Chemical nickel-plating method for carbon fiber

A technology of electroless nickel plating and carbon fiber, applied in liquid chemical plating, coating, metal material coating process and other directions, can solve the problems of many process steps, poor operability, easy volatilization, etc., to achieve simple process, low cost, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

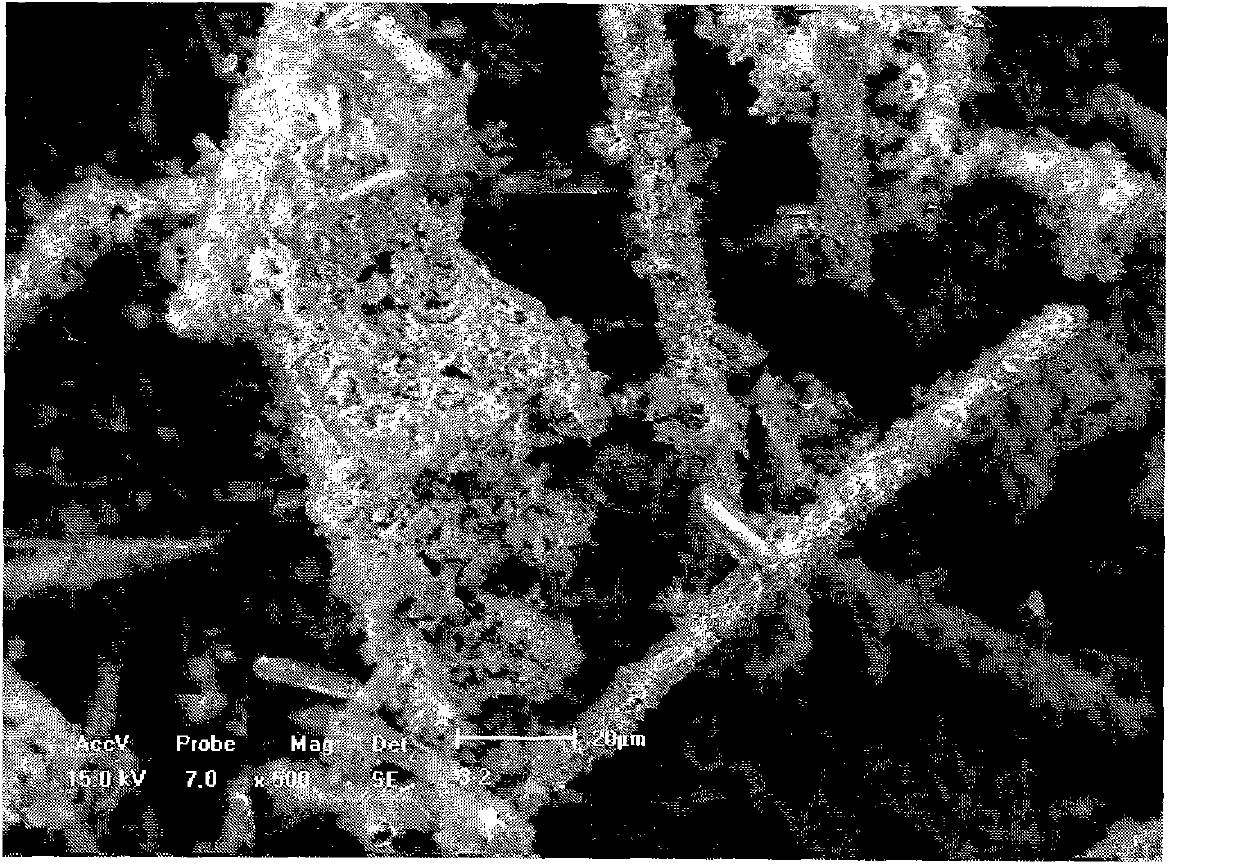

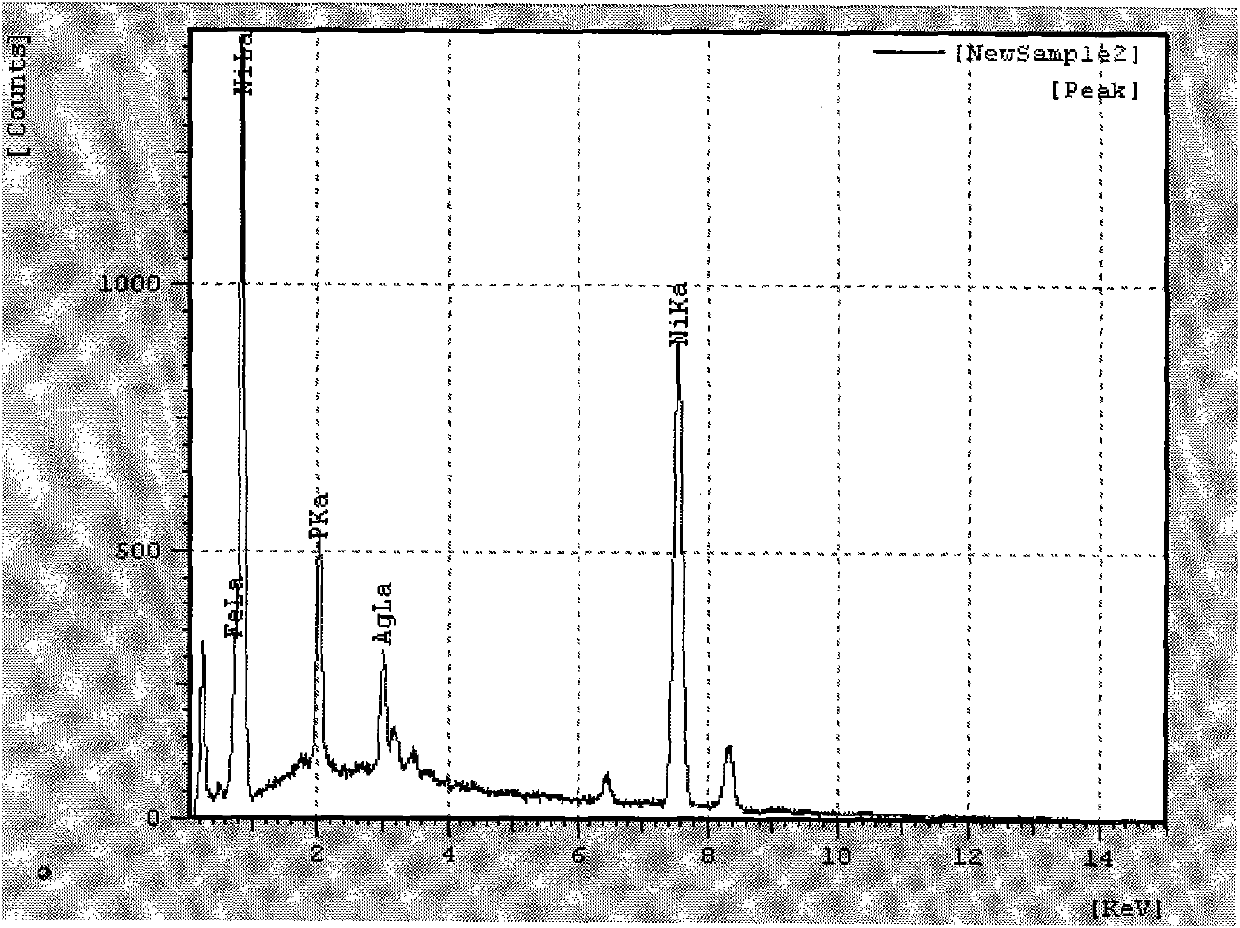

Image

Examples

Embodiment 1

[0036] A kind of electroless nickel plating method of carbon fiber:

[0037] The first step: pre-treatment of the substrate

[0038] Put the carbon fiber in a muffle furnace, burn it at a temperature of 400°C for 30 minutes to remove the glue, then soak it in absolute ethanol at a room temperature of 25°C and a power of 500W, and disperse with magnetic stirring for 30 minutes. Obtain the first reaction solution; add 900ml of deionized water to every 100ml of the first reaction solution for dilution; remove the supernatant after settling for 80min, and obtain the first product after repeating 2-3 times; coarsening treatment, at 30g / L Filter after magnetic stirring dispersion reaction 30min in sodium hydroxide (NaOH) solution, adjust the vacuum tightness of filter vacuum instrument to be-0.1MPa, obtain the second product after suction filtration time 8min; Sensitization treatment, at 30g / L stannous chloride (SnCl 2 2H 2 (0) immerse in the sensitizing solution, filter after ma...

Embodiment 2

[0042] A kind of electroless nickel plating method of carbon fiber, its preparation steps are as follows:

