Patents

Literature

293 results about "Load displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Load displacement. noun. : the displacement of a ship when loaded to the extent for which it was designed.

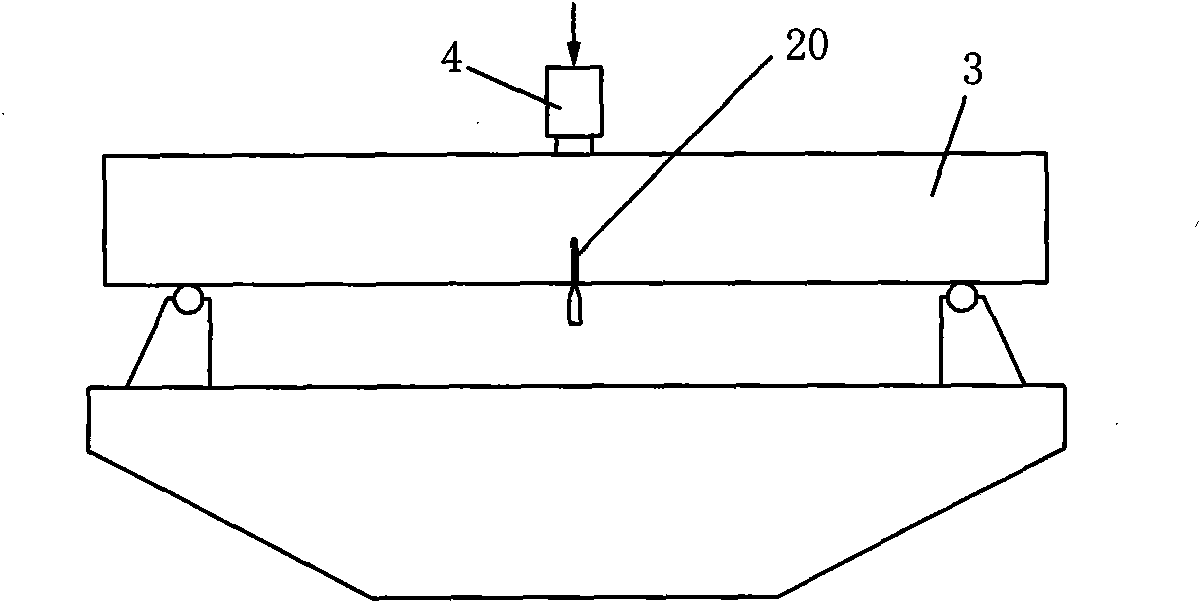

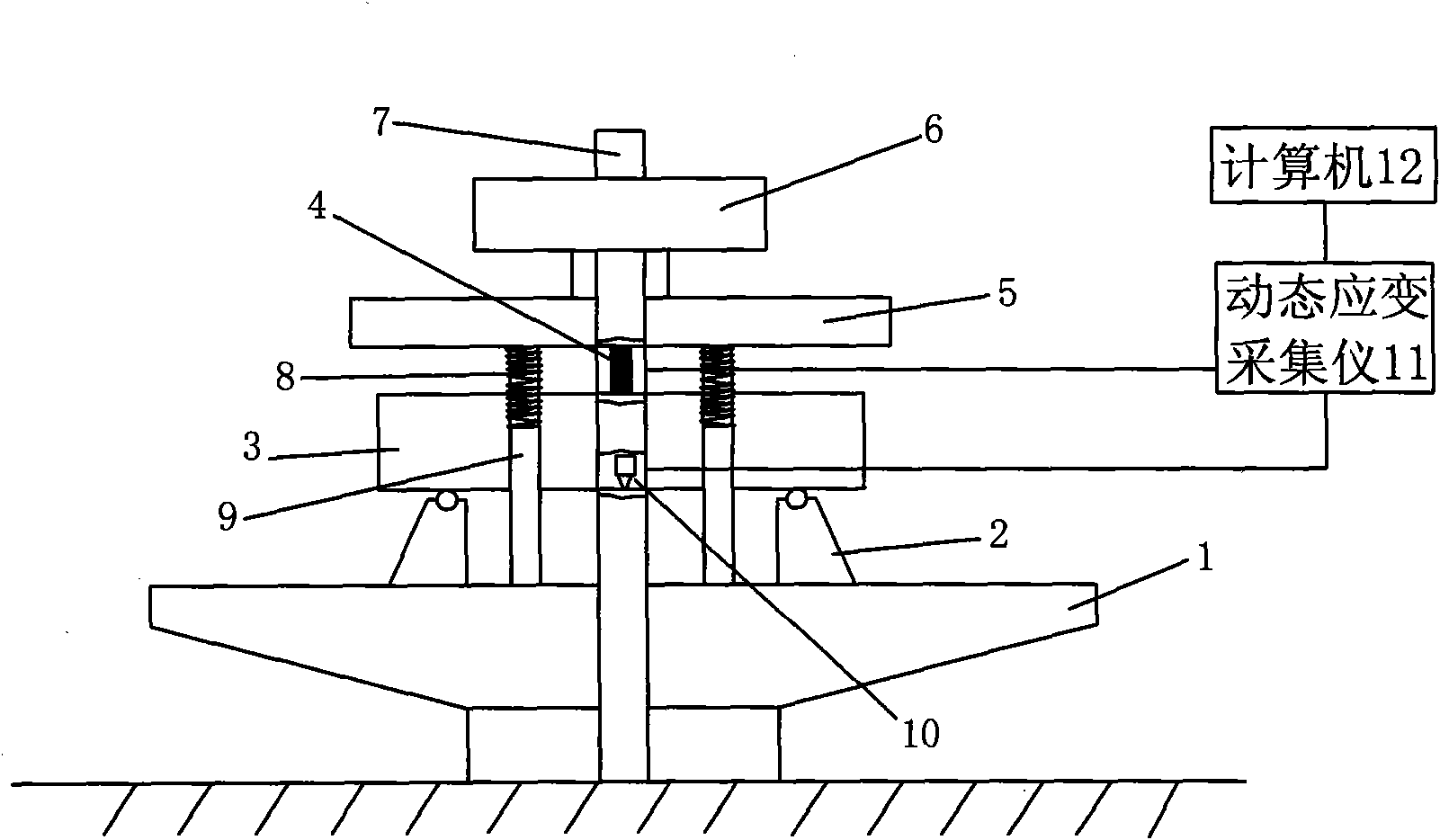

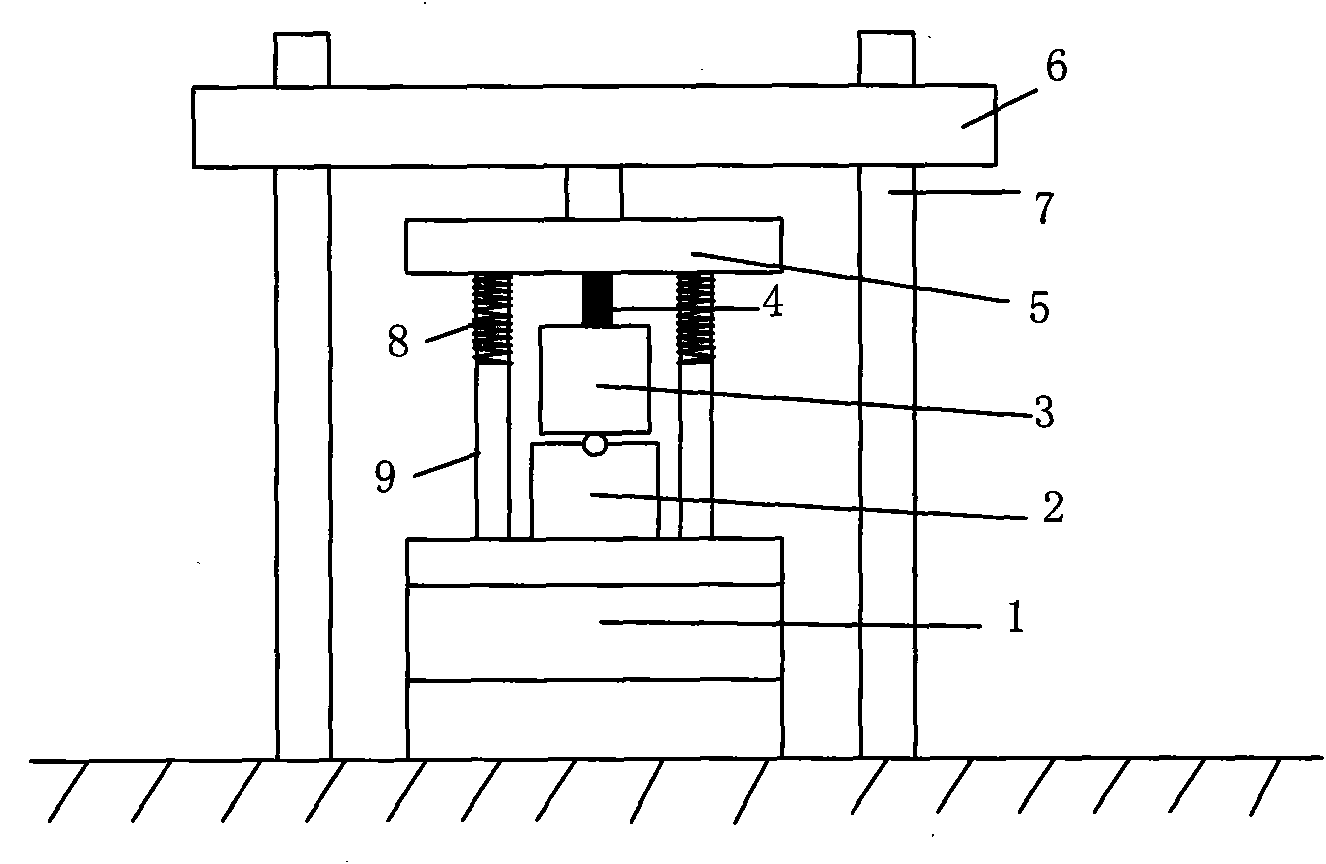

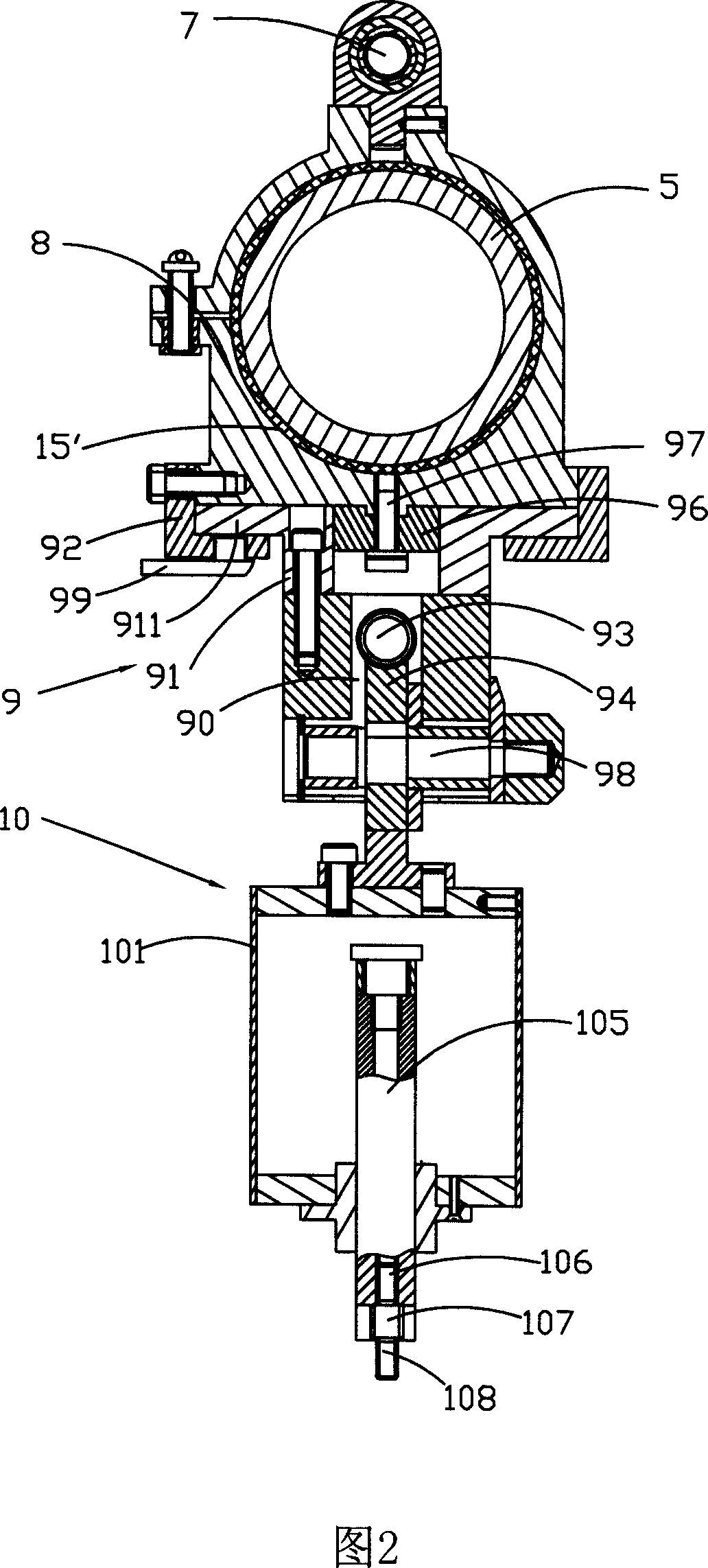

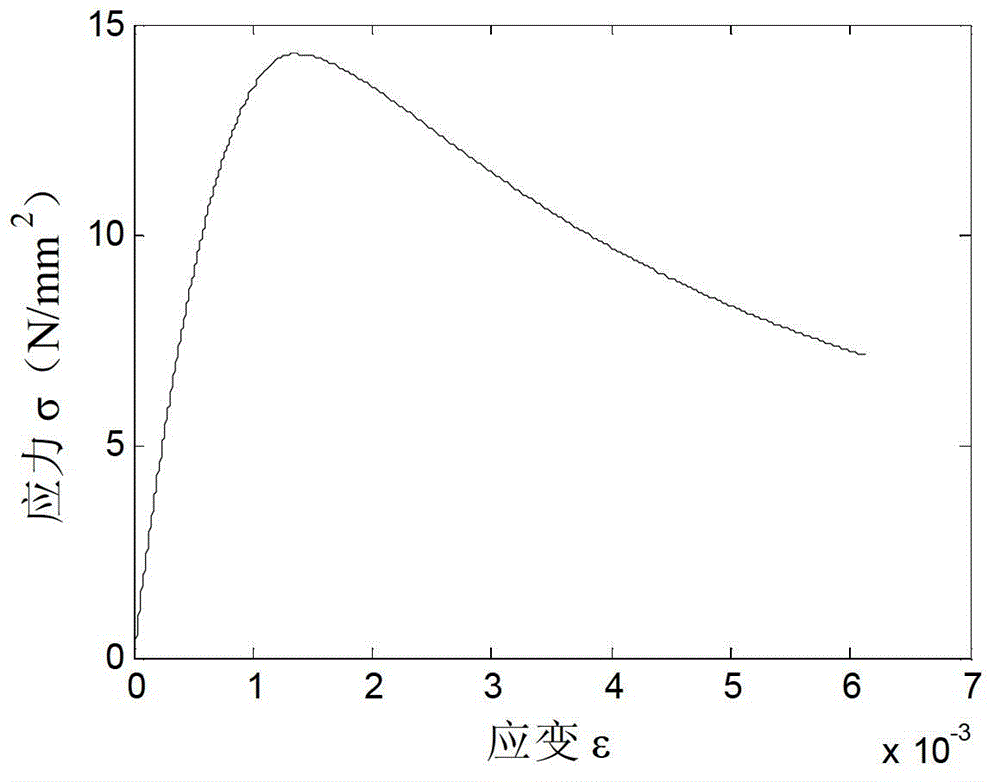

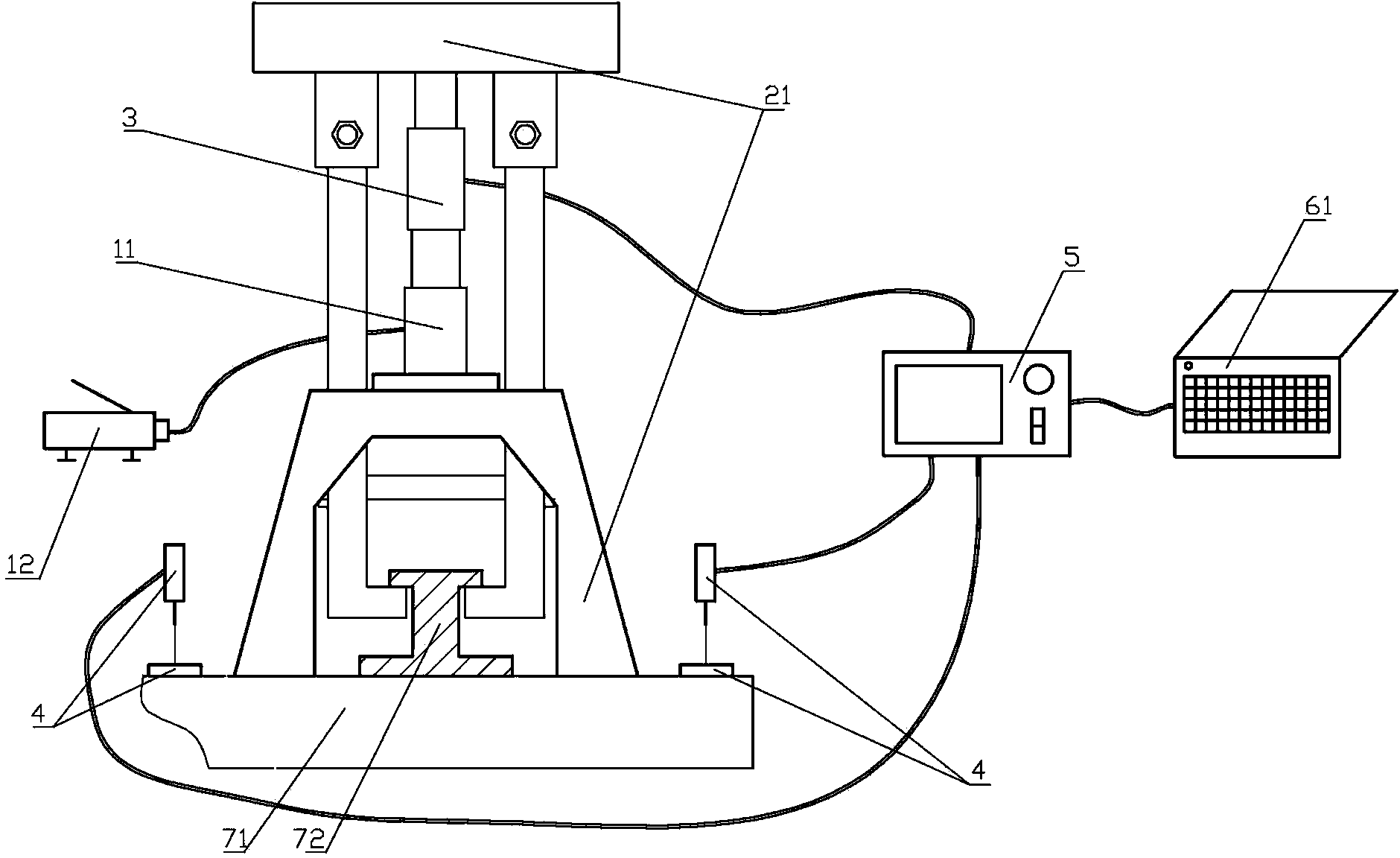

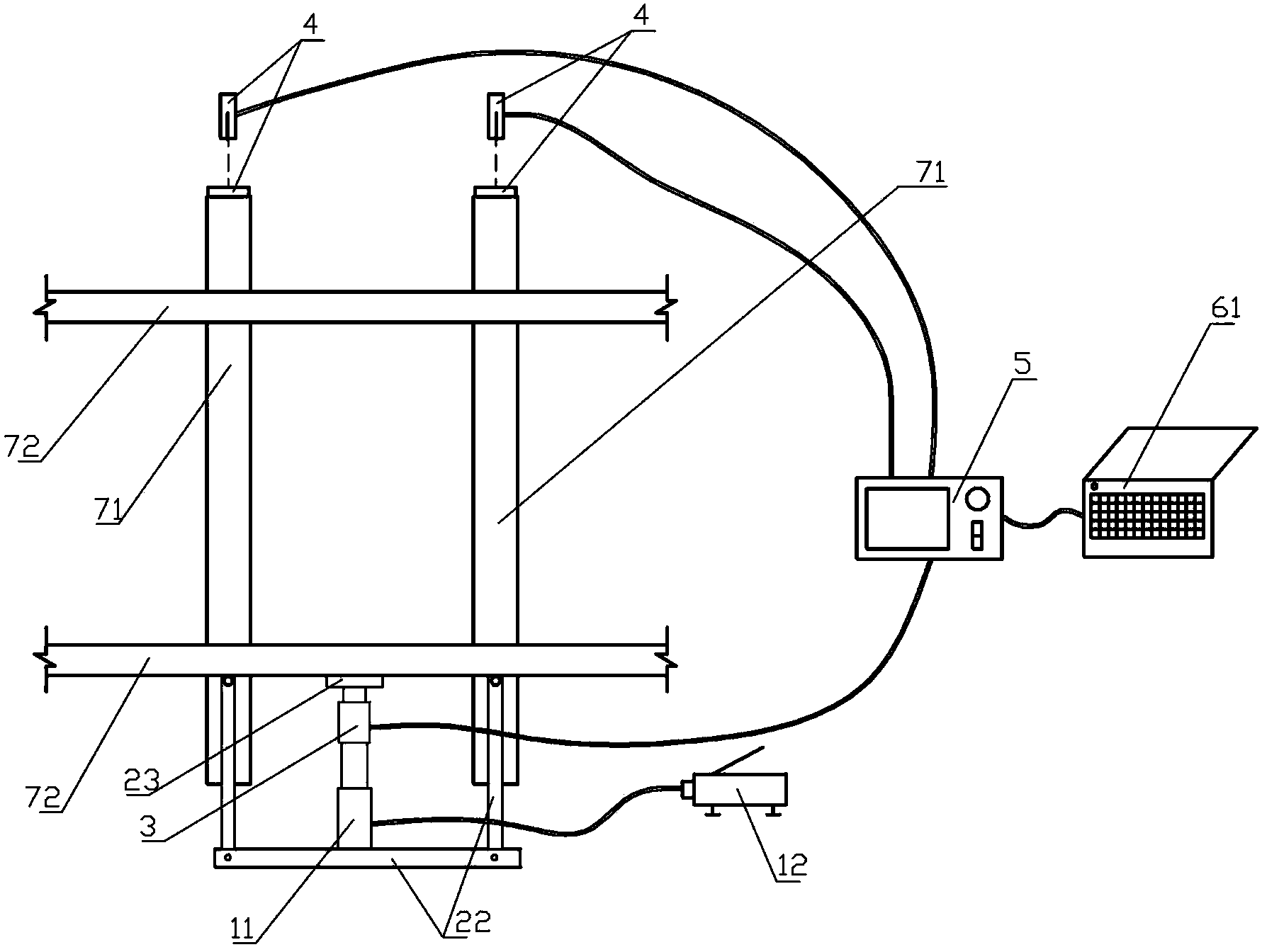

Concrete fracture test system and test method thereof

InactiveCN101975701ASmall loadMeet load rate requirementsMaterial strength using steady bending forcesContact pressureData acquisition

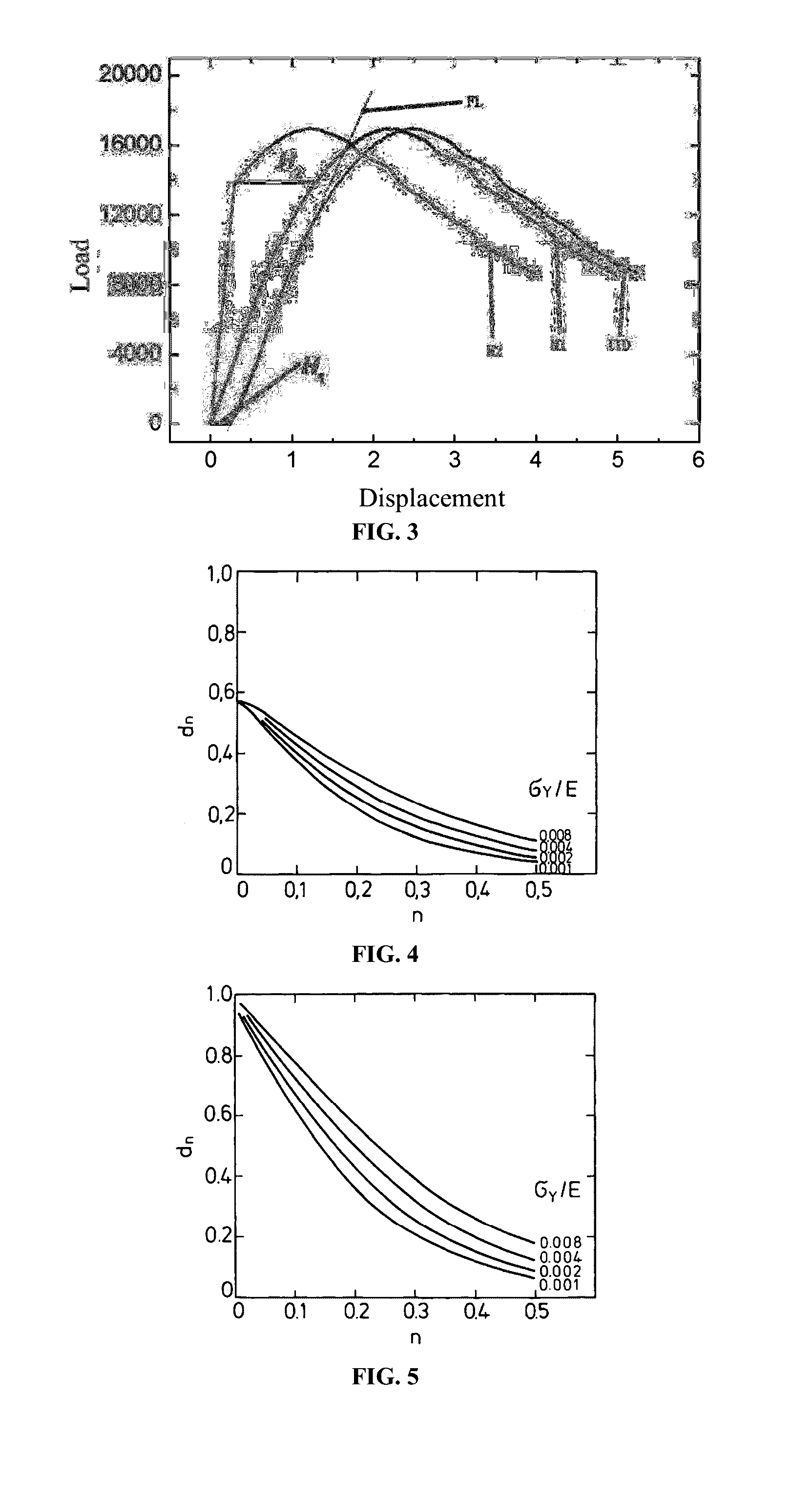

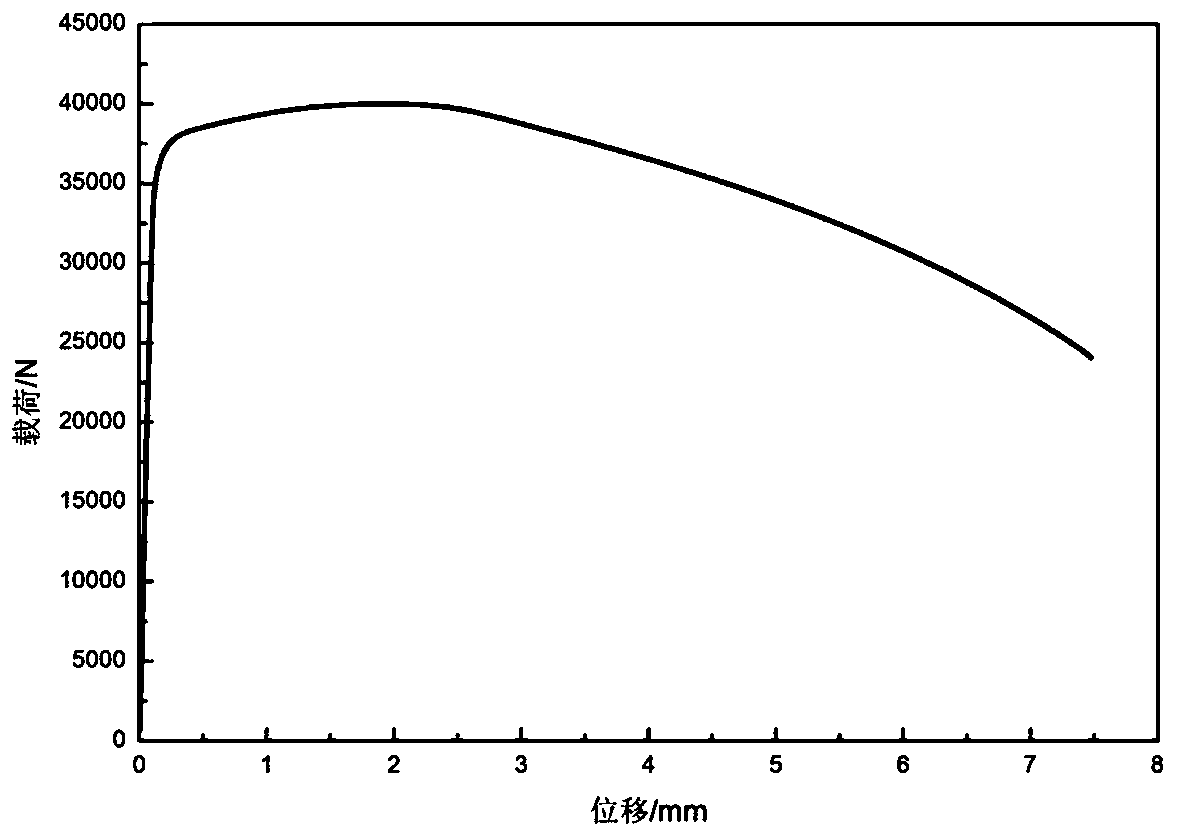

The invention relates to a concrete fracture test system and a test method thereof, and belongs to the technical field of concrete material performance test. The system comprises a measurement system and a data acquisition and processing system; a support for supporting a concrete test piece and even cushion posts symmetrically positioned on the surrounding side of the concrete test piece are arranged on a pressure tester platform of the measurement system; and springs which extend out of the tops of the cushion posts and are higher than pressure sensors are sleeved on the cushion posts. The method comprises the following steps of: when a top plate moves relative to the platform by adopting the system, making the top plate contact the springs and then contact the pressure sensors; when the top plate is contacted with the pressure sensors, controlling the load loaded onto the concrete test piece to be continuously loaded with low loading rate till the concrete test piece cracks, destabilizes and is damaged; and meanwhile, acquiring a load signal and a crack opening displacement signal and transmitting the signals to a computer. The system and the method can acquire a fine load-displacement curve so as to calculate an accurate concrete double-K fracture parameter.

