Patents

Literature

6229 results about "Sodium phosphates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium phosphate is a generic term for a variety of salts of sodium (Na⁺) and phosphate (PO₄³⁻). Phosphate also forms families or condensed anions including di-, tri-, tetra-, and polyphosphates. Most of these salts are known in both anhydrous (water-free) and hydrated forms. The hydrates are more common than the anhydrous forms.

Malleable putty and flowable paste with allograft bone having residual calcium for filling bone defects

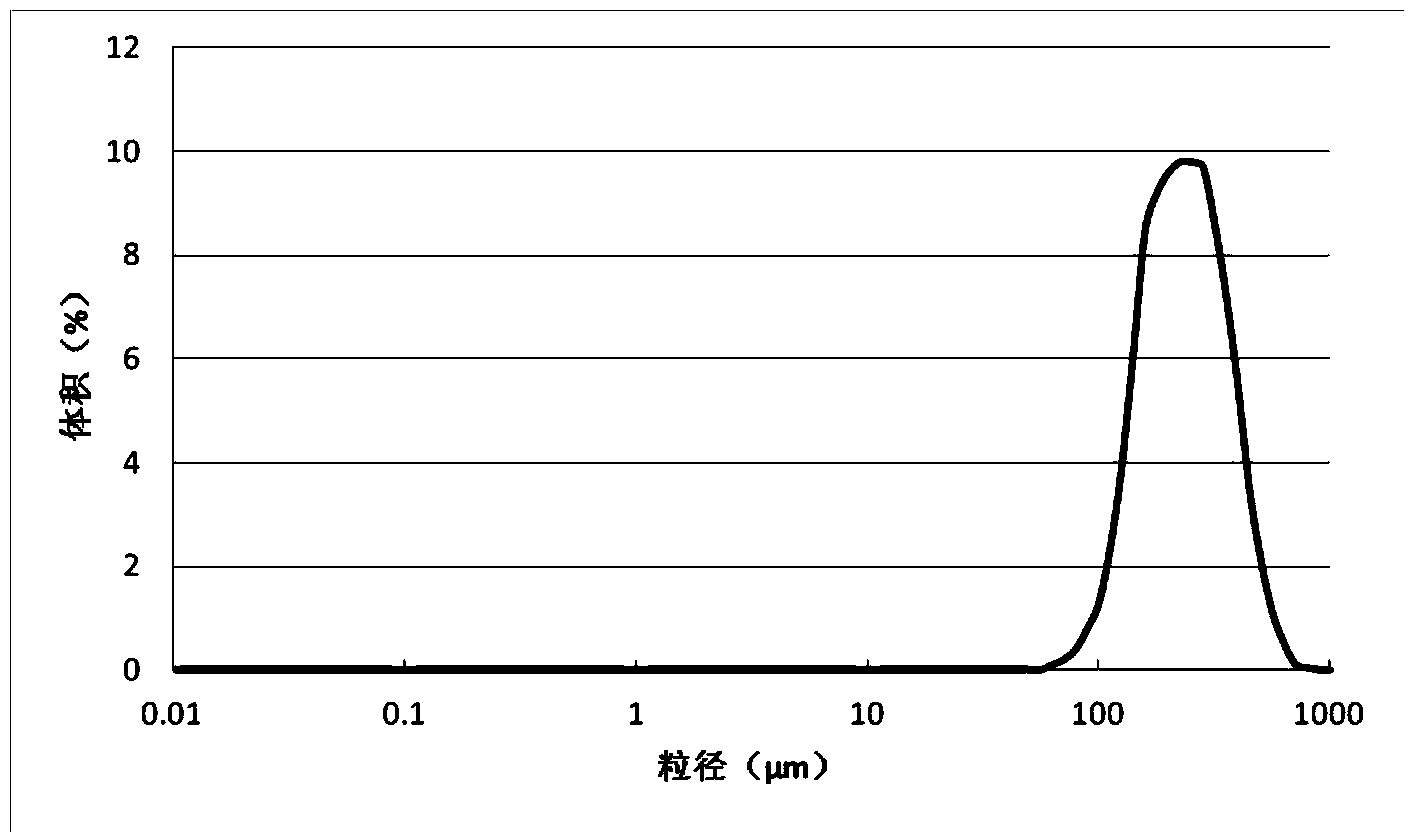

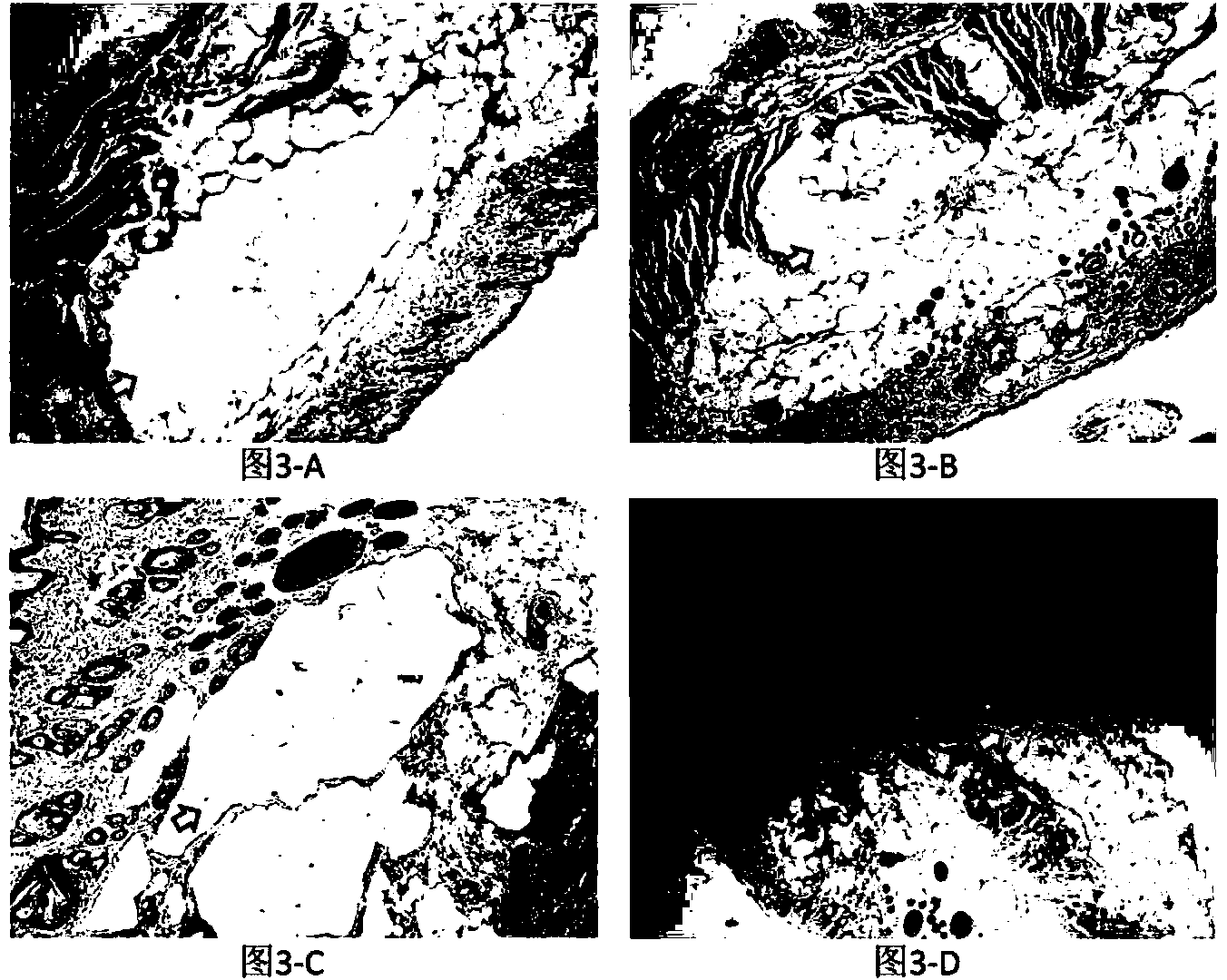

The invention is directed toward a malleable bone putty and a flowable pastel composition for application to a bone defect site to promote new bone growth at the site which comprises a new bone growth inducing compound of partially demineralized lyophilized allograft bone material having a residual calcium content ranging from 4 to 8% dry weight. The bone powder has a particle size ranging from about 100 to about 800 microns and is mixed in a high molecular weight hydrogel carrier containing a sodium phosphate saline buffer, the hydrogel component of the carrier ranging from about 1.00 to 50% of the composition and having a molecular weight of about at least 700,000 Daltons. The composition has a pH between 6.8-7.4 contains about 25% to about 35% bone powder and can be additionally provided with BMP's.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

Composition for filling bone defects

InactiveUS7019192B2Low tensile strengthIncrease delayBiocideSurgical adhesivesSodium phosphatesDemineralized bone

The invention is directed toward a formable bone composition for application to a bone defect site to promote new bone growth at the site which comprises a new bone growth inducing compound of demineralized lyophilized allograft bone particles. The particle size ranges from about 0.1 mm to about 1.0 cm and is mixed in a hydrogel carrier containing a sodium phosphate saline buffer, the hydrogel component of the carrier ranging from about 1.0 to 5.0% of the composition and a pH between 6.8–7.4 with one or more additives of a cellular material, growth factor, demineralized bone chips or mineralized bone chips.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

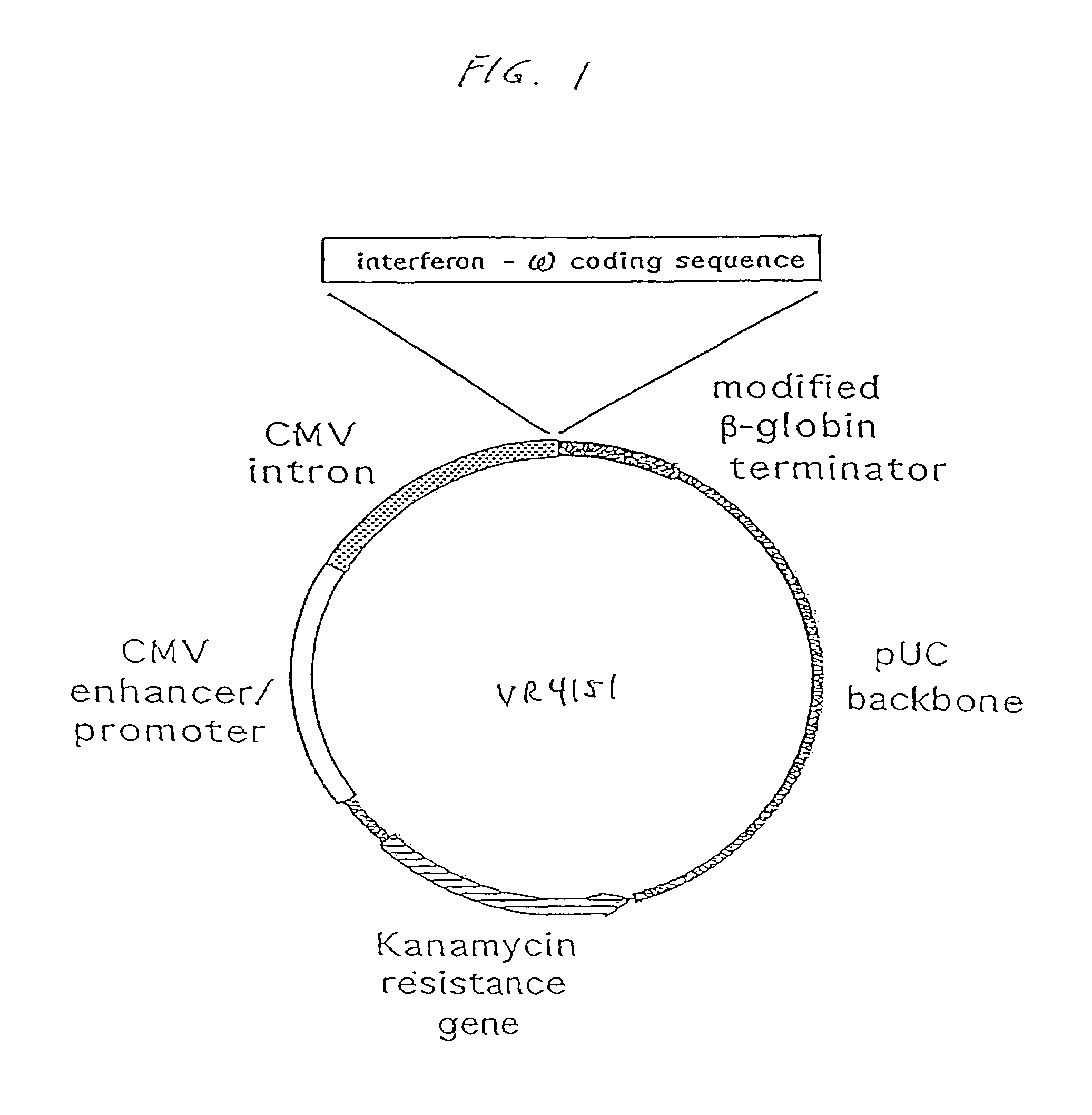

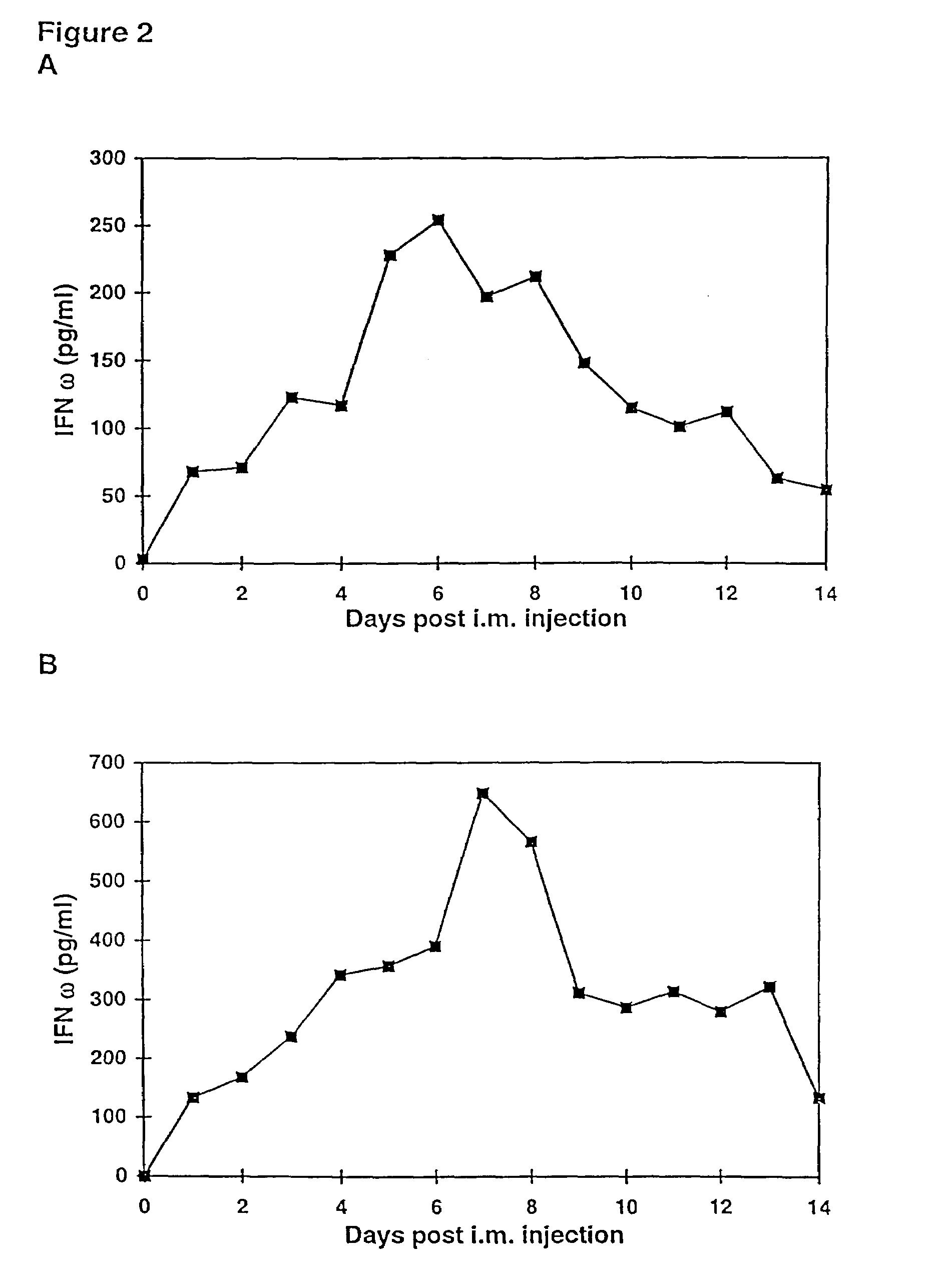

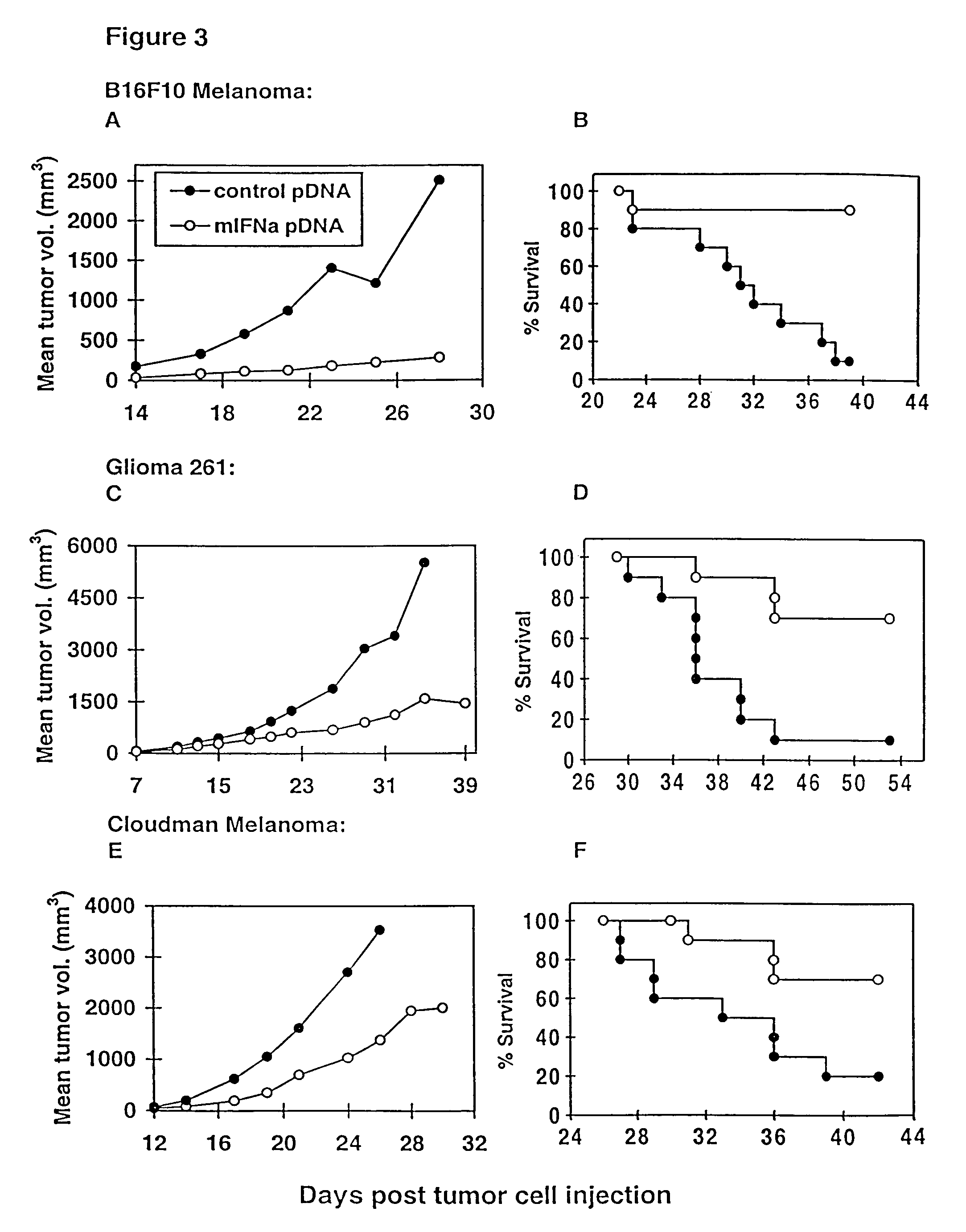

Methods for treating cancer using cytokine-expressing polynucleotides

InactiveUS7268120B1Improved in vivo polypeptide expressionMinimizing adverse side effectBiocideOrganic active ingredientsMammalSodium phosphates

The present invention provides a pharmaceutical composition, comprising a non-infectious, non-integrating polynucleotide construct comprising a polynucleotide encoding an interferon ω and one or more cationic compounds. The present invention also provides methods of treating cancer in a mammal, comprising administering into a muscle of the mammal a non-infectious, non-integrating DNA polynucleotide construct comprising a polynucleotide encoding a cytokine. In addition, the present invention also relates to the methodology for selective transfection of malignant cells with polynucleotides expressing therapeutic or prophylactic molecules in intra-cavity tumor bearing mammals. More specifically, the present invention provides a methodology for the suppression of an intra-cavity dissemination of malignant cells, such as intraperitoneal dissemination. Furthermore, the invention relates to compositions and methods to deliver polynucleotides encoding polypeptides to vertebrate cells in vivo, where the composition comprises an aqueous solution of sodium phosphate.

