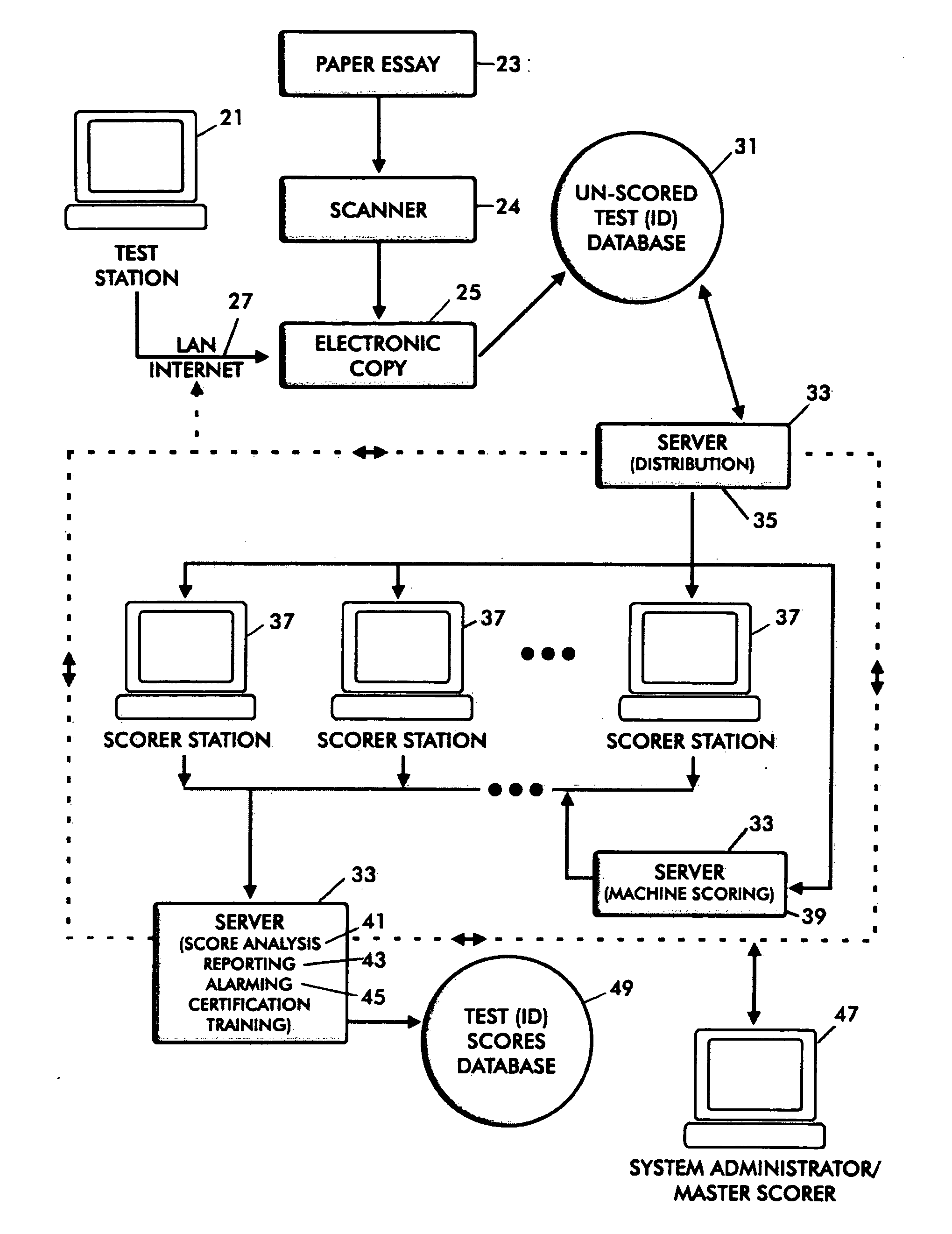

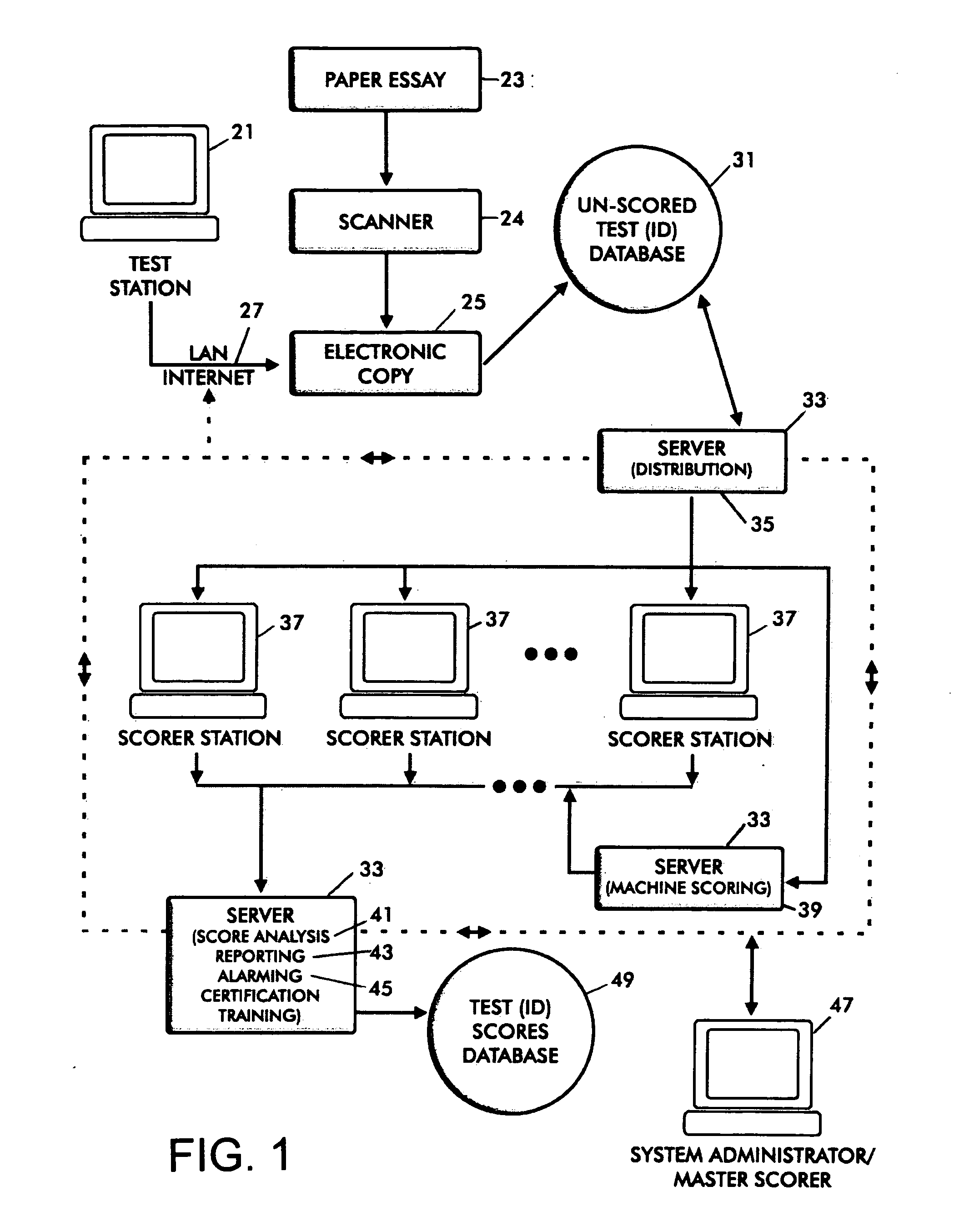

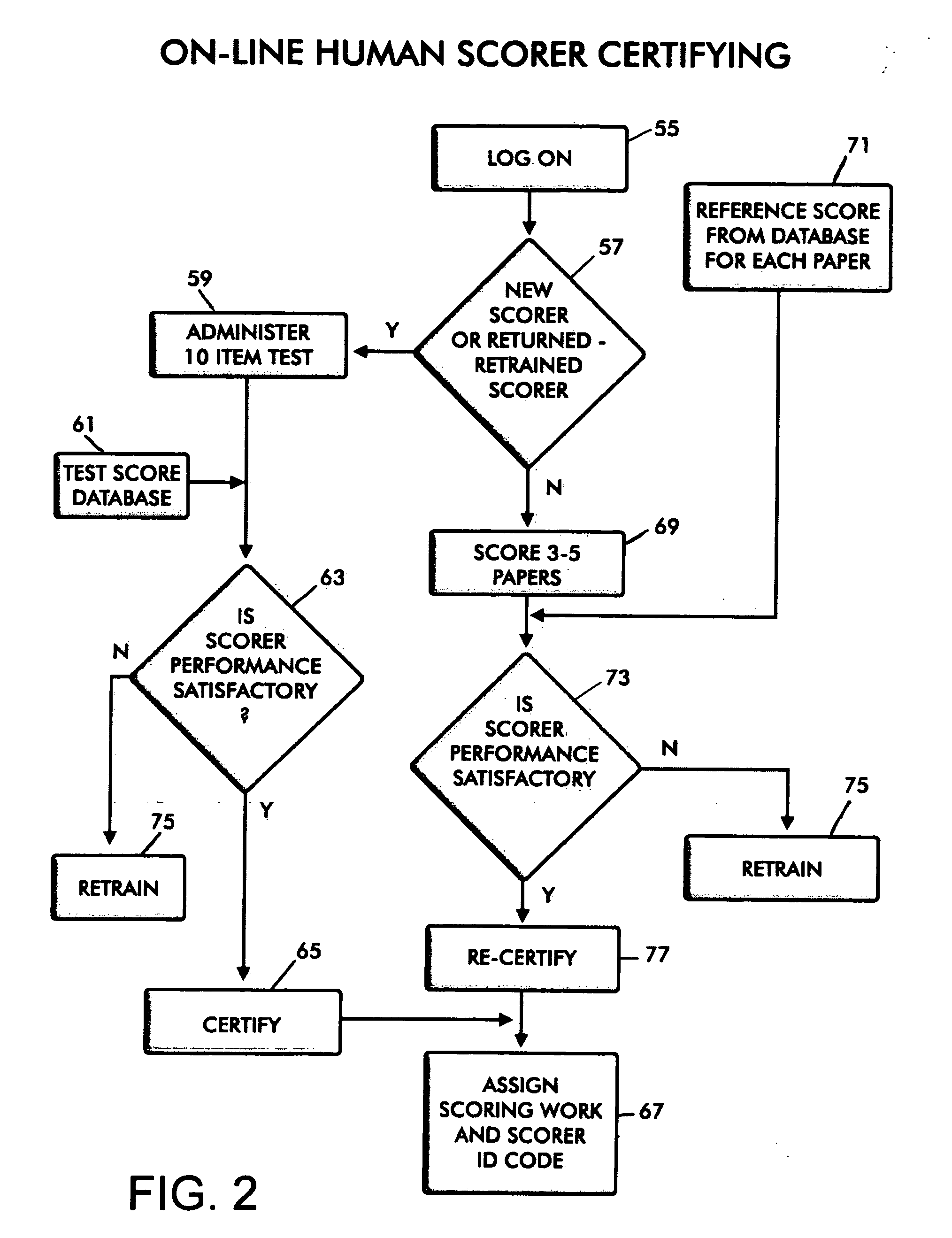

System for obtaining and integrating essay scoring from multiple sources

InactiveUS20070218450A1Electrical appliancesMechanical appliancesComputer scienceContinuous monitoring

A method and a web-based software apparatus for use in the automated scoring of assessment test papers, utilizes both a human and the machine scoring of each paper in a poly-metrological evaluation each assessment score. The scoring performance of each human scorer, in web-base assessment scoring production, is constantly monitored and evaluated, in real time, for score accuracy, bias, and other factors. Whereof, each human score performance is measured against machine score performance of the same assessment paper, and if need be, against a second human score performance in scoring the same assessment paper. Scores are resolved according to a subscriber approved algorithm. Irresolvable discrepancies are addressed by a chief or master human scorer. The score performance history of each production, human scorer is constantly monitored, in real time, and each human scorer is prompted or selected-out for retraining, as necessary, according to a selected, real time, evaluation algorithm. Scorer performance is judged according to exact agreement rates, and according to adjacent agreement rates.

Owner:VANTAGE TECH KNOWLEDGE ASSESSMENT

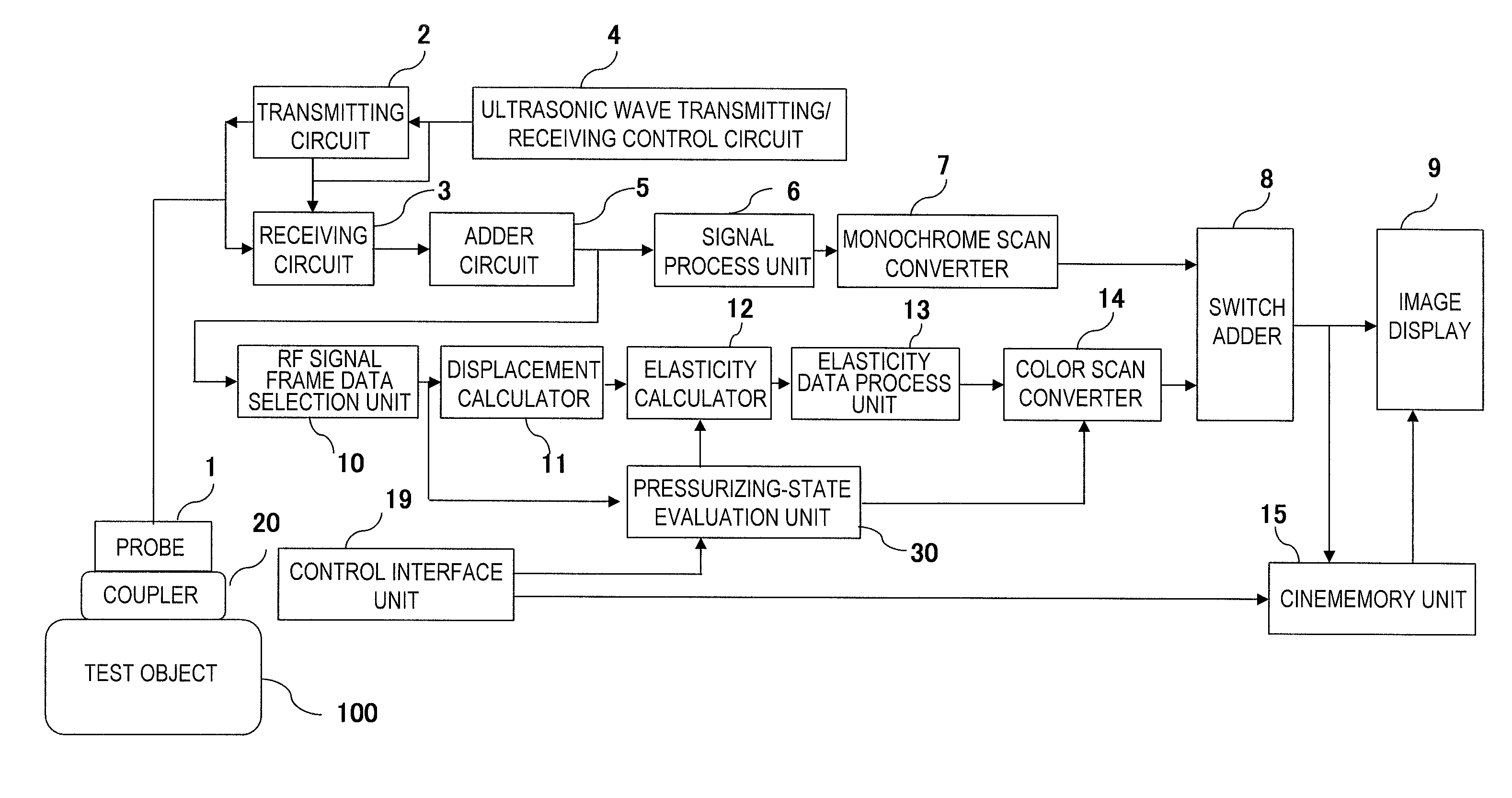

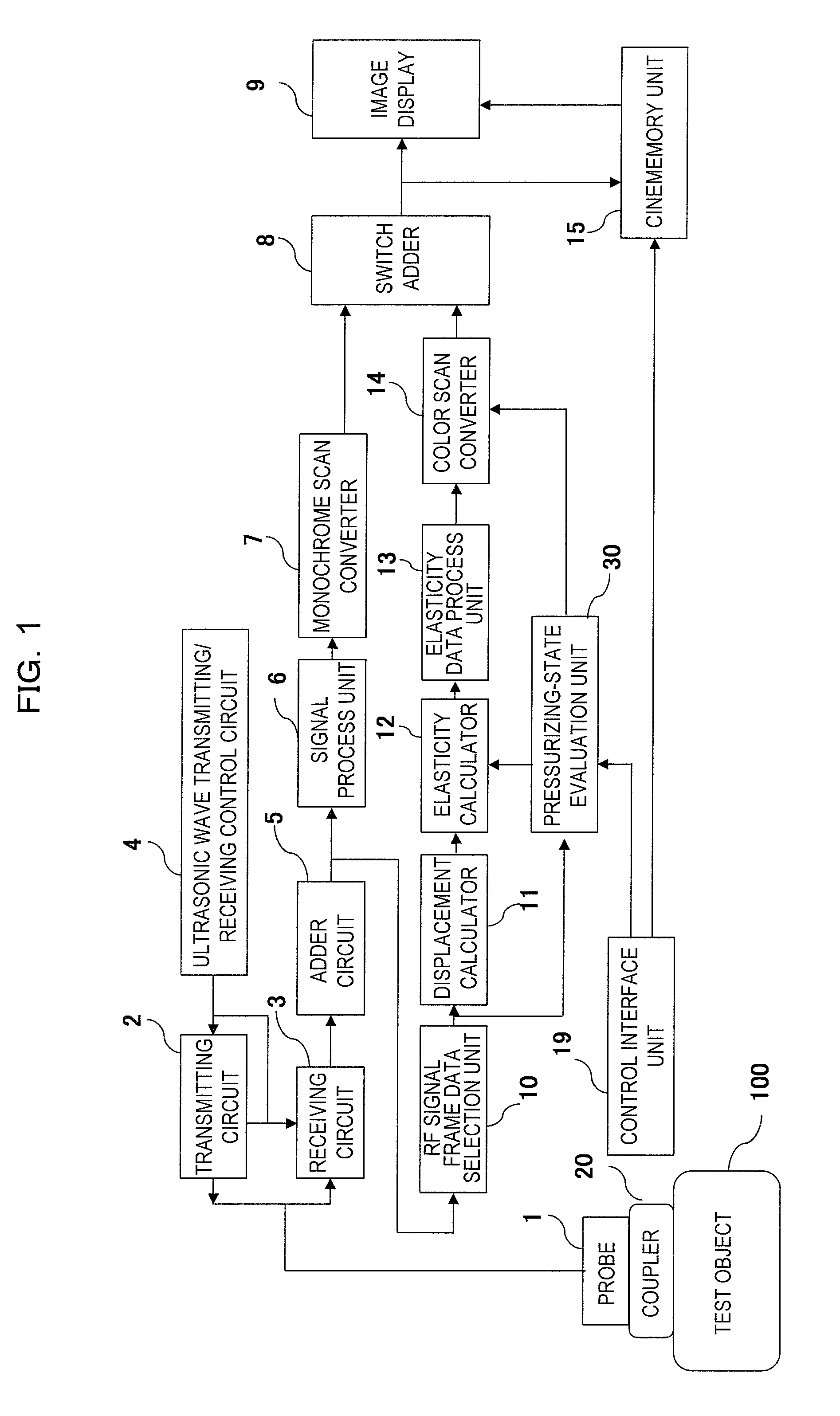

Ultrasonic diagnostic apparatus

InactiveUS20110040187A1Easy to operateImprove usabilityBlood flow measurement devicesDiagnostic recording/measuringHigh availabilityTest object

The invention was made to simplify the operation relating to the detection of an absolute pressure applied to a test body by an ultrasonic probe and thereby to enhance usability. The fact that an elastic coupler has been attached to the ultrasonic wave transmitter / receiver surface and the fact that the elastic coupler is in an initial state with no pressure are detected (S2, S3), an initial thickness of the elastic coupler in the initial state is obtained (S6), the fact that the elastic coupler is in the pressurized state is detected based on the disappearance of a multiple echo which is included in an RF signal and caused due to the elastic coupler, the thickness of the elastic coupler in the pressurized state is obtained by detecting the boundary between the test body and the elastic coupler in the pressurized state, the thickness change is obtained based on the thickness in the pressurized state and the initial thickness (S7), and the absolute pressure applied to the test object is evaluated based on the thickness change and the pre-set elasticity property of the elastic coupler (S8).

