Patents

Literature

513 results about "Iron filings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron filings are very small pieces of iron that look like a light powder. They are very often used in science demonstrations to show the direction of a magnetic field. Since iron is a ferromagnetic material, a magnetic field induces each particle to become a tiny bar magnet. The south pole of each particle then attracts the north poles of its neighbors, and this process repeated over a wide area creates chains of filings parallel to the direction of the magnetic field. Iron Filings are used in many places, including schools where they test the reaction of the filings to magnets. They are also used in some toys, most famously Wooly Willy, where they serve to mimic hair on a cartoon face.

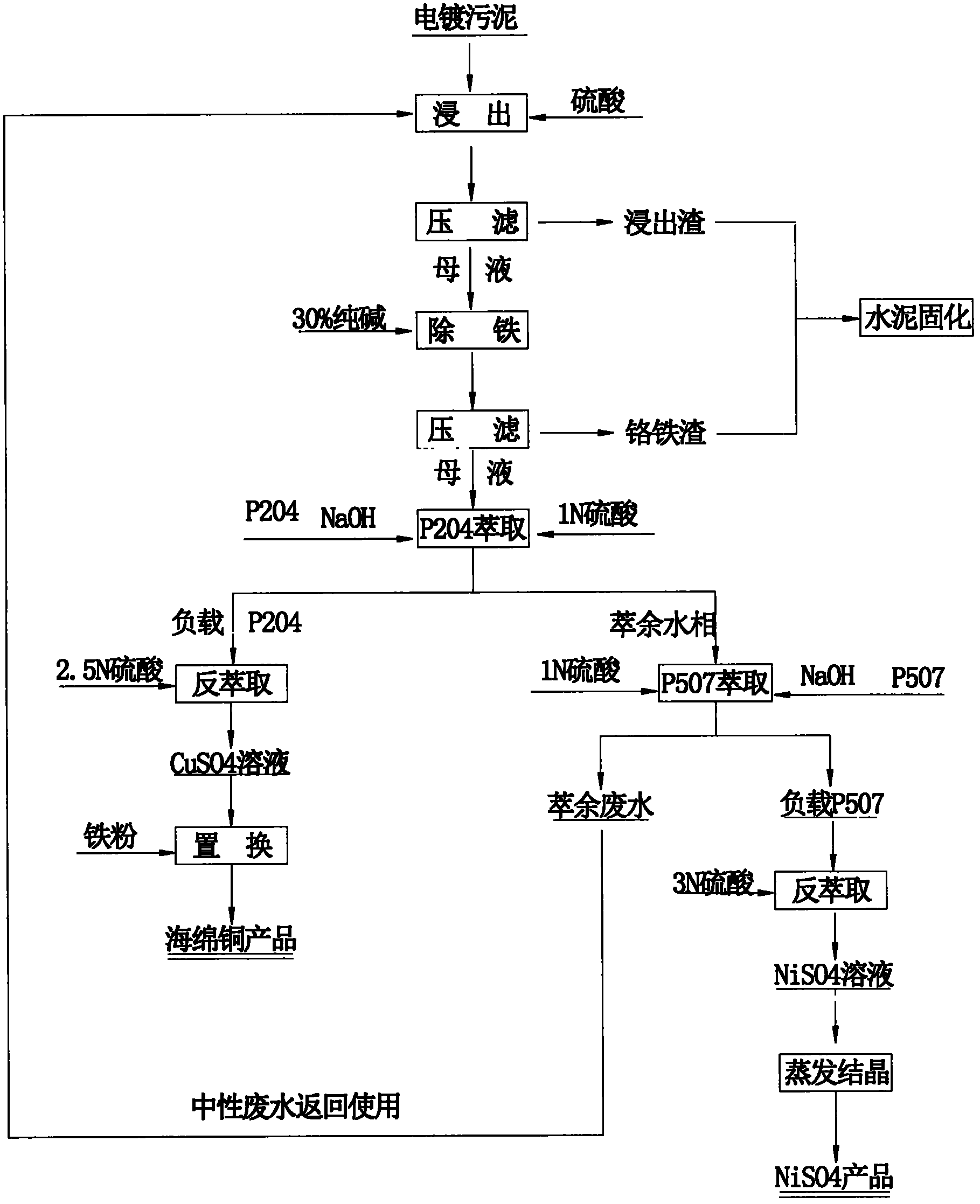

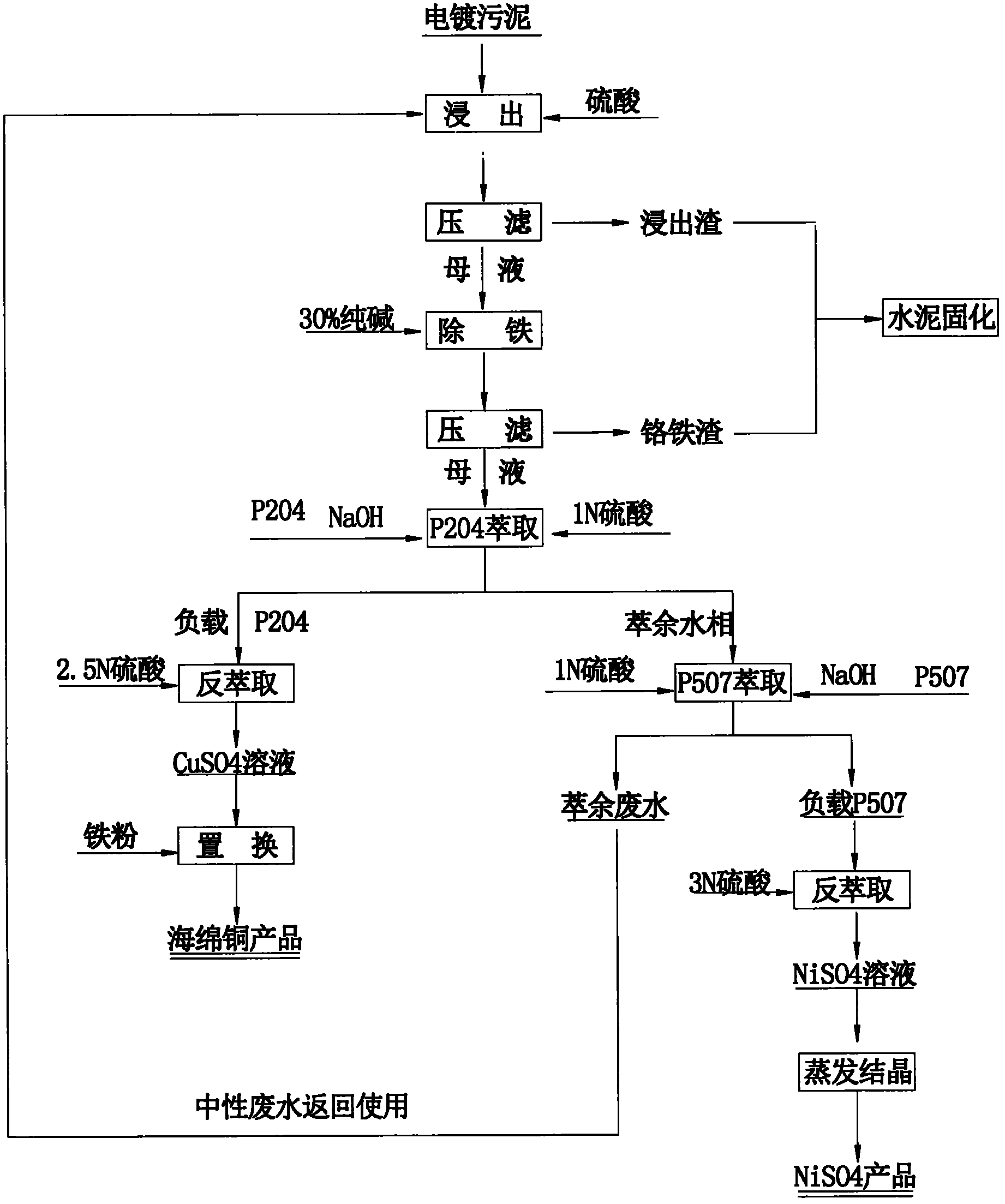

Method for recovering valuable metal from electroplating sludge

The invention relates to a method for recovering valuable metals from electroplating sludge. Electroplating sludge is used as a raw material; advanced theories and scientific means of leaching principle, redox principle, extraction principle, iron filing displacement principle and evaporation crystallization principle in a wet method metallurgy are integrally utilized; and a technology of ''acid decomposition of electroplating sludge-leachate purification to remove ferrochrome-P204 impurity removal-P507 enrichment-condensation crystallization'' is employed. Meanwhile, calcium and magnesium are removed by an extraction method, which substitutes a traditional sodium fluoride method for removing calcium and magnesium. A recovery rate of nickel reaches 95%, and copper content of recovered copper sponge is larger than 80%. Besides, acid dissolved slag and purifying slag can be solidified to reach requirements of environmental protection and will not cause secondary pollution; waste water can be recycled and has a strong technological versatility. The method is suitable for treating various routine electroplating sludge, has easily controllable technical conditions and low operating cost and is easy for realizing large scale production; therefore, the method is a practical novel technology for treating electroplating sludge in a way of quantitative reduction, harmlessness and resource.

Owner:朱小红

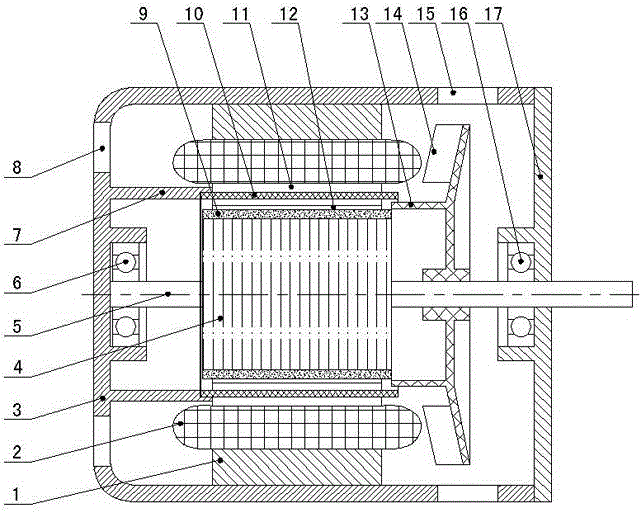

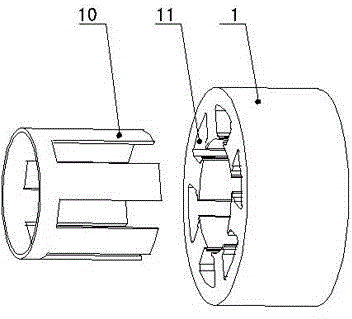

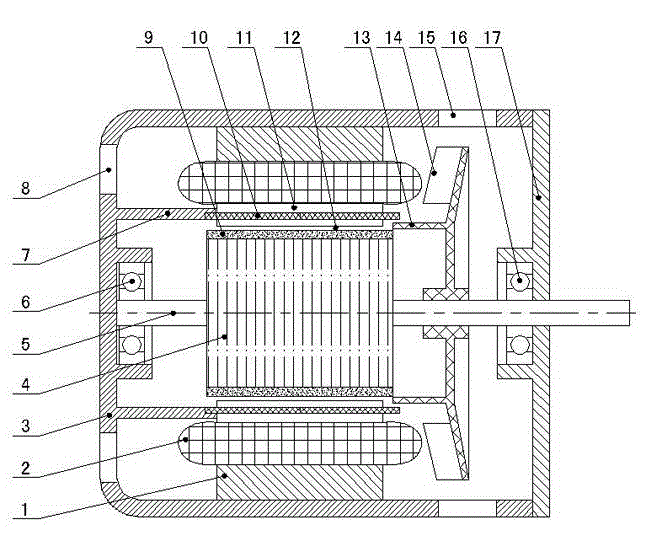

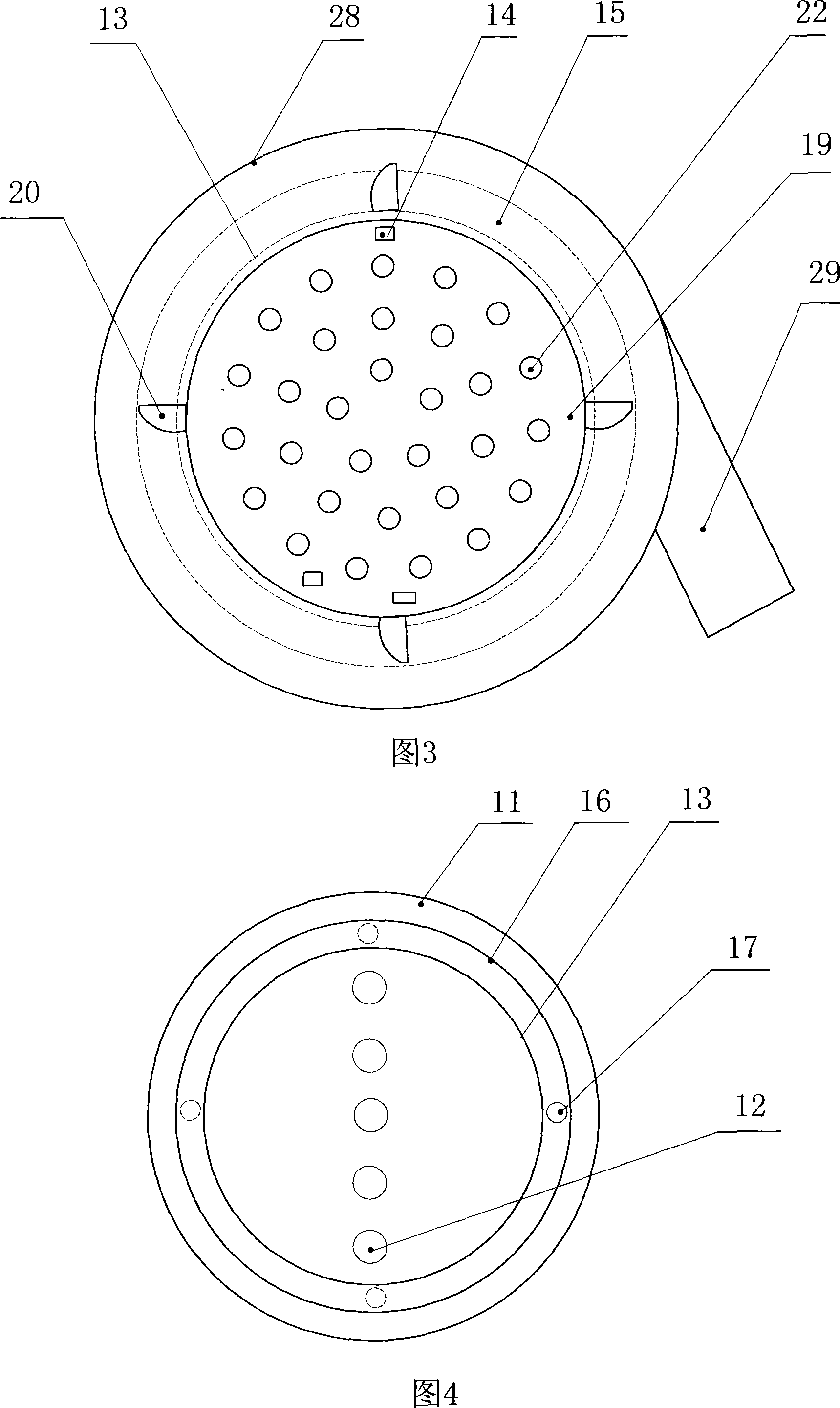

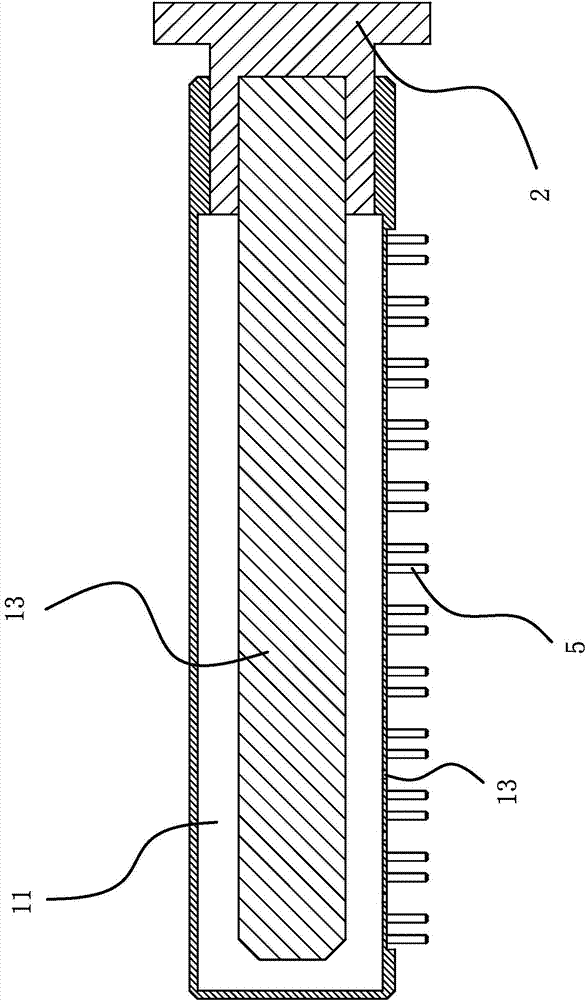

Permanent magnet brushless motor comprising rotor with dustproof structure

ActiveCN104539078AGuaranteed uptimeLong-term normal operationWindingsMagnetic circuit stationary partsPermanent magnet rotorBrushless motors

