Patents

Literature

682results about How to "Structural symmetry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

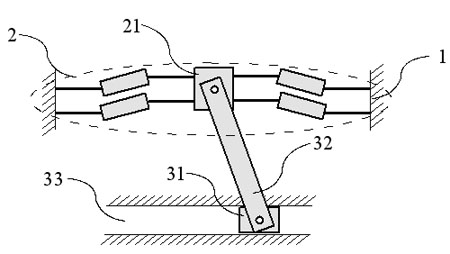

Four freedom parallel robot mechanism with passive bound branch

InactiveCN1644312ADoes not affect the nature of movementStructural symmetryProgramme-controlled manipulatorLarge fixed membersDegrees of freedomControl theory

A 4-freedom parallel robot structure with passive constraint branch is disclosed, which contains different two passive constraint branch structures and can be used for robot to realize one axial movement and three different rotations. Its advantages are high parallel rigidity and load-bearing power, simple structure, high precision and low cost.

Owner:YANSHAN UNIV

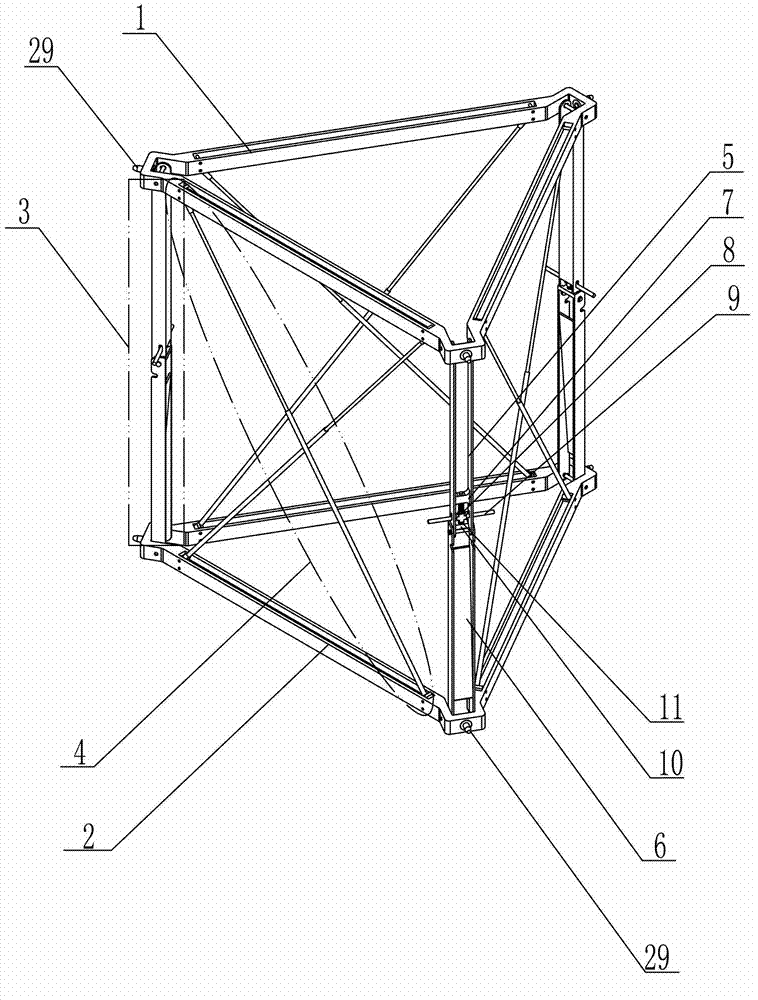

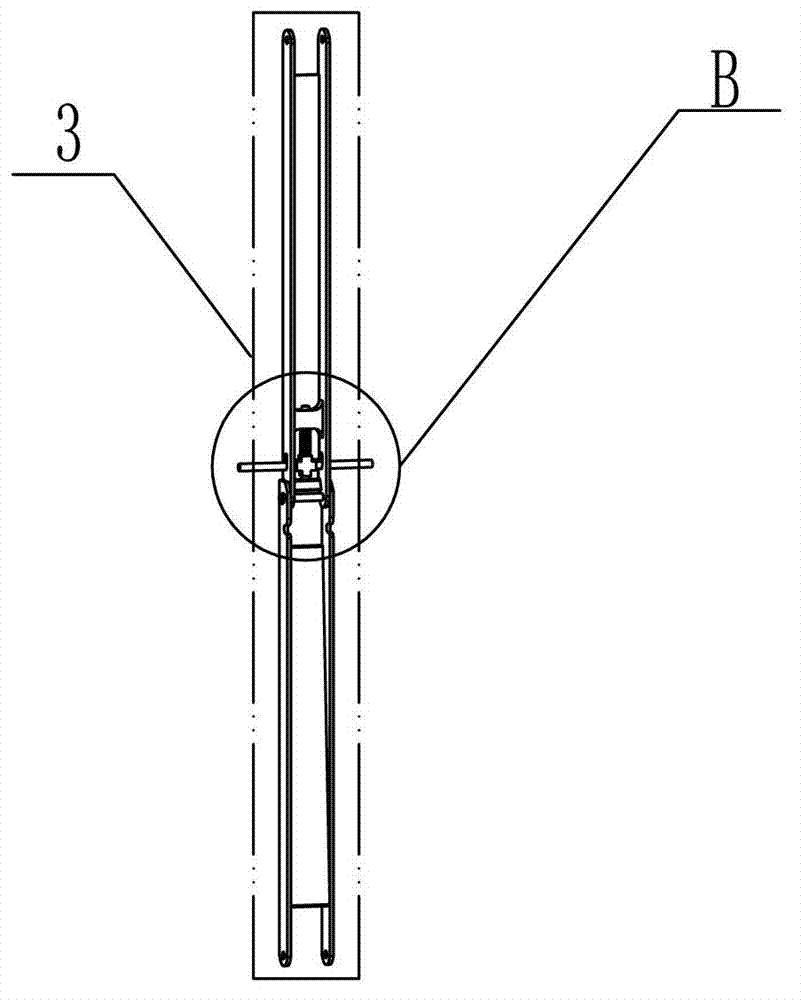

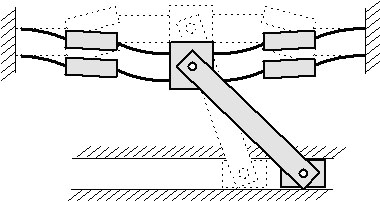

Unfoldable unit of triangular prism and unfoldable support arm consisting of unfoldable units

InactiveCN102923316AReduce volumeReduce weightPhotovoltaic supportsCosmonautic vehiclesSatelliteTriangular prism

The invention discloses an unfoldable unit of a triangular prism and an unfoldable support arm consisting of the unfoldable units, solving the problems that the existing hinged type support arm is large in folded size and low in repeated unfolding precision. According to the unfoldable unit, an upper triangular frame and a lower triangular frame are arranged from top to bottom in parallel; each corresponding top angle between the upper triangular frame and the lower triangular frame is respectively supported by a triangular prism folding arm and is rotatably connected with the triangular prism folding arm; a group of triangular prism inhaul cable assembly is arranged at the inner opposite angle of a rectangular plane formed by the upper triangular frame, the lower triangular frame and two adjacent triangular prism folding arms; and each two adjacent triangular prism unfoldable units are rotatably connected through a transit unfolding component. With the adoption of the inhaul cable component provided by the invention, the problem that inhaul cables at opposite corners are wound and move irregularly; and meanwhile the overall rigid and the repeated unfolding precision of the support arm are enhanced. The unfoldable unit is used in a satellite, a space station and a space probe.

Owner:HARBIN INST OF TECH

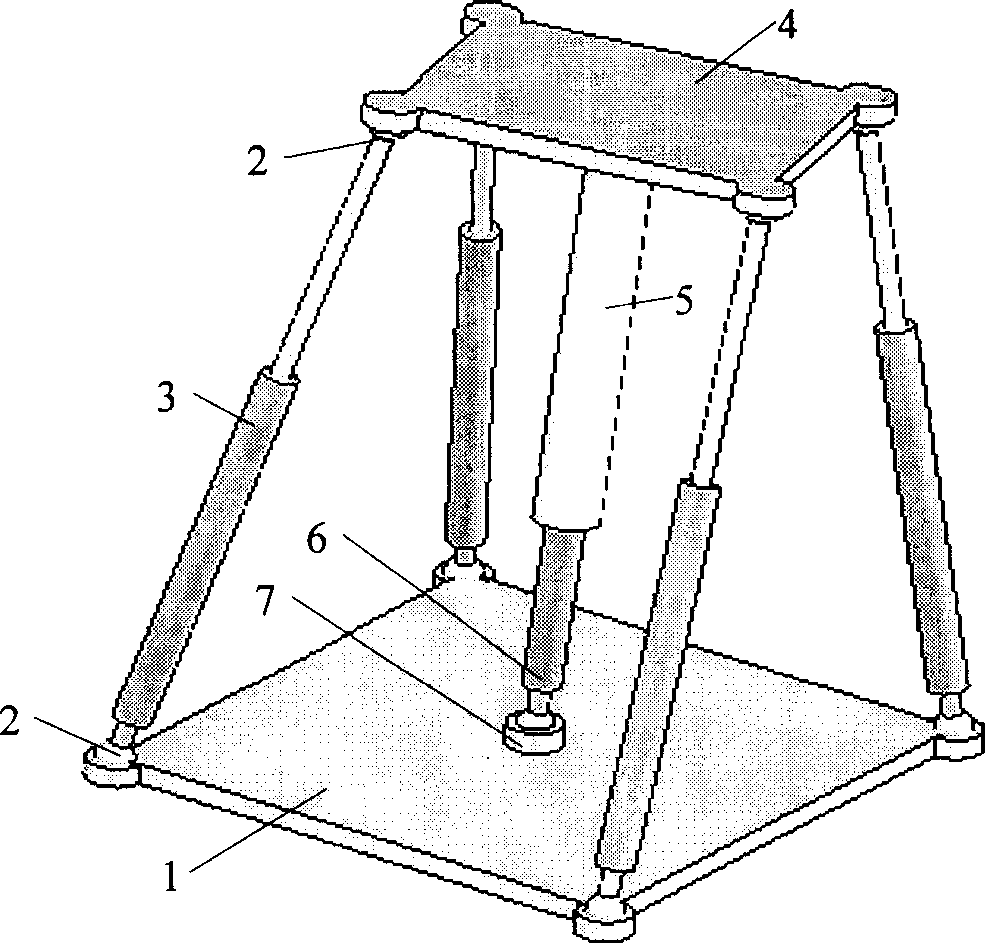

Adjustable 3,4,5-SPS type parallel mechanism experiment bench

InactiveCN1861328AHigh movement precisionIncrease freedomProgramme-controlled manipulatorLarge fixed membersEngineeringMachine tool

An adjustable experimental platform with 3,4,5-SPS type parallel mechanism for robot, machine-tool, or sensing element is disclosed. 3,4 or 5 linear drive branches are distributed between upper platform and base in polygonaly symmetrical mode. One of 4 or 5 linear drive braches is arranged in the center of platform and base. The both ends of each branch have a ball set consisting of the rotation set A formed by connecting one end of said branch with ring frame, the rotation set B formed by connecting ring frame with supporter, and the rotation set C formed by connecting supporter with axle sleeve. The vertical and transverse pins are used to change the freedom of ball set.

Owner:YANSHAN UNIV

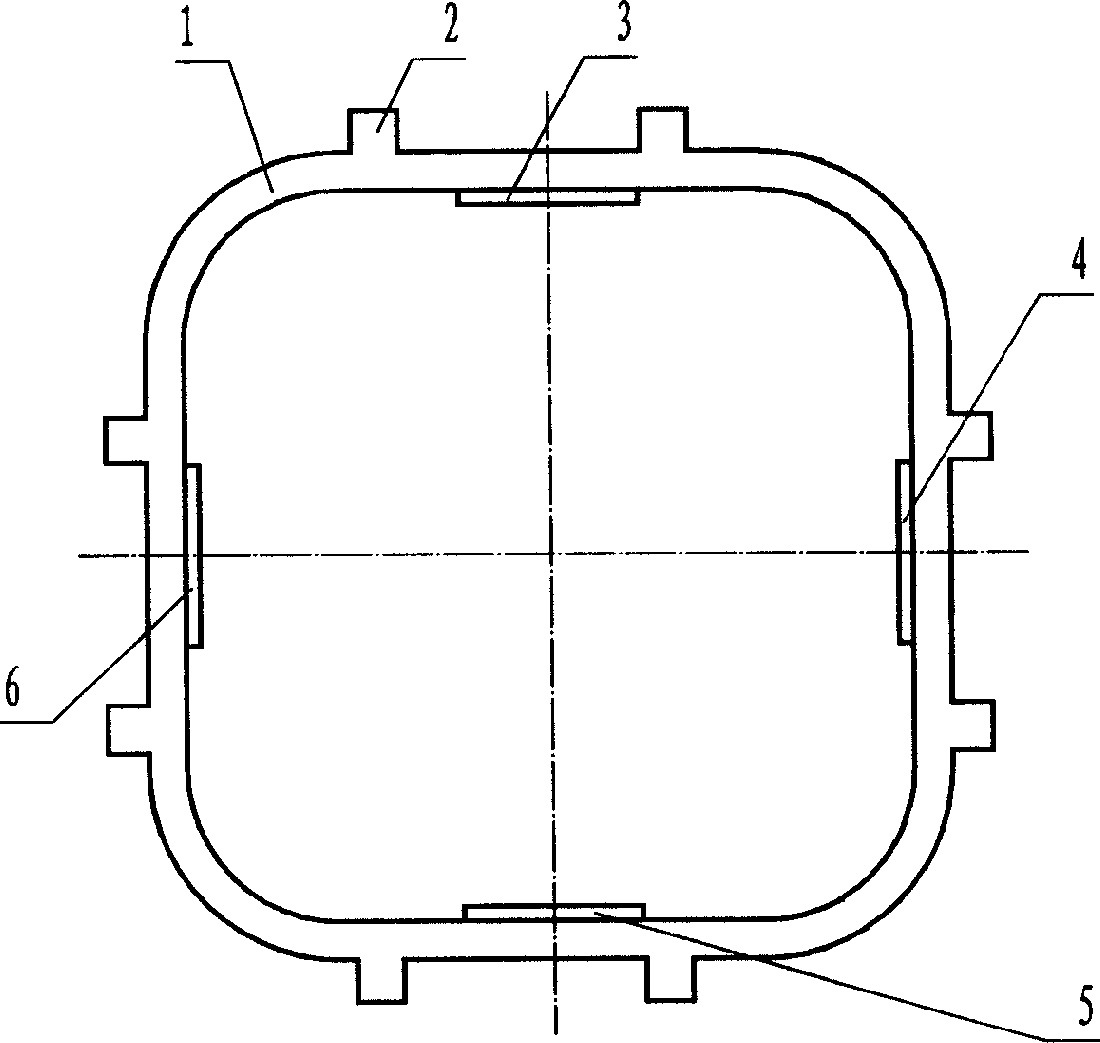

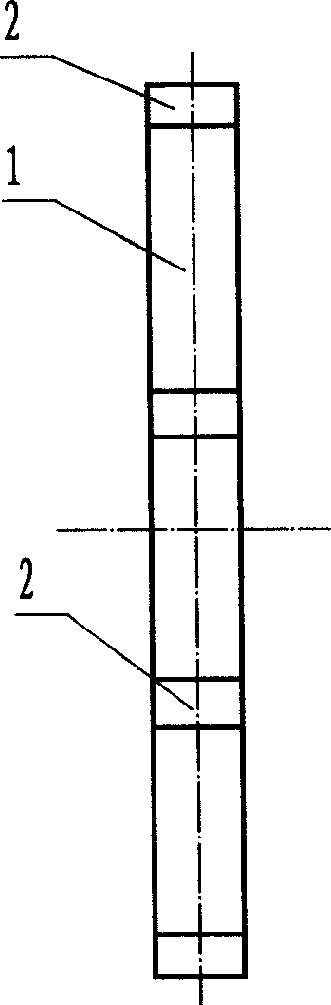

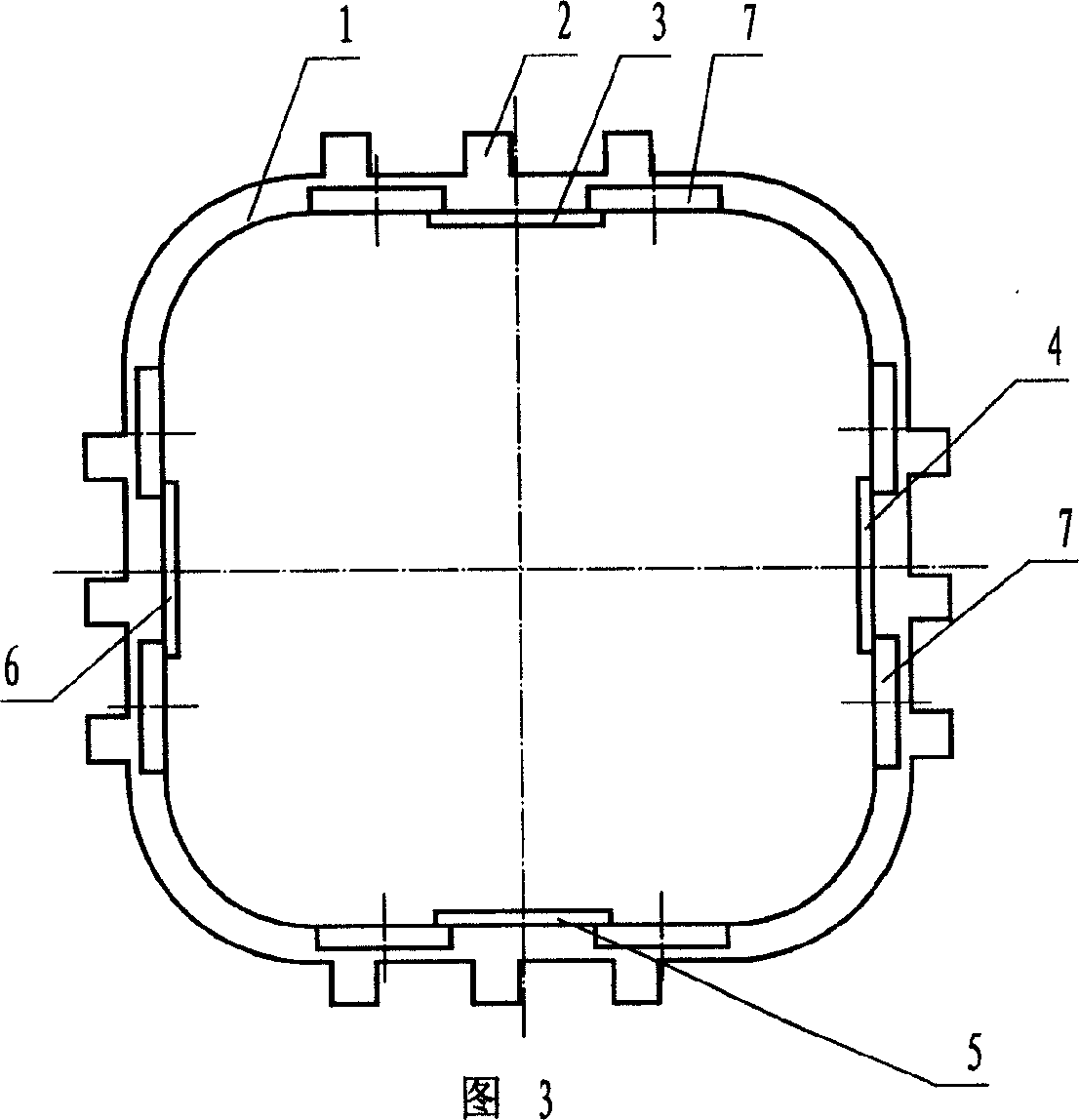

Annular standing wave linear ultrasonic motor oscillator

InactiveCN1665119AReduce manufacturing costSimple structurePiezoelectric/electrostriction/magnetostriction machinesElastomerUltrasonic motor

The invention discloses a vibrator of annular standing wave linear ultrasonic motor, solving the problems of different-order or ¿Ctype two-mode operation, complicated structure, uneasy design and high manufacturing cost; the invention is composed of metallic elastomer and piezoelectric ceramic piece, there are several vibrator teeth on the metallic elastomer and it is characterized in that: the said metallic elastomer is a square or long ring in shape, composed by the closing of straight beam segment and arc segment and works in internal-bending vibrating mode of two surfaces with the same order and frequency or the approximately same frequency; its advantages lie in: working by using the same order vibrating type and the same frequency, thus its driving circuit is simple and its manufacturing cost is lower; its structure is simple and easy to design; etc.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

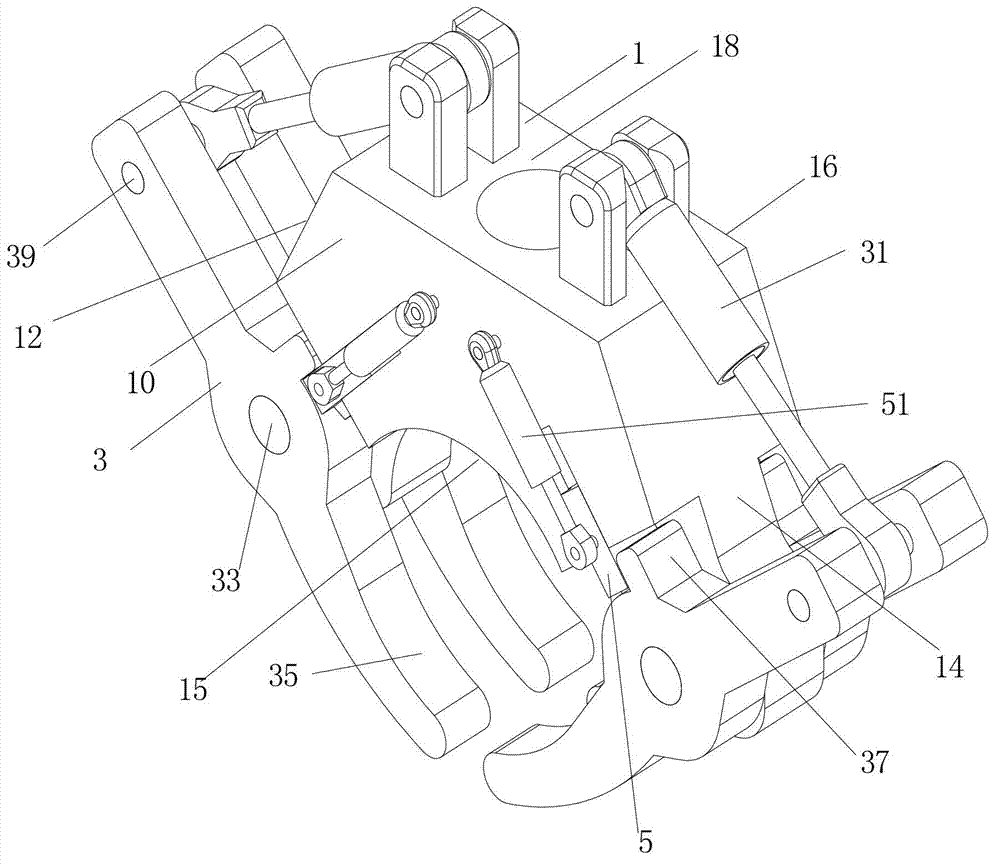

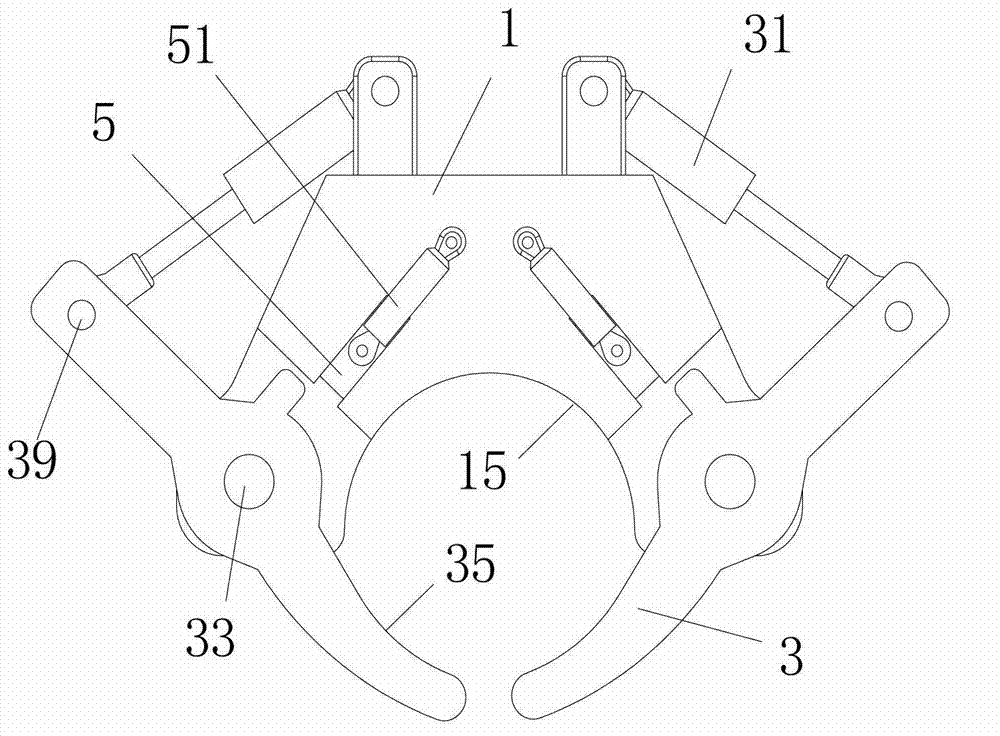

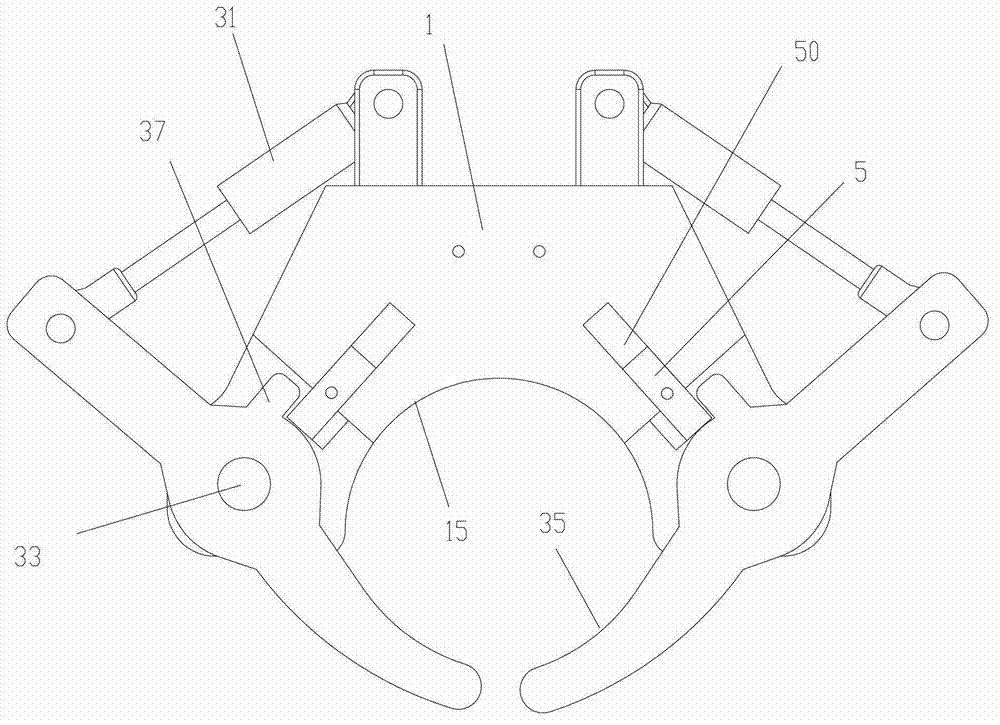

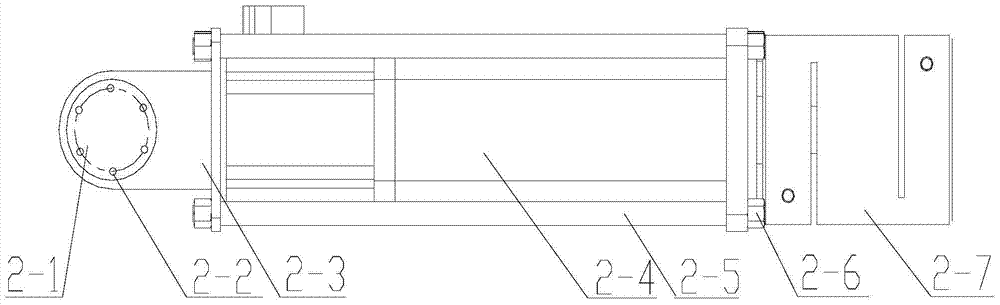

Pipeline clamping tool and pipeline lifting method

InactiveCN102730549ASolve the clamping instabilityTroubleshoot job failuresPipe laying and repairLoad-engaging elementsHydraulic cylinderIndustrial engineering

