Patents

Literature

200 results about "CAUSTIC ALKALIS" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An alkali is a basic ionic compound of an alkali earth metal or alkali metal element. Alkalies are most noted for their ability to neutralize or balance acidity. An alkali solution turns a red litmus paper blue. Caustic soda is a good example of an alkali.

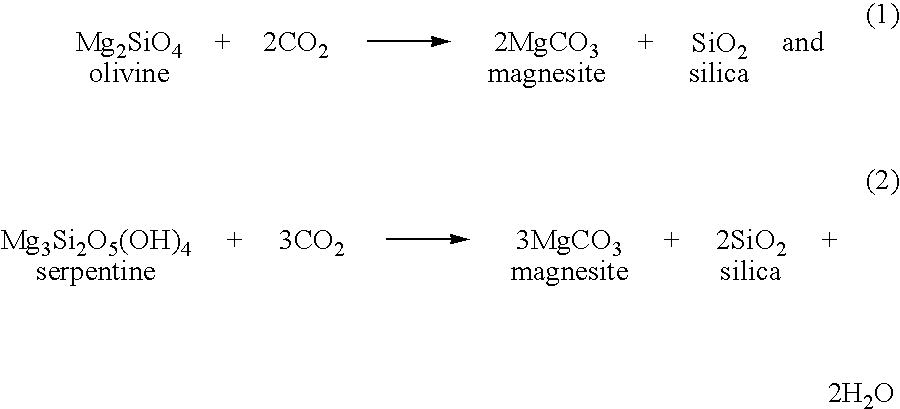

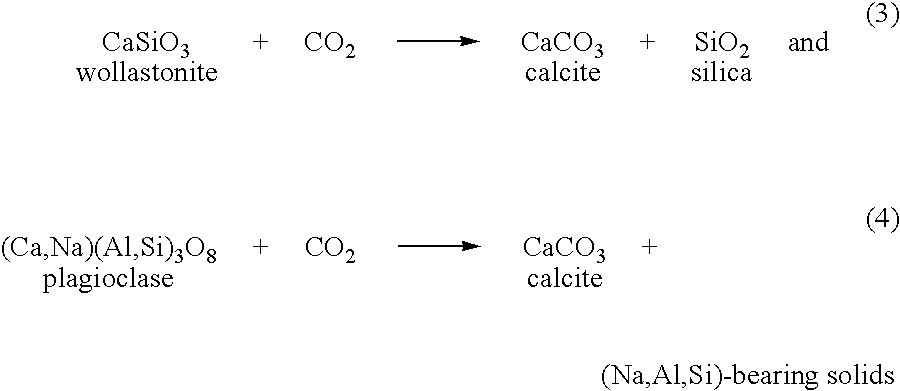

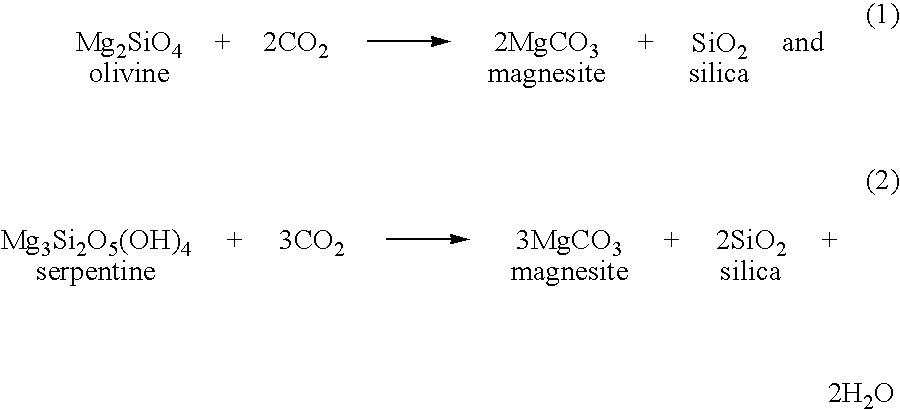

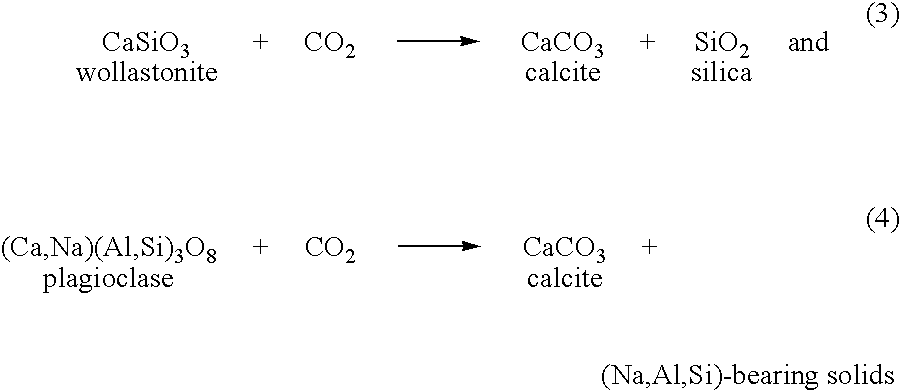

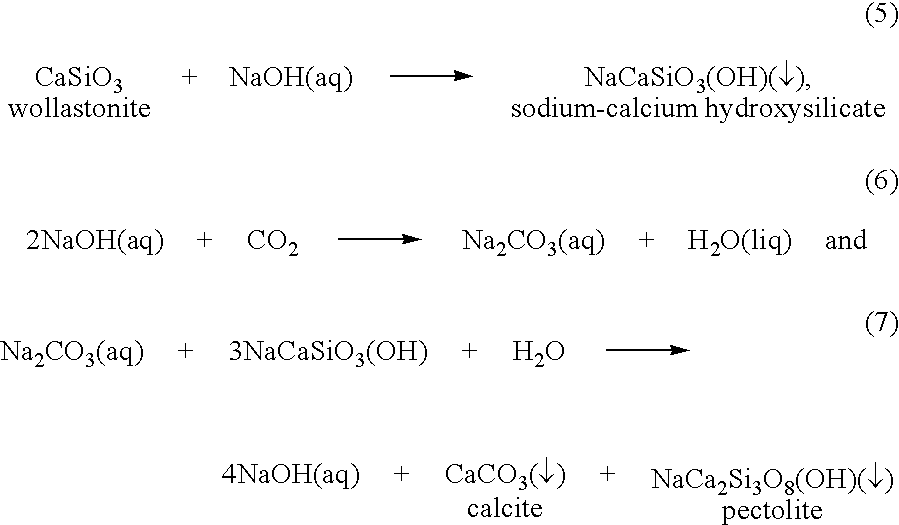

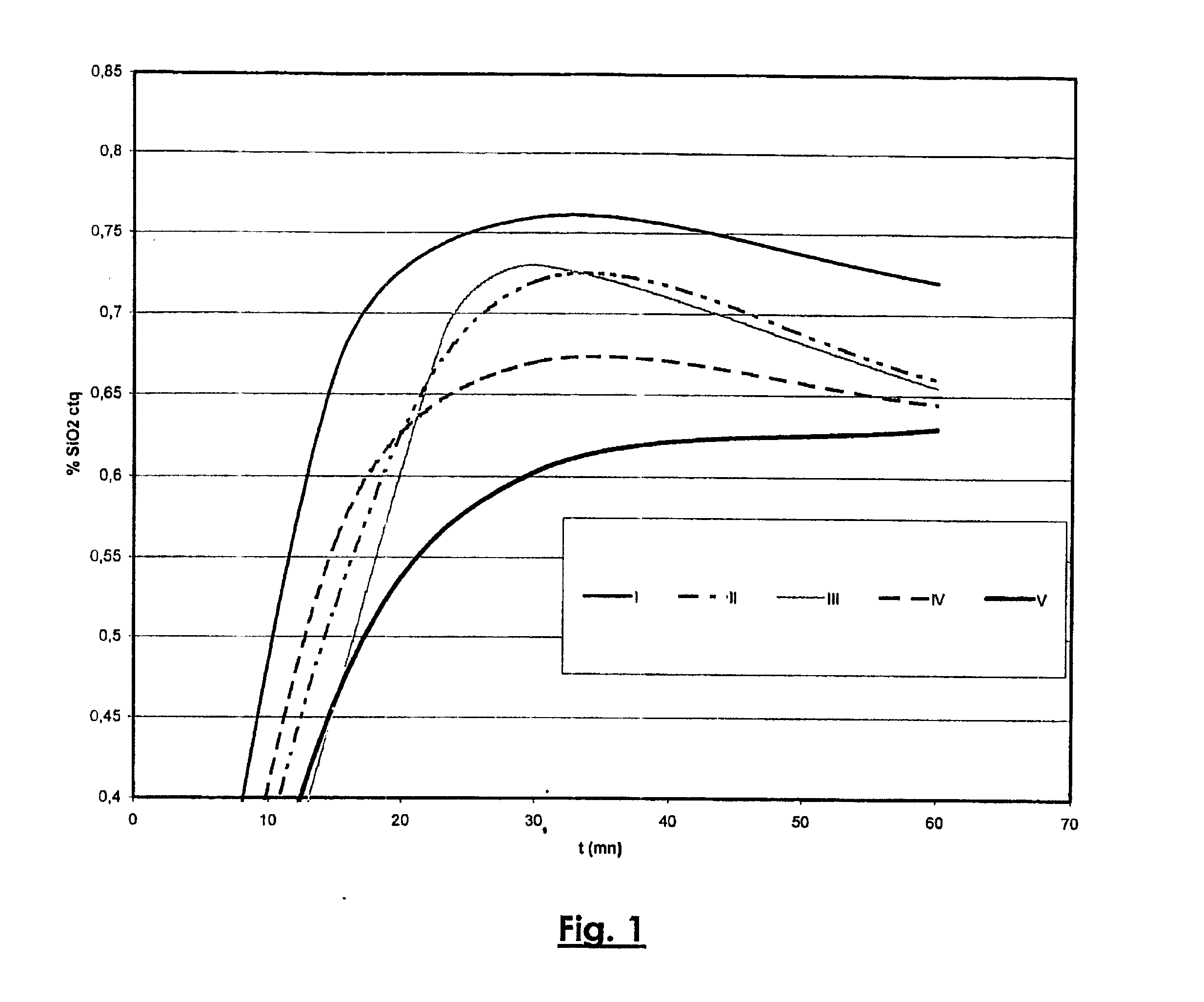

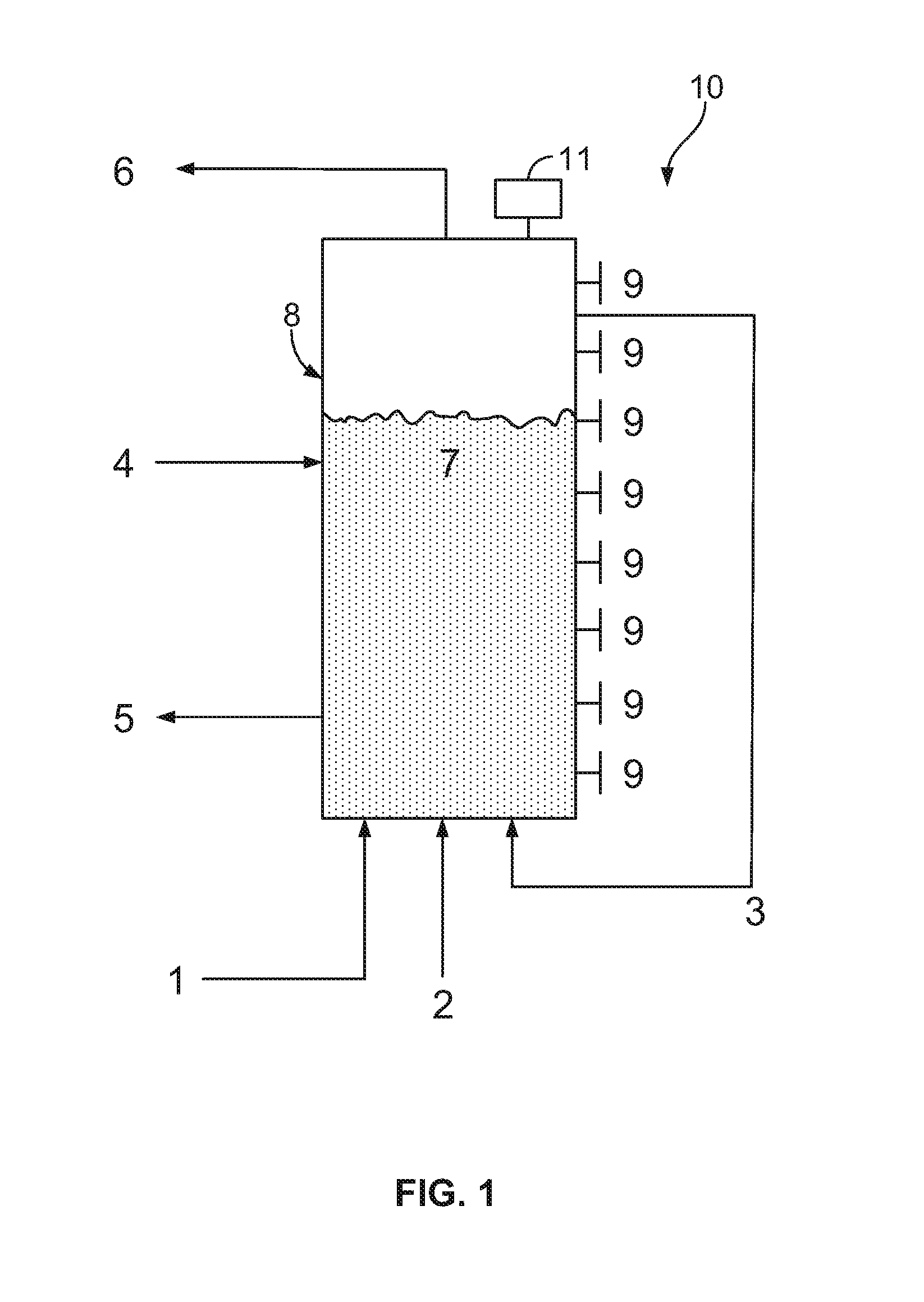

Carbonation of metal silicates for long-term co2 sequestration

In a preferred embodiment, the invention relates to a process of sequestering carbon dioxide. The process comprises the steps of: (a) reacting a metal silicate with a caustic alkali-metal hydroxide to produce a hydroxide of the metal formerly contained in the silicate; (b) reacting carbon dioxide with at least one of a caustic alkali-metal hydroxide and an alkali-metal silicate to produce at least one of an alkali-metal carbonate and an alkali-metal bicarbonate; and (c) reacting the metal hydroxide product of step (a) with at least one of the alkali-metal carbonate and the alkali-metal bicarbonate produced in step (b) to produce a carbonate of the metal formerly contained in the metal silicate of step (a).

