Patents

Literature

121 results about "Nickel sulfate hexahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel sulfate occurs as the rare mineral retgersite, which is a hexahydrate. The second hexahydrate is known as nickel hexahydrite (Ni,Mg,Fe)SO4·6H2O. The heptahydrate, which is relatively unstable in air, occurs as morenosite.

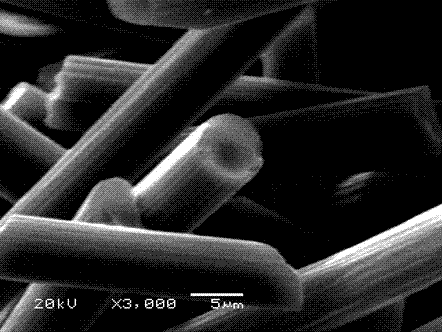

Chemical nickel-plating method for carbon fiber

InactiveCN102086517ALow costEasy to operateLiquid/solution decomposition chemical coatingFiberCarbon fibers

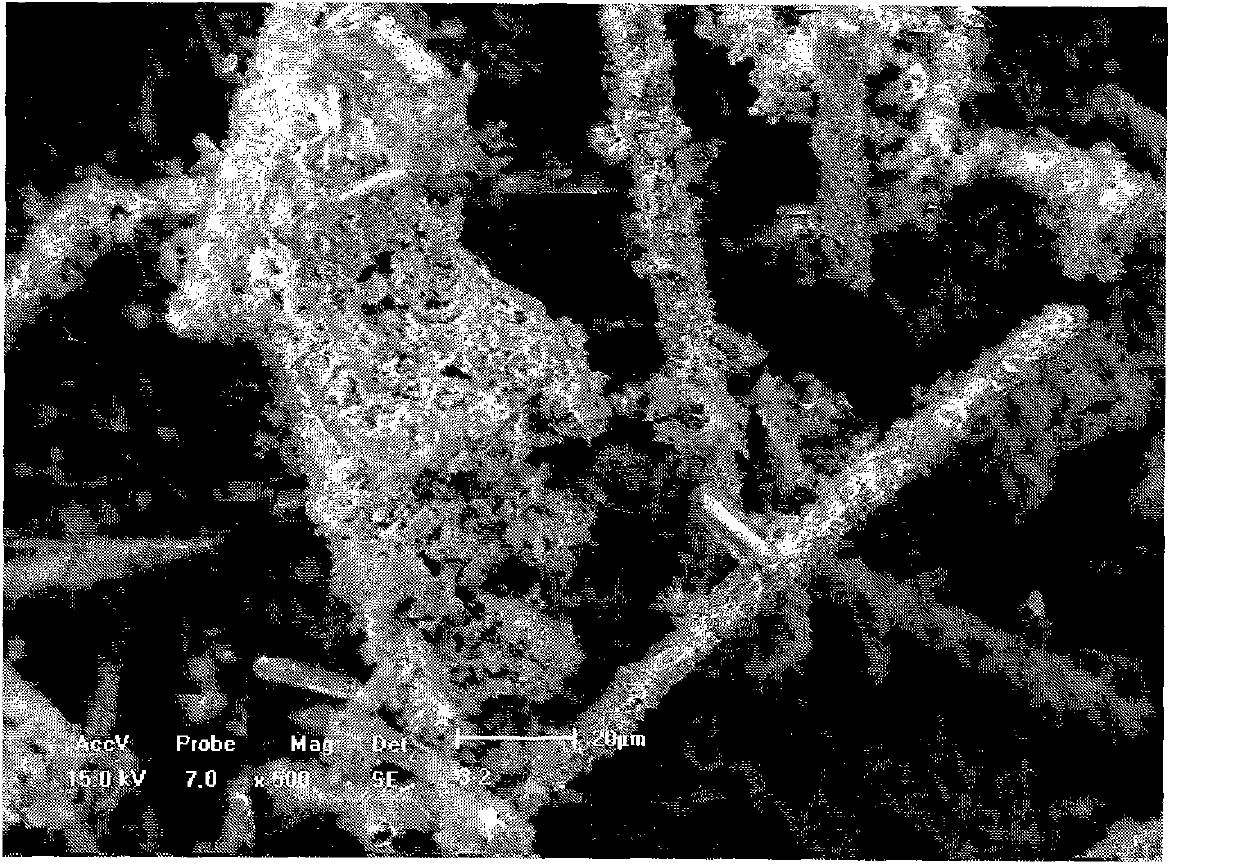

The invention discloses a chemical nickel-plating method for carbon fiber, which is designed for overcoming the disadvantages of high cost, a large number of process steps and poor operability existing in the prior art. In the method, a chemical plating process is adopted; and a pre-treatment is performed on a raw material and chemical plating solution is prepared before the chemical plating. The pre-treatment process comprises the steps of: calcining by using a muffle furnace to remove glue; soaking in solution of absolute ethanol to remove oil; performing surface roughening and activating treatment by using solution of sodium hydroxide and solution of silver ammonia; sensitizing by using a sensitizer, namely stannous chloride; and performing surface reduction by using solution of sodium hypophosphite. The chemical plating solution consists of nickel sulfate hexahydrate, sodium hypophosphite, sodium pyrophosphate and sodium citrate. The chemical nickel-plating on the carbon fiber is finished by placing a pre-treatment product of the chemical plating into the chemical plating solution, and reacting, standing, filtering and drying under a chemical plating condition. The method has the characteristics that: the product has a uniform surface, a compact plating layer and uniform particles.

Owner:沈阳临德陶瓷研发有限公司

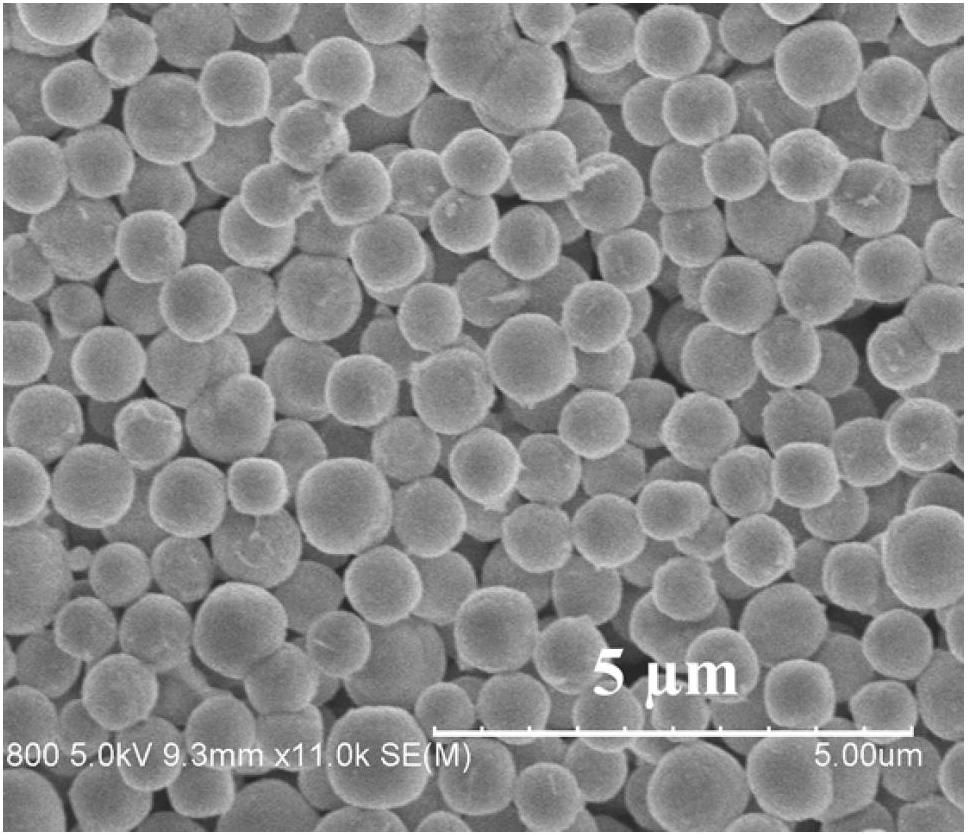

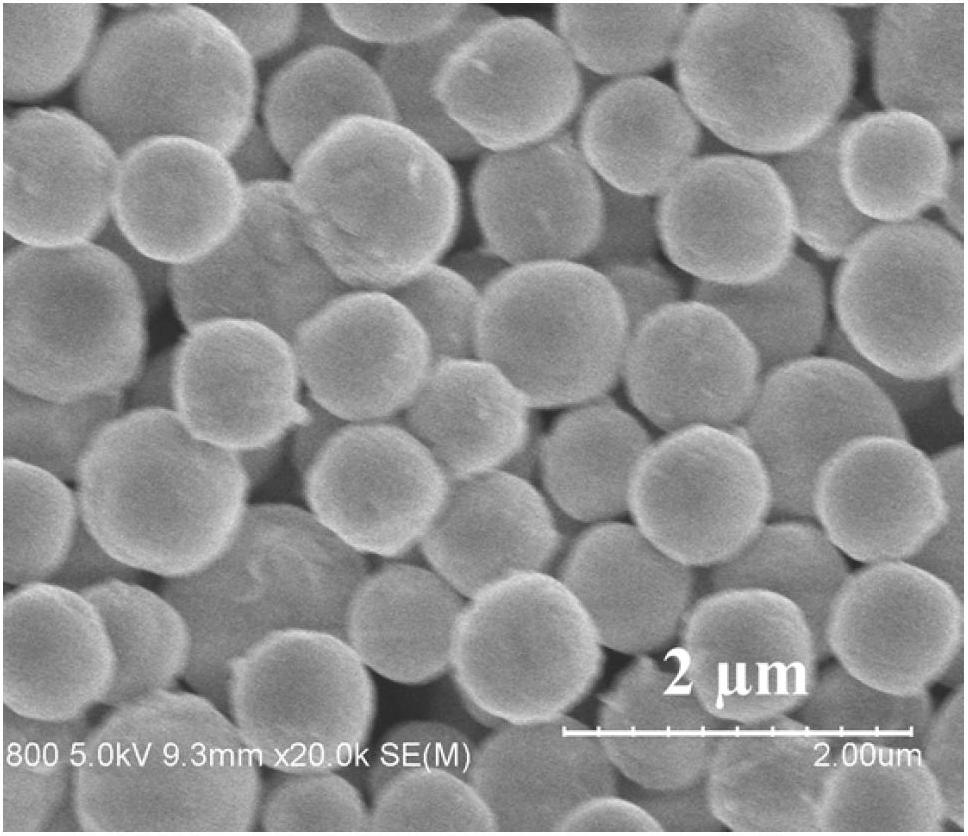

Preparation method of porous nickel oxide/tin dioxide micro/nano spheres

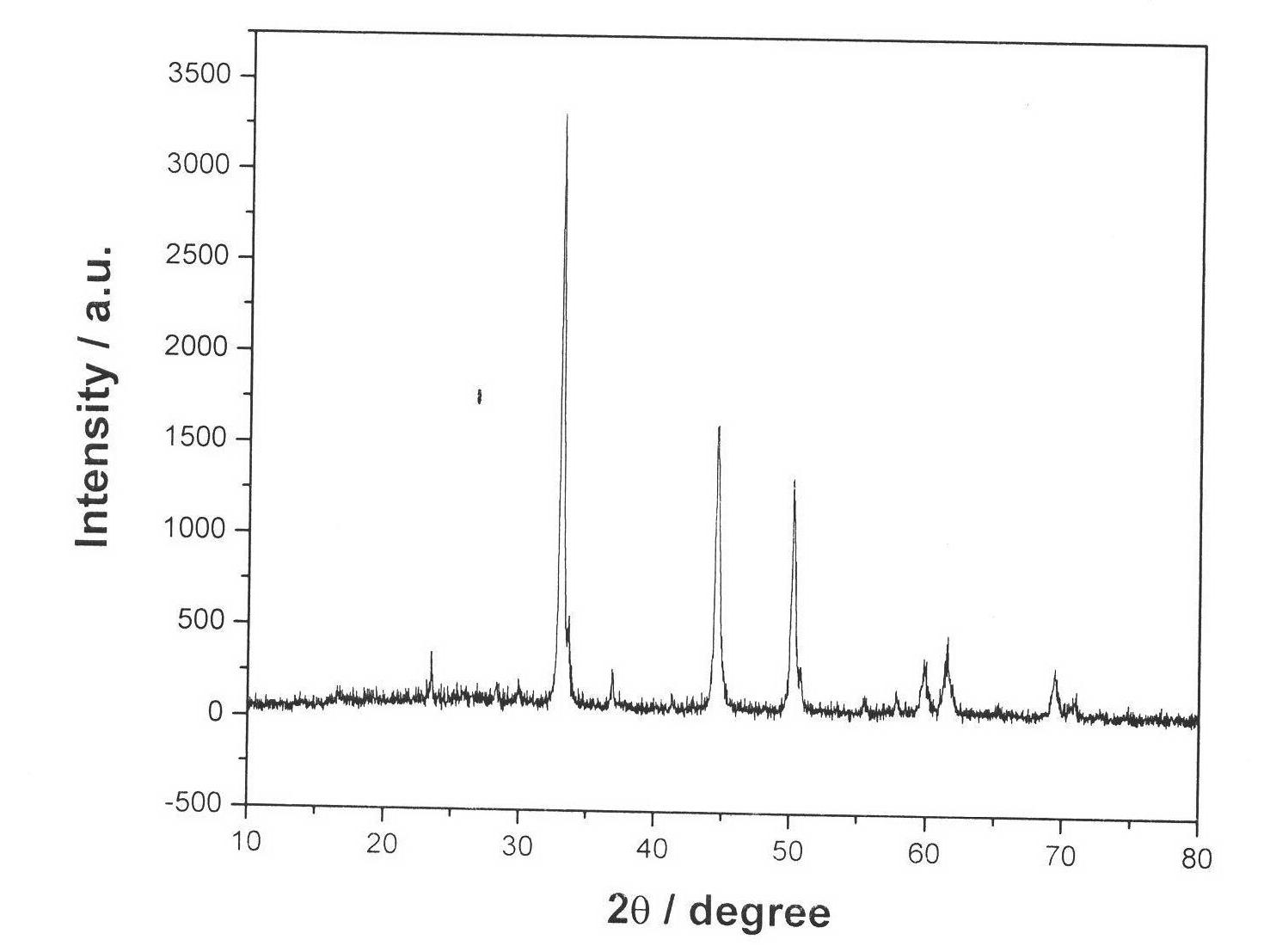

InactiveCN102680539AHigh purity powderPorous pore size distribution is uniformMaterial resistanceTin dioxideMicro nano

The invention discloses a preparation method of porous nickel oxide / tin dioxide micro / nano spheres, which comprises the following steps: stirring tin tetrachloride pentahydrate, nickel sulfate hexahydrate, sodium hydroxide and ammonia water which are used as raw materials, heating, separating, washing, drying and the like to obtain micro / nano spherical hydroxy nickel stannate; and roasting a micro / nano spherical NiSn(OH)6 precursor at high temperature, and cooling to respectively obtain porous micro / nano spherical NiO / SnO2 powder. The micro / nano spherical NiO / SnO2 product prepared by the method disclosed by the invention is light green powder, and has the advantages of large specific area and good product quality. The impedance gas sensing element prepared from the micro / nano spherical NiO / SnO2 powder has high sensitivity, and the sensitivity S value for 100ppm methylbenzene and formaldehyde gases is respectively up to 19.8 and 27.6.