Owner:HITACHI LTD

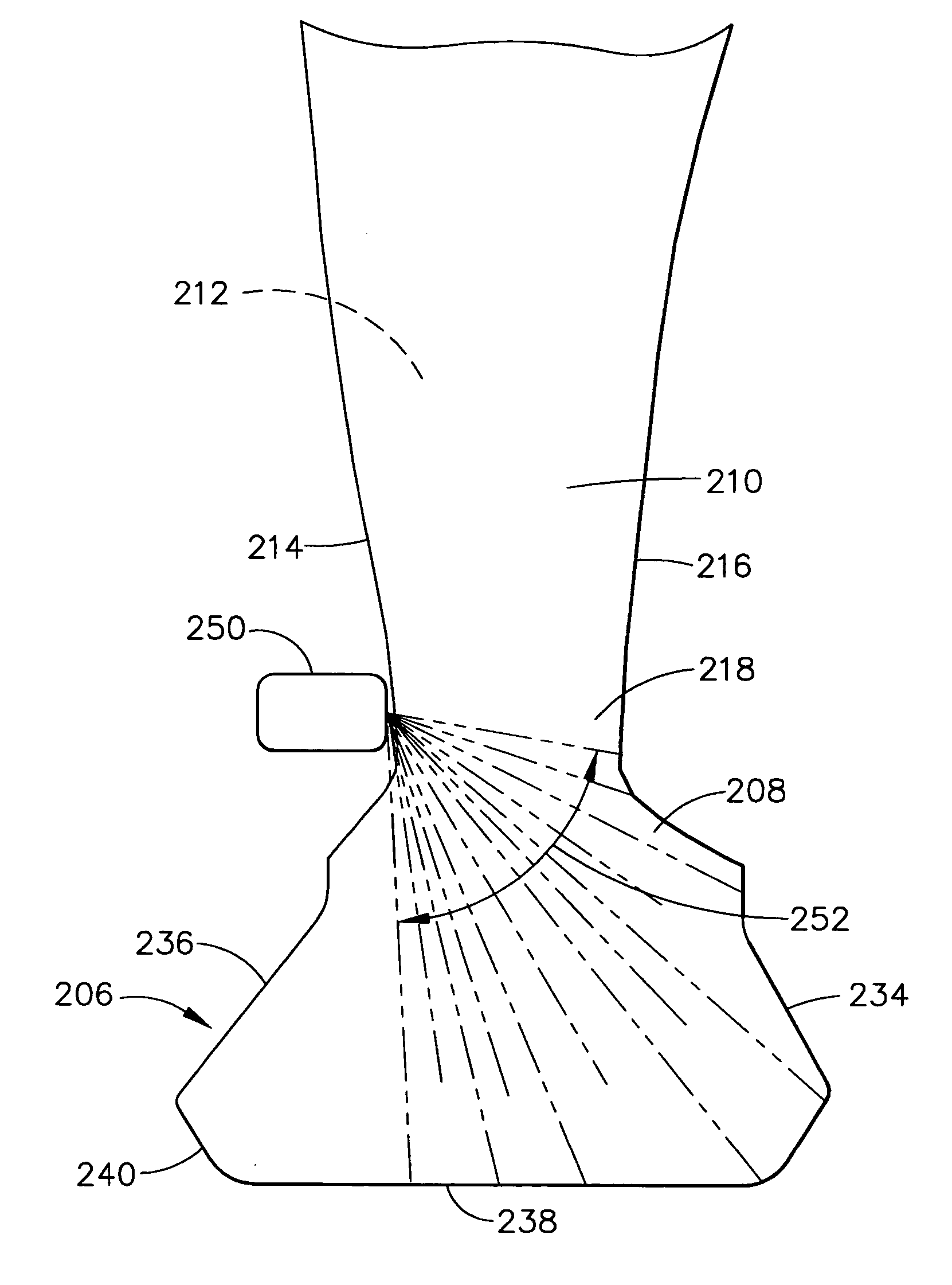

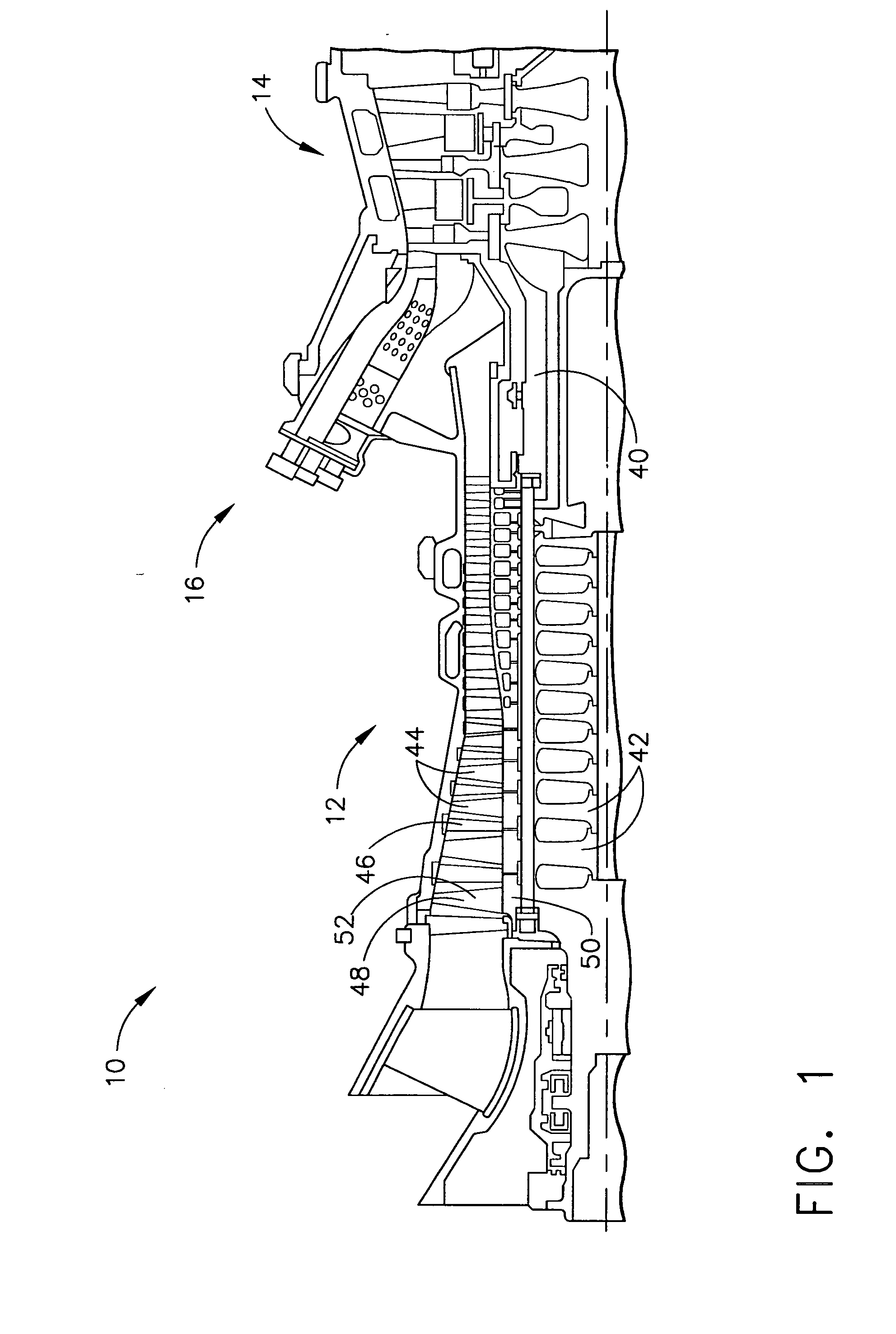

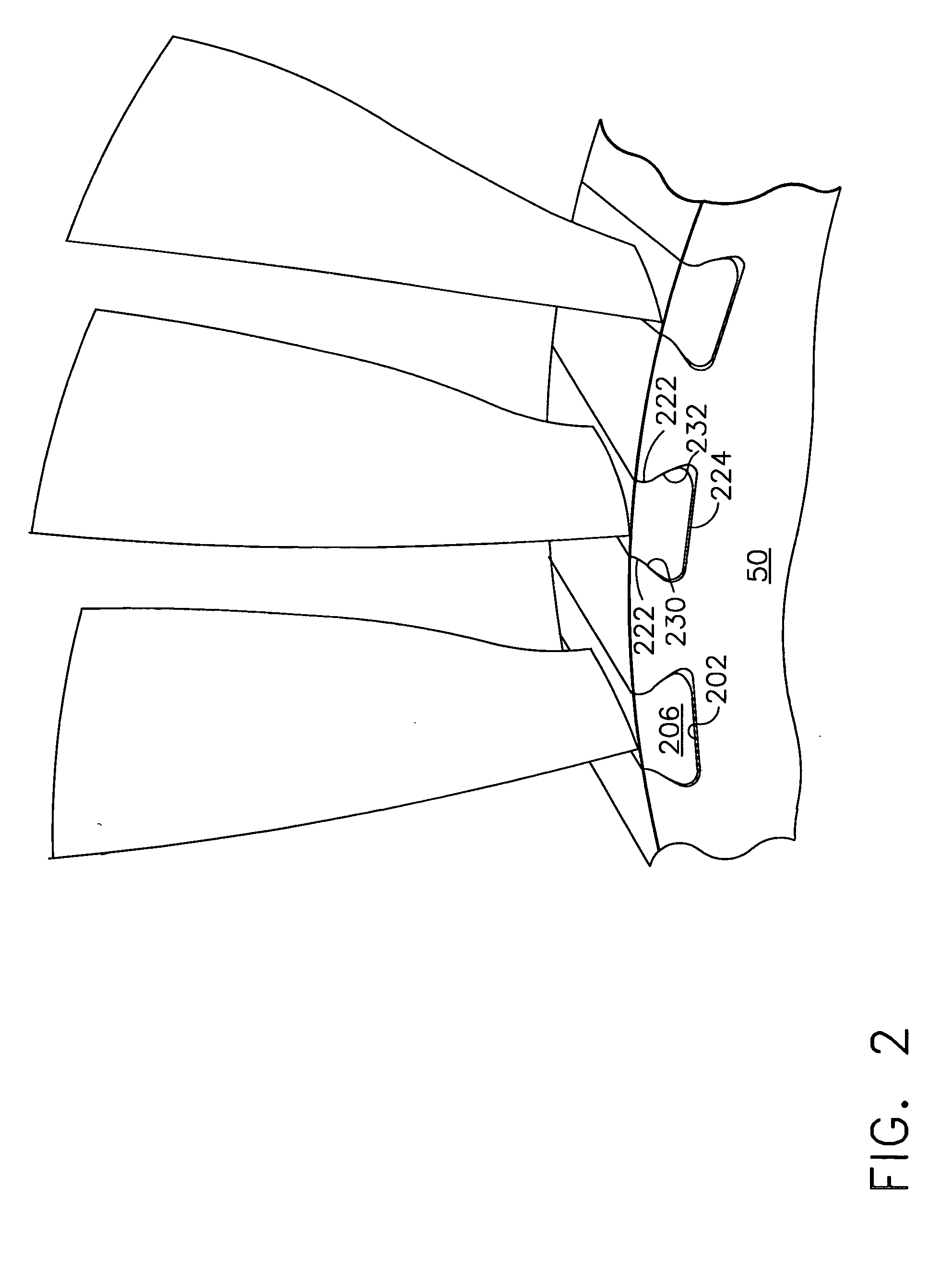

Methods and apparatus for rotary machinery inspection

ActiveUS20050126291A1Analysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by using resonanceNon destructiveSteering angle

A method of non-destructive evaluation (NDE) testing a component of an assembly is provided. The method includes positioning a transducer on a face of the component, transmitting ultrasonic waves into the component at a plurality of steering angles, receiving ultrasonic echoes, wherein each received echo is indicative of an acoustic impedance interface within the component, and analyzing the ultrasonic echoes.

Owner:GENERAL ELECTRIC CO

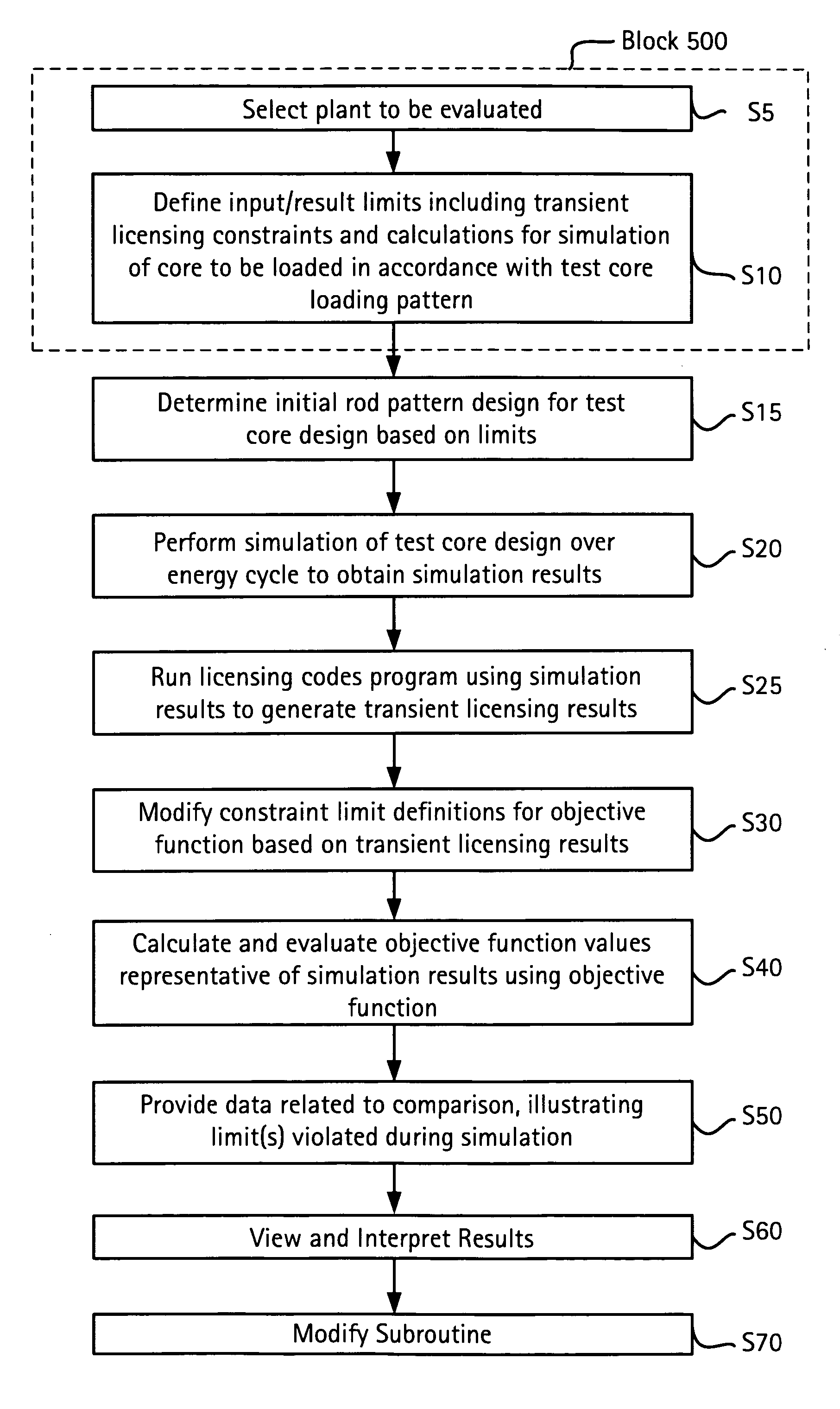

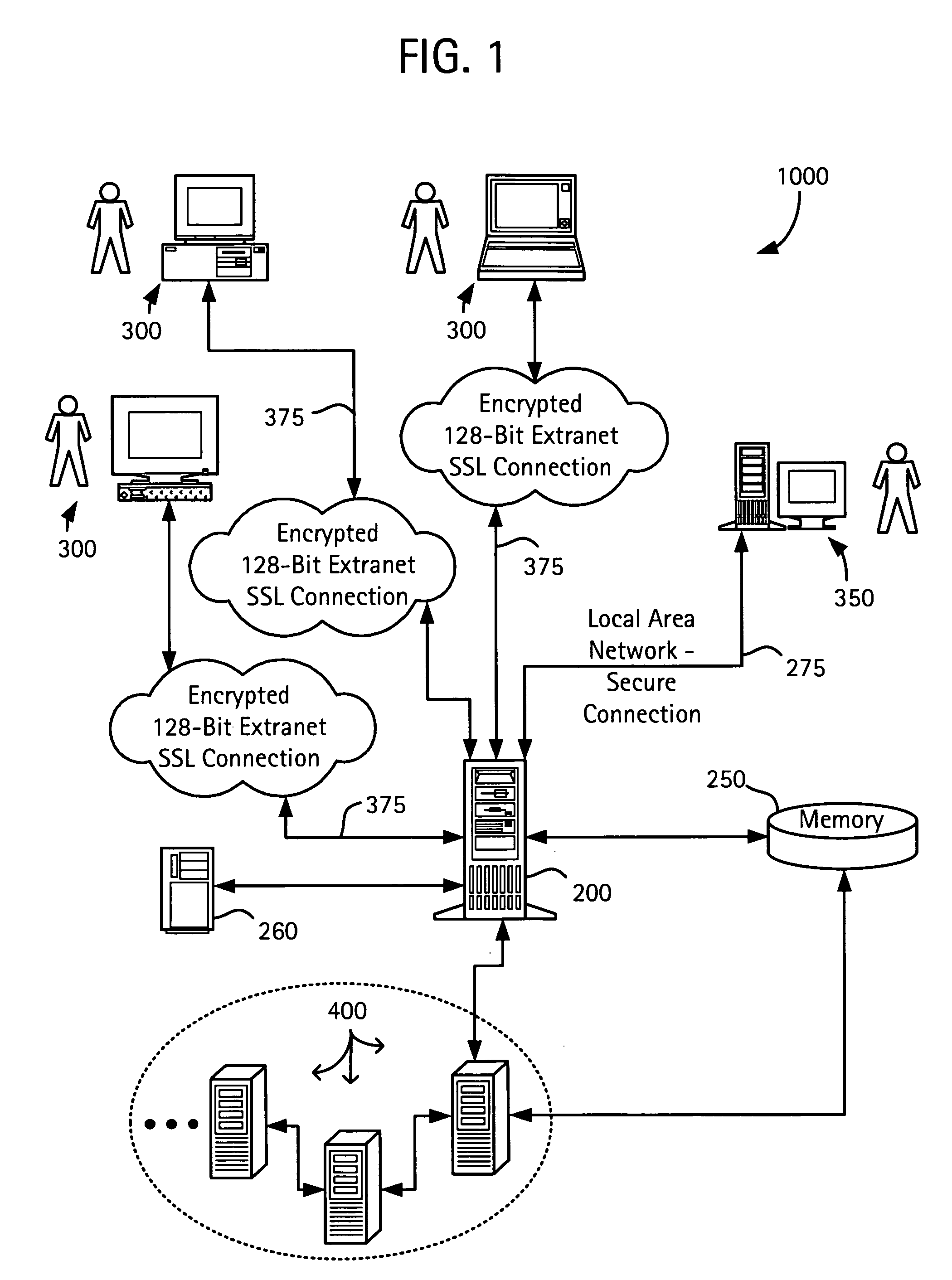

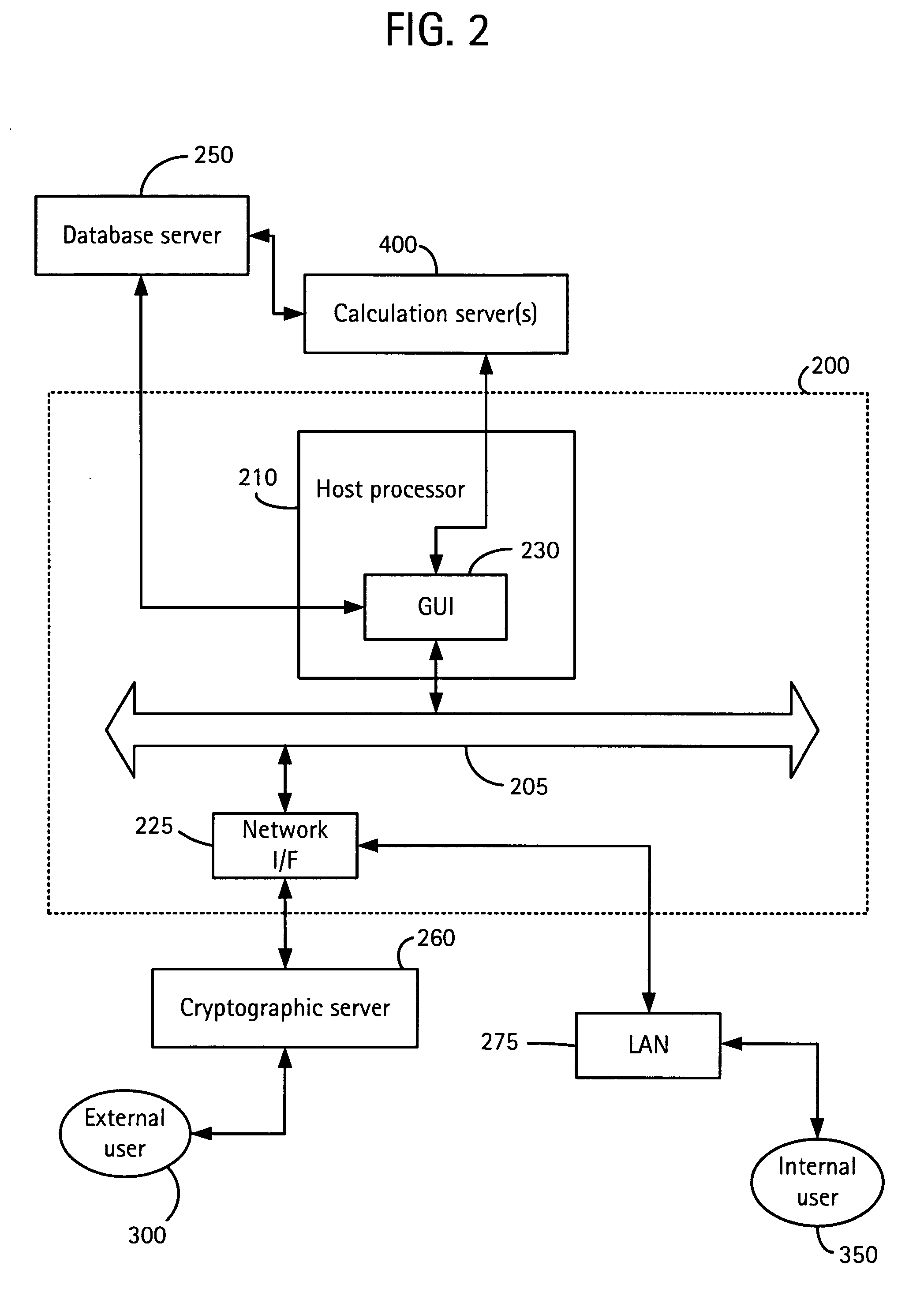

Computer-implemented method and system for designing a nuclear reactor core which satisfies licensing criteria

ActiveUS20070213959A1Power plant safety arrangementPlant parameters regulationNuclear reactor coreNuclear reactor

In a computer-implemented method of designing a nuclear reactor of a given reactor plant, an initial, test reactor core design is generated for the given plant based on a plurality of limits input by a user. The limits include a plurality of transient licensing constraints to be satisfied for operating the given plant. The method includes selecting, from a set of automated tools, one or more automated tools to evaluate the test core design, and operating one of more of selected automated tools to output data for display to the user. The displayed data is related to a core design that satisfies the limits inclusive of the transient licensing constraints.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