Owner:UT BATTELLE LLC +2

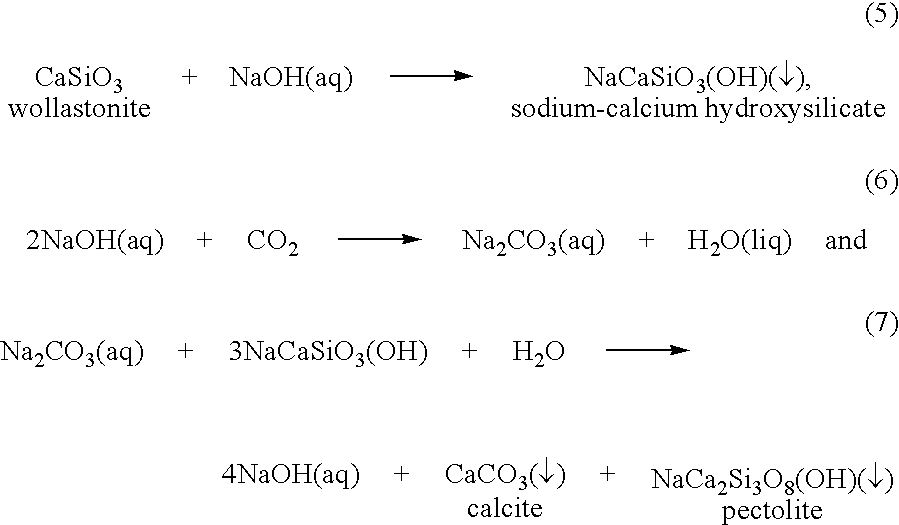

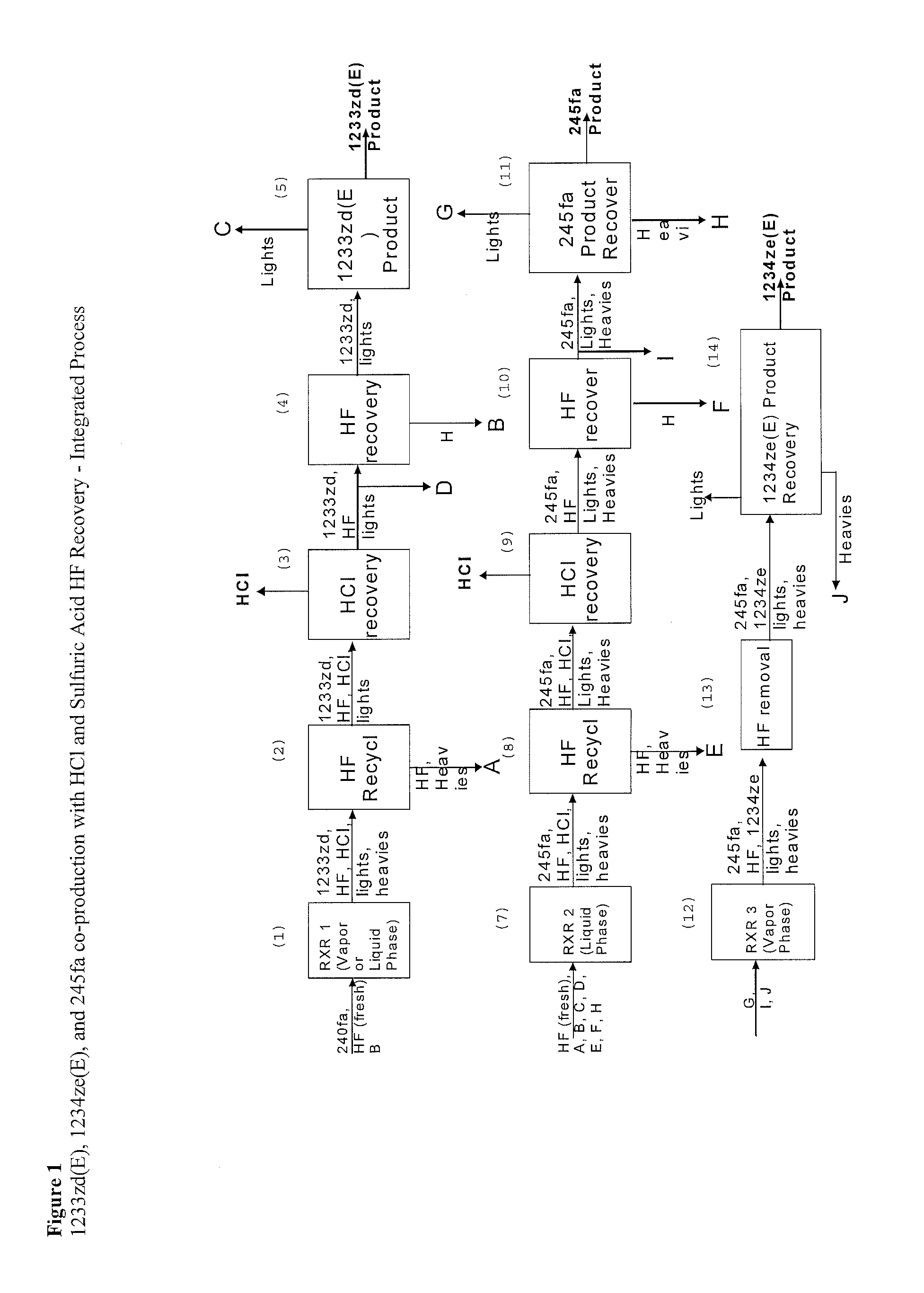

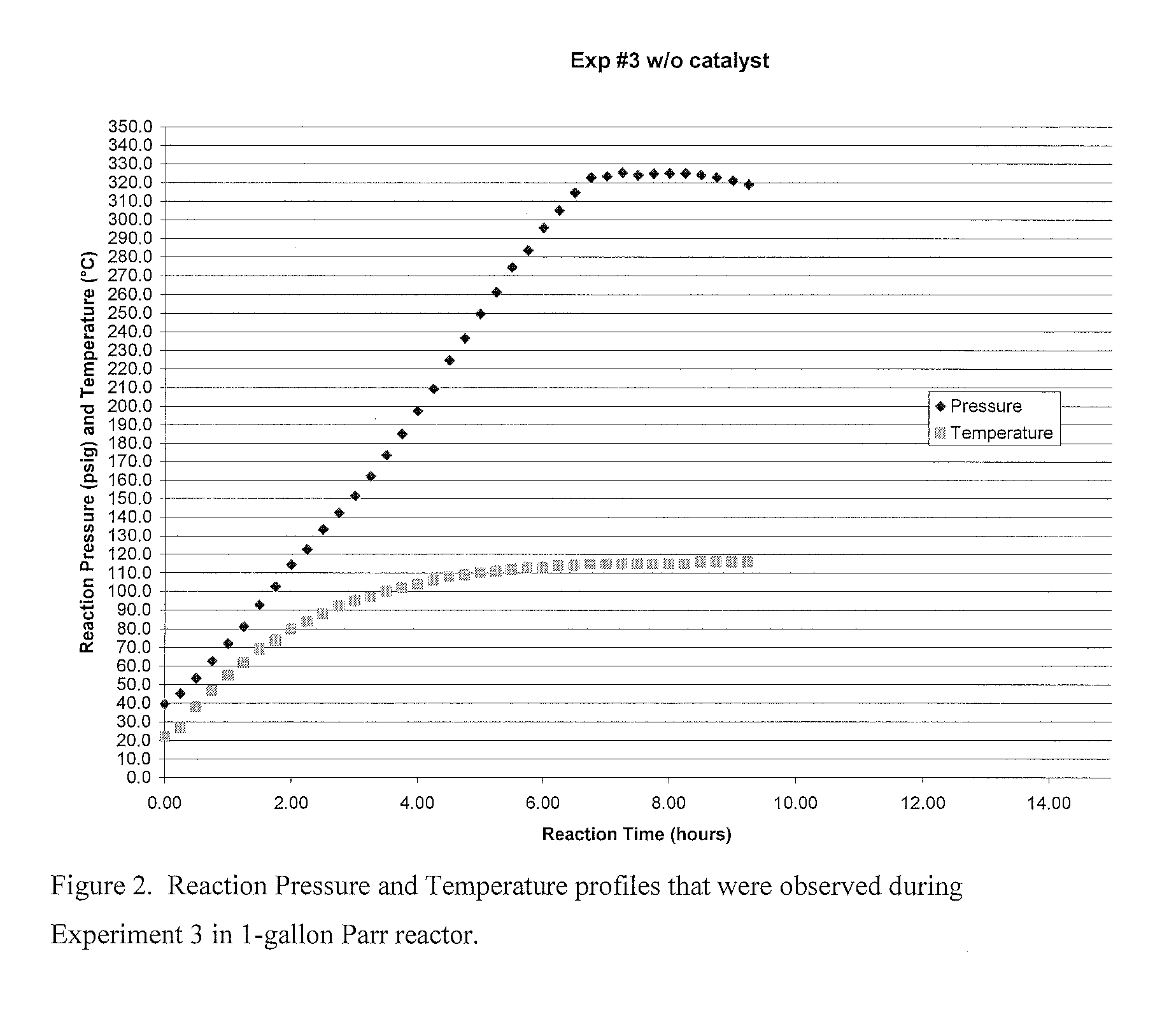

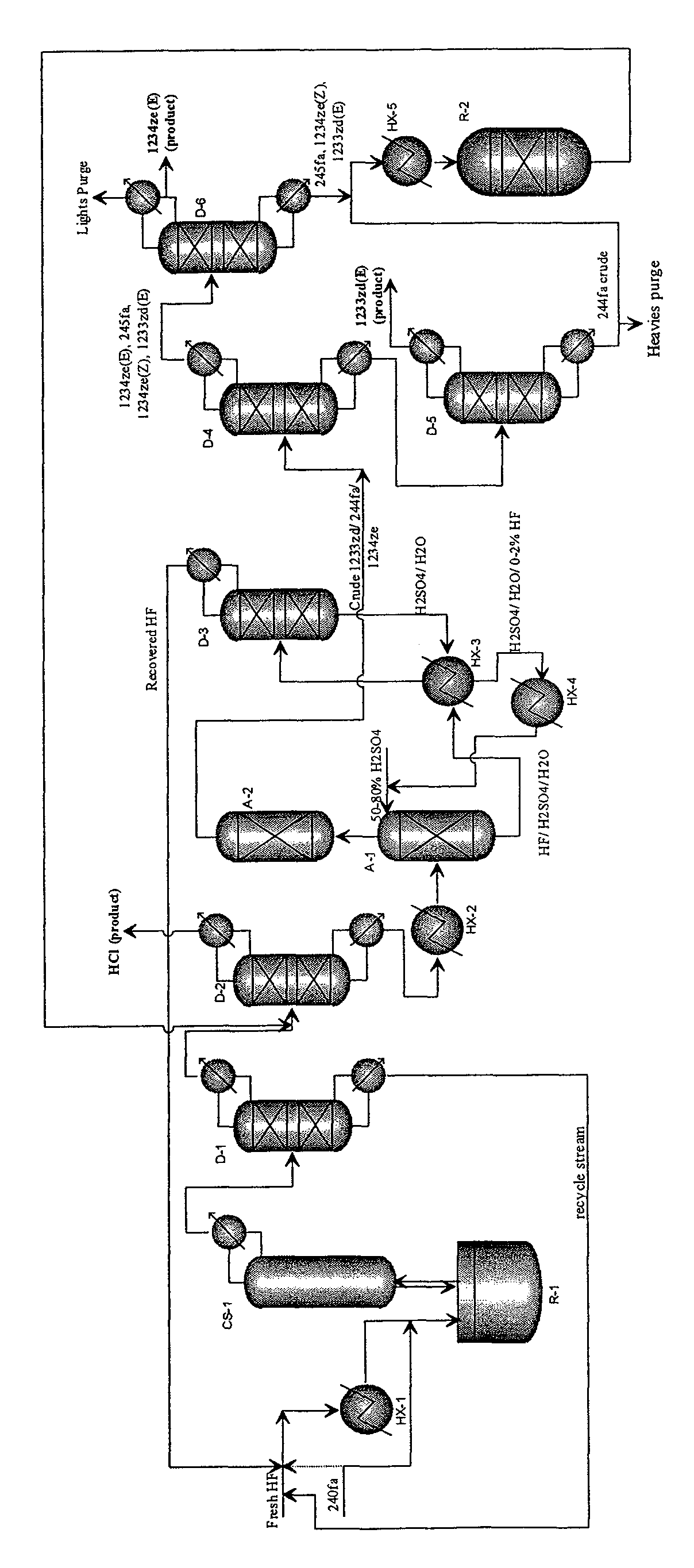

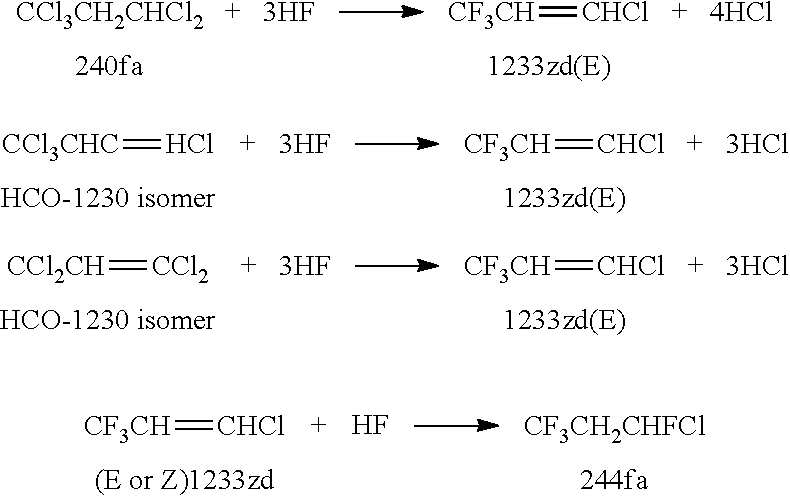

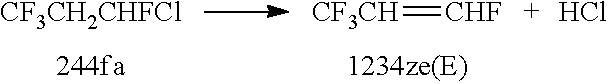

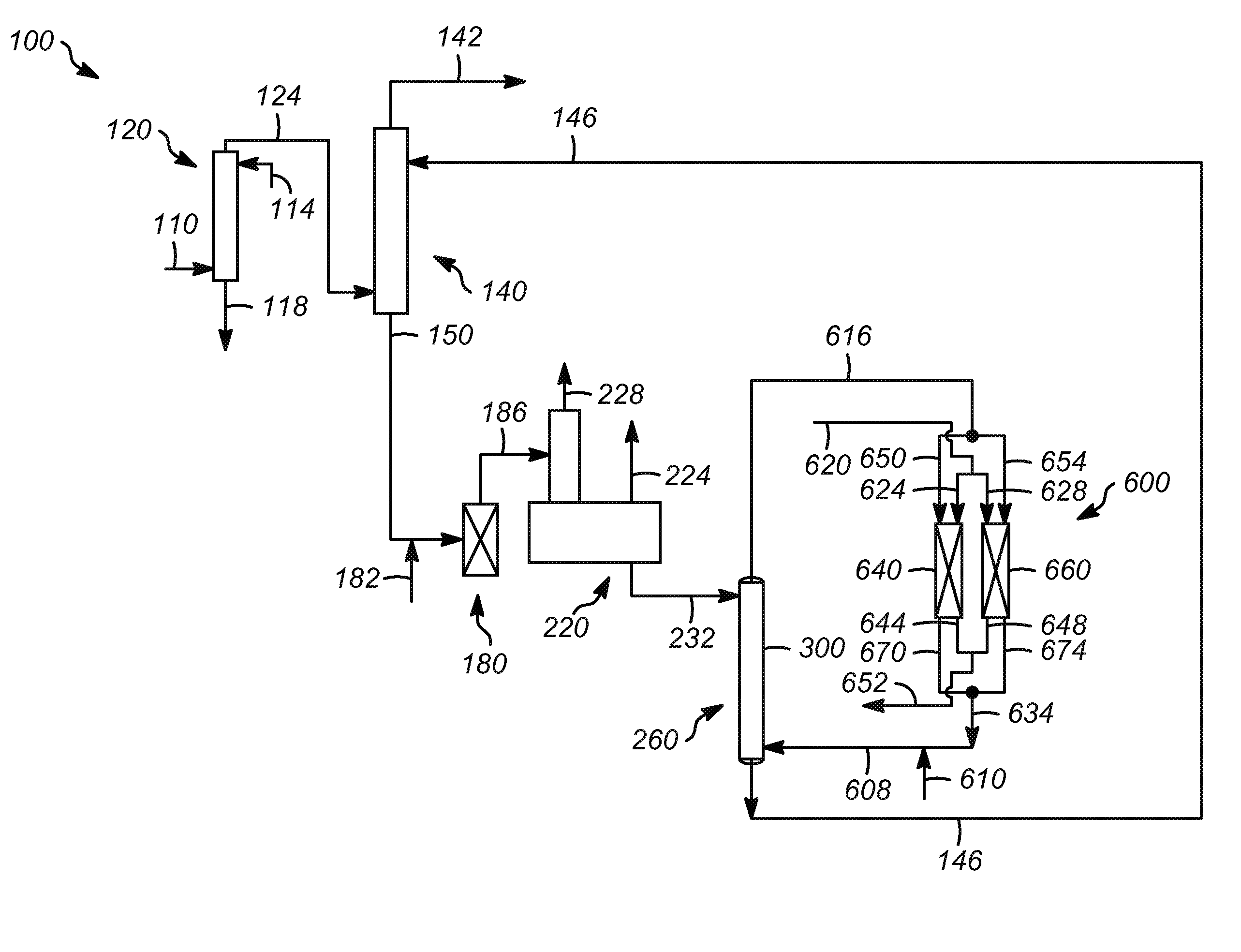

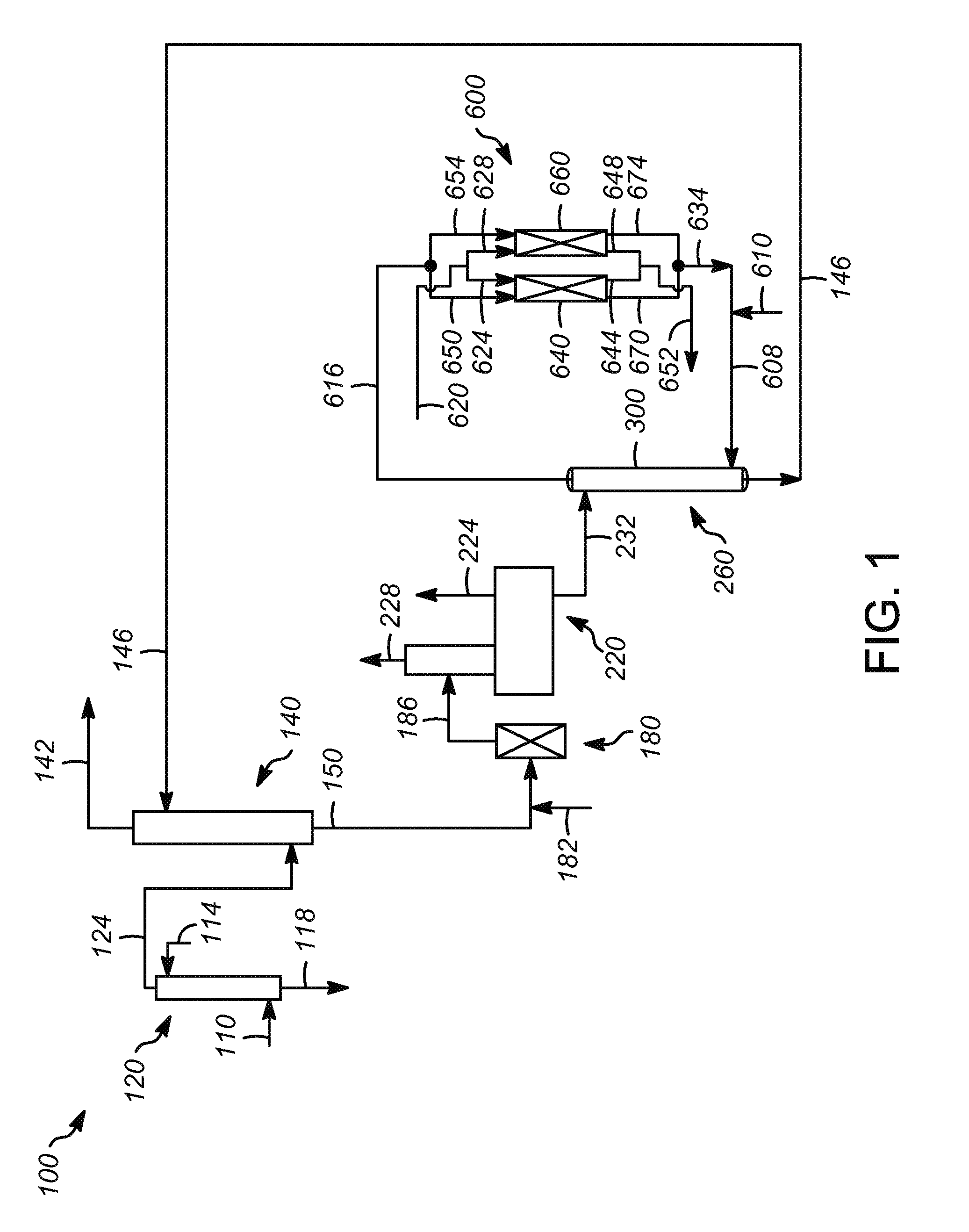

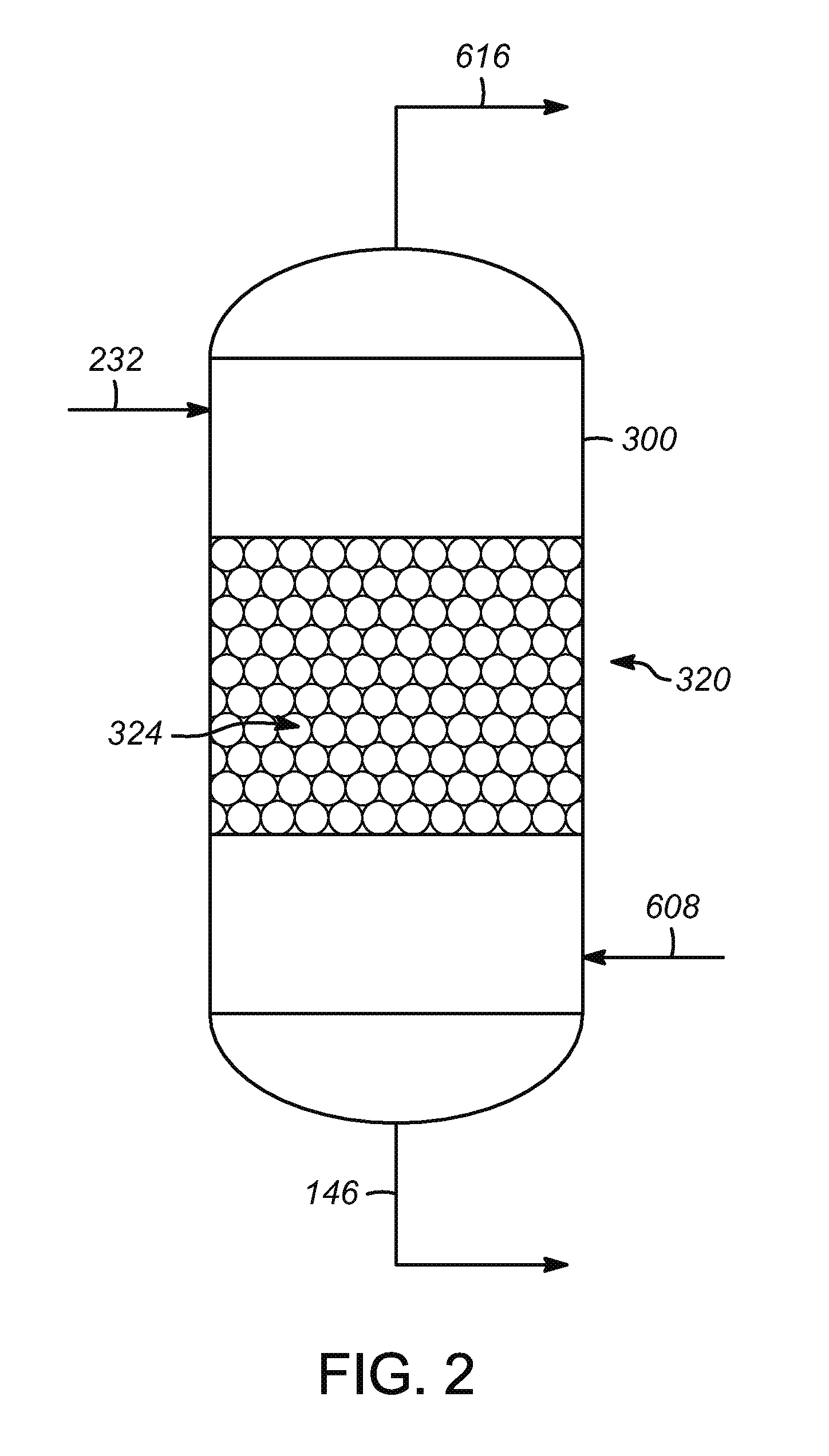

Integrated Process to Coproduce Trans-1-Chloro-3,3,3-Trifluoropropene, Trans-1,3,3,3-Tetrafluoropropene, and 1,1,1,3,3-Pentafluoropropane

ActiveUS20120059200A1High selectivityImprove production yieldPreparation by dehalogenationHydrocarbon from carbon oxidesGas phase1,3,3,3-Tetrafluoropropene

Disclosed is an integrated manufacturing process to co-produce (E)1-chloro-3,3,3-trifluoropropene, (E)1,3,3,3-tetrafluoropropene, and 1,1,1,3,3-pentafluoro-propane starting from a single chlorinated hydrocarbon feed stock, 240fa. The process includes a combined liquid or vapor phase reaction / purification operation which directly produces (E)1-chloro-3,3,3-trifluoropropene (1233zd(E)) from 240fa. In the second liquid phase fluorination reactor 1233zd(E) is contacted with HF in the presence of catalyst to produce 1,1,1,3,3-pentafluoropropane (245fa) with high conversion and selectivity. A third reactor is used for dehydrofluorination of 245fa to produce (E)1,3,3,3-tetrafluoropropene (1234ze(E)) by contacting in the liquid phase with a caustic solution or in the vapor phase using a dehydrofluorination catalyst. This operation may be followed by one or more purification processes to recover the 1234ze(E) product.

Owner:HONEYWELL INT INC

Method for preparing ternary material precursor and recovering lithium by using spent lithium-ion battery ternary cathode materials

ActiveCN108878866AGuaranteed uniformityHigh recovery rateCell electrodesWaste accumulators reclaimingManganeseCobalt

The invention belongs to the technical field of ternary material precursor preparation, and particular to a method for preparing a ternary material precursor and recovering lithium by using spent lithium-ion battery ternary cathode materials. Spent lithium-ion battery anode materials are roasted and screened to obtain ternary anode materials and aluminum foil; the ternary anode materials are leached out of a caustic soda solution and filtered to obtain filtrate and filter residues; carbonate is added to the filtrate to react to obtain lithium carbonate solid; the filter residues are leached with volatile acid; a reducing agent is added to the leaching solution and the volatile acid is removed by heating the solution to a boil; the molar ratios of nickel, cobalt and manganese in leaching solution are adjusted; and the leaching solution after adjusting the molar ratios of the nickel, the cobalt and the manganese is flow into a reaction kettle containing an ammonia water solution togetherwith the ammonia water solution and caustic solution, and coprecipitation is performed under inert gas protection. The method for preparing the ternary material precursor and recovering the lithium by using the spent lithium-ion battery ternary cathode materials realizes the preparation of the ternary material precursor and the recovery of the lithium at the same time, the production cost is reduced, product quality is high, economy is good, and the directional circulation of nickel-cobalt-manganese lithium resources is realized.