[0043] The first step: pre-treatment of the substrate

[0044] Calcinate the carbon fibers in a furnace at 300°C for 5min; soak in absolute ethanol for 60min; at room temperature, stir in 30g / L NaOH solution for 30min and then filter; 2 Immerse in the sensitization solution for 30min, filter; configure silver ammonia solution, stir at room temperature for 2h, filter; in 20g / L NaH 2 PO 2 Reduce in the solution for 5min, filter;

[0045] The second step: electroless plating treatment

[0046] Configure the plating solution (28g / L NiSO 4 6H 2 O, 26g / L NaH 2 PO 2 , 26g / L NaAC, 15g / L sodium citrate), pour the carbon fiber into the plating solution, heat to 80°C while stirring, and react for 2h. Others are the same as embodiment 1.

Embodiment 3

[0048] A kind of electroless nickel plating method of carbon fiber, its preparation steps are as follows:

[0049] The first step: pre-treatment of the substrate

[0050] Calcinate the carbon fibers in a furnace at 400°C for 5min; soak in absolute ethanol for 60min; at room temperature, stir in 20g / L NaOH solution for 30min and then filter; 2 Immerse in the sensitization solution for 30min, filter; configure silver ammonia solution, stir at room temperature for 1h, filter; in 10g / L NaH 2 PO 2 The solution was reduced for 3 minutes and filtered.

[0051] The second step: electroless plating treatment

[0052] Configure the plating solution (40g / L NiSO 4 6H 2 O, 40g / L NaH 2 PO 2 , 40g / L NaAC, 30g / L sodium citrate), pour the carbon fiber into the plating solution, heat to 90°C while stirring, and react for 1h. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com