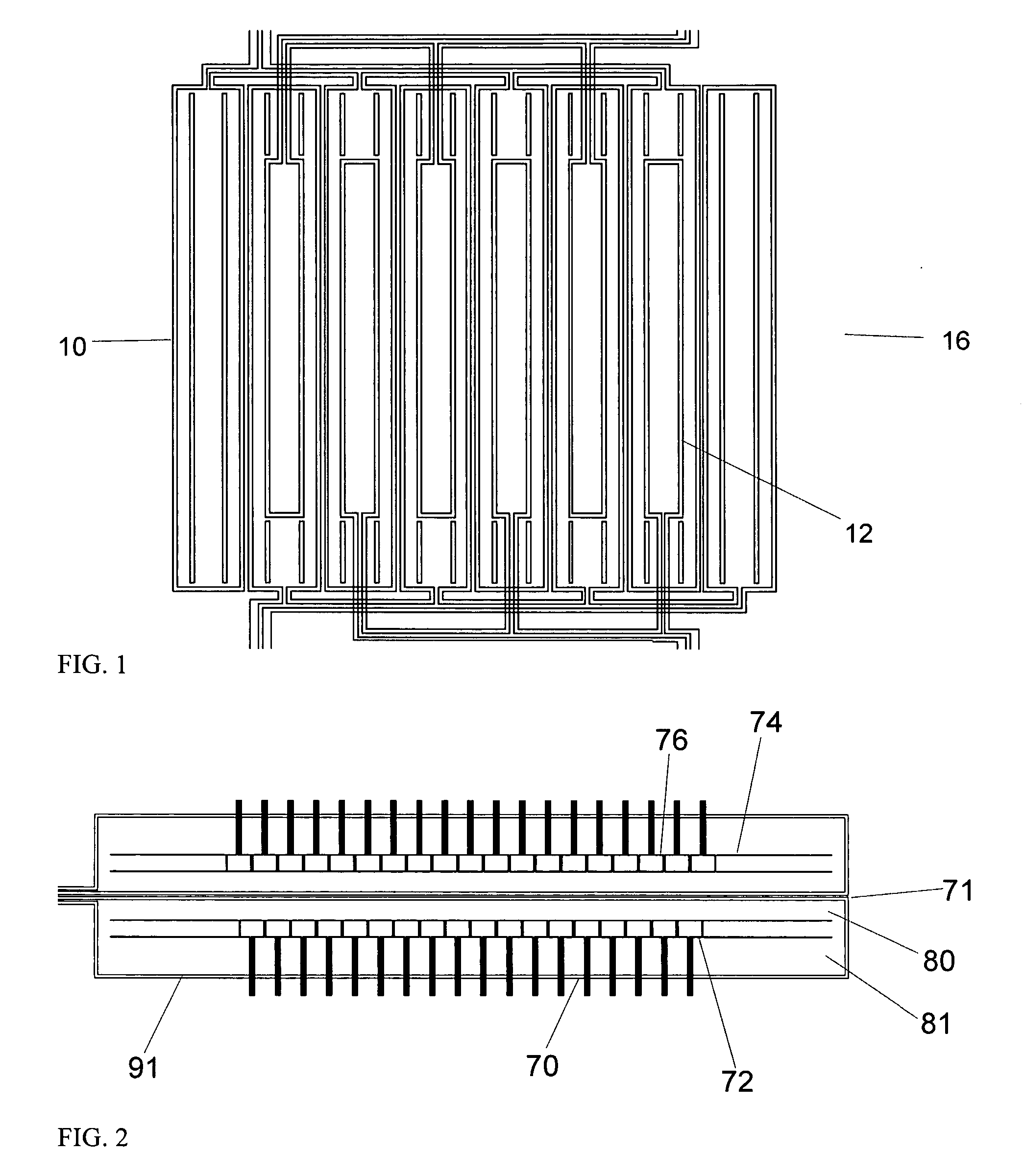

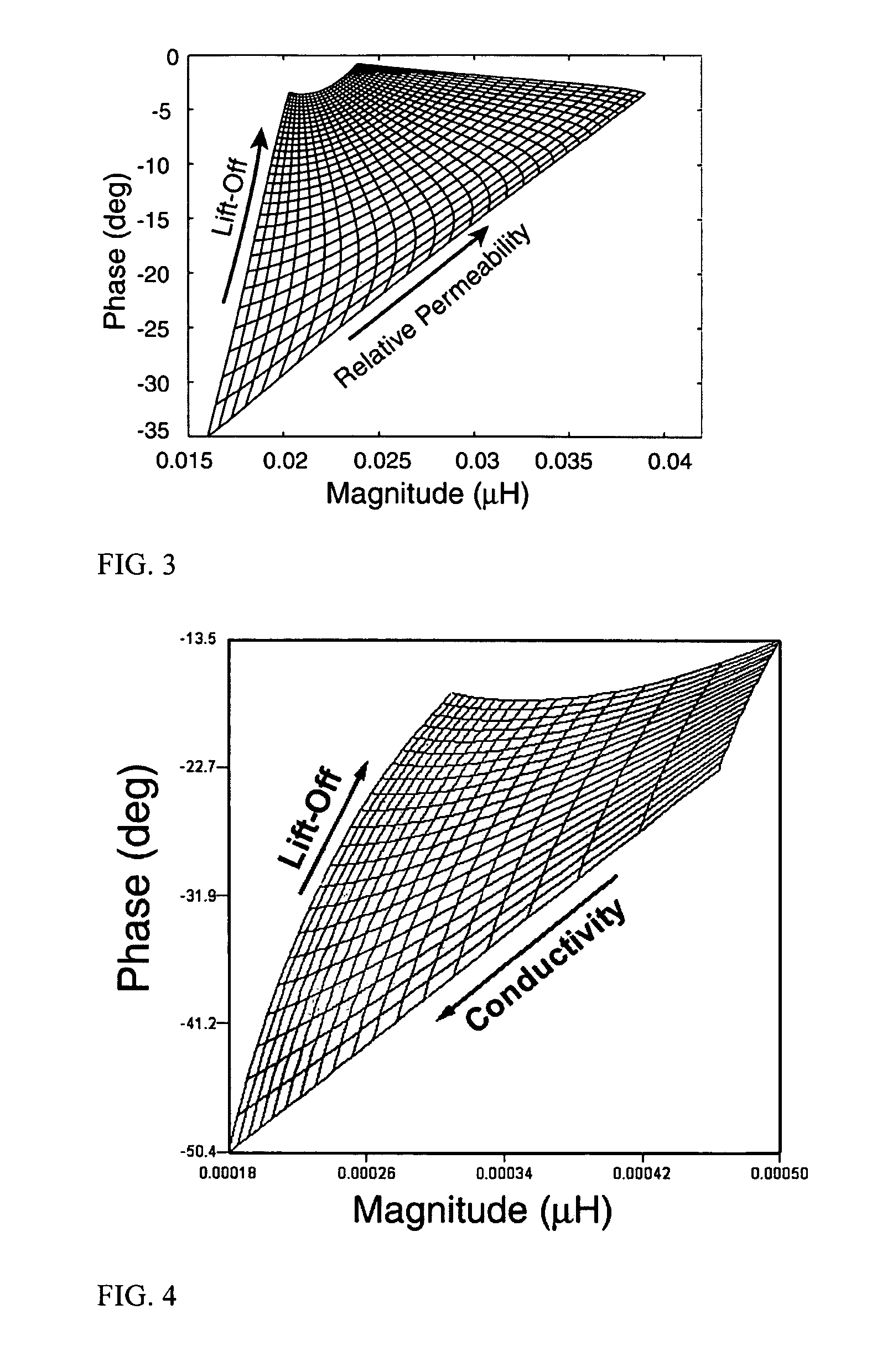

Material characterization with model based sensors

InactiveUS20070069720A1Improve crack detection reliabilityImprove reliabilityMaterial magnetic variablesSensor arrayElectric field sensor

Nondestructive material condition monitoring and assessment is accomplished by placing, mounting, or scanning magnetic and electric field sensors and sensor arrays over material surfaces. The material condition can be inferred directly from material property estimates, such as the magnetic permeability, dielectric permittivity, electrical property, or thickness, or from a correlation with these properties. Hidden cracks in multiple layer structures in the presence of fasteners are detected by combining multiple frequency magnetic field measurements and comparing the result to characteristic signature responses. The threshold value for indicating a crack is adjusted based on a high frequency measurement that accounts for fastener type. The condition of engine disk slot is determined without removal of the disk from the engine by placing near the disk a fixture that contains a sensor for scanning through the slot and means for recording position within the slot. Inflatable support structures can be placed behind the sensor to improve and a guide can be used to align sensor with the slot and for rotating the disk. The condition of an interface between a conducting substrate and a coating is assessed by placing a magnetic field sensor on the opposite side of the substrate from the coating and monitoring at least one model parameter for the material system, with the model parameter correlated to the interfacial condition. The model parameter is typically a magnetic permeability that reflects the residual stress at the interface. Sensors embedded between material layers are protected from damage by placing shims on the faying surface. After determining the areas to be monitored and the areas likely to cause sensor damage, a shim thickness is determined and is then placed in at least one area not being monitored by a sensor. The condition of a test fluid is assessed through a dielectric sensor containing a contaminant-sensitive material layer. The properties of the layer are monitored with the dielectric sensor and correlated to contaminant level.

Owner:JENTEK SENSORS

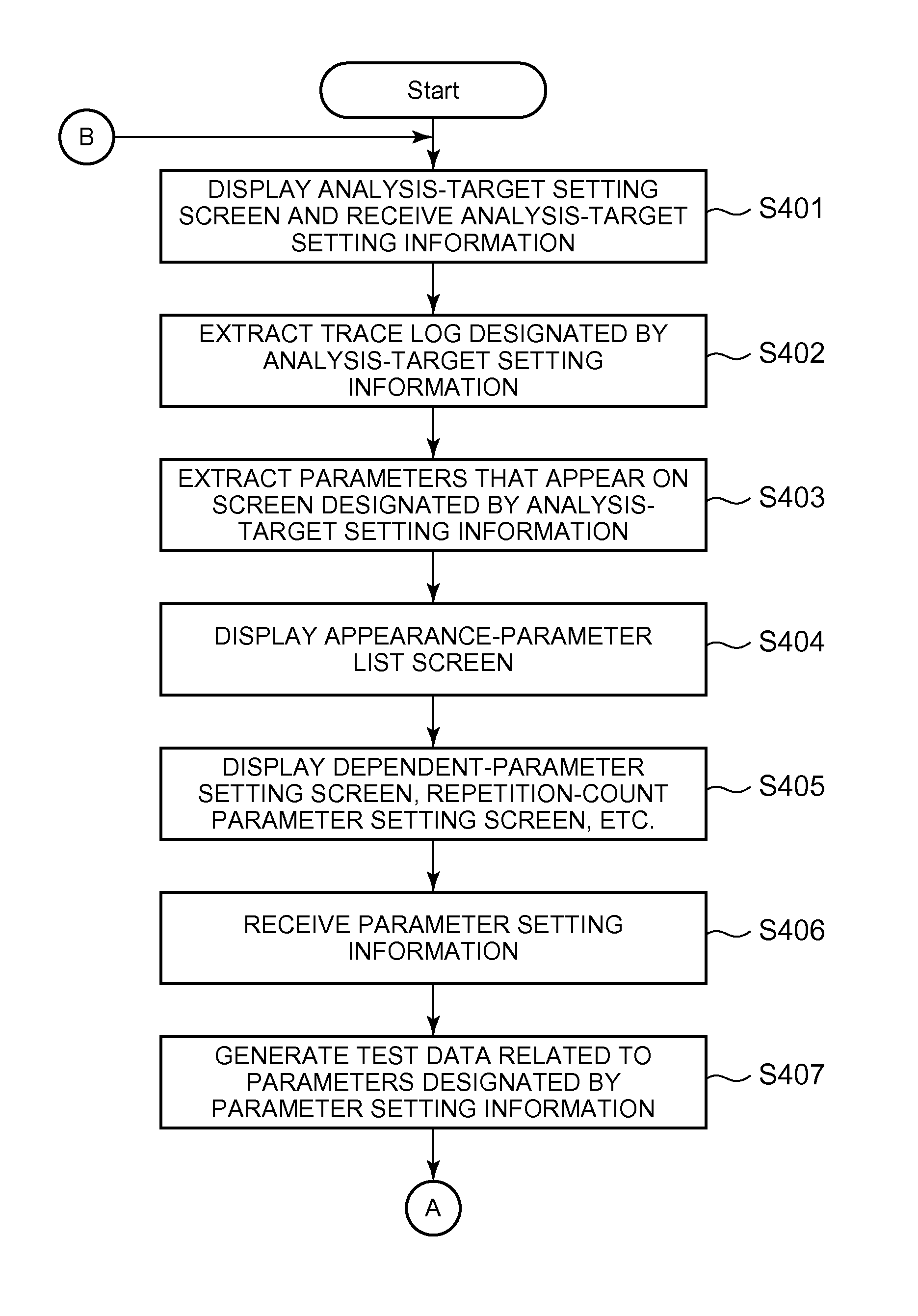

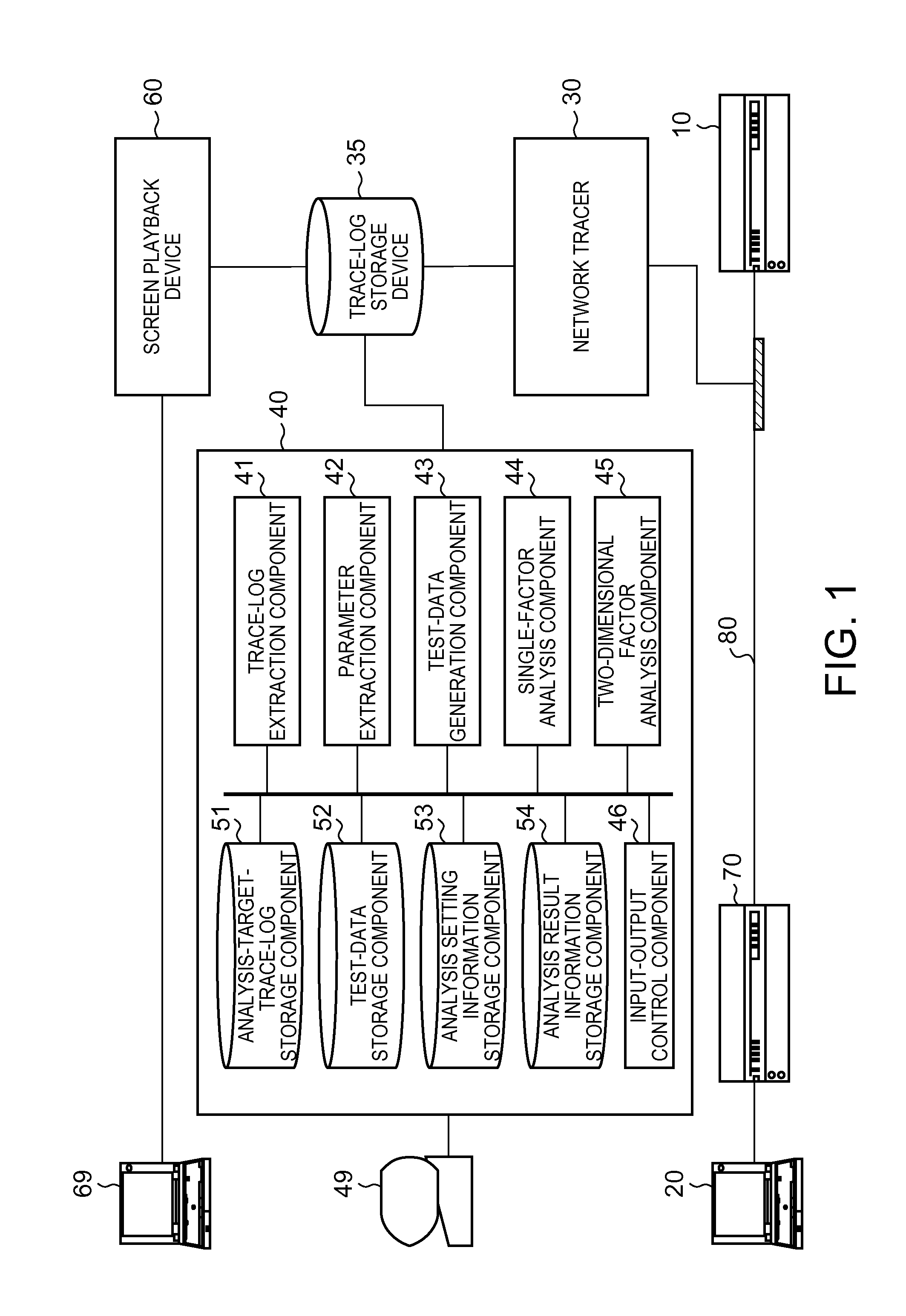

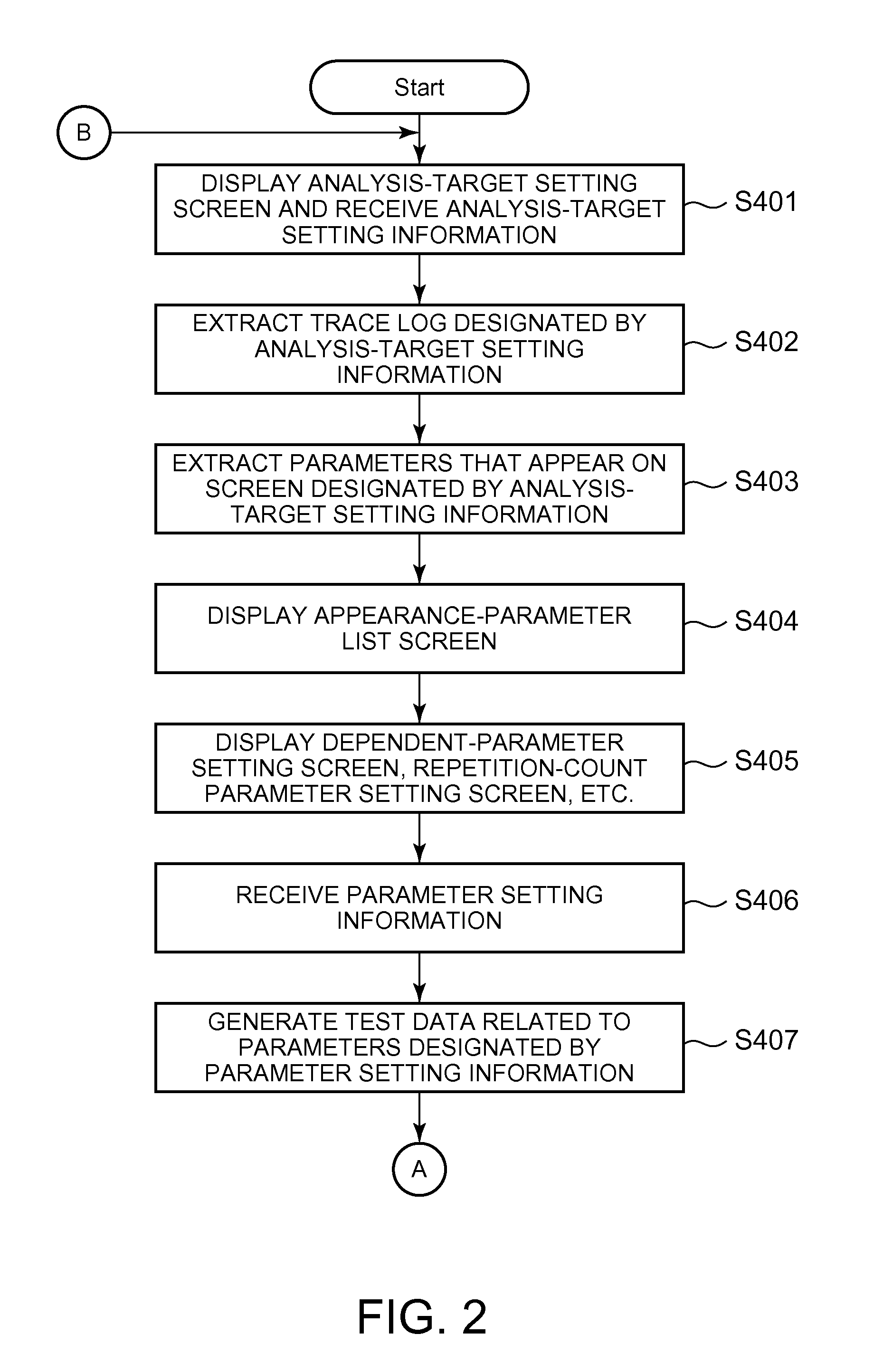

Evaluating Coverage of a Software Test

InactiveUS20120167059A1Software testing/debuggingSpecific program execution arrangementsEvaluation testingSoftware testing

Evaluating the coverage of a test, the evaluating including using an apparatus that includes a storage component, an analysis component, and an output component. The storage component is for storing log data of a plurality of tests. The log data includes a plurality of input values that are input to a specified input field on a specified screen and transmitted to a server in each of the plurality of tests that use the specified screen displayed on a client device. The analysis component is for performing analysis that includes analyzing to what extent the plurality of input values included in the log data stored in the storage component cover values that should be input to the specified input field in the plurality of tests. The output component is for outputting a result of the analyzing from the analysis component.

