Method for characterizing steel fatigue crack propagation behavior for casing drilling

A technology for fatigue crack propagation and casing drilling, which is applied in the field of casing, can solve the problems of unclear physical meaning of parameters, time-consuming and labor-intensive, etc., and achieves the effect of avoiding formula derivation and mathematical calculation, simple formula and eliminating background noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

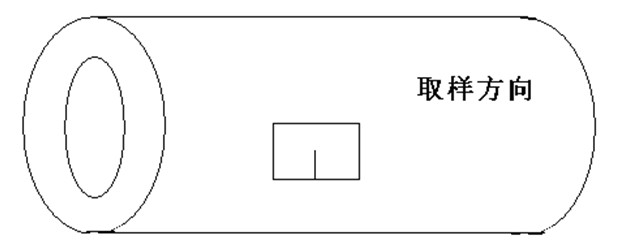

[0024] A method for characterizing the fatigue crack growth behavior of steel for casing drilling, comprising the following steps:

[0025] First, derusting, grinding and cleaning the CT samples of N80 casing steel;

[0026] Firstly, pre-crack the CT sample, the pre-crack length is 2 mm, derust with a hydrochloric acid solution with a molar concentration of 1.0%, and the soaking time is 1 minute; then clean it with ethanol and deionized water respectively, and the soaking time is 2 Minutes, after face grinding and polishing, use 200 ml of HNO with a molar concentration of 2% 3 solution, the HNO 3 The solution uses pure ethanol as a solvent, cleans it, takes it out, hangs it up, and blows it dry;

[0027] Second, the low-frequency noise test before fatigue is carried out on the N80 casing steel CT sample;

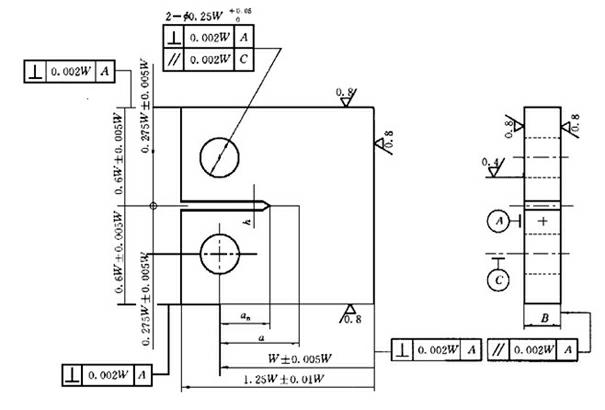

[0028] 1) Weld the lead wires of the CT samples of N80 casing steel after rust removal and cleaning. The present invention takes the fatigue crack monitoring point in the...

Embodiment 2

[0040] A new low-frequency noise characterization method for casing steel fatigue crack growth behavior, including the following steps:

[0041] First, derusting, grinding and cleaning of CT samples such as N80 casing steel;

[0042] Rust removal is carried out with a hydrochloric acid (HCl) solution with a molar concentration of 3.0%, and the soaking time is 2 minutes; then, it is cleaned with ethanol and deionized water, and the soaking time is 2 minutes. 4.0% HNO 3 Clean with the etchant of ethanol solution, take it out and hang it, and dry it;

[0043] Second, carry out low-frequency noise test on N80 casing steel samples before fatigue;

[0044] 1) Weld the leads on the CT samples of N80 casing steel after derusting and cleaning. In the present invention, the fatigue crack monitoring point in the conventional fatigue test is used as the potential reference point, and two lead wires are respectively welded on both sides of the prefabricated crack of the sample;

[0045...

Embodiment 3

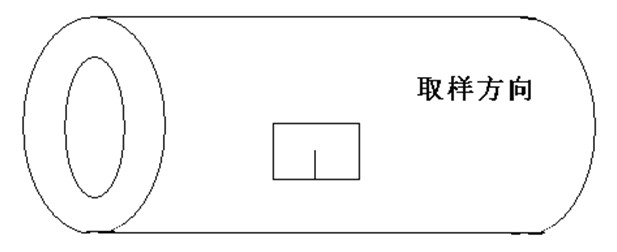

[0056] A new low-frequency noise characterization method for casing steel fatigue crack growth behavior, including the following steps:

[0057] First, derusting, grinding and cleaning of CT samples such as N80 casing steel;

[0058] Rust removal can be carried out with a hydrochloric acid (HCl) solution with a molar concentration of 5.0%, and the soaking time is 3 minutes; then, it is cleaned with ethanol and deionized water, and the soaking time is 2 minutes. 5% HNO 3 solution, the HNO 3 The solution uses pure ethanol as a solvent, cleans it, takes it out, hangs it up, and blows it dry;

[0059] Second, carry out low-frequency noise test on N80 casing steel samples before fatigue;

[0060] 1) Weld the lead wires of the CT samples of N80 casing steel after rust removal and cleaning. The present invention takes the fatigue crack monitoring point in the conventional fatigue test as the potential reference point, and welds two lead wires on both sides of the prefabricated cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com