Patents

Literature

54 results about "Biaxial tensile test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biaxial tensile test is a tensile testing in which the sample is stretched in two distinct directions. This technique is used to obtain the mechanical characteristics of anisotropic materials, such as composite materials, textiles, and soft biological tissues. There are three main types of biaxial tensile testing: Bursting test, based on a circular specimen clamped along the edge and inflated by air or water under pressure until the specimen bursts; Cylinder test, based on a hollow cylinder subjected to internal pressure and axial pressure or tension; Plane biaxial test which offers the best result because of the independent force introduction in the two main directions.

Data measuring and calculating method for uniaxial tensile test

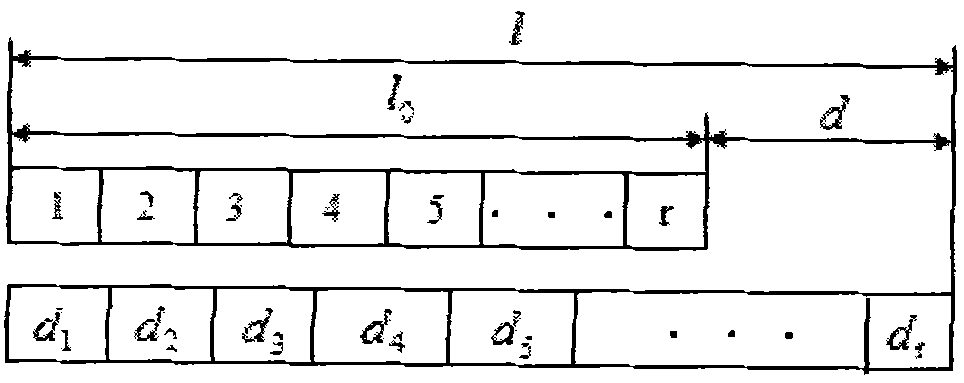

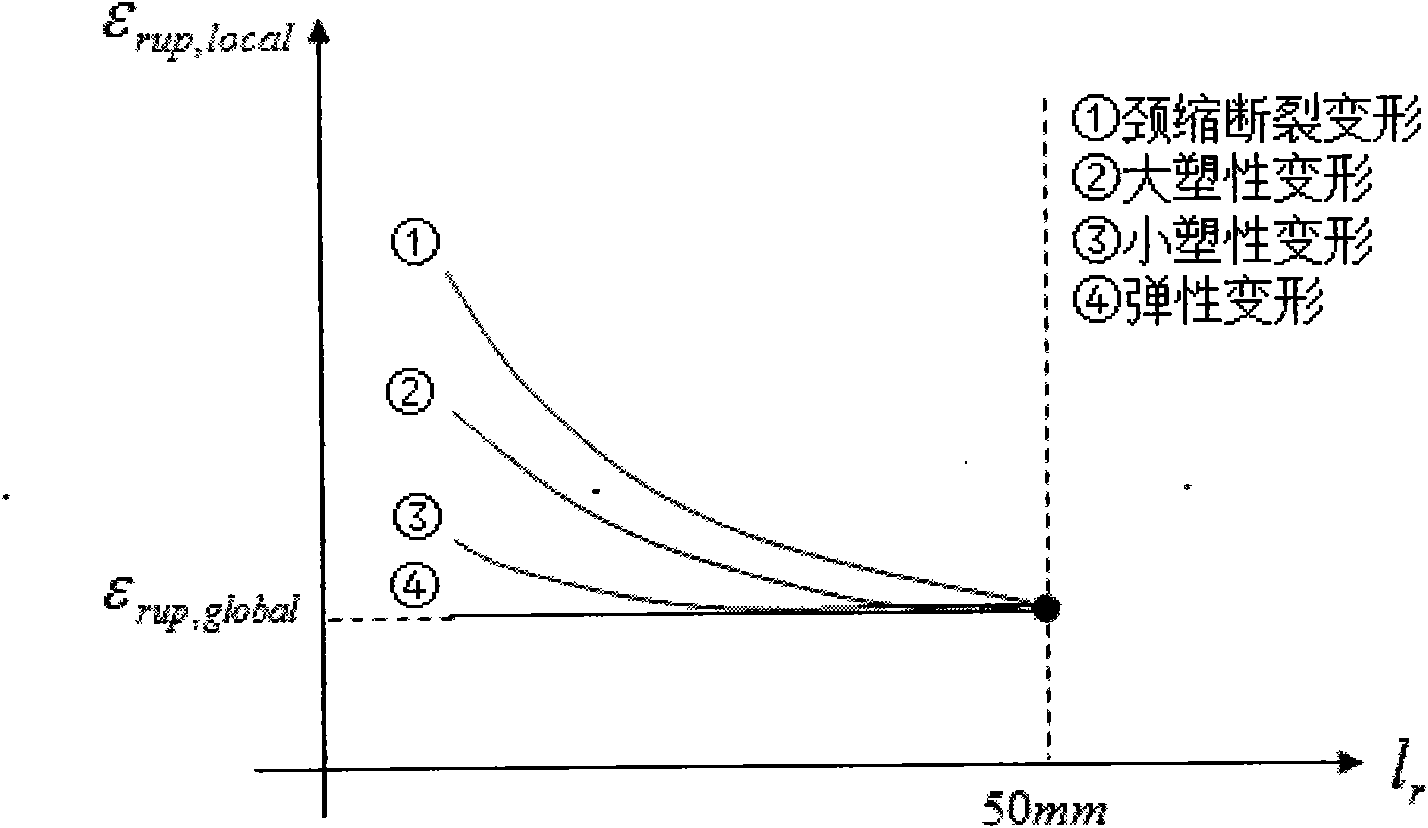

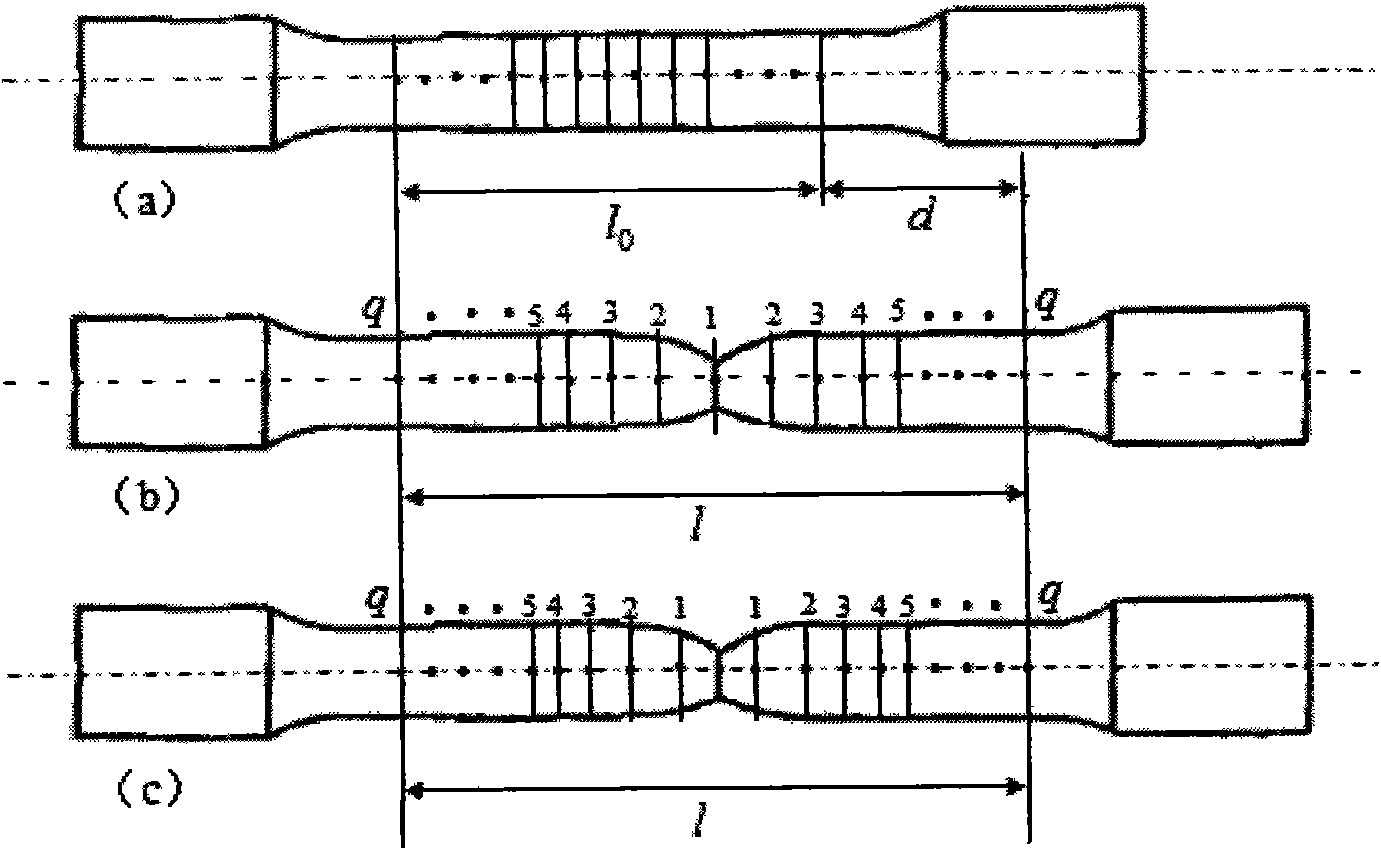

InactiveCN101975693AReduce calculation precisionDiscovery of the intensity effectMaterial strength using tensile/compressive forcesLength effectEnergy absorption

The invention discloses a data measuring and calculating method for a uniaxial tensile test, which comprises the following steps of: marking a measuring point; measuring test data; calculating real breaking strain stress; and drawing an engineering and real stress strain curve. The method of the invention can obtain engineering and real stress strain curves in different reference lengths in the same uniaxial tensile test, establishes a corresponding relationship between the reference length effect and the mesh size effect and provides a thorough solution for the mesh size effect problem in a finite element method, i.e. a real stress strain curve in the equal reference lengths is defined for the same material with different mesh sizes. Meanwhile, theoretical explanation is provided for the practical problems, such as mesh size effect, energy absorption, material strain invalidation, and the like according to a uniaxial tensile basic theory provided by the invention, therefore, the invention has important theory and engineering practical significance.

Owner:肖锋

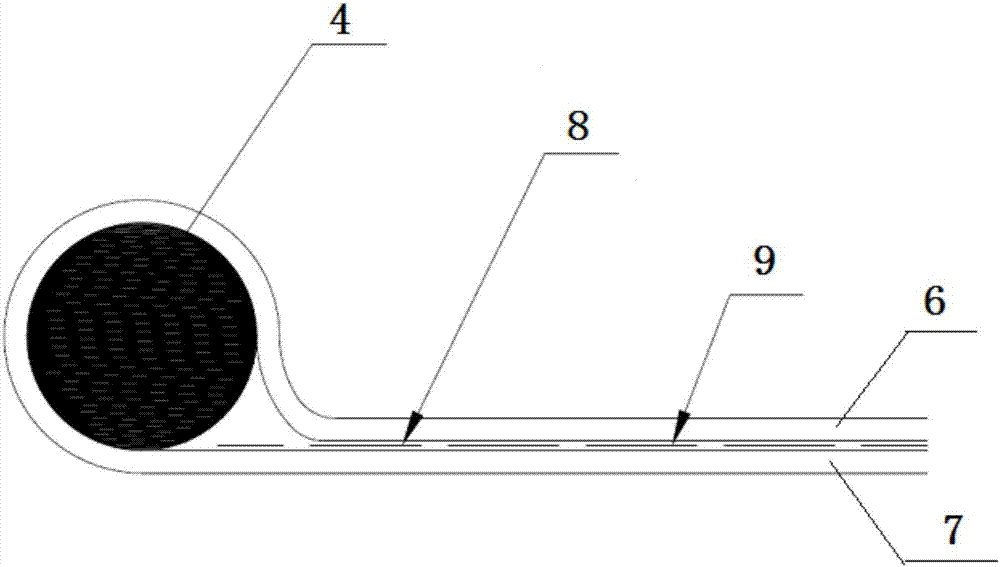

Biaxial extension test device

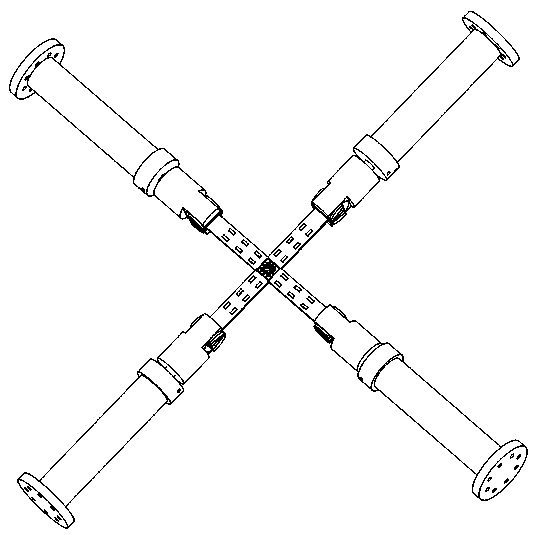

ActiveCN104568591ACompact structureWell formedMaterial strength using tensile/compressive forcesStress ratioEngineering

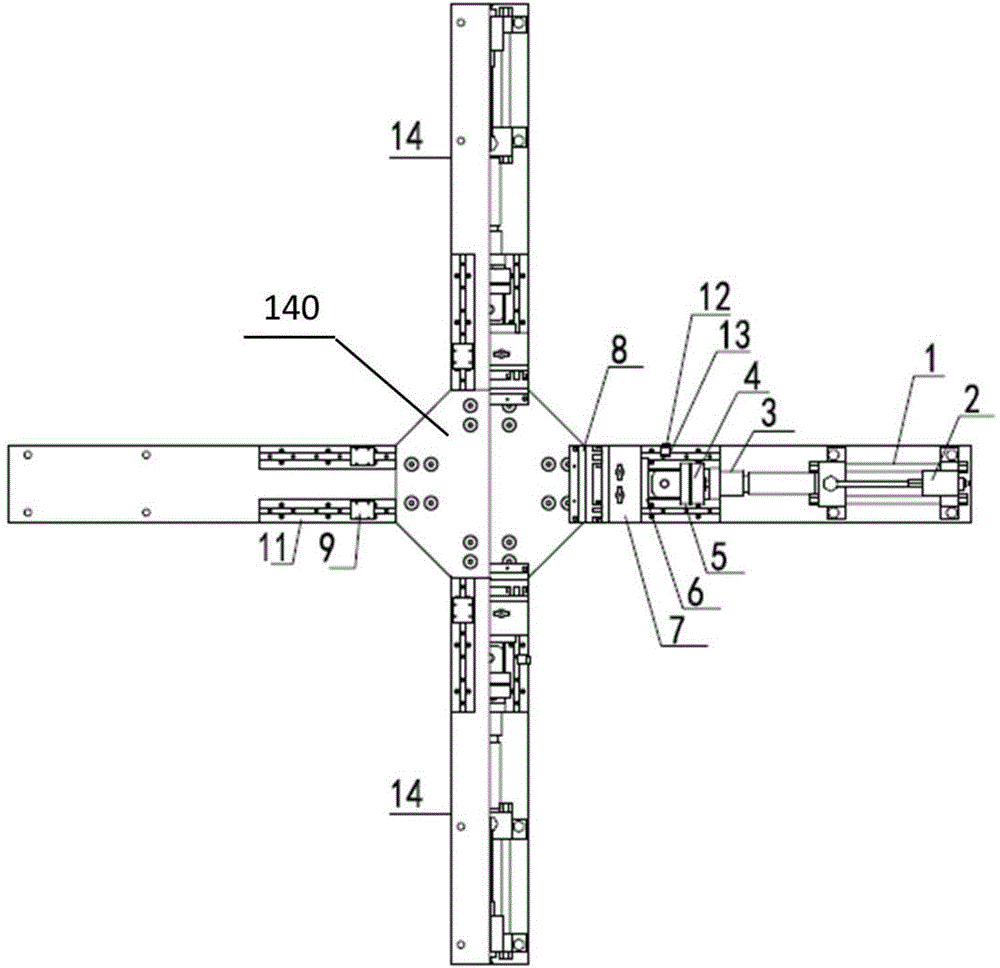

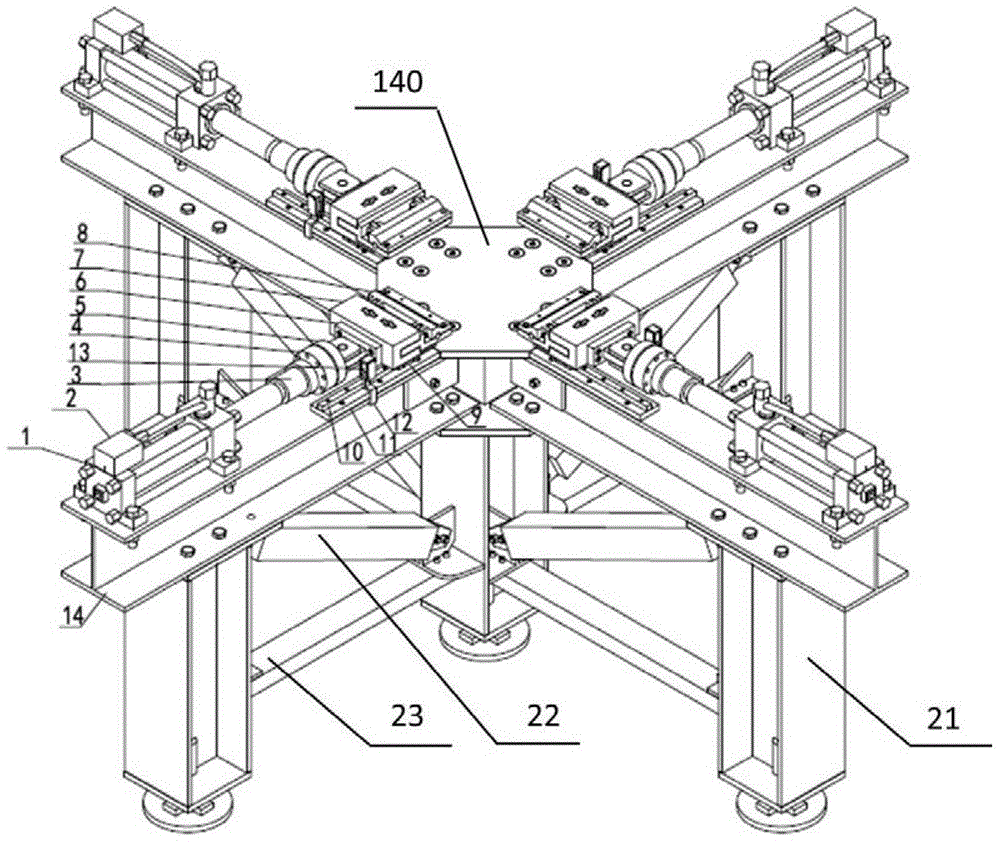

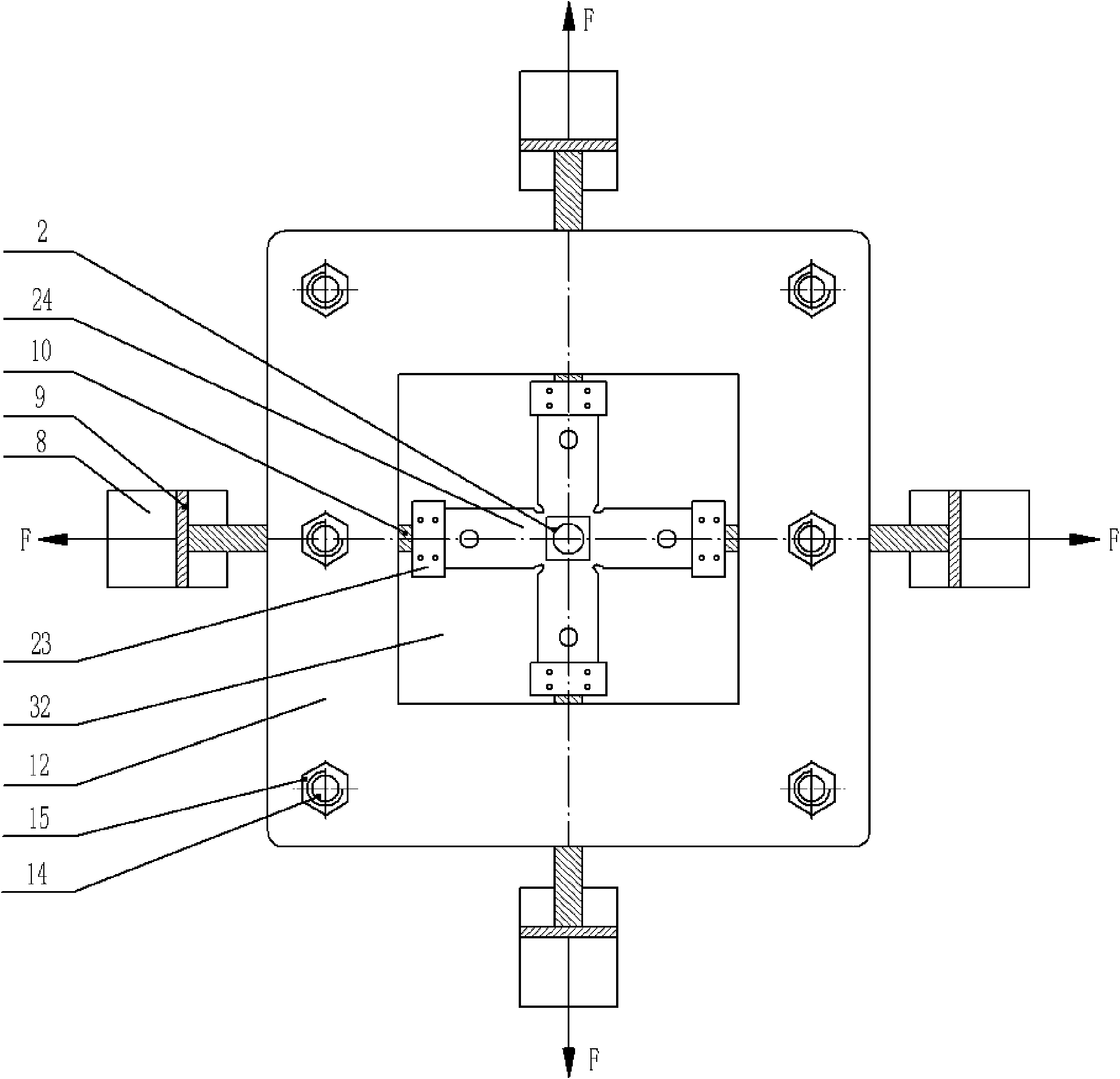

The invention discloses a biaxial extension test device. The biaxial extension test device comprises a horizontal rack which is an orthogonal cross, wherein a servo-cylinder is mounted at the end part of each of four arms of the horizontal rack and sequentially connected with a tension sensor and a combined fixture; a linear guide rail is arranged on the surface of each of the four arms of the horizontal rack; and the combined clamps are arranged on the linear guide rails, can move along the linear guide rails and are used for clamping test pieces. The invention also provides a method for the biaxial extension test device to perform biaxial extension test, and the method comprises a plurality of steps. The biaxial extension test device is compact in structure, concise in format, stable in operation and high in precision, has various test functions (unidirectional static extension, low-cycle reciprocating extension, bidirectional static tensile strength and optional biaxial stress ratio low-cycle reciprocating extension), and can be applied to uniaxial tensile test machines, biaxial tensile test machines and the like.