The invention provides a pipeline clamping tool and a pipeline lifting method. the pipeline clamping tool comprises a pedestal, a clamping part of the clamping pipeline which is hinged on the pedestal by a hinge shaft; a first hydraulic cylinder which drives the rotation of the clamping part and is arranged on the pedestal and is connected to the clamping part; and a locking part which is used for locking the clamping part and is arranged on the pedestal in a movable mode. The invention also provides a pipeline lifting method, the pipeline lifting method comprises the following steps: driving the rotation of the clamping part by the first hydraulic cylinder and clamping the pipeline, then driving the locking part, preventing the rotation of the clamping part, and then lifting the pipeline and stopping the oil supply on the first hydraulic cylinder during the lifting process.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

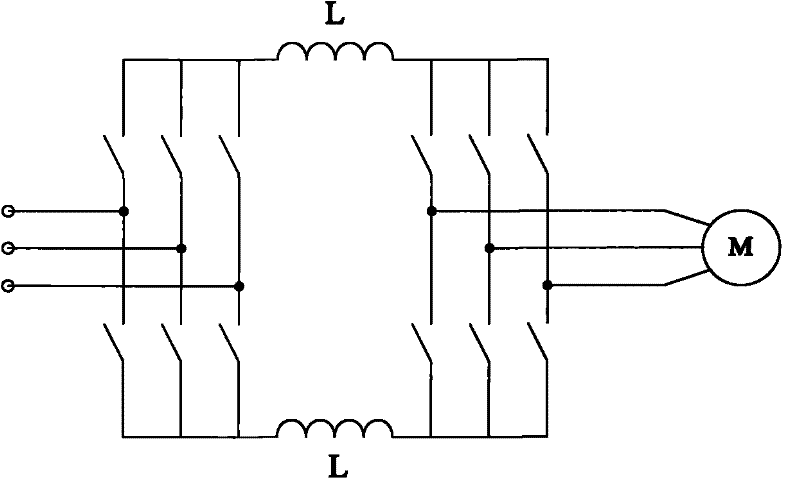

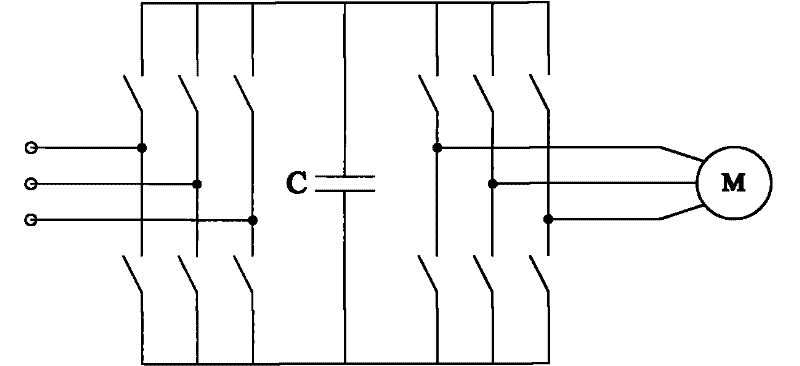

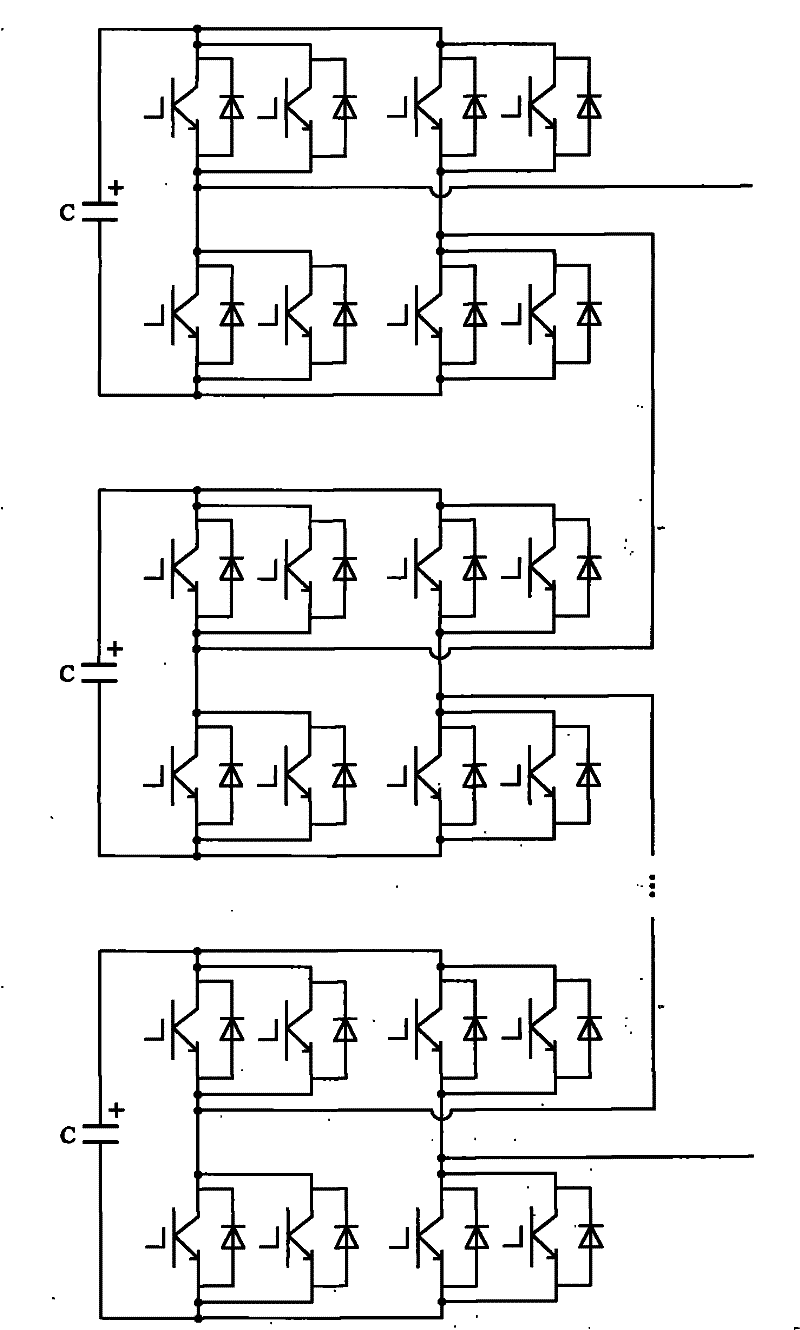

High-power converter based on parallel IGBT (Insulated Gate Bipolar Transistor) modules

ActiveCN102163926AStructural symmetryGood current equalization effectConversion with intermediate conversion to dcCooling/ventilation/heating modificationsPower applicationStray inductance

The invention particularly relates to a high-power converter based on parallel IGBT (insulated gate bipolar transistor) modules, belonging to the technical field of power electronic. Metal-film capacitors of the high-power converter adopt the high-power converter structure of a heteropolarity manner; and the polarities of the capacitors are staggered with each other. The high-power converter is featured with symmetrical circuit structure, good module current equalizing effect and low loop stray inductance so that the high-power converter is convenient for cascading chain joint modules so as to realize large power application. According to the invention, the problems that the capacity of the single IGBT module cannot meet the requirements of the high-power converter, and the current equalization of the parallel IGBT modules are solved.

Owner:CHINA EPRI SCIENCE & TECHNOLOGY CO LTD +2

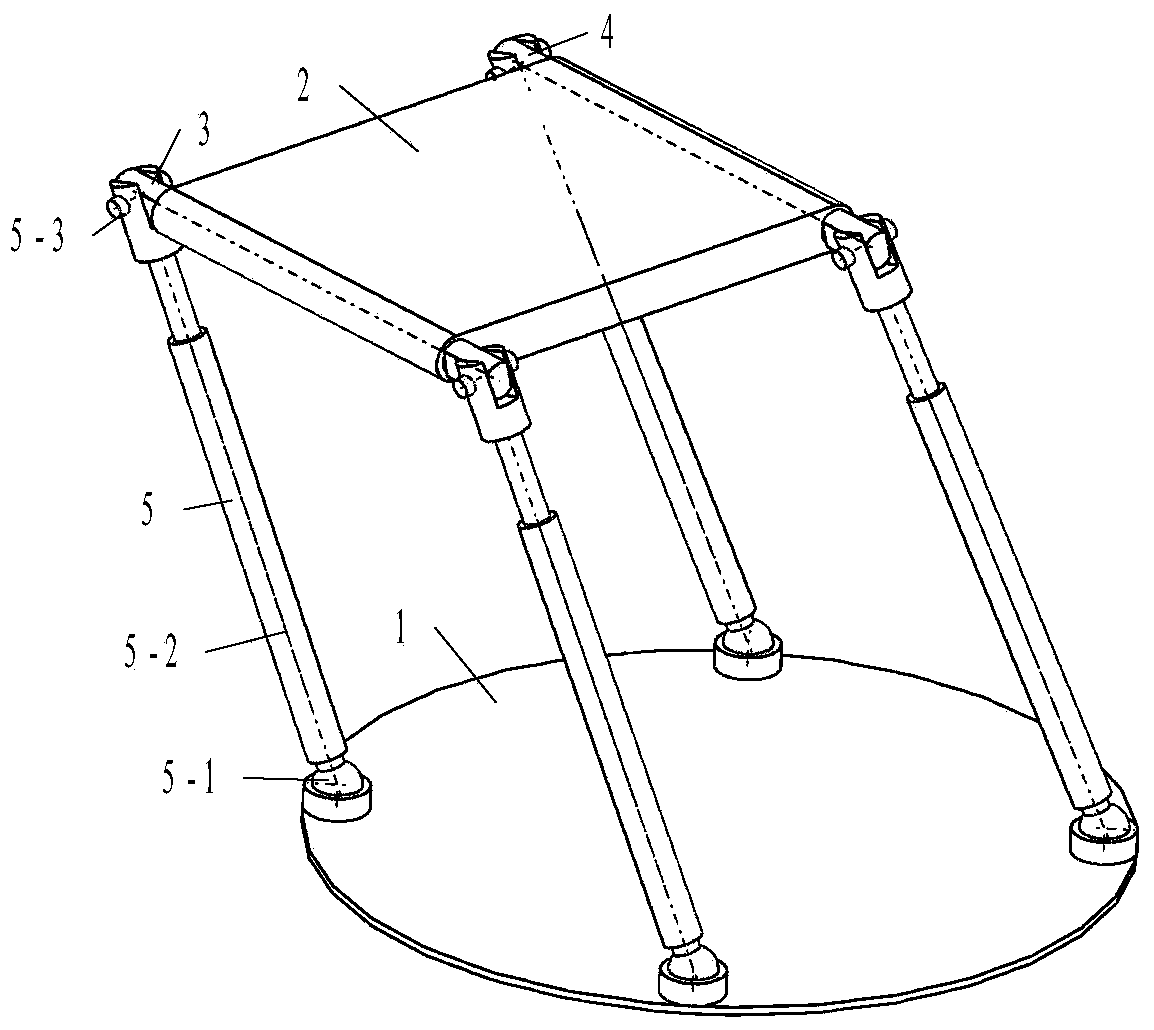

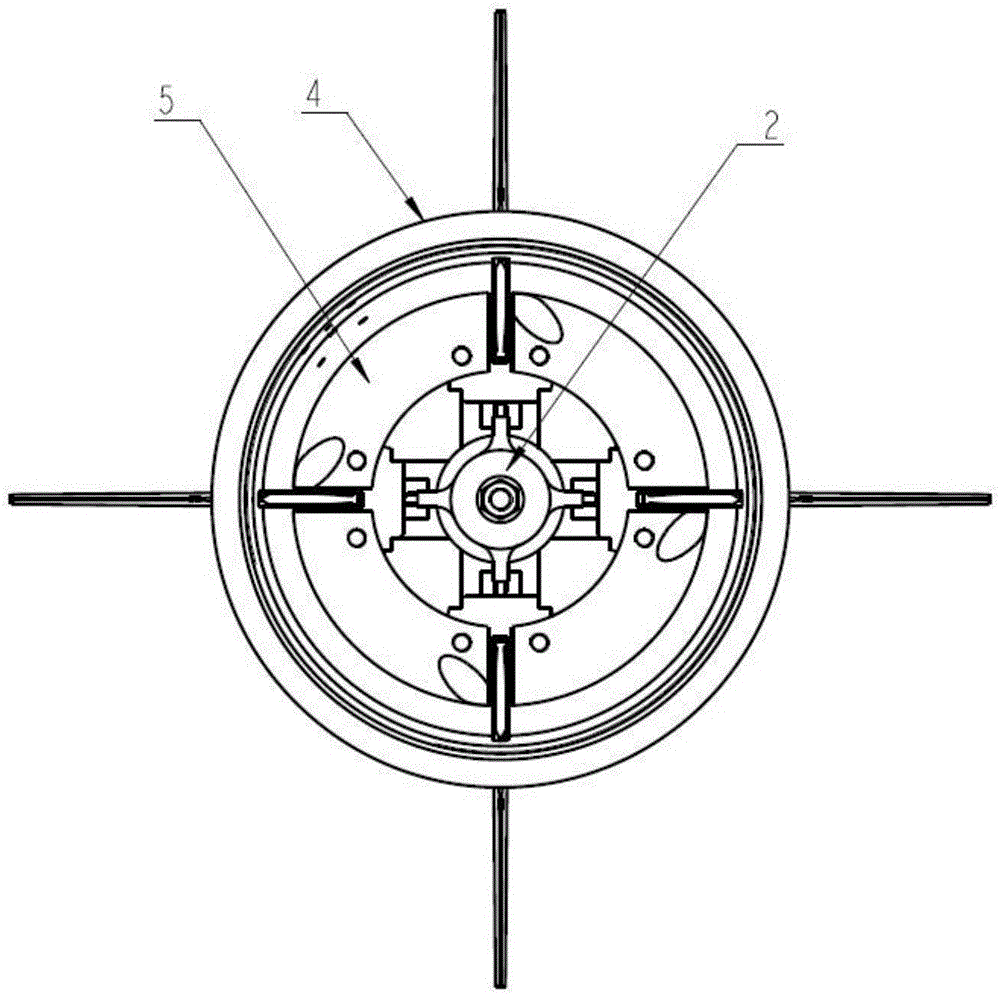

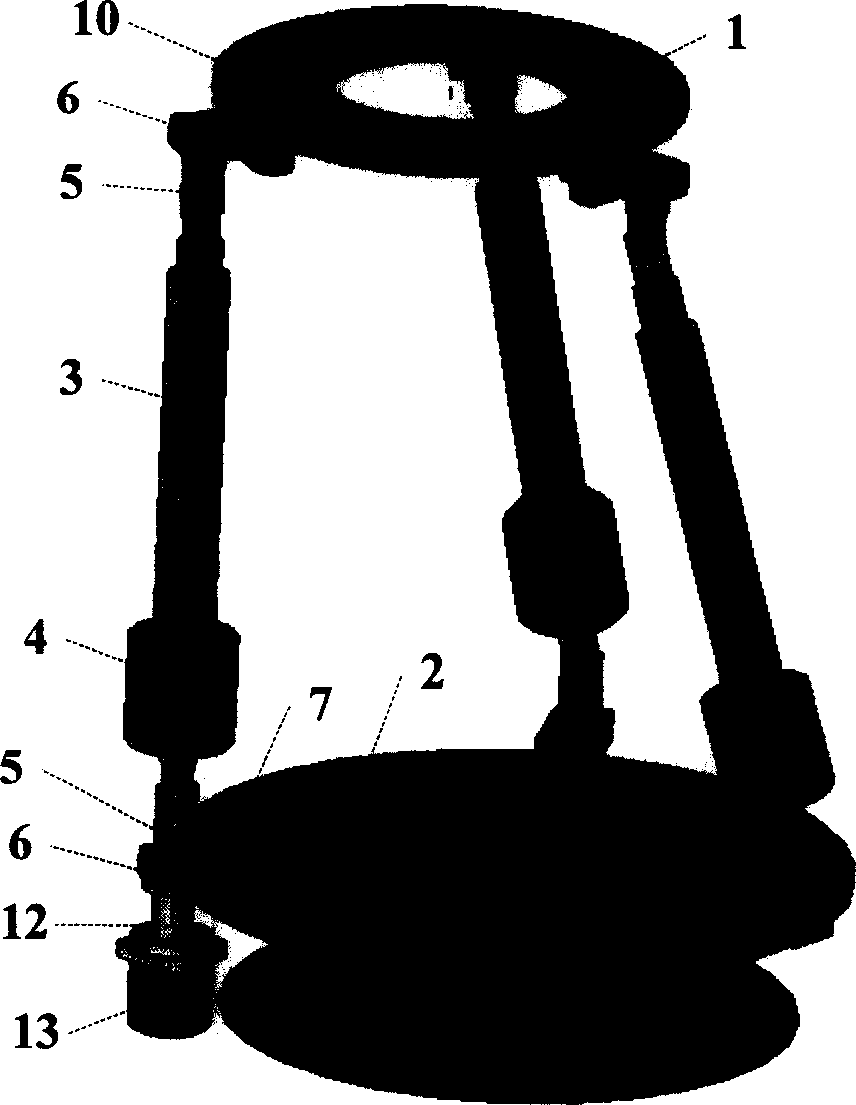

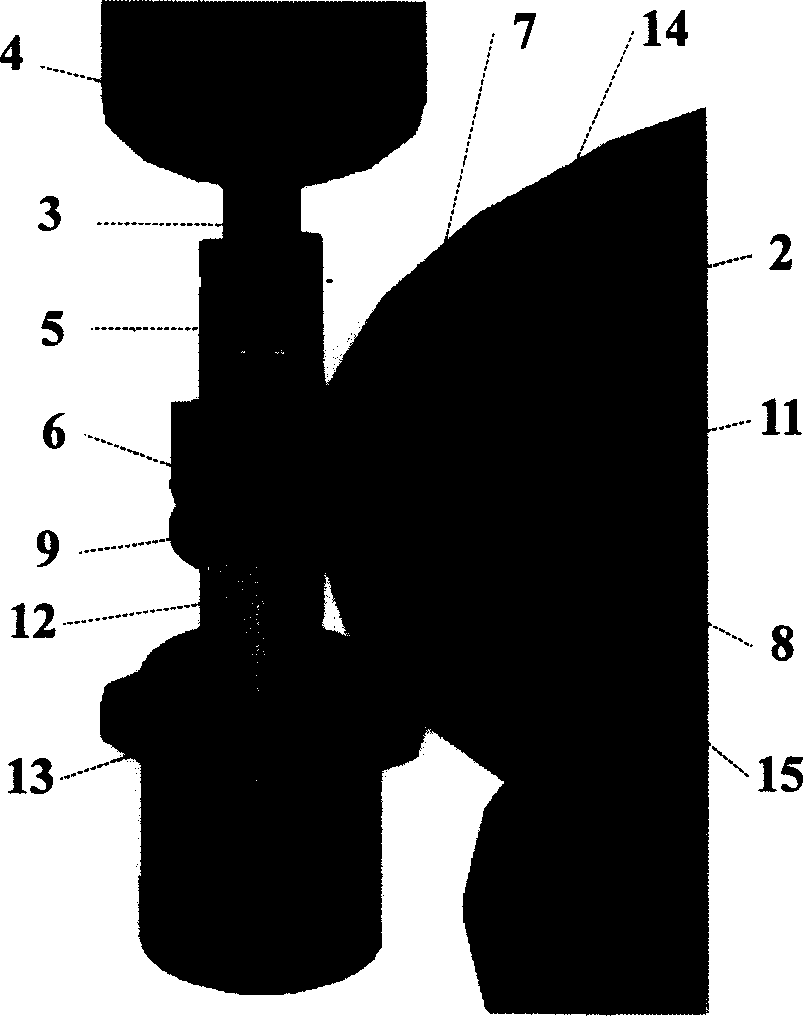

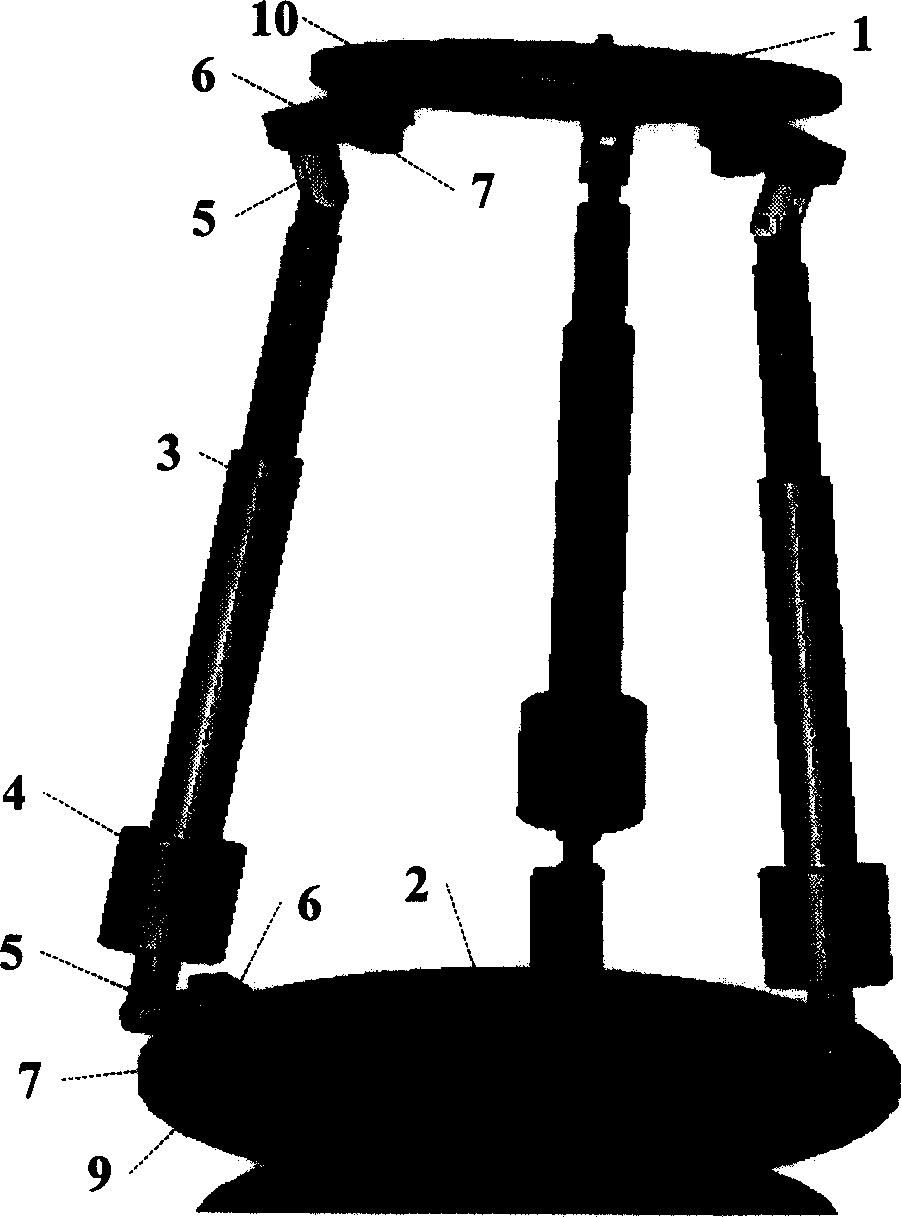

4SPR+2R type four-freedom-degree parallel mechanism

InactiveCN104369182AIsotropicStructural symmetryProgramme-controlled manipulatorTransverse axisEngineering

The invention provides a 4SPR+2R type four-freedom-degree parallel mechanism. A base is composed of four auxiliary rods, four ball pair seats evenly distributed on the circumferential side are arranged on a round plate of the base, a movable platform is composed of two auxiliary rods, parallel through holes are formed in the two opposite sides of a square plate of the movable platform respectively, a first cross shaft and a second cross shaft penetrate through the through holes of the movable platform respectively, through holes are formed in the two ends of the first cross shaft and the two ends of the second cross shaft, and the axes of the two through holes of each cross shaft are parallel and perpendicular to the cross shaft. Four SPR type linear drive branches with the same structure are evenly distributed circumferentially between the movable platform and the base, each SPR type linear drive branch is composed of a rotating pair at the upper end, a movable pair electric cylinder in the middle and a ball pair at the lower end, the ball pairs at the lower ends of the branches are connected with the ball pair seats of the base, the upper ends of two branches are connected with the two ends of the first cross shaft through the rotating pairs, and the upper ends of the other two branches are connected with the two ends of the second cross shaft through the rotating pairs respectively. The 4SPR+2R type four-freedom-degree parallel mechanism has the advantages of being simple in structure, large in work space, high in rigidity, good in translational motion characteristic in all directions and the like.

