Patents

Literature

1857 results about "Trisodium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trisodium phosphate (TSP) is the inorganic compound with the chemical formula Na₃PO₄. It is a white, granular or crystalline solid, highly soluble in water, producing an alkaline solution. TSP is used as a cleaning agent, builder, lubricant, food additive, stain remover, and degreaser.

Anti-emulsification water-soluble metal washing agent

The invention relates to an anti-emulsification water-soluble metal washing agent. Every 100 parts of the anti-emulsification water-soluble metal washing agent include the following components according to parts by weight: 3-7 non-ionic surfactant, 3-7 bi-ion active agent, 1-5 chelator, 1-5 rust preventive, 5-10 inorganic builder and the balance water, wherein the non-ionic surfactant is any one of fatty amine polyoxypropylene ether, alkylphenol ether and fatty amine polyoxyethylene alkyl ether ammonium sulfate, the bi-ion active agent is any one of alkyl dimethylin acetic acid betaine, lauramidopropyl betaine and cocamidopropyl betaine, the chelator is any one of sodium citrate, ethylenediaminetetraacetic acid tetrasodium salt and nitrilotriacetic acid sodium salt, the rust preventive is any one of sodium borate, sodium nitrite, sodium benzoate and long carbon chain carboxylic acid amine, and the inorganic builder is any one of trisodium phosphate, sodium metasillcate, sodium carbonate, sodium bicarbonate and sodium hydroxide. The anti-emulsification water-soluble metal washing agent has the advantage of higher cleaning capacity and reutilization capacity.

Owner:NANJING KERUN LUBRICANTS

Stainless steel cleaning agent

InactiveCN101135056AImprove cleaning efficiencySimple cleaning processPhosphoric acidCleansing Agents

The stainless steel detergent for washing stainless steel product is prepared with acids, basic salts, surfactant, assistant, stabilizer and water, and through stirring and reaction at normal temperature. Specifically, it consists of sodium carbonate, sodium tripolyphosphate, tartaric acid, citric acid, hydrofluoric acid, nitric acid, phosphoric aicd, JFC, OP-10, triethanolamine, urotropin, trisodium phosphate, acetic acid, alcohol and water in certain weight proportion. It has the features of simple preparation process, environment friendship, high cleaning efficiency, low cleaning cost, etc.

Owner:吴铭鑫

Paper sepiolite sustained-release antibacterial cat litters

InactiveCN103348922AGood antibacterial effectImprove adsorption capacityAnimal housingCarboxymethyl celluloseSodium phosphates

Owner:WUHU LEISURELY NURSING SUPPLIES POLYTRON TECH INC

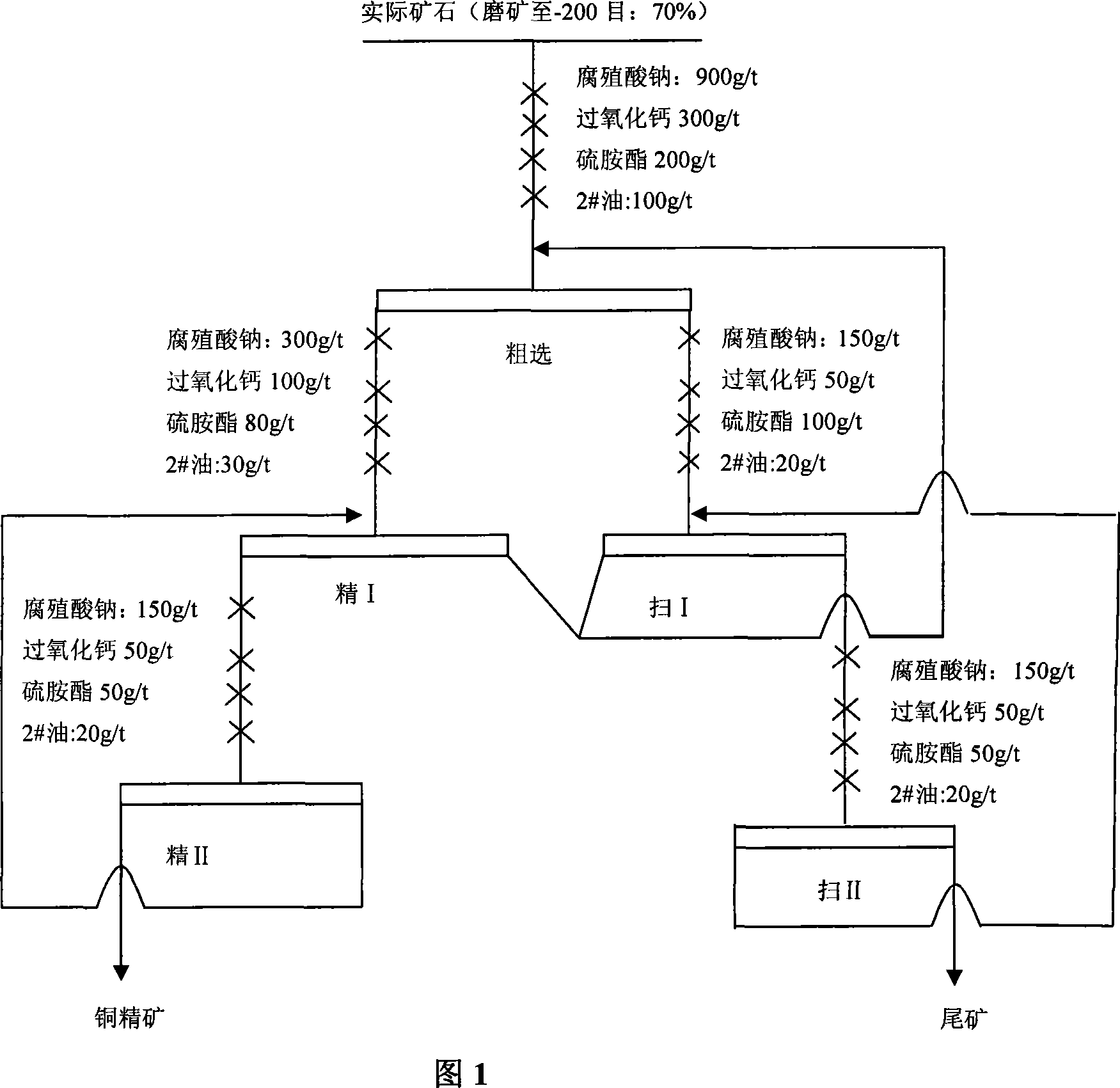

Highly effective composite restrainer of ferro-sulphur ore in complex vulcanizing ore and method of use thereof

The invention relates to a high-efficient combined inhabitor for pyrite in complex sulfide ores and the application method of the inhabitor. The inhabitor comprises calcium superoxide and HA-Na. The inhabitor of the invention can inhibit complex vulcanized iron-bearing minerals selectively, has better inhibition properties for magnetic pyrite, pyrite and arsonopyrite, and is an inhabitor of high selectivity. Compared with the prior inhibitors such as lime, cyanide, bichrome, potassium permanganate, sodium sulfide, sulphite, zinc sulphate and trisodium phosphate, the invention has the advantages of lower use level, good effects, no pollution, and other advantages.

Owner:CENT SOUTH UNIV

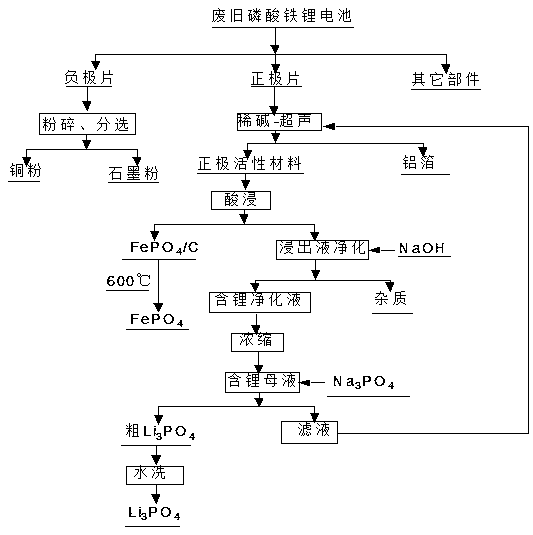

Recovery method for cathode material of waste lithium iron phosphate battery

InactiveCN107739830AEasy to separate naturallyLow costWaste accumulators reclaimingProcess efficiency improvementRecovery methodPhosphate

Owner:FUZHOU UNIV

Process for production of gypsum/fiber board

ActiveUS20050161853A1Increase ratingsIncreased rehydration rateSolid waste managementWood working apparatusSlurryCellulose fiber

An improved process calcining a gypsum / cellulosic fiber slurry to produce a composite gypsum / cellulosic fiber product resides in adding a selected crystal modifier to the gypsum / cellulosic fiber slurry prior to the heating step to reduce the time necessary to carry out the calcination process, to reduce the temperature at which the calcination process is run or to increase the aspect ratio of the acicular calcium sulfate alpha hemihydrate crystals formed during the calcination process. Useful crystal modifiers include aluminum sulfate, aluminum chloride, chlorine, zinc sulfate, iron (III) sulfate, aluminum sulfate hexadecahydrate, iron (II) sulfate heptahydrate, iron (III) sulfate pentahydrate, zinc sulfate heptahydrate, copper sulfate pentahydrate, copper chloride dehydrate, manganese sulfate monohydrate and trisodium phosphate.

Owner:UNITED STATES GYPSUM CO

Preparation method of drug and protein sustained-release alginate hybrid gel

InactiveCN103040727AGood biocompatibilityGood slow releasePeptide/protein ingredientsAerosol deliveryBiocompatibility TestingSolvent

The invention provides a preparation method of drug and protein sustained-release alginate hybrid gel. The preparation method comprises the steps of preparing calcium alginate hydrogel, then soaking the calcium alginate hydrogel in inorganic salt solutions including trisodium phosphate, diammonium hydrogen phosphate, sodium silicate, sodium carbonate, sodium oxalate and the like at certain concentration to swell for a certain period of time, and soaking the swelled calcium alginate hydrogel into an aqueous solution of drugs and proteins with calcium ions at certain concentration for crosslinking for a period of time, thus obtaining the drug and protein sustained-release alginate hybrid gel. The calcium alginate hydrogel disclosed by the invention can be in the shape of a membrane, a microballoon, a fiber and the like. The method disclosed by the invention is simple to operate and does not adopt any poisonous and harmful solvent; the activity of the immobilized protein is high; the materials are good in biocompatibility; and the drug and protein sustained-release alginate hybrid gel is good in slow release performance, and has good application prospect in the fields of tissue engineering, controlled release, medicine and health, and the like.

