Patents

Literature

1187 results about "Test region" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

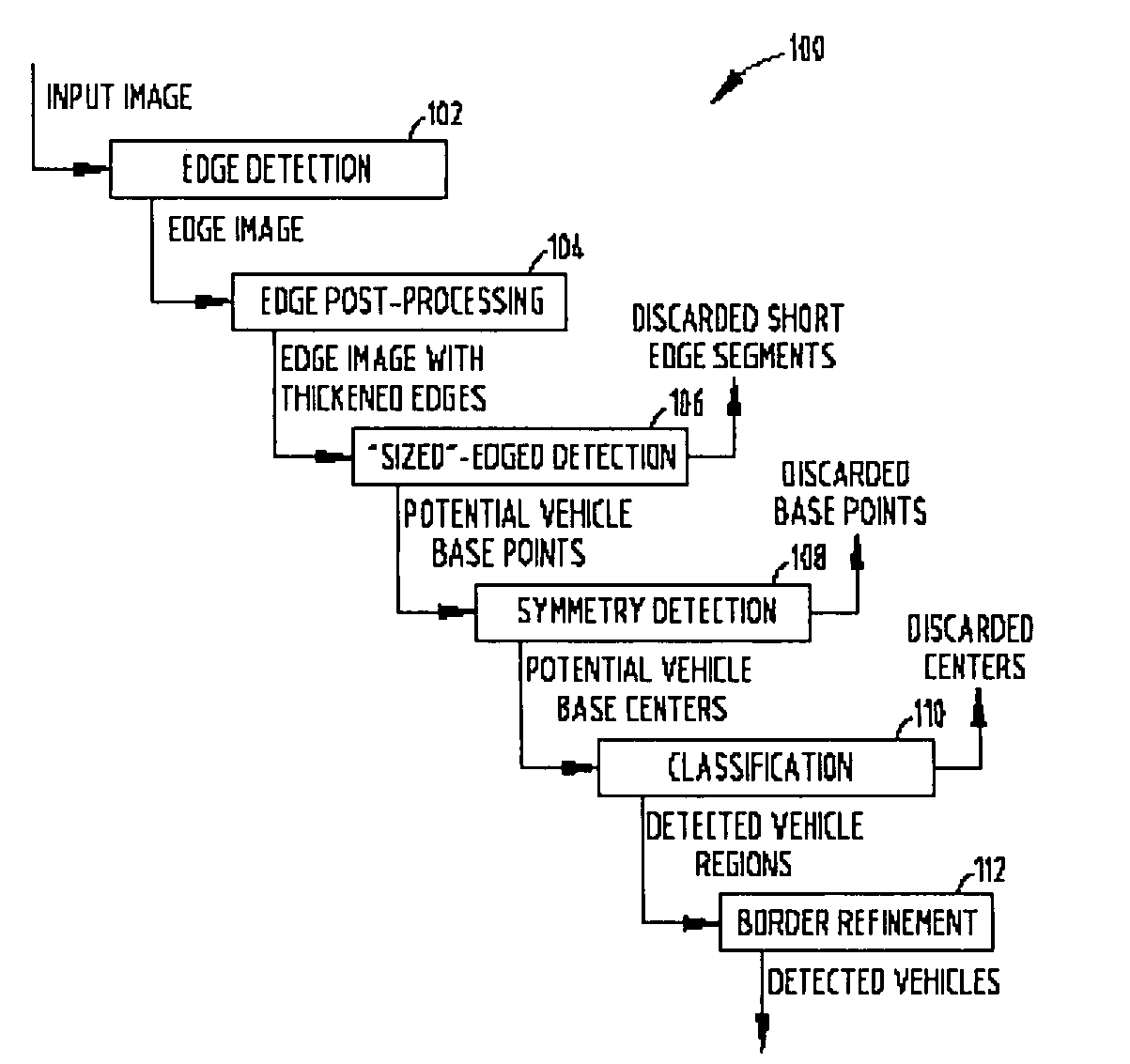

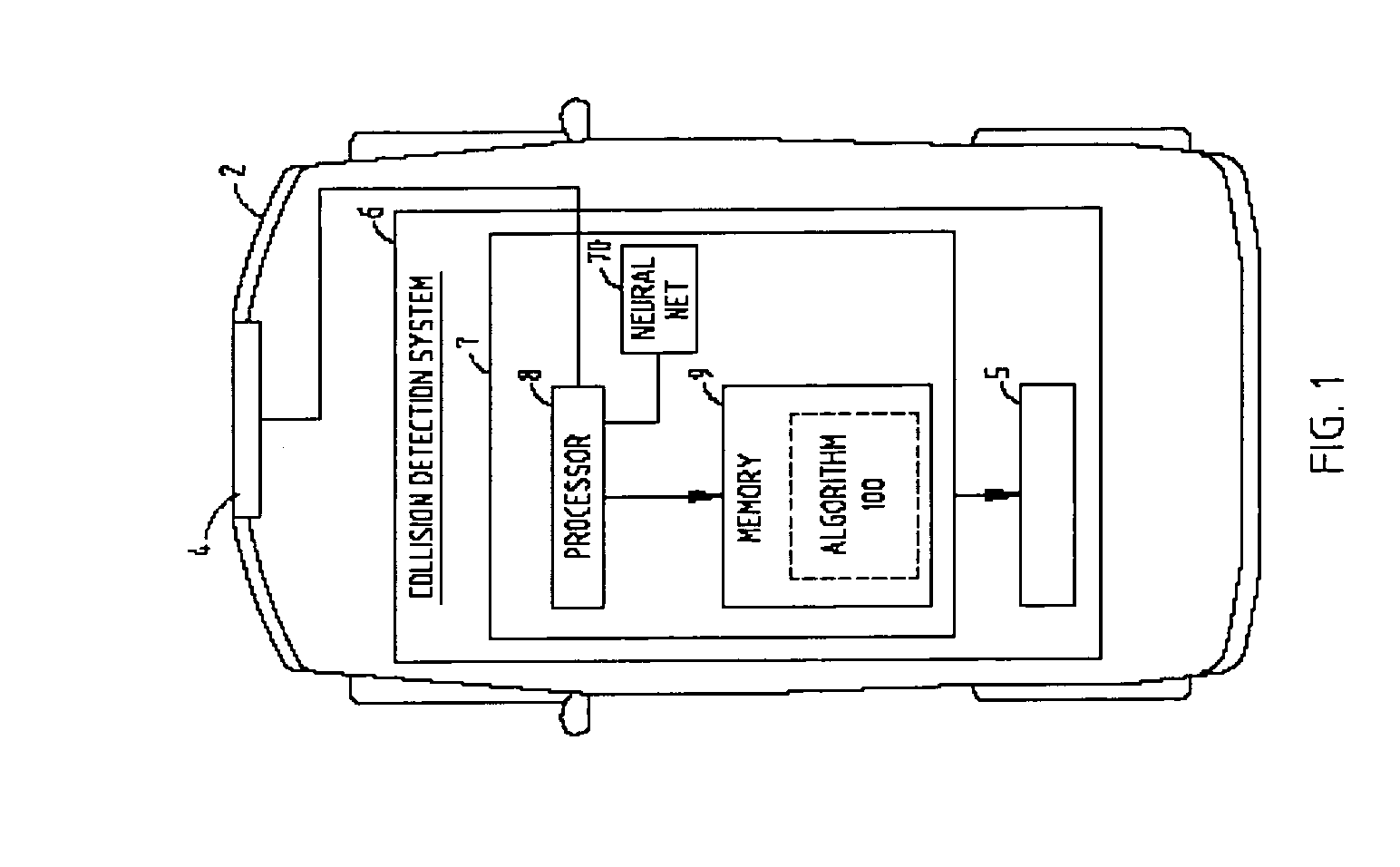

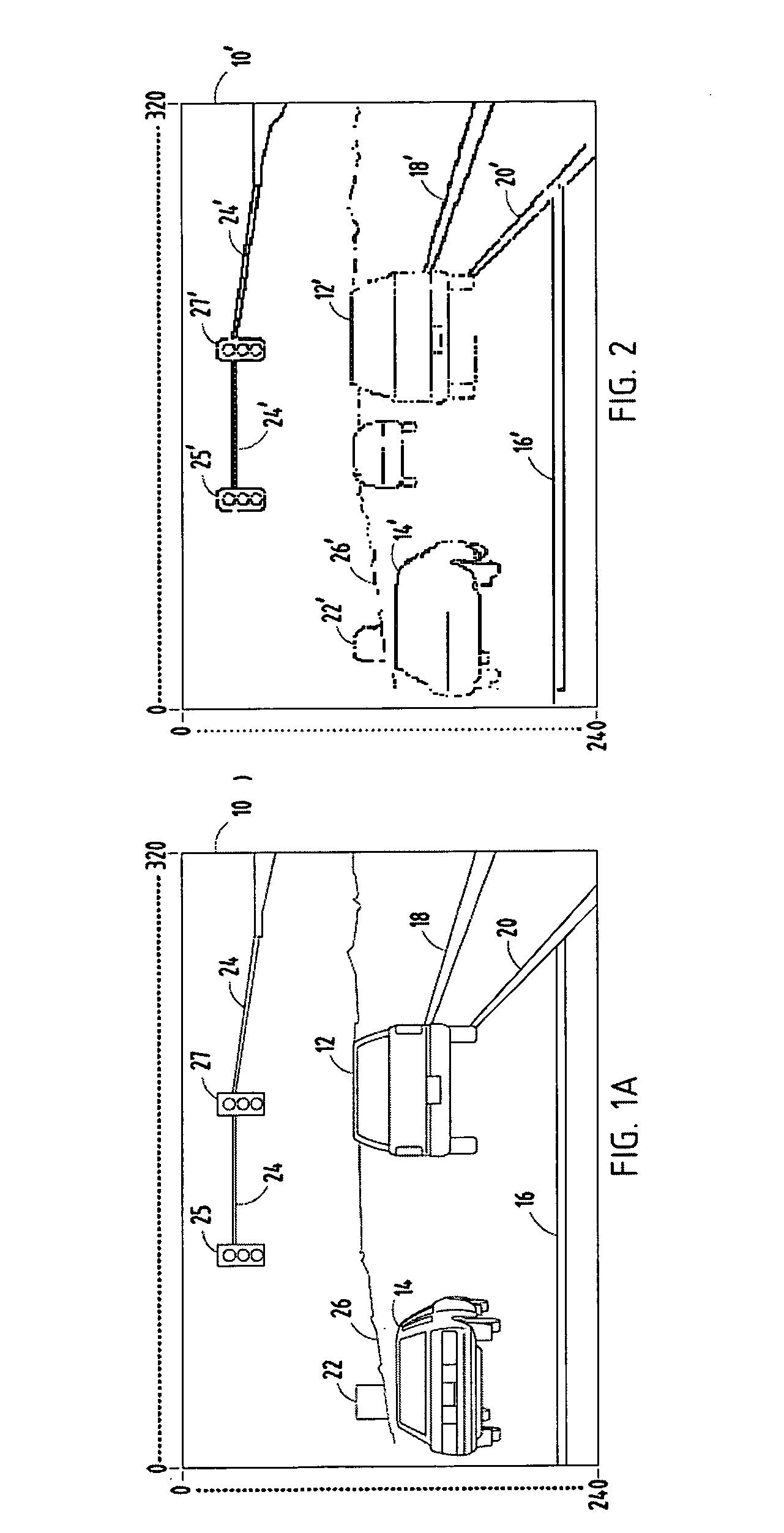

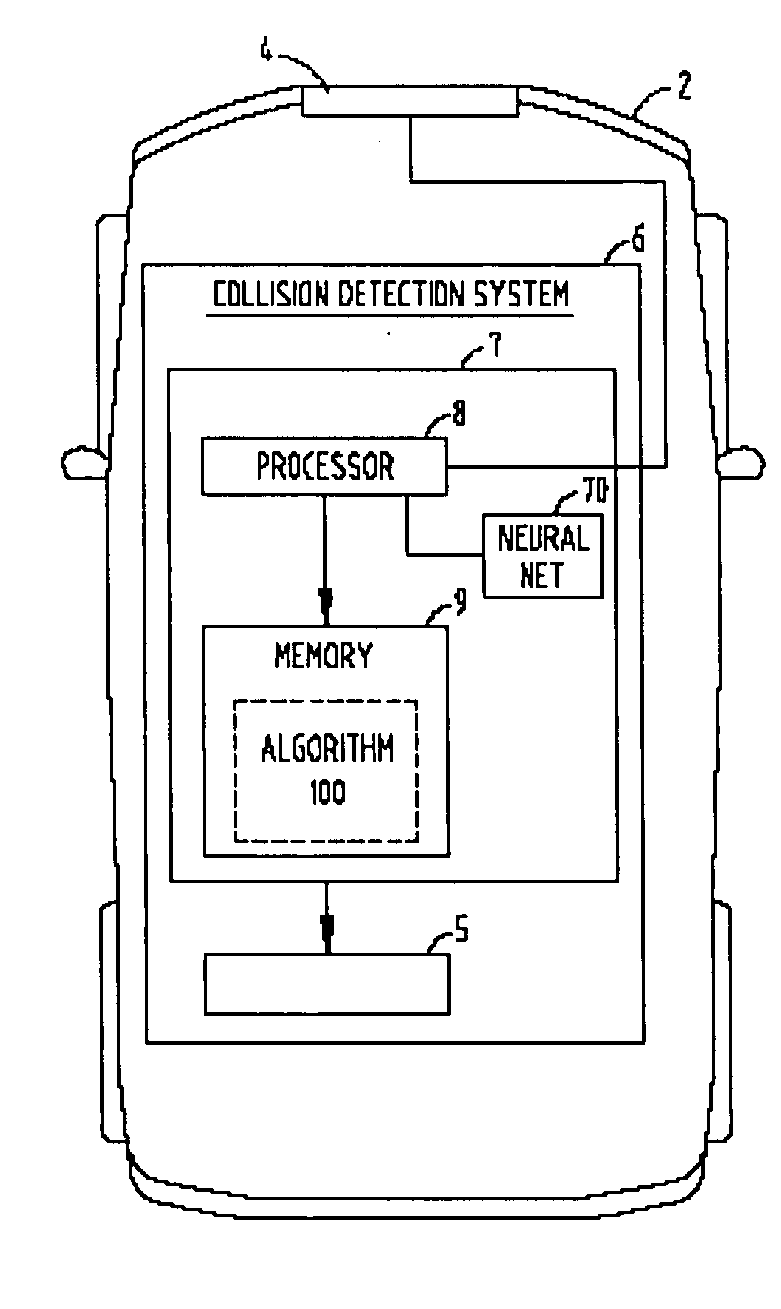

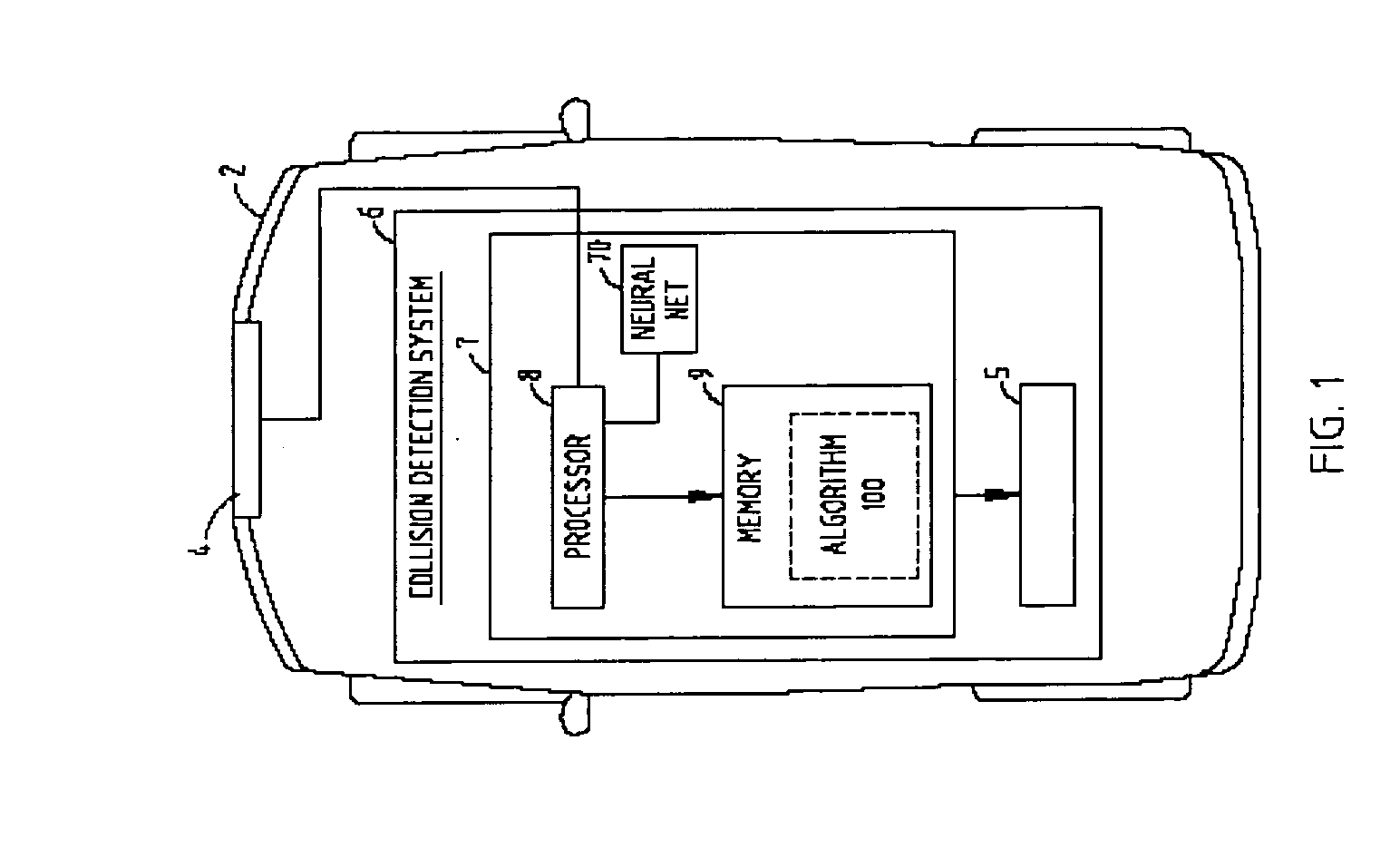

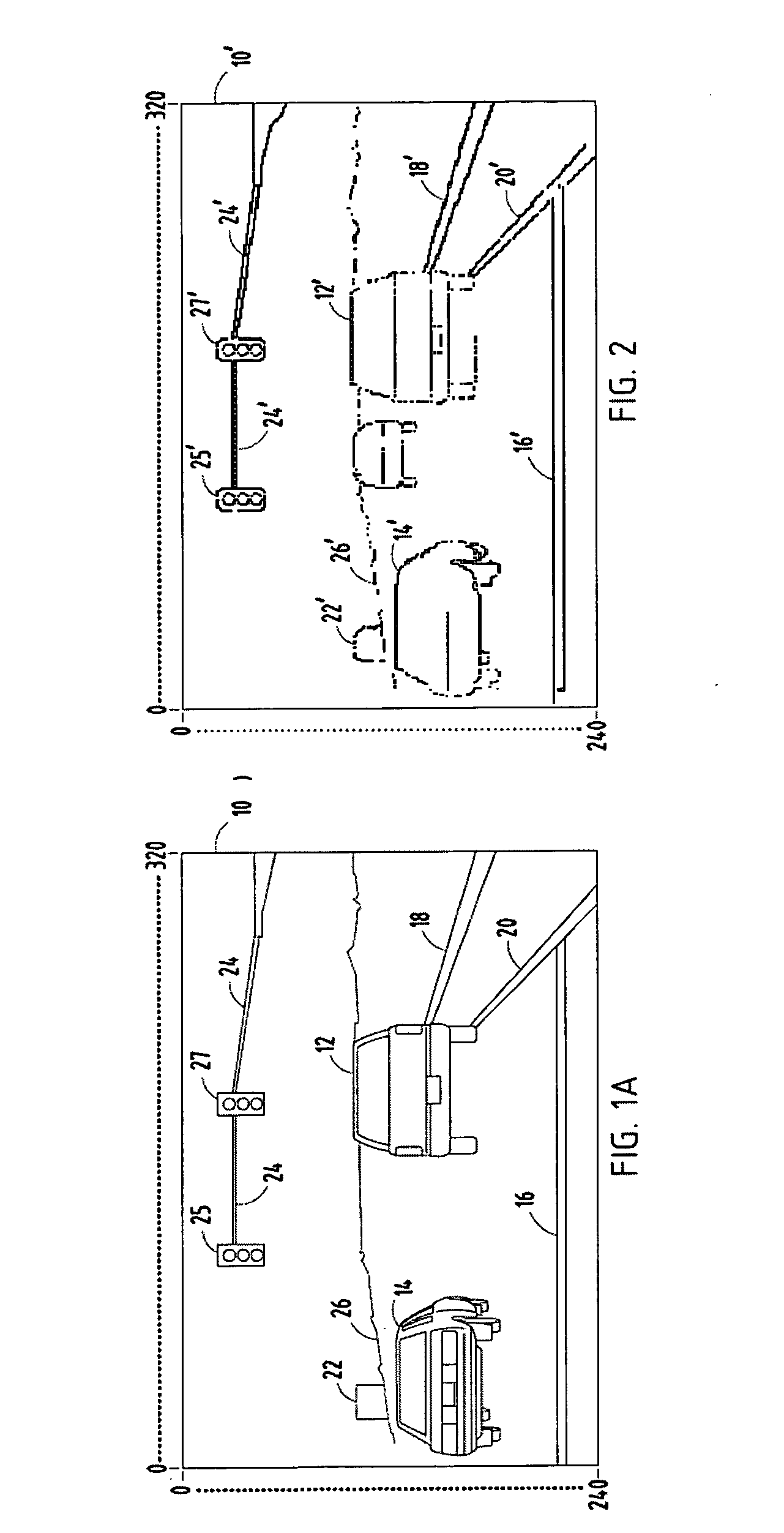

Method for identifying vehicles in electronic images

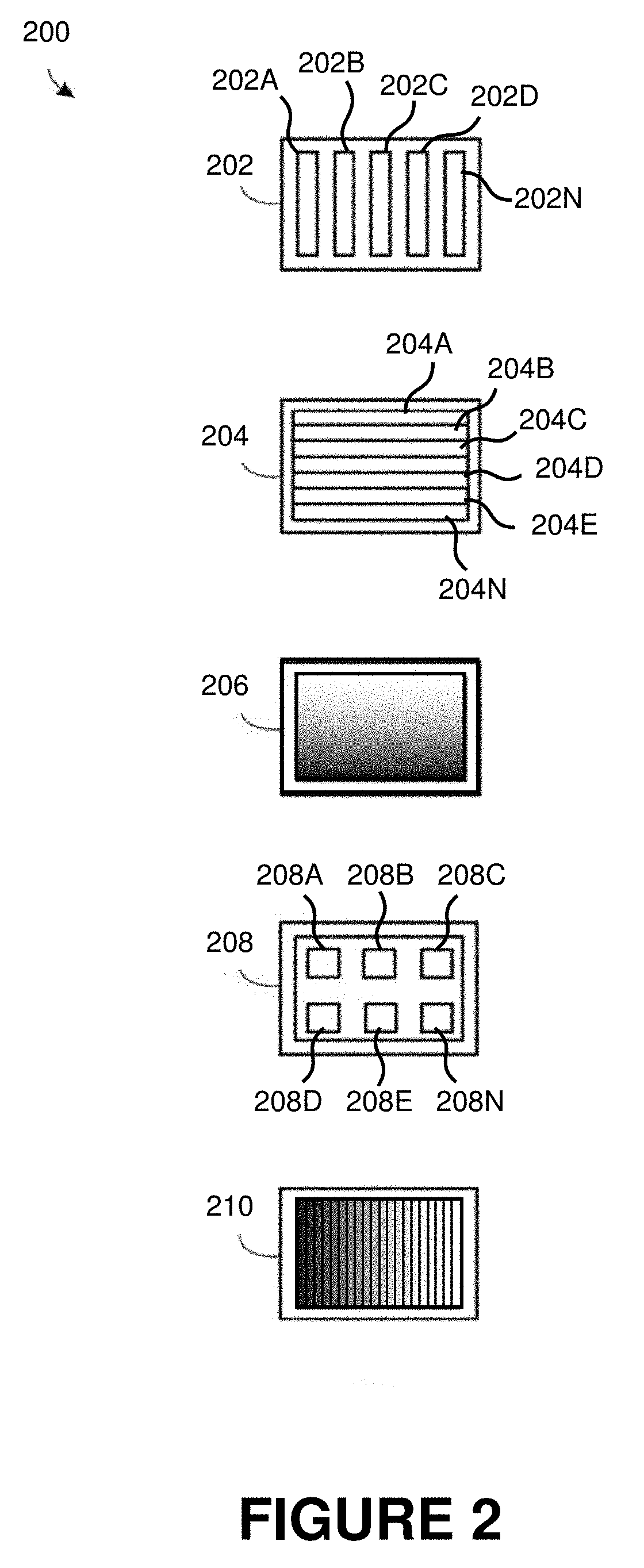

A method for identifying objects in an electronic image is provided. The method includes the steps of providing an electronic source image and processing the electronic source image to identify edge pixels. The method further includes the steps of providing an electronic representation of the edge pixels and processing the electronic representation of the edge pixels to identify valid edge center pixels. The method still further includes the step of proving an electronic representation of the valid edge center pixels. Each valid edge center pixel represents the approximate center of a horizontal edge segment of a target width. The horizontal edge segment is made up of essentially contiguous edge pixels. The method also includes the steps of determining symmetry values of test regions associated with valid edge center pixels, and classifying the test regions based on factors including symmetry.

Owner:APTIV TECH LTD

Analytical aid

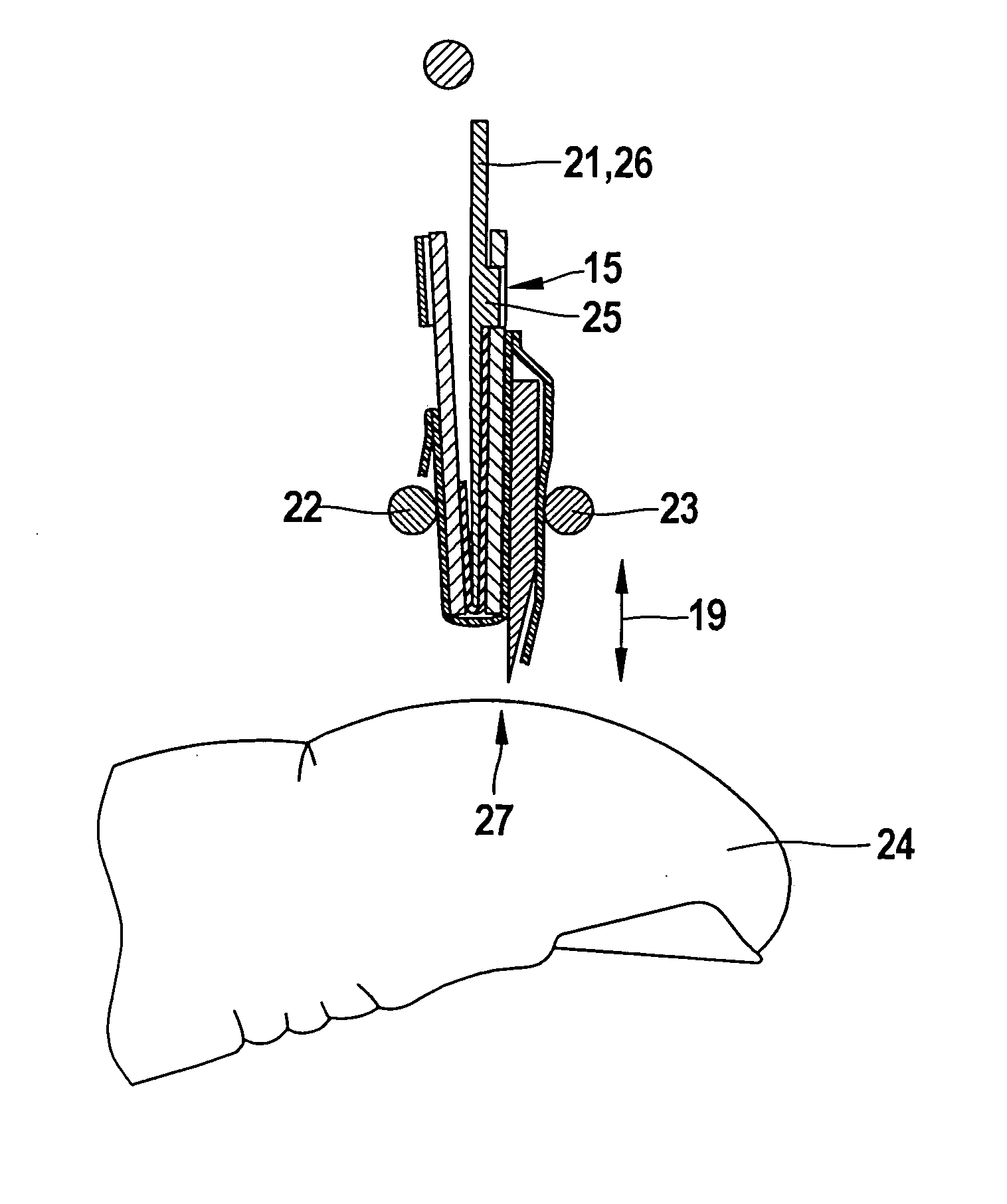

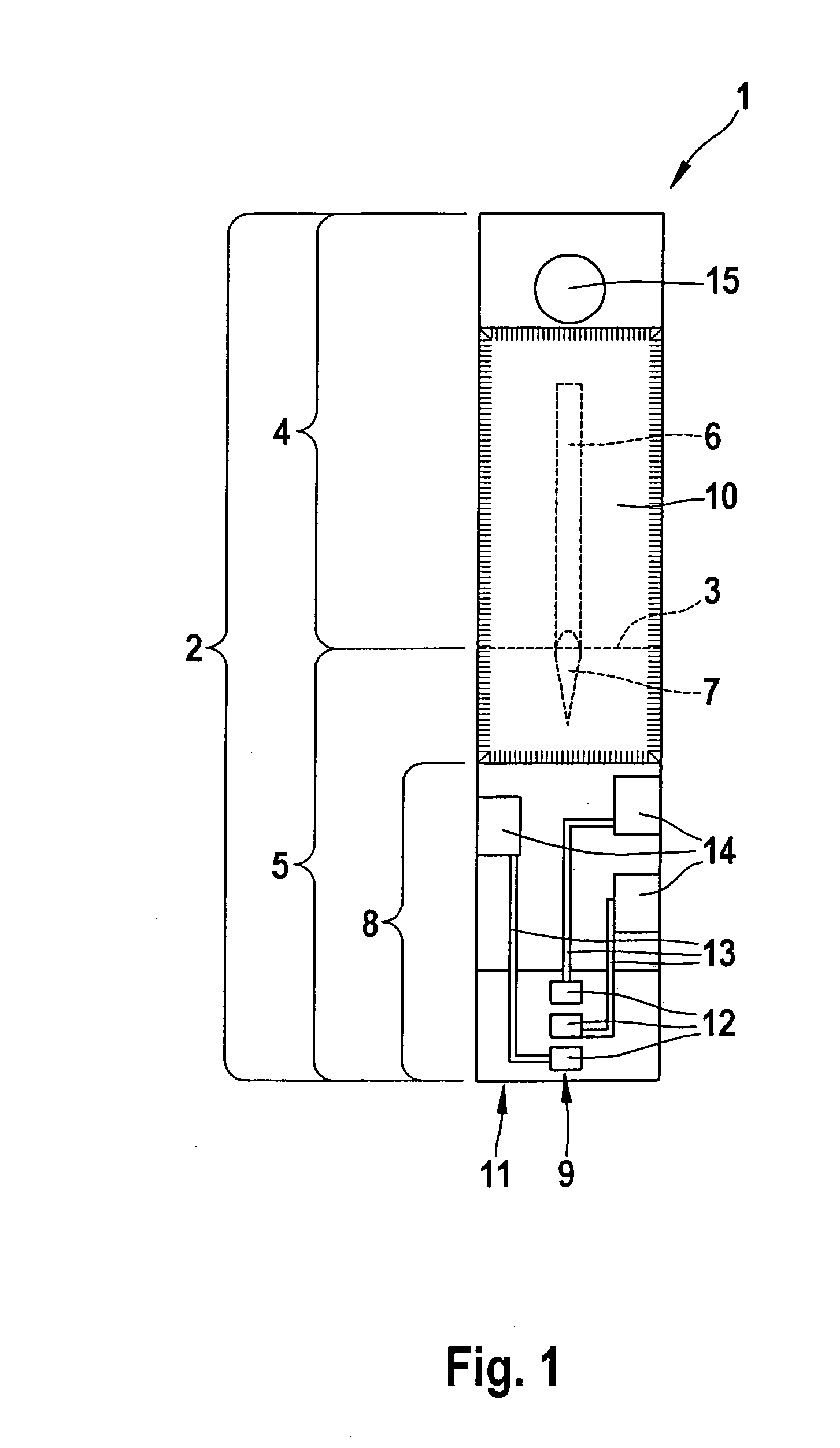

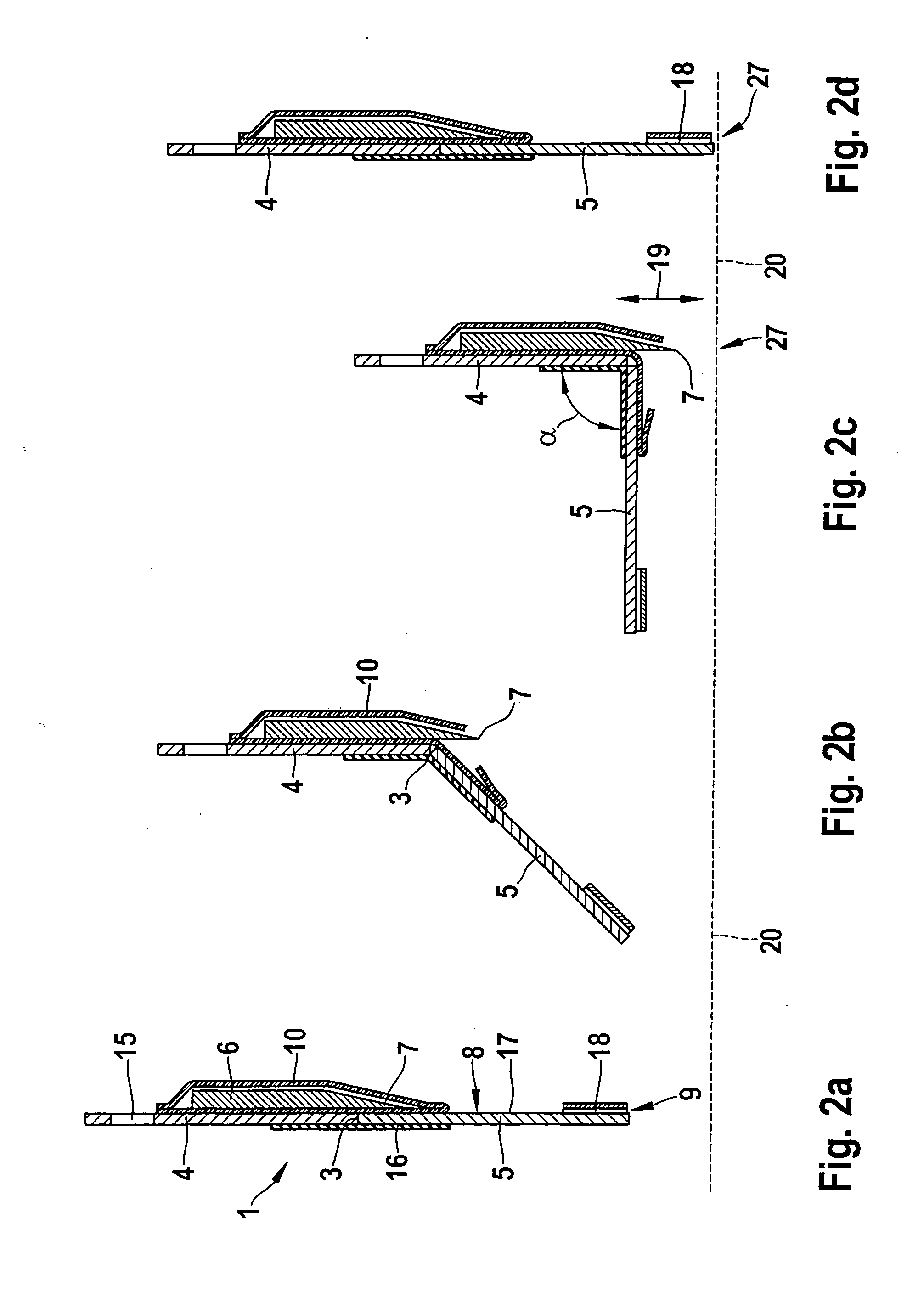

ActiveUS20060247555A1Rapid responseQuick eliminationCatheterDiagnostic recording/measuringEngineeringApplication site

The present invention relates to an analytical aid comprising a base body, a lancet and a test element. The base body comprises two subsidiary bodies hingedly connected to one another, the first subsidiary body carrying the lancet with lancet tip, and the second subsidiary body carrying the test element with test field and a sample application site. In an unused position of the analytical aid, the subsidiary bodies are arranged substantially in a common plane and the lancet is protected by a seal connected to the first subsidiary body and is separated from the test field of the test element. The two subsidiary bodies are pivotable relative to one another out of the common plane and the seal is openable so that the lancet tip is released for use.