Owner:SHANGHAI JIAO TONG UNIV

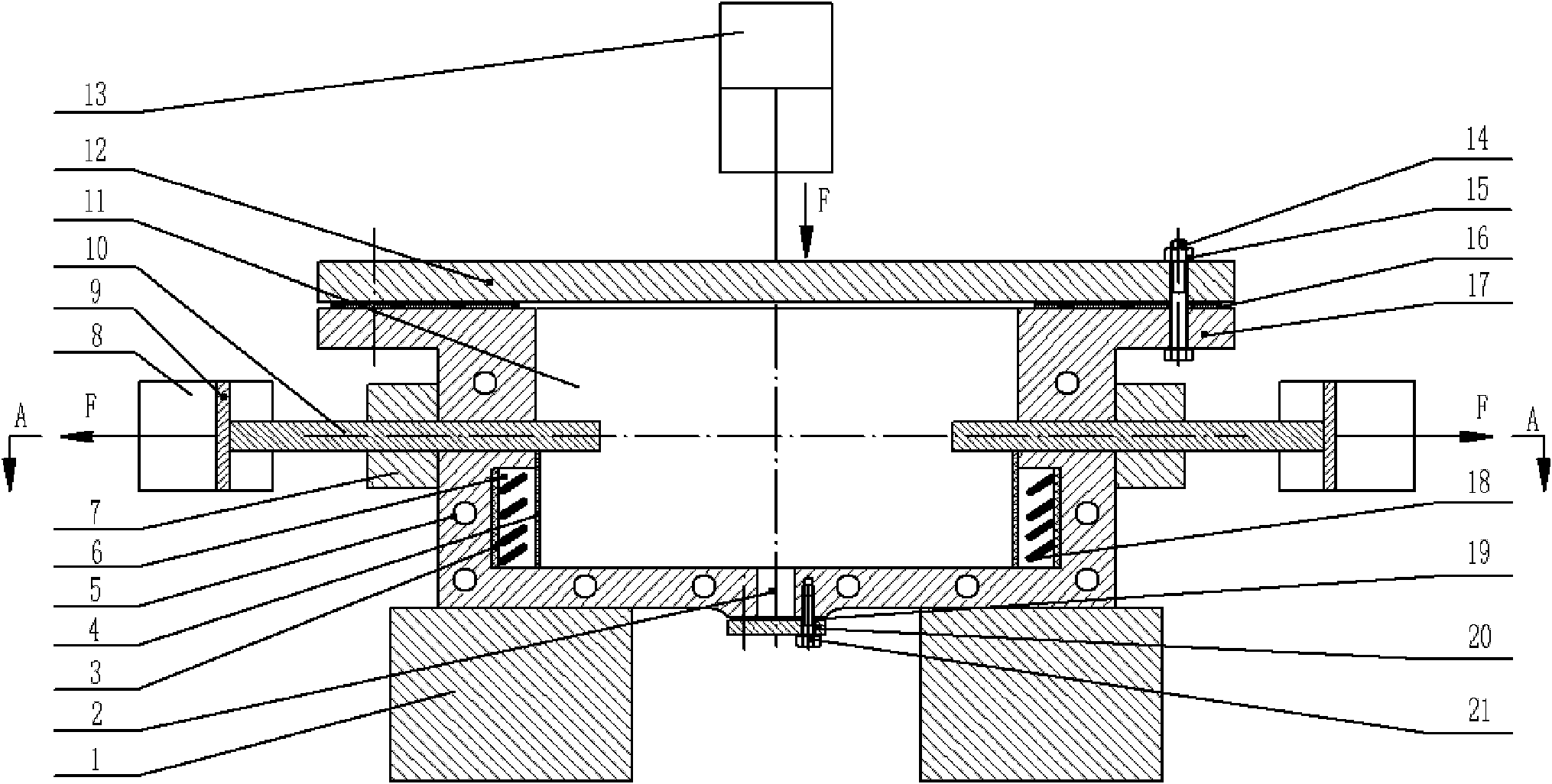

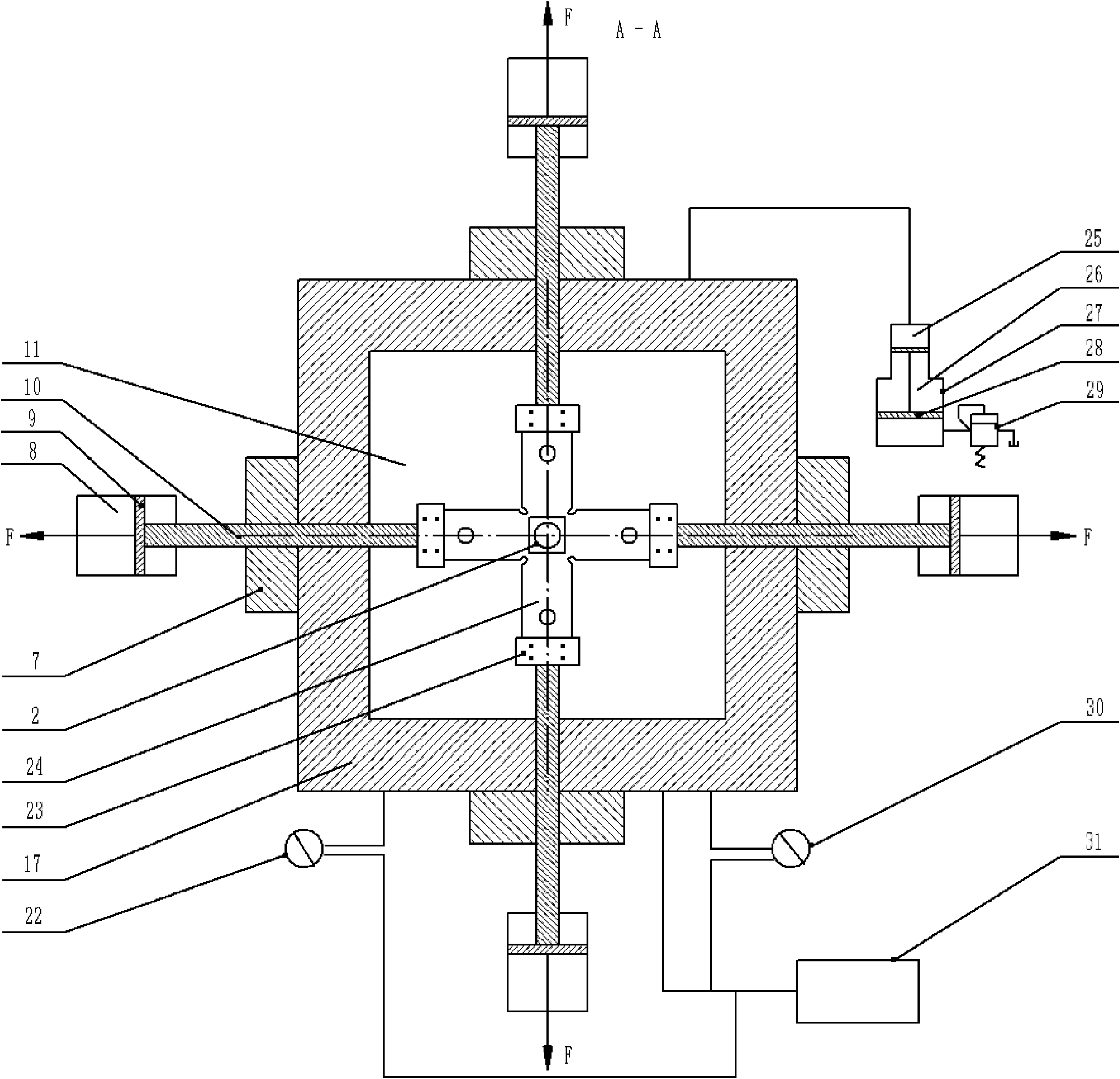

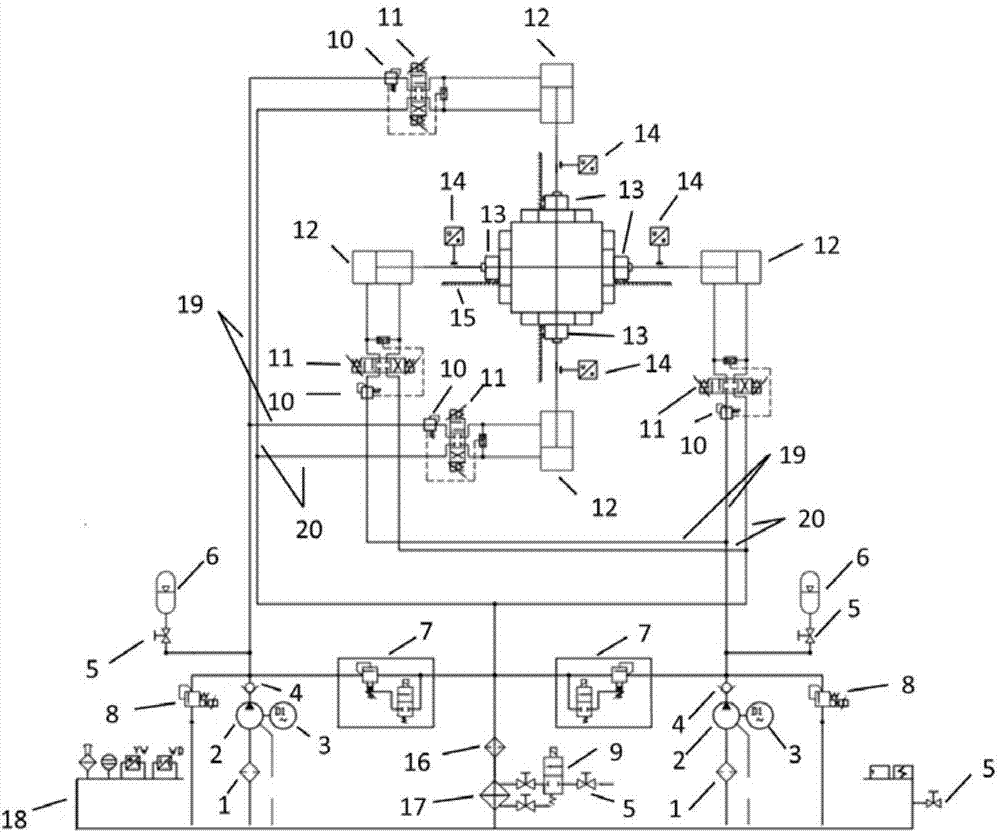

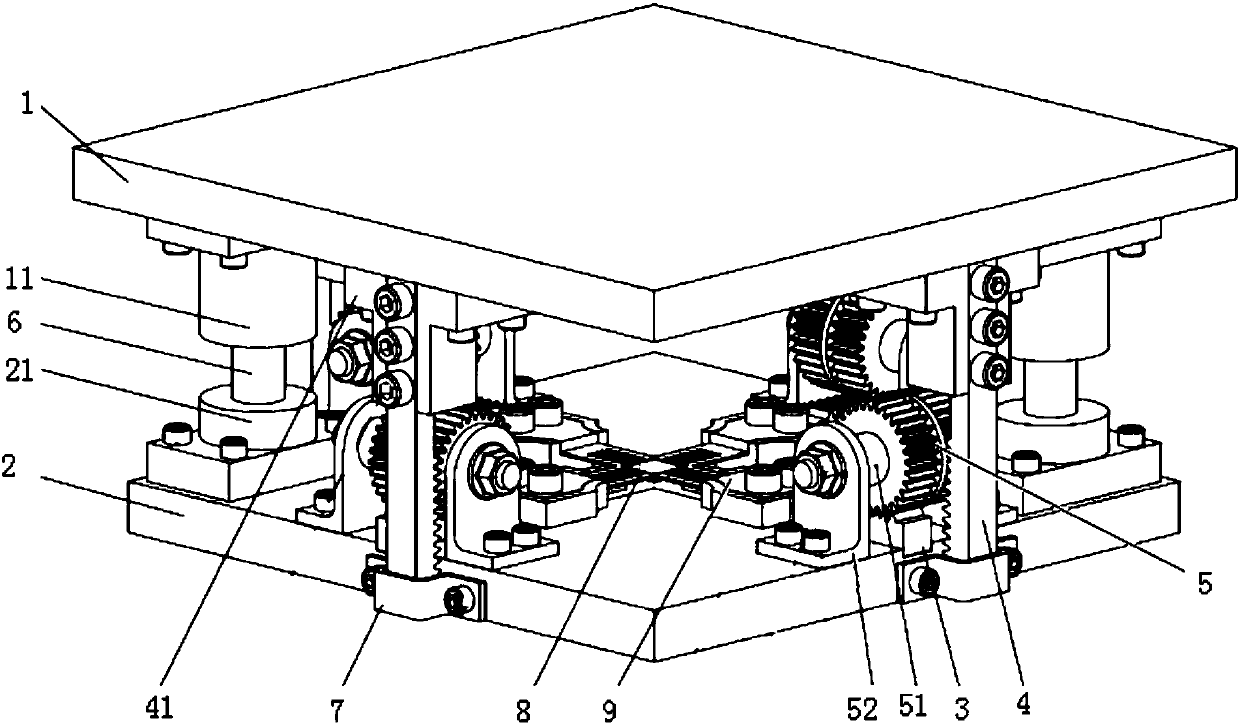

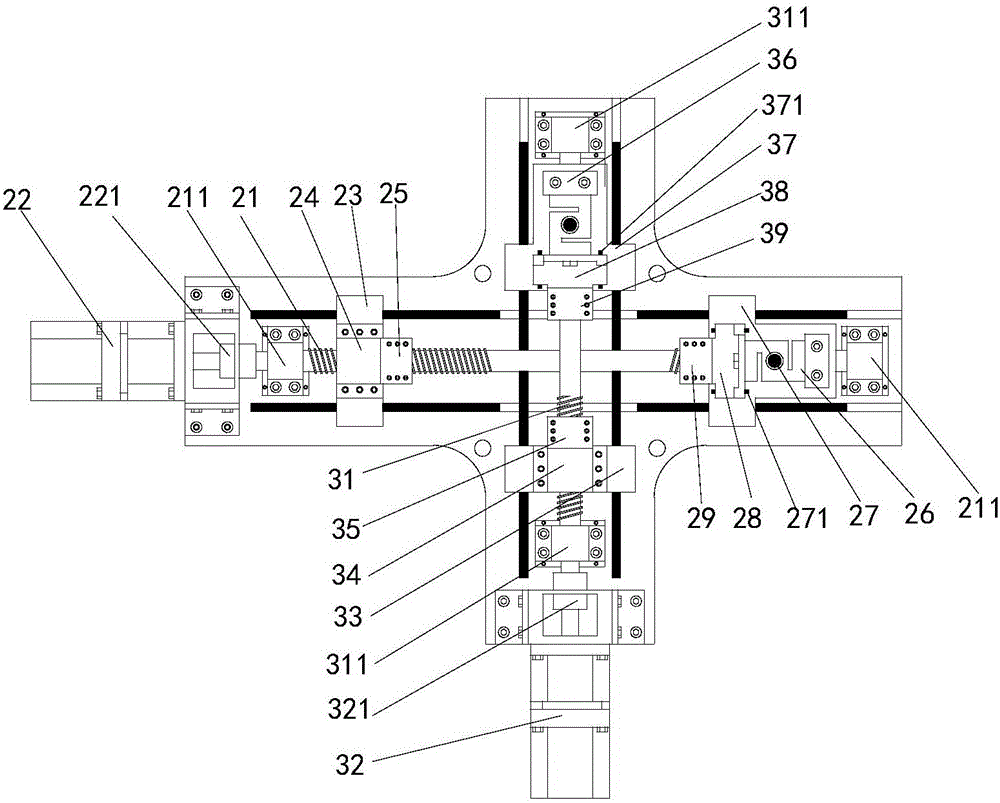

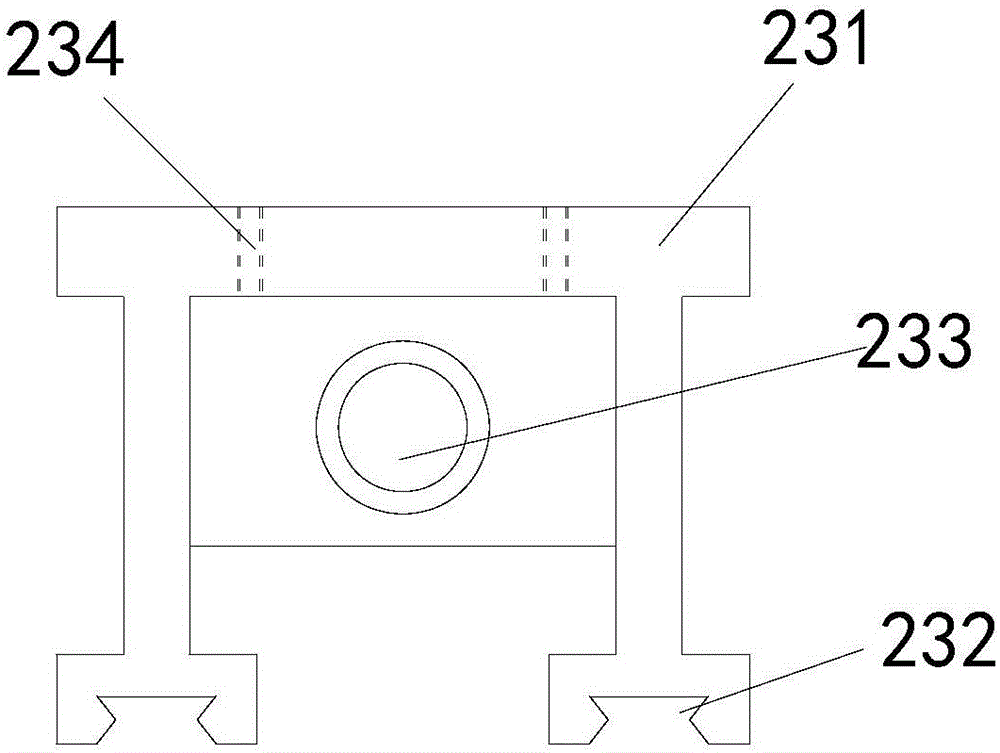

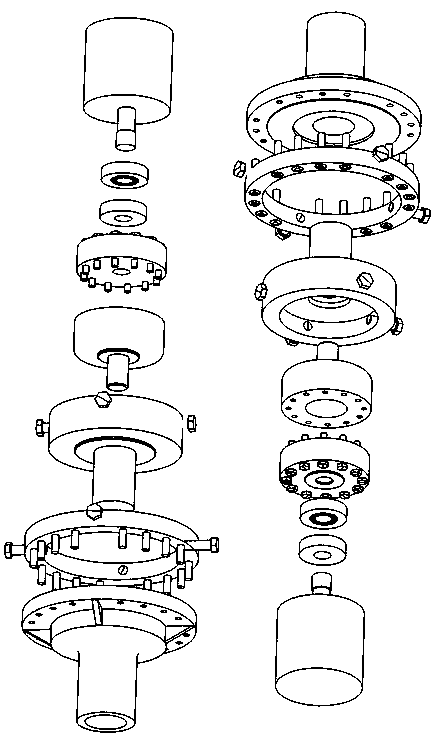

Material micro-mechanical property biaxial tension-fatigue test system and test method thereof

ActiveCN104913974ANovel structureCompact structureMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesFatigue loadingScientific instrument

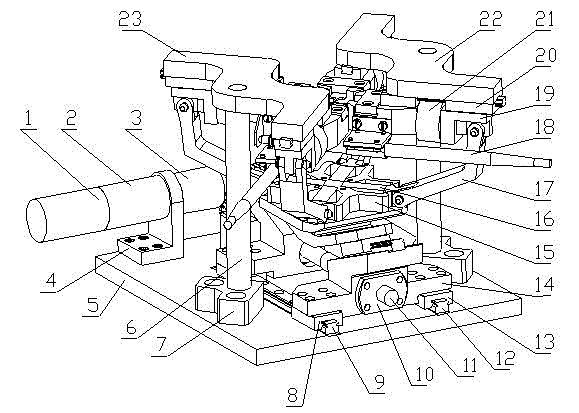

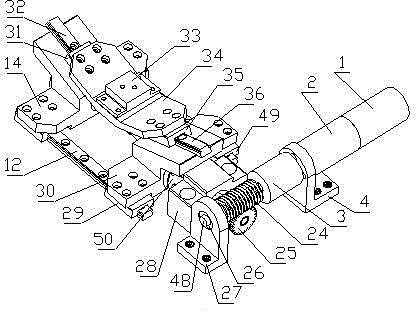

The invention relates to a material micro-mechanical property biaxial tension-fatigue test system and a test method thereof, and belongs to the field of precise scientific instruments. The test method is characterized in that orthogonal tensile load is applied to a test piece to make two mutually vertical tensions exist in one plane, and fatigue load can also be applied to the test piece on the basis of the tensile load in order to research the micro-mechanical properties of a material under different load forms and load sizes. The system is composed of a precise loading-transmitting unit, a fatigue unit, a mechanics and deformation signal detection unit, and a test piece clamping unit. The test system has the advantages of novel and compact structure, respective realization of uniaxial tension test, biaxial tension test, uniaxial tension-fatigue test and biaxial tension-fatigue test, good compatibility with an optical microscope, and dynamic research of the relationship between the microstructure of the material and the deformation damage mechanism under tension-fatigue load conditions.

Owner:JILIN UNIV

Dual-shaft synchronous stretching device

The invention discloses a dual-shaft synchronous stretching device, which comprises a fixed frame, a stretching stand and a stretching assembly, wherein a longitudinal clamp I is fixedly arranged on the stretching stand; and a transverse clamp I, a transverse clamp II and a longitudinal clamp II are respectively driven by the stretching stand to realize stretching motion. According to the dual-shaft synchronous stretching device disclosed by the invention, the fixed frame and the stretching stand are combined to form a steering wheel structure; the stretching stand is driven by a stretching and driving device to realize simultaneous stretching motion of dual-shaft four clamps, i.e. the dual-shaft synchronous stretching effect is achieved by uniaxial stretching so as to obtain more accurate stretching data and result; and in addition, the dual-shaft synchronous stretching device has a simple structure, can be used for realizing dual-shaft stretching on a uniaxial stretching tester and solving the problems of complex structure and high cost for bidirectional synchronous stretching in the prior art. The dual-shaft synchronous stretching device has extremely-low cost and is suitable for dual-shaft stretching tests of rubber and other materials.

Owner:萨固密渝锦(重庆)橡塑制品有限公司

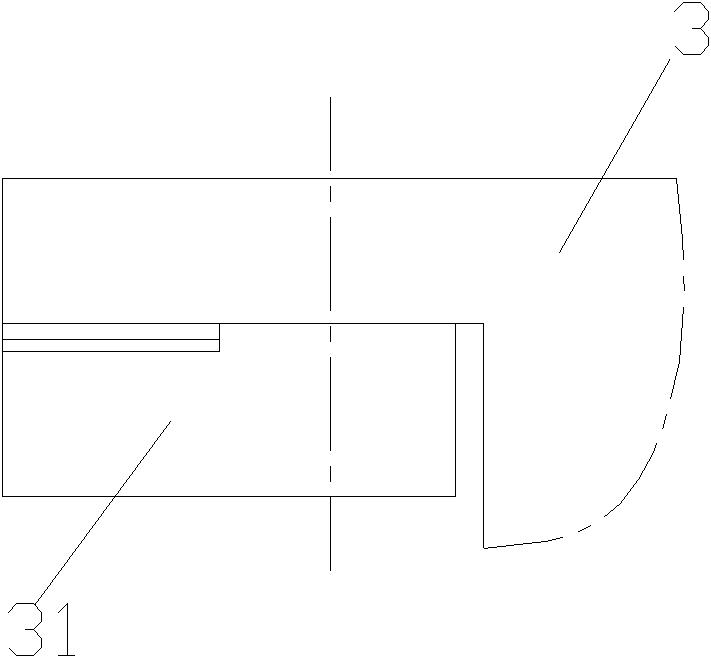

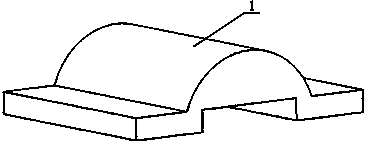

Centering device and method used for sheet-shaped material tensile test

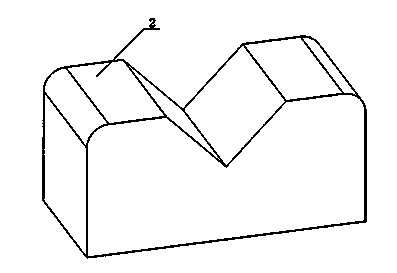

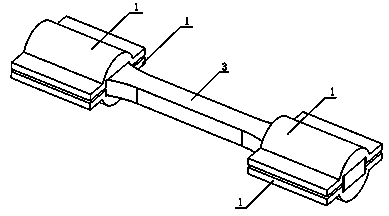

ActiveCN104297053AReliable alignmentGuaranteed accuracyStrength propertiesTest sampleVisual inspection

The invention discloses a centering device and method used for a sheet-shaped material tensile test. The centering device comprises a centering reinforcing sheet and a sticking compaction device, wherein the sticking compaction device comprises a supporting frame and compaction blocks; the compaction blocks are mounted on the supporting frame in pairs; the compaction blocks in each pair are correspondingly arranged up and down; the compaction blocks are mounted on the supporting frame by slide blocks and guide rails; V-shaped grooves are formed in the surfaces of the compaction blocks; the V-shaped grooves of each pair of the compaction blocks are opposite; one face of the centering reinforcing sheet is provided with a semi-cylindrical bulge and the other face of the centering reinforcing sheet is provided with a groove as long as the semi-cylindrical bulge. The centering method comprises the following steps: applying glue, sticking, compacting and the like. According to the centering device and the centering method, manual visual inspection for adjusting a centering position is not needed, and a limiting mechanism for assisting centering is omitted; and the operation process is simple, the reliable centering of a test sample and a chuck is guaranteed and the efficiency of batch tests is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

