Patents

Literature

531 results about "Hydrostatic test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydrostatic test is a way in which pressure vessels such as pipelines, plumbing, gas cylinders, boilers and fuel tanks can be tested for strength and leaks. The test involves filling the vessel or pipe system with a liquid, usually water, which may be dyed to aid in visual leak detection, and pressurization of the vessel to the specified test pressure. Pressure tightness can be tested by shutting off the supply valve and observing whether there is a pressure loss. The location of a leak can be visually identified more easily if the water contains a colorant. Strength is usually tested by measuring permanent deformation of the container. Hydrostatic testing is the most common method employed for testing pipes and pressure vessels. Using this test helps maintain safety standards and durability of a vessel over time. Newly manufactured pieces are initially qualified using the hydrostatic test. They are then re-qualified at regular intervals using the proof pressure test which is also called the modified hydrostatic test. Testing of pressure vessels for transport and storage of gases is very important because such containers can explode if they fail under pressure.

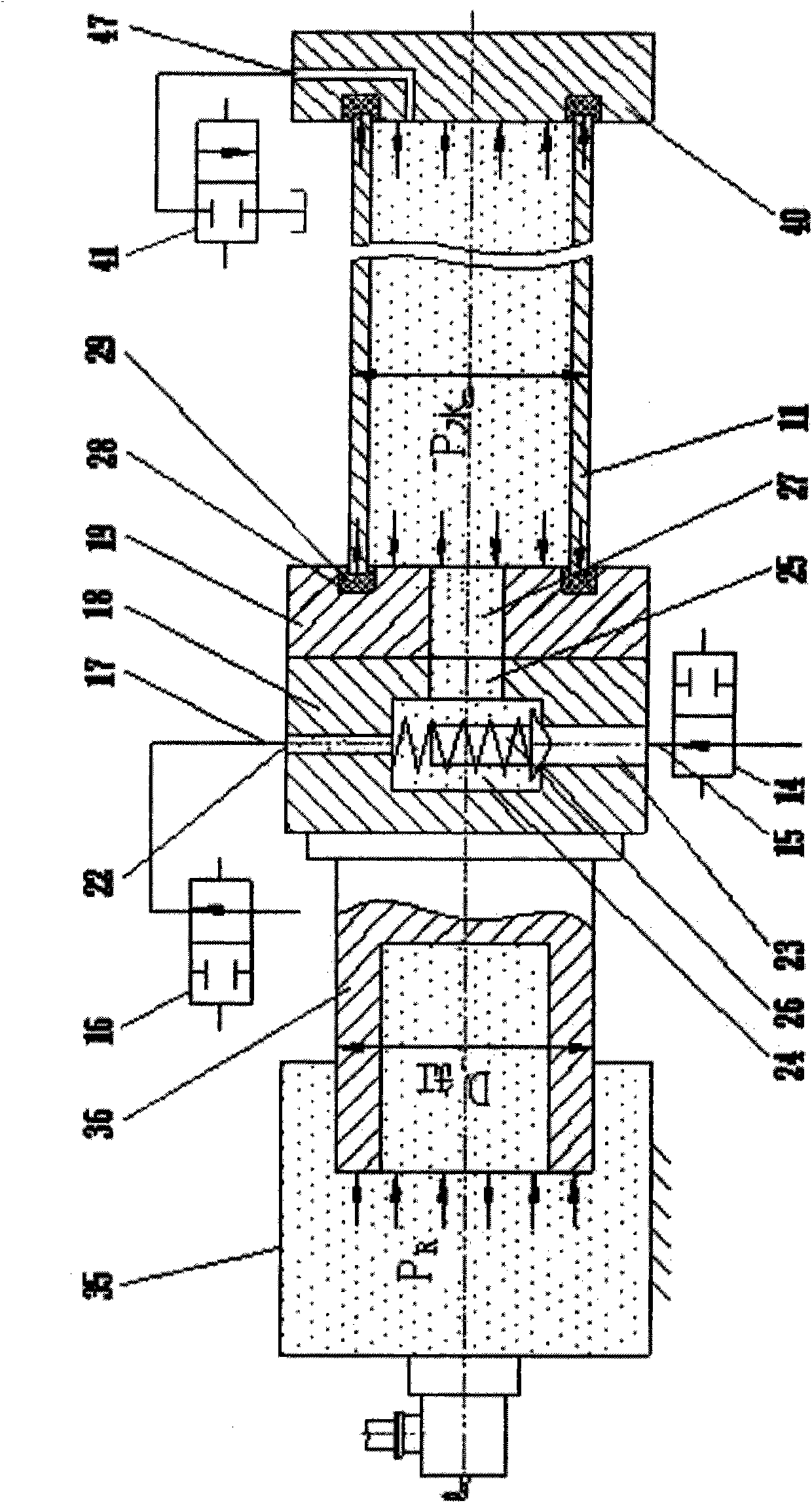

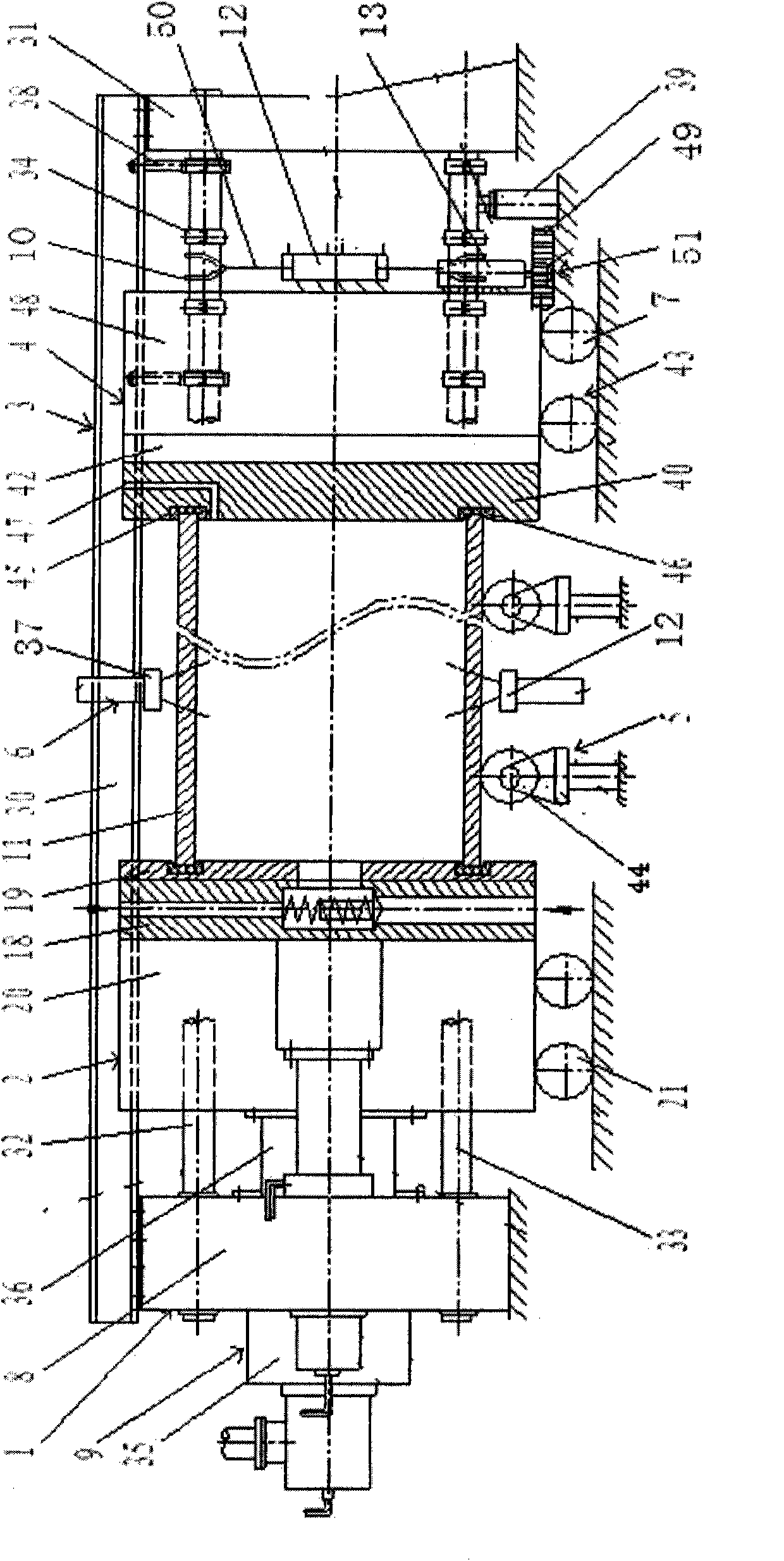

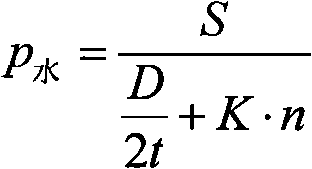

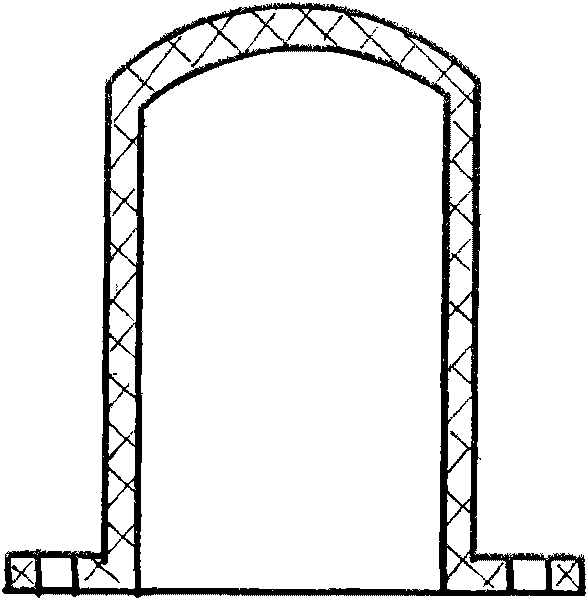

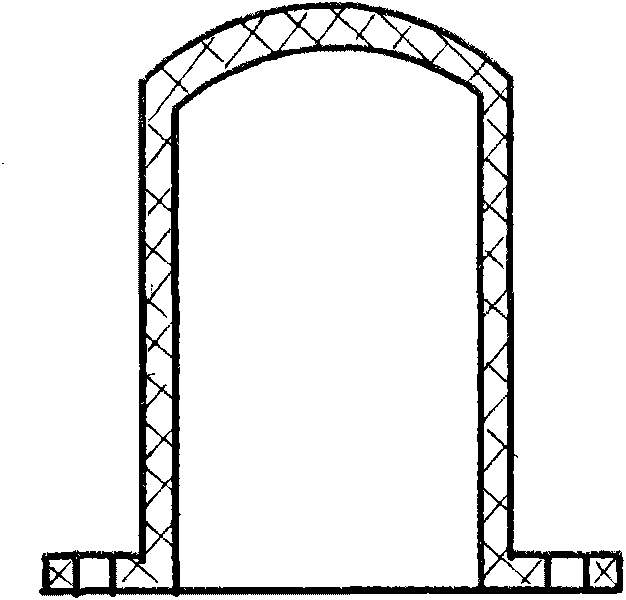

Method for detecting hydrostatic pressure of thin-wall steel pipe under end face seal condition

InactiveCN102042935AEasy to calculateCalculations are reliableMaterial strength using tensile/compressive forcesPore water pressureInlet valve

The invention relates to a method for detecting the hydrostatic pressure of a thin-wall steel pipe under the end face seal condition. Used equipment is an end face seal steel pipe hydrostatic pressure testing machine which comprises a testing machine body, a hydraulic system, a water pressure system and an electric control system. The method for detecting the hydrostatic pressure of the thin-wall steel pipe under the end face seal condition comprises the following steps of: 1) feeding the pipe and pre-clamping, namely respectively sealing the two pipe orifices of the pressure test thin-wall steel pipe by using two seal flat gaskets on a main pressure test head body and an auxiliary pressure test head body; 2) filling water, namely filling low-pressure water into the pressure test thin-wall steel pipe, exhausting, and closing a low-pressure water inlet valve, an exhaust port and a pressure relief port; 3) pressurizing, namely supplementing the water to the pressure test thin-wall steel pipe for pressurizing, pressurizing a main hydraulic cylinder synchronously, and determining a test pressure value according to a calculation formula; 4) stabilizing pressure, namely after the pressure of the water in the pressure test thin-wall steel pipe reaches a specified test pressure value, stabilizing the pressure until time specified by the test is up; and 5) relieving the pressure and discharging the water and the pipe. The detection method overcomes the defects of the conventional pipe making specifications, and the calculation process is simple, convenient and reliable.

Owner:马利芳

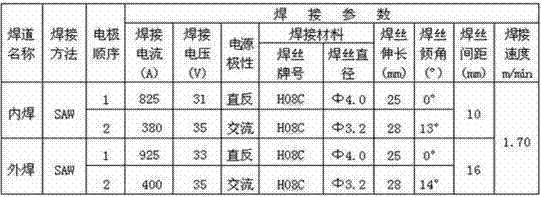

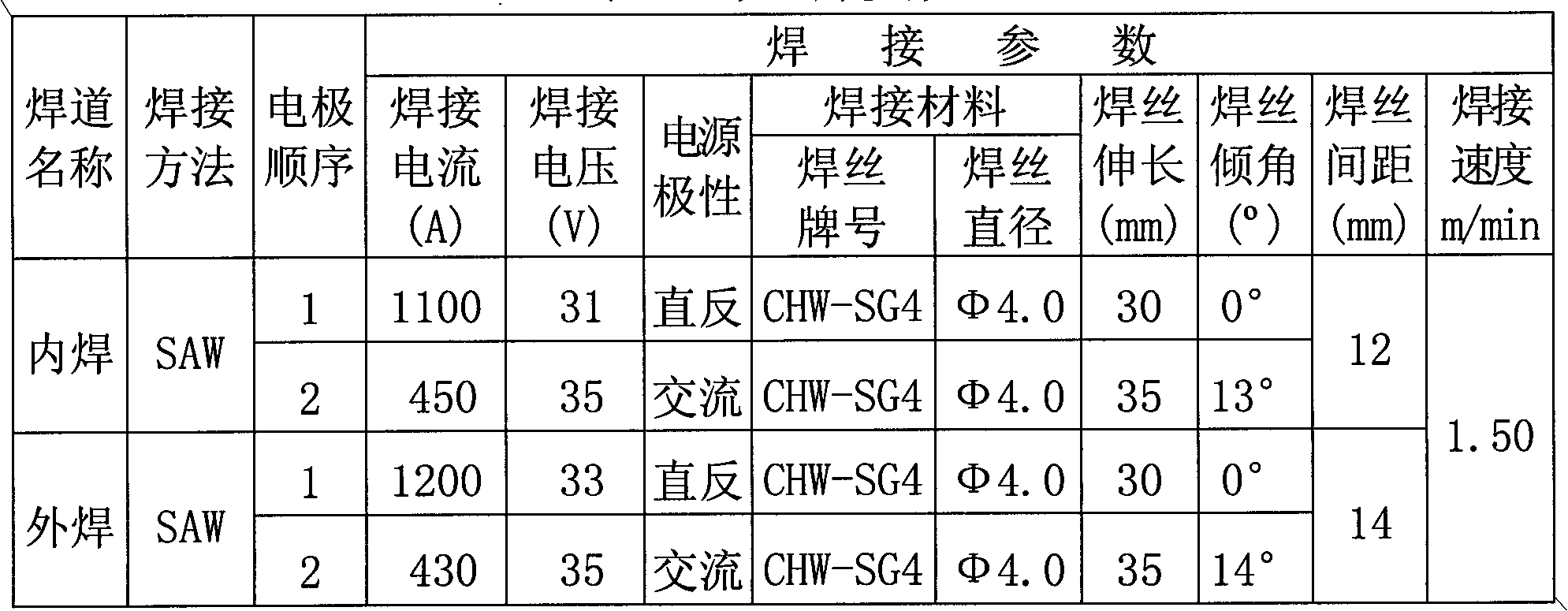

X65MS steel-grade spiral welded tube for acidic corrosion environment and manufacturing method thereof

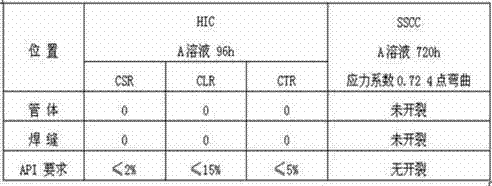

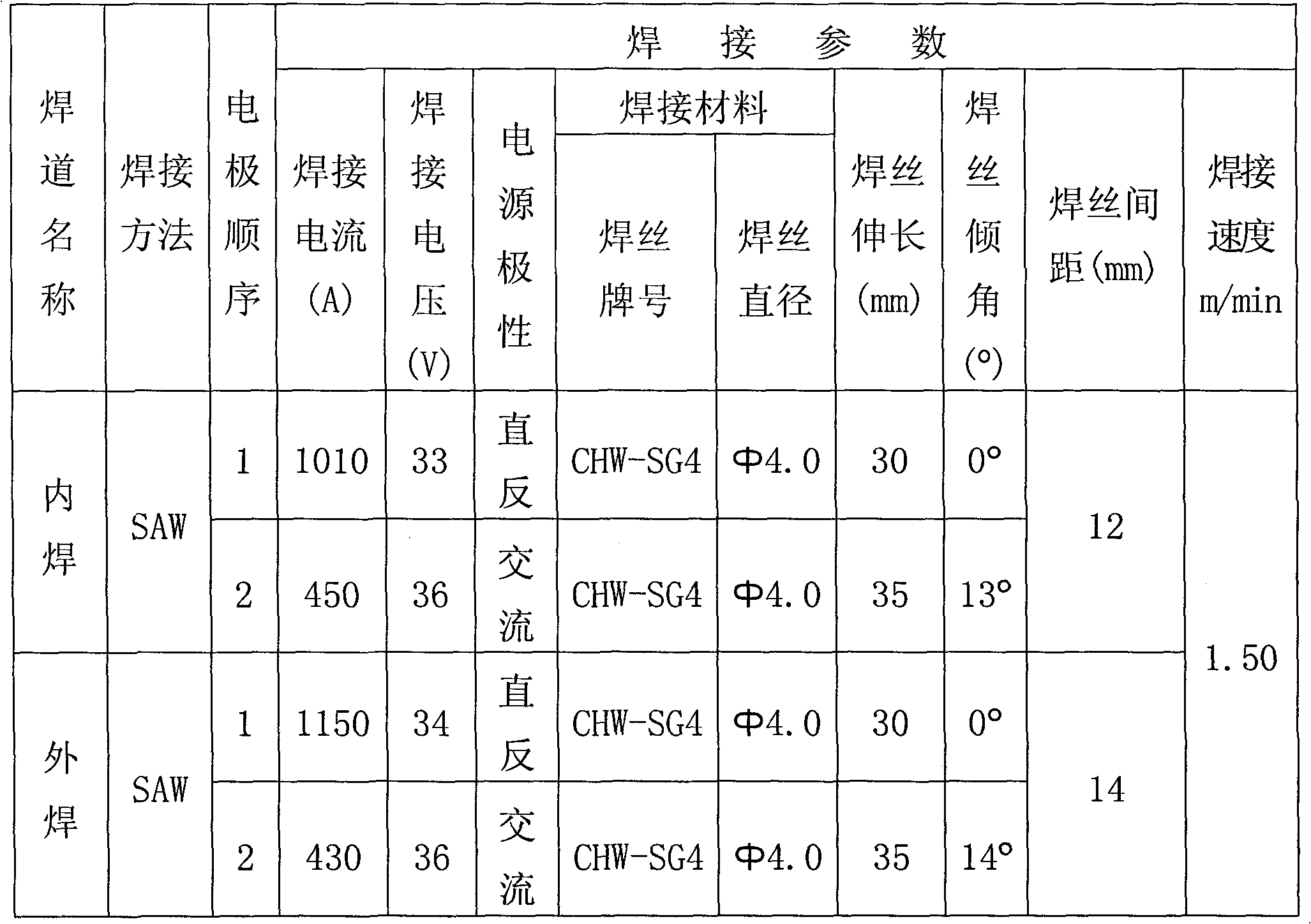

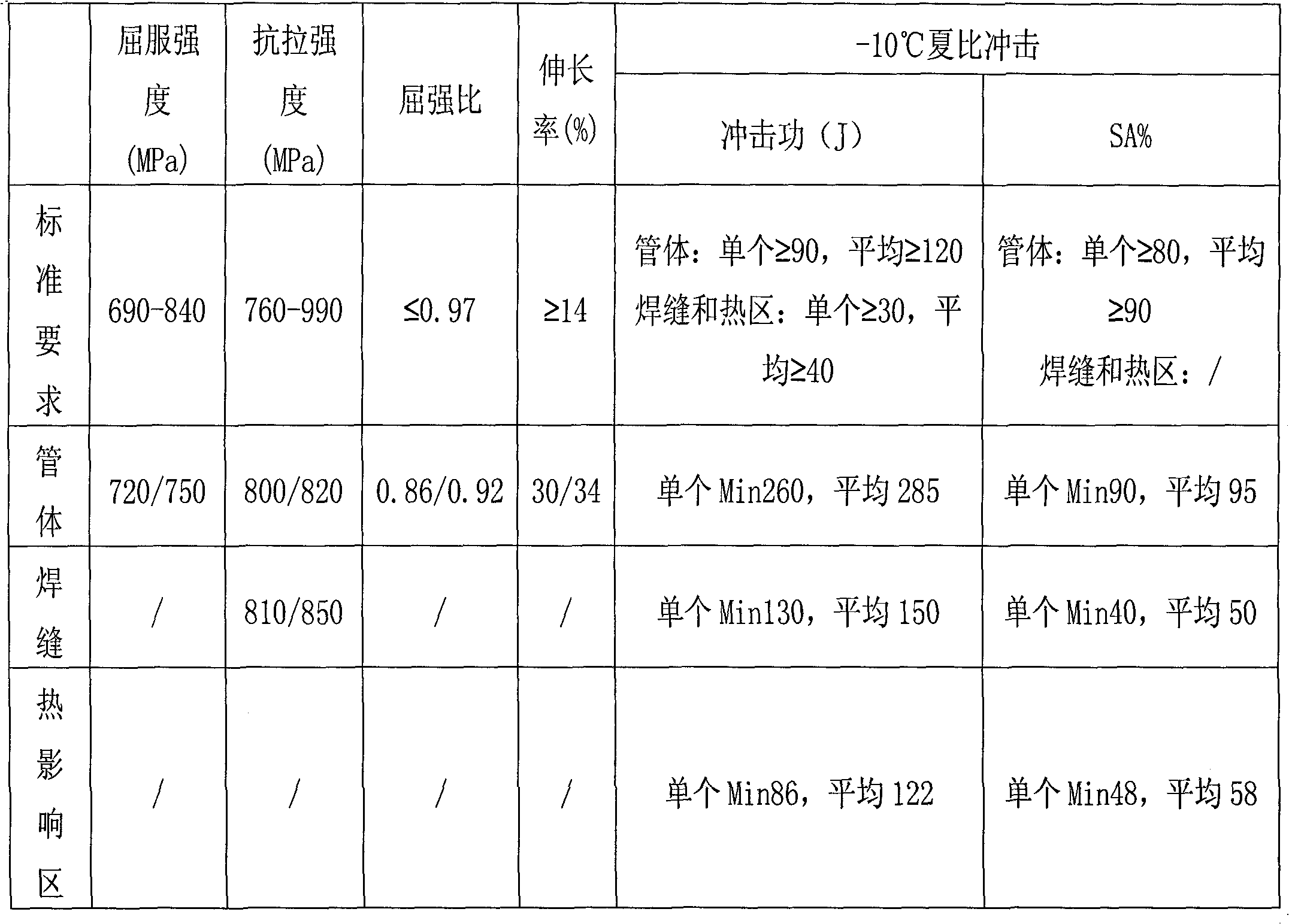

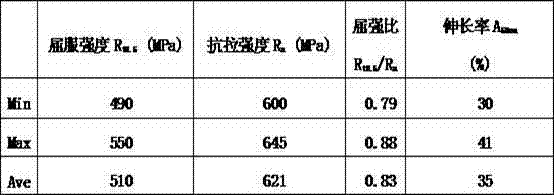

ActiveCN102330034ASolve the difficult problem of meeting the technical requirements of acid resistanceOptimizing the double milling processX-rayUltimate tensile strength

The invention discloses an X65MS steel-grade spiral welded tube for an acidic corrosion environment and a manufacturing method thereof. The spiral welded tube adopts an X65MS steel-grade coiled sheet. The processing procedures of the spiral welded tube comprise uncoiling, leveling, edge milling, pre-bending, forming, internal welding, external welding, tube end expanding, layering and ultrasonic inspection of a base material, X-ray inspection of a welding joint, hydrostatic test, ultrasonic inspection of the welding joint, tube end chamfering and inspection of the finished product. The X65MS steel-grade spiral welded tube disclosed by the invention has high strength and favorable acid resistance and is suitable for conveying an acid oil-gas medium.