Owner:YANSHAN UNIV

Missile-borne rudder wing spreading locking mechanism based on pin pusher actuation

A scheme that a rudder system with a wing spreading locking function pushes rudder sheets to spread simultaneously and lock the rudder sheets is adopted by the invention. After a rocket projectile is launched, the rudder system is powered by a missile-borne controller; after a rudder spreading command is emitted, the rudder system controller receives the rudder spreading command of the missile-borne control system; current amplification is performed after the rudder system controller receives a rudder spreading command signal, so that a pin pusher is started, and a pushing disc is pushed to spread the four rudder sheets simultaneously; after spreading angles reach 90 degrees, limiting is performed through the locking mechanism, and the whole wing spreading locking function is finished; and then, the missile-borne controller gives a rudder deflecting command, so that a rudder engine is controlled to drive the rudder sheets to swing, and a servo control function is realized. Meanwhile, for ensuring that the sailing posture of the rocket projectile is not affected, the spreading time of the four rudder sheets is very short and the asynchronism of spreading is very low.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

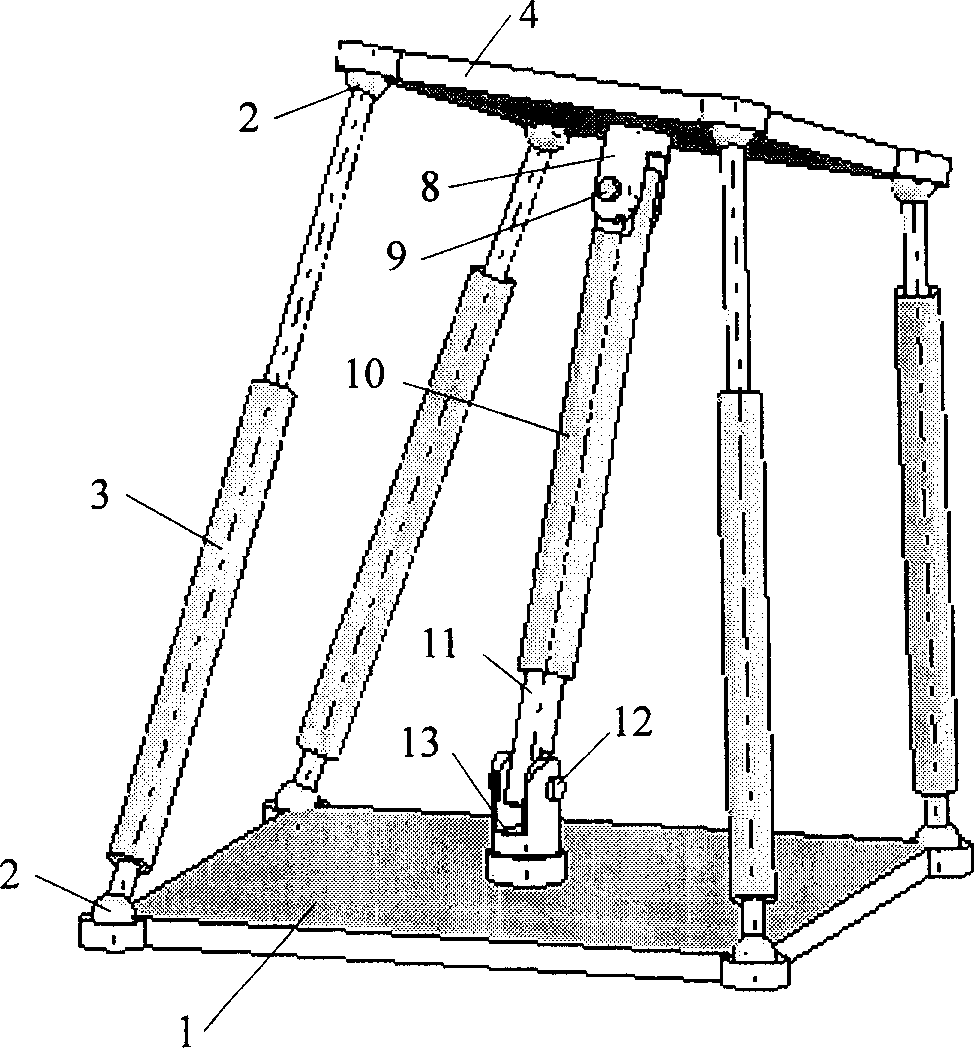

Experimental platform of parallel mechanism with 3 and 4 freedom and adjustable 3-UPU

InactiveCN1745986AHigh movement precisionAdjustable motion sub-poseProgramme-controlled manipulatorLarge fixed membersRotary stageUniversal joint

An experimental platform with adjustable 3-UPU parallel mechanism having 3-4 freedoms features that 3 linearly driven moving sets with same structure are symmetrically arranged on upper platform and base in equilateral triangle mode. Said linearly driven moving set is composed of a linear drive unit and a step motor. Its both ends are respectively linked with a universal joint which consists of a rotary axle connected to said linearly driven moving set to form a rotary set, a supporter connected to said rotary axle to form another rotary set, and a sectorial base. Said supporter is linked to upper platform and base via sectorial base and 4 pins. Its advantages are variable freedom and high moving accuracy.

Owner:YANSHAN UNIV

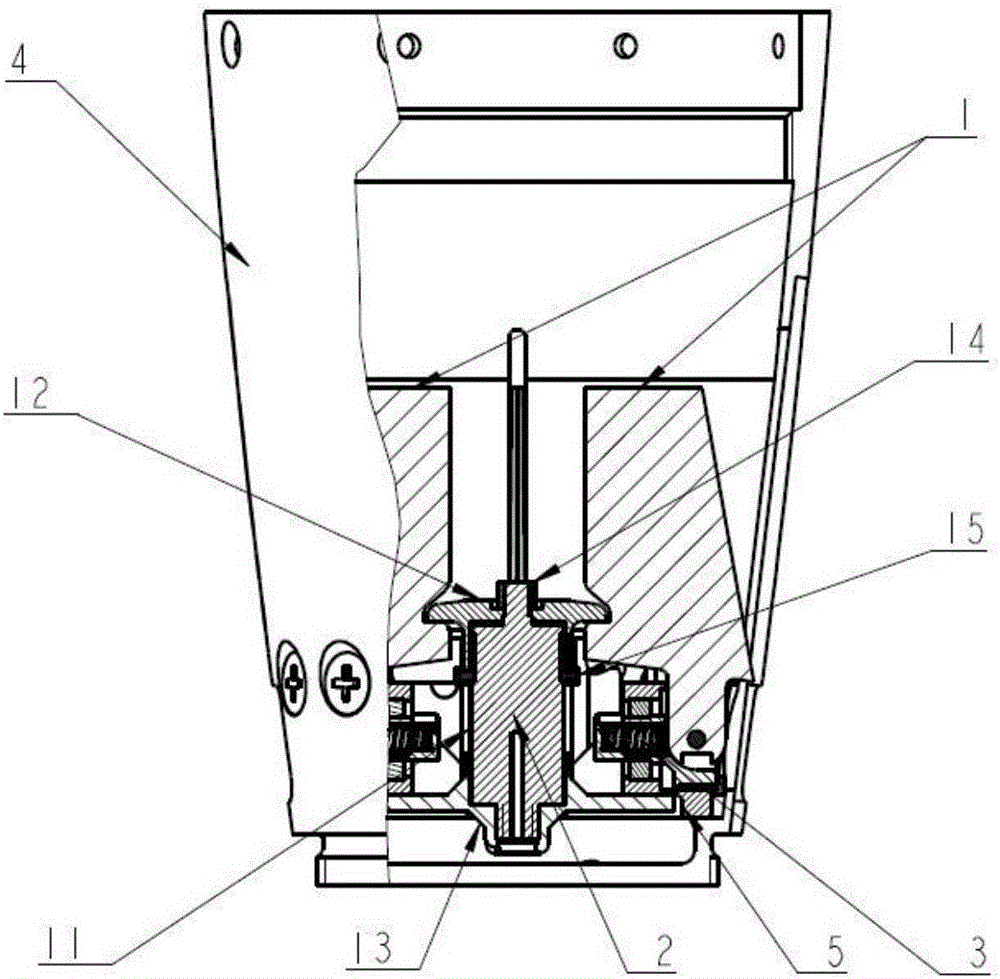

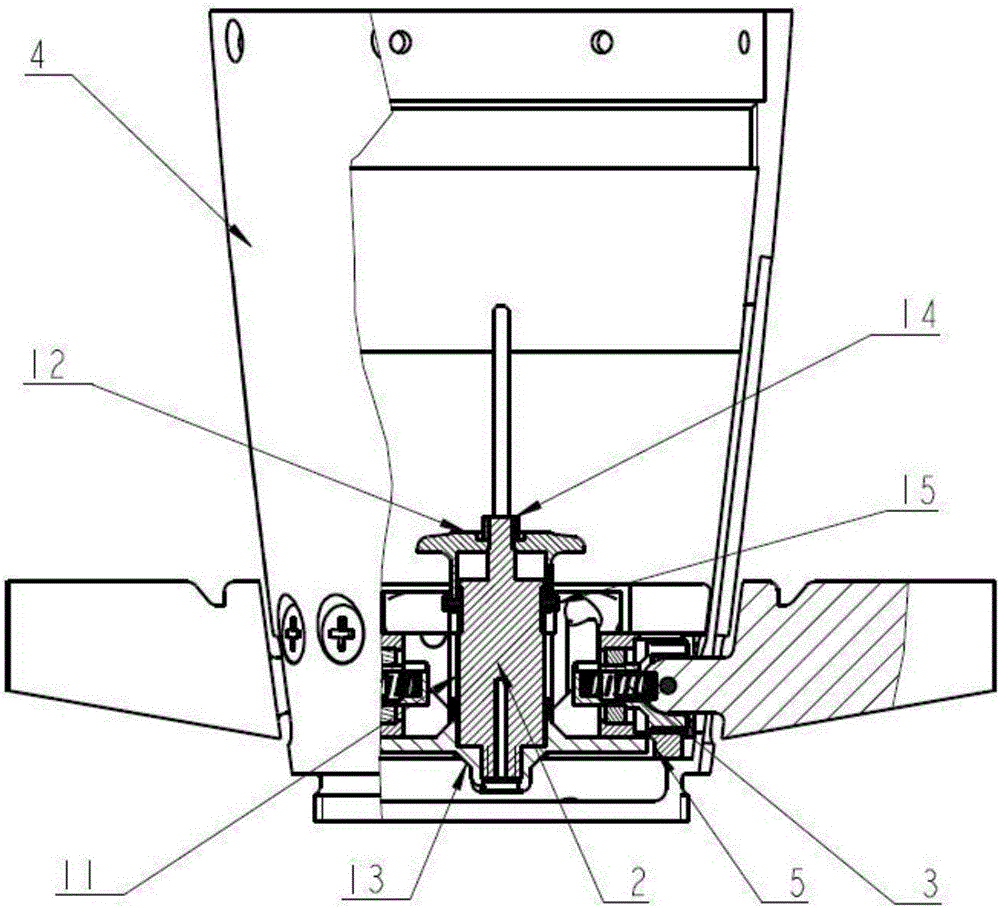

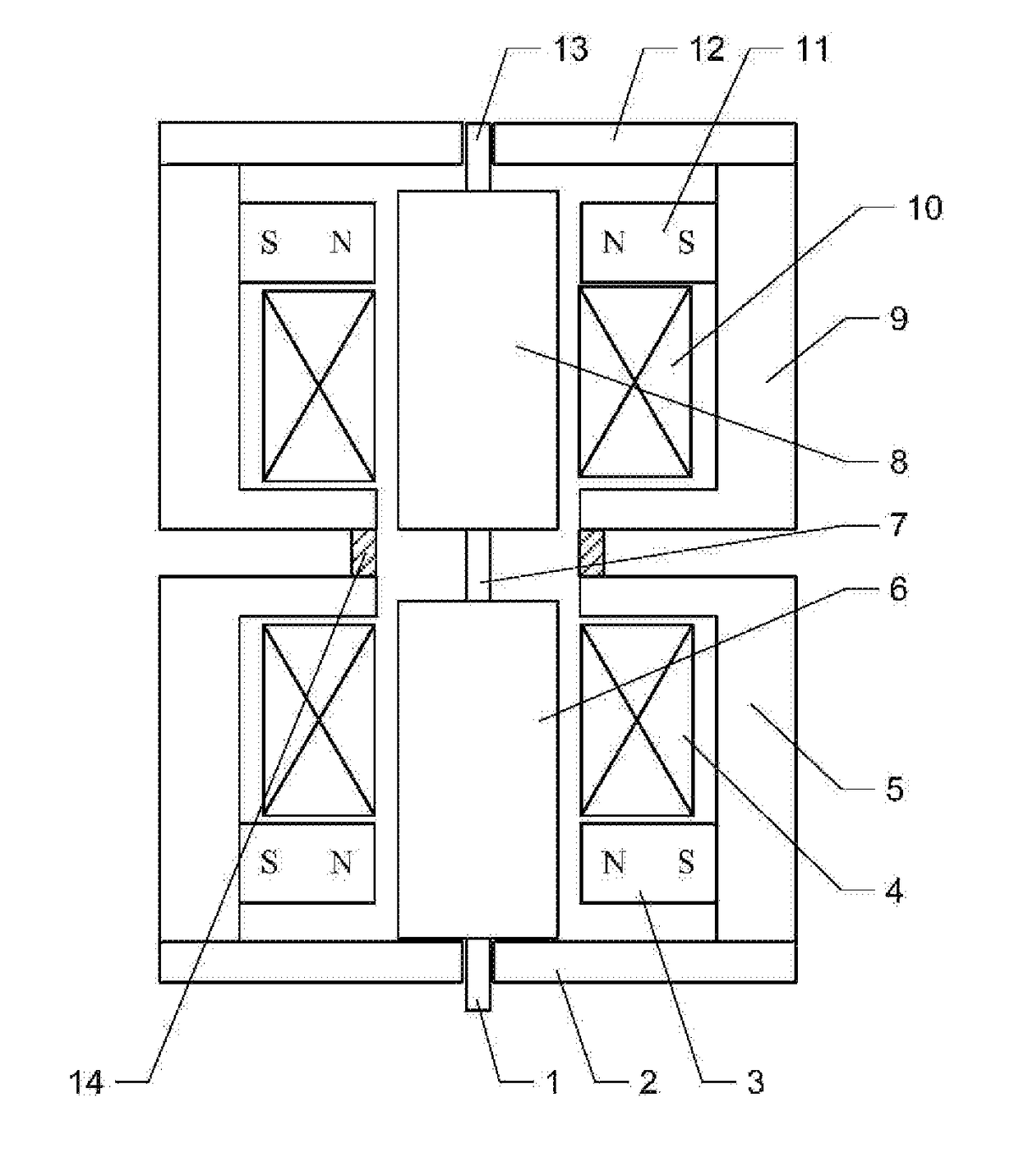

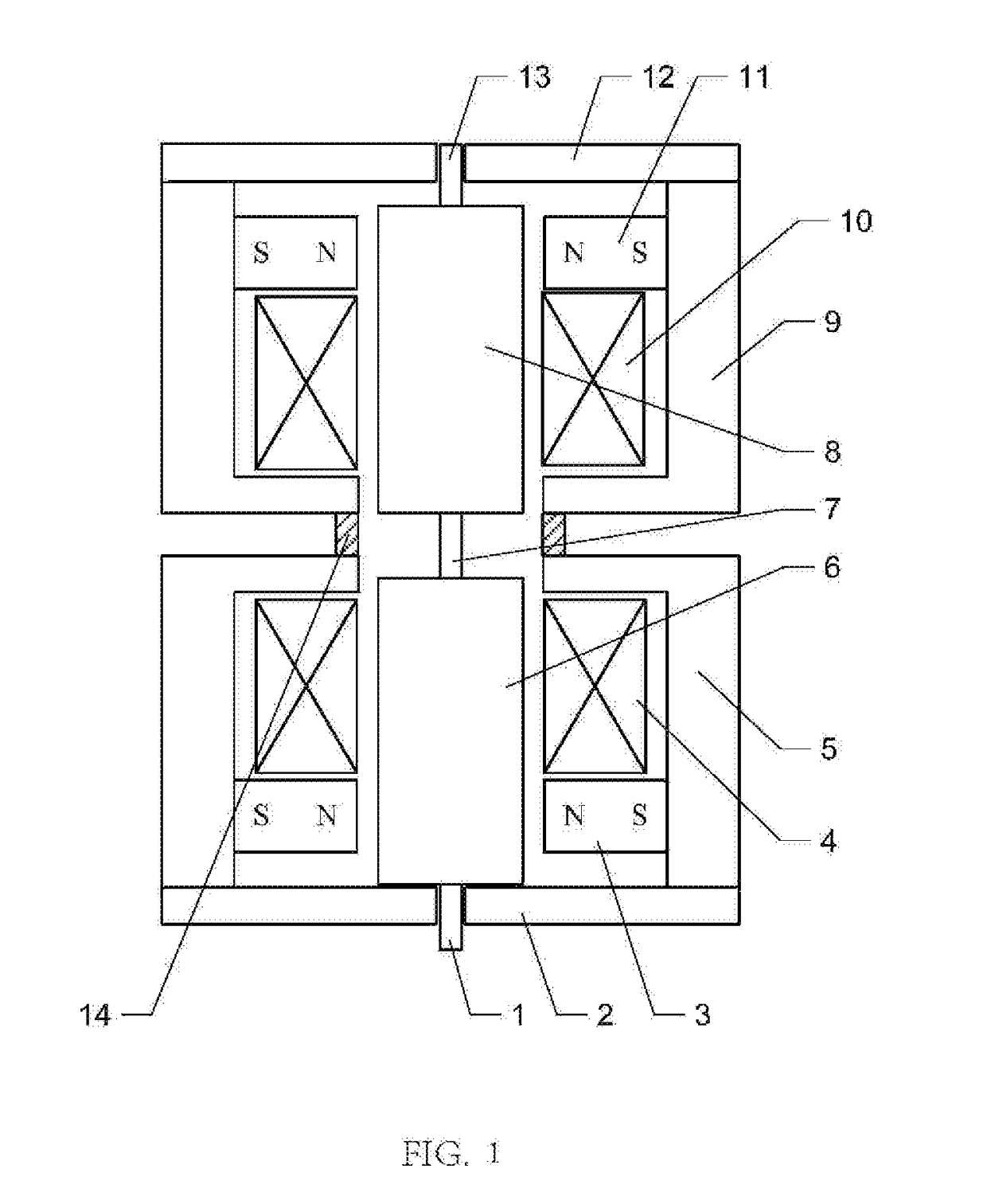

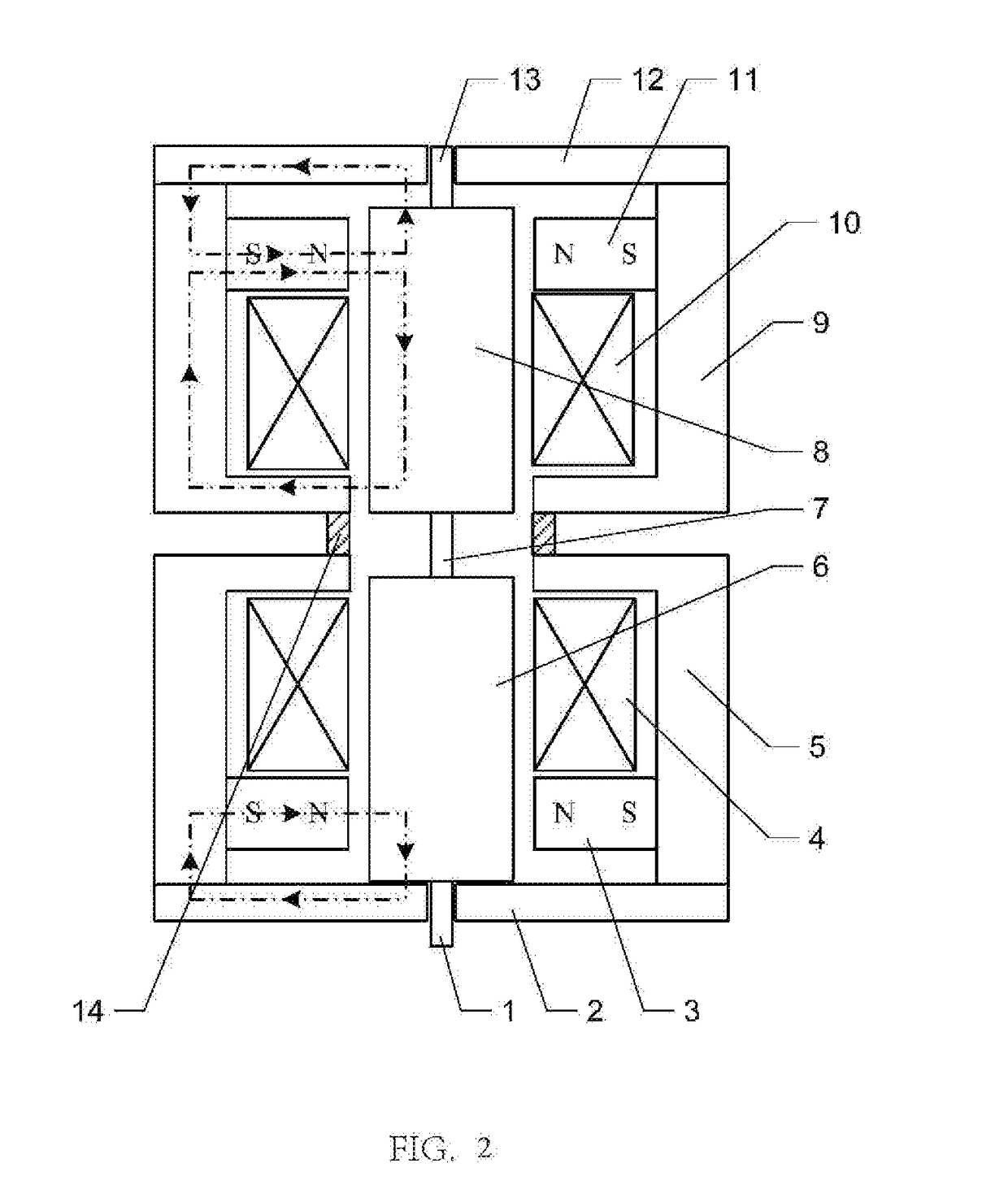

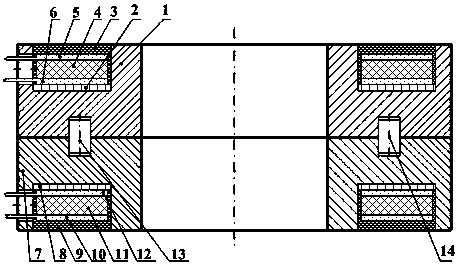

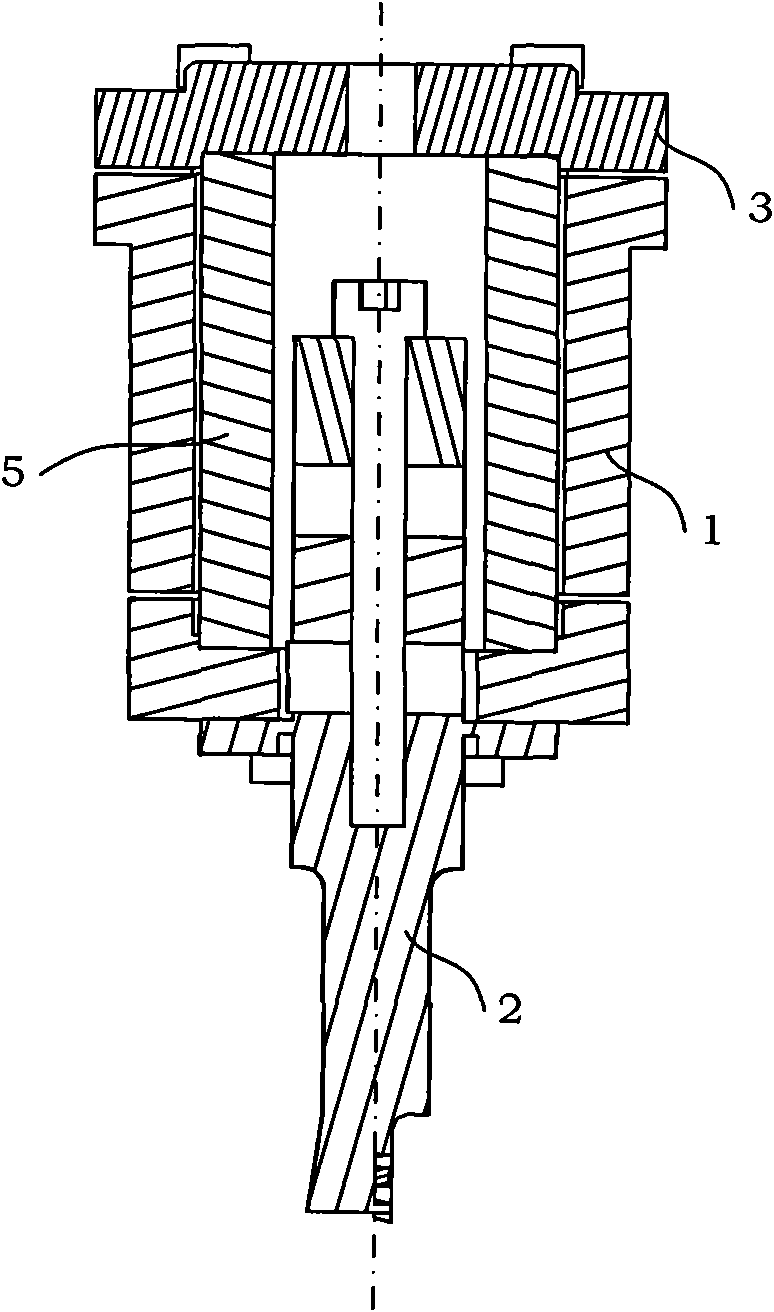

High-power bi-directional non-recovery spring magnetic valve comprising permanent magnet

ActiveUS20170074418A1Symmetrical in structureSimple assemblyOperating means/releasing devices for valvesTransformers/inductances casingsHigher PowerEngineering

A high-power bi-directional non-recovery spring magnetic valve including permanent magnets has an upper magnetic circuit part and lower magnetic circuit part symmetrically disposed and connected together via an armature connection rod and a housing connection ring, the upper magnetic circuit part comprises an upper iron core, an upper housing, an upper coil, an upper annular permanent magnet, an upper yoke iron and an upper push rod, the lower magnetic circuit part comprises a lower iron core, a lower housing, a lower coil, a lower annular permanent magnet, a lower yoke iron and a lower push rod. The magnetic valve comprising permanent magnets realizes bistable-state magnetic retaining, and has an adjustable retaining force for permanent magnet adjustment, quick response, and high output force.

