Patents

Literature

5106results about How to "Guaranteed machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

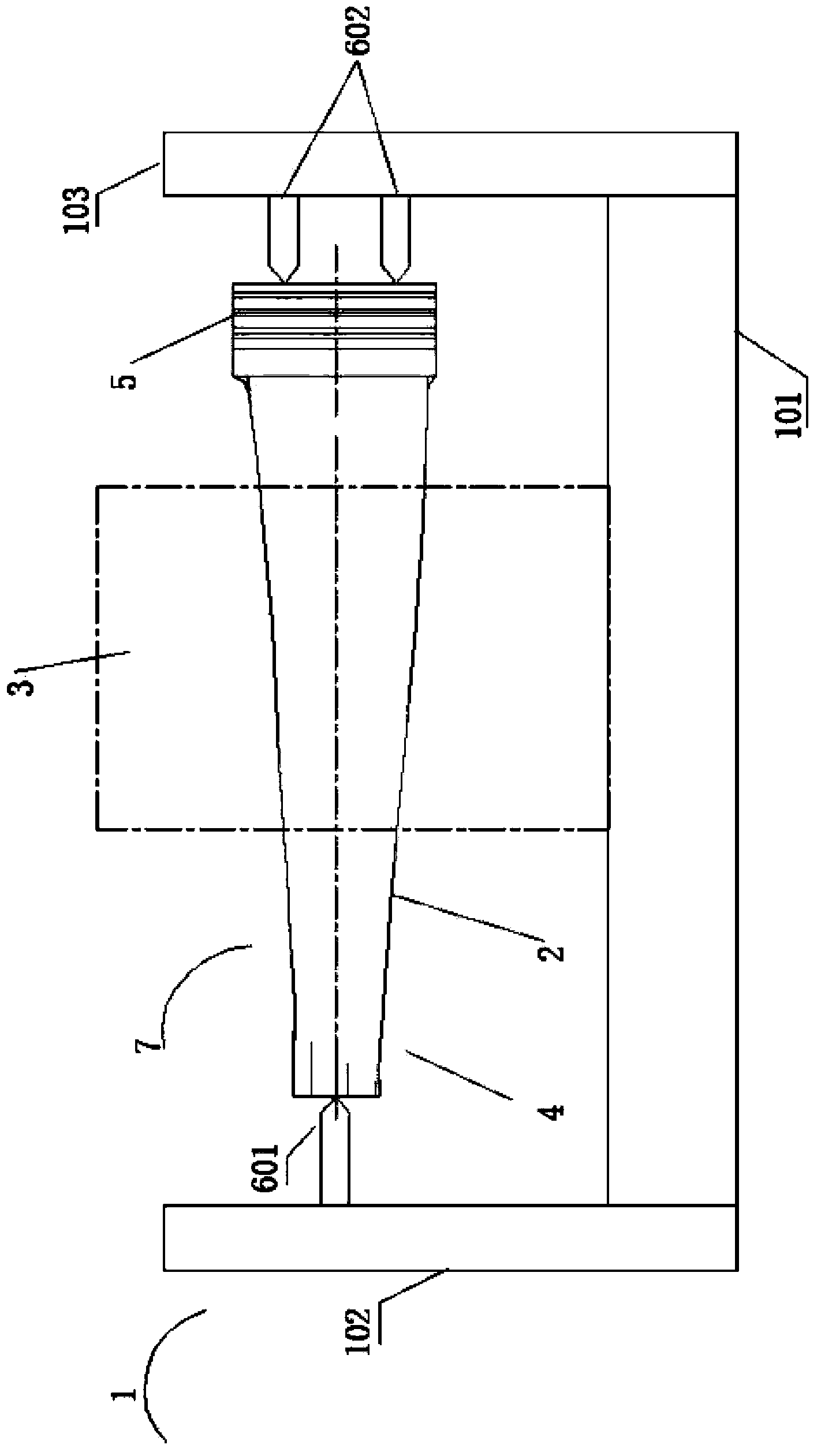

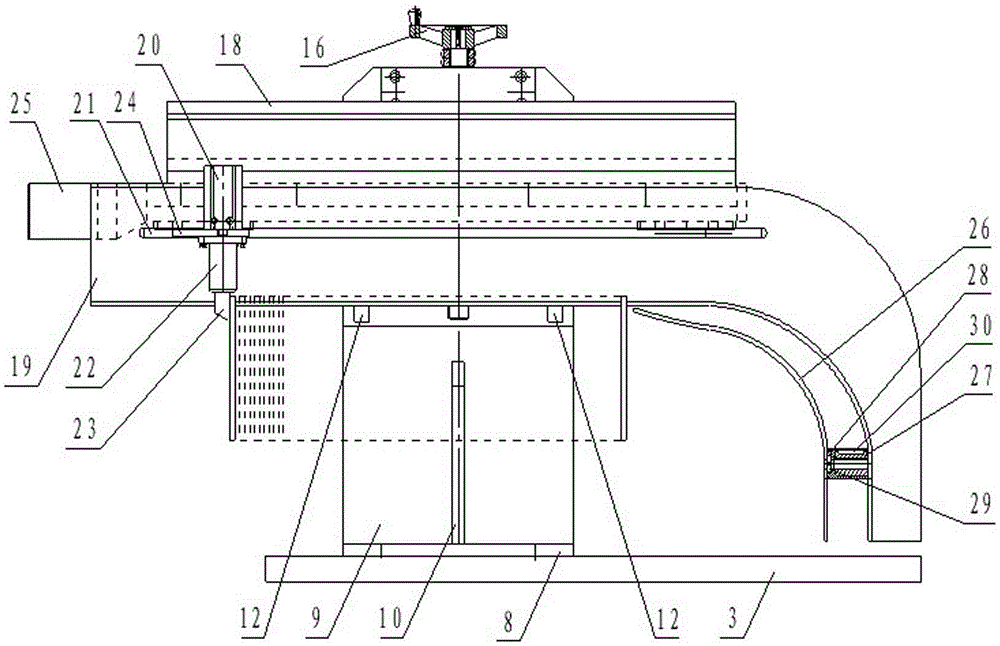

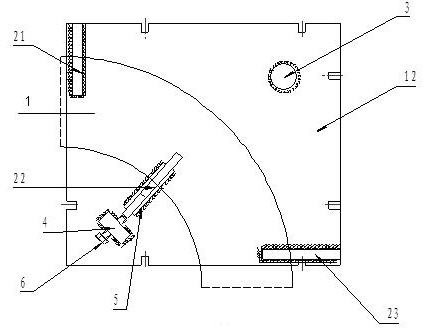

Selective laser melting rapid prototyping equipment for direct manufacturing of large parts

ActiveCN102266942AMeet the process requirementsReduce construction costsIncreasing energy efficiencySelective laser meltingLaser array

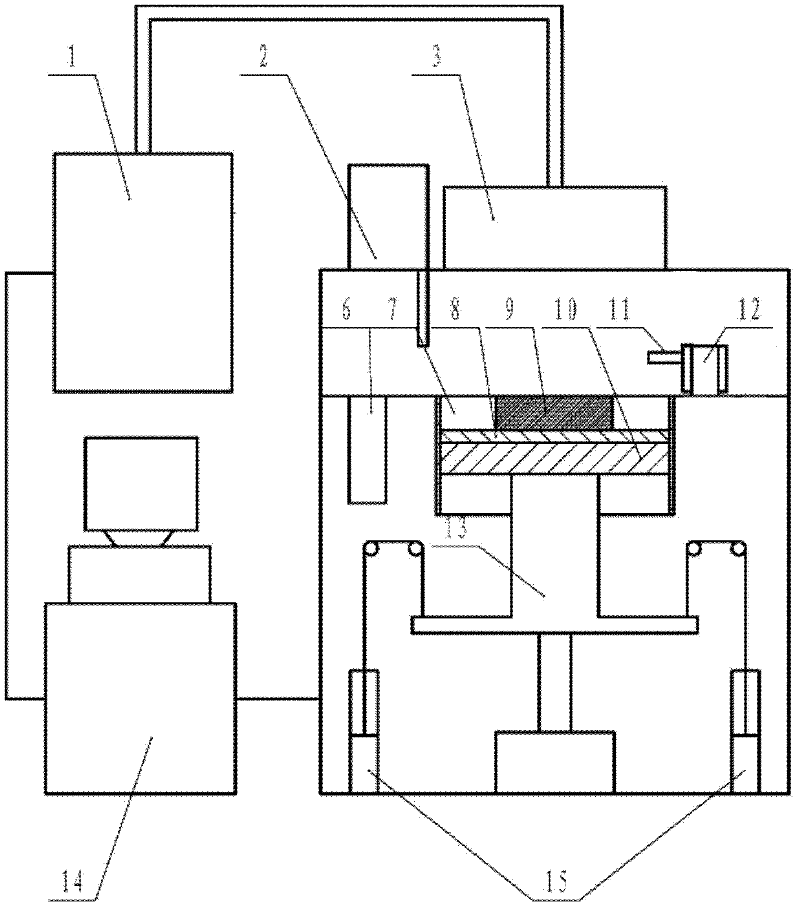

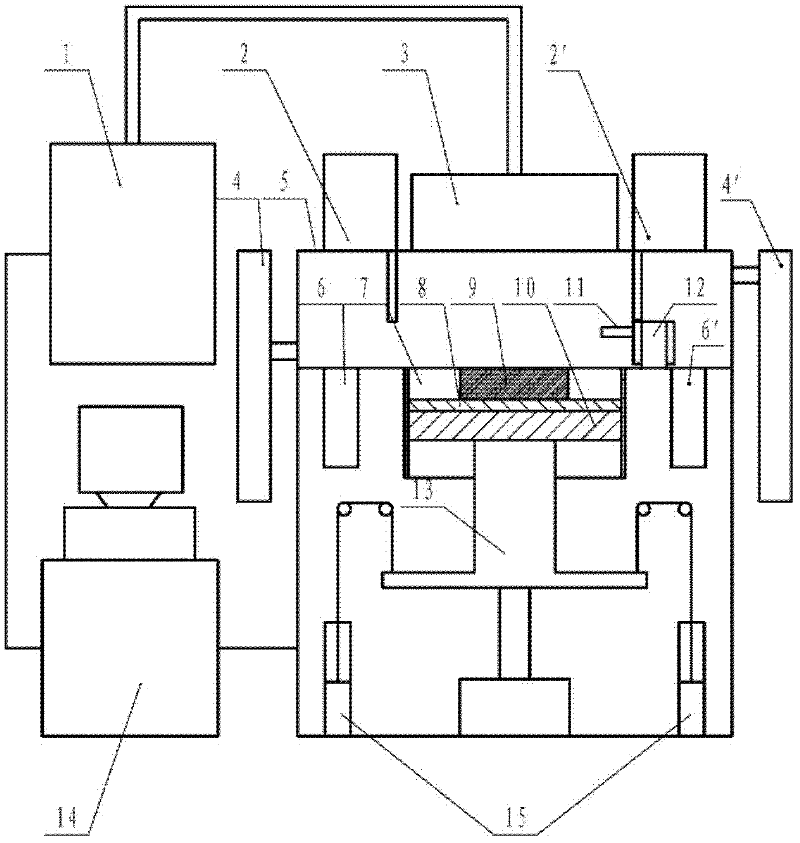

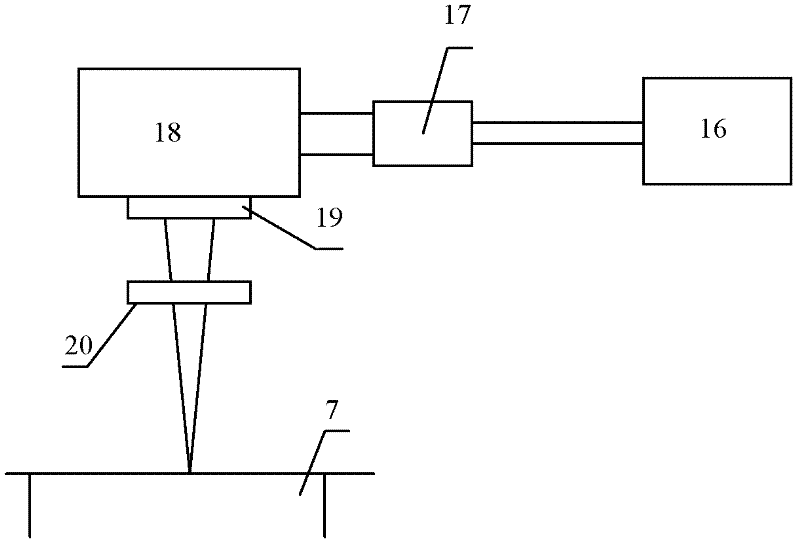

The invention discloses a selective laser melting rapid forming device for directly manufacturing large-size compact parts, which mainly comprises a laser array, an optical system array, a forming cylinder, a forming cylinder vertical sectional heating thermal-insulation structure, a forming cylinder weight balancing system, a substrate leveling device, a double-recovering cylinder, a double powder storing box, a double quantitative powder sending and discharging device, a powder paving device, a protective atmosphere cover, a gas purifying system and a control system, wherein an adopted optical system is composed of a plurality of optical system units and a mechanical moving platform, and the coverage area of the optical system can be randomly expanded or reduced. The size of the parts manufactured by using the selective laser melting rapid forming device provided by the invention is more than the size of the parts manufactured by using the existing national and foreign selective laser melting processes. The forming efficiency is multiplied while the forming precision, the parts complexity and the mechanical property are not changed.

Owner:TECH LASER TECH SHANGHAI CO LTD

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

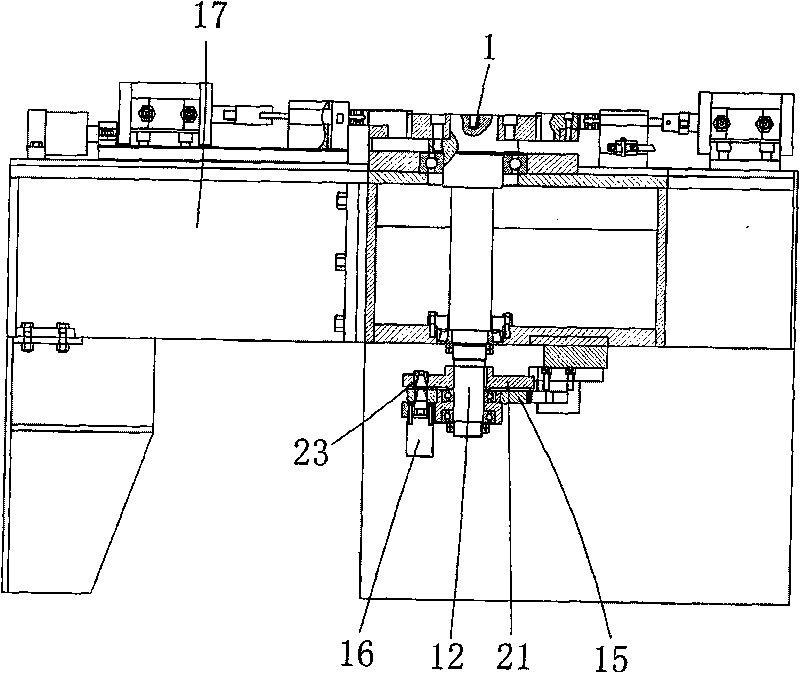

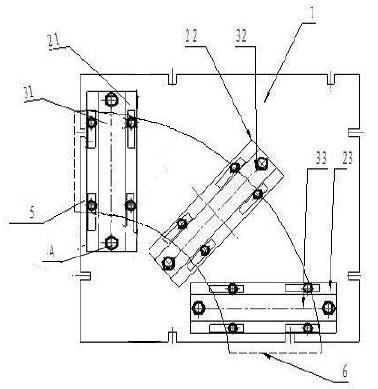

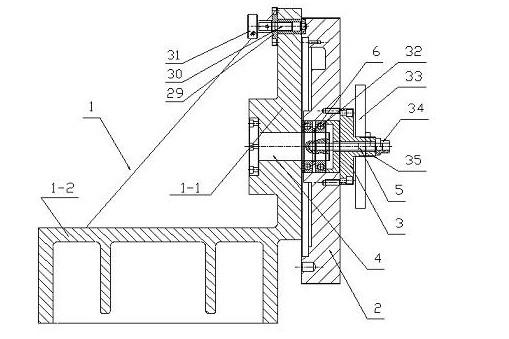

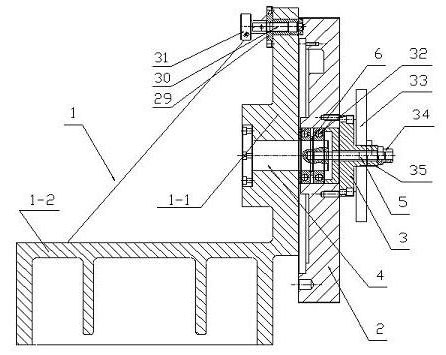

Autotracking centring clamping device for numerically controlled grinder

InactiveCN101116954AEliminate the effects of grindingEliminate the effects ofGrinding work supportsNumerical controlAxis of symmetry

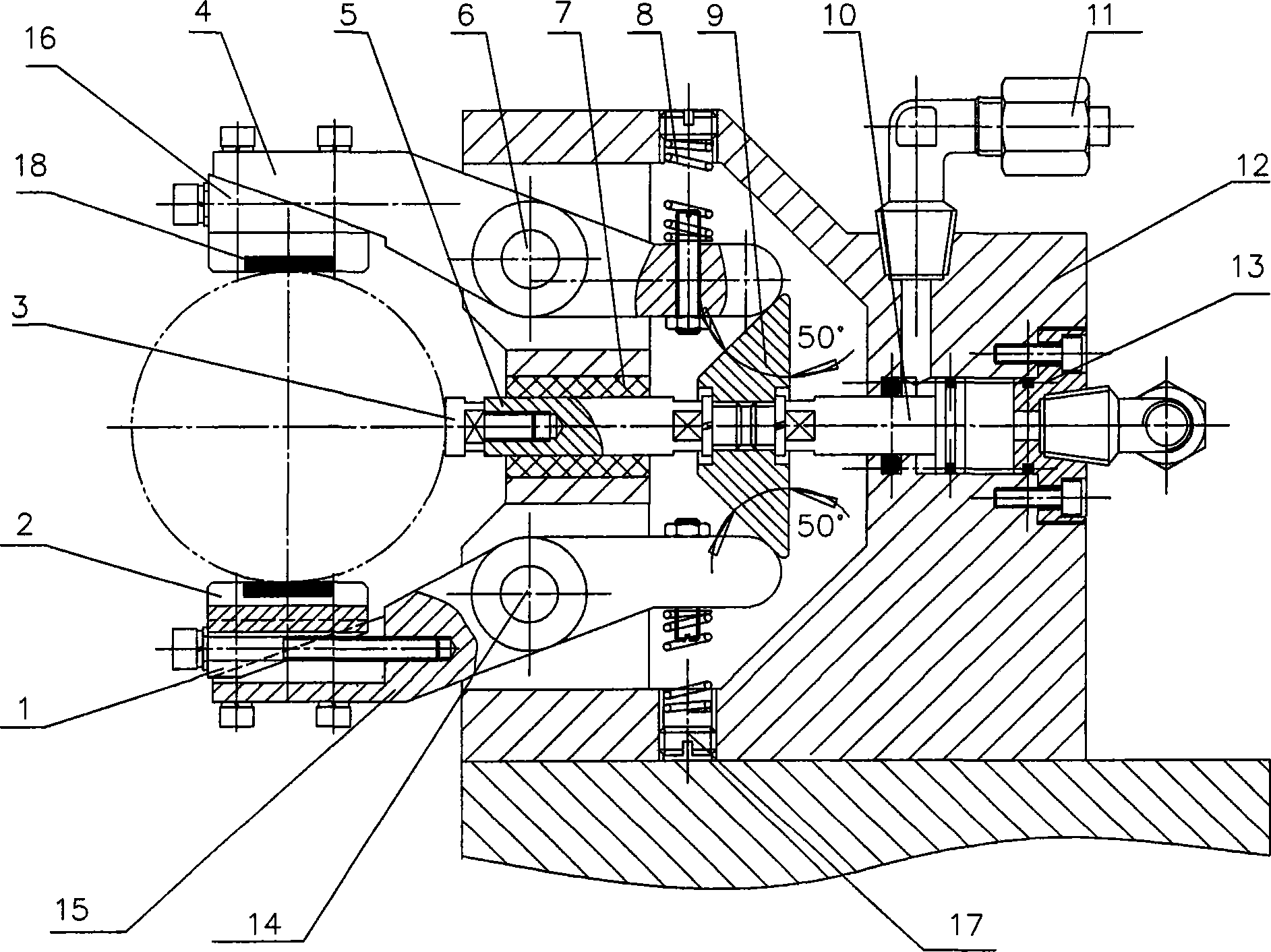

The invention discloses an automatic follow centering and clamping device for a numerical control grinder. A middle clamping rod (5) is sleeved in a sliding way on a supporting body (12) which is provided with a driving mechanism which drives the middling clamping rod (5) to reciprocatingly move axially. An upper lever clamping arm (4) and a lower lever clamping arm (15) are hinged on the supporting body (12) with the middle clamping rod (5) axis of symmetry. The clamping ends of the upper lever clamping arm (4) and the lower lever clamping arm (15) are corresponding to the clamping end of the middling clamping rod (5) which is provided with a symmetric cuniform-shaped block (9) corresponding to opening ends of the upper lever clamping arm (4) and the lower lever clamping arm (15). The supporting body (12) is provided with an elastic device which keeps the clamping ends of the upper lever clamping arm (4) and the lower lever clamping arm (15) open. The invention is an automatic follow centering and clamping device applying automatic follow and moving, automatic centering and automatic compensating to a numerical control grinder.