Owner:VICAL INC

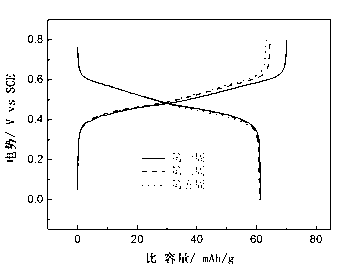

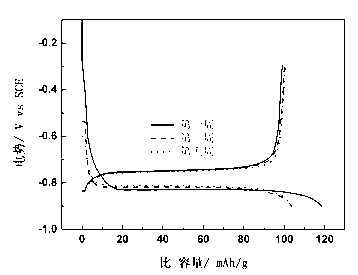

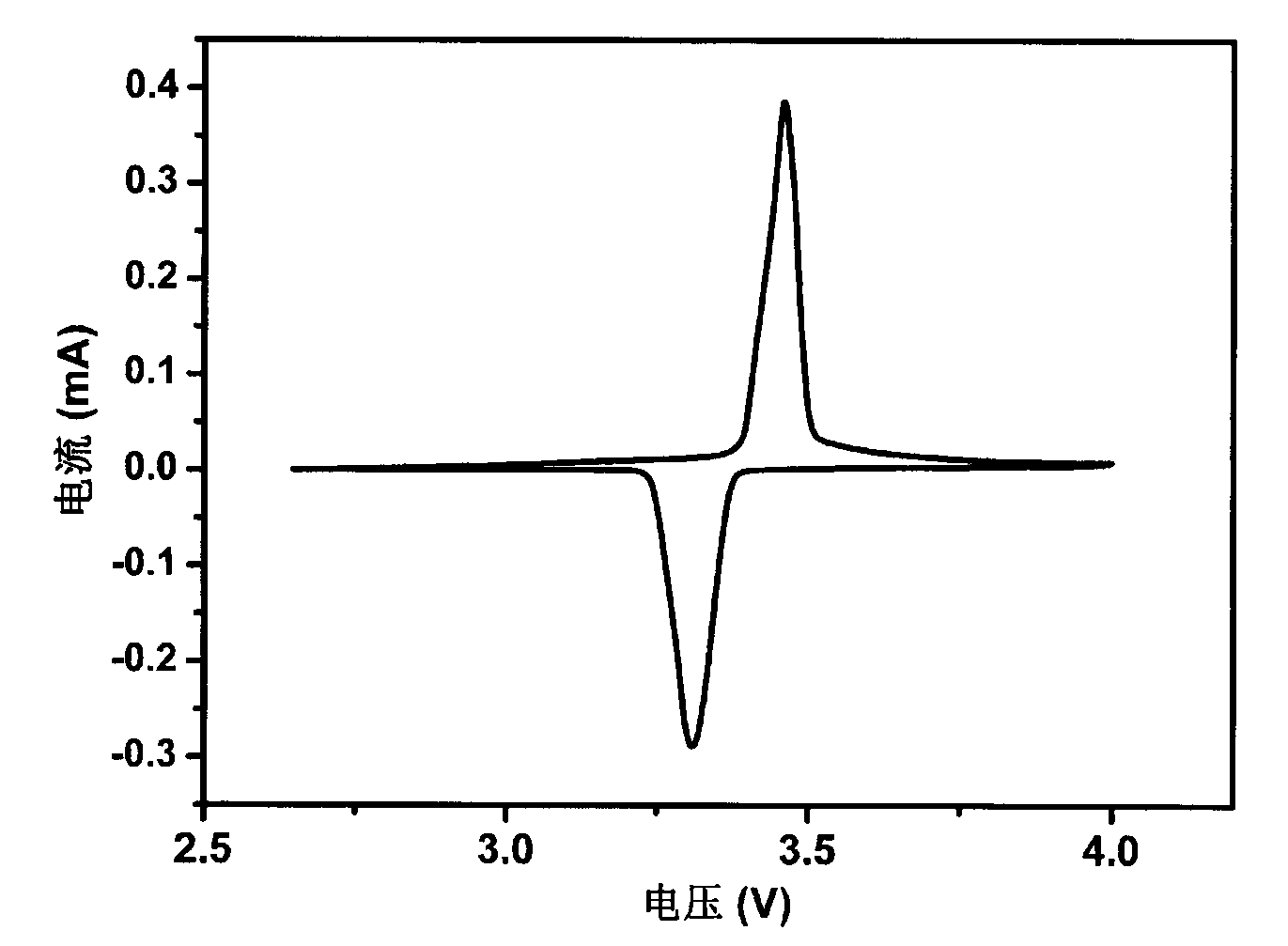

Water system chargeable sodium-ion battery

InactiveCN103022577AIncrease energy densityImprove cycle lifeCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention discloses a water system chargeable sodium-ion battery system. The system uses a concept of a 'rocking chair battery' of a lithium ion battery; and the entire battery system is formed by using sodium-based prussian blue matter as an embedded anode, titanium sodium phosphate as an embedded cathode, and sodium-contained inorganic salt solution as electrolyte. The system has the advantages of high discharge voltage, large specific capacity, good rate capability, long cycle life and the like, and further has the characteristics of green and environmental friendliness, and high security and no pollution. The system very hopefully becomes an electrochemical stored energy system with low price and environmental friendliness.

Owner:WUHAN UNIV

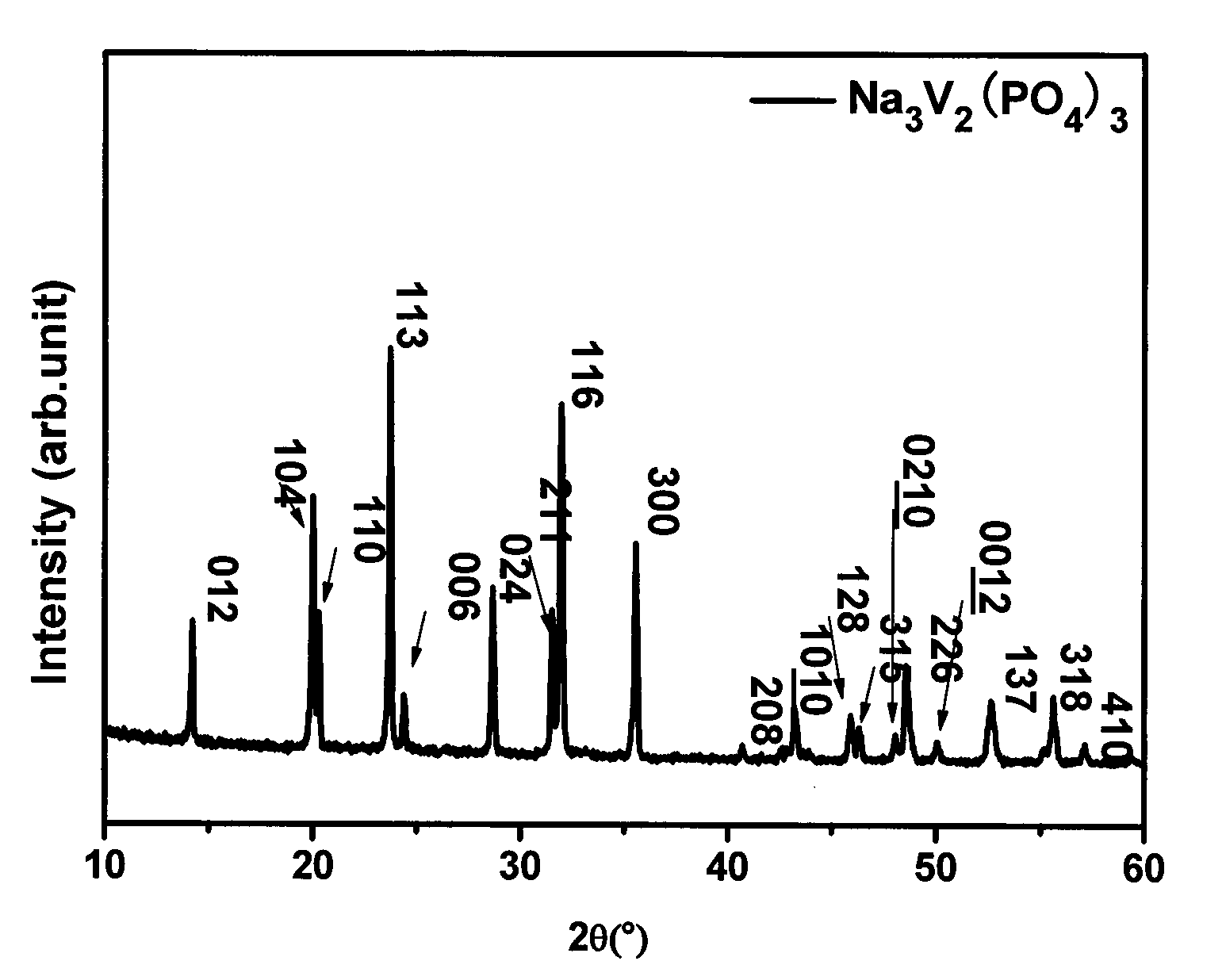

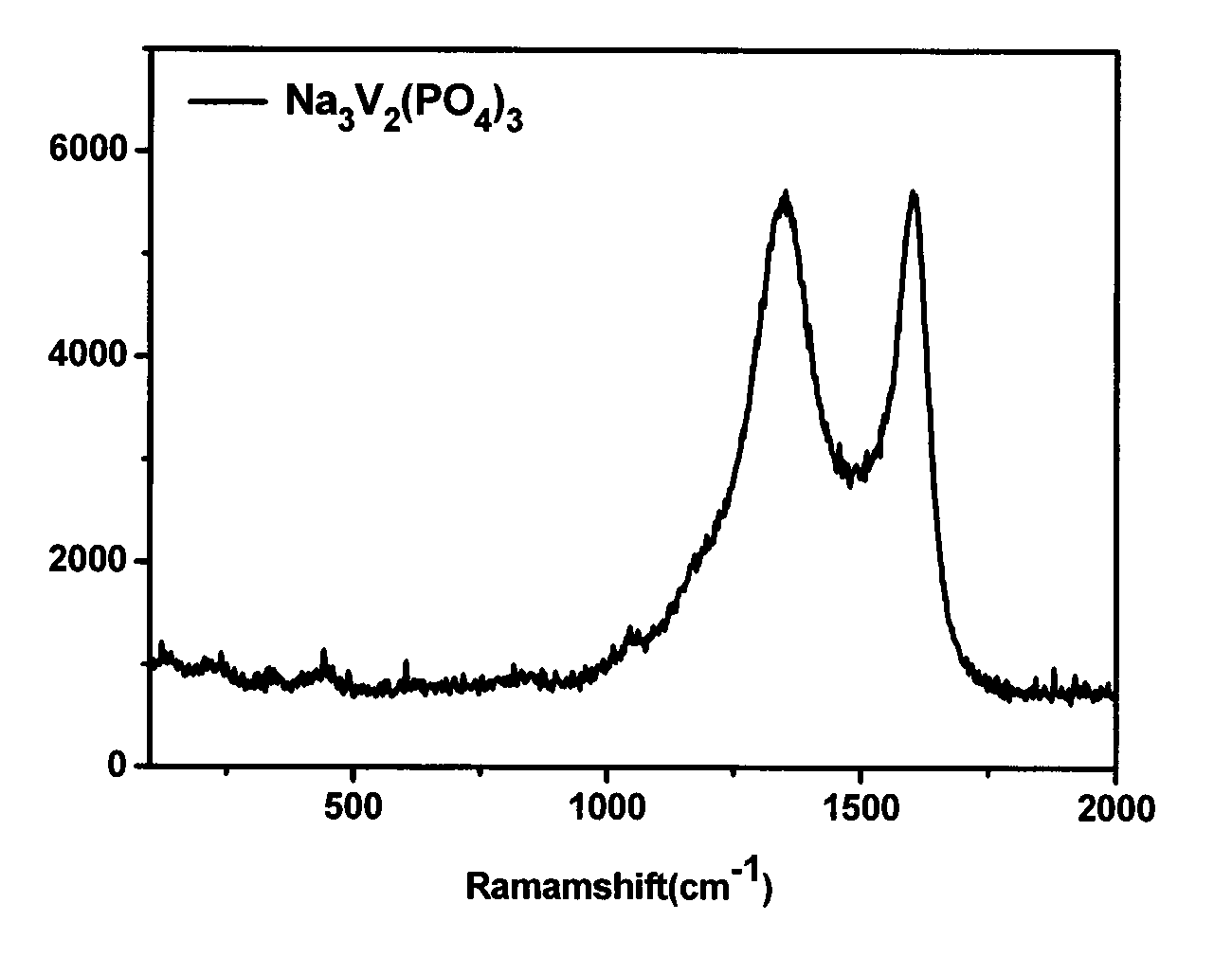

Vanadium sodium phosphate composite material as well as preparation method and application thereof

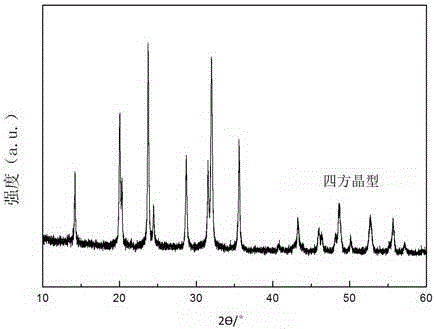

InactiveCN103000884AImprove cycle performanceImprove securityCell electrodesSodium phosphatesNitrogen

The invention relates to a vanadium sodium phosphate composite material as well as a preparation method and an application thereof. The general formula of the composite material provided by the invention is C1-xNx-LaNabMcVd(PO4)3, wherein C1-xNx is carbon or carbon doped with nitrogen, L is one or two selected from Li and K; M is one or more than one selected from Mg, B, Al, Ca, Ti, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ce, Y, Zr, Nb, Mo, Sn, La, Ta and W; and x, a, b, c and d are mol percents, wherein x is more than or equal to 0 and less than 1, a is more than or equal to 0 and less than 2, b is more than 1 and less than or equal to 3, c is more than or equal to 0 and less than or equal to 1, and d is more than or equal to 1 and less than or equal to 2. The invention also provides a preparation method and an application of the composite material. The vanadium sodium phosphate composite material can be taken as cathode or anode material of a secondary sodium-ion battery, especially vanadium sodium phosphate composite material coated with carbon and nitrogen has higher coulombic efficiency and ion and electron conductivity and better cycling performance, is high in safety, low in price, simple in process and wide in application range and can be applied to energy storage equipment, a backup power supply, a spare power supply and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

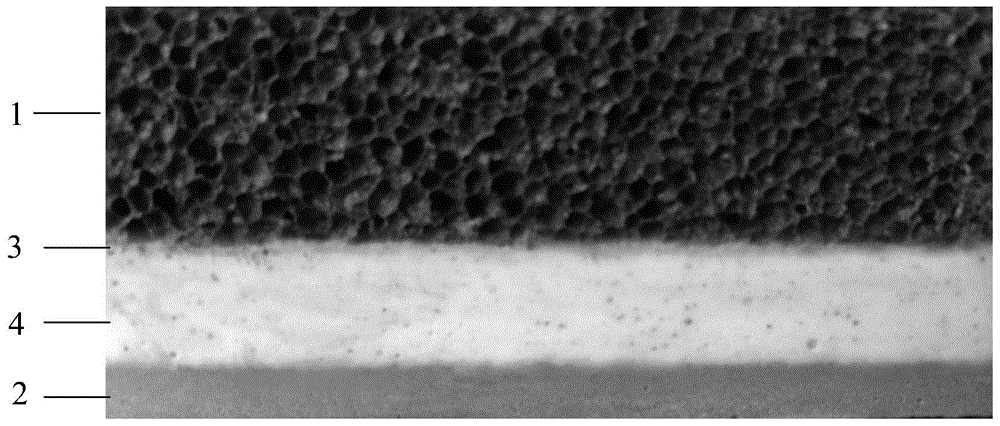

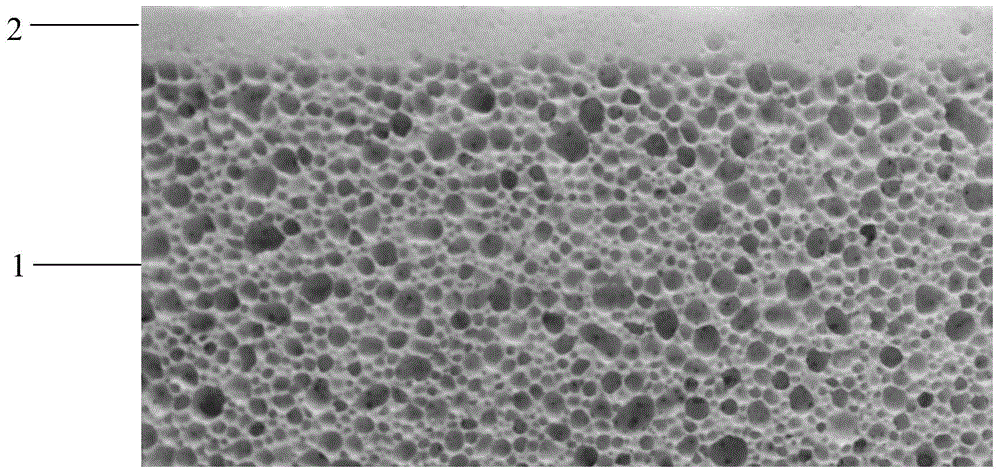

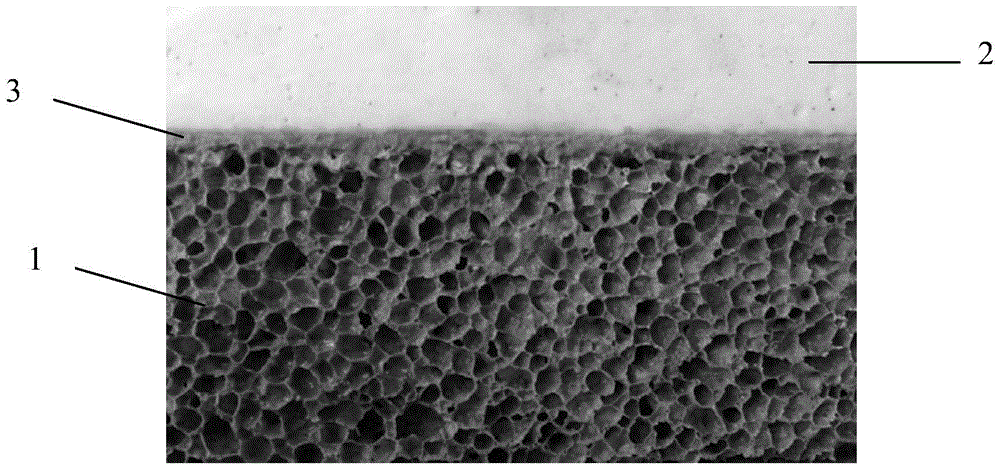

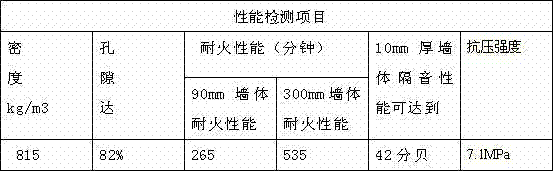

Inorganic thermal insulating decorative panel and production process thereof

ActiveCN104481101AHigh strengthImprove fire performanceCovering/liningsCeramic layered productsInorganic ChemicalFoaming agent