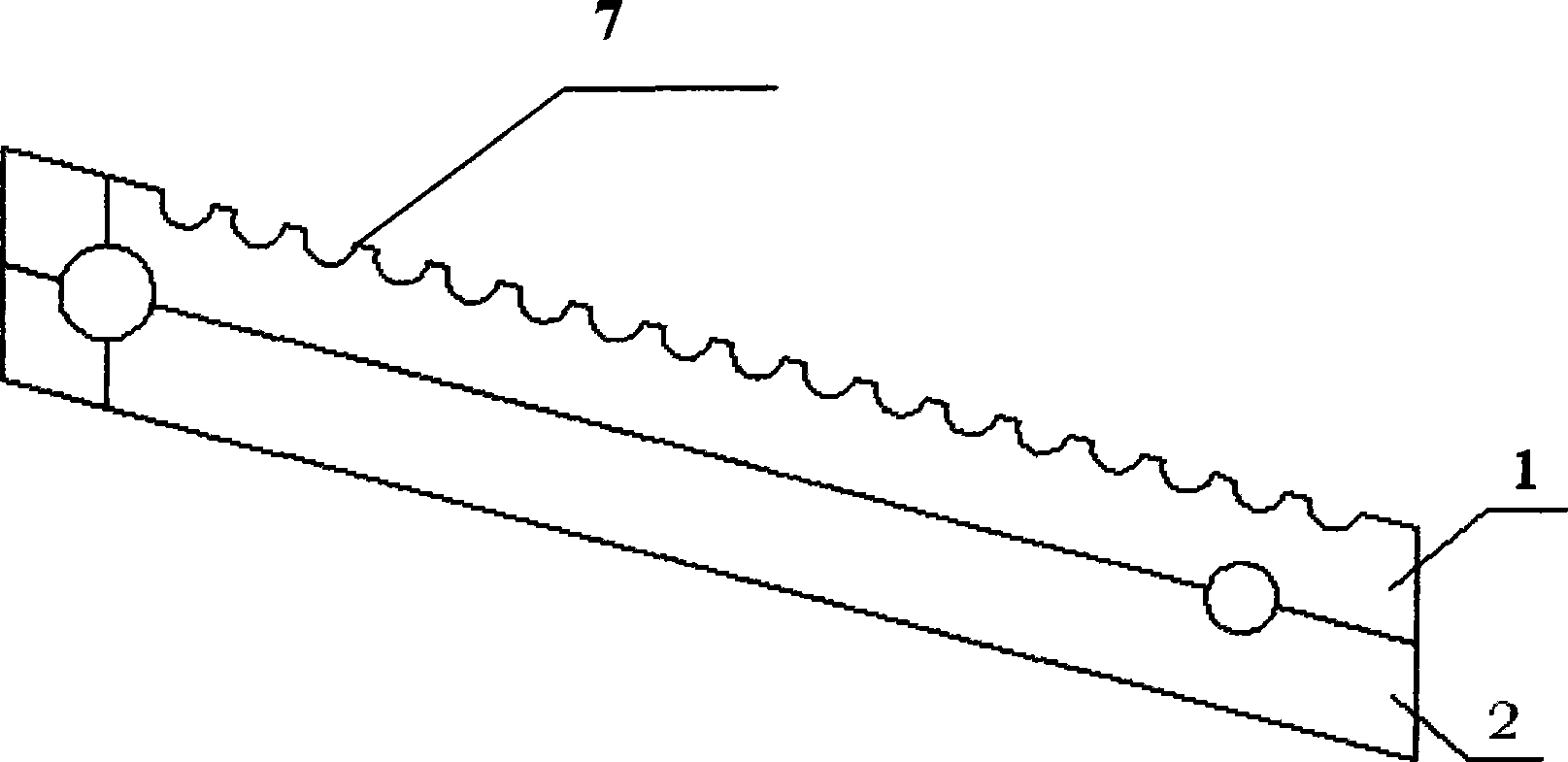

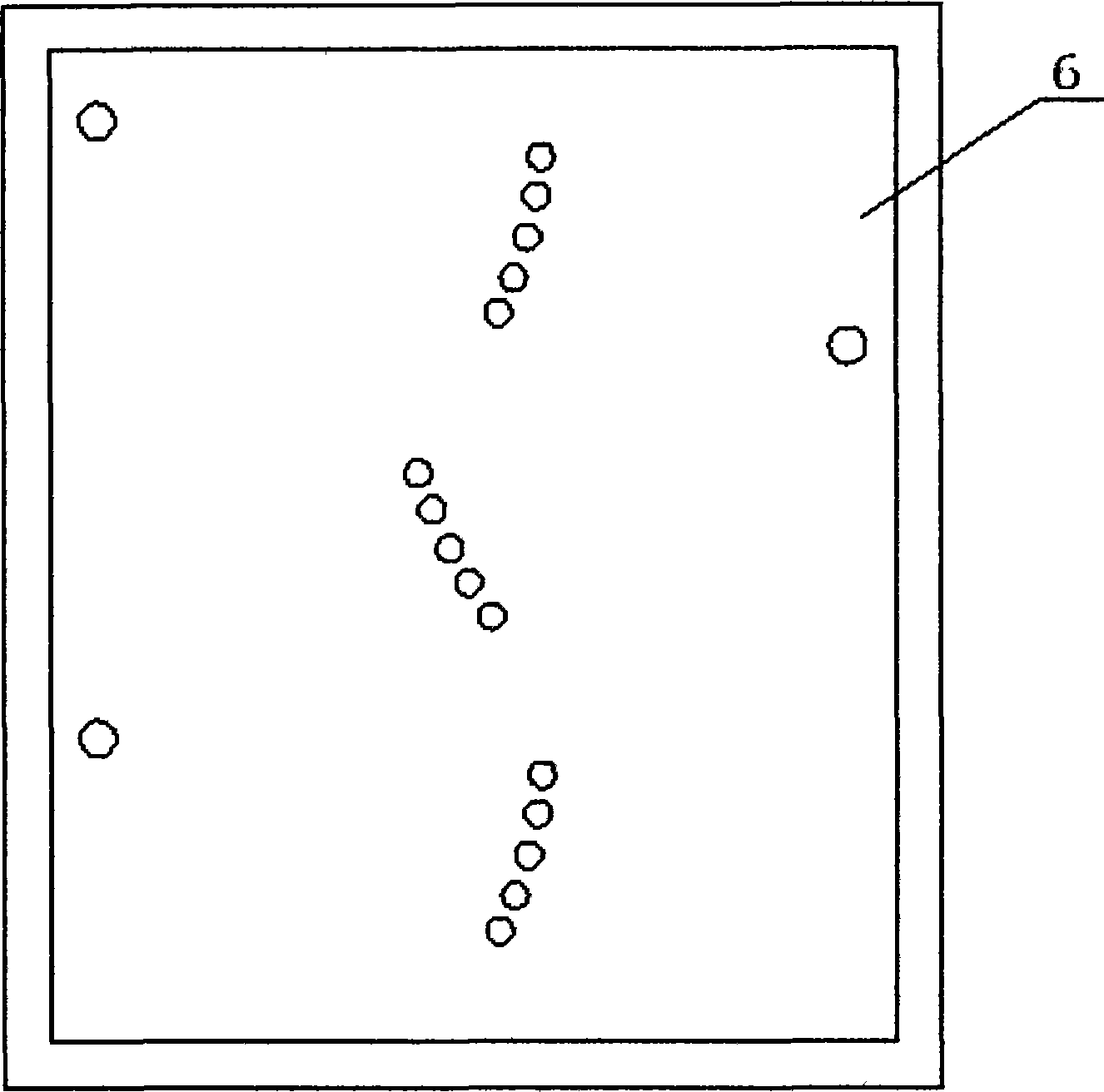

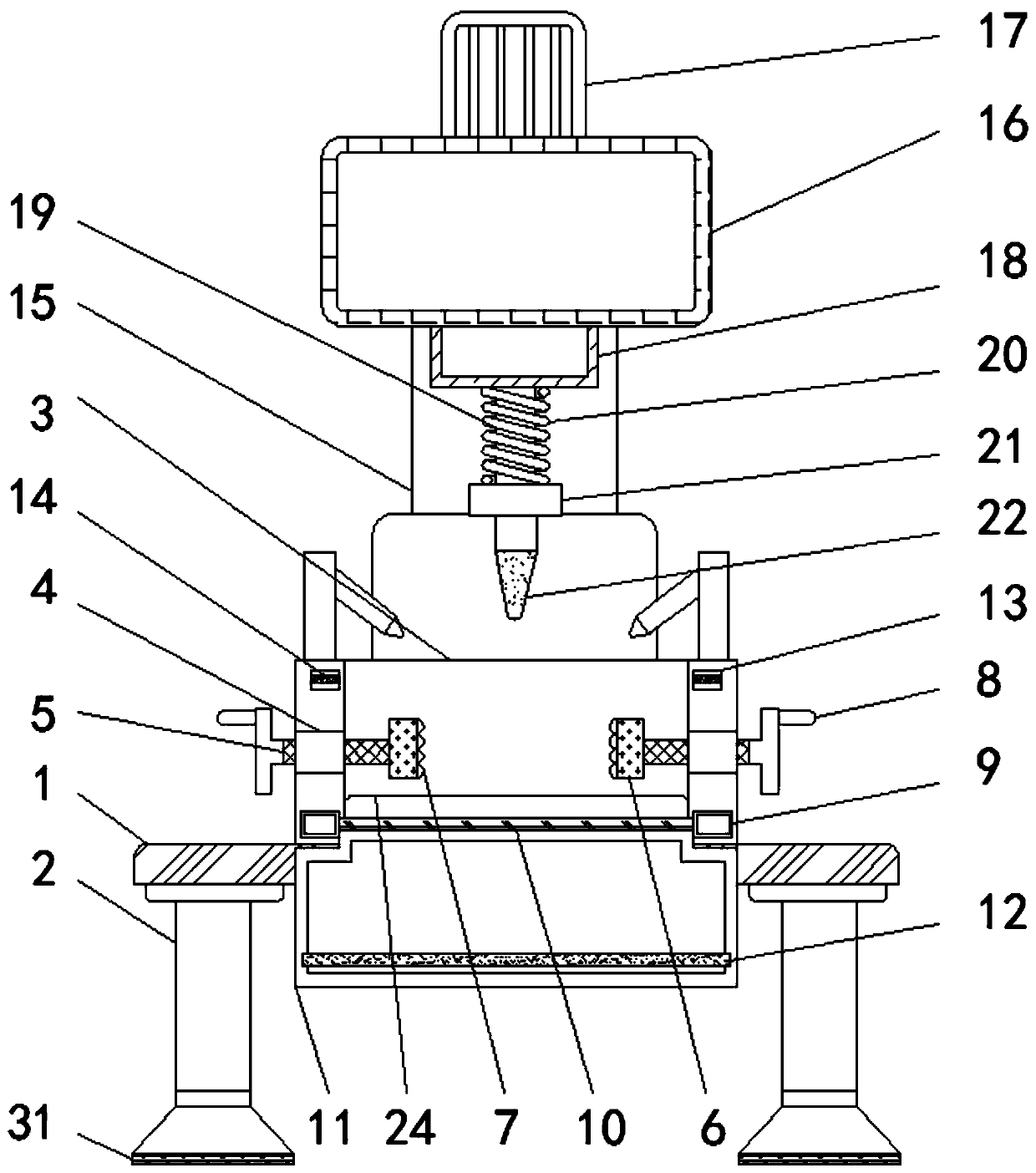

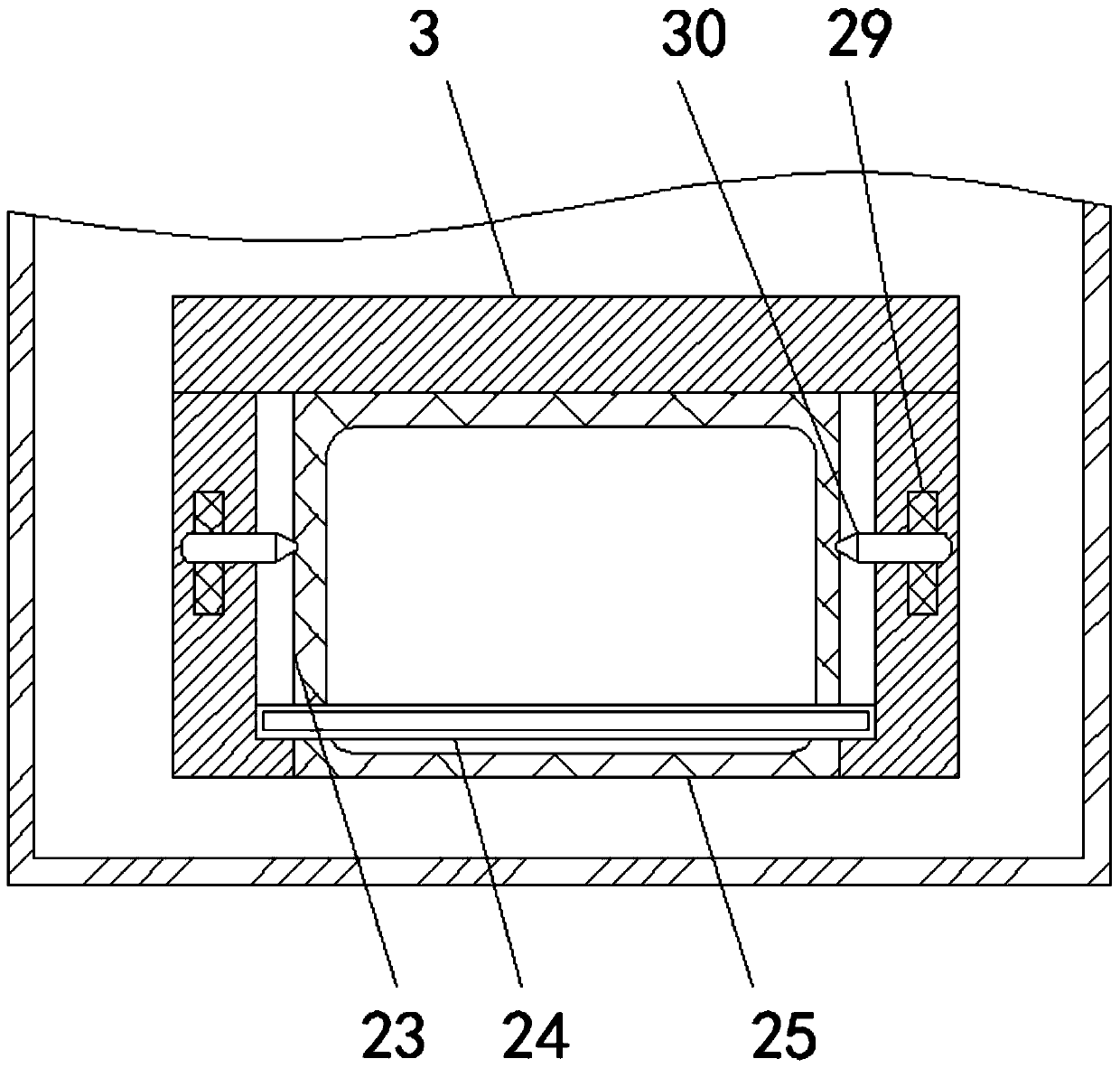

The invention discloses a permanent magnet brushless motor comprising a rotor with a dustproof structure, comprising a housing (3), a stator, a permanent magnet rotor (4), a rotor shaft (5), a cooling fan (14), and an end cap (17). The housing (3) is provided with an air inlet (8) and an air inlet (15). The stator includes a stator core (1) and an electromagnetic winding (2). The air inlet (8) side of the housing (3) is provided with a dust cover (7), and the dust cover (7) faces the end face of the stator core (1). The stator core (1) is provided with an isolating slot wedge (10) matched with openings of electromagnetic winding slots (11), and the isolating slot wedge (10) is made of insulating material. The isolating slot wedge (10) and the dust cover (7) are mutually sheathed, and the isolating slot wedge (10) and the teeth of all the electromagnetic winding slots (11) constitute a closed stator inner circle. By adopting the structure, the permanent magnet brushless motor of the invention has the advantages of simple and reasonable structure, convenient installation, good sealing performance of the rotor, capability of avoiding iron powder and iron filings adsorption on the surface of the permanent magnet rotor (4), long service life, and the like.

Owner:胡超

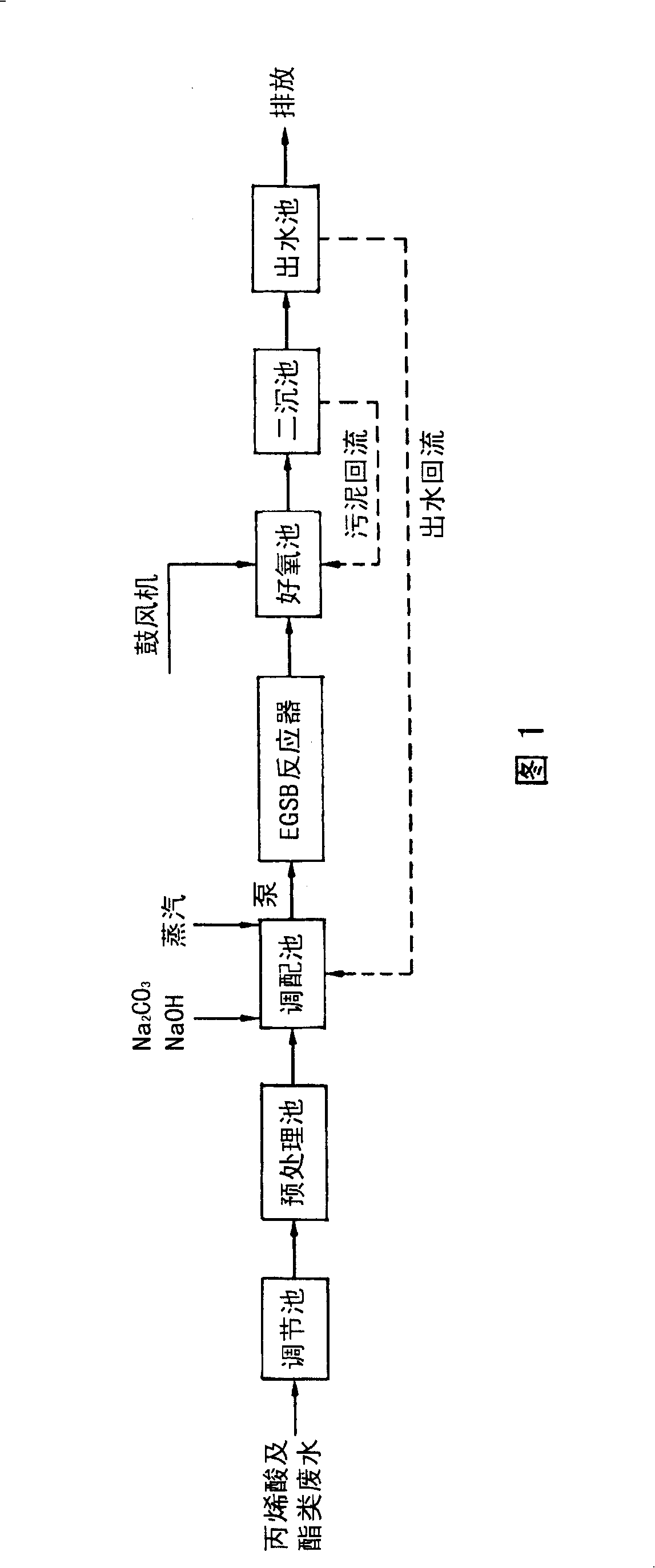

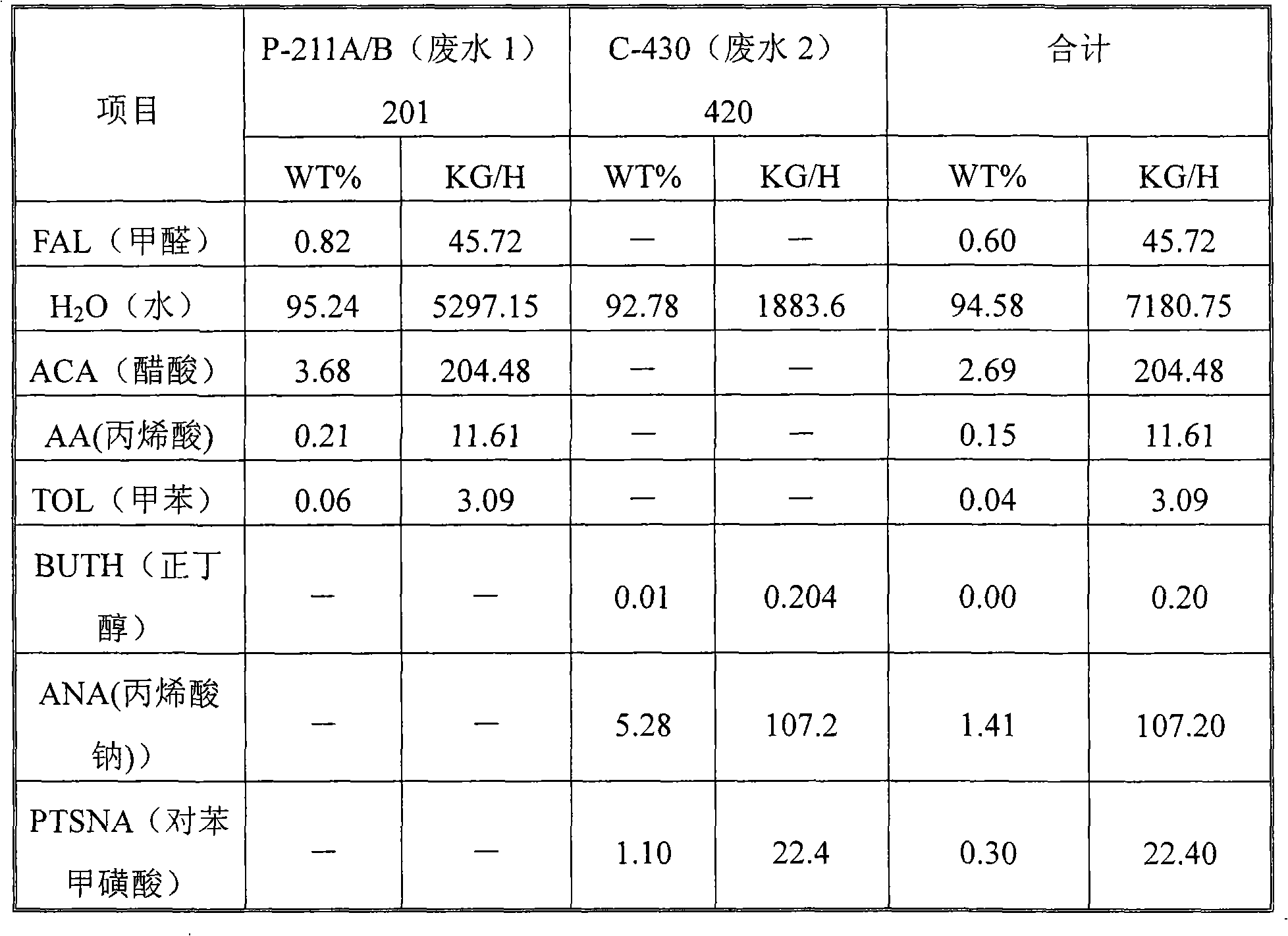

Waste water treating process of salt-containing propenoic acid and/or salt-containing propylene ester

InactiveCN101333050AReduce processing costsEfficient removalTreatment using aerobic processesTreatment with anaerobic digestion processesSalt contentOxygen

A method for treating the wastewater bearing salt of acrylic acid and / or acrylic ester comprises the following steps: A, the wastewater bearing salt of acrylic acid and / or acrylic ester is filtered through a layer of iron filing for pretreatment, with the hydraulic retention time reaching 2.0-5.0 hours; B, alkali is added to the pretreated wastewater to enable the pH value to reach 8-9; C, then, anaerobic granular sludge is added for anaerobic biological treatment; D, aerobic biological treatment is followed; E, the wastewater is then precipitated to get suspended solids removed so as to enable the drainage to reach discharge standards; F, the sludge precipitated in the step E is returned to the step D to rejoin the aerobic biological treatment. The invention enables pretreatment for acrylic acid and acrylic ester wastewater with high salt content (especially with high content of SO42-), as well as formaldehyde and other substances poisoning micro-organisms, so as to reduce the poisoning effect to the follow-up treatment due to vast amount of SO42- and formaldehyde existing in the wastewater, so that the follow-up biological treatment can go on smoothly.

Owner:北京中科国益环保工程有限公司

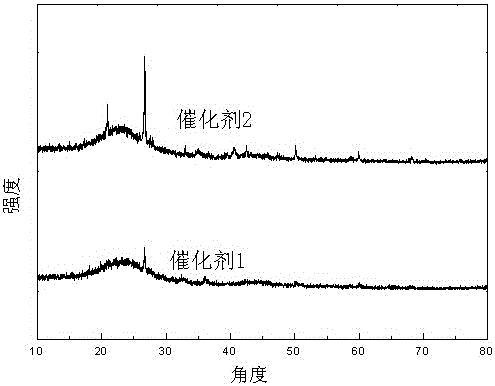

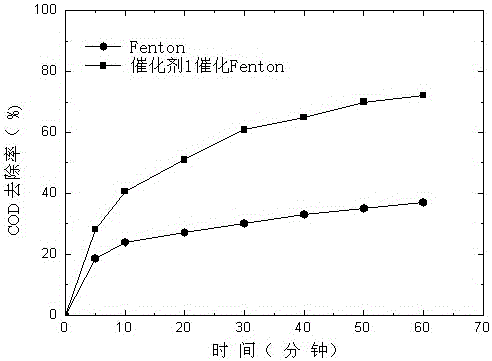

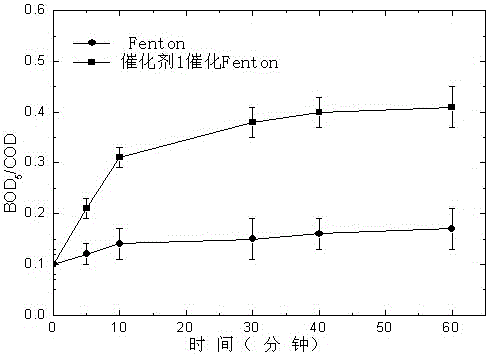

Method for preparing heterogeneous-phase Fenton catalyst and application thereof

ActiveCN106076335AThe preparation method is simple and matureLow costWater treatment compoundsWater contaminantsResource utilizationWastewater

The invention discloses a method for preparing a heterogeneous-phase Fenton catalyst and an application thereof, which belong to the fields of waste comprehensive utilization and water treatment. The method comprises the following steps: cleaning waste iron filings and biogas residue, drying the materials, crushing the materials, doping and dipping the materials, activating the materials at high temperature, pickling a sample and screening the sample to obtain the heterogeneous-phase Fenton catalyst. The method of the catalyst has the advantages of simple and easy operation, and saved preparation cost, effectively solves the resource utilization problem of waste iron filings and biogas residue, which belongs to the preparation technology of the sustainable development catalyst. The catalyst is used for processing difficultly-degraded waste water while being used for catalysis of Fenton, the pH value is not required to be adjusted, the pollutant removal effect is good, secondary pollution of iron filings and metal ions cannot be generated, the catalyst activity is not obviously changed through continuous operation with more than 600 hours, the catalyst has stable catalysis performance and good application performance, and is suitable for industrial popularization and application.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