Owner:HARBIN INST OF TECH

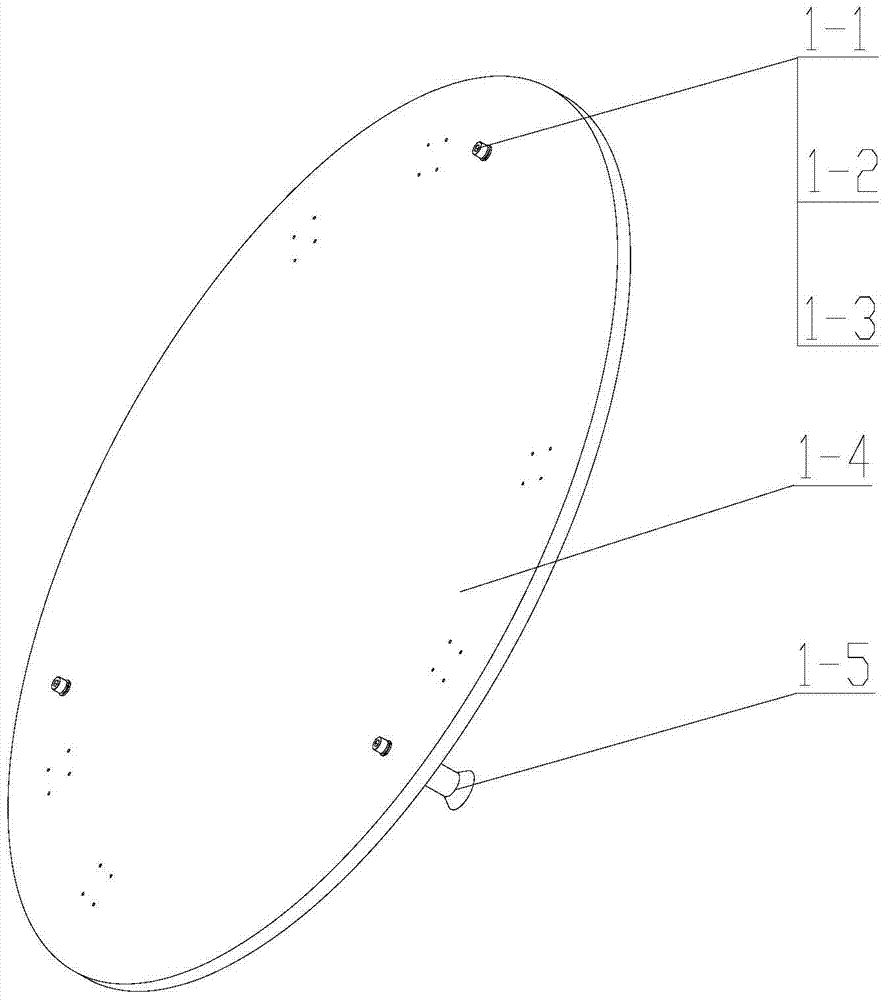

Piezoelectric intelligent material based bolt pre-tightening force sensor

InactiveCN103644997AImprove performanceNot easy to damageMeasurement of torque/twisting force while tighteningForce measurement using piezo-electric devicesStructural engineeringForce sensor

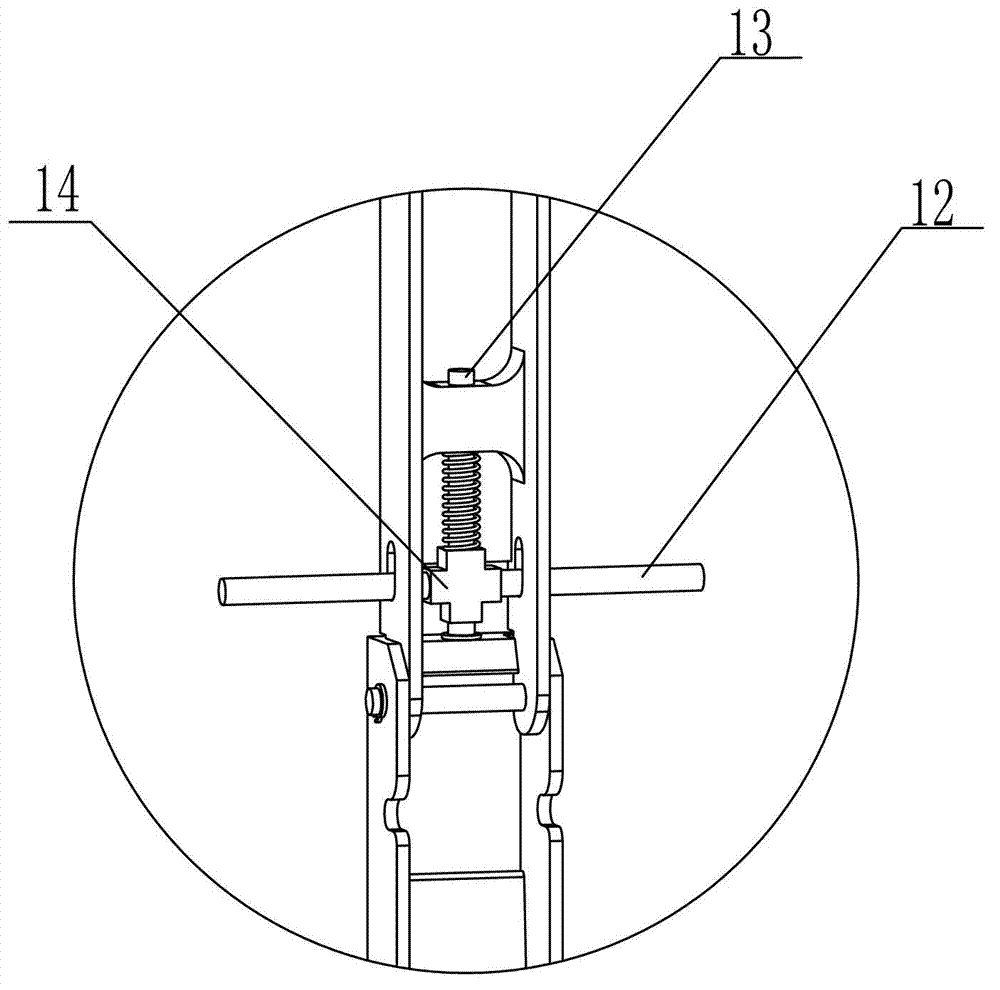

The invention relates to a piezoelectric intelligent material based bolt pre-tightening force sensor. According to the technical scheme, an upper gasket (1) and a lower gasket (7) of the bolt pre-tightening force sensor are fixed together back to back through a left positioning pin (13) and a right positioning pin (14); the front side of the upper gasket (1) is provided with a first annular groove concentrically; a wire leading hole is machined between the circumferential surface of the upper gasket (1) and the first annular groove; a first insulating layer (2) is brushed at the bottom of the first annular groove; a first upper electrode (5) and a first lower electrode (6) are pasted on the upper plane and the lower plane of a first annular piezoelectric ceramic (4) correspondingly to form a first annular piezoelectric ceramic assembly which is pasted on the first insulating layer (2) arranged at the bottom of the first annular groove; a first insulating sealant (3) is filled between the first annular piezoelectric ceramic assembly and the first annular groove; a first insulating sealant (3) is coated on the upper plane of the first annular piezoelectric ceramic assembly. The piezoelectric intelligent material based bolt pre-tightening force sensor has the advantages of being strong in universality, simple in structure, long in service life and low in cost.

Owner:WUHAN UNIV OF SCI & TECH

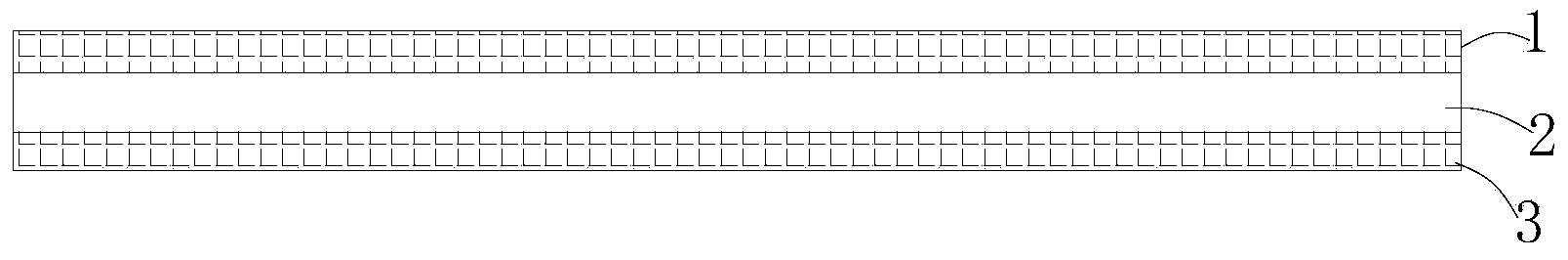

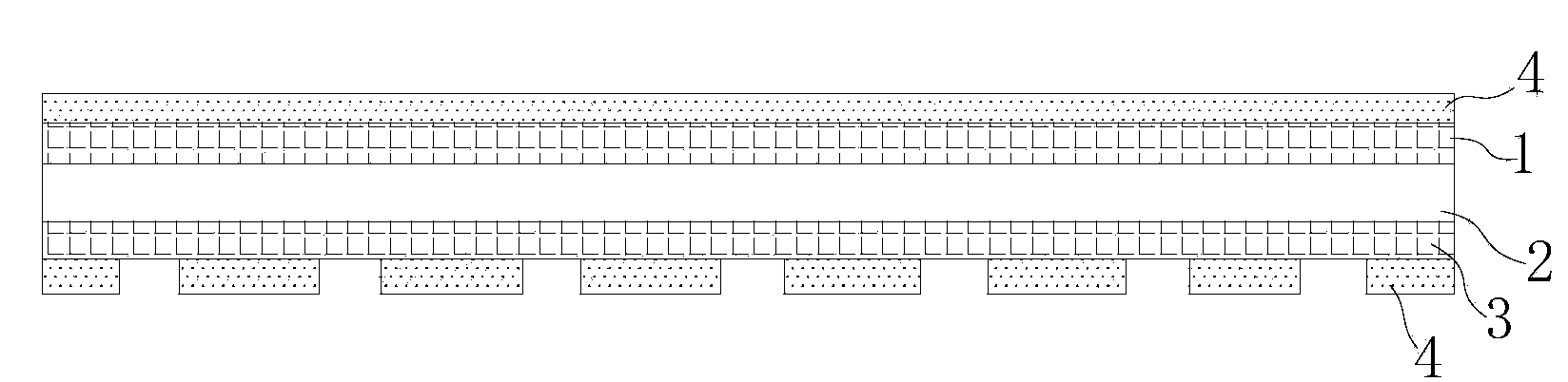

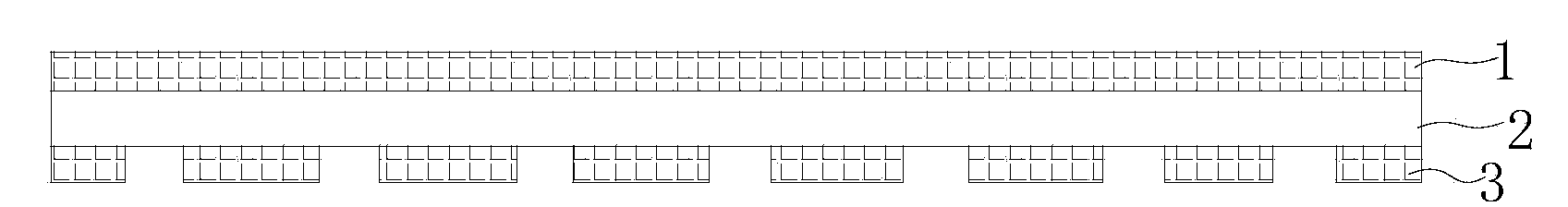

Manufacturing method for thin coreless substrate

ActiveCN104244616ALow costEmbeddingSemiconductor/solid-state device manufacturingMultilayer circuit manufactureEngineeringCopper foil

The invention discloses a manufacturing method for a thin coreless substrate. The method comprises the steps of a, sequentially stacking first copper foil, first prepreg and second copper foil for conducting pressing fit for the first time to obtain a first substrate, and manufacturing a second circuit on the second copper foil, wherein the second circuit comprises a first bonding pad, and the first bonding pad extends towards the periphery to form an electroplating frame; b, on the premise that the electroplating frame is exposed, sequentially stacking second prepreg and third copper foil on the second copper foil for conducting pressing fit for the second time to obtain a second substrate, and manufacturing a first circuit and a third circuit respectively so as to obtain a substrate workblank; c, conducting pressing fit for the third time; d, forming a first blind hole and a second blind hole, and filling the first blind hole and the second blind hole by the adoption of the electroplating hole filling technology respectively to obtain a substrate model. The thin coreless substrate is manufactured through the manufacturing method, is a three-layer coreless substrate, has the symmetric pressing-fit condition and the pressing-fit structure, and achieves internal layer circuit embedment.

Owner:NAT CENT FOR ADVANCED PACKAGING

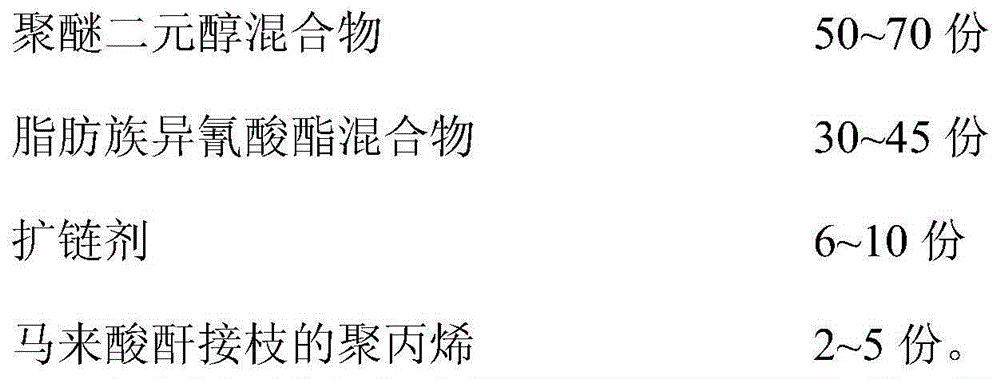

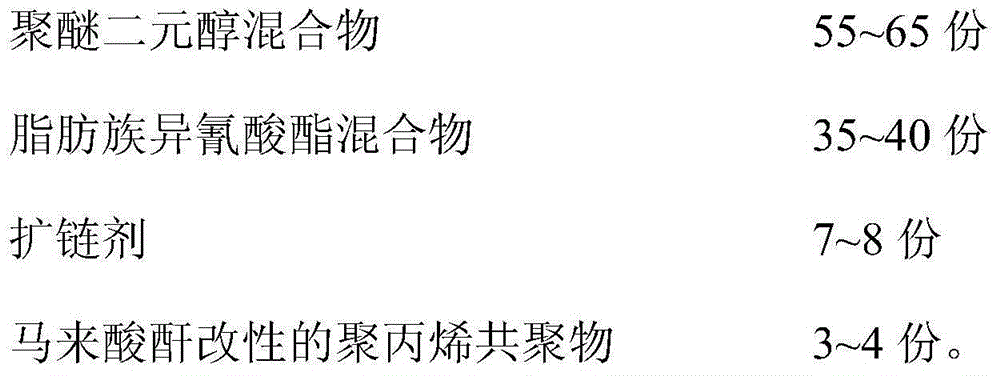

High-transparency polyurethane elastomer and preparation method thereof

The invention provides high-transparency polyurethane elastomer and a preparation method thereof. The high-transparency polyurethane elastomer is mainly prepared by adopting the following components: a polyether glycol mixture, an aliphatic isocyanate mixture, a chain extender and maleic anhydride grafted polypropylene; the polyether glycol mixture is a mixture of polytetramethylene ether glycol, polyoxytetramethylene glycol and polypropylene epoxy glycol; the aliphatic isocyanate mixture is a mixture of hexamethylene diisocyanate and isophorone diisocyanate; the chain extender is a mixture of 1,4-isophorone diisocyanate and diethylene glycol. By adjusting the dosage ratio of all components, by utilizing the synergism of HDI and IPDI, the transparency and transparent duration of the polyurethane elastomer are improved; the mixture of the 1,4-isophorone diisocyanate and diethylene glycol is used as the chain extender, so that the crystallization of a hard section of the polyurethane elastomer is inhibited, a plurality of small sections are formed, the specific surface area is increased, the deformation of a soft-section base material is effectively inhibited, and the mechanical performance is improved.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

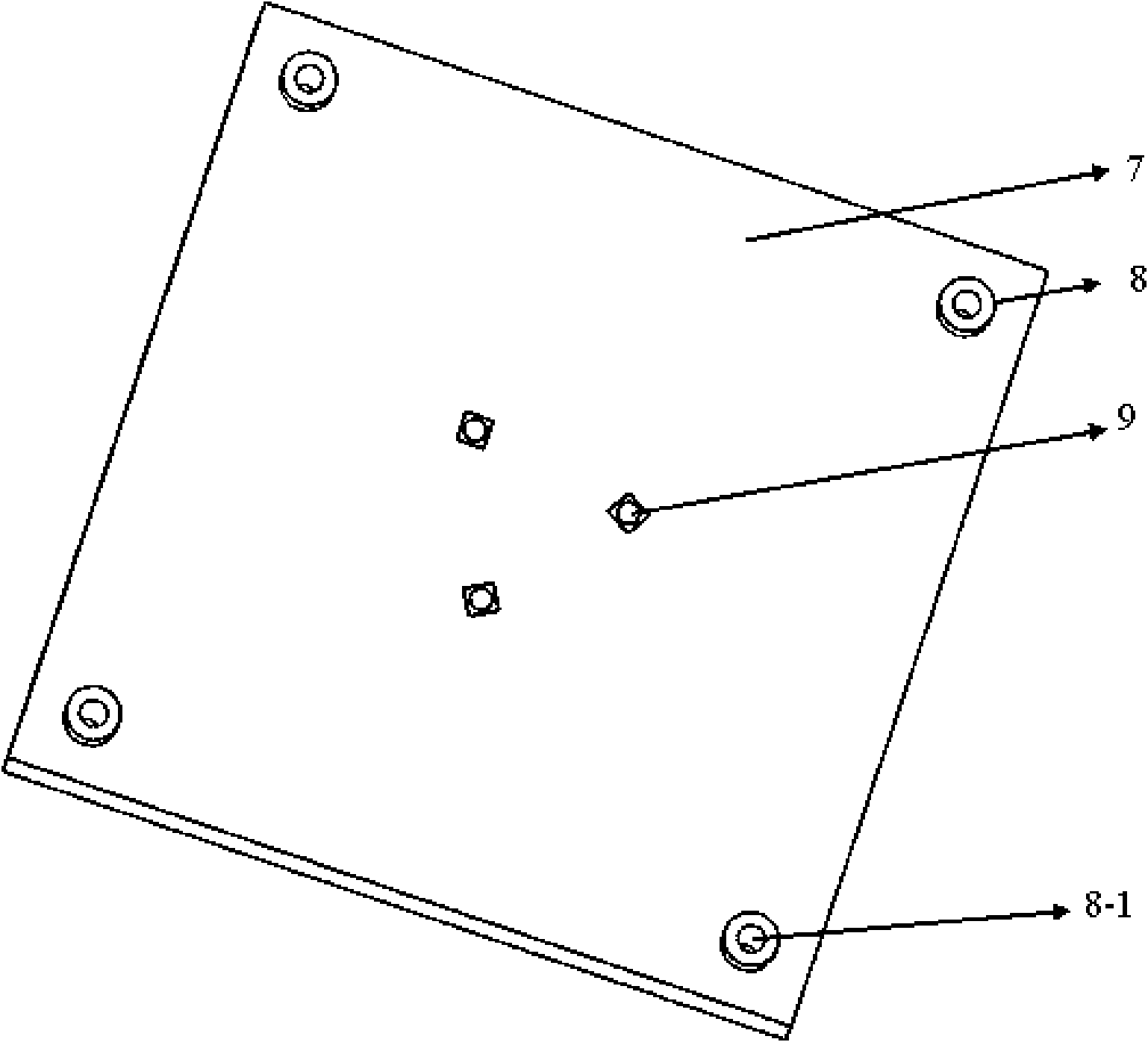

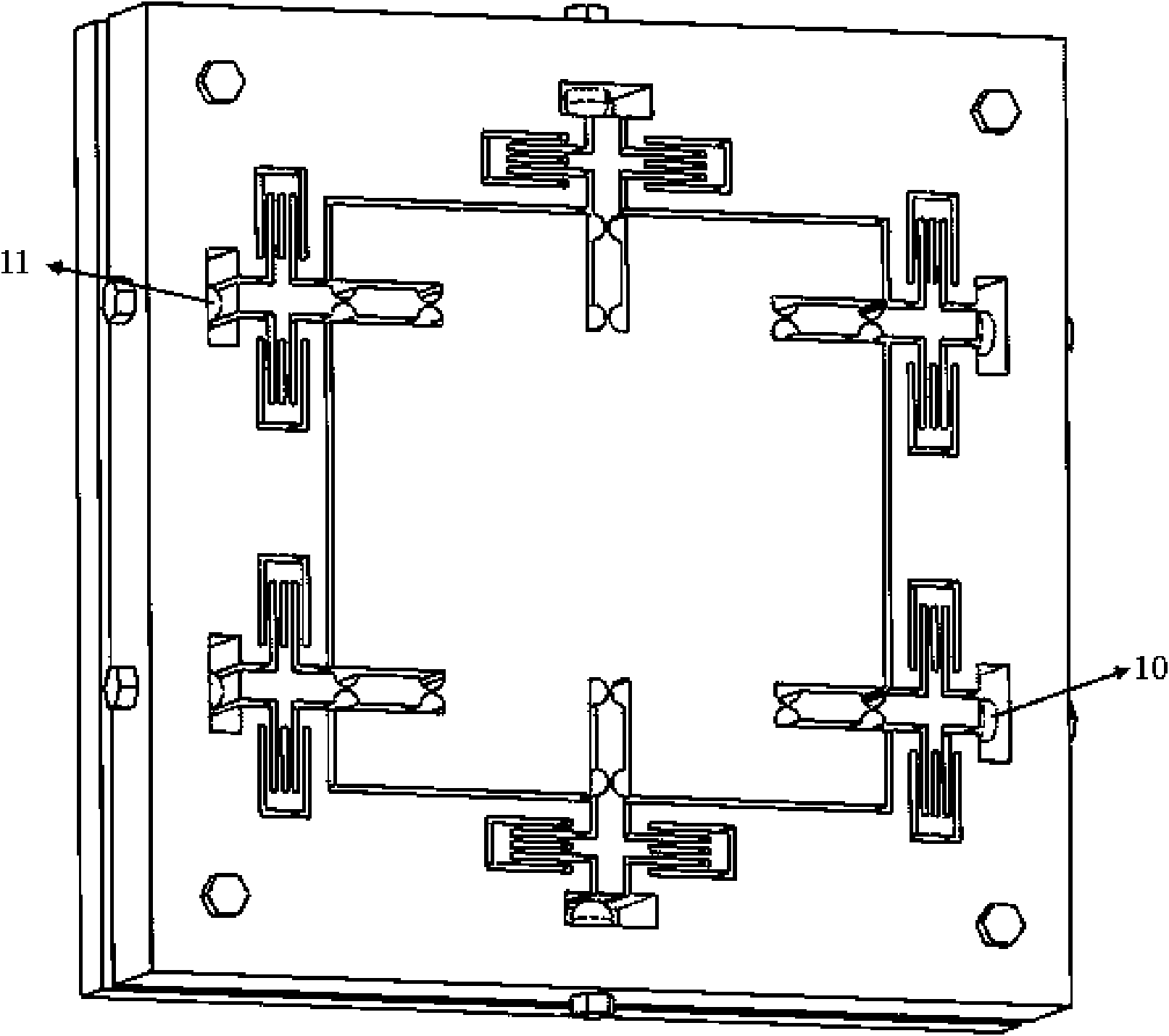

Three DOF micro-positioning workbench for nano-imprint lithography system

InactiveCN101776851AAvoid assemblyNo gapPhotomechanical exposure apparatusMicrolithography exposure apparatusFlexible MechanismsLithographic artist

The invention discloses a three DOF micro-positioning workbench for a nano-imprint lithography system, which comprises six piezoelectric ceramic drives; and each drive is connected with a base, and the top end is connected with a spherical connector by thread. The workbench also comprises six flexible fork chains of a flexible mechanism with totally consistent structure and a moving platform which is supported by the flexible fork chains; and three position sensors are used to measure the actual output of the moving platform, and are respectively fixed between a rigid support and the moving platform. The micro-positioning workbench is characterized by high resolution and high dynamic response speed, can serves as an auxiliary positioning platform of a nano-imprint lithography positioning system, and realize micro feeding and precise positioning.