Owner:ANHUI NORMAL UNIV

Non-toxic environment-friendly normal temperature steel nigrescence treating agent and preparation method thereof

InactiveCN102994996APromote environmental protectionQuality improvementMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a non-toxic environment-friendly normal temperature steel nigrescence treating agent, which consists of the following components by mass percent: 1-5% of blue copperas, 1-4% of zinc dihydrogen phosphate, 1-6% of zinc nitrate, 0.1-0.3% of citric acid, 1-2% of EDTA(ethylene diamine tetraacetic acid)-disodium, 1-6% of sodium thiosulfate, 1-4% of ammonium molybdate, 0.5-1.5% of nickel sulfate hexahydrate, 0.1-0.6% of hydroquinone, 0.5-1.5% of potassium dichromate and the balance of water. The steps of the preparation method is as follows in sequence: firstly adding water calculated and weighted into a reaction kettle, starting a stirrer, controlling the rotated speed within 60 turns per minute, then sequentially and slowly adding the blue copperas, nickel sulfate hexahydrate, citric acid, zinc dihydrogen phosphate, zinc nitrate, EDTA-disodium, sodium thiosulfate, ammonium molybdate, hydroquinone, and potassium dichromate that are calculated and weighted into the reaction kettle, wherein each raw material added into the reaction kettle needs to be stirred for complete dissolution so as to obtain yellowgreen white out uniform liquid finally.