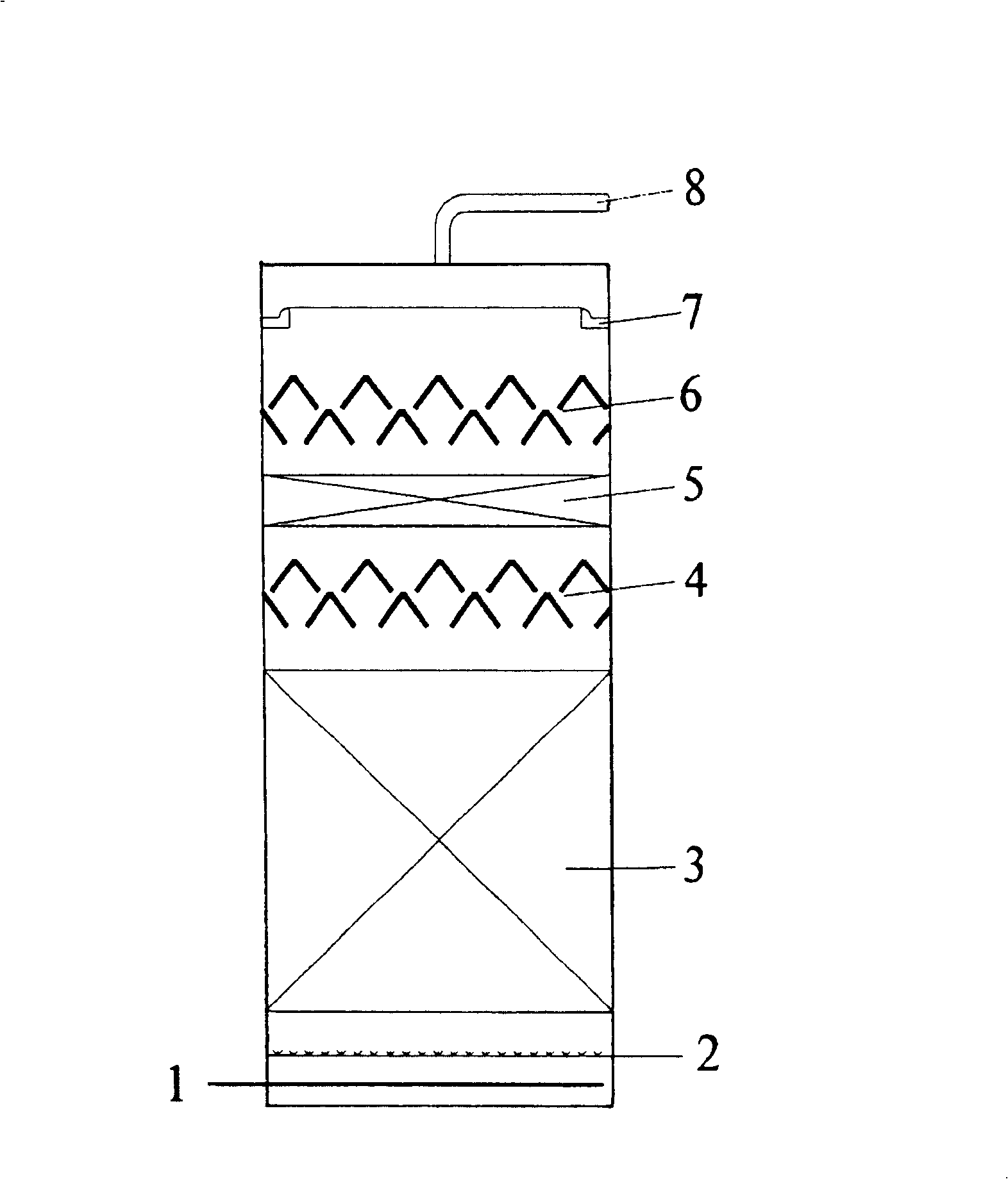

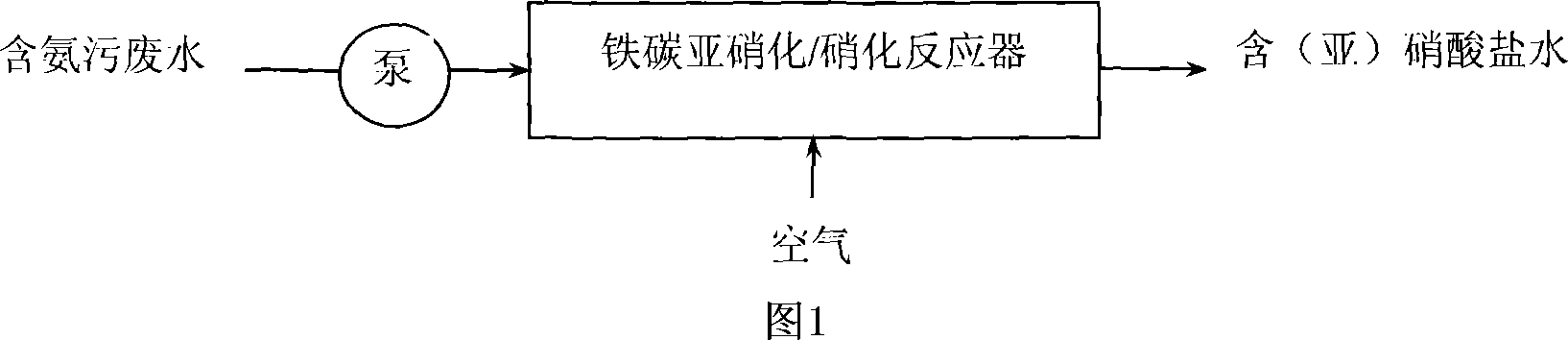

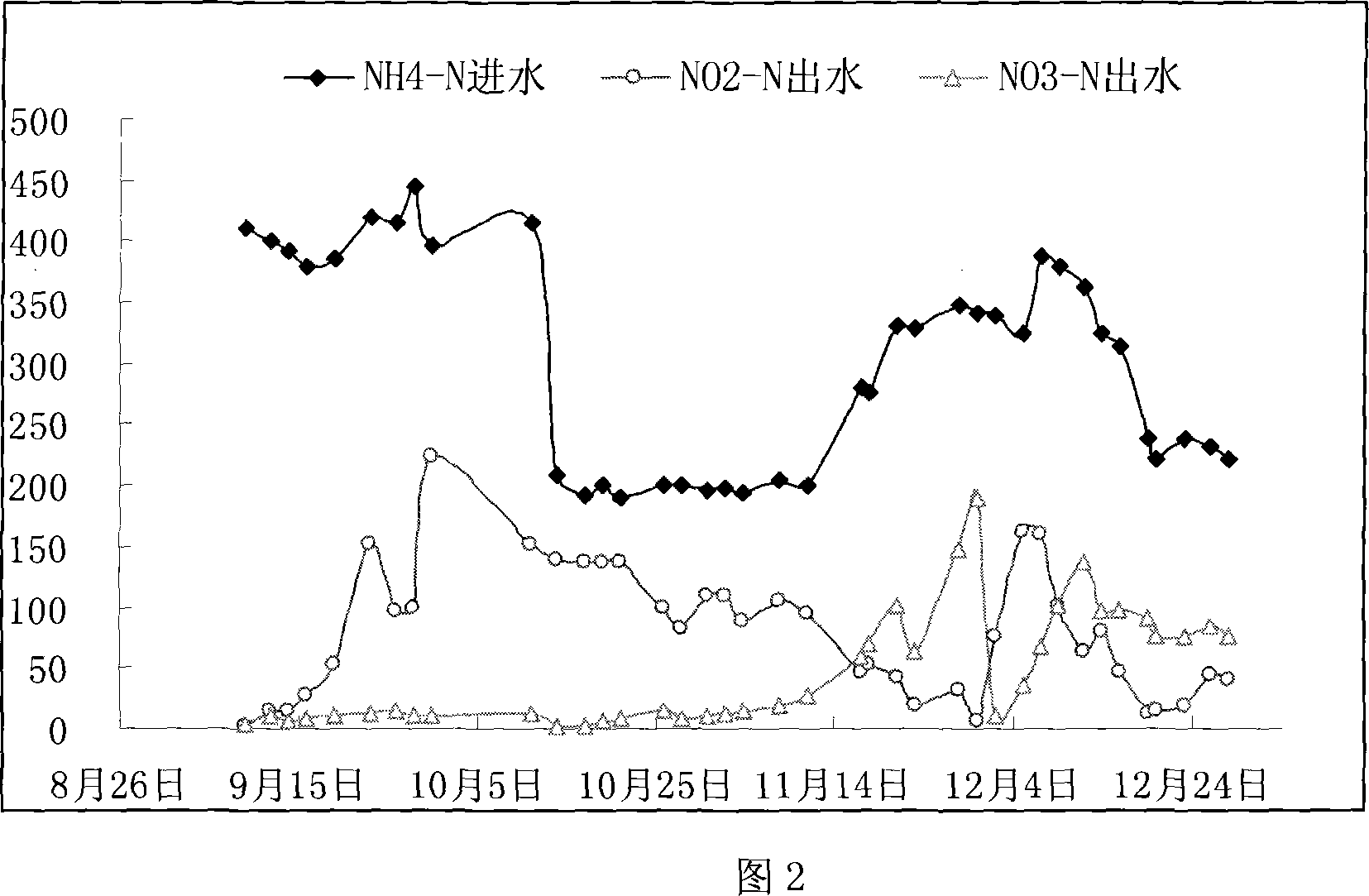

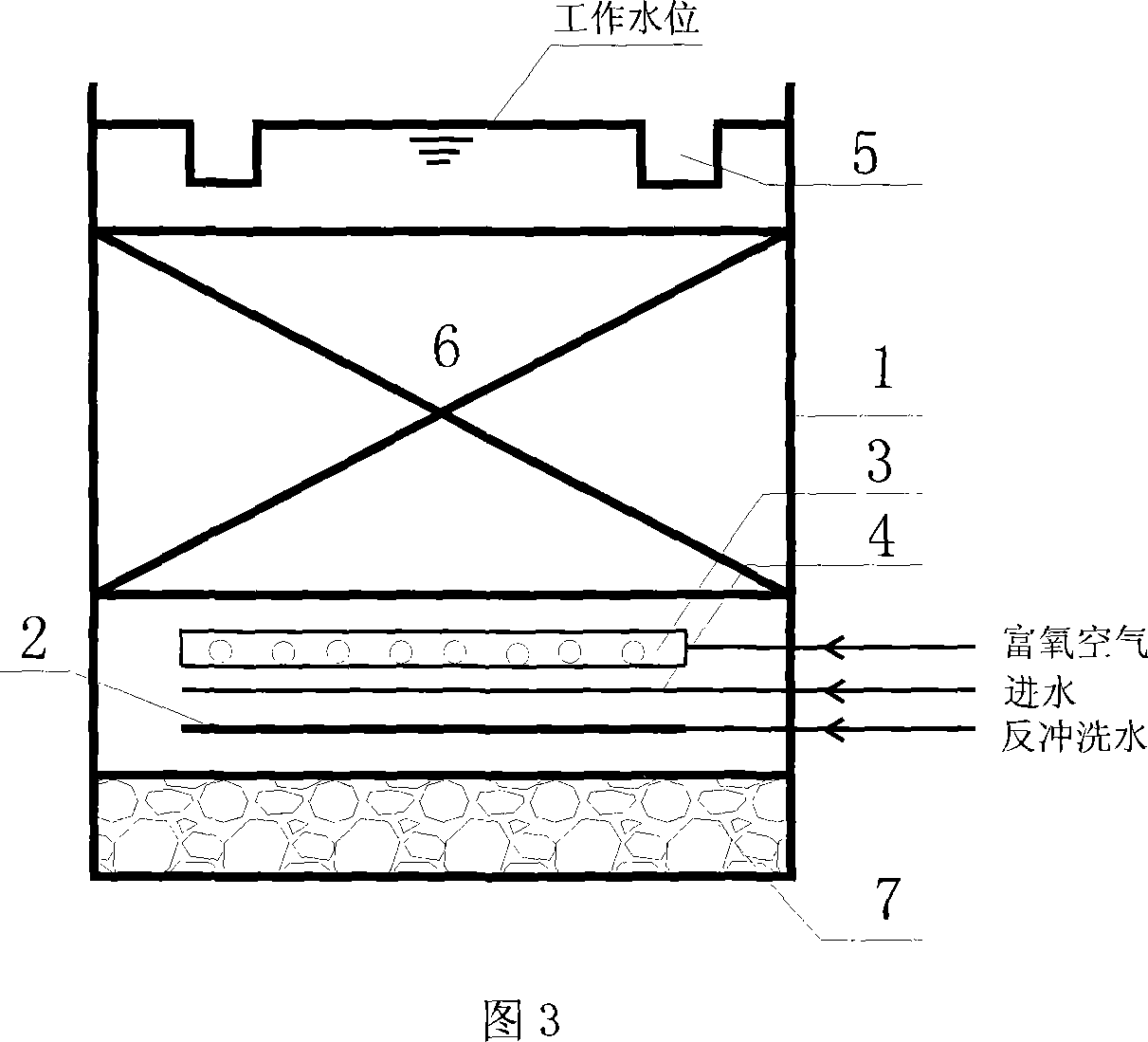

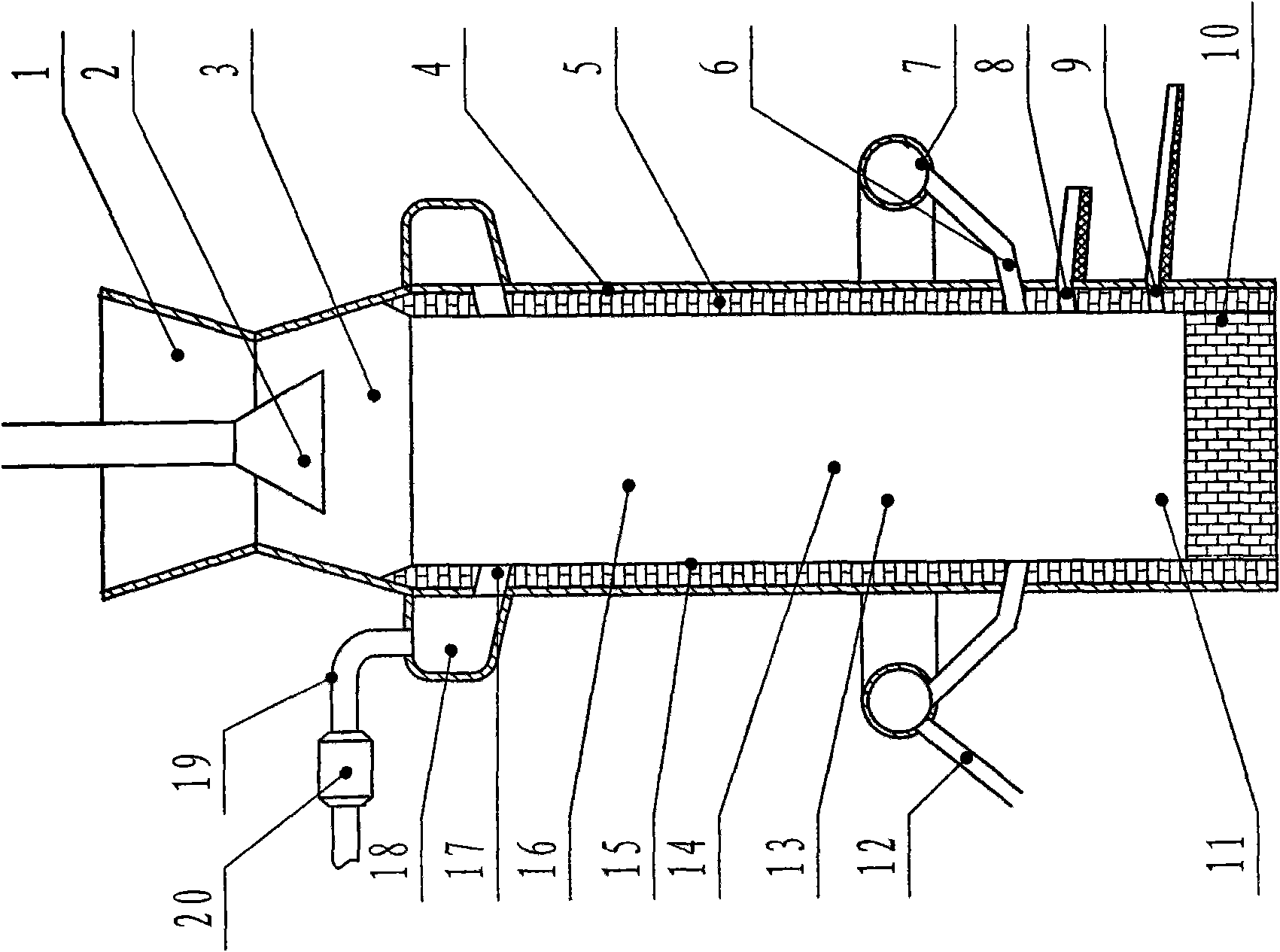

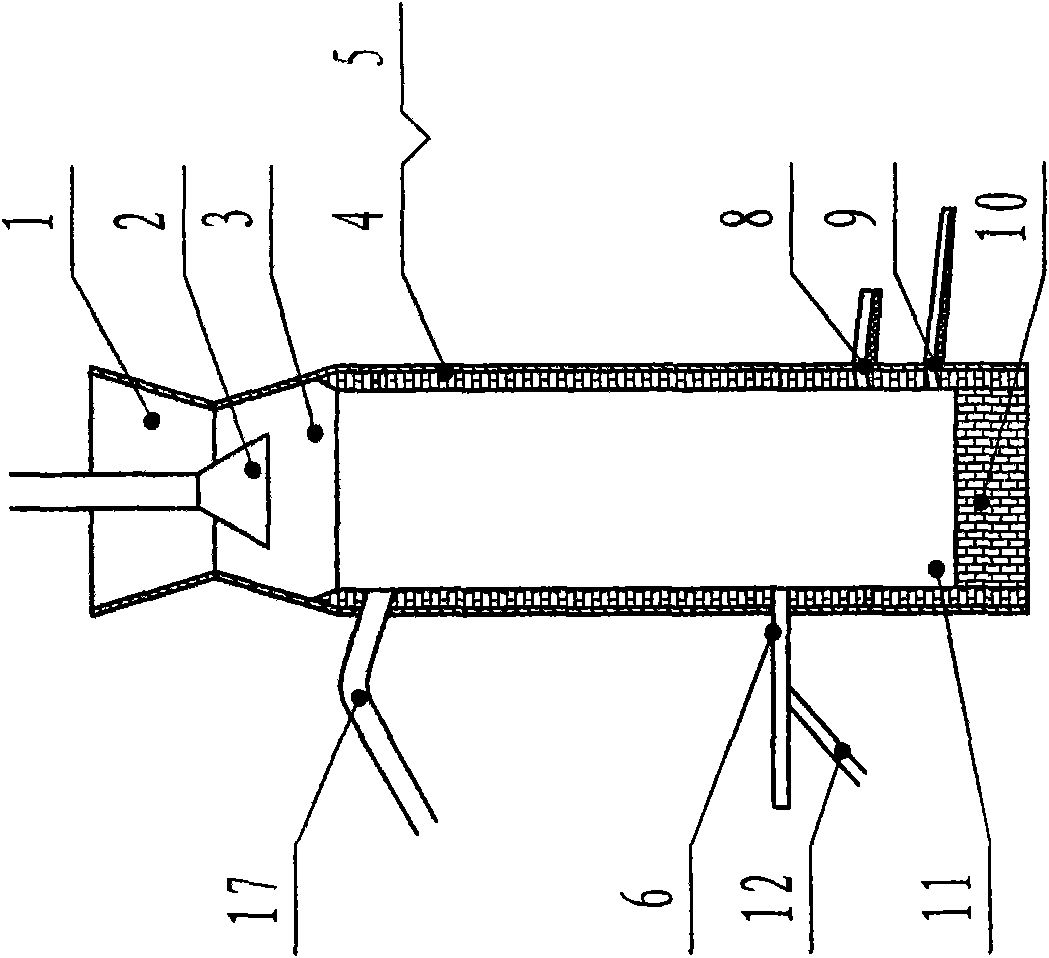

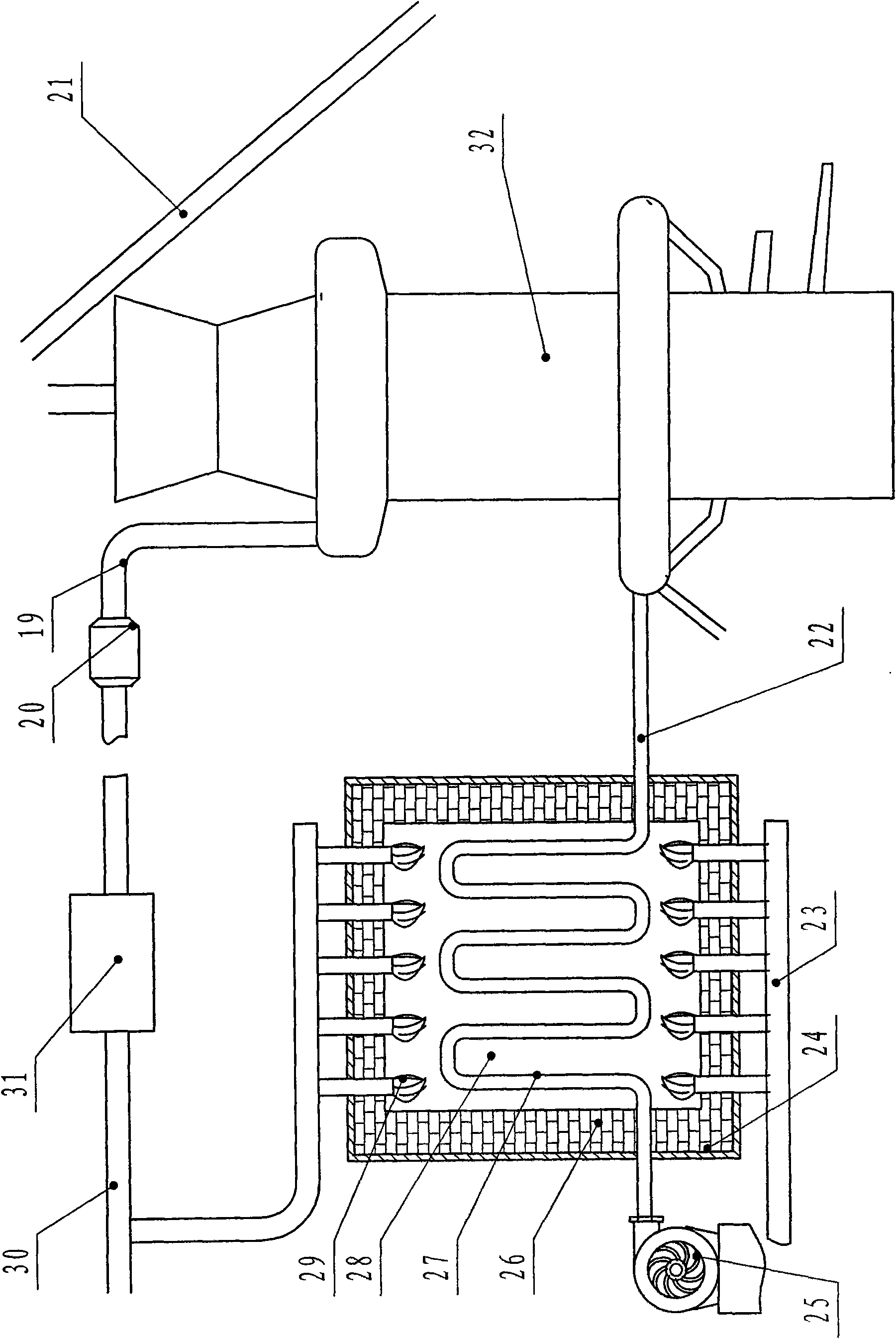

Nitrosation and nitration method for iron and carbon, reactor using the method and sewage denitrogenation method

ActiveCN101054226AProcess stabilityReaction is easy to controlWater contaminantsWater/sewage treatment by oxidationCarbon compositesNitration

The invention discloses a nitration method of iron-carbon nitrosation, a reactor therefor and a method of sewage water denitrogenation. Iron filings and active carbon are added in the reactor hierarchically or mixed, water containing ammonia nitrogen is supplied in the reactor and oxygen enriched air is blew in thereof, only inorganic iron-carbon in condition of aeration, ammonia nitrogen is conversed into nitrite and nitrate steadily. The reactor is composed of a supporting layer, a back purge system, a water-inlet- distribution device, a air diffuser, iron / carbon composite material, a drift eliminator and bed body, nitrosation or nitration is finished in action of ammonia sewage water. The reactor is combined with a denitrify reactor, a anaerobic bioreactor, or used as a aeration biological filter of biology filler to finish denitrification process of nitrogen sewage water. The reactor has advantages of stable performance, high efficiency, low power cost and simple maintenance. An integrated denitrification technics is formed in the reactor, denitrification efficiency of the whole flow is improved.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

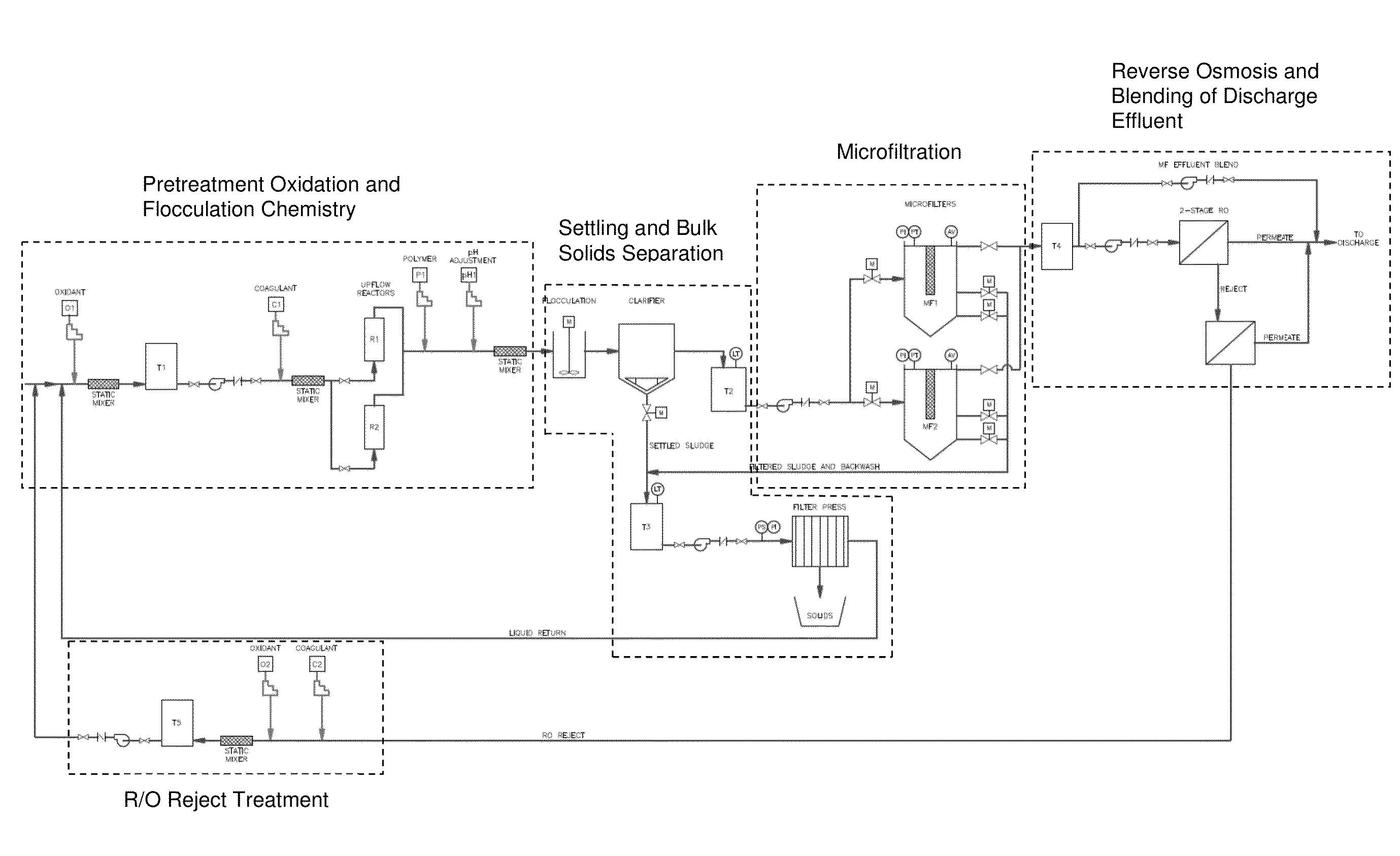

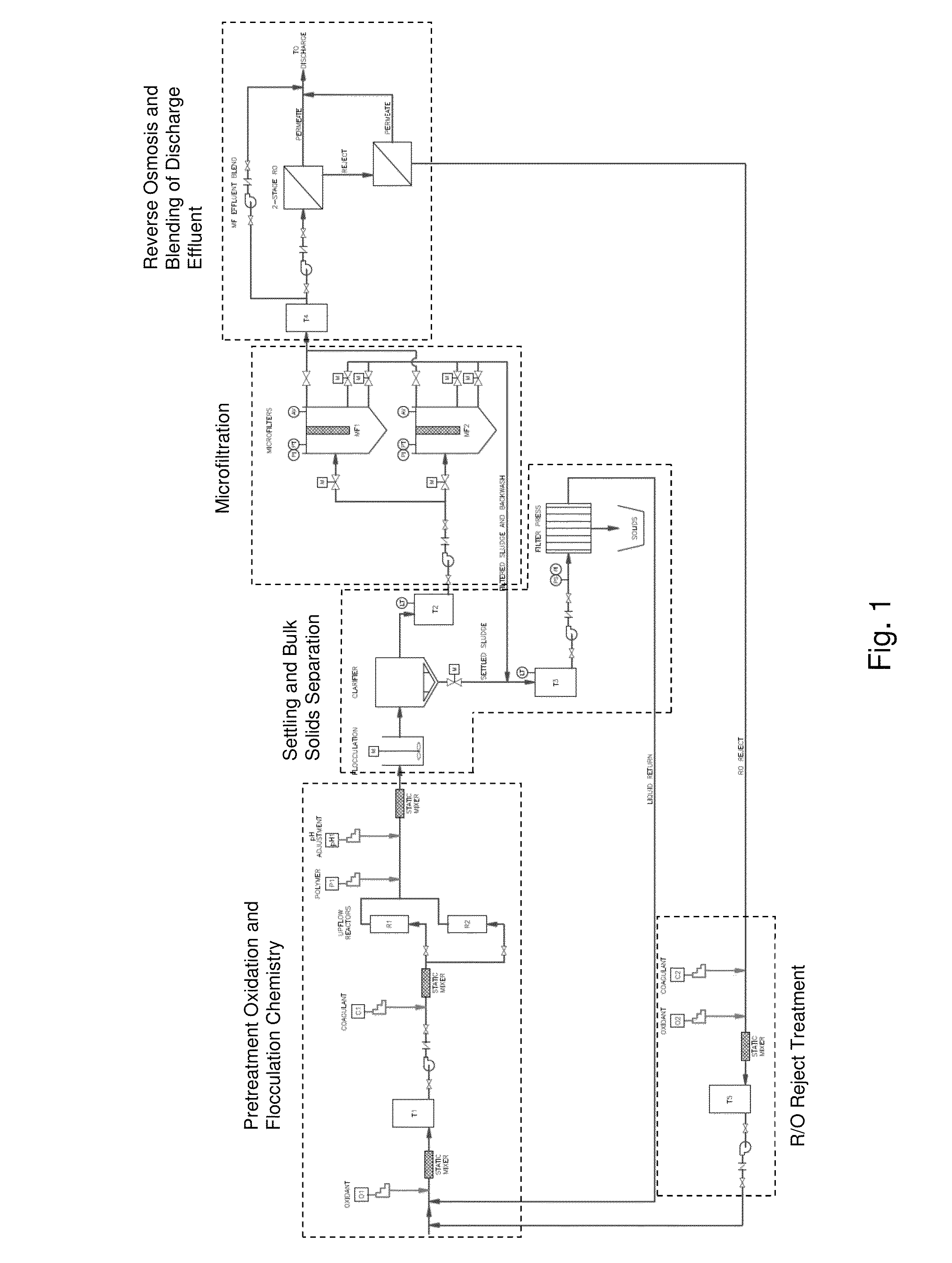

Treatment of contaminated impound water

ActiveUS20130270189A1Increased physical sizeLittle or no corrosionWaste water treatment from quariesSedimentation separationSteel woolWastewater

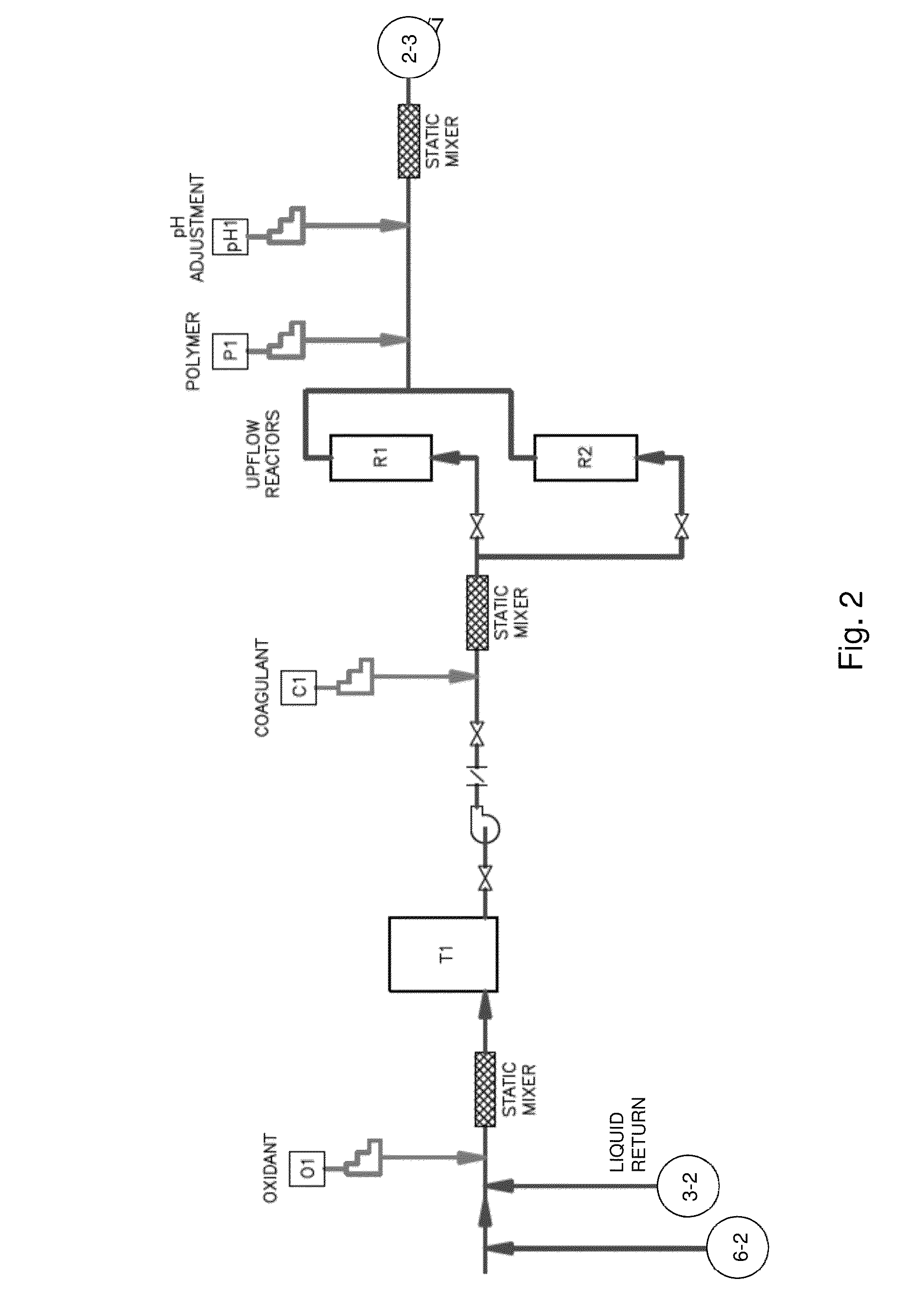

Systems and methods for treating contaminated impound water are disclosed which include a pretreatment stage wherein contaminated water is oxidized, pH adjusted, treated with a coagulant, and treated with a polymer to form a flocculent comprising bulk solids and fine particles. The oxidizing step may include two or more stages, one of which is a treatment with ferrous iron generated from iron filings or steel wool. Bulk solids are removed, and the liquid portion containing fine particles is applied to a low pressure microfiltration unit to remove the fine particles resulting in a microfilter effluent. The microfilter effluent may be directly fed to a reverse osmosis (R / O) unit. The R / O reject may be recycled to another R / O unit (second pass). The R / O permeate may be blended as needed with the microfiltration effluent to provide the final discharge effluent with reduced contaminant levels and maximized throughput. The R / O second pass reject water is further oxidized and recycled back to the front of the system to be retreated.