Owner:CNPC BOHAI EQUIP MFG +3

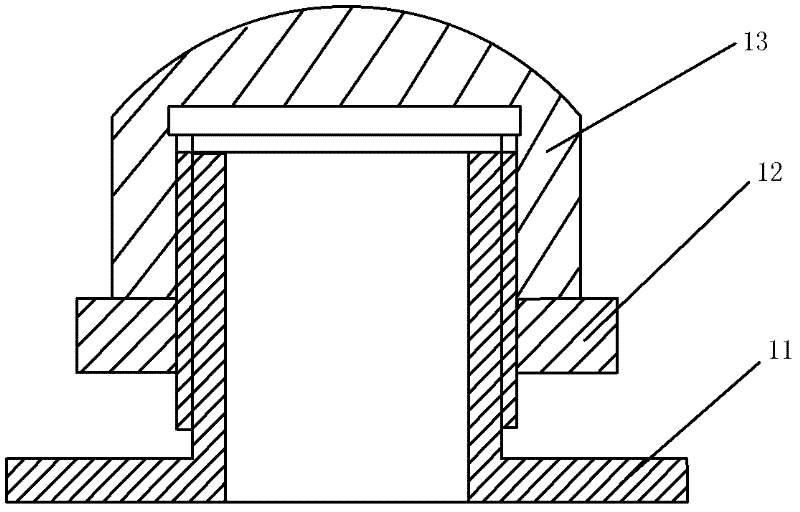

Method for manufacturing high-strength X100 steel grade spiral seam submerged arc welded pipe

ActiveCN101797600ATo achieve effective detectionFully automatedArc welding apparatusMilling equipment detailsProduct inspectionX-ray

The invention discloses a method for manufacturing a high-strength X100 steel grade spiral seam submerged arc welded pipe. The method comprises the following steps: uncoiling, flattening, edge milling, pre-springing, molding, inside welding, outside welding, pipe end belling, base metal layering ultrasonic examination, weld seam X ray inspection, hydrostatic test, weld seam ultrasonic inspection, pipe end chamfering and finished product inspection. In the technical steps of the preparation method, double edge milling process, pre-springing process and pipe end belling process are added so as to successfully solve the technical problems that the high-strength X100 steel grade spiral seam submerged arc welded pipe has poor molding stability, the welding joint performance cannot meet technical requirement and the like.

Owner:NORTH CHINA GASOLINEEUM STEEL PIPE +3

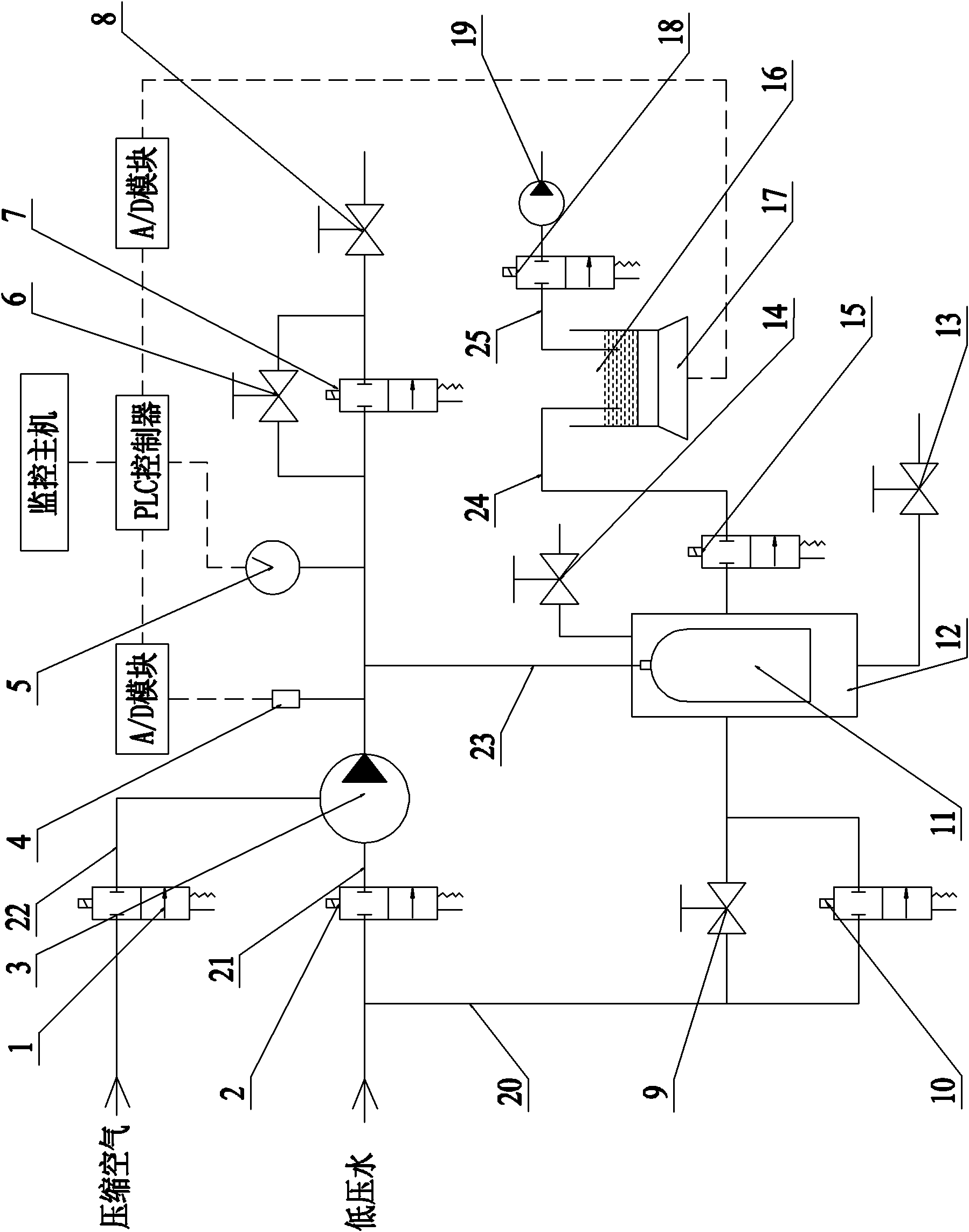

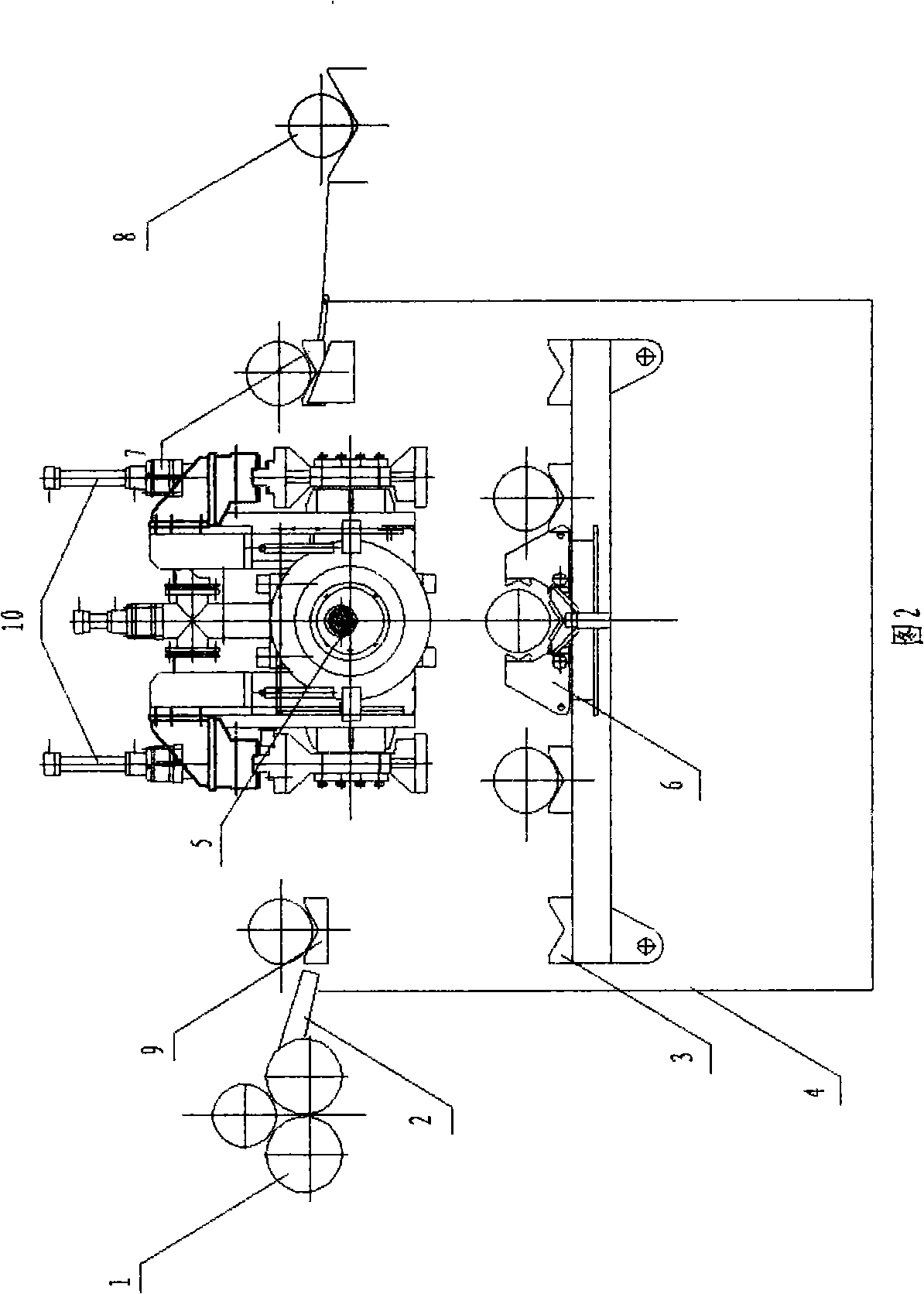

Automatic hydrostatic test control system using air-bottle outer measuring method

InactiveCN102033019AReduce labor intensityAutomate operationMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumControl systemGas cylinder

The invention relates to an automatic hydrostatic test control system using an air-bottle outer measuring method, comprising a hydrostatic test system, a control platform and a matched auxiliary system. The hydrostatic test system is used for the hydrostatic test of a tested air bottle and comprises a booster pump, a water jacket, a measuring cup, an electronic scale and a recycle pump, the auxiliary system comprises an automatic feeding device, a lifting sealing device and an automatic discharging device, wherein the automatic feeding device feeds the tested air bottle into a test position, the lifting sealing device loads tested air bottle in the water jacket or pulls the tested air bottle out of the water jacket, and the automatic discharging device conveys the tested air bottle out of the test position. The invention realizes the automatic operation of a hydrostatic test process, realizes the real-time and automatic detection and control of the test process, further lightens the labor intensity of operators, improves the detection efficiency and the detection accuracy and can realize the automatic operation of all auxiliary processes of the hydrostatic test by using the air-bottle outer measuring method.