Owner:胡少伟

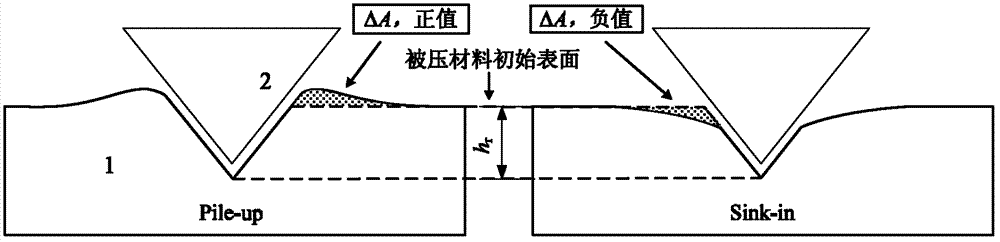

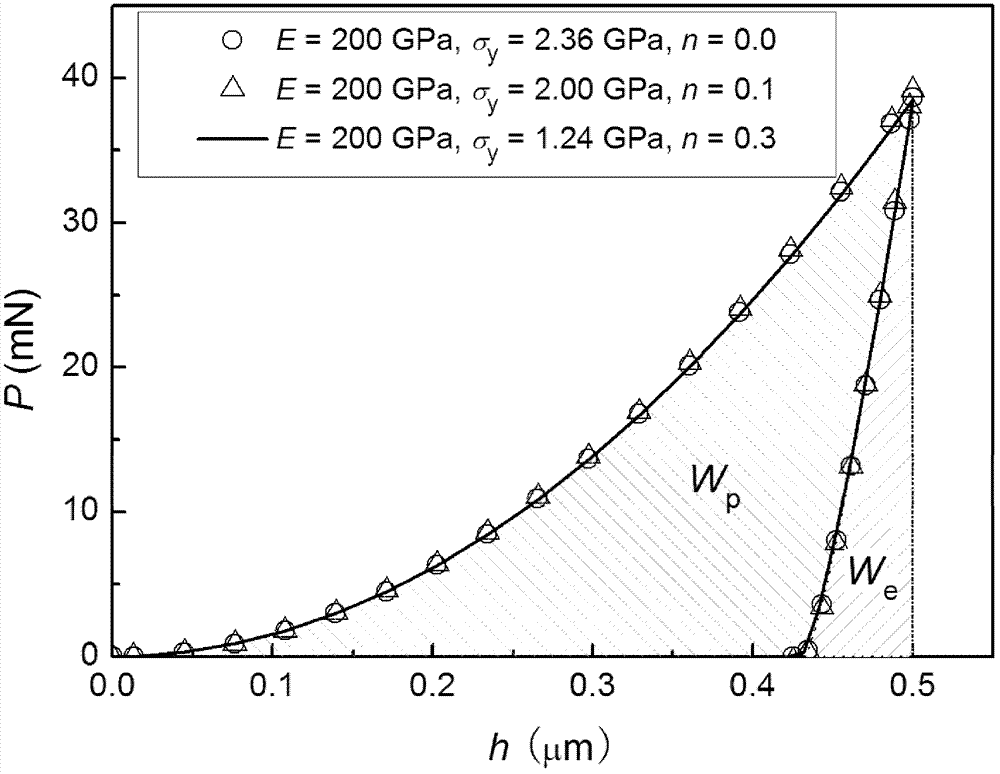

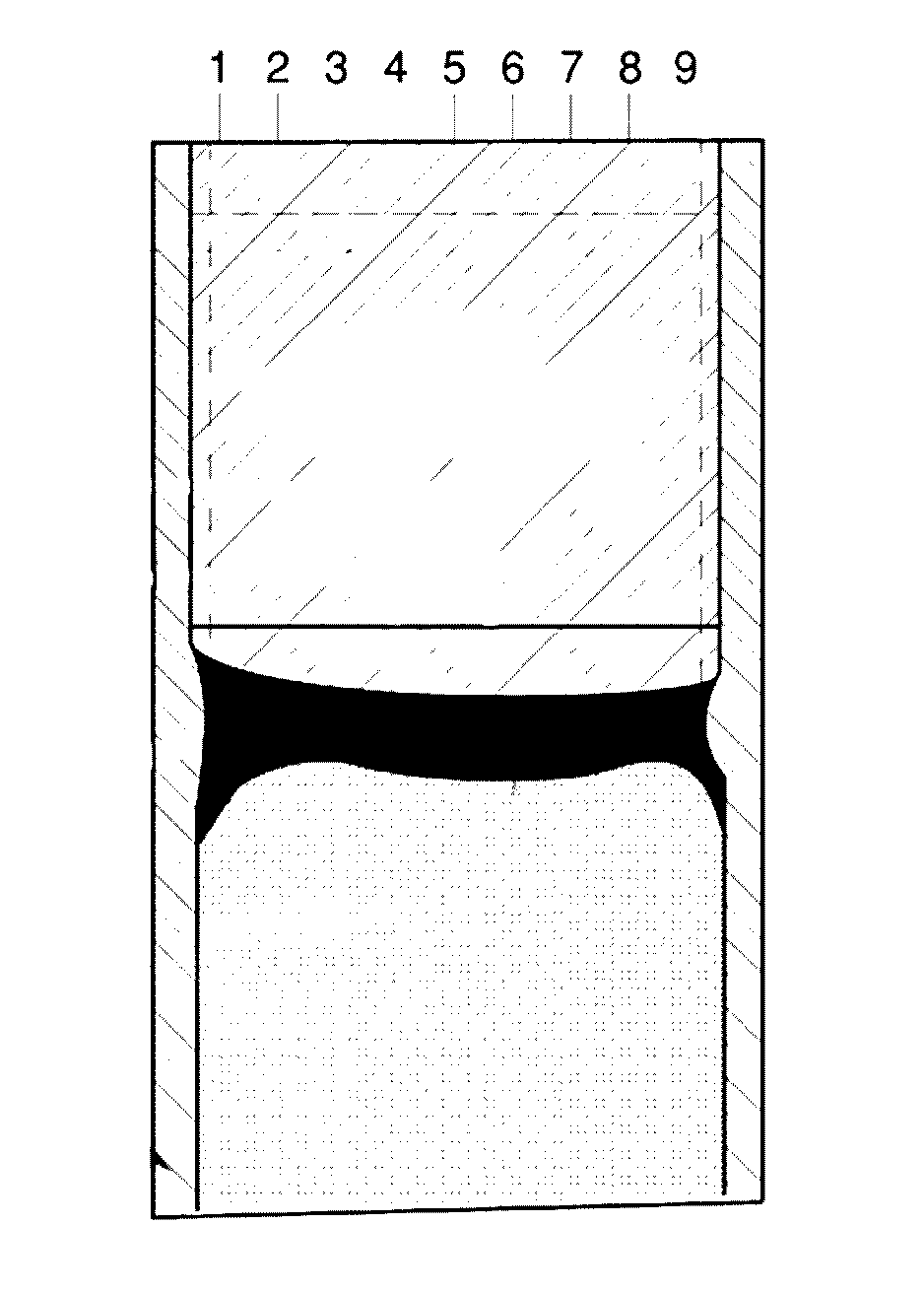

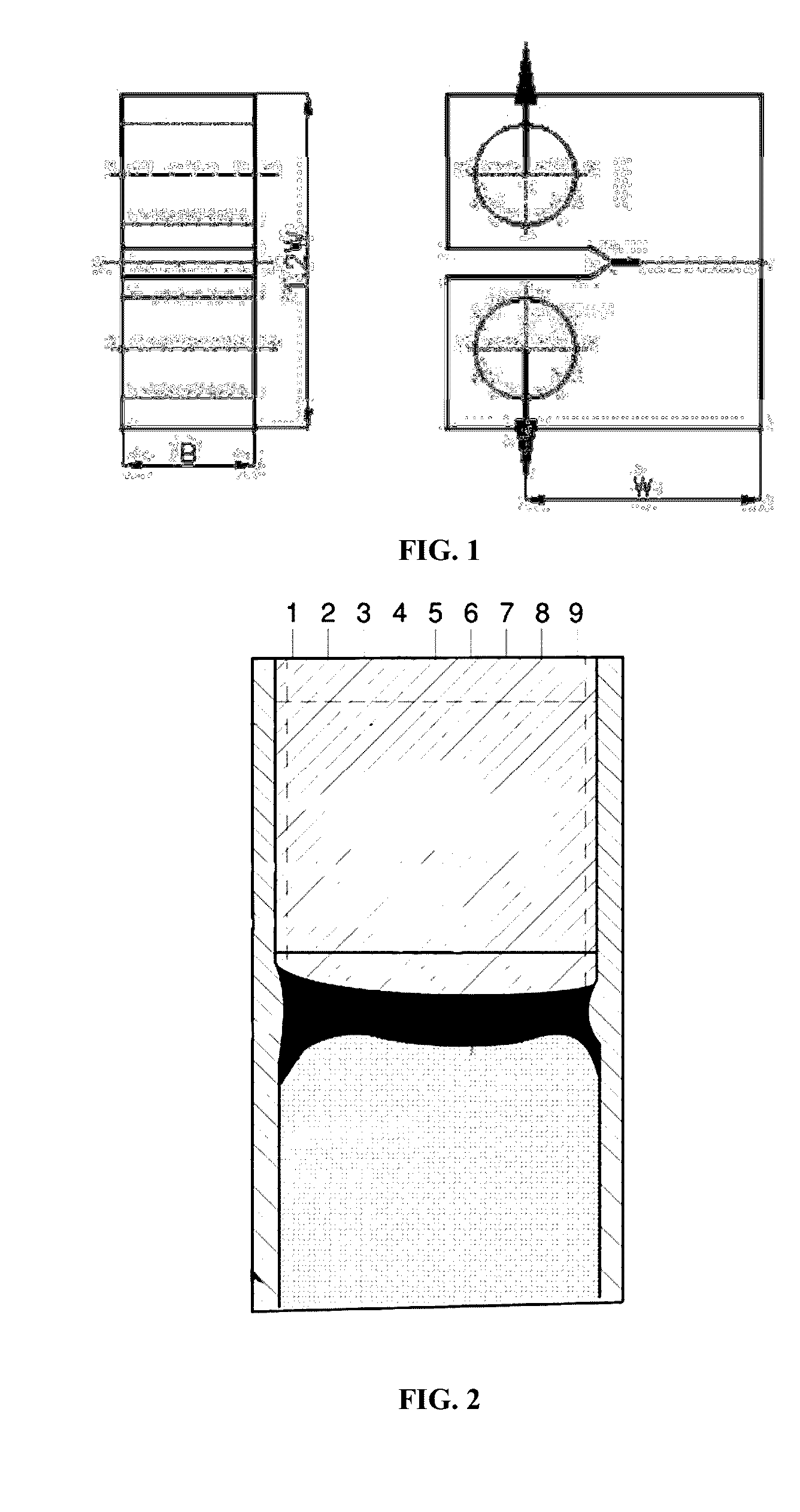

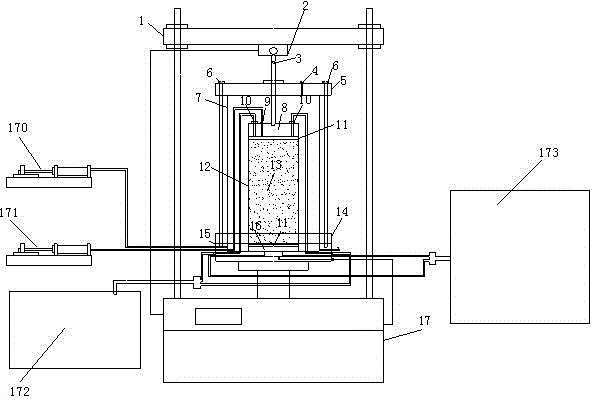

Process for characterizing elastoplasticity of metal material through indentation method

The invention discloses a process for characterizing the elastoplasticity of a metal material by introducing an extra residual area through an indentation method, belonging to the field of researches on the mechanical properties of a material. Experiment devices required by the method mainly comprise an indentor, and an atomic force microscope or a three-dimensional optical imaging system. The method mainly comprises the following steps: indenting a material to be tested through the indentor to obtain an indention load displacement curve, extracting relevant parameters from the indention load displacement curve, substituting the extracted parameters to an established model, and calculating to obtain the elastoplasticity of the material. The method mainly has the following advantages: different materials having similar indention curves can be successfully separated, and the obtained solution is only; and the solution obtained through back-stepping has a high precision. So the only high-precision elastoplasticity of the indented material can be obtained through back-stepping by utilizing the theoretic model in the invention.

Owner:XIANGTAN UNIV

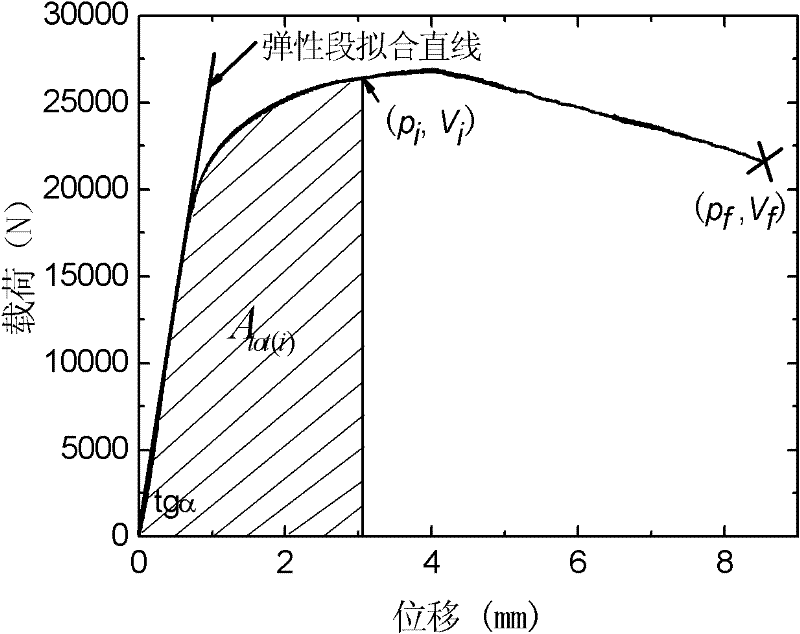

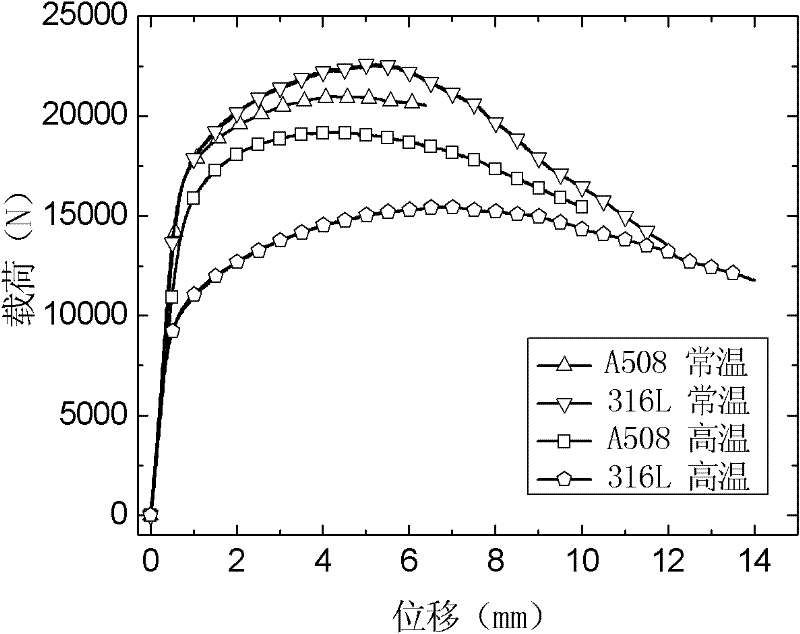

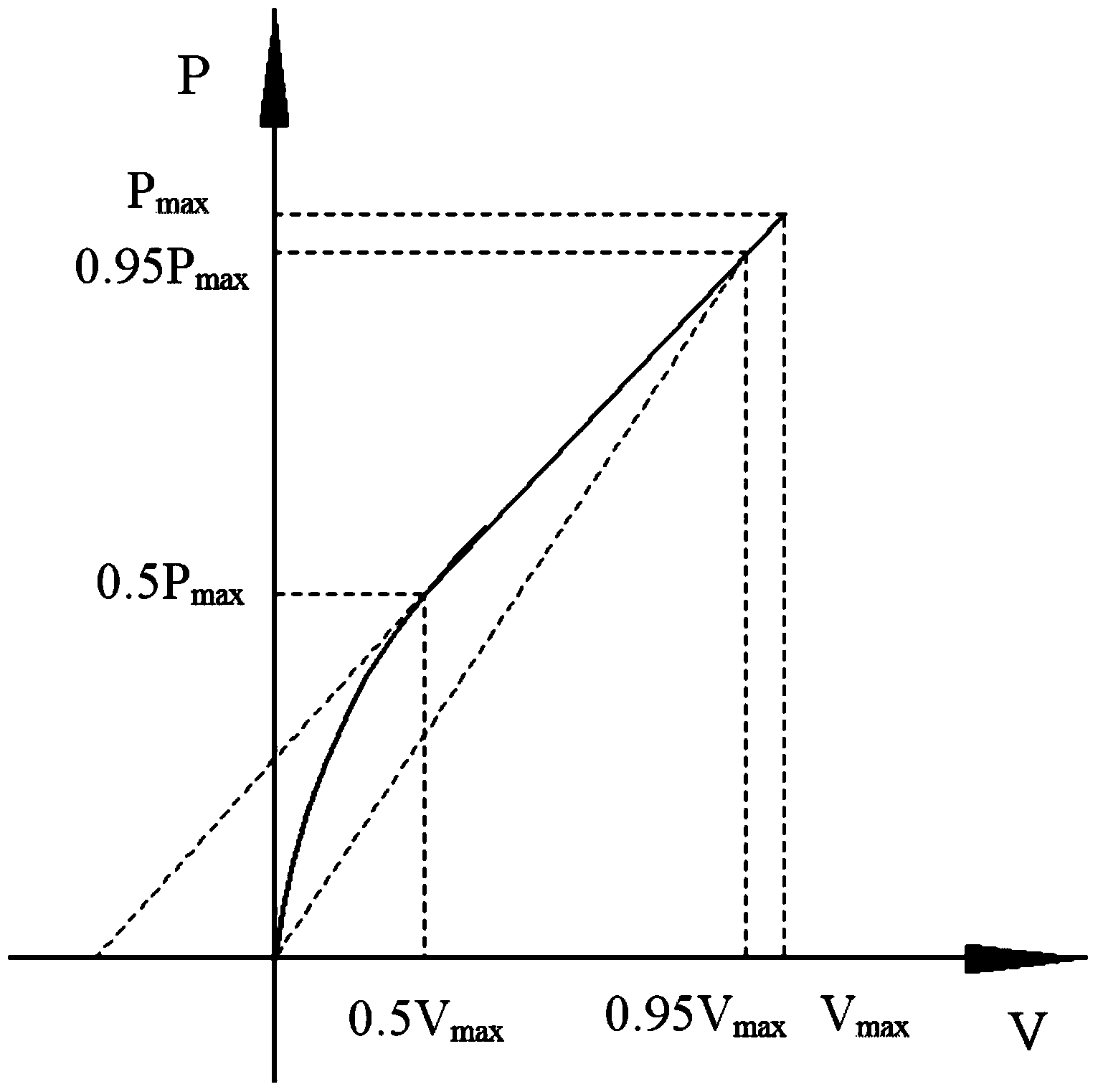

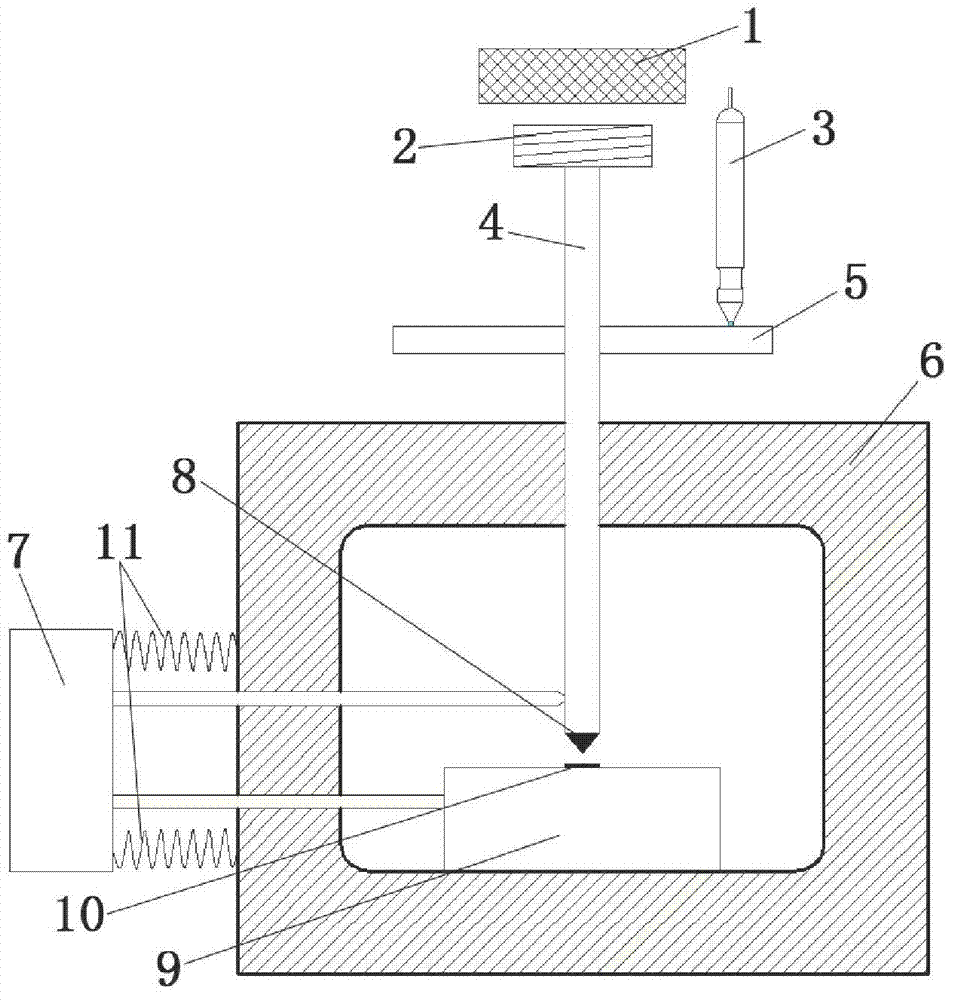

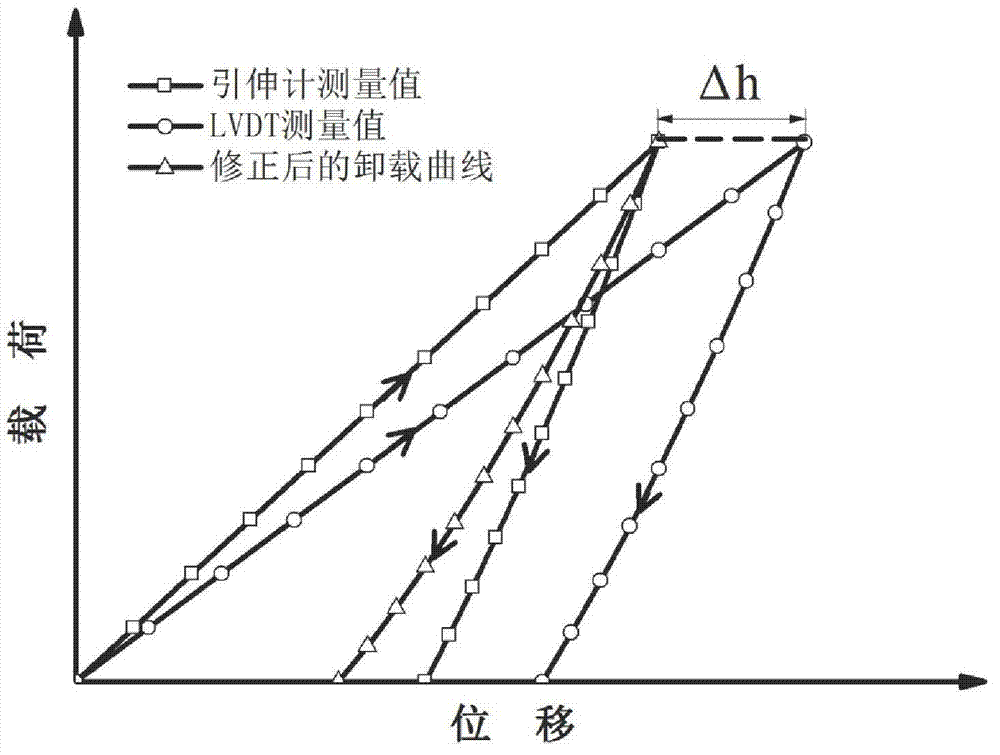

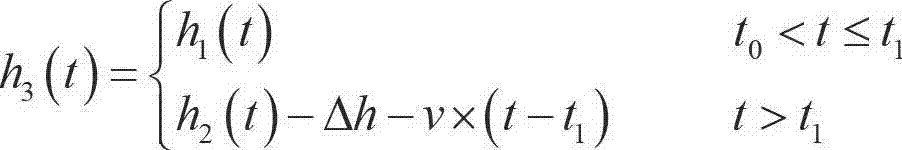

A method of measurement and determination on fracture toughness of structural materials at high temperature

ActiveUS20160299046A1Material strength using tensile/compressive forcesInvestigating material ductilityEquivalent weightFracture test

Disclosed is a method of measurement and determination on fracture toughness of structural materials at high temperature, comprising: preliminary assessing the ductility of a material based on a high-temperature uniaxial tensile test and the fracture characteristic; designing and manufacturing a CT specimen; conducting a monotonic loading fracture test on the CT specimen at high temperature; modifying a load-displacement curve output by a testing machine; determining a passivation coefficient M for the crack of the structural material; reversely recursing instant load-displacement data pairs corresponding to the instant crack length; calculating a J_R crack extension resistance curve of the tensile test; examining the validity of the J_R crack extension resistance curve and the fracture toughness JIC; calculating the fracture toughness per equivalent of the structural material KIC. The present invention overcomes the difficulty of placing an extensometer inside a high-temperature furnace.

Owner:EAST CHINA UNIV OF SCI & TECH +1

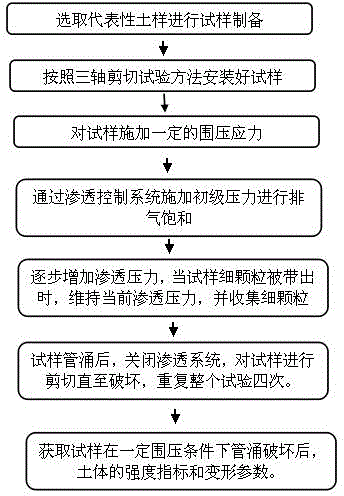

Test device and test method for testing strength change of soil body after occurrence of seepage deformation of dykes and dams

InactiveCN104833579AReal-time monitoring of deformationMaterial strength using tensile/compressive forcesControl systemEngineering

The invention discloses a test device and a test method for testing strength change of a soil body after occurrence of seepage deformation of dykes and dams. The test device includes a triaxial loading main machine, a confining pressure chamber pedestal, a specimen pedestal, a confining pressure chamber, a specimen, a heat shrinkable pipe, a covering cap, a porous steel plate, an axial pressing rod, a water outlet pipe, a vent hole, a hole pressure sensor, a load displacement sensor, a back pressure controller, a confining pressure controller, a water head control system, and a water-sand separation system. The device has novel design, can simulate influence of seepage deformation of the soil body under actual working conditions with different conditions on the soil body strength, and can realize data automatic recording and processing.