Owner:ROCHE DIABETES CARE INC

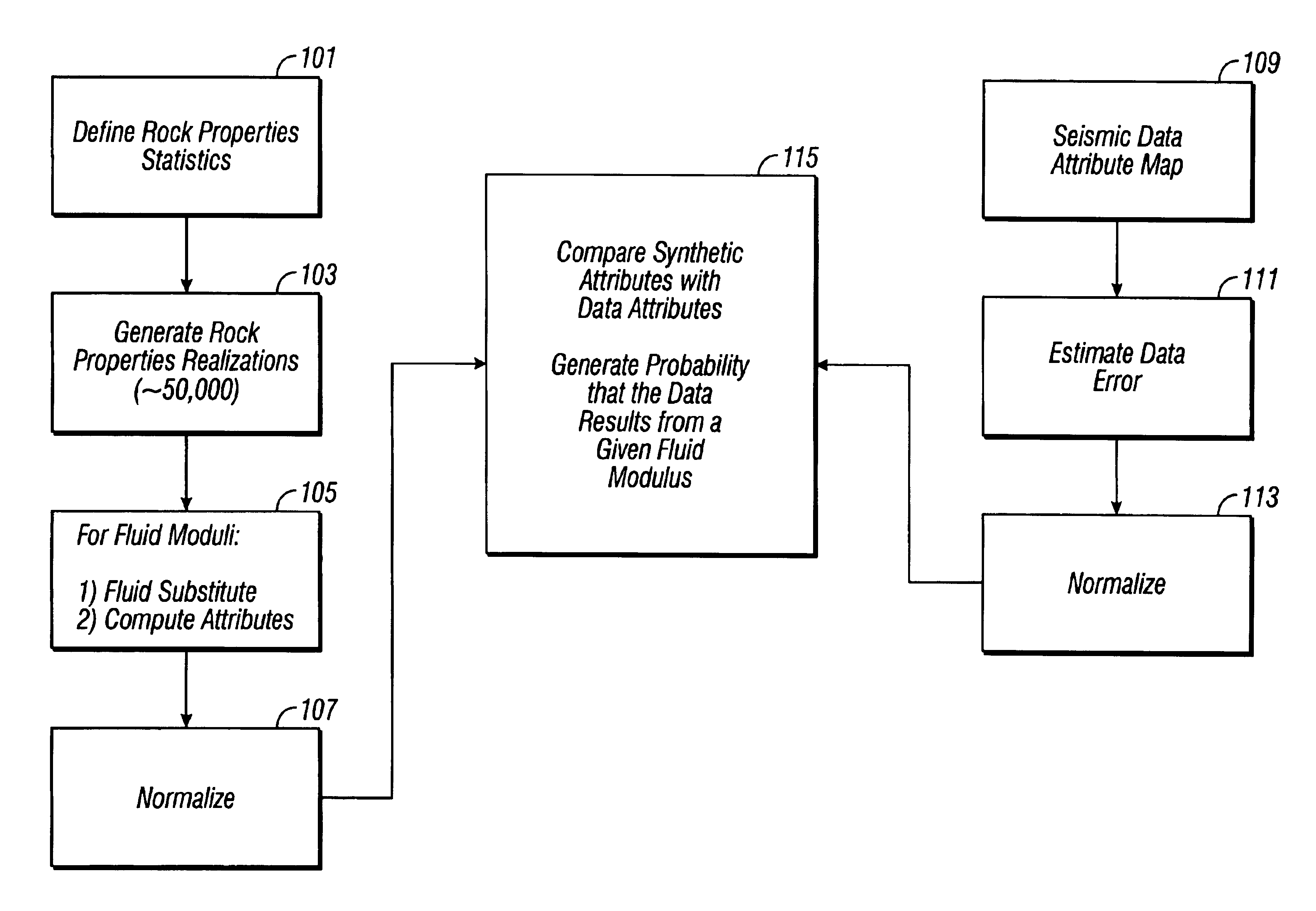

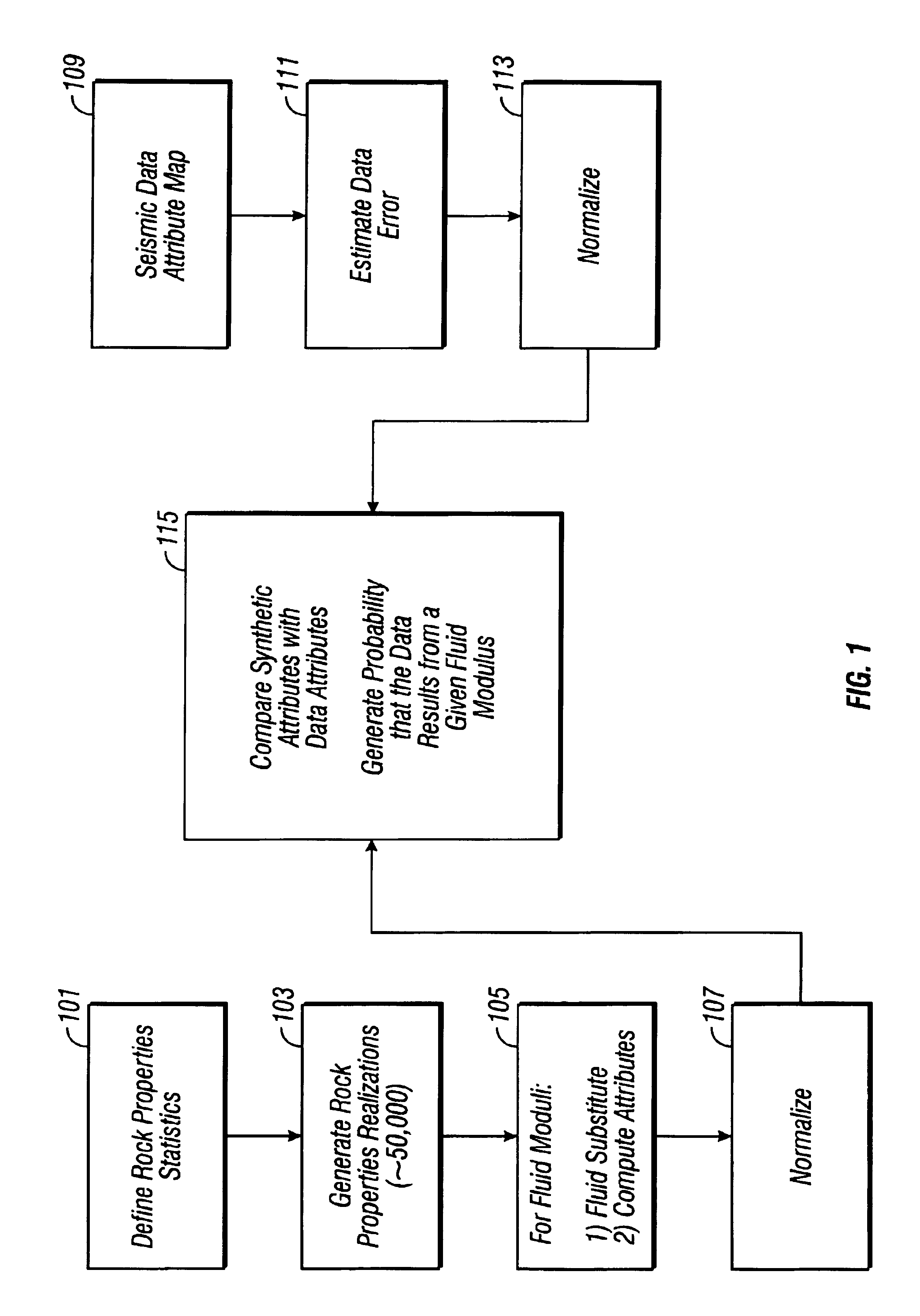

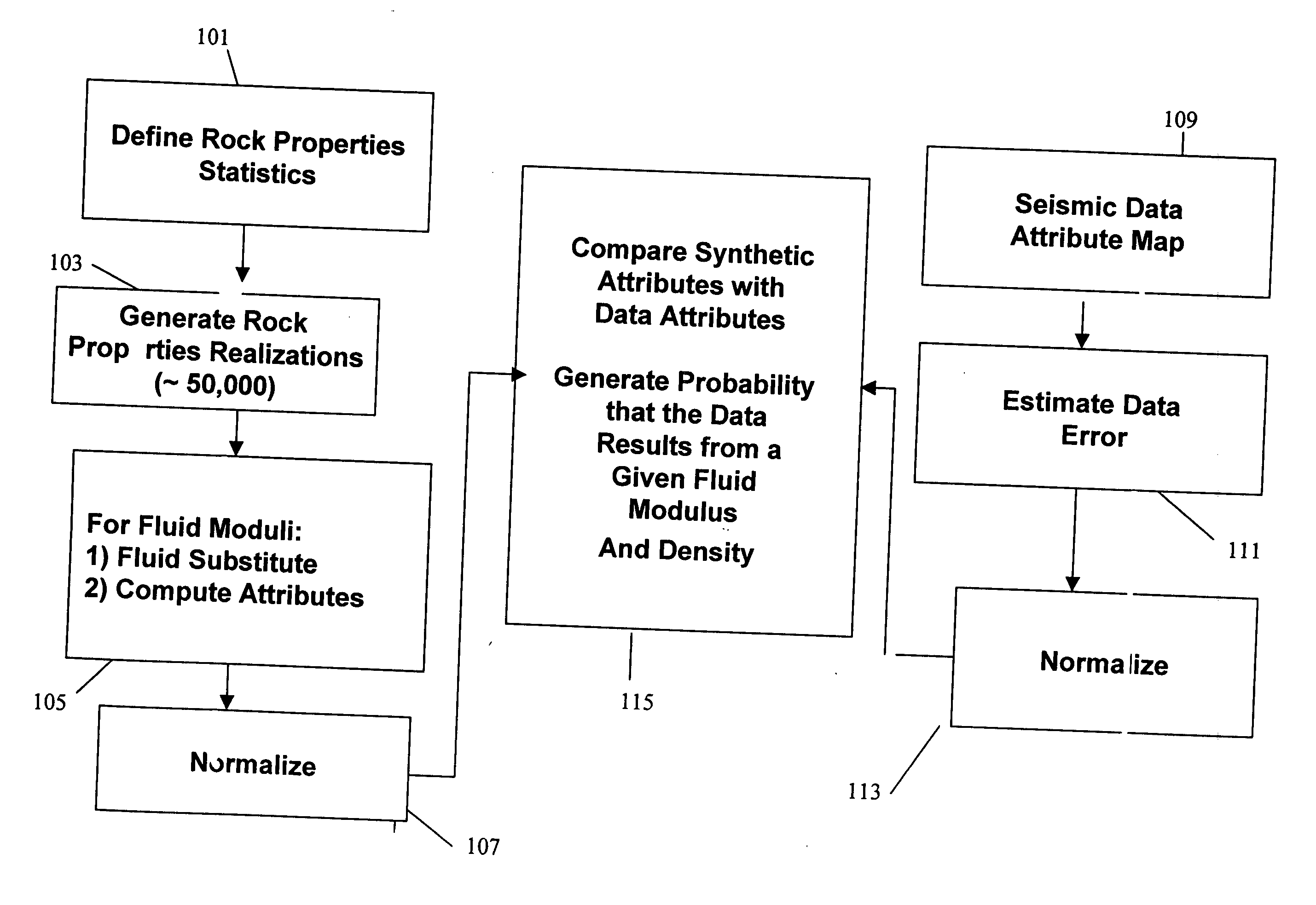

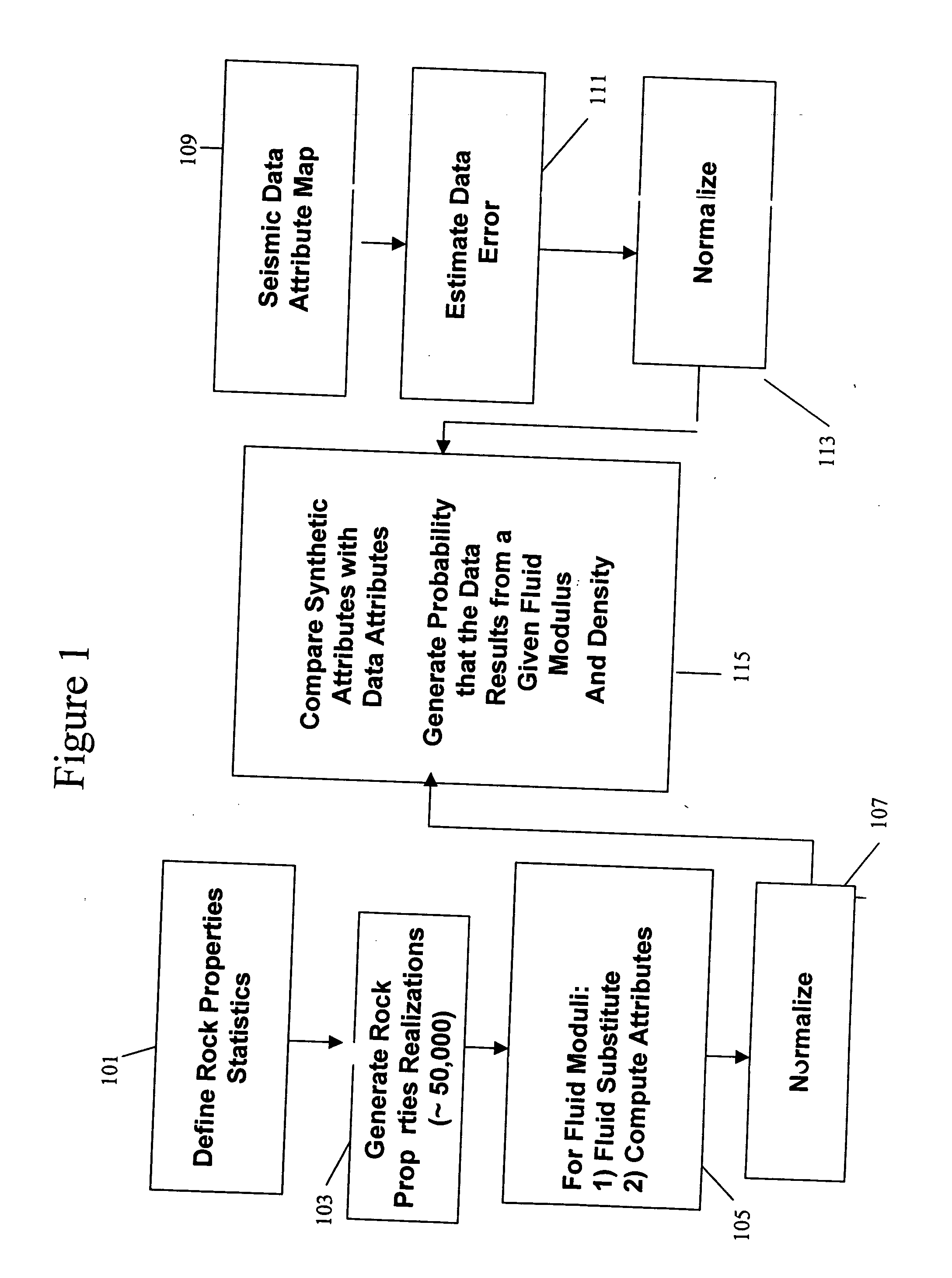

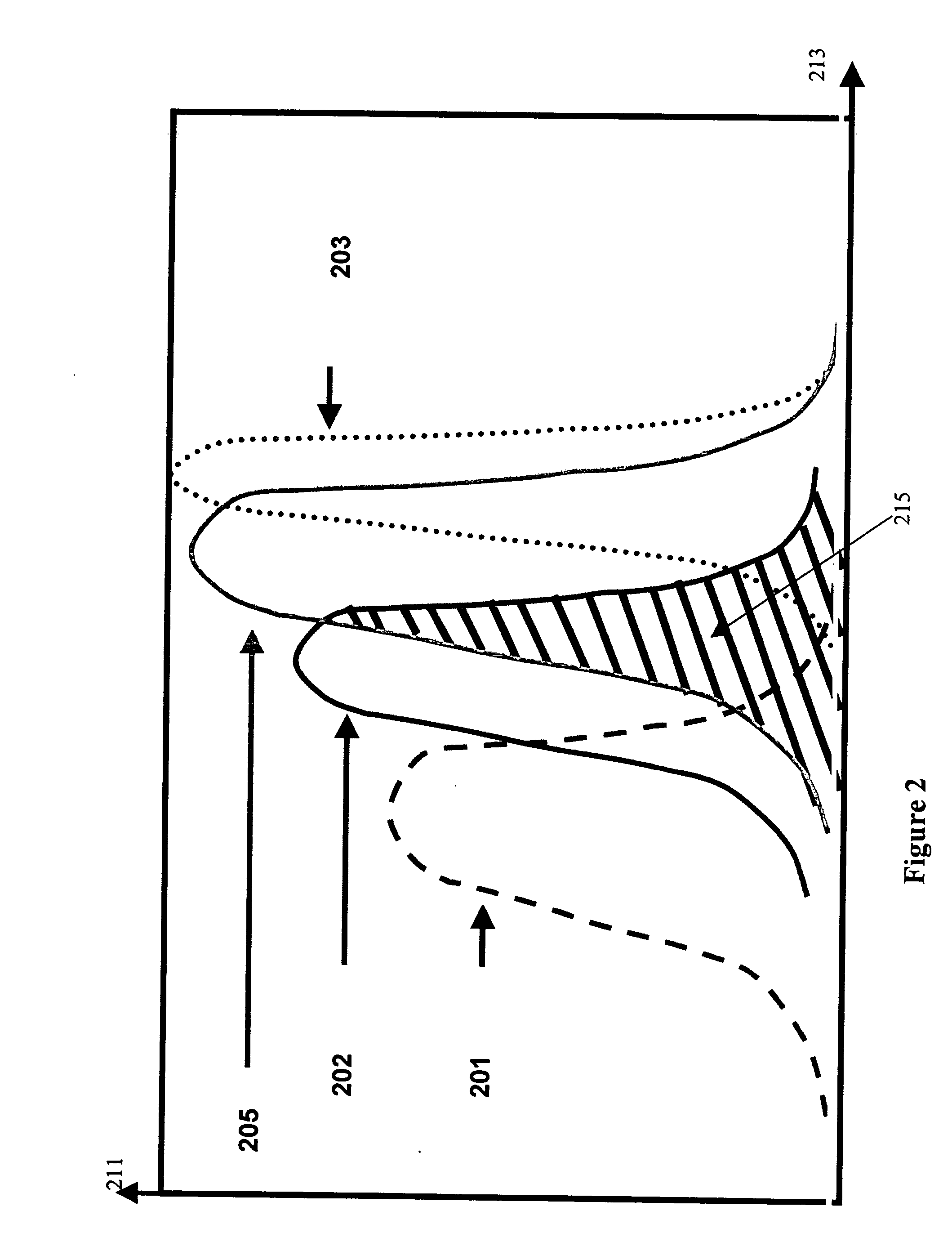

Determination of fluid properties of earth formations using stochastic inversion

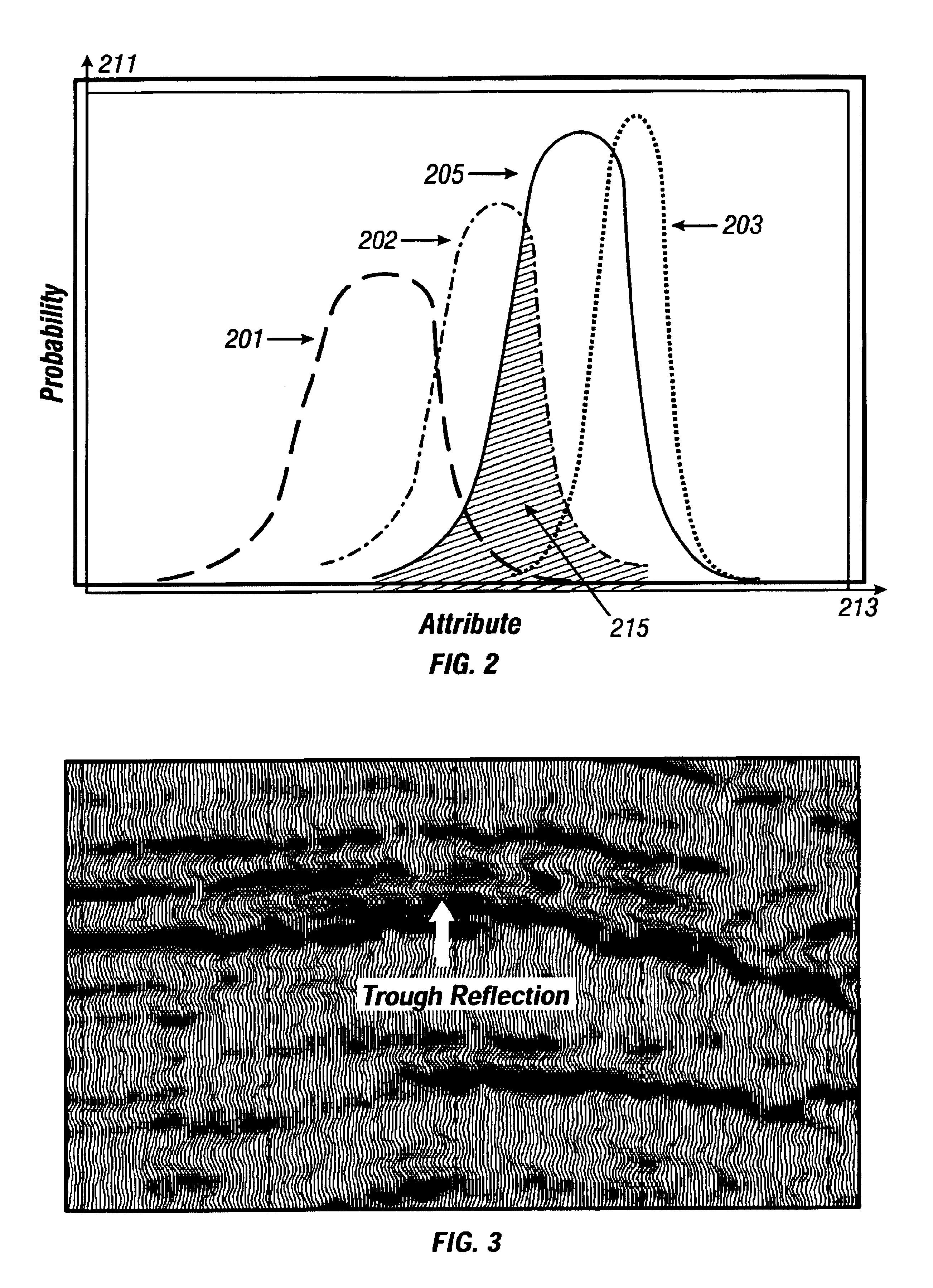

ActiveUS6970397B2Electric/magnetic detection for well-loggingSeismic signal processingSeismic attributeTest region

A method of determining a fluid property in a subsurface region of interest of an earth formation uses measurements of seismic attributes on seismic data. For a test region, a plurality of realizations of rock properties are specified, and for each of the realizations and a selected value of a fluid property, the seismic attribute is modeled. This defines a probability density function (PDF). Comparison of the PDF of the model output with the PDF on the measured seismic data is used to determine the likelihood of the selected fluid property.