Owner:IBM CORP

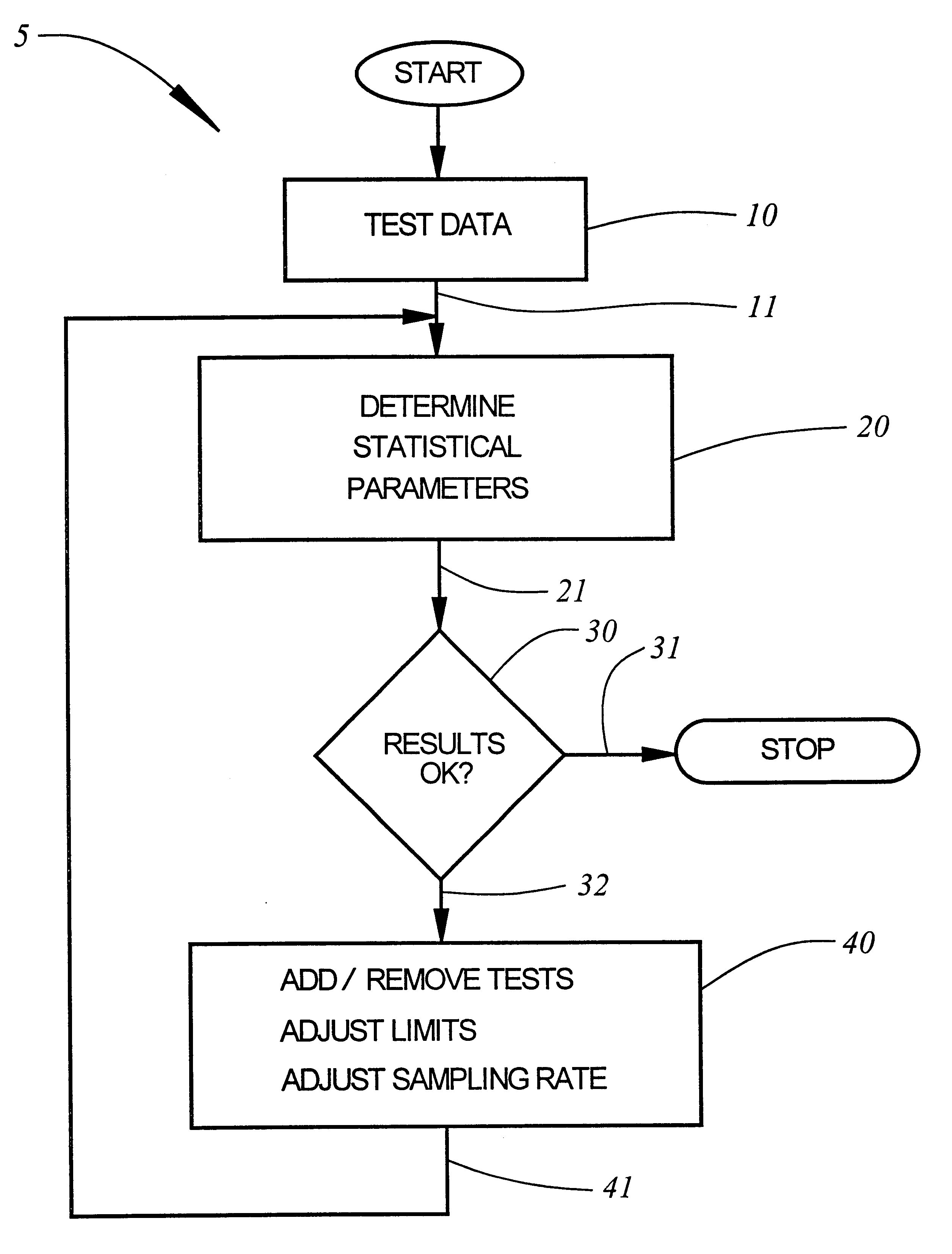

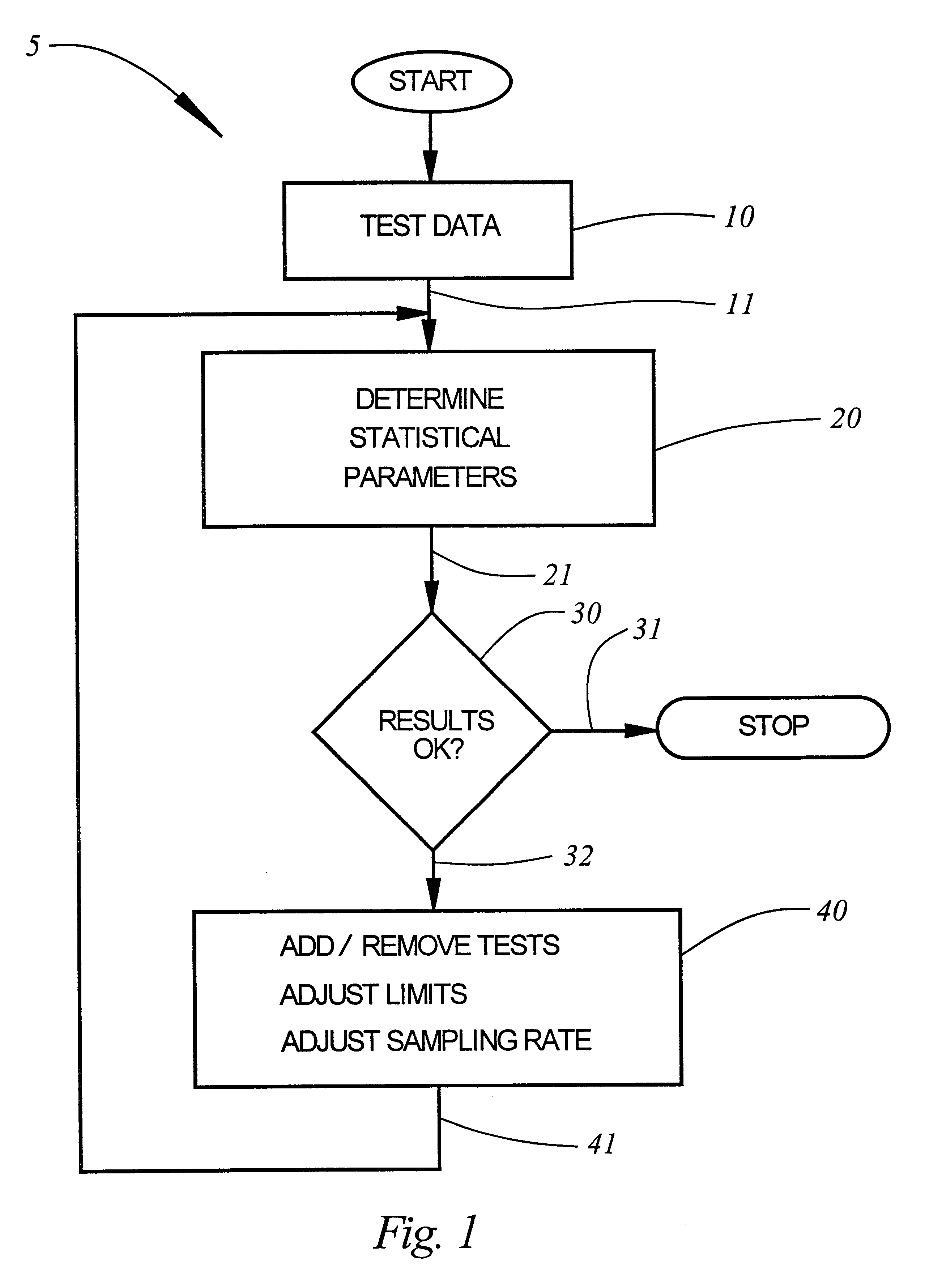

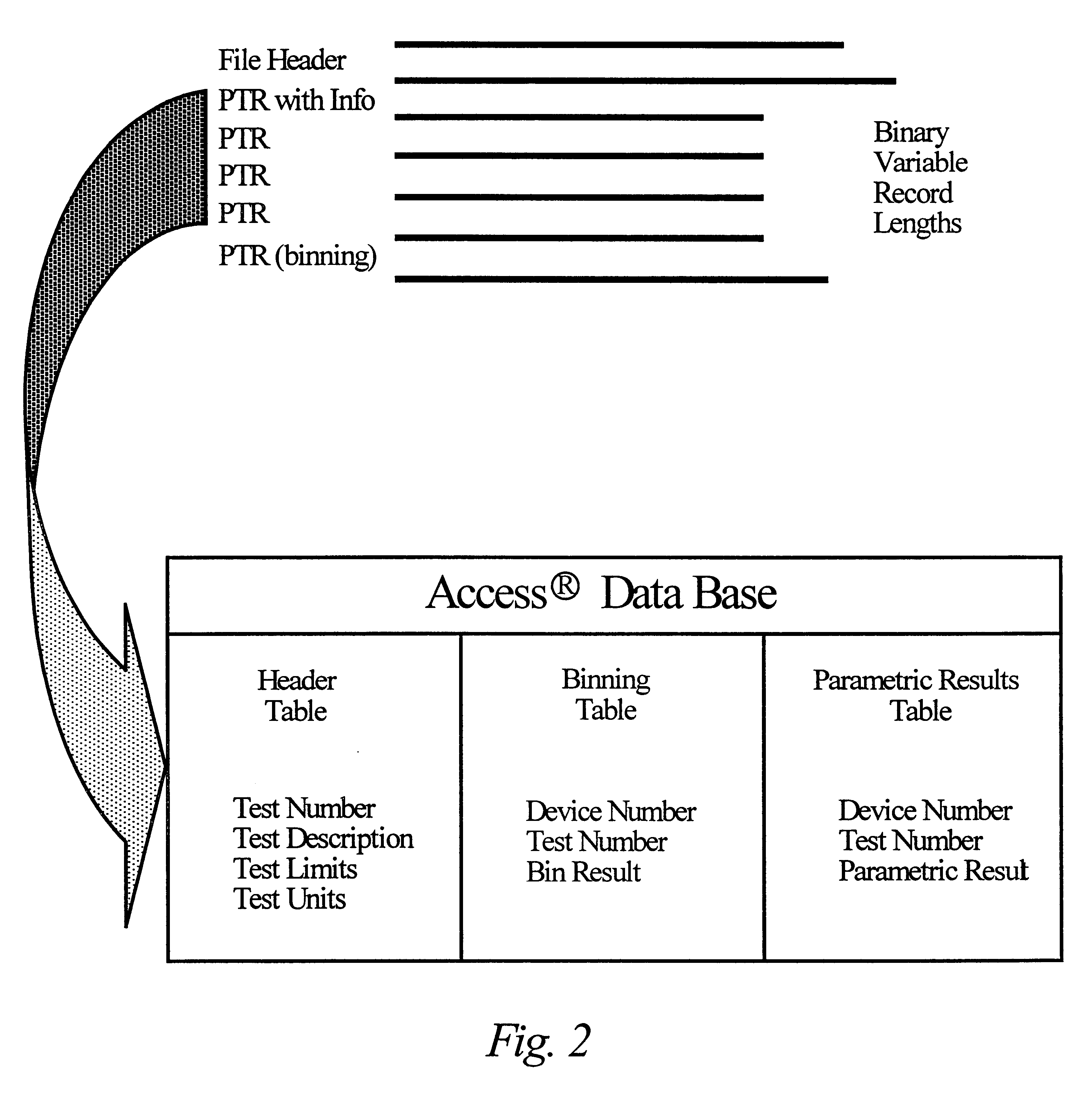

Method, apparatus and product for evaluating test data

Method, apparatus and product for analyzing a quality control regimen comprising one or more quality control tests, to determine if the tests are in statistical control, and therefore could be removed from the regimen or sampled at a different rate. On sample data relating to each of the tests, there is determined Cpi, a measure of the spread of the data, which is simply the ratio of the magnitude of the actual range of the data, to the magnitude of calculated statistical range of the data. There is also determined CPKi, which is a measure of how close the spread of the data is to the upper or lower limit of the data. For convenience, the magnitude of Cpi is represented as a vertical bar graph, with the value of CPKi shown as a position of the bar graph within normalized limits. Using Cpi and CPKi decisions regarding removal of each the test can be made. One or more tests are then selected for removal or to have a different sampling rate, and "What If" scenarios then performed to see how the testing regimen would have performed without the test(s) or at the different sampling rate.

Owner:PDF SOLUTIONS INC

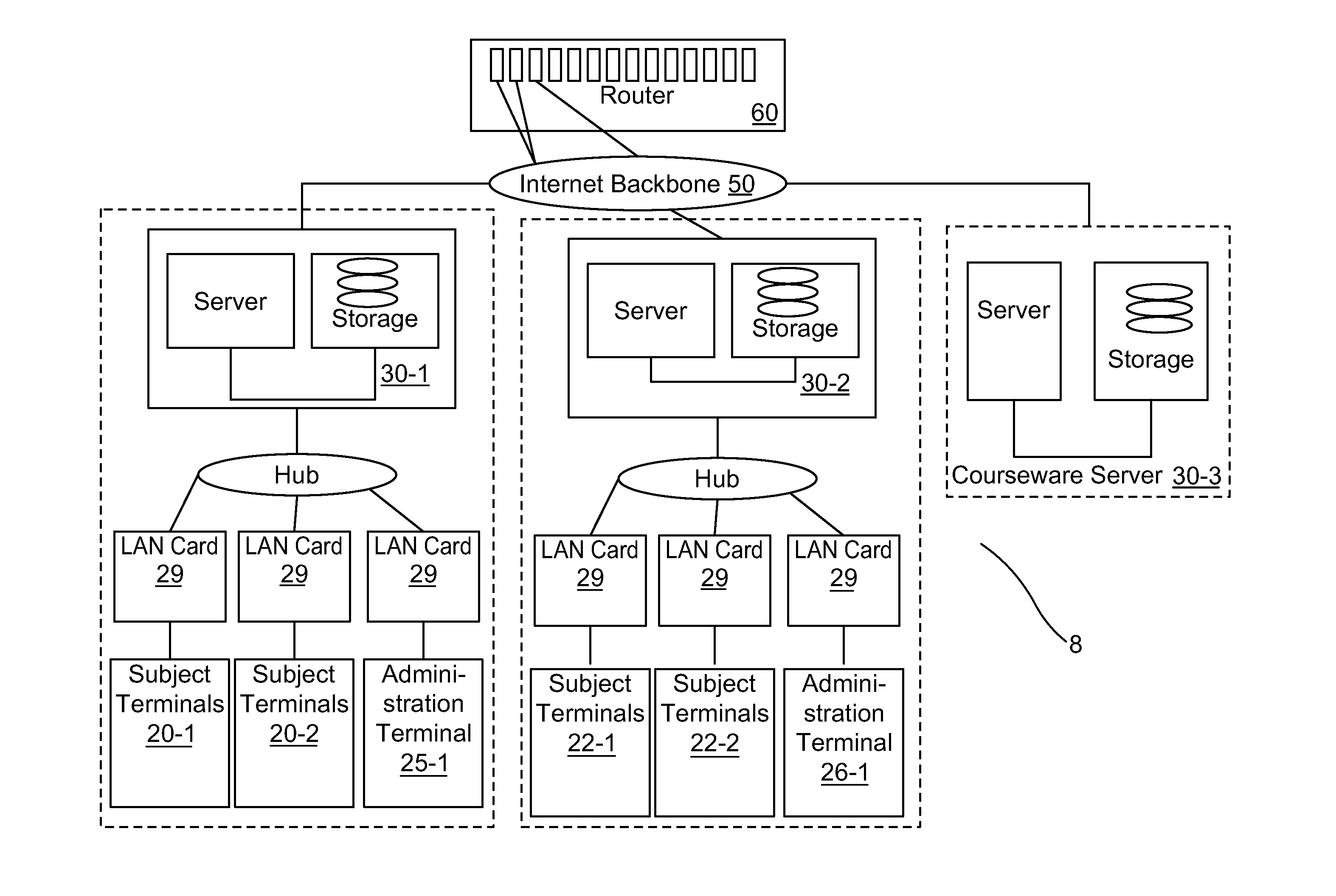

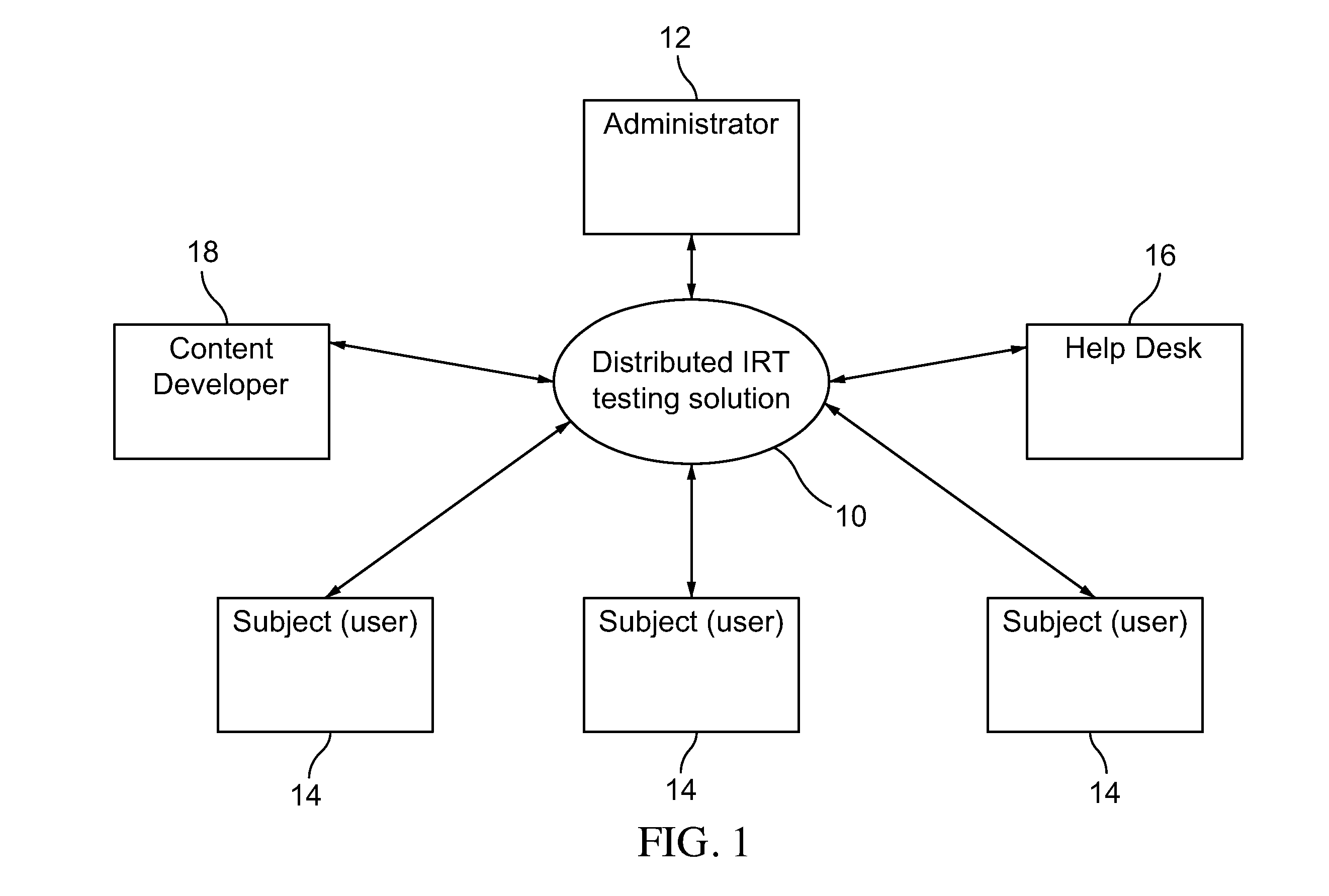

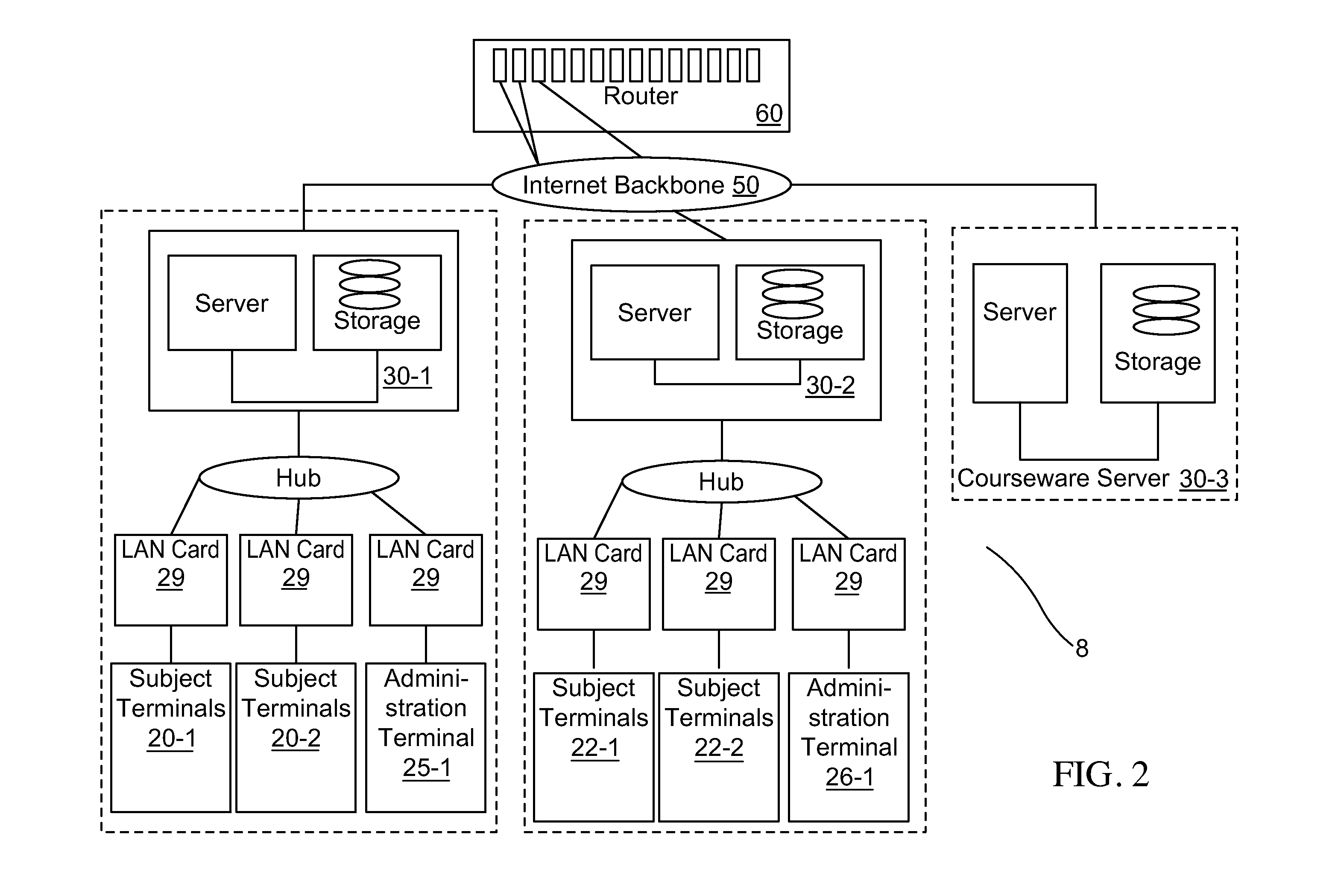

Method and System for Knowledge Assessment Using Confidence-Based Measurement

InactiveUS20110151425A1Accurate assessmentIncrease the number ofElectrical appliancesTeaching apparatusKnowledge managementKnowledge assessment

A system for knowledge assessment and encouraging learning comprises transmitting to the a terminal a plurality of multiple choice questions and two-dimensional answers thereto, the answers including a plurality of full-confidence answers consisting of single-choice answers, a plurality of partial-confidence answers consisting of sets of multiple single-choice answers, and an unsure answer. The system further administers a confidence-based assessment (CBA) test that presents to the test subject the plurality of multiple choice questions directed to categorical topics, and the two-dimensional answers thereto, by which the test subject indicates both their substantive answer and the level of confidence category of their answer. The system compiles a knowledge profile from the scored CBA test, and encourages learning so that the user can address knowledge deficiencies as identified through the CBA test.

