Testing method of soil mass triaxial breaking stress path based on negative confining pressure condition

A technology of failure stress and test method, which is used in soil material testing, testing material strength using stable tension/pressure, material inspection products, etc., and can solve problems such as difficult technical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

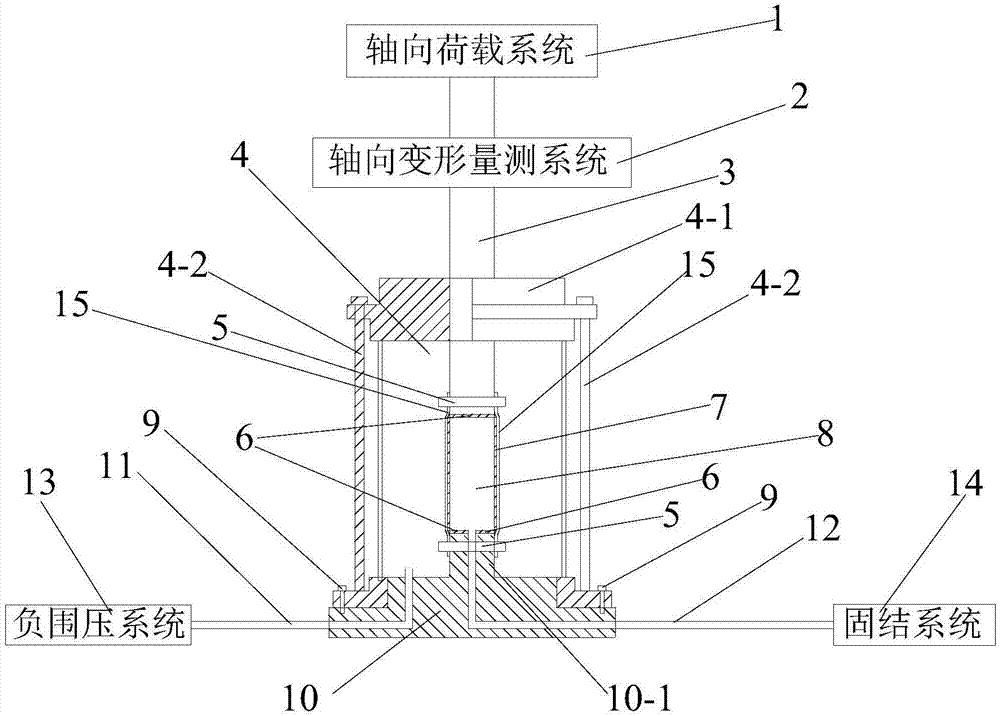

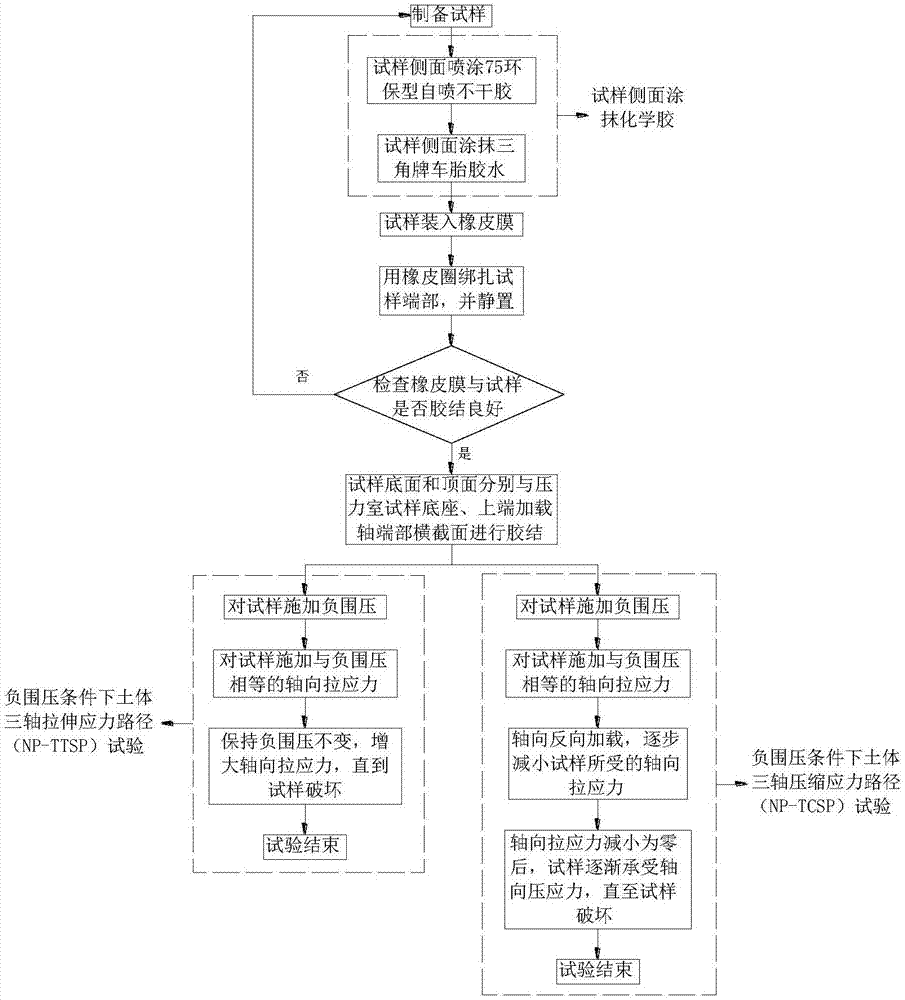

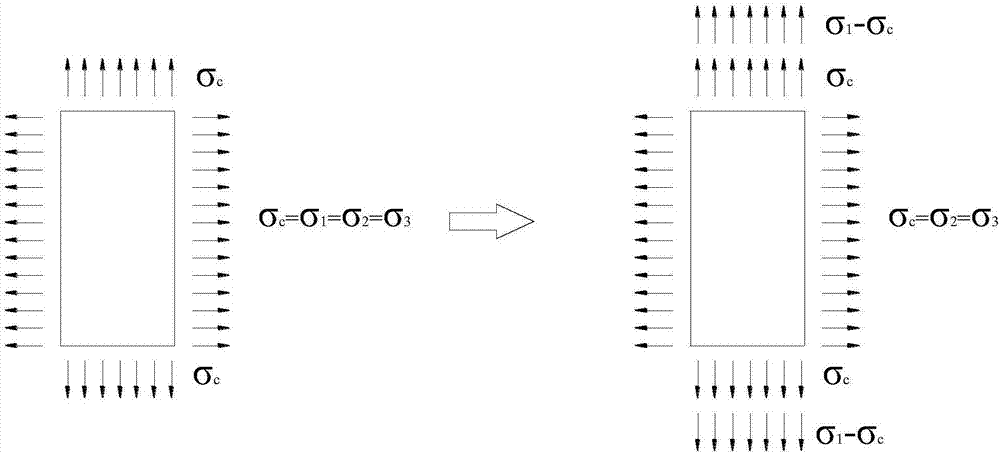

Method used

Image

Examples

Embodiment

[0070] Q 3 The loess is used as the sample soil, the depth of the soil is 5.5m ~ 6.5m, the color is yellow to brownish yellow, and the pores are relatively developed. The natural water content of the loess is 18.55%, and the relative density is 2.71. The specific steps are as follows:

[0071] Step 1. Adopt the method of layered compaction sample preparation to prepare a cylindrical sample 8 with a diameter of Φ39.1mm and a height of 80mm, and the moisture content of the sample 8 is 15%;

[0072] Step 2: Spray 75 environmentally friendly self-spraying self-adhesive evenly on the surface of the 8 sides of the sample obtained in Step 1, let it stand for 15-20 minutes, then apply a layer of Triangle tire glue evenly, and let it stand for 5-10 minutes Then put the rubber film 15 on the film-supporting tube, use ear washing ball to suck air from the air nozzle of the film-supporting tube, so that the rubber film 15 is close to the wall of the film-bearing tube, and then cover the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com