Patents

Literature

101results about How to "Excellent wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano composite hot melt type gage mark coating and preparation method thereof

InactiveCN1923929AExcellent wear resistanceImprove crack resistanceRosin coatingsTraffic signalsFiberAdjuvant

The invention discloses nanometer composite heat-fused reticle paint and preparing method, which comprises the following parts: 10-25% filming material, 3-8% dye, 40-70% filler, 0.5-4% specific reinforced material, 14-25% glass microball and 1-5% other adjuvants, wherein the specific reinforced material contains nanometer fiber, nanometer whisker, micrometer fiber, micrometer whisker. The preparing method comprises the following steps: pouring the filming material in the composite autoclave; adding adjuvant; stirring evenly; adding dye, filler, glass microball and specific reinforced material; stirring evenly; packing.

Owner:中科纳米涂料技术(苏州)有限公司

Manufacturing method of vermicular cast iron piston ring

InactiveCN103451510AMeet performance needsHigh tensile strengthPiston ringsFoundry mouldsWear resistanceToughness

The invention discloses a manufacturing method of a vermicular cast iron piston ring. The material of the vermicular cast iron piston ring comprises the following chemical components in percentage by weight: 3.4-4.0% of C, 2.4-3.2% of Si, not more than 0.3% of Mn, 0.2-0.4% of Cr, 0.2-0.6% of Mo, 0.5-1.0% of Cu, 0.05-0.15% of Ti, not more than 0.1% of P, not more than 0.05% of S, 0.009-0.02% of Mg and the balance of Fe and inevitable impurities. The manufacturing method of the vermicular cast iron piston ring comprises the following technical steps of moulding, smelting, casting, shaking out, shot blasting, mechanical processing, surface treatment and the like. By adopting the manufacturing method disclosed by the invention, the thinning of the piston ring is achieved, the production process is relatively simple, and the manufactured vermicular cast iron piston ring is high in elasticity, strength, toughness and wear resistance.

Owner:SHIJIAZHUANG JINGANG KAIYUAN POWER SCI & TECH

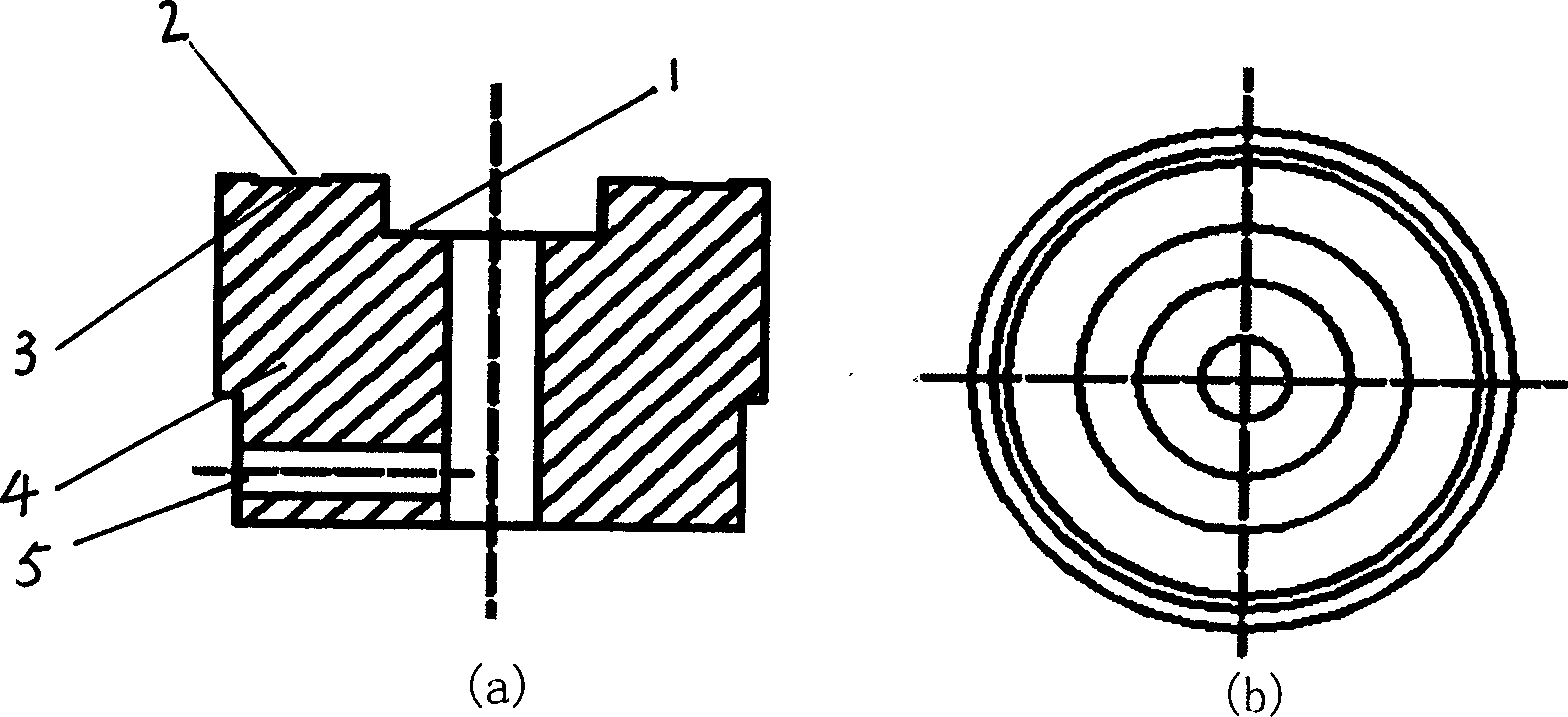

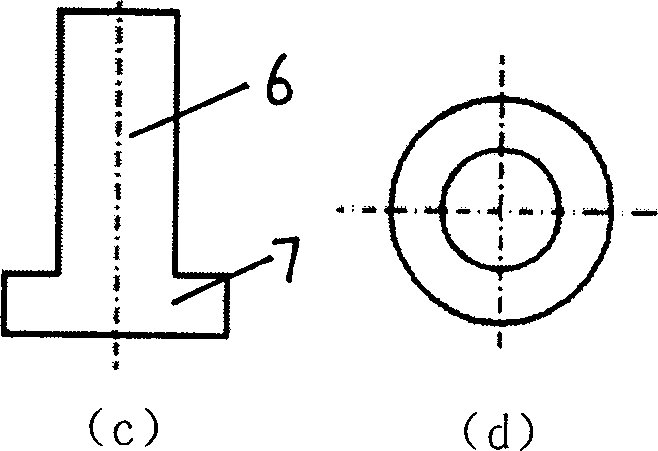

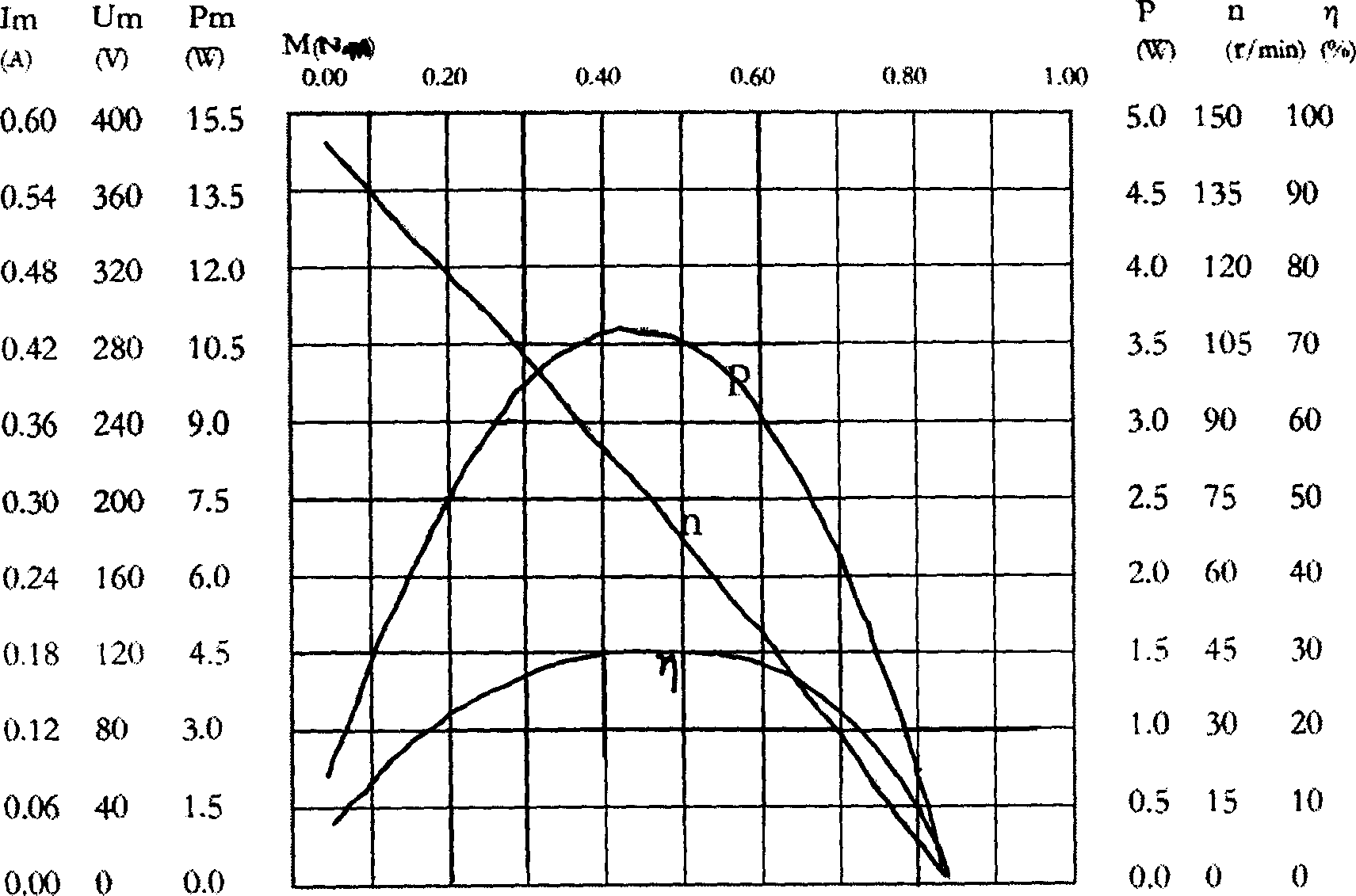

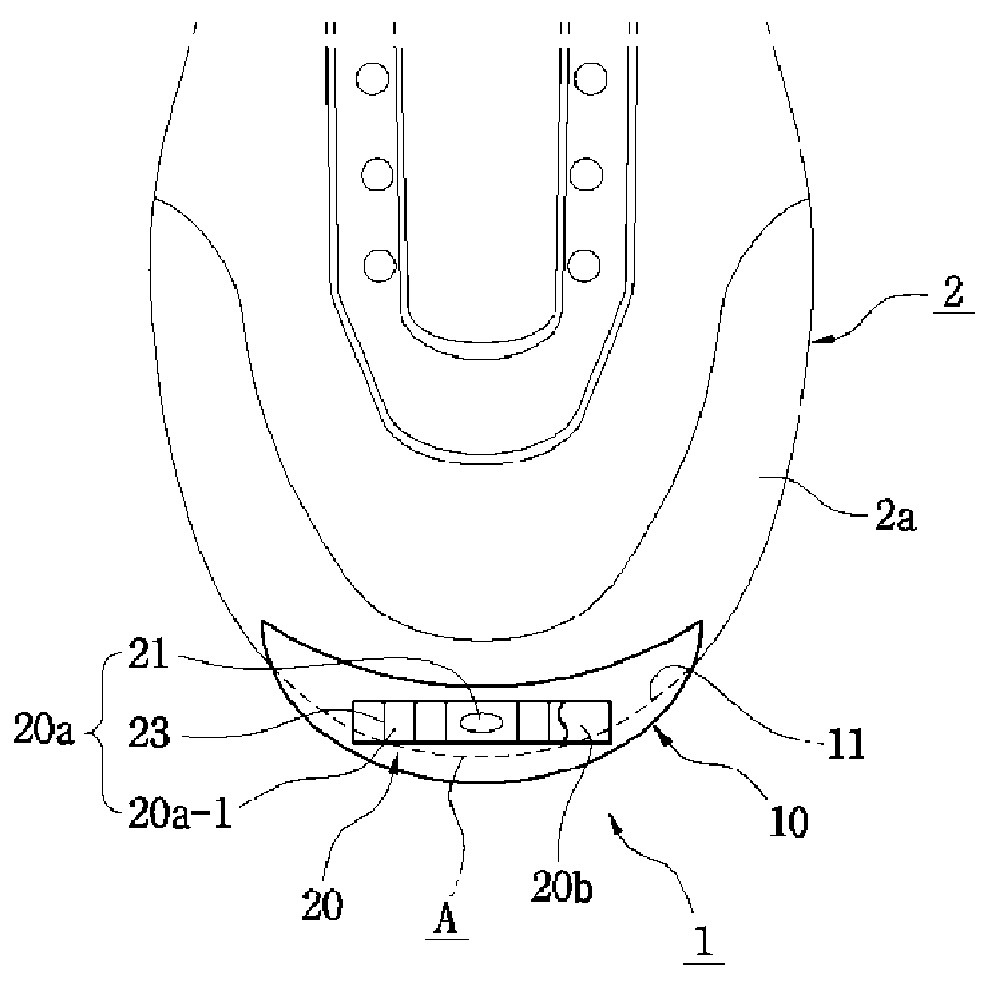

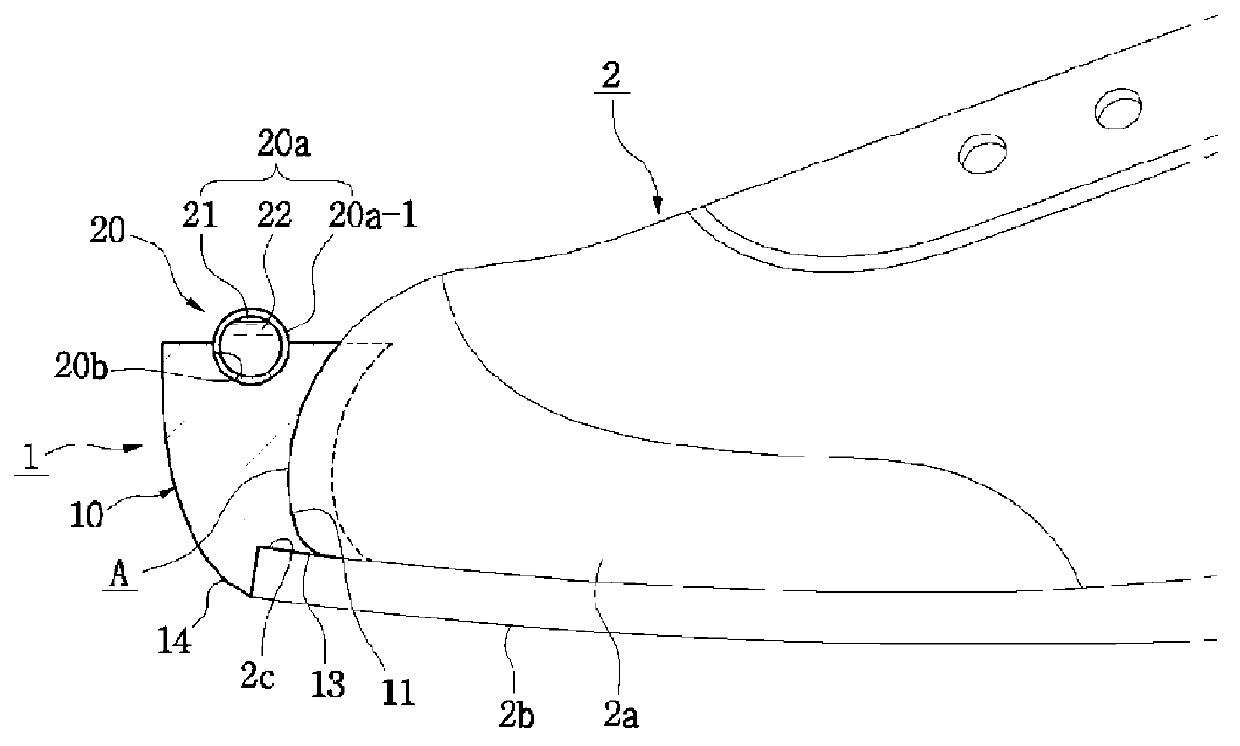

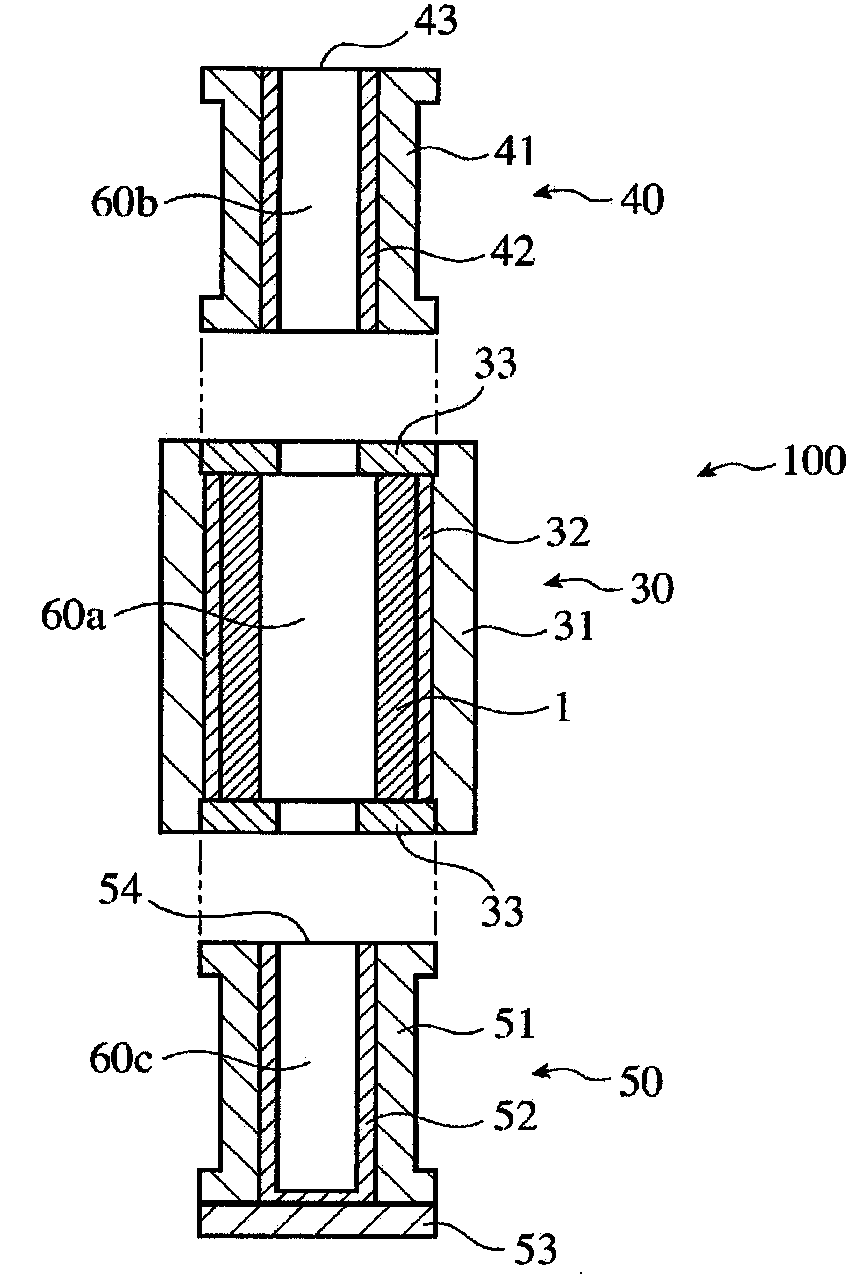

Supersonic motor thermosetting resin base friction material and friction layer manufacturing method and auxiliary tool

The invention relates to an ultrasound dynamo thermosetting resin radical friction material and friction layer making method and the assistant tools. The material is made up of 35-80% thermosetting resin, 0-34% curing agent, 5-15% nanometer antifriction powder, 5-15% carbon fiber, 0-10% copper oxide, 0-5% polytetrafluoroethylene, 5-10% copper powder, 2-10% graphite, 0-5% nitrile butadiene rubber, and 0-10% mineral substance. The invention has excellent wear resistance, suitable rigidity, good output characteristic, etc. And the method is low cost and simple. The assistant tool is made up of moving bar and base.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Solid lubricating composite material and manufacturing method thereof

InactiveCN101717682AReduce lubricationLow self-lubricating propertiesBase-materialsElectricityCarbon nanotube

