Patents

Literature

4183results about "Fluid-tightness measurement using fluid/vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Robust system for screening mail for biological agents

InactiveUS6887710B2Lower the thresholdReduce riskAnalysing fluids using sonic/ultrasonic/infrasonic wavesLiquid dispersion analysisParticulatesEngineering

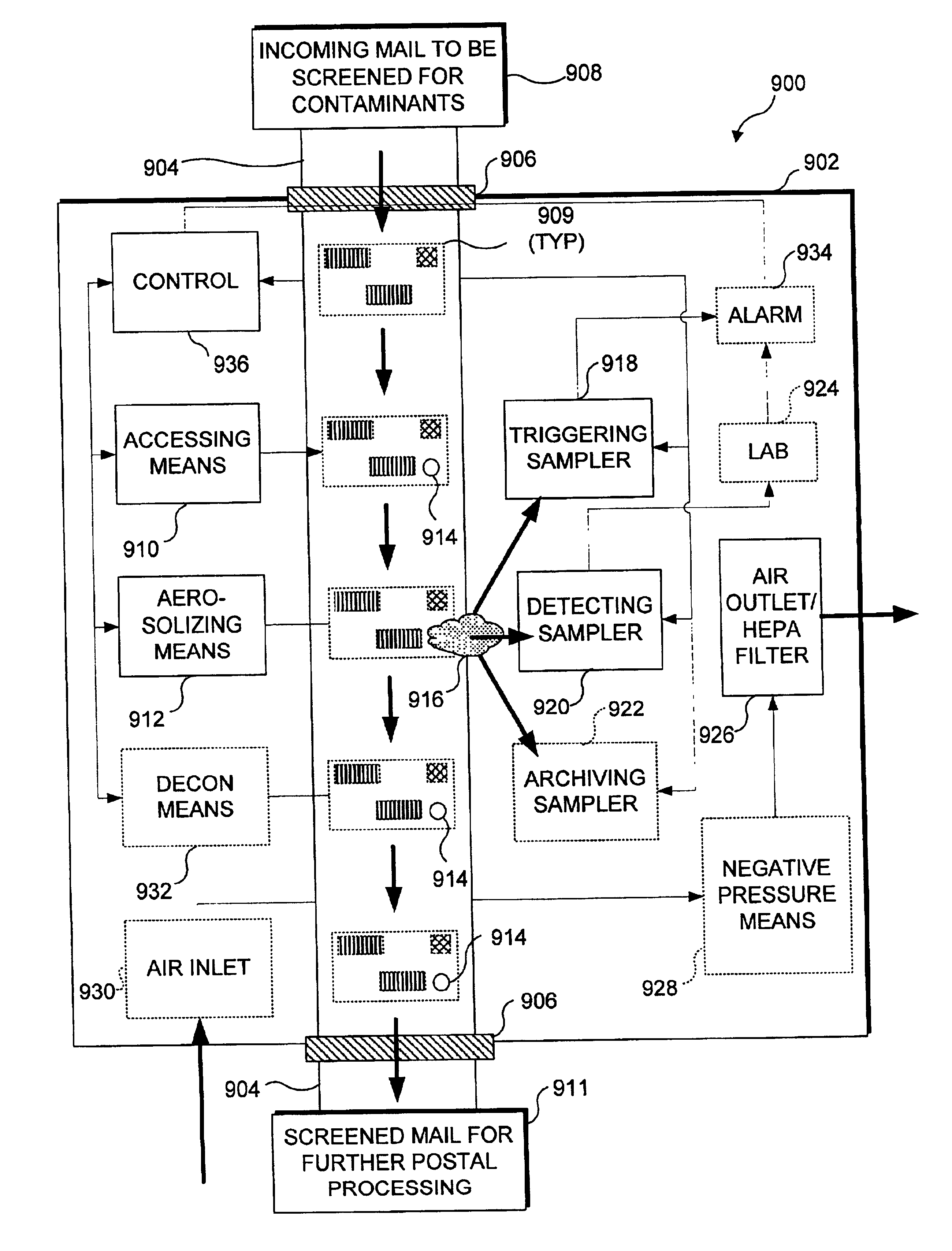

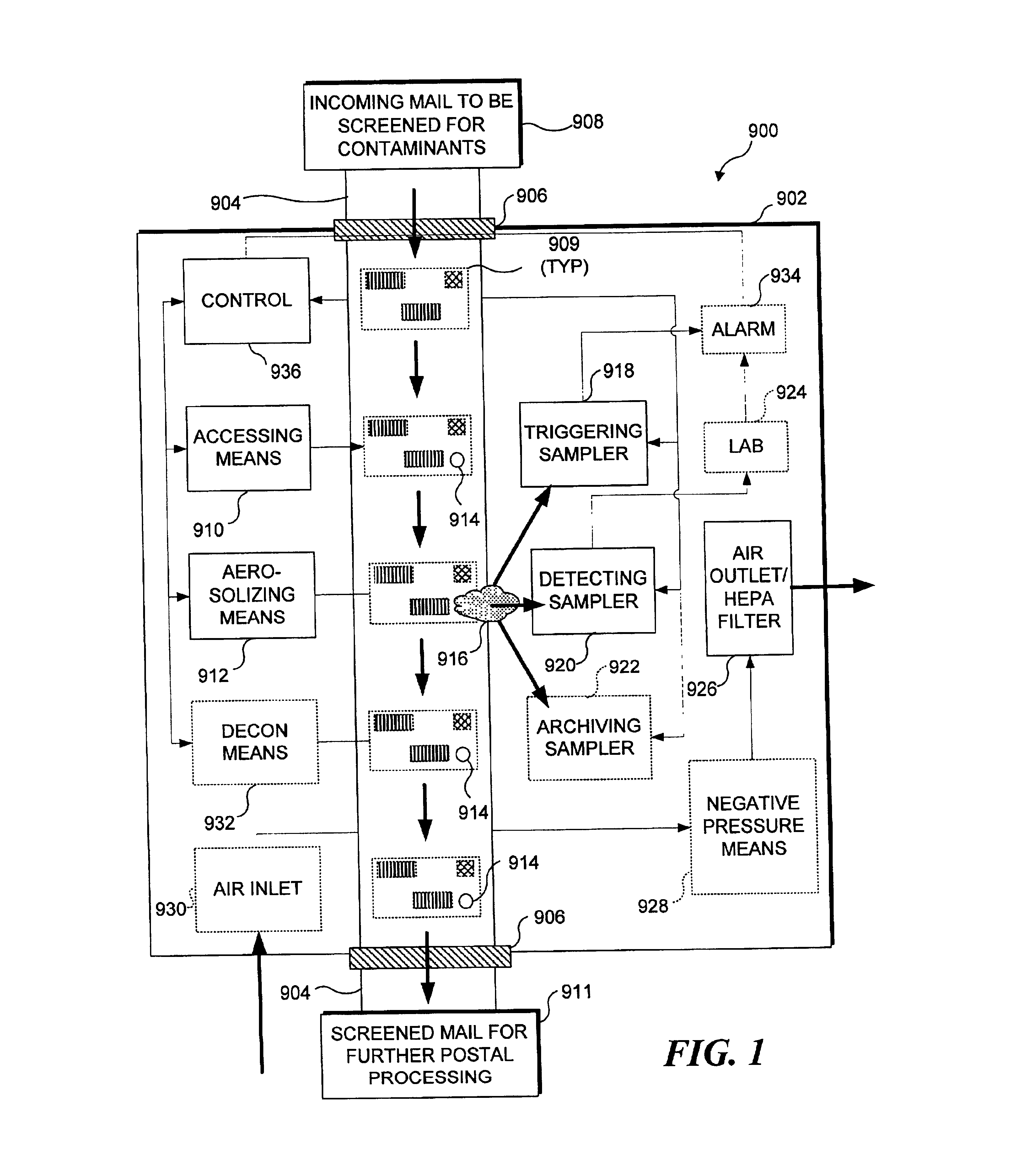

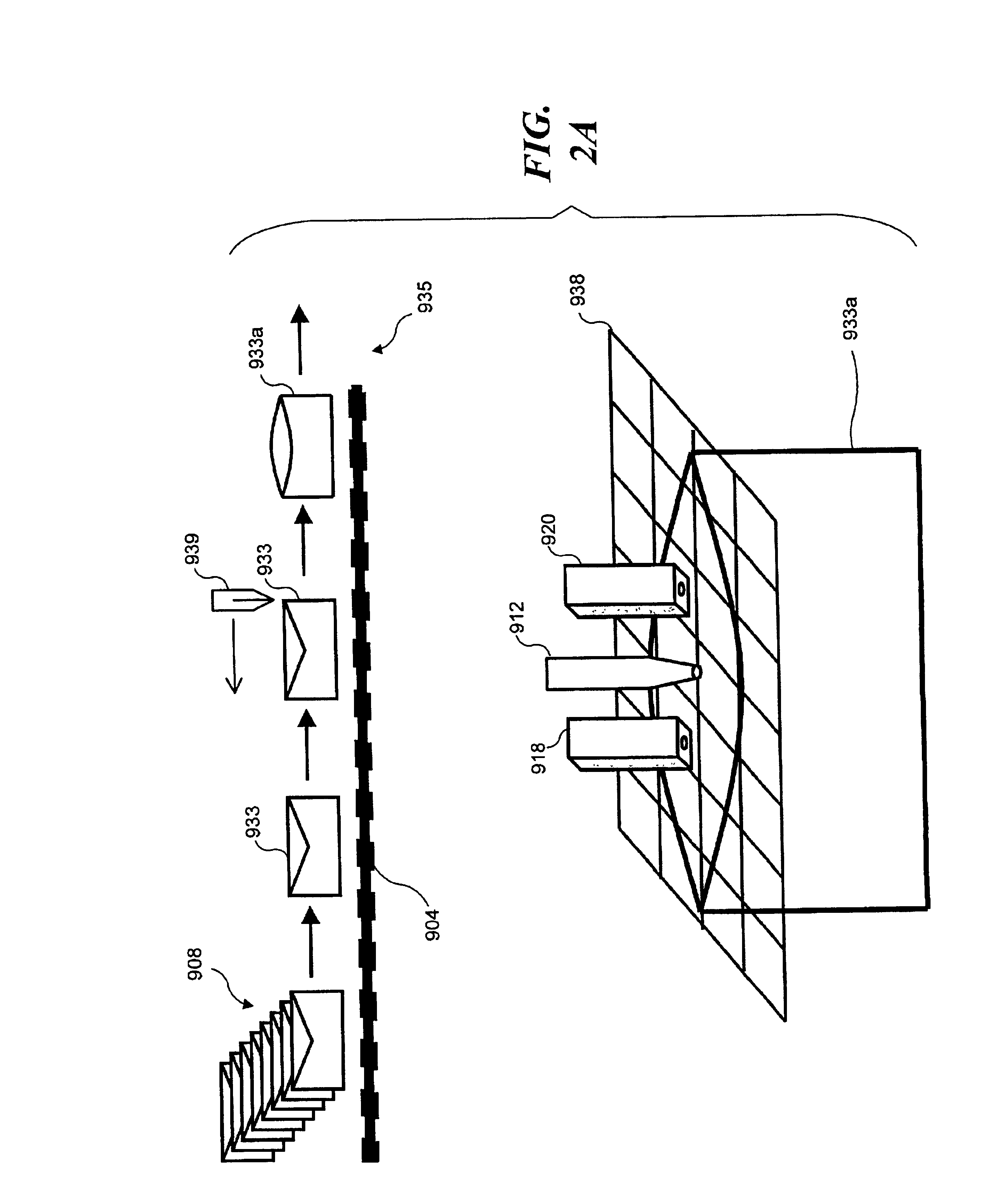

Items of mail are rapidly processed in a mail sampling system to determine if the mail is contaminated with a chemical or biological agent. The mail sampling system maintains a negative pressure in a containment chamber and includes a triggering sampler that makes a threshold determination regarding possible contamination, and a detecting sampler that obtains a sample for more detailed analysis in response to a signal from the triggering sampler. A sample of particulates collected from an item of mail is either removed for analysis or analyzed in the system to identify a contaminating agent. Optionally, the system includes an archiving sampler, which archives samples for subsequent processing and analysis, and a decontamination system, which is activated to decontaminate the mail if needed.

Owner:FLIR DETECTION

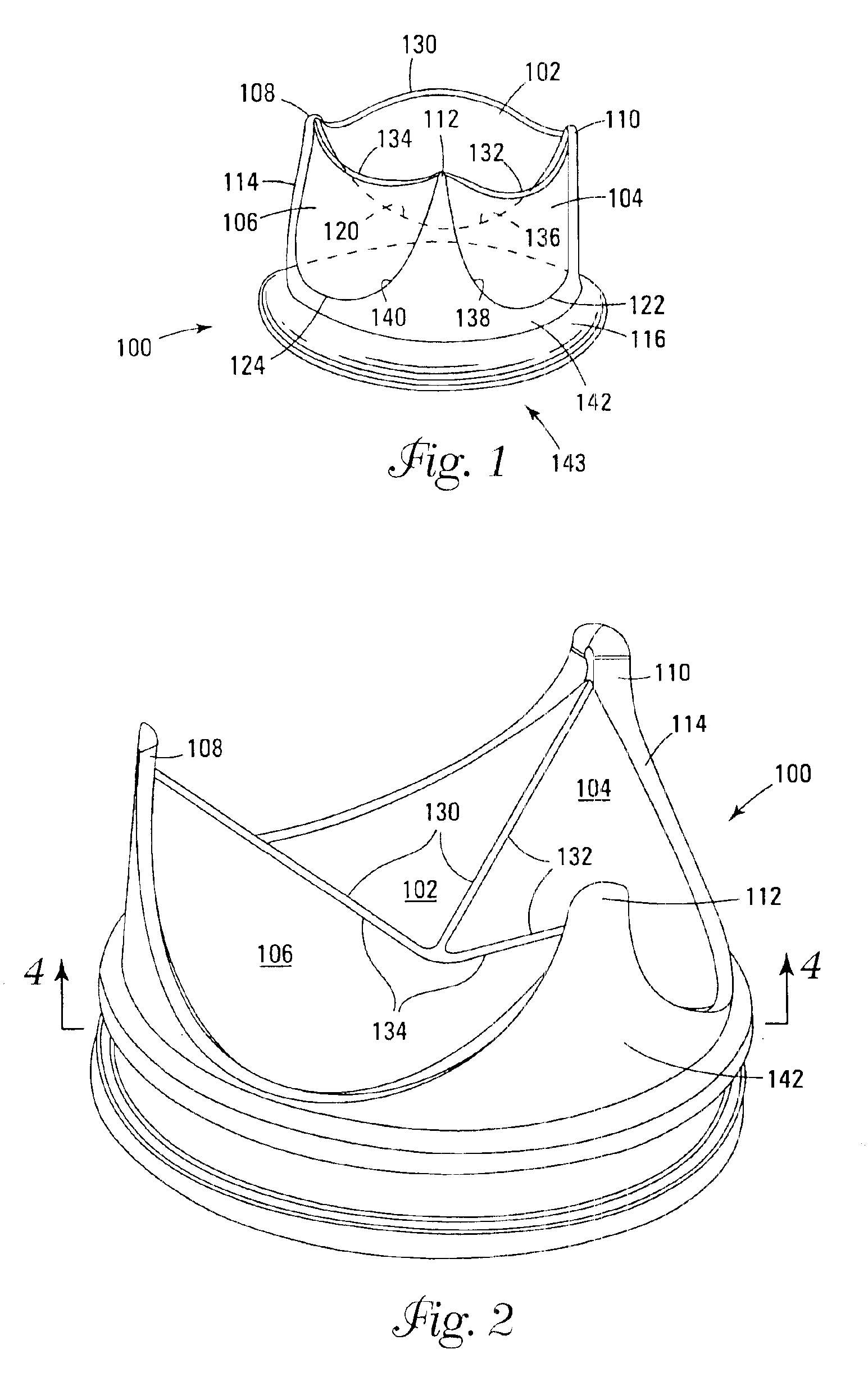

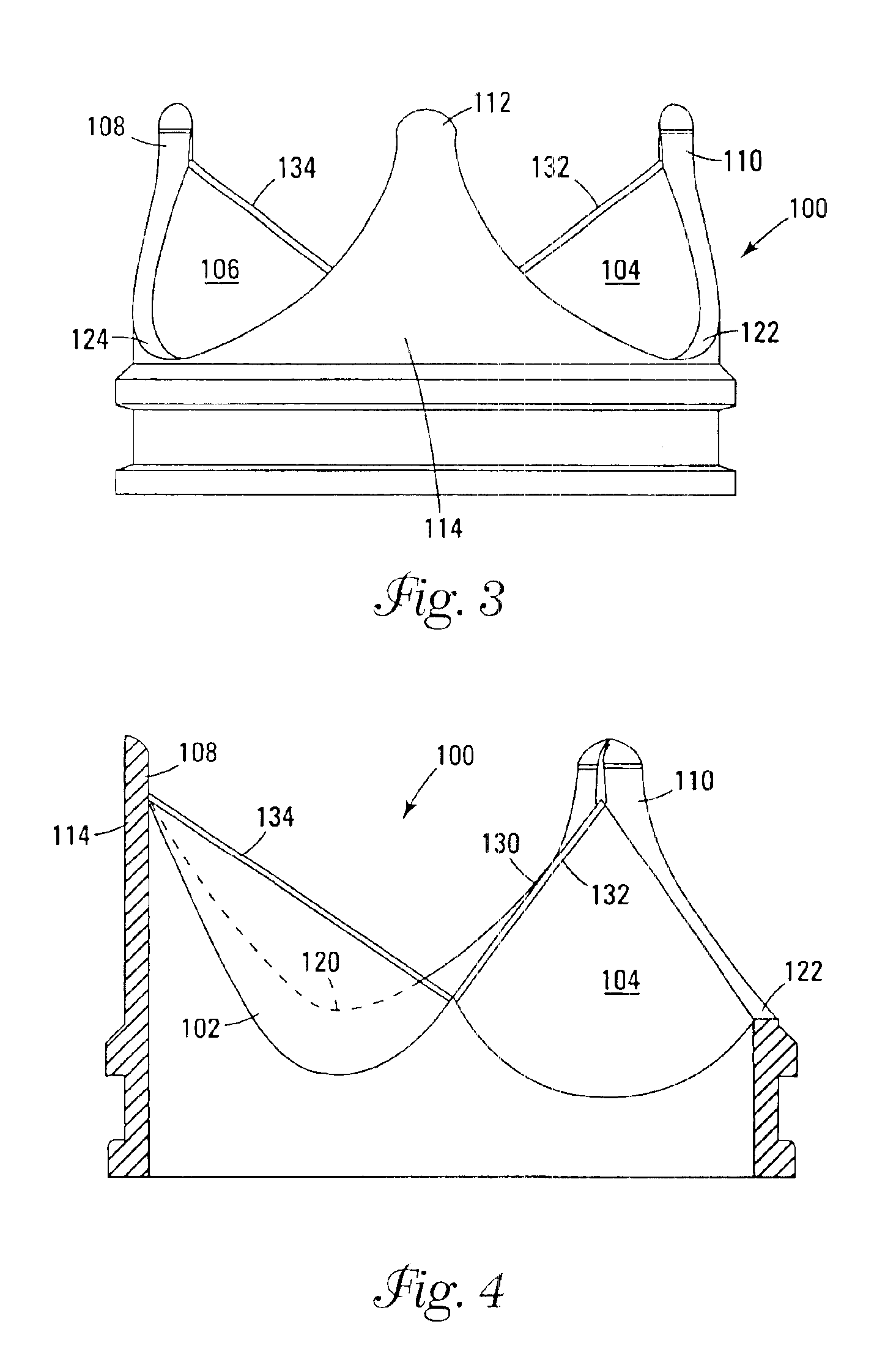

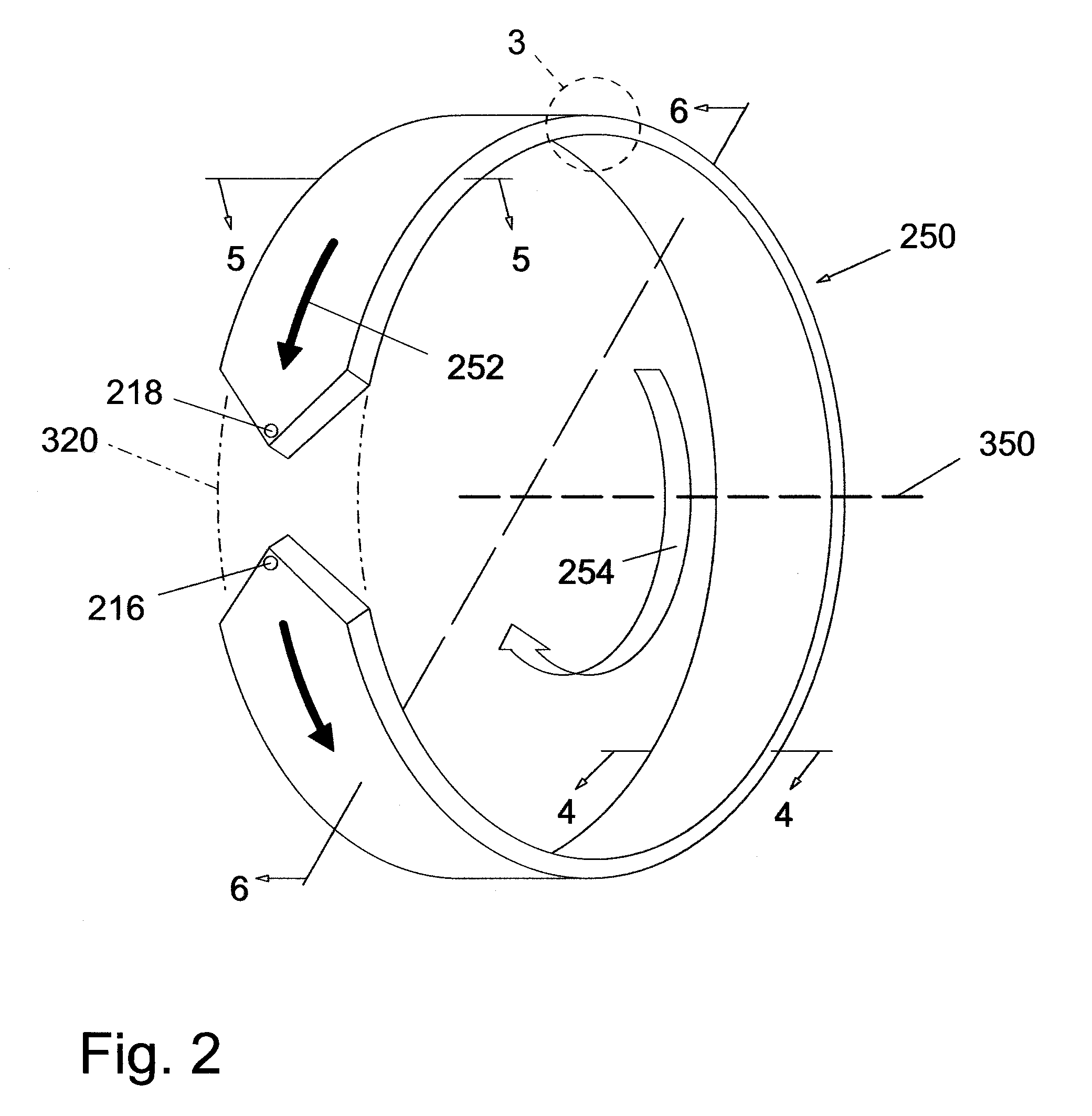

Fatigue test for prosthetic stent

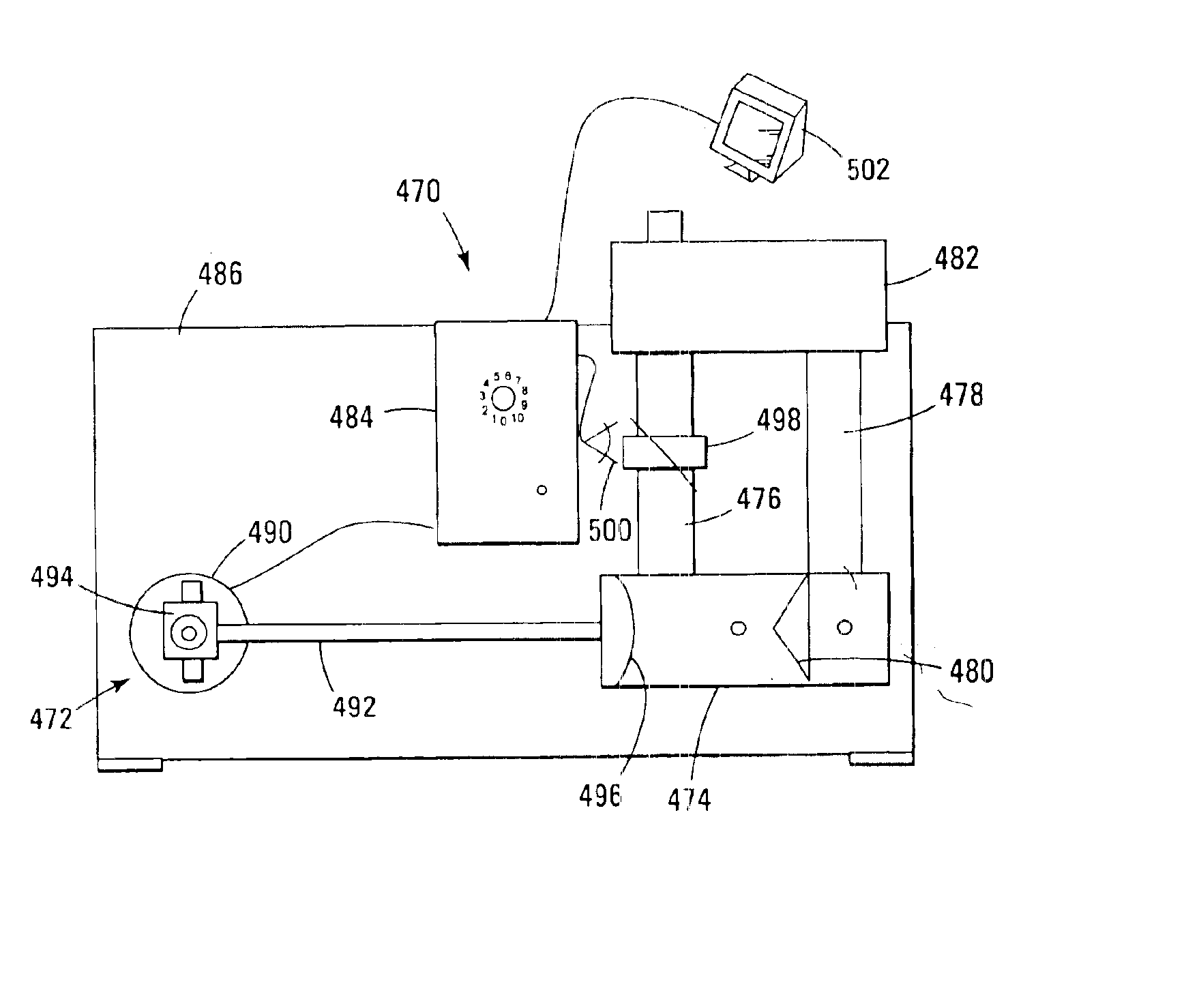

An improved method for testing a stent for a prosthetic valve includes applying a load with a fluid against a stented test structure in a backward direction with the stented test structure substantially blocking the flow of the fluid. The stented test structure includes a stent and a flexible membrane extending within the lumen defined by the stent with the flexible membrane having a plurality of contours connecting to the stent along the scallops. A corresponding testing apparatus includes a cyclic pressure applicator, a conduit connected to the cyclic pressure applicator, and a stented test structure mounted within the conduit to receive cyclic fluid pressures from the cyclic pressure applicator. The stented test structure includes a stent and a flexible membrane extending within the lumen defined by the stent. The flexible membrane substantially blocks flow of the fluid in a backward direction and does not fully open upon application of the fluid pressure in a forward direction.

Owner:ST JUDE MEDICAL

High throughput preparation and analysis of plastically shaped material samples

InactiveUS7013709B2Rapid throughput formationSynthesis fastSequential/parallel process reactionsOrganic chemistry methodsBiologyThroughput

A rapid throughput method for the preparation, analysis or both of libraries of material samples is provided. According to the method, a plurality of samples is provided. The plurality of samples is then formed into a plurality of films. Thereafter, the plurality of films is plastically deformed. Preferably, the plurality of films is deformed into a configuration appropriate for testing of properties or characteristics of the samples.