Owner:HOHAI UNIV

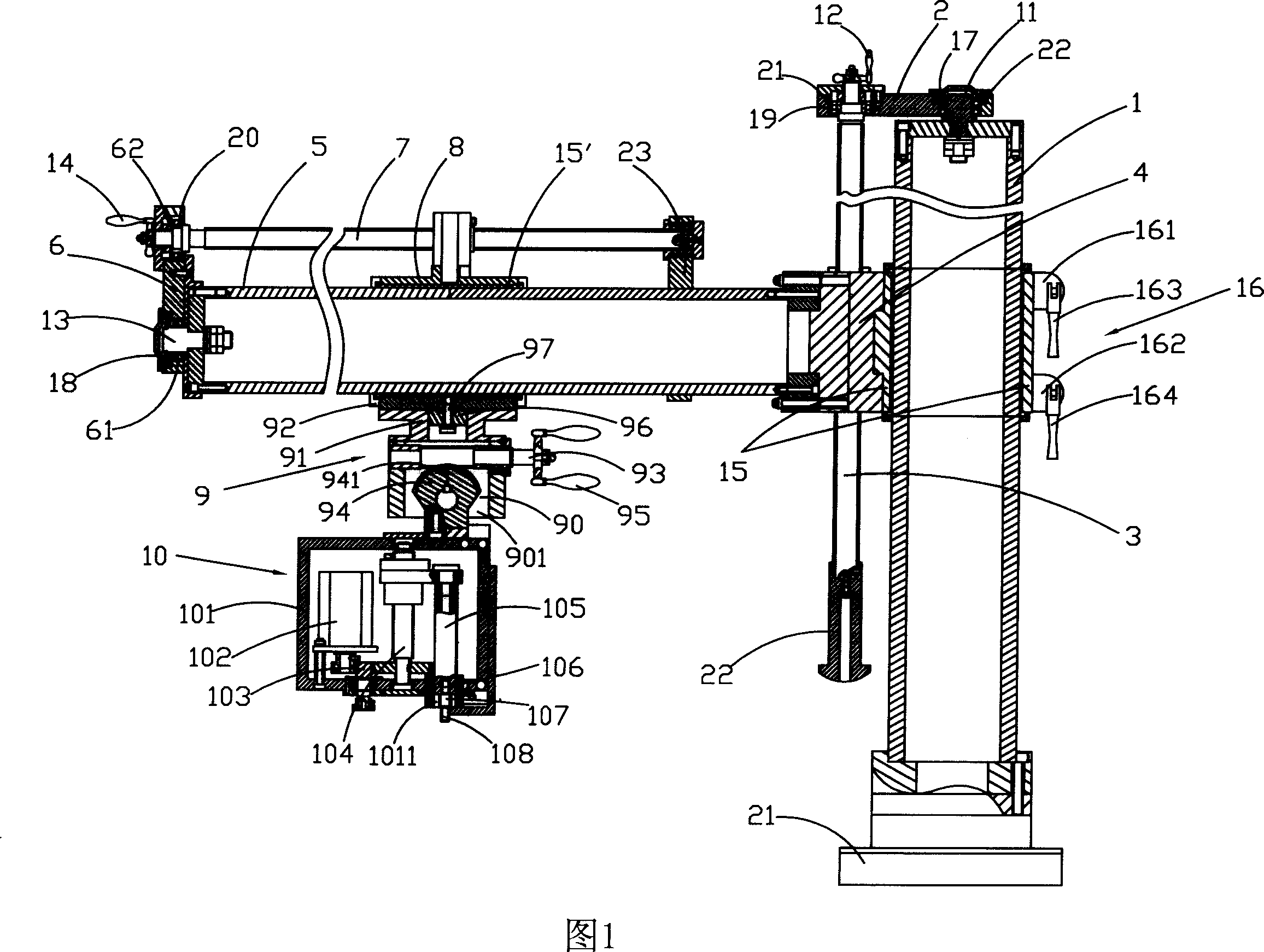

Portable vehicle exterior cladding element deformation stiffness tester

A portable type car outer cover component deforming stiffness test device which includes a carline and a beam of the first slid fixed on the cowl carline and it can drive the first slid moving up and down by the first screw stem so further drive the beam moving up and down and the second screw stem drives the second slid moving left and right; the load-on measuring mechanism connects with the second slid by the driving adjustment mechanism which includes the body, the electric engine set in it, the gear driving equipment, lead screw component, load-on light bar, and the displacement sensor, the pressure sensor. The test device of invention adopts the assemblage frame mechanism and it can adjust randomly for the experimental point of different cover component in the three-dimension space and it can measure the stiffness of cover component through applying the normal load to the experimental point also gives the load-displacement curve of the experimental point according it to judge the ability of outer cover component deforming stiffness, stability, and portable selection material of the car outer cover component.

Owner:BAOSHAN IRON & STEEL CO LTD

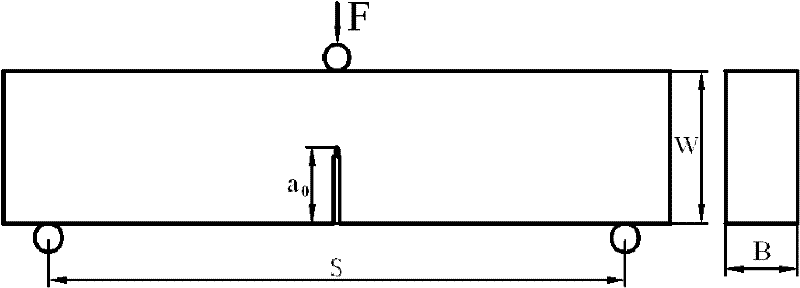

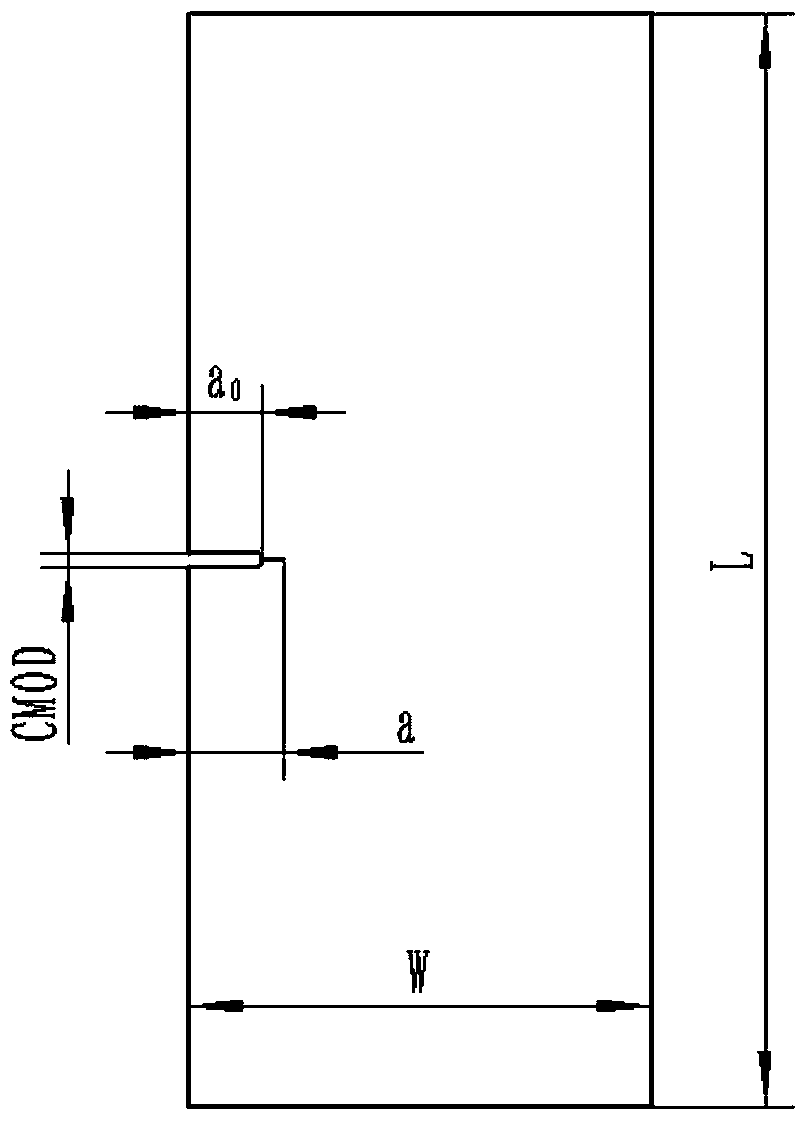

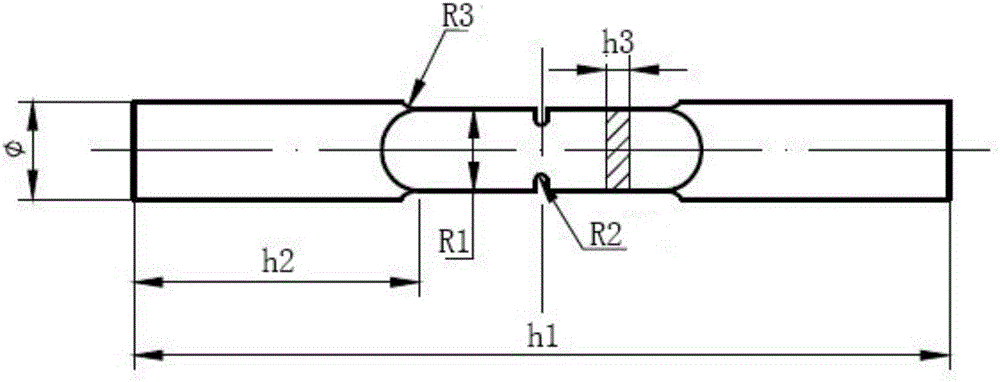

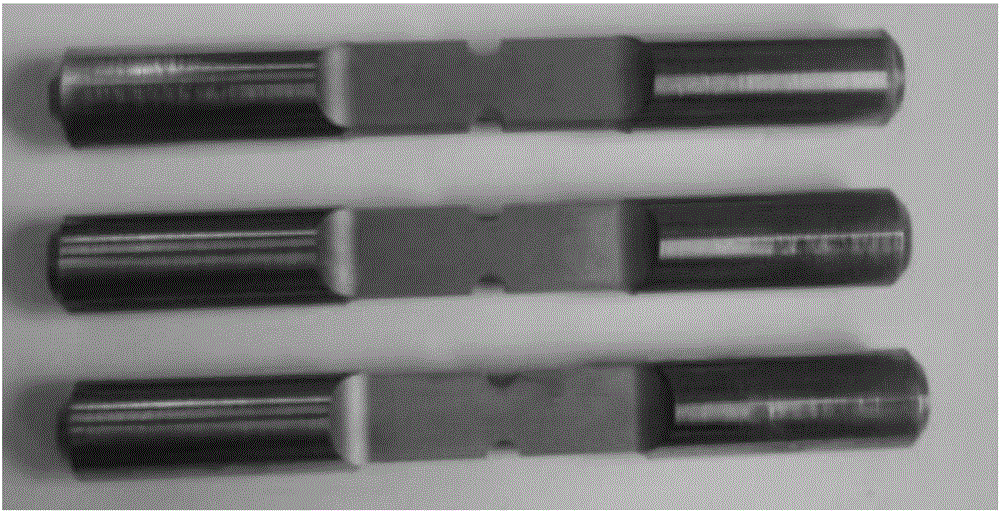

Test method for J-R resistance curve of high-toughness material

ActiveCN102353595AAvoid restrictionsMaterial strength using steady bending forcesMaterials testingLarge deformation

The invention relates to a test method for a J-R resistance curve of a high-toughness material. The method comprises the steps of sample processing, three point bending test, determination of crack length, calculation of J-integration at every load, establishment of a difference function, recursive calculation of crack length and p-V data pairs and construction of the J-R resistance curve. According to the invention, an extensometer is not employed for testing opening displacement and unloading flexibility of a crack mouth; instead, a testing machine is used for direct acquisition of deformation of a three point bending sample and a load-displacement curve in the whole process of fracture; then, the J-R resistance curve of the material is obtained through a series of calculation; therefore, the problem of restriction of testing apparatuses caused by large deformation of a sample in the testing of high-toughness materials is overcome, a J-R resistance curve in the situation of expandedlong size crack is measured, and the test method is applicable to measuring of J-R resistance curves of samples at different temperature and with different dimension.

Owner:EAST CHINA UNIV OF SCI & TECH

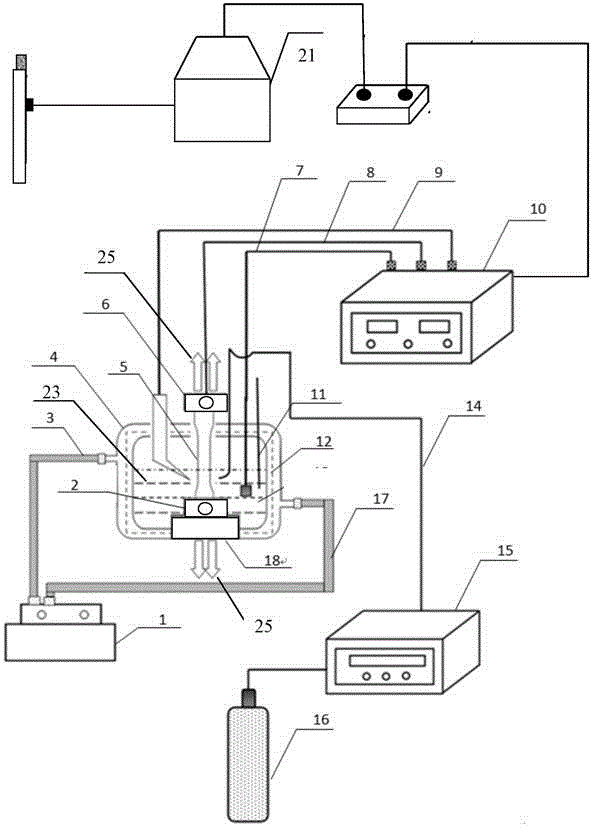

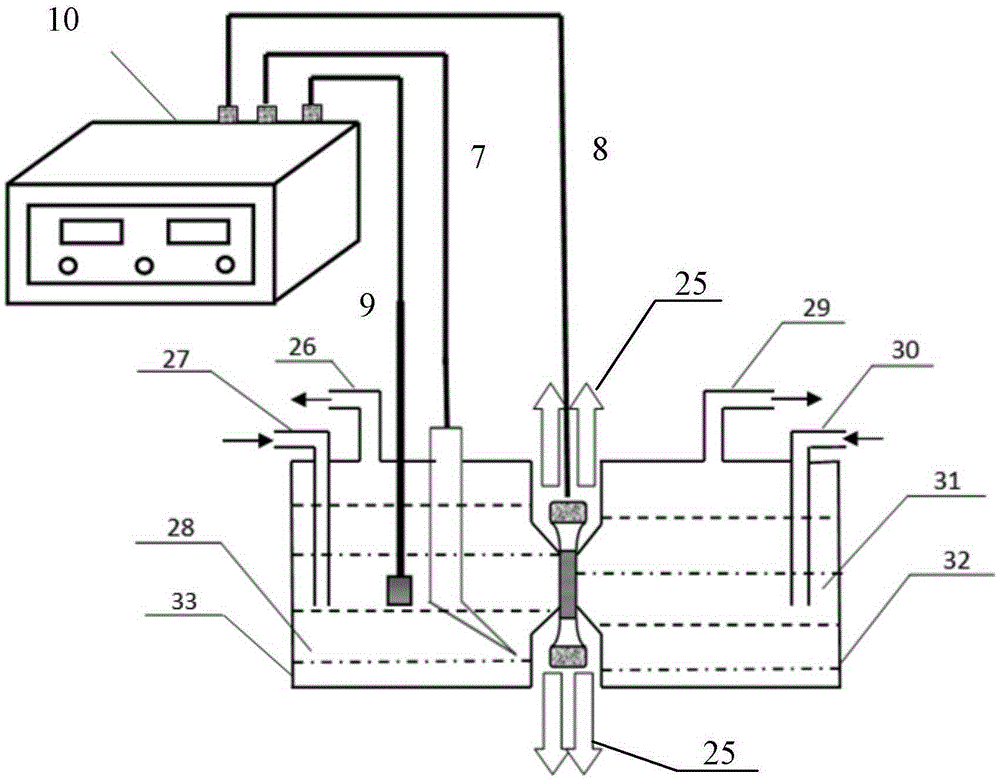

Stress corrosion and hydrogen measuring electrochemical in-situ measurement device under slow strain speed condition

ActiveCN105300874ARealize in situ electrochemical behavior detectionSample size adjustableWeather/light/corrosion resistanceMeasurement deviceMetallic materials

The invention provides a stress corrosion and hydrogen measuring electrochemical in-situ measurement device under a slow strain speed condition. The stress corrosion and hydrogen measuring electrochemical in-situ measurement device comprises an electrochemical work station, an auxiliary electrode, a working electrode, a reference electrode, a stretching test sample, a slow strain stretching machine, a computer, an isolation transformer, a corrosion device and a hydrogen measuring device. The stress corrosion and hydrogen measuring electrochemical in-situ measurement device has the effects that an electrochemical in-situ test can be carried out on stress corrosion and hydrogen permeation respectively under the slow strain speed condition through replacing a corrosion electrolytic tank; the device has the characteristics of adjustable test sample size, in-situ electrochemical measurement, accurate load-displacement readings, simple structure, convenience and flexibility in utilization, simplicity in operation and the like. The device can be used for simultaneously realizing in-situ electrochemical behavior detection of pull stress, corrosive liquid, corrosive gas and temperatures, and can be widely applied to researches of strain speeds, the pull stress, types and concentrations of corrosive media, pH values, temperatures, corrosive gas partial pressure and concentration and influences on corrosion of metal materials by hydrogen brittleness, and a damage evolution rule of materials can be analyzed through electrochemical data.

Owner:CIVIL AVIATION UNIV OF CHINA

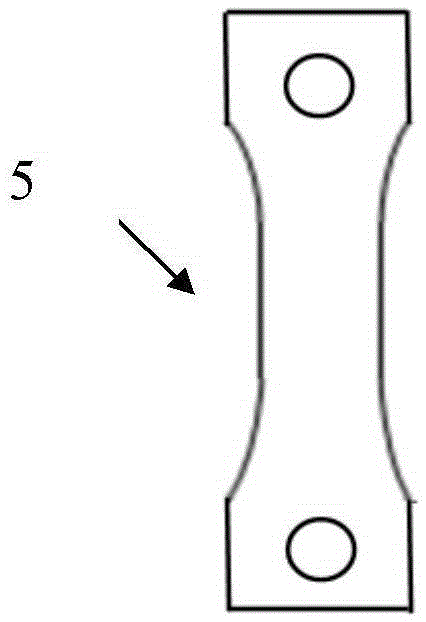

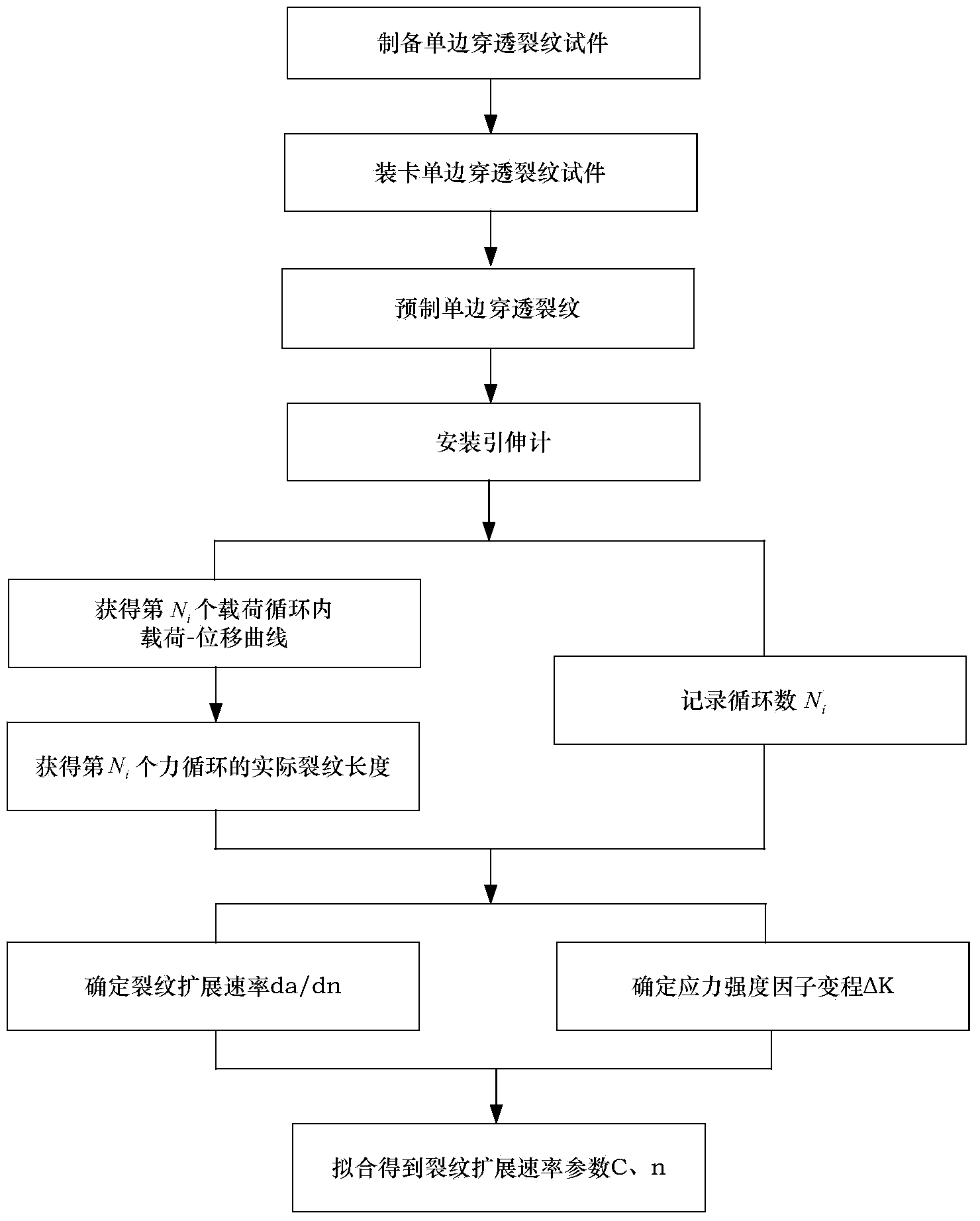

Crack propagation rate measurement method

InactiveCN103674741AAvoid invalid situationsSave materialMaterial strength using repeated/pulsating forcesStress intensity factorStress ratio

The invention discloses a crack propagation rate measurement method. The method comprises the steps of applying alternating load to a test piece with a single-side penetrated crack by a testing machine; measuring load-displacement curves at an interval of certain loading cycles and fitting a linear segment to obtain the non-dimensional flexibility value of the test piece; acquiring the length of the crack according to the relation of the non-dimensional flexibility value of the single-side penetrated crack and the length of the crack under a clamped boundary condition; recording the number of the current loading cycles to obtain a crack length-load cycle number curve, and determining the crack propagation rate; and calculating the corresponding stress intensity factor, acquiring discrete data and fitting to obtain the parameters of the crack propagation rate. The method has the advantages that the method is suitable for measuring the crack propagation rate under positive and negative stress ratios and can be used for measuring the crack length automatically; and the measurement system has wide application range and is particularly suitable for measuring the crack propagation rate of novel materials such as a metal laminated board, a metal / composite material laminated board, a ceramic matrix composite material, a welding material.

Owner:BEIHANG UNIV +1

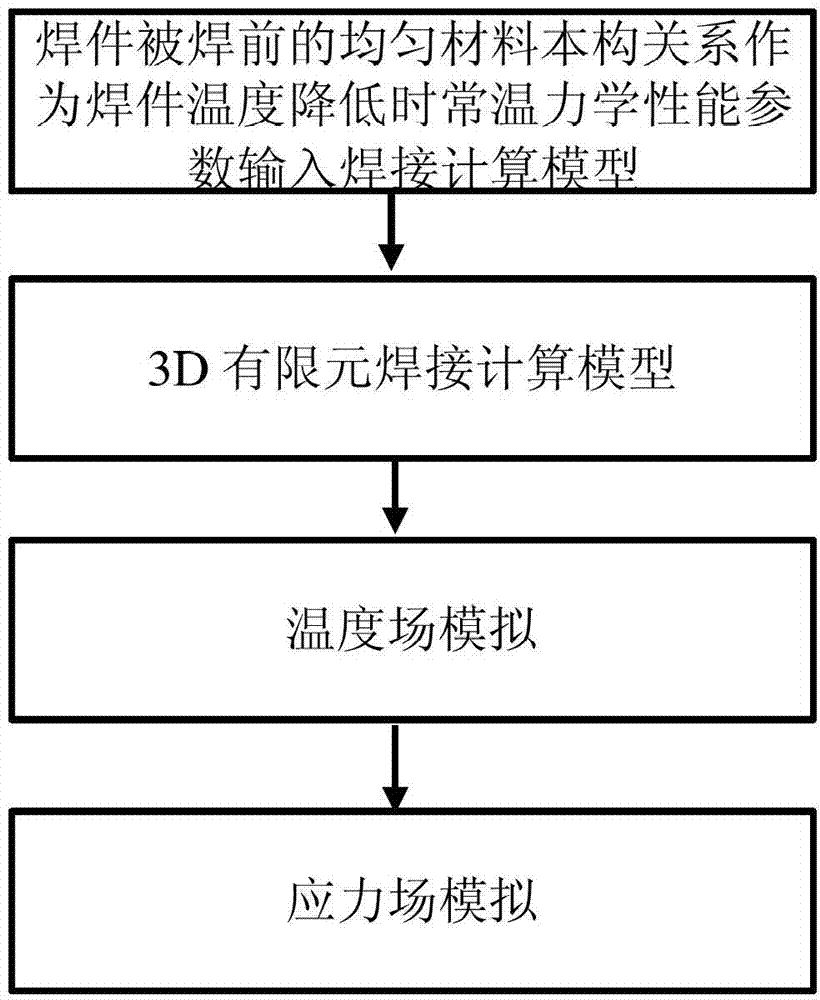

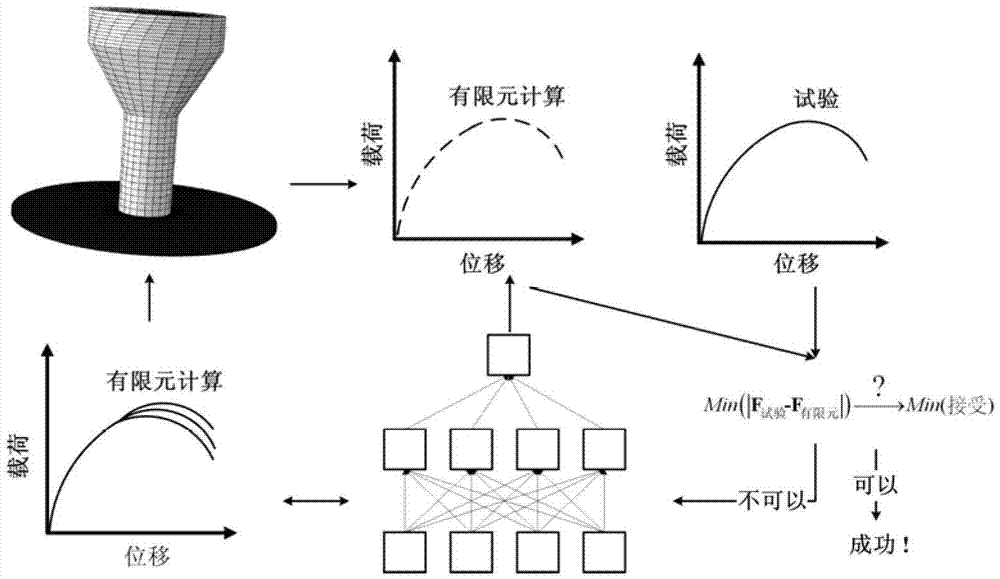

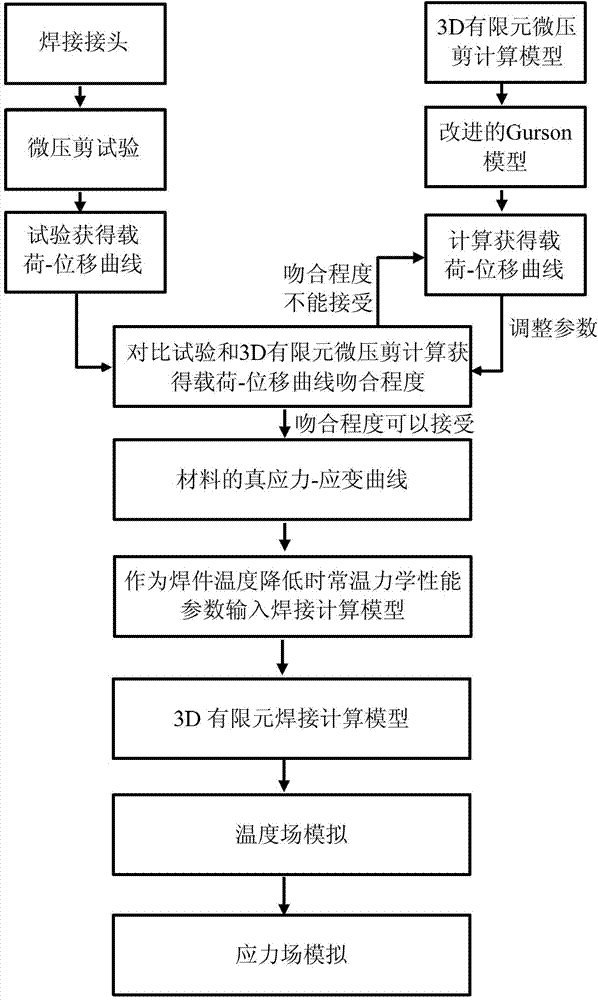

Welding microcell performance test based residual stress computing method

InactiveCN102759504AReduce mistakesAccurate calculationUsing mechanical meansMaterial analysisBacksteppingElement model

The invention provides a welding microcell performance test based residual stress detection method, which comprises the following steps of: carrying out a micro-compression-shear test on a welding microcell so as to obtain a load-displacement curve of the welding microcell, establishing a 3D (three-dimensional) finite element model of a micro-compression-shear test process, and carrying out a finite element reverse backstepping method based on an improved Gurson model so as to obtain a true stress-strain relation of the welding microcell; computing the welding residual stress, wherein in the process of carrying out computing on a welding temperature field, the influence of the mechanical property of the welding microcell on the change of the temperature field is not considered; and after the welding temperature field is obtained, in the process of carrying out computing on a welding stress field, taking normal-temperature mechanical property parameters (when the temperature of a weldment is reduced according to the true stress-strain relation of the welding microcell) into a welding computing model, and then obtaining the welding residual stress through computing. The accuracy of the method disclosed by the invention is higher than that of a result obtained by using a residual stress computing method which is implemented through not considering the mechanical property of the welding microcell.

