Patents

Literature

400 results about "Lead salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead salt. Lead salt was a chemical compound which contained lead. On Venus, Jeff Stone combined lead salt with sodium azide to make lead azide.

Lead regeneration method for recovering lead paste from waste lead acid storage battery by wet method

ActiveCN102618884AAvoid churnHigh recovery ratePhotography auxillary processesProcess efficiency improvementElectrolysisLead dioxide

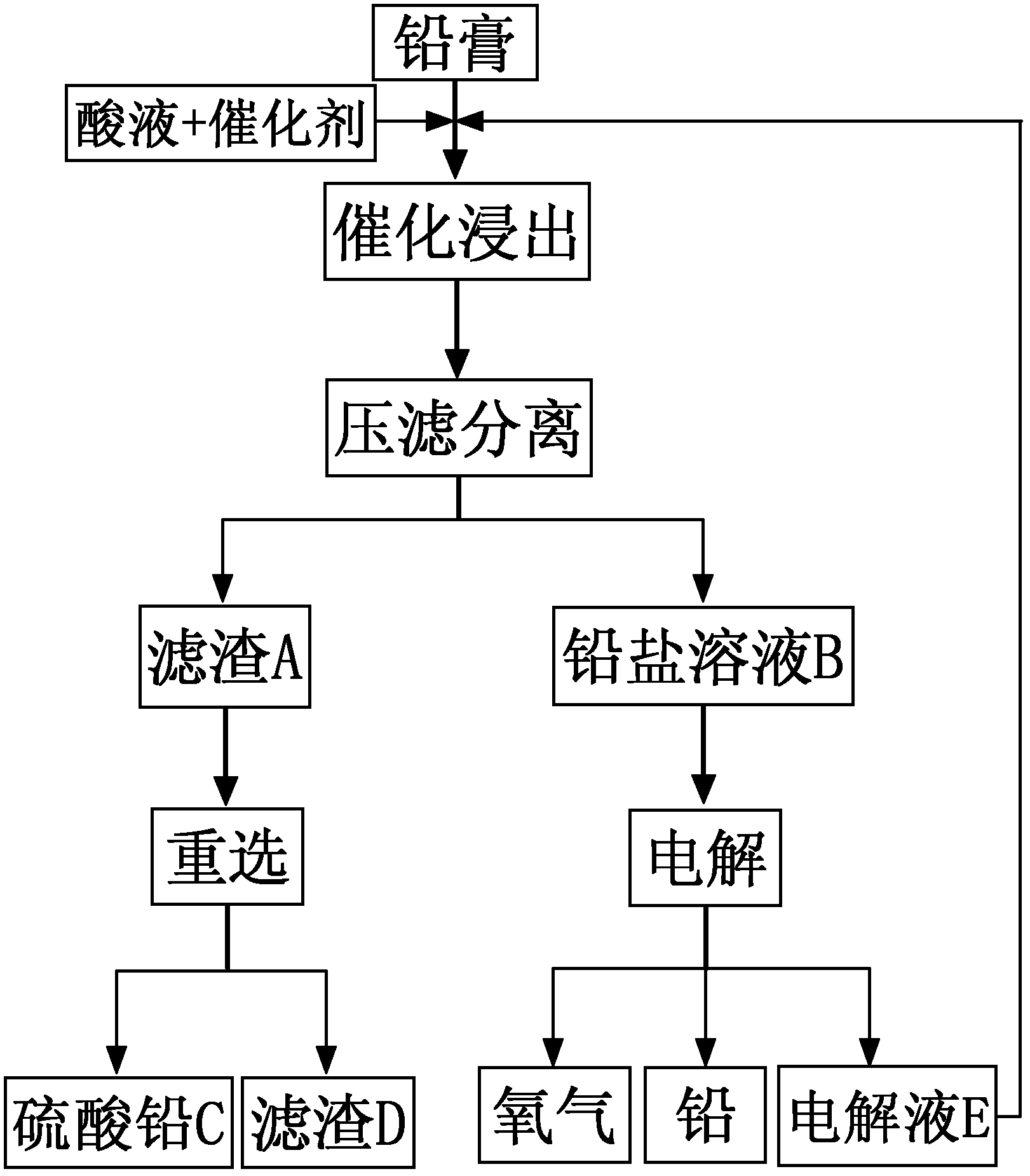

The invention discloses a lead regeneration method for recovering lead paste from a waste lead acid storage battery by a wet method, and belongs to the field of lead regeneration from the lead paste of the waste lead acid battery. The lead regeneration method comprises the following steps of: adding the lead paste into an acid liquor reaction kettle containing a catalyst to perform oxidation reduction reaction on lead and lead dioxide in the lead paste to obtain soluble lead salt solution; meanwhile, reacting lead oxide with acid to obtain lead salt; separating to obtain insoluble filter residue mainly containing soluble lead salt solution and lead sulfate; and electrolyzing the lead salt solution to obtain lead, oxygen and acidic electrolyte, wherein the electrolyte can be returned to a leaching process for recycling, and the filter residue A is treated by the conventional reselection process to obtain the lead sulfate and the filter residue D. According to the lead regeneration method, the production cost is reduced, and high comprehensive lead recovery rate is obtained.

Owner:北京绿色引领环保科技研究院有限公司

Method for recovering lead oxide from waste lead plaster

ActiveCN104141045AAtom economy is highIn line with the principles of atom economyLead-acid accumulatorsLead monoxideLead saltLead oxide

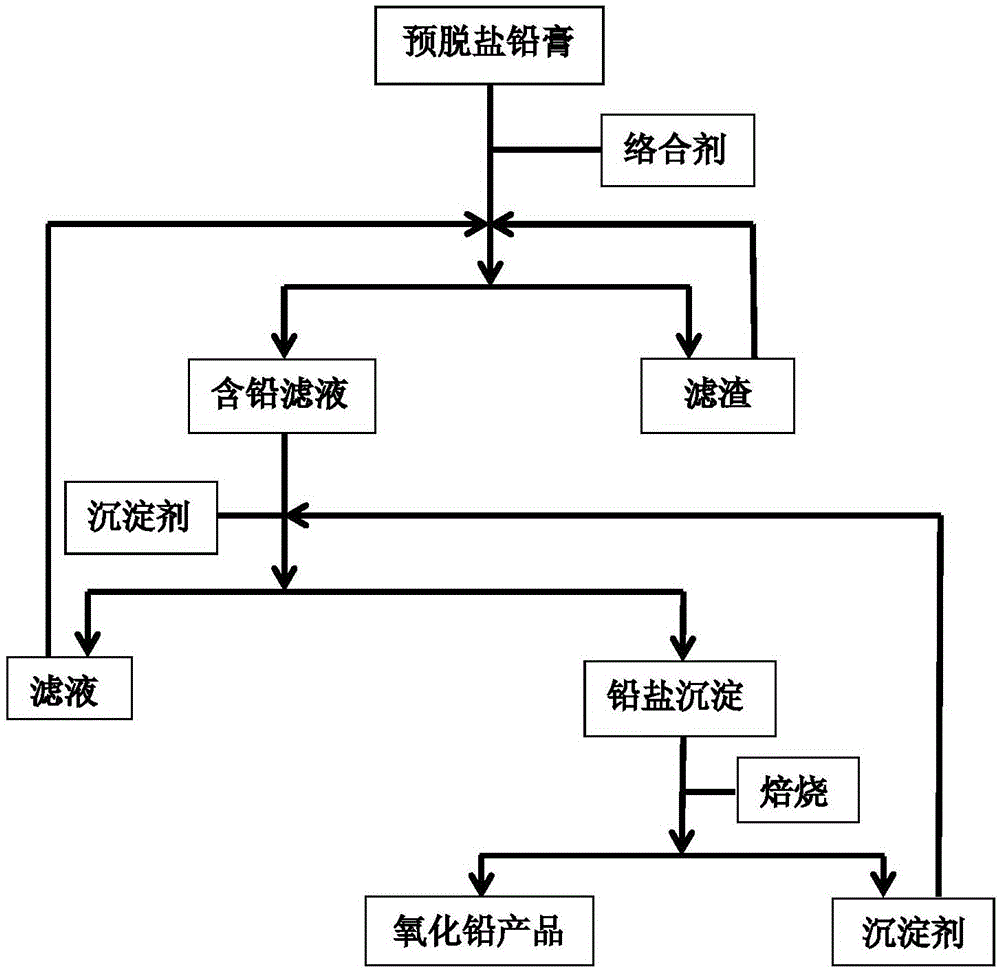

The invention provides a method for recovering lead oxide from waste lead plaster. The method comprises the following steps: a, dissolving pre-desalted lead plaster by using a complexing agent solution, and reacting all PbOs with a complexing agent to generate complexing ions so as to obtain a lead-containing solution and filter residues; b, adding a precipitating agent into the lead-containing solution, reacting the precipitating agent with the lead complexing ions to generate lead salt precipitation and the regenerated complexing agent; and c, roasting the lead salt precipitation to obtain lead oxide, and regenerating the precipitating agent. The method can be widely suitable for lead plaster formed by mixing various sources, the process conditions are relatively mild, a process is relatively environment-friendly, and the final recovery rate of lead oxide can reach more than 99%, so that the method has very high application values in the industry of recovery treatment of waste lead-acid batteries.