Owner:WATER SOLUTIONS TECH LLC

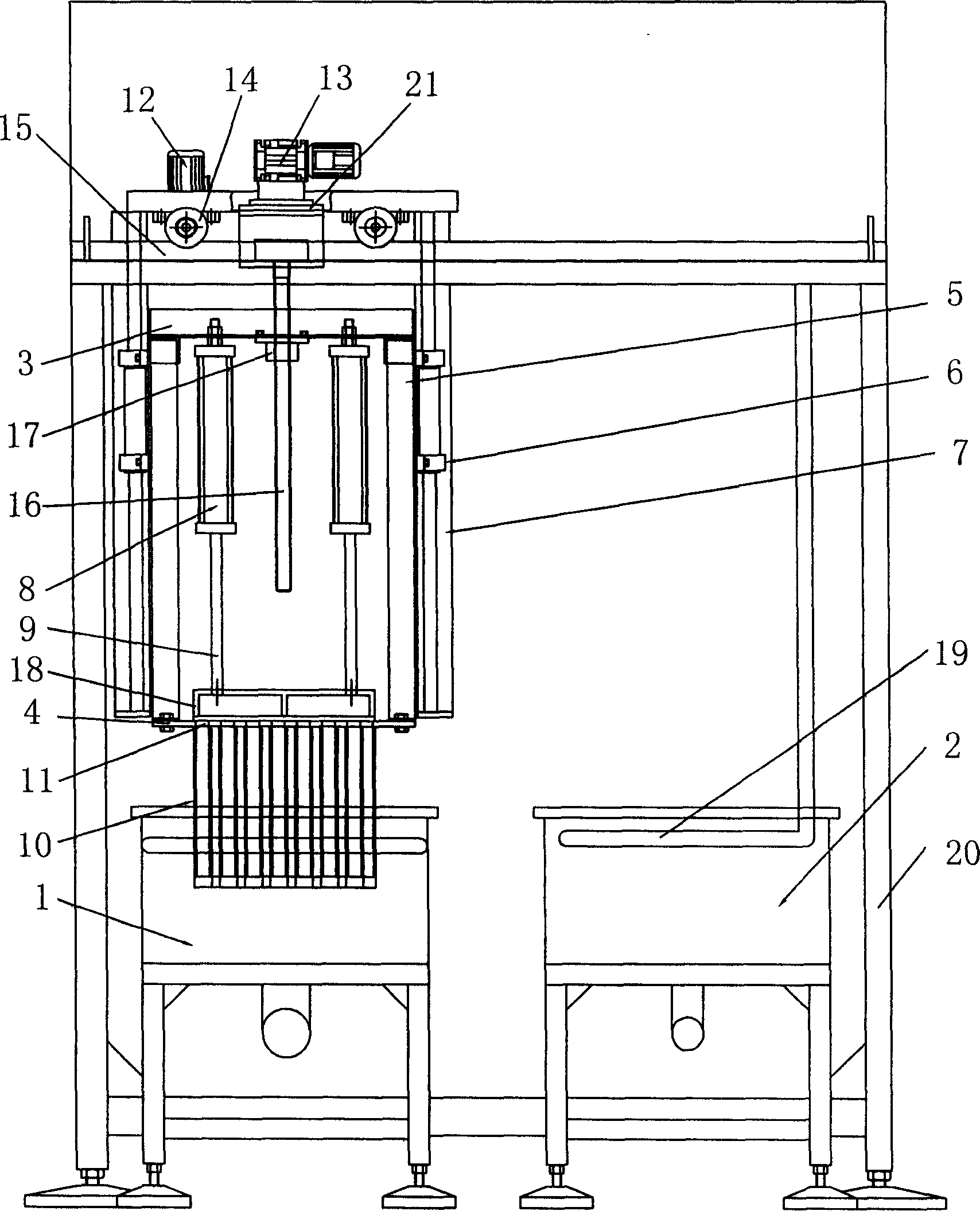

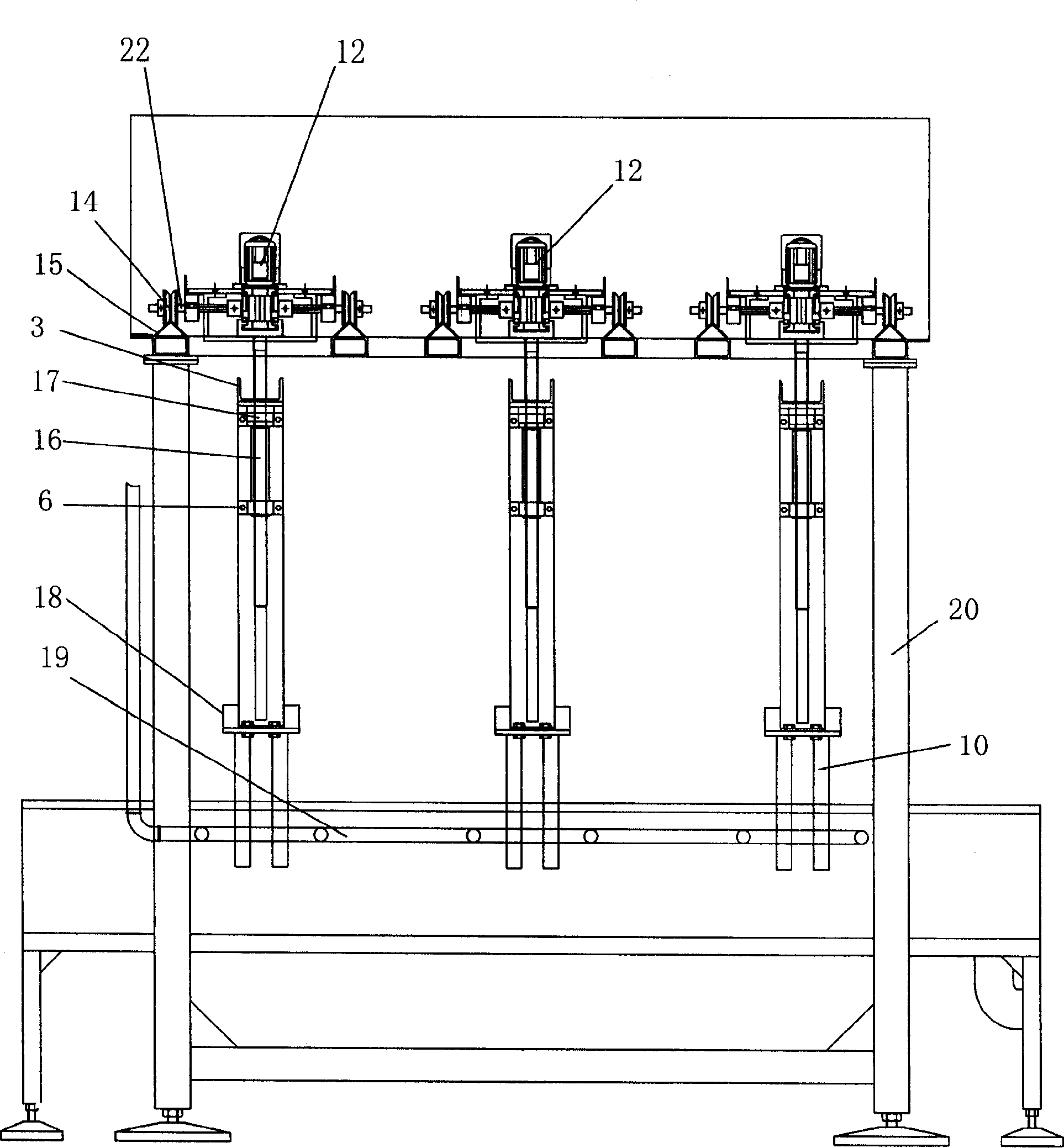

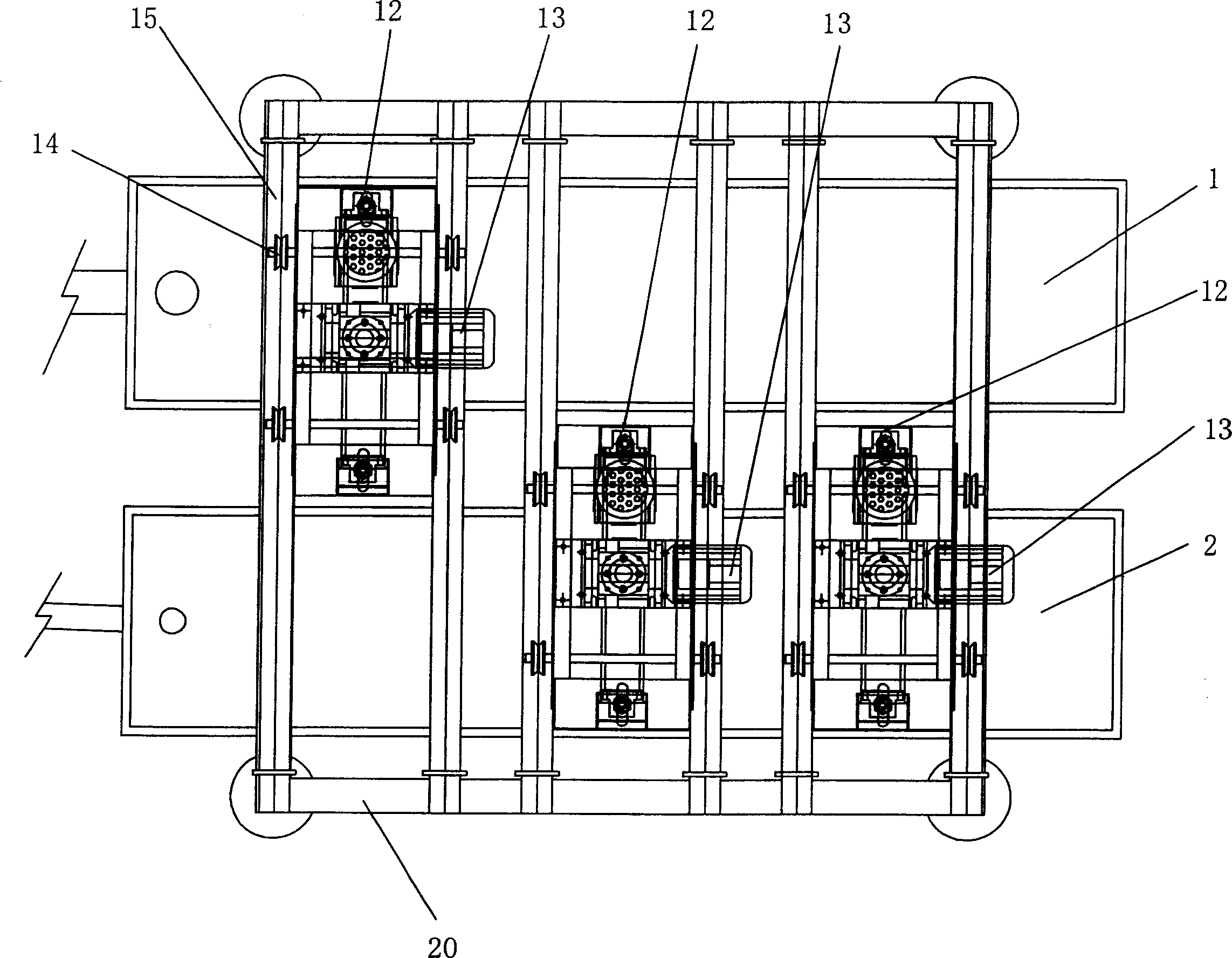

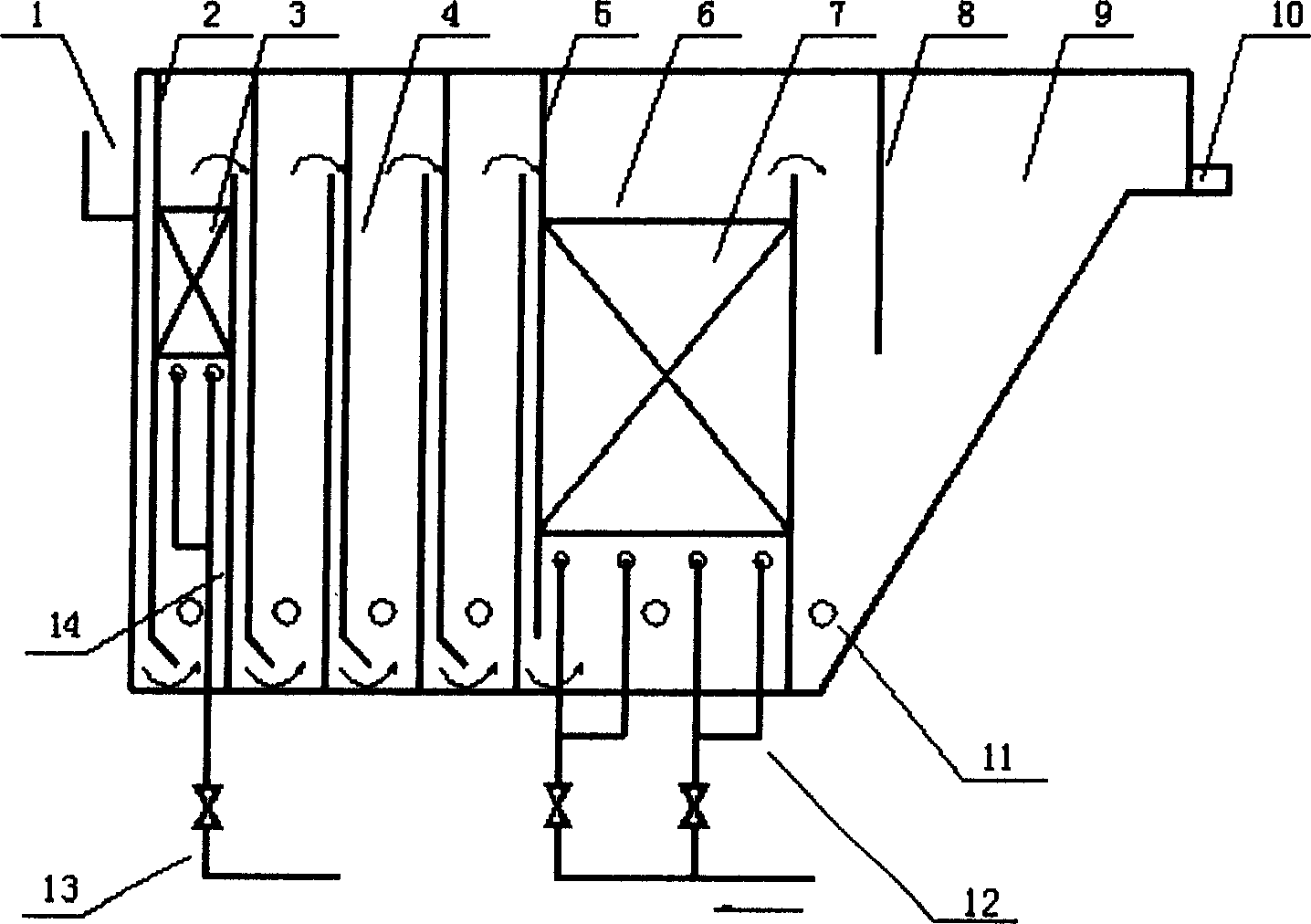

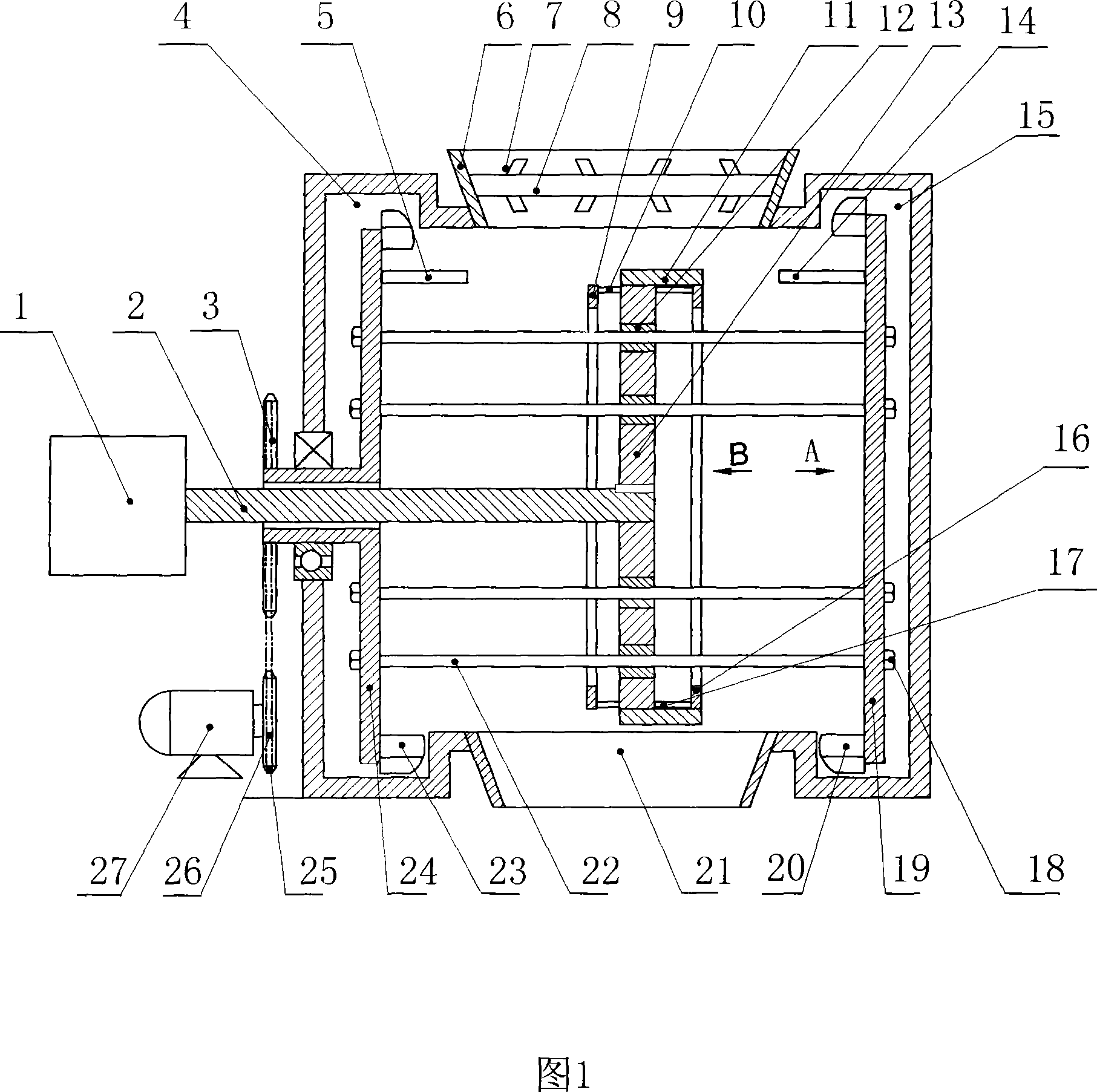

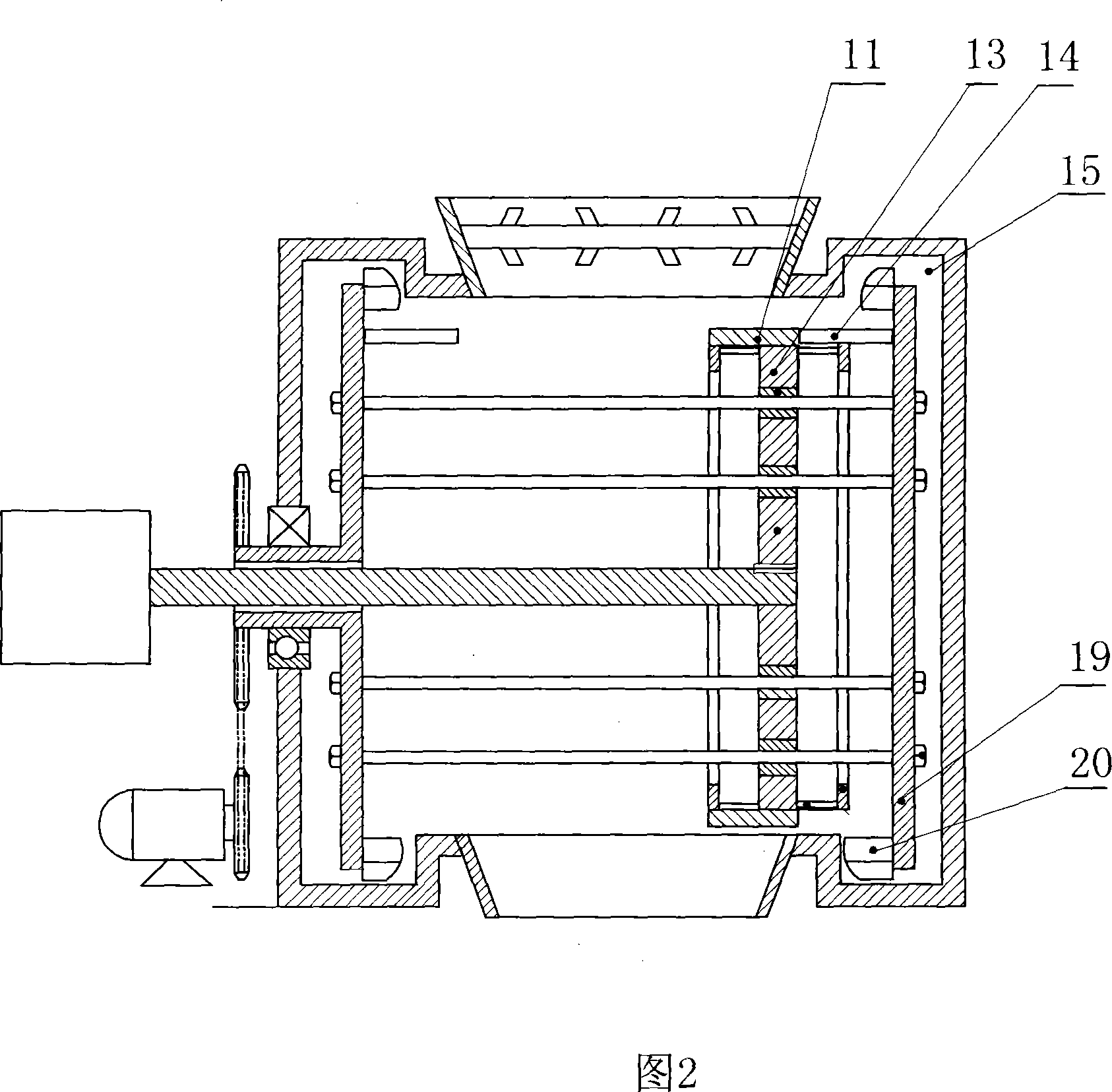

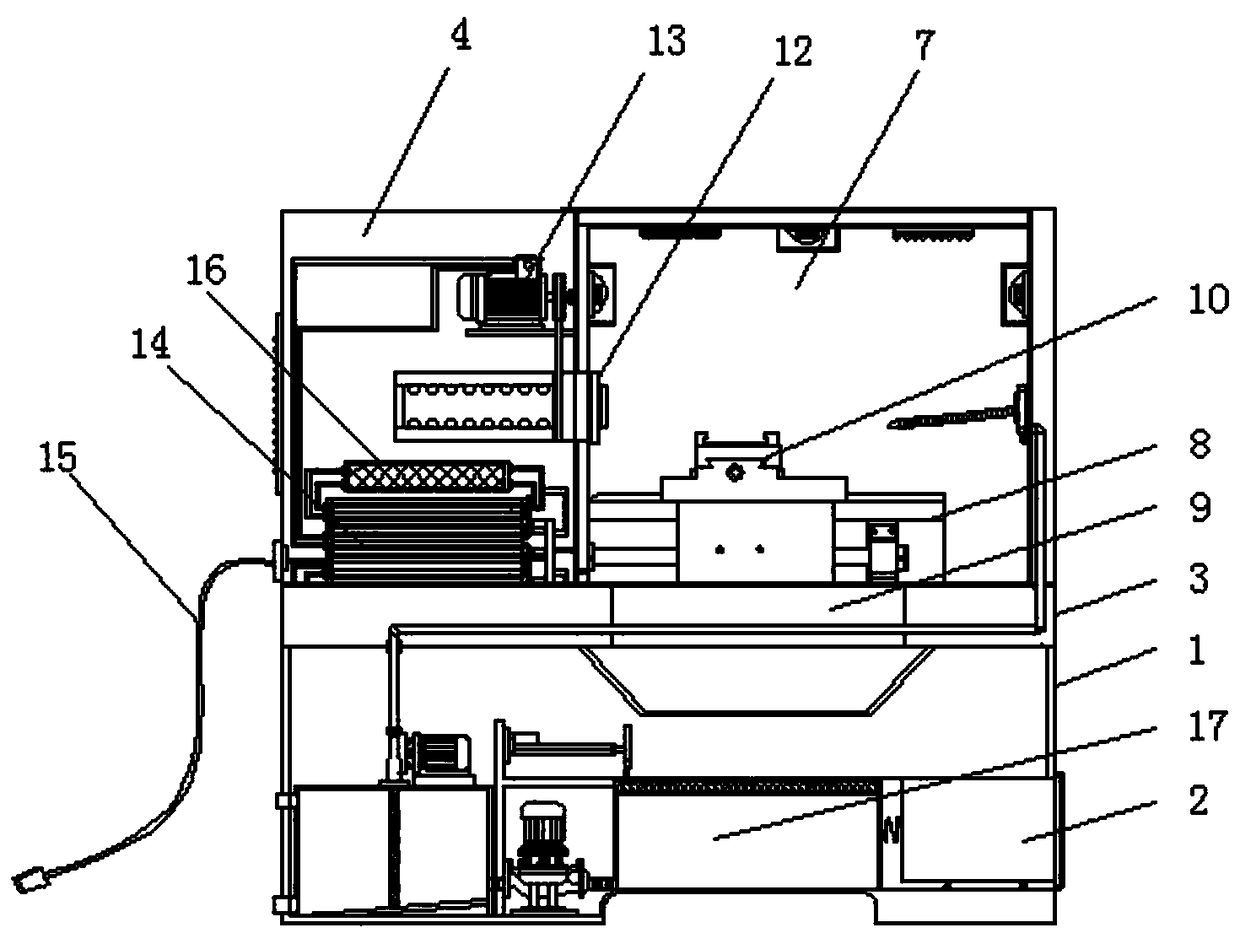

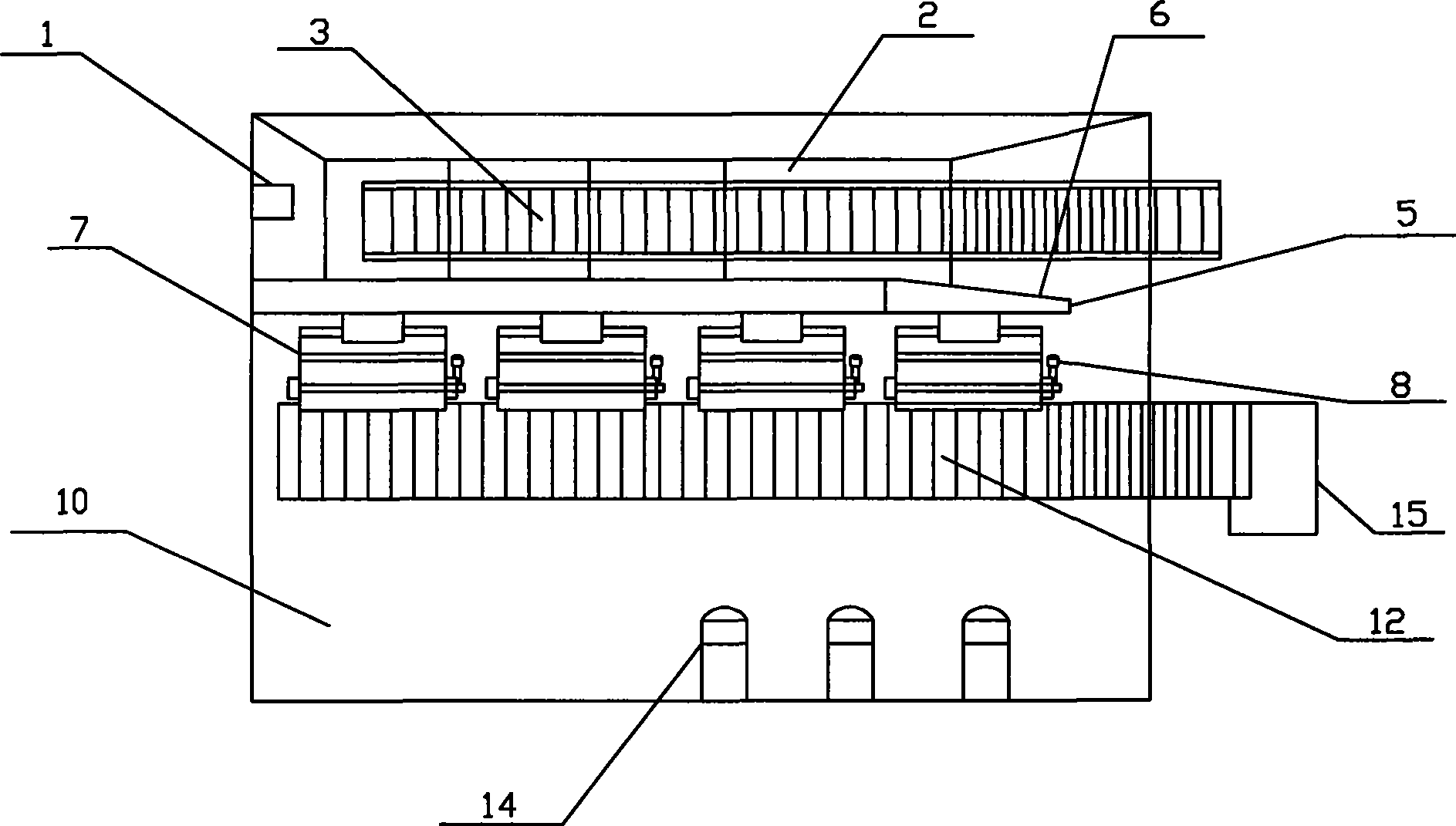

Automatic slurry deferrization machine

InactiveCN1883813AEasy to replaceEasy to trainMagnetic separationWet separationElectricityIron removal

The invention relates to an automatic slurry iron-removing machine, formed primarily from a slurry tank for removing iron dust in slurry; a cleaning tank for cleaning iron dust; an iron support assembly primarily comprising a top plate, a bottom plate, and two double-sided side plates; a group of permanent magnet iron rod fixed and connected to upper and lower lifting device; a group of magnetic rod sleeve fixed and connected to bottom plate for absorbing iron dust with permanent magnet iron rod; a sliding device for actuating the iron support assembly to slide between the slurry tank and cleaning tank; a lifting device for actuating the iron support assembly to move up and down; and a lifting device for actuating a group of permanent magnet iron rod to lift in magnetic rod sleeve. The advantage effect lies in : 1. compared to electric iron removal process, the slurry can not be polluted by cleaning water and cleaning is convenient; 2. permanent magnet iron can be replaced conveniently according to flow rate of slurry; 3. compared to conventional electric iron removal process, the cost of electricity is very low; 4. cleaned water can be reused after precipitation.