Owner:XI AN JIAOTONG UNIV

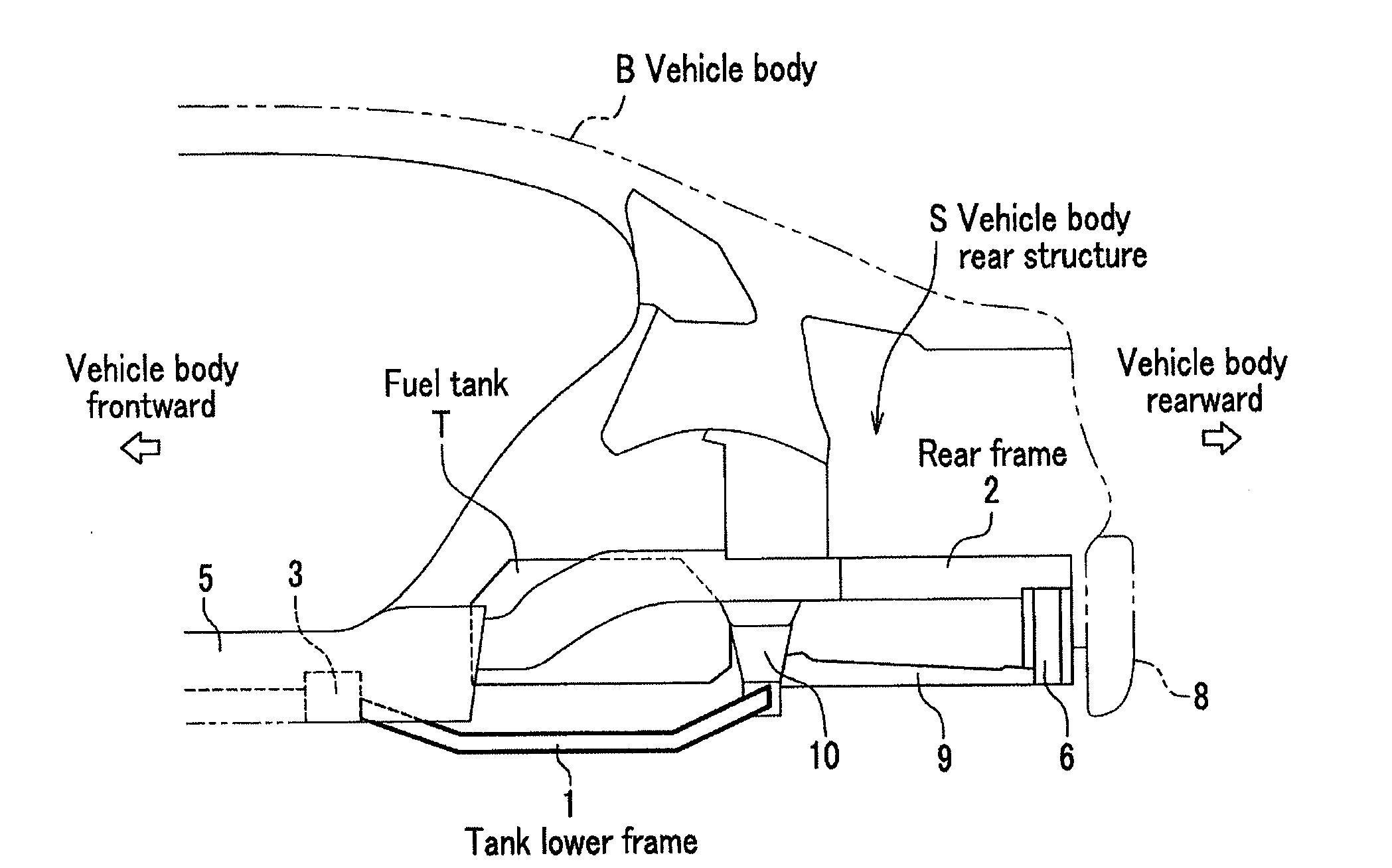

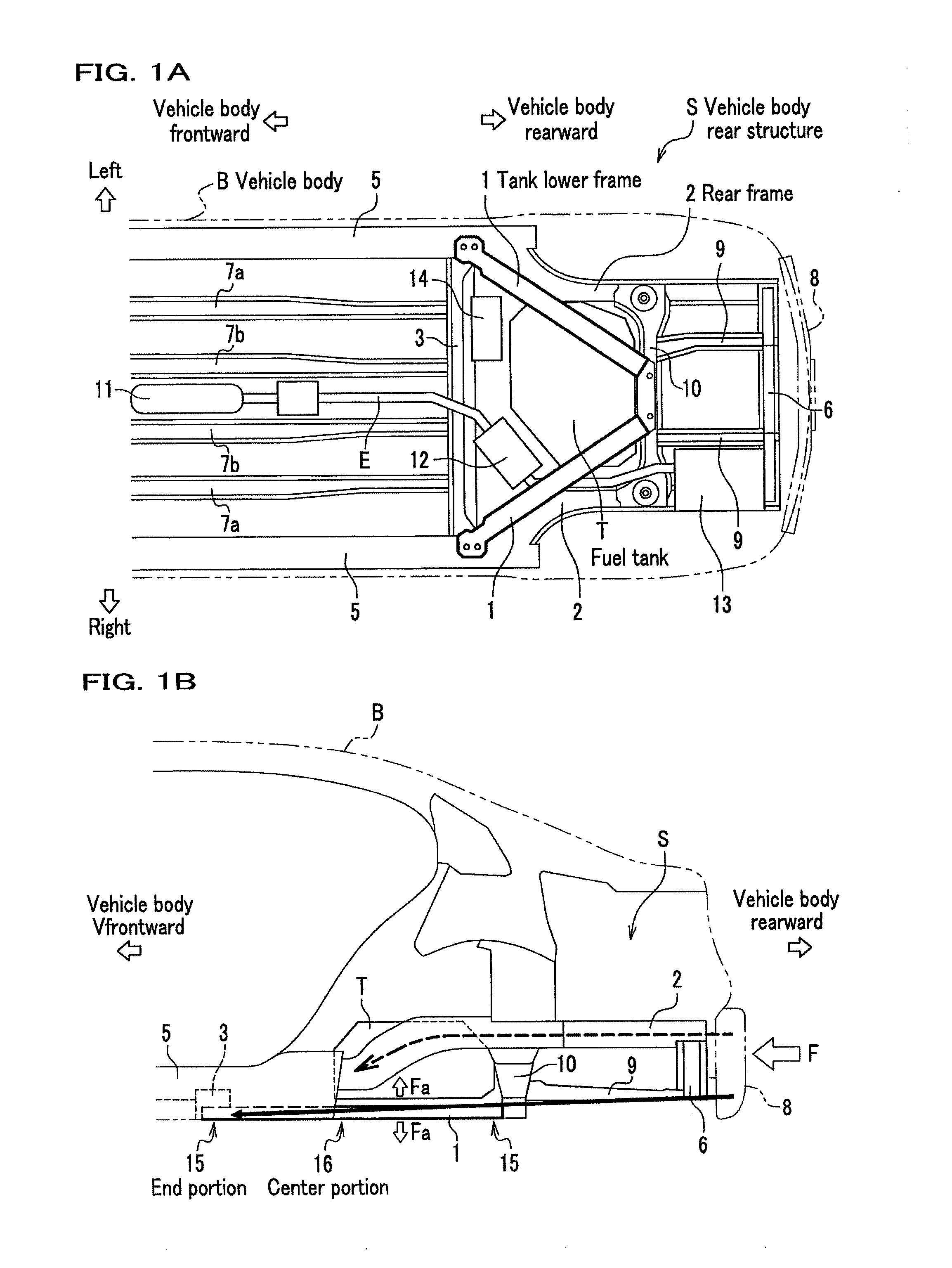

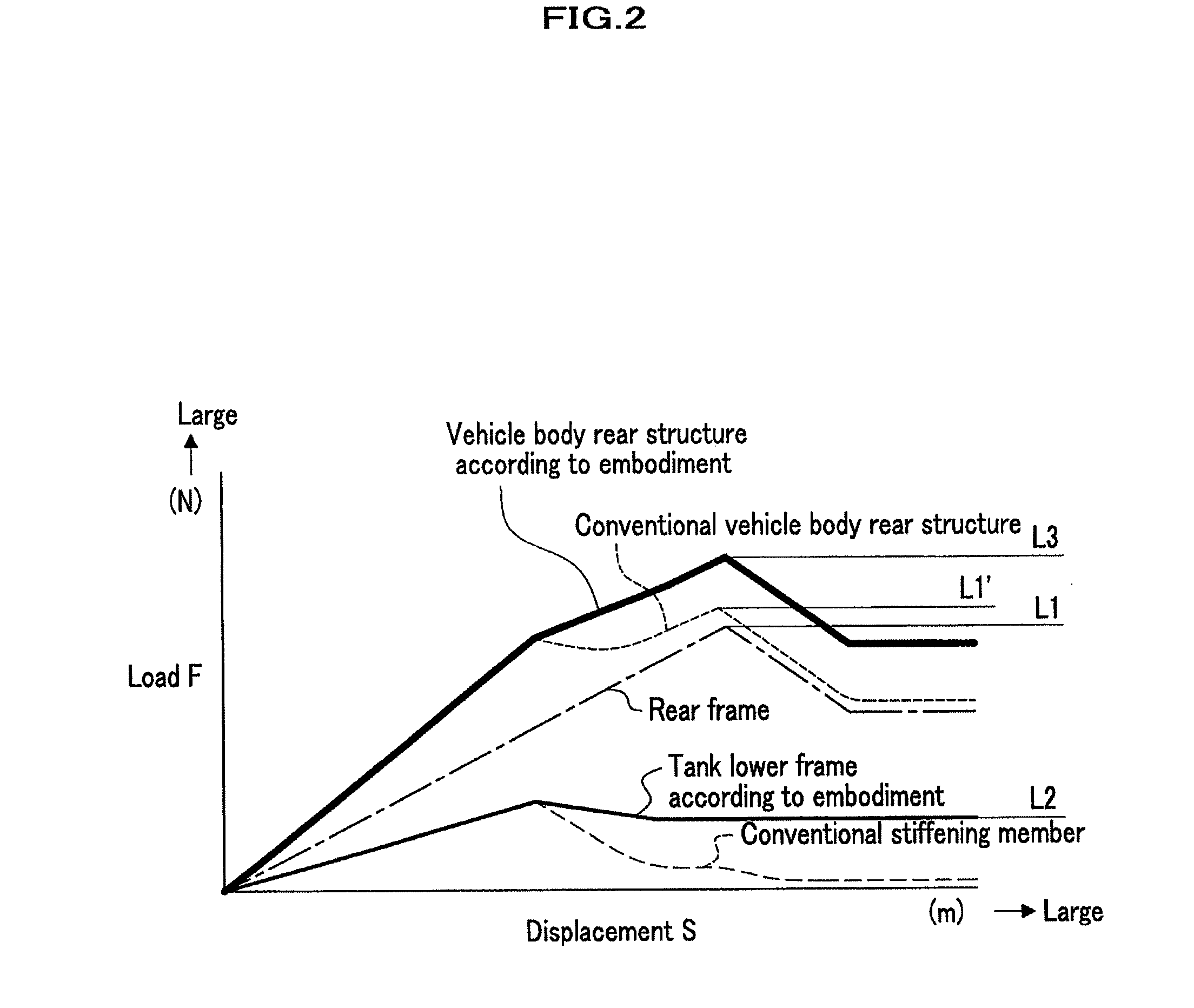

Vehicle body rear structure

InactiveUS20090001767A1Deformation in cross sectionHeavy loadVehicle seatsUnderstructuresVehicle frameFlexural strength

Owner:HONDA MOTOR CO LTD

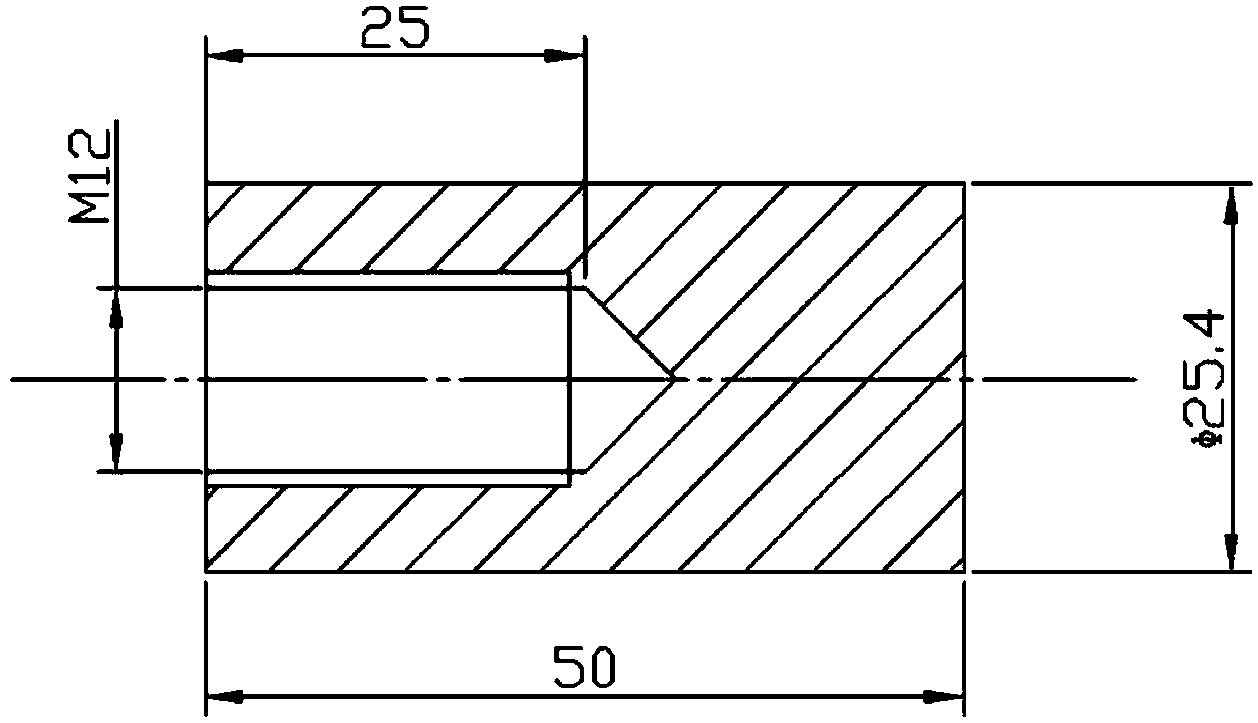

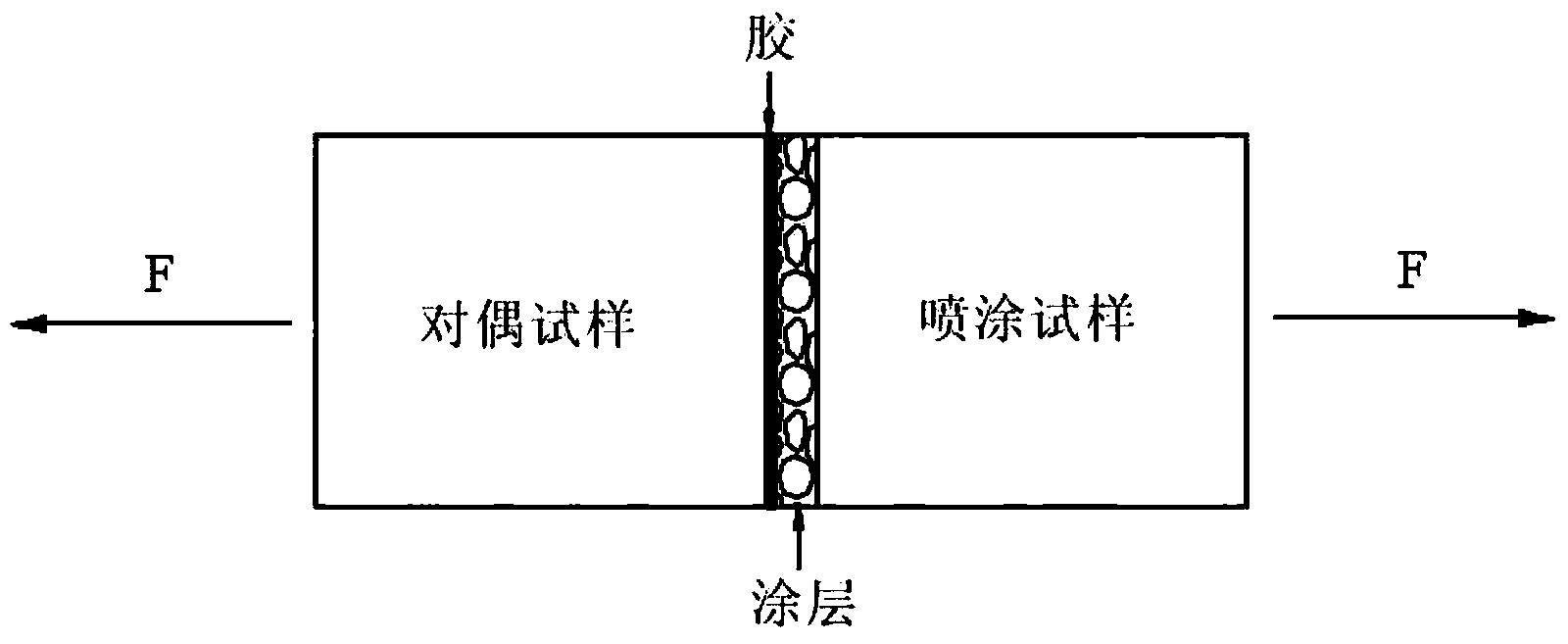

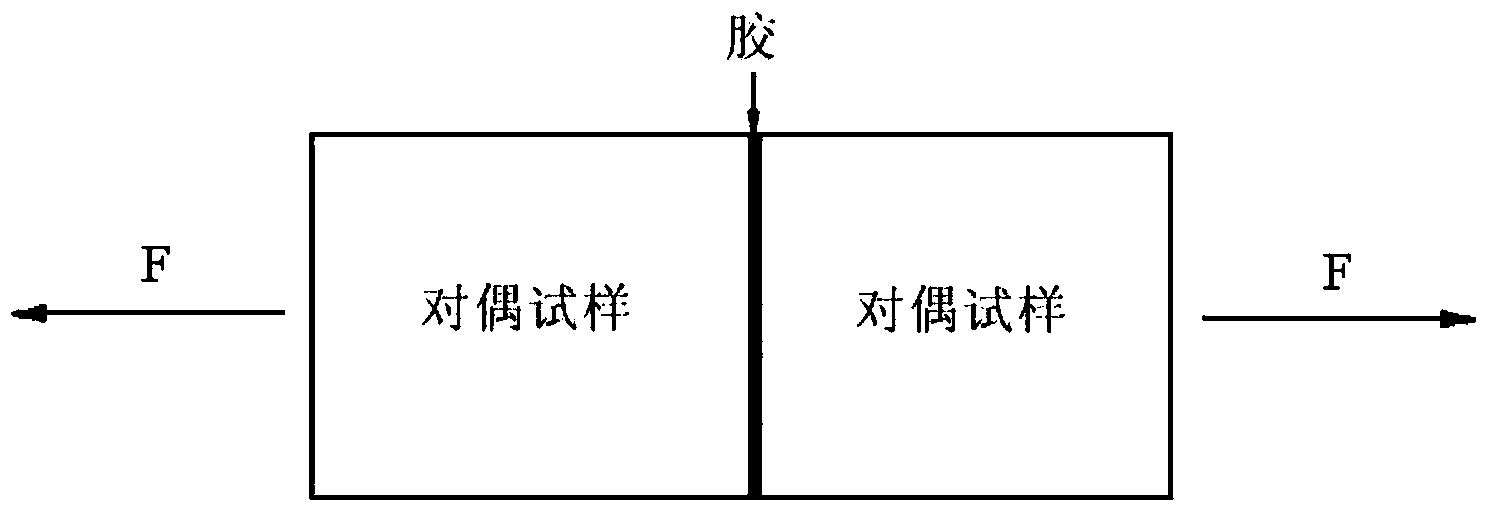

Method for testing elasticity moduli of coatings

InactiveCN103528885AAccurately measure the elastic modulus valueEasy to makePreparing sample for investigationMaterial strength using tensile/compressive forcesUltrasonic testingTensile testing

The invention provides a method for testing elasticity moduli of coatings. Coatings are deposited on surfaces of matrix samples and are boned with dual samples by using high-strength glue; load displacement curves of boned samples are tested by using a tensile testing machine; and the curves are compared with a tensile testing result of a sample formed by bonding two matrix samples with deposition layers, so that elasticity modulus values perpendicular to the surface directions of the coatings during tensile processes of the coatings are obtained. The method makes up various disadvantages of a conventional surface coating testing technology. The advantages are as follows: a bending method can only be used for testing coating elasticity moduli parallel to the surface directions; and an indentation method is only can be used for testing local mechanical properties of the coatings and complexity of an ultrasonic testing method. The technical requirement for testing the elasticity moduli perpendicular to the surface directions of the coatings conveniently and reliably can be met. The method is applicable to measurement of indexes of elasticity moduli perpendicular to the surface directions of various surface coatings.

Owner:TIANJIN UNIV

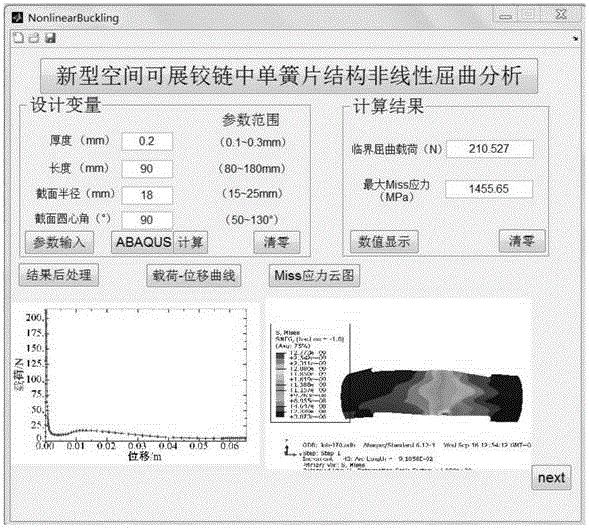

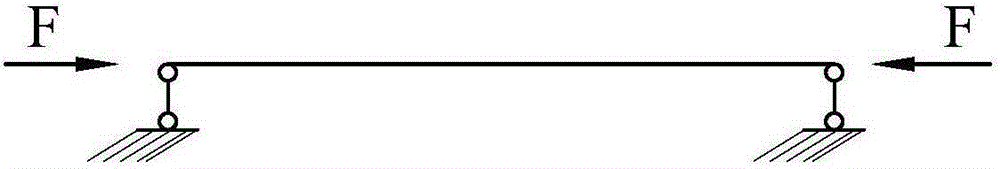

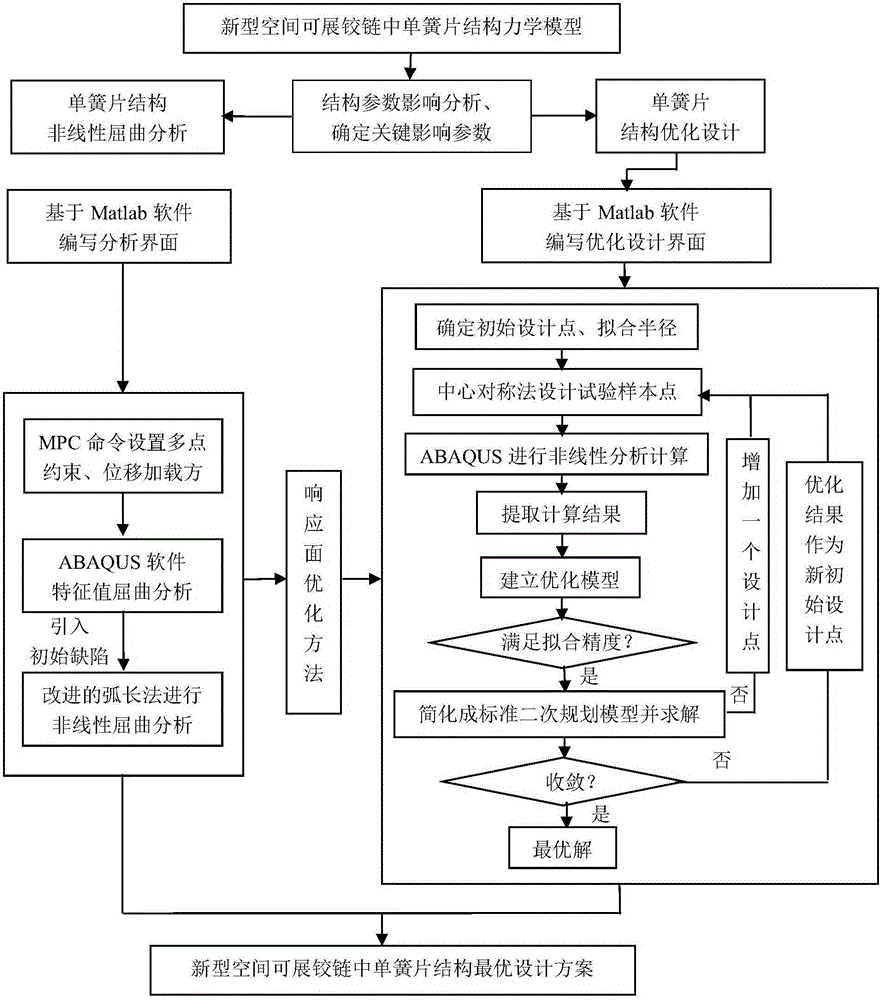

Response surface based optimization method for single reed structure in novel space deployable hinge

ActiveCN105224750AReliable Structural Stability Analysis MethodShorten the design cycleSpecial data processing applicationsStress distributionMechanical models

The present invention provides a response surface based optimization method for a single reed structure in a novel space deployable hinge. The method comprises: according to an actual operating environment of the single reed structure in the novel space deployable hinge, establishing a simplified mechanical model; performing equivalent processing on constraint and loading modes of the single reed structure; obtaining a first-five-order buckling mode and a buckling load of the structure based on ABAQUS; introducing an initial geometric defect to obtain a load-displacement curve, a critical buckling load and a stress distribution cloud chart of the structure; obtaining an optimization model with the maximum buckling bearing capacity under stress constraint of the structure; realizing explicit expressions of a constraint and an objective function based on a response surface method, checking the precision of fitting and updating the model; and simplifying the optimization model into a standard quadratic programming model, and then solving the model by a sequential quadratic programming method to obtain an optimal result. The present invention provides a reliable stability analysis method for the single reed structure, thereby shortening design cycle of the novel space deployable hinge, improving work efficiency and reducing design costs.