Owner:KNOWLEDGE FACTOR

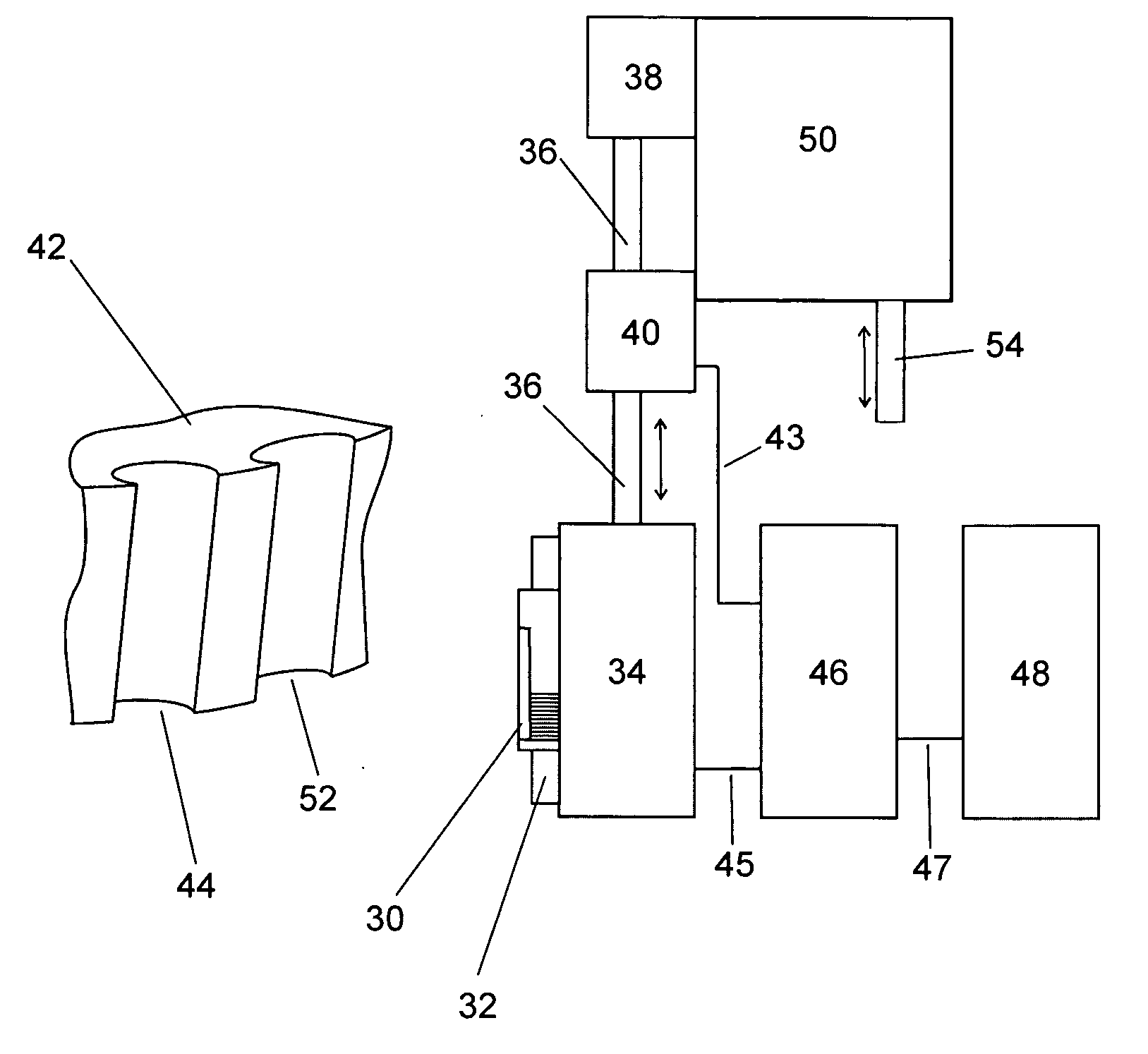

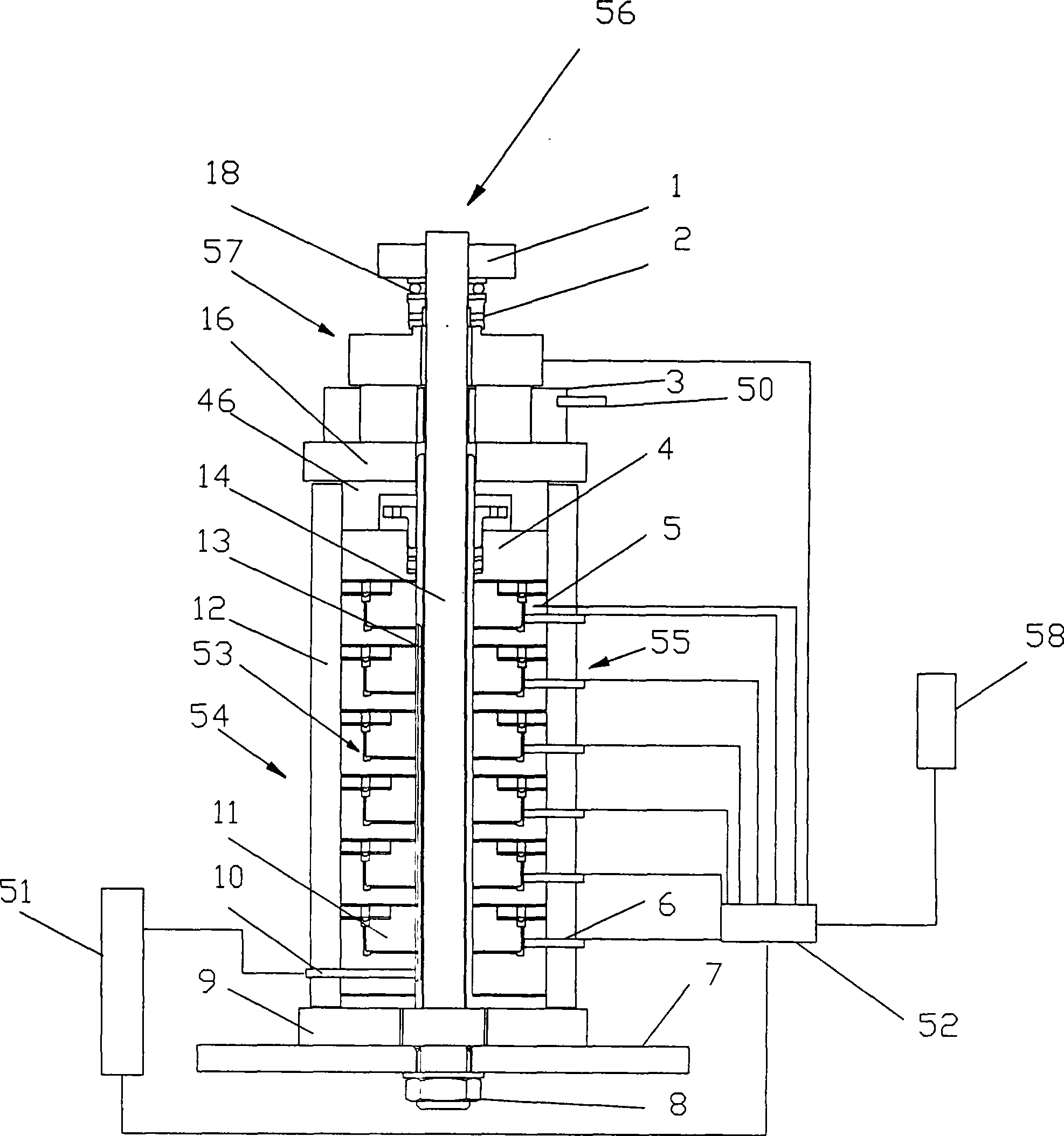

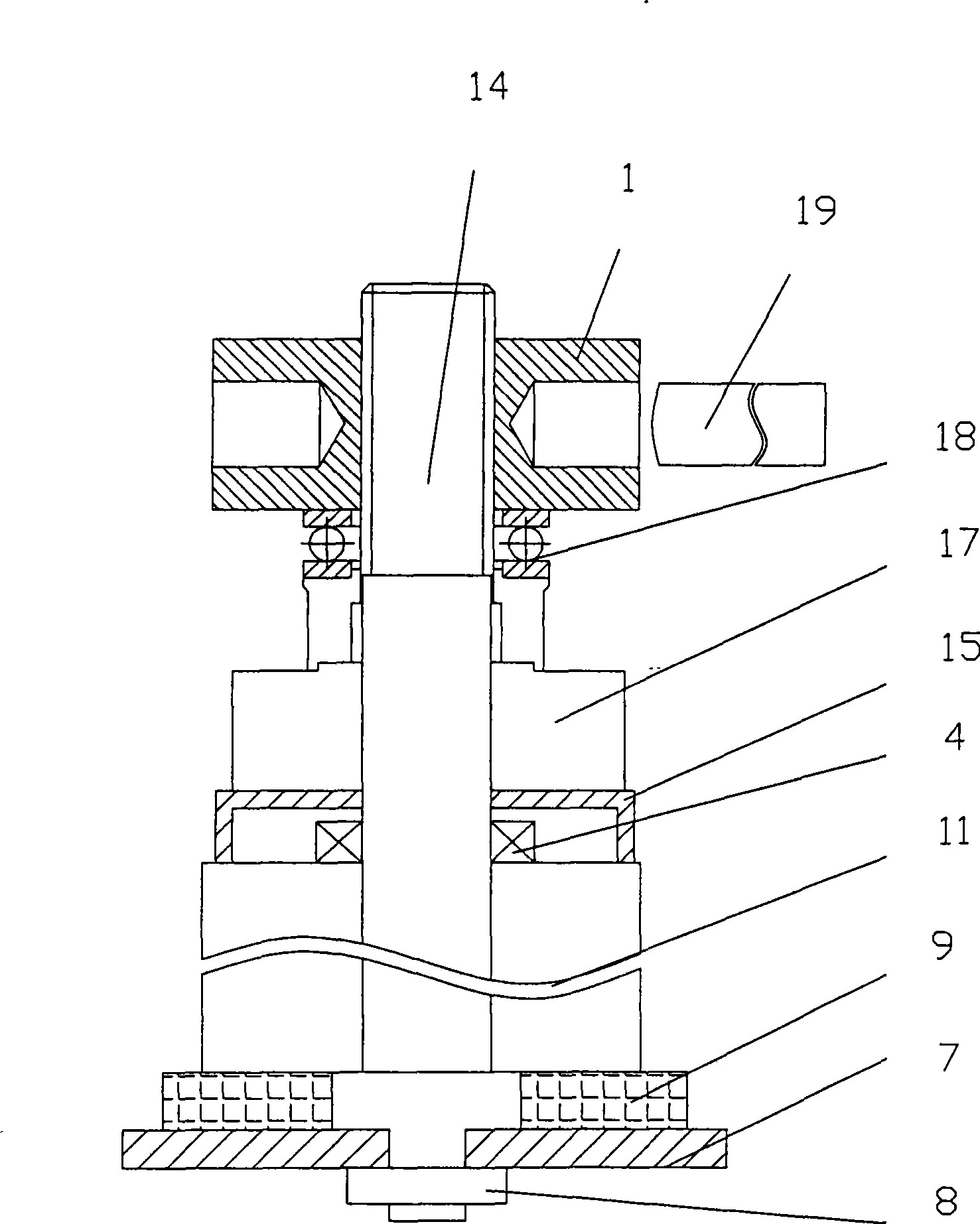

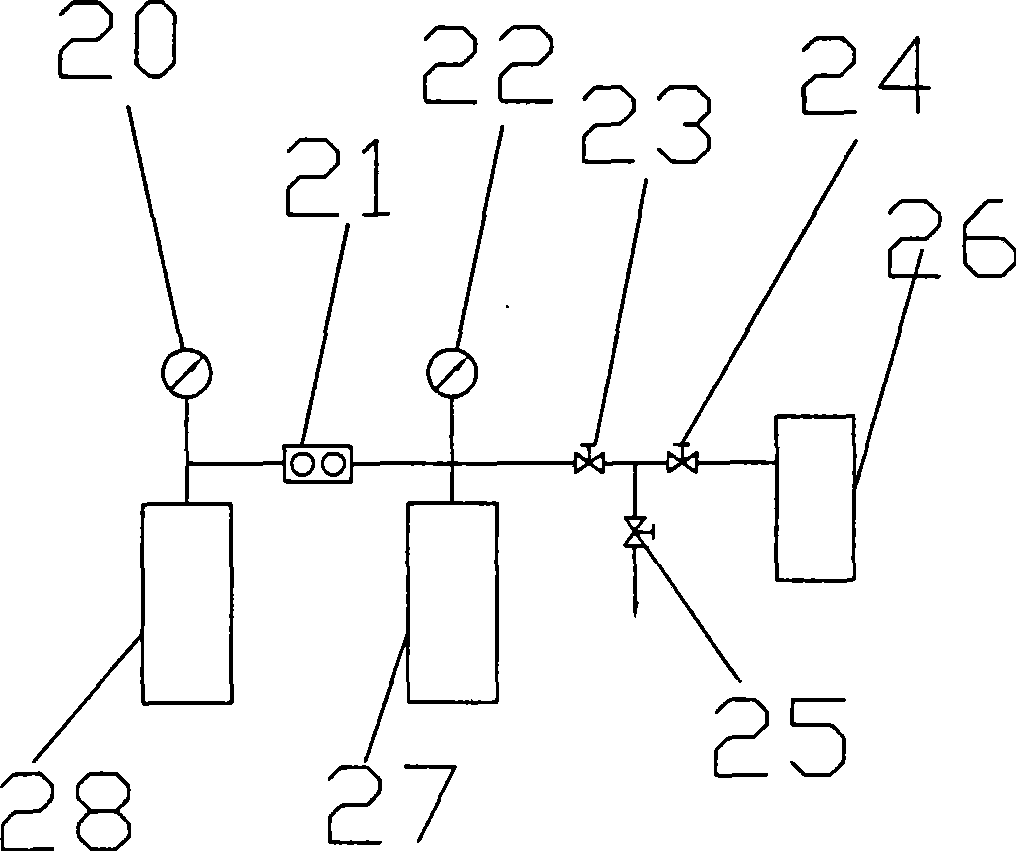

Multi-functional multi-specimen sealing gasket service life evaluation testing apparatus

InactiveCN101446510ARealize measurementEasy to controlMachine part testingFluid-tightness measurement using fluid/vacuumTemperature controlControl system

The invention relates to a multi-functional multi-specimen sealing gasket service life evaluation testing apparatus which comprises a gasket loading and load measuring system (56) and a medium given system (51). The apparatus is characterized in that the air given end of the medium given system (51) is connected with the air inlet end of a medium sealing system (53), the medium sealing system (53) is positioned inside of a temperature controlling and measuring system (54), a cooling thermal insulation system (57) is placed above the medium sealing system (53), and a leakage rate measuring system (55) is positioned on one side of the temperature controlling and measuring system (54); the medium sealing system (53), the temperature controlling and measuring system (54) and the cooling thermal insulation system (57) are connected respectively through stress bolts (14) of the gasket loading and load measuring system (56); and a data acquisition and control system (52) is respectively and electrically connected with the medium given system (51), the medium sealing system (53), the temperature controlling and measuring system (54), the leakage rate measuring system (55) and the cooling thermal insulation system (57).

Owner:NANJING TECH UNIV

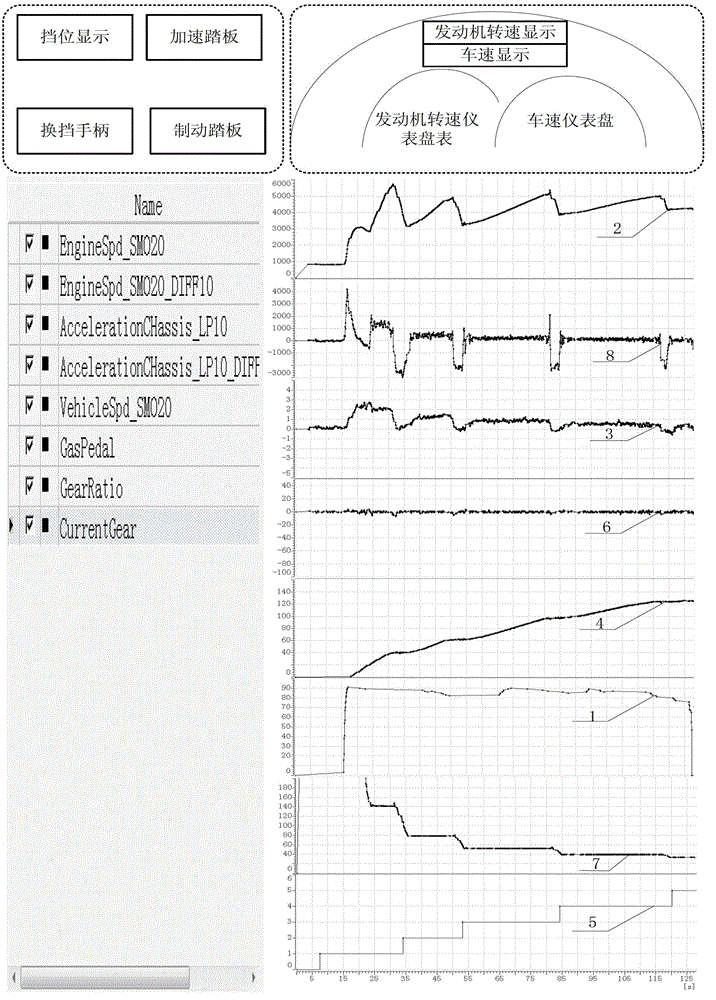

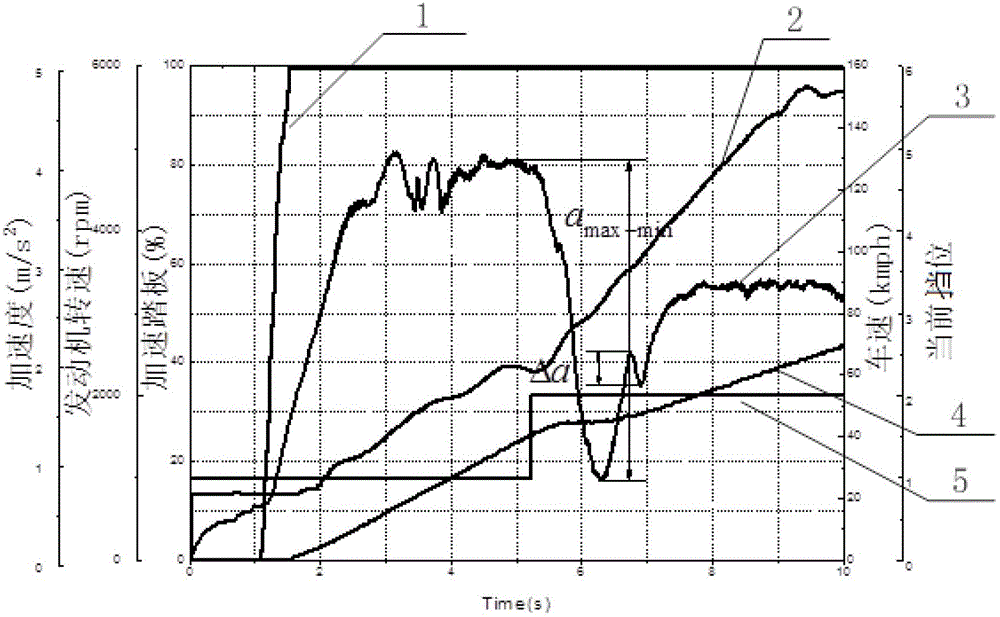

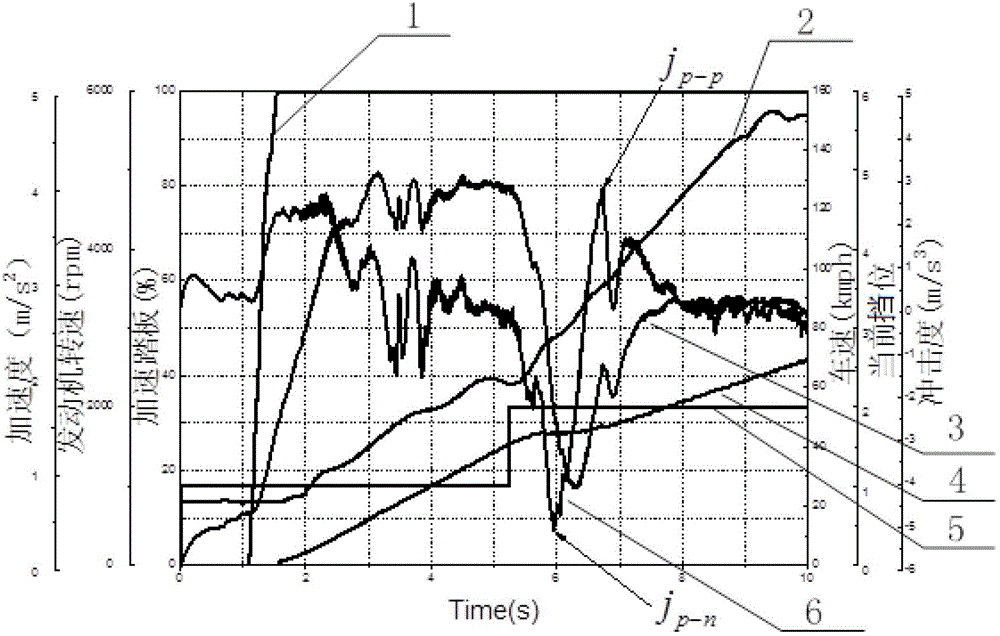

Vehicle gear-shifting quality evaluation testing method and system

The invention discloses a vehicle gear-shifting quality evaluation testing method, which comprises the steps of: 1) at a vehicle gear-shifting quality evaluation testing preparation stage: establishing a vehicle database by adopting an SQL (structured query language) server; establishing a vehicle gear-shifting quality evaluation module by adopting MATLAB / Simulink and determining the core algorithm of the vehicle gear-shifting quality evaluation module; and selecting the type of a vehicle to be tested and a testing system to be used; 2) at a vehicle gear-shifting quality testing stage: conducting gear-shifting rule testing, Tip in testing, Tip out testing, Fast Off testing, brake control logic testing, operability testing, start testing, acceleration testing and driving during a traffic jam; and 3) at a vehicle gear-shifting quality evaluation stage: calling data of the vehicle database as data input of the vehicle gear-shifting quality evaluation model and obtaining an evaluation result through data processing and the like; and outputting the evaluation result a graphical user and result display interface. The invention additionally provides a vehicle gear-shifting quality evaluation testing system.

