Buoyant box type water floating gantry crane pipeline sinking construction method

A construction method, the technology of the door crane method, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of uneven stress on local sections of pipelines, water surface drift and deformation, and high cost, etc., to achieve The construction principle is simple and easy, the repair operation is simple, and the effect of reducing the number of occupations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

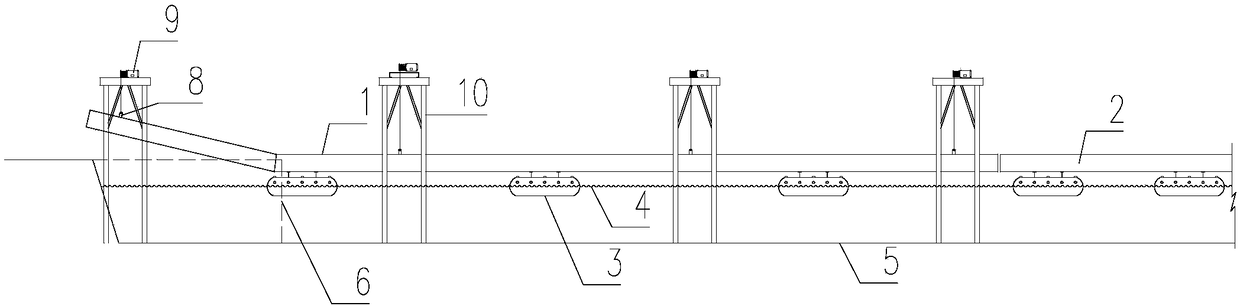

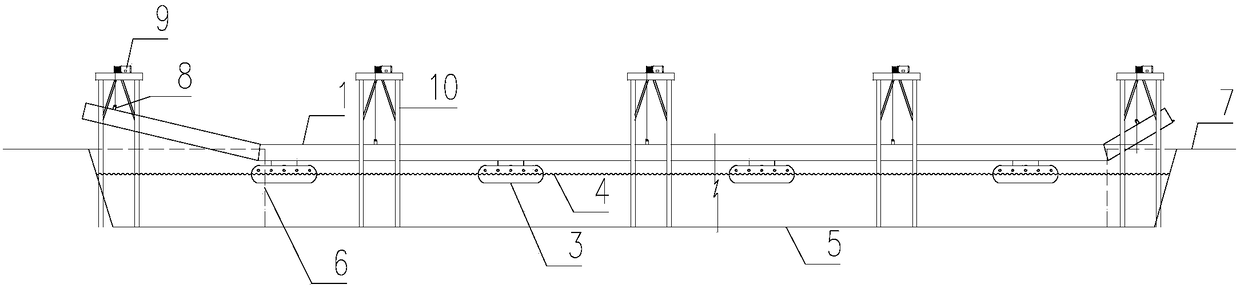

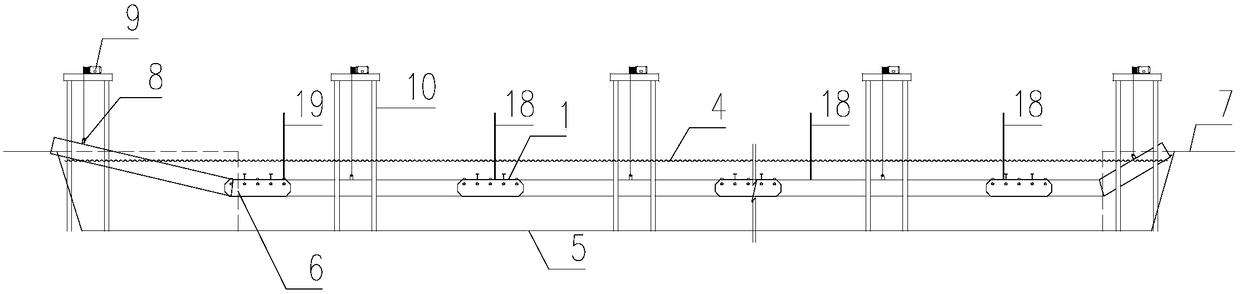

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0057] The detailed steps of the immersed tube construction method of the floating box type water floating gantry crane method are as follows:

[0058] Preparation:

[0059] First set up an on-shore processing site near the construction of the pipeline crossing the waterway, and carry out the welding and lengthening of the standard pipe section and the transition section of the pipeline to form a steel pipe for the long unit section to be connected.

[0060] According to the length of the integral steel pipe 1, steel pipe piles 17 are applied on the waterway as anchor points for fixing the controllable buoyancy tank 3, and are used to fix the steel pipes on the water surface during water operations to prevent them from drifting with the current.

[0061] A trench for filling the steel pipes is excavated in advance on the river bed.

[0062] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com