Owner:FREESLATE

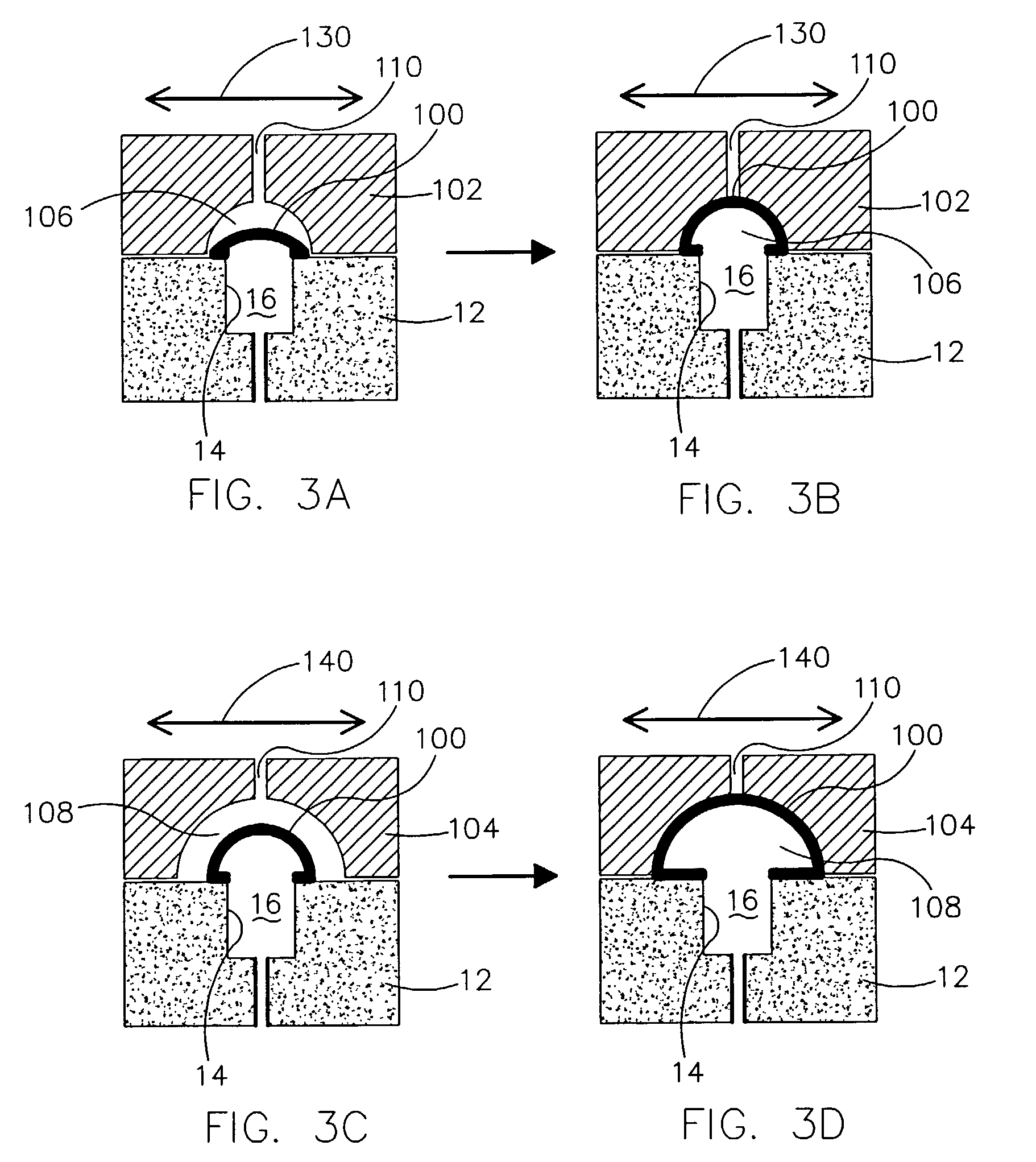

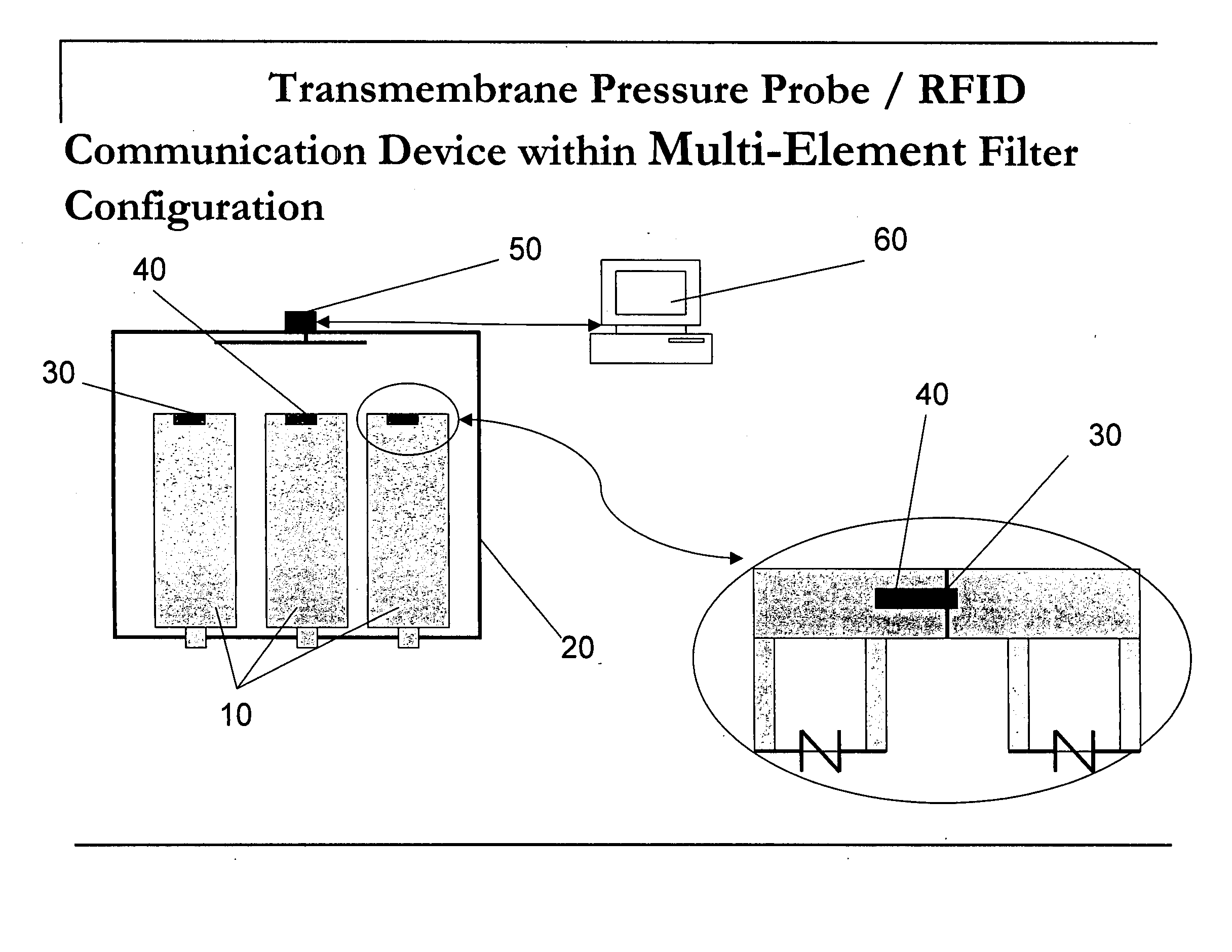

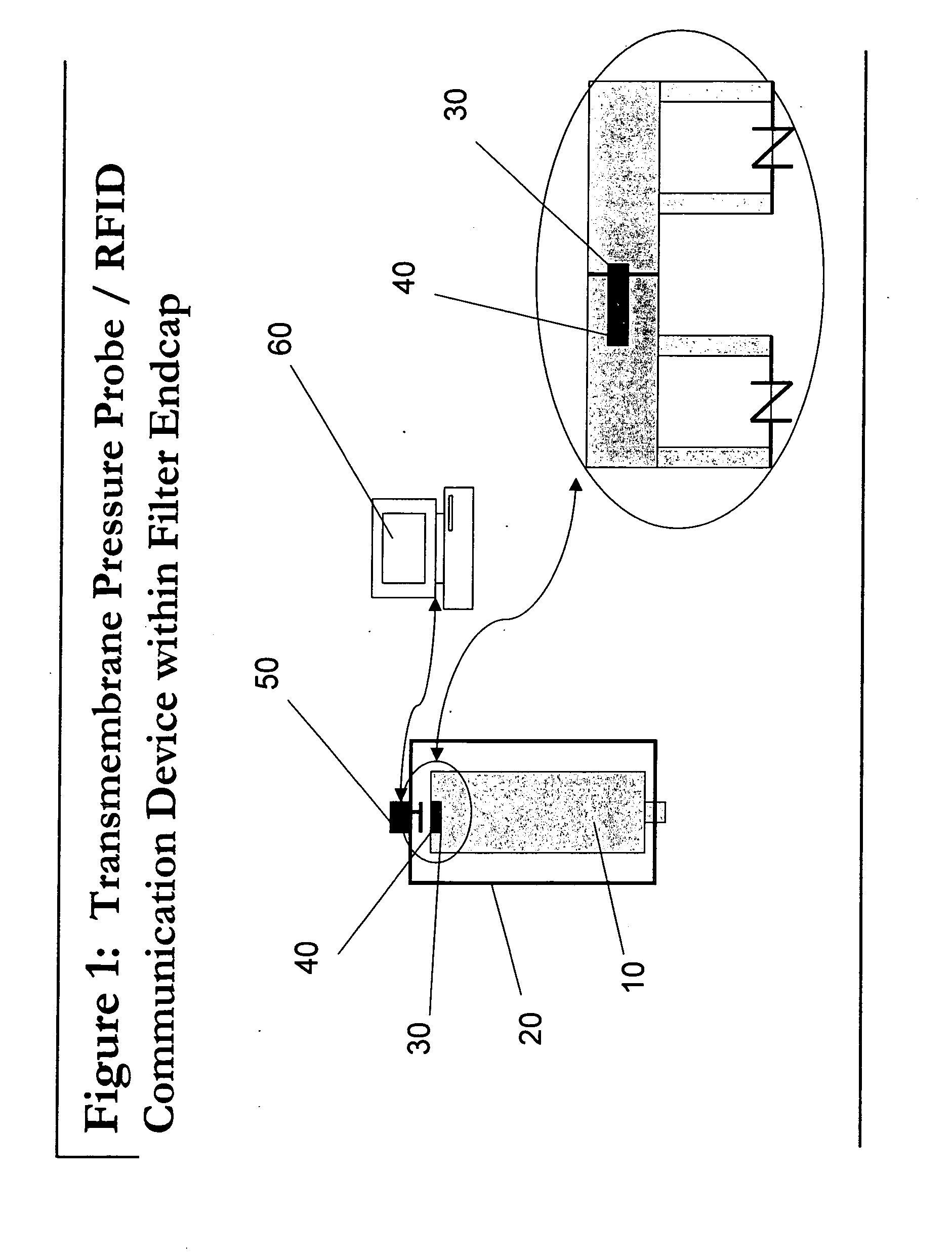

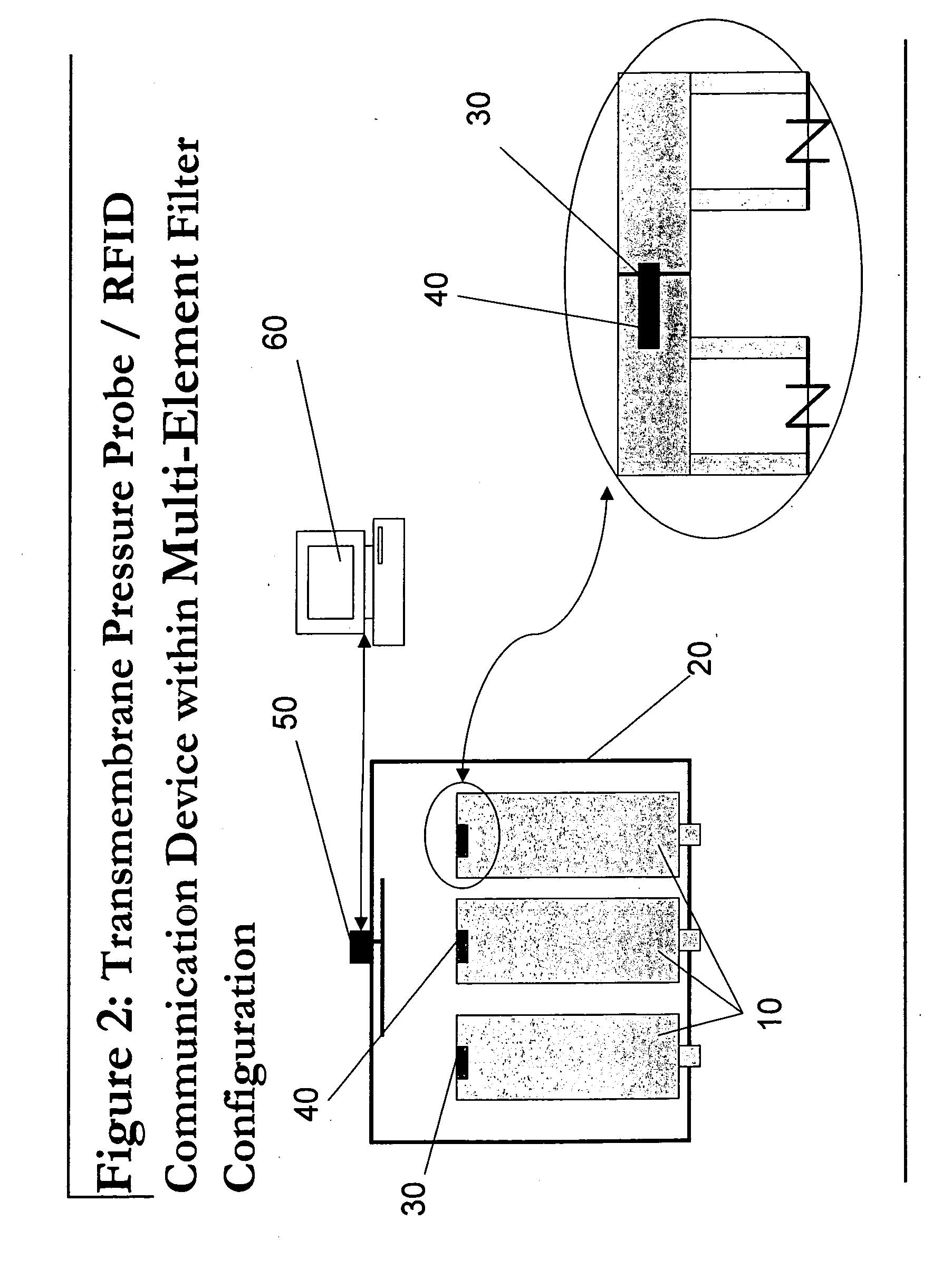

Filter with memory, communication and pressure sensor

ActiveUS20070240492A1Improve reliabilityImprove validityCombination devicesMembranesEngineeringIntegrity testing

The present invention describes a system and method for accurately measuring the pressure within a filter housing. A pressure sensor and a communications device are coupled so as to be able to measure and transmit the pressure within the filter housing while in use. This system can comprise a single component, integrating both the communication device and the pressure sensor. Alternatively, the system can comprise separate sensor and transmitter components, in communication with one another. In yet another embodiment, a storage element can be added to the system, thereby allowing the device to store a set of pressure values. The use of this device is beneficial to many applications. For example, the ability to read pressure values in situ allows integrity tests to be performed without additional equipment. In addition, integrity testing for individual filters within multi-filter configurations is possible.

Owner:MILLIPORE CORP

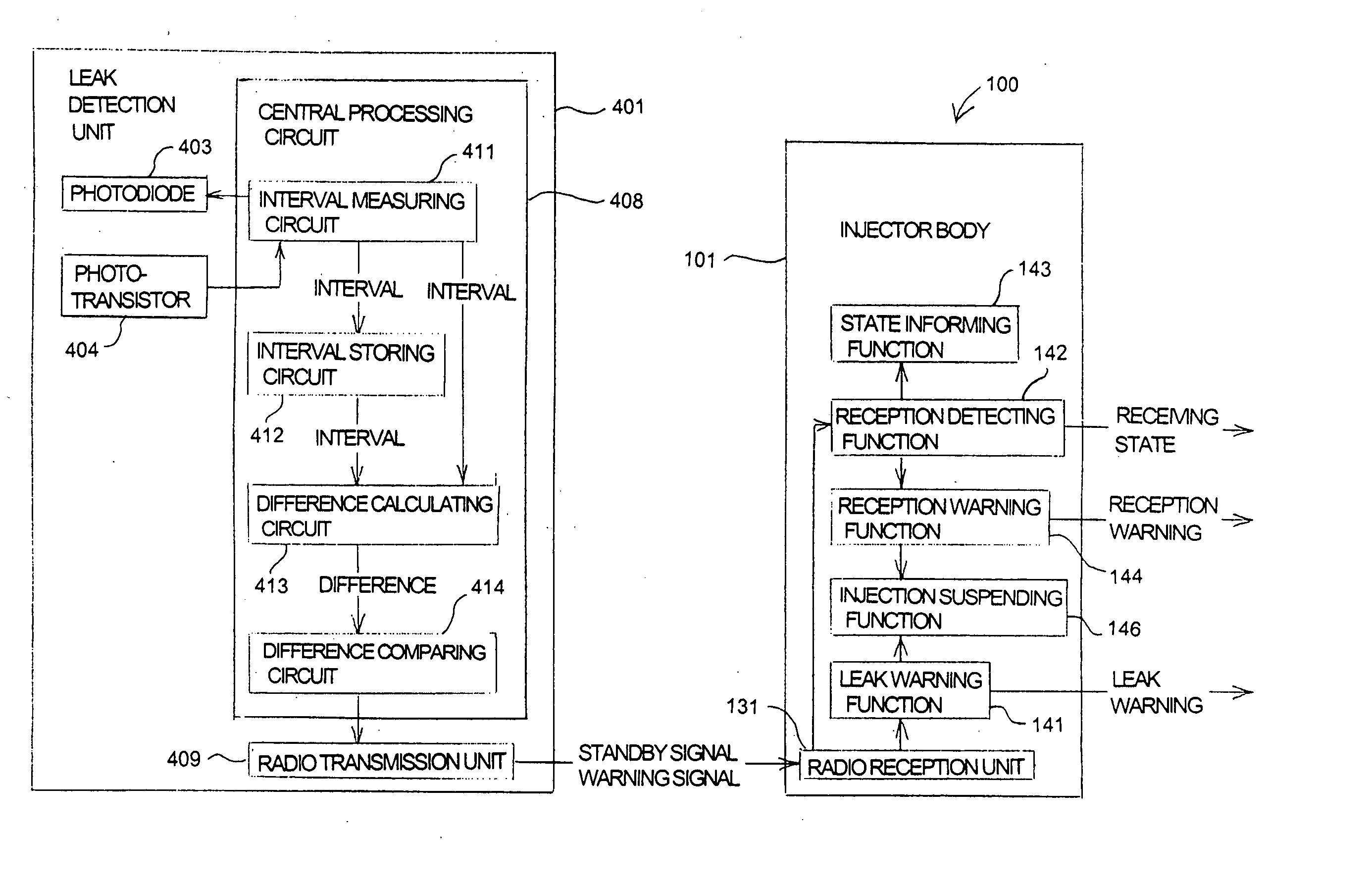

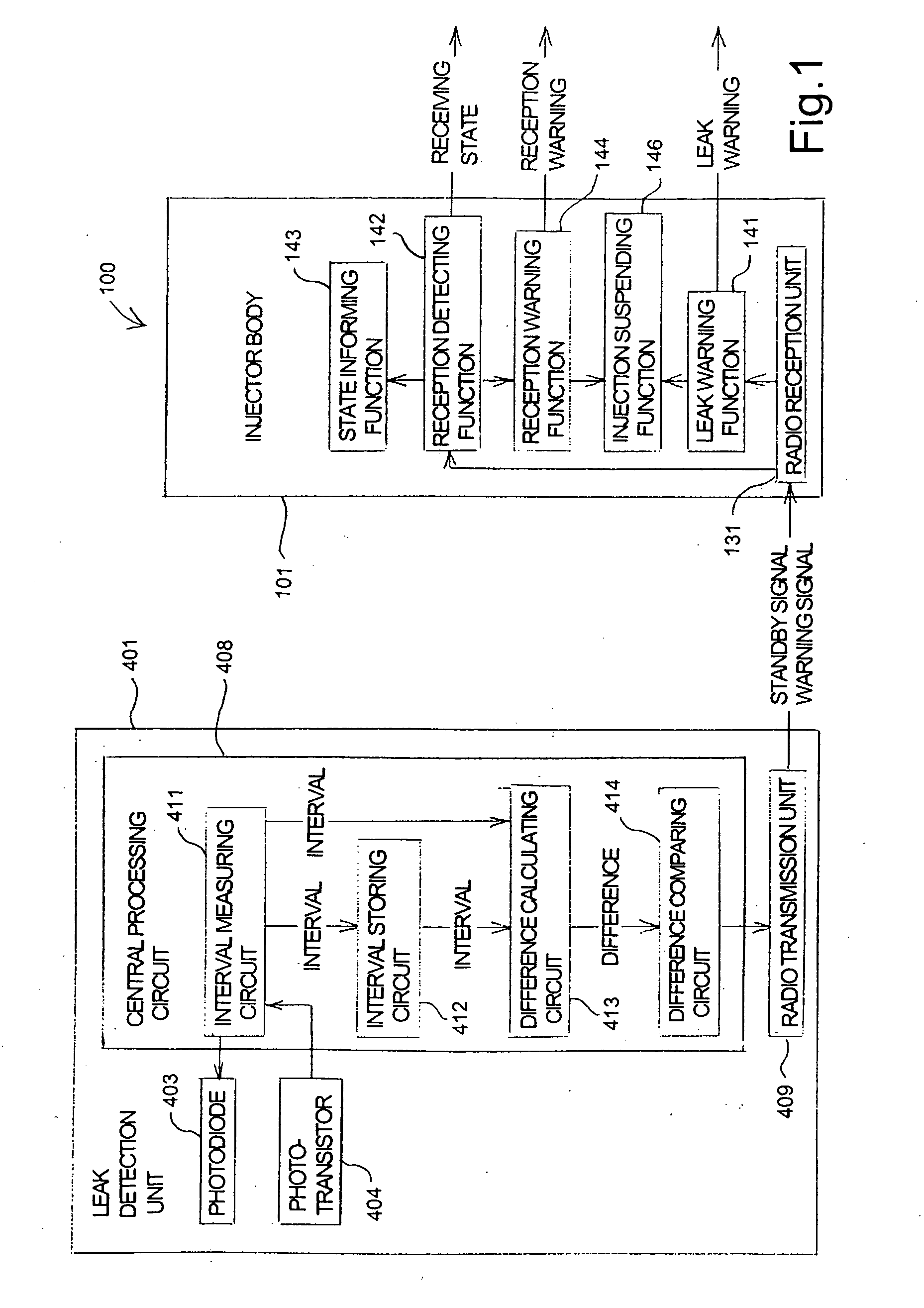

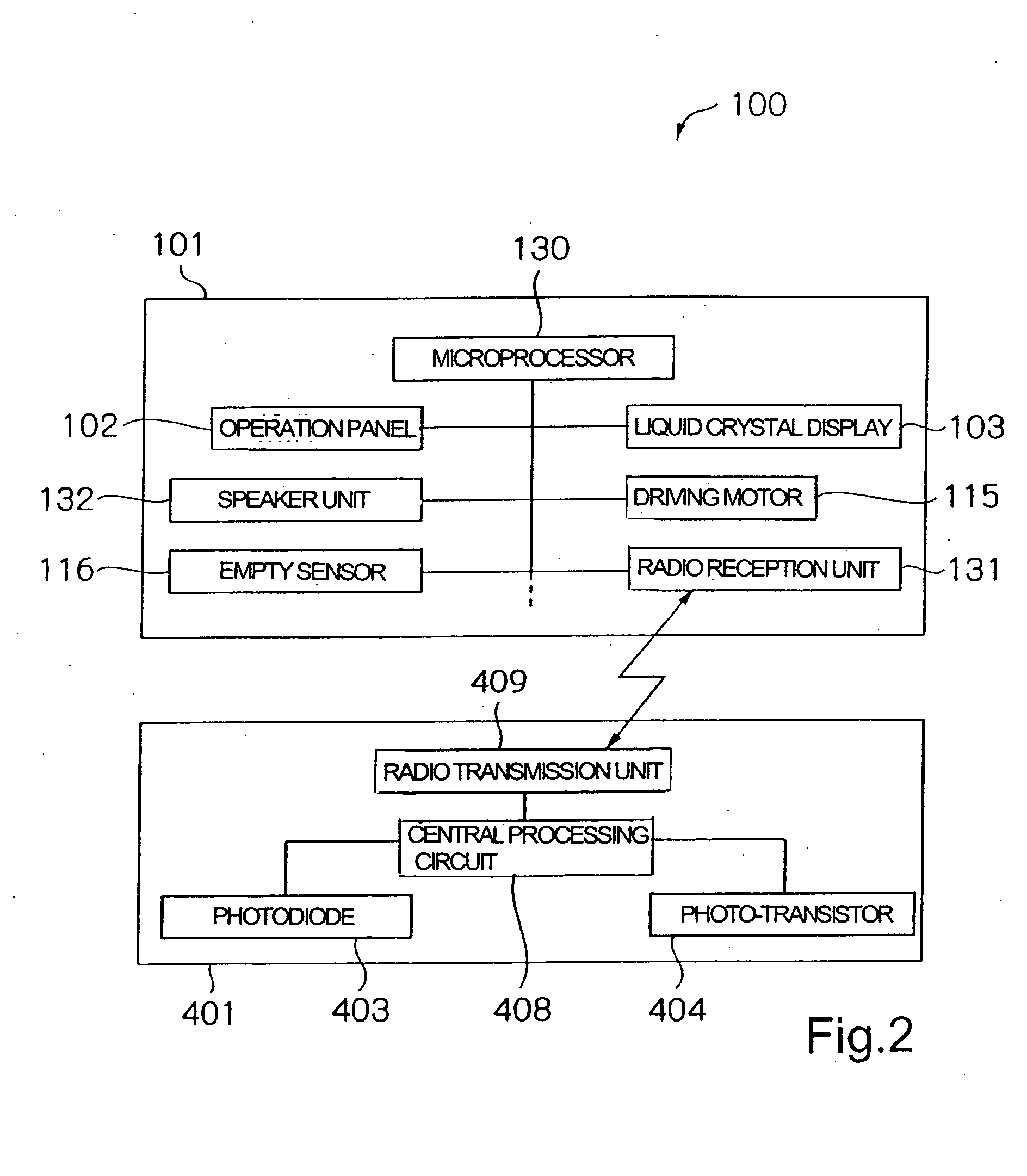

Leak detector for detecting leak of liquid injected into blood vessel using pulse signal

InactiveUS20040225255A1Reduce detection accuracySimple structureCircuit monitoring/indicationVolume/mass flow measurementAcousticsBlood vessel

A leak detector sequentially emits pulse signals toward a human body at a position at which a needle is inserted, detects pulse signals reflected inside of the human body, and measures a time interval between the emission and the detection for each of the pulse signals. Then, the leak detector calculates the difference between the measured interval and a predetermined time interval, and generates a leak warning for notification when the difference exceeds an acceptable range. Since a swelling on the surface of the human body causes a path of the pulse signal to extend, the leak detector can detect, based on the extended signal path, that the needle has come off a blood vessel.

Owner:NEMOTO KYORINDO KK

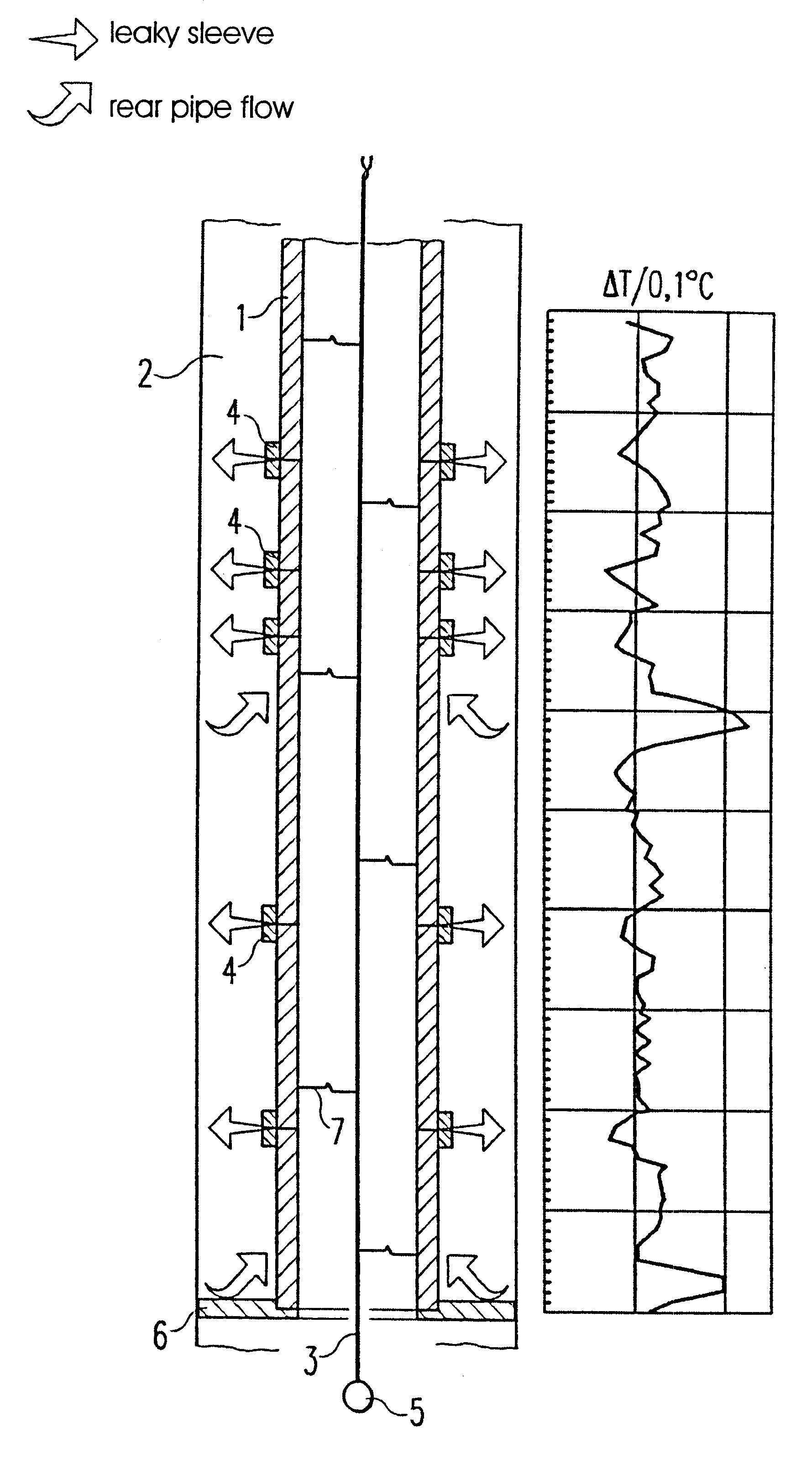

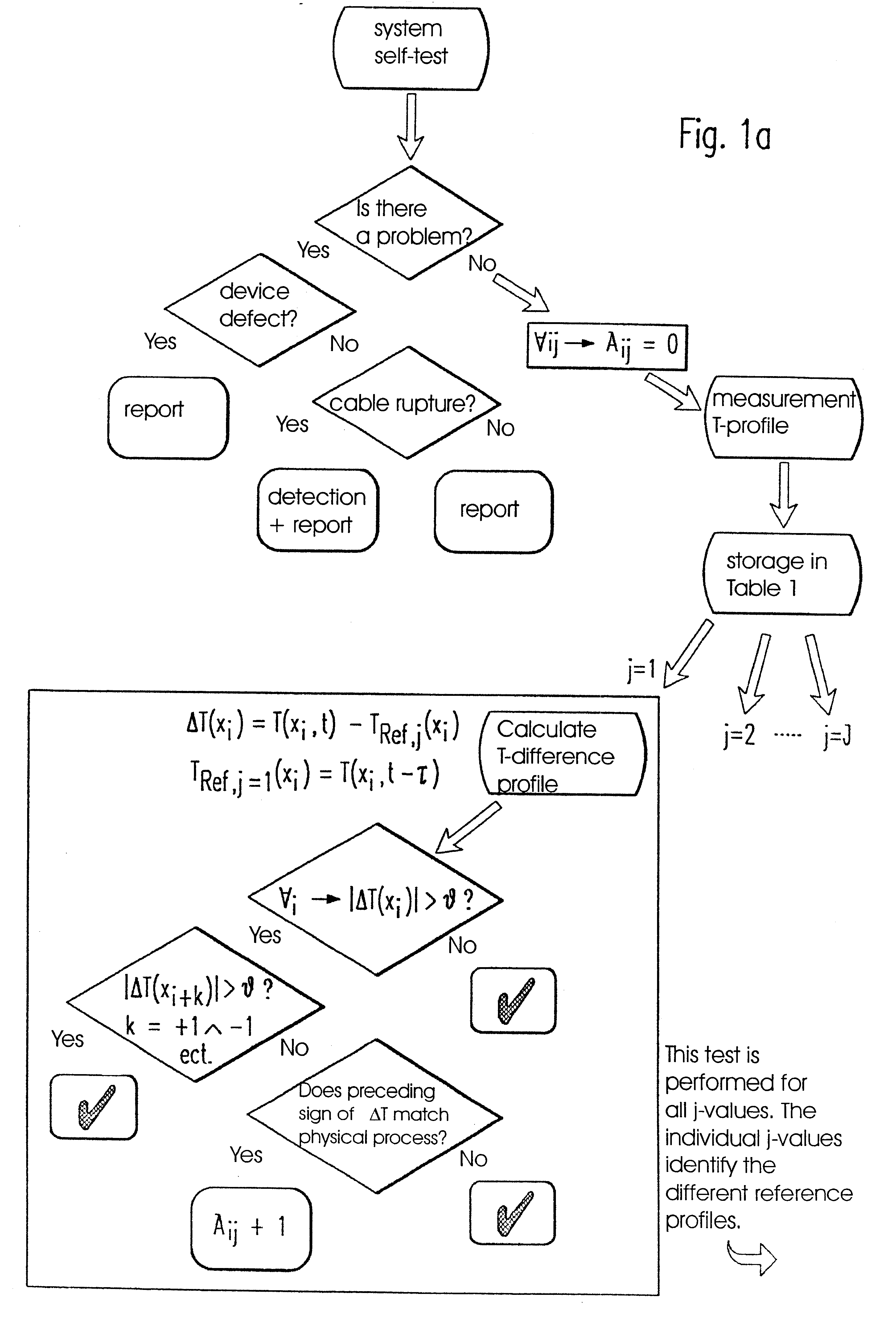

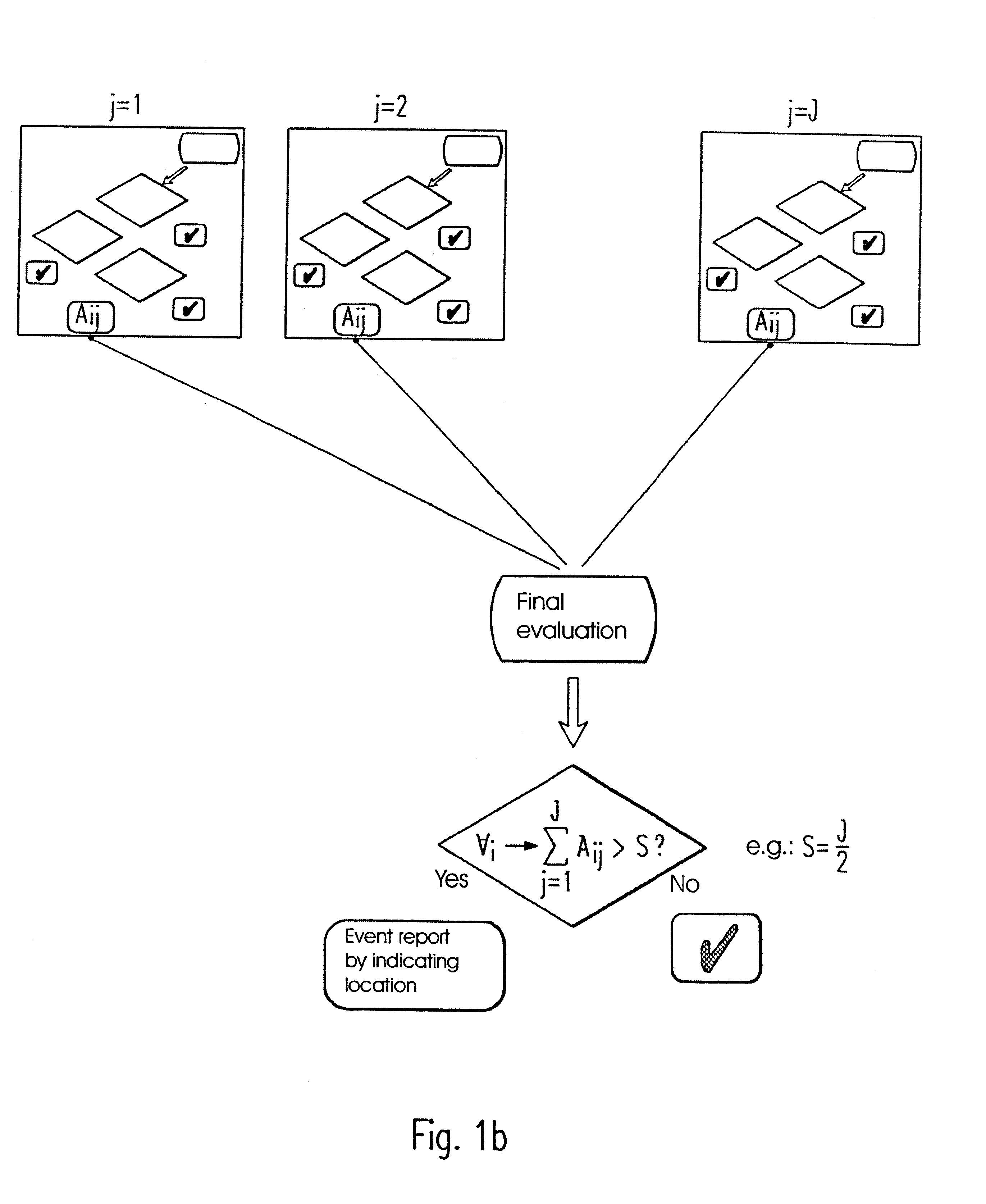

Device for monitoring temperature distribution on the basis of distributed fiber-optic sensing, and use of same

InactiveUS6547435B1Eliminate potential safety hazardsHigh resolutionThermometer detailsRadiation pyrometryFiberMonitoring temperature

The invention relates to a method and a device for monitoring, also permanently and automatically, temperature distributions and / or temperature anomalies on the basis of distributed fiber-optic temperature sensing as well as to the use of such methods. According to the invention the detection of local temperature extremes, i.e. minimums or maximums, in view of the evaluation is performed by an evaluation without numeric derivations. With the device for monitoring ascending and supply pipes surrounded by an annular space it is possible to check the safety of pressurized installations, particularly in the field of low-pressure gas storage, in a cost-efficient manner. Moreover, the position of an underground watershed or respectively the direction and flow rate of the flows in flooded drift sections can be determined on the basis of fiber-optic temperature measurements. The defined arrangement of preferably vertical sensor cables inserted into the bores also makes it possible to examine the tightness of base sole and lateral walls in building excavations. Finally, the virtually horizontal, meander-shaped arrangement of fiber-optic cables situated in several levels makes it possible to evaluate and control the efficacy and homogeneity of leaching processes in leaching dumps and fills.

Owner:O FUR SENSORIK GEOTECHNN UMWELTSCHUTZ & MATHEMATISCHE MODELLIERUNG MBH JENA

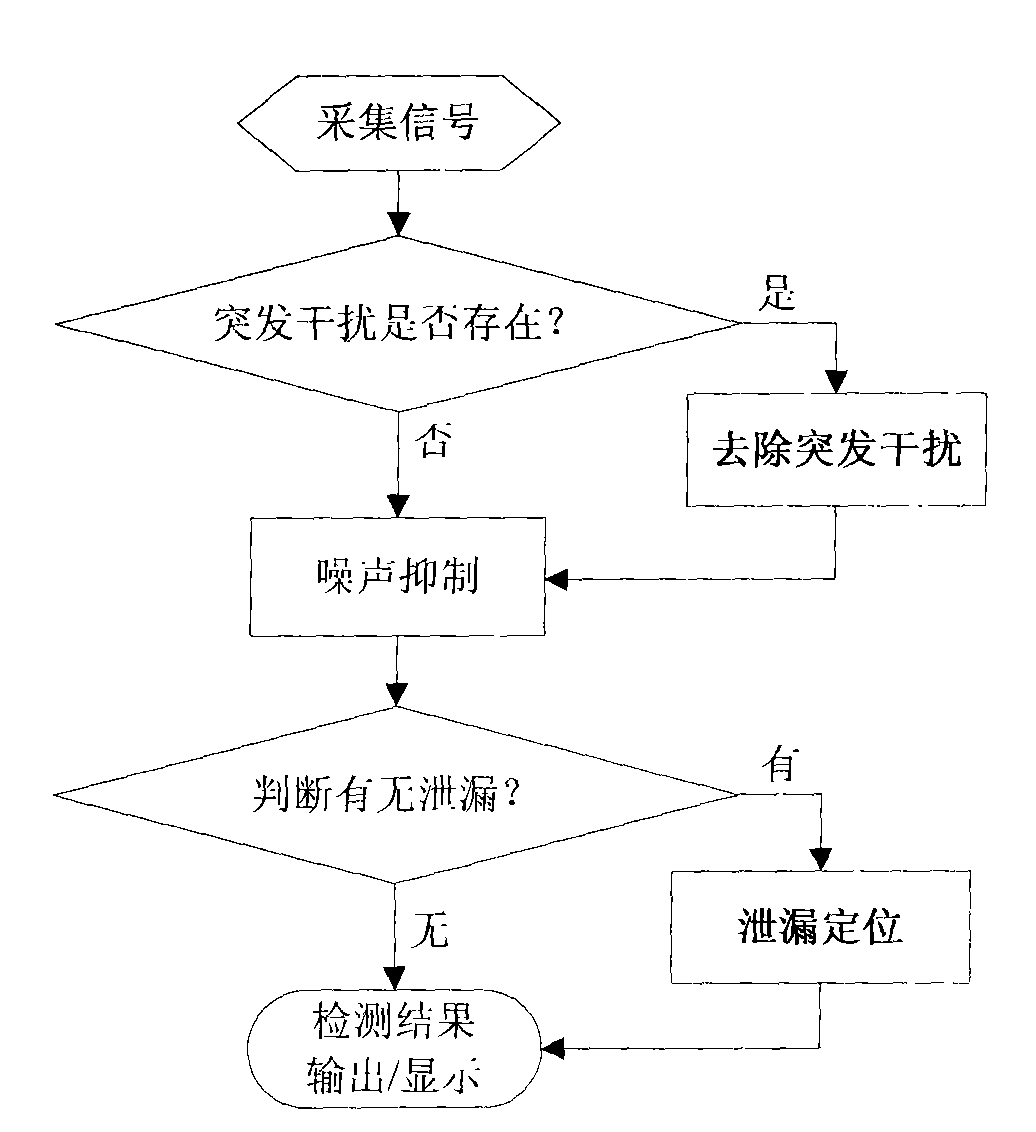

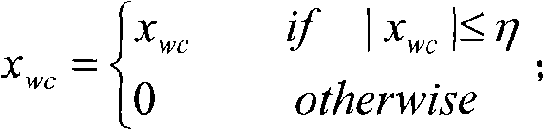

Water supply pipe leakage detection locating signal processing method

InactiveCN101551064AQuality improvementImprove accuracyPipeline systemsFluid-tightness measurement using fluid/vacuumSignal qualitySound sources

The invention discloses a water supply pipe leakage detection locating signal processing method. The method includes: firstly determining the burst interference exists to the acquired information, if the burst interference exists, performing burst interference removing process, if the burst interference does not exist or the burst interference has been removed, performing noise suppression process to the signal; as a whole de-noising pretreatment process is completed, determining whether the leakage exists according to the processed signal, and adding a function of identifying the difference from the true leakage to the fixed interference sound source during the determination, if the leakage does not exist, directly giving out the detecting result, if it passes the identification and the true leakage exists, further performing leak point positioning, and giving out the final test results and the leakage point position. The invention has beneficial technical effect of improving signal quality by removing burst interference in the acquired signal and noise restraining and the like de-noising processes when performing leakage detection to the water supply pipe, thereby enhancing the pipeline leak detection accuracy and leak-point positioning accuracy under complex noise environments; having practical value that it firstly determines whether true leakage acoustic singles are included in the acquired signal and then locates the leakage points.