Owner:杭州威呢斯陶瓷有限公司

Domestic sewage denitrifying-dephosphorizing method and apparatus

InactiveCN1709810AStrong resistance to shock loadsHigh removal rateWaste based fuelMultistage water/sewage treatmentSettling basinNitrobacter

One kind method and equipment for life sewage's denitrogenation and dephosphorization belongs to the water treatment domain. The method is that the sewage through obligate baffle reactor obligate sludge layer, spreads the phosphorus on the iron filings padding layer, remove the organic pollutant microorganism in obligate way, the not transformed organic pollutant is degraded in aerobic sunk-style biofilter biomembrane, the ammonia nitrogen transforms to nitrate nitrogen, then is removed again in obligate region by biomembrane counter- nitrobacter, again passes through the precipitation then discharges. The installment is made up of obligate baffle reactor mutually linking and in turn, the aerobic sunk-style biofilter and settling basin. The obligate baffle reactor compose of 3 - 4 baffle in, the partition board, obligate sludge separate room , 1st traverse has the iron filings padding layer, has counter- tube, in the aerobic sunk-style biofilter has the padding layer.

Owner:HUBEI UNIV

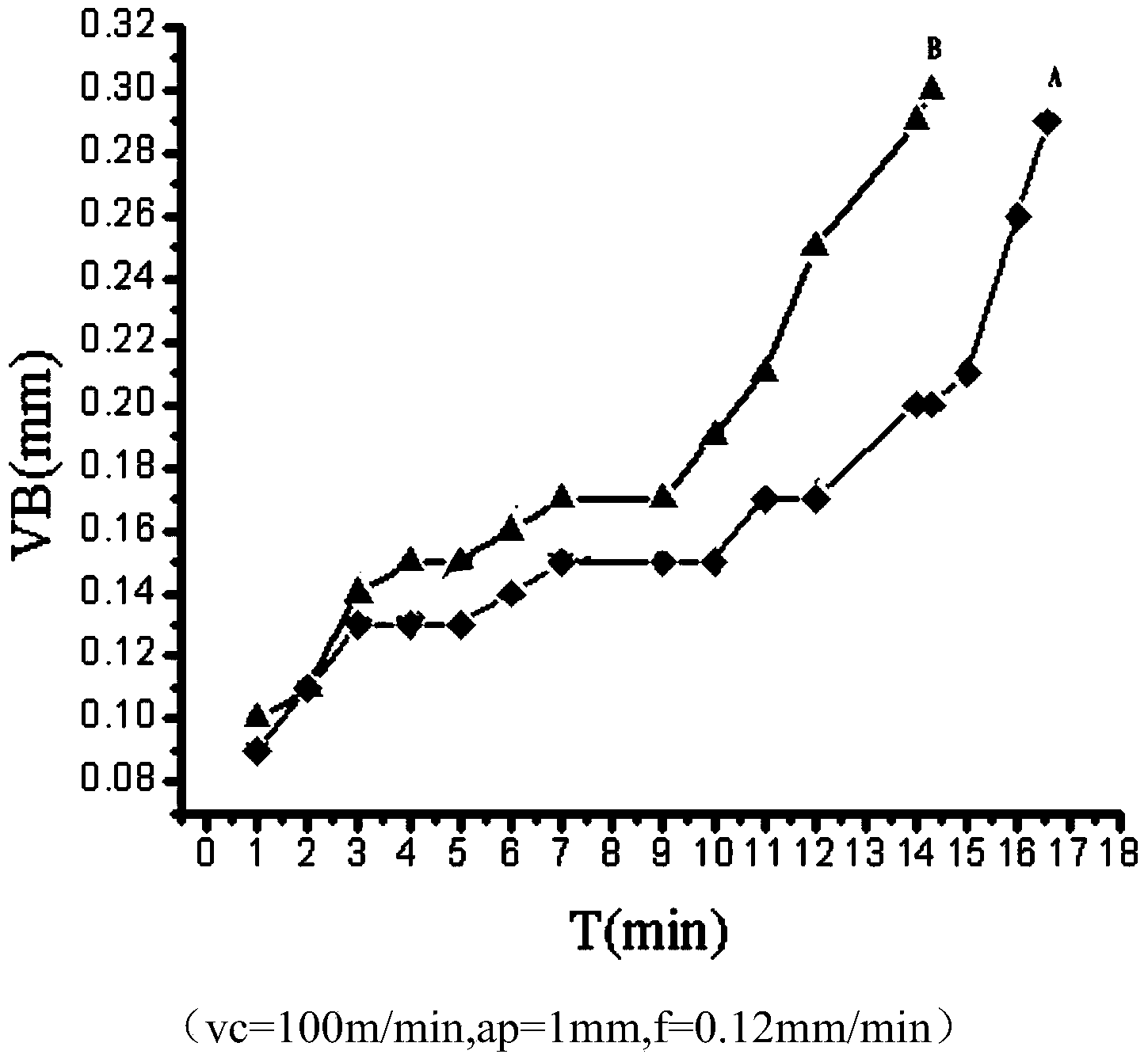

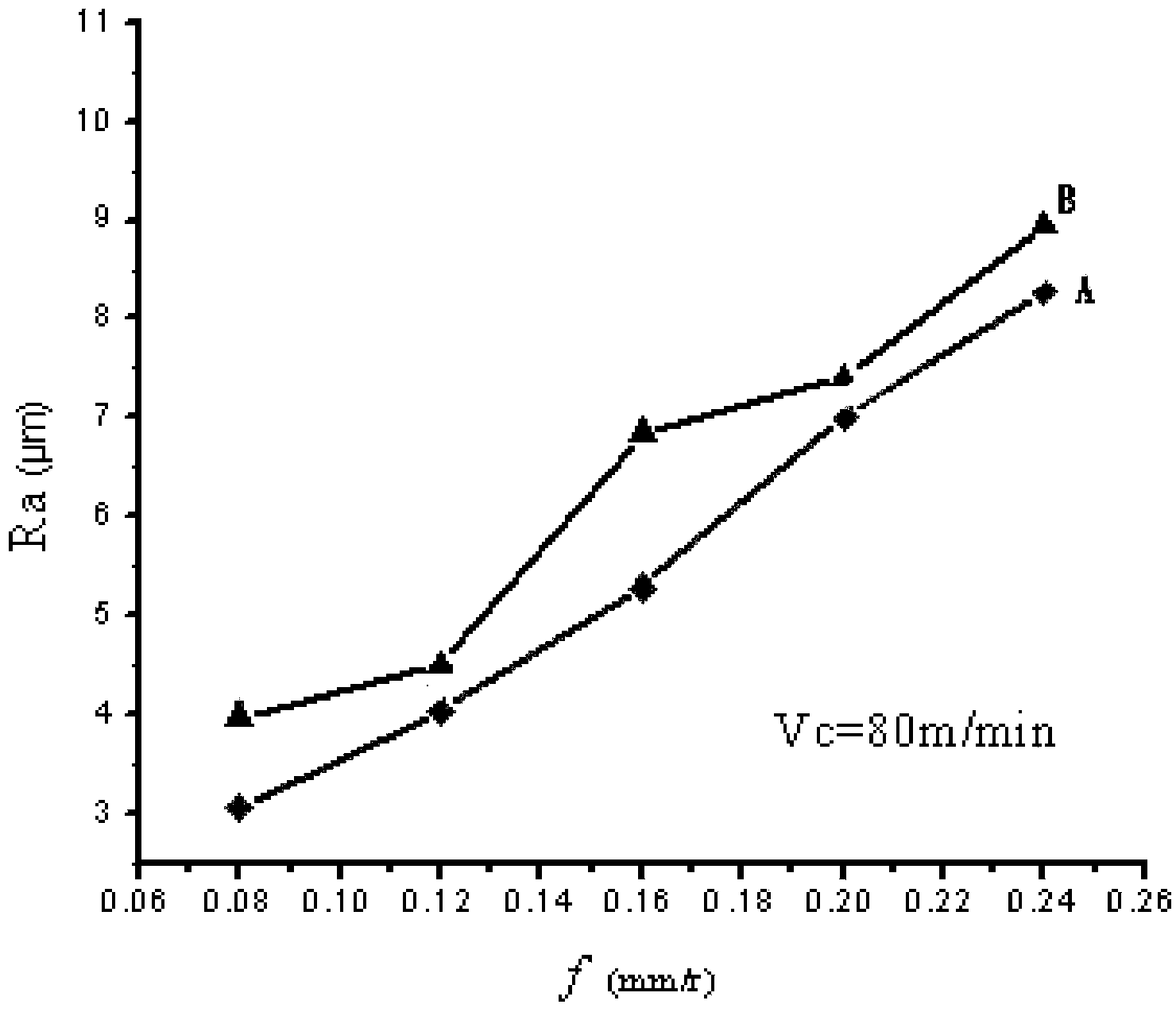

Totally-synthesized water-based stainless steel cutting liquid, and preparation method and using method thereof

ActiveCN103865622AGood instant solubilityEasy to cleanLubricant compositionWater basedPolyethylene glycol

The invention discloses a totally-synthesized water-based stainless steel cutting liquid. The cutting liquid contains the following components: a stainless steel water-based extreme-pressure agent, caprylic-capric acid, boric acid triethanolamine ester, polyethylene glycol, a cation quaternary ammonium salt metal filings settling agent, a dicarboxylic compound antirusting agent, a monobutyl ether coupling agent, a hard-water-resisting agent, a defoamer and distilled water. By virtue of an environmental-friendly total-synthesis formula, the cleaning and settling properties of the cutting liquid are enhanced; an environmental-friendly special water-based extreme-pressure lubricant is used to substitute for the traditional synthetic ester, thereby ensuring the long-time stability of the cleaning and settling properties of the cutting liquid. The cutting liquid plays a very good role in protecting non-ferrous metal and ferrous metal; by virtue of the cation quaternary ammonium salt settling agent, the problem of iron filings settling during the processing of stainless steel is eliminated, and the transparency and stability of the cutting liquid in long-time use are guaranteed.

Owner:苏州安美润滑科技有限公司

Method for smelting chromated-nickel-containing molten iron by stainless steel dedusting ash and iron scale companion material

ActiveCN101654738AMeet production needsLow process costBlast furnace detailsShaft furnaceSodium BentoniteSlag

The invention relates to a method for smelting chromated-nickel-containing molten iron by stainless steel dedusting ash and iron scale companion material, which comprises the steps of mixing, briquetting, dosing, smelting and producing the molten iron; wherein (1) mixing: evenly mixing the dedusting ash, bentonite, cement, solvent, iron scale or scrap iron and water; (2) briquetting: putting the mixed material into a briquetting machine to be briquetted; (3) dosing: 60-80 parts by weight of block mass, 30-50 parts by weight of coke and 3-12 parts by weight of solvent; or 60-80 parts by weightof block mass, 30-50 parts by weight of coke, 3-12 parts by weight of solvent and 6-20 parts by weight of slag-metal; (4) smelting: adding the prepared raw materials into a novel shaft furnace or a minitype blast furnace provided with a single iron notch and a single air inlet to be smelted; and (5) producing the molten iron: sending the smelted molten iron into steel plants or casting into iron ingots. Or in step (3), 6-20 parts by weight of slag-metal can be added into the material. The smelting method is low in production cost and high in content of chromium and nickel of the product.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