The invention discloses a solid lubricating composite material and a manufacturing method thereof. Raw materials for the solid lubricating composite material comprise carbon nano tube, boron oxide and polytetrafluoroethylene. The manufacturing method comprises the following steps: grinding the carbon nano tube in a ball mill to form sectional structures, adding ethanol and surface dispersant into the carbon nano substances of the sectional structures, and treating the mixture by ultrasonic wave to obtain carbon nano liquid; taking boron oxide powder, polytetrafluoroethylene powder and the carbon nano liquid in percentage by weight, and mixing the three substances and stirring the mixture at a high speed to disperse the carbon nano liquid into the boron oxide and polytetrafluoroethylene powder so as to obtain a mixture; and die-pressing and molding the mixture, and demoulding the mixture to obtain the finished product solid lubricating composite material. The solid lubricating composite material prepared from the combination of the carbon nano tube and the polytetrafluoroethylene with self-lubricating property greatly improves the technical indexes such as low friction coefficient, self-lubricating property, abrasion resistance and the like, can conduct heat and electricity and eliminate static electricity produced by friction, and can be continuously produced in batch with lower cost.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

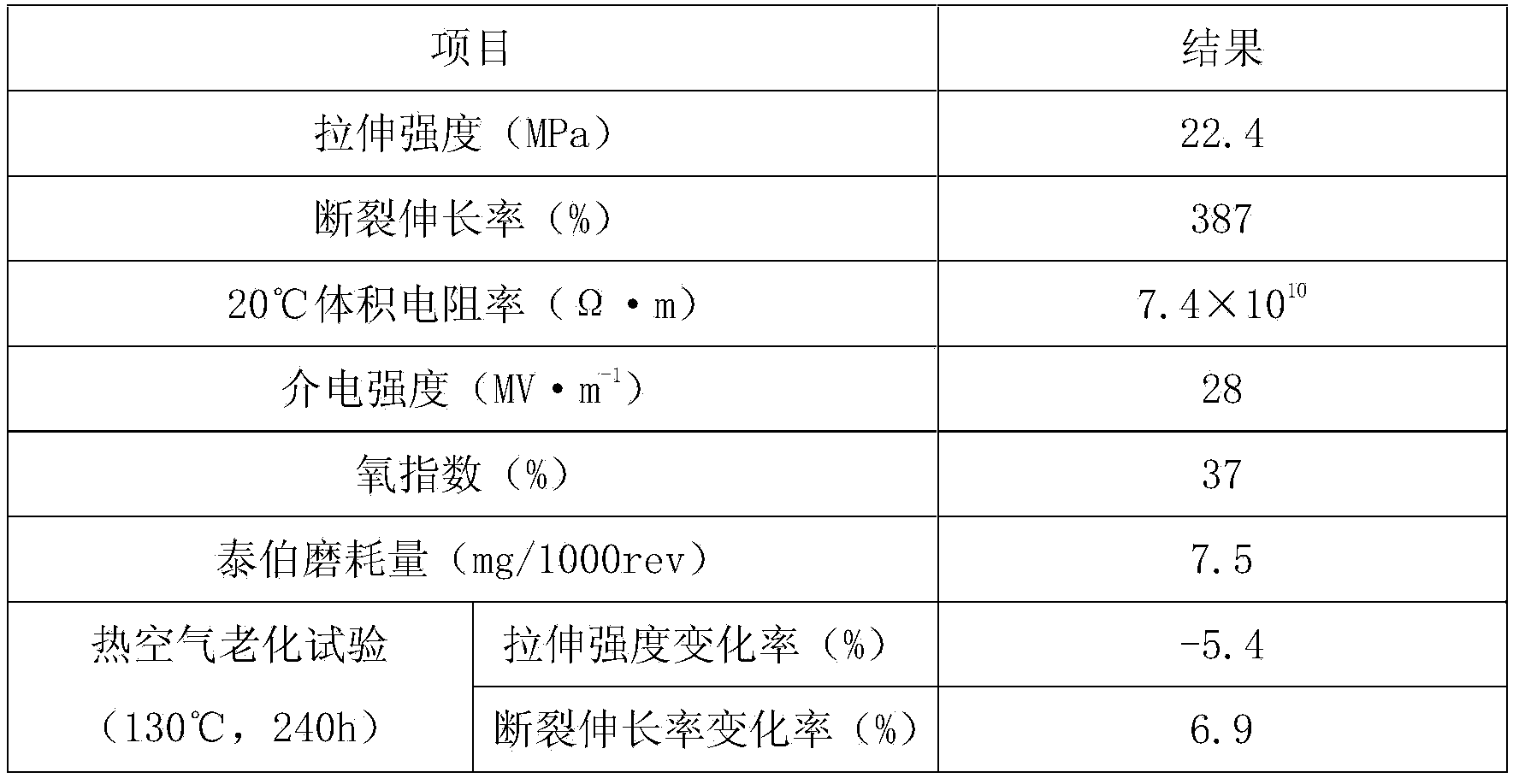

High-wearability insulating cable material and preparation method thereof

InactiveCN103881359AExcellent wear resistanceGood heat resistancePlastic/resin/waxes insulatorsDiamineChemistry

The invention discloses a high-wearability insulating cable material and a preparation method thereof. The high-wearability insulating cable material is prepared from the following raw materials in parts by weight: 70 to 90 parts of polyurethane rubber, 15 to 20 parts of polytetrafluoroethylene, 10 to 15 parts of nylon 6, 10 to 15 parts of polypropylene glycol adipate, 5 to 10 parts of dipropylene glycol dibenzoate, 5 to 10 parts of trel-butylphenyl diphenyl phosphate, 7 to 13 parts of antimonous oxide, 5 to 10 parts of decabromodiphenylethane, 4 to 8 parts of zinc borate, 2 to 3 parts of tert-butyl peroxybenzoate, 1.5 to 2 parts of zinc oxide, 2 to 3 parts of stearic acid, 3 to 6 parts of chlorcosane, 1 to 2 parts of accelerant ZDMC (Zinc Dimethyldithiocarbamate), 1 to 2 parts of accelerant CZ (N-cyclohexylbenzothiazole-2-sulphenamide), 15 to 20 parts of fumed silica, 10 to 15 parts of attapulgite nanoocomposites, 5 to 10 parts of nano zeolite, 10 to 15 parts of precipitated barium sulphate, 1.5 to 2.5 parts of antioxidant 1010, 2 to 3 parts of anti-aging agent TPPD (N-(p-toluene-sulphonylamido-N'-phenylene diamine)), and 3 to 6 parts of composite filler. The cable material is outstanding in wearability, particularly, the wearability is always several times and even dozen times that of the common electrical material under a terrible working condition in the presence of water, oil and other wetting medias; the cable material is also remarkable in heat resistance, flame resistance, ageing resistance, oil resistance, warping strength, impact resistance and tear resistance.

Owner:ANHUI WANGDA COPPER DEV

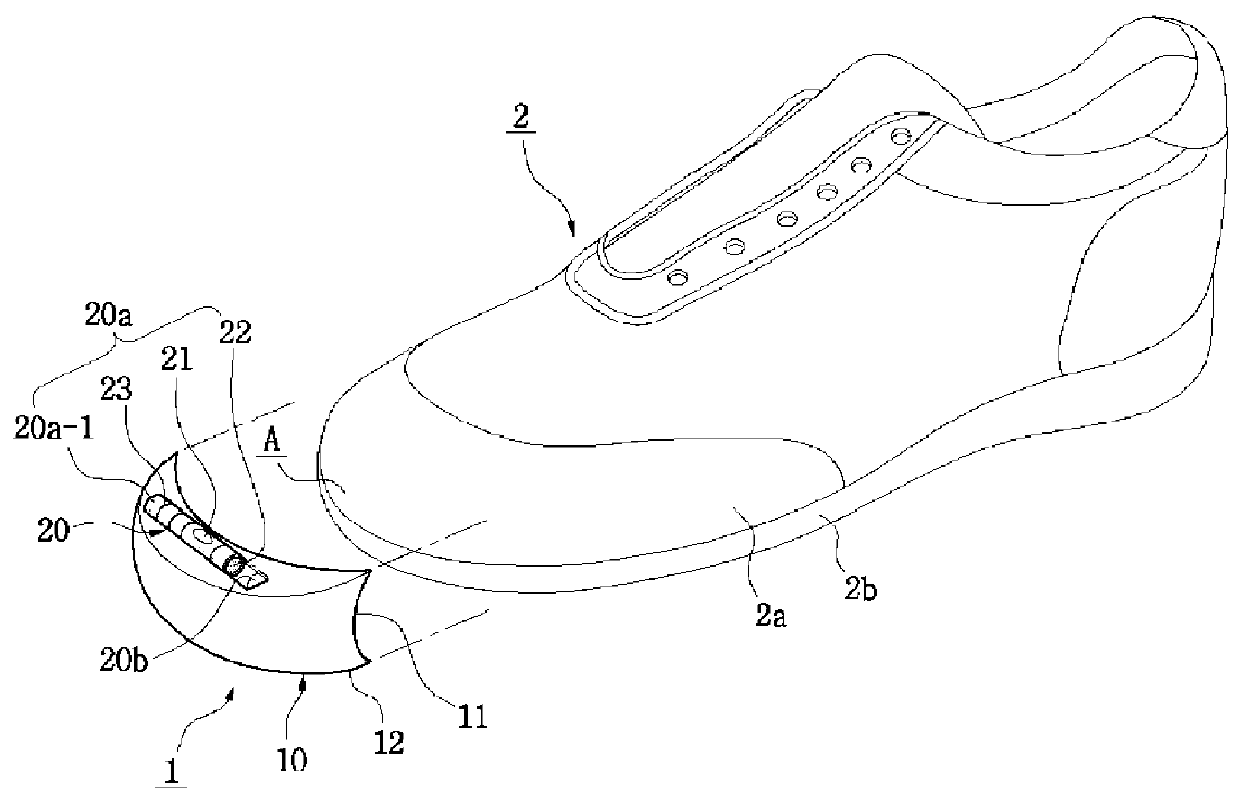

Level device for a shoe

InactiveUS20120137530A1Excellent wear-resistanceImprove impact resistanceUpperBootlegsEngineeringVisual perception

Owner:YUN JI HAE

Low-temperature chemical Ni-Cu-P plating solution and chemical Ni-Cu-P plating method applying the solution

InactiveCN102168261AReduce pollutionProtection securityLiquid/solution decomposition chemical coatingEnvironmental resistanceSodium acetate

The invention relates to chemical plating on the surface of a metal material, in particular to a low-temperature ultrasonic wave assisted chemical Ni-Cu-P plating solution used for the surface of a low-carbon steel base material as well as a chemical Ni-Cu-P plating method. The characteristics include adopting nickel sulfate and copper sulfate as the main salt of the plating solution, sodium hypophosphite as a reducing agent, sodium acetate as a buffer, trisodium citrate and lactic acid as complexing agents, succinic acid and glycine as well as ammonium hydrogen fluoride as combined accelerators, potassium iodide and thiourea as stabilizers to prepare the chemical Ni-Cu-P plating solution, and applying the chemical Ni-Cu-P plating solution on the surface of a low-carbon steel substrate by low-temperature ultrasonic wave chemical plating. In the invention, the formula of the plating solution is environment-friendly, meets the environment-friendly requirement of clean production and reduces pollution to environment. The method for chemically plating Ni-Cu-P on the surface of the low-carbon steel substrate obviously lowers the plating application temperature, enables the deposition speed to be fast and effectively improves the performance of the low-carbon steel substrate.

Owner:SHANDONG JIANZHU UNIV

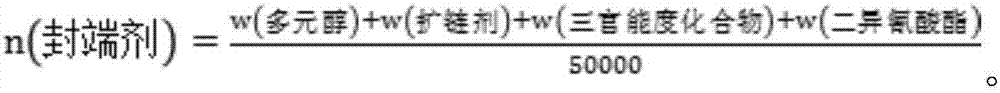

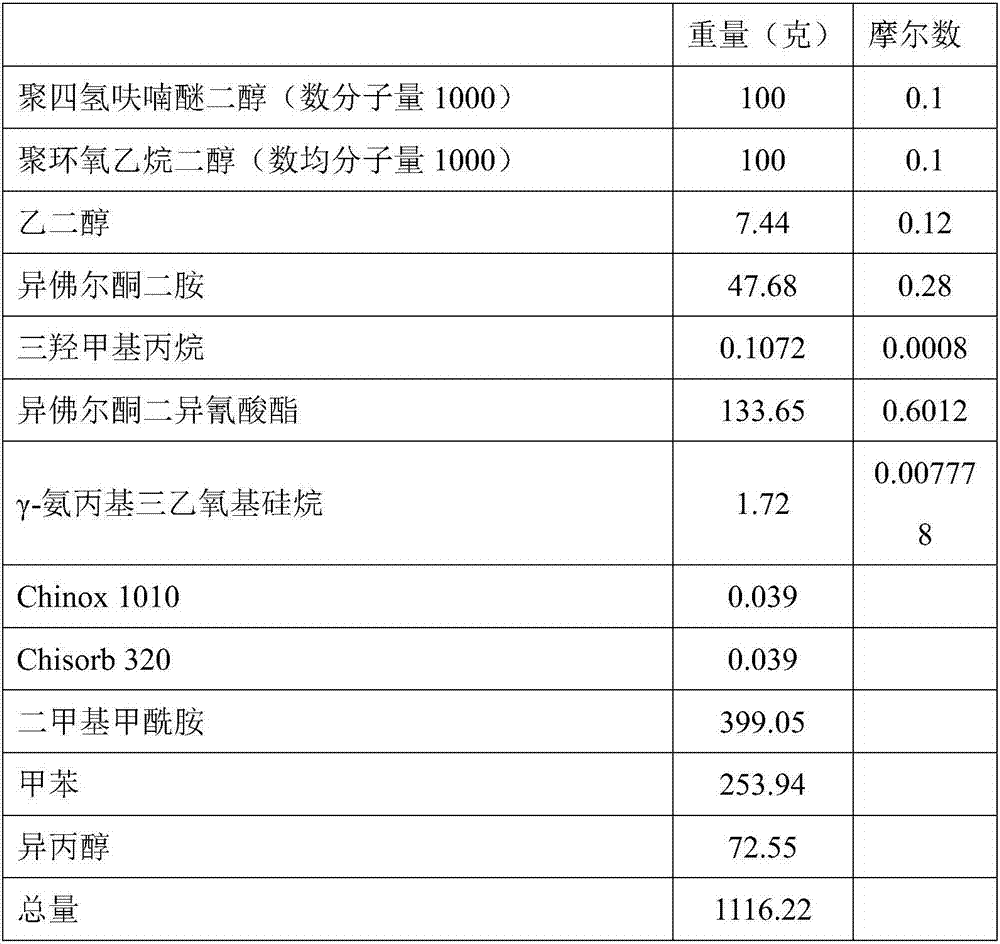

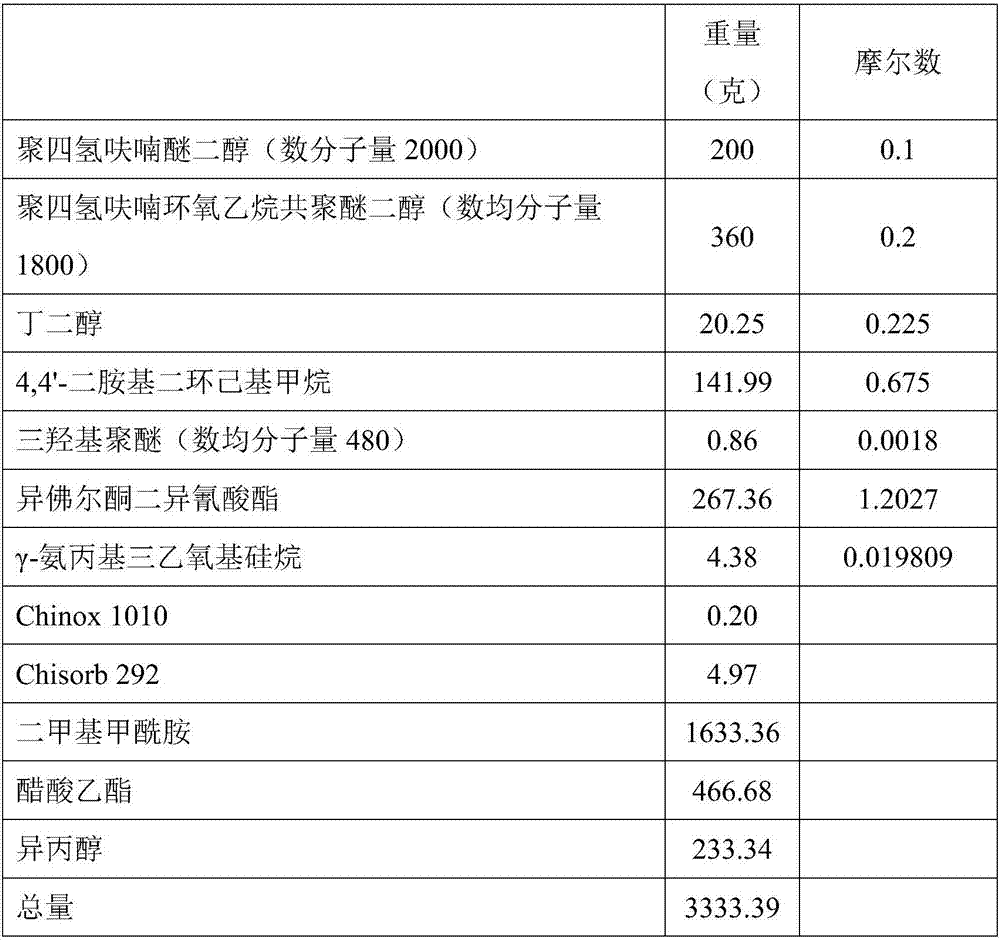

Surface layer polyurethane resin for waterproof and moisture permeable synthetic leather and preparation method of polyurethane resin

ActiveCN107501505AGood waterproof and moisture permeabilityExcellent wear resistancePolyurea/polyurethane coatingsTextiles and paperIsocyanateEpoxide

The invention discloses a surface layer polyurethane resin for waterproof and moisture permeable synthetic leather and a preparation method of the polyurethane resin. The surface layer polyurethane resin for the waterproof and moisture permeable synthetic leather is made from raw materials comprising polyol, chain extenders, a tri-functionality compound, diisocyanate and a sealing agent. The polyol contains polyol A and polyol B in a molar ratio of 1:1-1:3, wherein polyol A is selected from one or more of polytetramethylene ether glycol and polytetrahydrofuran propylene epoxide polyether diols, and the polyol B is selected from one or more of polytetrahydrofuran epoxyethane polyether diols, propylene epoxide epoxyethane polyether diols and polyepoxide glycol; the chain extenders comprise a dihydroxyl chain extender and a diamino chain extender; the tri-functionality compound is a trihydroxy compound; and the blocking agent is a monoamine silane coupling agent. The waterproof and moisture permeable polyurethane synthetic leather disclosed by the invention not only has excellent waterproof property and moisture permeability, but also has excellent wear resistance.

Owner:江苏华峰超纤材料有限公司

17-4PH steel surface reinforcement method

ActiveCN1844415AMeet the hardness conditionsExcellent corrosion resistanceFurnace typesIncreasing energy efficiencyHardnessSolid solution

The invention provides a method of strengthening 17-4PH steel surfaces; the method can solved the problem as follow: 17-4PH steel often use in two kinds of heat treatment condition as follow: first, solid solution time-effect condition; second, solid solution over aging condition. The first condition, the machine member strength machine member 1200Mpa, stress corrosion trend seriously, general solution method of adopting decrease working efficiency or enlarge the section size of machine member. The second condition, the machine member in low degree of hardness, badly abrasion-resistance, the shortly operating life of equipment. The invention key point as follow: firstly, pre-heating treatment: contain preventing internal break anneal after smith and solid solution + time-effect treatment, then stabilizing treatment; finally, final thermal treatment: contain surface solid solution treatment and surface time-effect treatment. The initiative effect of invention as follow: heating solid solution time-effect treatment though machine member surface induction, the hardness of machine member core less then 33, fitting the hardness condition that the steel utilize in acidic medium; the surface deck hardness 42-45 in the area of 0.8-1.5mm, the deck resistance to corrosion stress cracking function and abrasion-resistance are good.

