Zinc-nickel alloy plating liquid

A technology of zinc-nickel alloy and nickel-iron alloy, which is applied in the field of electroplating solution, can solve problems such as the unsatisfactory effect of alkaline zinc-nickel plating solution and the inability to meet high-standard electroplating requirements, and achieve good stability and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

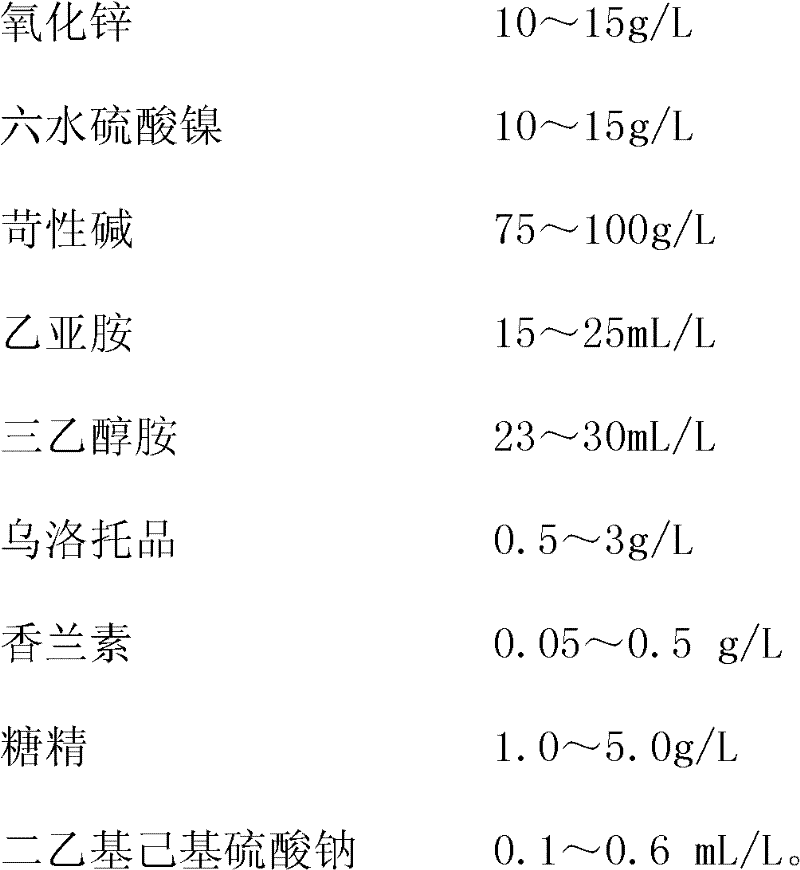

[0020] A kind of zinc-nickel alloy electroplating solution, its material is composed as follows according to parts by weight:

[0022] Nickel sulfate hexahydrate 15g / L

[0023] Sodium hydroxide 85g / L

[0024] Ethyleneimine 15mL / L

[0025] Triethanolamine 25mL / L

[0026] Urotropine 0.8g / L

[0027] Vanillin 0.1 g / L

[0028] Saccharin 2.8g / L

[0029] Sodium diethylhexyl sulfate 0.2 mL / L.

[0030] At 20~25℃, current density 2A / dm 2 , electroplating at a stirring rate of 700r / min for 1h. A commercially available B12 gasket was used as a sample. Plating process: Grinding→alkaline cleaning solution to remove oil→water washing→acid cleaning solution to remove rust→water washing→polishing→water washing→plating.

[0031] The area ratio of the cathode to the anode is 2:1, the test uses a discrete power supply, and the control I Zn : I Ni = 4:1.

[0032] The obtained silver-white coating is bright, smooth and dense, with a nickel content of 13% an...

Embodiment 2

[0034] A kind of zinc-nickel alloy electroplating solution, its material is composed as follows according to parts by weight:

[0036] Nickel sulfate hexahydrate 14g / L

[0037] Potassium hydroxide 78g / L

[0038] Ethyleneimine 20mL / L

[0039] Triethanolamine 30mL / L

[0040] Herotropine 3g / L

[0041] Vanillin 0.5 g / L

[0042] Saccharin 5.0g / L

[0043] Sodium diethylhexyl sulfate 0.5 mL / L.

[0044] At 20~25℃, current density 3A / dm 2 , electroplating at a stirring rate of 700r / min for 1h. A commercially available B12 gasket was used as a sample. Plating process: Grinding→alkaline cleaning solution to remove oil→water washing→acid cleaning solution to remove rust→water washing→polishing→water washing→plating.

[0045] The area ratio of the cathode to the anode is 2:1, the test uses a discrete power supply, and the control I Zn : I Ni = 4:1.

[0046] The obtained silver-white coating is bright, smooth and dense, with a nickel content of 14% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com