Piezoelectric intelligent material based bolt pre-tightening force sensor

A technology of bolt pre-tightening force and smart materials, which is applied to the measurement of the property force of piezoelectric devices and the measurement of torque/torsional force during tightening, can solve the problems of difficult accurate measurement and control of bolts, and achieve simple structure, The effect of strong versatility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

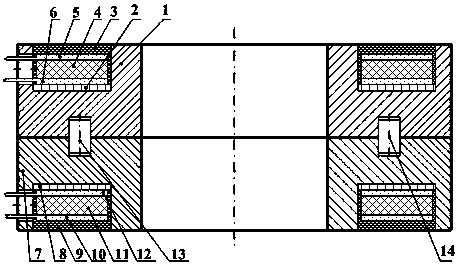

[0016] A bolt preload sensor based on piezoelectric smart materials. The bolt preload sensor is as figure 1 As shown, it is made up of an upper gasket 1 and a lower gasket 7, and the upper gasket 1 and the lower gasket 7 are fixed back to back by a left alignment pin 13 and a right alignment pin 14.

[0017] A first annular groove is concentrically formed on the front surface of the upper gasket 1, the cross section of the first annular groove is rectangular, and a lead hole is processed between the circumferential surface of the upper gasket 1 and the first annular groove. The bottom of the first annular groove is brushed with a first insulating layer 2, and a first upper electrode 5 and a first lower electrode 6 are correspondingly pasted on the upper and lower planes of the first annular piezoelectric ceramic 4 through conductive glue to form the first An annular piezoelectric ceramic component. Then paste the first annular piezoelectric ceramic component on the first ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com