The invention relates to a novel building material, particularly to an inorganic thermal insulating decorative panel and a production process thereof. The inorganic thermal insulating decorative panel and the production process thereof solves the defects that existing foam ceramic panels need to be bonded with microcrystalline composite boards during construction. The inorganic thermal insulating decorative panel is of a double-layer structure which is composed of a foam matrix layer and a decorative layer covering the matrix layer, wherein the foam base layer is a foam ceramic layer, and the decorative layer is a microcrystalline layer of a ceramic layer; the microcrystalline layer is made of microcrystalline materials, and the ceramic layer is made of ceramic materials; the foam matrix layer is composed of, by weight part, 100 parts of ceramic powder, 0.05-5 parts of foaming agent, 0.1-5 parts of foam stabilizer and 0.5-10 parts of sodium phosphate. The inorganic thermal insulating decorative panel is high in strength, fireproof performance and heat and sound insulating effects, low in density and good in comprehensive performance.

Owner:上饶市璞晶新材料有限公司

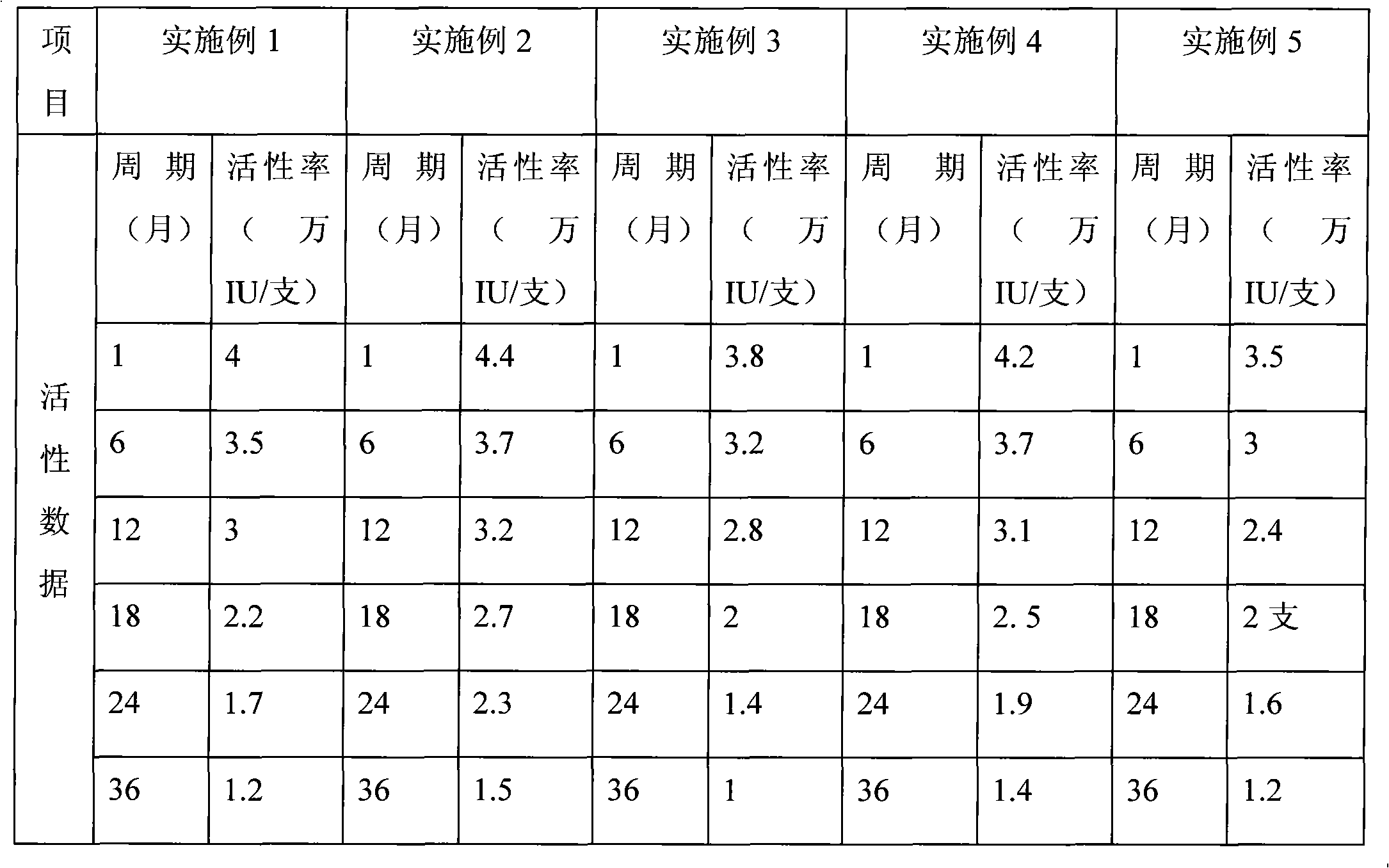

Injectable crosslinked hyaluronic acid gel and preparation method thereof

The invention relates to an injectable crosslinked hyaluronic acid gel and a preparation method thereof. The injectable crosslinked hyaluronic acid gel is prepared by blending hyaluronic acid gel granules and chlorinated sodium phosphate physiological buffer solution; the hyaluronic acid gel granules are prepared by comprising the steps of crosslinking treatment, emulsion crosslinking granulation, purification and drying and swelling, filling and sterilization technologies. The hyaluronic acid gel granules are uniform in granule size, the residual of the crosslinking agent is less than 0.2ppm, the injection pushing is proper, and the in-vivo degradation time can last more than 8-12 months. The implant has an excellent esthetical restoration effect, is applicable to being injected to and subcutaneous dermis deep layer to subcutaneous superficial layer, restoration of moderate to severe wrinkles or folds, and can satisfy the restoration demand of wrinkles or folds caused due to skin aging.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

Phase-change energy-storage material

InactiveCN103666381AImprove cycle stabilityRaise the ratioHeat-exchange elementsFiberSodium phosphates

The invention relates to a phase-change energy-storage material which comprises the following components in percentage by mass: 75%-99% of an energy storage main body material, 0.1%-10% of a thickening agent, 0.2%-15% of a nucleating agent and 0.01%-8% of a reinforcing material, wherein the energy storage main body material comprises crystal water and salt; the thickening agent comprises one or more of an inorganic thickening agent, fibers, polyacrylates, polyurethanes and a natural polymer thickening agent; the nucleating agent comprises one or more of sodium pyrophosphate, sodium phosphate decahydrate, calcium sulfate dihydrate, potassium sulfate, potassium borate, barium hydroxide octahydrate, sodium phosphate dibasic dodecahydrate and sodium sulfate; the reinforcing material comprises one or more of metal and metal oxide powder, carbon materials, nanoparticles and foam materials. By selecting proper materials and ratio, the supercooling degree and the phase separation phenomenon are reduced and good circulating stability is achieved; especially the reinforcing material is added into a system to form a heat-conducting network so as to improve the heat conductivity of the material by more than two times.