Owner:BEIJING UNIV OF TECH

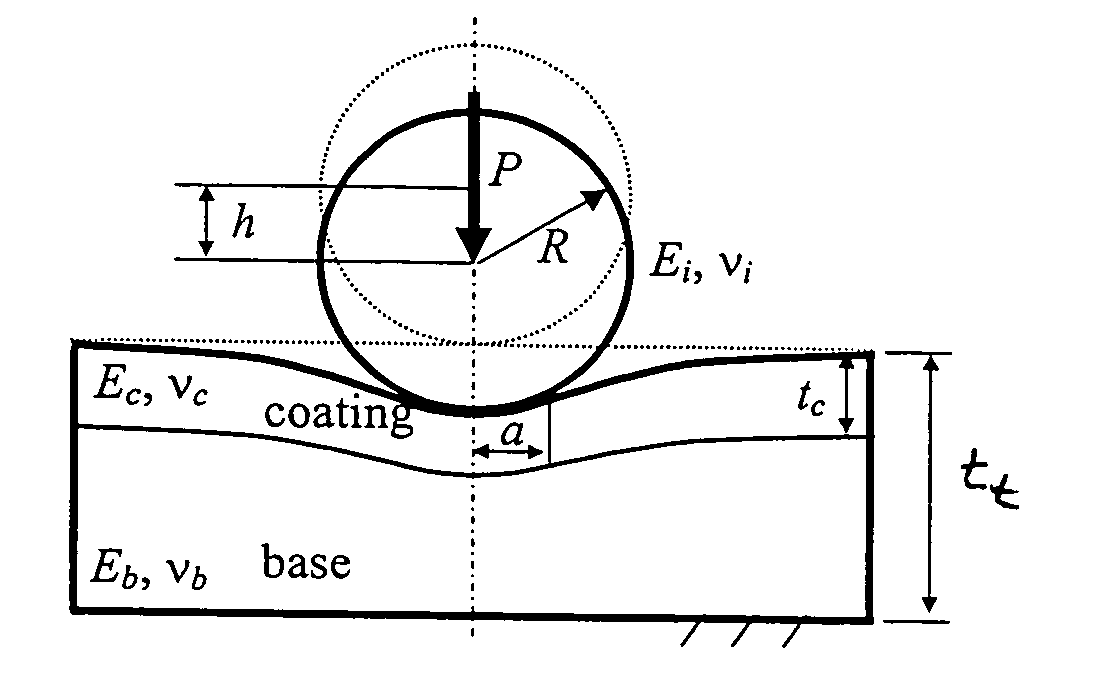

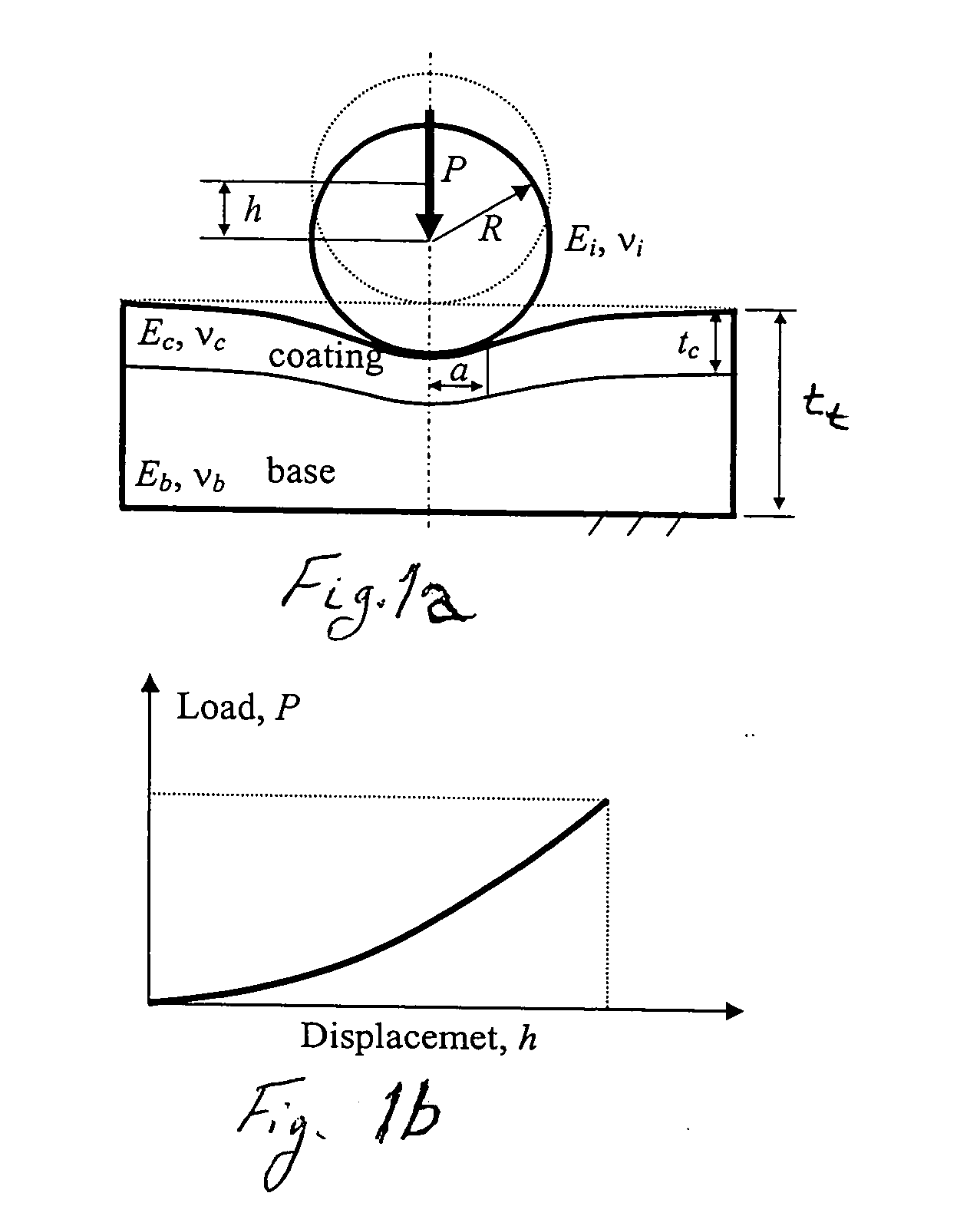

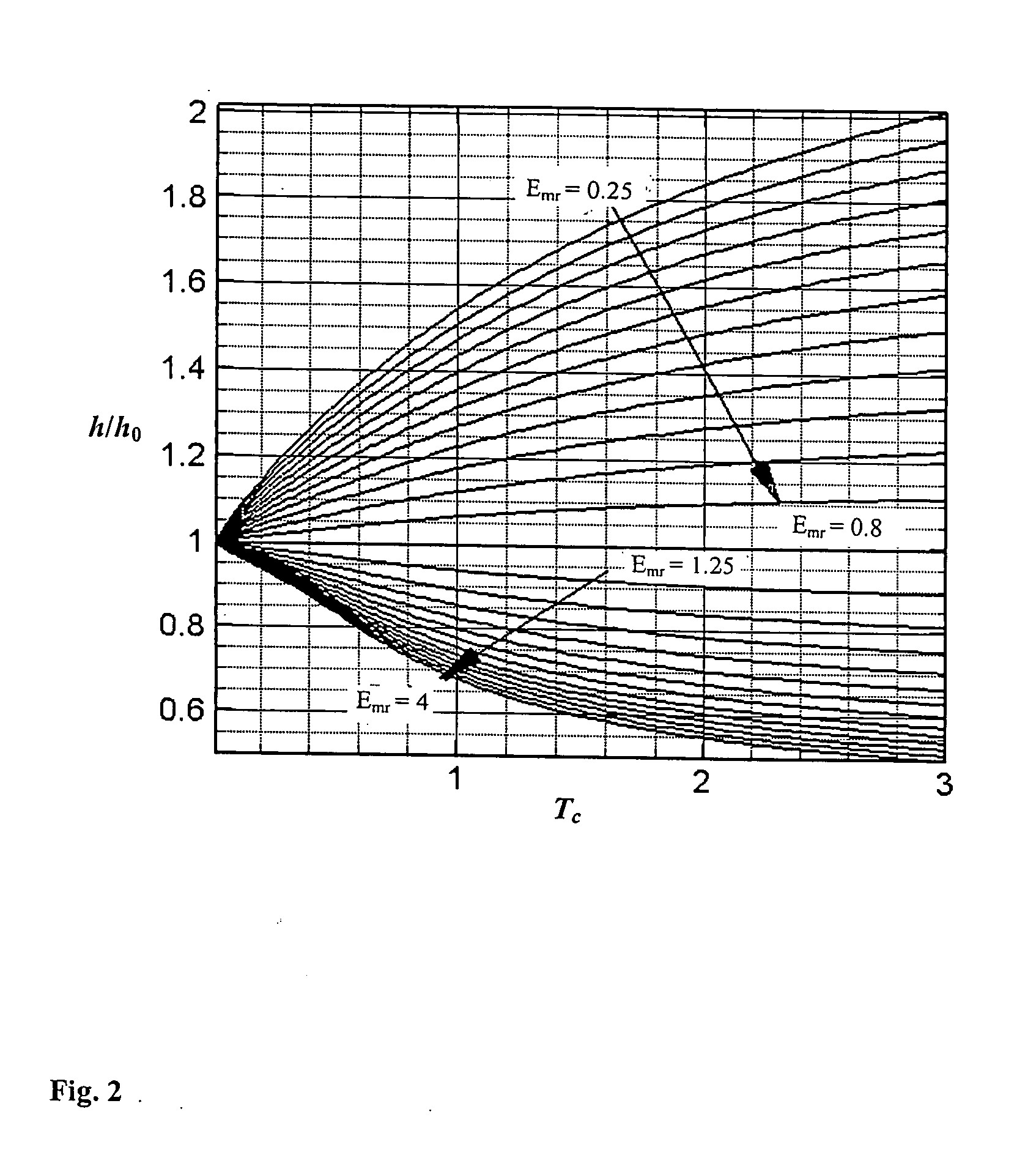

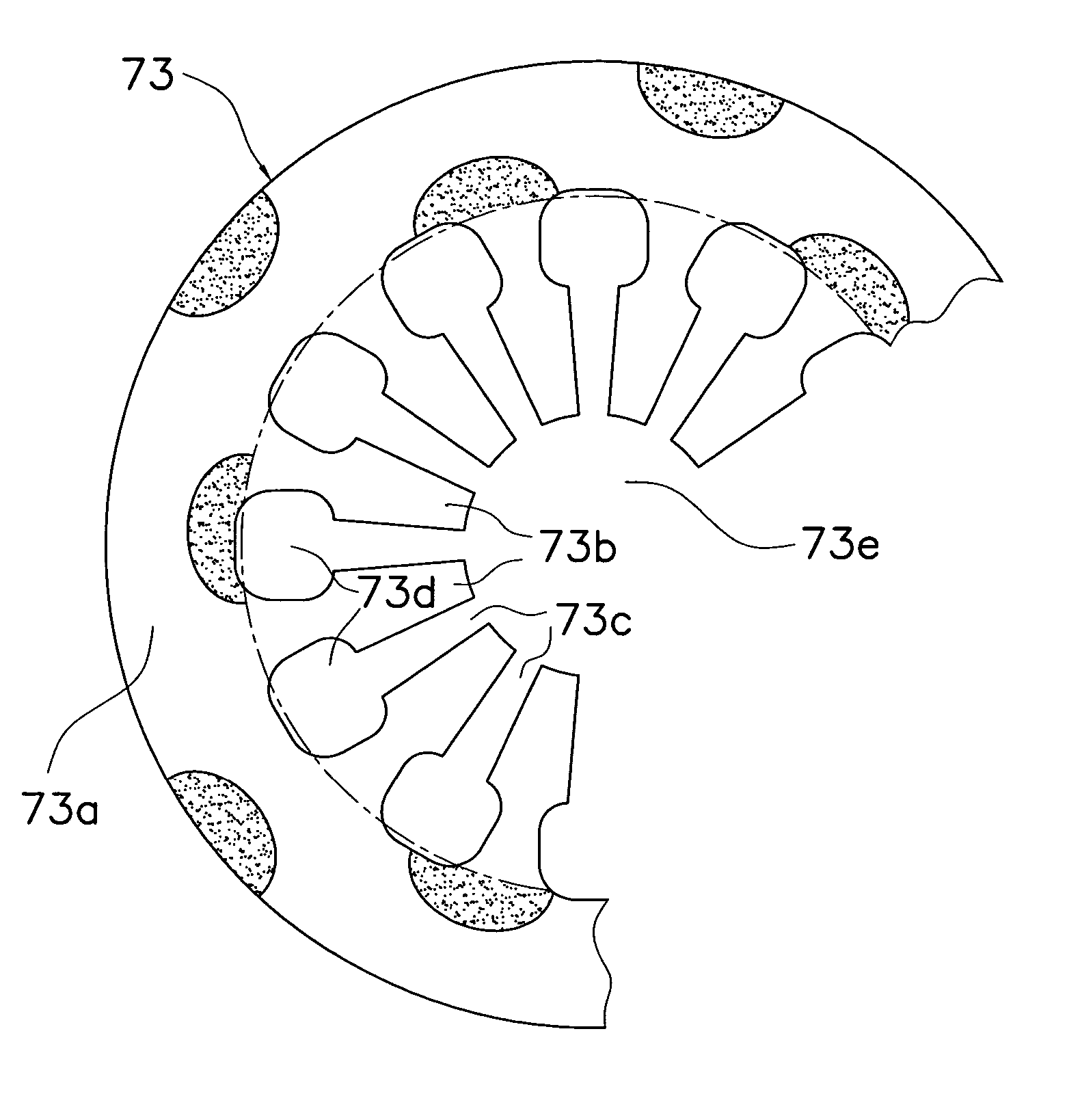

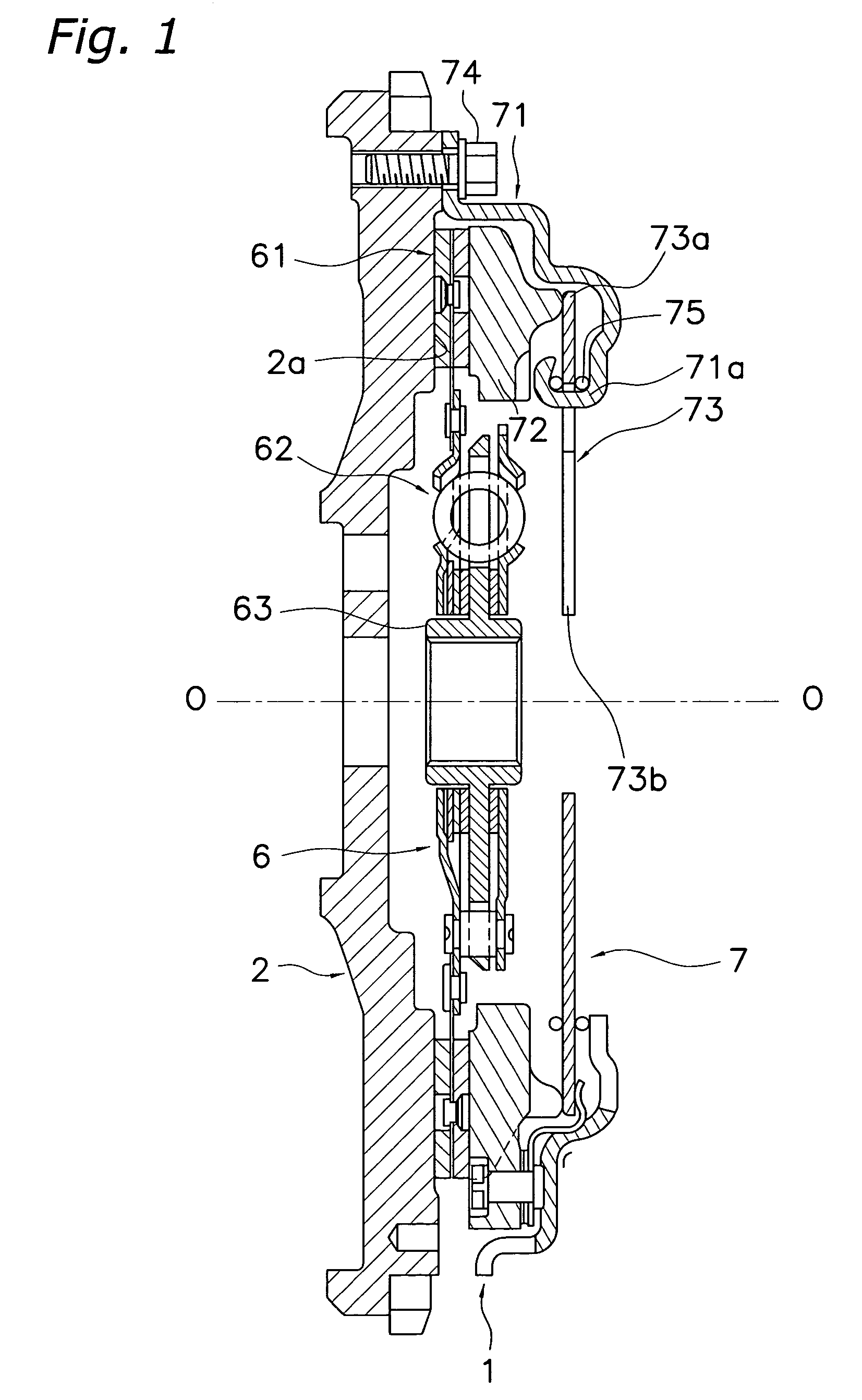

Determination of young's modulus and poisson's ratio of coatings from indentation data

InactiveUS20050103120A1Accurately, conveniently and non-destructively determine Young's modulusSimple processVolume/mass flow measurementMaterial strength using tensile/compressive forcesEngineeringYoung's modulus

A method is provided for determining Young's modulus and, if desired, Poisson's ratio of a coating on a substrate wherein load-displacement indentation data in the elastic region (either elastic loading or unloading) generated using an indenter is analyzed to interpret the elastic repsonse of a coated material. The data analysis pursuant to the invention is based on an extended Hertzian analysis developed for thin-film coatings.

Owner:NORTHWESTERN UNIV

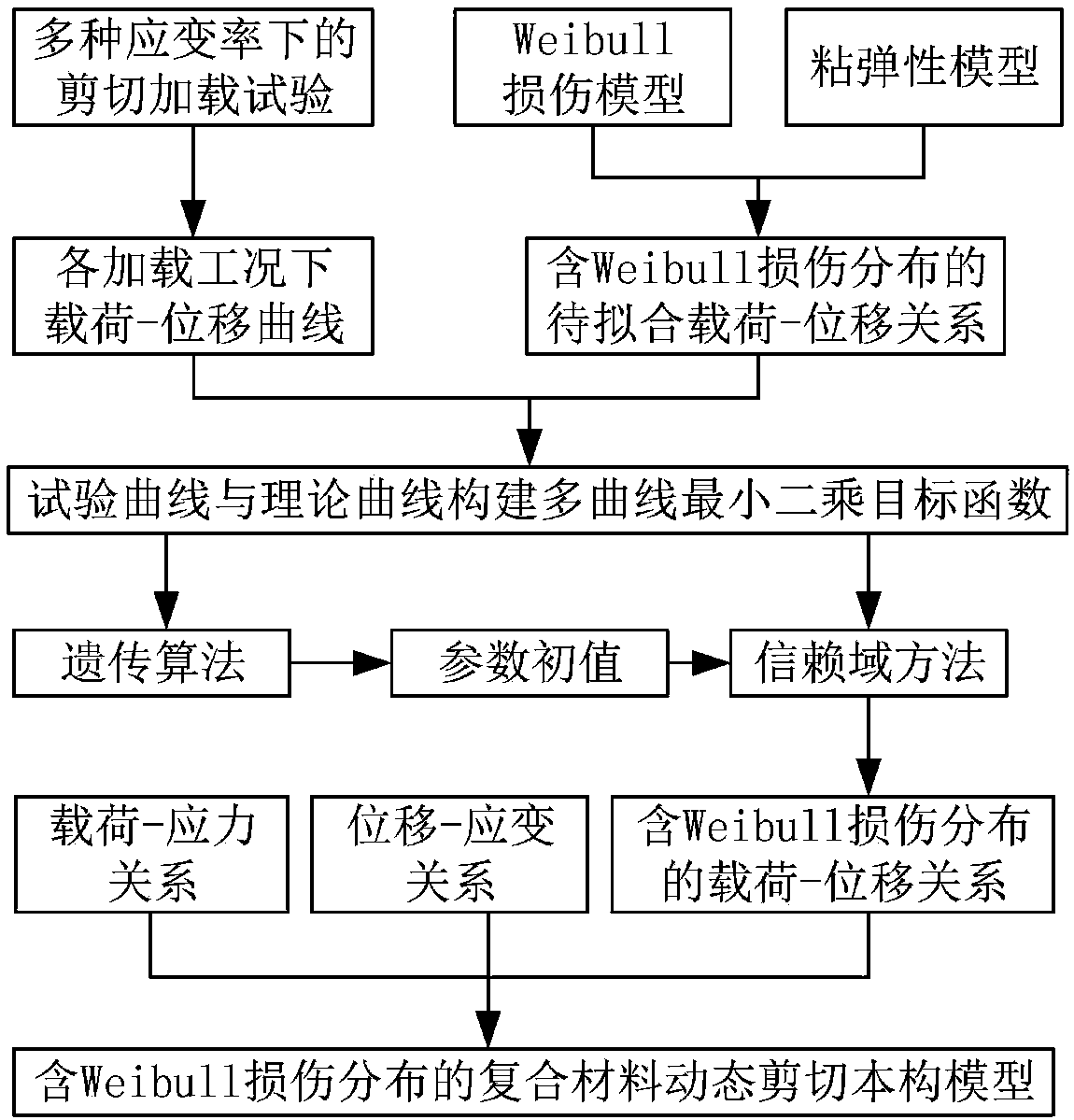

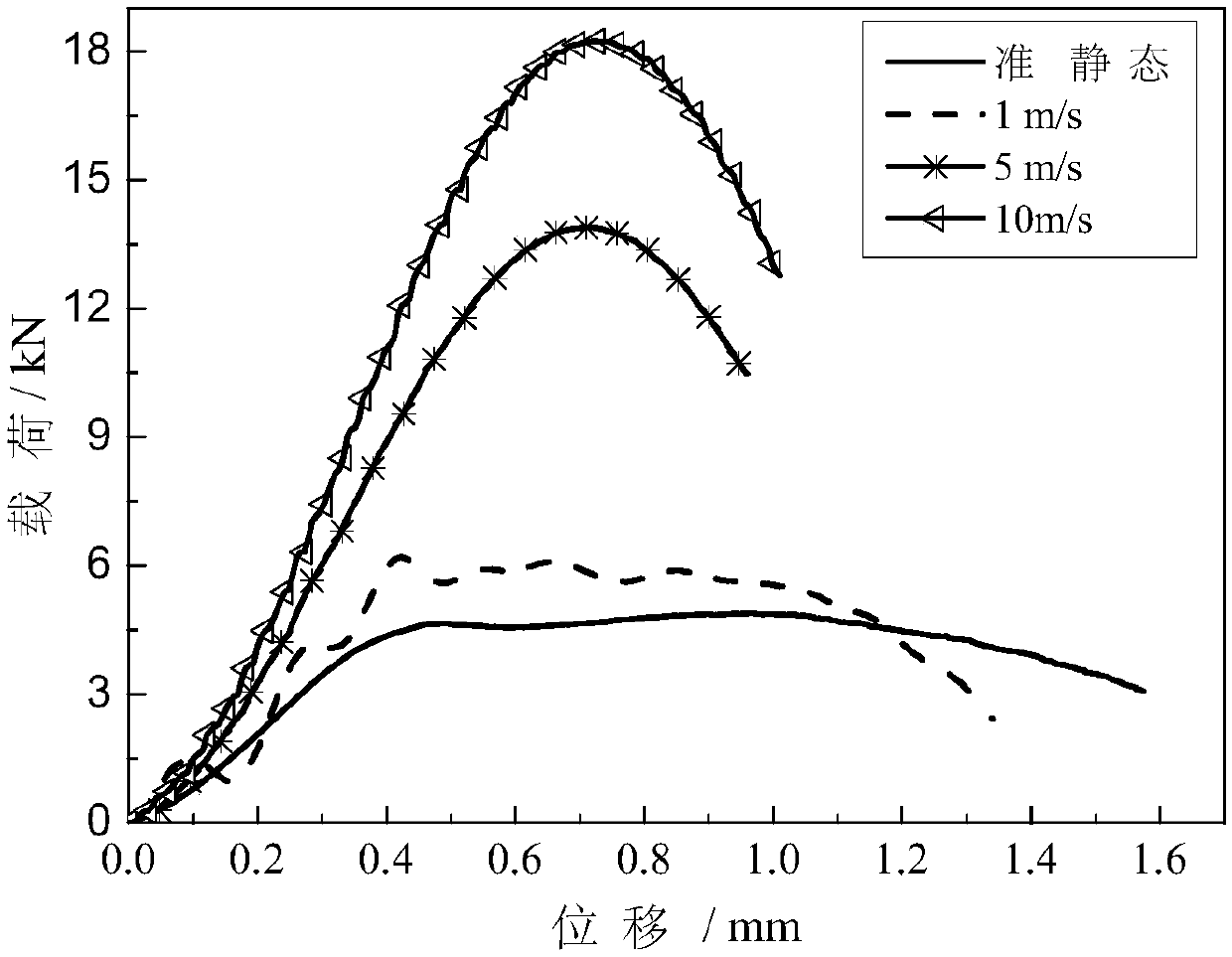

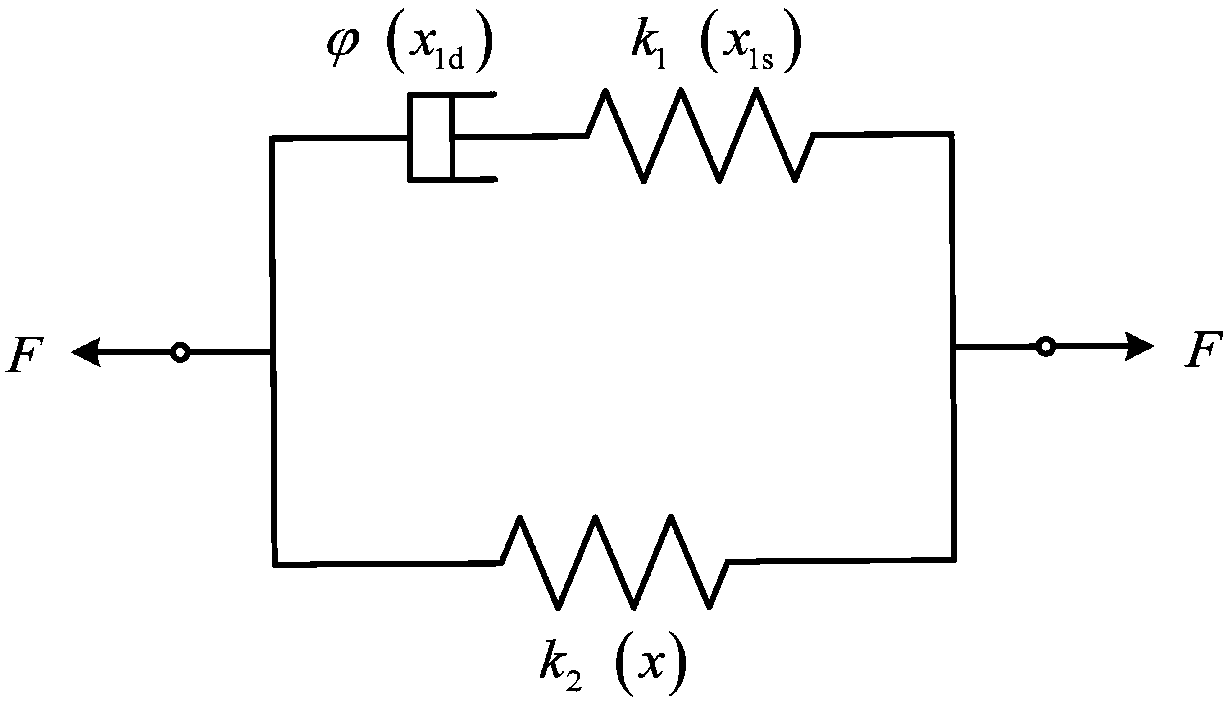

Construction method for dynamic shear constitutive model of fiber-reinforced composite material

ActiveCN107633120AUniqueness guaranteedGuaranteed accuracyGeometric CADDesign optimisation/simulationGenetic algorithmEngineering

The invention discloses a construction method for a dynamic shear constitutive model of a fiber-reinforced composite material. The method comprises the steps of 1, completing shear tests of the fiber-reinforced composite material under various strain rate loading working conditions to obtain a load-displacement curve under each working condition; 2, combining a Weibull damage model with a viscoelastic model to deduce a to-be-fitted load-displacement relation containing Weibull damage distribution; 3, constructing a multi-curve least-square objective function according to the load-displacementcurves and the load-displacement relation; 4, obtaining an initial value of a to-be-fitted parameter by use of a genetic algorithm, searching in the vicinity of the obtained initial value of the parameter through a trust-region method to finally obtain a high-precision parameter value and the determined load-displacement relation containing the Weibull damage distribution; and 5, deducing the dynamic shear constitutive model of the composite material containing the Weibull damage distribution according to a load-stress relation, a displacement-strain relation and the load-displacement relation. According to the construction method for the dynamic shear constitutive model of the fiber-reinforced composite material, a reliable basis can be provided for numerical simulation calculation of thefiber-reinforced composite material under the dynamic working conditions.

Owner:SOUTHEAST UNIV

Method for predicting tensile strength of nickel-base superalloy gap

InactiveCN105930553AGuaranteed accuracyPredicted strength limitDesign optimisation/simulationSpecial data processing applicationsElement modelHosford yield criterion

The invention discloses a method for predicting tensile strength of nickel-base superalloy gap. The method includes the following steps: acquiring an attribute parameter of a material to be tested through an experiment; performing secondary development on finite element software, and implanting an Hosford yield criterion and a required material hardening constitutive model into the finite element software; defining the material attribute in the finite element software; performing 3-dimensional finite element partition on a gap test model in the finite element software; applying constraint and displacement load on the finite element model; setting a solver; performing solution to acquire a finite element calculation result; extracting the reaction force of each node of an end surface of the finite element model and accumulating the reaction forces in a time postprocessor so as to acquire a load value of each time step; multiplying a Time value by an applied total displacement value to acquire a displacement value of each time step; and turning the result into a load-displacement curve. The method adopts the yield criterion and a failure criterion suitable for nickel-base superalloy, and then the ultimate strength of a gap can be accurately predicted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for measuring interface bonding strength of thermal barrier coating layer

ActiveCN107345898AAvoid disadvantagesMaterial strength using tensile/compressive forcesUsing mechanical meansTip positionAlloy

The invention relates to the measurement field of mechanical properties of materials and particularly relates to a method for measuring the interface bonding strength of a thermal barrier coating layer. The method comprises the following steps: (1) acquisition of stress-strain data: firstly preparing a measuring test piece, and acquiring and recording a load-displacement curve by virtue of a three-point bending method so as to acquire the stress-strain data; (2) calculation of crack length: representing the deformation of the measuring test piece by virtue of a digital image relevant method, and combining with the displacement of an open angle to determine a crack tip position, so as to calculate the crack length; and (3) calculation of energy release rate: after the stress-strain data and the crack length are acquired, calculating the energy release rate by virtue of a flexibility method. According to the method provided by the invention, by utilizing the characteristic that the breakable thermal barrier coating layer and a hard alloy matrix are different when being deformed by virtue of an external force, the external force is applied to an alloy basement by virtue of an improved three-point bending method, and the interface bonding strength of the thermal barrier coating layer with a deformed interface is represented by virtue of the digital image relevant method.