Owner:TIANJIN POLYTECHNIC UNIV

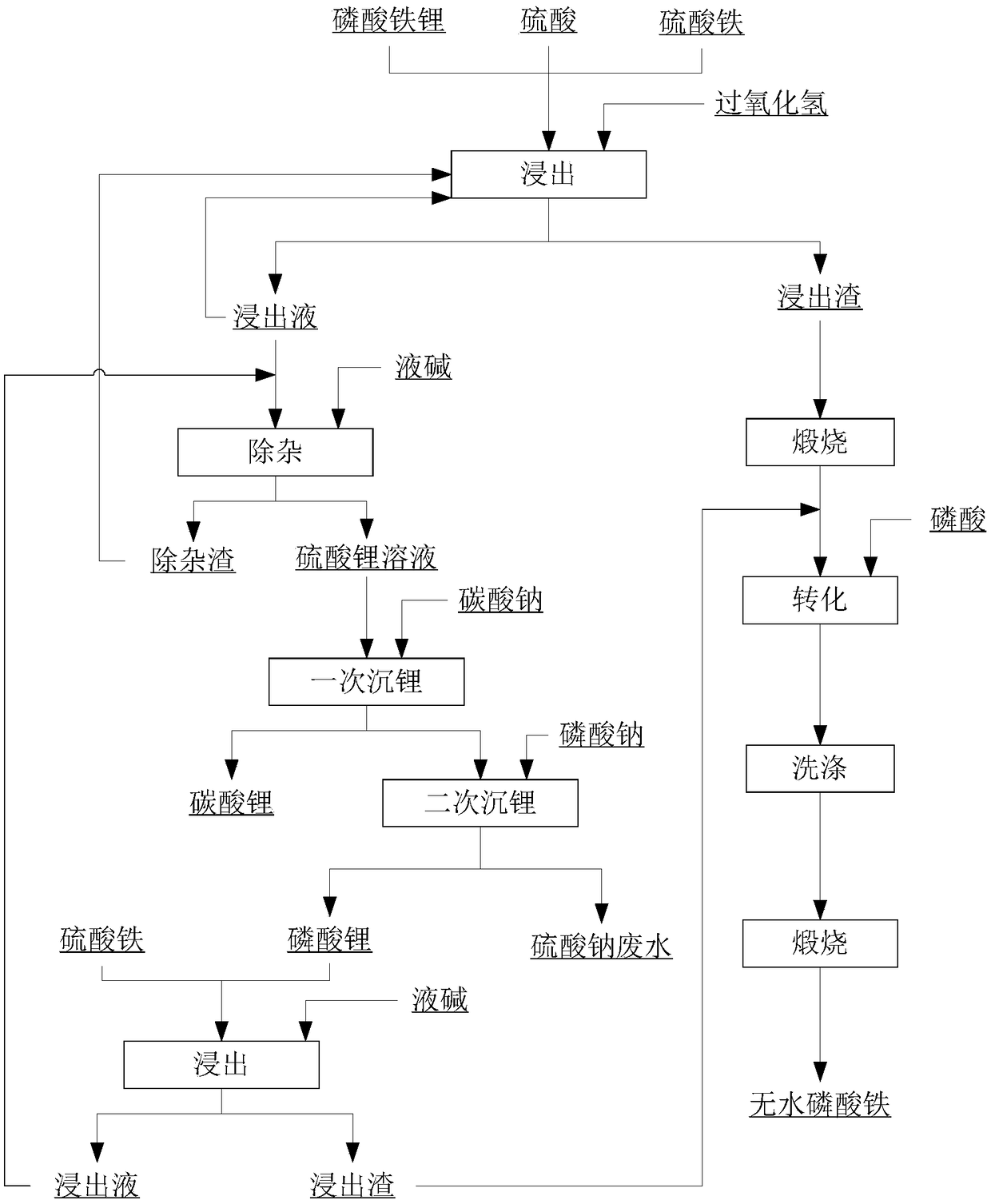

Method for recovering lithium from lithium iron phosphate

ActiveCN108899601ADoes not affect the leaching rateHigh purityWaste accumulators reclaimingProcess efficiency improvementFerric hydroxideIron sulphate

The invention discloses a method for recovering lithium from lithium iron phosphate. The method disclosed by the invention comprises the following steps: dissolving waste lithium iron phosphate slag with sulfuric acid and ferric sulfate, leaching iron, lithium and phosphorus, adding an oxidizing agent, reacting iron and phosphate radicals to produce an iron phosphate precipitate and a small amountof ferric hydroxide, converting lithium into a water-soluble lithium sulfate solution, filtering to obtain the lithium sulfate solution, adding sodium carbonate into the lithium sulfate solution to prepare a lithium carbonate product, and adding sodium phosphate or phosphoric acid to prepare lithium phosphate; dissolving the lithium phosphate with ferric sulfate again to obtain the lithium sulfate solution and a compound taking iron phosphate as a principle component, returning the lithium sulfate solution to the system to prepare lithium carbonate, and calcining the iron phosphate slag to remove organic matters and carbon in the slag; and slurrying to prepare cell grade iron phosphate. According to the method for recovering lithium from lithium iron phosphate disclosed by the invention,the lithium is totally converted into the product lithium carbonate in the method, the process flow is short, the cost is low, the lithium recovery rate is 97%, the metal lithium in the lithium iron phosphate can be effectively recovered, and all the slag is converted into the cell grade iron phosphate.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Core glaze for matte sand streak enamel glaze and production method thereof

The invention discloses a core glaze for a matte sand streak enamel glaze, belonging to the technical field of enamel glazes. The core glaze comprises, by weight, 20 to 35% of quartz sand, 20 to 30% of magnesium oxide, 18 to 28% of soda ash, 8 to 15% of potash feldspar, 2 to 5% of borax, 1 to 2% of fluorite, 1 to 3% of calcium carbonate, 2 to 5% of trisodium phosphate and 0.02 to 0.1% of cobalt oxide. Through cooperative usage of the core glaze with commercially available bright glazes, colorants and the like, matte sand streak glaze products of different colors and different texture can be conveniently and rapidly at a low temperature in a small scale.