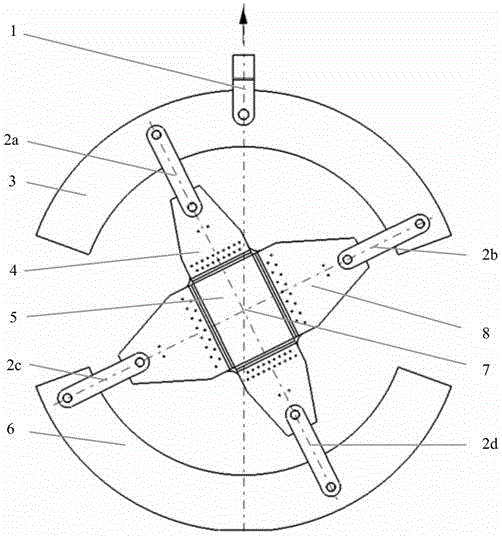

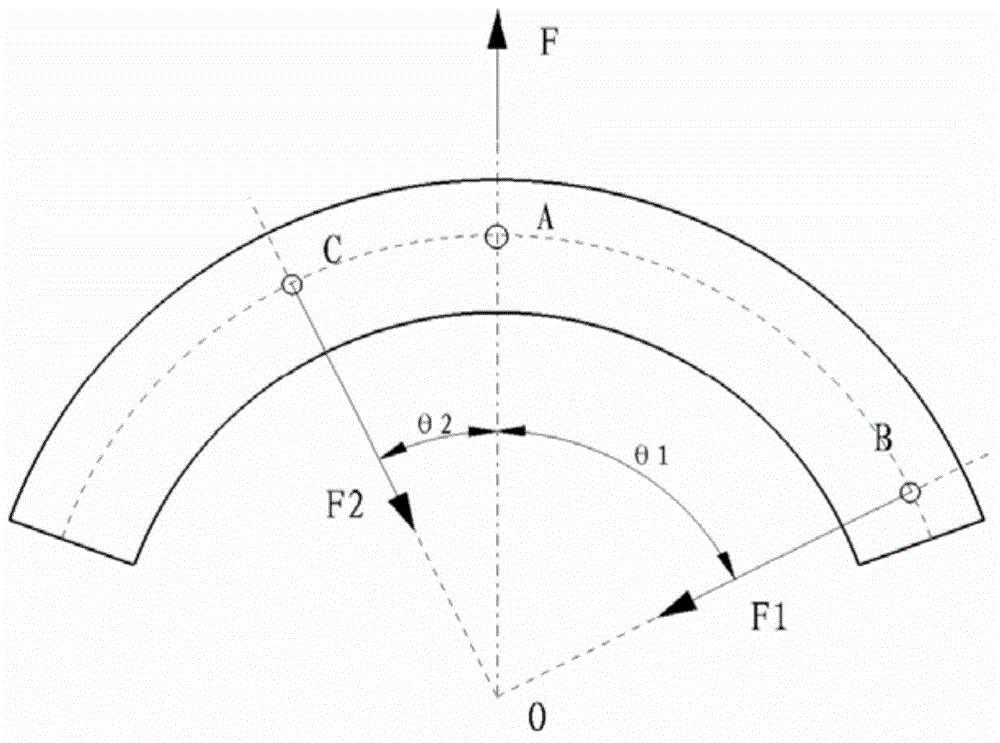

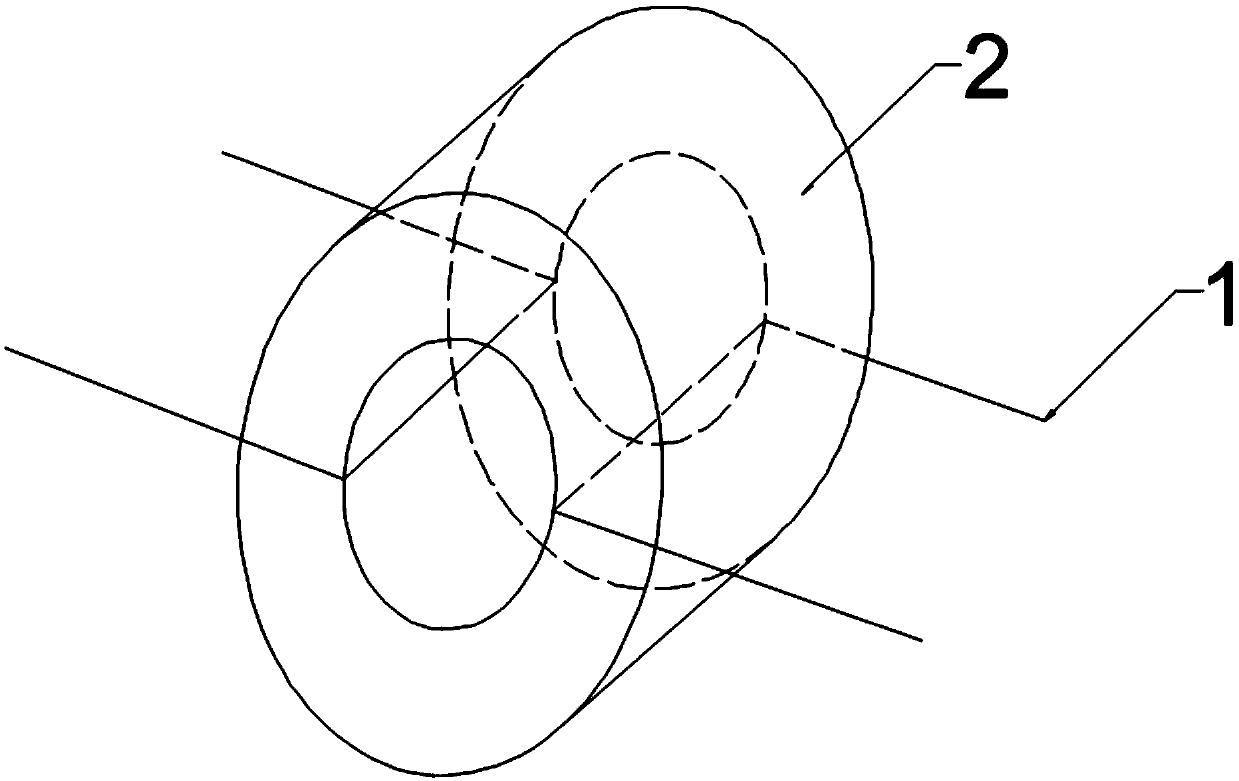

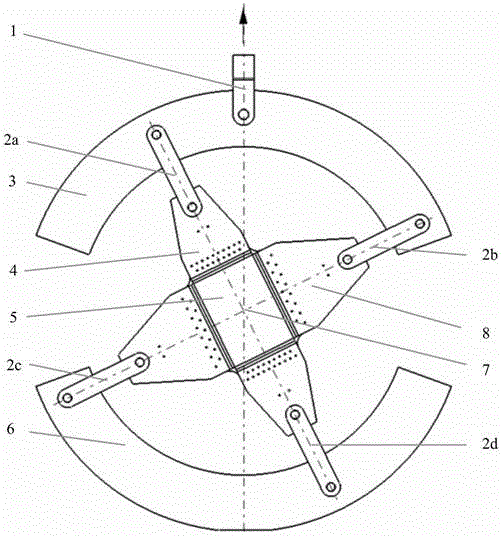

Loading method for two-way tensile test

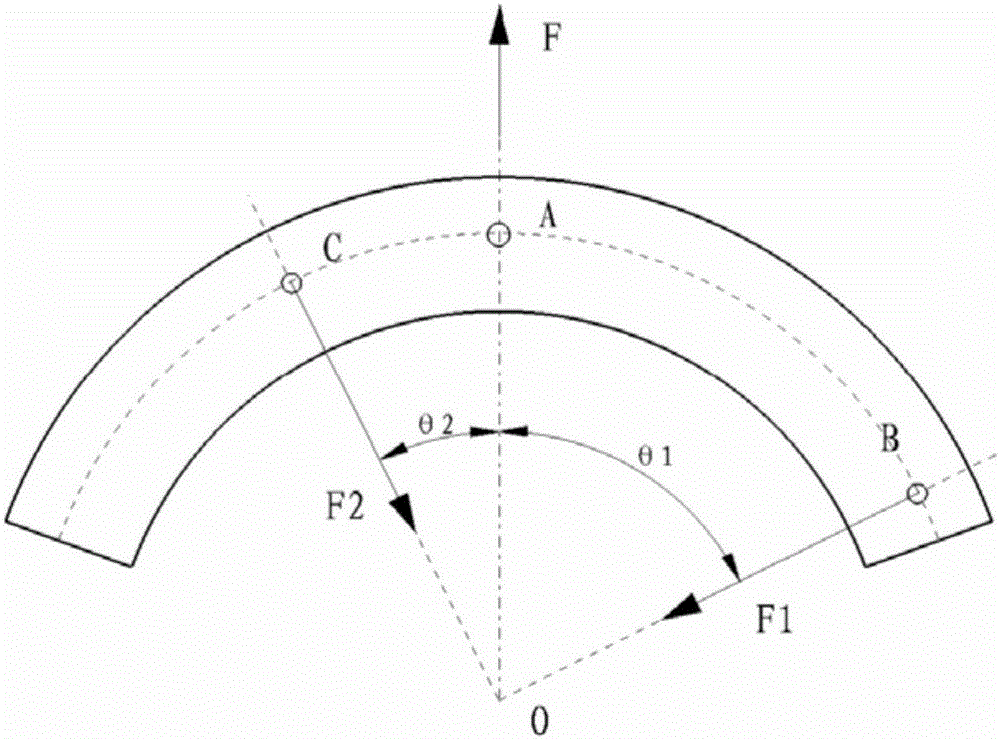

ActiveCN103604699AImplement synchronous bidirectional loadingNo synchronization issuesMaterial strength using tensile/compressive forcesLoad ratioEngineering

Belonging to tensile loading technologies, the invention in particular relates to a loading method for two-way tensile test. The loading method for biaxial tensile test provided by the invention makes use of a lever principle to decompose a one-way load into two-way loads through an annular load decomposer, then the two-way loads are loaded onto a test piece so as to realize two-way loading of two-way tensile test. The force transfer points of the load decomposer can be adjusted according to an actual loading ratio to meet the requirements of any load ratio, thus realizing synchronous two-way loading of the test piece. The synchronization problem does not exist in the loading system. At the same time, by changing the size of annular structures, two-way loading on large test pieces can be conducted, and the method also can be used for static and fatigue test. In addition, the annular load decomposer involved in the invention has a simple structure, the method occupies fewer test resources, and is low in cost, thus having great practical application value.

Owner:CHINA AIRPLANT STRENGTH RES INST

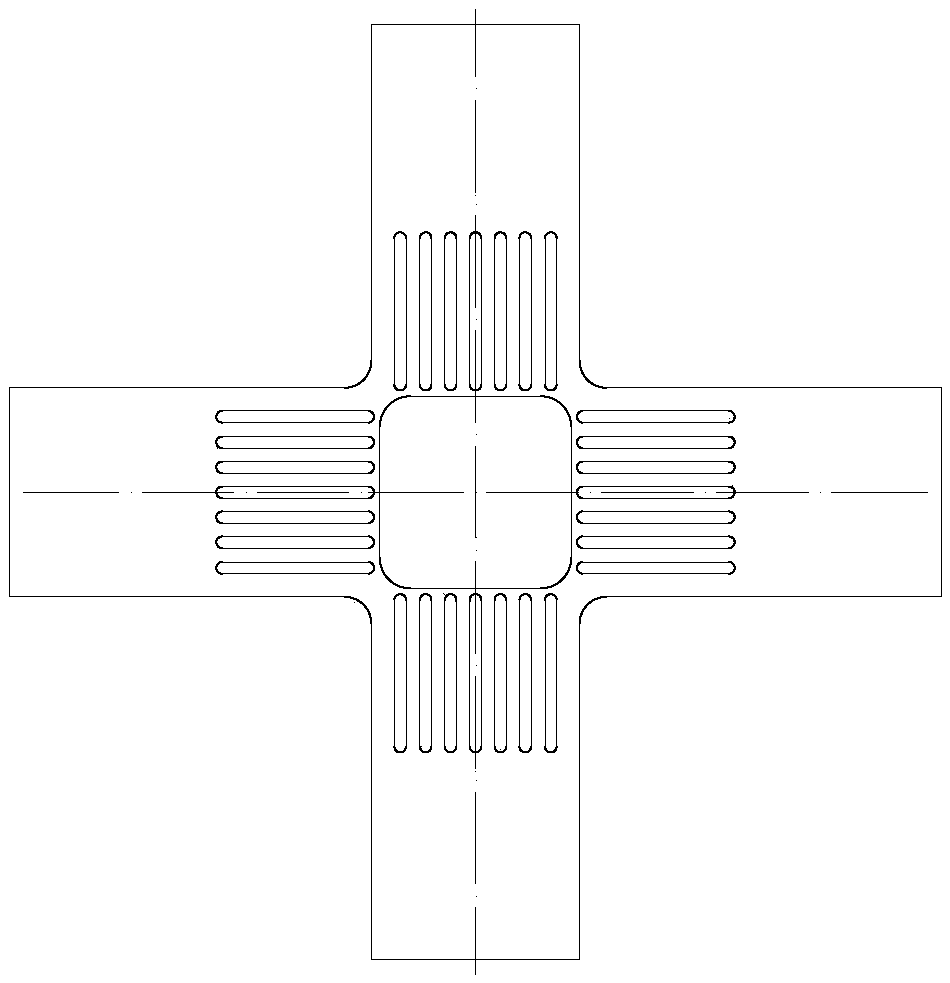

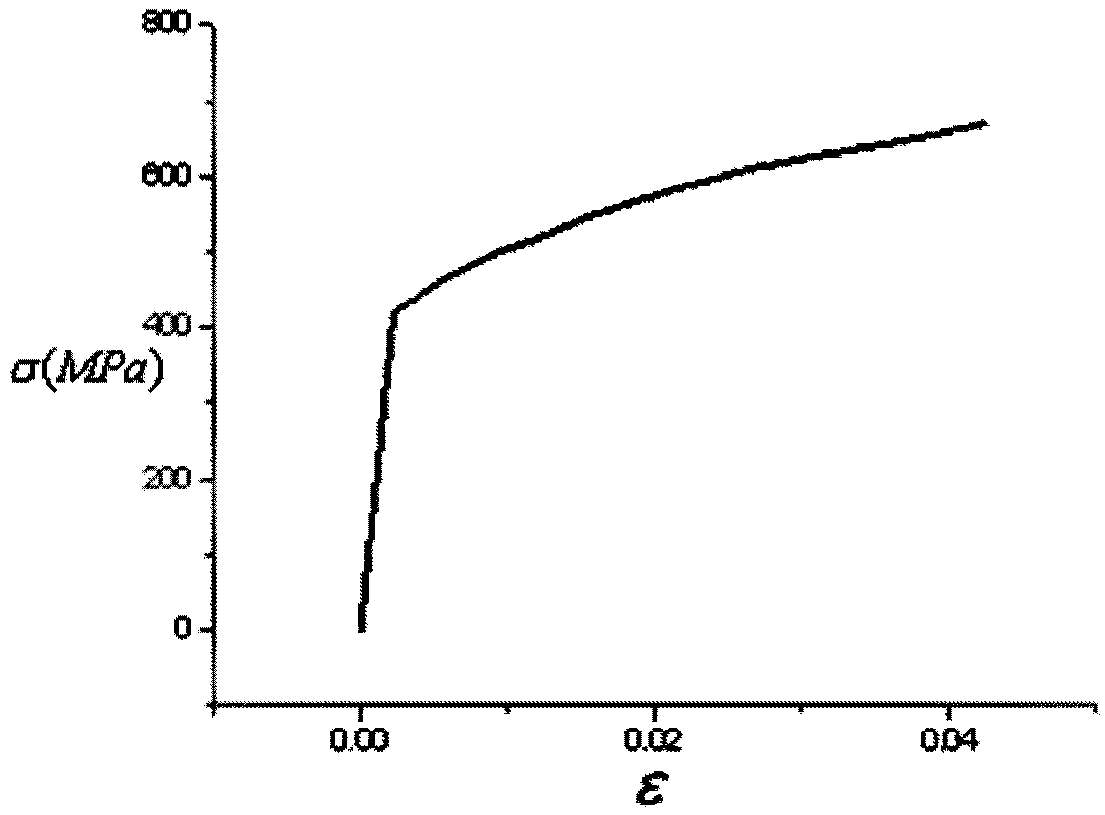

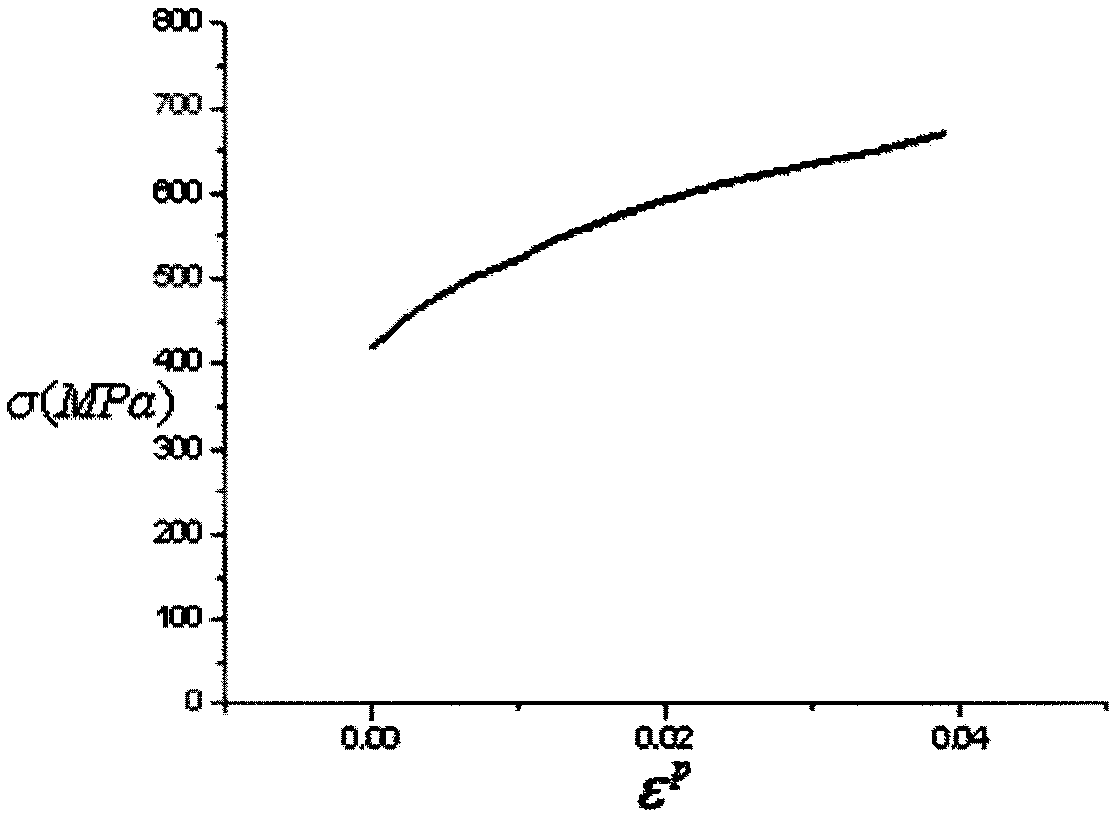

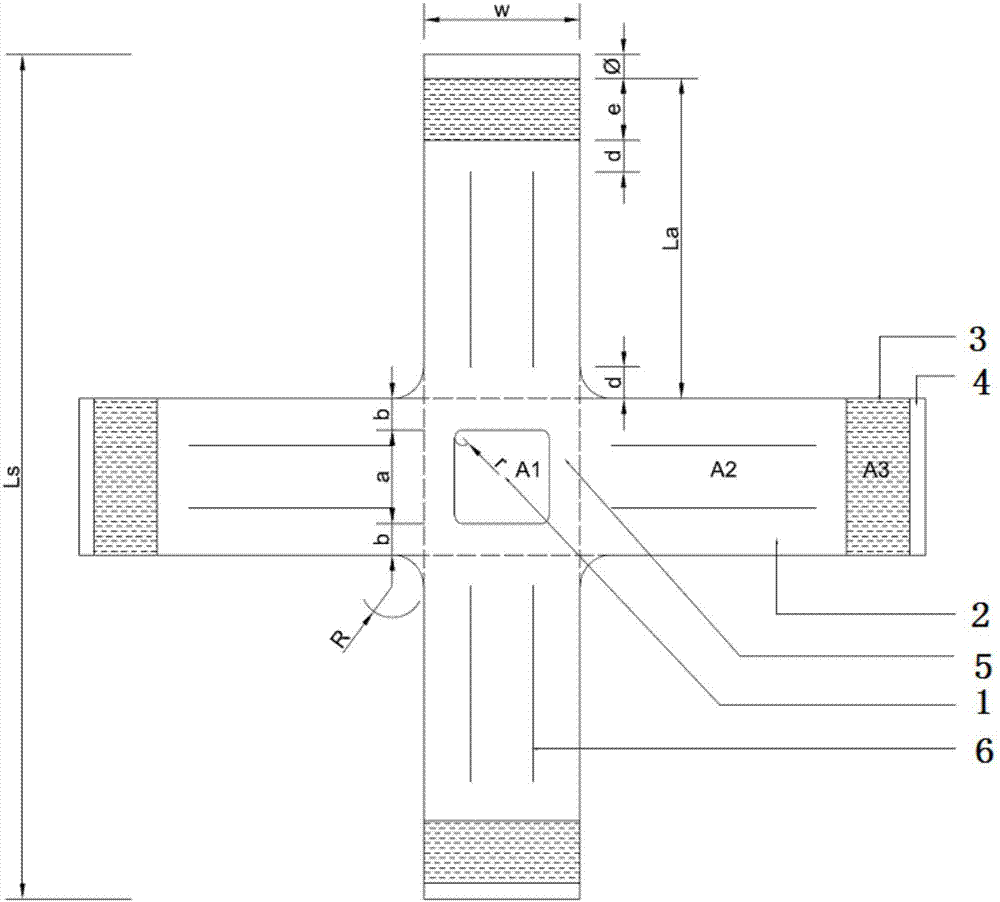

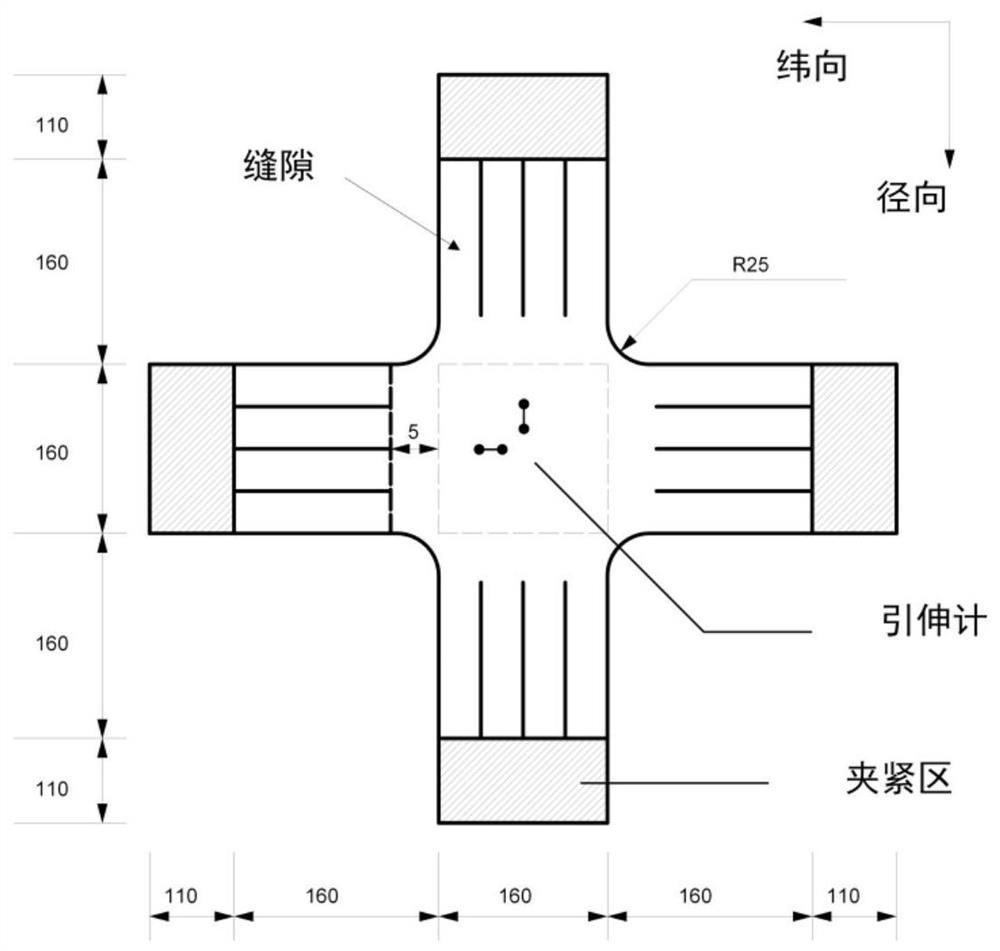

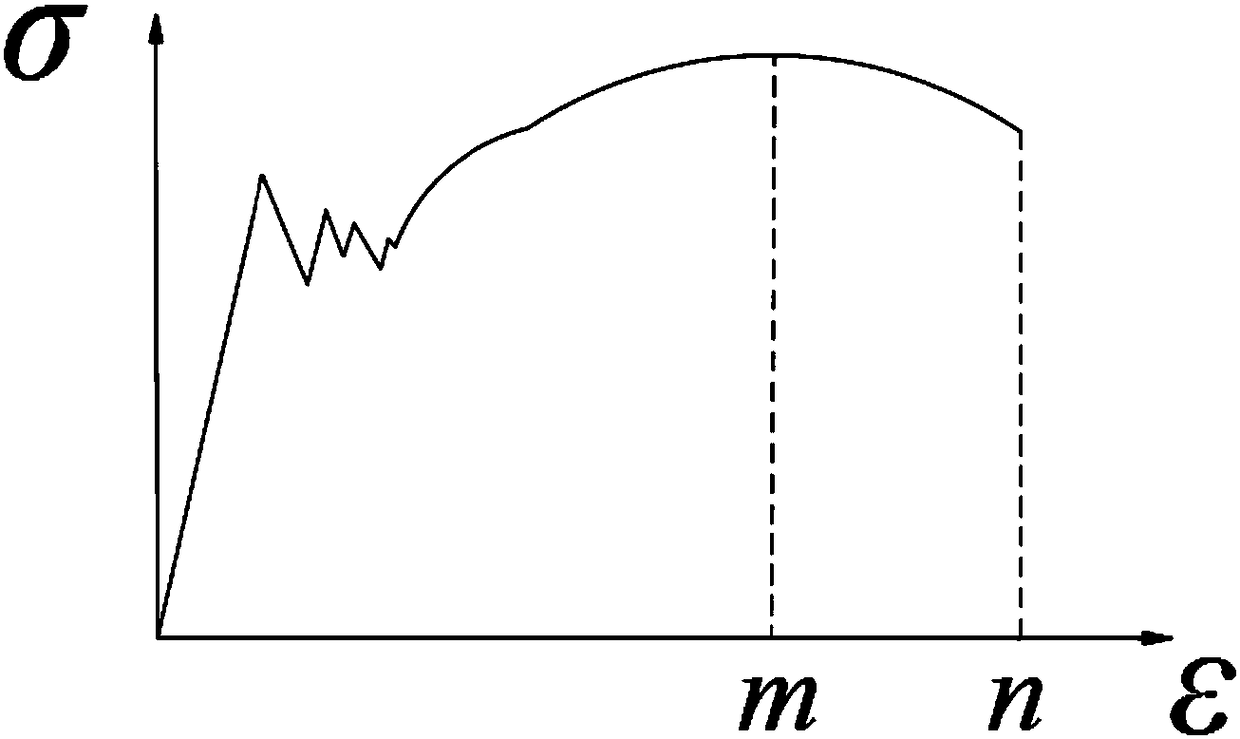

Cross-shaped test piece biaxial tensile test based yield criterion evaluation method

InactiveCN108844816AOvercome limitationsMaterial strength using tensile/compressive forcesCurve fittingEngineering

The invention provides a cross-shaped test piece biaxial tensile test based yield criterion evaluation method. According to the relation of the real stress in a rolling direction and plastic strain, the relation of biaxial directional stress and equivalent stress can be deduced by adopting a yield criterion, the relation of plastic strain in a biaxial direction and equivalent plastic strain can bededuced, the relation of biaxial directional strain and the equivalent plastic strain can be obtained, and therefore, the relation of stress and strain in the biaxial direction can be obtained; dataof the equivalent stress and the equivalent plastic strain can be measured by a test, so that data of elastic and plastic stages in the biaxial direction can be obtained; the expressions of two curvescan be obtained through curve fitting, contrast can be performed on the biaxial directional data measured by the test and the expressions, and the prediction precision of the deformational behavior of a material corresponding to the yield criterion can be evaluated. The contrast of the difference between the relation of stress and strain in the biaxial direction obtained by the test and the yieldcriterion in the whole plastic stage can be realized; and the limitation that traditional methods can only compare the difference between a test yield point and the yield criterion under a certain equivalent plastic strain can be overcome.

