Method for preparing heterogeneous-phase Fenton catalyst and application thereof

A heterogeneous, catalyst technology, applied in the fields of comprehensive utilization of waste and water treatment, can solve problems such as environmental hazards and heavy metal pollution, and achieve the effects of low cost, stable catalytic activity, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

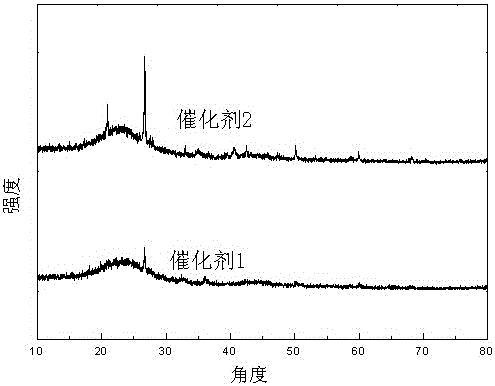

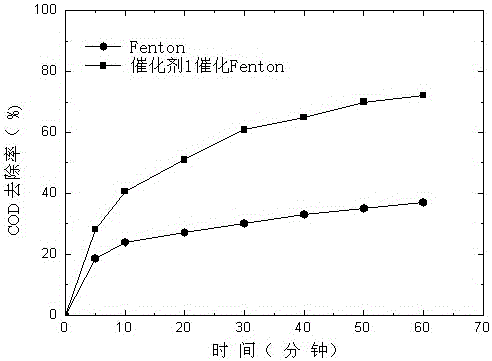

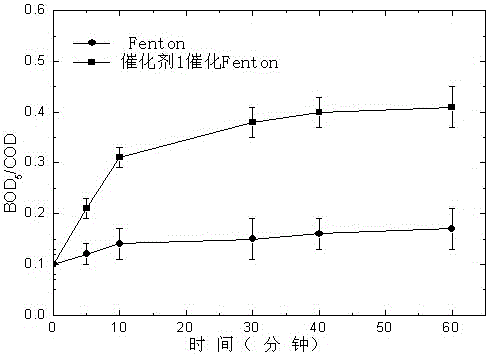

Embodiment 1

[0034] The iron slime and biogas residue are cleaned separately, dried at 80°C, crushed, and then sieved to obtain iron slime and biogas residue particles smaller than 200 meshes. The iron slime and biogas residue particles are mixed and mixed, and the iron slime and biogas residue The mass ratio is iron mud: biogas residue = 2:5, and then the activator ZnCl with a concentration of 3 mol / L 2 The solution is impregnated, and the impregnation ratio is ZnCl 2 Solution: Mixed sample = 3L: 100g, the immersion time is 2 hours, the stirrer is mixed at 100 rpm, and the solid sediment sample is collected after standing for 1 hour, and then the solid sediment sample is activated in a muffle furnace at high temperature , the muffle furnace pyrolysis temperature is 800 °C, the heating rate is 15 °C / min, and after reaching the required temperature, it is kept for 2 hours, nitrogen is used to isolate oxygen protection, the flow rate is 200 mL / min, and the concentration of the sample obtaine...

Embodiment 2

[0043] The iron slime and biogas residue are cleaned separately, dried at 80°C, crushed, and sieved to obtain iron slime and biogas residue particles smaller than 200 meshes, and the iron slime and biogas residue particles are mixed, and the iron slime and biogas residue particles are mixed. The mass ratio is iron mud: biogas residue = 1:5, and then the activator ZnCl with a concentration of 3 mol / L 2 The solution is impregnated, and the impregnation ratio is ZnCl 2 Solution: Mixed sample = 3L: 100g, the immersion time is 3 hours, the stirrer is mixed at 100 rpm, and the solid sediment sample is collected after standing for 1 hour, and then the solid sediment sample is activated at high temperature in the muffle furnace , the muffle furnace pyrolysis temperature is 800 °C, the heating rate is 15-20 °C / min, and after reaching the required temperature, keep it for 2 hours, nitrogen is used to isolate oxygen protection, the flow rate is 200 mL / min, and the concentration of the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com