Owner:CHONGQING UNIV

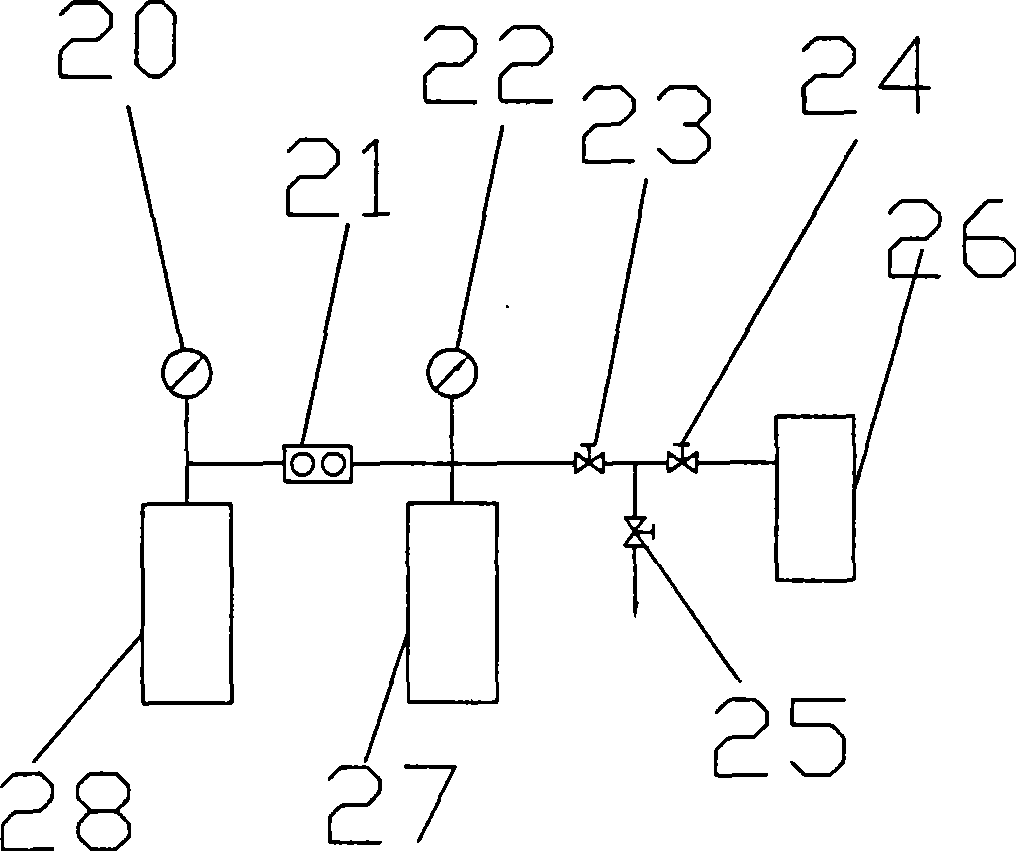

Device and method for detecting sealing property of sealing component

ActiveCN101799349AEasy to measureAccurate measurementFluid-tightness measurement using fluid/vacuumControl systemEngineering

The invention relates to a device and a method for detecting the sealing property of a sealing component. The device of the invention comprises a steam generator, an autoclave and a control system, wherein the steam generator is used for heating a medium to generate steam and pressure; the autoclave is provided with an inner cavity, and comprises an upper mold plate, a lower mold plate, a sealing component to be detected and an auxiliary seal ring, wherein the sealing component to be detected is loaded between the upper mold plate and the lower mold plate; the auxiliary seal ring is positioned outside the sealing component to be detected; a leak detecting cavity is enclosed between the sealing component to be detected and the auxiliary seal ring; the inner cavity of the steam generator is communicated with the inner cavity of the autoclave through a steam supply pipeline; the detecting device also comprises a detecting gas passage communicated with the leak detecting cavity and a working gas supply system communicated with the detecting gas passage; and a hygroscope positioned at downstream of the leak detecting cavity is arranged on the detecting gas passage. In the invention, dry working gas takes the steam leaked in the leak detecting cavity away, and the instant and average leakage rates of the sealing component are computed by measuring the moisture change of the working gas before and after passing through the leak detecting cavity.

Owner:SUZHOU BMC SEALING TECH CO LTD

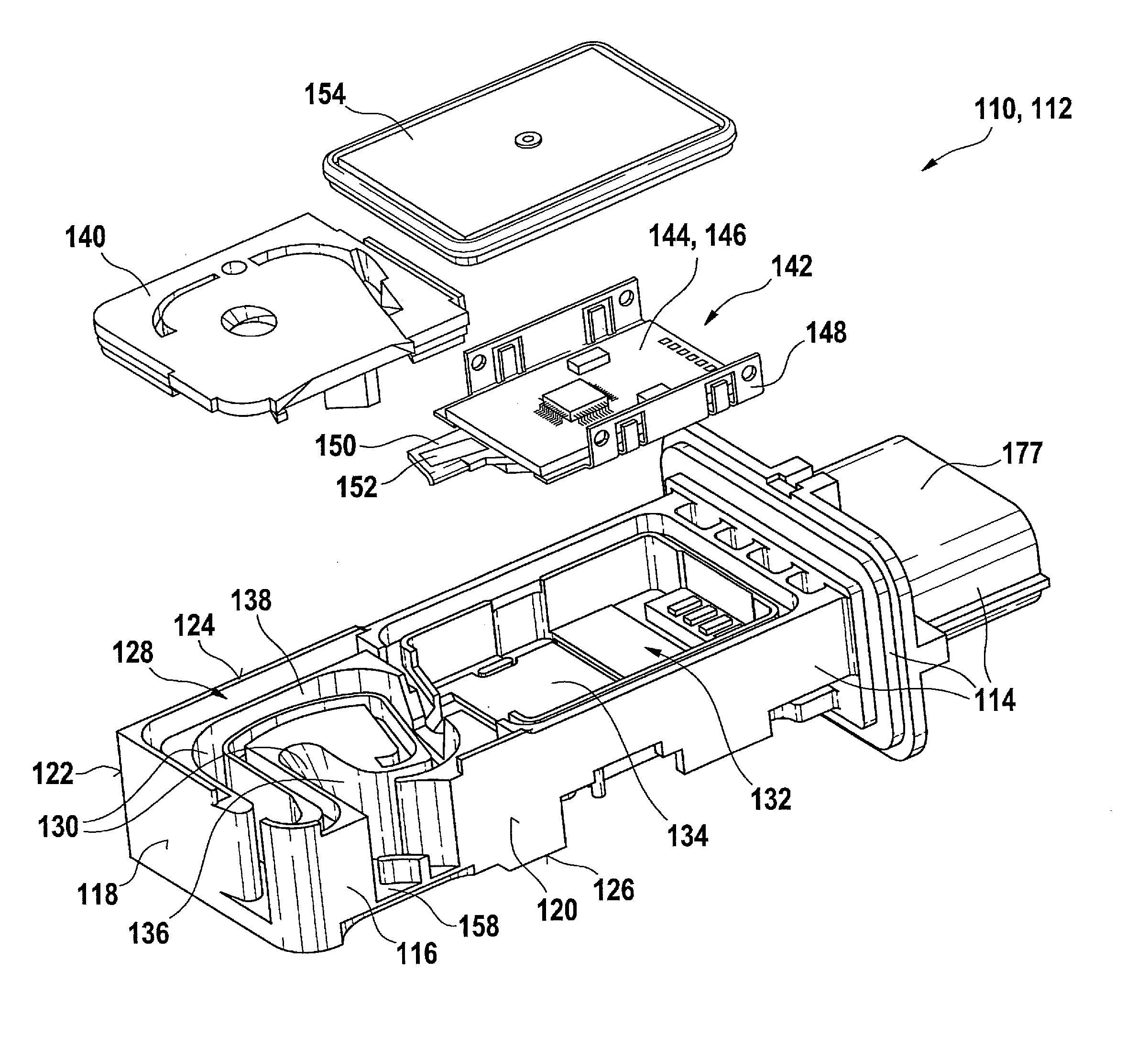

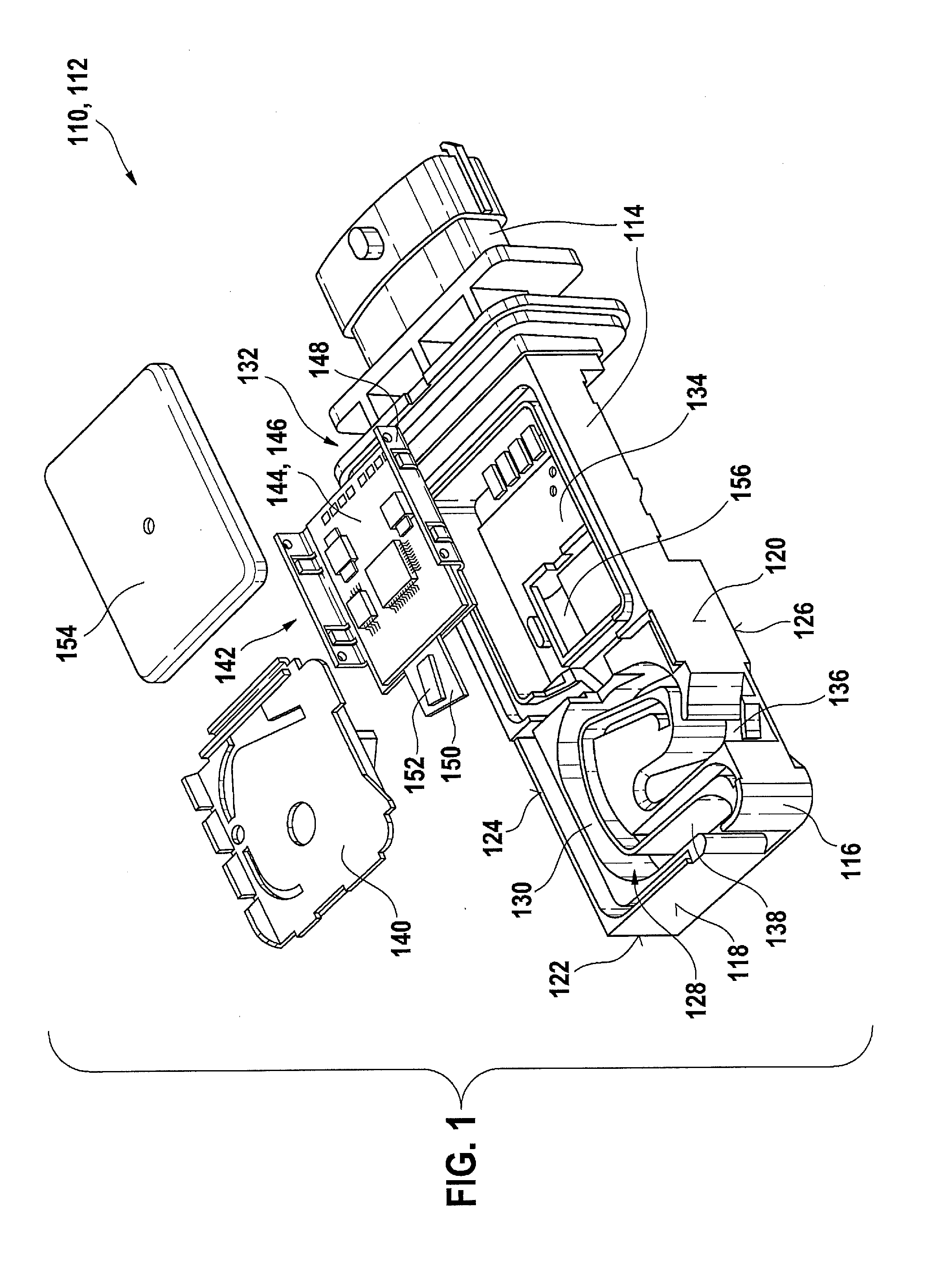

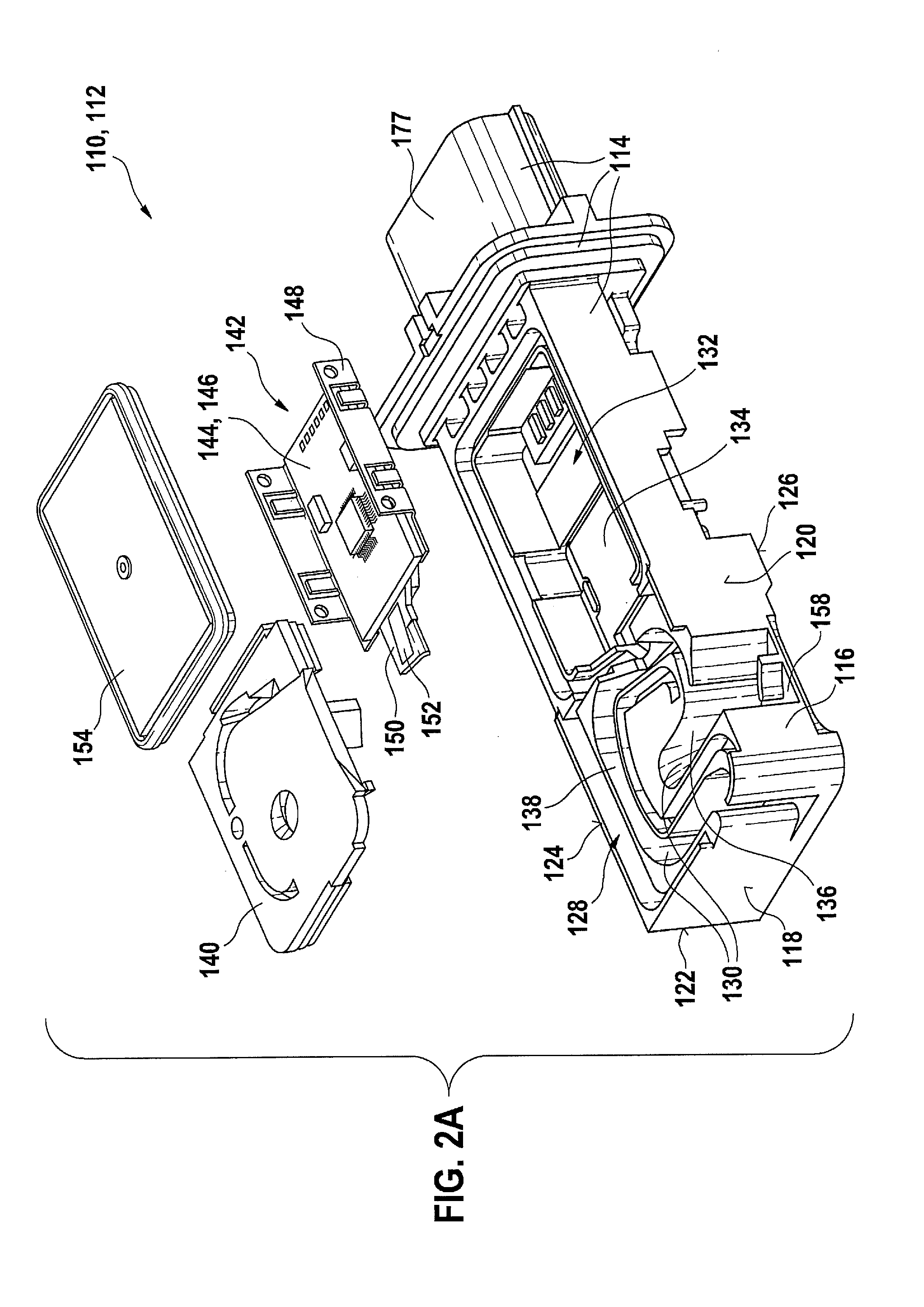

Sensor device for detecting a flow property of a fluid medium

ActiveUS20130269419A1Easy to manufactureCost-effective designElectrical controlVolume/mass flow by thermal effectsEngineeringMoisture sensor

A sensor device for detecting at least one flow property of a fluid medium. The sensor device includes at least one sensor housing, in which at least one electronic module having at least one flow sensor for detecting the flow property is accommodated. The electronic module is at least partially accommodated in at least one electronic space. Furthermore, at least one pressure sensor and at least one humidity sensor are accommodated inside the sensor housing. The pressure sensor and also the humidity sensor are at least partially accommodated in at least one sensor space, which is designed separately from the electronic space.

Owner:ROBERT BOSCH GMBH

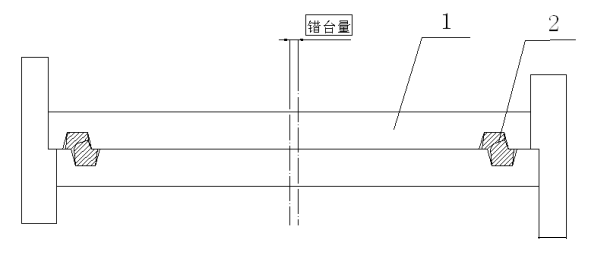

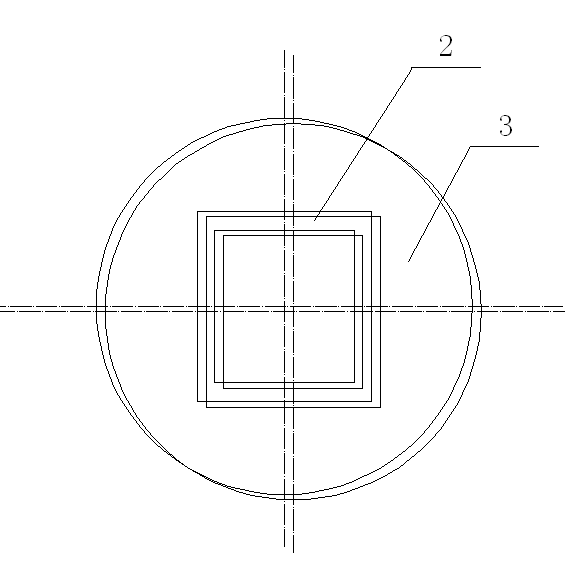

In-line water tightness testing device for elastic sealing gasket of shield tunnel

InactiveCN101929911AAccurately verify waterproof abilityAccurate evaluation systemMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumEngineeringWater tightness

The invention belongs to the field of tunnel engineering, and in particular relates to an in-line water tightness testing device for an elastic sealing gasket of a shield tunnel, which simulates the waterproof capacity of a waterproof sealing gasket of segment joints of the shield tunnel in a straight joint erecting state. The device of the invention comprises two abutted rectangular cover plates, wherein an air outlet hole and a water inlet hole are arranged on the cover plates; corresponding rectangular grooves are arranged in the central positions of the abutted surfaces of the two cover plates; the two cover plates are fastened and abutted by bolts distributed on the peripheries of the cover plates; and a spacing plate is installed laterally on the cover plate. The invention has the advantages that the device of the invention can precisely verify the waterproof capacity of the elastic sealing gasket under the conditions of different opening value of segments and different dislocation, thus the evaluating system of the waterproof capacity is more precise.

Owner:TONGJI UNIV

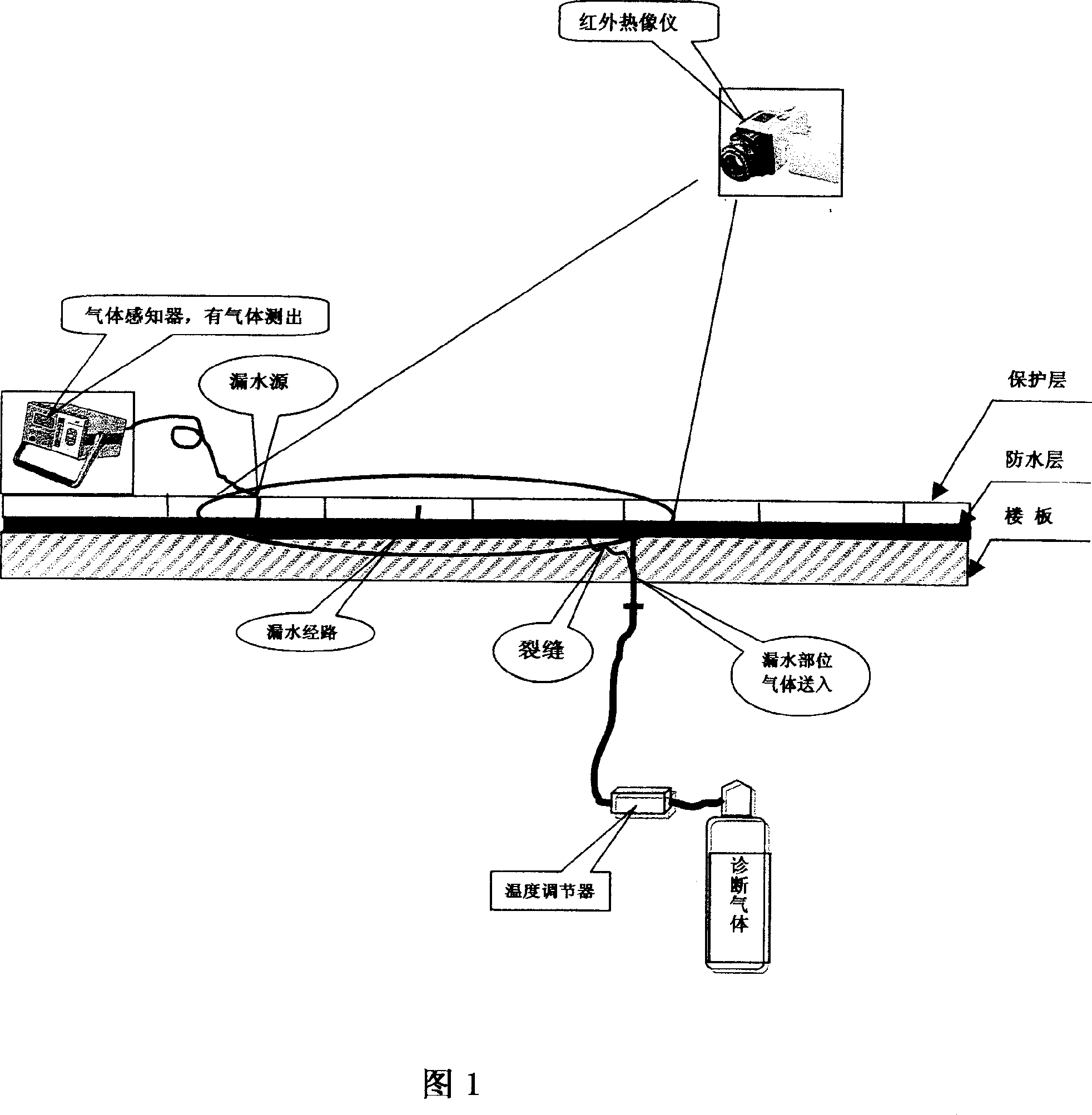

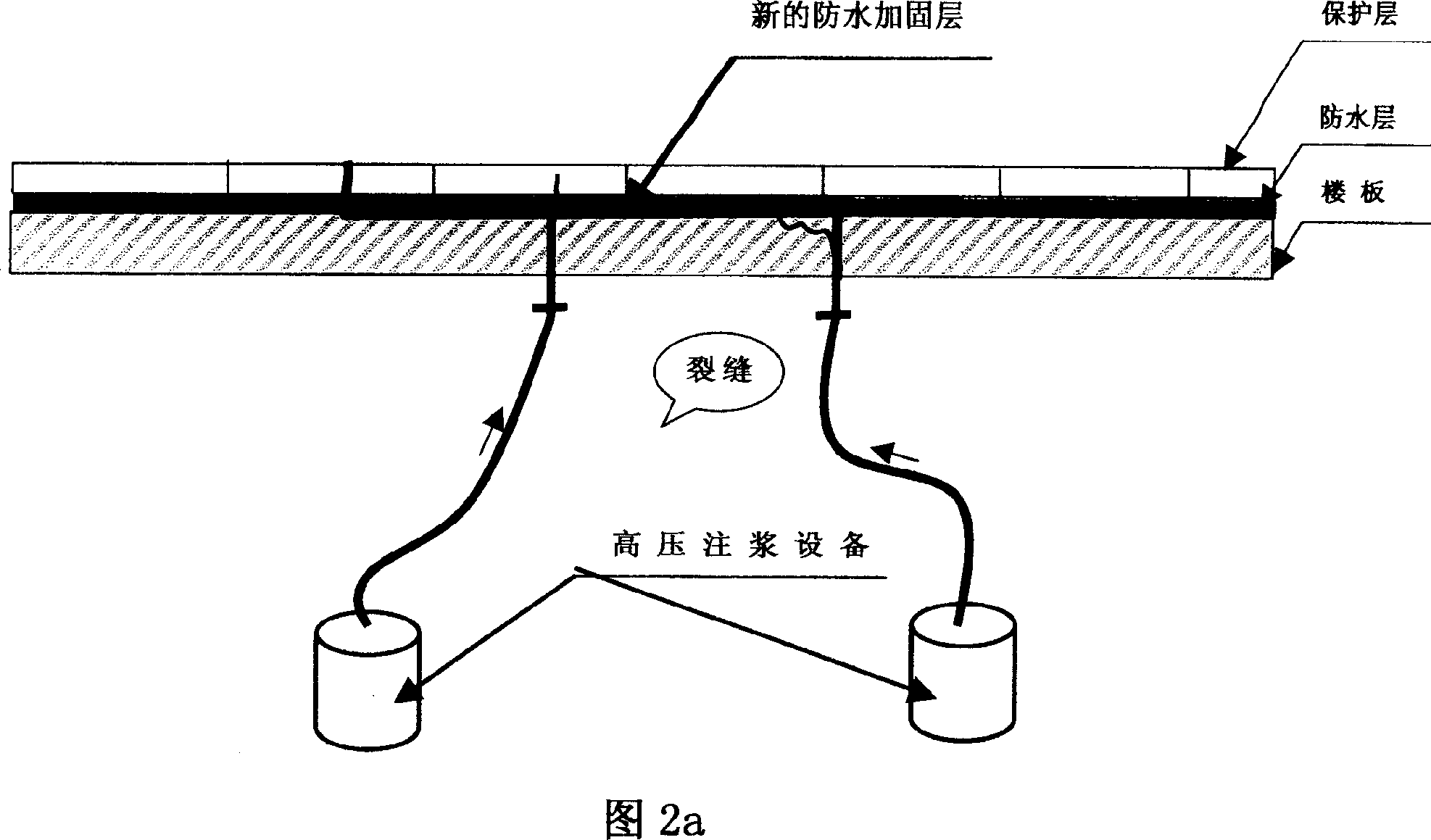

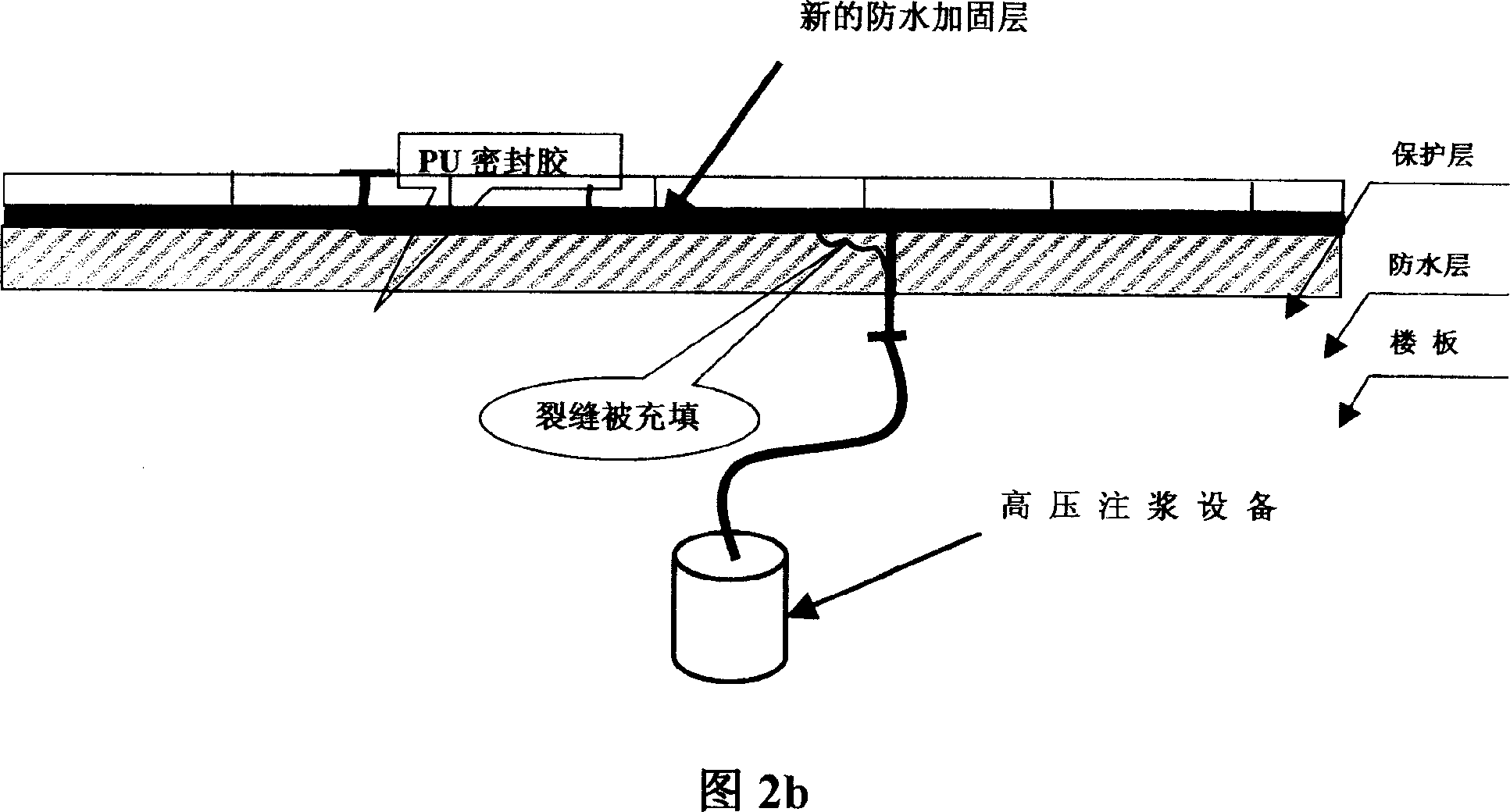

Method for detection and stopping leak for concrete buildings leakage source

InactiveCN1924534AIntuitiveImprove efficiencyBuilding insulationsFluid-tightness measurement using fluid/vacuumEmulsionWater leakage

This invention belongs to measurement technique field and fixing technique field which is suitable for concrete architecture water leakage test method, which comprises the following steps: sending carbon dioxide gas from the leakage part on the architecture; then testing the gas outside the architecture and judging the leakage source according to the gas sensor situation; injecting the liquid emulsion into the leakage path crack or honeycomb hollow part to seal the leakage, which is characterized by adopting the infrared sense for analysis technique testing to judge the leakage source; adopting pressure injection to seal the leakage separately.