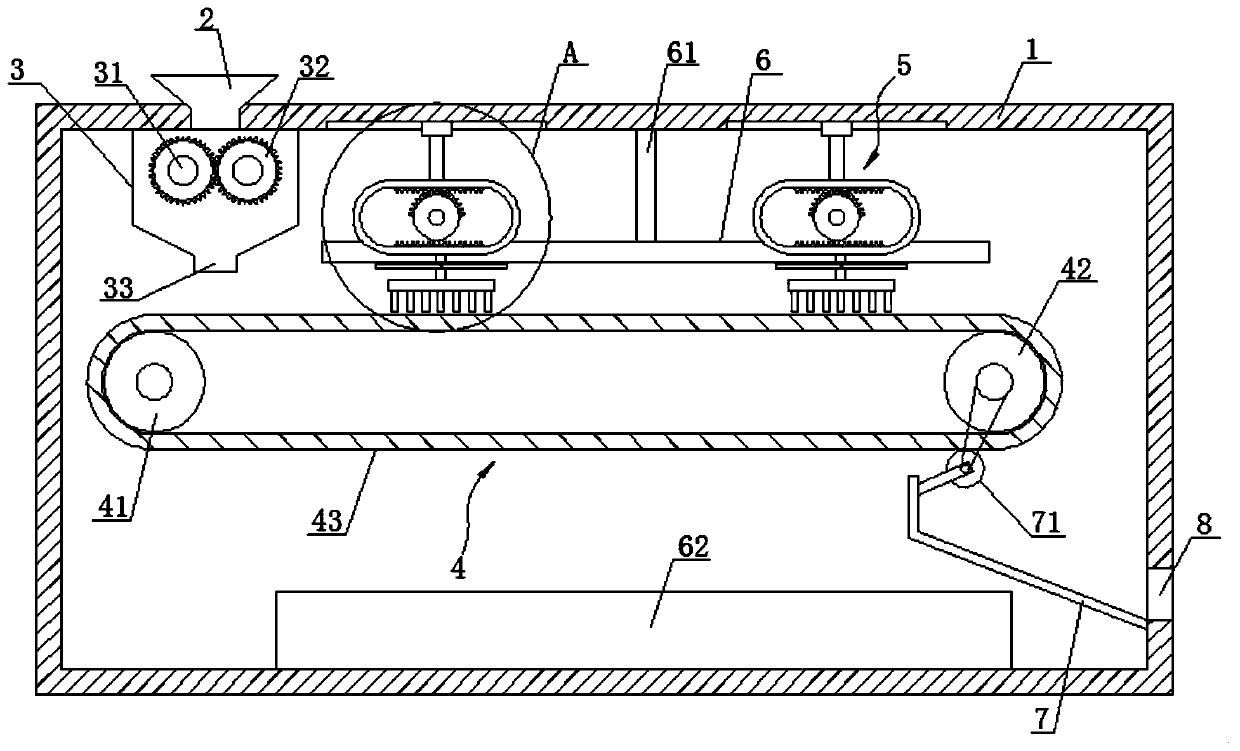

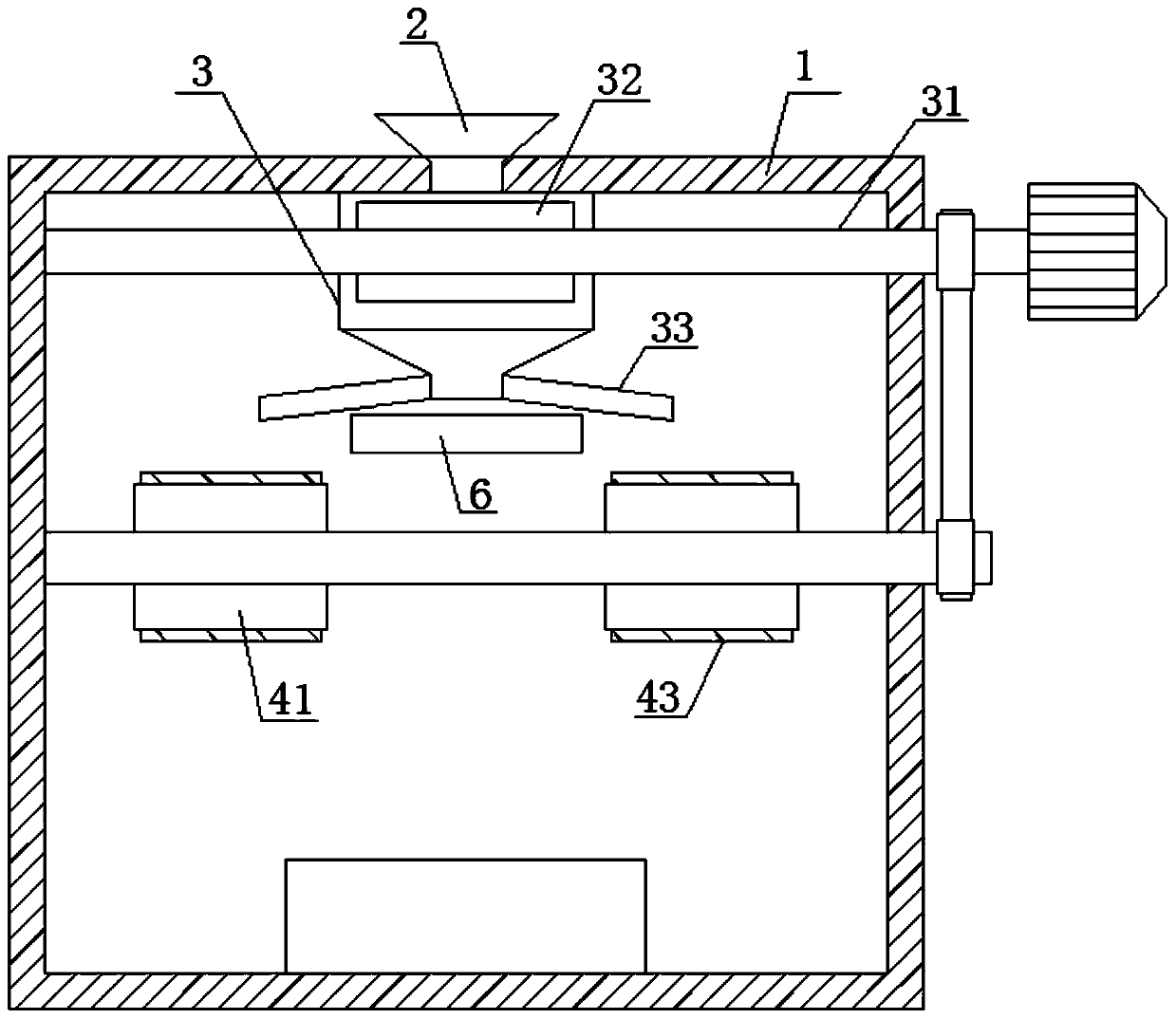

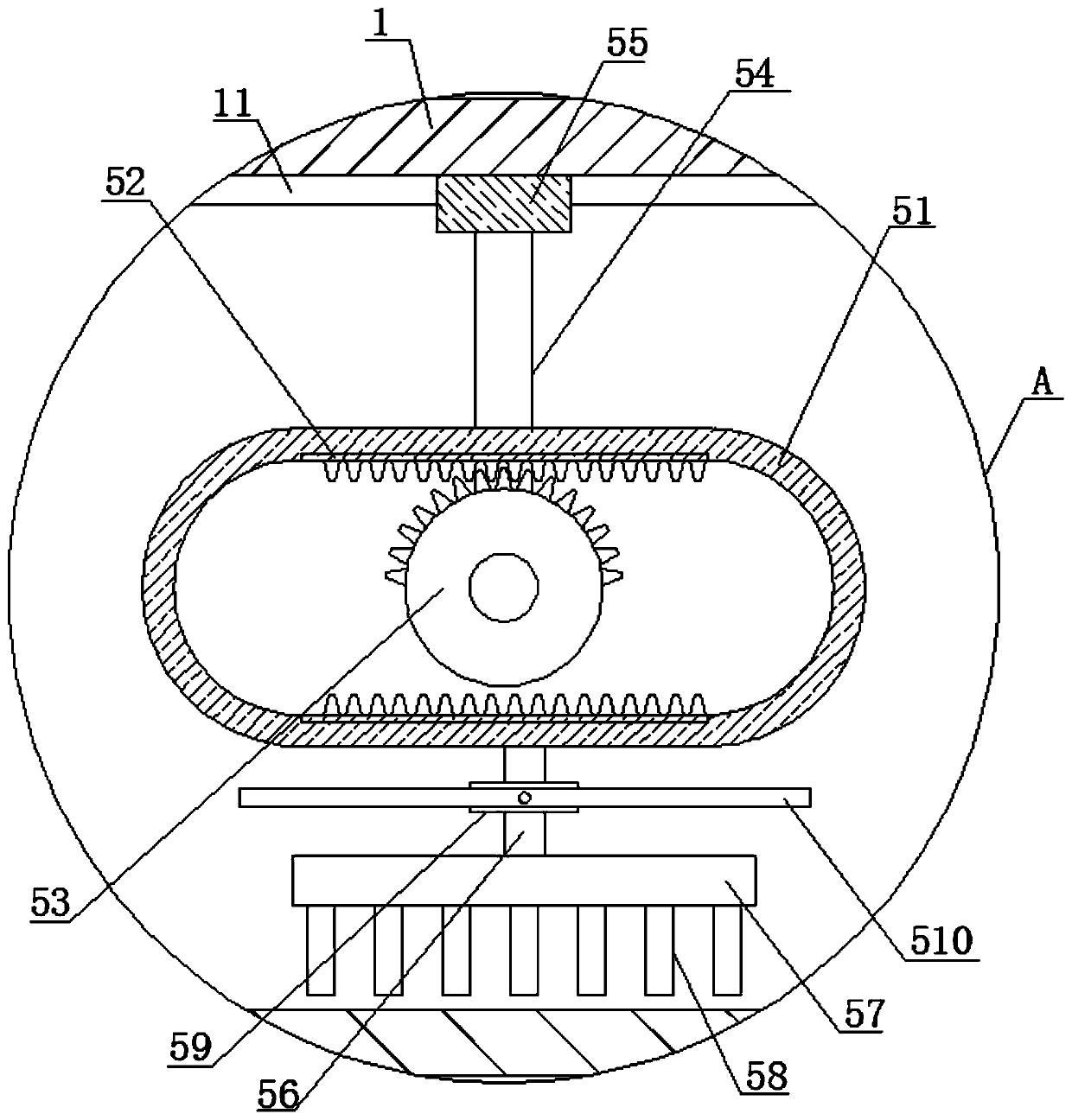

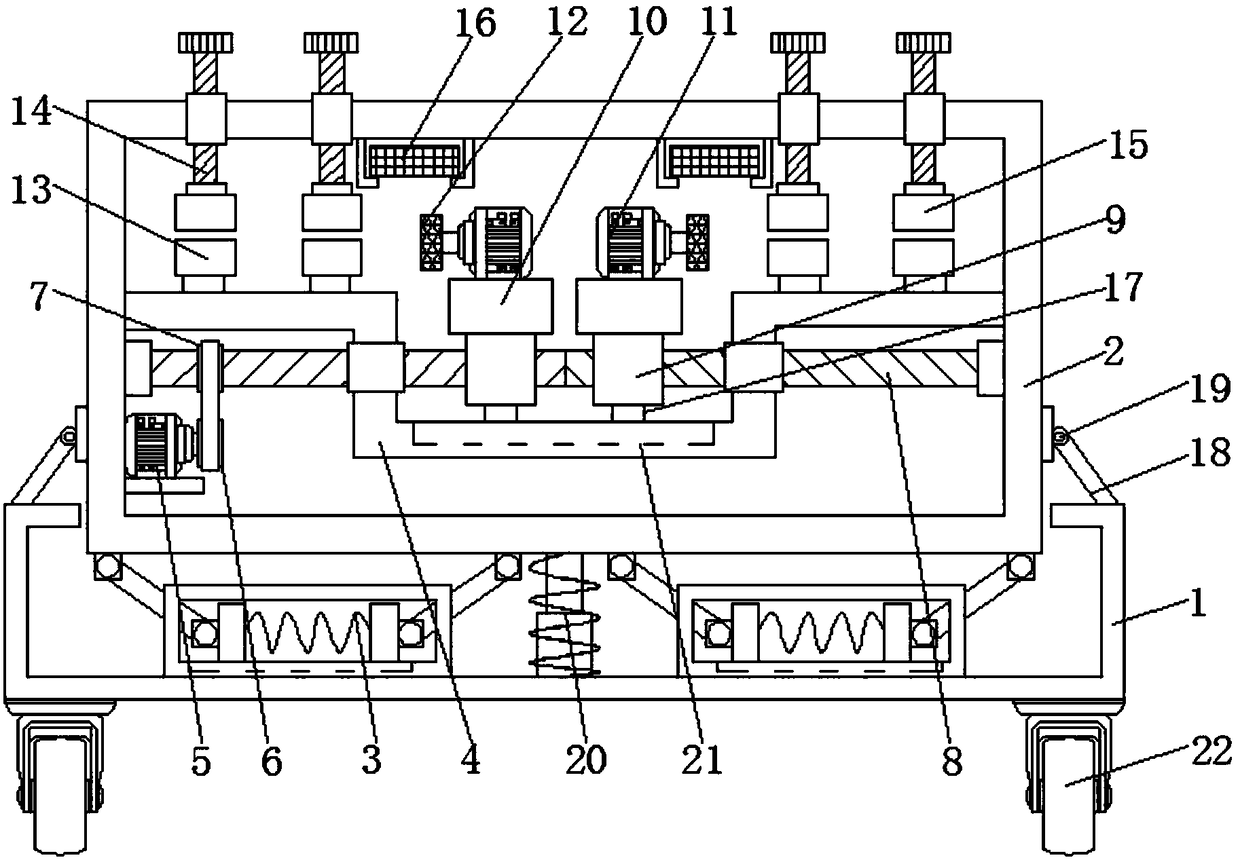

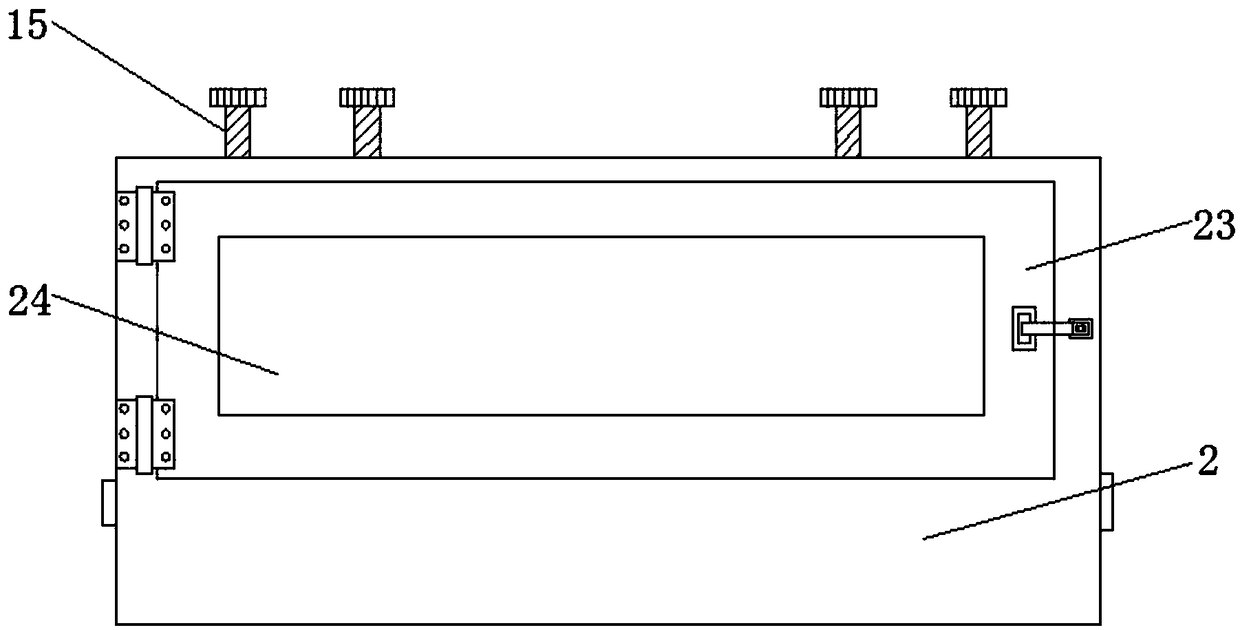

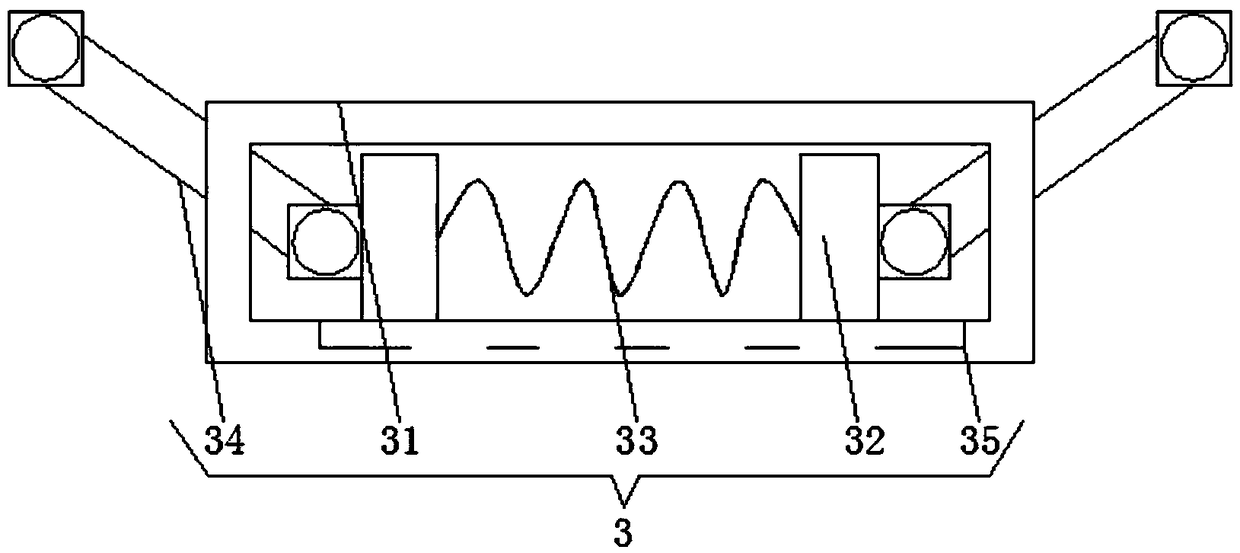

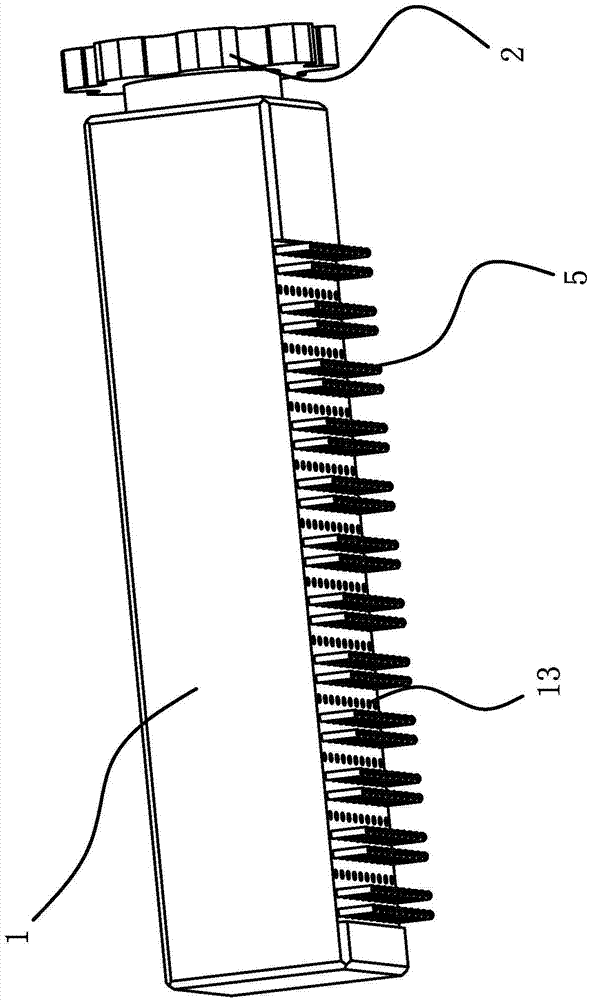

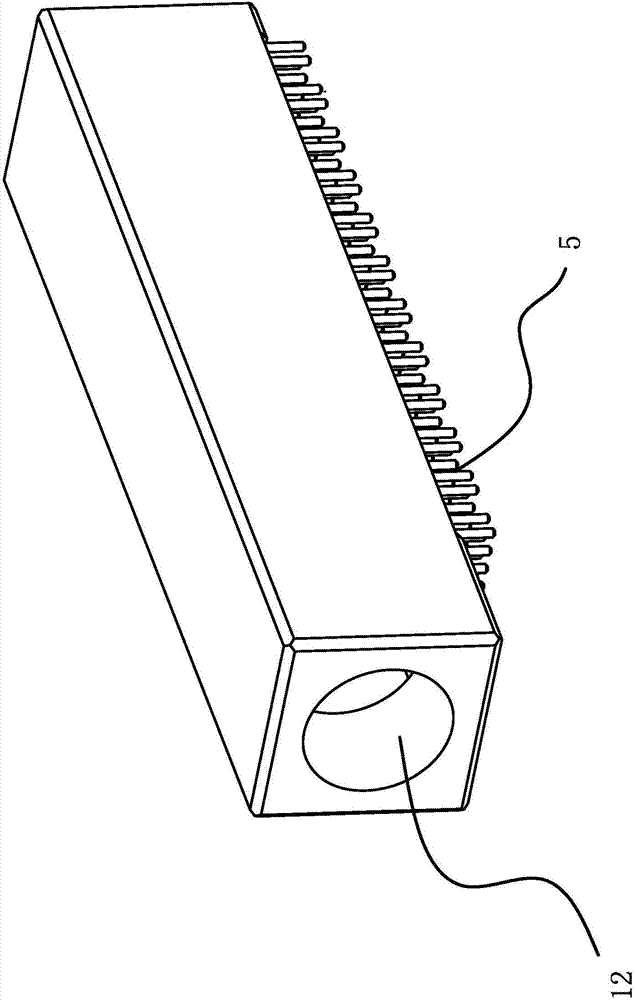

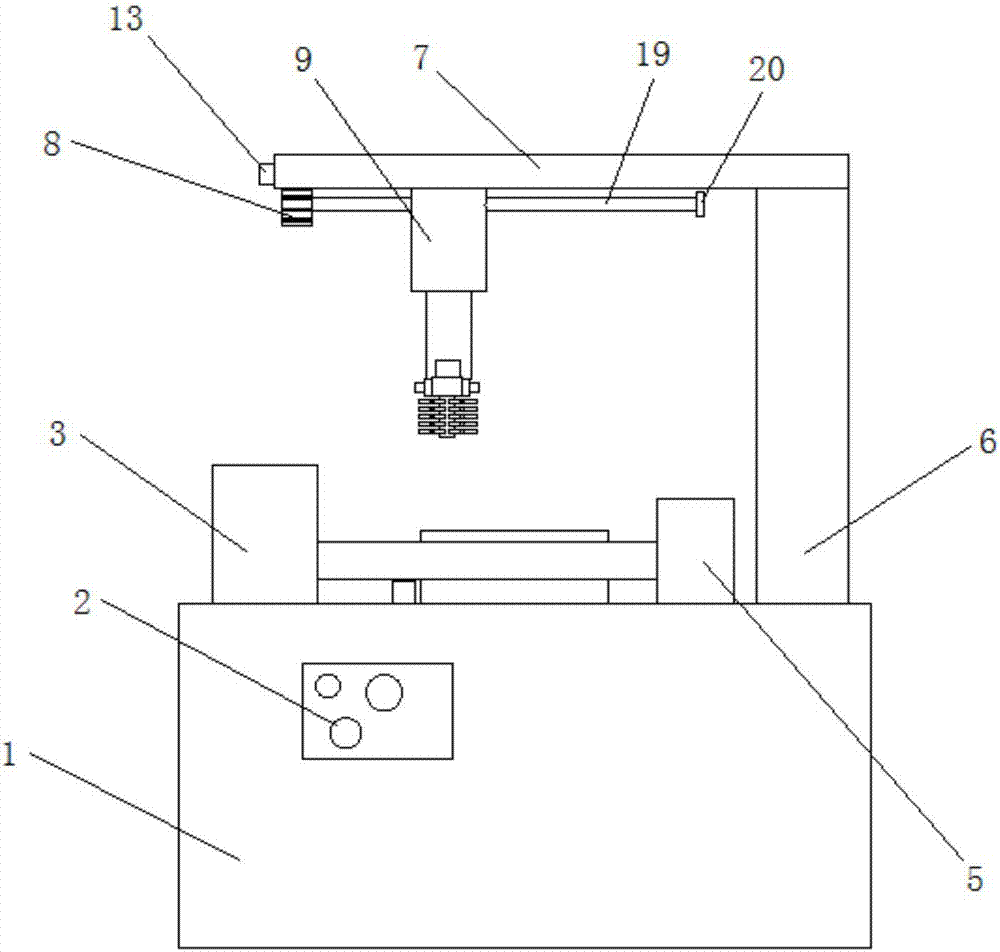

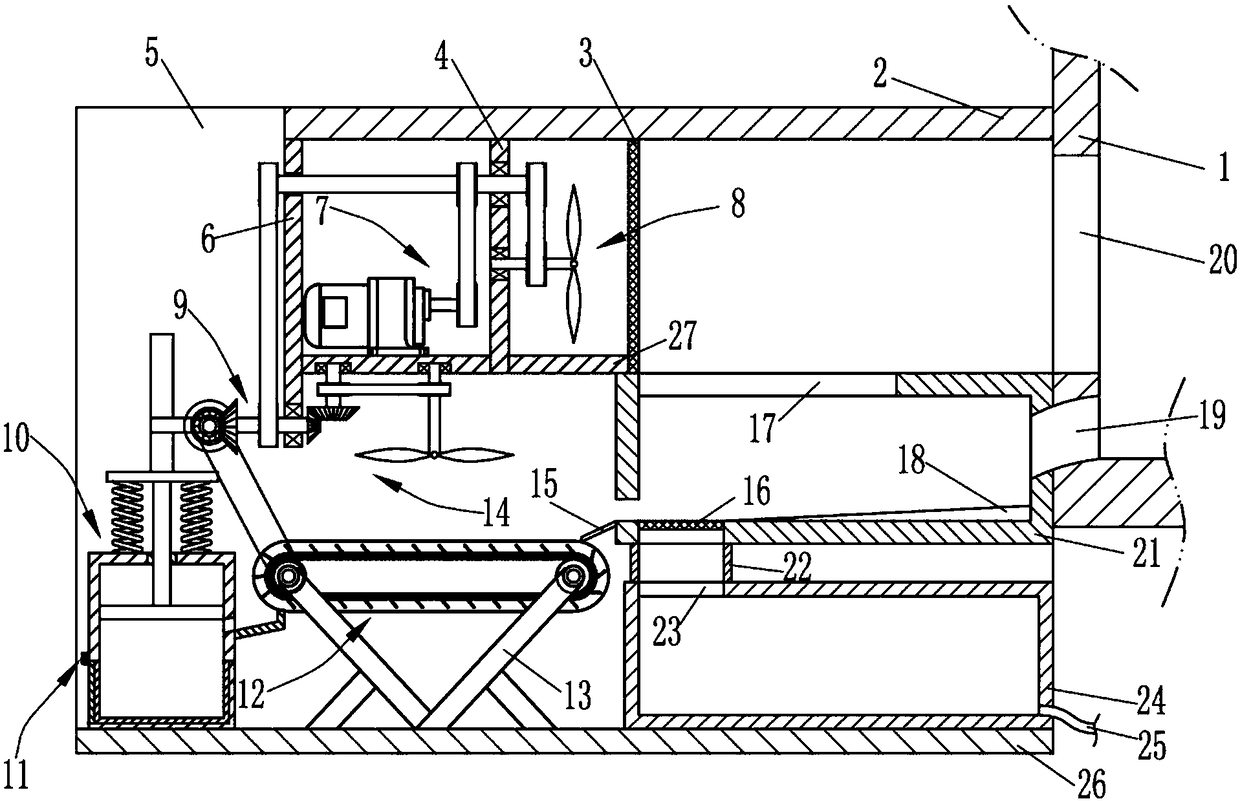

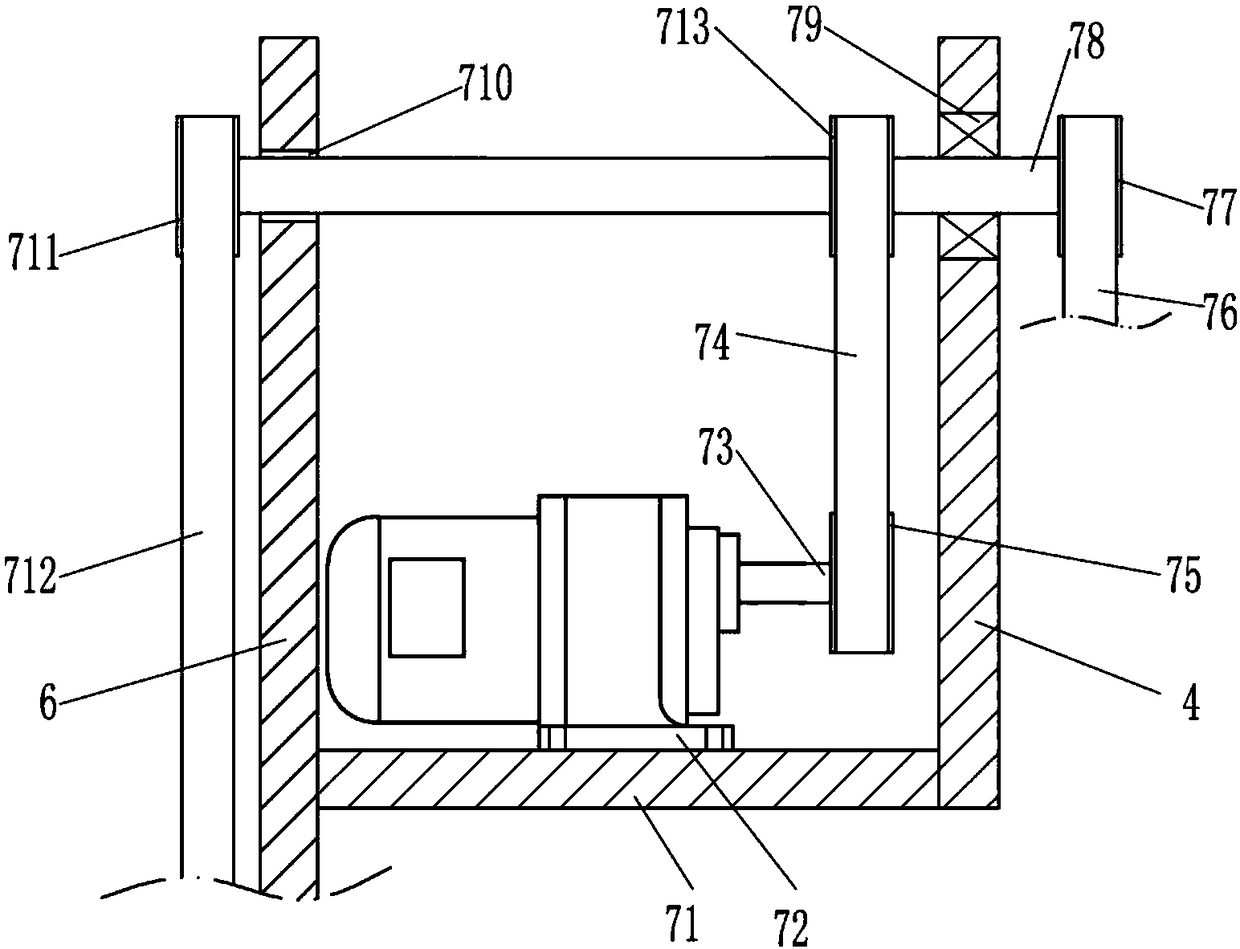

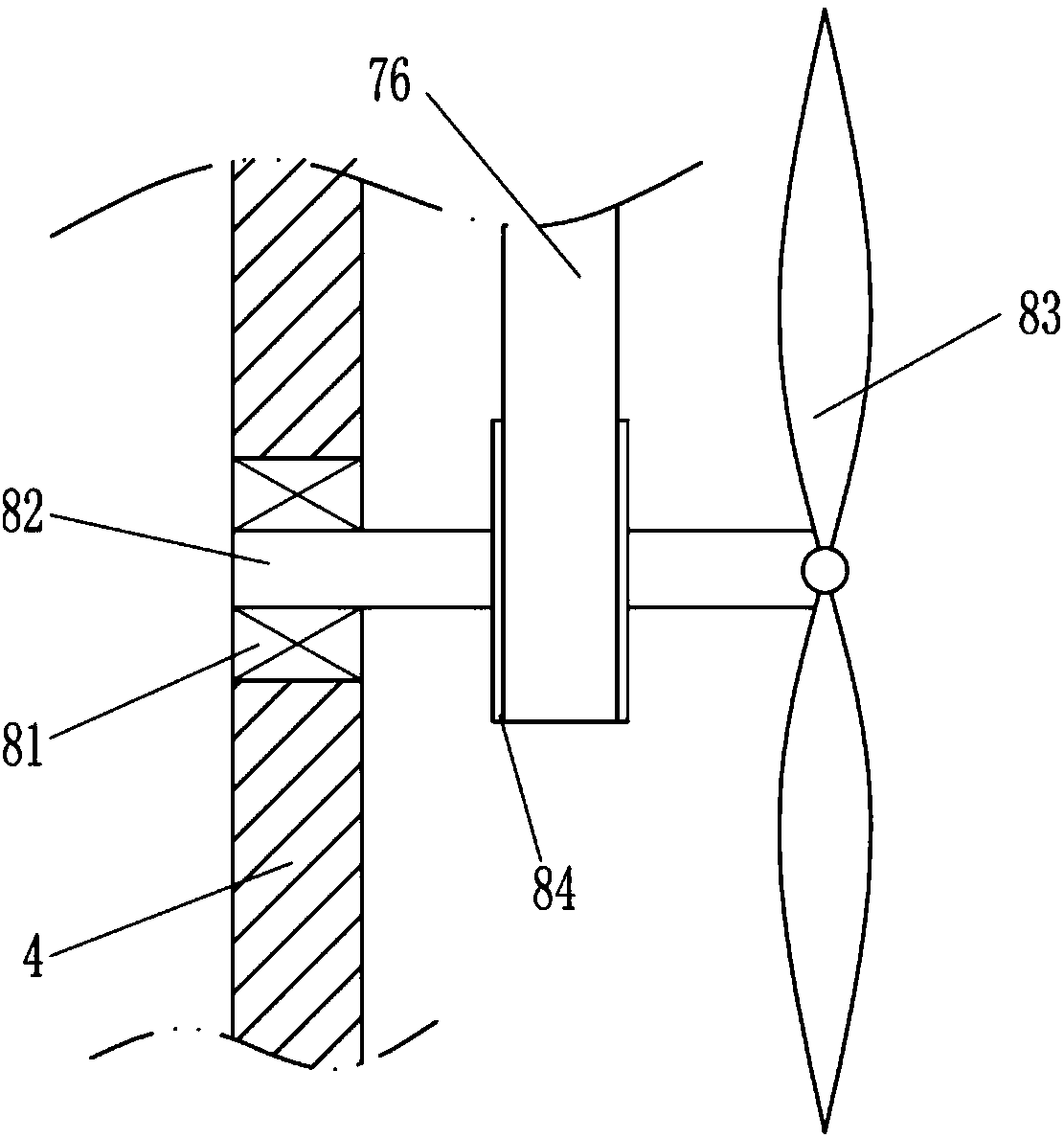

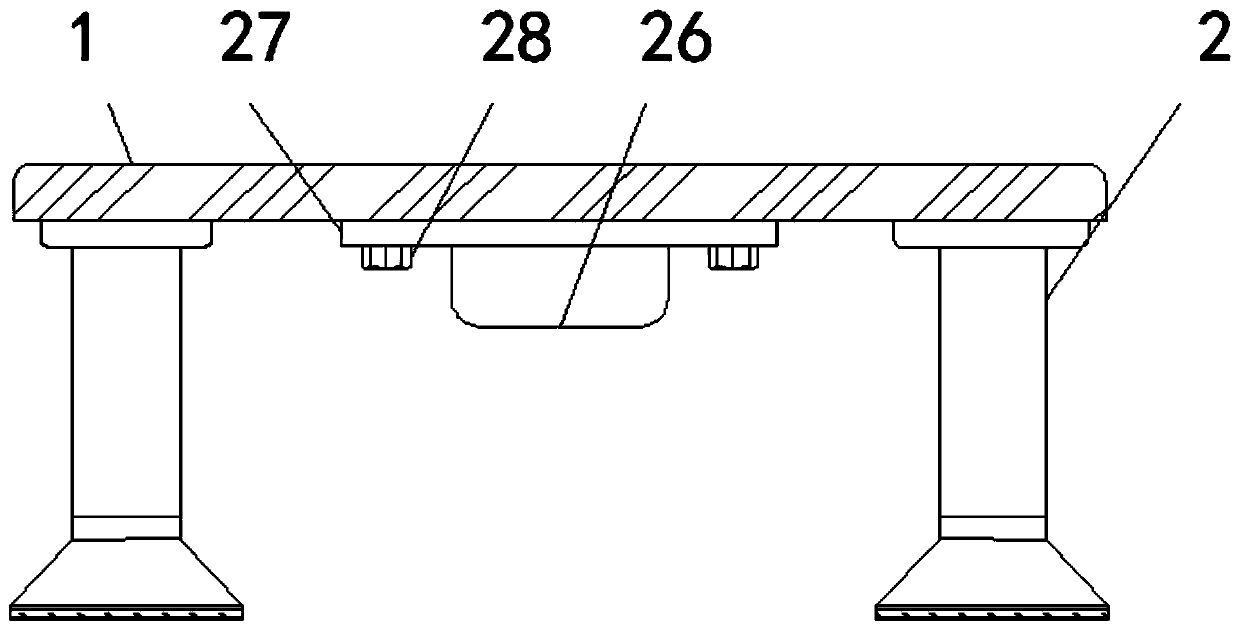

Full-automatic continuous feeding iron removing machine

The invention relates to a full automatic continuous feeding iron removing machine, and belongs to the magnetic separation field of the separation of solid materials from fluid body. The full automatic continuous feeding iron removing machine comprises a machine frame, a feeding hopper, a material falling opening, iron discharging openings, and a magnetic bar group, connecting plates are respectively arranged at the both ends of the magnetic bar group, and the end part of each magnetic bar is fixed on the connecting plates. The invention is characterized in that a scraper plate is suited on the magnetic bar group, the scraper plate is connected with a moveable controlling device, the iron discharging openings are arranged at the both ends of the magnetic bar group, the material falling opening is arranged at the lower part of the magnetic bar group and positioned between two iron discharging openings. Because the invention adopts the rotatable magnetic bar group, when materials are fallen, fine material can fully contact with magnetic bars, and the iron removing effect is greatly improved; because of adopting the scraper plate which can move along the magnetic bars, iron chips on the magnetic bars can be eliminated in time; because the iron discharging openings and corresponding iron discharging structures are evenly arranged at the both ends of the magnetic bar group, the bidirectional iron removing effect when the machine is not stalled is achieved. The invention realizes the full automatic continuous iron removing process, the iron removing effect is increased, without being manual, and the invention is suitable for industries of building material, and chemical industry, etc.

Owner:山东润科机电设备有限公司

Composite additive for spraying coal into blast furnace

InactiveCN101935572AImprove combustion performanceIncrease burn rateSolid fuelsBlast furnace detailsRare earthManganese oxide

The invention discloses a composite additive for spraying coal into a blast furnace, which comprises the following components in percentage by weight: 5-15 percent of iron ore powder, 15-35 percent of blast furnace dust, 10-30 percent of iron oxide scraps, 5-15 percent of steelmaking bulk stock dust, 5-20 percent of calcium oxide, 15-35 percent of calcium peroxide, 3-8 percent of manganese oxide and 1-5 percent of rare-earth metal oxide. The invention can effectively improve the combustion performance of coal power sprayed into the blast furnace and the combustion rate of the coal powder at an air opening and reduce unburnt coal power content, has the advantages of simple and convenient production process and adding way, easy acquisition of raw materials, low cost and recycling of beneficial components, basically does not change the traditional equipment and changes waste materials into things of value, and more than 50 percent of components are by-products in metallurgic production.

Owner:CHONGQING UNIV

Decorative metal powder paint

InactiveCN103509447AImprove the decorative effectGood weather resistancePowdery paintsPolyester coatingsSodium PyrithioneSulfonate

A disclosed decorative metal powder paint is composed of the following raw materials in parts by weight: 70 parts of 196 unsaturated polyester resin, 12 parts of high-density polyethylene, 3 parts of polybenzimidazoles, 5 parts of quartz sand, 18 parts of triglycidyl isocyanurate, 0.7 part of zinc pyrithione, 3 parts of dibutyltin dilaurate, 2.5 parts of petroleum sodium sulfonate, 2 parts of pentaerythritol, 0.6 part of silver powder, 3 parts of waste iron filings, 1 parts of zinc powder and 20 parts of a composite filling material. The powder paint of the invention is painted in one time for film forming, is low in construction cost, good in decorative effect and good in weatherability, and is especially applicable outdoors.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Intelligent device for garbage classification

InactiveCN110465360AImprove adsorption efficiencyImprove adsorption capacityMagnetic separationGrain treatmentsDrive motorEngineering

The invention relates to the technical field of garbage classification, in particular to an intelligent device for garbage classification. Two ends of a first rotating rod are rotationally connected to the inner side wall of a box body, one end of the first rotating rod passes through the box body to reach the outside of the box body and is connected with a driving motor arranged on the outer wallof the box body. Construction garbage is crushed into small-particle waste by a crushing roller, and the small-particle waste is flatly paved on a traveling conveyor belt without generating stacking.The electromagnet is electrified to generate magnetic adsorption of iron filings, iron blocks and other iron products located in the waste materials. In addition, when the waste materials walking ona conveying belt pass through a stirring device, the missing-gears alternately mesh with two first straight racks, so that the frame reciprocates along the running direction of the conveying belt, thewaste materials at the bottom are turned over, and the electromagnet is convenient to absorb the iron products at the bottom, thus improving the adsorption efficiency of the electromagnet. Accordingto the intelligent device for garbage classification, all devices needing rotation is realized through a driving motor, energy is saved, emission is reduced, cost is low and efficiency is high.

Owner:谢静如

Treatment of metal-contaminated leachates utilizing fish bones and fish hard parts

InactiveUS6217775B1Solid sorbent liquid separationWater/sewage treatment by ion-exchangeWaste streamEarth surface

The present invention uses fish bones and fish hard parts to remediate, clean-up, stabilize, immobilize, or otherwise treat metal-contaminated water, soil or waste of any sort. The fish bones and fish hard parts can be mixed in with soils and wastes, or emplaced as a permeable reactive barrier in a trench or excavation, or emplaced as a liner or barrier surrounding a waste form, disposal site, or contaminated site. All that is needed is intimate contact between the fish bones and fish hard parts and the contaminated waste form, soil particles, or water. In a system of, for example, soil, waste, groundwater, surface water, waste streams, or the digestive tracts of animals, the presence of fish bones and fish hard parts reduces the amount of metal that can mobilize and migrate out of the system. Fish bones and fish hard parts remove metals from waters passing through the system or originating within the system. Fish bones and fish hard parts reduce the bioavailability of metals to organisms coming into contact with the system and from water leaving the system. The fish bones and fish hard parts can be mixed with any other material, e.g., gravel, sand, clay, zeolites, soils of all types, iron filings, cement, compost, straw, or organics of all types.