Owner:PIONEER ENERGY JIANGSU

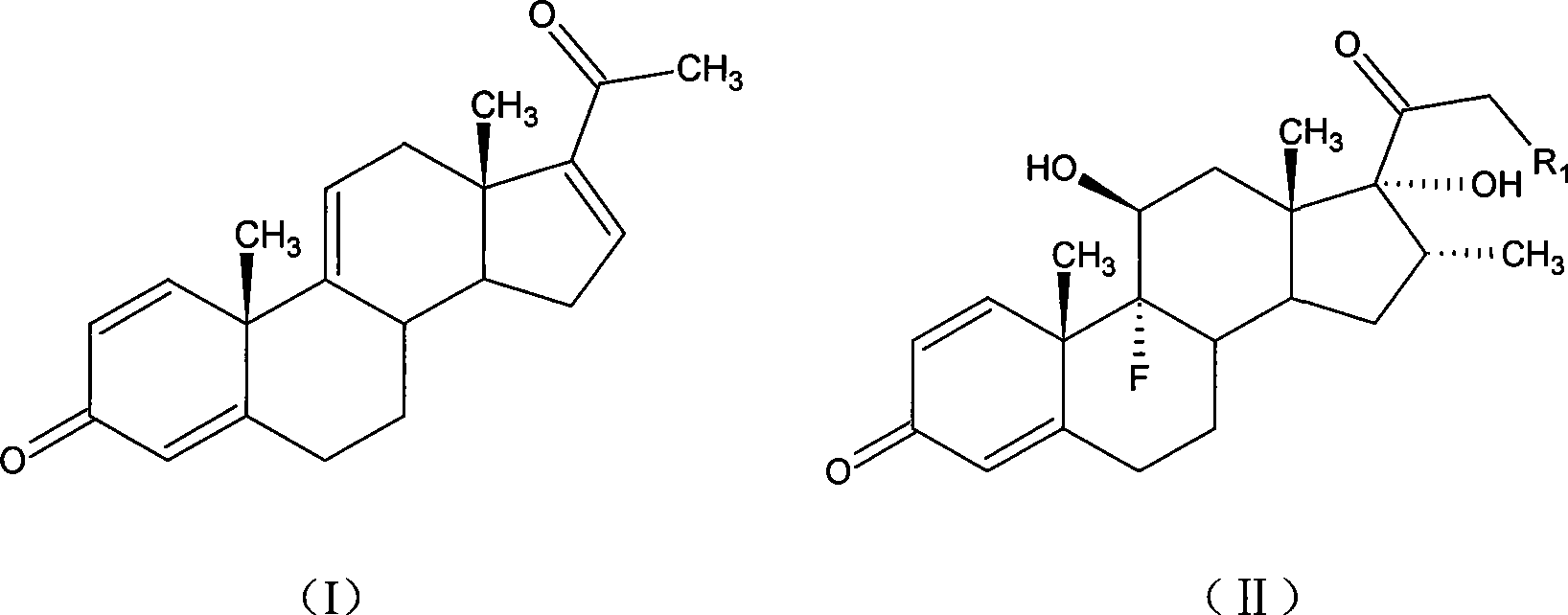

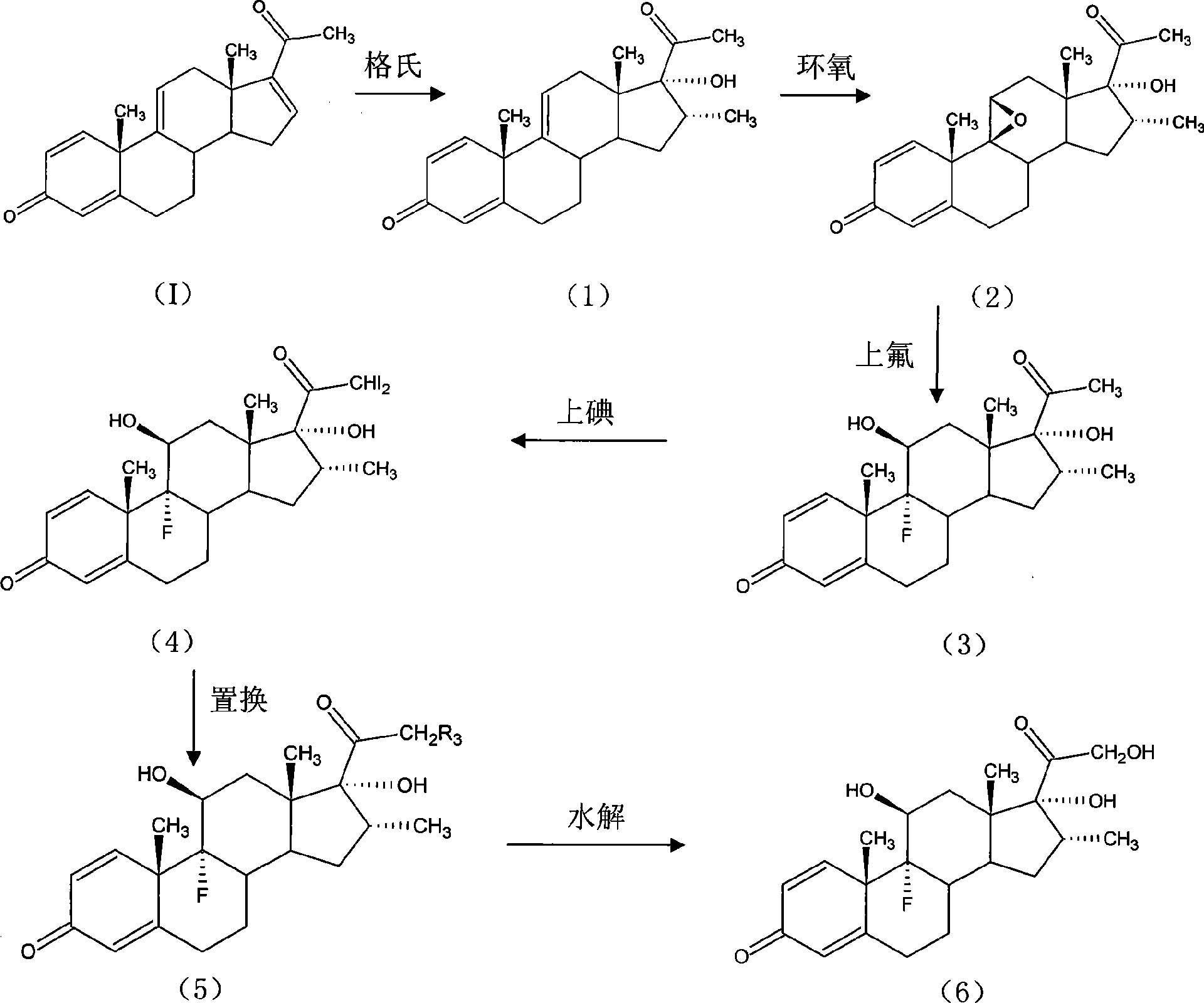

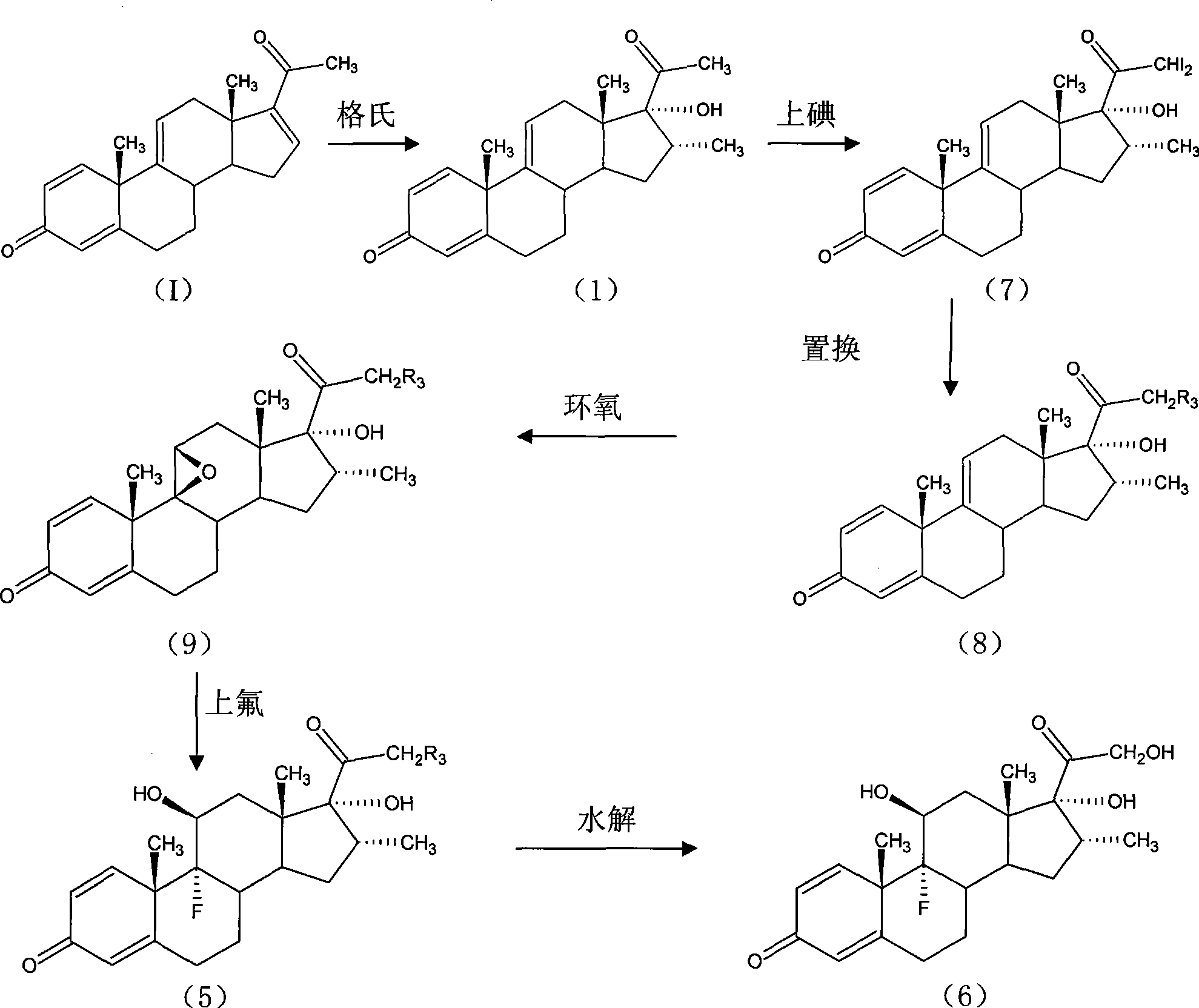

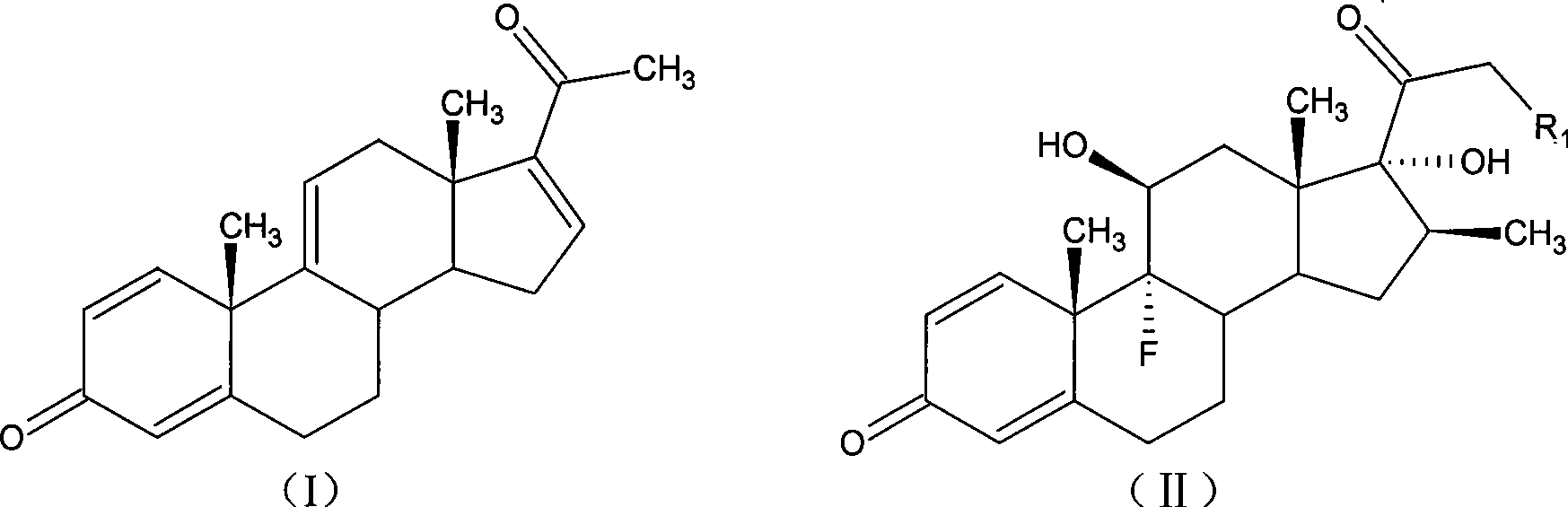

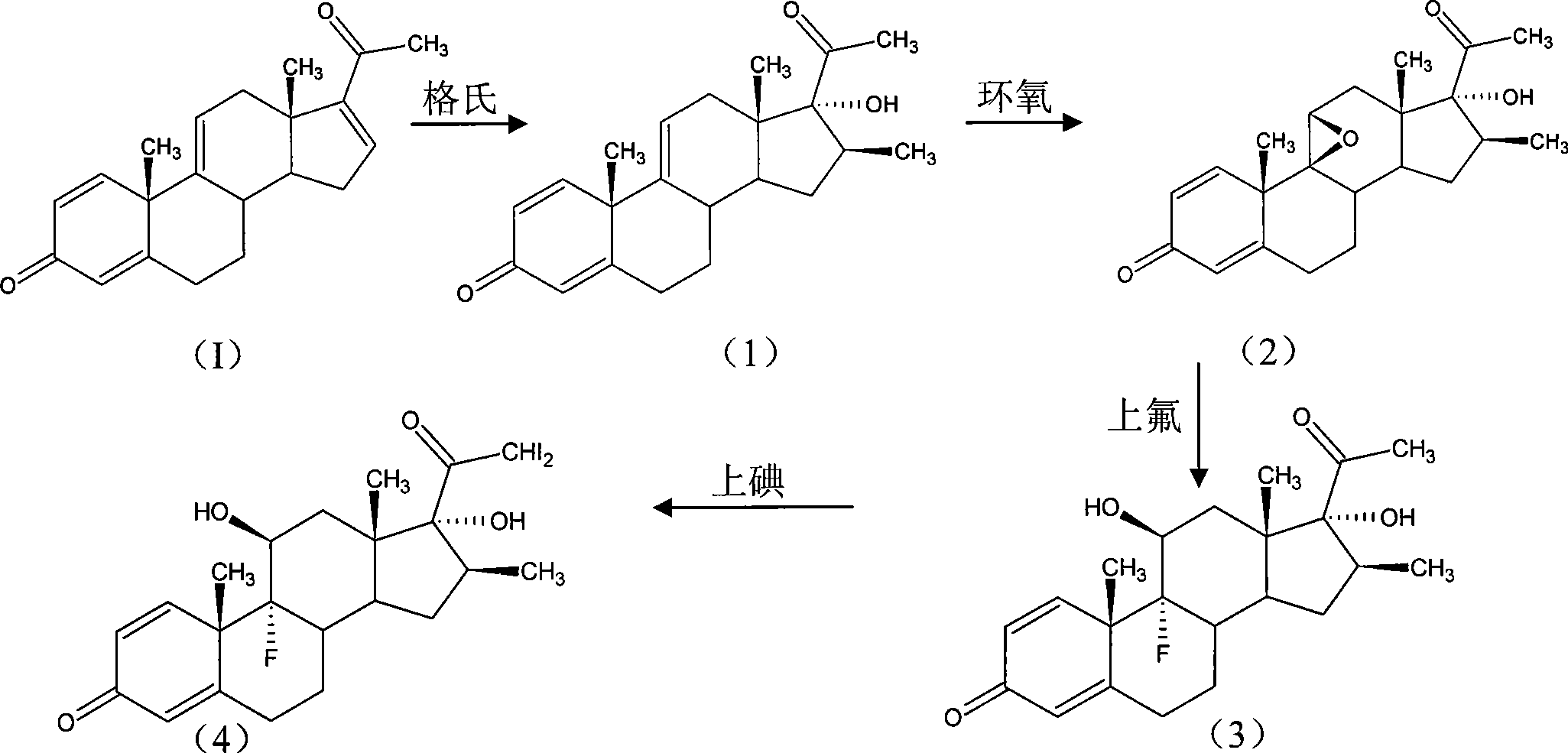

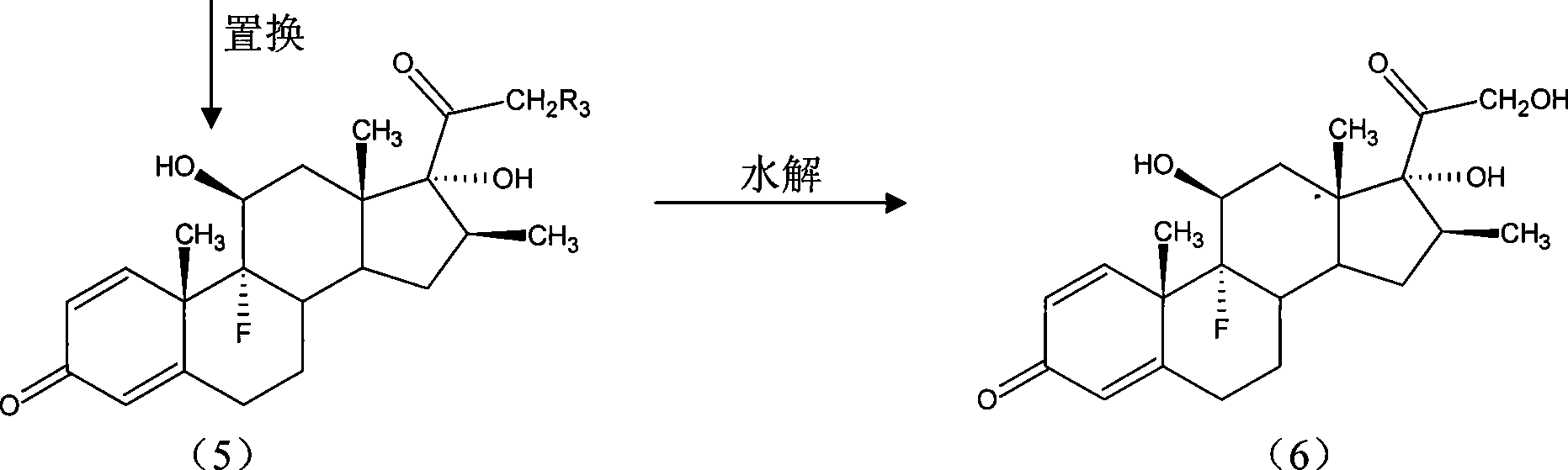

Method for preparing dexamethasone and series products thereof

The invention provides a completely new process route for synthesizing dexamethasone and series products thereof. The invention adopts 1, 4, 9, 16-tetraene-pregna-3, 20-diketone as the original material which is modified by 9, 11bits, 16, 17 bits and 21 bits so as to obtain the dexamethasone and the series products thereof such as dexamethasone acetate and dexamethasone sodium phosphate and the like. The process has the advantage that the invention adopts the existing intermediates of manufacturers as the original material; the route is simple; the materials are available; the use of expensive accessories is avoided; the yield and the cost are dramatically better than that of the prior methods used for synthesizing the dexamethasone and derivatives thereof; moreover, the adoption of the existing intermediates realizes the combined-line prodction of the betamethasone series products and the dexamethasone series products, thus greatly reducing the manufacturing cost and the industrial manufacturing condition.

Owner:TIANJIN TIANYAO PHARM CO LTD

Paper sepiolite sustained-release antibacterial cat litters

InactiveCN103348922AGood antibacterial effectImprove adsorption capacityAnimal housingCarboxymethyl celluloseSodium phosphates

Owner:WUHU LEISURELY NURSING SUPPLIES POLYTRON TECH INC

Method for preparing betamethasone and series products thereof

InactiveCN101397319ASimple lineRaw materials are easy to getSteroidsChemistryBetamethasone Sodium Phosphate

The invention provides a completely new process route for synthesizing betamethasone and series products thereof. The invention adopts 1, 4, 9, 16-tetraene-pregna-3, 20-diketone as the original material which is modified by 9, 11 bits, 16, 17 bits and 21 bits so as to obtain the betamethasone and the series products thereof such as betamethasone acetate and betamethasone sodium phosphate and the like. The process has the advantage that the invention adopts the existing intermediates of manufacturers as the original material; the route is simple; the materials are available; the use of expensive accessories is avoided; the yield and the cost are dramatically better than that of the prior methods used for synthesizing the betamethasone and derivatives thereof; moreover, the adoption of the existing intermediates realizes the combined-line production of the betamethasone series products and dexamethasone series products, thus greatly reducing the manufacturing cost and the industrial manufacturing condition.

Owner:TIANJIN TIANYAO PHARM CO LTD

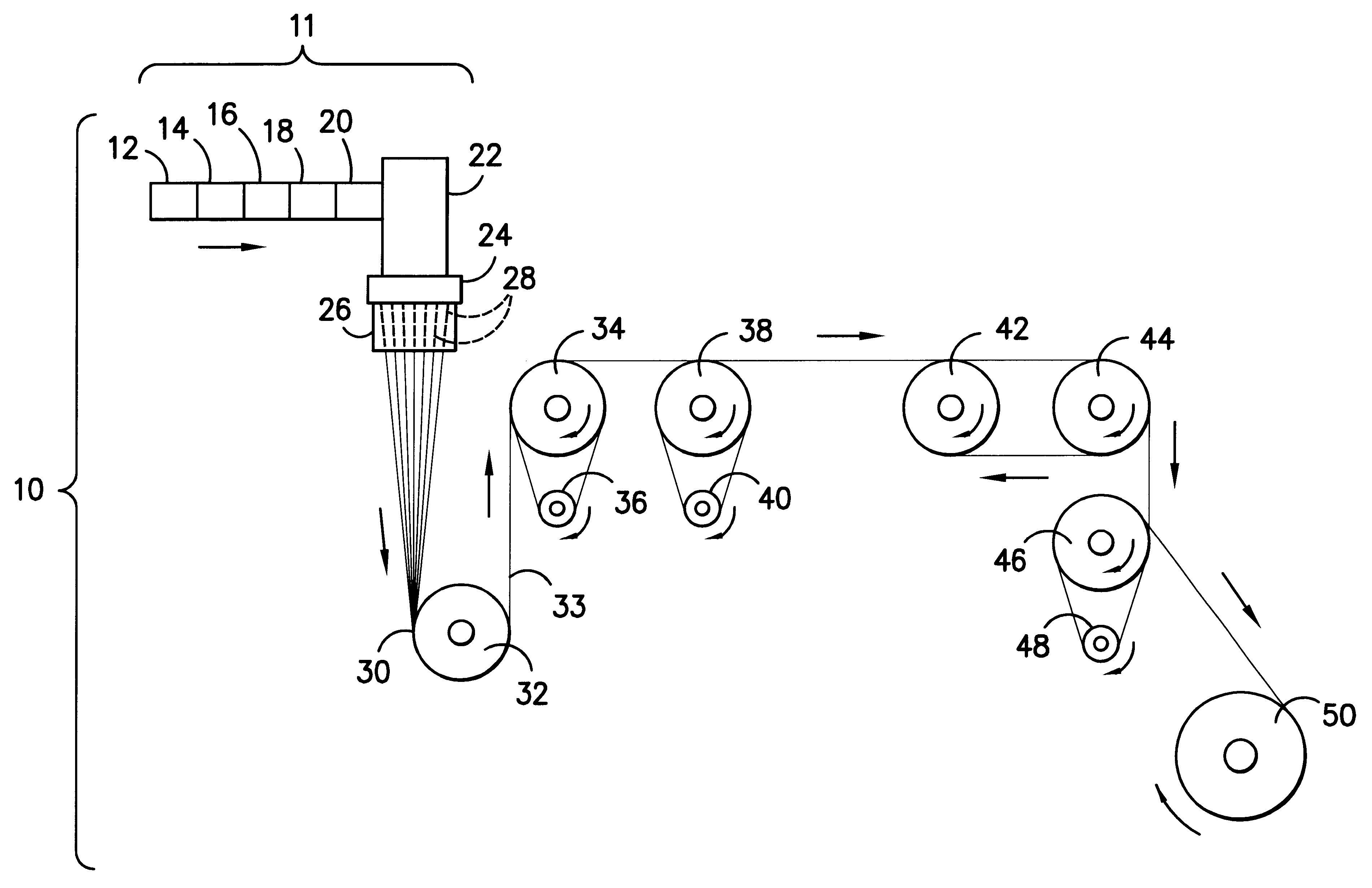

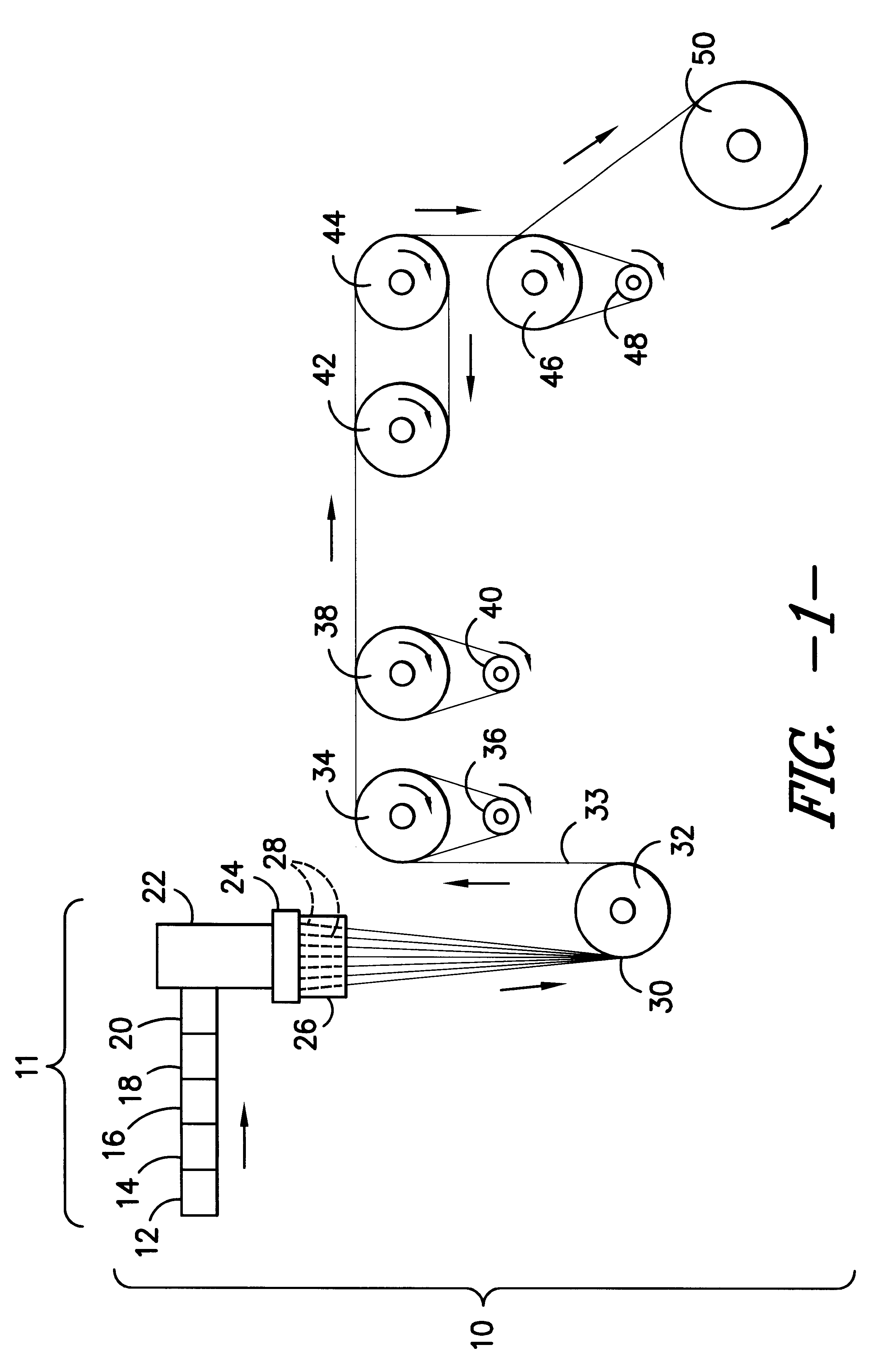

Methods of making low-shrink polypropylene fibers

InactiveUS6656404B2Monocomponent polypropylene artificial filamentWoven fabricsPhosphateLITHIUM PHOSPHATE

Improved polypropylene fibers exhibiting greatly reduced heat- and moisture-shrink problems and including certain compounds that quickly and effectively provide rigidity to the target polypropylene fiber after heat-setting are disclosed herein. In such a manner, the "rigidifying" compounds provide nucleation sites for polypropylene crystal growth. After drawing the nucleated composition into fiber form, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as sodium beuzoate, certain sodium and lithium phosphate salts (such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11).