Owner:BEIJING UNIV OF CHEM TECH

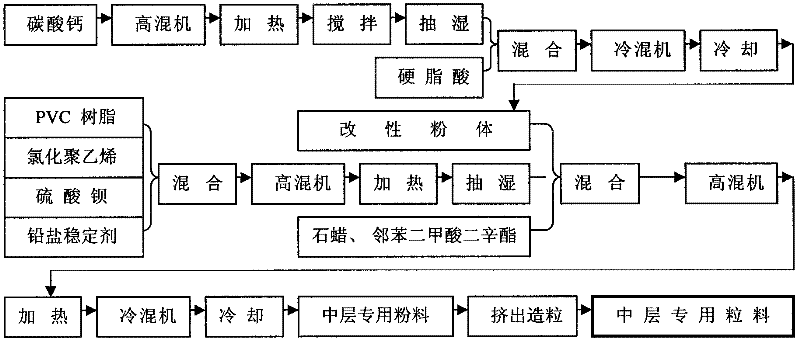

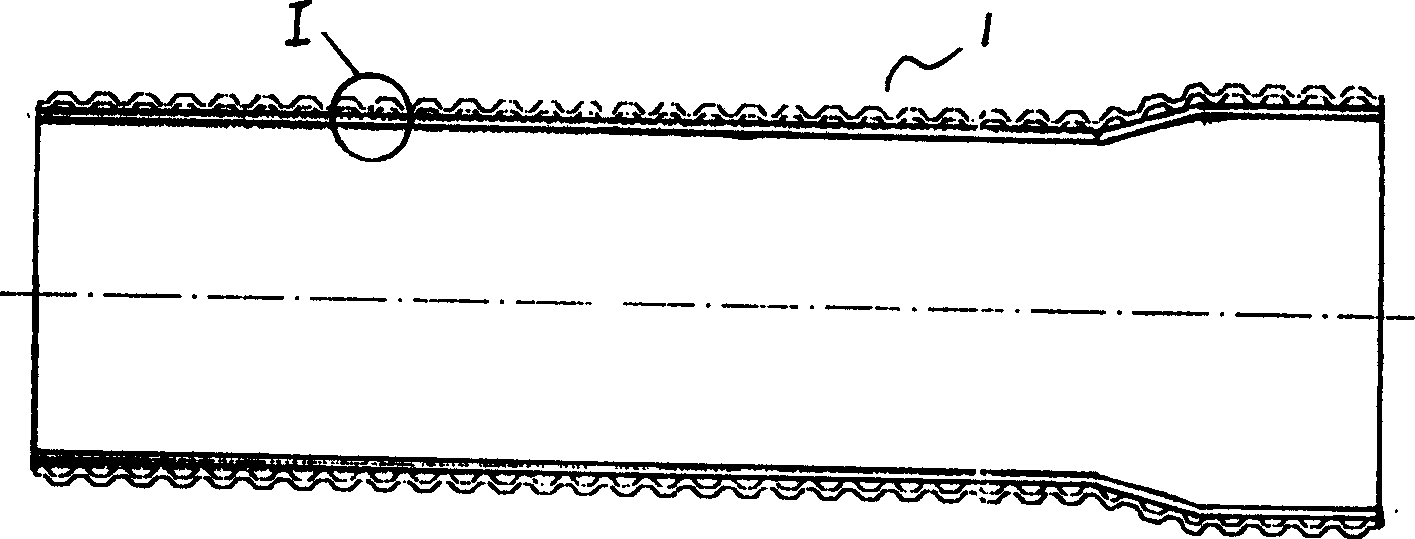

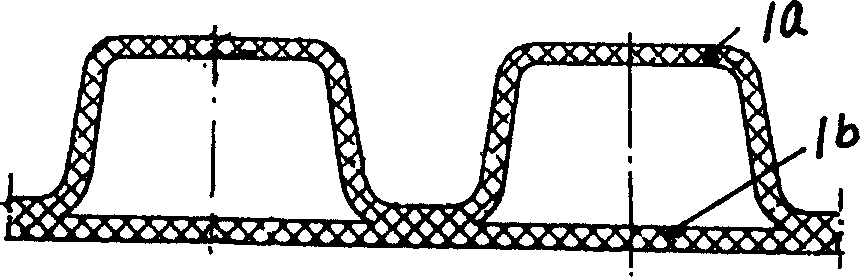

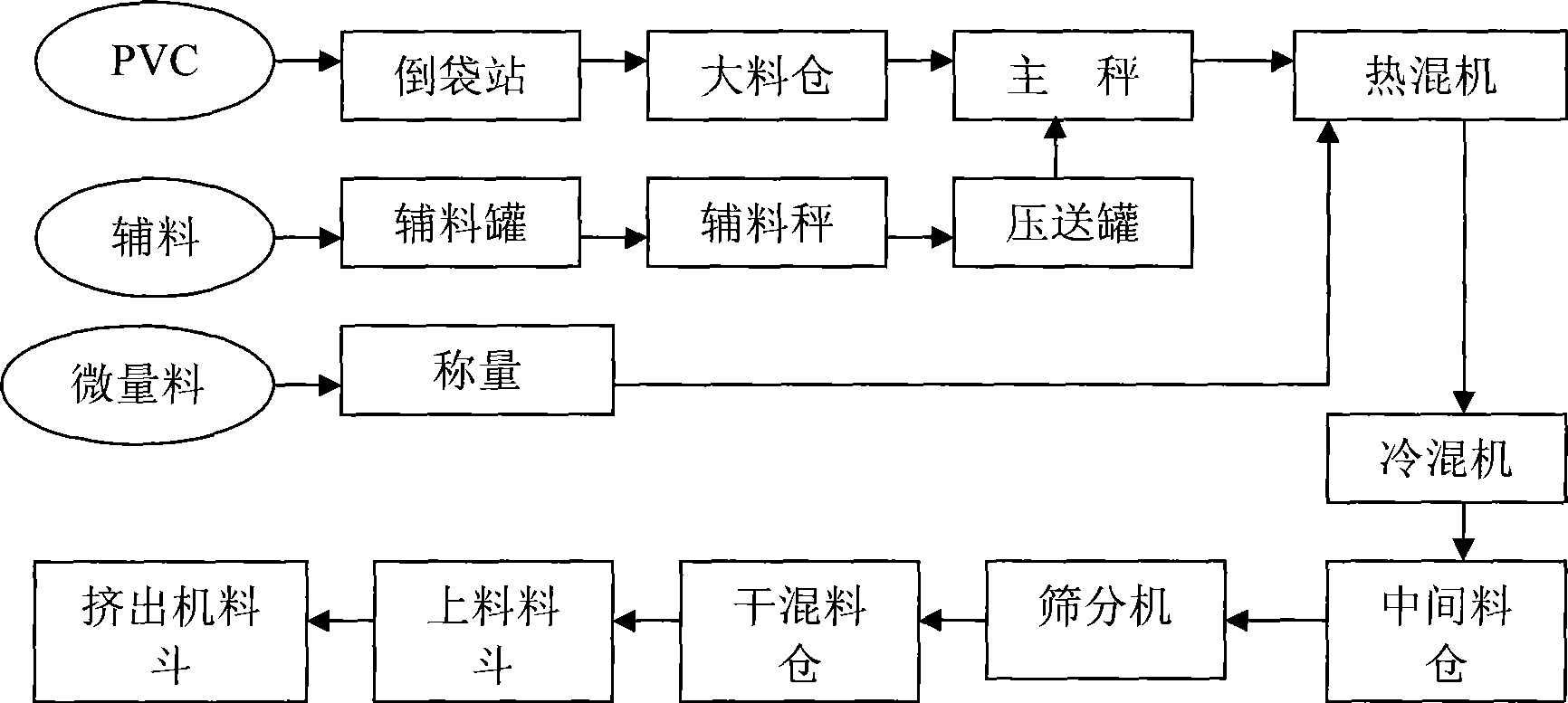

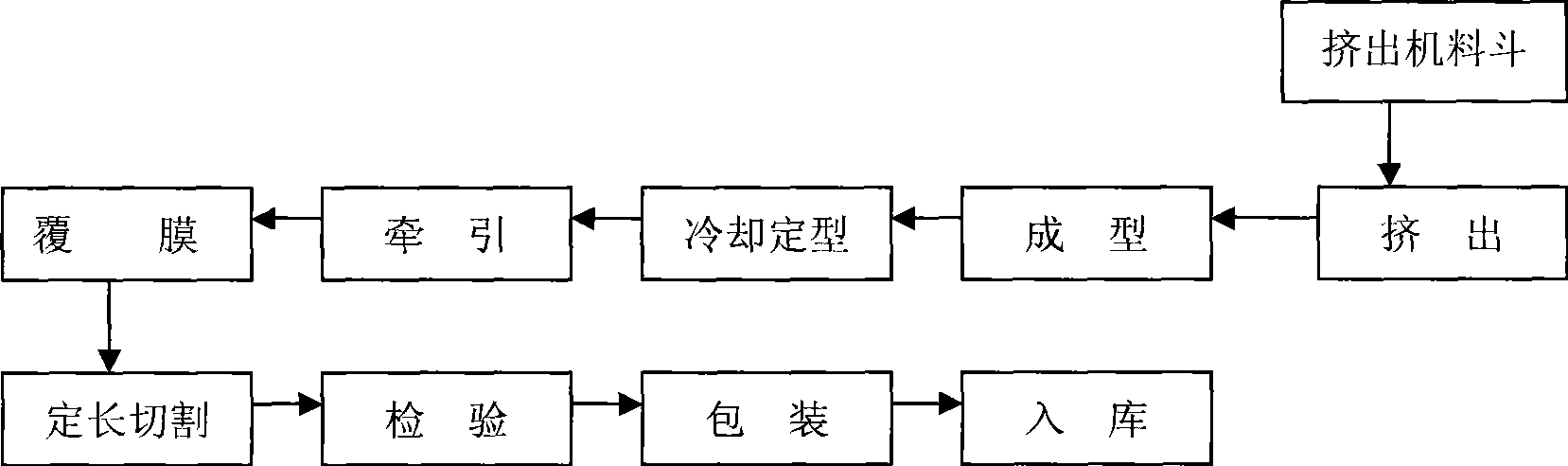

Three-layer noise reduction drainage pipe and manufacture method thereof

InactiveCN102313084AHigh strengthReduce impact noiseDomestic plumbingRigid pipesManufacturing cost reductionPolyvinyl chloride

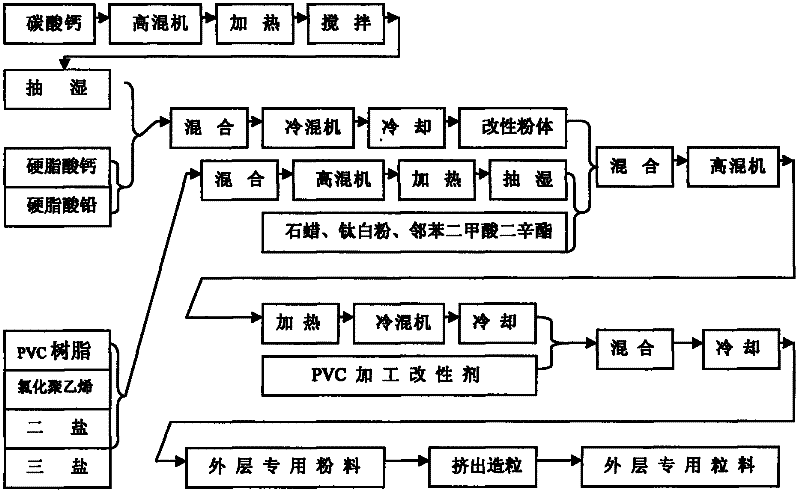

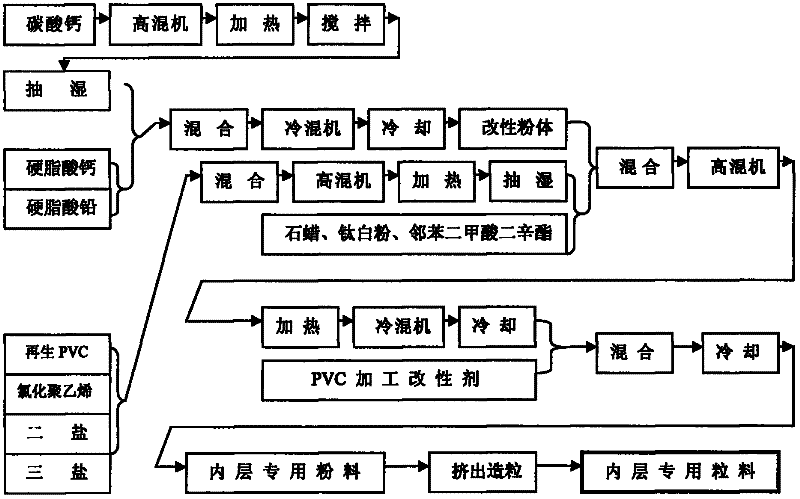

The invention discloses a three-layer noise reduction drainage pipe, which comprises a drainage pipe body, wherein the drainage pipe body is a three-layer co-extrusion composite pipe formed by an impact-resistance outer layer, a noise reduction middle layer and an impact-resistance inner layer through co-extrusion. The noise reduction middle layer is a sound-absorbing middle layer or a sound insulation middle layer made of expandable polyvinyl chloride composition materials. The above layers are prepared with the following materials. The impact-resistance outer layer is made of polyvinyl chloride resin, chlorinated polyethylene, dibasic lead phosphite, tribasic lead sulfate, calcium stearate, lead stearate, paraffin, PVC processing and modifying agent, active light calcium carbonate, titanium dioxide and dioctyl phthalate. The sound-absorbing middle layer is made of polyvinyl chloride resin, chlorinated polyethylene, lead salt stabilizer, calcium stearate, stearic acid, paraffin, dioctyl phthalate, active light calcium carbonate and barium sulfate. The sound insulation middle layer is made of polyvinyl chloride resin, methacrylic ester polymer and inorganic foaming agent. Compared with the outer layer, the impact-resistance inner layer comprises the same components with the outer layer, except that PVC is adopted instead of polyvinyl chloride resin. The noise of the drainage pipe can be effectively reduced and the intensity of the drainage pipe is enhanced.