Owner:TIANJIN UNIV

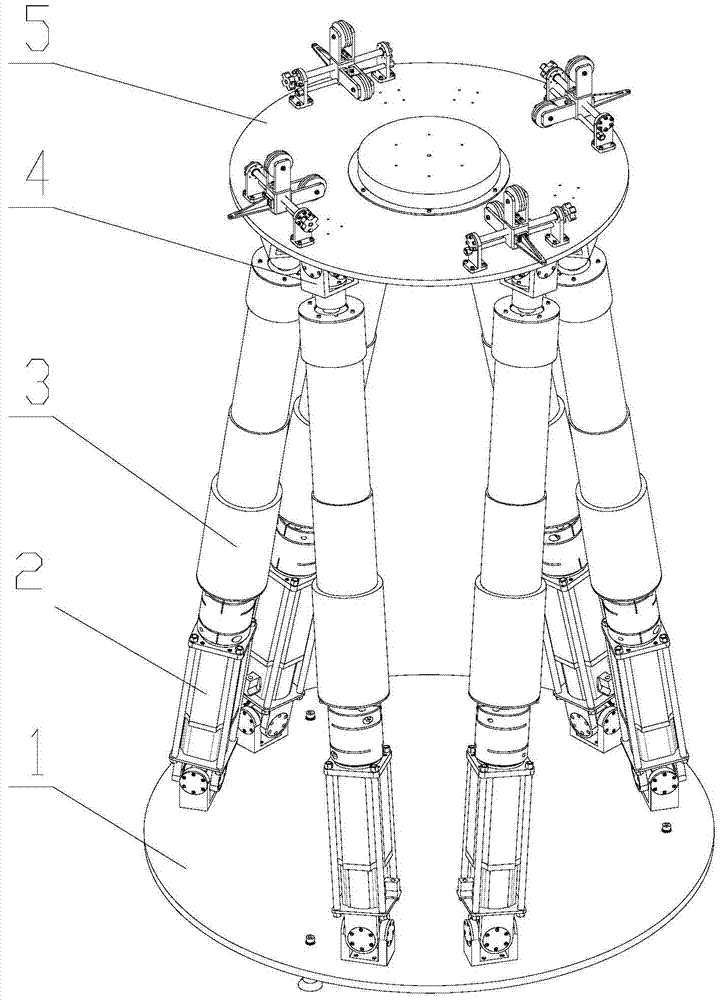

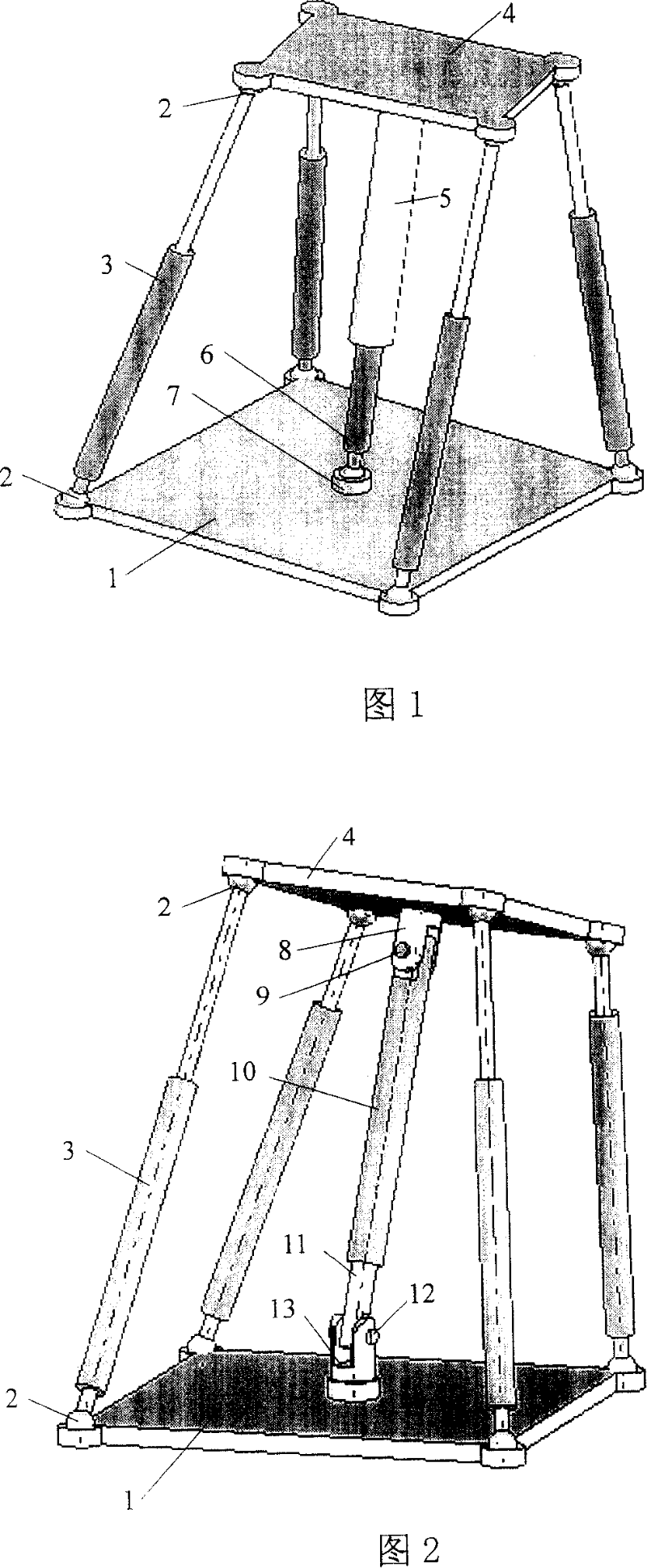

Multi-dimensional force sensor calibration device with controllable poses

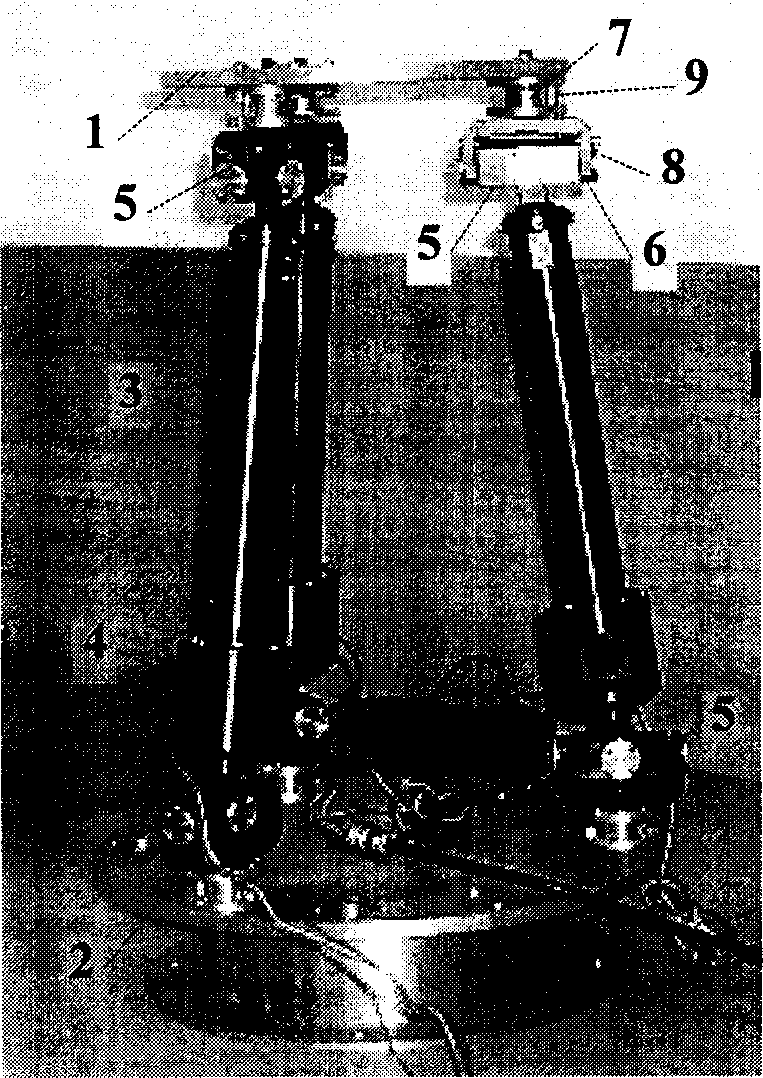

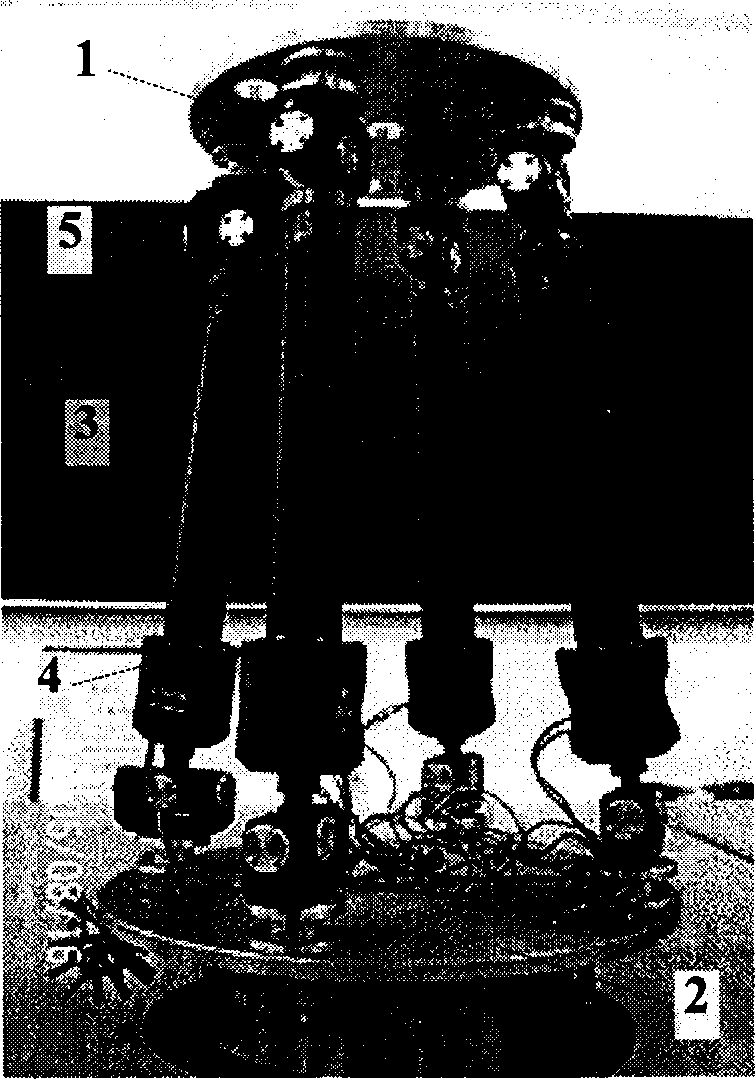

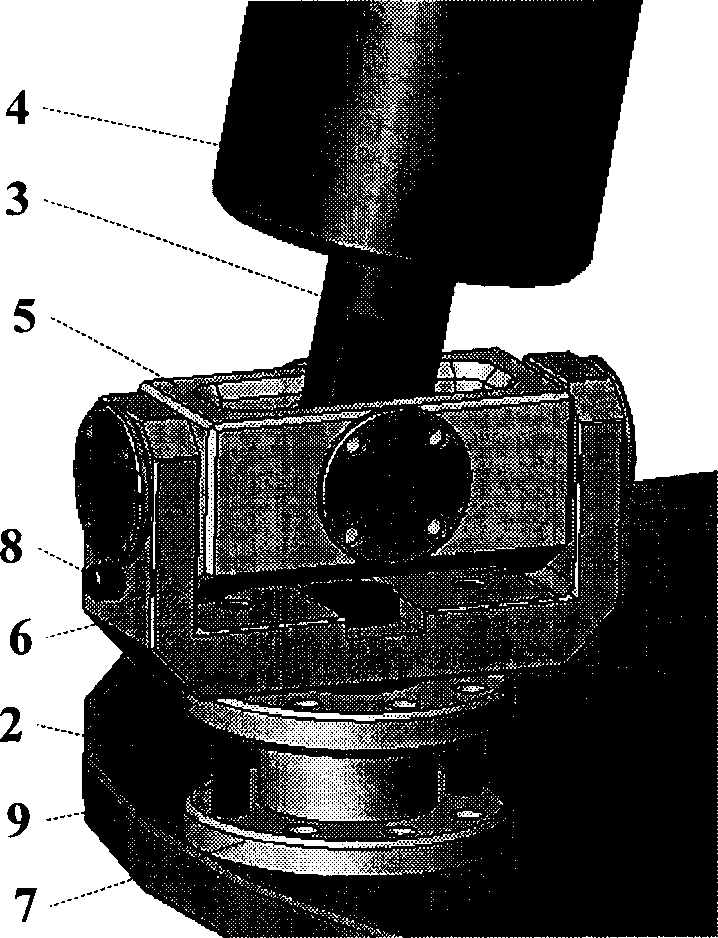

InactiveCN103926038ARealize dynamic calibrationRealize functionForce/torque/work measurement apparatus calibration/testingChinese charactersEngineering

The invention provides a multi-dimensional force sensor calibration device with controllable poses. The multi-dimensional force sensor calibration device comprises a fixing platform, drive mechanisms, connecting rod mechanisms and a moving platform. The upper ends of the drive mechanisms and the lower ends of the connecting rod mechanisms are connected to form drive connecting rod mechanisms. The upper ends of the six drive connecting rod mechanisms are hinged to the moving platform through universal hinges, and the lower ends of the six drive connecting rod mechanisms are hinged to a fixed platform to form a six-freedom-degree parallel mechanism. The six drive connecting rod mechanisms are divided into three groups. Every two adjacent drive connecting rod mechanisms form one group and are arranged in the mode shaped like a Chinese character 'ba'. The poses of a calibration platform can be controlled and changed, and the calibration device has the function of calibrating a sensor dynamically and statically, and is complete in function, convenient to operate, high in calibration precision and capable of being well applied to practical engineering.

Owner:HARBIN ENG UNIV

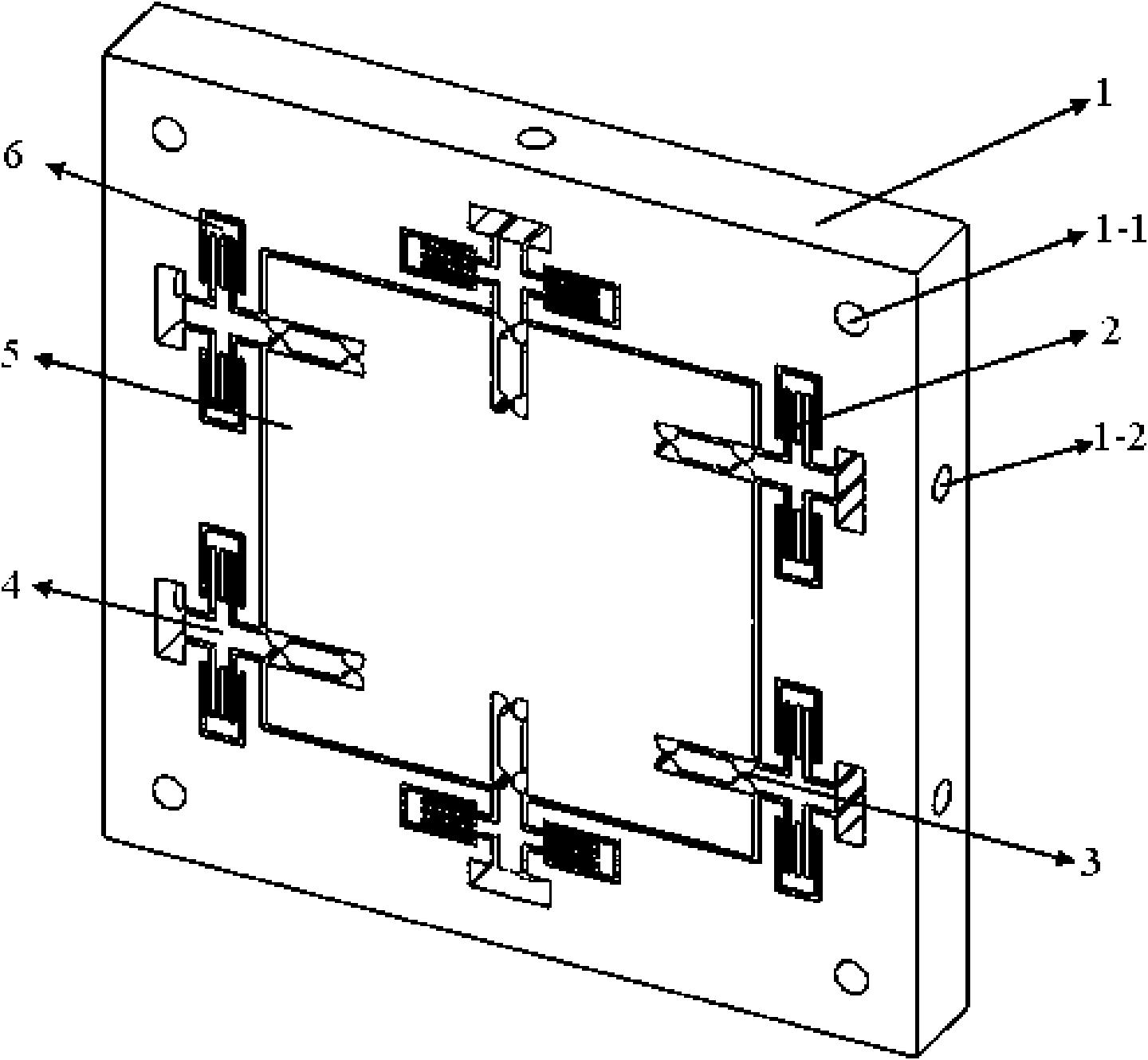

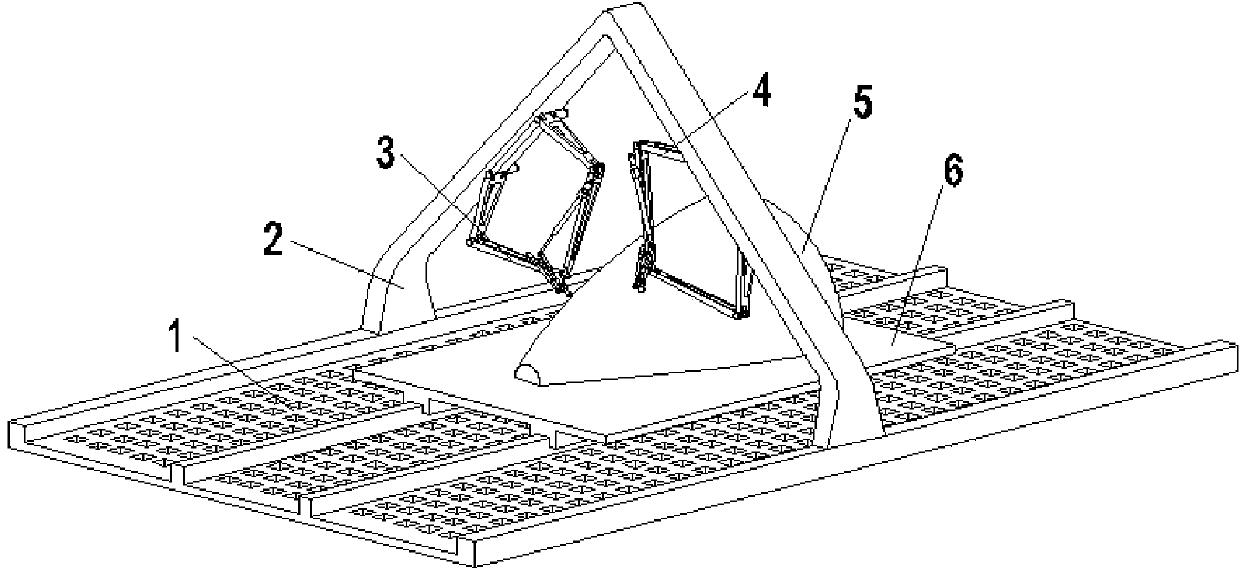

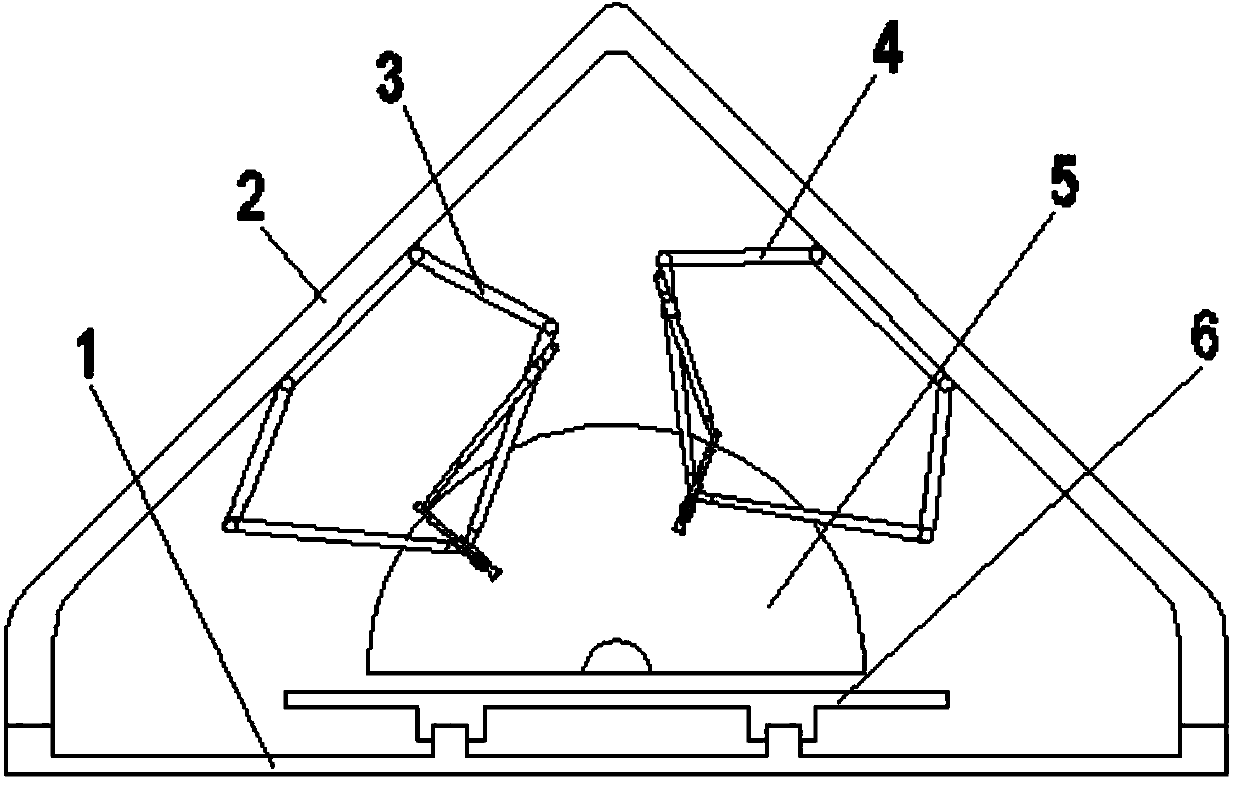

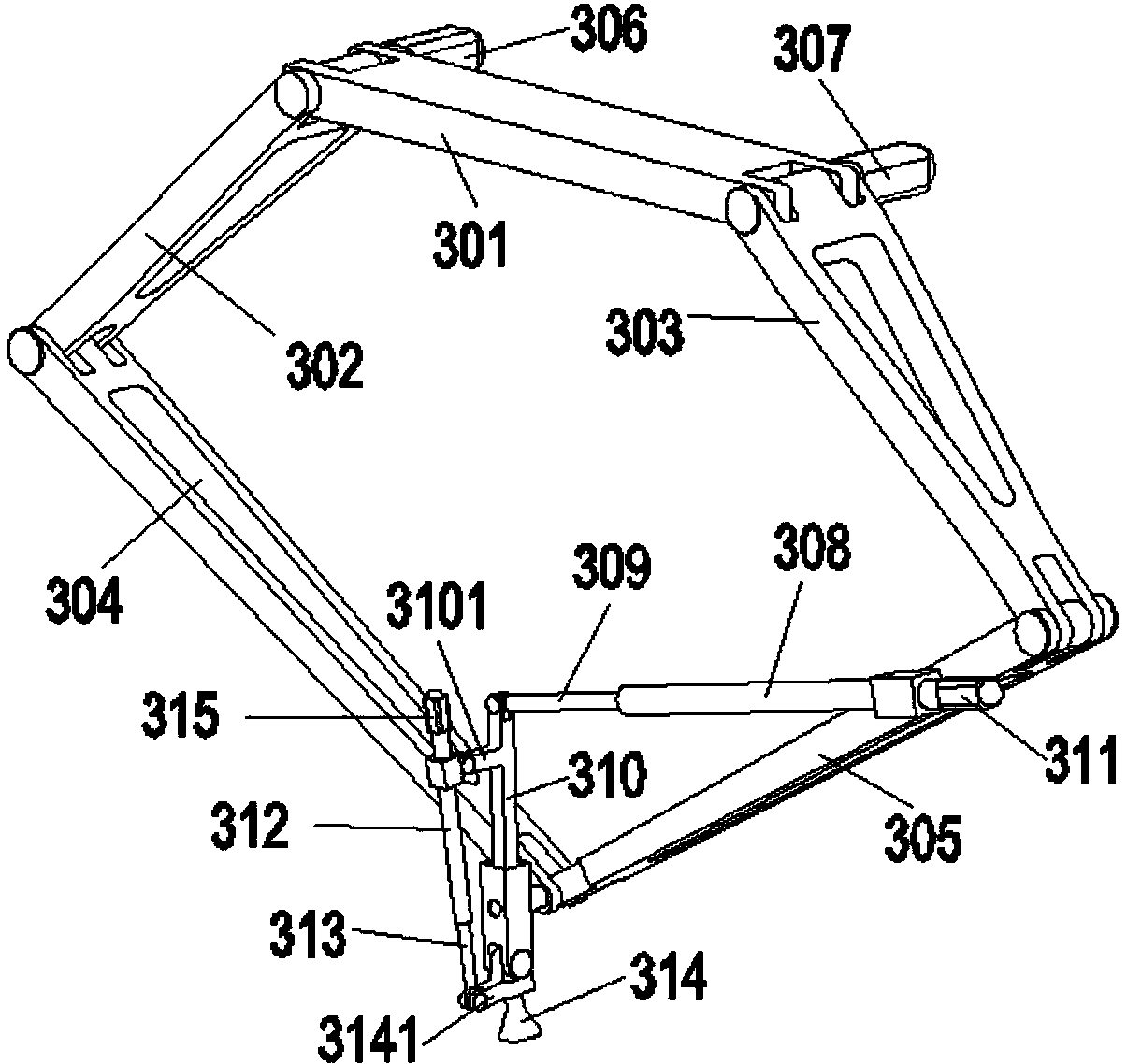

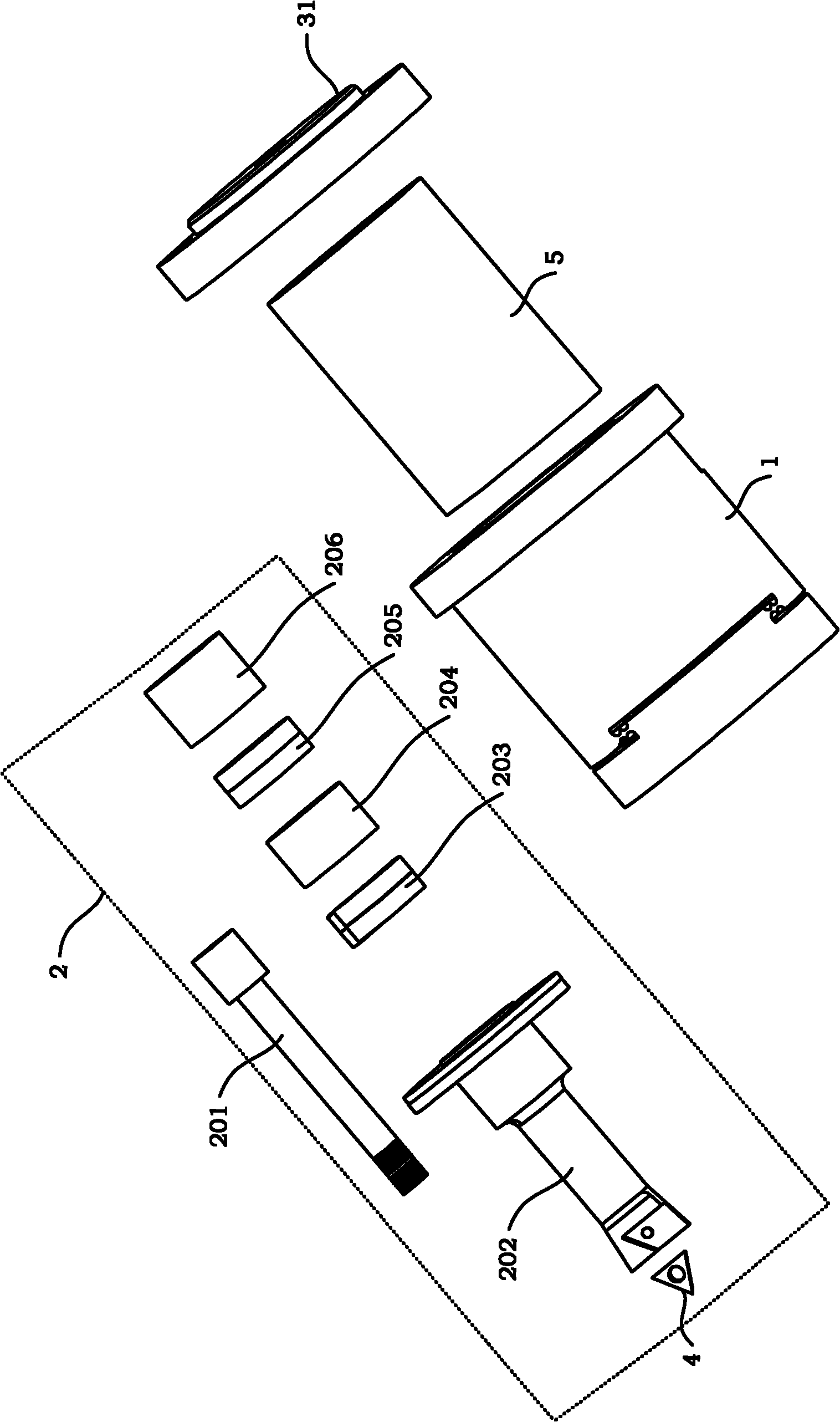

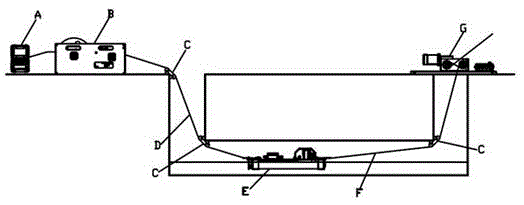

Spraying mechanism based on four-degree-of-freedom spraying module

ActiveCN103623971ALight in massReduce exerciseLiquid surface applicatorsCoatingsStructural symmetryEngineering

The invention relates to a spraying mechanism based on a four-degree-of-freedom spraying module and belongs to the field of machine manufacturing. The mechanism comprises a base, a gantry rack, a movable platform and a spraying work module, wherein the gantry rack is fixedly arranged on the base; the movable platform can realize translation on a guide rail along the base; the spraying work module comprises two spraying modules which have the same structure and can independently realize four-degree-of-freedom motions; the two spraying modules are symmetrically mounted on the gantry rack respectively. Each spraying module comprises a plane five-pair mechanism and two retraction mechanisms to form a space hybrid mechanism; a nozzle at the tail end of the mechanism is driven by four servo motors to move to realize two movable degrees of freedom and two rotary degrees of freedom. The motions of the moveable platform and the spraying work module are combined so that the spraying mechanism can realize the spraying work of the three movable degrees of freedom and the two rotary degrees of freedom. The spraying mechanism has structural symmetry, high sensitivity and high rigidity, and is easy to manufacture and convenient to control; the modularization is easy to realize.

