Method for obtaining uniaxial stress-strain relation of material through small punch test

A technology of strain relationship and bill of materials, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of low accuracy of results and cumbersome process, and achieve the effect of simple formula, sufficient theoretical basis, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

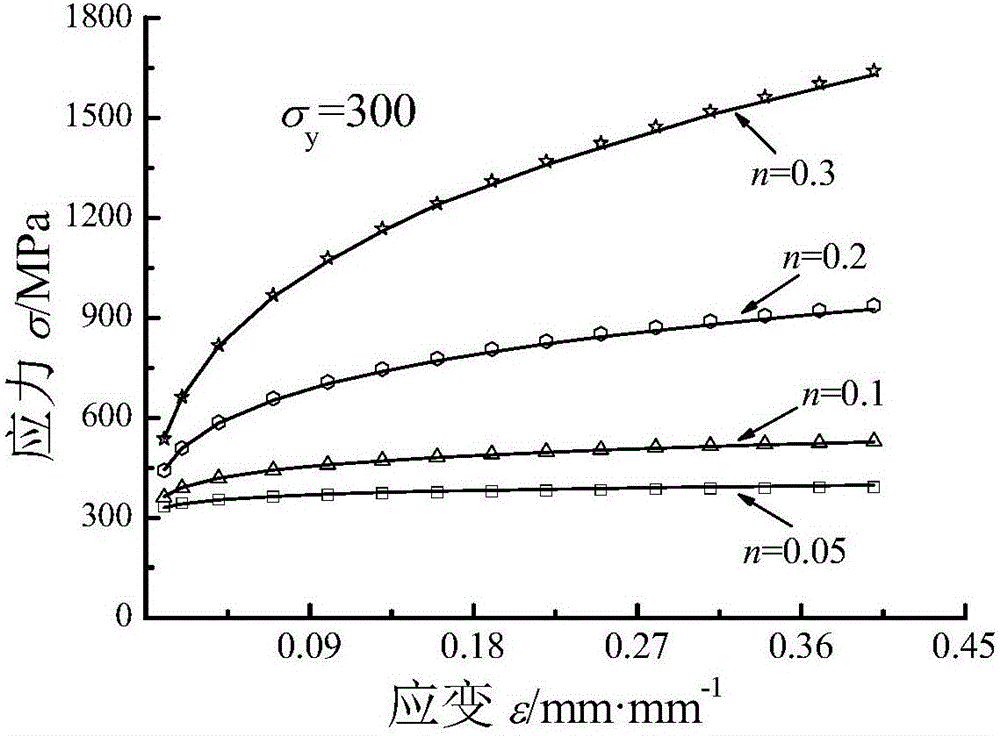

[0040] In the technical solution of the present invention, based on the derivation of equivalent energy theory and a small amount of finite element simulation, a technical theoretical system for obtaining the uniaxial stress-strain relationship of materials by using SPT is proposed.