Owner:ZHEJIANG SANLENG PLASTIC

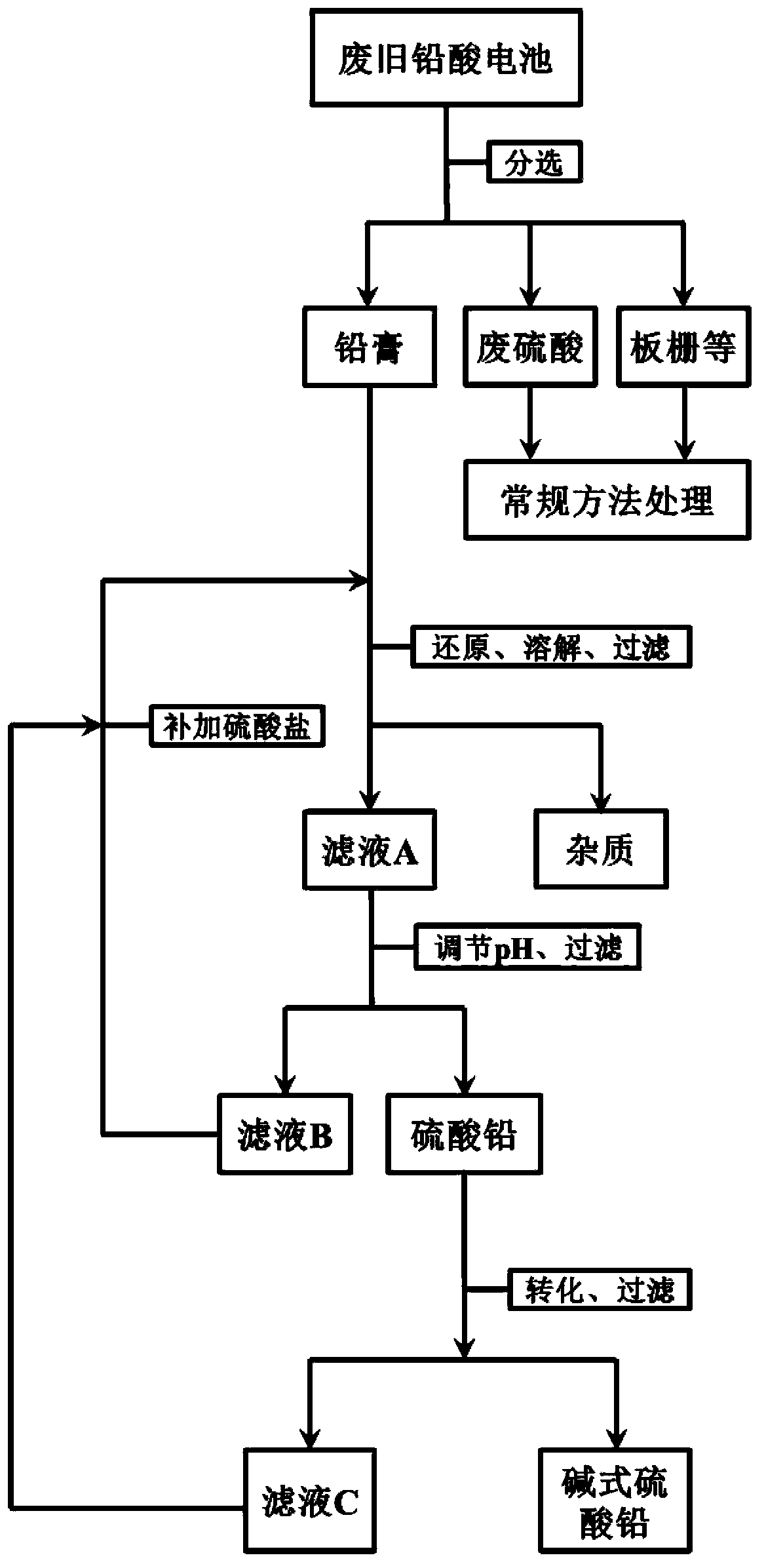

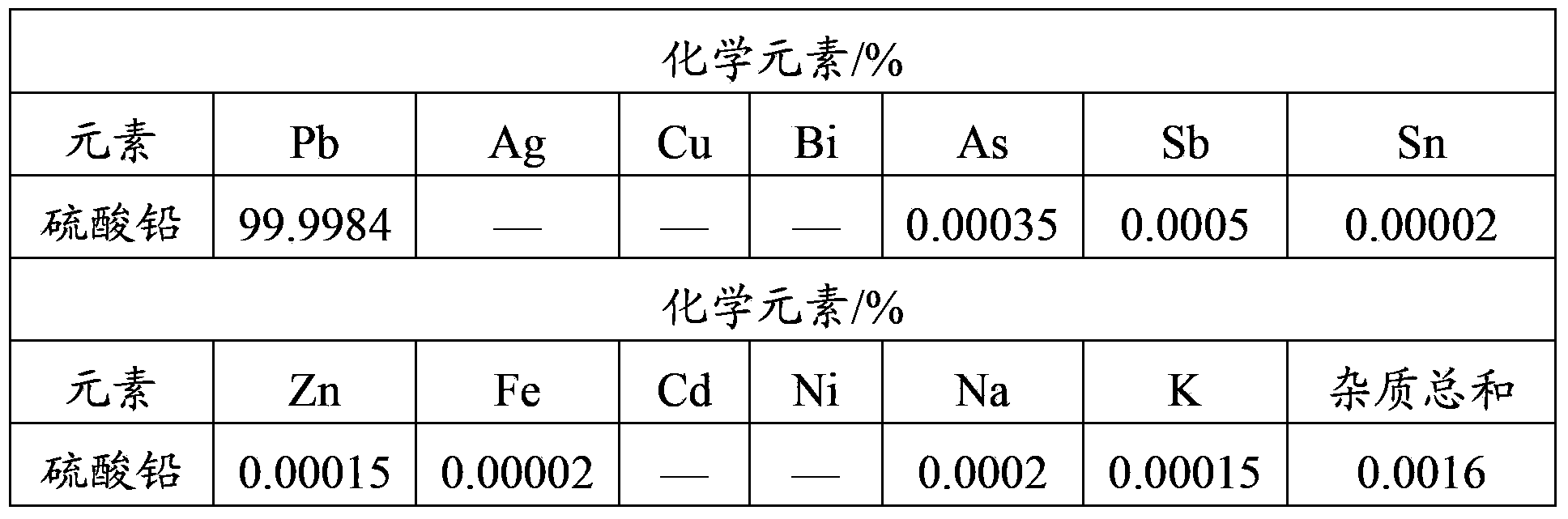

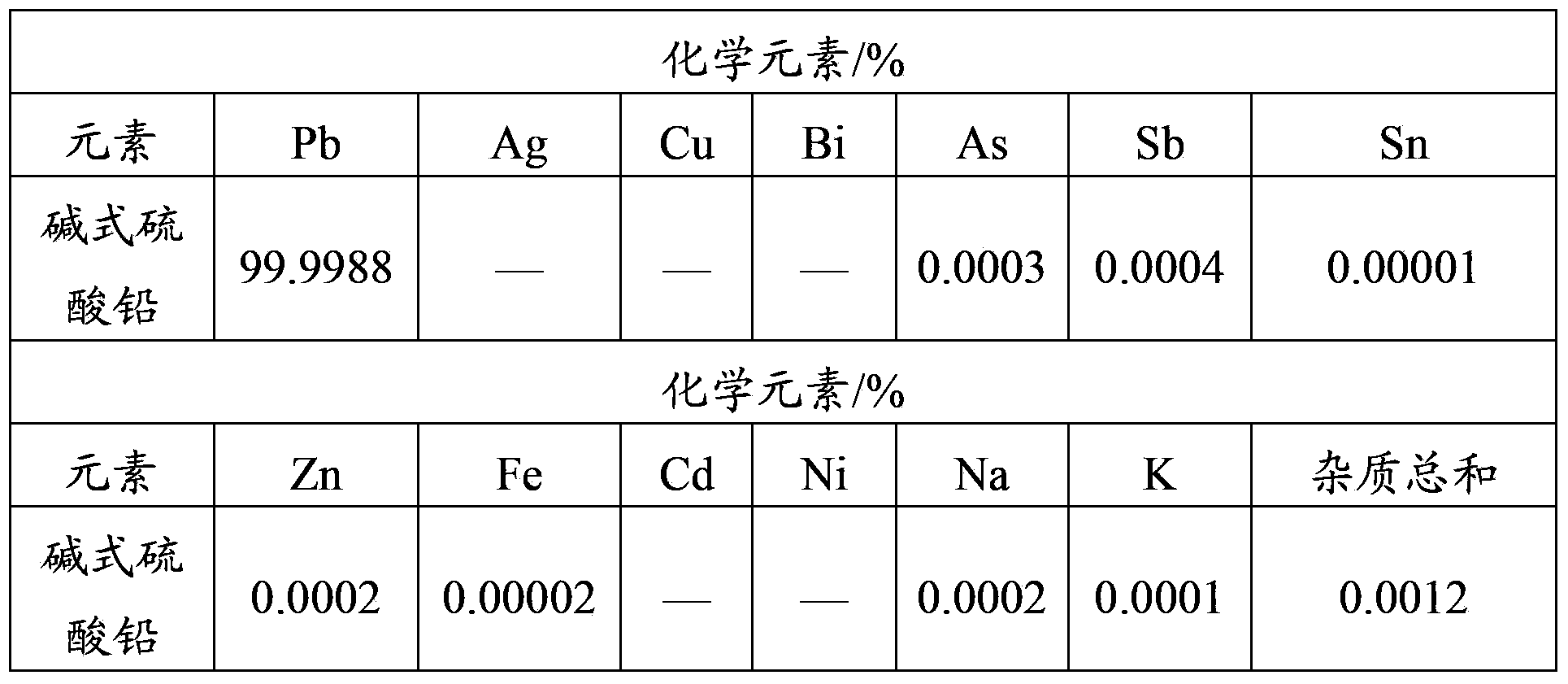

Method for recovering lead-containing raw material by using wet process

ActiveCN103526016AEnvironmentally Friendly Recycling MethodsEfficient recycling methodProcess efficiency improvementRecovery methodLead dioxide

The invention discloses a method for recovering a lead-containing raw material by using a wet process. The method comprises the steps: (1) leaching the lead-containing raw material by using a solution, adding a reducing agent to reduce lead dioxide or lead orthoplumbate in the lead-containing raw material into a soluble lead salt, after a lead compound is completely dissolved, filtering the solution, and separating to obtain a filtrate A and an insoluble substance, wherein the solution contains sulfate, a complexing agent and a catalyst; (2) adjusting the pH value of the filtrate A, separating to obtain lead sulfate and a filtrate B, and returning the filtrate B to the step (1) after sulfate radicals are replenished and the pH value is adjusted; (3) directly using lead sulfate as battery materials or commodities, subjecting a sulfate-containing alkaline solution and lead sulfate to reaction, and separating to obtain basic lead sulfates and a filtrate C, wherein the basic lead sulfates include tribasic lead sulfate and tetrabasic lead sulfate. The method can be used for purifying the lead-containing raw material to form lead sulfate and basic lead sulfates directly used for producing lead-acid batteries, thereby being an environment-friendly wet-process recovery method.