Owner:无锡昌华机电制造有限公司

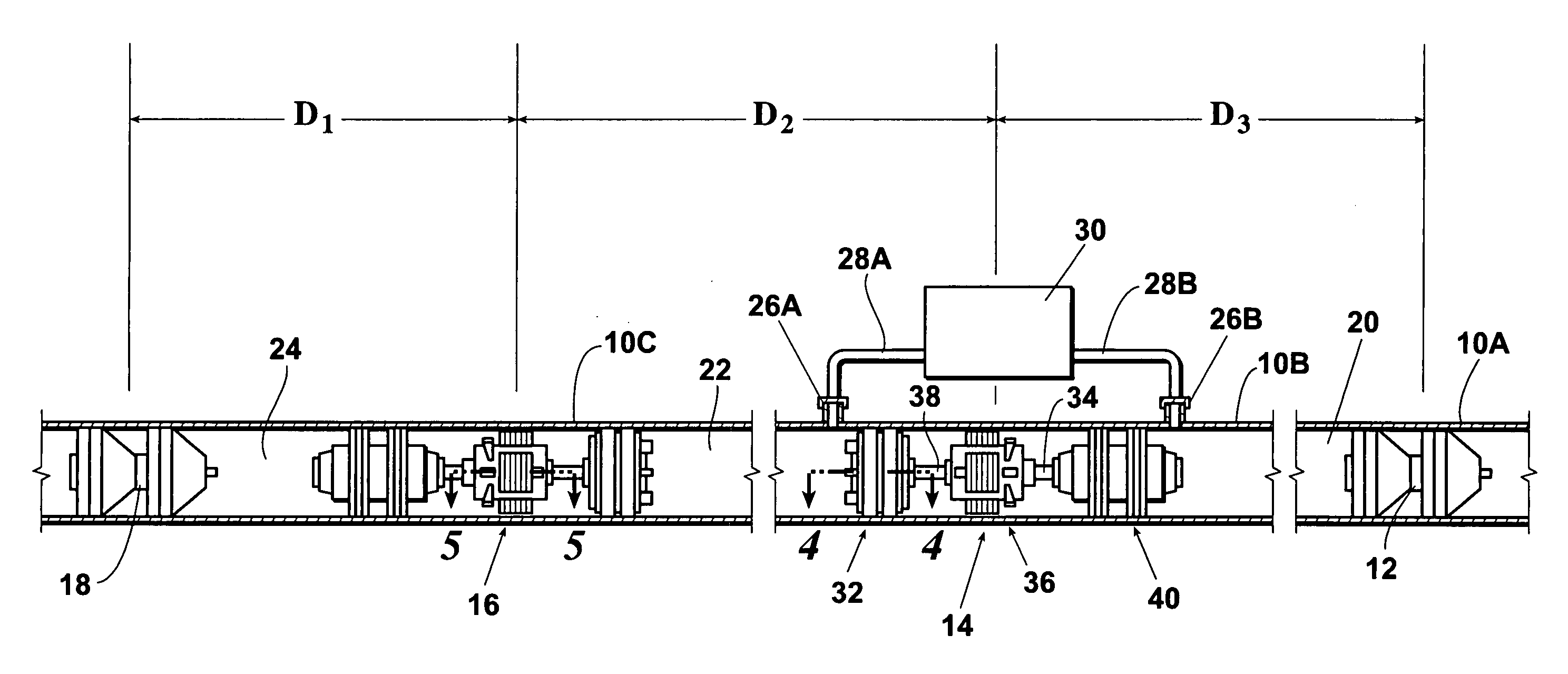

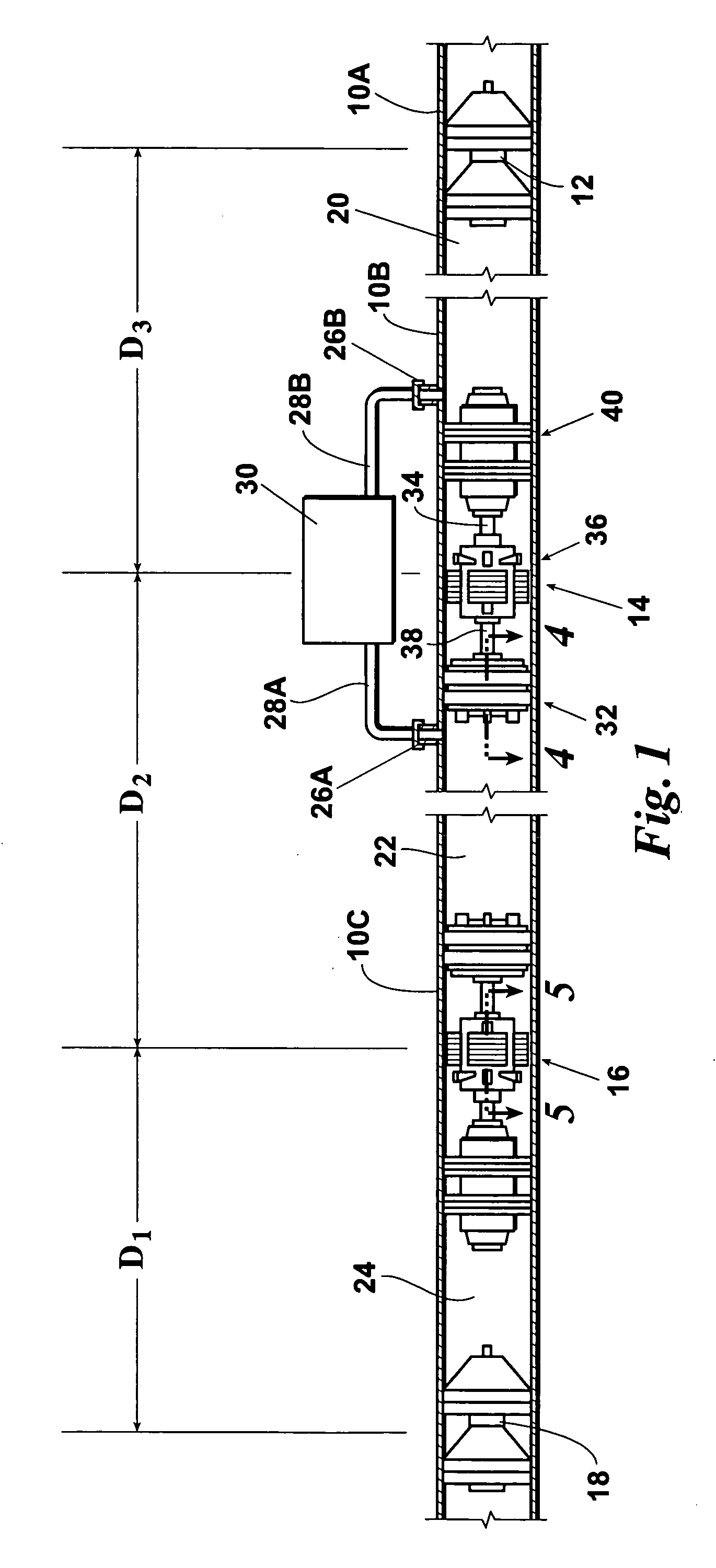

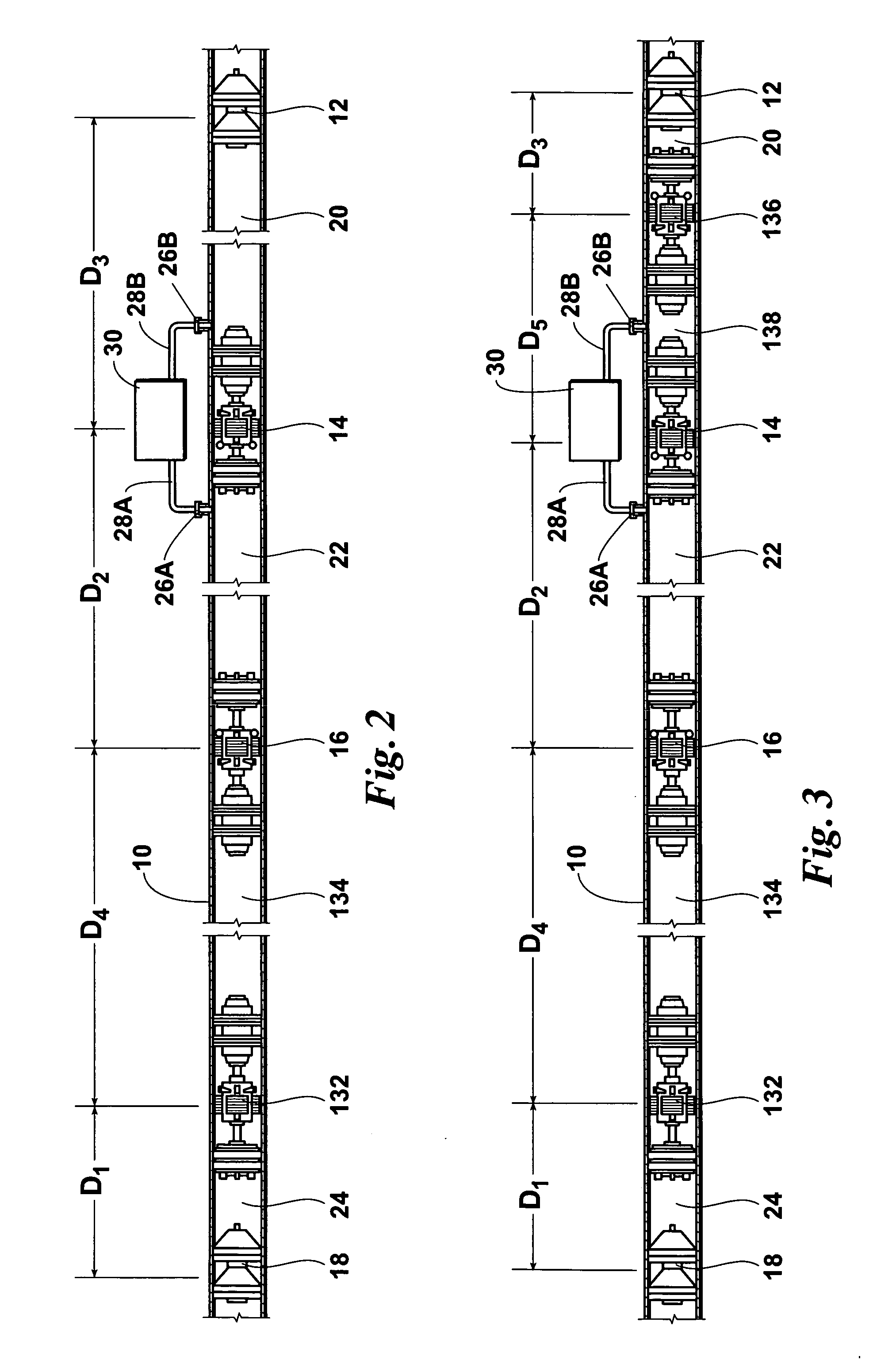

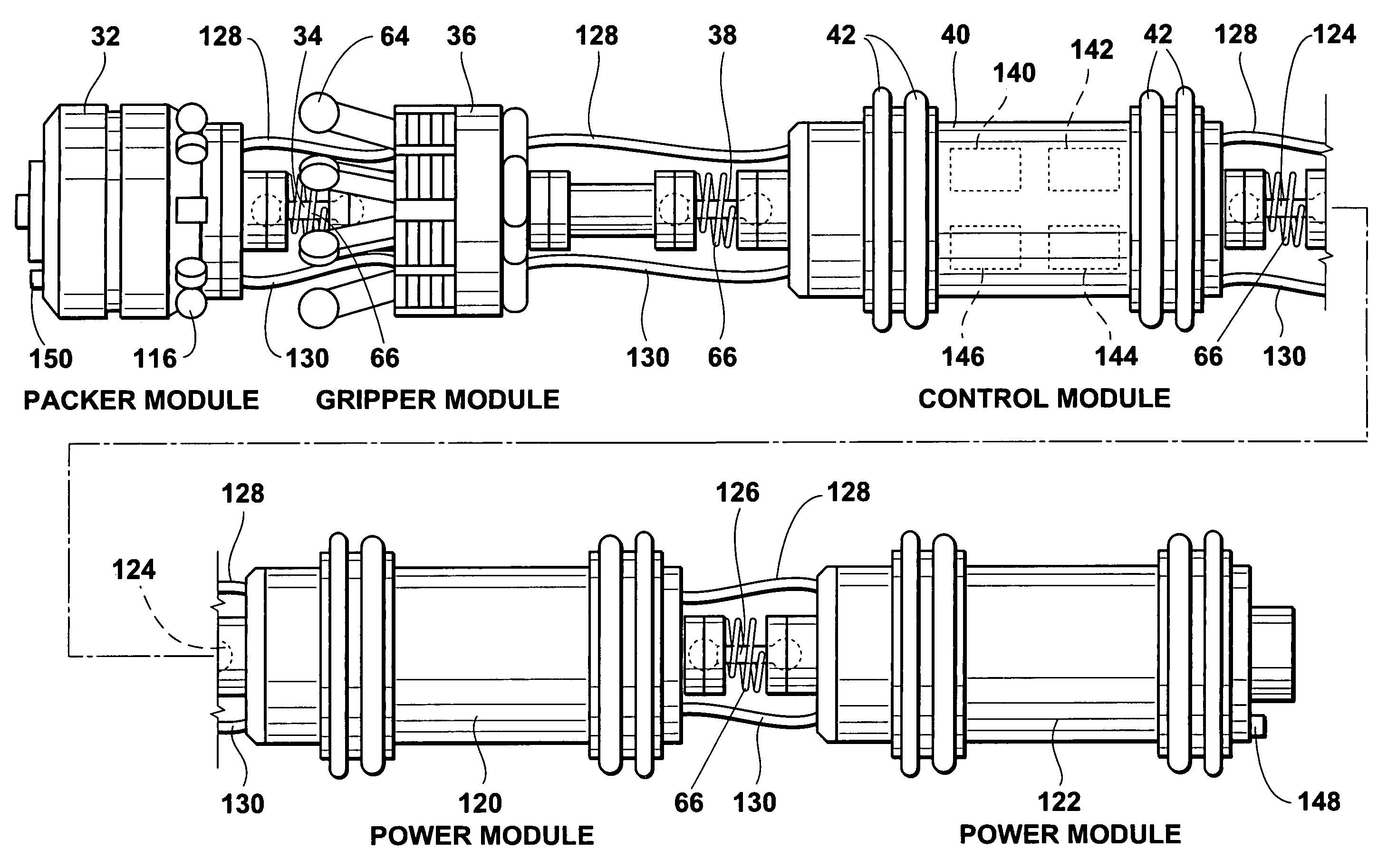

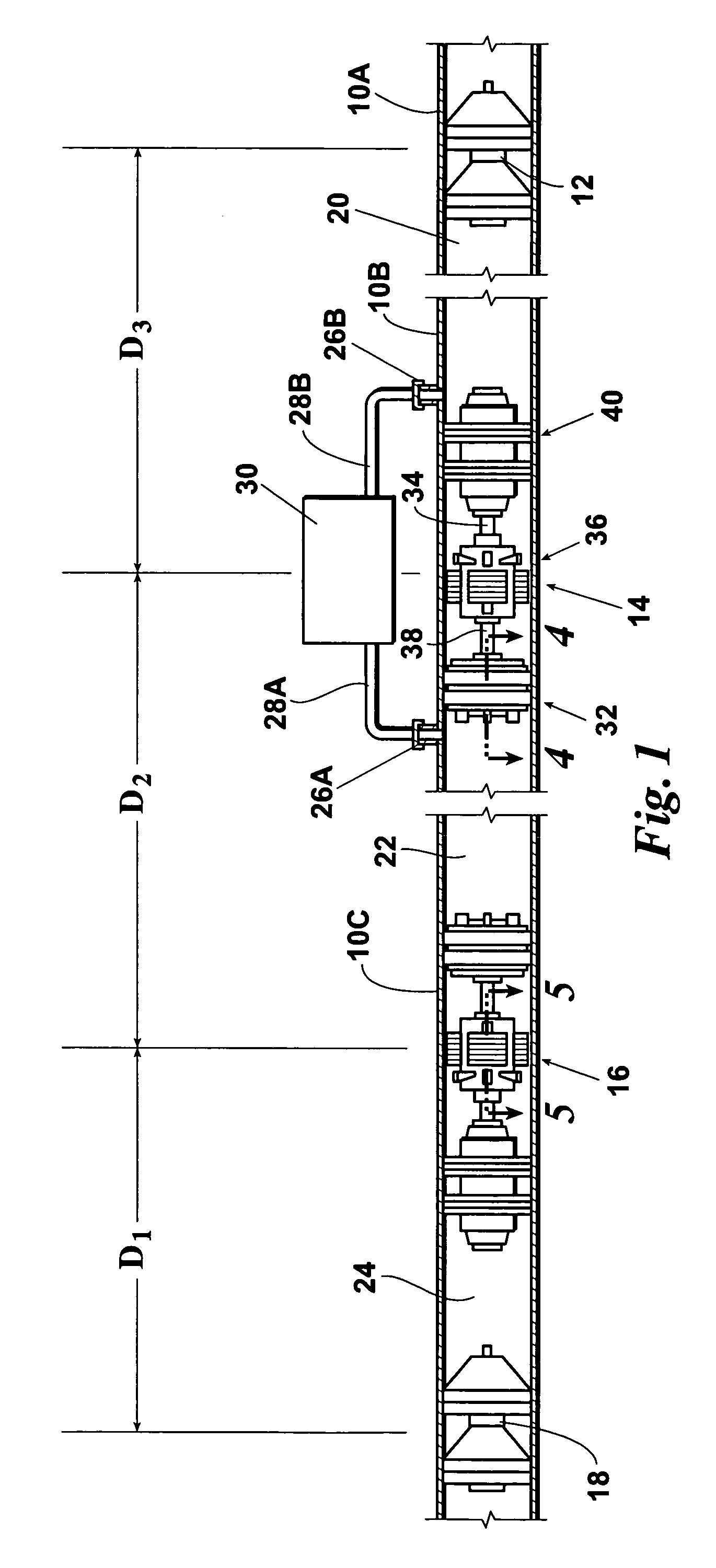

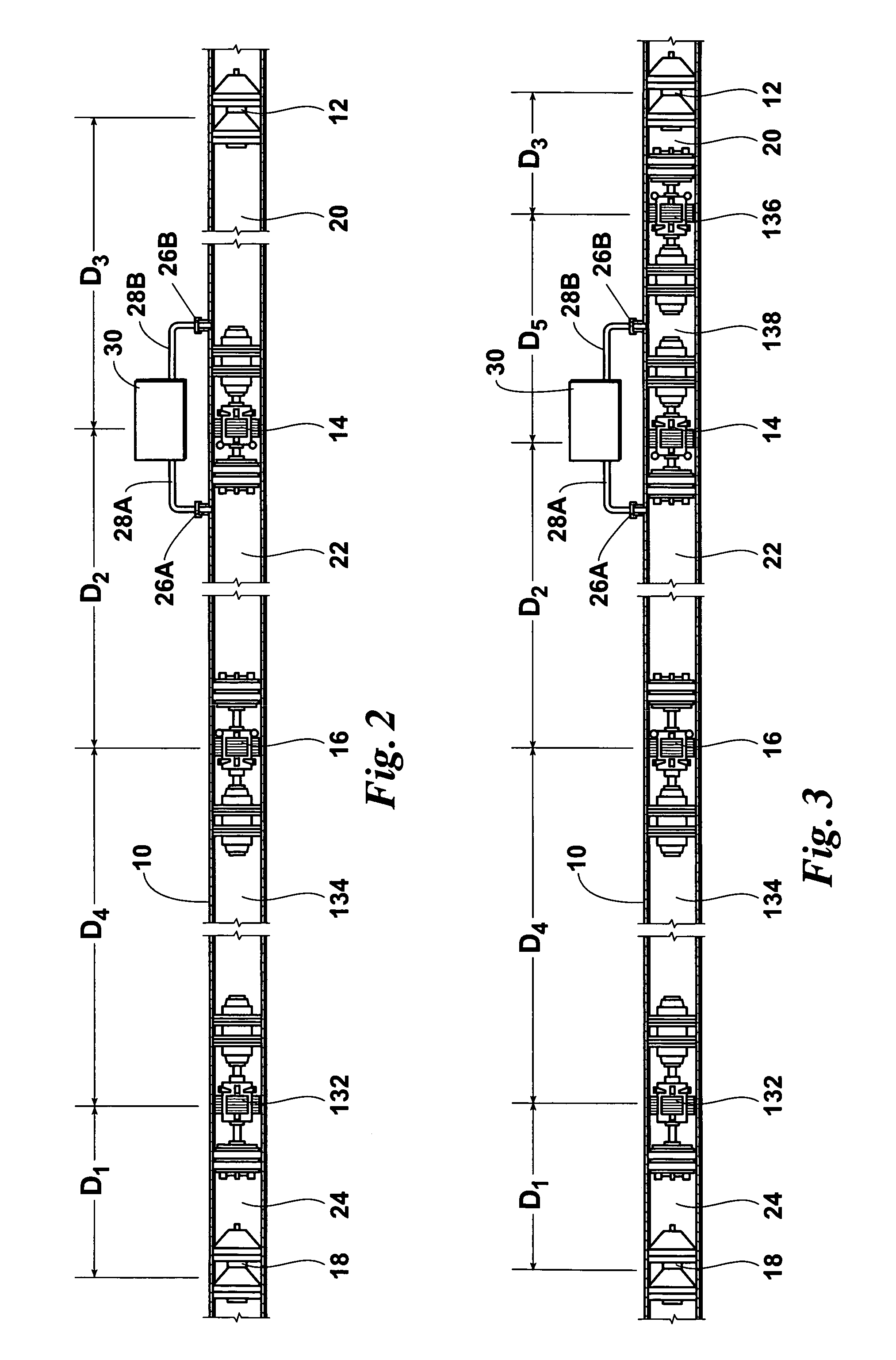

Methods and systems for hydrostatic testing a pipeline

ActiveUS20070113622A1Increase pressureRelieve stressDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesPiggingEngineering

A method of hydrostatic testing a selected section of a pipeline having fluid flow therethrough, including the steps of introducing into the pipeline a pig train including a leading seal pig, a supply liquid slug, a first isolation tool, a test liquid slug and a second isolation tool; permitting the train to traverse the pipeline interior by the force of fluid flow until the lead isolation tool is forwardly of and the second isolation tool is rearwardly of the selected selection of the pipeline; securing the position of the pig train by applying exteriorly of the pipeline appropriate signals to actuate the isolation tools to each engage and seal the interior of the pipeline trapping the test liquid slug therebetween; and pumping liquid from the supply liquid slugs into the test liquid slug to a hydrostatic testing pressure. In addition to testing, the pipeline can be repaired by moving the pig train into position where a defective area can be isolated by additional isolation tools.

Owner:TDW DELAWARE INC

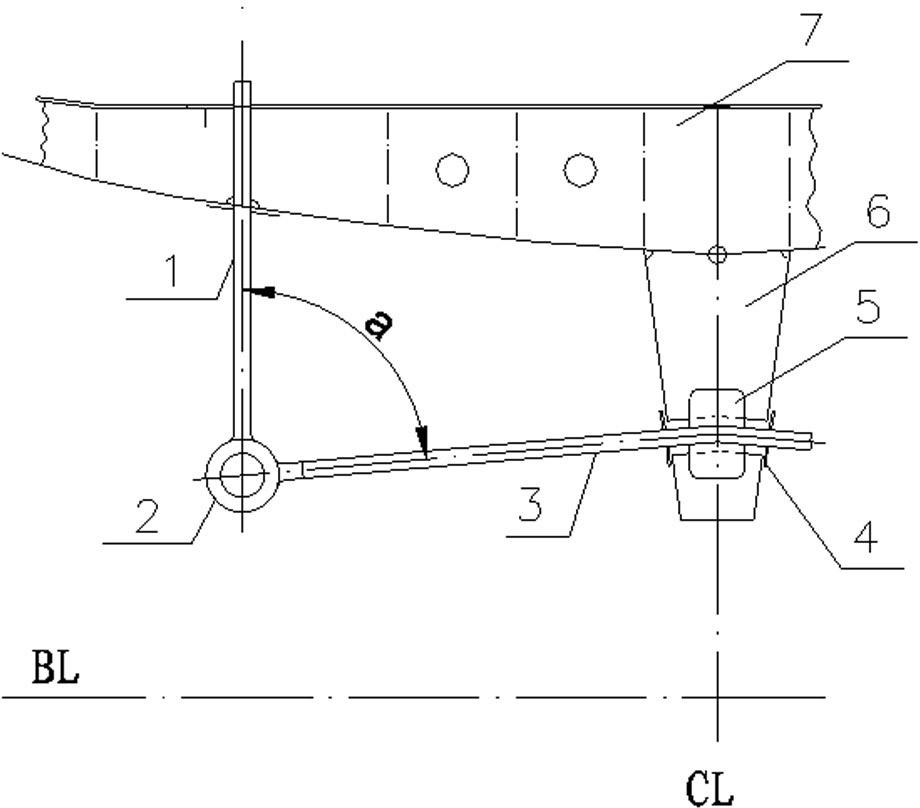

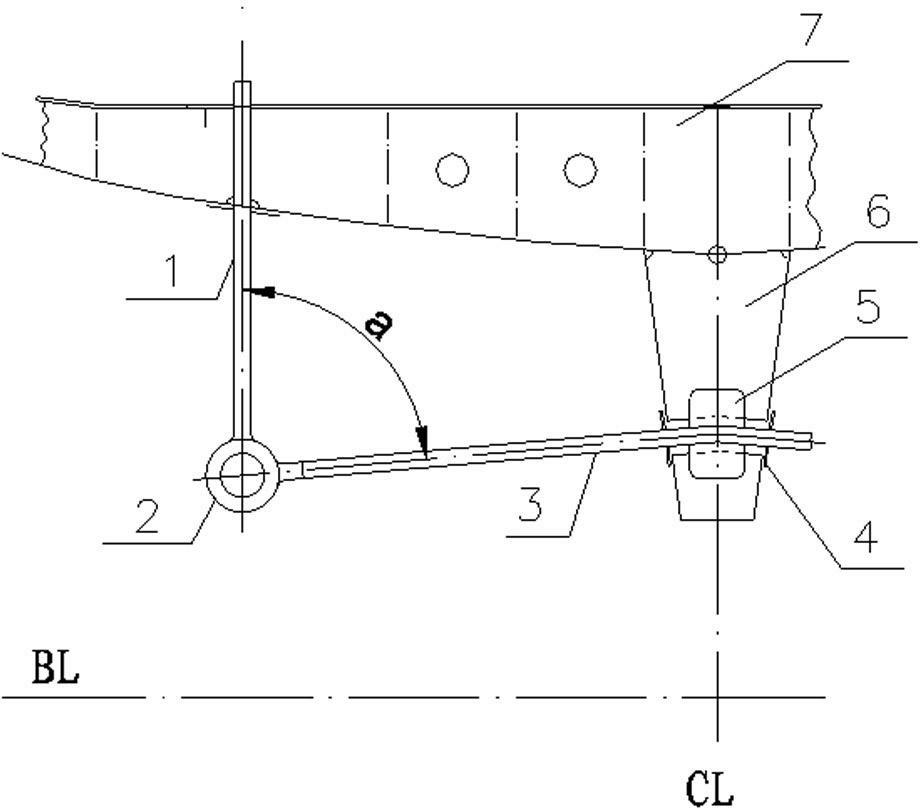

Assembly welding process for propeller shaft bracket

InactiveCN102303176AMixed flow and small forceAvoid correctionWelding/cutting auxillary devicesArc welding apparatusPropellerPore diameter

The invention relates to an assembly welding process for a propeller shaft bracket, and belongs to the technical field of ships. The process comprises the following steps of: before assembling a propeller shaft hub, performing a hydrostatic test of 0.2 MPa; correcting axes and pore diameters of front and rear end faces of the propeller shaft hub and sizes of four points on the left and right sides and upper and lower sides of the propeller shaft hub, and marking temporarily; cutting corresponding position holes on a bottom board and rib board of a ship body, and machining beveled edges of a supporting arm and the propeller shaft hub to perform point welding pre-positioning connection; allowing transverse arms in the horizontal direction to form an included angle alpha of 85 degrees with the supporting arm, splicing the supporting arm and the propeller shaft hub on a moulding bed in advance, and inserting into an open pore of the bottom board of the ship body to perform pre-welding positioning; after the supporting arm and the transverse arms are pre-positioned, welding and positioning the transverse arms and the propeller shaft hub according to a shafting bracing wire; and after welding, performing ultrasonic detection and magnetic particle detection on the propeller shaft bracket. The propeller shaft bracket assembled by the process is small in positional deviation and vibration quantity and low in noise, and the service life of the ships is prolonged greatly.

Owner:YANGFAN GROUP

Novel dual metal composite pipes and preparation method

ActiveCN101334119AImprove corrosion resistanceTroubleshoot Connection Sealing IssuesLayered productsRigid pipesCorrosion resistant alloyEngineering

The invention relates to a novel bimetallic composite pipe, which is applied in exploiting oil and natural gas fields. The novel bimetallic composite pipe is characterized in that an inner lining pipe is arranged in an outer wall pipe. Short joints are welded at both ends of the outer wall pipe, welding seams are arranged between the outer wall pipe and the short joints, and both end parts of the inner lining pipe are welded on the inner wall of the short joints. At least 1 through hole with the diameter of 2 to 10 millimeters is drilled on the wall of the outer wall pipe. Electric welding is adopted to completely weld the through hole after the water pressure test, namely, electric welding is used for solidly filling the through hole after the water pressure test. Screw threads are machined at both ends of the novel bimetallic composite pipe or the both ends of the novel bimetallic composite pipe are machined into two welding grooves. The novel bimetallic composite pipe has the advantages that a carbon steel pipe or a low alloy steel pipe is adopted as the substrate material of the outer wall pipe, to exert the superior capability of mechanics of machinery and the low price characteristic of the carbon steel pipe or the low alloy steel pipe; the inner lining adopting layer corrosion resistant alloy is provided with excellent corrosion resistant capability and superior capability of mechanics of machinery. The screw threads coupling connection sealing problem and the bimetallic composite pipe ground welding problem occurring when the prior bimetallic composite pipes are in use are thoroughly solved, the application field of the bimetallic composite pipe is enlarged, and the cost of the oil field exploitation is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

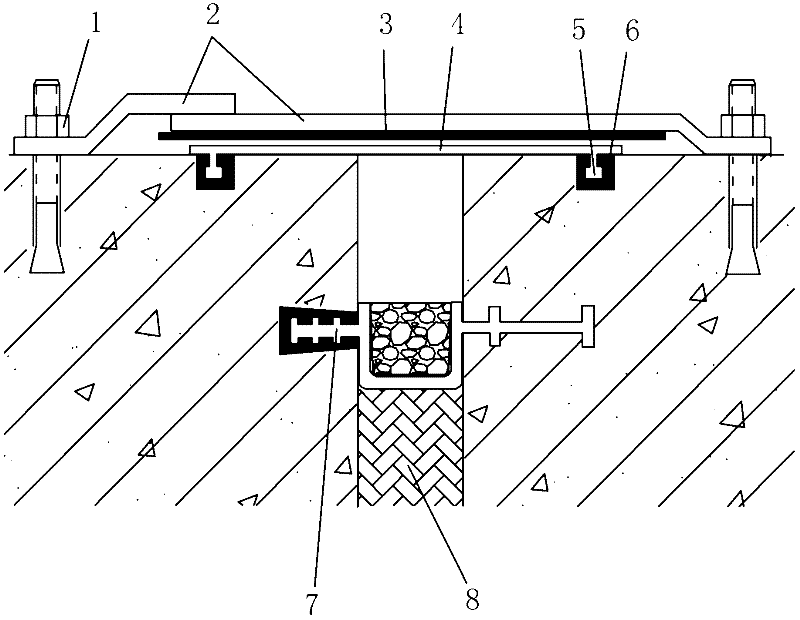

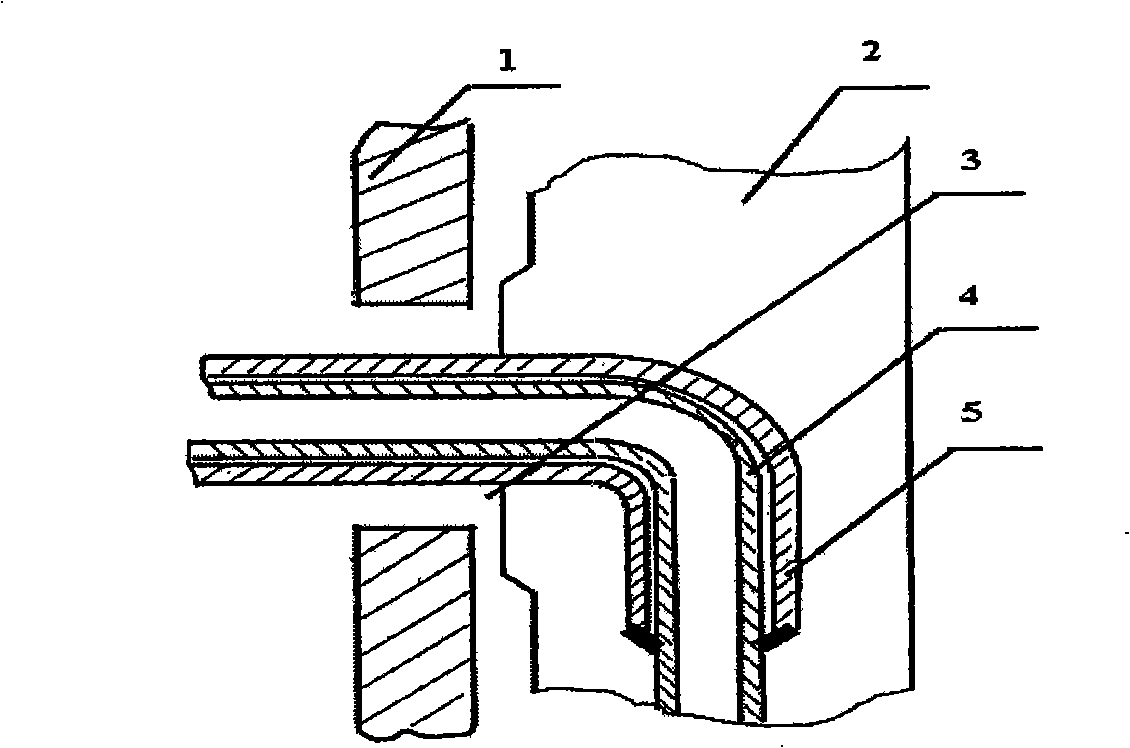

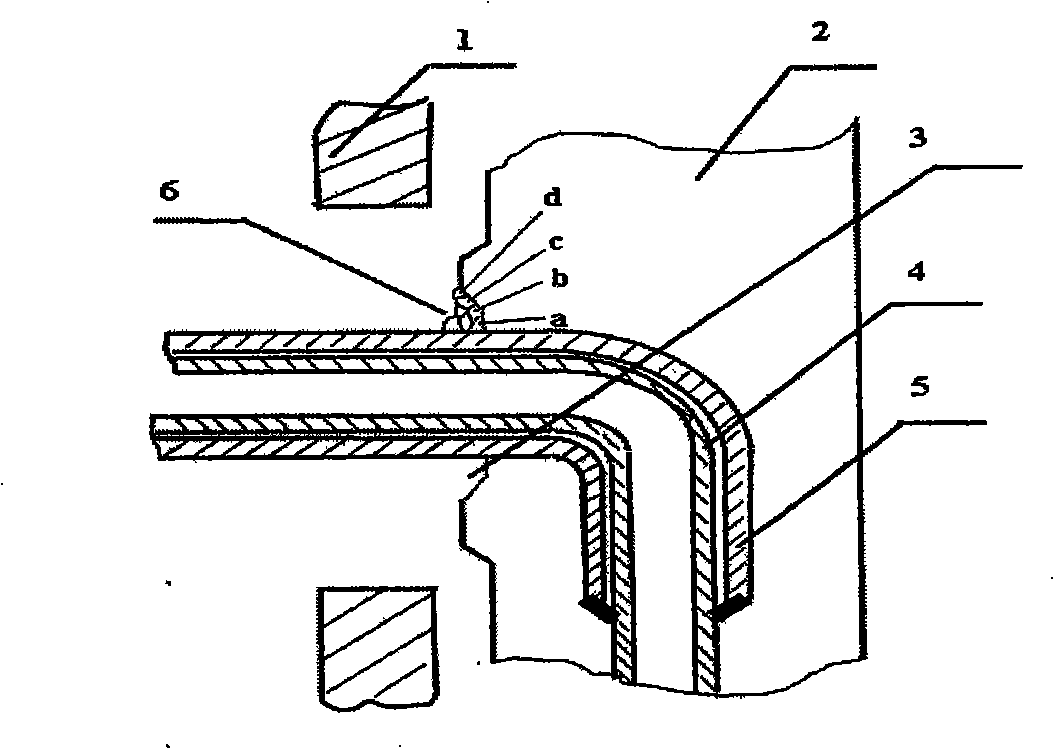

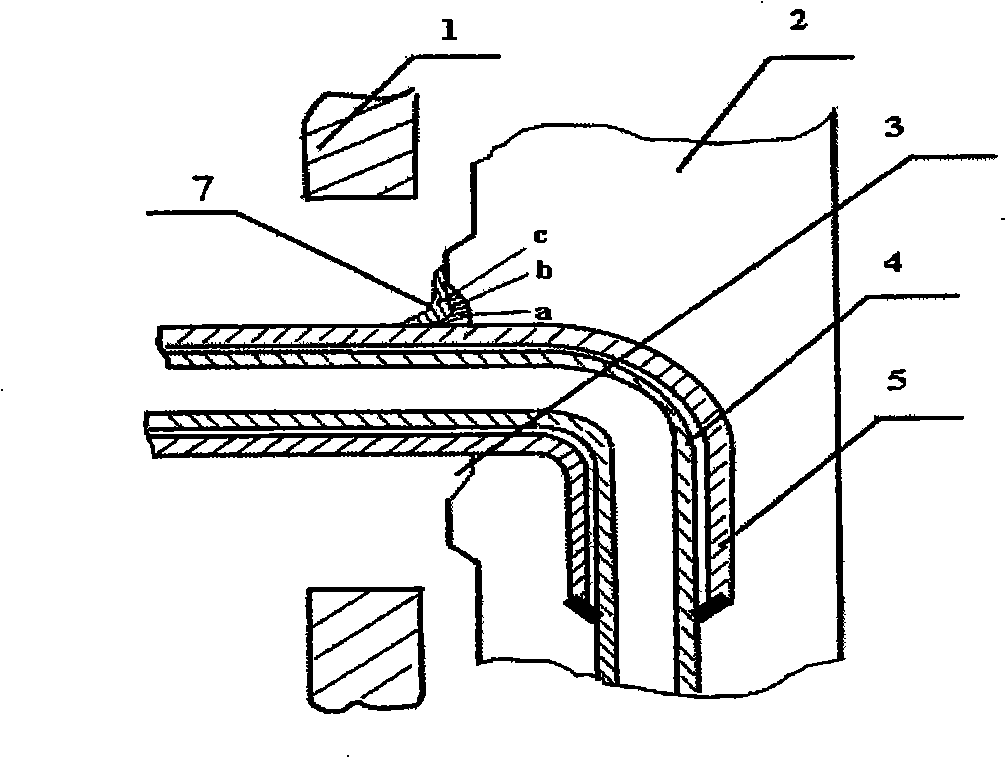

Field hydrostatic test method for water-proof system of building deformation joint

InactiveCN102331328AImprove reliabilityImprove waterproof reliabilityFluid-tightness measurement using fluid/vacuumAdhesiveEngineering

Owner:吴兆圣

Method for manufacturing high-strength X90 steel grade spiral submerged arc welded pipe

ActiveCN101886222AImprove docking efficiencySimple molding processArc welding apparatusWelding/soldering/cutting articlesHigh intensityWeld seam

The invention discloses a method for manufacturing a high-strength X90 steel grade spiral submerged arc welded pipe. The method comprises the following steps of: uncoiling; leveling; edge milling; pre-springing; forming; inside welding; outside welding; pipe end diameter expansion; layering and ultrasonic examination of a base material; X-ray examination of a welding seam; hydrostatic test; ultrasonic examination of the welding seam; and pipe end chamfering. By increasing the processes of double edge milling, edge pre-springing and pipe end diameter expansion in the processing steps, the manufacturing method successfully solves the technical problems of poor forming stability, the difficulty for the performance of the welded joint to meet the technical requirement and the like during the manufacturing of the high-strength X90 steel grade spiral submerged arc welded pipe.