Owner:李海军

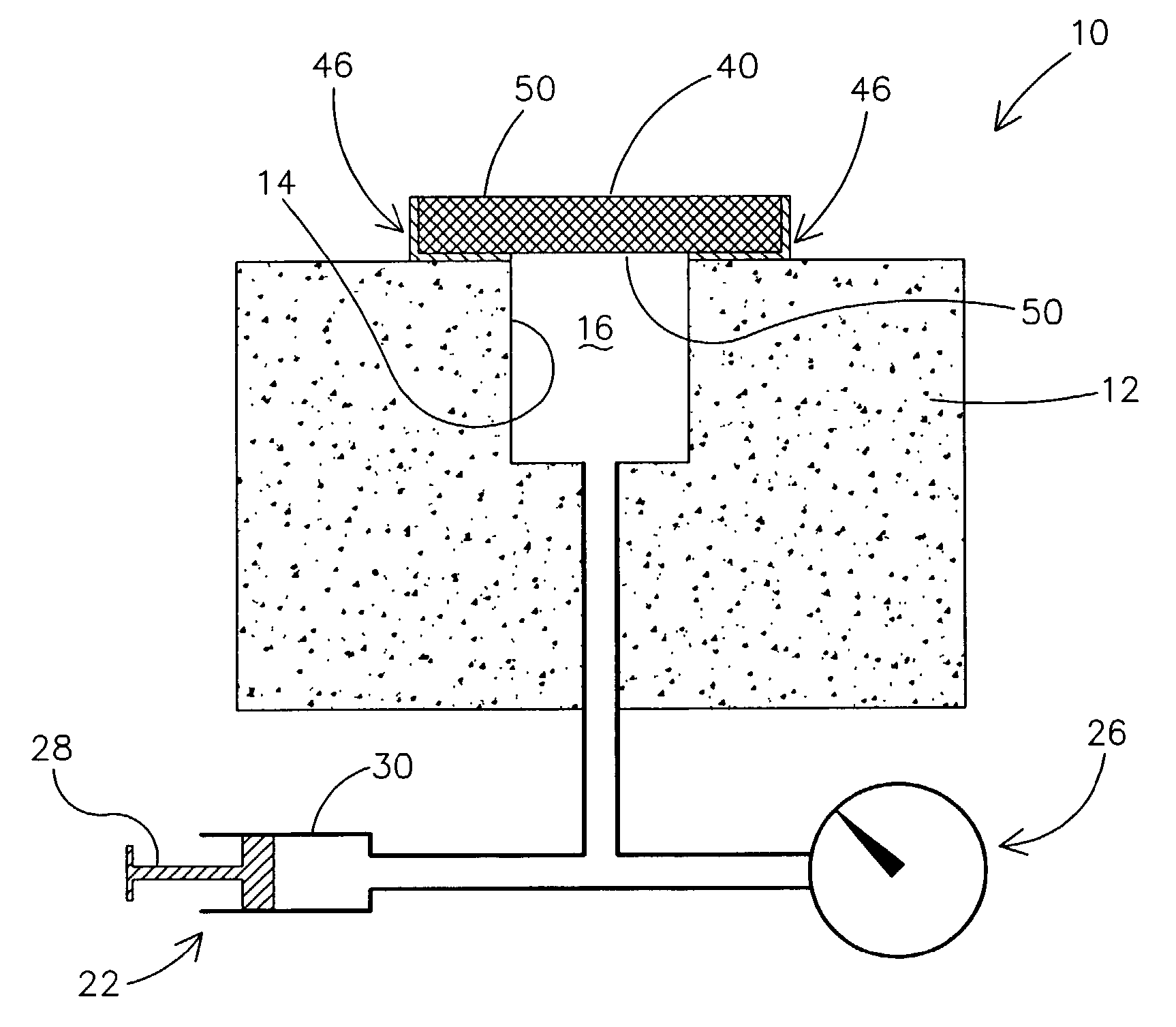

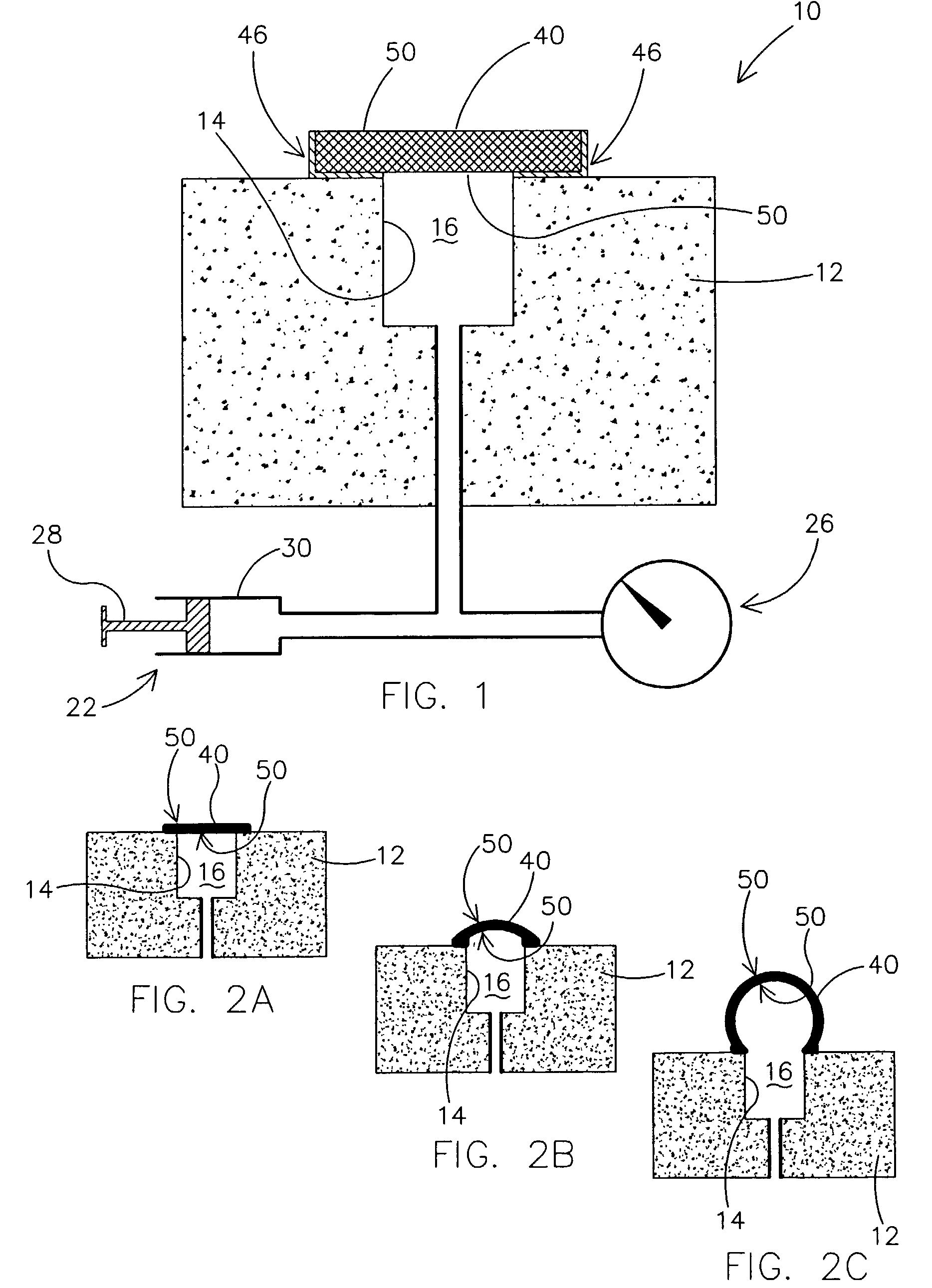

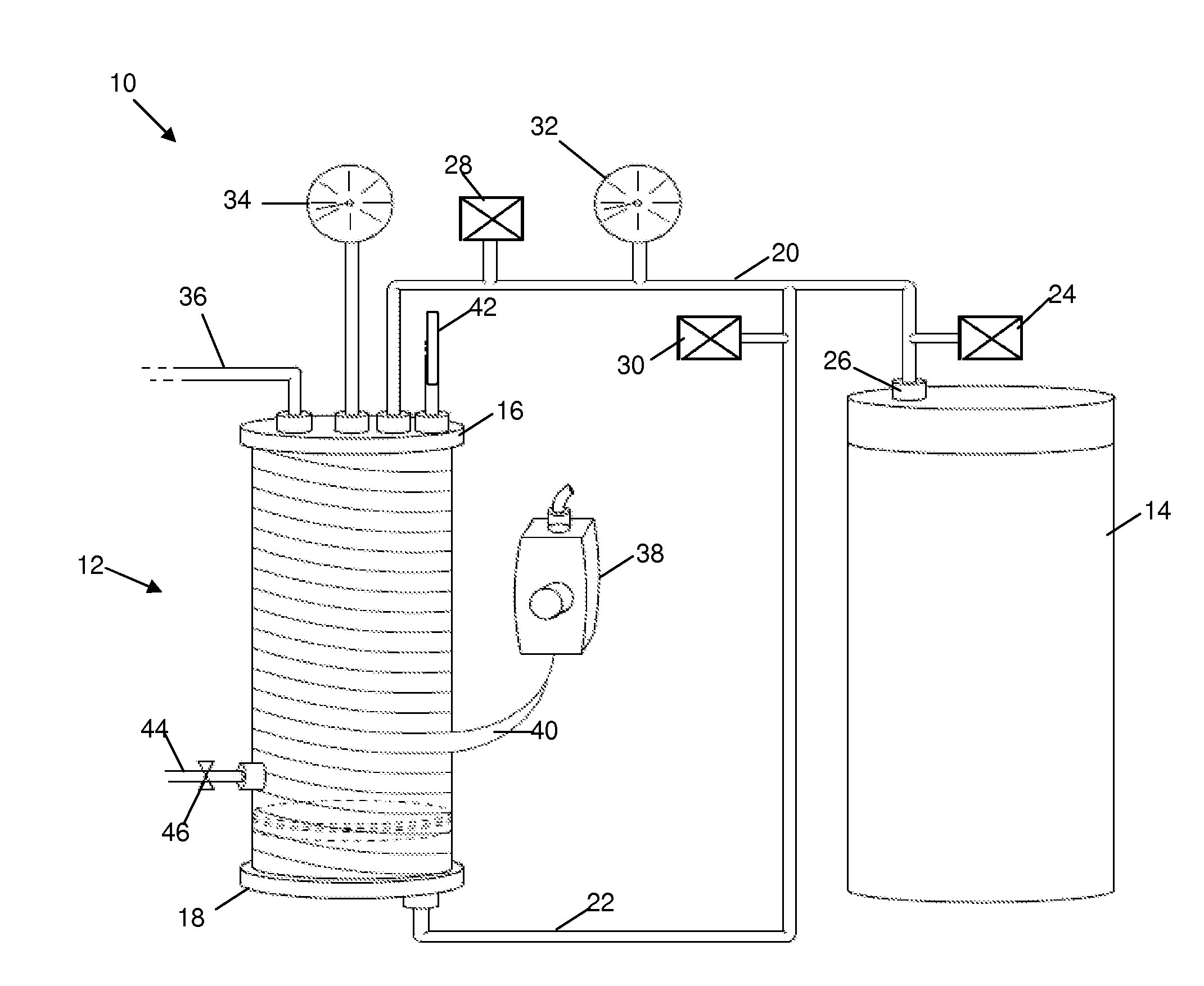

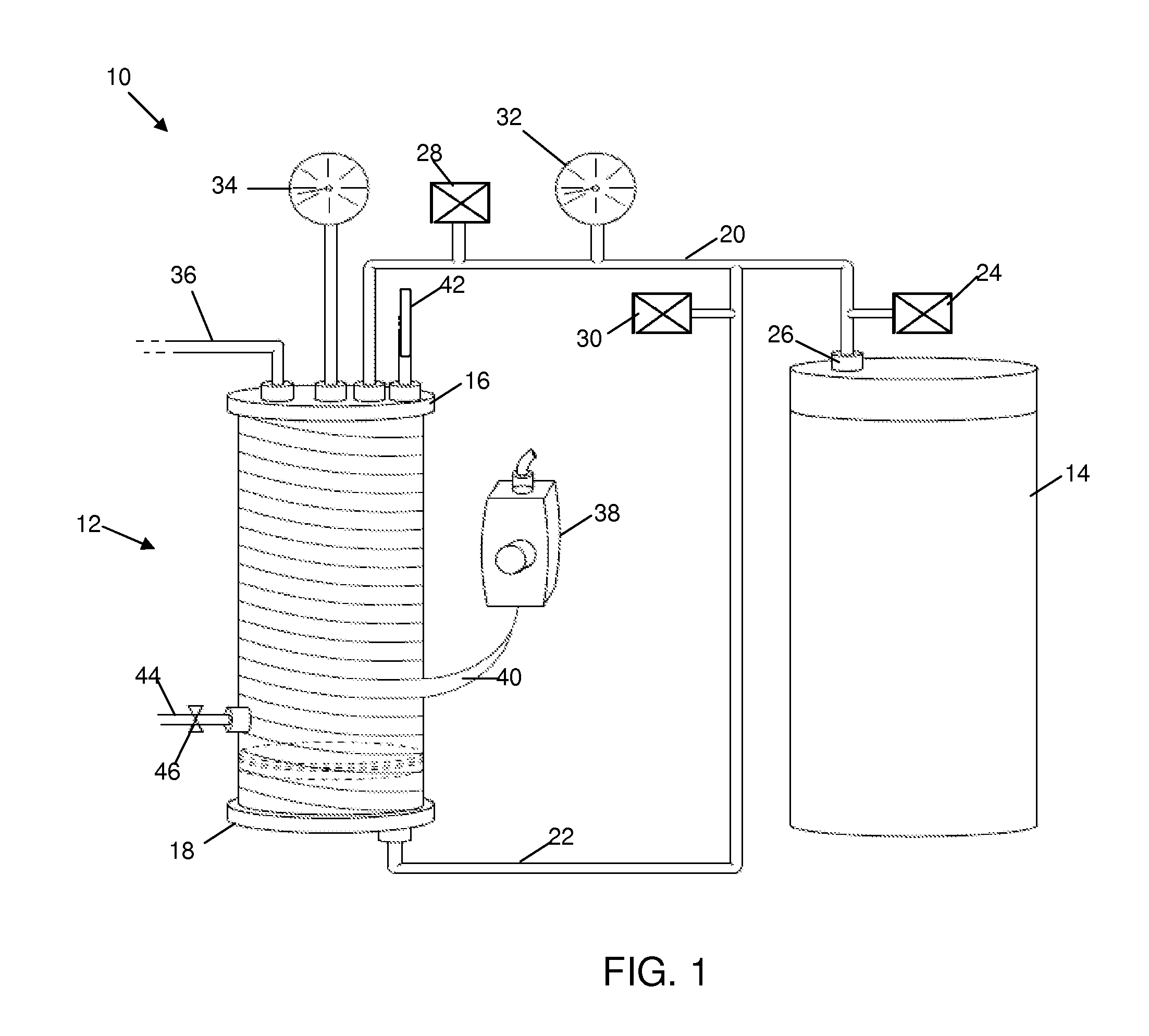

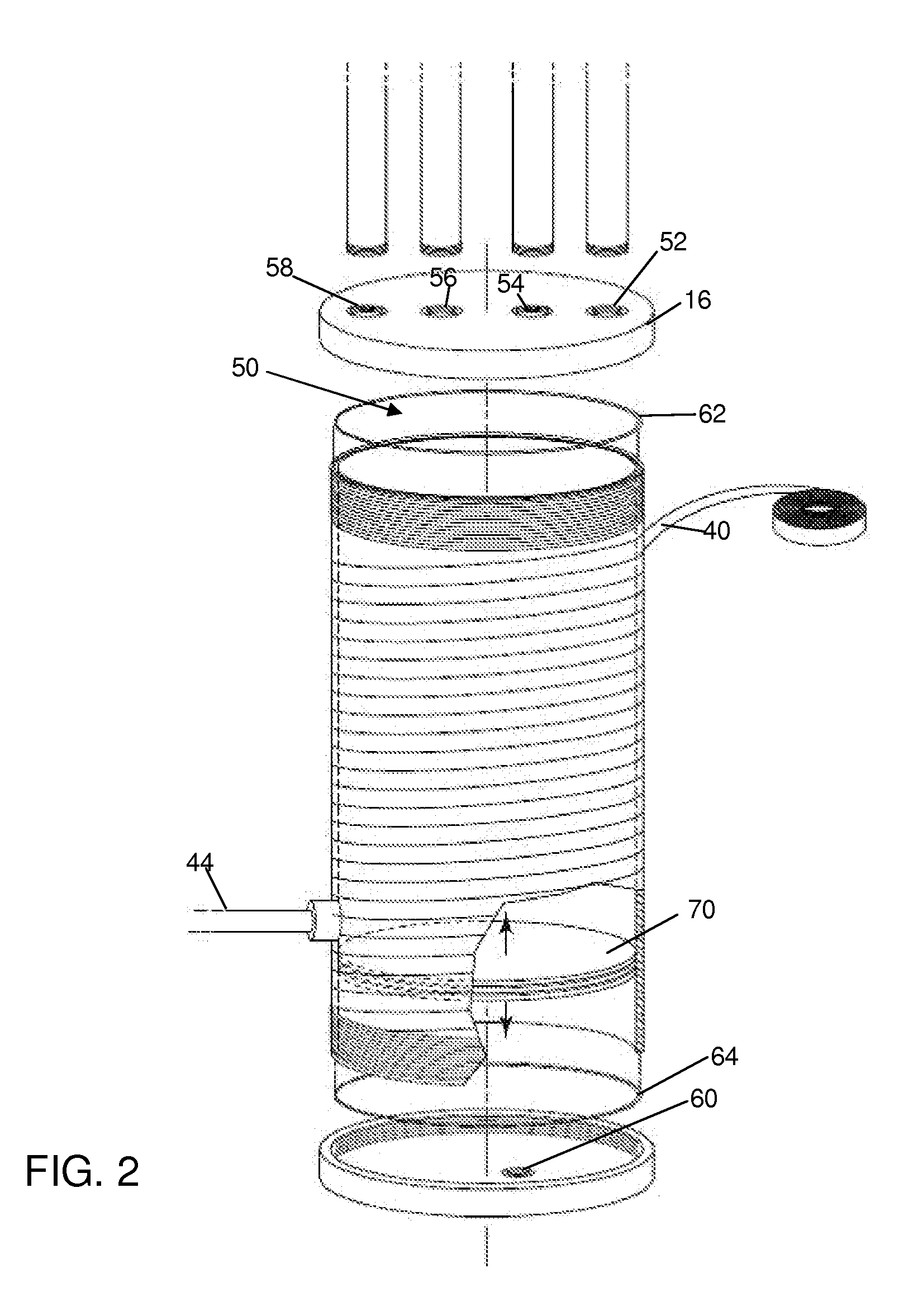

Pressurized and heated testing chamber

ActiveUS20110232368A1Quickly and conveniently be subjectedSurveySamplingQuality assuranceFracturing fluid

An apparatus and process for testing a sample of a hydraulic fracturing fluid is provided. A small quantity of a fracturing fluid sample to be observed and / or tested is placed in a chamber designed with suitable heat and pressure simulation apparatus. With the sample chamber, the efficacy of the fracturing fluid can be ascertained, improper fracturing fluid compositions and / or mixtures, e.g., caused by human error, can be detected, and contamination of the frac-tank can be determined. The overall apparatus is portable and can be transported to the site of the fracturing fluid tank, thereby allowing testing immediately prior to introduction into the well. The samples in the test chamber can be observed for quality control and quality assurance prior to, or during stimulation and water shutoff treatments in the field.

Owner:SAUDI ARABIAN OIL CO

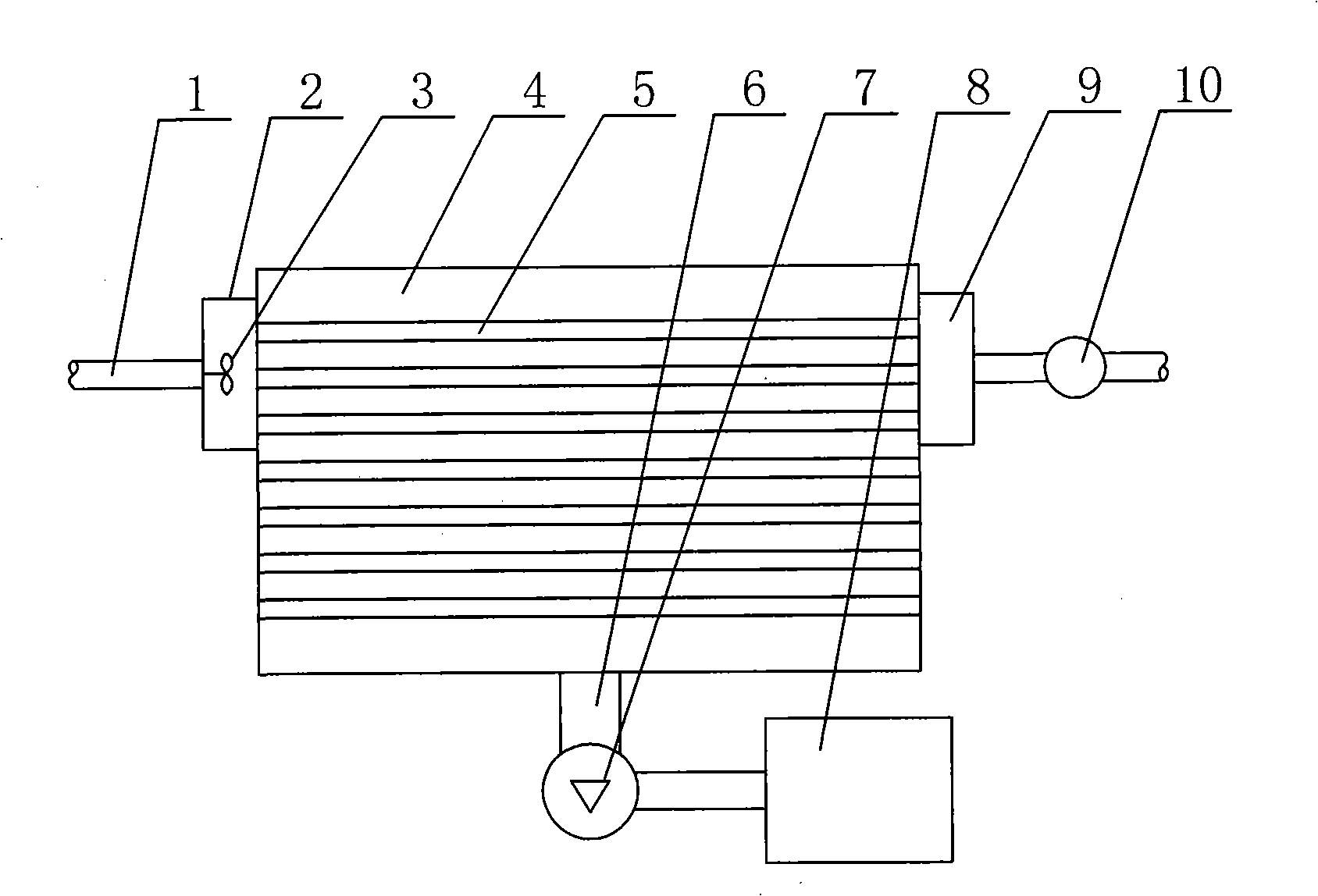

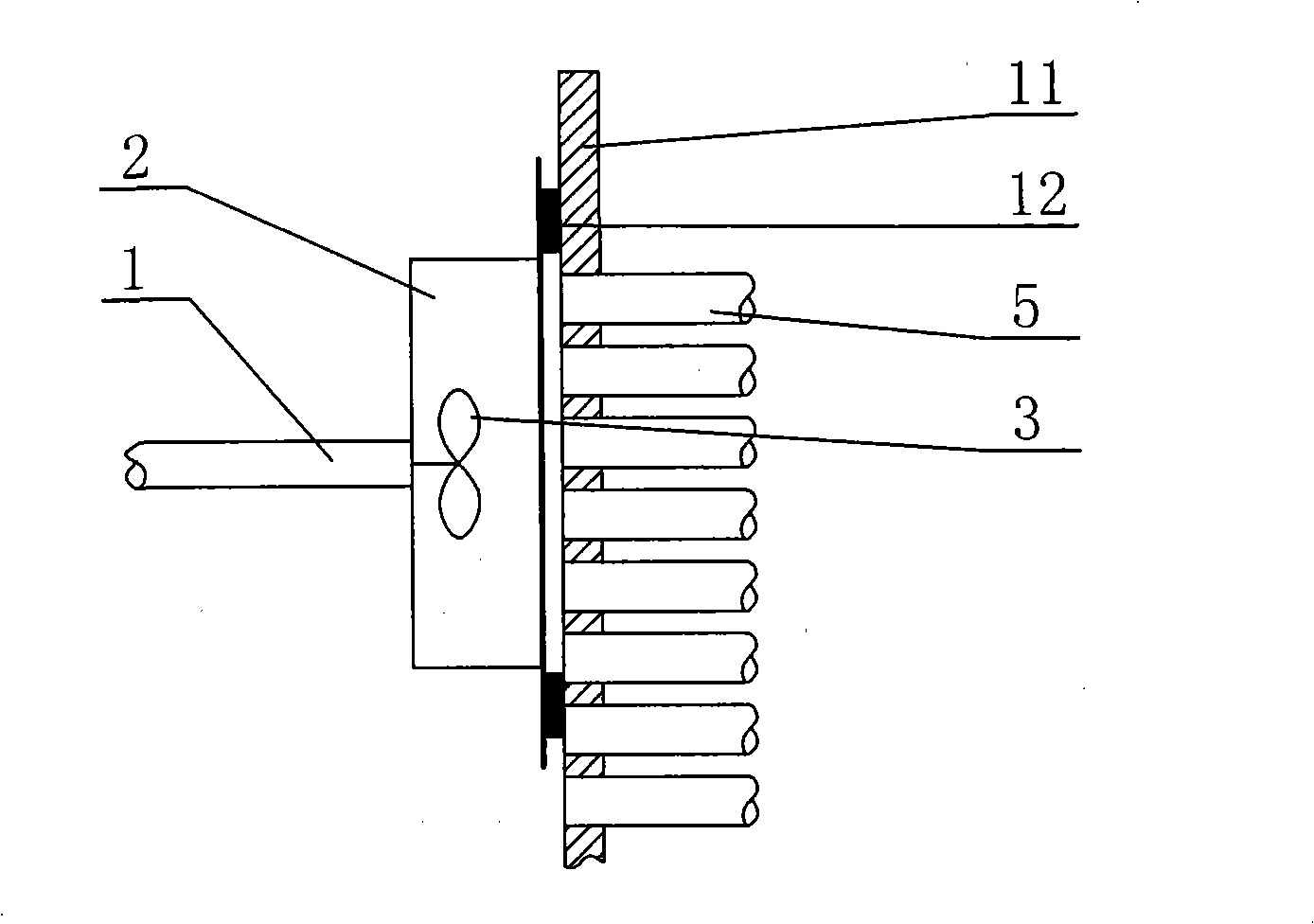

Method and device for detecting leakage of shell type heat exchanger

InactiveCN101408466AImprove detection accuracyImprove detection efficiencyFluid-tightness measurement using fluid/vacuumPlate heat exchangerShell and tube heat exchanger

The invention relates to a detection method and a device thereof, in particular to a leak detection method for a shell-and-tube heat exchanger and a device thereof. The detection device comprises a helium mass spectrometer leak detector and a vacuum pump, and is characterized in that an air inlet tube is arranged on an air intake hood which is hermetically connected with one end of the shell-and-tube heat exchanger, an exhaust hood is hermetically arranged on the other end of the shell-and-tube heat exchanger and is equipped with an exhaust tube on the exhaust hood, a vacuum pump clearance tube is arranged on the outer shell of the shell-and-tube heat exchanger, and an air inlet of the helium mass spectrometer leak detector is communicated with the outlet of the vacuum pump. The detection device can lock the leak situations of all the detected shells and tubes in the air intake hood and the exhaust hood which are respectively arranged on the shell-and-tube heat exchanger at one time, and can accurately determine the leaking shells and tubes by replacing hoods of different specifications, thus greatly enhancing the detection efficiency and lightening the labor intensity. Meanwhile, the helium mass spectrometer leak detector is used, thus enhancing the detection precision of the device and eliminates the external interference.

Owner:宁夏电力科技教育工程院

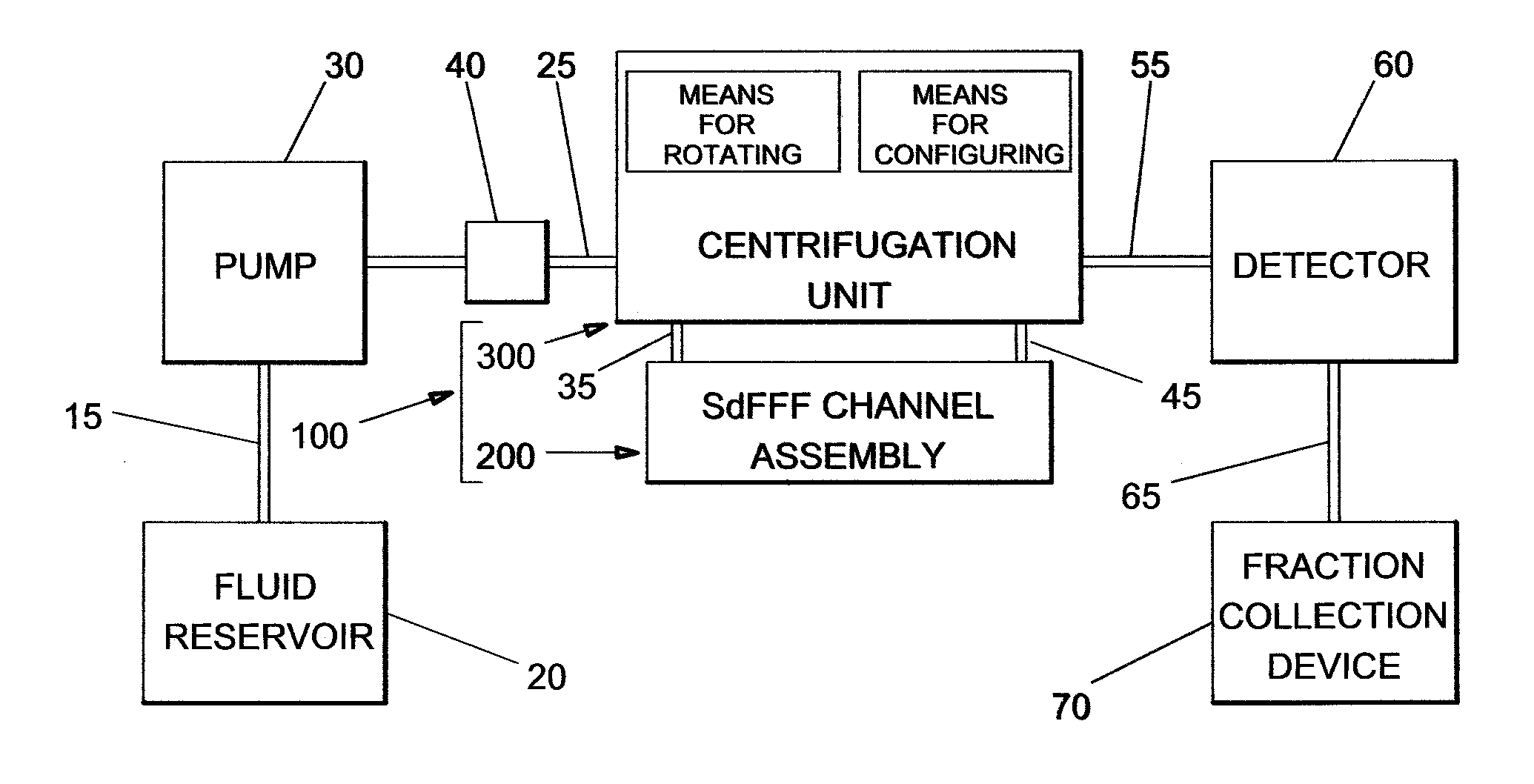

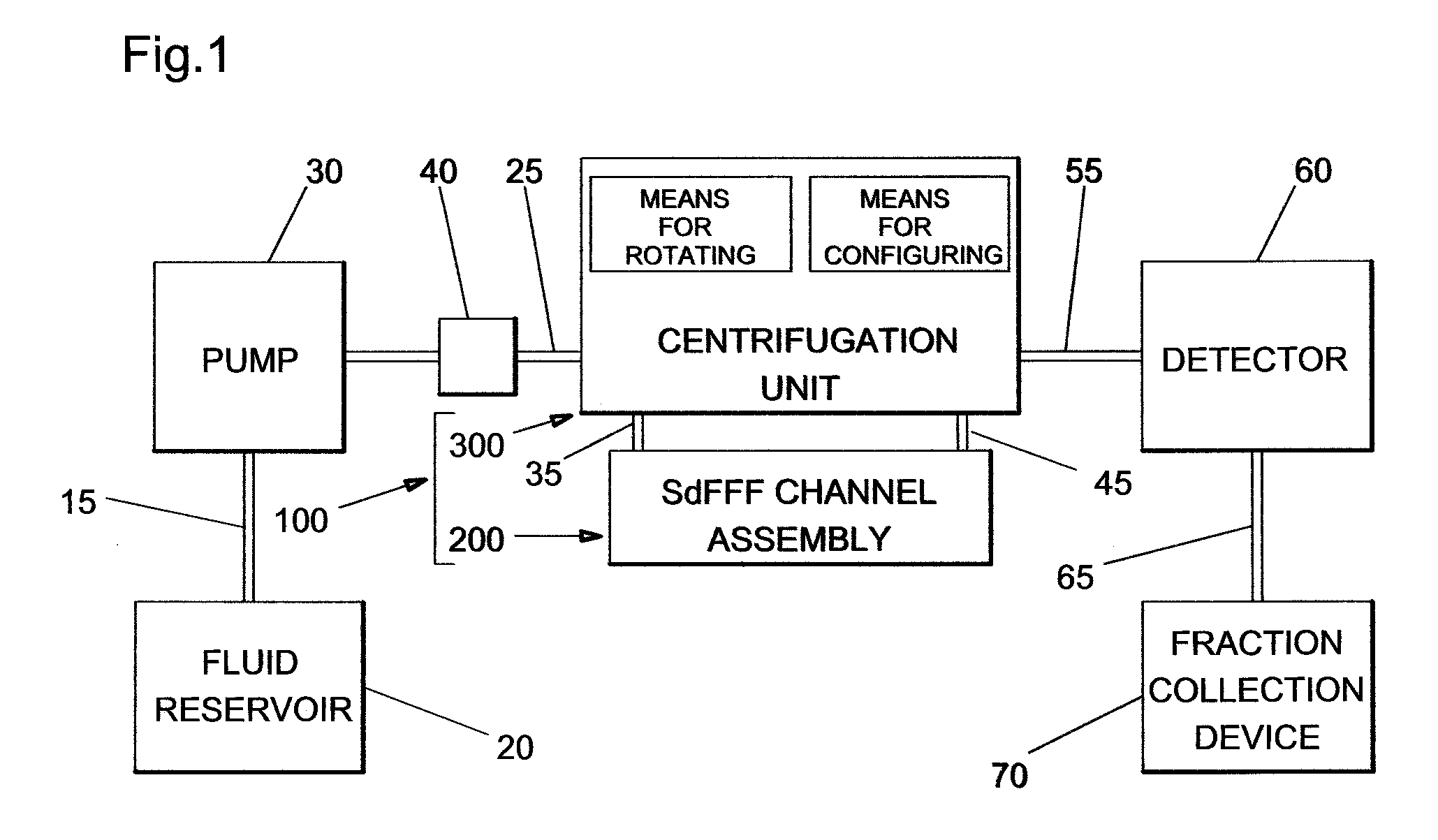

Apparatus and method for sedimentation field-flow fractionation

ActiveUS20120234731A1High selectivityEasy to separateComponent separationElectrostatic separationElectricityCentrifugation

Apparatuses and methods are described for the discrimination of particles using sedimentation field-flow fractionation operating without the use of rotating seals. Multiple lines of fluid and electrical communication are provided through a centrifugation unit comprising a fishhook-shaped umbilical conduit traveling from a stationary frame through a rotating guide frame to the separation channel. Twisting and tangling of the umbilical conduit enclosed communication lines are prevented by rotating the guide frame and separation channel in the same direction about an axis at an angular velocity ratio of 1:2. The design eliminates maintenance problems associated with rotating seals, simplifies channel installation and adjustment, and enables the use of multiple channels and the simultaneous application of multiple modes of field-flow fractionation either in concert or in a two-dimensional format. The design also enables the injector and / or detector to be mounted contiguously with the separation channel on the centrifugal rotor.

Owner:SENFTLEBER FRED C

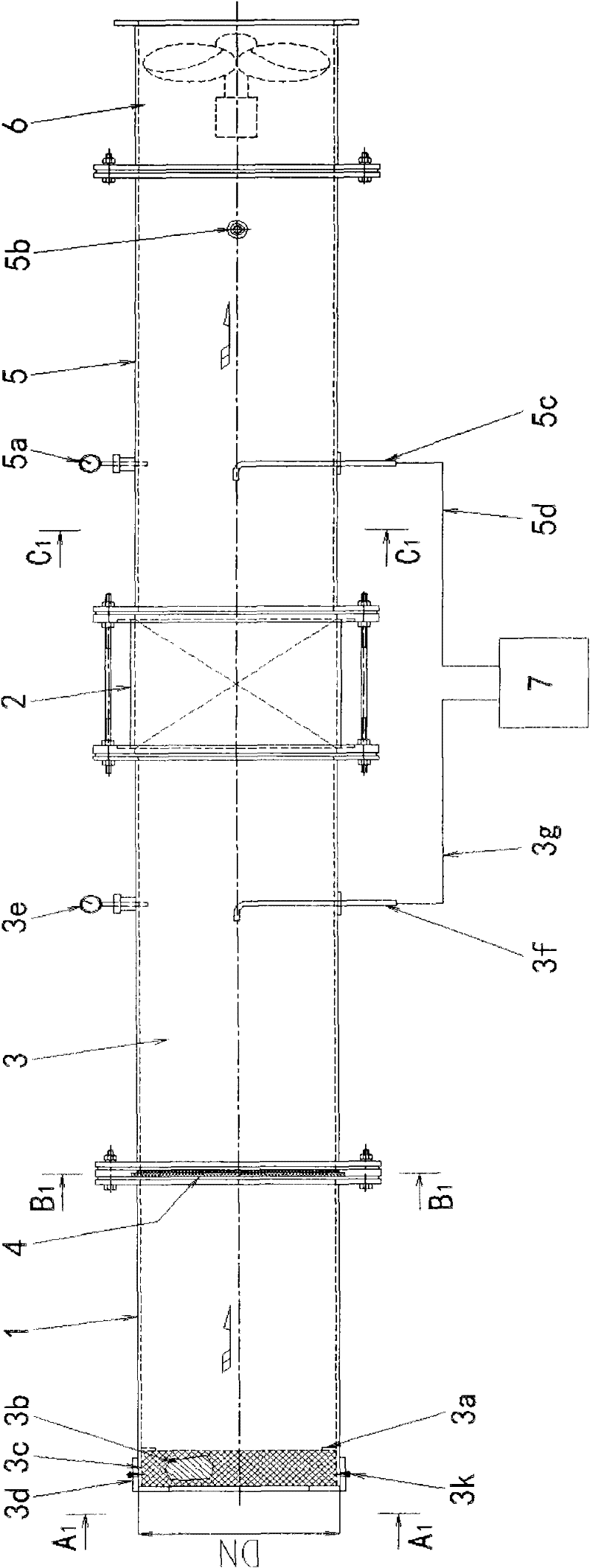

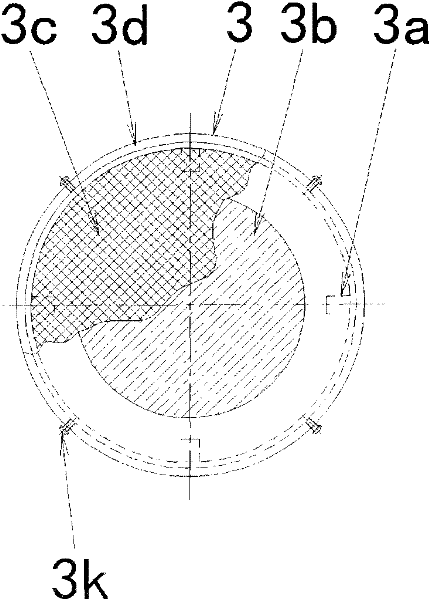

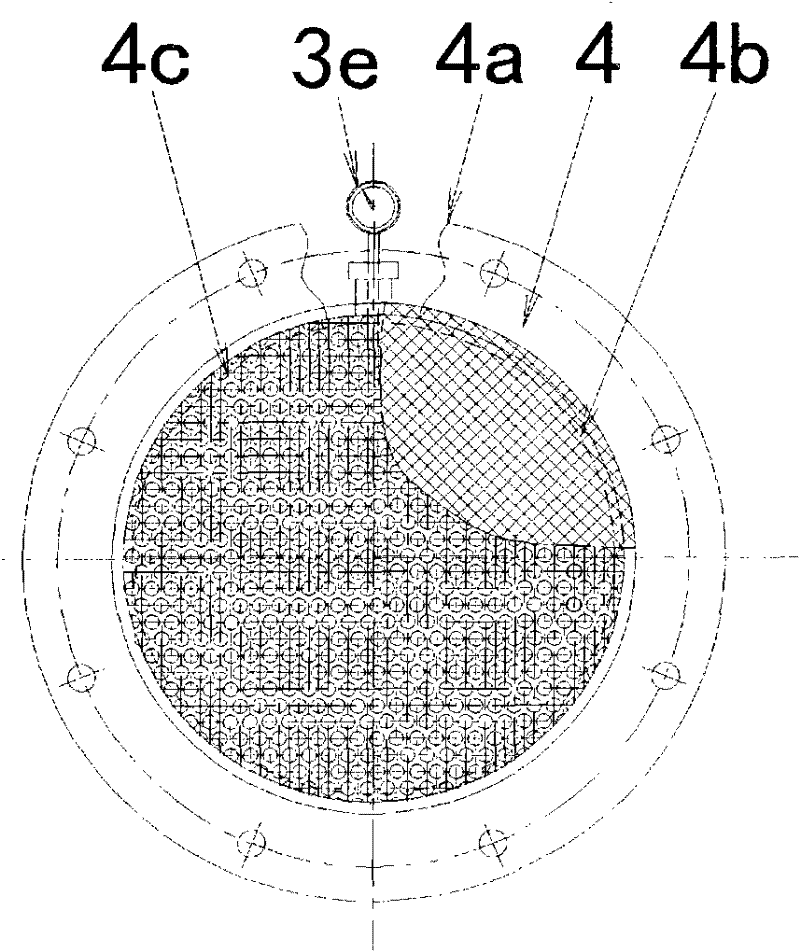

Method for performance testing and detection of natural ventilation filter device

InactiveCN102053019AAerodynamic testingFluid-tightness measurement using fluid/vacuumLow speedNatural ventilation

The invention relates to a method for performance testing and detection of a natural ventilation filter device. The method is characterized in that a testing apparatus is used for detecting the ventilation rate and the pressure difference, the particle size of the captured dust and the dust removing capability, the dehumidification efficiency and the rain-proof performance of the natural ventilation filter device through a low-speed wind tunnel testing apparatus; an exhaust fan is used as the power source for inducing air or feeding air; the inflowing air is filtered and purified after being rectified when the air flows into the testing apparatus at the rated pressure; the ventilation rate and the pressure difference before and behind the natural ventilation filter device, the particle size of the captured dust and the dust removing capability, the sprayed mist water and a rainwater spraying device are tested to obtain the corresponding data; and the particle size of the dust captured by the device is tested by a digital differential pressure gauge, a digital dust concentration testing instrument, an optical microscope and a humidity meter to observe whether or not water remains in a transparent organic tube. The method is simple, reasonable and effective.