Owner:北京中金瑞丰环保科技有限公司

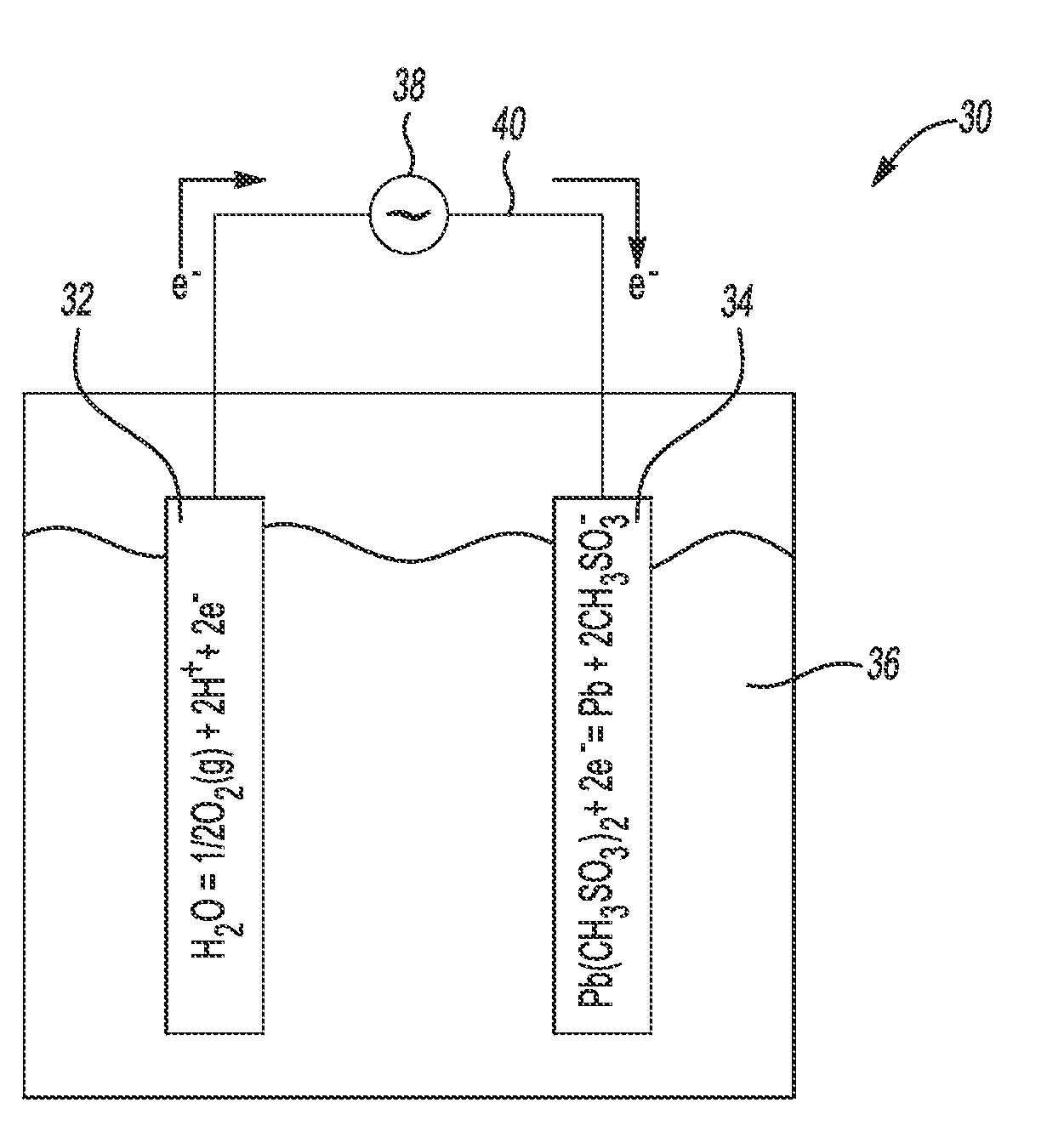

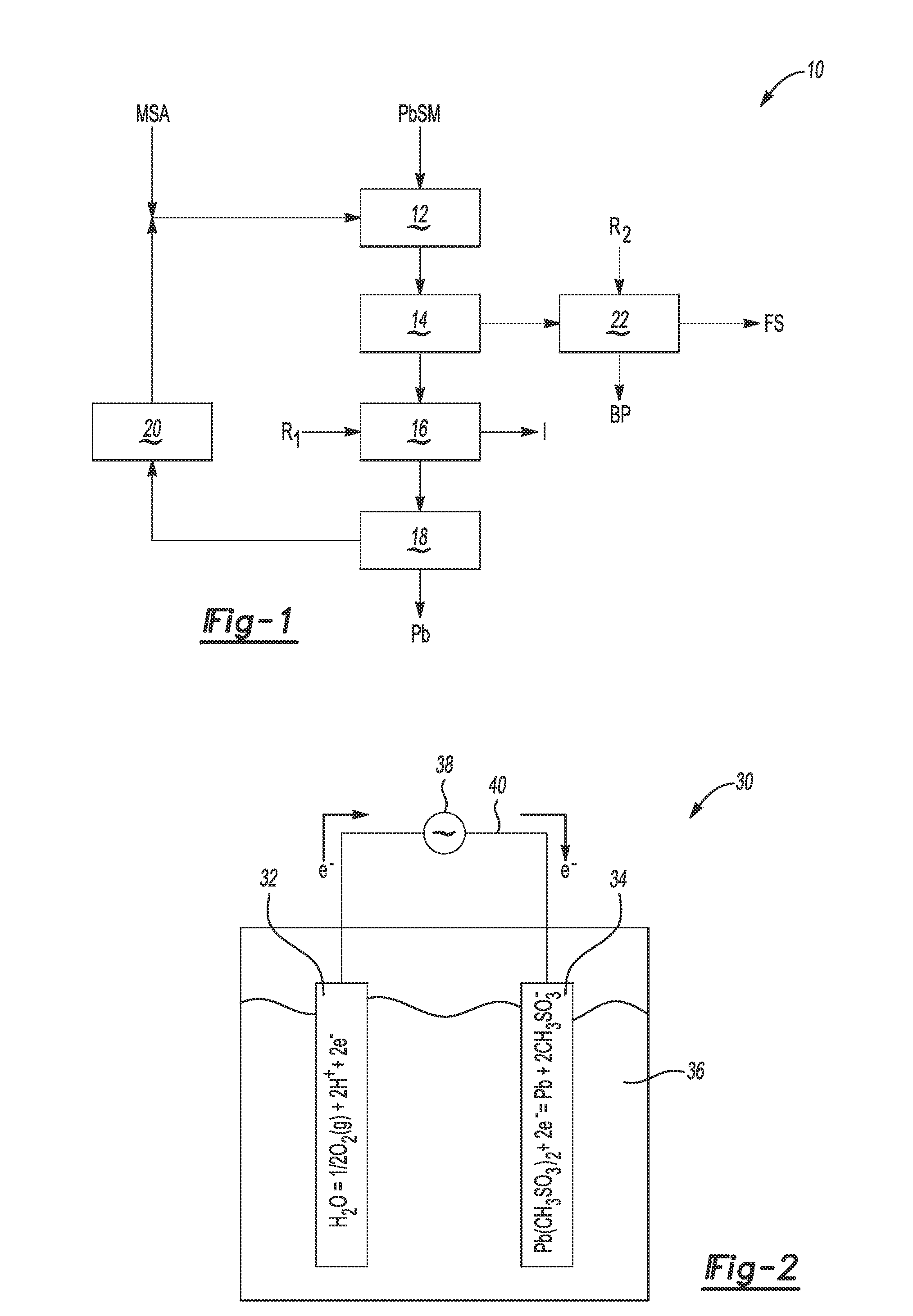

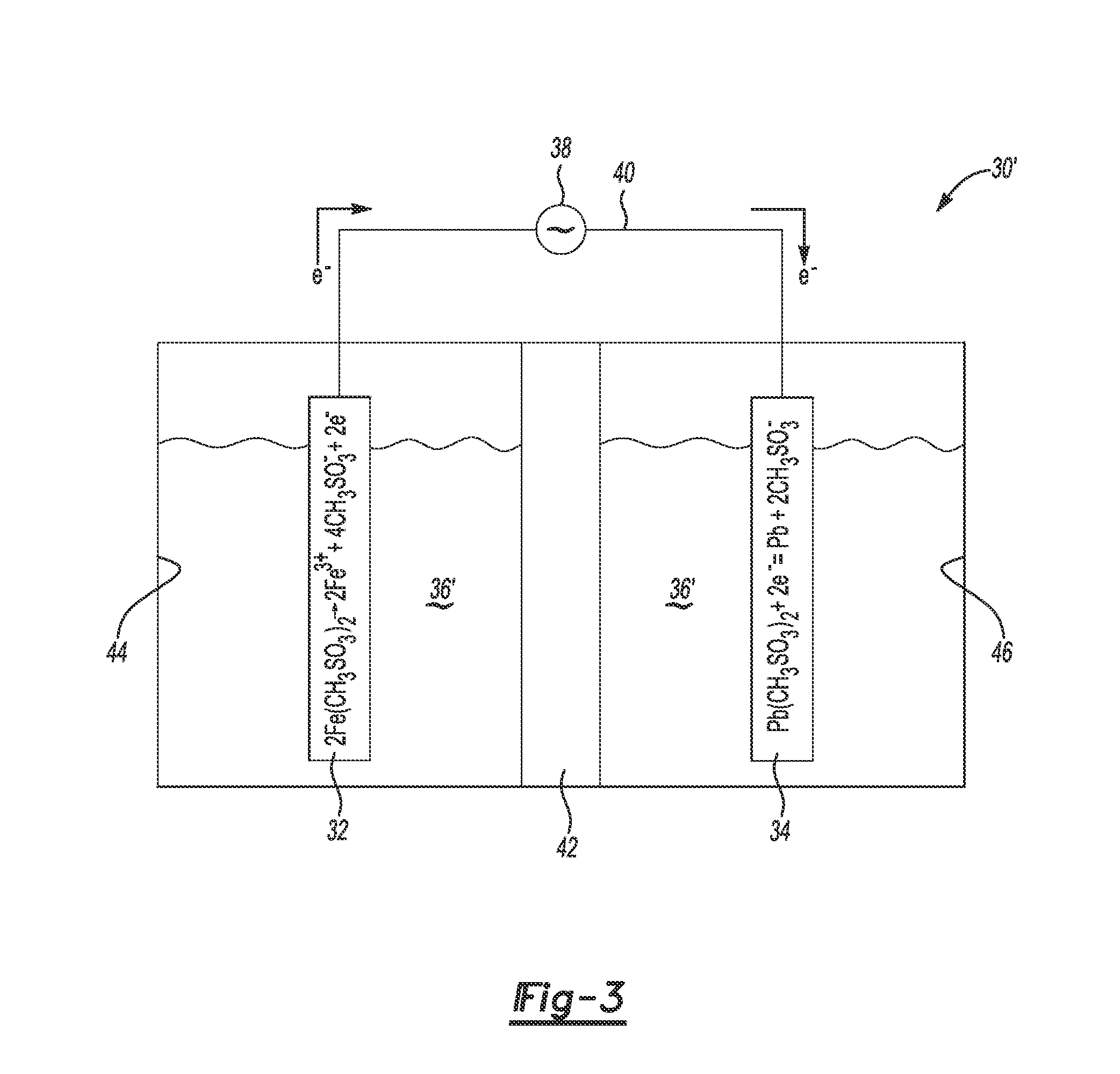

Recovering lead from a lead material including lead sulfide

In an example of a method for recovering lead from a lead material including lead sulfide, methane sulfonic acid is selected as a leaching acid for the lead material. The lead material is exposed to a solution including the methane sulfonic acid and i) ferric methane sulfonate or ii) oxygen, which leaches lead from the lead sulfide in the lead material, and generates a liquid leachate including a lead-methane sulfonate salt. The liquid leachate is purified, and lead is recovered from the purified liquid leachate using electrolysis.

Owner:THE UNIV OF BRITISH COLUMBIA

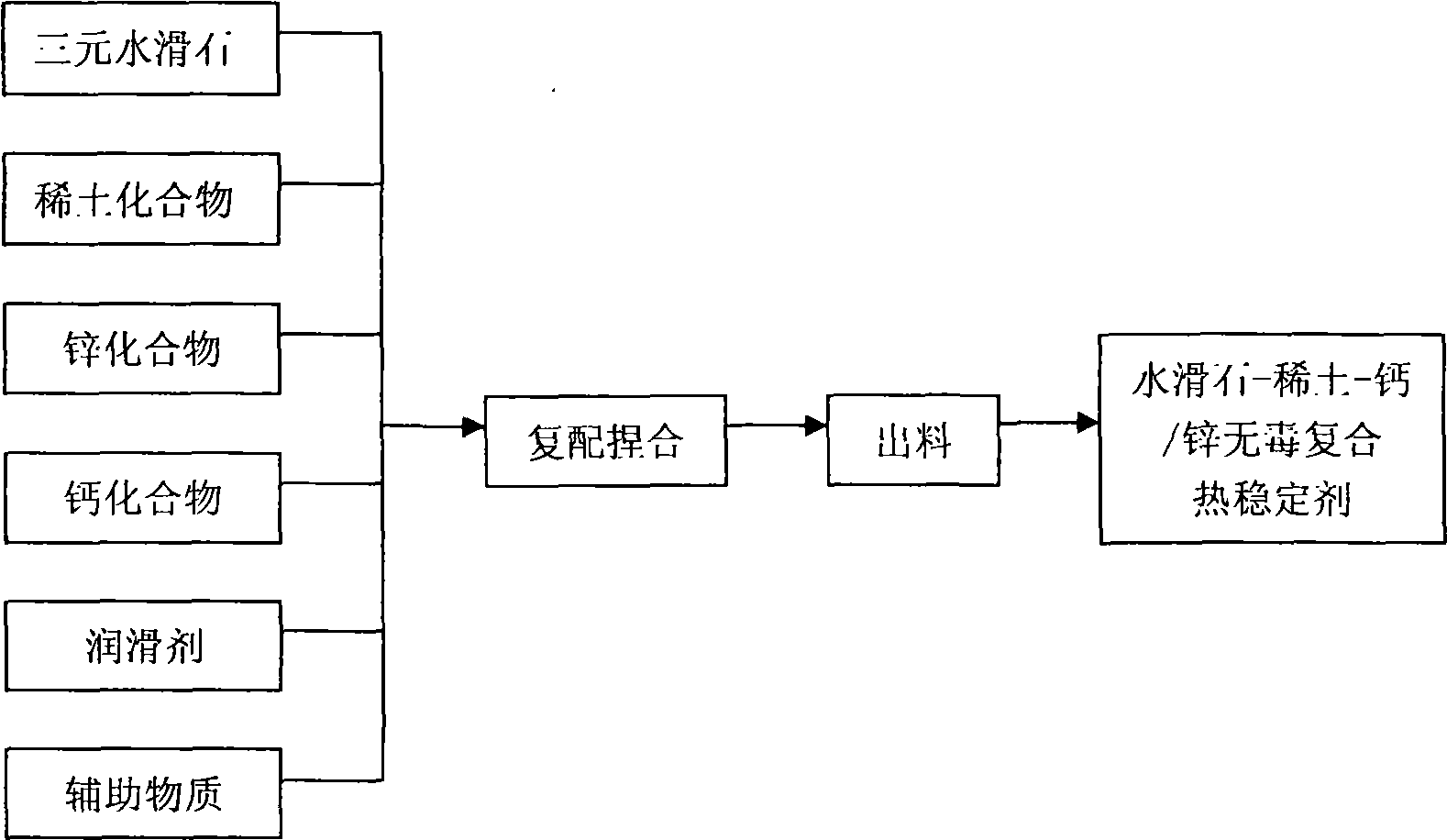

Ternary hydrotalcite-rare earth-calcium/zinc nontoxic composite heat stabilizer and preparation thereof

The invention relates to a preparation method of compound thermal stabilizer in plastic processing additive and pertains to the technical field of plastic processing additive. The invention discloses a ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer and a preparation method thereof. The invention comprises the materials of the stabilizer such as ternary hydrotalcite, organic rare earth compound, Ca compound and Zn compound, a synthetic preparation method thereof and an optimal compounding method of ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer. The ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer provided by the invention serves as a new generation high-efficiency innoxious stabilizer, can replace the traditional lead salt and expensive organic stannum thermal stabilizer and can be widely applied to the fields of PVC pipe material, section material, wire and cable, medical instrument and membrane, etc.