Owner:娄底湘信新材料科技有限公司

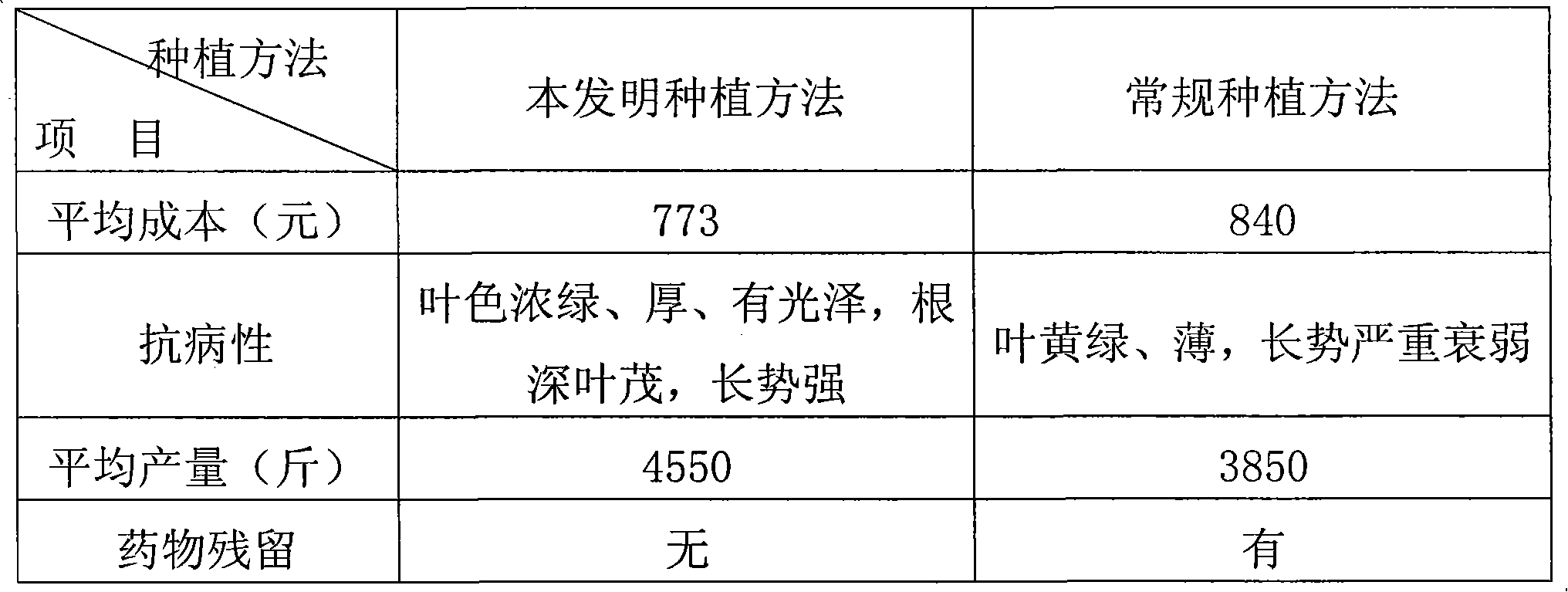

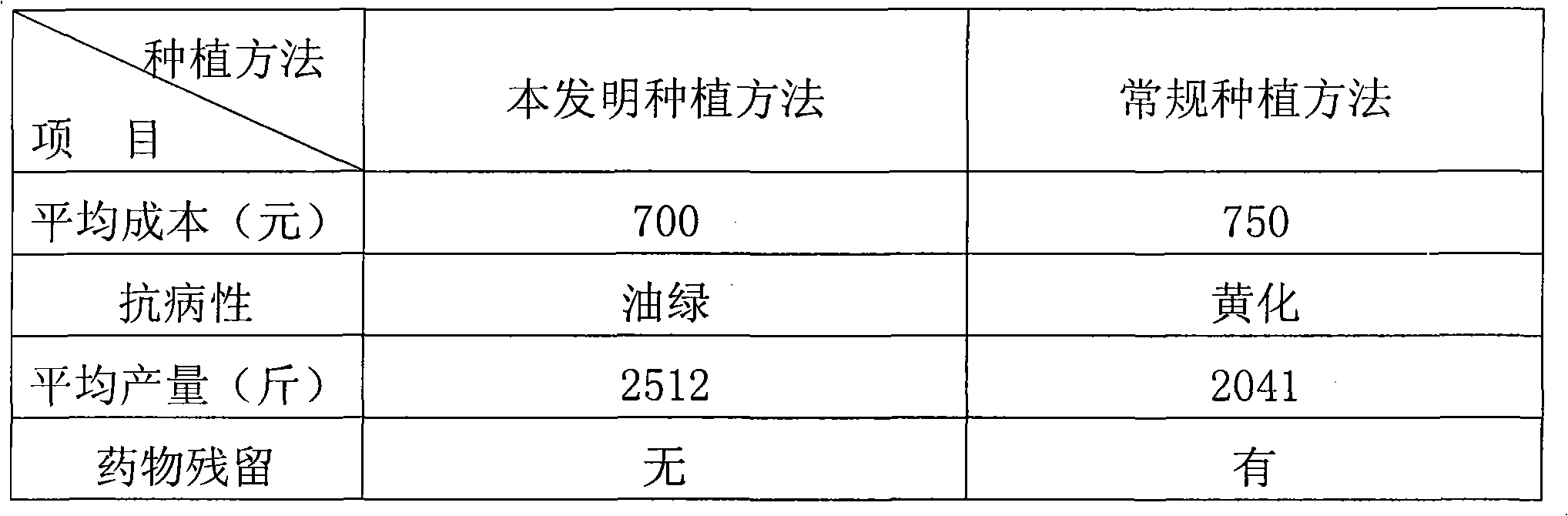

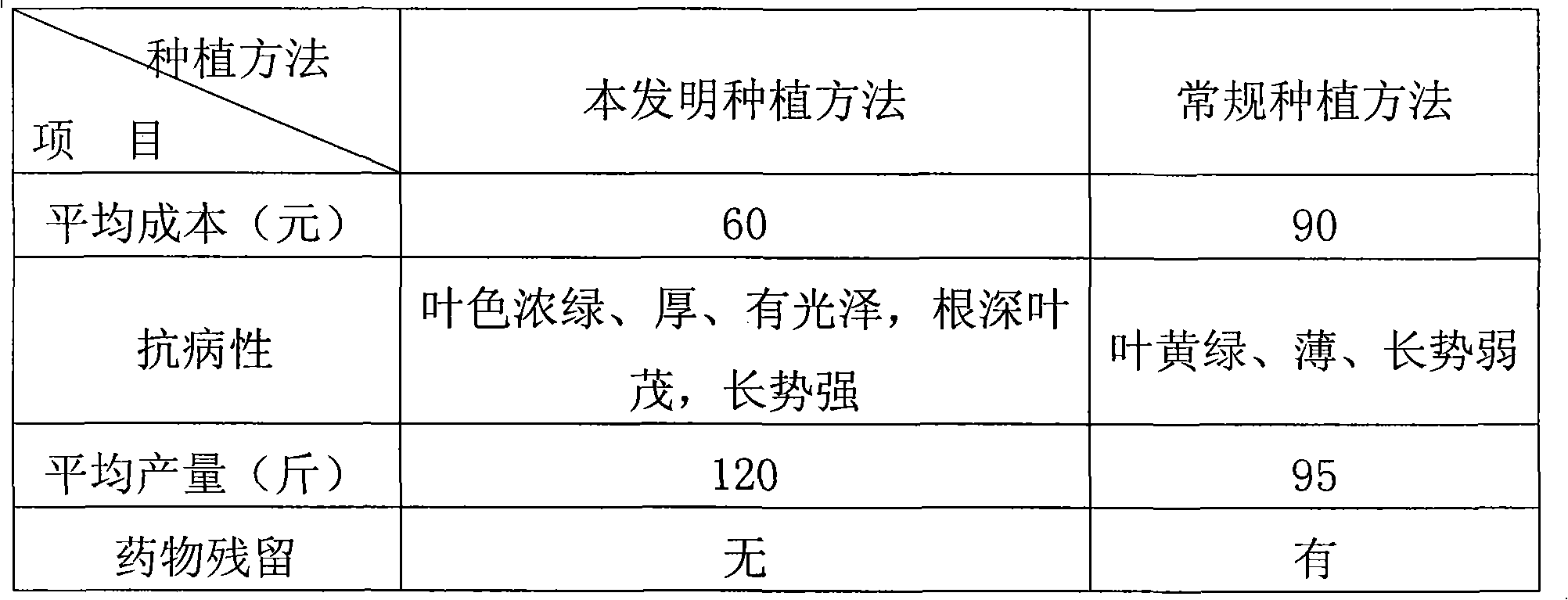

Vegetable planting method

ActiveCN101878714ANo pollution in the processAvoid root rotCultivating equipmentsOrganic fertilisersPlastic mulchInsect pest

The invention relates to a vegetable planting method. The method comprises a seed treating step, a seedbed seedling raising step, a fertilizer applying and uniform plowing step, a ridging and ditch feeding step, a bare root planting step, a black plastic film covering step and a field management step, wherein the seed treating step comprises the following specific steps of: irradiating seeds with ultraviolet rays for 10 to 45 minutes to sterilize the seeds; soaking the sterilized seeds in solution of potassium permanganate in a ratio of potassium permanganate to water of 1:500 for 10 minutes; cleaning the soaked seeds with water; and soaking the cleaned seeds in 10 percent solution of trisodium phosphate for 5 to 10 minutes for disinfecting; and mixing the soaked seeds by using lactobacillus. No chemical fertilizer or pesticide is used in a planting process, so that the produced vegetables are not polluted. Actinomycetes and the lactobacillus are used in the seedbed seedling raising step, the fertilizer applying and uniform plowing step and the field management step, so that vegetable root rotting can be prevented and the infestation of plant diseases and insect pests to root systems is reduced.

Owner:蒋德云

Harmless treatment method of electrolytic manganese residue

The invention relates to a harmless treatment method of electrolytic manganese residue. The method comprises the following steps of: (1) putting fresh electrolytic manganese residue into a mixer, adding sodium phosphate in a stirring state, and evenly stirring, wherein the mass ratio between the sodium phosphate and the dry electrolytic manganese residue is 3-5%; (2) adding calcium oxide in a continuously stirring state, evenly stirring, and continuously recovering ammonia gas generated in the stirring process, wherein the mass ratio between the calcium oxide and the dry electrolytic manganese residue is 5-10%; (3) unloading when the ammonia gas does not overflow from a mixture obtained in the step (2) to obtain the mixture after harmless treatment. The method not only can effectively fix soluble manganese left in the electrolytic manganese residue, but also can treat residual ammonia nitrogen and other impurities in the electrolytic manganese residue at the same time, thus being very beneficial to resource utilization. The method also has the advantages of being low in treatment cost and easy to operate.

Owner:CHONGQING UNIV

Cassia obtusifolia tea bag with functions of weight reduction, hypotension and hypoglycemic effect and its production process

The invention provides a cassia obtusifolia tea bag with functions of weight reduction, hypotension and hypoglycemic effect, which is characterized in that the production process comprises the following steps: washing, cleaning and drying the cassia obtusifolia stem, leaf and grain, crushing by a pulverizer to 280 meshes, uniformly stirring, packing, disinfecting to obtain the cassia obtusifolia tea bag with functions of lipid lowering, hypotension and hypoglycemic effect. The optimal composition and the weight part ratio of the tea bag are: 40-60 parts of dried cassia obtusifolia stem, leaf and grain, 10 parts of dried lotus leaf, 5 parts of haw, 5 parts of dried balsam pear, 5 parts of Chinese wolfberry, 10 parts of Pu'er tea, 10 parts of cassia seed, 5 parts of mulberry leaf, 5 parts of folium apocyni veneti, 5 parts of Chinese yam as medicine, 3 parts of rhubarb, 2 parts of chrysanthemum, 2 parts of honeysuckle flower, 1 part of boat-fruited sterculia, 5 parts of cassia seed, 5 parts of kudzu root and 10 parts of additive. The additive is composed of fatty acid sucrose ester, xylitol, mannitol crystal, natural menthol, citric acid, trisodium phosphate, sodium saccharin and steviosid; the above components are carried out the processes of crushing, mixing, uniformly stirring, packing and disinfecting to obtain the tea bag.

Owner:肖梅芬

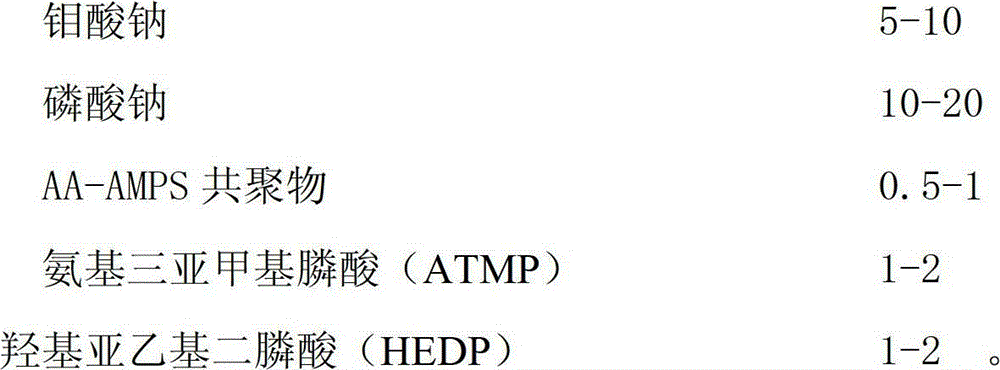

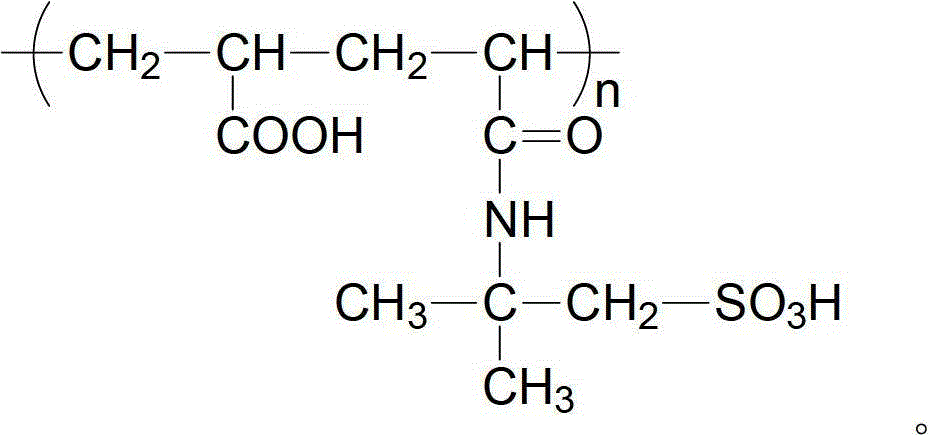

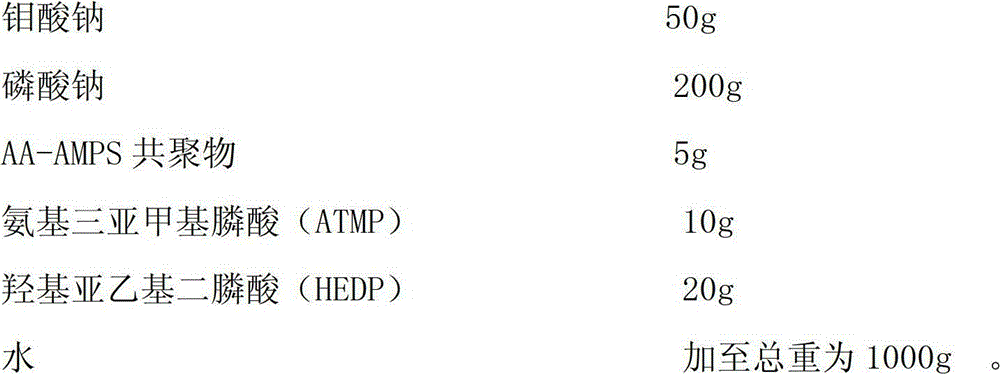

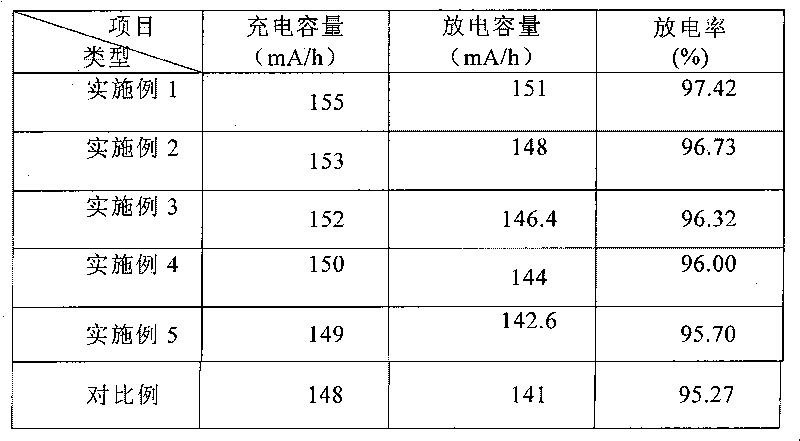

Oil field compound type anti-scale corrosion inhibitor and preparation method thereof

InactiveCN102911651AGood synergyGood scale and corrosion inhibitionBorehole/well accessoriesSodium phosphatesSimple component

The invention relates to an oil field compound type anti-scale corrosion inhibitor and a preparation method thereof, belonging to the technical field of corrosion inhibitor. The oil field compound type anti-scale corrosion inhibitor is characterized by comprising the components by mass percent: 5-10% of sodium molybdate, 10-20% of sodium phosphate, 0.5-1% of acrylic acid-2-acrylamido-2-methyl propane sulfonic acid (AA-AMPS) copolymer, 1-2% of amino trimethylene phosphonic acid and 1-2% of hydroxyl ethylidene diphosphonic acid (HEDP). The preparation method comprises the steps of: firstly, completely dissolving sodium molybdate and sodium phosphate by using water; then, adding the AA-AMPS copolymer under the condition of stirring until the copolymer is completely dissolved; subsequently, adding ATMP and the HEDP, and further stirring for dissolving; and finally, adding water until the concentration of the mixed solution is in accordance with the requirement, so as to obtain the oil field compound type anti-scale corrosion inhibitor. The inhibitor disclosed by the invention has the advantages of simple components, available raw materials, simple technology, high efficiency, low cost, low dosage, good scale inhibition, descaling and corrosion inhibition effects and the like, and is convenient to prepare, rapid.