Owner:HUNAN UNIV

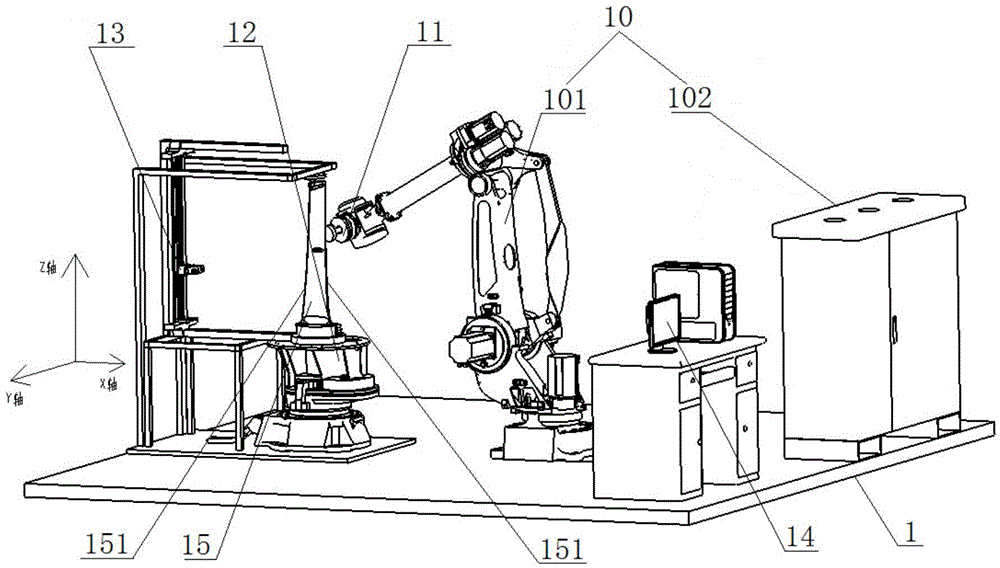

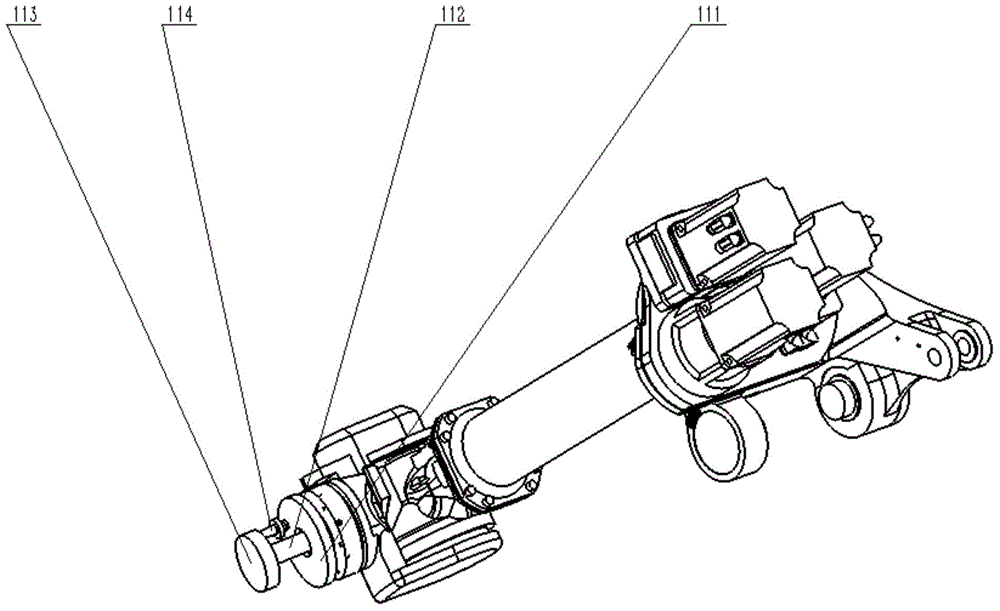

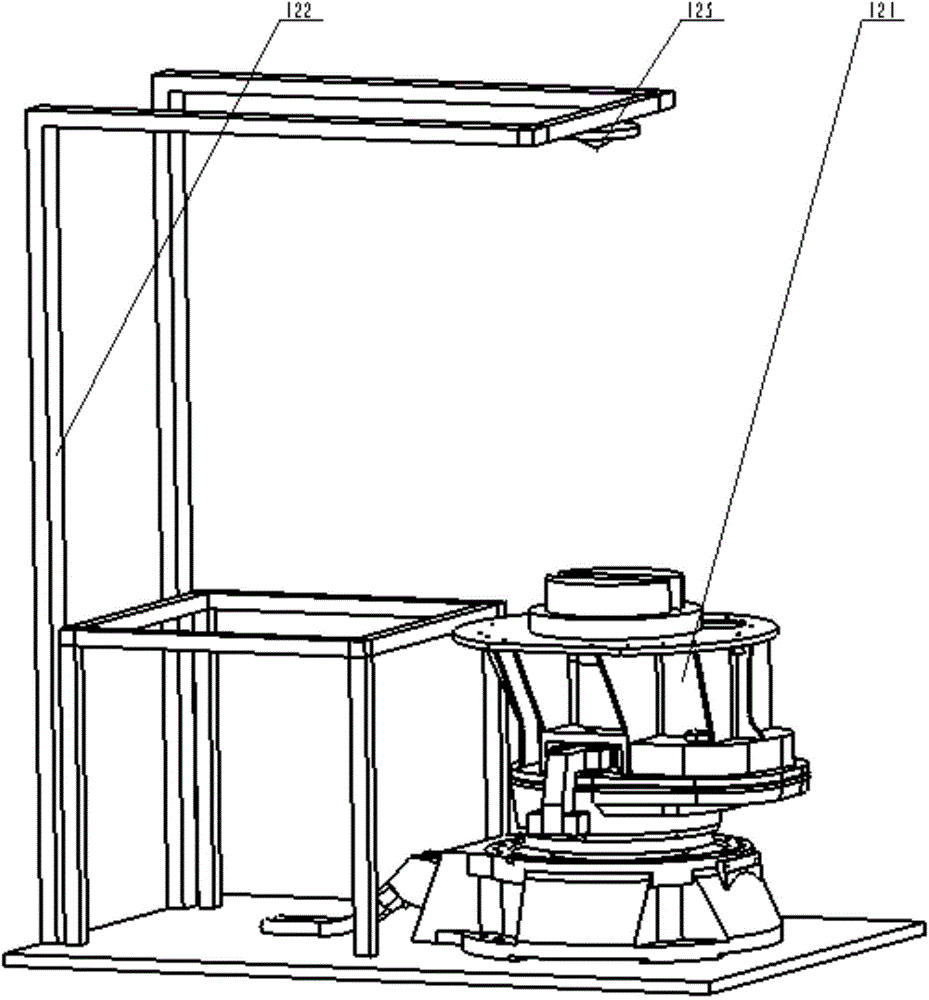

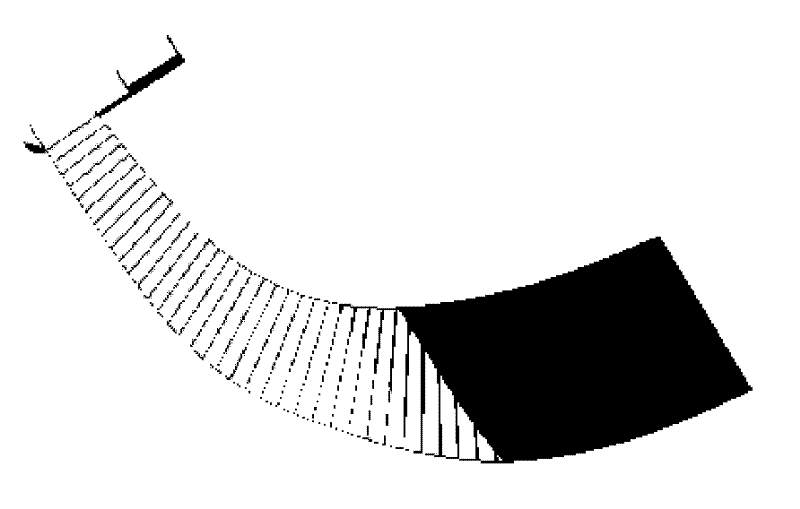

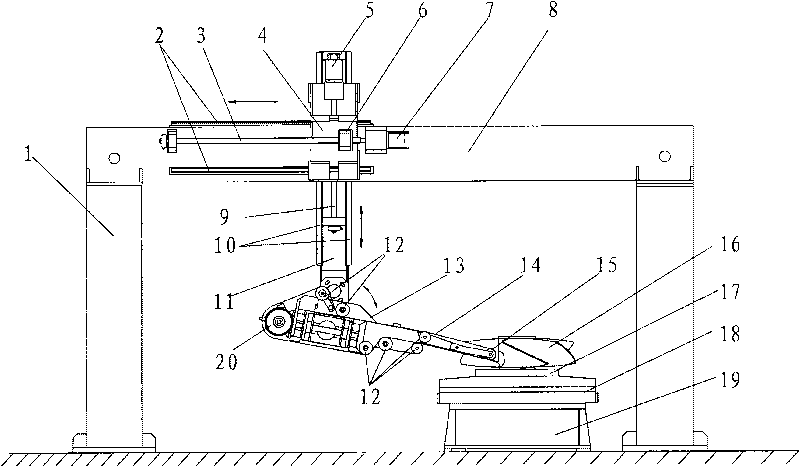

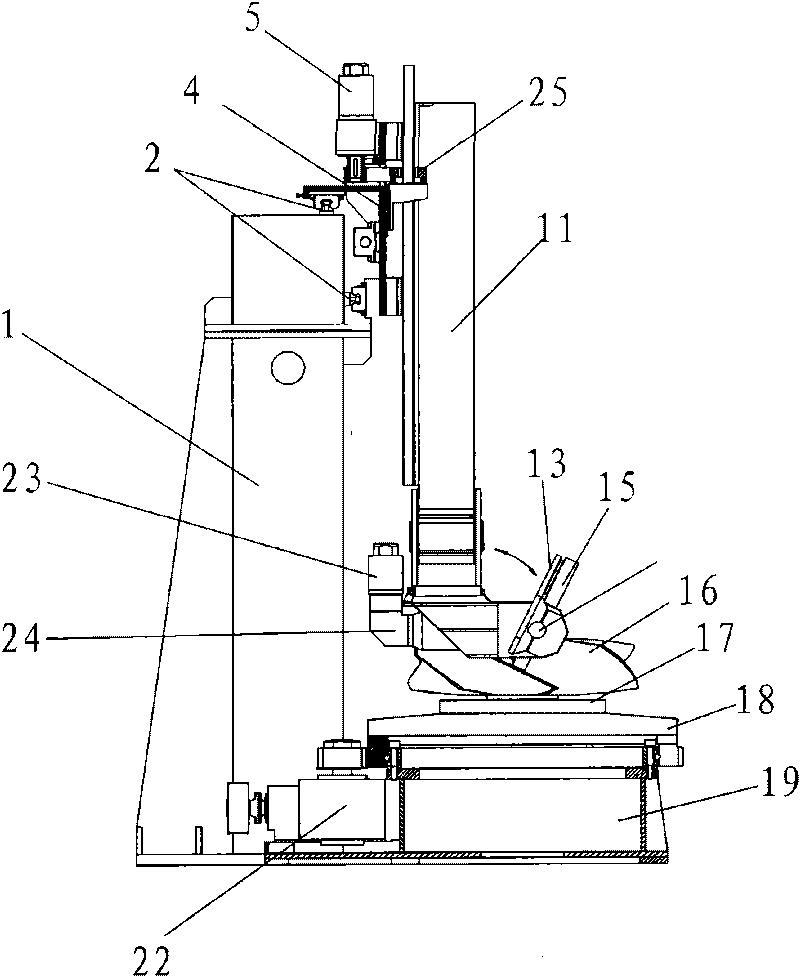

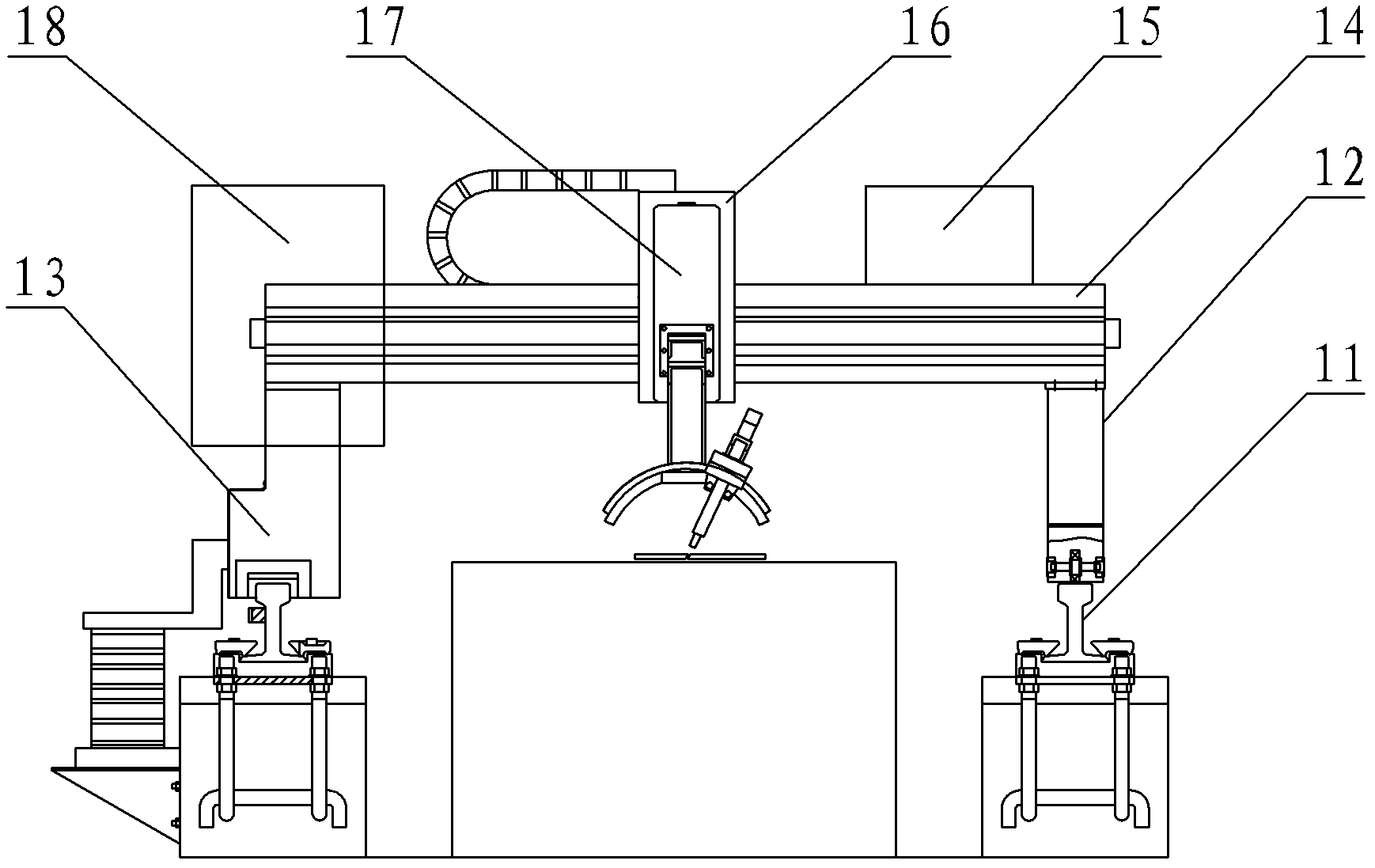

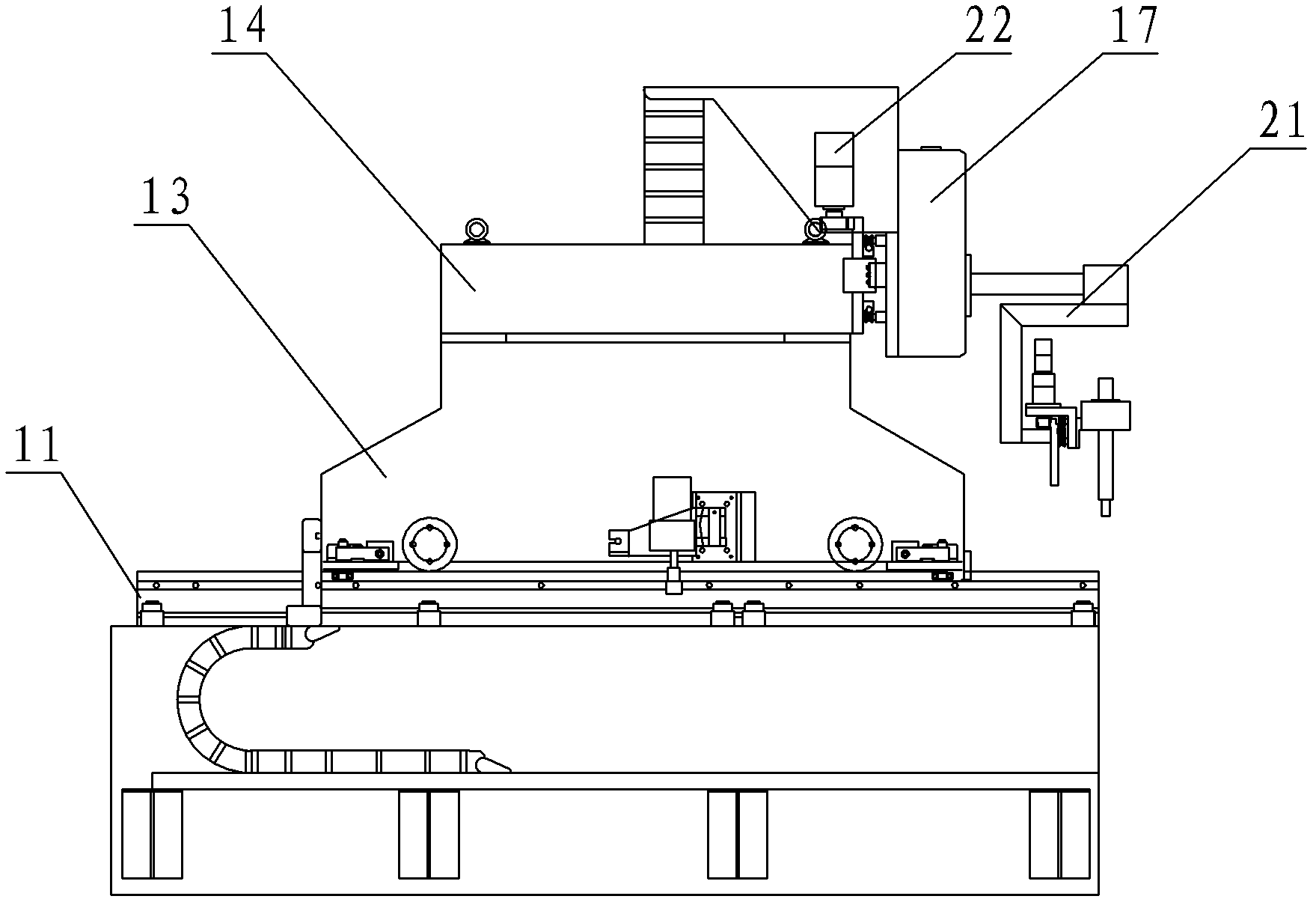

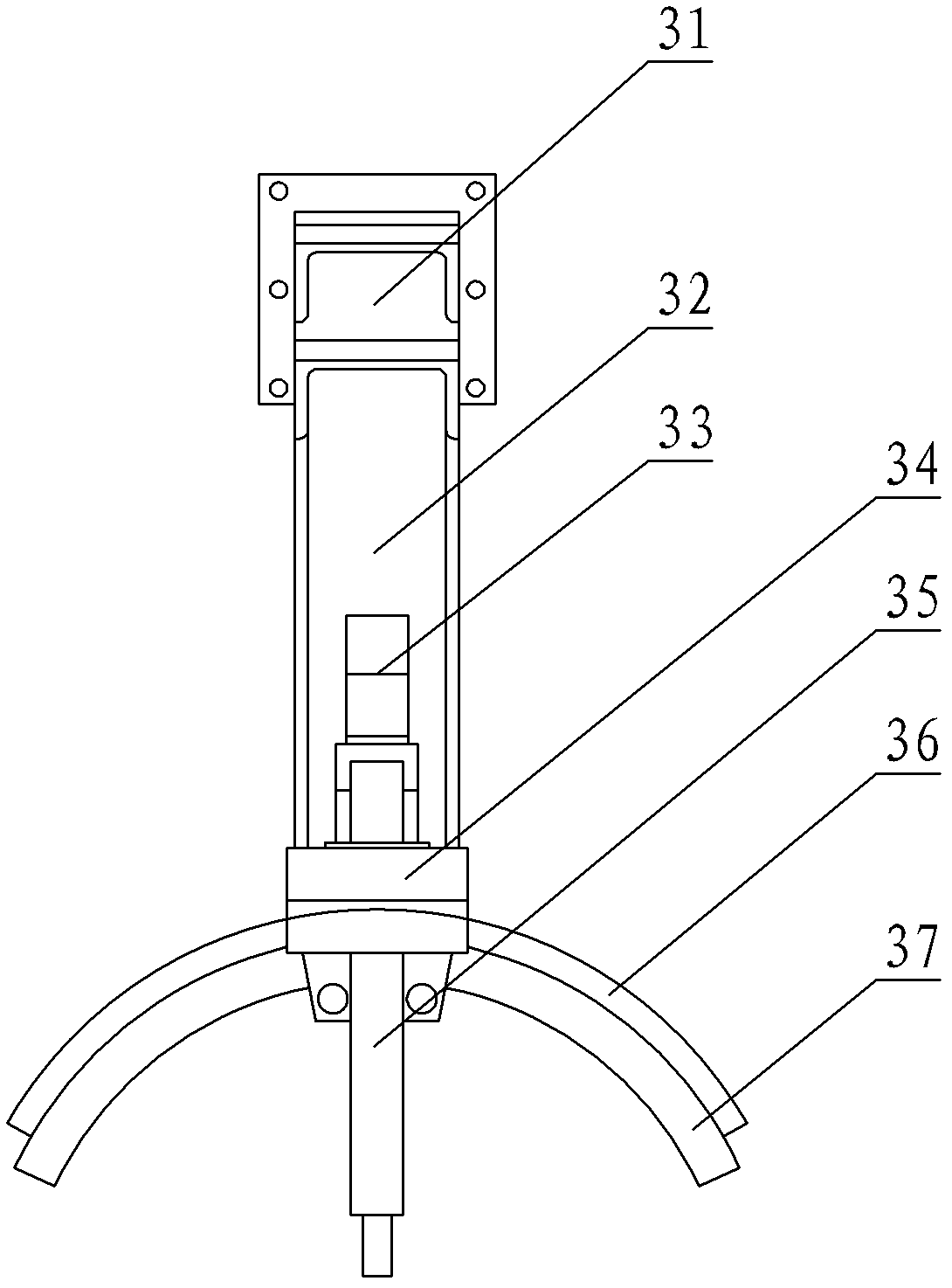

Automatic robot device for grinding air feeding and discharging edges of blade

ActiveCN104858748AGuaranteed machining accuracyGuaranteed grinding accuracyGrinding feed controlAutomatic grinding controlMeasurement deviceEngineering

The invention discloses an automatic robot device for grinding air feeding and discharging edges of a blade. The automatic robot device comprises a base station, a six-freedom-degree robot, a grinding device, a position changing machine, a three-dimensional laser measurement device and a system control host. The six-freedom-degree robot is arranged on the base station. The grinding device is used for grinding the air feeding and discharging edges of the blade. The position changing machine is arranged on the base station. The three-dimensional laser measurement device is arranged on the position changing machine and comprises a triaxial movement platform and a three-dimensional laser measurement device body. The three-dimensional laser measurement device body comprises two three-dimensional laser outline scanners. The system control host is connected with the six-freedom-degree robot and the three-dimensional laser measurement device. The system control host is used for planning the machining path of the grinding device and a moving path of the three-dimensional laser measurement device and sending the paths and commands to the six-freedom-degree robot to be executed. The automatic robot device integrates self-adaptive grinding and measurement functions, and can guarantee the machining precision of the outlines of the air feeding and discharging edges of the blade.

Owner:HUST WUXI RES INST

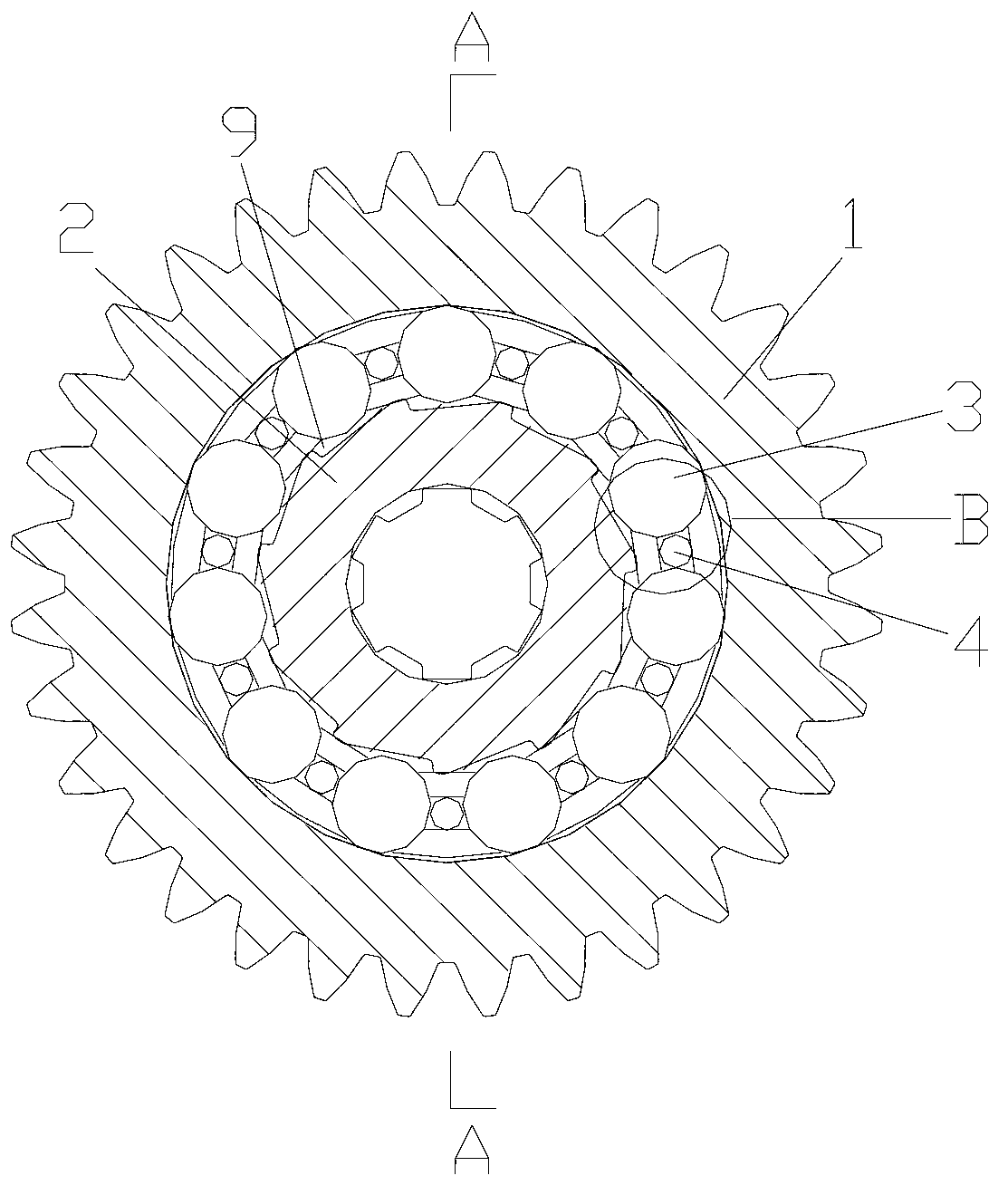

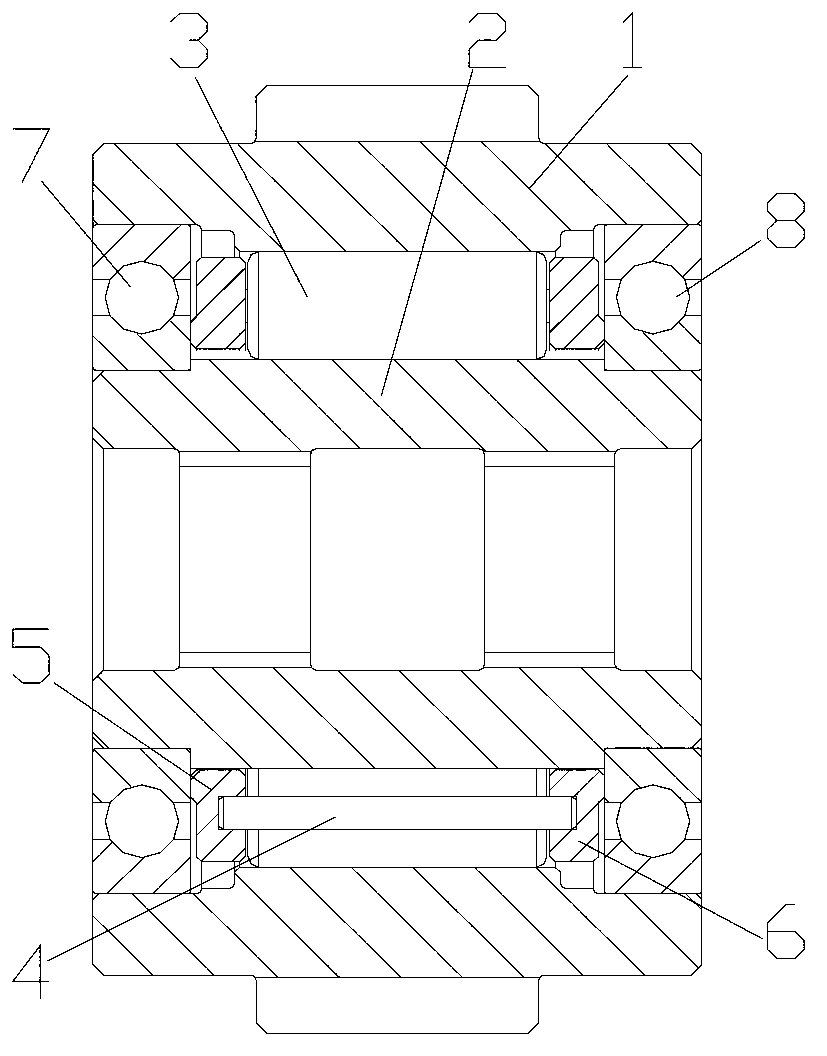

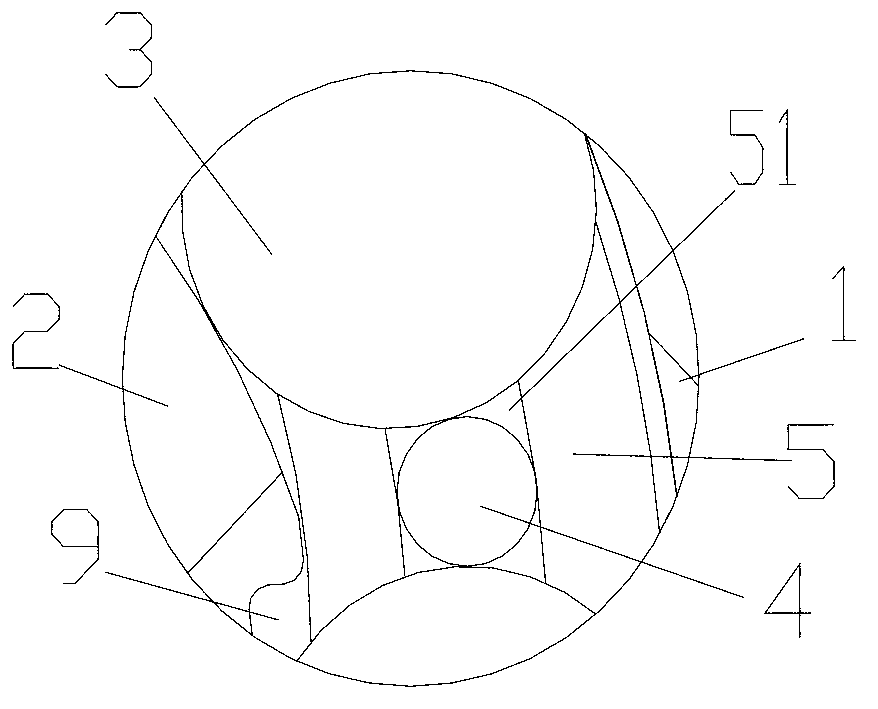

Floating auxiliary roller type overrun clutch

InactiveCN103307140AIncrease axial lengthIncrease the lengthFreewheel clutchesEngineeringMachining process

The invention discloses a floating auxiliary roller type overrun clutch which comprises an outer ring, an inner ring, rolling bodies and auxiliary rollers, wherein engagement spaces used for being engaged with or separated from the rolling bodies are formed between the outer ring and the inner ring; the auxiliary rollers are parallel to an axial line of the overrun clutch and are spaced from the rolling bodies; and the auxiliary rollers are arranged between the rolling bodies in such a way that the auxiliary rollers can move in a circumferential direction of the overrun clutch. According to the floating auxiliary roller type overrun clutch, the processing of a limiting seat is avoided, the processing process is simplified, the working efficiency is improved, and the processing cost is reduced; as the auxiliary roller structure is adopted, the axial length of the overrun clutch and the rolling bodies can be theoretically infinitely prolonged, the engagement length is prolonged, the bearing capacity of the overrun clutch is increased, the radial size of the overrun clutch under higher bearing capacity is reduced, and the service life of the overrun clutch is prolonged; and meanwhile, the probability of imbalance caused by application of a pretension force to point contact of each roller in the prior art is removed, thereby enabling each roller to keep parallel to the axial line of the inner ring.

