Patents

Literature

371 results about "Fatigue crack propagation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula of wheel-rack solid lubrication additive for railway traffic

The invention discloses a prescription of a wheeltrack lubricant additive, which is characterized by strong bearing capacity, high temperature resistance and long effective time upon one time coating, thereby solving the defect that factigue crack expansion of the wheeltrack is accelerated by traditional grease for the generation of oil wedge effect. The prescription comprises 1 percent-30 percent of metal powder, 3 percent-50 percent of high temperature solid lubricant material and 5 percent-50 percent of fatty acid by weight. The strip solid materials can be produced in virtue of other accessories by the prescription.

Owner:张念

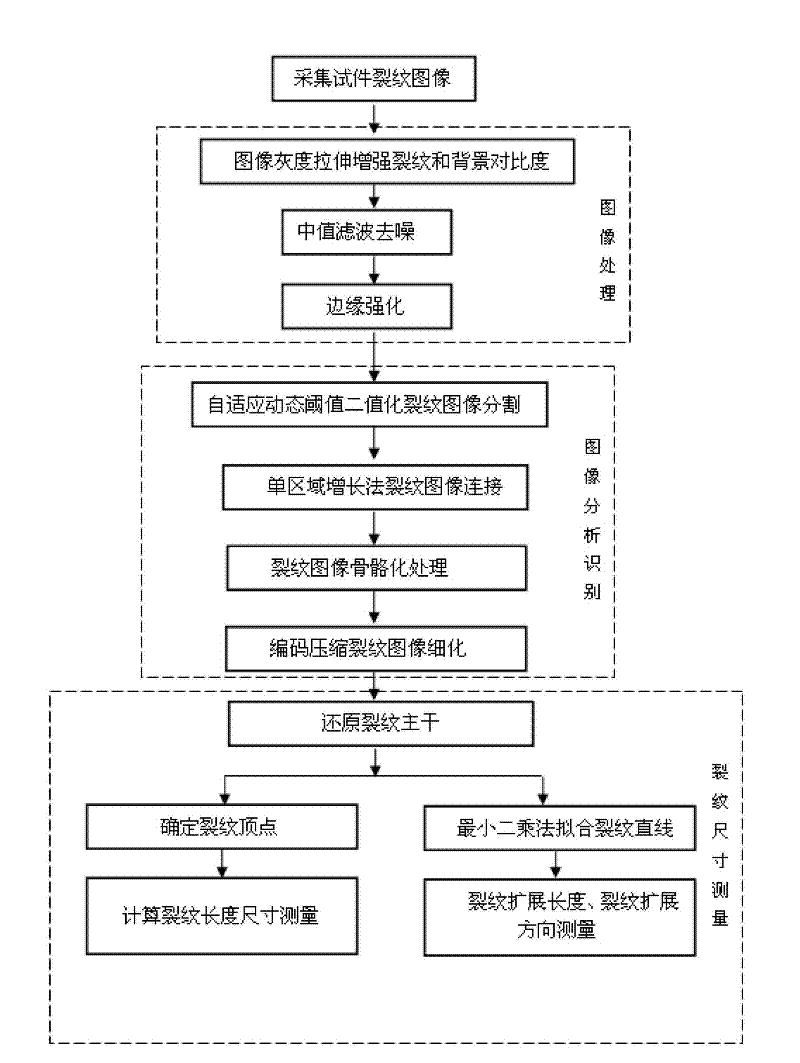

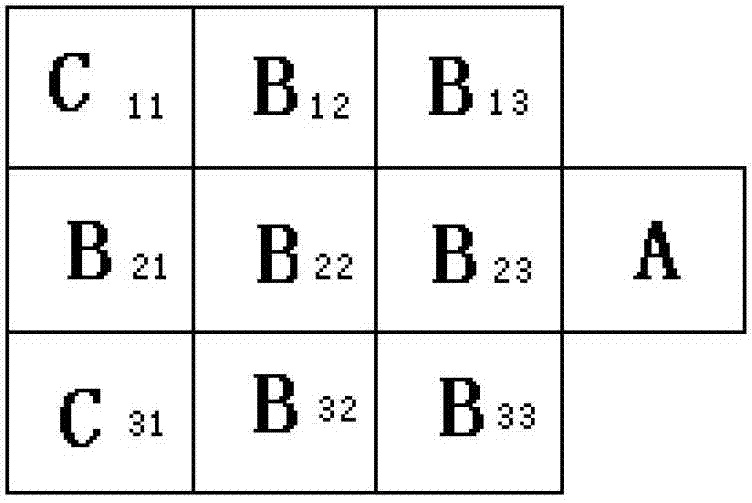

Dynamic crack length measurement method for machine vision fatigue crack propagation test

ActiveCN102692188AHigh measurement accuracyIntuitive visualization of the expansion processUsing optical meansMaterial strength using repeated/pulsating forcesAnti jammingInternational standard

The invention provides a dynamic crack length measurement method for a fatigue crack propagation test based on the machine vision technology. The method comprises the following steps: 1, performing machine vision crack measurement system calibration; 2, performing fatigue test, wherein a test piece with precracks begins to generate fatigue cracks along the direction of the precracks, and the fatigue cracks extend; 3, collecting crack images, wherein a mode of collecting single-face images of the test piece and a mode of collecting two-side images of the test piece are used in the fatigue crack propagation test; 4, reinforcing the collected images; 5, identifying the position of the trunk of cracks, as well as peaks and identifying directions of cracks by using the method of image analysis and crack identification; and 6, calculating the actual crack identifying length and crack length. The method has the advantages of simplifying the process and reducing work load; and by the method, the crack identifying process can be visually and accurately observed and recorded, the calculated crack length specified by the international standard can be measured accurately. The method also has the advantages of high measurement accuracy and good system anti-jamming performance.

Owner:平邑经济开发区投资发展有限公司

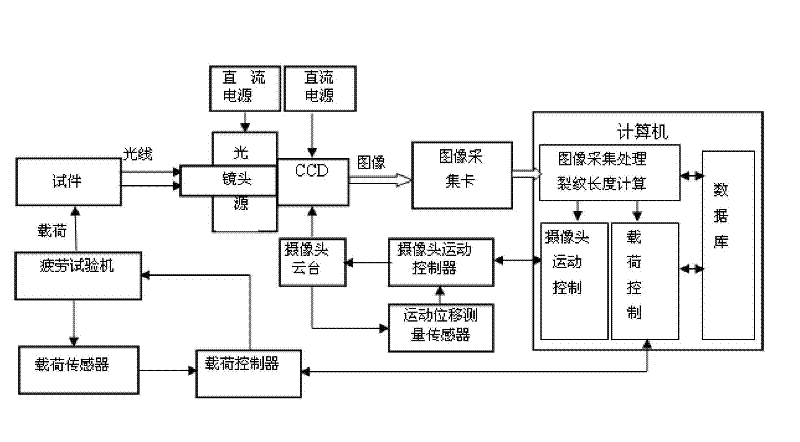

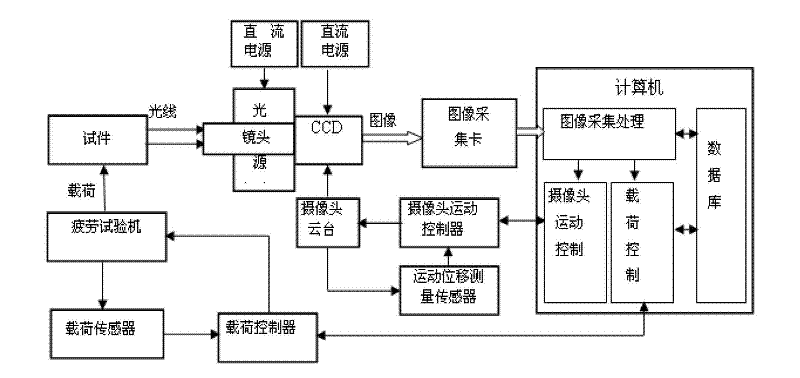

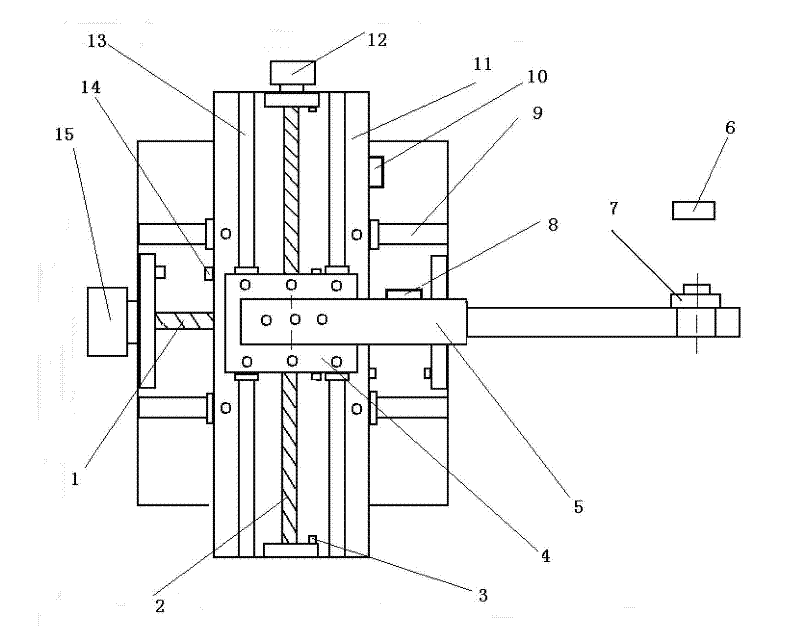

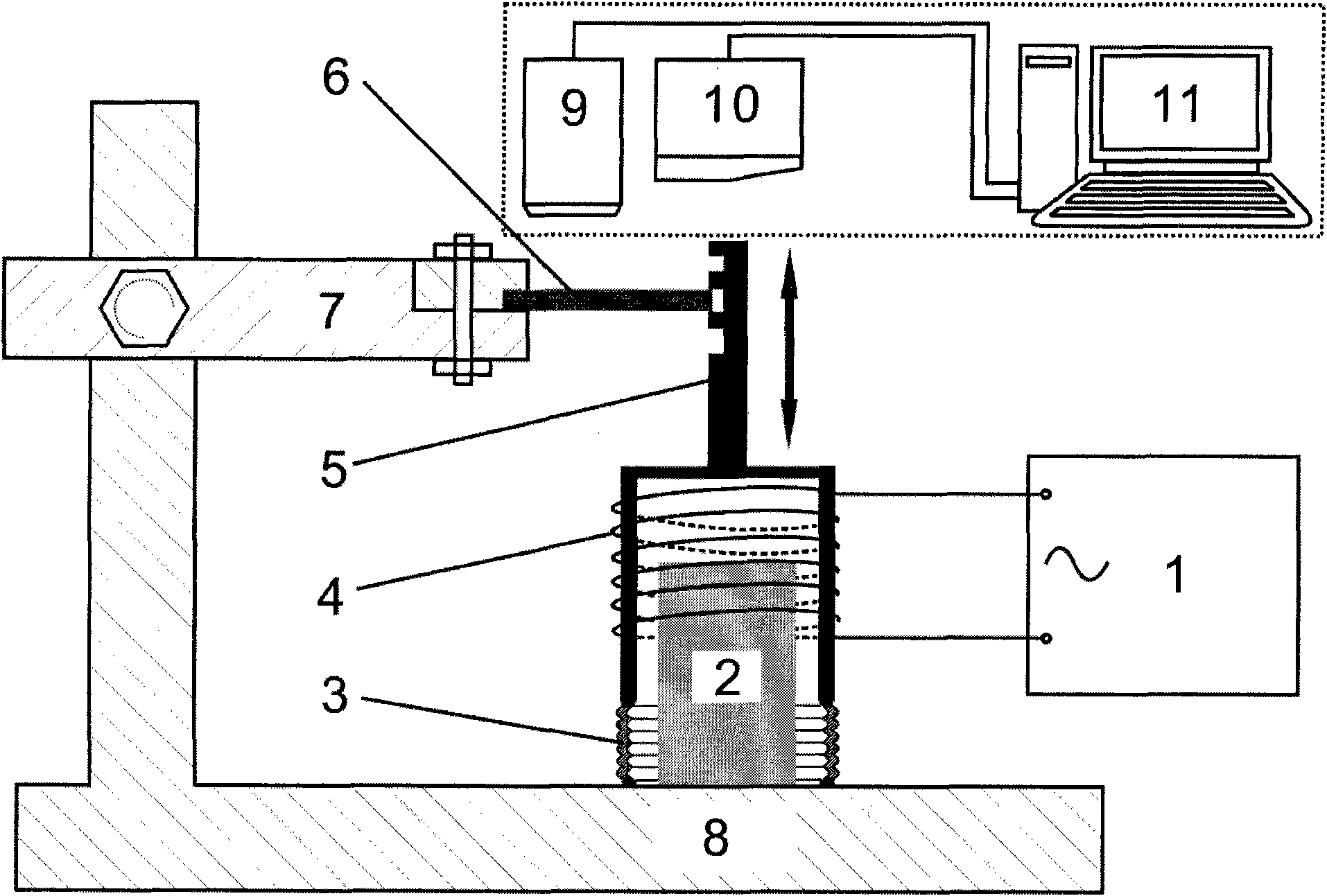

Camera automatic regulating image acquisition device and method for fatigue crack propagation test

InactiveCN102692347AAchieve regulationImprove work efficiencyTelevision system detailsColor television detailsControl systemComputer module

The invention relates to a camera automatic regulating crack image acquisition system for a fatigue crack propagation test, which comprises a crack image imaging and acquiring system, a camera position regulating system and a computer processing and analysis control system, wherein the crack image imaging and acquiring system comprises a CCD (Charge Coupled Device) camera, a lens, a light source illuminating device, a camera mounting bracket and an image acquiring card; the CCD camera, the lens and the light source illuminating device are arranged on the camera mounting bracket to form a crack image imaging unit; the image acquiring card is connected with a computer; a camera position regulating device comprises a stepping motor, a camera motion positioning cloud deck, a motion controller and a stepping motor driver; and the computer processing and analysis control system comprise the computer and a camera automatic regulating image acquisition module in an ARM motion controller. The invention also provides a camera automatic regulating crack image acquisition method for the fatigue crack propagation test. According to the camera automatic regulating image acquisition device and method for fatigue crack propagation test provided by the invention, the full-automatic operation is adopted; the control accuracy is high; and the real-time performance is excellent; and the labor intensity is reduced.

Owner:ZHEJIANG UNIV OF TECH

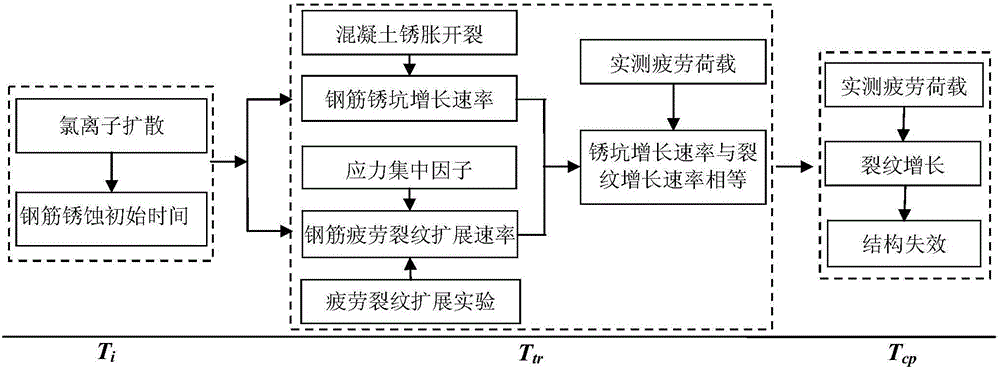

Method for evaluating fatigue life of aged reinforced concrete bridge

ActiveCN105825030AThe prediction method is reasonableGeometric CADForecastingStress concentrationCrazing

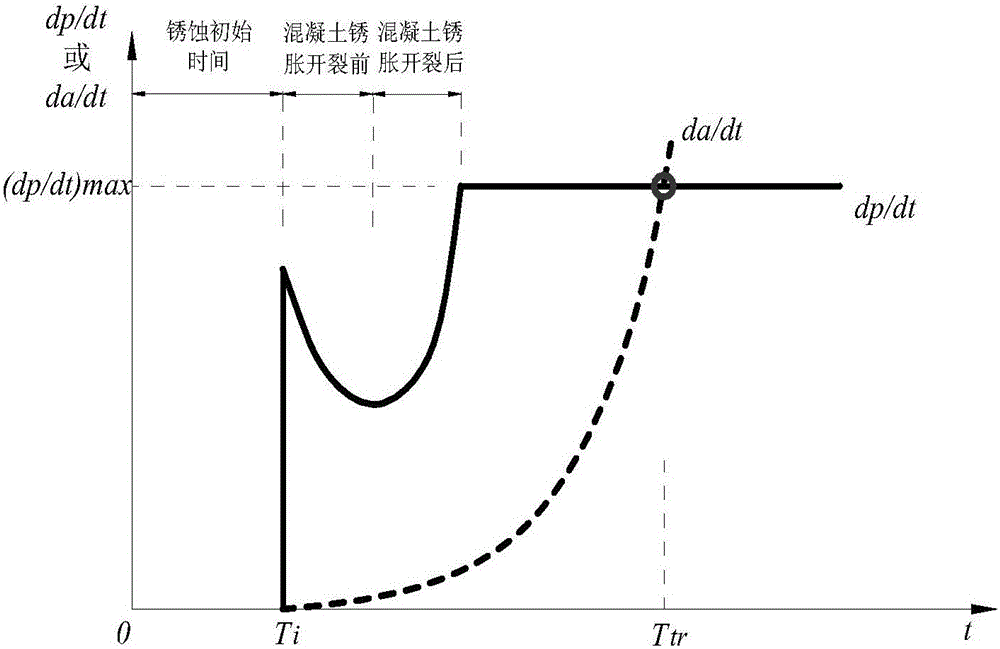

The invention discloses a method for evaluating the fatigue life of an aged reinforced concrete bridge. The method comprises the following steps of obtaining initial corrosion time of reinforcement in concrete based on the second diffusion law of Fick, and considering the influence of concrete cracking due to corrosion expansion in a corrosion rate model; adopting a small crack growth and near threshold growth analysis and determining relevant parameters of fatigue crack propagation rate of materials by developing a fatigue crack propagation test of reinforced concrete materials; performing a corrosion fatigue test or finite element analysis on corroded reinforcement to obtain stress concentration factors at different corrosion levels, and integrating into a stress intensity factor model to obtain the fatigue crack propagation rate of the reinforcement under the influence of corrosion; comparing the magnitude of a corrosion pit growth rate and the fatigue crack propagation rate and gradually converting into a single growth analysis on fatigue cracks of the reinforcement; meanwhile, combining with vehicle load observing information to realize life evaluation of a bridge at different service stages. The prediction method disclosed by the invention is reasonable and high in popularization, and can provide technical support for evaluating the life of the concrete bridges.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Mechanical structure crack expansion rate and crack expansion life span predication method

InactiveCN101122560ASave moneyShorten the development cycleUsing mechanical meansComplex mathematical operationsHysteresisCrazing

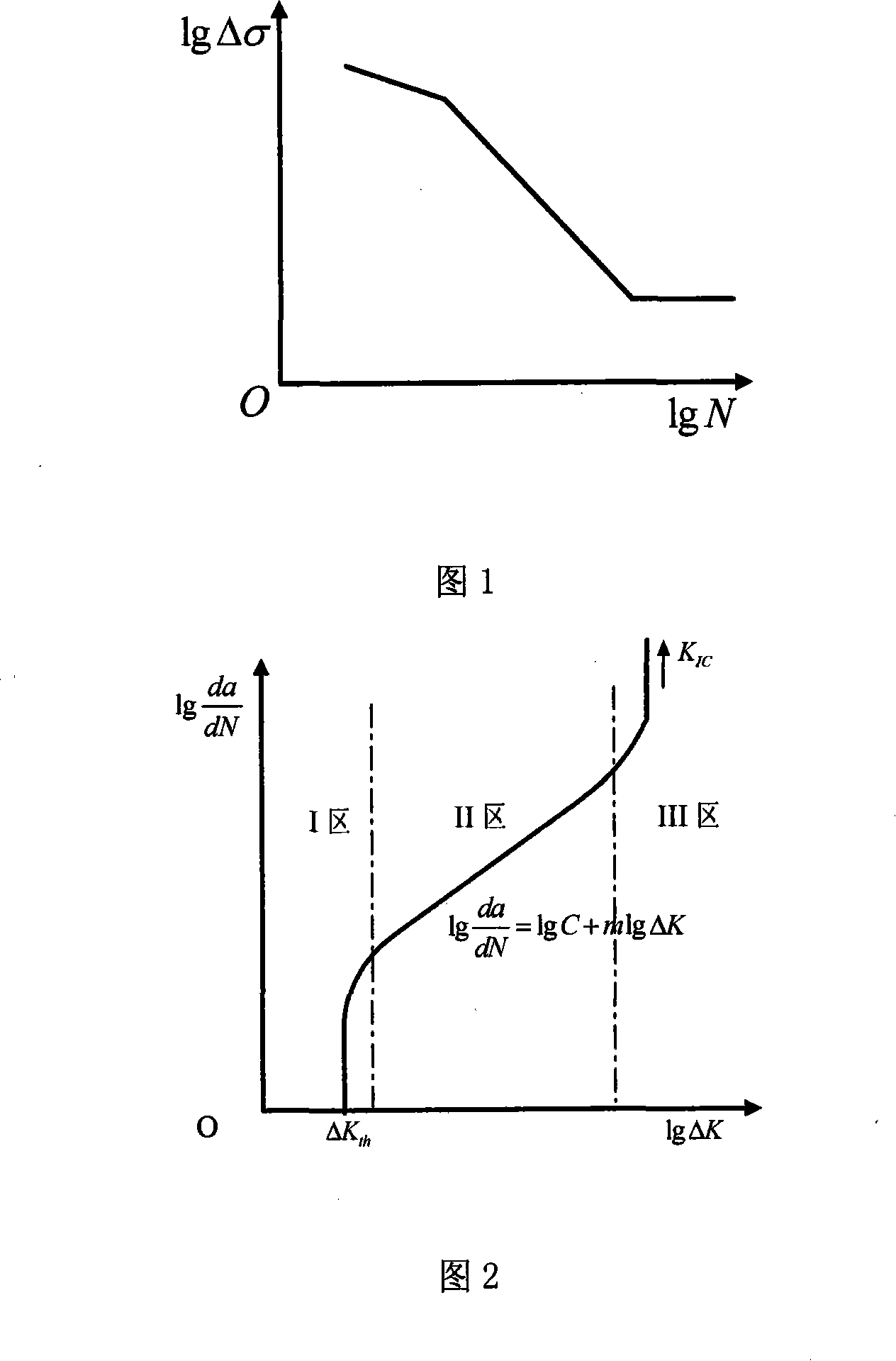

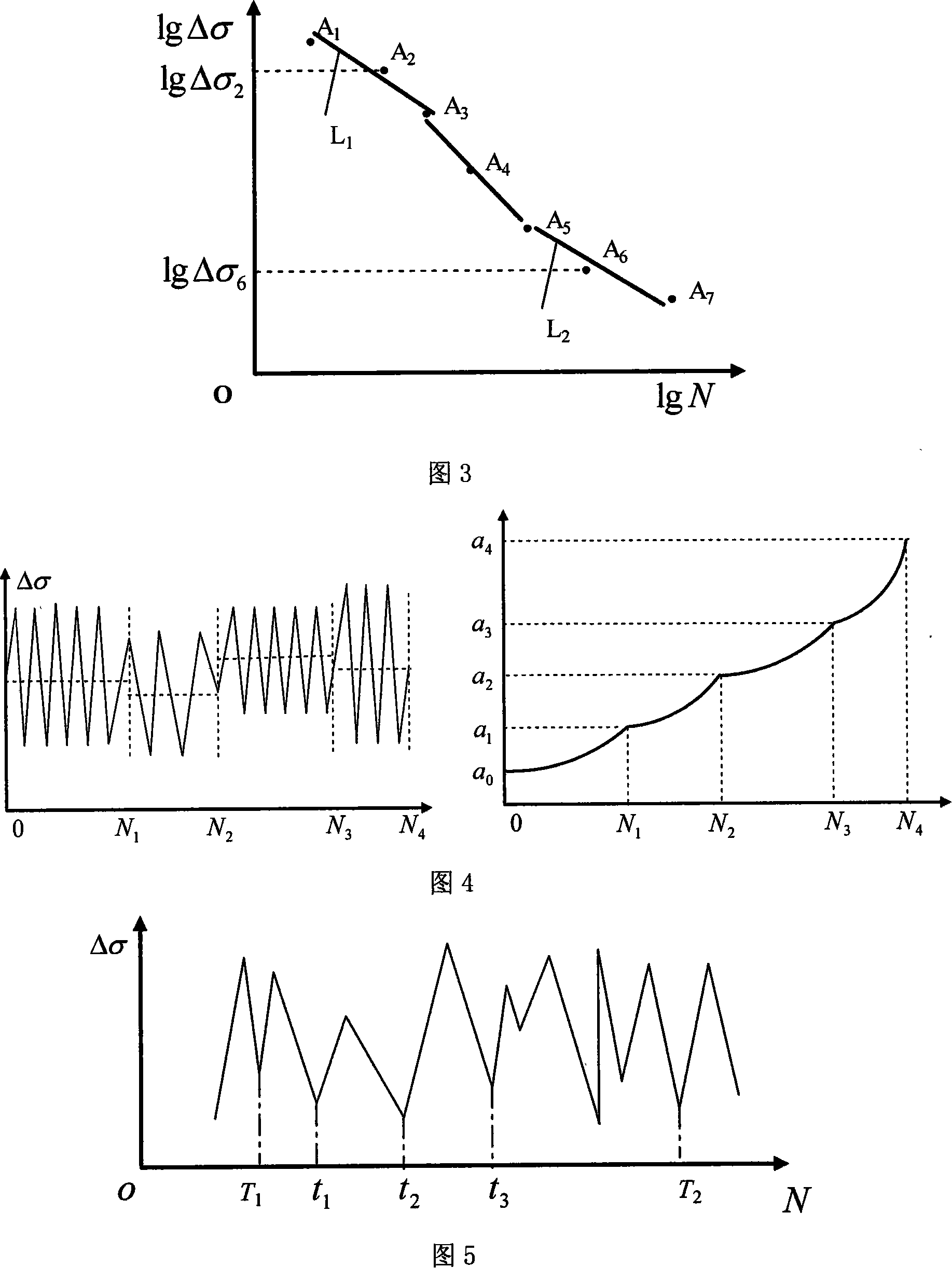

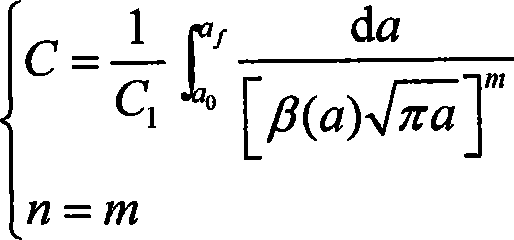

A crack growth rate and crack growth life prediction method for a mechanical structure belongs to a calculation method for fatigue crack growth rate and crack growth length of the mechanical structure. At first, a relationship between S-N and P-S-N curve expressions (power function form) and a crack growth rate curve expression (Paris formula) is built up in the method. A determination method of the crack growth rate under the conditions of block spectrum load, overload hysteresis load and random load is proposed. And a determination method of Paris curve parameters is provided when the S-N and P-S-N curves cannot be expressed in power function form. And a method for improving the prediction precision of the crack growth rate and the crack growth life is proposed. The S-N and P-S-N curves are used by the method to predict the crack growth rate and the crack growth life. Therefore, the method has the advantages of little dependence on tests and high precision and can shorten the product development period and save much manpower, material resources and financial resources.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