Owner:JIANGSU UNIV

Material fatigue performance obtaining method for sheet sample

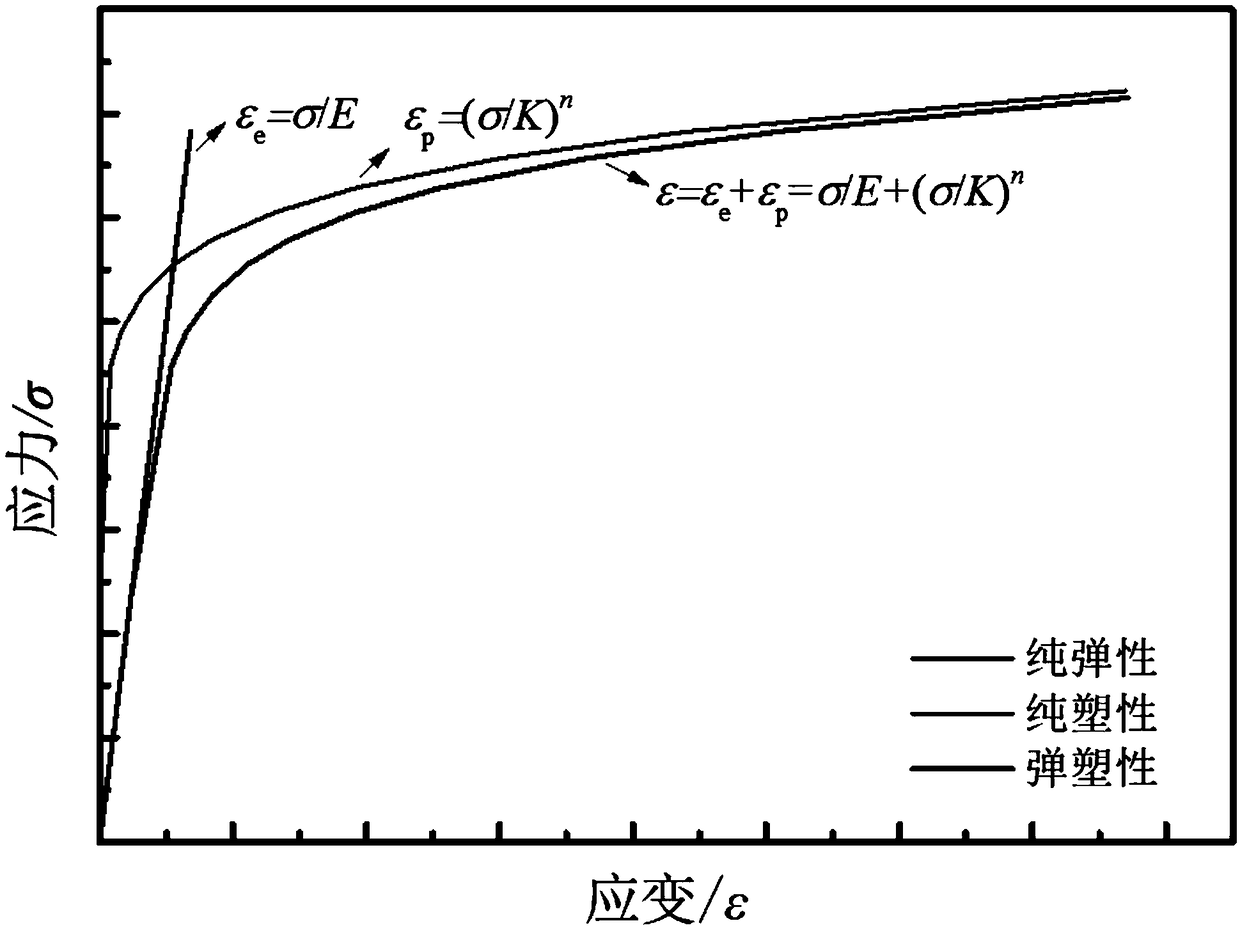

ActiveCN108693055AOvercome size limitationsMaterial strength using repeated/pulsating forcesHysteresisRamberg osgood

The invention discloses a material fatigue performance obtaining method for a sheet sample, which comprises the following steps: step 1: completing a tension-pressure symmetric cyclic loading test ofa multi-stage strain amplitude for the sheet sample under strain control to obtain a cyclic stable load-displacement curve; step 2: connecting load-displacement curve hysteresis loop tips as the cyclic load-displacement curve, and predicting a cyclic stress-strain relationship in accordance with a Ramberg-Osgood constitutive model with a cyclic load-displacement relationship; step 3: establishinga relationship between a true strain amplitude epsilon r, a stress amplitude sigma r and a measured and controlled strain amplitude epsilon eq of a fatigue source RVE by using the cyclic stress-strainrelationship as a material parameter; step 4: establishing a fatigue life estimation model according to epsilon r and sigma r to obtain the fatigue property of the material. According to the materialfatigue performance obtaining method, the material dimension limitations of the traditional fatigue performance test method are overcome, and the method does not rely on empirical formulas, and is applied to different materials and sample configurations.

Owner:SOUTHWEST JIAOTONG UNIV

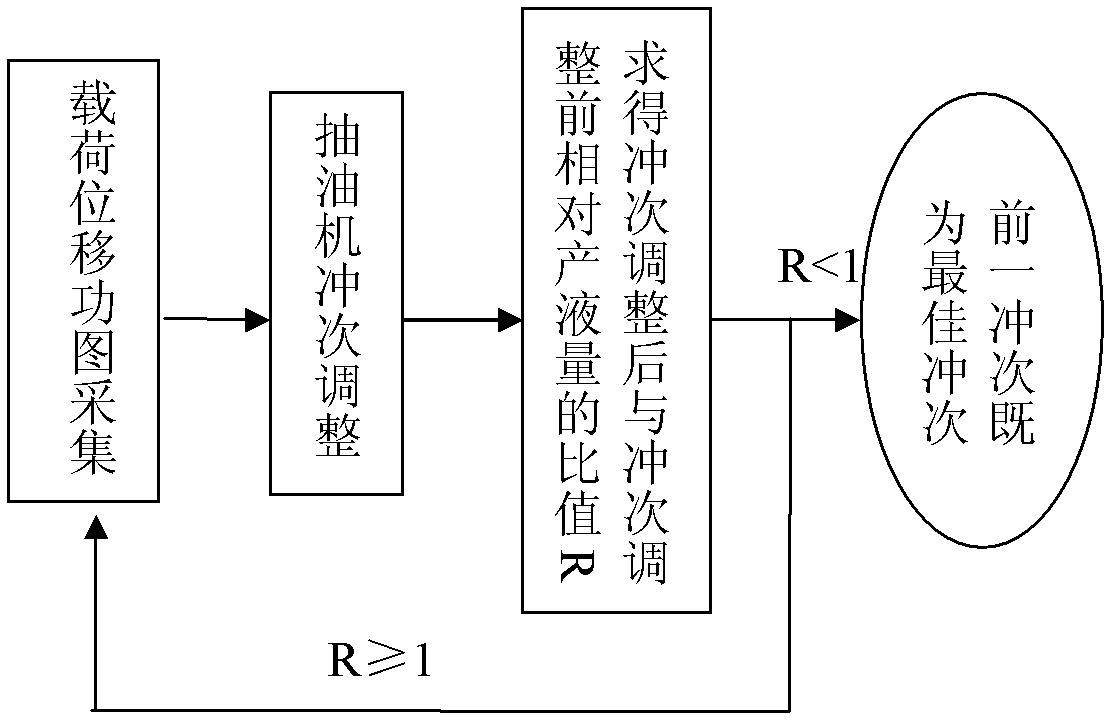

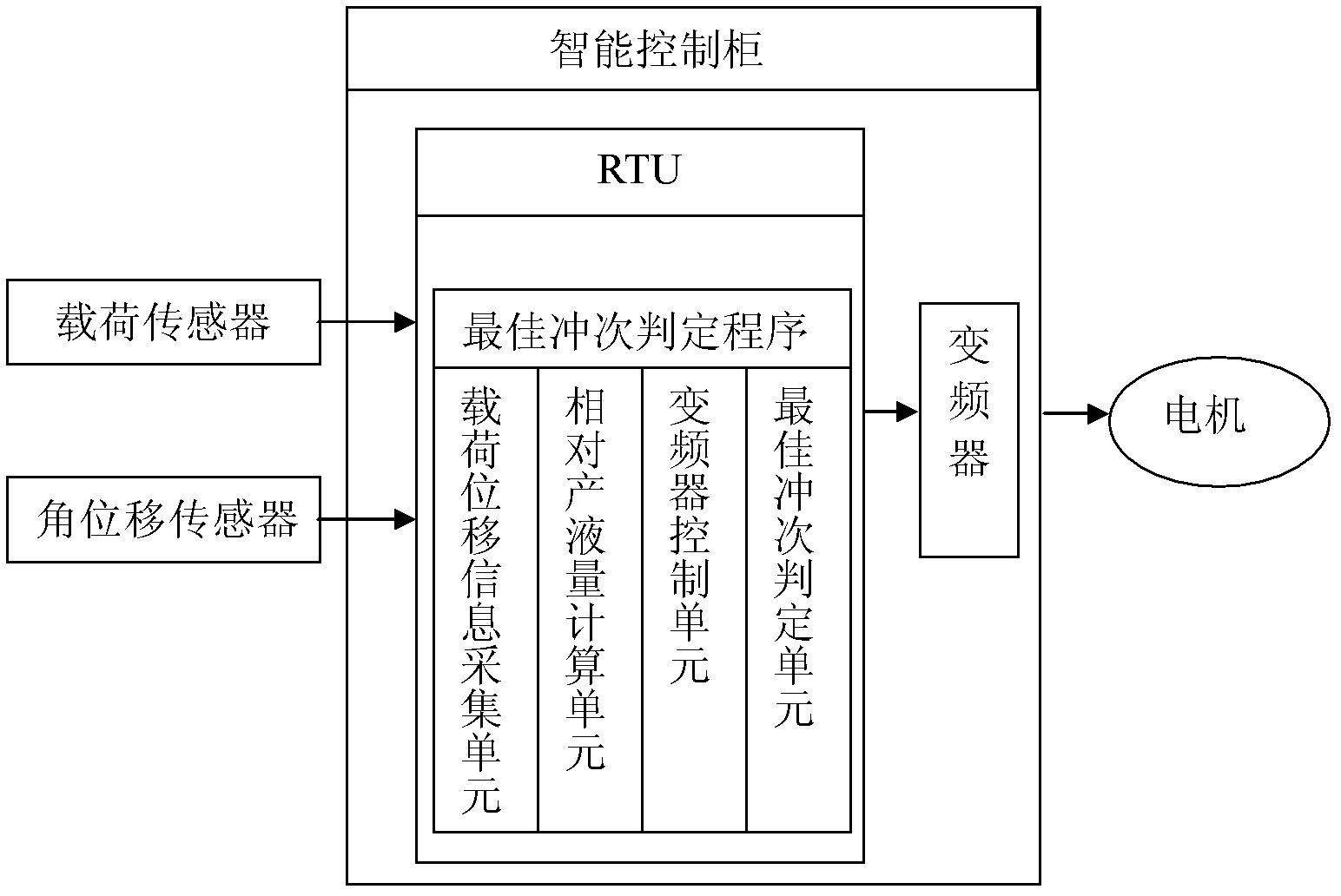

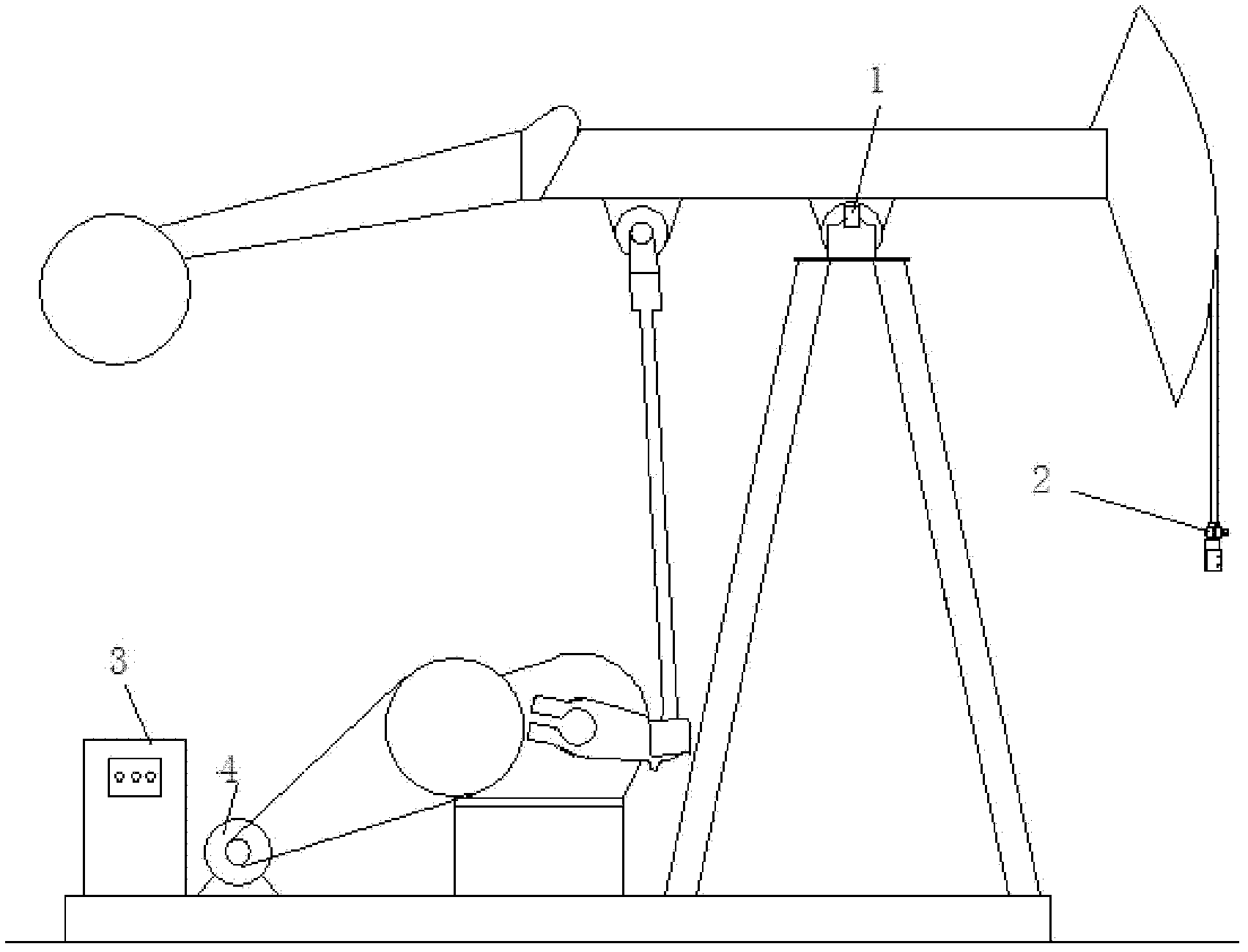

Method and device for judging optimal times of stroke of pumping unit

The invention discloses a method and a device for judging optimal the time of stroke of a pumping unit. The method comprises the following steps of: obtaining a current load displacement indicator diagram according to data of load and displacement sensors; changing the time of stroke, re-collecting the load displacement data to obtain the changed load displacement indicator diagram after the changing of the time of stroke; calculating relative liquid yield according to the ground indicator diagram before and after the changing of the time of stroke, judging the variation situation of the ratio of; and continuously running the programs until the minimal time of stroke is obtained under the maximal daily liquid yield, i.e., the optimal time of stroke is obtained. The device mainly comprises the load sensor, the angular displacement sensor, an RTU (remote terminal unit), a frequency changer, and on the like. Due to the fact that the optimal time of stroke judging program adopts the relative variation value of the daily liquid yield instead of the absolute value of the daily liquid yield, so the program is low in computing amount and small in occupied internal memory, and is capable of directly running on the RTU, further, the pumping unit can finish the data collection, computation and control independently by self without depending on the computation and the control of a host computer, and the system is ensured to run more reliably.

Owner:PETROCHINA CO LTD

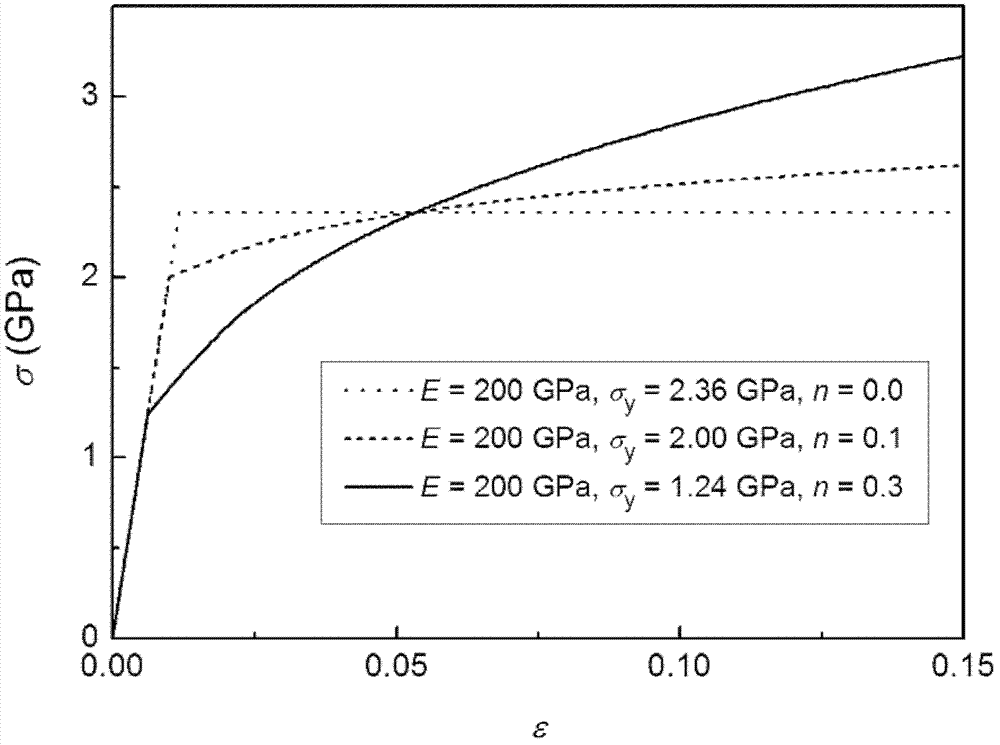

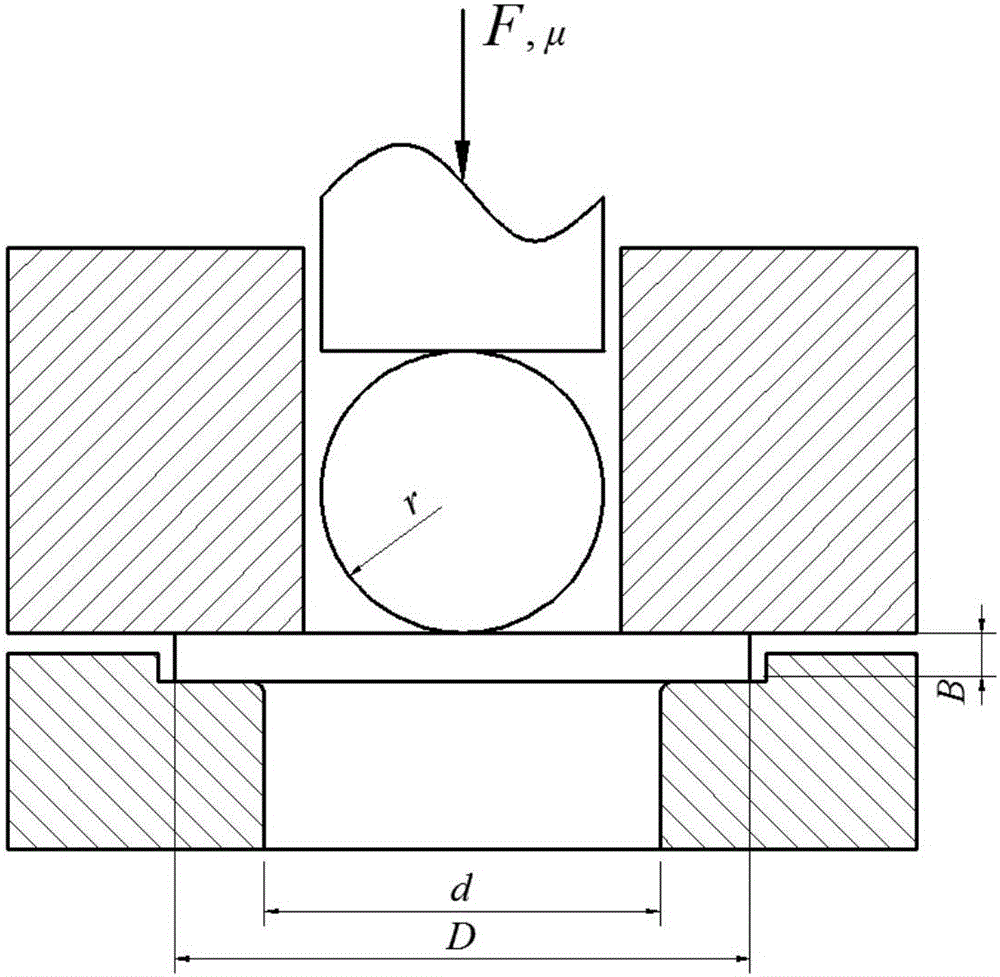

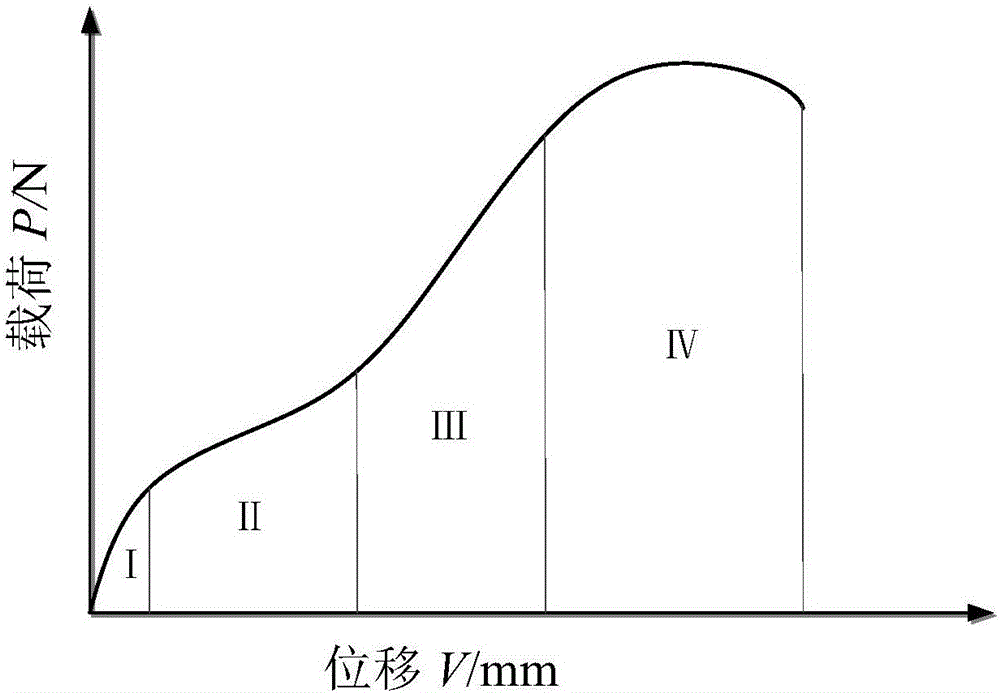

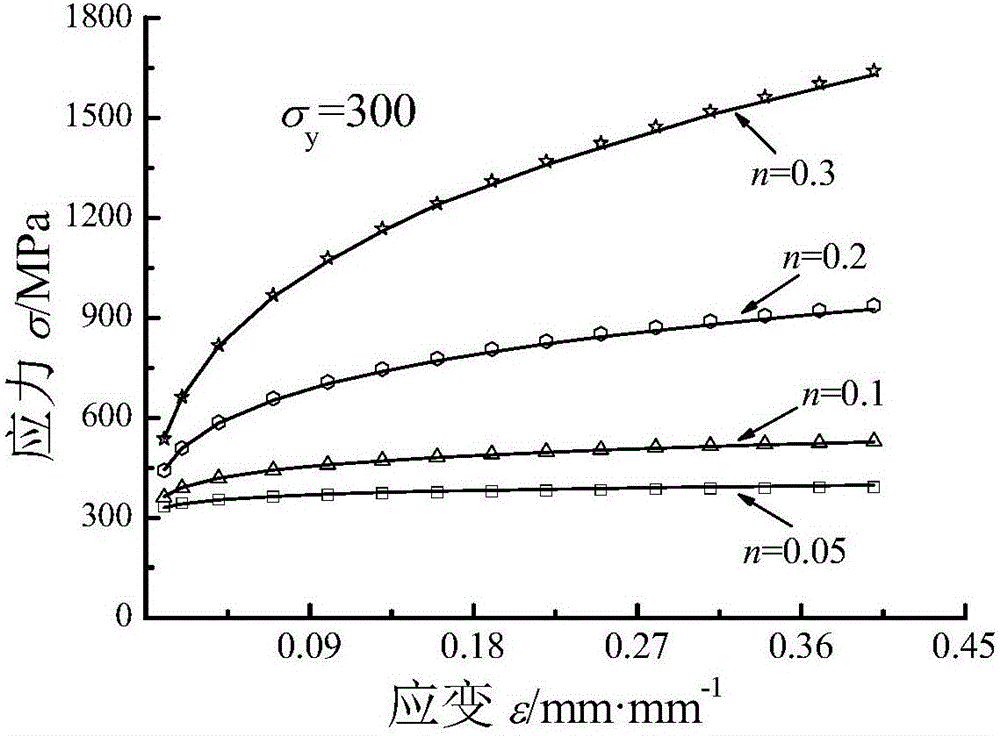

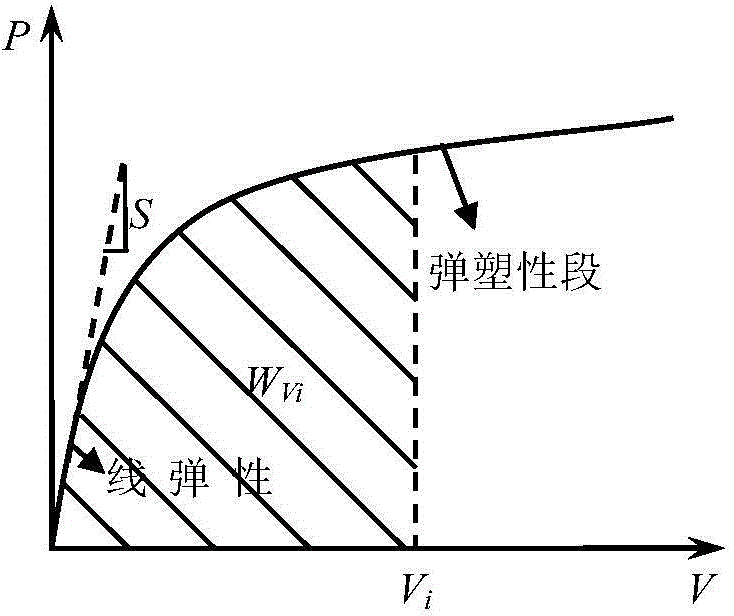

Method for obtaining uniaxial stress-strain relation of material through small punch test

ActiveCN106124293AQuantitative evaluation of degradation performanceTo overcome the shortcomings such as large size restrictionsStrength propertiesSmall sampleMaterials testing

The invention discloses a method for obtaining uniaxial stress-strain relation of a material through a small punch test. After a continuous load-displacement curve of a stamped wafer sample is obtained, power-law fitting is conducted on the stage III of the P-V curve, obtained load characteristics and displacement indexes are introduced to a Hollomon equation so as to obtain the uniaxial stress-strain relation of the material. The method is suitable for ductile and power-law isotropic hardening materials, the uniaxial stress-strain relation of the material can be obtained only by cutting out a small wafer sample from an existing member in special circumstances such as high temperature and irradiation, and accordingly the degradation properties of the material are assessed. The method has weaker destructiveness on the existing member, achieves the micro-damage detection, sample processing and testing principles are simpler, obtained results have higher accuracy, the shortcoming that a traditional uniaxial drawing test is largely limited by material size and the like is overcome, and the cost lower. The method has the greater advantages in testing of precious-metal servicing micro-force materials establishing constitutive relation of minimally invasive wafers and other small samples.

