Camera automatic regulating image acquisition device and method for fatigue crack propagation test

A technology of fatigue crack propagation and automatic adjustment, which can be used in measurement devices, image communication, television, etc., and can solve problems such as poor real-time performance, low work efficiency, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

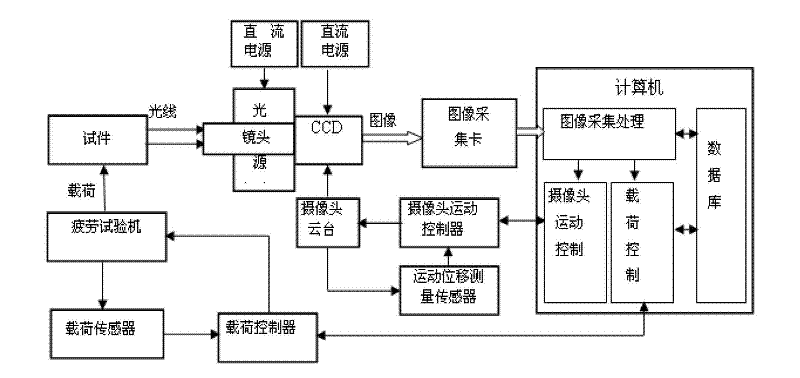

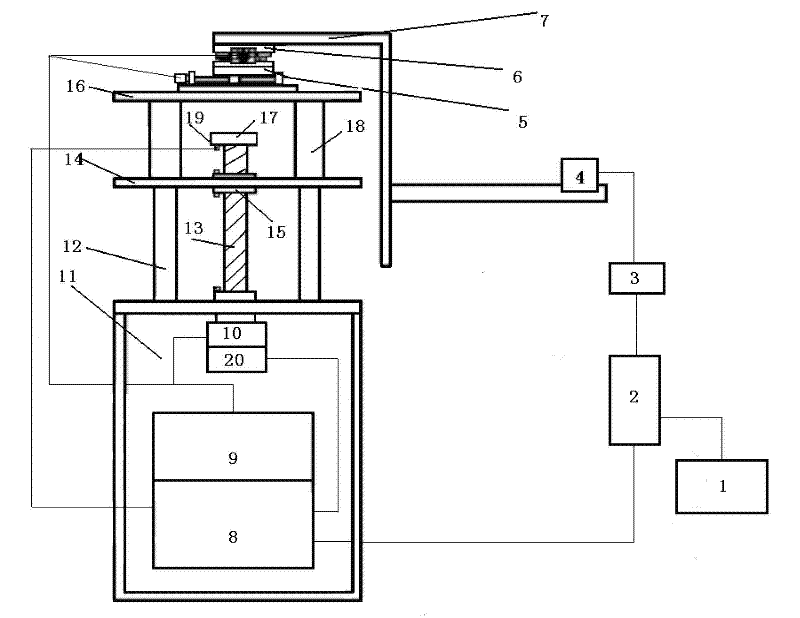

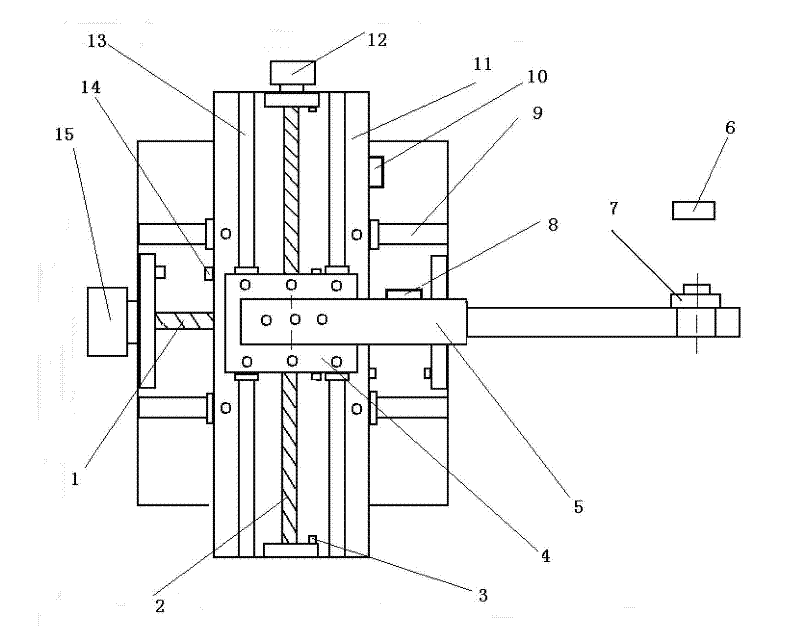

[0049] refer to Figure 1 to Figure 10 , a fatigue crack growth test camera automatically adjusts the image acquisition system, including the test piece, image imaging and acquisition system, camera position adjustment system and computer processing analysis control system. The necessary fatigue testing machine and fatigue testing machine load control system. The CCD camera, lens, and light source device are installed on the camera mounting bracket to form an image imaging unit. The CT compact specimen with prefabricated cracks is installed on a fatigue testing machine that generates a set alternating load. The specimen is under the action of the alternating load. The cracks continue to expand, and the light provided by the light source device shines on the surface of the test piece. The surface of the test piece is treated as slow reflection, and the uniformly reflected light is projected onto the CCD target surface through the lens. The CCD and the data acquisition card are ...

Embodiment 2

[0064] refer to Figure 1 to Figure 10 , a fatigue crack growth test camera automatically adjusts the image acquisition method: the system sends the camera movement mode and distance control signal to the camera motion controller by the computer, and the camera motion controller selects the stepping motor control mode according to the received command, and sends the control instruction to control Camera movement positioning PTZ movement, such as for crack expansion camera tracking and positioning image acquisition, the camera position adjustment is carried out through the ARM motion controller for movement displacement closed-loop control, after the position adjustment is completed, the system continues to image acquisition, processing, and crack length calculation and other tasks, the specific implementation methods are as follows Image 6 , Figure 7 As shown; if the image is collected during the automatic focusing process of the camera, the computer image processing softwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com