Owner:SHANDONG UNIV OF TECH

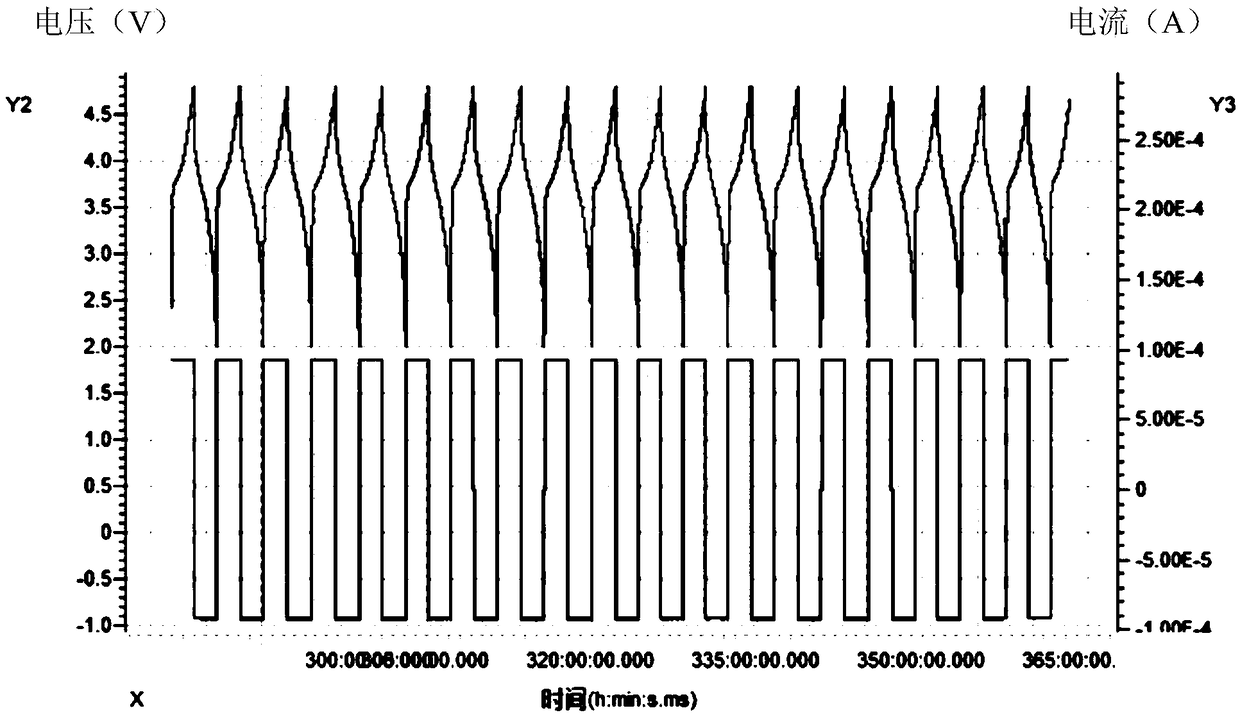

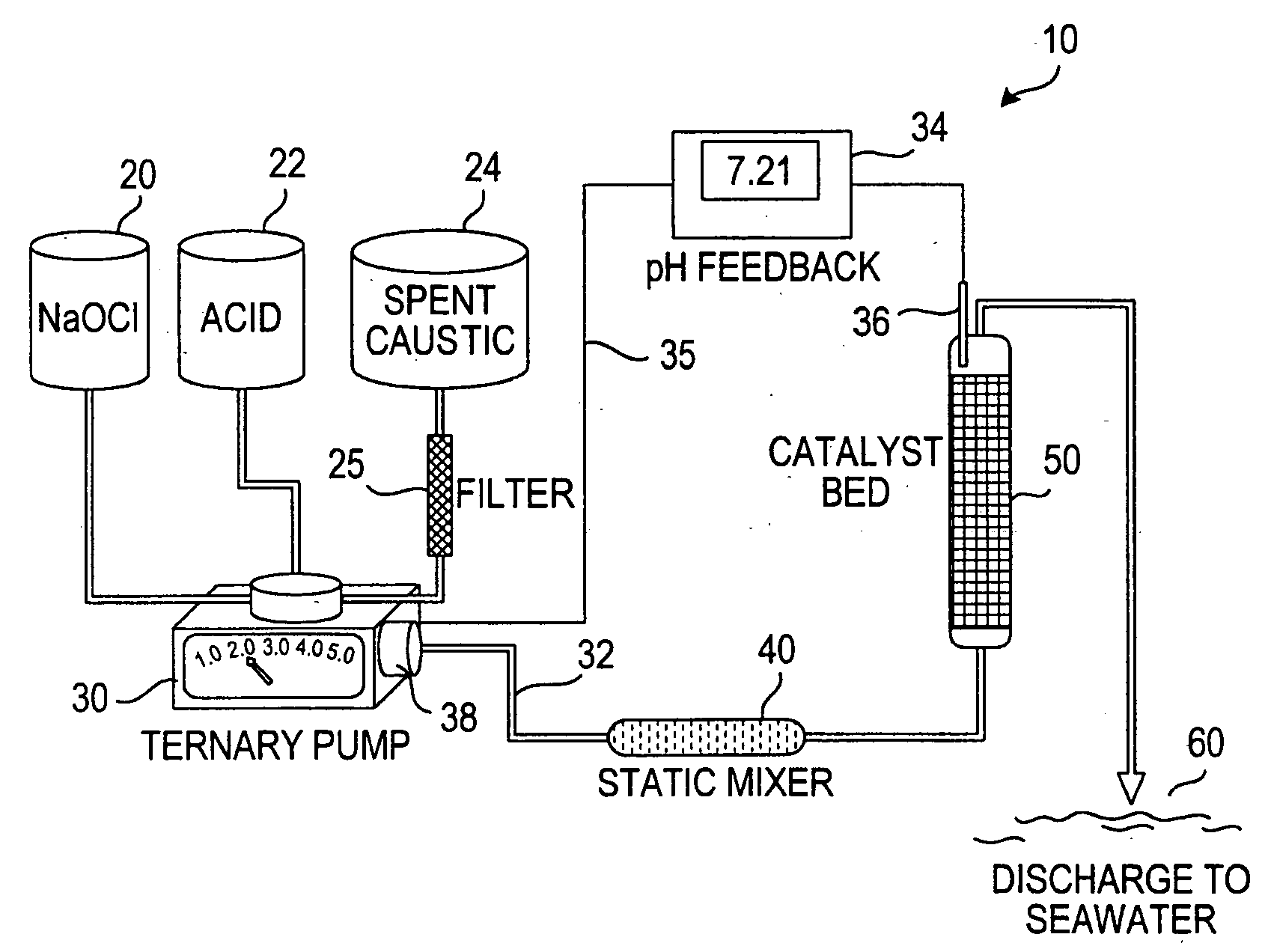

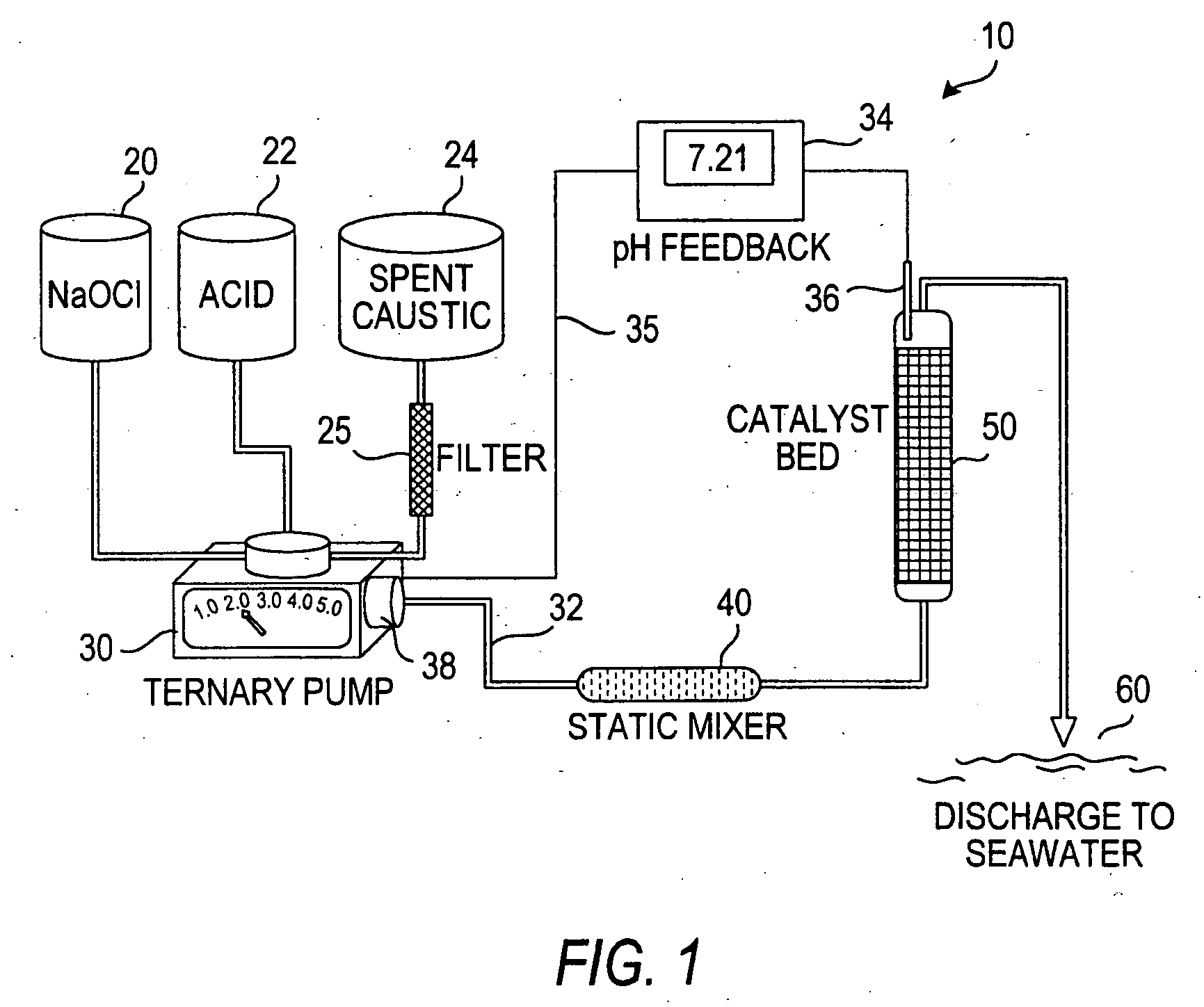

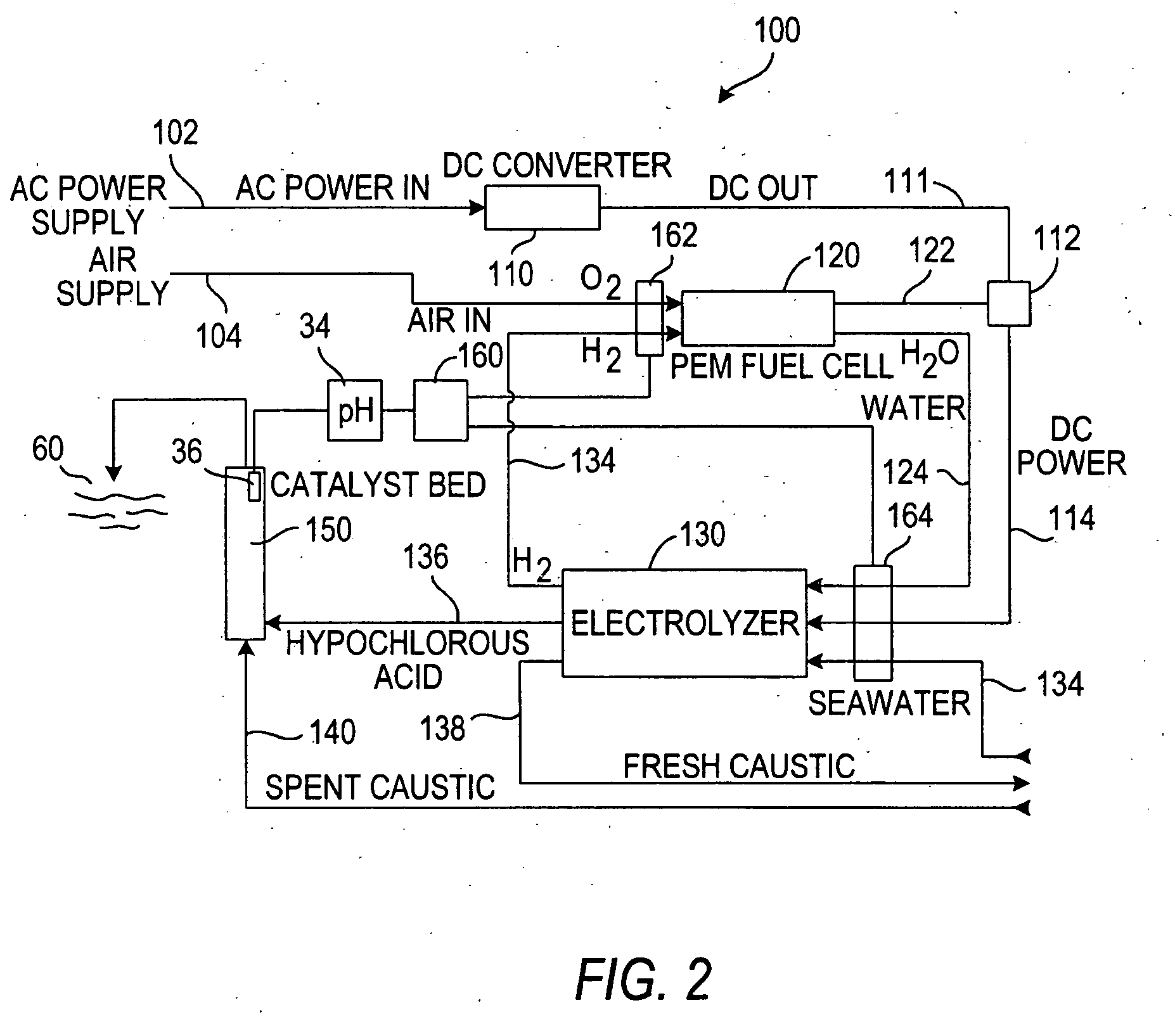

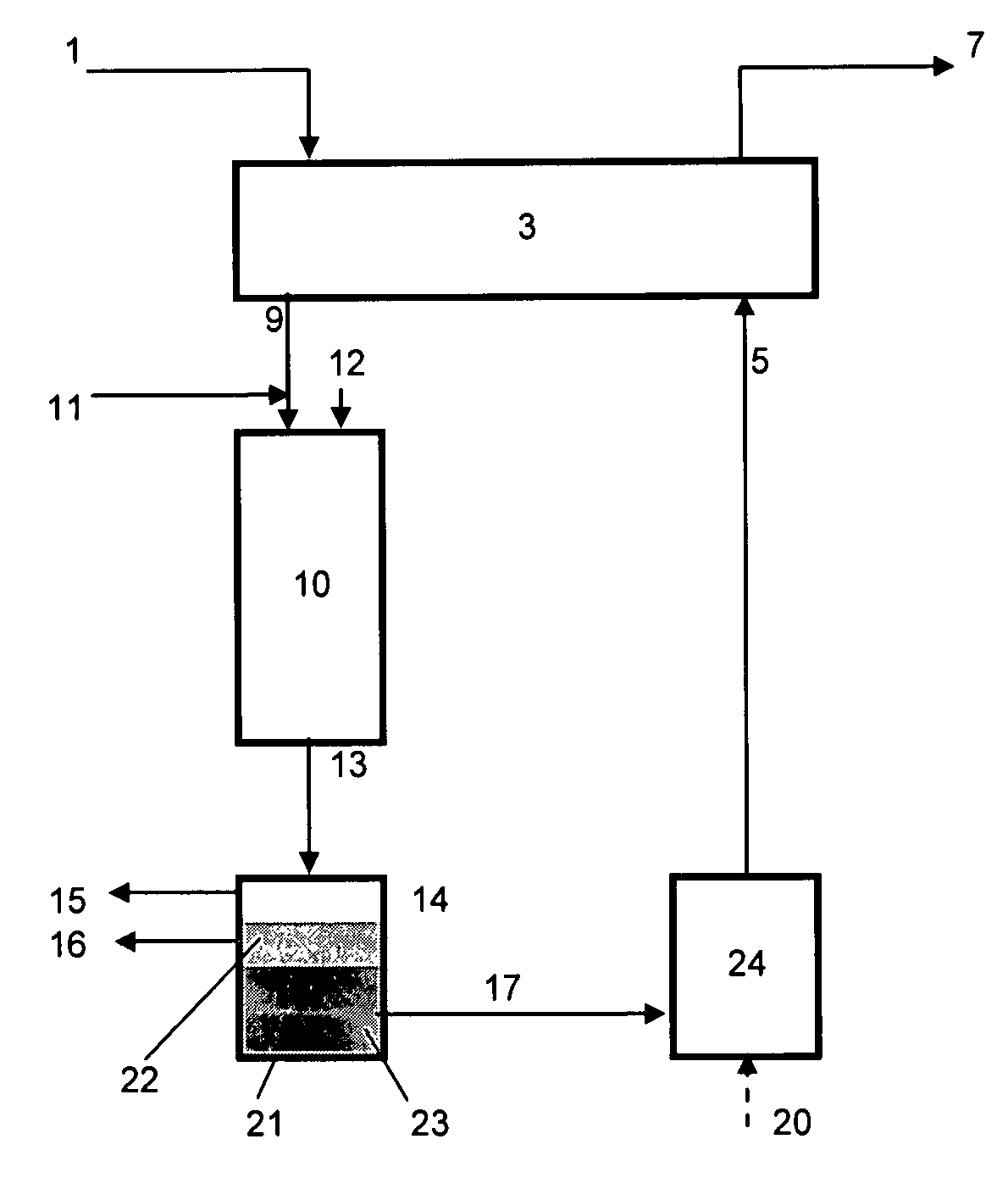

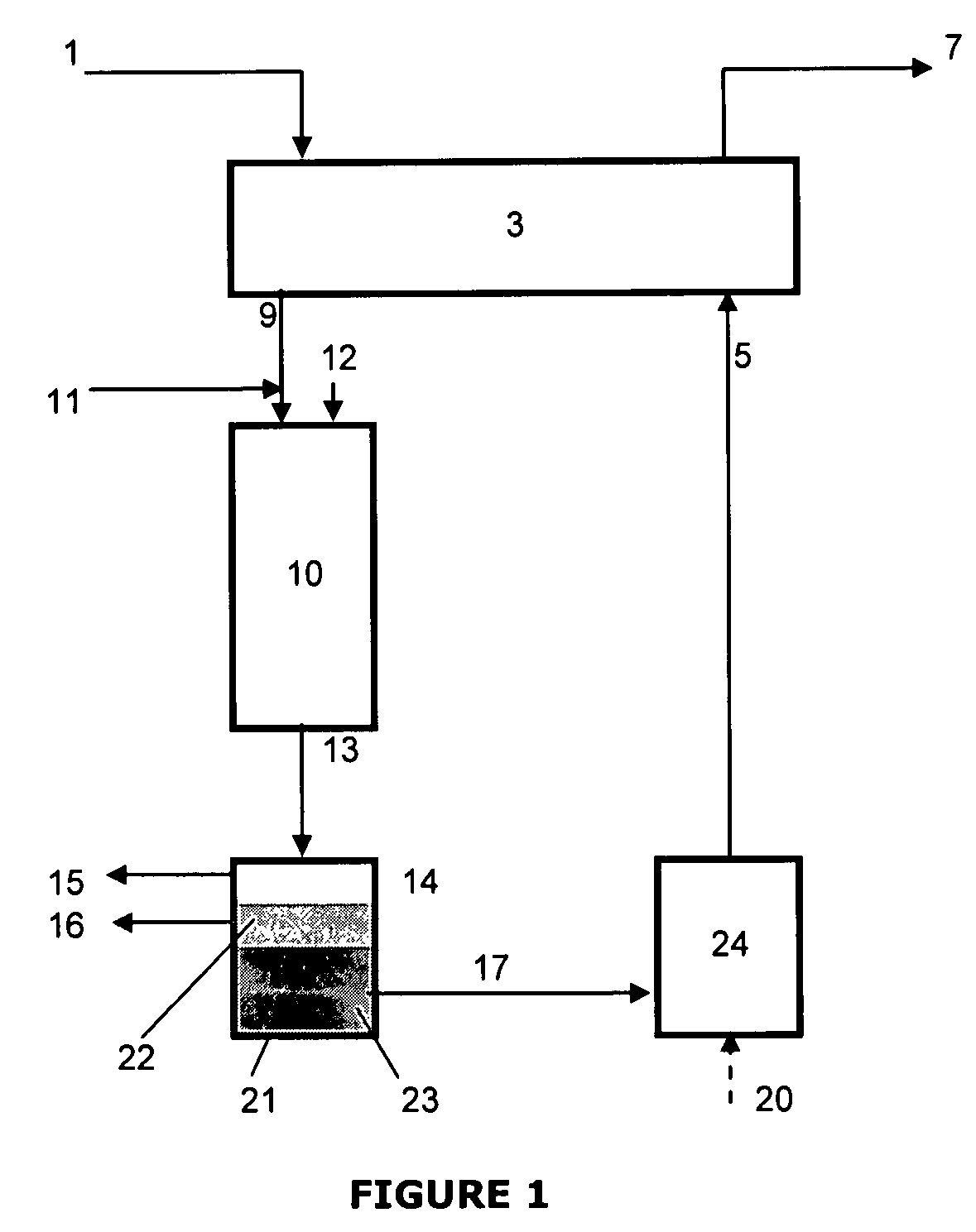

Process for treating a sulfur-containing spent caustic refinery stream using a membrane electrolyzer powered by a fuel cell

ActiveUS20060254930A1Simple and inexpensive and effectiveReduce investmentPhotography auxillary processesElectrolysis componentsSodium sulfateSulfur containing

A continuous method for the treatment of a spent aqueous caustic stream used to scrub a hydrocarbon process stream to remove oxidizable sulfur-containing compounds includes: a. mixing an oxidizing hypochlorous acid stream produced from an aqueous brine solution with the aqueous caustic stream to form a reactive mixed feedstream; b. contacting the reactive mixed feedstream with at least one catalyst to promote the oxidation of the sulfur-containing compounds and the neutralization of the sodium hydroxide; and c. recovering a neutral treated product stream comprising aqueous sodium sulfate, sodium carbonate and sodium chloride that is odorless, non-toxic and environmentally acceptable for discharge into the sea or into a conventional sewage treatment system. Preferably, the hypochlorous acid is produced by an electrolyzer that also produces a (1) hydrogen stream that is directed to a PEM fuel cell to generate at least a portion of the electrical power requirement of the electrolyzer, and (2) water that is combined with fresh sodium hydroxide from the electrolyzer to form a fresh caustic stream for use in scrubbing the hydrocarbon process stream.

Owner:SAUDI ARABIAN OIL CO

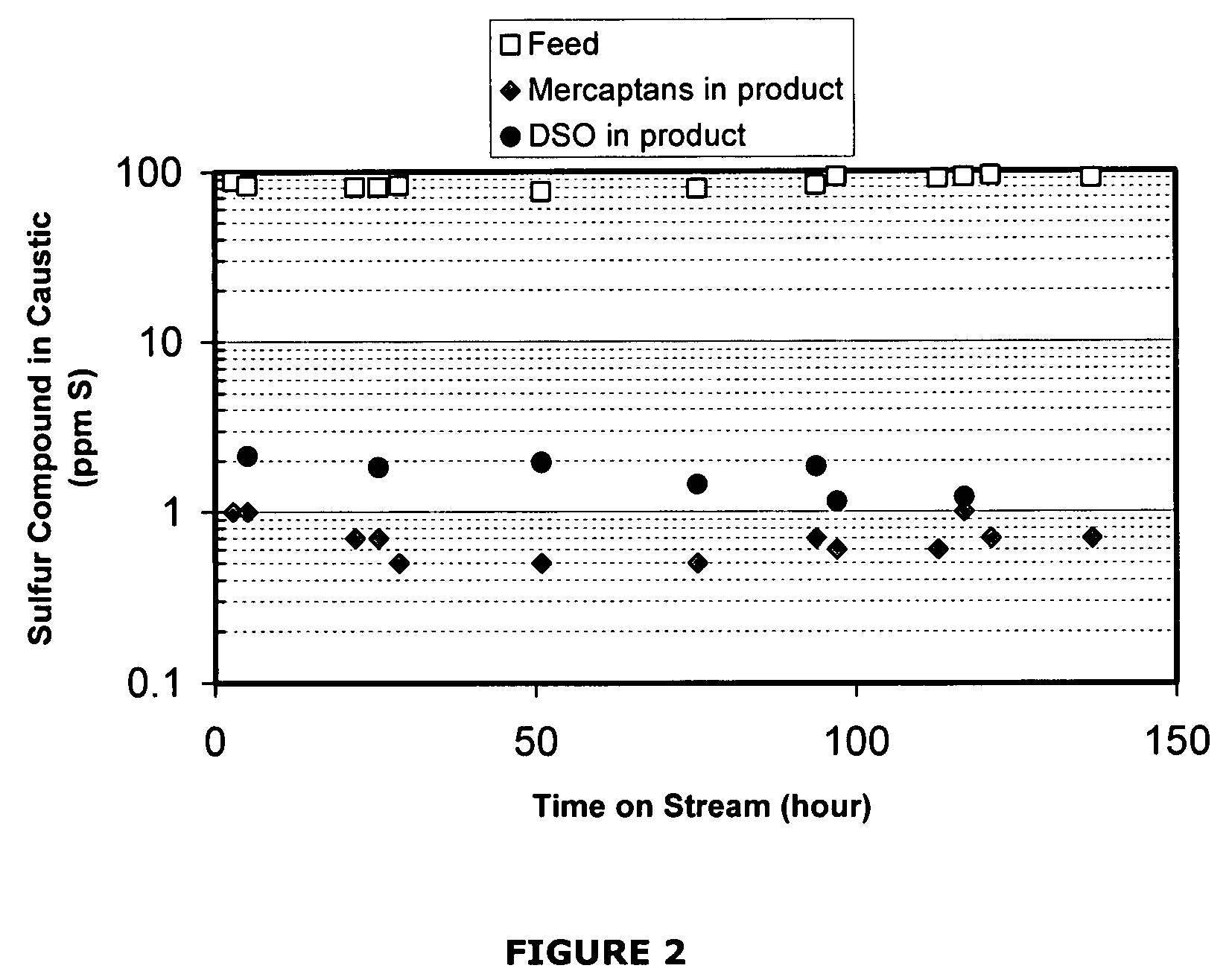

Removal of residual sulfur compounds from a caustic stream

Owner:MERICHEM CO

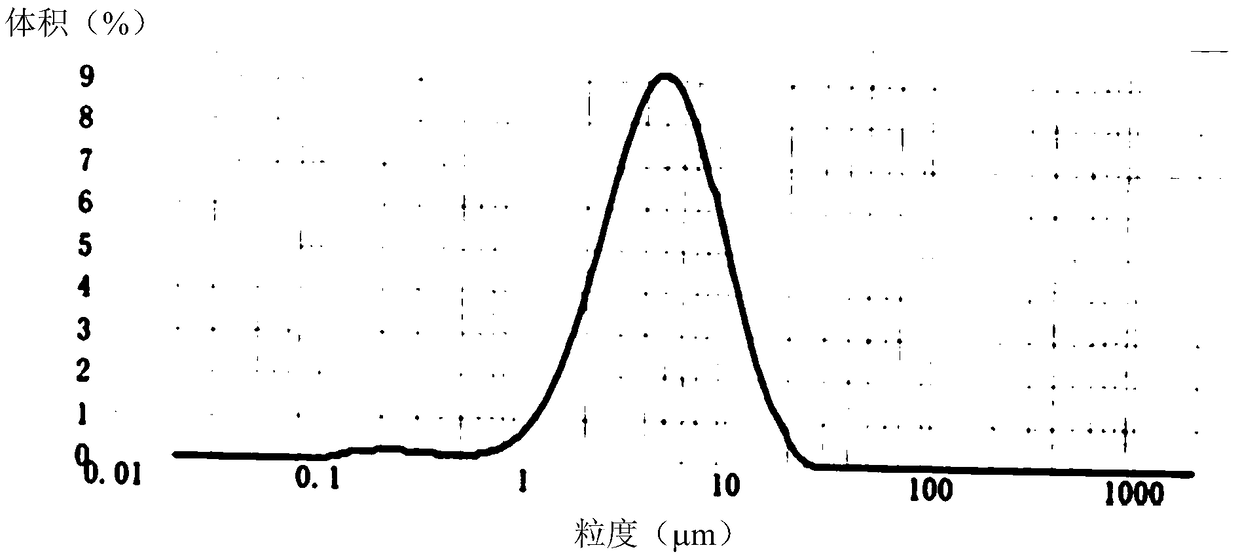

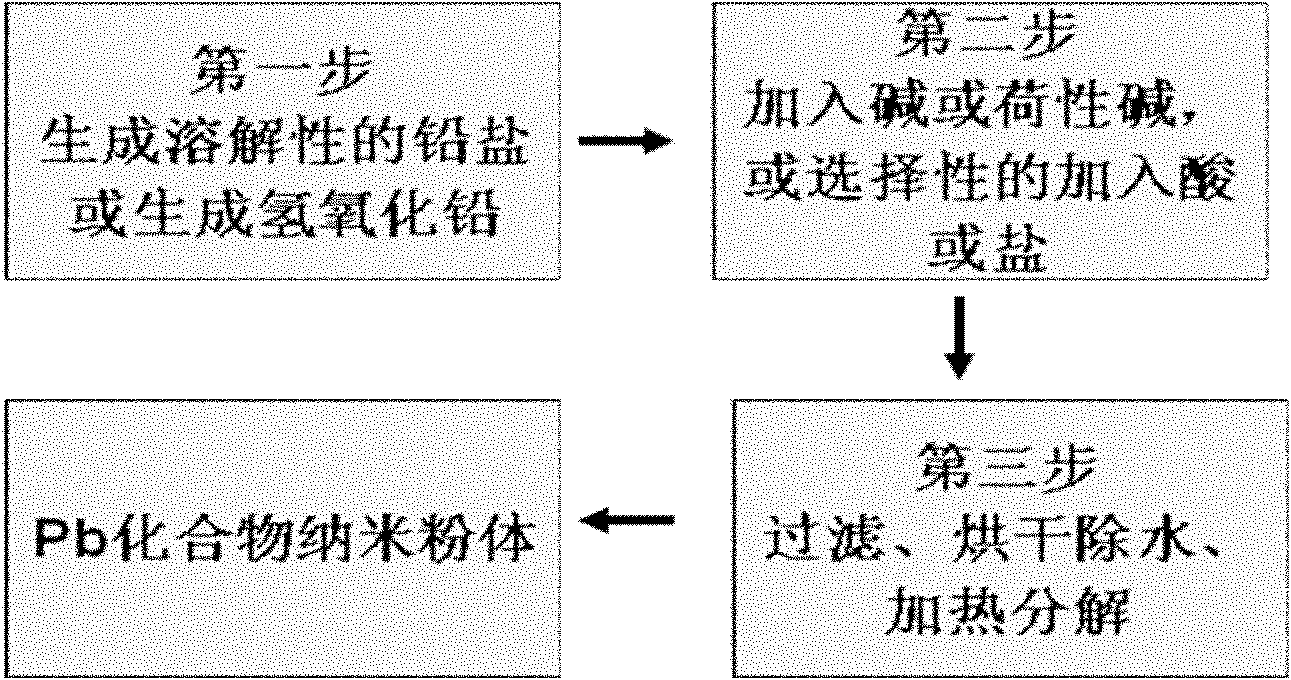

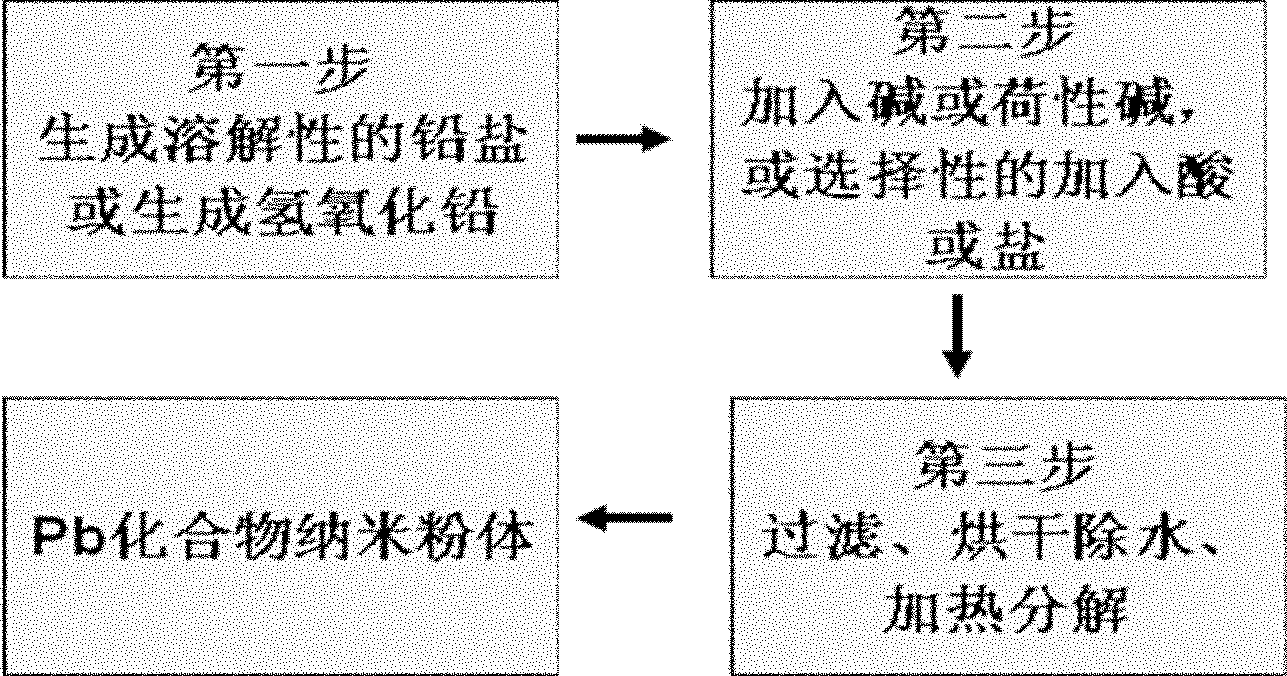

Lead compound nano-powder preparation method for recovery and manufacture of lead-acid battery

ActiveCN102689922AEnvironmental recyclingEnvironmental productivityLead monoxideNanotechnologySolubilityLead salt

The invention discloses a lead compound nano-powder preparation method for recovery and manufacture of lead-acid battery. The lead compound nano-powder preparation method comprises the following steps that 1, lead, a lead salt or waste lead-acid battery lead paste reacts with one or more organic or inorganic compounds to produce a soluble lead salt solution or a lead hydroxide solution; 2, one or more alkalis or caustic alkalis are added into the soluble lead salt solution, or a part or excess amount of H2CO3 or CO2, sulfuric acid, one or more organic acids or their salts are added into the lead hydroxide solution, and 3, lead oxide or lead hydroxide precipitates obtained by the step 2 are filtered and are subjected to drying and pyrolysis to form the lead compound nano-powder. The lead compound nano-powder preparation method realizes environmentally friendly recovery and production, has low energy consumption, greatly reduces a production cost, and shortens a production period. The lead compound nano-powder obtained by the lead compound nano-powder preparation method is conducive to improvement of technical product performances.

Owner:杨春晓

Integrated process to co-produce trans-1-chloro-3,3,3-trifluoropropene and trans-1,3,3,3-tetrafluoropropene

ActiveUS8426656B2Low costPreparation by dehalogenationPreparation by hydrogen halide split-offPtru catalystFluid phase

The disclosed integrated manufacturing process includes a combined liquid phase reaction and purification operation which directly produces trans-1-chloro-3,3,3-trifluoropropene and 3-chloro-1,1,1,3-tetrafluoropropane which is a precursor to the manufacture of trans-1,3,3,3-tetrafluoropropene. The mixture of co-products is easily separated by conventional distillation and 3-chloro-1,1,1,3-tetrafluoropropane is then dehydrochlorinated to produce trans-1,3,3,3-tetrafluoropropene by contacting in the liquid phase with a caustic solution or in the vapor phase using a dehydrochlorination catalyst.

Owner:HONEYWELL INT INC

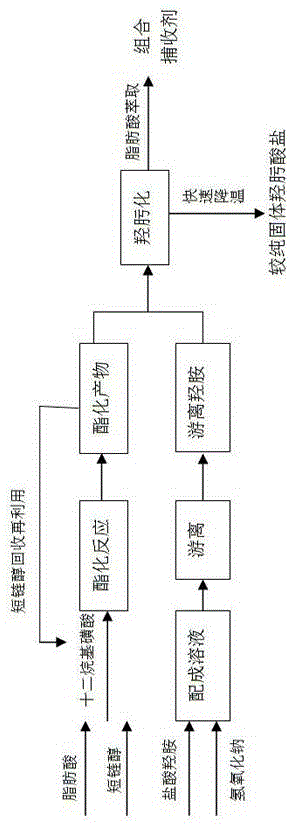

Synthesis method of hydroxyoximate

InactiveCN104447409AAvoid it happening againAvoid corrosionOrganic chemistryFlotationAlcoholSynthesis methods

The invention relates to a synthesis method of hydroxamate. The hydroxamate is synthesized from fatty acid, short chain alcohol, dodecyl sulfonic acid, hydroxylamine hydrochloride and caustic alkali by two steps; and the synthesis method comprises the following steps of adding fatty acid, short chain alcohol and dodecyl sulfonic acid into a reactor, stirring and reacting at a constant temperature of 75 DEG C-100 DEG C; carrying out reduced pressure distillation on the reactants to obtain fatty acid ester; adding hydroxylamine hydrochloride into another reactor, adding caustic alkali in batches while stirring, and mixing; adding fatty acid ester and reacting for 3-5 hours at 40 DEG C-60 DEG C to obtain a hydroxamate solution; and rapidly cooling the hydroxamate solution to obtain the solid hydroxamate. By the synthesis method, the conversion between acid-alkali environment for the esterification and hydroximation two-step reaction is avoided, the synthesized product needs not to be subjected to processing steps such as acidification, impurity removal and purification and the obtained product can be organically combined with flotation industry. The synthesis method has the advantages that the operation is simple, the yield of the product is high, the generation of a large amount of acidic wastewater is avoided and the cost of chemical agents is effectively decreased.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Multifunctional bio-charcoal and preparation method thereof

The invention relates to a multifunctional bio-charcoal and a preparation method thereof. According to the technical scheme, the preparation method comprises the steps of dipping biomass into 1-15wt% caustic alkali solution for 1-50h, washing with water to be neutral, and drying to obtain treated biomass; then charring the treated biomass in a tube furnace in mixed gas at 300-900 DEG for 1-130h to obtain the multifunctional bio-charcoal. The biomass is one of rice straw, wheat straw, sawdust, wood, green grass, fruit peel and animal tissue waste; the biomass contains 30-60wt% of volatile organic carbon of charcoal, 10-40wt% of fixed carbon, 1-30wt% of ash and 10-60wt% of water. The preparation method disclosed by the invention has the characteristics of low production cost, high yield, simple process, controllable production process and environment friendliness, and the prepared multifunctional bio-charcoal has a good adsorption effect on heavy metals and high stability and can be used for repairing water bodies, solid matrixes and soil which are polluted by heavy metals.