Owner:DALIAN SANDAAOKE CHEM

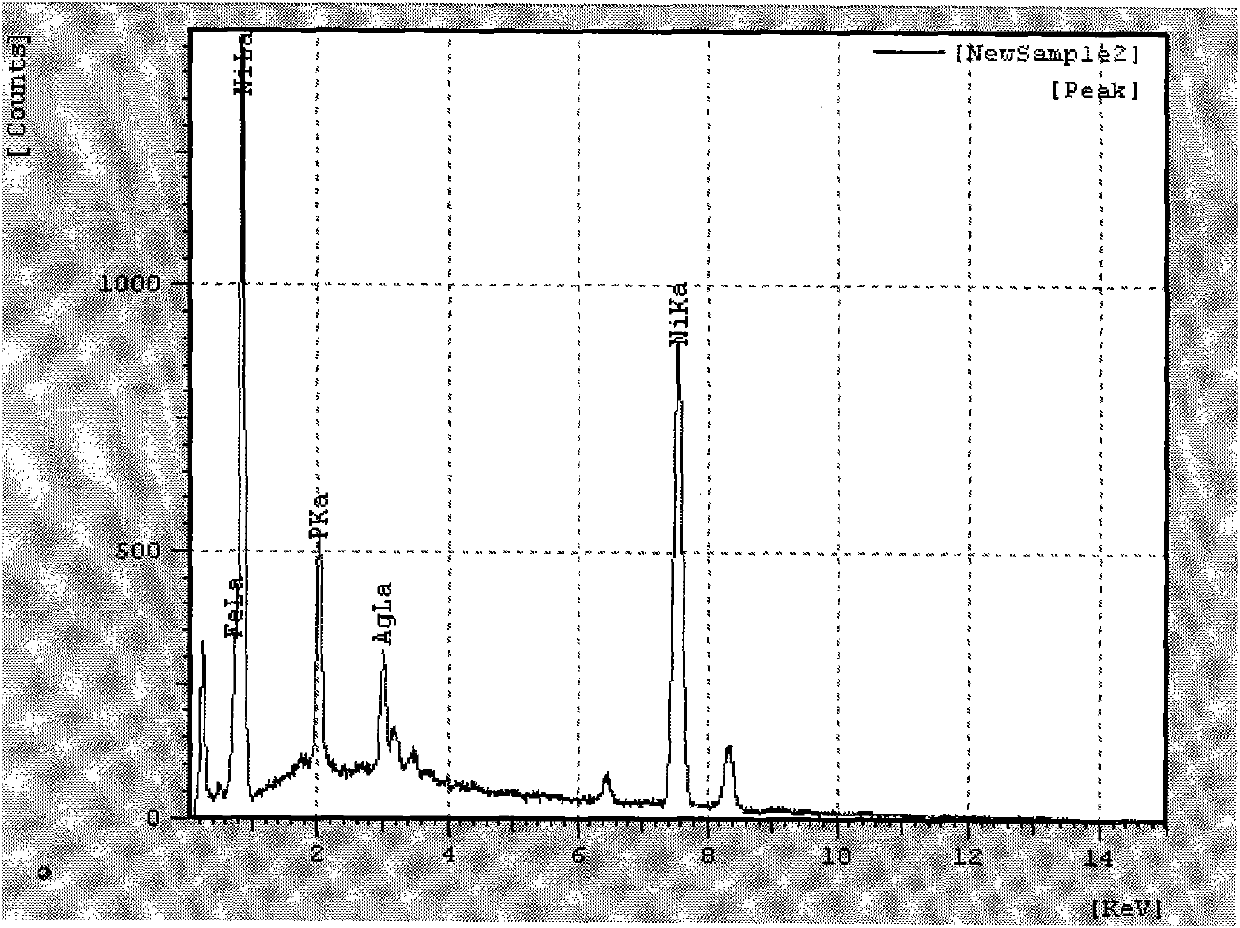

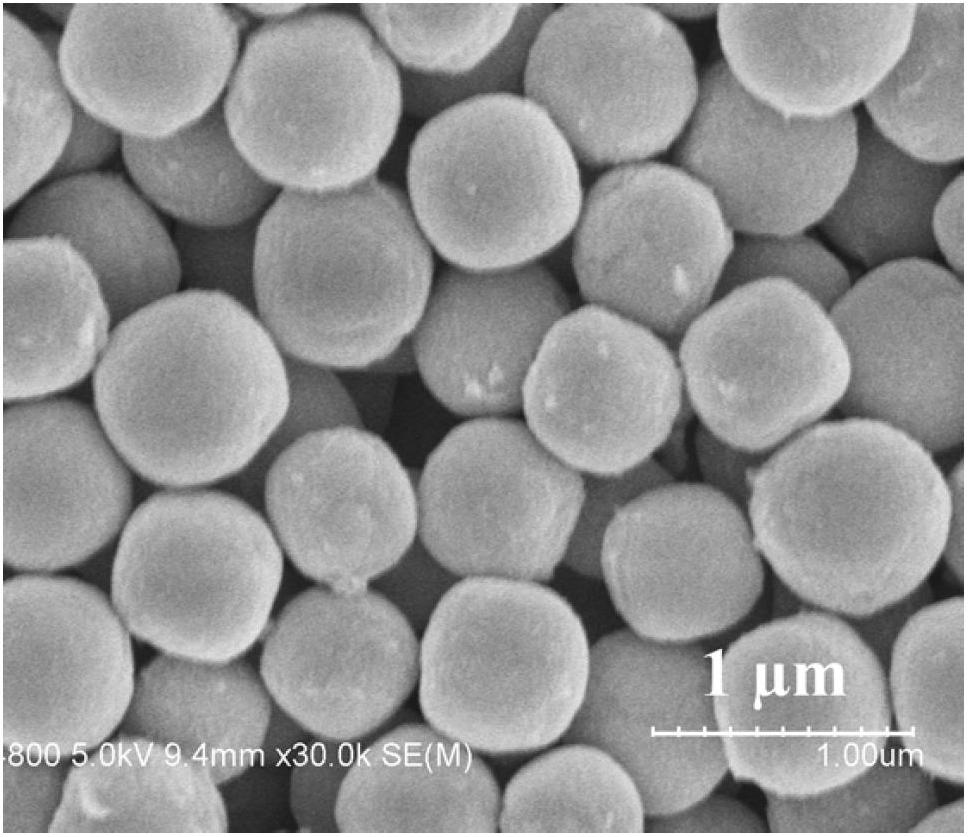

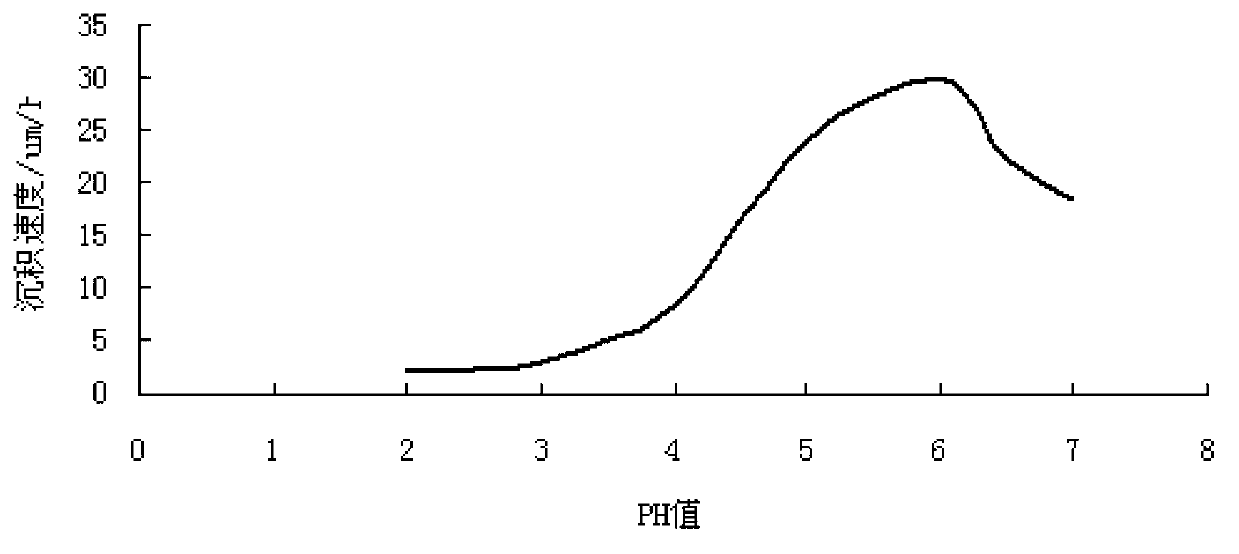

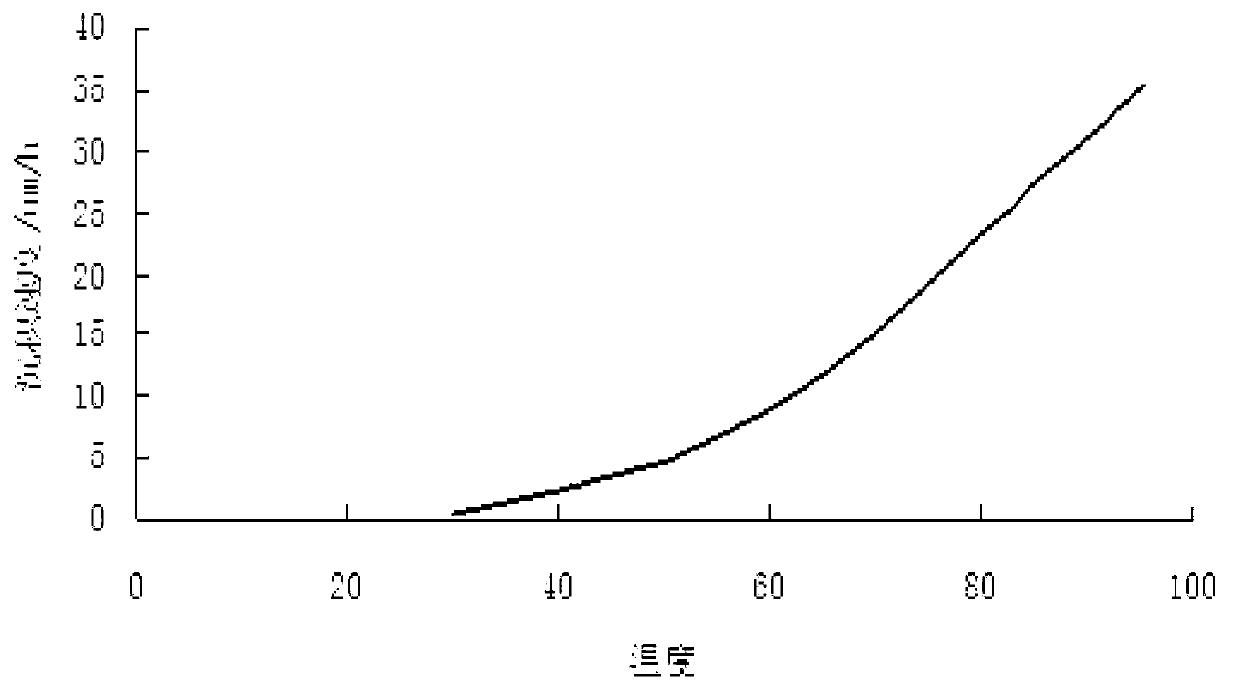

Method for producing surface-activated superfine nickel powder

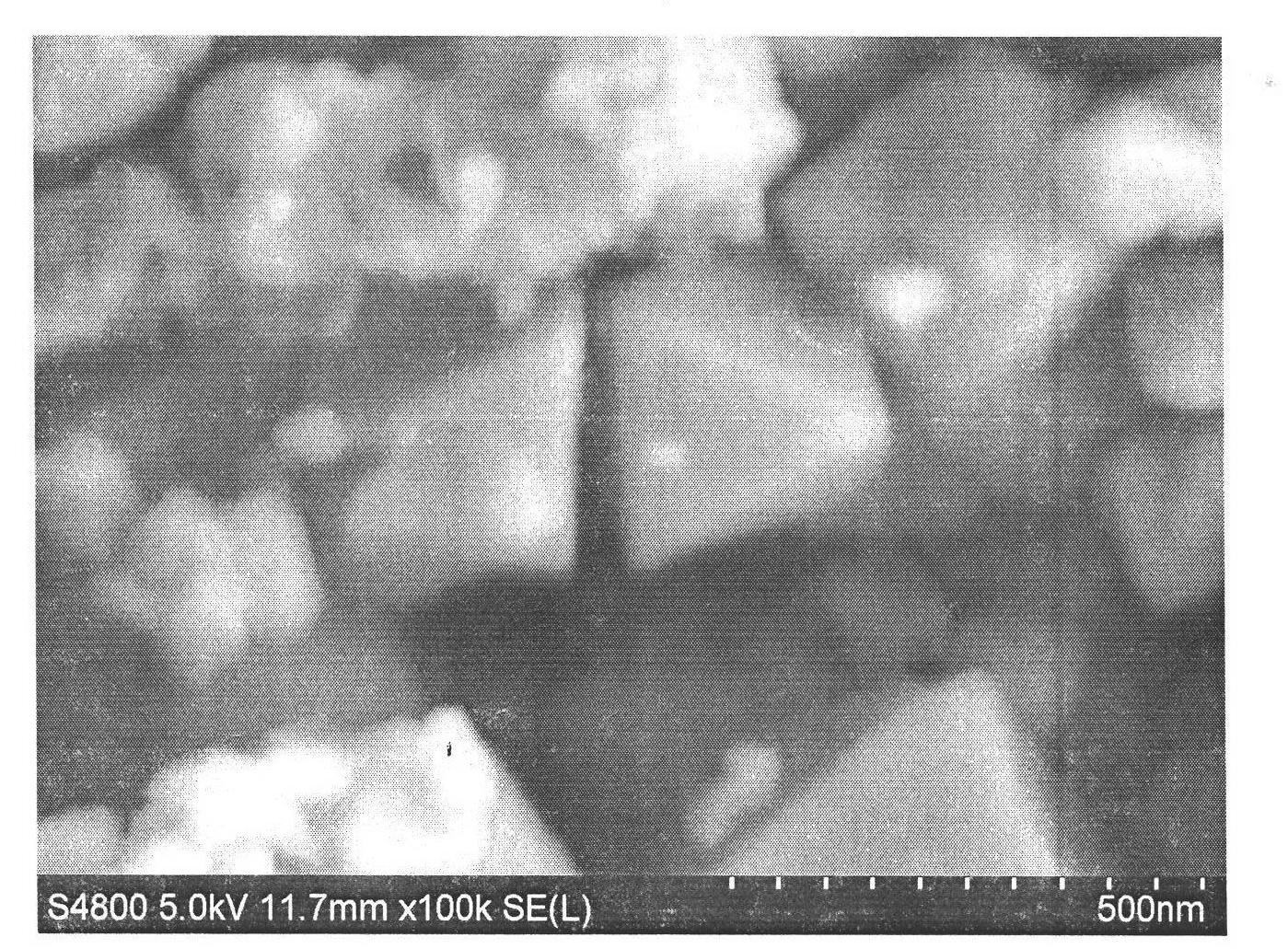

InactiveCN101797650AGuaranteed purityEasy for industrial implementationActive agentNickel sulfate hydrate

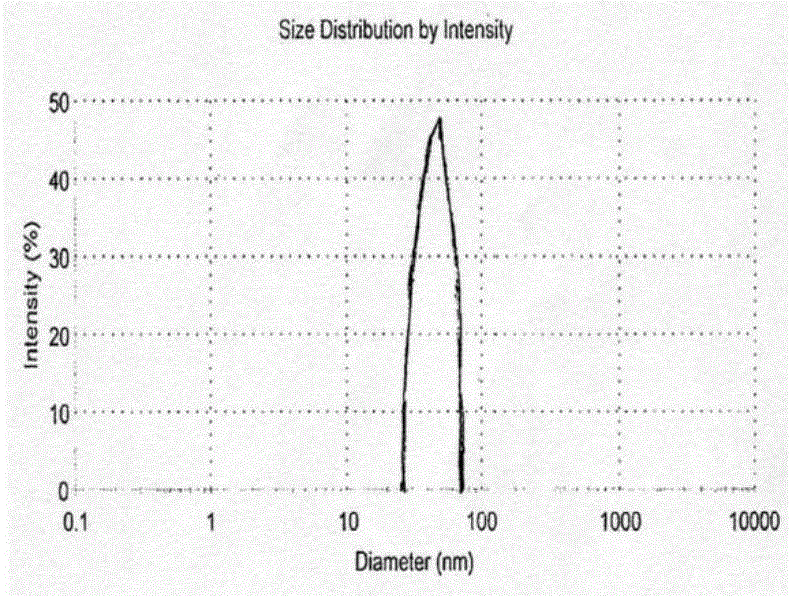

The invention discloses a method for producing surface-activated superfine nickel powder. The process comprises the following steps of: dissolving nickel sulfate hexahydrate in water; reacting the obtained solution with prepared alkaline liquor to produce nickel hydroxide precipitate; adding a certain amount of noble metal ruthenium trichloride into the precipitate so as to activate the surface of a precursor; directly adding nickel hydroxide paste into a pressure container for liquid-phase hydrogen reduction without being filtered and washed, wherein the temperature and pressure for the liquid-phase hydrogen reduction are controlled to be fixed values; performing liquid-solid separation and washing the solid after the reaction is performed for a fixed time; and drying the solid in a baking box and transferring the dried solid into a hydrogen reducing furnace for reduction at the temperature of between 300 and 500 DEG C for a certain time so as to obtain the superfine nickel powder. The method has the advantages that: the conventional high-temperature and high-pressure hydrogen reduction conditions are weakened by adopting a liquid-solid combined reduction method so as to make large-scale industrial production easy; and simultaneously, the noble metal consumption cost is reduced and the average particle diameter of the prepared superfine nickel powder is less than 2 microns because the noble metal ruthenium trichloride is used as an active agent in place of palladium chloride.

Owner:KUNMING INST OF PRECIOUS METALS

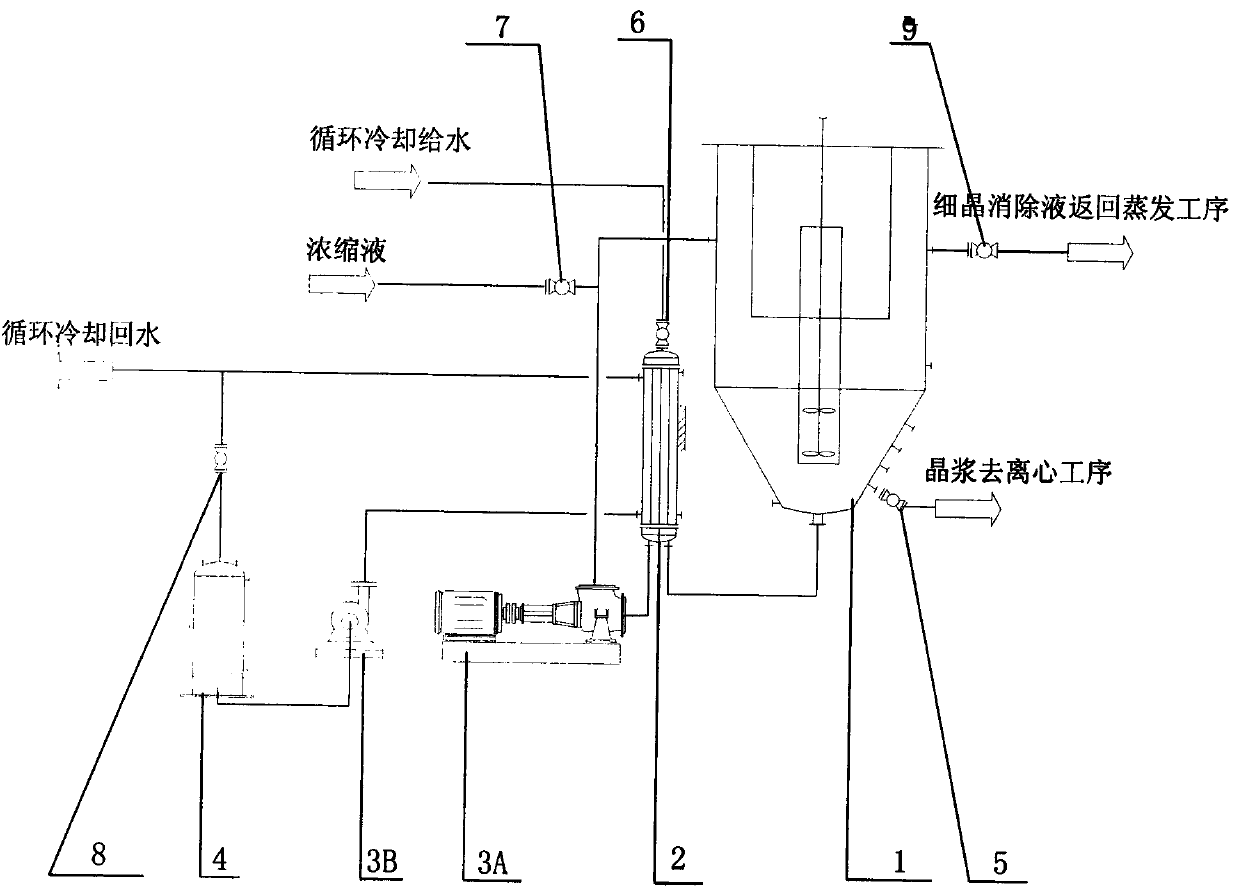

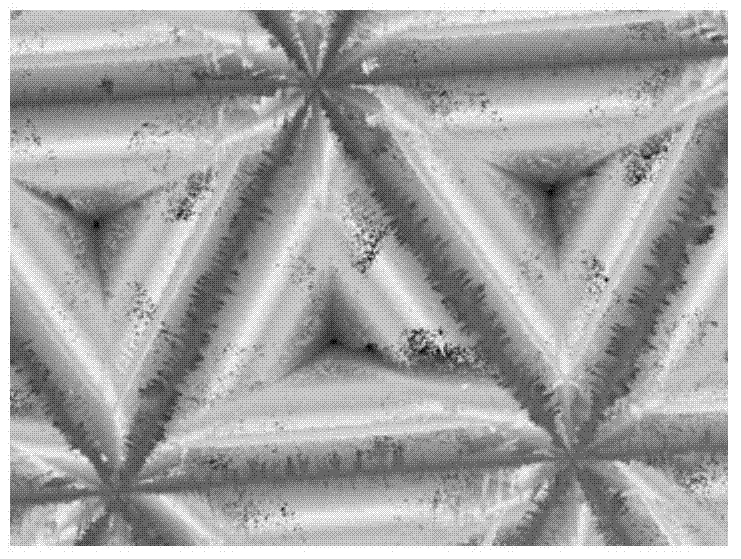

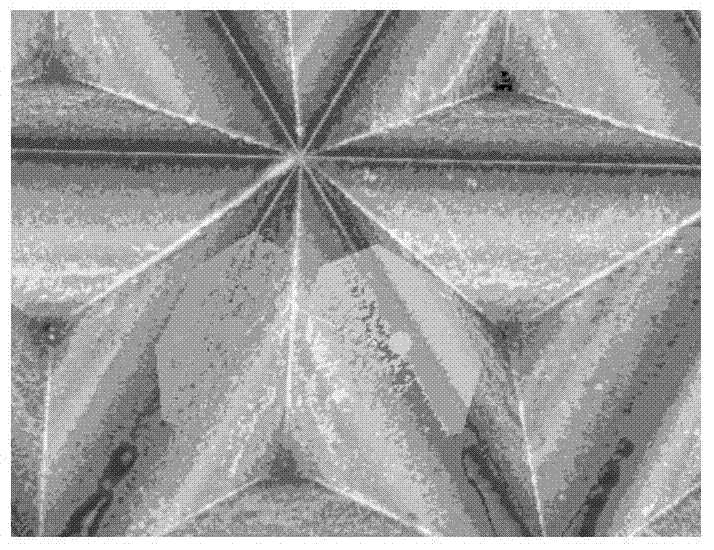

Nickel-cobalt sulfate continuous-crystallizing process

ActiveCN104192917AImprove energy savingRealize continuous productionNickel sulfatesEvaporationSlurry