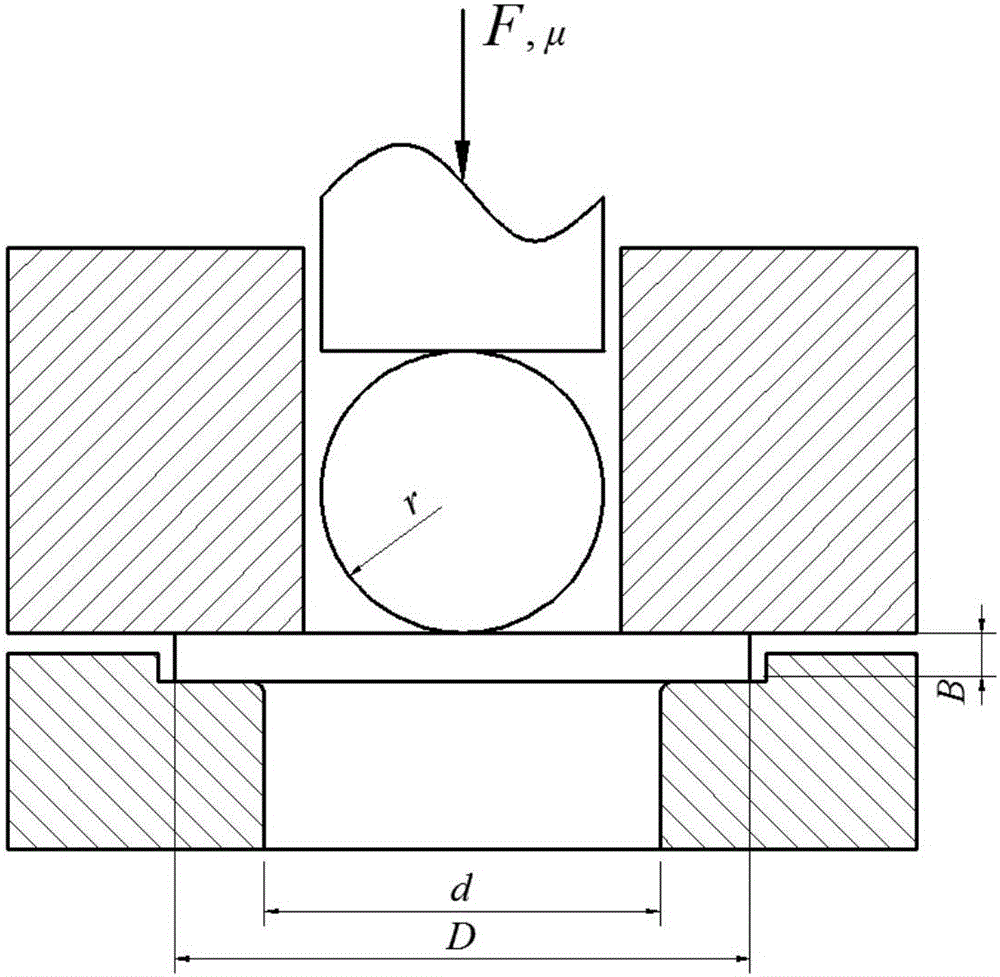

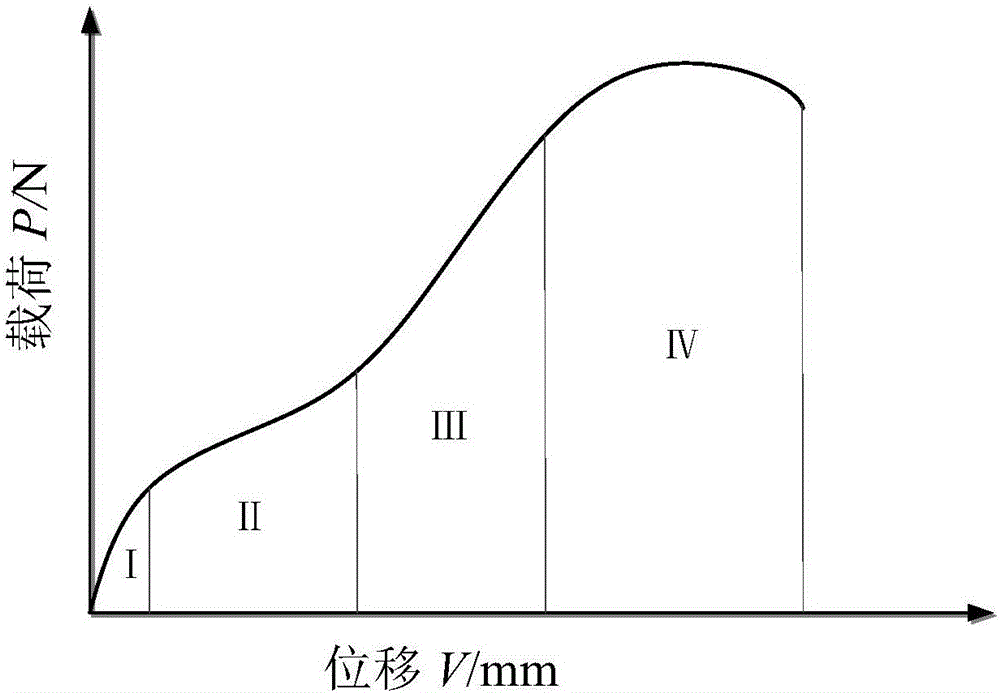

[0041] According to the small punch test device and sample size recommended by the national standard GB / T 29459.2-2012, the finite element simulation model was established in ANSYS commercial software, and the same yield strength, different hardening exponents, and the same hardening exponent, different yield strength multiple The finite element simulation is carried out for each working condition, and the corresponding load-displacement curves are obtained. The third stage of the curve is fitted with a power law to obtain the characteristic load and displacement exponent, which are brought into equation (2) to solve the simultaneous equations, and the mechanical performance parameter σ of the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com