Patents

Literature

214results about How to "Simple formula" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

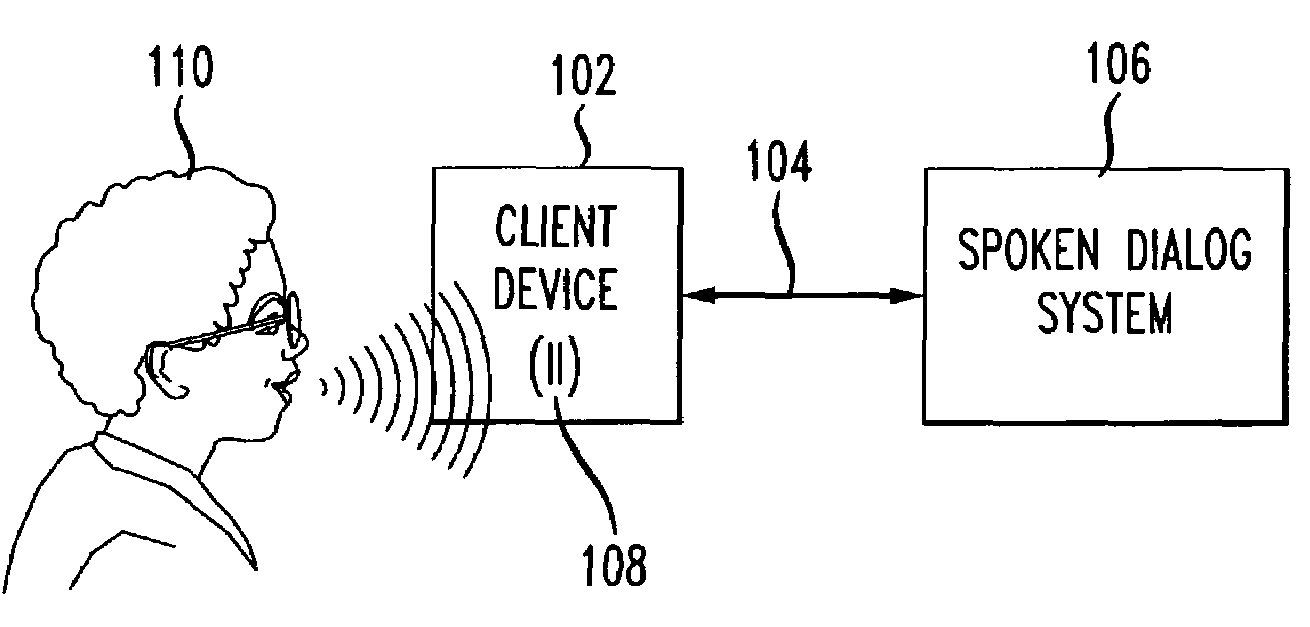

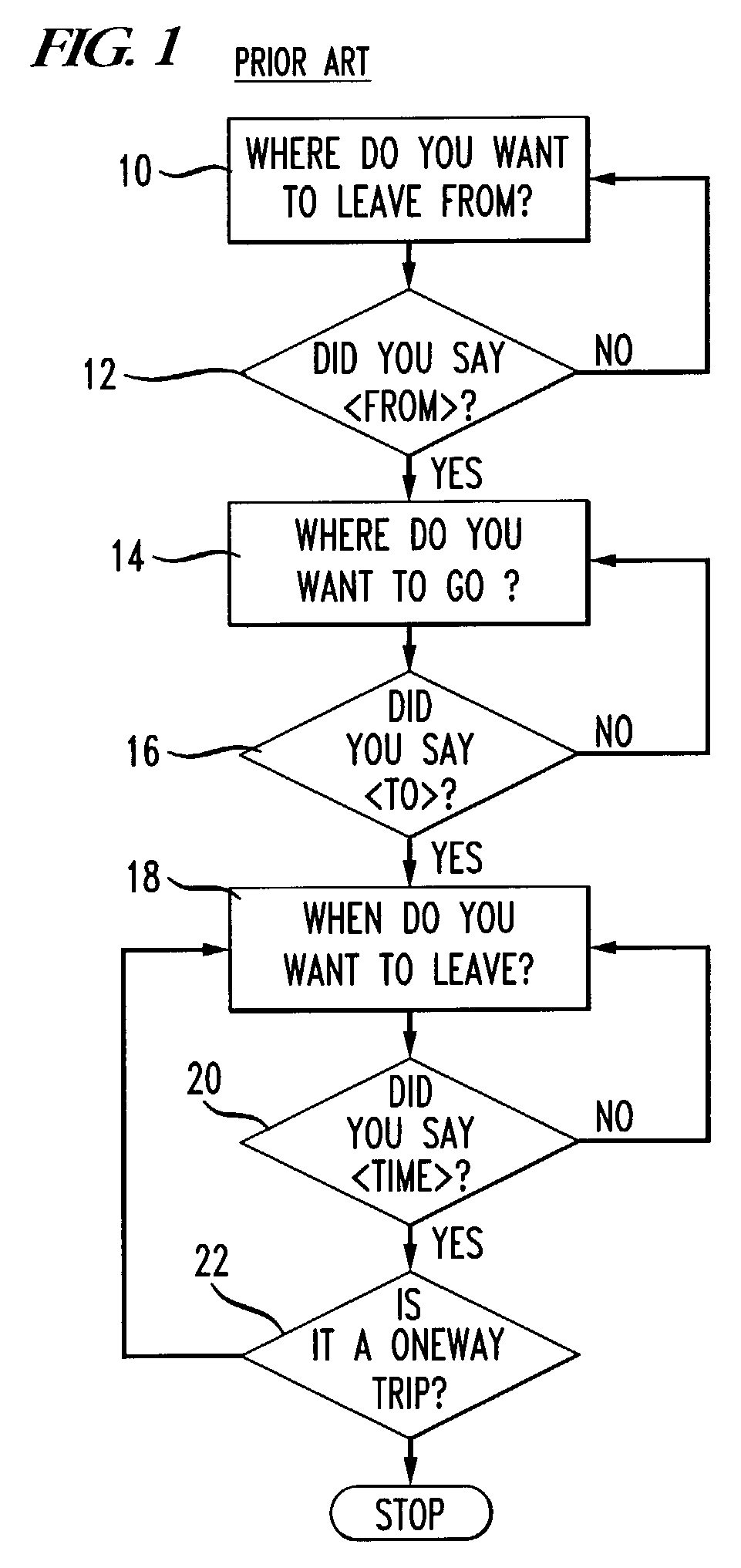

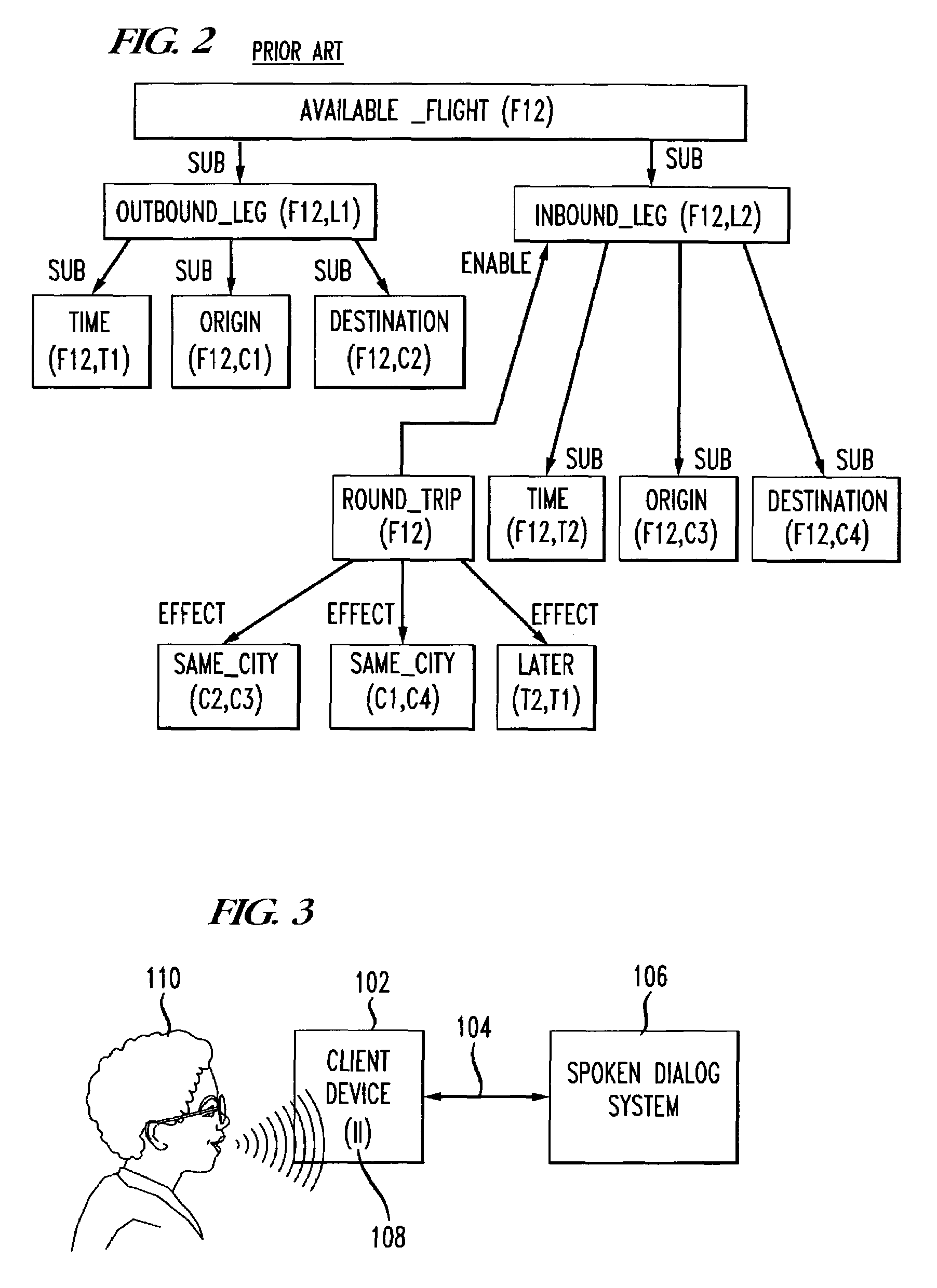

System for dialog management

ActiveUS7139717B1Simple formulaEasy to implementAutomatic exchangesSpeech recognitionSystem usageContinuation

A spoken dialog system having a dialog management module is disclosed. The dialog management module includes a plurality of dialog motivators for handling various operations during a spoken dialog. The dialog motivators comprise error-handling, disambiguation, assumption, confirmation, missing information, and continuation. The spoken dialog system uses the assumption dialog motivator in either a-priori or a-posteriori modes. A-priori assumption is based on predefined requirements for the call flow and a-posteriori assumption can work with the confirmation dialog motivator to assume the content of received user input and confirm received user input.

Owner:NUANCE COMM INC

O/W emulsion

InactiveUS20030202948A1High degree of dispersionHigh stabilityCosmetic preparationsSugar derivativesEmulsionOrganosilicon

O / W emulsions, contain at least one organosilicon compound bearing a glycoside radical and at least one metal oxide are present. The emulsions are stable with respect to pH and exhibit a high degree of dispersion of the metal oxide. The emulsions are particularly useful as cosmetic formulations, in particular as sun screen lotions and creams.

Owner:WACKER CHEM GMBH

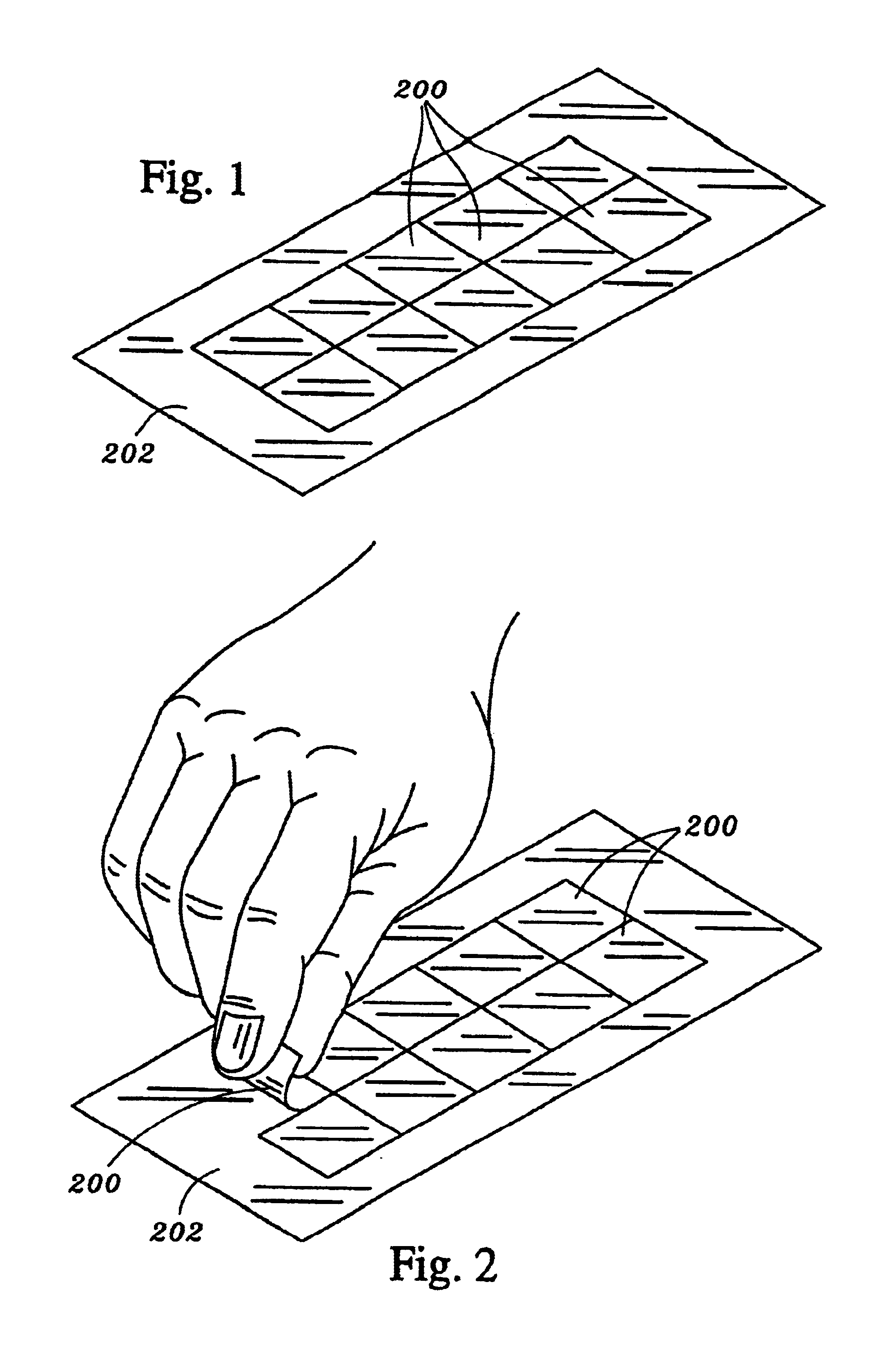

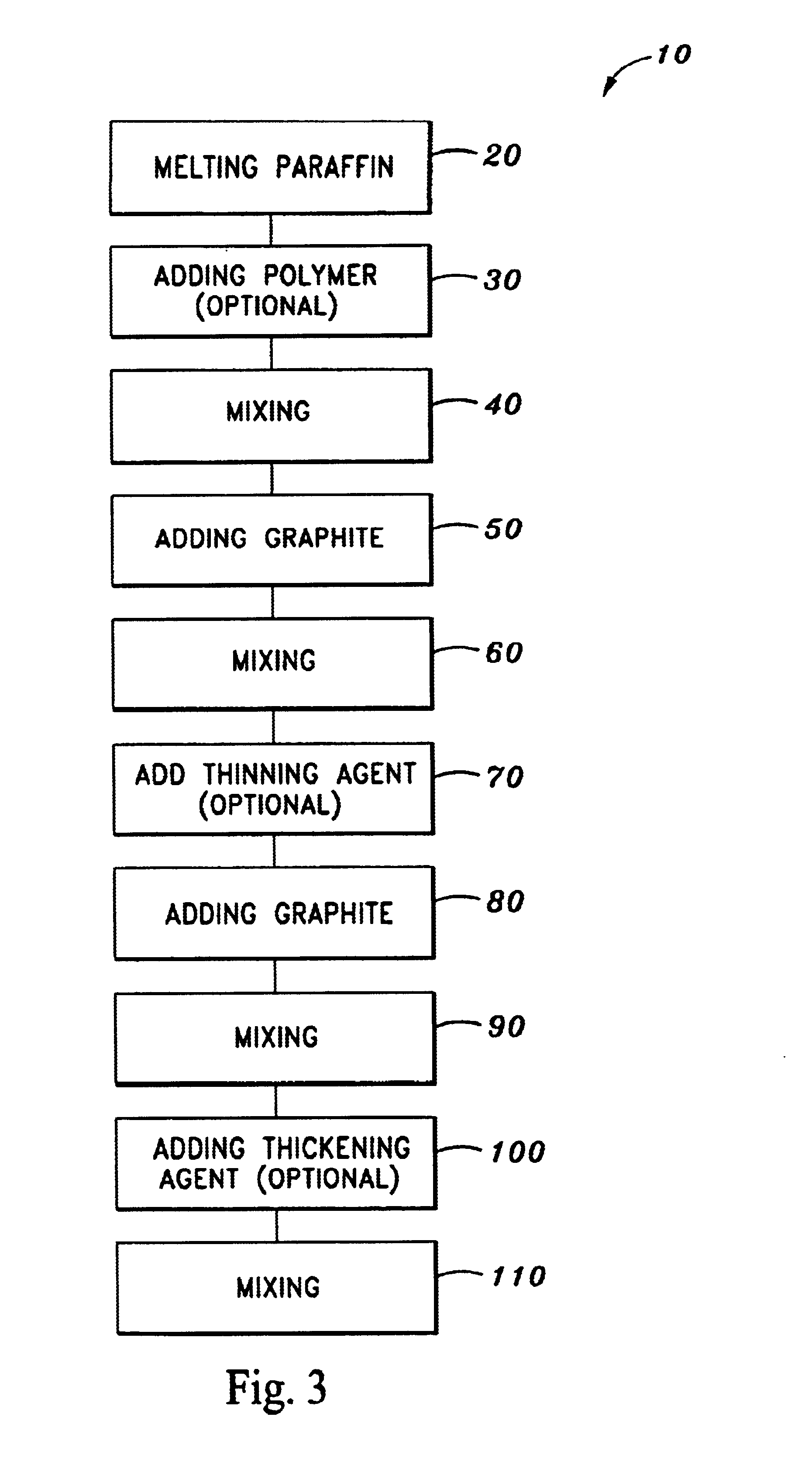

Phase change thermal interface composition having induced bonding property

InactiveUS6869642B2Easy to packEasy to shipSemiconductor/solid-state device detailsSolid-state devicesParaffin waxRoom temperature

An improved, more durable heat conductive composition for transferring heat from a heat-dissipating component to a heat dissipater and method of producing the same. The composition preferably comprises a base consisting of paraffin and, optionally, paraffin and petrolatun having electrically-conductive particles suspended therein, which preferably include graphite diamond, or elemental metals such as silver. In the preferred embodiment, the composition further includes a resin polymer to increase durability. The composition is formulated to be solid in the range of normal room temperatures, but liquify once subjected to temperatures just below the range at which heat generating electronic semi conductor devices typically operate. The present invention further comprises processes for packaging the compositions of the present invention, as well as applying the heat conductive composition to an interface between a heat-dissipating component and a heat sink.

Owner:LOCTITE

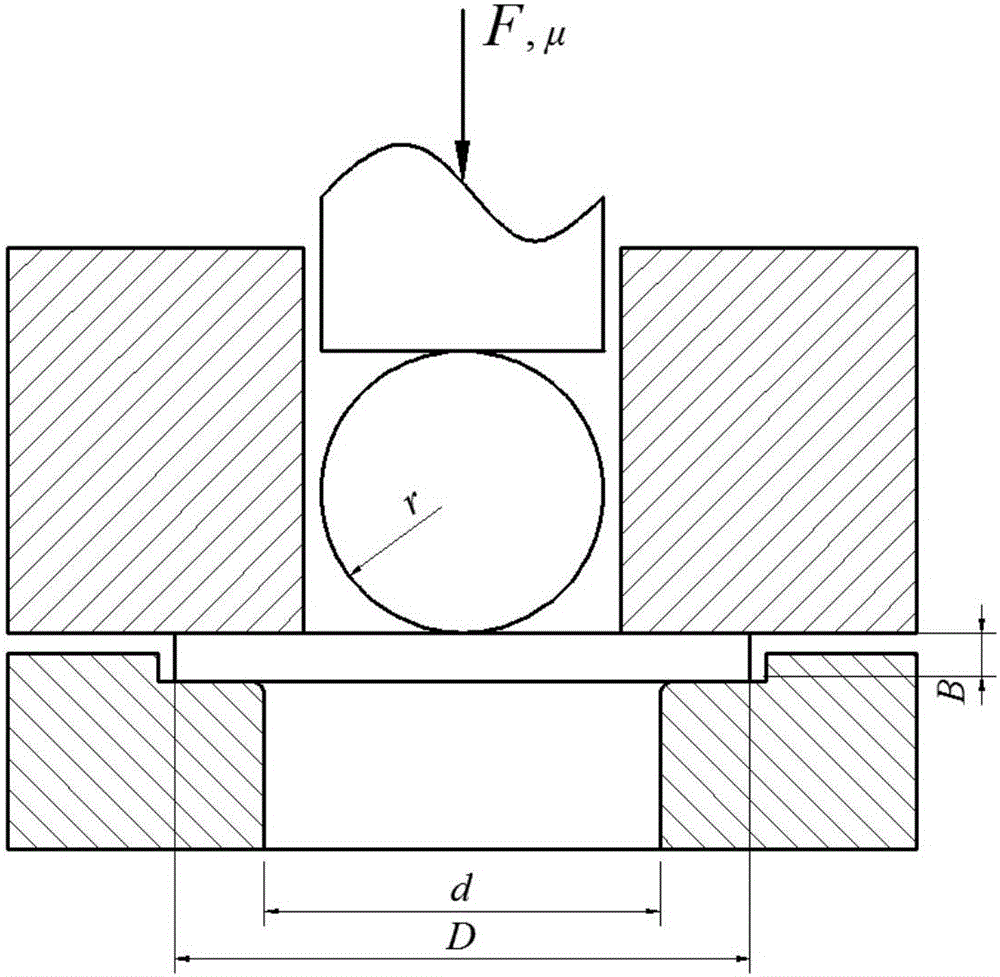

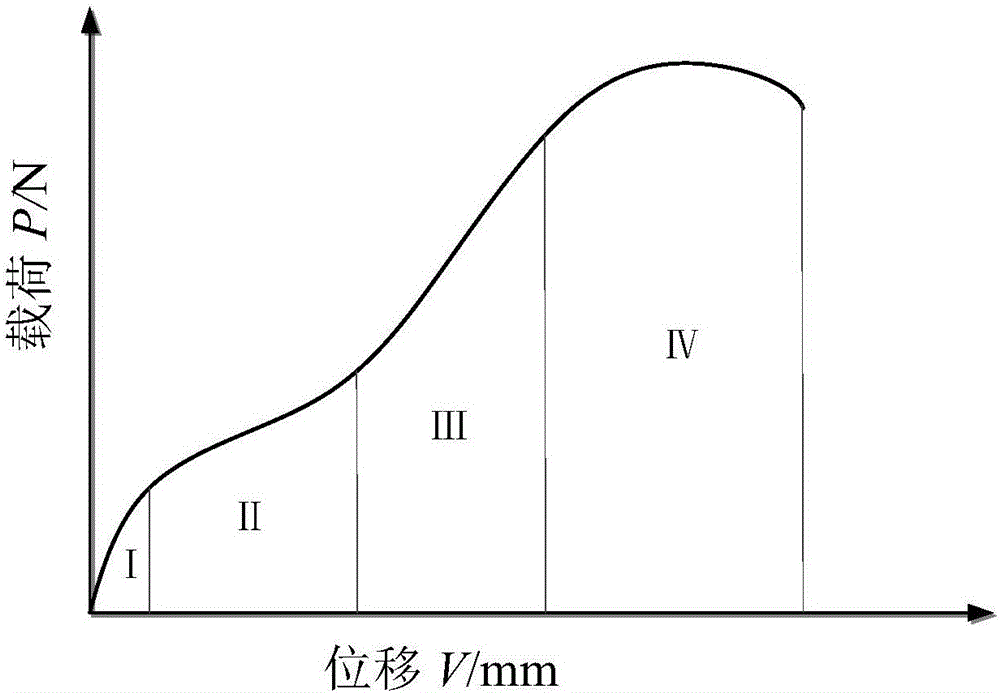

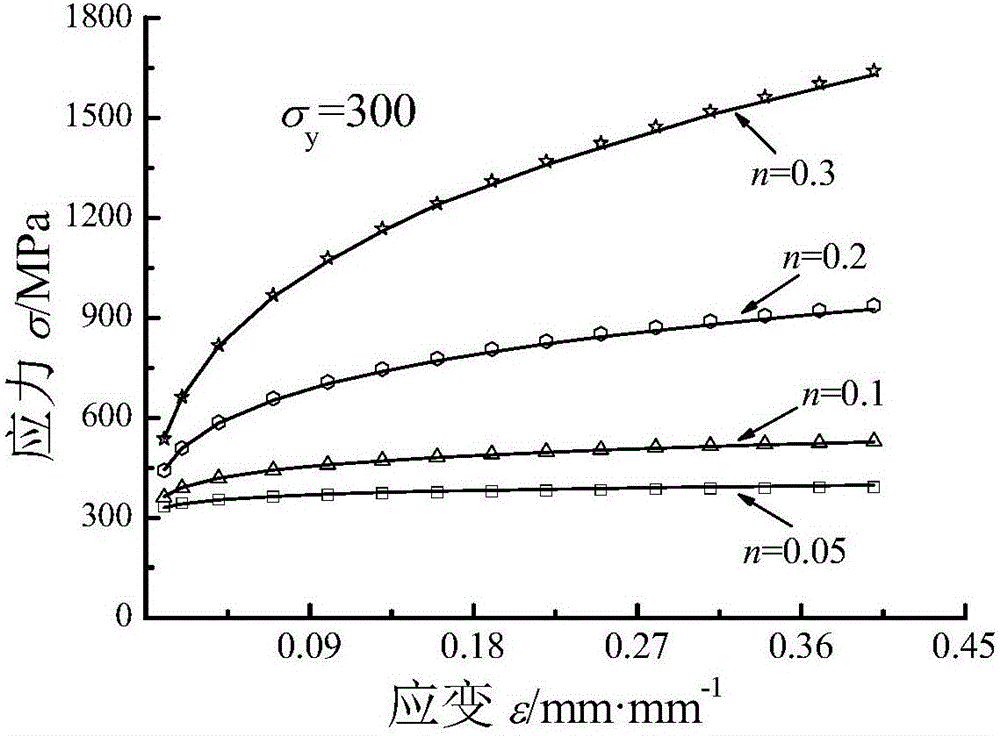

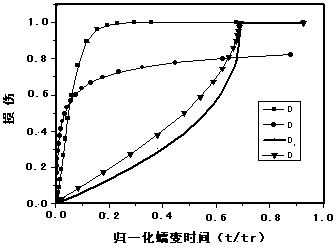

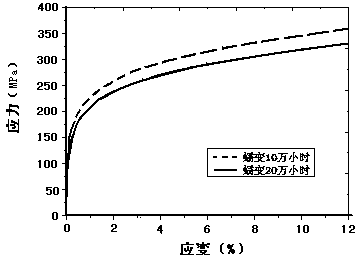

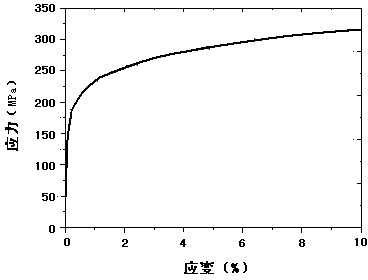

Method for obtaining uniaxial stress-strain relation of material through small punch test