Owner:SOUTHWEST JIAOTONG UNIV

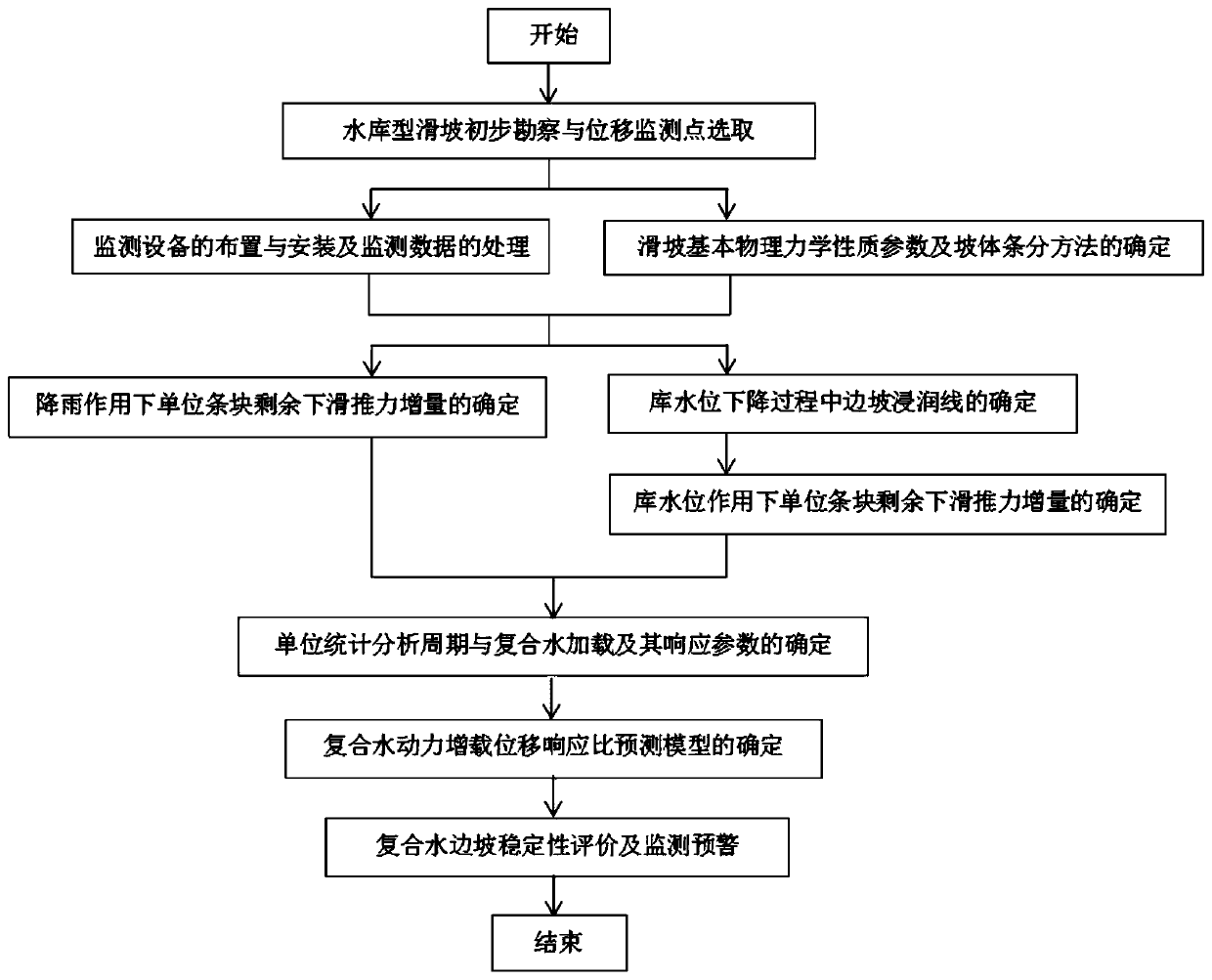

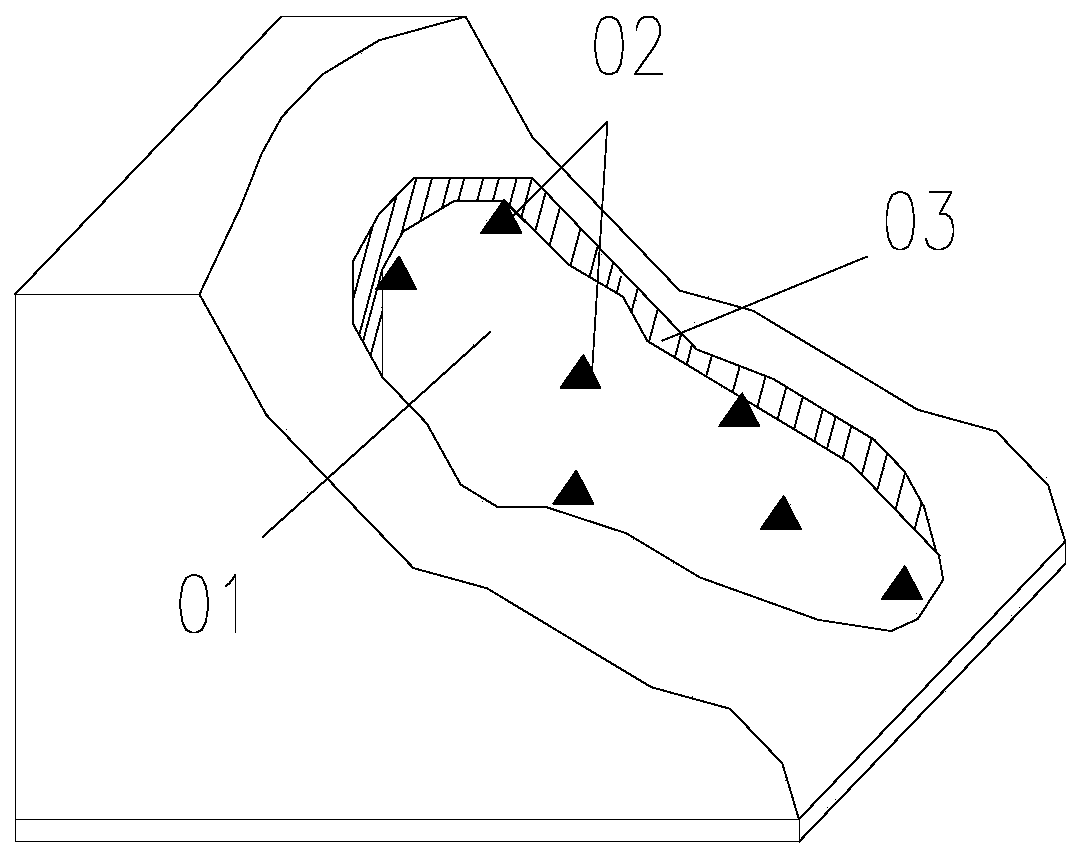

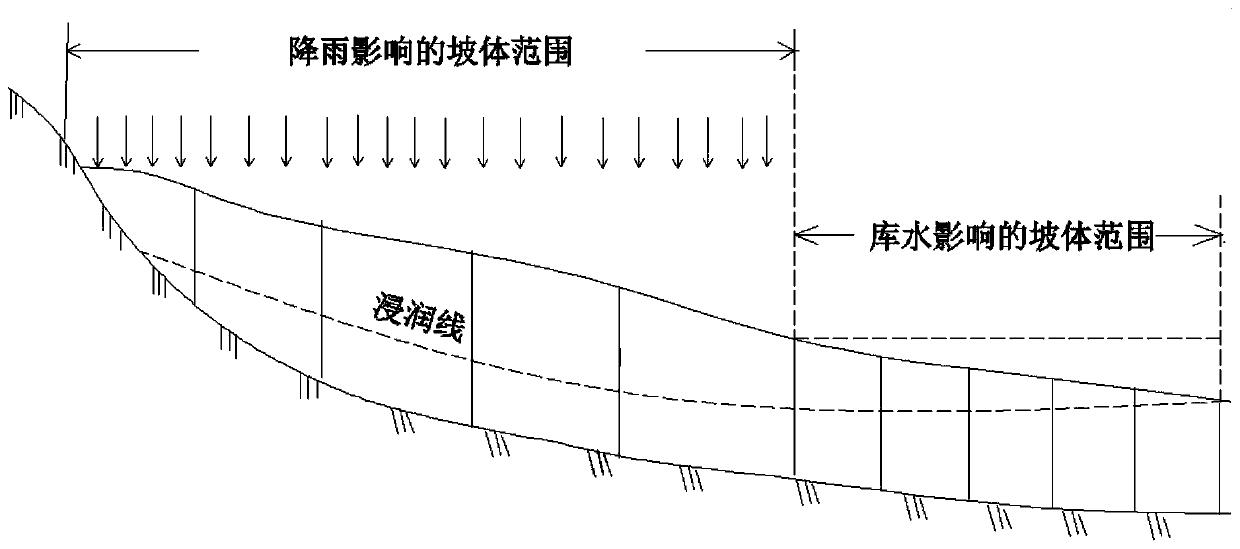

Composite hydrodynamic reservoir bank slope stability prediction method

The invention relates to a composite hydrodynamic reservoir bank slope stability prediction method, which belongs to the technical field of slope stability evaluation and landslide disaster monitoringand early warning. The method comprises the following steps of preliminary investigation of a reservoir-type landslide, selection of a displacement monitoring point, arrangement and installation of monitoring equipment, processing of monitored data, determination of landslide basic physical and mechanical property parameters and a slope slicing method, determination of overall residual downward thrust increment of the slope above a water line under effects of rainfall, determination of a slope saturation line during a reservoir water line decreasing process, determination of residual downwardthrust increment of the slope in a water line change range under effects of the reservoir water line, determination of reservoir-type landslide composite water loading and response parameters, determination of a composite hydrodynamic increased load displacement response ratio prediction model, and evaluation and monitoring and early warning of the composite hydrodynamic slope stability. The corresponding relationship between the reservoir-type landslide composite hydrodynamic increased load displacement response ratio parameters and the landslide stability is disclosed, and on the basis, a reservoir-type slope stability evolution law is analyzed and evaluated.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method of producing a plate spring

InactiveUS20040016278A1Improve fatigue strengthIncrease freedomBelleville-type springsFriction clutchesFree stateEngineering

A method of producing a plate spring is disclosed which allows one to adjust the load-displacement characteristics thereof to a desired degree. The method includes stamping slits and a small diameter hole from a disk-shaped plate member, and forming the plate spring into a cone shape. Shot-peening is then performed on a resilient portion of the plate spring that retains a flat cone shape in the free state. Furthermore, shot-peening is performed on only a portion of the resilient portion and not on the entire surface of the plate spring.

Owner:EXEDY CORP

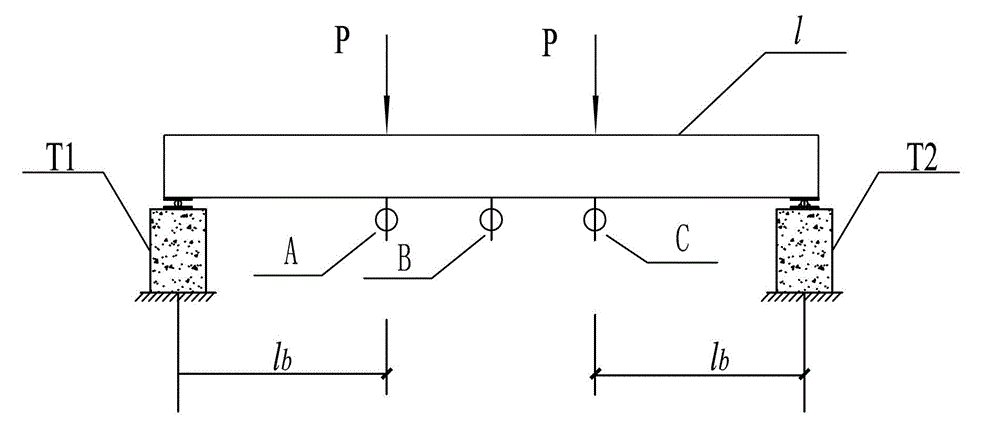

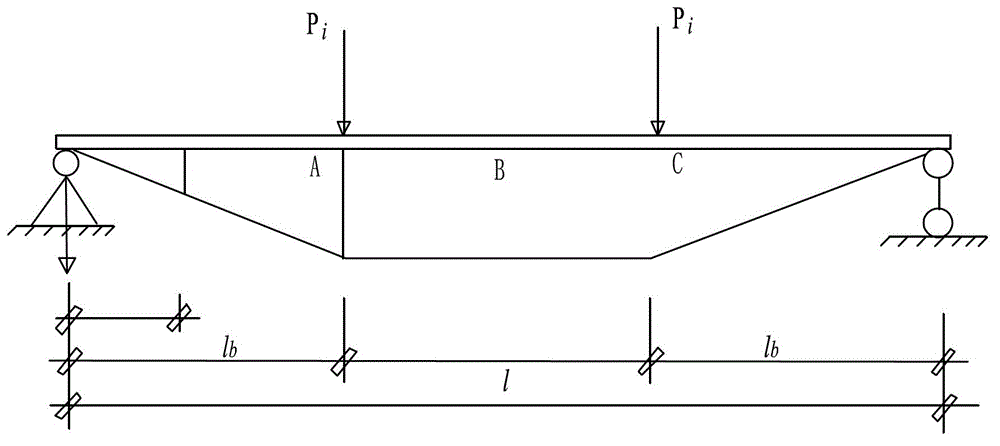

Method for recognizing cross-section bending moment and curvature relation of reinforced concrete beam

InactiveCN102914473AReasonable designAnalytical mechanical propertiesMaterial strength using steady bending forcesReinforced concreteNonlinear bending

The invention discloses a method for recognizing the cross-section bending moment and curvature relation of a reinforced concrete beam. The method includes: using macroscopic displacement measured by a bending member for recognizing the cross-section bending moment and curvature relation of the reinforced concrete beam, namely, using the load-displacement relation under loads at each level, combining a conjugate beam method, and recognizing the cross-section bending moment and curvature relation of the bending member by a least square method, so that analysis of nonlinear bending member mechanical properties is benefited. The method has the advantages that the cross-section bending moment and curvature relation of the bending member is recognized accurately, so that corresponding materials can be selected accurately according to engineering structure forms, and the member can be designed reasonably.

Owner:DALIAN NATIONALITIES UNIVERSITY

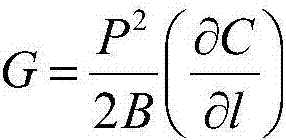

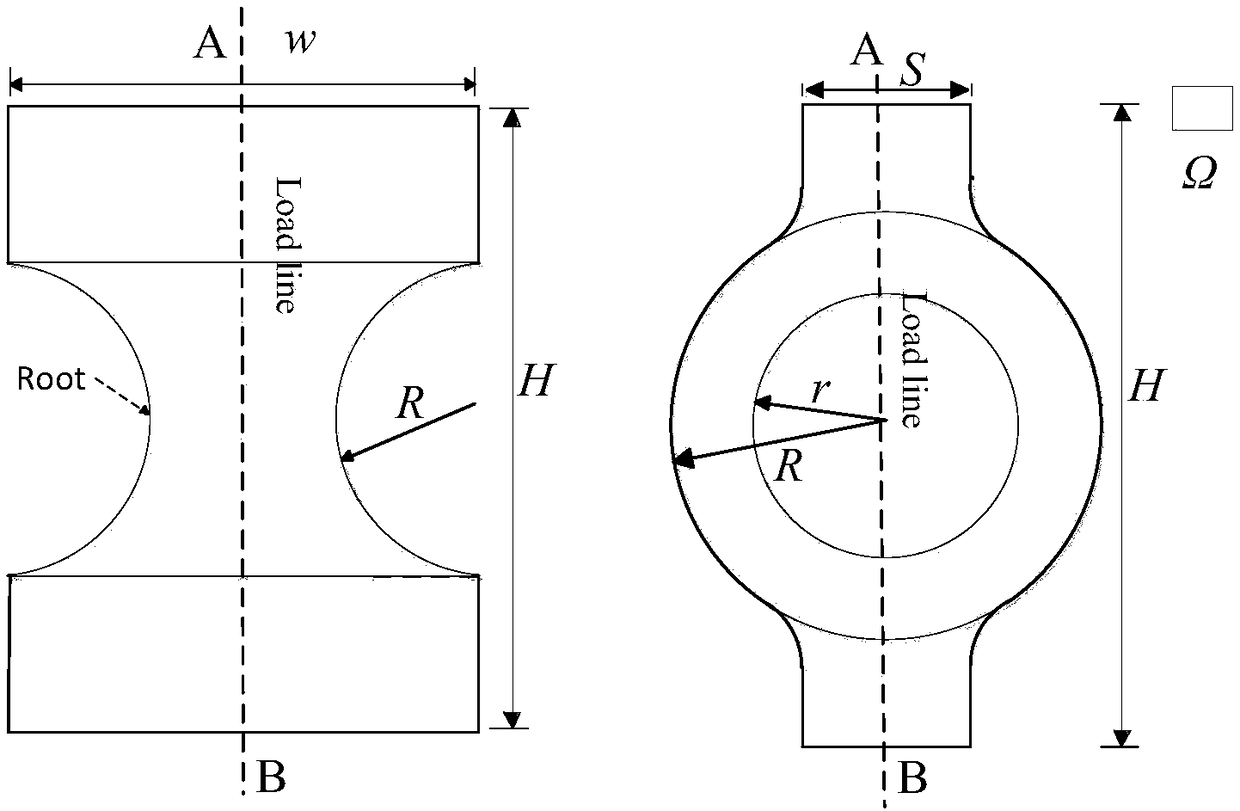

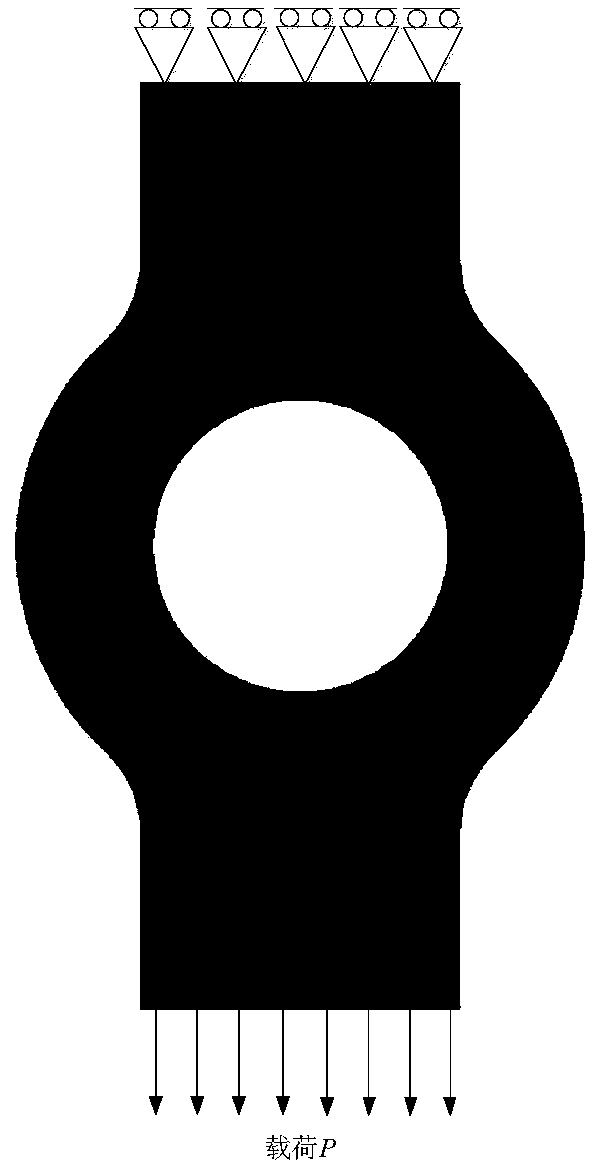

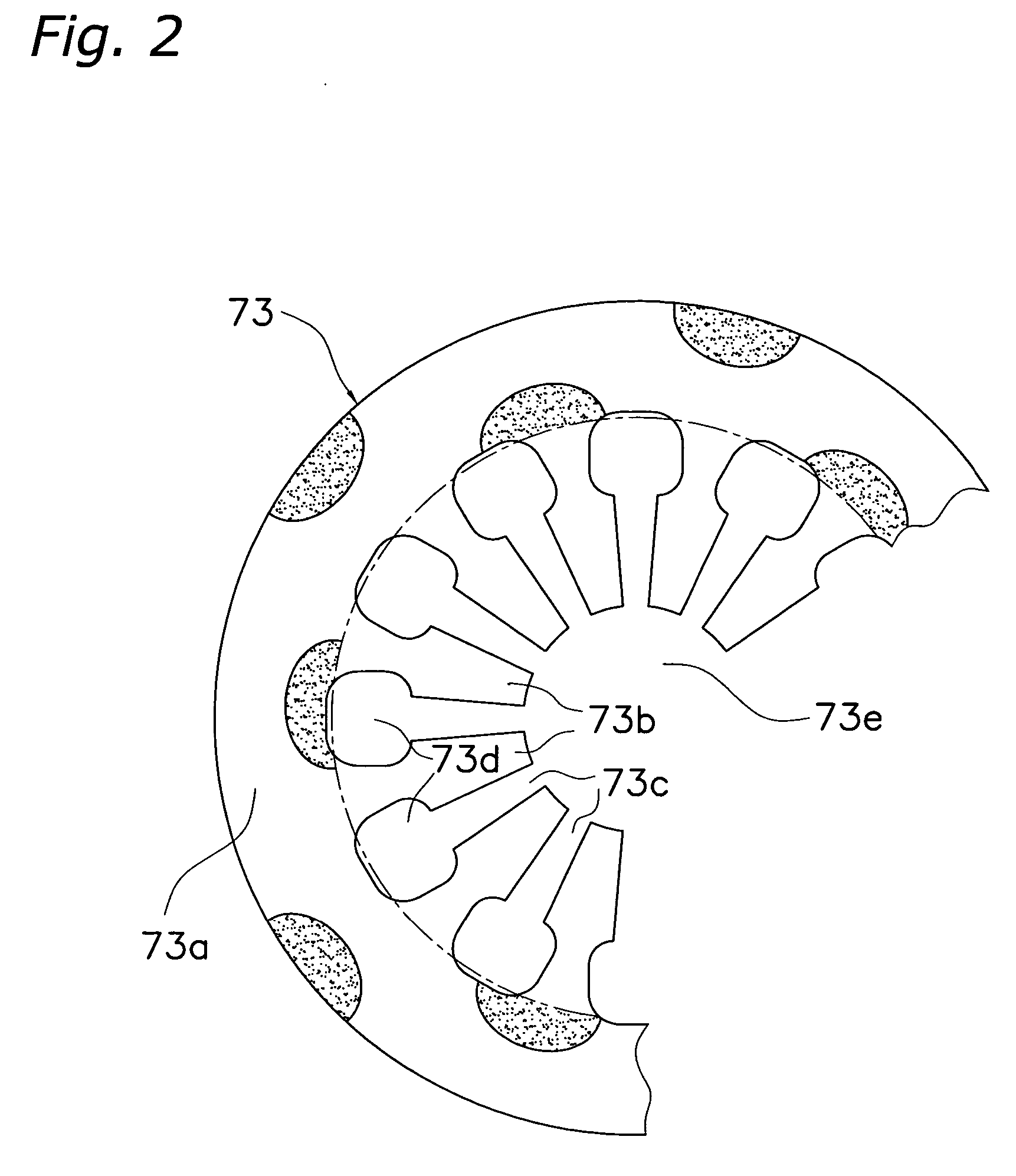

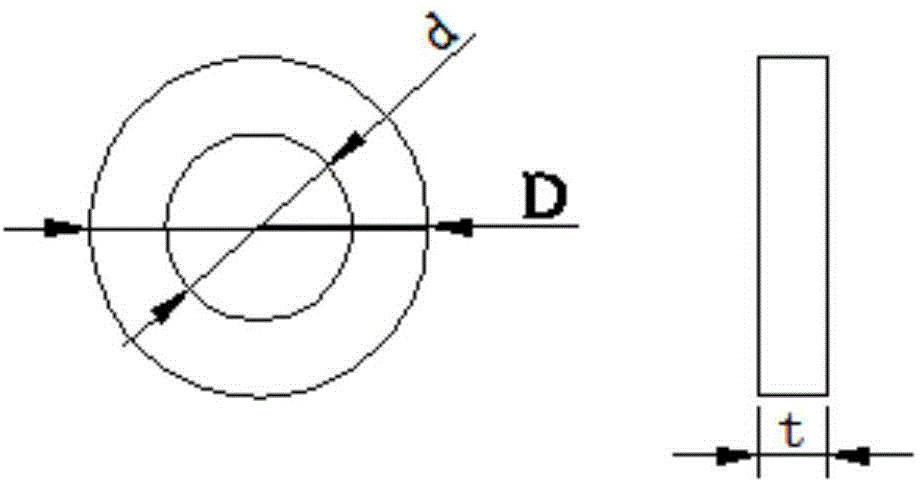

Determination method for predicting material uniaxial constitutive relation through circular ring radial compression energy

InactiveCN104931348AConvenient and effective accessGood effectMaterial strength using tensile/compressive forcesSpecial data processing applicationsCompressive stiffnessNuclear power

The invention discloses a determination method for predicting material uniaxial constitutive relation through circular ring radial compression energy. According to the method, quasi-static pressing loading is carried out on a size-variable circular ring by adopting a compression clamp with a limiting groove, after a continuous load P- displacement V curve is obtained, radial compressive stiffness S of the circular ring is marked though the elastic region data of the load-displacement curve, and the material uniaxial constitutive relation is predicted through post processing. By adopting the method, the defects that both time and labor are consumed since finite element iteration is required to be carried out for multiple times and astringency cannot be evaluated in advance in the prior art are overcome, obtaining of the material uniaxial constitutive relation can be realized simply, conveniently and efficiently and an ideal effect is realized. Particularly, the method has important significance in obtaining of the material uniaxial mechanical properties of important pipeline structures existing in aerospace, nuclear power, high-speed rail, oil and gas transportation and other key projects.

Owner:SOUTHWEST JIAOTONG UNIV

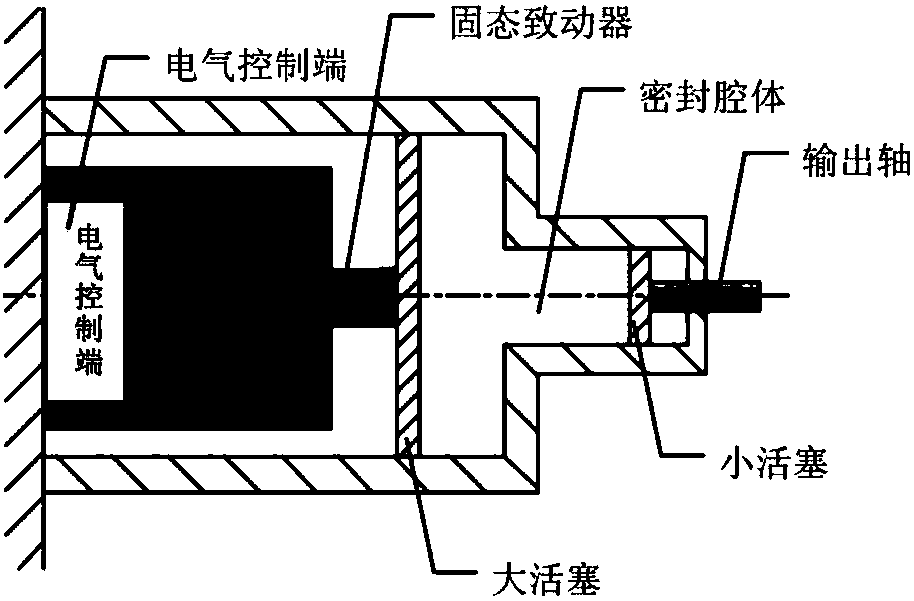

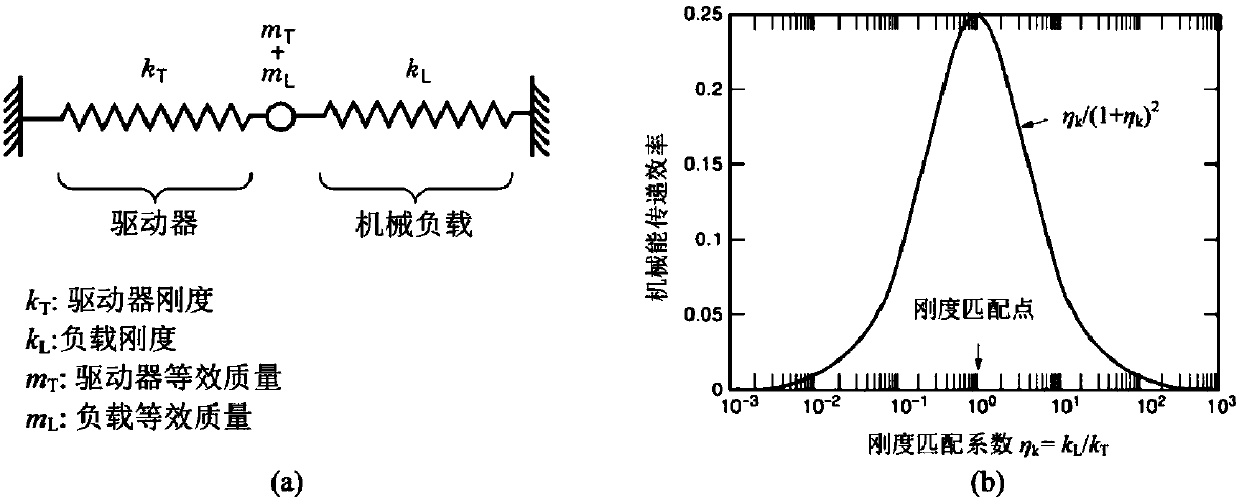

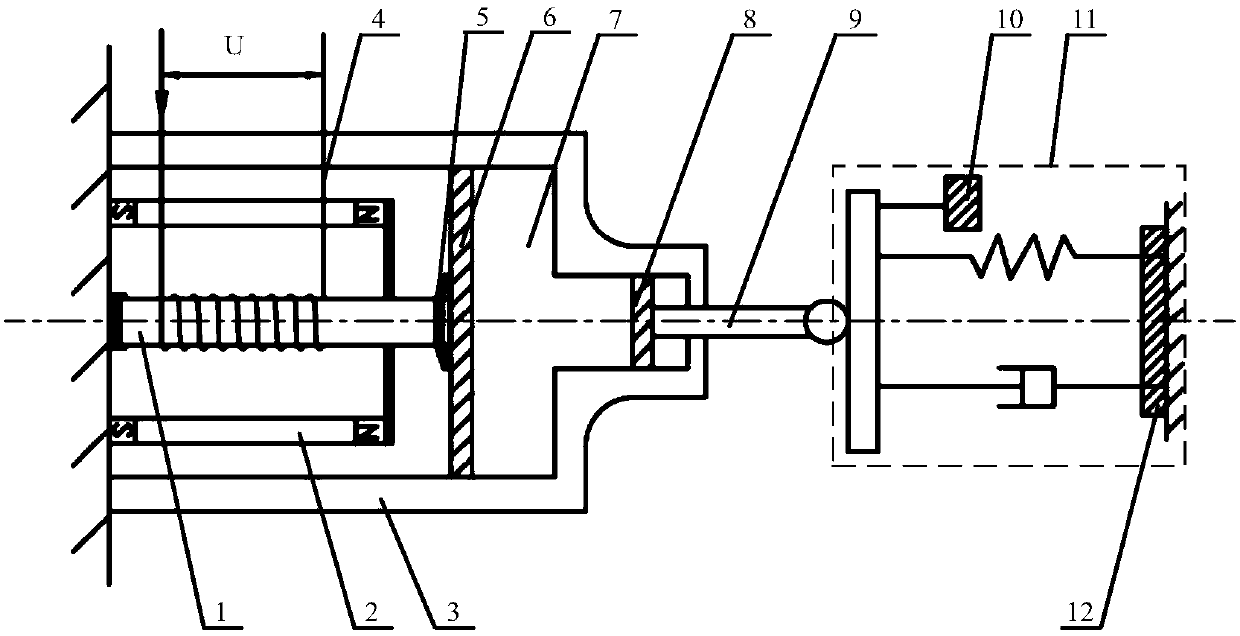

Variable-rigidity hydraulic driving mechanism based on giant magnetostrictive material and variable-rigidity control method thereof

InactiveCN108167264AIncrease energy densityQuick responseFluid-pressure actuator testingPiezoelectric/electrostriction/magnetostriction machinesForce sensorDirect current

The invention discloses a variable-rigidity hydraulic driving mechanism based on a giant magnetostrictive material and a variable-rigidity control method thereof. The mechanism comprises a shell, a GMM rod arranged in the shell, a GMM rod driving control device, a hydraulic device, and a load displacement and stress feedback device; the GMM rod driving control device comprises an electromagnetic coil and a direct-current bias coil; and the load displacement and stress feedback device comprises a displacement sensor and a force sensor. The mechanism further comprises a variable-rigidity controller; the variable-rigidity controller receives sensing signals of the displacement sensor and the force sensor, and calculates the rigidity of a mechanical load; and the variable-rigidity controller adjusts input voltage of the direct-current bias coil according to the rigidity of the load, so that the driving rigidity of the GMM rod output to the mechanical load through the hydraulic device is matched with the rigidity returned by the mechanical load. The mechanism has the advantage of solving the problems of frequency response and transmission efficiency in a traditional hydraulic driving mechanism.