Owner:SHENYANG BLOWER WORKS GROUP CORP

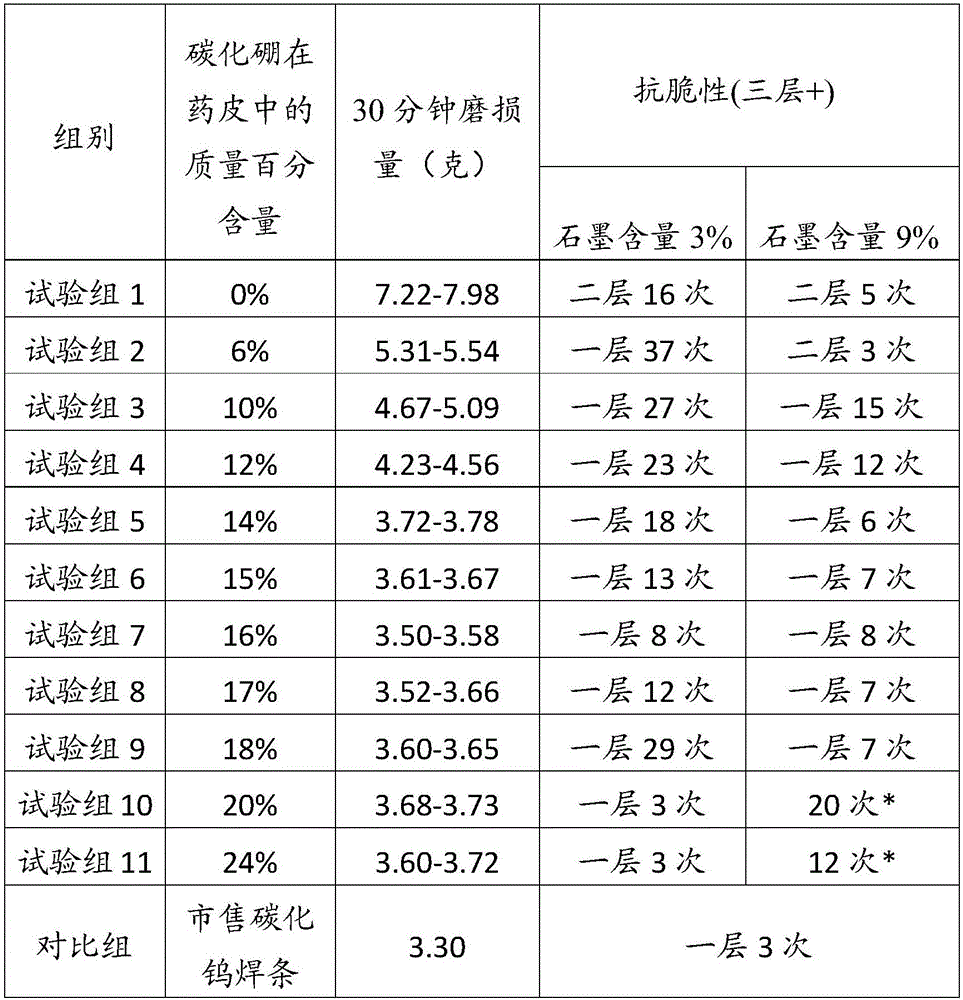

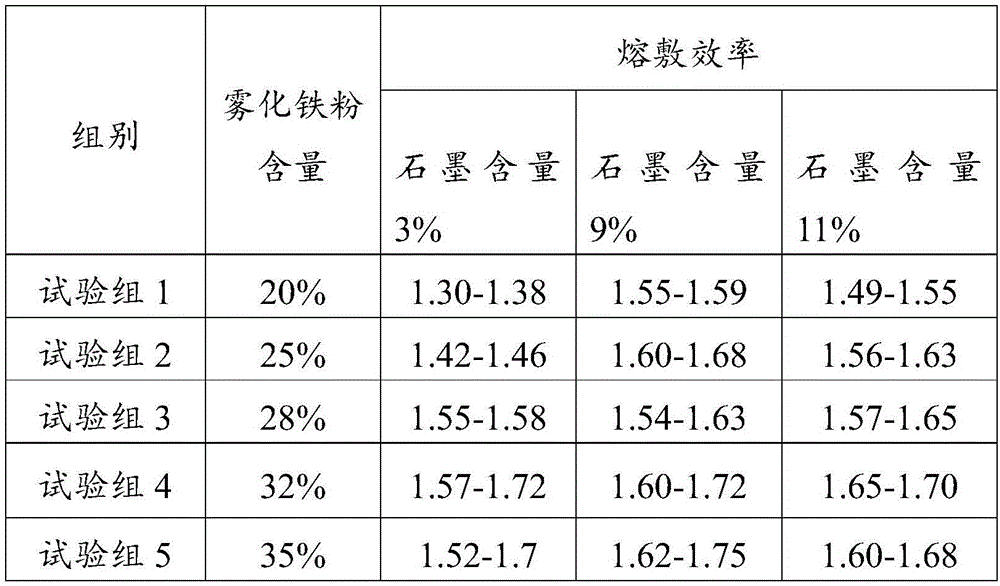

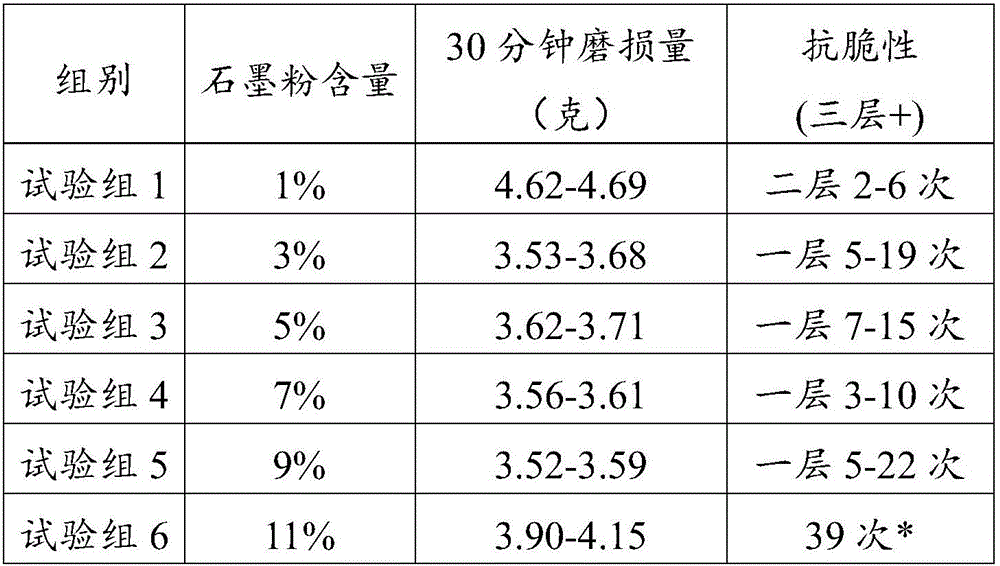

Hardfacing electrode covering and electrode containing same

ActiveCN105689923AStrong anti-brittleImprove conductivityWelding/cutting media/materialsSoldering mediaNiobiumFerrosilicon

The invention discloses a hardfacing electrode covering and an electrode containing the same. The covering is prepared from the following components in percentage by mass: 14 to 18 percent of boron carbide, 28 percent of atomized iron powder, 0 to 6 percent of atomized ferrosilicon, 0 to 41 percent of high-carbon ferro-chrome, 0 to 33 percent of micro-carbon ferro-chrome, 0 to 20 percent of ferroniobium, 0 to 8 percent of cobalt powder, 3 to 9 percent of graphite powder, 0 to 4 percent of medium-carbon ferromanganese, 0 to 4 percent of ferrovanadium, and 0 to 20 percent of chromium metal. The hardfacing electrode covering disclosed by the invention is low in melting point, high in melting speed, convenient to perform welding and attractive in molding; metal on a surfacing layer of the hardfacing electrode covering has high hardness, high wear resistance and a certain brittleness resistance; moreover, in the using process, the hardfacing electrode covering is relatively high in cost performance. Meanwhile, the invention further discloses the electrode containing the hardfacing electrode covering and a preparation method of the electrode.

Owner:广州鑫钻新材料科技开发有限公司

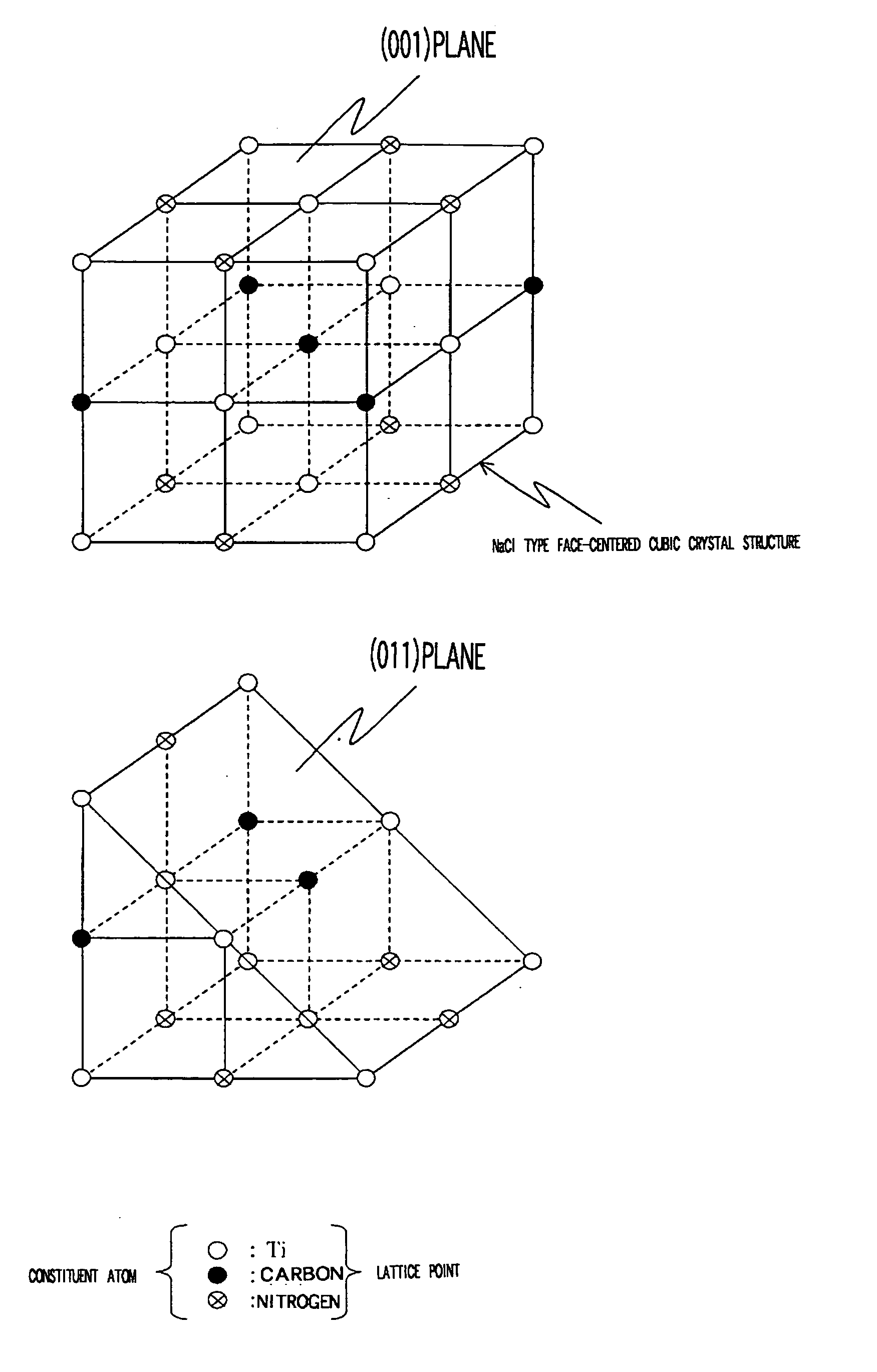

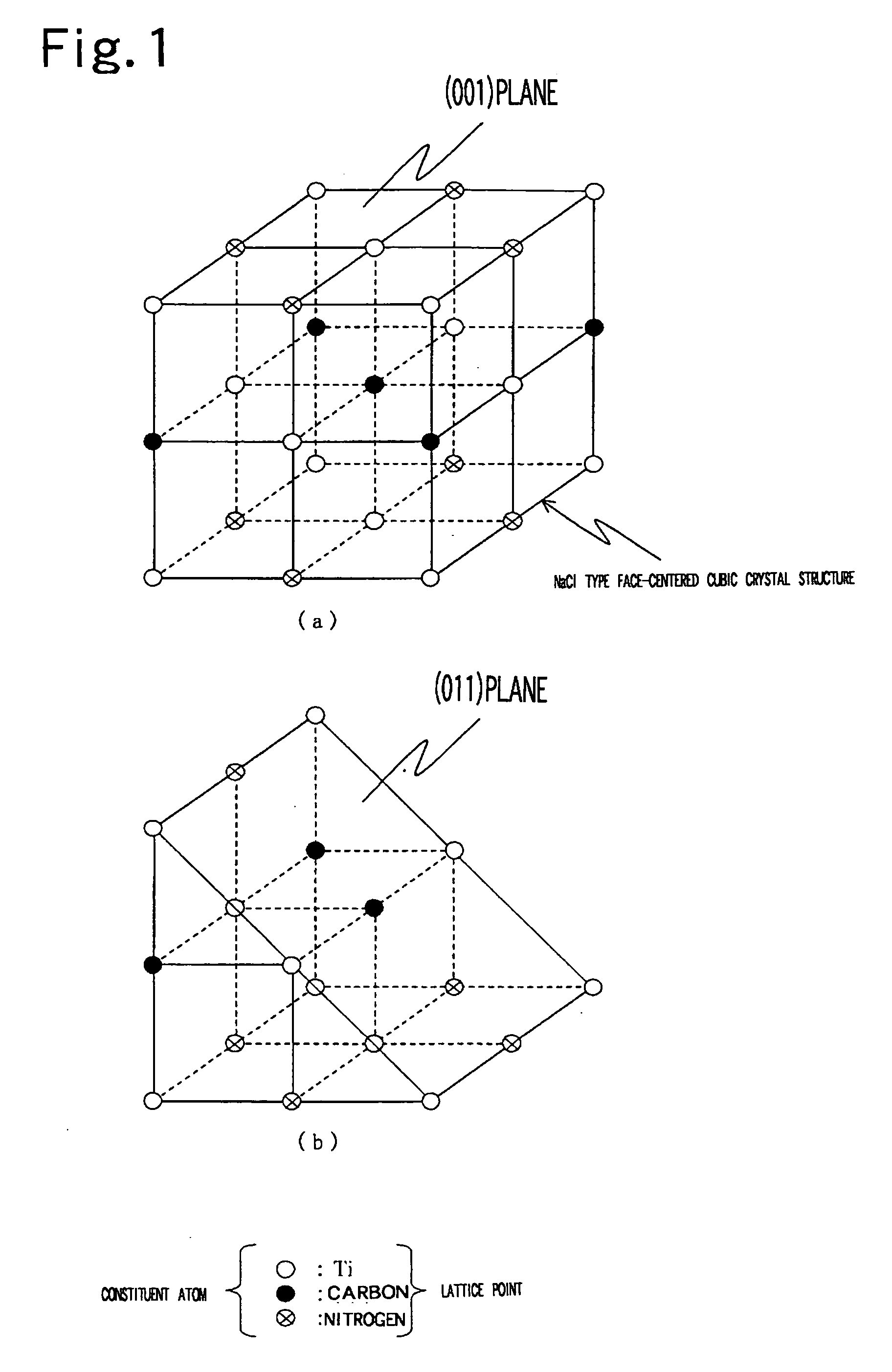

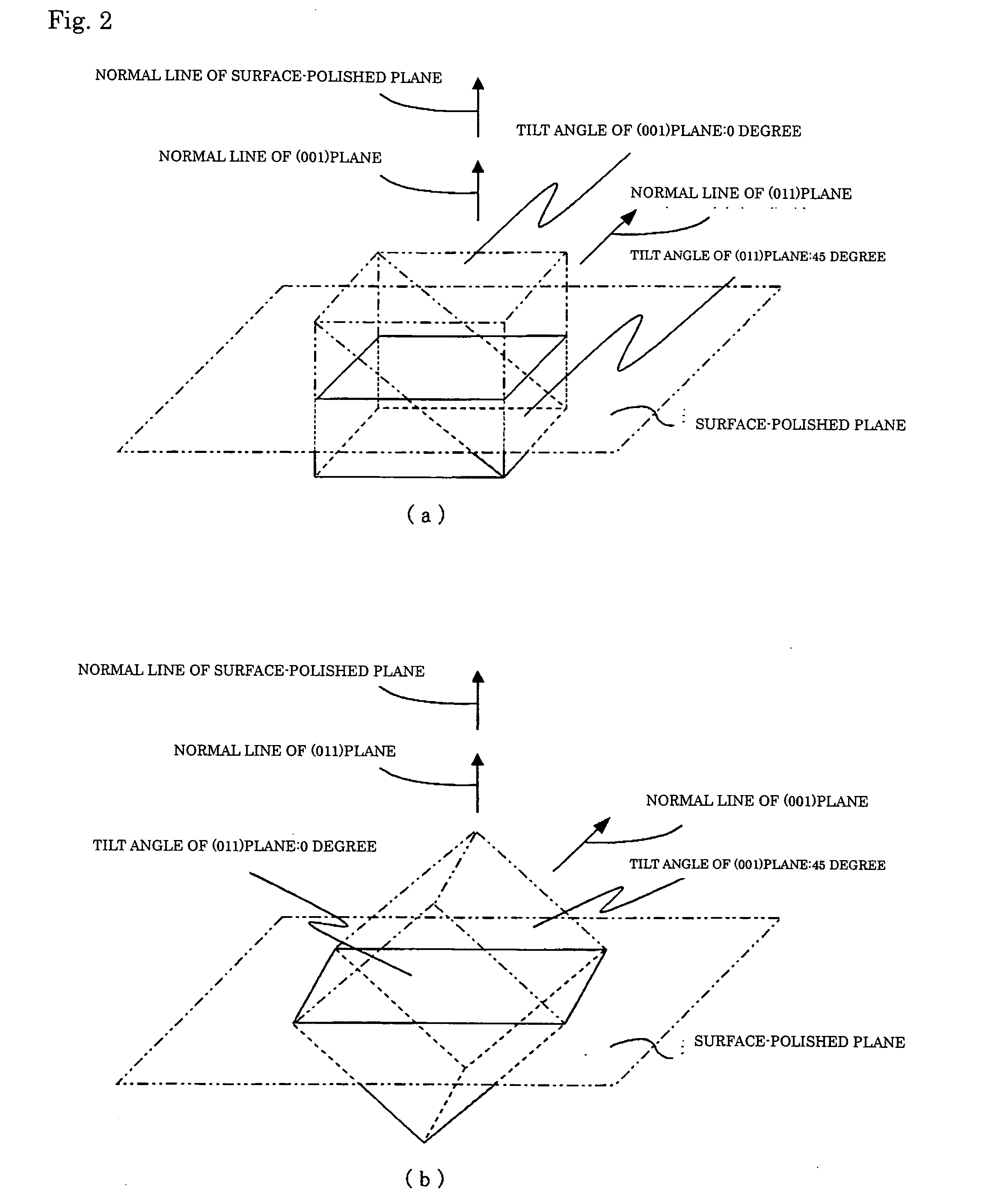

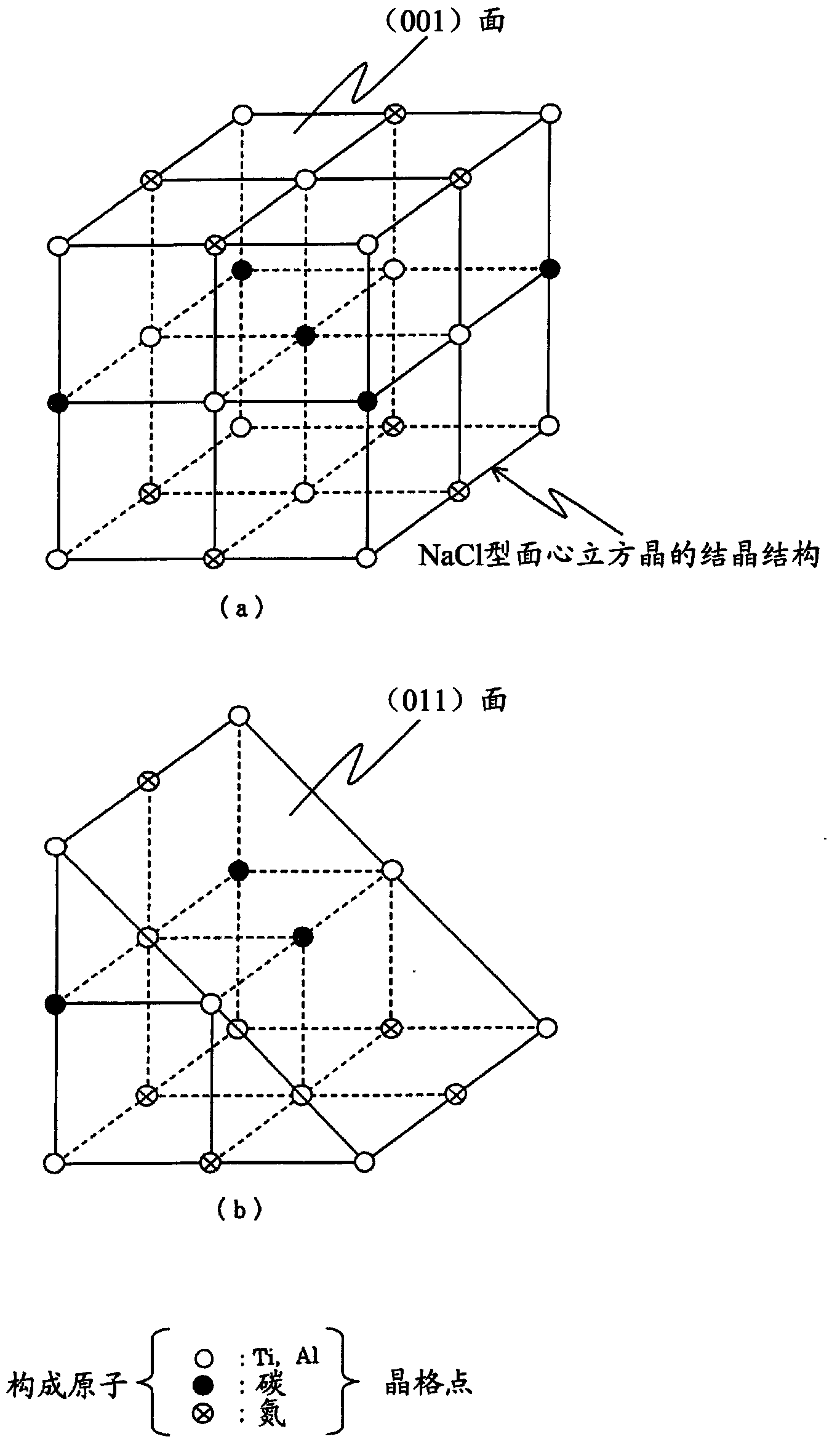

Surface-coated cermet cutting tool with hard coating layer having excellent chipping resistance in high-speed intermittent cutting work

ActiveUS20060035111A1Excellent wear resistanceHigh mechanical and thermal impactPigmenting treatmentOther chemical processesTitanium carbonitrideCermet

A surface-coated cermet cutting tool with a hard coating layer in a high-speed intermittent cutting work is provided. The hard-coating layer includes lower and upper layers. One of the lower layers is a titanium carbonitride layer, which has the highest peak in Σ3 and a distribution ratio of the Σ3 to ΣN+1 ranges 60% to 80% in the atom sharing lattice point distribution graph.