Owner:E TECH ENERGY TECH DEV CORP

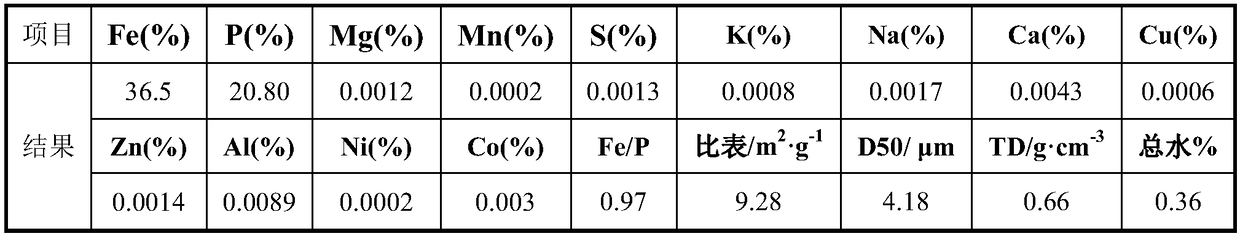

Method for synthesizing iron phosphate with doped metallic elements

InactiveCN101692488AEasy to operateImprove performanceElectrode manufacturing processesPhosphoric acidReaction temperature

The invention relates to a method for synthesizing iron phosphate with doped metallic elements. The method comprises the following steps of: (1) using sulfate, chloride or nitrate of iron as an iron source, mixing any one of substances containing other metal cation elements with the iron source, accurately weighting each material in a mol ratio, and adding distilled water into the materials to prepare a mixed solution, wherein the total mol concentration of the mixed solution is 0.1 to 5 mol / L; (2) using one or a mixture of more than one of ammonium dihydrogen phosphate, ammonium phosphate, ammonium hydrogen phosphate and trisodium phosphate as a phosphorus source, and preparing phosphorus solution of which the mol concentration is 1 to 5 mol / L; (3) using ammonia water as a complexing agent and a neutralizing agent; (4) controlling the reaction temperature to between 20 and 98 DEG C, pumping the mixed solution doped with the doped metallic elements and the phosphorus solution into a reactor respectively, controlling the pH value by the ammonia water, and stirring the mixture to ensure that the mixture is continuously co-precipitated in the reactor to generate the iron phosphate with spherical doped metallic elements; and (5) aging, spin-drying, washing and drying the reaction solution to obtain the iron phosphate with the doped metallic elements. The method has the advantages of simple operation, stable performance, low manufacturing cost, sterility and no pollution.

Owner:HENAN KELONG NEW ENERGY CO LTD

Light and color glazed tile for building

The invention discloses a light and color glazed tile for a building, which is obtained by the following steps: adding 0.4 to 0.6 kg of magnesium oxide to each kilo of a magnesium chloride solution; agitating the mixture for 6 to 8 minutes; successively adding 0.05 to 0.1 kg of magnesium silicate, 0.02 to 0.03 kg of urea-formaldehyde resin, 0.06 to 0.1 g of ammonium carbonate, 2 to 3 g of trisodium phosphate and 2 to 3 g of pigment; agitating the obtained mixture for 20 to 30 minutes; pouring the agitated mixture to a glass fiber cloth; scraping and compacting the poured mixture; and performing natural cure and drying to obtain the light and color glazed tile for the building. In the way above, the light and color glazed tile for the building has the advantages of smooth and clean surface, bright color, color retention, fracture resistance, compression resistance, thermal and cooling shock resistance, acid and alkali resistance, freezing resistance, light weight, low water absorption, good thermal insulation, good sound insulation and low cost.

Owner:CHINA CHANGSHU CONSTR GRP

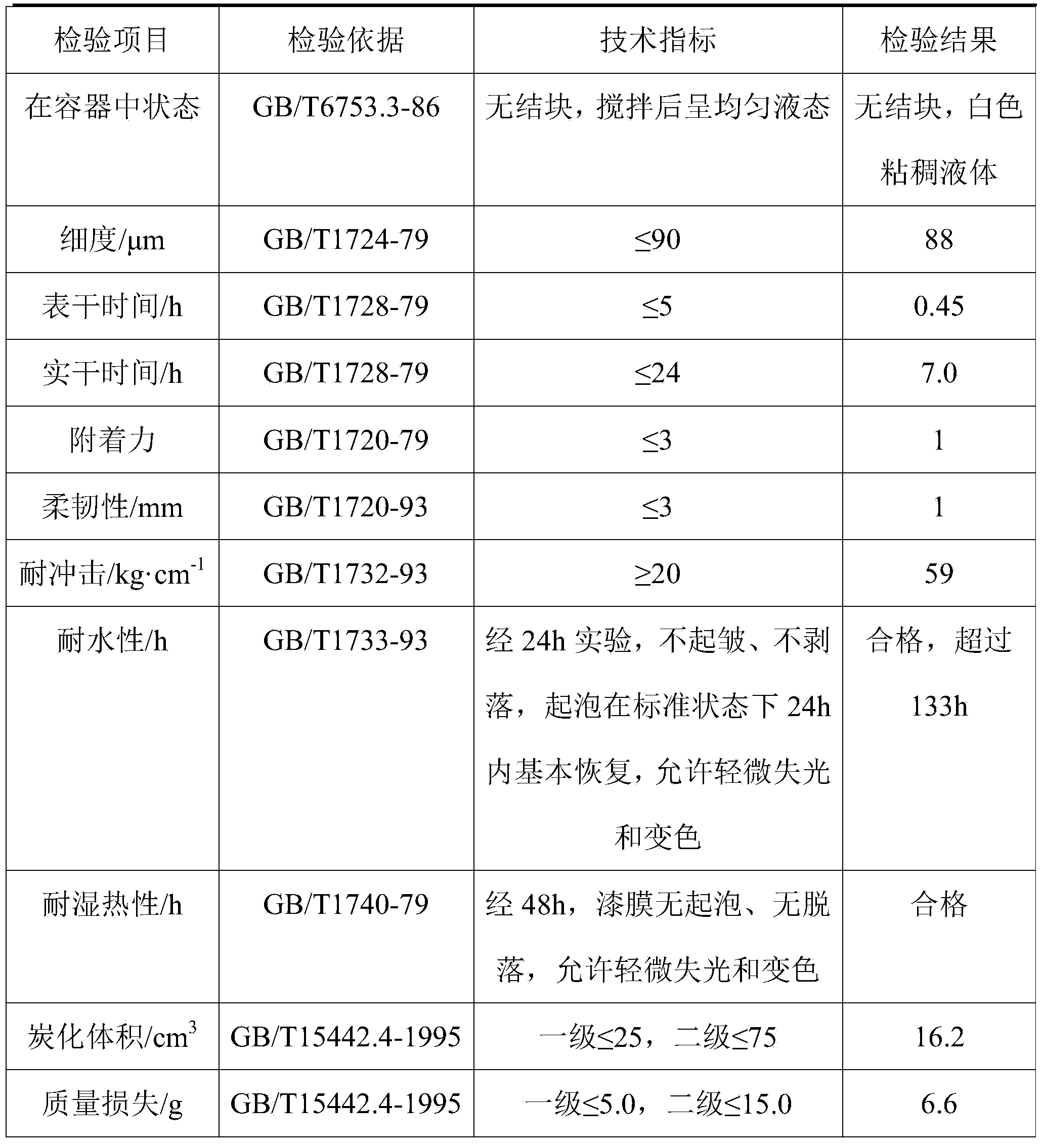

Water-based facing type fireproof paint and preparation method thereof

ActiveCN104277607AImprove fire performanceImprove water resistanceFireproof paintsEpoxy resin coatingsWater basedFoaming agent

The invention discloses water-based facing type fireproof paint. The water-based facing type fireproof paint is prepared from the following raw materials in mass fraction: 18.0-20.0wt% of film forming matter, 23-23.5wt% of a carbon forming catalyst, 10-11wt% of a carbon forming agent, 12-13wt% of a foaming agent, 9-11wt% of pigment filler, 0.49-1.13wt% of auxiliaries, 20-27.5wt% of water, 0-0.8wt% of trisodium phosphate and 0-0.4wt% of a silane defoaming agent. The invention further discloses a preparation method of the water-based facing type fireproof paint. The water-based facing type fireproof paint prepared by the preparation method disclosed by the invention has good fireproof performance, good water resistance, strong adhesive force for a combustible matrix and good decorativeness, and can be used for surface coating of buildings and decorative materials.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Micro-arc oxidation process for reducing surface friction coefficient of titanium alloy

InactiveCN101280450AImprove bindingHigh hardnessSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

Disclosed is micro-arc oxidation process to reduce the friction coefficient of titanium alloy surface, which has the process steps of (1) the chemical degreasing, (2) the micro-arc oxidation that the basic parameters are trisodium phosphate of 1-30g / L, tungsten sodium of 0-10g / L, sodium silicate of 0-50g / L, tartaric acid of 0-20g / L, glycerol of 0-10g / L and sodium hydroxide of 5-10g / L, (3) the post-processing that the hot oil immersion treatment is proceeded for the film after the oxidation. Through the invention, the high-performance ceramic membrane with strong cementing property, high hardness and low coefficient friction can be obtained on the titanium surface. Through the testing of a high-temperature friction and wear testing machine of MM-U5G screen material end surface, the friction coefficient of the titanium micro-arc oxidation film is 0.1 to 0.5. During the observation of the oxidation film after the experiment, the shedding and wear phenomenon is not found.

Owner:NANCHANG HANGKONG UNIVERSITY

Biological complex enzyme toothpaste and preparation method thereof

ActiveCN101721324AAvoid drug resistanceKill completelyAntibacterial agentsCosmetic preparationsCelluloseTriclosan

The invention relates to biological complex enzyme toothpaste and a preparation method thereof. The toothpaste is prepared from the following components by weight percentage: 5-10% of sorbierite, 15-20% of hydrous silica, 10-20% of aluminum hydroxide, 10-20% of glycerin, 2-3% of sodium lauroyl sarcosine, 1-1.3% of flavor, 0.8-1.2% of cellulose gum, 0.3-0.6% of carrageenin, 0.3-0.5% of droxyethylcellulose, 0.5-1.2% of sodium phytate, 0.15-0.3% of saccharin sodium, 0.3-0.5% of strontium chloride, 0.1-0.3% of trisodium phosphate, 0.00003-0.00008% of staphylococcus lysozyme, 0.00005-0.00015% of muramidase, 0.00001-0.00004% of proteolytic enzyme, 0.00002-0.00005% of glycosidic hydrolase, 0.00002-0.00005% of peroxydase, 0.08-0.15% of borneol, 0.1-0.15% of borax, 0.08-0.1% of vermilion, 0.1-0.15% of natrii sulfas exsiccatus, 0.05-0.1% of triclosan, 0.1-0.4% of allantoin, and the balance of water. The total weight percentage of the components is 100%. The biological complex enzyme toothpaste has complete function.