Owner:陈妙生

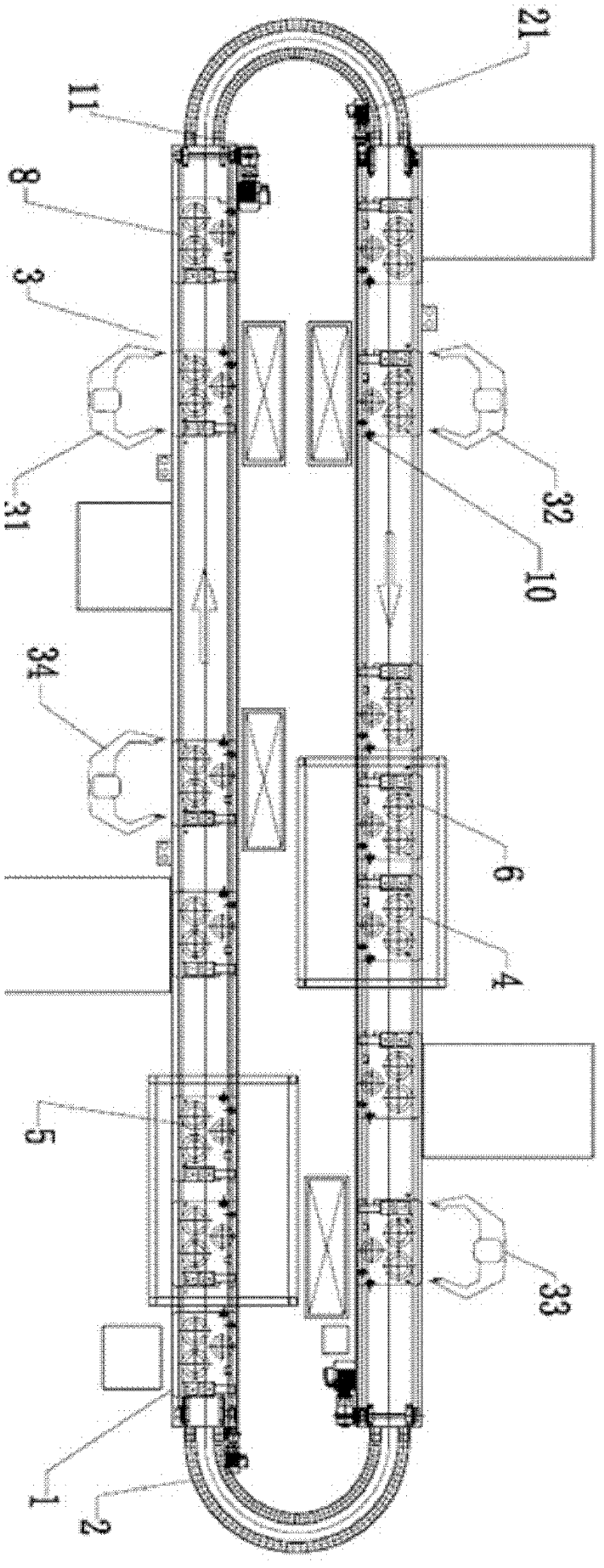

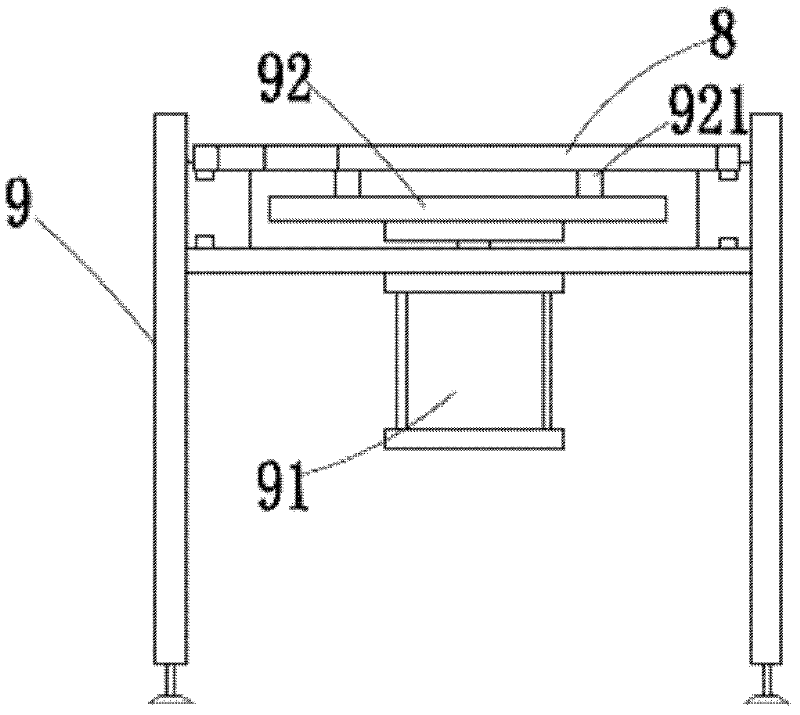

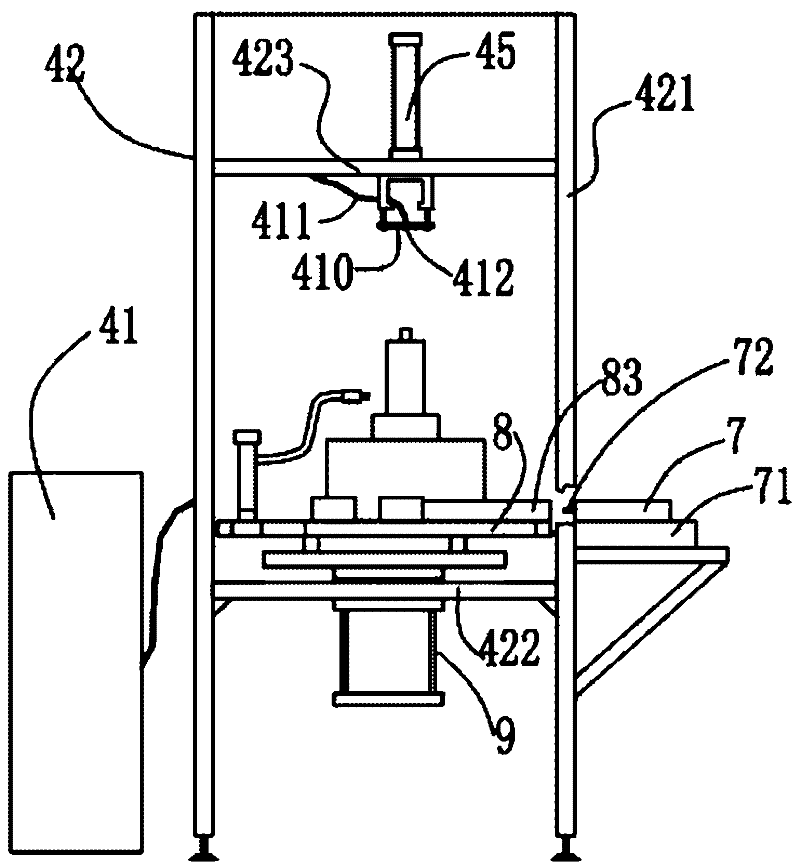

Water pump automatic circulation assembly line

ActiveCN102284860AAccurate detectionOptimizationPump testingAssembly machinesDifferential lineEngineering

The invention discloses an automatic flow assembly line for a water pump. The automatic flow assembly line comprises a circulated flow line mainly consisting of a differential chain line and an arc flat chain line and is characterized in that the circulated flow line is provided with an automatic water pump comprehensive testing platform, an air tightness testing unit, a main sealing automatic pressing table and more than two manual placement stations. The circulated flow line is also provided with circularly delivered tool plates. The automatic water pump comprehensive testing platform, the air tightness testing unit, the main sealing automatic pressing table and the manual placement stations are respectively provided with a tool plate jacking unit and a positioning stopper. In the automatic flow assembly line for the water pump, a part to be assembled can be conveniently placed on the tool plate for corresponding installation during assembly, and different automatic tests can be performed on different stations, so the labor intensity is reduced, and the production efficiency is improved.

Owner:JUNHE PUMPS HLDG

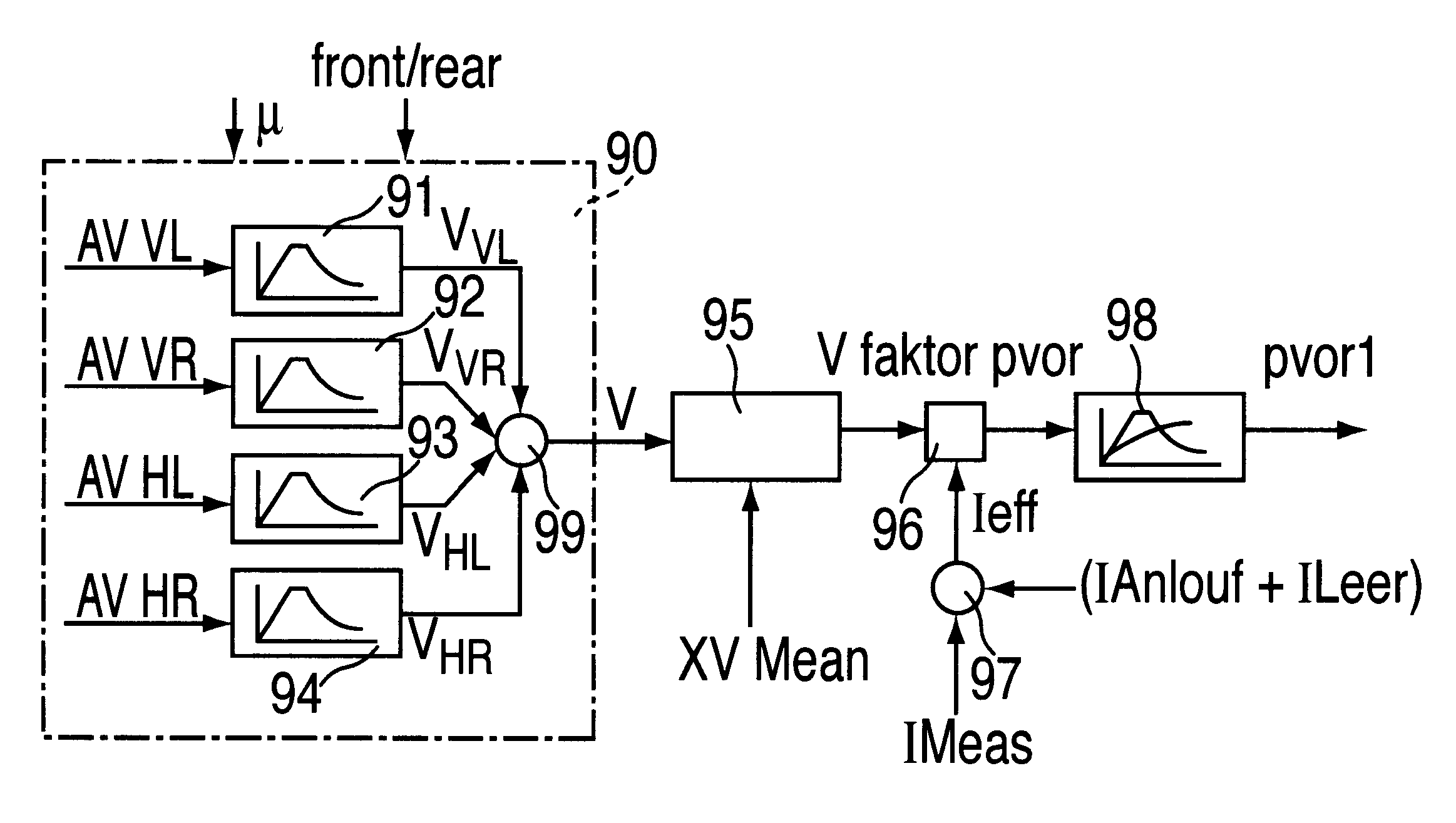

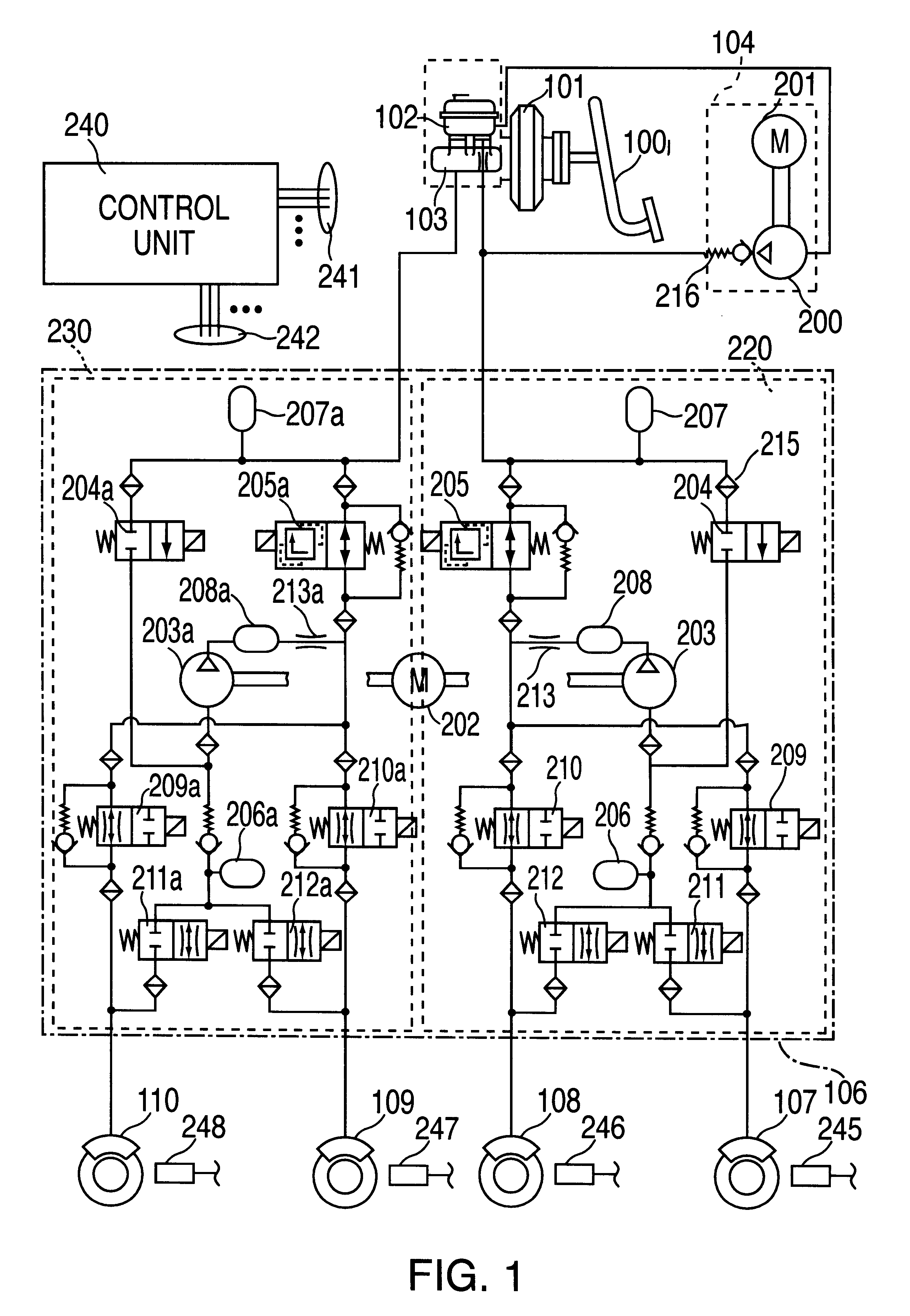

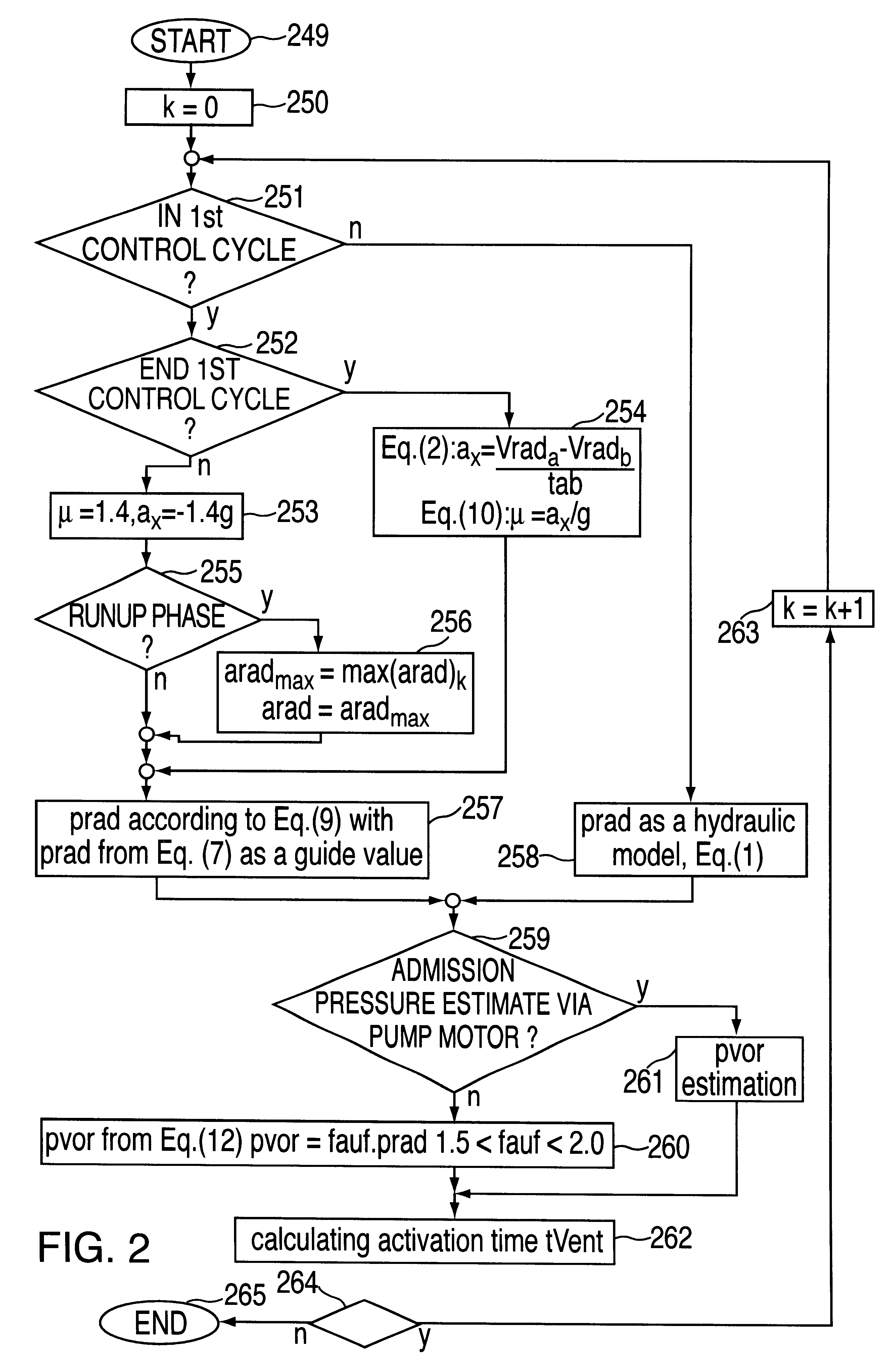

Method and device for determining the pressure in brake systems

InactiveUS6446490B1Improve driving stabilityImprove securityFluid braking transmissionApplication and release valvesEngineeringActuator

Device and method for determining a wheel braking pressure and / or an admission pressure in a braking system in which pressure medium is introduced from a reservoir for the pressure medium having an admission pressure into a wheel brake through at least one shutoff device for inlet and / or outlet and / or passage of a pressure medium, it being possible to remove pressure medium from the wheel brake through at least one means delivering the pressure medium. In so doing, a pressure quantity representing the admission pressure is estimated, at least one operating state of at least one actuator in the braking system is detected and the wheel braking pressure is estimated as a function of the estimated admission pressure and the detected operating states.

Owner:ROBERT BOSCH GMBH

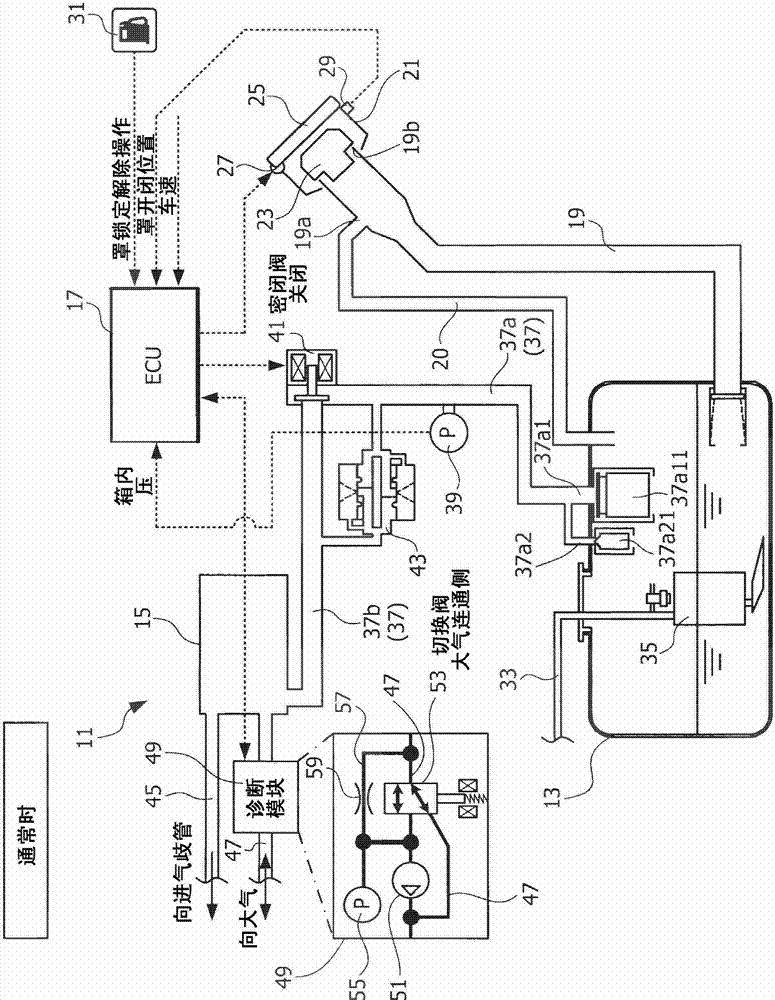

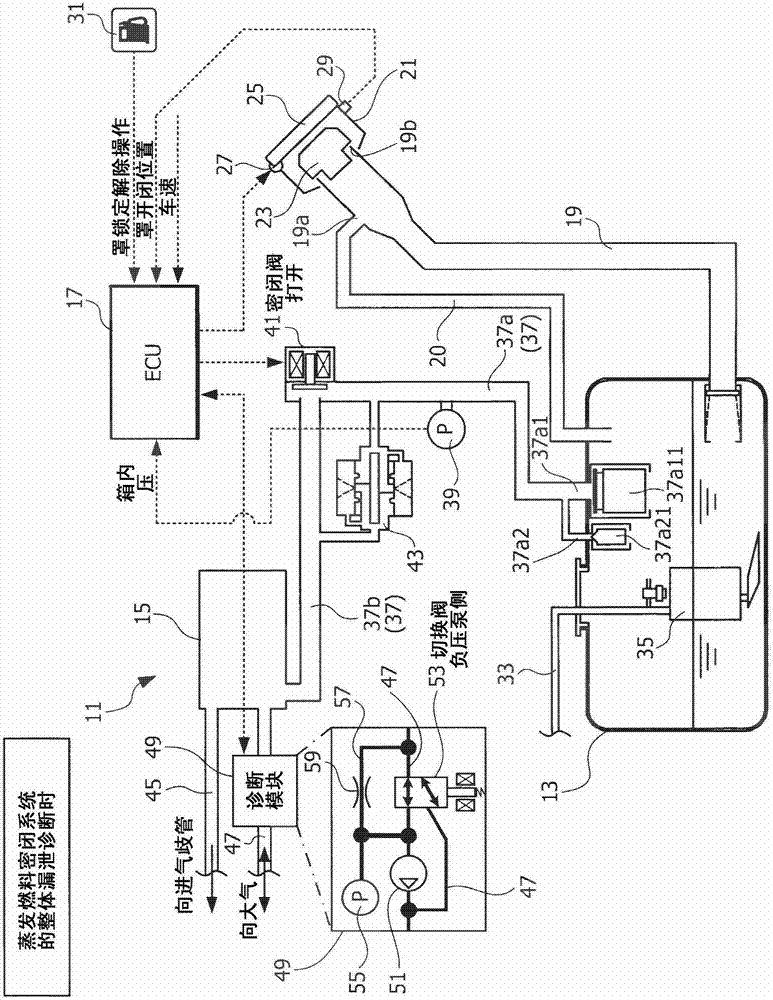

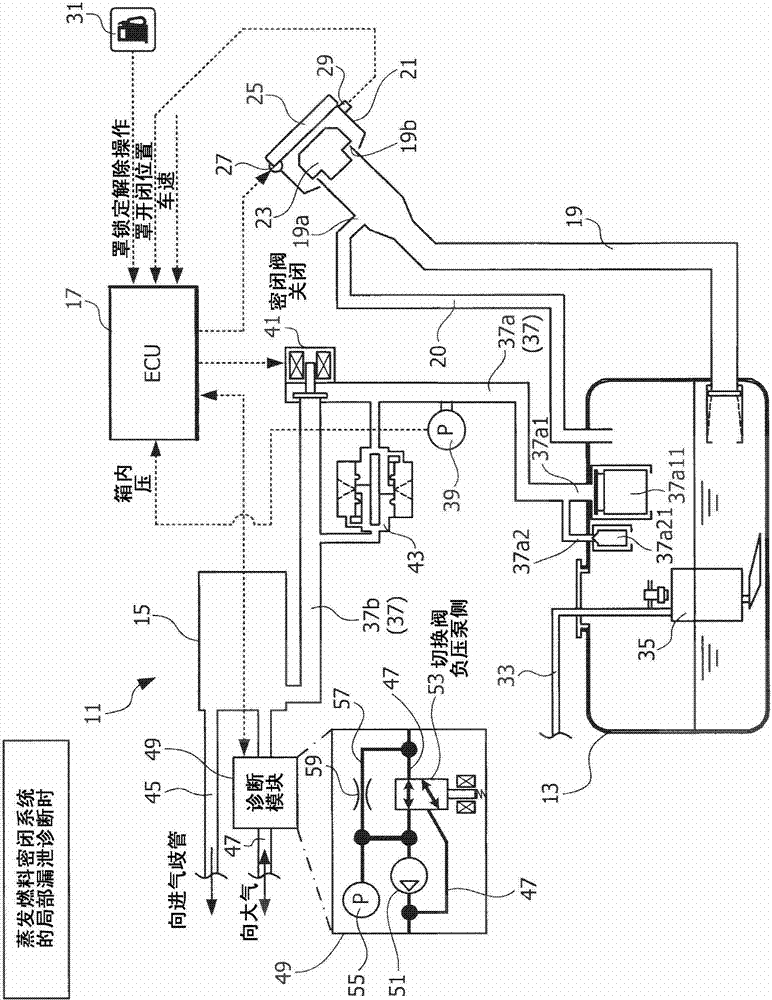

Evaporated fuel processing device and method for diagnosing evaporated fuel processing device

ActiveCN103899446AAccurate Functional DiagnosisNon-fuel substance addition to fuelMachines/enginesInternal pressureAtmospheric air

Owner:HONDA MOTOR CO LTD

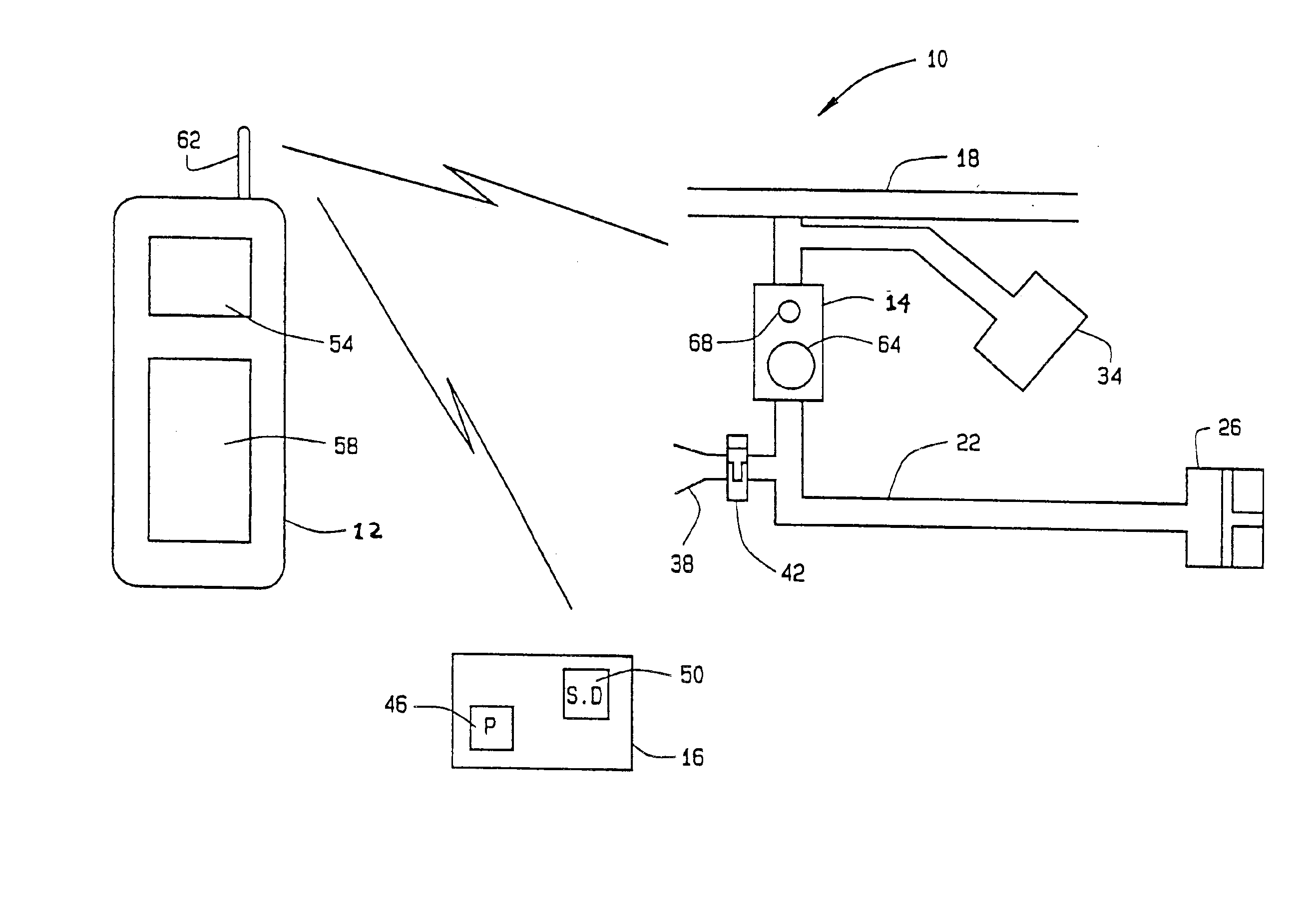

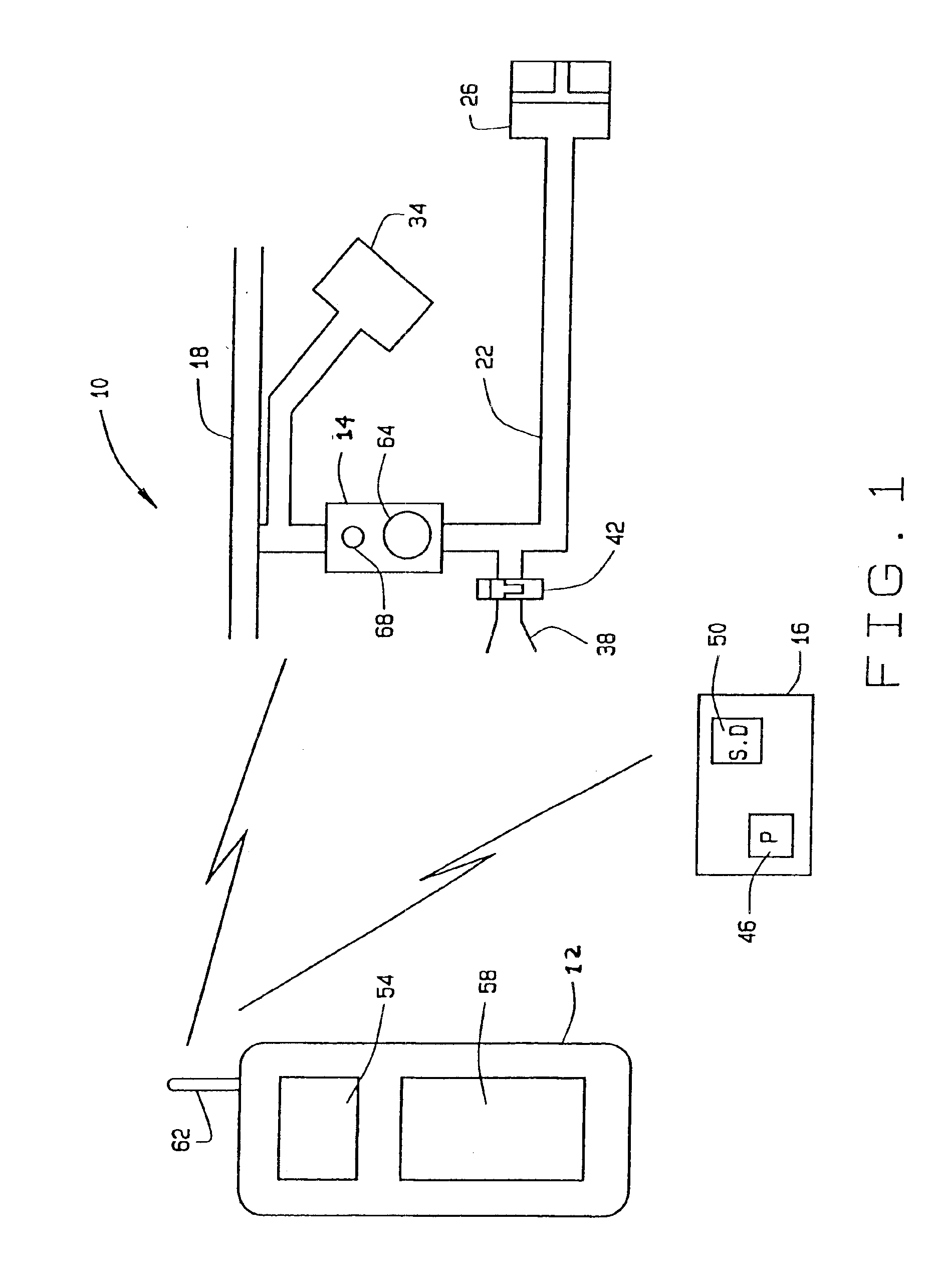

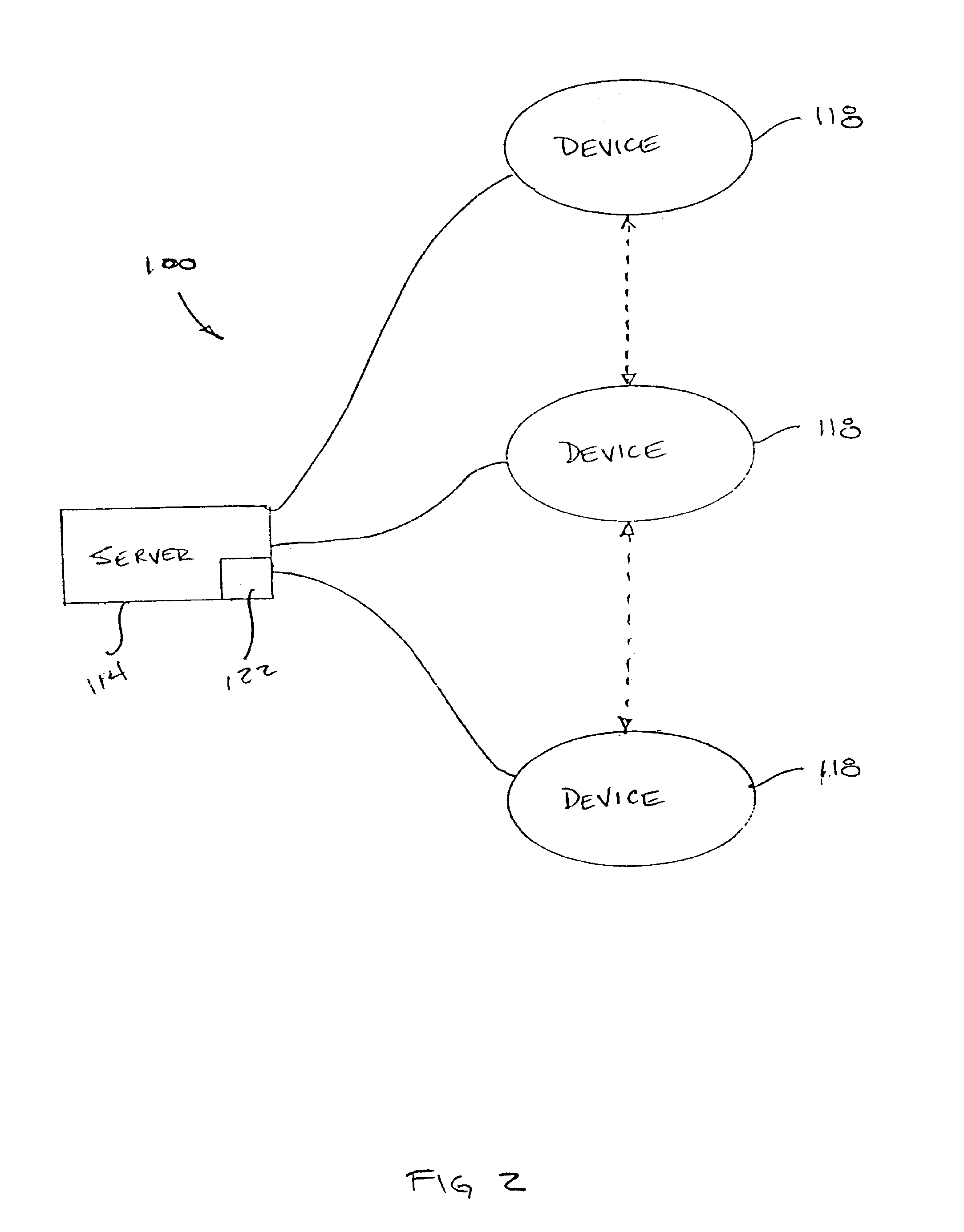

Brake system diagnostic using a hand-held radio device

A method for diagnosing a braking system using a system including a radio-based hand-held analyzer, at least one radio-based feed valve, and at least one mobile data unit. The braking system includes at least one brake pipe section, a reservoir, and at least one brake cylinder. The brake pipe section connects to the reservoir, the brake cylinder, and the radio-based feed valve. The hand-held radio-based analyzer communicates with the mobile data unit and the radio-based feed valve. The method includes retrieving brake system data and information using the hand-held analyzer, interpreting the retrieved data and information, and performing maintenance functions based on the interpretation of the data and information.