Owner:SOUTHWEST UNIVERSITY

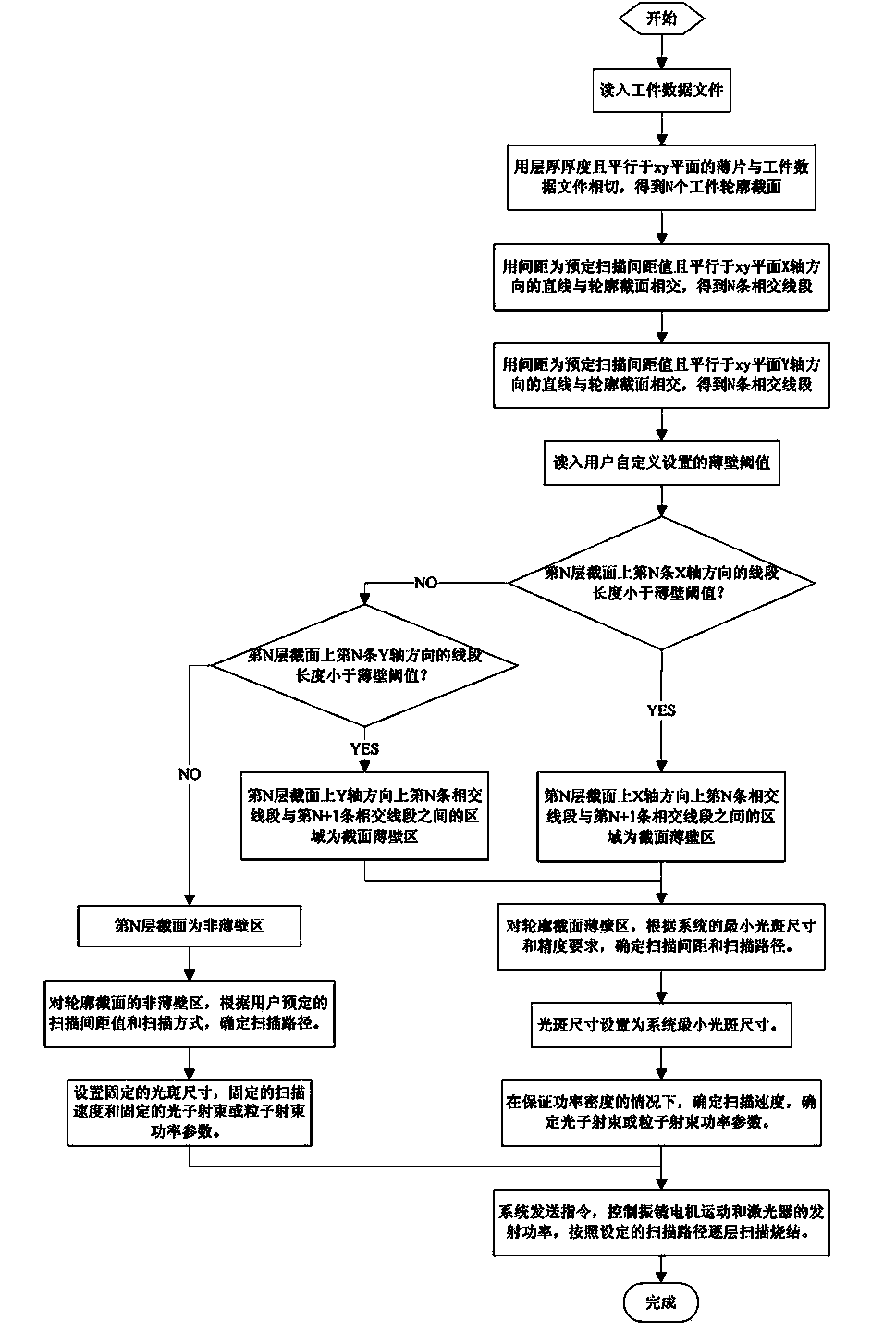

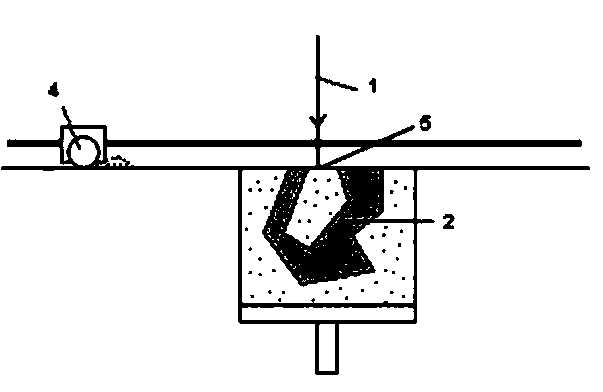

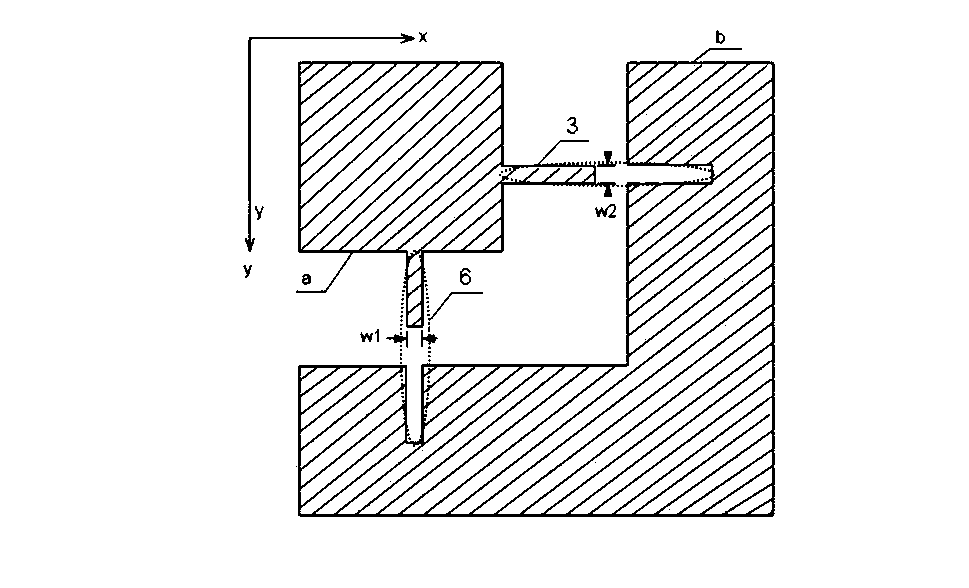

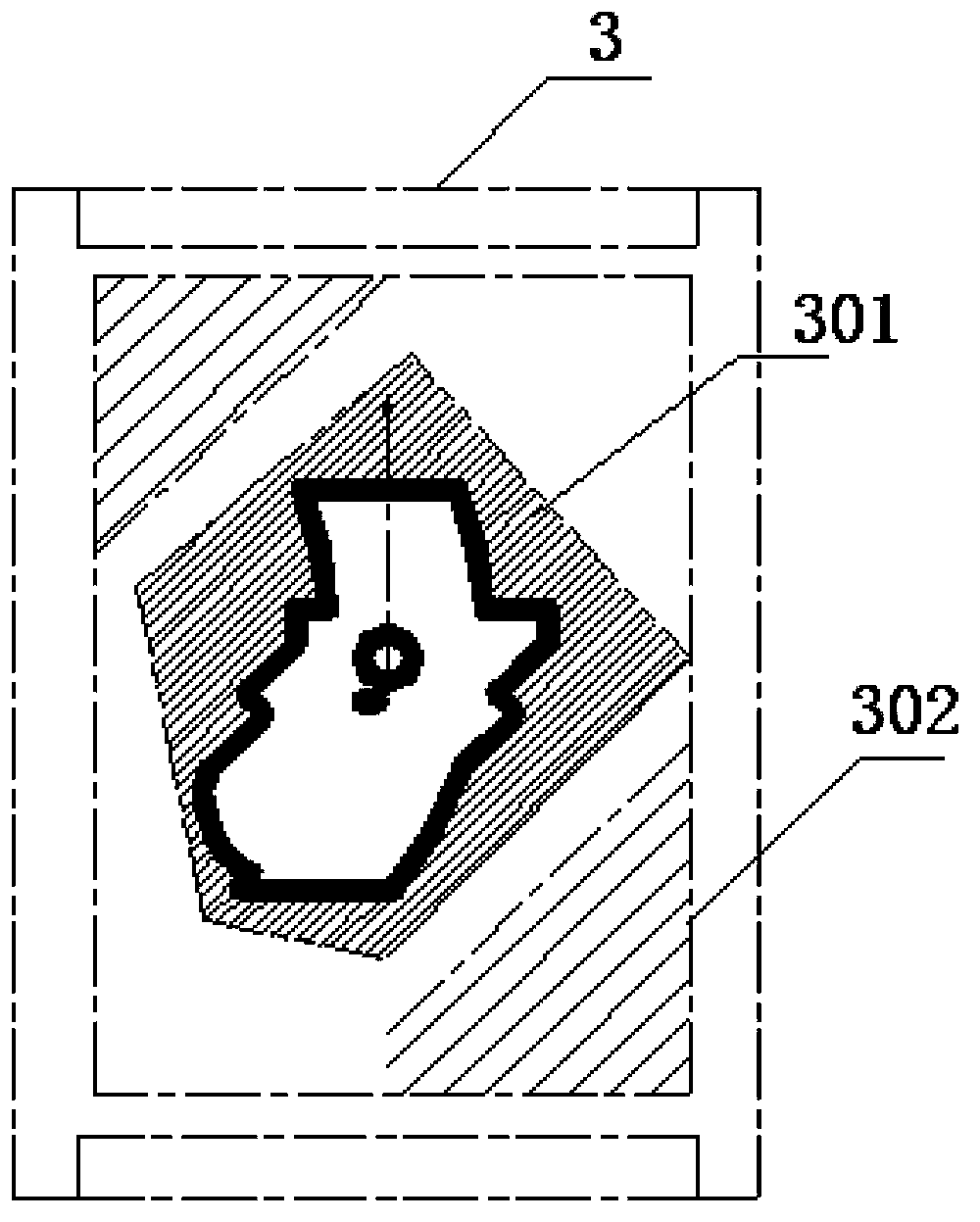

Scanning method for manufacturing three-dimensional object layer by layer

ActiveCN103639411AUniform efficiencyEqualization accuracyAdditive manufacturing apparatusCeramic shaping apparatusMachine partsParticle beam

A scanning method for manufacturing a three-dimensional object layer by layer comprises the following steps: (1), dividing each section layer of a three-dimensional object to be manufactured into a thin-wall area and a non-thin-wall area: setting a threshold of the gap width of the section profile of the three-dimensional object, and according to the gap width of the section profile in x / y direction, dividing a coating area required to be scanned into a thin-wall area and a non-thin-wall area, wherein the thin-wall area is an area of which the gap width of the section profile is smaller than the threshold and the non-thin-wall area is an area of which the gap width of the section profile is greater than or equal to the threshold; (2), according to the thin-wall area and the non-thin-wall area, scanning area by area, wherein the non-thin-wall area is scanned, relatively high photon beam or particle beam power and relatively large light spot diameter are selected, and when the thin-wall area is scanned, relatively low photon beam or particle beam power and relatively large light spot diameter are selected. By the scanning method, constraints of efficiency and precision in the process of manufacturing the three-dimensional object layer by layer are balanced to the maximum extent, so that the efficiency is ensured and the accuracy and the surface quality of a machined part are ensured.

Owner:HUNAN FARSOON HIGH TECH CO LTD

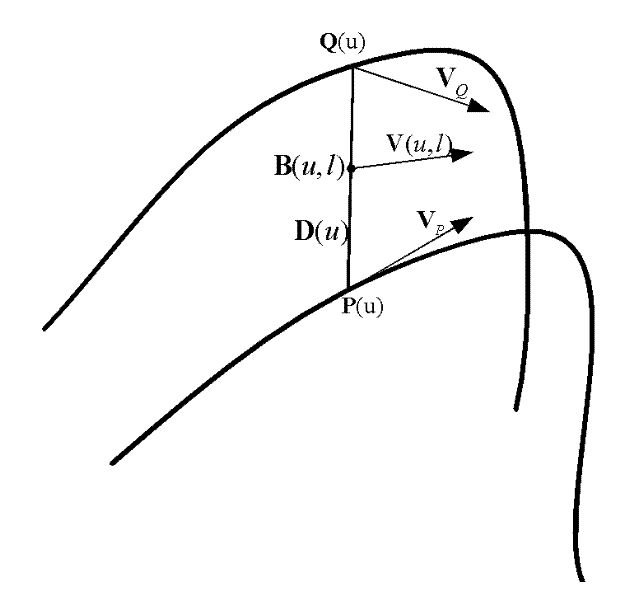

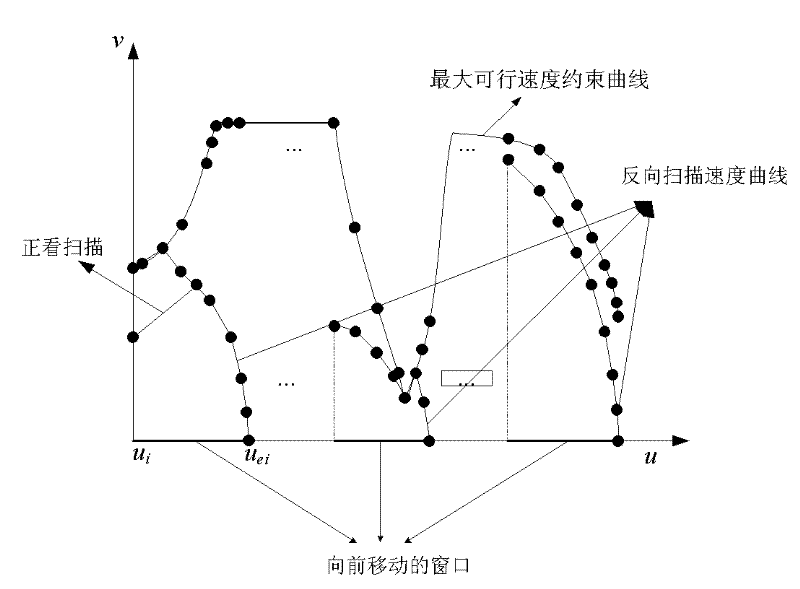

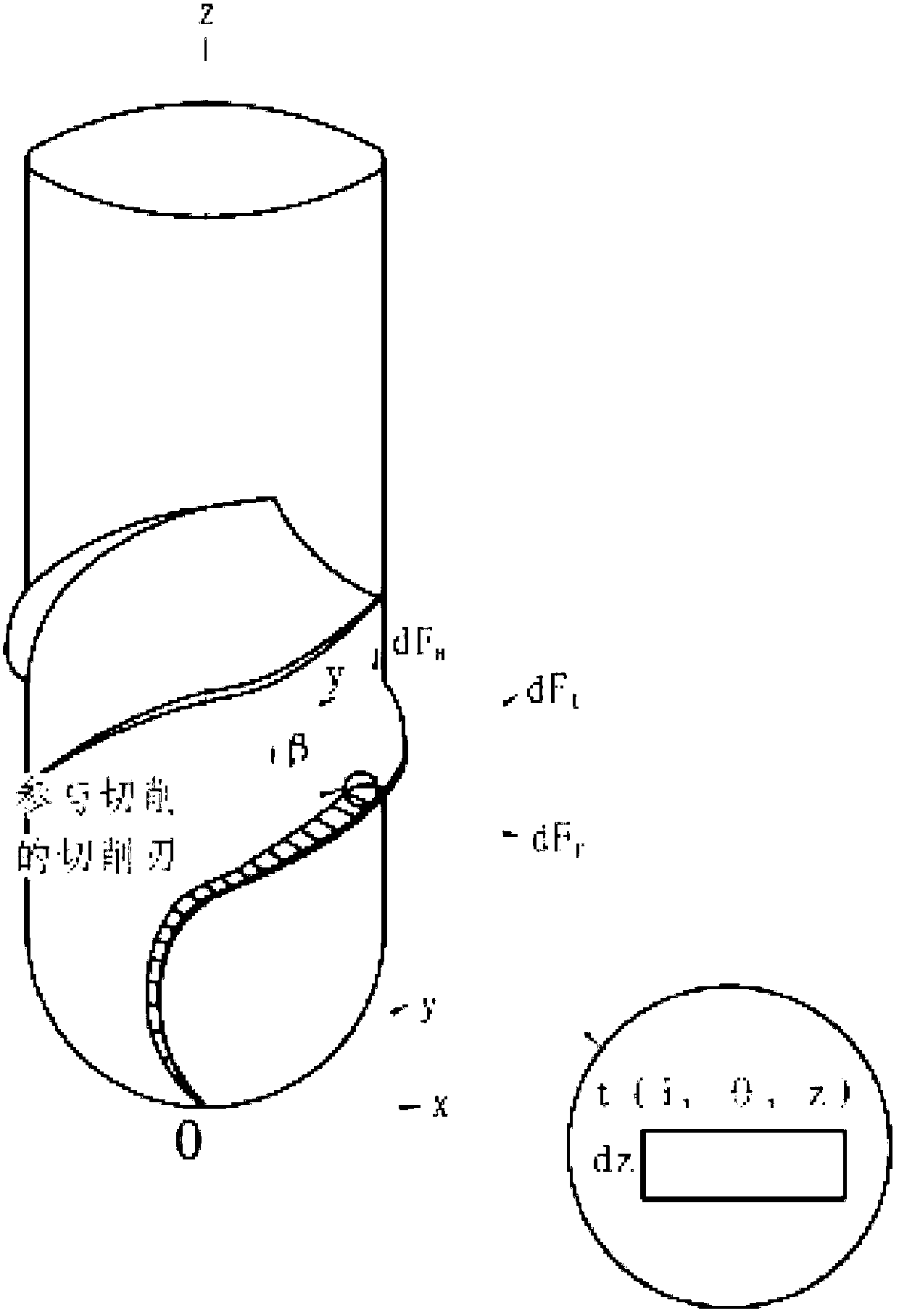

Velocity Planning Method of Double Nurbs Tool Trajectory in Five-axis NC Machining

ActiveCN102298358AOvercome technical difficulties affecting machining accuracyImprove computing efficiencyProgramme controlComputer controlNumerical controlCurrent velocity

The invention discloses a NURBS (Non-Uniform Rational B-Splines) tool path speed planning method for five-axis numerical control machining. The method comprises the following steps of: 1, creating synthesized constraints oriented to double NURBS cure tool path route interpolation, synthesizing the constraints to solve a maximum speed and an acceleration of the tool in a moving process, and establishing a synthesized constraint space in a machine tool interpolation process; 2, performing bidirectional speed planning based on window scanning, taking the current speed as basis, scanning forwardsfrom a window start pint to a window tail end in a viable speed domain to obtain a feeding speed of a current period. The method ensures that the path is machined with the highest speed under a condition of meeting the requirements on servo capability and machining performance of the machine tool, and implements a high-quality and high-efficiency machining process.

Owner:SHANGHAI JIAO TONG UNIV +1

Inner ring grinding device and grinding method for rotating disc type bearing machining

InactiveCN109648411AImprove the fixing strengthImprove poor stabilityGrinding carriagesRevolution surface grinding machinesStructural stabilityEngineering

The invention discloses an inner ring grinding device and grinding method for rotating disc type bearing machining. The inner ring grinding device comprises a base, wherein a motor frame is welded toone side of the upper surface of the base, and the upper portion of the motor frame is connected with a speed reducer through bolts; a first motor which is in transmission connection with an input shaft is fixed to the side wall where the input shaft of the speed reducer is located through bolts, and a rotating seat is fixed on the other side of the upper surface of the base through bolts; and a supporting rod is movably connected with the interior of the rotating seat through a bearing, and a rotating disc is welded to the top of the supporting rod. According to the inner ring grinding deviceand grinding method, four bearing brackets can be controlled to move oppositely by only rotating a central rod, and the height and speed can be adjusted; the bearing brackets can clamp the outer wall, the upper surface and the lower surface of the bearing, and the fixing strength of the bearing is improved; and an upper movable frame is slidably connected in a lower supporting frame, and a movable block with the bottom provided with four pulleys is slidably connected inside a sliding frame, so that the stability of a milling cutter control structure is improved, and the machining precision ofan inner ring of the bearing is guaranteed.

Owner:MAANSHAN YUEMEI METAL PROD TECH IND

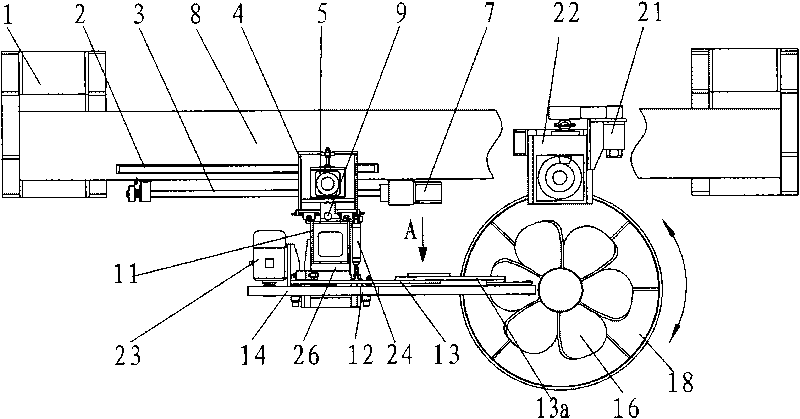

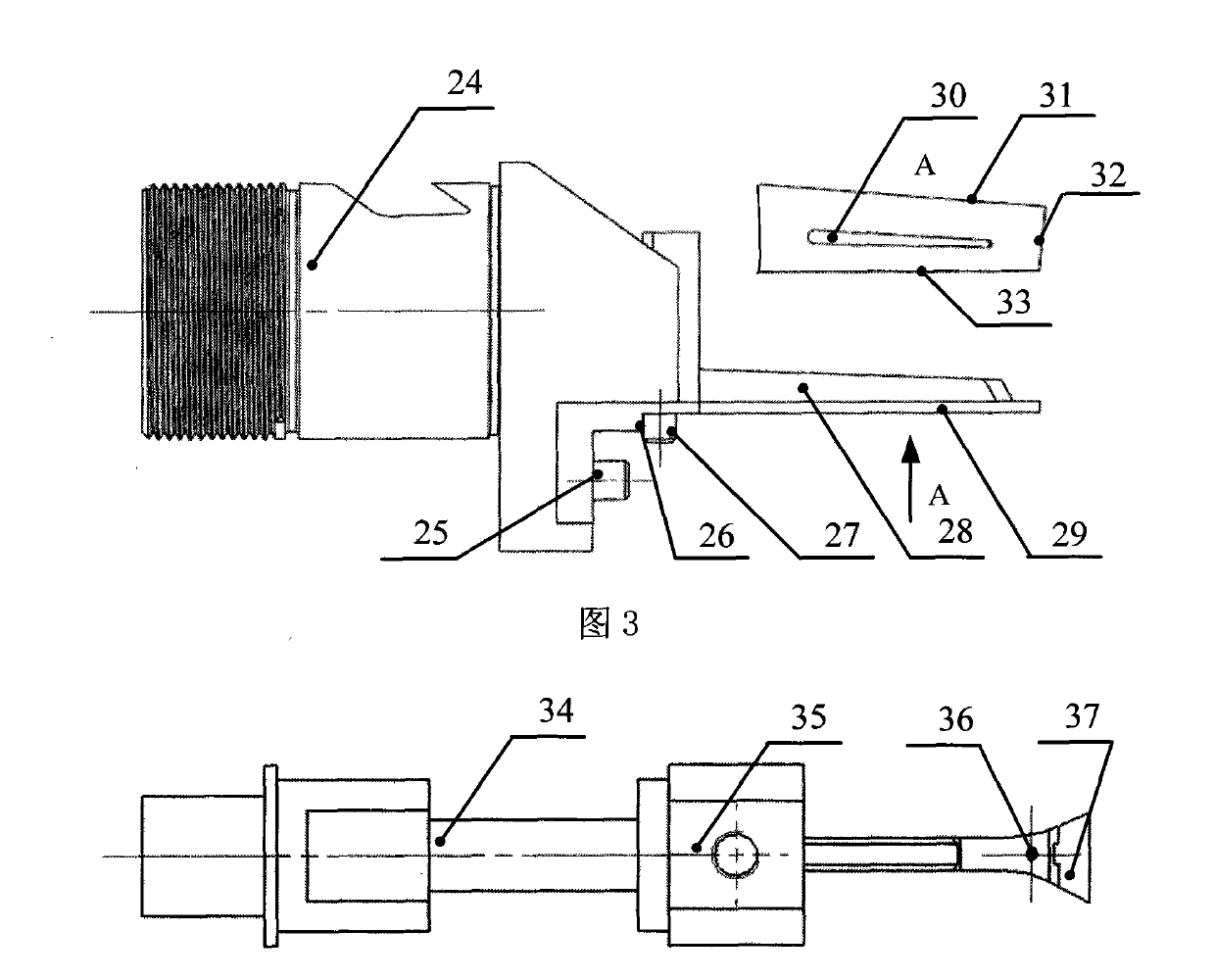

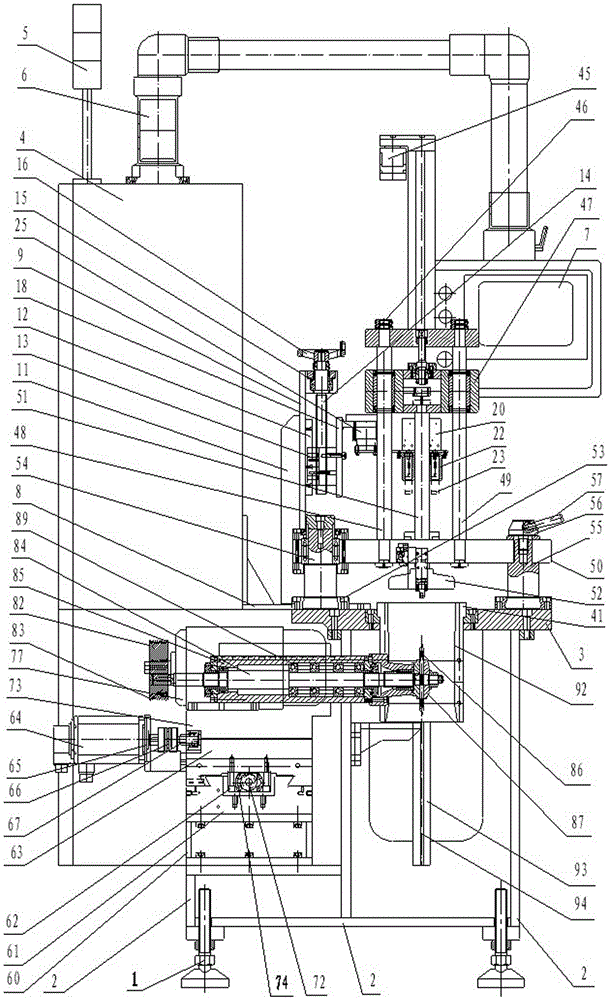

Gantry propeller integral blade abrasive belt grinding machine

InactiveCN101733690AImprove stabilityImprove rigidityBelt grinding machinesPropellerDegrees of freedom

The invention discloses a gantry propeller integral blade abrasive belt grinding machine, which comprises a machine body, a grinding head mechanism, a grinding head feed mechanism and a workpiece azimuth adjusting mechanism. The grinding head feed mechanism comprises an axial feed mechanism, a radial feed mechanism with respect to a work piece, and a grinding head deflection driving mechanism. The whole grinding machine has high stability and ensures the grinding precision. By reasonably distributing grinding head feed and adjusting the work piece azimuth and through the combination of four spatial degrees of freedom by a relatively short transmission chain, the grinding head mechanism has high and low degrees of freedom of pitch in a relatively small range, the integral blade can be directly ground, and the blades on the integral blade and other parts are all completely machined. The grinding head mechanism and a work piece clamping mechanism have good rigidity, the working efficiency is improved, and synchronously, the machining precision and the surface quality can be ensured. The grinding thickness in the process of polishing a curved surface is uniform, the quality of a molded surface is ensured, the labor intensity of workers is decreased, and the management cost and the production cost are reduced.

