Hardfacing electrode covering and electrode containing same

A technology for surfacing electrodes and coatings, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of decreased concentration, decreased hardness and wear resistance, etc., to reduce pores, strong brittleness, Beautifully shaped effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

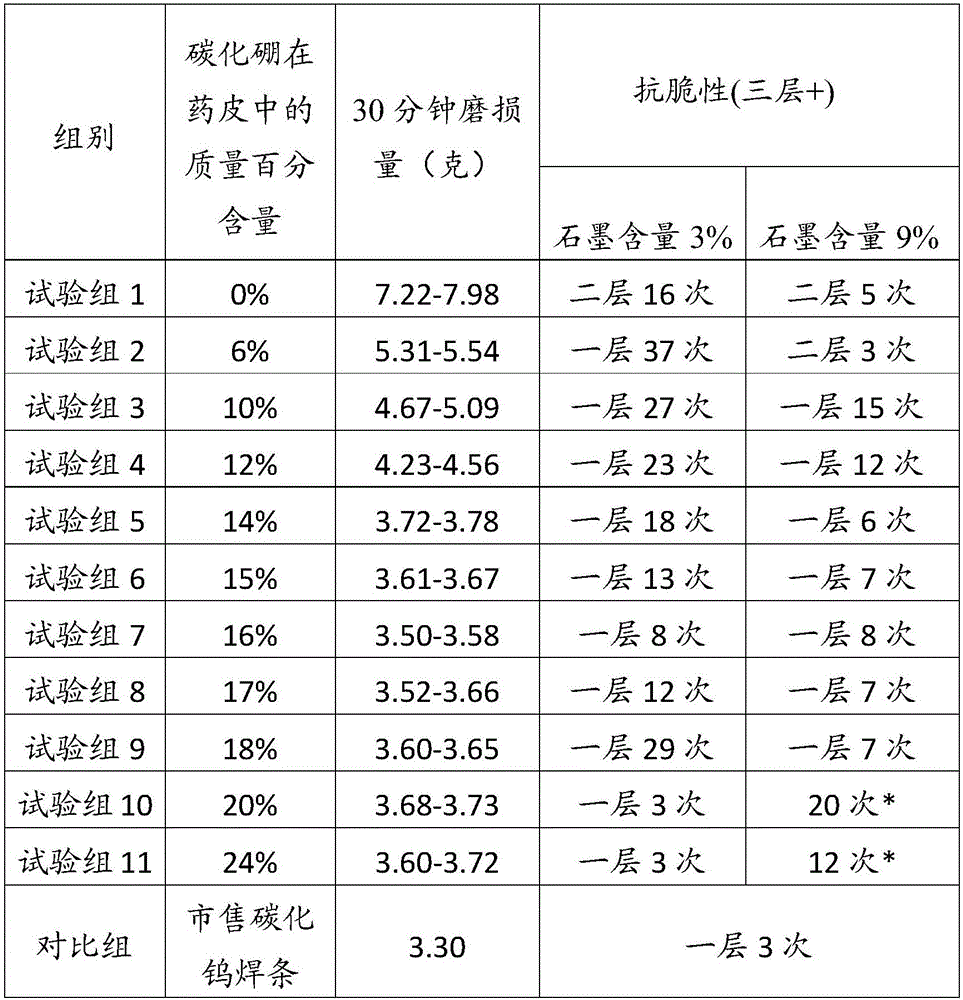

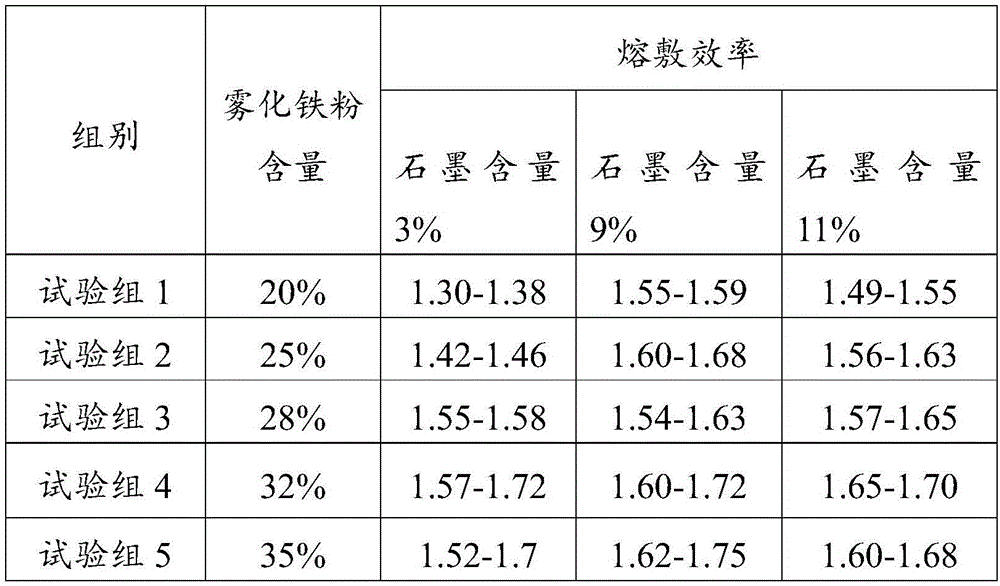

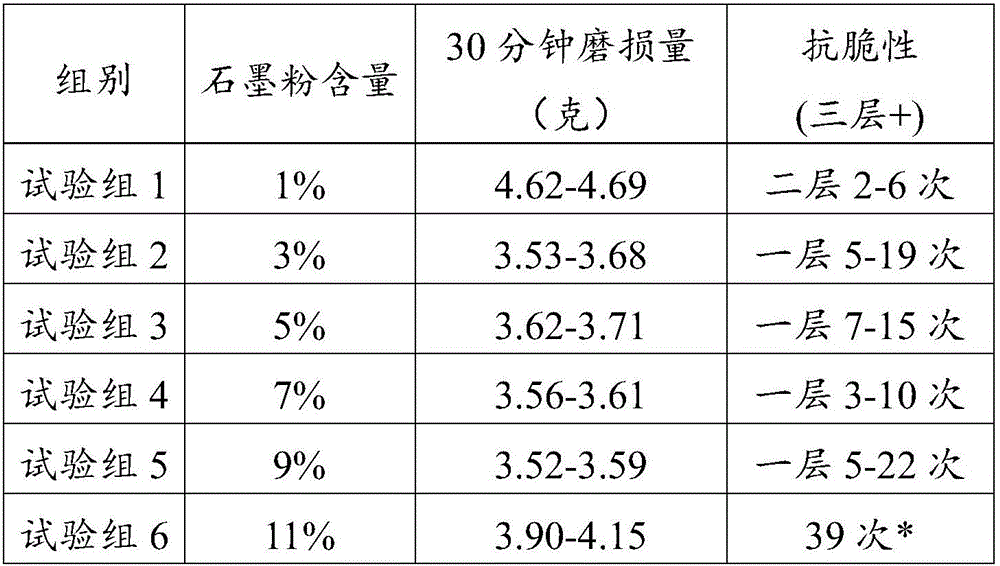

Method used

Image

Examples

Embodiment 1

[0035] An embodiment of the electrode of the present invention, the electrode described in this embodiment includes a welding core and a coating, the material of the welding core is carbon steel H08A, and the coating contains the following components in mass percentage: boron carbide 18% , atomized iron powder 28%, atomized ferrosilicon 6%, high carbon ferrochrome 41%, mica 4%, graphite powder 3%. The welding core described in this embodiment has a diameter of Φ4.0 mm and a length of 400 mm, and the outer diameter of the welding rod is Φ7.0 mm.

[0036] The electrode described in this embodiment can be prepared by the general electrode production process in the prior art. The difference is that the adhesive used in the electrode preparation process described in this embodiment is to add 0.5% of the weight of the adhesive used. Potassium permanganate, the modulus is M2.2-2.4, the concentration is Baume degree 48-50 degrees, potassium water glass: sodium water glass is 3:1 mixed...

Embodiment 2