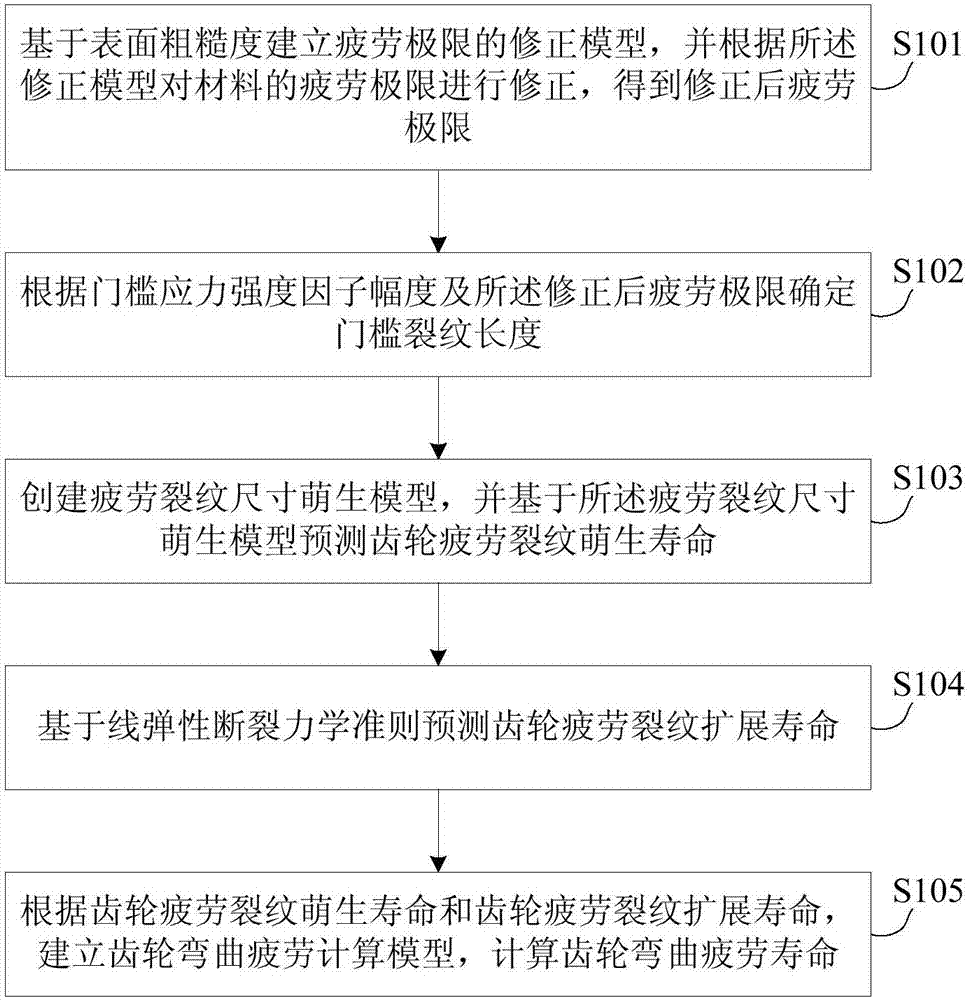

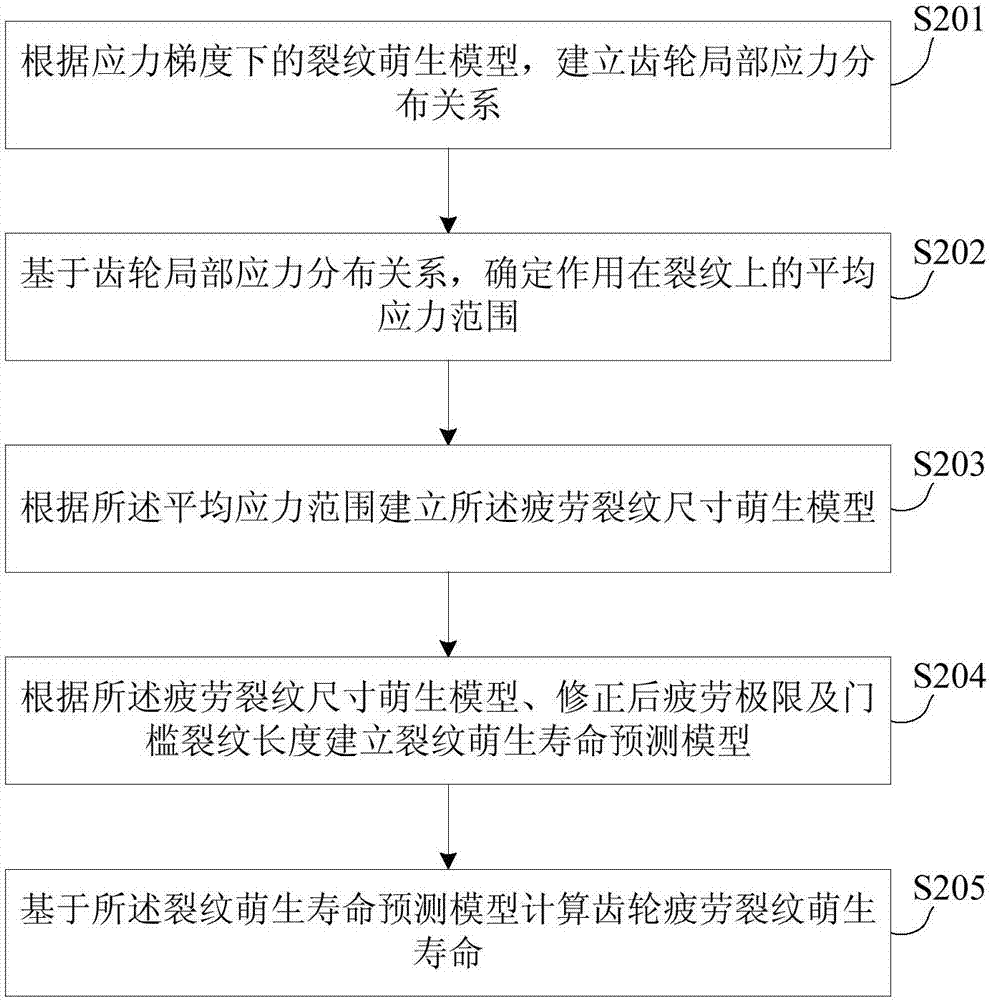

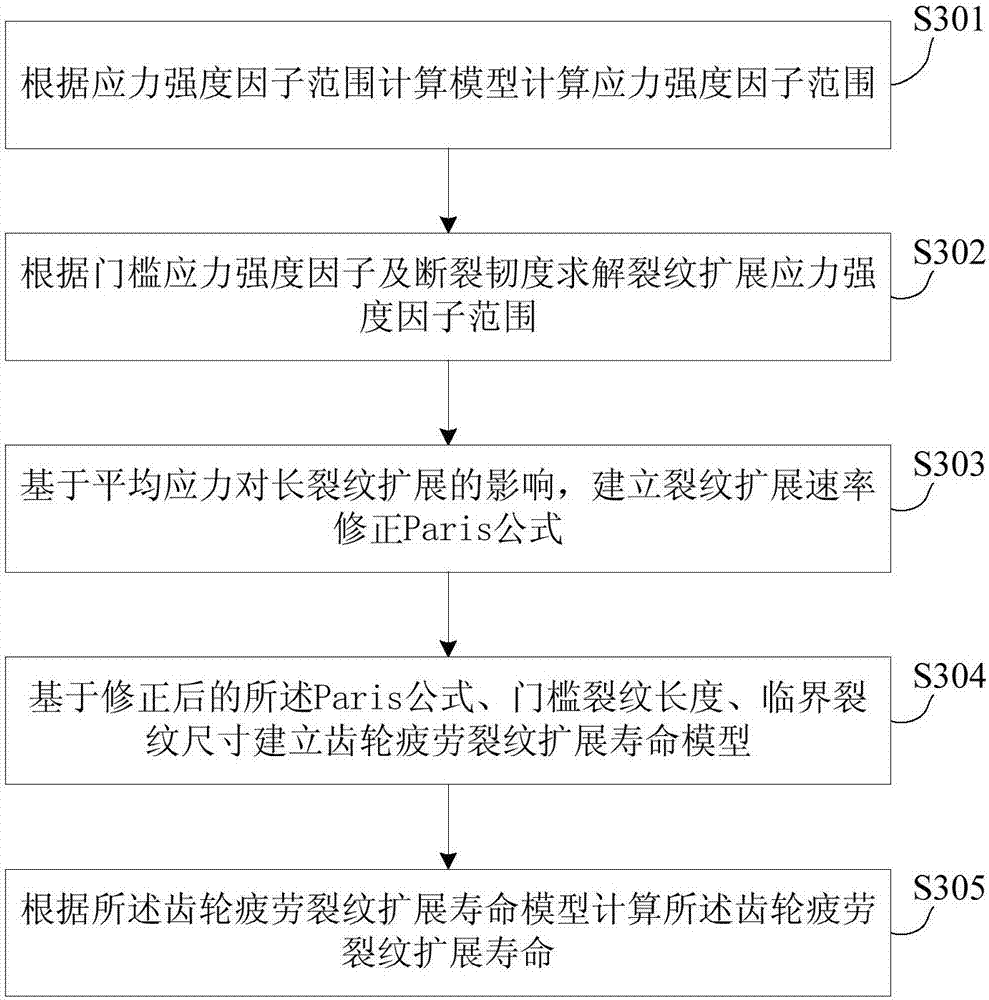

Gear bending fatigue life forecast method and apparatus

ActiveCN106886663ASimplify the operating life prediction processPredicting Flexural Fatigue LifeGeometric CADDesign optimisation/simulationGuidelineSurface roughness

The invention provides a gear bending fatigue life forecast method and a device. The gear bending fatigue life forecast method comprises the steps that a fatigue limit amendment model is built based on the surface roughness, and the fatigue limit of materials is amended according to the amendment model, the fatigue limit after the amendment is obtained; the threshold crack length is determined according to the threshold stress strength factor range and the amended fatigue limit; a fatigue crack size initiation model is created, and gear fatigue crack initiation life is forecasted based on the fatigue crack size initiation model; gear fatigue crack propagation life is forecasted based on the linear elastic fracture mechanics guidelines; according to the gear fatigue crack initiation life and gear fatigue crack propagation life, a gear bending fatigue calculation model is built, to calculate the gear bending fatigue life.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