Owner:MILLIKEN & CO

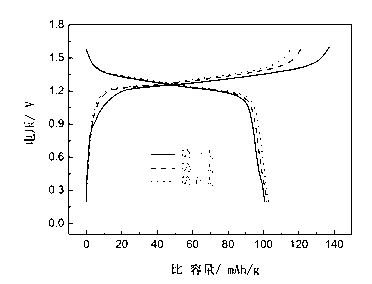

Preparation method of carbon coated vanadium sodium phosphate positive electrode material

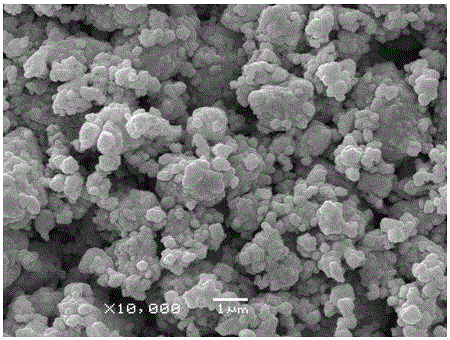

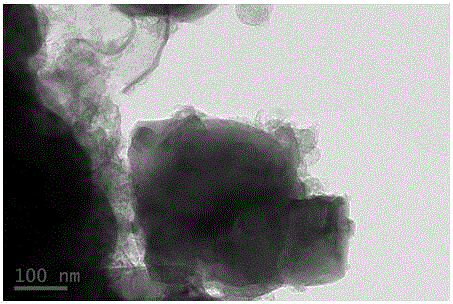

InactiveCN105336924AEasy diffusion distanceImprove electrochemical performanceNon-aqueous electrolyte accumulatorsCell electrodesSodium phosphatesElectrical battery

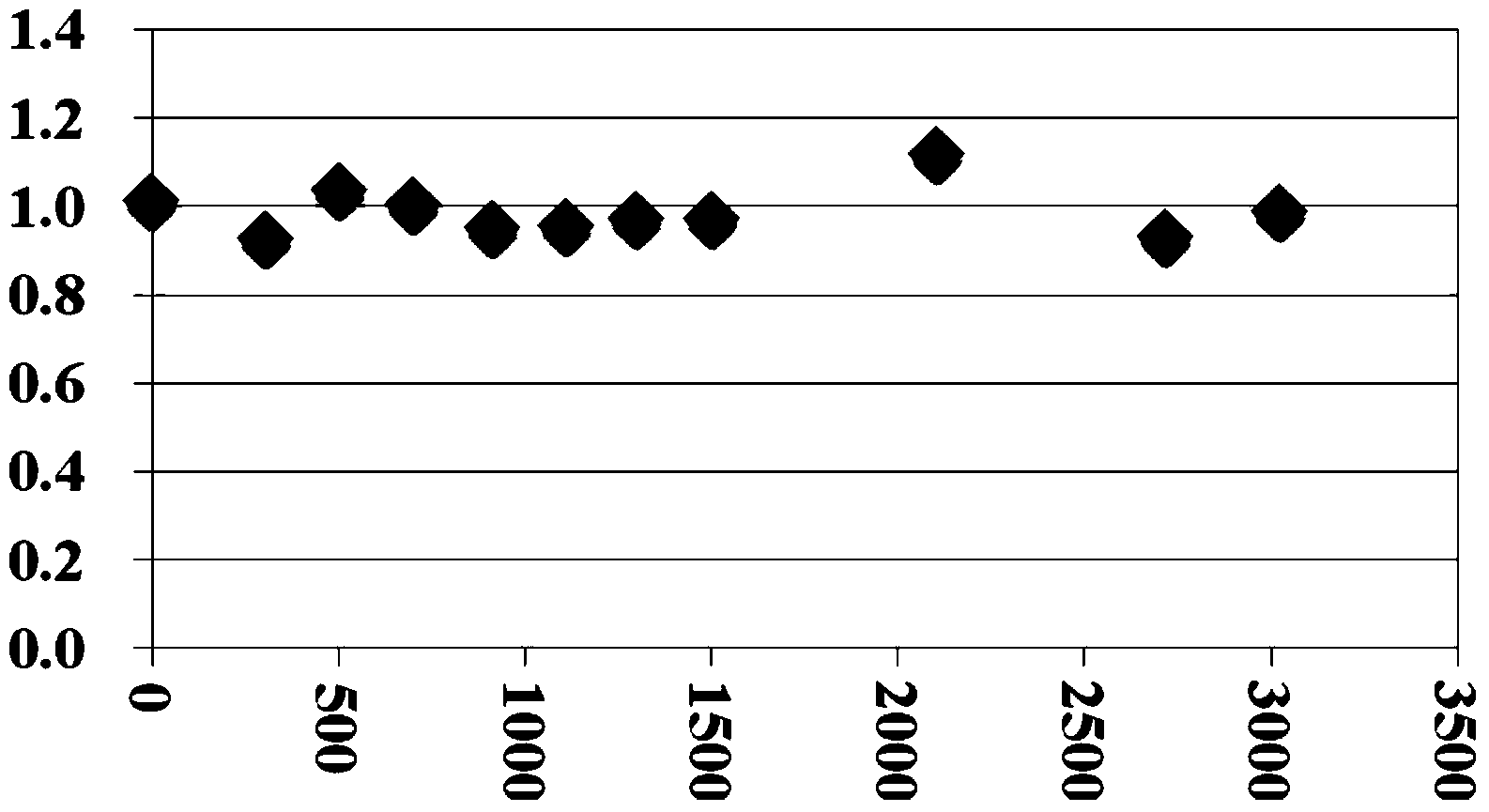

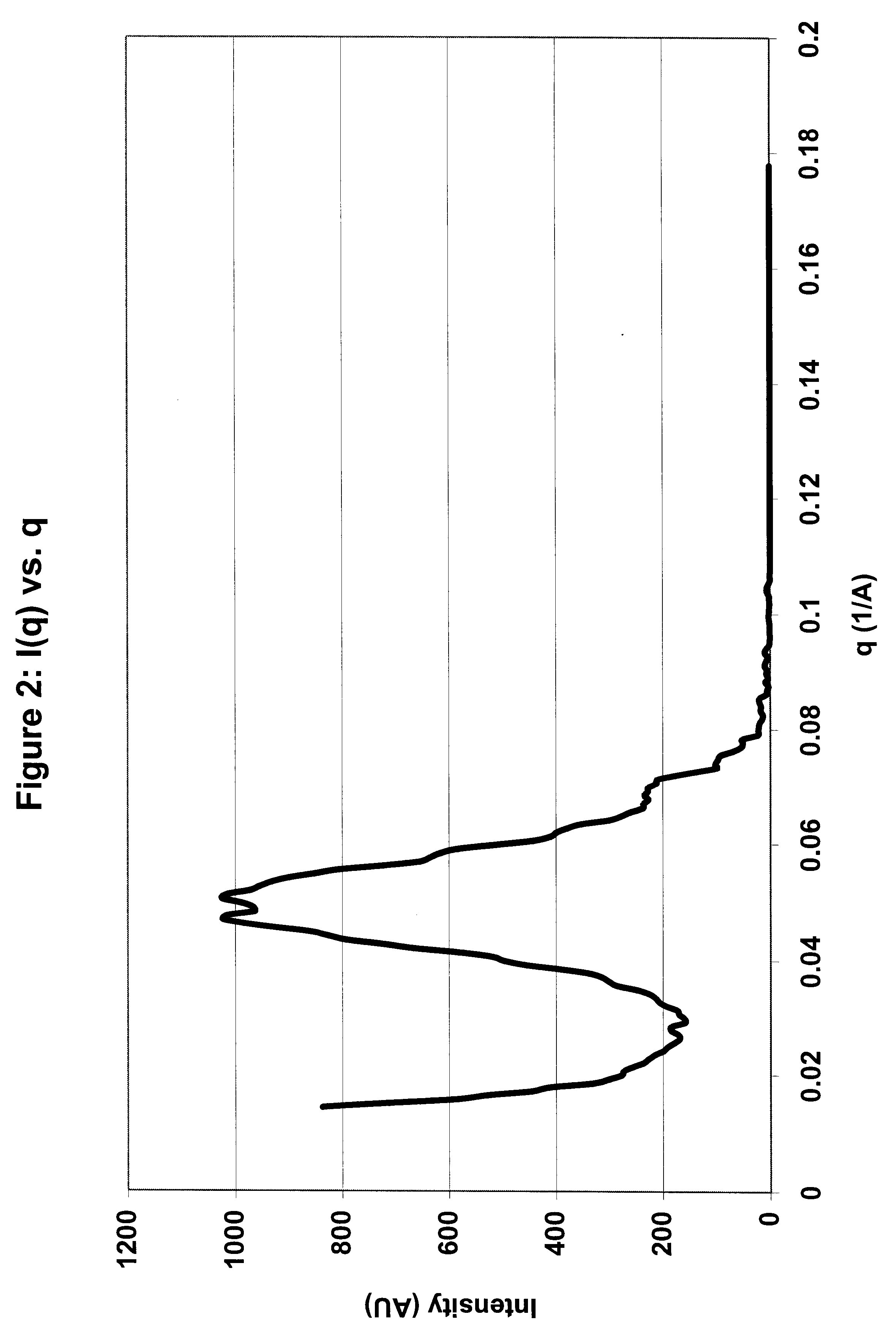

A preparation method of a carbon coated vanadium sodium phosphate positive electrode material comprises the steps: with glucose as a reducing agent and a carbon source and water as a dispersant, carrying out ball milling of NH4VO3, NaH2PO4.2H2O and glucose in water, carrying out spray drying, calcining, and thus obtaining the carbon coated vanadium sodium phosphate positive electrode material. The method has the advantages of low synthesis temperature, simple steps, easily obtained raw materials, and advantageous industrialization; the obtained carbon coated vanadium sodium phosphate positive electrode material has a structure with uniform primary particles, has the particle size of 100-200 nm, and has the characteristics of short sodium ion diffusion distance, fast transmission speed, high specific surface area, high electrical conductivity and fast ion transmission and the like. The obtained carbon coated vanadium sodium phosphate positive electrode material is assembled into a battery; in a voltage scope of 2.0-3.75 V and under 1 C multiplying power, the highest first charge and discharge capacity per gram can reach 93.5 mAh*g<-1>, the capacity retention rate can be up to 97.7% after cycling for 50 circles with the 1C multiplying power, and excellent electrochemical performance is showed.

Owner:CENT SOUTH UNIV

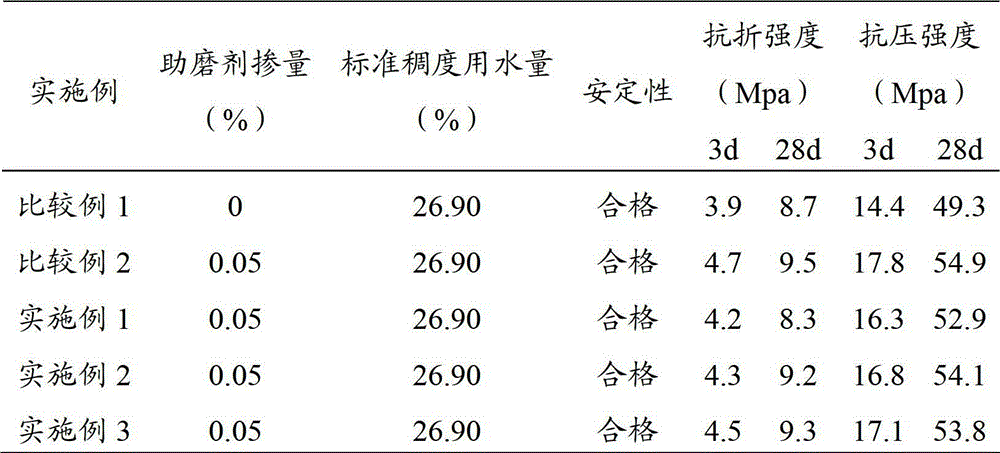

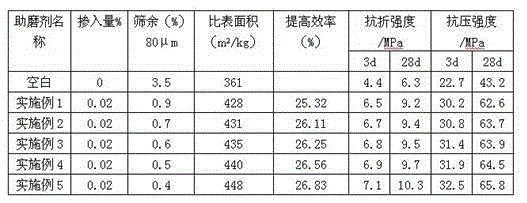

Grinding aid for slag cement

The invention provides a grinding aid for slag cement. The grinding aid provided by the invention comprises the following components by weight percent: 5-20wt% of alcohol amine compound, 0.1-5wt% of hydroxypropyl methyl cellulose, 5-30wt% of polyhydric alcohol compound, 0.5-10wt% of sodium hexametaphosphate, 1-10wt% of soluble sulfate, 1-8wt% of sodium dodecyl benzene sulfonate and the balance of water. In the grinding agent provided by the invention, the hydroxypropyl methyl cellulose is beneficial for stimulating the activity of the slag, forming stable hydrous products in the reaction process, improving the property of the cement, improving the strength of the cement and improving the stability of the liquid grinding aid at the same time. Experimental result shows that the grinding aid is capable of increasing the breaking strength of the cement to 9.5MPa and increasing the compressive strength to about 55MPa.

Owner:SHANDONG HONGYI TECH +1

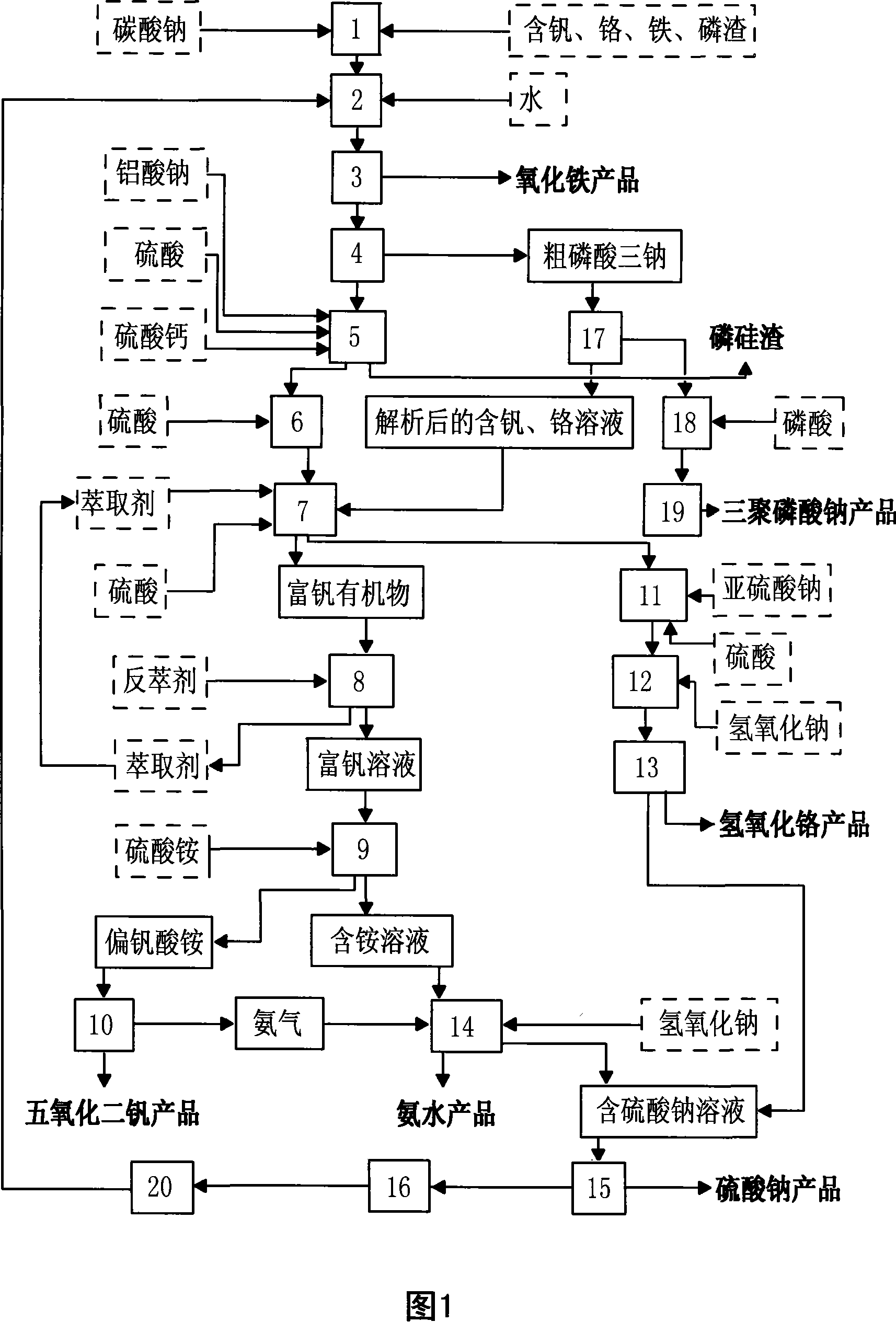

Method of reclaiming chemical industry products by using industrial slag containing vanadium, chromium, iron and phosphorous

ActiveCN101058853ATake advantage ofUsefulRaw phosphate material treatmentProcess efficiency improvementChemical industrySlag

The invention discloses a recovering chemical product method with a V, Cr, Fe and P industrial muck in the chemistry field, which comprises the following steps: roasting raw materials; heating and leaching the clinkers; separating ferric oxide from the solution containing V, Cr, Fe and P; crystallizing the solution in order to removing to P; removing P deeply; removing Si; adjusting the acidity of the solution containing V and Cr; extracting V; extracting V reversely; settling V; roasting metammonium vanadate; reducing Cr; settling chromic hydroxide; separating chromic hydroxide from sodium sulfate; removing NH3; getting sodium sulfate crystallization; purifying sodium sulfate mother liquor; adsorbing V, Cr, tertiary sodium phosphate solution with rough tertiary sodium phosphate refining resin and reacting with phosphoric acid; drying and roasting sodium tripolyphosphate; getting V, Cr, Fe and P from the industrial muck containing V, Cr, Fe and P and separating the secondary product of ammoniacal liquor and sodium sulfate in the heat exchange procedure. The invention saves the energy, which adapts to an industrial appliance.

