Rotary fixture special for drilling automobile flywheel shell and machining method

A technology of rotating fixtures and flywheel shells, applied in metal processing equipment, metal processing mechanical parts, clamping and other directions, can solve the problems of high labor intensity of operators, easy generation of defective and scrap products, and high processing costs. The effect of reducing labor intensity, avoiding defective and scrapped products, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

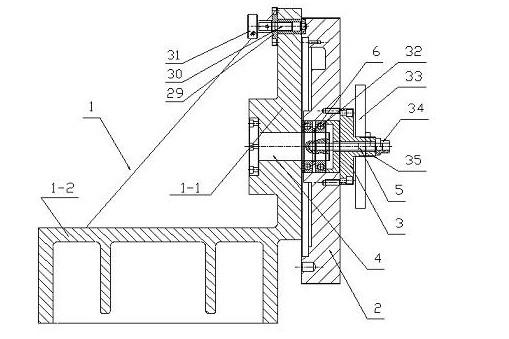

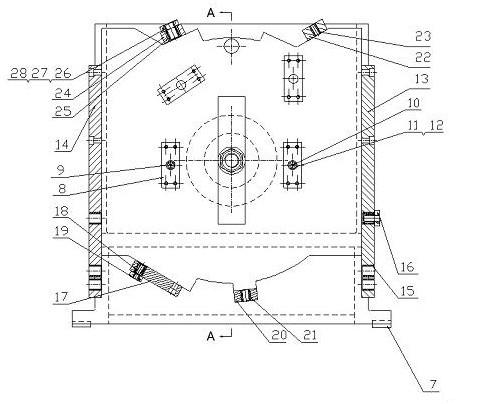

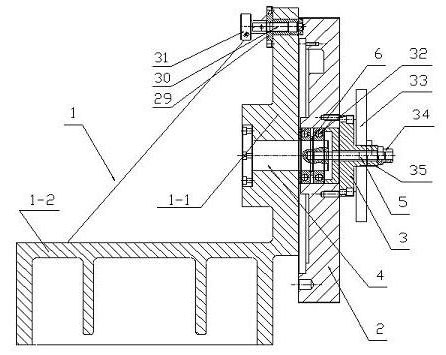

[0010] Embodiment 1: with reference to attached figure 1 and 2 . A special rotating jig for drilling the flywheel shell of an automobile. The rotating jig base 1 is composed of a vertical plate 1-1 and a vertical plate seat 1-2 to form an integral structure (finishing after casting). The central shaft 4 is fixed in the shaft hole in the vertical plate 1-1 and the central shaft 4 is exposed outside. The rotating part 2 is sleeved on the central shaft 4 through the deep groove bearing 32 and is rotatable. The pile head 3 is a boss structure, and the boss The center is a through hole, the pile head 3 is fixed on the rotating part 2 and the center hole of the pile head 3 is pierced with a screw 5, one end of the screw 5 is connected with the screw connecting hole on the end face of the central shaft 4, and the center hole of the large pressure plate 33 passes through 5 sets of screws On the protruding head of pile head 3, long nut 34 locks big pressing plate 33, and guide sleeve...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, a processing method for processing an automobile flywheel housing using a special rotary fixture for drilling an automobile flywheel shell, assembling the fixture according to the connection relationship, and then connecting the rotating fixture base 1 with the machine tool, Adjust the drilling module 13 on the right side of the jig and the drilling template 14 on the left side of the jig to the vertical position, fix it with the long nut 34, align the workpiece to be processed with the two positioning pin holes through the balance crane, and press the workpiece tightly with the large pressure plate 33 , and then loosen the long nut 34 with a wrench to rotate the rotating part 2, then the handle 31 is positioned by the positioning pin 30, and then the rotating part is compressed by the long nut 34 for processing, that is, the hole in one position is completed Processing, and so on, until all the processing positions are process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com