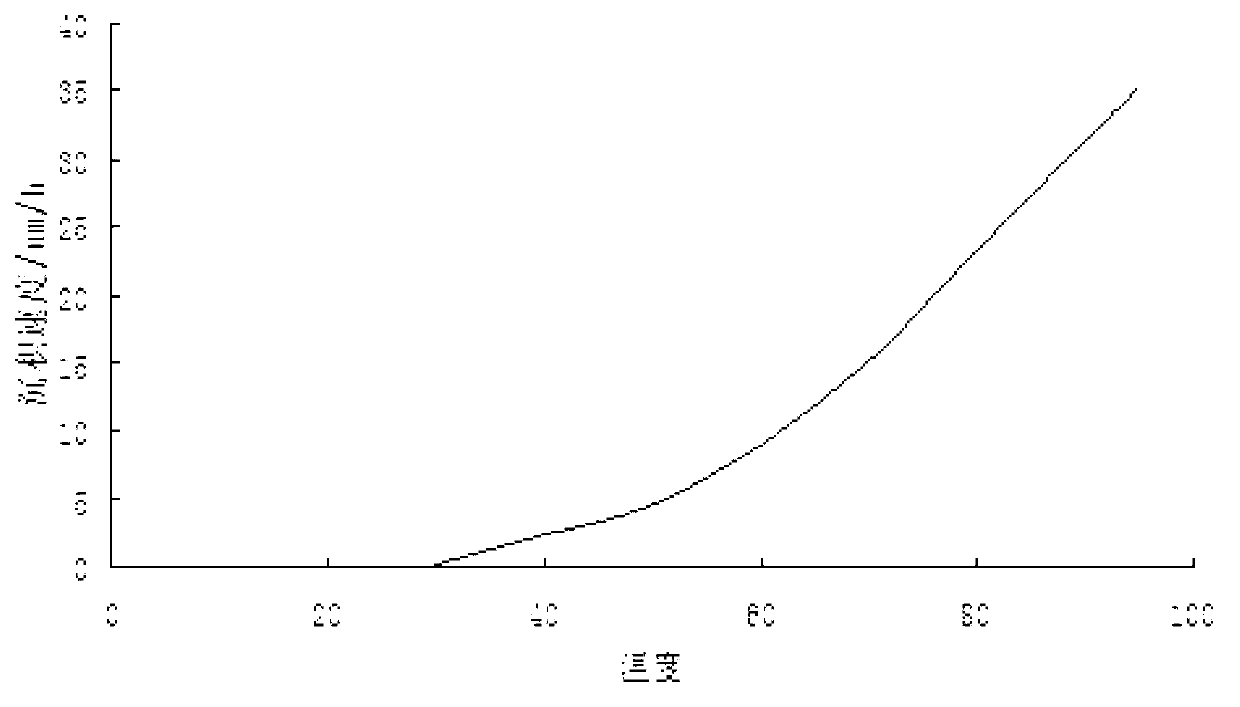

The invention discloses a nickel sulfate hexahydrate crystal and cobalt sulfate heptahydrate crystal continuous-crystallizing process which comprises the following steps: firstly carrying out MVR evaporation concentration on a high-purity solution produced through an extraction procedure to 30%-39%, and secondly continuously cooling and crystallizing through an improved cooling type internal-circulating continuous crystallizer; continuously discharging crystal slurry from the bottom of the crystallizer for centrifugal solid-liquid separation; and continuously drying a crystal product at low temperature to produce product crystals with large granularity and uniform size distribution, and recovering a mother solution to an evaporation process. Compared with the traditional periodic crystallization process, the nickel sulfate hexahydrate crystal and cobalt sulfate heptahydrate crystal continuous-crystallizing process disclosed by the invention has the advantages of low evaporation energy consumption, fewer crystallization control process parameters, stability in operation, high automation degree, high production efficiency and the like and is easy to control, and operators are reduced.

Owner:ZHEJIANG HUAYOU COBALT

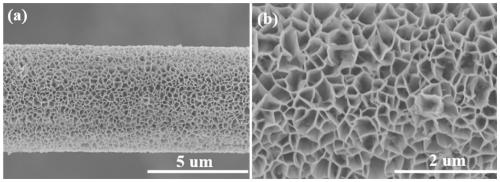

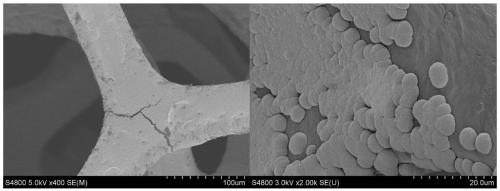

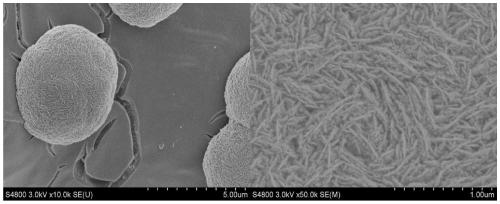

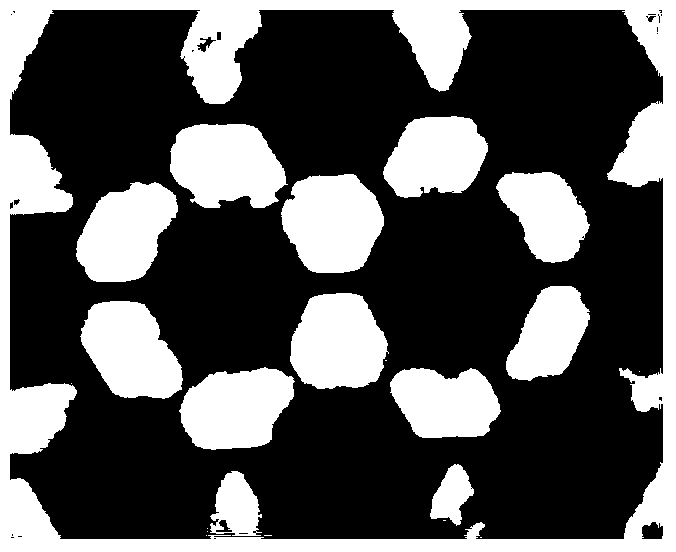

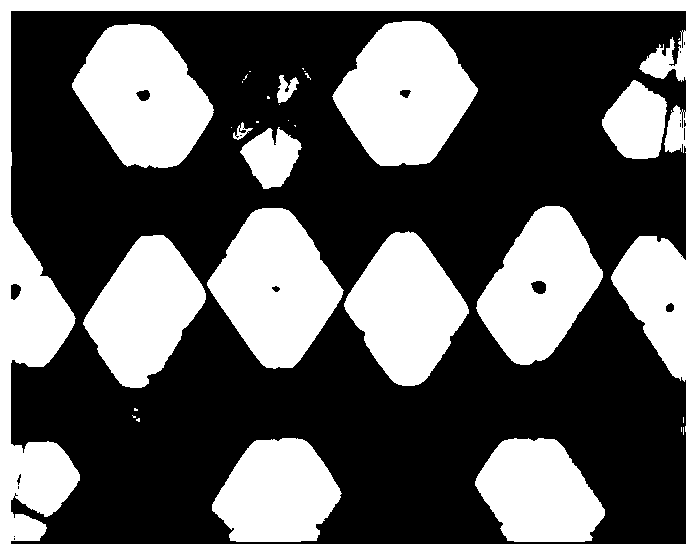

Preparation method for nickel hydroxide/polyether amine modified carbon fiber

The invention discloses a preparation method for nickel hydroxide / polyether amine modified carbon fiber. The preparation method comprises the following steps: cleaning and oxidizing the surface of thecarbon fiber; preparing nickel sulfate hexahydrate, potassium persulfate and deionized water deposition liquor; adopting a chemical-bath deposition method and a soaking method for cleaning and dryingthe carbon fiber by filling deposition liquor and a polyether amine organic solvent solution, thereby accomplishing modification, on the fiber, of the nickel hydroxide / polyether amine. The method sufficiently utilizes excellent electrochemical oxidization-reduction reaction characteristic of nickel hydroxide and an amino group of polyether amine to improve electrochemical performance of the fiber; and meanwhile, a three-dimensional honeycomb structure of the nickel hydroxide and reaction performance of the polyether amine are utilized to improve interface bonding strength of the composite material, so that a green, environment-friendly, simple and efficient method is provided for modification and application of the carbon fiber.

Owner:SHAANXI UNIV OF SCI & TECH

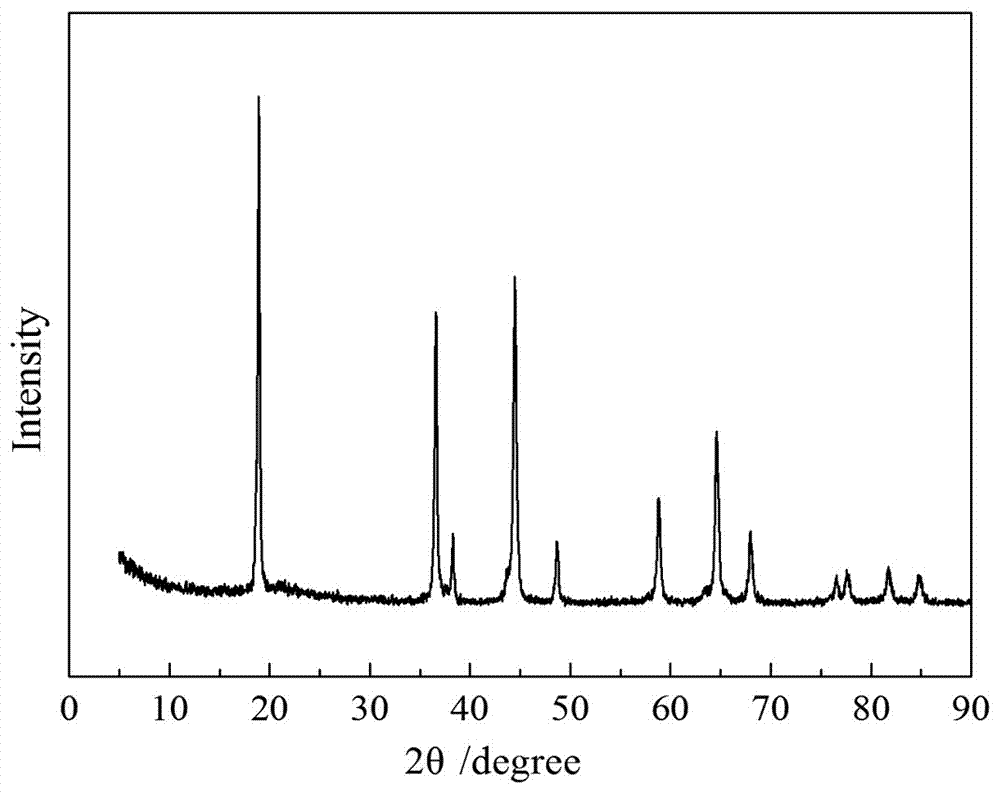

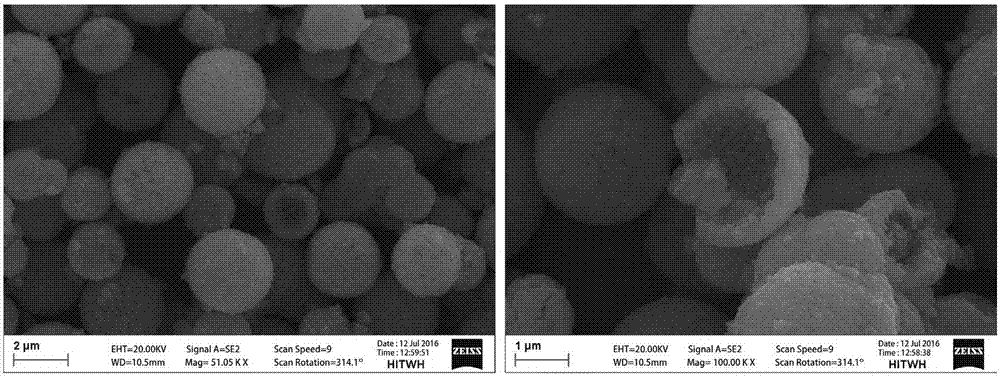

Preparation method of high-voltage lithium ion battery positive electrode material hollow spherical LNMO

InactiveCN106981654AHigh specific capacityImproved magnification performanceCell electrodesSecondary cellsElectrical batteryManganese

The invention relates to a preparation method for high-voltage lithium ion battery positive electrode material hollow spherical LNMO, and belongs to the technical field of a chemical battery. The preparation method comprises the steps of obtaining a hollow spherical Ni-Mn precursor by a co-precipitation method and by taking manganese sulfate hydrate as a manganese source, nickel sulfate hexahydrate as a nickel source and ammonium bicarbonate as a co-precipitation agent, performing stirring and drying after the precursor and a soluble lithium salt solution are mixed, and sintering a mixture to obtain the hollow spherical LNMO positive electrode material with a diameter being 600-2,000 nanometers. The preparation method has the advantages of simple process, environmental friendliness and rich raw material, and is convenient to operate, and mass production is easy.

