Manufacturing method of vermicular cast iron piston ring

A technology of vermicular graphite cast iron and a manufacturing method, which is applied in the directions of piston rings, manufacturing tools, casting and molding equipment, etc., can solve the problems of increasing the production cost of ductile iron piston rings, poor wear resistance of ductile iron, and difficult processing of piston rings, etc. The effect of low wear resistance and toughness, and high comprehensive yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A vermicular graphite cast iron piston ring. High-quality raw materials are selected for raw material proportioning. The design targets for the chemical components and weight percentages in the piston ring are: C: 3.7% to 3.8%, Si: 2.6% to 2.8%, Mn: 0.1%~0.2%, Cr: 0.25%~0.3%, Mo: 0.35%~0.45%, Cu: 0.55%~0.6%, Ti: 0.1%~0.15%, P≤0.08%, S≤ 0.03%, Mg: 0.011% ~ 0.015%, the rest is Fe and unavoidable impurities.

[0037] The manufacture method of compacted graphite cast iron piston ring comprises the following steps:

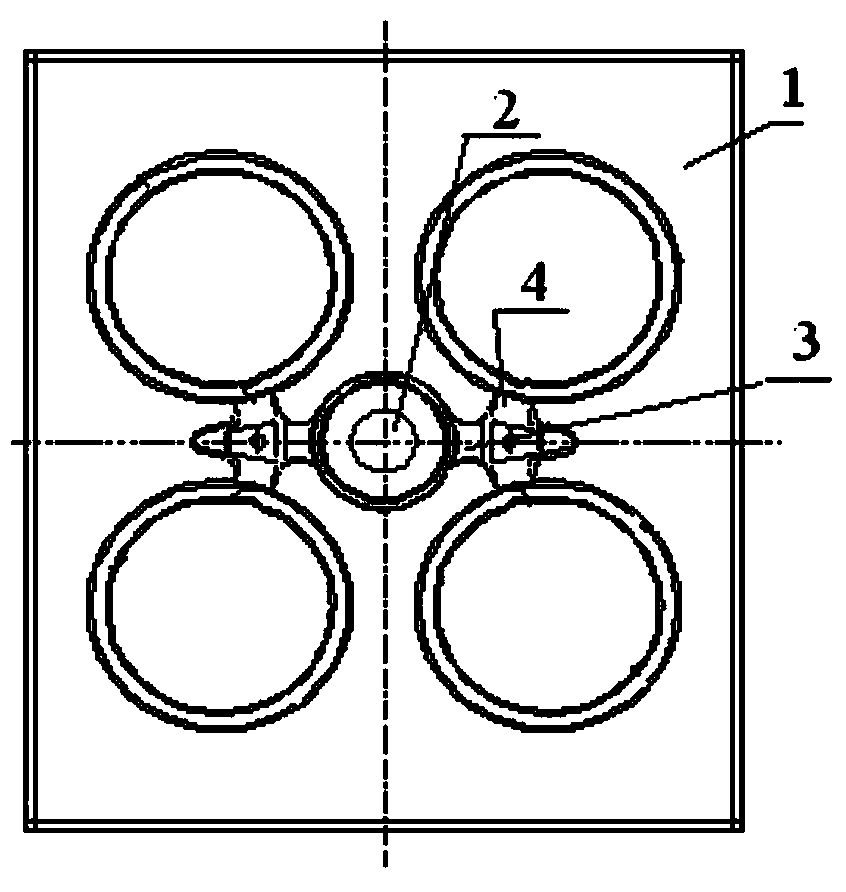

[0038] A. Use a special template for molding, that is, make sand molds on a pneumatic vibration molding machine, and then place the prepared sand molds at the pouring station. Dedicated templates such as figure 1As shown, it includes a bottom plate 1 , four piston ring models fixed on the bottom plate 1 , and a pouring system arranged on the bottom plate 1 . The gating system mainly includes a sprue 2 , a runner 3 and an inrunner 4 . The sprue 2 is arranged ...

Embodiment 2

[0054] Processing condition in the present embodiment, manufacturing method are identical with embodiment 1, and the difference with embodiment 1 is:

[0055] The design target of the chemical composition and the weight percent content in the vermicular graphite cast iron piston ring in the present embodiment is:

[0056] C: 3.6%~3.7%, Si: 2.6%~2.7%, Mn: 0.1%~0.3%, Cr: 0.2%~0.3%, Mo: 0.25%~0.3%, Cu: 0.55%~0.6%, Ti: 0.1%~0.15%, P≤0.08%, S≤0.03%, Mg: 0.011%~0.015%, the rest is Fe and unavoidable impurities.

[0057] Carry out chemical composition analysis to the compacted graphite cast iron piston ring blank that step B obtains, the chemical composition and weight percentage in the obtained piston ring are:

[0058] C: 3.6%, Si: 2.6%, Mn: 0.2%, Cr: 0.2%, Mo: 0.3%, Cu: 0.55%, Ti: 0.1%, P: 0.08%, S: 0.03%, Mg: 0.015%.

[0059] In this embodiment, by adjusting the chemical components in the material and using a reasonable casting production process, the hardness of the vermicular...

Embodiment 3

[0062] Processing condition in the present embodiment, manufacturing method are identical with embodiment 1, and the difference with embodiment 1 is:

[0063] The design target of the chemical composition and the weight percent content in the vermicular graphite cast iron piston ring in the present embodiment is:

[0064] C: 3.7%~3.8%, Si: 2.7%~2.8%, Mn: 0.1%~0.3%, Cr: 0.2%~0.3%, Mo: 0.35%~0.45%, Cu: 0.65%~0.7%, Ti: 0.05%~0.1%, P≤0.1%, S≤0.05%, Mg: 0.011%~0.015%, the rest is Fe and unavoidable impurities.

[0065] Carry out chemical composition analysis to the compacted graphite cast iron piston ring blank that step B obtains, the chemical composition and weight percentage in the obtained piston ring are:

[0066] C: 3.75%, Si: 2.75%, Mn: 0.15%, Cr: 0.24%, Mo: 0.4%, Cu: 0.7%, Ti: 0.05%, P: 0.08%, S: 0.05%, Mg: 0.02%.

[0067] In this embodiment, by adjusting the chemical components in the material and using a reasonable casting production process, the hardness of the vermicu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com