Owner:CNPC BOHAI EQUIP MFG +1

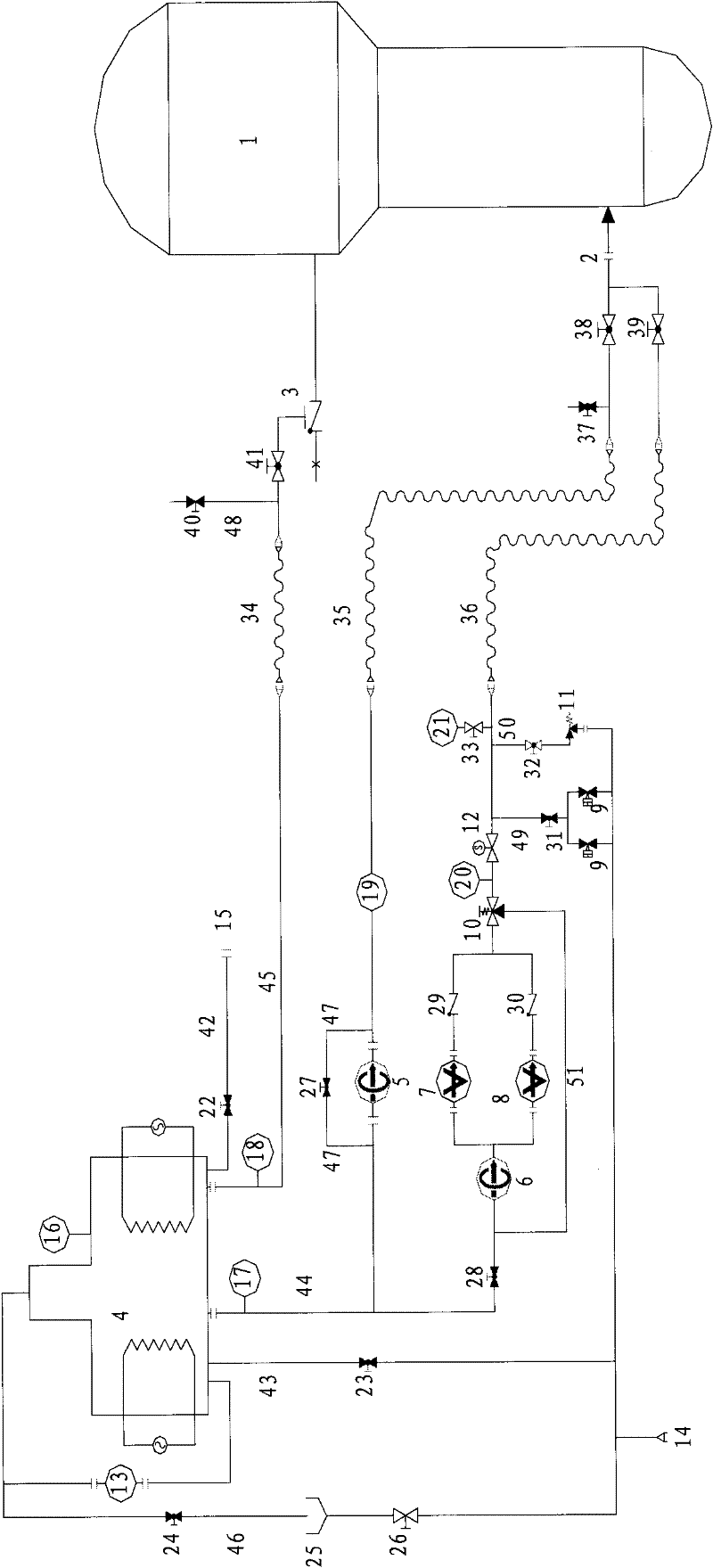

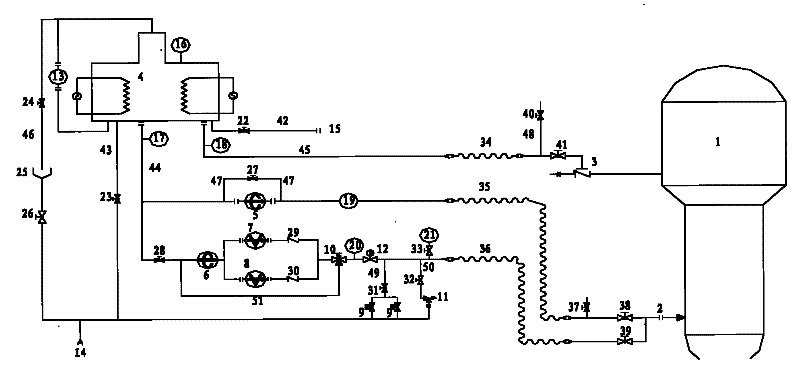

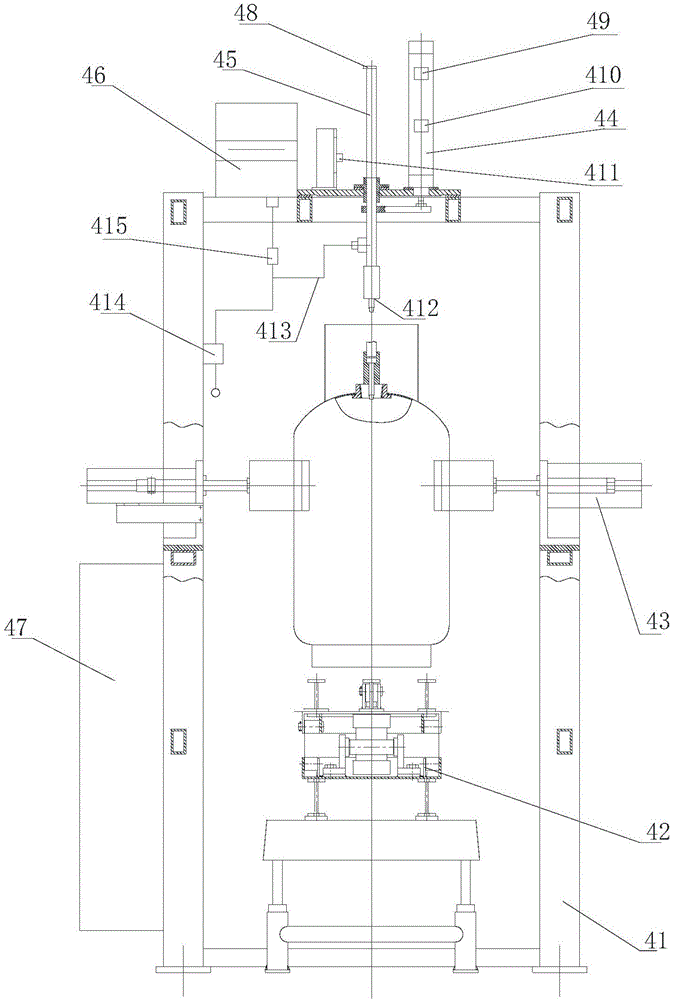

Pre-service hydrostatic test integrated system on secondary side of steam generator

ActiveCN102194535AEvenly heatedHeating up fastNuclear energy generationNuclear monitoringElectricityPressurized water reactor

The invention belongs to the field of pressurized water reactor nuclear power plants, particularly disclosing a pre-service hydrostatic test integrated system on a secondary side of a steam generator of the pressurized water reactor nuclear power plant. The system comprises a pressurizing pump capable of pressurizing to the secondary side of the steam generator, an electric heating water tank anda circulating pump, wherein the pressurizing pump is connected with the circulating pump in parallel; both an inlet of the pressurizing pump and a suction port of the circulating pump are communicated with a water tank outlet pipe of the electric heating water tank; both an outlet of the pressurizing pump and an outlet of the circulating pump are communicated with a hand hole temporary port on the secondary side of the steam generator; and a water tank water return pipe of the electric heating water tank is communicated with a high-position temporary port on the secondary side of the steam generator. The system has stable and reliable performance, can realize uniform and rapid temperature rise of a shell on the secondary side of the steam generator, can be safely and stably pressurized and unpressurized during pressurizing test, and has a small size and high safety, stability and adjusting accuracy; test period can be effectively shortened; and efficiency can be increased.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