Owner:WUHAN UNIV OF SCI & TECH

Carbonation of metal silicates for long-term CO2 sequestration

InactiveUS8114374B2Calcium/strontium/barium carbonatesMagnesium fertilisersProcess engineeringEnvironmental engineering

Owner:UT BATTELLE LLC +2

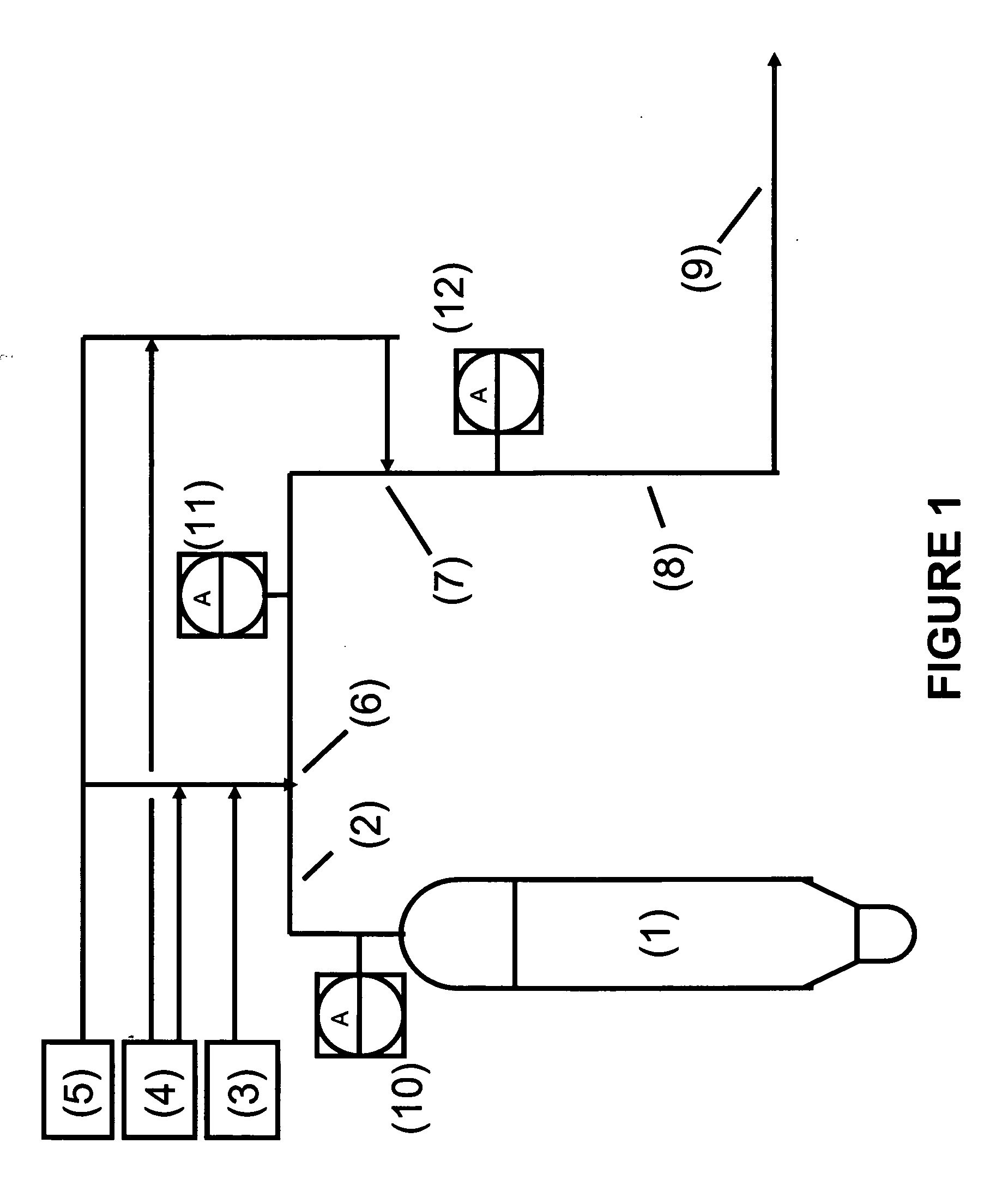

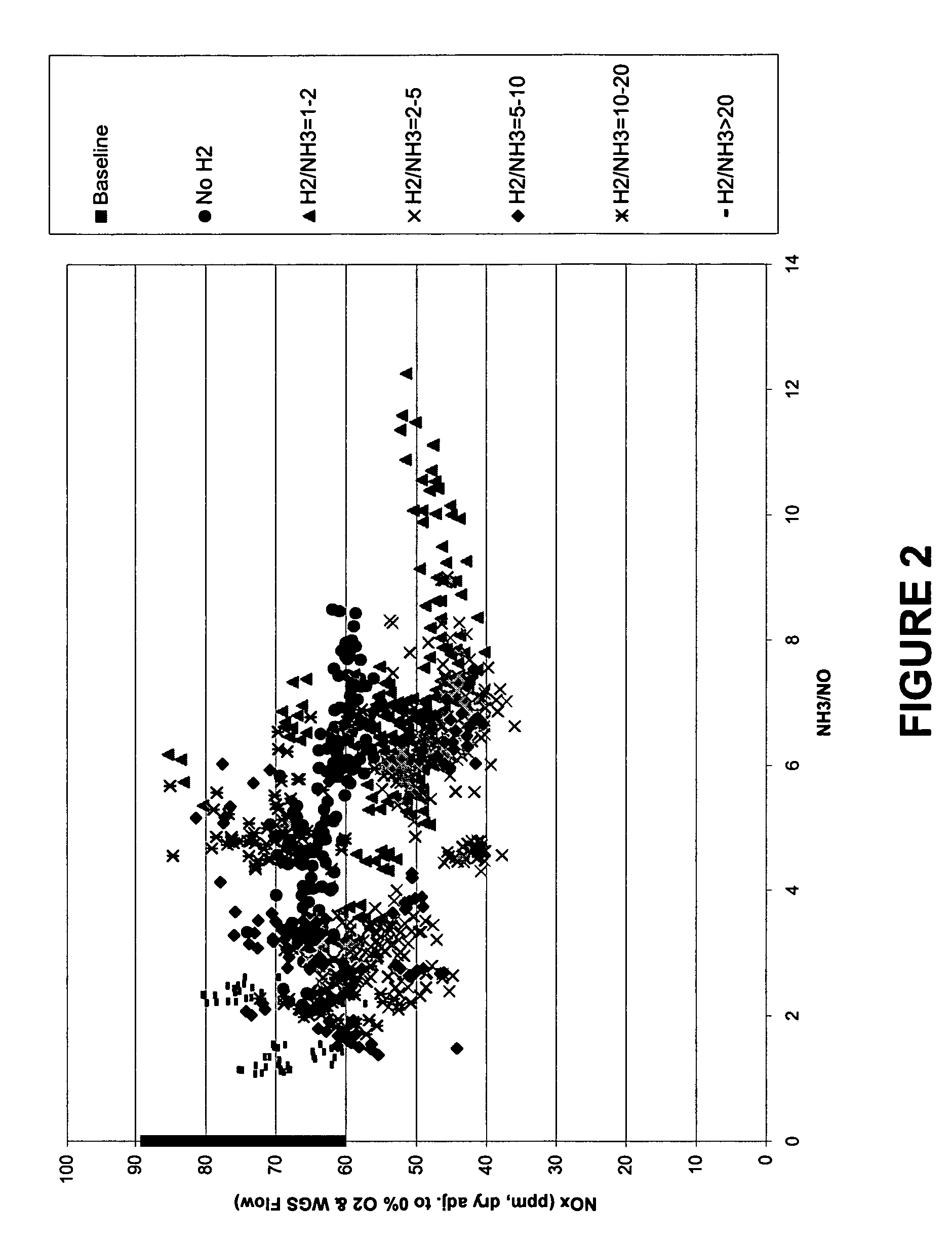

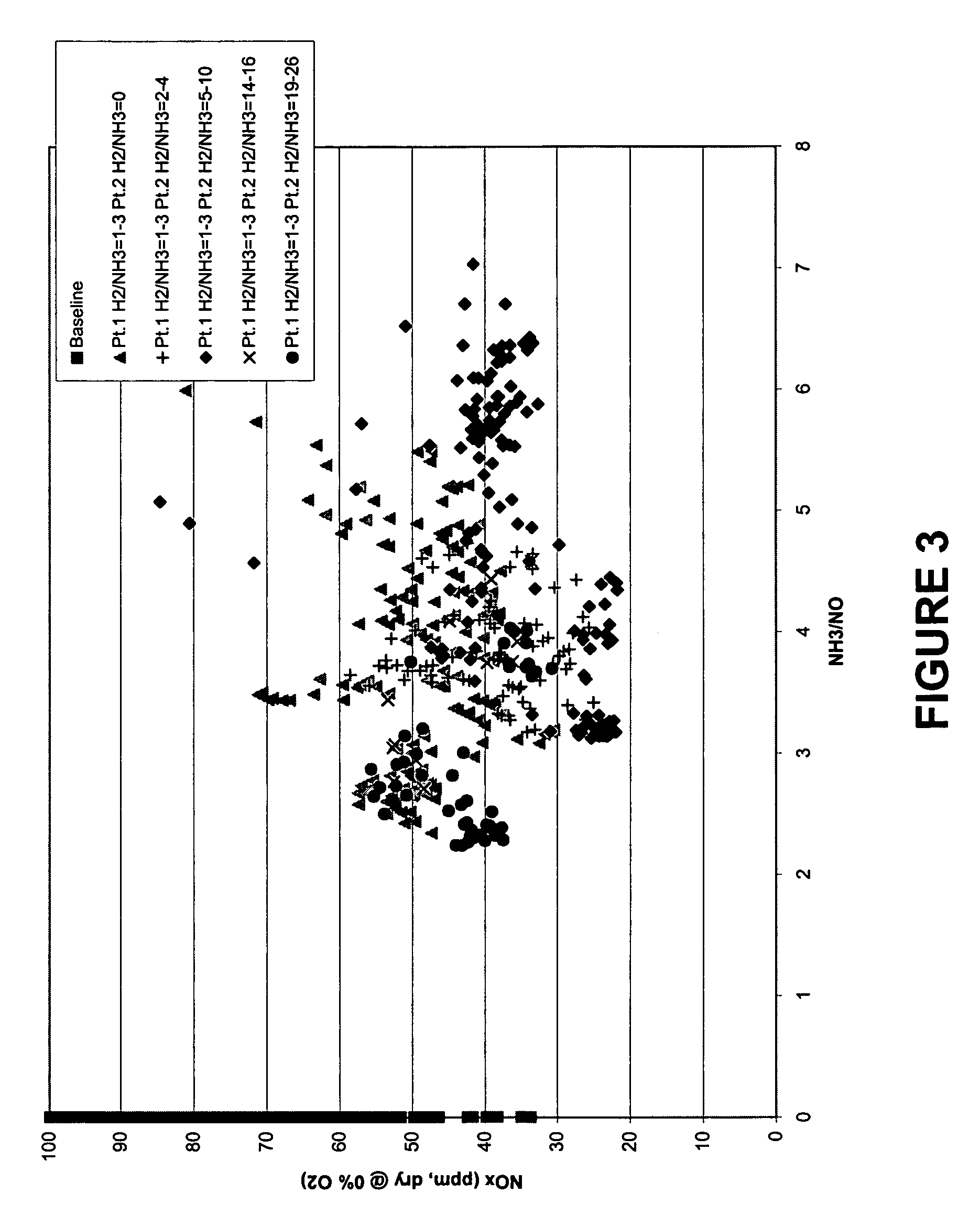

Non-catalytic reduction and oxidation process for the removal of NOx

InactiveUS20060233688A1Reduce concentrationCatalytic crackingNitrogen compoundsReducing agentScrubber

The present invention relates to a non-catalytic process for reducing NOx concentrations in the regenerator off-gas stream of a fluid catalytic cracking unit. More particularly, the present invention relates to the injection of a reducing agent in combination with a readily-oxidizable gas into a regenerator off-gas stream to reduce at least a portion of the NO in the regenerator off-gas stream, then contacting the regenerator off-gas stream with an effective amount of a treating solution under conditions such that at least a fraction of the oxidizable NOx species present in the regenerator off-gas stream is oxidized to higher oxides, and subsequently removing at least a fraction of these higher oxides from the off-gas stream. One embodiment of this invention also relates to the use of a reacted caustic solution from a wet gas scrubber for the removal of at least a fraction of the higher oxides.

Owner:EXXON RES & ENG CO

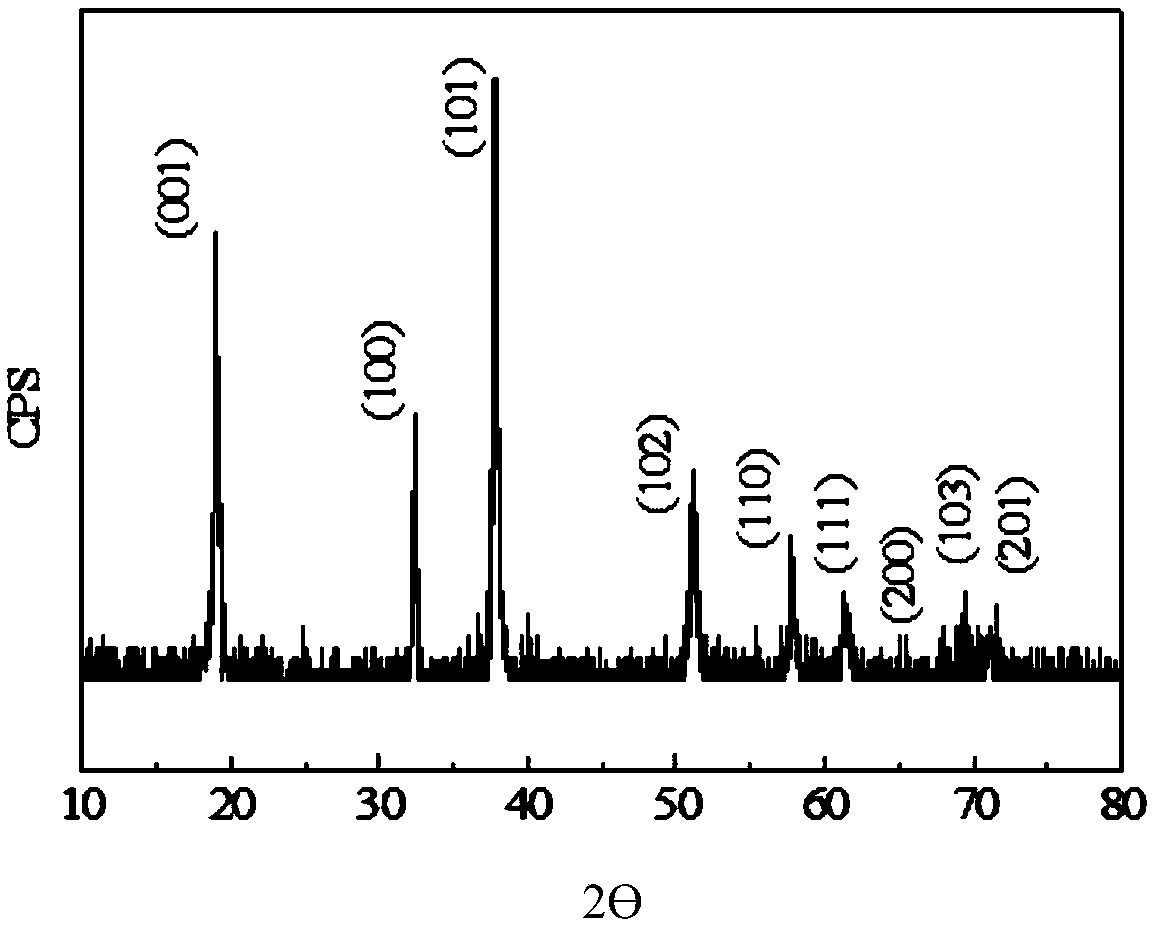

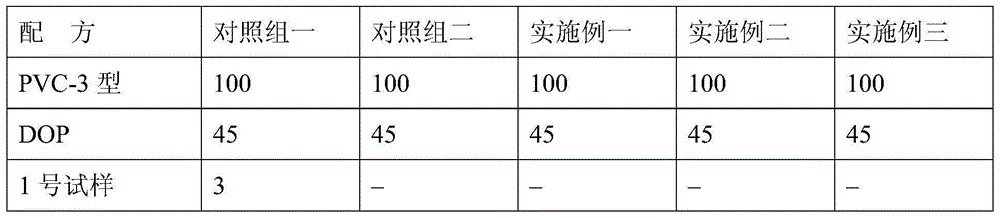

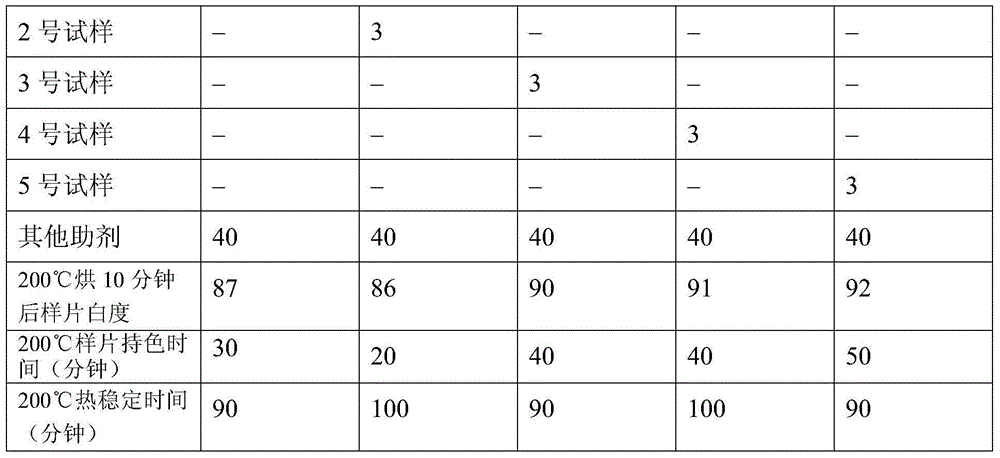

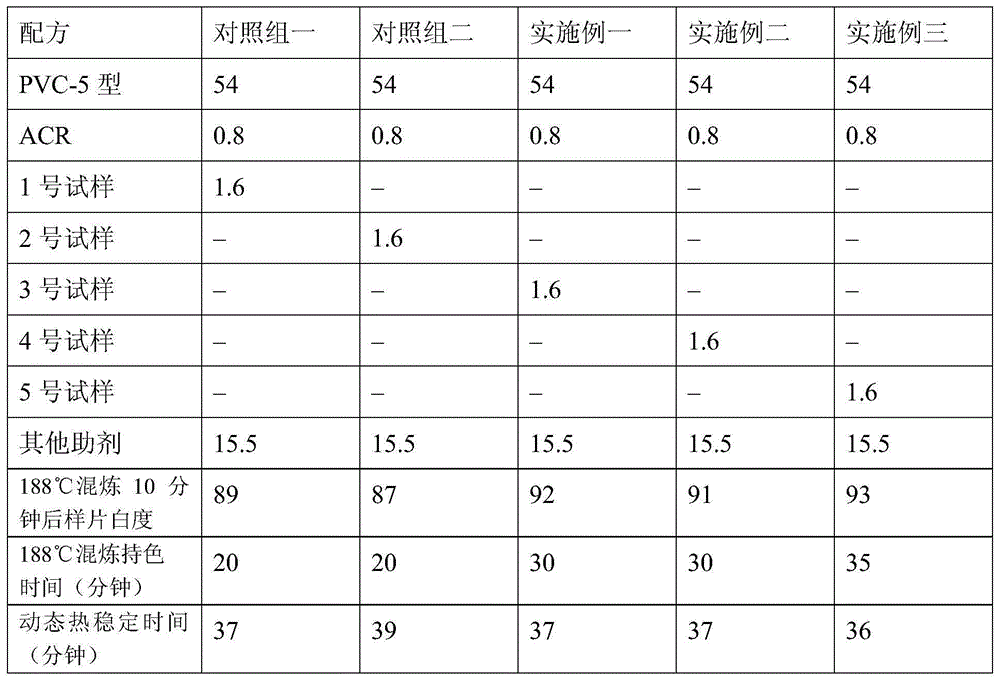

Synthesis method for hydrocalumites and hydrocalumites based PVC complex heat stabilizer

ActiveCN104150518AEasy to operateEase of industrial productionCalcium/strontium/barium compoundsAluminium chlorideSynthesis methods

The invention relates to a synthesis method for hydrocalumites and a hydrocalumites based PVC complex heat stabilizer. The synthesis method comprises the following steps: performing co-precipitation reaction on the water solution of calcium salt and the water solution of aluminium salt under the existence of soluble carbonate and caustic alkali, so as to synthesize hydrocalumites, wherein the calcium salt comprises hydrated calcium chloride, the aluminium salt comprises aluminium chloride and sodium metaaluminate, the soluble carbonate comprises Na2CO3 or K2CO3, the caustic alkali comprises NaOH or KOH, and the typical structure of the hydrocalumites is Ca6Al2(OH)16CO3 . 4H2O and Ca4Al2(OH)12CO3 . 4H2O; preparing the hydrocalumites based PVC complex heat stabilizer from the hydrocalumites , calcium soaps, zinc soaps, a lubricant, a chelating agent and an antioxygen according to an appropriate proportion. Compared with the conventional PVC complex heat stabilizer, the hydrocalumites based PVC complex heat stabilizer provided by the invention has better preliminary hue and longer color-maintaining effect on the PVC and other superpolymers containing chlorine, and the long-term heat stability is excellent; besides, the PVC complex heat stabilizer has the characteristics of no toxicity, environmental protection, low cost, rich raw materials, and great convenience for manufacture and the like.