Owner:GAS TECH INST

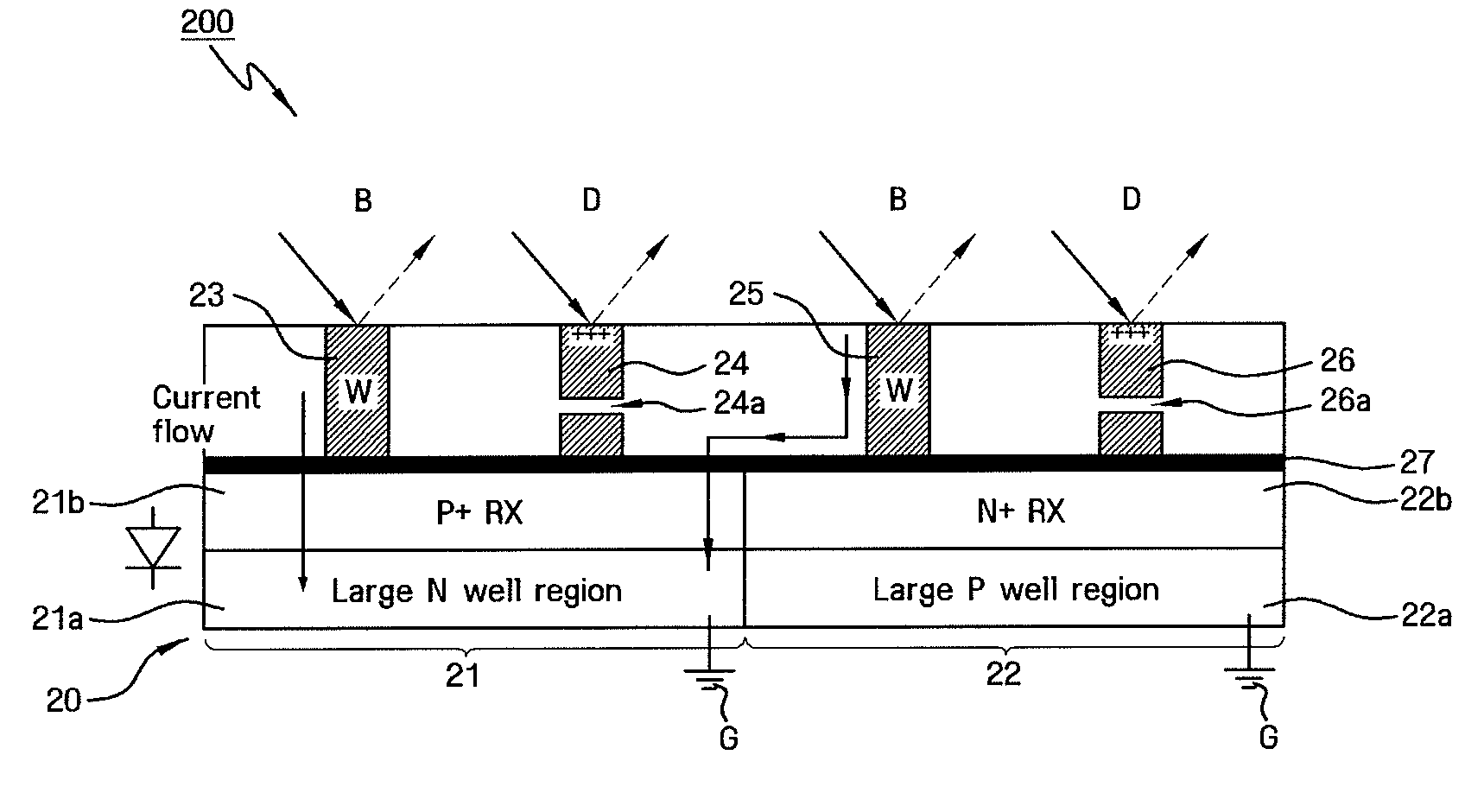

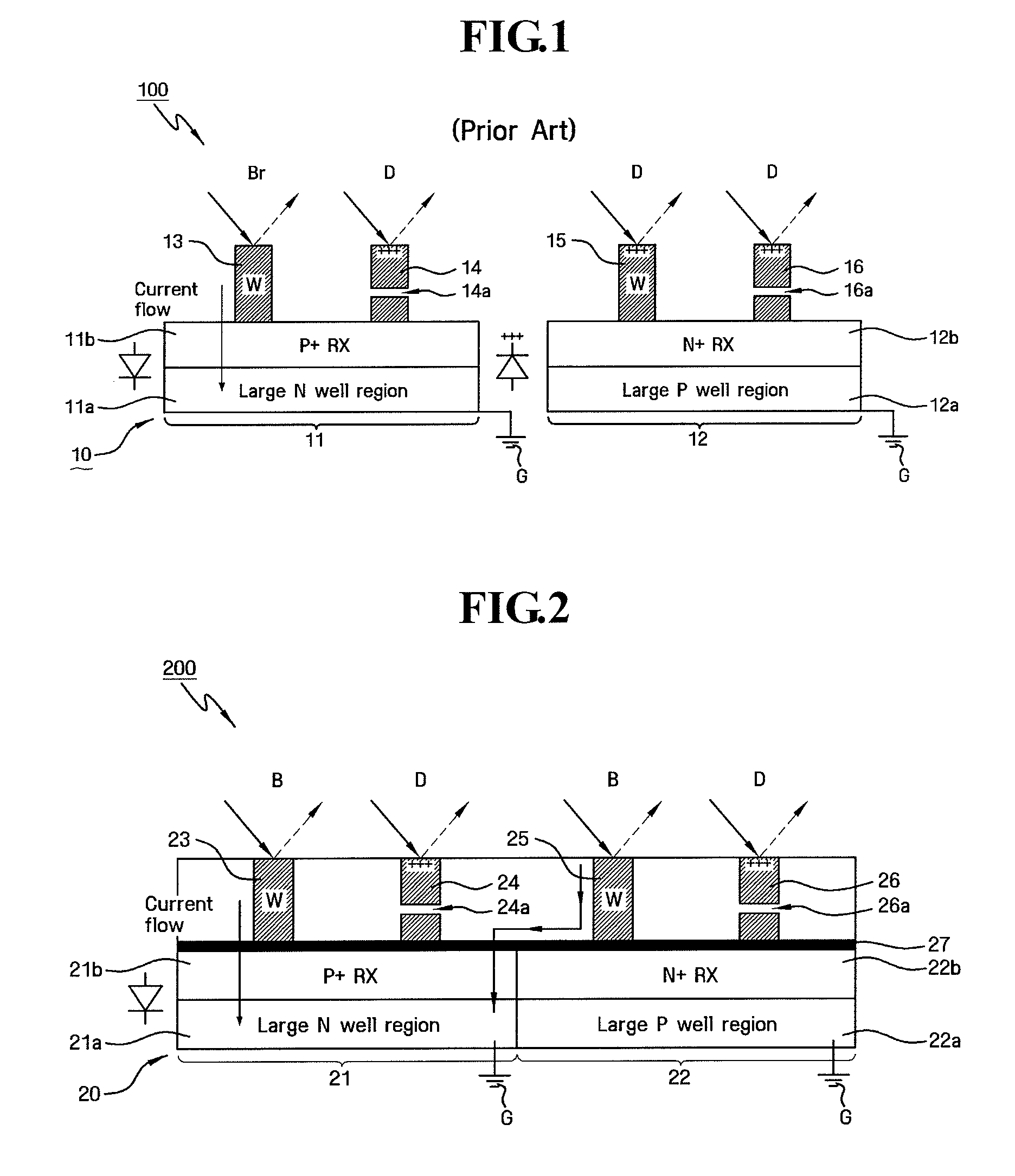

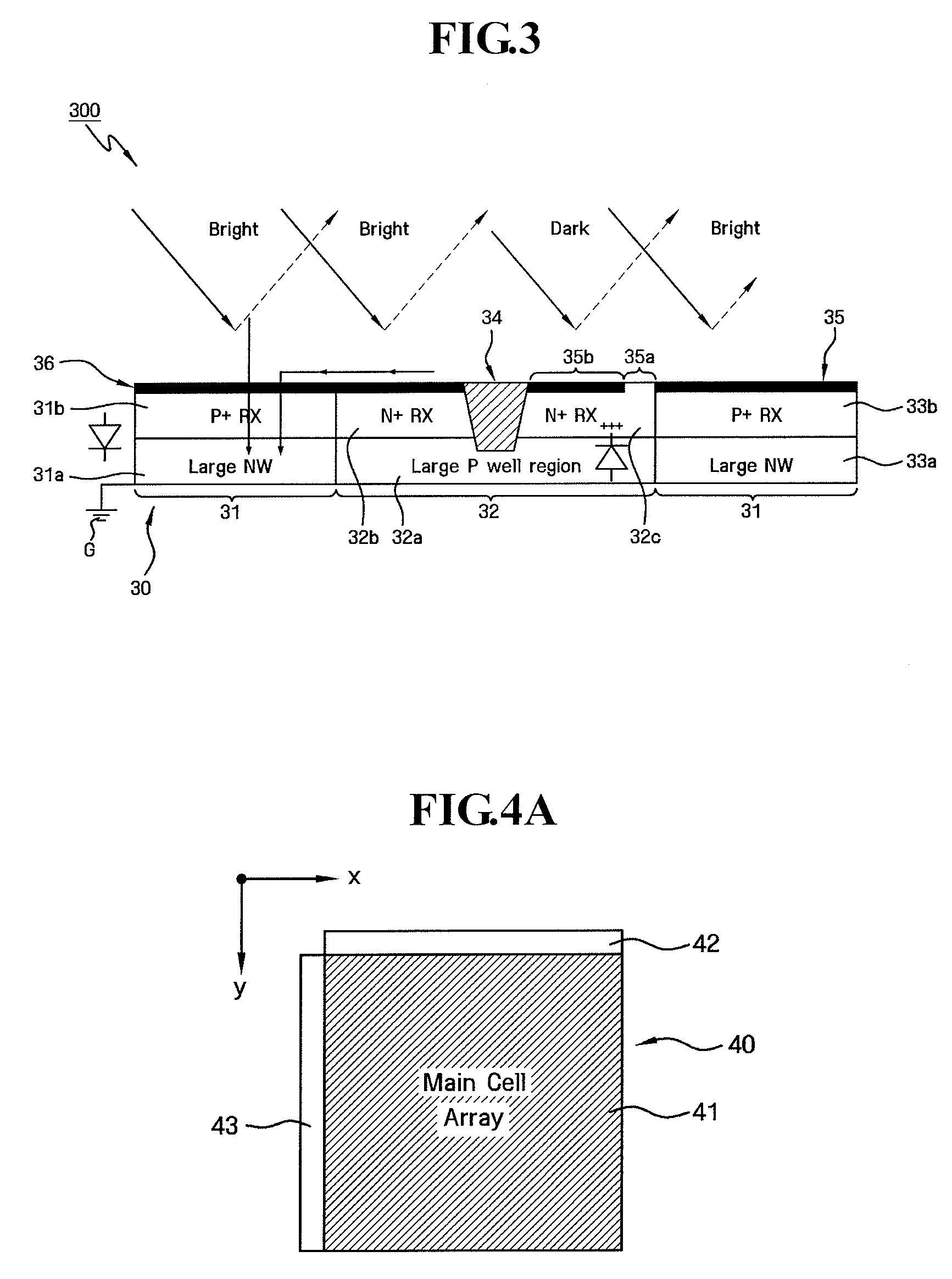

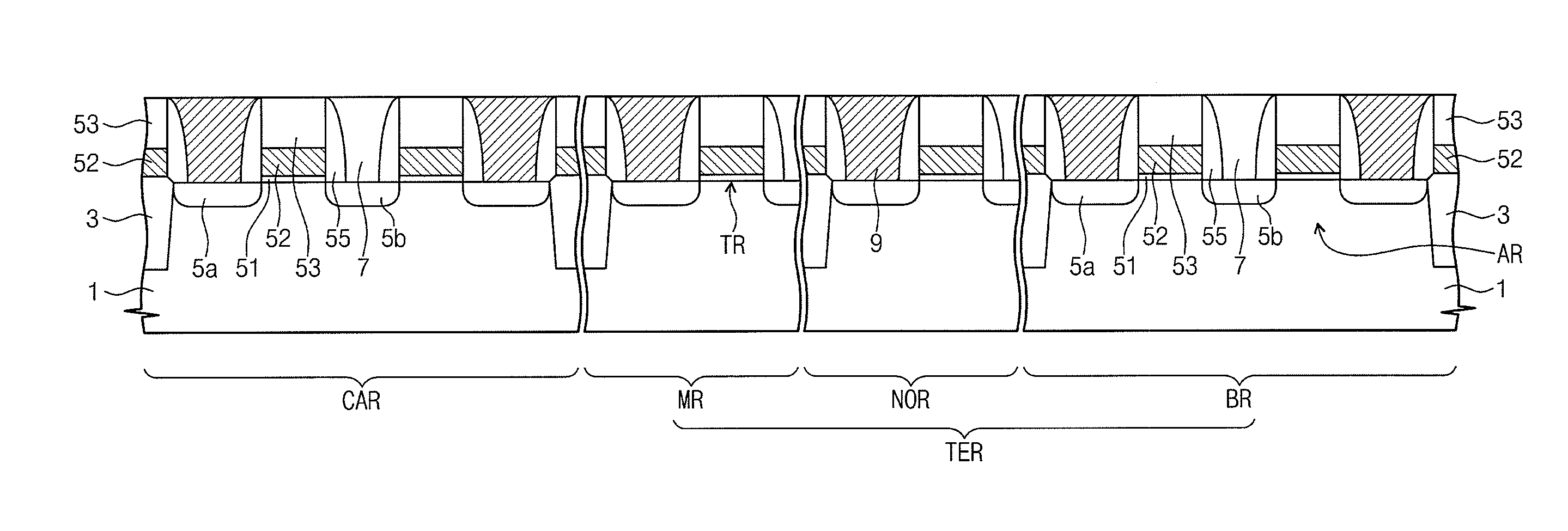

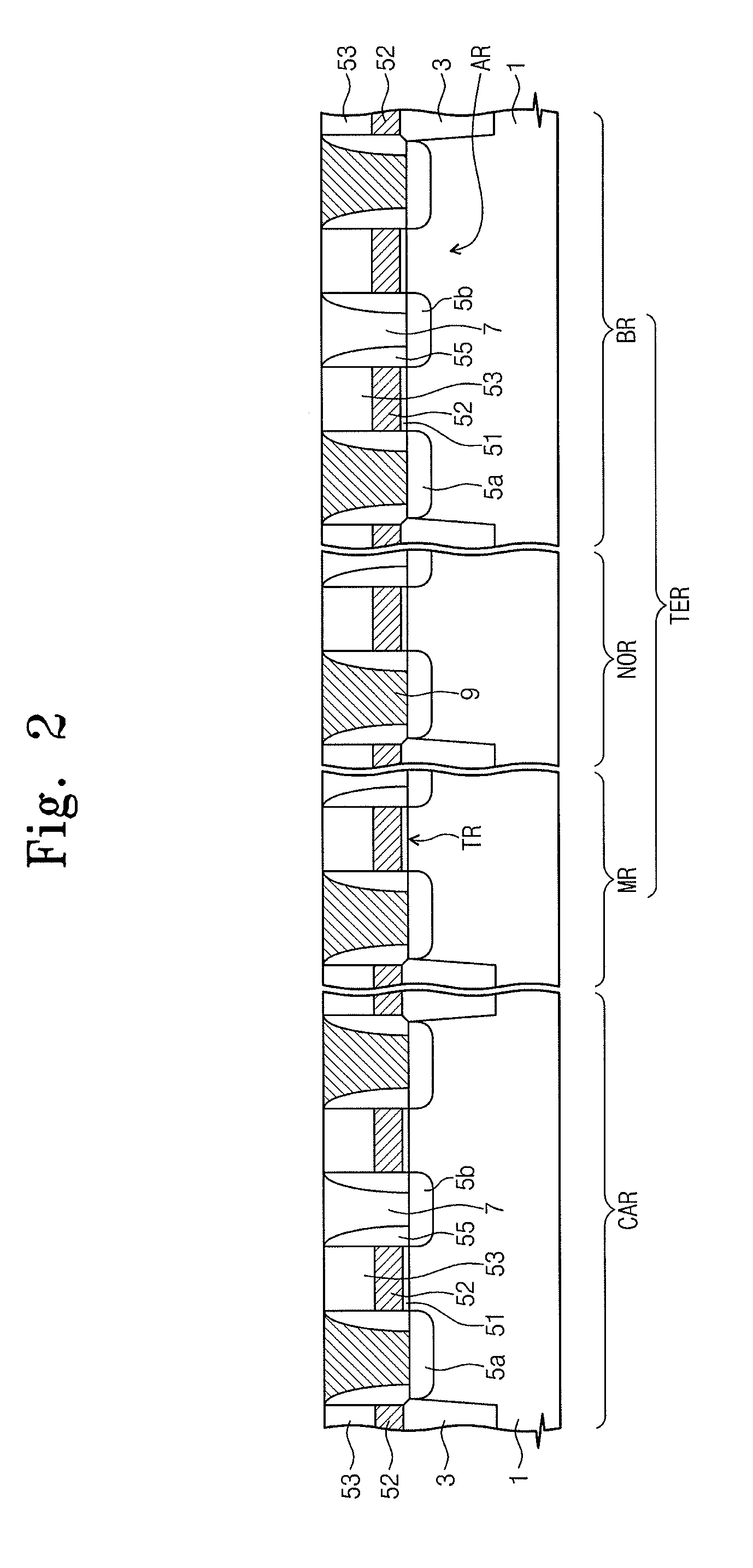

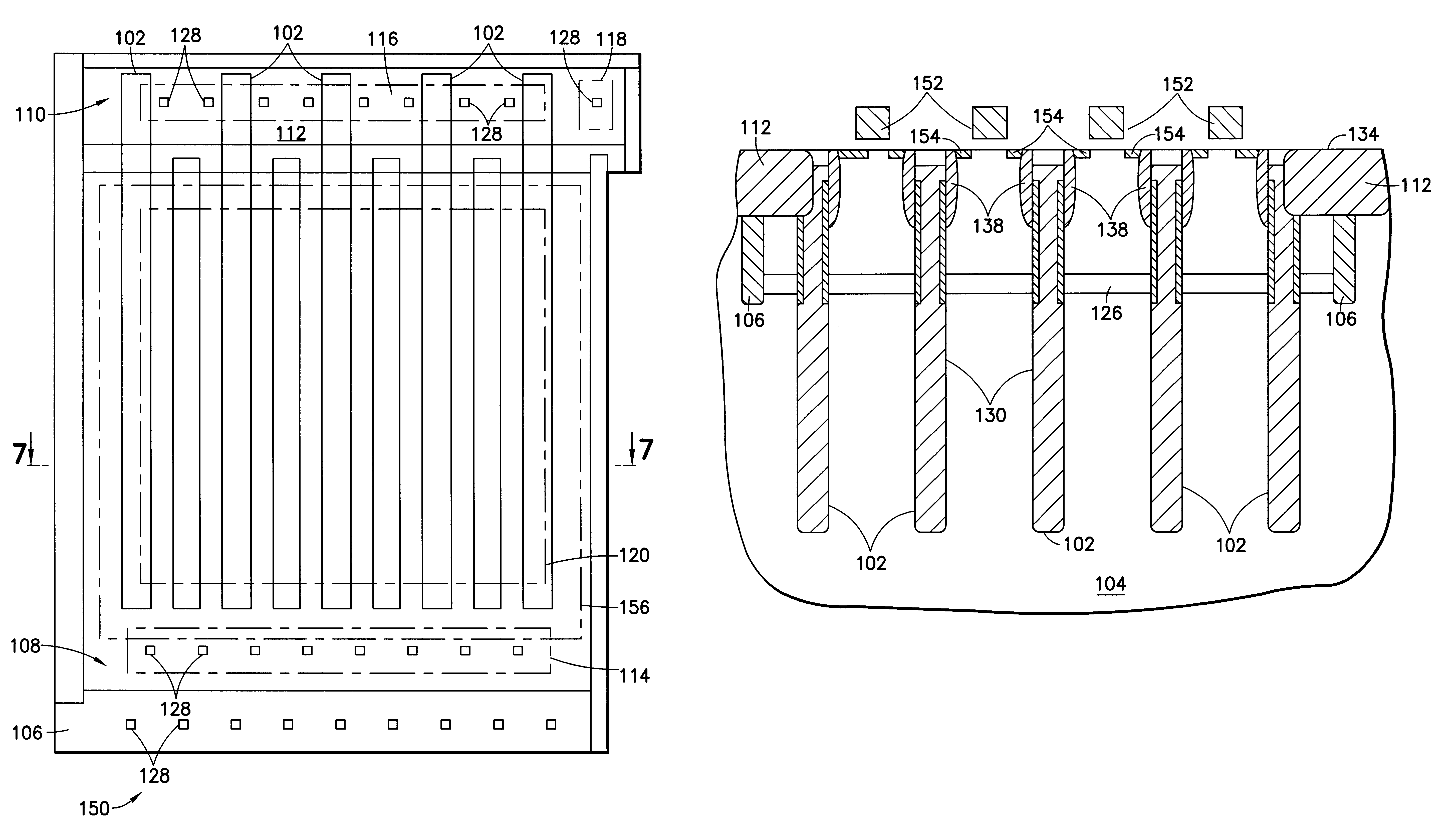

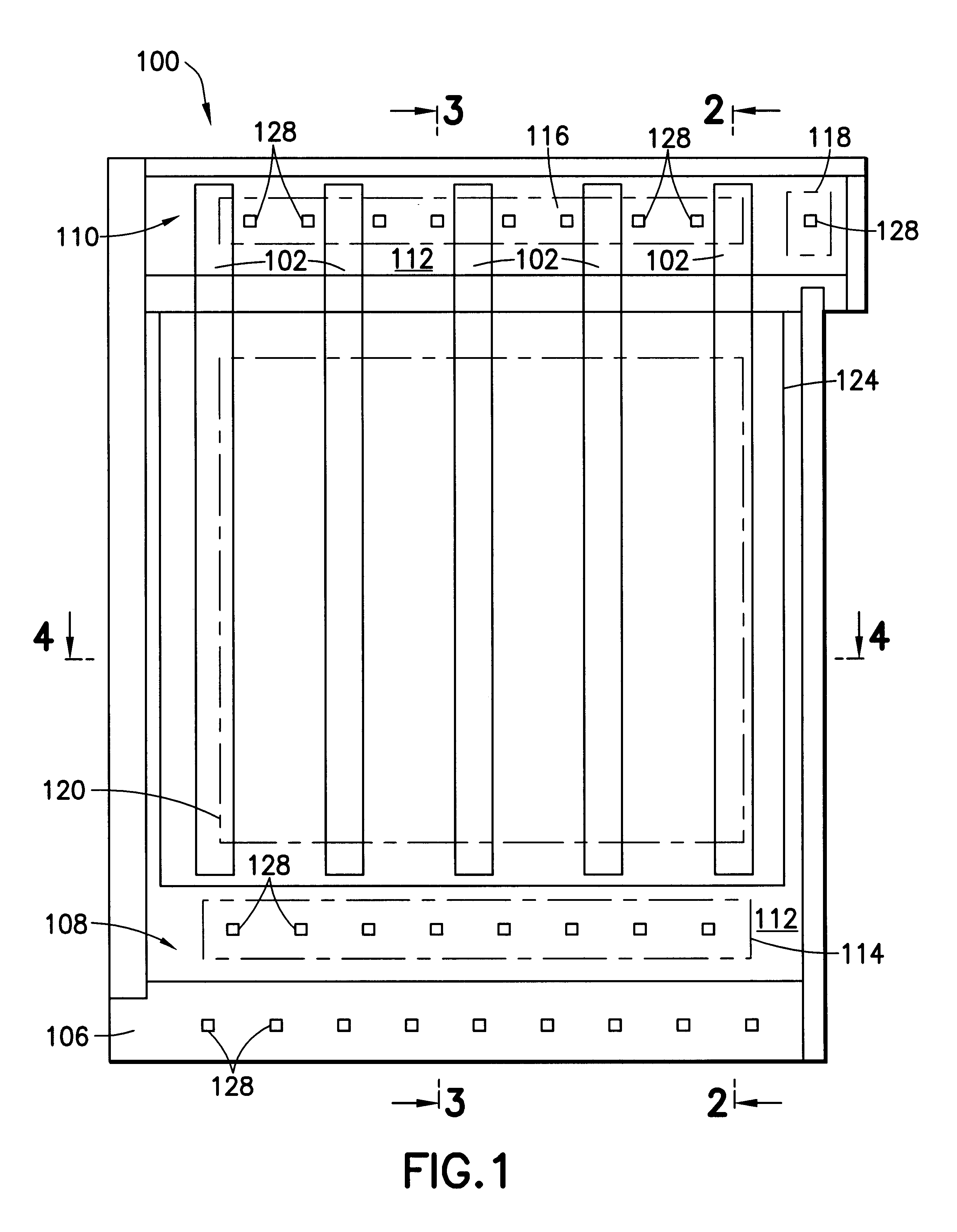

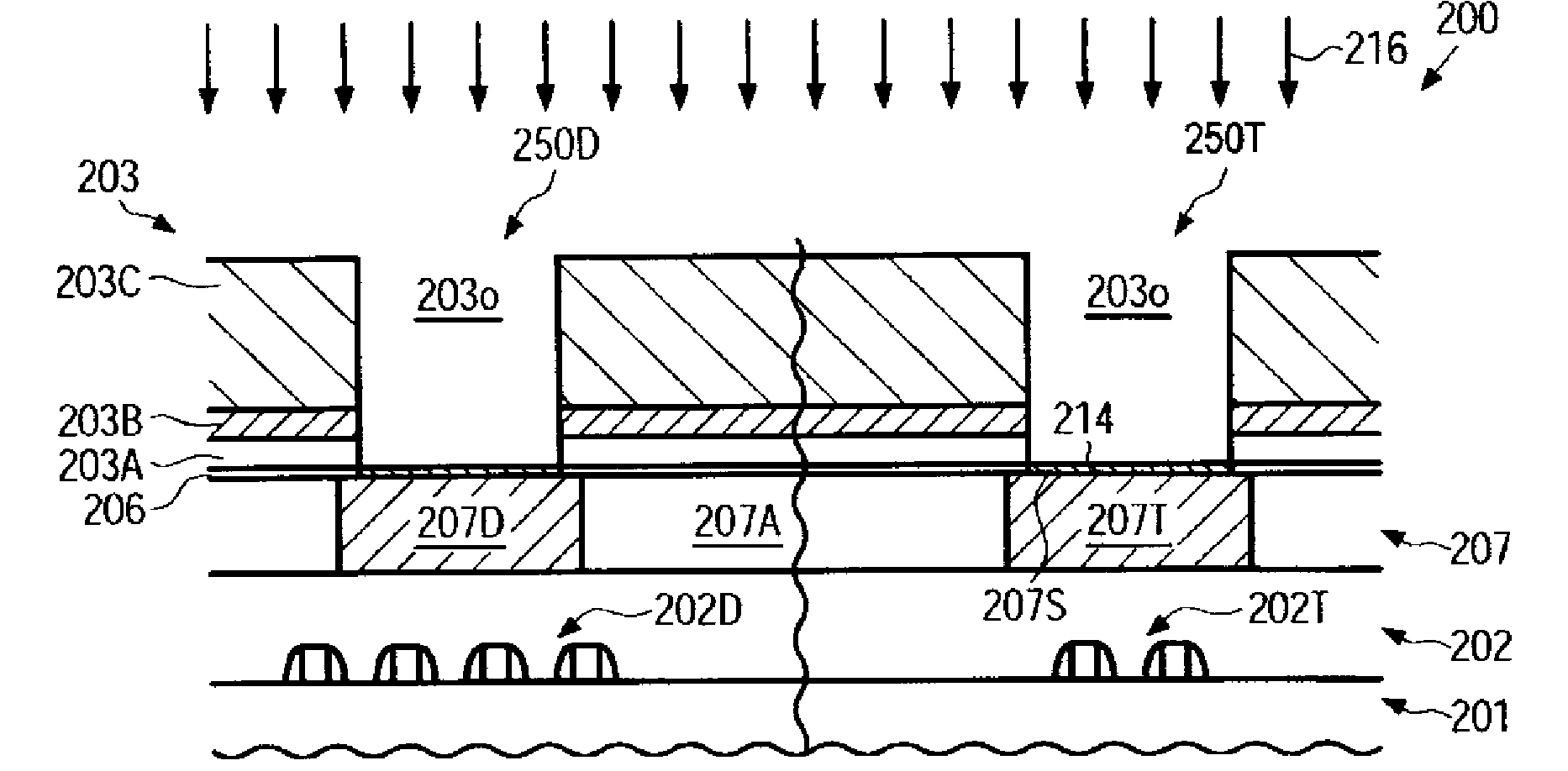

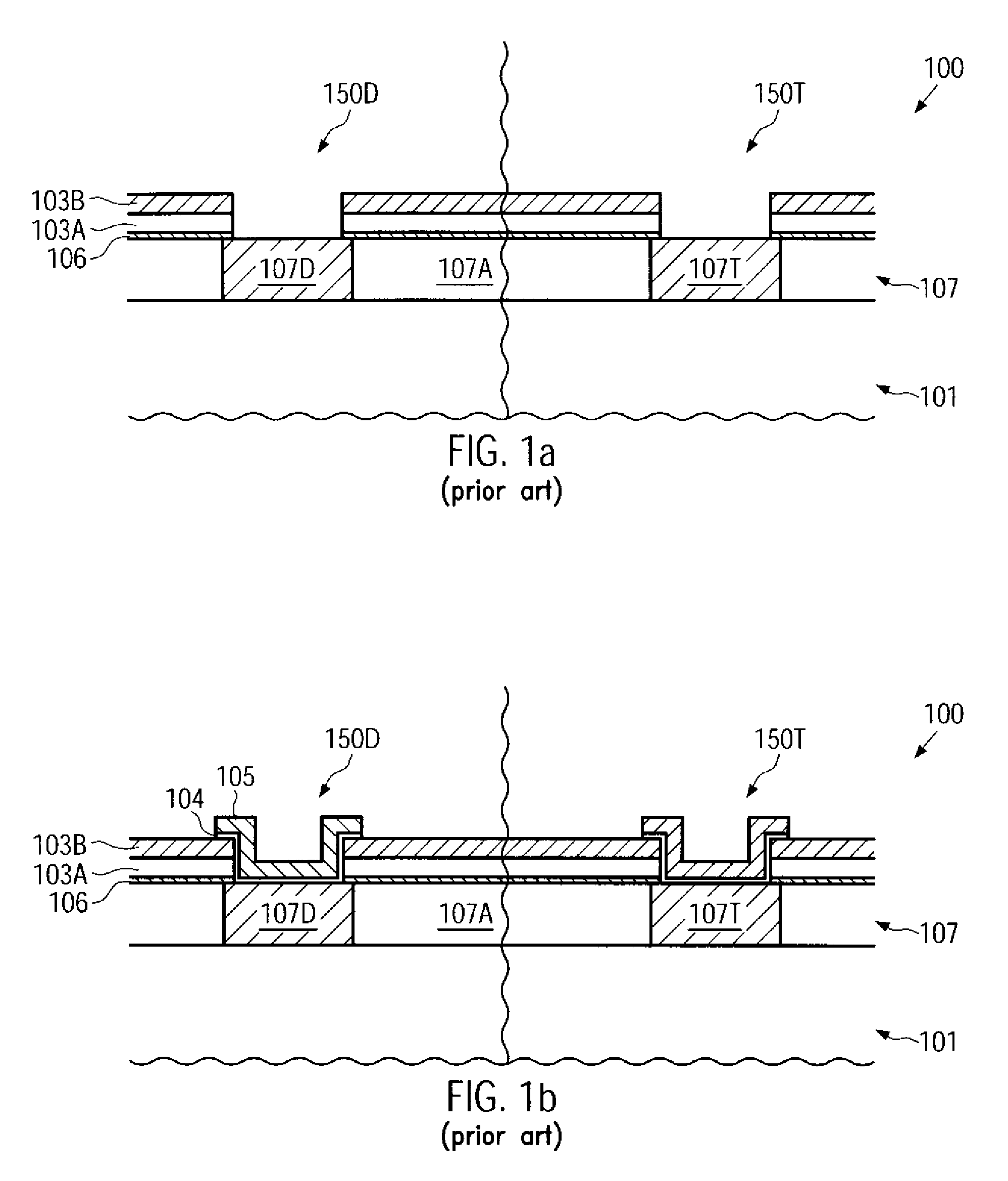

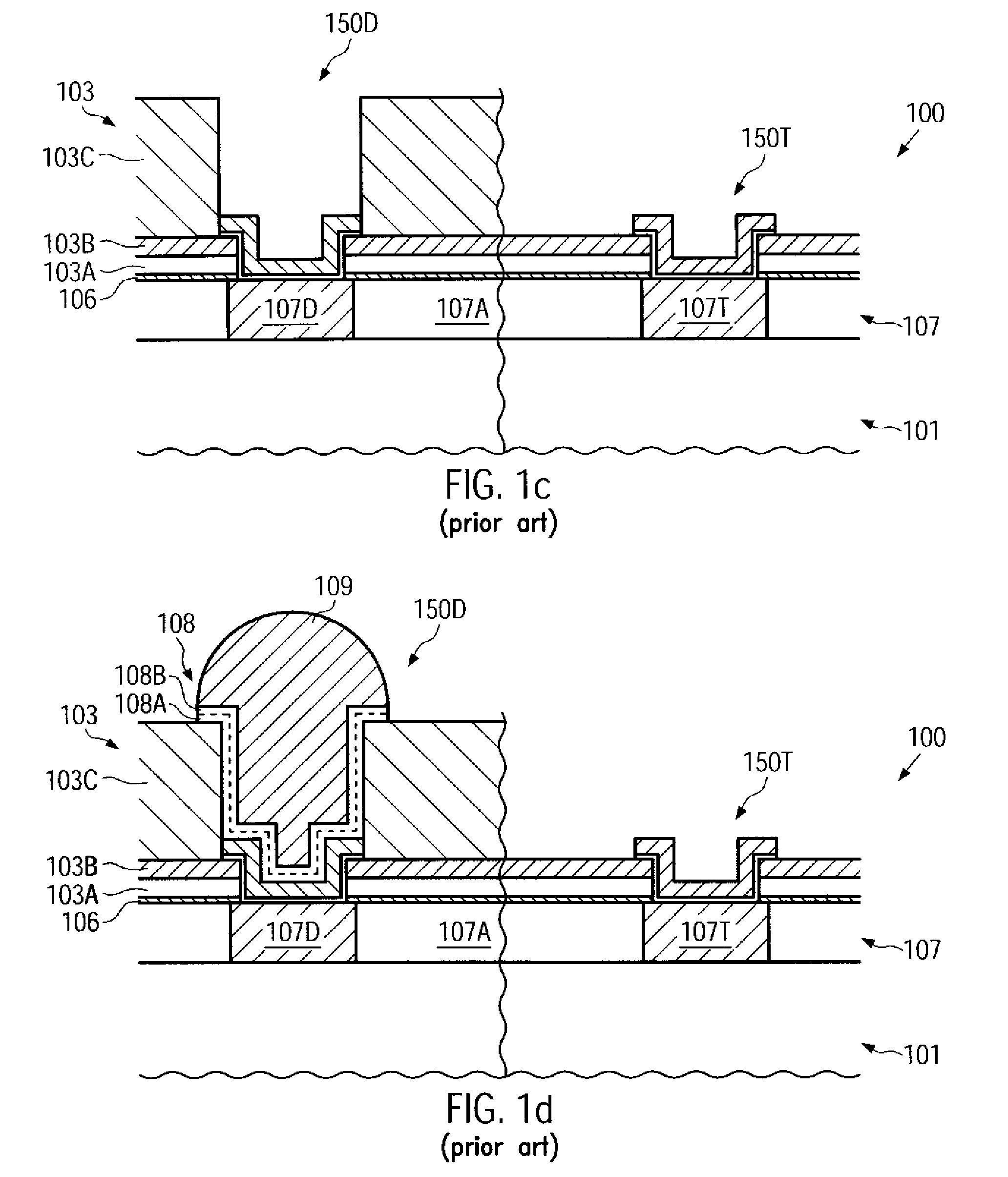

Semiconductor integrated test structures for electron beam inspection of semiconductor wafers

ActiveUS7679083B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCMOSEngineering

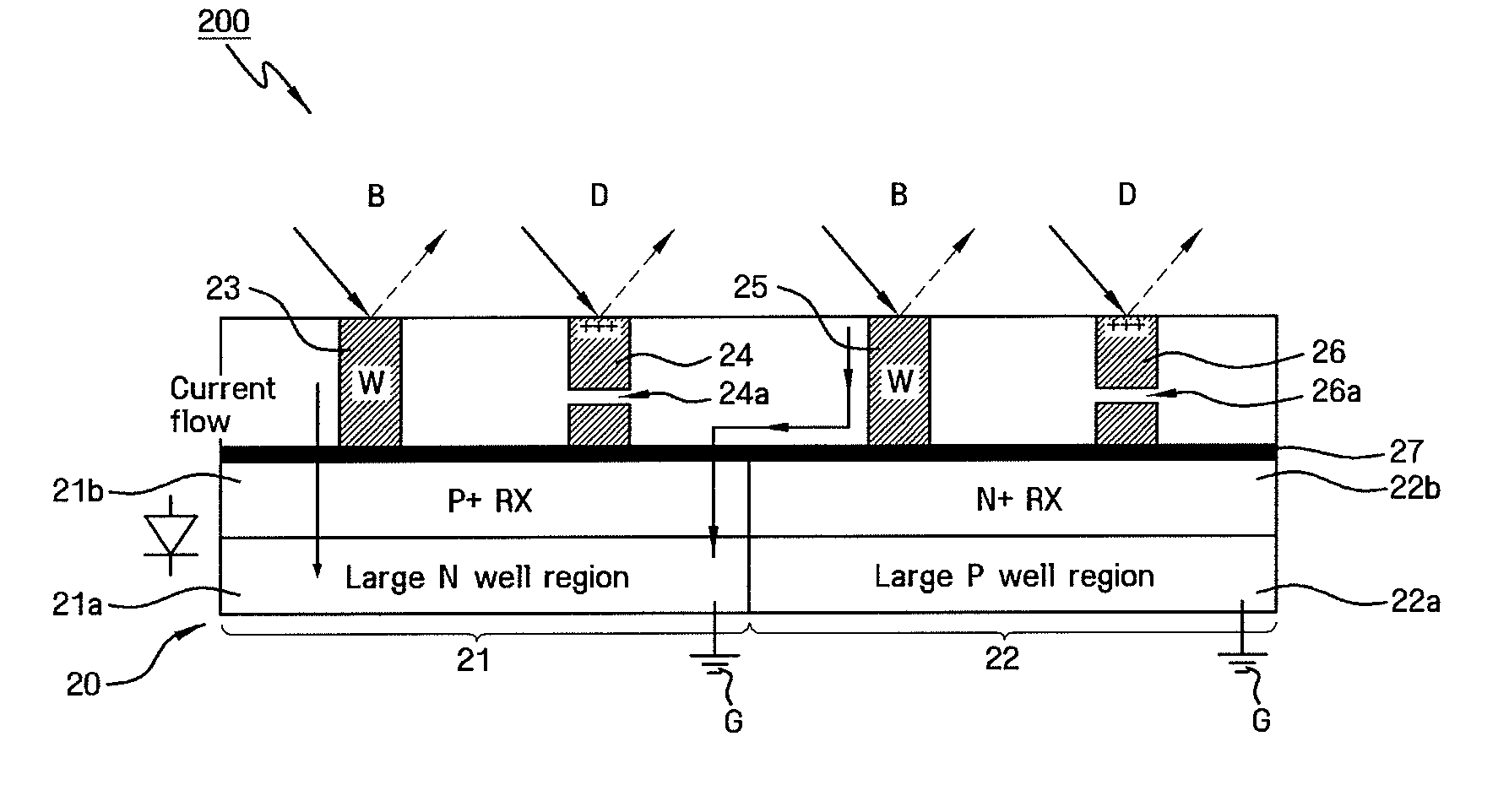

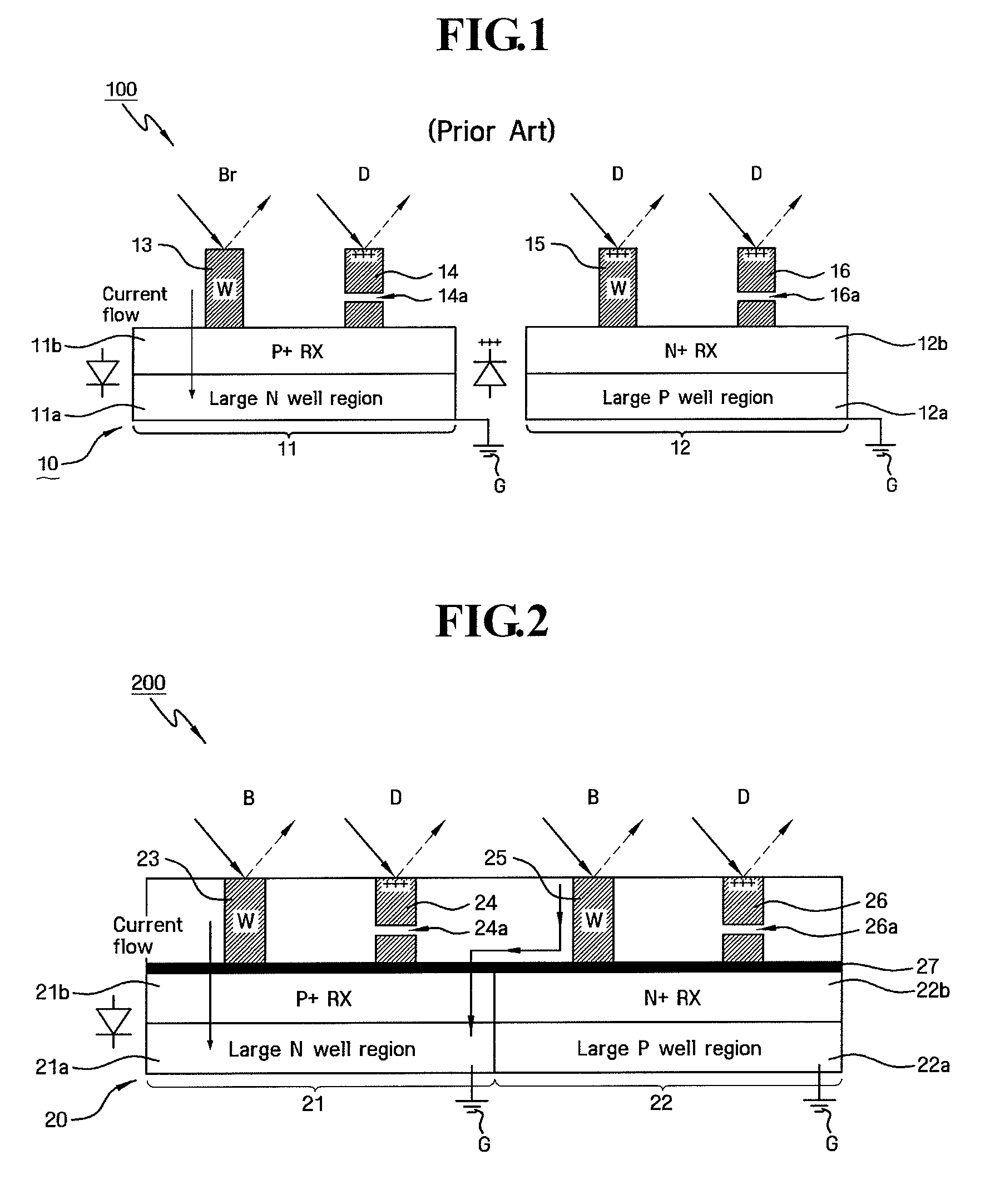

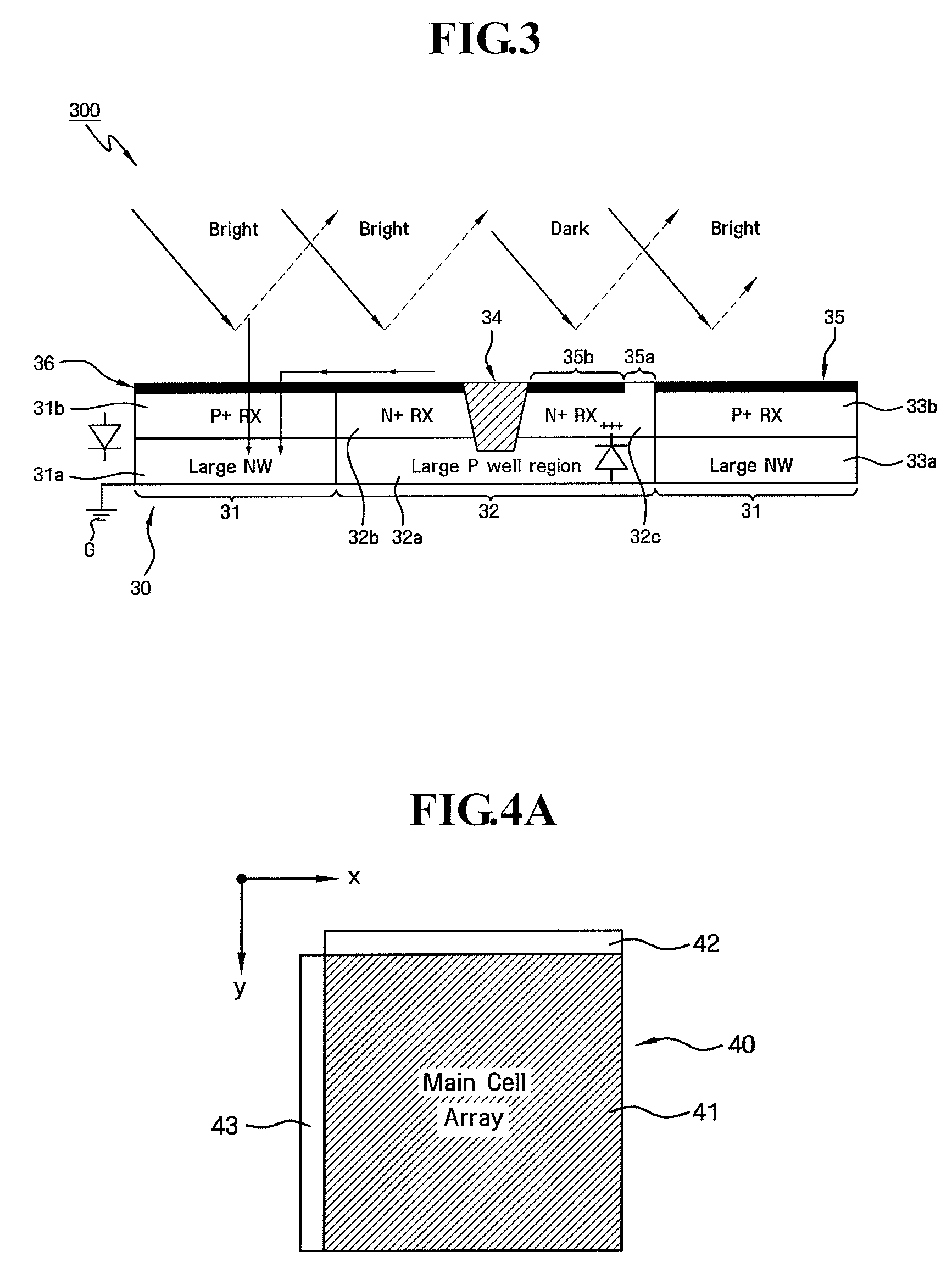

Semiconductor integrated test structures are designed for electron beam inspection of semiconductor wafers. The test structures include pattern features that are formed in designated test regions of the wafer concurrently with pattern features of integrated circuits formed on the wafer. The test structures include conductive structures that are designed to enable differential charging between defective and non-defective features (or defective and non-defection portions of a given feature) to facilitate voltage contrast defect detection of CMOS devices, for example, using a single, low energy electron beam scan, notwithstanding the existence of p / n junctions in the wafer substrate or other elements / features.

Owner:SAMSUNG ELECTRONICS CO LTD +2

Semiconductor Integrated Test Structures For Electron Beam Inspection of Semiconductor Wafers

ActiveUS20080237586A1Easy to detectSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCMOSEngineering

Semiconductor integrated test structures are designed for electron beam inspection of semiconductor wafers. The test structures include pattern features that are formed in designated test regions of the wafer concurrently with pattern features of integrated circuits formed on the wafer. The test structures include conductive structures that are designed to enable differential charging between defective and non-defective features (or defective and non-defection portions of a given feature) to facilitate voltage contrast defect detection of CMOS devices, for example, using a single, low energy electron beam scan, notwithstanding the existence of p / n junctions in the wafer substrate or other elements / features.

Owner:SAMSUNG ELECTRONICS CO LTD +2

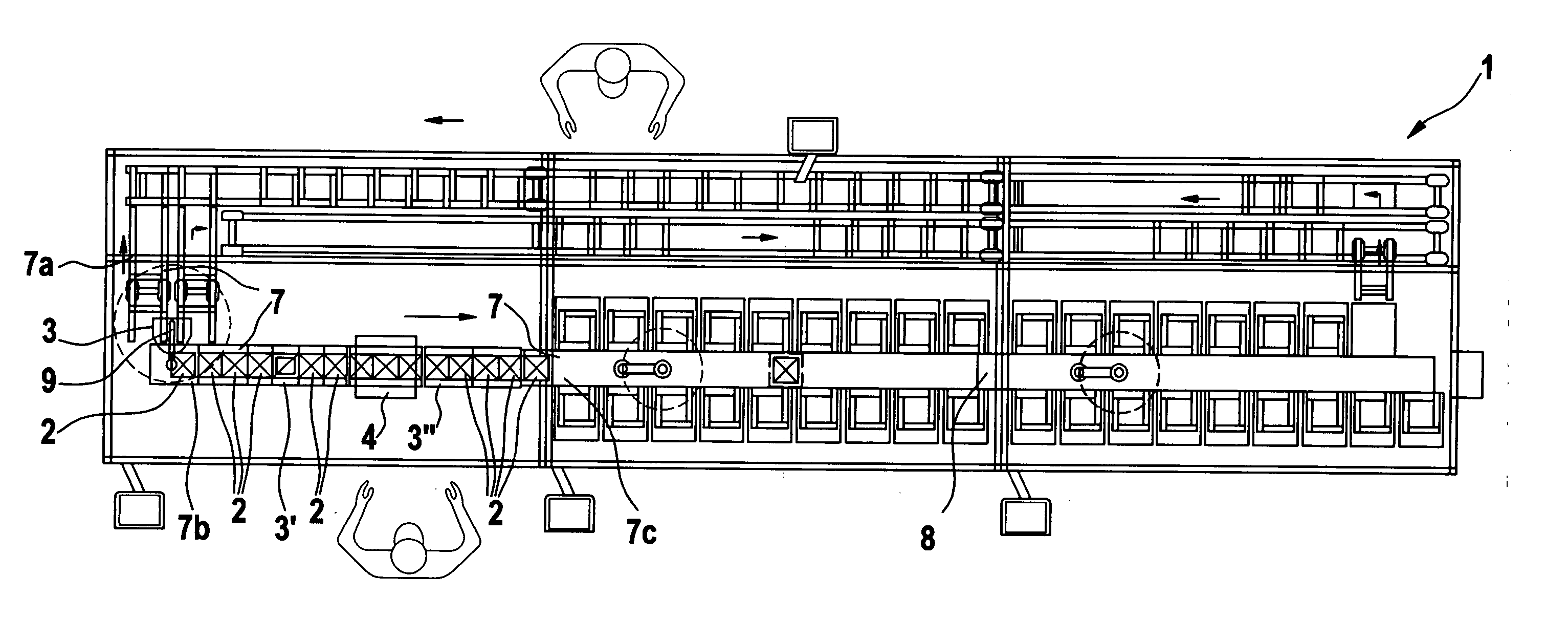

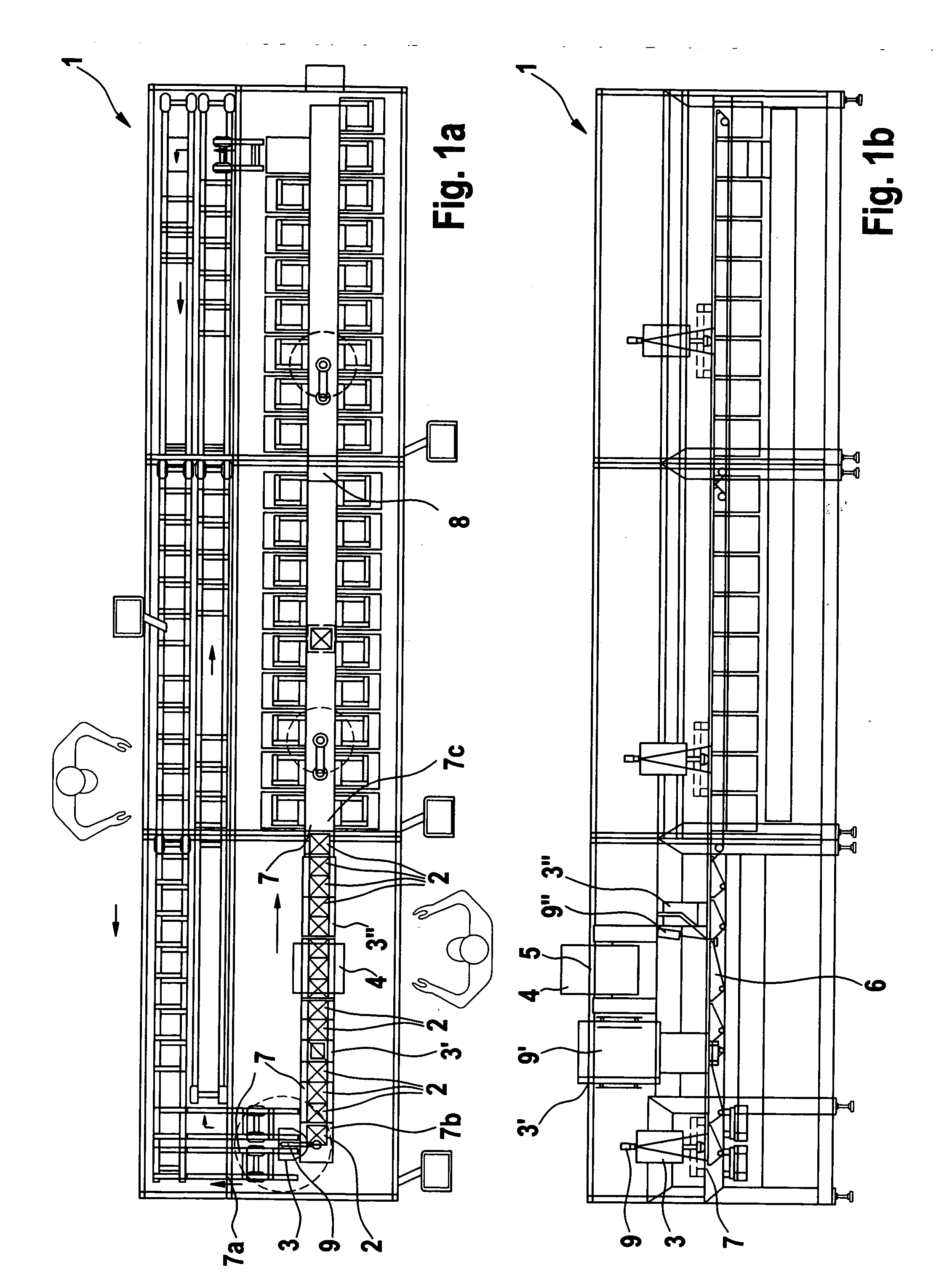

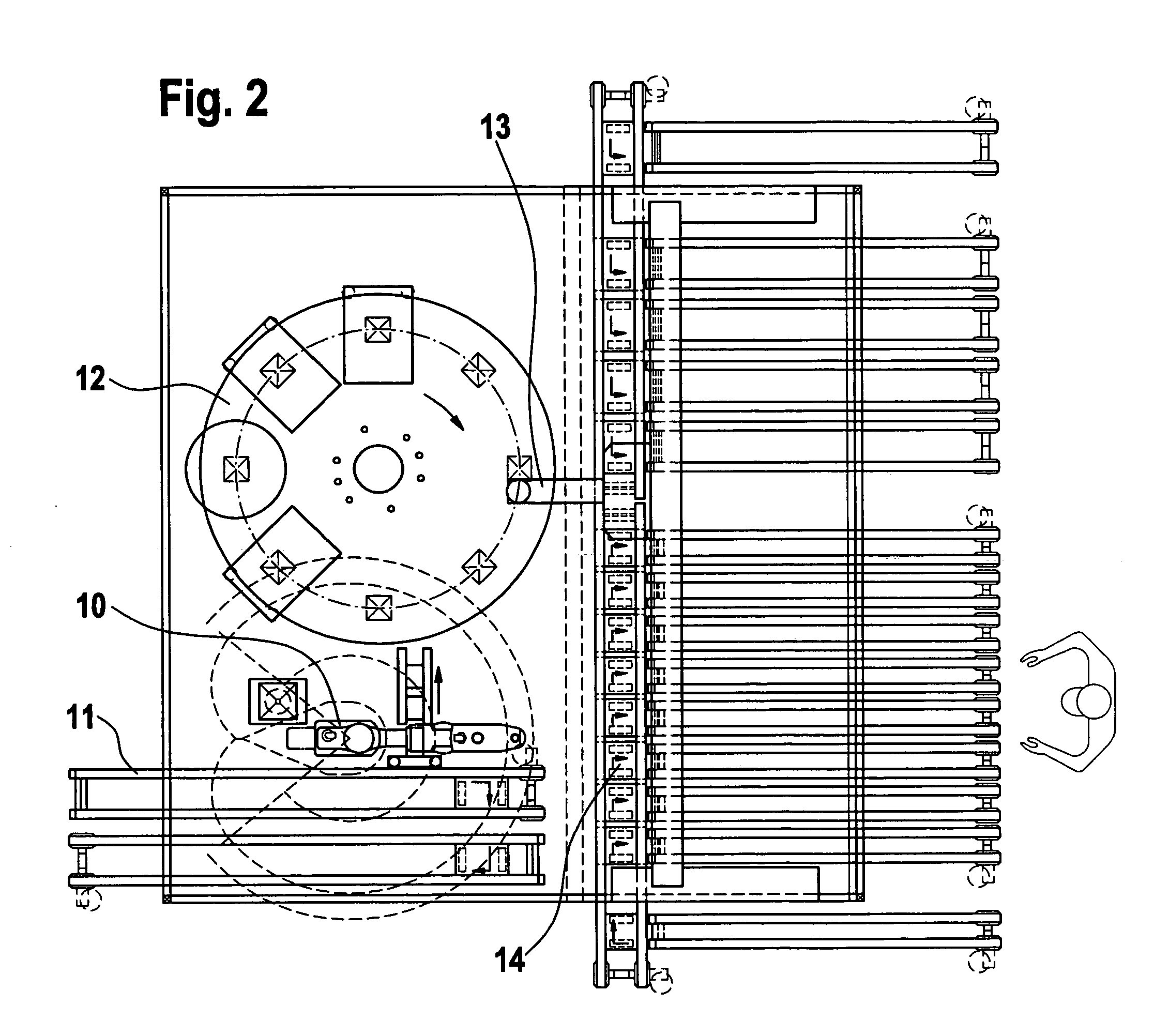

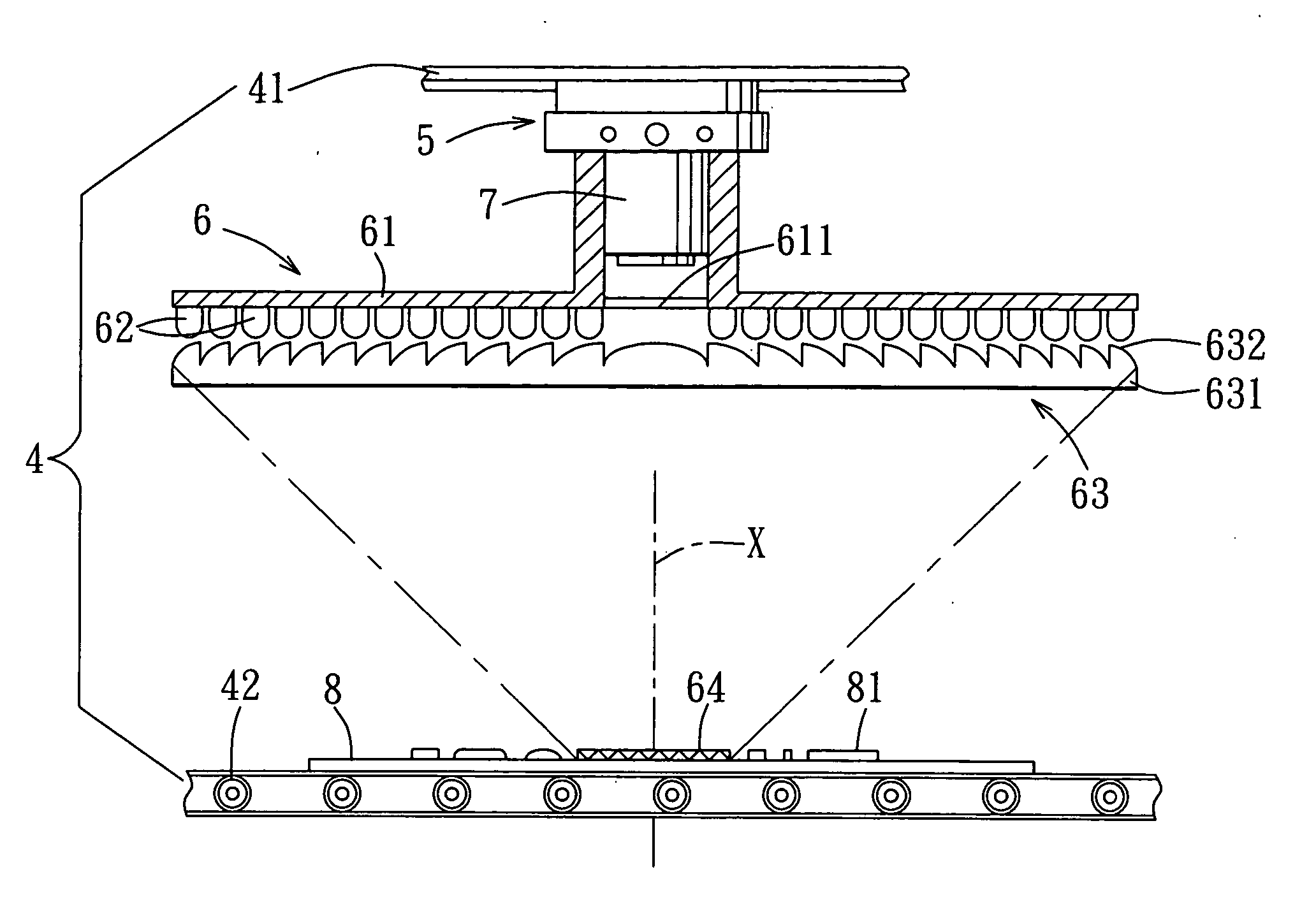

Testing system for solar cells

InactiveUS20060103371A1Improve refinementShorten cycle timePhotovoltaic monitoringElectronic circuit testingElectricityElectrical battery

A testing system for optical and electrical monitoring of a production quality and / or for determining optical and electrical properties of solar cells, comprising a first conveyor device for conveying the solar cells to a test region, a second conveyor device for moving the solar cells through the test region, a third conveyor device for conveying the solar cells out of the test region, an optical checking device located in the test region for visual checking of the solar, and an electrical checking device also located in the test region for checking electrical functions of the solar cells, the electrical checking device including an illumination device for shining light on light-sensitive surfaces of the solar cells and also including an electrical contacting device for picking up voltages and / or currents and electrical contacts of the solar cells, the first, second and third conveyor devices including a common, linear conveyor belt system which passes through the test region and has a vacuum suction device for holding the solar cells on a surface of a conveyor belt system.