Owner:GE TRANSPORTATION SYST GLOBAL SIGNALING +1

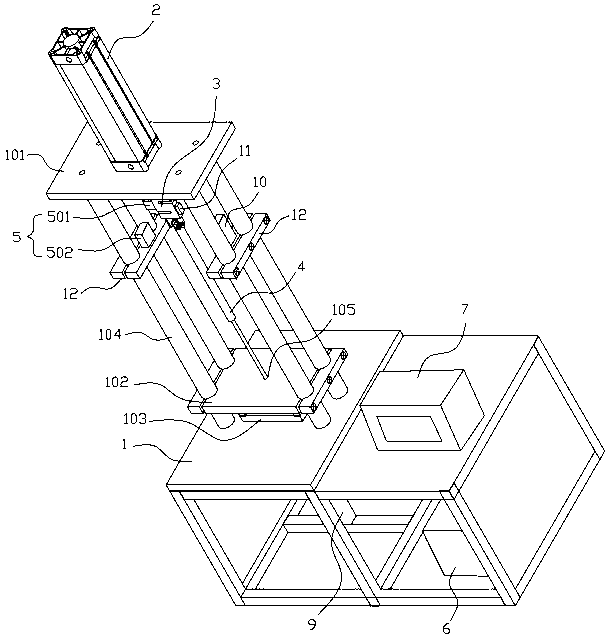

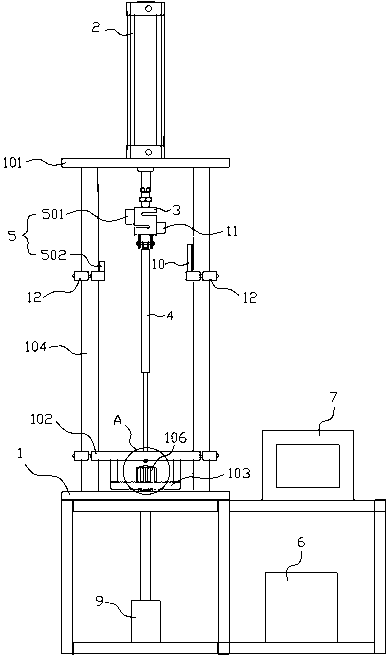

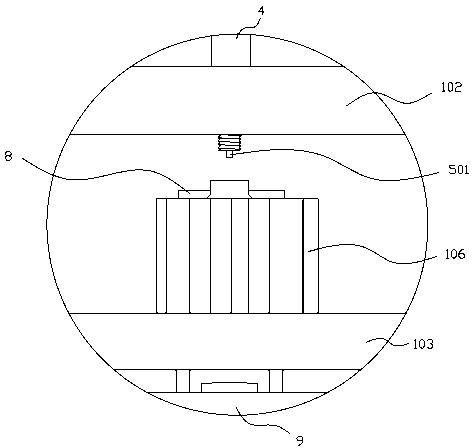

Air spring testing device

ActiveCN103018025ACheck tightnessSmall footprintMachine part testingUsing optical meansAir springDisplay device

The invention discloses an air spring testing device which comprises a working table (1), a first cylinder (2) connected with an air source, a tension and pressure sensor (3) and a grating ruler displacement sensor (5). A piston rod of the first cylinder (2) can push a tested air spring to extend and contact, the grating ruler displacement sensor (5) is used for measuring the route of the air spring (4), and a controller (6) and a displayer (7) are arranged on the working table (1). The air spring testing device can perform detection on airtightness, accuracy, service life and force value changing during the route of the air spring.

Owner:宁波禾采医疗器械有限公司

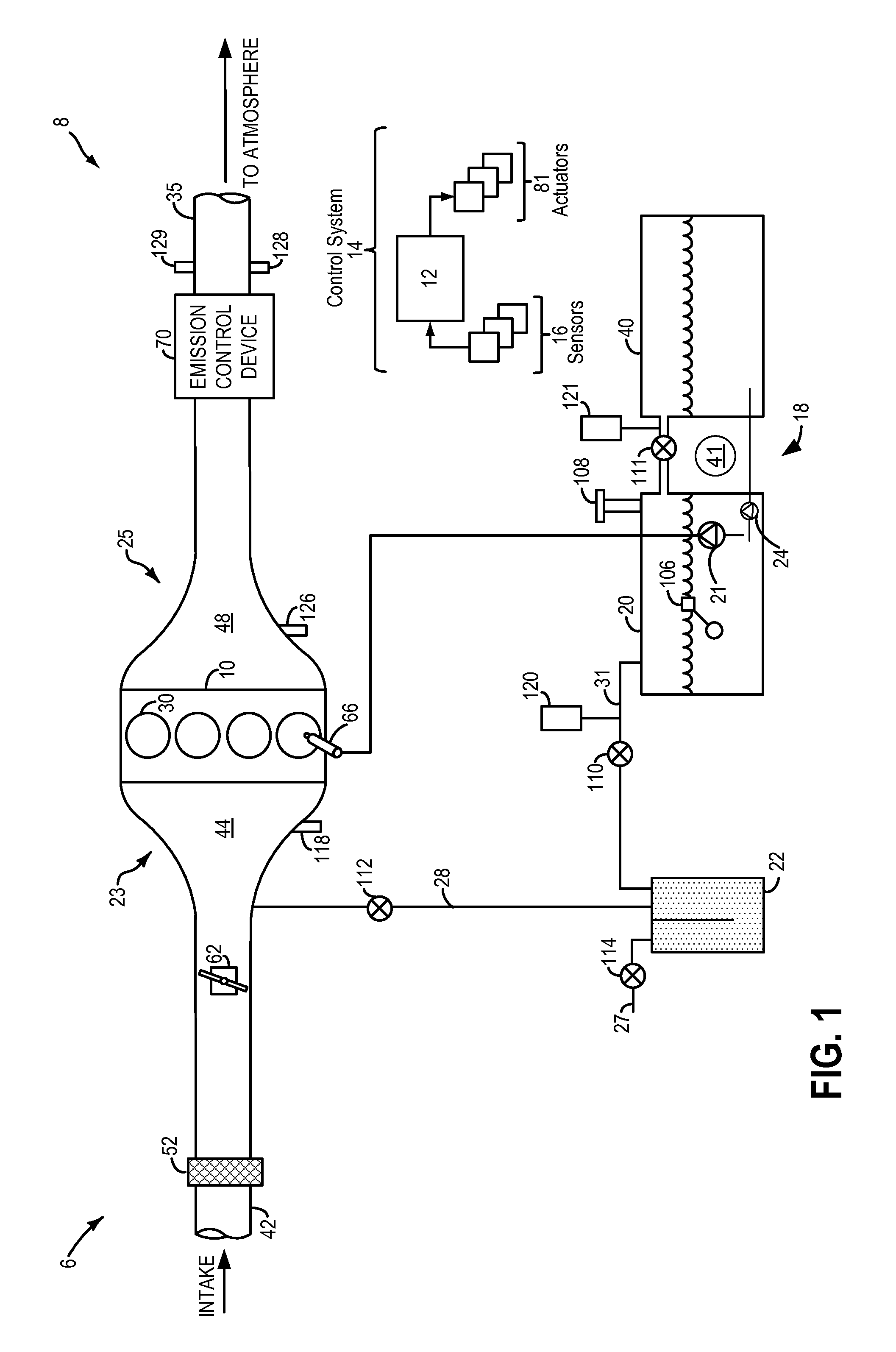

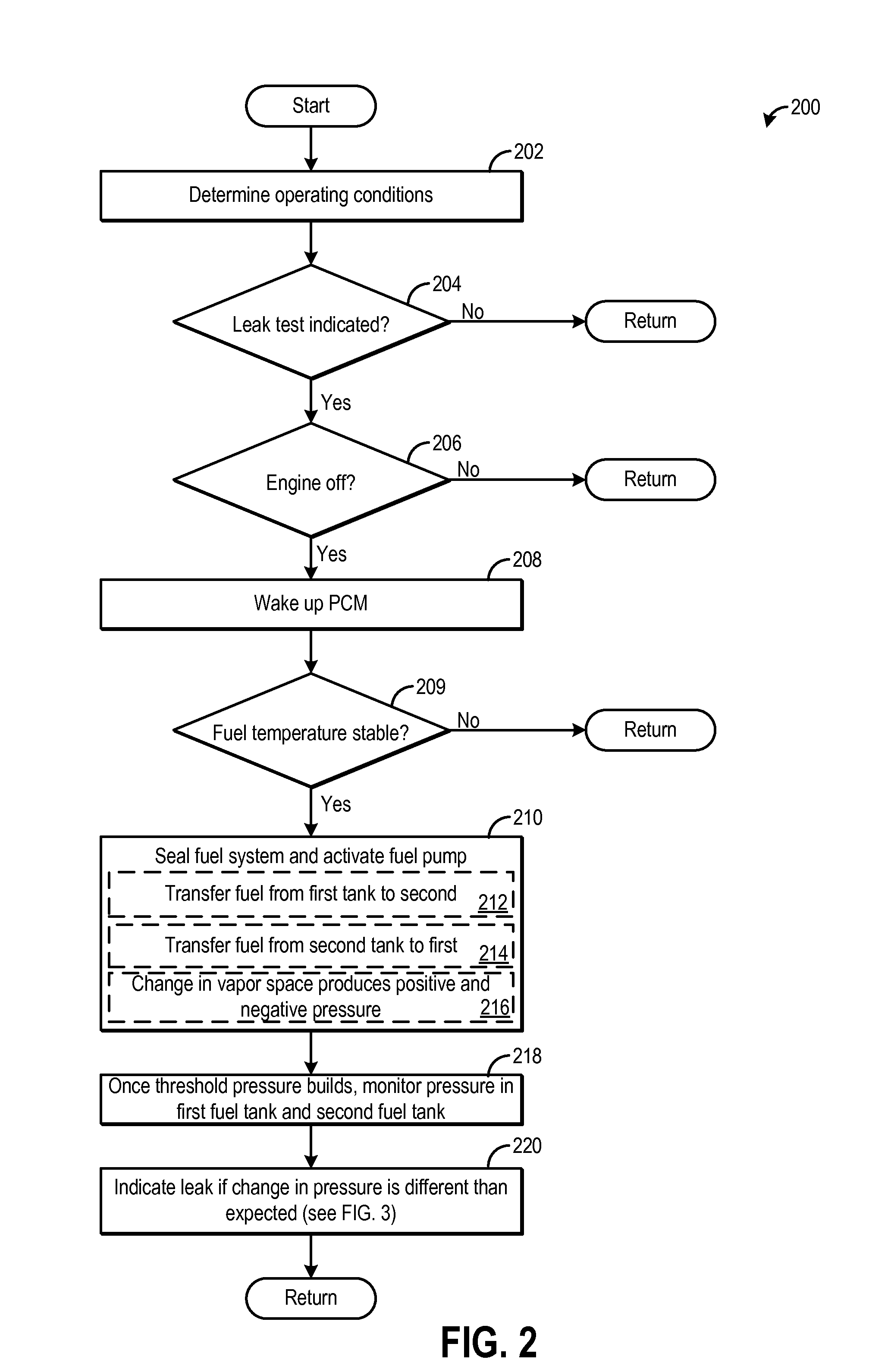

Fuel system degradation test using two fuel tanks

ActiveUS20140107906A1Saving engine packaging spaceImprove engine efficiencyHybrid vehiclesAnalogue computers for vehiclesSystem pressureFuel tank

Embodiments for monitoring fuel system degradation are provided. In one example, a method for a vehicle comprises evacuating fuel from a first fuel tank to a second fuel tank, and indicating fuel system degradation in response to a change in fuel system pressure following the evacuation of fuel. In this way, fuel system degradation may be indicated without use of a separate pressure building device.

Owner:FORD GLOBAL TECH LLC

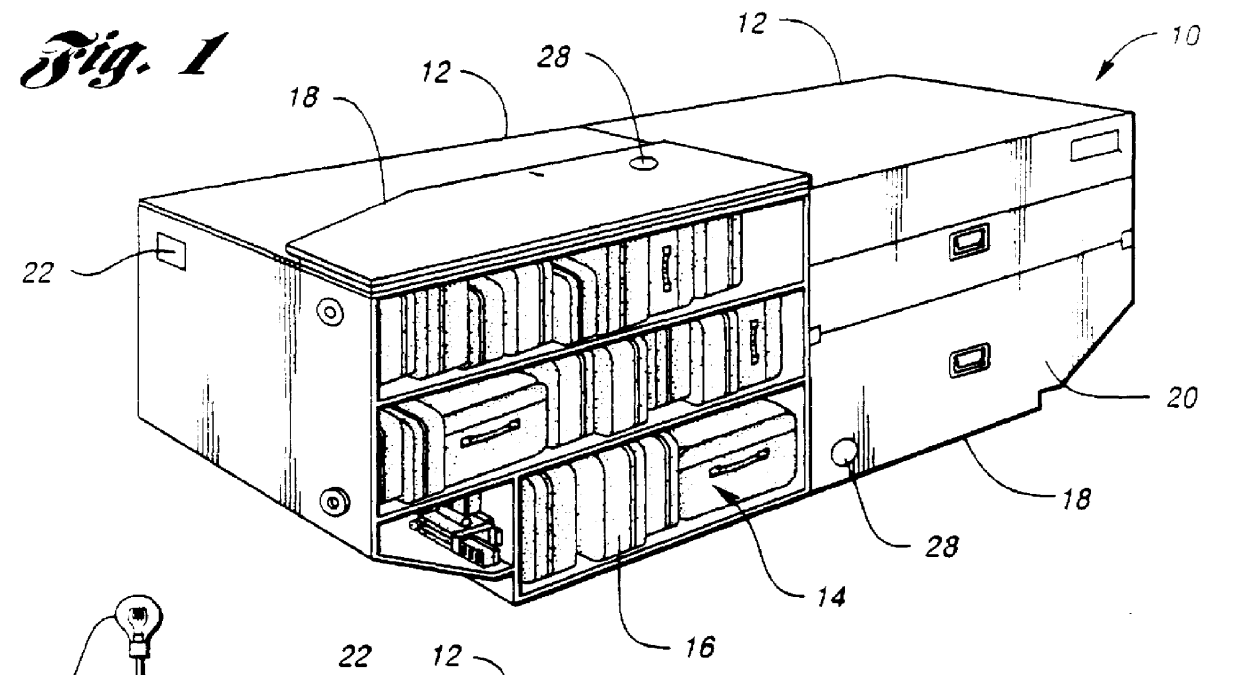

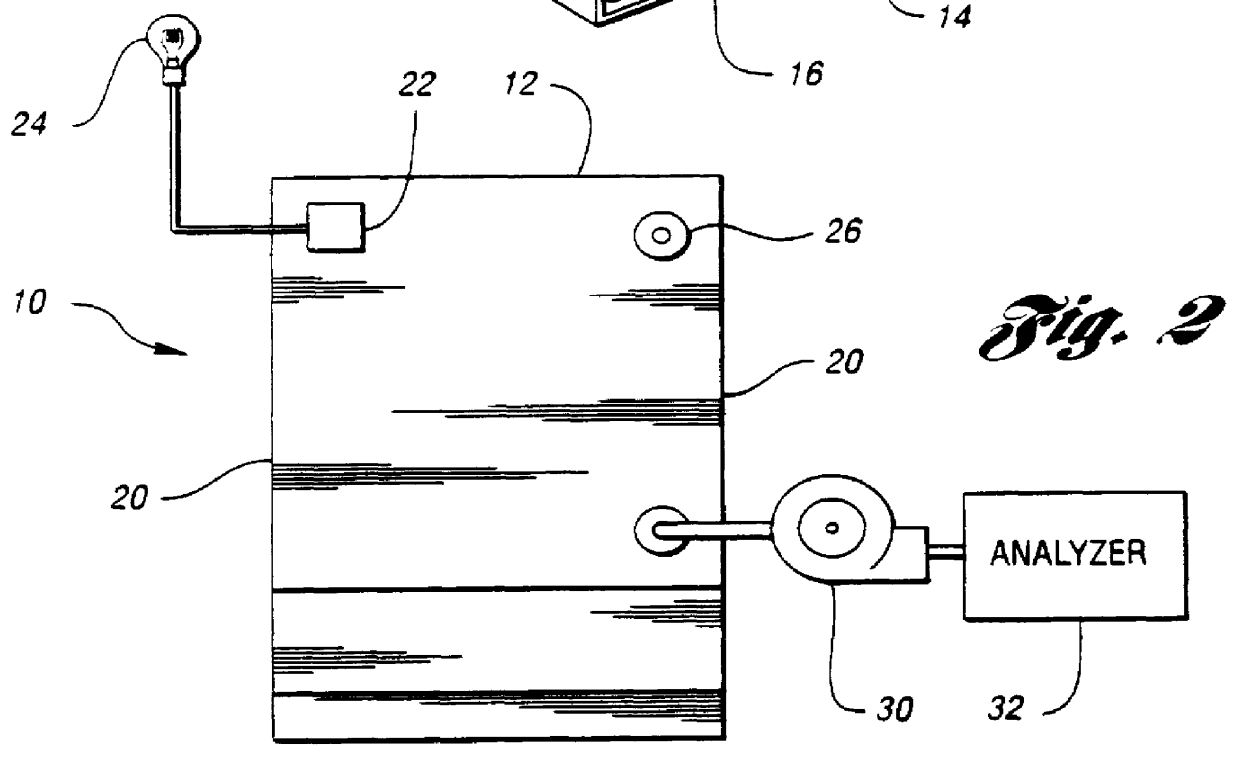

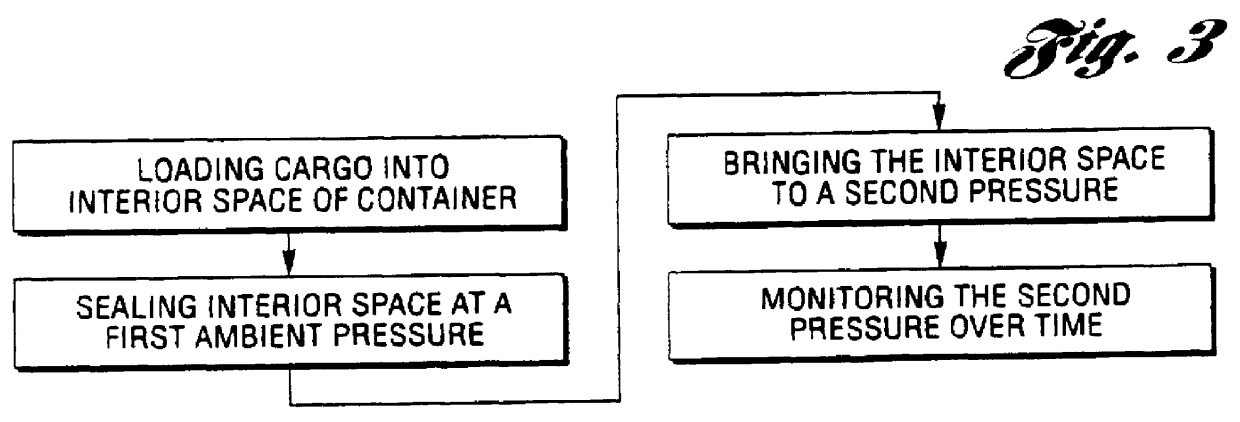

Air cargo container

InactiveUS6047588AFacilitates bulk inspectionAnalysing fluids using sonic/ultrasonic/infrasonic wavesWithdrawing sample devicesInternal pressureInterior space

An air cargo container includes a relatively-rigid housing defining an air-tight interior space of nominal volume within which to receive cargo. The housing substantially maintains the nominal volume of the interior space upon pressurizing or evacuating the interior space relative to ambient pressure, whereby a differential interior pressure is achieved before loading the container aboard an aircraft. Where the differential interior pressure is achieved by pressurizing the interior space, air or another suitable gas is injected under pressure into the housing. Where the differential interior pressure is obtained by evacuating the housing's interior space, or where the process of pressurizing the interior space includes a prior evacuation step, the gases drawn from within the housing are preferably analyzed to detect the presence of contraband within the received cargo. Sensors on the housing confirm that an achieved interior pressure is substantially maintained over time.

Owner:MCDONNELL DOUGLAS

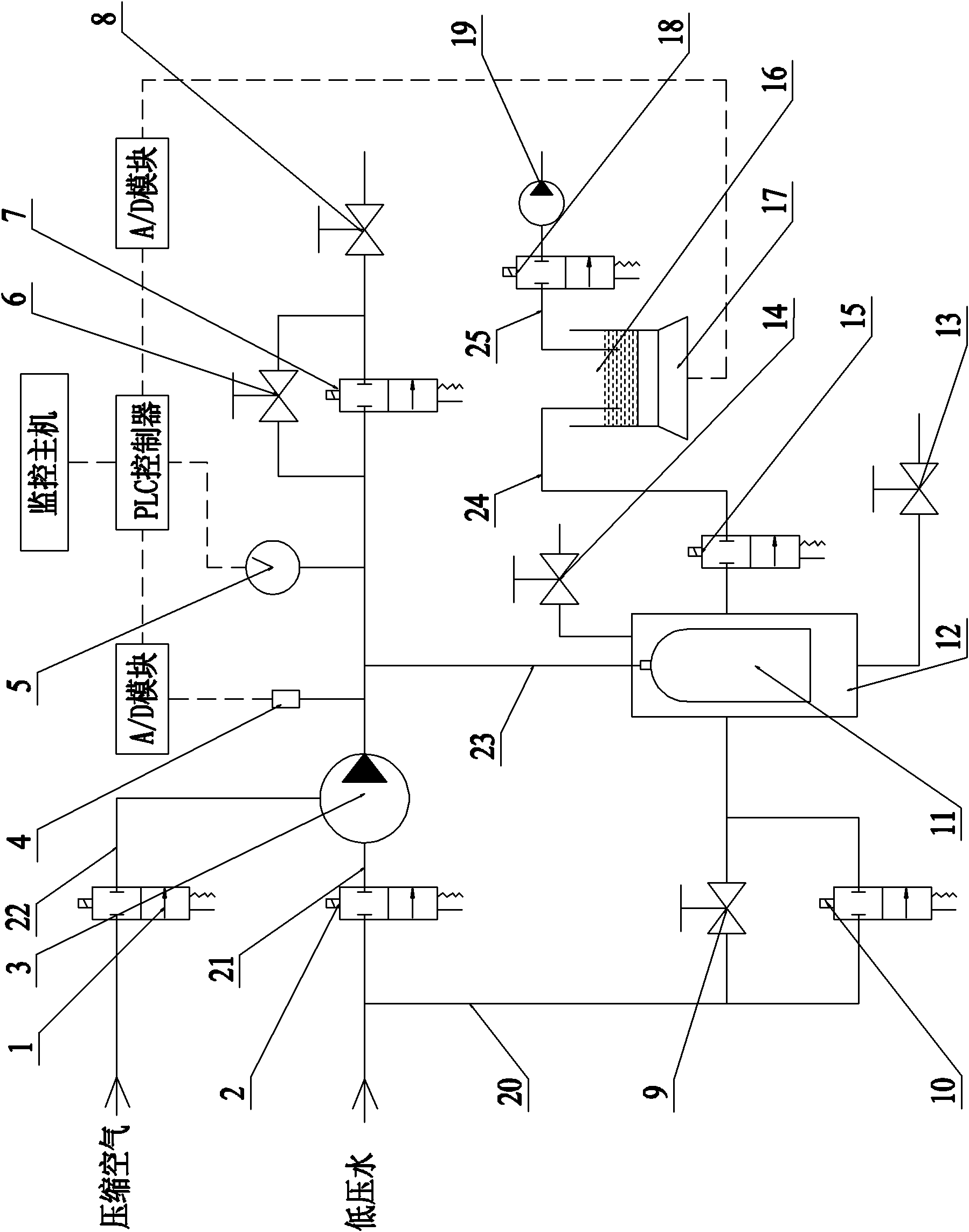

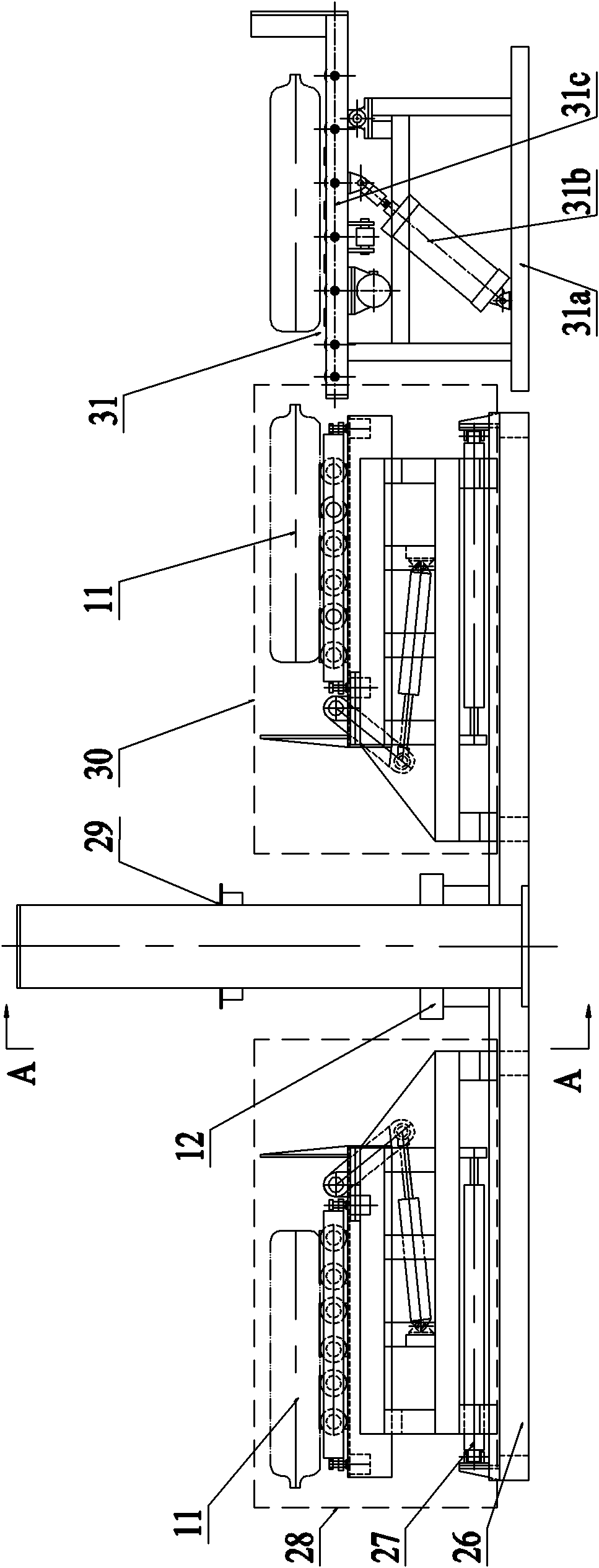

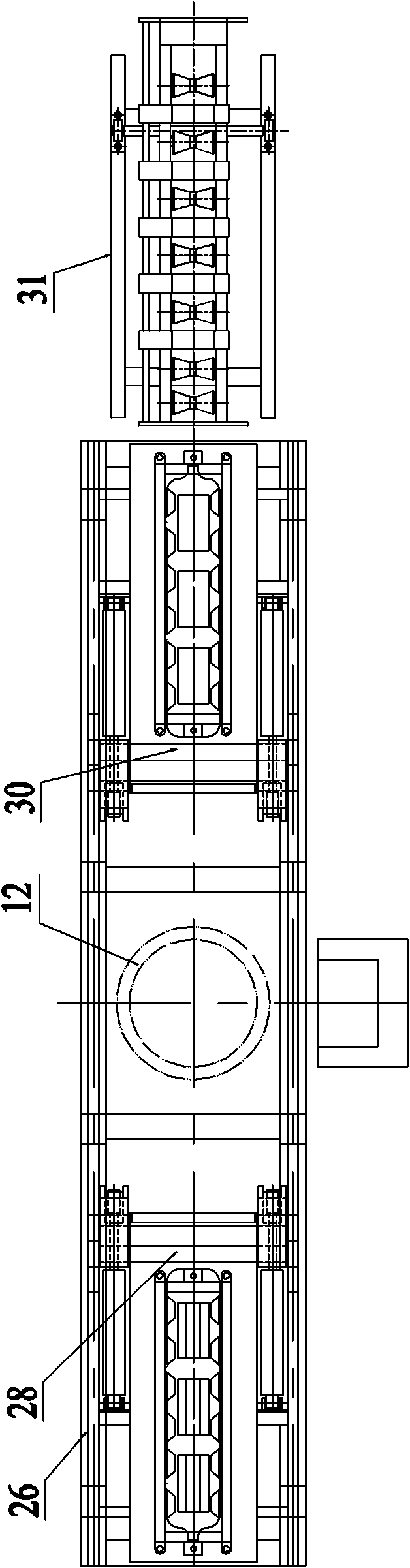

Automatic hydrostatic test control system using air-bottle outer measuring method

InactiveCN102033019AReduce labor intensityAutomate operationMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumControl systemGas cylinder

The invention relates to an automatic hydrostatic test control system using an air-bottle outer measuring method, comprising a hydrostatic test system, a control platform and a matched auxiliary system. The hydrostatic test system is used for the hydrostatic test of a tested air bottle and comprises a booster pump, a water jacket, a measuring cup, an electronic scale and a recycle pump, the auxiliary system comprises an automatic feeding device, a lifting sealing device and an automatic discharging device, wherein the automatic feeding device feeds the tested air bottle into a test position, the lifting sealing device loads tested air bottle in the water jacket or pulls the tested air bottle out of the water jacket, and the automatic discharging device conveys the tested air bottle out of the test position. The invention realizes the automatic operation of a hydrostatic test process, realizes the real-time and automatic detection and control of the test process, further lightens the labor intensity of operators, improves the detection efficiency and the detection accuracy and can realize the automatic operation of all auxiliary processes of the hydrostatic test by using the air-bottle outer measuring method.