ActiveCN106124293AQuantitative evaluation of degradation performanceTo overcome the shortcomings such as large size restrictionsStrength propertiesSmall sampleMaterials testing

The invention discloses a method for obtaining uniaxial stress-strain relation of a material through a small punch test. After a continuous load-displacement curve of a stamped wafer sample is obtained, power-law fitting is conducted on the stage III of the P-V curve, obtained load characteristics and displacement indexes are introduced to a Hollomon equation so as to obtain the uniaxial stress-strain relation of the material. The method is suitable for ductile and power-law isotropic hardening materials, the uniaxial stress-strain relation of the material can be obtained only by cutting out a small wafer sample from an existing member in special circumstances such as high temperature and irradiation, and accordingly the degradation properties of the material are assessed. The method has weaker destructiveness on the existing member, achieves the micro-damage detection, sample processing and testing principles are simpler, obtained results have higher accuracy, the shortcoming that a traditional uniaxial drawing test is largely limited by material size and the like is overcome, and the cost lower. The method has the greater advantages in testing of precious-metal servicing micro-force materials establishing constitutive relation of minimally invasive wafers and other small samples.

Owner:SOUTHWEST JIAOTONG UNIV

Lavatory cleansing devices

A liquid dispensing unit for a toilet bowl comprises a first container containing a first, liquid formulation, a second container containing a second formulation, which may be a solid tablet. The liquid from container flows onto a delivery surface from where it is washed into the toilet bowl by the flush water. Some flush water also washes over the second formulation to take components into solution and deliver them into the toilet bowl through aperture. The constituents of the two formulations are thus kept separate until they enter the toilet bowl. The second formulation may also be a liquid.

Owner:BROOMCO4290 LTD

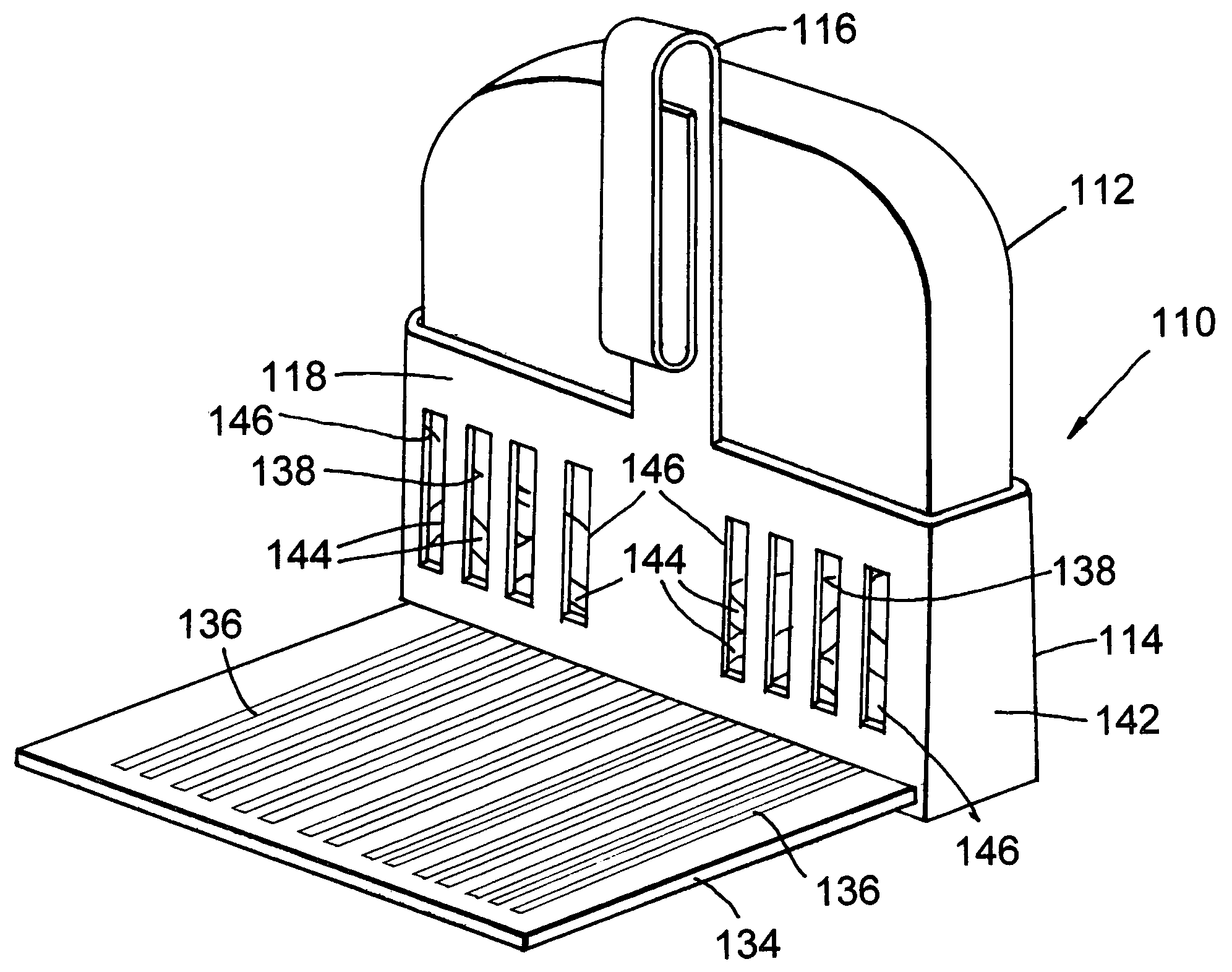

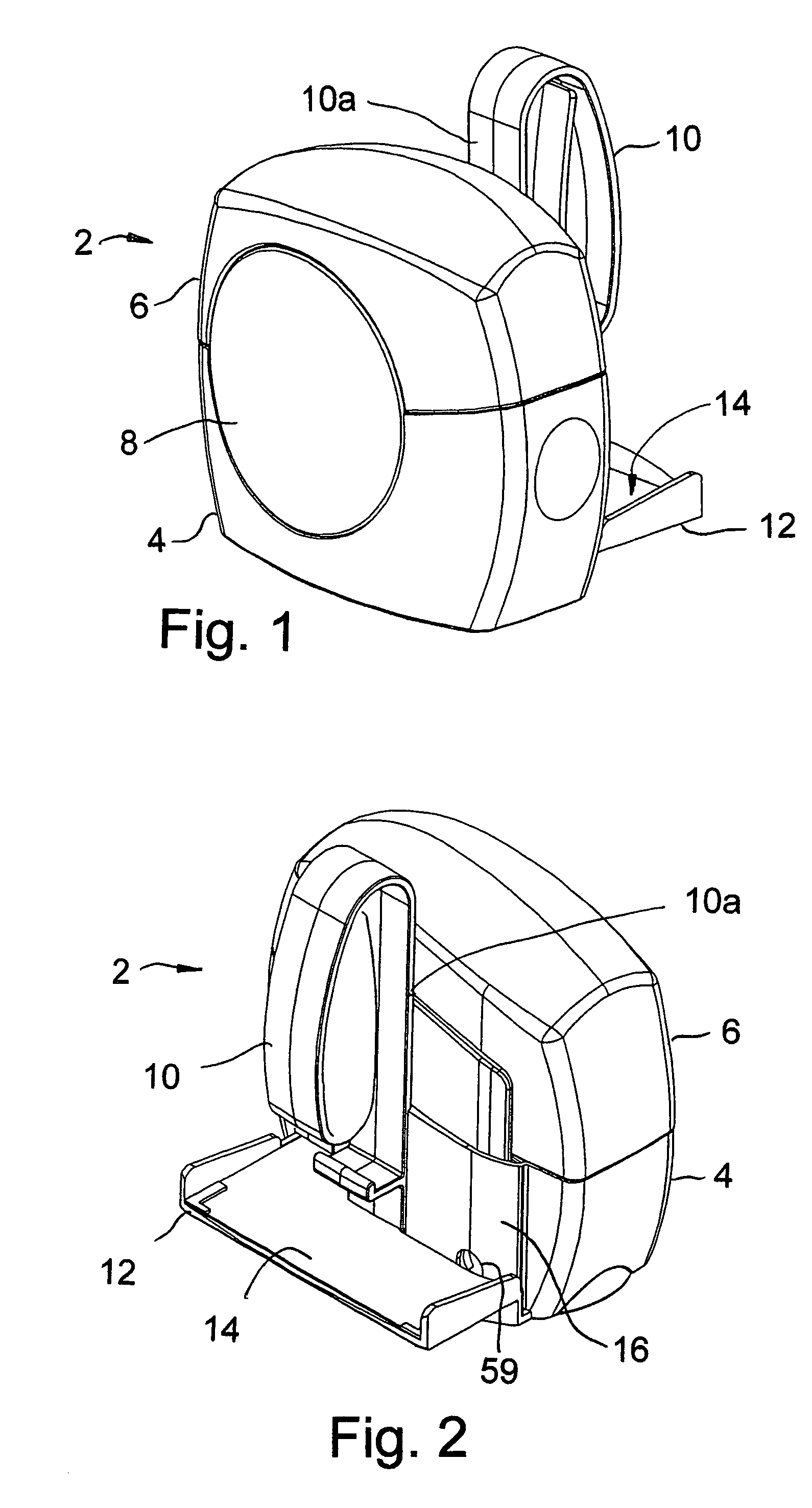

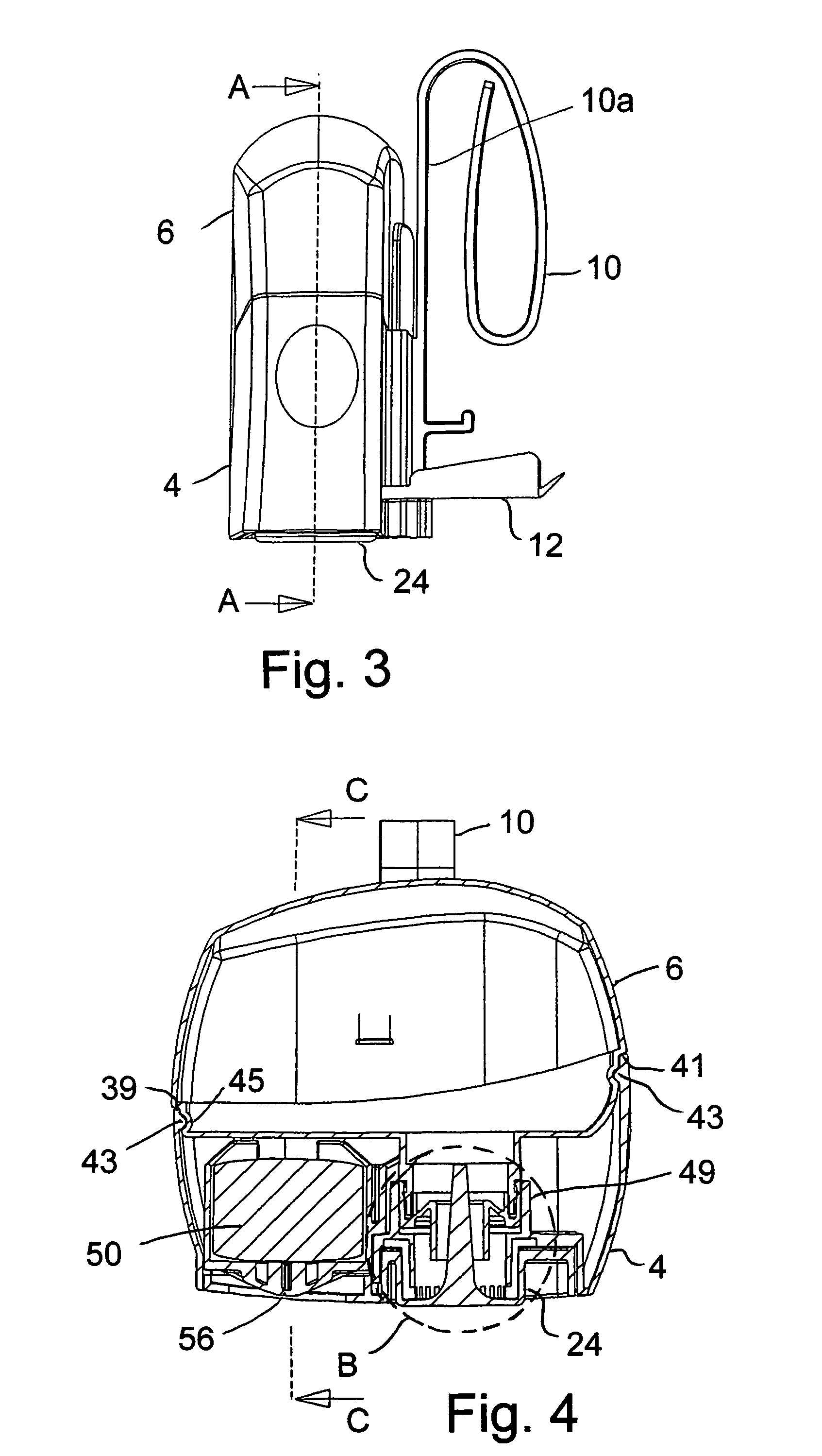

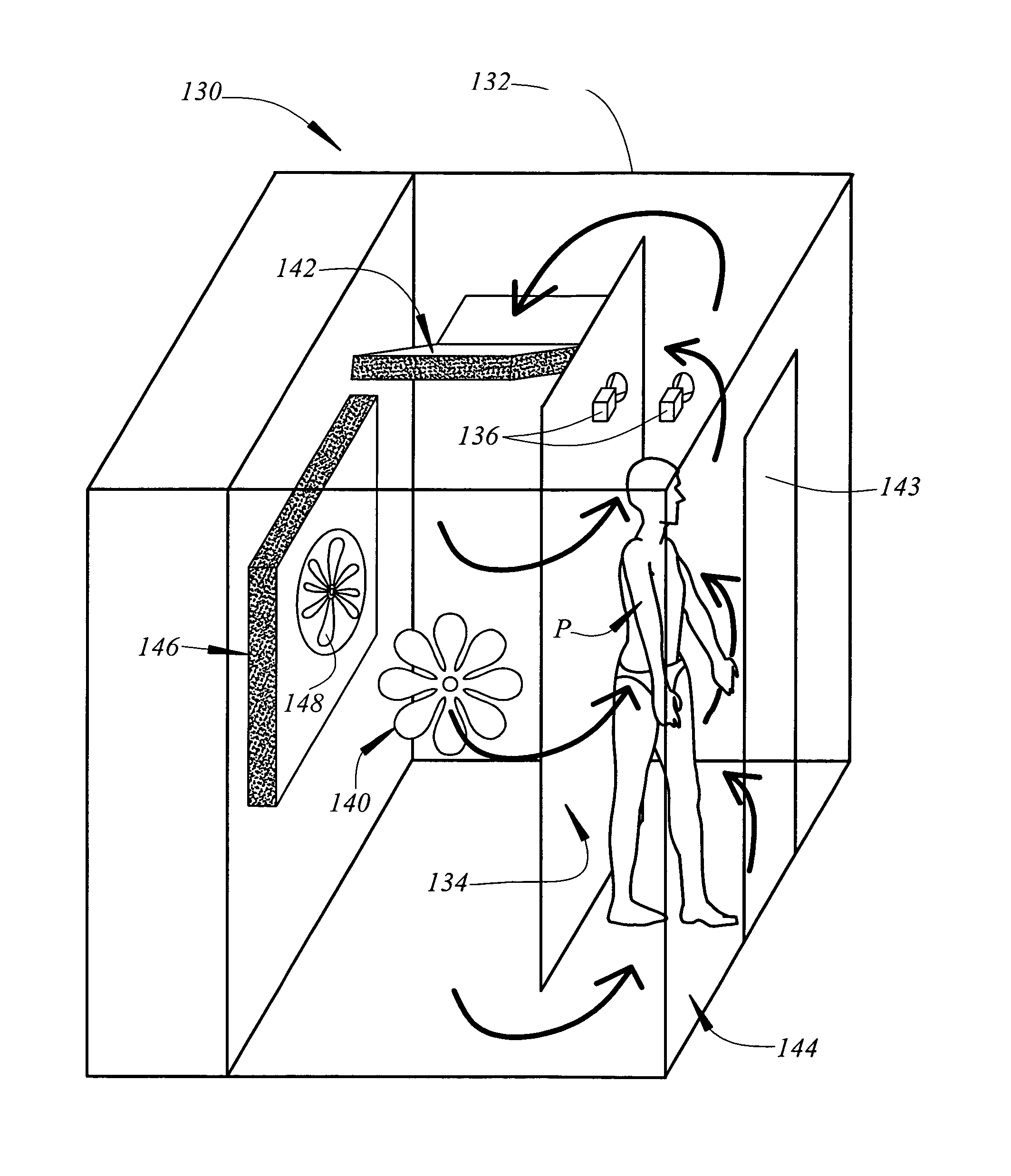

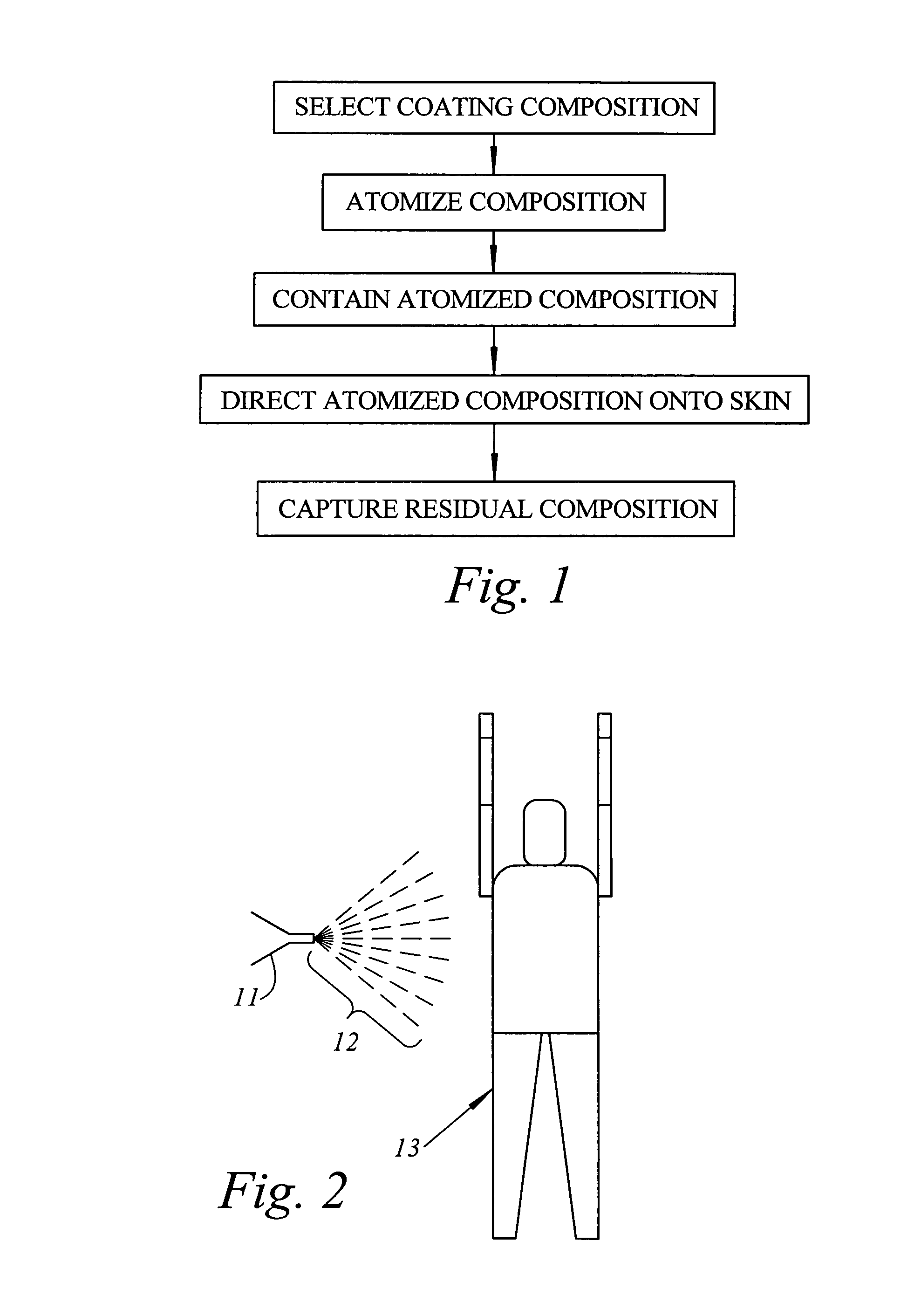

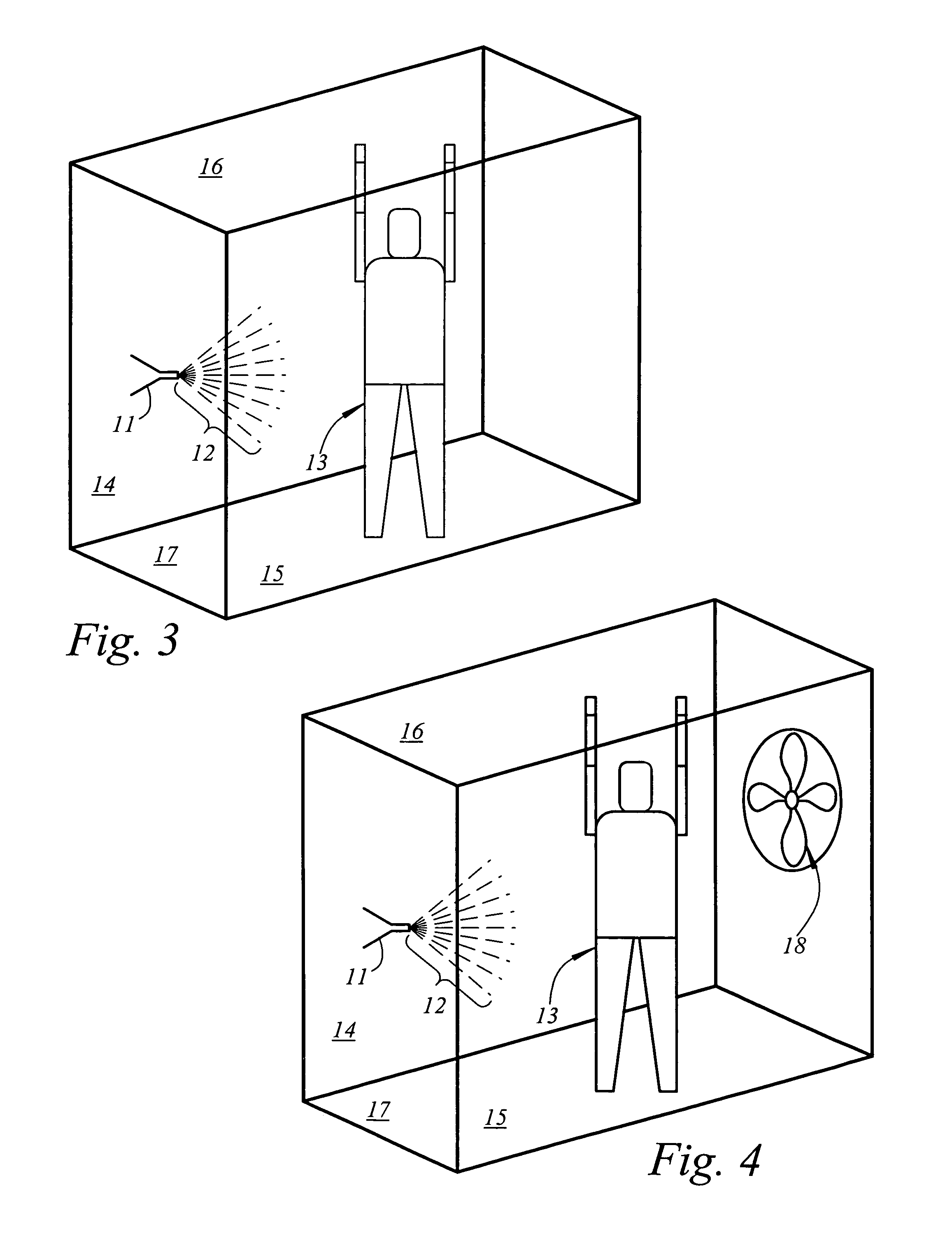

Automated system for coating the human body: virtual motion

InactiveUS7041089B2Improve coating uniformityImprove uniformityCosmetic preparationsLiquid surface applicatorsVirtual locomotionBiomedical engineering