Owner:MANZ AUTOMATION

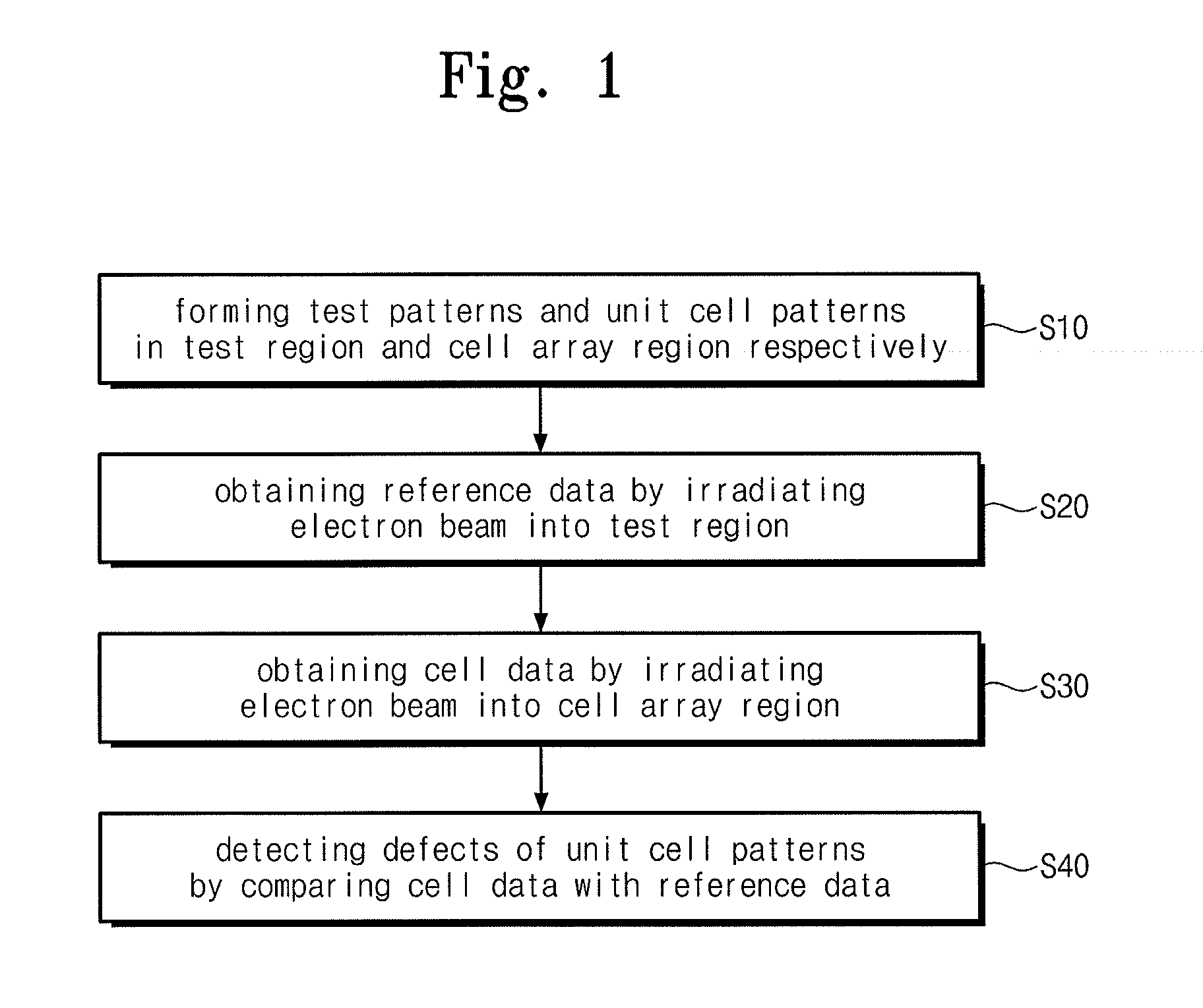

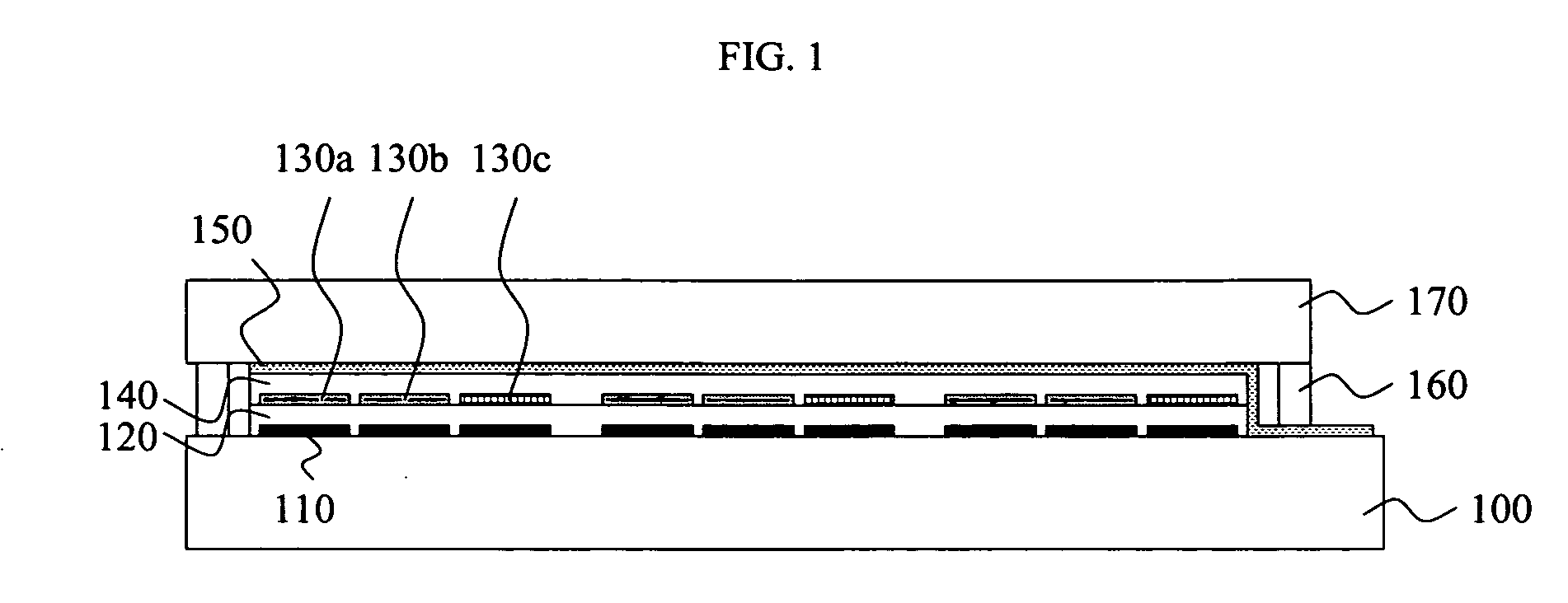

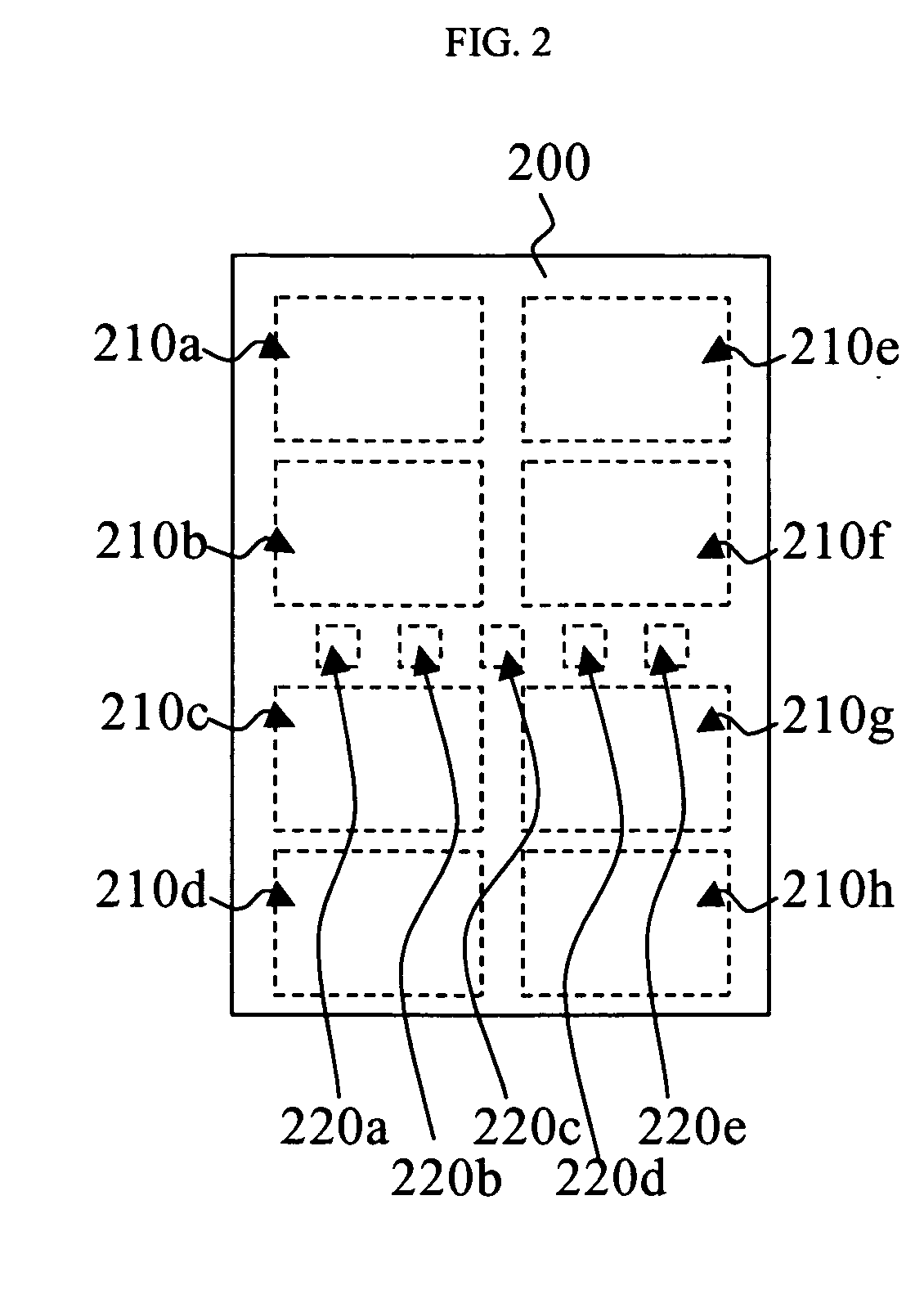

Method of detecting defects in a semiconductor device and semiconductor device using the same

ActiveUS20120268159A1Semiconductor/solid-state device testing/measurementSolid-state devicesCell patternDevice material

A method of detecting a defect of a semiconductor device includes forming test patterns and unit cell patterns in a test region a cell array region of a substrate, respectively, obtaining reference data with respect to the test patterns by irradiating an electron beam into the test region, obtaining cell data by irradiating the electron beam into the cell array region, and detecting defects of the unit cell patterns by comparing the obtained cell data with the obtained reference data.

Owner:SAMSUNG ELECTRONICS CO LTD

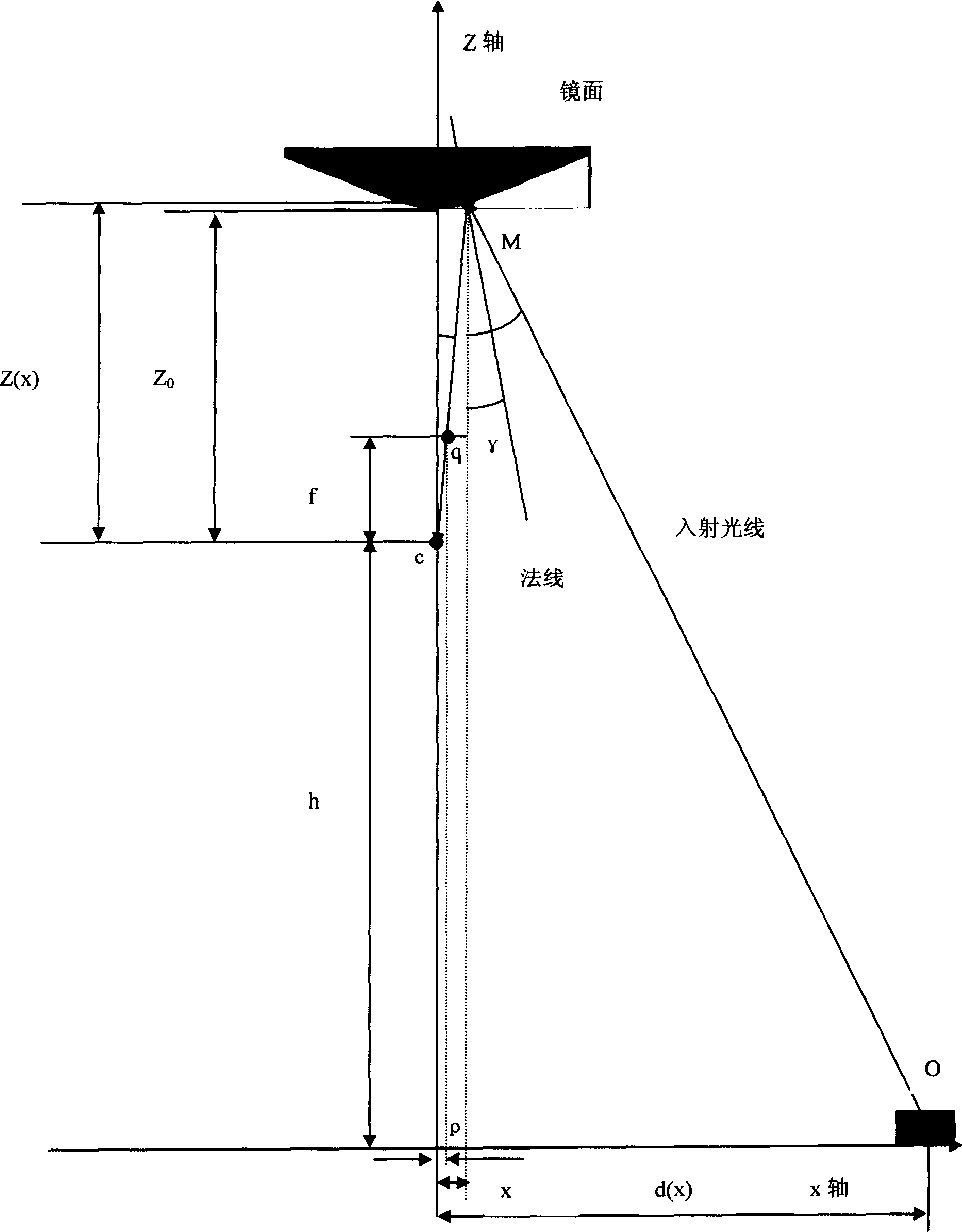

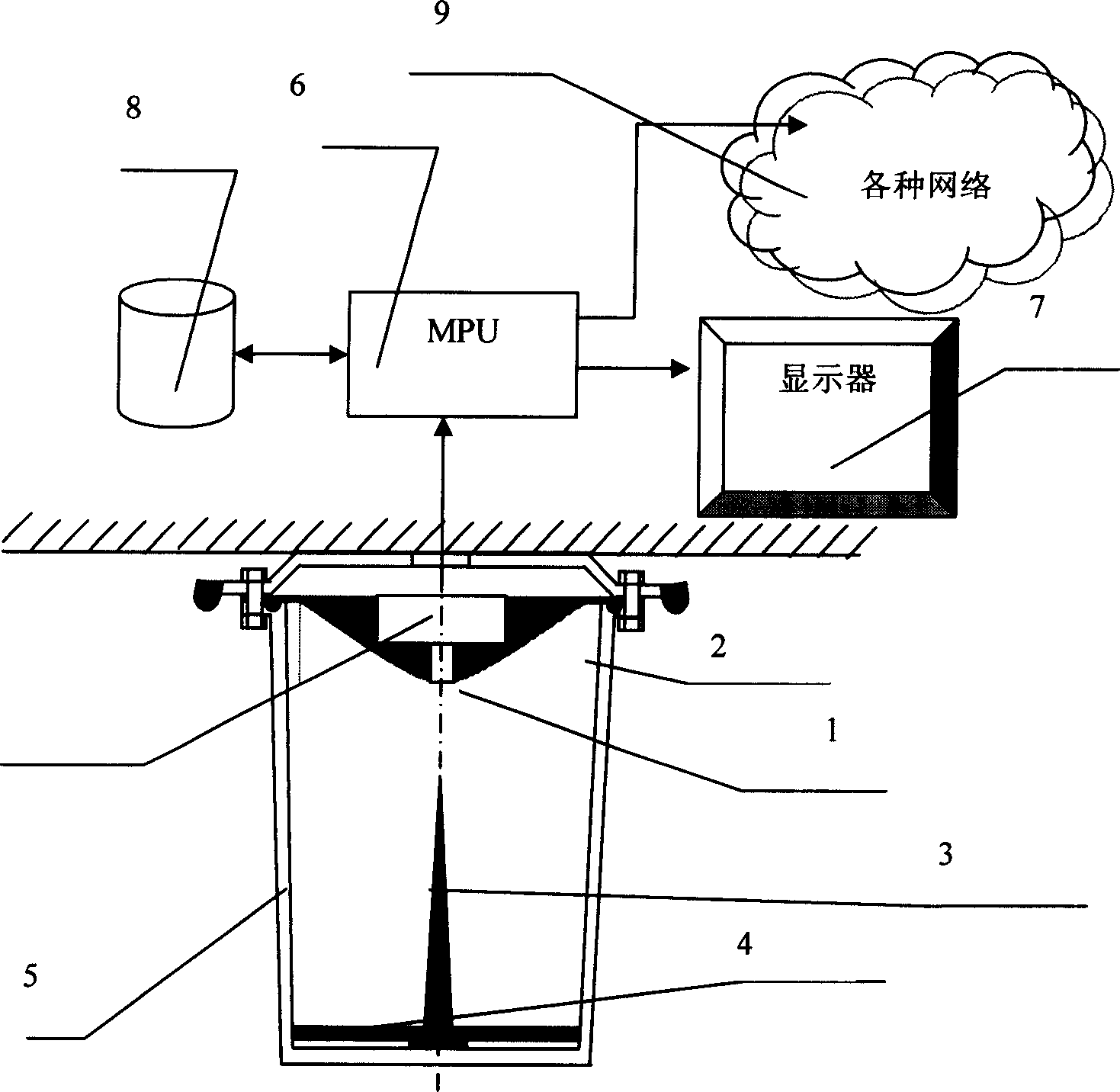

Device for monitoring vehicle breaking regulation based on all-position visual sensor

InactiveCN1912950AFree installation positionReliable acquisitionControlling traffic signalsDetection of traffic movementTraffic signalProcess module

This invention relates to a device for monitoring peccancy cars based on omnibearing vision sensors including a microprocessor, a monitor sensor monitoring road situations and traffic signal lamps, in which, the sensor, an omnibearing vision sensor, is connected with the microprocessor including: an image data read module, an image data file storage module, a sensor rating module, a virtual test line designing module, a designing module for roadway transit directions, a designing module for traffic signal lamp state test regions, an image spread process module, a color space transforming module, an adaptive background deduction process module, a connected region identification module, a moving car tracing module and a car paccancy judgment module with a road paccancy judgment unit for directions and a road paccancy judgment unit without roadway directions.

Owner:ZHEJIANG UNIV OF TECH

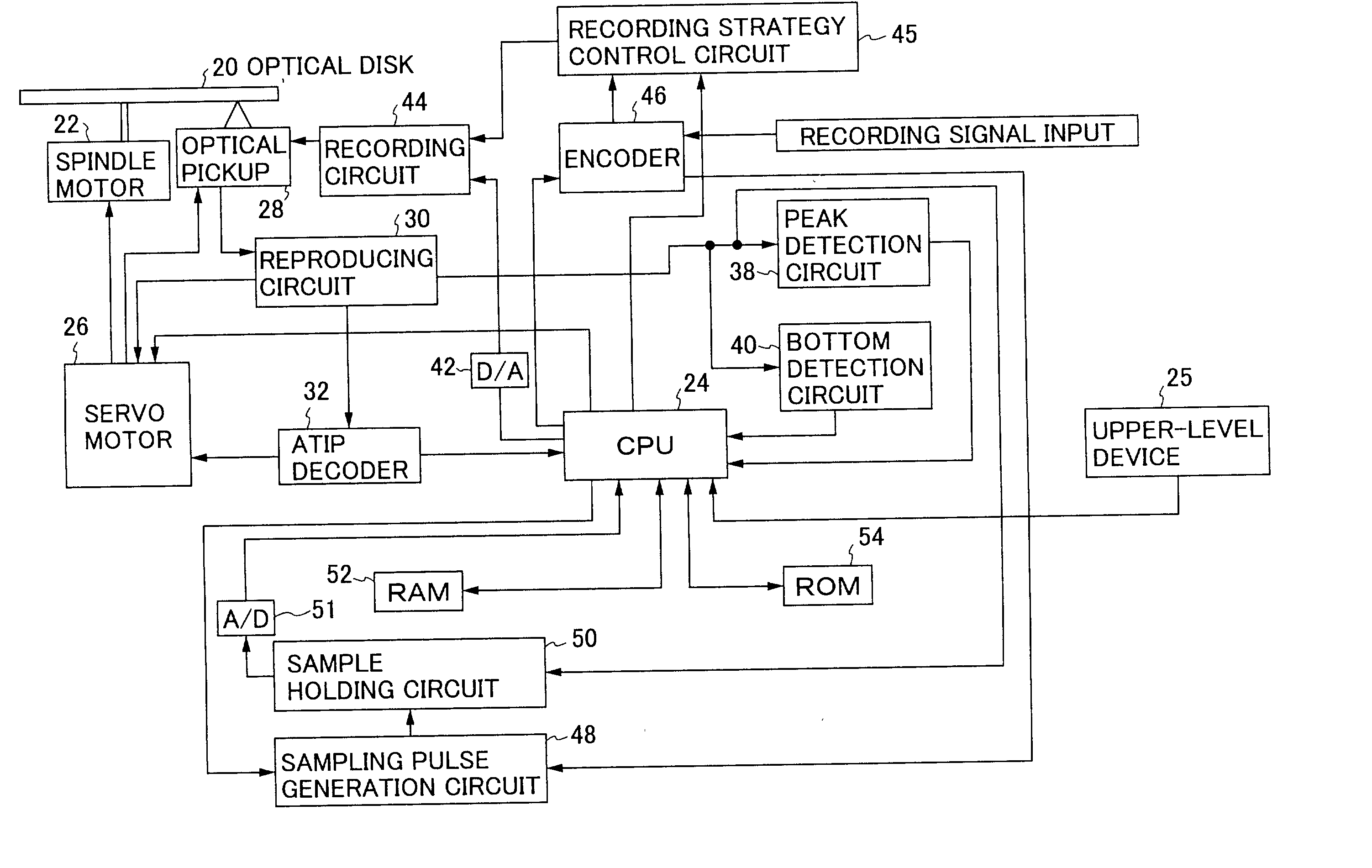

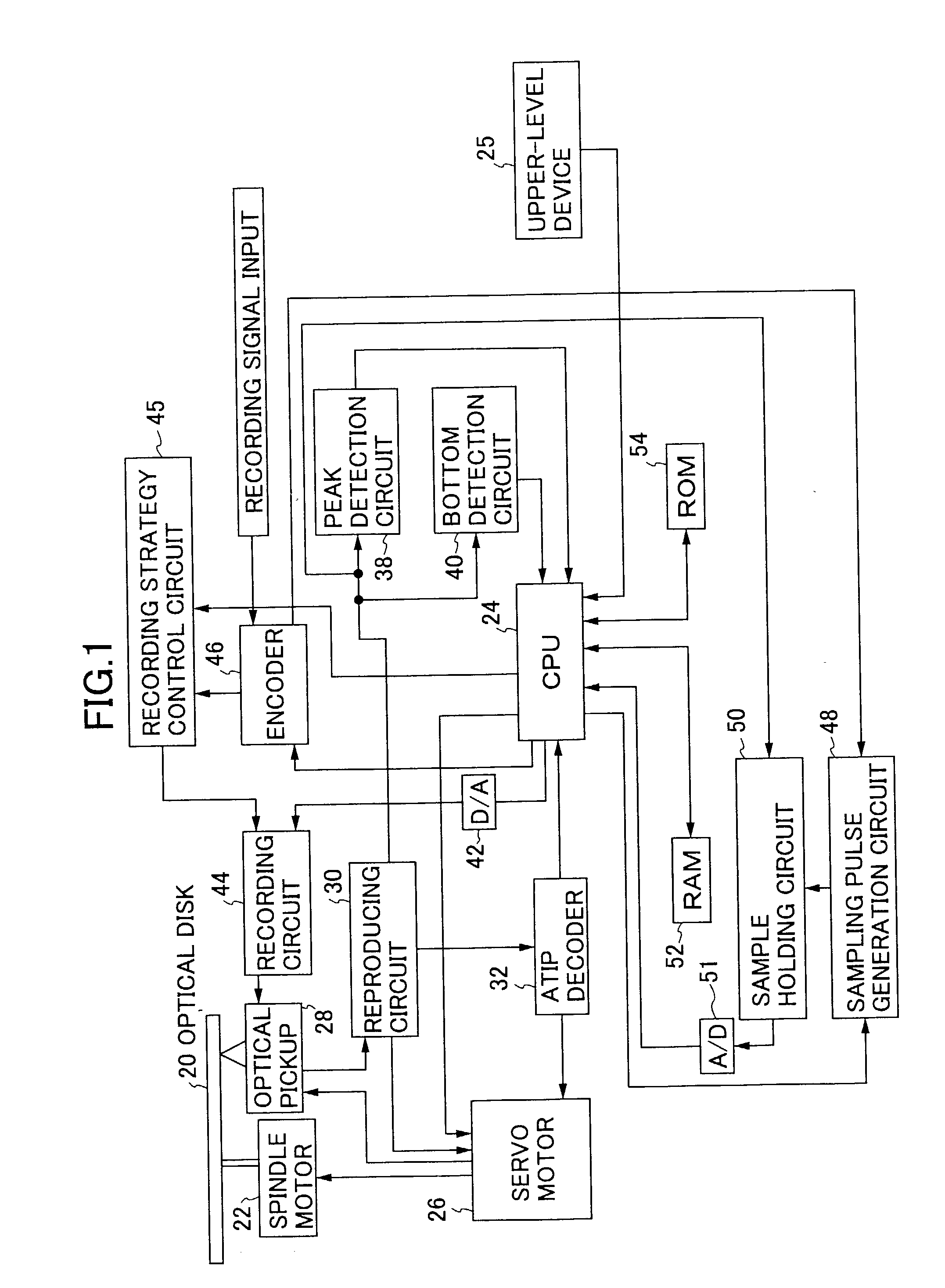

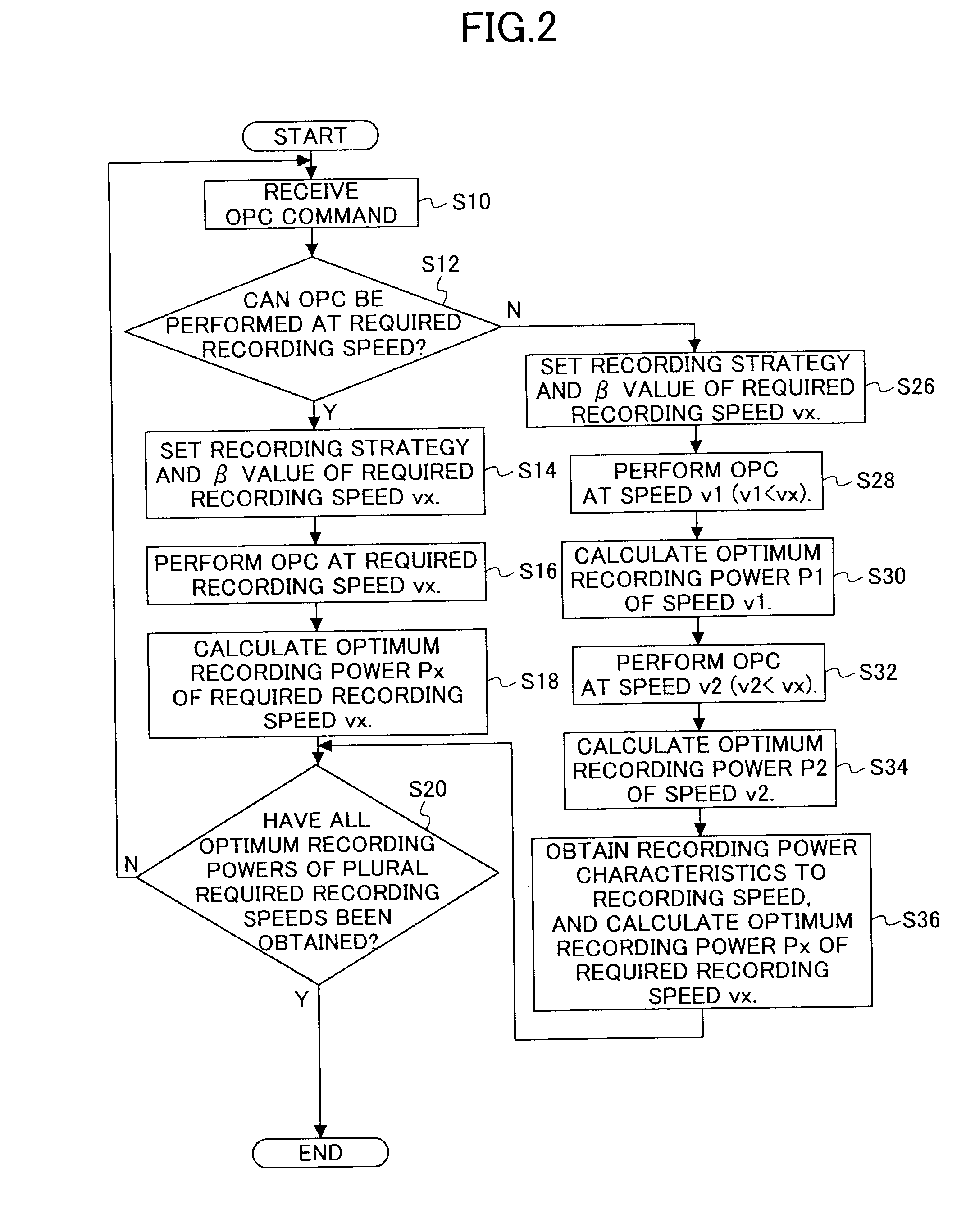

Optical disk device

InactiveUS20030086346A1Avoid timePrevent the PCA from being largely consumedFilamentary/web record carriersOptical beam sourcesEngineeringTest region

An optical disk device for estimating optimum recording power for high speed recording at an outer part of an optical disk, with high accuracy, even when an OPC for high speed recording at the outer part cannot be performed. The optical disk device includes a first optimum recording power calculation part for performing test recording at a first speed lower than the maximum recording speed of a test area by using recording parameters of a required recording speed to calculate first optimum recording power, and a second optimum recording power calculation part for performing test recording at a second speed to calculate second optimum recording power. The first speed is different from the second speed. The optical disk device further includes an estimation part for estimating optimum recording power for based on the first optimum recording power and the second optimum recording power.