[0039] An embodiment of the electrode of the present invention, the electrode described in this embodiment includes a welding core and a coating, the material of the welding core is carbon steel H08A, and the coating contains the following components in mass percentage: boron carbide 16% , Atomized iron powder 28%, mica 2%, graphite powder 7%, ferro-niobium 20%, metal chromium 20%, micro-carbon ferro-chromium 3%, medium-carbon ferromanganese 4%. The welding core in this embodiment has a diameter of Φ3.2mm and a length of 350mm, and the outer diameter of the welding rod is Φ6.0mm. The preparation method of the welding rod described in this embodiment is the same as that in Embodiment 1.

[0040] Also measure the hardness of the surfacing layer according to the standard: one to three layers of HRC67-69. Use the welding rod of this embodiment to build up two layers on the conical screw propeller of the charcoal machine (small screw, 520mm long, the outer diameter of the big end ...

Embodiment 3

[0042] An embodiment of the electrode of the present invention, the electrode described in this embodiment includes a welding core and a coating, the material of the welding core is carbon steel H08A, and the coating contains the following components in weight percentage: boron carbide 14% , 28% atomized iron powder, 33% micro-carbon ferrochrome, 8% cobalt powder, 4% mica, 9% graphite powder, 4% ferrovanadium. The welding core described in this embodiment has a diameter of Φ5.0 mm and a length of 500 mm, and the outer diameter of the welding rod is Φ8.8 mm. The preparation method of the welding rod described in this embodiment is the same as that in Embodiment 1.

[0043] Also measure the hardness of the surfacing layer according to the standard: one to three layers of HRC65-67. Use this welding rod to surfacing on the large screw of the rubber-plastic double-cone extruder (length 1800mm, the outer diameter of the large end is Φ300mm, and the material is 38CrMoAl nitrided ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com