Owner:辽宁虹京实业有限公司

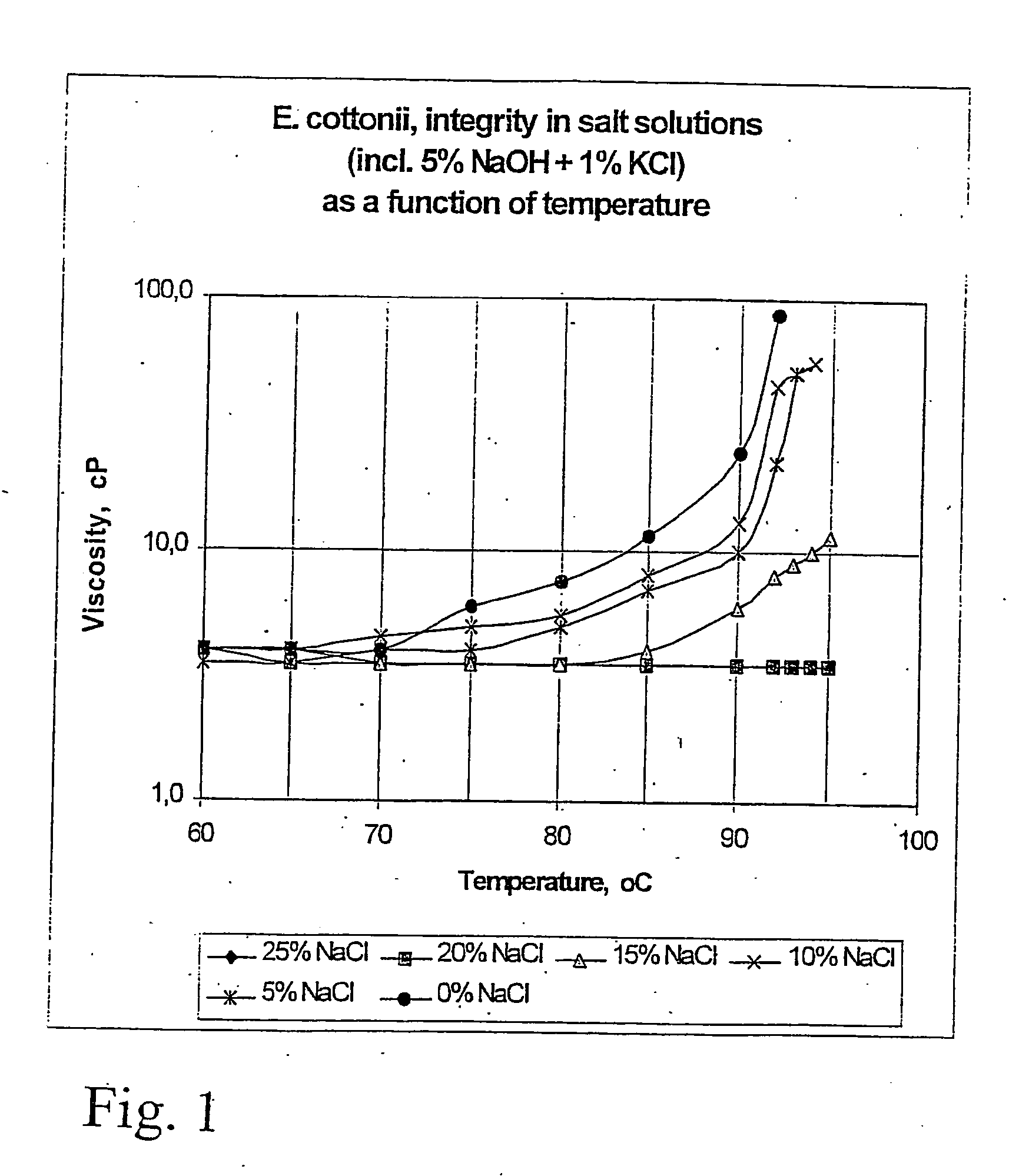

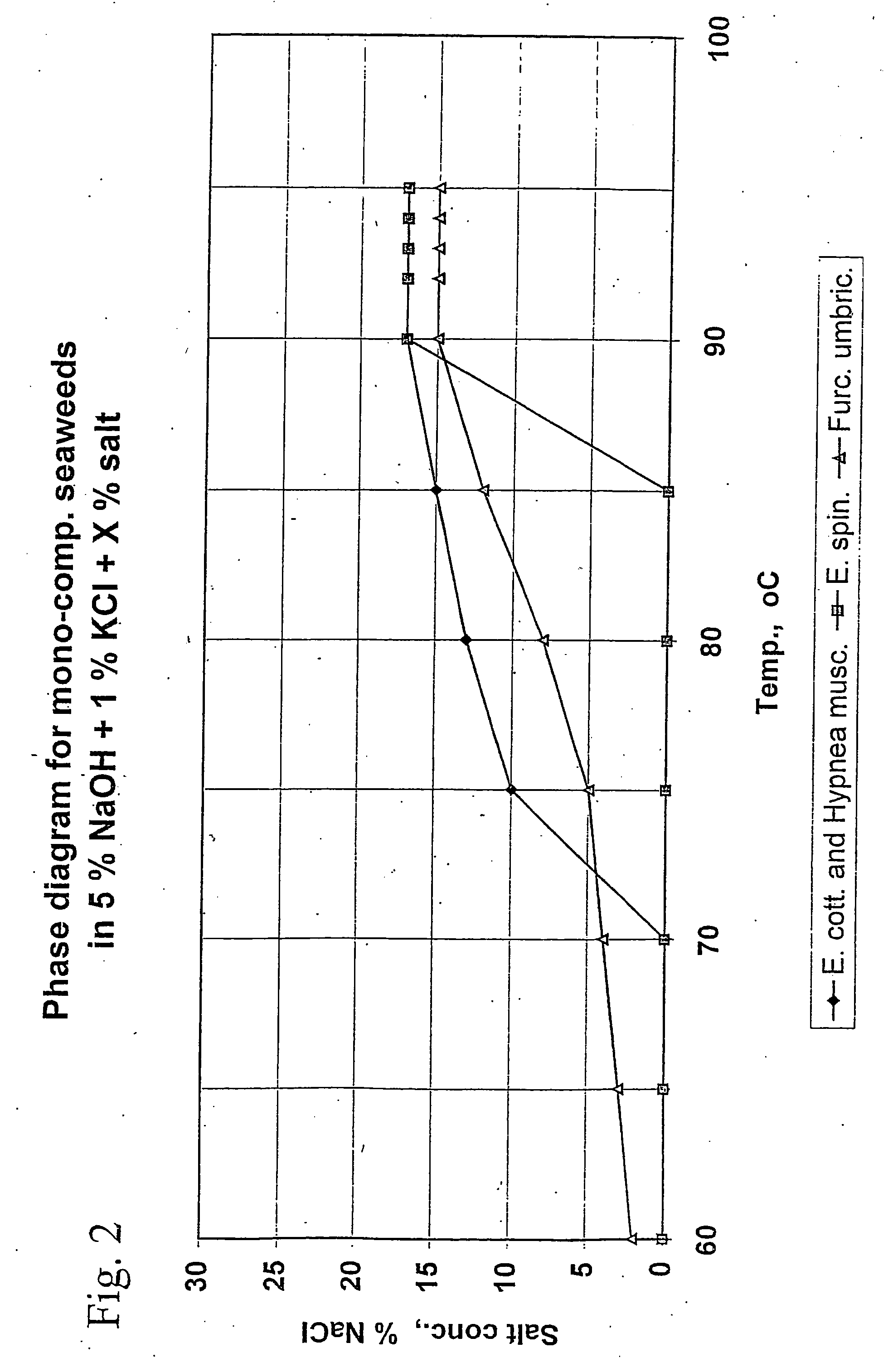

Heterogeneous carrageenan manufacturing process from mono component seaweed with reduced use of level of koh

InactiveUS20050020828A1Reduction in alkali costReduce the amount requiredEsterified saccharide compoundsSugar derivativesCarrageenanPhosphate

An improved method for the manufacture of gelling carrageenens from seaweed, wherein mono-component seaweed is subjected to a heterogeneous reaction step, one or more washing step (s), and further workup provides for substantial savings in alkali costs as non-expensive alkalis, such as NaOH, Na2CO3,Na-phosphates, K2CO3, K-phosphates, ammonia may be used in the heterogeneous reaction step.

Owner:CP KELCO

Method for forming ultrahigh-voltage anode foil for aluminum electrolytic capacitors

ActiveCN102610390AImprove compactnessIncrease costSurface reaction electrolytic coatingCapacitor electrodesConvertersPhosphorous acid

The invention relates to the production of electronic components, and discloses a method for forming anode foil for electrolytic capacitors. The ultrahigh-voltage anode foil is formed through six stages, wherein from the stage 1 to stage 5, each stage has a formation tank, and in the stage 6, three formation tanks are connected in parallel; and an acid fluid mixture containing a boric acid, a citric acid or an azelaic acid (the electric conductance and pH value thereof are adjusted by using carbon-containing inorganic salts) and ammonium hypophosphite or sodium monophosphate for improving the boiled performance of an oxidation film is filled in each formation tank. Correspondingly, the processing step is also adjusted, and the produced anode foil not only can be applied to the fields and industries of aerospace and automotive frequency converters and industrial frequency converters and the like meeting the ultrahigh voltage requirements on a withstand voltage of 700-1200V, but also is dense in oxidation film surface, high in specific volume and short in boosting time.

Owner:新疆金泰新材料技术股份有限公司

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

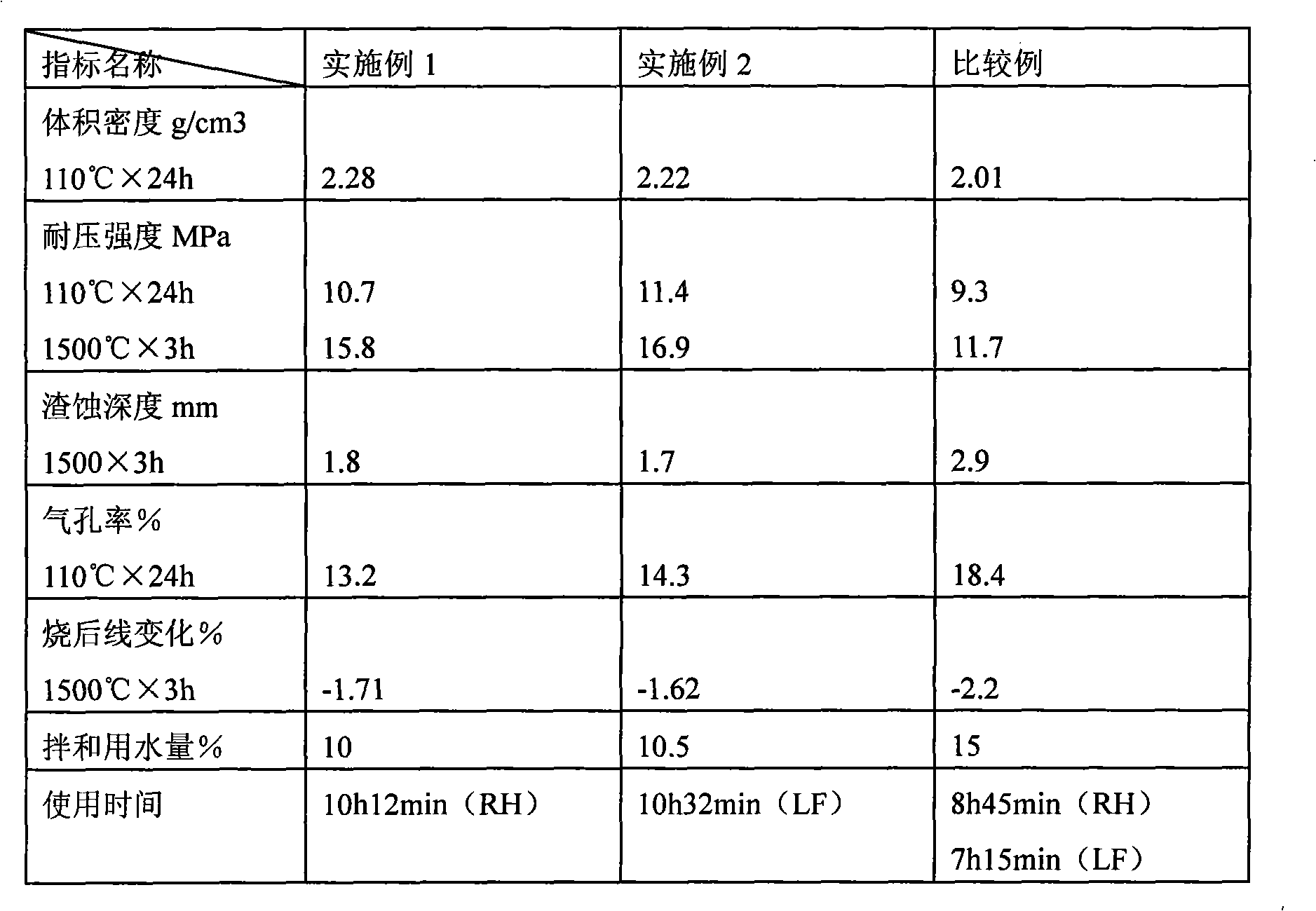

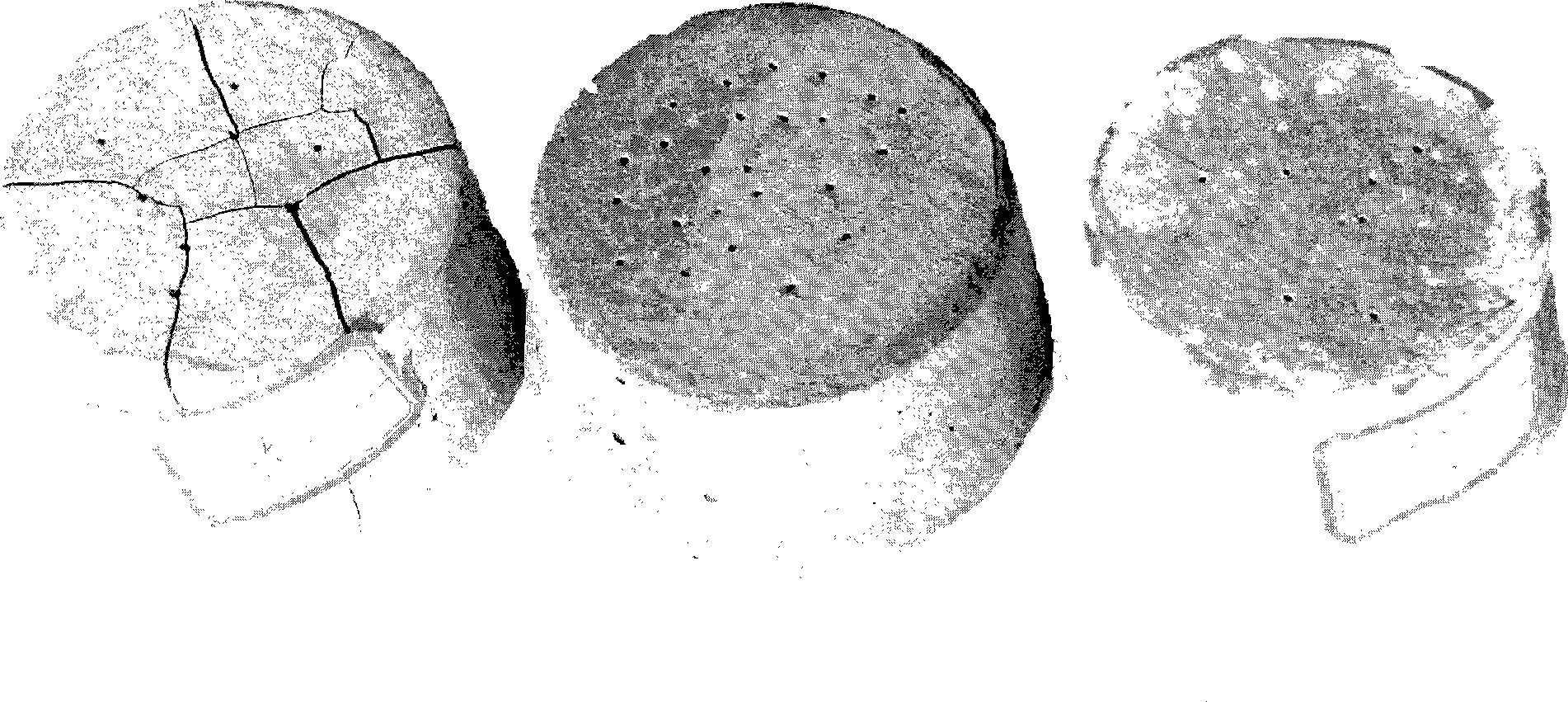

Antisticking coating mixture for steel-smelting and preparation method threreof

The invention relates to an anti-sticking daubing material applied in steelmaking as well as the preparation method thereof, and is characterized in that the daubing material is composed of the following components by weight percentages as follows: 65 to 80 percent of 0 to 3 mm waste magnesia-carbon brick powder, 10 to 30 percent of waste magnesia-carbon brick powder, 5 to 30 percent of fused magnesia powder, 1 to 4 percent of fine silica powder, 1 to 4 percent of fine Alpha-Al2O3 powder, 0.1 to 1 percent of sodium hexameta phosphate, 0.1 to 0.8 percent of calcium lignosulfonat and 1 to 5 percent of soft clay. The daubing material can prevent the penetration of molten slag by utilizing the lubricating property of graphite in the waste magnesia-carbon bricks, and the slag is not easy to be hung on the surface, thereby not only effectively utilizing the waste magnesia-carbon bricks, but also prolonging the service life and reducing the cost.

Owner:PANZHIHUA SHUNTENG GRP METALLURGY MATERIAL

Anti-crack alkalis excited ecological cement

The invention relates to anti-cracking alkali exciting ecological cement, which consists of A, B and C, and solid-phase mass ratio of the A to the B to the C is 5-10:75-90:5-15. The A is exciting agent, which comprises the following components by mass percentage: more than or equal to 80 percent of water glass of which modulus is 0.7 to 1.4, and less than or equal to 20 percent of one or a plurality of sodium sulfate, sodium phosphate, sodium carbonate, sodium chloride and magnesium chloride; and the A is prepared into solution containing more than or equal to 40 percent of solid for use. The B is a mineral additive, which comprises the following components by mass percentage: 30 to 70 percent of slag powder, and 30 to 70 percent of other additives, wherein the other additives comprise one or a plurality of siliceous dust, coal ash, metakaolin, red mud, burnt shale, colliery waste, steel slag and alloy slag, and is grinded to powder of which specific surface is 350 to 800m<2> / g. The C is active magnesium oxide, wherein mass content of MgO is more than or equal to 70 percent. The active magnesium oxide is calcined at a temperature of between 700 and 1,000 DEG C and then mixed and grinded with the B to become powder. The cement is the low-carbon discharge ecological cement with the advantages of high-early strength, durability, permeability resistance, corrosion resistance, freezing and thawing resistance, low heat of hydration, good cracking resistance, economy and environmental protection, and is used for civil construction, water conservancy, national defense, and oil well and mine passage support engineering.

Owner:WUHAN UNIV OF TECH

Full vanadium ion fluid cell electrolyte and preparing process thereof

InactiveCN1719655ASimple production processLow costConductive materialRegenerative fuel cellsIonChemistry

This invention relates to an electrolyte of a full-vanadium ionic fluid-flow battery composed of V salt sulfate, H2So4, water, alcohol and additives, which are Na2SO4, Na pyrophosphate, salufer and hydrogen peroxide. This invention also provides a preparation method: pumping qualified V liquid from a V-plant into a reaction tank, regulating the PH value of the solution and inletting liquid SO2 into it to be recovered, then the PH value of the solution is regulated with Na2SO4 to deposit VO2 to be dissolved in the solution containing H2SO4, water and alcohol to be added with the additives to be electrolyzed in the tank to get the V electrolyte with 50% of 3valence and 4 valence V separately and density of 1.0mol / L~4.2mol / L .