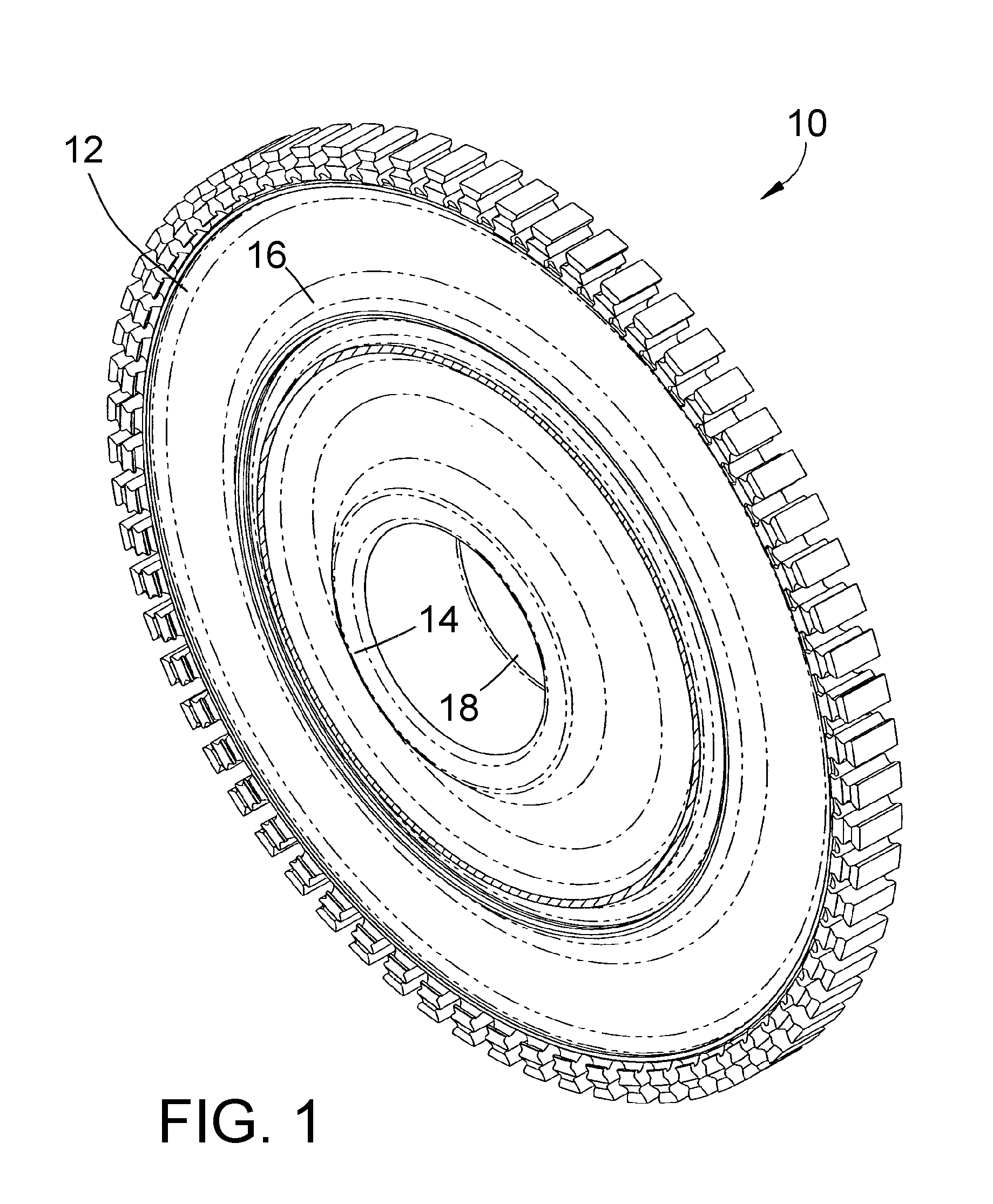

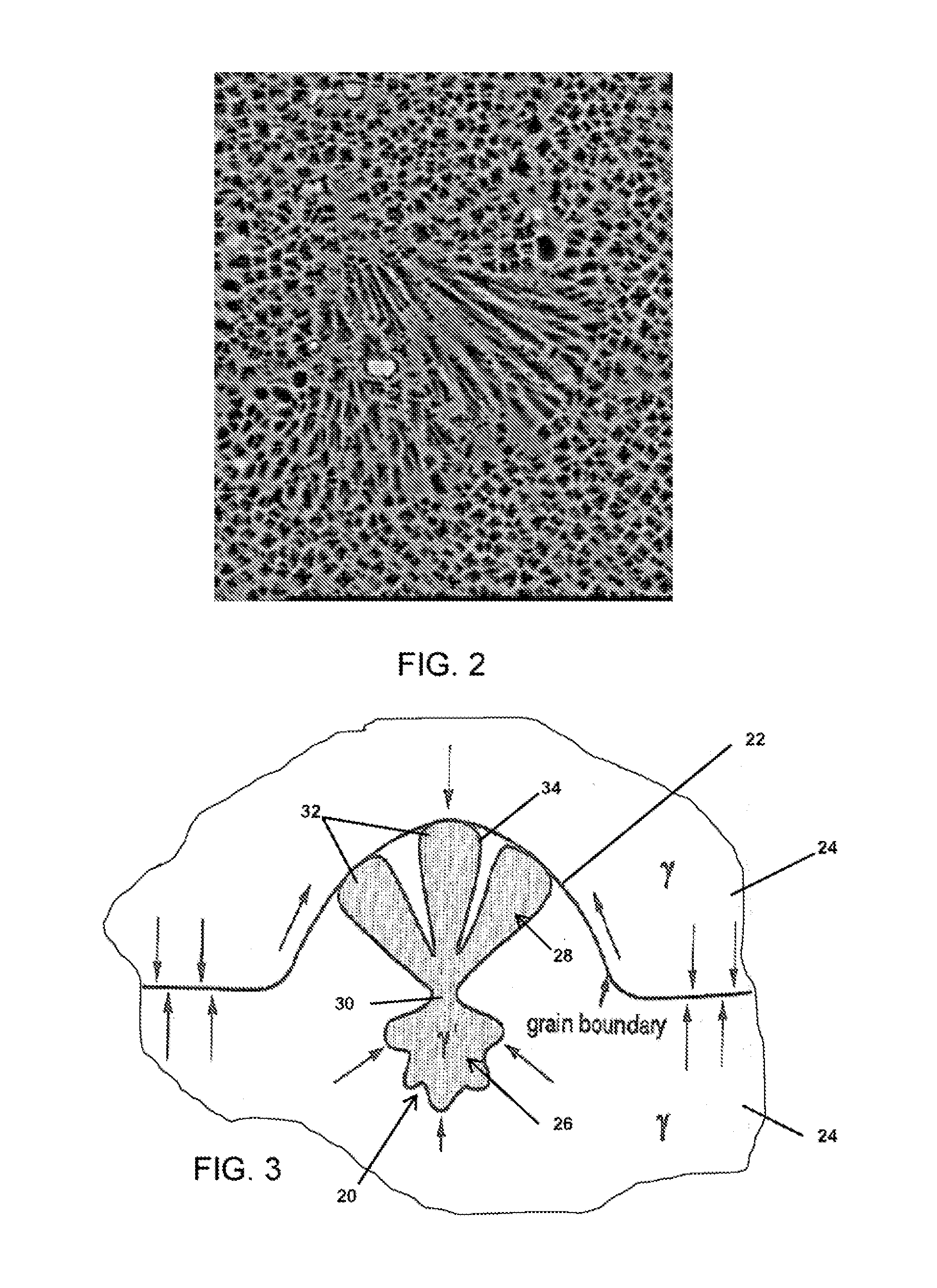

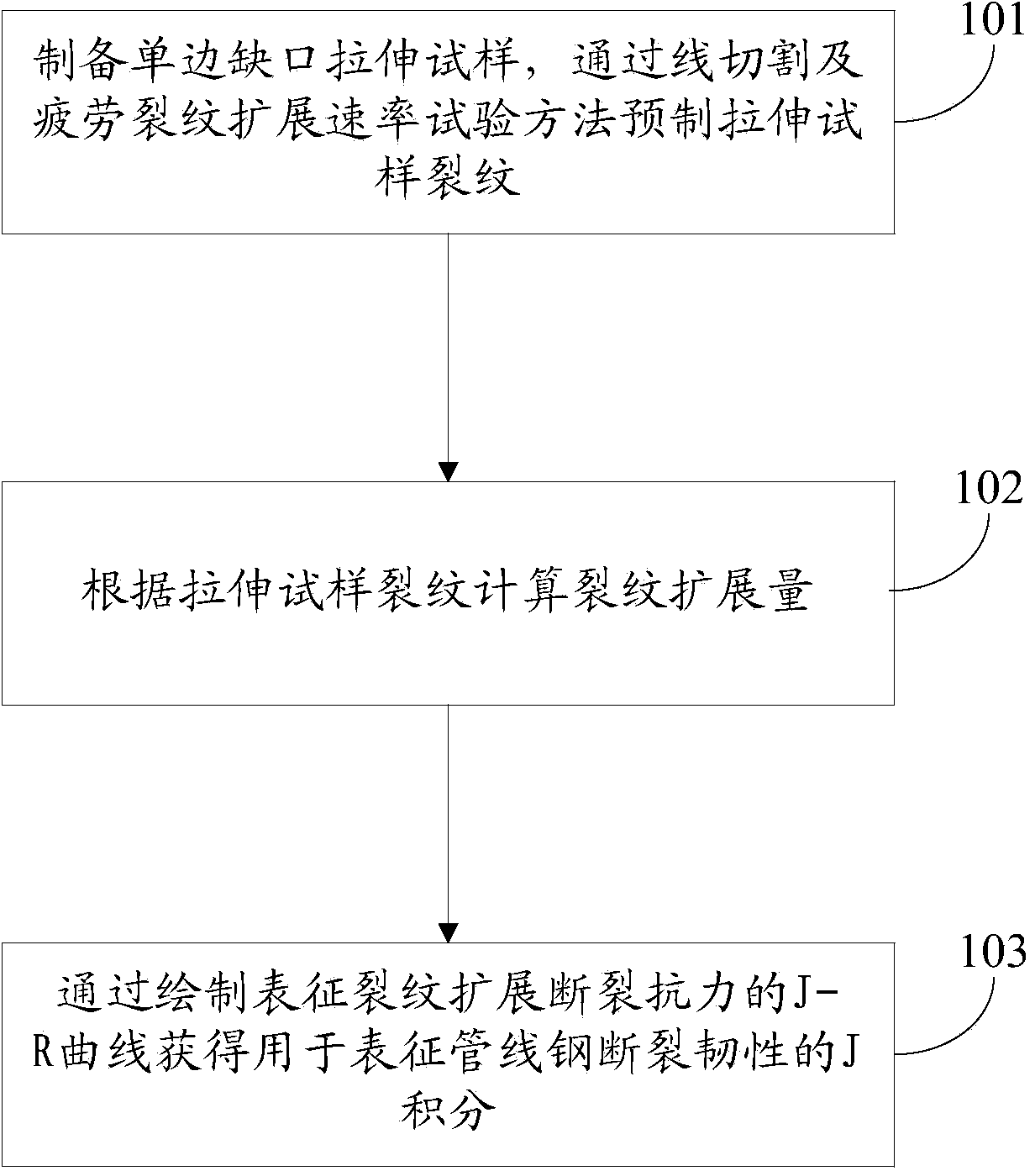

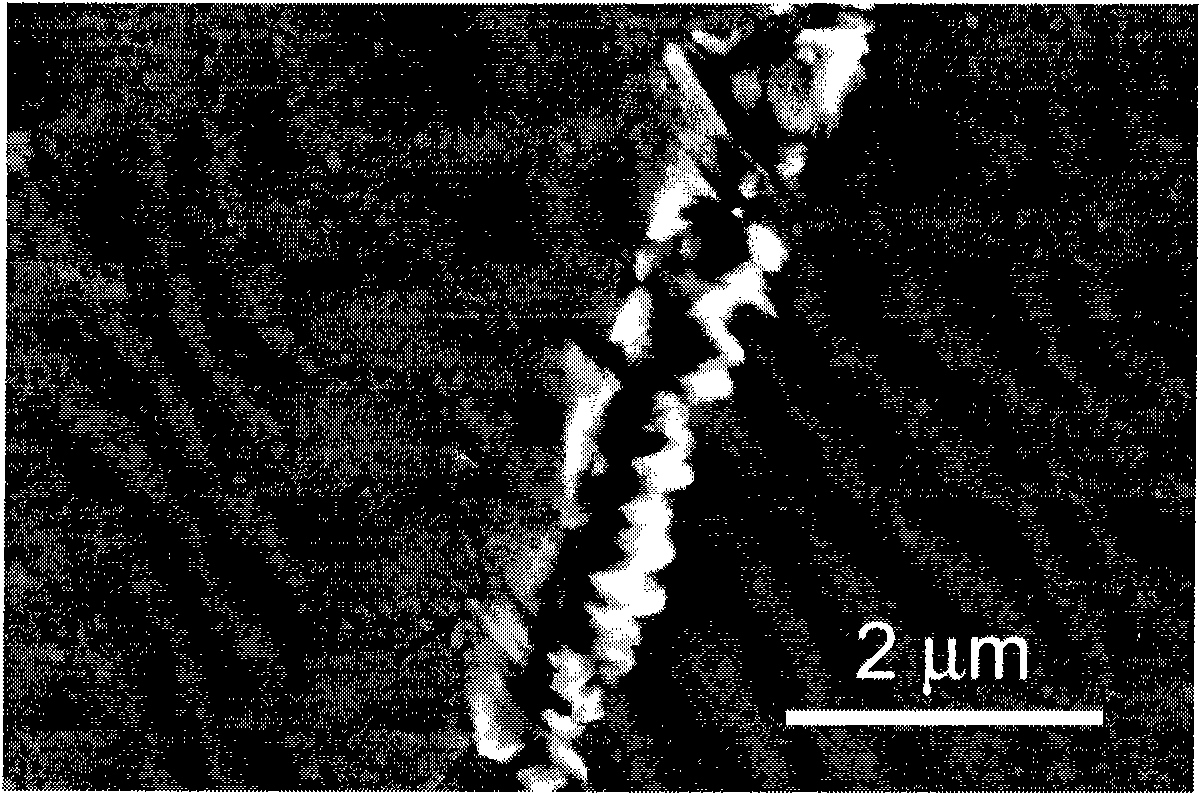

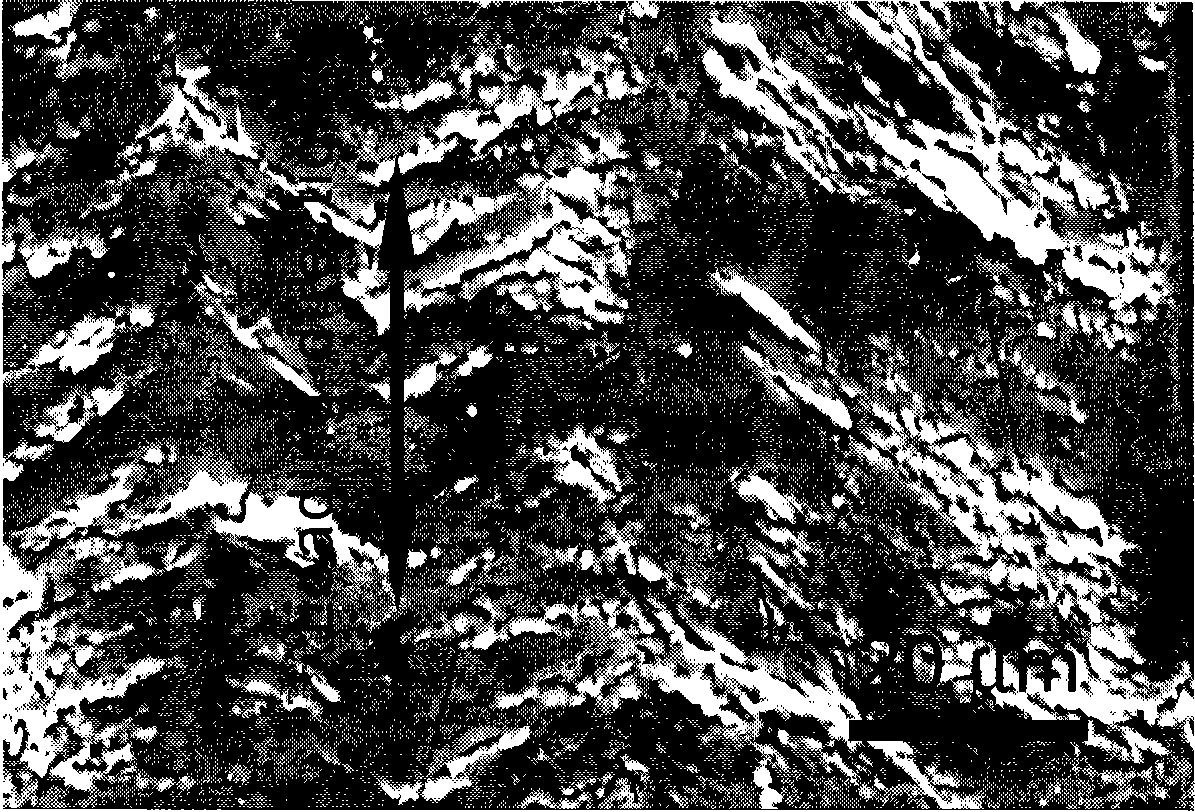

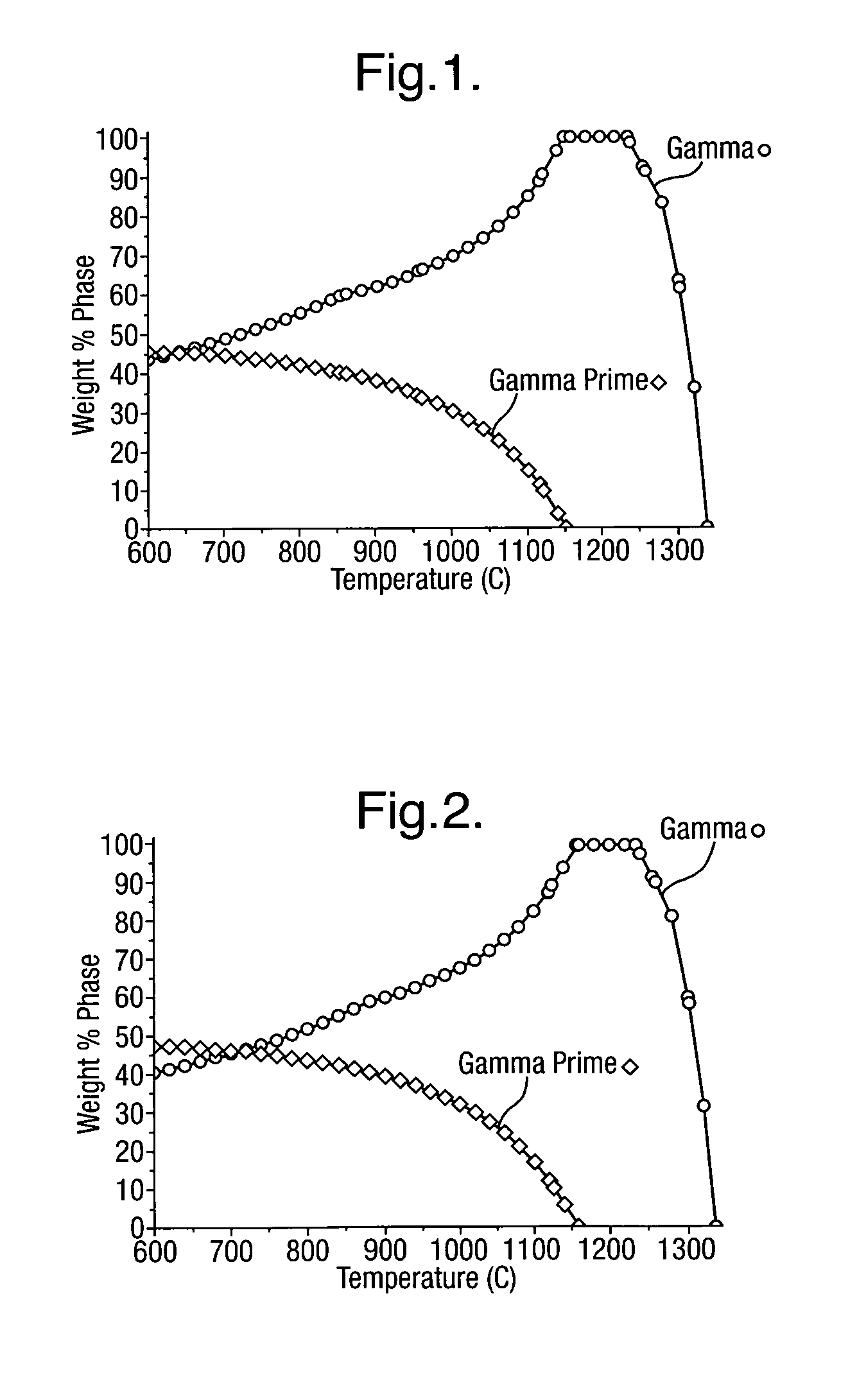

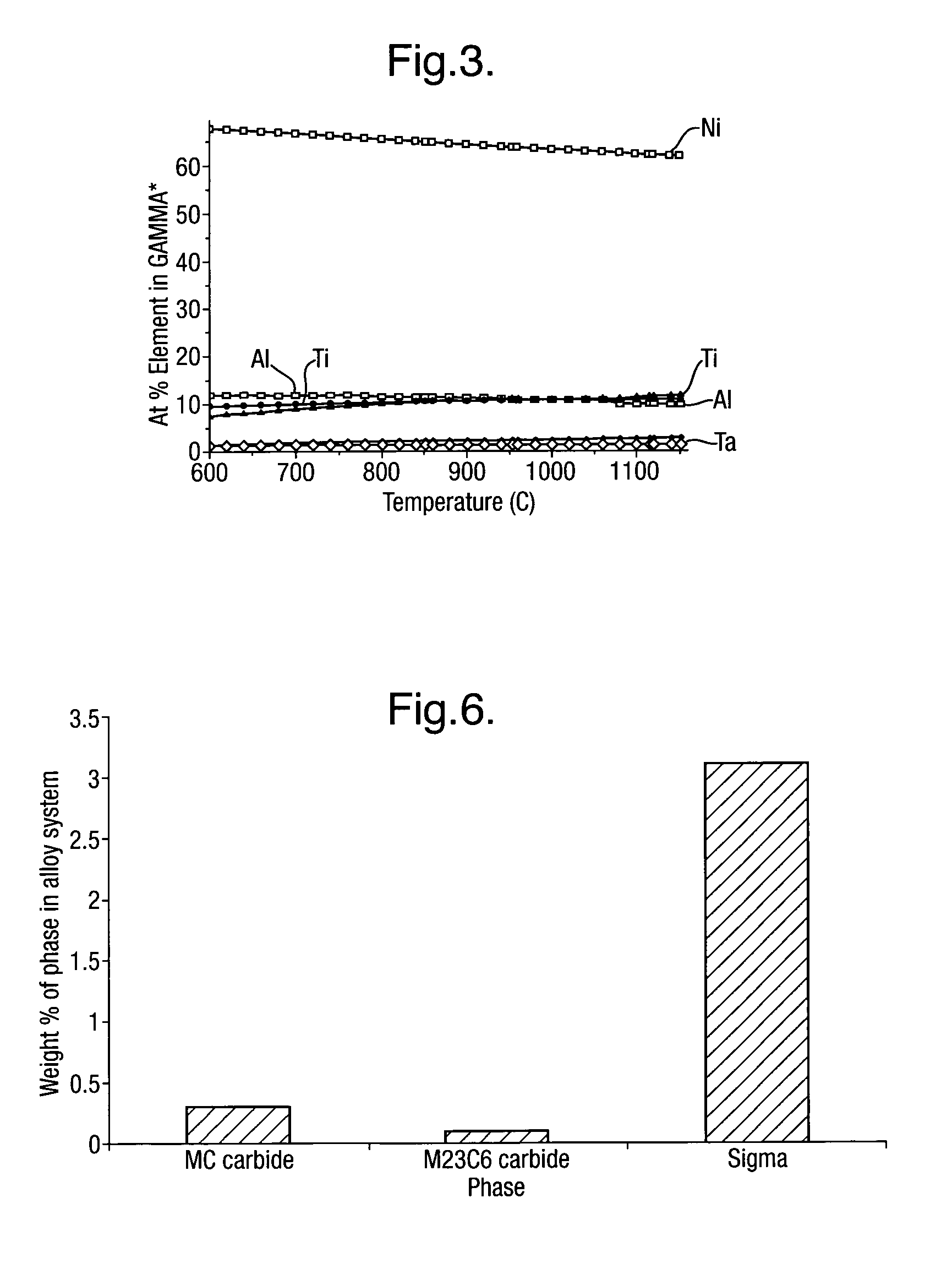

Nickel-base alloy, processing therefor, and components formed thereof

A gamma prime nickel-base superalloy and components formed therefrom that exhibit improved high-temperature dwell capabilities, including creep and dwell fatigue crack growth behavior. The superalloy contains, by weight, 10.00 to 22.0% cobalt, 10.0 to 14.0% chromium, 4.0 to 6.0% tantalum, 2.0 to 4.0% aluminum, 2.0 to 6.0% titanium, 1.5 to 5.0% tungsten, 1.5 to 5.0% molybdenum, 1.0 to 3.5% niobium, 0.05 to 0.6% hafnium, 0.02 to 0.10% carbon, 0.01 to 0.40% boron, 0.02 to 0.10% zirconium, the balance essentially nickel and impurities, wherein the titanium:aluminum weight ratio is 0.7 to 1.5. The superalloy is hot worked and heat treated to contain cellular gamma prime precipitates that distort grain boundaries, creating tortuous grain boundary fracture paths that are believed to promote the fatigue crack growth resistance of the superalloy.

Owner:GENERAL ELECTRIC CO

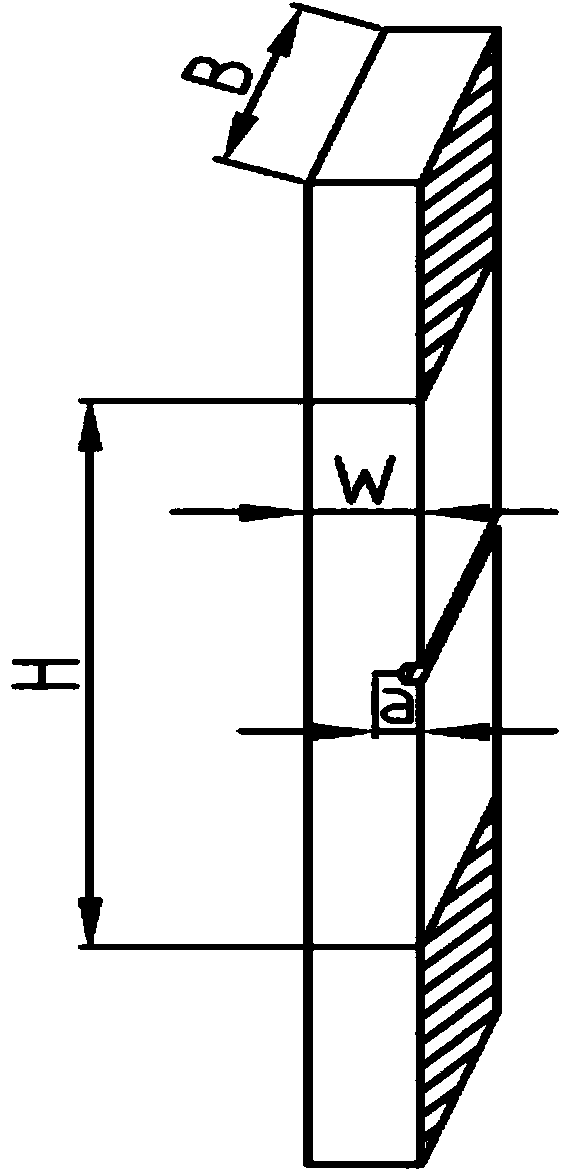

Method for measuring fracture toughness of pipeline steel by using unilateral notched tensile test

ActiveCN103604694AAvoid wastingReasonable fracture toughness valueMaterial strength using tensile/compressive forcesCrack resistanceStress intensity factor

The invention discloses a method for measuring fracture toughness of pipeline steel by using a unilateral notched tensile test. The method is characterized by comprising the steps of preparing a unilateral notched tensile test sample; prefabricating a tensile sample crack by wire-electrode cutting and fatigue crack growth rate test method; calculating crack growth amount according to the tensile sample cracks; and acquiring J integration and stress intensity factor K for characterizing the fracture toughness of the pipeline steel by drawing a J-R curve for characterizing crack resistance of the crack growth. The method measures the fracture toughness of the pipeline steel by using tensile samples (SENT samples), overcomes the defects that the scope of measurement results of tensile samples (SENT samples) by a conventional technology is so small that the fracture toughness of the pipeline steel can not be evaluated; the crack toughness value of the tensile samples (SENT samples) can be more reasonable; waste of test for pipeline steel materials can be prevented; and the method has the advantages of high measurement accuracy.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Self-diagnosis system for wind-induced cumulative fatigue damage of pull lug node substructure of mast structure

InactiveCN101825522AEnsure safetyMaterial analysis using acoustic emission techniquesForce measurementFatigue damageReal time analysis

The invention discloses a self-diagnosis system for wind-induced cumulative fatigue damages of a pull lug node substructure of a mast structure. The system comprises a displacement measuring apparatus, a pull rope tension determination module, a welding residual stress determination module, a pull lug substructure wind-induced stress field determination module, a fatigue crack initiation degree real-time analysis module and a man-machine interaction interface, so that the system can timely inform a user of the degree of the cumulative fatigue at the danger point position of the pull lug node substructure of the mast structure and the time when the cumulative fatigue crack initiation occurs and make early warning on cumulative fatigue cracks when the pull lug node substructure of the mast structure is in a good condition. In addition, the system also comprises an acoustic emission sensor, a strain transducer, a fatigue crack growth determination module and an ultimate crack length and fracture analysis module, so that the system can timely inform the user of the degree of the cumulative fatigue crack growth and the time when the fracture occurs, timely repair the crack and ensure the safety of the mast structure when the cumulative fatigue cracks of pull lug node substructure of the mast structure occur.

Owner:WUHAN UNIV OF TECH

Test system and test method for dynamic bending fatigue property of thin film material

InactiveCN101571467AEasy and fast clampingWide range of loading frequencyMaterial strength using repeated/pulsating forcesVibration testingFatigue loadingEngineering

The invention relates to a test system and a test method for the dynamic bending fatigue property of a small-scale thin film material. The test system comprises an electromagnetic driving part, a sample holding part and a measuring and observing part, and the system provides functions and a test method for dynamic bending fatigue property test for the thin film materials used for various micro / nanoelectronic mechanical systems and supported with matrix or without matrix, the metalized interlinking body foil material used for an integrated circuit and various two-dimensional thin plate type materials and can record in-situ real-time monitoring and analysis to the appearance of the tested sample. The free end of the cantilever beam sample is driven under the electromagnetic force of the electrified coil in the stationary magnetic field to reciprocate relatively to the equilibrium position thereof, thus various types of cyclic fatigue loads can be applied to various material samples, and the precision of the applied fatigue loads can reach the millinewton magnitude. The invention can be used to evaluate the fatigue property and the fatigue crack growth behaviors of various thin film materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

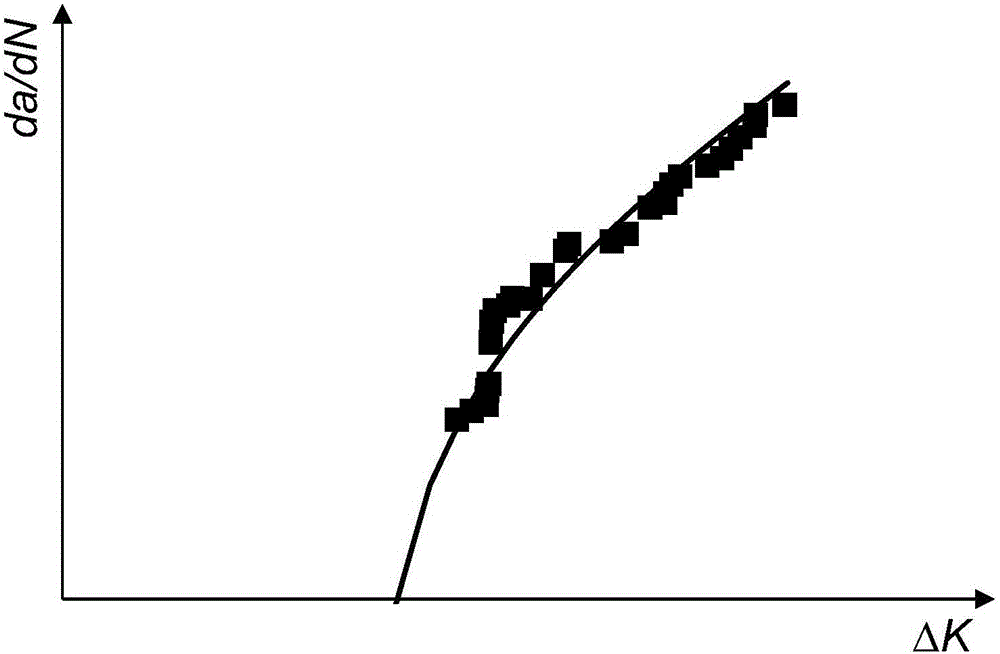

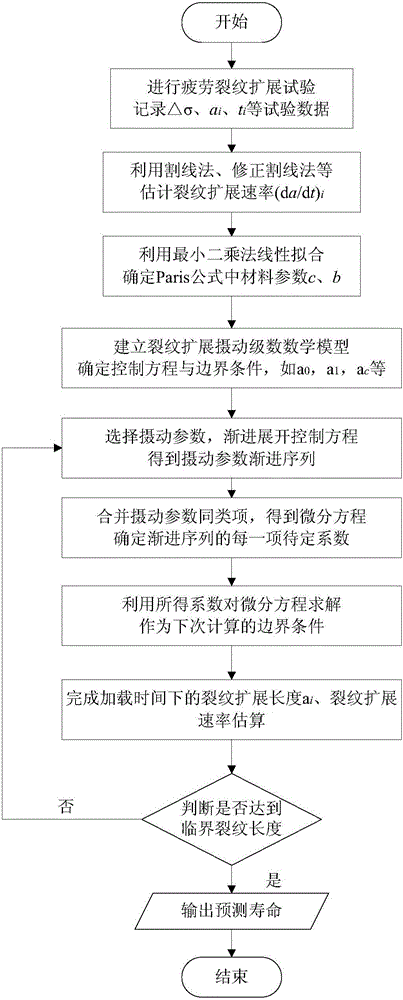

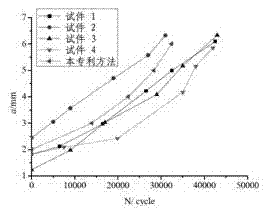

Method capable of carrying out fatigue crack propagation rate estimation and life prediction

InactiveCN105956315AEasy to understandEasy to acceptDesign optimisation/simulationSpecial data processing applicationsMetallic materialsLeast squares

The invention discloses a method capable of carrying out fatigue crack propagation rate estimation and life prediction. The method comprises the following steps: (1) carrying out a fatigue crack test, and recoding data including crack length, time and the like; (2) processing the data to estimate a propagation rate corresponding to the crack length; (3) taking a Paris formula as a least-squares fit line to determine metal material parameters; (4) establishing a crack propagation perturbation series model to obtain a control equation and a boundary condition; (5) selecting a perturbation parameter asymptotic expansion control equation to form a perturbation parameter asymptotic sequence; (6) combining like terms to obtain differential equations under different powers to determine a coefficient to be determined, and carrying out iterative solving on the differential equations to obtain boundary conditions during next calculation; and (7) utilizing a calculation result to finish crack propagation rate estimation, judging whether the crack length exceeds a critical crack or not, jumping to (5) if the crack length exceeds the critical crack, and finishing fatigue life prediction if the crack length exceeds the critical crack. The method can effectively estimate the crack propagation rate and predict the fatigue life, and improves calculation precision.

Owner:BEIHANG UNIV

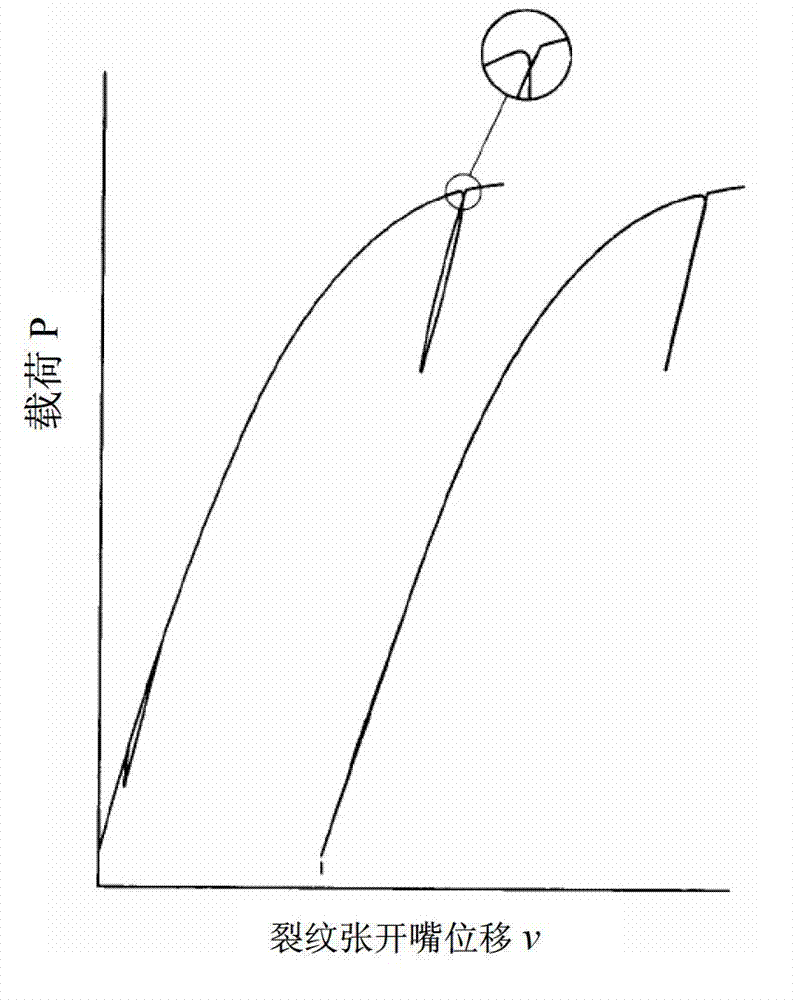

Metal structure fatigue crack propagation life prediction method based on material R curve

InactiveCN102778404APredicted Extended LifeStrength propertiesFatigue loadingCrack growth resistance curve

The invention relates to a metal structure fatigue crack propagation life prediction method based on a material R curve and is technically characterized in that based on the material crack propagation resistance curve (R curve) and crack propagation energy release rate theory, the effective energy release rate under fatigue load is defined as energy for crack propagation after a fatigue crack is completely expanded, the energy is equal to the consumed energy characterized by the crack propagation resistance curve in the same loading cycle, so that a fatigue crack propagation life prediction model capable of reflecting the physical nature of the crack propagation is proposed. By adopting the model, the crack propagation amount in each loading cycle can be calculated, the crack propagation life can be predicated through the accumulative calculation of the crack propagation amount, and the metal structure fatigue crack propagation life prediction method is suitable for predicting the fatigue crack propagation life of a metal structure in engineering and provides a reference method for tolerance evaluation of a structural damage.

Owner:AIR FORCE UNIV PLA

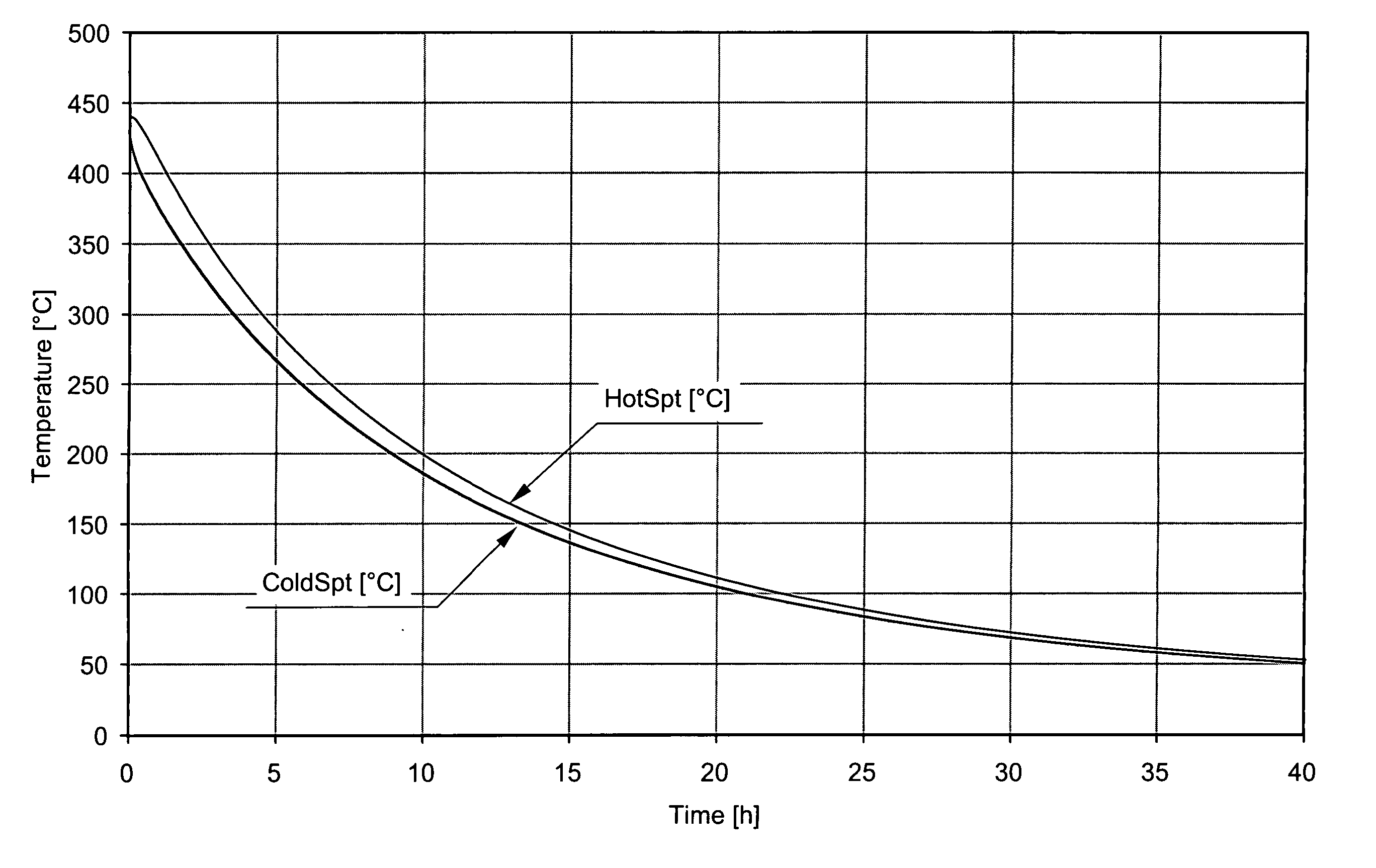

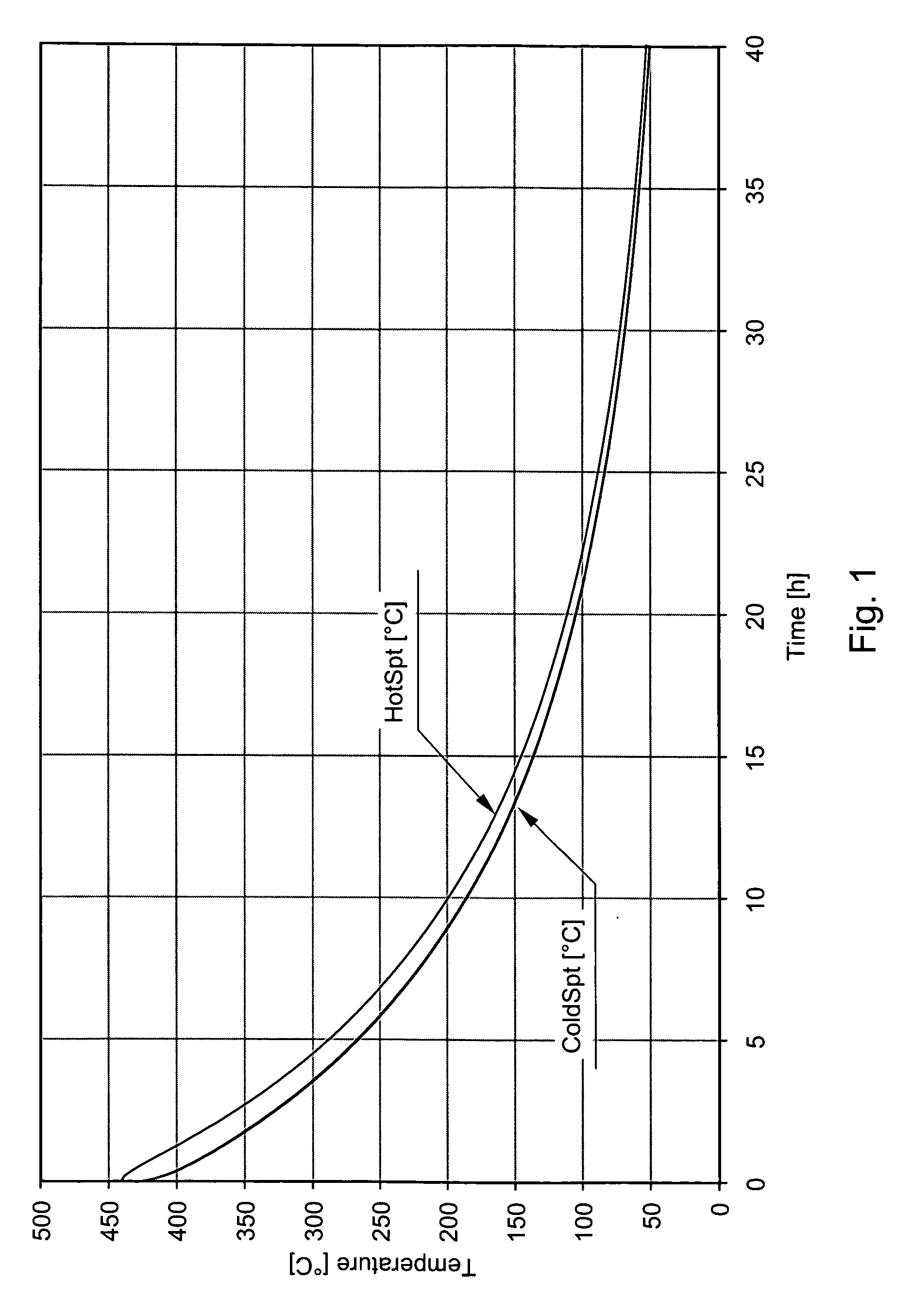

Method for producing a high damage tolerant aluminium alloy

The present invention relates to a method of producing a high damage tolerant aluminium alloy rolled product a high toughness and an improved fatigue crack growth resistance, including the steps of: a.) casting an ingot having a composition selected from the group comprising AA2000, AA5000, AA6000, and AA7000-series alloys; b.) homogenising and / or pre-heating the ingot after casting; c.) hot rolling the ingot into a hot rolled product and optionally cold rolling the hot rolled product into a cold rolled product, wherein the hot rolled product leaves the hot rolling mill at an hot-mill exit temperature (TExit) and cooling the hot rolled product from the TExit to 150° C. or lower with a controlled cooling cycle with a cooling rate falling within the range defined by: T(t)=50−(50−TExit)eαt and wherein T(t) is the temperature (° C.) as function in time (hrs), t is the time (hours) and α is in the range of −0.09±0.05 (hrs−1).