Owner:JILIN UNIV

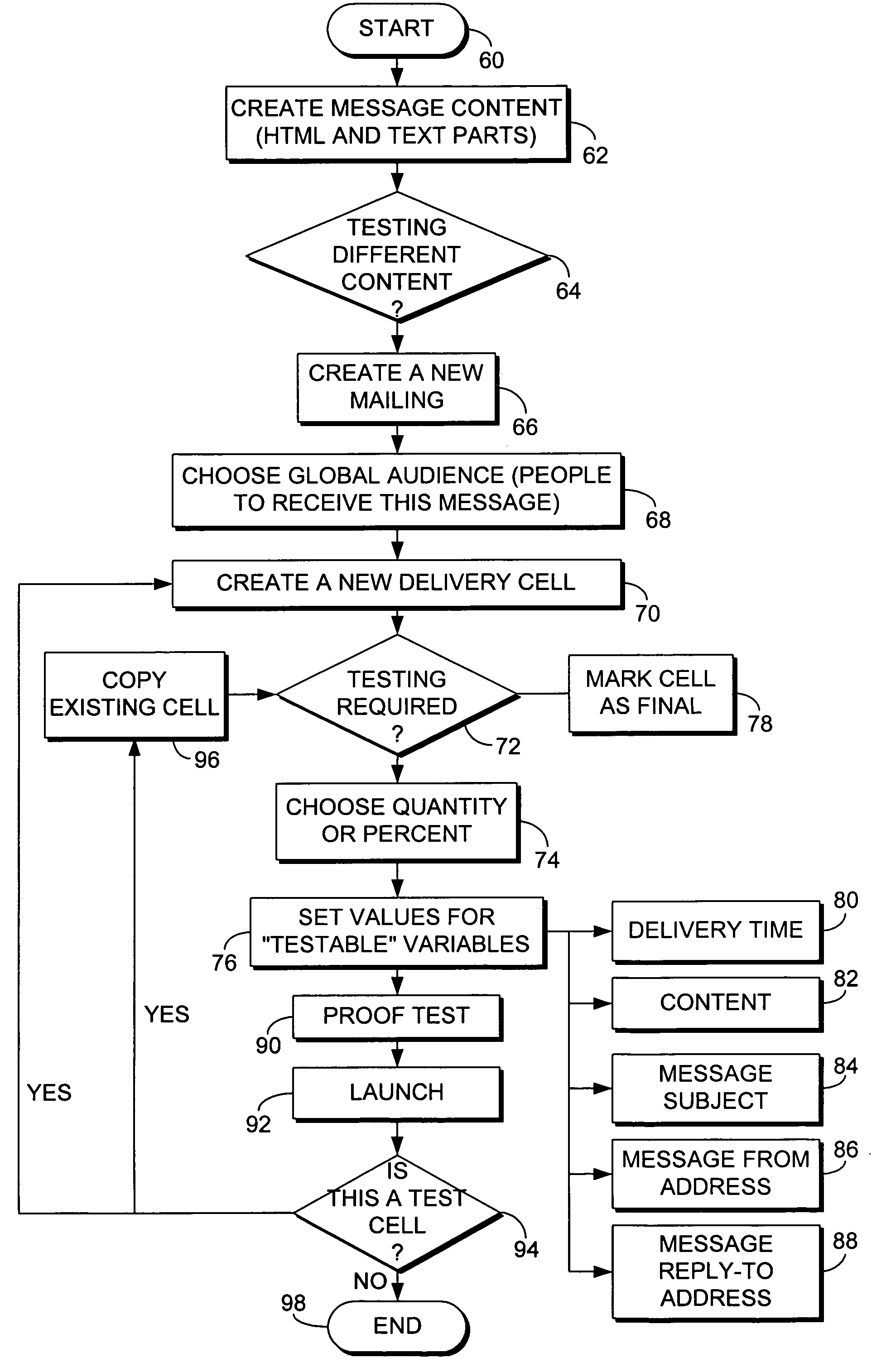

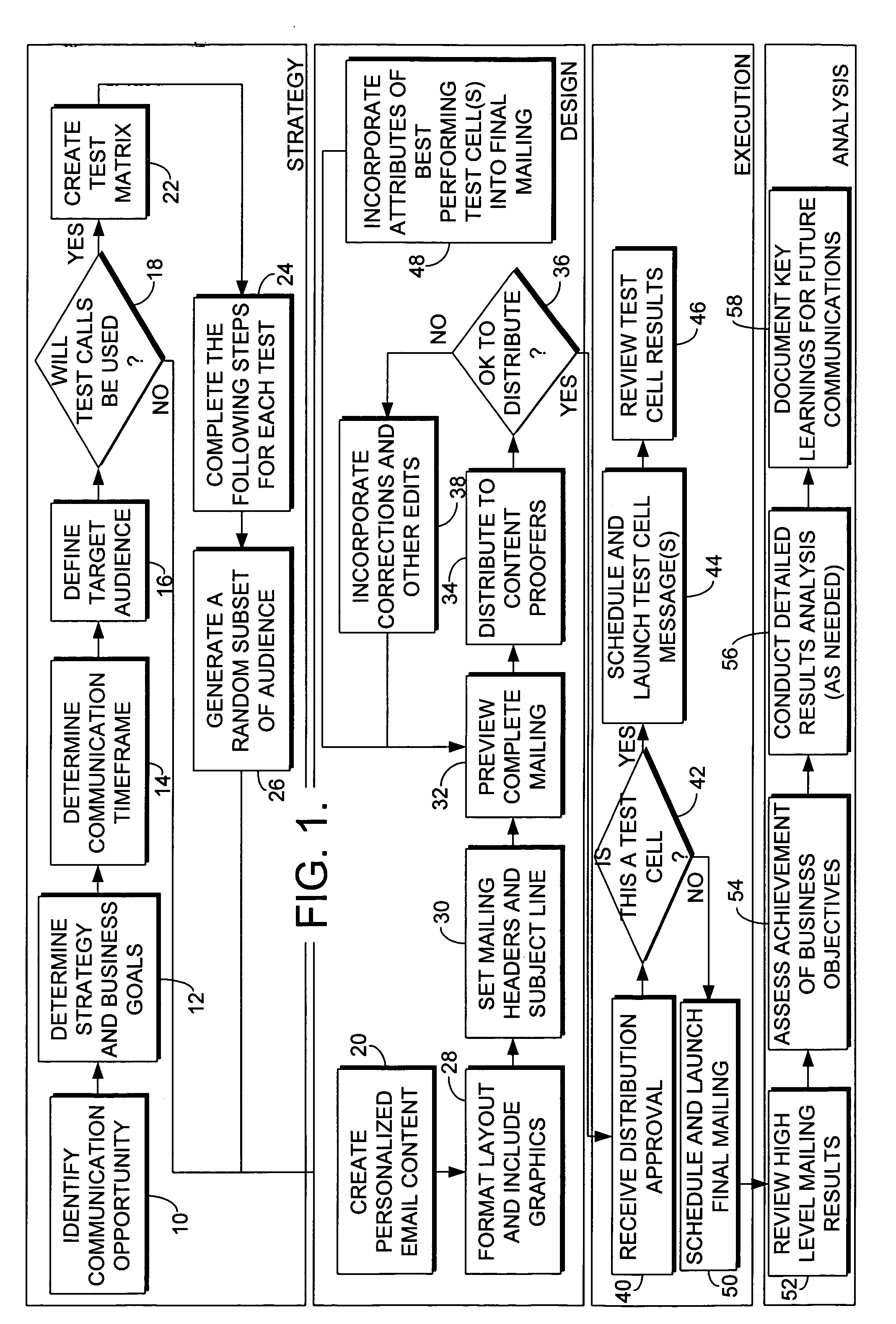

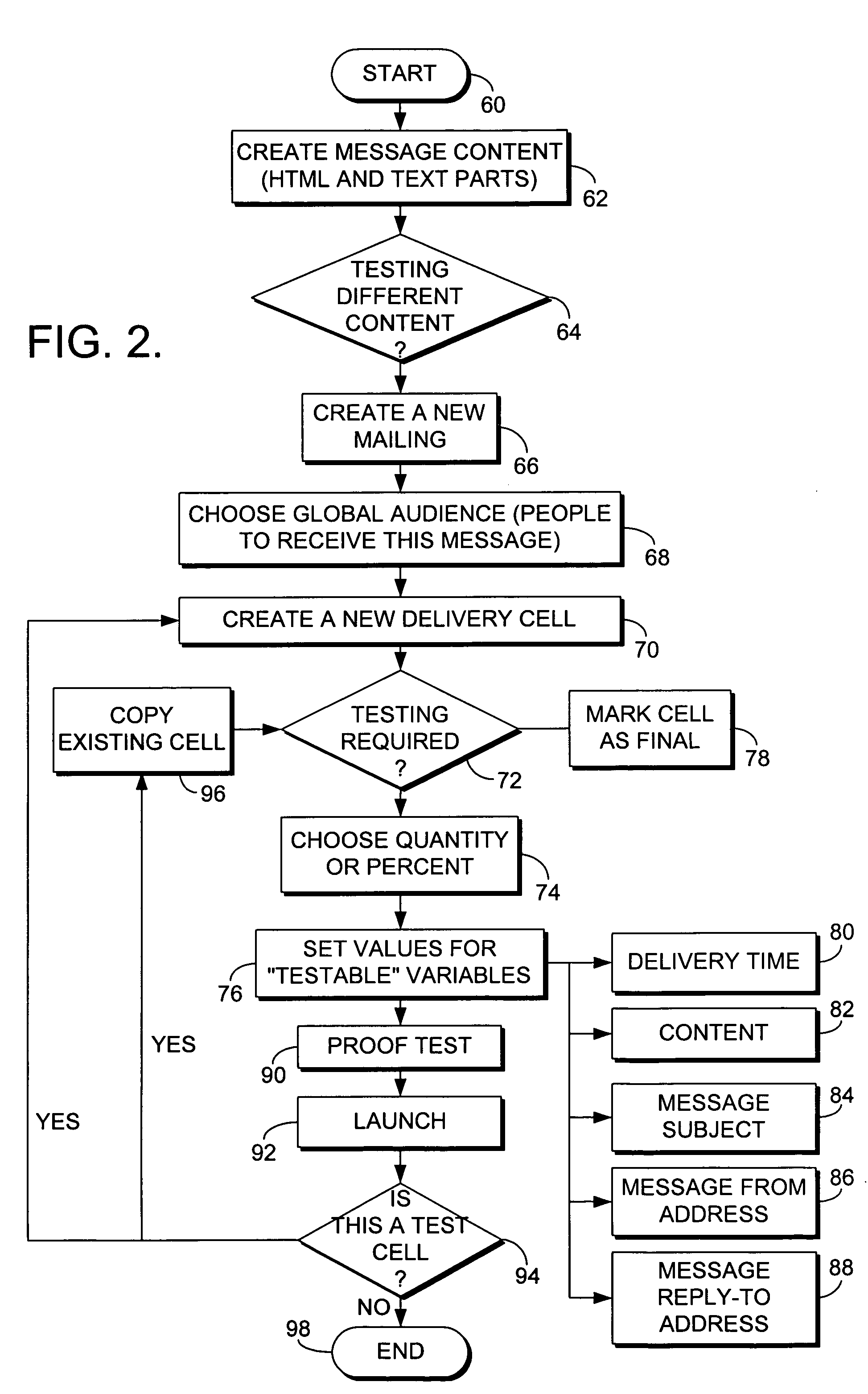

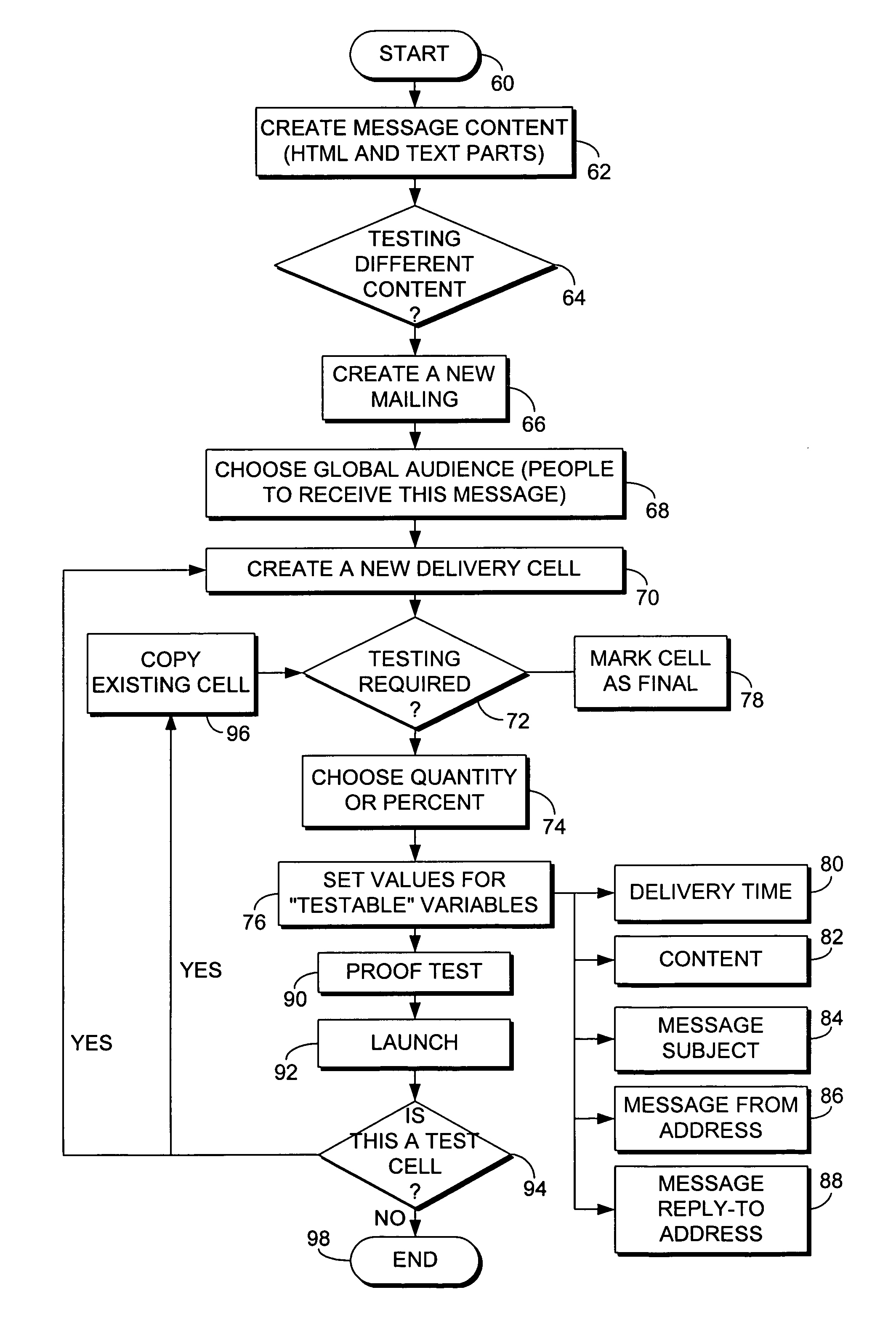

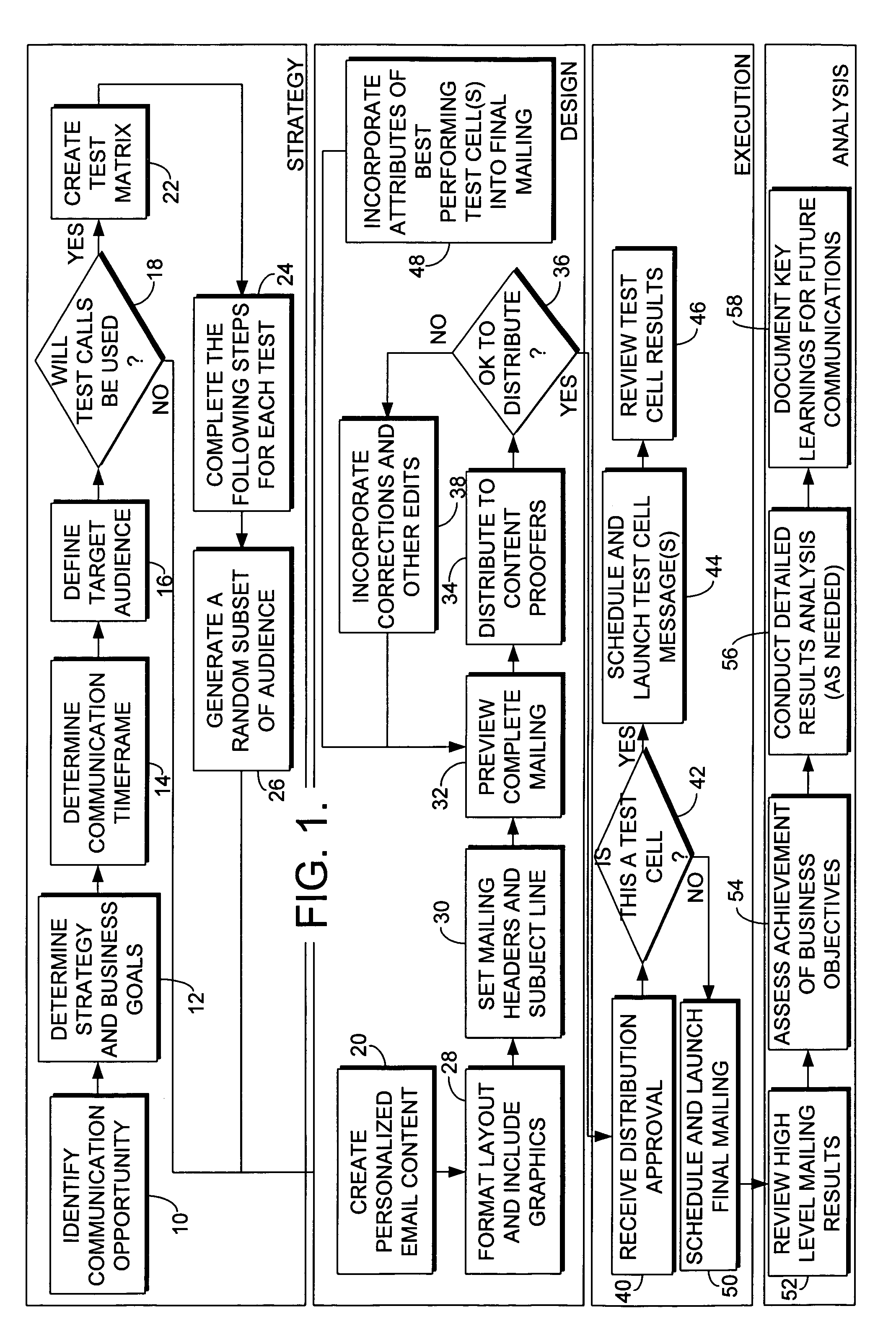

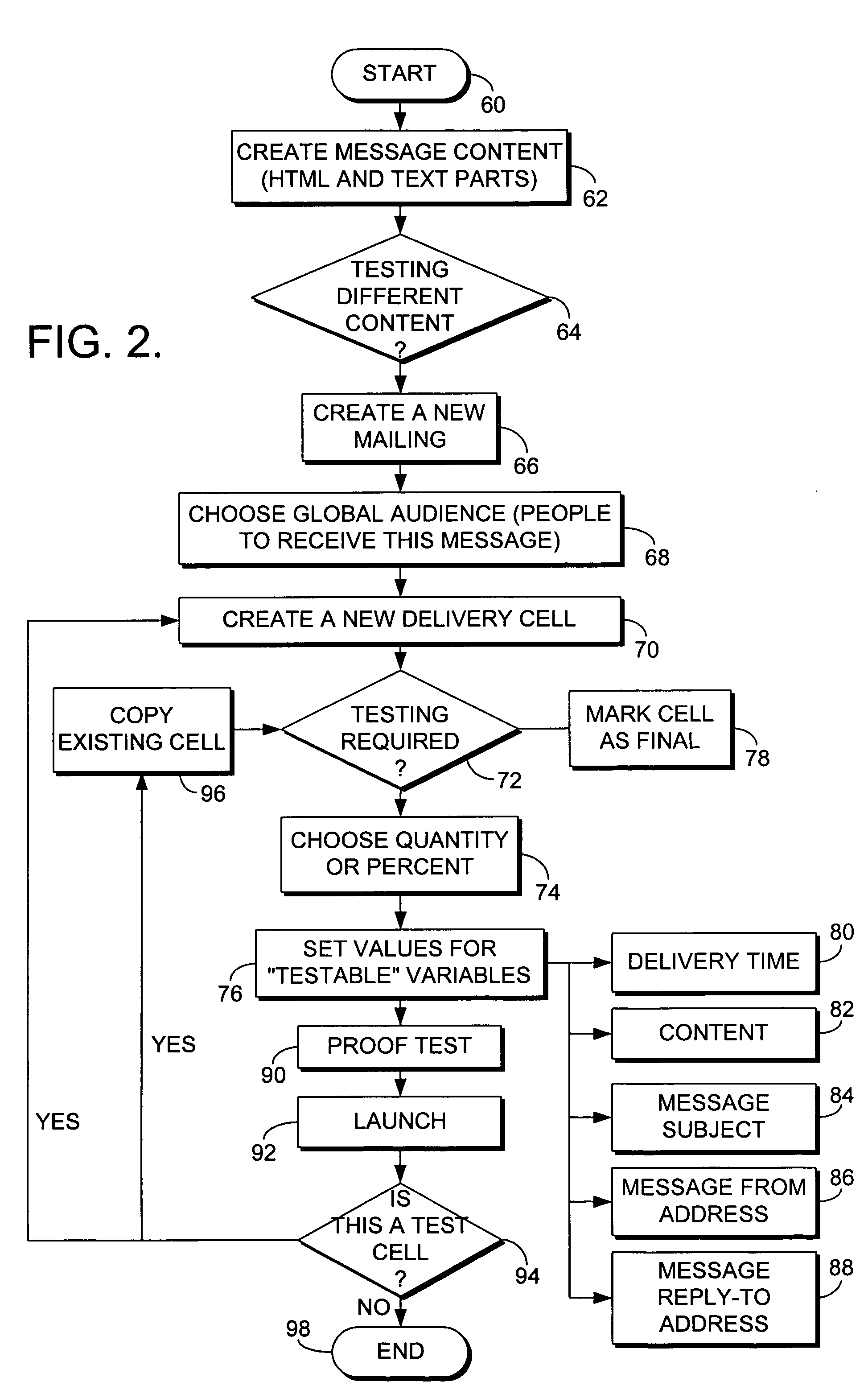

Method and system for sending bulk electronic messages

ActiveUS20050188019A1Facilitates and expeditesSave effortMultiple digital computer combinationsElectric digital data processingComputer hardwareElectronic mail

A method and system for sending massive e-mail messages that include test messages sent to selected small portions of the global targeted audience. A message containing the text or content part of the message can be stored and retrieved for inclusion in each test message so that the content does not need to be repeatedly retyped. The audience members are selected randomly for each test so that the tests provide statistically valid results. The test results are conveniently grouped for ease of evaluation of the test feedback.