Owner:JIANGSU XUE BAO DAILY CHEM CO

Process for preparing magnesium alloy chemical conversion coating

ActiveCN1880503AEliminate hazardsImprove corrosion resistanceMetallic material coating processesSodium iodideFluohydric acid

The invention discloses a chemical transmission film preparing technology of magnesium alloy, which comprises the following steps: a. proceeding degreasing disposal for magnesium or magnesium alloy through sodium hydroxide or one or multiple hybrid solutions of sodium phosphate with sodium hydroxide, sodium carbonate and sodium silicate solution; b. proceeding acid cleaning disposal for degreased magnesium or magnesium alloy through hybrid solution of phosphoric acid and sodium phosphate; c. proceeding activating disposal for acid cleaned magnesium or magnesium alloy through hybrid solution of fluohydric acid and sodium phosphate; d proceeding chemical synthesizing disposal for activated magnesium or magnesium alloy through composite solution of calcium nitrate hydrate, sodium nitrite, sodium iodide and hydrogen dioxide solution; e. packing hole of synthetic magnesium or magnesium alloy through deionized water. The invention doesn't utilize chromic composition, which eliminates danger for environment.

Owner:靖江市华信科技创业园有限公司

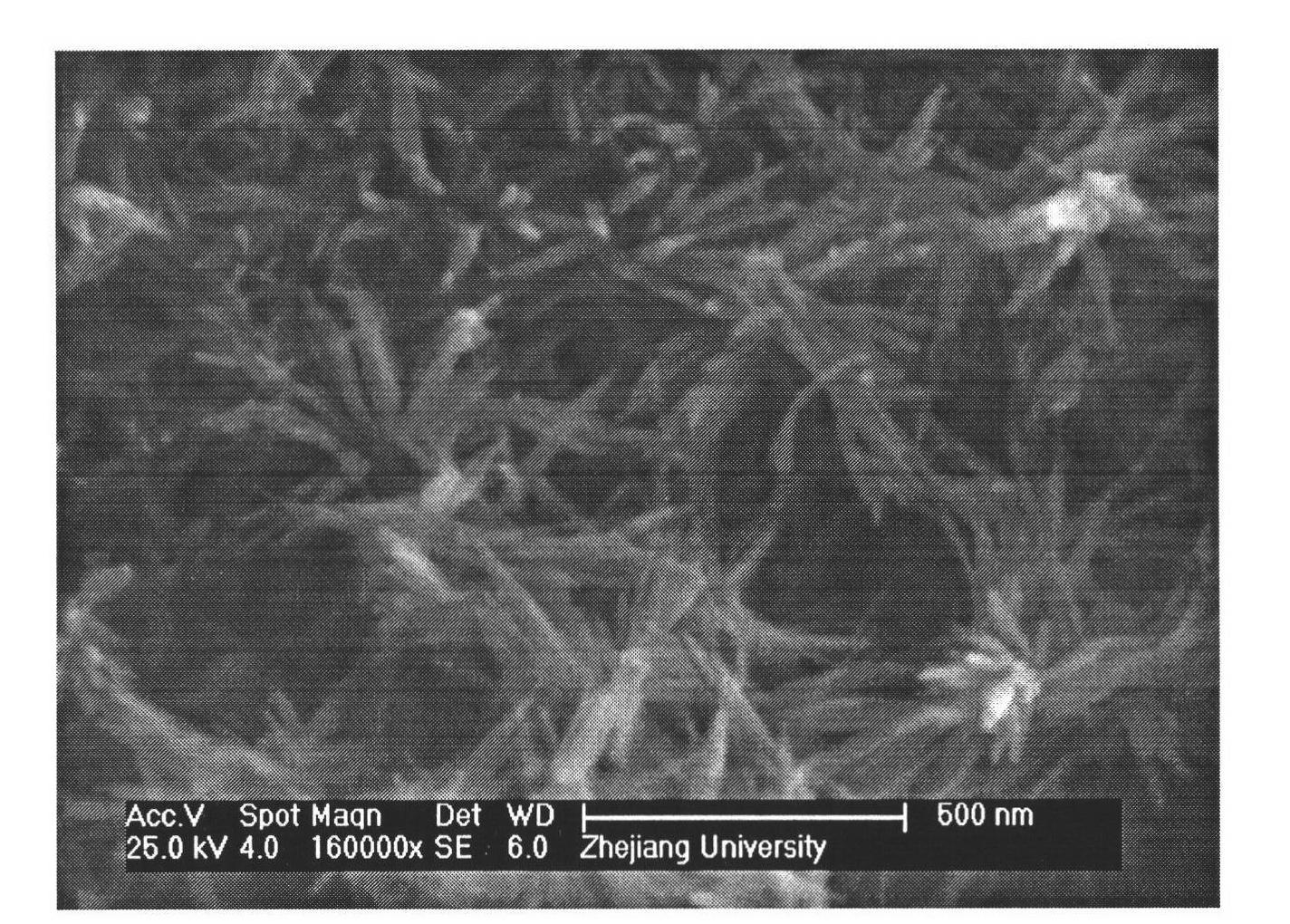

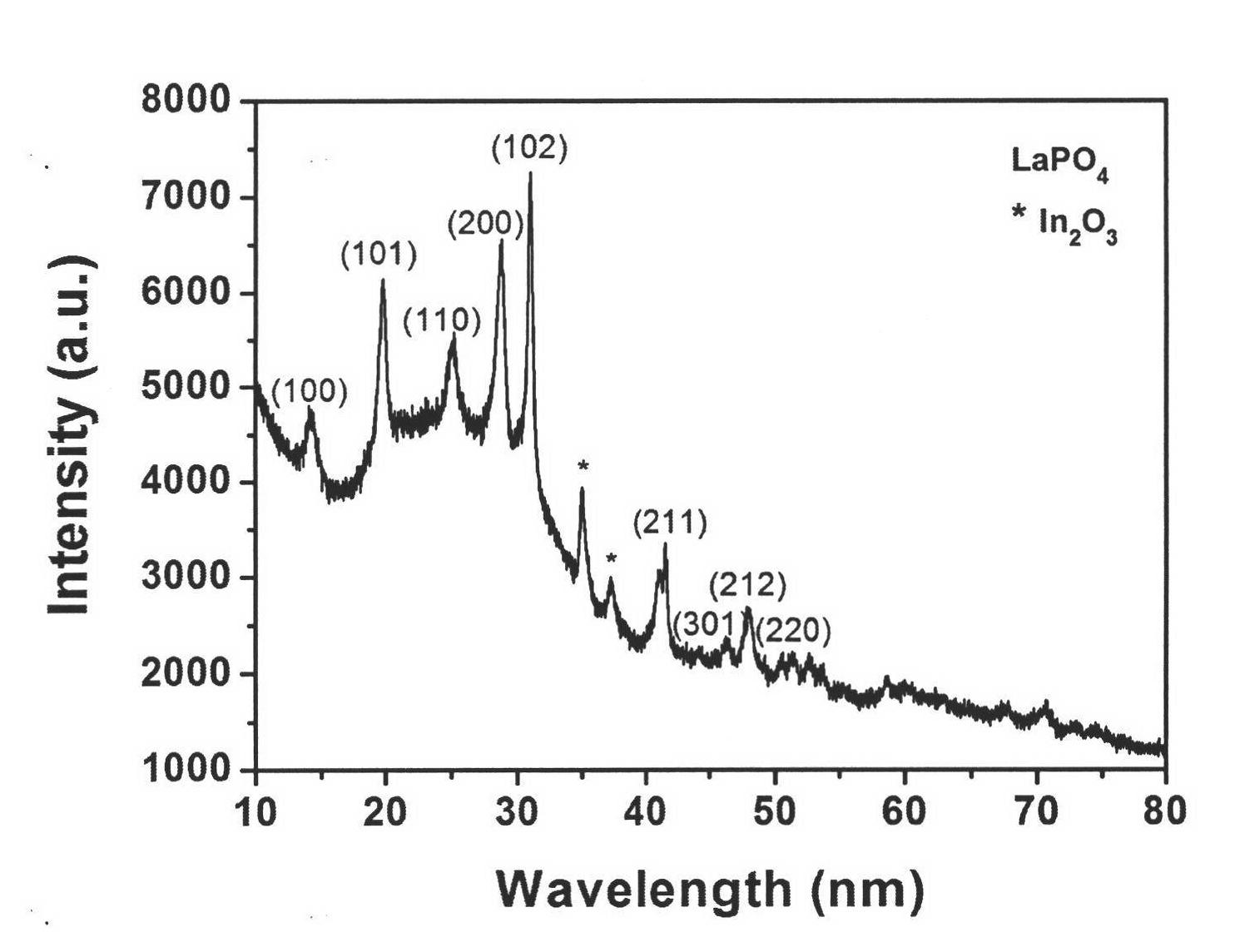

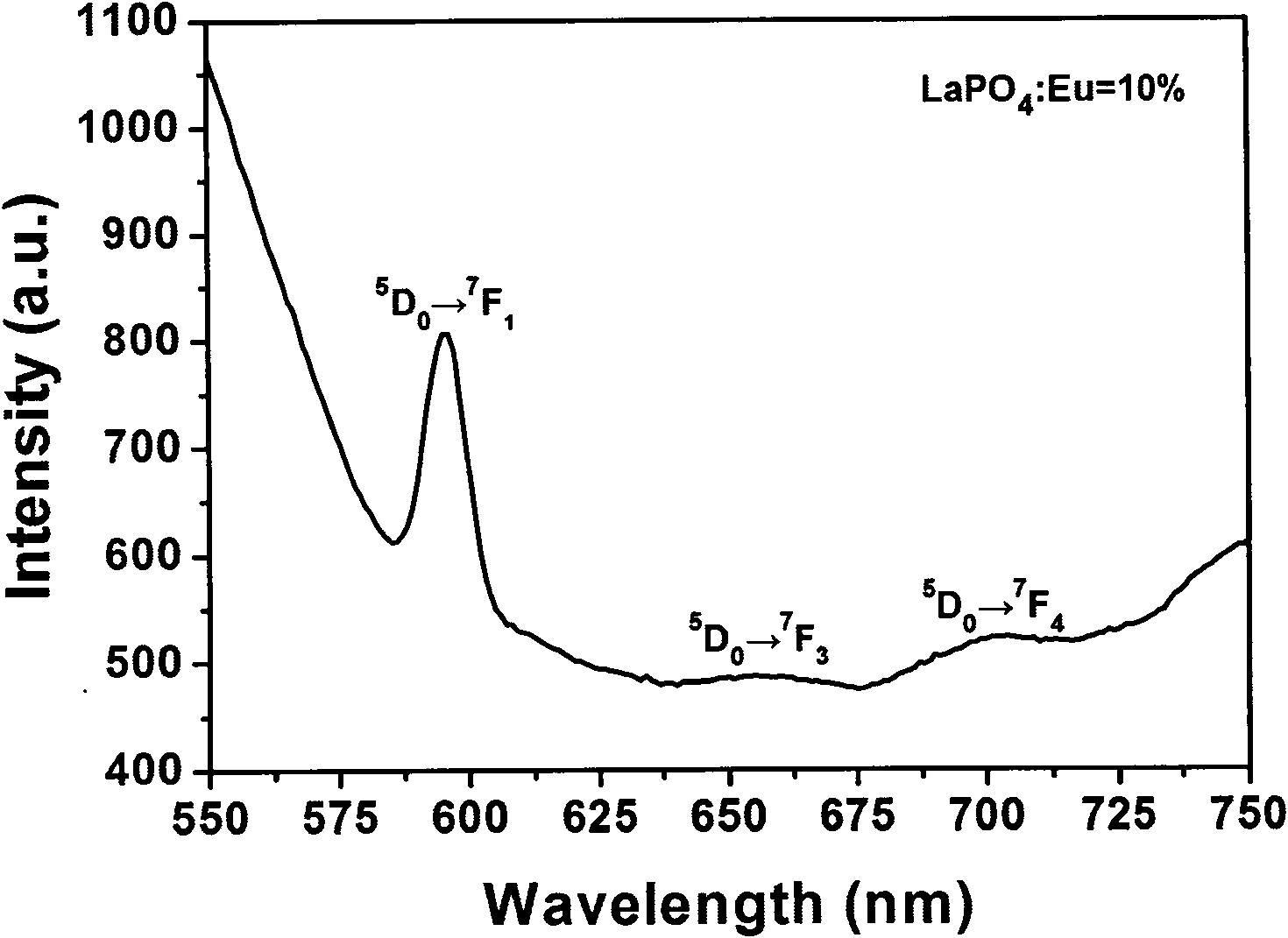

Electrochemical preparation method of lanthanum phosphate or rare earth doped lanthanum phosphate film