Owner:CHONGQING SANMO HAIDA GRINDING MACHINE

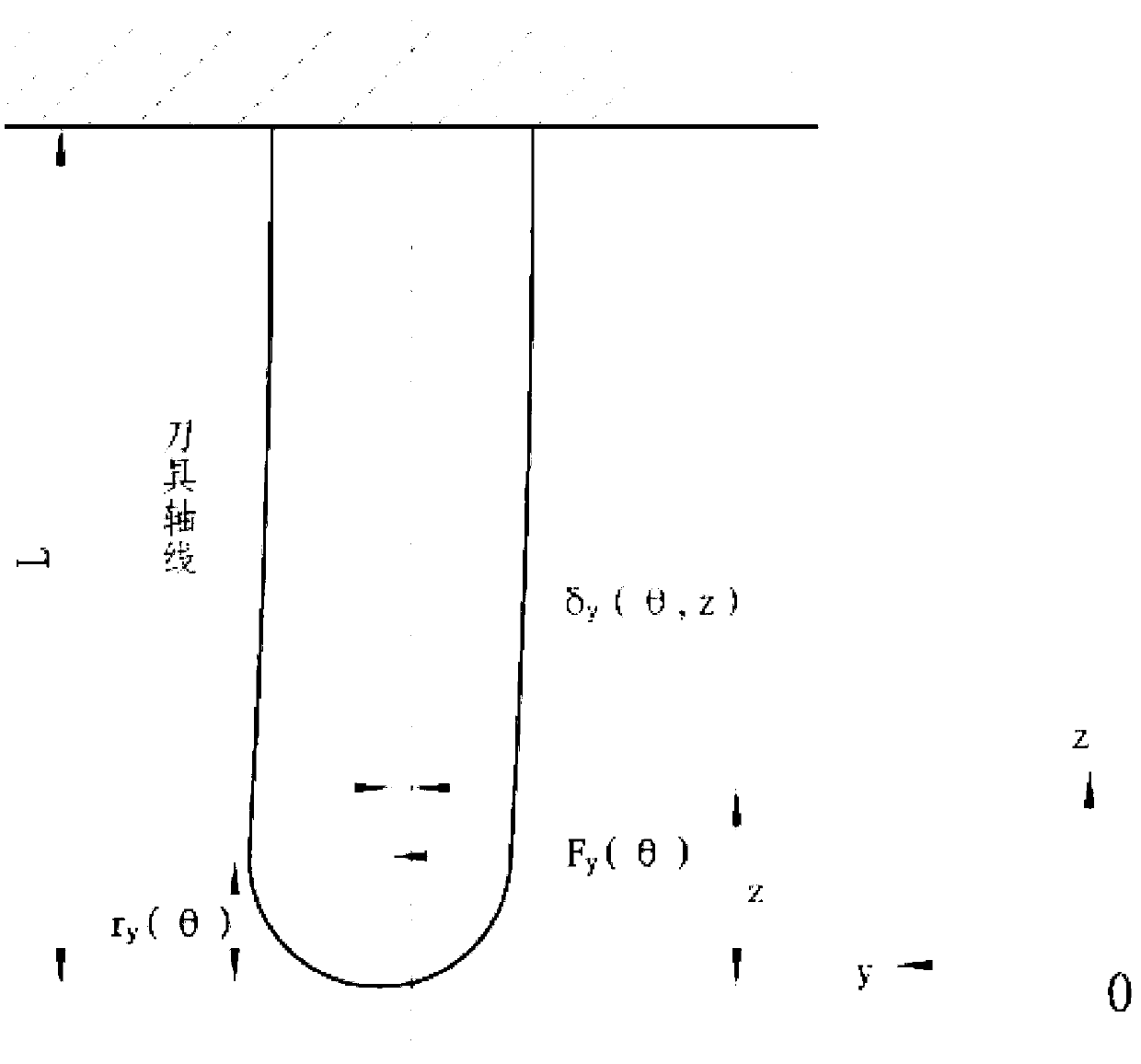

Precision numerical control milling method for thin-wall parts

InactiveCN101602122AReduce stiffnessGuaranteed machining accuracyMilling equipment detailsNumerical controlEngineering

The invention discloses a precision numerical control milling method for thin-wall parts, and provides a processing method for reducing the milling deformation of the thin-wall parts and improving processing precision and surface quality. When a thin-wall part is finished by fine processing through end milling, the machining allowances of the side wall and a web plate are larger than those of the prior process, and are between 2 and 5mm respectively; when the side wall is processed, the axial depth ap is between 0.2 and 0.8mm, and the radial cutting width is 60 to 80 percent of the diameter of a cutting tool; and when the web plate is processed, the axial depth ap is between 2 and 5mm, and the radial cutting width ae is 10 to 20 percent of the diameter of the cutting tool. The processing method effectively slows down the reduction of the self-rigidity of workpieces and control the cutting force in the thin-wall direction when the processing efficiency is ensured, thereby effectively reducing and controlling the processing deformation of the thin-wall parts, and ensuring the processing precision and surface quality of the parts.

Owner:TIANJIN UNIV OF COMMERCE

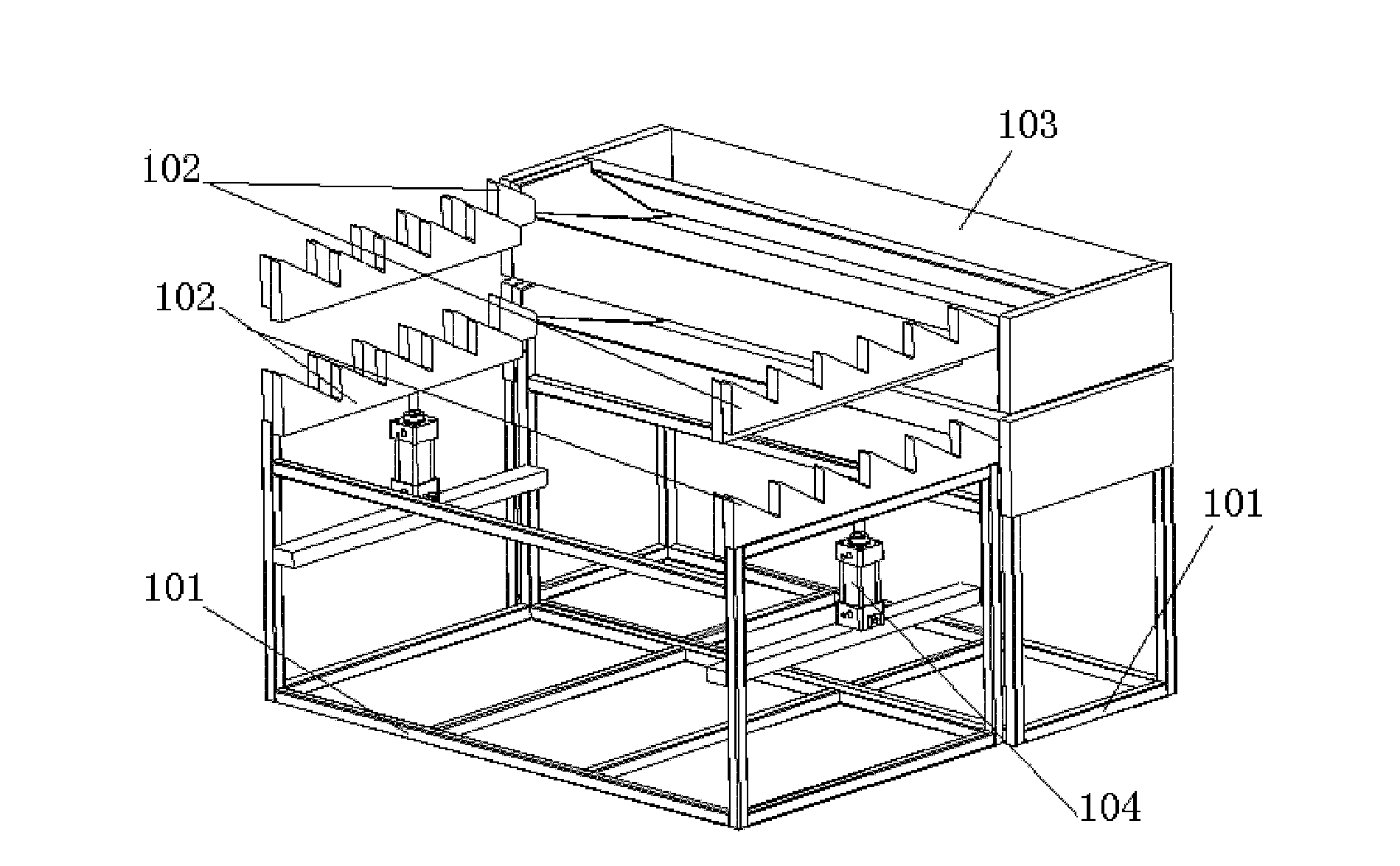

Automatic feeding and discharging device

ActiveCN102430953AGuaranteed machining accuracyMake up for the errorMetal working apparatusMechanical engineeringJoint action

The invention discloses an automatic feeding and discharging device, which comprises a distribution mechanism, a dropping mechanism and a conveyance mechanism. The conveyance mechanism is arranged between the distribution mechanism and the dropping mechanism and consists of a base, a feeding mechanism, a lifting mechanism and a conveying mechanism are disposed on the base, the lifting mechanism is arranged between the feeding mechanism and the conveying mechanism, and the feeding mechanism is connected with the distribution mechanism, and is also connected with the dropping mechanism. By the aid of the joint action of the distribution mechanism, the feeding mechanism, the lifting mechanism, the conveying mechanism and the dropping mechanism, automatic feeding and discharging of pipes can be realized, labor intensity of feeding and discharging of the pipes can be greatly reduced, production efficiency is enhanced, and production cost is lowered.

Owner:CHERY AUTOMOBILE CO LTD

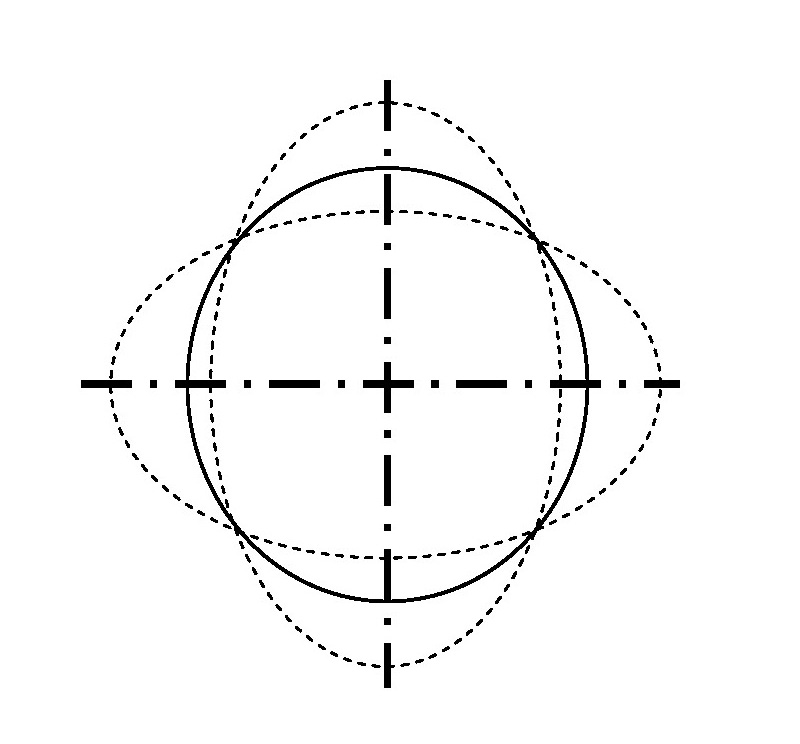

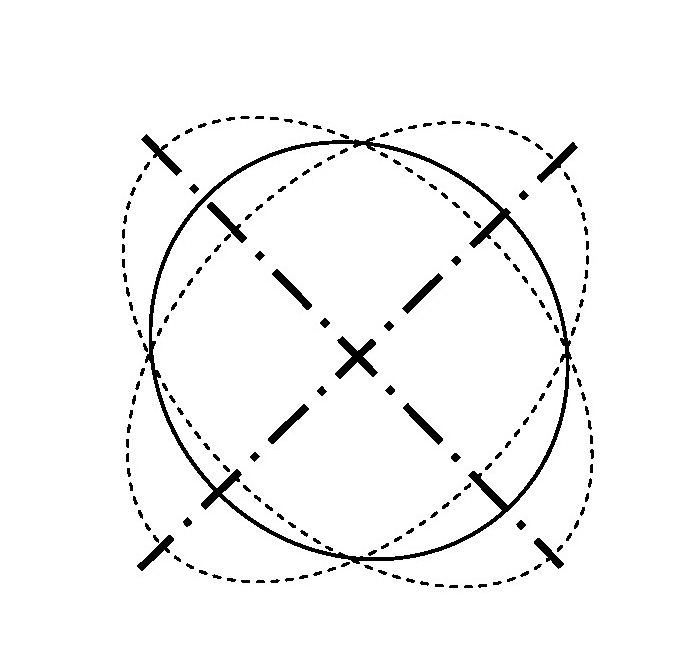

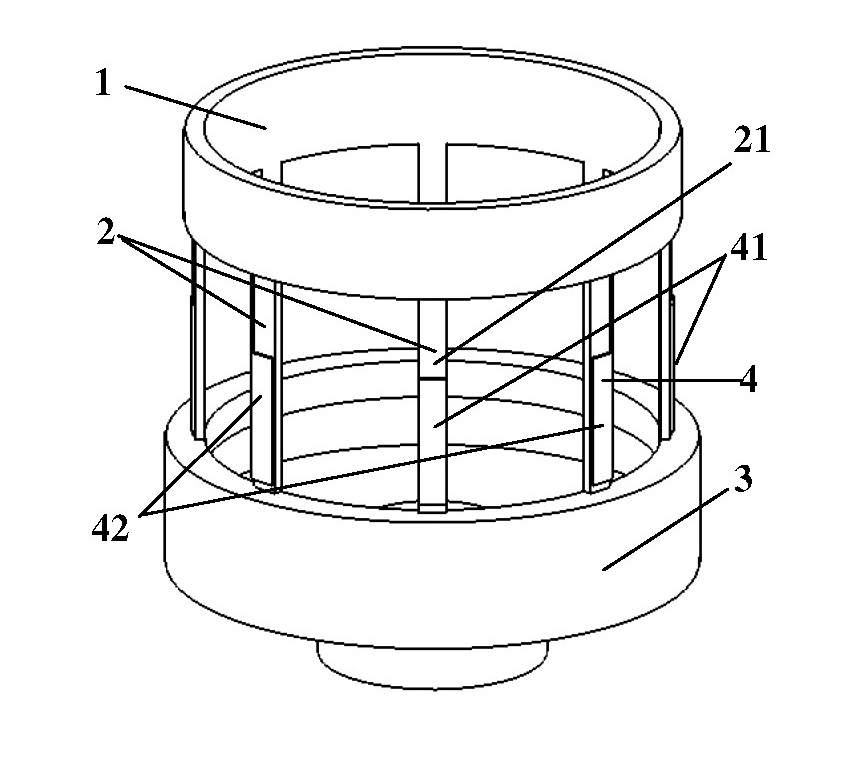

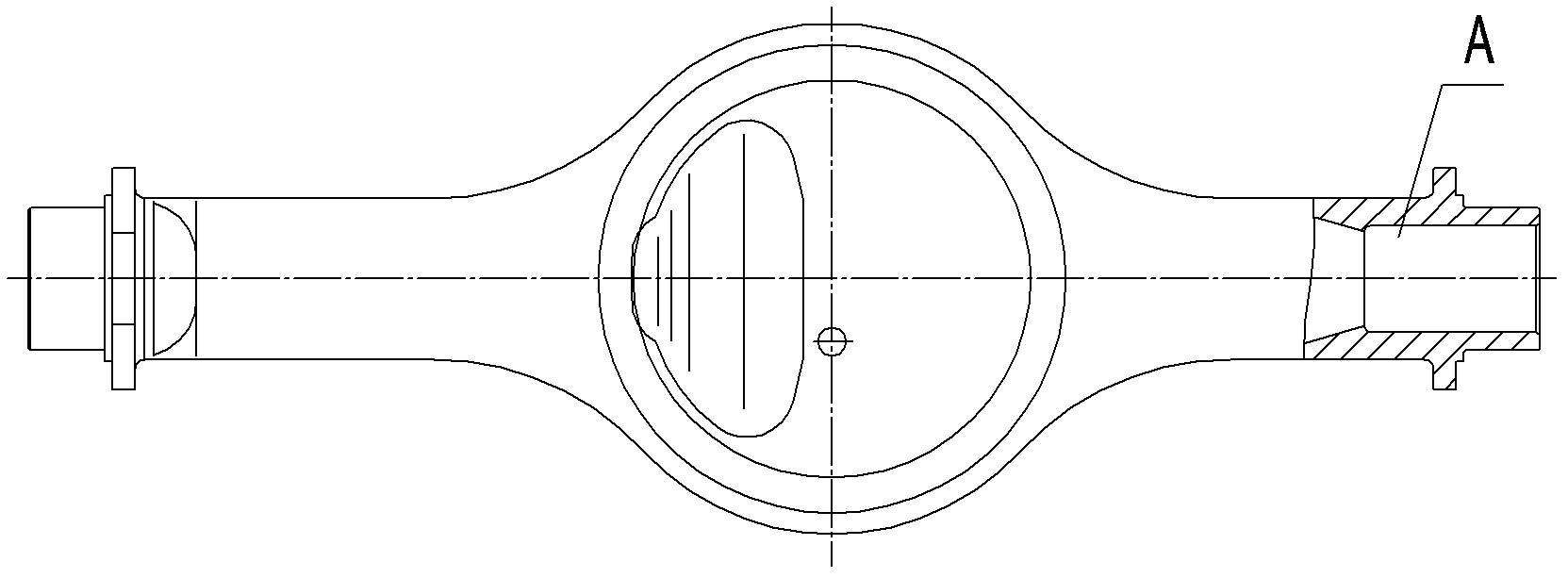

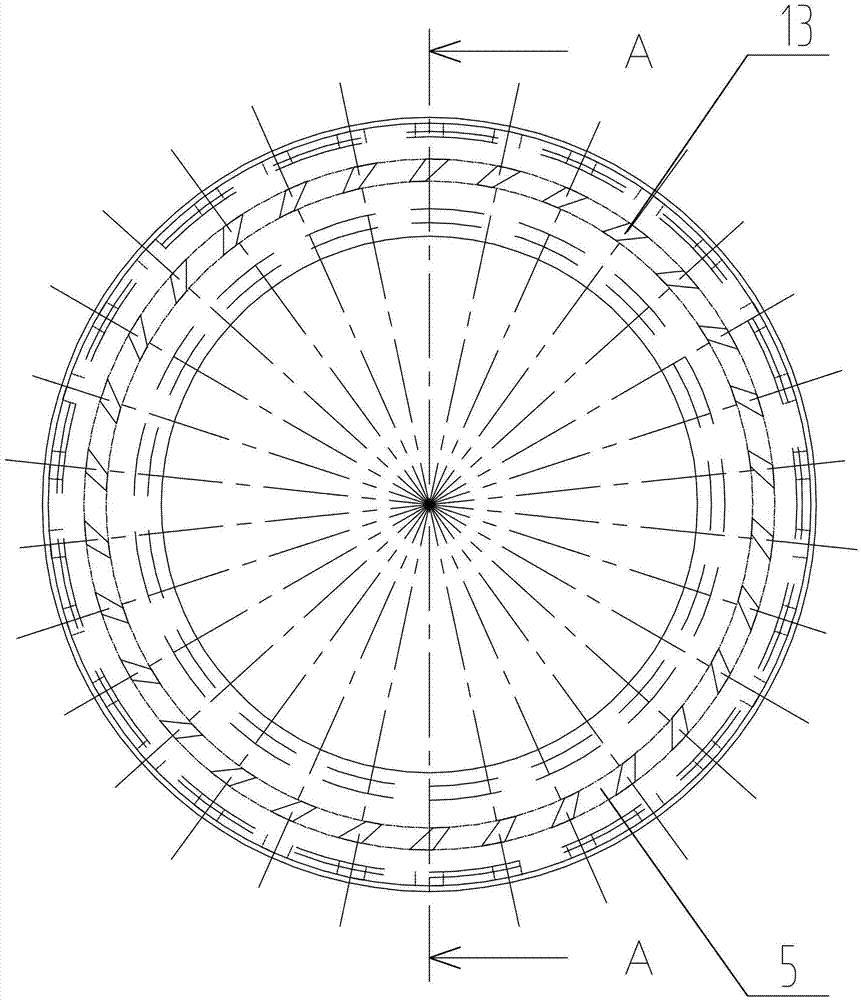

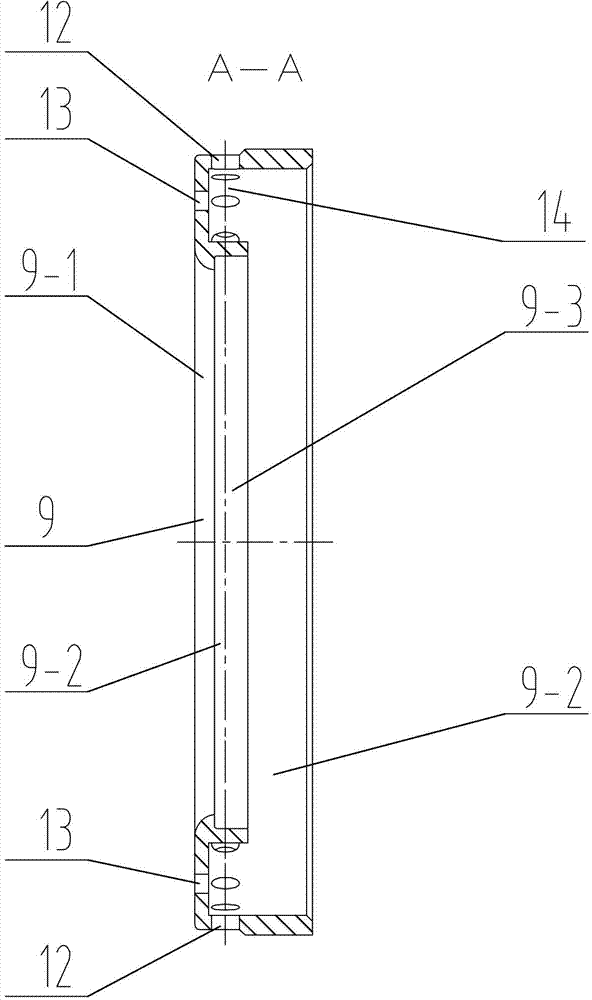

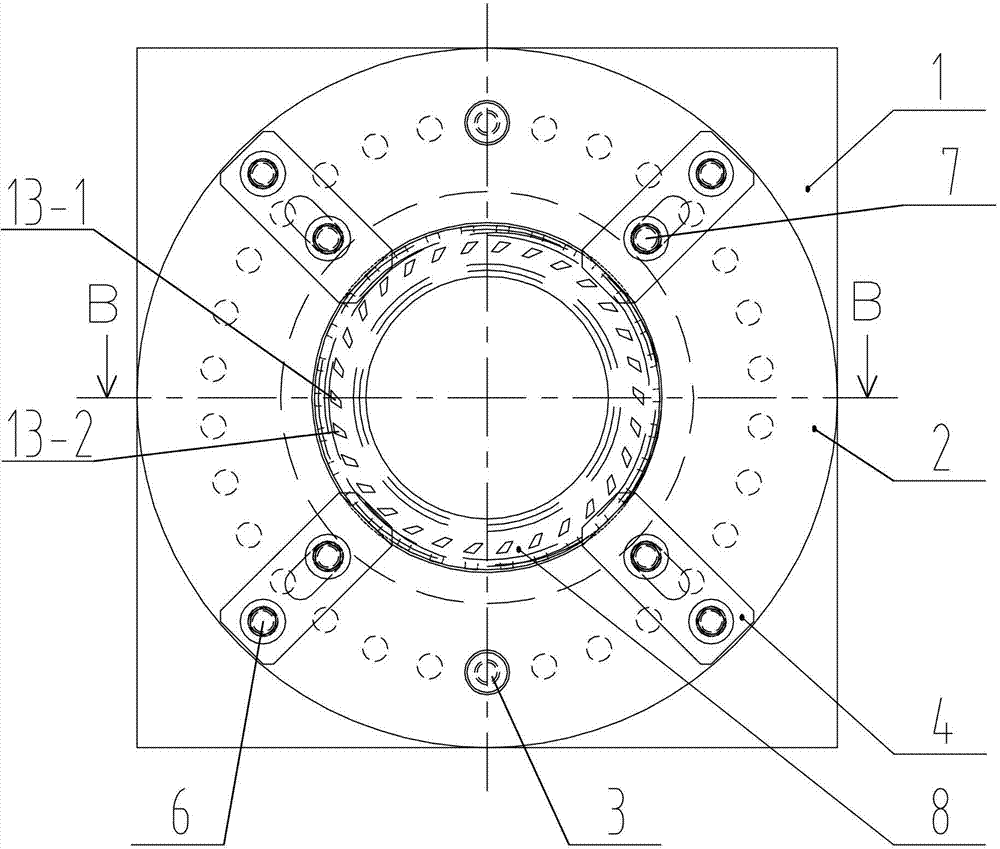

Harmonic oscillator of solid fluctuation gyro and solid fluctuation gyro

ActiveCN101936734ALean structureReduce air dampingSpeed measurement using gyroscopic effectsTurn-sensitive devicesElectricityResonance

The invention discloses a harmonic oscillator of a solid fluctuation gyro, which comprises a resonance ring (1), a resonance transmission part (2), a chassis (3) and a piezoelectric element (4), wherein, the resonance ring (1) is connected with the chassis (3) through the resonance transmission part (2), the resonance transmission part (2) is composed of support beams (21) which are uniformly distributed in the circumferential direction, and the piezoelectric element (4) is arranged on the support beams (21). The invention further discloses the solid fluctuation gyro provided with the harmonic oscillator. The solid fluctuation gyro and the harmonic oscillator of the invention have the advantages of high sensitivity, good sensing effect, convenient machining, low machining cost, simple mechanical balance procedure and the like.