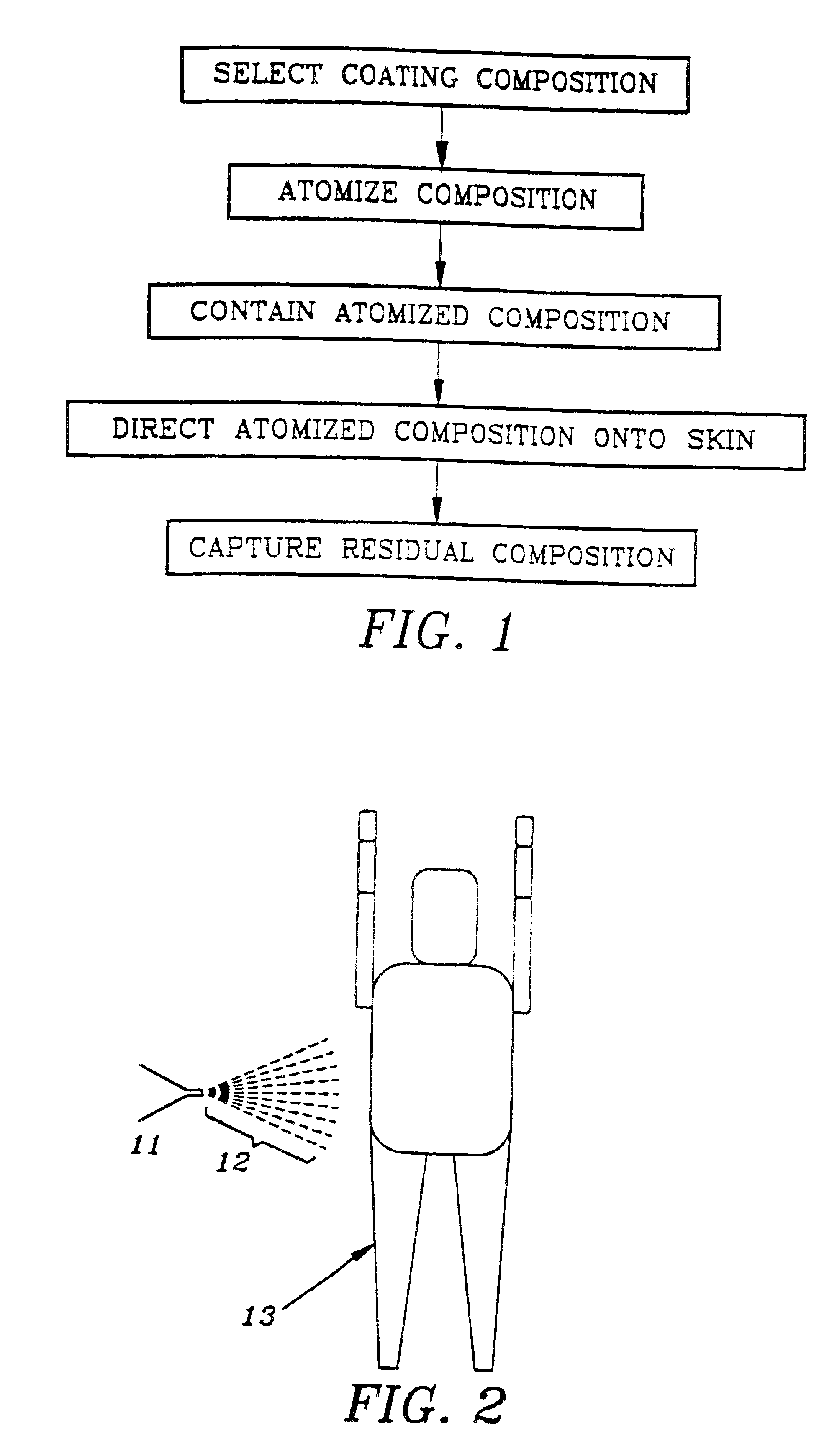

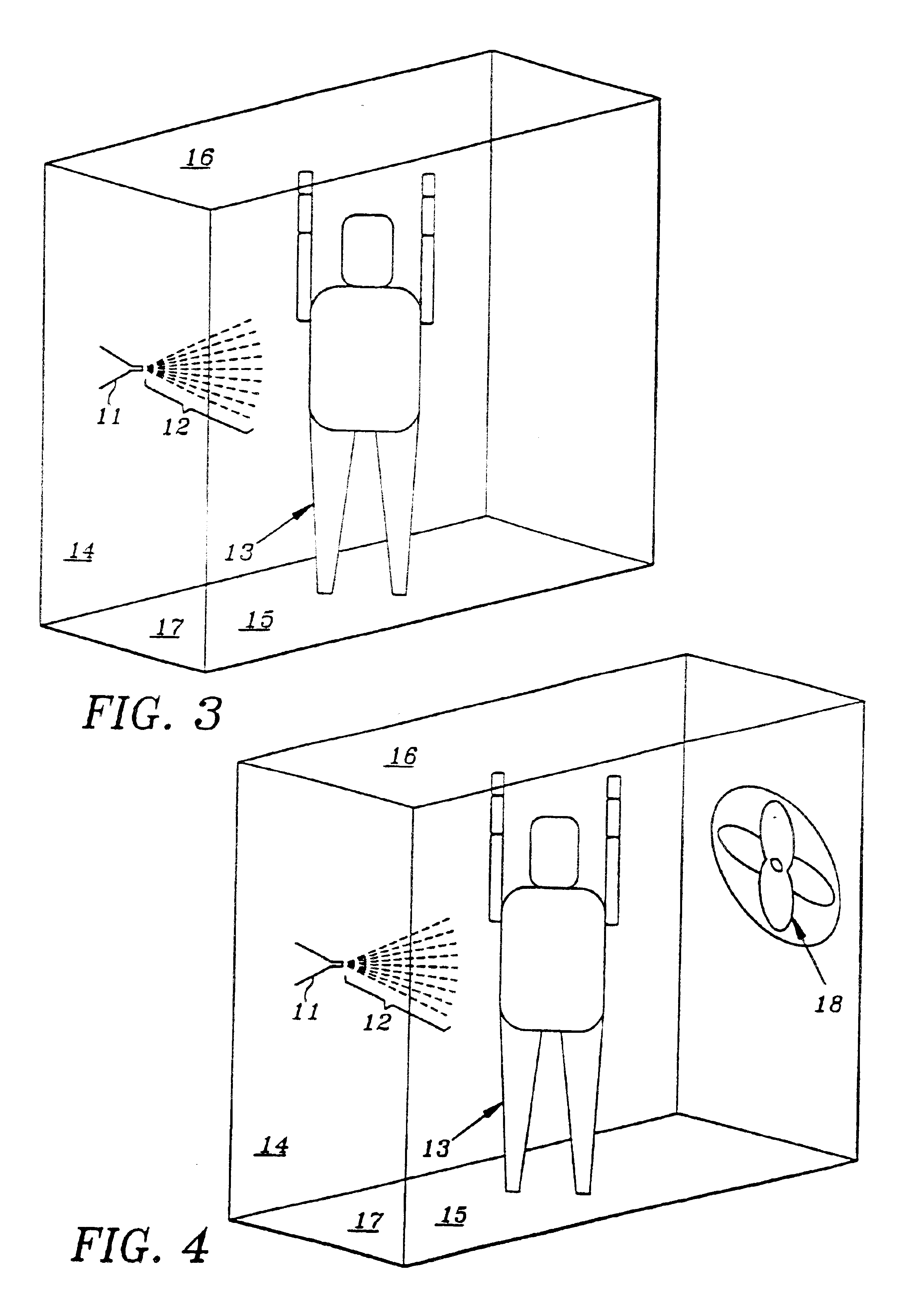

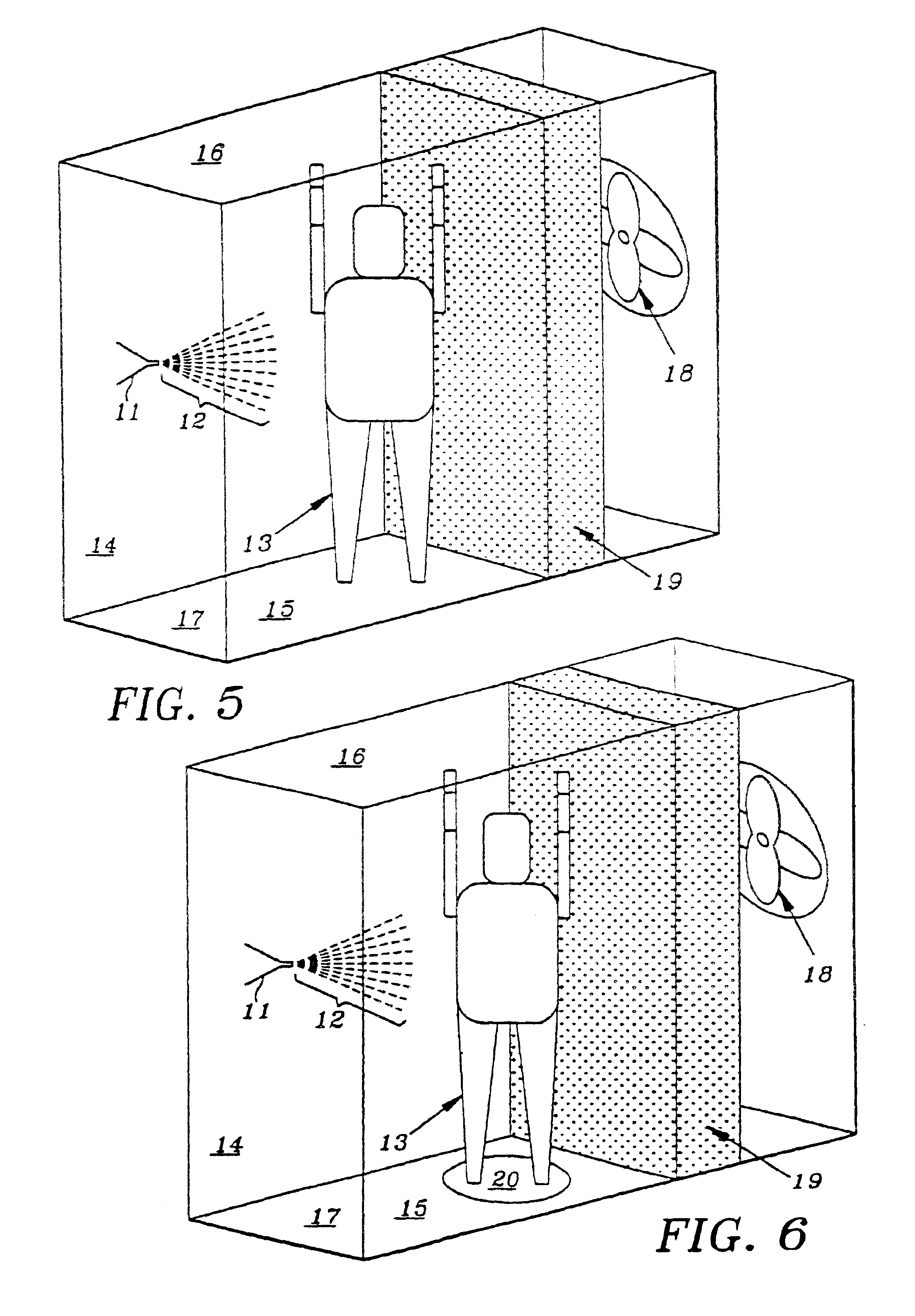

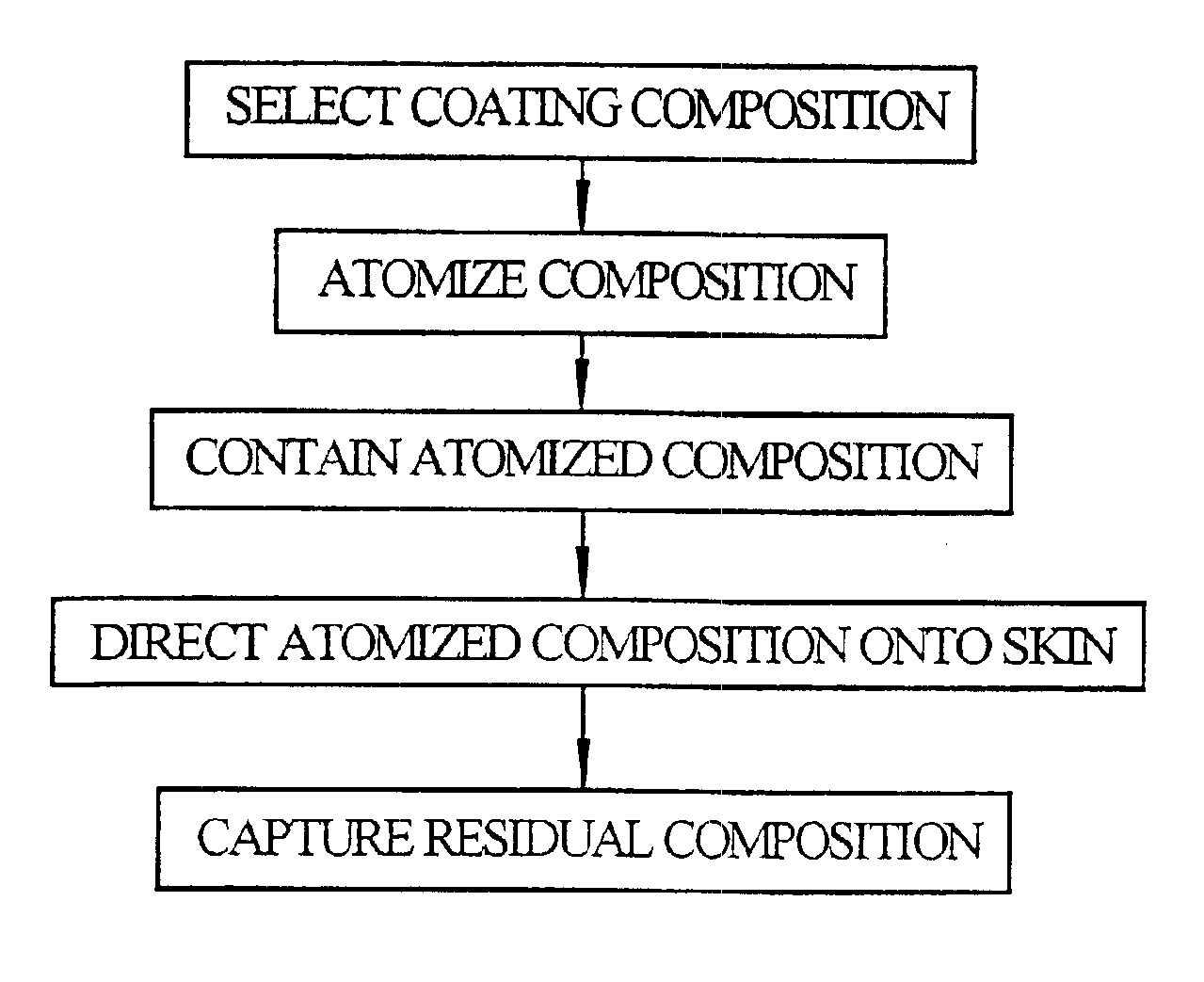

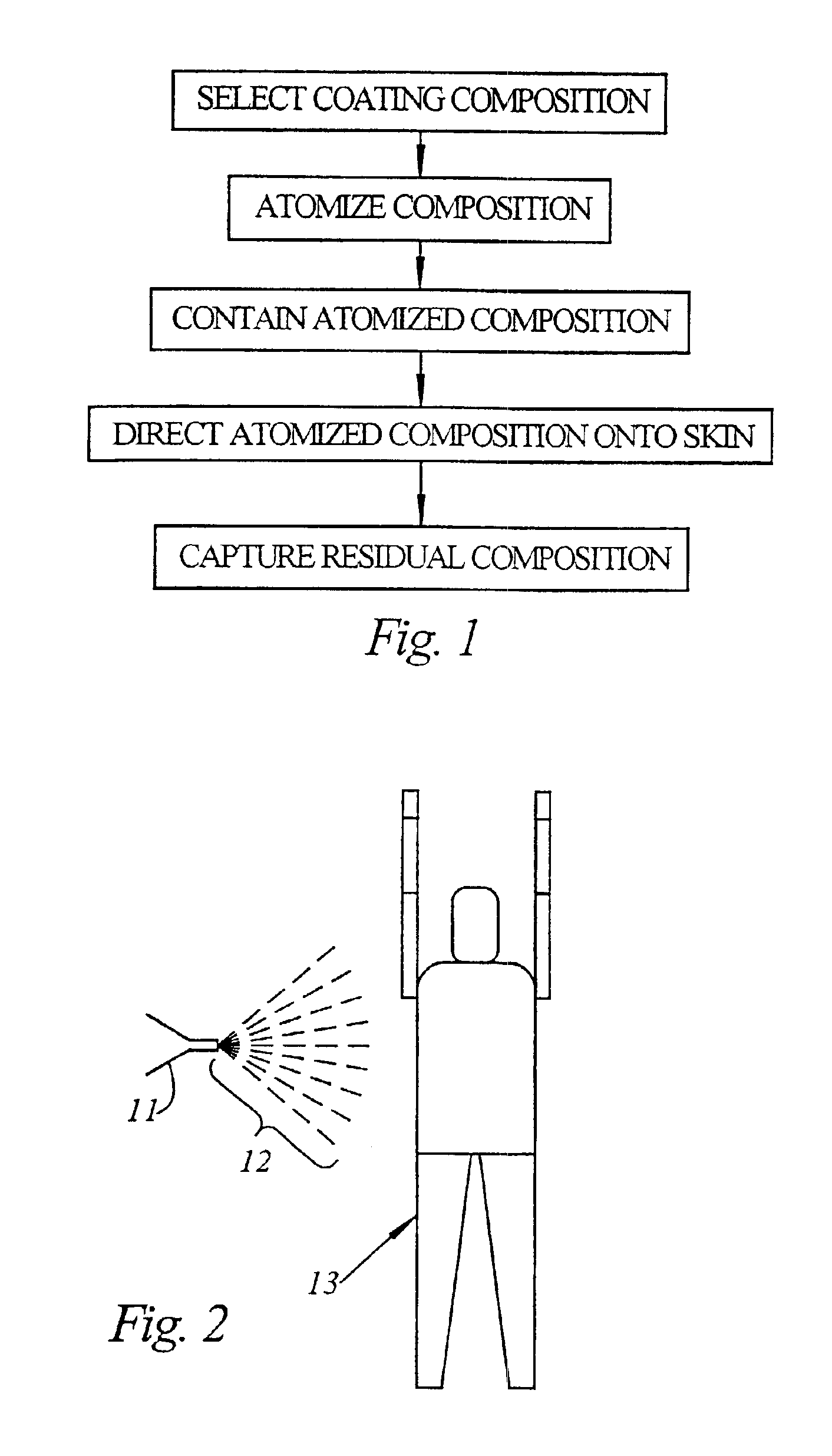

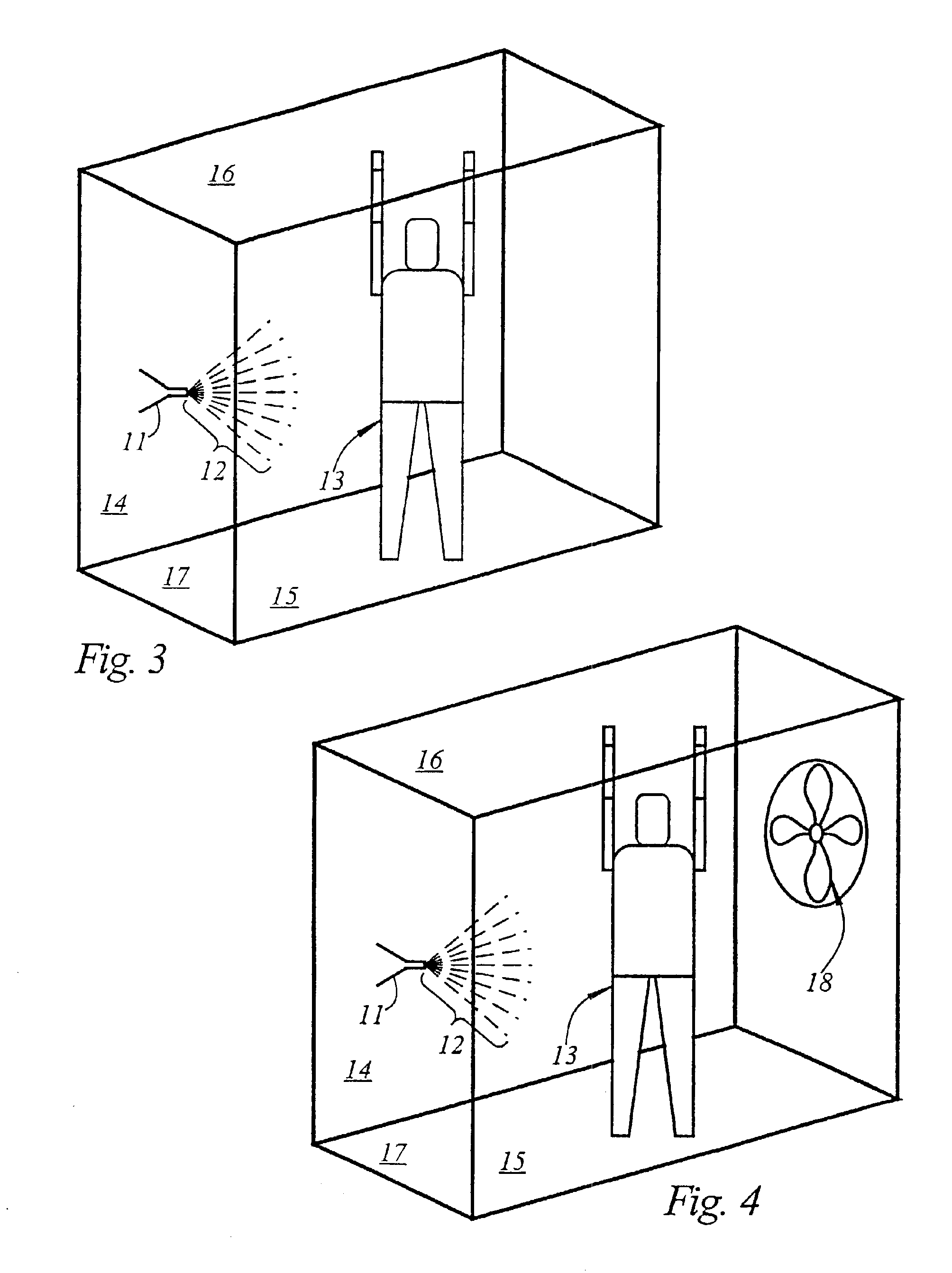

In a system for coating human skin, a coating composition, such as a cosmetic or medical formulation, is uniformly coated over the entire body or selected parts of the body of the person being coated. The system includes atomization of the coating composition, containment of the atomized spray, and residual recovery which together yield a novel method for applying coating compositions.