Owner:TSINGHUA UNIV

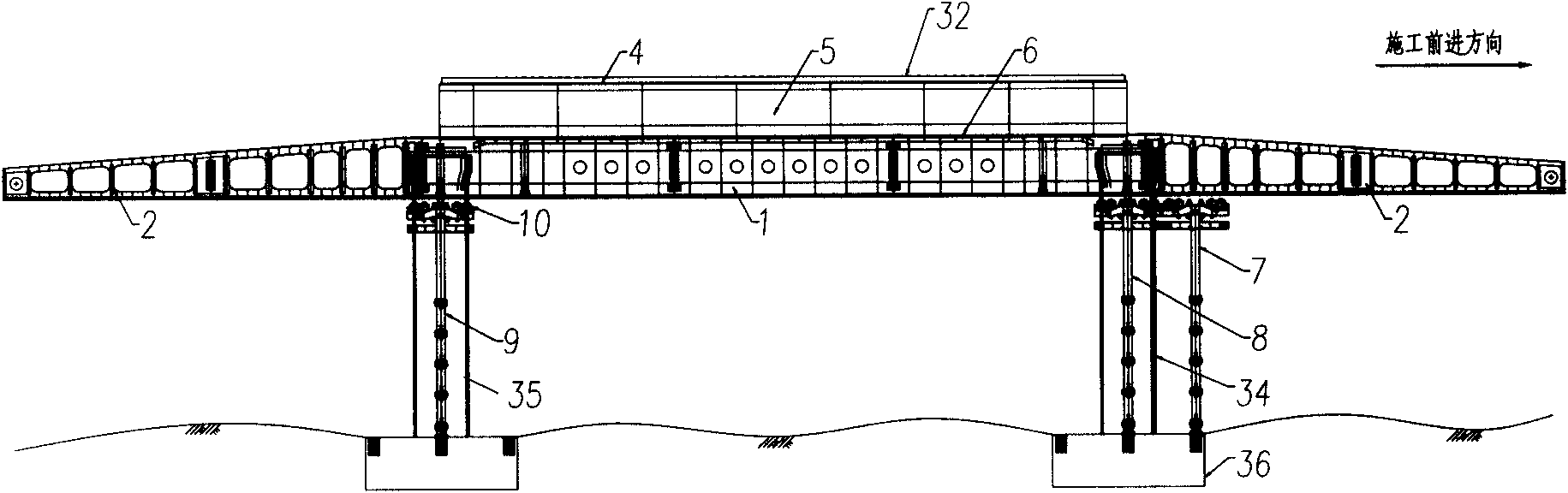

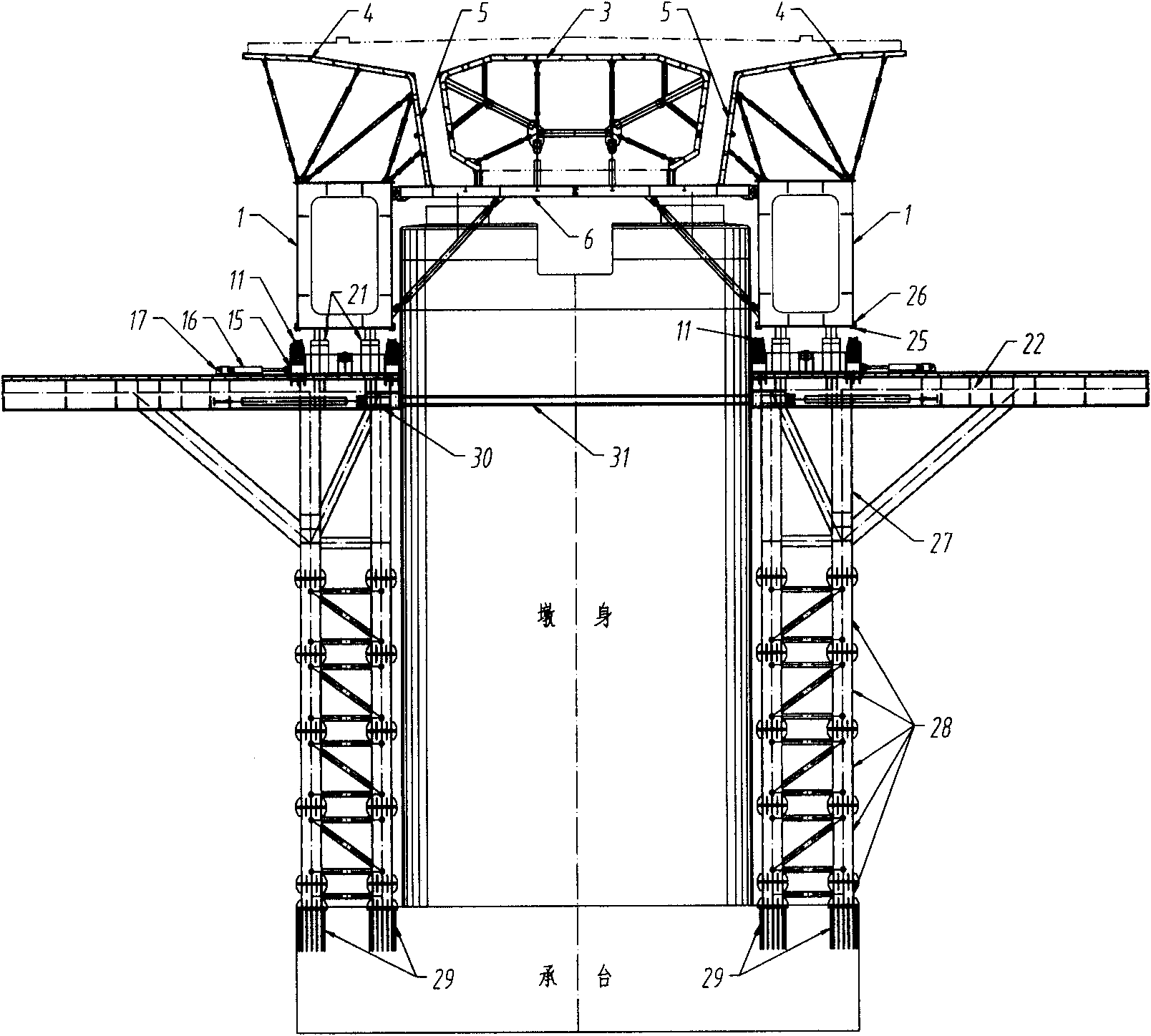

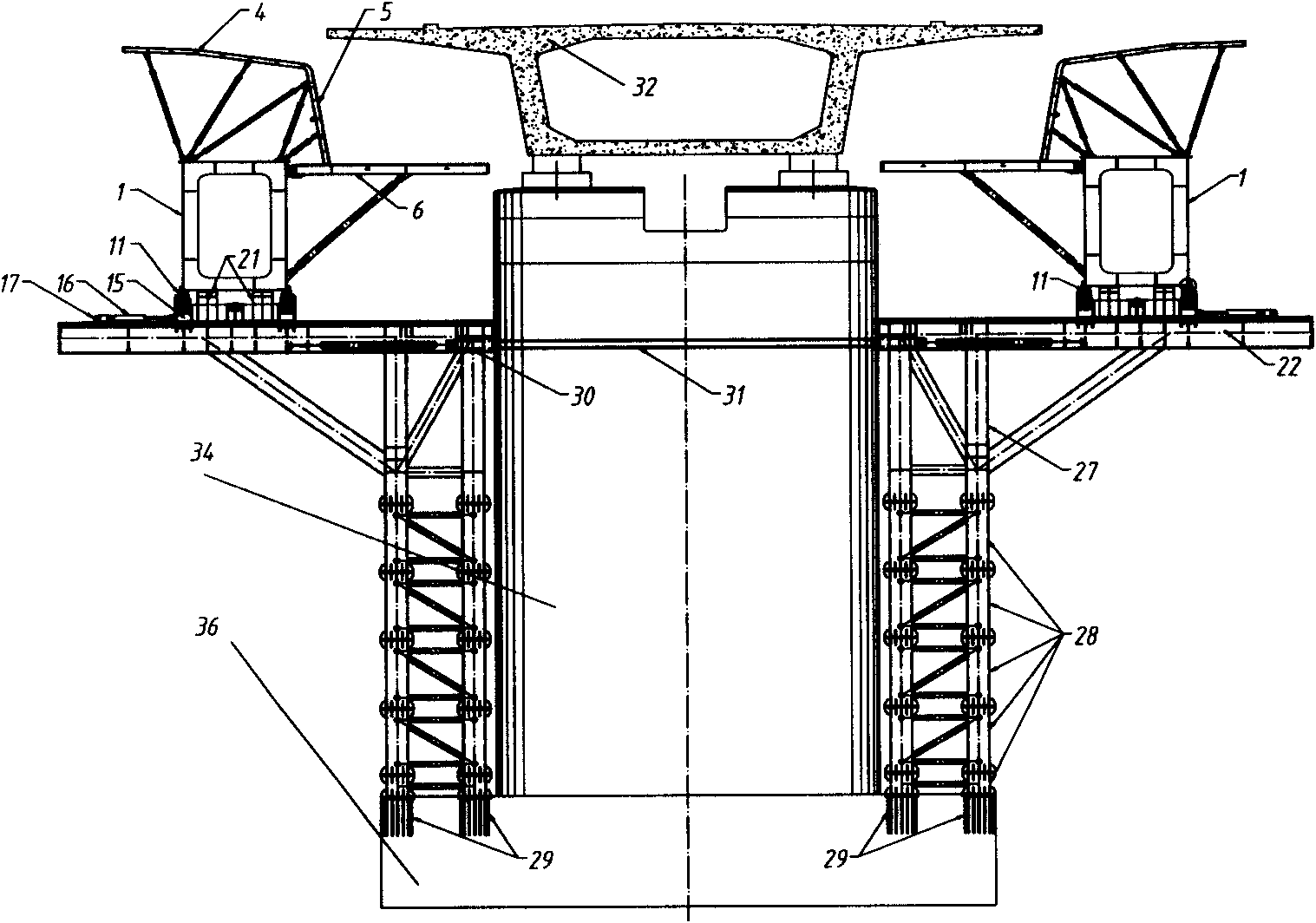

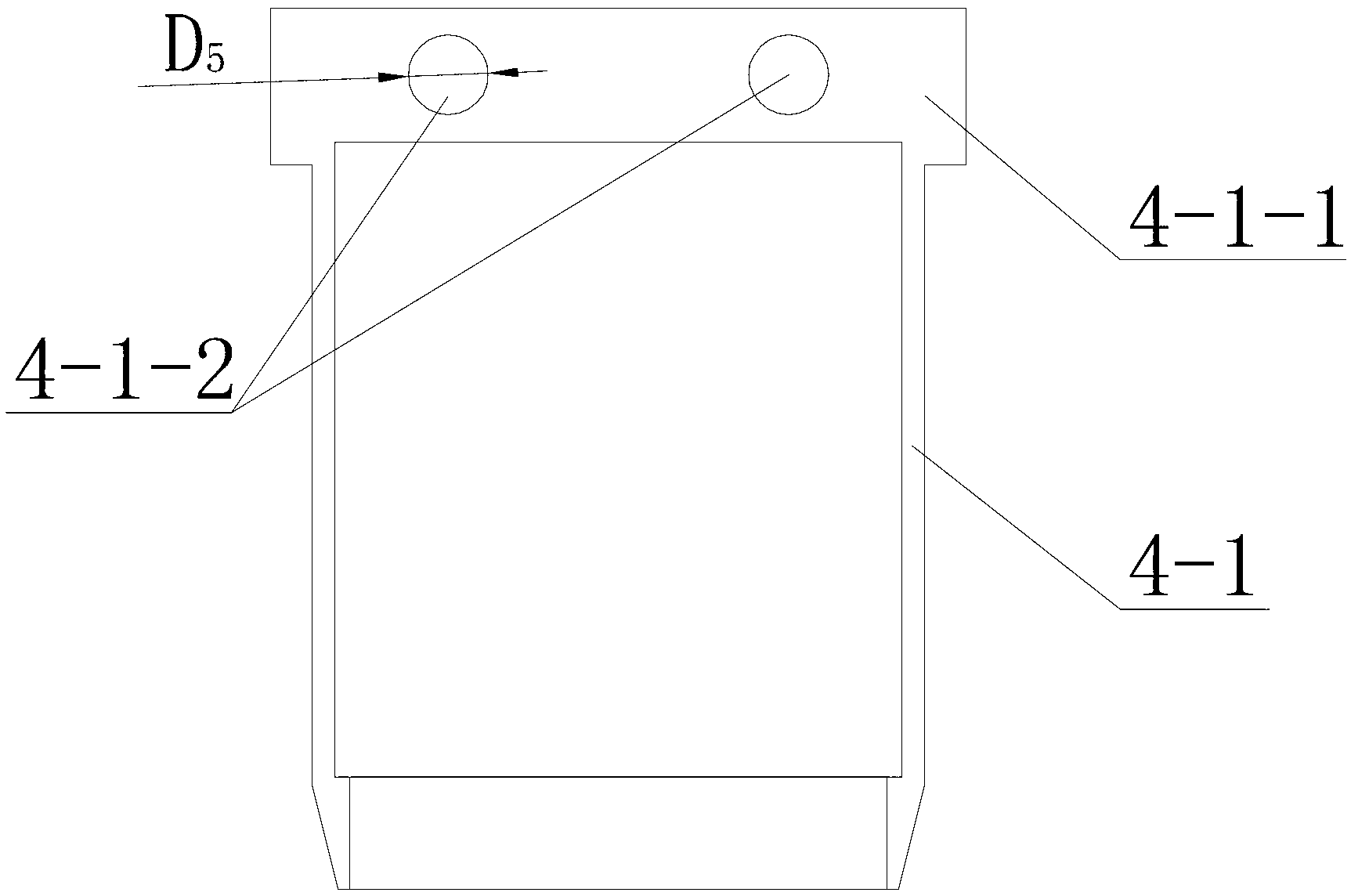

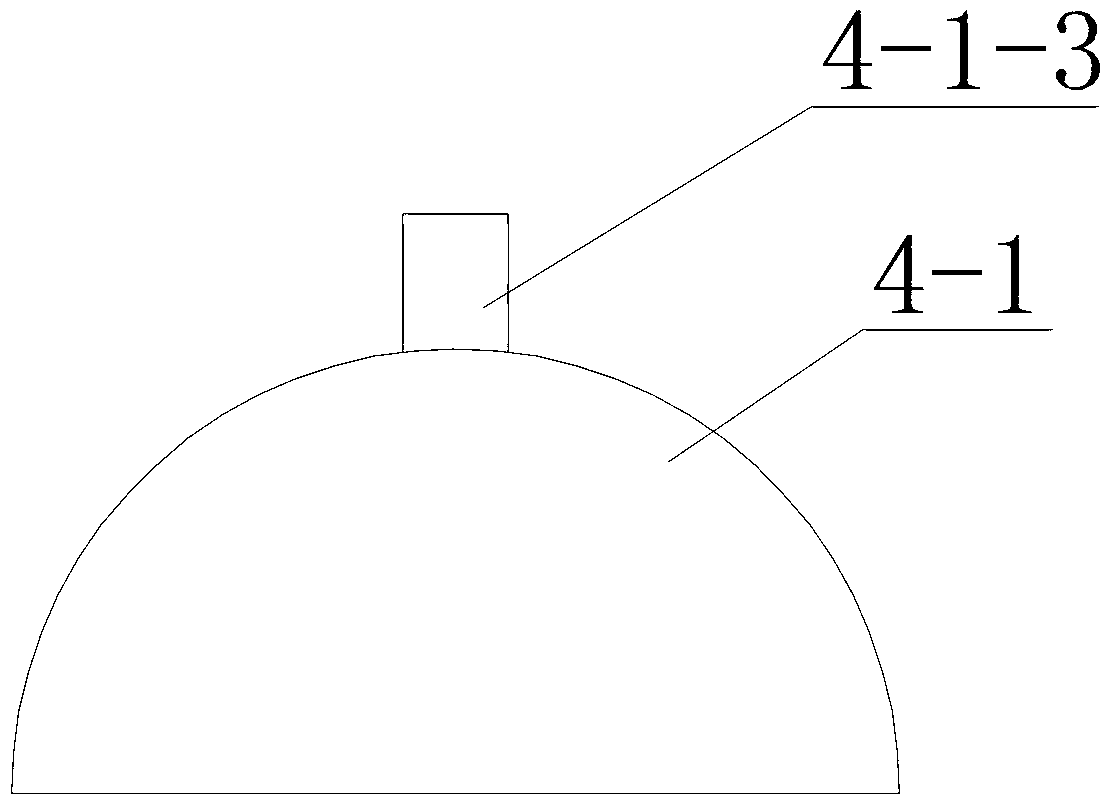

Downlink movable mould frame and walking method thereof

ActiveCN101581073AIngenious ideaReasonable designBridge erection/assemblyEngineeringStructural engineering

The invention discloses a downlink movable mould frame and a walking method thereof. The downlink movable mould frame comprises a girder, a guide beam connected at two ends of the girder and a mould frame system arranged on the girder. The downlink movable mould frame is characterized in that: three groups of legs are arranged below the girder; the leg comprises a middle leg and a rear leg arranged at the front end and rear end of the girder; the front guide beam is closed to the front leg arranged below the girder; a longitudinal and transverse beam system of the leg, the girder and the guide beam and a lifter of the girder and the guide beam are arranged between the middle leg the rear leg, the front leg and the girder and the guide beam. The invention realizes walking automation of the movable mould frame and needs no extra cranes so as to strengthen the adaptability of the movable mound frame and enhance the economic competitiveness; the girder carries the external template to move transversely so that the transverse devices of the templates are reduced, and the amount of the transverse oil cylinders of the total set of movable mould frames is reduced by above 60percent; the invention realizes demoulding and mould closing integrally without regulating templates one by one, thereby reducing the labour amount, simplifying the procedure and greatly improving the degree of mechanization.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Completely split type rapid ecological soil sampler

The invention relates to an?ecological soil sampler, and in order to solve the problems of difficult sample output after sampling, easy disturbance of soil layers, easy change of soil biological patterns and easy biomass loss existing in existing soil collectors, the invention further provides a completely split type rapid ecological soil sampler. Two plug pins are inserted into two jacks correspondingly to fixedly connect a first semicylindrical body and a second semicylindrical body into a complete sampling cylinder. Two inverted L-shaped sockets that are centrosymmetric with respect to a socket pipe cap central axis are processed on the lower outer wall of a socket pipe cap. A handle is in threaded connection with the upper end of an upright pipe through a second pipe hoop, and the upright pipe lower end is fixedly connected to the center of the socket pipe cap upper end. The upper end of the sampling cylinder is sheathed on the lower end inner wall of the socket pipe cap, and a first cylindrical pin and a second cylindrical pin are respectively clamped in the two inverted L-shaped sockets of the socket pipe cap. The ecological soil sampler provided in the invention is used for collecting ecological soil samples.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

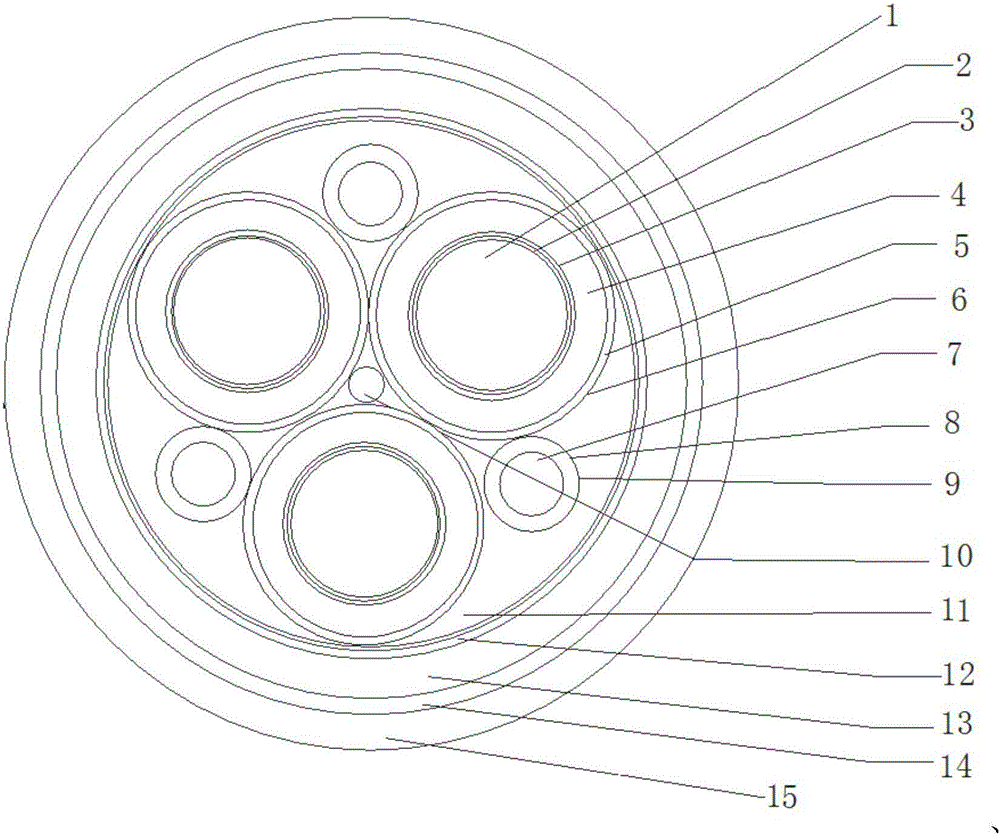

Wear-resistant, drag-resistant and low-temperature resistant flexible cable and fabrication method thereof

ActiveCN106373646AStable structureStructural symmetryPower cables with screens/conductive layersFlexible cablesCopper conductorCross-link

The structure of a wear-resistant, drag-resistant and low-temperature resistant flexible cable comprises a cable core, wherein the cable core is formed by twisting three main wire cores, three ground wire cores and a cable core gap semiconductive filler, each main wire core comprises a cross-linking wire core formed by co-extruding a conductor, a semiconductive nylon strap, a conductor shielding layer, an insulation layer and an insulation shielding steam continuous vulcanization layer, each ground wire core comprises a conductor and a semiconductive material steam continuous vulcanization extruded on a surface of the conductor, an isolation strip, an inner sheath, a fiber weaving reinforcement piece and an outer sheath are sequentially applied outside the cable core to form a finished cable, the conductors adopt tin-plated annealed copper conductors, filaments of the tin-plated annealed copper conductors are more slim, and the diameter ranges of the filaments are 0.1-0.41 millimeter. A cable fabrication method comprises the steps of fabricating the main wire cores and the ground wire cores; fabricating the cable core; winding an isolation strip; extruding the inner sheath; weaving the reinforcement layer; and performing steam continuous vulcanization extruding or radiating the cross-linking outer sheath. The cable fabricated according to the method can conform to the design and application requirements, and meanwhile, the qualified rate reaches over 99%.