Owner:PIMS NW

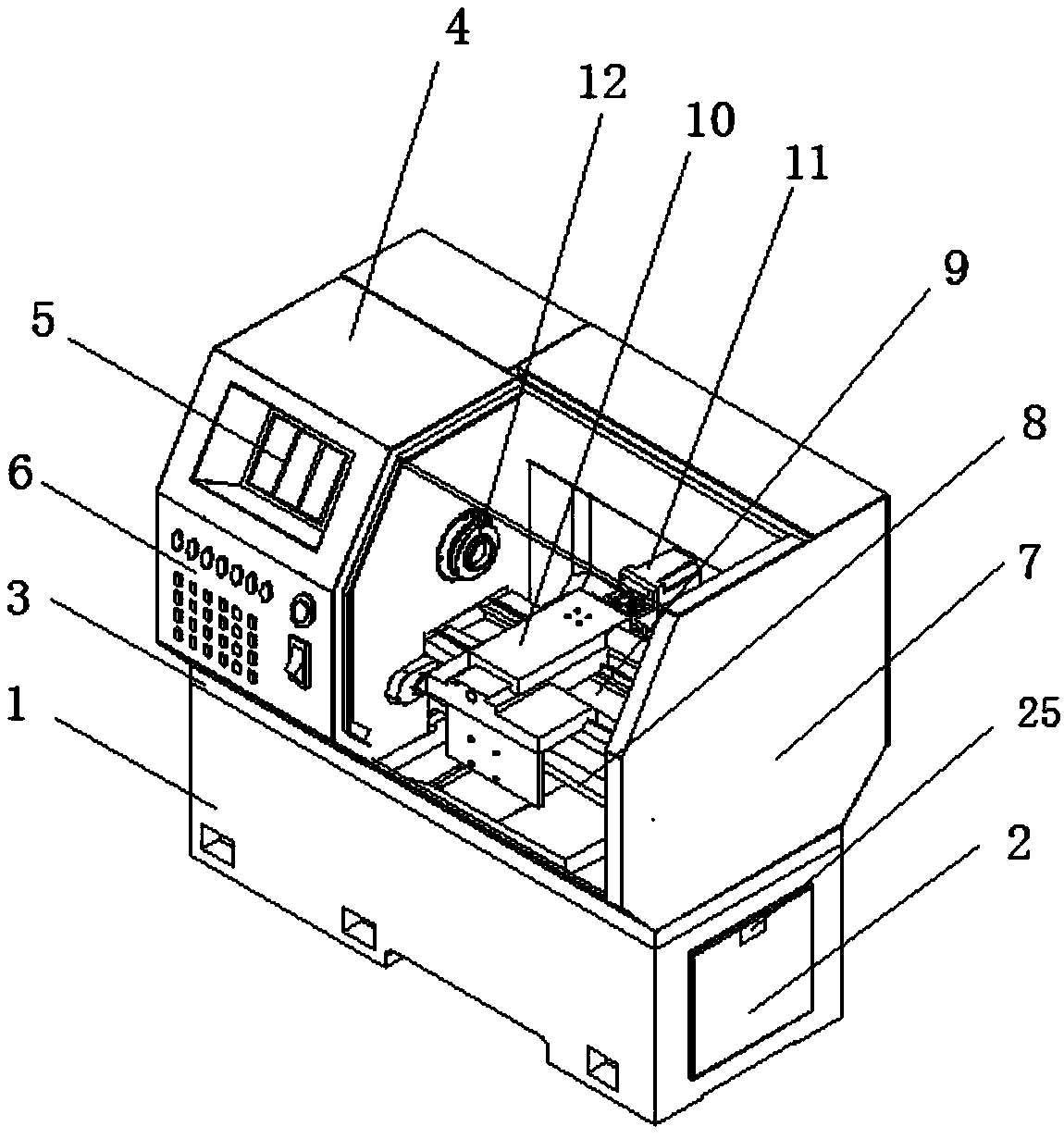

Numerical control lathe capable of recycling cutting fluid

ActiveCN109454494AAccurate collectionWon't scatterMaintainance and safety accessoriesNumerical controlMicrocomputer

The invention discloses a numerical control lathe capable of recycling cutting fluid. The numerical control lathe comprises a bottom box, a display screen, a processing chamber, a workbench, a first motor, a cutting fluid recycling device, a first camera, a second camera, a third camera and a light, wherein a waste box is arranged at the right end of the bottom box; a connection seat is welded tothe upper end of the bottom box; the cutting fluid is collected by a recycling tank through the filtration of a first filter screen; at the same time, iron filings are pushed into the waste box by a pushing mechanism so that the cutting fluid cannot be wasted and the iron filings cannot be scattered and can be convenient to remove subsequently; the collected cutting fluid is pumped into a liquid collecting tank by a first liquid suction pump through a second filter screen and is pumped by a second liquid suction pump to be conveyed to a hydrojet pipe to spray, so that after recycling, the effect of reusing is achieved; the first camera, the second camera and the third camera monitor processing conditions in a processing chamber in real time; and after being processed by a single chip microcomputer, the processing conditions are displayed on the display screen so that the worker can observe the processing conditions in real time.

Owner:SUZHOU CHANGHENG PRECISION METAL DIE CASTING

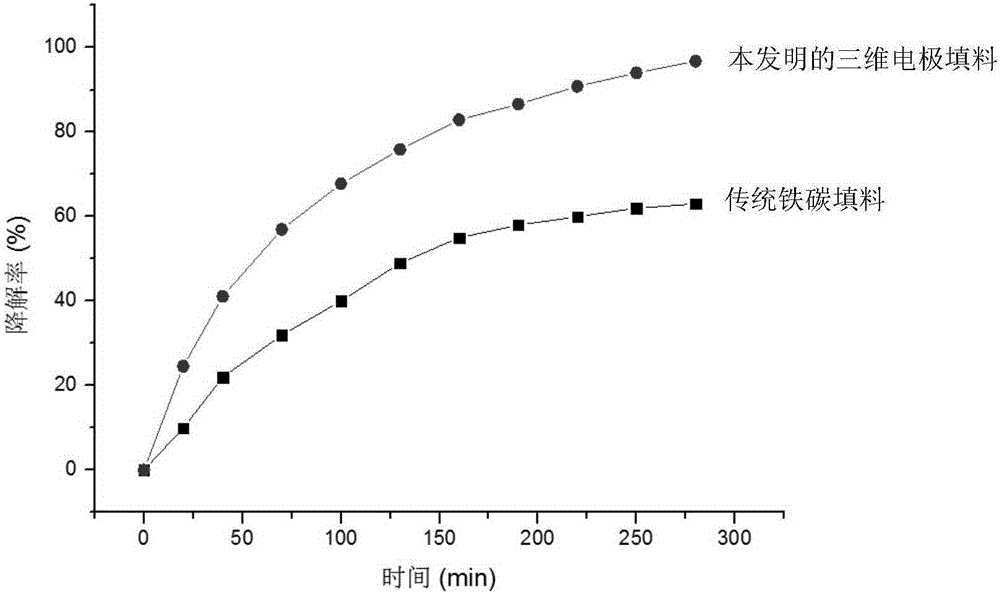

Three-dimensional electrode filling material and preparation method thereof

ActiveCN105198048AImprove ductilityExtended service lifeWater contaminantsWater/sewage treatmentCopper platingOxygen

The invention discloses a three-dimensional electrode filling material and a preparation method thereof. The preparation method mainly comprises the following steps: subjecting iron filings to activation including oil removal and rust removal, copper plating and nickel plating so as to obtain improved iron filings; and uniformly mixing the improved iron filings obtained after nickel plating with powdery active carbon and mixed clay in proportion so as to prepare a granular filling material with a diameter of 5 to 10 mm, drying the granular filling material, sintering the granular filling material at 600 DEG C for 2 h under the condition of isolation of oxygen and then carrying out cooling so as to obtain the three-dimensional electrode filling material. The main characteristic of the three-dimensional electrode filling material is that the surfaces of the iron filings are plated with a stable nickel coating, which enables the service life of the iron-carbon filling material to be substantially prolonged. When the three-dimensional electrode filling material is used to treat waste water containing phenol, the degradation rate of phenol is more than 80%, and biodegradability of a water sample is greatly improved. When a recovered three-dimensional electrode filling material is repeatedly used, the degradation rate of phenol can also reach more than 60%, so waste water treatment cost is reduced.

Owner:ABA CHEM CORP

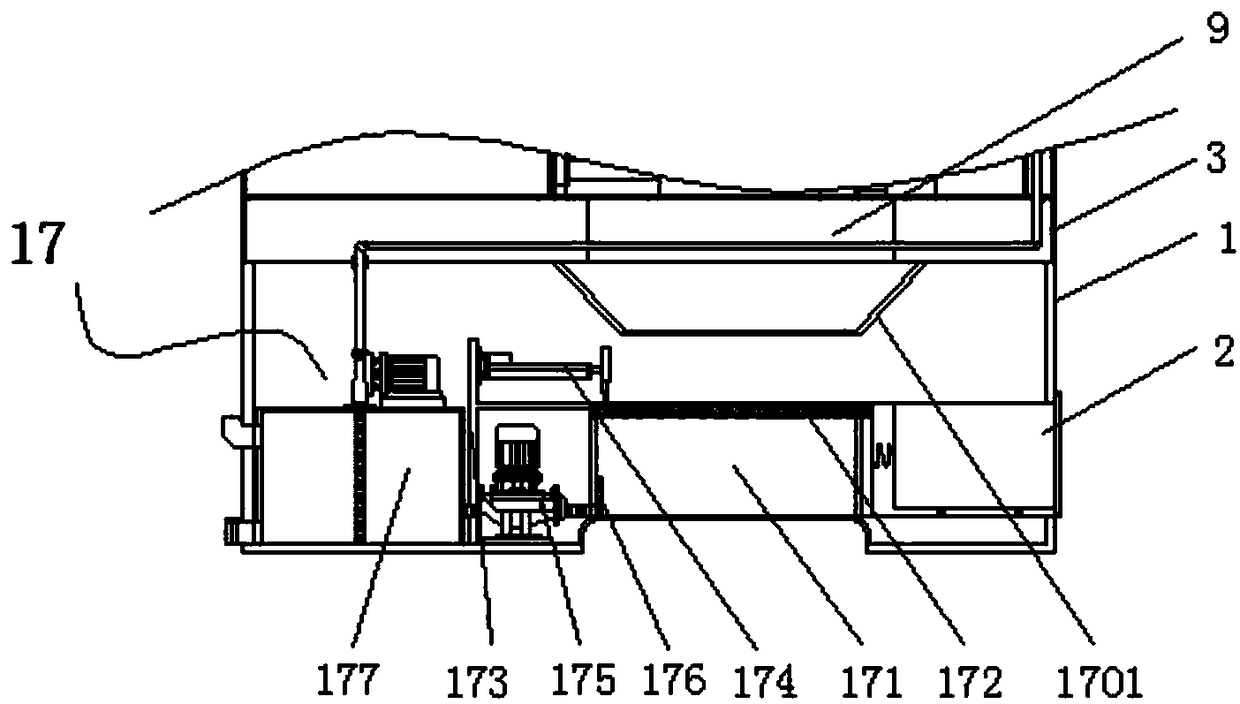

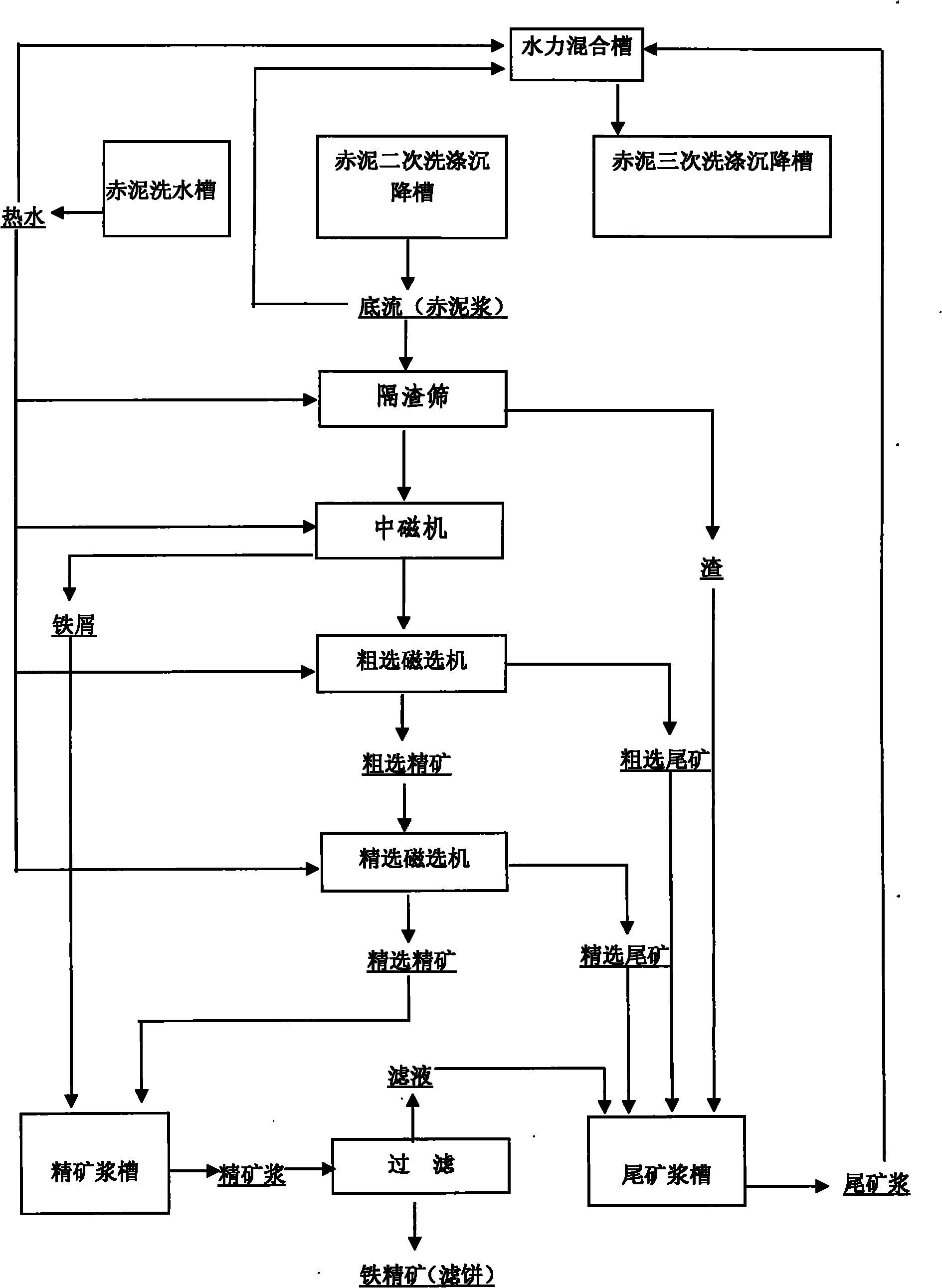

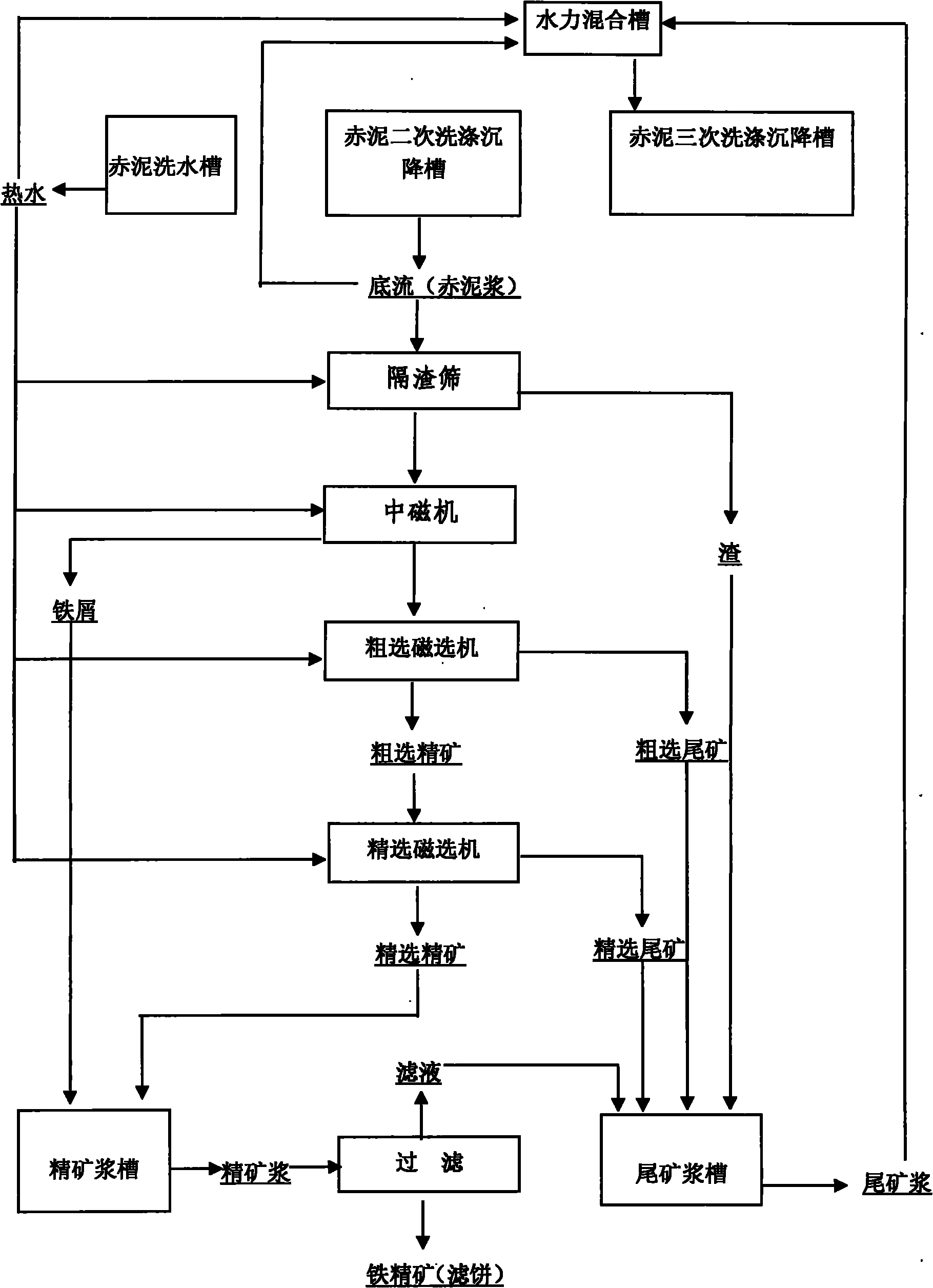

Method for magnetic separation of iron ore concentrate in red mud slurry in alumina production flow by Bayer process

ActiveCN101912814AReduce water use in magnetic separation processIncrease consumptionMagnetic separationWet separationSlagRed mud

The invention relates to a method for magnetic separation of iron ore concentrate in red mud slurry in an alumina production flow by a Bayer process. The method comprises the steps of: leading the red mud slurry to flow under a secondary cleaning subsider of red mud in alumina production; removing slag by a slag screen, and removing scrap iron by a medium magnetic machine; entering a two cascade stage magnetic separator and carrying out magnetic separation; putting the magnetically extracted ore concentrate and the scrap iron removed by the medium magnetic machine into an ore concentrate slurry tank; filtering and dehydrating the ore concentrate slurry to obtain an iron ore concentrate filter cake; adding the slag removed by the slag screen, gangues obtained by magnetic separation and filtered and dehydrated filter liquor of the ore concentrate slurry in a gangue slurry tank; and returning the gangue slurry in a water mixing tank in the cleaning process of alumina production to enter a third red mud cleaning subsider. The invention has the advantages that the cleaning water of the red mud in the alumina production is used as magnetic separation process water without consuming additional fresh water. The invention has the characteristics of simple process and low cost, and is especially suitable for processing ferric red mud in the production of alumina.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

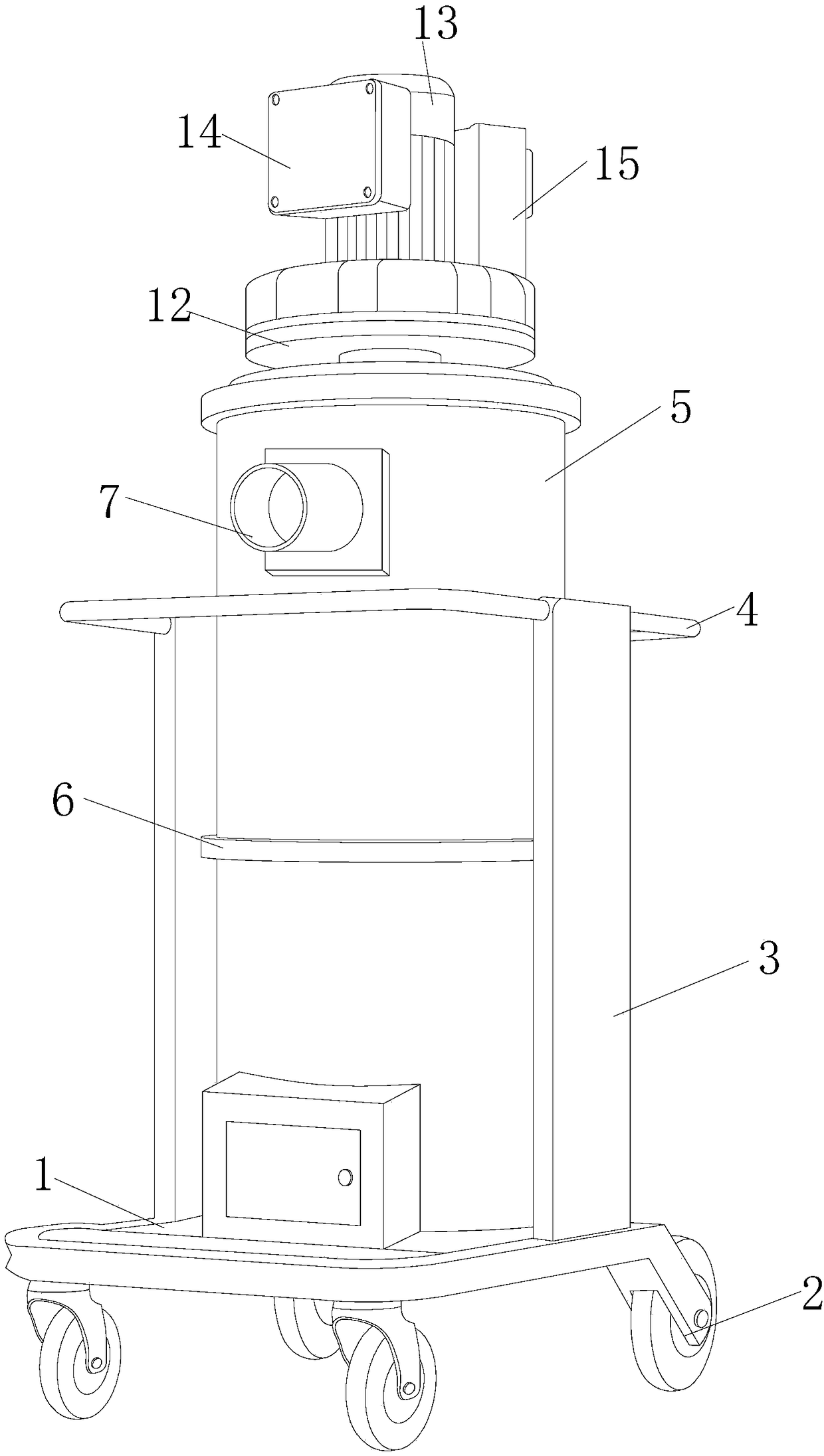

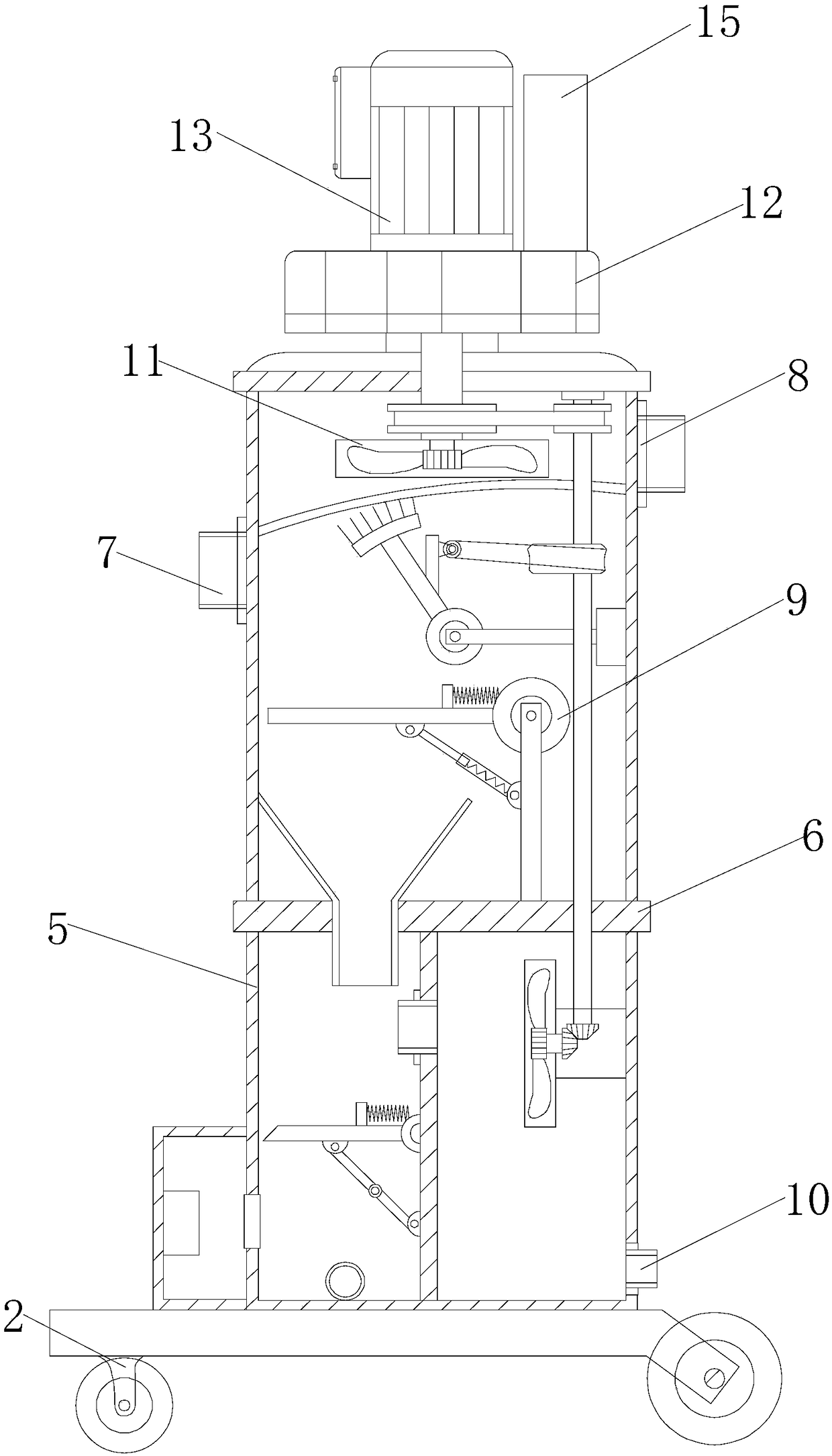

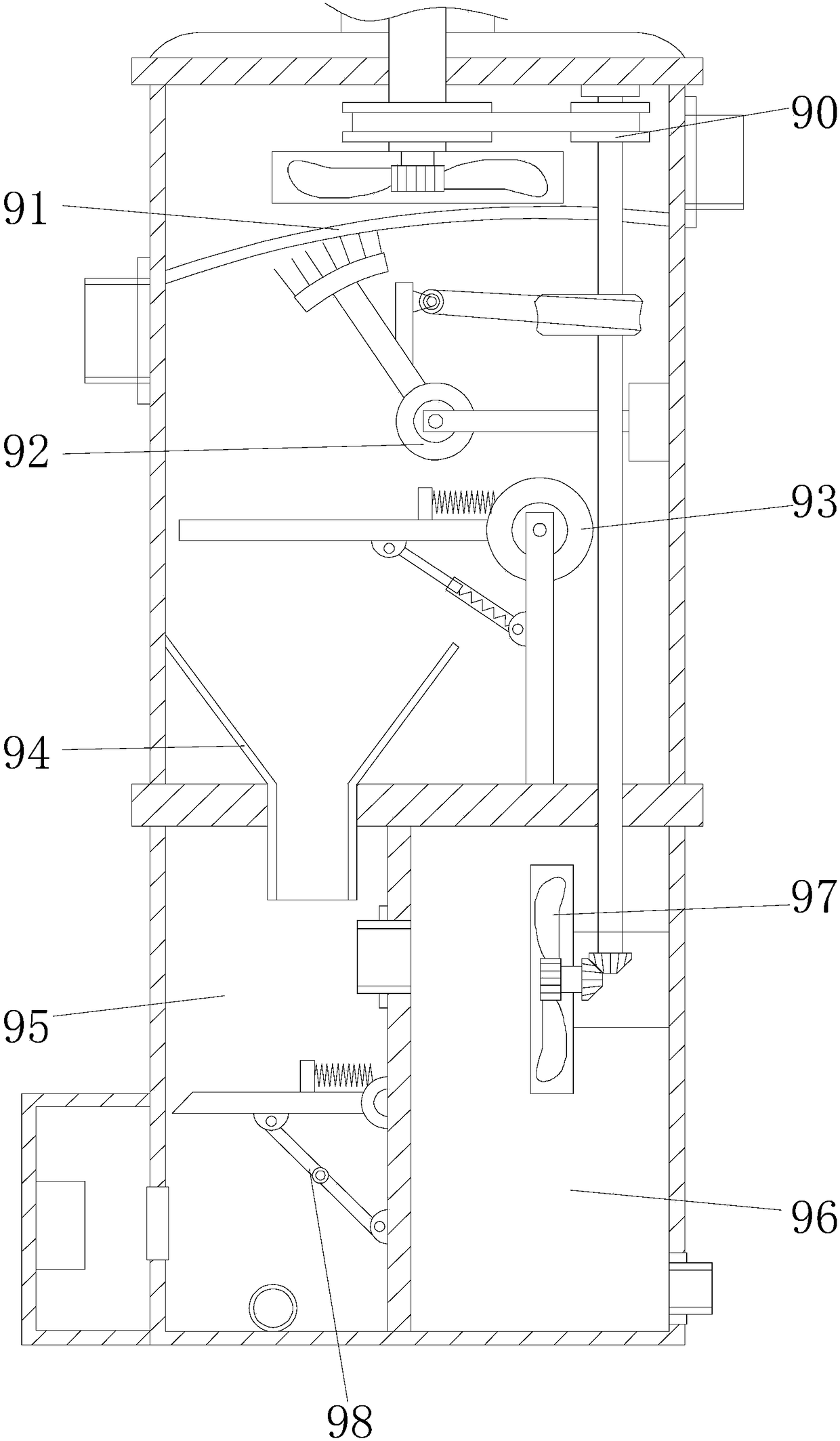

Environmental-protection air cleaning equipment used for hardware production workshop

ActiveCN108159818AImprove environmental performanceAvoid wastingCombination devicesGas treatmentElectricityAir cleaning

The invention discloses environmental-protection air cleaning equipment used for a hardware production workshop. The environmental-protection air cleaning equipment comprises a movable sweeping board,universal wheels, a support plate rack, a fixed rod frame, an air cleaning cylinder, a separation plate, an air-inlet pipe, an air-outlet pipe, a multiple screening processing apparatus, a dust-emission pipe, a turbine air-exhaust fan, a turbine air-exhaust apparatus, a servo motor, an electricity-connection box, and a distribution box. The movable sweeping board is in a rectangular stricture, the universal wheels are arranged at four ends below the movable sweeping board, and connected through screws in a spiral mode. The multiple screening processing apparatus can separate iron filings, metal shreds and dust collected during an air cleaning process, air purifying is realized, resource can be reutilized and classified for recovery, resource waste can be prevented, the utilization rate ofthe resource is increased, and the environmental-protection air cleaning equipment can effectively enhance the environmental protection performance for the air cleaning equipment.