Owner:LAUGHLIN PROD

Safety assessment method for pressure-bearing structure with creep damages and volume defects

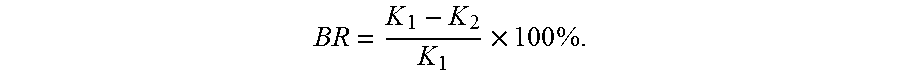

ActiveCN103995957ASimple formulaEasy to calculateSpecial data processing applicationsInternal pressureFinite element method

Owner:EAST CHINA UNIV OF SCI & TECH

Oral films

InactiveUS20160303038A1Disintegrates quicklySimple formulaCosmetic preparationsNervous disorderPolyvinyl alcoholPolyethylene glycol

The invention relates to an oral film made from a copolymer of polyvinyl alcohol and polyethylene glycol and at least one gum. The oral films may further contain a medicated active and a non-medicated component. The film upon application, depending upon the quantity of gum and other additives may quickly disintegrate releasing its contents in the mouth or stay adhered for the period of greater than an hour, greater than two hours and preferably for around four hours or more.

Owner:PAWAR HARSHAL ASHOK +1

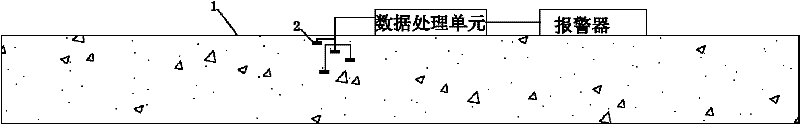

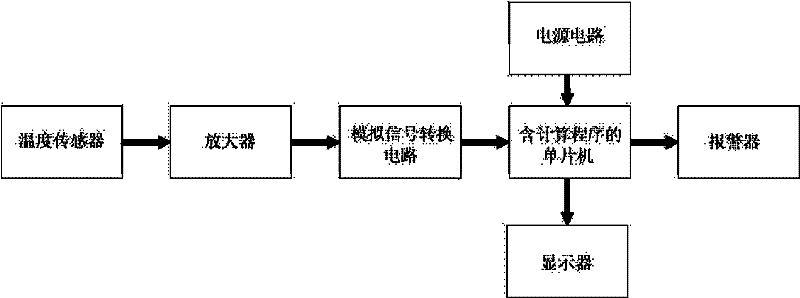

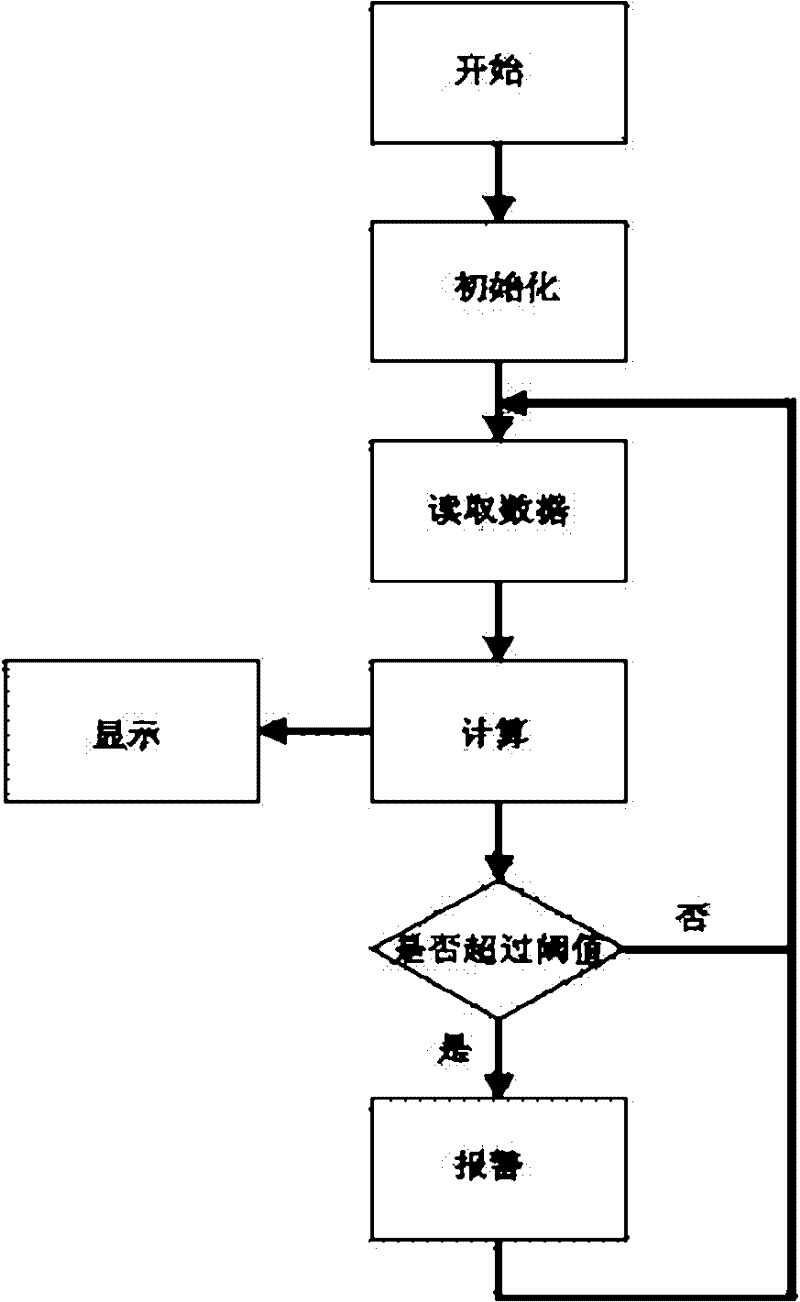

Early-warning system and method for temperature cracks on surface of concrete

ActiveCN102393258AEasy programmingSimple formulaThermometers using value differencesEarly warning systemTemperature gradient

The invention provides an early-warning system and method for temperature cracks on a surface of concrete and relates to a method for measuring and calculating the temperature gradient of concrete and alarming for a dangerous working condition. For the invention, an alarm judging position and the temperature gradient threshold of the position are preset according to the actual engineering need and the concrete properties; a temperature sensor, a data processing unit and an alarm which are ordinary are used; the temperature gradients of all points are calculated according to the formula by measuring the temperature of the concrete in the range 0.5m from the surface of the concrete; and the alarm gives an alarm when the temperature gradient at the judging position is more than the preset threshold. The early-warning system has the characteristics of timely and accurate alarming and simplicity and convenience in operation, and has obvious effect in the aspects of preventing the temperature cracks on the surface of the large-volume concrete.

Owner:TSINGHUA UNIV

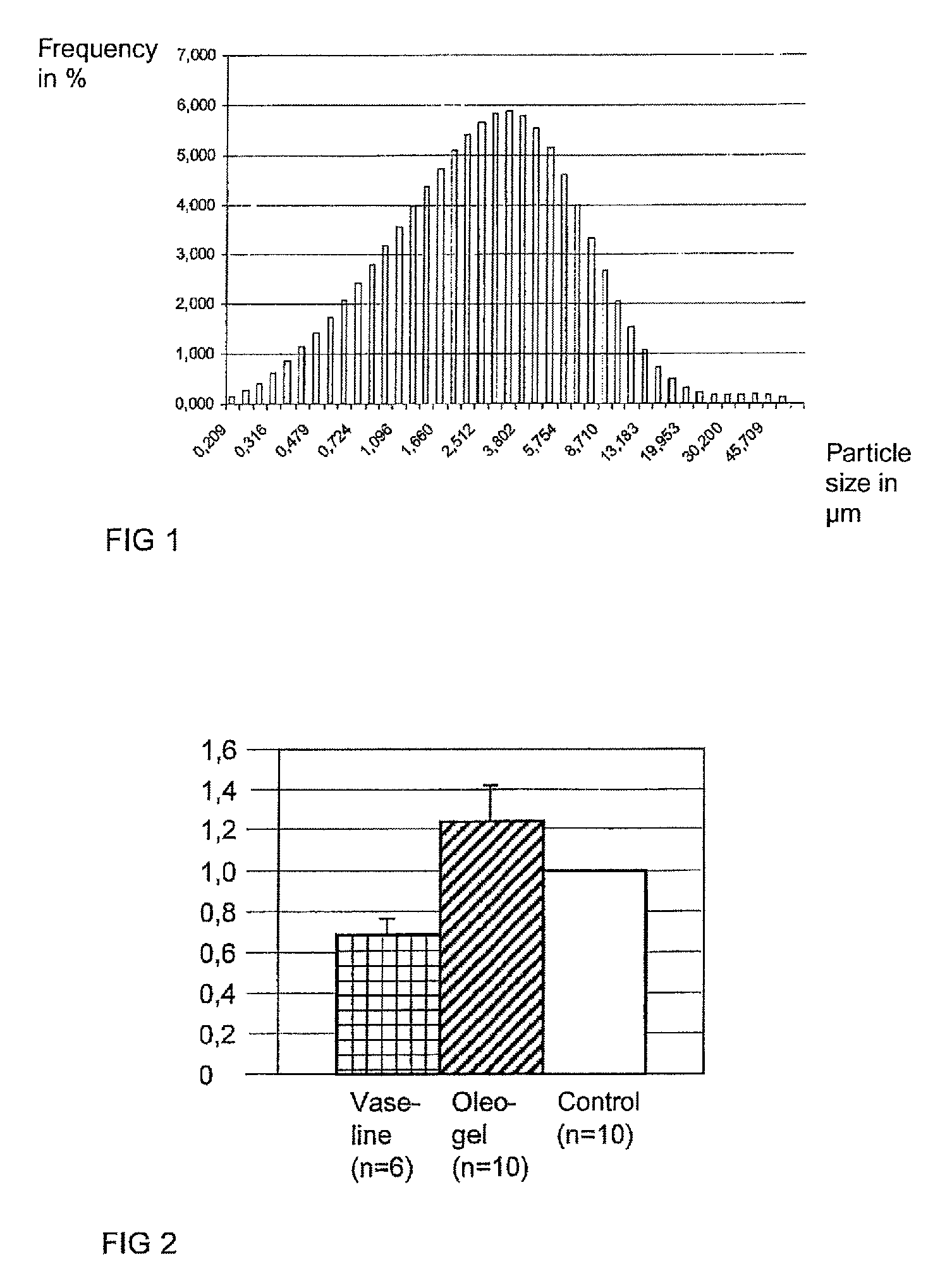

Triterpene-containing oleogel-forming agent, triterpene-containing oleogel and method for producing a triterpene-containing oleogel

The invention relates to an oleogel-forming agent which comprises at least one highly dispersed triterpene. The invention also relates to an oleogel which comprises a nonpolar liquid in an amount ranging from 80% by weight to 99% by weight based on the total weight of the oleogel and an oleogel-forming agent comprising a highly dispersed triterpene in an amount ranging from 1% by weight to 20% by weight based on the total weight of the oleogel. The invention also relates to a method for producing an oleogel.

Owner:AMRYT PHARM DESIGNATED ACTIVITY CO

Method, apparatus, and composition for automatically coating the human body with plural components

InactiveUS6881417B1Improve coating uniformityImprove uniformityCosmetic preparationsLiquid surface applicatorsBiomedical engineeringChemical composition

In a system for coating human skin, a chemical composition, such as a cosmetic or medical formulation, is uniformly coated over the entire body or selected parts of the body of the person being coated. The system includes atomization of the coating composition, containment of the atomized spray, and residual recovery which together yield a novel method for applying chemical compositions. An improved self-tanning composition is useful in conjunction with the system is also disclosed. Also disclosed is a plural component self-tanning system.

Owner:LAUGHLIN PROD

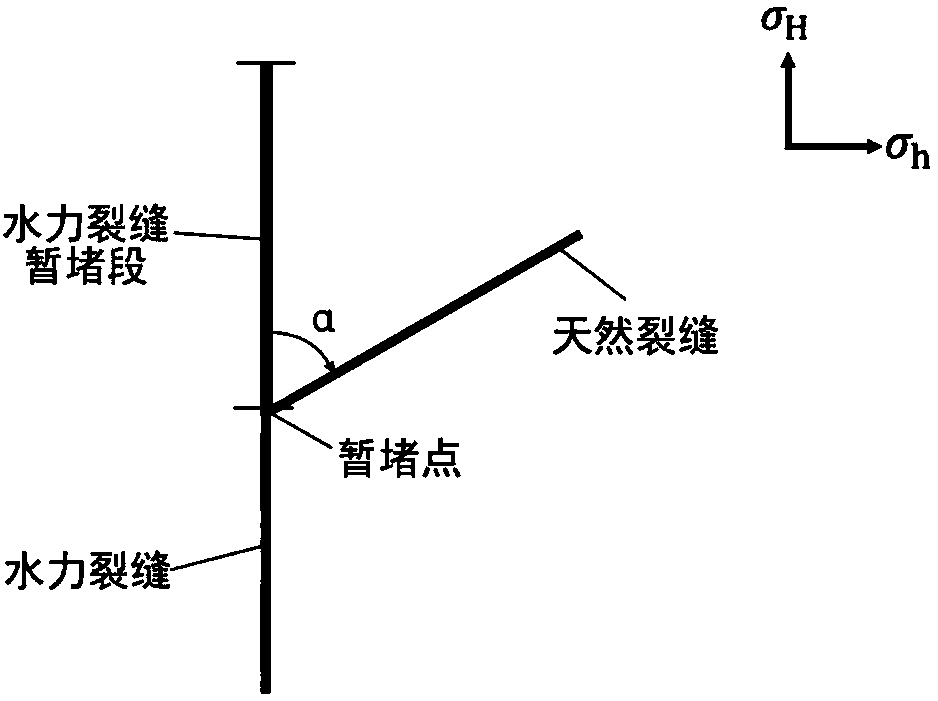

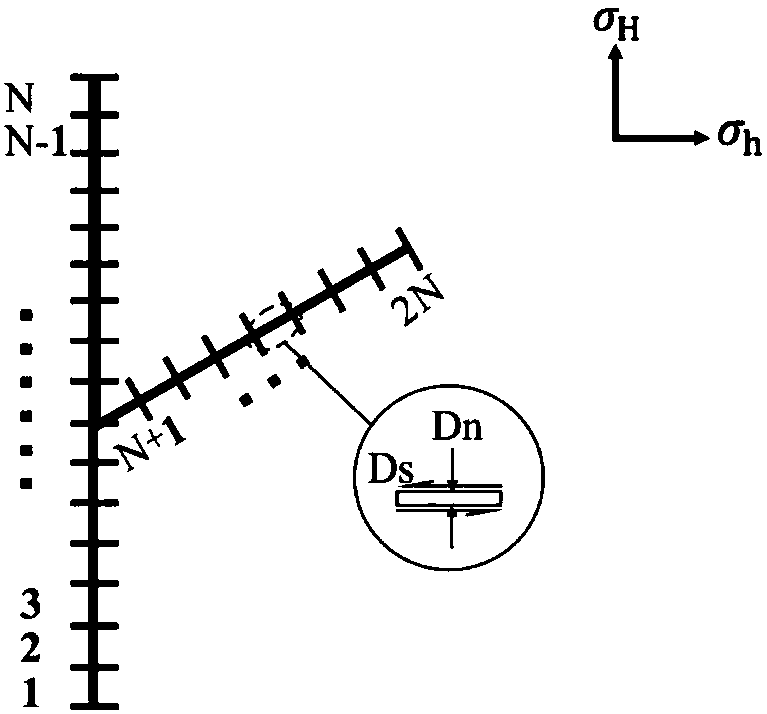

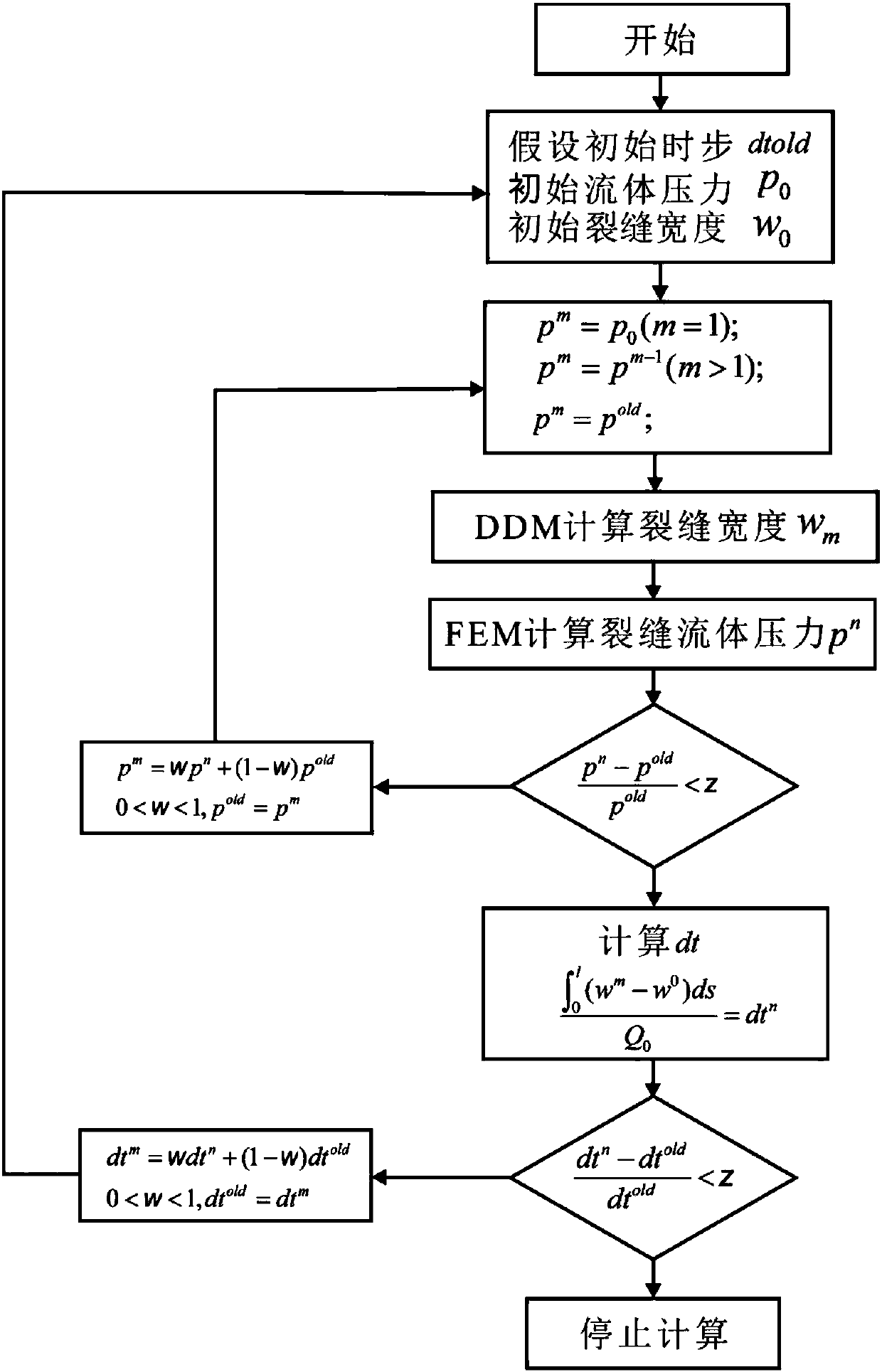

Method for calculating turning fracture initiation pressure in shale refracturing

ActiveCN107609258ASimple formulaEliminate Inadequacies in Initiation Pressure CalculationsSpecial data processing applicationsInduced stressEnvironmental geology

The invention discloses a method for calculating turning fracture initiation pressure in shale refracturing. The method comprises the following steps of: 1, collecting parameters of fractures, inputting the parameters into a computer to form a fracture system, dispersing the fracture system into 2N fracture units through the computer; 2, substituting the fracture units in the step 1 and related fracturing parameters according to a calculation formula, and calculating system fluid pressure distribution of the fracture units; 3, under the condition of achieving a balance, establishing a dispersed fracture unit stress balance equation through influences, on rock deformation, of pressure distribution points; 4, coupling fluid flow in the fracture system with fracture deformation through the fracture unit pressure distribution and a stress balance condition, and calculating an induced stress acting on the dispersed fracture unit; and 5, calculating turning fracture initiation pressure through the induced stress obtained in the step 4. The invention innovatively discloses the method for calculating turning fracture initiation pressure in shale refracturing, and the method can be used forinstructing fracturing construction.

Owner:SOUTHWEST PETROLEUM UNIV

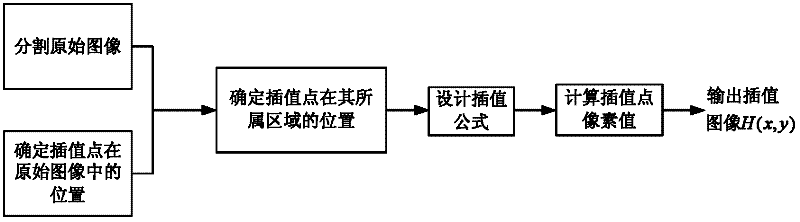

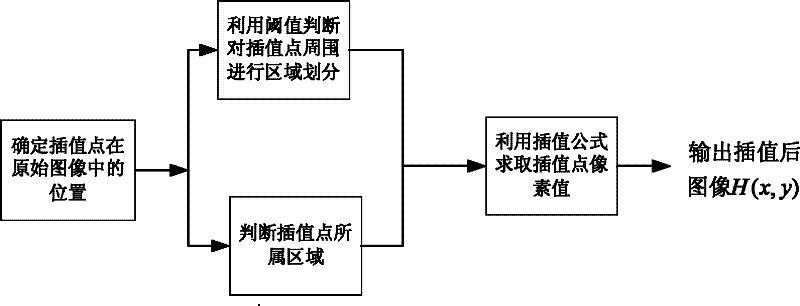

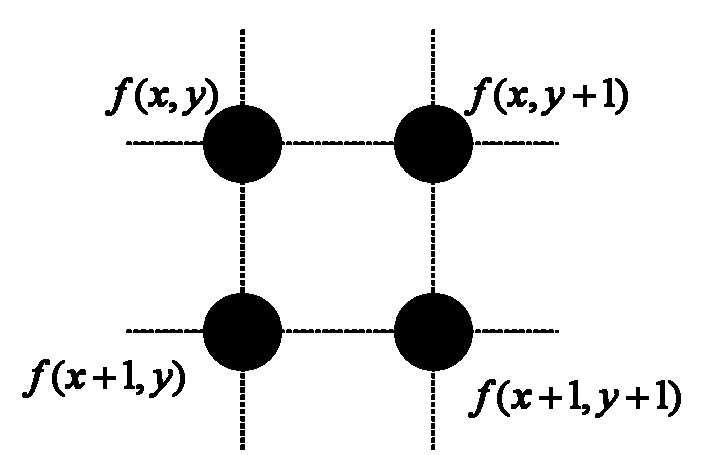

Image interpolation algorithm based on region consistency

ActiveCN102609900AImprove visual effectsReduce complexityGeometric image transformationStandards conversionInternal memoryComputation complexity

The invention provides an image interpolation algorithm based on region consistency, and the algorithm comprises the following steps of: firstly confirming the positions of interpolation points in an original image; carrying out region division on the periphery of the interpolation points by means of the judgment of a threshold value, judging the regions to which the interpolation points belong, obtaining the pixel value of the interpolation points by virtue of an interpolation formula, and outputting the interpolated image. The technical problems of lower image quality, high computation complexity, more occupied internal memory and difficulty in realization based on hardware caused by inaccurate edge region division in the conventional interpolation algorithm can be solved. Compared with an edge adaptive algorithm, the algorithm provided by the invention has the advantages that on the premise that the image quality is not observably reduced, the complexity of the algorithm is greatly reduced, so that the interpolated image is better in visual effect, and therefore, the algorithm is an image-amplifying interpolation algorithm which is simple to operate, good in effect, and easy to realize based on hardware.

