Inorganic heat preserving decorating building plate

An inorganic thermal insulation and building board technology, applied in construction, building construction, manufacturing tools, etc., can solve problems such as poor fire performance, and achieve the effects of speeding up construction, saving a lot of costs, and improving service life and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

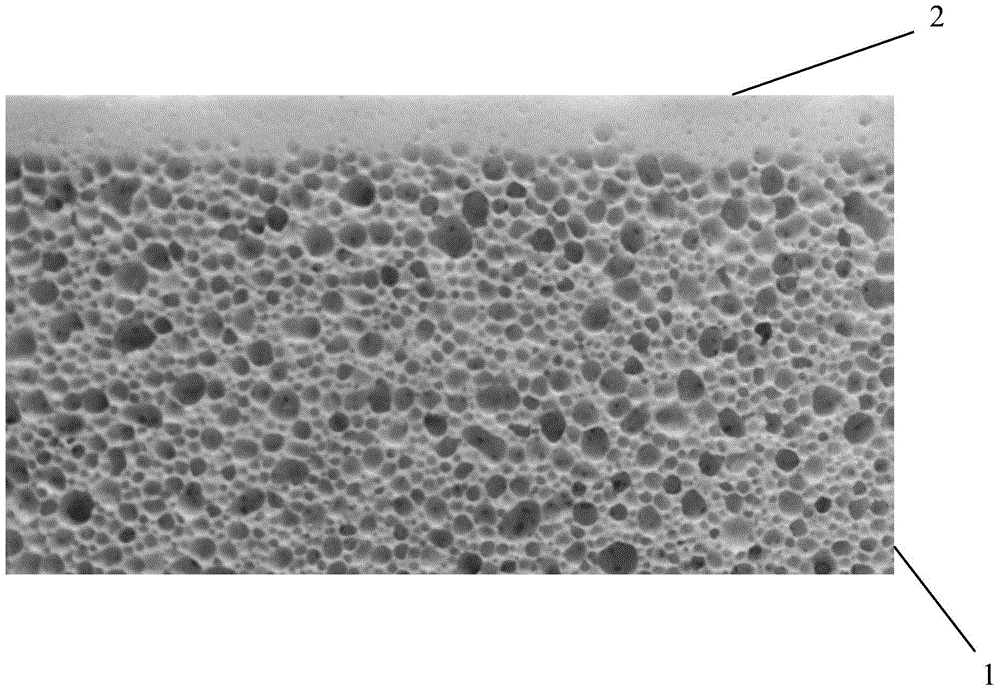

Image

Examples

Embodiment 1

[0092] The preparation method of the inorganic thermal insulation decorative building board provided by the invention comprises the following steps:

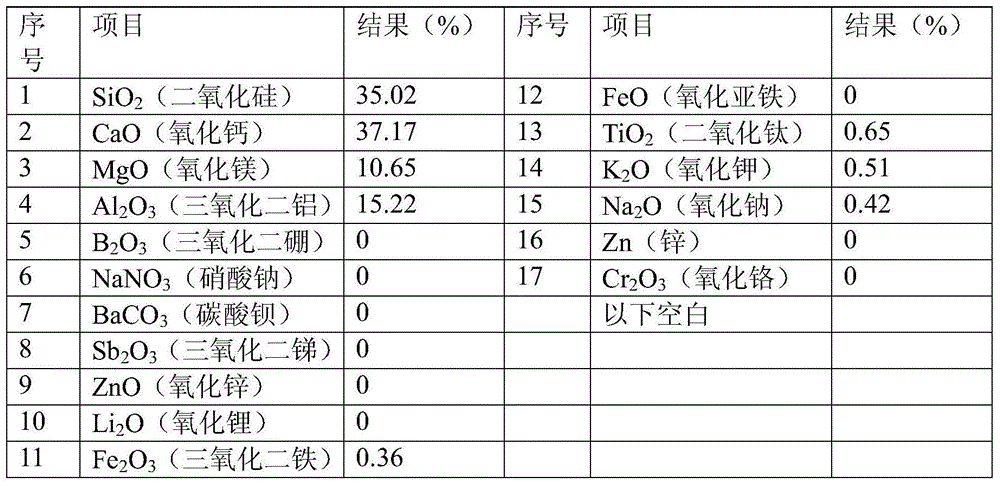

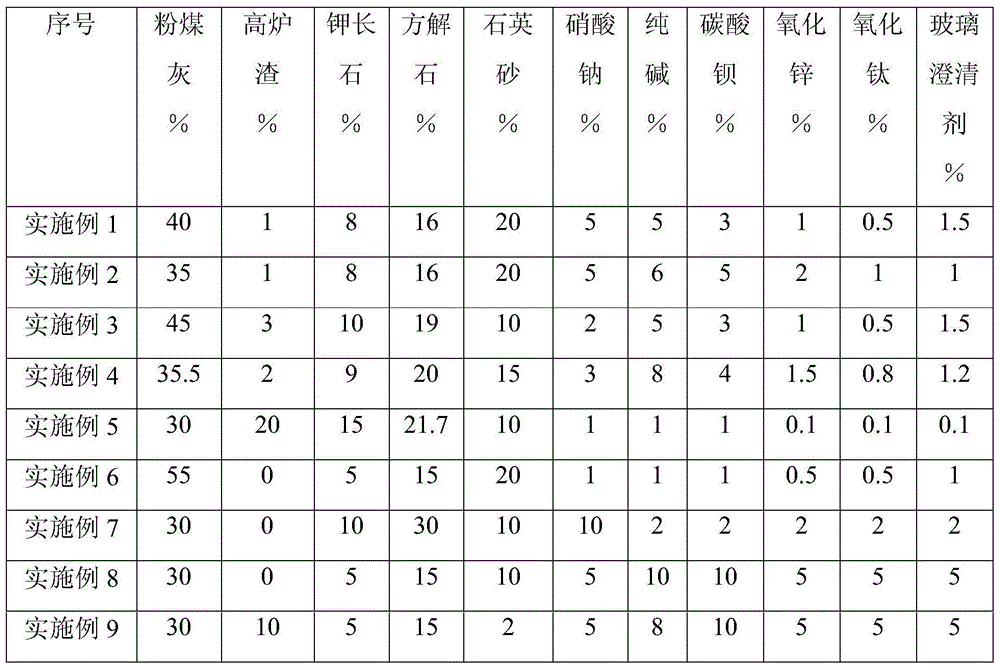

[0093] (1) Batching: the obtained glass powder, foaming agent and foam stabilizer as shown in table 4 are prepared in proportion to obtain glass mixture;

[0094] (2) Wet mixing: add the prepared glass mixture to 30% water and 6% trisodium phosphate, and fully mix to obtain a mixed solution;

[0095] (3) Drying and granulation: pass the obtained mixed solution into an atomization dryer for atomization and drying treatment, the dried powder contains 5-10% of the total mass of the glass mixture, and the atomized and dried The material is added to the granulator to complete the granulation. The particle size of the foamed material after granulation is 20-100 mesh sieve; the purpose of granulation is to facilitate sintering;

[0096] (4) cloth: complete in the cloth machine, divide two-layer cloth, the first layer is glass grain (d...

Embodiment 2

[0103] The preparation method of the inorganic thermal insulation decorative building board provided by the invention comprises the following steps:

[0104] (1) Batching: the obtained glass powder, foaming agent and foam stabilizer as shown in Table 4 are prepared in proportion to obtain glass mixture;

[0105] (2) Wet mixing: add 30% water and 7% trisodium phosphate to the prepared glass mixture, and fully mix to obtain a mixed solution;

[0106] (3) Drying and granulation: pass the obtained mixed solution into an atomization dryer for atomization and drying treatment. The dried powder contains 5% of the total mass of the material, and the atomized and dried material is added to granulate The granulation is completed in the machine, and the particle size of the foamed material after granulation is 20-100 mesh sieve; the purpose of granulation is to facilitate sintering;

[0107] (4) cloth: complete in the cloth machine, divide two-layer cloth, the first layer is the glass p...

Embodiment 3

[0114] The preparation method of the inorganic thermal insulation decorative building board provided by the invention comprises the following steps:

[0115] (1) Batching: the obtained glass powder, foaming agent and foam stabilizer as shown in Table 4 are prepared in proportion to obtain glass mixture;

[0116] (2) Wet mixing: add 40% water and 8% trisodium phosphate to the prepared glass mixture, and fully mix to obtain a mixed solution;

[0117] (3) Drying and granulation: pass the obtained mixed solution into an atomization dryer for atomization and drying treatment, the dried powder contains 10% of the total mass of the material, and the atomized and dried material is added to granulate The granulation is completed in the machine, and the particle size of the foamed material after granulation is 20-100 mesh sieve; the purpose of granulation is to facilitate sintering;

[0118] (4) cloth: complete in the cloth machine, divide two-layer cloth, the first layer is the glass pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com