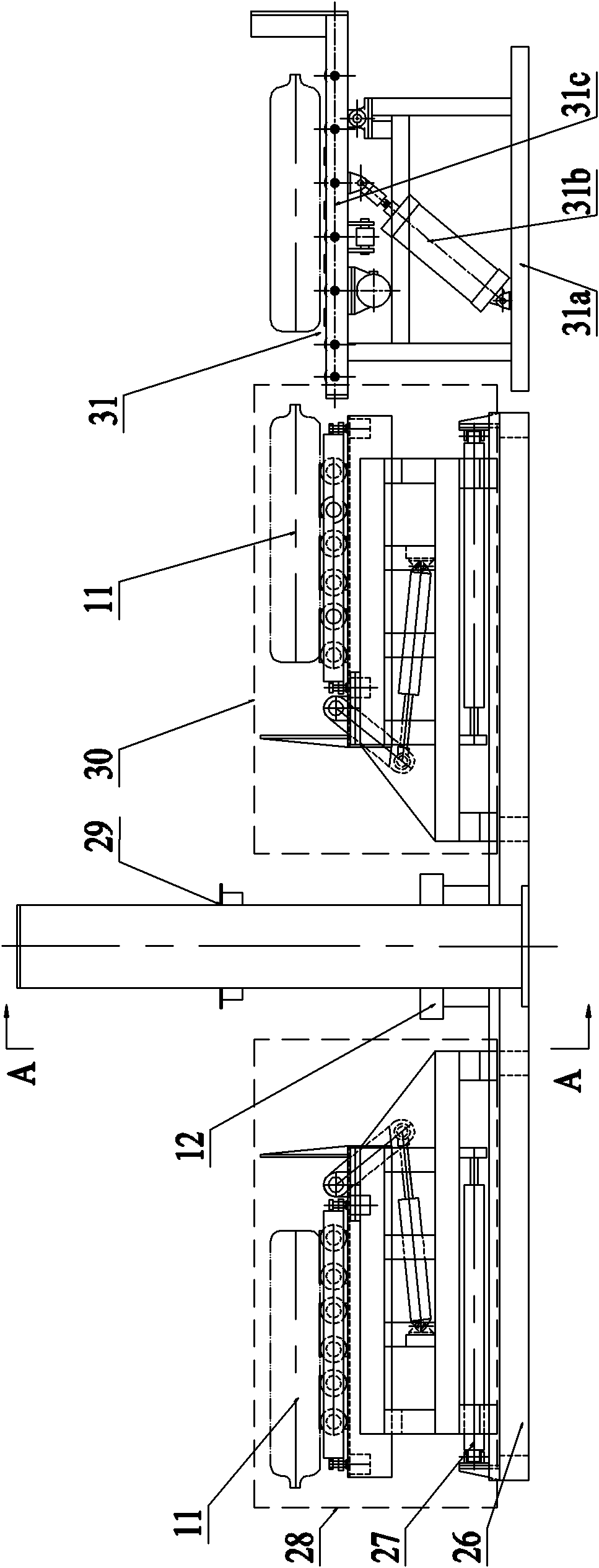

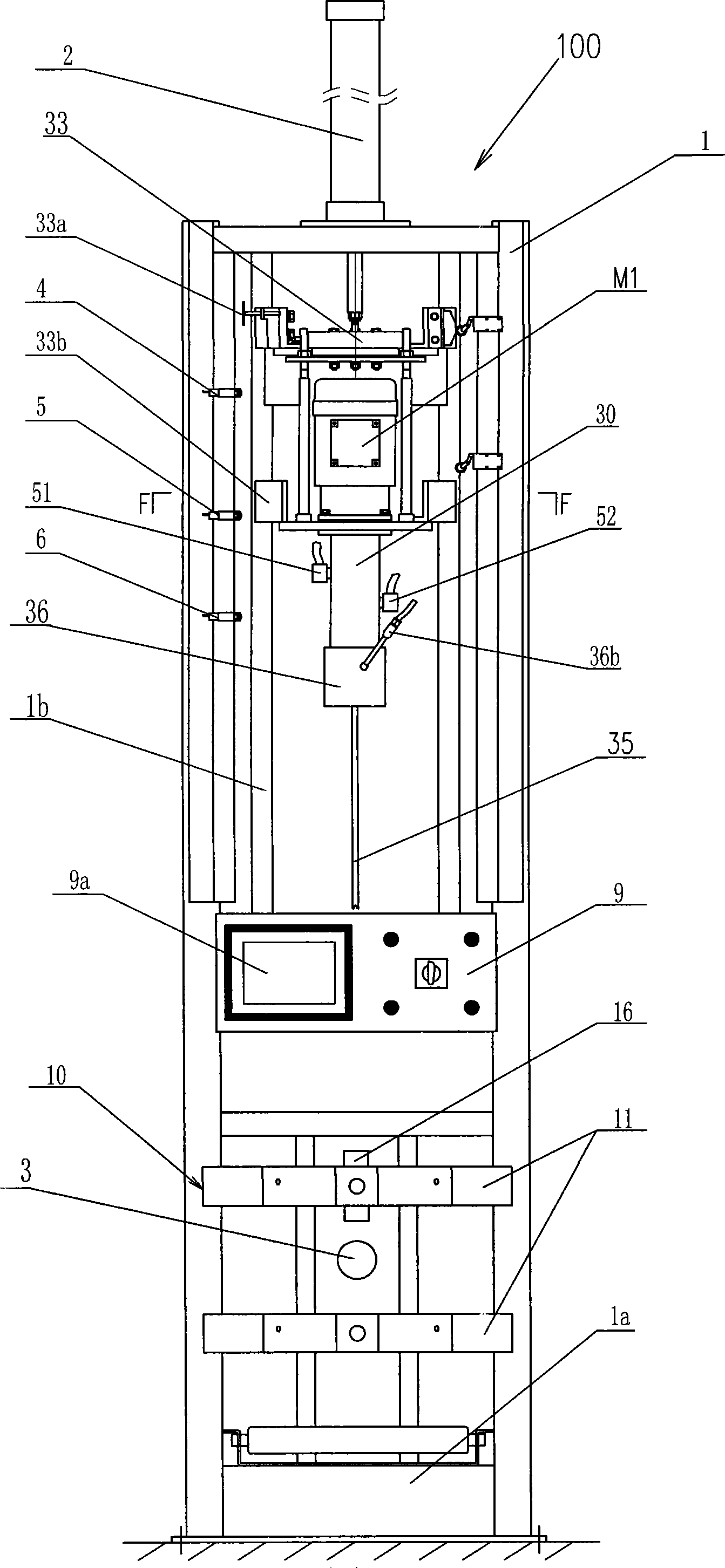

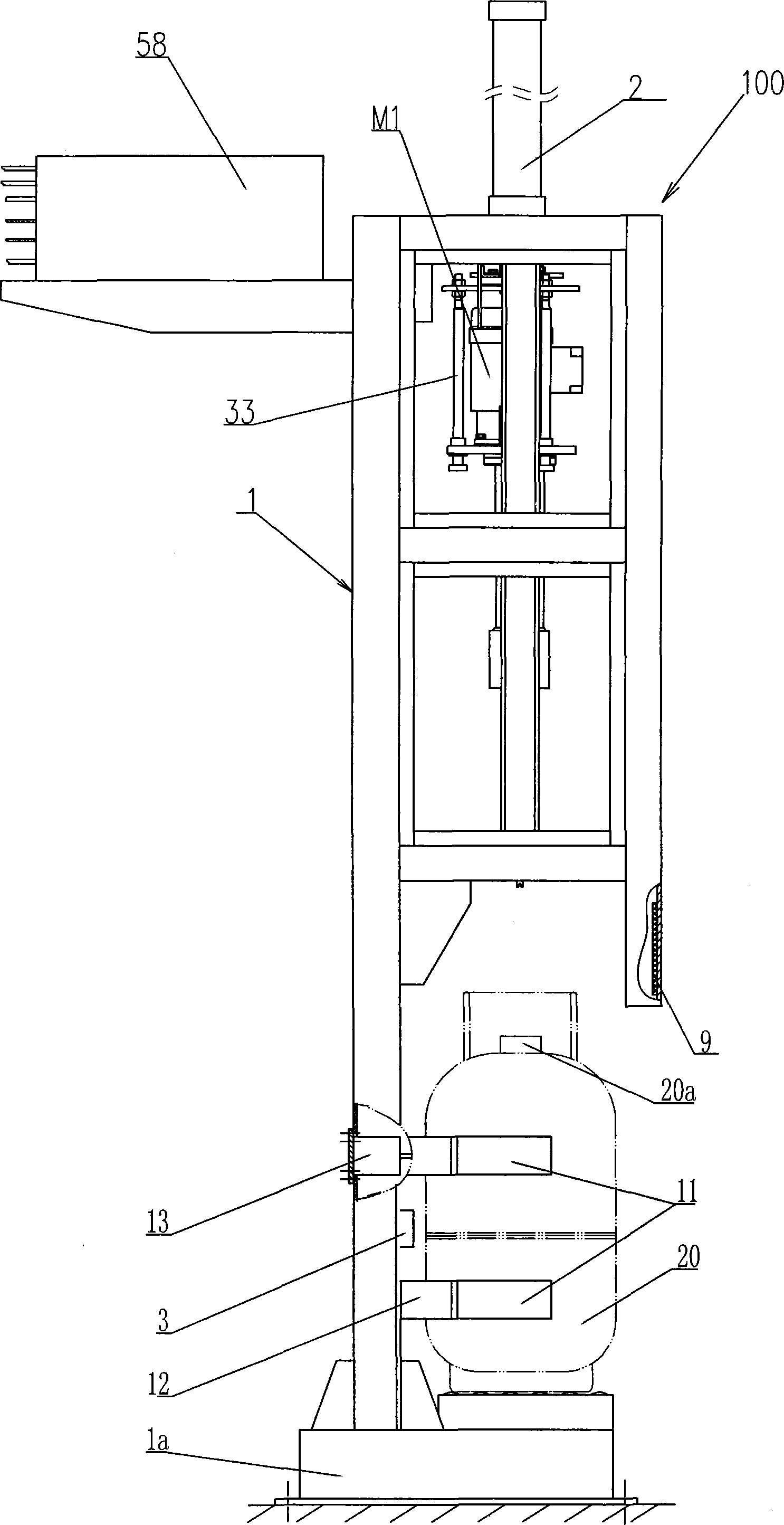

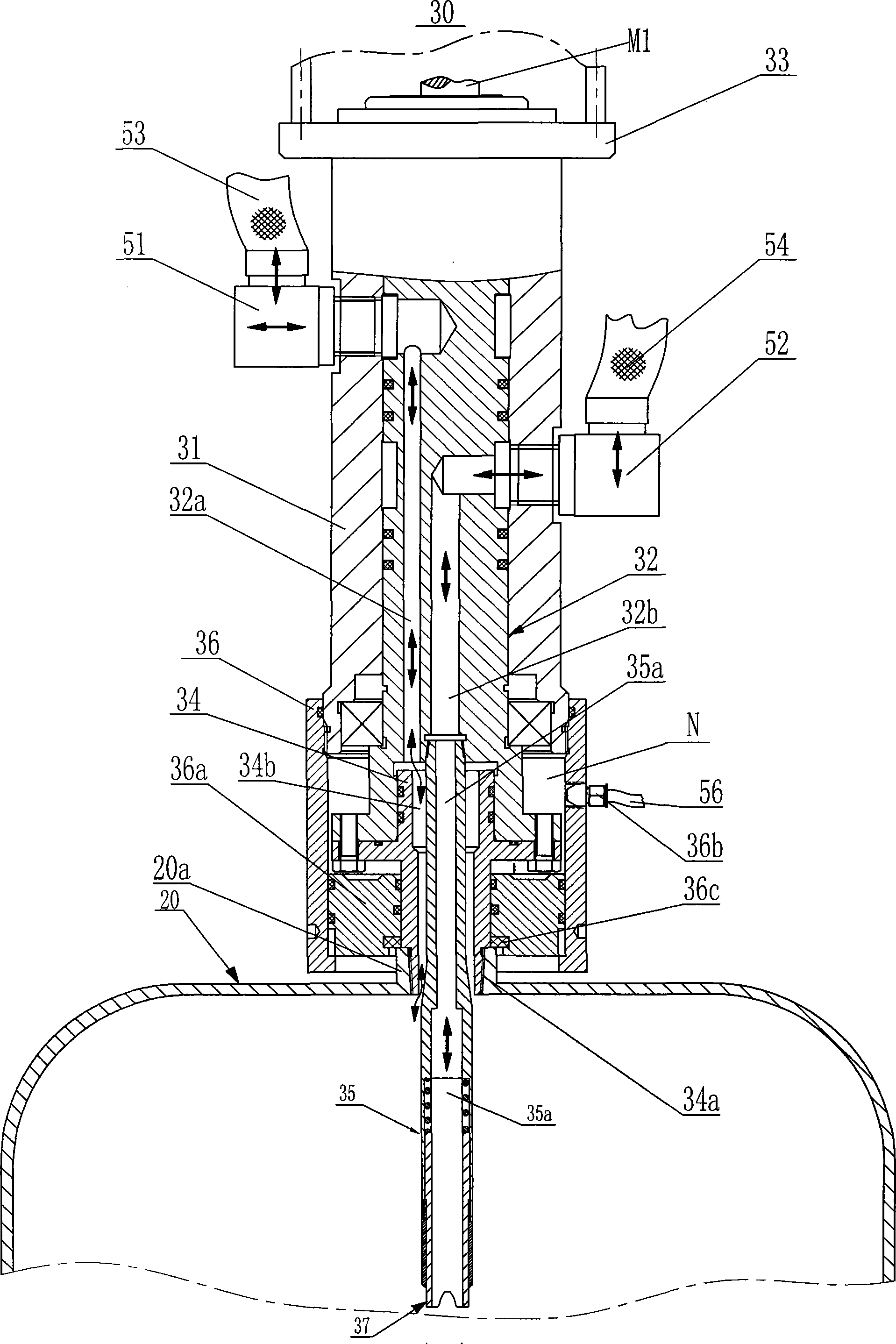

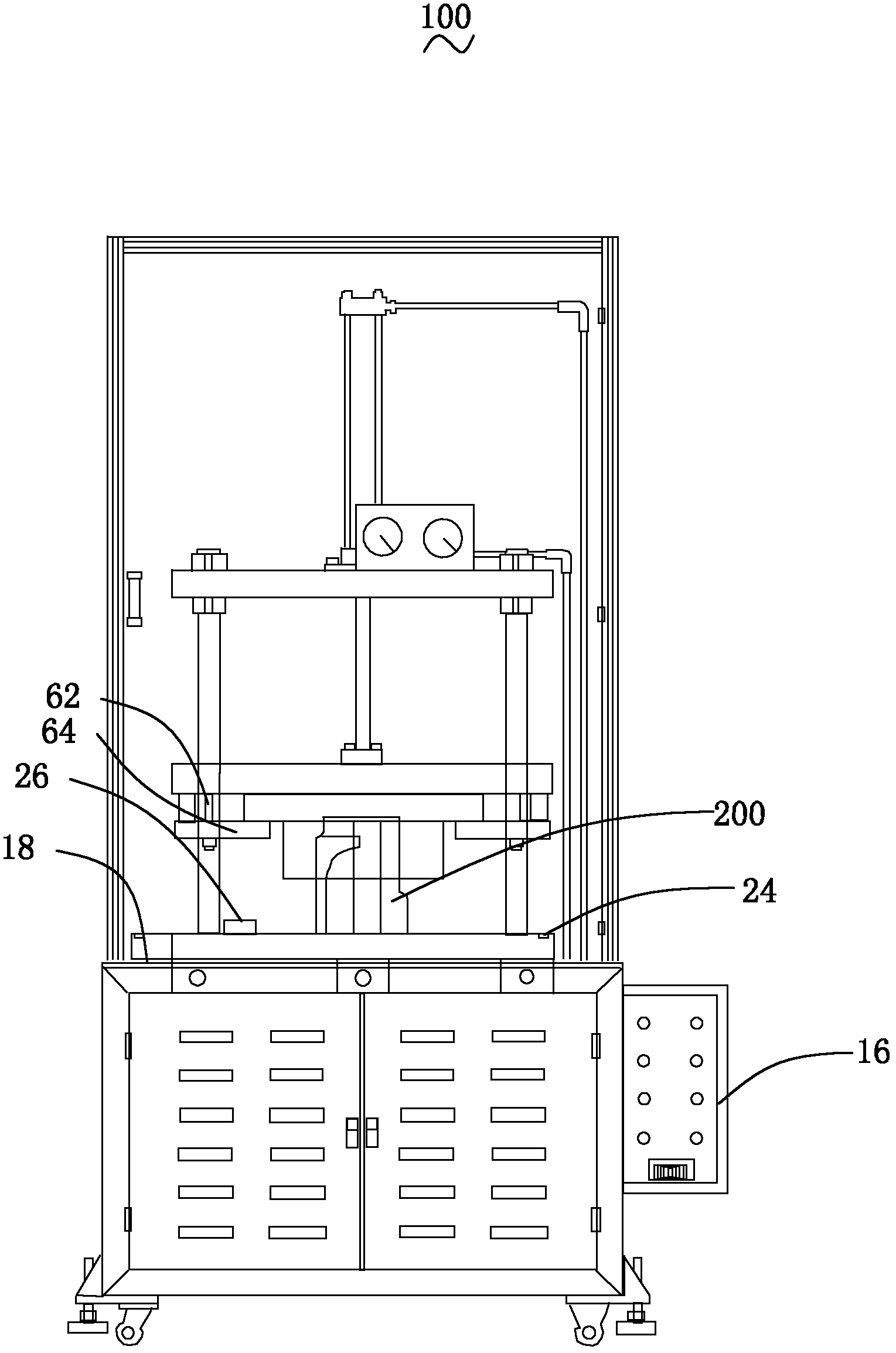

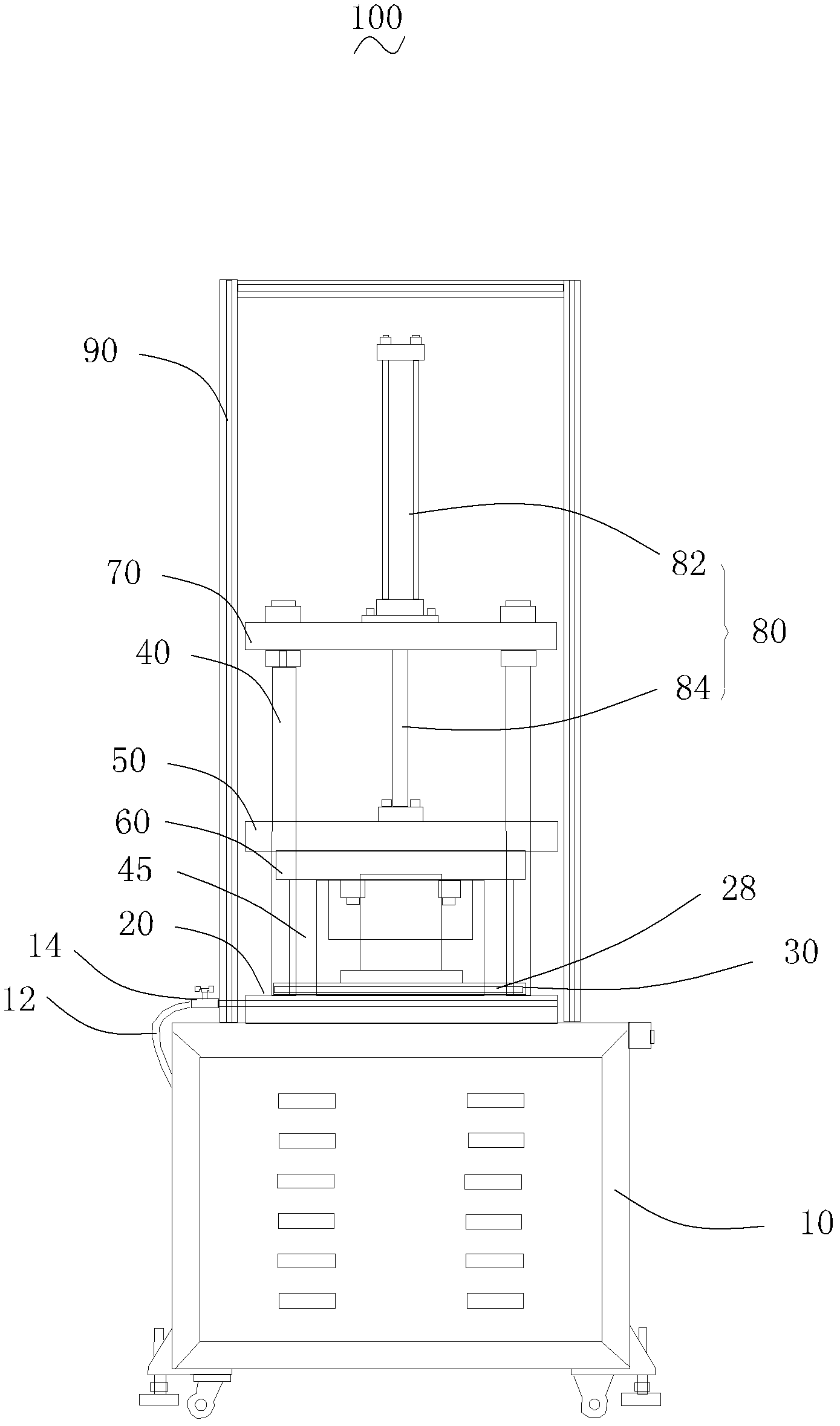

Automatic testing machine of gas cylinder hydrostatic test

ActiveCN103926150ANo deformationImplement automated testingMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumGas cylinderEngineering

The invention discloses an automatic testing machine of a gas cylinder hydrostatic test. The automatic testing machine structurally comprises a rack, and an automatic cylinder clamping device, a sealing rod, a plurality of proximity switches, a touch screen and a circuit control board are arranged on the rack, wherein the sealing rod is connected with a movable driving mechanism and a rotary driving mechanism; the movable driving mechanism is used for driving the sealing rod to move up and down to be inserted in a gas cylinder or retreated from the gas cylinder; the rotary driving mechanism is used for driving the sealing rod to rotate to be hermetically and rotationally assembled in a valve seat threaded hole of the gas cylinder so as to conveniently insert the sealing rod in the gas cylinder to inject gas or water to perform a hydrostatic test. The automatic testing machine has the beneficial effects that an automatic test is achieved; the sealing rod is screwed in the valve seat threaded hole of the gas cylinder by threads to seal the upper plane of the valve seat of the gas cylinder, a cylinder body is free of external force, and thus no cylinder body deformation caused by external force is generated; the automation degree is high, the labor intensity of an operator is reduced, and the turntable type automatic testing machine of a gas cylinder hydrostatic test does not need to be manually carried; the gas cylinder hydrostatic test efficiency is high, the measurement precision is high and the safe use of the gas cylinder is ensured.

Owner:天津市长龙宏业燃气设备有限公司

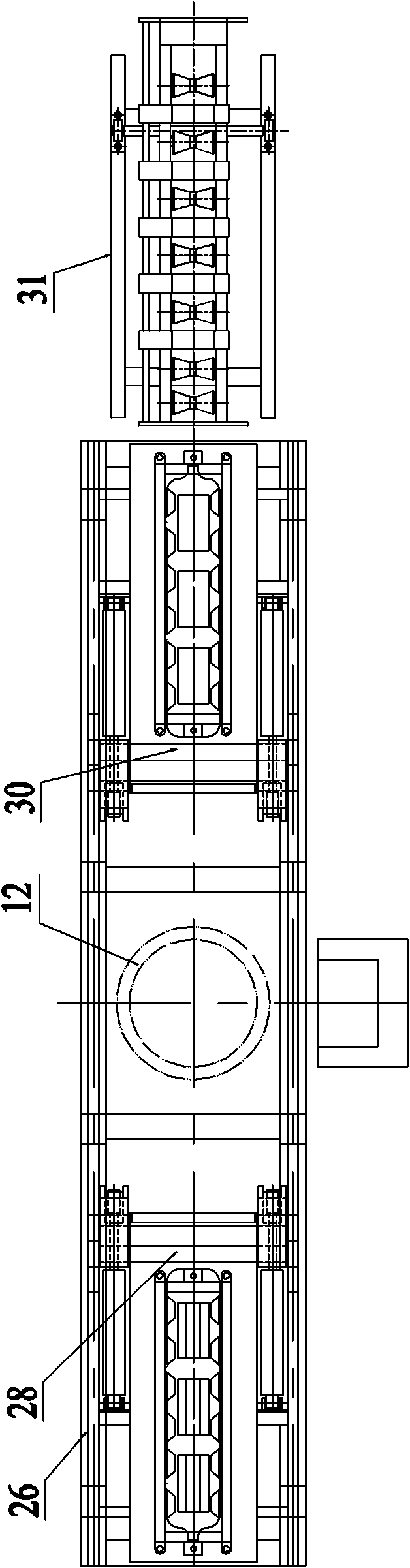

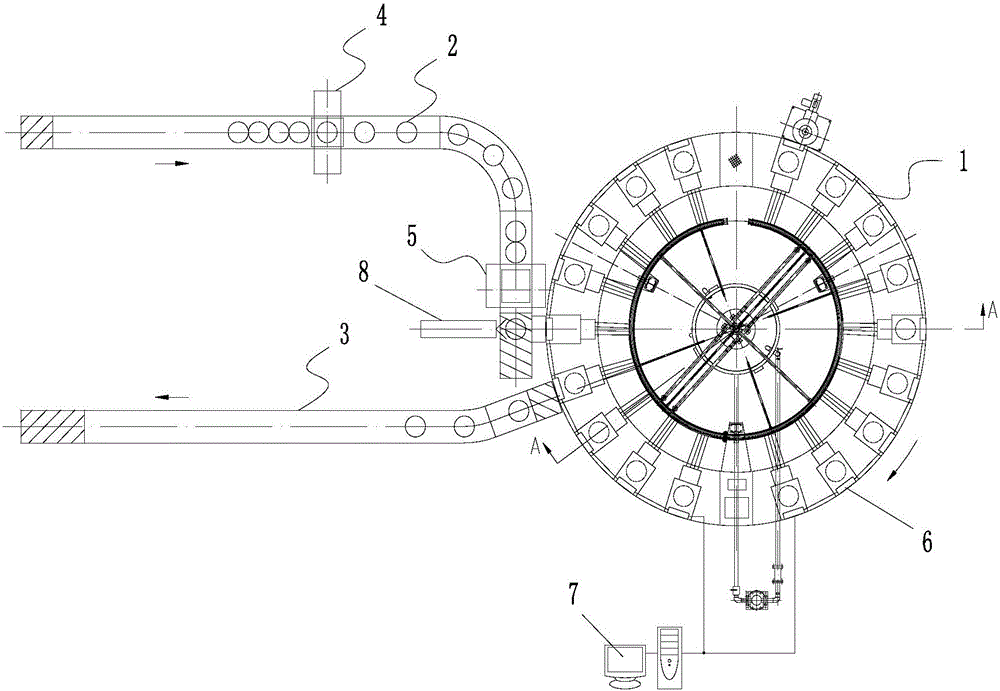

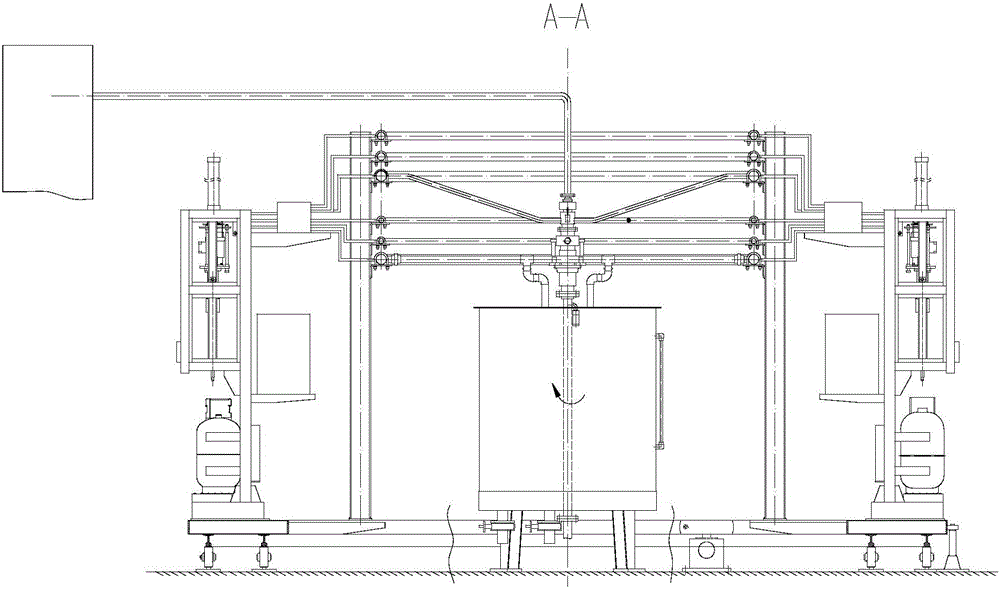

Intelligent rotating plate type quick hydrostatic test line for liquefied petroleum gas cylinders

ActiveCN106053243ASolve the problem of "one by one detection" of compressive strengthDetection speedMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesMeasurement deviceVisual test

The invention relates to the technical field of safety of liquefied petroleum gas cylinders, in particular to an intelligent rotating plate type quick hydrostatic test line for liquefied petroleum gas cylinders. The intelligent rotating plate type quick hydrostatic test line comprises a multi-station automatic tester, a cylinder feeding conveying belt, a cylinder discharging conveying belt, a liquid spraying capacity measurement device, a cylinder weighing device and a dynamic cold reading device. A detection device at each station of the multi-station automatic tester is provided with a PLC (programmable logic controller) control unit and transmits data signals to a master computer. The cylinder feeding conveying belt is arranged on one side of one station of the multi-station automatic tester, and a cylinder feeding push cylinder is arranged at the tail end of the cylinder feeding conveying belt and used for pushing cylinders to the stations. The cylinder discharging conveying belt is arranged on one side of the station close to the cylinder feeding conveying belt. The intelligent rotating plate type quick hydrostatic test line has advantages that high-precision intelligent instruments and a manual intelligent test method are adopted for substitution of a visual test method, and accordingly test precision is greatly improved, and test speed is increased greatly.

Owner:天津市长龙宏业燃气设备有限公司

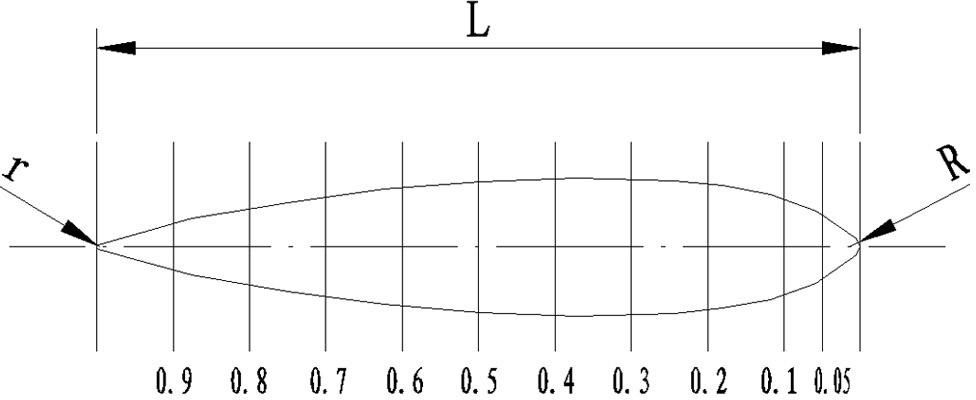

Production method of corrosion-resistant bimetal composite pipe

InactiveCN103350320AExcellent metallurgical bonding interfaceQuality improvementWelding apparatusComposite plateHeat treated

The invention relates to a production method of a corrosion-resistant bimetal composite pipe. The production method comprises the following steps: performing explosion composite operation on a corrosion-resistant alloy thin plate and a steel plate, performing heat treatment, leveling, cutting and trimming, and entering a pipe making workshop; forming by a JCO process, pre-welding, externally welding, internally welding, expanding diameter, performing a hydrostatic test, trimming end, performing flaw detection and marking to prepare corrosion-resistant bimetal composite pipe. The production method adopts an explosion composite process to prepare a bimetal composite plate, and obtains an excellent metallurgical bonding interface which is different from the mechanical interface bonding obtained through explosive expansion of the traditional embedded combined pipe, so the quality of the bimetal composite pipe is improved; production and manufacturing of a composite pipe with a large-caliber metallurgical bonding interface can be realized; the production method is particularly suitable for a submerged arc longitudinal welded pipe with the diameter being larger than 400 mm or 16 inches; high-strength metallurgical bonding of various dissimilar metals can be realized, and a brittle compound layer does not exist on the interface or is reduced to the minimal degree; the cladding coating ratio is high, so noble rare metal can be saved and the cost is low.

Owner:EAST CHINA UNIV OF SCI & TECH

Repairing method for cooling staveleakage

InactiveCN101333569AFix cooling functionRestoring coolingLiquid surface applicatorsArc welding apparatusLeaking waterSlag

The invention belongs to a repairing method of iron-making blast furnace equipment, which relates to a cooling wall leakage repairing method. The method mainly solves the technical problems that grouting can stop leakage but can not repair big gaps and the conduction cooling capacity is reduced after grouting. The repairing method of cooling wall leakage is characterized in that the method comprises the following steps of: a. shell opening: including opening holes with apertures of 150 to 250mm on the furnace shell around water pipes on a cooling wall; b. root grooving: including opening grooves at the root part of the cooling wall around the leaking water pipes and sheaths for eliminating cracks as well as molding sand, slag inclusion and loosening on the surface of the cooling wall; c. surface pretreatment: comprising eliminating the grooving parts and residual oxidative metal and oxide films on the surface around the grooves for exposing the metallic luster; d. leakage repairing: the leakage repairing method includes one process of a welding process and a high-molecular polymeric metal bonding process or a composite process combining the two processes; and e. hydrostatic test: after the repairing work, water is supplied for testing the pressure for 30min so as to check the leakage condition. The method is mainly used for repairing cooling wall leakage of blast furnaces.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

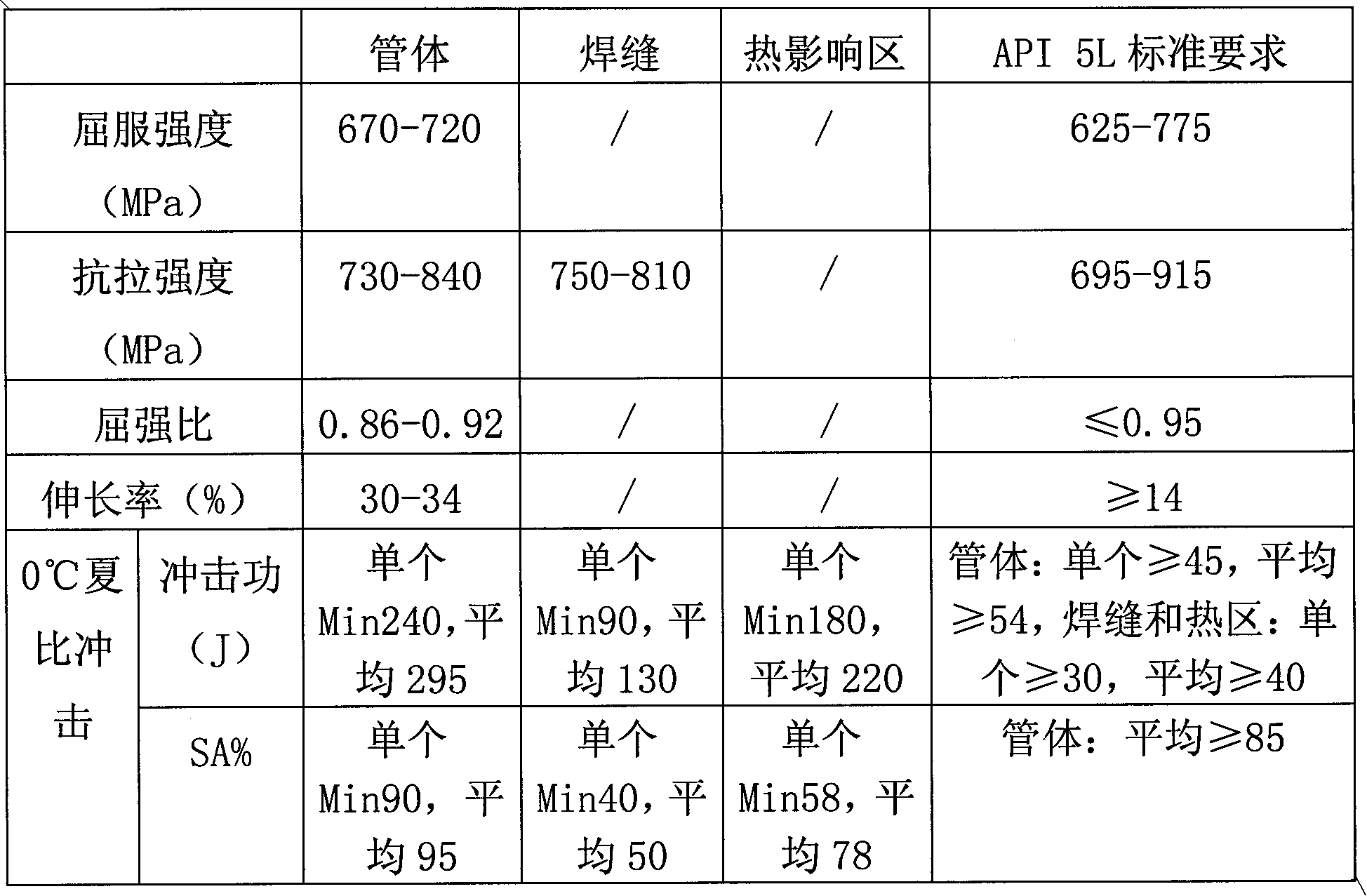

Method for manufacturing low-cost high-toughness X70 steel spiral submerged arc welded pipe