Owner:HARBIN INST OF TECH AT WEIHAI

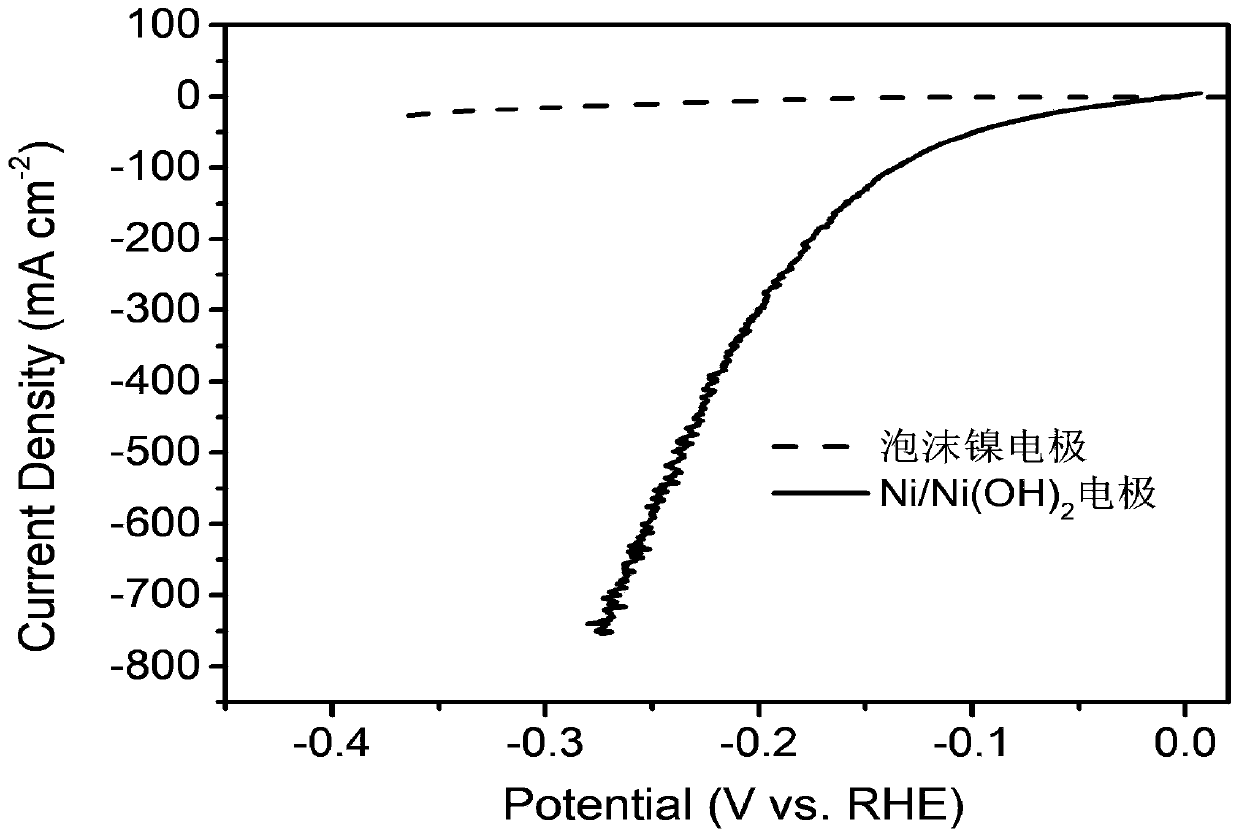

Efficient Ni/Ni(OH)2 hydrogen evolution electrode and preparation method thereof

ActiveCN110129825ALarge specific surface areaCatalytic hydrogen evolution activity is highAnodisationElectrolytic inorganic material coatingNanoparticleNickel sulfate hydrate

The invention relates to an efficient Ni / Ni(OH)2 hydrogen evolution electrode, which is characterized in that nickel sulfate hexahydrate and nickel chloride are adopted as sources of nickel elements,and nickel and hydroxide nanoparticles thereof are uniformly doped into a catalyst layer through a direct-current electrodeposition method in combination with subsequent oxidation-reduction treatment,so that the efficient Ni / Ni(OH)2 hydrogen evolution electrode is prepared. The invention also relates to a preparation method of the high-efficiency Ni / Ni(OH)2 hydrogen evolution electrode, which comprises the following steps: (1) pretreating the conductive substrate; (2) carrying out DC electrodeposition to prepare a catalyst layer formed by stacking nano flaky nickel and hydroxide thereof; and(3) carrying out anodic oxidation treatment to obtain the Ni / Ni(OH)2 hydrogen evolution electrode. The Ni / Ni(OH)2 hydrogen evolution electrode is scientific and reasonable in design and has the advantages of being high in catalytic hydrogen evolution activity, low in cost, low in energy consumption, stable in use, good in electrical conductivity and the like. The invention provides the Ni / Ni(OH)2hydrogen evolution electrode and the preparation method thereof with relatively high innovativeness.

Owner:天津市大陆制氢设备有限公司

Preparation method of Ni-Co-Al2O3 gradient composite coating

ActiveCN104099647AHigh hardnessImprove corrosion resistanceElectrolytic coatingsImpulse frequencyNickel sulfate hexahydrate

The invention relates to a preparation method of an Ni-Co-Al2O3 gradient composite coating. The method includes: employing deionized water to prepare nickel sulfate hexahydrate, cobalt sulfate hepathydrate, nickel chloride hexahydrate and boric acid into a plating solution, adding nano-aluminum oxide particles as a strengthening phase and cationic-type hexadecyl trimethyl ammonium bromide as a dispersing agent, using high-frequency impulse power with impulse frequency of 10kHz-200kHz, and changing the duty ratio according to the required coating thickness to conduct electrodeposition. The method controls the content of Co in the coating by adopting the 10kHz-200kHz high-frequency impulse power and changing the duty ratio of the power, so that the cobalt content of the coating is in gradient distribution, i.e. the Co content increases gradually from the coating surface to the interface of the coating and the substrate. And the content of Ni gradually decreases, so that the Co-Ni coating not only has high hardness but also ensures good corrosion resistance. The method provided by the invention is simple and safe to operate, and is economical and environment friendly.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Nickel-chromium alloy electroplate liquid

The invention relates to nickel-chromium alloy electroplate liquid. A liter of the electroplate liquid comprises from 25g to 35g of nickel sulfate hexahydrate, from 80g to 100g of chromium trichloride hexahydrate, from 30ml to 40ml of formic acid, from 20g to 30g of boric acid, from 1g to 60g of urea, from 30g to 80g of ammonium chloride, from 40g to 60g of potassium chloride, from 30g to 60g of critic acid, from 0.1g to 0.12g of sodium dodecyl sulfate, from 1.5g to 2.5g of saccharin, from 2ml to 4ml of nickel plating brighteners and the balance water. The urea is used as a coordination additive, and the performance of the electroplate liquid is greatly improved, so that behaviors of electrodes, the covering power and the dispersing power of a cathode and the stability, the coating performance and the contamination status of the electroplate liquid are greatly improved.

Owner:LUDONG UNIVERSITY

Nickel-phosphorus-cobalt ternary alloy electroless plating solution for alloy steel workpieces and production method

InactiveCN102433556AReduce usageLow costLiquid/solution decomposition chemical coatingRare earthSuccinic acid

The invention discloses nickel-phosphorus-cobalt ternary alloy electroless plating solution for alloy steel workpieces. The solution is characterized by comprising the following raw materials by weight percent: 5-10% of nickel chloride, 5-10% of sodium hypophosphite, 5-10% of cobalt chloride, 5-10% of ammonium chloride, 1-6% of lactic acid, 10-15% of sodium citrate, 0.3-0.5% of compound complexing agent, 1-3% of rare earth additive and the balance of water. A production method comprises the following steps: adding calculated and weighed water to a reactor, raising the temperature to 38-42 DEG C, starting a stirrer, controlling the rotating speed of the stirrer to be 120r / min, then slowly adding the calculated and weighed nickel sulfate hexahydrate, sodium hypophosphite, sodium citrate, succinic acid, ammonium sulfate, stabilizing agent and compound complexing agent to the reactor in sequence, stirring the materials while adding until the solution becomes green transparent liquid and carrying out emptying and packaging when the solution is cooled to the room temperature.

Owner:DALIAN SANDAAOKE CHEM

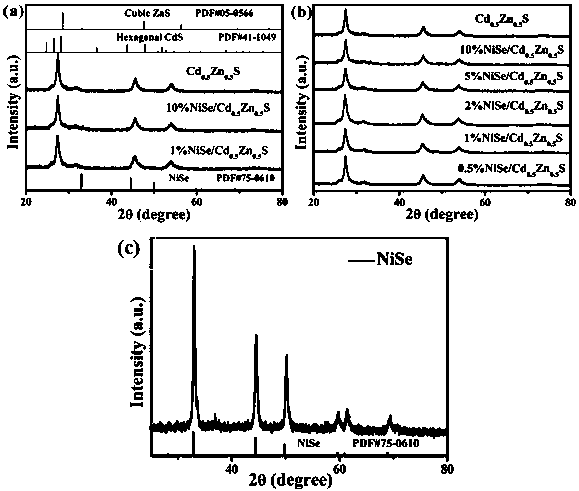

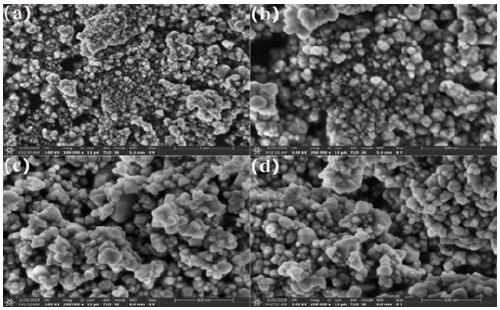

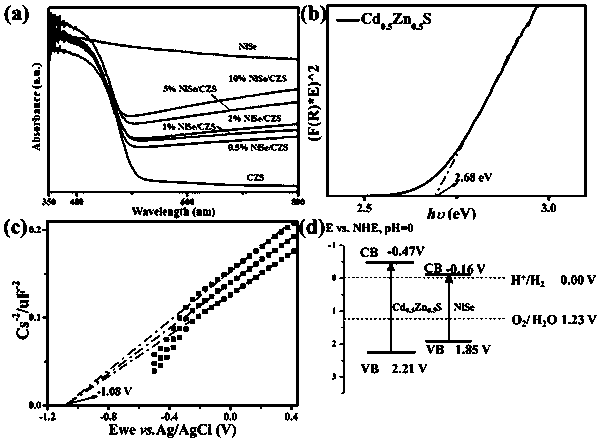

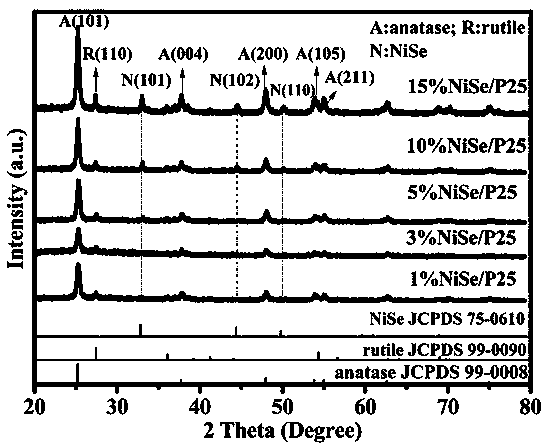

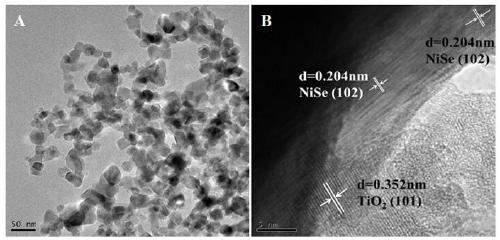

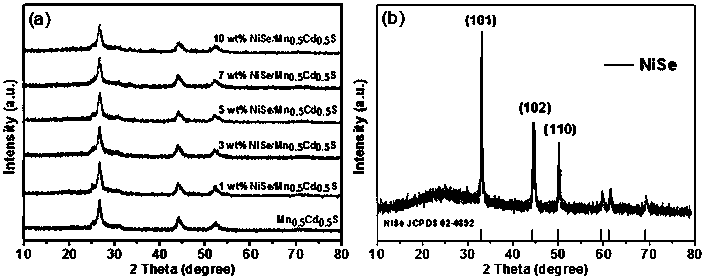

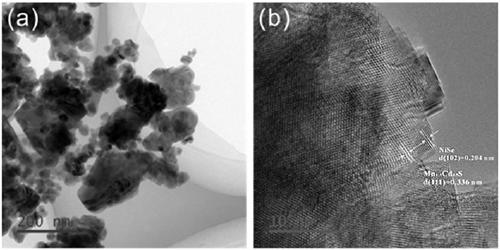

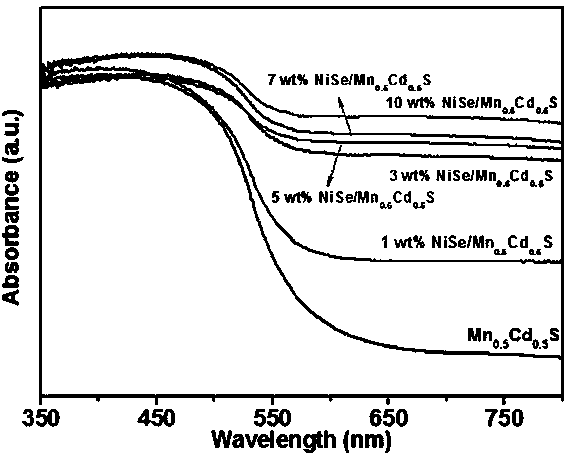

Efficient heterojunction photocatalyst taking NiSe as aid as well as preparation method and application thereof

InactiveCN110075875ASimple thermal reactionEasy to makePhysical/chemical process catalystsHydrogen productionHeterojunctionNickel sulfate hydrate

The invention discloses a visible light driven NiSe-based heterojunction photocatalyst for performing efficient photocatalysis on water to perform pyrolysis to produce hydrogen. The heterojunction photocatalyst is prepared by the following steps: preparing Cd0.5Zn0.5S sosoloid by taking cadmium acetate, zinc acetate and thioacetamide as cadmium, zinc and sulfur sources correspondingly and adoptinga precipitation-hydrothermal method; and taking nickel sulfate hexahydrate, sodium selenite and the synthesized Cd0.5Zn0.5S sosoloid as substrates, taking glycol as a solvent and a reducing agent, and synthesizing a NiSe / Cd0.5Zn0.5S heterojunction photocatalyst through a one-step solvent-thermal method. The maximum hydrogen production rate of the heterojunction photocatalyst under visible light reaches 70.3 mmol / h / g, and the activity of the heterojunction photocatalyst is 2.35 times that of pure Cd0.5Zn0.5S sosoloid; furthermore, the preparation method is green, environmentally-friendly, simple to operate and stable in activity, the utilization rate of sunlight, particularly visible light by the photocatalyst is greatly increased, and higher economic benefit can be achieved.