Owner:NAT UNIV OF DEFENSE TECH

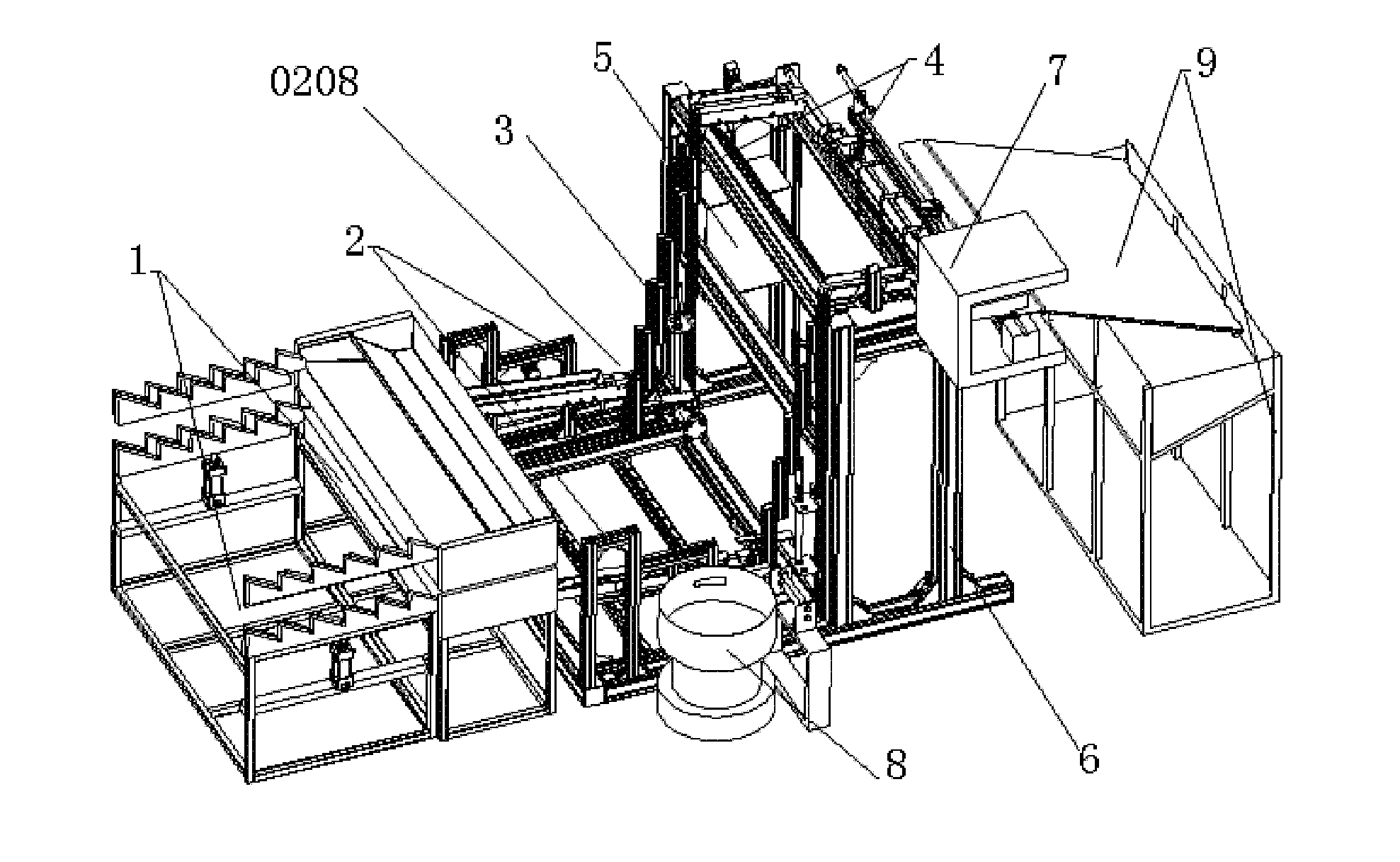

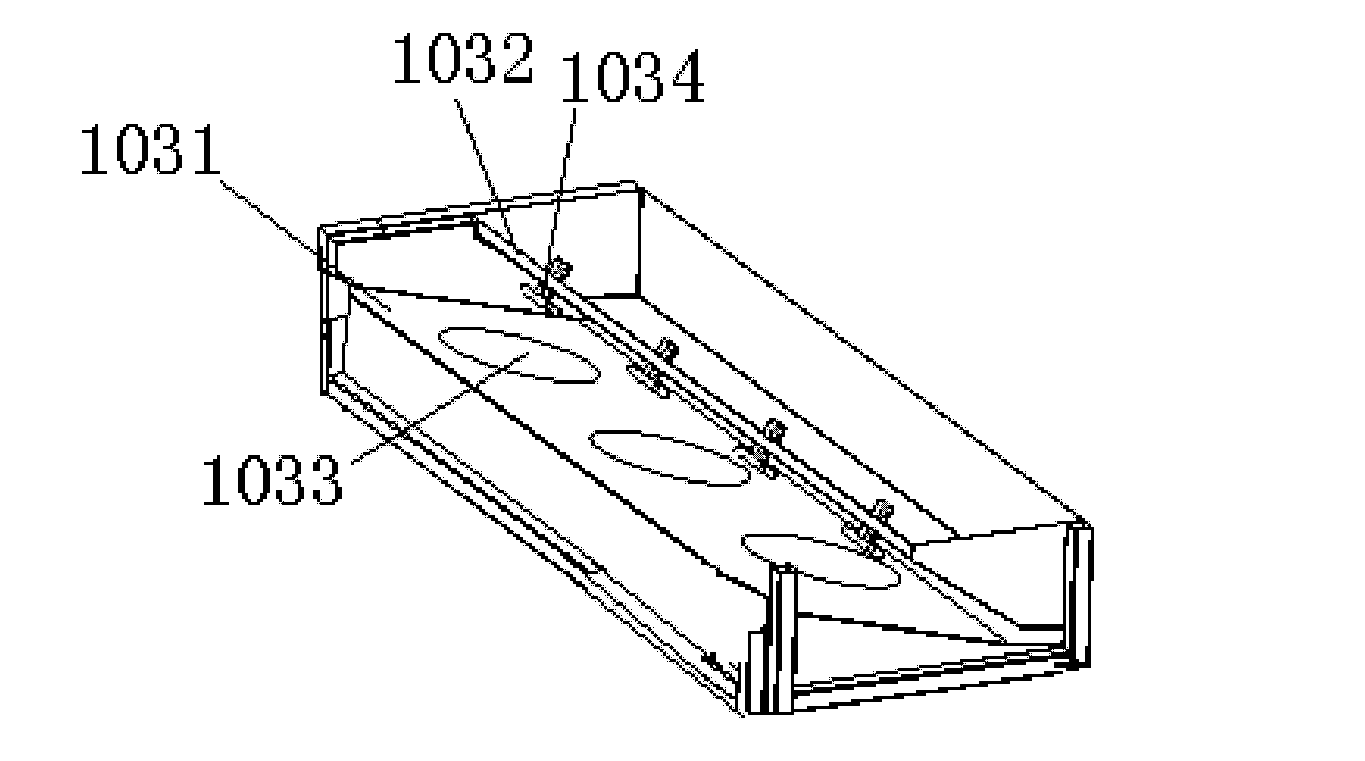

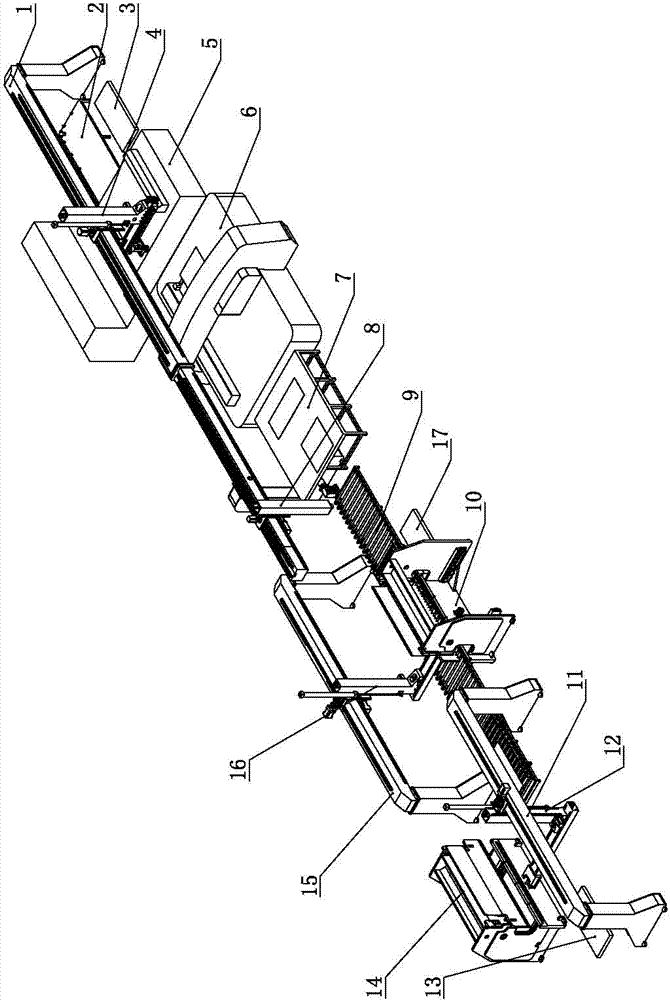

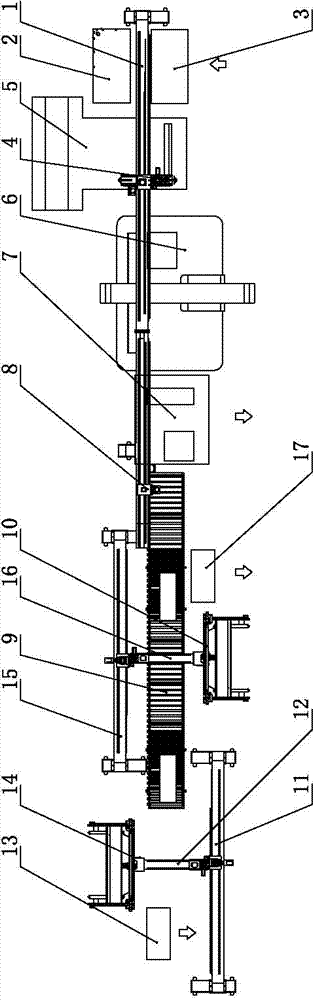

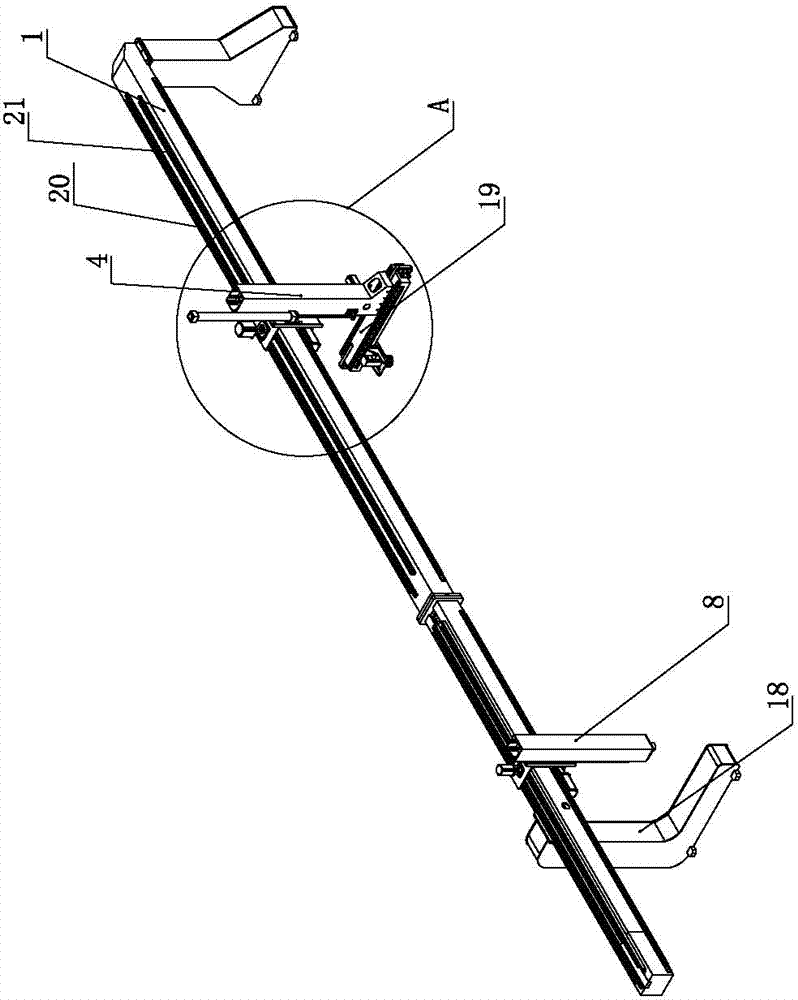

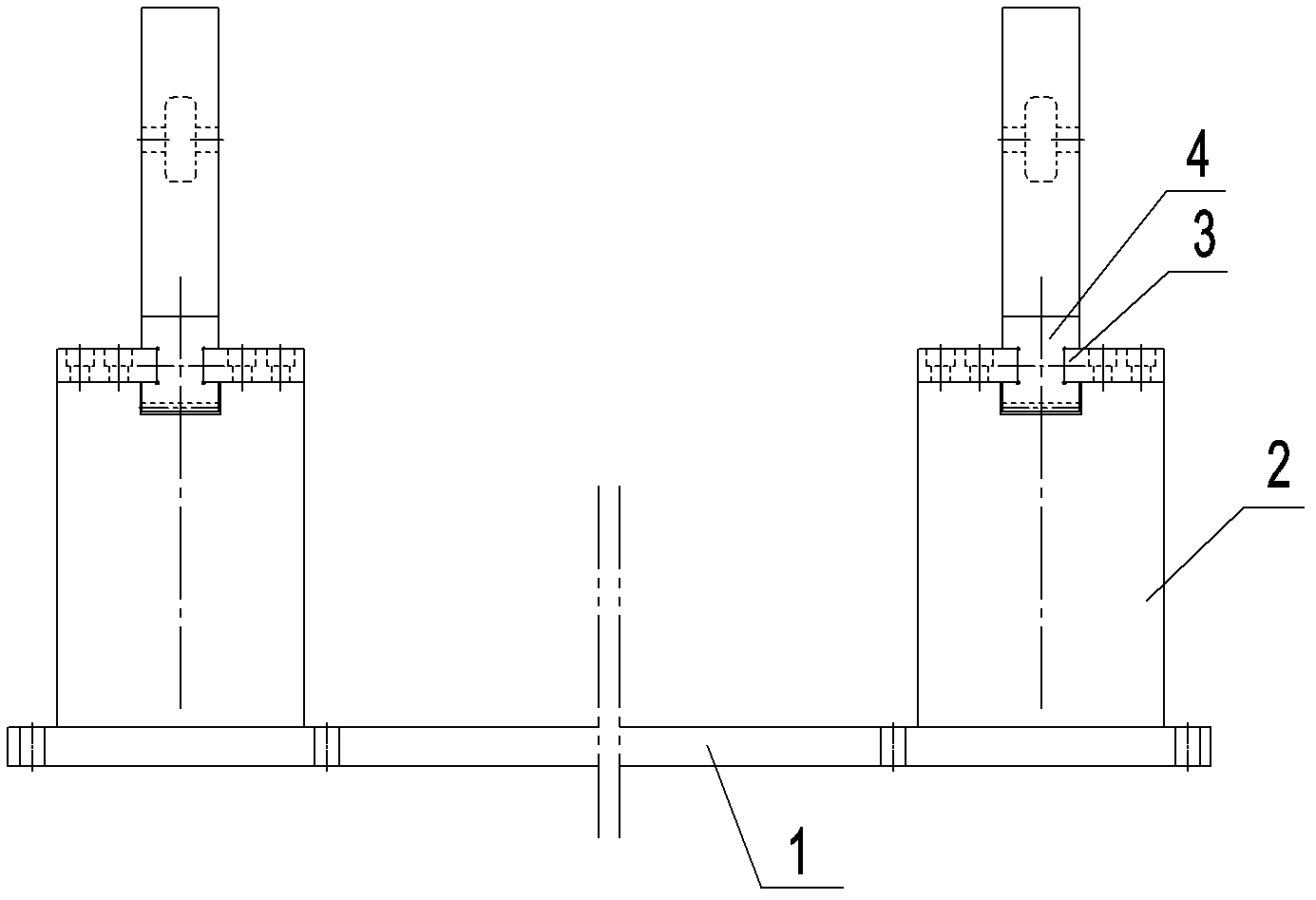

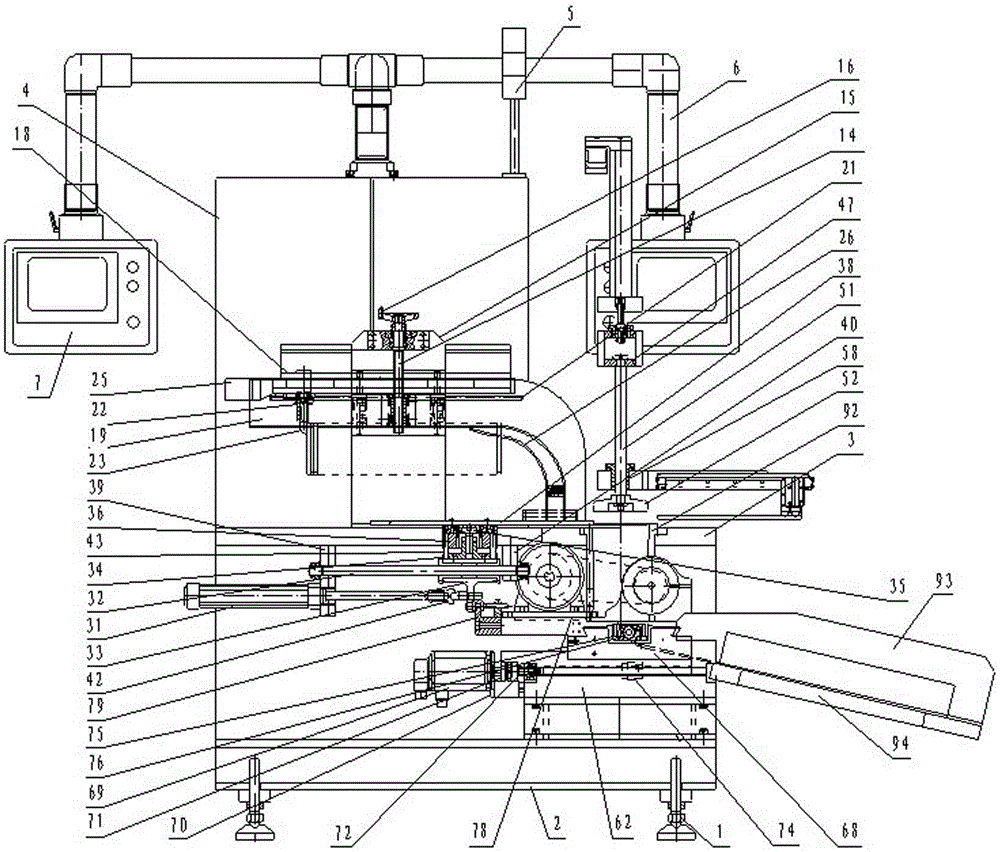

Machining production line for sheet metal

ActiveCN104759894ACompact structureImprove matchOther manufacturing equipments/toolsProduction lineNumerical control

The invention belongs to the field of sheet metal machining equipment and discloses a machining production line for sheet metal. The machining production line comprises a numerical control shearing machine, a numerical control punching machine and two or more numerical control bending machines which are arranged in sequence, the feeding side of the numerical control shearing machine is provided with a raw material rack and a locating platform, a first cross beam is arranged above the numerical control shearing machine and the numerical control punching machine, the two ends of the first cross beam are arranged across the numerical control shearing machine and the numerical control punching machine, the raw material rack and the locating platform are arranged below the two sides of the front end of the first cross beam respectively, the font end of the first cross beam is provided with a feeding mechanical arm, the rear end of the first cross beam is provided with a discharging mechanical arm, a temporary storage rack is arranged at the discharging side of the numerical control punching machine, the discharging mechanical arm corresponds to the temporary storage rack, and the numerical control bending machines are arranged at the two sides of a multistation conveying device respectively. According to the machining production line, the automation degree is high, cooperative work can be conducted without interference, and the consistency of the cooperative work is good.

Owner:YANGZHOU HENGJIA AUTOMATION EQUIP CO LTD

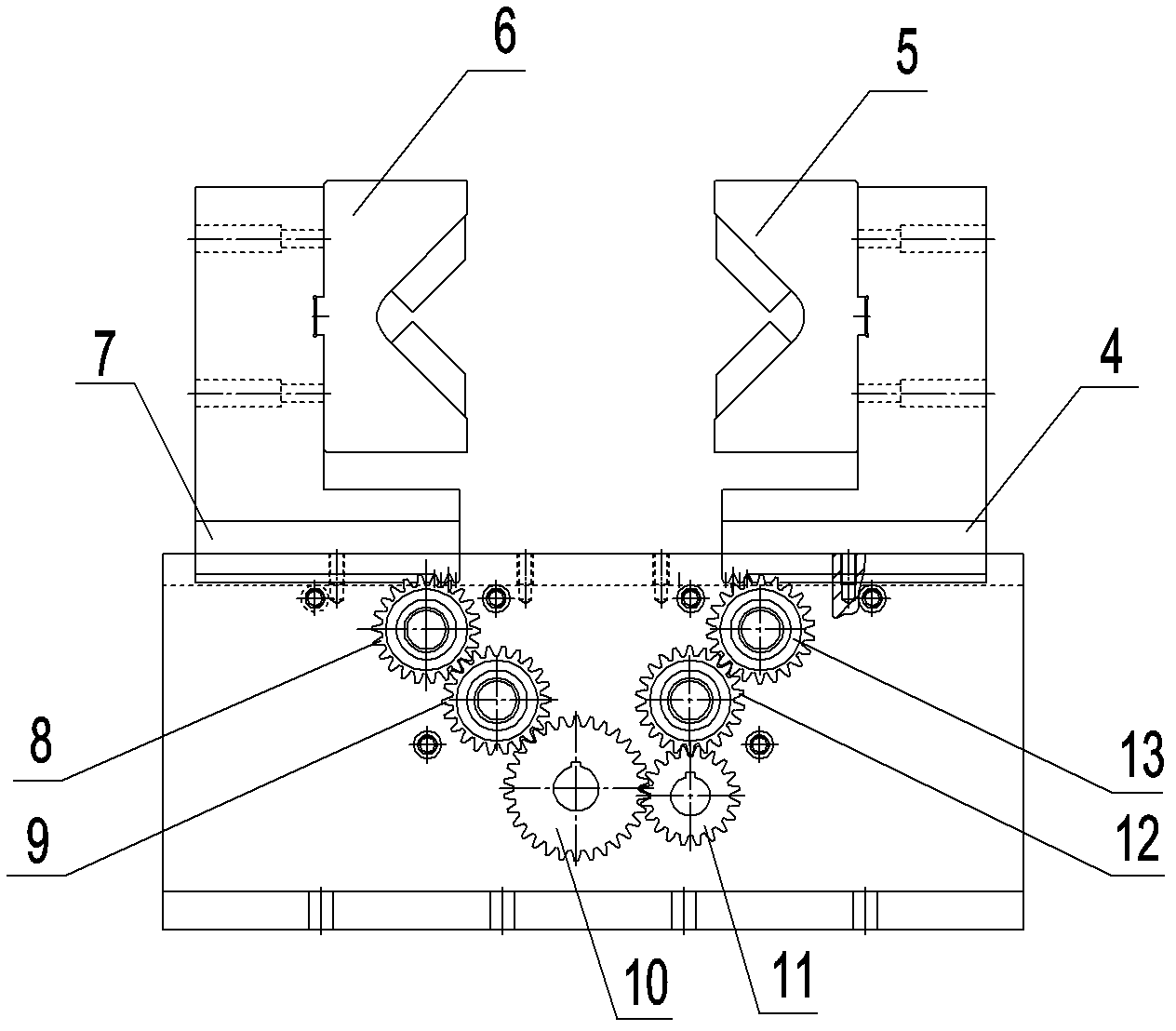

Boring automatic centering clamp of drive axle housing

InactiveCN102581641AGuaranteed machining accuracyImprove work efficiencyPositioning apparatusMetal-working holdersControl theoryMechanical engineering

The invention provides a boring automatic centering clamp of a drive axle housing, relating to a clamp for the mechanical processing field. The boring automatic centering clamp comprises a fixing base, and two sets of clamping positioning devices symmetrically connected to two ends of the fixing base, wherein each set of clamping positioning devices comprises a transmission case, a sliding block I, a sliding block II, a clamping block I and a clamping block II; a slide rail is mounted on the top wall of the transmission case; the sliding block I and the sliding block II are glidingly connected to the slide rail, and protruded on the upper surface of the top wall of the transmission case; the clamping block I is connected to the sliding block I, while the clamping block II is connected to the sliding block II; symmetrically mounted clamping parts having the same shape are concavely arranged in the clamping block I and the clamping block II, respectively; and the transmission case is internally provided with a transmission mechanism for sliding the sliding block I and the sliding block II to reversely move on the lead rail in order to control the clamping block I and the clamping block II to clamp or release the drive axle housing. The boring automatic centering clamp provided by the invention has the advantages of automatically aligning the axes of the sleeve holes at two ends of the drive axle housing, and quickly performing positioning and clamping.