Owner:TEAC CORP

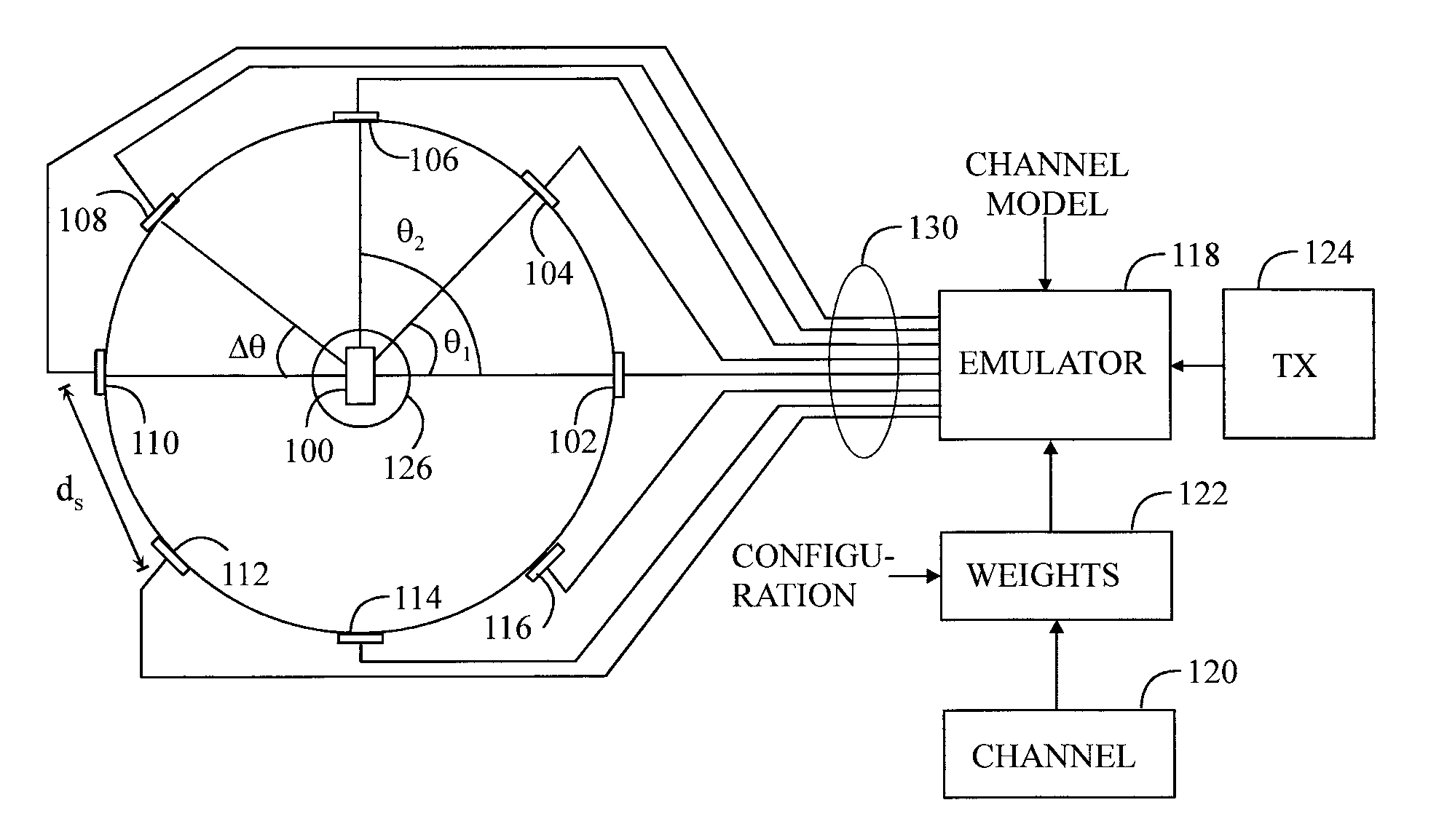

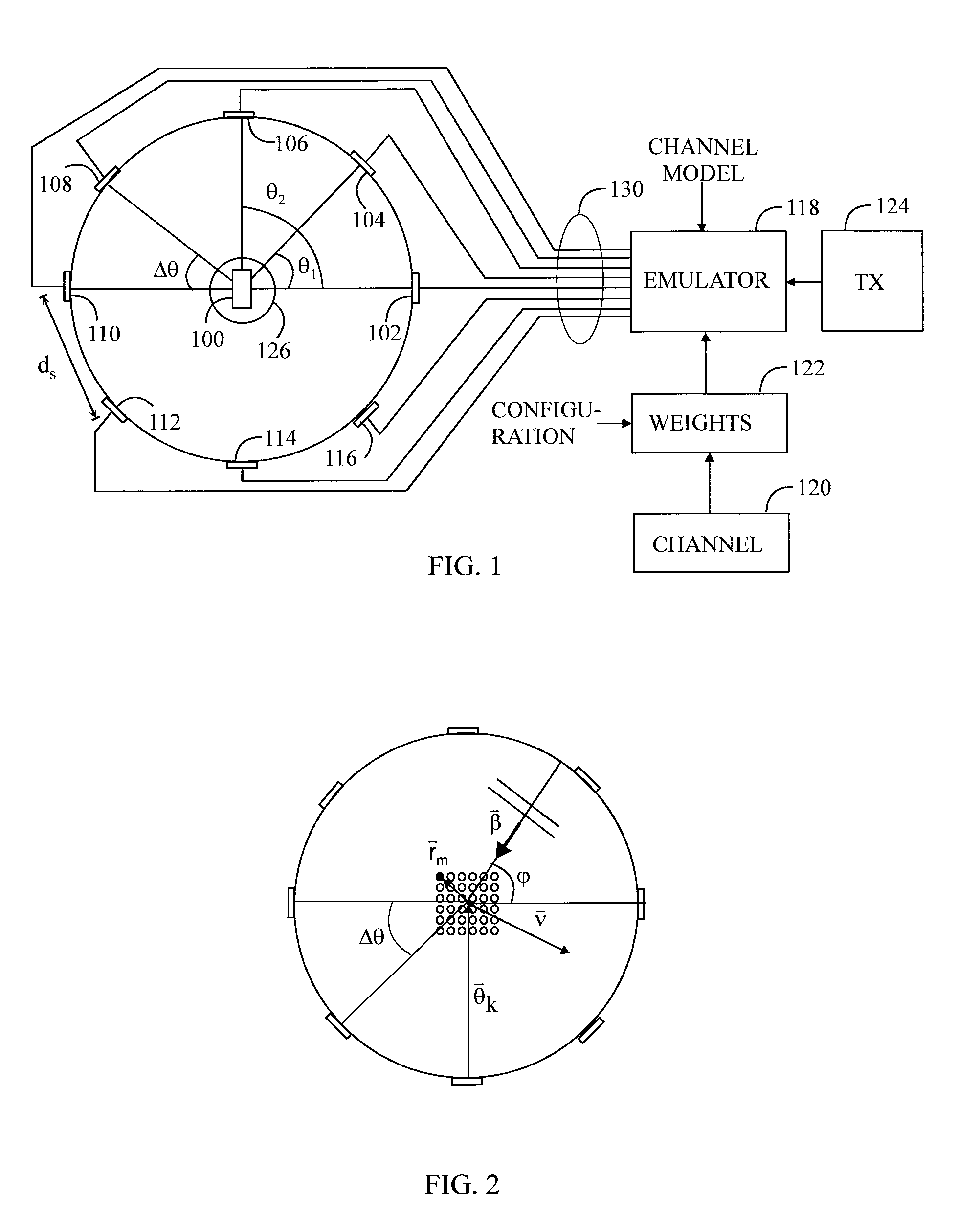

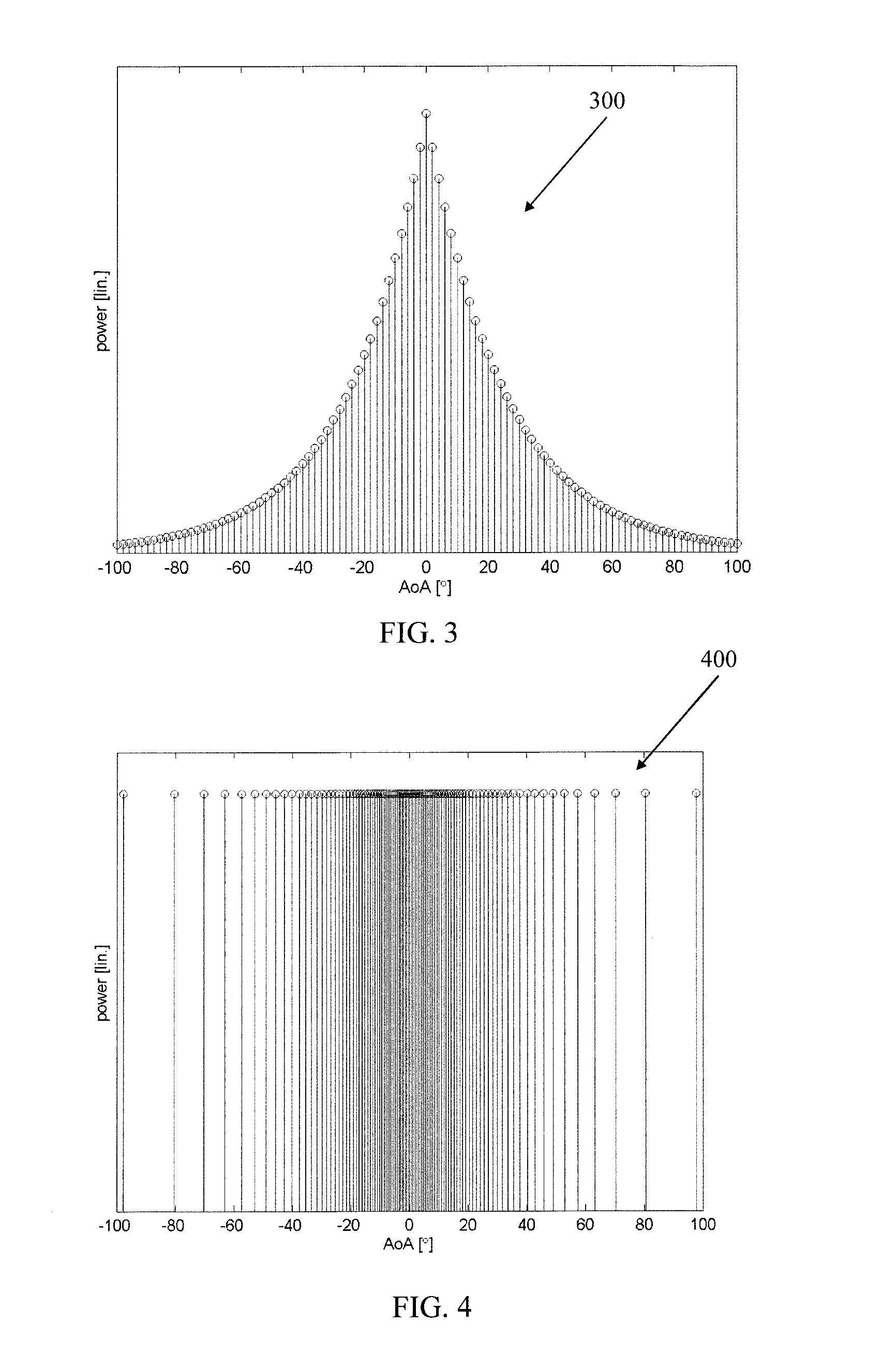

Over-the-Air Test

An apparatus forms a weight for each signal path associated with an antenna of a plurality of antennas around a test zone in an over-the-air chamber by a comparison of a desired target electric field based on a radio channel model and an electric field obtainable by the plane waves associated with the test zone, the plane waves being transmittable by the antennas and being based on at least one basis waveform in each signal path.

Owner:KEYSIGHT TECH SINGAPORE (SALES) PTE LTD

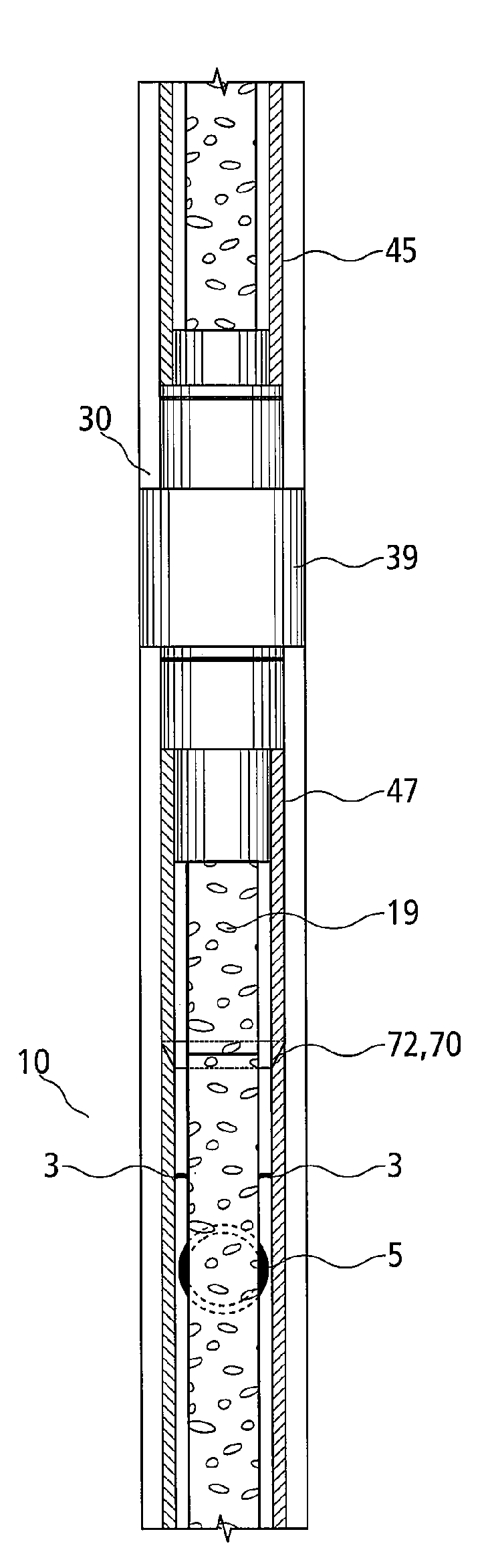

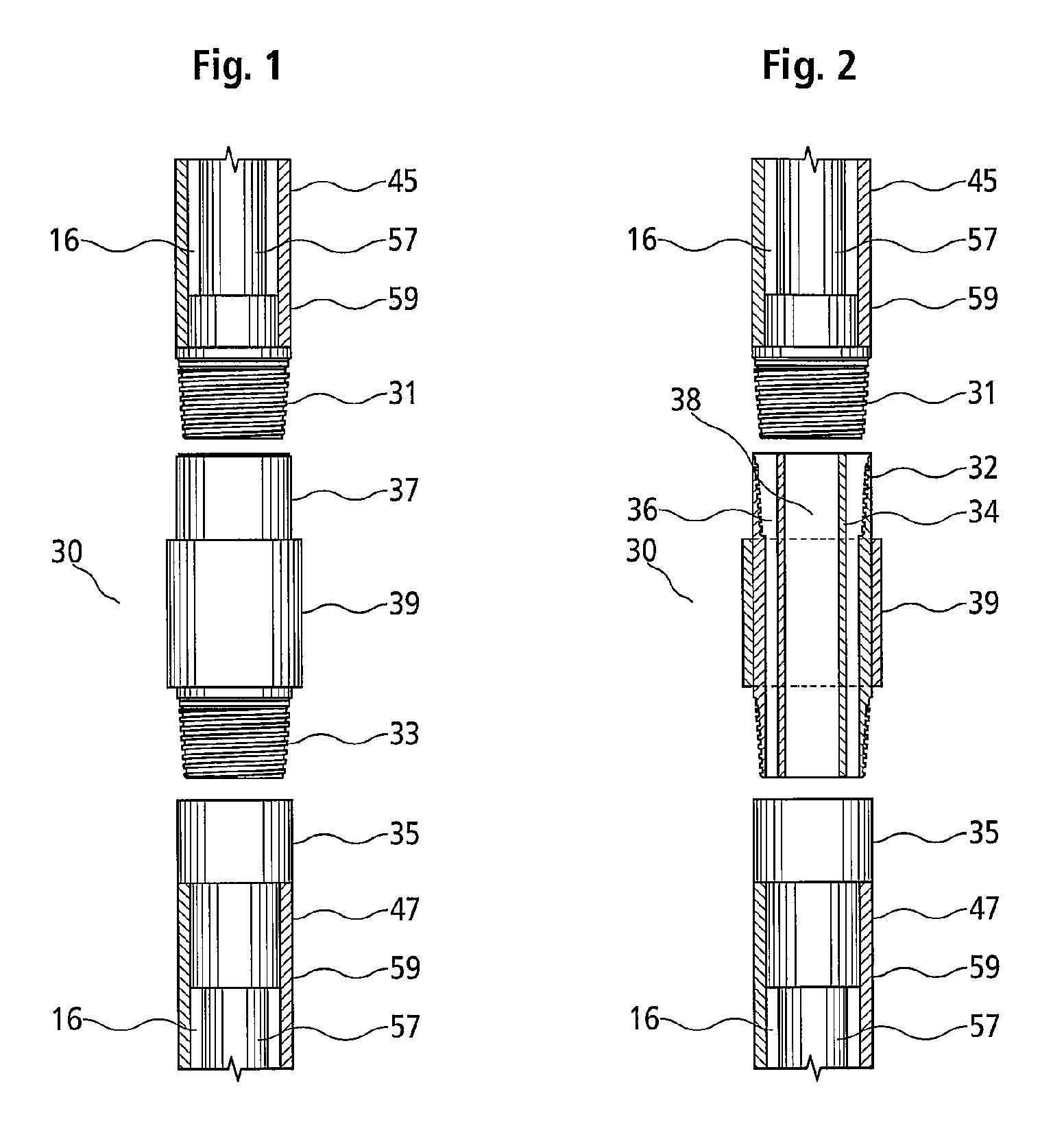

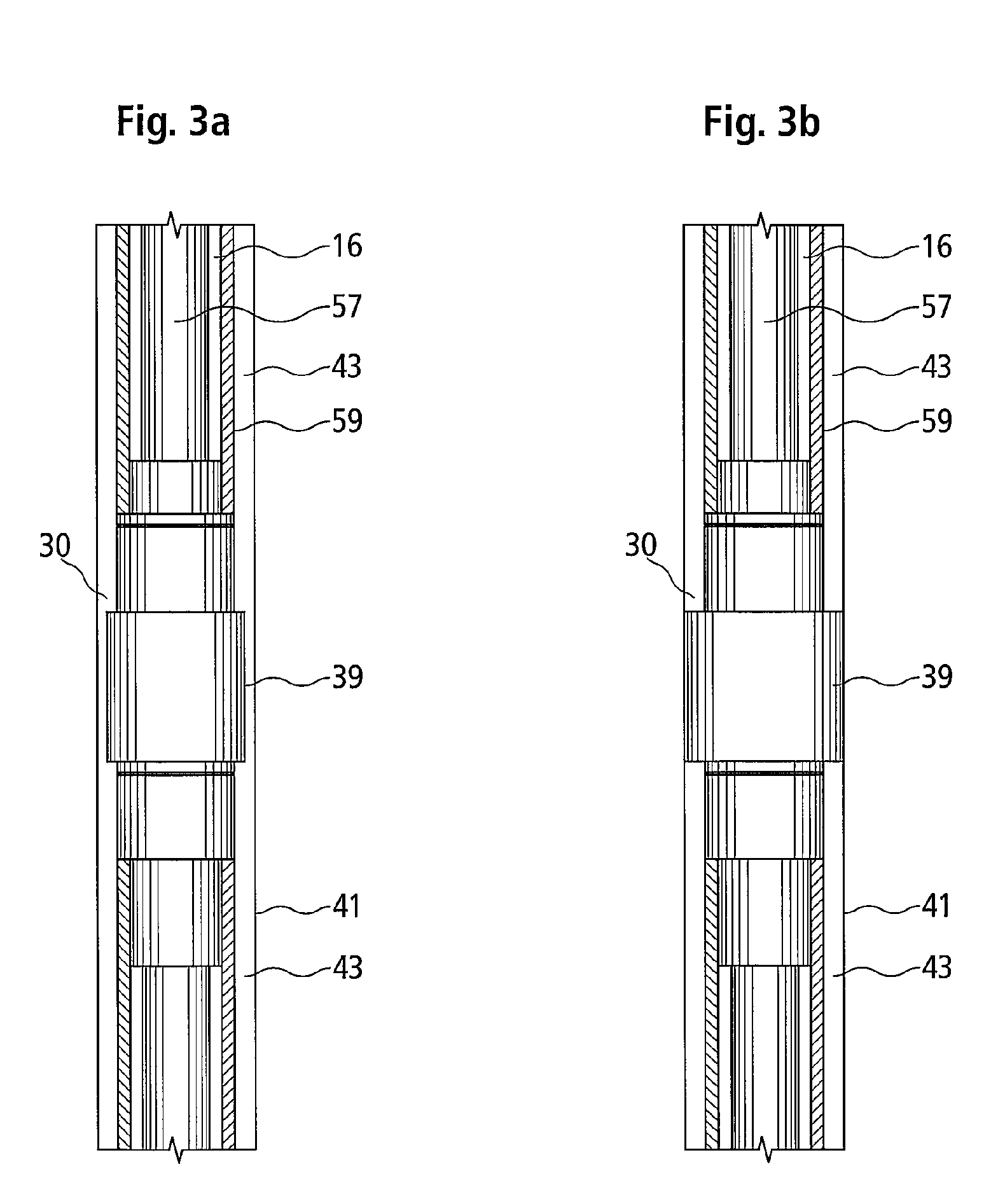

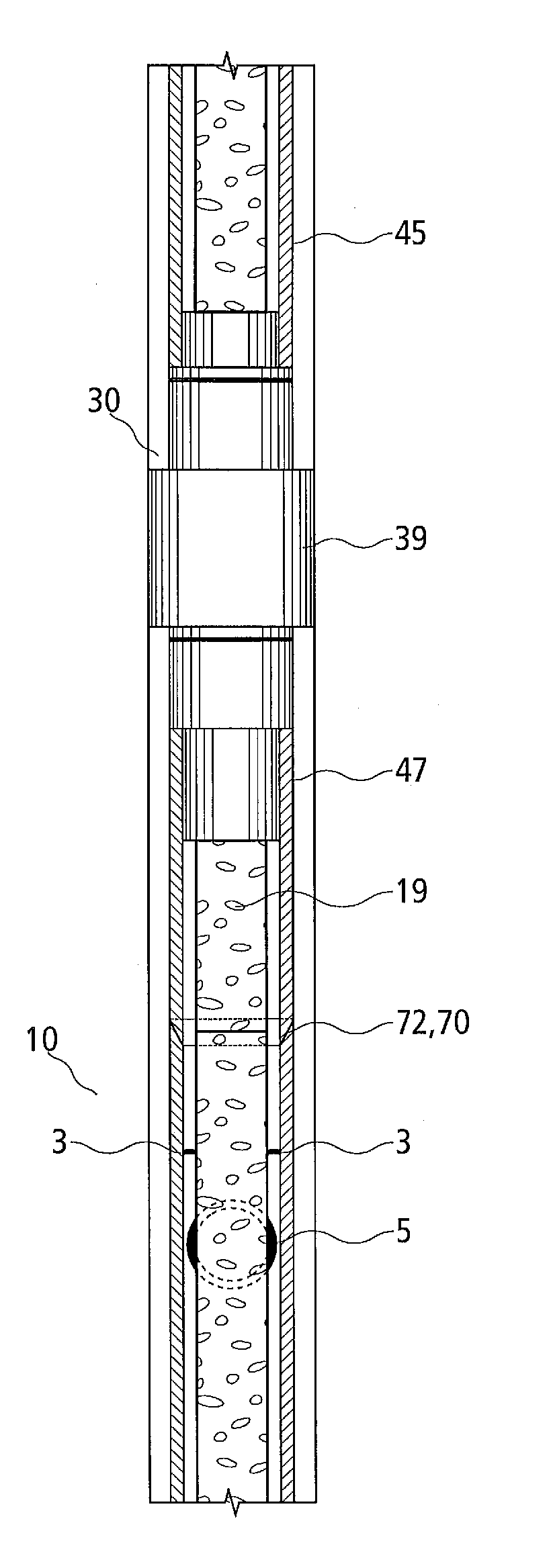

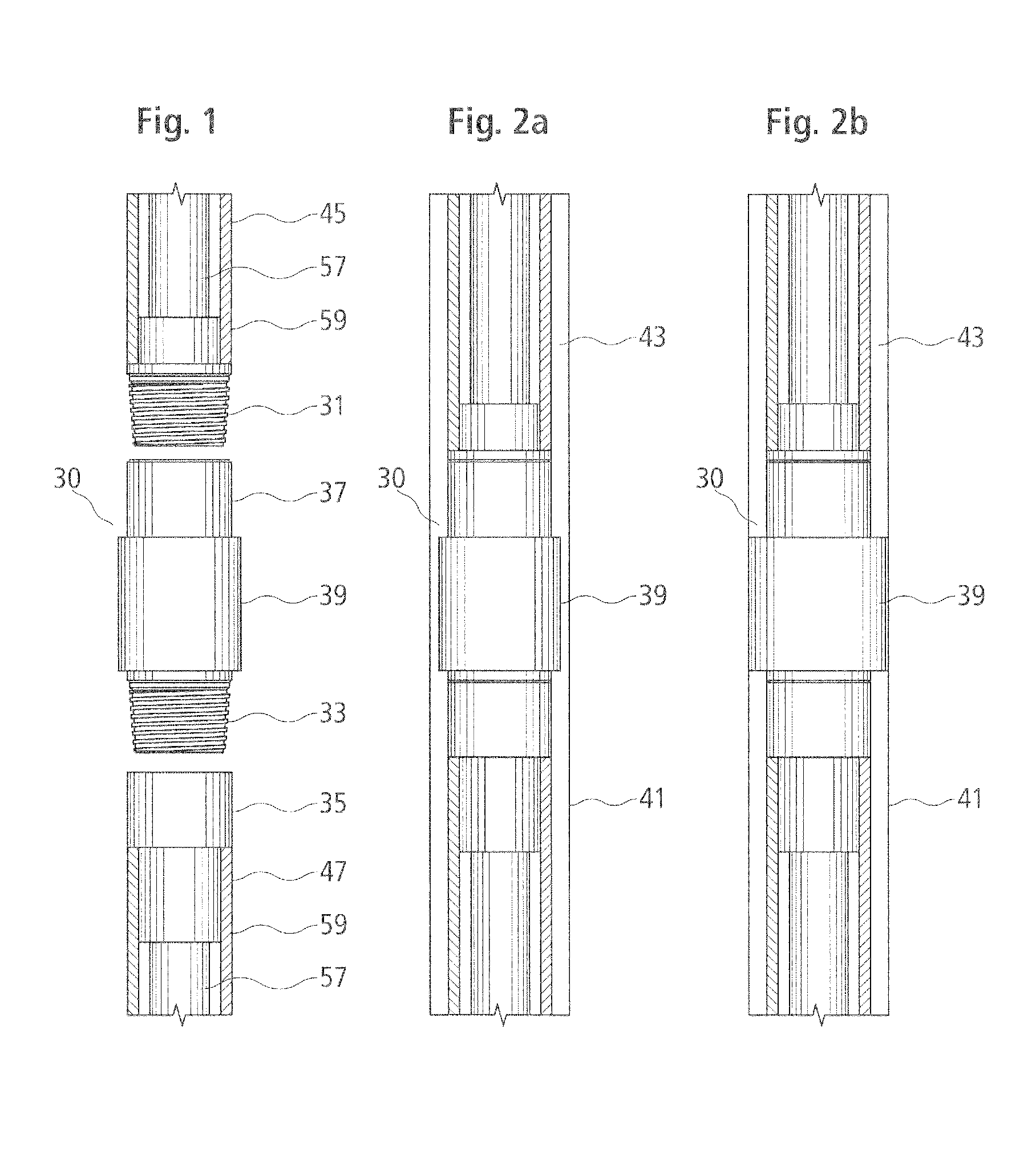

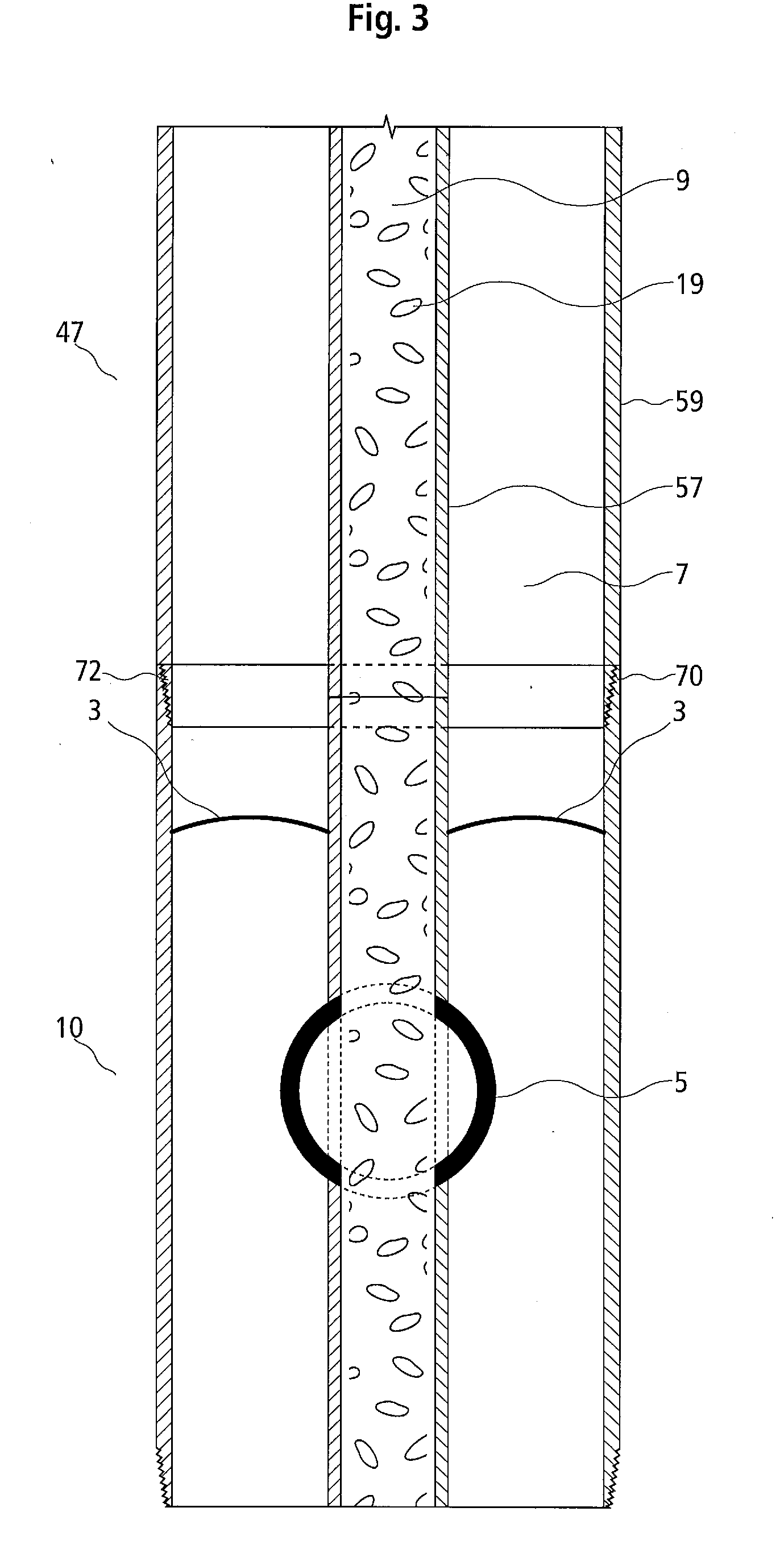

Method and apparatus for isolating and testing zones during reverse circulation drilling

A zone isolating and testing apparatus comprising an isolation tool and a downhole flow control means and a method of using such apparatus. The zone isolating and testing apparatus is particularly useful for testing zones during reverse circulation drilling using concentric drill string such as concentric drill pipe or concentric coiled tubing. The isolation tool of the zone isolating and testing apparatus comprises an expandable packer means and is adapted to connect to concentric drill string near the drilling means and be in fluid communication with the concentric drill string. The downhole flow control means of the zone isolating and testing apparatus comprises at least two valves, one for closing off the annular conduit between the inner tube and outer tube of the concentric drill string and the other for closing off the inner conduit of the inner tube. The downhole flow control means is also adapted to connect to concentric drill string near the drilling means and be in fluid communication with the concentric drill string. During testing, the isolation tool seals off the annular passage between the concentric drill string and the walls of the wellbore and the downhole flow control means seals off either the annular conduit or the inner conduit of the concentric drill string.

Owner:PRESSSOL

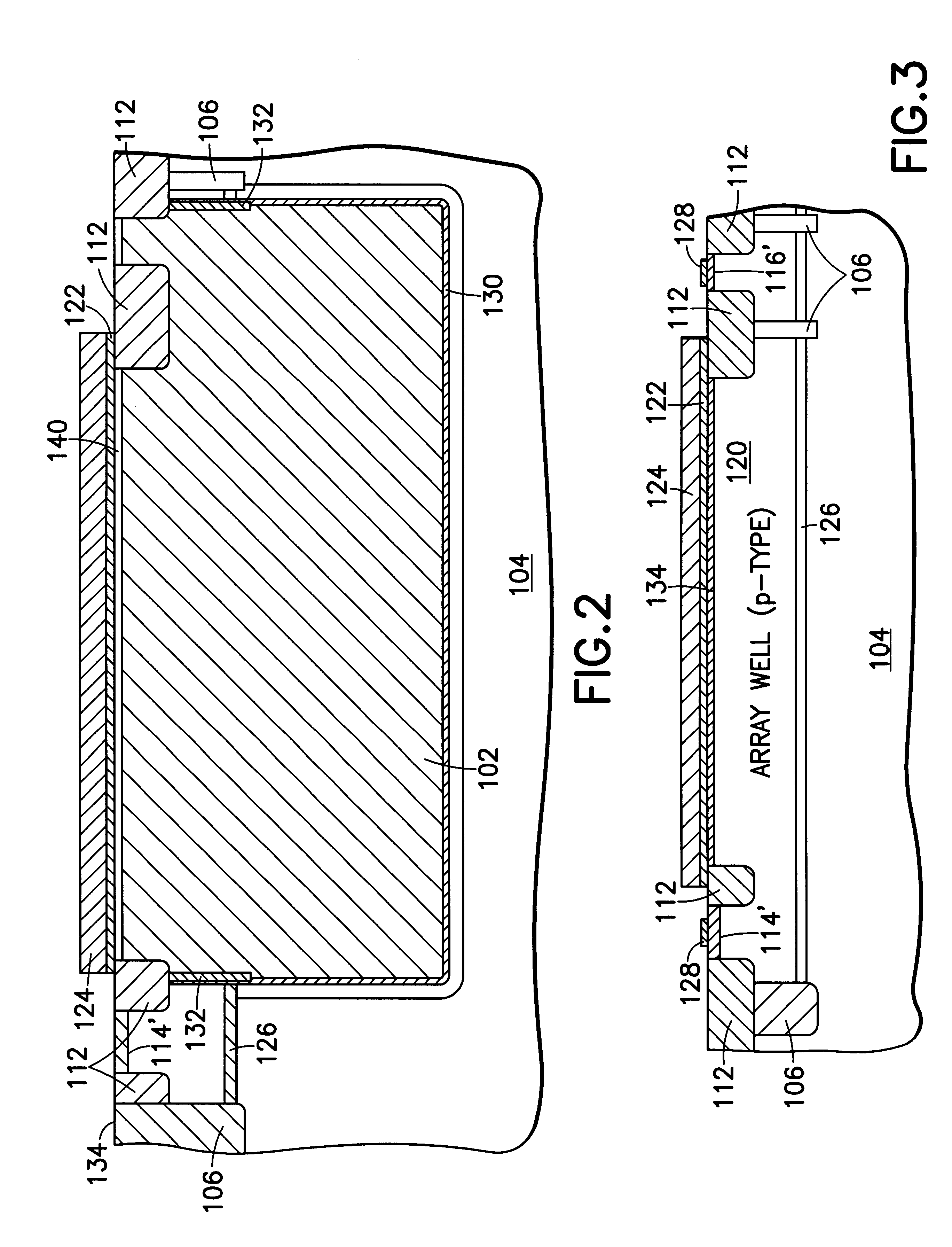

DRAM cell buried strap leakage measurement structure and method

InactiveUS6339228B1TransistorSemiconductor/solid-state device testing/measurementDiffusionEngineering

A test structure and method for determining DRAM cell leakage. The cell leakage test structure includes a pair of buried strap test structures. Each buried strap test structure includes multiple trench capacitors formed in a silicon body. Each trench capacitor is connected to a trench sidewall diffusion by at least one buried strap. An n-well ring surrounds each buried strap test structure and divides the buried strap test structure into two separate array p-wells, one being a contact area and the other a leakage test area. The contact area includes contacts to the trench capacitor plates for the corresponding buried strap test structure. In one buried strap test structure, a layer of polysilicon, essentially covers the trench capacitors in the leakage test area to block source / drain region formation there. The other of the two buried strap test structures includes polysilicon lines simulating wordlines with source and drain regions form on either side. A buried n-band contacts the n-well rings, essentially forming an isolation tub around each array well. Cell leakage is measured by measuring leakage current in each buried strap test structure, individually, and then extracting individual leakage components from the measured result.

Owner:IBM CORP

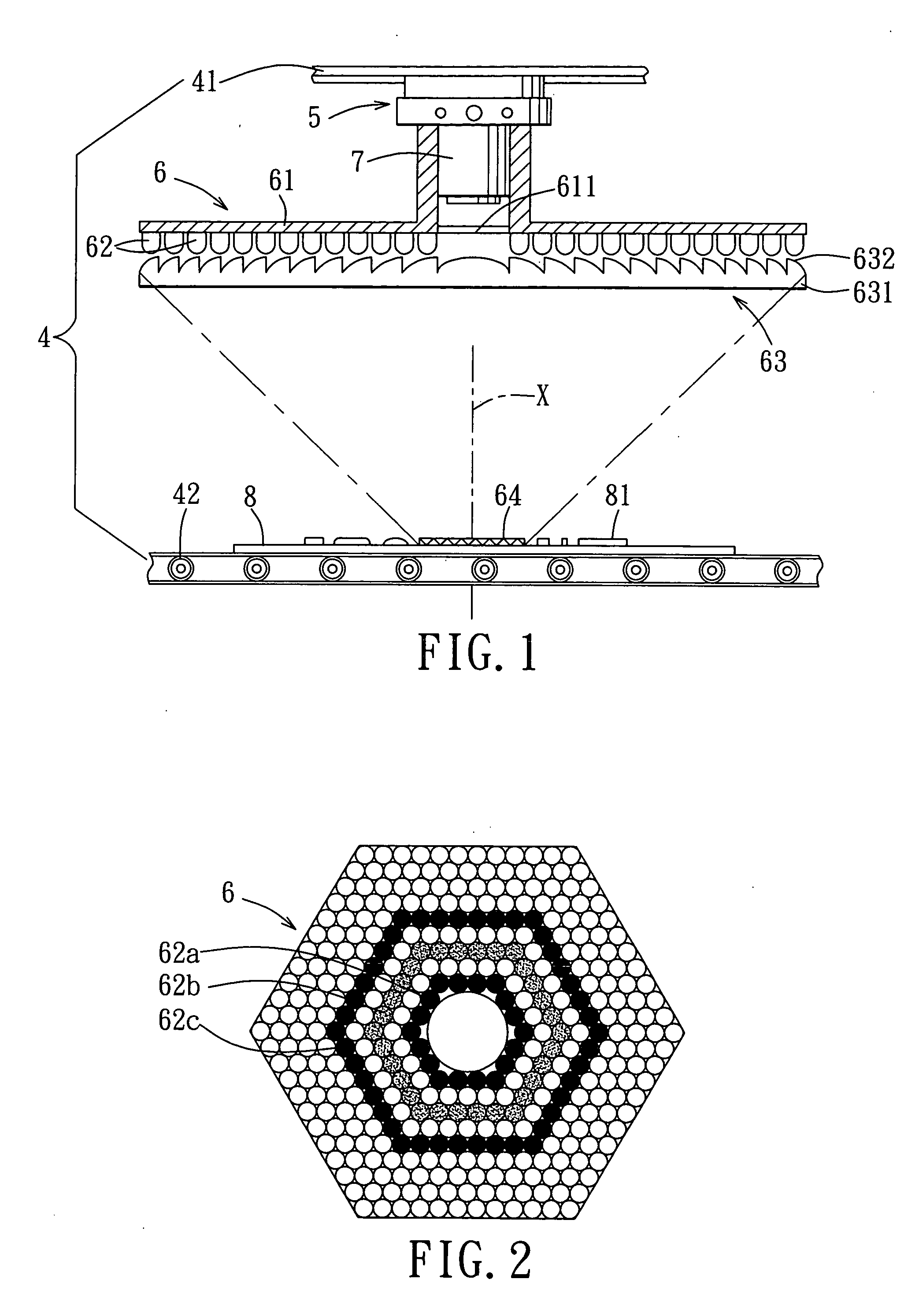

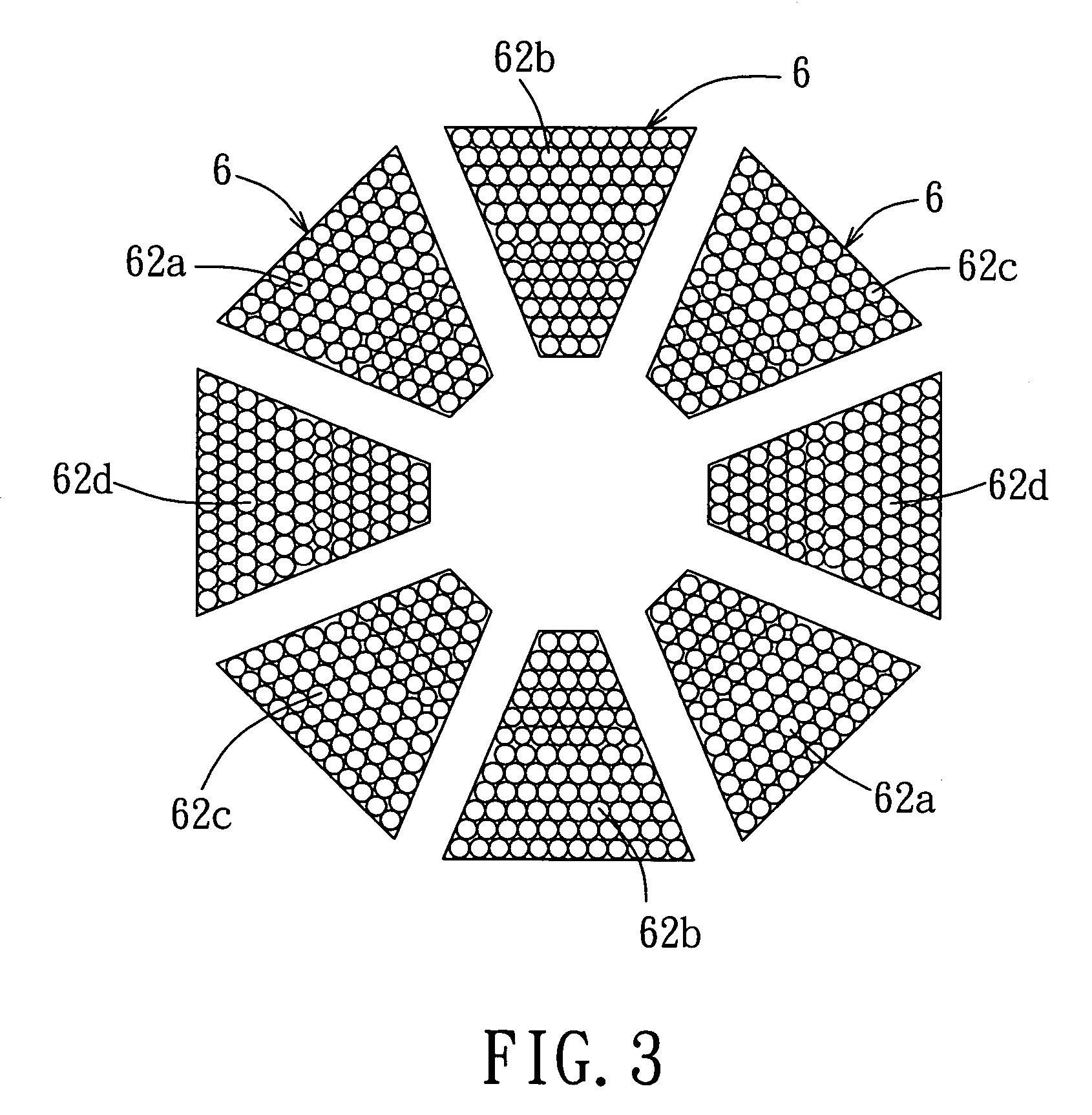

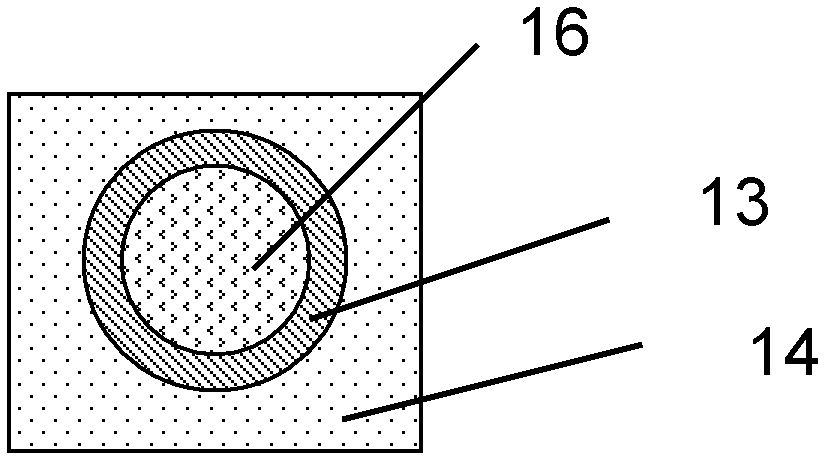

Apparatus for feature detection

InactiveUS20070019186A1Overcomes drawbackOptically investigating flaws/contaminationTest objectTest region

An apparatus for feature detection of a test object includes at least one light source module and at least one image capturing unit. The light source module provides light to illuminate a test region of the test object, and includes a substrate, a set of light-emitting components, and a light-focusing unit. The light-emitting components are mounted on the substrate for emitting light in parallel directions that are generally transverse to the substrate. The light-focusing unit is to be disposed between the light-emitting components and the test object, receives the light emitted by the light-emitting components, and focuses the light on the test region of the test object. The image capturing unit captures an image of the test object at the test region.