Owner:北京倚天升科技开发有限公司

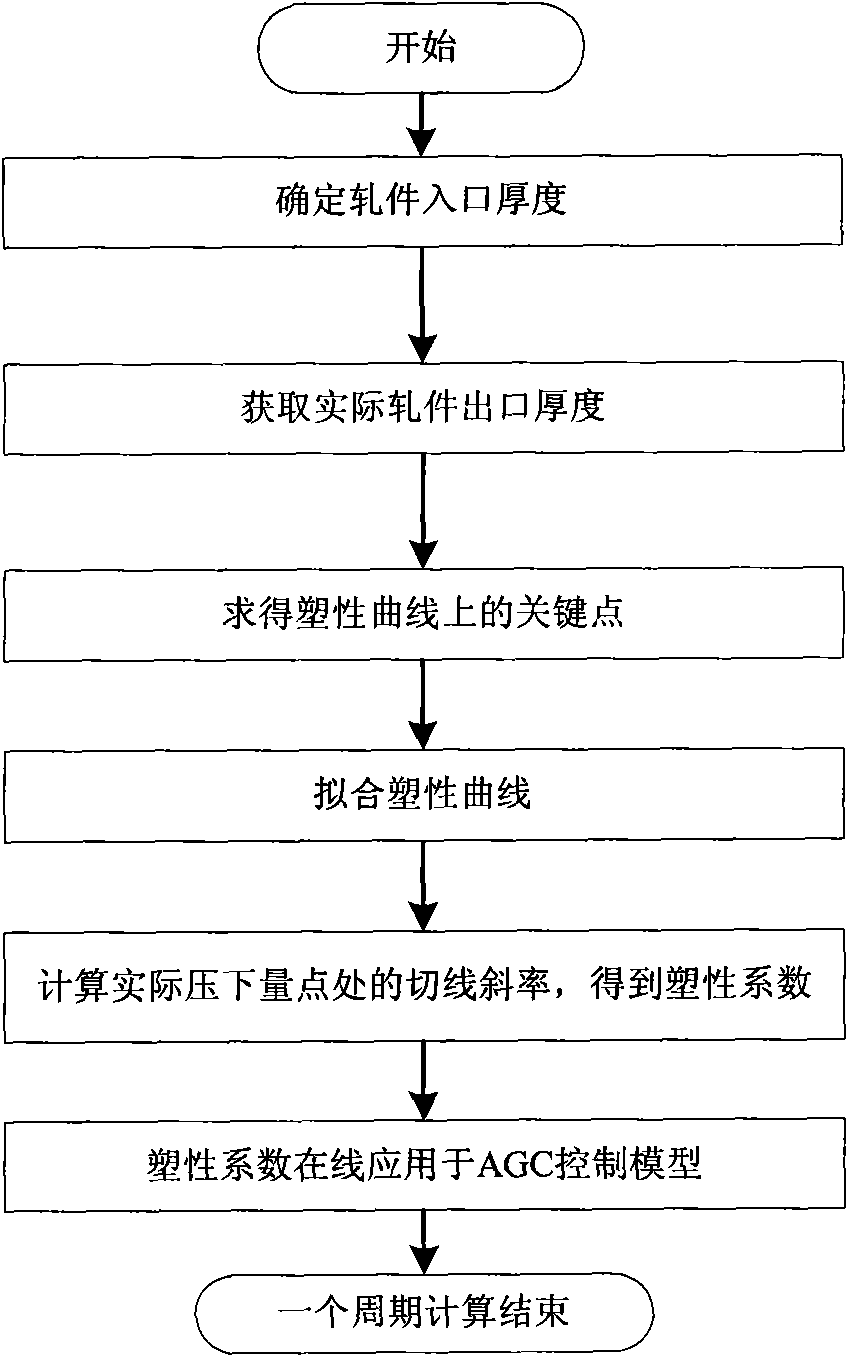

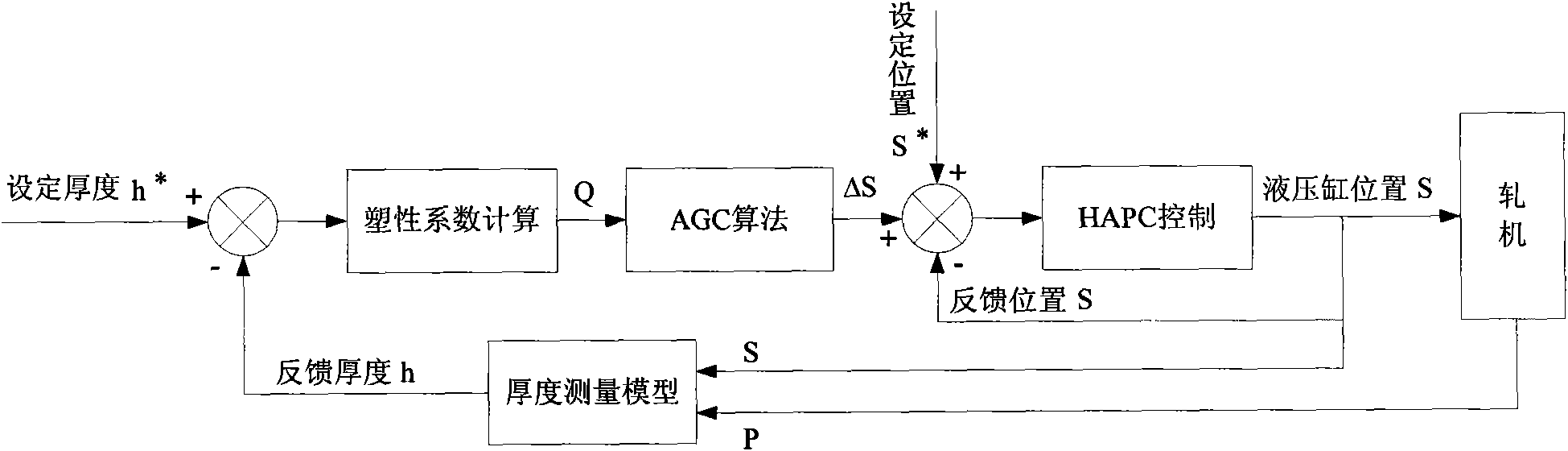

On-line acquisition method for plasticity coefficient of rolled piece during rolling of medium plate

InactiveCN101566538AImprove thickness compensation accuracySimple formulaProgramme control in sequence/logic controllersStrength propertiesControl modelsPlastic property

The invention relates to an on-line acquisition method for plasticity coefficient of a rolled piece during rolling of a medium plate, and belongs to the technical field of rolling. The method comprises the following steps: (1) determining the inlet thickness of the rolled piece; (2) acquiring the actual outlet thickness of the rolled piece; (3) solving key points on a plastic curve; (4) fitting the plastic curve; (5) calculating the tangent slope at the actual pressing measurement point to obtain the plasticity coefficient; (6) applying the solved plasticity coefficient to an AGC control model on line; and (7) triggering next period, turning to step (1) and reacquiring the plasticity coefficient according to the acquired data. The method has the advantages that the method does not depend on the investment of process computers and is not influenced by complex factors in a production field; the result has no jump phenomenon; and the acquisition process is stable, can be directly embedded into basic automation to be applied, and continuously correct the plasticity coefficient along with the rolling process according to the change of a roll force and the change of a roll gap so as to improve the thickness compensation precision of an AGC system and apply to high-precision AGC control.

Owner:NORTHEASTERN UNIV

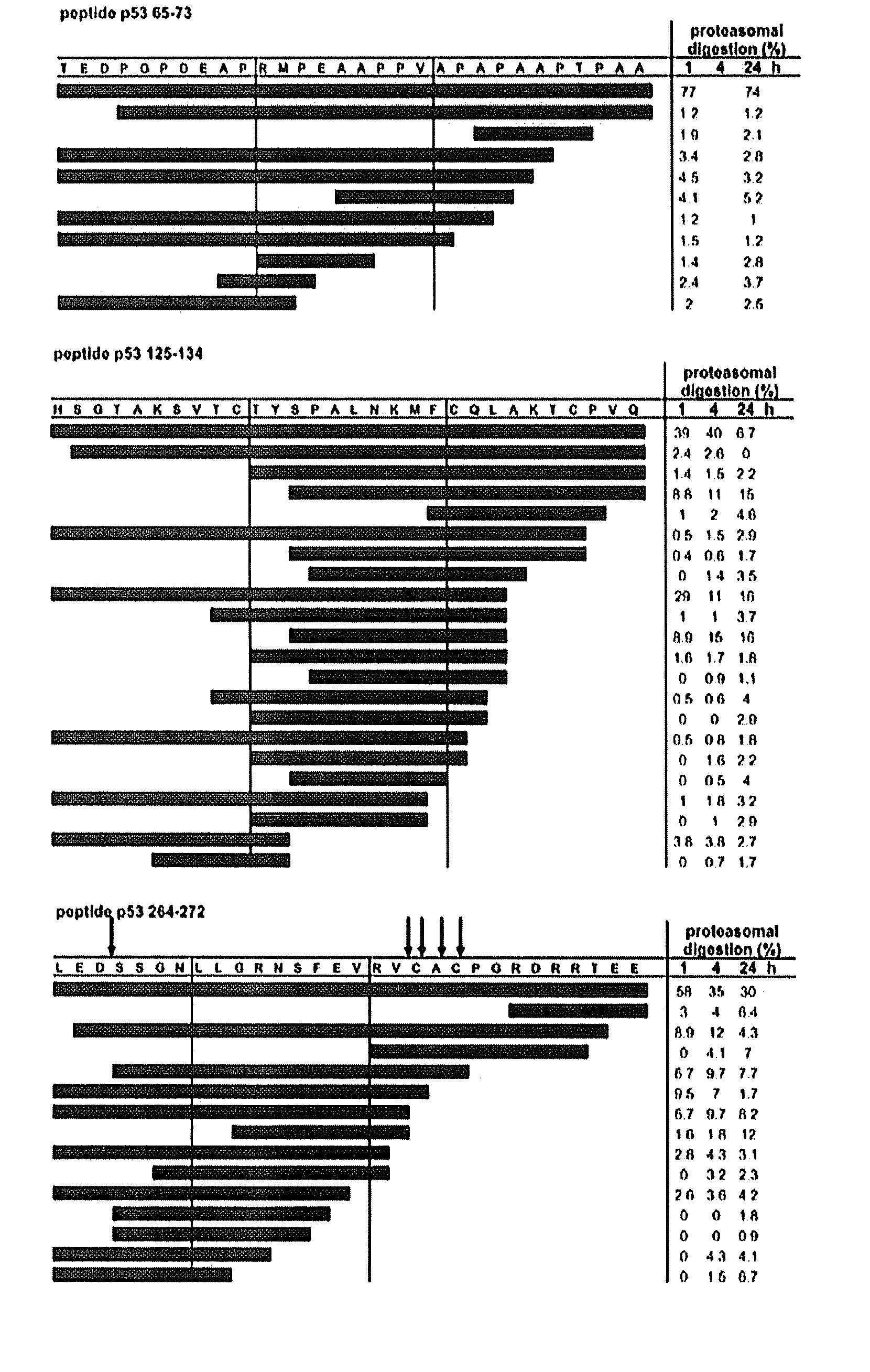

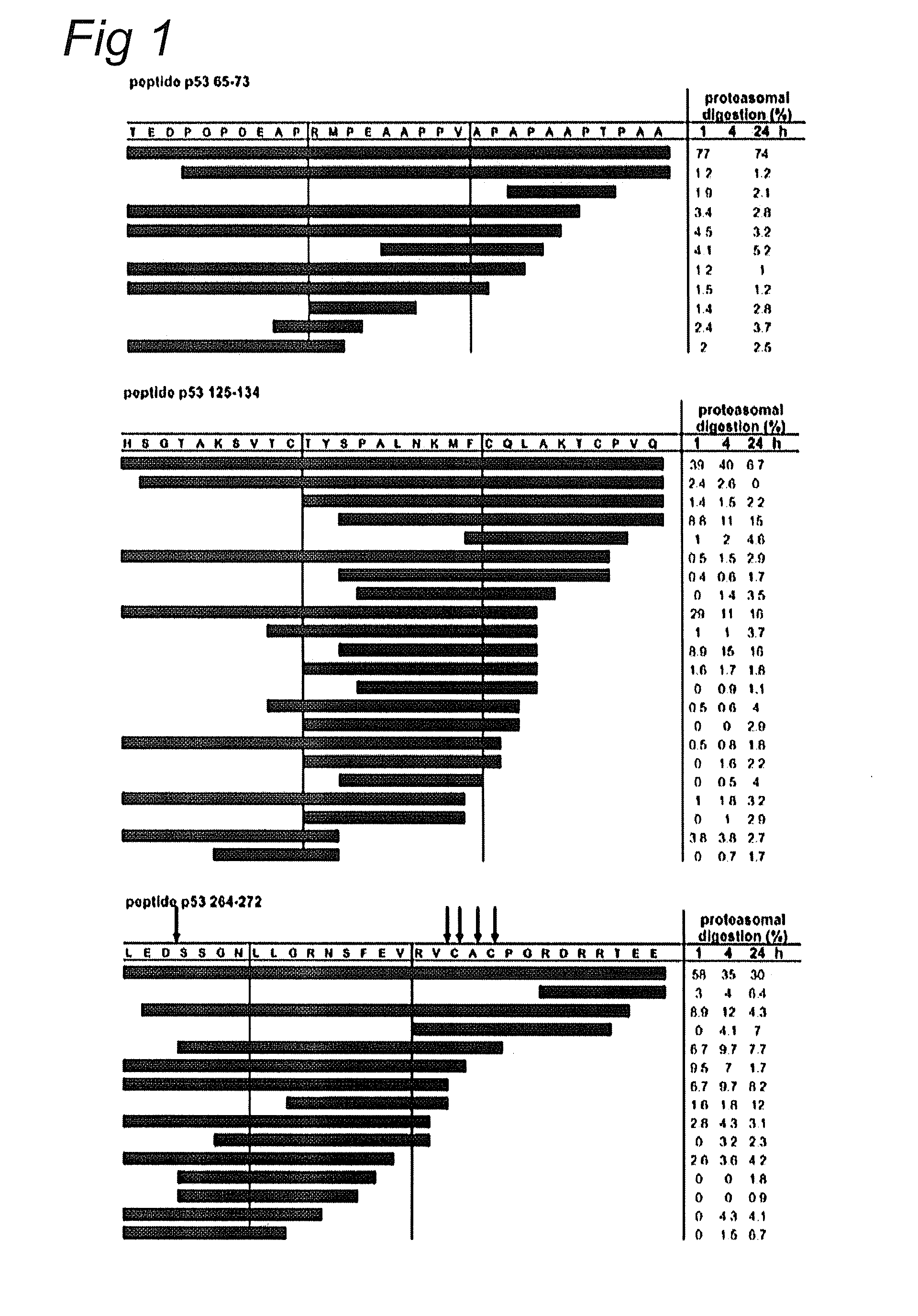

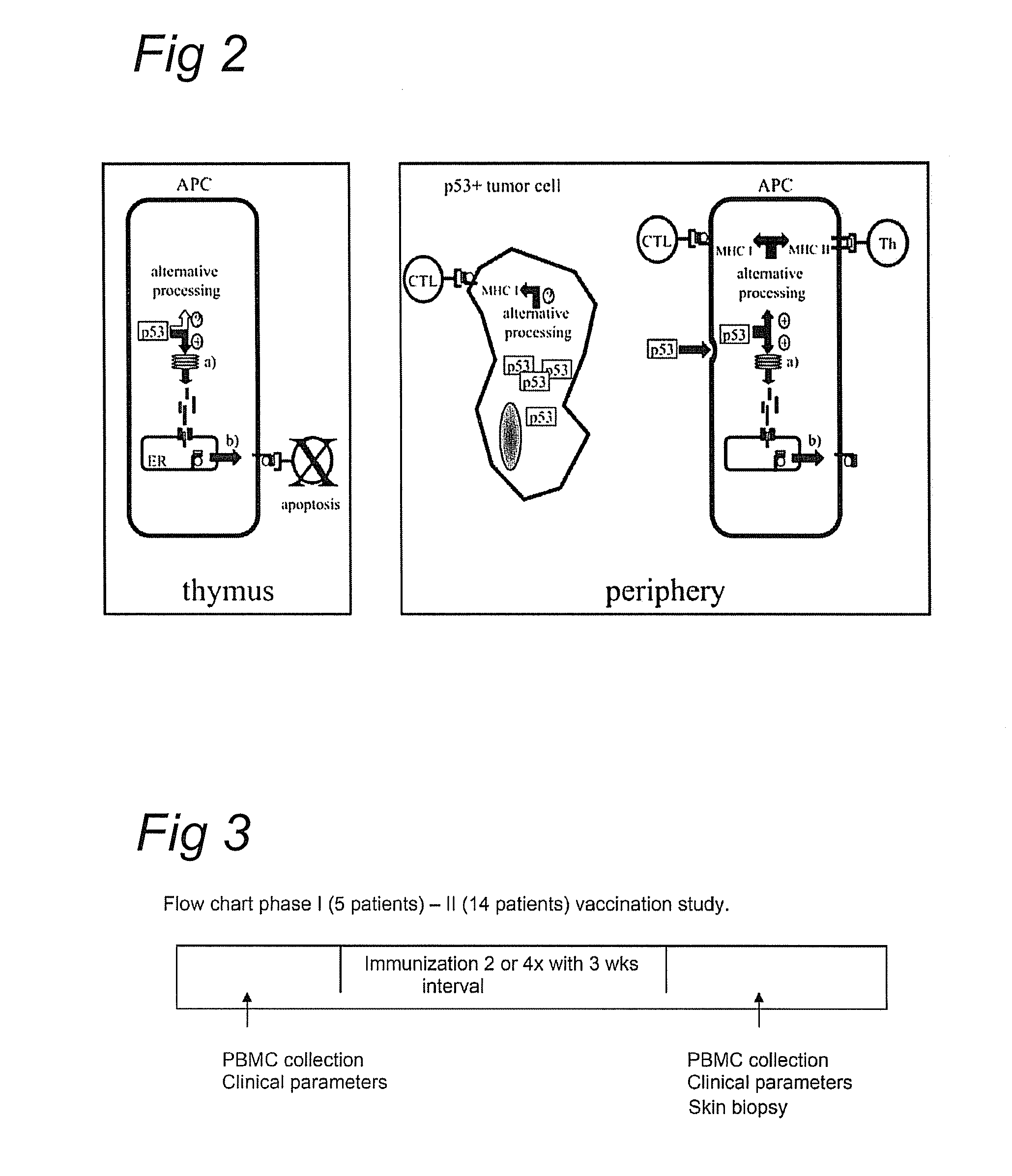

P53 peptide vaccine

InactiveUS20100210529A1Easy to synthesizeReduce the amount requiredPeptide/protein ingredientsP53 proteinPeptideP53 Peptide Vaccine

Owner:ACADEMISCH ZIEKENHUIS BIJ DE UNIV VAN AMSTERDAM ACADEMISCH MEDISCH CENT

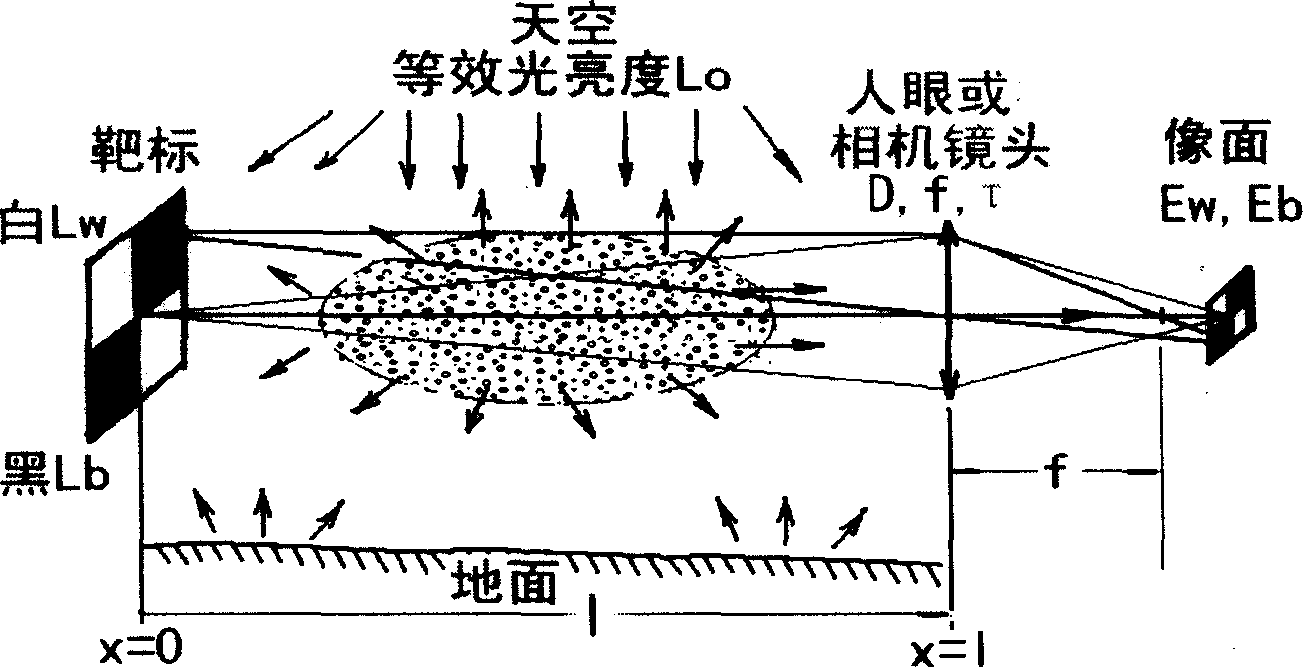

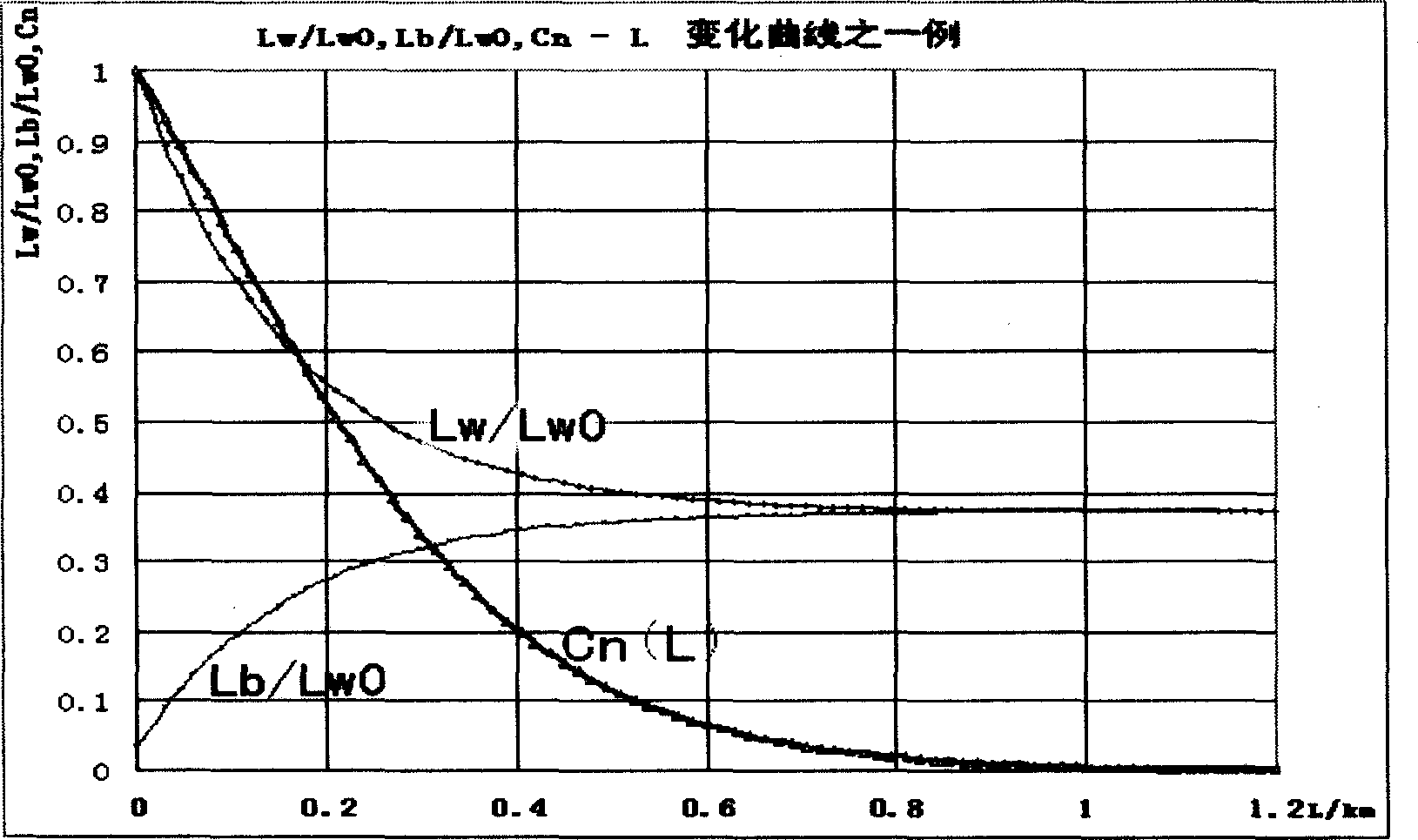

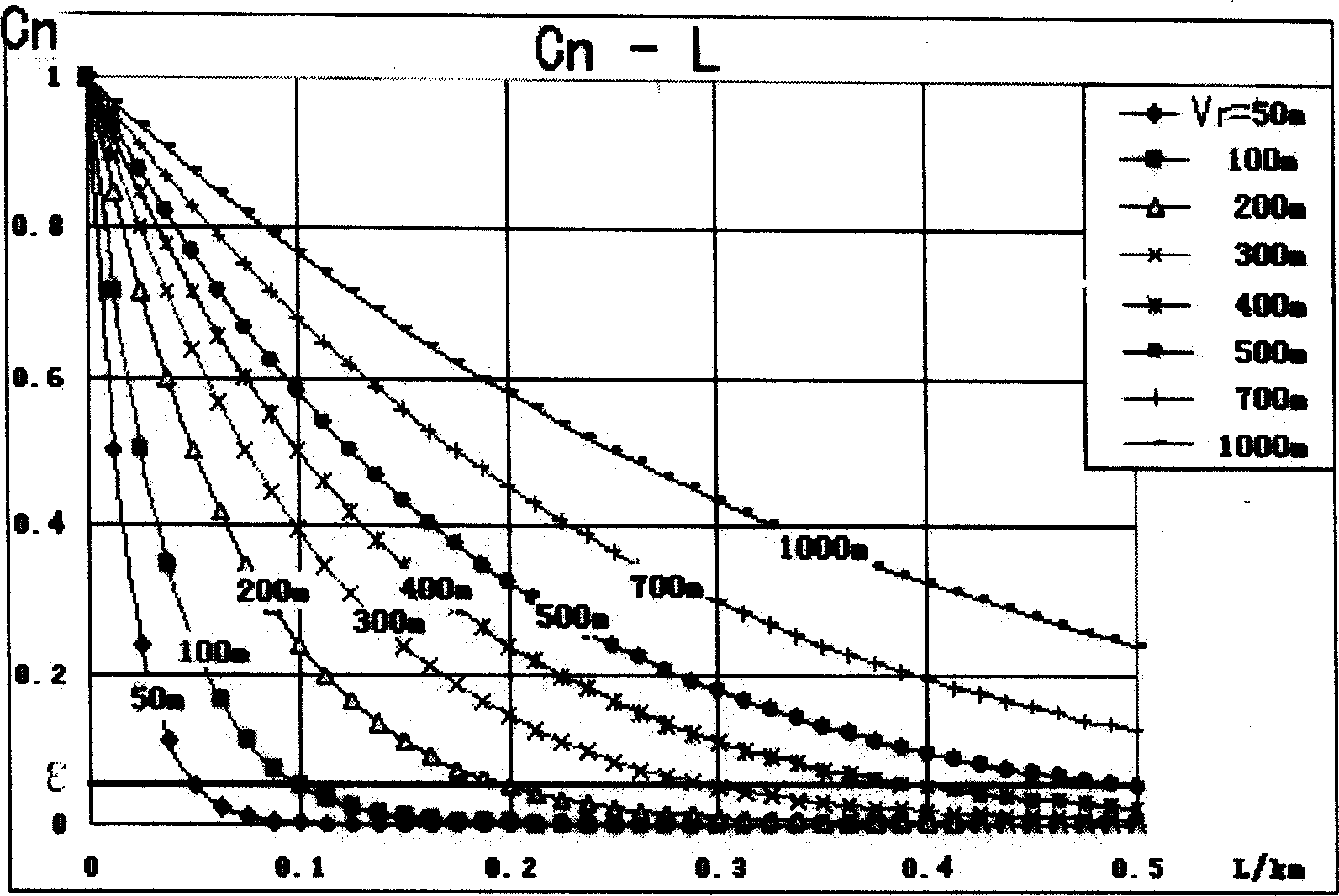

Self-calibrating atmosphere visibility measuring method and measuring system thereof

InactiveCN1804588AImprove accuracyEliminate the hassle of pre-calibrationScattering properties measurementsOn-screen displayVisual perception

The invention discloses a method and system for measuring the self-aligning atmosphere visual degree. It takes photo of the image of all the target and uses the mode near to human eyes character to process the image to auto compute the normalizing diversity of the target light brightness and the visual degree value and transmits the data to the monitoring center and the LED large screen display of the high speed road inlet and outlet port by GPRS wireless mode.