Owner:ORACLE OTC SUBSIDIARY

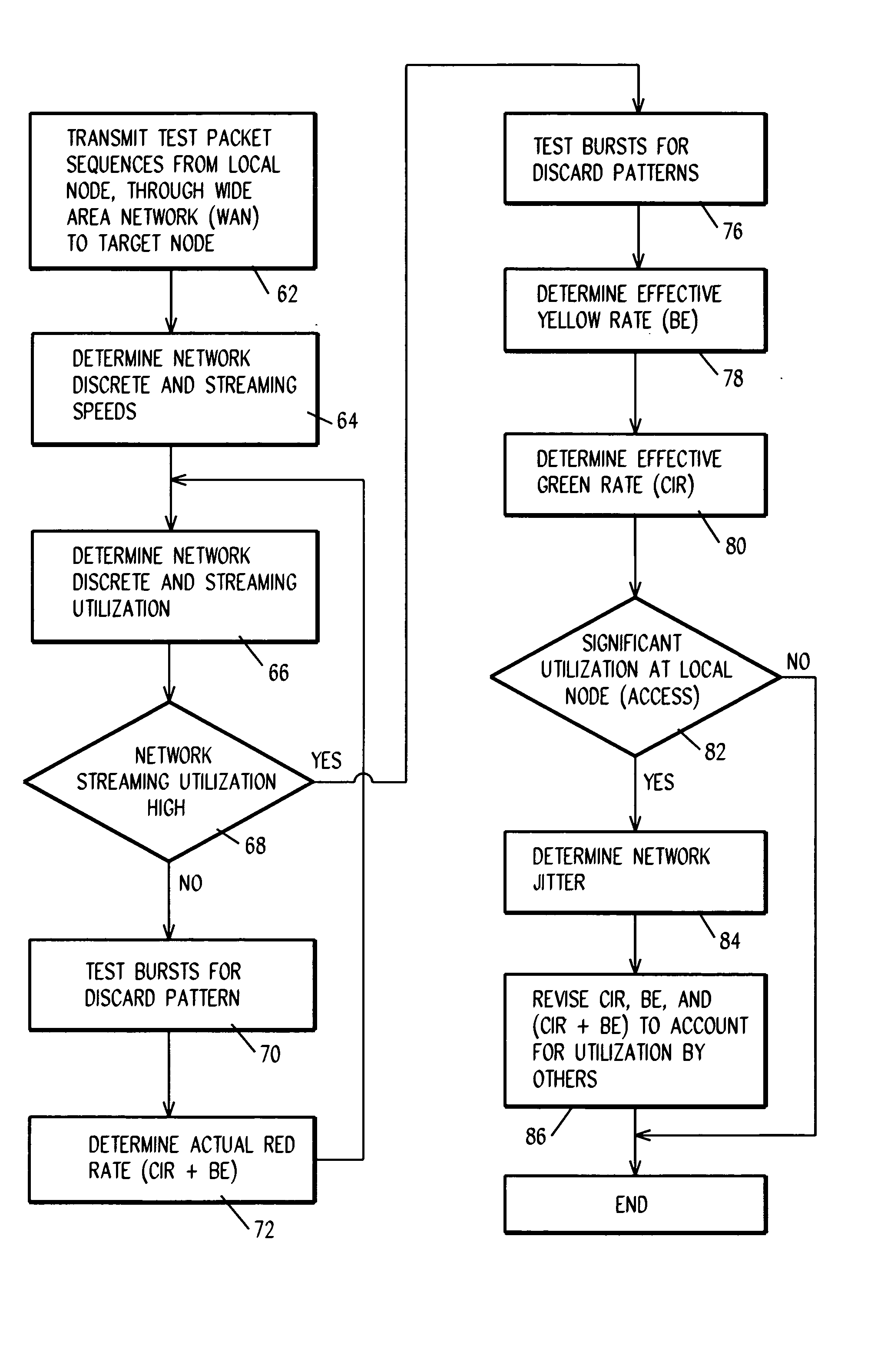

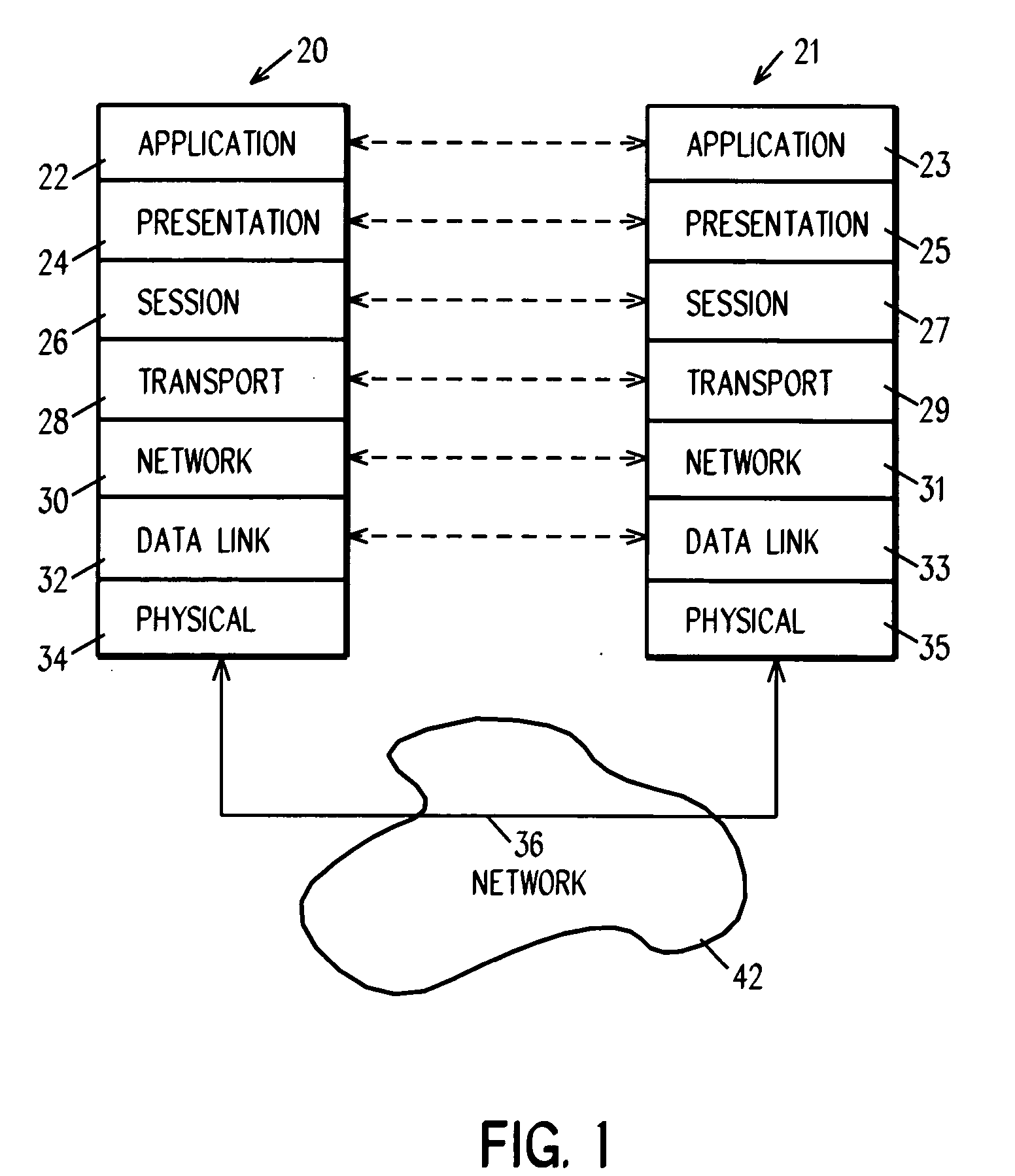

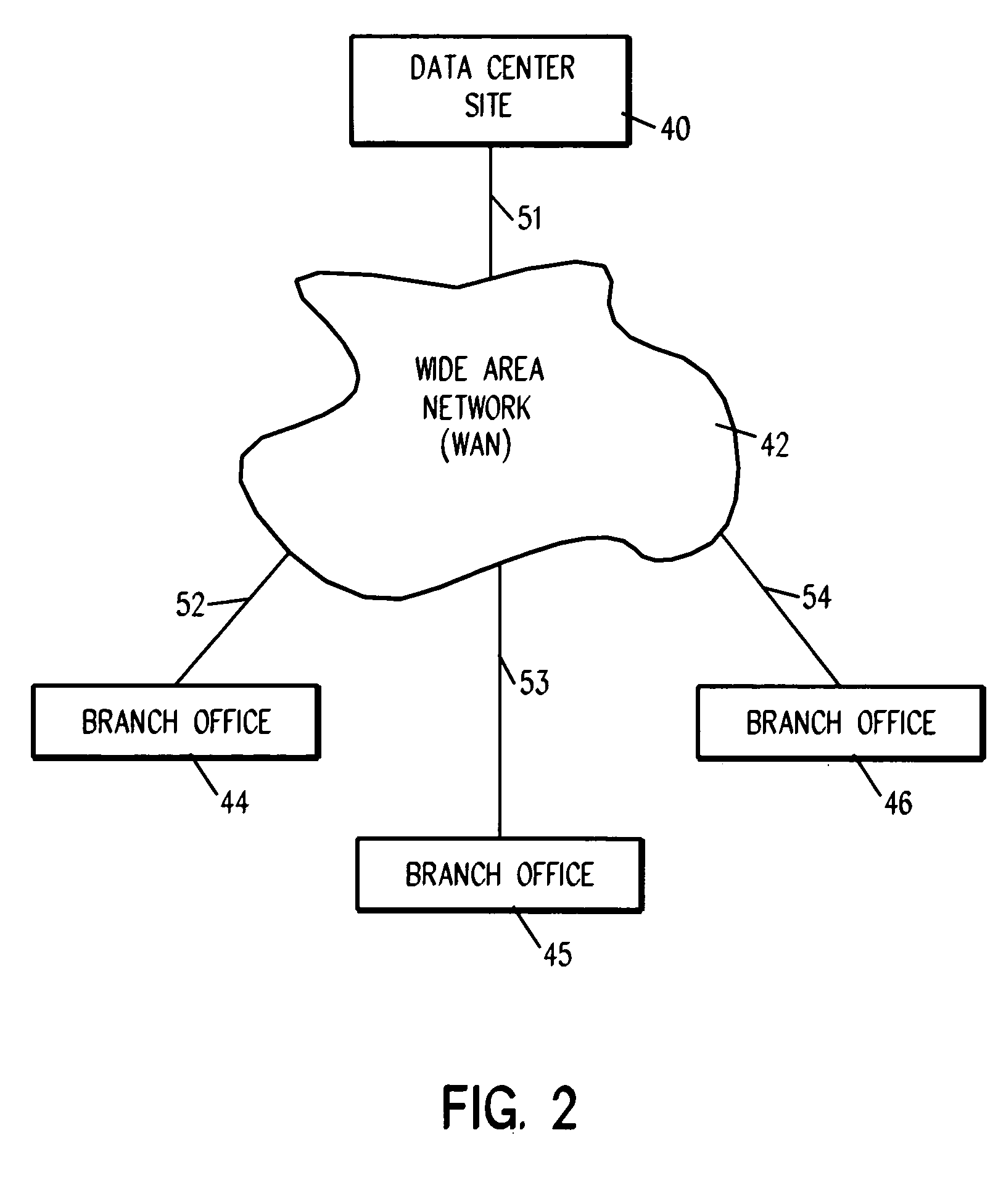

System and method for testing differentiated services in a value add network service

InactiveUS20050128947A1Error preventionTransmission systemsDifferentiated servicesValue-added network

A system for determining network characteristics includes a processor including a packet generation component and a packet evaluation component. The packet generation component generates send test packets for communication into the network. The packet evaluation component is responsive to receive test packets for determining network speed and utilization; upon detecting that the network streaming utilization is not significantly high, evaluates the test packet sequences for a first discard pattern representing actual discard red rate; and upon detecting that the network streaming utilization is significantly high, evaluates the test packet sequences for a second discard pattern representing effective discard yellow rate and effective non-discard green rate.

Owner:IBM CORP

System and method for defect detection threshold determination in an workpiece surface inspection system

ActiveUS20080075353A1High sensitivity and reliabilityMaterial analysis by optical meansCharacter and pattern recognitionLaser lightDetection threshold

A method and system for inspecting a surface of a semiconductor workpiece comprises providing a surface inspection system and using the surface inspection apparatus to cause laser light to impinge upon a test location on the workpiece surface and thereby cause the laser light to emerge from the surface as returned light comprising at least one of reflected light and scatter light; collecting the returned light and generating a signal from the returned and collected light, the signal comprising a signal value representative of a characteristic of the workpiece surface at the test location; providing a plurality of threshold candidates and causing the surface inspection system to select a threshold from among the plurality of threshold candidates; comparing the threshold to the signal value to obtain a difference value; using the difference value to assess the characteristic of the workpiece surface at the test location; and using the surface inspection system to automatically cause the method to be repeated for a plurality of test locations on the workpiece surface.