Owner:CHROMA ATE

Wire bonding of aluminum-free metallization layers by surface conditioning

InactiveUS20090166861A1Reduce contact failureHigh similaritySemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

In sophisticated semiconductor devices including copper-based metallization systems, a substantially aluminum-free bump structure in device regions and a substantially aluminum-free wire bond structure in test regions may be formed on the basis of a manufacturing process resulting in identical final dielectric layer stacks in these device areas. Moreover, reliable wire bond connections may be obtained by providing a protection layer, such as an oxide layer, after exposing the respective contact metal, such as copper, nickel and the like, thereby providing highly uniform process conditions during the subsequent wire bonding process. The number of process steps may be reduced by making a decision as to whether a substrate is to become a product substrate or test substrate for estimating the reliability of actual semiconductor devices. For example, nickel contact elements may be formed above copper-based contact areas wherein the nickel may provide a base for wire bonding or forming a bump material thereon.

Owner:GLOBALFOUNDRIES INC

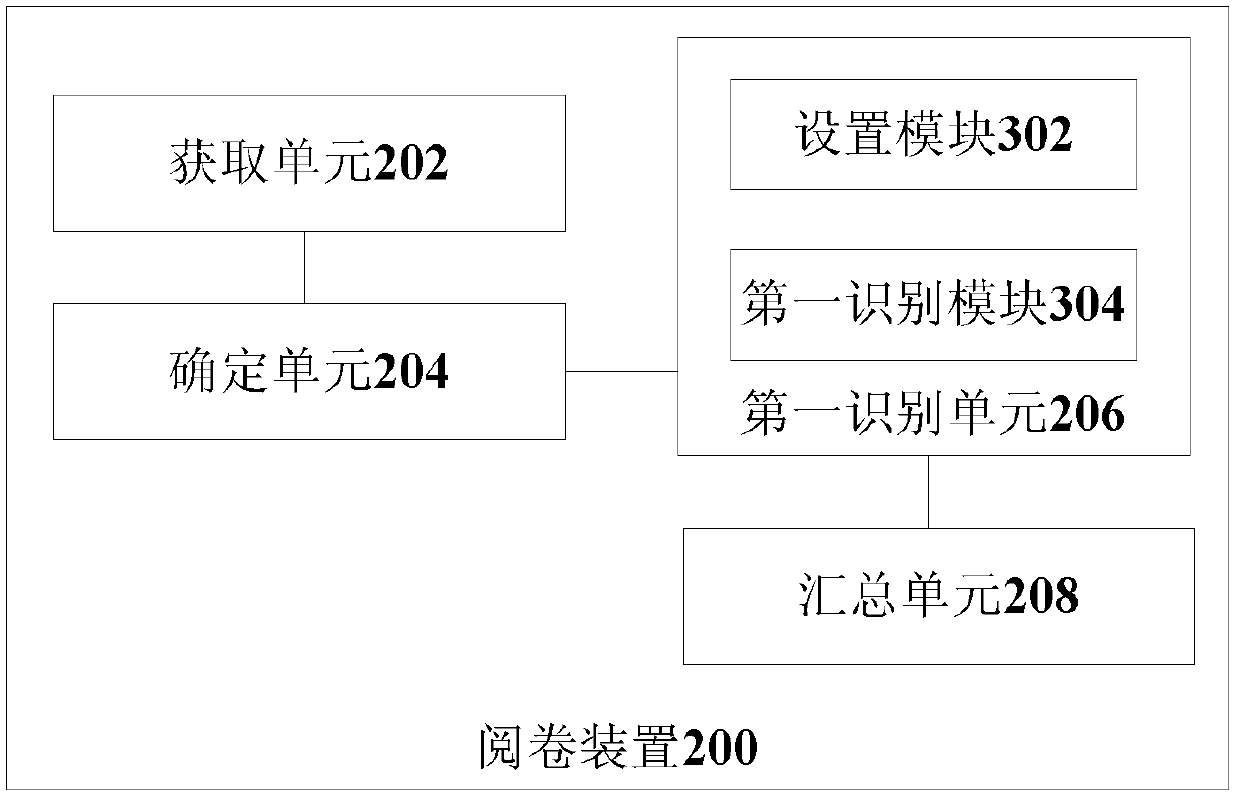

Paper inspection method and device

InactiveCN103310082ARealize mechanized markingCharacter and pattern recognitionSpecial data processing applicationsAlgorithmData mining

The invention discloses a paper inspection method and a paper inspection device. The method comprises the steps of obtaining an electronic test paper, wherein the electronic test paper comprises one or a plurality of test regions, each test region corresponds a question and comprises a topic region, an answer region and / or a grading region; determining the position of the answer region and / or the position of the grading region of each test in the electronic test paper; utilizing the answer regions and / or the grading regions as regions to be identified, and identifying the grade of each test from the region to be identified; and summarizing the grades of the topics in the electronic test paper. A mode for automatically inspecting the papers with the test regions and the grading regions on the same page is provided.

Owner:IEFREE BEIJING TECH

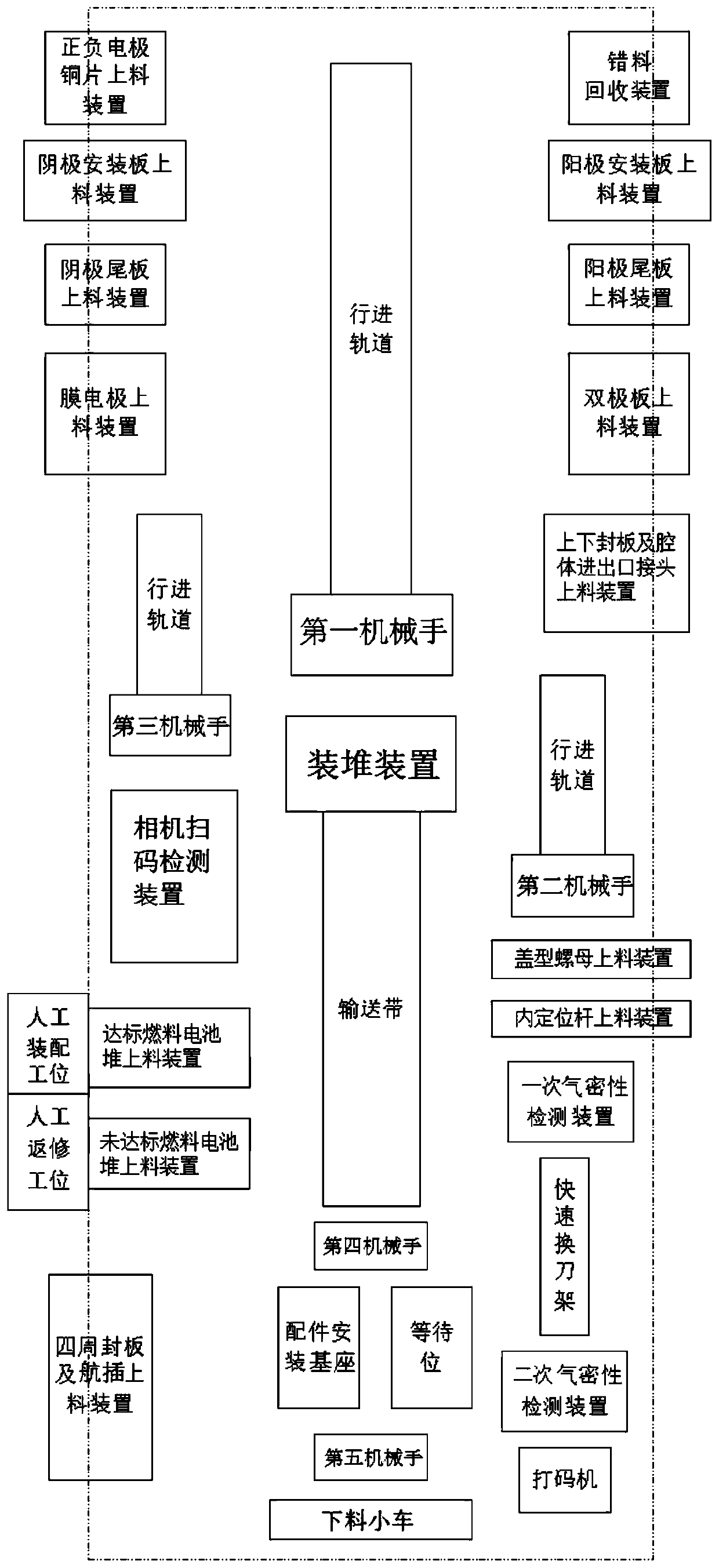

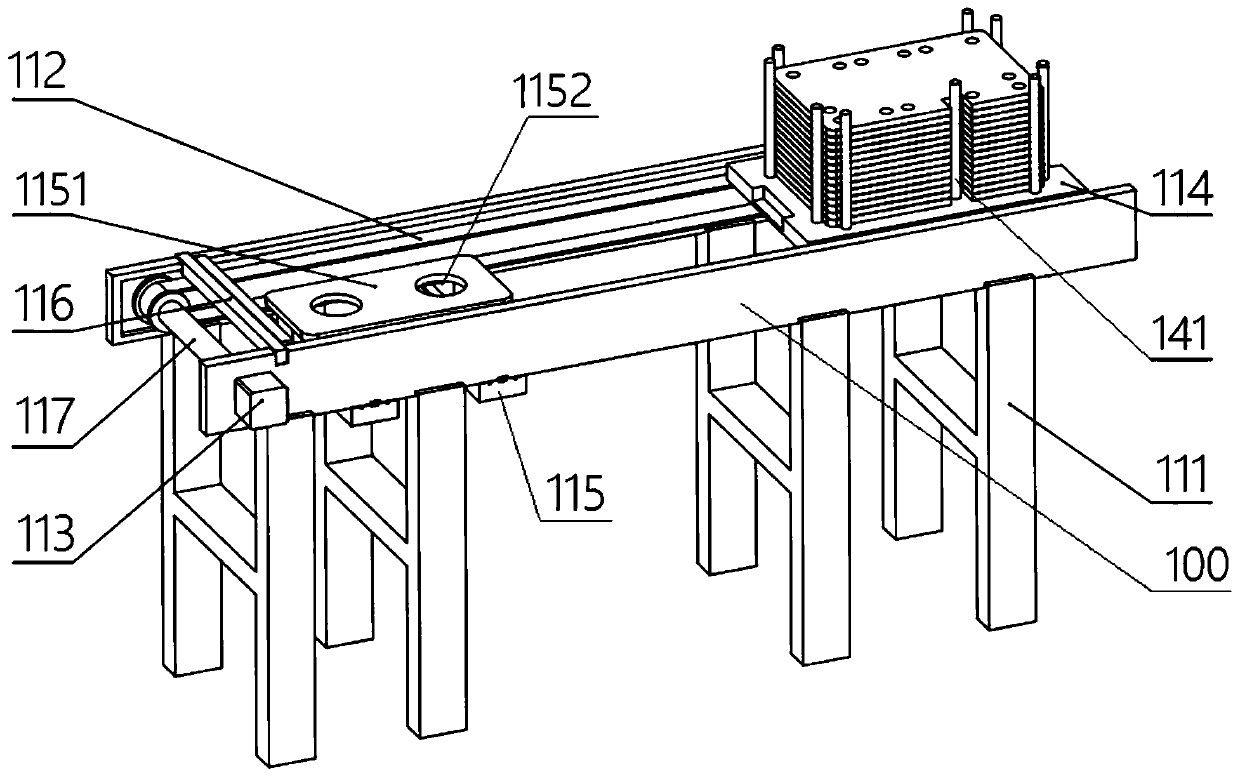

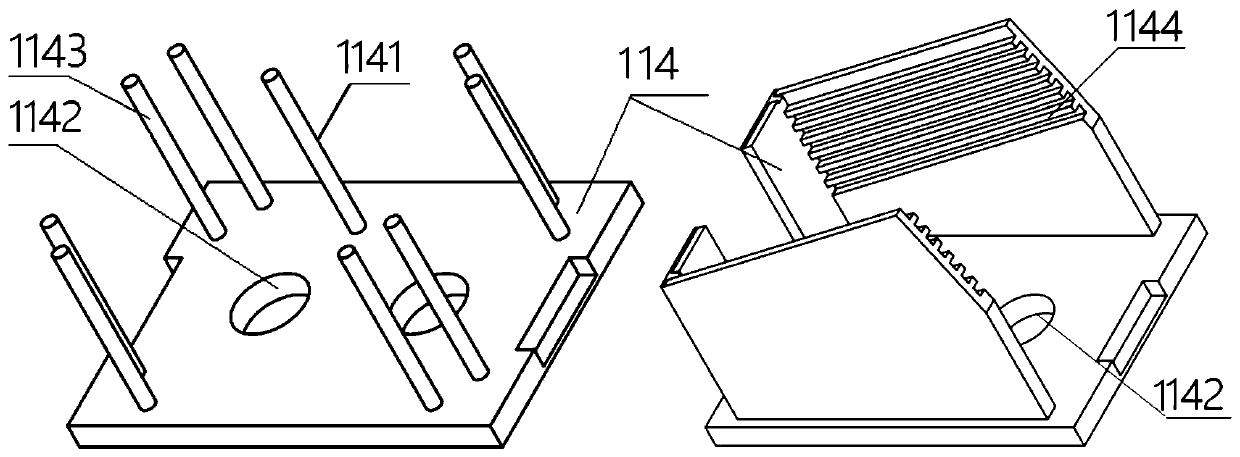

Automatic production line of fuel cell stack

PendingCN110021772AIncreased load-bearing capacityImprove handling efficiencyFinal product manufactureFuel cellsProduction lineFuel cells

The invention relates to an automatic production line of a fuel cell stack. The automatic production line comprises a material taking and placing region, a stack lamination fastening region, a primaryperformance test region, an artificial assembly region, an artificial rework region, a part installation region, a secondary performance test region, a product off-line region, a manipulator and a control server, wherein the manipulator comprises a first manipulator, a second manipulator, a third manipulator, a fourth manipulator and a fifth manipulator, and the manipulators can slide along respective rails in a reciprocating way to take and place materials. In the automatic production line, a large part of production operation is completed by a mechanical program, high automation is achieved, modular and large-scale production of a fuel cell is easy to achieve, the continuity of production links is maintained, the production efficiency is substantially improved, the production cost is reduced, the automatic production line is suitable for producing different specifications of cell panels, is wide in application range and is flexible and simple to adjust, each production equipment isindependent, the production line is compact in layout, high in design flexibility, and compatibility, upgrading and transformation are easily achieved.

Owner:BEIJING NOWOGEN TECH CO LTD

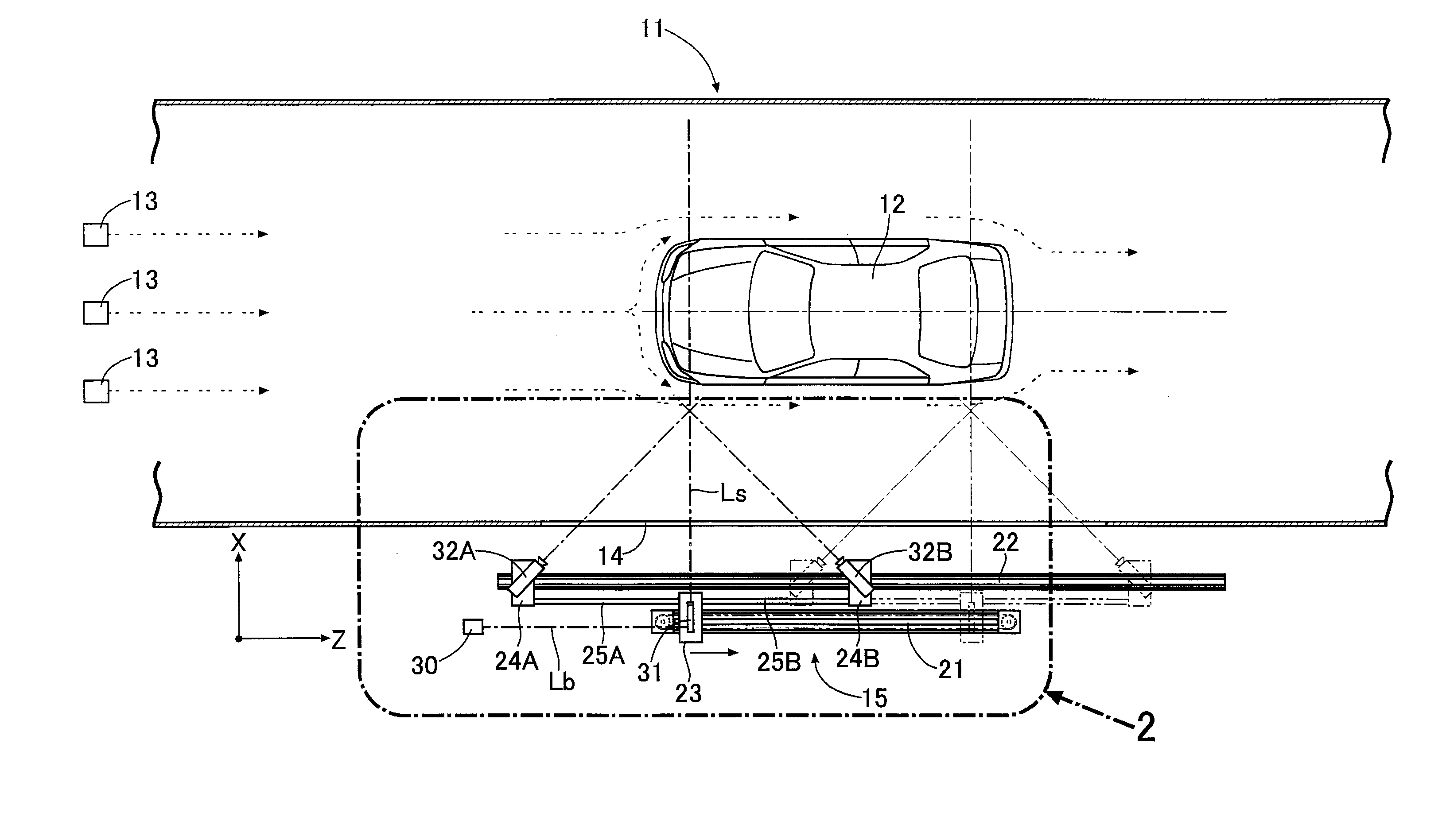

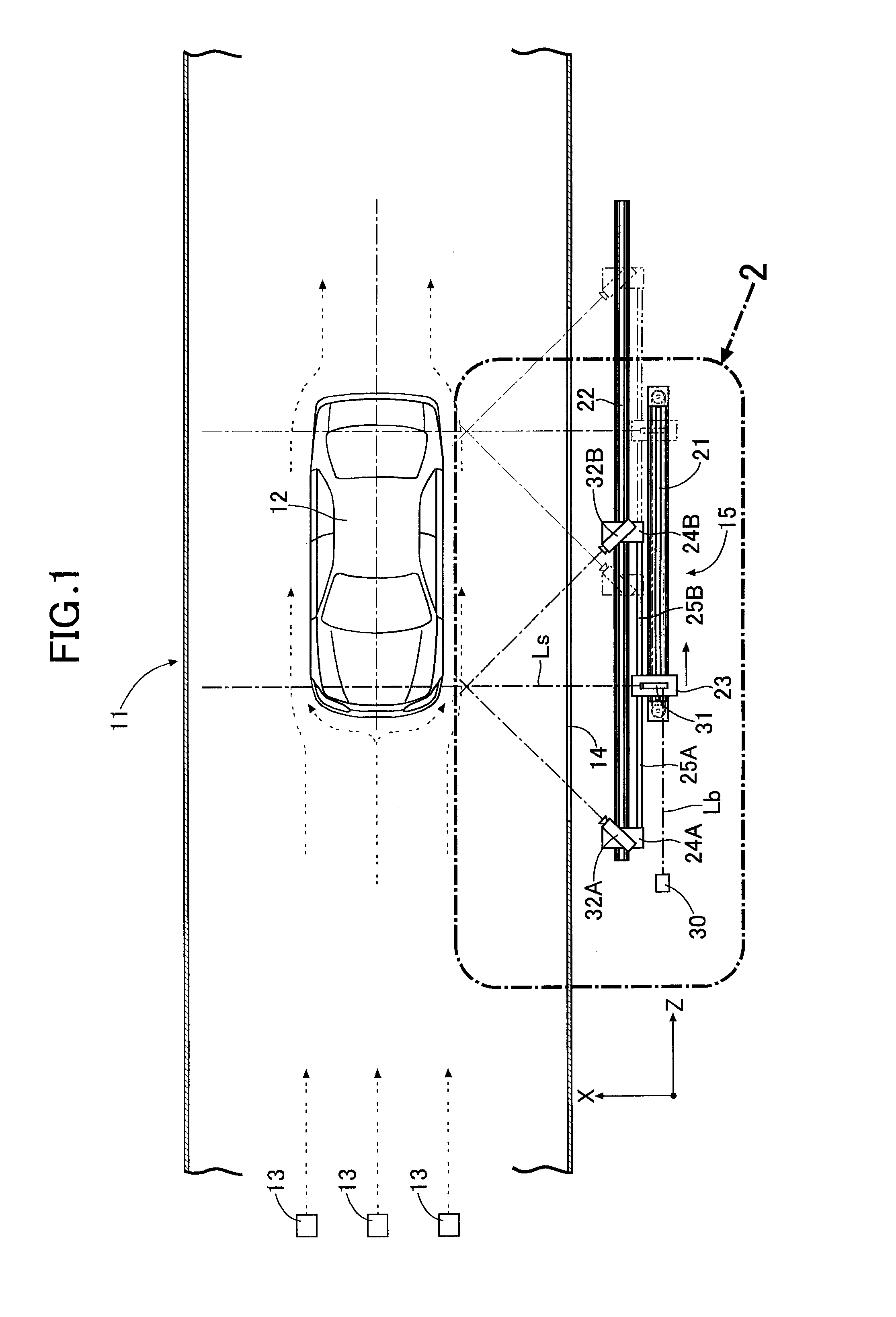

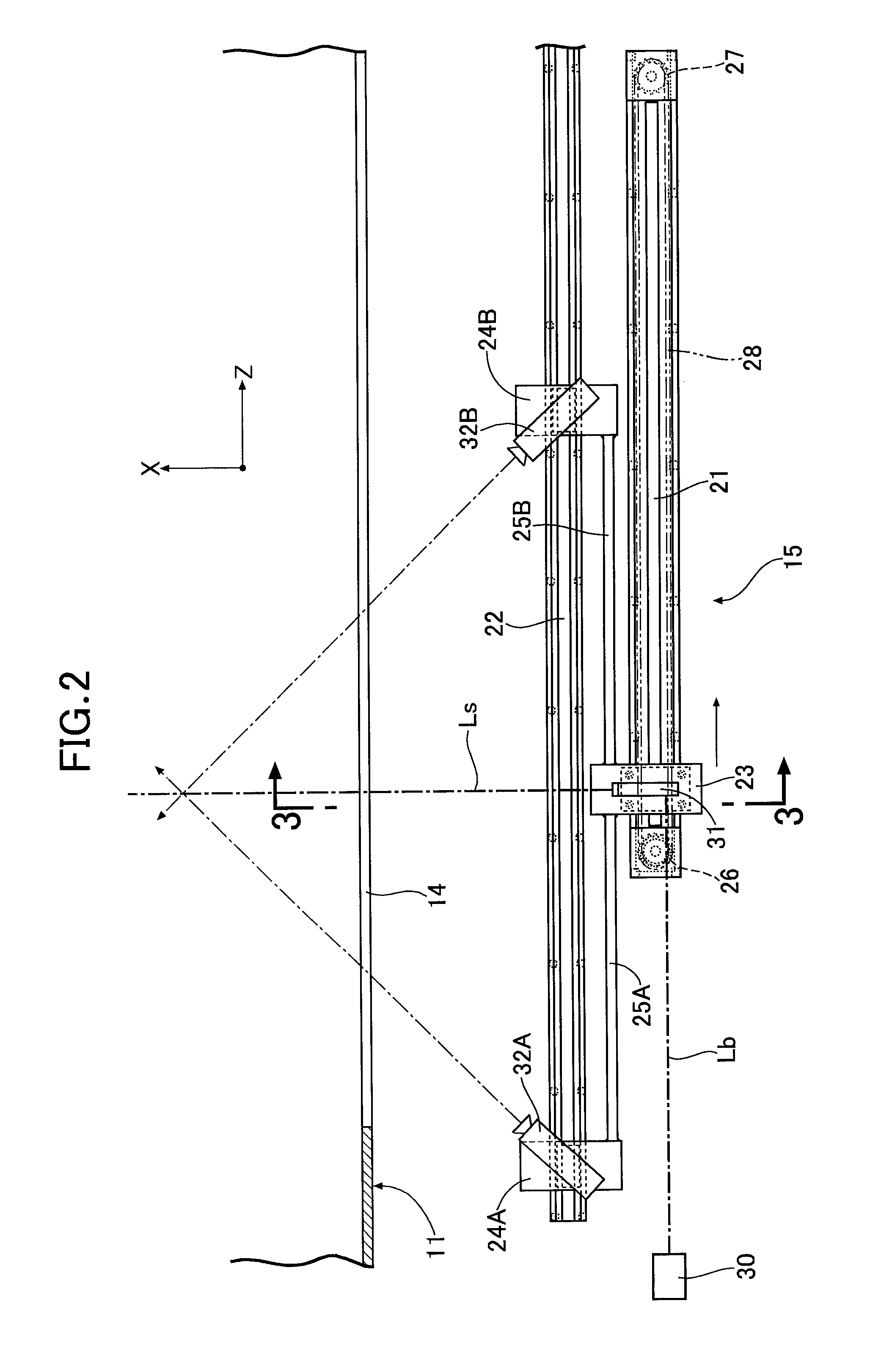

Particle image velocimetry method, particle image velocimetry method for 3-dimensional space, particle image velocimetry system, and tracer particle generating device in particle image velocimetry system

InactiveUS20120105628A1High precisionReliably excluding erroneous vectorsAerodynamic testingColor television detailsLaser lightPeak value

A particle image velocimetry system is provided which supplies tracer particles to a flow field around an object (12) from tracer particle supply means, takes an image of reflected light by imaging means (32A, 32B) by irradiating the tracer particles twice with laser light at different times, and determines a velocity vector of the flow field based on the two images obtained of the tracer particles. The two images are each divided into a plurality of test regions, and when first peak value (fp) / second peak value (sp)≧1.2 is satisfied by comparison between a first peak value fp and a second peak value sp of a cross-correlation value of a luminance pattern of tracer particles in each test region of the two images, it is determined that the reliability of the velocity vector is high. Thus, it is possible to enhance the precision of measurement of the state of flow by reliably determining erroneous vectors.

Owner:HONDA MOTOR CO LTD

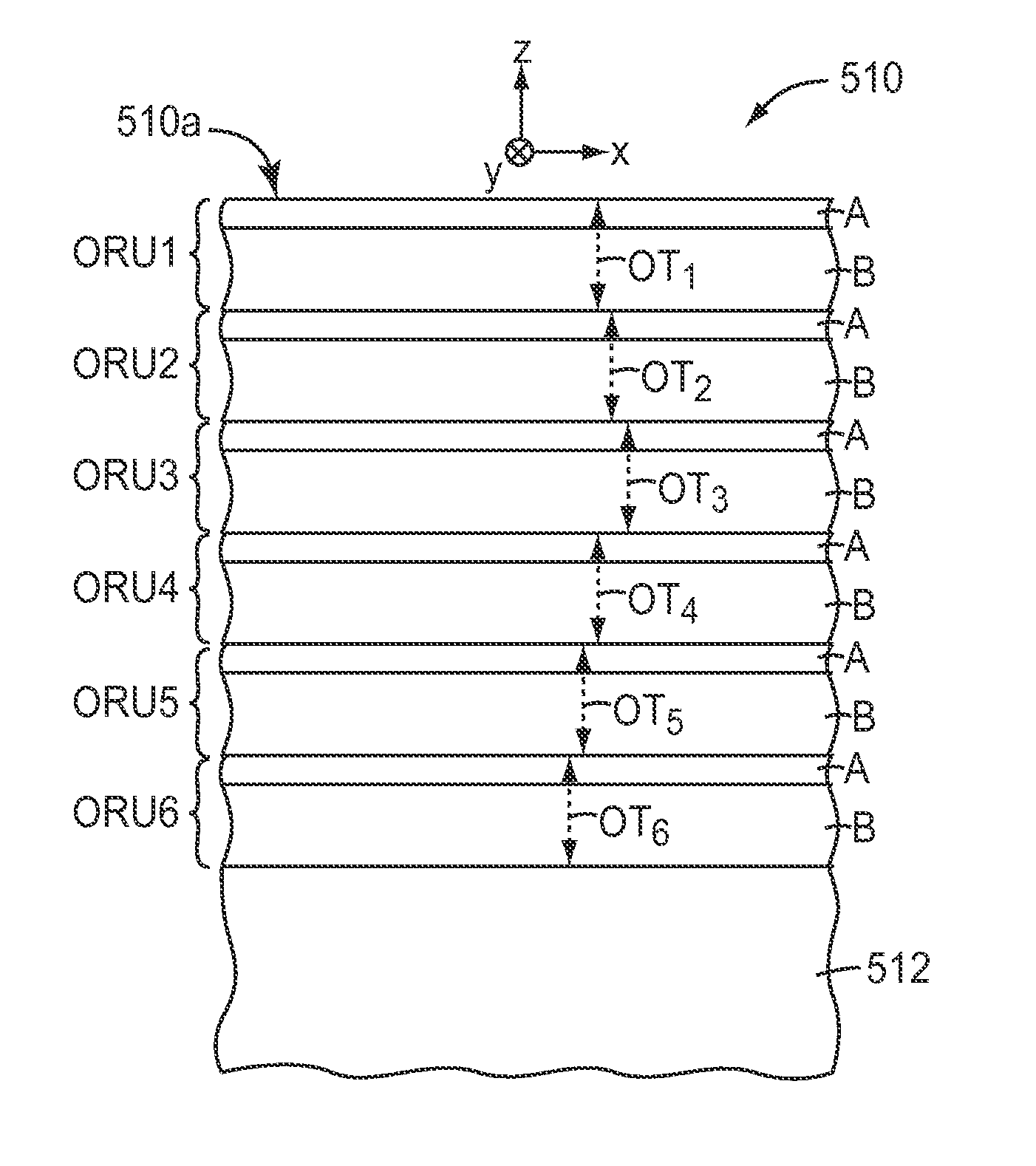

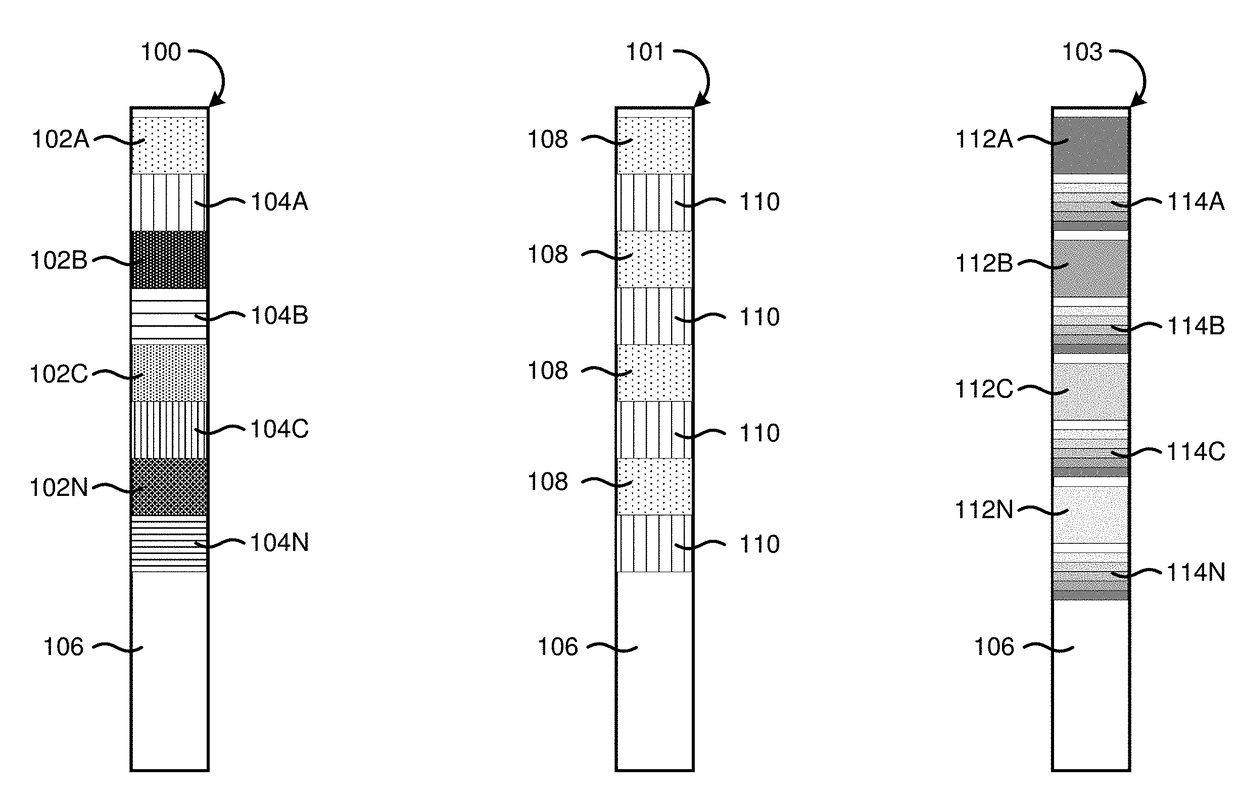

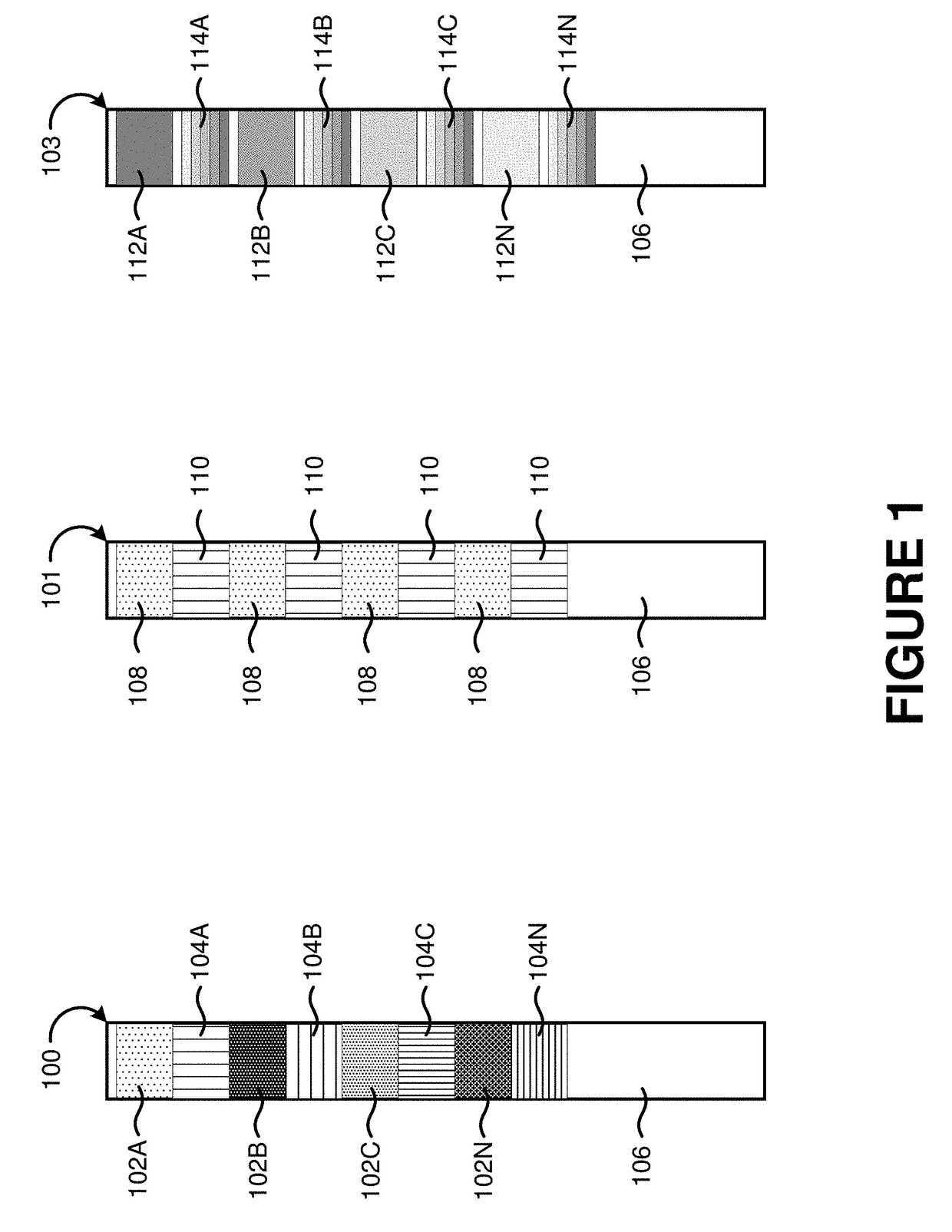

Partially reflecting multilayer optical films with reduced color

ActiveUS20130063818A1High-frequency variabilityOptical filtersLaminationFrequency spectrumTest region

A multilayer optical film body includes a first and second packet of microlayers. Each packet partially transmits and partially reflects light over an extended wavelength range, such as the visible region, for normally incident light polarized along a first principal axis of the film body. In combination, the first and second packets have an intermediate reflection and transmission (e.g. 5-95% internal transmission, on average) for the normally incident light, and similar intermediate reflection / transmission (e.g. 10-90% internal transmission, on average) for oblique light. The packets are laminated or otherwise connected so that light can pass through the packets sequentially. In at least a first test area of the film body, a high frequency spectral variability of the combination of packets is less than a high frequency spectral variability of the first packet by itself, and may also be less than a high frequency spectral variability of the second packet by itself.

