Unidirectional and bidirectional tensile test device for mesoscopic structure in-situ online observation

A unidirectional and bidirectional tensile and testing device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, to achieve the effect of easy movement, small size, and no noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The device of the present invention is further described below in conjunction with examples: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following examples .

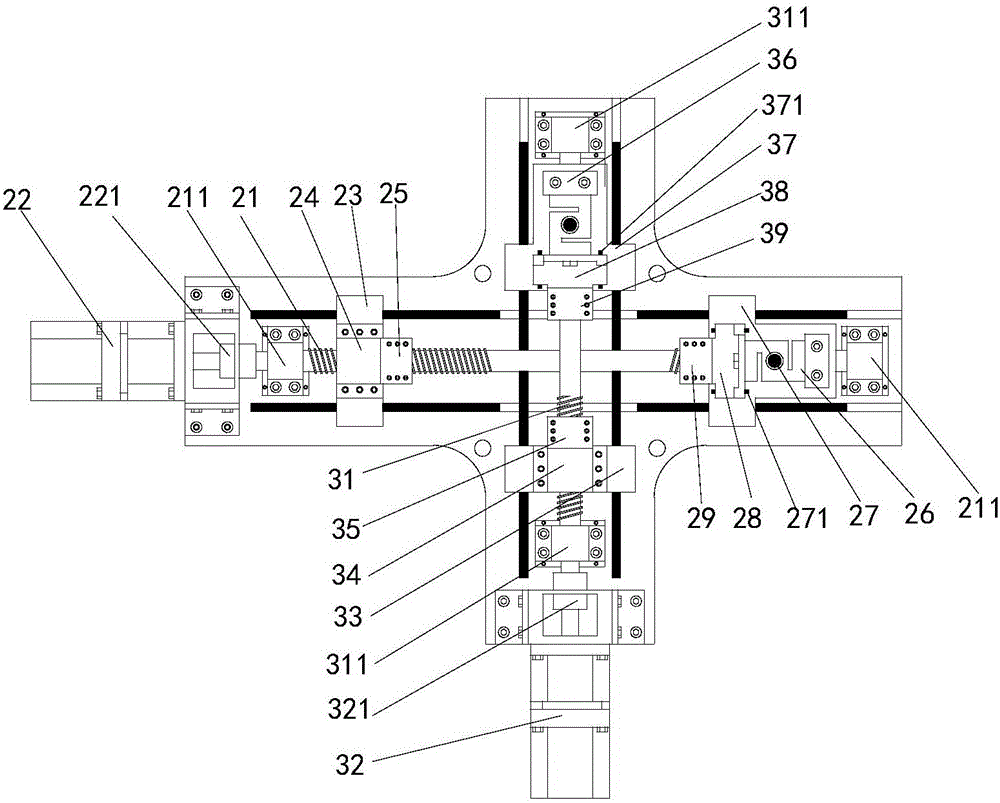

[0024] Such as Figure 1-7 As shown, the single-bidirectional tensile test device for in-situ on-line observation of mesoscopic tissue in the present invention includes a frame 1, and a transverse tensile mechanism 2 and a longitudinal tensile mechanism 3 installed on the frame.

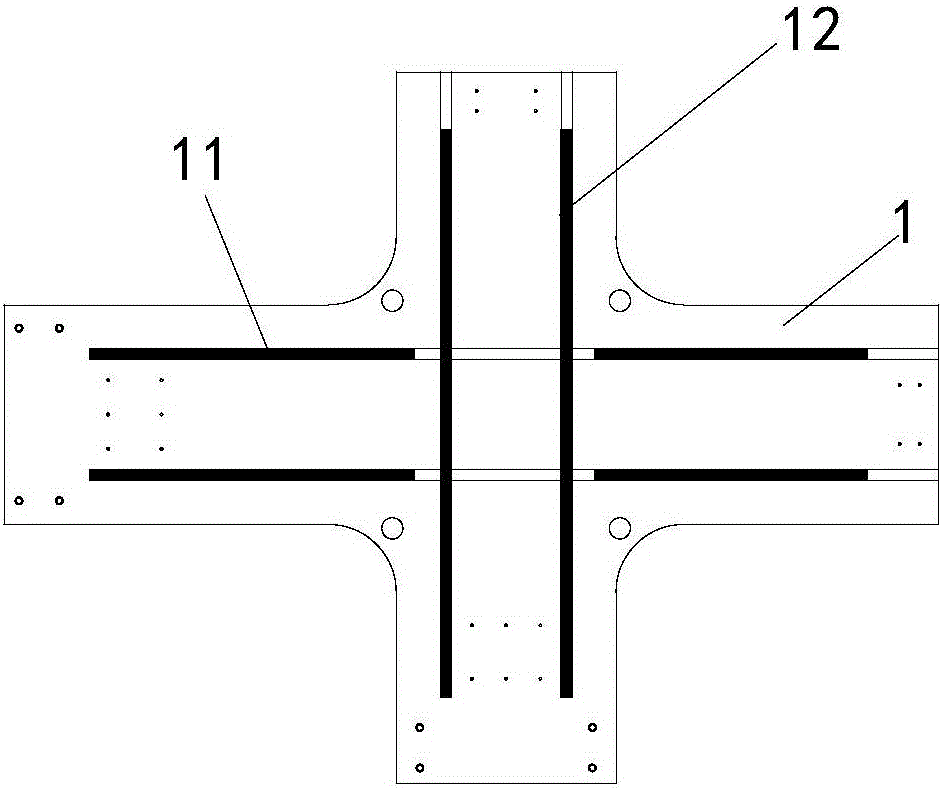

[0025] see figure 2 , the frame 1 among the present invention comprises a cross-shaped base plate, on which a transverse guide rail 11 and a longitudinal guide rail 12 are installed; the transverse guide rail 11 and the longitudinal guide rail 12 are all double rails, and are orthogonally arranged on the same plane, wherein The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com