Owner:成都易航信息科技有限公司

Triterpene-containing oleogel-forming agent, triterpene-containing oleogel and method for producing a triterpene-containing oleogel

The invention relates to an oleogel-forming agent which comprises at least one highly dispersed triterpene. The invention also relates to an oleogel which comprises a nonpolar liquid in an amount ranging from 80% by weight to 99% by weight based on the total weight of the oleogel and an oleogel-forming agent comprising a highly dispersed triterpene in an amount ranging from 1% by weight to 20% by weight based on the total weight of the oleogel. The invention also relates to a method for producing an oleogel.

Owner:AMRYT RES LTD

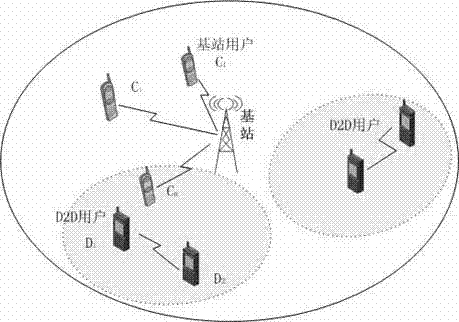

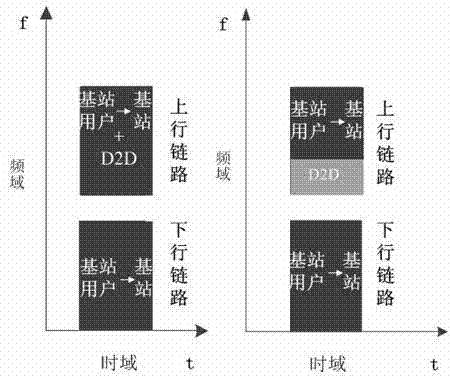

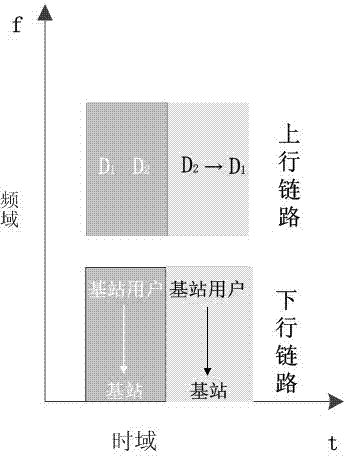

Distance ratio based D2D (dimension to dimension) link spectrum allocation method

InactiveCN102821391AResolve interferenceEasy to optimizeNetwork planningFrequency spectrumInterference problem

The invention discloses a distance ratio based D2D (dimension to dimension) link spectrum allocation method, belonging to the technical field of wireless communication. The method disclosed by the invention is implemented through selecting a D2D link which carries out communication by using a cell uplink in a cell, firstly selecting a base station user according with distance-ratio conditions in the cell, and sharing the spectrum resources of the base station user with the D2D link; and if the spectrum can not be shared, separately allocating a spectrum to the D2D link. Through the method, the interference problem in a D2D system is solved, thereby obtaining the capacity enhancement and ensuring the reliable D2D communication; and meanwhile, the spectrum selection criteria of D2D links is greatly simplified, thereby helping a base station to rapidly complete the spectrum allocation of D2D links.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

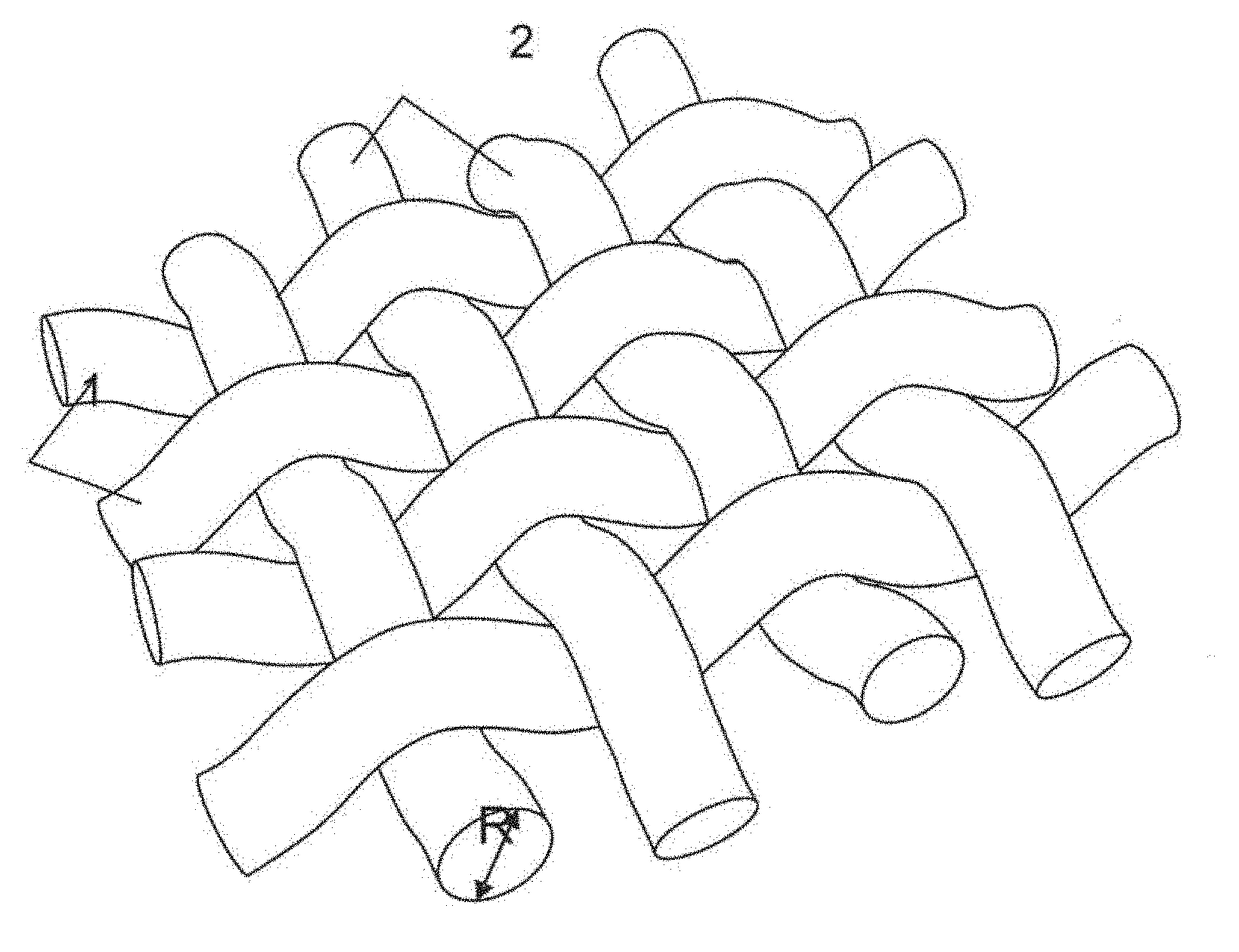

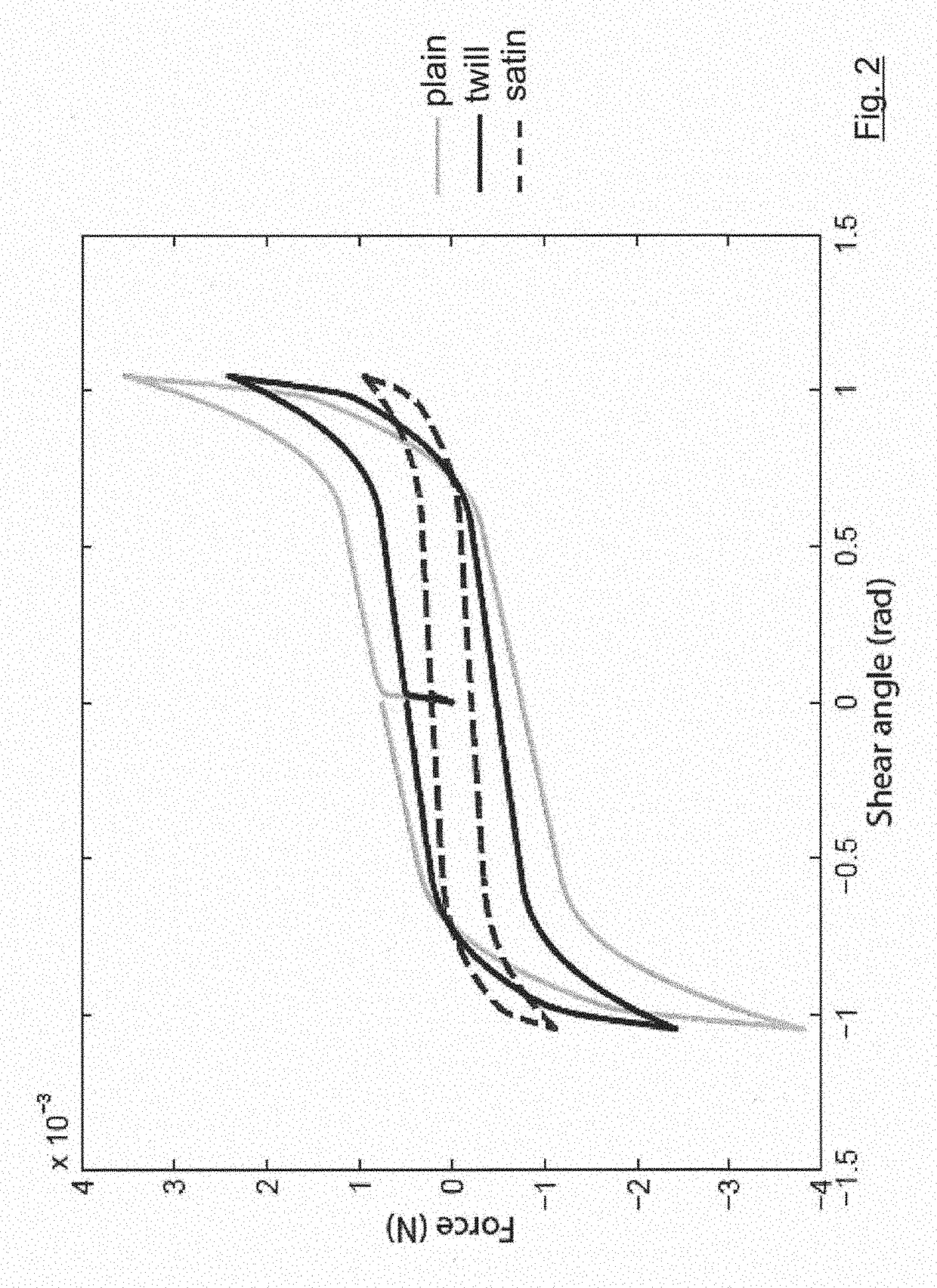

Computerized method, computer program product and system for simulating the behavior of a woven textile interwoven at thread level

ActiveUS20170337303A1Avoid contactSimple formulaDesign optimisation/simulationImage generationWoven fabricEquations of motion

Computer implemented method, system and computer program product for simulating the behavior of a woven fabric at yarn level. The method comprises:retrieving the layout of warp yarns (1), weft yarns (2) and yarn crossing nodes (3);describing each yarn crossing node (3) by a 3D position coordinate (x) and two sliding coordinates, warp sliding coordinate (u) and weft sliding coordinate (v) representing the sliding of warp (1) and weft (2) yarns;measuring forces on each yarn crossing node (3) based on a force model, the forces being measured on both the 3D position coordinate (x) and the sliding coordinates (u, y);calculating the movement of each yarn crossing node (3) using equations of motion derived using the Lagrange-Euler equations, and numerically integrated over time, wherein the equations of motion account for the mass density distributed uniformly along yarns, as well as the measured forces and boundary conditions.

Owner:SEDDI INC

Method of and apparatus for automatically coating the human body

InactiveUS7082948B2Improve coating uniformityImprove uniformityCosmetic preparationsLiquid surface applicatorsChemical compositionHuman skin

In a system for coating human skin, a chemical composition, such as a cosmetic or medical formulation, is uniformly coated over the entire body or selected parts of the body of the person being coated. The system includes atomization of the coating composition, containment of the atomized spray, and residual recovery which together yield a novel method for applying chemical compositions.

Owner:LAUGHLIN PROD

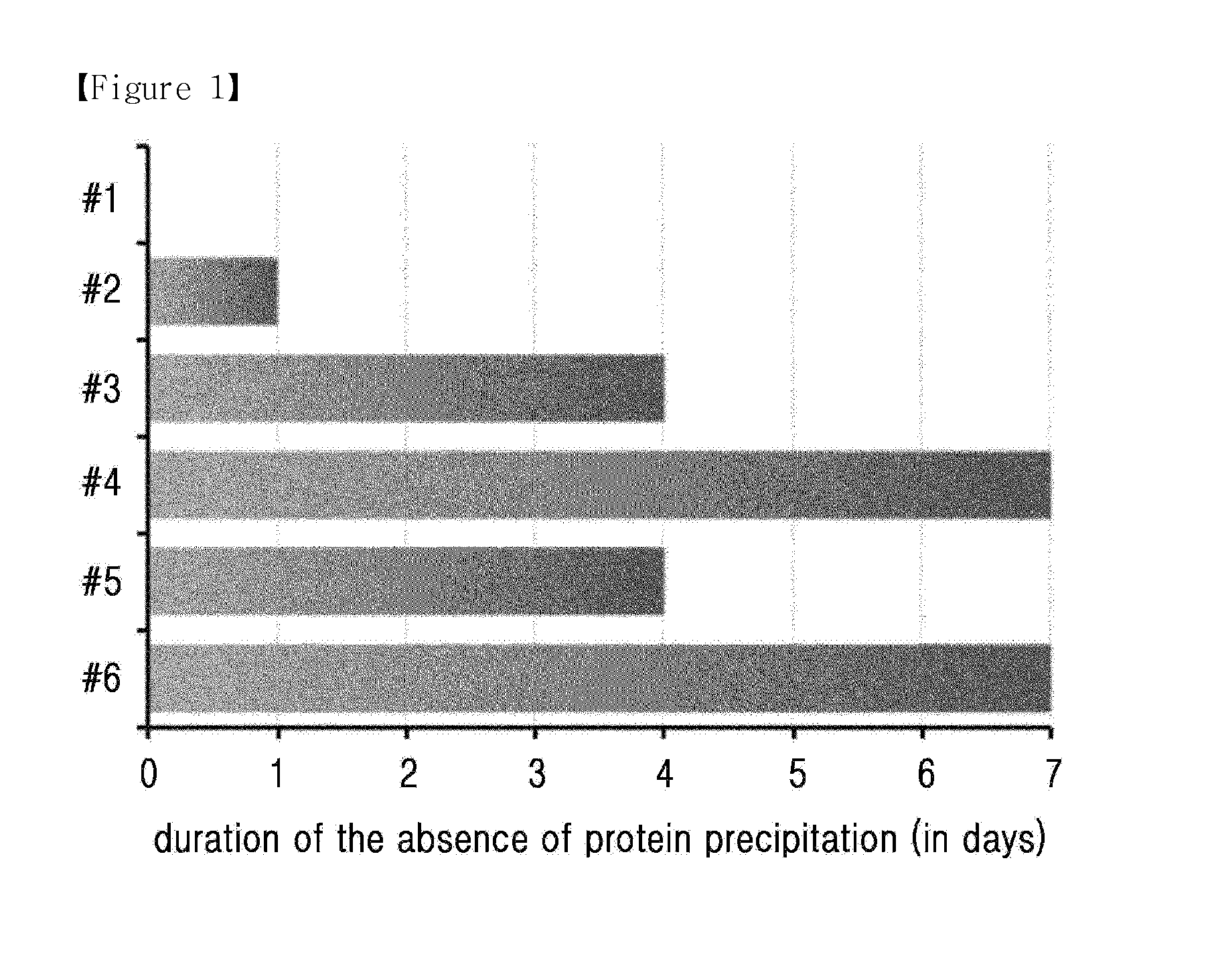

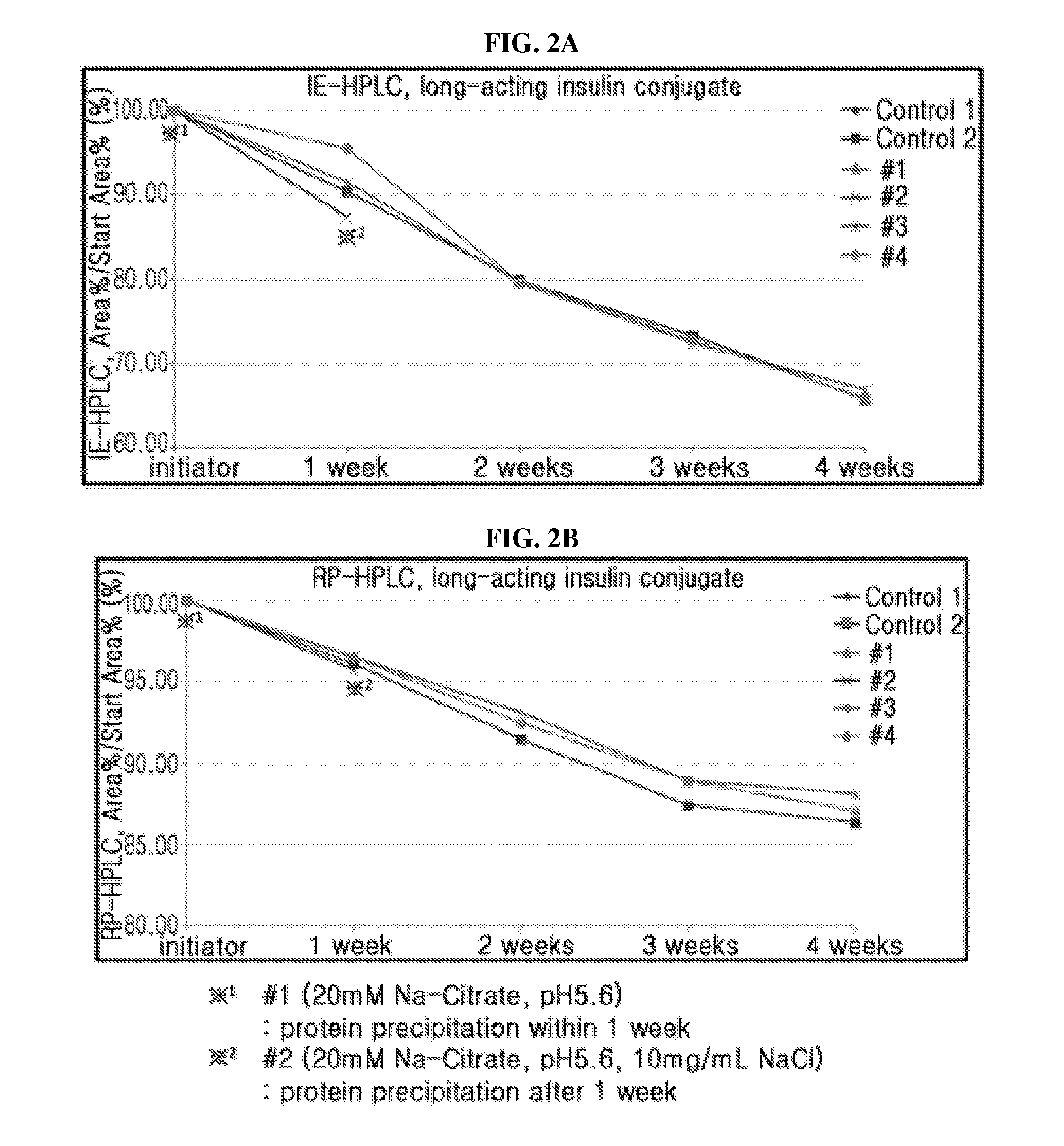

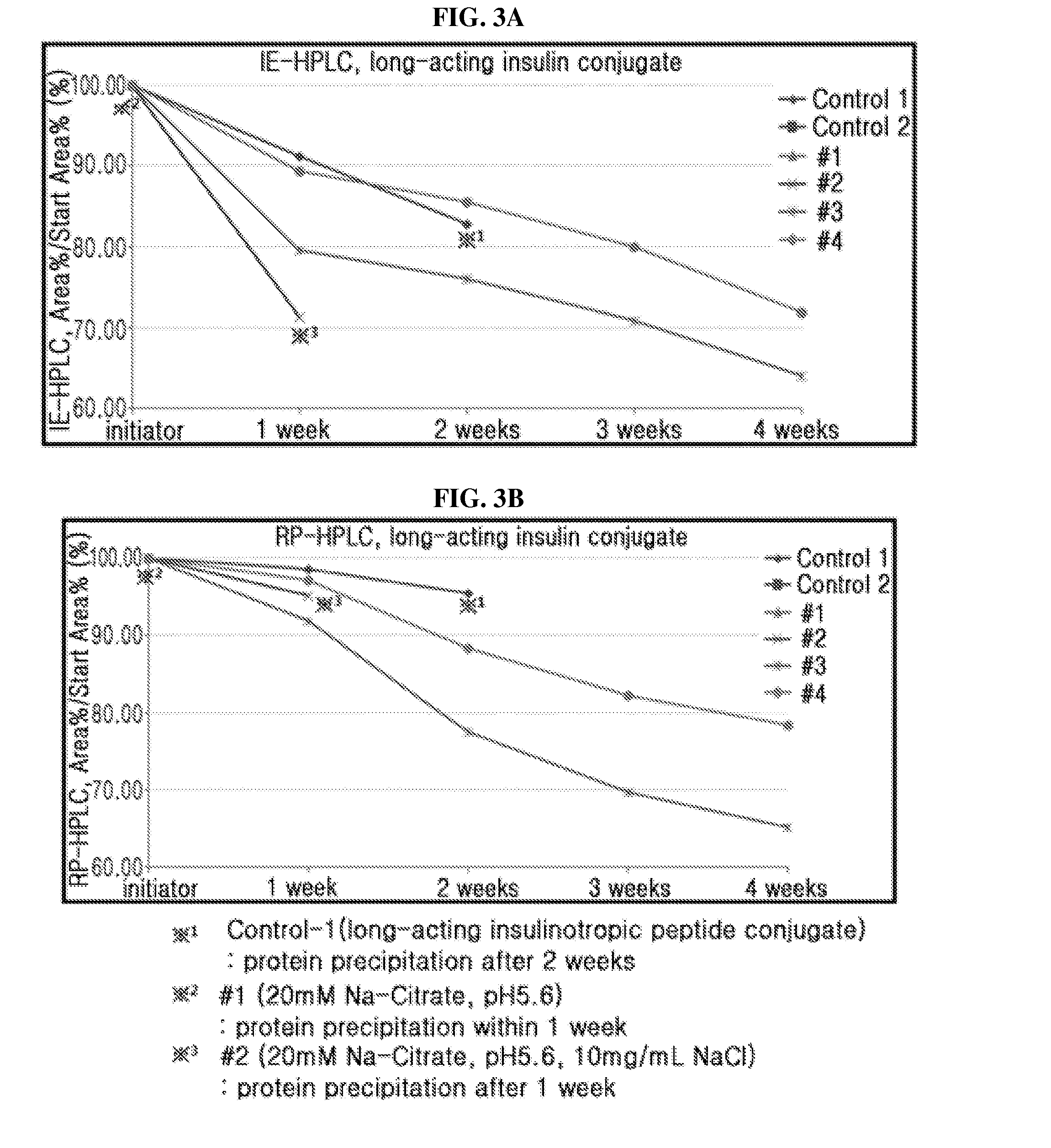

Liquid formulation of long-acting insulin and insulinotropic peptide

ActiveUS20150190528A1Good storage stabilityMaintain activityPeptide/protein ingredientsMetabolism disorderHigh concentrationAlcohol sugars

The present invention relates to a liquid formulation of a combination of long-acting insulin and insulinotropic peptide, comprising insulin which is a physiologically active peptide, insulinotropic peptide, and albumin-free stabilizer, wherein the stabilizer comprises a buffer, a sugar alcohol, a non-ionic surfactant, and an isotonic agent; and a method for preparing the liquid formulation. The liquid formulation of the present invention does not contain a human serum albumin and potentially toxic factors to the body, and thus it has excellent storage stability for insulin conjugate and insulinotropic peptide conjugate at high concentration, without a risk of viral contamination.