Owner:3M INNOVATIVE PROPERTIES CO

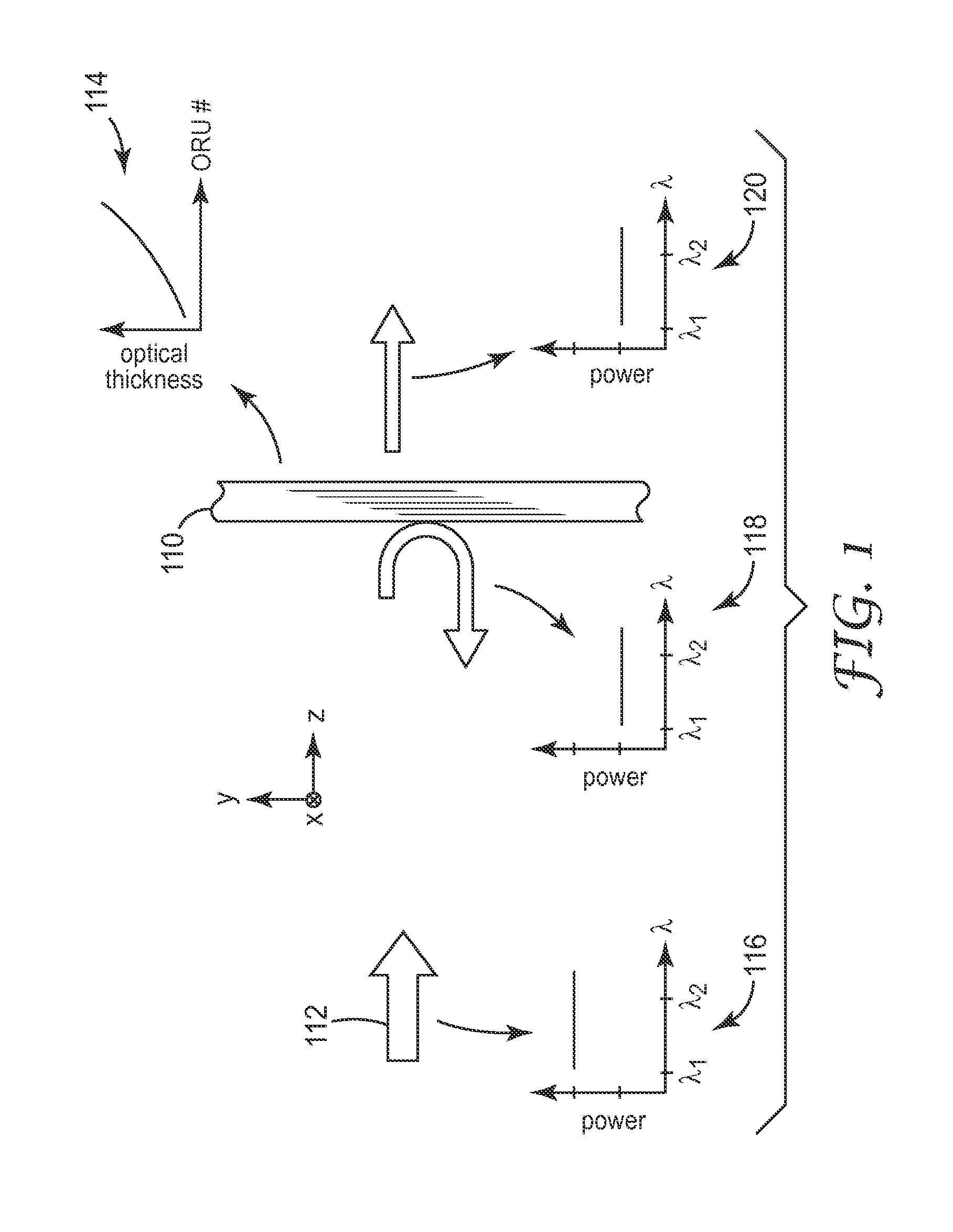

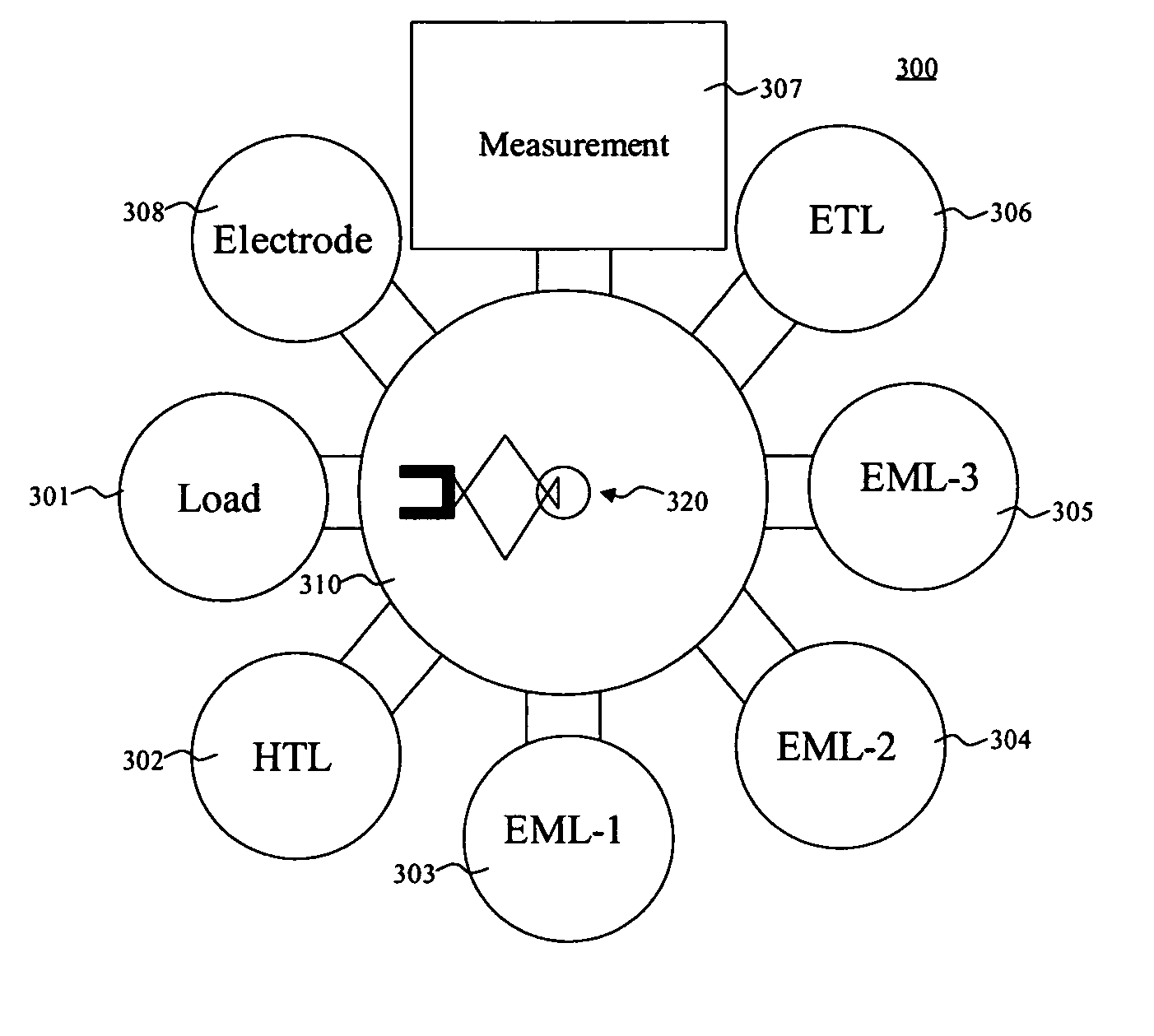

Monitoring the deposition properties of an oled

ActiveUS20050208698A1Easy to controlReduce generationDischarge tube luminescnet screensSemiconductor/solid-state device testing/measurementOrganic layerDeposition process

A method for making an OLED device includes providing a substrate having one or more test regions and one or more device regions, moving the substrate into a least one deposition chamber for deposition of at least one organic layer, and depositing the at least one organic layer through a shadowmask selectively onto the at least one device region and at least one test region on the substrate. The method also includes measuring a property of the at least one organic layer in the at least one test region, and adjusting the deposition process in accordance with the measured property.

Owner:GLOBAL OLED TECH

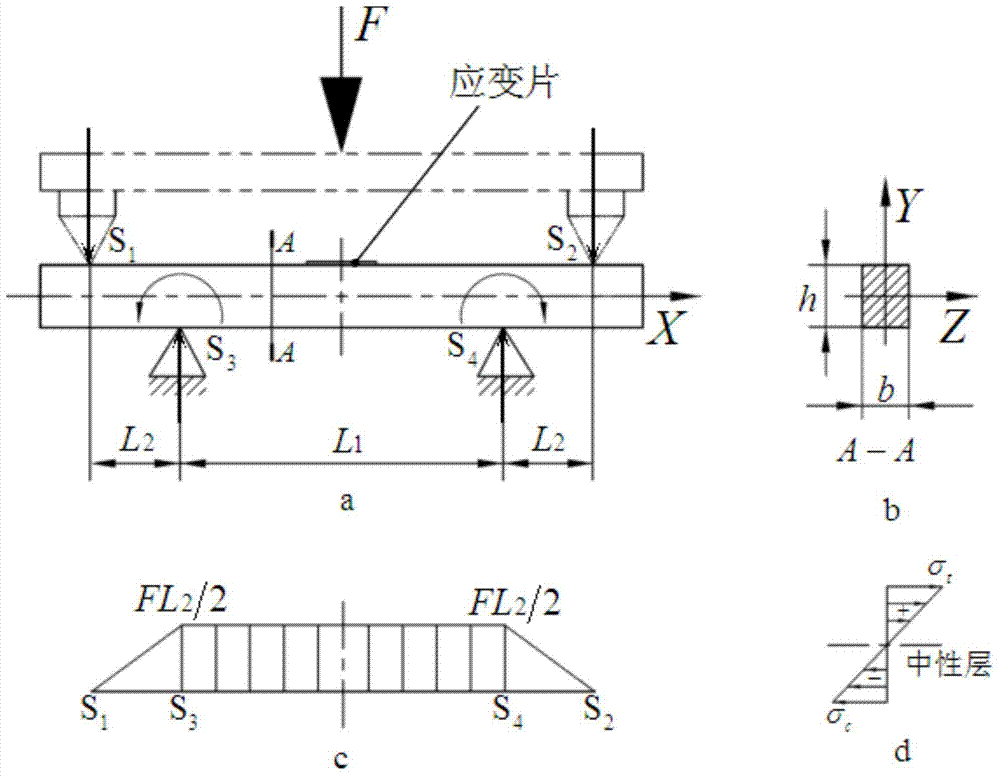

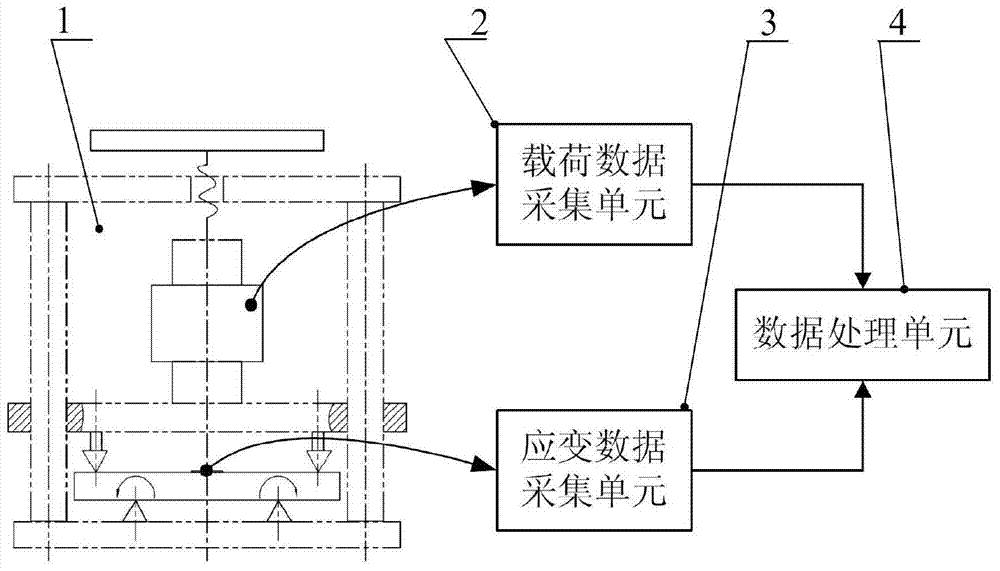

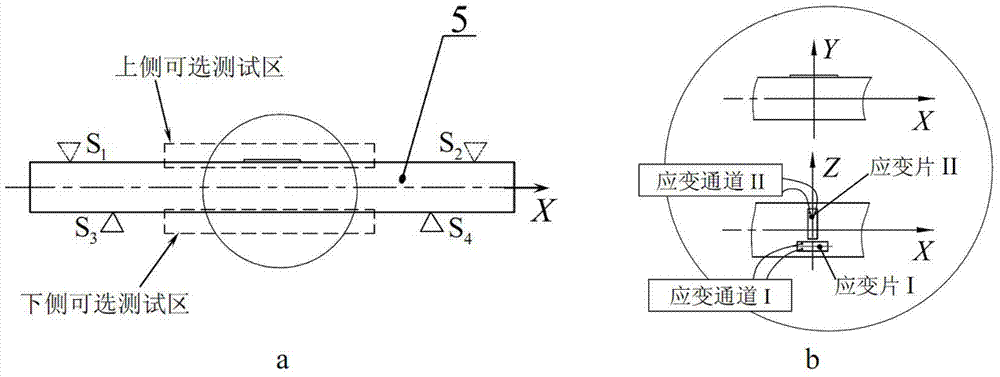

Four-point bending elastic parameter measuring method and four-point bending elastic parameter measuring system

InactiveCN103698225AMeasurement advantageAdvantages of measurement methodMaterial strength using steady bending forcesEngineeringStressed state

The invention discloses a four-point bending elastic parameter measuring method and a four-point bending elastic parameter measuring system, belonging to the field of elastic parameter measurement, and solving the problems in the prior art. The four-point bending elastic parameter measuring method provided by the invention comprises the steps that an ideal uniaxial drawing (or compression) stress state is formed in a testing region by utilizing a four-point bending principle of a rectangular section beam, a determined theory relation exists among the stress value, a sample structure size and an applied load value, the strain value of a measuring point in axial and horizontal mutual orthogonal directions can be obtained by utilizing a strain paster measuring method, and further an elastic modulus and a poisson ratio of the sample can be calculated. The four-point bending elastic parameter measuring system comprises a testing loading device, a load data collecting unit, a strain data collecting unit and a data processing unit. The method provided by the invention has the advantages that the principle is simple, the test precision is high, the application range is wide, the realization is easy, the development cost is low, and the measuring system is miniaturized, desk type and manual operation equipment and has large popularizing capacity.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

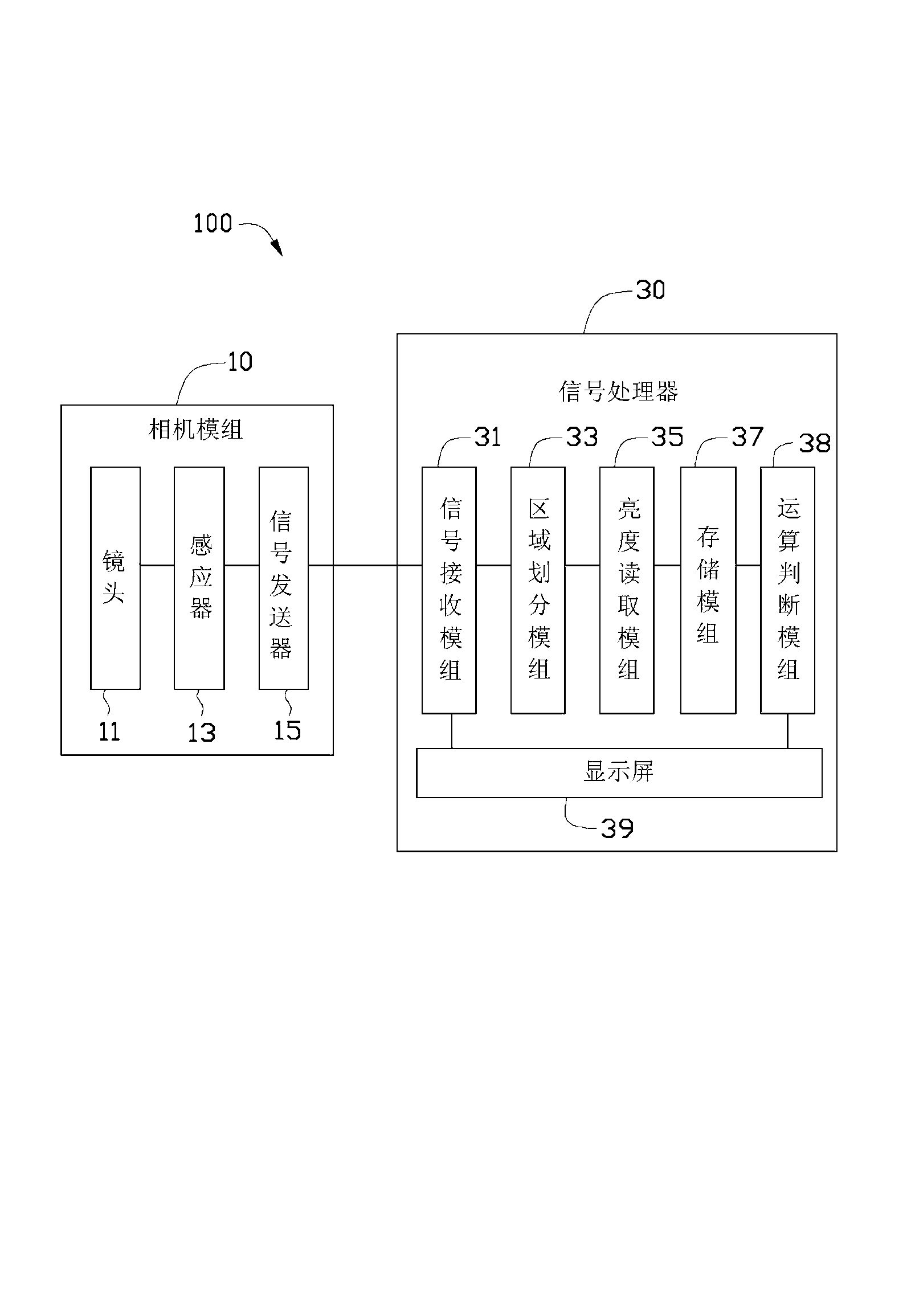

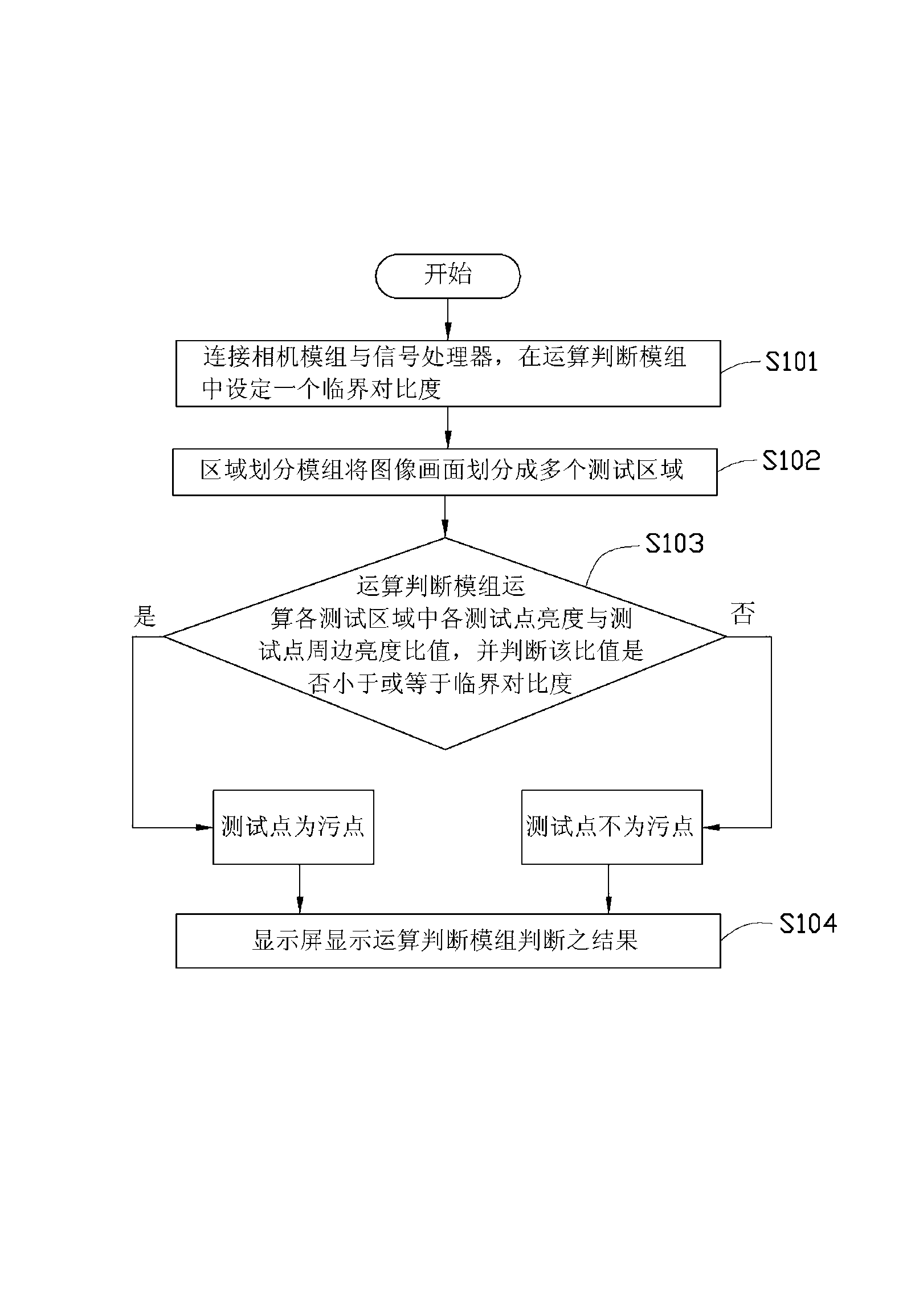

System and method for testing camera module stains

InactiveCN103179428AAccurate judgmentImprove efficiencyOptically investigating flaws/contaminationTelevision systemsCamera moduleTest region

The invention provides a system for testing camera module stains. The system comprises a camera module and a signal processor connected with the camera module. The signal processor comprises a region division module, a brightness reading module and a calculation determination module. The region division module is used for dividing a picture acquired by the camera module into a plurality of test regions, the brightness reading module is used for reading brightness values of test points of the plurality of the test regions in the picture, the calculation determination module presets a critical contrast ratio for calculating contrast ratios between the test points and peripheral brightness, and the test points are stains if the contrast ratios are smaller than or equal to the preset critical contrast ratio. The invention further provides a method for testing camera module stains. According to the system and the method for testing camera module stains, the pictures acquired by the camera module is subjected to region division by the region division module, and the calculation determination module compares the brightness of the test points of the regions with the peripheral brightness of the test points and determines whether the contrast ratios are smaller than or equal to the preset critical contrast ratio, so that the determination is accurate, and the efficiency is high.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

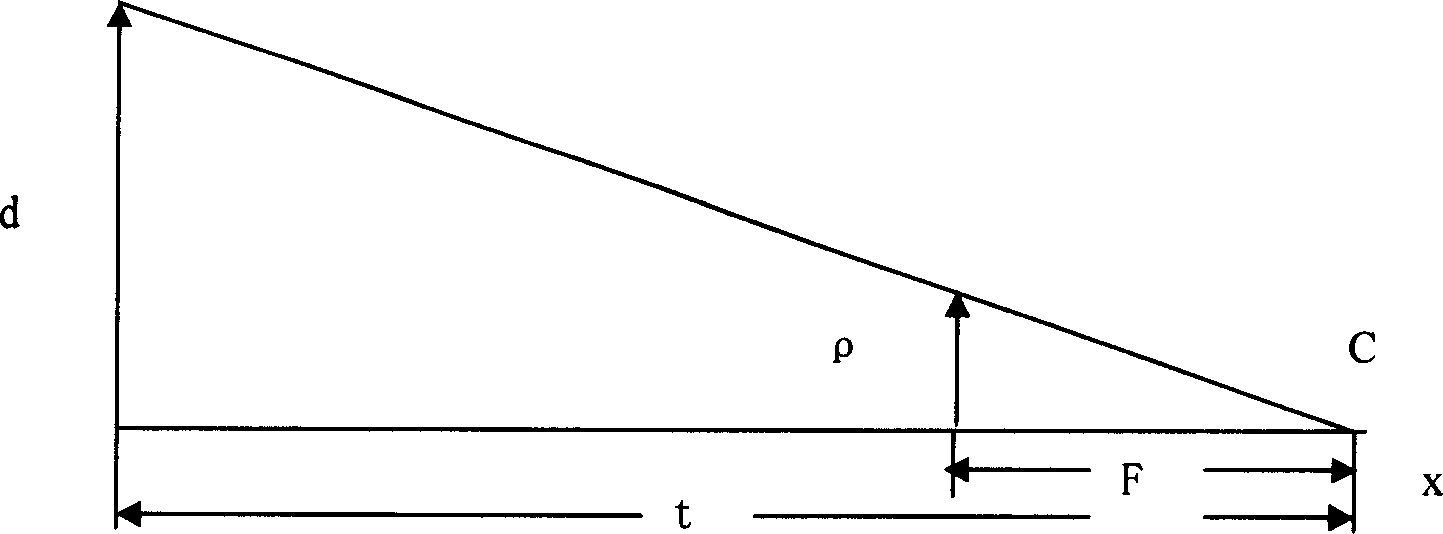

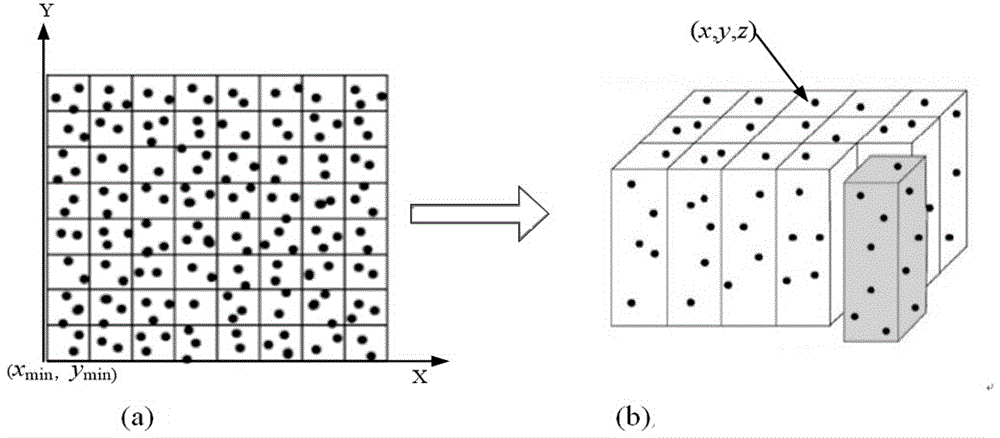

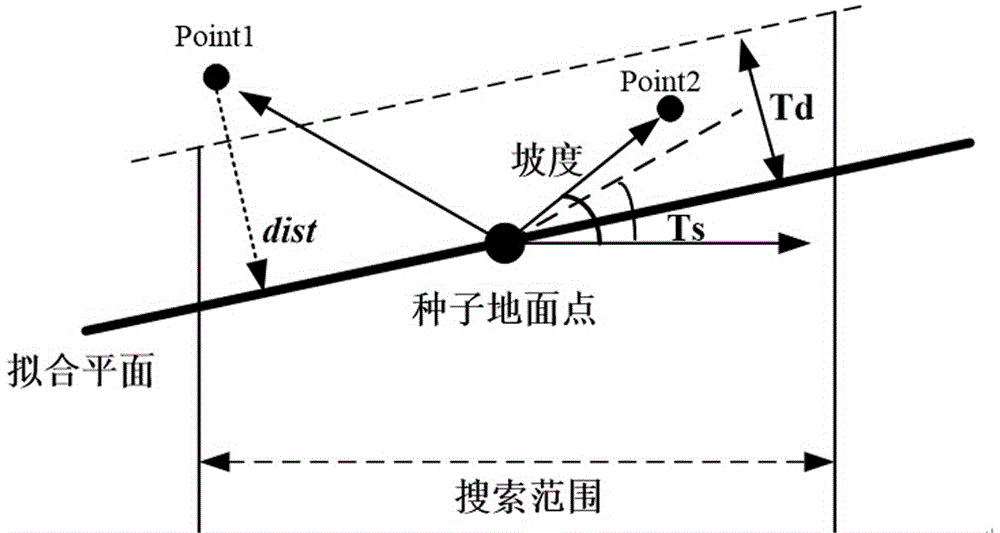

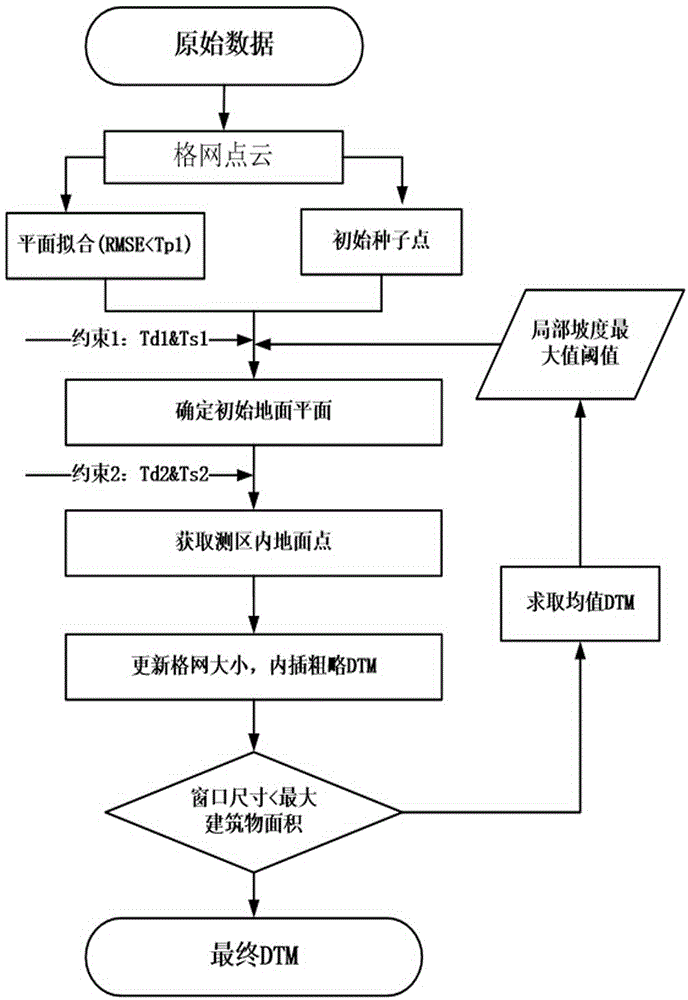

Unmanned aerial vehicle airborne LiDAR point cloud filtering method based on adaptive gradient

ActiveCN106529469AImprove search efficiencyKeep the original informationImage enhancementImage analysisTerrainPoint cloud

The invention provides an unmanned aerial vehicle airborne LiDAR point cloud filtering method based on adaptive gradient. The method comprises the following steps: obtaining point cloud data in a test region and carrying out filtering on the point cloud data; 2) establishing index for the point cloud data; 3) carrying out calculation and keeping an optimal plane in a grid; 4) selecting an elevation lowest point in a preset window as an initial seed point of a ground point; 5) calculating the distance between the optimal plane and the ground point and gradient from the ground point to the center of the optimal plane, and obtaining a ground point set according to gradient threshold; 6) serving a point in the initial ground point set as a base point, and generating a digital terrain model through an inverse distance weighted interpolation method; and 7) through the newly-generated digital terrain model, obtaining update value of the gradient threshold, repeating the steps 4)-6) and obtaining a final ground point set. The filtering method based on adaptive gradient improves algorithm operation efficiency.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