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

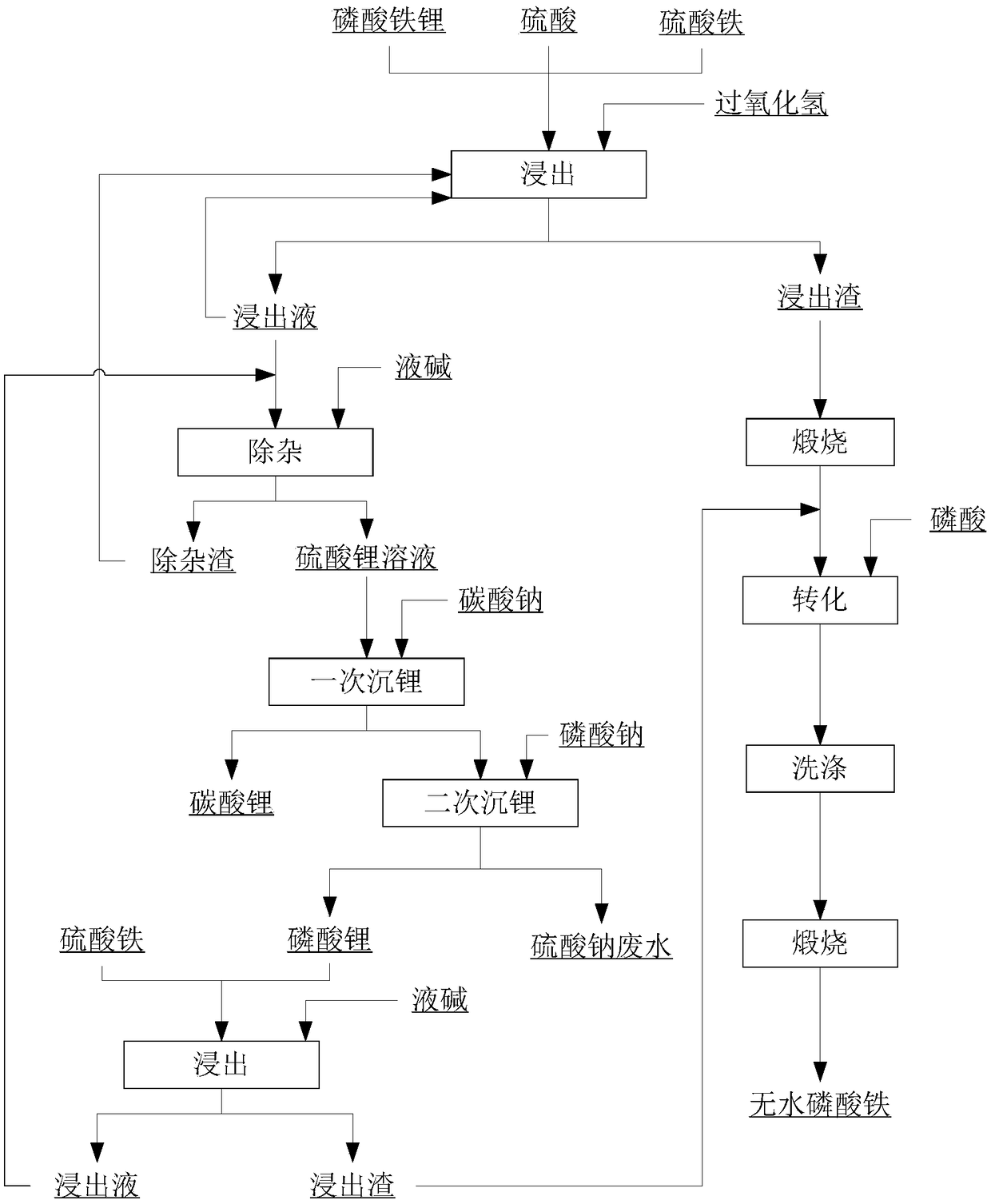

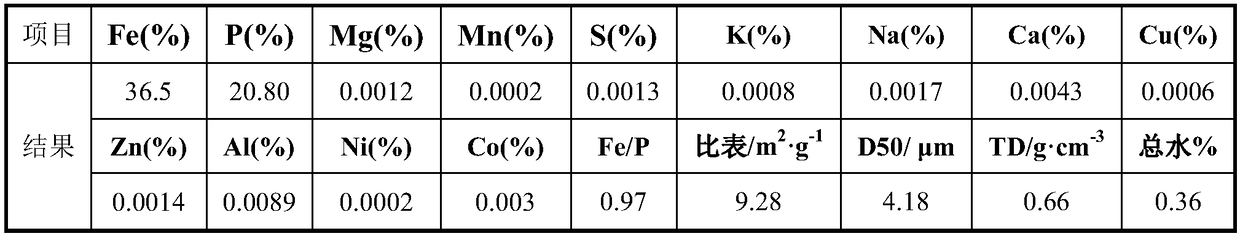

Method for recovering lithium from lithium iron phosphate

ActiveCN108899601ADoes not affect the leaching rateHigh purityWaste accumulators reclaimingProcess efficiency improvementFerric hydroxideIron sulphate

The invention discloses a method for recovering lithium from lithium iron phosphate. The method disclosed by the invention comprises the following steps: dissolving waste lithium iron phosphate slag with sulfuric acid and ferric sulfate, leaching iron, lithium and phosphorus, adding an oxidizing agent, reacting iron and phosphate radicals to produce an iron phosphate precipitate and a small amountof ferric hydroxide, converting lithium into a water-soluble lithium sulfate solution, filtering to obtain the lithium sulfate solution, adding sodium carbonate into the lithium sulfate solution to prepare a lithium carbonate product, and adding sodium phosphate or phosphoric acid to prepare lithium phosphate; dissolving the lithium phosphate with ferric sulfate again to obtain the lithium sulfate solution and a compound taking iron phosphate as a principle component, returning the lithium sulfate solution to the system to prepare lithium carbonate, and calcining the iron phosphate slag to remove organic matters and carbon in the slag; and slurrying to prepare cell grade iron phosphate. According to the method for recovering lithium from lithium iron phosphate disclosed by the invention,the lithium is totally converted into the product lithium carbonate in the method, the process flow is short, the cost is low, the lithium recovery rate is 97%, the metal lithium in the lithium iron phosphate can be effectively recovered, and all the slag is converted into the cell grade iron phosphate.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Preparation method for wear resistant fire-retardant coating

ActiveCN101570650AImprove working environmentImprove work efficiencyFireproof paintsO-Phosphoric AcidSodium phosphates

The invention provides a preparation method for wear resistant fire-retardant coating with simple construction process, good wear resistance and relatively low cost. The raw material of the wear resistant fire-retardant coating selects plate-shaped tabular alumina, brown alumina and high-quality bauxite chamotte as aggregate, selects plate-shaped tabular alumina powder, flint clay powder, alpha-Al2O3 micropowder and ceramic powder as fine powder, selects 42.5 mass percent industrial phosphoric acid solution, solid aluminium dihydrogen phosphate and clay powder as bonding agents, selects fused magnesite as a curing agent and selects sodium borate and sodium hexametahposphate as sintering aids. The wear resistant fire-retardant coating can be directly smeared on the surfaces of a wear resistant fire-retardant material liner and a water cooling wall pipe, fills up technical blank of resisting the wear on metal by using a non metal coating at a high temperature of 900 DEG C, provides a new repairing method for a non metal wear resistant fire-retardant material liner, has simple construction process, can obviously improve working environment of workers, reduce the labor intensity and improve the working efficiency of maintaining a circulating fluid bed boiler heated surface metal pipe wall and the wear resistant fire-retardant material liner.

Owner:TONGDA REFRACTORY TECH CO LTD

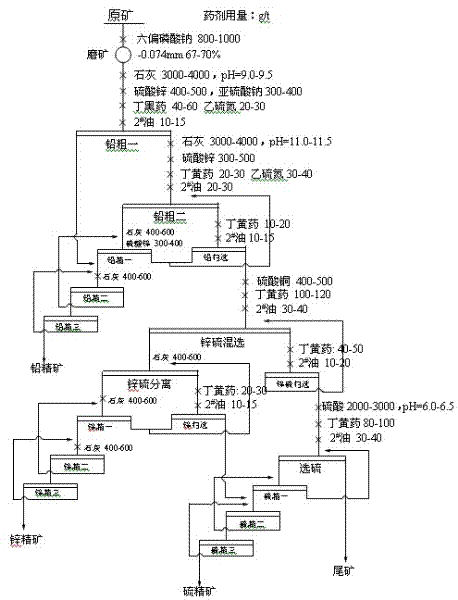

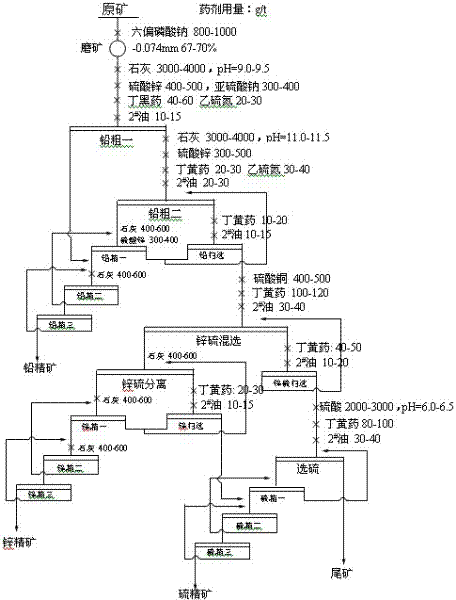

Technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity

The invention discloses a technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity. During grading of the lead and zinc sulfide ores, sodium hexametahposphate is taken as a dispersion agent and directly added into a ball mill, the ores are ground till the ores with the size of 0.074mm account for 67%-70%, lime is taken as an adjusting agent, zinc sulfate and sodium sulfite are taken as inhibitors, dithiophosphate BA and diethyldithiocarbamate are taken as collectors, and selective flotation of part of lead minerals with good floatability can be performed under low alkalinity; then xanthate and the diethyldithiocarbamate are taken as collectors, and the flotation of the lead minerals is further performed under high alkalinity; copper sulfate is added in lead flotation tailings for activation, butyl xanthate is further taken as the collector for flotation of zinc blende and part of pyrite, and zinc-sulfur separation flotation is further performed on zinc-sulfur mixed concentrate; and sulfuric acid is added in zinc flotation tailings for activation, and the xanthate is taken as the collector for flotation of the remaining pyrite. By adopting the technology, the lead-silver recovery rate can be improved, the using amount of lime and sulfuric acid can be reduced, the circulating amount of middlings can be reduced, the ore dressing cost can be reduced and the grade of the concentrate can be improved.

Owner:KUNMING UNIV OF SCI & TECH

Acetylene sludge aerated concrete block and preparation method thereof

ActiveCN102875070ALow bulk densityGood heat insulationSolid waste managementCeramicwareSODIUM METAPHOSPHATEParaffin wax

The invention provides an acetylene sludge aerated concrete block, which is prepared by processing the following raw materials in part by weight: 20-30 parts of acetylene sludge, 25-30 parts of coal ash, 5-10 parts of cement, 4-6 parts of modified attapulgite, 5-10 parts of water treatment sludge, 5-10 parts of soda residue, 5-10 parts of light calcium powder, 10-15 parts of lime, triethanolamine, 4-5 parts of gypse, 0.02-0.08 part of aluminium powder, oxidized paraffin wax soap, 0.01-0.02 part of calcium bicarbonate, 2-3 parts of chelky slag, 1-2 parts of lignocellulose, 0.3-0.5 part of water glass, 0.03-0.05 part of borax, 1-2 parts of sodium hexametaphosphate, 1-2 parts of hydroxy propyl methyl cellulose sodium and 1-2 parts of superfine polyvinyl alcohol, wherein the weight of the triethanolamine is 0.1-0.3 percent of that of the lime, and the weight of the oxidized paraffin wax soap is 3-5 percent of that of the aluminium powder. According to the invention, the acetylene sludge is added into the raw materials of the aerated concrete block, and meanwhile other conventional additives and modified nano additives are added; the aerated concrete block is prepared by adopting a proper technology and is low in cost and good in performance; the circulating economy effect of changing waste into valuable is realized; the pollution is reduced; and the prepared aerated concrete block has the characteristics of light volume weight, high thermal insulation performance, good sound absorption effect and high strength and can be used for non-bearing or bearing wall bodies.

Owner:广东合盛建筑工程有限公司

Liquid cement grinding aid

InactiveCN101318792AEasy to measureChange the production processSodium phosphatesTriterpenoid saponin

The invention relates to a liquid cement grinding aid which can obviously reduce the dosage of trolamine and does not contain urea. The grinding aid comprises the following compositions in weight percentage: 1 to 10 percent of trolamine, 5 to 10 percent of diglycol, 1 to 10 percent of trimeric sodium phosphate, 10 to 30 percent of molasses, 0 to 20 percent of sodium thiosulfate, 0 to 10 percent of air entraining component and the balance being water, wherein the air entraining compositions are triterpenoid saponin air entraining agent, sodium lignin sulfonate or a mixture of the triterpenoid saponin air entraining agent and the sodium lignin sulfonate at any proportion. The invention obviously reduces the dosage of the trolamine, does not contain the urea, lowers product cost and simultaneously facilitates the environmental protection. The sodium thiosulfate has the function of exciting mixed materials of cement and can improve the initial strength and the later strength of the cement, thereby effectively improving the service performance of the cement grinding aid. The triterpenoid saponin air entraining agent and the sodium lignin sulfonate have the action of the auxiliary aided grinding and simultaneously properly entrain air to reduce the water consumption of the cement standard consistence.

Owner:NANJING YONGNENG MATERIALS

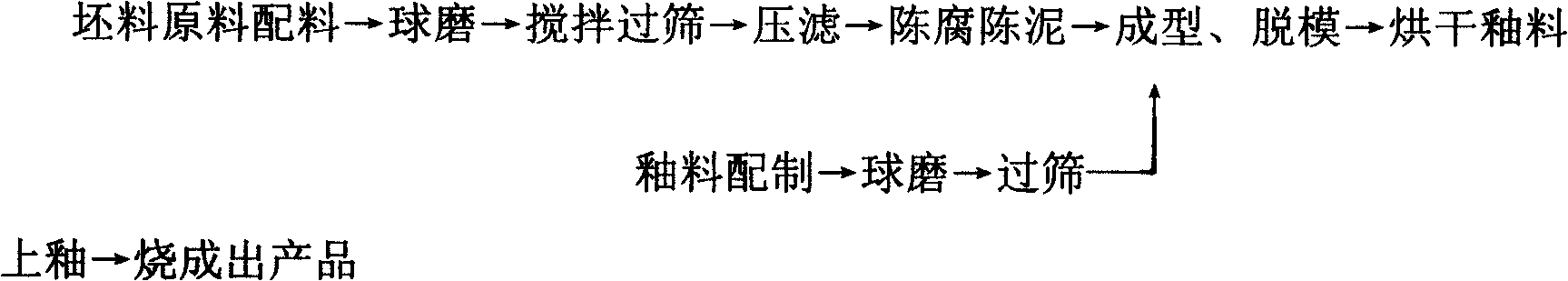

Heat resisting red porcelain chinaware

The invention discloses a heat-resistant purple sand ceramic tool. The manufacture material includes stock and glaze; wherein, the stock is formed by the following components according to weight percentage: 1 to 15 percent of purple sand soil, 25 to 38 percent of triphane, 5 to 30 percent of bauxite clay, 5 to 30 percent of kaolin, 2 to 6 percent of talc, 5 to 20 percent of alum clay, 5 to 20 percent of grog and 5 to 25 percent of attaclay; the glaze is formed by the following components according to weight percentage: 20 to 35 percent of paste, 10 to 25 percent of petalite, 15 to 25 percent of grog, 8 to 15 percent of clinker, 12 to 25 percent of yellow earth, 6 to 9 percent of iron red, 0 to 0.15 percent of trimeric sodium phosphate and 1 to 2 percent of water glass. The adoption of triphane in the material of ceramics can largely enhance the heat-resistant capability, and the ceramics can be heated by electricity or fire and even the firing without water causes no crack. The heat-resistant purple sand ceramics can be adopted either as tableware or as drinking vessel.