Owner:湖南雄创新材料科技有限公司

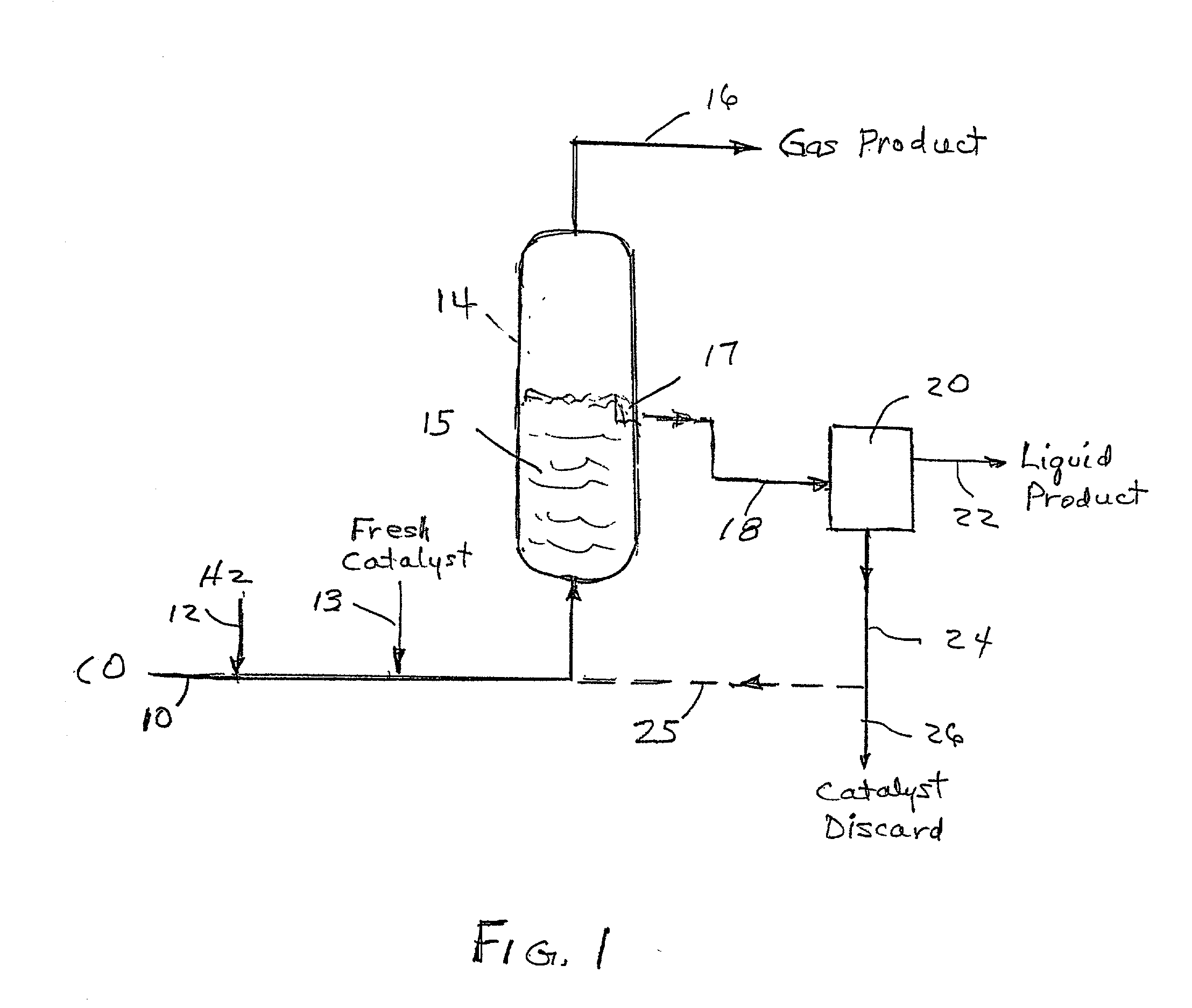

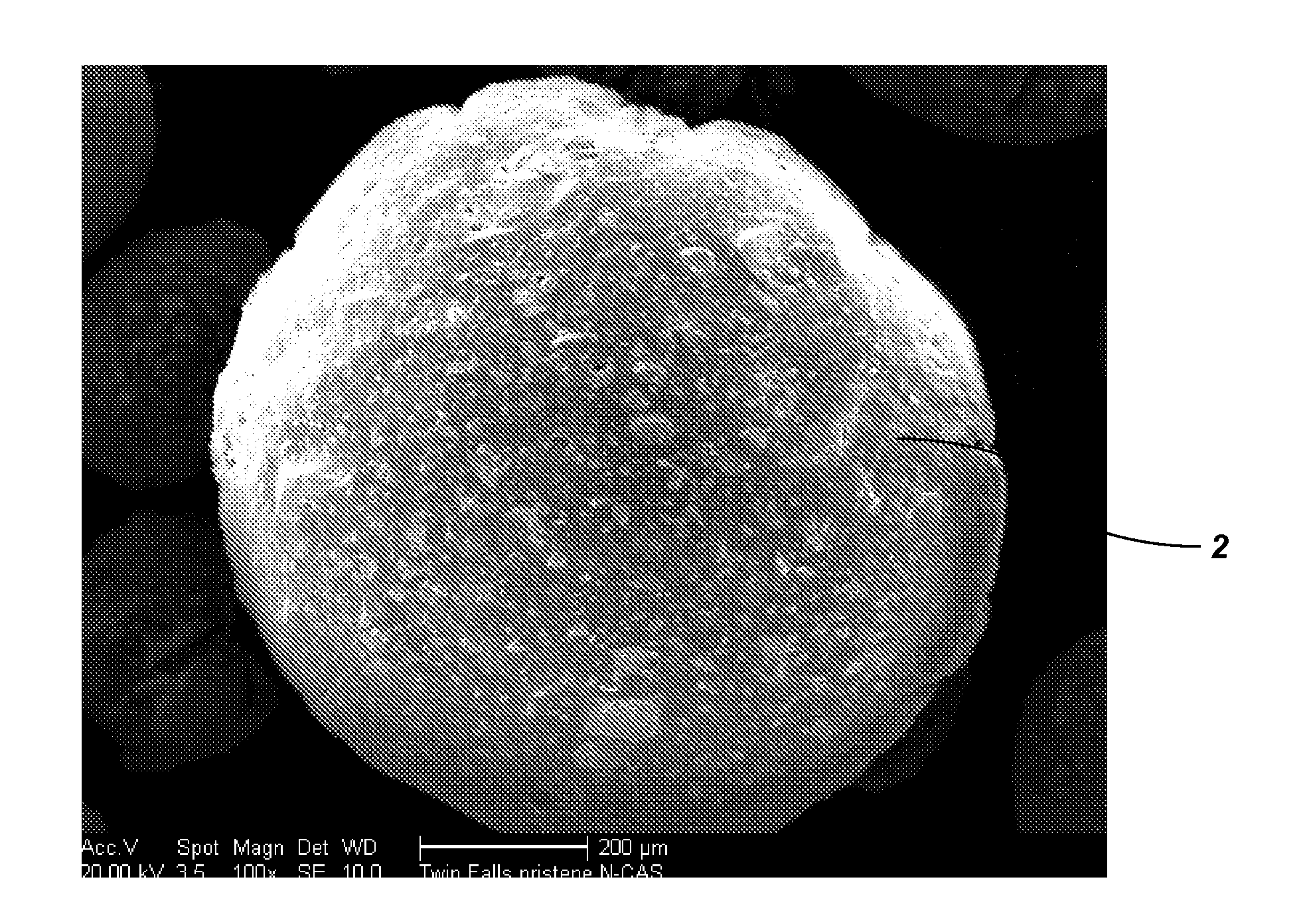

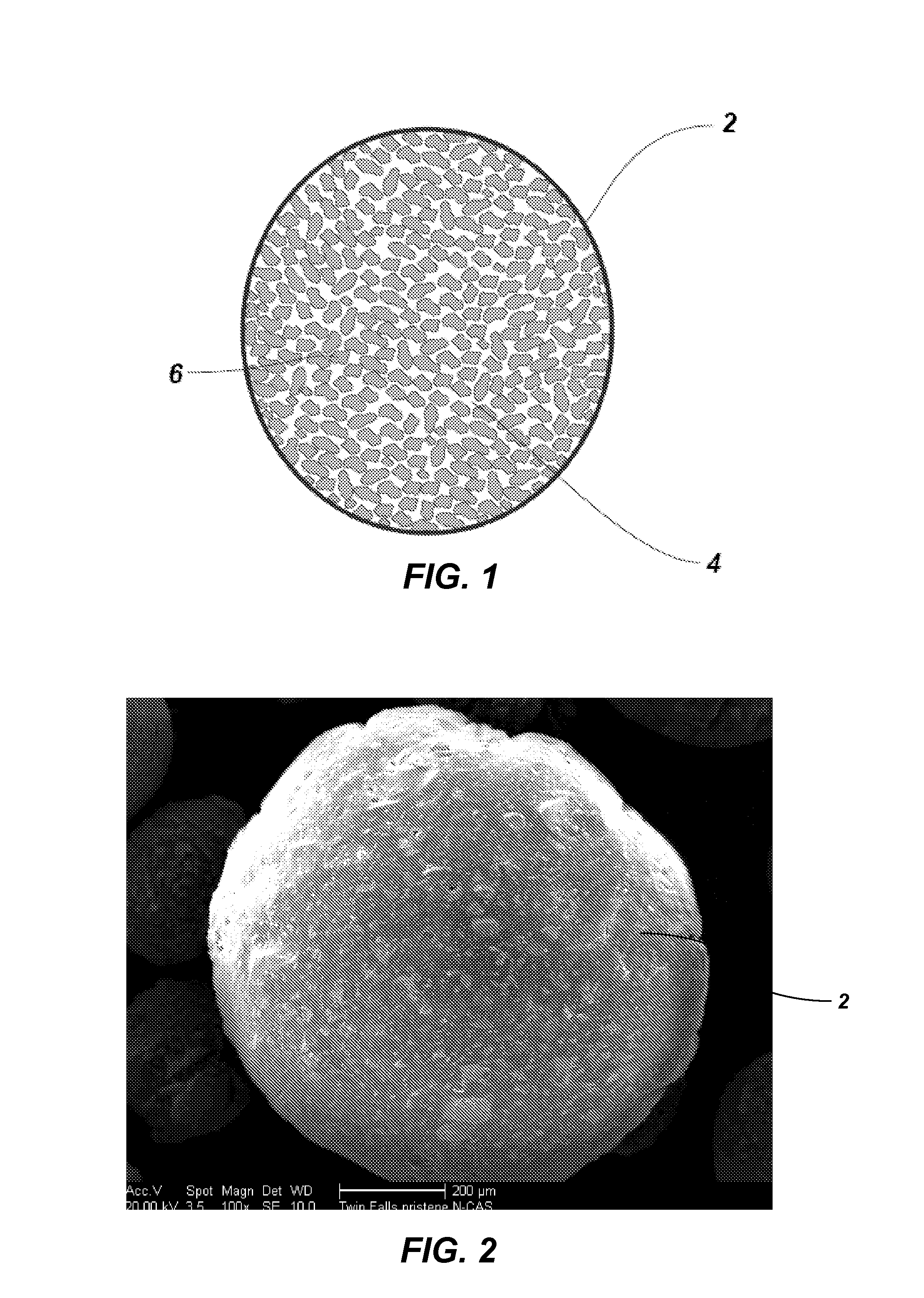

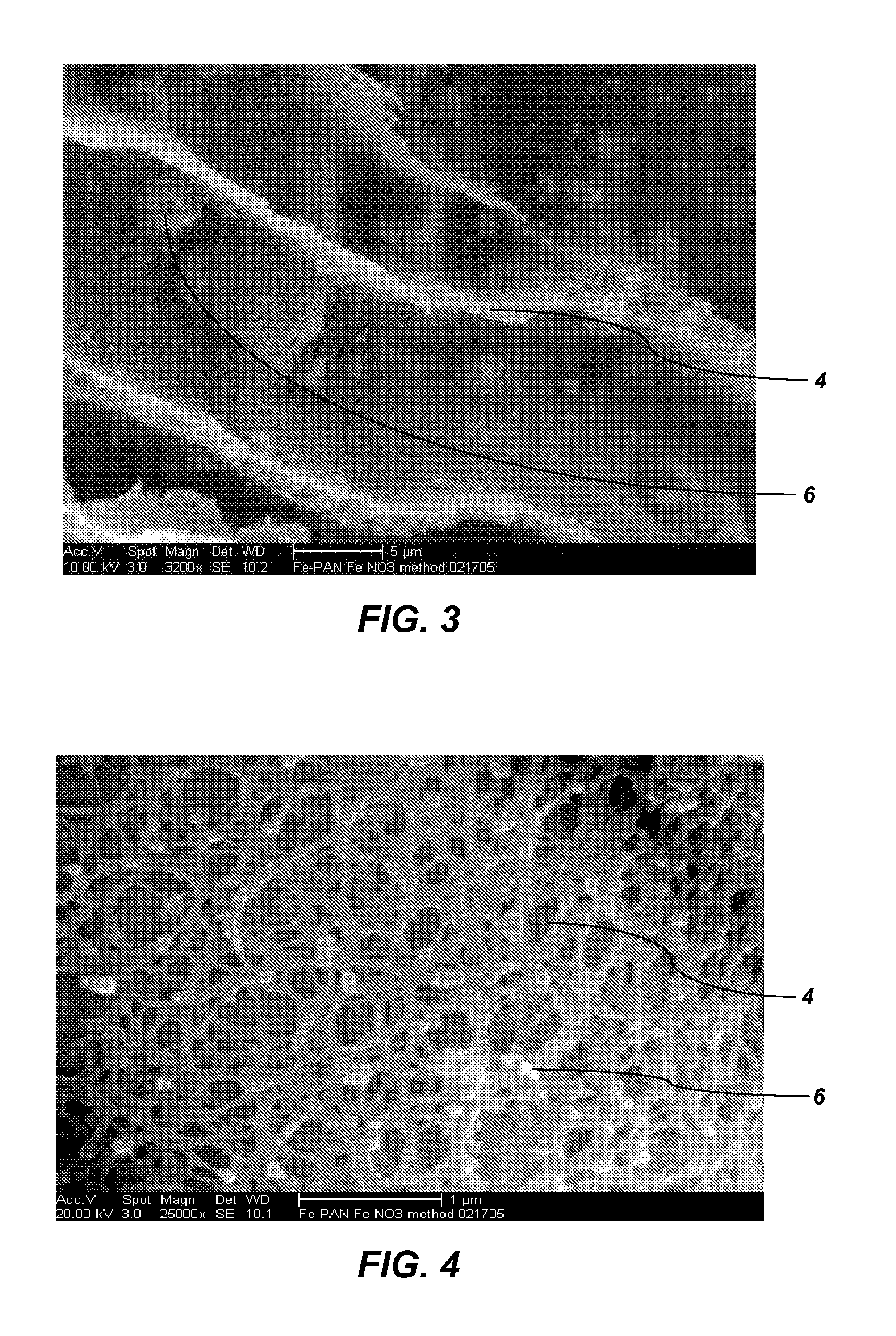

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS20020052423A1Good particle strength and attrition resistanceHigh yieldHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size (62-1000 micron), 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous metal powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % initial iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy precursor particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen so as to provide smaller sized skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-500° C. temperature, 0.5-5.0 mPa pressure, and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:HYDROCARBON TECH

Method for preparing composite modified starch

The invention discloses a method for preparing composite modified starch. The method comprises the following steps: 1) slurrying a raw material, namely a natural starch, and adjusting pH value of the natural starch by caustic alkali; 2) adding an oxidizing agent into the starch slurry to carry out oxidation modification treatment; 3) filtering, washing and drying the starch slurry into a powdered semi-finished product for standby; 4) spraying a catalyst and composite phosphate into the semi-finished product to carry out dry modification treatment; and 5) cooling the semi-finished product to a temperature of between 25 and 35 DEG C, adjusting the pH value of the semi-finished product to 6-8 to carry out secondary drying, and crushing the product to obtain a finished product. The product obtained by the method greatly improves dispersibility of the starch slurry, can be easily stewed with stable slurry, cannot be frozen, can completely replace the chemical synthetic slurry to size pure coarse cotton and medium yarns, and can replace the synthetic slurry in large scale to size high grade cotton yarns and union yarns, thereby greatly reducing yarn sizing cost, facilitating desizing, and contributing to environment-friendly waste water treatment.

Owner:GUANGDONG HUIMEI STARCH SCI & TECH

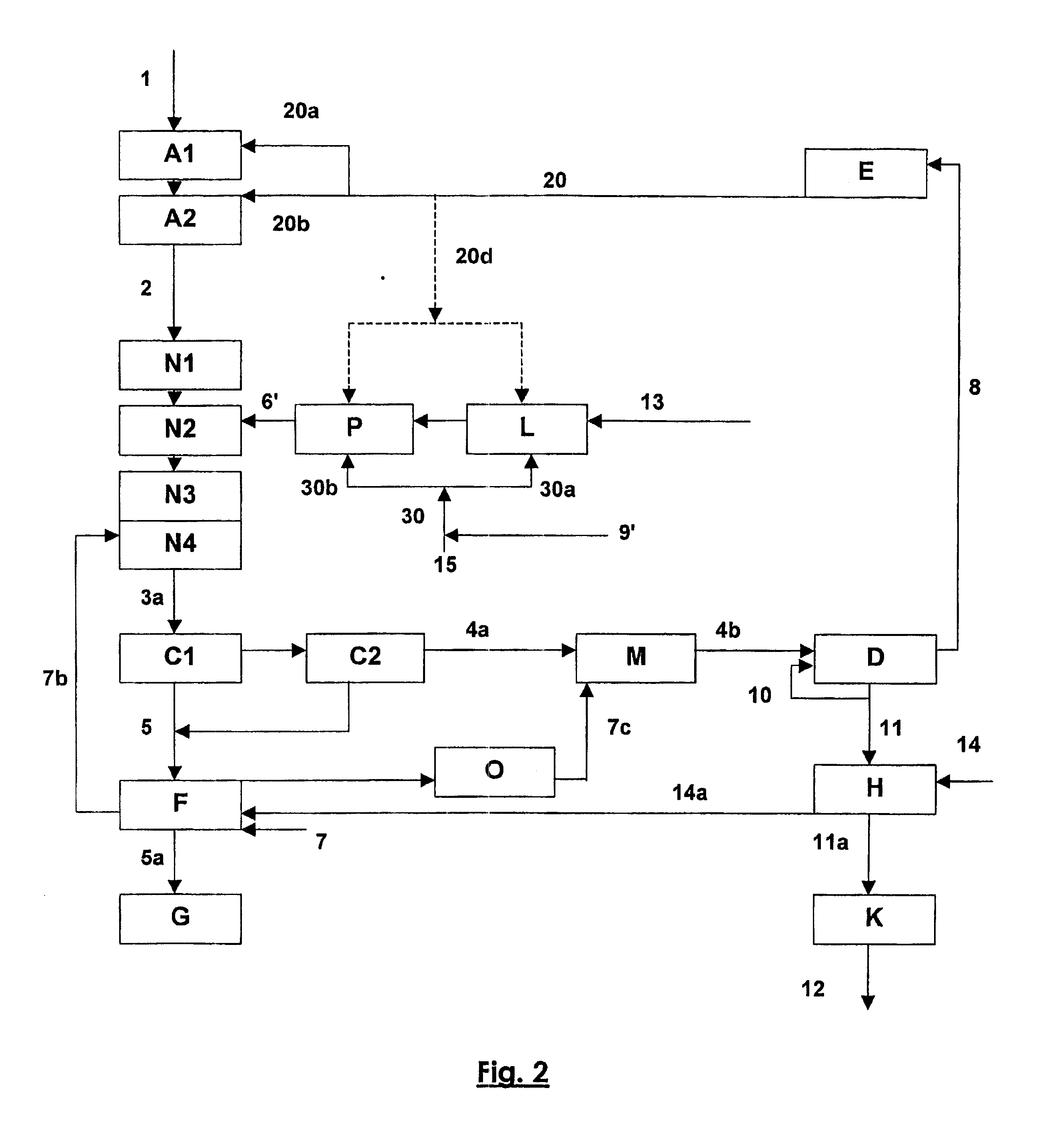

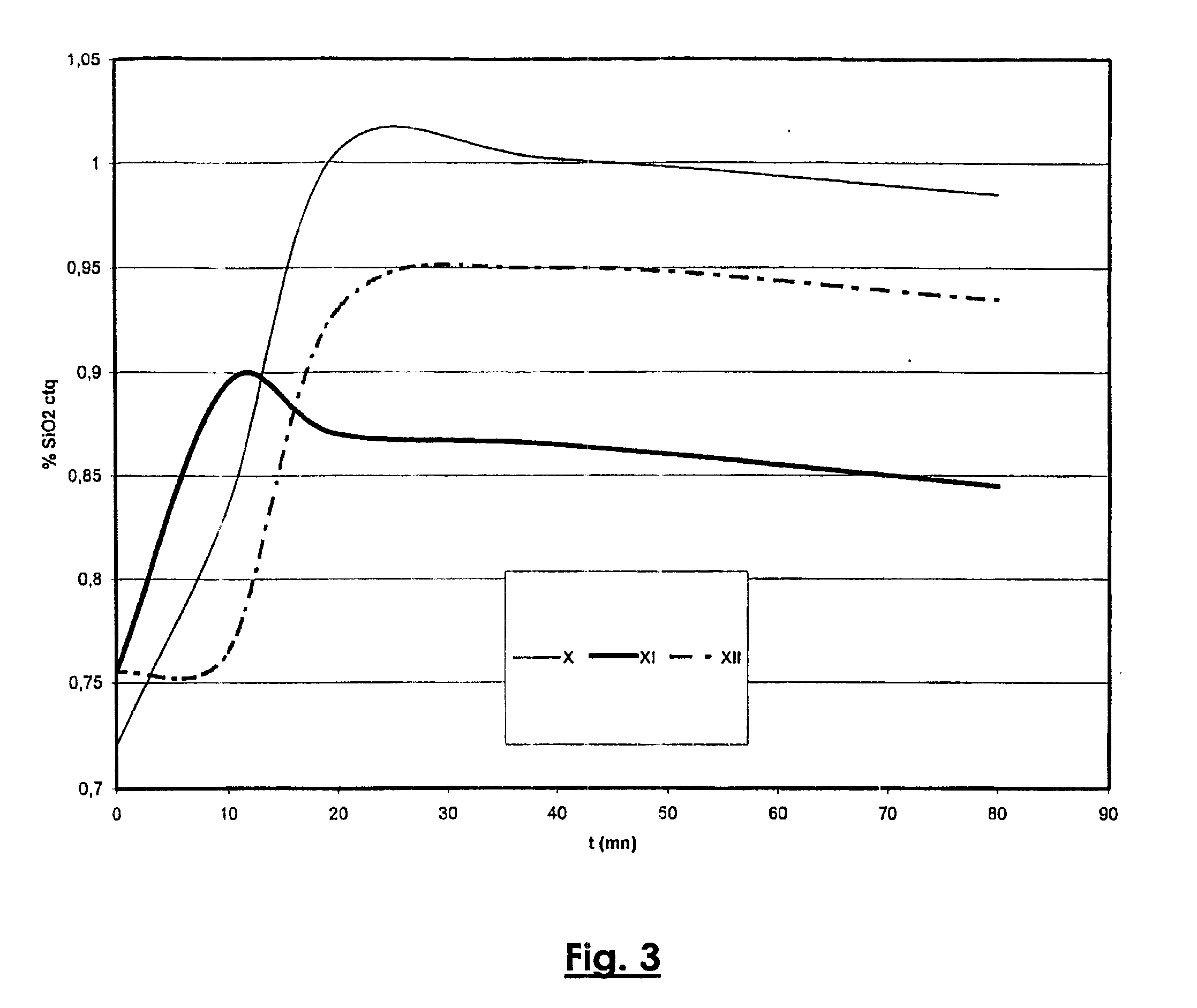

The bayer process for production of alumina trihydrate by alkaline digestion of bauxite, the process comprising a predesilication step

InactiveUS20070178041A1Reduce silica levelReduced silica contentAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationChemistryInsoluble residue

Bayer process, comprising grinding (L, B) and then digestion (N2, A) of a bauxite by bringing it into contact with a sodium aluminate liquor (20b, 120b). Digestion consists of forming a slurry (3a, 103) that is then treated to separate insoluble residues (5a, 105a) from the sodium aluminate liquor. The liquor is then crystallized (D) and recycled back to green liquor (20, 120) after having been separated from the alumina trihydrate (11, 111) precipitated during crystallization. The process comprises a predesilication treatment (P) during which the ground bauxite is brought before digestion into contact with an aqueous sodic solution that has a content of carbonates, sulphates and possibly chlorides which, expressed as a percentage related to the caustic concentration, is less than half the corresponding impurities content of the spent liquor (8, 108). Preferably, the pure caustic soda used to compensate for caustic soda losses in the Bayer circuit that was previously injected just after evaporation is now added in the aqueous sodic solution for the predesilication treatment.