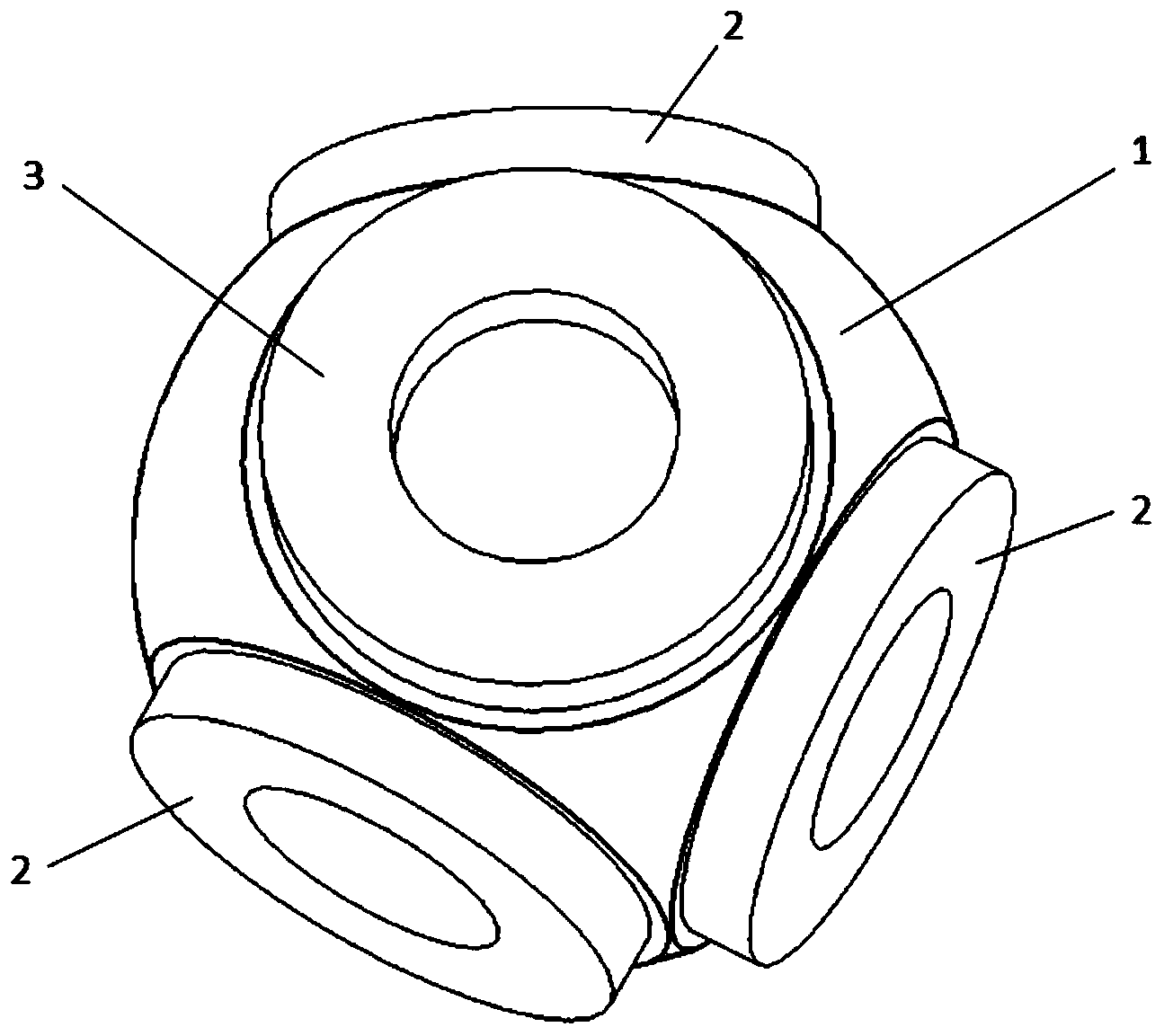

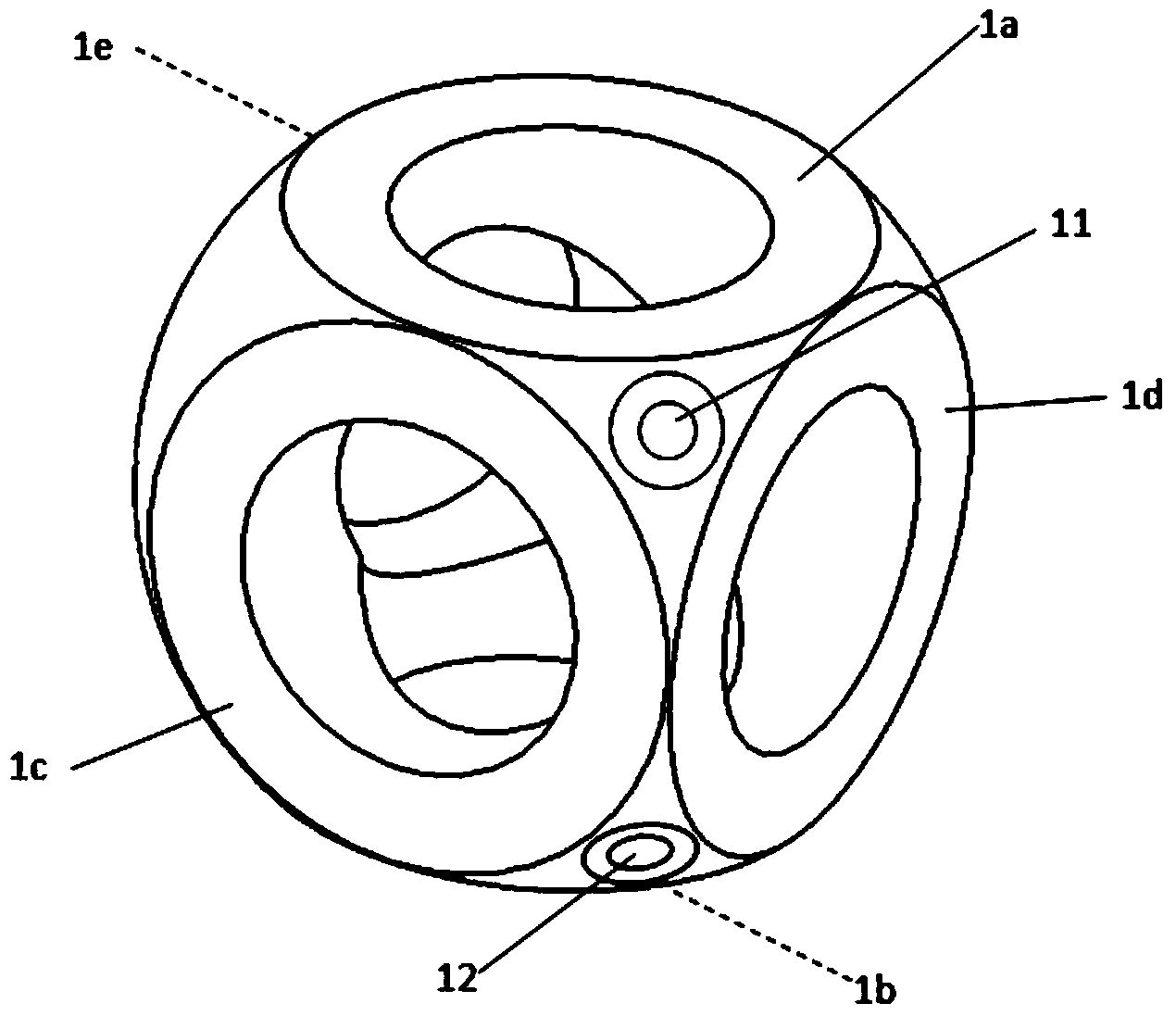

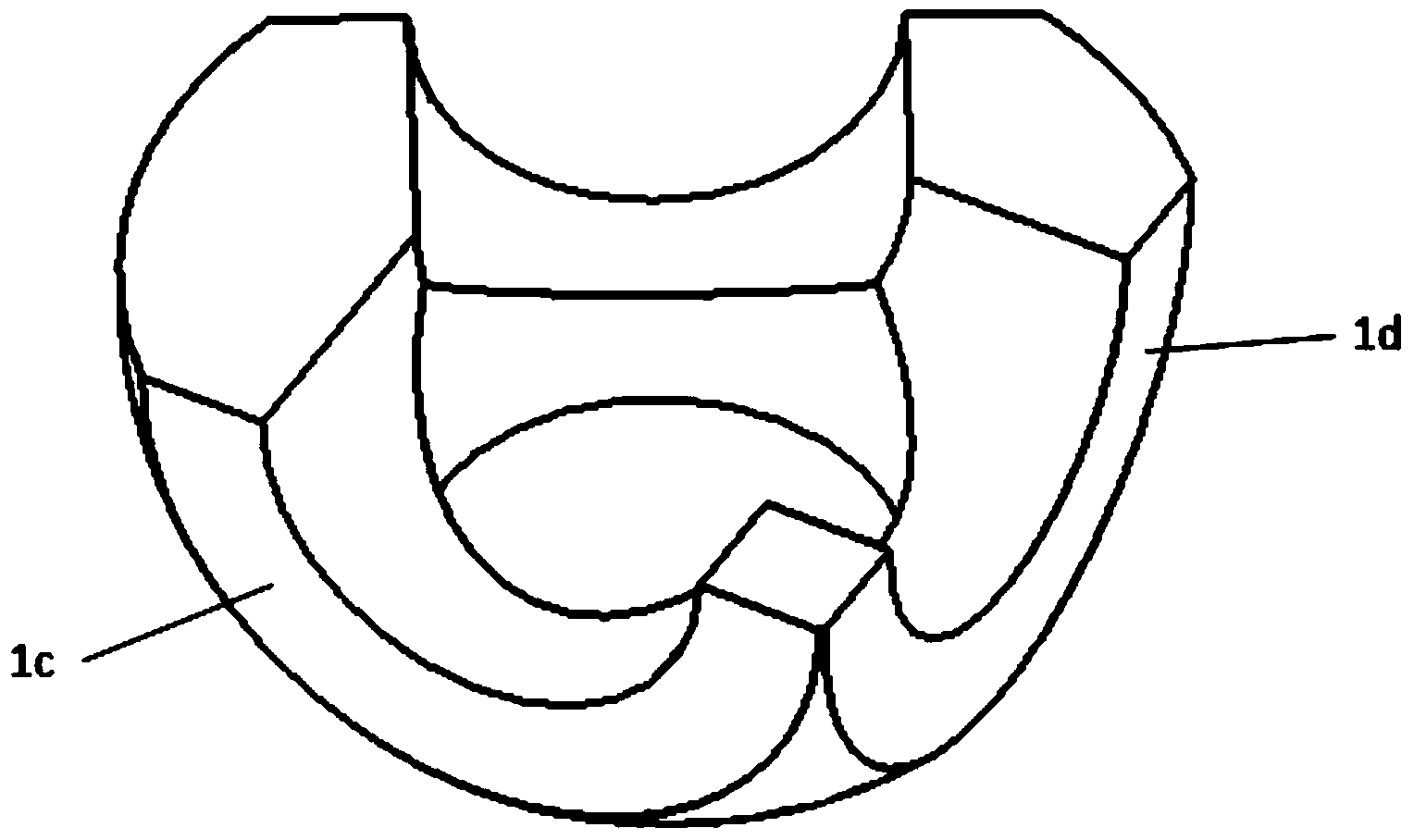

Spherical multifunctional constant volume bomb

ActiveCN103926196AEasy to processEasy to installMaterial analysis by optical meansPlanar laser-induced fluorescencePresent method

The invention discloses a spherical multifunctional constant volume bomb. The spherical multifunctional constant volume bomb comprises a body with a spherical shape and more than two window holes in the spherical body, wherein the axes of the window holes are intersected at the sphere center of the body; the area close to the sphere center is a hollow test area; a through hole pointing to the test area is reserved between the window holes. The spherical multifunctional constant volume bomb is simple in structure, convenient to machine, compact in structure and light in bomb body weight, and can bear high strength; the temperature field of the test area is uniform; all sealing pieces of a volume bomb adopt non-cooling sealing; the internal temperature and the pressure are easily controlled; continuous test at a high temperature and a high temperature can be realized; an optical system and an injector are arranged flexibly; the test range is wide; a plurality of test methods, such as planar laser-induced fluorescence, a laser absorption and scattering method, a Phase Doppler method, a schlieren method and Mie scattering, combination of various test methods and simultaneous measurement can be realized for spraying, evaporating, mixing, combusting, soot forming and the like; a testing optical circuit can be arranged at any angle; the spherical multifunctional constant volume bomb has universality.

Owner:平湖瓦爱乐发动机测试技术有限公司

Determination of fluid properties of earth formations using stochastic inversion

ActiveUS20050007876A1Electric/magnetic detection for well-loggingSeismic signal processingSeismic attributeTest region

A method of determining a fluid property in a subsurface region of interest of an earth formation uses measurements of seismic attributes on seismic data. For a test region, a plurality of realizations of rock properties are specified, and for each of the realizations and a selected value of a fluid property, the seismic attribute is modeled. This defines a probability density function (PDF). Comparison of the PDF of the model output with the PDF on the measured seismic data is used to determine the likelihood of the selected fluid property.

Owner:GAS TECH INST

Method and apparatus for isolating and testing zones during reverse circulation drilling

InactiveUS20050178562A1Quick opening and closingEasy to measureSurveyDrilling rodsInterior spaceWell drilling

A zone isolating and testing apparatus comprising an isolation tool and a downhole flow control means and a method of using such apparatus is disclosed. The zone isolating and testing apparatus is particularly useful for testing zones during reverse circulation drilling using concentric drill string such as concentric drill pipe or concentric coiled tubing. The isolation tool of the zone isolating and testing apparatus comprises an expandable packer means and is adapted to connect to concentric drill string near the drilling means. The downhole flow control means of the zone isolating and testing apparatus comprises two valves, one for closing off the annulus between the inner tube and outer tube of the concentric drill string and the other for closing off the inner space of the inner tube. The downhole flow control means is also adapted to connect to concentric drill string near the drilling means. During testing, the isolation tool seals off the annulus between the concentric drill string and the walls of the wellbore and the downhole flow control means seals off either the annulus between the inner tube and outer tube of the concentric drill string or the inner space of the inner tube of the concentric drill string.

Owner:PRESSSOL

Reagent test strips comprising reference regions for measurement with colorimetric test platform

InactiveUS20170184506A1Material analysis by observing effect on chemical indicatorTesting water hardnessReagent stripAnalyte

Disclosed is a reagent strip comprising test region(s) and reference region(s). The reference region(s) display a predetermined response to a range of possible concentrations of an analyte applied to the corresponding test region(s). Furthermore, the reference region(s) and the test region(s) are arranged on the reagent strip so as to facilitate analysis of a qualitative state of the analyte and optionally, calculation of a quantitative value of the analyte at point-of-collection. Also disclosed is a method of manufacturing such reagent strips, first involving printing the reference region(s) and the test region(s) in a continuous and alternating series on a test strip precursor substrate. The method also involves cutting the test strip precursor substrate perpendicularly to the printed columns to obtain one or more reagent strips. Also disclosed is a method encompassed in a mobile application for determining a qualitative state and optionally calculating a quantitative state of the analyte.

Owner:SPARK DIAGNOSTICS LLC

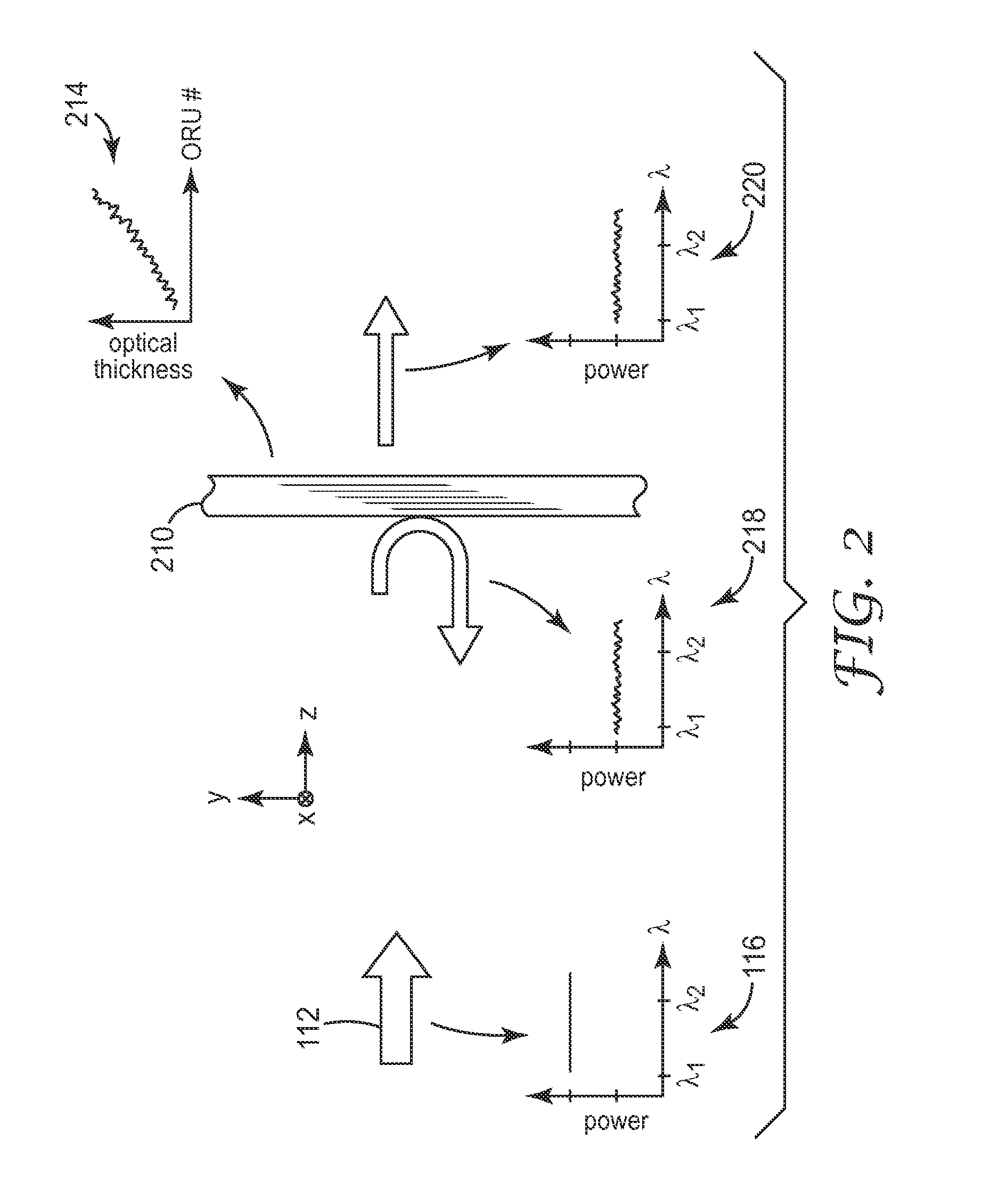

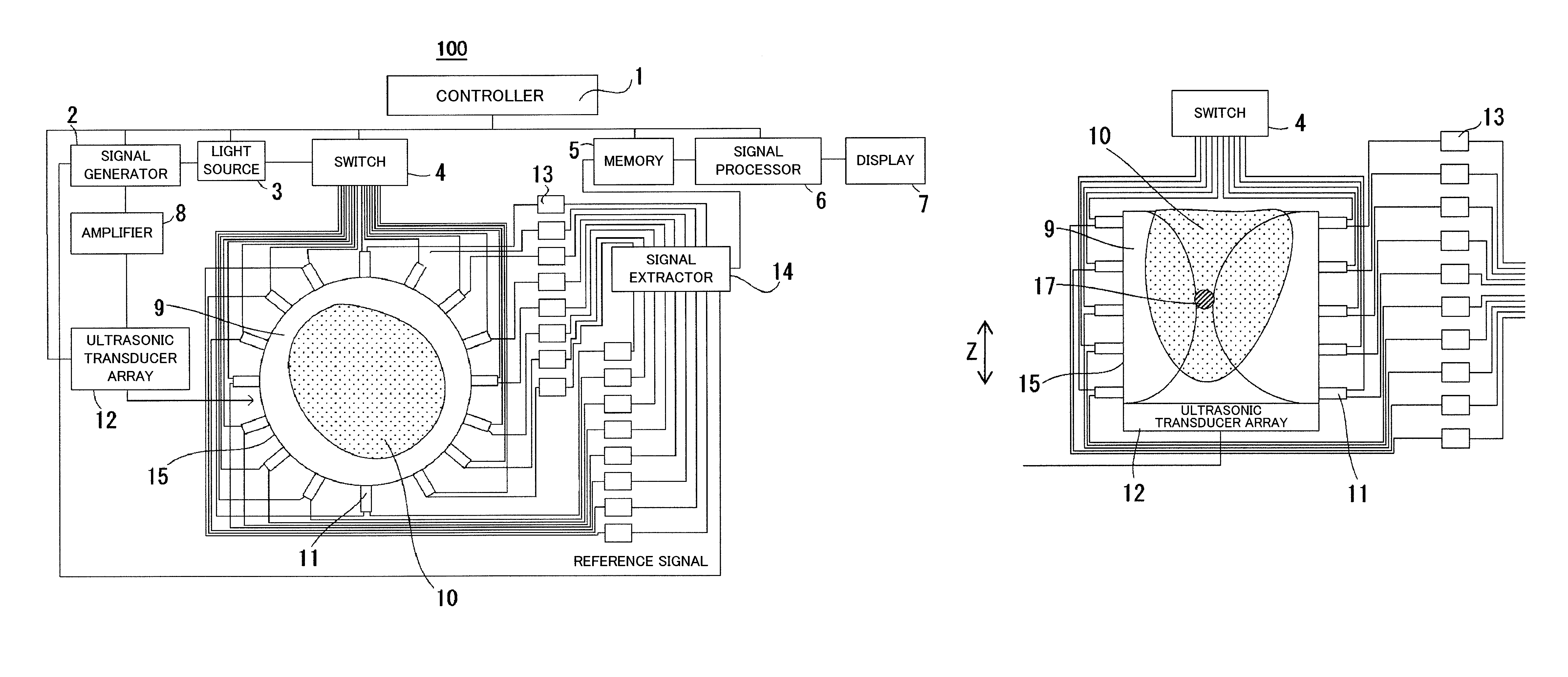

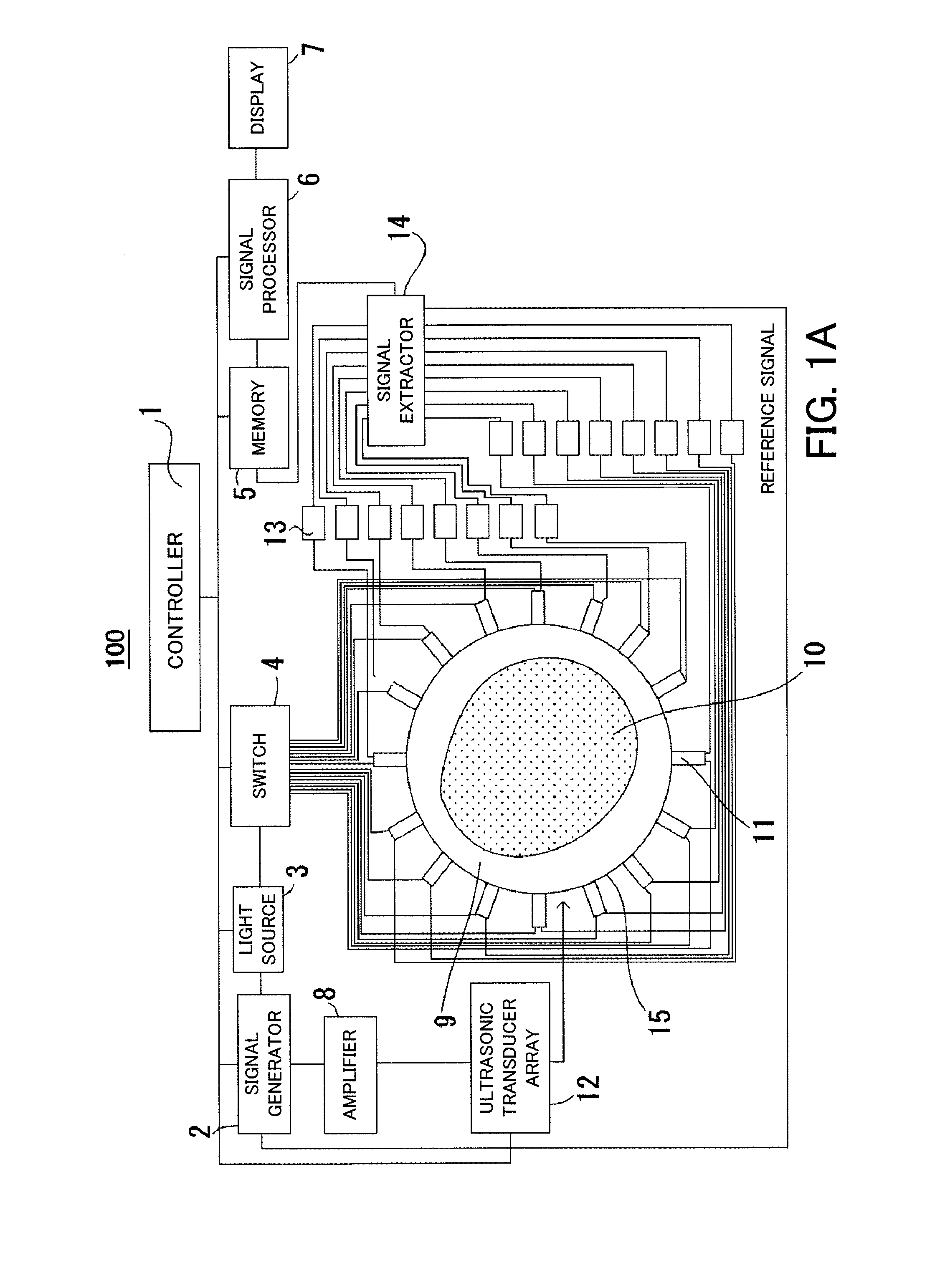

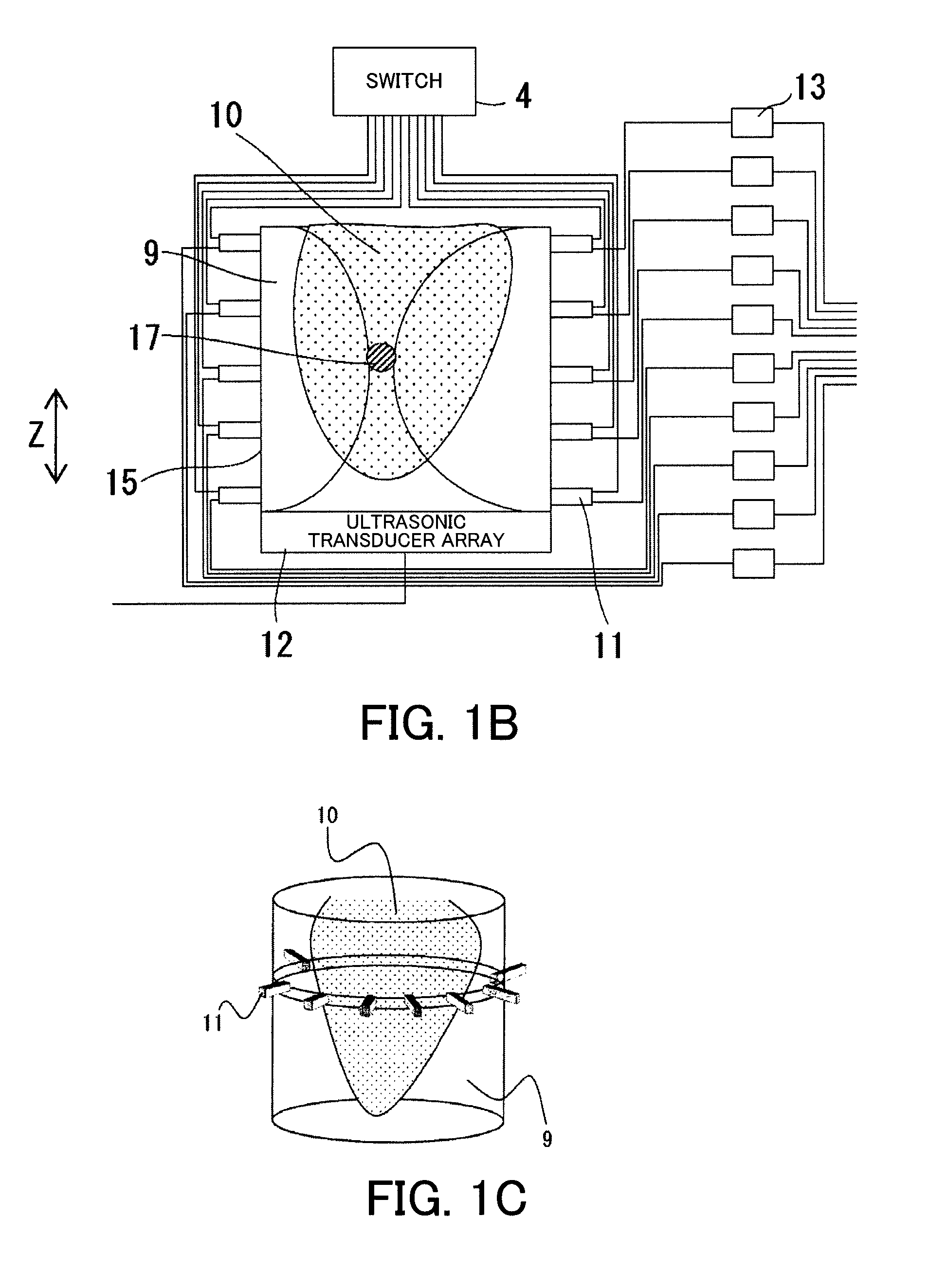

Measurement apparatus and measurement method

InactiveUS8289502B2Accurate measurementOptical radiation measurementUltrasonic/sonic/infrasonic diagnosticsChemical physicsTest object

A measurement apparatus includes a DOT measurement unit, an AOT measurement unit, and a controller configured to calculate at least one of an absorption characteristic and a scattering characteristic of a test region set in an test object by utilizing one of the DOT measurement unit and the AOT measurement unit, whichever one has the smaller measurement size.

Owner:CANON KK

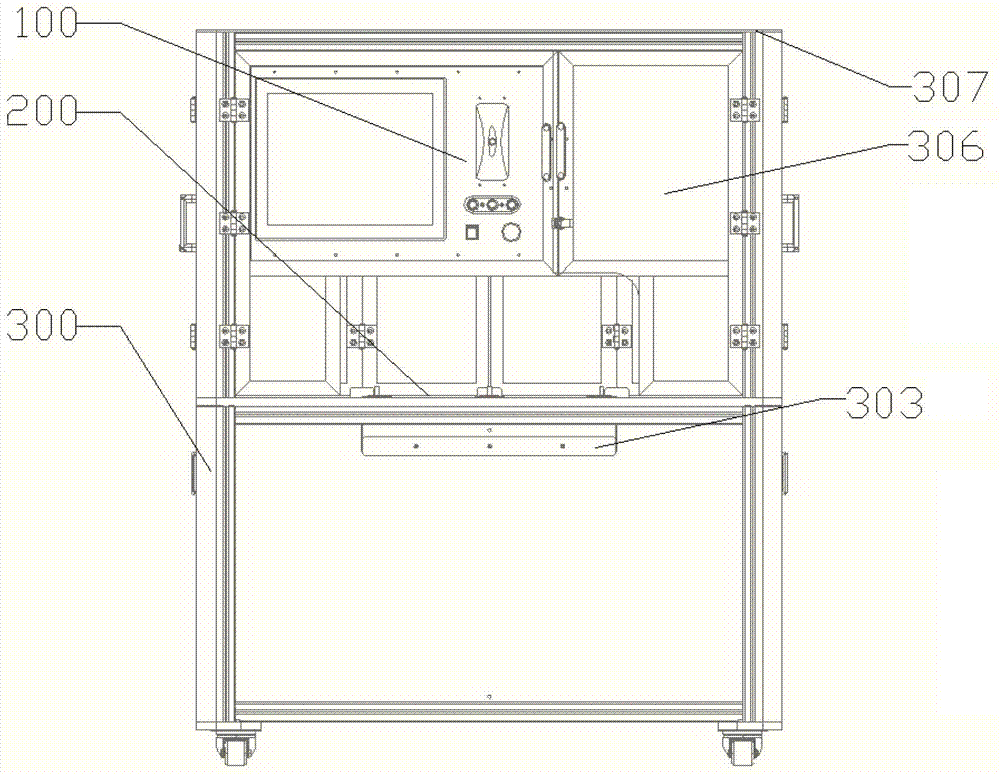

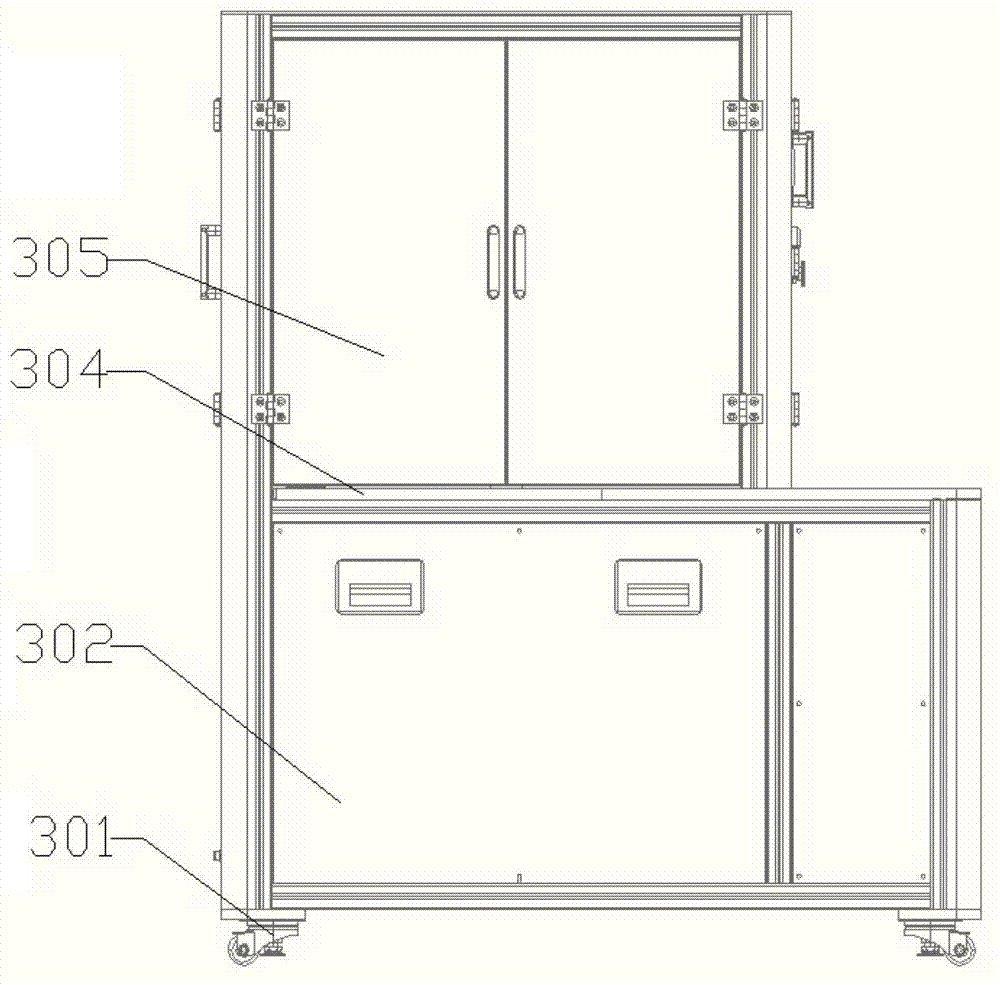

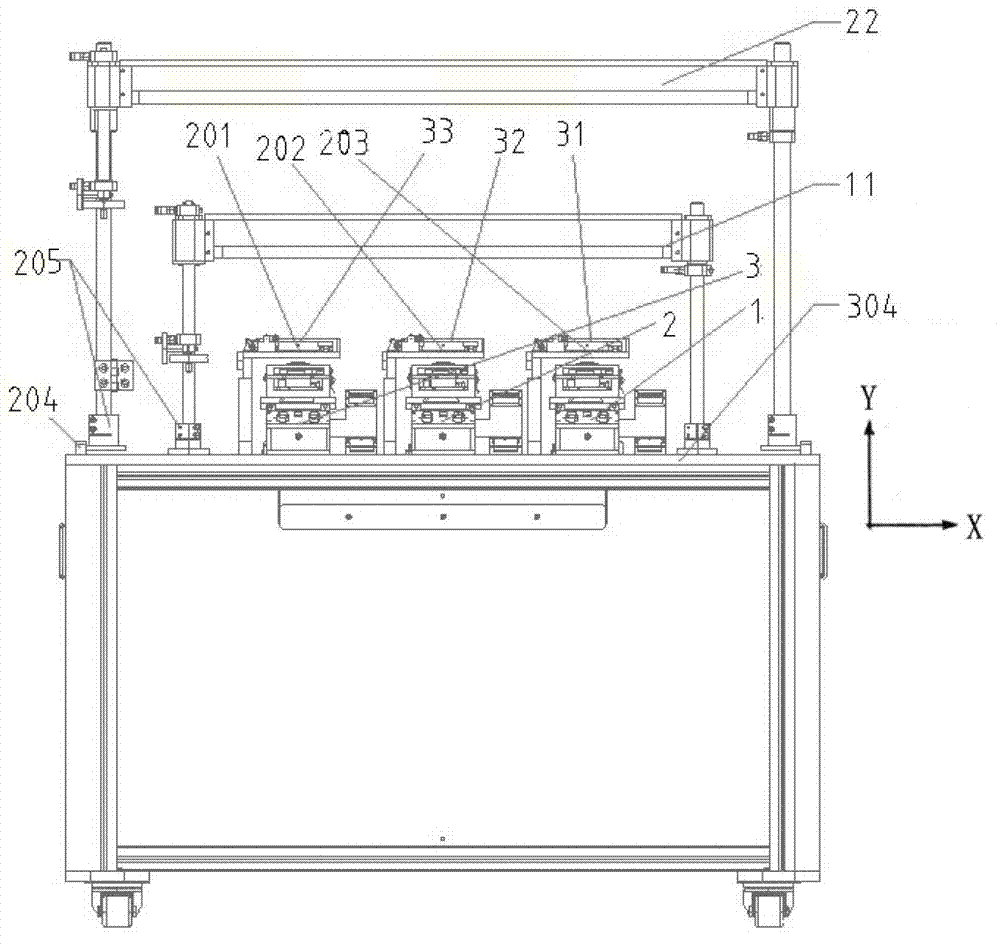

Novel mobile phone camera module automatic test machine

ActiveCN103162940AImprove test efficiencySmall footprintTesting optical propertiesTest efficiencyTest region

The invention provides a novel mobile phone camera module automatic test machine which comprises a control panel, a test area and a work machine frame, wherein a work table top and a keyboard support are arranged in the middle of the work machine frame. The test area comprises a test position and a test light source located above the test position, the test position is arranged on the work table top, the test position comprises a reset switch, a starting switch, a display signal device, a test main board, a tank chain, a product fixing mechanism, an X-Y horizontal-movement sliding platform, a light barrier, a sliding rail, a sliding sleeve and a limiting sensor, the sliding sleeve can freely slide on the sliding rail front and back, the X-Y horizontal-movement sliding platform is fixed on the sliding sleeve, and the test main board is fixed on the X-Y horizontal-movement sliding platform. Automatic test of a mobile phone camera module, comprising MTF test, stain test, damaged point test, noisy point test, VCM curve test, color uniformity and luminance uniformity test, and the like is ahieved through the novel mobile phone camera module automatic test machine. The novel mobile phone camera module automatic test machine is high in test efficiency, and suitable for modules of different pixel levels.

Owner:NINGBO SUNNY OPOTECH CO LTD

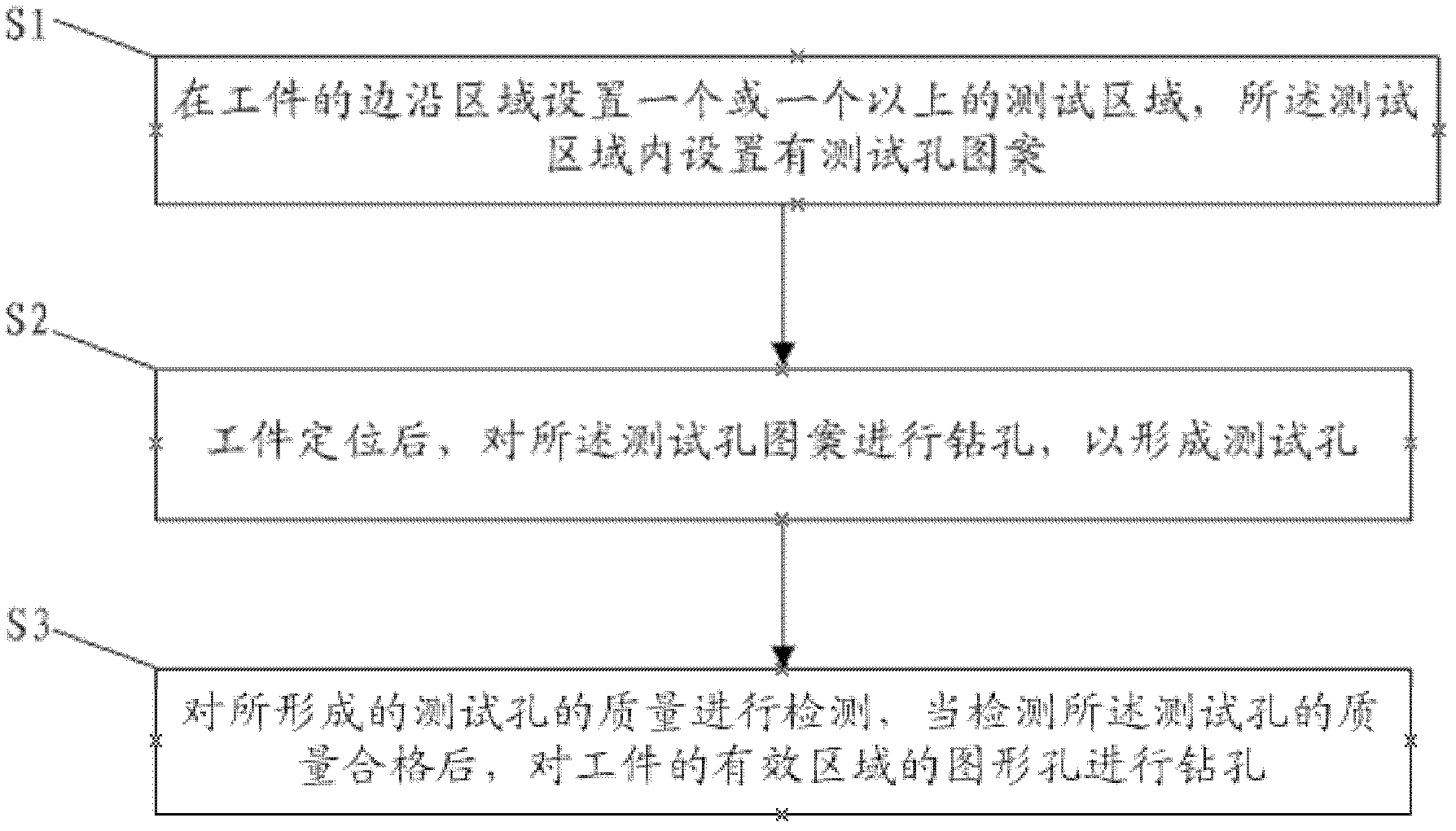

Quality detection method of boring on printed circuit board

ActiveCN103185733AImprove processing yieldReduce drilling scrap rateMaterial analysis using wave/particle radiationTest regionProduct processing

The invention provides a quality detection method of boring on a printed circuit board, which comprises the following steps: 1) setting one or more test areas at edge area of a workpiece, arranging a test hole pattern in the test area; 2) positioning the workpiece, boring according to the test hole pattern to form a test hole; and 3) detecting the quality of the formed test hole, and boring the pattern aperture on an effective area of the workpiece when the detected test hole is qualified,. The boring quality detection method can effectively reduce the boring disability rate of the workpiece, product processing yield rate during a boring technology can be increased, and the production cost is reduced.

Owner:NEW FOUNDER HLDG DEV LLC +1

Method for identifying vehicles in electronic images

A method for identifying objects in an electronic image is provided. The method includes the steps of providing an electronic source image and processing the electronic source image to identify edge pixels. The method further includes the steps of providing an electronic representation of the edge pixels and processing the electronic representation of the edge pixels to identify valid edge center pixels. The method still further includes the step of proving an electronic representation of the valid edge center pixels. Each valid edge center pixel represents the approximate center of a horizontal edge segment of a target width. The horizontal edge segment is made up of essentially contiguous edge pixels. The method also includes the steps of determining symmetry values of test regions associated with valid edge center pixels, and classifying the test regions based on factors including symmetry.

Owner:APTIV TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com