Cable traction automobile coating conveyor

A conveyor and coating technology, applied in the direction of trolley cranes, coatings, cranes, etc., can solve the problems of high manufacturing and installation process requirements, complex structures, etc., achieve weight reduction, reasonable and simple structure, and avoid treatment liquid residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

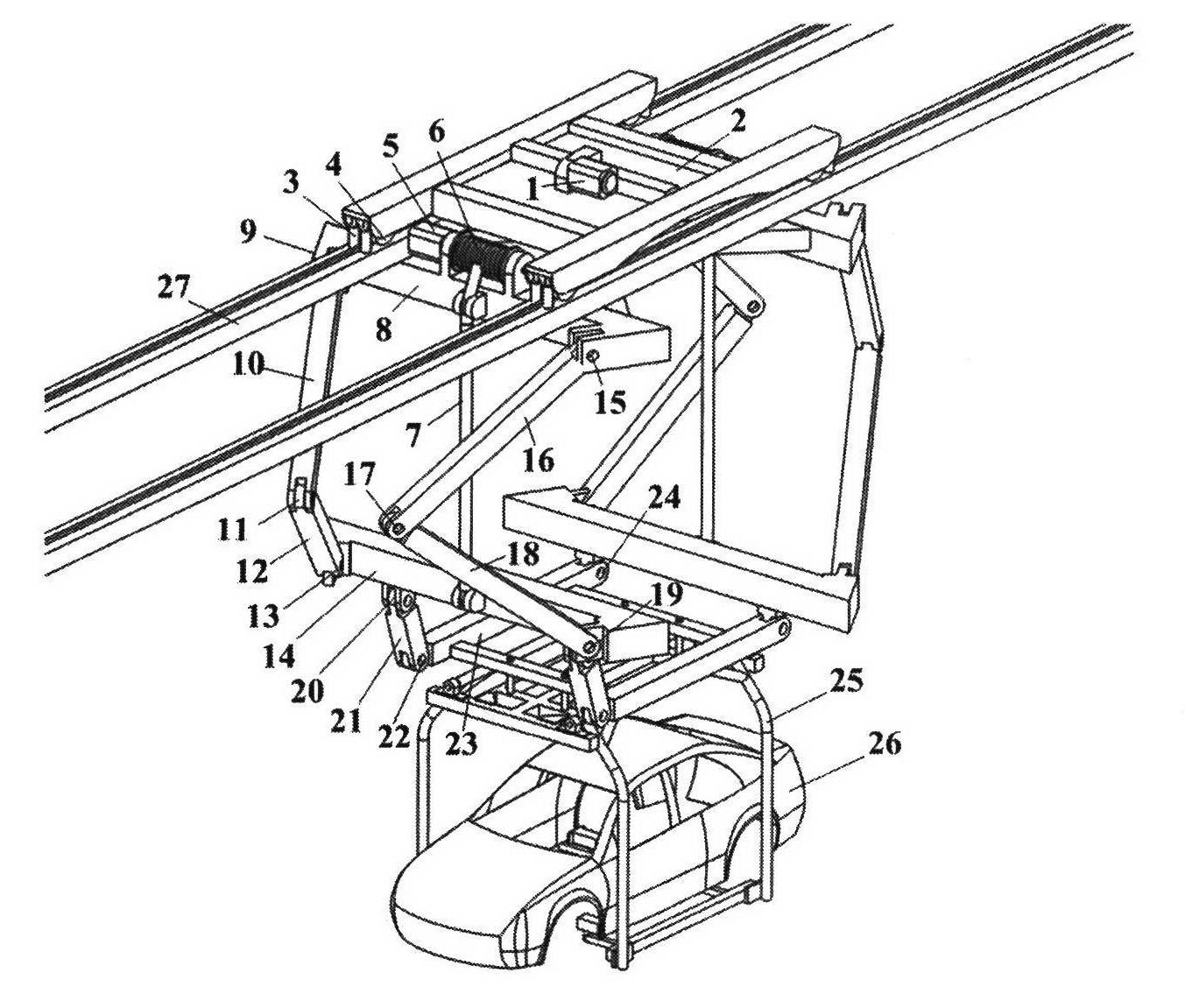

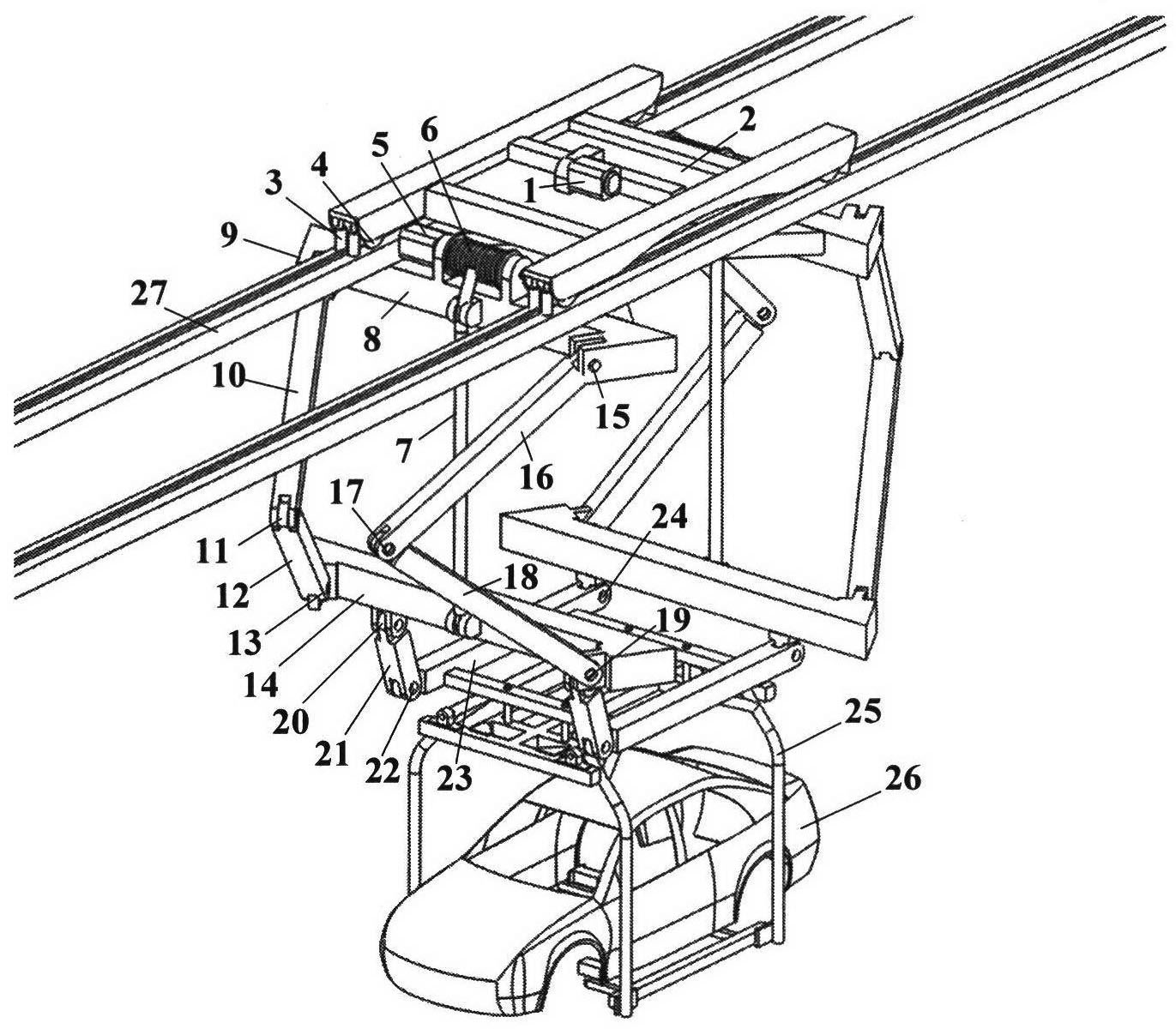

[0014] Automobile coating conveyer of the present invention is described in detail as follows in conjunction with accompanying drawing and embodiment:

[0015] Embodiments of the invention are exemplified with a conveyor. In the present invention figure 1 In the shown first embodiment, the conveyor according to the present invention includes two functional parts: a traveling mechanism and a lifting and turning mechanism. The walking mechanism includes: a walking driver 1, a walking base 2, a plurality of guide wheels 3 and a plurality of walking wheels 4; the walking driver 1 is fixedly installed on the walking base 2, and the guiding wheels 3 and the traveling wheels 4 are also installed on the walking base Above, through the cooperation of a plurality of road wheels 4 and the guide rail 27, and the orientation of the plurality of guide wheels 3 on the guide rail 27, the traveling mechanism is driven by the travel driver 1 to realize the walking motion. The lifting and turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com