Owner:LIUZHOU CITY LONGCHEN AXLE PARTS MFG

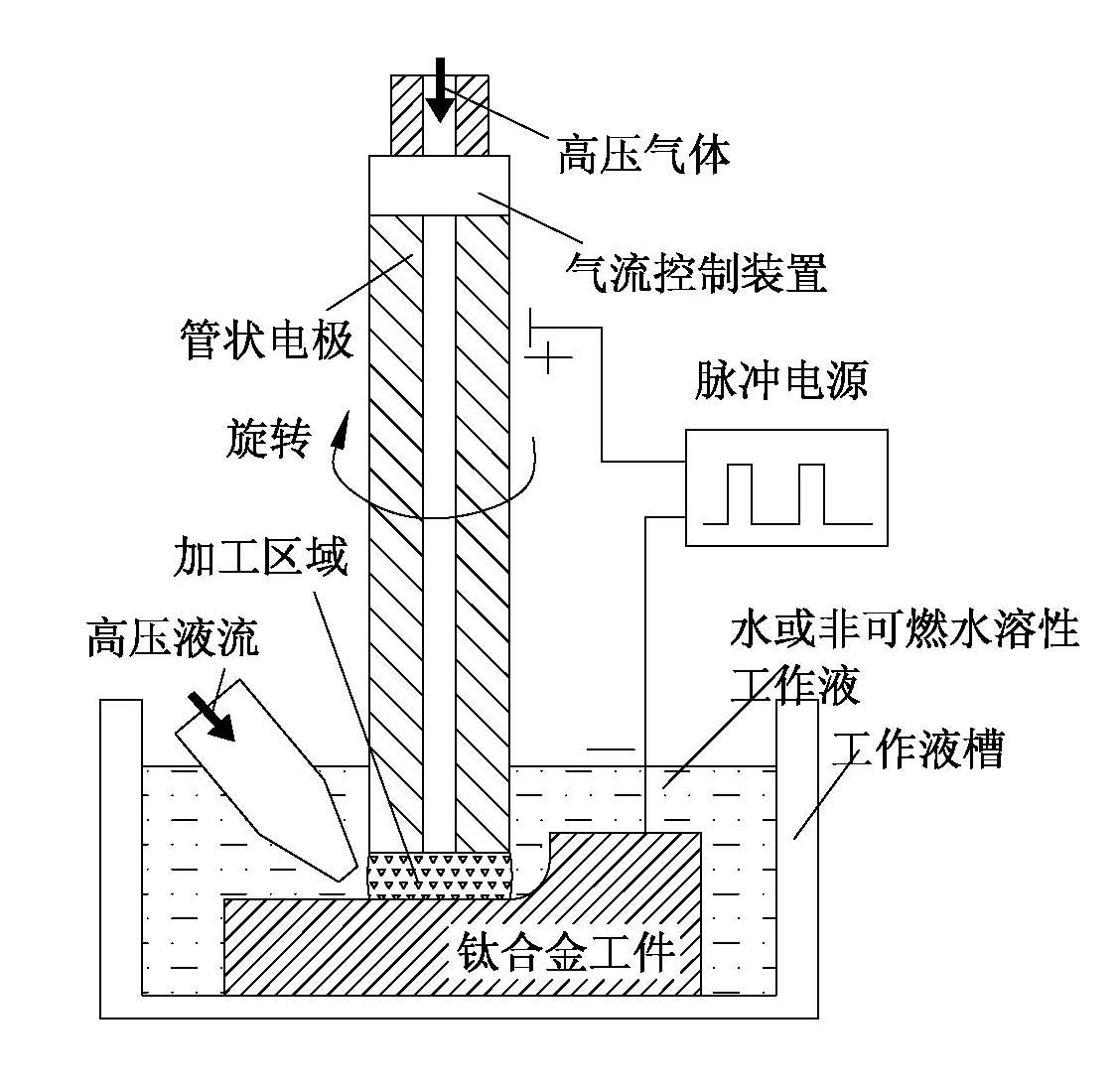

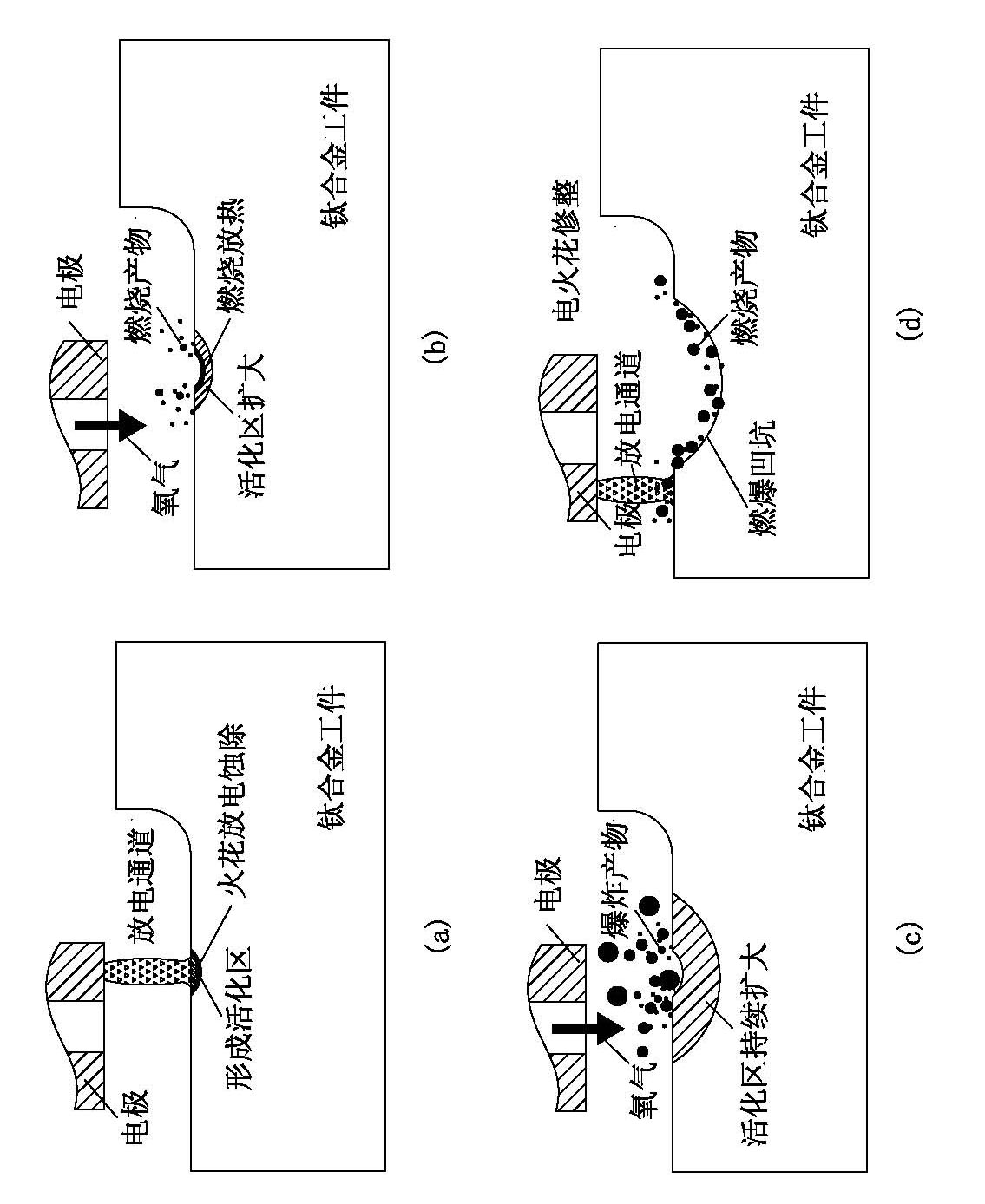

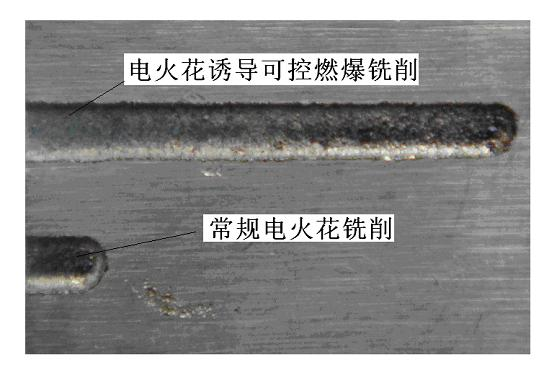

Processing method for corroding titanium or titanium alloy by burning and exploding under electric spark induction effect

The invention relates to a processing method for corroding titanium or a titanium alloy by burning and exploding under the electric spark induction effect, which is characterized in that a gas which can generate vigorous exothermic oxidation and burning and exploding effects with a titanium or titanium alloy materal to be processed is introduced in a processing area intermittently in the conventional process for processing the titanium or titanium alloy under the electric spark induction effect so that the titanium or titanium alloy of which the surface is activated under the electric spark induction effect and the introduced gas are subjected to burning and exploding reactions and a new activated layer can be exposed, and the process is carried out repeatedly so that the surfaces of titanium or titanium alloy substrate materials can be corroded rapidly and continuously in large quantities. Compared with the conventional method for corroding the titanium or titanium alloy under the electric spark induction effect, the invention can improve the material corroding rate by dozens of times or even hundreds of times. The invention can be used for processing through the relative motion of small-scale equipment on a large-scale structural component, can solve the problems on the size, the rigidity and the like of a large-scale structural component processing machine tool and has the advantages of high efficiency, low loss, low cost, safety and no pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Numerical control cutting machine

InactiveCN102303175AFull range of mobilityQuality improvementGas flame welding apparatusControl systemEngineering

The invention discloses a numerical control cutting machine, which comprises a longitudinal guide rail, a machine frame arranged on the longitudinal guide rail, and a numerical control system, a cutting control system, a transverse movement system, a lifting mechanism and a deflection device which are arranged on the machine frame, wherein a longitudinal driving rack is arranged on the longitudinal guide rail and is matched with a longitudinal driving gear; the longitudinal driving gear is arranged on the machine frame; the lifting mechanism is arranged on the transverse movement system; and the deflection device is arranged on the lifting mechanism. The numerical control cutting machine has the advantages of high production efficiency, quality of beveled edges and accuracy, low labor intensity of workers and the like and is controlled automatically in the whole process, angles of the beveled edges are easy to ensure, and the generality of workpieces is high.

Owner:昆山芬特机器制造有限公司

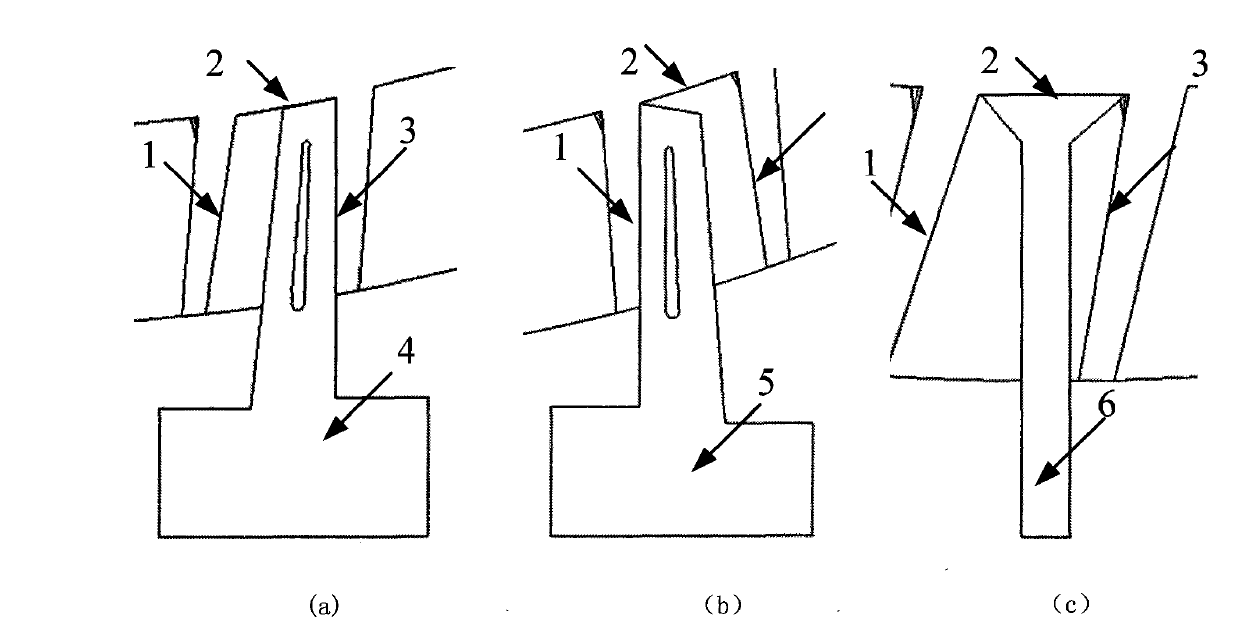

Low-melting-point alloy casting positioning technology in turbine blade machining

ActiveCN103350213AGuaranteed machining accuracyShorten the timePositioning apparatusMetal-working holdersSteam turbine bladeAlloy

The invention discloses a low-melting-point alloy casting positioning technology in turbine blade machining. The low-melting-point alloy casting positioning technology is achieved through the following steps: (1) conducting rough machining on a blade; (2) matching the blade with a positioning tool, wherein the blade is transversely arranged after the rough machining on the blade is completed, a blade crown at the head of the blade is abutted against a single tip of the positioning tool, a blade root at the tail of the blade is abutted against double tips of the positioning tool, and a blade steam passage in the middle of the blade penetrates through a positioning square box; (3) casting tin-bismuth alloy molten liquid molten at a certain temperature in the positioning square box, and casting and cooling the positioning square box at the same time until tin-bismuth alloy is solidified and fixed; (4) conducting fine machining on the blade crown and the blade root; (5) melting the tin-bismuth alloy again, pouring out the tin-bismuth alloy molten liquid from the positioning square box, and removing the positioning square box; (6) conducting fine machining on the blade steam passage. The low-melting-point alloy casting positioning technology in the turbine blade machining can meet the requirements for machining blades of various shapes and sizes, the positioning effect is good, and raw materials are greatly saved.

Owner:常州市三维技术成套设备有限公司

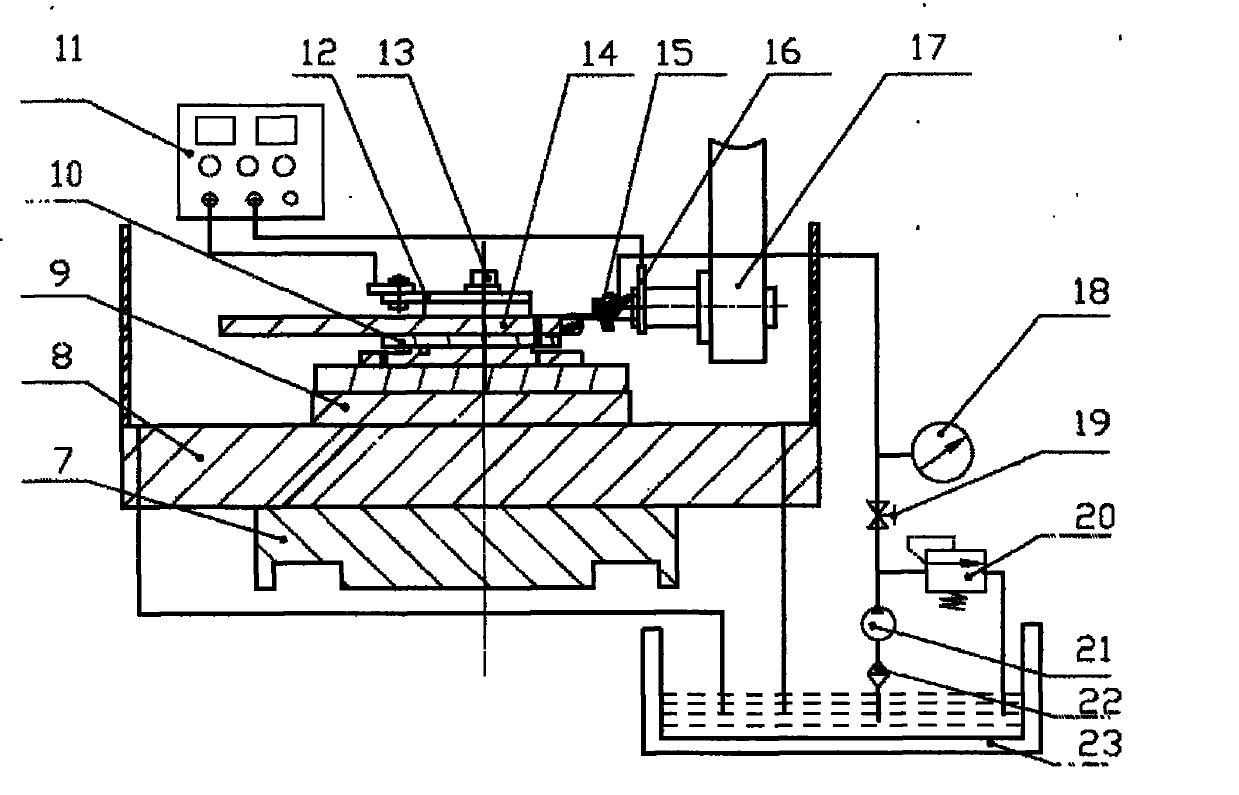

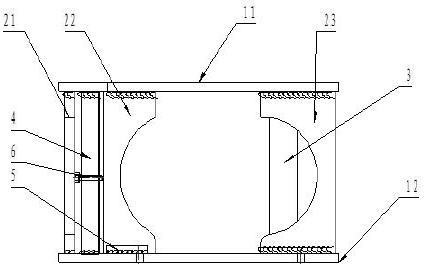

Step and zone type integral impeller electrolytic processing process and device

InactiveCN101767233AGuaranteed machining accuracyImprove machining accuracyElectrochemical machining apparatusImpellerElectrolysis

The invention discloses step and zone type integral impeller electrolytic processing process and device, which belong to the field of impeller electrolytic processing. The integral impeller electrolytic processing has three processing procedures of impeller disc, impeller back and impeller root. The impeller back is firstly processed, then the impeller disc is processed, and the impeller root is processed. The impeller disc, the impeller back and impeller root can be respectively processed along the respective profile by a sweeping forming method. The device comprises an X-axis slide unit, a Y-axis slide unit, a Cw-axis rotary table, an index plate, a processing power supply, an anode conductive plate, a center shaft, a cathode, a cathode conductive plate, a pressure gauge, a ball valve, a water pump, a filter and an electrolytic tank. The invention effectively solves the problem of blade processing of the integral impeller, and is suitable for processing the integral impellers of aerospace engines and advanced power units.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