The invention discloses a method for manufacturing a low-cost high-toughness X70 steel spiral submerged arc welded pipe. The processing process of the method comprises the following steps of: uncoiling; leveling; milling an edge; pre-bending; forming; performing internal welding; performing external welding; expanding diameter at a pipe end; performing layered ultrasonic examination on a base material; performing weld joint X ray examination; performing a hydrostatic test; performing weld joint ultrasonic examination; chamfering the pipe end; and examining a finished product, wherein an bevel angle in the edge milling step is 70-80 degrees, and the bevel depth is 3-4 mm. Mo, Ni and Cu are not added into the base material adopted for manufacturing the low-cost high-toughness X70 steel spiral submerged arc welded pipe, and the content of alloy elements of Nb and the like is reduced, so that the production cost is reduced; in addition, by optimizing a forming process and a welding process, the manufactured spiral submerged arc welded pipe has the superior performance of low-temperature impact resistant toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

PPR/EVOH/POE (Pentatricopeptide Repeats/Ethylene-Vinyl Alcohol/Polyolefin Elastomer) blending high-impact barrier pipe and manufacturing method thereof

The invention discloses a PPR / EVOH / POE (Pentatricopeptide Repeats / Ethylene-Vinyl Alcohol / Polyolefin Elastomer) blending high-impact barrier pipe and a manufacturing method thereof, belonging to the field of novel polymeric composite materials. A blending system is formed through physical blending by compositely using PPR, EVOH and POE and compatibilization is carried out on the blending system by adopting a PP-g-MAH (Polypropylene-grafting-Maleic Anhydride) nucleating agent, thus the problems of low temperature brittleness, oxygen and permeability resistance, corrosion resistance, ageing resistance, heat resistance, processability, and the like of a PPR pipe are effectively solved. The PPR / EVOH / POE blending high-impact barrier pipe has the following performances that: drawing yield pressure is 48 MPa, the impact strength of a freely supported beam is 3.6 KJ / m<2>, and oil absorption rate is 0.5%, longitudinal retraction rate is 1%; seepage and crack do not exist in hydrostatic tests and heat stability tests in hydrostatic states; and the PPR / EVOH / POE blending high-impact barrier pipe meets the safety evaluation criterion of domestic drinking water delivery and distribution equipment and protective materials. The invention can be widely applied to the fields of municipal and building water supply, heating, gas supply, electric power, communication, industry, agriculture, and the like.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

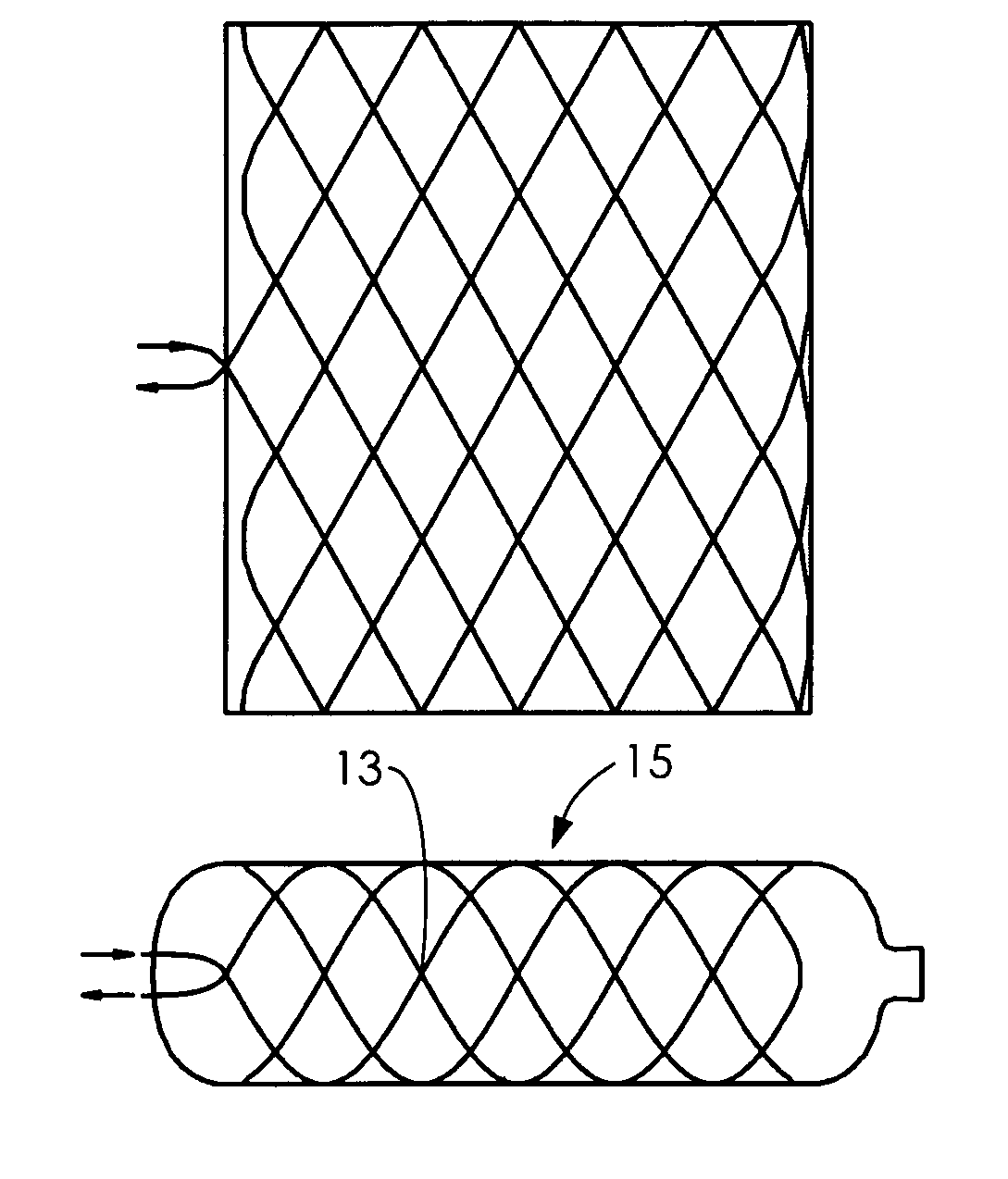

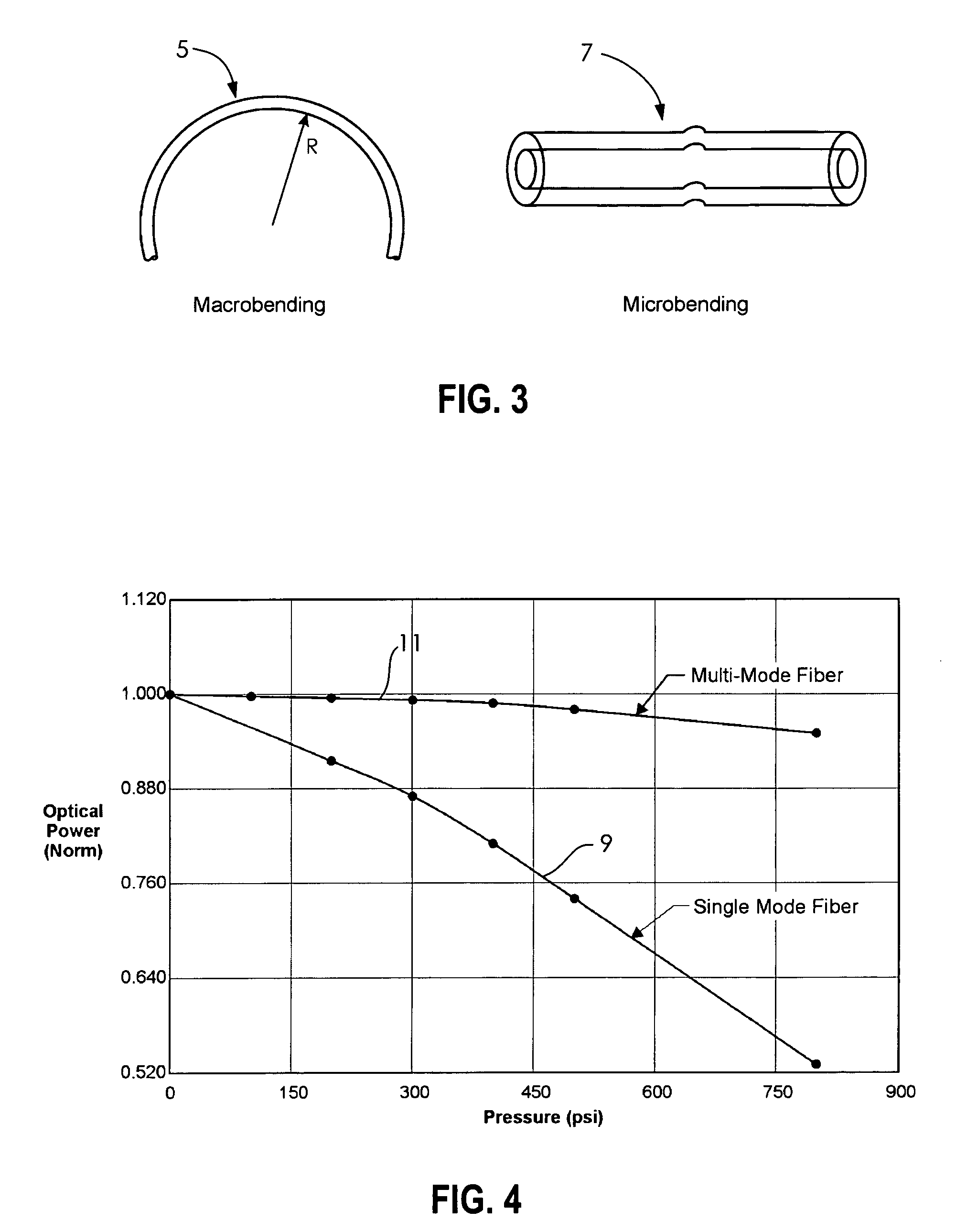

Fiber optic sensors for composite pressure tanks with micro bend pinch points

InactiveUS7687764B1Substantial maintenance cost savingSimple and safe operationRadiation pyrometryMeasurement apparatus componentsCost savingsAirplane

A low-cost fiber-optic sensor system for composite pressure tanks detects structural degradation of composite material pressure tanks. Light power attenuation in embedded optical fiber simulates tank volume change and replaces hydrostatic tank testing. Current U.S. Department of Transportation rules require that all pressure tanks be hydrostatically tested to verify structural integrity. Tanks do not have to be removed from service for testing. With the invention, testing can be done in-situ. For composite LNG tanks used on vehicles or emergency inflation devices used on aircraft for escape ramps, in-situ testing offers substantial maintenance cost savings. because of the simplicity of the test procedure, more frequent structural checks can be made economically to improve the safe operation of composite tanks.

Owner:KNAPP RONALD H

Processing method of nonmetal isolating sleeve for magnetic pump

The invention relates to a processing method of a nonmetal isolating sleeve for a magnetic pump, comprising the following steps of: uniformly stirring 65%-70% of polybenzimidazole and 30%-35% of polyetheretherketone, wherein the heating temperature is controlled to 350-370 DEG C, and the time is controlled to 1.2-1.8 hours; injecting the melted ingredients into a mould cavity to be formed, wherein the injection pressure is 7.0-8.0 MPa, and the injection time is 8-12 seconds; carrying out pressure-maintaining formation and then cooling 6-8 minutes along with air; taking out a formed product blank, cutting off burrs and flashing and smoothly grinding and finishing; inspecting according to the requirements of a drawing; performing a hydrostatic-pressure test of 3.0-5.0 MPa on the isolating sleeve on a special fixture, wherein the pressure-maintaining time is 15-25 minutes, and the phenomena of leakage and sweating do not exist; and then performing an air-tight sealing test on the isolating sleeve, if the isolating sleeve has no the phenomenon of air leakage, and then the product is a qualified product. The product enables the heat of magnetic force to not be gathered so that the demagnetization of magnetic steel can not be caused and the service life of the pump is prolonged.

Owner:江苏海天科技有限公司

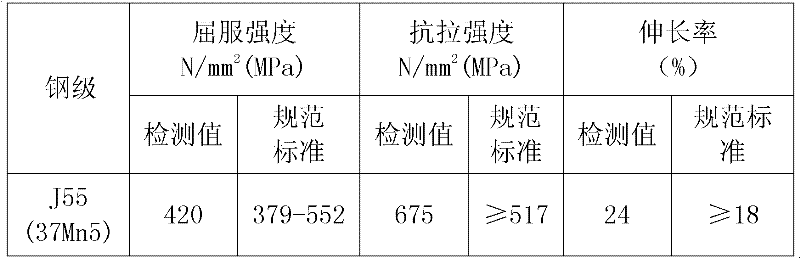

Waste and old oil well pipe performance recovery process

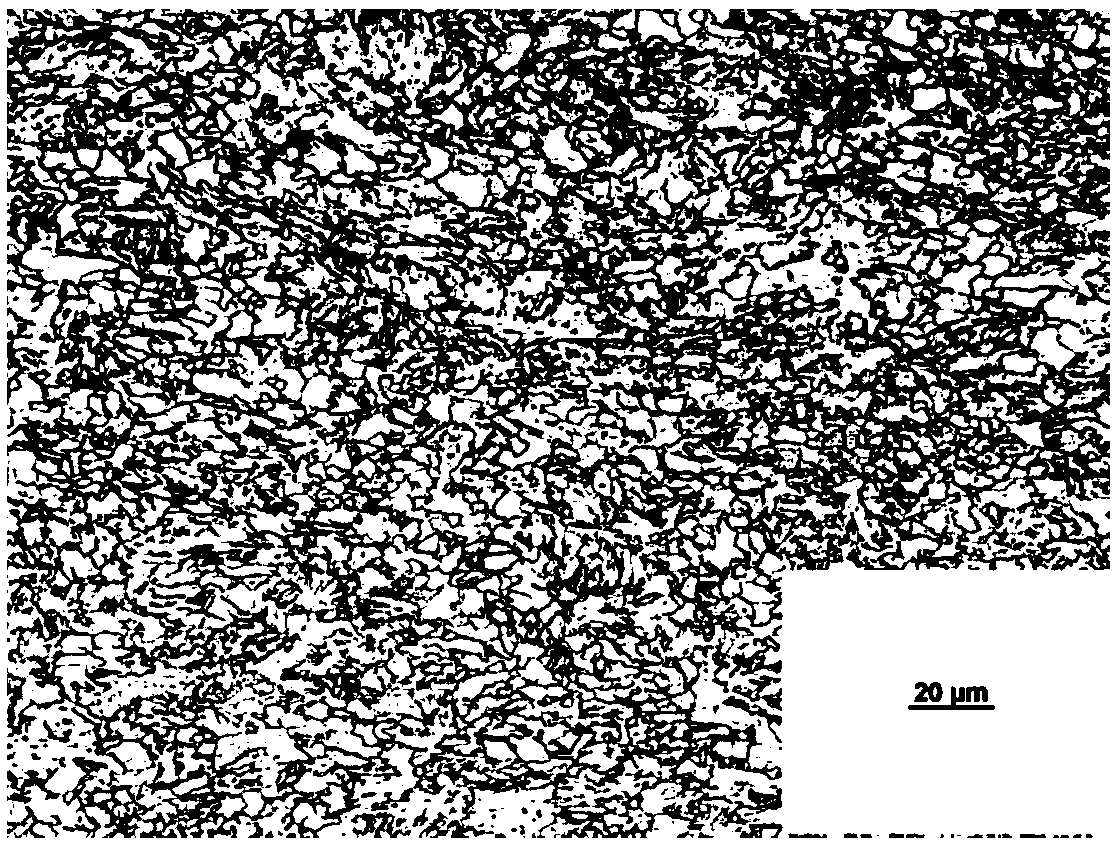

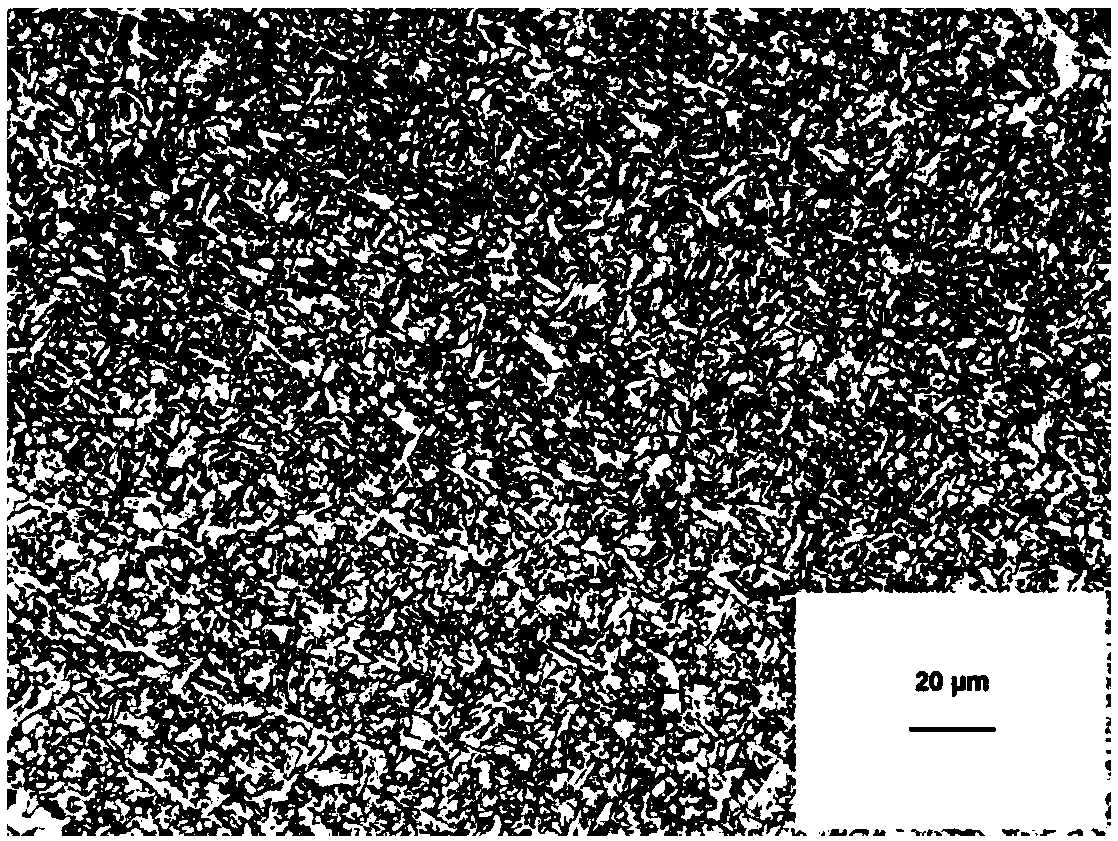

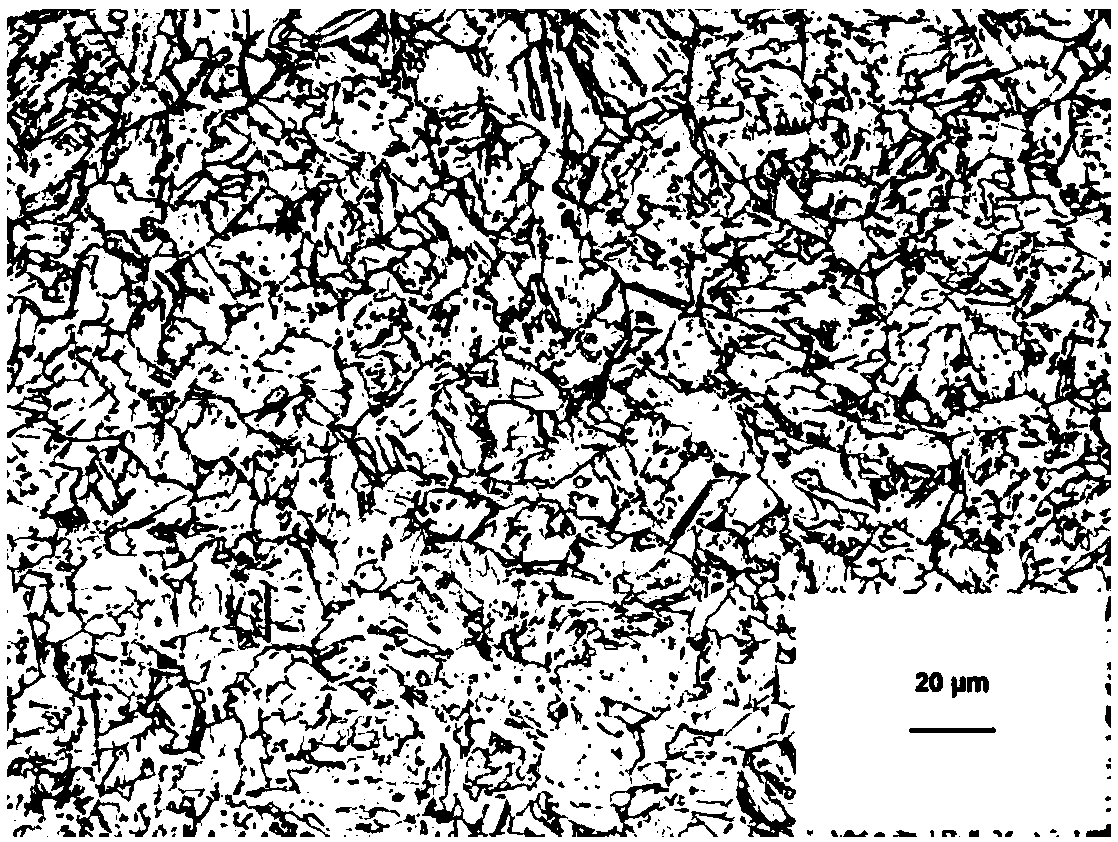

ActiveCN102581542ADense tissueAchieve energy saving and consumption reductionPulp and paper industryPerformance recovery

The invention discloses a waste and old oil well pipe performance recovery process which comprises the following steps: (1) heating; (2) sorting; (3) carrying out constant-diameter wall reducing; (4) carrying out heat diffusion; (5) carrying out negative-tension diameter reducing; (6) sorting and dimensioning; (7) stretching and carrying out a hydraulic test: stretching the sorted and dimensioned waste and old oil well pipes, and carrying out the hydraulic test; and (8) packaging: packaging the detected and qualified waste and old oil well pipes, and putting into service. The waste and old oil well pipe performance recovery process has the advantages that the waste and old oil well pipes are reforged, so that the repaired oil well pipes are more compact in internal structures, higher in corrosion resistance and higher in wear resistance, the waste and old oil well pipes are subjected to same-specification regenerative repair to meet the specification and the API (American Petroleum Institute) standard requirements, and the purposes of saving energy, reducing consumption and changing waste materials into valuable materials are achieved.