Owner:熊禄生

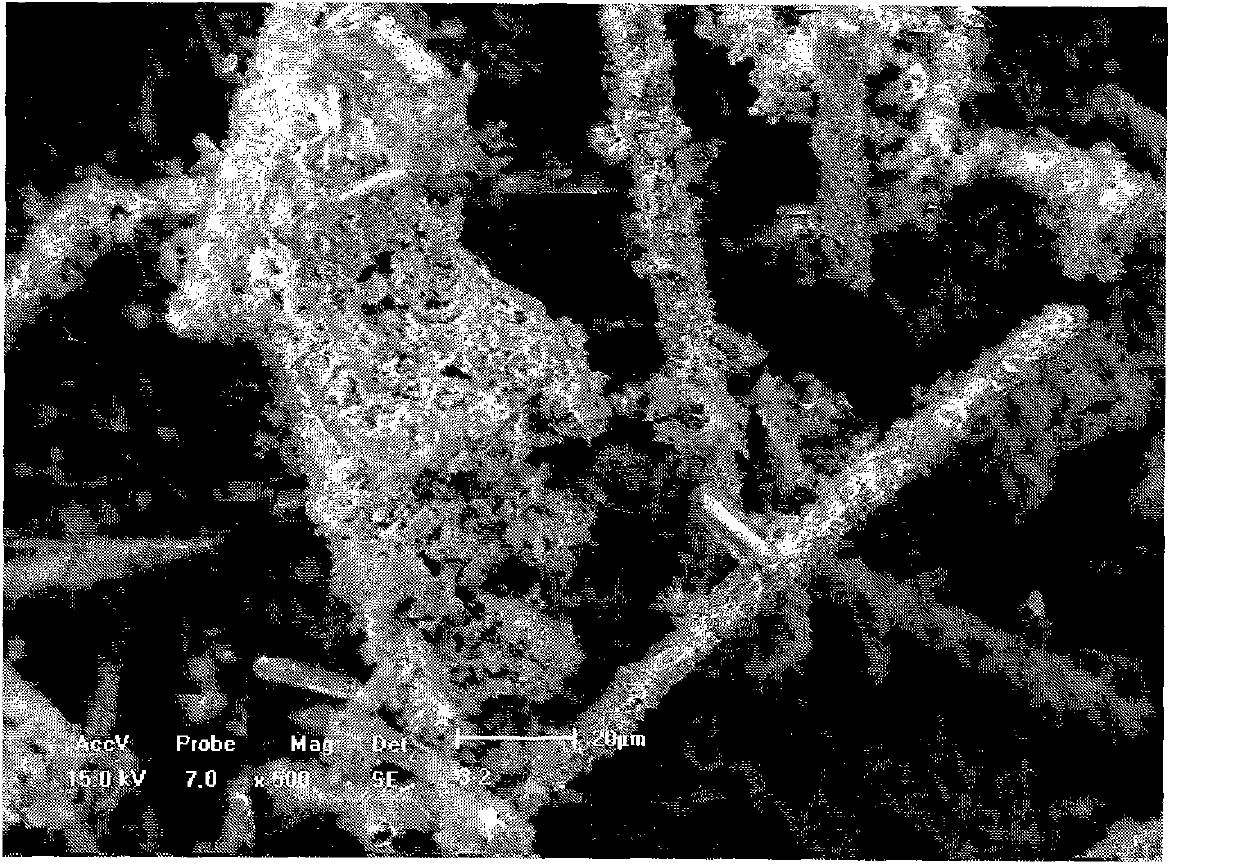

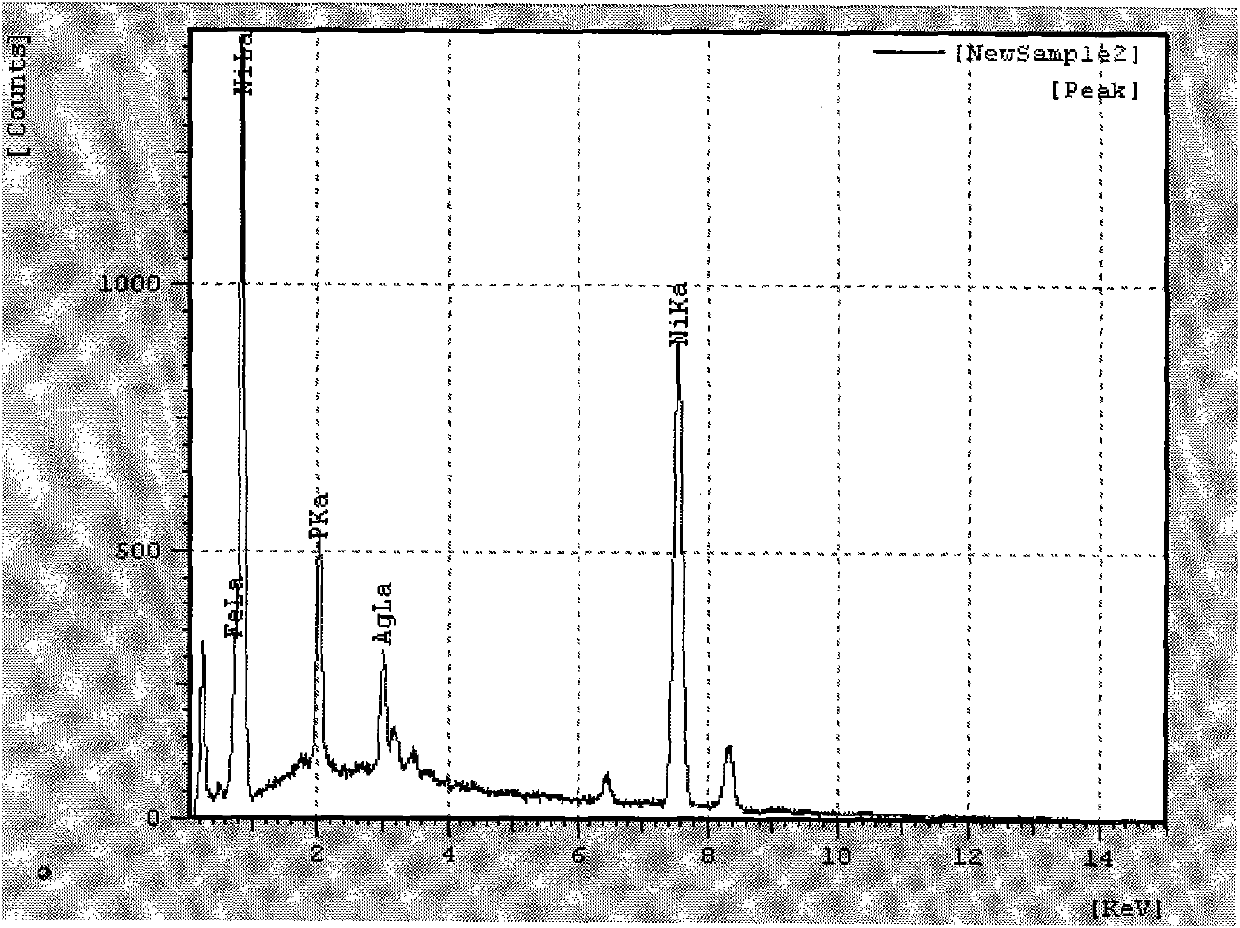

Chemical nickel-plating method for carbon fiber

InactiveCN102086517ALow costEasy to operateLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a chemical nickel-plating method for carbon fiber, which is designed for overcoming the disadvantages of high cost, a large number of process steps and poor operability existing in the prior art. In the method, a chemical plating process is adopted; and a pre-treatment is performed on a raw material and chemical plating solution is prepared before the chemical plating. The pre-treatment process comprises the steps of: calcining by using a muffle furnace to remove glue; soaking in solution of absolute ethanol to remove oil; performing surface roughening and activating treatment by using solution of sodium hydroxide and solution of silver ammonia; sensitizing by using a sensitizer, namely stannous chloride; and performing surface reduction by using solution of sodium hypophosphite. The chemical plating solution consists of nickel sulfate hexahydrate, sodium hypophosphite, sodium pyrophosphate and sodium citrate. The chemical nickel-plating on the carbon fiber is finished by placing a pre-treatment product of the chemical plating into the chemical plating solution, and reacting, standing, filtering and drying under a chemical plating condition. The method has the characteristics that: the product has a uniform surface, a compact plating layer and uniform particles.

Owner:沈阳临德陶瓷研发有限公司

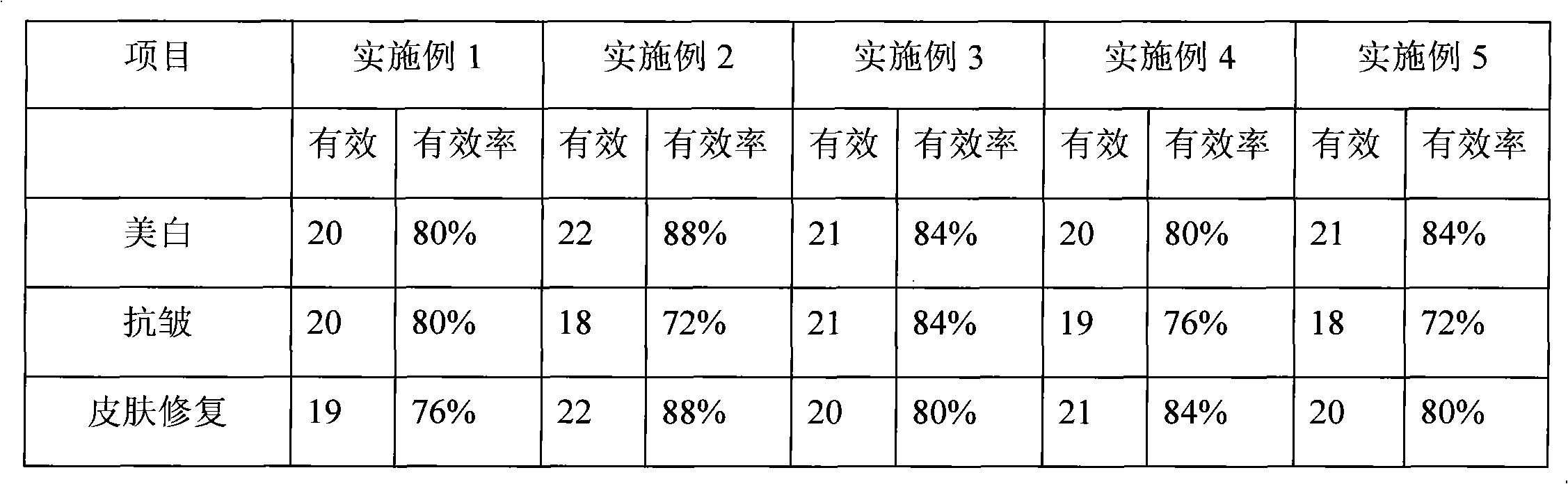

Whitening cosmetic product, preparation method and application thereof

ActiveCN101816620AGood whitening effectFor long-term storageCosmetic preparationsToilet preparationsVitamin CSide effect

The invention discloses a whitening cosmetic product, a preparation method and application thereof. The whitening cosmetic product comprises the components in percentage by mass: 0.00001to 0.001 percent of recombined human angiogenin, 0.00001 to 0.001 percent of metallothionein, 0.00001 to 0.001 percent of human epidermal growth factor, 0.00001to 0.001 percent of IL-1RA, 0.1 to 0.5 percent of superoxide dismutase, 0.1 to 0.5 percent of low molecular liquaemin, 1 to 5 percent of arbutin, 5 to 25 percent of stabilizer, 0.02 to 0.3 percent of hyaluronic acid, 0.5 to 5 percent of methylpropanediol, 0.5 to 3.5 percent of lactobacillus / mung bean fermentation liquid, 0.5 to 5 percent of dissolved protease, 0.5 to 8 percent of vitamin C sodium phosphate, 0.3 to 0.7 percent of 1,2-hexanediol or 1,2-capryl glycol, 1 percent to 5 percent of oat Beta-glucan, 1 to 5 percent of soy isoflavone and the balance of water. The whitening cosmetic product can be preserved for a long time, has no side effect on skin and is suitable for long term use.

Owner:广州泰润合投资有限公司

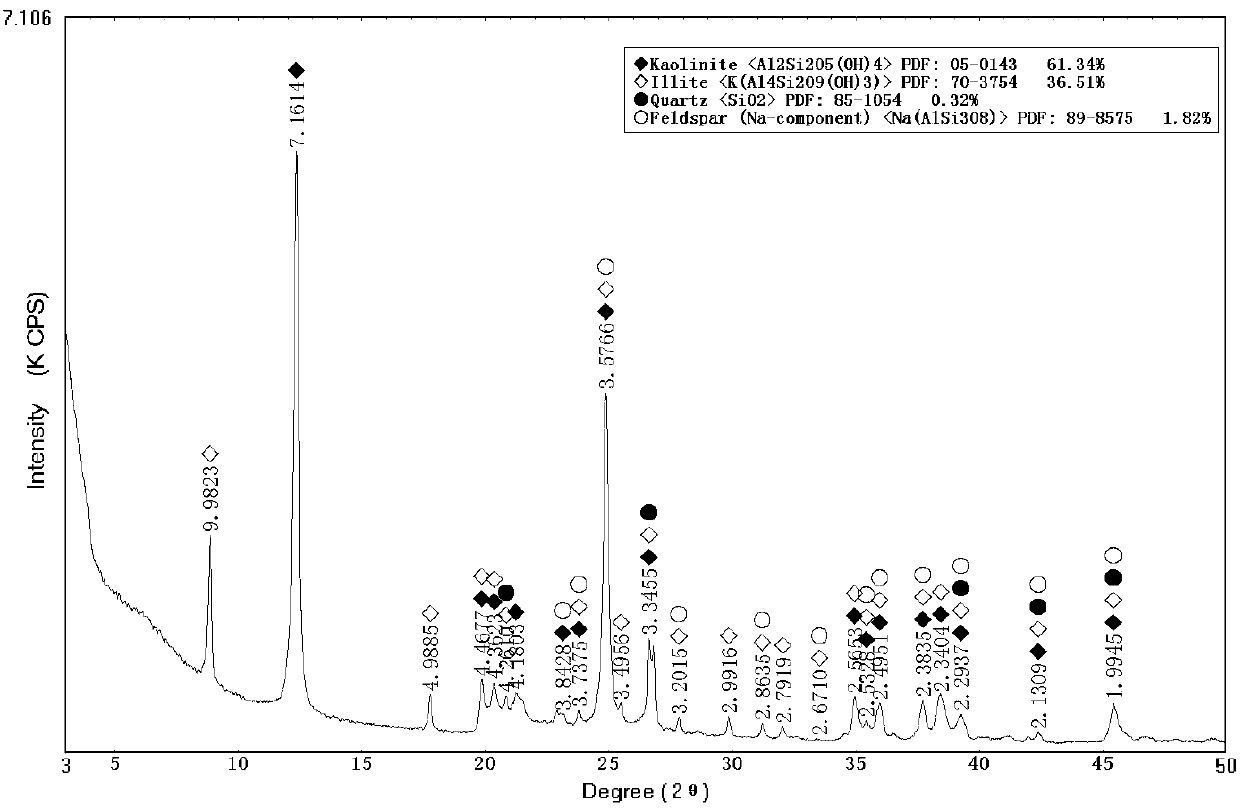

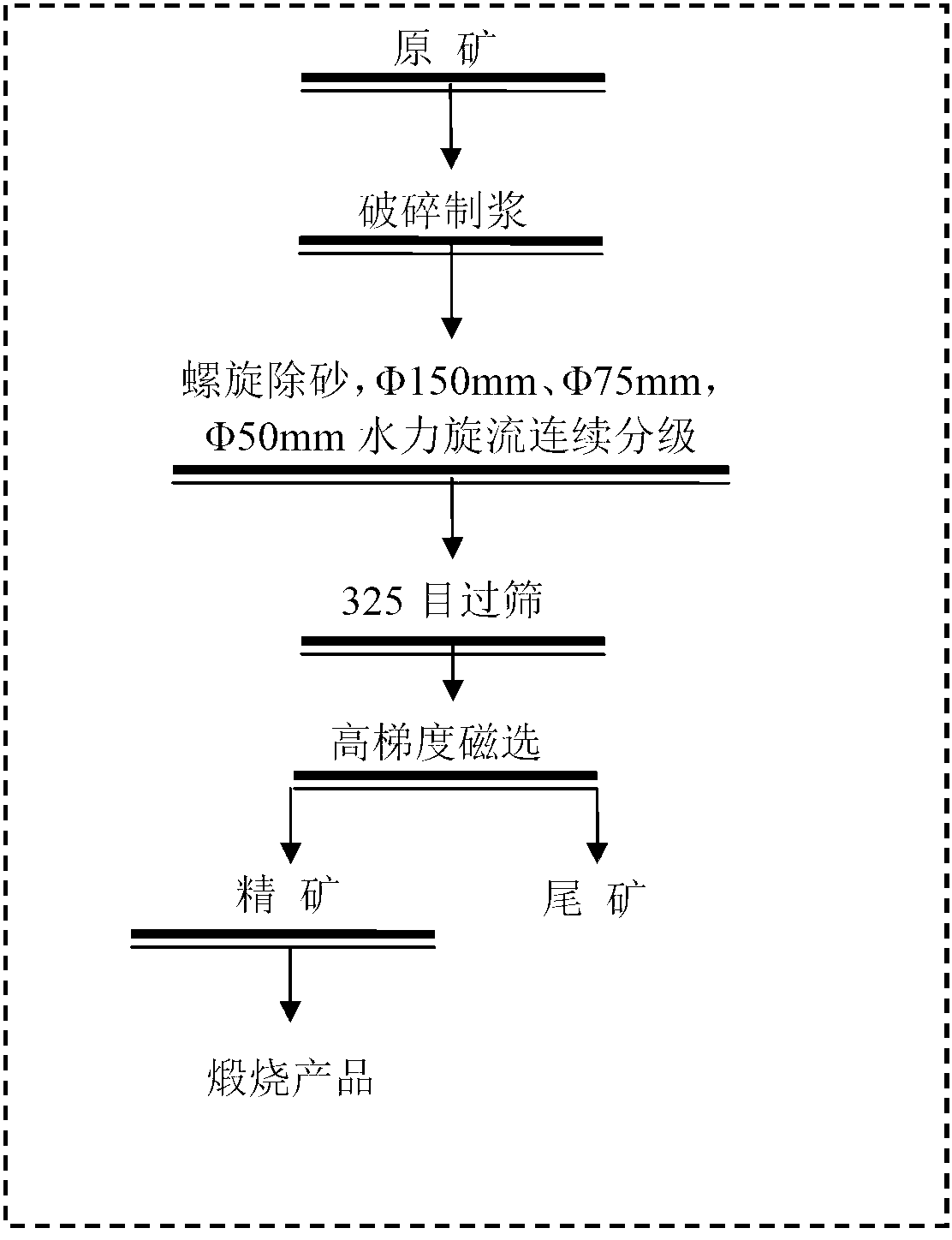

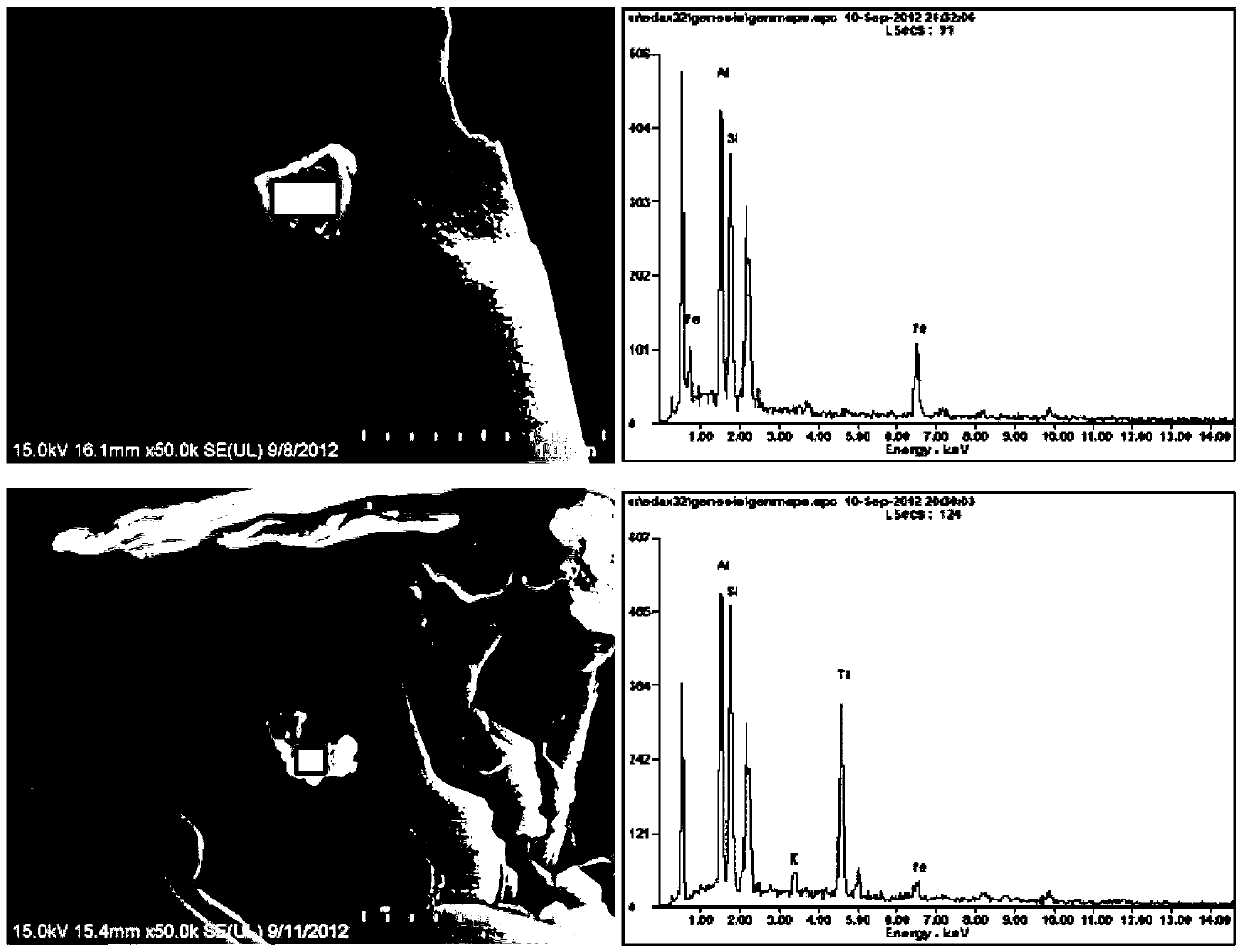

Technique for efficiently removing iron from kaolin

The invention relates to a technique for efficiently removing iron from kaolin by magnetic separation, which is characterized by comprising the following steps: (1) purifying kaolin raw ore to obtain a magnetic separation raw material; (2) adding water to the magnetic separation raw material obtained in the step (1) to prepare a mixed slurry with the solid content of 10-20 wt%, adding sodium hexametaphosphate accounting for 0.2-0.6 wt% of the magnetic separation raw material, slurrying, stirring for 20 minutes, and passing through a 325-mesh wet sieve; (3) carrying out high-gradient magnetic separation on the undersize slurry of the 325-mesh sieve in the step (2): while controlling the magnetic field intensity of the high-gradient magnetic separator at 1.0-1.8T and the slurry flow rate at 0.8-1.8cm / s, the slurry is subjected to magnetic separation by the high-gradient magnetic separator to obtain a concentrate slurry; (4) adding alum accounting for 1-6 wt% of the concentrate slurry into the concentrate slurry obtained in the step (3), flocculating, carrying out pressure filtration, drying, and packaging to obtain a magnetic concentrate; and (5) calcining the magnetic concentrate obtained in the step (4) to obtain the calcined kaolin. The technique has the advantages of high iron removal efficiency and obvious whitening effect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com