Owner:MITSUBISHI MATERIALS CORP

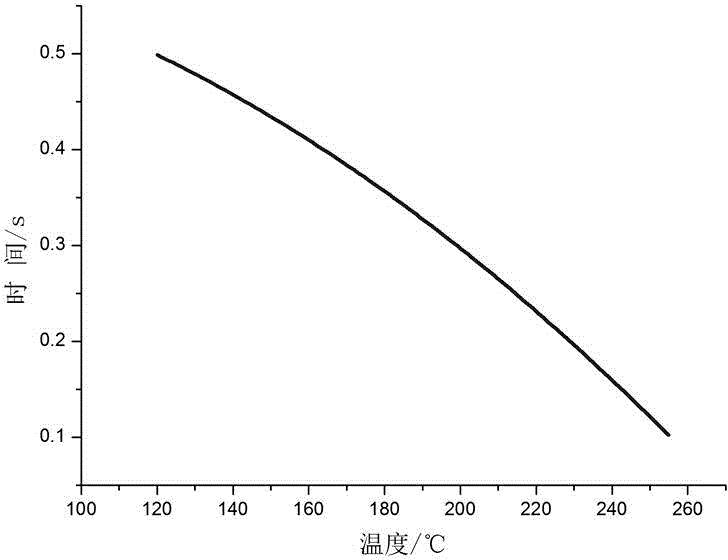

Preparation method and application of protective film in full lamination with mobile terminal

ActiveCN104592908AExcellent wear resistanceHigh strength and light transmittanceFilm/foil adhesivesSynthetic resin layered productsPolyesterPolymer chemistry

The invention relates to the technical field of optical films and in particular relates to a preparation method and an application of a protective film in full lamination with a mobile terminal. The preparation method of the protective film comprises the following steps: putting a polyester film substrate and a first release film into a film coating and laminating wheel, carrying out hot-press lamination, wherein a curve equation of lamination temperature and time is shown as follows: T=429X2-83X+(261-271)s; coating the other surface of the polyester film substrate with an adhesive material, coating the adhesive material with a second release film, putting the film substrate in a drying oven, and drying to obtain the protective film. The protective film prepared by the method is high in tension and is capable of laminating the picture surface, the back surface and side surface of the mobile terminal at 360 degrees; the protective film is integrally molded, and is low in production cost and high in impact resistance; the mobile terminal is low in sable thickness; the preparation method is simple and can be used for effectively solving the problem that the protective film is not liable to coil because the material is softened during processing at a high temperature.

Owner:JIANGSU ZHONGHAI HUA HE ENVIRONMENTAL PROTECTION CO LTD

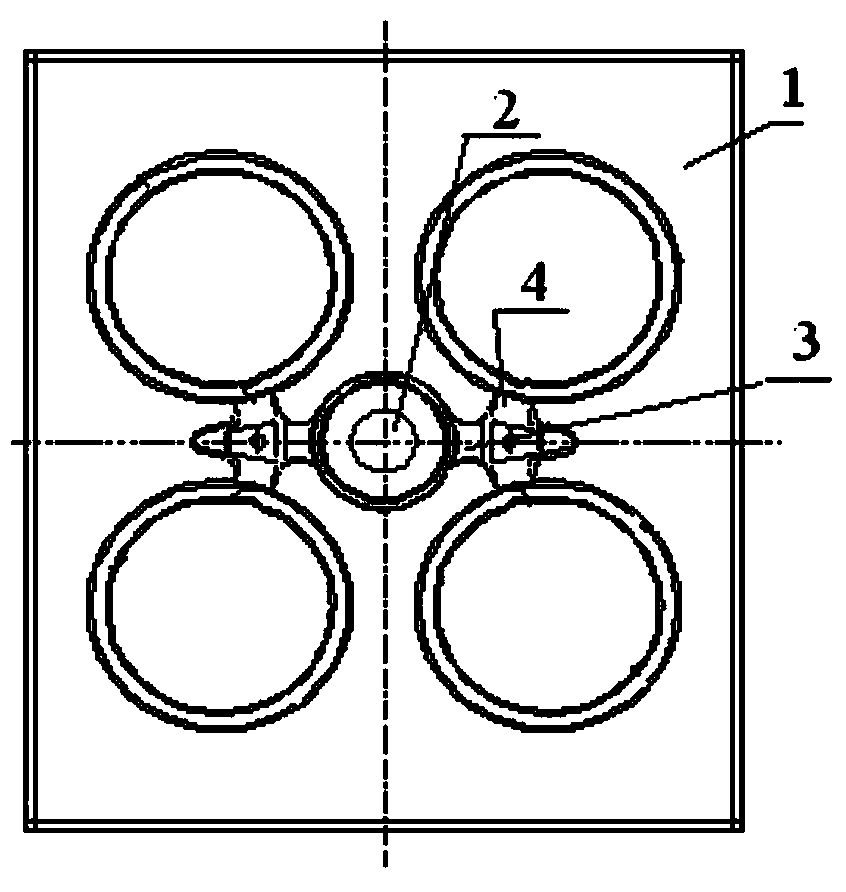

Filtering device comprising piezoelectric composite material and application thereof in atmosphere particle absorption

ActiveCN109746120ALow priceSimple manufacturing methodExternal electric electrostatic seperatorElectric supply techniquesParticulatesHigh absorption

The invention discloses a filtering device comprising piezoelectric composite material and application thereof in atmosphere particle absorption. A filtering layer in the filtering device does not need an external power supply, charges are generated only by deformation under a simulation effect of external pressure, thus, the filtering device can be repeatedly charged, the charges can be stably stored, and the service lifetime is prolonged. The filtering device can be used for absorbing the atmosphere particle, polarity fine particle in atmosphere can be directly captured, and neutral particlealso can be polarized and then is captured; and the method has no selectivity on a size of particle and particularly has relatively high absorption efficiency on micronano-scale fine particle.

Owner:北京中科艾加科技有限公司

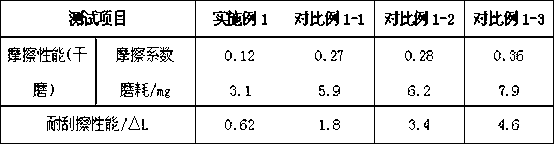

Liquid crystal polymer/cubic boron nitride master batch and preparation method for same

ActiveCN103013058AMake up for wear resistanceMake up for the defects of scratch-resistant masterbatchCrystallographyPhysical chemistry

The invention discloses a liquid crystal polymer / cubic boron nitride master batch prepared from a liquid crystal polymer, cubic boron nitride and dimethyl silicon oil, and a preparation method thereof. The liquid crystal polymer / cubic boron nitride master batch disclosed by the invention is mainly used as a wear-resistant and scratch-resistant master batch in a high-temperature-resistant polymer, and capable of obviously improving the wear resistance and scratch resistance of the high-temperature-resistant polymer. By using a cross scratch resistance instrument and a colorimeter for detecting the scratch resistance, the minimum Delta L value is 0.21, which fully shows that the liquid crystal polymer / cubic boron nitride master batch disclosed by the invention is greatly excellent in the wear resistance and the scratch resistance of the high-temperature-resistant polymer.

Owner:HEFEI GENIUS NEW MATERIALS

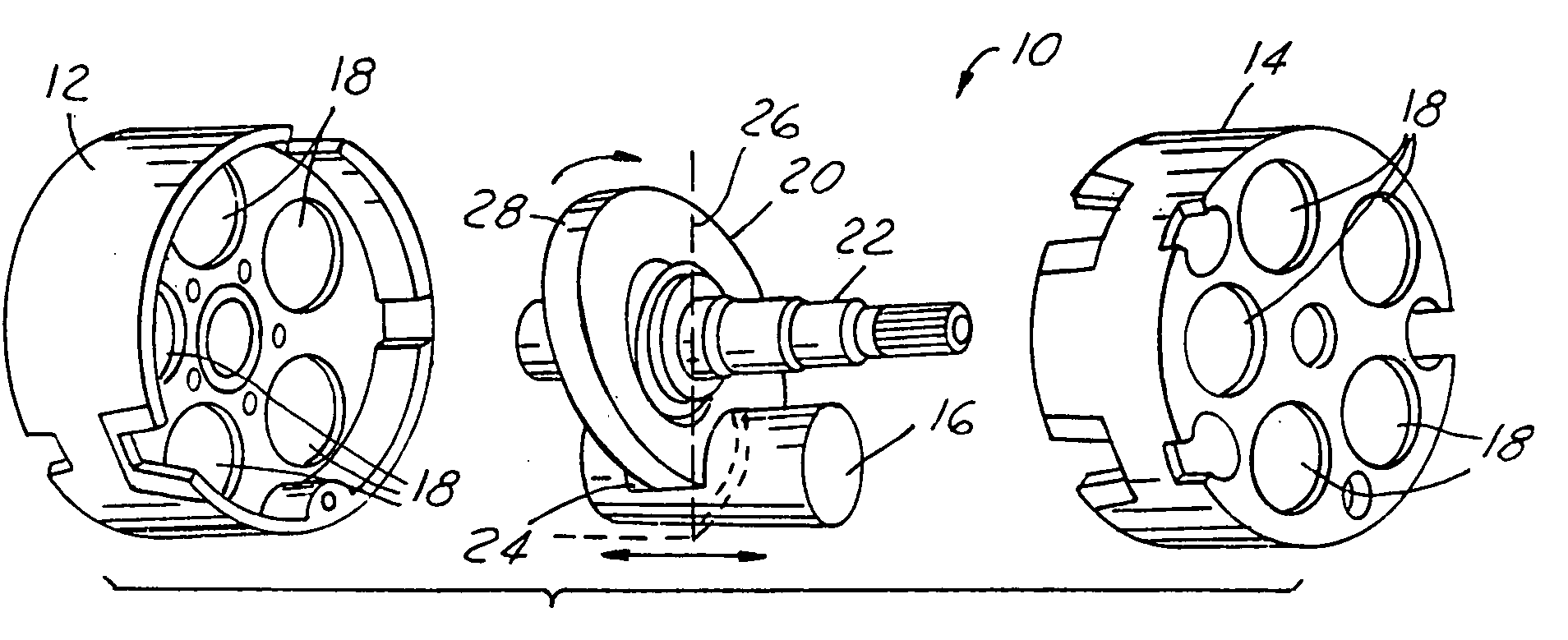

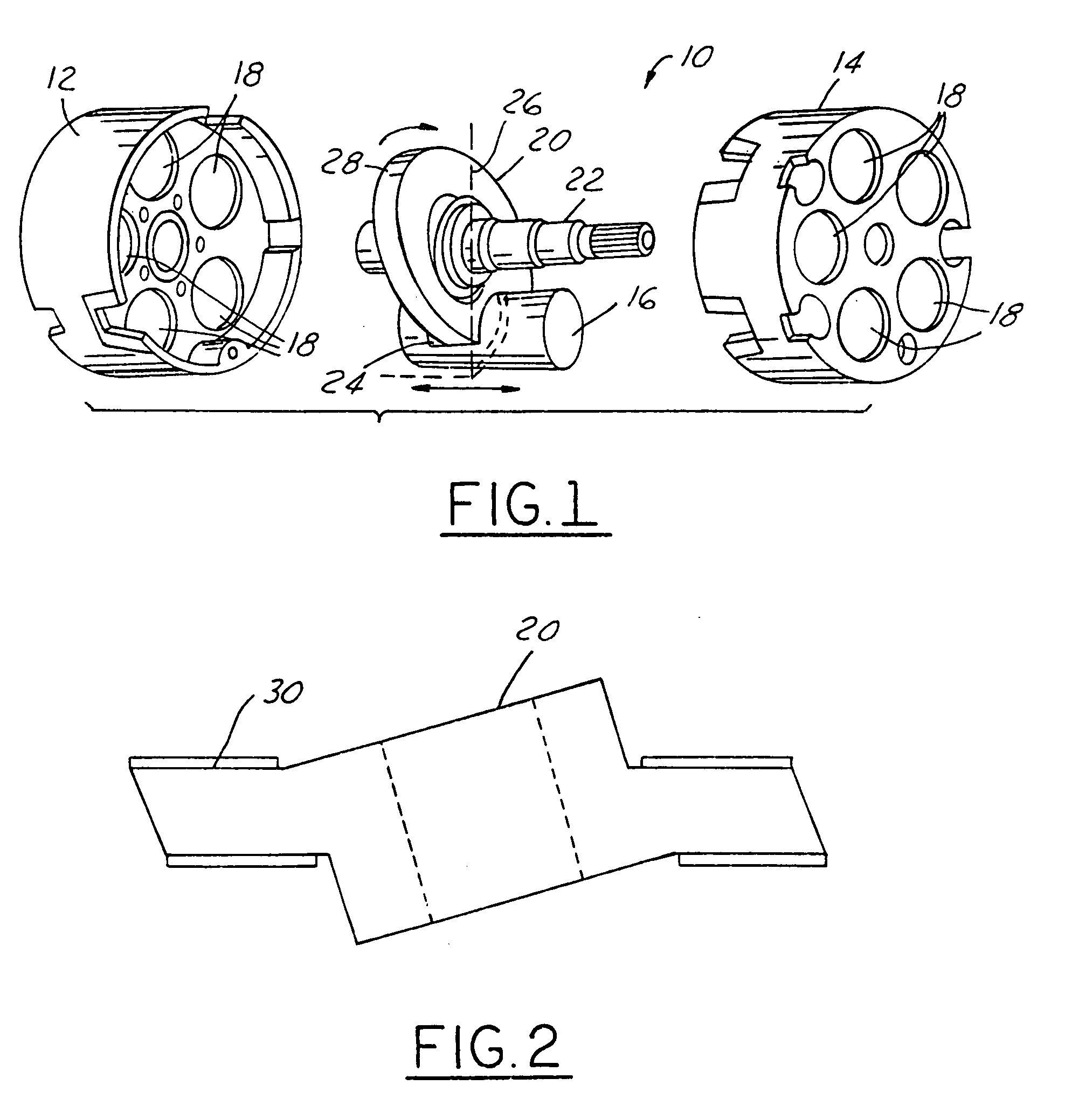

Composite steel part and manufacturing method for the same

ActiveUS20120267009A1Eliminate needExcellent wear resistanceSolid state diffusion coatingMetal layered productsHigh densityCooling rates

A manufacturing method for a composite steel part including preparing an intermediate product in which an extra portion, which has a thickness equal to or more than that of a carburized layer to be formed in a subsequent carburizing step, has been added to a welding expected portion, carburizing the intermediate product by heating to an austenitizing temperature or more in a carburizing atmosphere, then cooling the intermediate product at a cooling rate less than a rate at which martensitic transformation occurs and without completing structural transformation due to the cooling, quenching a portion of the intermediate product after heating to an austenitizing range by high-density energy and thereafter cooling to cause martensitic transformation to form a carburized quenched portion, removing an extra portion of the intermediate product; and then welding a second steel part to the welding expected portion.

Owner:AISIN AW CO LTD

Lead-free copper-based coatings with bismuth for swashplate compressors

InactiveUS6926779B1Improve wear and lubricityExcellent wear resistanceMetallic material coating processesEngine componentsChromiumNickel

A surface of aluminum alloy or iron alloy coated, on at least a part, with a lead-free copper-based coating layer comprising, by weight, 0.2–15% bismuth, and at least one metal selected from the group consisting of 5–40% nickel, 1–20% chromium, 1–20% iron, and 1–10% cobalt, the balance being copper which is more than 55%. The surface may be of a swashplate used in swashplate type compressors.

Owner:VISTEON GLOBAL TECH INC

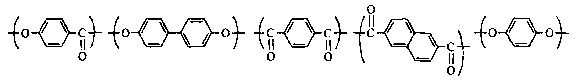

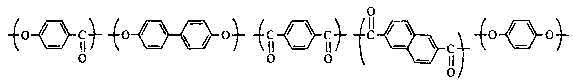

Polytetrafluoroethylene alloy and preparation method thereof

The invention relates to a polymer alloy, which mainly comprises the following components in percentage by weight: 60 to 97 percent of polytetrafluoroethylene, 3 to 40 percent of main chain polyester liquid crystal polymer and the balance of auxiliary material. The auxiliary material is one or two of carbon fiber and glass fiber, wherein the carbon fiber is 0 to 15 weight percent of the auxiliary material; the glass fiber is 0 to 15 weight percent of the auxiliary material; and the auxiliary material comprises 0 to 5 weight percent of graphite. The wear-resistant polytetrafluoroethylene alloy has the advantages of high wear resistance, high hardness, low creep property, low friction coefficient and abrasion coefficient and the like.

Owner:浙江超维新材料有限公司

Thermal underwear fabric

InactiveCN105926121AExcellent wear resistanceGuaranteed comfortWeft knittingWarp knittingThermal insulationSynthetic fiber

The invention discloses thermal underwear fabric. A preparation technology of the thermal underwear fabric is implemented through the step as follows: blended yarn prepared from Cuqing fibers, other common cellulose fibers, synthetic fibers and wool fibers is subjected to weaving and after-finishing processes. The thermal underwear fabric has the advantages as follows: the density of the Cuqing fibers is 1.17 g / cm<3> and is lower than that of cashmere, and the fibers are lighter; the heat-conducting property of the Cuqing fibers is 0.051 W / (m*DEG C) and is lower than that of the cashmere, and the heat-conducting property of cashmere is 0.055 W / (m*DEG C), so that the thermal insulation performance of the Cuqing fibers is better than that of the cashmere when the Cuqing fibers are taken as the raw material for weaving thermal underwear; the blended yarn prepared from the Cuqing fibers, the other cellulose fibers and the wool fibers through blending is subjected to weaving and after-finishing processes for preparation of the fabric, the antistatic property of the fabric can meet the level-A standard, the anti-pilling performance can reach level-4 or higher, and meanwhile, the fabric has excellent wear resistance, so that the service life of the thermal underwear is prolonged effectively while the comfort of the thermal underwear is guaranteed.