Owner:ALERIS ALUMINUM KOBLENZ GMBH

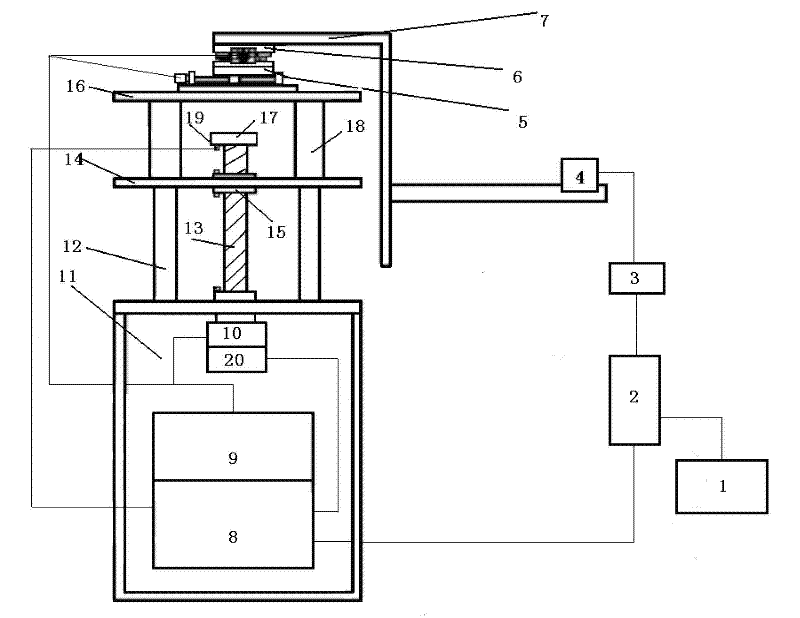

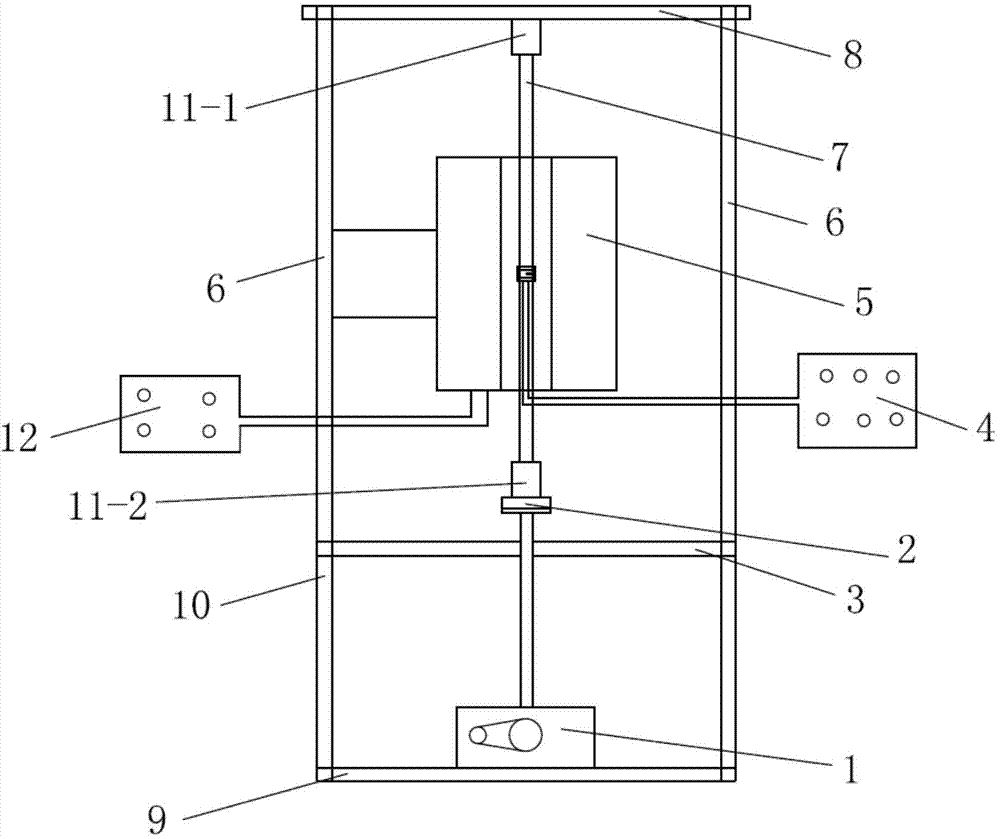

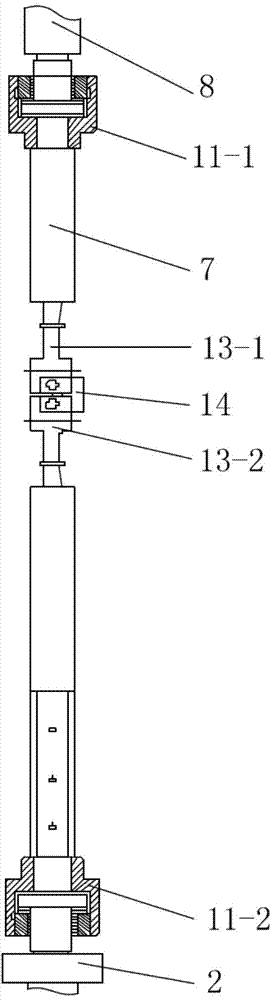

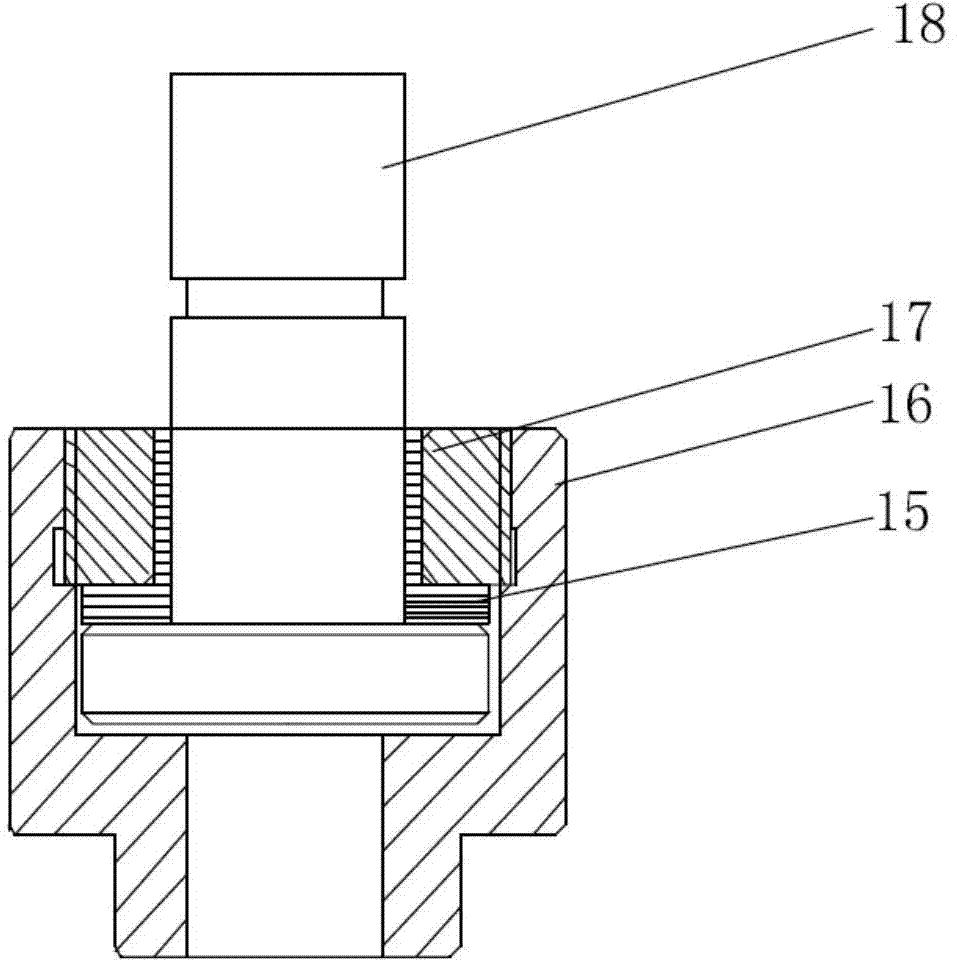

Creep deformation-fatigue crack growth testing device and corresponding testing method

InactiveCN103884603ACompact structureEasy to operateMaterial strength using tensile/compressive forcesCollection systemLength measurement

The invention relates to a creep deformation-fatigue crack growth testing device and a corresponding testing method. The device comprises a loading system, a temperature control system and a measurement and collection system, wherein the measurement and collection system comprises a load linear displacement measurement system and a crack length measurement system; the upper and lower ends of a test sample are fixedly connected with an upper clamp and a lower clamp respectively; a high temperature furnace is connected with the temperature control system and the measurement and collection system; the test sample is loaded by an alternating current servo motor and a controller. The invention further relates to the corresponding testing method. The testing device provided by the invention is compact in structure and convenient to operate; the testing device adopts an insulating chuck and the insulating chuck ensures that constant-current current passing through the test sample is stable; aiming at the test sample of a creep deformation-fatigue crack growth test, the clamps are designed and machined; the temperature in the furnace is high so that a high-temperature clamping type extensometer is used for introducing load linear displacement out of a heating furnace to be measured. The testing method is simple and convenient to operate; the crack length is measured by using an electric potential method and the continuous test can be carried out for long time.

Owner:EAST CHINA UNIV OF SCI & TECH

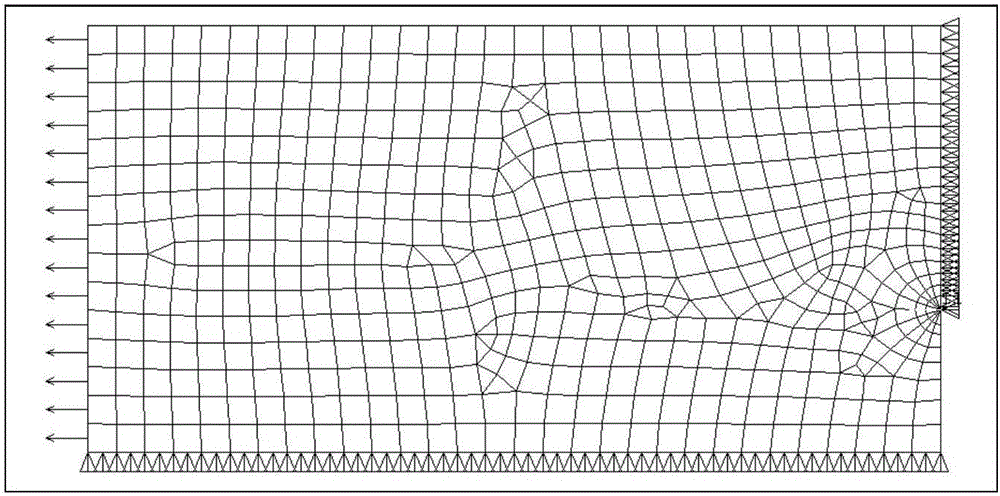

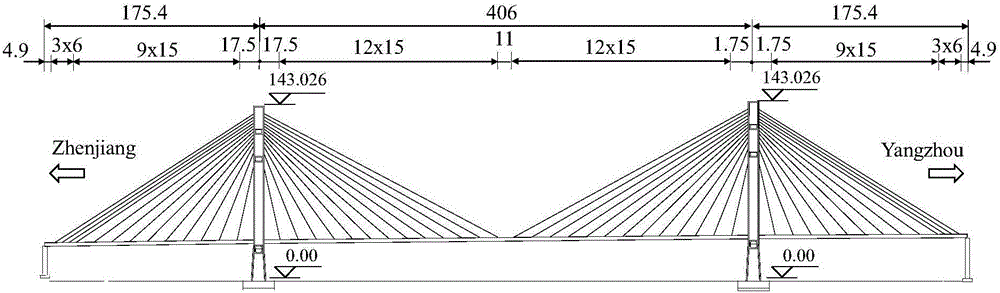

Method for assessing detail fatigue crack propagation of steel bridge

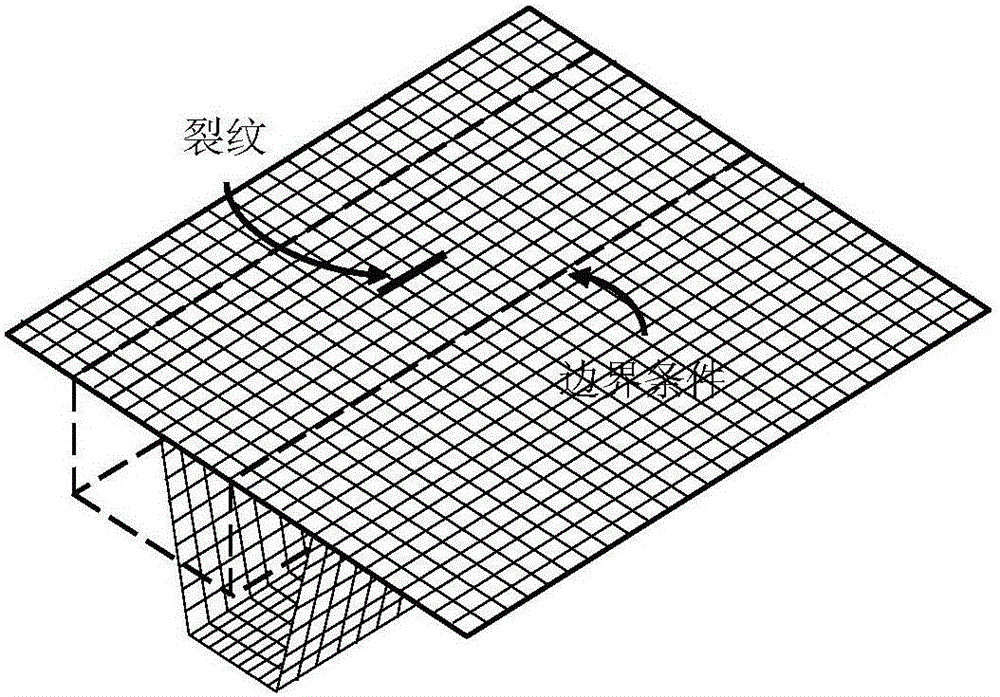

ActiveCN106055784AGuaranteed reliabilityImprove computing efficiencySpecial data processing applicationsStress intensity factorElement analysis

The invention discloses a method for assessing the detail fatigue crack propagation of a steel bridge. Aiming at a steel bridge which is widely used in a road bridge system and is severe in fatigue crack dangers, the method comprises the steps: firstly building a bridge model and a local zone crack submodel through finite elements, obtaining an existing bridge load according to the definition and sampling of a vehicle and other random variables, and obtaining the boundary conditions of the submodel based on the whole bridge finite element analysis and the submodel technology; secondly updating the submodel through employing local remeshing, and carrying out the crack propagation finite element analysis; thirdly extracting a stress intensity factor amplitude, calculating a mean crack propagation rate, a mean crack propagation angle, the circulating number of times of each crack propagation step, the mean number of the stress intensity factor amplitude caused by a single vehicle, and the fatigue life; finally achieving the simulation of the fatigue crack of the steel bridge and the assessment of the fatigue life, so as to guide the subsequent maintenance and reinforcing operation.

Owner:SOUTHEAST UNIV

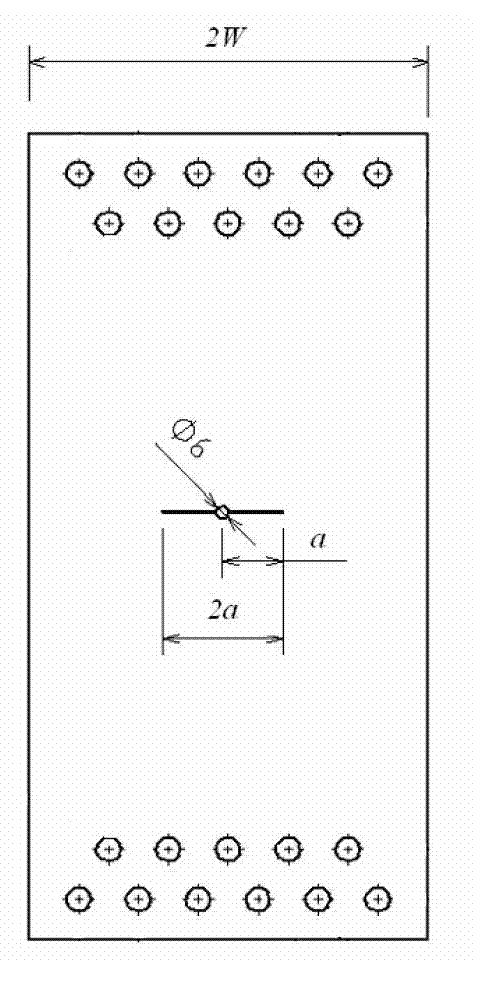

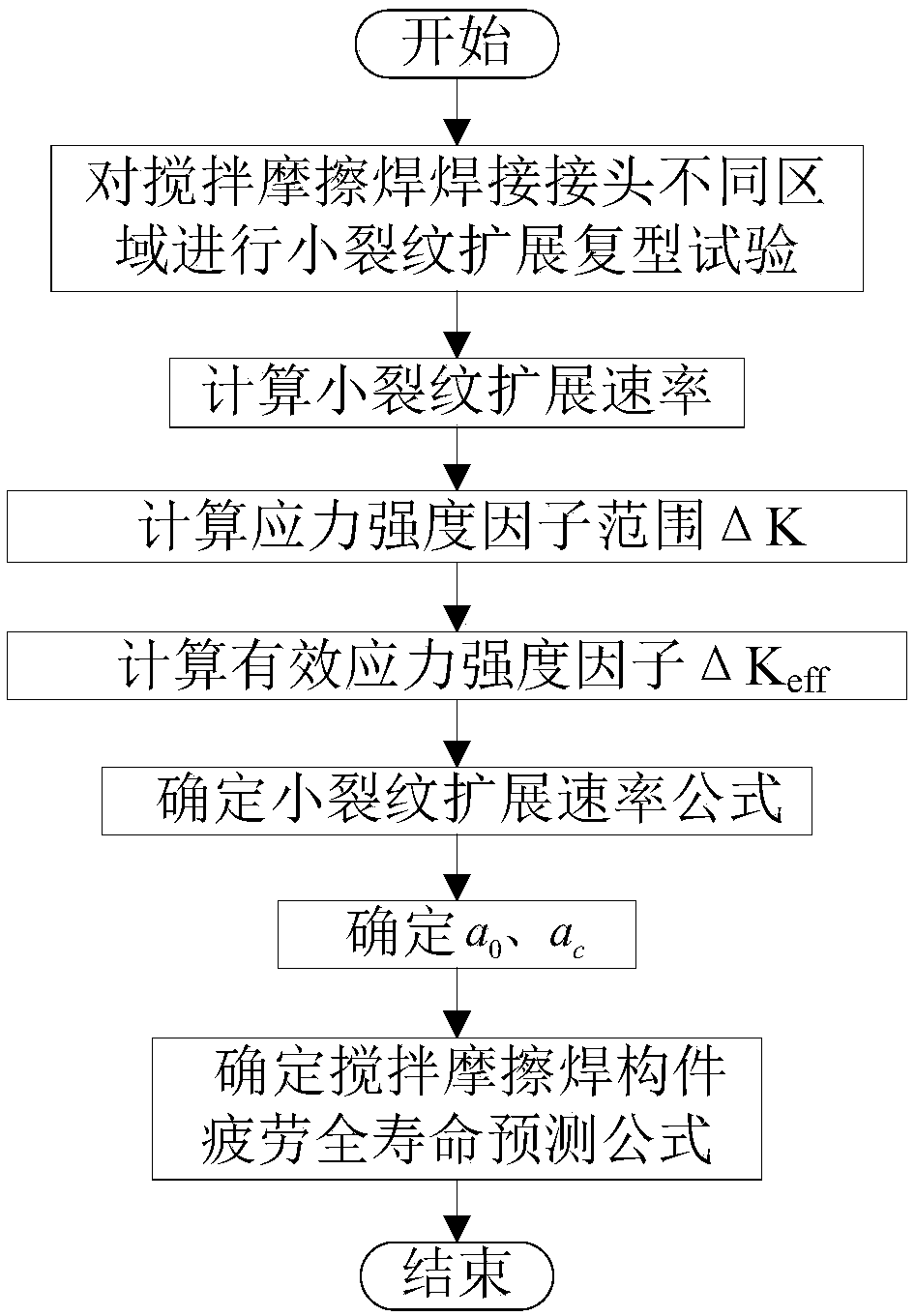

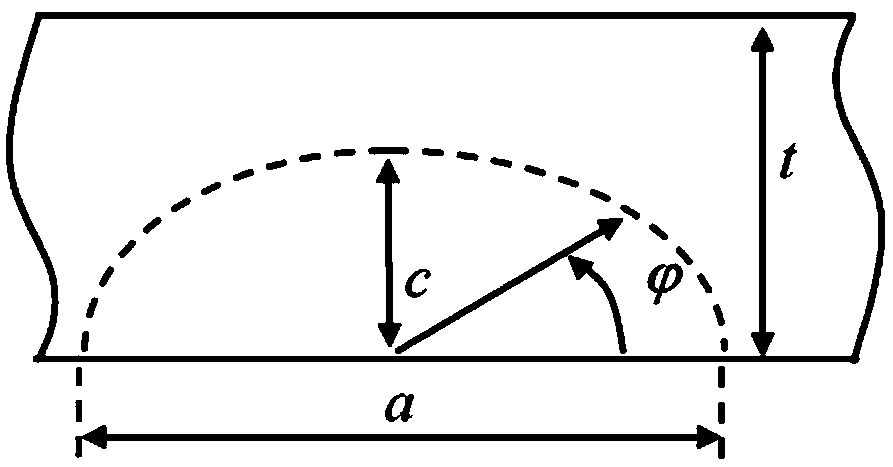

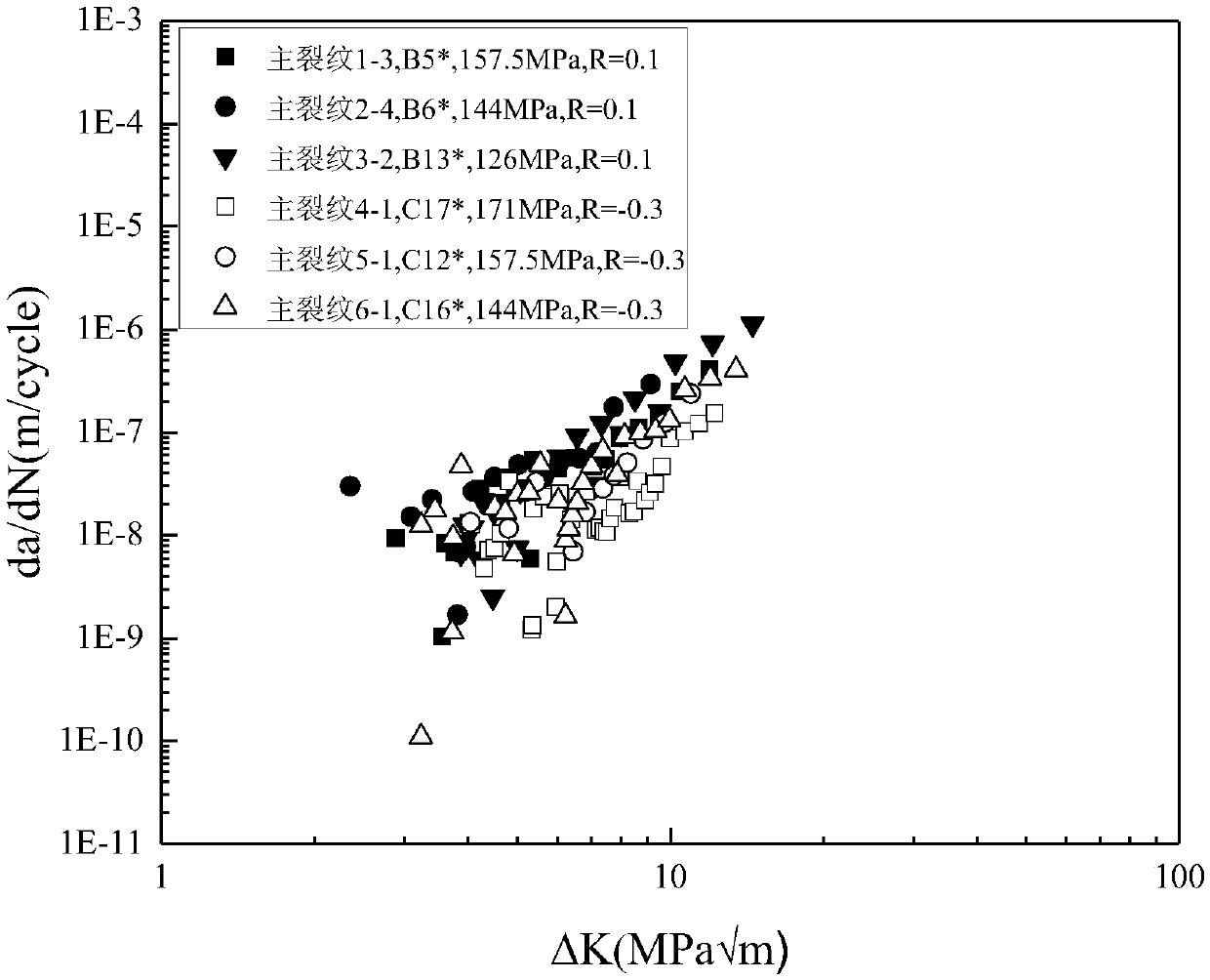

Fatigue life prediction method for friction stir welded component based on small crack propagation

ActiveCN108920792AEasy to calculateThe calculation method is accurateDesign optimisation/simulationSpecial data processing applicationsBone shapeMaterials science

The invention discloses a fatigue life prediction method for a friction stir welded component based on small crack propagation, and belongs to the technical field of fatigue diagnosis and analysis ofmechanical structures. The method comprises the steps that a bone-shaped flat plate sample is prepared, fatigue small crack propagation replica tests under different stress loads and different stressratios are conducted on different areas of a joint, and a secant method is adopted for calculating the propagation rate of small cracks; a New-Raju model is adopted for calculating the stress intensity factor range of the small cracks of the joint; c values in the depth direction and a / 2 values in the vertical direction of semi-arc shapes of fatigue crack propagation zones in fracture shapes of different areas of the joint, and the depth-to-length ratio 2c / a of the cracks is calculated; a curve of the propagation rate of the cracks along with the change of the stress intensity factor range isdrawn; an effective stress intensity factor is calculated; a formula of the propagation rate of the small cracks is determined; an initial crack size a0 and a critical crack size ac are determined; the formula of the propagation rate of the small cracks is integrated to obtain the fatigue life of the welded component. By means of the scheme, the fatigue life of the friction stir welded component can be more easily and accurately predicted.