Owner:WENZHOU UNIVERSITY

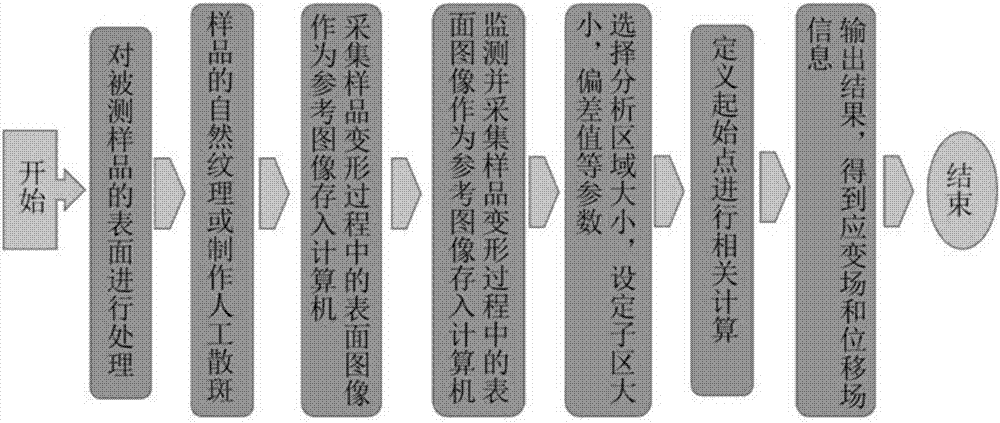

Method for measuring and representing microcosmic interface phases of asphalt concrete

InactiveCN105259034AHelpful for analysisDeepen understandingMaterial strength using tensile/compressive forcesInvestigating material hardnessEpoxySurface phase

The invention discloses a method for measuring and representing microcosmic interface phases of asphalt concrete. According to the method, a small asphalt concrete piece is wrapped with epoxy resin AB glue and cured into a flat cylindrical test piece in a mold to prevent the small asphalt concrete piece from being stripped and deformed in the follow-up polishing process and improve the polishing flatness; the test piece is polished with metallographic abrasive paper, and then a final test piece meeting the requirements is obtained after ultrasonic cleaning is performed on the test piece when polishing is completed; the test piece enters a measuring step, all surface phases of the test piece are observed through amplification with a nanoindentation instrument, a measuring region containing all the phases is selected, equally-spaced dotting measuring is performed, and a load-displacement curve and a microscope image are recorded; after the test is finished, the Young modulus and hardness of all the points are computerized according to the load-displacement curve, and then the modulus and hardness indexes of all the phases are obtained by combining the phases where the measured points are located; finally, the size and the mechanical characteristics of a microcosmic interface transition area between asphalt and aggregates in the test piece can be analyzed and estimated according to the changing condition of the distance among the measured points and the mechanical indexes.

Owner:SOUTHEAST UNIV

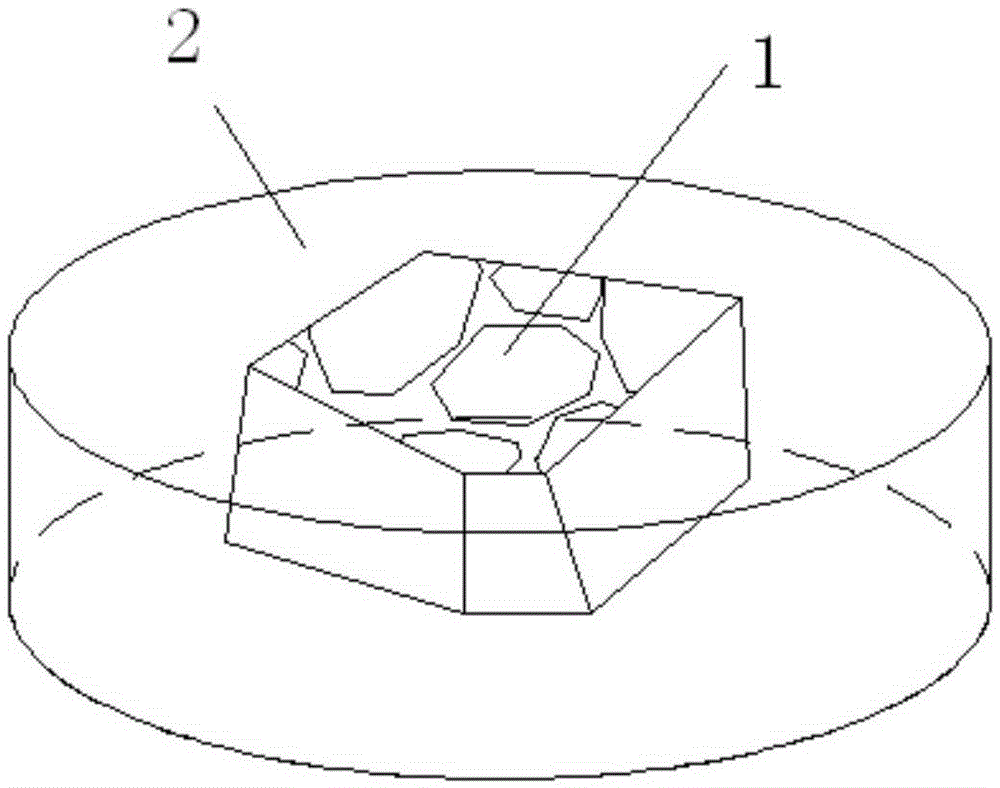

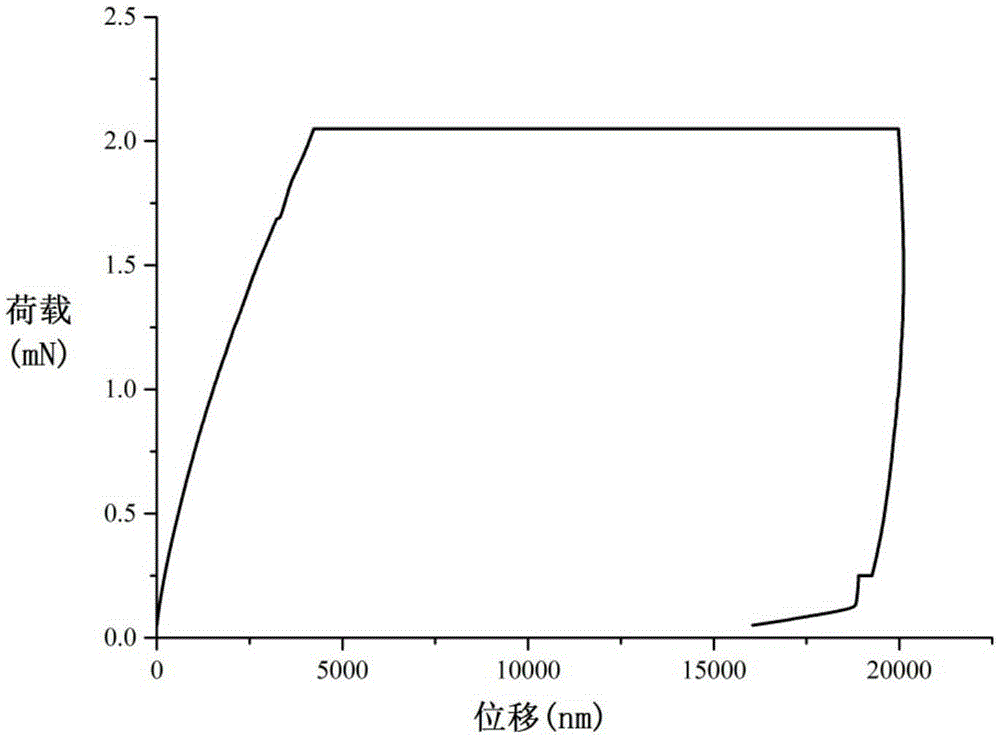

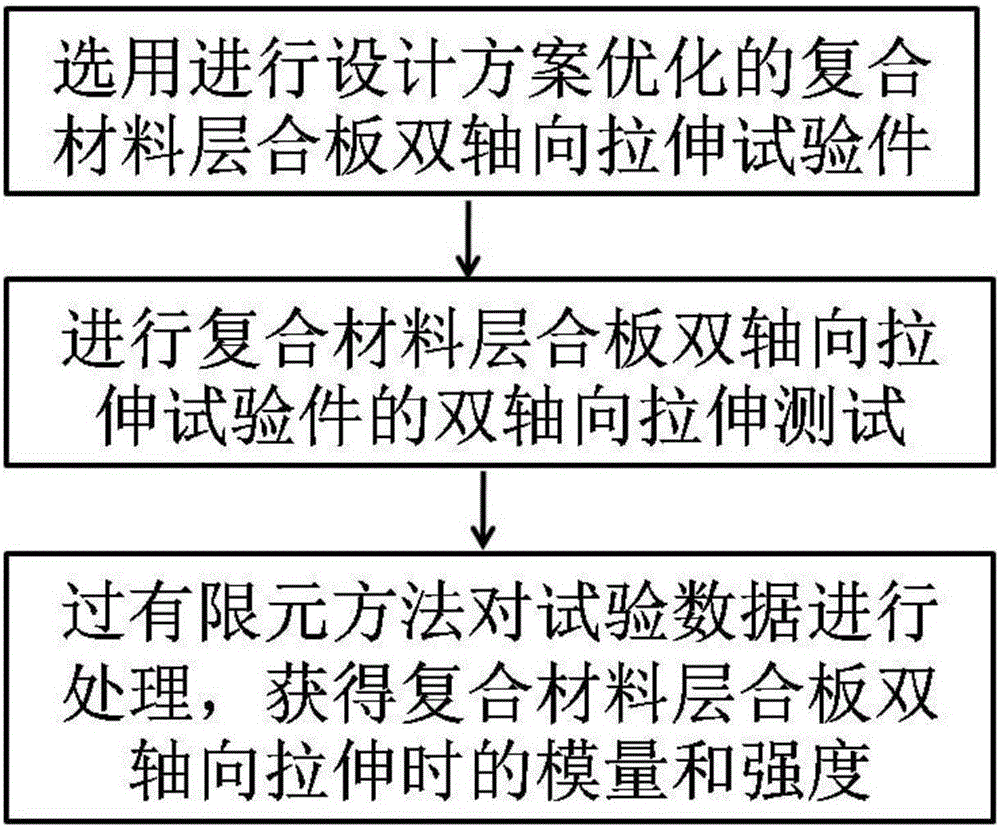

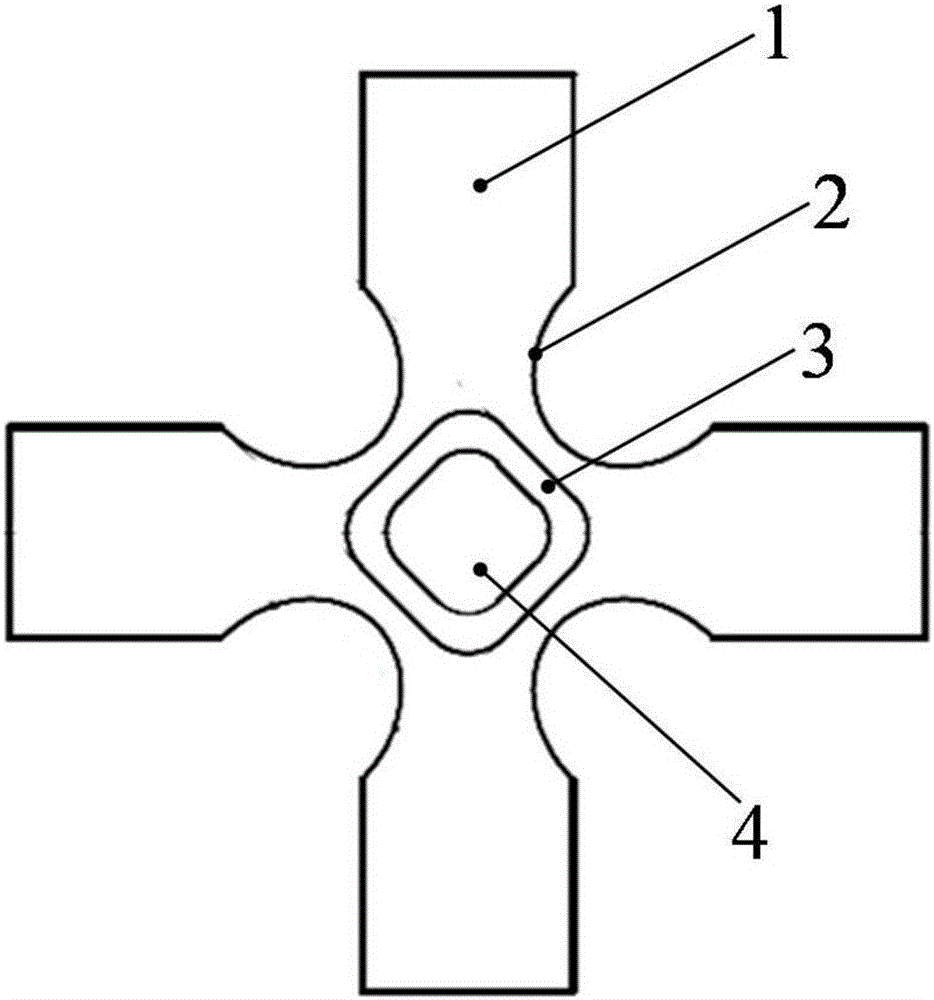

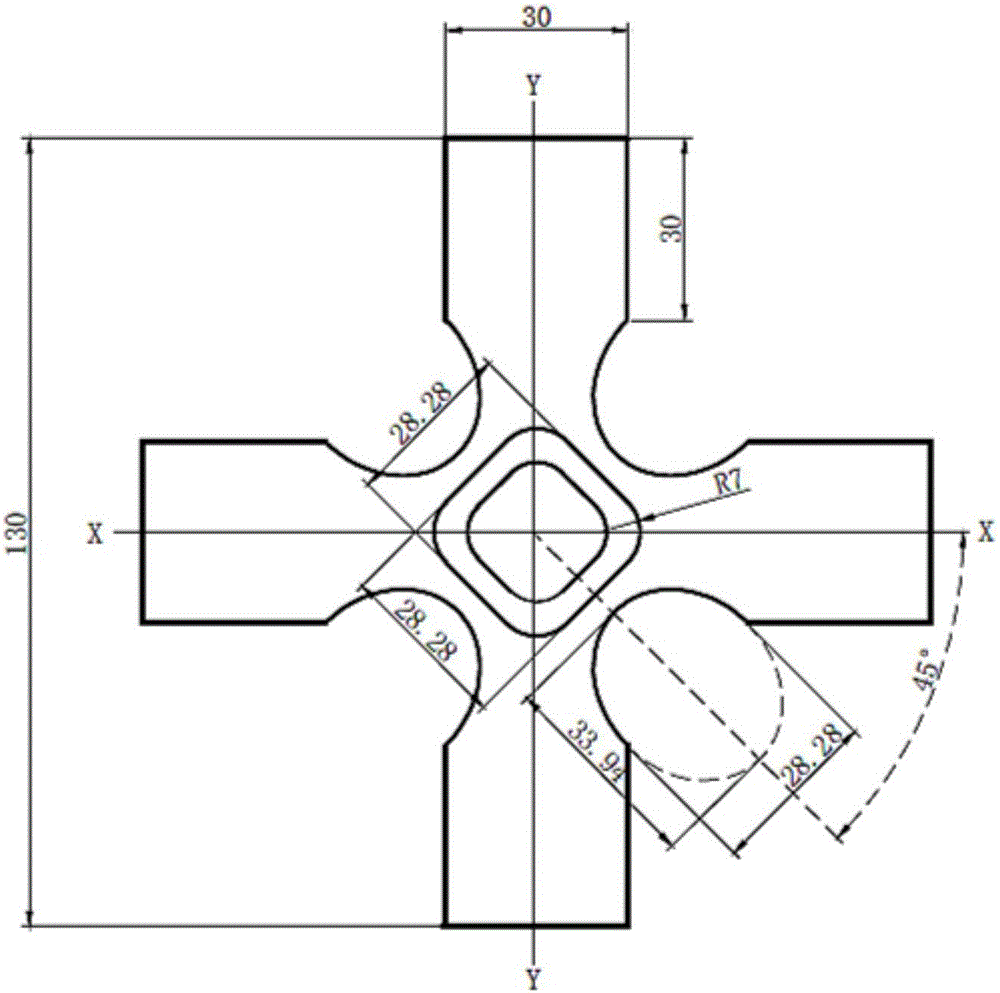

Method for testing biaxial stretching performance of composite material laminate

ActiveCN106198219AMaterial strength using tensile/compressive forcesFinite element methodEngineering

The invention provides a method for testing biaxial stretching performance of a composite material laminate. The method comprises three steps: firstly, a biaxial stretching test piece of a composite material laminate which is optimized by a design scheme is selected, and the test piece comprises a clamping zone, an elliptical transition zone, a central thinning chamfering zone, and a central thinning calibration zone; then, a biaxial stretching test is carried out for the biaxial stretching test piece of the composite material laminate, and a load-displacement curve of the clamping zone and a load-strain curve of a central thinning calibration zone during a loading process are measured; finally, a finite element method is used for processing test data, and modulus and strength during biaxial stretching of the composite material laminate are obtained. The method has the beneficial effects that the optimized scheme of the biaxial stretching test piece of a composite material laminate and the method for testing biaxial stretching performance of the composite material laminate are designed, and the scheme and the method are simple and convenient for application.

Owner:北京堂仁翔科技有限公司

Device and method for testing ultrahigh-temperature indentation load-displacement curve

ActiveCN102967508AAchieve mechanical propertiesRealize researchMaterial strength using tensile/compressive forcesObservational errorEngineering

The invention discloses a device and a method for testing an ultrahigh-temperature indentation load-displacement curve. A to-be-tested ultrahigh-temperature material test piece is placed on a test piece loading platform in a high temperature furnace; one end of a loading rod is connected with a loading device located outside the high temperature furnace, a press head is arranged at the other end of the loading rod, and the other end of the loading rod stretches into the high temperature furnace and contacts the test piece; an ultrahigh-temperature extensometer for measuring displacement of the loading rod in the furnace is arranged on the high temperature furnace; a precise displacement sensor is used for measuring the displacement of the loading rod outside the high temperature furnace; and the test piece and the press head are heated to an experiment temperature by the high temperature furnace, after the temperature is stable, the test piece is loaded and unloaded by adopting the loading device, meanwhile, the ultrahigh-temperature extensometer close to the test piece and the precise displacement sensor away from the test piece are adopted to measure indentation displacement, and the ultrahigh-temperature extensometer and the precise displacement sensor are cooperated to measure the ultrahigh-temperature indentation load-displacement curve with high precision. According to the device and the method for testing the ultrahigh-temperature indentation load-displacement curve, measuring error of the extensometer caused by reverse motion idle running in the transforming process from loading to unloading is eliminated by two displacement sensors, and the measurement precision is improved.

Owner:PEKING UNIV

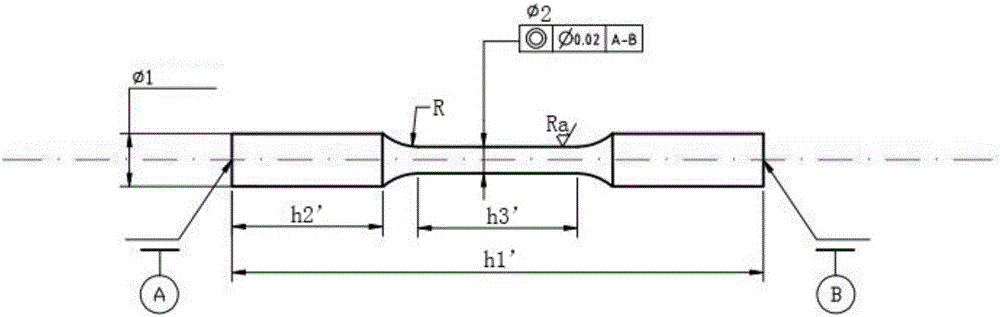

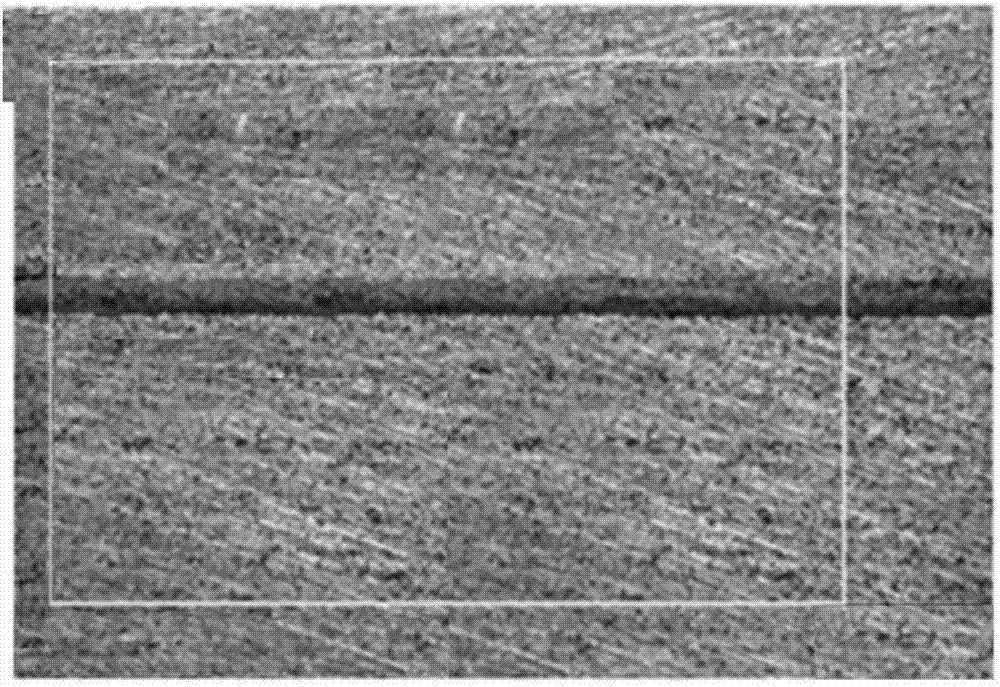

Method for measuring uniaxial tension large-strain-range hardening curve of metal round bar specimen

InactiveCN109883825AReduce demandEliminate cumbersome measurement linksMechanical diameter measurementsMaterial strength using tensile/compressive forcesMetallic materialsModel parameters

The invention discloses a method for measuring a uniaxial tension large-strain-range hardening curve of a metal round bar specimen, and belongs to the field of mechanical property testing of metal materials. The method only needs to perform the following steps of: measuring the radius of the cross section of a round bar tension specimen, calculating the stress strain value at the time of fracture,and fitting the stress strain values before necking and at the time of fracture by adopting a hardening model to determine an initial value of hardening model parameters; and then, generating a plurality of hardening parameter combinations by adopting an experimental design method, inputting hardening curves determined by the parameters into finite element software for tension simulation, outputting the corresponding simulated load displacement curves, calculating the sum of the absolute area differences between the simulated and experimental load displacement curves, constructing a responsesurface model by taking the value as the response and the hardening parameters as independent variables, taking the minimization of a response surface function as an optimization objective, optimizingan objective function by adopting a quadratic programming method, and determining that an optimal solution is a large-strain-range hardening curve of an experimental material. The scheme of the invention has the advantages of small calculation amount and high measurement accuracy.

Owner:JILIN UNIV

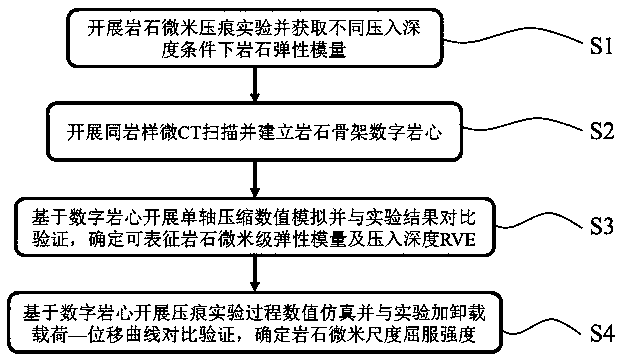

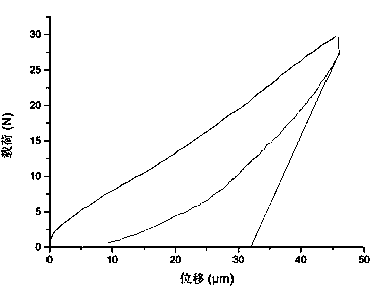

Method for obtaining rock micrometer-scale elasticity modulus and yield strength

ActiveCN109060539ASolve defects that cannot be applied to the micro scaleMaterial strength using tensile/compressive forcesRock sampleMesh grid

The invention discloses a method for obtaining the rock micrometer-scale elasticity modulus and yield strength. The method comprises the steps that a rock micrometer indentation experiment is carriedout through a micron-sized pressure head, a load-displacement curve in the loading process is obtained, and the rock elasticity modulus under different displacement conditions can be obtained by combining an indentation experiment formula; micro-CT scanning is carried out on a rock sample, and a finite element mesh model of a rock skeleton in an indentation area is built; the elasticity modulus obtained through the micrometer indentation experiment serves as an input parameter to simulate the rock uniaxial compression process, the model overall elasticity modulus is obtained and compared witha rock core uniaxial compression experiment, and the pressing depth RVE effectively representing the rock micrometer elasticity modulus is determined; and then, rock sample indentation experiment numerical simulation under different yield strength conditions is carried out, the simulated loading and unloading load-displacement curve is compared with the indentation experiment to be verified, and thus the rock micron-sized yield strength is determined.

Owner:SOUTHWEST PETROLEUM UNIV

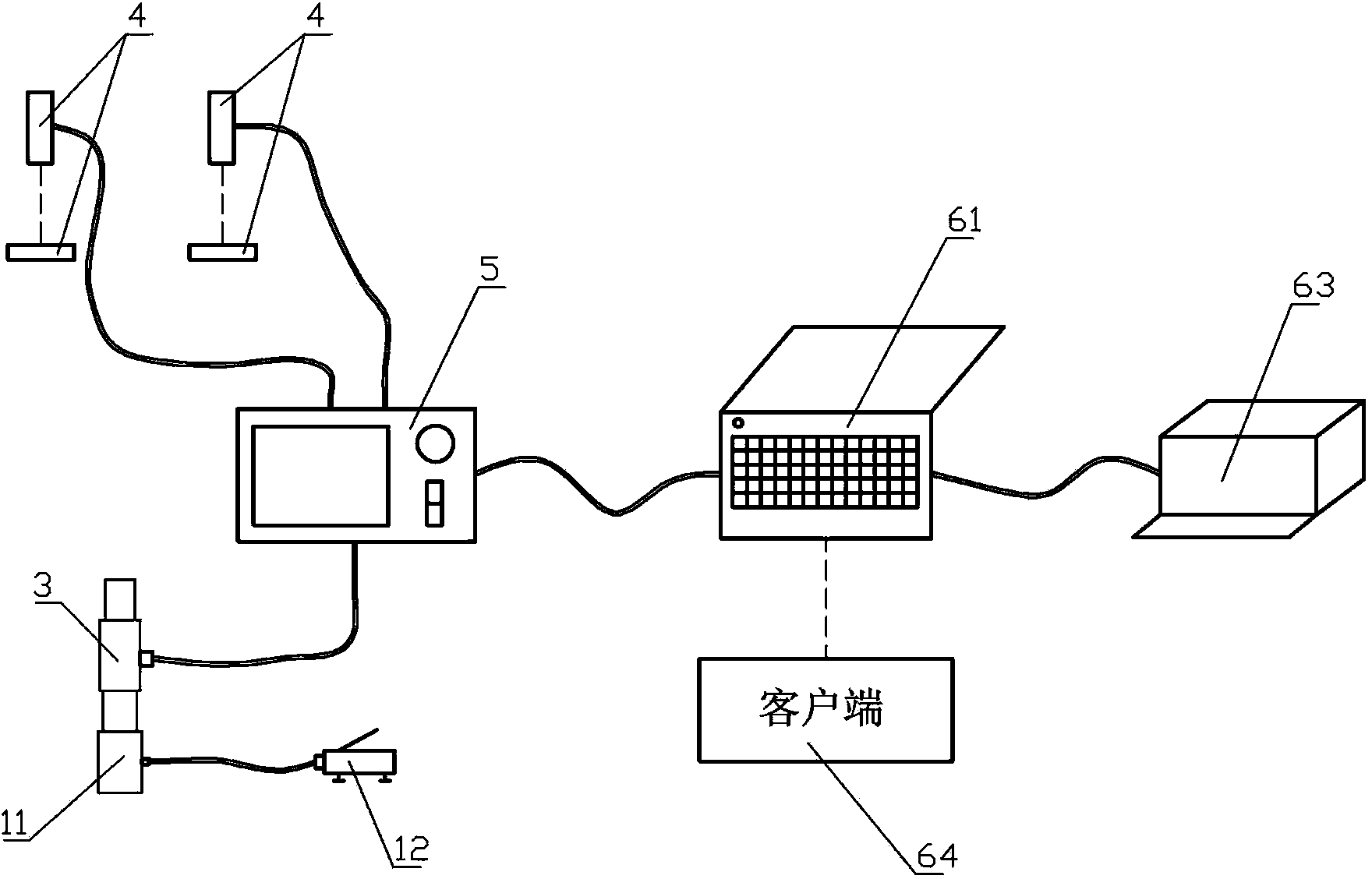

Railroad sleeper detection data acquisition device and system

ActiveCN104048820ARealize automatic collectionHigh precisionMachine part testingUsing electrical meansData processing systemProcess module

The invention discloses a railroad sleeper detection system. The railroad sleeper detection system comprises a railroad sleeper detection data acquisition device and a data processing system. The railroad sleeper detection data acquisition device comprises a force exerting device, a pressure sensor (3), a displacement sensor (4) and a multi-channel data acquisition instrument (5). The pressure sensor (3) and the displacement sensor (4) conduct sleeper pressure measurement and sleeper displacement measurement and are connected with the multi-channel data acquisition instrument (5) through cables respectively. The multi-channel data acquisition instrument (5) is further connected with the data processing system. The data processing system comprises a digital processing device (61), a load displacement analyzing and processing module and a data output device. The load displacement analyzing and processing module is arranged in the data processing device (61). The railroad sleeper detection system can detect the load displacement of a rail and is high in detection speed, high in precision, high in stability, less in error, little in manual work, high in efficiency, safe and reliable.

Owner:HUNAN TECHN COLLEGE OF RAILWAY HIGH SPEED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com