Owner:江西宏远化工有限公司

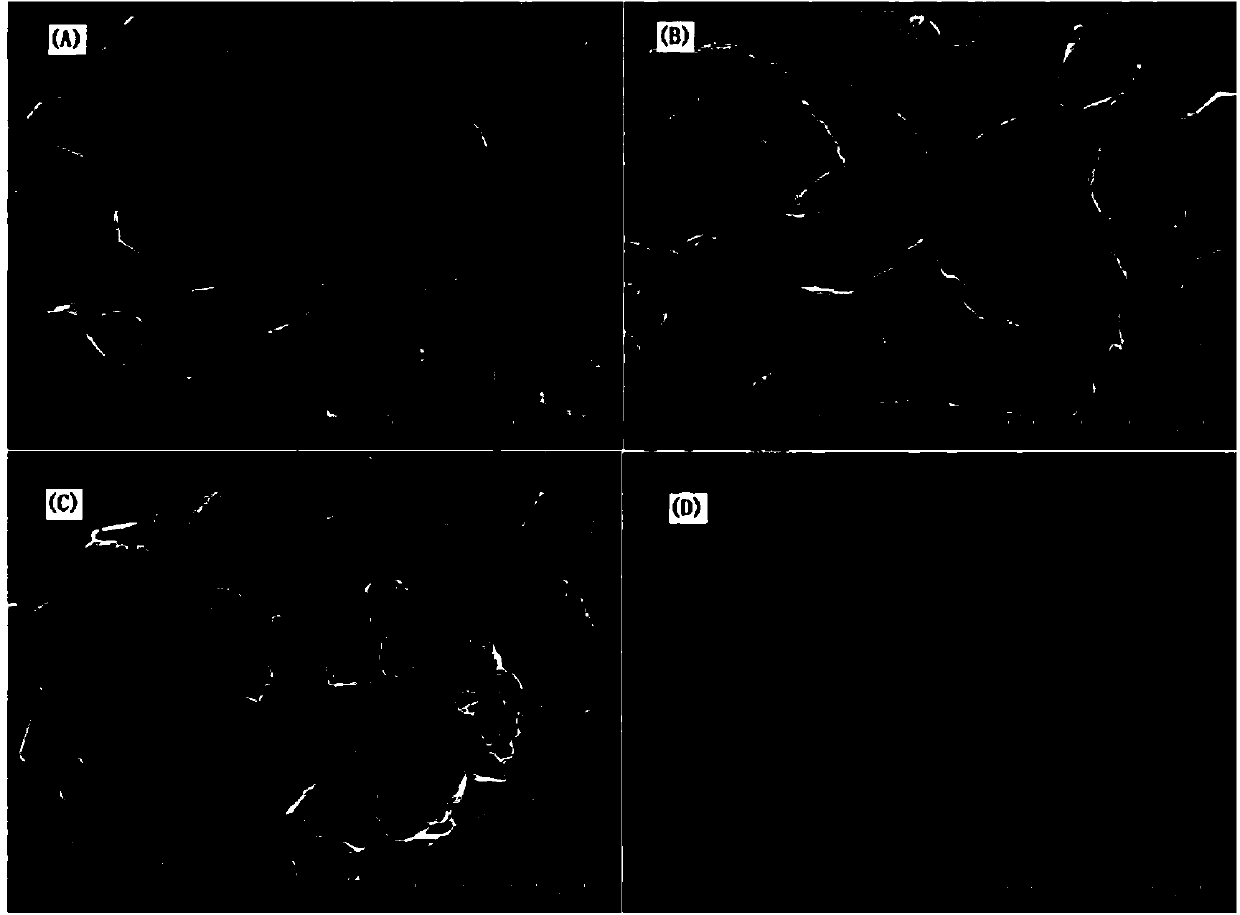

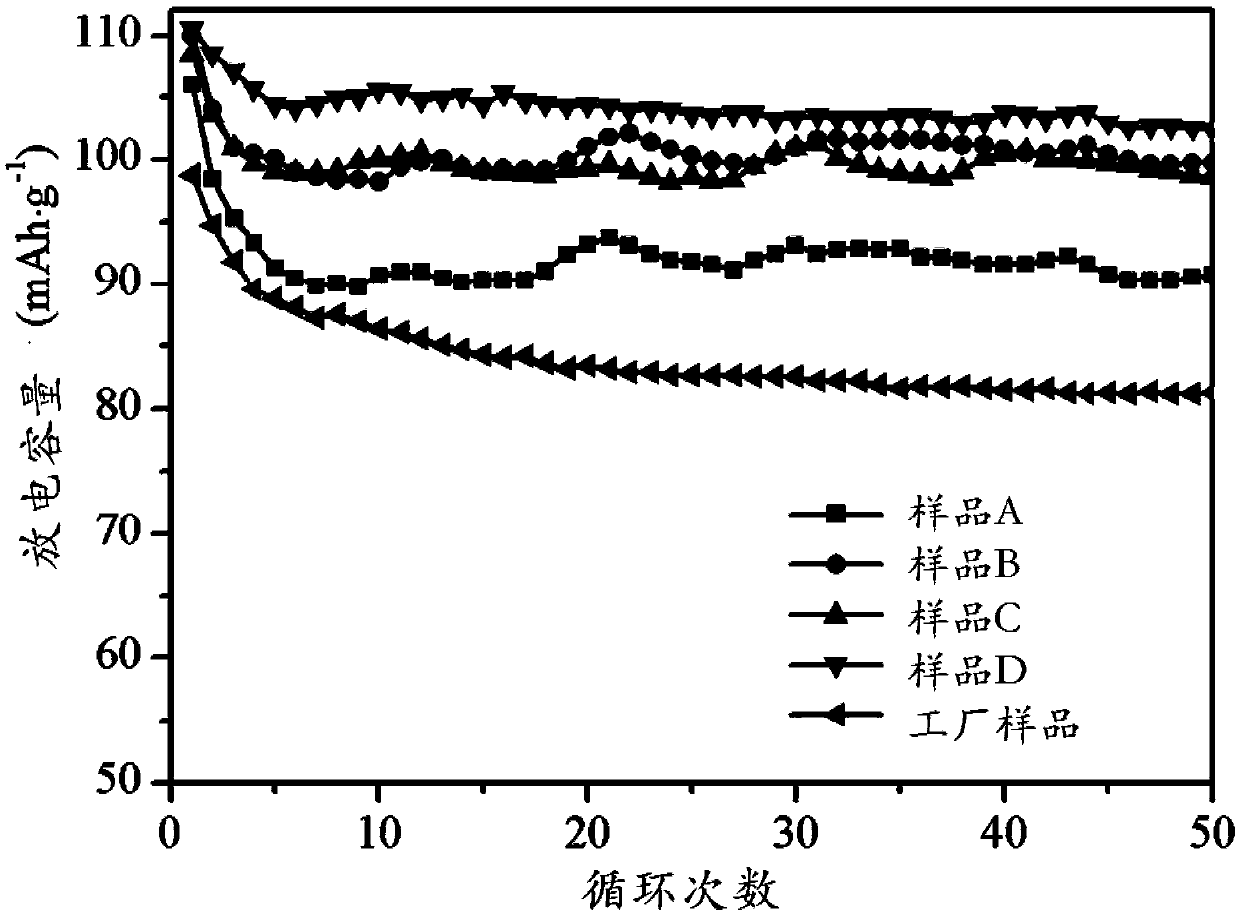

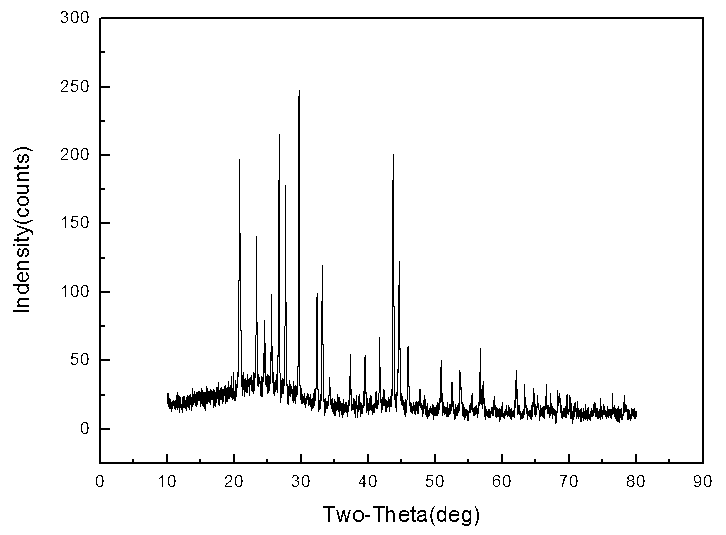

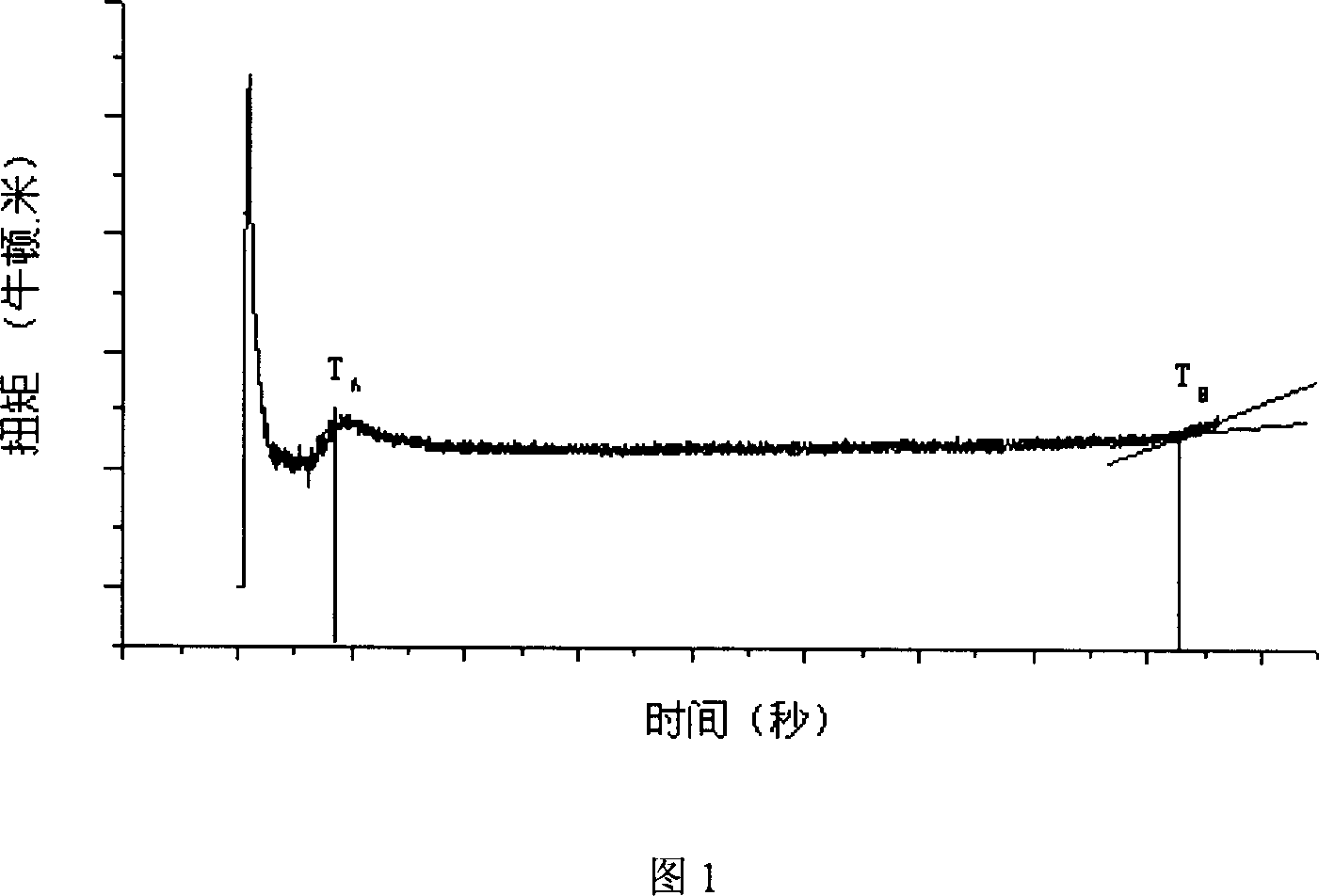

Preparing method for nano micron lead sulfate with electrochemical activity and method adopting lead sulfate to prepare lead-acid cell

ActiveCN103723761AShorten the production cycleShorten board making timeMaterial nanotechnologyLead-acid accumulator electrodesFiberSulfate

The invention discloses a preparing method for nano micron lead sulfate with electrochemical activity and a method adopting the lead sulfate to prepare a lead-acid cell. The preparing method for nano micron lead sulfate includes the following steps: using a morphological control agent for controlling the crystal growth of lead sulfate; enabling a water solution of soluble lead salt to react with a water solution of soluble sulfate / sulfuric acid, or enabling an aqueous dispersion of lead elementary substance / insoluble lead compound to react with a water solution of sulfuric acid in a clash flow reactor; finally obtaining the nano micron lead sulfate. The preparing method for the lead-acid cell includes the following steps: adopting the lead sulfate as active substances for an anode and a cathode; preparing a positive plate and a negative plate through adding fibers, a conductive agent, an expanding agent and the like; adding membranes between the two poles; then placing the two plates in a cell box for battery charging and formation. The invention has the advantages that the nano micron lead sulfate is high in electrochemical activity; the performance of the lead-acid cell is high and the service life of the lead-acid cell is long after the nano micron lead sulfate is adopted as the active substances of the lead-acid cell; besides, the preparing methods for the lead sulfate and the lead-acid cell are simple and feasible and have the characteristics of energy conservation and environmental protection.