Owner:HANMI PHARMA

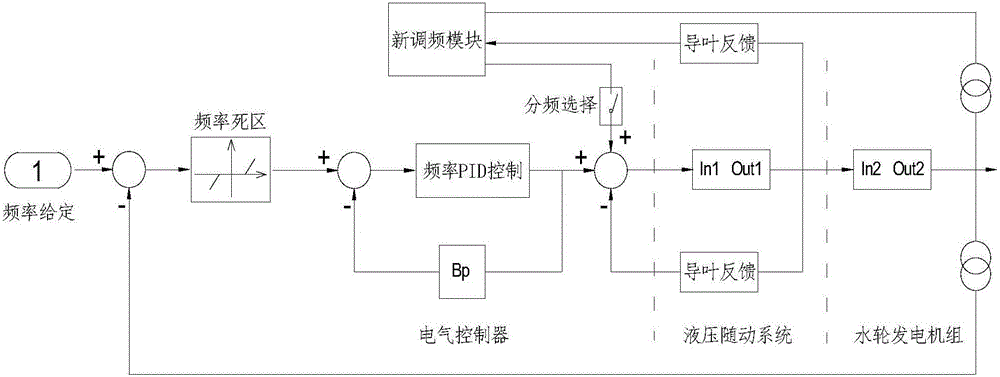

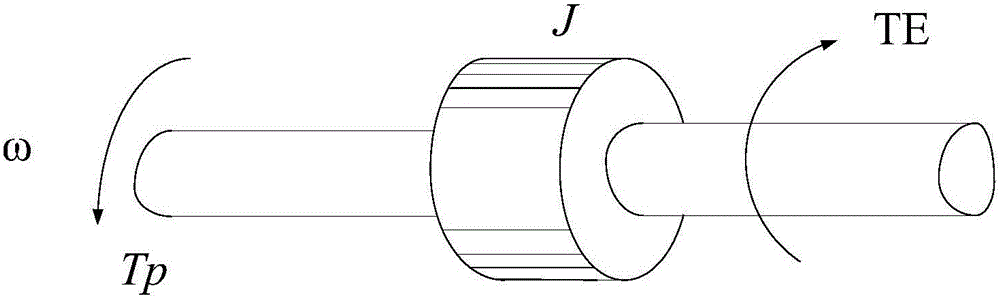

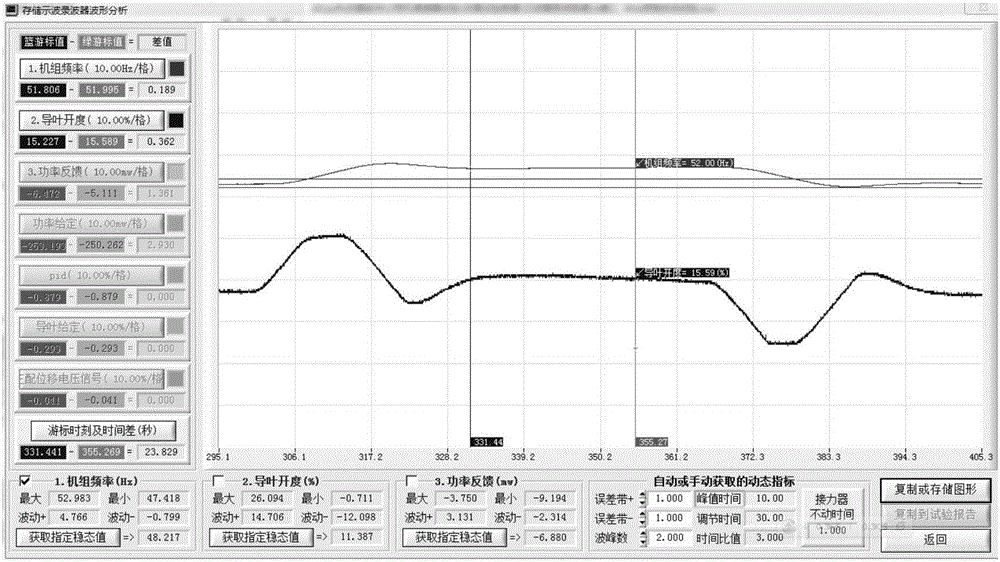

Control method for frequency regulation of electric power isolated network system

ActiveCN105743107ASimple formulaClear formulaPower oscillations reduction/preventionPower qualityInstability

The invention discloses a control method for frequency regulation of an electric power isolated network system. The control method is characterized by comprising the following steps of step 1, setting the permanent rotating-speed difference coefficient bp, PID parameters, frequency modulation dead zone 0.05Hz, and a frequency range from minus and plus 0.05Hz to minus and plus <theta>Hz for retrieving a frequency modulation module according to power grid requirements, wherein <theta> is a positive number greater than 0.05; step 2, detecting the current unit frequency by a speed regulator; step 3, obtaining a difference value <delta>f between the current unit frequency and a rated frequency 50Hz; and step 4, performing regulation according to the numerical value range of the frequency difference <delta>f. By adoption of the method, the problems of high frequency control error, low precision and instability of the electric power system, particularly the isolated network system can be solved; therefore, accurate and stable control of the power grid frequency is realized; the electric energy quality of the power system is ensured; power grid accident extension is prevented; and rapid recovery of the power grid in faults can be realized.

Owner:NANJING NARI GROUP CORP +1

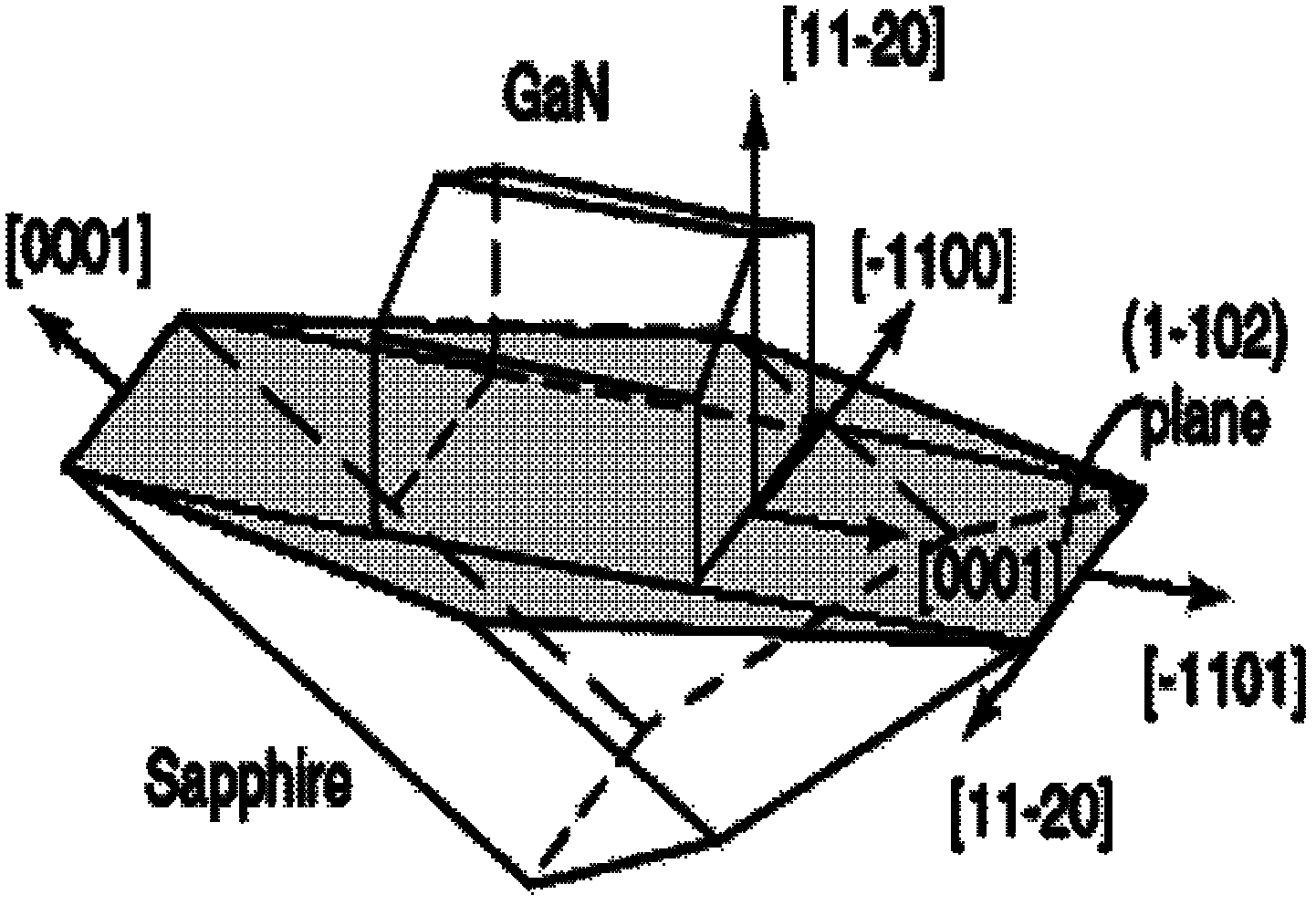

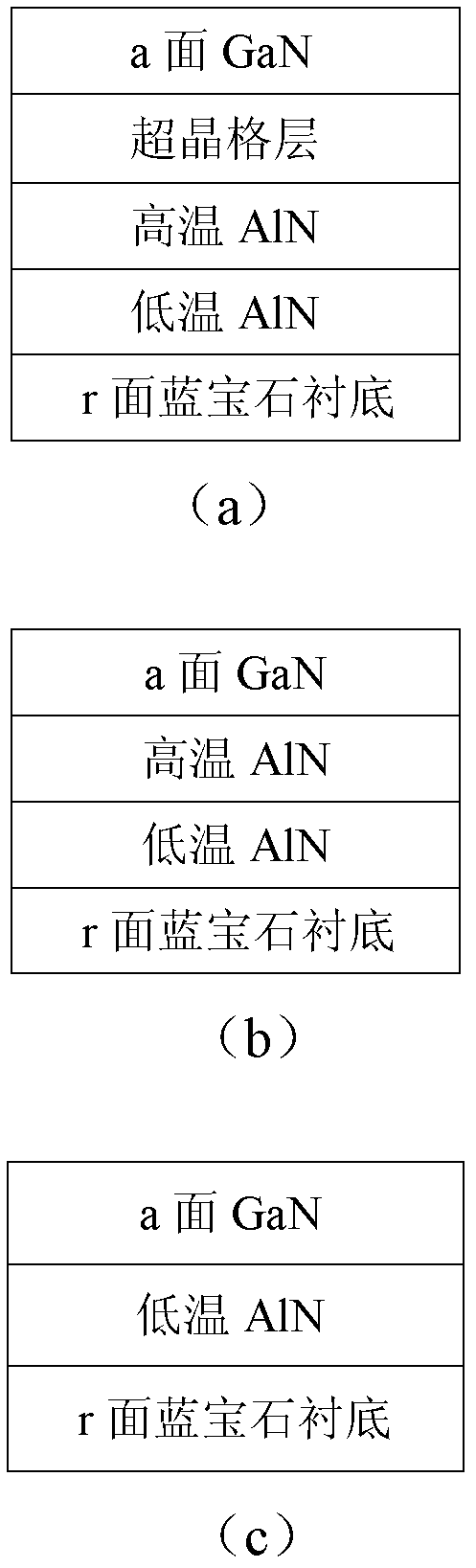

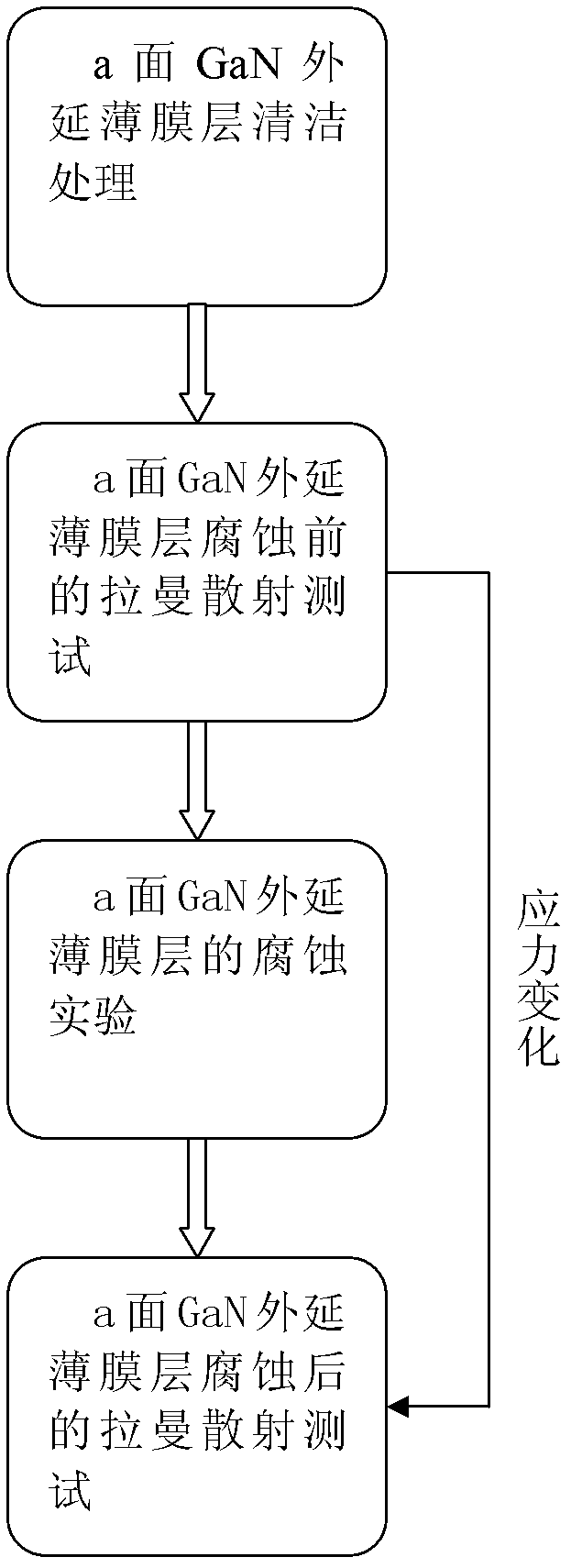

Raman characterization method of corrosion stress of alpha surface GaN epitaxial layer film

ActiveCN102359956AAvoid formula derivation and mathematical calculationsSimple formulaRaman scatteringRaman scatteringCorrosion

The invention discloses a Raman characterization method of corrosion stress of an alpha surface GaN epitaxial layer film. The Raman characterization method comprises the following steps of 1, cleaning the surface of an alpha surface GaN epitaxial layer film, 2, carrying out a Raman scattering test on the alpha surface GaN epitaxial layer film to obtain a frequency shift value of an uncorroded E2 phonon mode, 3, carrying out a KOH solution corrosion test and decontamination treatment on the alpha surface GaN epitaxial layer film, and carrying out a Raman scattering test on the corroded alpha surface GaN epitaxial layer film to obtain a frequency shift value of a corroded E2 phonon mode, and 4, according to an offset delta E2 which is the difference of the frequency shift value of the corroded E2 phonon mode of the alpha surface GaN epitaxial layer film and the frequency shift value of the uncorroded E2 phonon mode of the alpha surface GaN epitaxial layer film, calculating corrosion stress of the alpha surface GaN epitaxial layer film by a formula of sigma xx=delta E2 / k, wherein k is a constant. Through adopting two Raman scattering tests on an alpha surface GaN epitaxial layer filmbefore and after the corrosion, the Raman characterization method eliminates the influence from a substrate on alpha surface GaN epitaxial layer film stress, wherein when a conventional Raman characterization method is adopted, the influence exists. Through the Raman characterization method, calculated corrosion stress of an alpha surface GaN epitaxial layer film has a small error. Therefore, theRaman characterization method can be utilized for characterization of corrosion stress of alpha surface GaN epitaxial layer films having different structures.

Owner:云南凝慧电子科技有限公司

Use of an oleogel containing triterpene for healing wounds

ActiveUS9352041B2Process stabilitySimple formulaBiocideHydroxy compound active ingredientsTriterpenePharmacology

An oleogel comprising a non-polar liquid and a powder containing triterpene is provided as an oleogel that may be used for healing wounds.

Owner:AMRYT RES LTD

Novel aging-resistant aerosol generating agent and a preparation method thereof

InactiveUS20120273711A1High fire suppression efficiencyImprove performanceWood working apparatusFire rescuePotassium nitrateReducer

The present invention relates to a novel aging-resistant aerosol generating agent and preparation method thereof. The aging-resistant aerosol generating agent in the present invention comprises oxidizer, reducer and bonding agent, wherein the oxidizer is potassium nitrate, the bonding agent is phenolic resin, and the reducer is melamine; the weight percentages of the three constituents are: potassium nitrate: 60˜80%, phenolic resin: 8˜15%, and melamine: the rest. In the preparation process, phenolic resin is dissolved in ethanol to give phenolic resin solution at concentration by 40˜50 wt %; the oxidizer and reducer are pulverized, mixed, and then the phenolic resin solution is added to the mixed powder; next, the mixture is agitated, pelletized, dried, and shaped by pressure molding. Compared to that in the prior art, the aerosol generating agent in the present invention has higher fire suppression efficiency and higher fire suppression rate, and greatly improved aging resistant performance.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

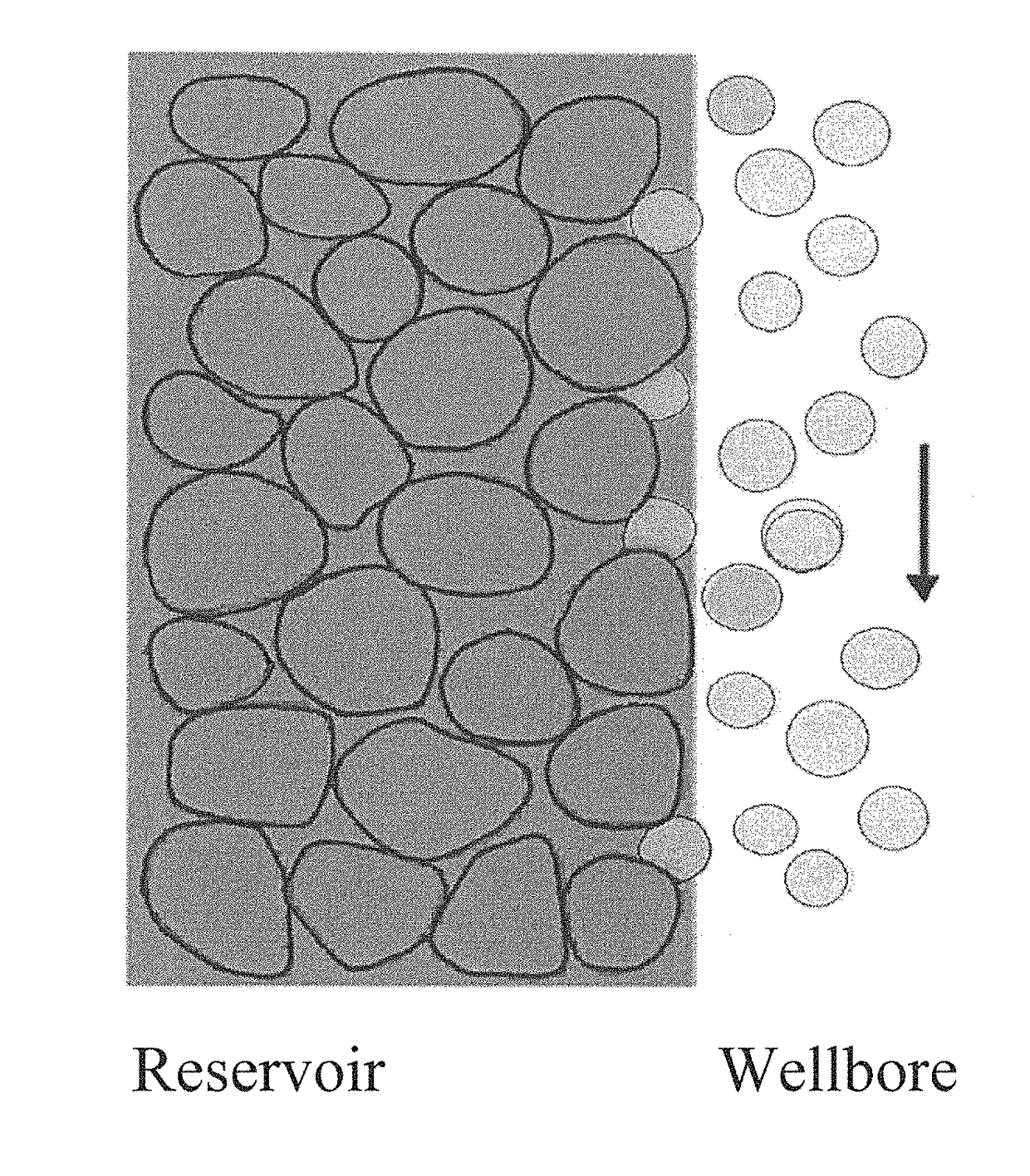

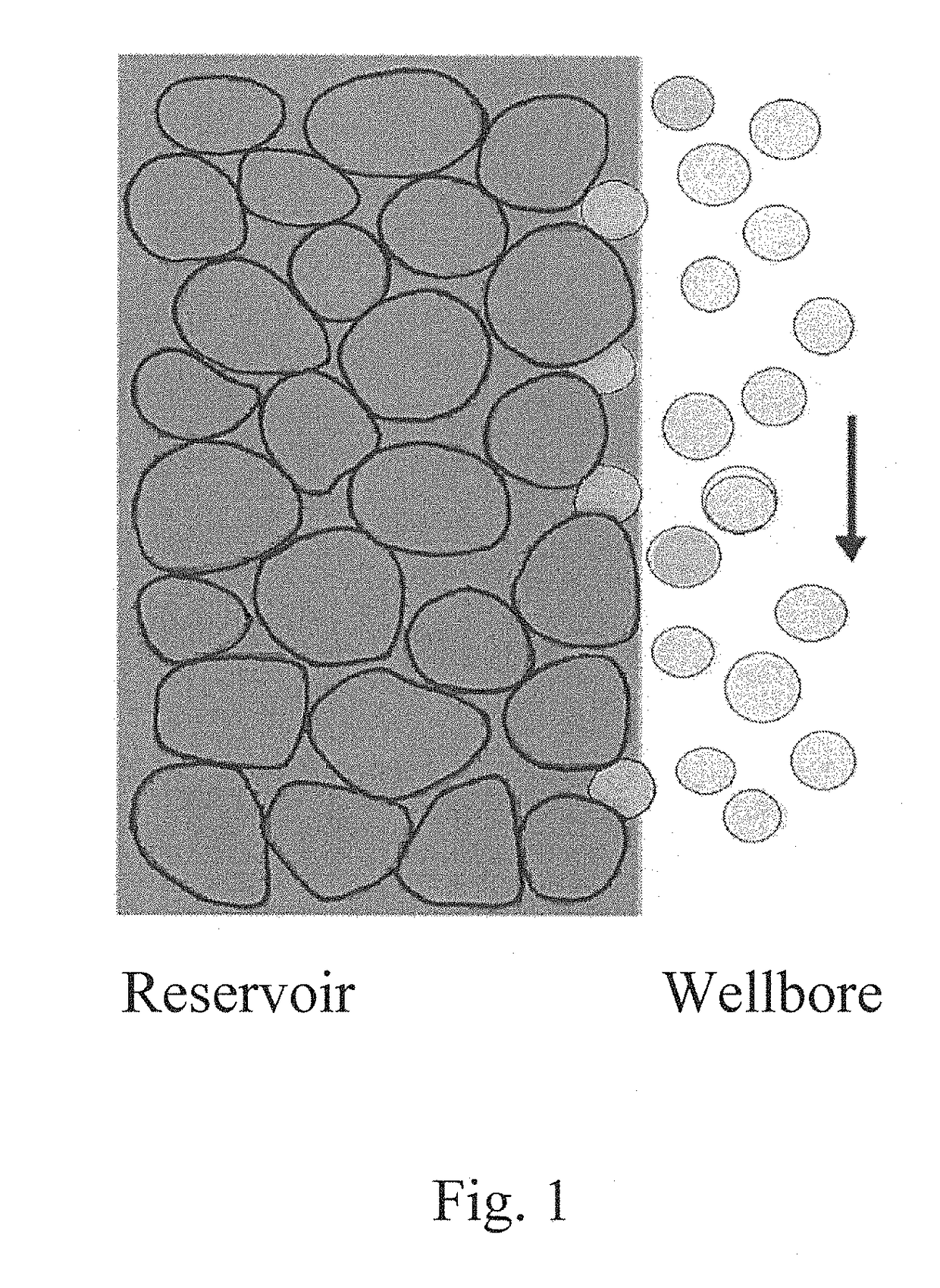

Water-based drilling fluid for protecting high-permeability reservoirs, and preparation method and use thereof

Disclosed herein are water-based drilling fluids for protecting high-permeability reservoirs. The drilling fluid comprises bentonite, a tackifier, a thinner, a filtrate reducer, an anti-collapse agent, a reservoir protectant, a lubricant, and water.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

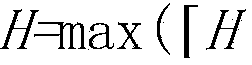

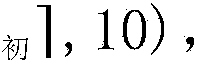

Method for calculating height of venting riser of natural gas transmission pipeline

ActiveCN103699758ACalculation process is clearSimple formulaSpecial data processing applicationsShortest distanceEngineering

The invention relates to a method for calculating the height of a venting riser of a natural gas transmission pipeline. The method comprises the steps of: (A) collecting basic parameters of the main trunk pipeline to which the venting riser belongs and environmental parameters of the area in which the riser is located; (B) calculating related parameters needed by the calculation of the height of the natural gas venting riser according to the basic data collected in the step (A); (C) selecting the shortest distance to a horizontal building according to the level of the area in which the venting riser is located and the venting flame thermal radiation radius calculated in the step (B); and (D) calculating the initial value, H-initial, of the height of the natural gas venting riser according to the step (B) and the step (C), and comparing the H-initial with the height h of a highest building within 10m, wherein if the H-initial is greater than (h+2), the height H of the venting riser is equal to max([H-initial], 10), but if the H-initial is less than (h+2), the height H of the venting riser is equal to max([h+2], 10). The method provided by the invention is clear in calculation flow, and simple and convenient in formula; the method is capable of obtaining the accurate height value of the natural gas venting riser and providing an important basis for the design and safety guarantee of the natural gas transmission pipeline.