Owner:万腾钣金(深圳)有限公司

Circular tube mouth grinding device for machine manufacturing

InactiveCN108058076AImprove practicalityReduce vibrationEdge grinding machinesGrinding carriagesArchitectural engineeringPulley

The invention discloses a circular tube mouth grinding device for machine manufacturing. The circular tube mouth grinding device comprises a base, a box body penetrates through the top of the base, and damping devices are fixedly connected between both sides of the bottom of the box body and both sides of the base; a concave plate is fixedly connected between the two sides of the inner wall of thebox body, and the bottom of the left side of the inner wall of the box body is fixedly connected to a first motor through a motor base; an output shaft of the first motor is fixedly connected with afirst belt pulley, and a second belt pulley is connected to the surface of the first belt pulley through a belt in a transmission mode, and the invention relates to the technical field of machine manufacturing equipment. According to the circular tube mouth grinding device for the machine manufacturing, different sizes of circular tubes can be fixed and clamped for grinding, the vibration generated during the operation of the grinding device is reduced, the grinding effect is improved, the generated noise is lowered, the iron filings generated during grinding can be adsorbed, the workload of the staff is reduced, the grinding process is facilitated, and accidents during the grinding can be detected in time.

Owner:HEFEI DONGLU MACHINERY MFG

Process for treating domestic sewage combined by aerobic biological fluid-bed and micro electrolysis tech.

InactiveCN1792872ASolve the blockageReduce in quantityTreatment using aerobic processesWater/sewage treatment by electrochemical methodsElectrolysisFluidized bed

A process for treating lift sewage by combination of aerobic biologic fluidized bed with micro-electrolysis includes such steps as continuously making sewage flow in fluidized bed, beginning aeration, adding active sludge, proportionally adding the mixture of iron filings and granular activated carbon, which is used as carrier, attaching microbes to surface of carrier, culturing for 2-5 days until the concentration of microbes reaches 7-9 g / L, and normal running. The removal rate of CODCT is 96-98%.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of pre-melting electroslag

The preparation method for premelting electroslag comprises: loading the material with 0.20-0.65 fluorite, 0.15-0.32 raw bauxite, 0-0.10 high raw magnesiteú¼0.05-0.32 high calcium material and 0-0.6 recovered slag in the arc furnace with material height as 0.5-1m; spreading carbon powder and iron filling on material top to arc and burn for melting after electrifying; cooling, and breaking with size as 1-40mm. this invention avoids slag segregation to ensure its chemical stability, has no dust pollution, and conserves energy.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Scrap iron cleaning device

InactiveCN103567063AClean up comprehensivelyGood effectCleaning using toolsMagnetic separationMetalSmall hole

The invention provides a scrap iron cleaning device, belongs to the technical field of surface coating production of automobiles or other metal, and solves the problem that scrap iron relatively tightly adhered to the surface of an automobile body is difficult to clean by a conventional scrap iron cleaning device. The scrap iron cleaning device provided by the invention comprises a casing provided with an inner chamber; the casing is provided with a working face opposite to the surface of a to-be-cleaned object; a brush capable of cleaning scrap iron is fixedly connected to the working face; a plurality of small holes allowing the inner chamber to be communicated with the outside are formed in the working face; a magnetic component capable of sucking scrap iron into the inner chamber from the small holes is arranged in the casing; the brush works with the magnetic component. The scrap iron cleaning device can clean scrap iron on the surface of metal with any profile and scrap iron on the surface of metal with a relatively large inner chamber, can suck certain scrap iron that the brush can not reach easily, and has the advantages of double effects, completeness in cleaning, and good effect.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

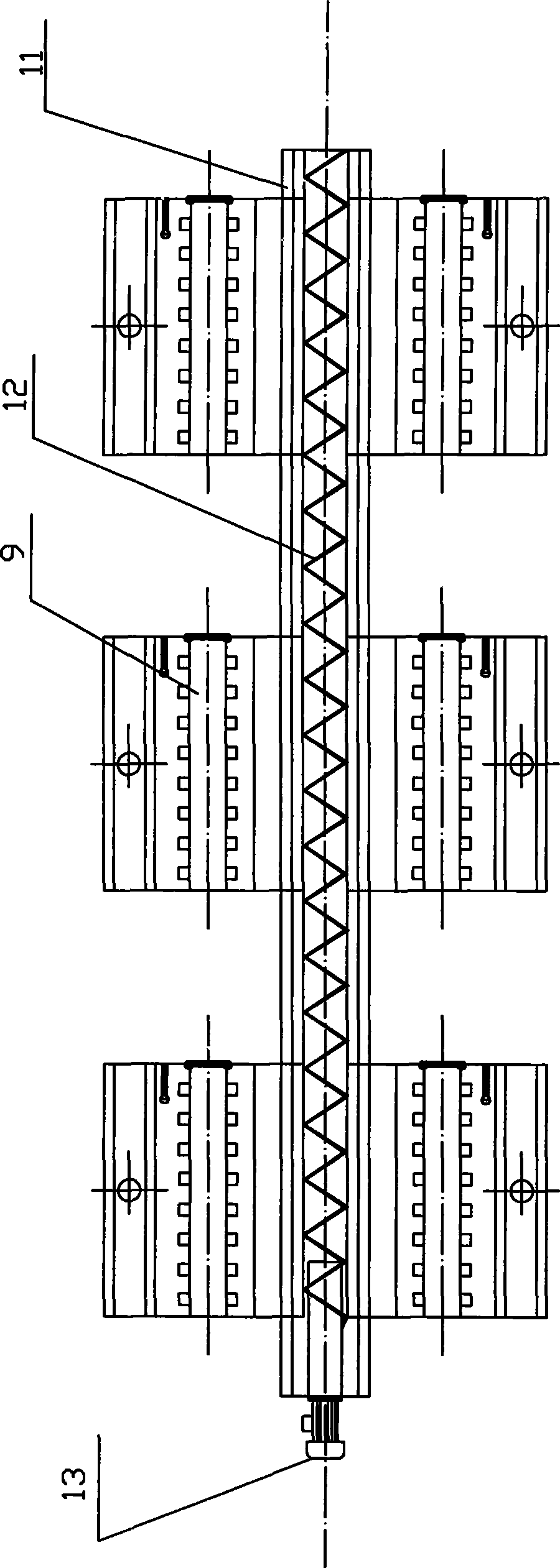

Numerical control lathe provided with lead screw guiding rail cleaning brushes

PendingCN107234480AEasy to fall intoOptimize locationMaintainance and safety accessoriesNumerical controlEngineering

The invention discloses a numerical control lathe provided with lead screw guiding rail cleaning brushes. The numerical control lathe comprises a main body; a PLC is arranged on the side surface of the main body; the input end of PLC is electrically connected with the output end of an externally-arranged power supply; the upper surface of the main body is provided with a spindle box and a tailstock; a lead screw guiding rail is arranged between the spindle box and the tailstock which are arranged on the upper surface of the main body; a motor is arranged inside the main body; an output shaft of the motor penetrates out of the upper surface of the main body and is connected with a rotating column; a mounting plate is arranged at the top end of the rotating column; and a driving motor is arranged on the lower surface of the mounting plate. According to the numerical control lathe provided with the lead screw guiding rail cleaning brushes, the cleaning effect is improved, iron filings generated in the production process can be cleaned up, subsequent machining is not affected, and the working efficiency is improved; second electromagnets can make the cleaning steel brushes to produce magnetism to attract the iron filings on the lead screw guiding rail, so that cleaning is more convenient and complete; and an electric telescopic rod can drive a cleaning device to rise and fall, and the automation degree is increased.

Owner:杭州富阳正成机械设备厂

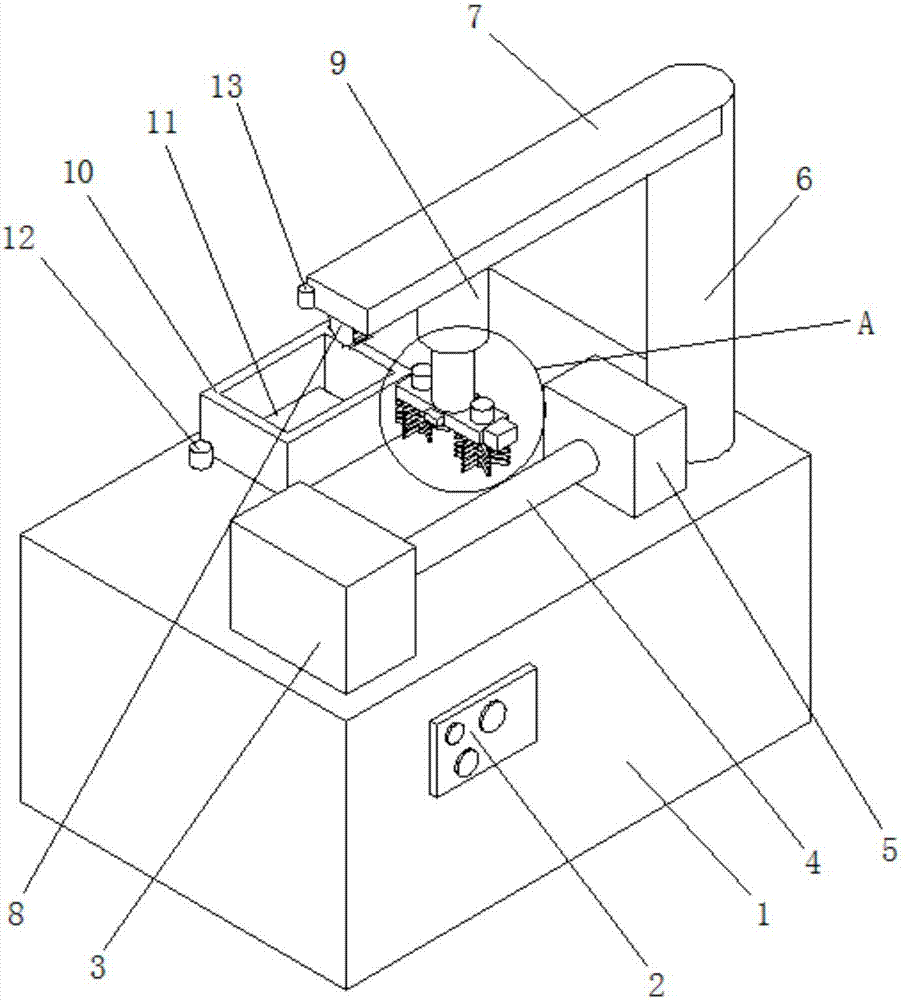

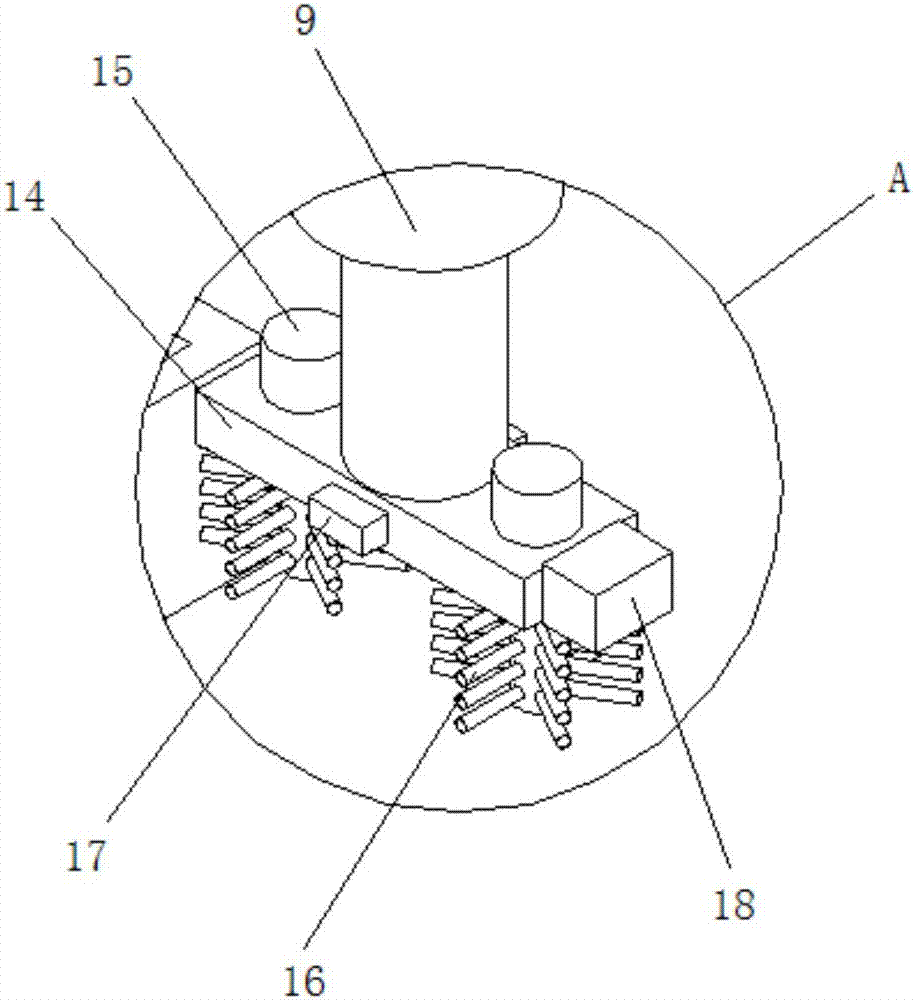

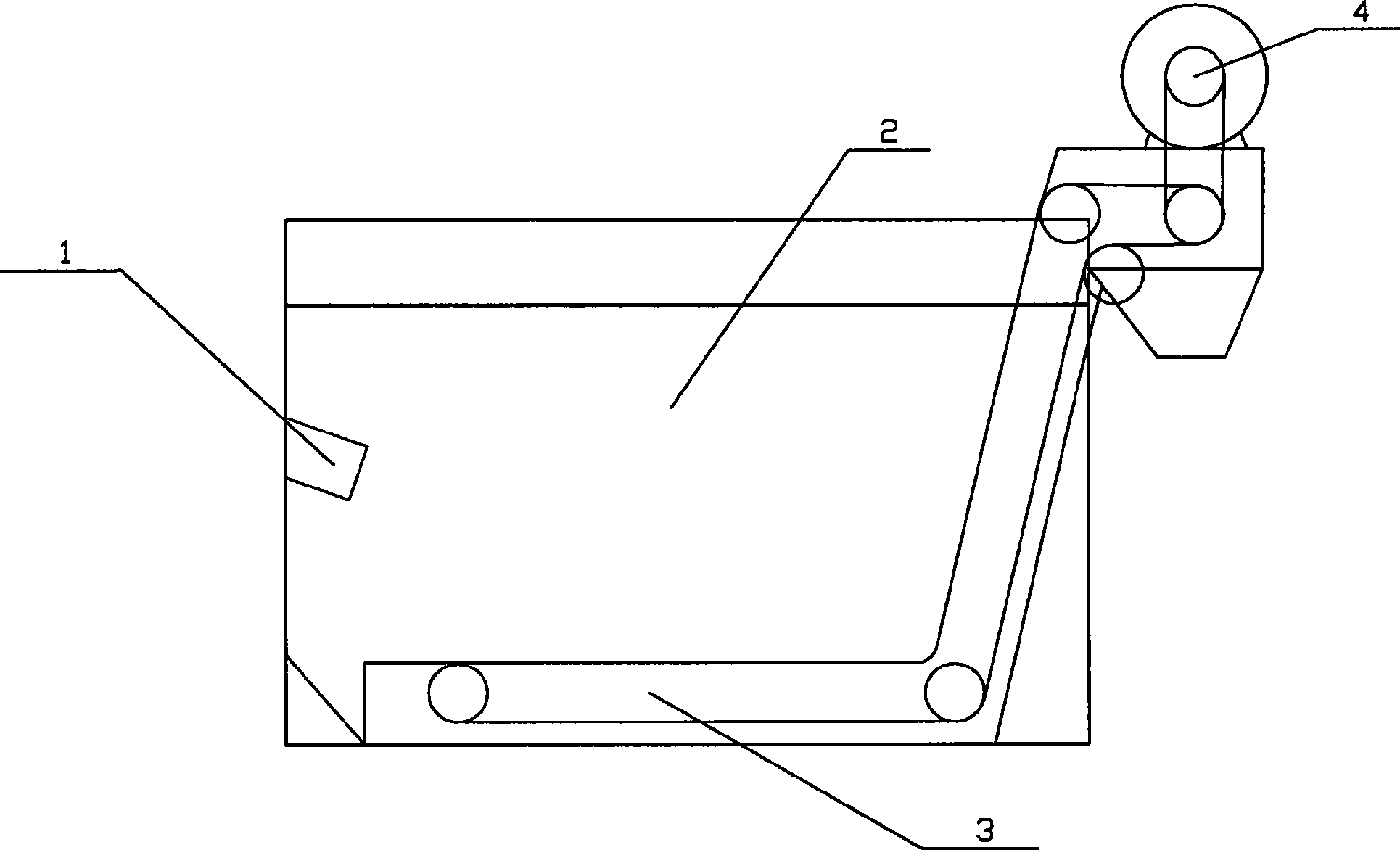

Centralized processor for iron shaving in ball-grinding feed liquid

The invention discloses a centralized treatment device for scrap iron of grinding-ball liquid supply, which comprises a precipitate slag dragging tank and a magnetic separation tank, wherein the horizontal position of the precipitate slag dragging tank is above the magnetic separation tank; a baffle is arranged between the two tanks; the precipitate slag dragging tank and the magnetic separation tank are communicated through a plurality of water inlets; each water inlet corresponds to one magnetic separating machine; each magnetic separating machine is provided with a magnetic separating pump and a magnetic roller, and is provided with continuously cyclic metal doctor blades clinging to the magnetic roller; and the insides of the precipitate slag dragging tank and the magnetic separation tank are both provided with a scrap-remover magnetic roller and a conveying device. The centralized treatment device for scrap iron of grinding-ball liquid supply has the advantages of changing the prior situation of using a single-machine water tank to supply liquid and depending on manual work to clear grinding slag, improving the cyclic utilization rate of grinding liquid and simultaneously reducing cost and labor intensity, along with a simple structure and easy implement.

Owner:JIANGSU LIXING GENERAL STEEL BALL

Scrap iron recycling device for milling machine

ActiveCN108581608AEasy to transportEasy to processMaintainance and safety accessoriesWorking environmentEngineering

The invention relates to a scrap iron recycling device, and particularly relates to a scrap iron recycling device for a milling machine. The invention aims to provide the scrap iron recycling device for the milling machine, which has the advantages that the working efficiency is high, the working environment is effectively improved, scrap iron and cutting fluid can be effectively separated, and the recycling effect is increased. The scrap iron recycling device for the milling machine comprises the milling machine, a top plate, a first screen plate, a first mounting plate, a second mounting plate, a third mounting plate, a driving mechanism, a dust collection mechanism, a driven mechanism, a compressing mechanism, a first fixing mechanism, a conveying mechanism, a support frame, a drying mechanism, a guide plate, a second screen plate, an inclined plate, a feeding pipe, a collecting frame, a liquid conveying pipe, a liquid storage frame, a liquid outlet pipe, a bottom plate and a firstconnecting plate, wherein the top plate is fixedly connected to one side of the milling machine, and the second mounting plate is fixedly connected to the back side of the bottom plate. The scrap ironrecycling device has the effects of improving the working efficiency, improving the working environment and effectively separating scrap iron from cutting fluid.

Owner:山东中洲增材制造有限公司

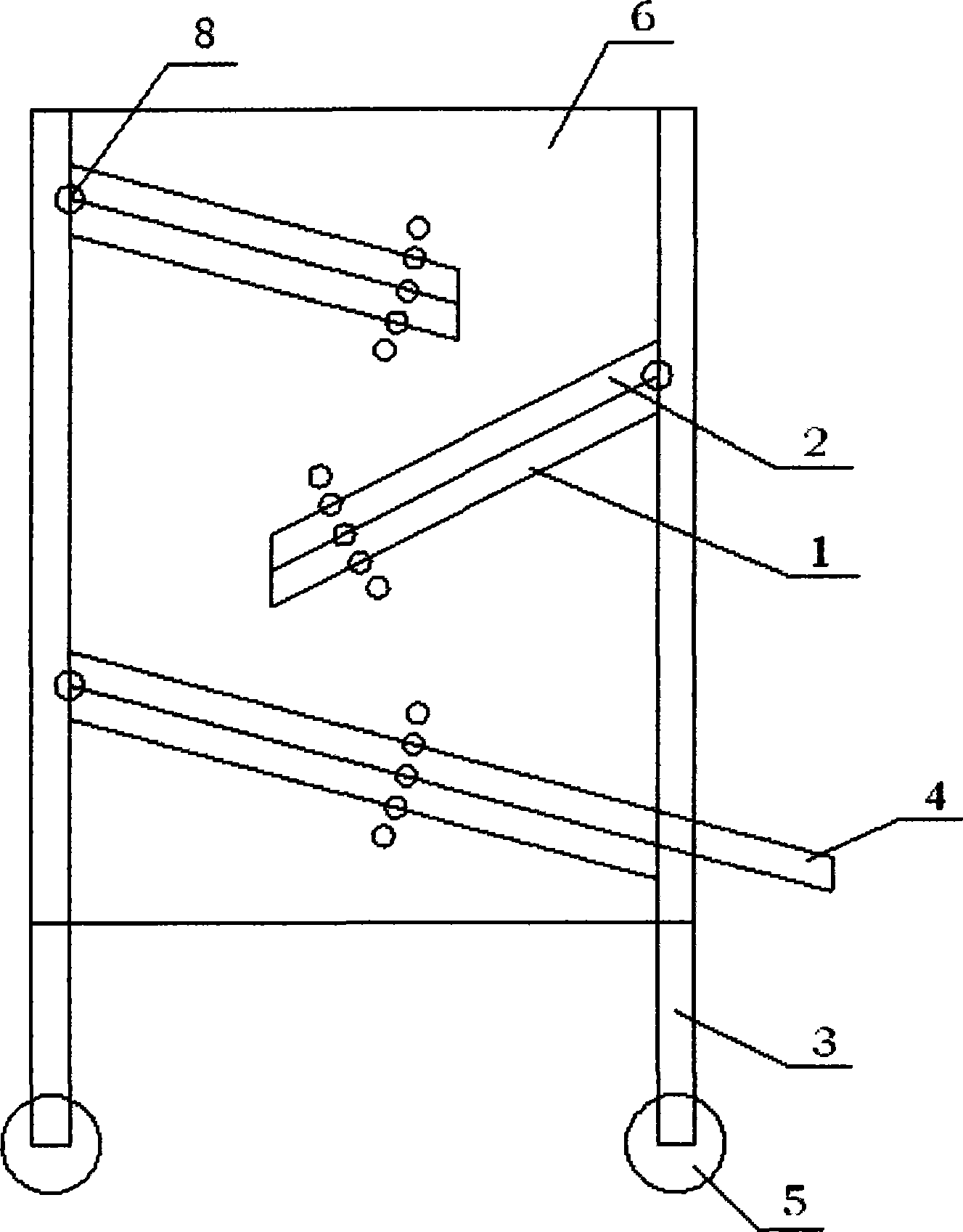

Combined magnetic force separating mechanism for removing iron dust in plastic

The invention relates to a plastic compound magnetic separation device for removing iron chips which consists of five parts of a permanent magnetic block, separating plates, a support frame, a baffle and a discharge hole. The device is characterized in that: A. the separating plates (2) which are embedded with the permanent magnetic block (1) are arranged on the support frame (3) from up to down in left-right dislocation state by a screw (8) until the separating plate at the bottommost layer is connected with the discharge hole (4); B. the surface of the separating plates (2) is provided with an absorption tank (7) which is vertical to the flowing direction of materials. Due to the composite rough separating plates with large area in different directions, large metal chips even metal blocks can be separated effectively. Plastic particles have certain elasticity and can eject and move downwards when being in contact with the surfaces of the separating plates. Drop pits on a plane can ensure more effectively than drop pits on a traditional magnetic rod that absorbed iron chips cannot be rolled into the solid flow of the plastic particles again. One time or a plurality of times of over-magnetic effect can be effectively guaranteed in the production application. The production efficiency is obviously improved.

Owner:上海金玺实验室有限公司

Bench drilling machine facilitating scrap iron collection with good protecting effect

InactiveCN110480046AEasy to collectImprove the protective effectPositioning apparatusMaintainance and safety accessoriesEngineeringDrilling machines

The invention relates to the technical field of bench drilling machines and discloses a bench drilling machine facilitating scrap iron collection with a good protecting effect. According to the benchdrilling machine facilitating scrap iron collection with the good protecting effect, by arranging three striker plates, a material needed to be drilled is placed in a space defined by the three striker plates, a rotating wheel is rotated, so that two clamping blocks move oppositely to clamp the material, and finally, a front baffle plate is rotated, so that a mounting bar is pressed into a mounting sleeve to be clamped, and therefore, material splashing is prevented, staffs are protected, and it is ensured that fragments generated by drilling only fall into the space defined by the three striker plates and the front baffle plate. The scrap iron is collected conveniently, and a scraper blade is pushed, so that the scrap iron on a supporting table is completely scraped to a drain hole to fall into a scrap iron collecting box, and therefore, a role of collecting the scrap iron quickly is achieved. After the scrap iron collecting box is filled with the scrap iron fully, a screw is taken out, so that fixation of the scrap iron collecting box and the supporting table can be removed, and the scrap iron is disposed. The bench drilling machine achieves a purpose of collecting the scrap ironconveniently and being good in protecting effect.

Owner:GAOYOU YONGFA MACHINERY

Synthetic processing method of hydroxyethylidene pre-plated copper waste water

InactiveCN101624244AReduce power consumptionLess investmentWaste water treatment from metallurgical processMultistage water/sewage treatmentFlocculationWastewater

Owner:南京友盛环保科技有限公司

Alumina-base fused high-purity spinel and its prepn

The present invention provides alumina-base fused high-purity spinel and its preparation process. The alumina-base fused high-purity spinel is prepared with light burned high-aluminum alumina and light burned magnesite as main material and granular coke or graphite and iron filings as supplementary material, and through reducing smelting, oxidizing smelting and refining. It has lowered cost, excellent performance, spinel phase and bulk density greater than 3.4, and contains Al2O3+MgO >97 wt%, MgO 21-32 wt% and SiO2 <1 wt%. It is used widely as high temperature functional material in high temperature industry, especially steel ladle material.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com