Owner:SOUTHEAST UNIV

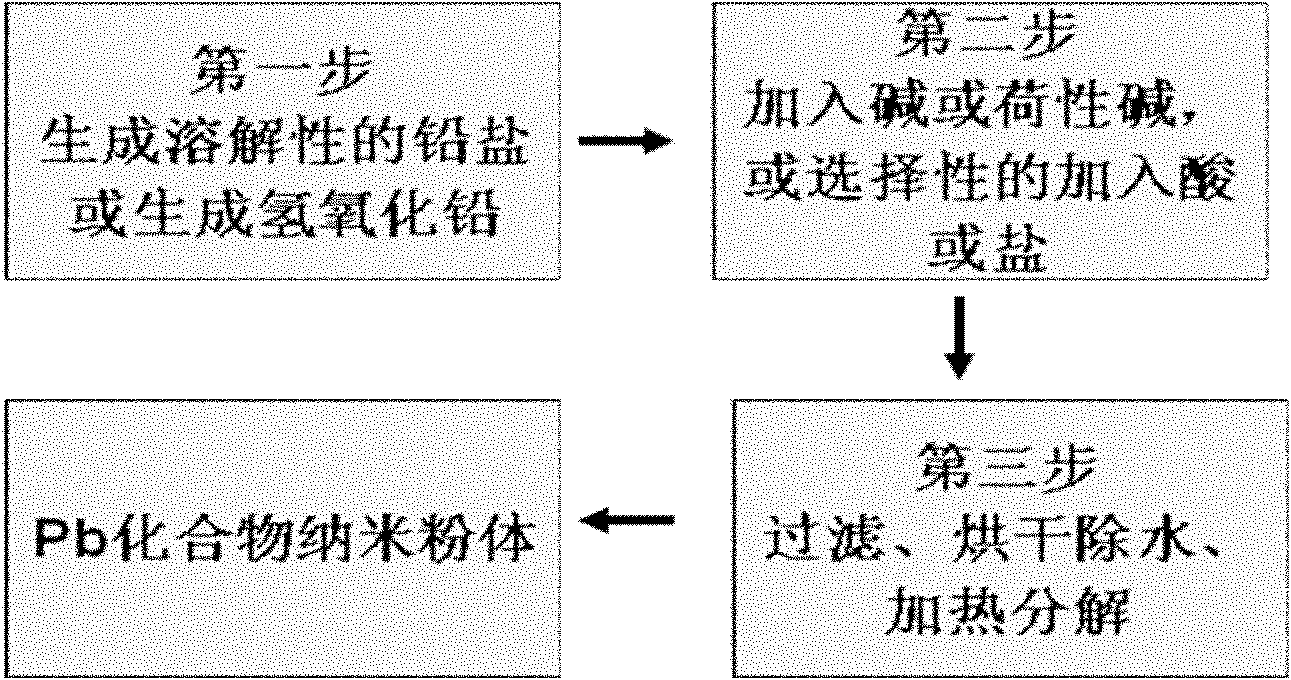

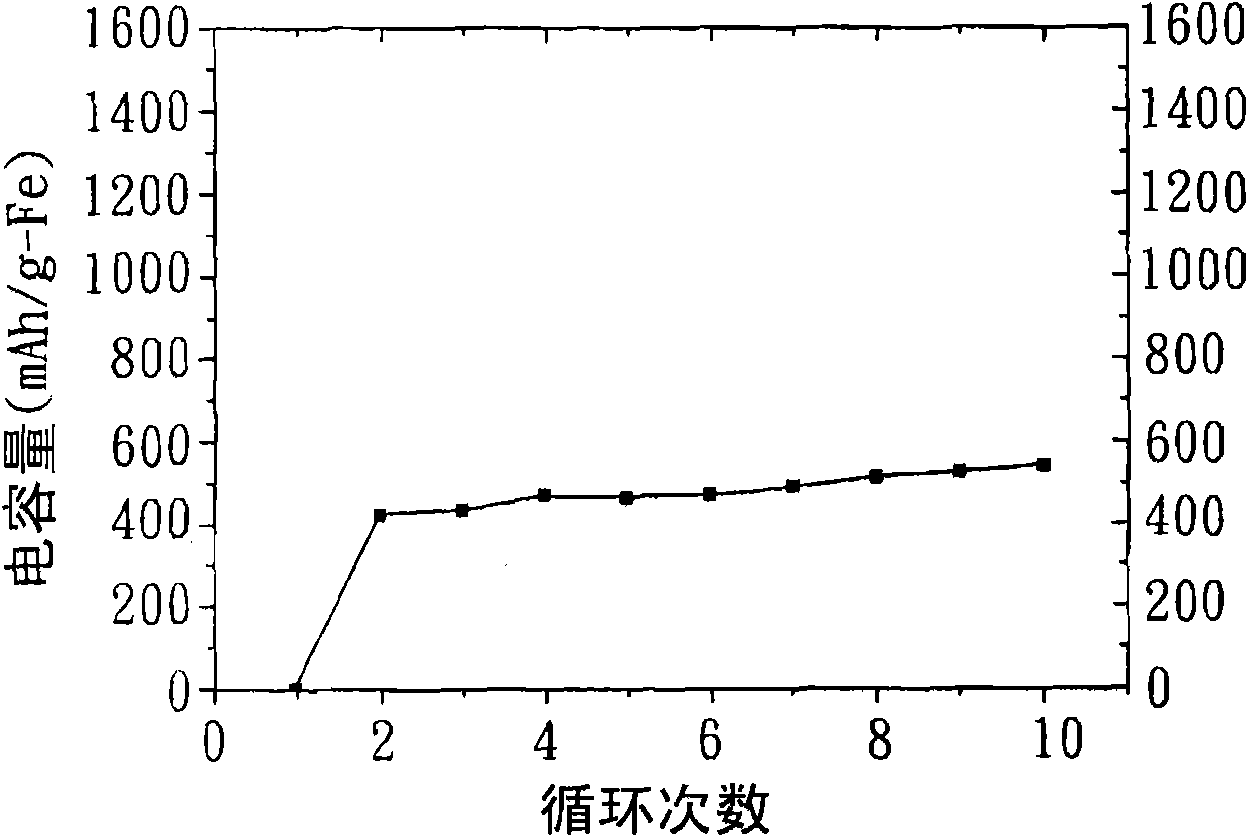

Lead compound nano-powder preparation method for recovery and manufacture of lead-acid battery

ActiveCN102689922AEnvironmental recyclingEnvironmental productivityLead monoxideNanotechnologySolubilityLead salt

The invention discloses a lead compound nano-powder preparation method for recovery and manufacture of lead-acid battery. The lead compound nano-powder preparation method comprises the following steps that 1, lead, a lead salt or waste lead-acid battery lead paste reacts with one or more organic or inorganic compounds to produce a soluble lead salt solution or a lead hydroxide solution; 2, one or more alkalis or caustic alkalis are added into the soluble lead salt solution, or a part or excess amount of H2CO3 or CO2, sulfuric acid, one or more organic acids or their salts are added into the lead hydroxide solution, and 3, lead oxide or lead hydroxide precipitates obtained by the step 2 are filtered and are subjected to drying and pyrolysis to form the lead compound nano-powder. The lead compound nano-powder preparation method realizes environmentally friendly recovery and production, has low energy consumption, greatly reduces a production cost, and shortens a production period. The lead compound nano-powder obtained by the lead compound nano-powder preparation method is conducive to improvement of technical product performances.

Owner:杨春晓

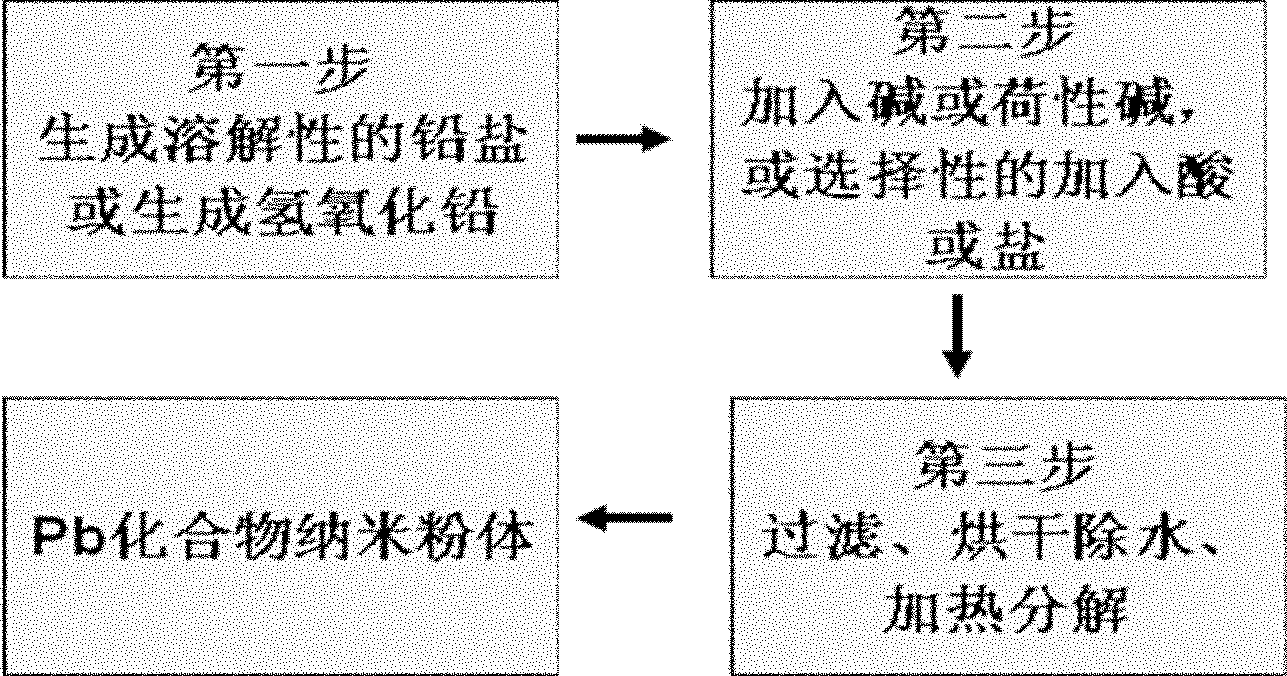

Preparation method of Pb oxide nano powder for recovery and manufacture of lead acid battery

ActiveCN102689921AEnvironmental recyclingEnvironmental productivityLead monoxideNanotechnologyDecompositionLead salt

The invention discloses a preparation method of a Pb oxide nano powder for recovery and manufacture of a lead acid battery. The method comprises the steps of: (1) reacting lead salt or waste lead acid battery lead paste with an organic or inorganic compound capable of complexing with Pb atom / ion, so as to realize desulphurization or reloading of acid radical; and (2) carrying out treatment processes of filtering, drying for removing water and heating for decomposition, so as to obtain the Pb oxide nano powder. The method of the invention realizes an environment-friendly and energy-efficient recovery and production process with substantially reduced production cost; meanwhile, the prepared Pb oxide powder is beneficial for enhancement of product performance.