Owner:SOUTHEAST UNIV

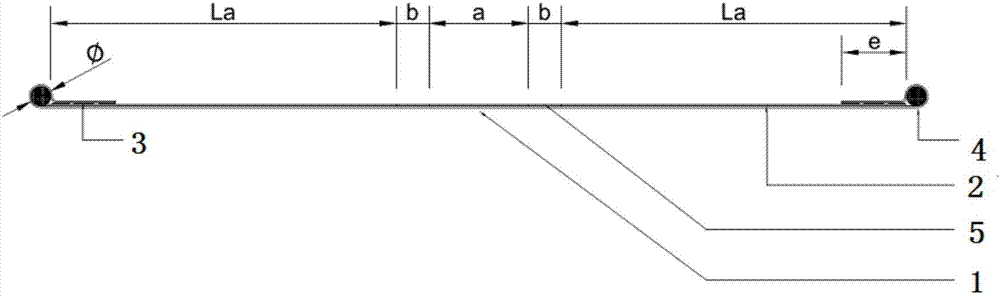

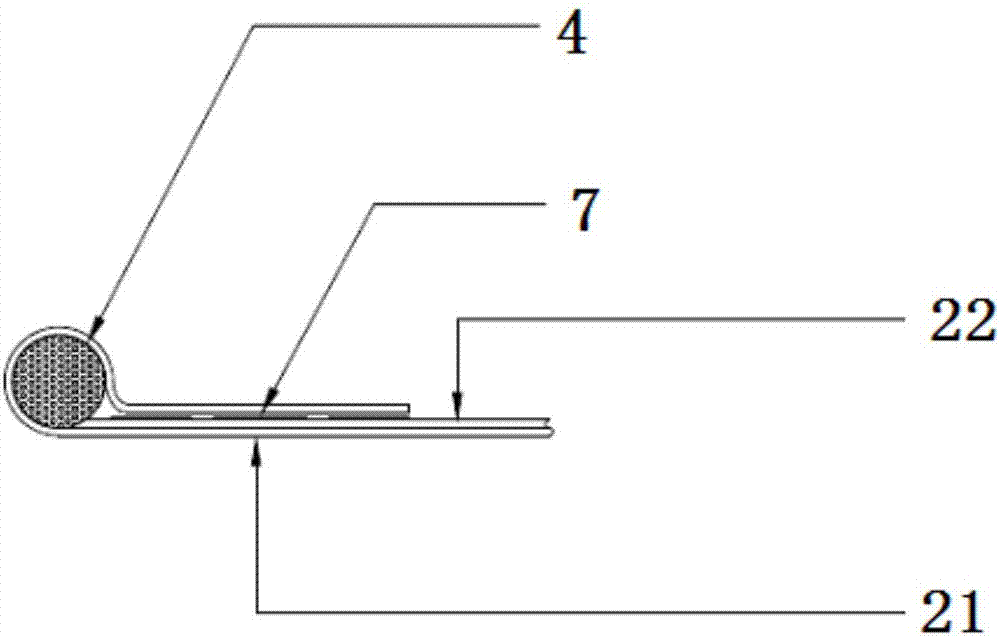

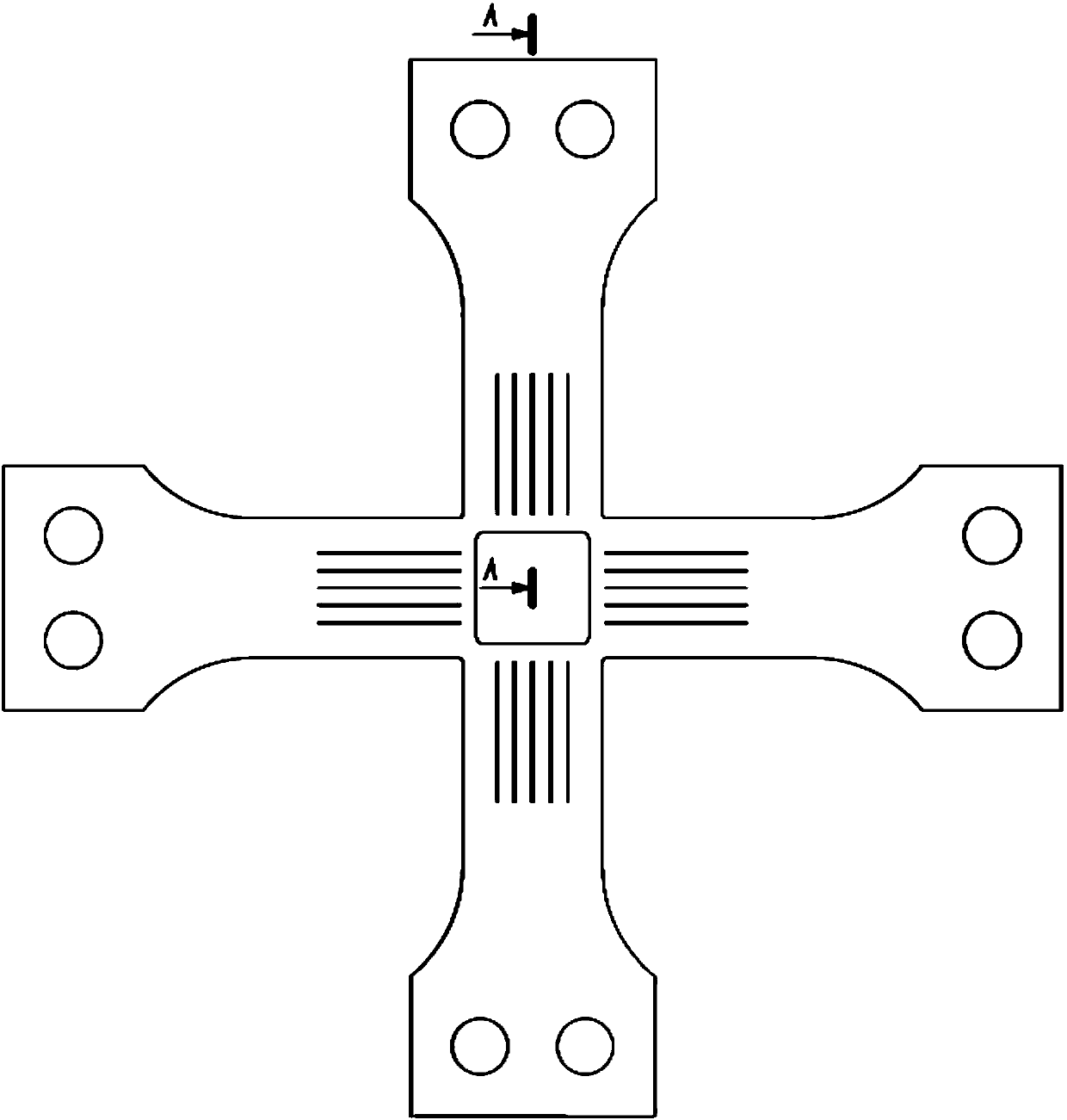

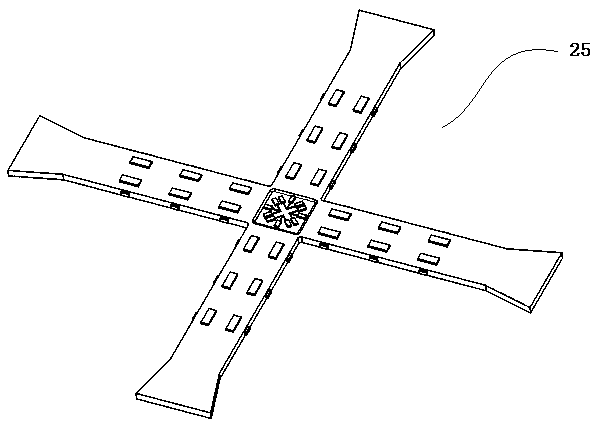

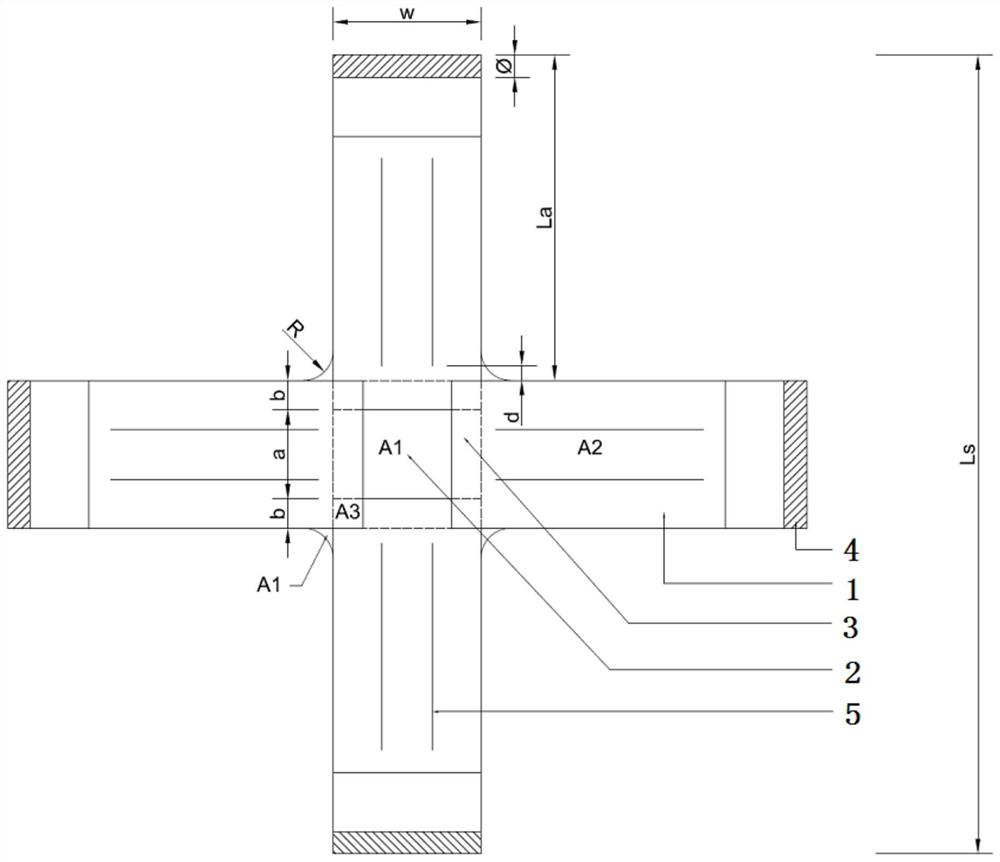

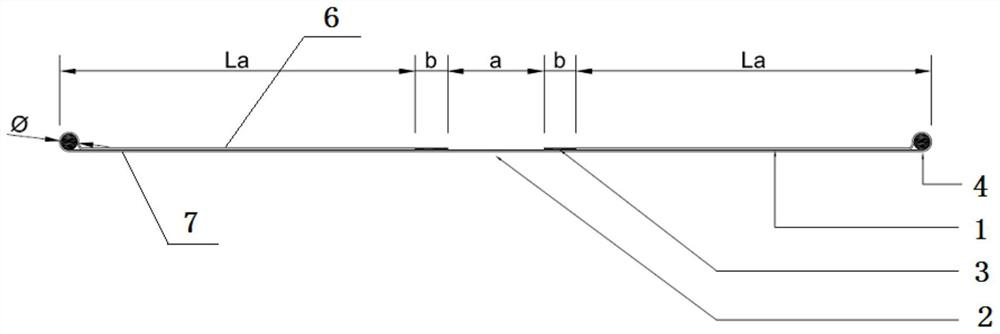

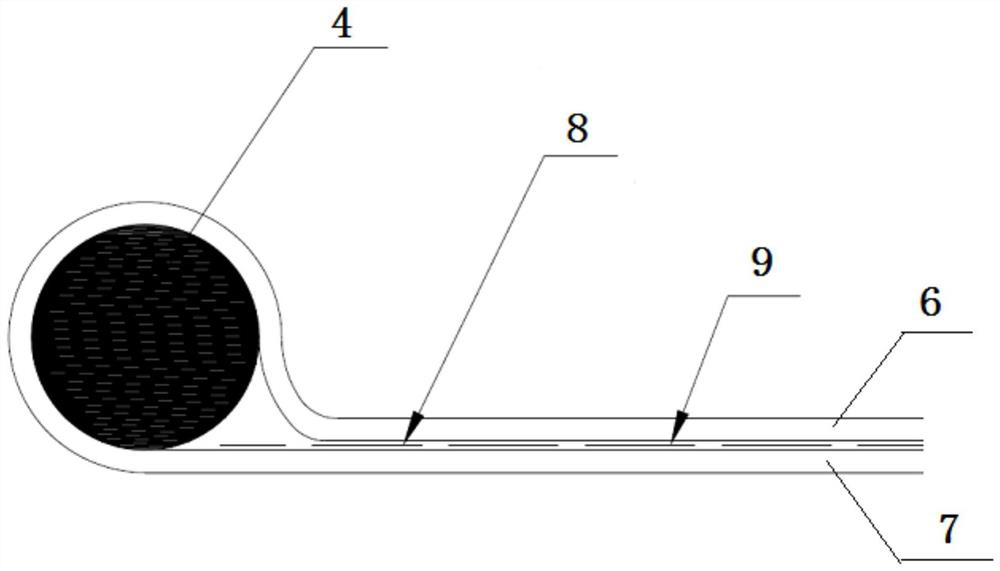

Double-cross-shaped composite fabric membrane double-axis tensile strength test piece and manufacturing method thereof

InactiveCN107340184APreparing sample for investigationMaterial strength using tensile/compressive forcesCantileverBiaxial tensile test

The invention discloses a double-cross-shaped composite fabric membrane double-axis tensile strength test piece. The test piece comprises a center core area and four cantilevers extending outsides around the center core area to form a cross shape, each cantilever is connected to the center core area through an edge transition area, the end of each cantilever is a clamping section provided with a clamping end rubber rod, and the clamping end rubber rod is used for connecting a clamp of a double-axis tensile test machine; the clamping section is divided into three layers, each cantilever and the edge transition area have double layers, the center core area has a single layer, and the edge transition area is a quadrangle of which four angles have fillets. The invention further provides a manufacturing method of the test piece. The double-cross-shaped composite fabric membrane double-axis tensile strength test piece can test and represent the fabric membrane double-axis tensile strength, destruction happens at the single-layer test area, the cantilevers and edge transition areas are strengthened and later destructed, and the test piece can be applied to building membrane, airship envelops, other industrial fabric fields and the like.

Owner:SHANGHAI JIAOTONG UNIV

A biaxial tensile test device with third-direction stress provided by fluid pressure and its application

InactiveCN102269675AImprove practicalityRaise the forming limitMaterial strength using tensile/compressive forcesTemperature controlRoom temperature

The invention provides a biaxial tensile testing device with thirdly directional stress provided by fluid pressure and application thereof. The biaxial tensile testing device with thirdly directional stress provided by fluid pressure comprises a stretching device, a sealed box, a heating system, a fluid pressure system, a temperature detecting device, a pressure measuring device, a cooling systemand a data collecting and processing device. The biaxial tensile testing device with thirdly directional stress provided by fluid pressure, provided by the invention, can be used for improving a forming limit of a material to some extent by considering the influence of the fluid pressure on a biaxial tensile test, is not only suitable for testing the performance of a constant-temperature material, but also is suitable for testing the performance of a high-temperature material; the heating system is used for carrying out heating and constant-temperature control on a testpiece to be tested and has a high temperature-raising efficiency and a small error; the device also comprises the cooling system which is used for carrying out necessary cooling on a box body in the test process of testing the performance of the high-temperature material so that the service life of the testing device is prolonged, and the efficiency of the testing device is improved.

Owner:BEIHANG UNIV

Uniaxial tensile test measurement method for water gel material based on test piece in shape of Chinese character HUI

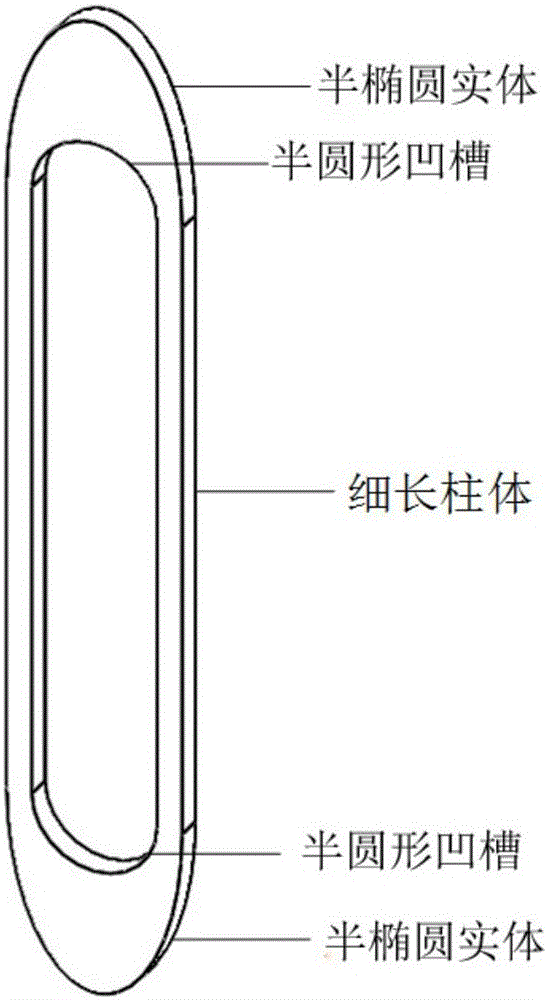

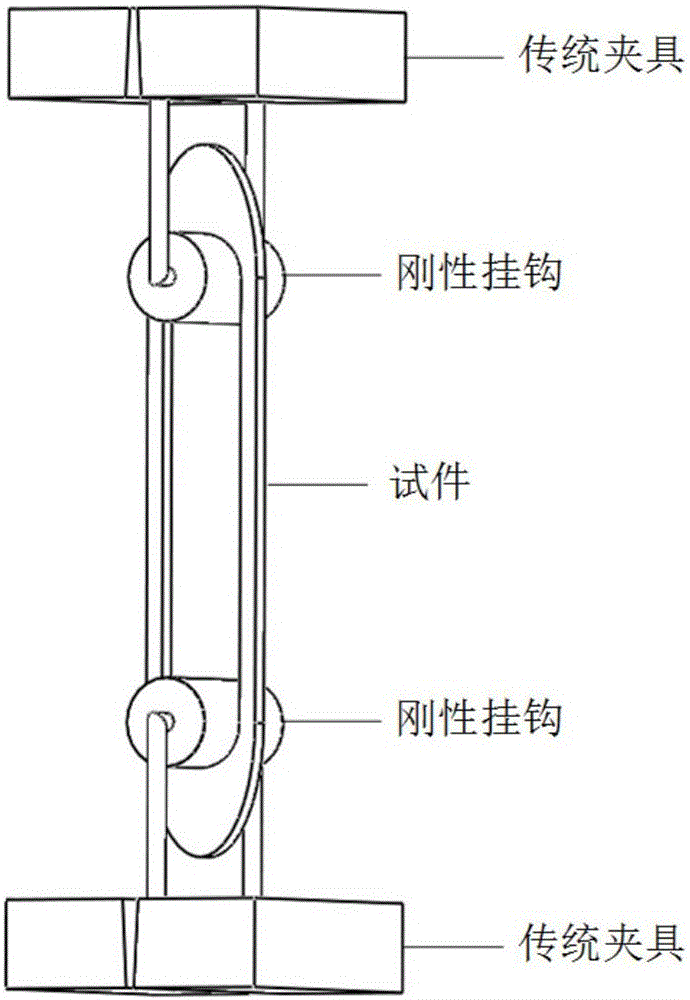

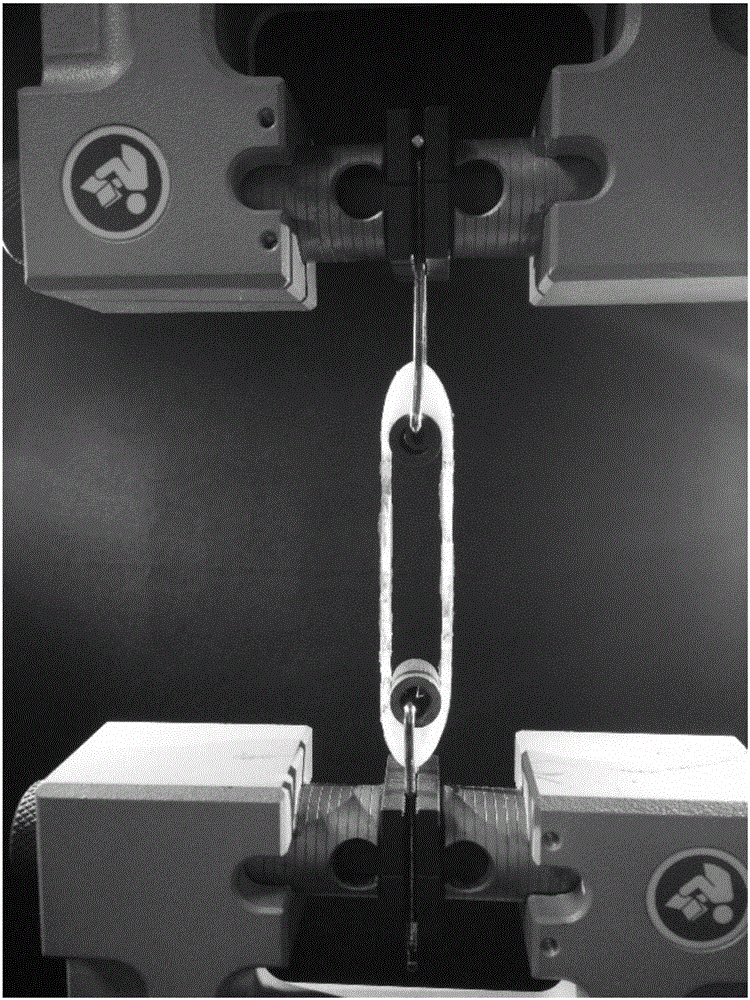

ActiveCN105928761ASolve the problem that it is difficult to clamp and fix on the testing machineUnderstanding Mechanical PropertiesPreparing sample for investigationMaterial strength using tensile/compressive forcesStress concentrationChinese characters

The invention discloses a uniaxial tensile test measurement method for a water gel material based on a test piece in the shape of Chinese character HUI. The uniaxial tensile test measurement method comprises the following steps: (1) preparing a water gel test piece in the shape of Chinese character HUI; (2) mounting the water gel test piece; (3) carrying out a tensile test, recording deformations of the middle parts of two parallel slender column bodies, namely positions away from the end parts of the column bodies, of the test piece by using a digital image related method in a test process, recording a load reading on a test machine, and obtaining a load-displacement curve of the PVA water gel material in a quasi-static uniaxial tensile test after the test according to test piece strain obtained by the digital image related method and a load acquired on the test machine. According to the method, by the adoption of the test piece in the shape of Chinese character HUI, the problem of clamping of the water gel test piece on the test machine can be well solved, so that the uniaxial tensile test of the water gel material can be successfully carried out; the problem of stress concentration can be eliminated, so that breakage points of the test piece are uniformly distributed. Meanwhile, the deformation of the middle part of the test piece can be obtained by the digital image related method, so that test data of the water gel material in the uniaxial tensile test can be acquired more accurately.

Owner:SOUTH CHINA UNIV OF TECH

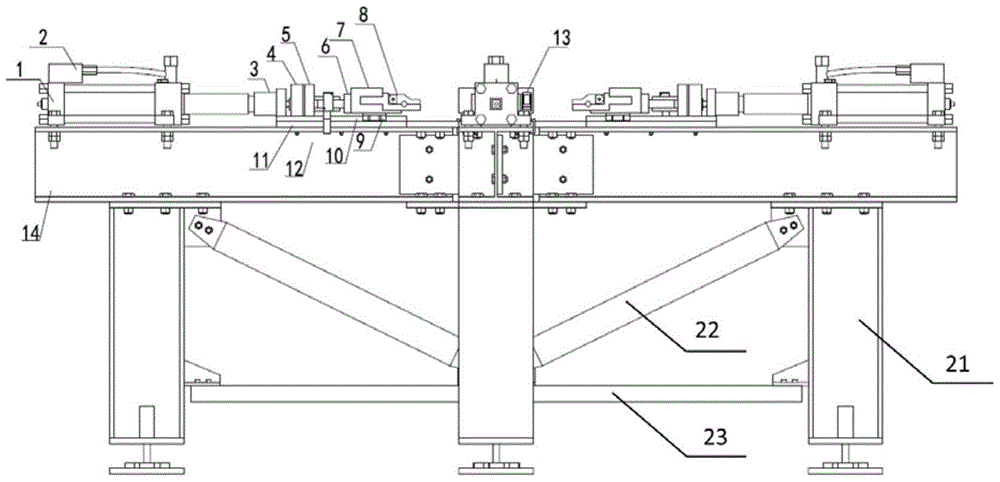

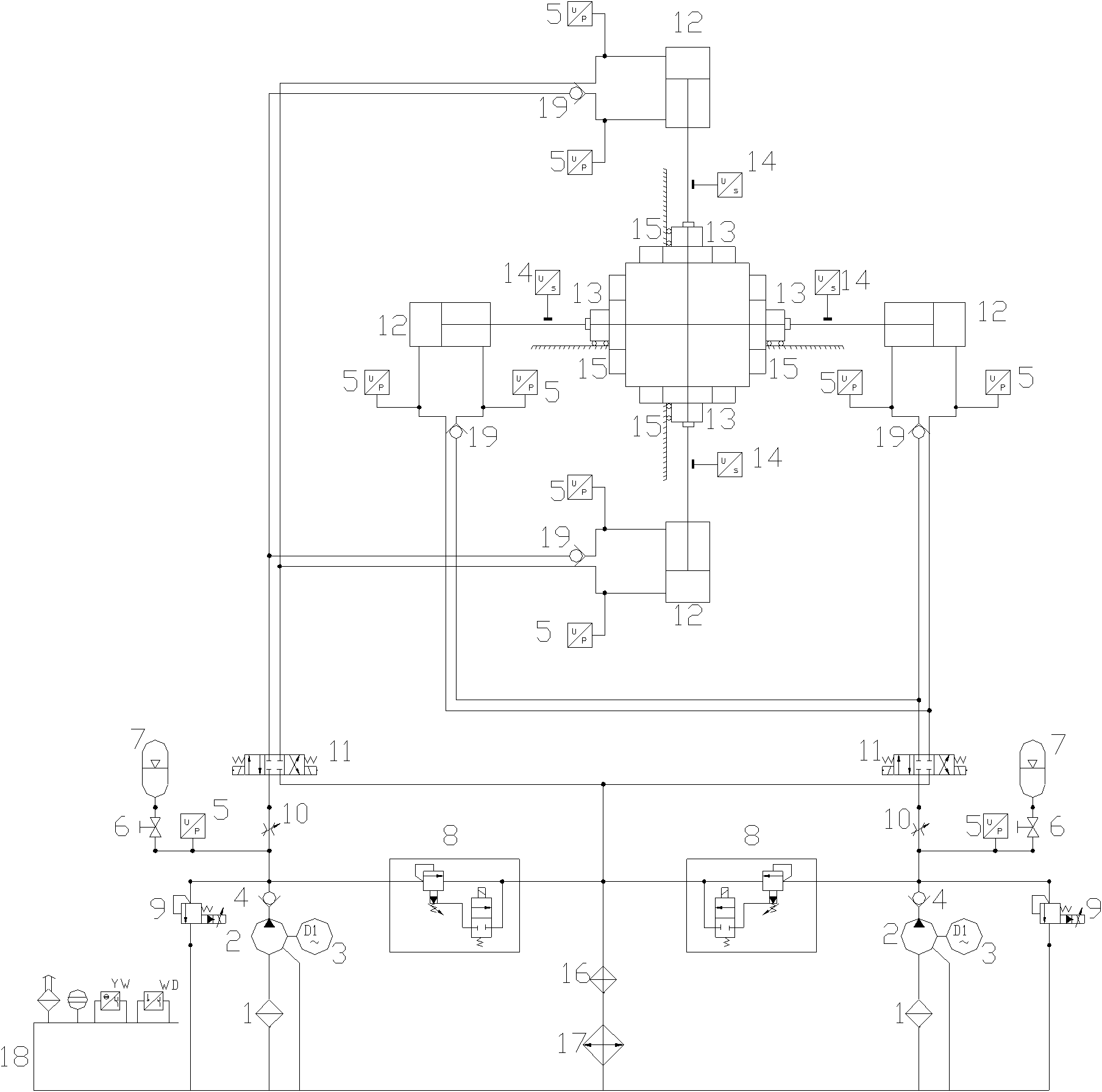

Electromechanical hydraulic loading system for film biaxial tensile test

ActiveCN102269671AStrong pullHigh precisionMechanical apparatusStrength propertiesHydraulic cylinderSkin test

The invention provides an electro-hydraulic loading system of a thin-film biaxial tensile testing machine, belonging to the technical field of mechanics of materials and building materials. The system provided by the invention comprises a low-pressure filter, a hydraulic pump, a motor, a check valve, a pressure sensor, a stop valve, a power accumulator, an electromagnetic unloading valve, a proportional overflow valve, a throttling valve, an electromagnetic directional valve, four servo hydraulic cylinders, a drawing force and compression force sensor, a displacement sensor, a mechanical clamp, a filter, a cooler, an electromagnetic water valve, an oil tank and a unidirectional intercept valve. The system provided by the invention has the advantages of great drawing force, high precision,fast control response, simplicity, special purpose, movability and independent use and can be used for the thin-film composite material biaxial tensile testing machines of construction film material tests, airship skin tests and the like.