Owner:BEIJING UNIV OF TECH

High-quality steel plate capable of resisting fatigue crack growth and manufacturing method thereof

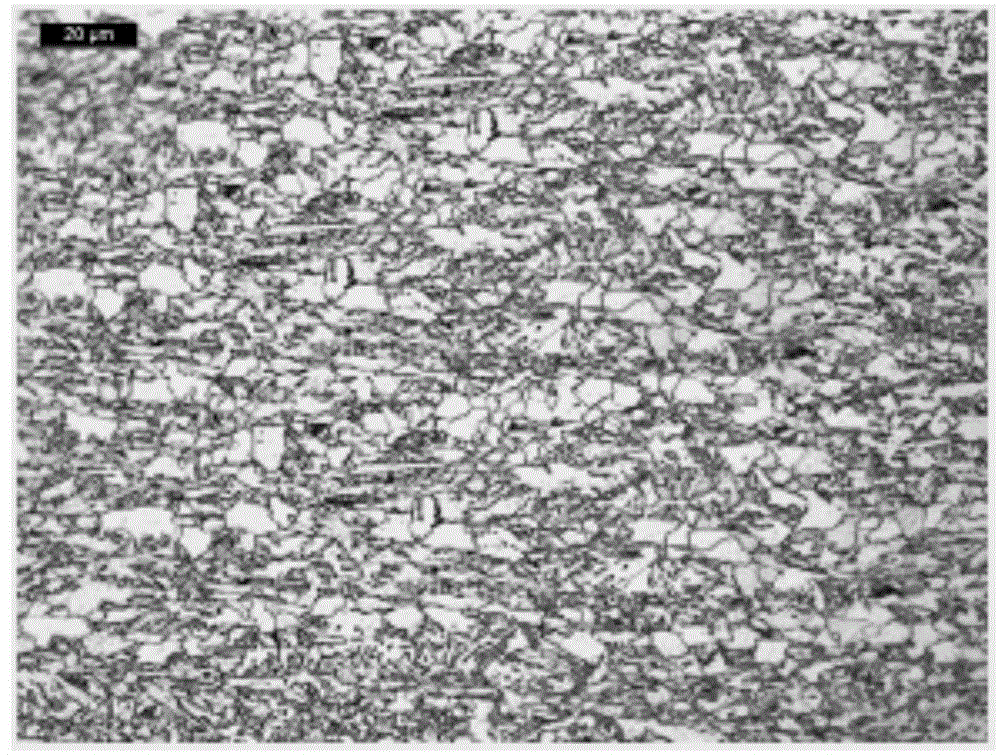

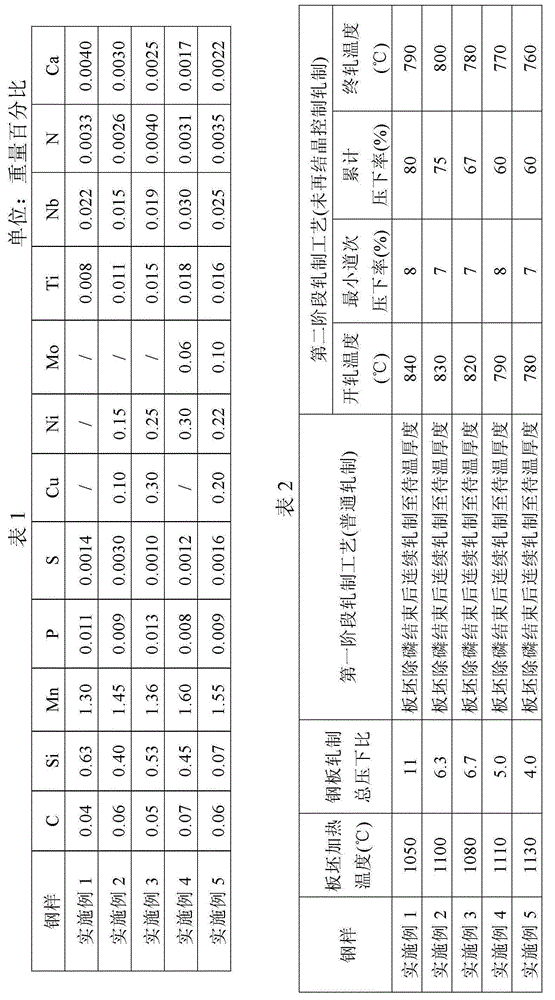

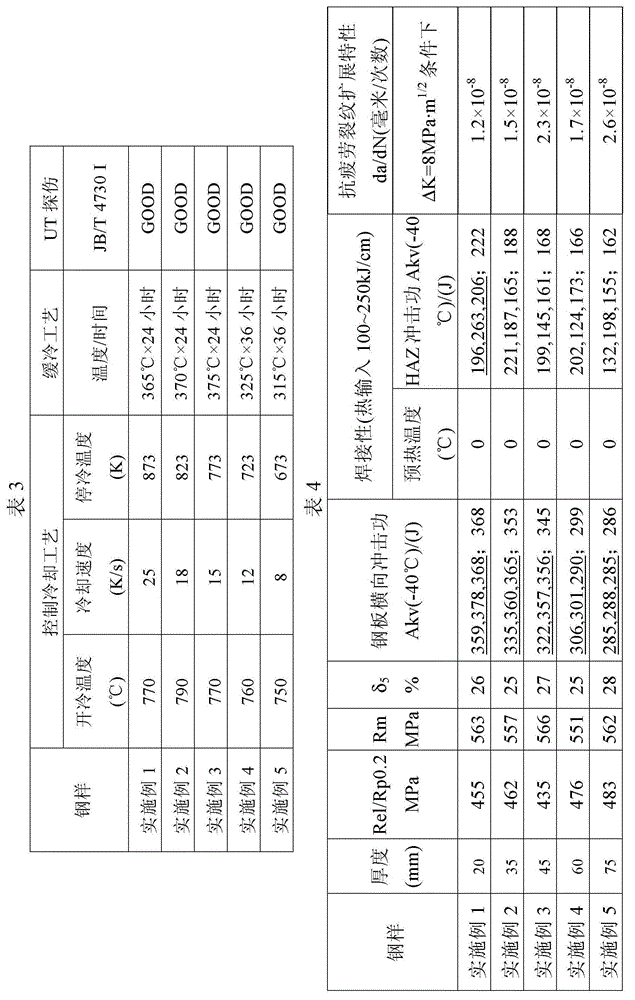

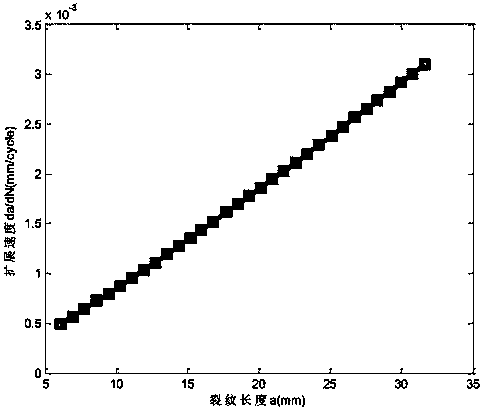

ActiveCN104561796AShorten the manufacturing cycleIncrease added valueFurnace typesHeat treatment furnacesMetallurgyImpurity

The invention discloses a high-quality steel plate capable of resisting fatigue crack growth and a manufacturing method thereof. The high-quality steel plate comprises the following constituents in percentage by weight: 0.040-0.070% of C, 0.40-0.70% of Si, 1.30-1.60% of Mn, less than or equal to 0.013% of P, less than or equal to 0.003% of S, less than or equal to 0.30% of Cu, less than or equal to 0.30% of Ni, less than or equal to 0.10% of Mo, 0.008-0.018% of Ti, 0.015-0.030% of Nb, less than or equal to 0.0040% of N, 0.0010-0.0040% of Ca, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps: using the ultra-low carbon C-high Si-intermediate Mn-Nb system low alloy steel as a base, controlling [%C]*[%Si] to be 0.022-0.042 and {([%C]+3.33[%Nb])*[%Si]}*V cooling velocity / T cold shutdown to be from 1.15*10<-4> to 2.2*10<-3>, carrying out Ca treatment, enabling Ca / S to be equal to 1.0-3.0 and (%Ca)*(%S)<0.28> to be smaller than or equal to 1.0*10<-3>, optimizing the TMCP technology, enabling the finished product steel plate microscopic structure to become a ferrite and uniformly dispersed bainite dual-phase structure, and allowing the average grain size of the microscopic structure to be 10 microns below.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

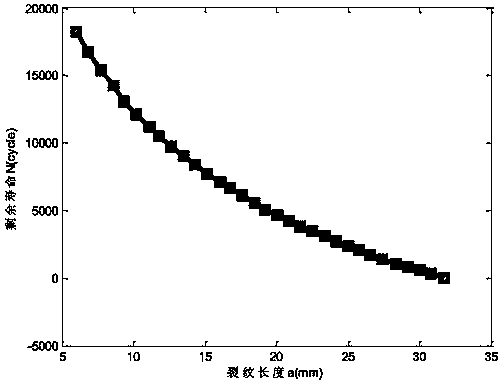

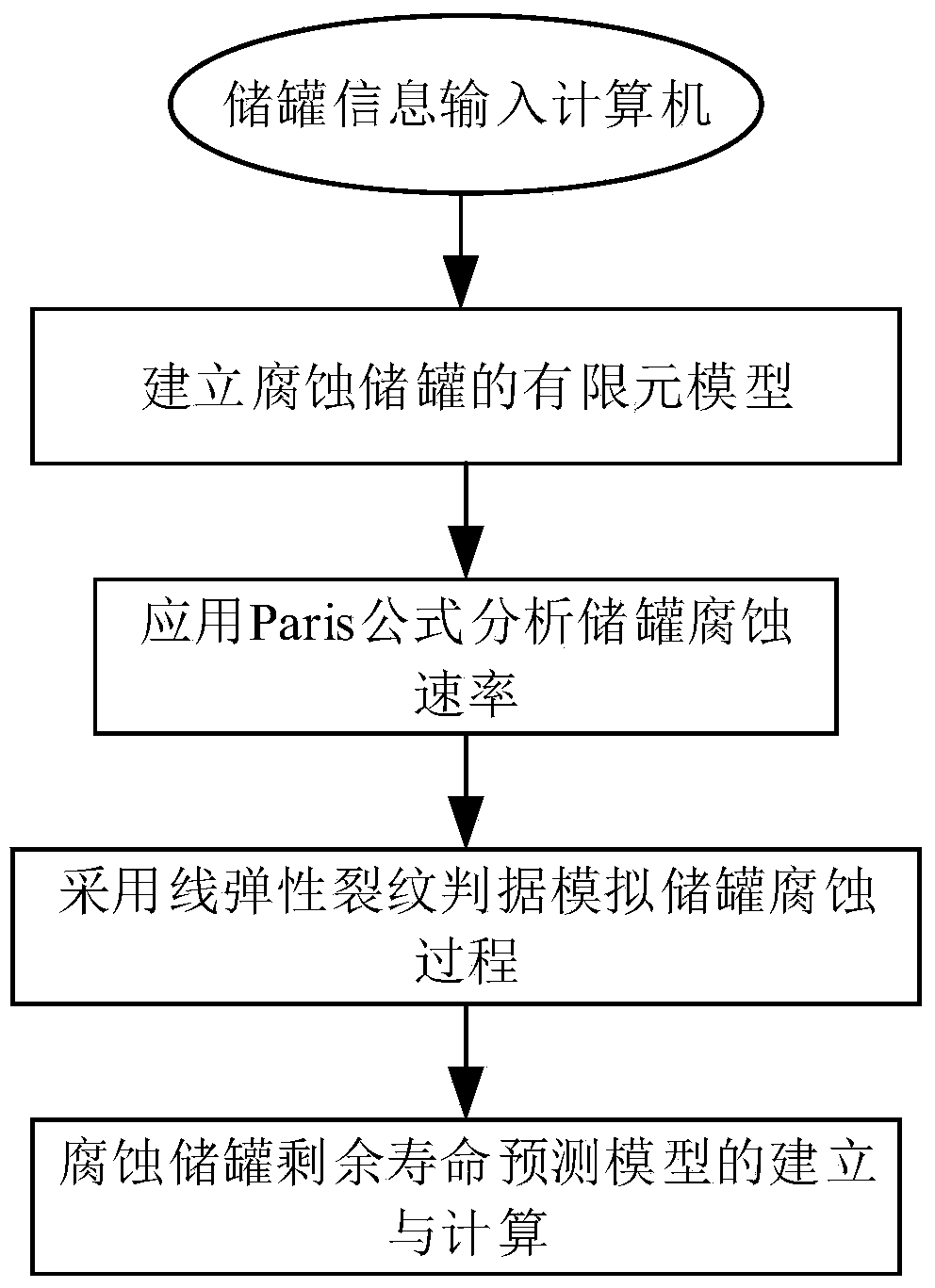

Method for predicting residual life of storage tank

InactiveCN103870662AEfficient prediction of remaining lifeTimely maintenanceSpecial data processing applicationsElement modelComputer support

The invention relates to a method for analyzing the residual life of a storage tank through ANSYS software. The method mainly comprises the following steps that (1) a computer supporting ANSYS is used, collected storage tank data are input to the computer in the form of a database or a text, a finite element model of the corroded storage tank is established through the ANSYS software, and corresponding boundary conditions and an external load are applied to the finite element model according to the actual stress condition of the storage tank; (2) regression processing is conducted on experimental data points through a fatigue crack propagation law Paris formula, and a corrosion fatigue rate equation under the corresponding conditions is obtained; (3) the critical invalid wall thickness when the storage tank loses efficacy is determined according to a predicted value of the corrosion rate; (4) according to the critical invalid wall thickness when the storage tank loses efficacy due to corrosion, a storage tank residual life prediction model is established, and the approximate analysis method is used for calculating the residual life of the storage tank under the condition of uniform corrosion.

Owner:QINGDAO UNIV OF SCI & TECH

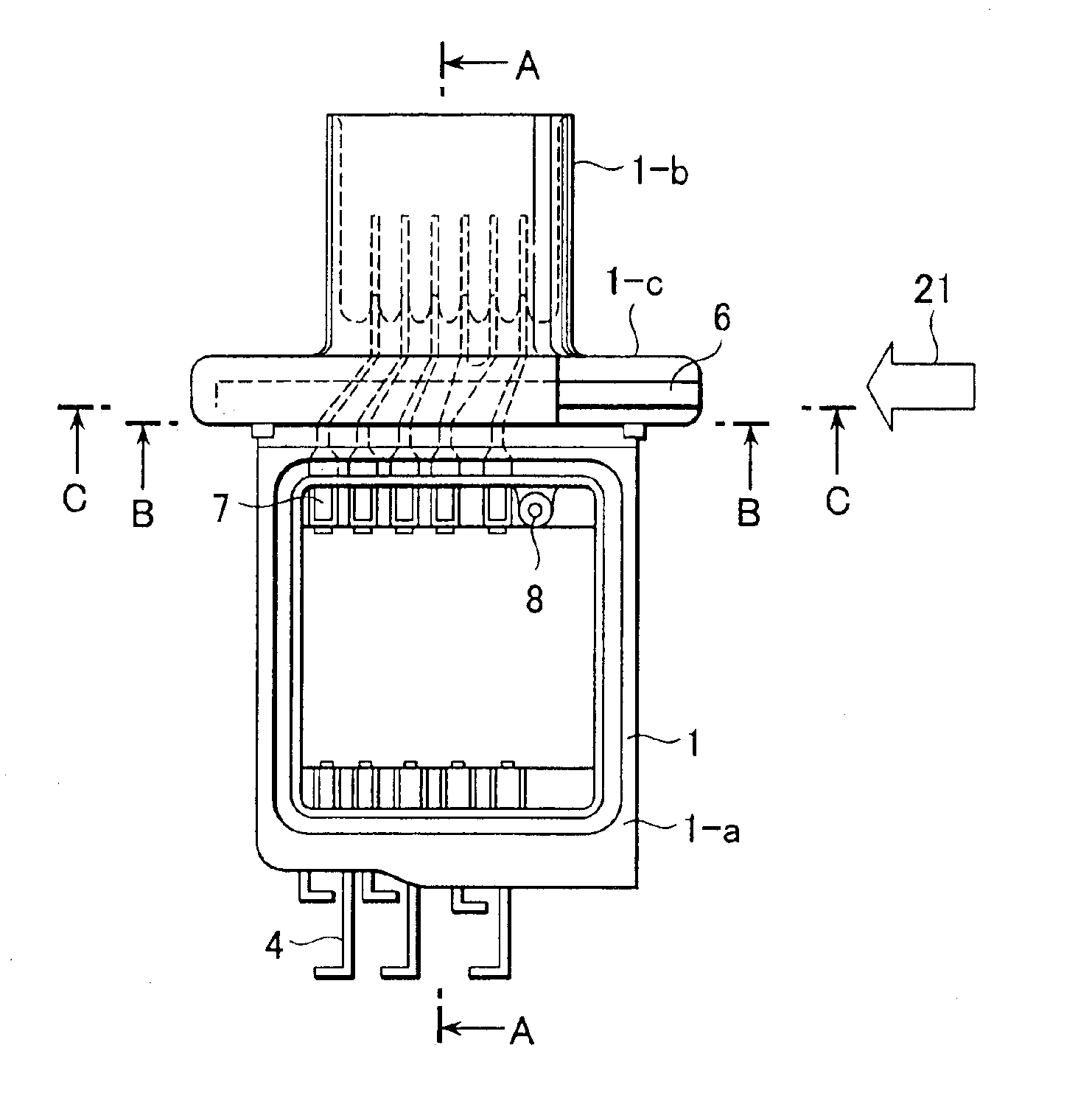

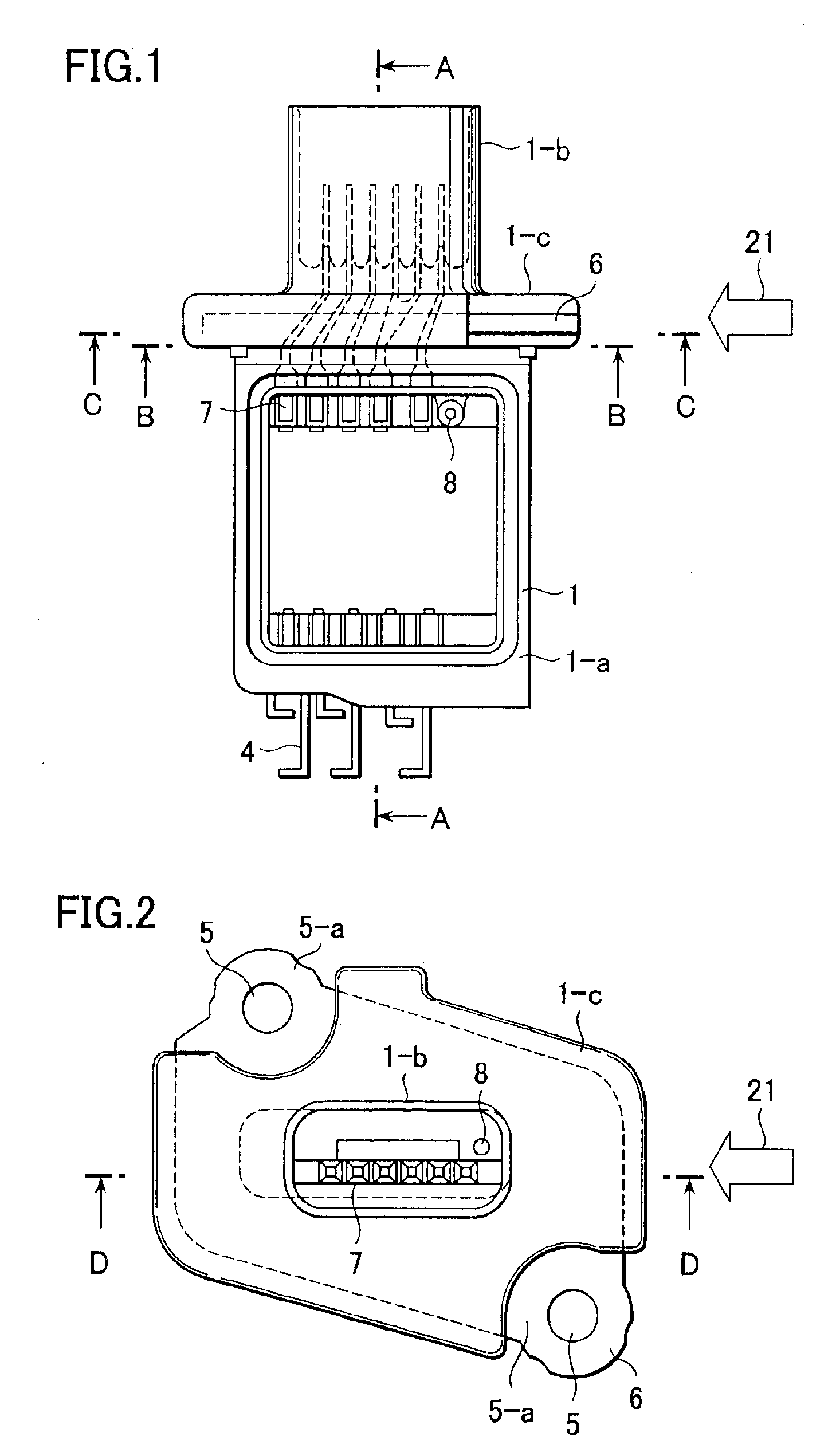

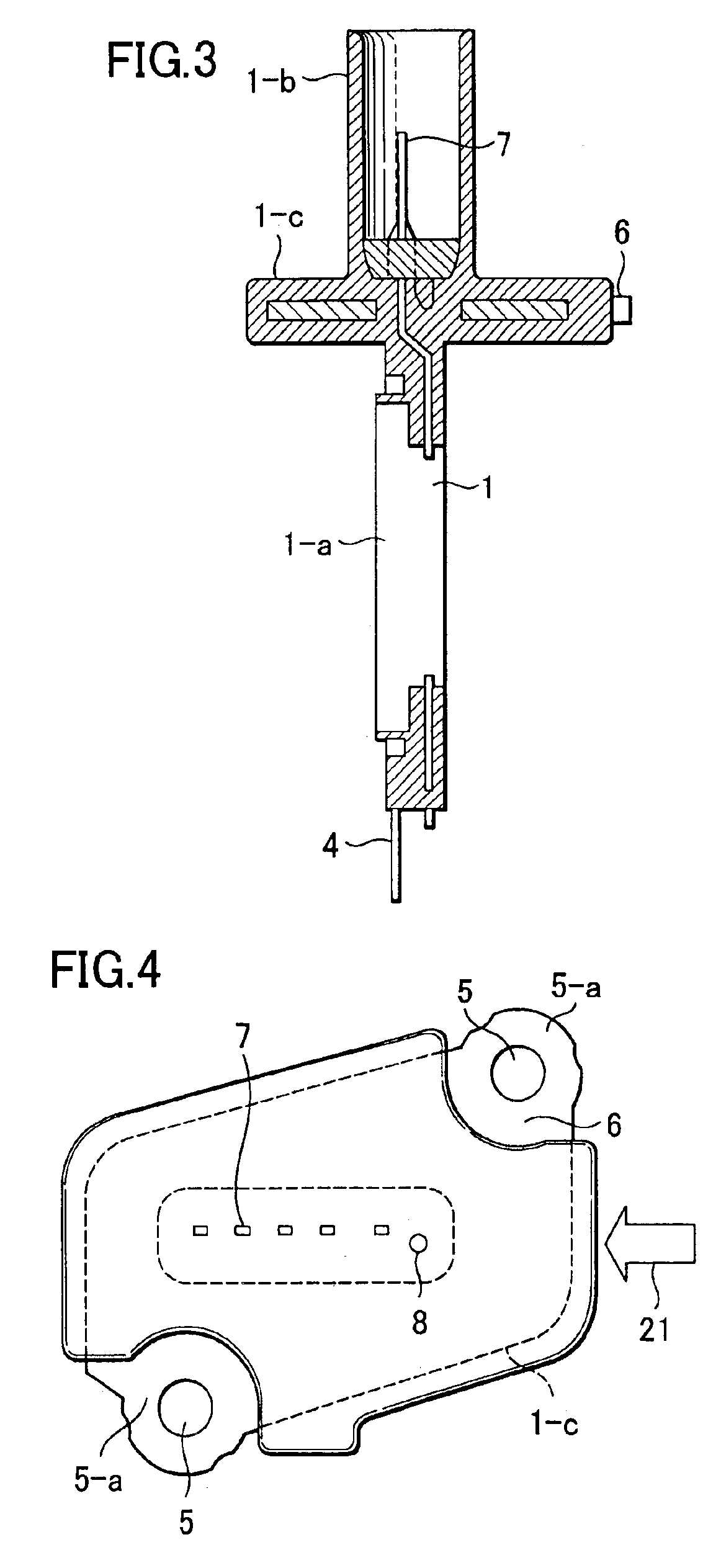

Thermal type flow measuring instrument with mold casing in metal insert

InactiveUS7010972B2Improve rigidityPreventing lowering of resonant frequencyElectrical controlVolume/mass flow by thermal effectsMeasuring instrumentEngineering

The invention is intended to improve reliability of a thermal type air flow measuring instrument employing a molded part formed by integral molding together with a metal plate. A slot or opening allowing only a resin to pass through the same is formed in the metal plate in an area or thereabout subjected to higher stresses. A part of connector terminals, which is not required from the intrinsic object, is disposed in the vicinity of a area where the resin has a larger thickness and the temperature difference between the inside and the outside of the resin is locally increased. An injecting direction is set so as to prevent a weld line and a void from being generated in a combined way. In the molded part with the metal plate inserted therein, the occurrence of cracks and an increase of the fatigue crack growth rate can be suppressed and reliability can be improved.