Owner:无锡昌华机电制造有限公司

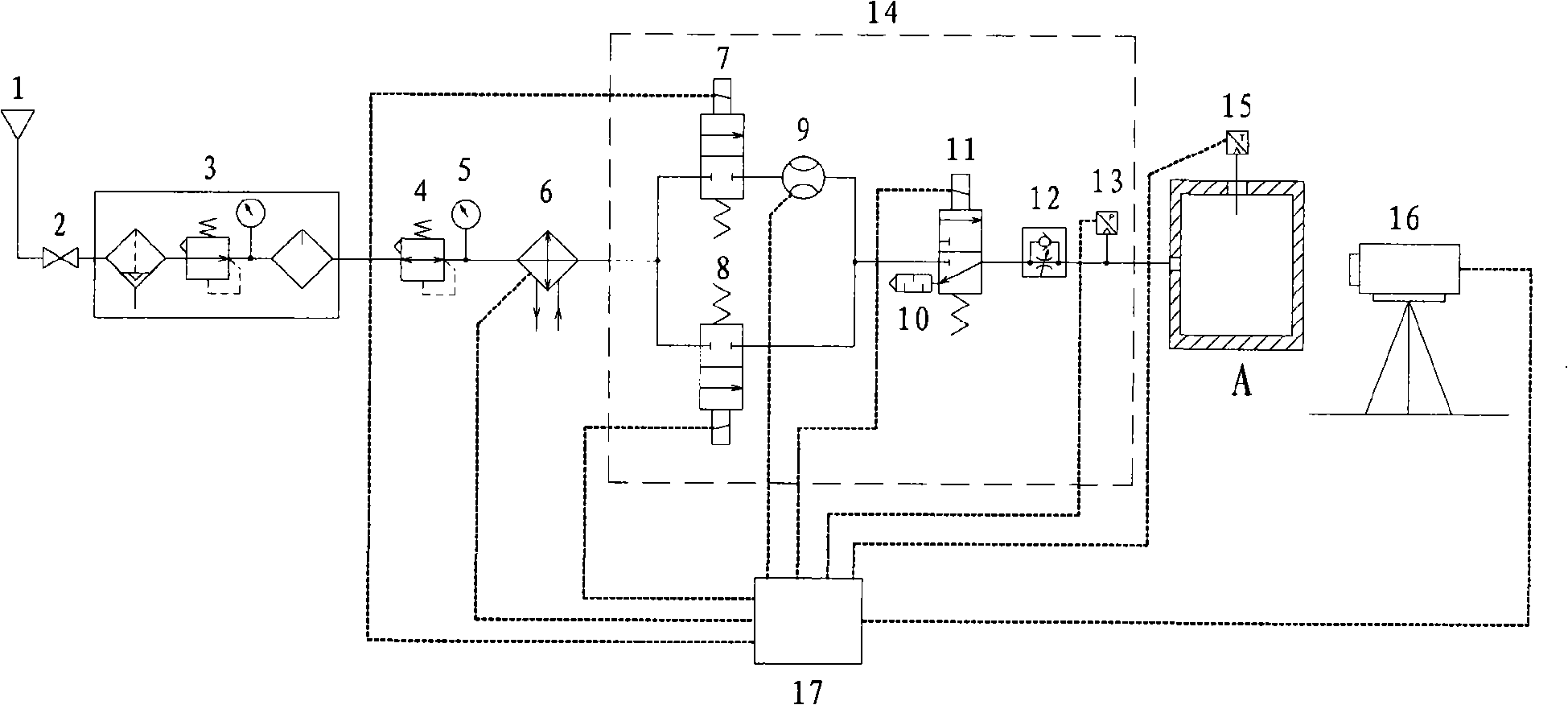

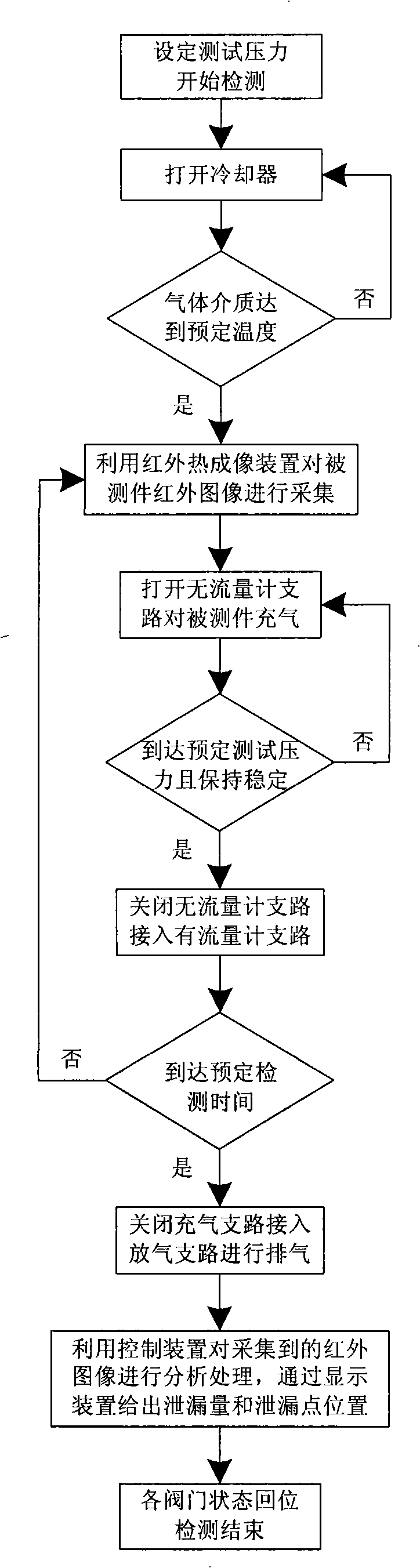

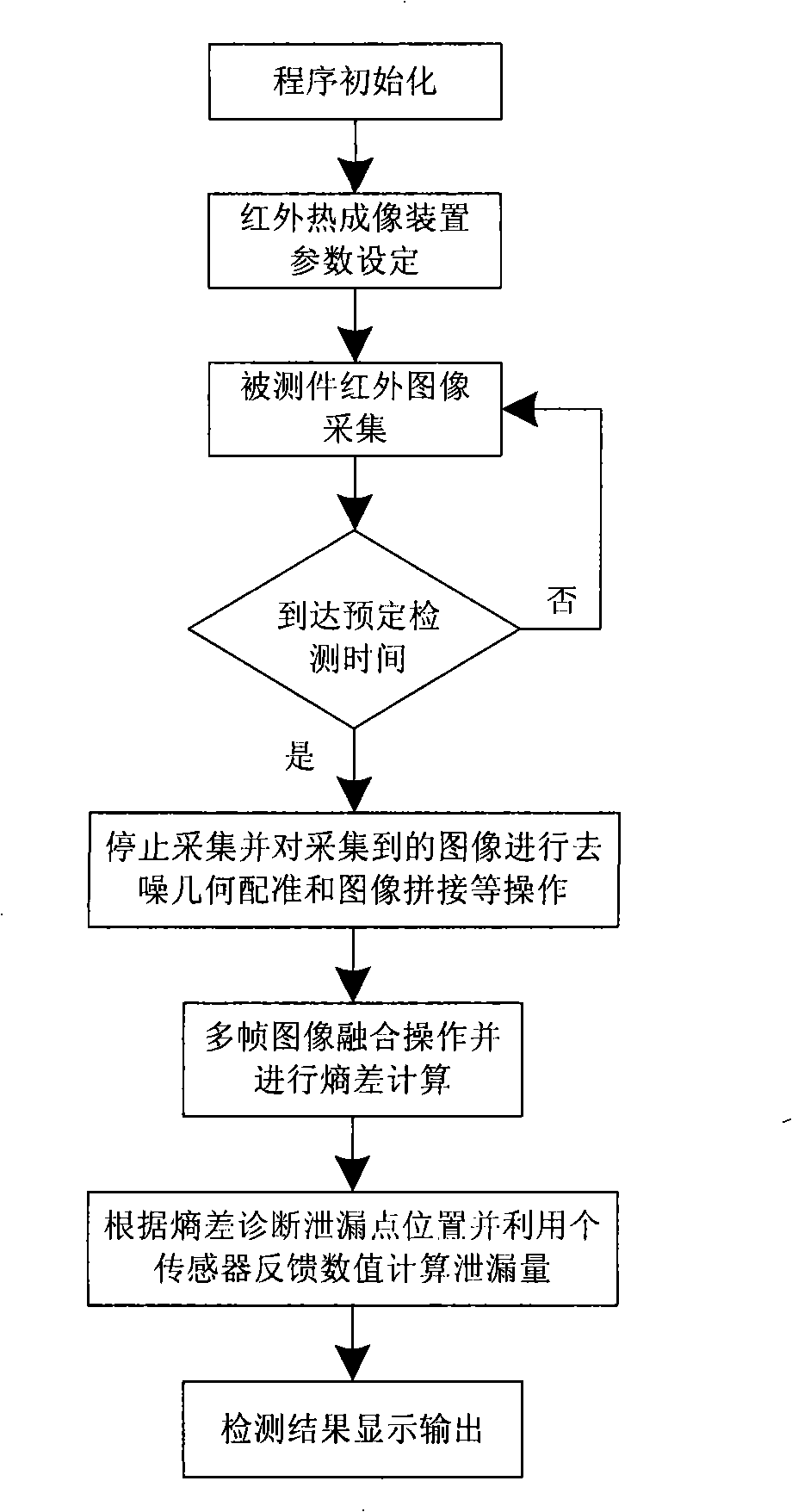

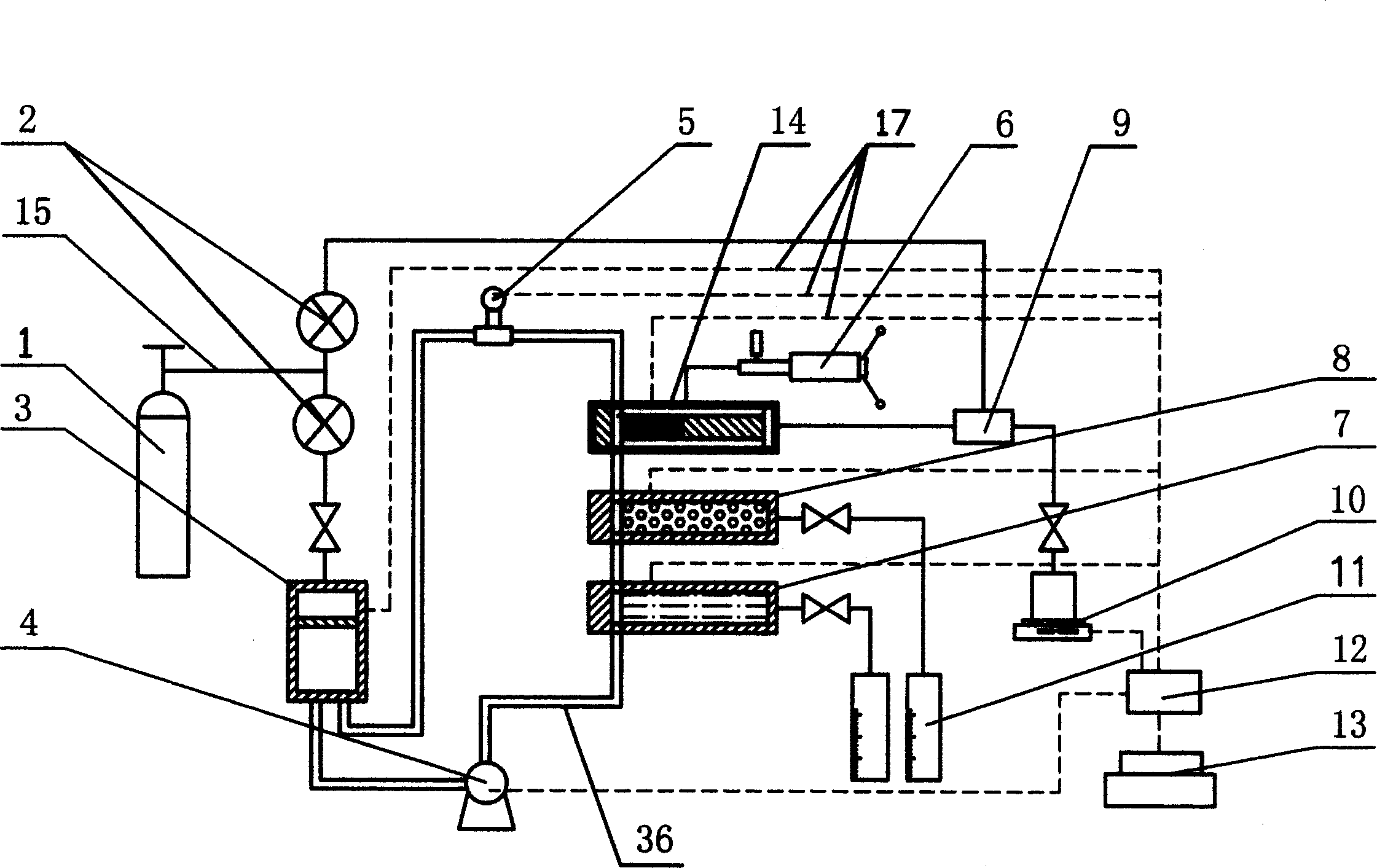

Method and system for detecting and positioning leakage based on infrared imaging technique

InactiveCN101281079AAddressing Disadvantages of Immersion InspectionMeet the needs of online testingFluid-tightness measurement using fluid/vacuumImaging processingDisplay device

The invention relates to a leakage detection and location method and a system thereof based on infrared imaging technology, belonging to the detection technology field. The leakage detection and location system comprises a control device, an infrared imagery device, a cooling device, a sensing unit, an air charging system and a display device. Gas with certain pressure is cooled by the cooling device to be used as test medium, each value is driven by the control device to implement aeration completion timing control on a measured object, and the system state is detected by the sensing unit, a infrared picture of the measured object is collected by the infrared imagery device and then transmitted to the control device to undergoing a series of image processing operations for analysis, leakage amount calculation and leakage point location, the test results is showed on the display device. The invention has high detection precision, high-efficiency for leak point locating, strong anti-interference ability and can take non-contact automatic measurement.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

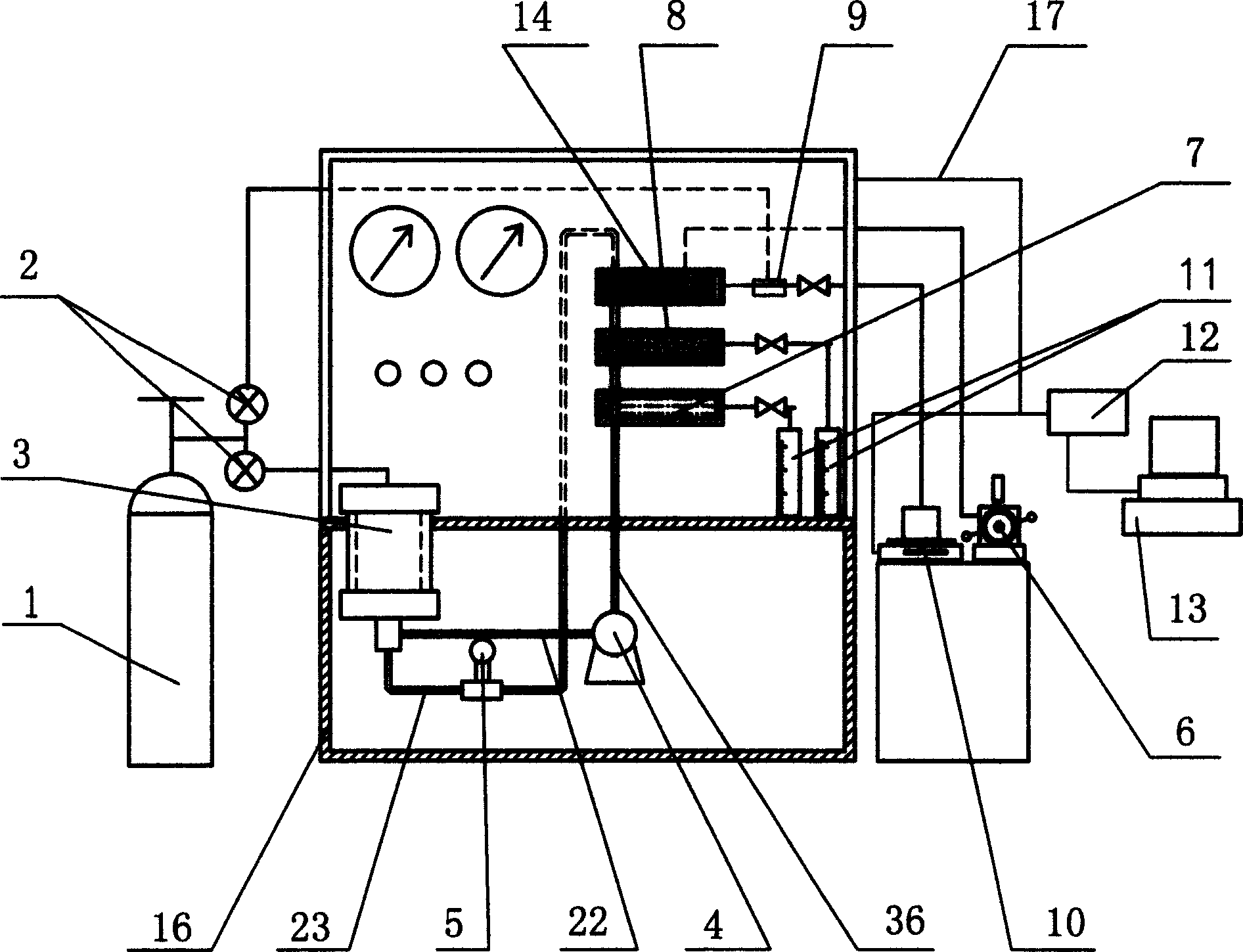

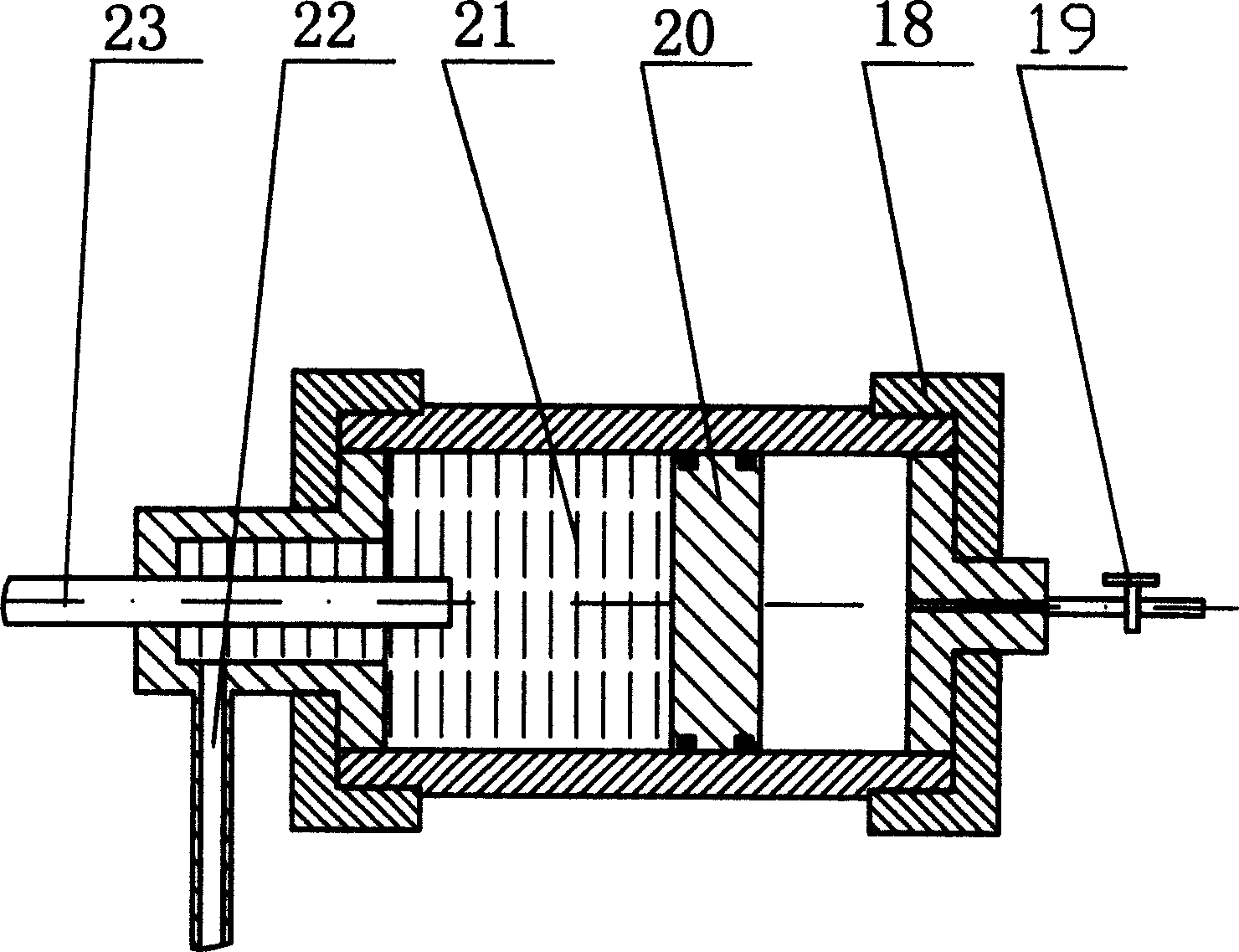

Intelligent high-temperature high-voltage experimental instrument for dynamic leak stopping evaluation

InactiveCN1731176AGood plugging effectFluid-tightness measurement using fluid/vacuumMaterial analysisControl lineData acquisition

The invention relates to an intellectual high temperature high pressure dynamic stopping leak appraisal device in the field of oil exploration and development excremental device. it is formed by a gas source, a mud pump, a piston-type high temperature high pressure mud bottle, a steel leaked bed holder, a work holder, a rock core holder, a flow-meter, an electric dissimilar, a ring pressure pump, a return pressure controller, a liquid circulating pipe, a control line, a data collector, a computer and a printer and so on. It arranges the drilling fluid of the leak agent into the mud bottle on the condition of temperature, pressure, flow speed of the simulated formation; it then uses mud pump to drive the borehole fluid of the piston-type high temperature high pressure mud bottle and dose leak damage experiment to the steel leaked bed holder, the artificial slit plate and the formation rock core to achieve the indoor correct evaluation of the leak effect of the drilling fluid and the well completion fluid.

Owner:JINGZHOU MODERN PETROLEUM TECH DEV CO LTD

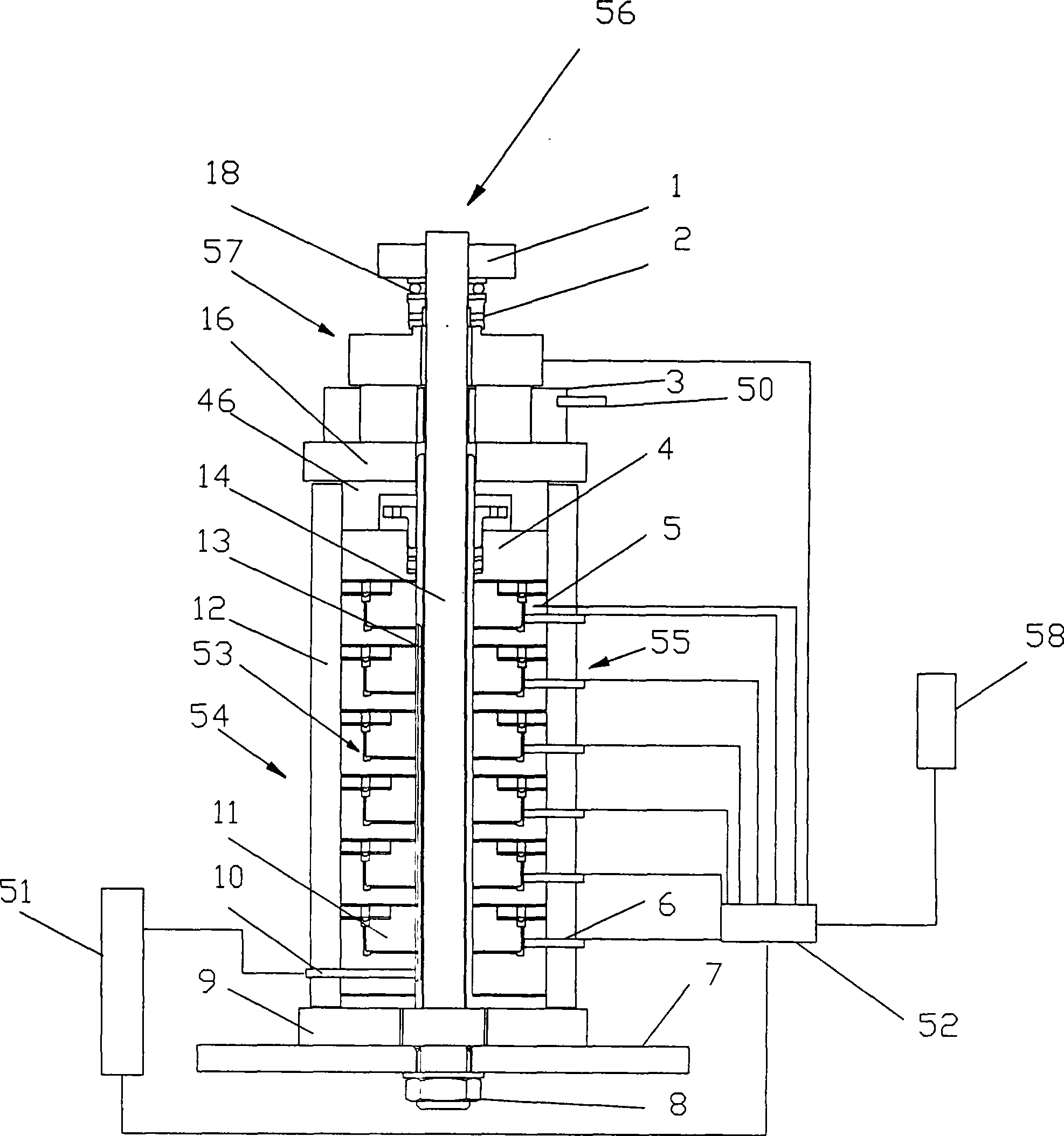

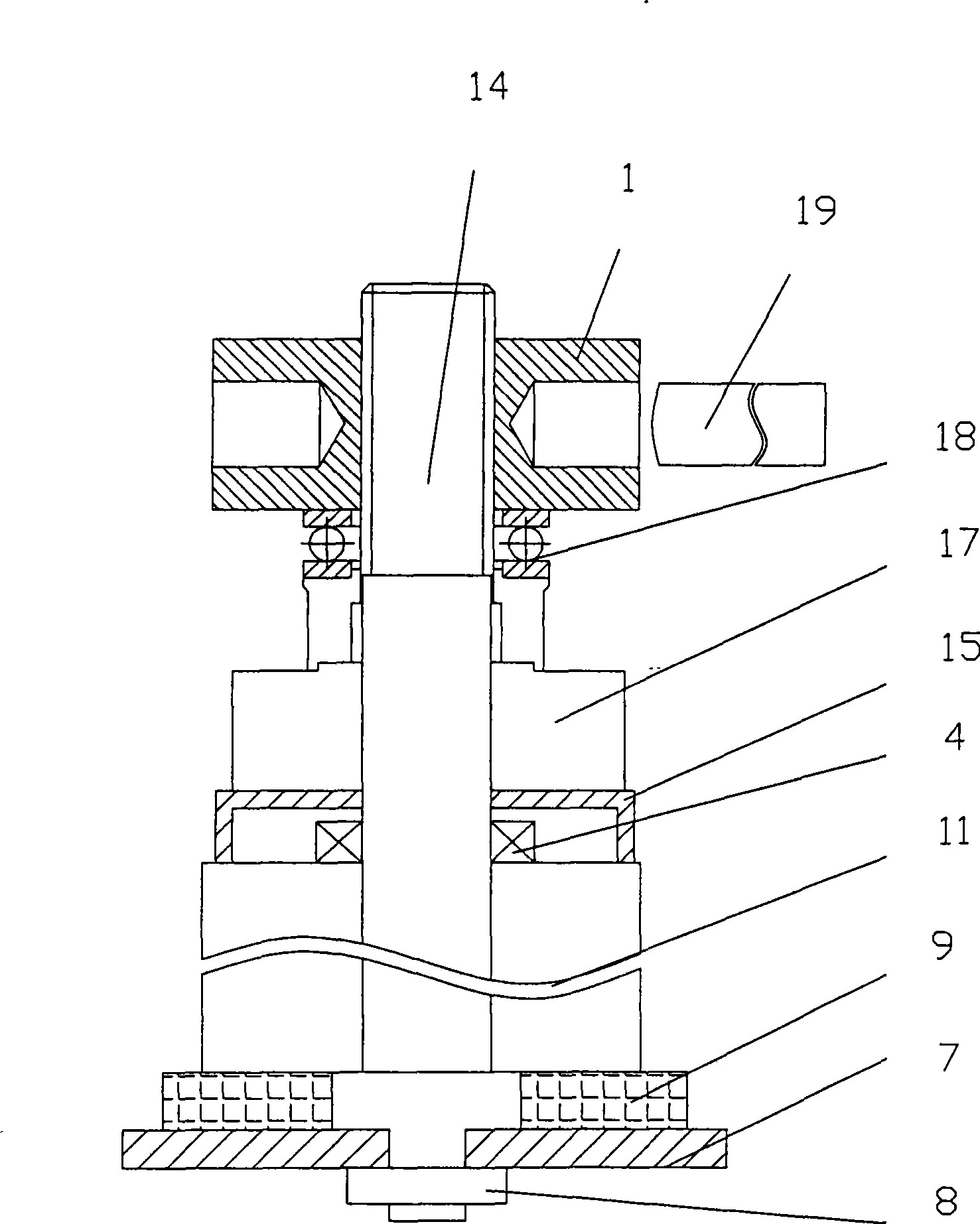

Multi-functional multi-specimen sealing gasket service life evaluation testing apparatus

InactiveCN101446510ARealize measurementEasy to controlMachine part testingFluid-tightness measurement using fluid/vacuumTemperature controlControl system

The invention relates to a multi-functional multi-specimen sealing gasket service life evaluation testing apparatus which comprises a gasket loading and load measuring system (56) and a medium given system (51). The apparatus is characterized in that the air given end of the medium given system (51) is connected with the air inlet end of a medium sealing system (53), the medium sealing system (53) is positioned inside of a temperature controlling and measuring system (54), a cooling thermal insulation system (57) is placed above the medium sealing system (53), and a leakage rate measuring system (55) is positioned on one side of the temperature controlling and measuring system (54); the medium sealing system (53), the temperature controlling and measuring system (54) and the cooling thermal insulation system (57) are connected respectively through stress bolts (14) of the gasket loading and load measuring system (56); and a data acquisition and control system (52) is respectively and electrically connected with the medium given system (51), the medium sealing system (53), the temperature controlling and measuring system (54), the leakage rate measuring system (55) and the cooling thermal insulation system (57).