Owner:杨春晓

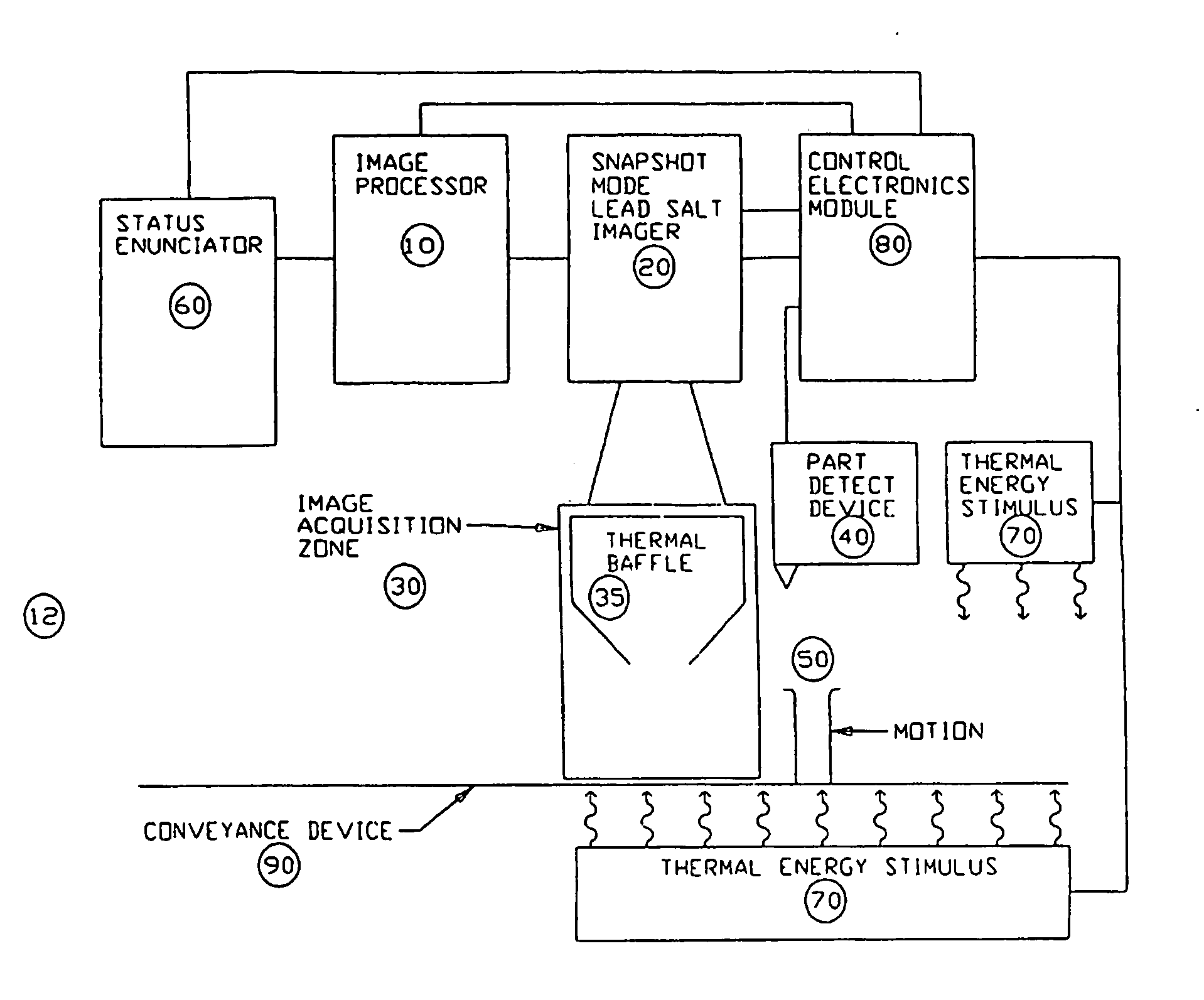

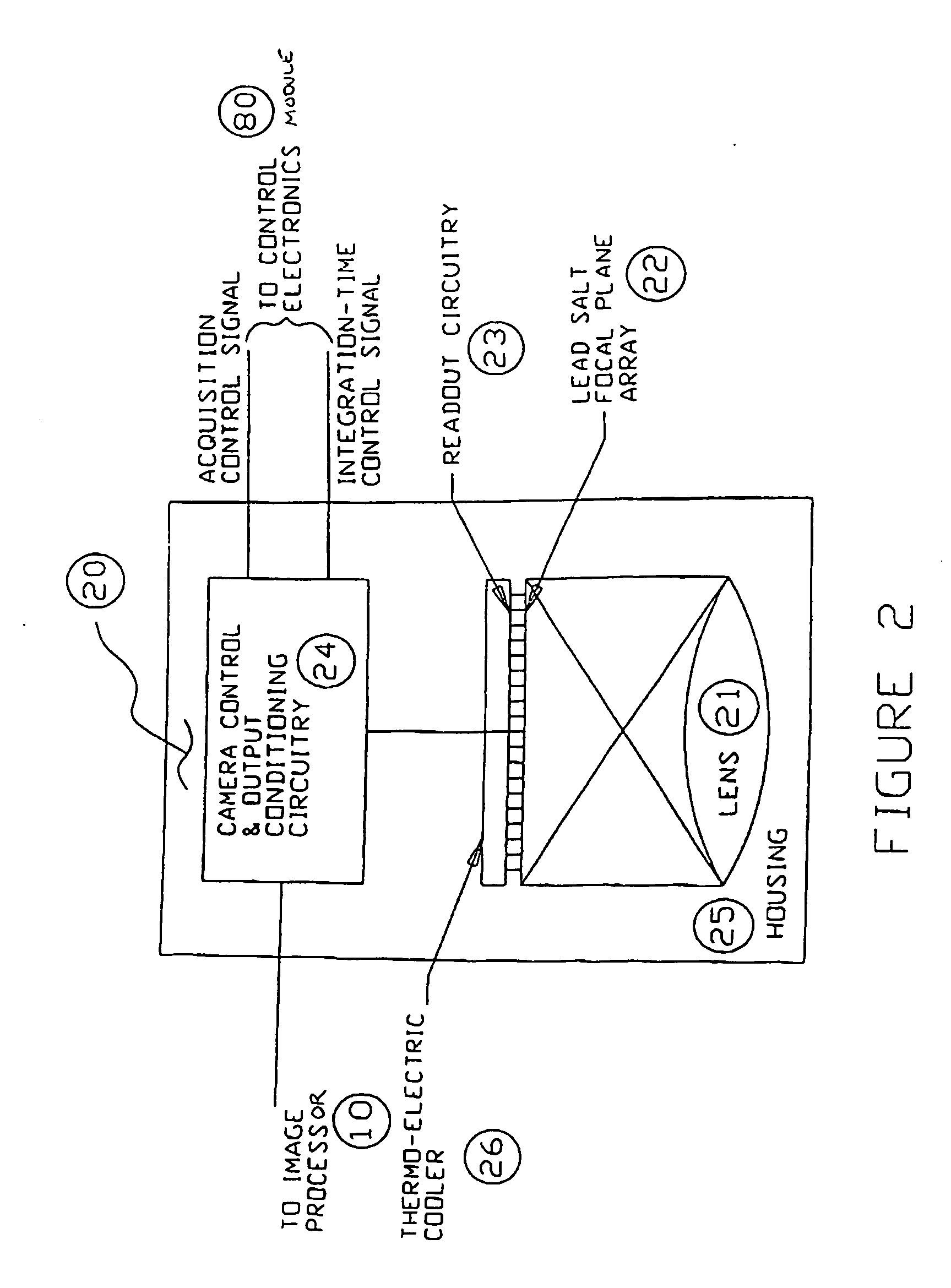

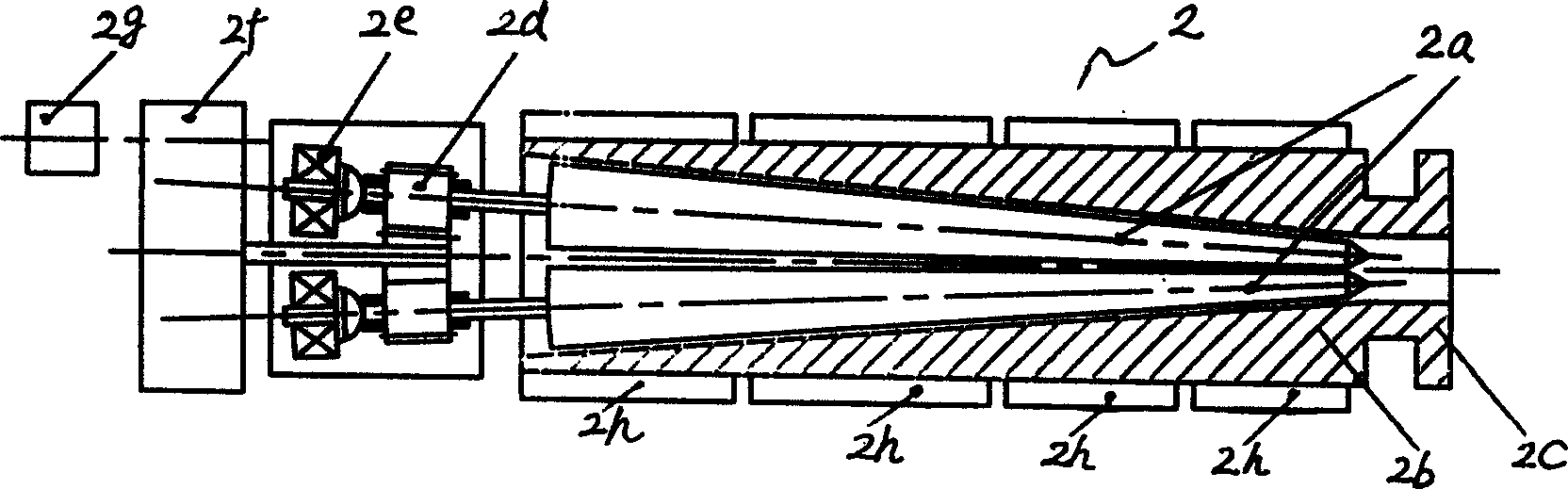

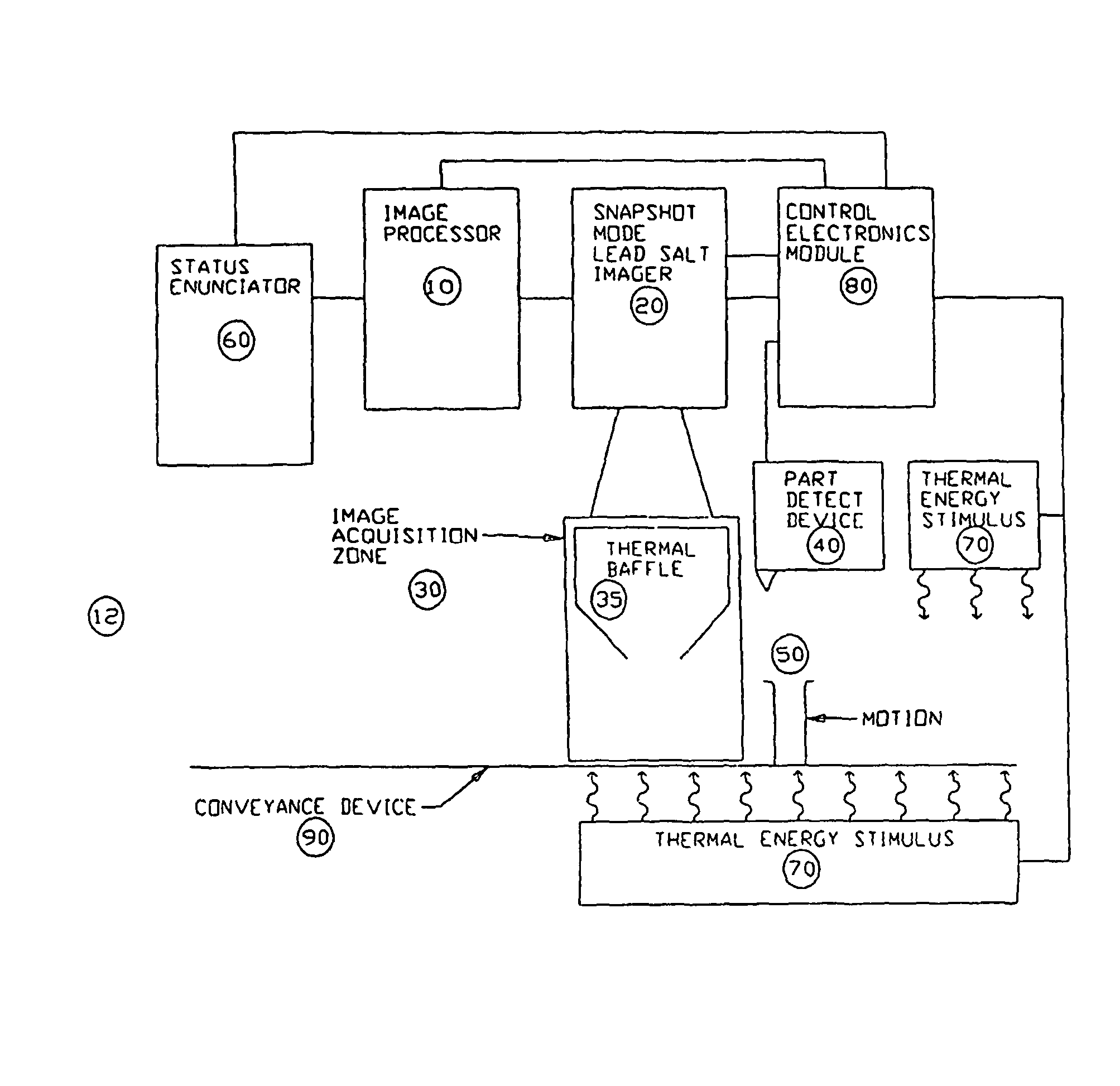

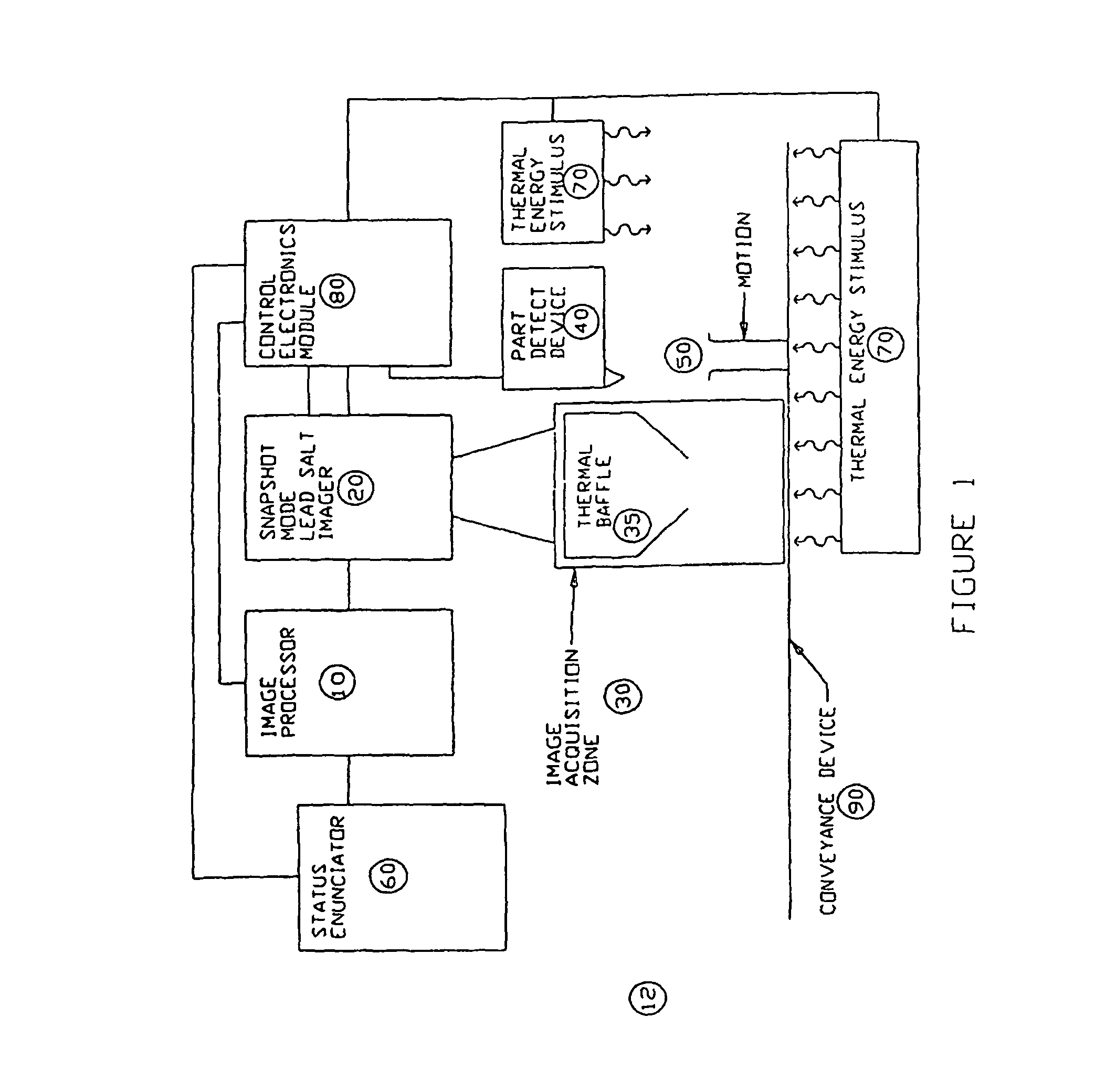

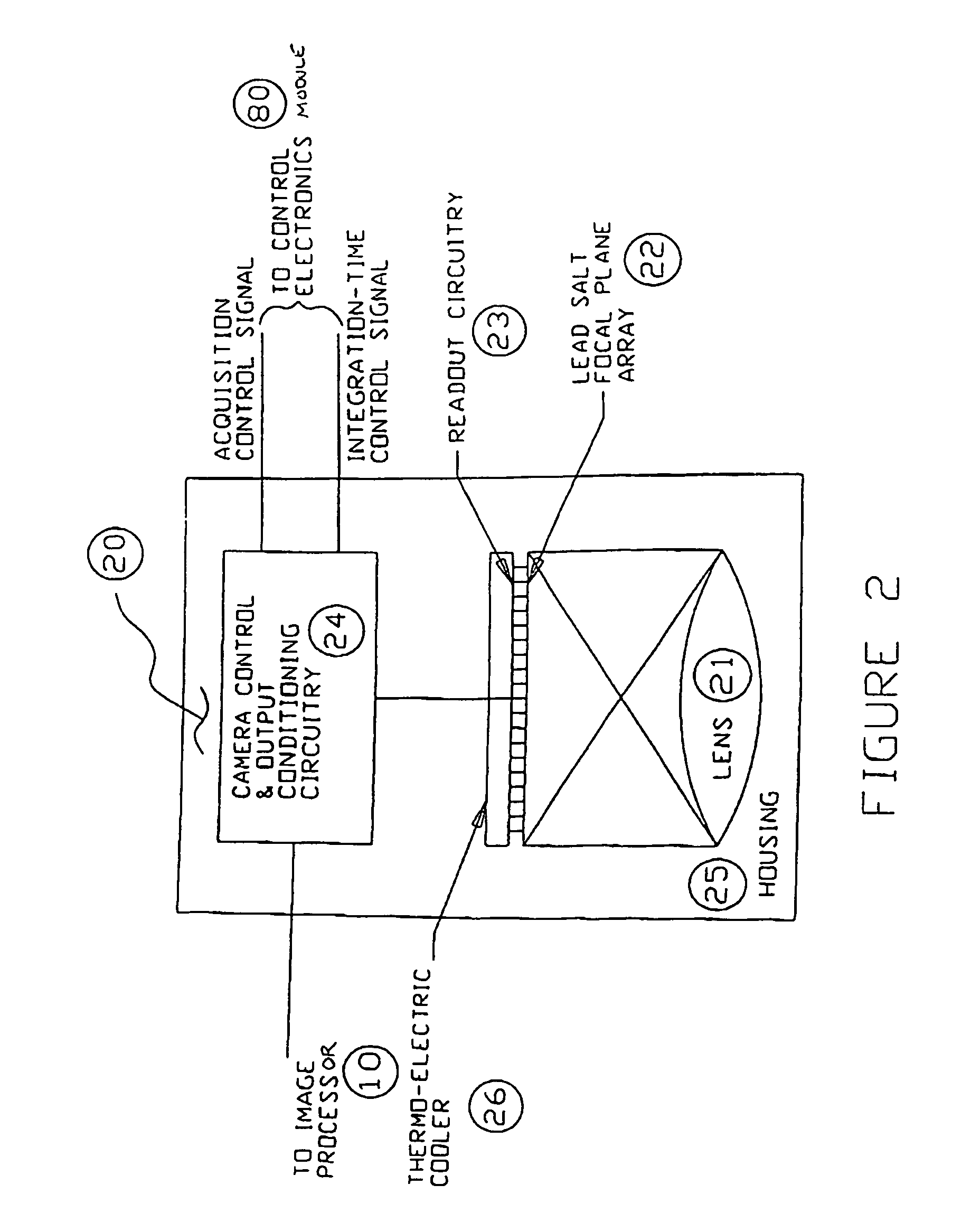

Apparatus and method for providing snapshot action thermal infrared imaging within automated process control article inspection applications

ActiveUS20060232674A1Robust structural integrity inspection capabilityHigh sensitivityTelevision system detailsRadiation pyrometryMachine visionLead salt

This application relates to an apparatus and method for providing snapshot action thermal infrared imaging within automated process control article inspection applications. More specifically, it pertains to the use of snapshot mode lead salt area-array imaging sensors (20) as the imaging front-end in high-speed