Owner:HITACHI ASTEMO LTD

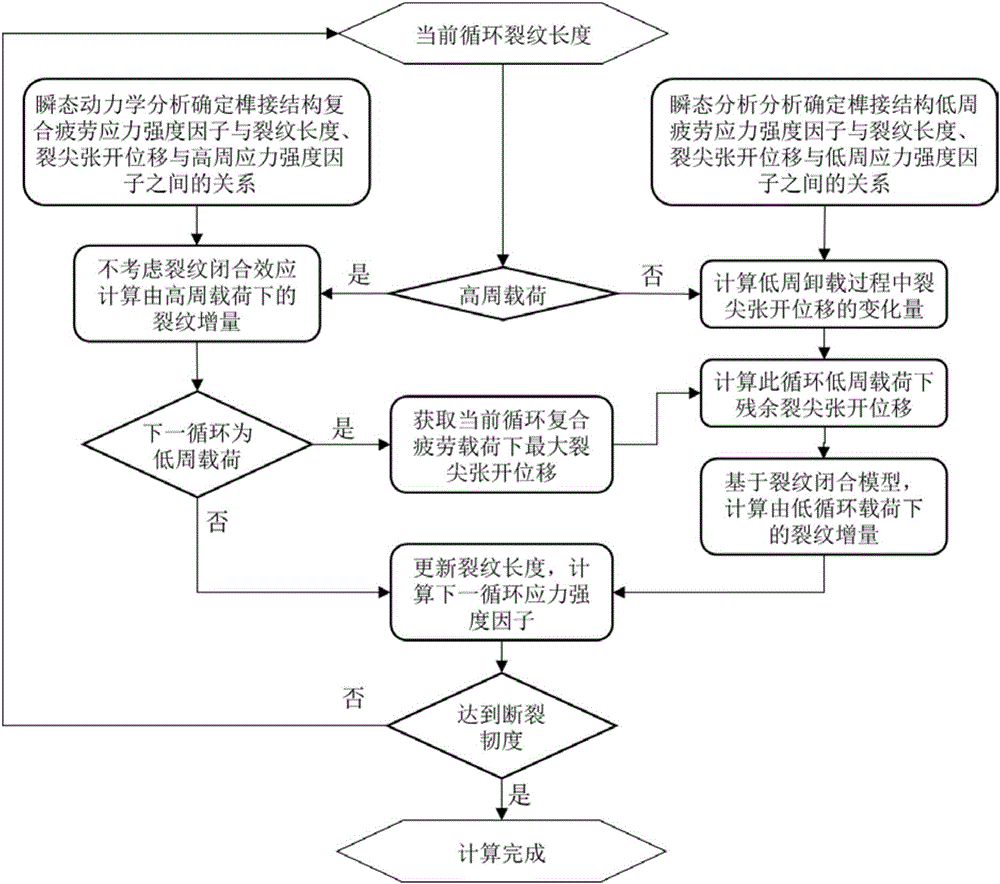

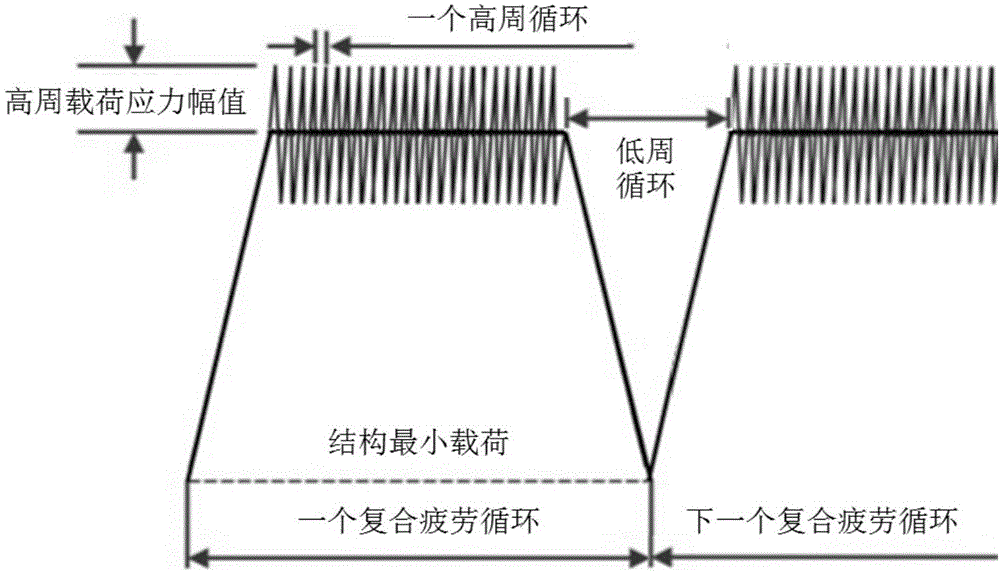

Method for predicting high-low-cycle composite fatigue crack growth life of turbine joggle structure

ActiveCN106644490AImprove scalabilityInhibit expansionEngine testingCrack tip opening displacementEngineering

The invention relates to a method for predicting the high-low-cycle composite fatigue crack growth life of a turbine joggle structure, and the method comprises the steps: (1), building a crack growth model giving consideration to a crack closure effect; (2), determining a high-cycle load stress intensity factor model; (3), determining a low-cycle load stress intensity factor model; (4), judging whether a current cycle is a high-cycle load or not: executing step (5) if the current cycle is the high-cycle load, or else executing step (6); (5), calculating a composite fatigue lower crack increment, judging whether a next cycle is a low-cycle fatigue load or not: obtaining the maximum crack tip opening displacement of the current cycle if the next cycle is the low-cycle fatigue load, and executing step (7), or else executing step (8); (6), calculating the variance of the low-cycle load lower crack tip opening displacement; (7), calculating the residual crack tip opening displacement and crack increment according to the results inputted at steps (5) and (6); (8), updating the crack length, repeatedly carrying out the steps (4)-(7) if the maximum stress intensity factor is less than the fracture toughness, or else completing the calculation, and obtaining the crack growth life.

Owner:BEIHANG UNIV

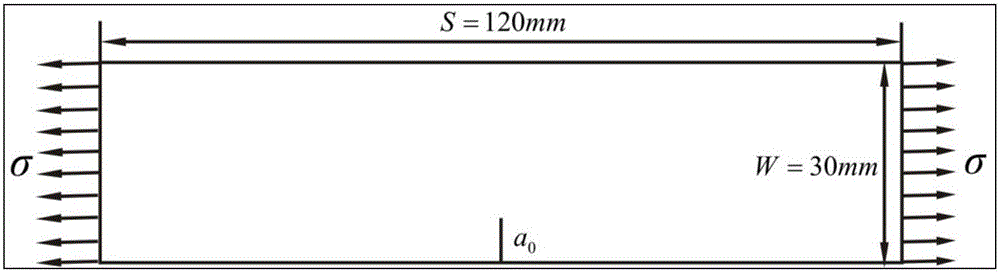

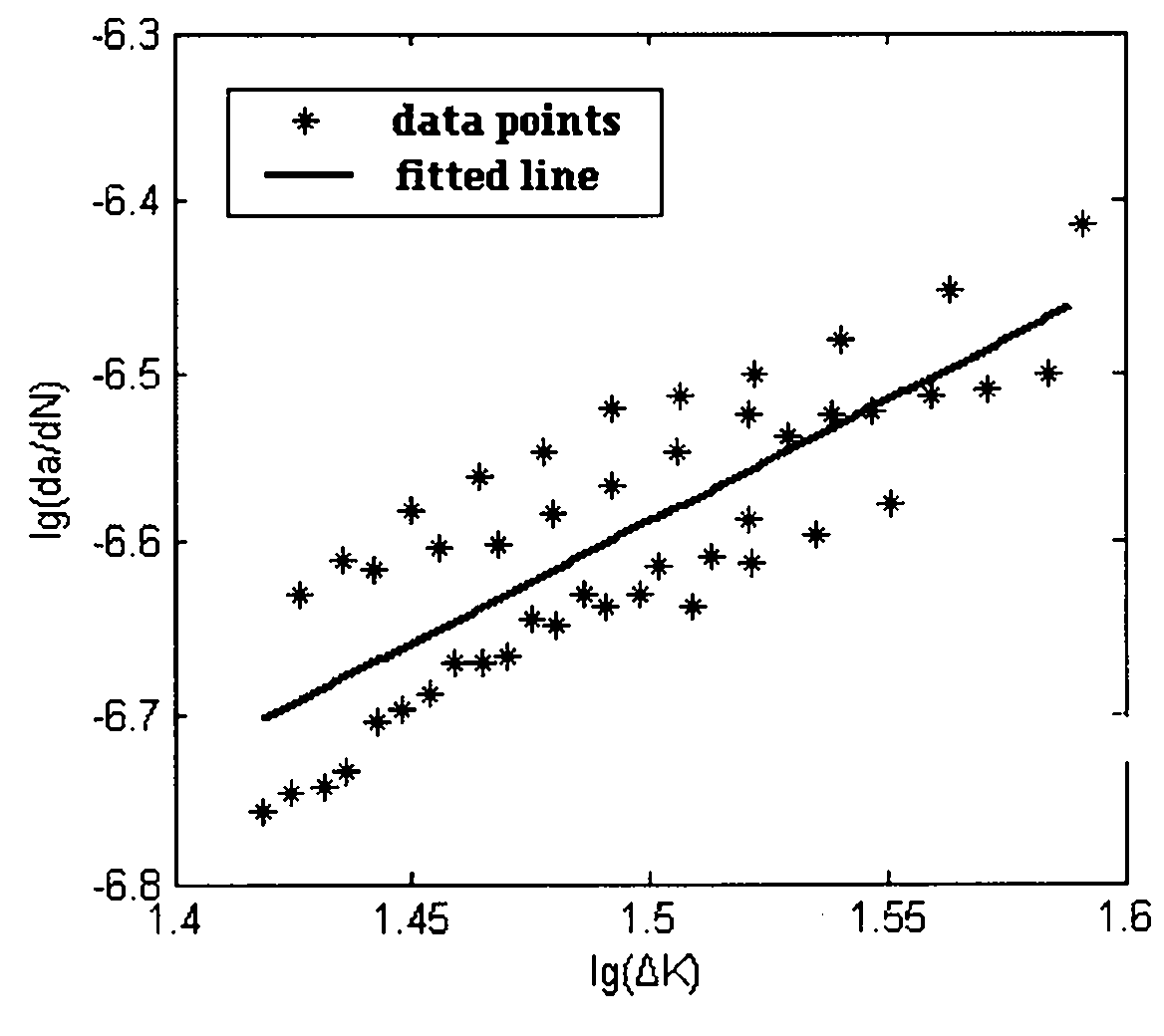

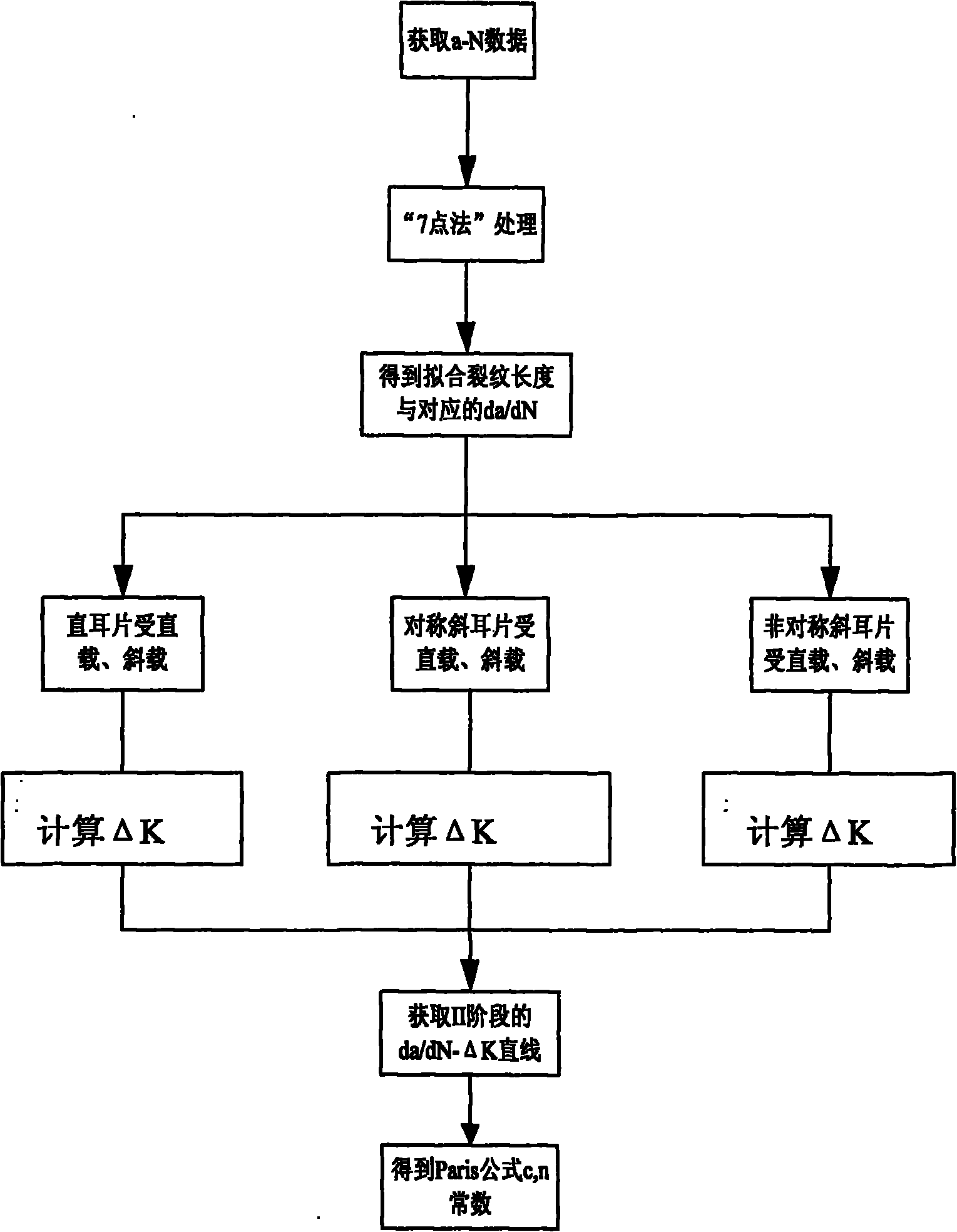

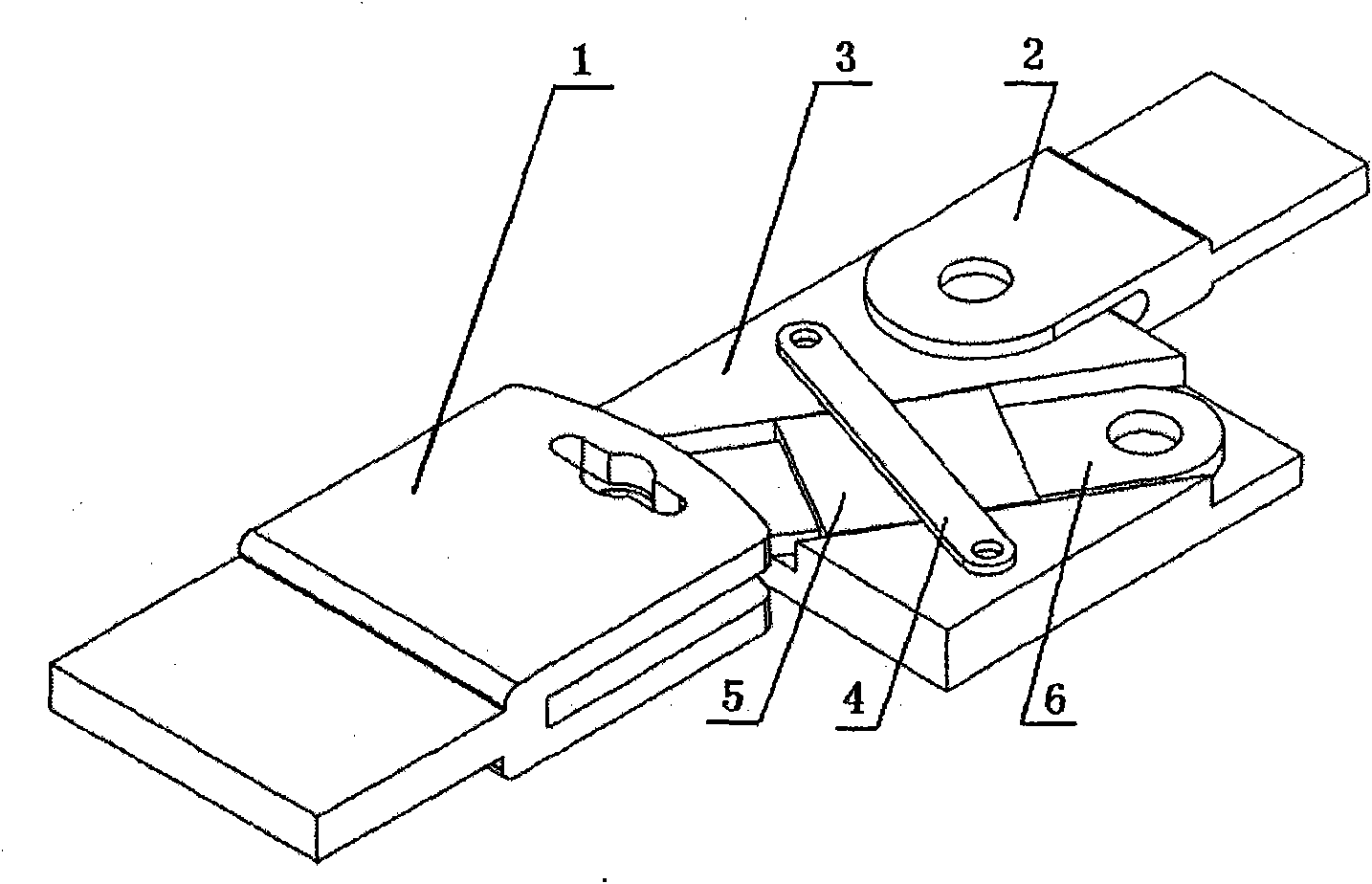

Test analysis method for bolt connecting piece fatigue crack expanding

InactiveCN102023116AClear principleWide applicabilityMaterial strength using tensile/compressive forcesStress intensity factorStress ratio

The invention relates to a test analysis method for lug connecting piece fatigue crack expanding, which is technically characterized by installing a test lug on a testing machine; then loading and producing fatigue crack on the lug; adopting a stress intensity factor comprising a straight lug pulled and loaded lengthwise, the straight lug loaded obliquely smaller than 45 degrees, a symmetrical oblique lug pulled and loaded lengthwise, the symmetrical oblique lug loaded obliquely smaller than 45 degrees, an asymmetrical oblique lug pulled and loaded lengthwise and the asymmetrical oblique lug loaded obliquely smaller than 45 degrees to the corresponding delta K; taking a slope factor of 1g(da / dN)-1g(delta K) line as a constant n in the Paris formula, an intercept of a straight line and axis y as a constant C in the Paris formula, and obtaining the Paris formula when the stress ratio is R; and the lug fatigue crack expanding life NC is estimated according to the obtained Paris formula. The invention has the advantages that the applicability is wide, and the test analytical method plays a directive role in researching the lug hole edge fatigue crack expanding properties under various pulling and loading conditions.

Owner:AIR FORCE UNIV PLA

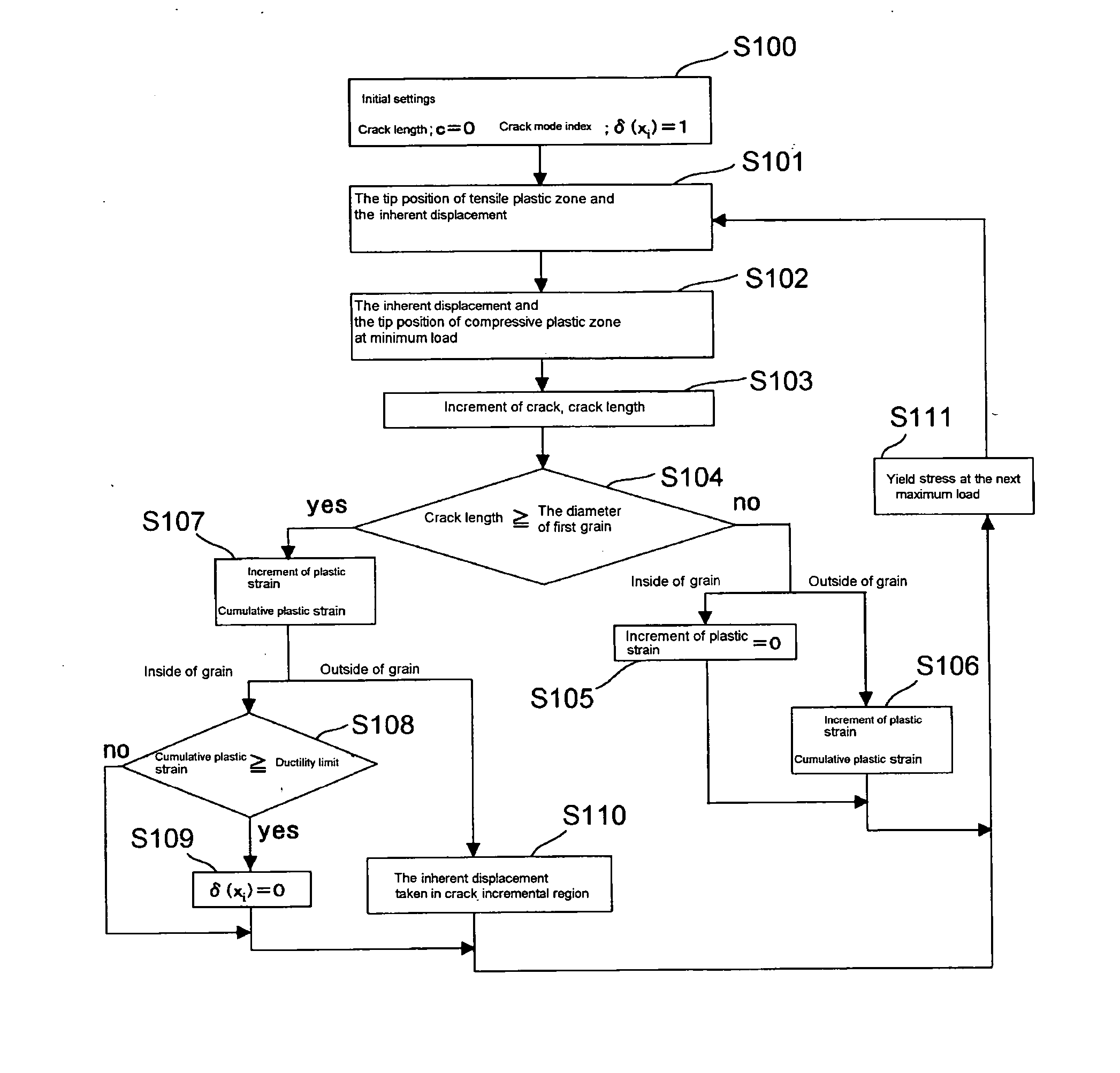

Fatigue Crack Growth Curve Estimation Method, Estimation Program, And Estimation Device