Owner:ALUMINUM PECHINEY

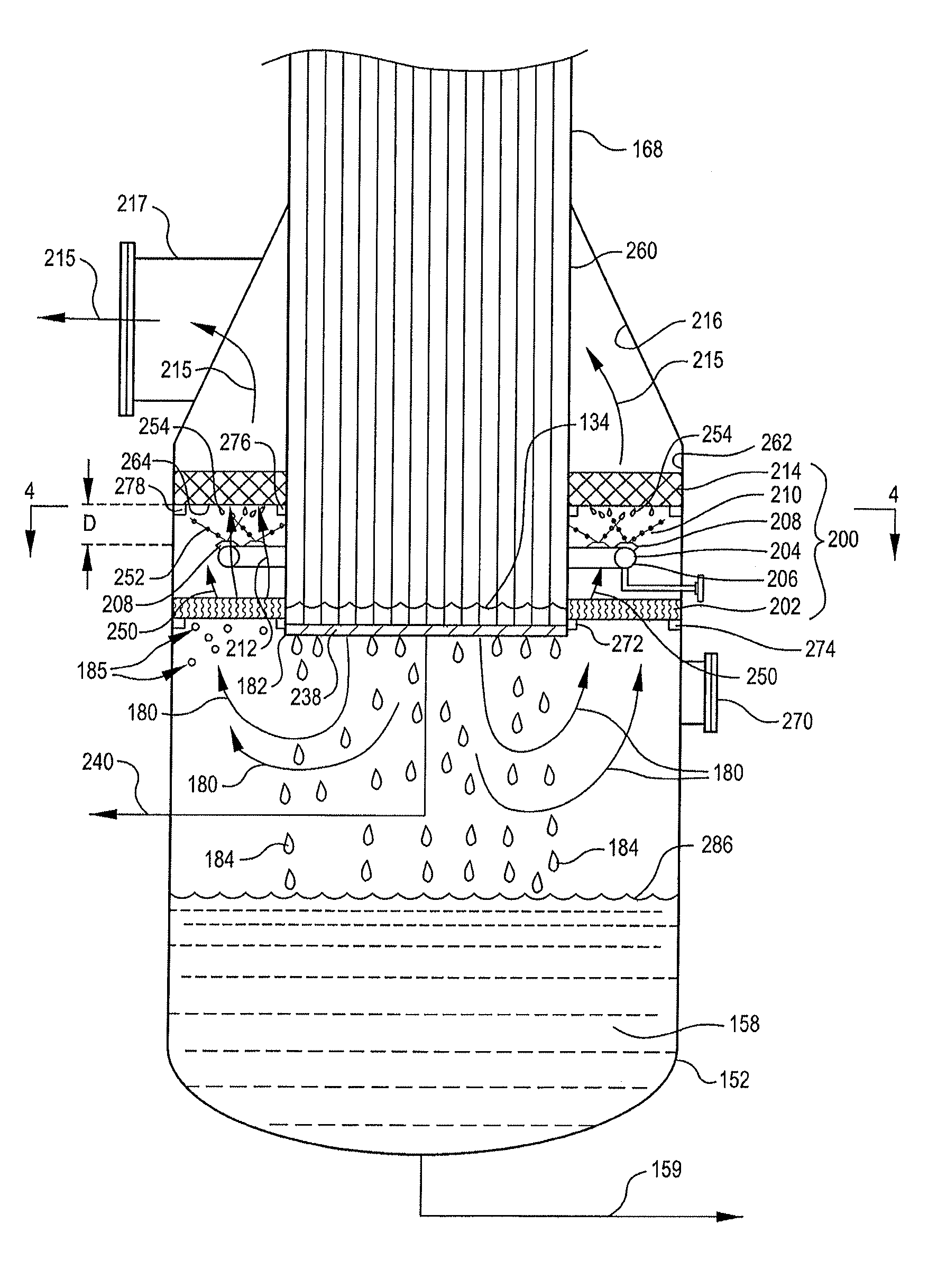

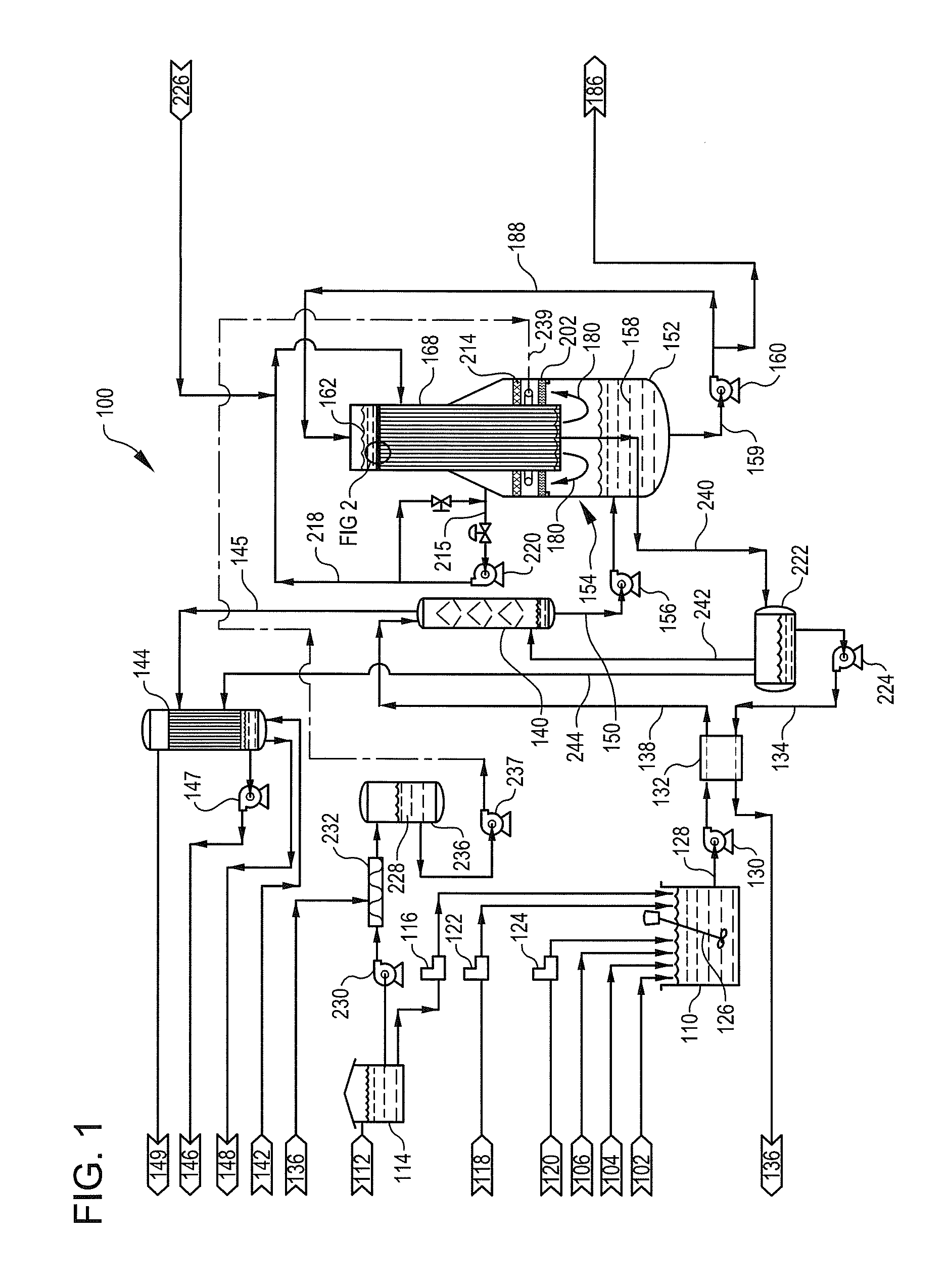

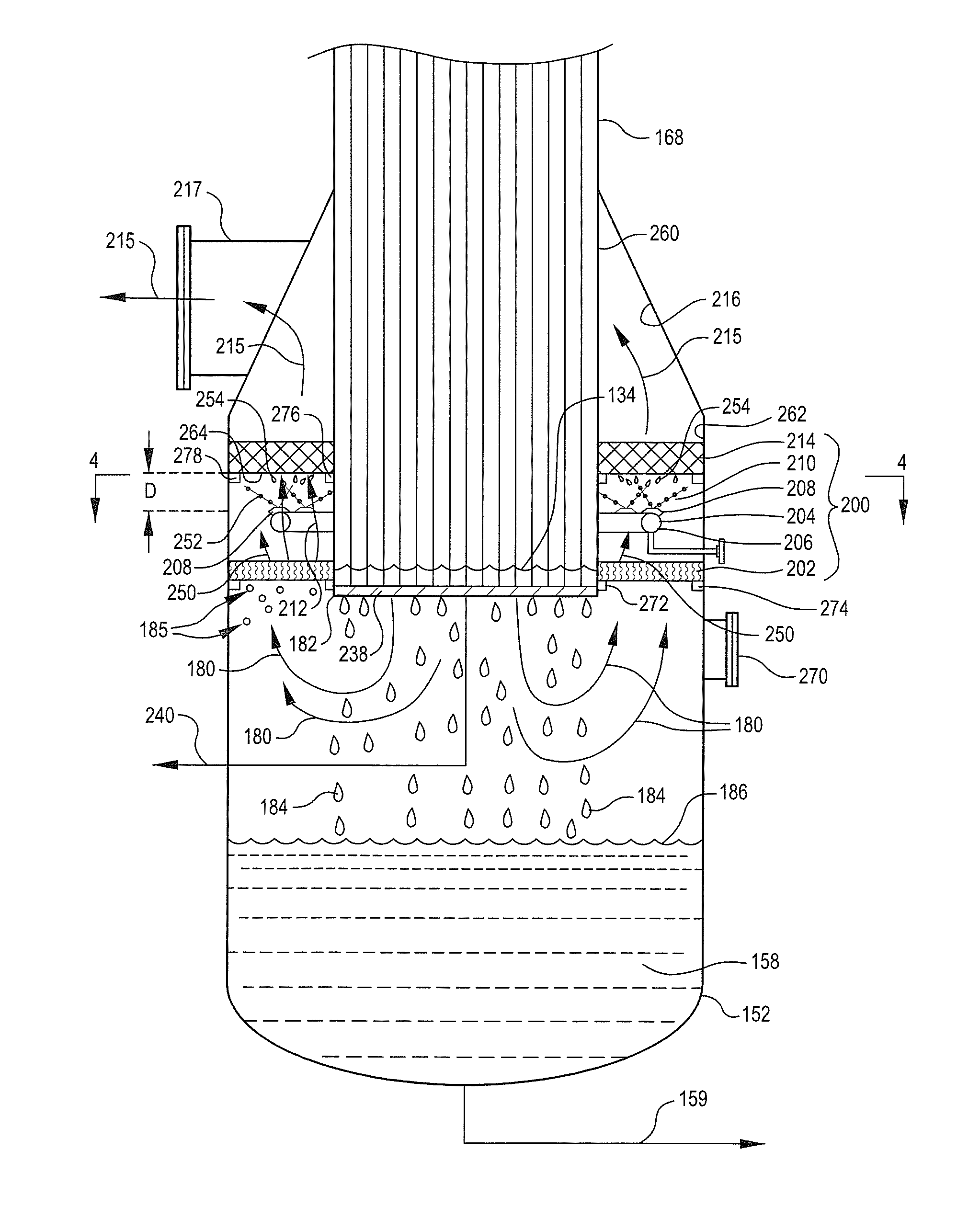

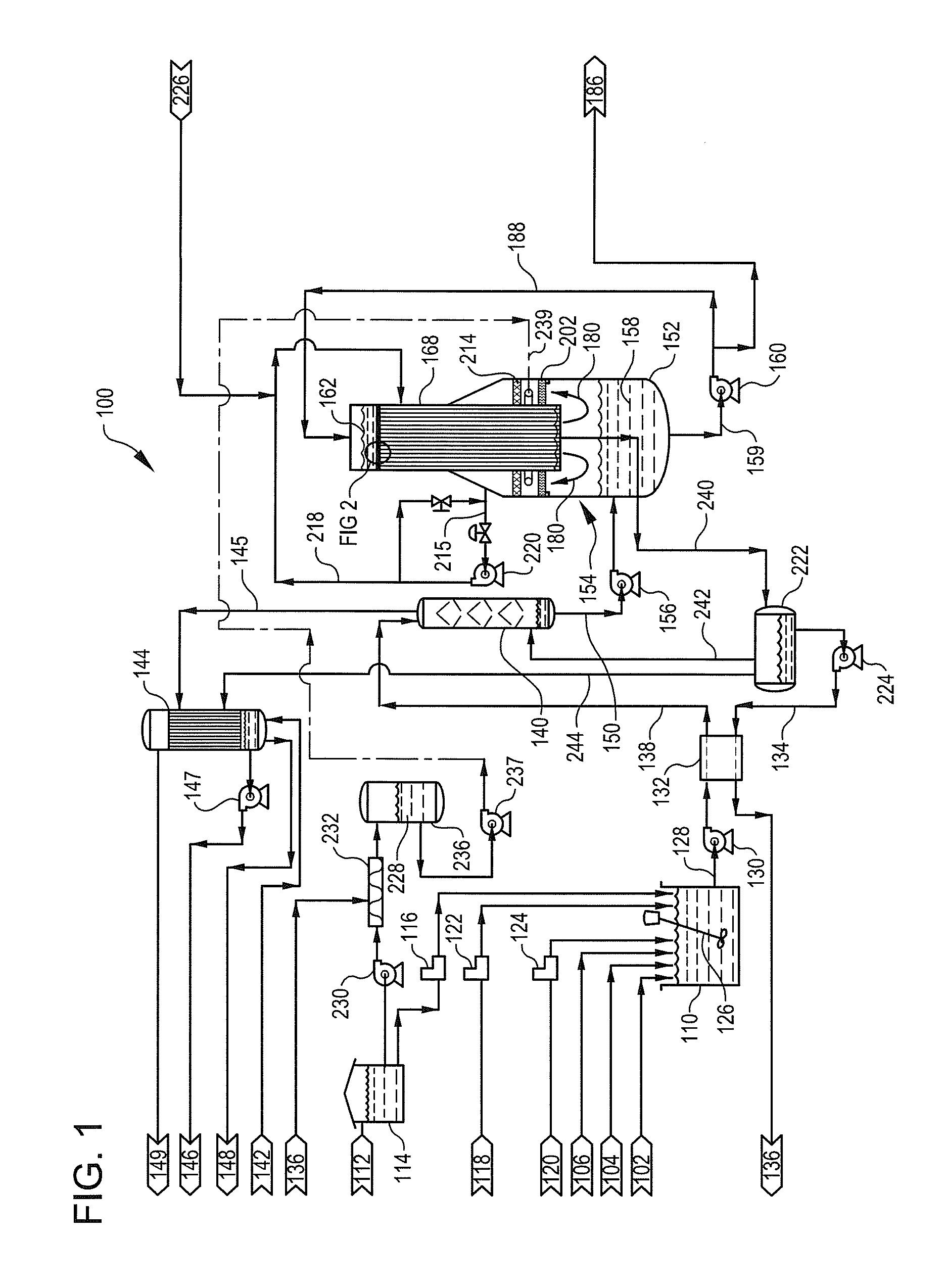

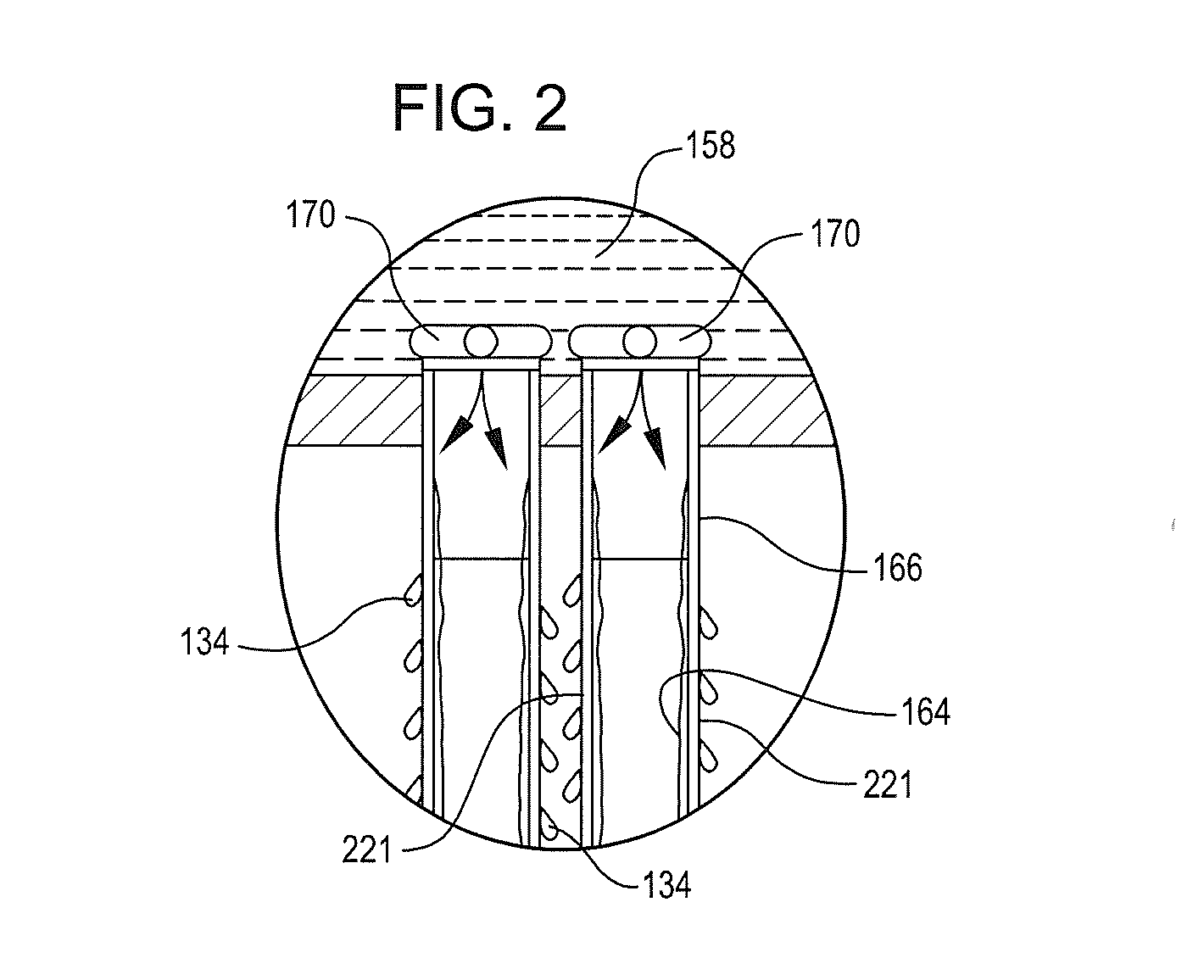

Method for reduction of contaminants in evaporator distillate

ActiveUS8603301B2Drying using combination processesLiquid degasificationHydrocotyle bowlesioidesWater vapor

A method and apparatus for producing high purity distillate in evaporators. is useful for evaporation of waters where volatile silica or organic compounds are encountered such as in production of hydrocarbons from geological formations. An evaporator having a contaminant reduction system is provided. The contaminant reduction system includes an upflow first mist eliminator portion to remove entrained liquid droplets and produce an intermediate purity water vapor stream. A continuous spray system provides a spray of dilute caustic solution in a selected spray configuration for mass transfer contact with the passing intermediate purity water vapor stream, to remove volatile silica compounds therefrom, and produce a partially decontaminated steam stream having mist particles therein. An upflow second mist eliminator portion is provided to remove the residual mist particles, and produce a high purity water vapor stream. The high purity water vapor stream is condensed to provide a high purity distillate stream.

Owner:BL TECH INC

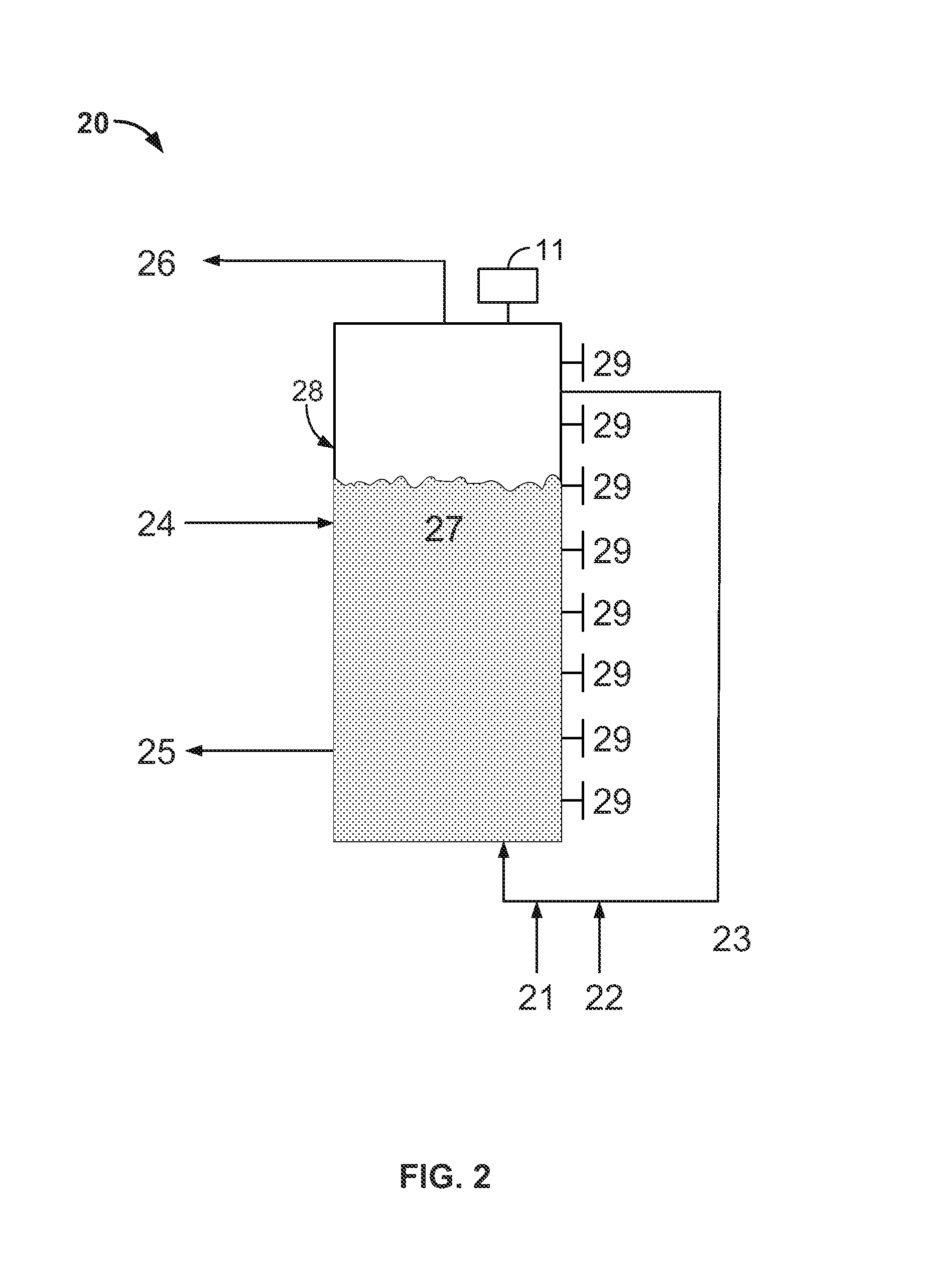

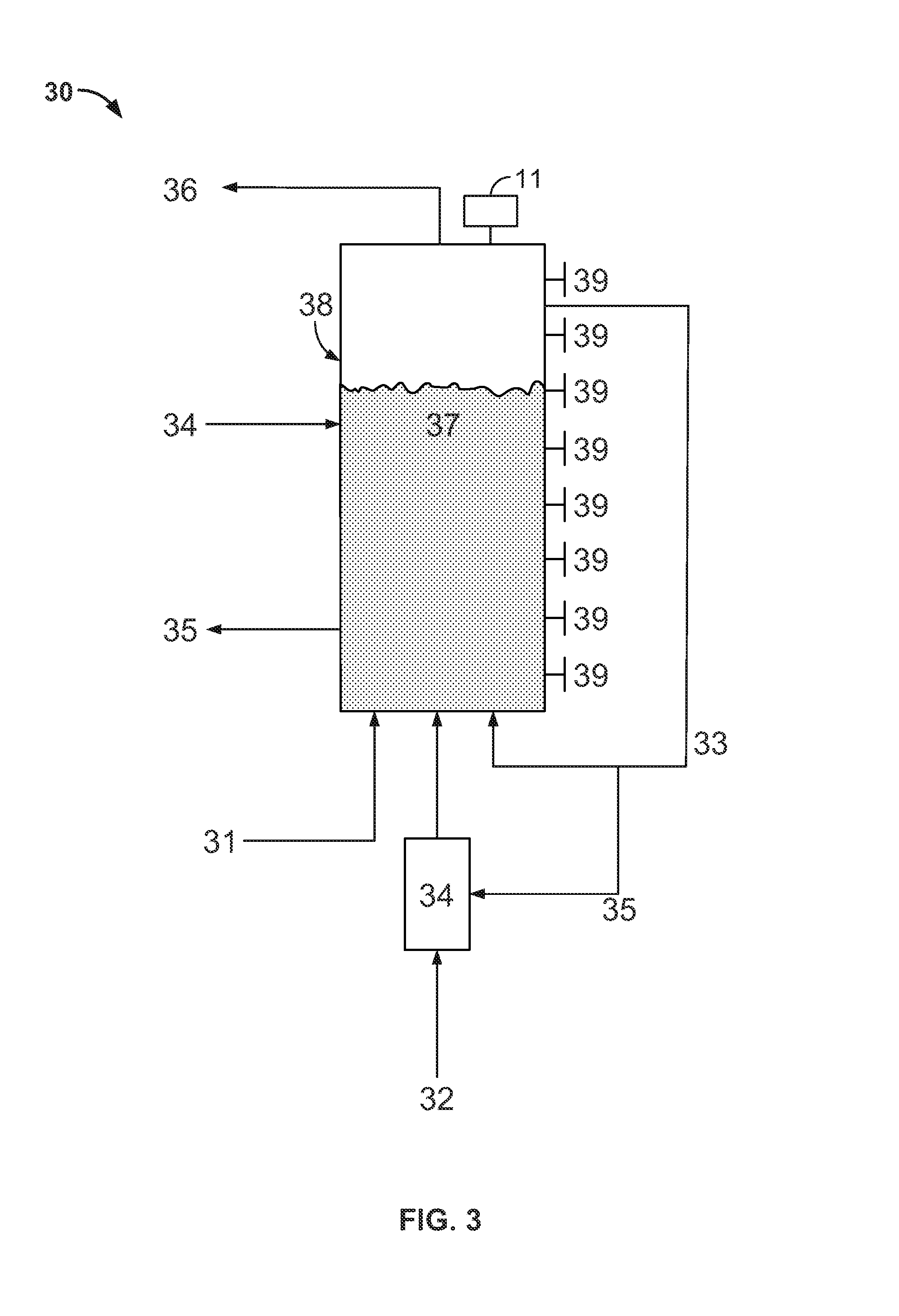

Recovering a caustic solution via calcium carbonate crystal aggregates

ActiveUS20150329369A1Reduce porosityHigh hardnessCalcium/strontium/barium carbonatesPulp liquor regenerationFluidized bedSlurry

Techniques for growing crystalline calcium carbonate solids such that the crystalline calcium carbonate solids include a volume of 0.0005 mm3 to 5 mm3, include a slaker to react quicklime (CaO) and a low carbonate content fluid to yield a slurry of primarily slaked lime (Ca(OH)2); a fluidized-bed reactive crystallizer that encloses a solid bed mass and includes an input for a slurry of primarily slaked lime, an input for an alkaline solution and carbonate, and an output for crystalline calcium carbonate solids that include particles and an alkaline carbonate solution; a dewatering apparatus that includes an input coupled to the crystallizer and an output to discharge a plurality of separate streams that each include a portion of the crystalline calcium carbonate solids and alkaline carbonate solution; and a seed transfer apparatus to deliver seed material into the crystallizer to maintain a consistent mass of seed material.

Owner:CARBON ENG LTD

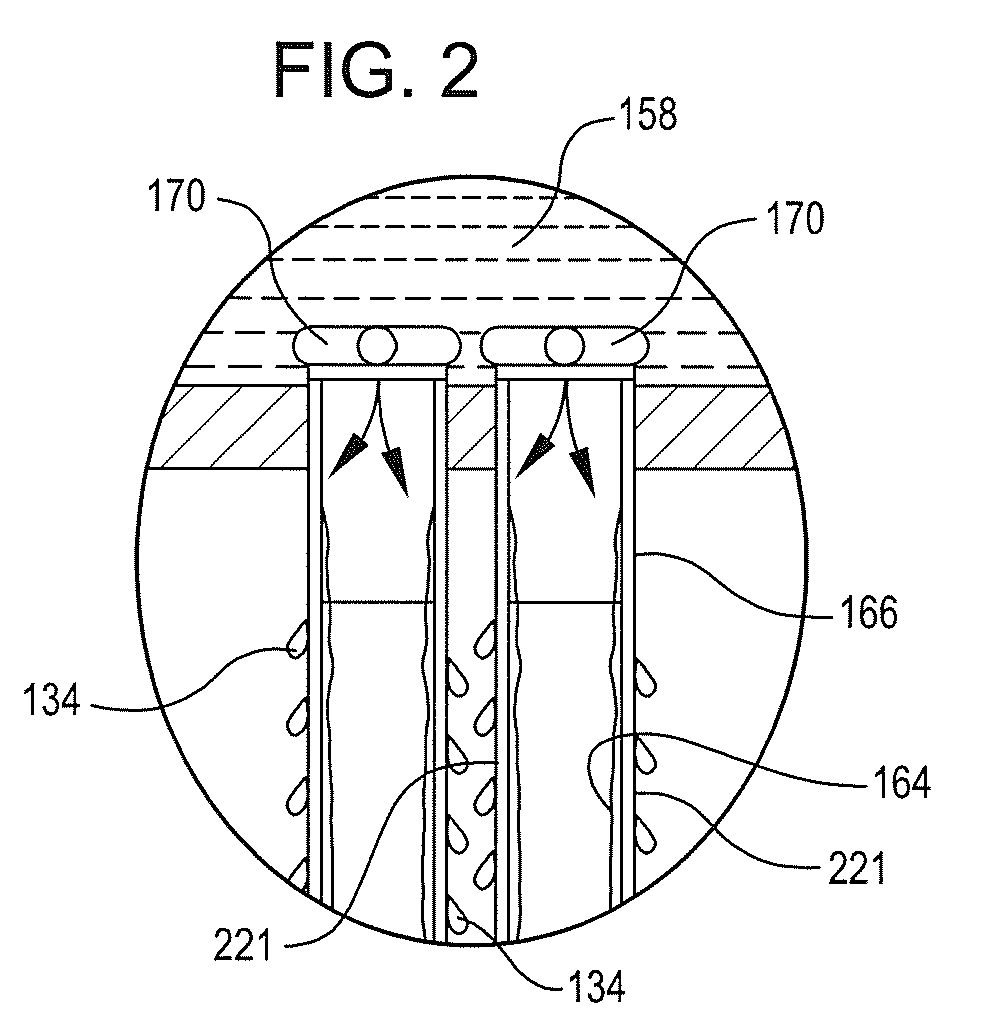

Method and apparatus for reduction of contaminants in evaporator distillate

ActiveUS20110079503A1Drying using combination processesLiquid degasificationHydrocotyle bowlesioidesWater vapor

Method and apparatus for producing high purity distillate in evaporators. The method and apparatus is useful for evaporation of waters where volatile silica compounds are encountered, and in cases where volatile organic compounds are encountered, such as in production of hydrocarbons from geological formations. An evaporator having a contaminant reduction system is provided. The contaminant reduction system includes an upflow first mist eliminator portion to remove entrained liquid droplets and produce an intermediate purity water vapor stream. A continuous spray system provides a spray of dilute caustic solution in a selected spray configuration for mass transfer contact with the passing intermediate purity water vapor stream, to remove volatile silica compounds therefrom, and produce a partially decontaminated steam stream having mist particles therein. An upflow second mist eliminator portion is provided to remove the residual mist particles, and produce a high purity water vapor stream. The high purity water vapor stream may be first compressed, but in any event is condensed to provide a high purity distillate stream.

Owner:BL TECH INC

Mixed phosphate and caustic alkali solution for preparing monocrystal silicon textured surfaces

InactiveCN101671850AImprove uniformityGood surface consistencyAfter-treatment detailsPhosphateSilicon solar cell

The invention discloses a mixed phosphate and caustic alkali solution for preparing monocrystal textured surfaces, and relates to the technical field of preparation of solar cells, in particular to preparation of textured surfaces in production technology of monocrystal silicon solar cells. The mixed phosphate and caustic alkali solution is prepared from phosphates, caustic alkali and isopropanol.The solution overcomes the defects of uneven pyramid size, chromatic aberration on the surface of silicon wafers and the like which are caused by the prior monocrystal silicon etching corrosive solution. The solution uses the phosphates instead of silicates to obtain a different monocrystal silicon etching corrosive solution. Practice proves that the solution can be used for preparing textured-surface monocrystal silicon wafers with even size and uniform surfaces.

Owner:EOPLLY NEW ENERGY TECH

Method for preparing aromatic methyl ether compound

ActiveCN103012074AAchieve recyclingEfficient recyclingEther preparation by ester reactionsReaction temperatureKetone

The invention discloses a method for preparing aromatic methyl ether, which comprises the step of reacting an aromatic phenol compound, caustic alkali, water and mono-chloro methane for 2hours to 8hours at the temperature of 60 DEG C to 100 DEG C under the pressure of 0.5Mpa to 2.5Mpa, so as to obtain the aromatic methyl ether, wherein the molar ratio of the aromatic phenol compound to the caustic alkali to the mono-chloro methane is 1:(1.0-2.0):(1.0-5.0), and the weight ratio of the caustic alkali to the water is 1:(4-10). The preparation method disclosed by the invention not only has the advantages that cost is low, yield is high, reaction is easy to implement and the like; by adding the phase transfer catalyst, the gas-liquid two-phase reaction can be effectively prompted, the reaction temperature range is moderate, both the reaction conversion ratio and the selectivity are relatively high, the purity of the aromatic methyl ether can reach more than 99.5%, the reaction yield is 95-97%, and the method has very high value in industrialization. In addition, the problem of exhaust emission in the 1,2-benzo-iso-thiazoline ketone production process is solved, the mono-chloro methane is effectively recycled, and the zero-emission production technology is achieved.

Owner:DALIAN BIO CHEM

Methods of producing metal oxides, a method of producing adsorption media including the same, and a precursor of an active component including the metal oxide

Methods of producing a metal oxide are disclosed. The method comprises dissolving a metal salt in a reaction solvent to form a metal salt / reaction solvent solution. The metal salt is converted to a metal oxide and a caustic solution is added to the metal oxide / reaction solvent solution to adjust the pH of the metal oxide / reaction solvent solution to less than approximately 7.0. The metal oxide is precipitated and recovered. A method of producing adsorption media including the metal oxide is also disclosed, as is a precursor of an active component including particles of a metal oxide.