Owner:RUGAO CITY DINGYAN TEXTILE

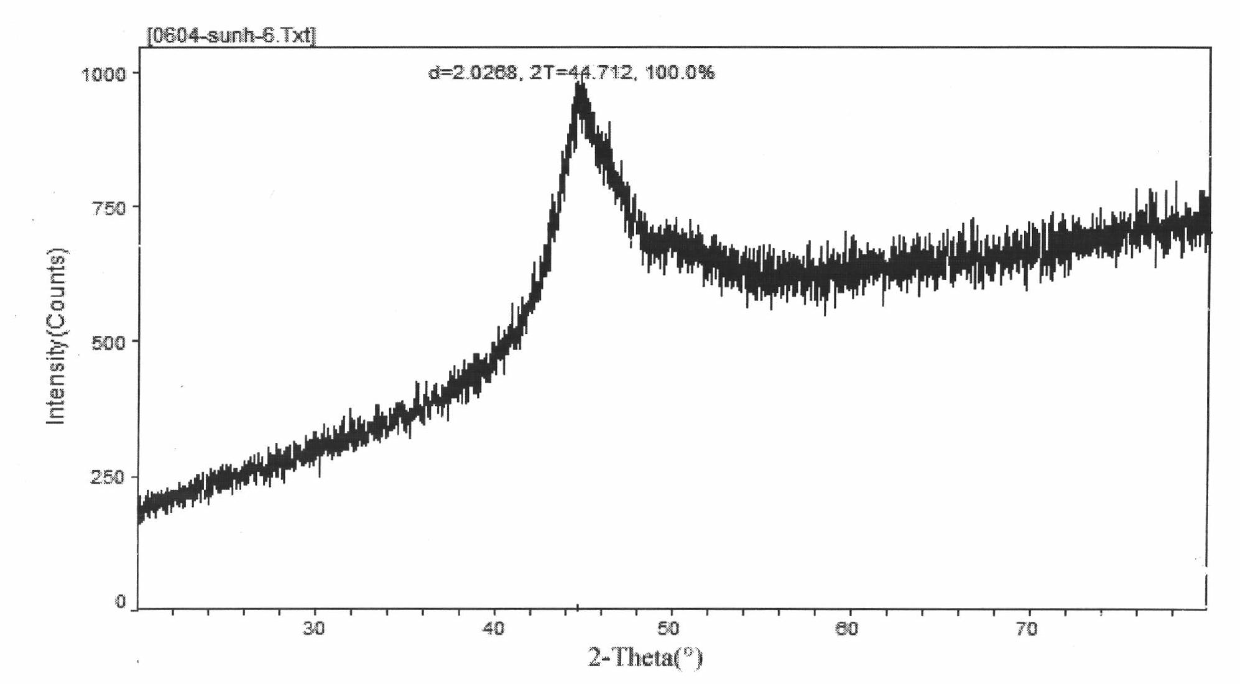

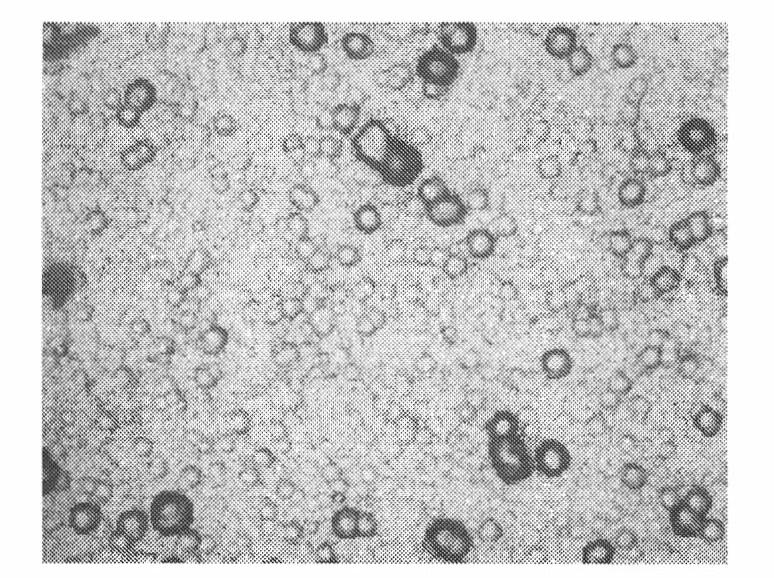

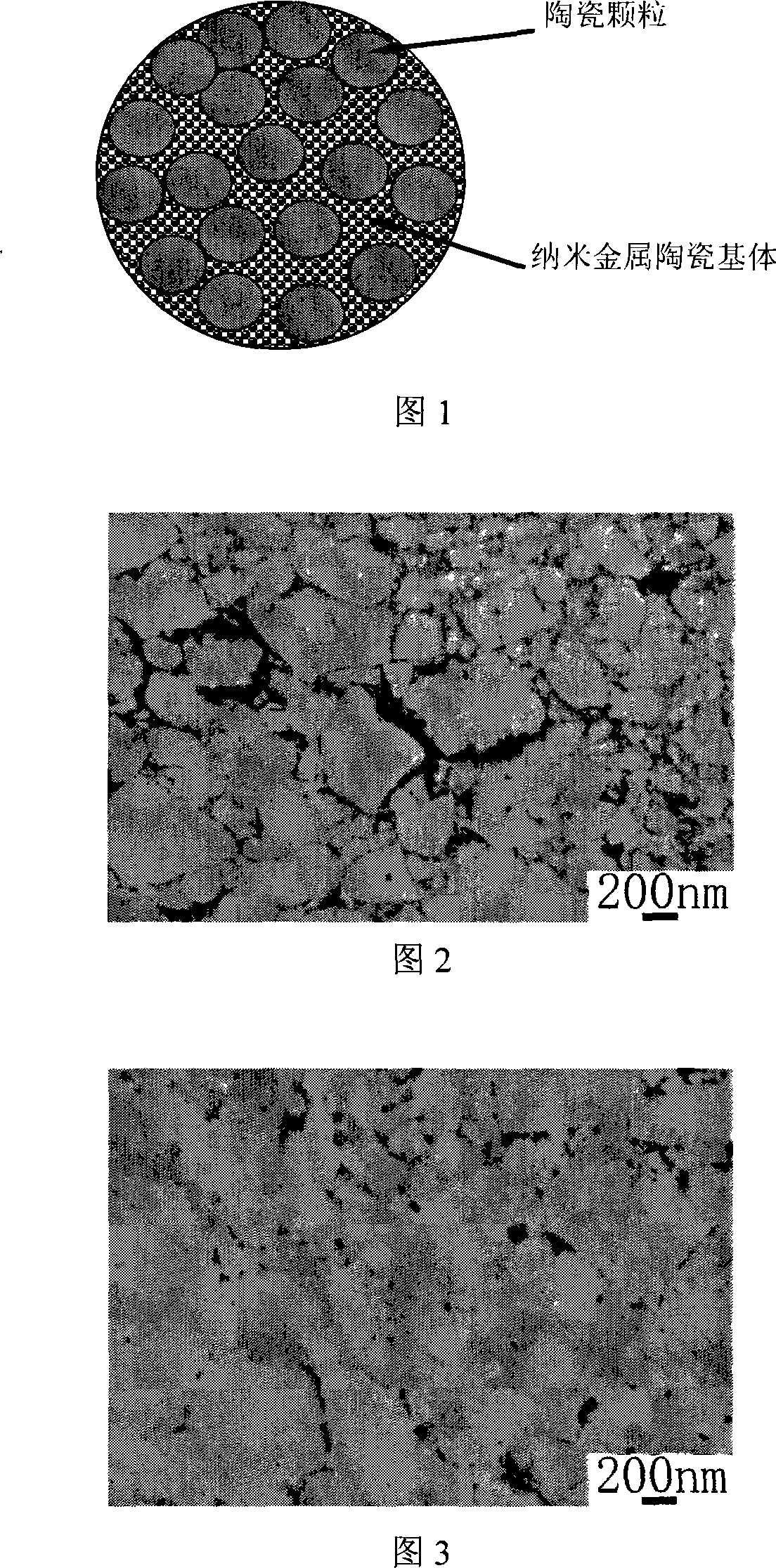

Method for preparing nano-ceramet-base metal ceramic

ActiveCN101126135AExcellent wear resistanceHas high strength and high hardnessMetallic material coating processesCermetBase metal

The invention discloses a method for preparing high strength, high tenacity and super hard metallic porcelain with Nami metallic ceramic matrix. The method comprises the steps as follow: adopt cold spraying method and take high voltage helium gas as the acceleration gas; spray the metallic porcelain powder which takes the Nami metallic ceramic as the matrix or the metallic porcelain powder containing components which can produce Nami porcelain precipitated phase into sediment to prepare metallic porcelain with metastable structure; the interface between the porcelain phase of the metallic porcelain and the metal phase, the metal phase and the metal phase and the spraying powder deformation particle in the metastable structure produces diffusion and interface reaction to gain high strength, high tenacity and super hard metallic porcelain with Nami metallic ceramic matrix. As the metallic porcelain takes the normal micron and submicron porcelain phase as the hardening and reinforcing phase; and takes the high strength and supper hard metallic porcelain as the matrix, the invention not only has the characters of high strength and supper hard of the metallic porcelain material, but also has the characters of high tenacity and better wear-proof property. The invention is a new method for preparing high strength, high tenacity and high wear-proof property metallic porcelain coating.

Owner:芜湖舍达激光科技有限公司

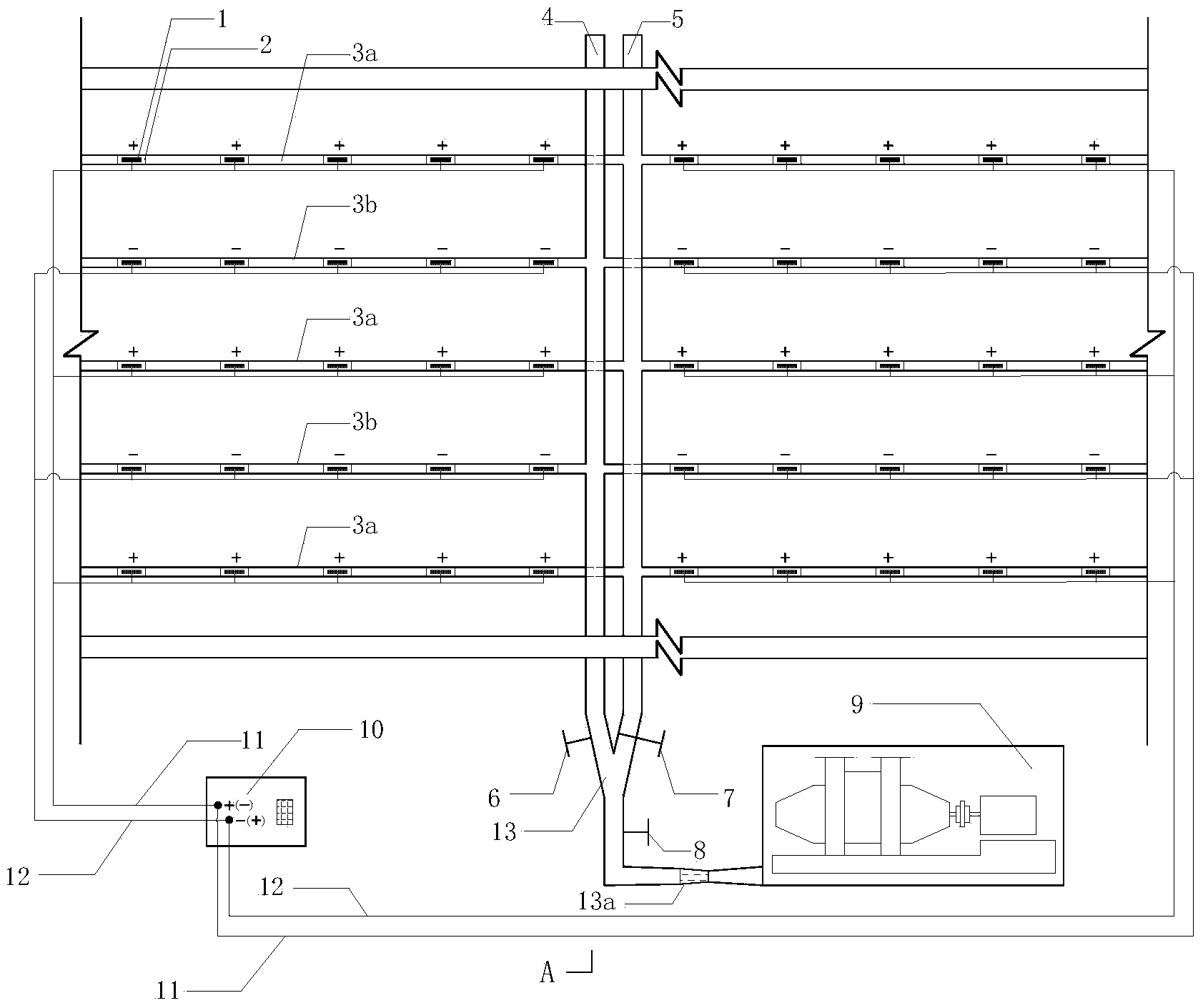

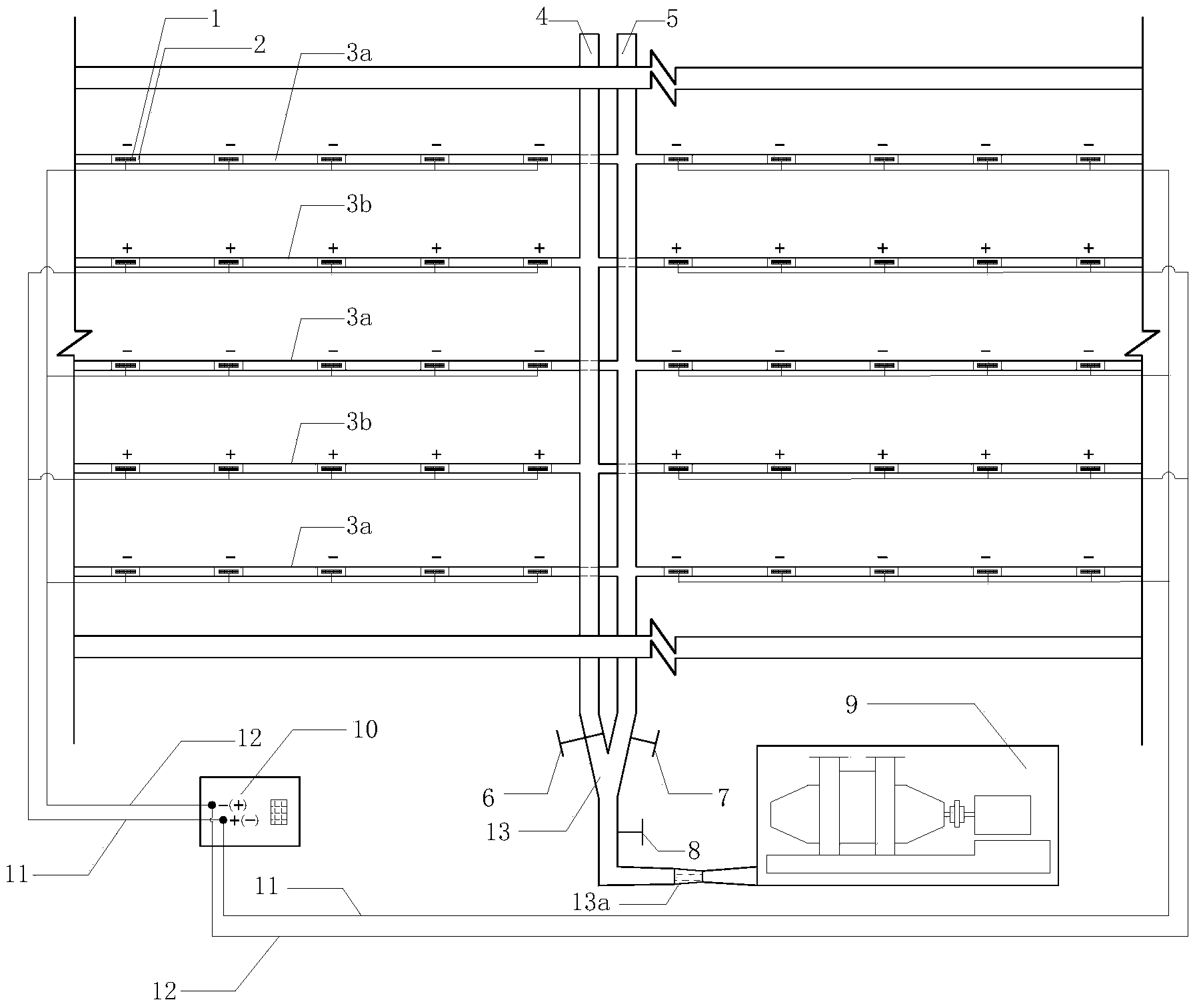

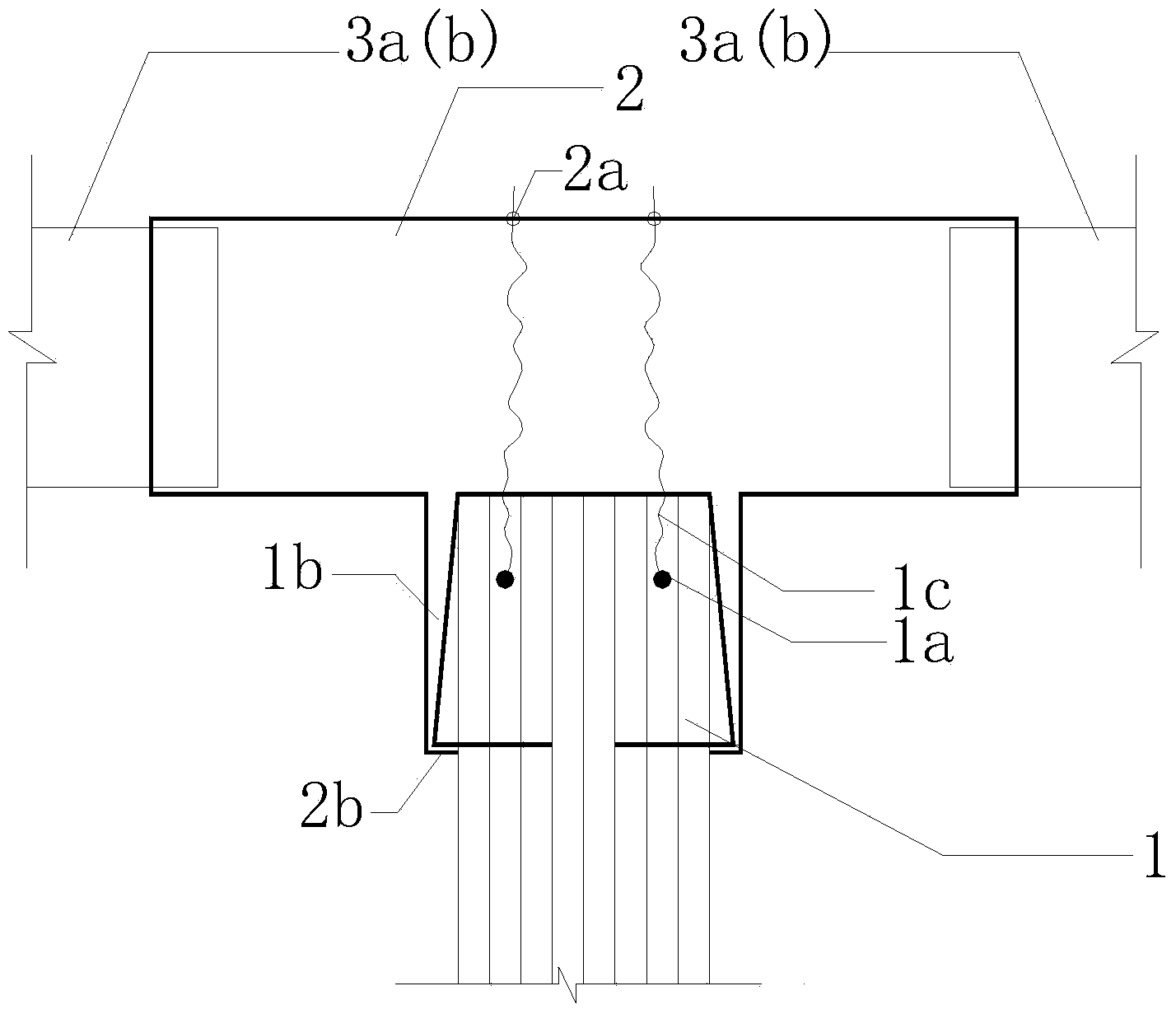

Method and device for accelerating ultra-soft soil solidification through dual-passage variable-polarity vacuum electroosmosis

ActiveCN103866760AGood electrical conductivityExcellent wear resistanceSoil preservationSoil scienceVacuum pressure

The invention relates to a method and a device for accelerating ultra-soft soil solidification through dual-passage variable-polarity vacuum electroosmosis. The method comprises the following steps: 1) laying a geotextile; 2) inserting composite drainage plates in rows; 3) laying a dual-passage closed vacuum drainage PVC (Polyvinyl Chloride) main pipe and branch pipes; 4) connecting the composite drainage plates with the branch pipes by using closed quick plate and pipe connectors which can be connected with conducting wires; 5) serially connecting the composite drainage plates by using electroosmosis conducting wires to form an electroosmosis electrode array and laying a vacuum membrane; 6) starting a vacuum electroosmosis combined working mode and dynamically controlling polarity variation of a vacuum drainage main valve and composite drainage plates according to parameters such as water output. The device comprises the composite drainage plates, dual-passage vacuum pre-pressing drainage main and branch pipes and an electroosmosis variable-polarity system. The method and the device for accelerating ultra-soft soil solidification through dual-passage variable-polarity vacuum electroosmosis have the remarkable advantages that the effective superposition for facilitating water migration through the production of a vacuum pressure field and an electric field is realized, the loss of a single anode is reduced, the energy consumption per unit time is reduced, the drainage and solidification efficiency is improved by 2-5 times, the construction is simple and convenient to perform, the load time is short and the cost is saved.