Owner:SHANGHAI JIAO TONG UNIV

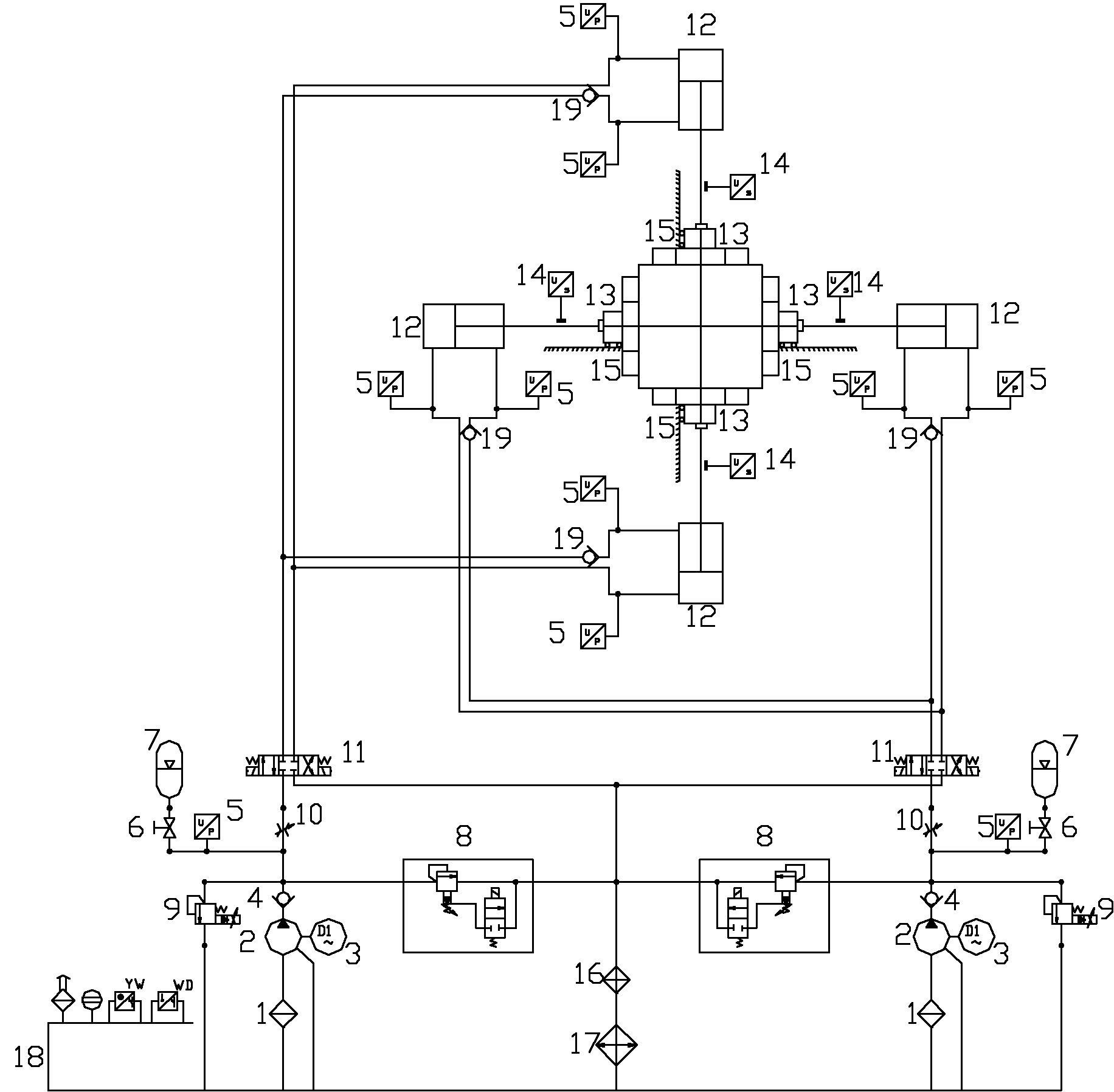

Electro-hydraulic loading system of film biaxial tensile testing machine

InactiveCN103884586ASimple structureStrong pullMechanical apparatusStrength propertiesHydraulic cylinderSkin test

The invention discloses an electro-hydraulic loading system of a film biaxial tensile testing machine. The electro-hydraulic loading system comprises a low-pressure filter, hydraulic pumps, a motor, a one-way valve, a stop valve, an energy storage device, an electromagnetic unloading valve, a proportional overflow valve, a pressure compensator, a proportional directional valve, a servo hydraulic cylinder, a pull pressure sensor, a displacement sensor, a mechanical fixture, a filter, a cooler and an oil tank, wherein the two hydraulic pumps share the one oil tank, and two independent loading hydraulic loops can be formed, so that the manufacturing cost and the installation space are greatly saved. Furthermore, the servo hydraulic cylinder can be controlled by the single set of pressure compensator and proportional directional valve, so that loading synchronism and stability can be guaranteed. The electro-hydraulic loading system of the film biaxial tensile testing machine has the characteristics of being simple in structure, large in tensile force, high in loading synchronism and accuracy, rapid in control response and the like, and can be used for film composite material biaxial tensile testing machines such as an architectural membrane material tester and an airship skin test as well as a uniaxial drawing tester.

Owner:SHANGHAI JIAO TONG UNIV

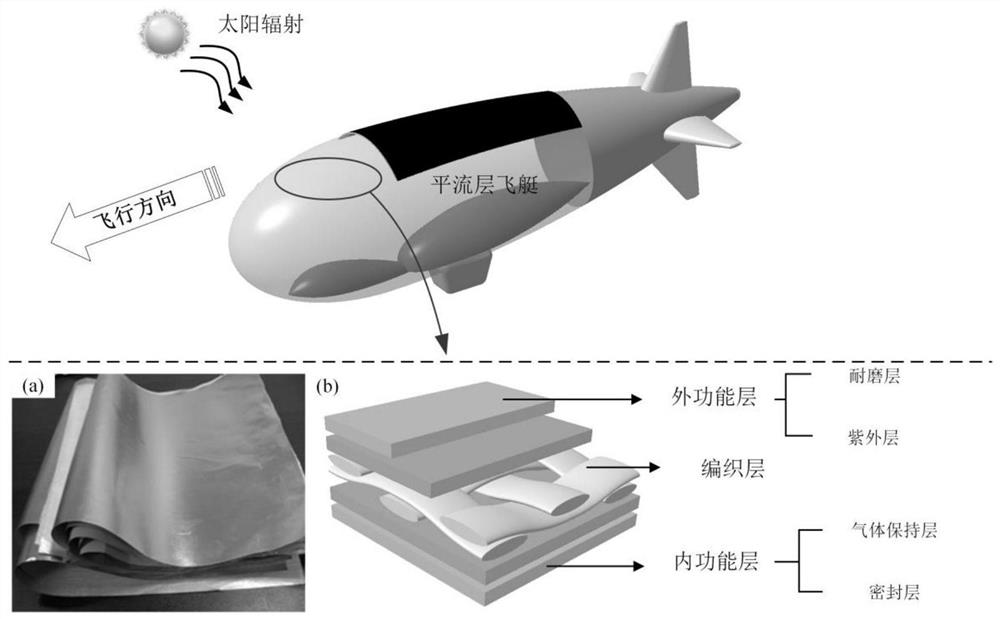

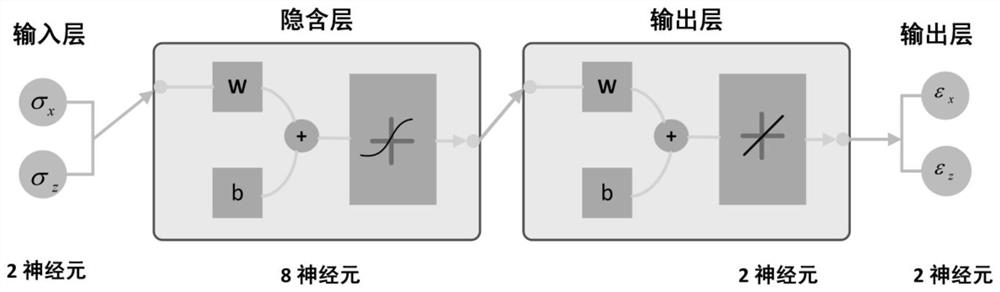

Method for predicting stratospheric airship skin material deformation by using neural network

InactiveCN112507625AConvenient and accurate constructionConvenient and accurate predictionDesign optimisation/simulationNeural architecturesHidden layerAlgorithm

The invention relates to a method for predicting stratospheric airship skin material deformation through a neural network, and belongs to the technical field of damage analysis. The implementation method comprises the following steps: aiming at the true deformation of a stratospheric airship skin material in a complex working environment close to non-proportional biaxial tension, carrying out biaxial tension tests under various stress ratio conditions, and collecting training sample data required by a neural network; constructing a Bayesian neural network comprising an input layer, a hidden layer and an output layer so as to establish a deformation behavior simple expression model of the skin material; and adopting the trained neural network to predict the deformation behavior of the skinmaterial in real time. The method for predicting the stratospheric airship skin material deformation by using the neural network provided by the invention is relatively high in prediction precision, relatively good in stability and strong in popularization capability, can meet the requirement of accurately predicting the skin material deformation behavior in real time, and provides a new method for optimizing the material design and guiding the stratospheric airship structure design.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Test method for accurately measuring uniaxial tensile strength of rock

InactiveCN109632508AEasy to implementGuaranteed accuracyMaterial strength using tensile/compressive forcesPresent methodUniversal testing machine

The invention discloses a test method for accurately measuring the uniaxial tensile strength of a rock. The method comprises the following steps of 1, making a plurality of known uniaxial tensile strength rocks into hollow cylindrical test pieces; 2, placing the hollow cylindrical test pieces on a universal testing machine, carrying out a tensile test and recording a tensile force when the test pieces are broken; 3, taking the tensile force as an abscissa and taking the uniaxial tensile strength of the rock as an ordinate, and drawing a tensile force-tensile strength curve graph; 4, manufacturing the hollow cylindrical test pieces of the rocks to be tested; 5, carrying out operation which is the same with the operation in the step2; and 6, using a graphing method to find the uniaxial tensile strength of the rock corresponding to the tensile force. The method has the following advantages that 1, the traditional mode of testing rock mechanical parameters through directly stretching the cylindrical test pieces can be cleverly converted into the mode of stretching the hollow cylindrical test pieces, and an experiment is easy to implement; 2, through one-to-one correspondence, the uniaxial tensile strength of the test pieces can be known according to the measured tensile force; and 3, there is no special requirements to the samples, and the complexity of making the samples is reduced.

Owner:ANHUI UNIV OF SCI & TECH

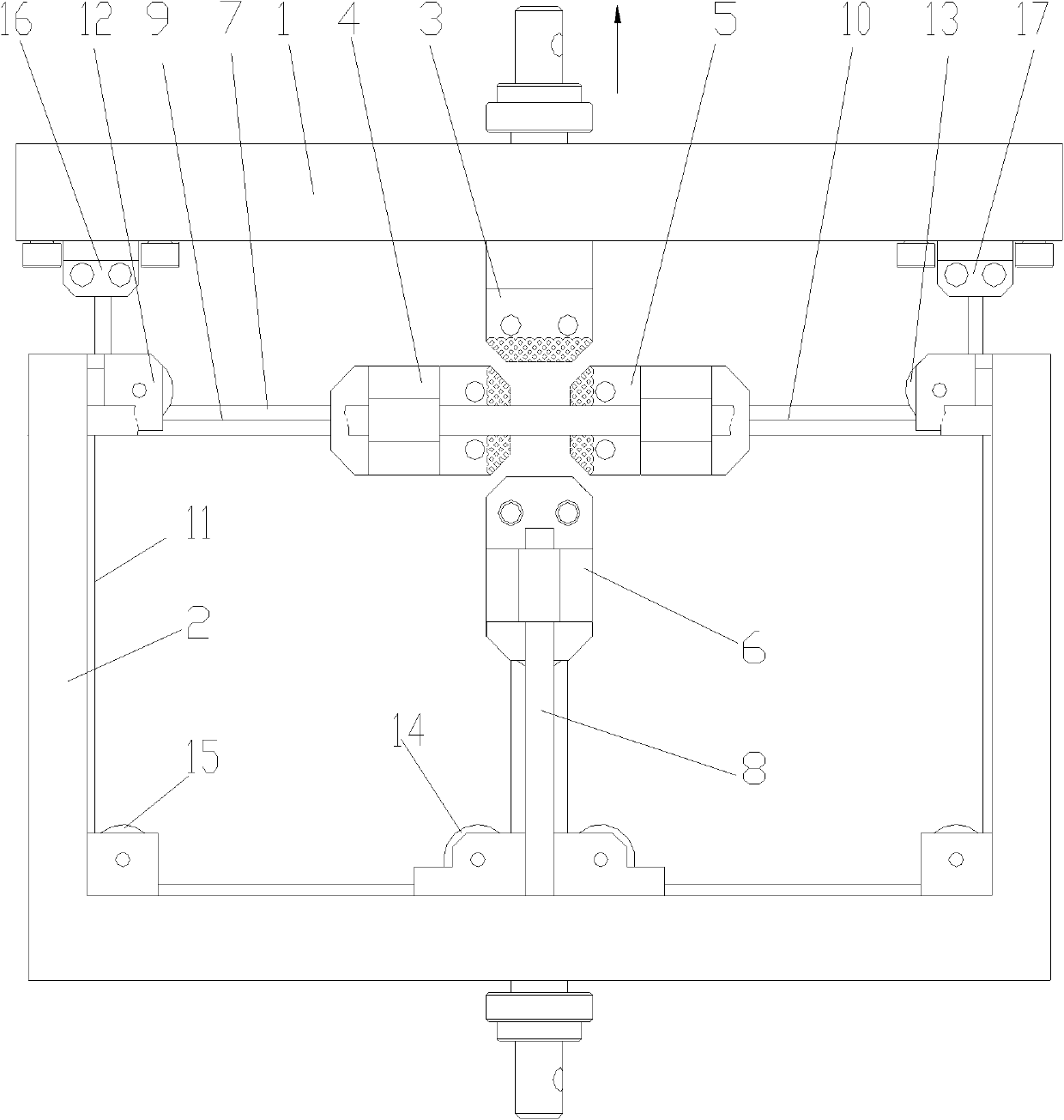

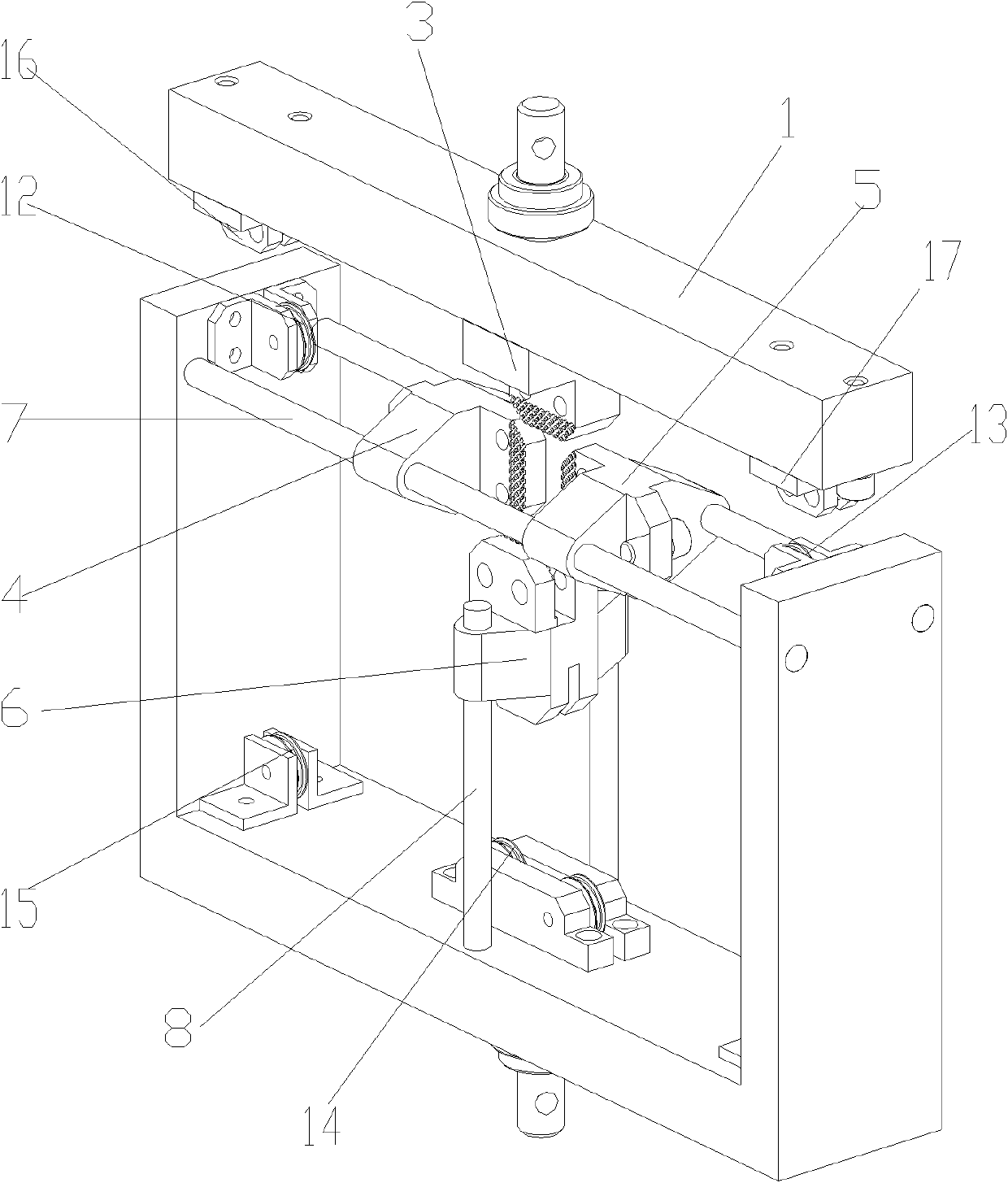

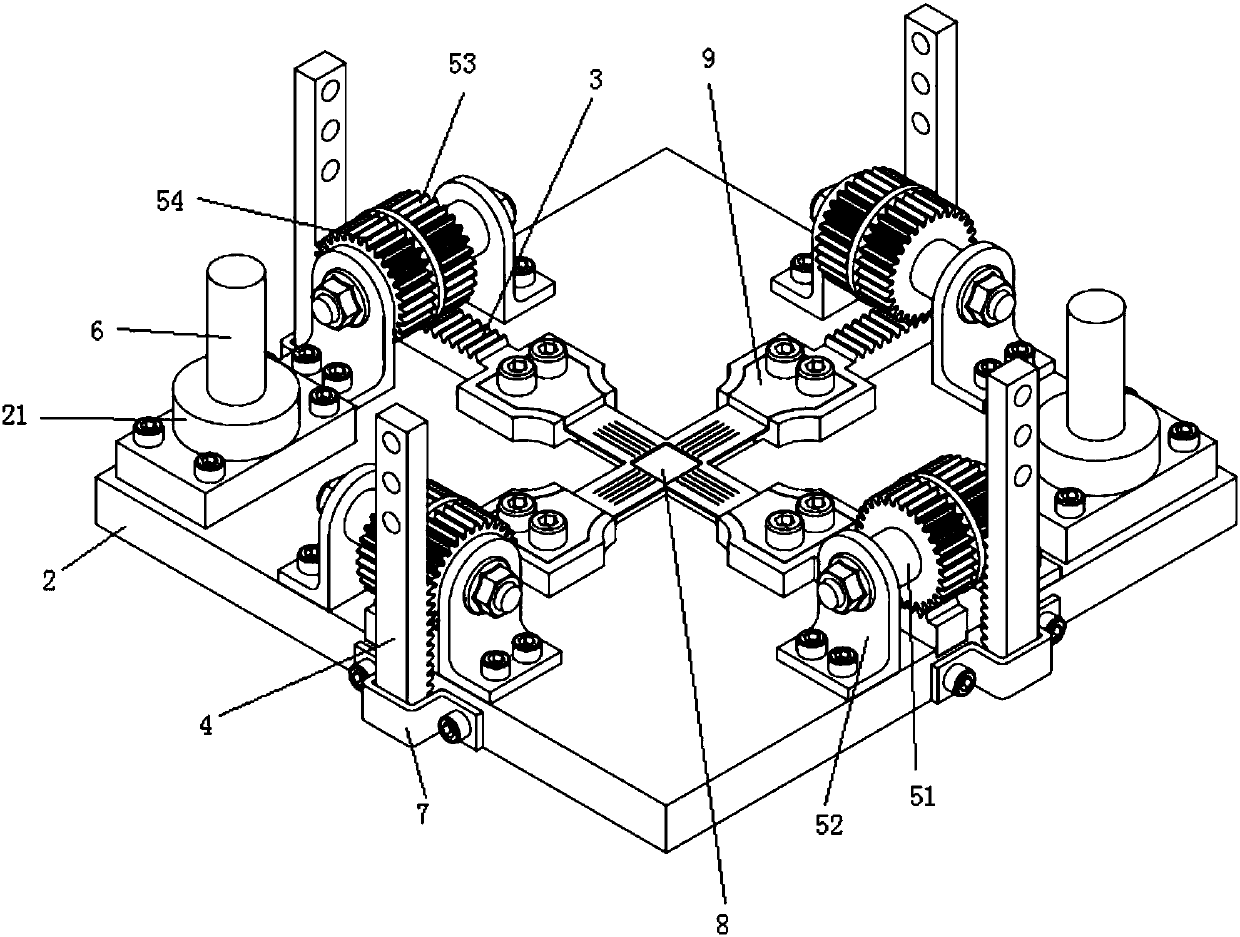

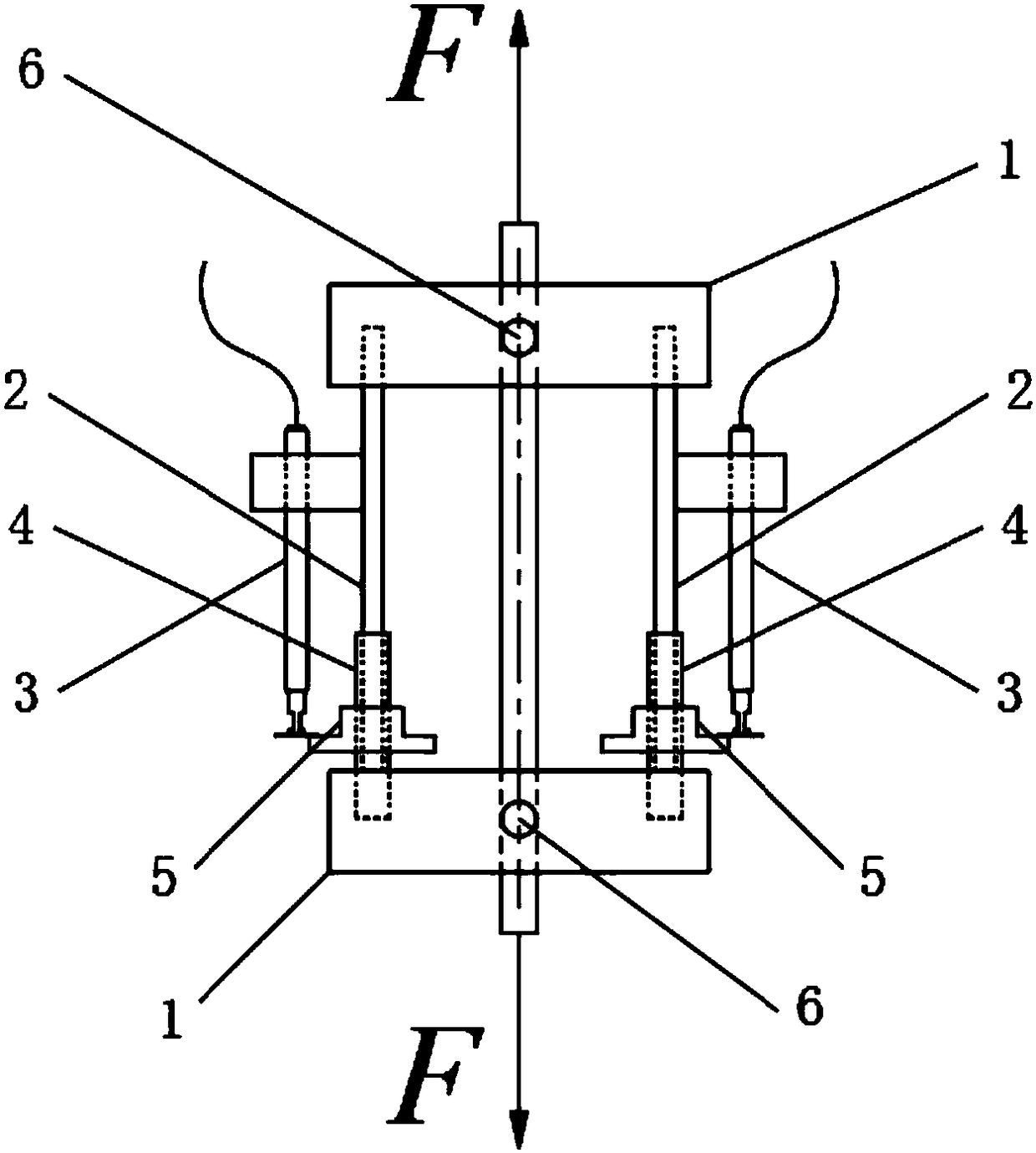

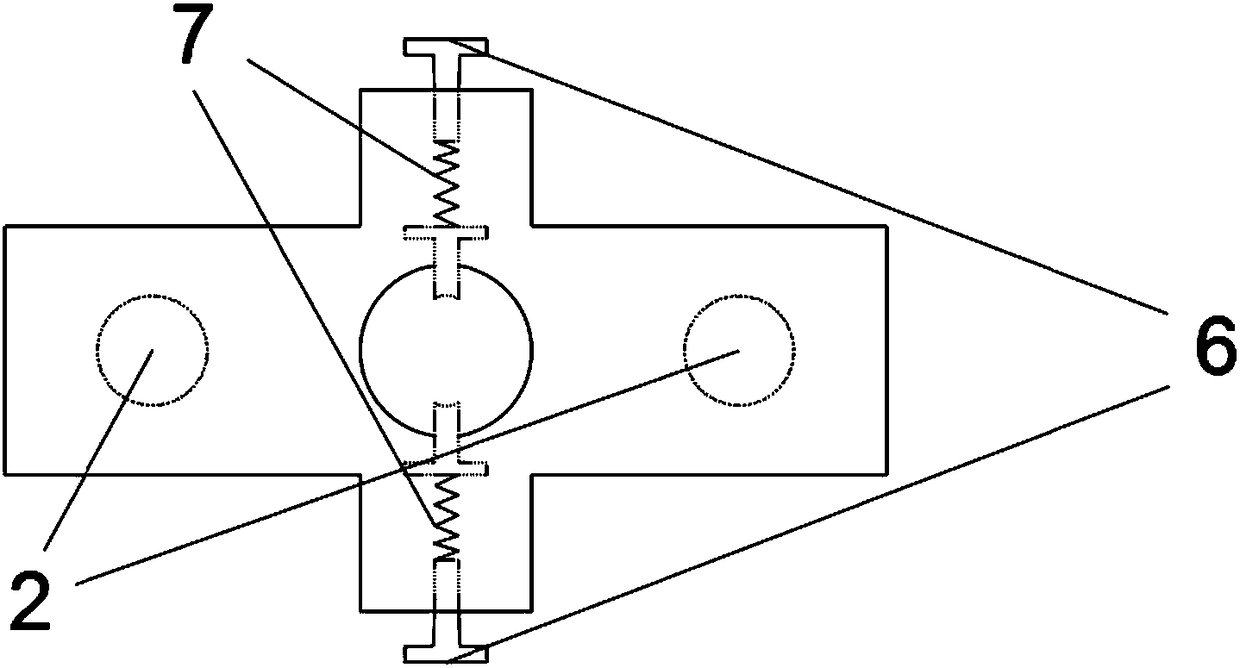

Pinion-and-rack type biaxial tensile test device

The invention discloses a pinion-and-rack type biaxial tensile test device. The device is characterized in that it includes an upper mould base, a lower mould base, and four synchronous tensile apparatuses located between the upper mould base and the lower mould base, the four synchronous tensile apparatuses are in cross-shaped distribution, the upper mould base and the lower mould base are connected by two guide apparatuses in diagonal arrangement, and the guide apparatuses are located between adjacent two of the synchronous tensile apparatuses. The upper mould base is fixed on a press machine. The pinion-and-rack type biaxial tensile test device provided by the invention has the advantages of convenient use, simple structure, low cost, small volume and the like, and can fulfill the requirements of biaxial tensile test.