Owner:NANJING TECH UNIV

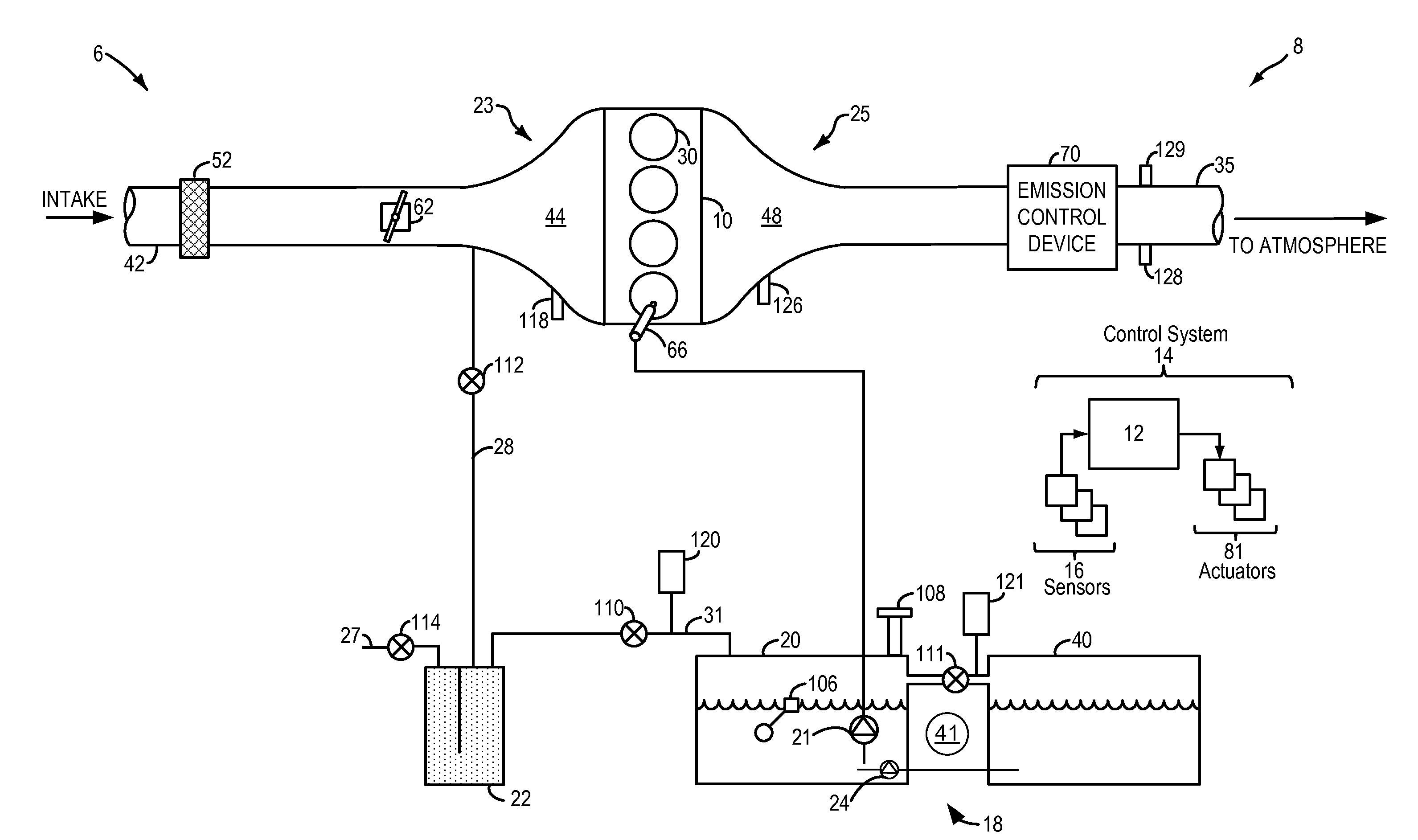

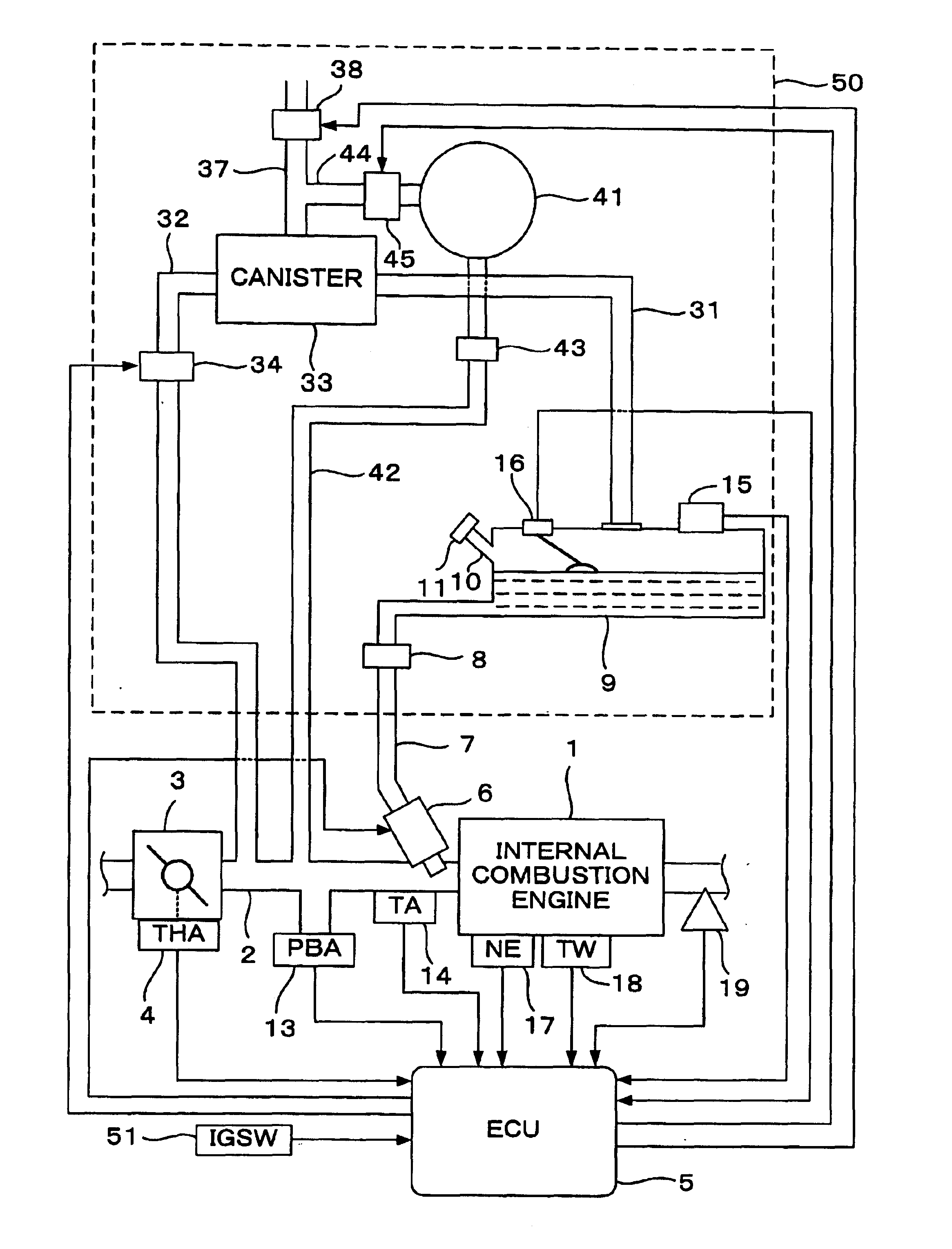

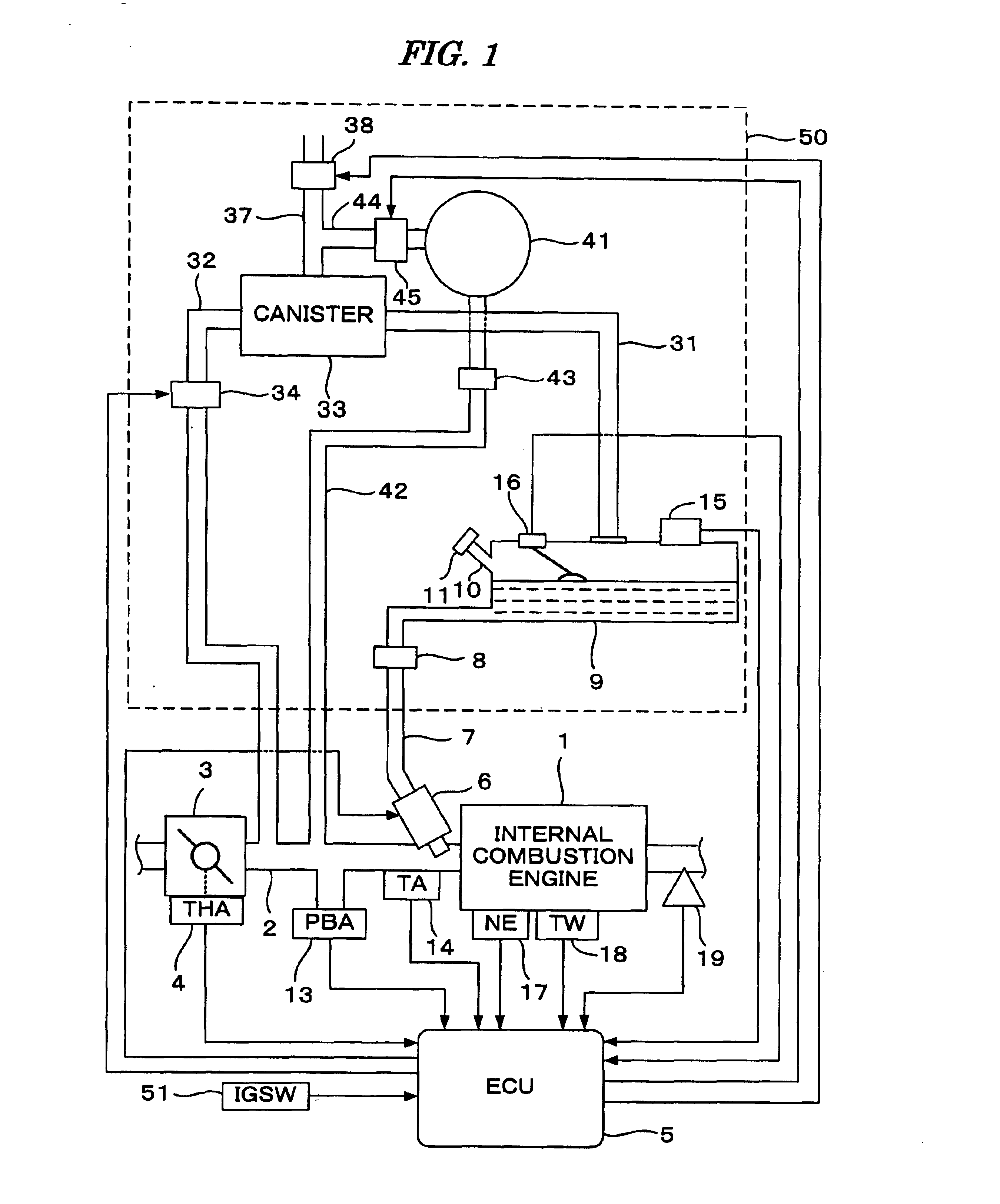

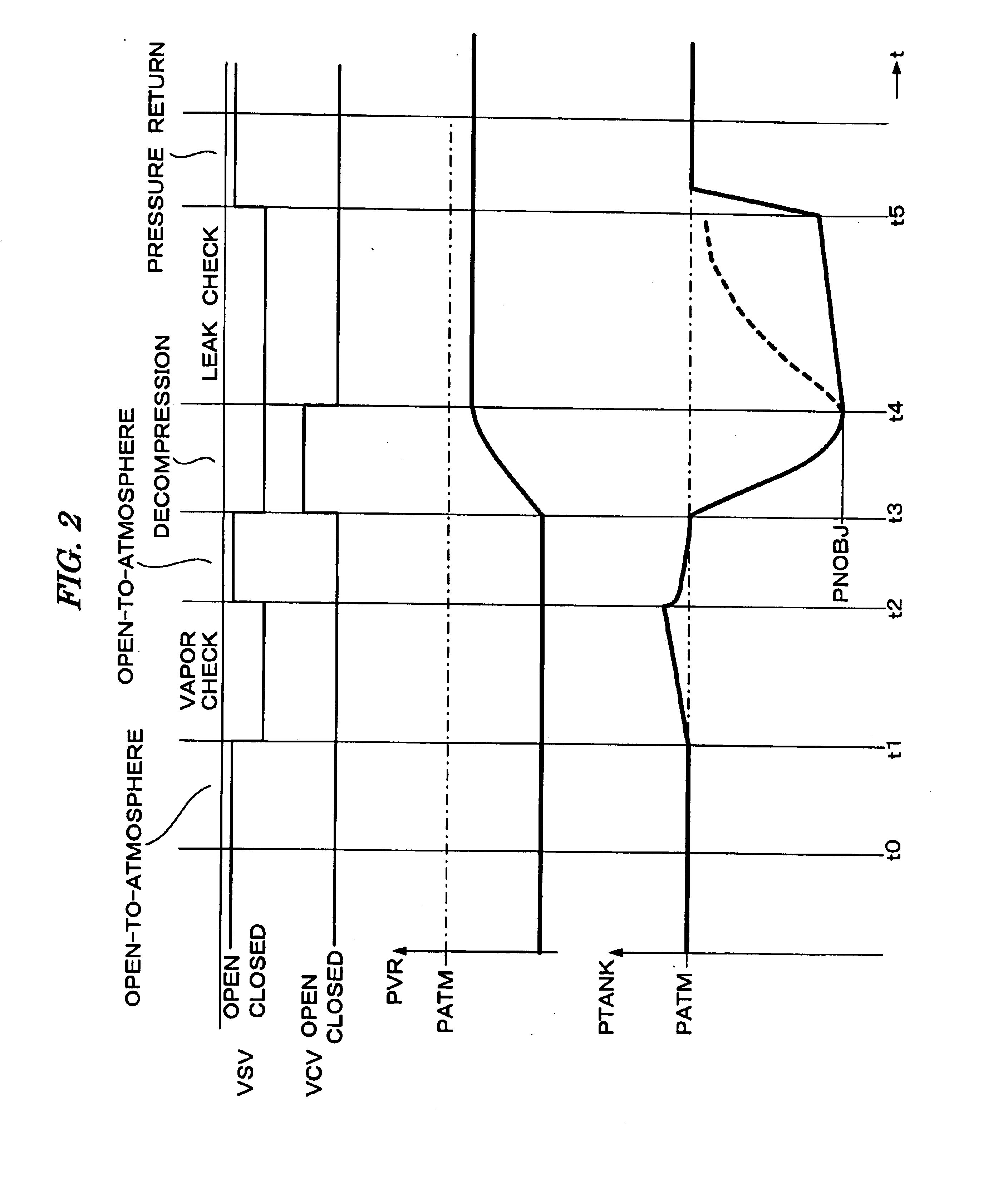

Failure diagnosis apparatus for evaporative fuel processing system

InactiveUS6950742B2Addressing slow performanceSimple configurationAnalogue computers for vehiclesNon-fuel substance addition to fuelAtmospheric airFuel tank

A failure diagnosis apparatus for diagnosing a failure of an evaporative fuel processing system. The system includes a fuel tank, a canister having adsorbent for adsorbing evaporative fuel generated in the fuel tank, an air passage connected to the canister and communicating the canister with the atmosphere, a first passage for connecting the canister and the fuel tank, a second passage for connecting the canister and an intake system of an internal combustion engine, a vent shut valve for opening and closing the air passage, and a purge control valve provided in the second passage. A pressure in the evaporative fuel processing system is detected. Negative pressure in the intake system is reserved in a negative pressure reservoir during operation of the engine. The purge control valve and the vent shut valve are closed to introduce the reserved negative pressure into the evaporative fuel processing system, when stoppage of the engine is detected. It is determined whether or not there is a leak in the evaporative fuel processing system, based on the pressure detected during a predetermined determination period after introduction of the negative pressure.

Owner:HONDA MOTOR CO LTD

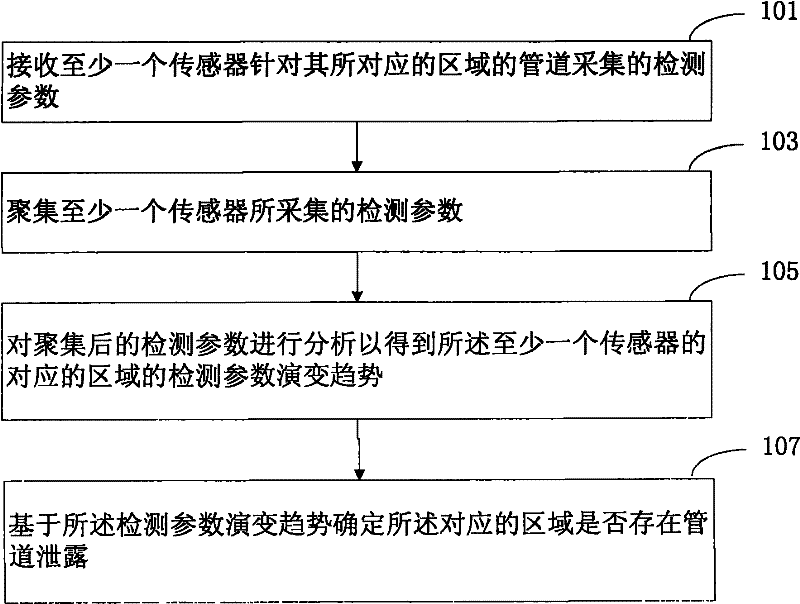

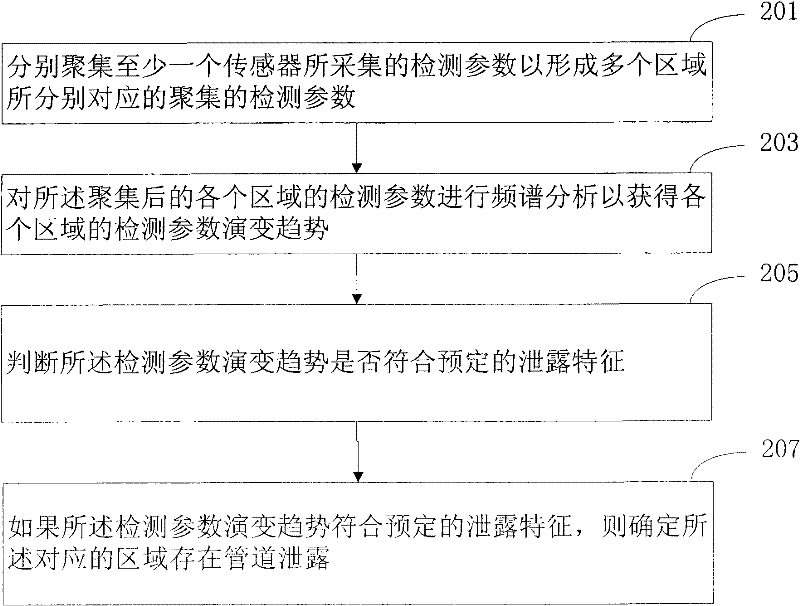

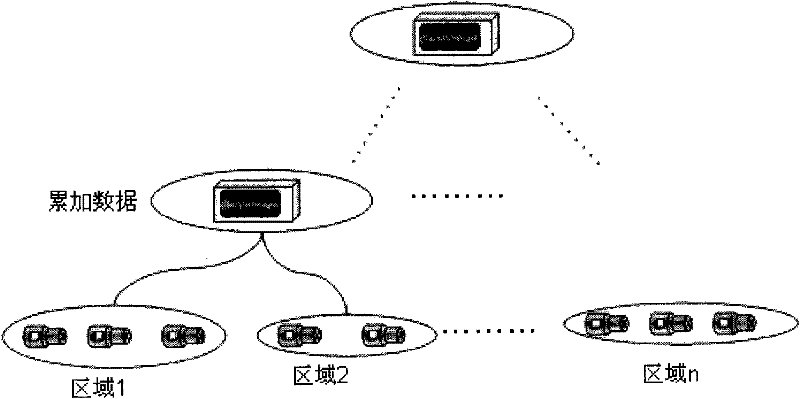

Data processing method and system for checking pipeline leakage

ActiveCN102235575APrecise positioningSurveySub-station arrangementsData processing systemResource based

The invention provides a data processing method and a data processing system for checking pipeline leakage. The method comprises the following steps of: receiving detection parameters acquired by at least one sensor for a pipeline in an area corresponding to the at least one sensor; gathering the detection parameters acquired by the at least one sensor; analyzing the gathered detection parameters to obtain an evolution trend of the detection parameters of the area corresponding to the at least one sensor; judging whether the evolution trend of the detection parameters accords with the predetermined leakage characteristic or not; and determining that the pipeline leakage exists in the corresponding area if the evolution trend of the detection parameters accords with the predetermined leakage characteristic. By the method and the system, a leakage area with low-flow leakage can be determined, and a method for positioning an area with the pipeline leakage to be detected based on resource constraint can be provided for a user.

Owner:IBM CORP

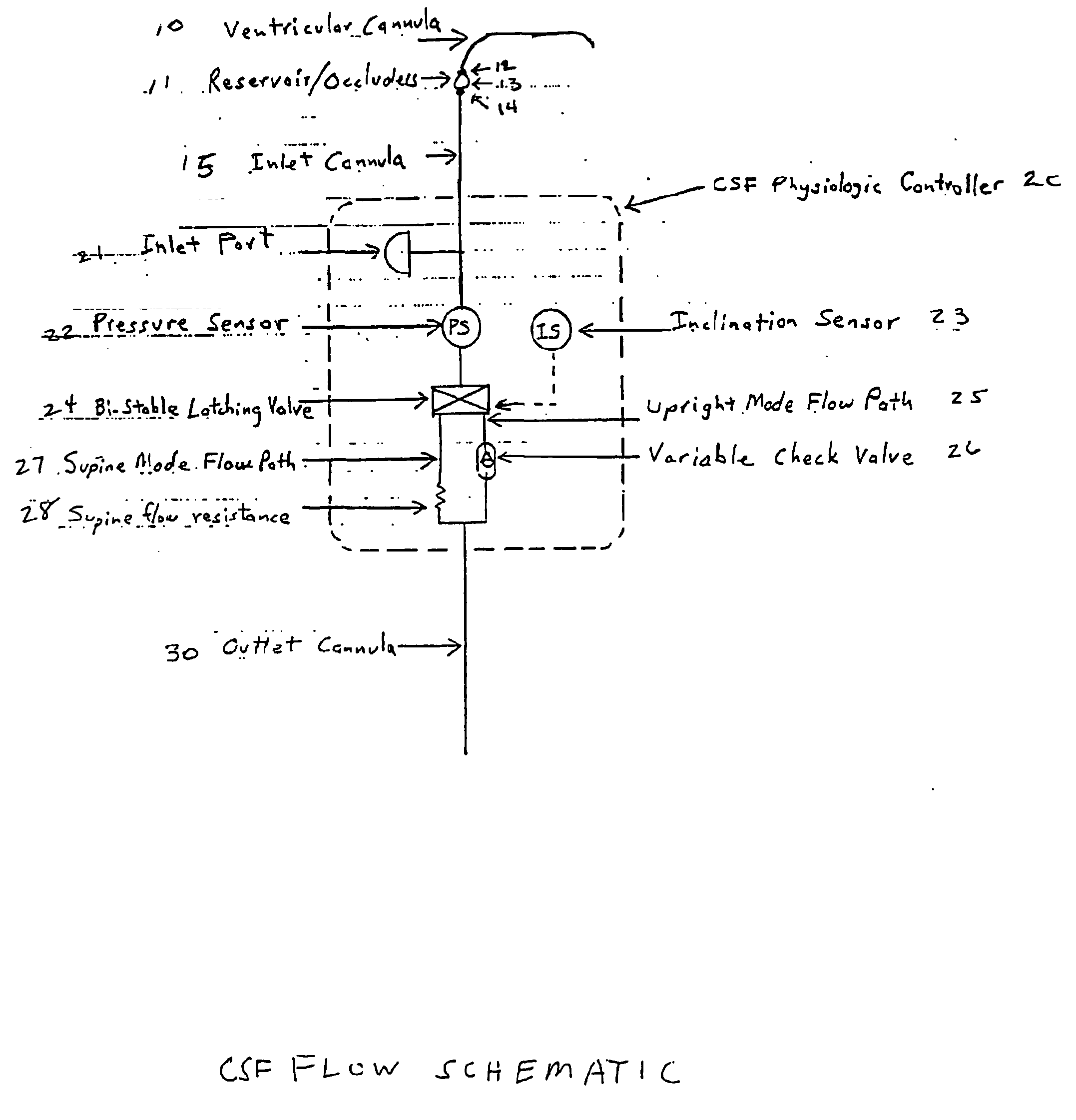

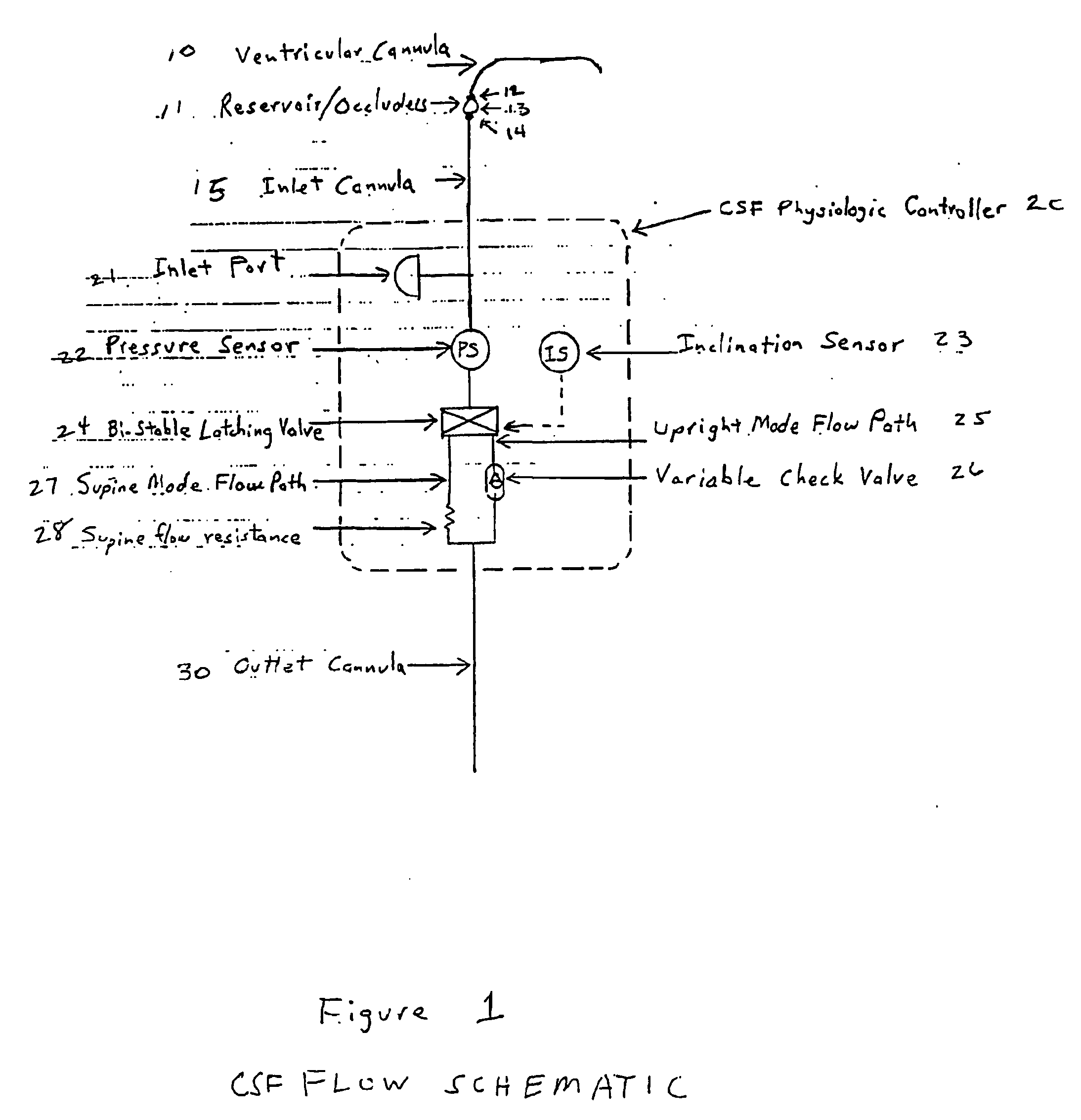

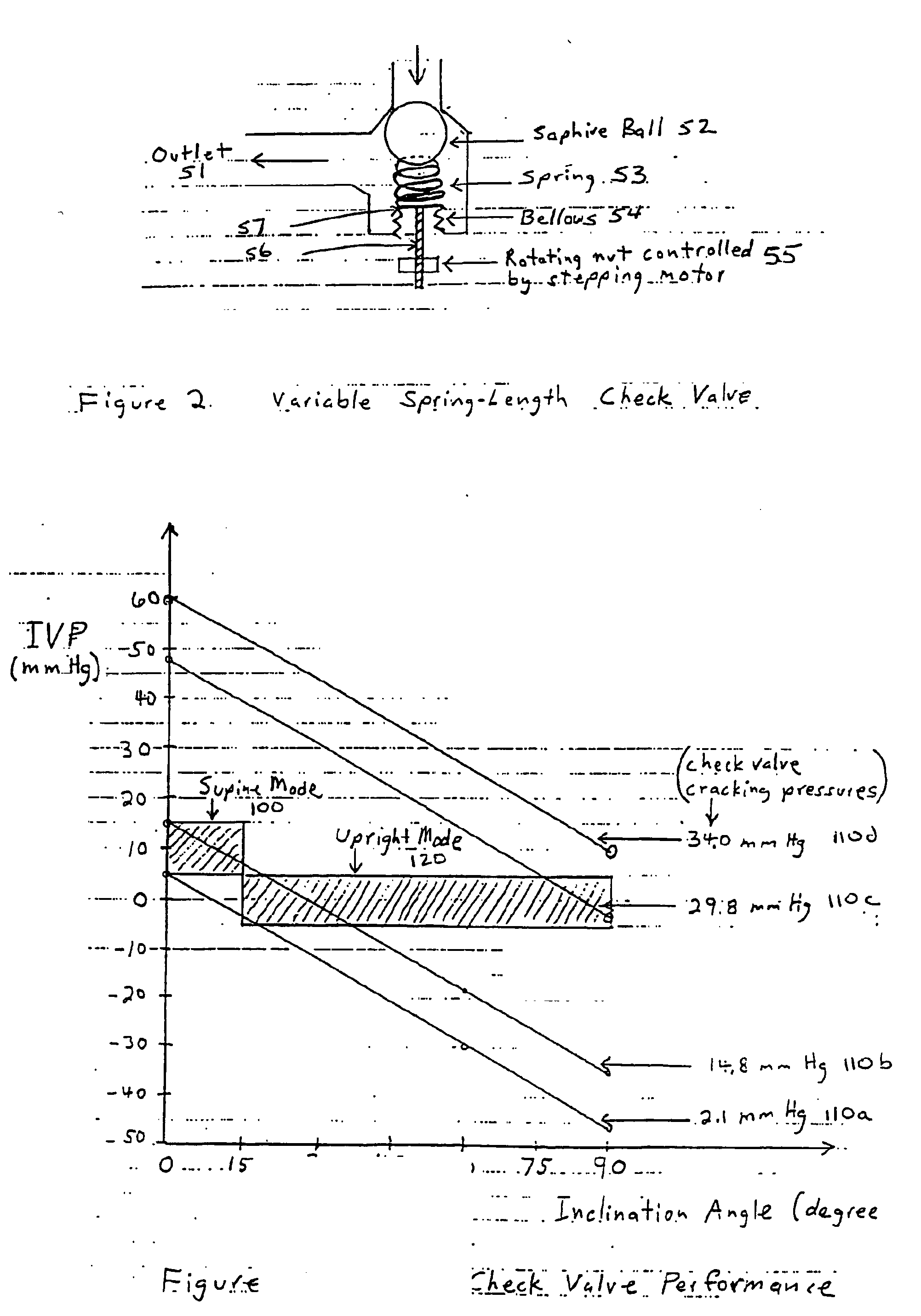

Diagnostic algorithms for a csf physiologic controller

InactiveUS20050020962A1Overcomes shortcomingOvercome limitationsWound drainsIntravenous devicesIntensive care medicineMicroprocessor

The Cerebrospinal Fluid (CSF) Physiologic Controller is an implantable active battery-operated device that is microprocessor controlled via algorithms stored in its memory. The controller also contains numerous diagnostic features, which enable the physician to monitor the operation of the system, as well as several key patient parameters non-invasively, by performing a set of algorithms.

Owner:KUCHTA JOHN

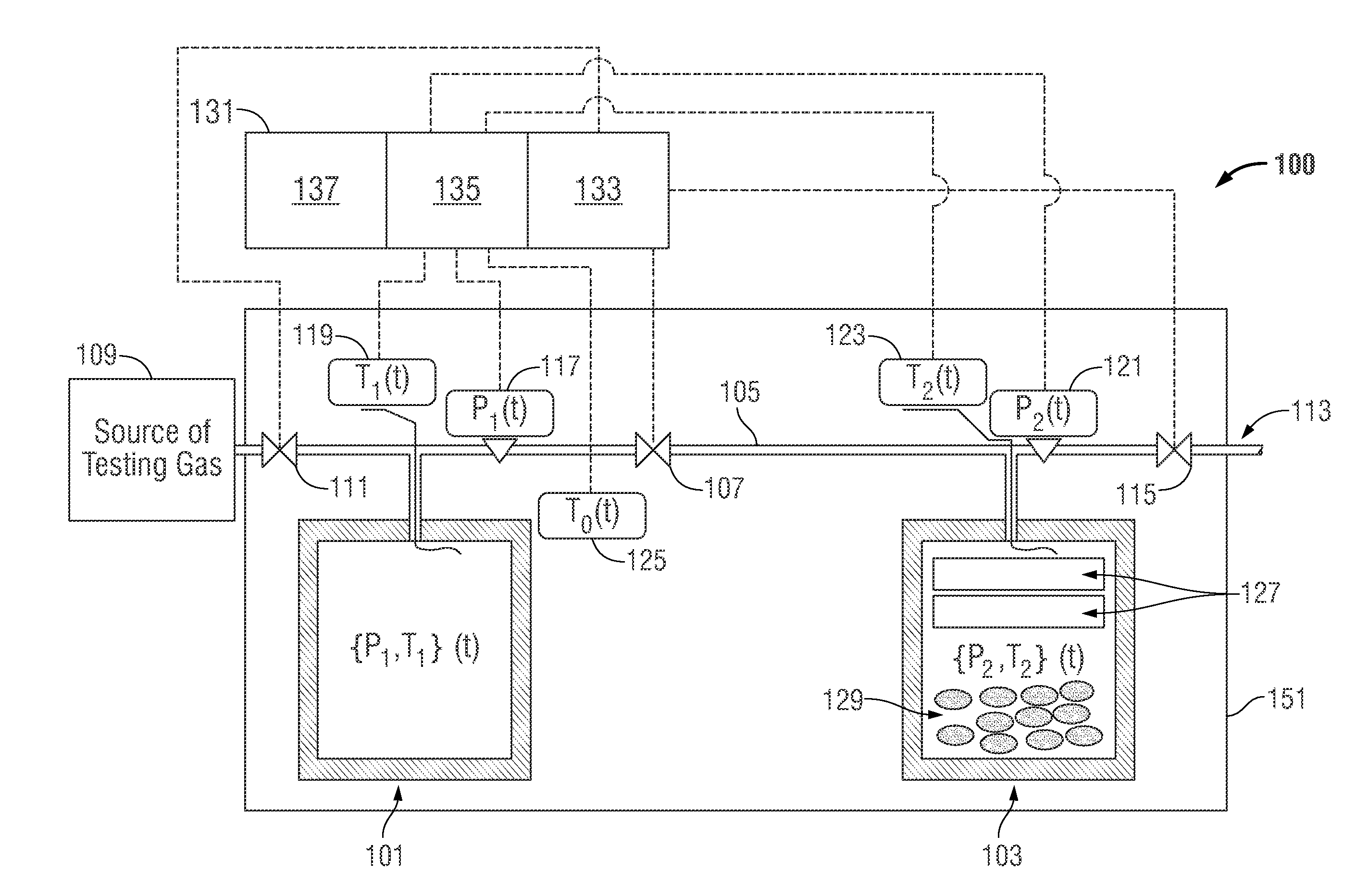

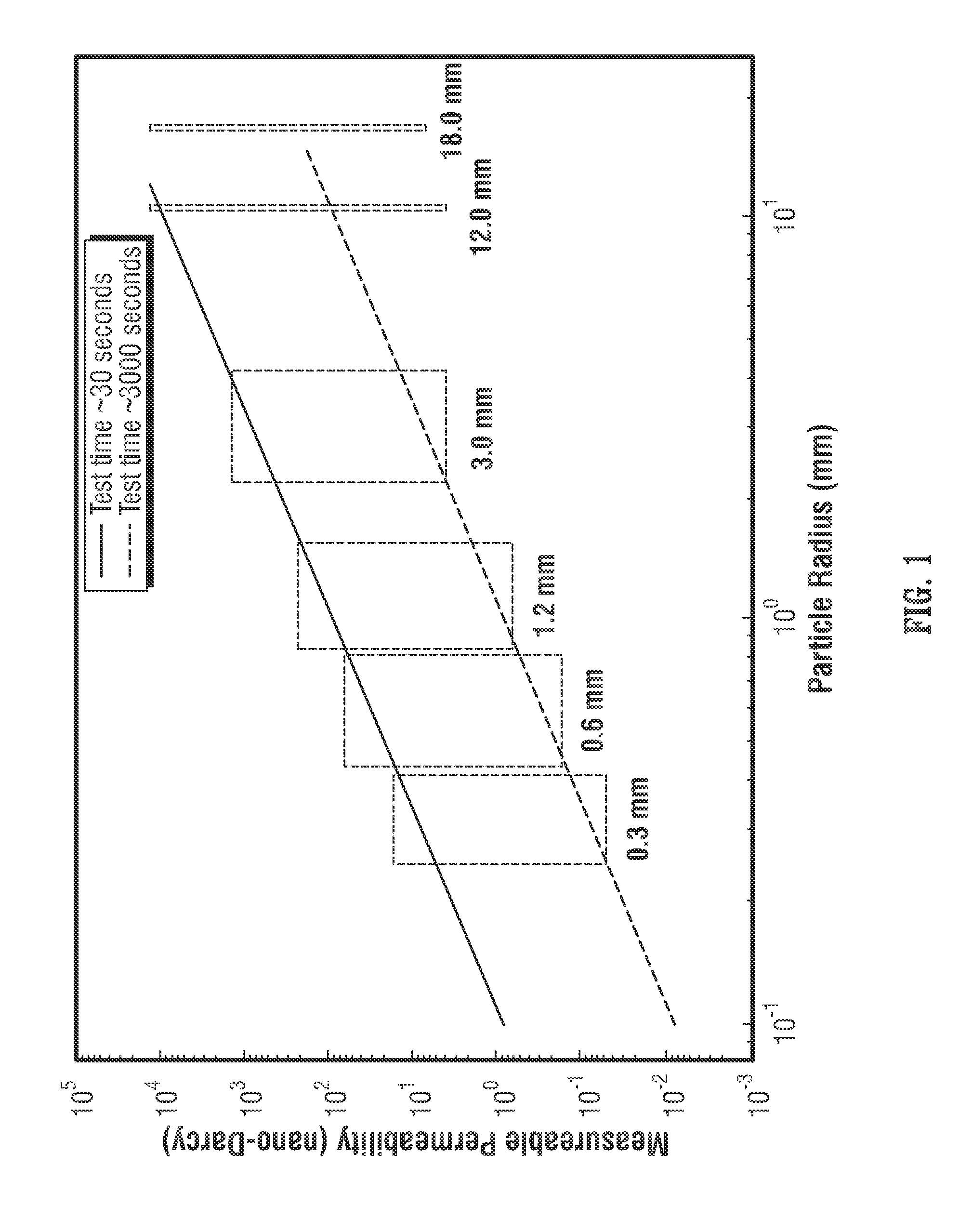

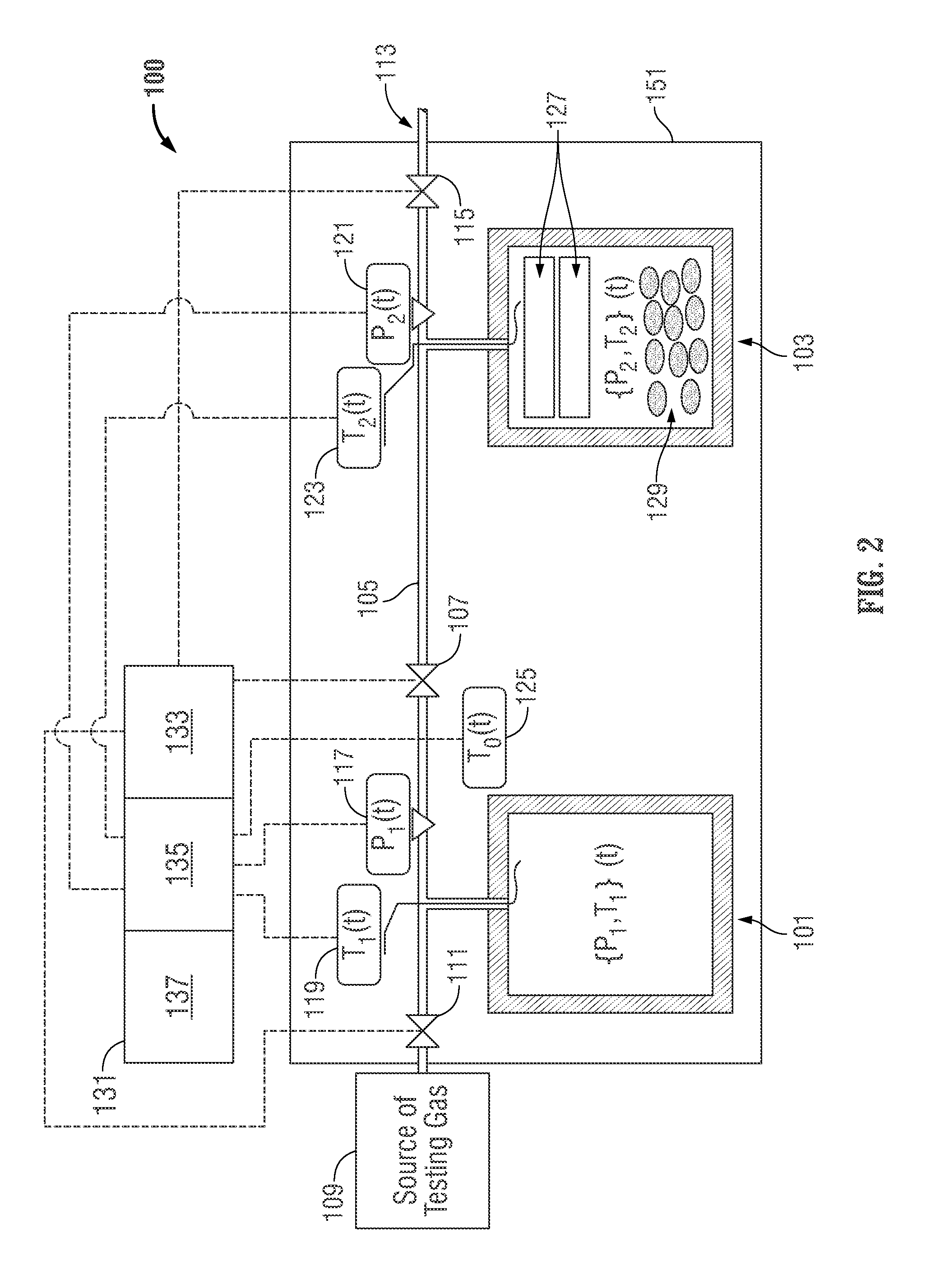

Apparatus and methodology for measuring properties of microporous material at multiple scales

ActiveUS20150362419A1Rapid temperature measurementLarge heat capacityEarth material testingPermeability/surface area analysisIsolation valveExhaust valve

A test apparatus (and method of operation) for characterizing properties of a sample under test (such as porous material, for example, samples of reservoir rock) that operates in conjunction with a source of test fluid. The test apparatus includes an intake valve fluidly coupled to the source of test fluid, a reference cell fluidly coupled to the source of test fluid via the intake valve, a sample cell that holds the sample under test, an isolation valve fluidly coupled between the reference cell and the sample cell, an exhaust port, an exhaust valve fluidly coupled between the sample cell and the exhaust port, a first pressure sensor associated with the reference cell for measuring pressure within the reference cell, and a second pressure sensor associated with the sample cell for measuring pressure within the sample cell. The method of operation includes calibration procedures to compensate for systematic measurement errors.

Owner:SCHLUMBERGER TECH CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com