Owner:湖北水总水利水电建设股份有限公司

Method for preparing chromium-carbon nano tube composite coating in trivalent chromium plating solution

InactiveCN101768772AImprove wear resistanceImprove corrosion resistanceElectrolytic coatingsCarbon nanotubeChloride

The invention discloses an electrodeposition method for preparing a chromium-carbon nano tube composite coating in trivalent chromium plating solution. The invention adds a carbon nano tube in a basis electrolyte comprising chromic chloride to prepare the chromium-carbon nano tube composite coating with smooth surface and firm combination with the substrate by controlling the proper process conditions. The invention has the advantages that the prepared chromium-carbon nano tube composite coating has a thickness of more than 5mum, and has higher hardness, abrasion resistance and corrosion resistance than the hexavalent chromium plating coating; and the method can replace the conventional hexavalent chromium plating process under a certain friction working condition.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

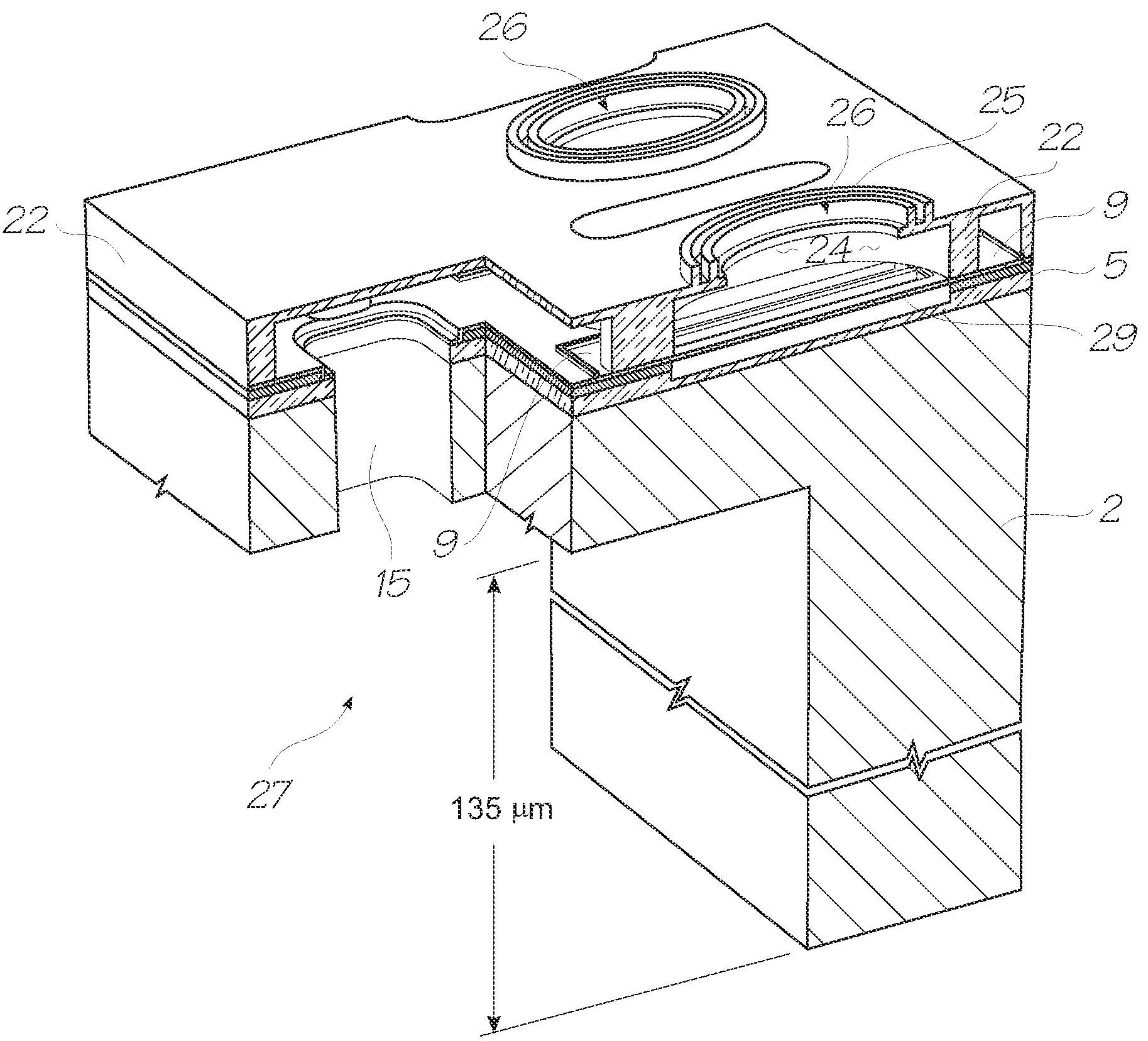

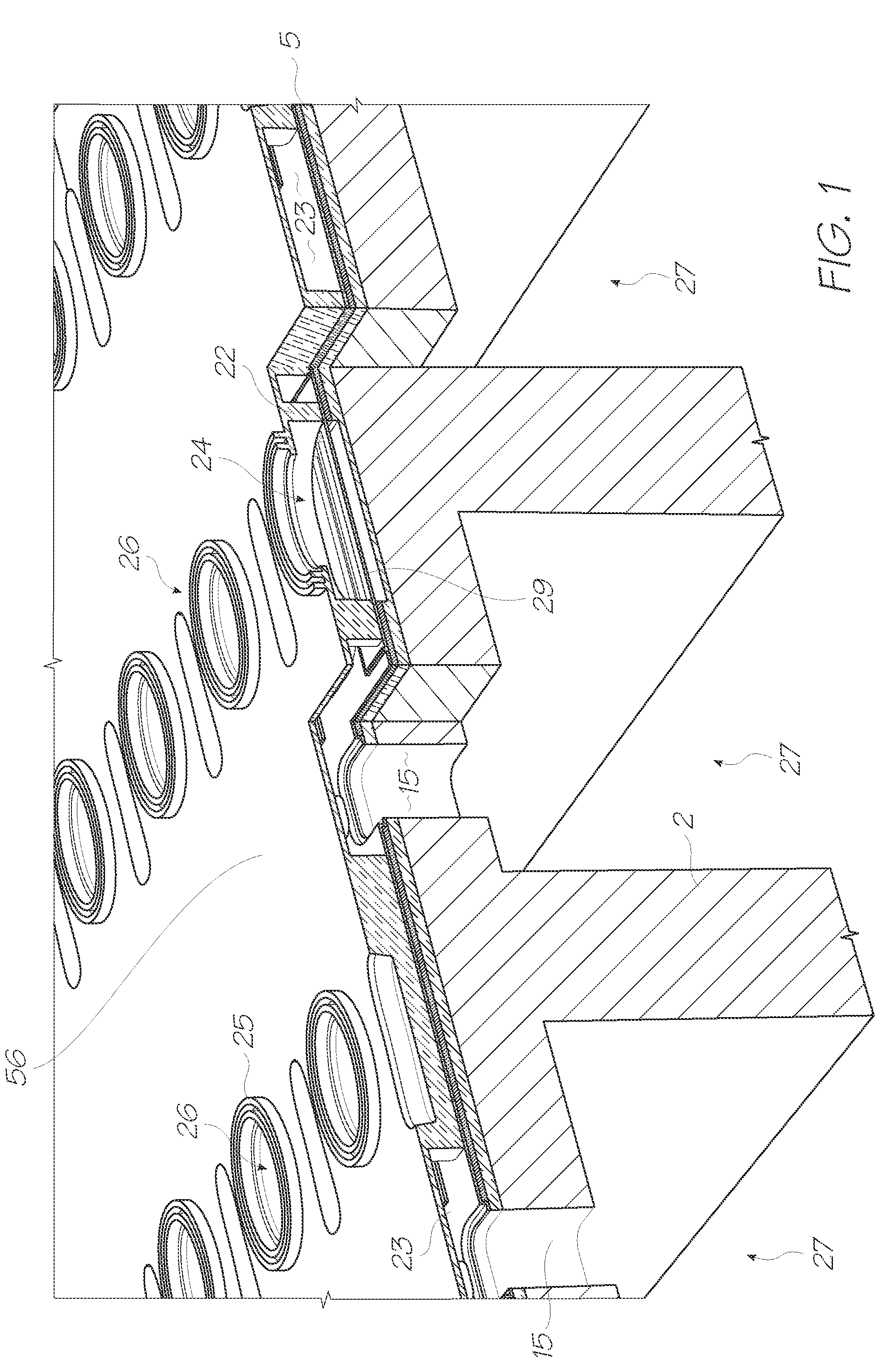

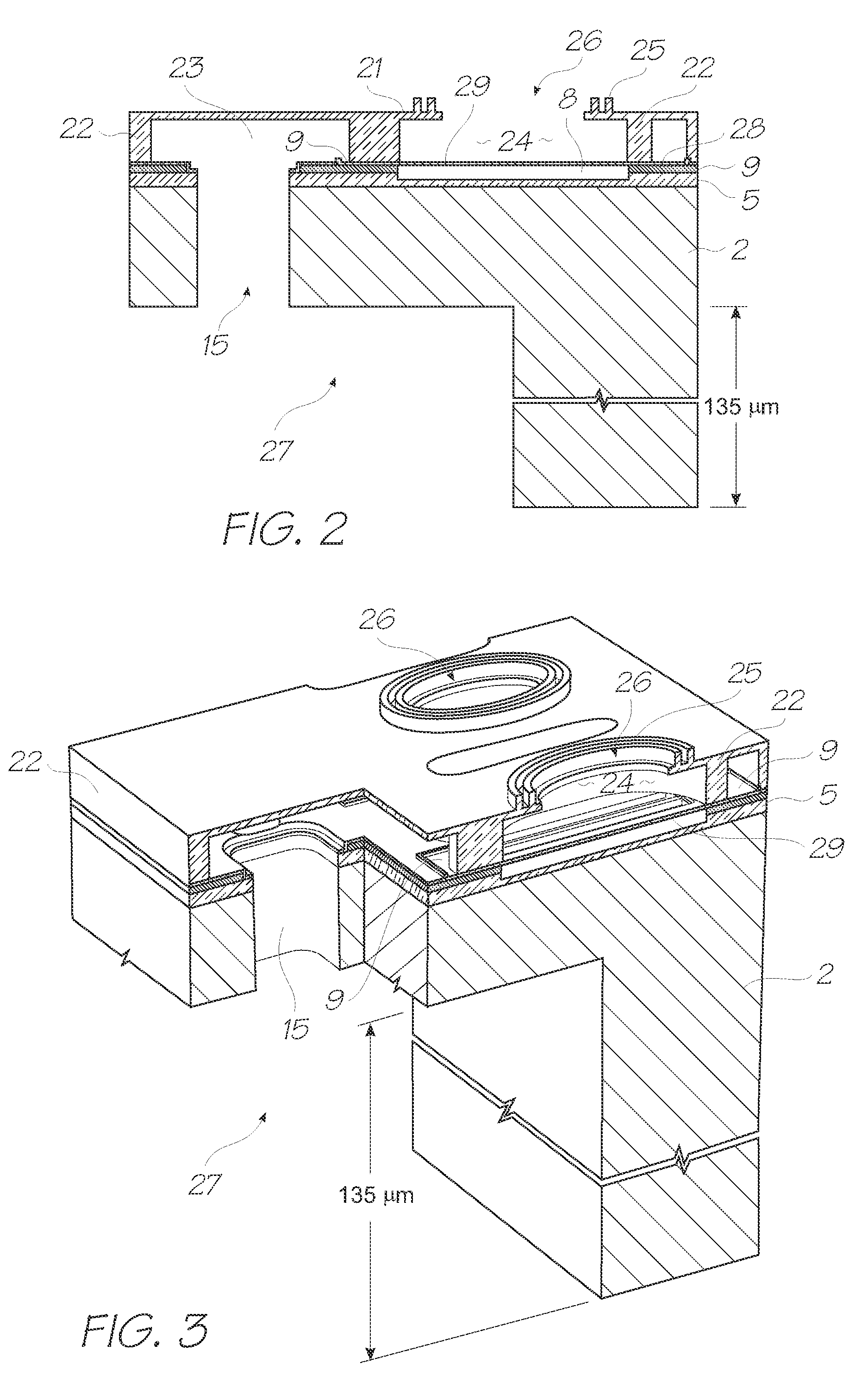

Printhead having polymer incorporating nanoparticles coated on ink ejection face

A printhead having an ink ejection face, wherein at least part of the ink ejection face is coated with a polymeric material. The polymeric material is comprised of a polymerized siloxane incorporating nanoparticles. The printhead may be compatible with various printhead maintenance operations, ink characteristics and inkjet nozzle types.

Owner:SILVERBROOK RES PTY LTD

Anti-corrosion oil-pollution-resistant spray paint and spraying method

ActiveCN104004439AExcellent wear resistanceExcellent non-stick performancePretreated surfacesAnti-corrosive paintsOrganosiliconEnvironmental resistance

The invention discloses spray paint and a process for spraying the paint. The paint and the process can achieve anti-corrosion and oil-pollution-resistant effects. The spray paint comprises primer and a finishing coat. The primer comprises the following components of epoxy resin, fluorinated alkene resin, ceramic fine powder, ethyl acetate, polyurethane, heptadeceny imidazoline and butanedioic acid salt; the finishing coat comprises the following components of organic silicon resin, amino resin, polymethacrylate, nano-silica, organosilicon leveling agents, simethicone, film-forming resin, an acid catalyst and a manganese drier. A coating formed through the spray paint has good abrasion resistance and oil pollution resistance, and is high in smoothness and good in adhesive force. The formed coating does not contain chromium, is nontoxic and environmentally friendly, and is particularly suitable for spraying of inner panels and outer panels of kitchen electric appliances.

Owner:CHUZHOU HONGYUAN SPRAYING

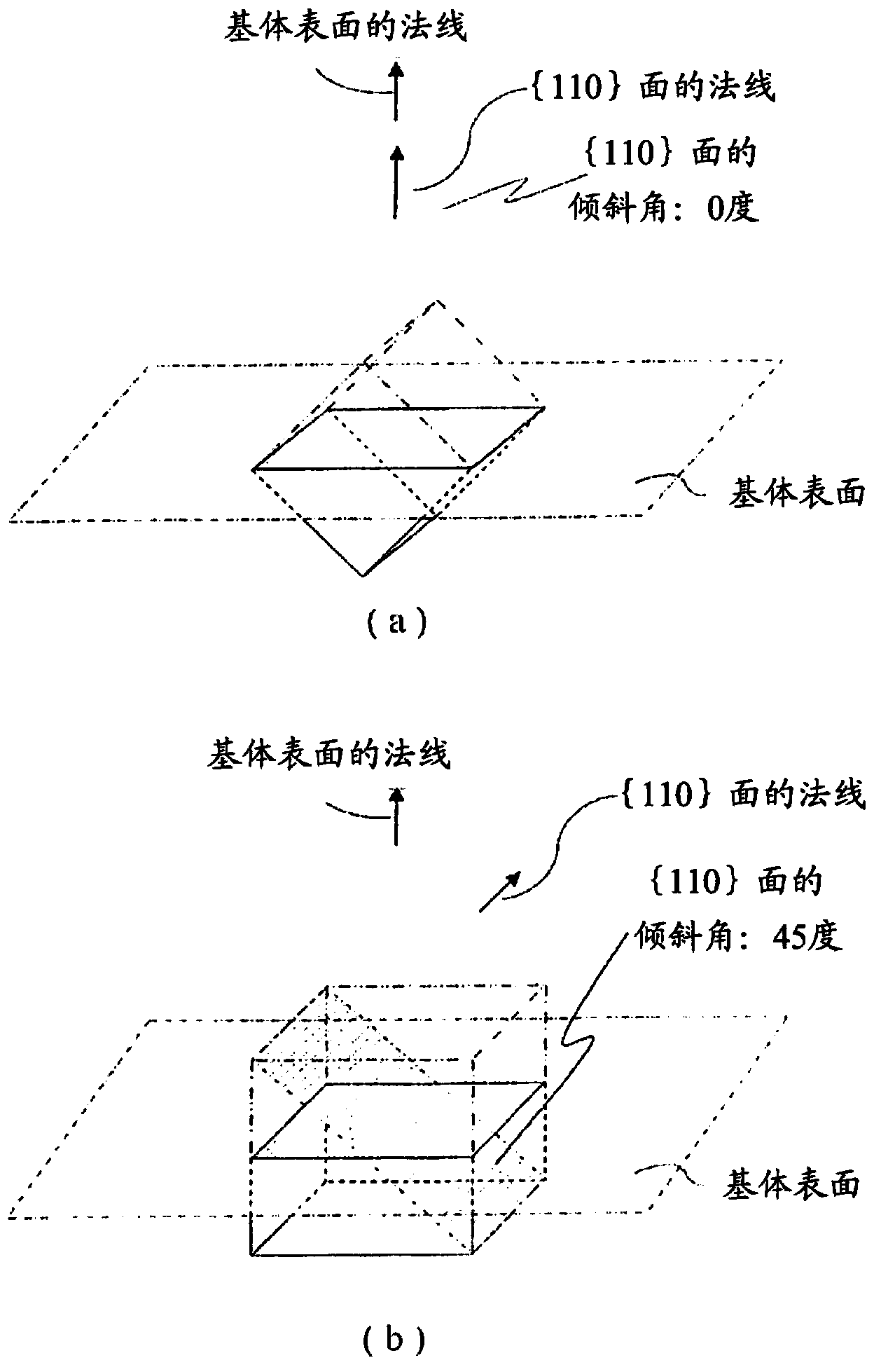

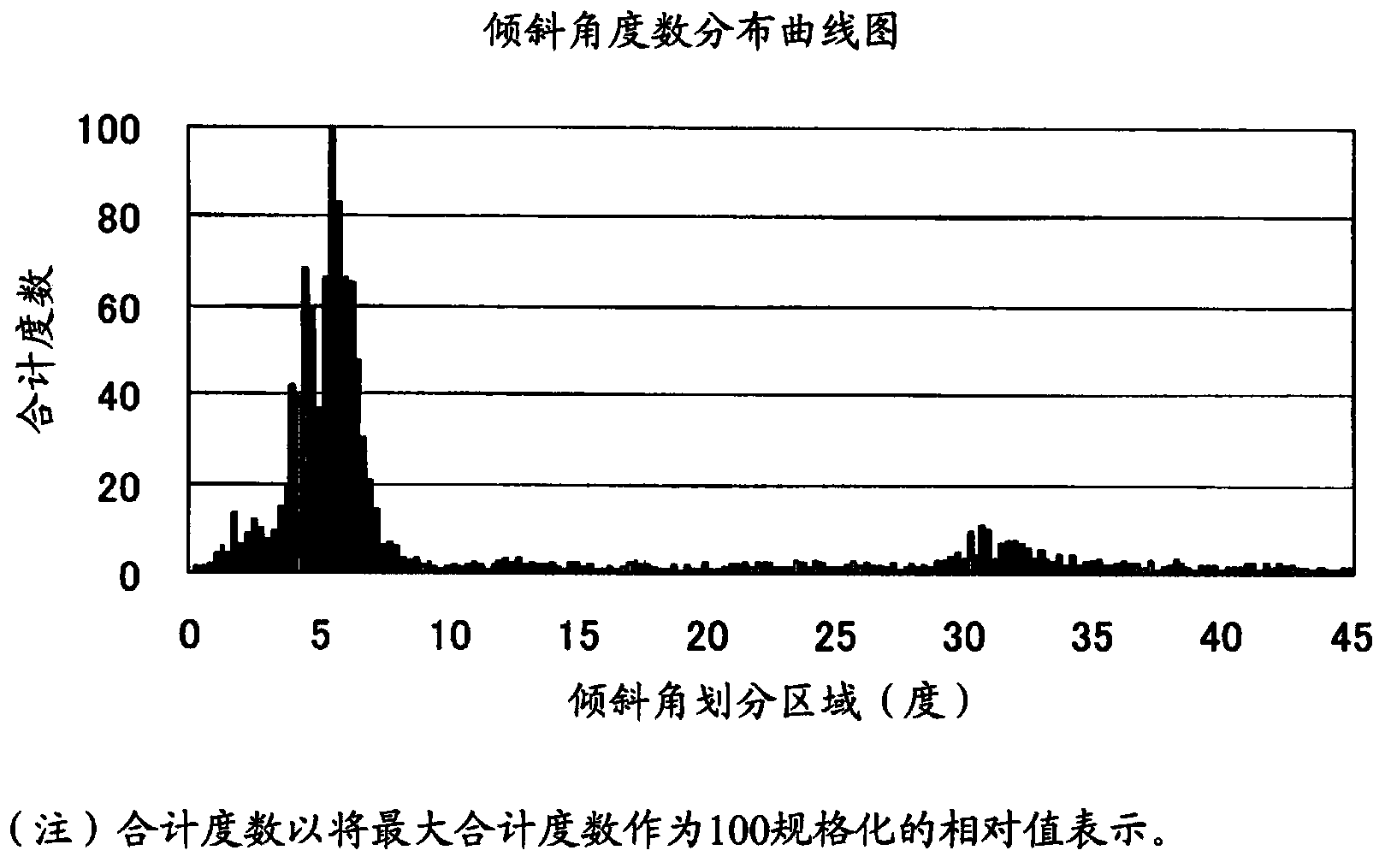

Surface coating cutting tool provided with hard coating layer having excellent anti-tipping performance

InactiveCN103447600ASuppresses chippingExcellent wear resistanceMilling cuttersTurning toolsCrystallitePeak value

The invention provides a surface coating cutting tool. According to the surface coating cutting tool, a base surface is covered by a hard coating layer constituted by a (Ti1-XA1X)(CYN1-Y) layer having a cubic crystal structure, which adopts the chemical vapor deposition film formation method using the A1(CH3)3 as the reaction gas. The atomic ratio of X,Y are 0.55<=X<=0.95, 0.0005<=Y<=0.005. The hard coating layer is provided with an area A layer and an area B layer. During the measurement of an inclined angle between a normal of a (110) surface of a grain and a normal direction of the base surface, the inclined angle value distribution can be acquired. A highest peak value exists in the inclined angles of the area A layer in a range from 2 to 12 degrees, and the degree ratio in a range from 2 to 12 degrees is more than 45% of the whole degrees. A highest peak value exists in the inclined angles of the area B layer in a range from 25 to 35 degrees, and the degree ratio in a range from 25 to 35 degrees is more than 60% of the whole degrees. The area A layer and the area B layer exist alternatively, and are respectively more than one layer.