Owner:四川庆达实业集团有限公司

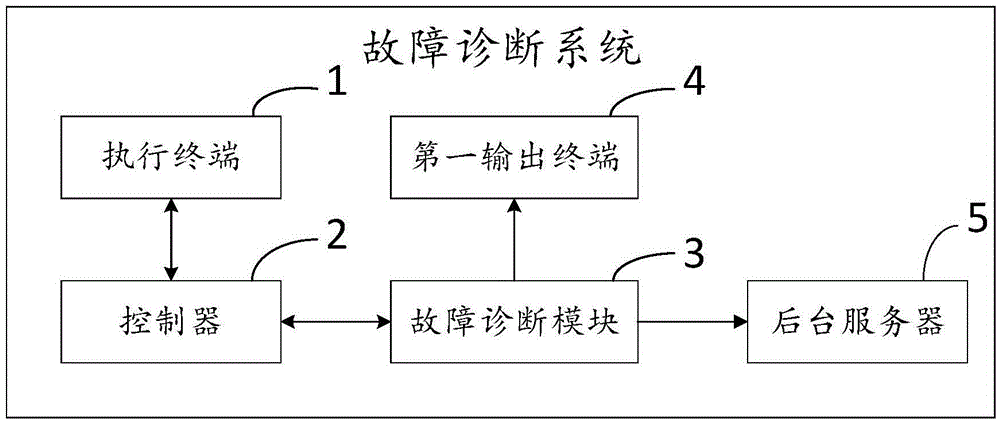

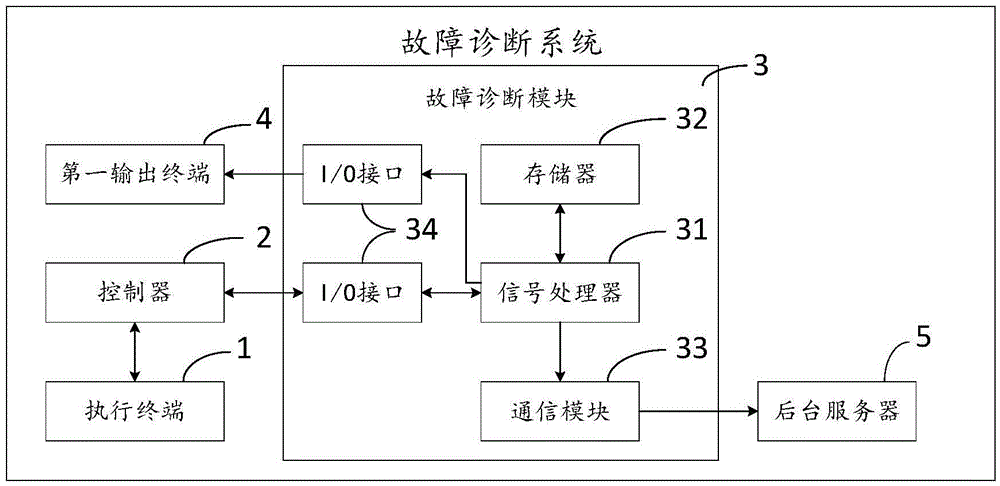

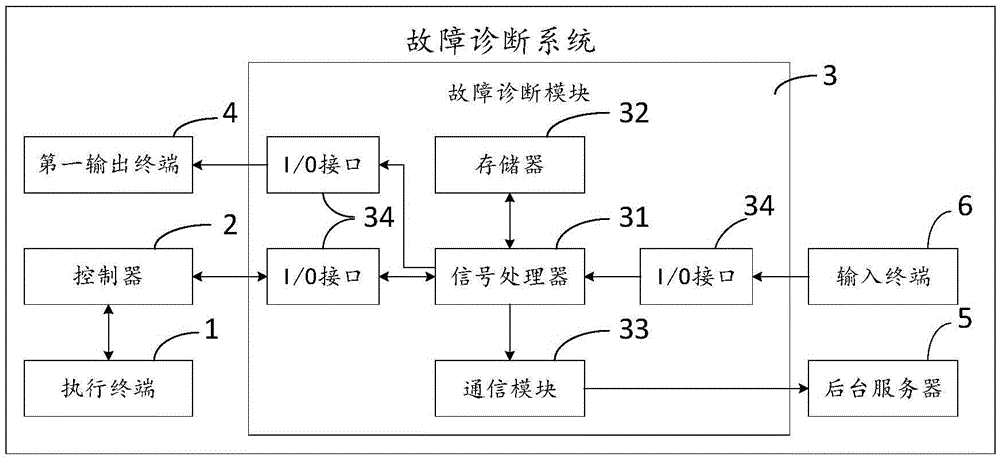

Fault diagnosis system

ActiveCN105607615AImprove accuracyAvoid mistakesElectric testing/monitoringEngineeringPerformed Diagnosis

The invention provides a fault diagnosis system. The fault diagnosis system includes an execution terminal, a controller, a fault diagnosis module, a first output terminal and a background server; the execution terminal is arranged in a vehicle and is connected with the controller, and monitors the operation signals of various components in the vehicle; the controller is connected with the fault diagnosis module, monitors the fault diagnosis module, and transmits monitored first monitoring signals and received operation signals to the fault diagnosis module; the fault diagnosis module monitors the controller, receives the first monitoring signals and the operation signals, and performs diagnosis; and the background server receives abnormal signals and judges the fault condition of the vehicle. Thus, the controller and the fault diagnosis module in the fault diagnosis system can monitor each other and give feedback to each other, so that errors in detection results caused by the damage of the controller or the fault diagnosis module can be avoided.

Owner:NINGBO RUYI

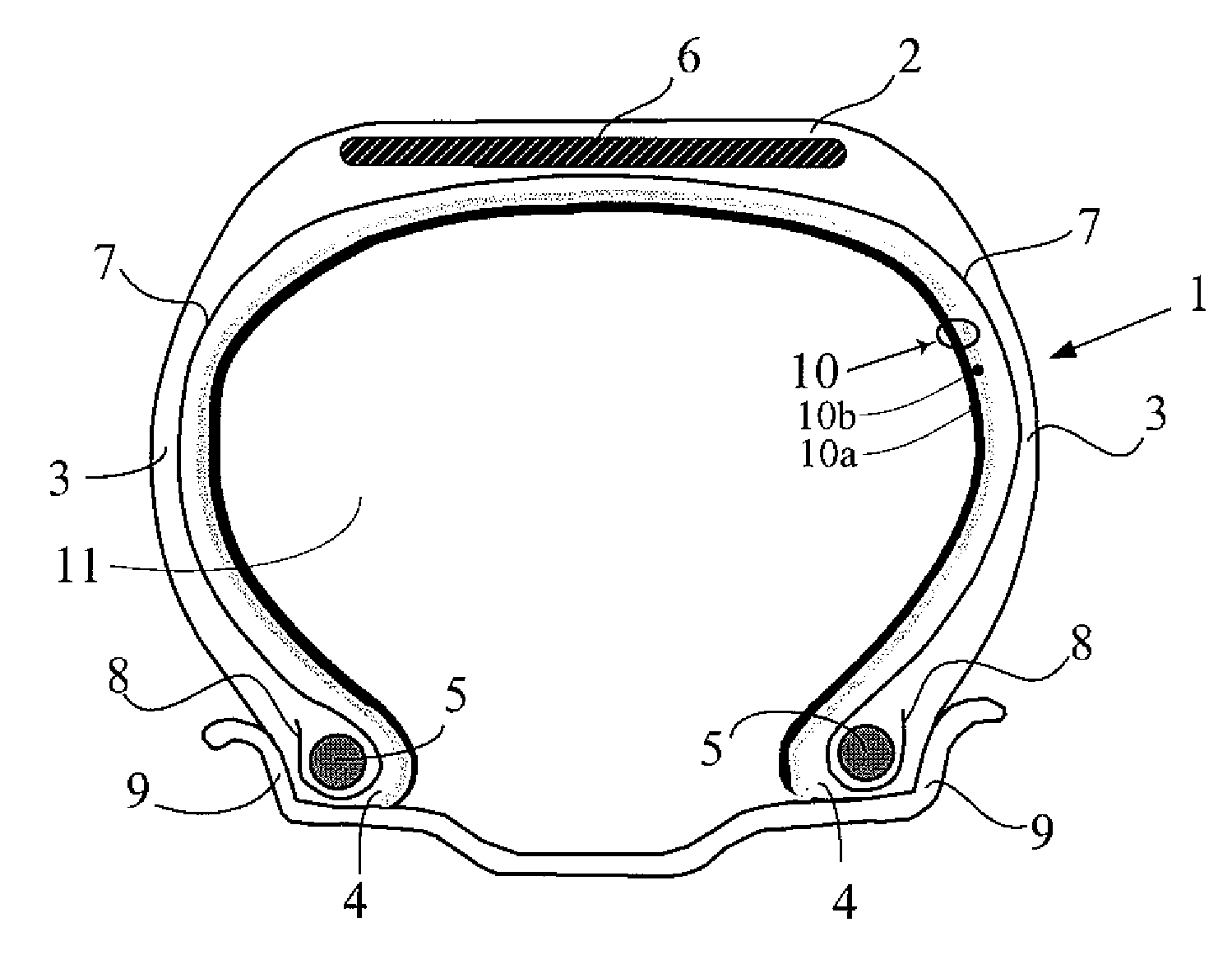

Self-sealing elastomer composition

ActiveUS8871852B2Increase speedSimple formulaDomestic sealsPlastic/resin/waxes insulatorsElastomerButyl rubber

Self-sealing elastomer composition that can in particular be used as puncture-resistant layer in an inflatable article, comprising at least 30 phr of a saturated thermoplastic styrene elastomer, at most 70 phr of an unsaturated thermoplastic styrene elastomer and more than 200 phr of an oil extender. Inflatable article, such as a tire, provided with a puncture-resistant layer comprising, as self-sealing composition, an elastomer composition according to the invention. Advantageously, the puncture-resistant layer is combined with an airtight layer, for example based on butyl rubber, so as to constitute, in the inflatable article, a puncture-resistant airtight laminate.

Owner:MICHELIN RECH & TECH SA +1

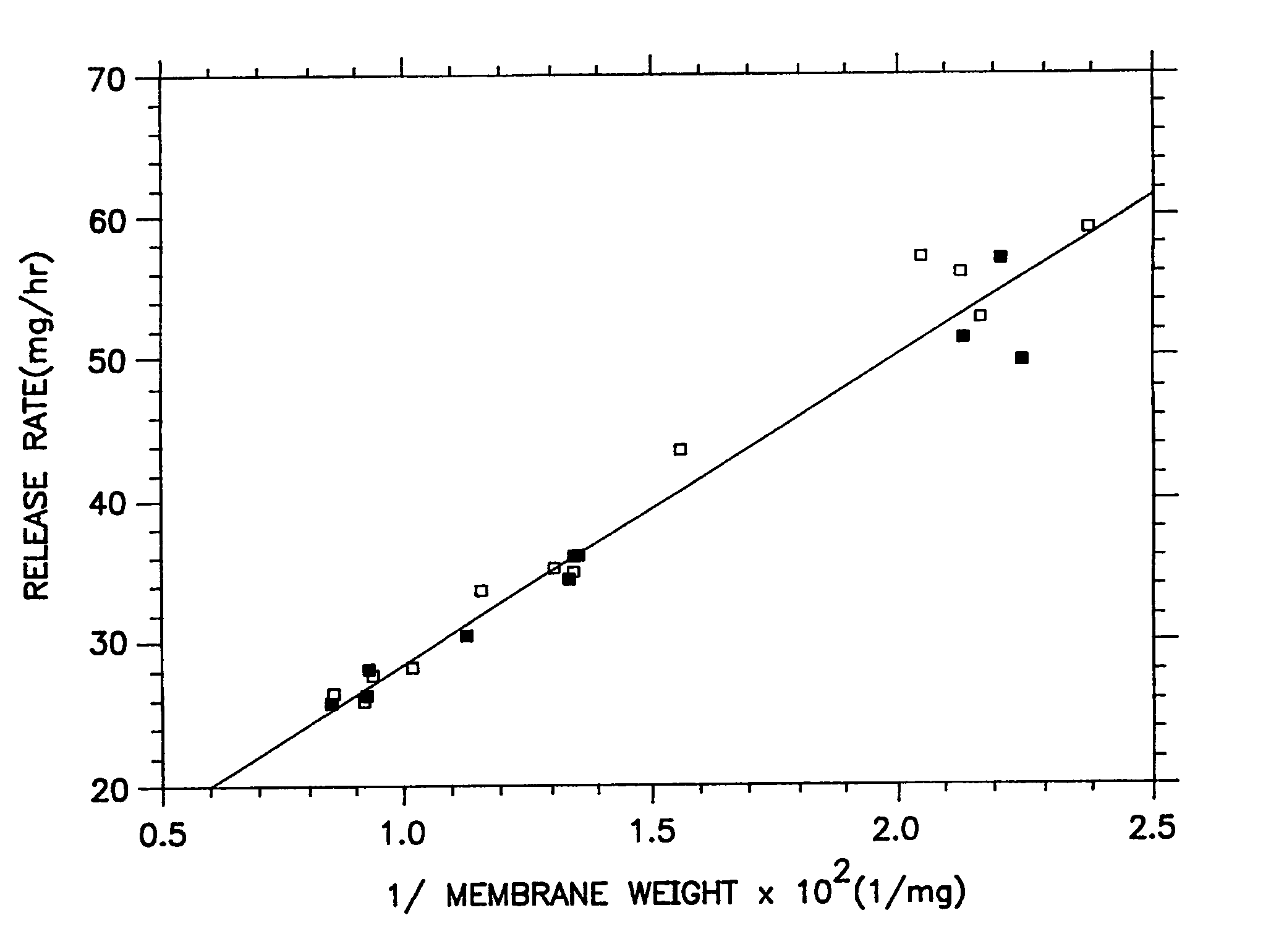

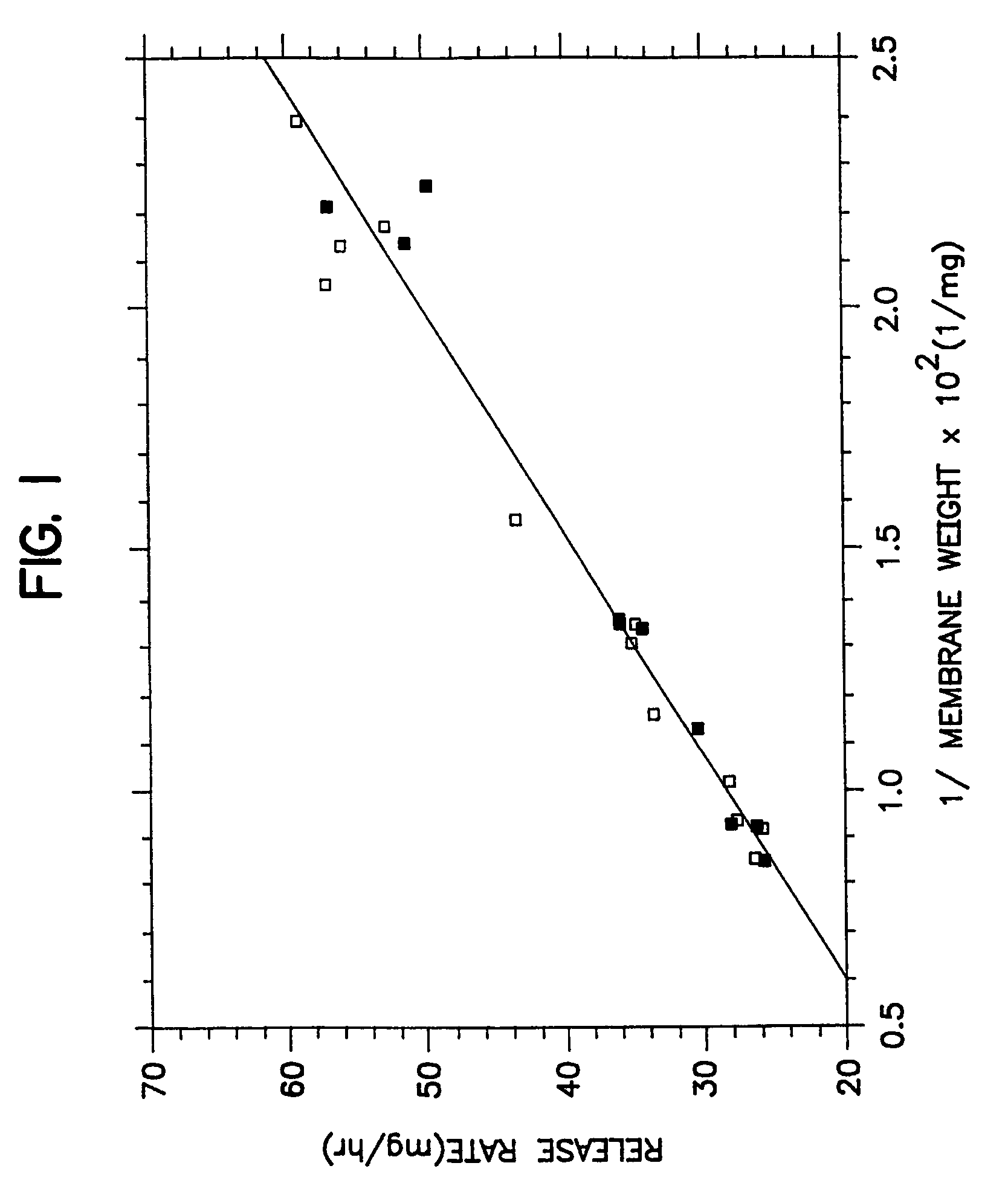

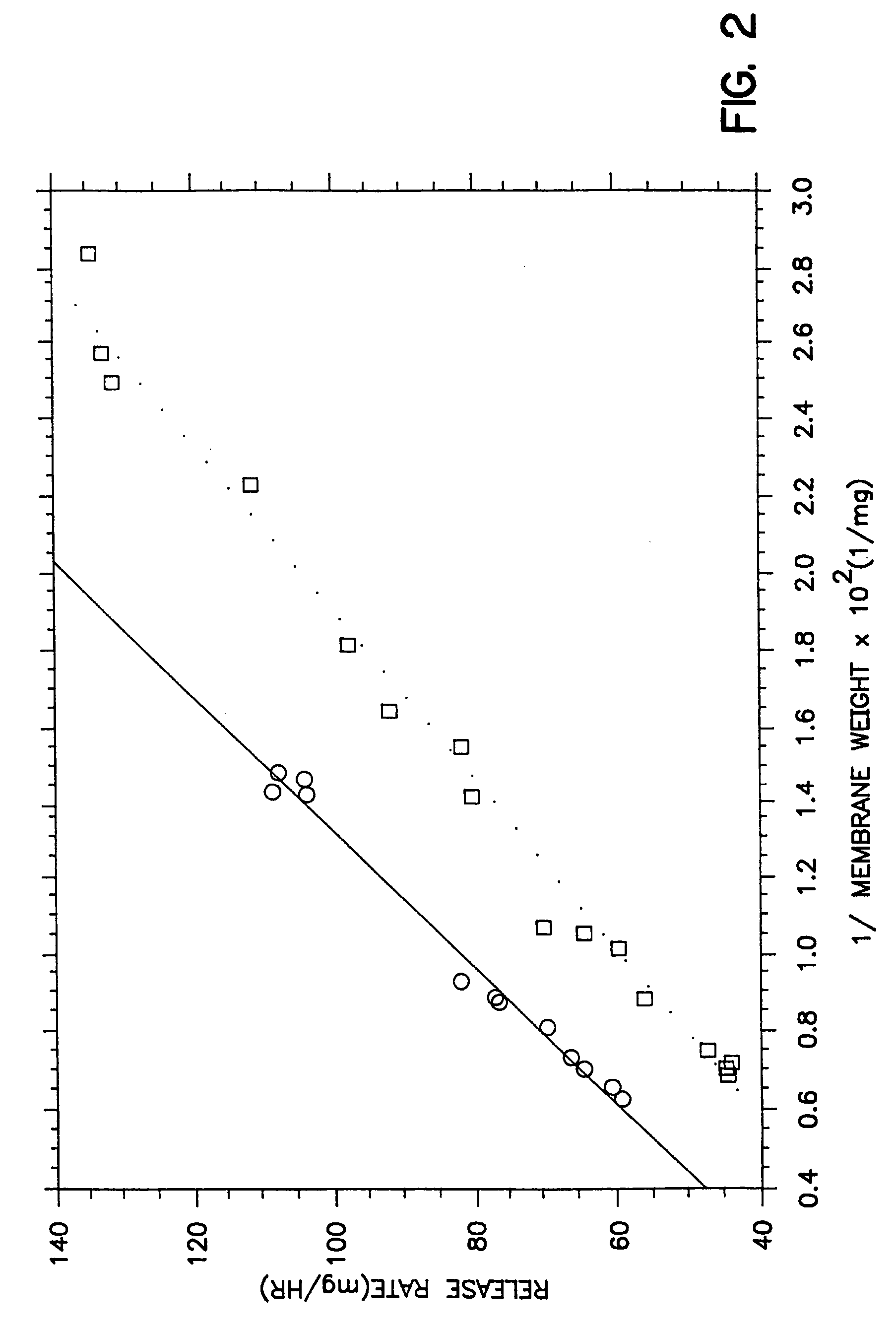

Pharmaceutical coating composition and method of use

A composition is disclosed comprising a polymer and a surfactant in a solvent exhibiting a common solubility for the polymer and the surfactant. The composition provides a dosage form for administering a drug over time.

Owner:ENCINAL PHARMA INVESTMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com