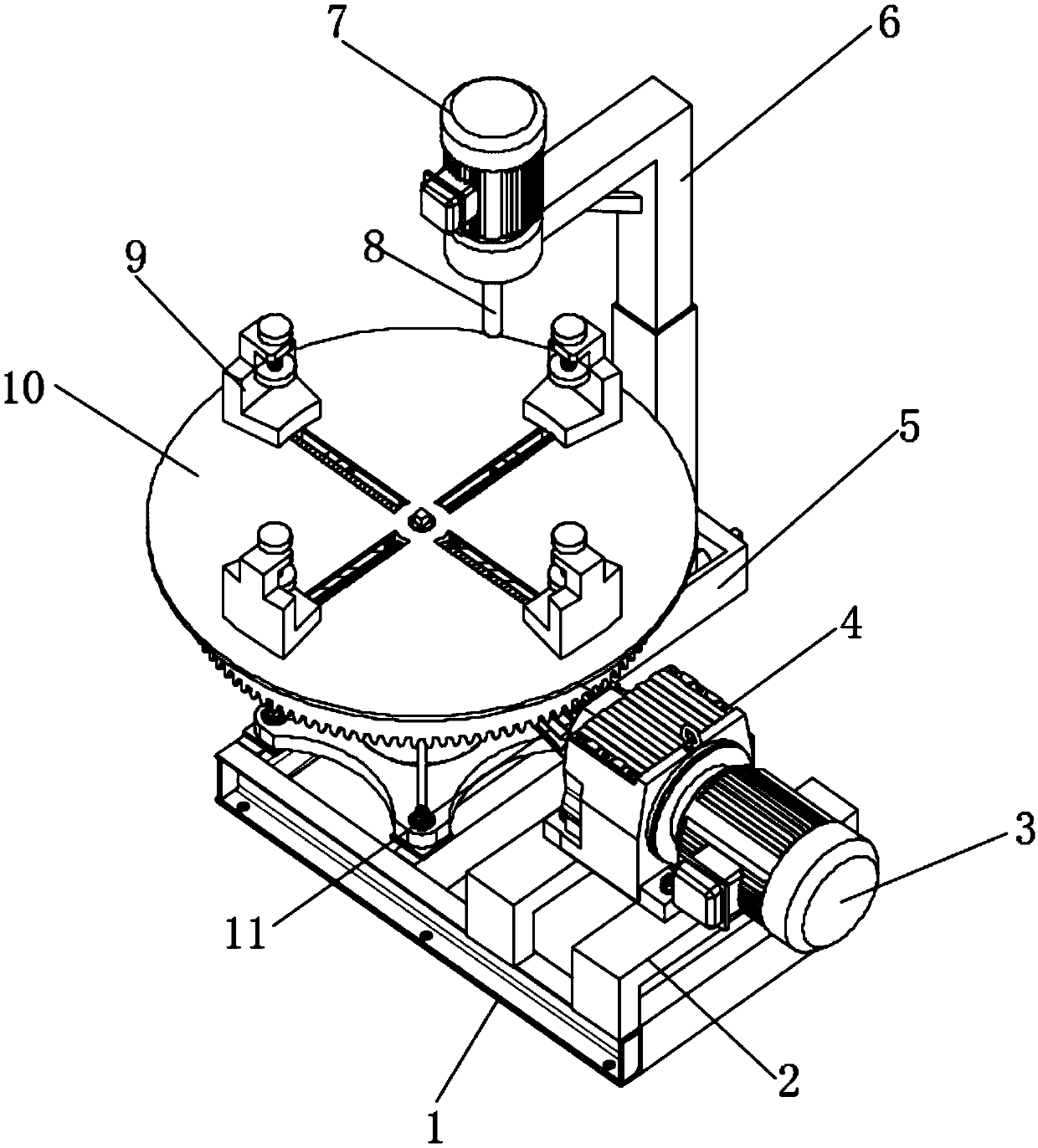

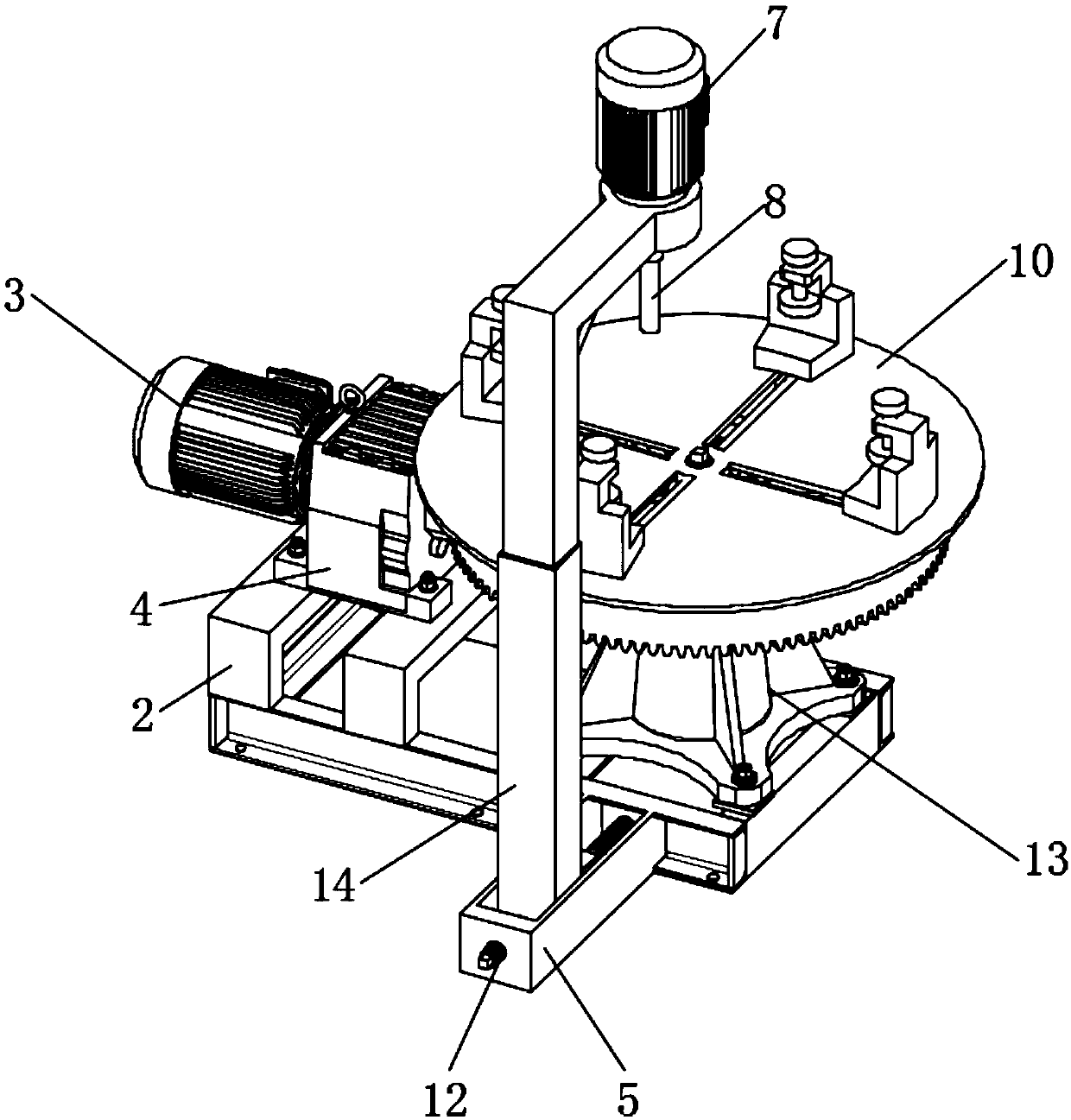

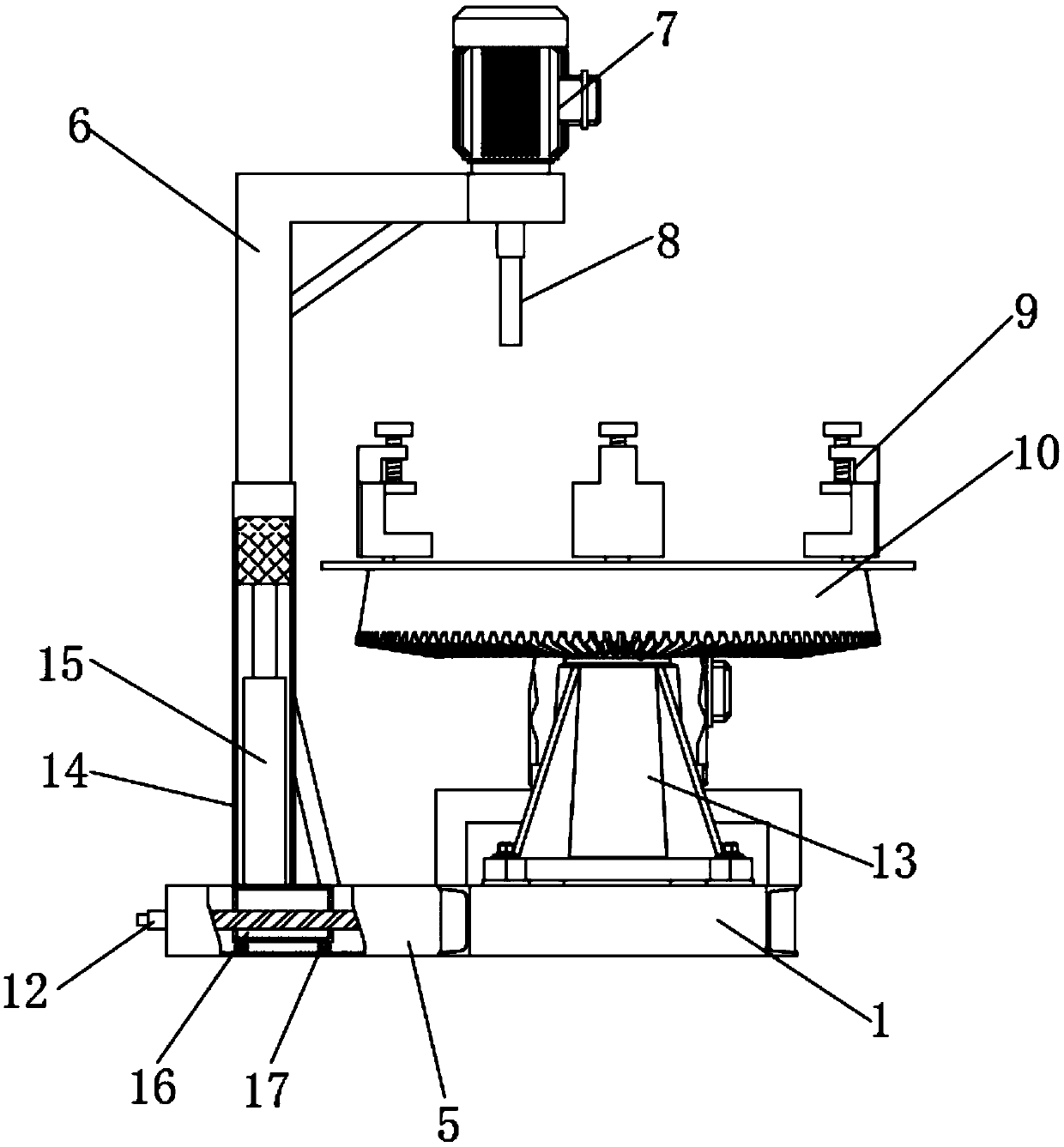

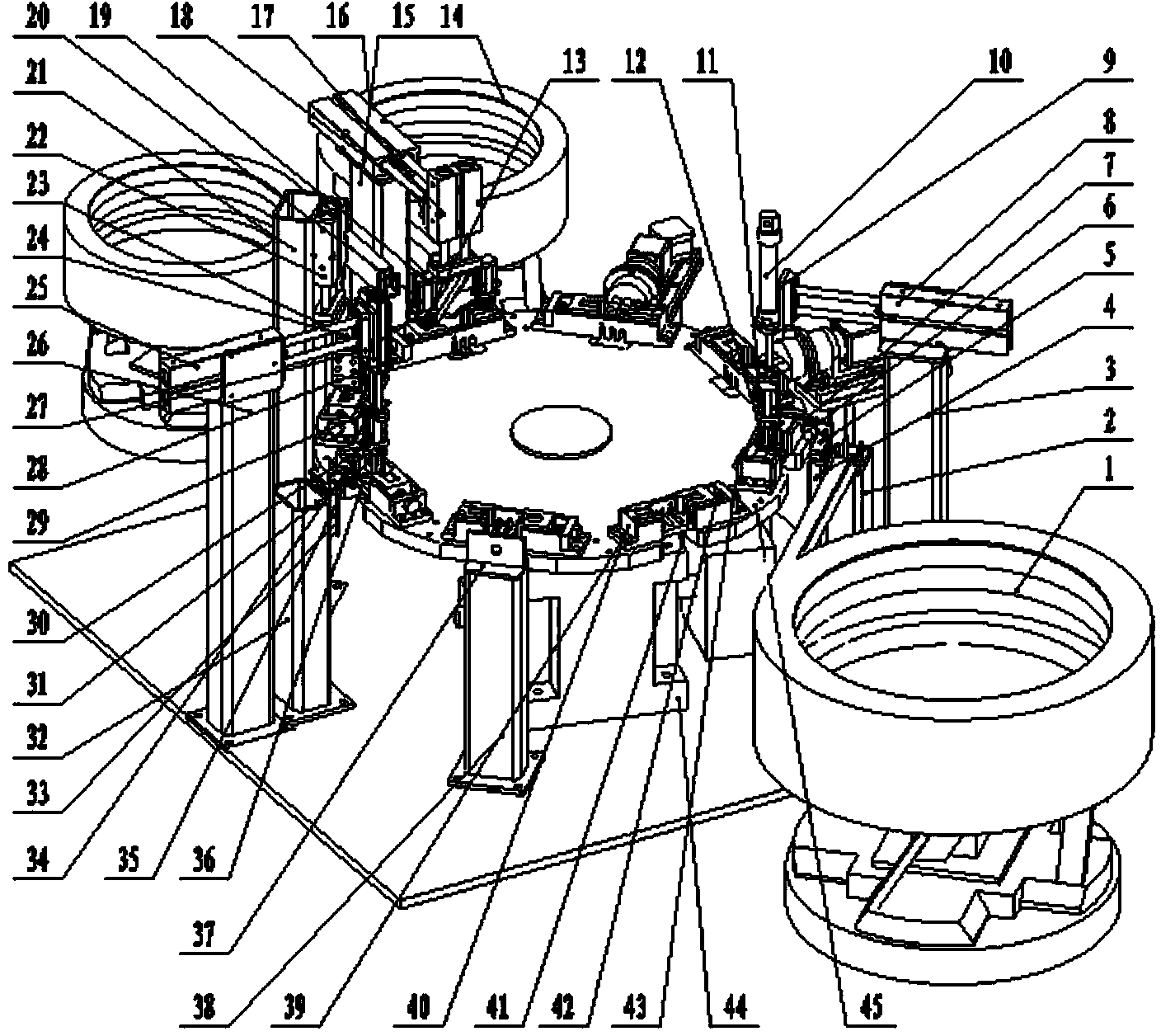

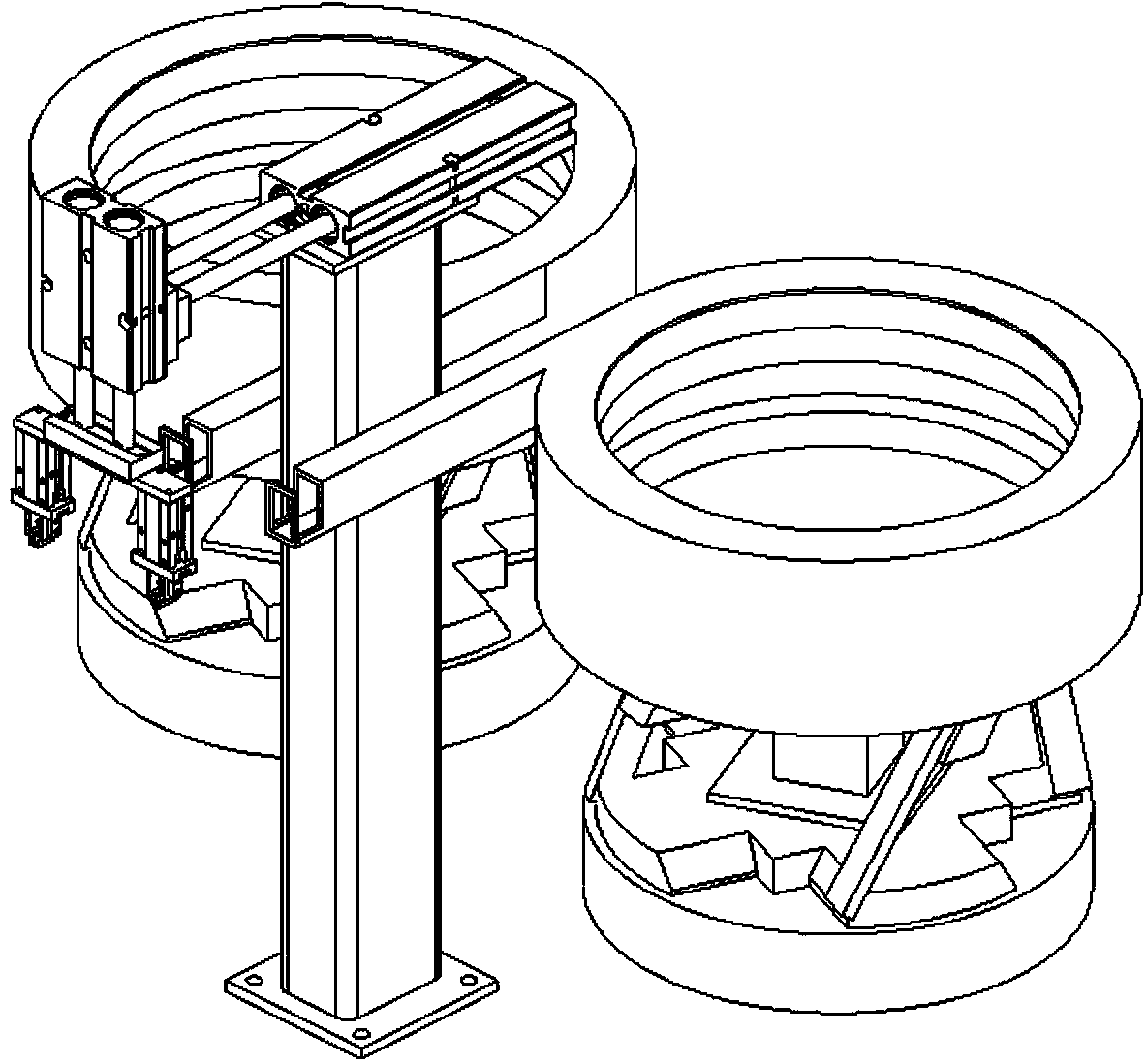

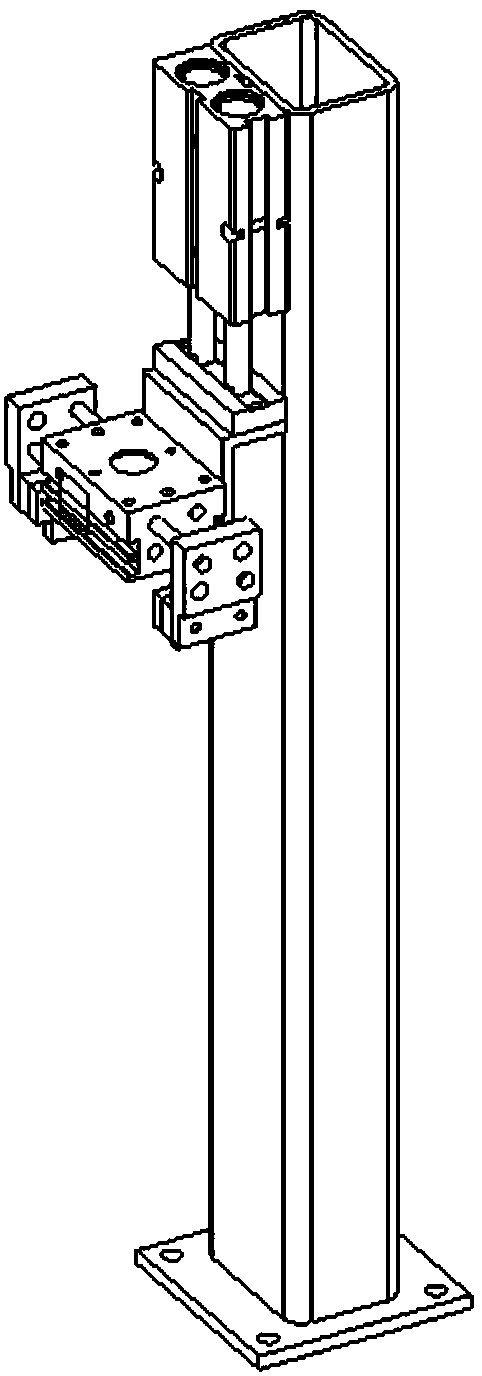

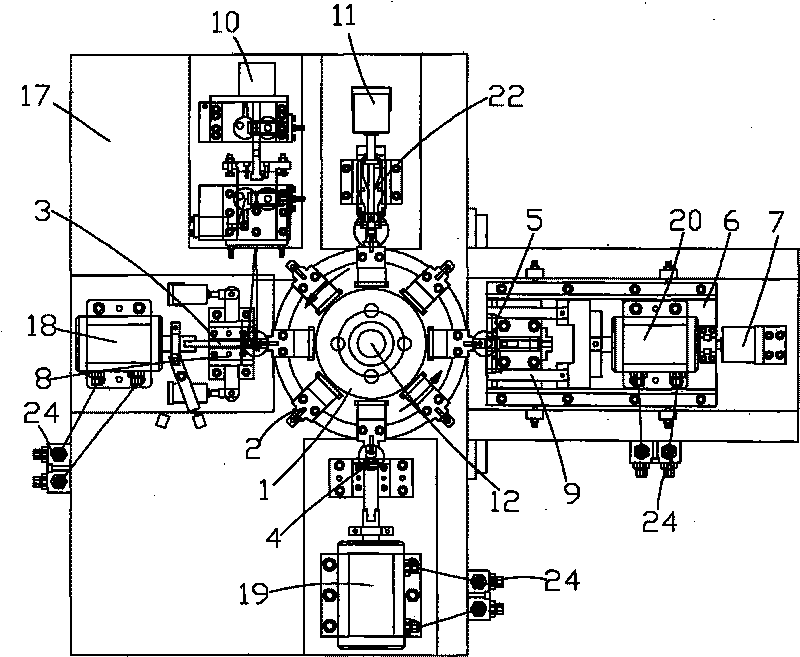

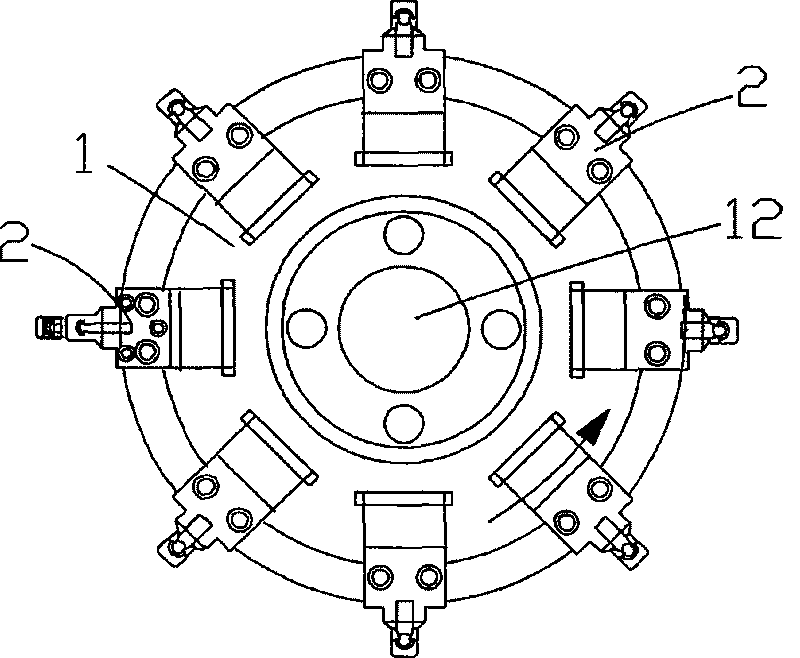

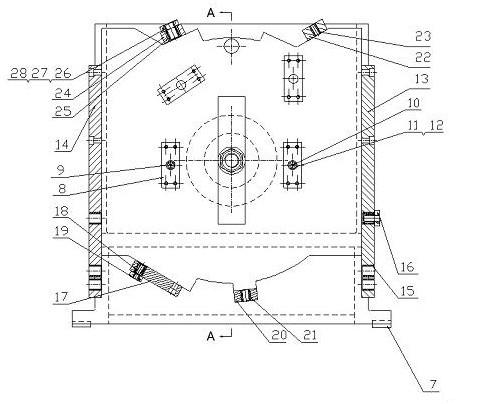

Irregular-shaped radiating fin automatic assembling device

InactiveCN103551849ARealize automated assemblyPrecise positioningPrecision positioning equipmentOther manufacturing equipments/toolsProduction lineEngineering

An irregular-shaped radiating fin automatic assembling device belongs to the automatic assembling field and is composed of a fixed bottom plate, a divider, a turntable, a feeding mechanical mechanism, a drilling mechanism, a tapping mechanism, a welding pin feeding mechanism, a welding pin clamping mechanism, a discharging mechanical mechanism, a slag removing mechanism and clamps. The whole assembling system adopts a rotary production line and is accomplished by using eight working positions; each working position is provided with one clamp for fixing the radiating fin. The irregular-shaped radiating fin automatic assembling device has the beneficial effects of realizing automatic assembling of the irregular-shaped radiating fin, increasing the assembling efficiency, saving labor force and cost, guaranteeing the machining precision as the self-produced clamps clamp the radiating fin automatically and position the radiating fin exactly by utilizing springs, and guaranteeing scale division quality as the divider divides the scale of each working position exactly by utilizing a cam division mechanism.

Owner:杜桂林

Machining process of middle-long thin-wall blades

ActiveCN103008741AReduce cumulative errorReduce processing stress deformationMilling equipment detailsEngineeringMachining process

The invention discloses a machining process of middle-long thin-wall blades, which belongs to the technical field of machining of blades. The machining process is implemented by a detailed process of integrated rough machining and integrated fine machining, wherein the integrated rough machining comprise the specific steps of rough machining of each surface of a blade tip, each surface of a blade root and a molded surface of a steam passage; and the integrated fine machining comprises the specific steps: semifinishing of each surface of the blade tip and each surface of the blade root, fine machining of each surface of the blade tip, each surface of the blade root and each residue, semifinishing of the steam passage and fine machining of the steam passage. According to the machining process of the middle-long thin-wall blades, the operation is simple and convenient, the use is convenient and fast, the cost is low, the machining efficiency is high, and the operation is easy and labor-saving; and the deformation of the middle-long thin-wall blades is controlled within 0 to 0.8mm, the normal machining of a subsequent mold correction process is facilitated, and the machining of each blade is finished once.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

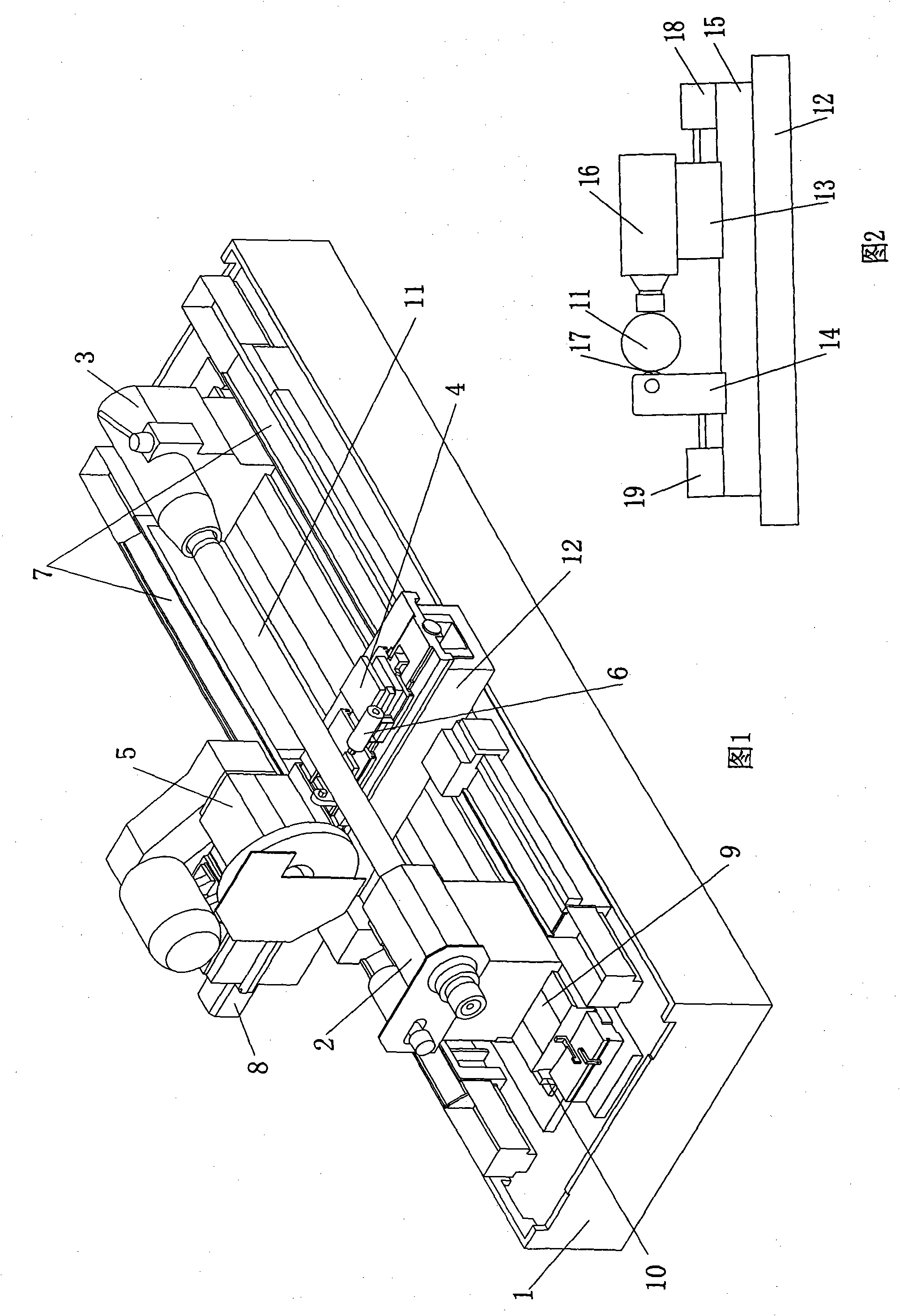

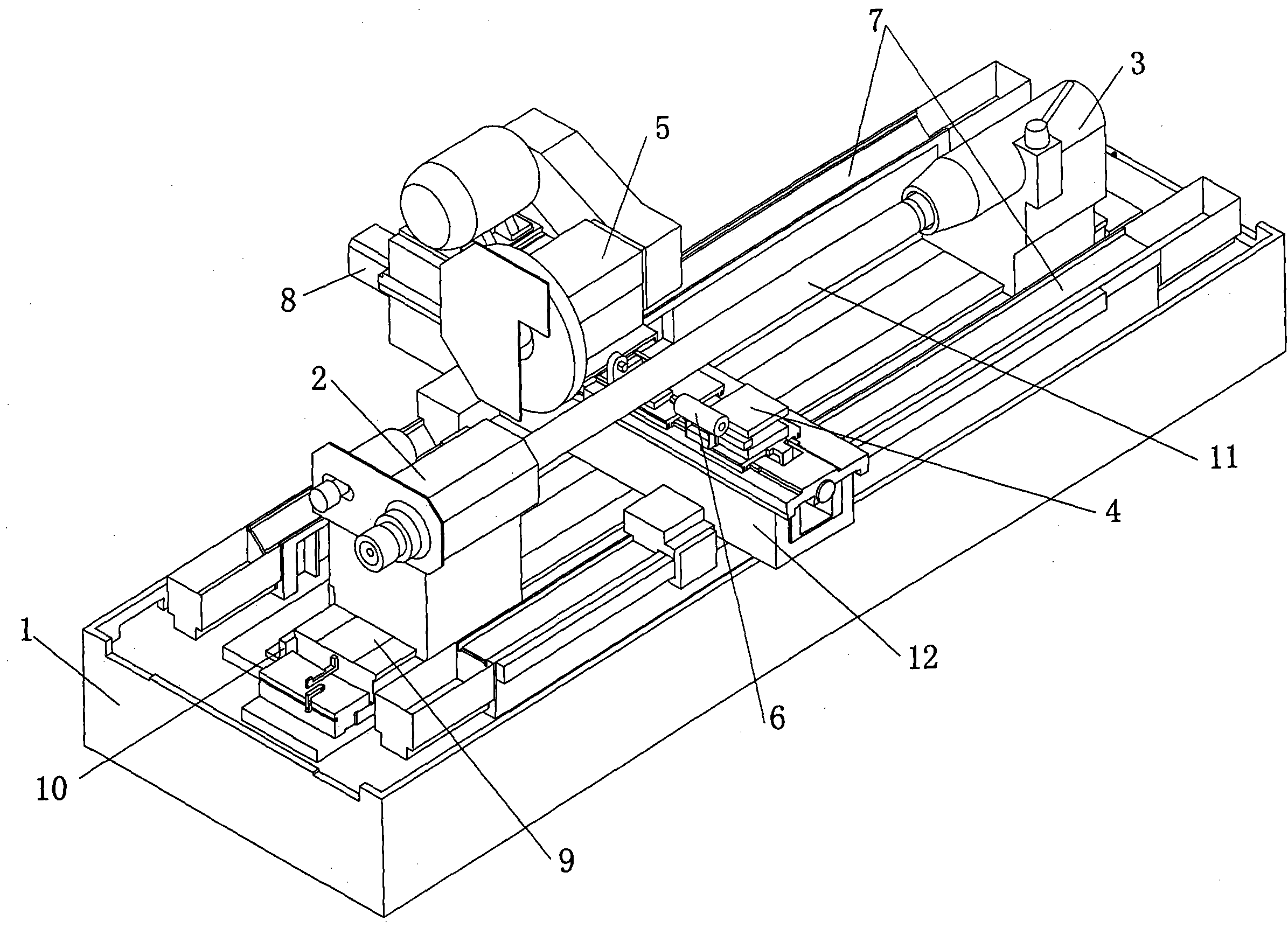

Shaft-like workpiece multi-operation composite processing machine tool

InactiveCN101890640AReduce surface roughnessGuaranteed machining accuracyFeeding apparatusOther manufacturing equipments/toolsUltrasonic machiningSurface roughness

The invention provides a shaft-like workpiece multi-operation composite processing machine tool, which comprises a machine tool body, a worktable, a headstock, a tailstock, a saddle, turning fixture, a milling device and an ultrasonic processing device, wherein the machine tool body is provided with two longitudinal guide rails, the saddle is arranged on the two longitudinal guide rails of the machine tool body, a screw feeding mechanism is arranged on the machine tool body, and the saddle is connected with the screw feeding mechanism; the worktable is arranged on the machine tool body and between the two longitudinal guide rails, and the headstock and the tailstock are arranged at two ends of the worktable respectively; and the turning fixture, the milling device and the ultrasonic processing device are all arranged on the saddle of the guide rails. In the invention, through one time of clamping, the three functions required for processing shaft-like workpieces, namely turning, milling and ultrasonic surface processing, can be completed, a milling or turning device can be used to meet the requirements on dimensional tolerance, shape tolerance and the like of parts, and the ultrasonic processing device can be used to complete reducing surface roughness of the parts.