InactiveCN101962805ALow growth temperatureHigh crystallinityPolycrystalline material growthElectrolytic inorganic material coatingSodium phosphatesRare earth

The invention discloses a method for preparing a lanthanum phosphate or rare earth doped lanthanum phosphate film through electrodeposition, which comprises the following steps of: (1) cleaning ITO (Indium Tin Oxide) conducting glass 2-3 times with acetone, cleaning the ITO conducting glass with deionized water for 10-30 min in an ultrasonic cleaner, activating the ITO conducting glass in a 10 vol% saltpeter solution for 10-30 s, and cleaning with deionized water for later use; (2) adding a sodium phosphate solution into a 0.005-0.5 mol / L complex solution of ethylene diamine tetraacetic acid and lanthanide ions, and regulating the pH value to 4-6 to obtain an electrolyte for later use; and (3) placing the ITO conducting glass used as a working electrode, a platinum electrode used as a counter electrode and a calomel electrode used as a reference electrode in the electrolyte for electrodeposition to obtain the lanthanum phosphate film, wherein the positive deposition potential relative to the calomel electrode is 1.2-1.8 V. The invention has the advantages of simple equipment, low cost, normal pressure and low temperature. The method not only is applicable to scientific research, but also is hopeful for realizing large-scale industrial production.

Owner:ZHEJIANG UNIV

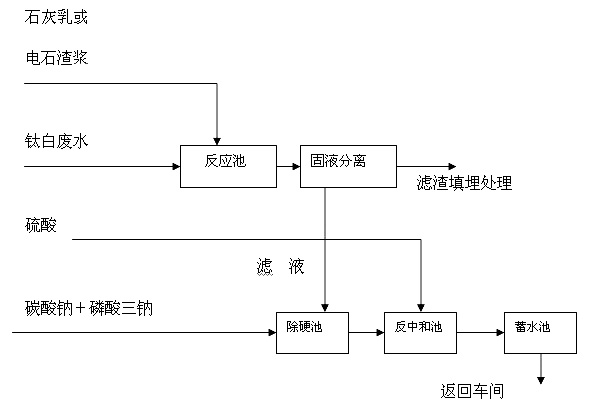

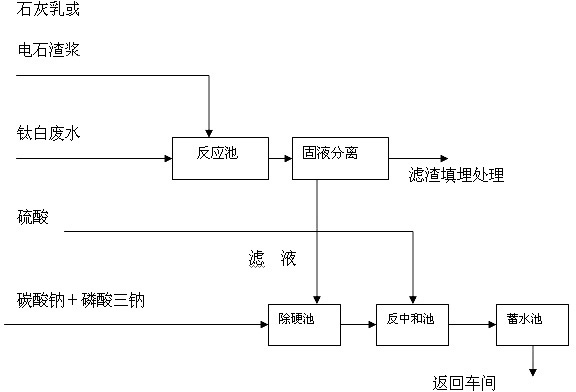

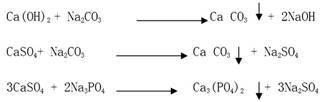

Method for purifying titanium white wastewater

InactiveCN101962239AReduce consumptionReduce decalcification costsMultistage water/sewage treatmentWater/sewage treatment by neutralisationSlagTechnical standard

The invention relates to a method for purifying titanium white wastewater, which is characterized by comprising the following steps of: adding excess lime milk or carbide slag slurry, performing a neutralization reaction with stirring to obtain precipitate-containing wastewater, wherein the pH value of the wastewater is between 9 and 12; performing solid-liquid separation on the obtained precipitate-containing wastewater, adding sodium carbonate into filter liquor to perform a reaction for 30 to 50 minutes, and adding trisodium phosphate to perform a reaction, and decalcifying; adding sulfuric acid into the decalcified wastewater for reverse neutralization, and regulating the pH value to be between 6 and 9 to obtain purified water. The method has the characteristics of simple flow, no specific requirement on equipment, low consumption of raw materials and the like; and by the method, the treated wastewater can reach the technical standard of national recycling water, so that the wastewater is recycled to production departments, and for a large amount of the generated titanium white wastewater, the method solves the problem of high treatment cost, and has the technical and economic feasibility of industrial application.

Owner:HUNAN HEAO YUJIE ENVIRONMENT TECH CO LTD

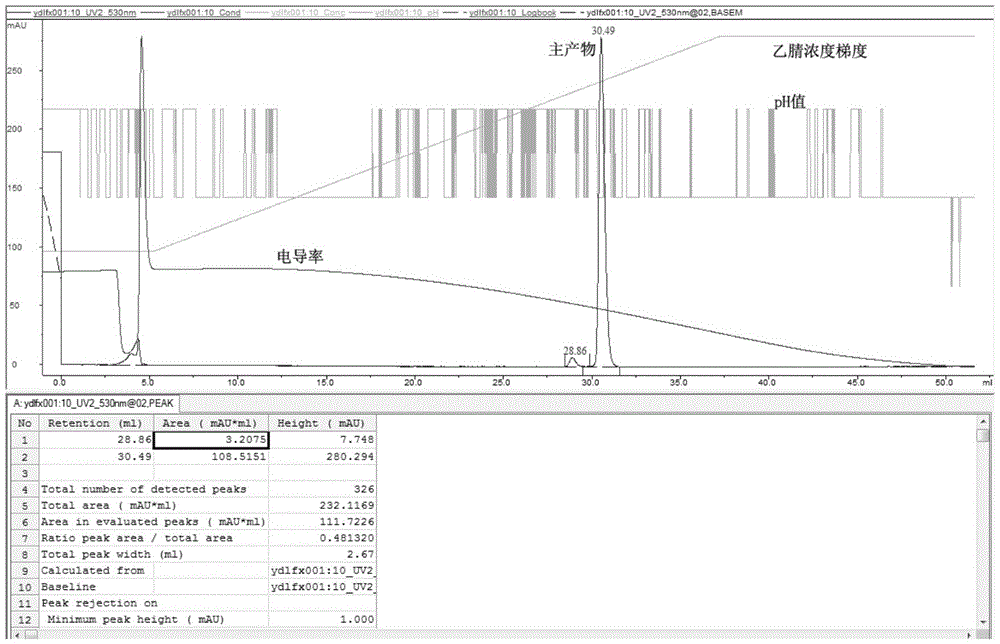

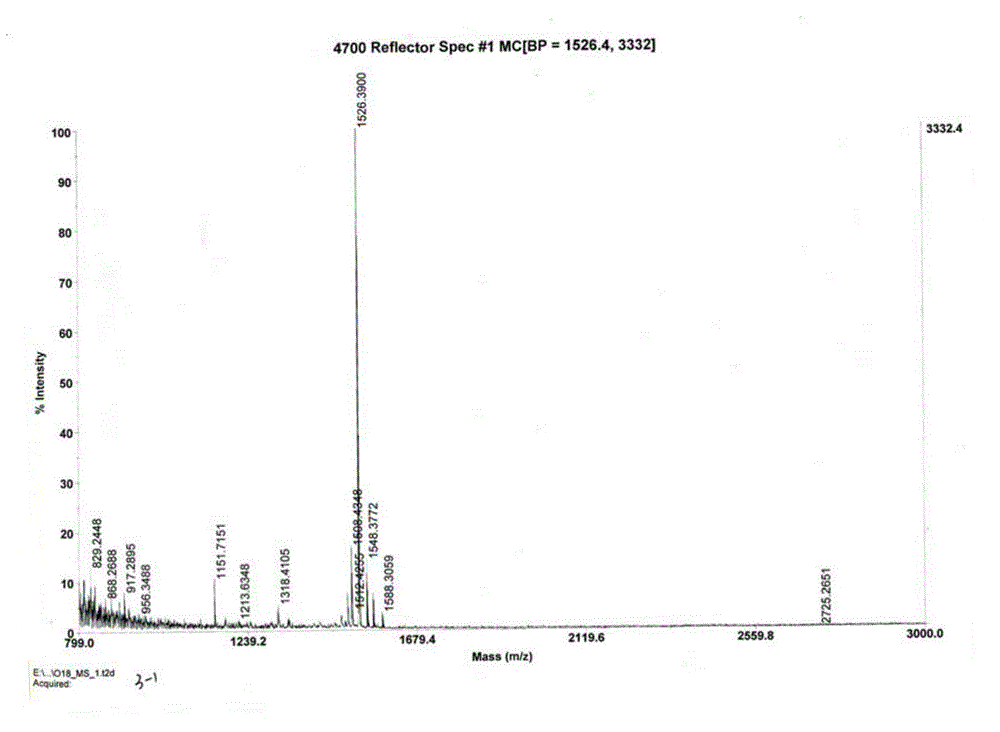

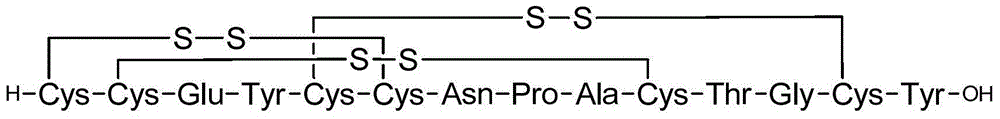

Preparation method for linaclotide

InactiveCN104628826AGuaranteed stabilitySuitable for oxidation capacityPeptide preparation methodsBulk chemical productionSide chainWang resin

The invention provides a preparation method for linaclotide. The method includes: utilizing a standard Fmoc technology to connect a side chain protected amino acid with Wang resin, adding a condensing agent HBTU and alkali DIPEA, carrying out condensation reaction in a DMF solvent, employing a DMF solution containing 20% hexahydropiperidine to perform de-Fmoc protection, then conducting cutting from the solid phase resin, adding elemental iodine into a sodium phosphate buffer solution to carry out Cysteine oxidation, thus obtaining linaclotide. The preparation method for linaclotide provided by the invention is the technology for highyield synthesis of linaclotide, simplifies the cyclization process and enhances the cyclization yield, and the final product yield reaches 30%-60%. The preparation method has the advantages of simplicity, mild reaction conditions, high yield, and high product purity, is a feasible preparation method for industrialization of linaclotide, and provides good prospects for industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Cataluminescence sensitive material for rapidly determining formaldehyde and carbon monoxide

InactiveCN104849263ARapid determinationAccurate measurementChemiluminescene/bioluminescenceNickel saltSodium phosphates

A cataluminescence sensitive material for rapidly determining formaldehyde and carbon monoxide is a nanometer composite powder material composed of graphene supported Pd, CeO2 and NiO. A preparation method of the material comprises the following steps: adding natural flake graphite into concentrated sulfuric acid, stirring, adding sodium phosphate and potassium permanganate, heating, adding hydrogen peroxide, heating, stirring, carrying out pumping filtration, and carrying out water washing to obtain graphene oxide; and dissolving palladium dichloride, a cerium salt and a nickel salt in an aqueous solution of hydrochloric acid, adding citric acid and sodium citrate, adding the graphene oxide, stirring, adding hydrazine hydrate, stirring, standing, ageing, filtering, drying, grinding, and roasting to obtain the nanometer composite powder material composed of graphene supported Pd, CeO2 and NiO. A formaldehyde and carbon monoxide detection gas sensor made by using the sensitive material provided by the invention can be used to rapidly and accurately determine a tiny amount of formaldehyde and carbon monoxide in air on the scene without interference by common concurrent.