Owner:梅河口市弘业无缝钢管有限公司

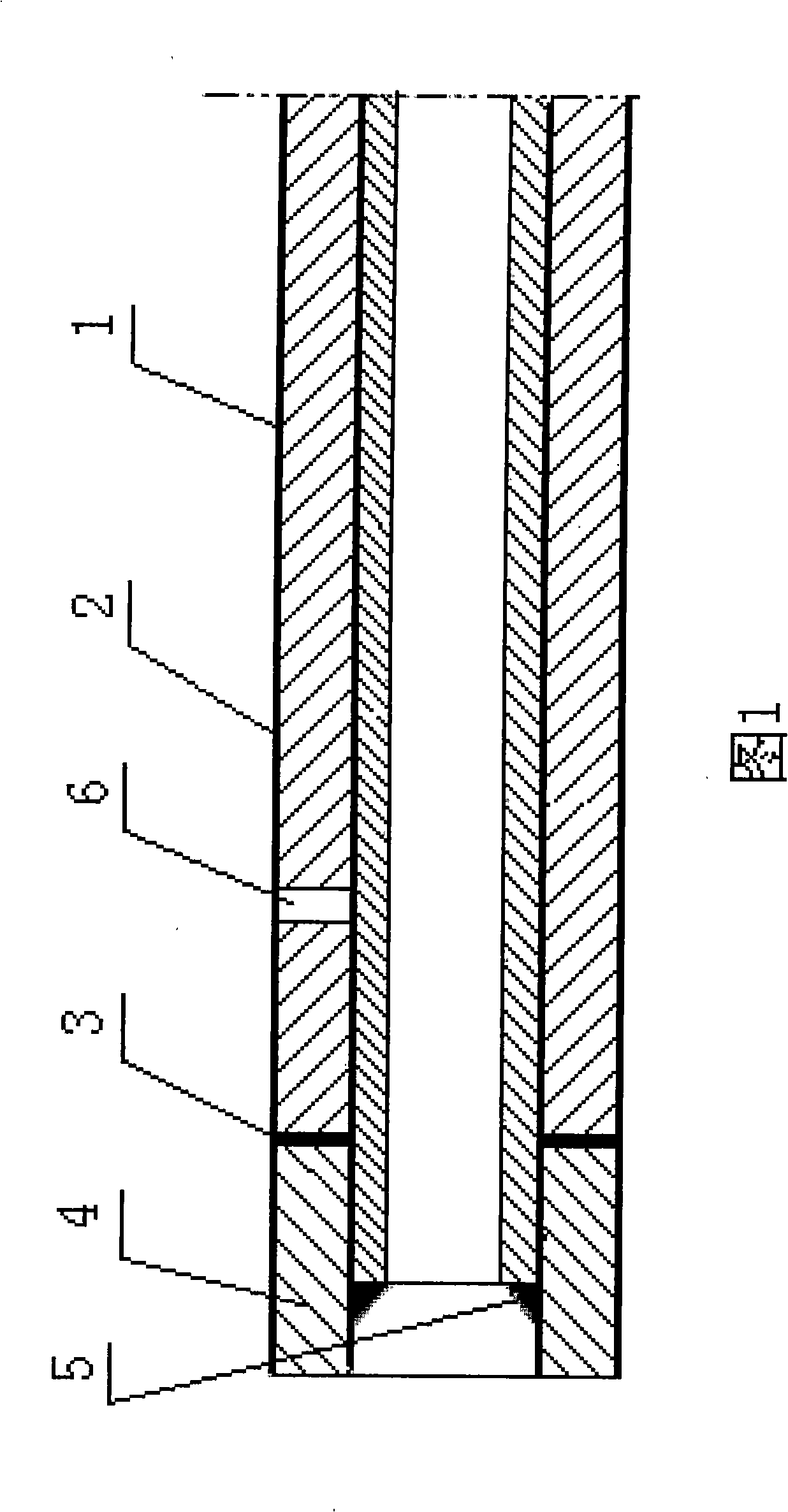

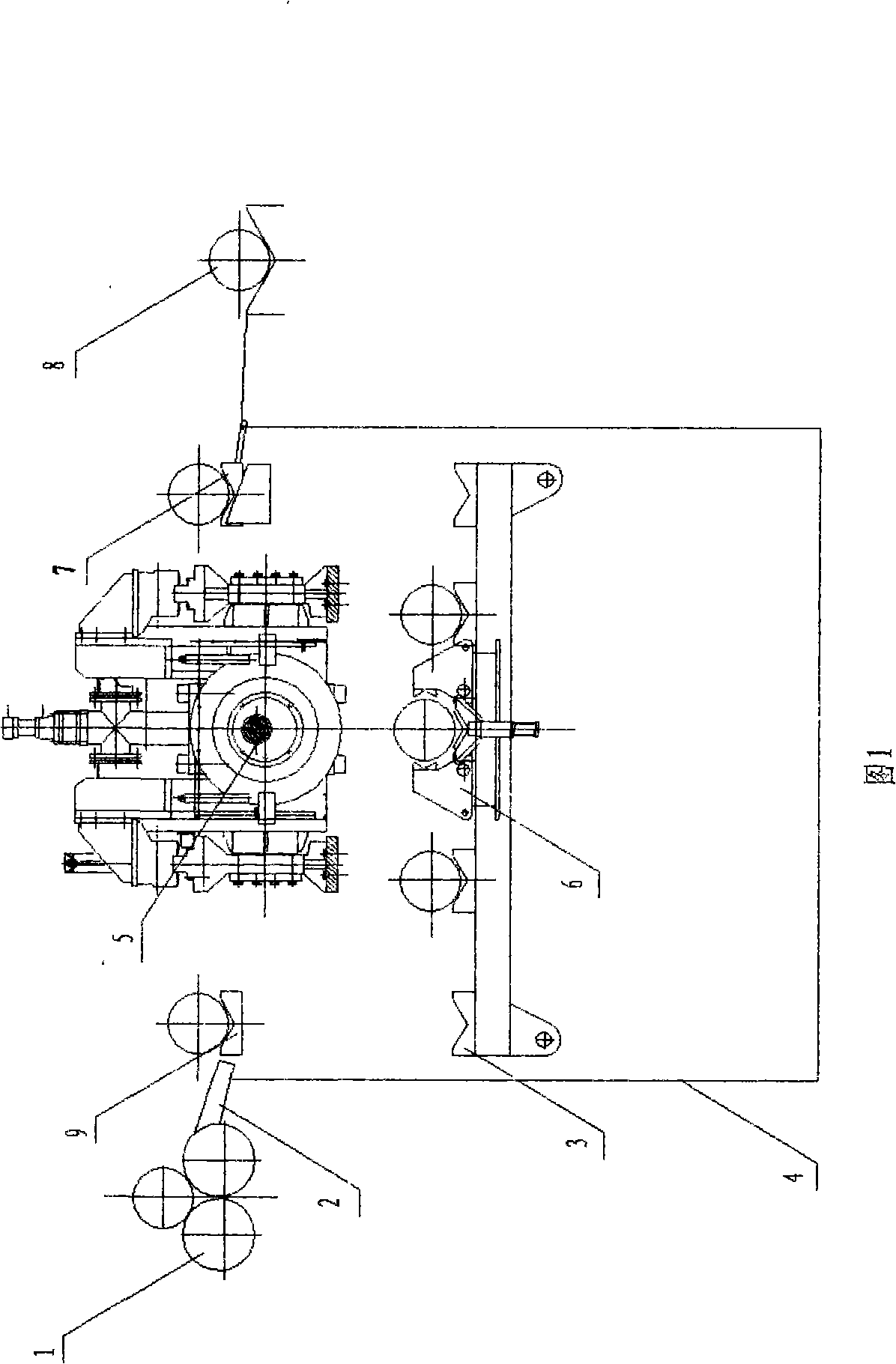

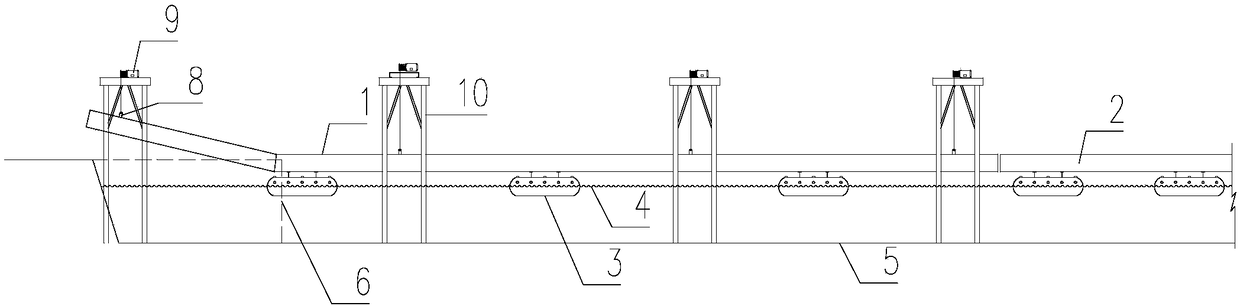

Pre-water filling steel tube hydraulic test method and special-purpose equipment thereof

InactiveCN101281084AOutstanding FeaturesHighlight significant progressMeasurement of fluid loss/gain rateEngineeringSteel tube

The invention discloses a hydrostatic test method and the dedicated device thereof for a water pre-filling steel pipe, comprising a rotary type washing mechanism (1) connected with one end of a feed mechanism (2), the other end of the feed mechanism (2) is connected with a elevating mechanism (9), a media tank (4) is arranged below the elevating mechanism (9), a pipe-moving mechanism (3) is arranged in the media tank (4),a clamping mechanism (6) is arranged on the pipe-moving mechanism (3), a hydrostatic test mechanism (5) is arranged above the clamping mechanism (6),the pipe-moving mechanism (3) is corresponding to a discharging mechanism (7) arranged upside, the discharging mechanism (7)is connected with a water control mechanism (8);the hydrostatic test method utilizing the device is showed as follows: rinsing the internal surface of the steel pipe, immerging the steel pipe in bulge medium, sealing the two ends of the steel pipe by a bulge head when the inside cavity of the steel pipe is filled with bulge medium, bulging and dwelling directly, and then discharging last; the method mentioned above does not take up the effective operation time and the device has high hydrostatic test efficiency.

Owner:烟台鲁宝钢管有限责任公司

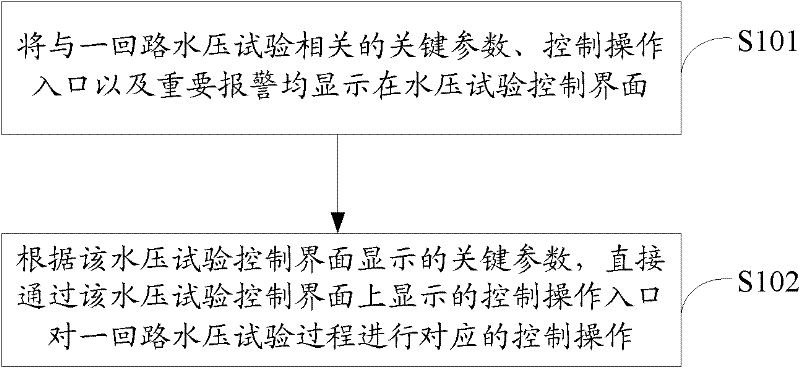

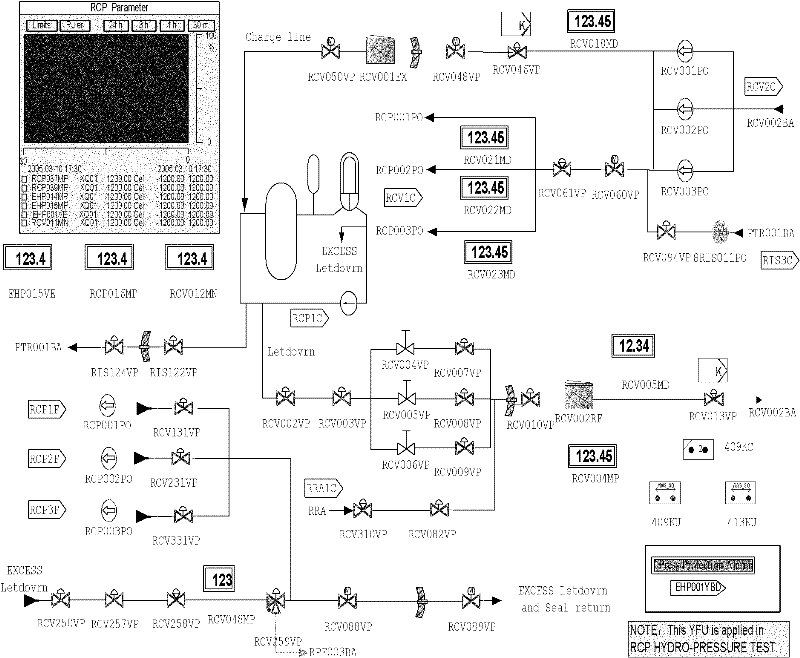

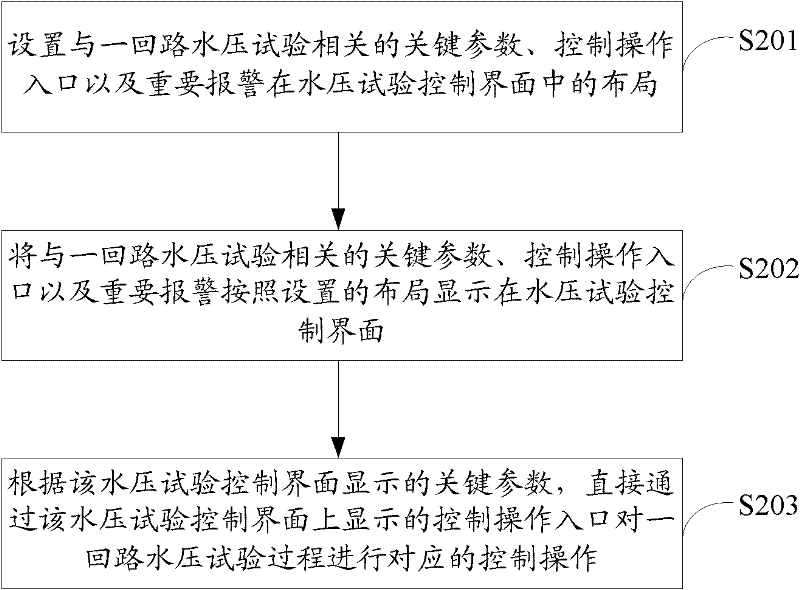

Digital control method and system of primary circuit hydrostatic test of pressurized water reactor nuclear power station

InactiveCN102163051AEasy to controlQuick controlNuclear energy generationNuclear monitoringPressurized water reactorNuclear power

The invention provides a digital control method and a digital control system of a primary circuit hydrostatic test of a pressurized water reactor nuclear power station, suitable for the nuclear power control field. The method comprises the following steps of: displaying key parameters, a control operation inlet and important alarming related to the primary circuit hydrostatic test on a hydrostatic test control interface; and directly controlling the primary circuit hydrostatic test process through the control operation inlet displayed on the hydrostatic test control interface according to the key parameters displayed by the hydrostatic test control interface. By the method of the invention, the key parameters, the control operation inlet and the important alarming related to the primary circuit hydrostatic test are displayed on the hydrostatic test control interface, and the primary circuit hydrostatic test process is directly controlled through the control operation inlet displayed on the hydrostatic test control interface according to the key parameters displayed by the hydrostatic test control interface, so as to visually and rapidly control the primary circuit hydrostatic test process.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

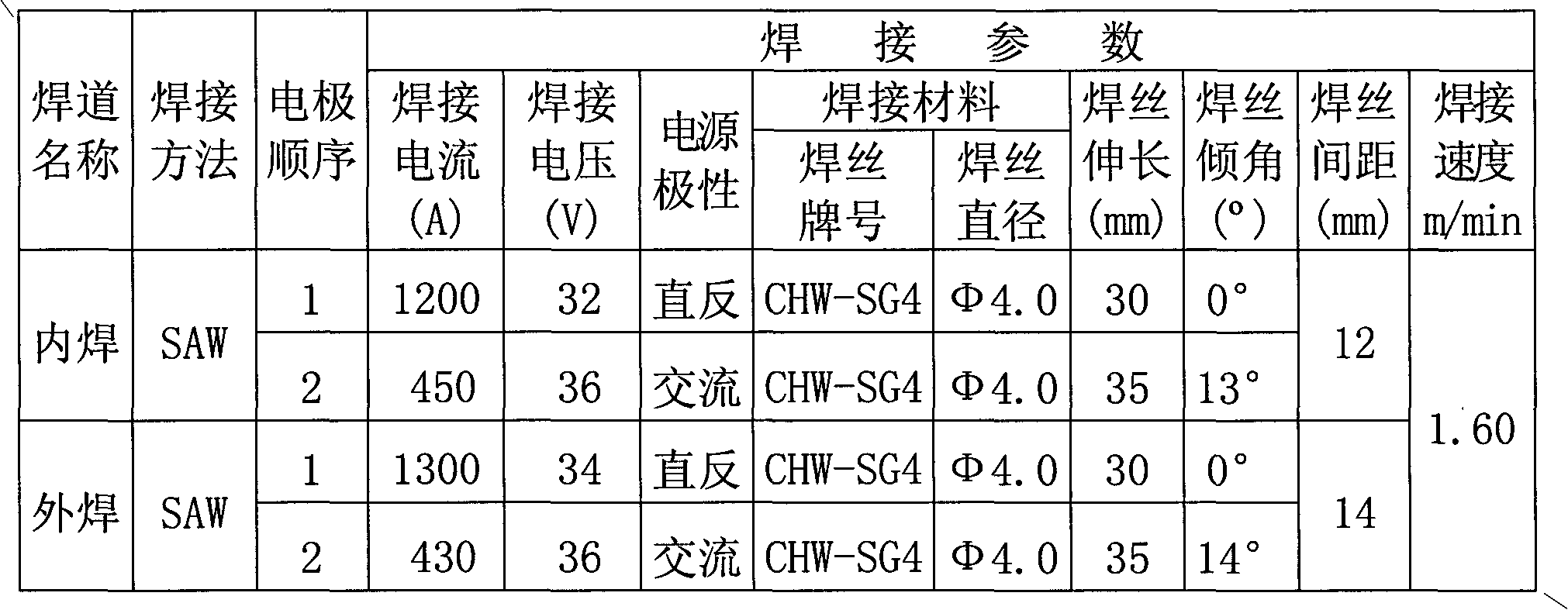

X80 large-diameter thick-wall longitudinal submerged arc welding pipe applicable to low temperature and manufacturing method thereof

ActiveCN108796364AReduce intakeHigh strengthArc welding apparatusWelding/cutting media/materialsX-rayWeld seam

The invention discloses an X80 large-diameter thick-wall longitudinal submerged arc welding pipe applicable to the low temperature and a manufacturing method thereof. A parent material of the weldingpipe comprises, by mass percentage, 0.04-0.08% of C, 0.15-0.30% of Si, 1.60-1.85% of Mn, less than or equal to 0.004% of S, less than or equal to 0.010% of P, 0.15-0.30% of Ni, 0-0.30% of Cr, 0.1-0.3%of Cu, 0.05-0.10% of Nb, 0.005-0.04% of V, 0.015-0.03% of Ti, 0.10-0.35% of Mo, 0.02-0.05% of Al, less than or equal to 0.008% of N and 0.0003-0.0005% of B. The manufacturing method comprises the steps of preparing a hot rolled steel plate according to the mass percentages of the chemical compositions; and conducting ultrasonic inspection, edge milling, pre-flanging, JCO formation, prewelding, inner welding, outer welding, welding seam X-ray inspection, steel pipe expanding, hydrostatic testing, welding seam ultrasonic testing, pipe end X-ray inspection, chamfering, pipe end magnetic particletesting and appearance quality inspection on the steel plate. A welding joint of the welding pipe is good in low-temperature toughness; and on the premise that heat treatment is not conducted on thewelding pipe after pipe manufacturing, the welding pipe can be directly used at the temperature of minus 45 DEG C or even lower.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

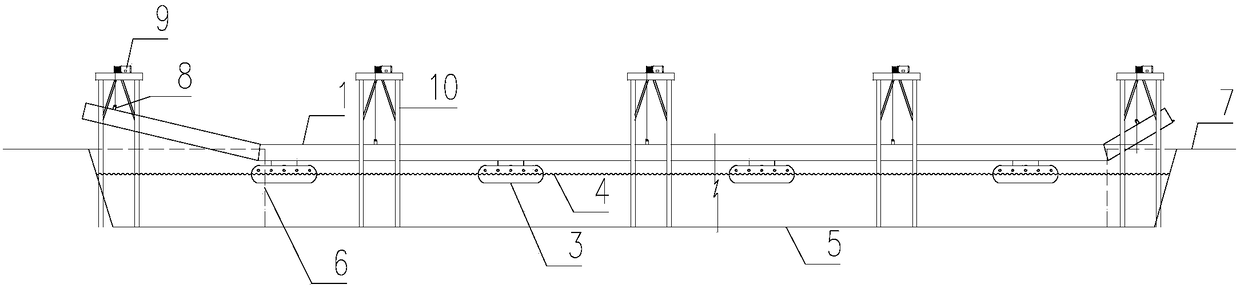

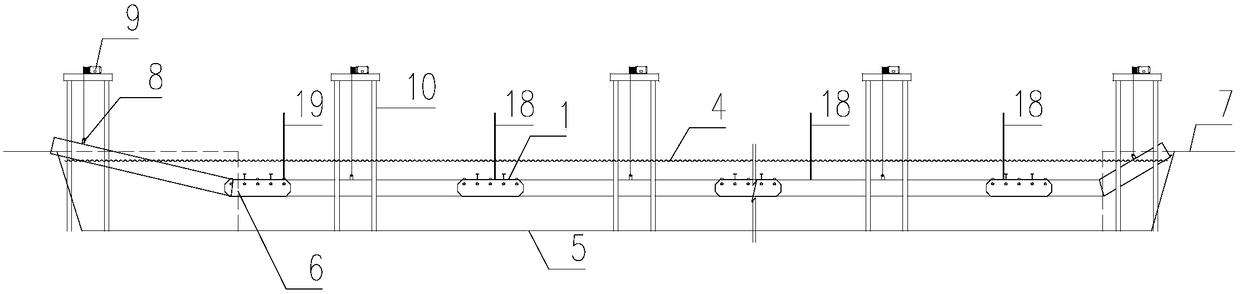

Buoyant box type water floating gantry crane pipeline sinking construction method

ActiveCN108571621ASimple construction principleLow costPipe laying and repairButt weldingWater channel

The invention discloses a buoyant box type water floating gantry crane pipeline sinking construction method. The method comprises steps as follows: step 1, long steel pipes are welded ashore and lifted onto a controllable buoyant box on the water surface; step 2, all small sections of steel pipes floated by the controllable buoyant box on the water surface are welded into a large section of steelpipe; step 3, a gantry crane lifts steel pipes with inclined pipe sections to be welded with the large section of steel pipe; step 4, a hydrostatic test of the steel pipes is conducted after the wholesection is mounted; step 5, the controllable buoyant box is reversely buckled on the steel pipes, and water is injected into two ends of the steel pipes to make the steel pipes to gradually sink; step 6, after the steel pipes sink, the controllable buoyant box is dismounted, the dismounted controllable buoyant box is inflated to automatically float on the water surface, and trenches are backfilled. Interface butt welding, water surface transportation, pipeline pressure test, sinking and other procedures of pipelines spanning long-distance water channels can be realized. The construction principle is simple and easy to implement, construction machinery such as a large crane is not required, the sinking positions are accurate, and the method is low in cost, safe and reliable.