Owner:DALIAN UNIV OF TECH

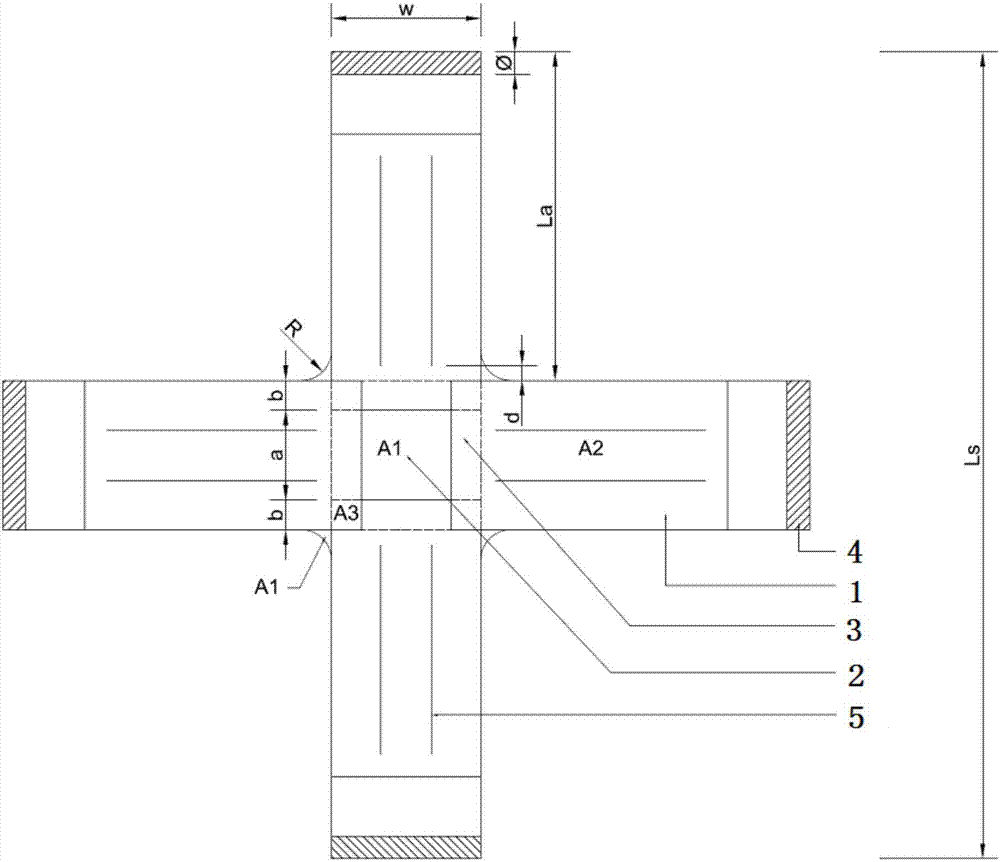

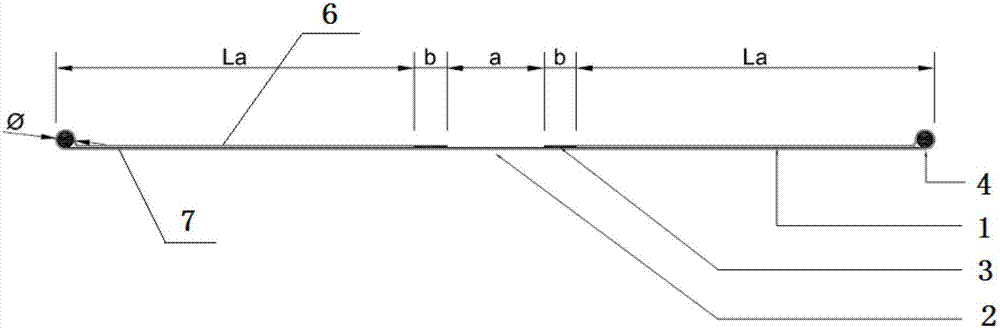

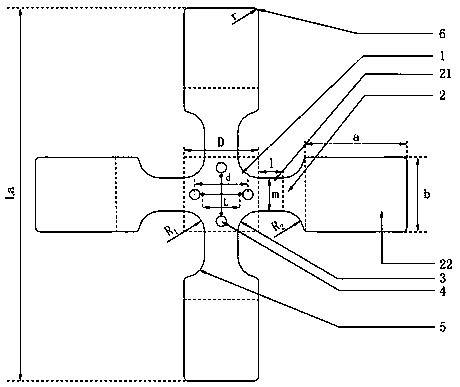

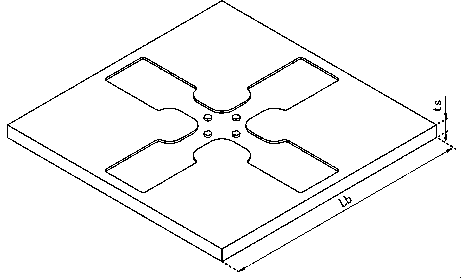

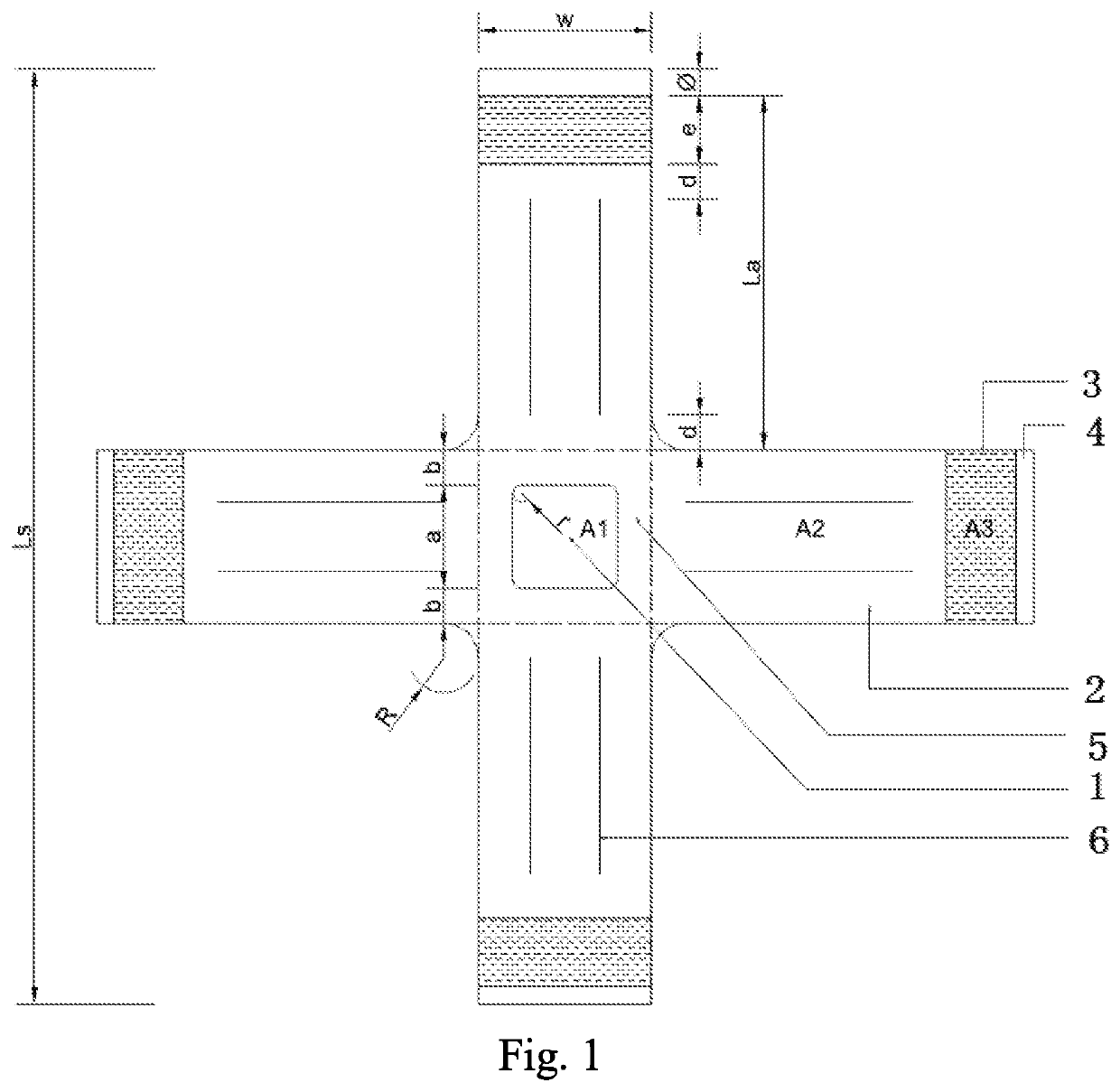

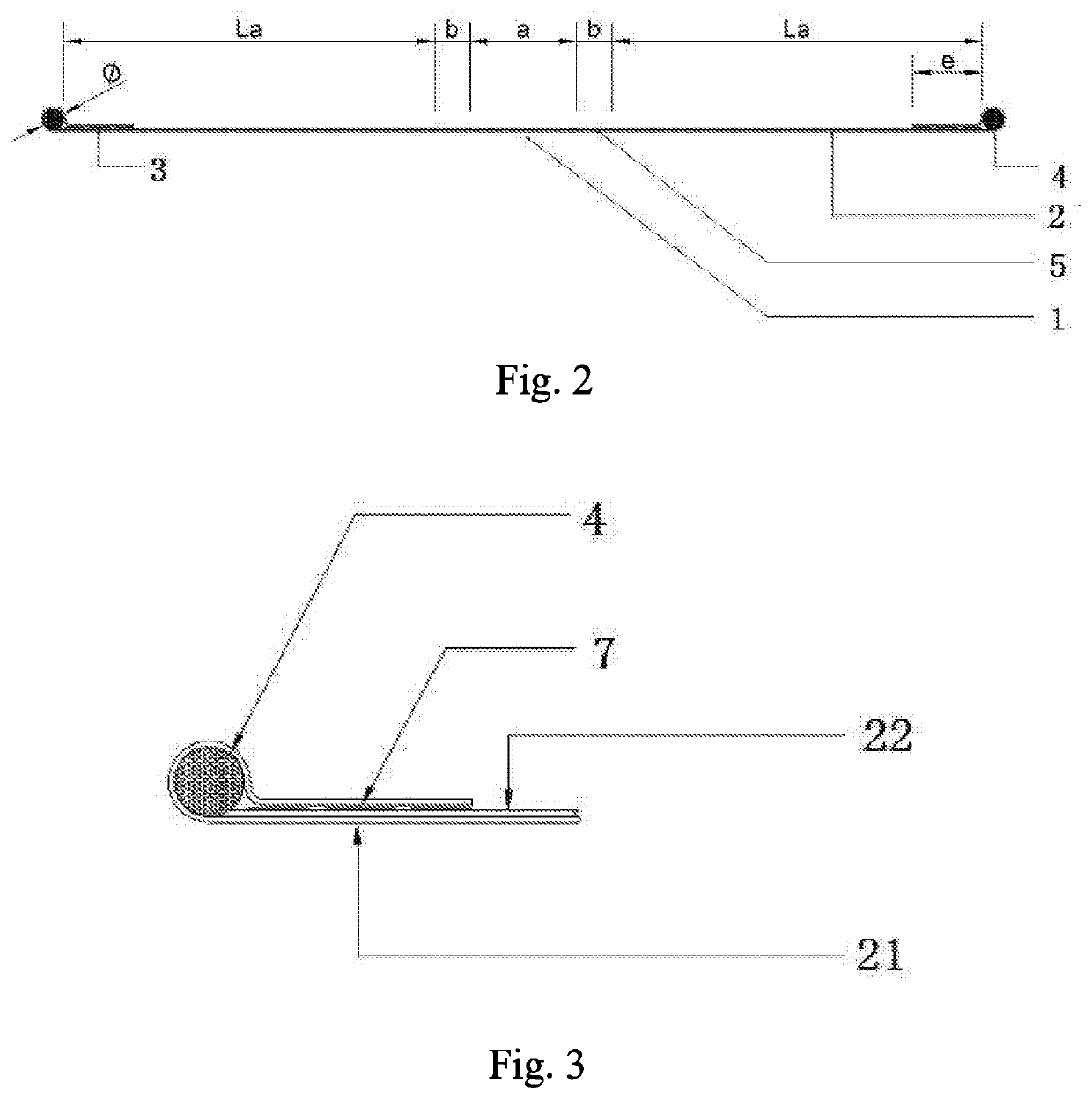

Crossed test piece for biaxial stretching strength test and manufacturing method thereof

ActiveCN107271275APreparing sample for investigationMaterial strength using tensile/compressive forcesPull forceEngineering

The invention discloses a crossed test piece for a biaxial stretching strength test. The crossed test piece comprises a middle core region and four stretching arms, wherein the four stretching arms extend outward around the middle core region to form a cross shape; each stretching arm is connected with the middle core region through a transition region; a clamping end is arranged at the end part of each stretching arm and a clamping end rubber rod is arranged at each clamping end; the clamping end rubber rods are used for connecting a clamp of a biaxial stretching testing machine; the crossed test piece for the biaxial stretching strength test is configured as follows: when the biaxial stretching strength test is carried out, the stretching arms are used for transmitting a pull force of the biaxial stretching testing machine to the transition region; finally, the pull force is applied to the middle core region; the middle core region is a core region of the biaxial stretching strength test; stretching damage firstly occurs in the middle core region. The invention further provides a manufacturing method of the crossed test piece for the biaxial stretching strength test. The crossed test piece disclosed by the invention can be used for determining and characterizing the biaxial stretching strength of a fabric membrane material; the damages occur in a single-layer testing region; after being reinforced, the stretching arms and the transition region are damaged; the crossed test piece can be applied to the fields of building membrane materials, airship skins and other industrial fabrics and the like.

Owner:SHANGHAI JIAO TONG UNIV

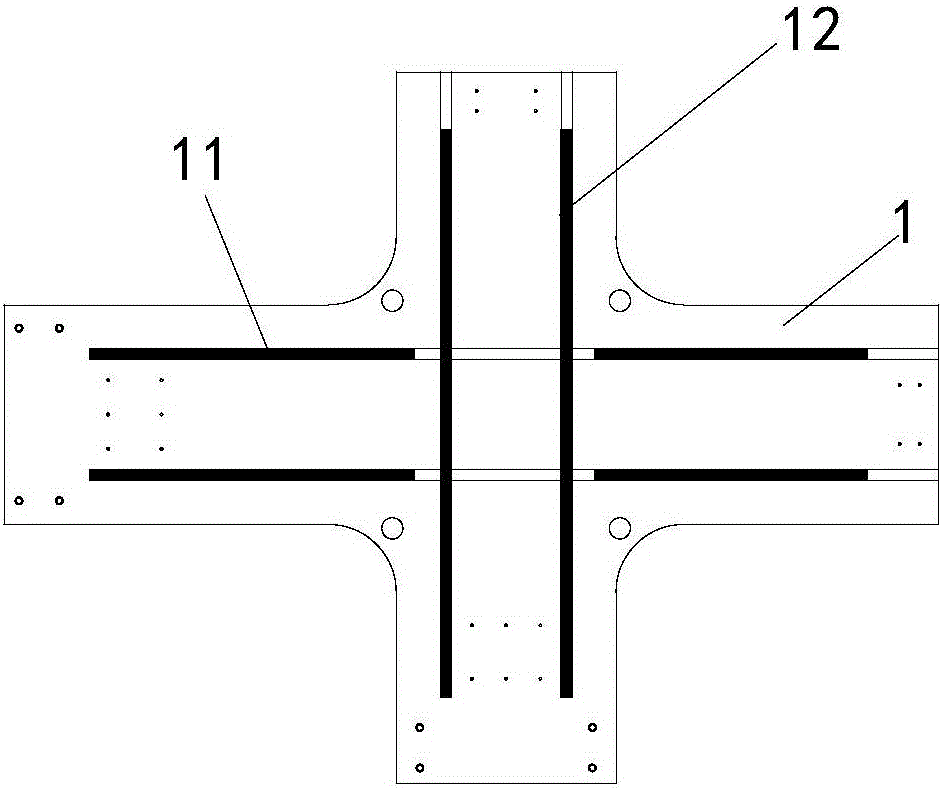

Unidirectional and bidirectional tensile test device for mesoscopic structure in-situ online observation

InactiveCN105043871AImprove deformationNo noise pollutionMaterial strength using tensile/compressive forcesEngineeringBiaxial tensile test

The invention provides a unidirectional and bidirectional tensile test device for mesoscopic structure in-situ online observation. The test device includes a rack, and a transverse tensile mechanism and a longitudinal tensile mechanism mounted on the rack. A transverse guide rail and a longitudinal guide rail are mounted on the rack. The transverse tensile mechanism is mounted on the transverse guide rail, and the longitudinal tensile mechanism is mounted on the longitudinal guide rail. A single-shaft or double-shaft specimen is mounted on the test device through a clamping mechanism, single-shaft or double-shaft tensile test can be realized, and in the tensile process, in-situ observation of the mesoscopic structure can be realized through a metallographic observation platform. Compared with the prior art, the test device provided by the invention has the advantages of strong versatility, small volume, simple and compact structure, simple and flexible operation, and no noise pollution, etc.

Owner:SHANGHAI JIAO TONG UNIV

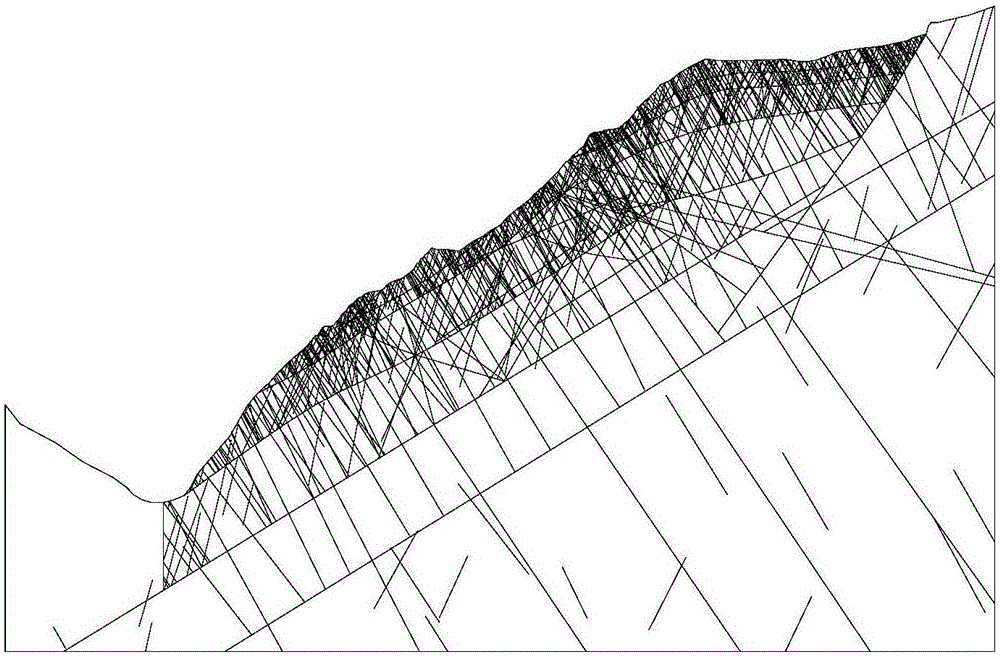

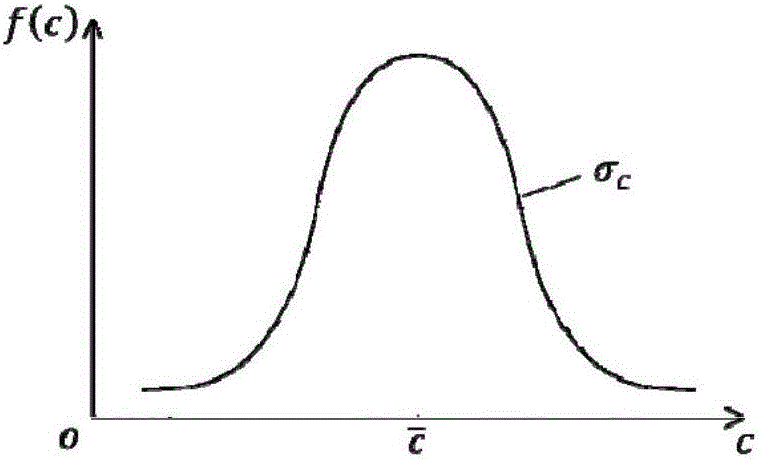

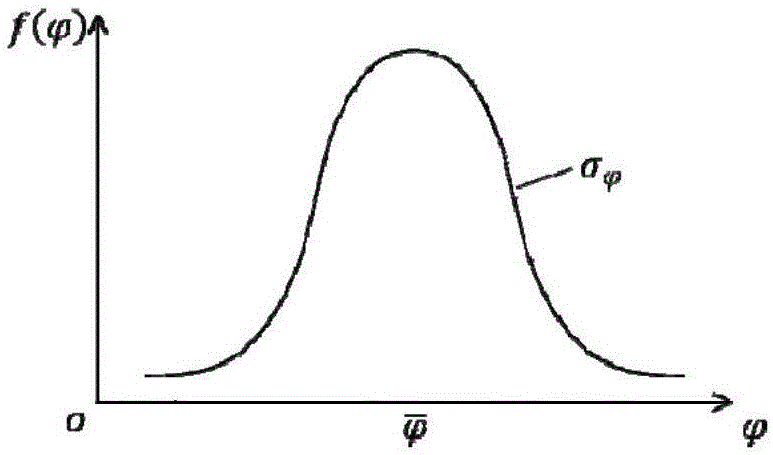

Discontinuous deformation analysis method based on random strengths of rock mass structure surfaces

ActiveCN106682347AThe calculation result is accurateThe analysis result is accurateDesign optimisation/simulationSpecial data processing applicationsUltimate tensile strengthFriction force

The invention provides a discontinuous deformation analysis method based on random strengths of rock mass structure surfaces. Firstly, the structure surfaces in the rock masses are classified, strength parameters corresponding to the different types of structure surfaces are obtained through relevant mechanical tests, including mean values and standard deviations of cohesive forces, frictional angles and single-axial tensile strengths; secondly, the random strengths of the corresponding structure surfaces are generated by utilizing a coordinate transformation method according to the mean values and standard deviations of the strength parameters of the types of structure surfaces; finally, based on the random strengths of the structure surfaces, discontinuous deformation analysis is conducted on the rock masses, including calculation of sliding friction force based on the random strengths and contact judgement, opening-closing state solution and the like based on the random strengths. By the adoption of discontinuous deformation analysis method, structure surface strength values are close to the actual situations of the rock masses, and calculation results of discontinuous deformation analysis are accurate and real.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

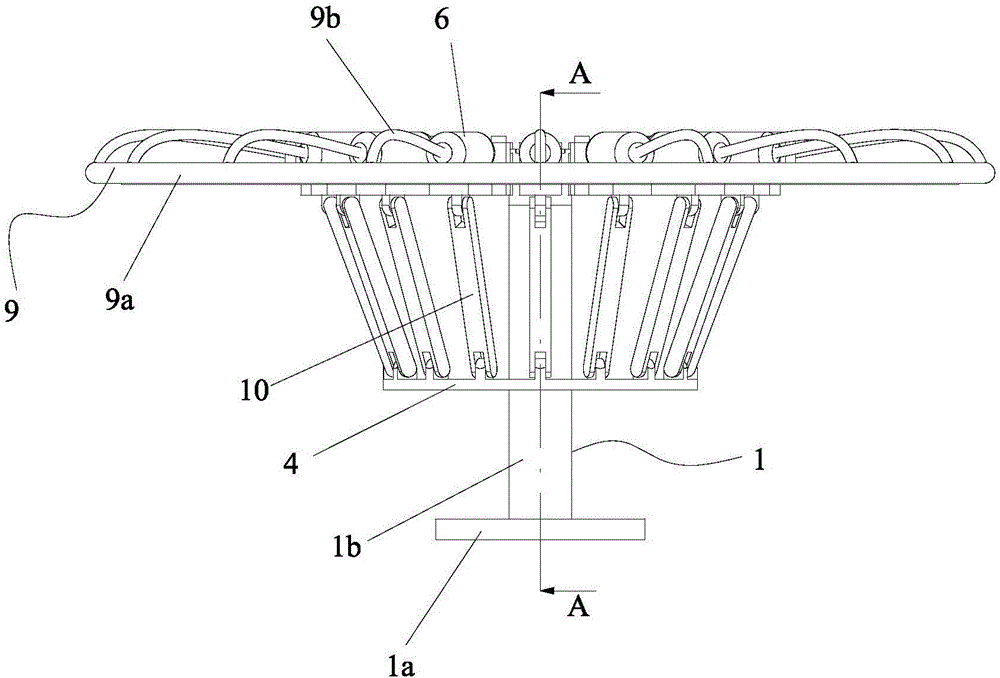

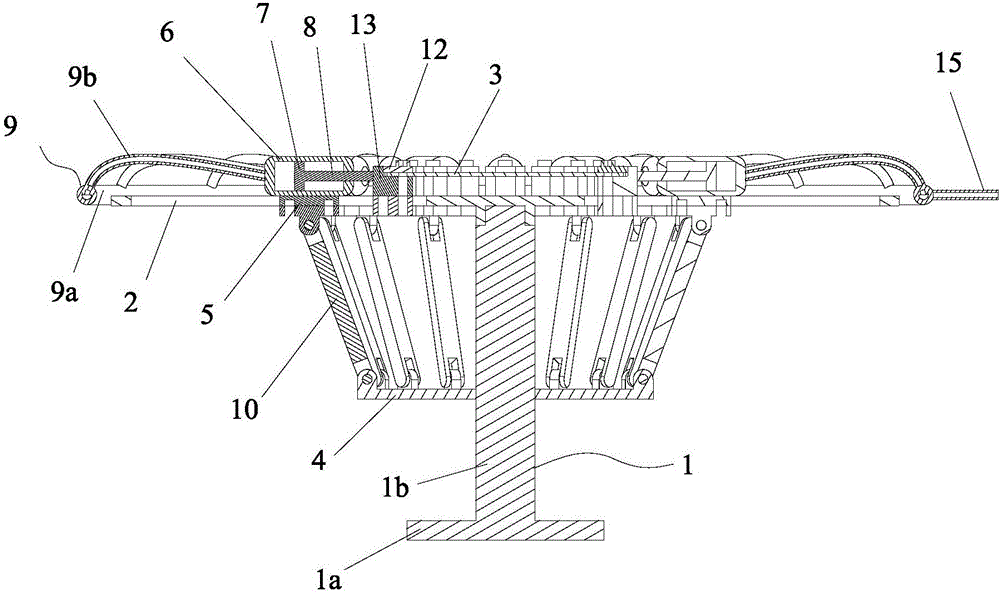

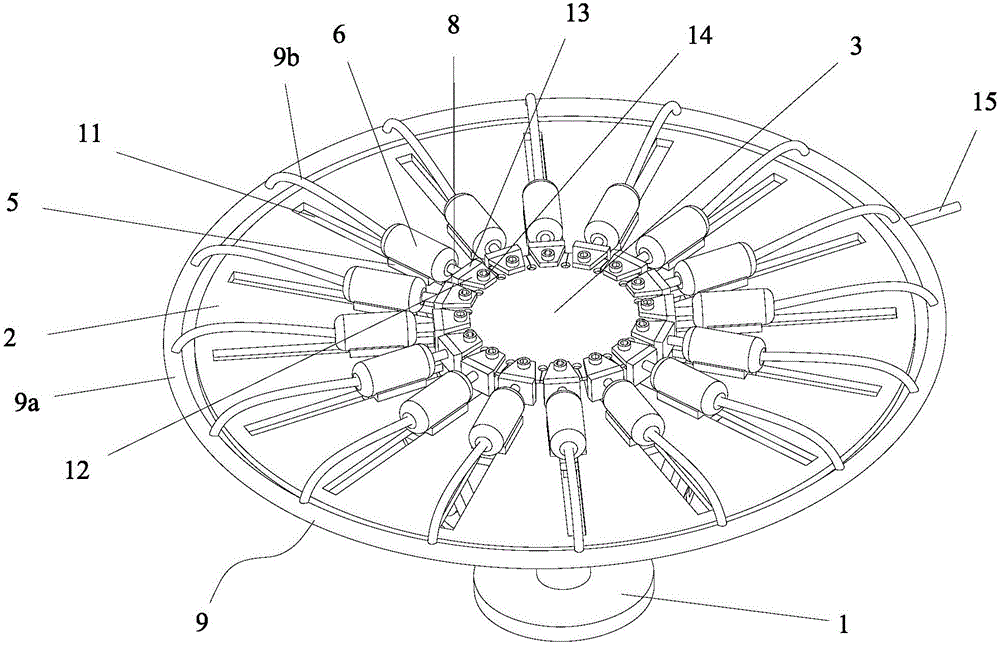

Equal biaxial tensile test device

ActiveCN106525593AAvoid uneven deformationSimple structureMaterial strength using tensile/compressive forcesPhotovoltaic energy generationHydraulic cylinderHydraulic pump

The invention relates to an equal biaxial tensile test device. The device includes a support plate used for placing a test piece, a plurality of connection mechanisms connected with the test piece and a plurality of traction discs connected with the connection mechanisms. Each connection mechanism includes a clamping unit, a driving unit and a traction unit, wherein the clamping unit is used for clamping the test piece, the driving unit is connected with the clamping unit and the two ends of the traction unit are connected with the driving unit and one traction disc respectively. Each driving unit includes a sliding block, a hydraulic cylinder, a piston and a piston rod, wherein the sliding block is slidingly connected with the support plate, the hydraulic cylinder is fixedly arranged on the sliding block and has an inner cavity, the piston is arranged in the hydraulic cylinder, one end of the piston rod is fixedly connected with the piston and the other end of the piston rod is fixedly connected with the clamping unit; the test device further includes a hydraulic pipe, a pipe cavity of the hydraulic pipe is filled with hydraulic oil, each hydraulic cylinder is connected with the hydraulic pipe, and the inner cavity of each hydraulic cylinder is communicated with the pipe cavity of the hydraulic pipe. The device can automatically adjust the uniformity of a force in each drawing direction through the hydraulic pressure, uniform force loading is achieved, and therefore the uneven deformation of the test piece is avoided.