Owner:JIANGSUSNGSHANG CABLE GROUP

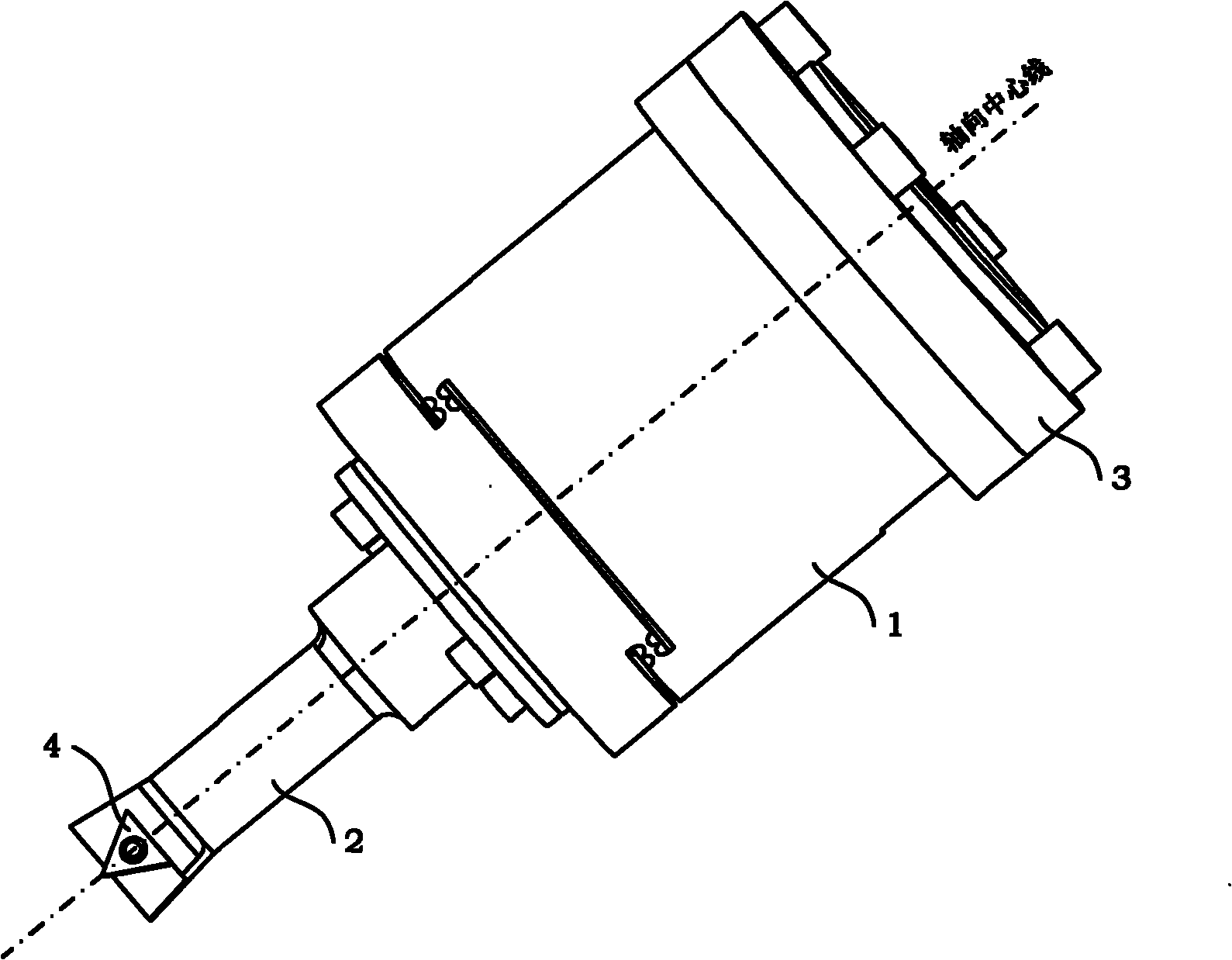

Composite ultrasonic elliptical vibratory cutting device suitable for making shark skin imitation structural skin

InactiveCN101879685AImprove processing efficiencyGuaranteed machining accuracyMechanical vibrations separationFeeding apparatusProcessing accuracyCeramic

The invention discloses a composite ultrasonic elliptical vibratory cutting device. The device consists of an ultrasonic vibrating unit, a cylindrical servo cutter frame, hollow piezoelectric ceramic and a base, wherein a cutter is arranged at the output end of the ultrasonic vibrating unit; the ultrasonic vibrating unit is arranged in the hollow piezoelectric ceramic; the hollow piezoelectric ceramic is arranged in the cylindrical servo cutter frame; the base is arranged on the end part of the cylindrical servo cutter frame; and the cylindrical servo cutter frame is provided with four elastic hinge structures. Due to the design of symmetrical hinges, cylindrical ceramic is prevented from being deviated while driving the cutter; and the processing accuracy of the surface appearance of a nanoscale three-dimensional micro-structure of the cutter is realized through the gapless transmission of the elastic hinges. The ultrasonic vibrating unit adopts two exciting sources with different structures, so that ultrasonic vibration of the cutter in a longitudinal direction and a bending direction is realized during processing. The cutting device of the invention can be suitable for making shark skin imitation structural skin.

Owner:BEIHANG UNIV

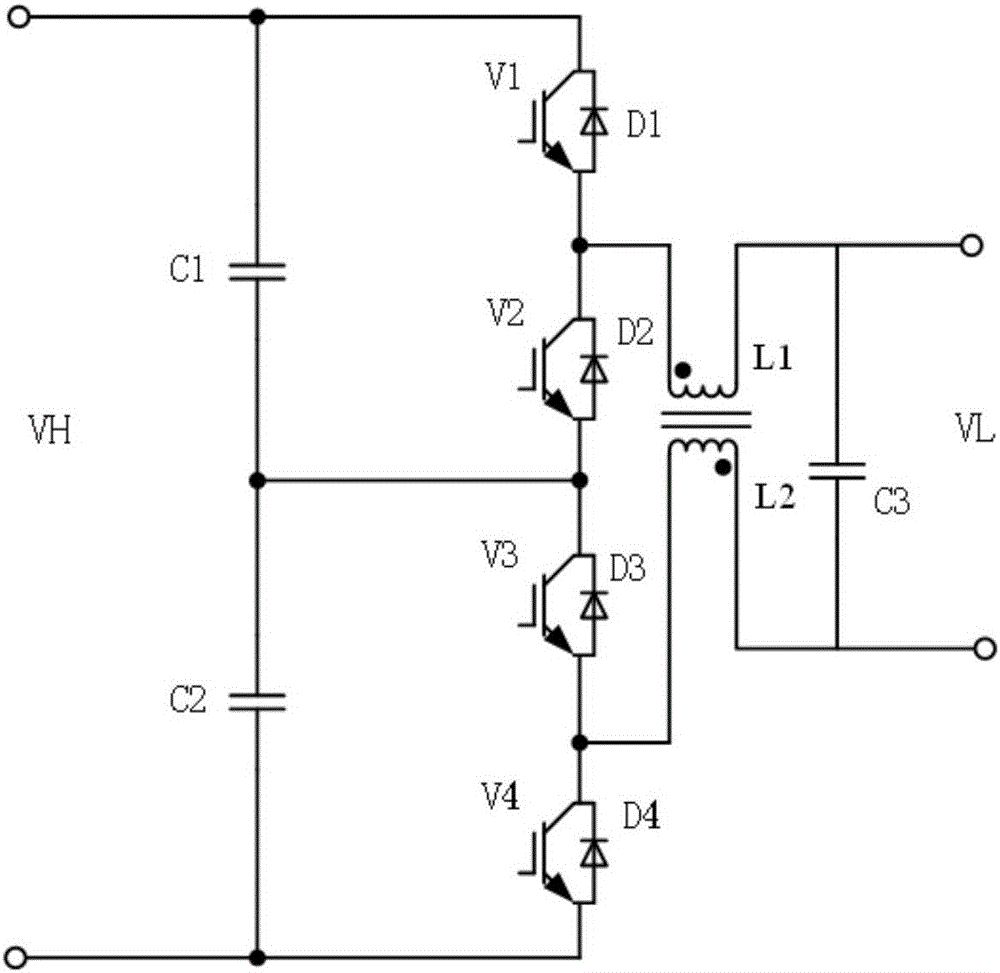

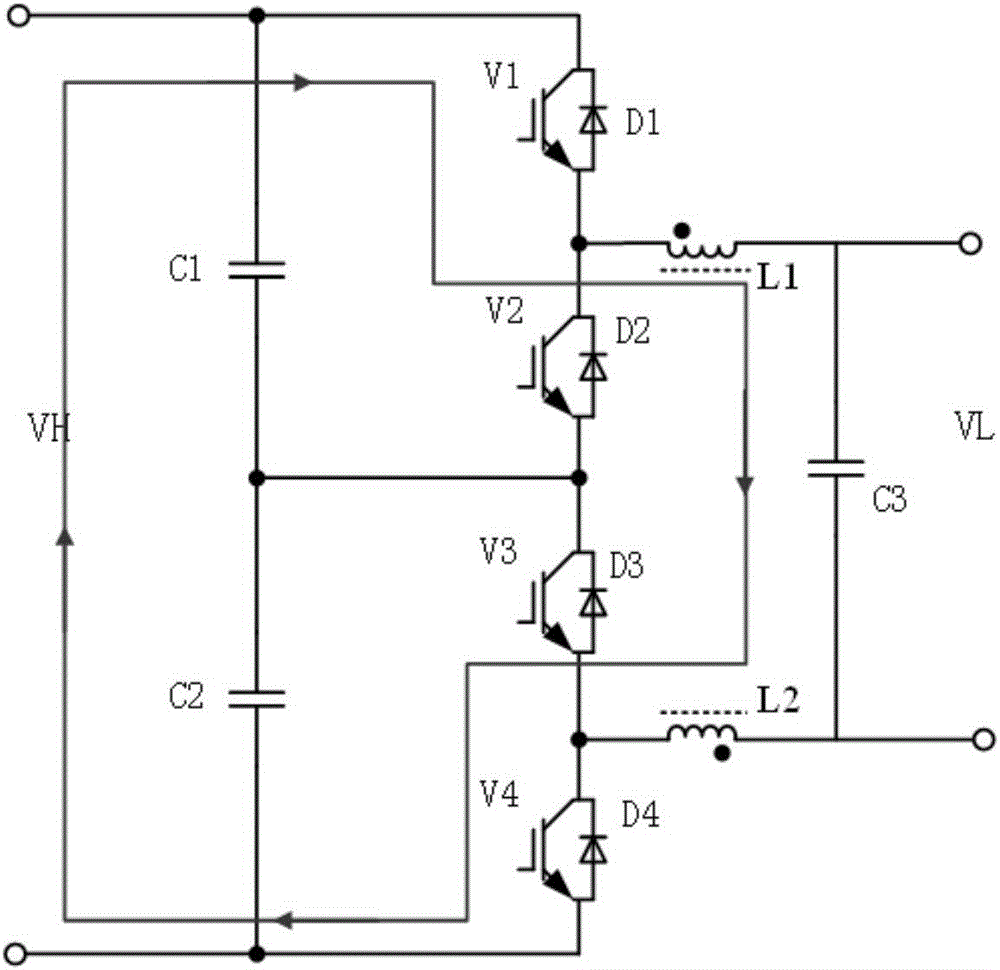

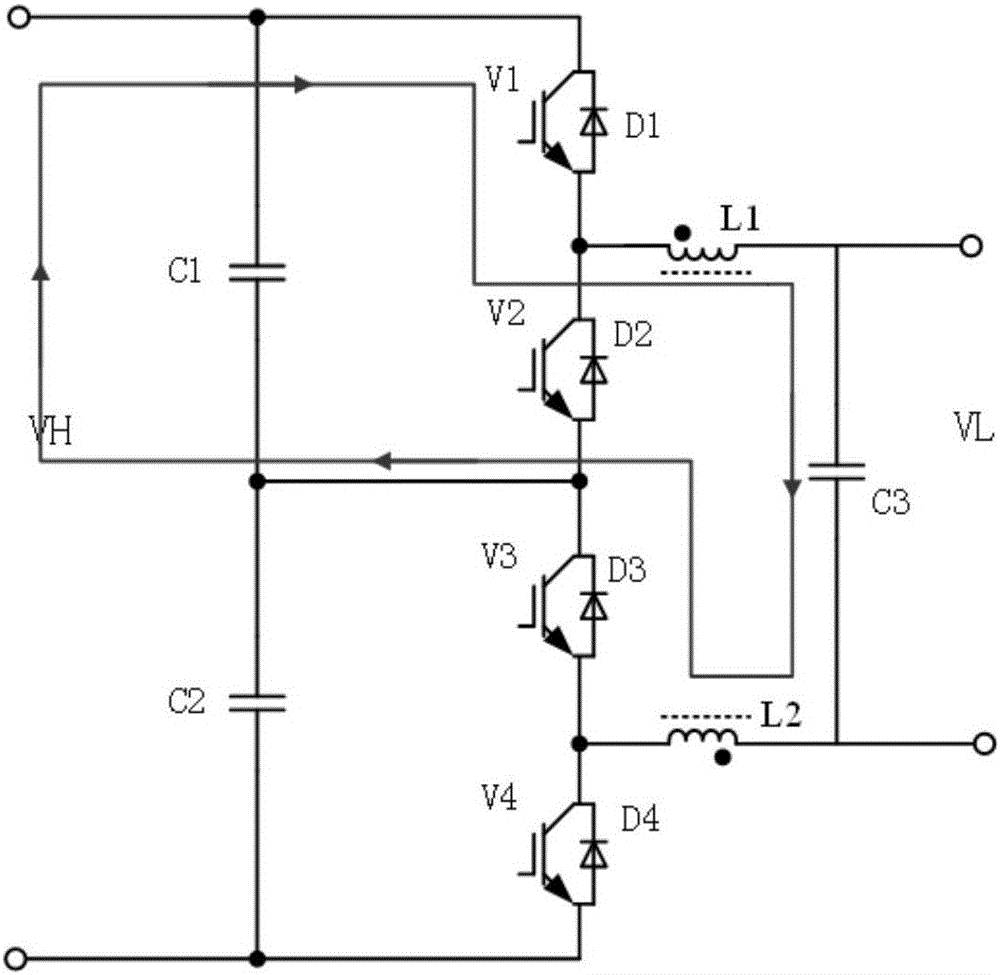

Isolated three-level bidirectional DC-DC converter with coupling inductor

InactiveCN105743344AReduce withstand voltage and switch stressIncrease the ripple frequencyDc-dc conversionElectric variable regulationThree levelCapacitance

The invention discloses an isolated three-level bidirectional DC-DC converter with a coupling inductor. The isolated three-level bidirectional DC-DC converter comprises a high-voltage side input capacitor, a low-voltage side input capacitor, a high-voltage side power supply, a low-voltage side power supply, a first power switching tube, a second power switching tube, a third switching tube, a fourth power switching tube, a first diode, a second diode, a third diode, a fourth diode, a first coupling filter inductor, a second coupling filter inductor, wherein the first coupling filter inductor and the second coupling filter inductor are coupled to each other. The isolated three-level bidirectional DC-DC converter has the advantages of small output current ripple and low loss of switching tubes, and is also relatively simple in structure.

Owner:XIAN XJ POWER ELECTRONICS TECH

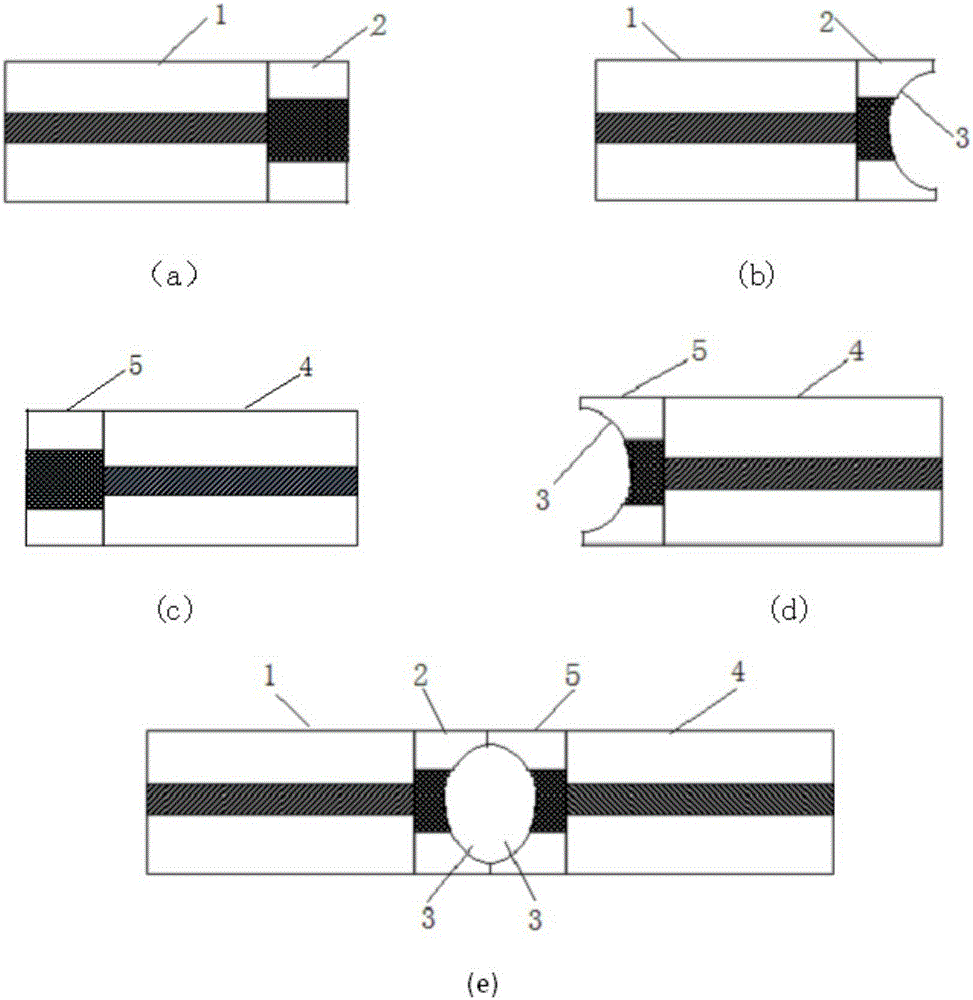

Multistable mechanism realizing method based on single bistable mechanism and external characteristics thereof

InactiveCN101837947ASimple structureStructural symmetryMicrostructural devicesStable stateHorizontal axis

The invention belongs to the field of flexible mechanisms, relating to a multistable mechanism realizing method based on a single bistable mechanism and external characteristics thereof. A framework and a flexible bistable mechanism in the framework are comprised. The left end and the right end of the flexible bistable mechanism are fixed in the framework. The multistable mechanism realizing method is characterized in that connecting rod slide block mechanisms are in parallel to a horizontal axis of the flexible bistable mechanism; the connecting rod slide block mechanisms comprise lead rails, slide blocks and connecting rods; the slide blocks are in the lead rails; the lead rail of the next level of the connecting rod slide block mechanism is mutually vertical with the adjacent lead rail of the upper level of the connecting rod slide block mechanism; the connecting rod of the first-level connecting rod slide block mechanism is connected with a shuttle of the flexible bistable mechanism; and the last-level slide block is in the stable position of N=2M+1 through movement of the slide block in each level of the connecting rod slide block mechanism and the change of the upper position and the lower position of the shuttle of the flexible bistable mechanism, wherein M is the number of the connecting rod slide block mechanisms; and the minimum value of the M is 1. The invention depends on elastic potential energy stored in the flexible bistable mechanism to keep stable state, and does not need durative action of external forces.

Owner:XIDIAN UNIV

Spherical surface two-freedom symmetrical parallel connection robot mechanism with redundancy drive

InactiveCN101214647AOptimize layoutStructural symmetryProgramme-controlled manipulatorKinematic pairEngineering

The present invention discloses a spherical 2-degree-of-freedom symmetric parallel robot mechanism with redundant actuation. A composite turning pair, which is composed of three turning pairs hinged with the same axial line, is connected with a fixed platform via three branches with the same structure, the two connecting bars of each branch, between which one turning pair is connected, are respectively connected with the composite turning pair and the fixed platform via two turning pairs, all the kinematic pairs of the three branches are the turning pairs, and the axial lines of all the turning pairs are converged at a rotating spherical center. When three base turning pairs are selected as the input of the robot mechanism and the composite turning pair as the output of the mechanism, the composite turning pair has two degrees of freedom while moving along a spherical surface. The present invention has the advantages of symmetric distribution of the structure and driving, no singular configuration, high rigidity and bearing capacity, easy production and assembly, etc.

