Method for testing biaxial stretching performance of composite material laminate

A composite material layer and testing method technology, applied in the direction of analyzing materials, using stable tension/pressure testing material strength, measuring devices, etc., can solve the problems of no test standards, difficult implementation, affecting the utilization efficiency and potential of composite materials, etc. , to achieve the effect of simple and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

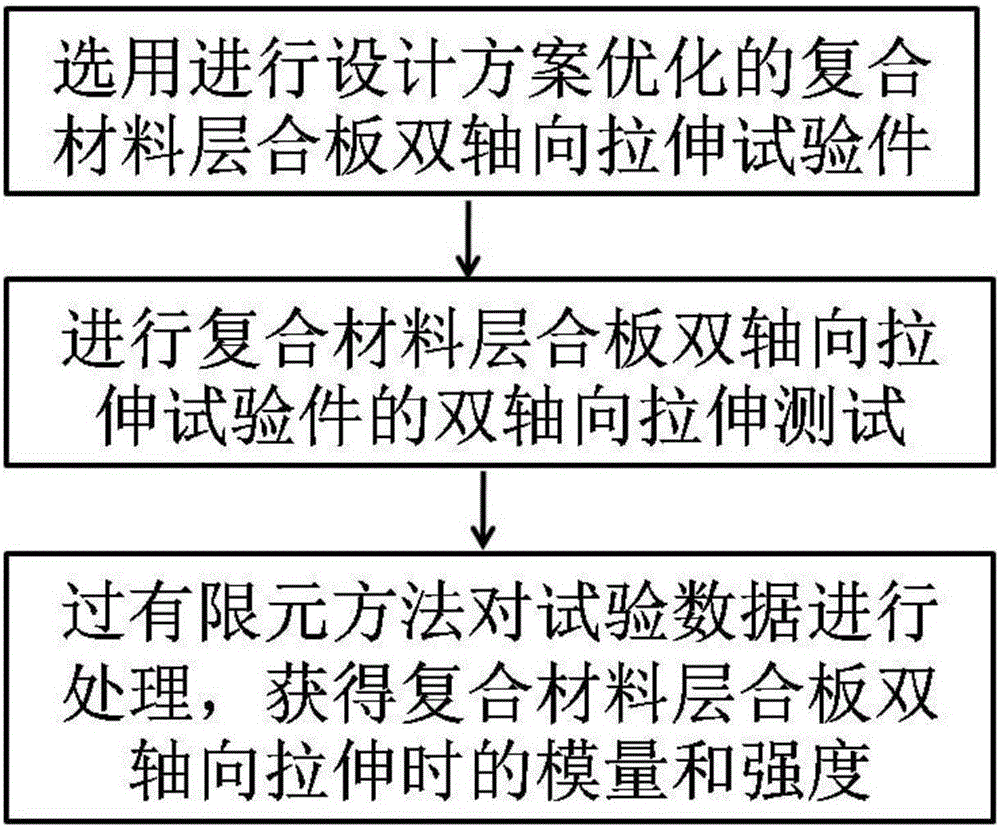

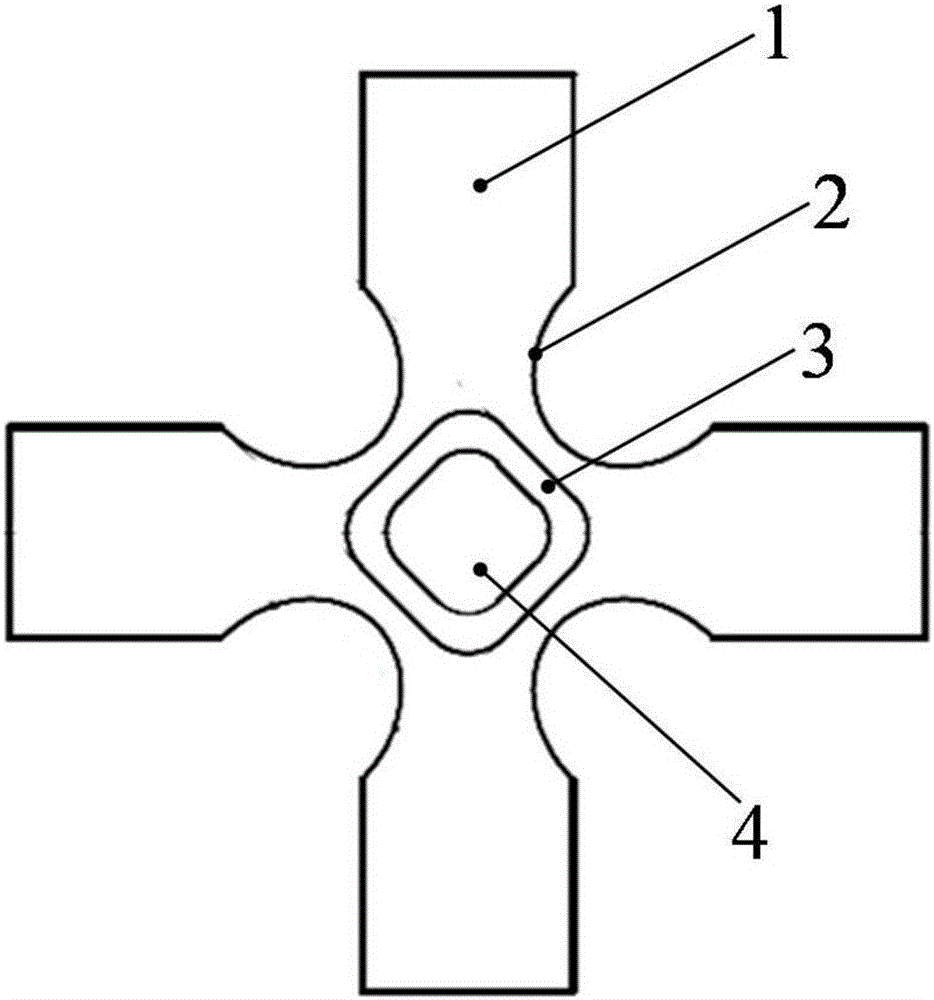

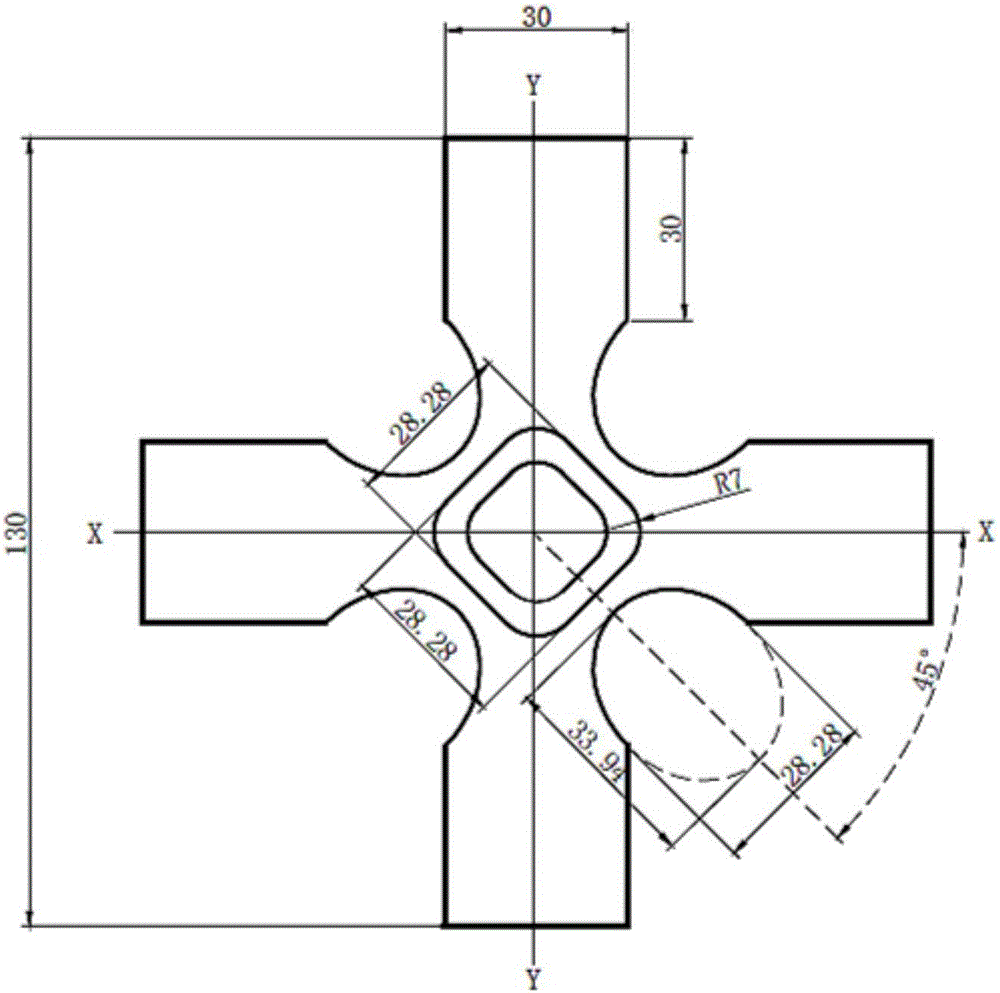

[0026] The flow chart of the present invention is as figure 1 As shown in Fig. 1, the biaxial tensile test piece of the composite laminate was first selected for design optimization, which is composed of clamping area 1, elliptical transition area 2, central thinning and chamfering area 3 and central thinning calibration area 4. Then carry out the biaxial tensile test of the biaxial tensile test piece of the composite laminate, record the load-displacement curve of the clamping zone 1 and the load-strain curve of the central thinning calibration zone 4 in the loading process, and finally pass The finite element method is used to process the test data to obtain the modulus and strength of the composite laminate in biaxial tension. Concrete implementation steps of the present invention are as follows:

[0027] Step 1: select the biaxial ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com