Owner:AUTOMOBILE RES INST OF TSINGHUA UNIV IN SUZHOU XIANGCHENG

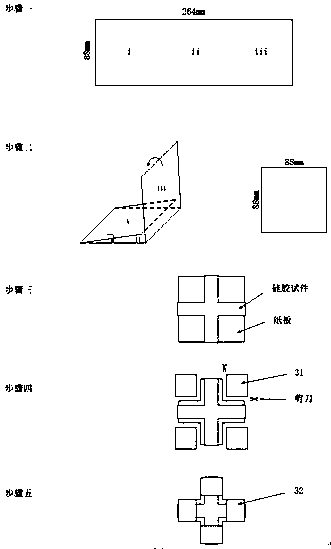

Cross silica gel biaxial tensile test piece, and preparation method and tensile test method thereof

ActiveCN110296882ARaise the level of strainAccurate measurementPreparing sample for investigationMaterial strength using tensile/compressive forcesEngineeringStructural engineering

The invention relates to a cross silica gel biaxial tensile test piece, and a preparation method and tensile test method thereof. The test piece comprises a square central area and four extension walls; the four extension walls outwardly extend around the centre area, and form a cross structure; four edge transition rounded corners are at the junction of the four extension walls; the cross axis inthe middle part of the centre area is upwardly provided with four circular holes, which are distributed circumferentially and symmetrically along the centre of the test piece; the parts of the four extension walls near the centre area are connection areas; the end parts of the extension walls are clamping areas; two sides of the connection part of the connection area and the clamping area are each provided with transition circular arc; the corner of the test piece is adopted with a rounded corner process; and furthermore, a preparation method and a tensile test method thereof are provided. According to the cross silica gel biaxial tensile test piece, and the preparation method and tensile test method thereof in the invention, the nominal stress and strain relationship of a silicon gel material can be determined; therefore, constitutive model parameters thereof can be determined; and the cross silica gel biaxial tensile test piece, and the preparation method and tensile test method thereof in the invention can be applied to the technical field of mechanical test of silicone rubber super elastic materials.

Owner:SHANGHAI UNIV

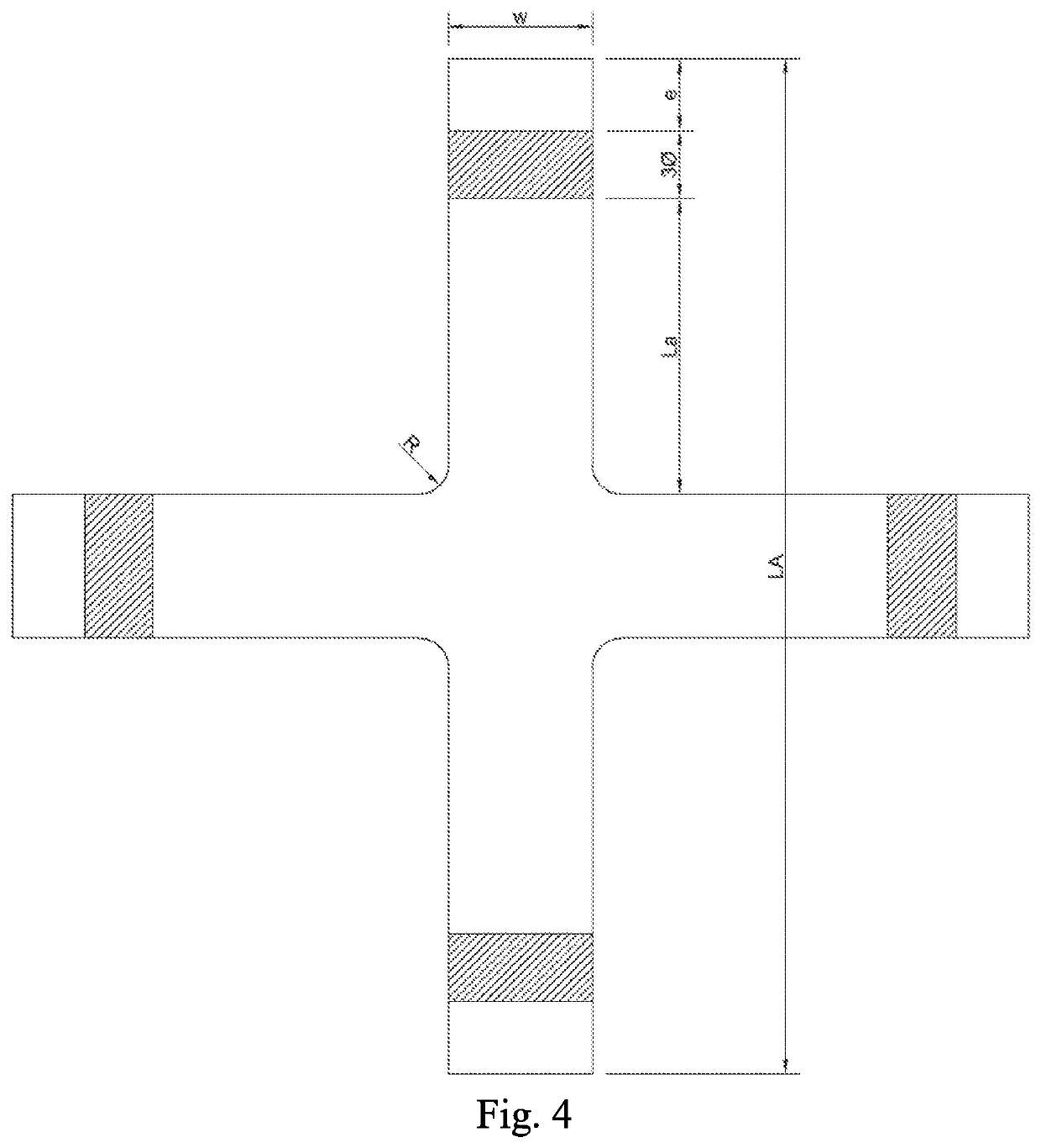

Double-cross composite fabric membrane biaxial tensile strength test piece and manufacturing method thereof

ActiveUS20200116606A1Preparing sample for investigationMaterial strength using tensile/compressive forcesCantileverTest region

Disclosed is a double-cross composite fabric membrane biaxial tensile strength test piece, comprising a core region and four cantilevers. The four cantilevers extend outwards around the core region and form a cross shape. Each cantilever is connected to the core region via an edge transition region. An end portion of the cantilever is a clamping section. The clamping section is provided with a clamping end rubber rod. The clamping end rubber rod is used for connecting to a clamp of a biaxial tensile testing machine. The clamping section is three-layered. The cantilever and the edge transition region are double-layered. The core region is single-layered. The edge transition region is in the shape of a quadrangle rounded at four corners. A manufacturing method of the test piece is also disclosed. By means of the method, the biaxial tensile strength of a fabric membrane can be measured and characterized, damage occurs in the single-layered test region, and the cantilever and the transition region are damaged later due to being strengthened. The method may be applied to architectural membranes, airship skins, and other industrial fabric fields.

Owner:SHANGHAI JIAO TONG UNIV

Four-axis centering adjustment system and method for biaxial tensile testing machine

ActiveCN110726636ASolve problems that cannot be adjusted in real timeSolve the uncontrollable accuracy of manual assembly adjustmentMechanical measuring arrangementsStrength propertiesControl engineeringMachine

The invention relates to a four-axis centering adjustment system and method for a biaxial tensile testing machine and belongs to the field of testing machine technologies. The system comprises a spindle loading chain, a centering adjustment device, a centering sensor, a feedback device and a rack, wherein the centering adjustment device is installed on the spindle loading chain, the spindle loading chain is installed on the rack, and a detection and feedback mechanism is installed on the rack and is used for detecting and controlling the adjustment amount. The system has the advantages that adjustment at five degrees of freedom can be realized, and precision is correspondingly matched with a detection device; the system is connected with a complete machine loading chain, the strength of the whole device is improved, and damage to a loading shaft is reduced; and the system is high in adaptability, can match loading chains in different forms and multiple types of fixtures, occupies a small space, is easy to operate and high in repeated adjustment precision, improves experimental precision and makes measured data more precise.

Owner:JILIN UNIV

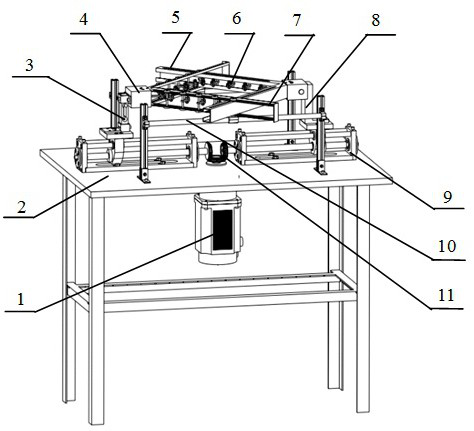

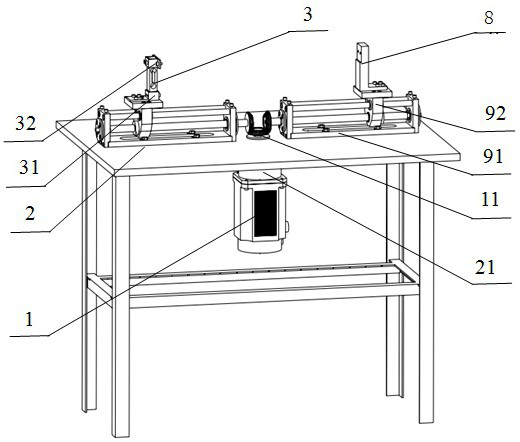

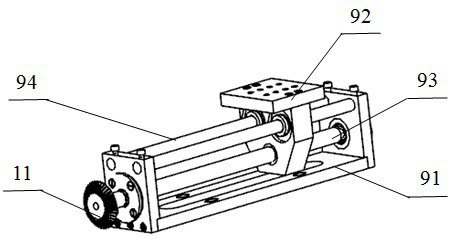

Multifunctional hyperelastic film biaxial tension test bench

PendingCN112213192AAdjustable rotation angleReach a large strokeMaterial strength using tensile/compressive forcesEngineeringBiaxial tension

The invention discloses a multifunctional hyperelastic film biaxial tension test bench, which comprises a workbench, a force sensor, a lead screw nut mechanism, a transmission mechanism for driving the lead screw nut mechanism to rotate, a telescopic mechanism driven by the lead screw nut mechanism to stretch out and draw back, two angle adjusting mechanisms for adjusting the angle of the telescopic mechanism, and a clamping mechanism, the two angle adjusting mechanisms comprise a left angle adjusting mechanism and a right angle adjusting mechanism, the transmission mechanism, the lead screw nut mechanism and a sliding way support are fixedly arranged on the workbench, the transmission mechanism is meshed with the lead screw nut mechanism, the left angle adjusting mechanism is fixedly arranged at the left end of the lead screw nut mechanism through a force sensor, or the right angle adjusting mechanism is fixedly arranged at the right end of the lead screw nut mechanism through the force sensor, the two ends of the telescopic mechanism are each fixedly connected with one angle adjusting mechanism, and the clamping mechanism is slidably arranged on the telescopic mechanism. The device is used for detecting biaxial tensile test items of elastic film materials with different length-width ratios.

Owner:NANJING COLLEGE OF INFORMATION TECH

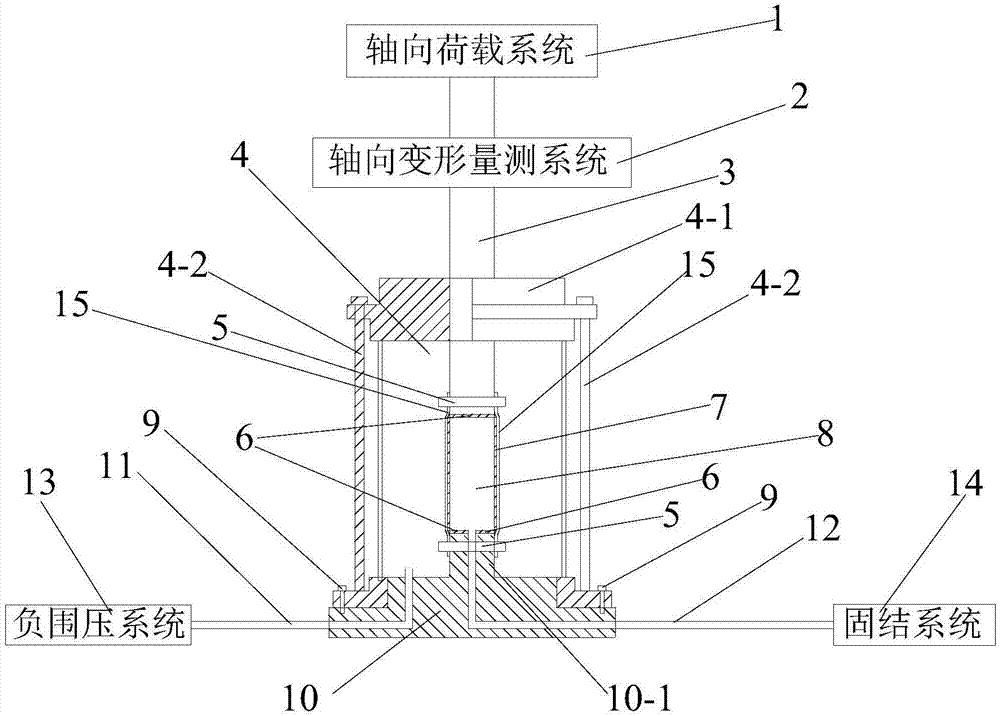

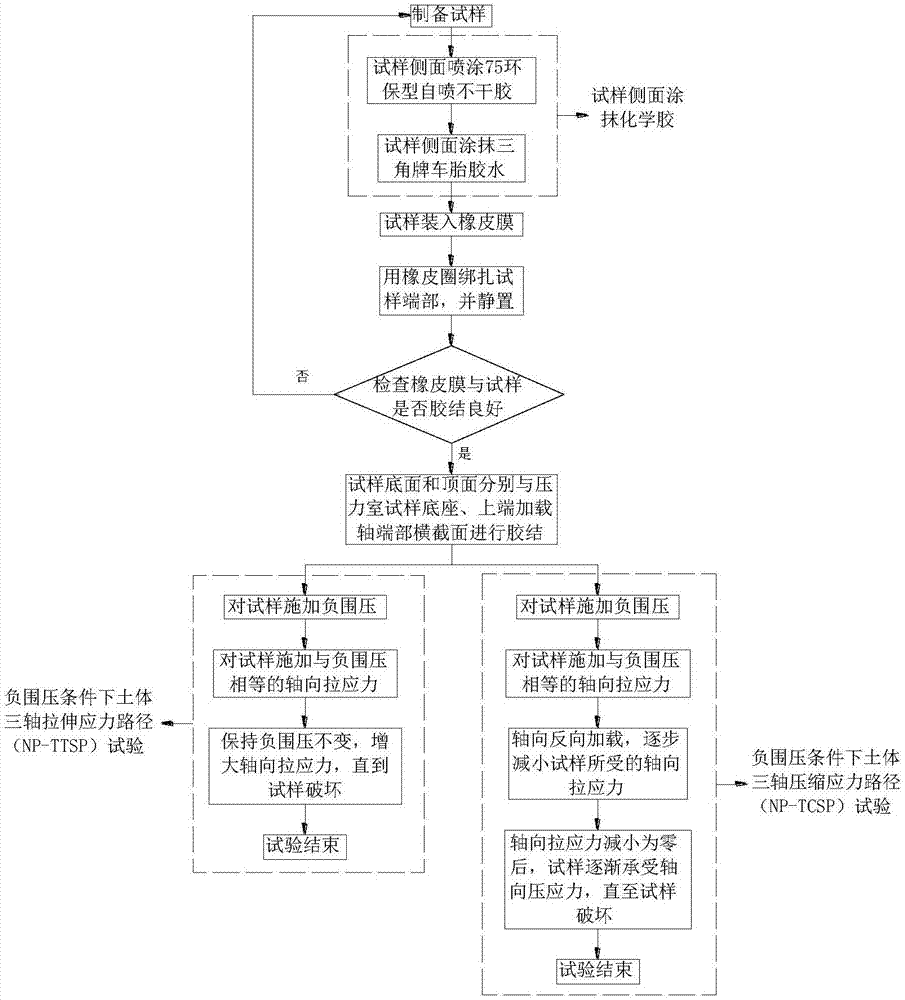

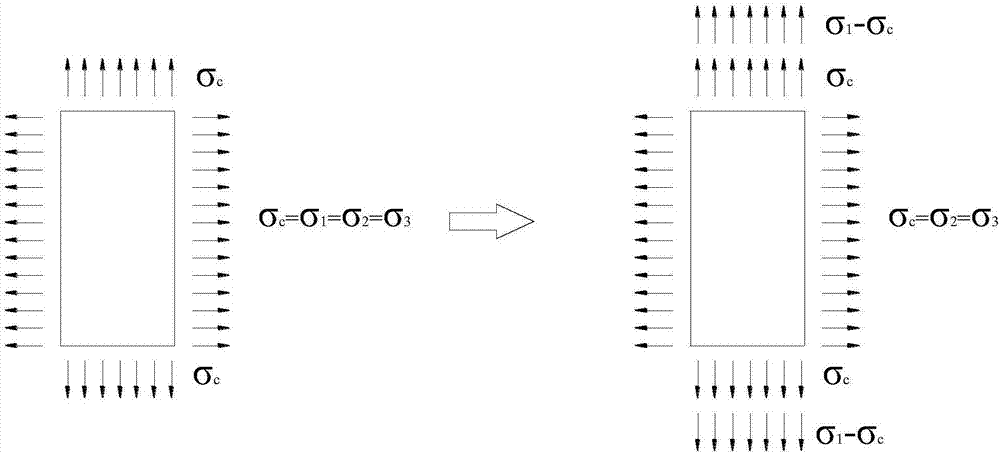

Testing method of soil mass triaxial breaking stress path based on negative confining pressure condition

ActiveCN107478513ASolve the technical problems of emptyingMaterial strength using tensile/compressive forcesEarth material testingShear stressRubber membrane

The invention discloses a testing method of a soil mass triaxial breaking stress path based on a negative confining pressure condition. The testing method is based on a uniform section loading axis triaxial instrument. The testing method comprises the following specific steps: preparing a cylindrical sample; applying chemical glue on the side surface of the sample, and putting the sample into a rubber membrane; gluing the sample with a pressure chamber sample base and the end part of a loading axis through super glue after the rubber membrane is glued with the sample; finally performing two types of testing on the sample: performing soil mass triaxial tensile stress route testing in a negative confining pressure condition (NP-TTSP): ensuring that the sample is under isotropic equal tensile stress and the negative confining pressure is not changed, and gradually increasing the axial tensile stress till the sample is broken; performing soil mass triaxial compression stress route testing in a negative confining pressure condition (NP-TCSP): ensuring that the sample is under isotropic equal tensile stress and the negative confining pressure is not changed, and gradually applying axial tensile stress when the axial tensile stress is reduced to zero till the sample is broken. The testing method lays a foundation for the development of strength characteristic research on loess in a tension and shear stress route condition.