Owner:赵显华

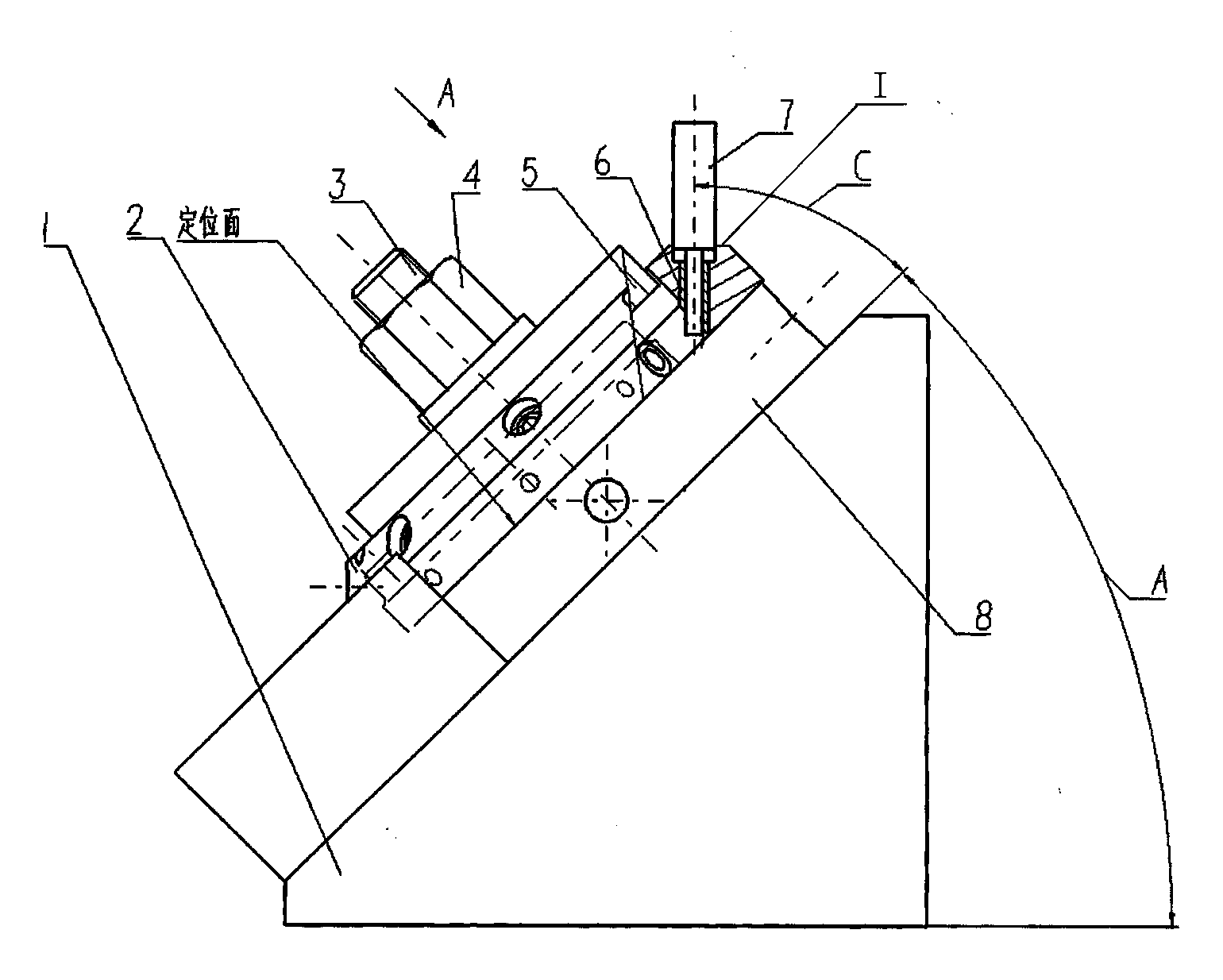

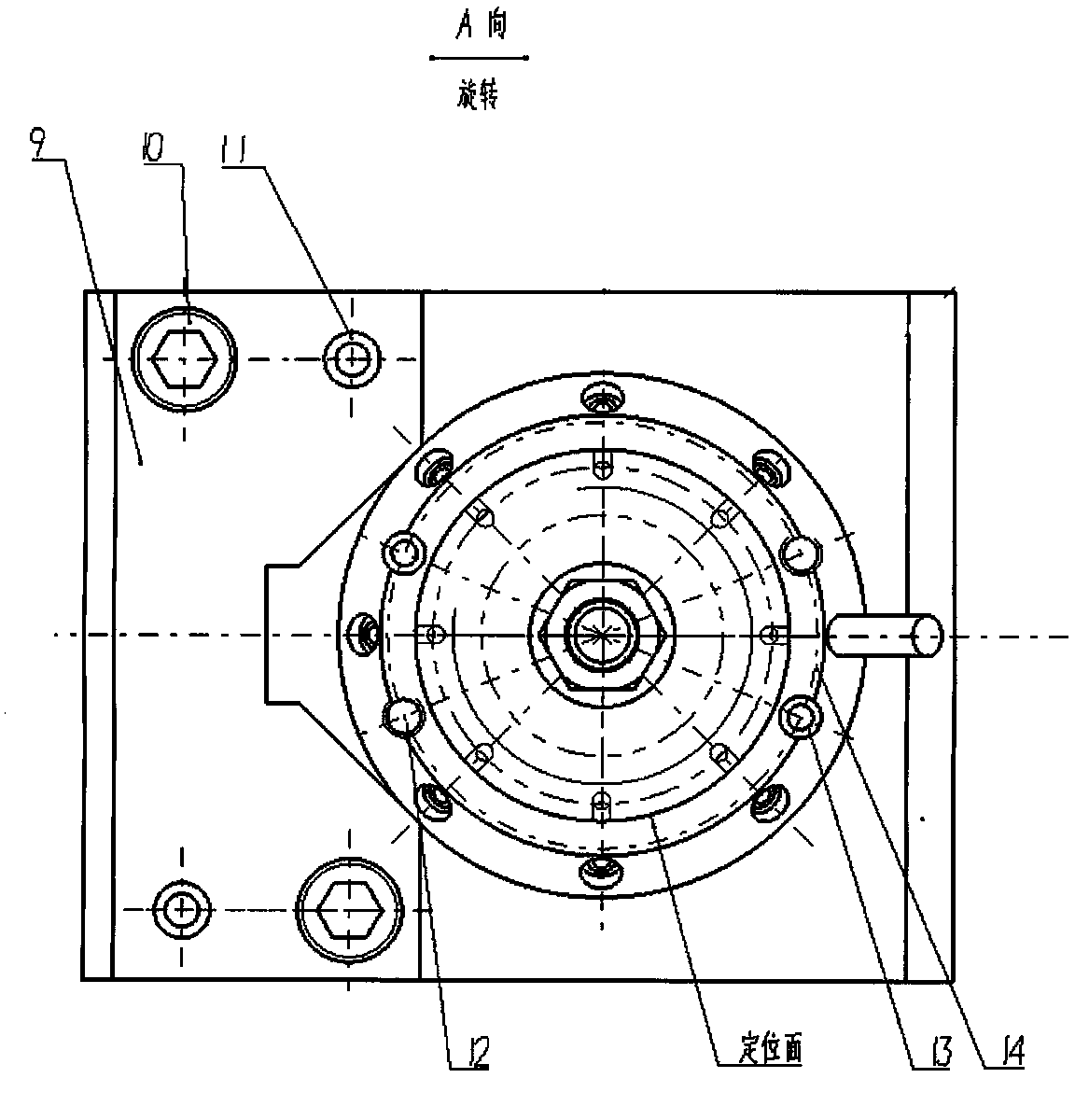

Method for machining oblique angle holes distributed in shaft parts

ActiveCN104029051AGuaranteed machining accuracySave labor timeDrilling/boring measurement devicesPositioning apparatusEngineeringOblique angle

The invention provides a method for machining oblique angle holes distributed in shaft parts. A flexible fixture composed of an angle plate, a V-shaped block and a part positioning and clamping device is adopted, wherein the V-shaped block is fixed on the angle plate through inner hexagon screws and cylindrical pins, and a V-shaped notch of the V-shaped block is in clearance fit with the outer circle of the part positioning and clamping device; the part positioning and clamping device comprises a drill plate, a pressure plate and a positioning plate, a hollow-shaft part is arranged above the positioning plate and is fitted to the same, the drill plate sleeves the hollow-shaft part, the pressure plate is arranged above the hollow-shaft part, the tail portion of a double-end bolt penetrates the pressure plate and the hollow-shaft part to be vertically and fixedly connected with the positioning plate, and the head of the double-end bolt is in threaded connection with a shouldered nut. The flexible fixture can be used repeatedly and can provide service to multiple machining objects, labor time can be saved, production efficiency can be improved, simplicity in operation is achieved, clamping is facilitated, and machining precision of the oblique angle holes is guaranteed.

Owner:SHENYANG AIRCRAFT CORP

Four-position full automatic locker moulding machine and method thereof

InactiveCN101745806AIncrease profitImprove production efficiencyOther manufacturing equipments/toolsPosition shiftRadian

The invention relates to a four-position full automatic locker moulding machine and a method thereof. The four-position full automatic locker moulding machine comprises a feeding mechanism, a cutting mechanism, a moulding mechanism, a discharging mechanism and a position shifting mechanism all mounted on a platform. The position shifting mechanism comprises a core turntable arranged above the platform and an edge trimming mechanism, and the edge trimming mechanism, the discharging mechanism, the cutting mechanism and the moulding mechanism are distributed anticlockwise with the same radian according to the core turntable. The feeding mechanism is arranged on the corner between the discharging mechanism and the cutting mechanism, and the discharge end of the feeding mechanism is arranged just opposite the charging end of the cutting mechanism. Eight core seats are fixed on the periphery of the core turntable with the same radian, and the core seats can be matched with the edge trimming mechanism, the discharging mechanism, the cutting mechanism and the moulding mechanism face to face in turn after being rotated. The method of the four-position full automatic lock moulding machine comprises steps of charging, cutting, position shifting, moulding, edge trimming and discharging. The four-position full automatic lock moulding machine can manufacture finished products of high unity, can produce engine lockers of various specifications through replacing cores and moulding cavities, and has the advantages of simple replacement and high production efficiency.

Owner:蒋正启 +1

A kind of automatic piston ring trimming machine

ActiveCN103753374BImprove machining accuracyMeet the process requirementsGrinding machinesGrinding headsNumerical controlPiston ring

Owner:NANTONG JUNQI MACHINERY

Clamping deformation resistant jig for machining large-diameter elbow

InactiveCN102139457AGuaranteed machining accuracyAbundant resourcesPositioning apparatusMetal-working holdersThin walledEngineering

The invention discloses a clamping deformation resistant jig for machining a large-diameter elbow. Three combined clamping blocks are arranged on a clamping base plate, each combined clamping block consists of an upper clamping block, a lower clamping block, a base plate and connecting bolts, inner sides of the upper clamping blocks and the lower clamping blocks are provided with circular arc-shaped gaps and form a circle consistent with the outer circumference of an elbow to be machined after closed, the upper clamping blocks and the lower clamping blocks are connected and fastened by the connecting bolts, and the base plates are arranged at the bottoms of the lower clamping blocks and are provided with chutes. Lock bolts pass through the chutes on the base plates of the combined clamping blocks and fix the combined clamping blocks on the clamping base plate after being fastened. In the invention, the large-diameter elbow is clamped by adopting a way of directly clamping a pipe blank in a surface-contact manner, thus the elbow does not generate a radial compaction force in the clamping process and is not easy to generate the radial forced deformation and the torsional moment; in addition, the clamping deformation resistant jig disclosed by the invention is applied to machining of a large-diameter thin-wall elbow machine, thereby ensuring the machining precision of the elbow.

Owner:扬州华宇管件有限公司

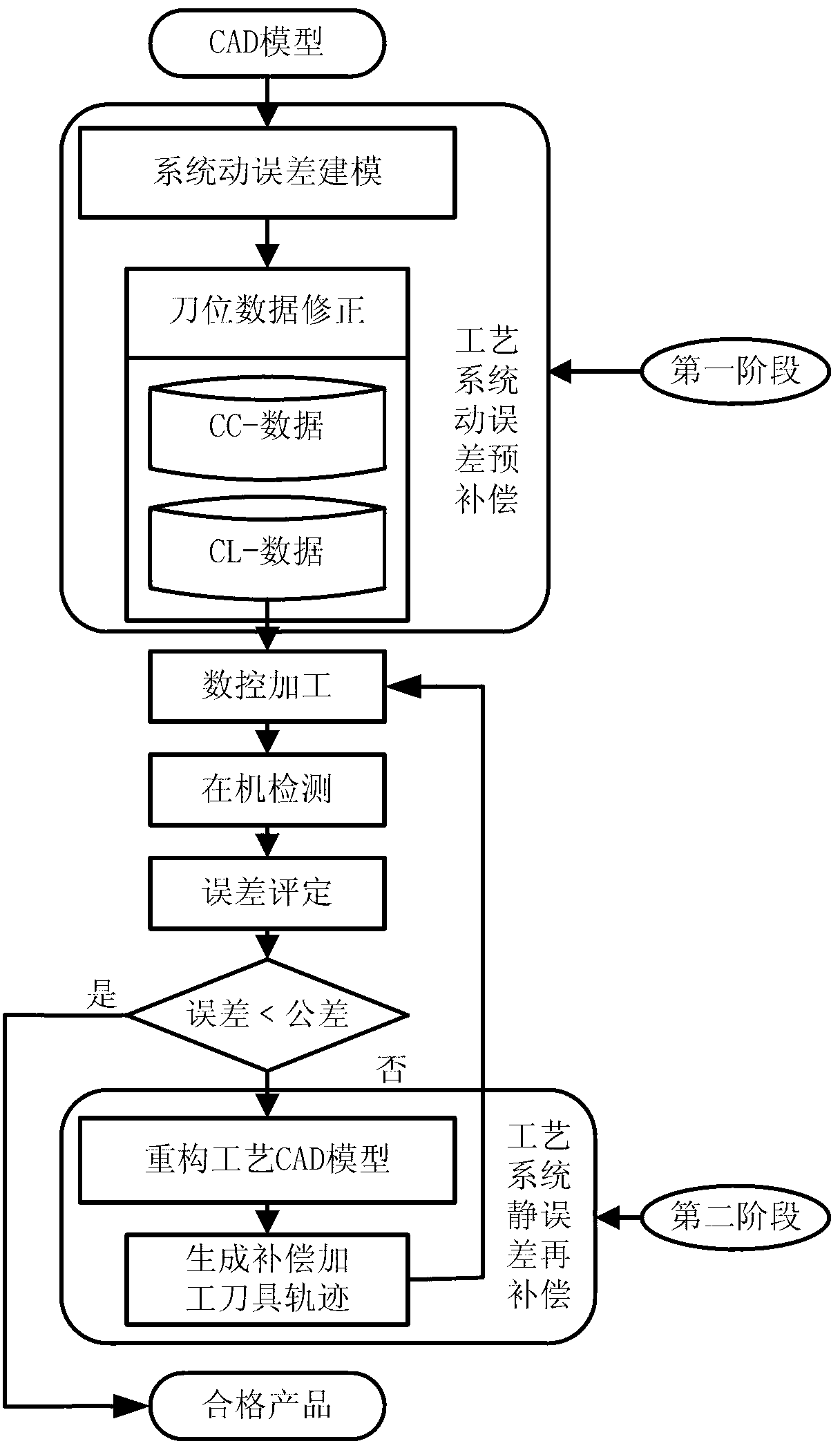

In-process evaluation based complex spatial surface error feedback compensating method

ActiveCN103218475AAvoid repeated positioning errorsReduce handlingSpecial data processing applicationsComputer Aided DesignCutter location

The invention discloses an in-process evaluation based complex spatial surface error feedback compensating method. The method comprises the following steps of processing a complex surface cutting force module through a ball-end cutter, performing dynamic compensation for a target cutter location point for workpiece pre-processing; performing in-process detection for the pre-processed workpiece to obtain geometrical information of an actual contour; evaluating error for the pre-processed workpiece through a contour degree error evaluation model; when the contour error is greater than tolerance, determining a compensation point position U1 corresponding to each contact point; guiding the compensation point position corresponding to each contact point to three-dimensional CAD (Computer-Aided Design) to obtain a compensating process contour to generate a compensating processing tool track; and performing static compensation and processing for the pre-processed workpiece and finishing the flow. Under the premise of ensuring the processing precision of part surface, the processing precision of the part is detected in process without investing fund to purchase more detection devices, so that the conveying and loading time of workpieces is shortened.

Owner:TIANJIN SAIXIANG TECH

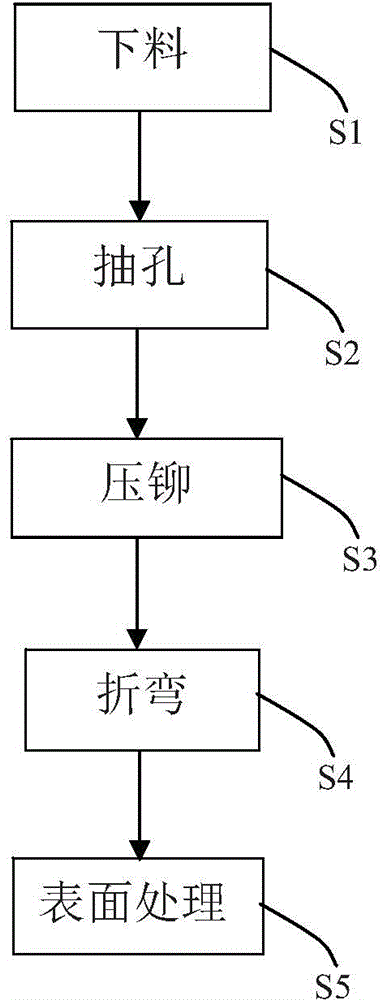

Processing technology for sheet metal parts

The invention provides a processing technology for sheet metal parts. The processing technology comprises steps as follows: S1, blanking: a sheet metal part raw material plate is provided and cut into corresponding sheet metal part blank materials with a machining or laser cutting mode; S2, hole drawing: basic holes are machined and formed in the blank materials, and processing broadening and then tapping are performed on the basic holes; S3, rivet pressing: nuts and screws are riveted on the blank materials; S4, bending: bending processing is performed according to processing dimensions; and S5, surface treatment: the bent blank materials are subjected to surface treatment, and the final sheet metal parts are formed. The processing technology for the sheet metal parts is simple in technological process, convenient to operate and high in processing efficiency; the machining precision of the sheet metal parts is guaranteed through reasonable arrangement of processing steps, meanwhile, surface treatment is performed on the blank materials, and the surface performance of the sheet metal parts is improved.

Owner:苏州华创特材股份有限公司

Rotary fixture special for drilling automobile flywheel shell and machining method

InactiveCN102009212AReduce labor intensityAvoid it happening againPositioning apparatusMetal-working holdersWaste productEngineering

The invention relates to a rotary fixture special for drilling an automobile flywheel shell and a machining method. The holes of the automobile flywheel shell can be quickly and accurately machined. The machining method comprises the following steps of: assembling the fixture according to the connection relationship, connecting the fixture with a machine tool through a rotary fixture base, adjusting a drilling module on the right side of the fixture and a drilling template on the left side of the fixture to a vertical position and fixing by using long nuts; aligning a workpiece to be machined with two positioning pin holes by using a balance crane, pressing the workpiece by using a large pressing plate, loosening the long nuts by using a spanner to make the workpiece rotate; positioning a handle through a positioning pin, and pressing a workpiece rotary piece through the long nuts for machining the hole at one position; and repeating the steps until the holes at all positions are machined, adjusting the fixture to an initial clamping position and making the workpiece fall down to finish machining. The rotary fixture and the machining method have the advantages that: 1, machining efficiency is high, and the labor intensity of operators is greatly reduced; and 2, machining accuracy is high, defective products and waste products are avoided, and machining cost is greatly reduced.

Owner:HANGZHOU JIULONG MACHINERY MFG

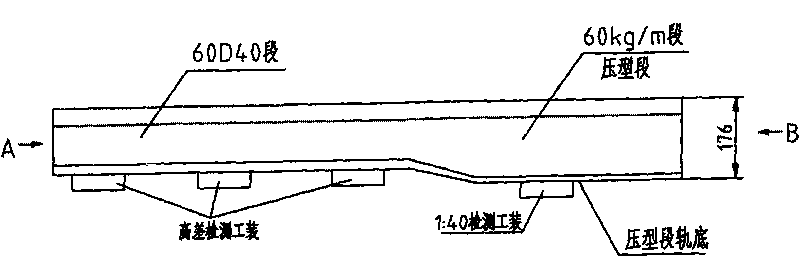

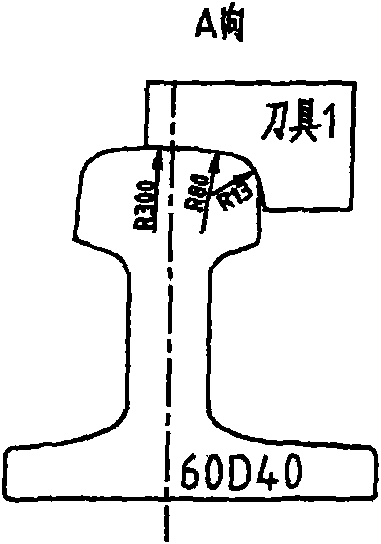

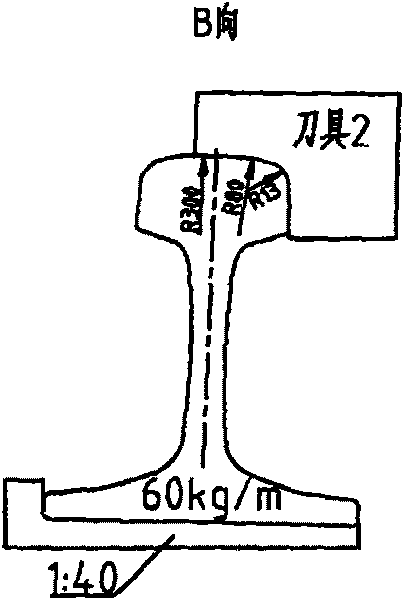

Processing technique for top surface of rail

ActiveCN101716717AMake a smooth transitionSolve deviationMilling equipment detailsQuenchingMechanical engineering

The invention relates to a processing technique for the top surface of a rail, which is implemented by the following process flows: primary baiting; saw cutting; press molding; secondary baiting; aligning; milling a compressed section rail base; fine tuning; drilling; milling blot grooves of the rail base and rail web; milling a working edge and a non-working edge of a rail head; milling a rail top and derating; quenching; and leveling. The fine turning flow comprises the following steps of: firstly, leveling the rail base of the rail, ensuring that the flatness of the rail base is less than or equal to 0.5mm; secondly, obtaining the relative altitude difference of the rail base, a rail top surface and two sides of the rail head, detecting the straightness of the two sides of the compressed section rail head and the straightness of the rail top surface by using a leveling ruler, ensuring that an idle line between the two sides of the molded section rail head and raw materials of the rail is 1mm, and the top surface of the molded section rail is 1.5mm higher than the top surface of the raw materials of the rail; and finally, detecting the 1:40 inclination of a heal end and the altitude difference of the rail base by using an altitude difference testing tool and 1:40 inclined testing equipment. According to the processing technique, a novel copying tool is used for machining the rail top surface of the 60D40 rail, so the molded section and a transition section are in smooth transition with the raw materials; the fitting degree of the machined top surface of the 60D40 rail is more complete; and the machining accuracy of the products is guaranteed.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Method for realizing machining of combustion-compression ring bushes by using combustion-compression ring bush cutting clamp

ActiveCN102950479ASmall amount of deformationGuaranteed machining accuracyPositioning apparatusMetal-working holdersCombustionWork in process

The invention discloses a method for realizing the machining of combustion-compression ring bushes by using a combustion-compression ring bush cutting clamp, relating to a machining method for ring parts. The invention aims to solve the problems that because the existing combustion-compression ring bush is a thin-walled workpiece, the existing combustion-compression ring bush is easy to deform in the process of machining, so that the machining quality of the combustion-compression ring bush is affected, and meanwhile, the 30-equated positions of 30 molded holes of a combustion-compression ring bush machined by using the existing machining method are poor in accuracy. The clamp used in the invention comprises a base plate, a turntable, two positioning pins and four pressing plates. The method disclosed by the invention comprises the following steps of: 1, roughly turning an inner hole, an outer circumferential surface and two planes of a blank; 2, relieving stress of a semi-finished combustion-compression ring bush product; 3, carrying out finish turning on an inner hole, an outer circumferential surface and two planes of the semi-finished combustion-compression ring bush product; 4, drawing center position lines of radial holes and molded holes; 5, drilling 30 radial holes with a diameter of 5 mm; and 6, cutting and machining 30 molded holes. The method disclosed by the invention is used for machining combustion-compression ring bushes.

Owner:HARBIN TURBINE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com