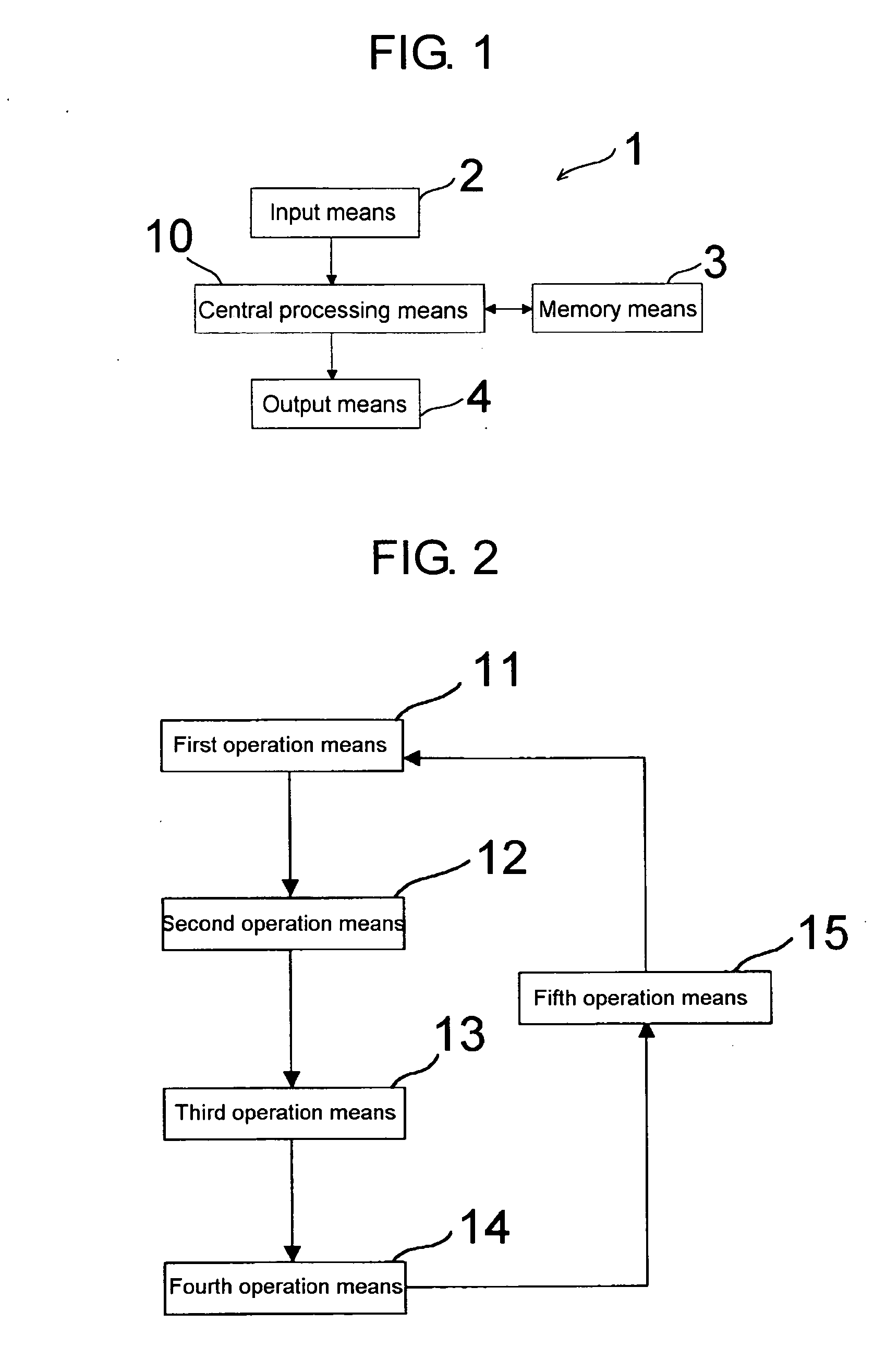

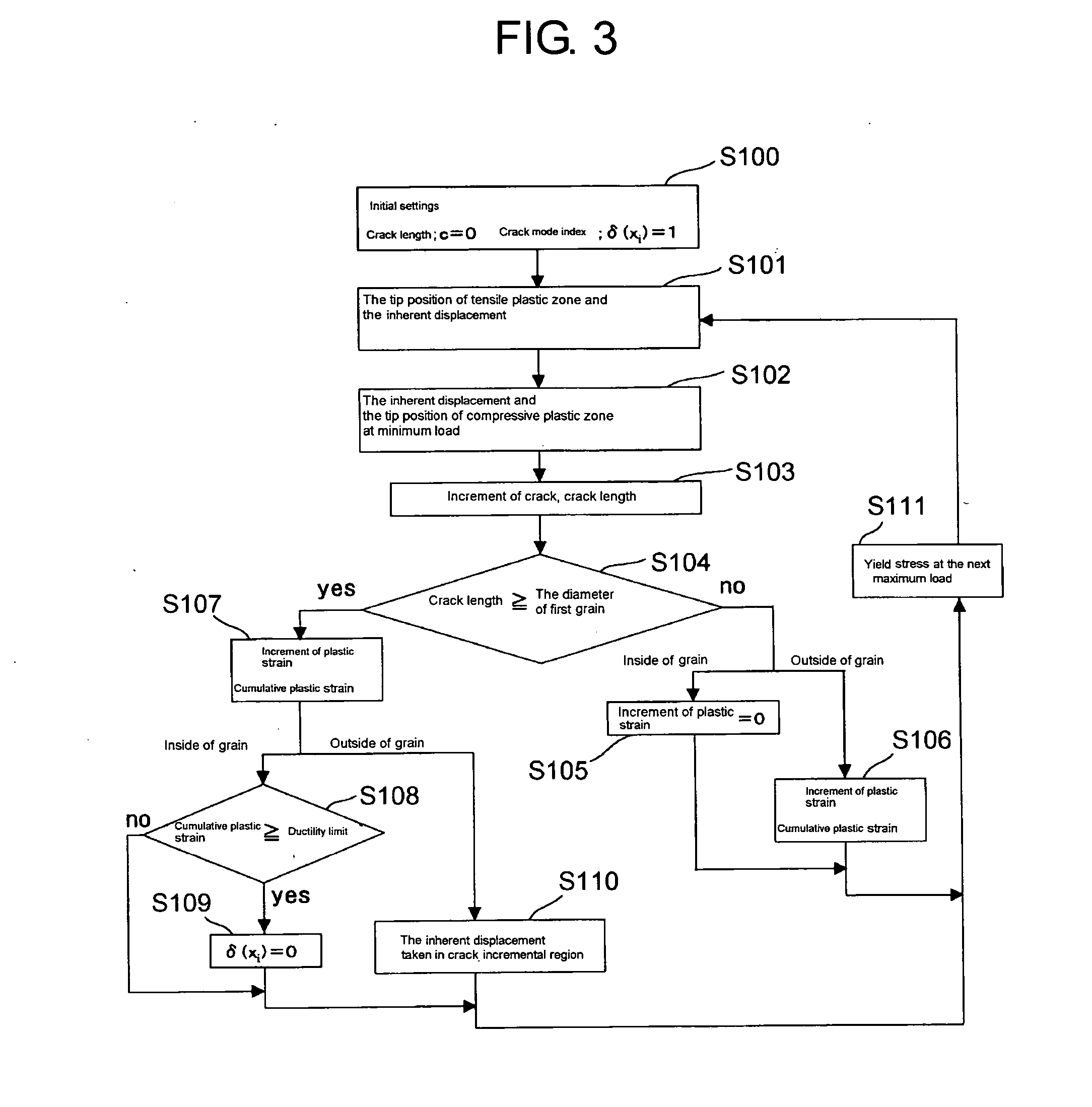

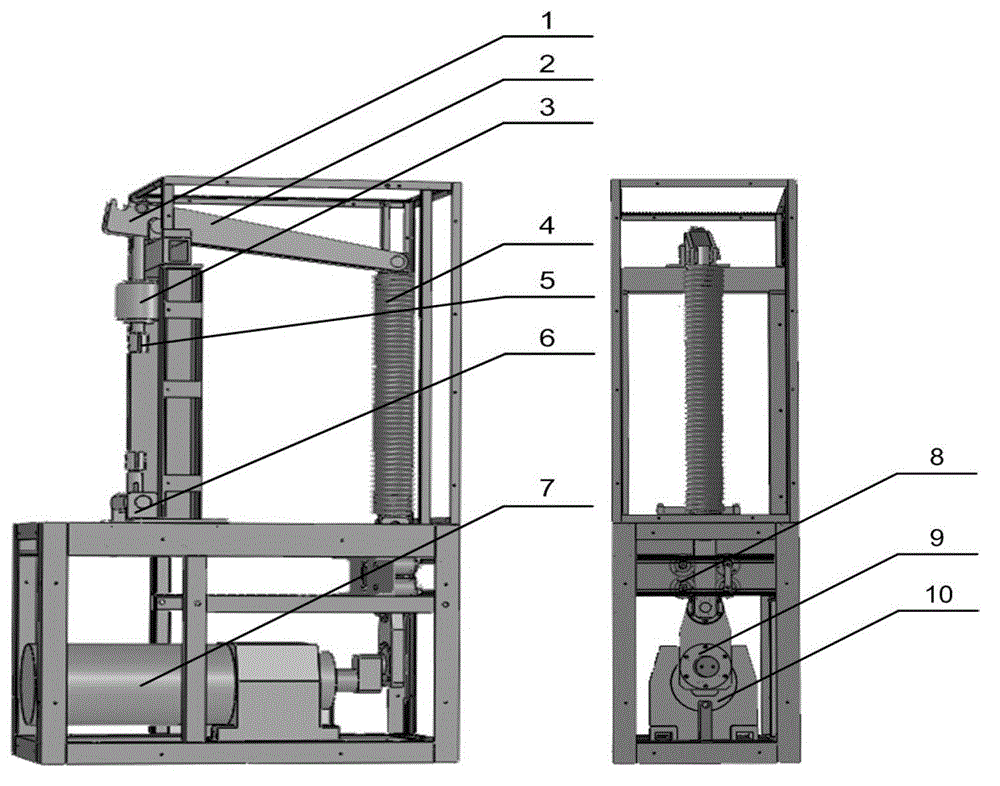

There are provided a fatigue crack growth curve estimation method, an estimation program, and an estimation device capable of strictly estimating the detail of the metal fatigue end and the crack growth detail. The fatigue crack growth curve estimation device (1) uses a first calculation means (11), second calculation means (12), third calculation means (13), fourth calculation means (14), and fifth calculation means (15) to strictly estimate the detail of growth of a crack generated and growing in a first grain while omitting a calculation on the load pair not contributing to growth of the crack.

Owner:SANGAKU RENKEI KIKO KYUSHU KK

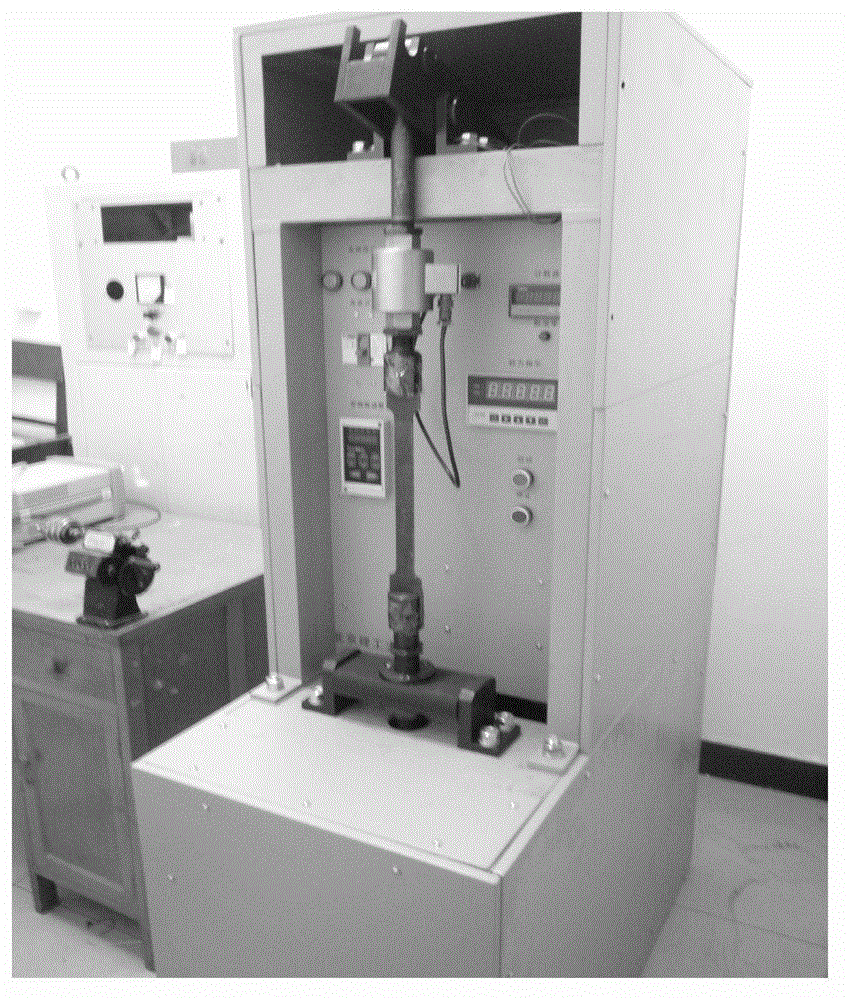

Spring-lever energy storage type fatigue tension test machine

InactiveCN102914478ALow costReduce the impact of vibration shockMaterial strength using repeated/pulsating forcesReduction driveEngineering

The invention relates to a novel mechanical structure design scheme, which is used for testing test pieces made of various metal and alloy materials at room temperature and bearing tension fatigue characteristic, fatigue life and fatigue crack expansion test of mechanical parts (such as various mechanical connecting pieces). According to the scheme, a motor drives a speed reducer to rotate, the spring is subjected to energy storage by an eccentric shaft coupler and a crank connecting rod mechanism, the spring is controlled by four guide wheels to do vertical reciprocating motion, the potential energy of the spring is converted into moment through a lever, and extension and compression of the spring are reinforced by a lever mechanism, so that tension bars are separated vertically and the stretching effect is achieved; and force amplitude is changed through connecting points at different positions of the lever, so that fatigue tension tests of different frequency and different amplitude are realized. The invention is simple in structure and low in manufacturing cost, adopts a mechanical structure, can meet the basic performance requirement of the fatigue tension test, and can be applied to the tensile fatigue test under the lab environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

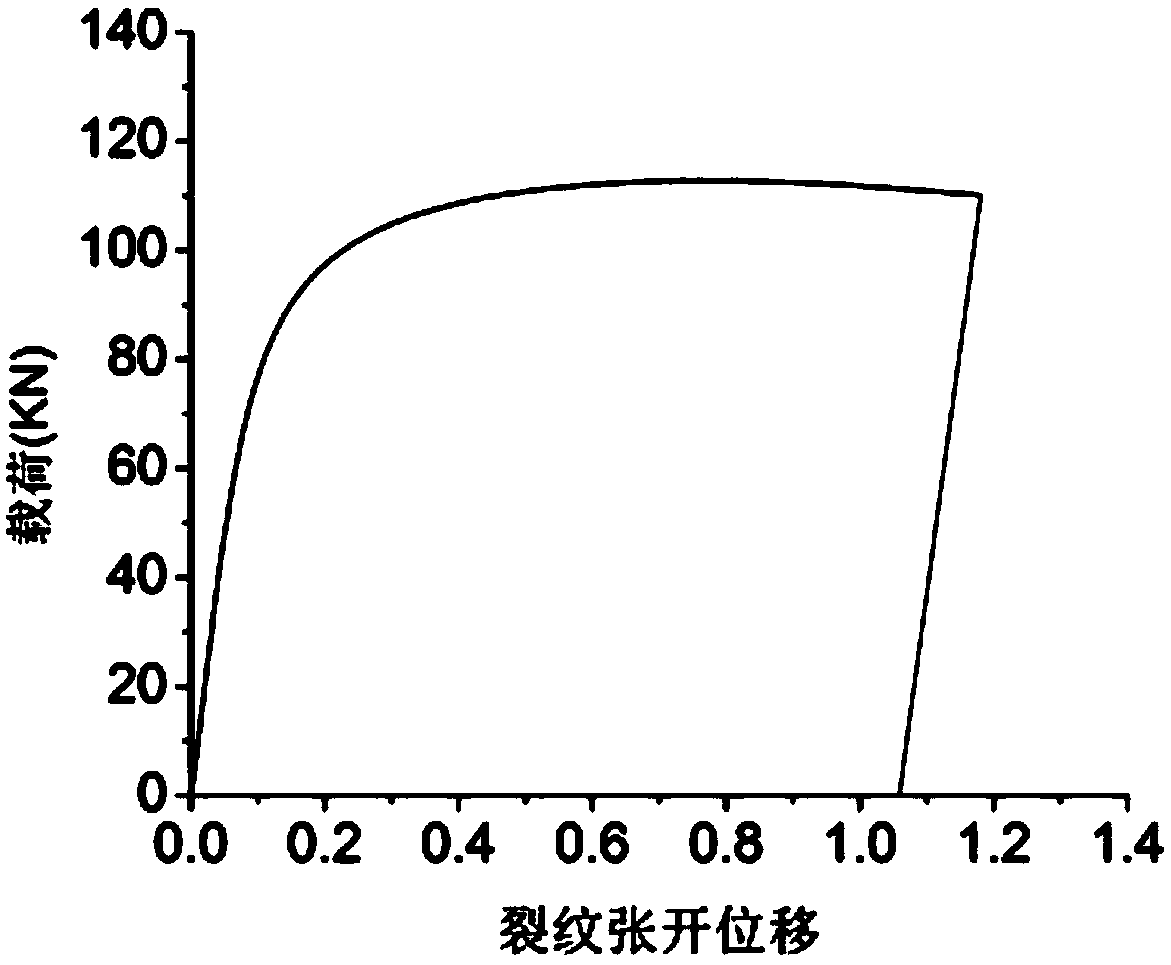

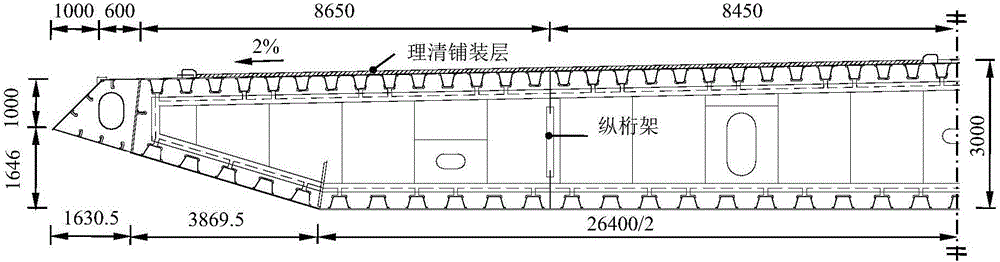

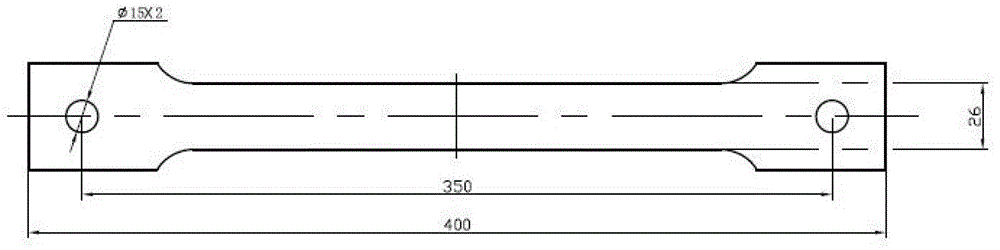

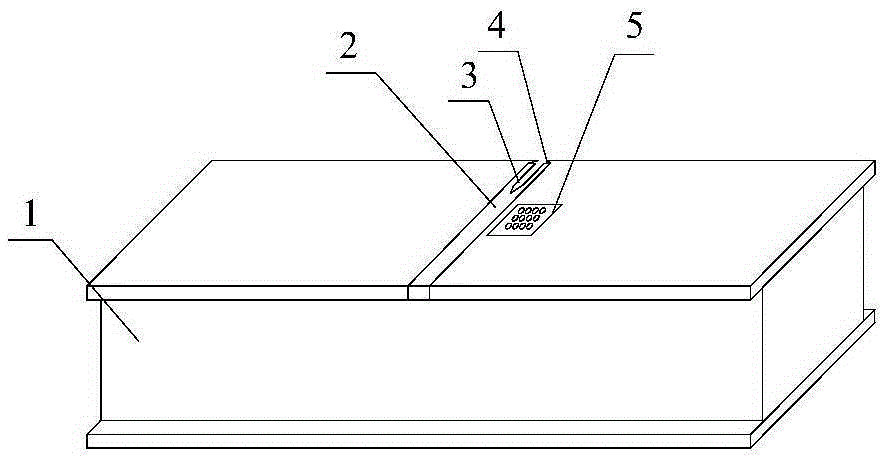

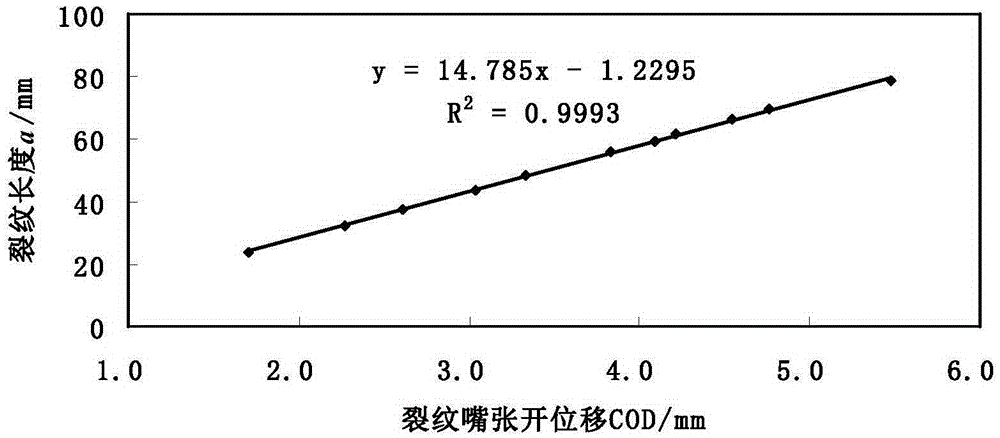

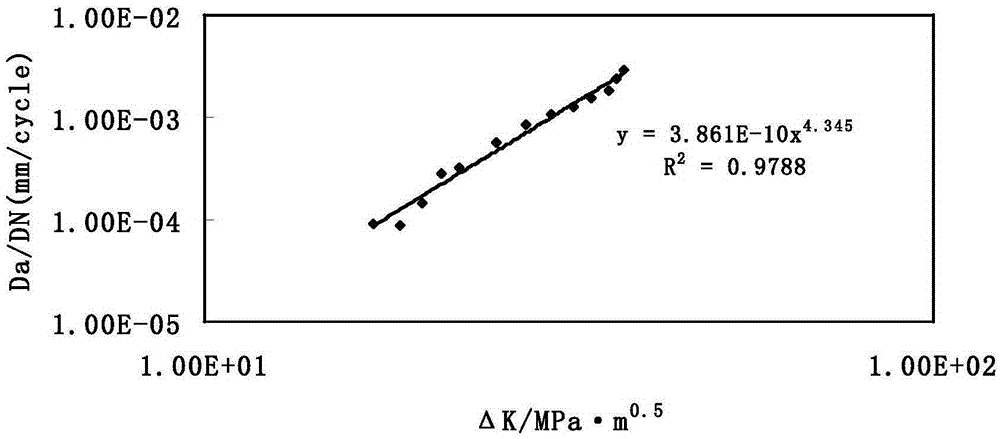

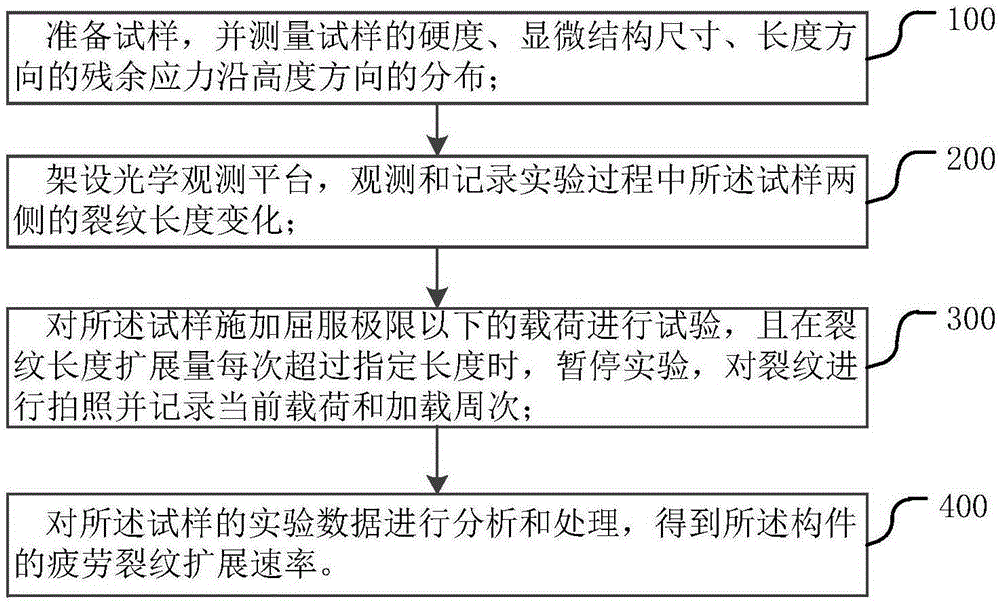

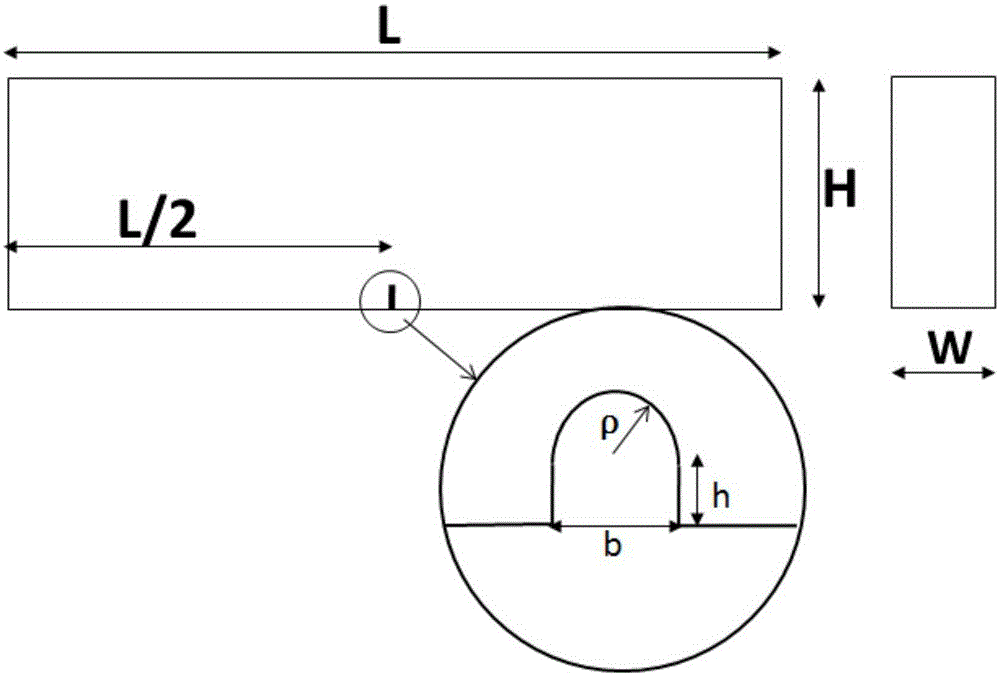

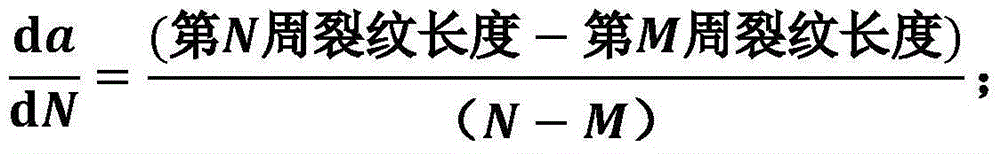

Fatigue crack propagation rate testing method of steel box girder

ActiveCN105352800AThe rate of expansion is real and reliableAffect accuracyMaterial strength using tensile/compressive forcesTest efficiencyVernier scale

The invention discloses a fatigue crack propagation rate testing method of a steel box girder. The fatigue crack propagation rate obtained by structure solid tests of the method is truer and more reliable than that obtained by the Paris equation obtained by present material tests for fatigue crack propagation. The Paris equation of the method is more instructive when being used for predicating residual life in a service period of a structure. When being used for measuring crack lengths, the method is different from conventional methods that shut down and measure with a vernier caliper. According to the method, a COD clip gauge is mounted to the front end of a mechanical gap of a steel box girder test piece, the linear relation between the COD clip gauge and the crack length a measured by the vernier caliper is calibrated through static load tests, the linear relation is applied to dynamic tests for the fatigue crack propagation rate and the real crack length a is measured directly through reading of the COD clip gauge, and therefore influences on accuracy of fatigue test results, which are caused by crack-tip plastic blunting caused by middle shutdown in dynamic fatigue tests, are avoided, time of shutting down tests and testing crack lengths is saved, and the test efficiency is increased.

Owner:武汉钢铁有限公司

Measuring method for surface strengthening member fatigue crack expansion rate

ActiveCN105181492AEnsure consistencyRealize determinationMaterial strength using repeated/pulsating forcesCurrent loadTested time

The invention provides a measuring method for a surface strengthening member fatigue crack expansion rate. The method comprises the following steps: sample preparation is carried out, and hardness, a microscopic structure size, distribution of a residual stress in the length direction along the height direction of a sample are measured; an optical observation platform is erected, crack length changes of two sides of the sample during the test process are observed and recorded; a load less than a yield limit is applied to the sample for test, when the crack length expansion amount exceeds an appointed length every time, the test is paused, the cracks are shot and the current load and loading cycles are recorded; the test data of the sample is subjected to analysis and processing, and the fatigue crack expansion rate of the member is obtained. In the measuring method, a sample is cut from a whole-size member directly, and the consistency of the sample and the member is kept. The problems are solved effectively that whole-size member test time is long, the material cost is high, a lot of test data is difficult to obtain, and measuring of the surface strengthening member fatigue crack expansion rate is achieved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

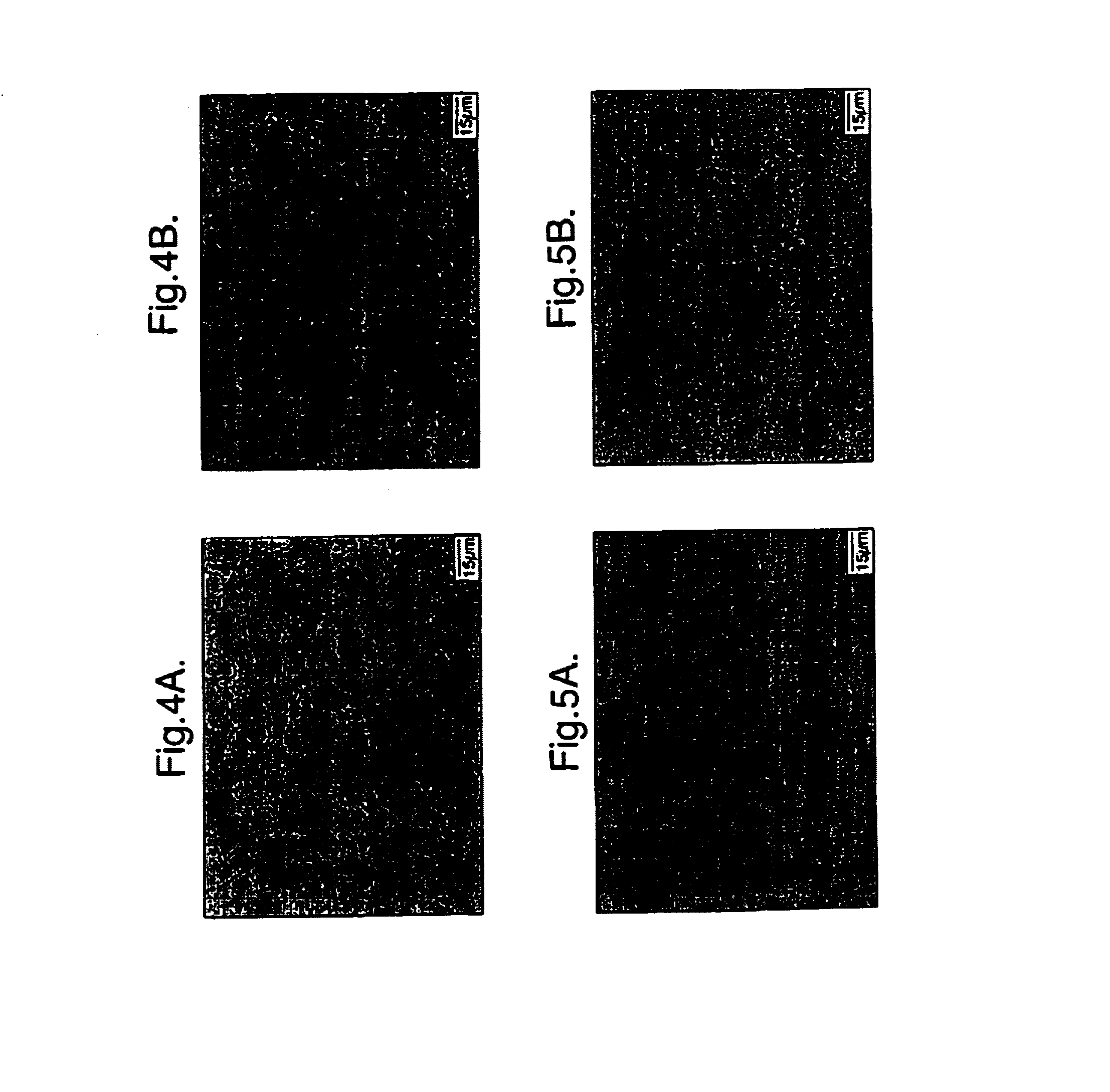

Nickel base superalloy

A nickel base superalloy comprising 14.0 to 20.0 wt % cobalt, 13.5 to 17.0 wt % chromium, 2.5 to 4.0 wt % aluminium, 3.4 to 5.0 wt % titanium, 0 to 3.0 wt % tantalum, 3.8 to 5.5 wt % molybdenum, 0.035 to 0.07 wt % carbon, 0.01 to 0.04 wt % boron, 0.055 to 0.075 wt % zirconium, 0 to 0.4 wt % hafnium and the balance nickel plus incidental impurities. The nickel base superalloy is suitable for use as gas turbine engine high pressure compressor rotor discs or turbine discs. It is capable of operation at temperatures above 700° C. and has good fatigue crack propagation resistance, creep resistance and tensile strength.