Owner:BEIJING UNION UNIVERSITY

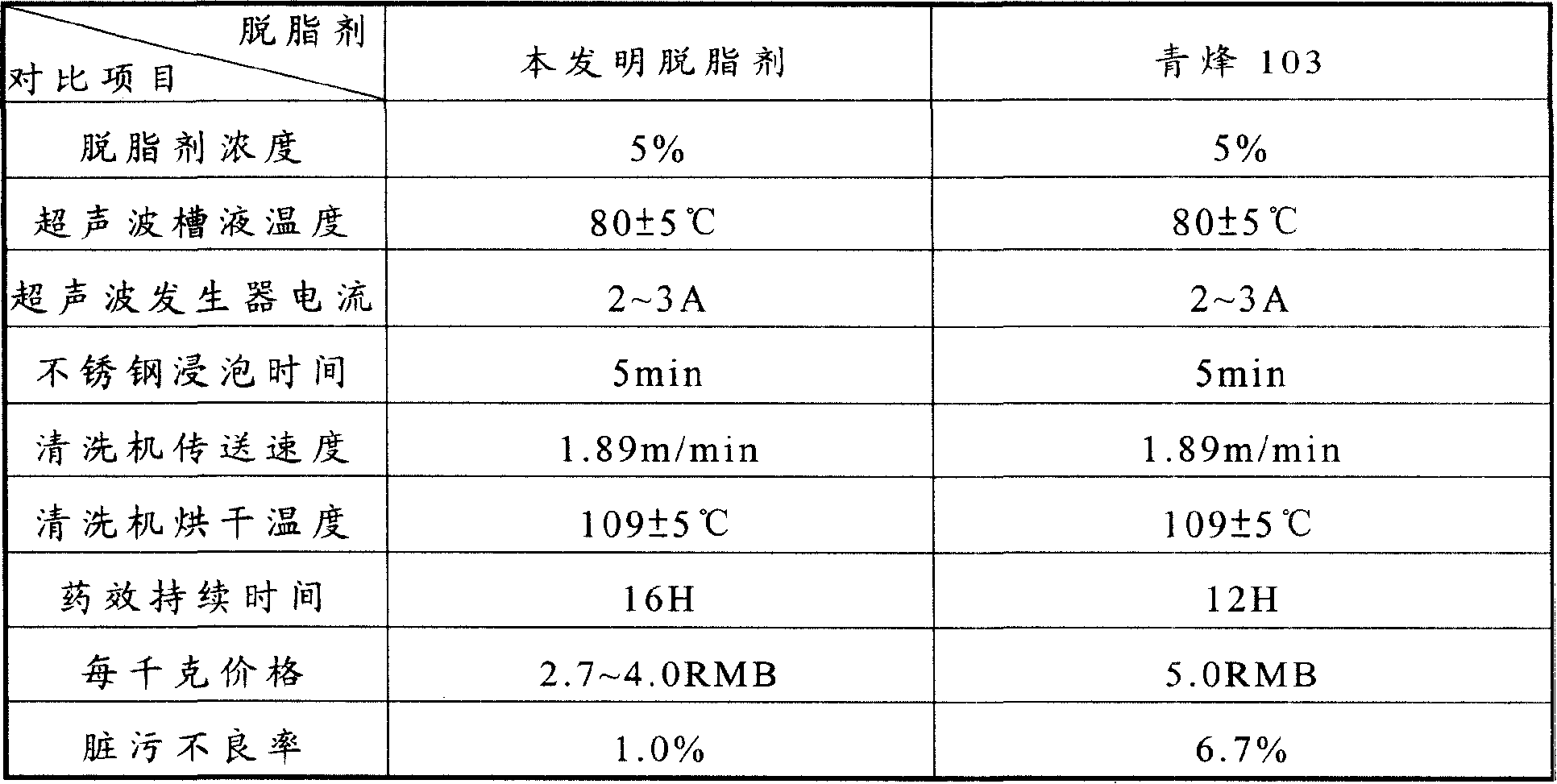

Degreasing agent and preparing method therefor

InactiveCN101200804ALong-lasting effectLow costInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium silicateTrisodium phosphate

The invention relates to a degreaser, including trisodium phosphate, sodium silicate, sodium carbonate, sodium dodecyl benzene sulfonate, sodium hydroxide and octylphenol polyoxyethylene ether. Used for cleaning metal surface, the degreaser has the advantages of long efficacy duration, low cost and good degreasing effect.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

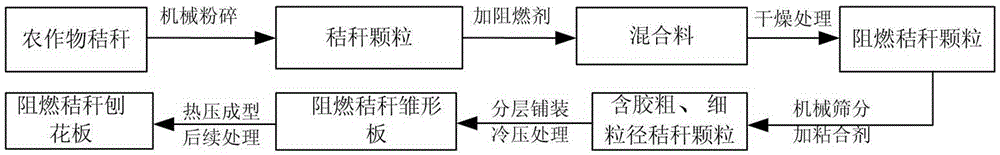

Flame-retardant straw shaving board and manufacturing method thereof

ActiveCN105345911AStable structureWaterproofDomestic articlesFlat articlesPolyvinyl alcoholPhosphoric acid

The invention provides a flame-retardant straw shaving board. The flame-retardant straw shaving board comprises, by weight, 7-9 parts of straw particles, 0.5-1.5 parts of flame retardants and 0.3-1.0 part of binders, wherein the flame retardants comprise magnesium oxide, magnesium chloride, trisodium phosphate, polyvinyl alcohol and ammonium polyphosphate. The flame-retardant straw shaving board is good in flame retardance, water resistance and insect resistance and low in formaldehyde content and has good physical and mechanical performances; a wooden shaving board can be replaced by the flame-retardant straw shaving board which can be applied to the field of decoration of various buildings and manufacturing of furniture. The invention further provides a manufacturing method of the flame-retardant straw shaving board. The hot press molding technology is mainly adopted for modifying and shaping the raw materials, so that not only is the wood resource saved, but also the whole production process is environmentally friendly and free of pollution.

Owner:信阳美丽真好秸秆新材科技有限公司

Metal cleaning agent

The invention provides a metal washing agent which is formed by the reactions of a surface promoting agent, oleic acid, sodium hydroxide, sodium nitrite, sodium molybdate, benztotriazole, trisodium phosphate, trolamine, polyether61 and distilled water. The weight portions of each component are: 10 to 15 portions of the surface promoting agent, 4 to 8 portions of the oleic acid, 0.5 to 1.1 portions of the sodium hydroxide, 0.1 to 0.5 portions of the sodium nitrite, 0.3 to 0.84 portions of the sodium molybdate, 0.08 to 0.15 portions of the benztotriazole, 1.5 to 2.5 portions of the trisodium phosphate, 1.5 to 3.0 portions of the trolamine, 0.5 to 0.9 portions of the polyether61 and the rest portions are the distilled water. The metal washing agent provided by the invention has good washing effect and can maintain the metal materials after being washed without rust in 15 to 20 days.

Owner:ZHEJIANG UNIV

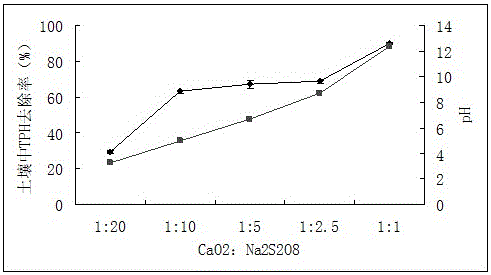

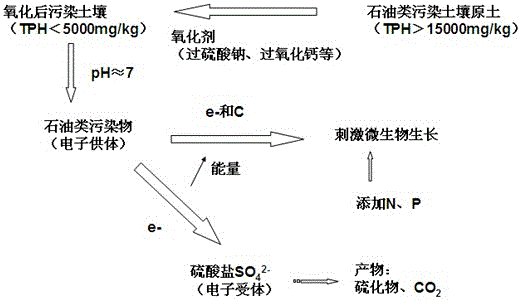

In-situ combined remediation method for petroleum contaminated site soil

ActiveCN105772499ASimple processOperations Management SecurityContaminated soil reclamationSodium phosphatesSodium sulfate

The invention discloses an in-situ combined remediation method for petroleum contaminated site soil and relates to a soil remediation method. According to the in-situ combined remediation method, a chemical oxidation reagent is prepared from the following components including sodium persulfate as an oxidant, sodium hydroxide or calcium peroxide as an activator and sodium thiosulfate as a sustained-release agent; a microorganism simulation nutrient is prepared from the following components including sodium phosphate and ammonium sulfate; the molar ratio of the sodium persulfate and the activator is 5:1; the quantity of the sustained-release agent is 1-5 percent of the quantity of the oxidant and the activator; the molar ratio of C, N and P as the nutrients for promoting growth of microorganisms is 120: 10: 1; a phosphorus source is the sodium phosphate (Na3PO4.12H2O); a nitrogen source is the ammonium sulfate ((NH4)2SO4); and a carbon source is petroleum pollutants and is estimated according to the actual pollutant degree. The in-situ combined remediation method for the petroleum contaminated site soil can reach the purpose of completely remediating the long-term petroleum contaminated site soil, and thus solving the problems of difficulty in remediating aged contaminated soil microorganisms, higher chemical oxidation cost and larger environmental influence and lowering the remediation cost.