Owner:XIAN UNIV OF TECH +1

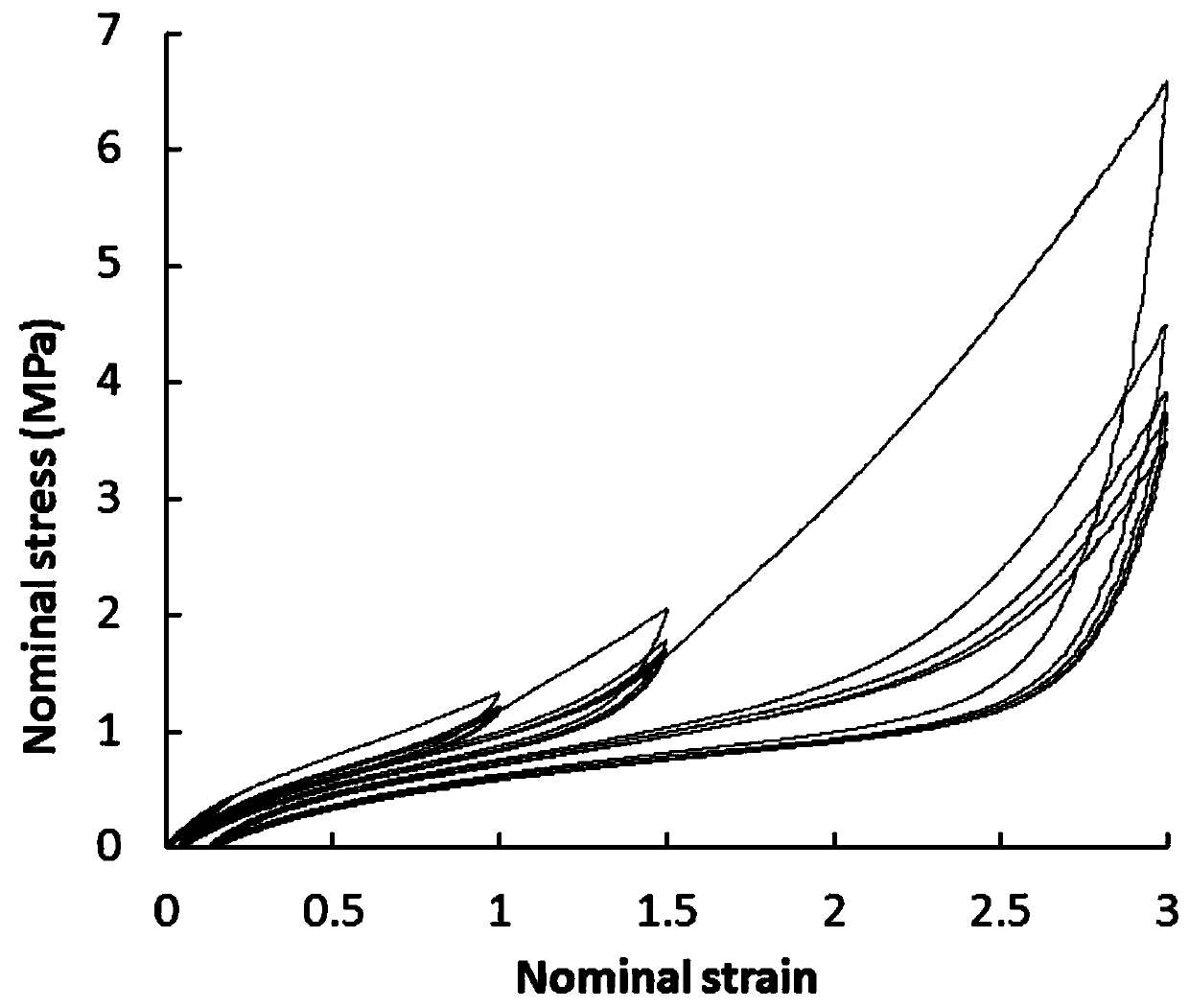

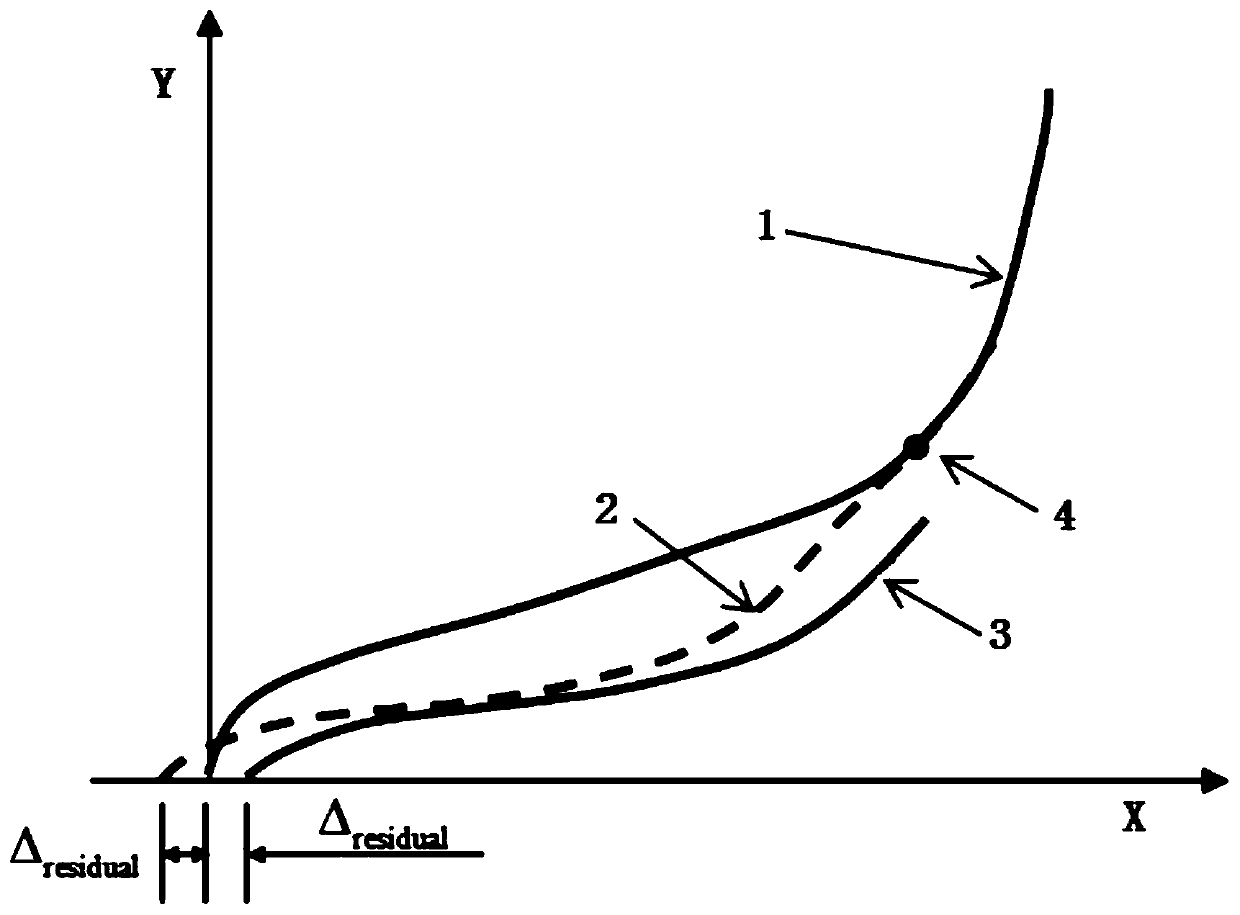

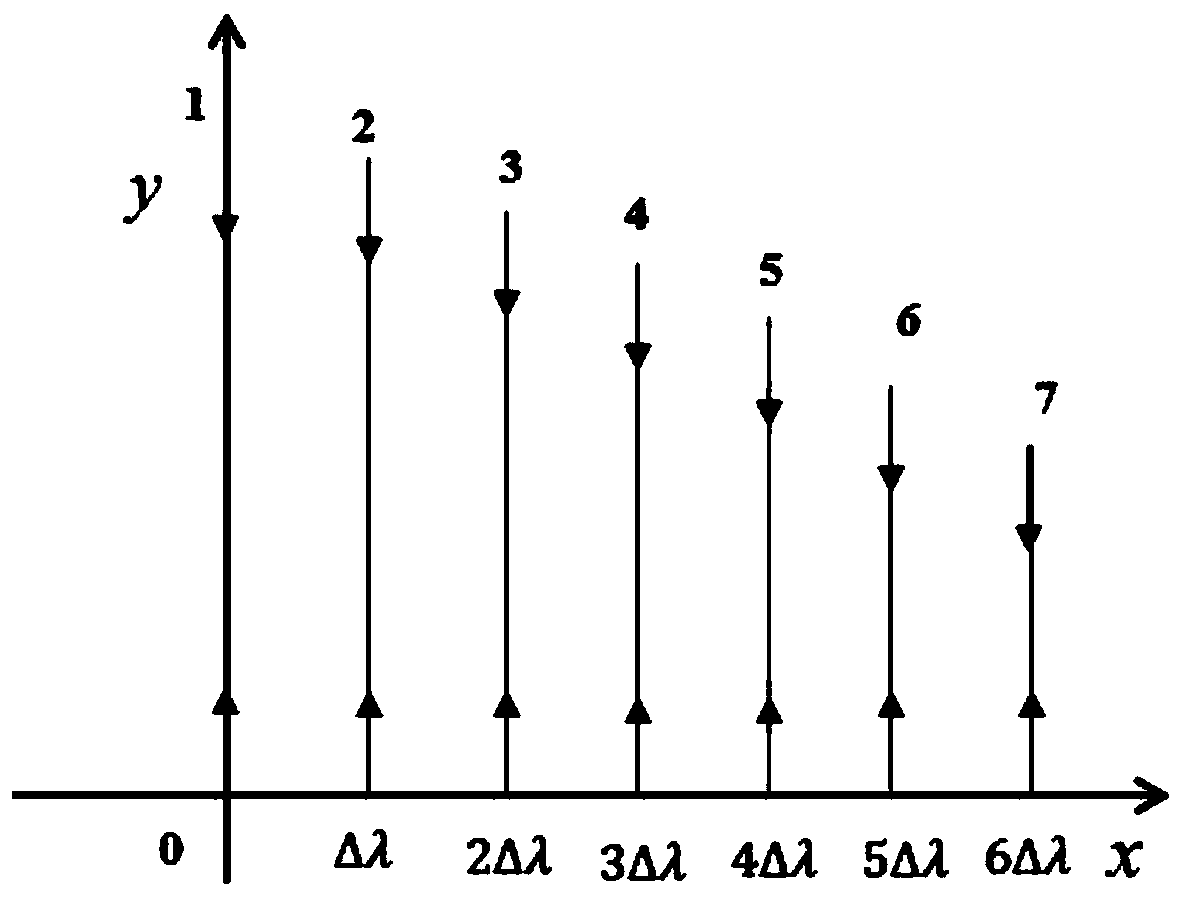

Multi-axial tensile test method for rubber material under same Mullins effect

ActiveCN110579403ANo damage statusReflect elastic propertiesMaterial strength using tensile/compressive forcesRubber materialStrength of materials

The invention provides a multi-axial tensile test method for a rubber material under the same Mullins effect, and relates to the technical field of mechanical property experiments of the rubber material. The method comprises the following steps that tensile test is carried out on the initial state of the material; multi-axis cyclic loading mechanical property test is carried out; a tensile curve with fixed elongation rates on different side surfaces is loaded subsequently, a starting point can be translated to the original point, curves with the same loading frequency are selected as multi-axis tensile data under the same Mullins effect, parameter fitting is carried out to determined a proper material model and related parameters, and thus, finite element numerical simulation of material mechanical properties or theoretical calculation of the material rigidity is realized. According to the method, the tensile length of experiment is controlled correspondingly, damage state of the material is not changed constantly during test, measurement experiment data measured by the experiment corresponds to the same material state, large errors are not generated, and serious problems in scientific research and engineering application are avoided.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Displacement measuring device and tester suitable for material tensile test

PendingCN108562489AAccurate measurementAvoid damageMaterial strength using tensile/compressive forcesLarge sizeBiaxial tensile test

The invention provides a displacement measuring device suitable for a material tensile test. The device comprises upper and lower fixed stations, and further comprises linear displacement sensors of which number is two or above, wherein the linear displacement sensors detect generated displacement during stretching and analyze equipment signal connection. The invention further provides a tester suitable for the material tensile test. The tester adopts the displacement measuring device. The displacement measuring device and tester suitable for the material tensile test have the advantages thatthe requirements of the displacement measurement of the whole process of the material tensile test can be well satisfied, a material stress-strain whole process curve can be accurately obtained; an extensometer is not adopted, the problems that the extensometer needs to be loosened in advance in an extensometer measurement method and the stress-strain whole process curve cannot be measured are solved, the extensometer is prevented from being damaged when a sample breaks; the operation steps of the material tensile test are simplified; the use range is wide, and the device is not limited by thesize of materials or breakage elongation, and can be applied to the displacement measurement in large-size materials and tensile tests with large breakage elongation.

Owner:BEIJING JIAOTONG UNIV

A loading method for bidirectional tensile test

ActiveCN103604699BImplement synchronous bidirectional loadingNo synchronization issuesMaterial strength using tensile/compressive forcesLoad ratioEngineering

Belonging to tensile loading technologies, the invention in particular relates to a loading method for two-way tensile test. The loading method for biaxial tensile test provided by the invention makes use of a lever principle to decompose a one-way load into two-way loads through an annular load decomposer, then the two-way loads are loaded onto a test piece so as to realize two-way loading of two-way tensile test. The force transfer points of the load decomposer can be adjusted according to an actual loading ratio to meet the requirements of any load ratio, thus realizing synchronous two-way loading of the test piece. The synchronization problem does not exist in the loading system. At the same time, by changing the size of annular structures, two-way loading on large test pieces can be conducted, and the method also can be used for static and fatigue test. In addition, the annular load decomposer involved in the invention has a simple structure, the method occupies fewer test resources, and is low in cost, thus having great practical application value.

Owner:CHINA AIRPLANT STRENGTH RES INST

A kind of cross-shaped specimen for biaxial tensile strength test and its making method

ActiveCN107271275BPreparing sample for investigationMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention discloses a crossed test piece for a biaxial stretching strength test. The crossed test piece comprises a middle core region and four stretching arms, wherein the four stretching arms extend outward around the middle core region to form a cross shape; each stretching arm is connected with the middle core region through a transition region; a clamping end is arranged at the end part of each stretching arm and a clamping end rubber rod is arranged at each clamping end; the clamping end rubber rods are used for connecting a clamp of a biaxial stretching testing machine; the crossed test piece for the biaxial stretching strength test is configured as follows: when the biaxial stretching strength test is carried out, the stretching arms are used for transmitting a pull force of the biaxial stretching testing machine to the transition region; finally, the pull force is applied to the middle core region; the middle core region is a core region of the biaxial stretching strength test; stretching damage firstly occurs in the middle core region. The invention further provides a manufacturing method of the crossed test piece for the biaxial stretching strength test. The crossed test piece disclosed by the invention can be used for determining and characterizing the biaxial stretching strength of a fabric membrane material; the damages occur in a single-layer testing region; after being reinforced, the stretching arms and the transition region are damaged; the crossed test piece can be applied to the fields of building membrane materials, airship skins and other industrial fabrics and the like.

Owner:SHANGHAI JIAO TONG UNIV

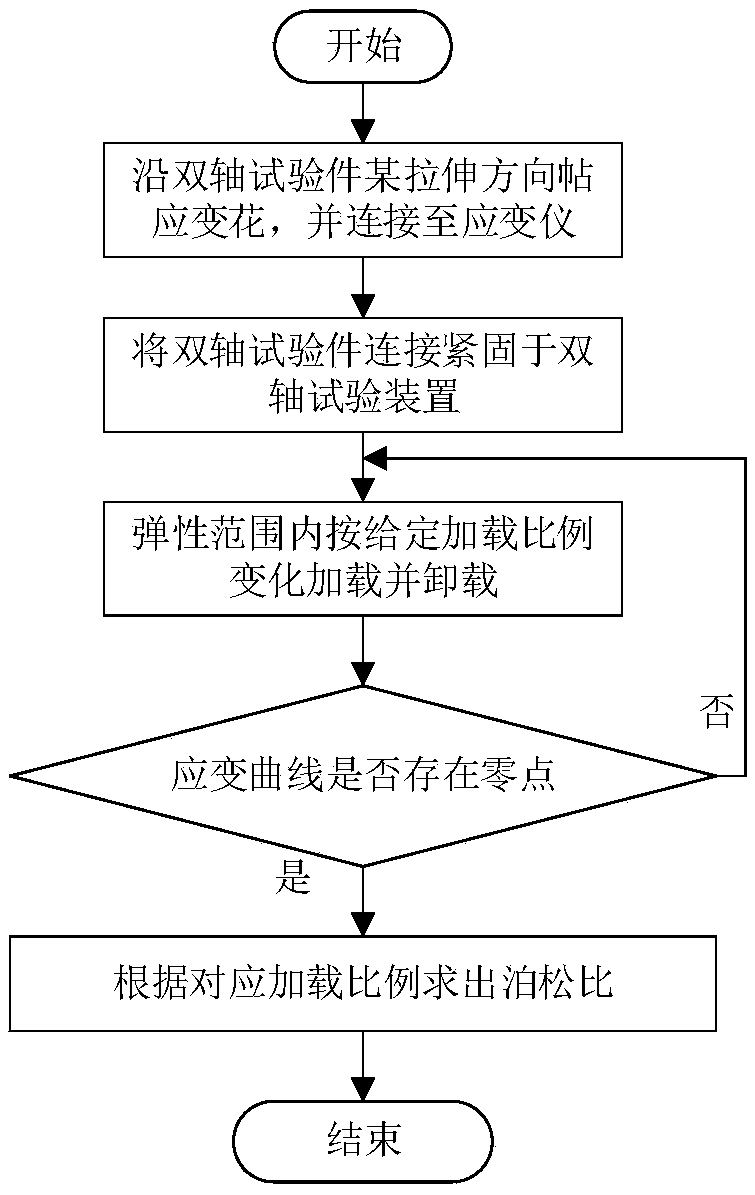

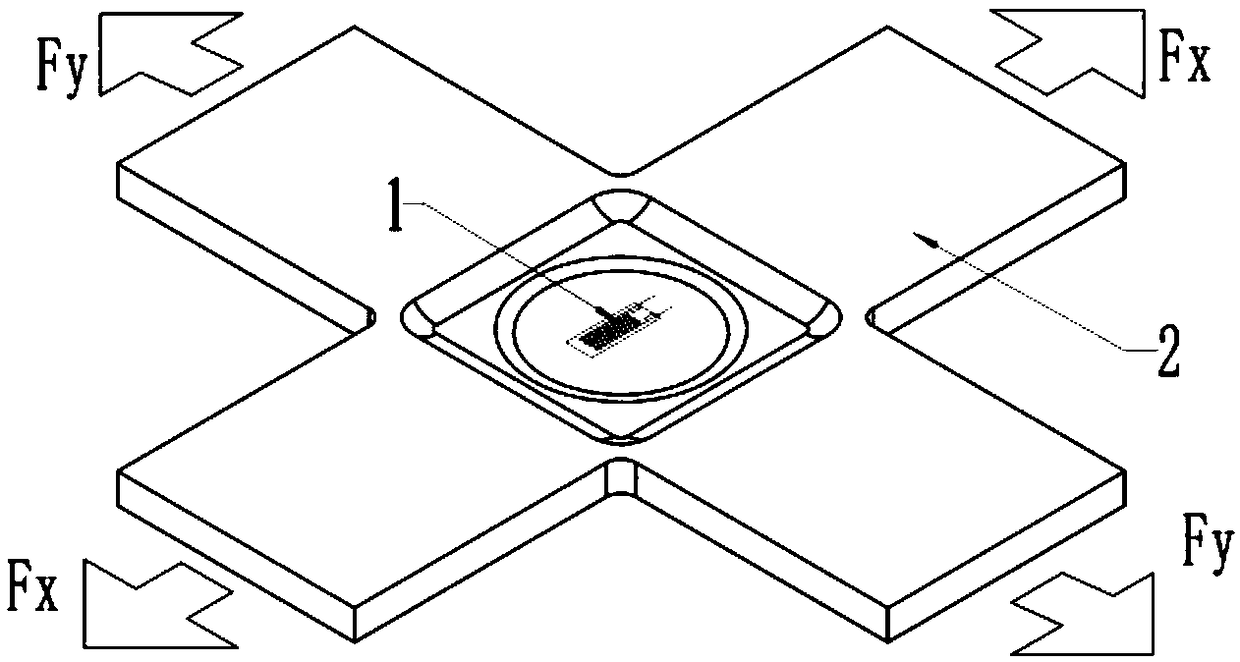

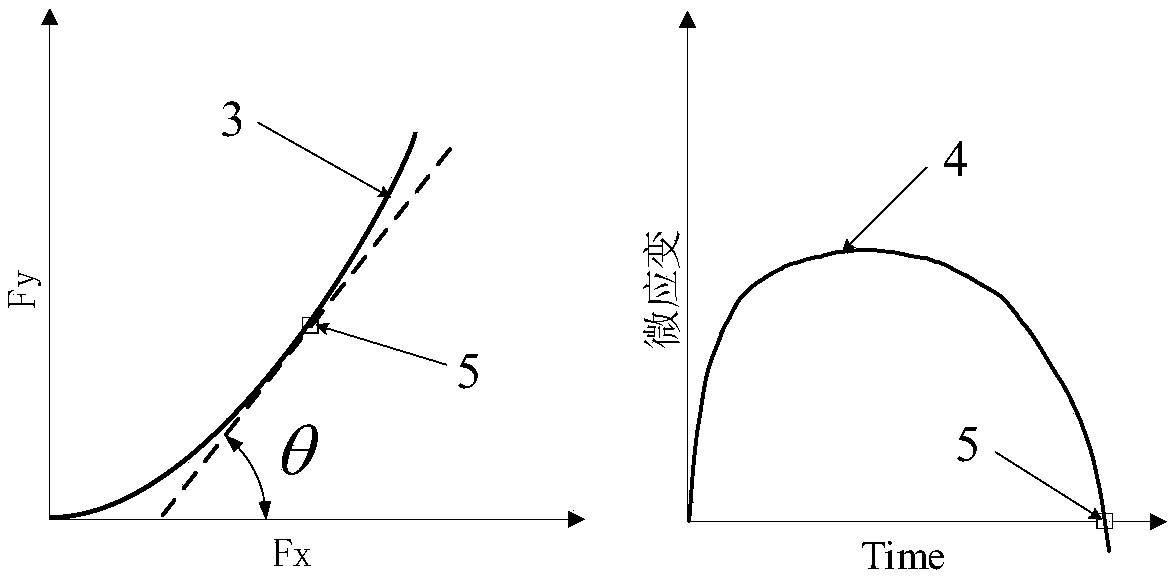

Method for measuring poisson ratio of material based on biaxial stretching test

ActiveCN109187180AThe method steps are simpleEasy to implementMaterial strength using tensile/compressive forcesStrain gaugeBiaxial tensile test

The invention discloses a method for measuring the poisson ratio of a material based on a biaxial stretching test. The method comprises the following steps: pasting a strain gauge along a certain stretching direction of a biaxial test piece, connecting with a strain meter, connecting and fastening the biaxial test piece to a biaxial testing device, operating the biaxial testing device, carrying out elastic loading and unloading according to a given loading track to obtain a curve that a strain value of the strain gauge is changed with time, determining a zero point and a corresponding positionof the loading curve at the moment, and calculating the poisson ratio mu of the material based on a formula according to the value of the position. The method is simple in steps, easy to implement, capable of measuring the poisson ratio by using a single chip and suitable for measuring the poisson ratio of a complex material or a novel material.

Owner:SOUTHEAST UNIV

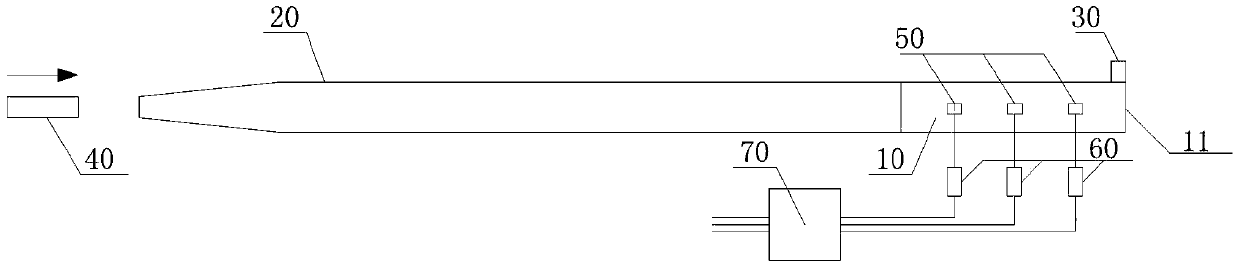

Measuring method of axial tensile strength of concrete based on Hopkinson's principle

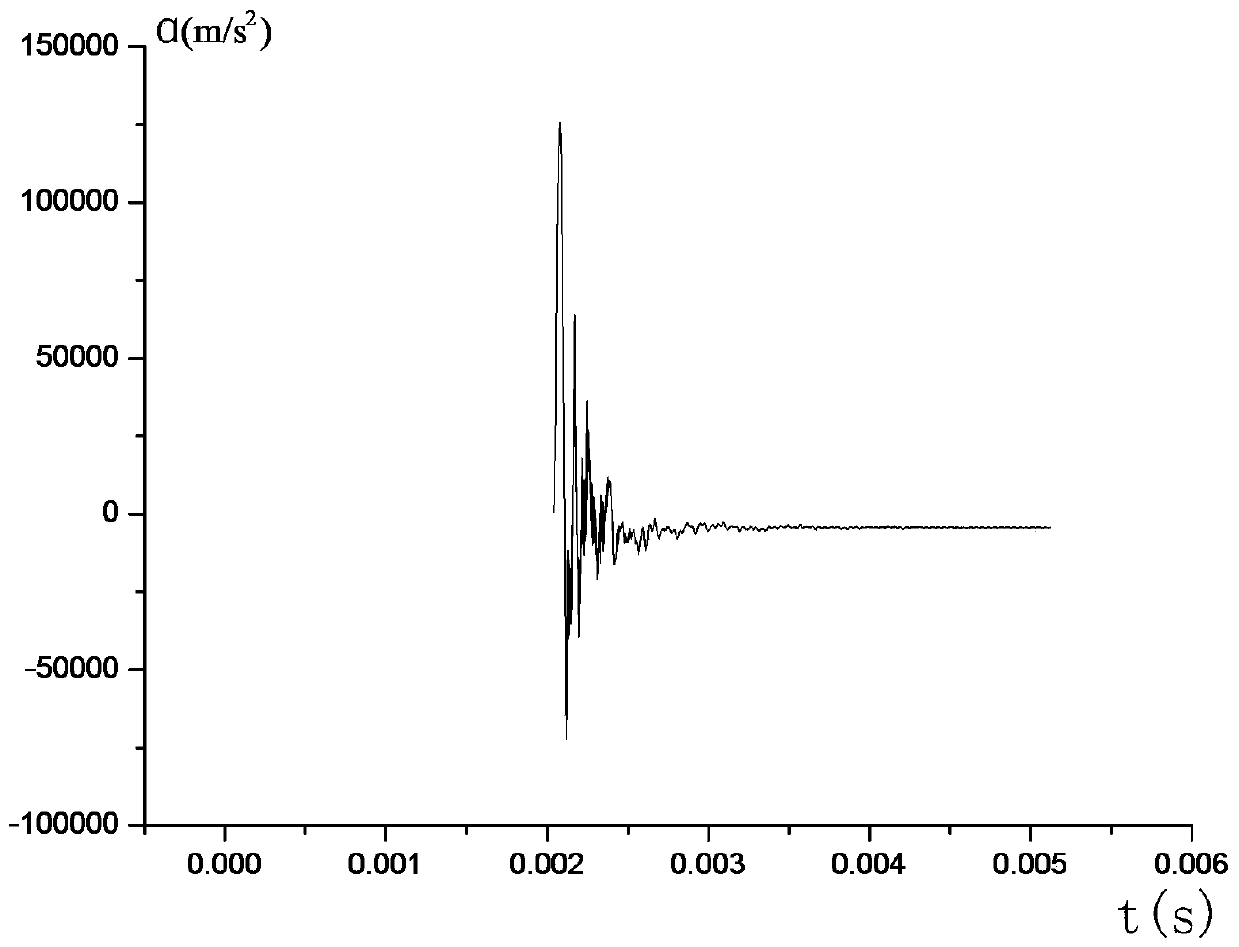

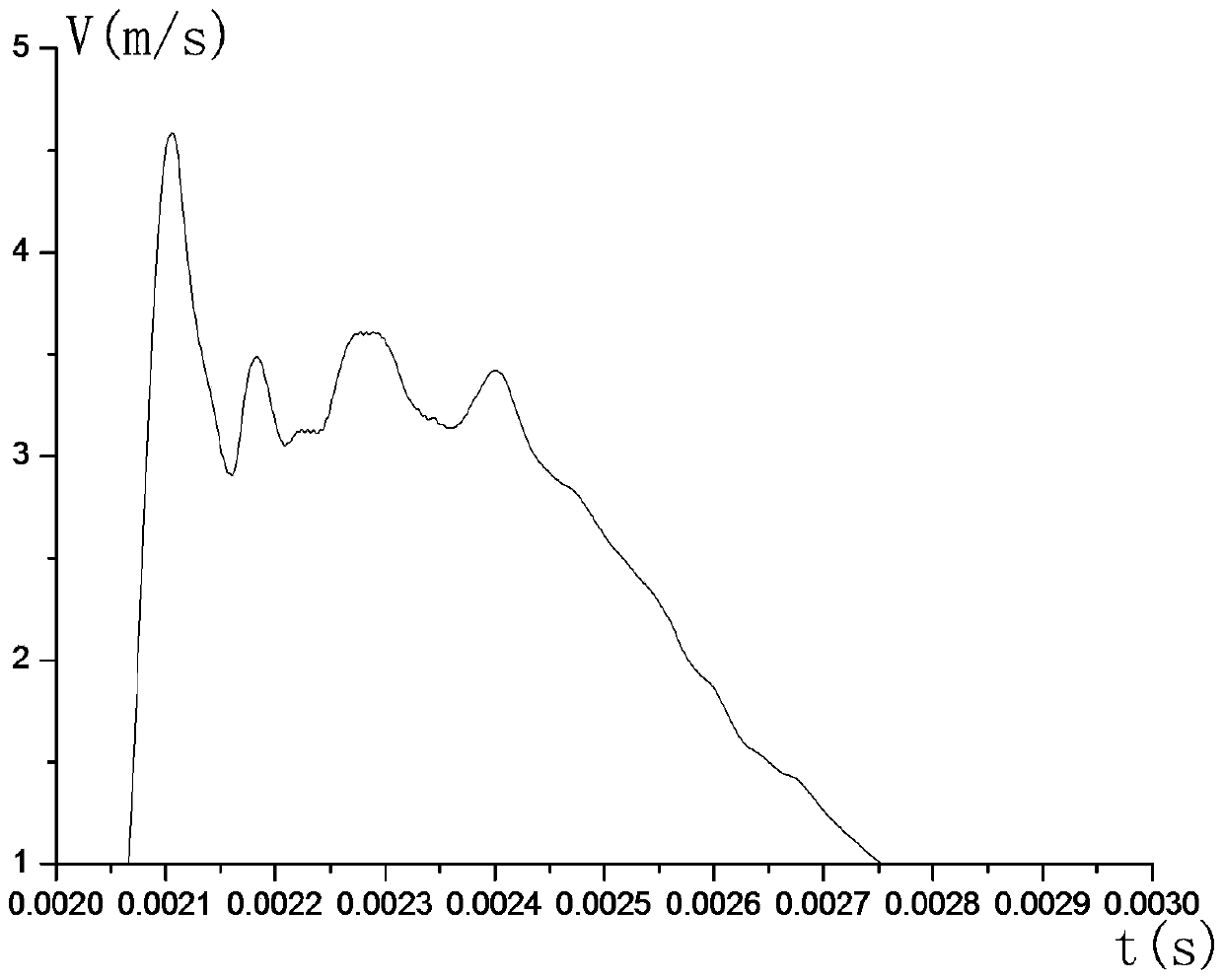

InactiveCN104913988BHigh precisionEasy to determine tensile strengthStrength propertiesAccelerometerUltimate tensile strength

The invention discloses a method for measuring the axial tensile strength of concrete based on Hopkinson's principle. The axial tensile strength of a concrete specimen (10) is measured using a Hopkinson compression bar device, which is characterized in that: removing the The transmission rod in the Hopkinson pressure rod device; the test piece (10) is provided with a group of strain gauges (50) at the distance from the impact end; the free end (11) of the concrete shaft test piece (10) An accelerometer (30) is set; the acceleration of the free end of the test piece (11) is obtained by analyzing the waveform diagram monitored by the accelerometer (30); the free end of the test piece ( 11) Surface velocity; measure the velocity of the free end (11) of the test piece, and then measure the axial tensile strength of the concrete test piece (10) through calculation and analysis. The invention can accurately measure and calculate the tensile strength of the concrete axis under the condition of medium and high strain rate.

Owner:POWERCHINA XIBEI ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com