Owner:FUZHOU UNIV

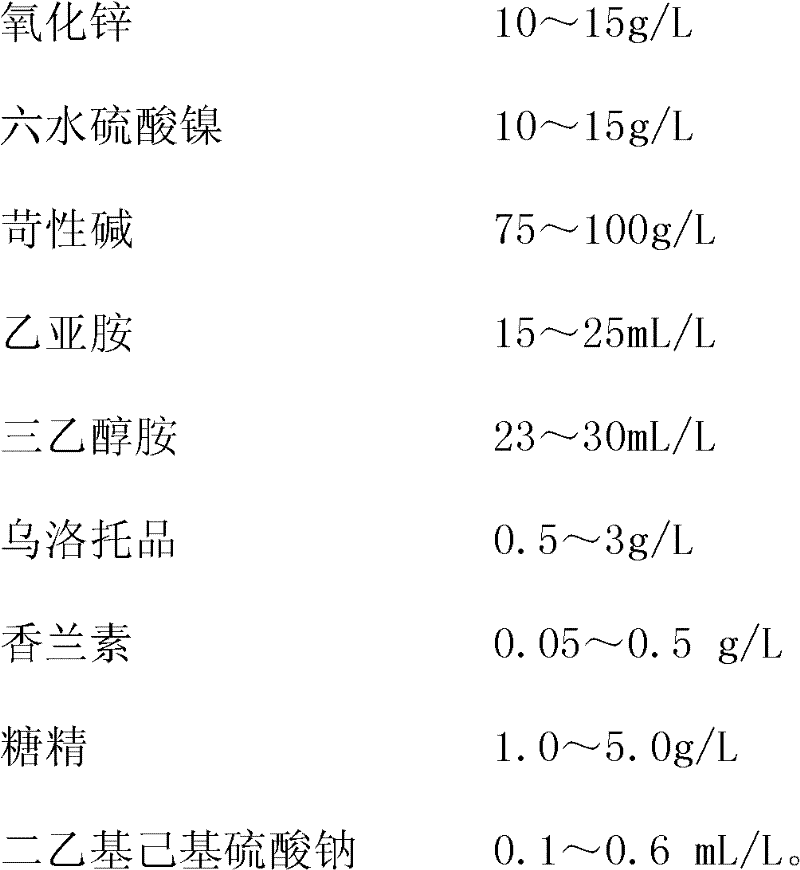

Zinc-nickel alloy plating liquid

The invention discloses zinc-nickel alloy plating liquid, which comprises the following materials: 10 to 15 g / L of zinc oxide, 10 to 15 g / L of nickel sulfate hexahydrate, 75 to 100 g / L of caustic alkali, 15 to 25 ml / L of ethyliminum, 23 to 30 ml / L of triethanolamine, 0.5 to 3 g / L of urotropin, 0.05 to 0.5 g / L of vanillin, 1.0 to 5.0 g / L of saccharin and 0.1 to 0.6 mL / L of diethylhexyl sodium sulfate. After a zinc-nickel alloy is plated by the zinc-nickel alloy plating liquid, the obtained plating layer is silvery white, bright, smooth and compact, the nickel content is between 11 and 14, and the zinc-nickel alloy plating liquid has high corrosion resistance.

Owner:张家港舒马克电梯安装维修服务有限公司镀锌分公司

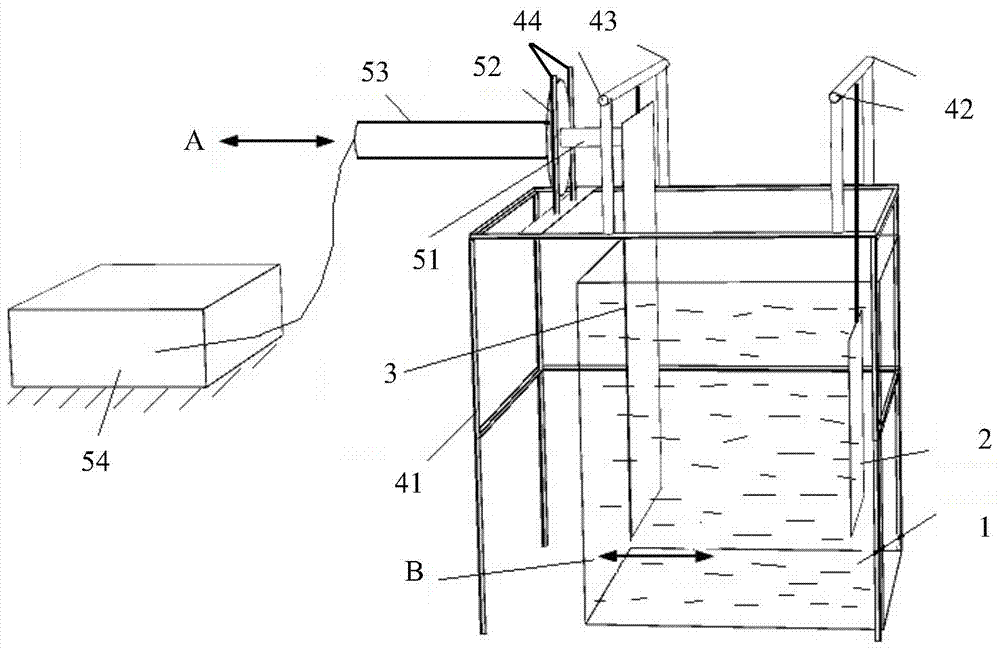

Method for making high-reflectance microprism reflecting film working mould with ultrasound-pulse electroforming

ActiveCN103422128AEasy to adjustControl retroreflection coefficientElectroforming processesPrismDissolution

The invention relates to a microprism, in particular to a method for making a high-reflectance microprism reflecting film working mould with ultrasound-pulse electroforming. Electroforming liquid is prepared, namely hot water is added into an electroforming groove, then nickel sulfate hexahydrate and nickel chloride are added in sequence, hot water is added into a container, then boric acid is added, boiling is carried out, then lauryl sodium sulfate is added, after dissolution, liquid is poured into the electroforming groove, saccharin and 2-butyne-1,4-diol are added into the electroforming groove, then water is injected until the electroforming groove is full, pH is adjusted to 4.2; an anode nickel plate is placed into an anode basket and is connected to a positive electrode, a nickel master mould is connected to a negative electrode, ultrasound power is adjusted to 210-300W, frequency is adjusted to 30-50kHz, pulse current density is adjusted to 1-6A / dm<2>, current frequency is adjusted to 1000Hz, working time ratio of forward currents and backward currents is adjusted to 5:1, duty ratio is adjusted to 10%-30%, electroforming is carried out, and the high-reflectance microprism reflecting film working mould is obtained after cathode demoulding.

Owner:福建跃发光新材料股份有限公司

Preparing method of environment-friendly type stainless steel welding wire not plated with copper

InactiveCN106086975AImprove securityHigh hardnessWelding/cutting media/materialsSoldering mediaCopper platingSodium phosphates

The invention discloses a preparing method of an environment-friendly type stainless steel welding wire not plated with copper and belongs to the technical field of welding wire machining. A degreasing solution is prepared by using sodium hydroxide, sodium carbonate, sodium phosphate dodecahydrate and sodium silicate as raw materials, a low-carbon steel wire is soaked in the degreasing solution for ultrasonic washing after being polished, and the low-carbon steel wire is connected with a power supply with a pure nickel bar, placed in an electroplating solution prepared by mixing nickel sulfate hexahydrate, nickel chloride, titanium dioxide and the like for electroplating, and dried after being fully electroplated so as to obtain the environment-friendly type stainless steel welding wire not plated with copper. The preparing method obviously improves the ductility, toughness and high temperature resistance of the welding wire by electroplating one layer of nickel and titanium dioxide on the surface of the low-carbon steel wire, avoids the problems of environment pollution and physical health hazards, caused in an original welding wire copper plating production process, improves the safety of a welding wire preparing process, and has wide application prospects.

Owner:NINGBO JIANGDONG YONGFENG IND DESIGN

Graphite nickel plating method

InactiveCN108277480AImprove conductivityHigh tensile strengthTransportation and packagingMetal-working apparatusCopper platingArginine

The invention provides a graphite nickel plating method. The graphite nickel plating method comprises the steps of adding a graphite matrix into a nickel plating solution, and carrying out a reactionso as to obtain nickel plated graphite, wherein the nickel plating solution comprises the following components by content: 20 g / L to 35 g / L of nickel sulfate hexahydrate, 8 g / L to 30 g / L of lactic acid, 2 g / L to 18 g / L of triethanolamine, 20 g / L to 45 g / L of sodium citrate, 10 g / L to 35 g / L of ammonium chloride, 30 g / L to 45 g / L of sodium hypophosphite, 0.01 mg / L to 0.2 mg / L of L-arginine and 0.1mg / L to 10 mg / L of potassium ferrocyanide, pH is adjusted to be 8 to 9 through aqueous ammonia, and the temperature of the nickel plating solution is 30 DEG C to 45 DEG C. According to the graphite nickel plating method, complex technologies like surface degreasing, sensitization, metal palladium activation and peptization are eliminated, so that production efficiency is greatly improved; preciousmetal catalysis is not utilized, so that cost is reduced; and further, graphite powder is firstly subjected to copper plating and then is subjected to nickel plating, so that graphite powder has better electrical conductivity and tensile strength.

Owner:ZHEJIANG SAINTYEAR ELECTRONICS TECH

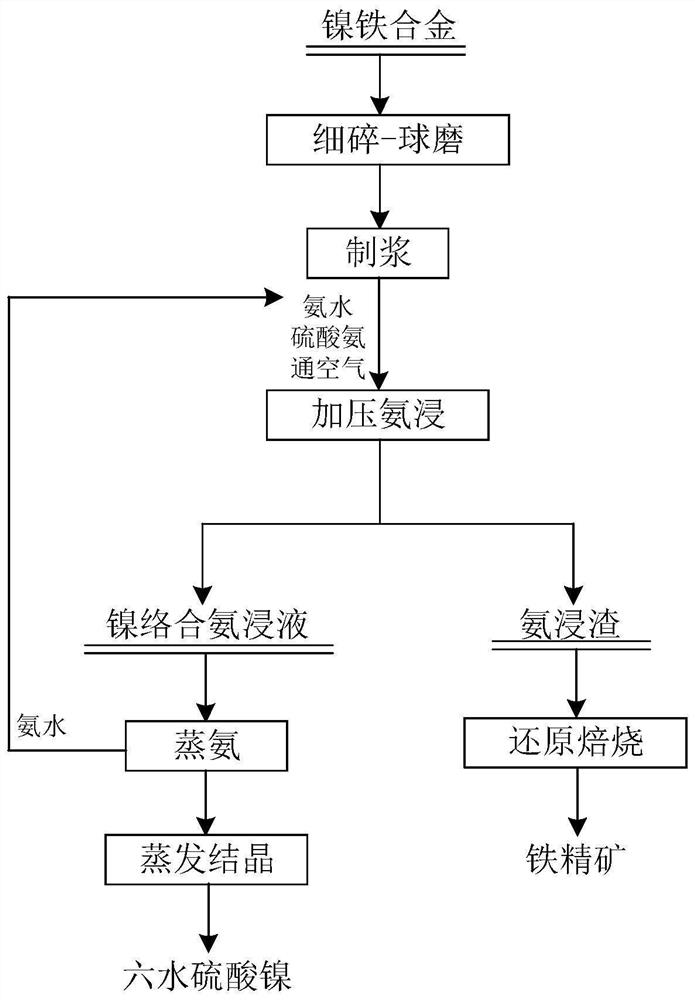

Recovery method of rough ferro-nickel alloy and application of recovery method

The invention belongs to the field of nonferrous metallurgy, and discloses a recovery method of rough ferro-nickel alloy and application of the recovery method. The recovery method comprises the following steps: crushing and ball-milling the crude ferro-nickel alloy, adding ammonium salt and ammonia water, mixing and stirring, heating and pressurizing for ammonia leaching reaction to obtain slurry, and filtering to obtain nickel complex leaching solution and iron slag; adding a reducing agent into the iron slag for reduction roasting to obtain iron ore concentrate; and adding an alkaline buffer solution into the nickel complex leaching solution to adjust the pH value for alkaline reaction, and heating for ammonia distillation to obtain nickel sulfate. According to the recovery method, the rough ferro-nickel alloy is subjected to crushing and ore grinding, pressurized ammonia leaching, filtering and evaporative crystallization, a sulfuric acid system is adopted in pressurized ammonia leaching, and after ammonia leaching and ammonia distillation, high-value class I nickel sulfate hexahydrate (the purity is 99.7%) and high-grade marketable refined iron powder (the recovery rate is larger than 99.99%, and the purity is larger than 98%) can be directly obtained.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Device and method for making high-reflectance microprism working mold

The invention discloses a device and a method for making a high-reflectance microprism working mold and relates to a microprism. An electroforming groove, an anode, a cathode, a bracket device and an ultrasonic system are arranged on the device, wherein a frame body, an anode, a cathode and a flange fixing rod are arranged on the bracket device; the anode, the cathode and the flange fixing rod are fixedly connected to the top of the frame body; a tool head, a flange, an amplitude-change pole and an ultrasonic power supply are arranged on the ultrasonic system; the front end of the tool head is arranged on the outer side of the cathode; the back end of the tool head is connected with the front end of the amplitude-change pole by virtue of the flange; the back end of the amplitude-change pole is connected with the ultrasonic power supply. The method comprises the following steps: adding water into the electroforming groove, and adding nickel sulfate hexahydrate and nickel chloride in sequence; adding boric acid into hot water, boiling, adding dodecyl sodium sulfate, dissolving, pouring into the electroforming groove, adding saccharin and 1,4-butynediol into the electroforming groove, and filling the electroforming groove with water to obtain an electroforming liquid; putting the anode into an anode basket, connecting a positive pole, connecting a nickel master mold with the cathode, and connecting the upper end of the cathode with the foremost end of the tool head; electroforming, and demolding to obtain the working mold.

Owner:福建跃发光新材料股份有限公司

Automatic inducing culture medium for expressing recombinant protein of escherichia coli

InactiveCN103276032AReduce pollutionReduce manufacturing costMicroorganism based processesFermentationEscherichia coliGlycerol

The invention relates to an automatic inducing culture medium for expressing recombinant protein of escherichia coli. Each liter of the culture medium comprises components in parts by weight as follows: 5-10g of tryptone, 3-5g of a yeast extract, 0.1-8 g of sodium succinate hexahydrate, 0.1-1g of sodium citrate dehydrate, 5-15g of glycerinum, 0.1-1g of glucose, 1-4g of lactose, 2-5g of disodium hydrogen phosphate, 2-5g of monopotassium phosphate, 1-4g of ammonium chloride, 0.2-0.9g of sodium sulfate, 0.1-1g of magnesium sulfate heptahydrate, 0.1-0.4g of ferric chloride hexahydrate, 1-3mg of calcium chloride, 0.01-3mg of tetrahydrate manganese chloride, 0.01-5mg of zinc sulfate heptahydrate, 0.01-1mg of cobalt chloride hexahydrate, 0.01-0.5mg of copper chloride dehydrate, 0.01-0.5mg of nickel sulfate hexahydrate, 0.01-1mg of sodium molybdate pentahydrate, 0.04-0.1mg of sodium selenate pentahydrate, 0.001-0.01mg of boric acid, 1-100g of n-hexane and 0.1-10g of calcium peroxide. The automatic inducing culture medium is used for expressing foreign protein, the expression amount of the foreign recombinant protein of the automatic inducing culture medium is increased when compared with that of foreign recombinant protein of an LB (Luria-Bertani) ordinary culture medium, the production cost is saved, environmental pollution is reduced, and the yield can be increased by more than ten times.