Owner:MITSUBISHI MATERIALS CORP

Automobile brake lining

InactiveCN105202075AGood strengthExcellent wear resistanceOther chemical processesBraking membersBrake liningOxide

An automobile brake lining is prepared from, by weight, 14%-18% of ceramic fibers, 3%-6% of carbon fibers, 3%-7% of cellulose fibers, 8%-13% of aramid fibers, 8%-13% of modified phenolic resin, 2%-4% of aluminium oxide, 3%-5% of barium sulphide, 6%-9% of graphite, 4%-6% of zirconite, 8%-12% of quartz sand, 1%-2% of bauxite, 1%-2% of zinc oxide, 2%-4% of chemigum, 1%-4% of antimony sulfide, 7%-10% of friction powder and 6%-9% of nanometer silicon carbide. According to the automobile brake lining, a ceramic brake pad is kept to be stable in braking, low in noise and the like, the mechanical strength of the brake lining is further improved, and the service life of the brake lining is prolonged; meanwhile, recession and expansion of the high temperature can be avoided, and the automobile brake lining has the advantages of being good in braking performance and abrasion resistance, stable in braking, less in dust, moderate in hardness and good in high temperature recovery performance.

Owner:刘桂华

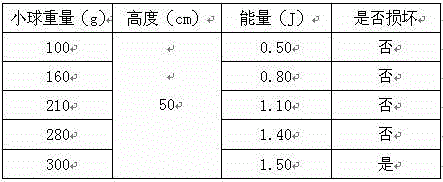

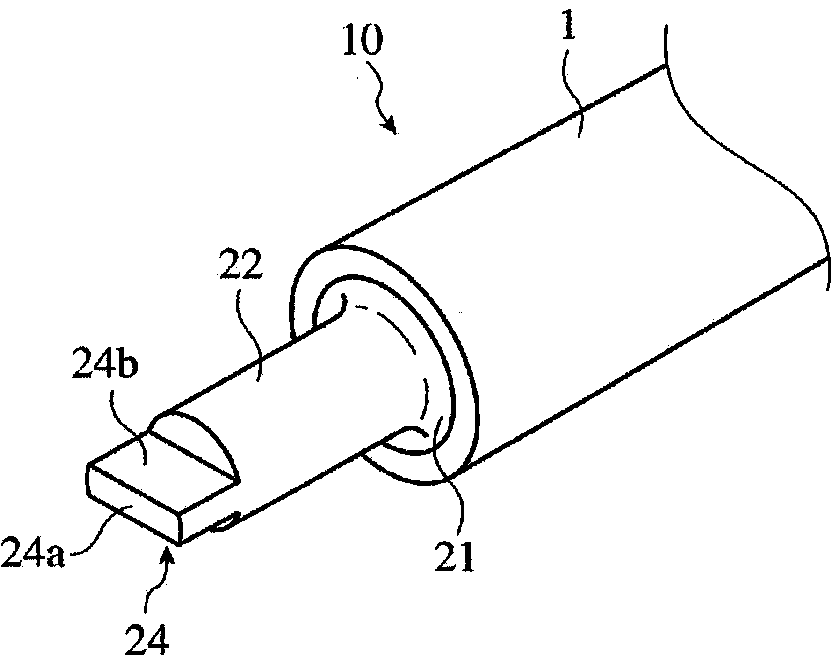

Rotary tool

InactiveUS20130087604A1Excellent wear resistanceHigh joining strengthVacuum evaporation coatingWelding/cutting auxillary devicesFriction stir weldingMass ratio

A friction stir welding tool is provided which allows for excellent wear resistance and high joining strength even in a process of joining difficult-joining materials. A friction stir welding tool of the present invention is used for a friction stir welding process and includes a base material. The base material includes a hard phase and a binder phase. The hard phase includes TiCN. The binder phase is made of an iron group metal. A mass ratio Bs of the binder phase to the base material in a region having a thickness of 20 μm from a surface of the base material is smaller than a mass ratio Bi of the binder phase to the base material in a region beyond the thickness of 20 μm from the surface of the base material.

Owner:SUMITOMO ELECTRIC IND LTD

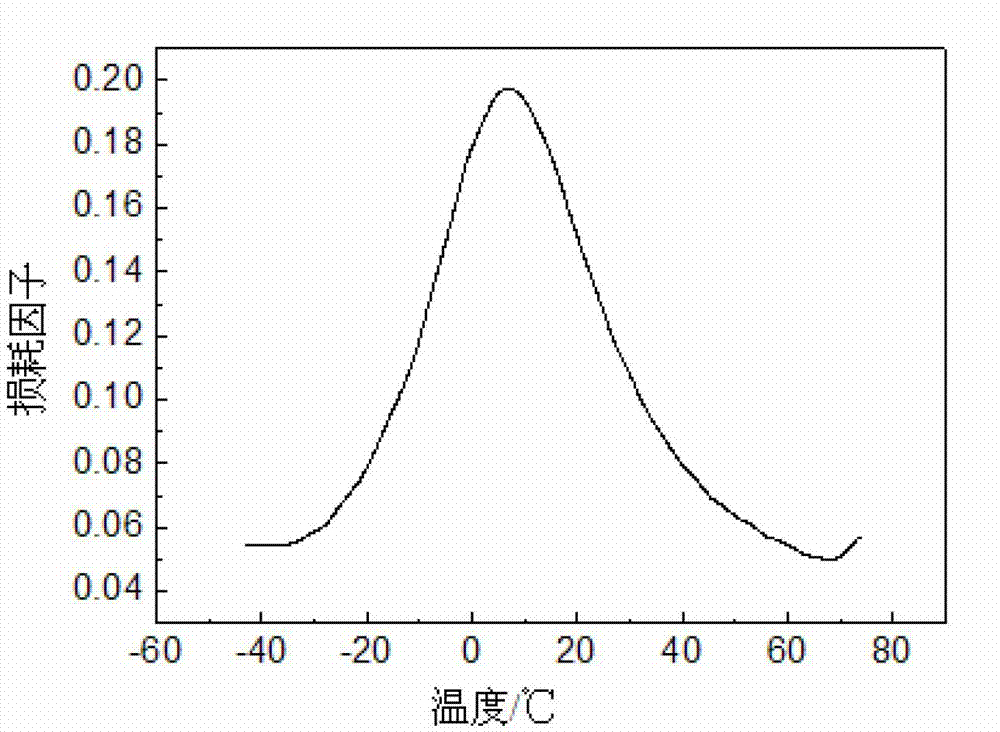

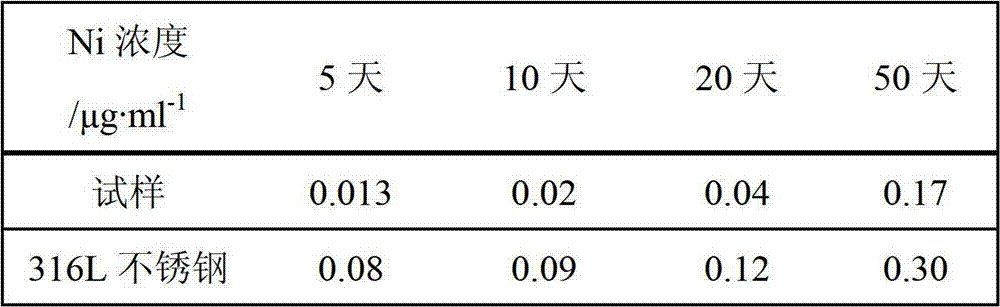

Nickel titanium memory alloy/polyurethane compound damping panel and preparation method thereof

InactiveCN102896836AHigh strengthHigh hardnessLamination ancillary operationsLaminationSurface layerTitanium

The invention provides a nickel titanium memory alloy / polyurethane compound damping panel and a preparation method thereof and relates to a compound damping panel and the preparation method thereof. The invention aims to solve the technical problems that the present surface layer is a 316L stainless steel compound steel panel, the tensile strength is low, the corrosion resistance is inferior and the present compound damping material has inferior damping effect. The preparation method according to the invention comprises the following steps: placing a nickel titanium memory alloy panel and a polyurethane panel into a hot press, and then pressing for 5-20min under the conditions of 185-195 DEG C temperature and 40-50N pressure, and taking out and cooling in air. The tensile strength of the compound damping panel provided by the invention is 600-800MPa; the precipitation volume of nickel ions in Nacl solution is 0.17ug / ml; the tensile strength is high; the corrosion resistance is excellent; a damping loss factor can reach 0.2; the vibration-reducing and noise-reducing effects are good; and the compound damping panel can be widely applied to passenger cars, trains, ships and buildings.