Owner:ROLLS ROYCE PLC

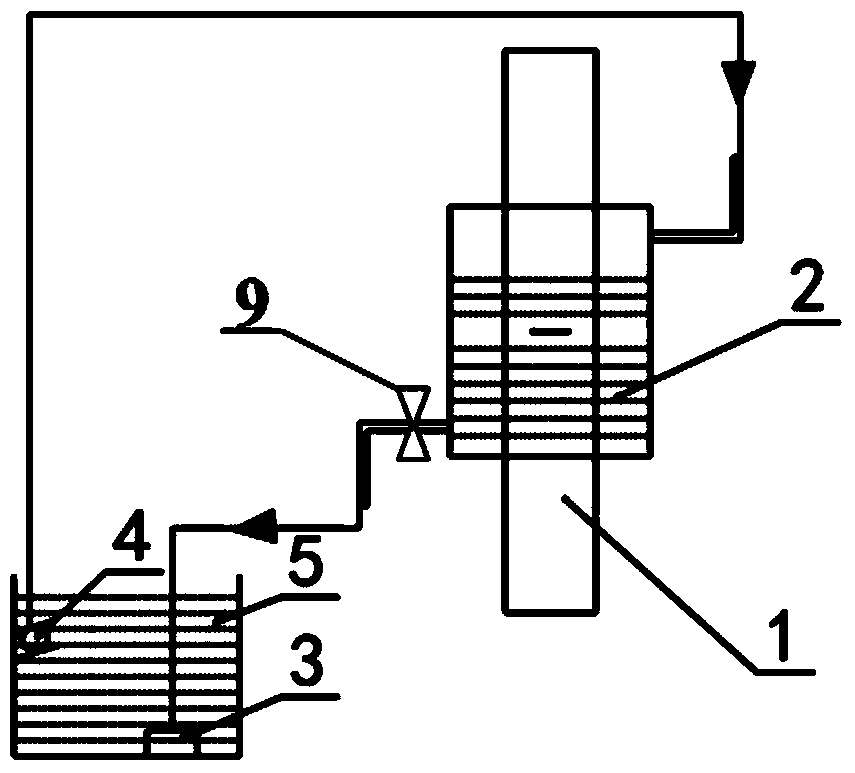

System for testing fatigue crack propagation in corrosion environment

InactiveCN103439199AConvenient fatigue crack growth testPrecise Fatigue Crack Growth Experimental TestingInvestigating material ductilityTest sampleDamage tolerance

A system for testing fatigue crack propagation in a corrosion environment comprises a fatigue testing machine, a medium box, a solution circulating pump, a filter, a flow control valve, a solution tank, a clamp, a crack observing system and a test sample, wherein the test sample is mounted on the clamp, the clamp is connected with the fatigue testing machine, the medium box is arranged on the test sample in a sleeving manner, so that the liquid level of the solution is higher than the to-be-observed part of the test sample, the solution circulating pump conveys an etchant solution filtered by the filter to the medium box from the solution tank, the solution in the medium flows back to the solution tank after the flow speed of the solution is controlled by the flow control valve, and the crack observing system with a microscope records the crack propagation condition through a computer. The system for testing the fatigue crack propagation in the corrosion environment is scientific in conception, simple in structure and convenient in operation and can be used to test the fatigue crack propagation property in the corrosion environment, and the test result has a great important engineering application value for assessing the damage tolerance of a material and a structure in the corrosion environment.

Owner:BEIHANG UNIV

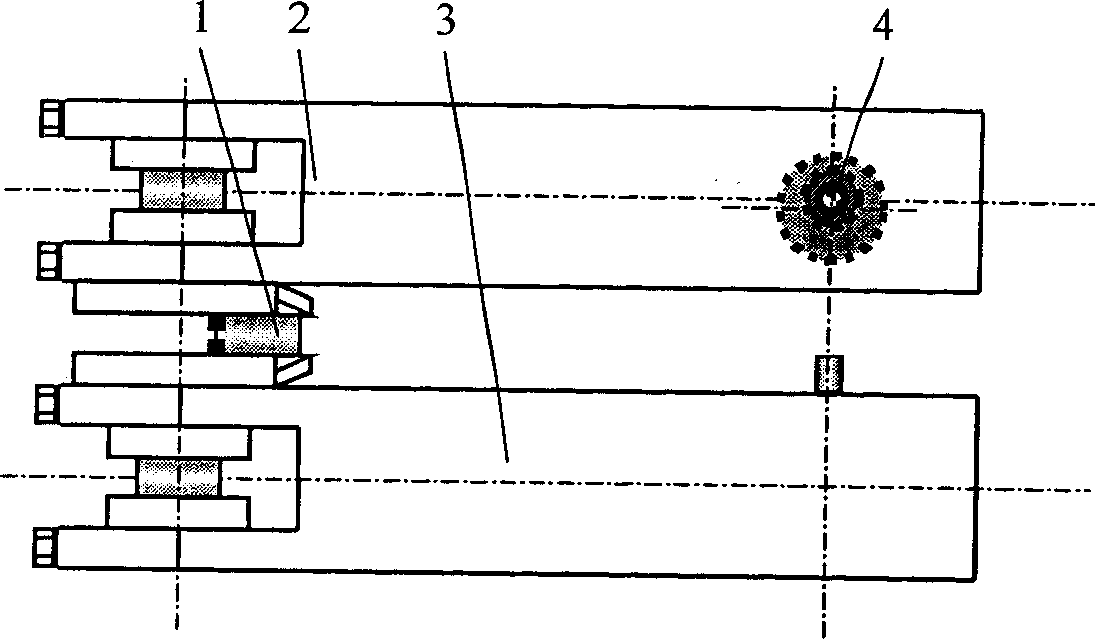

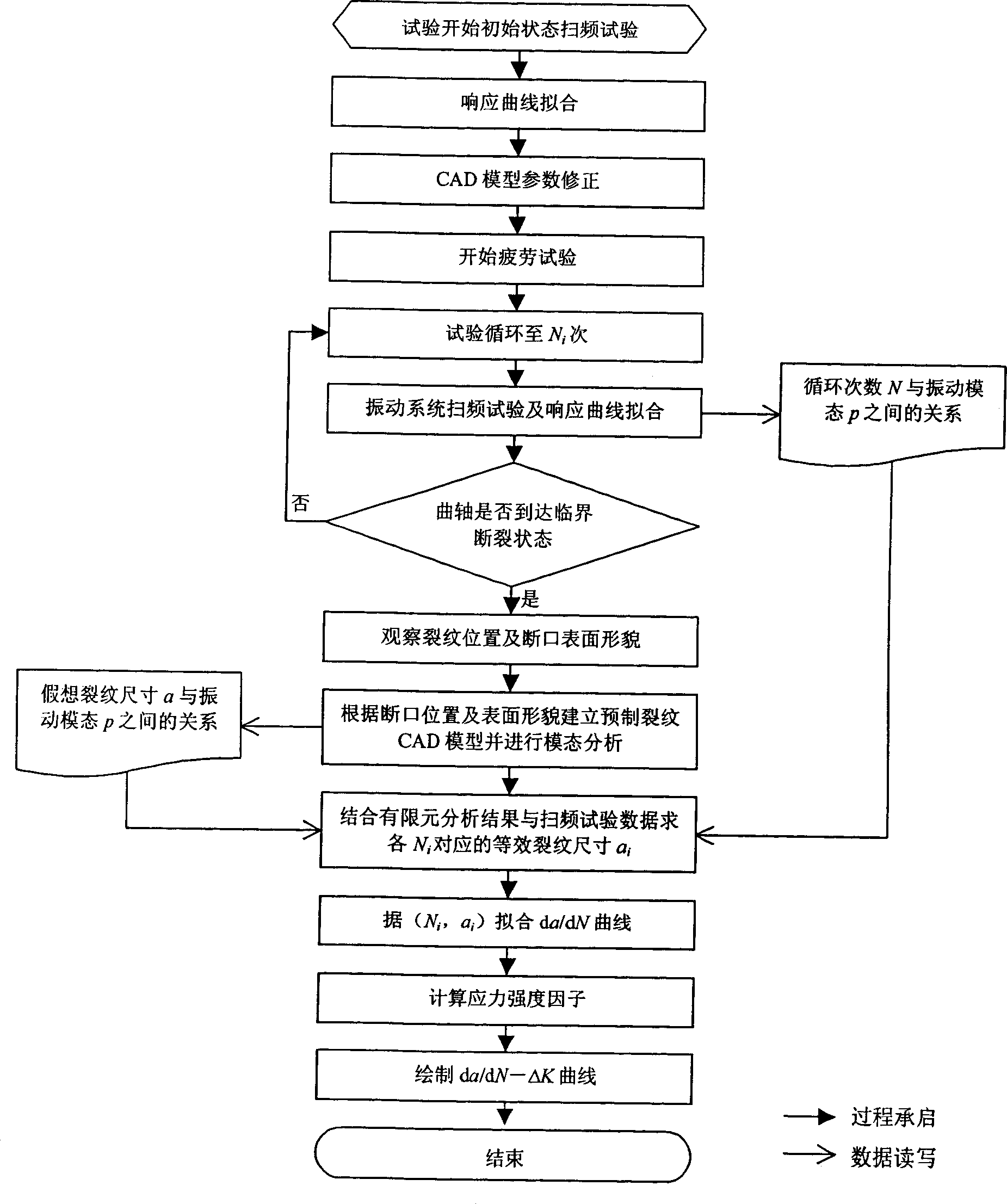

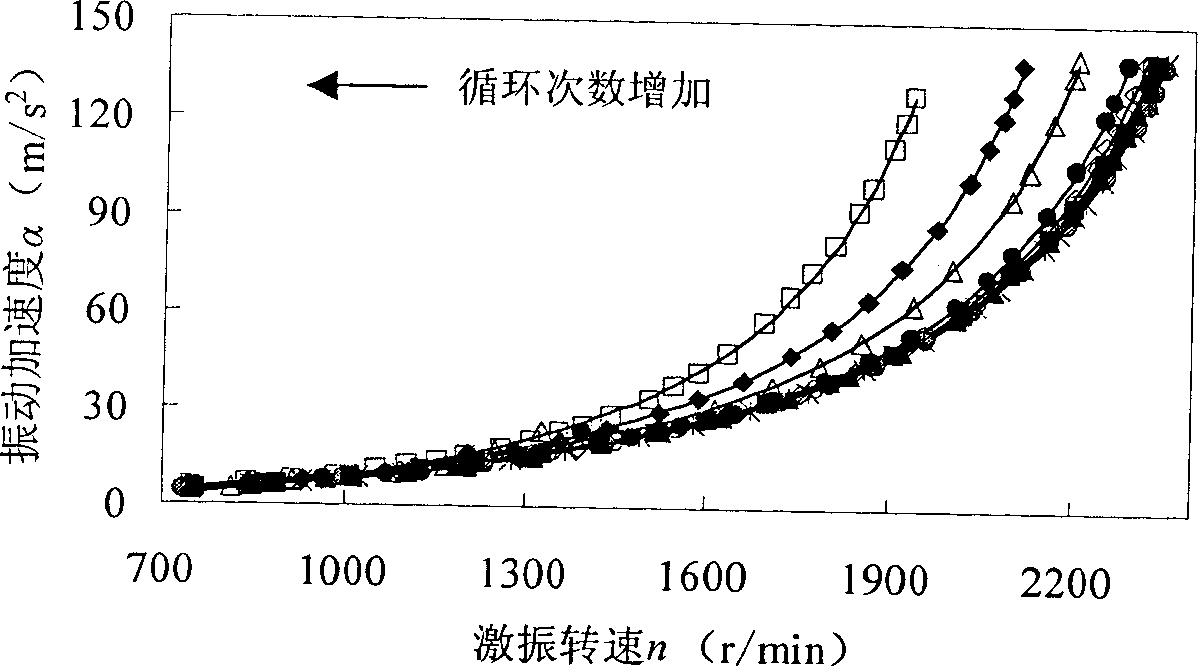

Method for investigating fatigue crack expansion

The invention discloses a fatigue crack extension testing method, making a sweeping test in the fatigue test course and obtaining the variation condition of vibration response of the test system varies with test piece crack extension on the forced vibration condition; using a numeric method to make sweeping data fitting and obtaining variation curve of resonant frequency with number of circulating times; after the test piece is broken, according to actually observed crack size and shape, prefabricating crack of a CAD model and making finite model analysis and obtaining a curve of resonant angular frequency of the system against test piece size, using the curve and able to obtain dynamic extension rule of test piece crack and then obtaining its curve of variation rate; and finally combining with calculation of stress strength factor range Delta K, and able to obtain a curve of crack extension rate.

Owner:ZHEJIANG UNIV

Method for characterizing steel fatigue crack propagation behavior for casing drilling

InactiveCN102607948AEliminate the effects of background noiseSimple formulaMaterial strength using tensile/compressive forcesWell drillingNoise

The invention discloses a method for characterizing a steel fatigue crack propagation behavior for casing drilling. The method comprises the steps of: firstly, sampling casing drilling steel, preparing a sample and cleaning; secondly, carrying out low-frequency noise testing on the sample before fatigue; thirdly, carrying out fatigue testing on the sample; fourthly, carrying out low-frequency noise testing on the sample after fatigue; and fifthly, analyzing, extracting and processing low-frequency noise data before and after the fatigue testing according to low-frequency l / f noise information before and after the fatigue, and characterizing a fatigue crack propagation behavior of the sample. Through two times of low-frequency l / f noise testing before and after the fatigue propagation, the influence of background noise of the sample is eliminated, more complex formula derivation and mathematical calculation in common characterizing methods are avoided, no strict requirements are required for the shape of the sample, the fatigue testing quantity is favorably reduced, the testing cost is lowered, and the fatigue crack propagation behaviors of various samples can be conveniently subjected to sampling and fatigue service life estimation; and the method has the characteristics of convenience in use, low cost and convenience in popularization.

Owner:XI'AN PETROLEUM UNIVERSITY

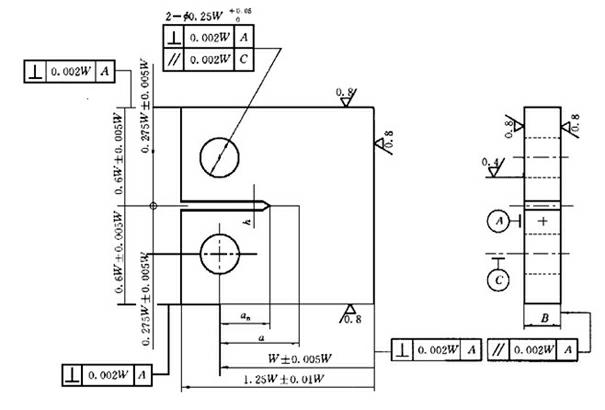

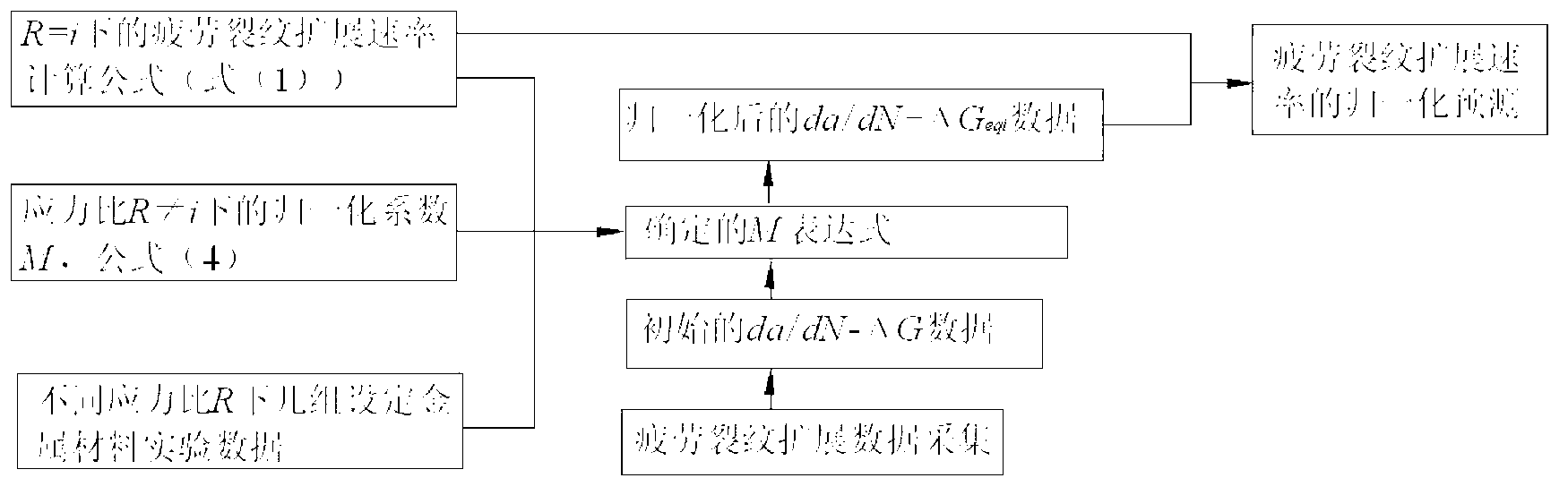

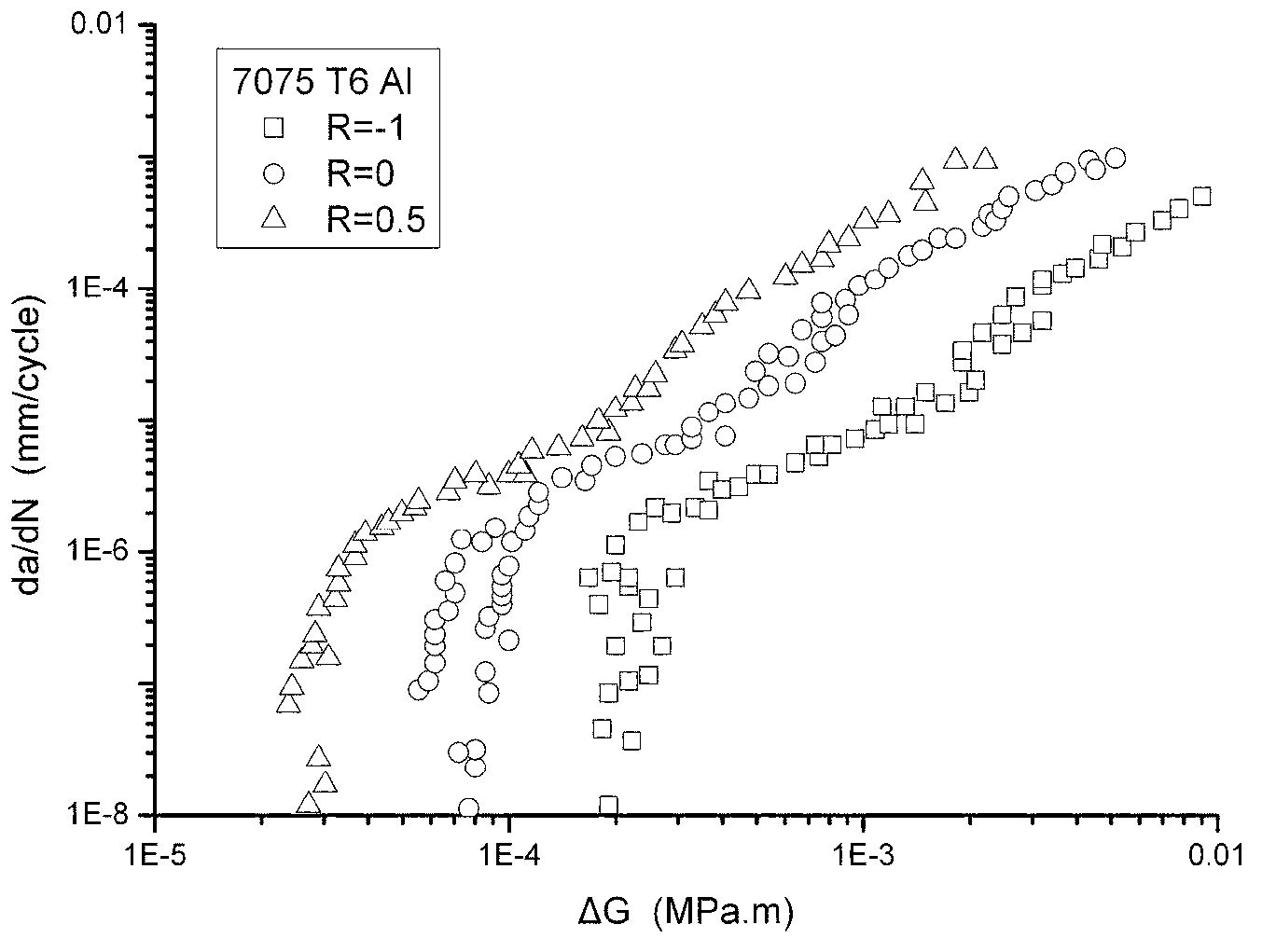

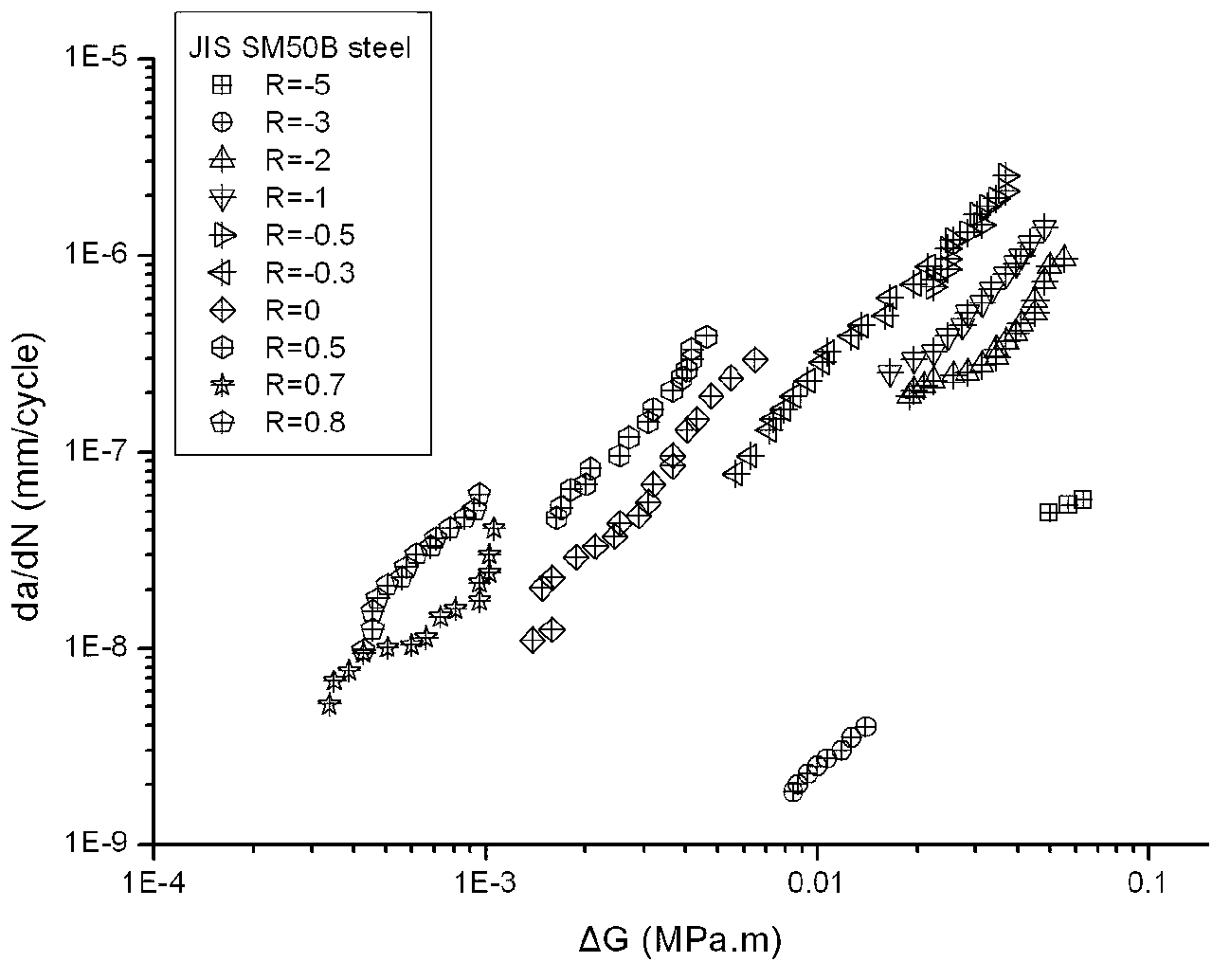

Fatigue crack spreading rate normalization forecasting method

ActiveCN103308381ASimple methodWell formedSpecial data processing applicationsStrength propertiesApplicability domainStress ratio

The invention relates to the field of forecast of a fatigue crack spreading rate of a material, and in particular relates to a fatigue crack spreading rate normalization forecasting method based on the energy release rate. The method comprises the following steps of: drawing a data map for setting a metal material to be under different stress ratios; constructing a fatigue crack spreading rate calculation formula for the metal material under the stress ratio of R:i of 1:1, FORMULA, and expressing the formula as a function; determining experiment constants and curves of the expression under the stress ratio of R:i of 1:1; constructing normalization method expressions of experiment data under different stress ratios that R is not equal to i, and obtaining the normalization method expressions, FORMULA; determining the value Alpha and a math expression Alpha=f(R), and determining an expression of a stress ratio normalization coefficient M and an expression of a data normalization method; and forecasting normalized data through the fatigue crack spreading rate formula under the determined stress ratio of R:i of 1:1. The method has the characteristics of simplicity, wide application range and the like and is favorable for engineering application.

Owner:HEFEI GENERAL MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com