Grouting processing method for stopping water leakage of underwater concrete

A technology of underwater concrete and treatment method, which is applied in the direction of construction and infrastructure engineering, etc., can solve the problems of increasing construction period, cumbersome operation, difficult handling, etc., and achieve the effect of saving construction period, simple construction principle and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

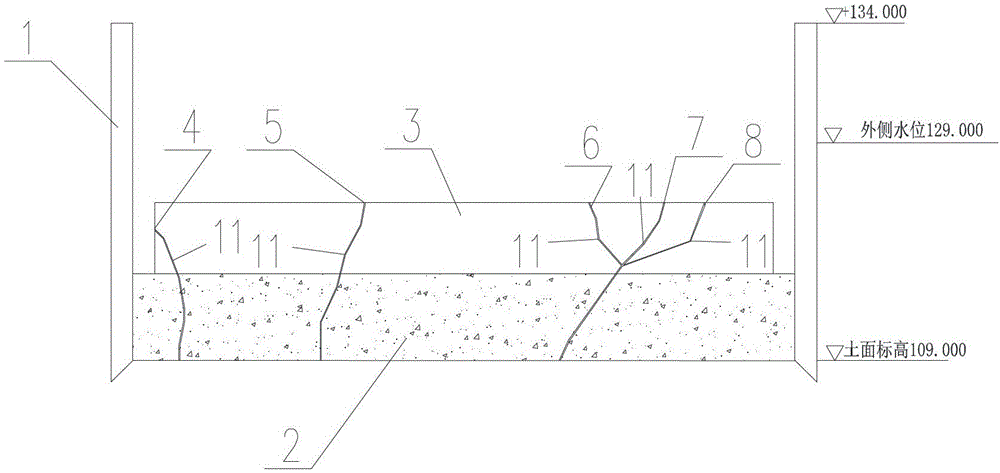

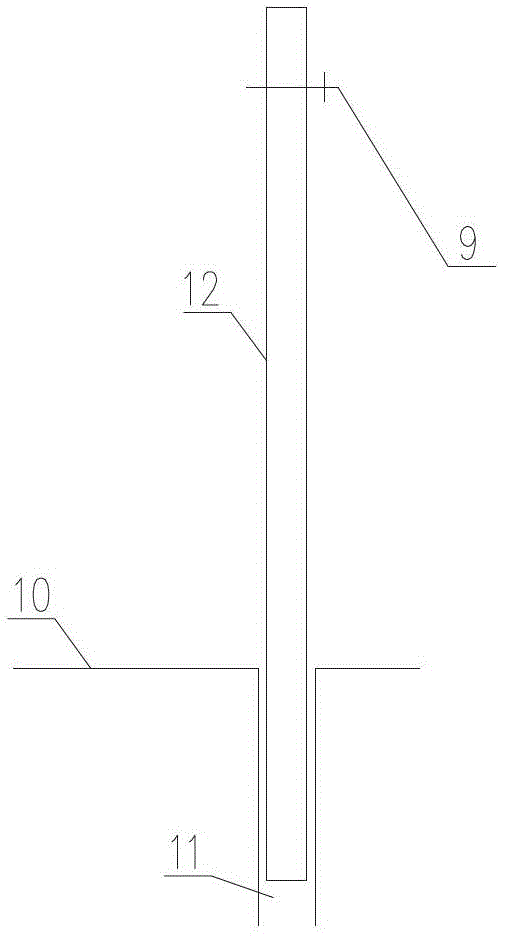

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] The purpose of the invention is to treat the seepage of underwater concrete so as to ensure the quality of concrete pouring. In order to achieve this purpose, the present invention provides a grouting treatment method for water seepage plugging of underwater concrete, the steps of which are as follows:

[0027] Step 1. Treat each water outlet point and lead it out with a steel pipe with a valve.

[0028] Step 2: Perform pressure water test on each water outlet point one by one to test the distribution and connection of seepage channels, and divide the seepage channels into two categories: connected seepage channels and independent seepage channels.

[0029] Step 3, judging the optimal route of grouting through the test results,

[0030] Step 4, make the implementation grouting layout according to the optimal route,

[0031] Step 5, perform grouting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com