Owner:HARBIN ENG UNIV

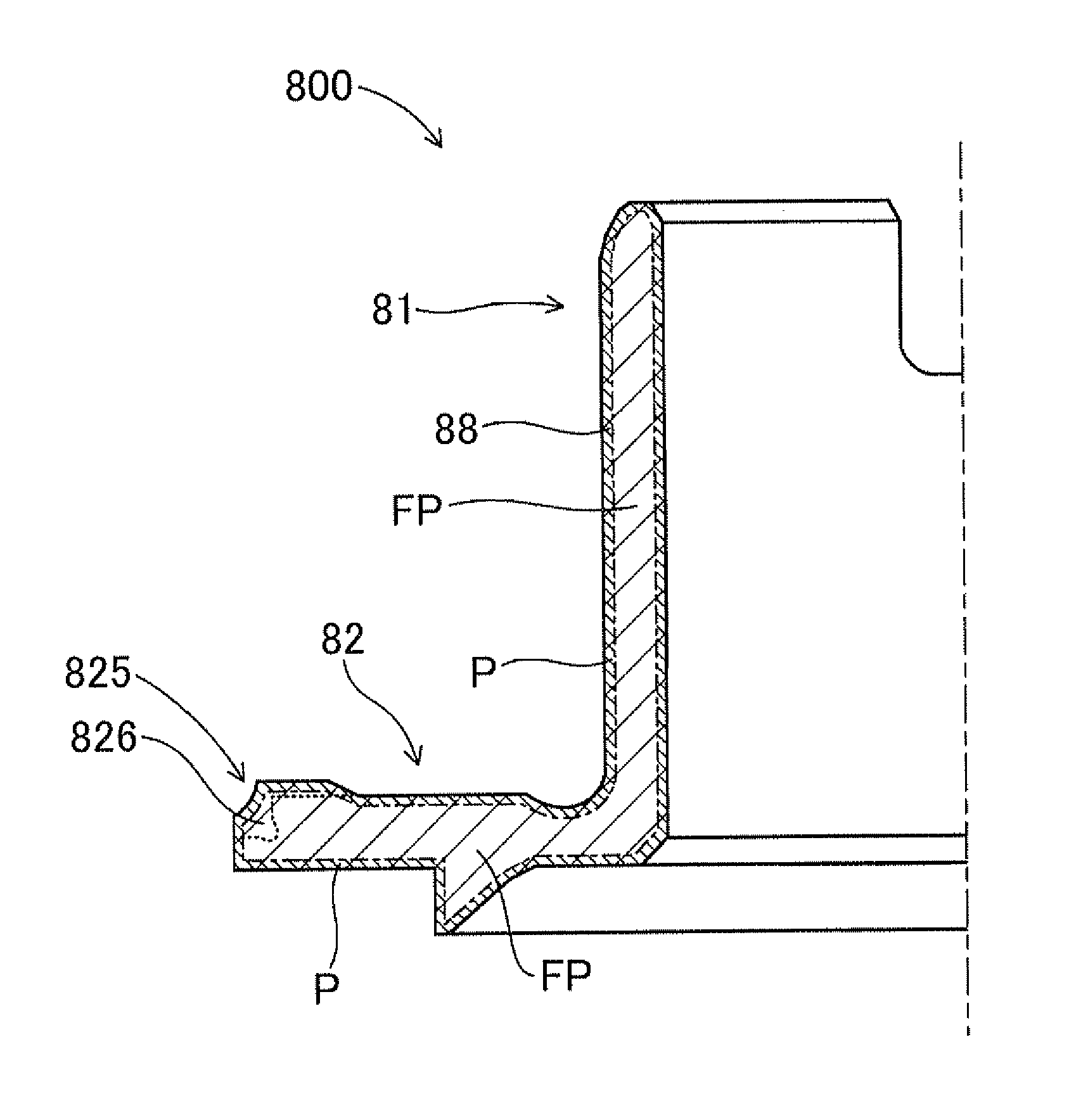

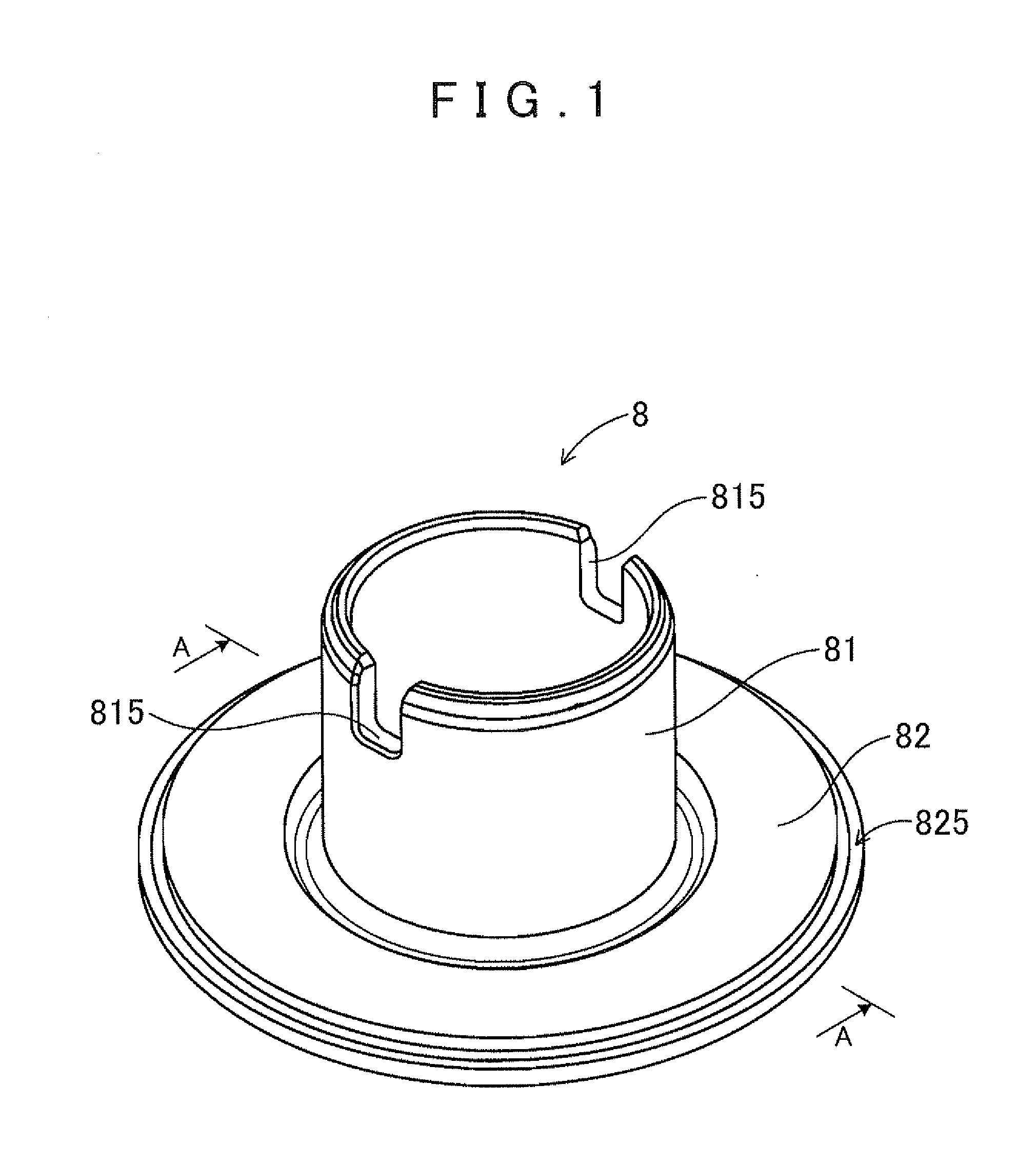

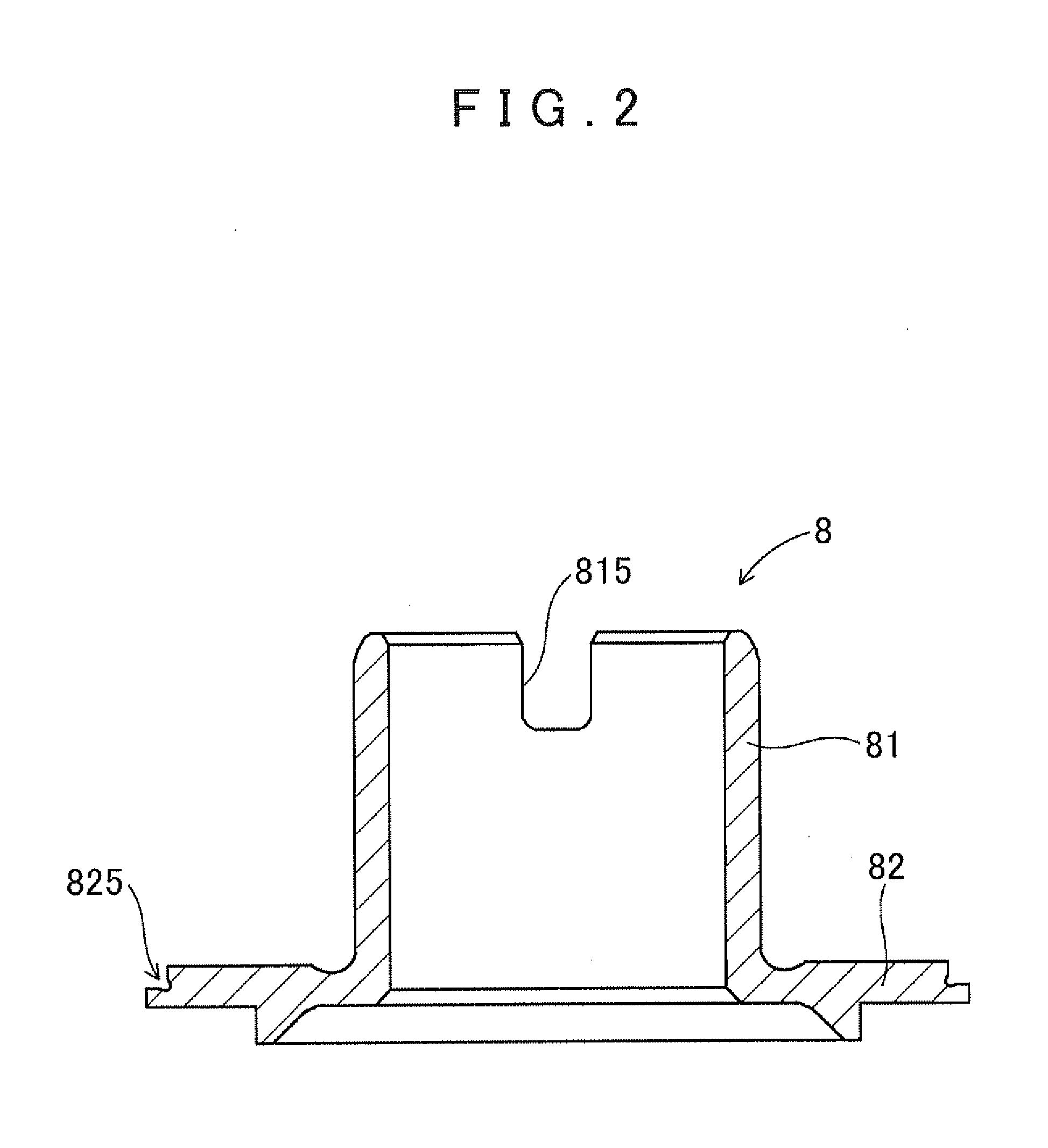

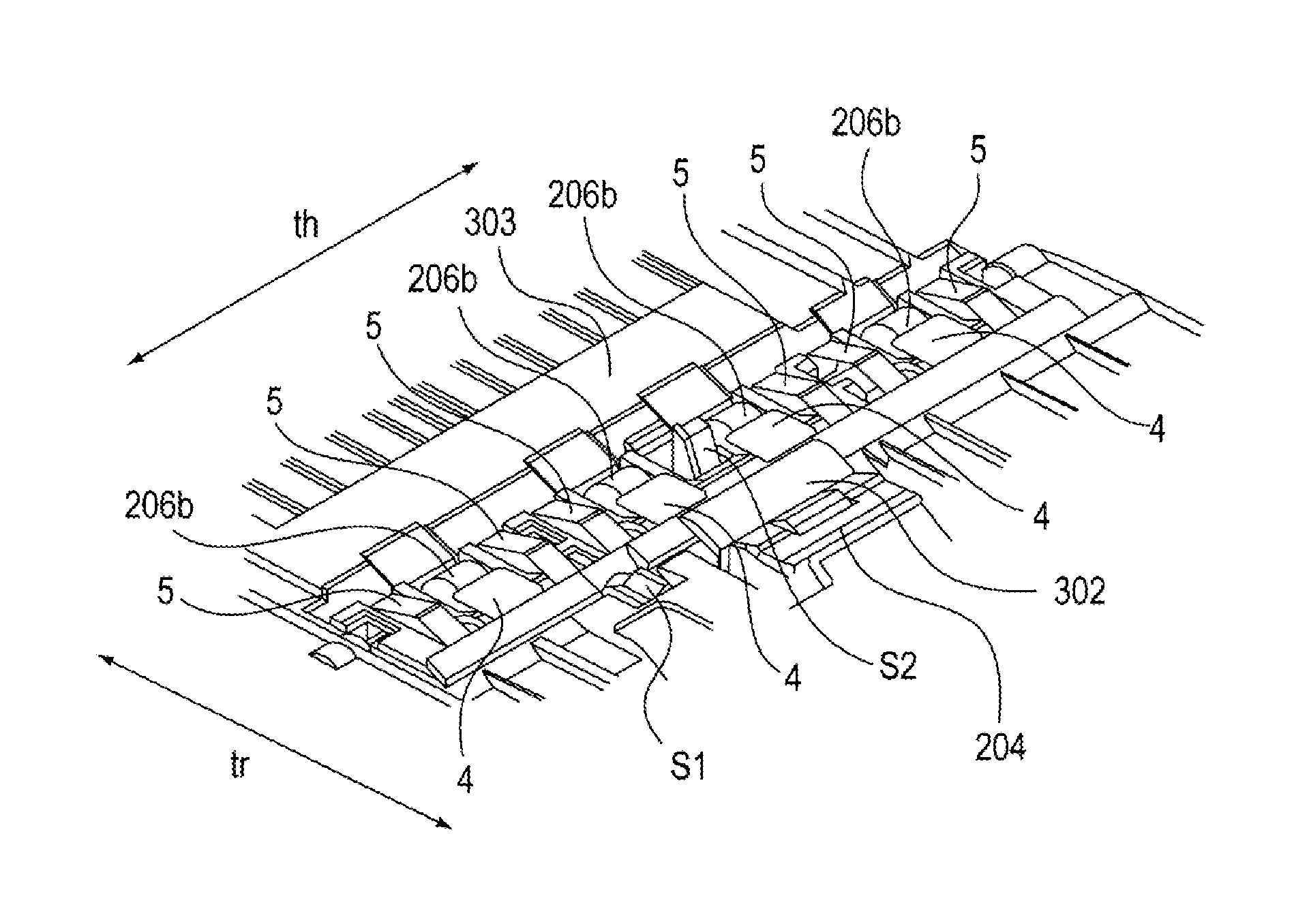

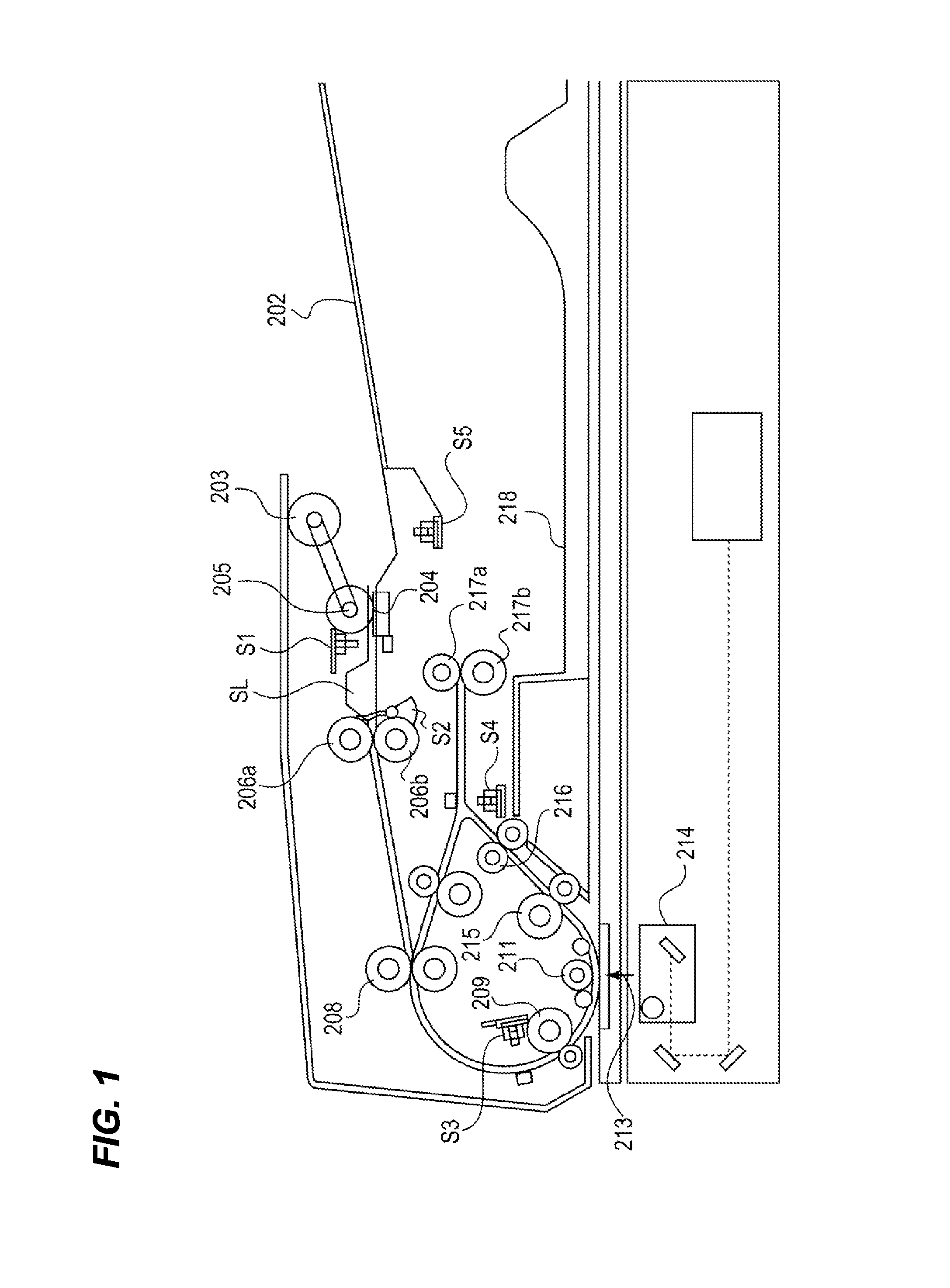

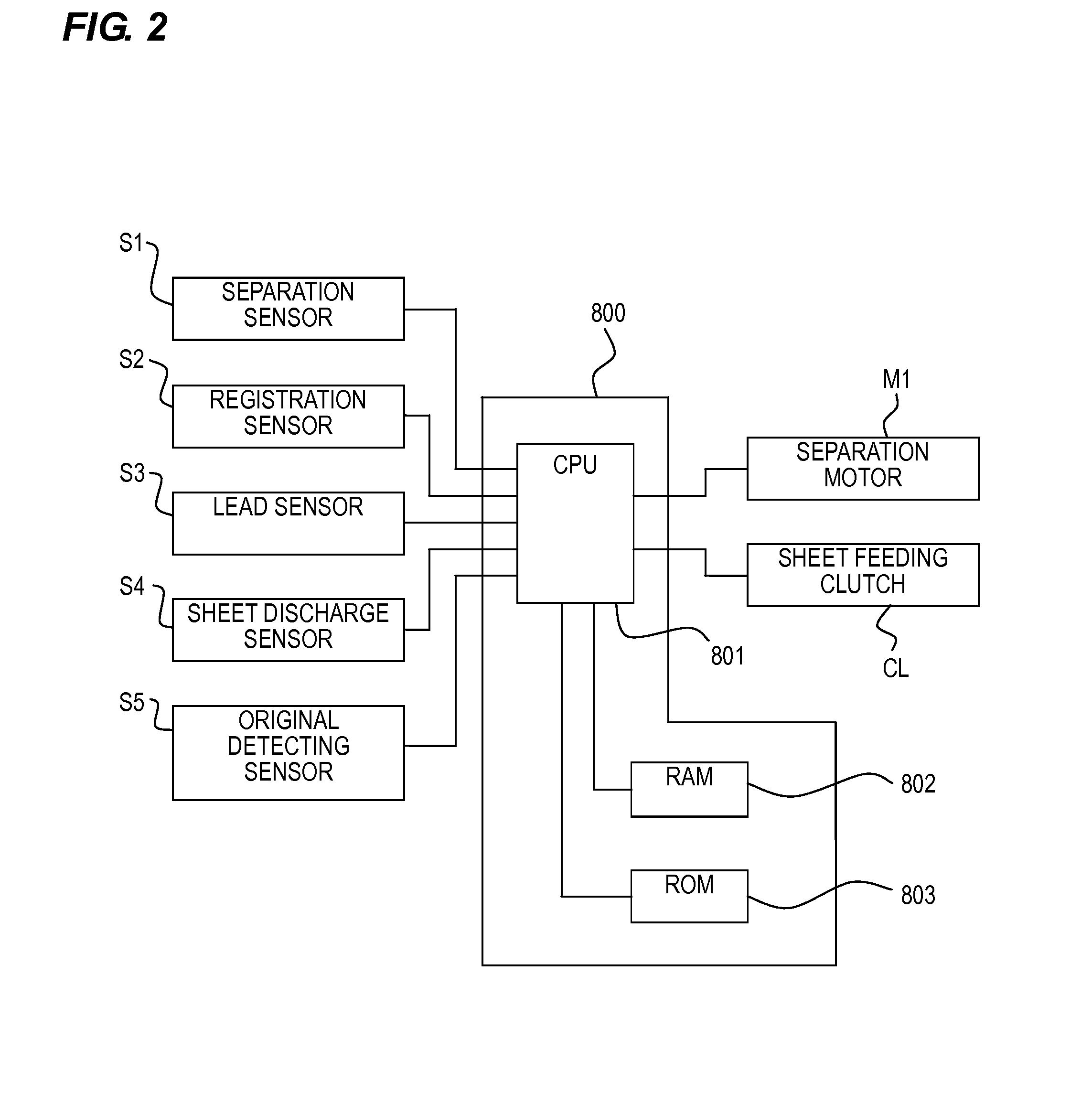

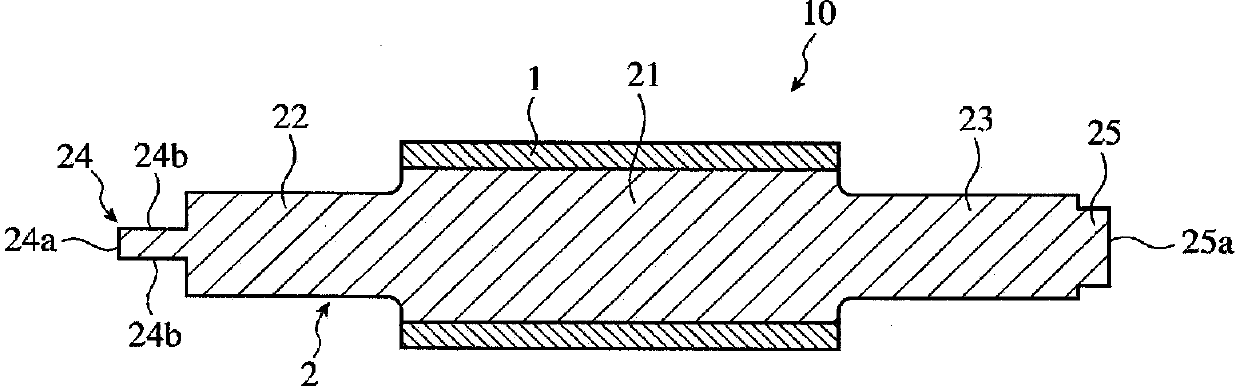

Sheet conveying apparatus

ActiveUS20130341851A1Excellent wear resistanceRegistering devicesFunction indicatorsPaper sheetEngineering

Owner:CANON KK

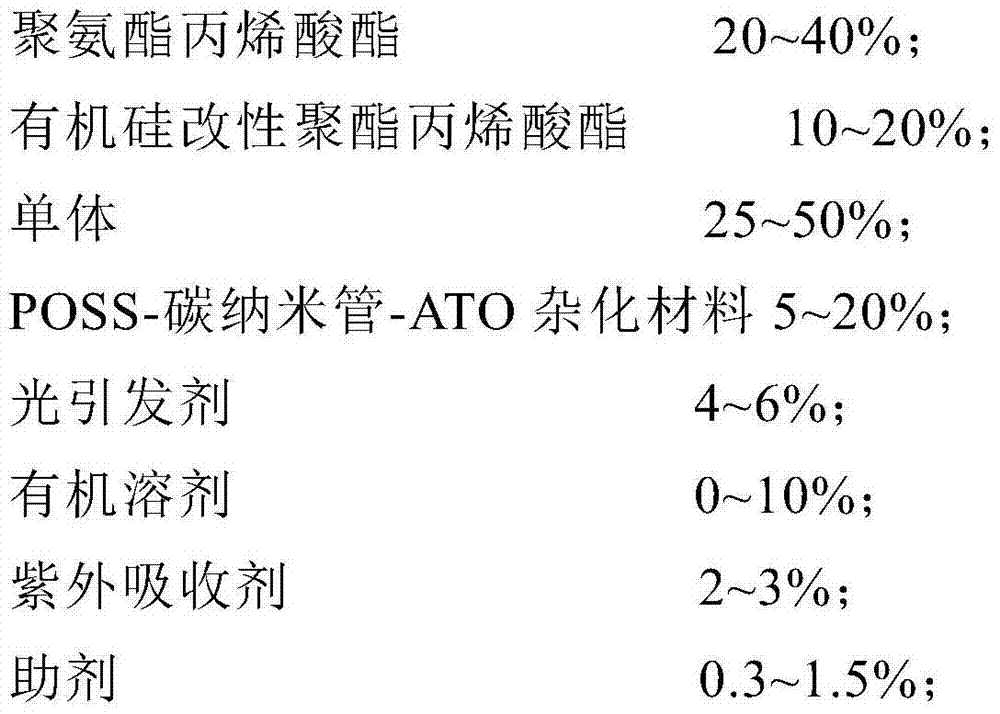

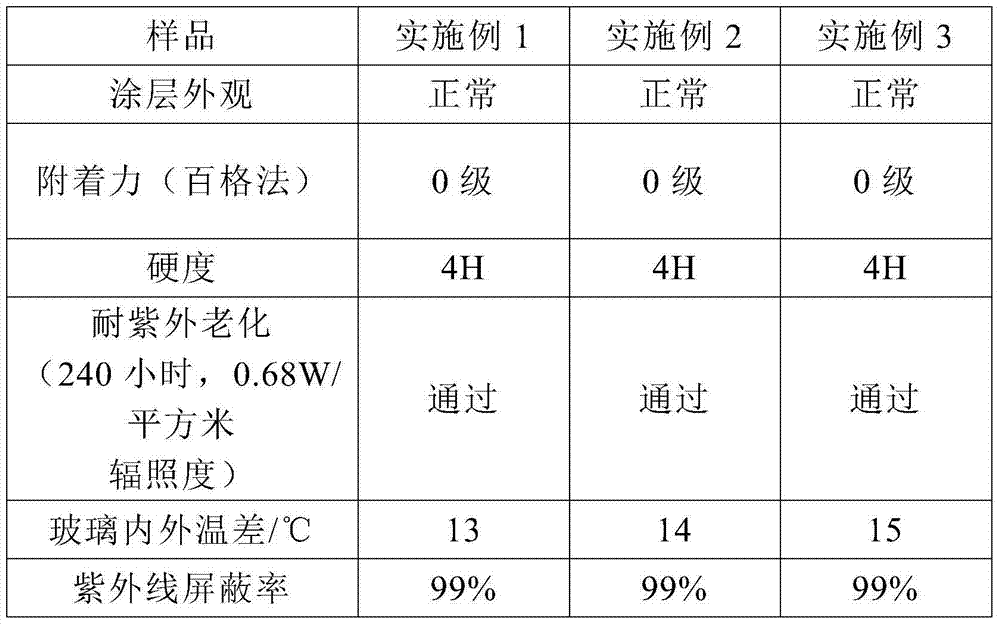

Transparent heat insulation film and preparation method thereof

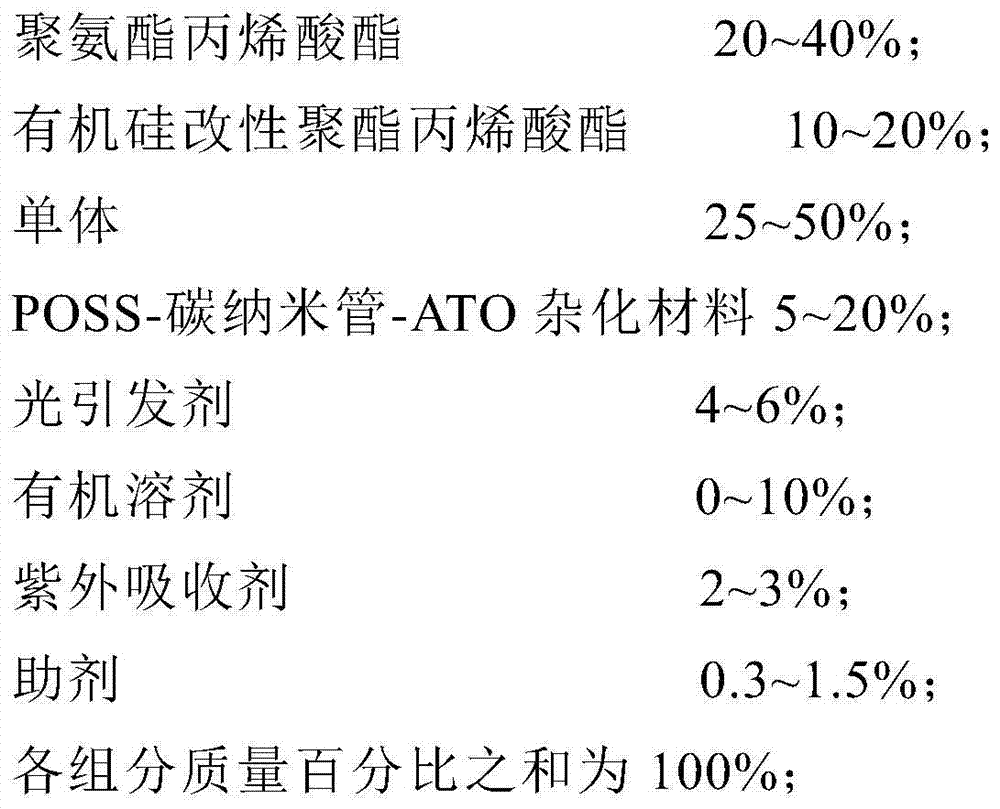

ActiveCN104231910AImproves UV resistanceImprove performancePolyurea/polyurethane coatingsPolyester coatingsPolyesterCarbon nanotube

The invention discloses a transparent heat insulation film which is characterized by comprising a transparent film substrate and a heat insulation coating; the heat insulation coating comprises the following components in mass percent: 20%-40% of polyurethane acrylate, 10%-20% of organosilicon modified polyester acrylate, 25%-50% of monomer, 5%-20% of POSS-carbon-nano-tube-ATO hybrid material, 4%-6% of photoinitiator, 0-10% of organic solvent, 2%-3% of ultraviolet absorber, and 0.3%-1.5% of additive; the sum of the mass percent of all the components is 100%, wherein through the use of the POSS-carbon-nano-tube-ATO hybrid material, not only is the heat insulation effect enhanced, but also the ultraviolet ageing resistance and the wear resisting property of the coating can be improved. The invention further provides a preparation method of the transparent heat insulation film; the prepared transparent heat insulation film is good in transparency, heat insulation effect and anti-ultraviolet effect, is simple in technology and low in cost.

Owner:JIANGHAN UNIVERSITY

Centrifugally cast composite roller and method for manufacturing same

ActiveCN104220192AIncrease durabilityEasy to processRollsThin material handlingChemical compositionAlloy

A centrifugally cast composite roller in which an outer layer formed by centrifugal casting and an inner layer made from ductile cast iron are integrally welded, wherein: the outer layer has a chemical composition containing at least 0.8 to 3.0% of Cr, 1.5 to 6.0% of Mo, and 1.8 to 5.5% of V, by mass, and comprises an Fe-based alloy in which the graphite area ratio in the metal structure is 0.3 to 10%; the inner layer has a body core part welded to the outer layer, and shaft parts extending integrally from both ends of the body core part, the total amount of Cr, Mo, and V at end sections of both shaft parts being 0.15 to 2.0 mass%, and the difference in the total amount of Cr, Mo, and V between one shaft part and the other shaft part being equal to or greater than 0.2 mass%.

Owner:PROTERIAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com