Owner:VIVA BIOTECH

Heterojunction photocatalyst for hydrogen production and alcohol oxidation by high-efficiency photocatalytic water-cracking

ActiveCN108993546AImproving the hydrogen production performance of photocatalytic water splittingEasy to makePhysical/chemical process catalystsHydrogen productionHeterojunctionLight energy

The invention discloses a heterojunction photocatalyst for hydrogen production and alcohol oxidation by high-efficiency photocatalytic water-cracking, and belongs to the field of photocatalyst preparation and application. According to the invention, nickel sulfate hexahydrate, sodium selenite and titanium dioxide are taken as reactants, glycol is taken as a solvent and a reducing agent, and then aNiSe / TiO2 heterojunction photocatalyst is synthesized according to a one-step solvothermal method. The heterojunction photocatalyst prepared by the invention has a photocatalytic hydrogen productionperformance 9 times higher than that of pure TiO2, and shows good stability in the long-cycle operation. Furthermore, simple alcohols are taken as sacrificial agents, and chemicals of high-value fuel(hydrogen), small molecular acids, aldehydes and the like are prepared through the photocatalytic water cracking under illumination of simulated sunlight. In addition, the heterojunction photocatalystused in the invention is green and simple in preparation method, rich in material sources, low in cost and stable in activity, and combines the small molecular alcohols as the sacrificial agents, sothat economic benefits of photocatalysis and the utilization rate of absorbed light energy can be greatly improved.

Owner:FUZHOU UNIV

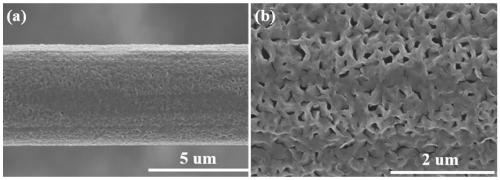

Carbon fiber surface chemical nickel plating method

ActiveCN107058986AImprove surface propertiesUniform and continuous distributionLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention provides a carbon fiber surface chemical nickel plating method. The method specifically comprises the steps that (1) pretreatment is conducted, and carbon fiber pretreatment is divided into degreasing treatment, roughing treatment, sensitization treatment and activation treatment; (2) plating solution preparation is conducted, specifically, deionized water is used as a solution, and the following components of main salt, a compounding ingredient, a stabilizer and a complexing agent are sequentially added into the solution, wherein the main salt is nickel sulfate hexahydrate with the density being 30-45 g / L, the compounding agent is ammonium chloride with the density being 25-30 g / L, and the stabilizer and the complexing agent are prepared in the mode that sodium citrate with the density being 15-25 g / L is prepared, and the PH value of the sodium citrate is adjusted to 10-11 through a sodium hydroxide solution; (3) pretreated carbon fibers are soaked into the plating solution prepared in the step two, and after the temperature of the plating solution rises to 80-100 DEG C, a hydrazine hydrate solution with the density being 25 ml / L is slowly dropwise added into the plating solution for reduction; and (4) the reduced carbon fibers are stored in a vacuum drying box with the temperature being 80-100 DEG C to be dried. According to the carbon fiber surface chemical nickel plating method, the nickel plated carbon fibers are prepared through the method of hydrazine hydrate direct reduction, and other harmful elements are not introduced into the nickel plating process.

Owner:HENAN UNIV OF SCI & TECH

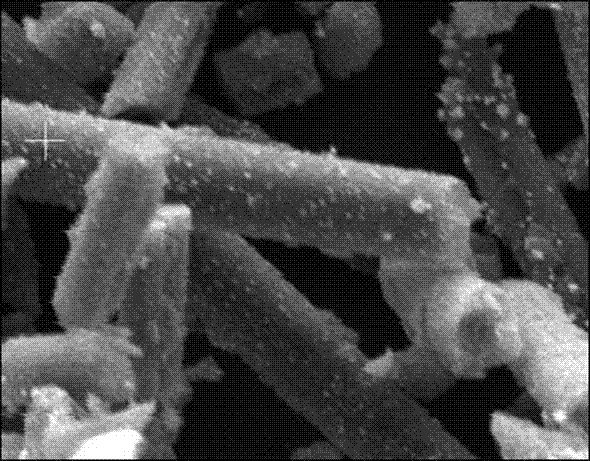

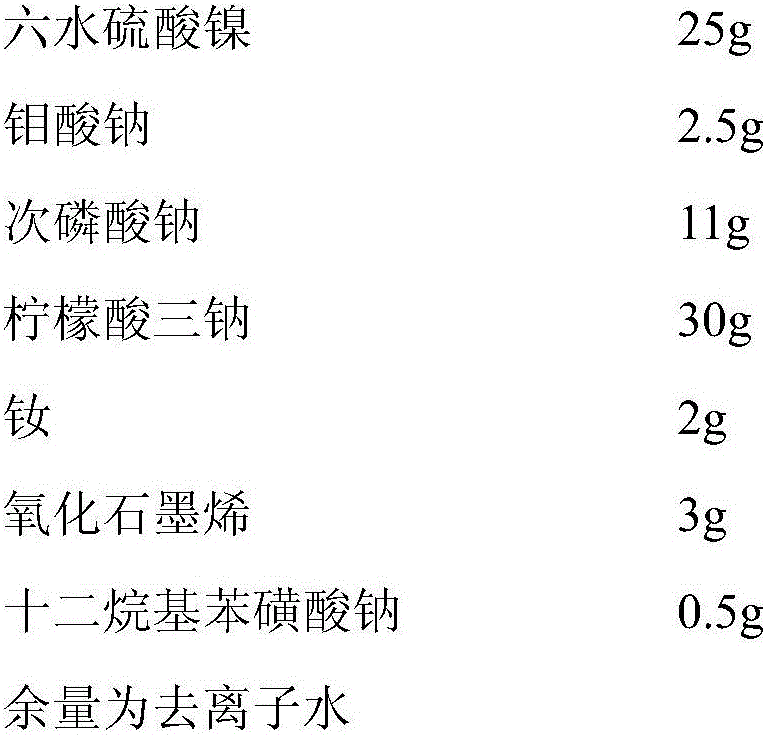

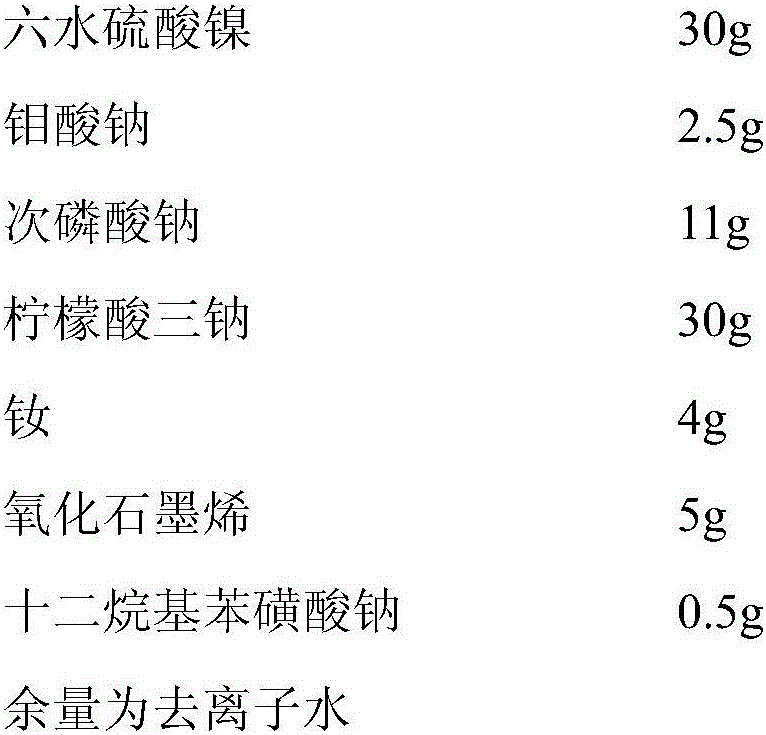

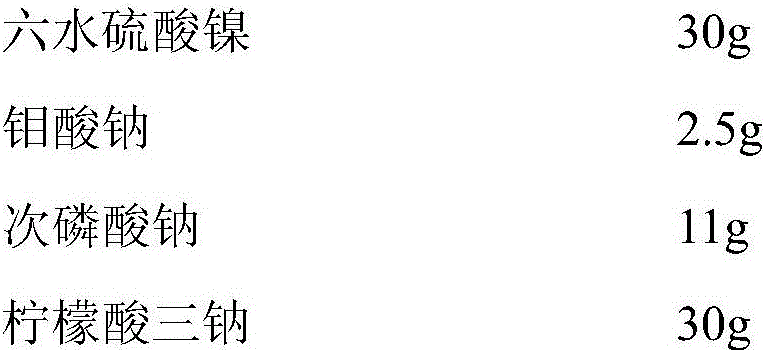

Nd-Ni-Mo-P/Go chemical composite deposition layer and preparation method thereof

ActiveCN106637158AImprove wear resistanceAccelerated corrosionLiquid/solution decomposition chemical coatingChemical platingSODIUM DODECYL BENZENE SULFONATE

The invention discloses an Nd-Ni-Mo-P / Go chemical composite deposition layer and a preparation method thereof. The preparation method comprises the steps of putting low-carbon steel into Nd-Ni-Mo-P / Go chemical composite deposition liquid and then carrying out ultrasonic-assisted treatment on the low-carbon steel so as to obtain the Nd-Ni-Mo-P / Go chemical composite deposition layer on the surface of the low-carbon steel, wherein every liter of composite deposition liquid is prepared from 20-50g of nickel sulfate hexahydrate, 2-5g of sodium molybdate, 5-20g of sodium hypophosphite, 20-50g of trisodium citrate, 0.1-5g of Nd, 1-10g of graphene oxide and 0.5g of sodium dodecyl benzene sulfonate. The preparation method has the beneficial effects that on the basis of a chemical plating technology and an ultrasonic technology, the nanocomposite deposition layer is prepared on the surface of the low-carbon steel. The composite deposition layer prepared by the method can effectively improve the performances such as corrosion resistance, surface hardness and wear resistance of the low-carbon steel, and can effectively solve the problem that particles crack.

Owner:SHANGHAI INST OF TECH

High-strength moisture-proof starch glue and preparation method and application method thereof

ActiveCN104449461AImprove bindingImprove moisture resistanceNon-macromolecular adhesive additivesStarch adhesivesOligomerAdhesive

The invention relates to the technical field of adhesives, particularly to a high-strength moisture-proof starch glue and a preparation method and application method thereof. The high-strength moisture-proof starch glue is composed of the raw materials including, by weight part, 100 parts of corn starch, 4-20 parts of phenolic oligomer, 2-10 parts of polylactic acid, 0.5-3 parts of borax, 0.5-5 parts of nickel sulfate hexahydrate, 2-15 parts of sodium peroxide, 1-5 parts of tributyl phosphate and 200-300 parts of water. The h high-strength moisture-proof starch glue is high in bonding strength in humid environments, product bonding stability and moisture-proofness, has anti-mildew effects and avoids environmental pollution when degraded. The preparation method of the h high-strength moisture-proof starch glue is simple and convenient to apply.

Owner:广东省汇林包装科技集团有限公司

Nickel-phosphorus nanometer silicon dioxide composite plating of magnesium alloy and method for preparing nickel-phosphorus nanometer silicon dioxide composite plating

InactiveCN105887057AFree from corrosionLow costLiquid/solution decomposition chemical coatingChemical platingAcid washing

The invention relates to methods for treating magnesium alloy surfaces, in particular to nickel-phosphorus nanometer silicon dioxide composite plating of magnesium alloy and a method for preparing the nickel-phosphorus nanometer silicon dioxide composite plating. The method includes mechanical polishing, oil removing, acid washing and alkali washing pretreatment. Chemical plating includes two steps implemented by the aid of fluorine-containing plating solution A without nanometer silicon dioxide and nanometer-silicon-dioxide-containing plating solution B without fluorine. The nickel-phosphorus nanometer silicon dioxide composite plating and the method have the advantages that composite nanometer silicon dioxide is added into the plating solution B, so that the corrosion resistance of the nickel-phosphorus nanometer silicon dioxide composite plating can be enhanced; preparation of nanometer oxide concentrated solution or pretreatment on the nanometer silicon dioxide can be omitted, inexpensive nickel sulfate hexahydrate is used as major salt, only the fluorine-containing plating solution is applied at the first step in plating processes, the plating solution for the second step does not contain fluoride, accordingly, the usage of fluorine can be effectively reduced, and the cost can be lowered.