Owner:BATTELLE ENERGY ALLIANCE LLC

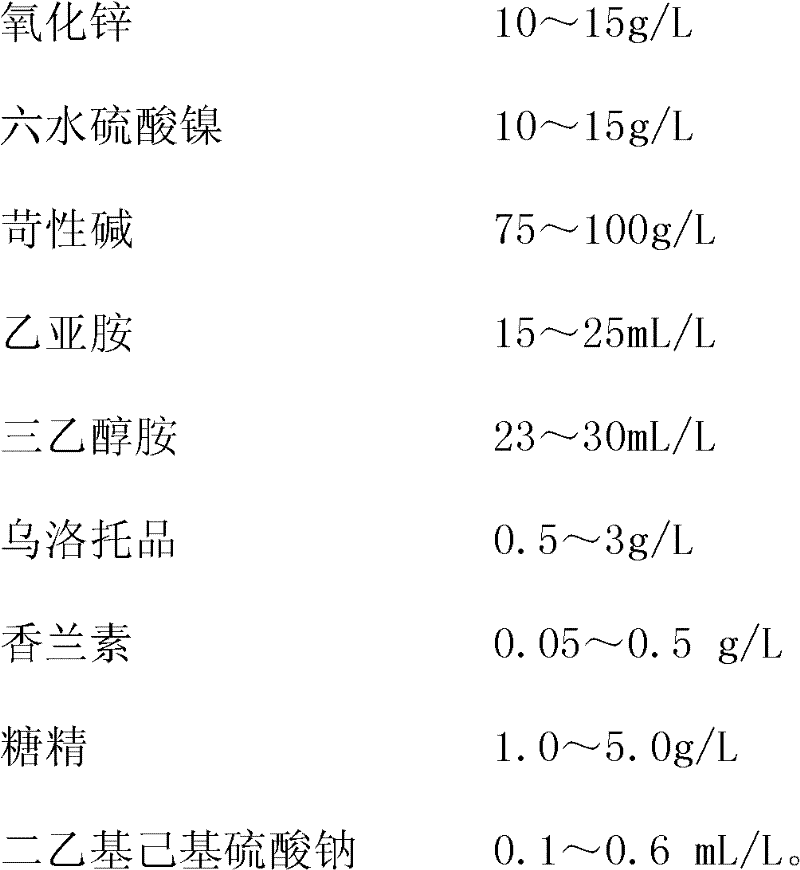

Zinc-nickel alloy plating liquid

The invention discloses zinc-nickel alloy plating liquid, which comprises the following materials: 10 to 15 g / L of zinc oxide, 10 to 15 g / L of nickel sulfate hexahydrate, 75 to 100 g / L of caustic alkali, 15 to 25 ml / L of ethyliminum, 23 to 30 ml / L of triethanolamine, 0.5 to 3 g / L of urotropin, 0.05 to 0.5 g / L of vanillin, 1.0 to 5.0 g / L of saccharin and 0.1 to 0.6 mL / L of diethylhexyl sodium sulfate. After a zinc-nickel alloy is plated by the zinc-nickel alloy plating liquid, the obtained plating layer is silvery white, bright, smooth and compact, the nickel content is between 11 and 14, and the zinc-nickel alloy plating liquid has high corrosion resistance.

Owner:张家港舒马克电梯安装维修服务有限公司镀锌分公司

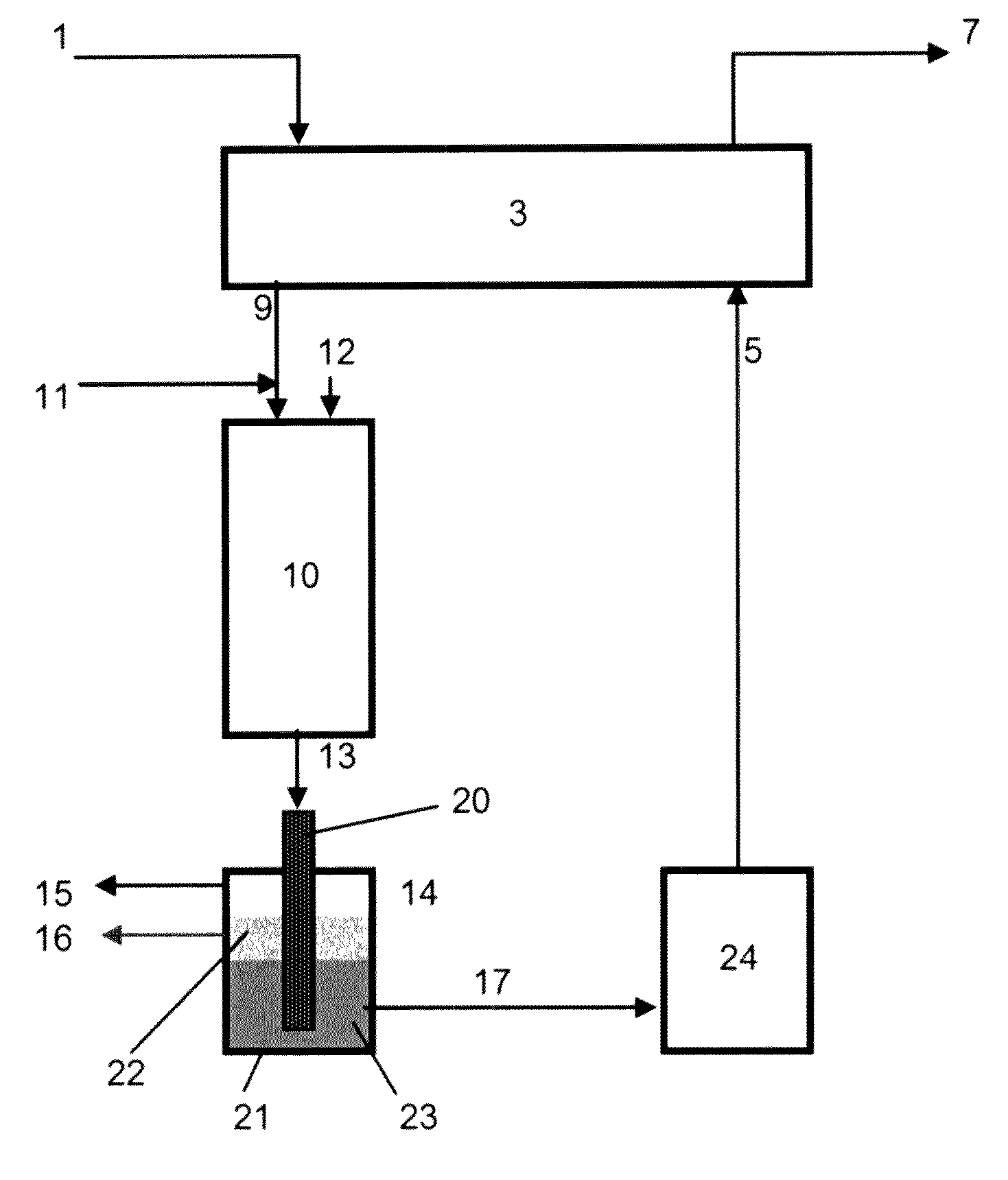

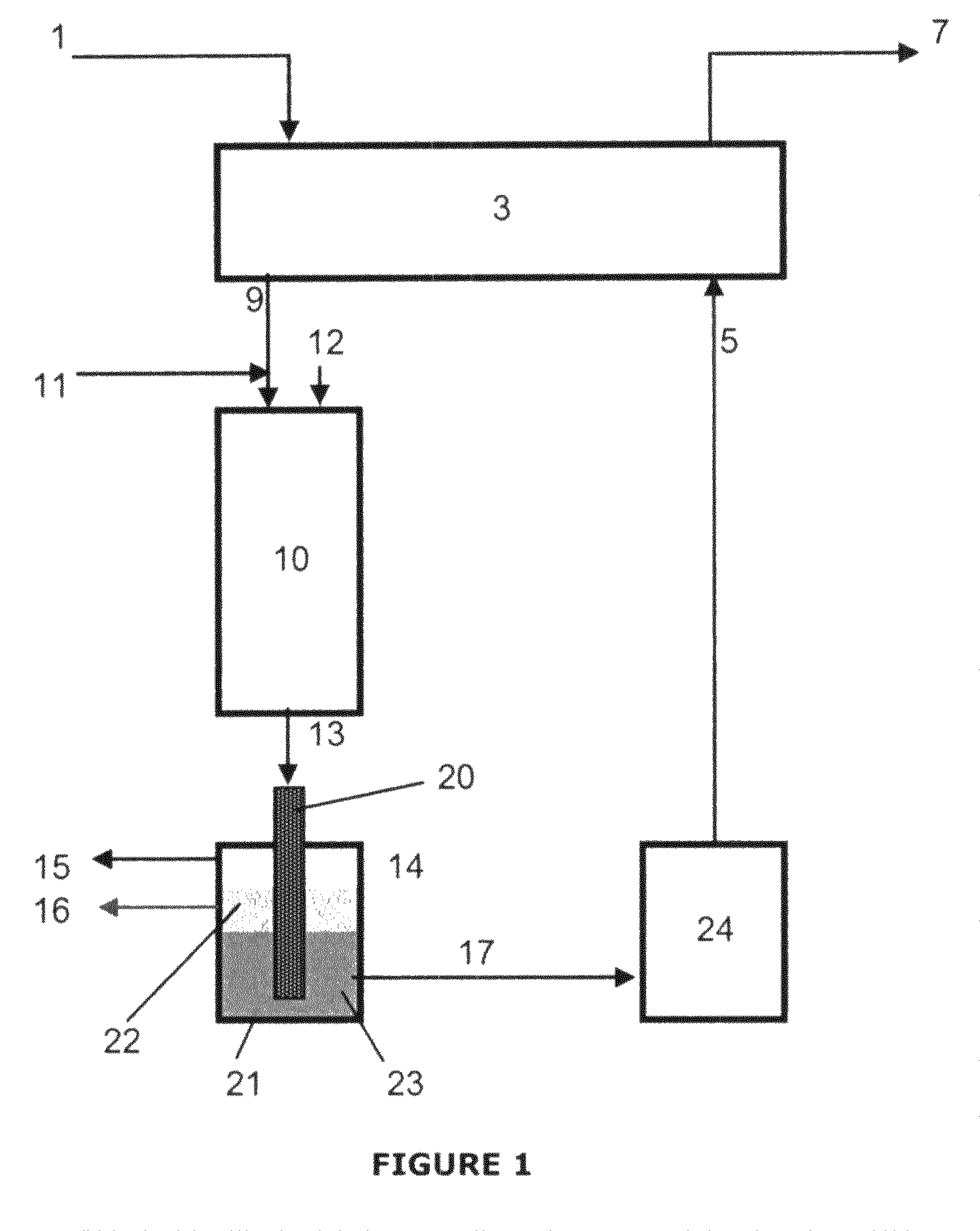

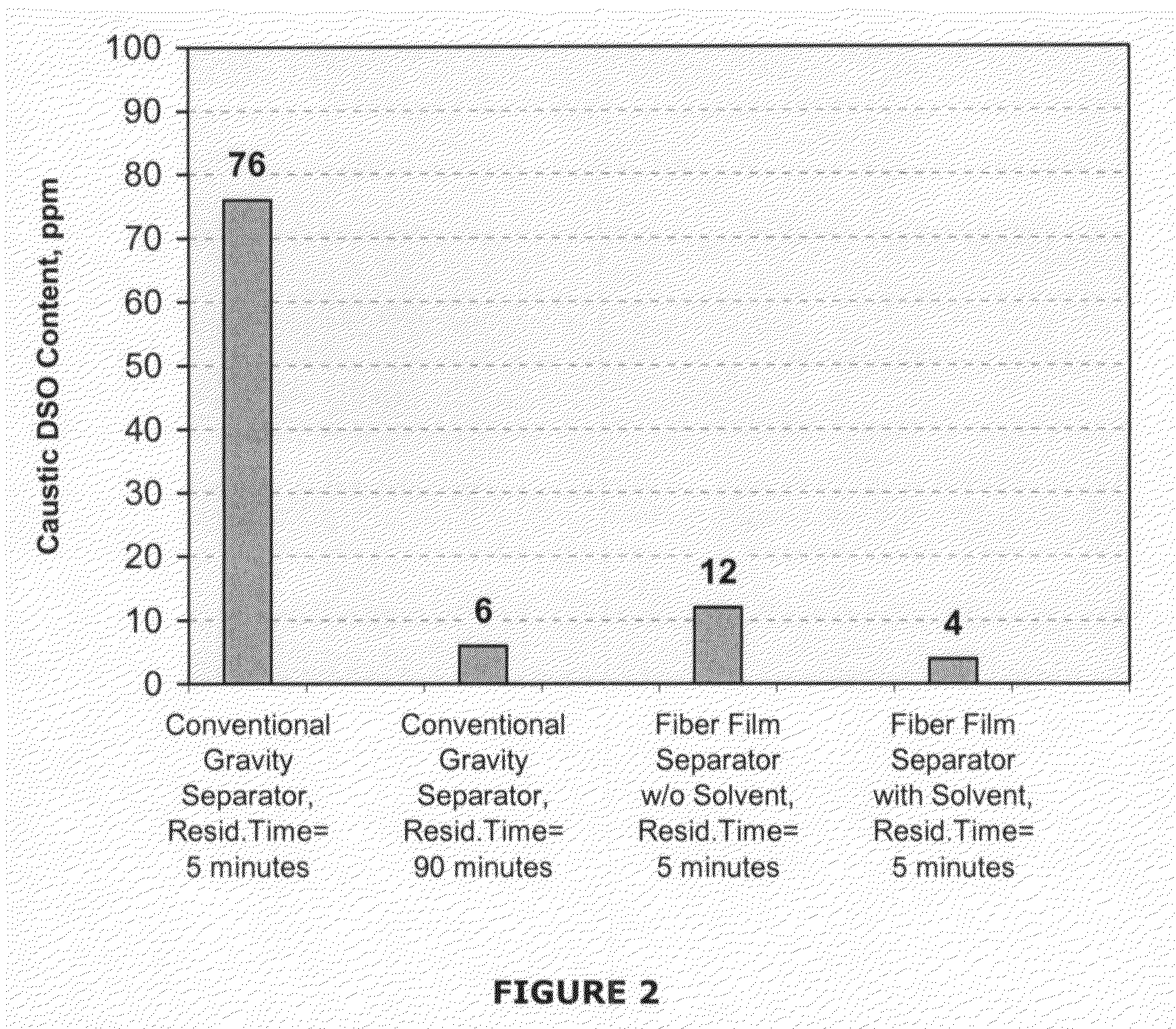

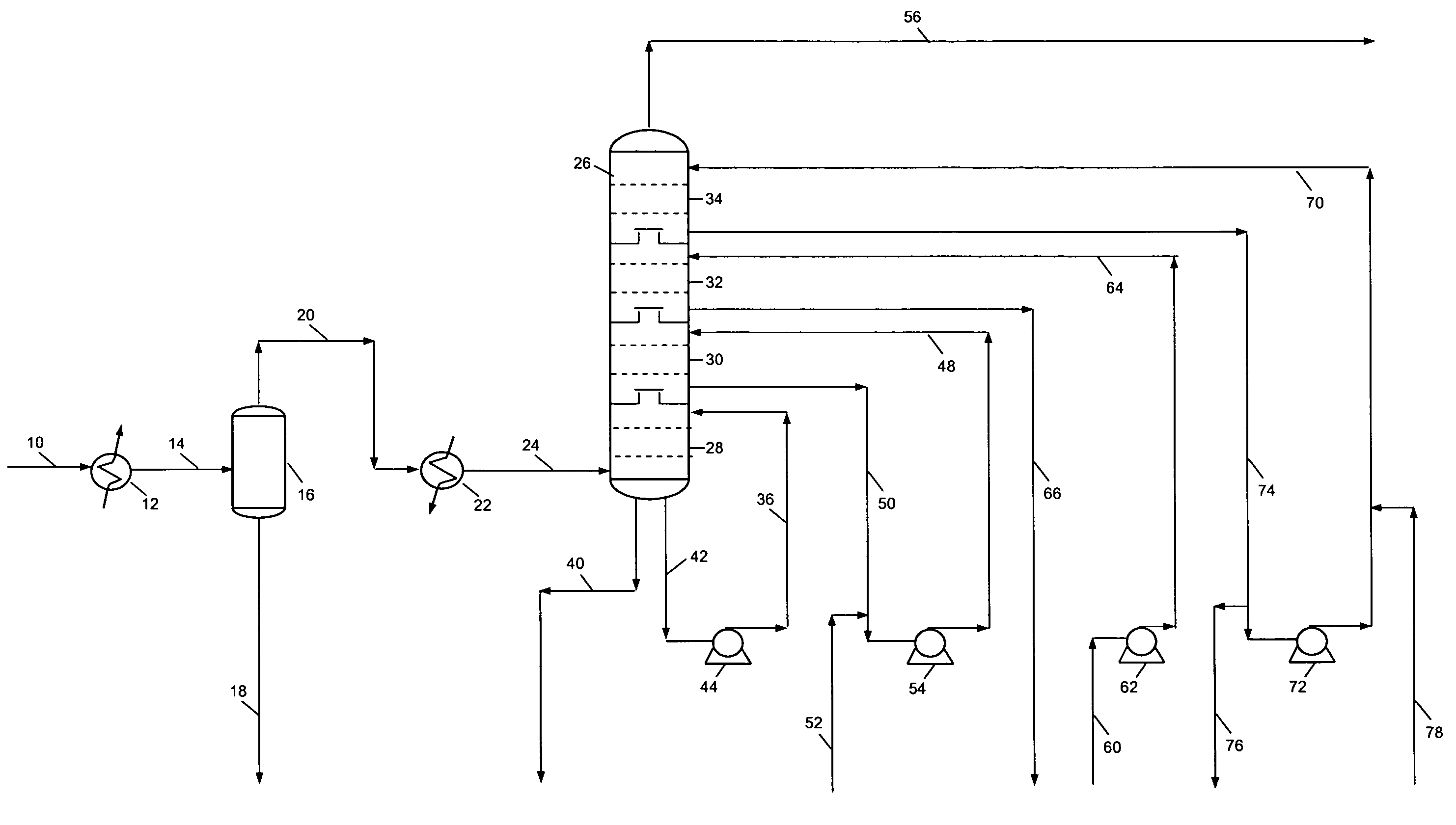

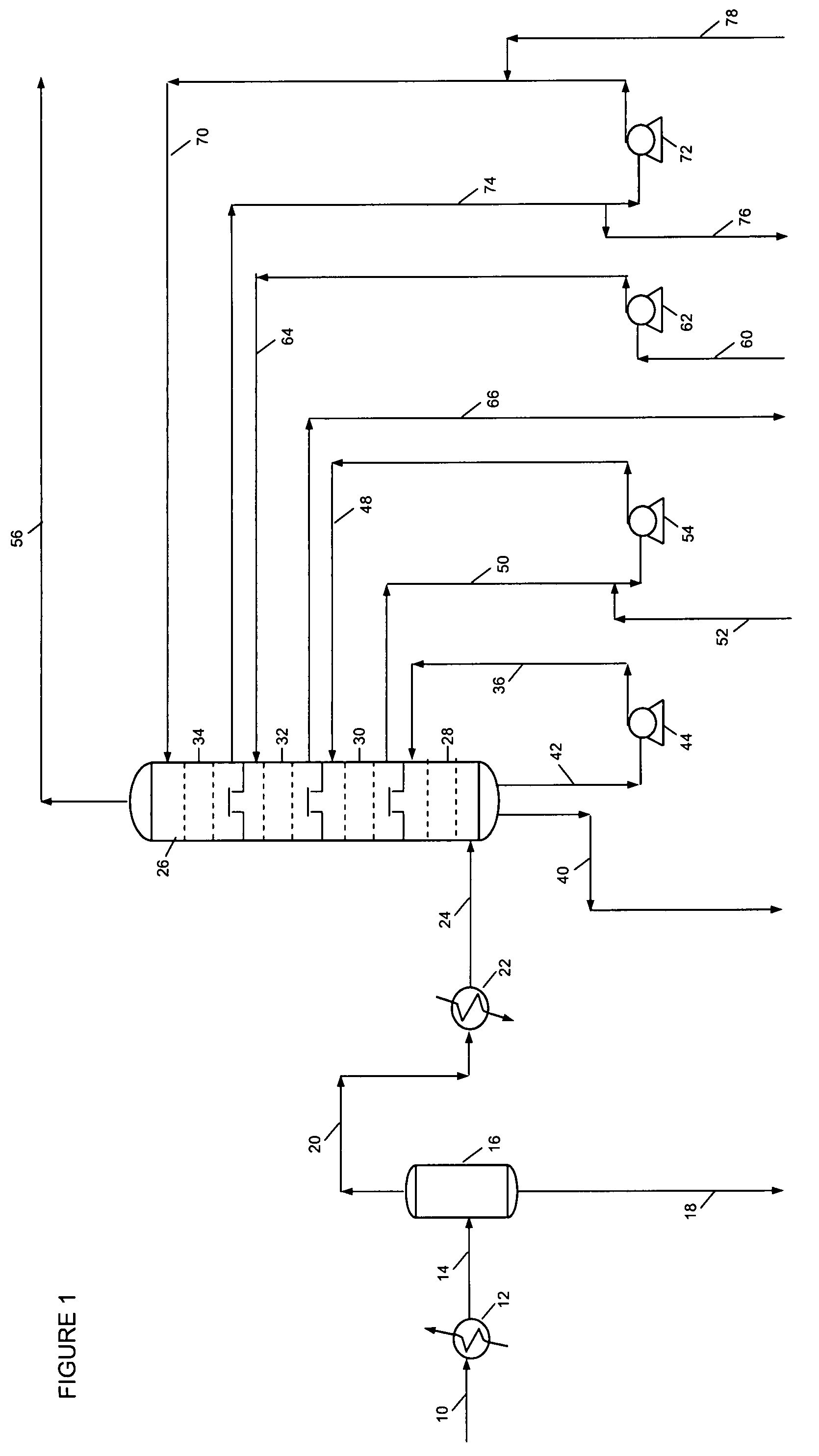

Separation process

ActiveUS7833499B2Separation in timeEasy to separateDewatering/demulsification with mechanical meansLiquid suspension thickening by filtrationFiberSulfur

A separation process for separating two or more immiscible liquids using fiber-film technology is disclosed. This separation process is especially useful in the separation of disulfide oil formed during the oxidation of spent caustic solution that was used to remove sulfur contaminates from light hydrocarbons.