Owner:YANSHAN UNIV

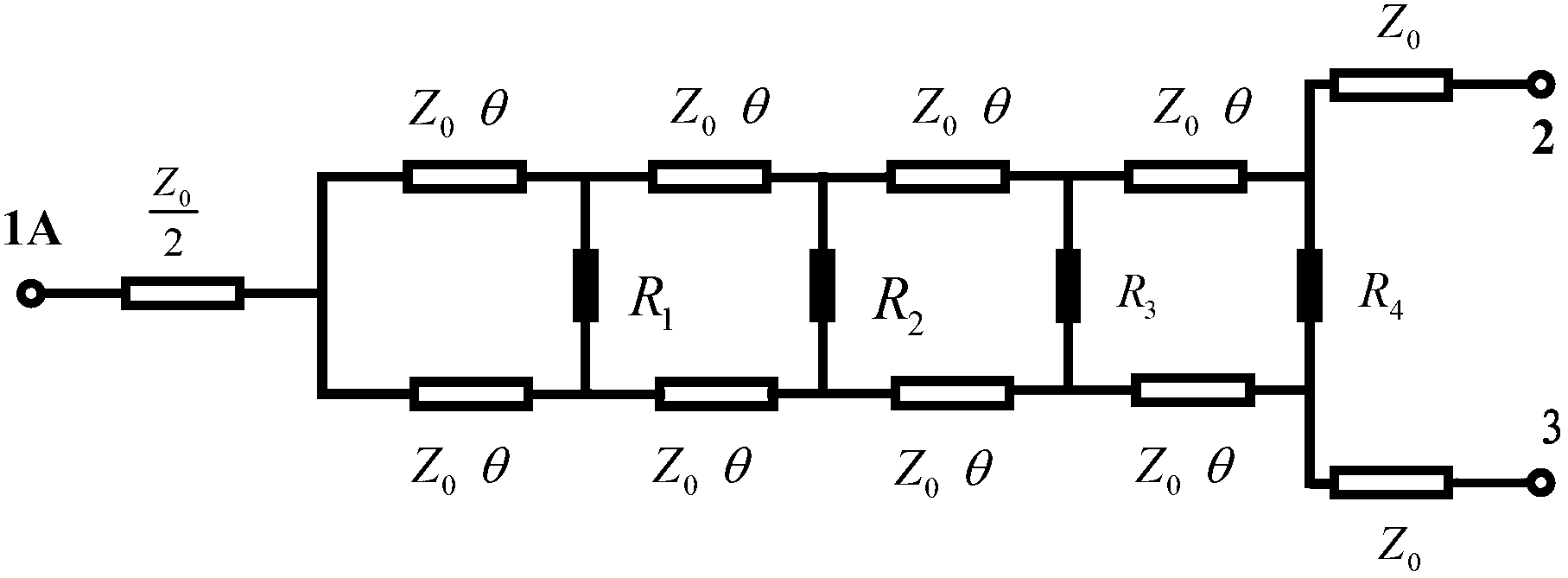

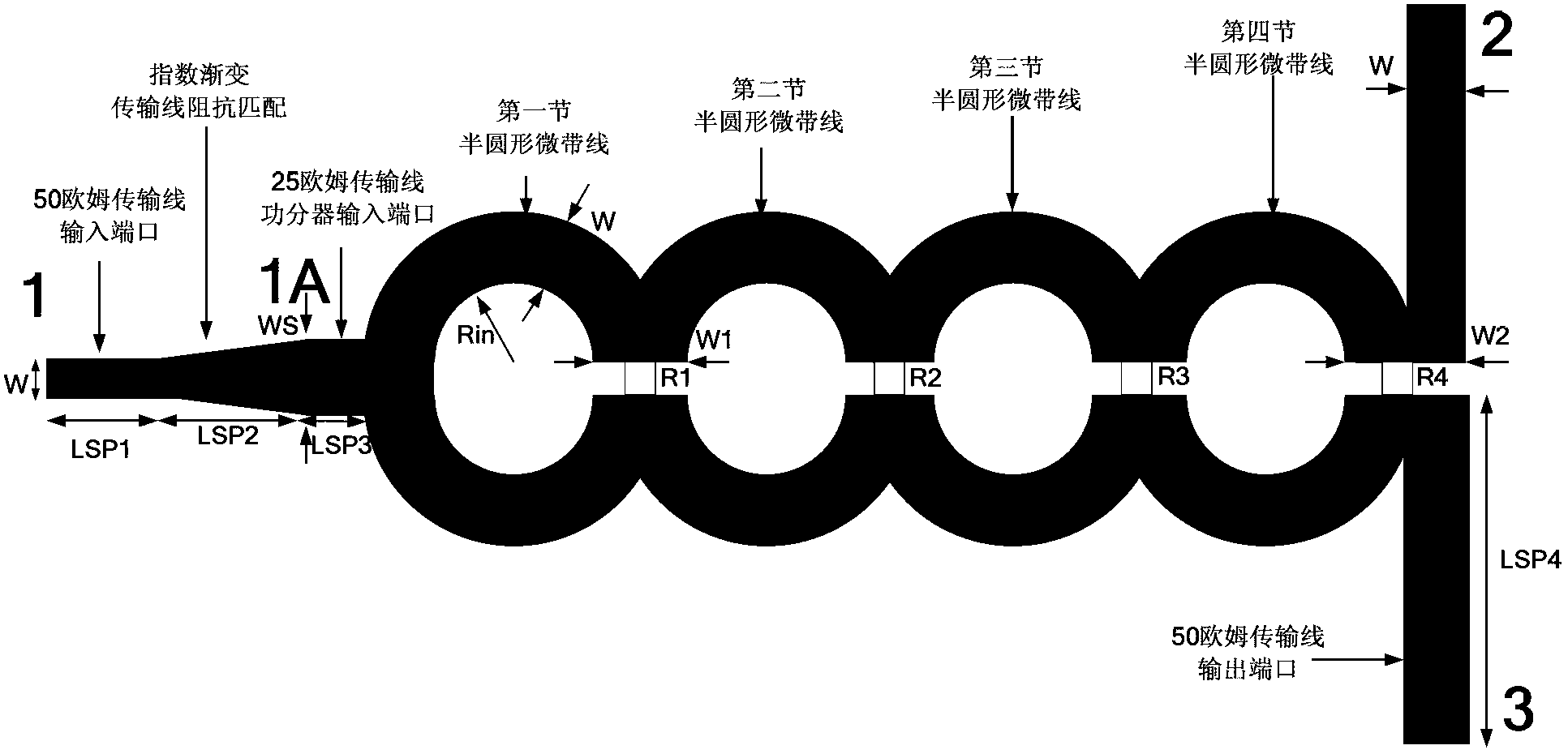

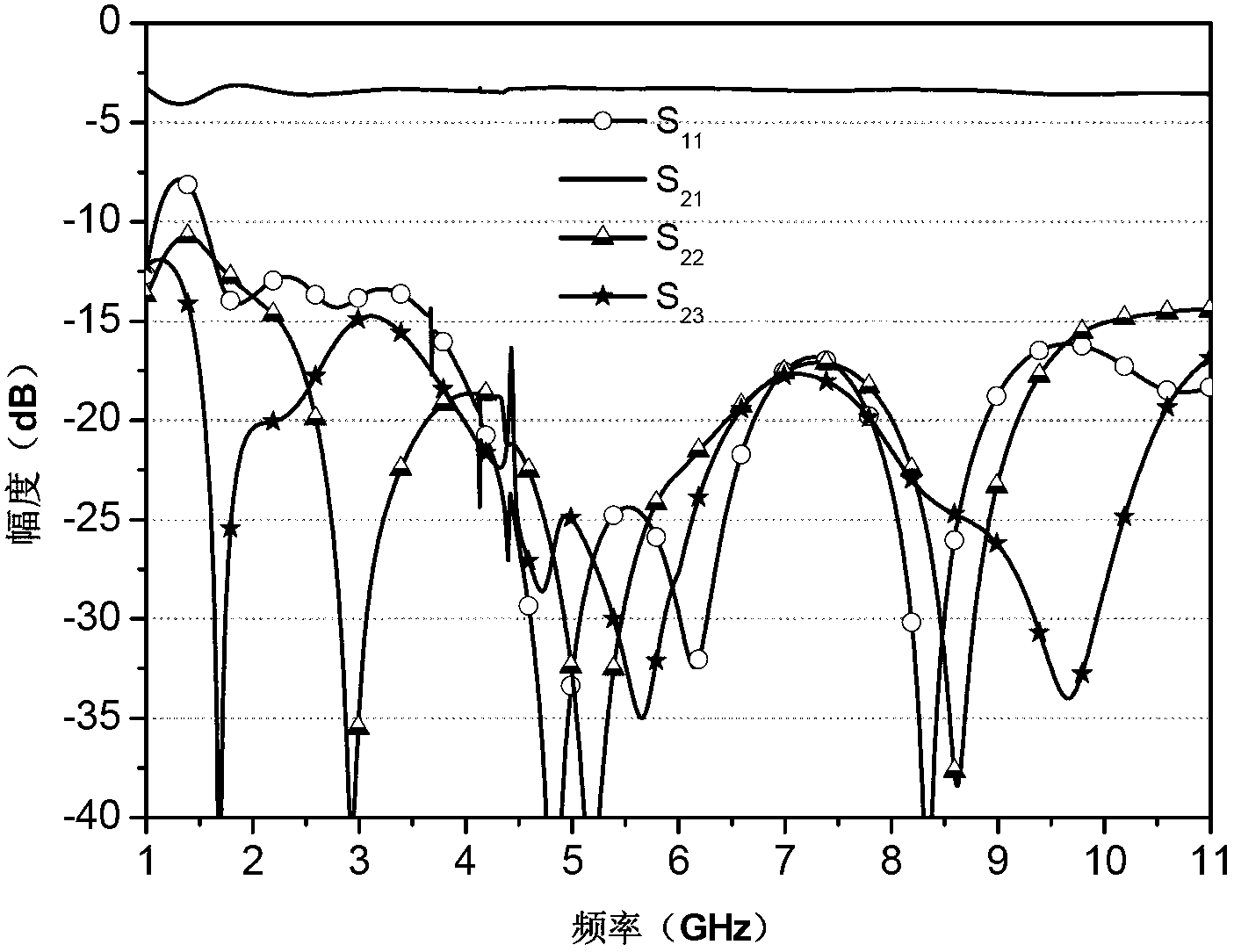

Ultra-wideband power divider based on exponential gradient

Disclosed is an ultra-wideband power divider based on an exponential gradient. The ultra-wideband power divider is composed of microstrip lines and ports of the microstrip lines, wherein the microstrip lines are located on a dielectric slab and used as a power divider body, and achieve matching and transmission characteristic transformation. The ultra-wideband power divider is provided with one input port, two equi-amplitude and in-phase output ports, an impedance conversion circuit and an ultra-wideband power distribution circuit, wherein the impedance conversion circuit and the ultra-wideband power distribution circuit are located between the input port and the output ports. The characteristic impedance of each of the microstrip lines of the three ports is 50omega, and the whole circuits are vertically symmetrical. One microstrip line based on the exponential gradient is adopted for the input port, the microstrip line with a characteristic impedance of 50omega is matched to an input end of the ultra-wideband power distribution circuit, the microstrip lines with a characteristic impedance of 25omega are divided into two vertically-symmetrical output paths, four sections of semicircular microstrip lines are in cascade connection to output equi-amplitude and in-phase signals, the characteristic impedance of each section of semicircular microstrip line is 50omega, the electrical length of each section of semicircular microstrip line is pi / 2, an isolating resistor is connected between each pair of microstrip lines arranged up and down, and the isolating resistors are different from one another. The ultra-wideband power divider based on the exponential gradient is good in transmission performance, and relative bandwidth can reach more than 100%.

Owner:BEIJING UNIV OF POSTS & TELECOMM

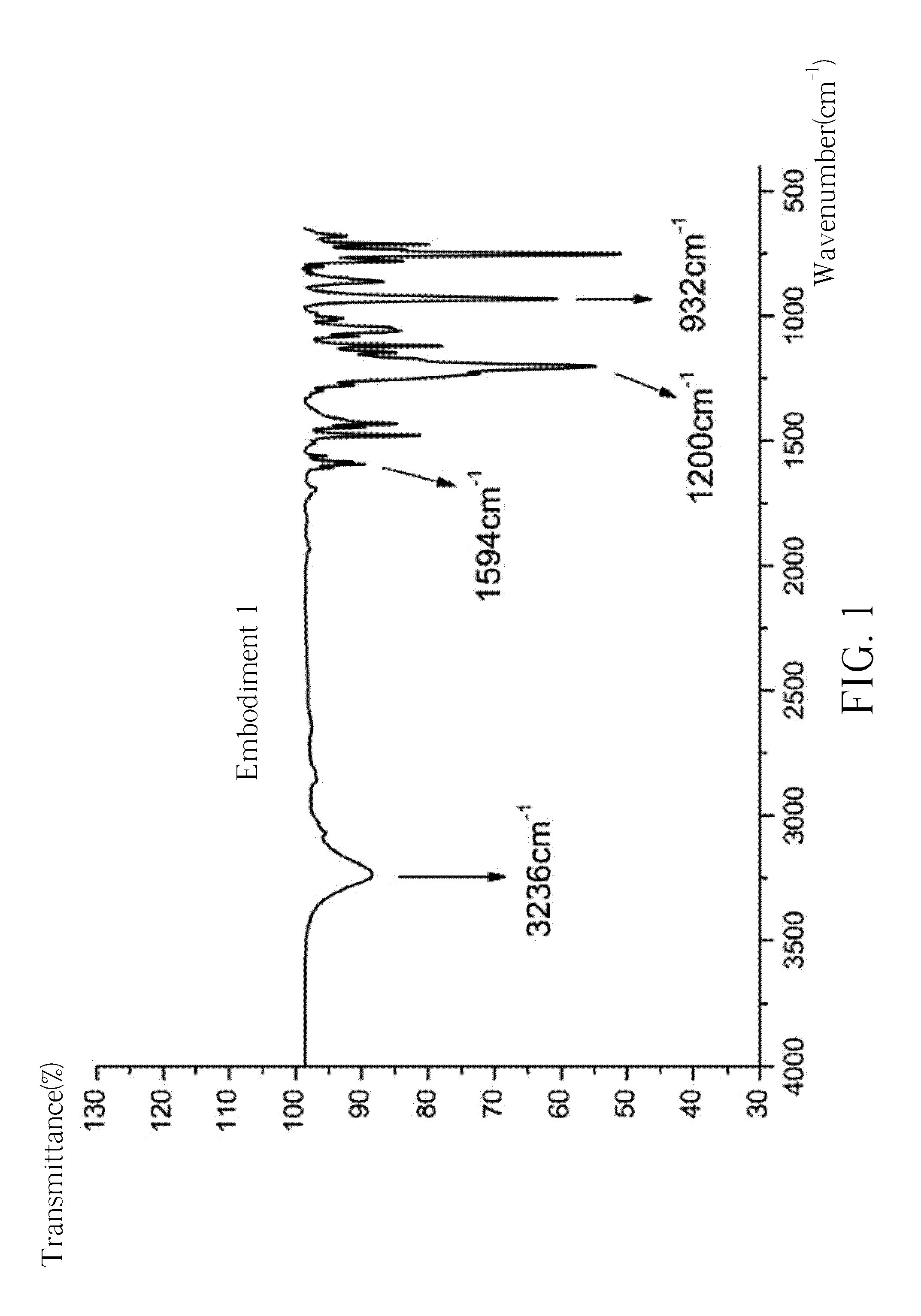

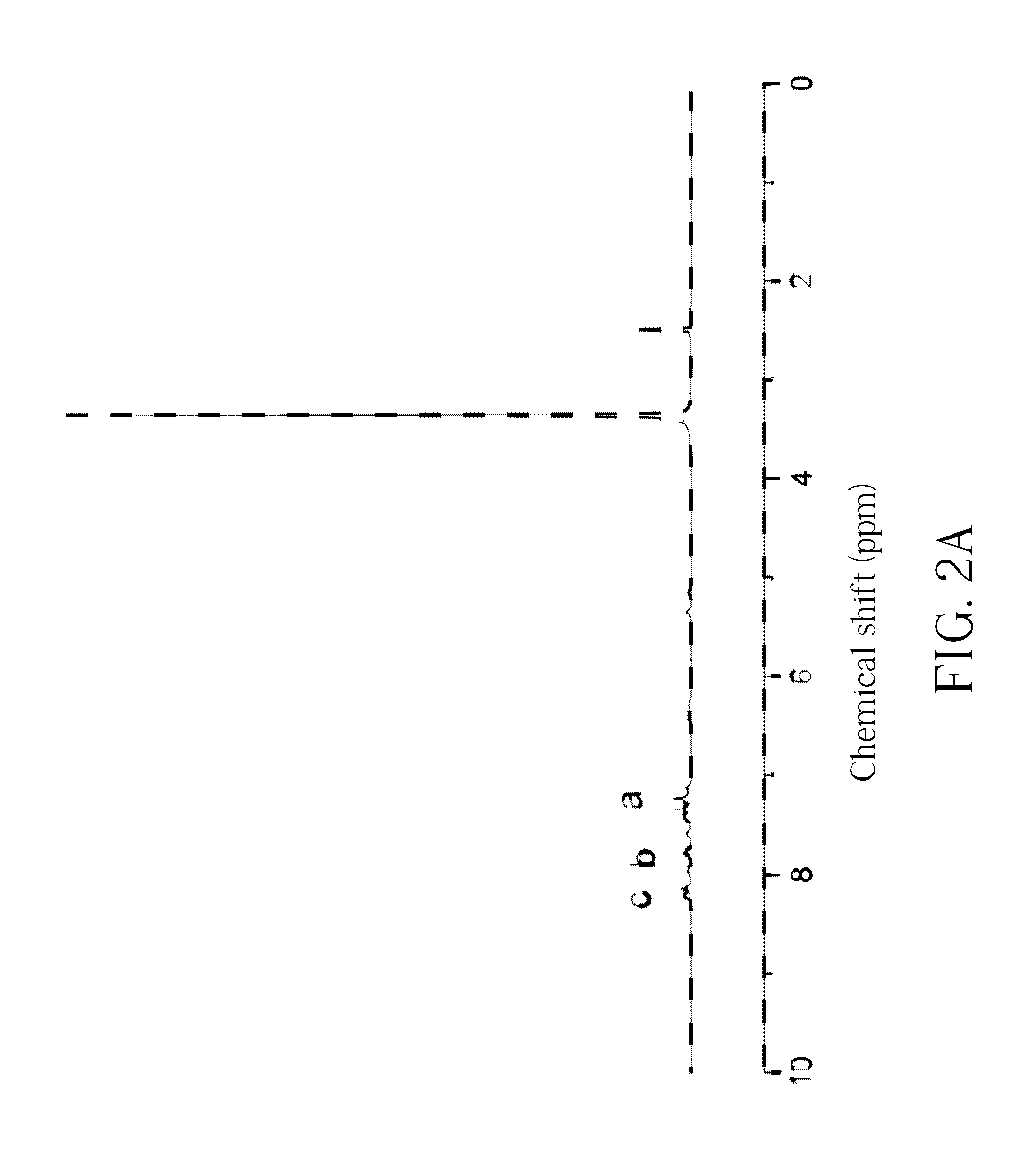

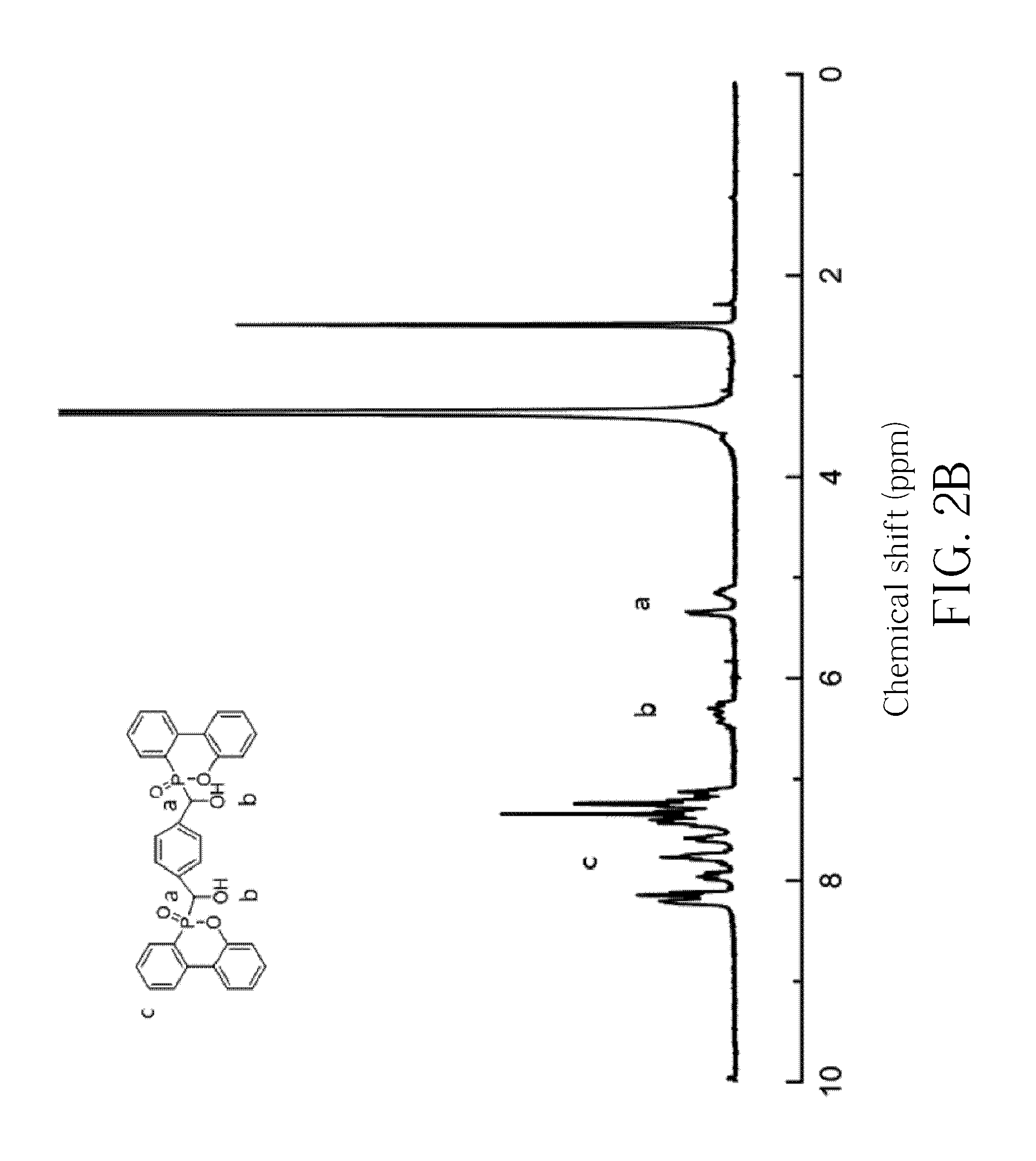

Phosphaphenanthrene-based compound and related preparation method and application

ActiveUS20170022228A1Reduction factorLow thermal expansionGroup 5/15 element organic compoundsPolymer sciencePrinted circuit board

Provided is a phosphaphenanthrene-based compound represented by the following chemical structure:The phosphaphenanthrene-based compound can be added in a resin composition and made into a prepreg or resin film. The prepreg or resin film made from such resin composition has low coefficient of thermal expansion, low dielectric constant and dissipation factor, and flame retardancy, thereby being suitable for copper-clad laminate or printed circuit board.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

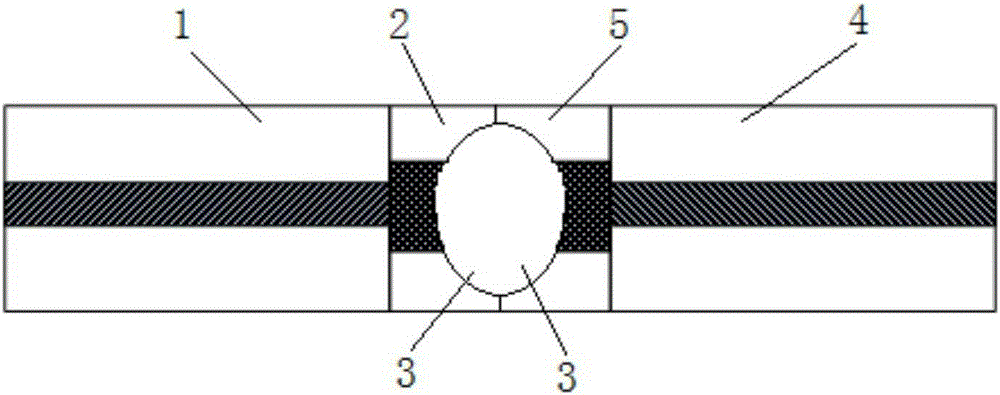

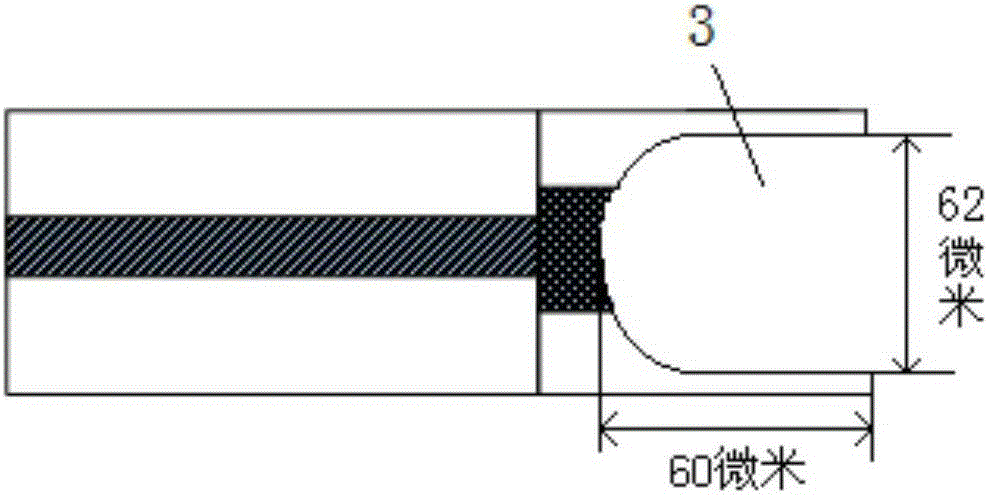

Symmetrical all-fiber Fabry-Perot sensor and manufacturing method thereof

ActiveCN105180980AStructural symmetryCompact structureConverting sensor output opticallyButt jointFourier transform on finite groups

The invention discloses a symmetrical all-fiber Fabry-Perot sensor, a first single-mode fiber is welded with a first multi-mode fiber, and a second single-mode fiber is welded with a second multi-mode fiber; tail ends of the first multi-mode fiber and the second multi-mode fiber are provided with concave cavities; the concave cavities of the first multi-mode fiber and the second multi-mode fiber are in butt joint with each other to form an FP cavity. According to the symmetrical all-fiber Fabry-Perot sensor and the manufacturing method thereof provided by the invention, the structure is small and exquisite, manufacture is easy and cost is low, the fiber sensor can utilize a chemical corrosion method to obtain a long Fabry-Perot cavity, is symmetrical in structure and low in stripe fineness, is little affected by temperature, and can utilize a phase method based on Fourier transform to realize measurement of pressure and strain under high temperature.

Owner:广州顶盛益电子科技有限公司

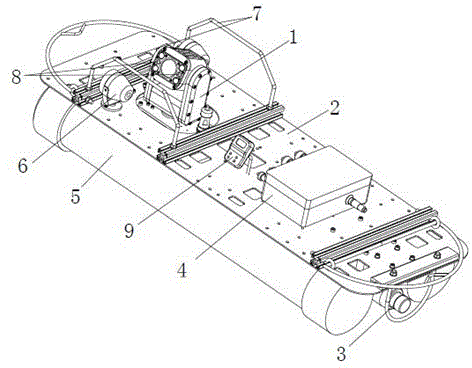

Comprehensive detecting device for detecting internal defects of drainage pipeline

ActiveCN104359922ARealize detectionRealize remote detectionUsing subsonic/sonic/ultrasonic vibration meansMaterial analysis by optical meansMarine engineeringSonar sensor

The invention discloses a comprehensive detecting device for detecting internal defects of a drainage pipeline. The comprehensive detecting device comprises an equipment carrier capable of floating on water, wherein a camera capable of detecting the part above the pipeline water is arranged on a water part of the equipment carrier, and a camera illuminating lamp is arranged; a sonar sensor capable of detecting the pipeline underwater part is arranged on an underwater part of the equipment carrier; and controlling and receiving signals of the camera and the controlling and receiving signals of the sonar sensor are respectively connected with a controller by virtue of a cable. The comprehensive detecting device disclosed by the invention has the characteristics of complete functions, wide detecting range, safe and reliable work, and the like, and can be used for comprehensively detecting the internal conditions of the drainage pipeline.

Owner:BAODING JINDI SCI INSTR

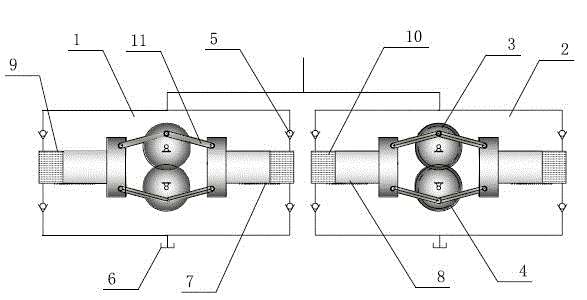

Double-acting plunger pump

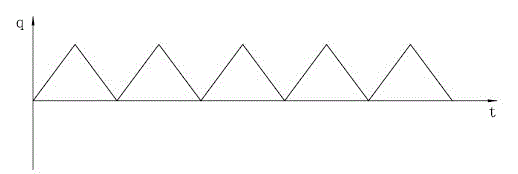

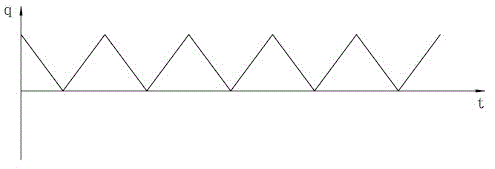

InactiveCN102207066BRealize constant current outputStructural symmetryPiston pumpsPositive-displacement liquid enginesFuel tankHydraulic pump

The invention discloses a double-acting plunger pump comprising a left hydraulic pump and a right hydraulic pump. The double-acting plunger pump is characterized in that the hydraulic pumps comprise a left hydraulic mechanism and a right hydraulic mechanism which are symmetrically arranged; a driving gear is arranged between the left hydraulic mechanism and the right hydraulic mechanism and is meshed with a driven gear; the actuation end of the driving gear is connected with a servo motor; the left hydraulic mechanism and the right hydraulic mechanism are connected with the driving gear and the driven gear by a crank connecting rod transmission mechanism; the oil outlets of the left hydraulic mechanism and the right hydraulic mechanism are respectively connected with an actuating mechanism by a check valve; and the oil return openings of the left hydraulic mechanism and the right hydraulic mechanism are respectively connected with an oil tank by the check valve. In the double-acting plunger pump, output flow can be subjected to constant-flow output, and the double-acting plunger pump has smaller friction and vibration, small noise pollution and a simple structure.

Owner:SUZHOU UNIV

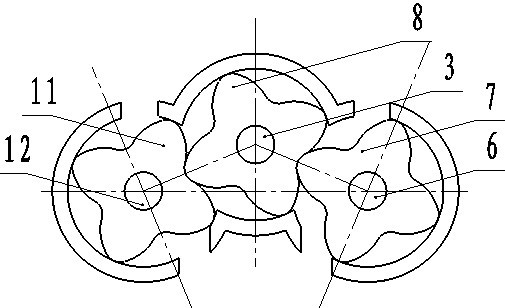

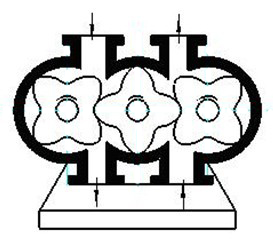

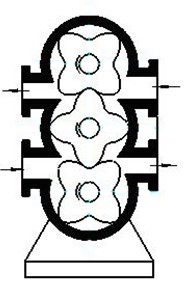

Three-axis Roots vacuum pump

ActiveCN101985935AImprove balanceCompact structureRotary piston pumpsRotary piston liquid enginesDrive shaftGear wheel

The invention relates to a vacuum pump, in particular to a three-axis Roots vacuum pump, which comprises a motor, a spindle and driven shafts, wherein the spindle is provided with a driving gear; driven gears meshed with the driving gear are arranged on the driven shafts; Roots rotors are arranged on the spindle and the driven shafts; and the two driven shafts are parallelly and symmetrically arranged on two sides of the spindle. The three-axis Roots vacuum pump has the characteristics of compact and symmetric structure, air suction under the action of the three axes and no oil in a pump cavity and realizes a high air suction speed.

Owner:NORTHEASTERN UNIV +1

Four freedom parallel robot mechanism with passive bound branch

InactiveCN100354068CDoes not affect the nature of movementStructural symmetryProgramme-controlled manipulatorLarge fixed membersDegrees of freedomControl theory

A 4-freedom parallel robot structure with passive constraint branch is disclosed, which contains different two passive constraint branch structures and can be used for robot to realize one axial movement and three different rotations. Its advantages are high parallel rigidity and load-bearing power, simple structure, high precision and low cost.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com