Hydrophone possessing on-line self calibrating function

A self-calibration and hydrophone technology, applied in the field of sensors, can solve difficult problems and achieve the effect of eliminating background noise and high signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

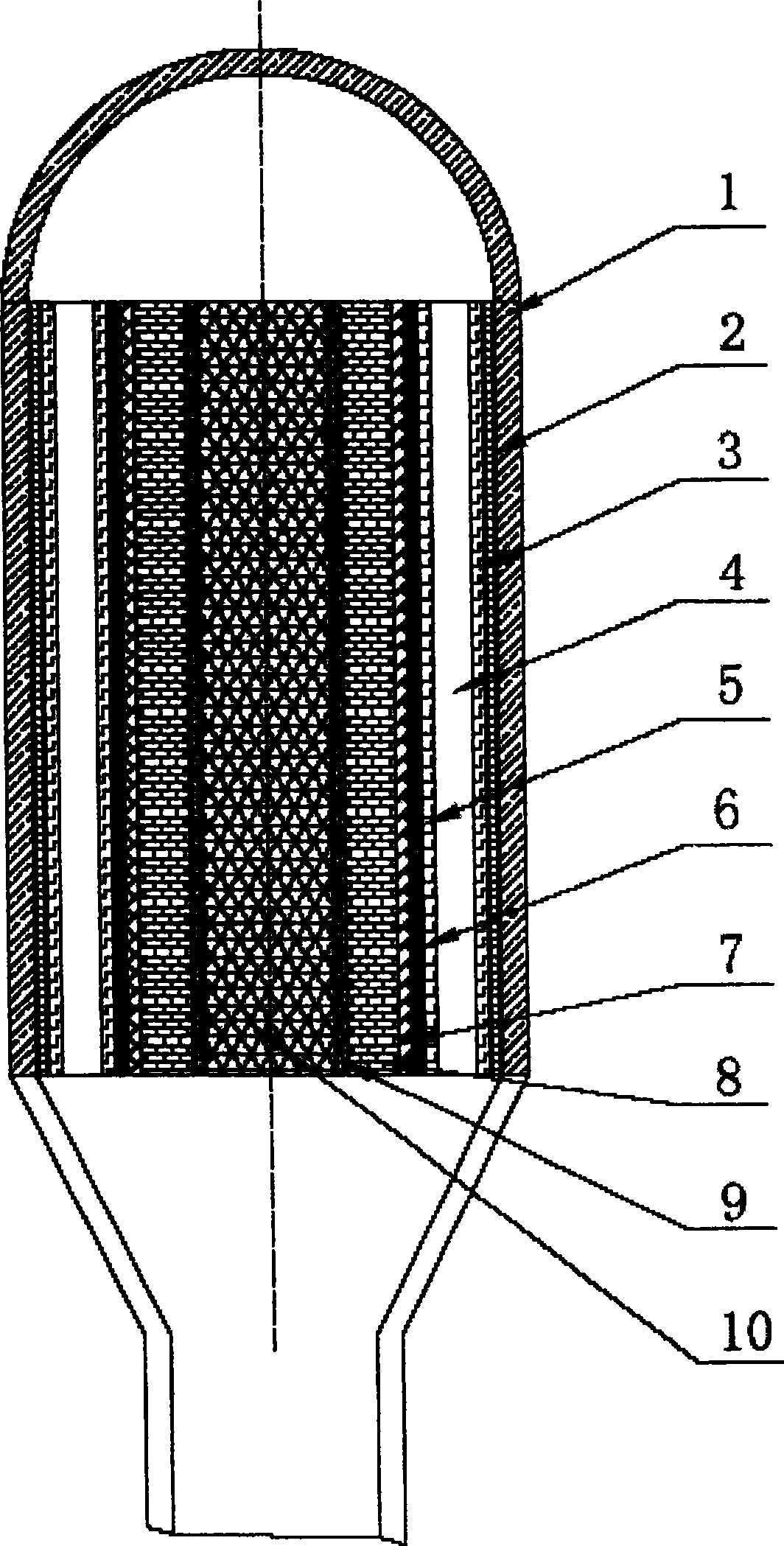

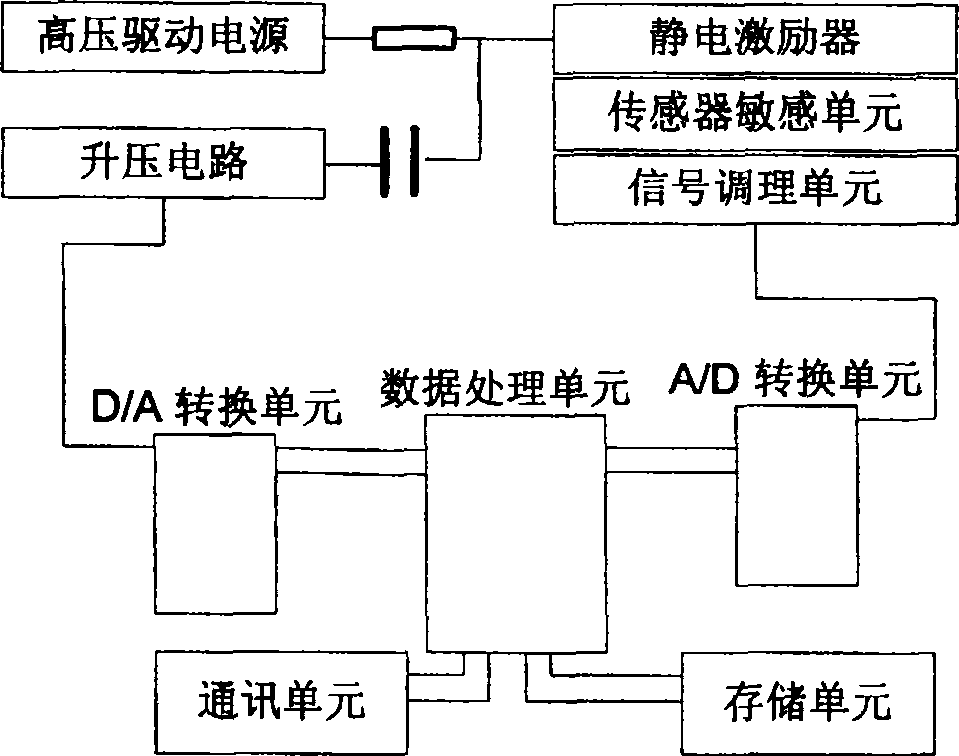

[0024] The present invention will be described below by taking a cylindrical piezoelectric hydrophone as an example. Such as figure 1 As shown, the outermost surface of the hydrophone is a sealed casing 1, which is generally made of stainless steel and has a certain pressure resistance. A layer of outer insulating layer 2 is attached to the inner surface of the housing. In this embodiment, the insulating layer is made of ceramic electronic insulating material AL203. The making material of insulating layer of the present invention is not limited to ceramic material, also can be other insulating materials, as, mica, resin etc., but requires larger rigidity (its rigidity is greater than 3 to 6 times of sensitive element), promptly in The amount of deformation is very small when the force is applied (under the same force, the deformation is less than 1 / 10 of the sensitive element). Install a layer of metal mesh on the inner surface of the insulating layer to form the external ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com