Owner:MERICHEM CO

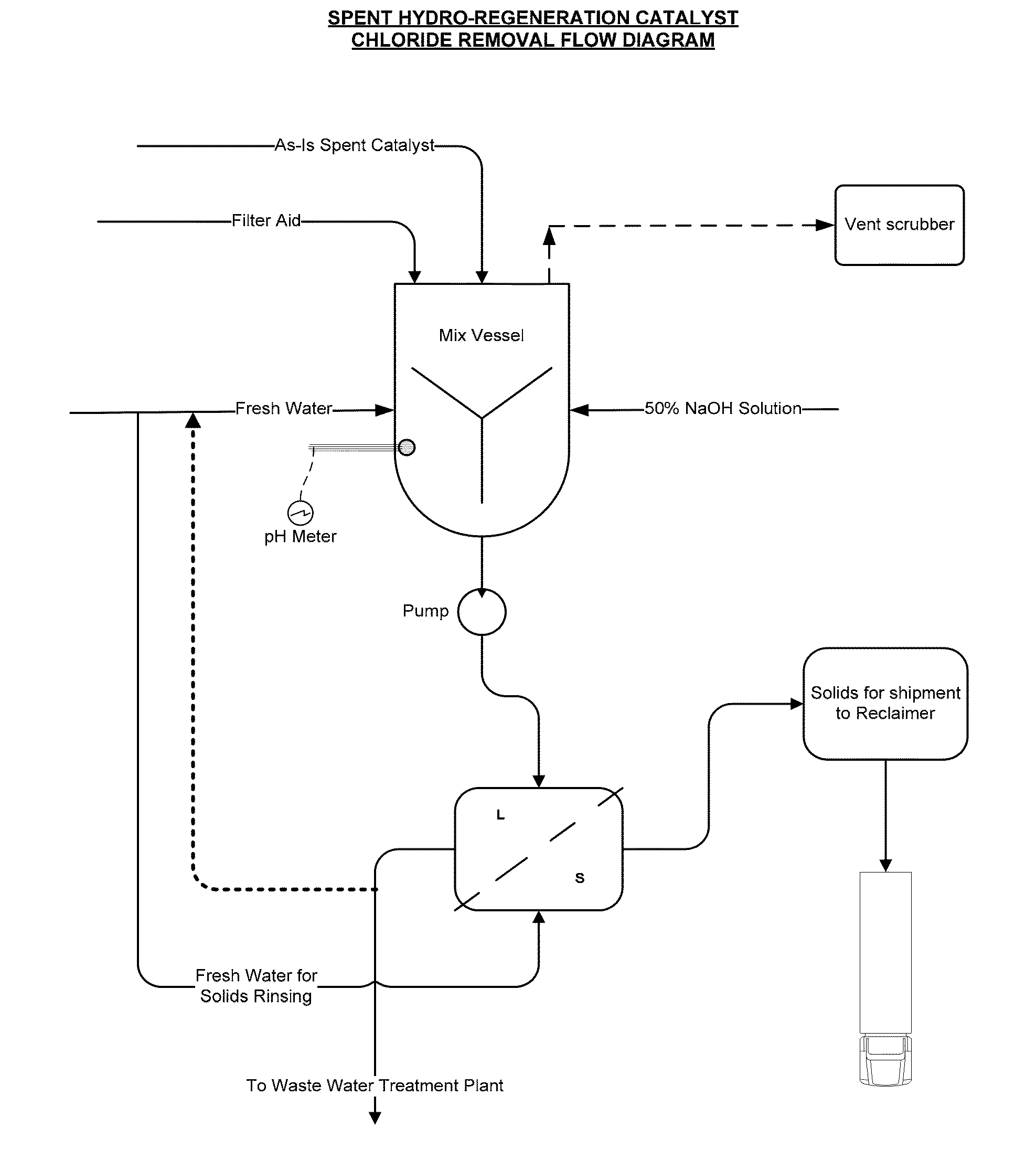

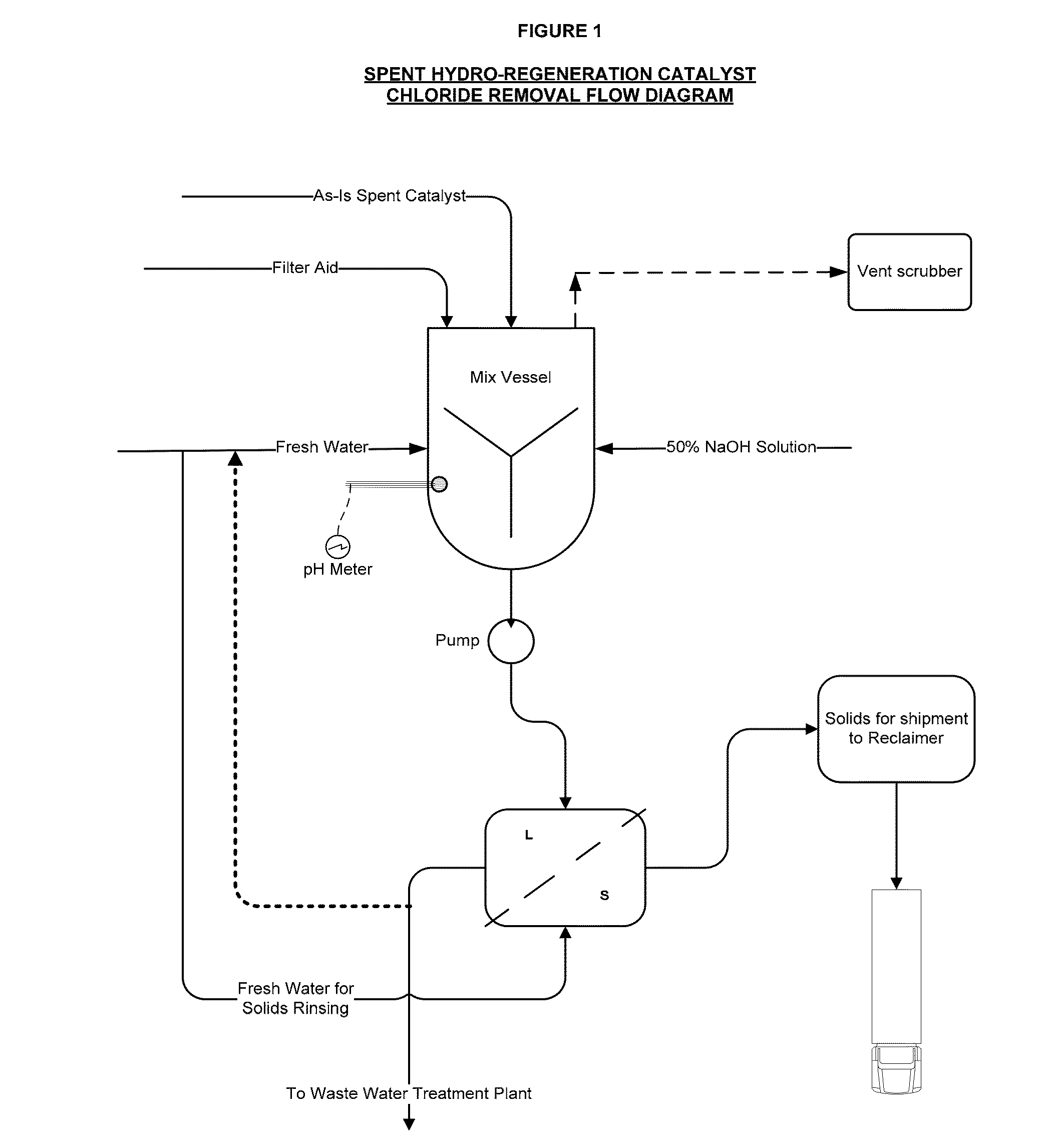

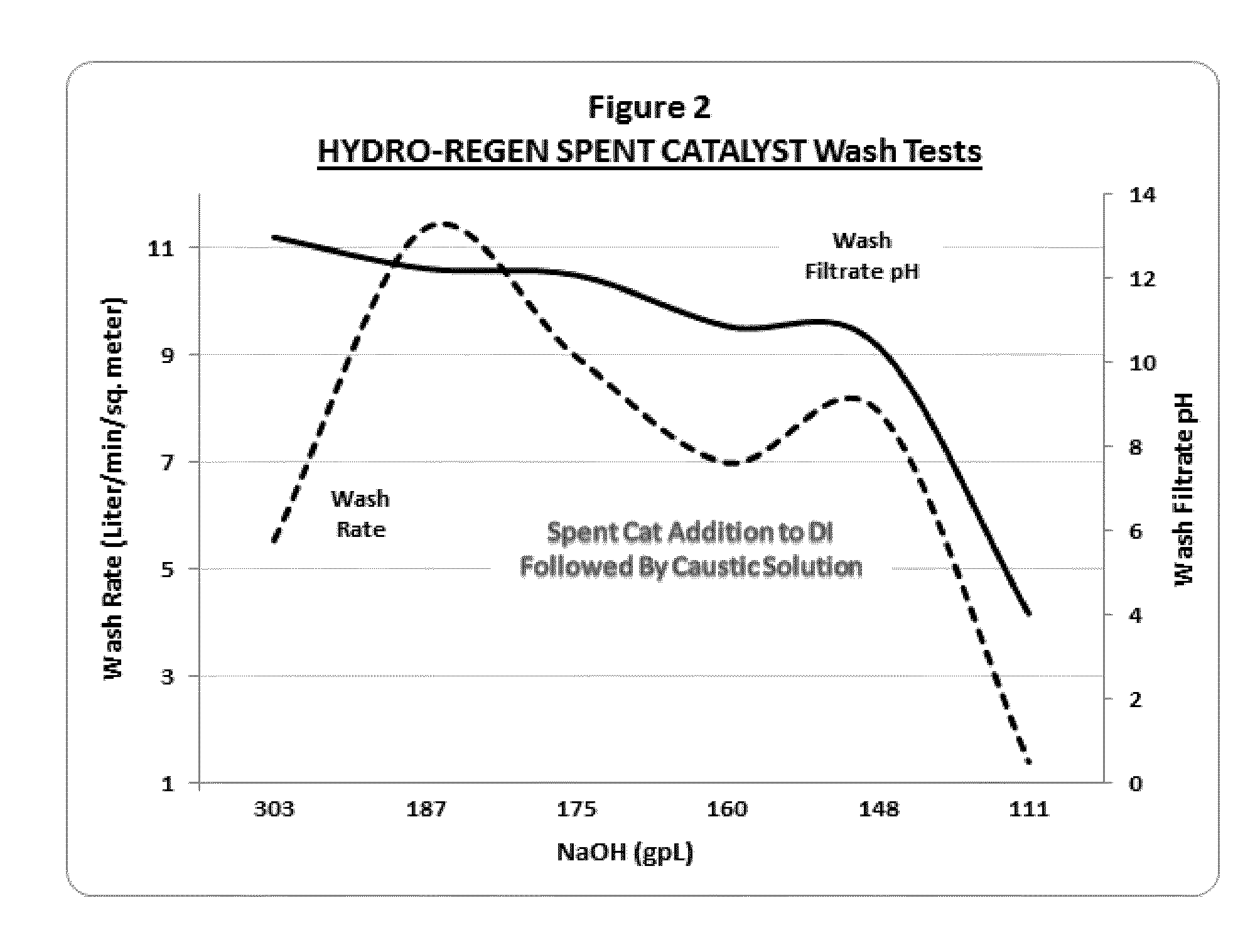

Process for preparing a spent catalyst for precious metals recovery

A process is provided for preparing a spent noble metal fixed-bed catalyst for precious metals recovery, comprising: a) adding the catalyst to a caustic solution to wash the spent catalyst and to make a wash slurry having an alkaline pH, wherein the spent catalyst has been in contact with chloroaluminate ionic liquid catalyst, and wherein the spent catalyst comprises from 5 to 35 wt % chloride; and b) filtering the wash slurry and collecting: i) a filter cake having from at least 70 wt % of the chloride in the spent catalyst removed and having the noble metals retained, and ii) a wash filtrate. Also provided is a filter cake comprising a washed consolidated cake having 40 to 75 wt % solids, a cake moisture content from 25 to less than 60 wt %, 0.1 to 1.5 wt % total noble metals, and a residual chloride content of from zero to less than 4 wt %.

Owner:CHEVROU USA INC

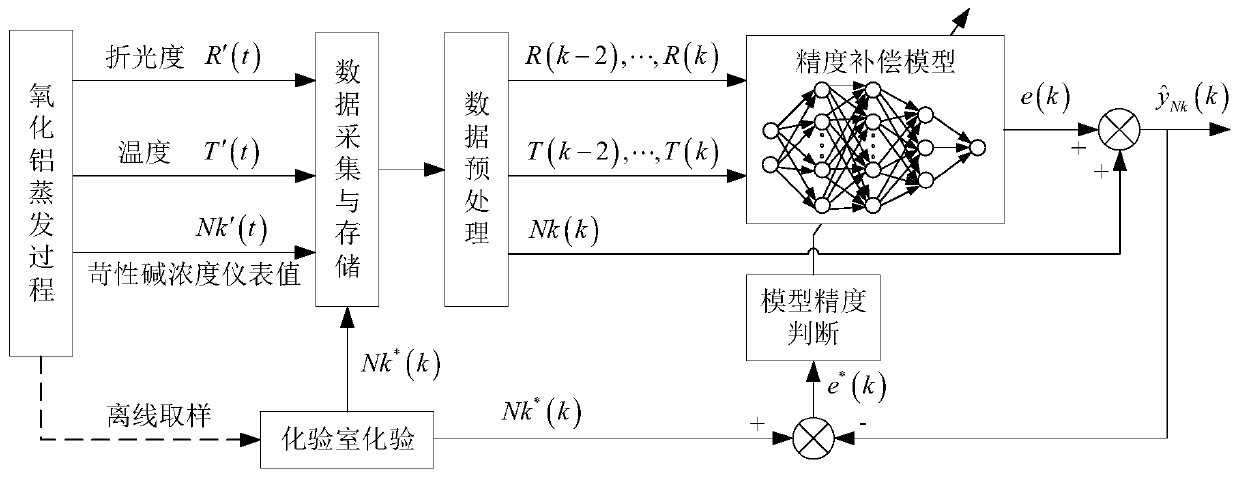

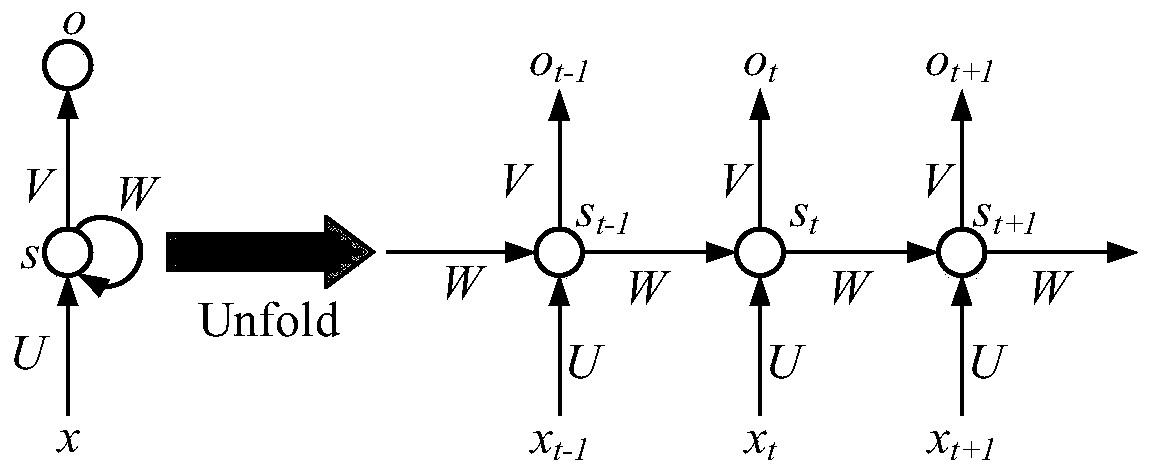

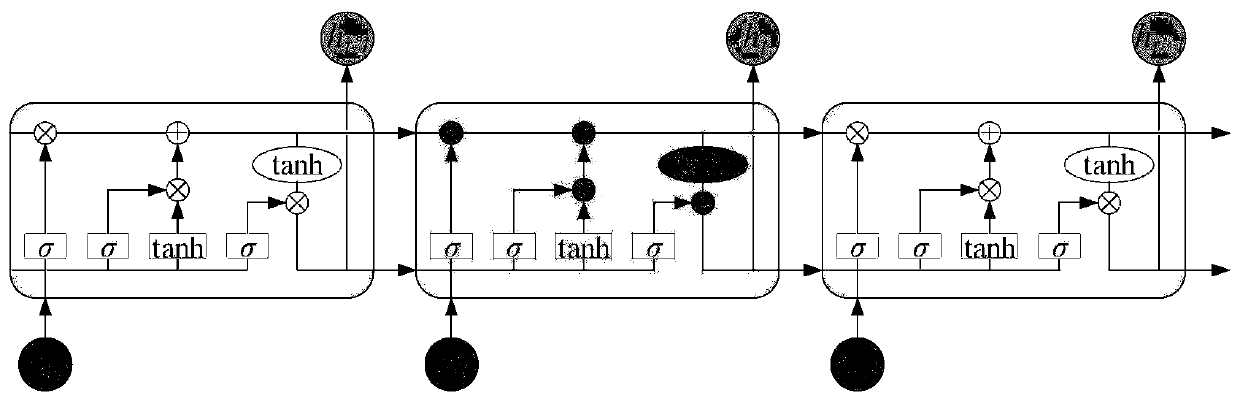

Evaporation process discharge caustic alkali concentration measurement device accuracy compensation method

ActiveCN110794093AStable productionReduce manufacturing costNeural learning methodsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationMoving averageAssay

The invention relates to an evaporation process discharge caustic alkali concentration measurement device accuracy compensation method. The evaporation process discharge caustic alkali concentration measurement device accuracy compensation method comprises the following steps of: S1, carrying out data acquisition, i.e., acquiring process data of an alkali liquor diopter, a temperature, a caustic alkali concentration instrument value and a laboratory value in the evaporating process; S2, carrying out data preprocessing, i.e., carrying out moving average filtering processing, timing matching andnormalization processing on the process data acquired in the step 1 so as to obtain the preprocessed process data; S3, inputting the preprocessed process data into a caustic alkali concentration measurement device accuracy compensation model to acquire a compensation value; and S4, adding the caustic alkali concentration instrument value with the compensation value so as to implement online compensation of caustic alkali concentration. According to the compensation method provided by the invention, the online instrument concentration value can be relatively accurately compensated, and the concentration value after compensation can follow up the tendency of an actual change; and measurement accuracy can meet the demand of actual production.

Owner:NORTHEASTERN UNIV LIAONING

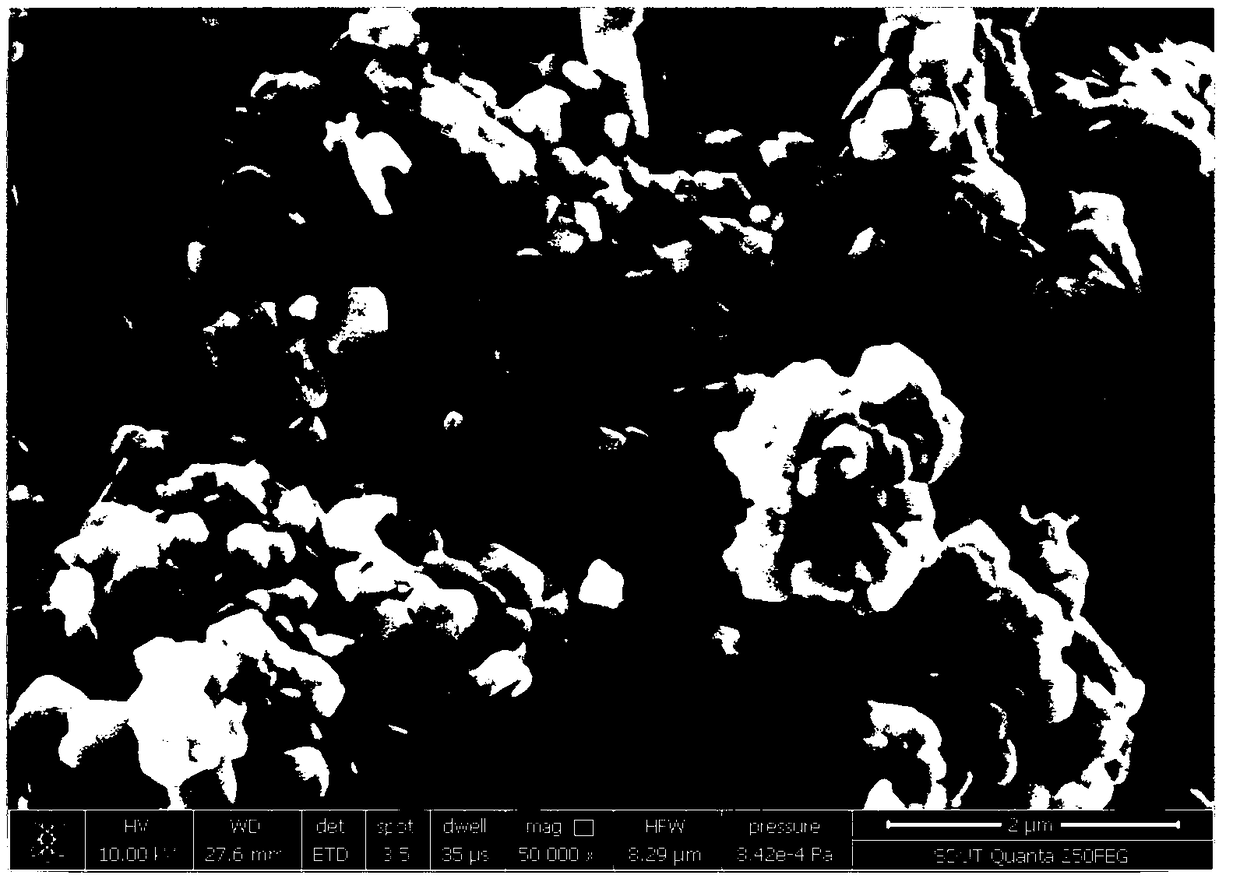

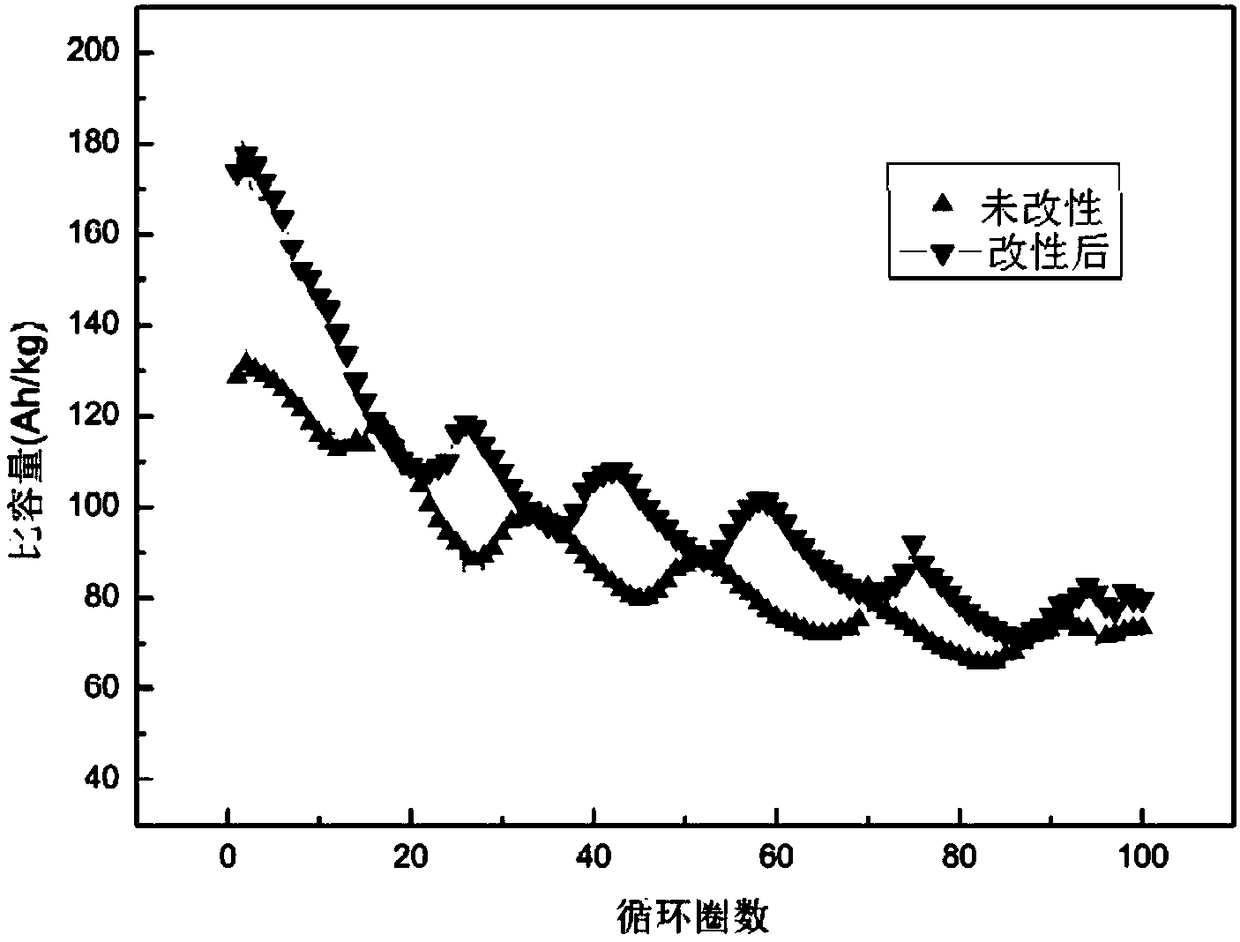

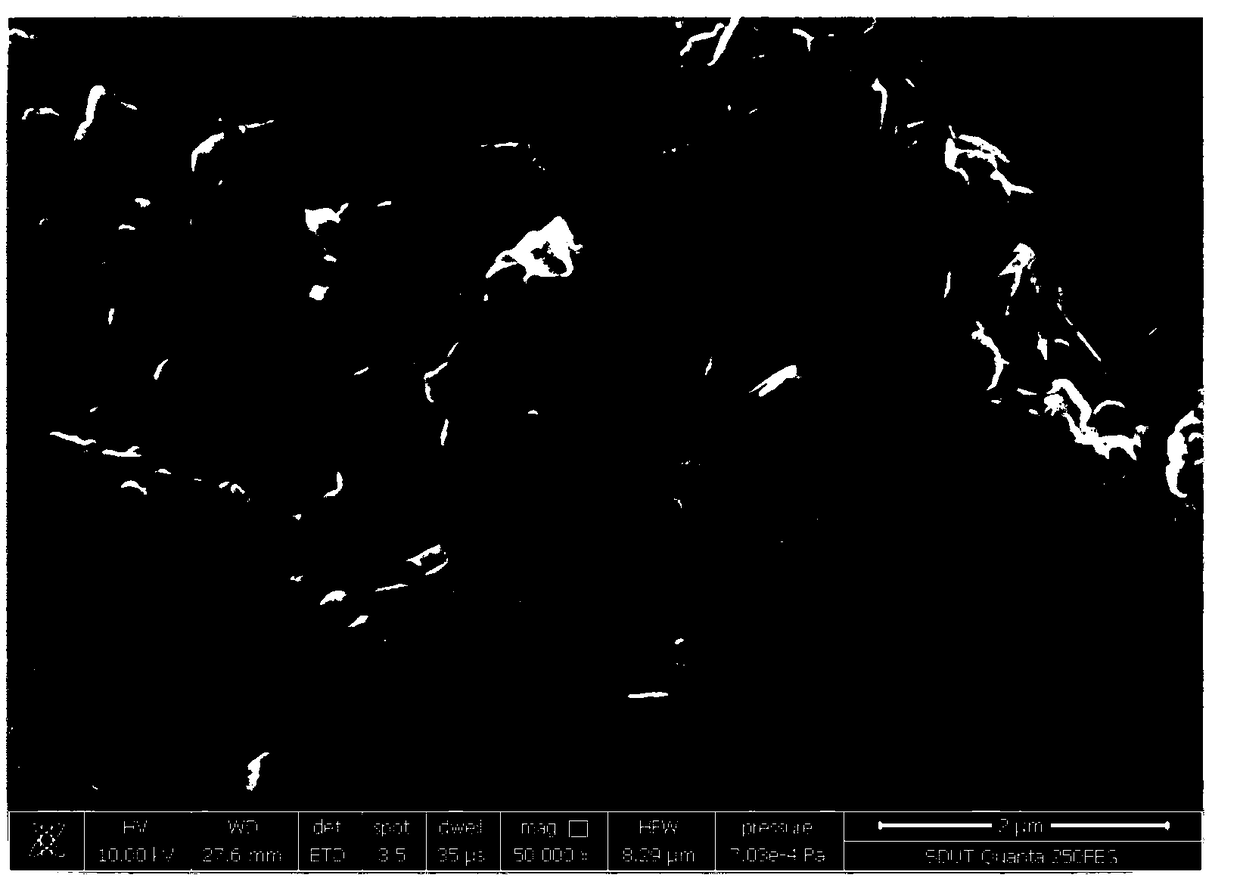

Method for preparing lithium aluminate modified ternary anode material based on spent lithium-ion battery cathode materials

ActiveCN108878837AGuaranteed uniformityAchieving cryogenic recoveryCell electrodesWaste accumulators reclaimingLithium aluminateCobalt

The invention belongs to the technical field of ternary material precursor preparation, and particularly to a method for preparing lithium aluminate modified ternary anode materials based on spent lithium-ion battery cathode materials. The method comprises the steps that anode materials are separated from spent lithium-ion batteries; the anode materials are leached in a caustic solution and filtered; lithium carbonate is obtained by adding carbonate to filtrate; a filter cake is leached with sulfuric acid and leaching liquid is obtained; an adjustment solution is obtained by adjusting the molar ratios of nickel, cobalt and manganese in a leaching solution; the adjustment solution, an ammonia water solution and a caustic solution are flow into a reaction still together, and the ternary material precursor is prepared by coprecipitation; then the ternary material precursor is mixed with lithium carbonate for roasting, and ternary anode materials are obtained; and the lithium aluminate modified ternary anode materials are prepared by adding sec-butyl alcohol, lithium methoxide and the ternary anode materials in a mixture of ethyl acetoacetate, ethanol and water for reaction and roasting. The ternary anode materials have good structure stability, good electrochemical performance, lower production cost and high product quality, and realize the directional circulation of nickel-cobalt-manganese lithium resources.

Owner:SHANDONG UNIV OF TECH

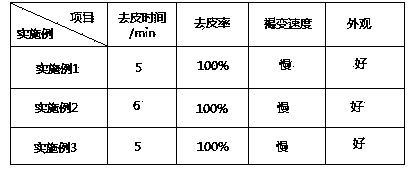

Apple peeling agent

InactiveCN103462182AMeet processing requirementsNot easy to brownVegetable peelingBiotechnologyBrowning

The invention discloses an apple peeling agent, which comprises the following components in percentage by mass: 3% to 5% of caustic alkali, 0.5% to 0.8% of surface active agent, 0.2% to 0.3% of additive, and the balance of water. An apple is peeled by the peeling agent, the peeling can be completed at the temperature of 60 to 70 DEG C, the peeling rate is 100%, the browning difficultly occurs, the appearance is good, and the processing requirements of foods are met.

Owner:句容市白兔镇唐庄富民葡萄专业合作社

Process for removing one or more sulfur compounds from a stream

InactiveUS8597501B2Lowered disulfide contentReducing and eliminating undesiredRefining with aqueous alkaline solutionsHydrocarbon oils treatmentThiolSulfur

One exemplary embodiment can be a process for removing one or more disulfide compounds from a caustic stream. The process can include passing the caustic stream, previously contacted with a hydrocarbon stream for removing one or more mercaptans, through a column to remove the one or more disulfide compounds downstream of a mercaptan oxidation zone.

Owner:UOP LLC

Preparation method and applications of alkyl phosphite

ActiveCN103923119AWide variety of sourcesEasy to produceGroup 5/15 element organic compoundsFlotationPhosphoric Acid EstersAlcohol

The invention relates to a preparation method of alkyl phosphite. The prepared alkyl phosphite can be used for a non-sulfide ore floatation collecting agent. The preparation method comprises the following steps: firstly adding fatty alcohol and water into a reaction kettle, slowly dropwise adding phosphorus trichloride at room temperature and continuously stirring, and reacting at 30DEG C-90DEG C after the dropwise addition of phosphorus trichloride is completed, wherein the fatty alcohol is linear-chain fatty acid alcohol of C6-C18, benzene ring fatty alcohol or different carbon chains of mixed alcohol; adding caustic alkali at 30DEG C-90DEG C and continuously stirring, and reacting for 0.5-1.5 hours at 30DEG C-60DEG C after stopping adding of the caustic alkali, thus obtaining the alkyl phosphate. The method for preparing alkyl phosphite is simple in production technology, low in the cost of raw materials, convenient for industrial production, and aiming at different types of ores, different alkyl phosphite can be prepared by changing raw materials fatty alcohol.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Removal of acid gases and sulfur compounds from hydrocarbon gas streams in a caustic tower

ActiveUS7772449B2Avoid poisoningFully removedThermal non-catalytic crackingCatalytic crackingThiolSulfur

Owner:STONE & WEBSTER PROCESS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com