Automatic production line of fuel cell stack

A technology for automated production lines and fuel cell stacks, applied in fuel cells, electrochemical generators, circuits, etc., can solve problems such as poor product quality consistency and low production efficiency, and achieve improved production efficiency, strong bearing capacity, and high handling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

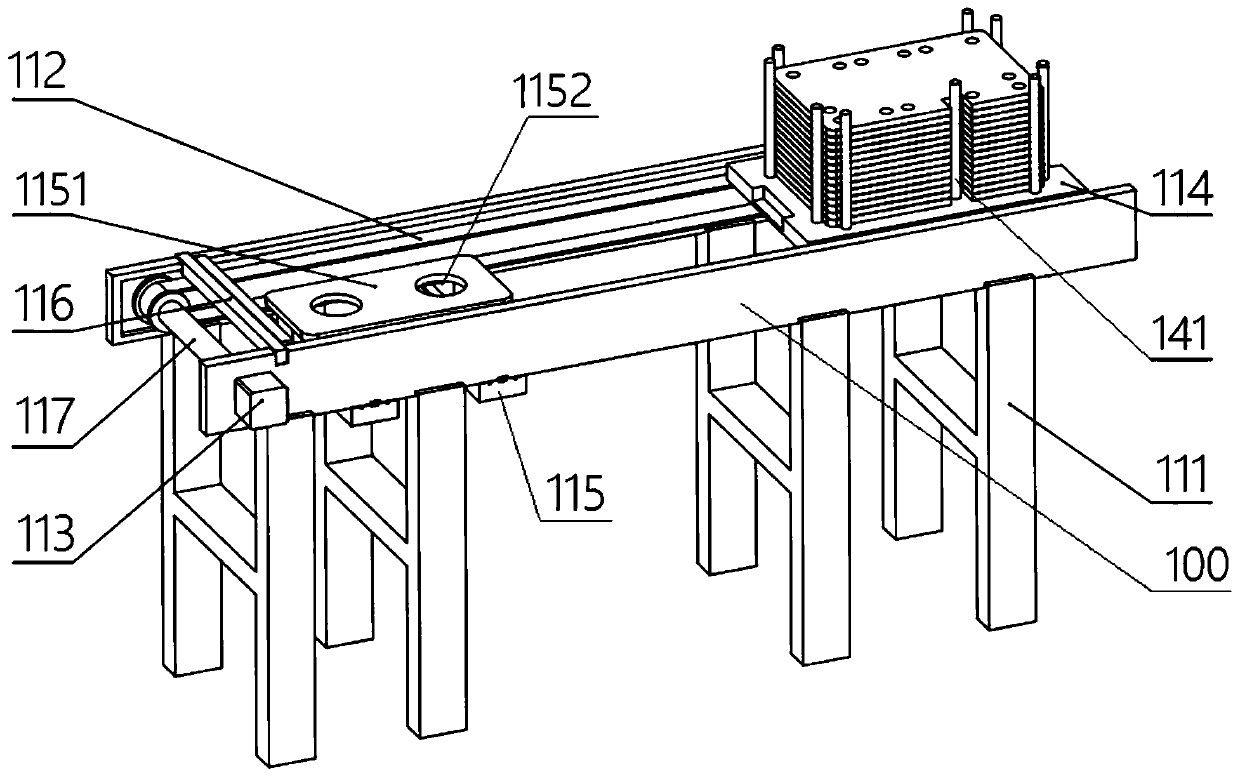

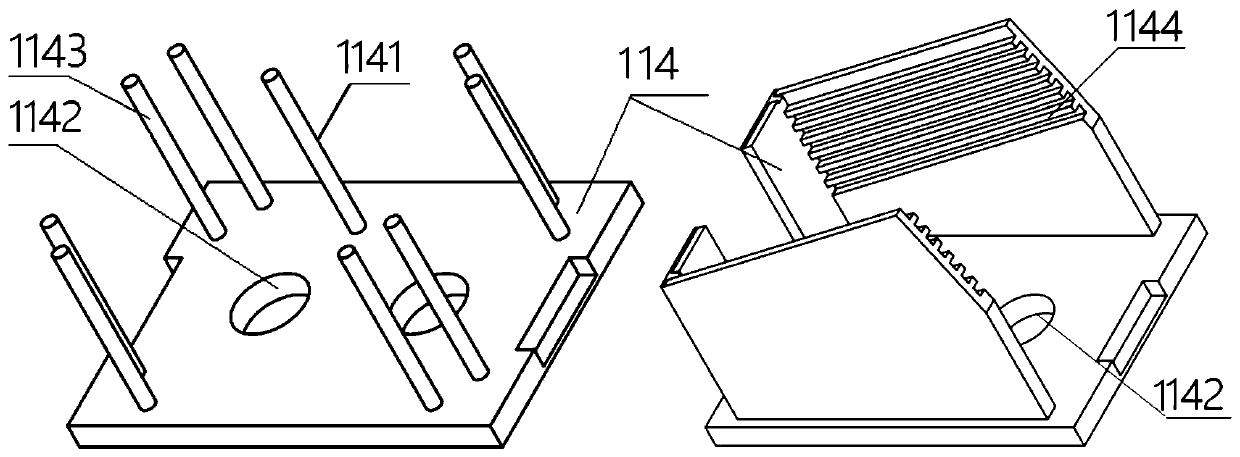

[0047] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

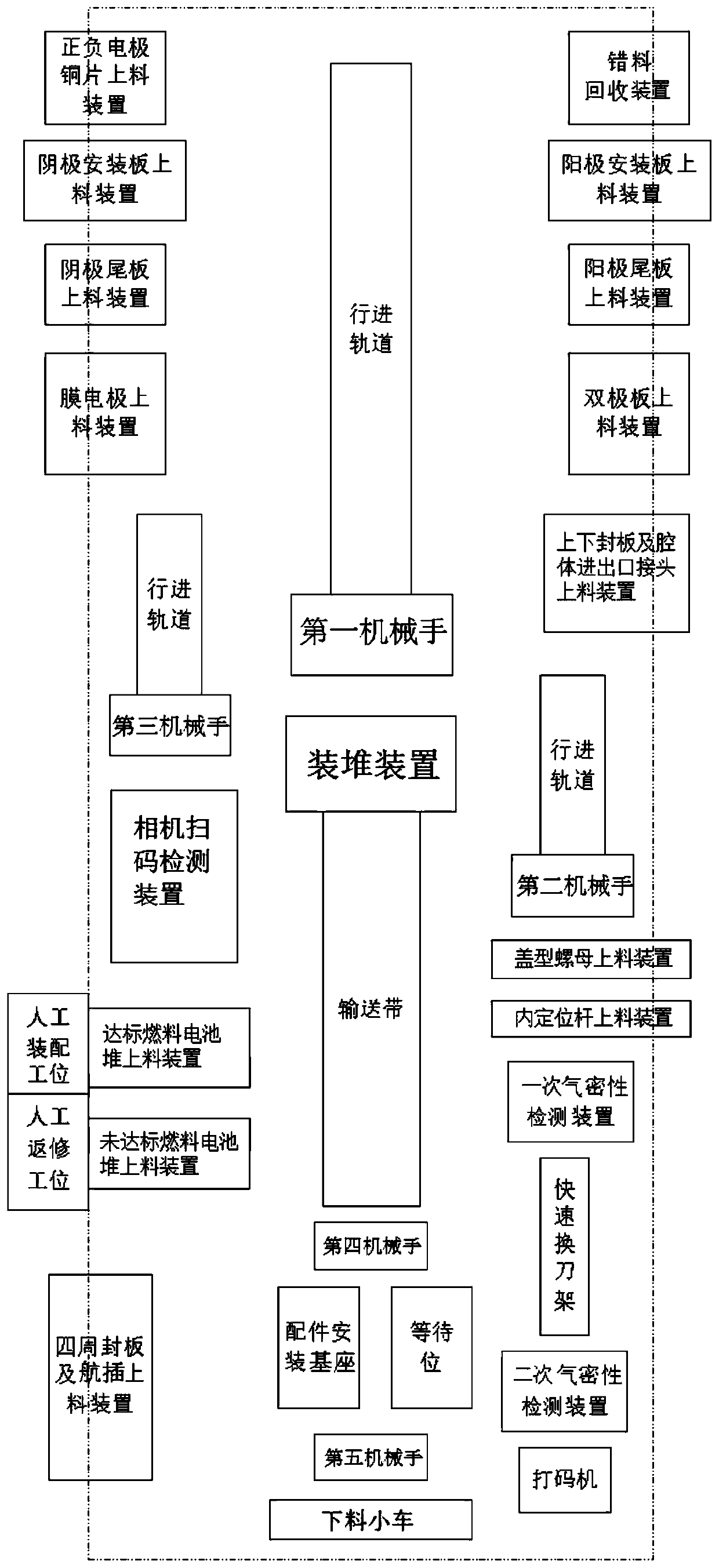

[0048] refer to figure 1 , an automatic production line for a fuel cell stack of the present invention, including a material pick-and-place area, a stacking pressing and fastening area, a primary performance testing area, a manual assembly area, a manual repair area, an accessory installation area, a secondary performance testing area, and a product End-of-line area, manipulators and control mechanisms. The manipulator includes the first manipulator, the second manipulator, the third manipulator, the fourth manipulator and the fifth manipulator. The manipulator is a six-axis manipulator, which can rotate 360 degrees in all directions. Put the material.

[0049] The material pick-and-place area is equipped with a material feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com