In-situ combined remediation method for petroleum contaminated site soil

A technology for joint remediation and contaminated soil, applied in the field of soil remediation, can solve the problems of only remediating specific pollutants, secondary sulfate pollution, long phytoremediation time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

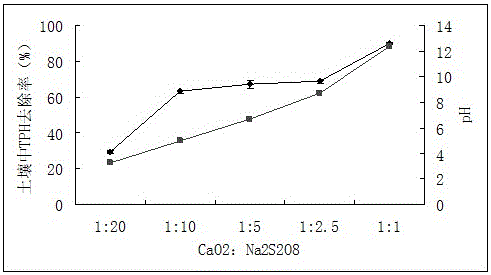

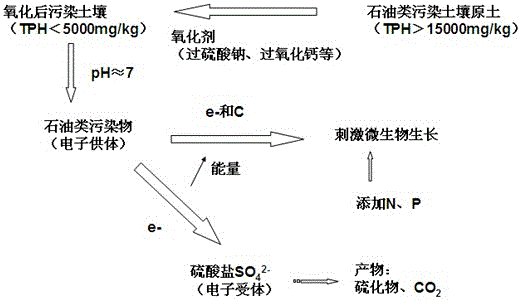

[0027] Take 10g of actual polluted soil (petroleum concentration 15000mg / kg), add 5g of sodium persulfate, 0.25~2g of calcium peroxide, 0.1g of sodium thiosulfate, and react for 24 hours. Take 10g of polluted soil after oxidation (calcium peroxide: sodium persulfate = 1:5), the concentration of petroleum after reaction is about 5000mg / kg, the pH is about 6.67, add 0.018g of ammonium sulfate and 0.011g of sodium phosphate, and cultivate for 30 days .

Embodiment 2

[0029] Take 10g of actual polluted soil (petroleum concentration 15000mg / kg), add 5g of sodium persulfate, 0.25~2g of calcium peroxide, 0.1g of sodium thiosulfate, and react for 24 hours. Take 10g of contaminated soil after oxidation (calcium peroxide: sodium persulfate = 1:5), the concentration of petroleum after reaction is about 5000mg / kg, the pH is about 6.67, add 0.018g of ammonium sulfate, 0.011g of sodium phosphate, and add exogenous Sulfate-reducing bacteria, cultivated for 30 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com