Owner:丹东市金山投资建设发展有限公司

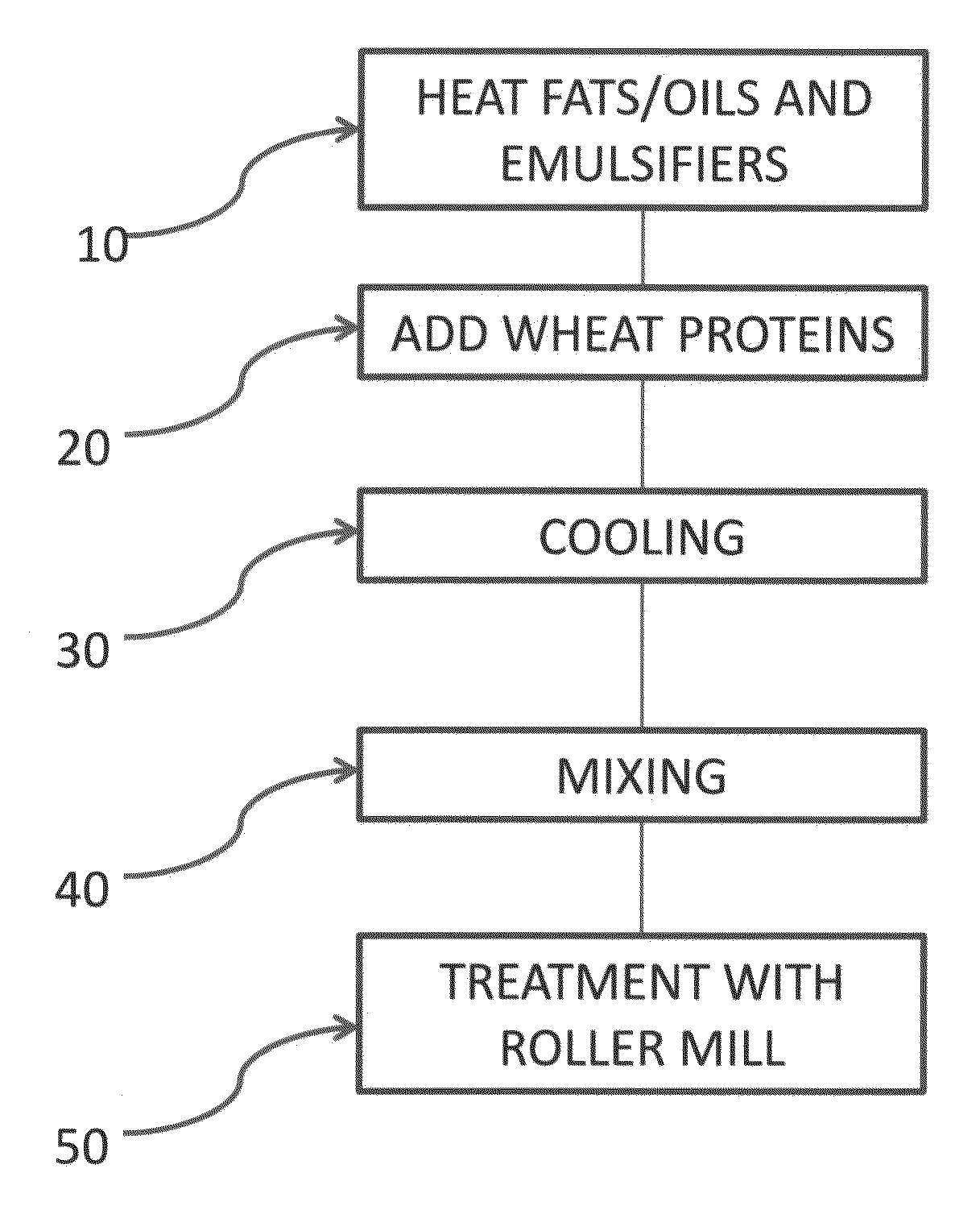

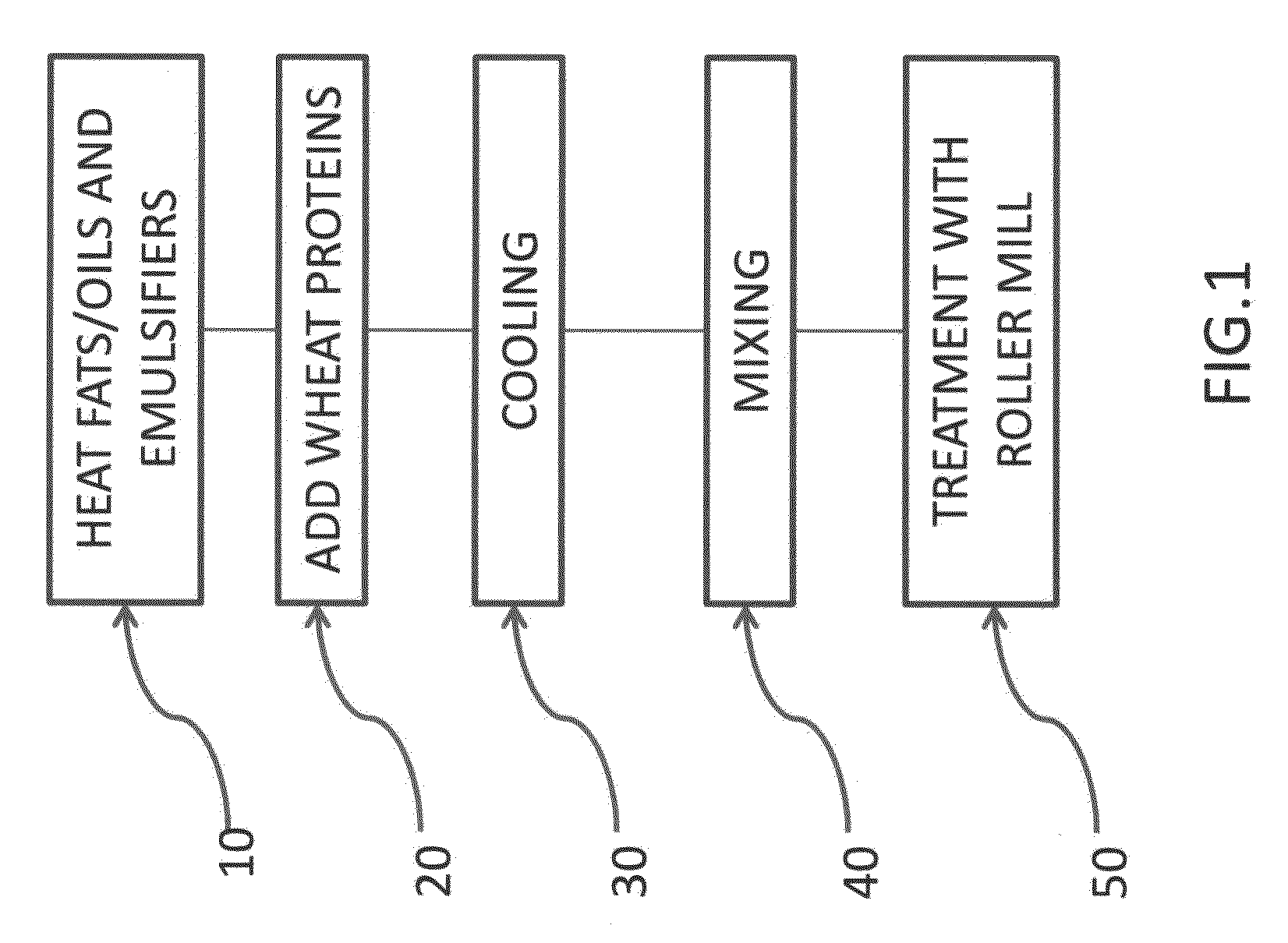

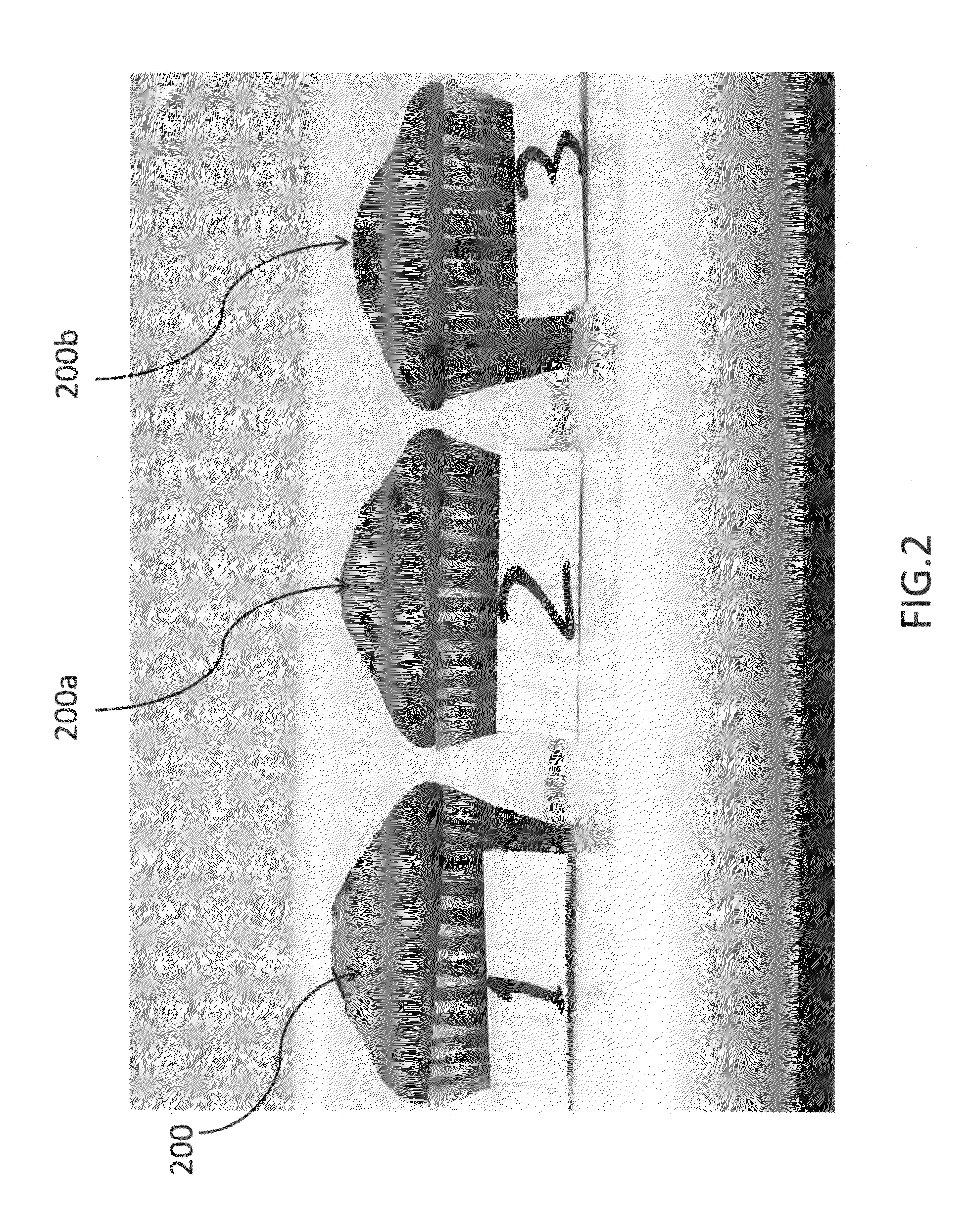

Egg substitute and method of producing same

InactiveUS20130052304A1Dough treatmentFatty substance preservation using additivesFerrous saltsSodium phosphates

An egg substitute composition comprising wheat protein, emulsifiers, at least one fat or oil, and polysaccharides, and optionally supplementary proteins and food gums. The composition preferably includes 1-90% wheat protein, 1-30% fat or oil and 5-30% polysaccharides. Optionally 0-50% supplementary proteins, 0-30% emulsifiers, 0-10% food gums, 0-3% reducing-oxidant agents and 0-5% calcium and ferrous salts. The composition also includes 0.01-1% sodium phosphate and disoldium phosphate in liquid form egg replacer.

Owner:LI WEILI

Light heat-insulating honeycomb ceramic and preparation method thereof

The invention provides a light heat-insulating honeycomb ceramic and a preparation method thereof. The light heat-insulating honeycomb ceramic comprises a heat insulating layer and a decoration layer combined with the heat insulating layer into a whole; and the heat insulating layer is prepared by sintering mineral powder of tuff, mineral powder of pearlite, expanded and vitrified microsphere powder, glass powder, a pore-forming agent and sodium phosphate. The light heat-insulating honeycomb ceramic has high strength and low water absorption, ensures that the decoration layer is firmly connected with the heat insulating layer, has a heat insulating function and also has an exterior wall decorating effect; and the preparation method has the advantages of simple process and low production cost.

Owner:安徽瑞蒙科技有限公司

Separation and recovery method of sodium phosphate and sodium fluoride in mixed rare earth concentrate alkaline smelting process

InactiveCN102277484ASeparation and recovery stabilityEfficient use ofSolution crystallizationAlkali metal fluoridesRecovery methodWash water

The invention relates to a method for separating and recovering sodium phosphate and sodium fluoride in the alkaline smelting process of mixed rare earth concentrate. The characteristics are: after the mixed rare earth concentrate is roasted, acid leached, and alkali decomposed, the product after alkali decomposition is washed with water to obtain a washing solution, and sodium phosphate and sodium fluoride are separated and recovered from the washing solution, and sodium hydroxide is realized. effective use. The water washing adopts the method of countercurrent washing, and after three steps of heating crystallization, condensation crystallization and concentration, sodium fluoride, sodium phosphate crystals and excess sodium hydroxide concentrated solution or crystals are obtained in sequence. No other impurities are added in the whole process, no three wastes are produced, the recycling cost is low, less water is used, waste is turned into treasure, and it has strong stability, which completely solves the problem of phosphorus and fluorine recovery in the smelting process of mixed rare earth ore.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com