Owner:CHINA WEST NORMAL UNIVERSITY

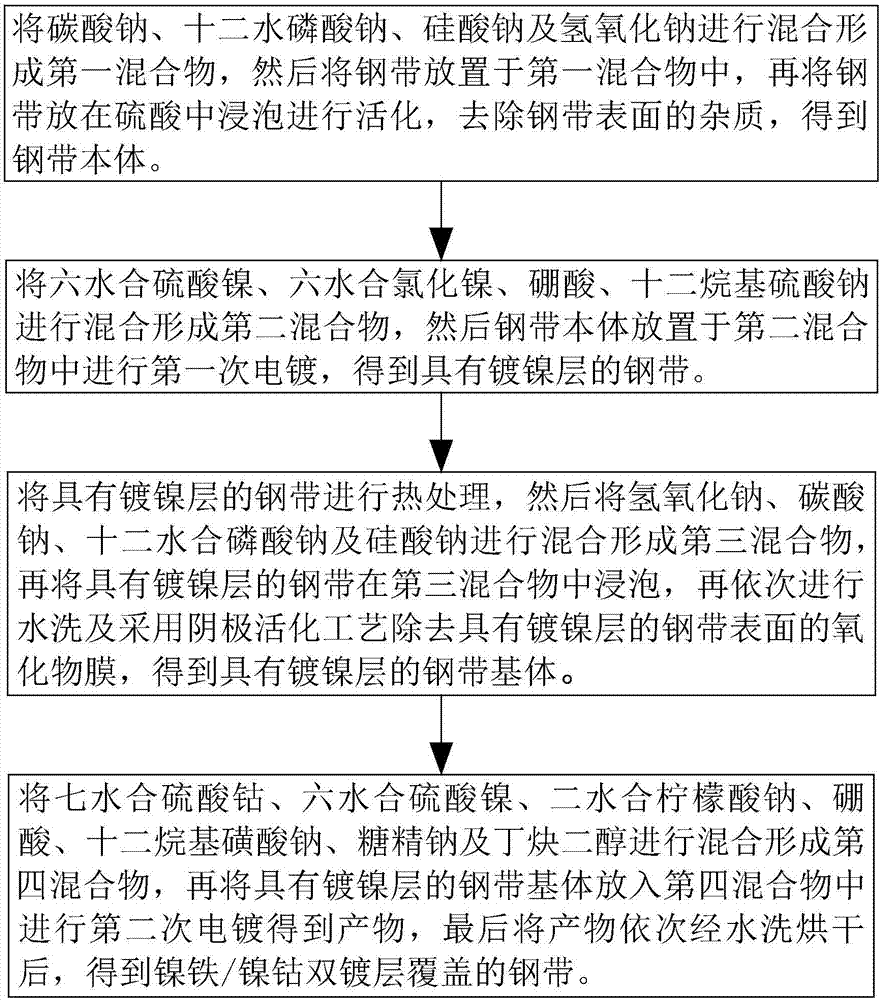

Preparation method of steel strip covered by ferronickel/nickel-cobalt double coatings

A preparation method for a steel strip covered by a nickel-iron / nickel-cobalt double coating, comprising the following steps: Step 1: mixing sodium carbonate, sodium phosphate dodecahydrate, sodium silicate and sodium hydroxide, and placing the steel strip in the first mixture , the steel strip is soaked in sulfuric acid to activate and remove impurities; step 2: nickel sulfate hexahydrate, nickel chloride hexahydrate, boric acid, and sodium lauryl sulfate are mixed, and the steel strip body is placed in the second mixture for the first electroplating; Step 3: heat-treat the steel strip with the nickel-plated layer, mix sodium hydroxide, sodium carbonate, sodium phosphate dodecahydrate and sodium silicate, soak the steel strip with the nickel-plated layer in the third mixture, wash with water and perform cathodic activation process Removing the oxide film of the steel strip with the nickel-plated layer; step 4: mixing cobalt sulfate heptahydrate, nickel sulfate hexahydrate, sodium citrate dihydrate, boric acid, sodium dodecylsulfonate, sodium saccharin and butynediol , the steel strip substrate with the nickel-plated layer is put into the fourth mixture for the second electroplating, and is successively washed and dried.

Owner:SHENZHEN ANDING NEW ENERGY TECH DEV CO LTD

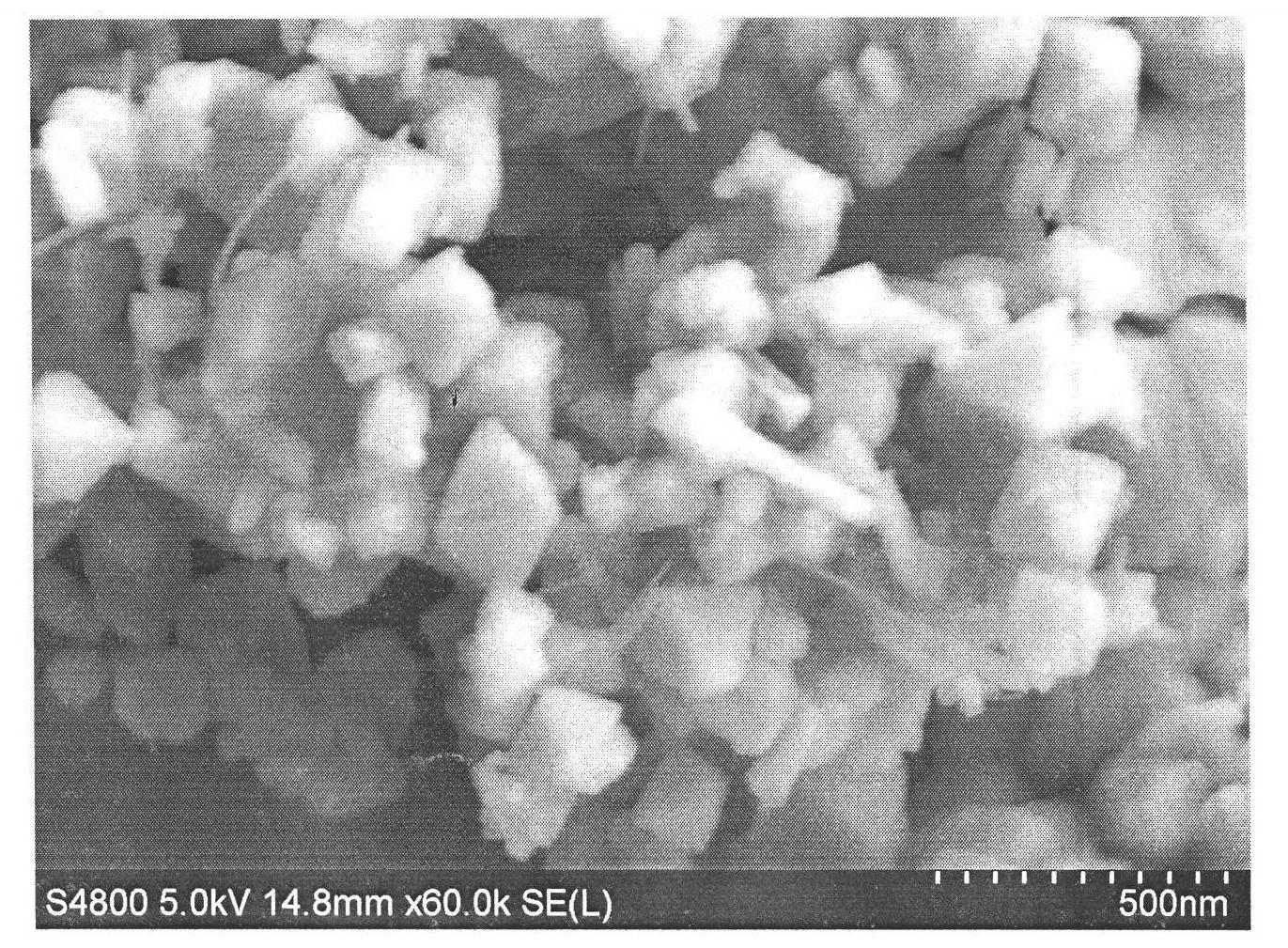

Method for preparing nano nickel selenide with octahedral structure

InactiveCN102583273AGood effectEfficient decompositionChemical industryNanotechnologyHydration reactionActive agent

The invention provides a method for preparing nano nickel selenide with an octahedral structure, and belongs to the technical field of preparation of nano materials. The method is characterized by comprising the following steps of: adding 0.1314 gram of nickel sulfate hexahydrate and 0.0866 gram of sodium selenite into a 25-milliliter high-pressure reaction kettle with a polytetrafluoroethylene lining, adding 20 milliliters of ethylene glycol, stirring for 20 minutes, closing the reaction kettle, putting into a digital display temperature control furnace, and reacting for 24 hours at the temperature of 180 DEG C; and performing three times of centrifugal washing on the obtained sample, drying, and thus obtaining the product. An organic template and a surfactant are not required in the method, and the nano nickel selenide is synthesized in one step and has high yield and the octahedral structure; the method is simple, energy-saving and suitable for industrialized production; and the obtained octahedral nickel selenide has a good catalytic effect on decomposition of hydrazine hydrate.

Owner:ANHUI UNIVERSITY

Chemical nickel-phosphorus alloy plating solution

InactiveCN102953054AImprove autocatalytic activityImprove stabilityLiquid/solution decomposition chemical coatingSodium acetrizoateSodium acetate

The invention relates to chemical nickel-phosphorus alloy plating solution. Each liter of plating solution comprises 20 to 45g of nickel sulfate hexahydrate, 20 to 45g of sodium hypophosphite dihydrate, 15 to 25ml of lactic acid, 10 to 15g of sodium acetate, 2 to 15g of urea and the balance of water. According to the invention, the urea is used as an additive; a coordination complex is formed by the urea and nickel ions; a deposition mechanism of a nickel-phosphorus alloy is changed, so that a deposition temperature is greatly reduced and a better coating can be obtained at lower temperature; the production cost is reduced; and the benefits are increased for enterprises.

Owner:LUDONG UNIVERSITY

Supported photocatalyst and preparation method thereof

ActiveCN110302809AEasy transferEnhance photocatalytic hydrogen production activityPhysical/chemical process catalystsHydrogen productionHeterojunctionNickel sulfate hydrate

The invention discloses a supported photocatalyst NiSe / Mn0.5Cd0.5S and a preparation method thereof. The supported photocatalyst is prepared by firstly synthesizing a Mn0.5Cd0.5S solid solution by using a gentle one-step hydrothermal method, and by secondly, enabling the solid solution to react with nickel sulfate hexahydrate and sodium selenite. NiSe and Mn0.5Cd0.5S are tightly combined to form heterojunctions in the composite catalyst, migration of photon-generated carriers can be facilitated, combination of photon-generated electron holes is inhibited, and the photocatalysis hydrogen production activity of the Mn0.5Cd0.5S solid solution can be remarkably improved. The novel NiSe / Mn0.5Cd0.5S photocatalyst disclosed by the invention is simple to prepare, can be massively prepared, is highin photocatalysis activity and good in stability, and has wide application prospects in clean energy development.

Owner:FUZHOU UNIV

Waterproof cement slurry resistant to chemical harmful erosion

The invention belongs to the technical field of building materials, in particular to waterproof cement slurry resistant to chemical harmful erosion. The waterproof cement slurry comprises the following raw materials: cement, hydroxy-terminated lactic acid oligomer with a molecular weight of 800-2000, a surface-active substance, a composite filler, glycollic acid, nickel sulfate hexahydrate, starchsodium octenylsuccinates, terpenyl epoxy resin and acrylate emulsion. Compared with the prior art, the waterproof cement slurry disclosed by the invention has the advantages that a powdered flexiblewaterproofing material made from multiple active chemicals is doped into cement, wherein ephedra fiber powder can contribute to improving the flexibility of the cement slurry and effectively improvingthe penetrating function and chemical harmful erosion, and the waterproof cement slurry has ultra-strong penetration capacity and excellent impervious performance, and is high in harmful chemical erosion resistance, capable of automatically and rapidly repairing micro-cracks, safe, environment friendly and excellent in waterproof performance.

Owner:安徽力峰建材科技有限公司

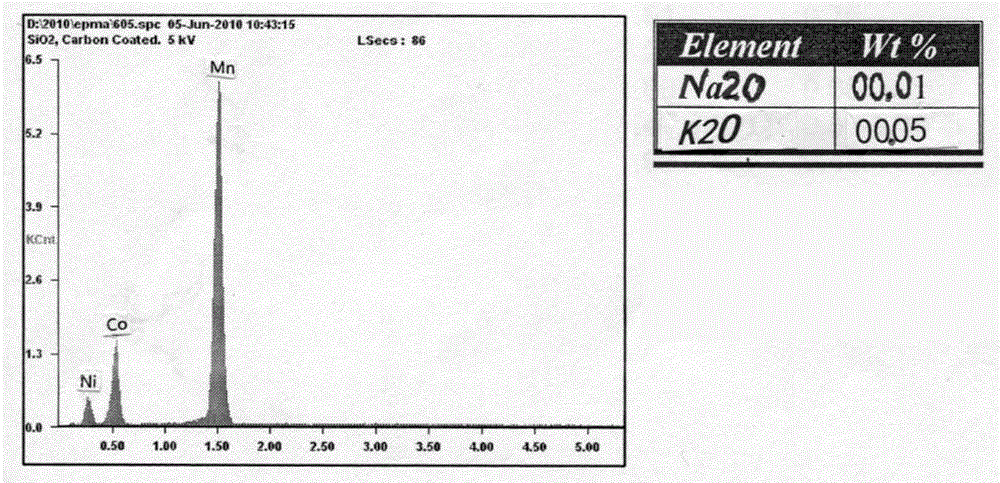

Preparation method for cobalt-manganese-nickel oxides

InactiveCN105140505AEvenly distributed ingredientsImprove uniformityCell electrodesSecondary cellsManganeseNickel sulfate hydrate

The invention discloses a preparation method for cobalt-manganese-nickel oxides. The preparation method comprises steps of separately dissolving industrial products including manganese sulfate monohydrate, cobaltous sulfate heptahydrate and nickel sulfate hexahydrate by hot water, gradually adding a NH4HCO3 solution for performing a neutralization reaction and a precipitation reaction, then continuing to add a KOH solution to react, discharging, filtering, washing by water until SO42-ions disappear, drying, roasting by a high-temperature furnace at the temperature of 820 DEG C for 2-3 hours, ball milling and smashing, stirring and washing by hot water, then filtering, washing, drying and smashing to obtain the cobalt-manganese-nickel oxides. The preparation method is simple, easy to operate, and low in production cost; and the prepared cobalt-manganese-nickel oxides are excellent in product uniformity, stability and electric property, and low in production cost, and can be used for industrial production.

Owner:GUIZHOU ACADEMY OF TESTING & ANALYSIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com