Owner:CHINA FIRST METALLURGICAL GROUP

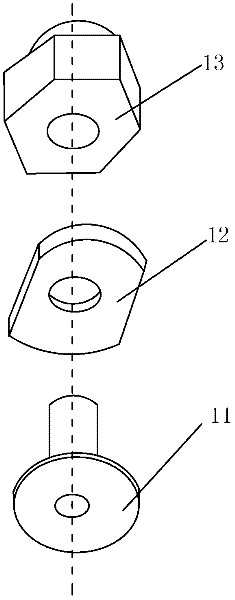

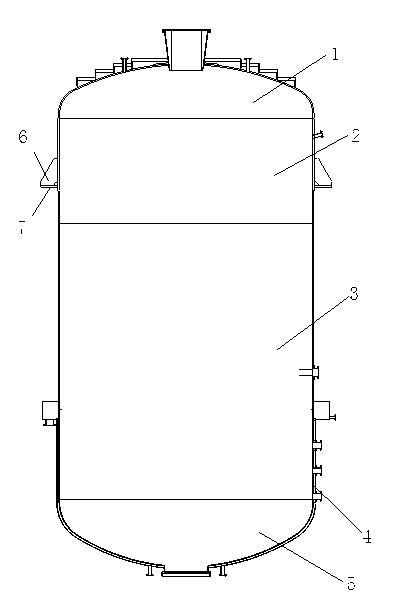

Hydrostatic pressure test machine

ActiveCN102854065AImprove general performanceMachine part testingMaterial strength using tensile/compressive forcesHydrostatic testEngineering

A hydrostatic pressure test machine comprises an operating platform, a guide piece, a drive piece, a compacting piece in spaced arrangement with the operating platform, and a first position piece and a second positioning piece both disposed on the operating platform. The first position piece can slide with respect to the operating platform along a first direction, and the second positioning piece can slide with respect to the operating platform along a second direction perpendicular to the first direction; the operating platform is provided with a water inlet hole; the guide piece is fixed on the operating platform; and the compacting piece is driven by the drive piece and can slide along the guide piece to regulate distance between the compacting piece and the operating platform. The hydrostatic pressure test machine has high universality.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

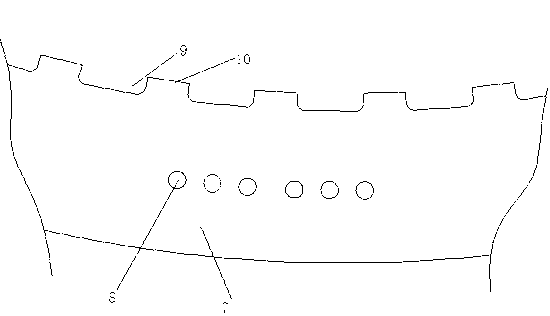

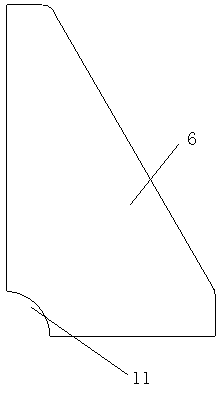

Making and construction method of chlorination furnace

ActiveCN103265066AGuarantee the construction qualityImprove construction progressTitanium halidesBench grinderPlanishing

The invention discloses a making and construction method of a chlorination furnace. The making and construction method comprises the following steps of carrying out processing and blanking in a factory, carrying out installation on a construction site, carrying out integral heat treatment, carrying out a hydraulic pressure test and an air-tight test, and carrying out equipment painting. The chlorination furnace comprises an upper head, an upper cylindrical shell, a lower cylindrical shell and an outer jacket. The upper head is arranged on the upper cylindrical shell. The upper cylindrical shell is arranged on the lower cylindrical shell. The outer jacket surrounds the lower cylindrical shell. Support annular plates are welded on the upper cylindrical shell. Multiple support rib plates and water holes are arranged on the support annular plate at equal intervals. The support rib plate is provided with a water groove. The upper head is provided with four water outlet weir plates. The water outlet weir plates are provided with concave-convex teeth and water holes. A lower part of the lower cylindrical shell is provided with a lower head. The wall plate groove of 50mm is made by butt joint of steel plates having different thickness, and then is processed. In construction, the groove is manufactured by flame machining and is rubbed flat by a grinding machine so that the construction period is reduced and grinding wheel sheet consumption is greatly reduced and manpower is saved.

Owner:CHINA CHEM ENG SECOND CONSTR +1

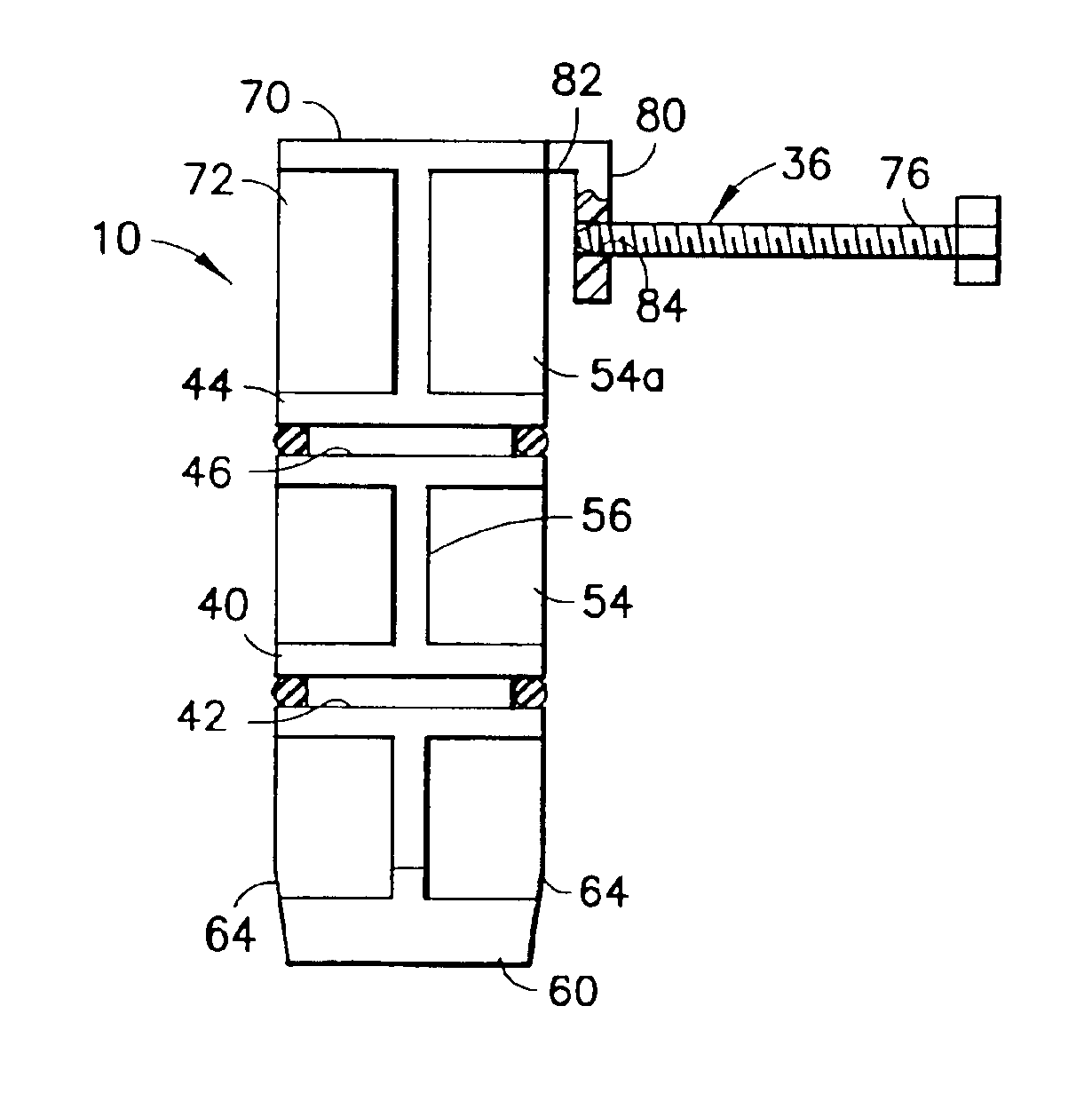

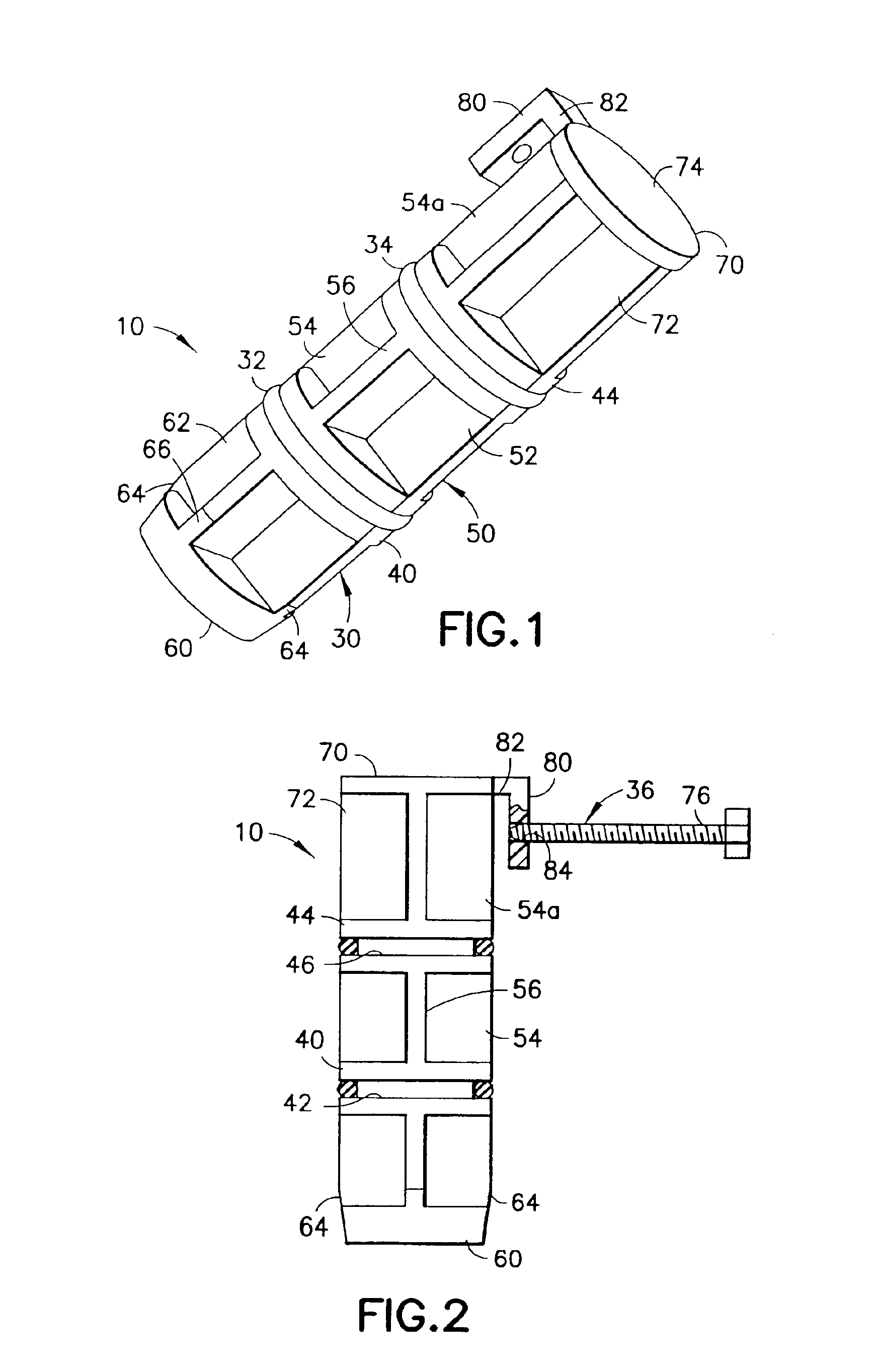

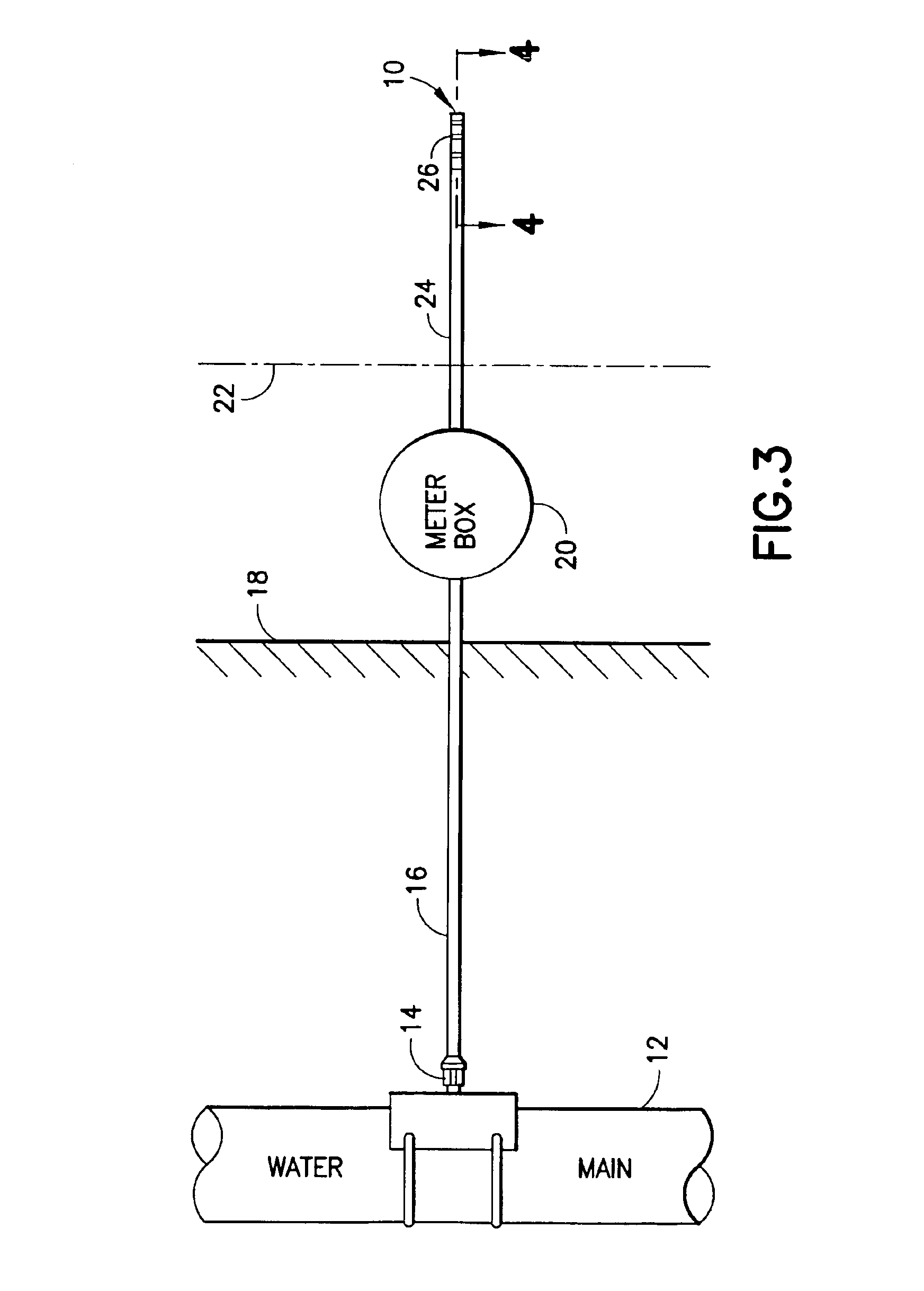

Hydrostatic test plug for water service line

InactiveUS6843108B1Low costEasy to installDetection of fluid at leakage pointPipe elementsWater utilityBody size

A pipe test plug for scaling and pressure testing a water utility supply line or other pressurized pipe has a plug body sized and shaped for insertion into an open end of a water supply line. The plug body has an inner and an outer end, with first and second spaced apart annular seals supported on the plug body. The annular seals and plug body together seal the water supply line when the pipe test plug is inserted therein. A securing member extends through at least one portion of the water supply line and into the plug body inserted therein for securing the pipe test plug in the water supply line under test pressure, the securing member being received in the plug body between the second annular seal and the other end of the plug body. The plug body may include first and second cylindrical seal plates each defining a peripheral groove for respectively receiving and supporting the first and second annular seals. The cylindrical seal plates are connected by web portions. A mounting tab joined with the plug body and extending generally along the plug body and spaced therefrom to accommodate the distal end of a water supply line. The mounting tab defining an opening for guiding the securing member through the supply line and into the plug body. An insertion stop positions the test plug in the water service line.

Owner:MUELLER INT LLC

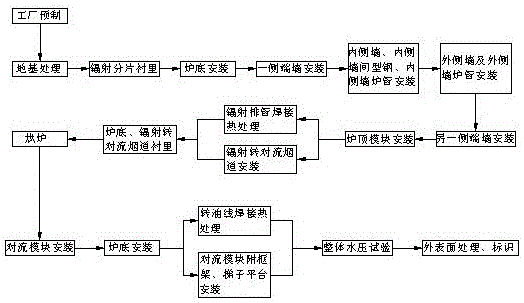

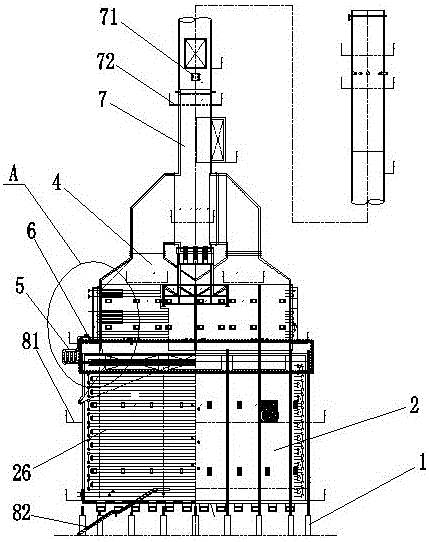

Modular manufacturing method for heating furnace and heating furnace manufactured through method

PendingCN106839775AShorten the manufacturing cycleReduce manufacturing costFurnace componentsFurnace repairRadiation transferHeating furnace

The invention discloses a modular manufacturing method for a heating furnace. The method comprises the following steps that all modules and radiation fragments are prefabricated in a factory; foundation treatment is performed; the radiation fragments are lined; a furnace bottom is mounted; end walls on one sides are mounted; inner side walls, connecting profile steel among the inner side walls and inner side wall furnace tubes are mounted; outer side walls and outer side wall furnace tubes are mounted; end walls on the other sides are mounted; furnace top modules are mounted; radiation exhaust pipes are subjected to welding heat treatment; a radiation transfer convection gas flue is mounted; the furnace bottom and the radiation transfer convection gas flue are lined; the furnace is baked; convection modules are mounted; a stack is mounted; oil transfer lines are subjected to welding heat treatment; a convection module attached frame and a ladder platform are mounted; an overall hydrostatic test is performed; and outer surface treatment is performed, and identifications are marked. The modular manufacturing method for the heating furnace has the advantages that advantages of modular manufacturing are fully played, the manufacturing period is shortened, the manufacturing cost is lowered, and the manufacturing quality is improved.

Owner:NINGBO LIANTONG EQUIP MFG

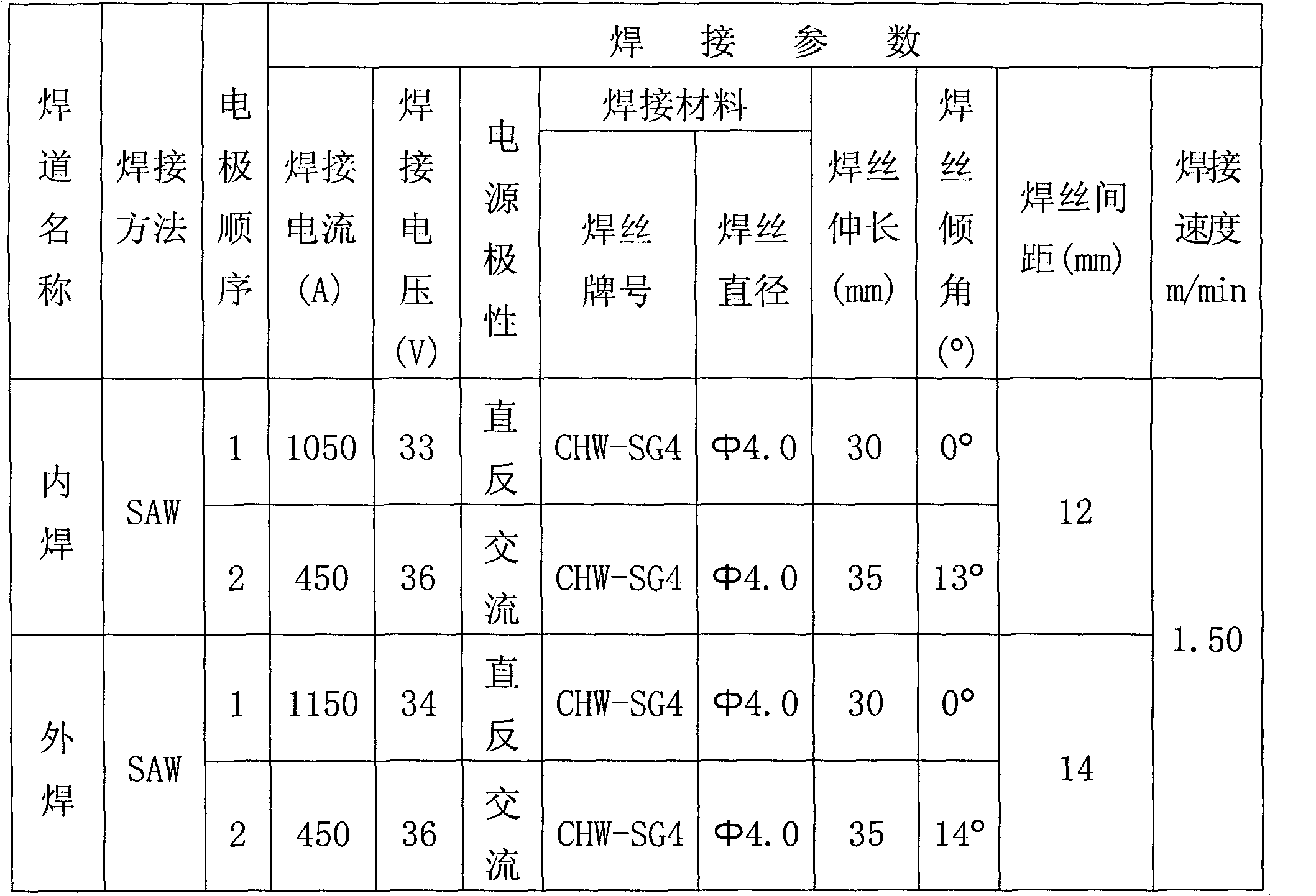

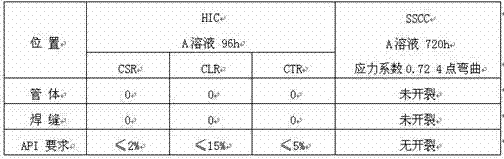

Acid-proof X70MS steel-grade spiral welded pipe and manufacturing method thereof

The invention discloses an acid-proof X70MS steel-grade spiral welded pipe and a manufacturing method thereof. The spiral welded pipe is made of X70MS steel-grade plate coils. The processing process for the spiral welded pipe comprises the following steps of: uncoiling, flattening, milling edges, prebending, molding, internally welding, externally welding, expanding the end of the pipe, performing laminated ultrasonic inspection on a base material, performing X-ray inspection on welding seams, performing a hydrostatic test, performing ultrasonic inspection on the welding seams, chamfering theend of the pipe and inspecting a finished product. The X70MS steel-grade spiral seam submerged-arc welding pipe has high intensity and high acid resistance and is suitable for conveying acid oil gas media.

Owner:CNPC BOHAI EQUIP MFG +2

Overpressure protection method for reactor startup/shutdown condition of PWR (pressurized water reactor) nuclear power plant

ActiveCN104332206AImprove abilitiesConvenient overpressure protectionPower plant safety arrangementNuclear energy generationPressurized water reactorNuclear engineering

The invention relates to an overpressure protection method for reactor startup / shutdown condition of a PWR (pressurized water reactor) nuclear power plant. The method comprises the following steps: the step 1) carrying out power plant reactor shutdown condition overpressure protection; and the step 2) carrying out power plant reactor startup condition overpressure protection: 2.1 carrying out temperature rise period overpressure protection which comprises the following steps: 2.1.1 carrying out temperature rise alarming operation; 2.1.2 carrying out pressure stabilizer safety valve function switching operation; and 2.1.3 carrying out normal temperature rise operation; and 2.2 carrying out hydrostatic test overpressure protection comprising the following steps: 2.2.1 setting coolant protection temperature of the hydrostatic test to be T1=70-120 DEG; 2.2.2 carrying out temperature rising operation according to the temperature rise period overpressure protection operation in the step 2.1, and when the temperature reaches a set temperature T1, switching the low temperature protection mode after the reactor shutdown to the normal operation protection mode; and 2.2.3 carrying out hydrostatic test on a reactor coolant system. The method helps to improve the capability of the RCS for coping with overpressure transient event, and reduce pressure boundary integrity damage risk of the coolant system greatly; and the method facilities the RCS overpressure protection under the operating conditions of reactor startup / shutdown, and hydrostatic test and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Methods and systems for hydrostatic testing a pipeline

ActiveUS7475591B2Fast and low costRelieve stressDetection of fluid at leakage pointMeasurement of fluid loss/gain rateSlugHydrostatic test

A method of hydrostatic testing a selected section of a pipeline having fluid flow therethrough, including the steps of introducing into the pipeline a pig train including a leading seal pig, a supply liquid slug, a first isolation tool, a test liquid slug and a second isolation tool; permitting the train to traverse the pipeline interior by the force of fluid flow until the lead isolation tool is forwardly of and the second isolation tool is rearwardly of the selected selection of the pipeline; securing the position of the pig train by applying exteriorly of the pipeline appropriate signals to actuate the isolation tools to each engage and seal the interior of the pipeline trapping the test liquid slug therebetween; and pumping liquid from the supply liquid slugs into the test liquid slug to a hydrostatic testing pressure. In addition to testing, the pipeline can be repaired by moving the pig train into position where a defective area can be isolated by additional isolation tools.

Owner:TDW DELAWARE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com