Owner:KLA CORP

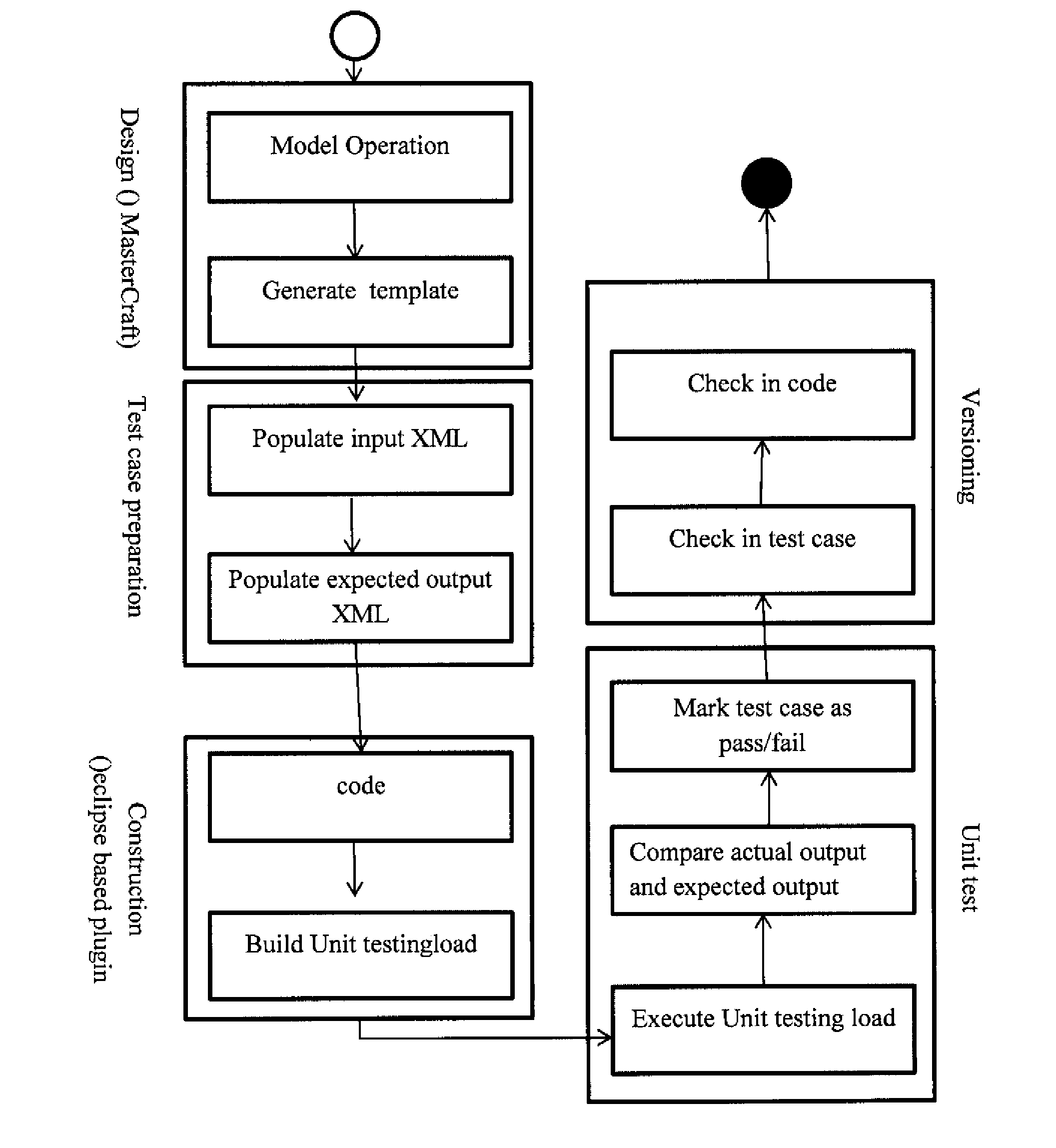

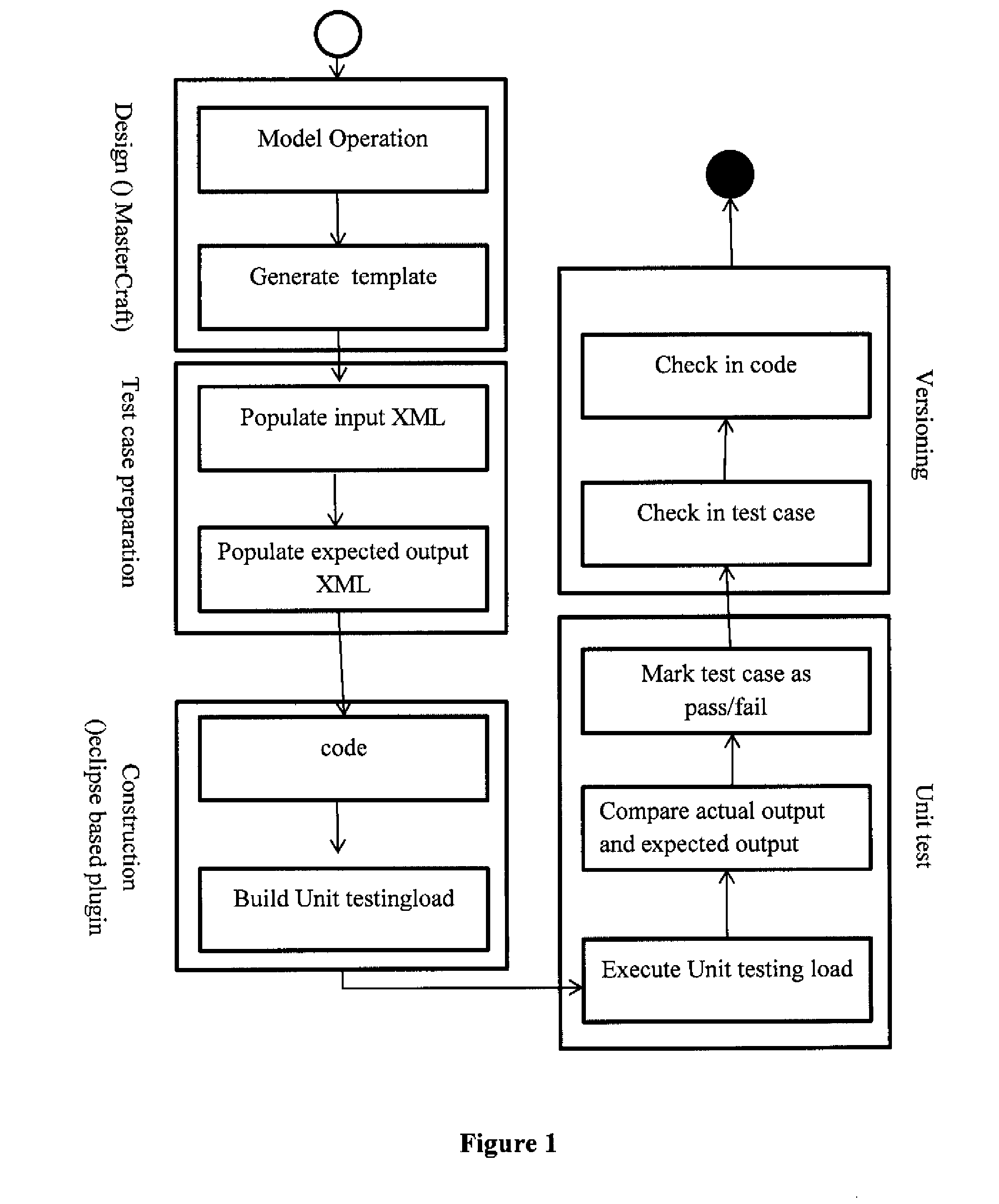

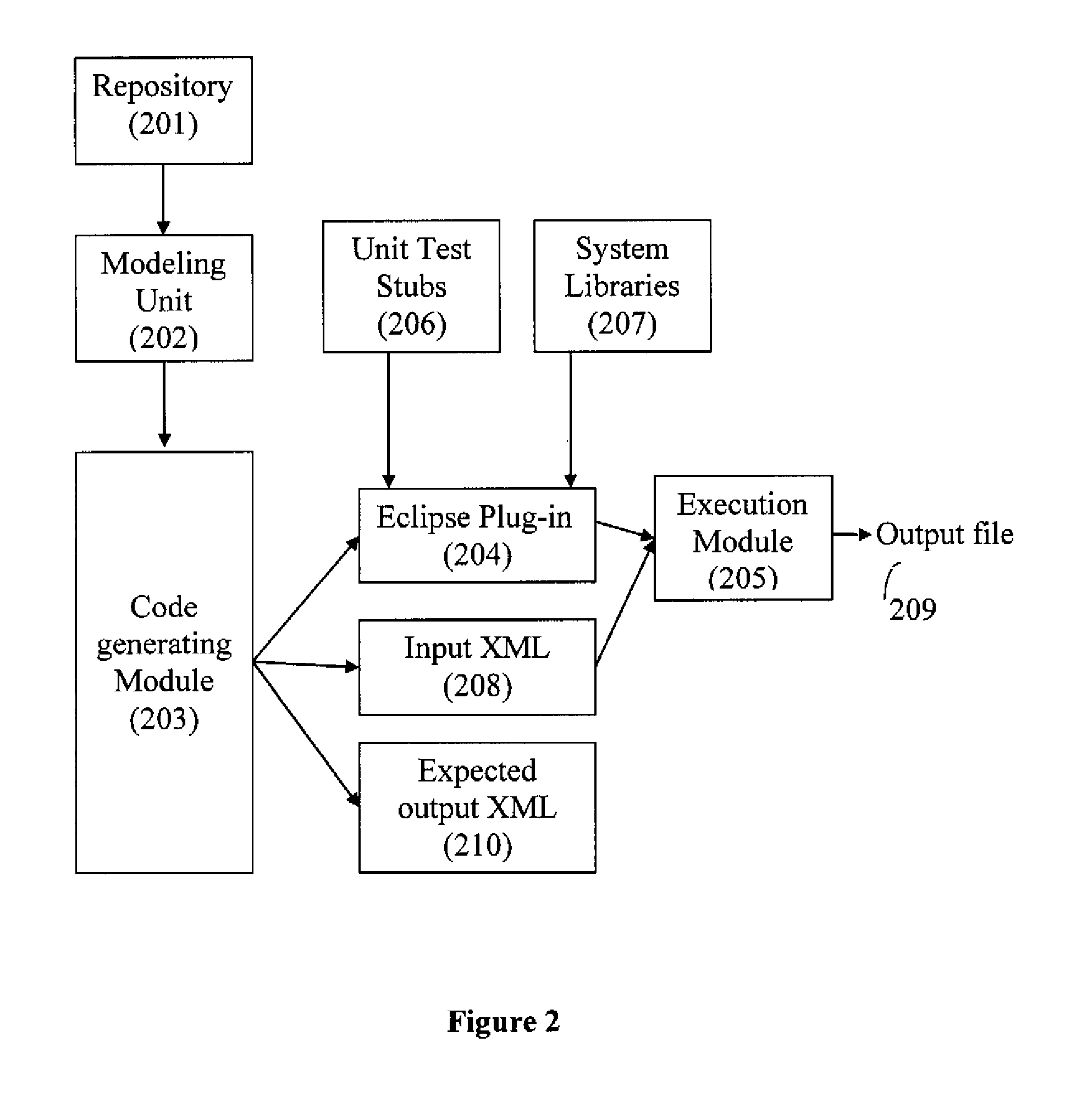

Agile Unit and Regression Testing Framework for Domain Specific Languages

ActiveUS20130159963A1Good flexibilityError detection/correctionSpecific program execution arrangementsRegression testingTheoretical computer science

According to one aspect of the invention, a system and method for unit and regression testing has been developed. The system is capable to automate unit / regression test case preparation, remote execution, provide XML based assert mechanism to evaluate test results, maintenance and versioning. The present system enables model driven testing of domain specific languages and provides a user friendly mechanism to perform Unit and Regression Testing.

Owner:TATA CONSULTANCY SERVICES LTD

Method and system for sending bulk electronic messages

ActiveUS7574478B2Save effortShorten the timeMultiple digital computer combinationsElectric digital data processingElectronic mailElectronic messaging

Owner:ORACLE OTC SUBSIDIARY

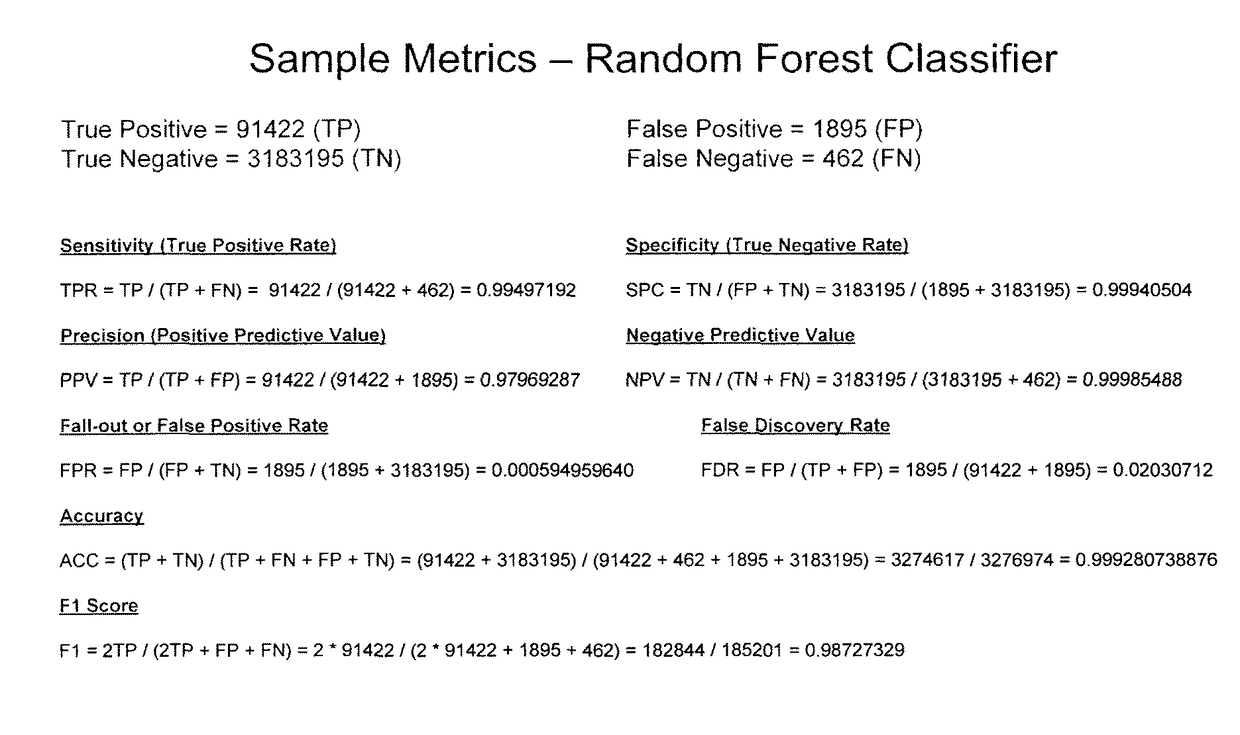

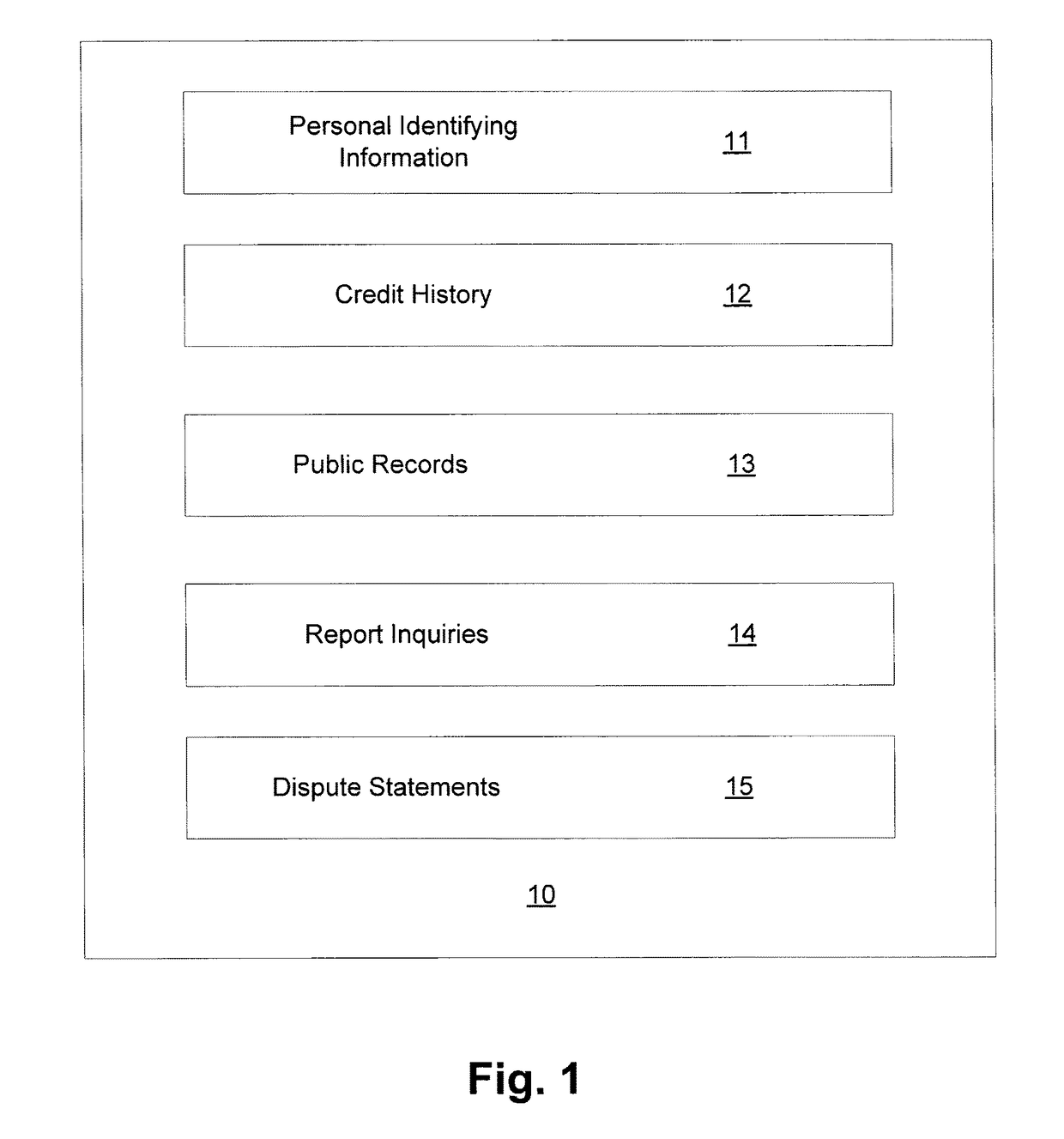

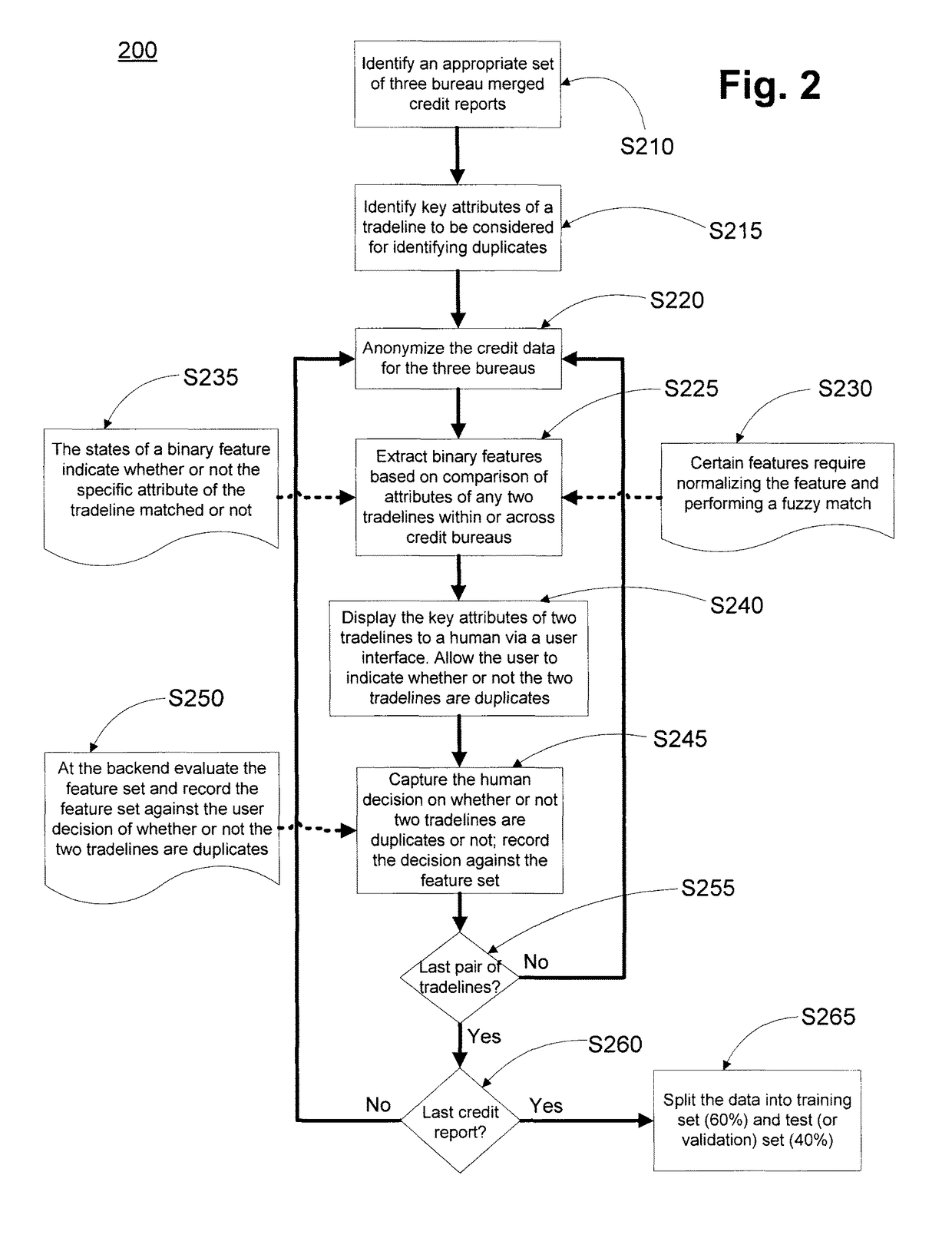

Supervised machine learning of data de-duplication

A system, method, and computer program includes a communications interface configured to receive a set of industry reports from multiple industry sources, and circuitry to compare one or more attributes of at least two trade lines to identify whether the at least two trade lines are duplicates. The circuitry characterizes as a binary indication whether the comparing indicates the one or more attributes are a match, and display a representation of the binary indication and receive a user-identified indication whether the at least two trade lines are duplicates. The circuitry trains a classifier, records the indication whether the at least two trade lines are duplicates and removes at least one of the at least two trade lines from the set of industry reports, and runs the classifier. Subsequently, a supervised machine learning classifier is trained to fit on the training data and is evaluated for accuracy of the testing data.

Owner:CORELOGIC CREDCO LLC

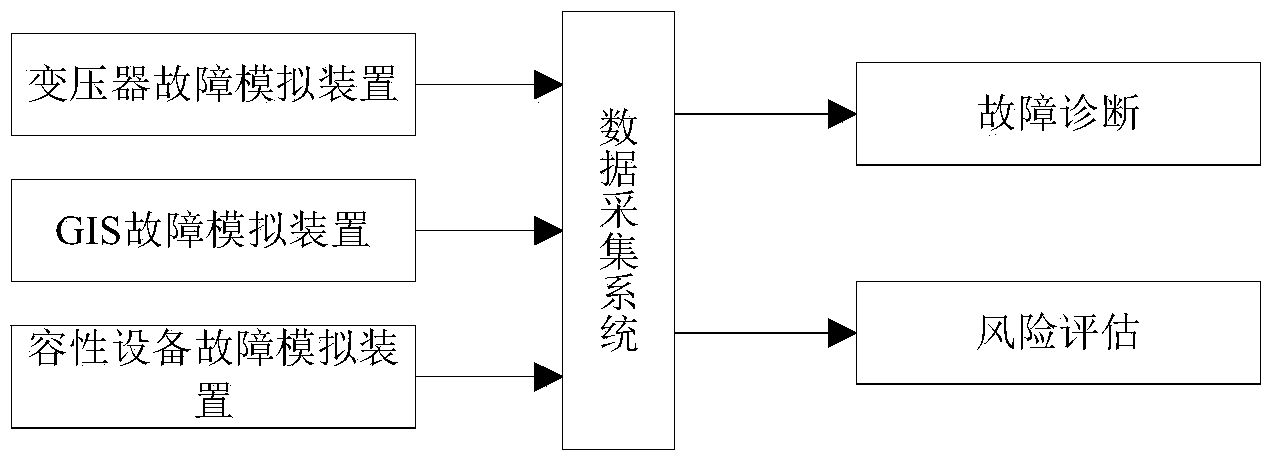

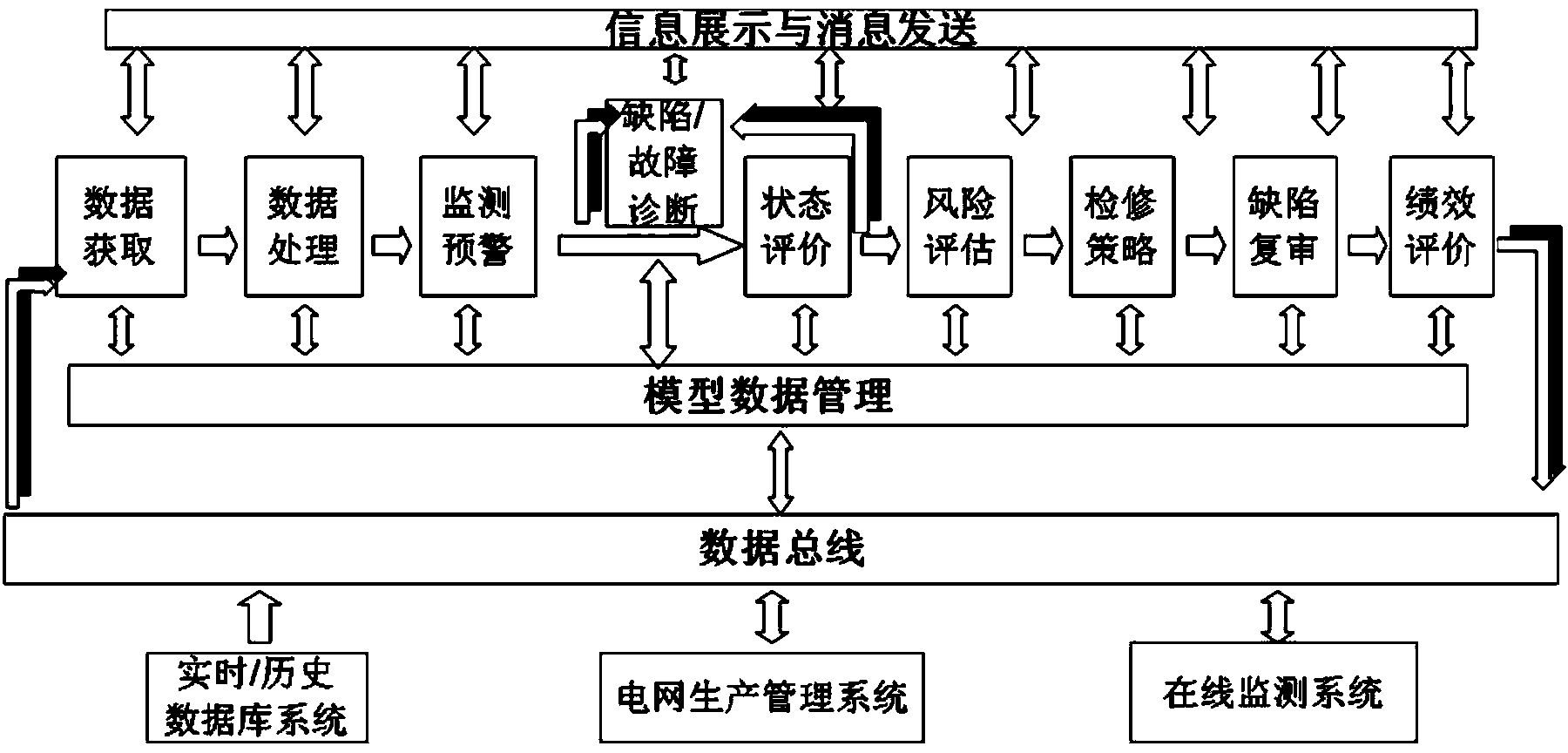

Grid equipment state inspection and evaluation training system

InactiveCN103559648AVerify correctnessVerify reliabilityData processing applicationsEducational modelsData informationData acquisition

The invention discloses a grid equipment state inspection and evaluation training system. The grid equipment state inspection and evaluation training system comprises an equipment failure simulation module, a data information acquisition module, a state evaluation module and a risk evaluation module. According to the grid equipment state inspection and evaluation training system, grid data are generated through operation of the equipment failure simulation module and then transmitted to a background analysis module through a data acquisition system for failure diagnosis and risk elevation. According to the grid equipment state inspection and evaluation training system, the actual condition of a grid is simulated through equipment, that is to say, the big grid is moved into a laboratory; a novel and open advanced application comprehensive training system is established, an electric transmission and transformation equipment state information advanced application system and a dynamic simulation system are combined together organically, the correctness of an electric transmission and transformation equipment failure simulation system is verified through advanced application software, the correctness and reliability of the advanced application software also can be verified on the contrary, the combination realizes reuse of the grid equipment state inspection and evaluation training system, and therefore resources are saved greatly.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com