machine vision inspection systems (12). the relatively low-cost, good measurement sensitivity at temperatures consistent with thermo-electric cooling means, and the ability to be operated in snapshot mode enables lead salt-based image acquisition sensors (20) to be used in a variety of automated process control and article inspection applications.

Owner:PRESSCO TECH INC

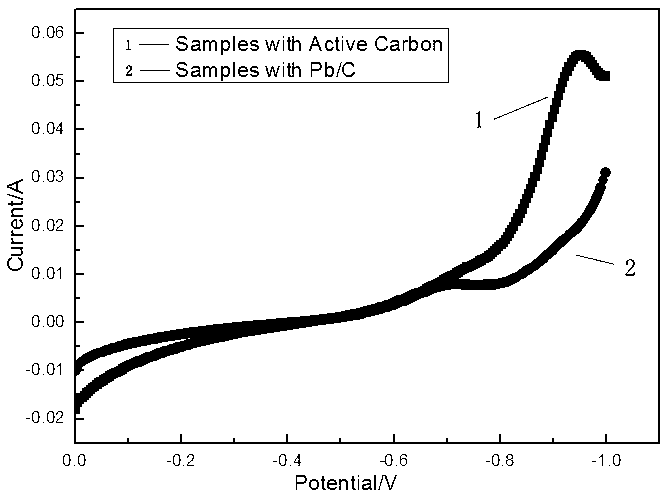

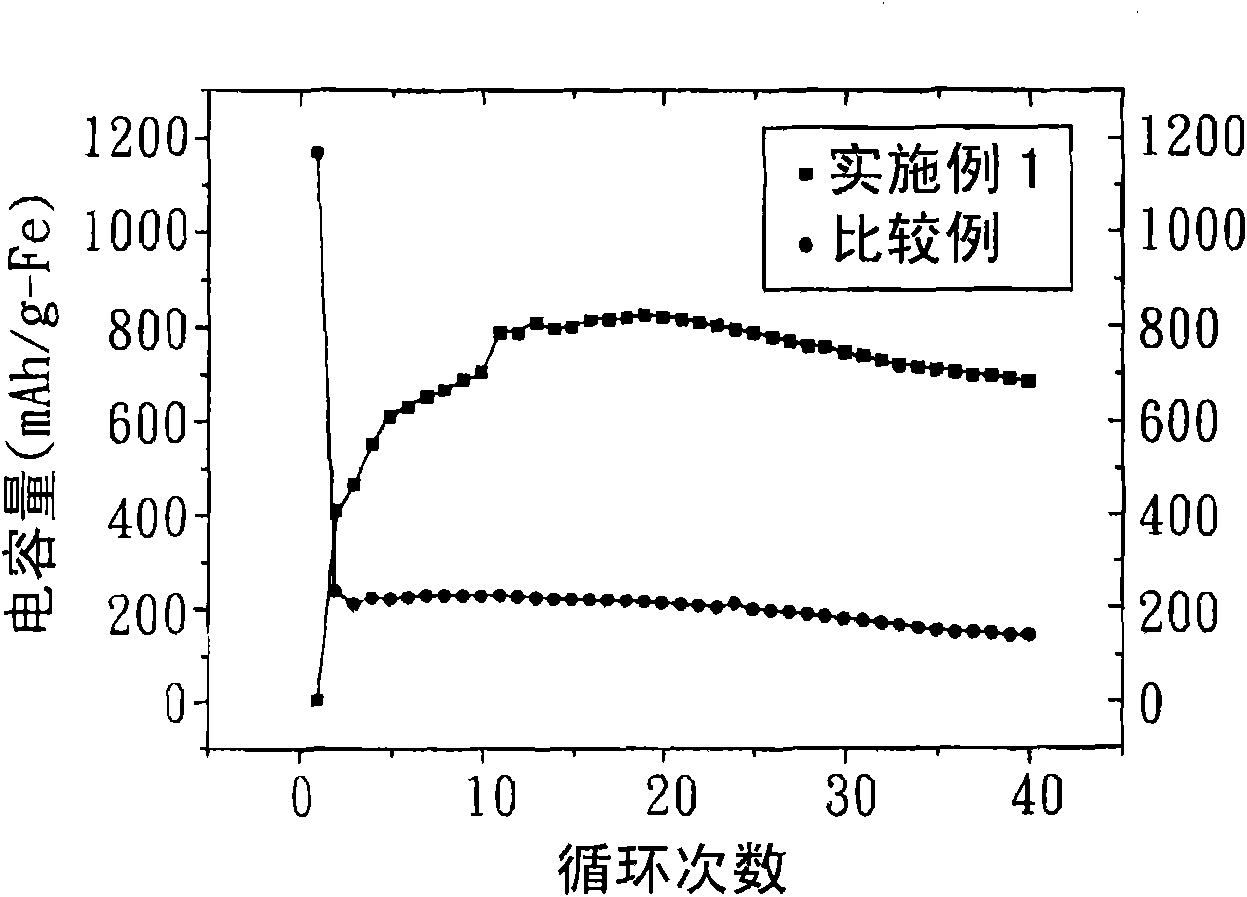

Lead/carbon composite for storage battery and preparation method of lead/carbon composite material

ActiveCN103137955AIncrease the proportionAvoid uneven mixingCell electrodesCarbon compositesCharge current

The invention discloses a lead / carbon composite for a storage battery. The lead / carbon composite is prepared from the following raw materials in percent by weight: 85-99.9 percent of lead-salt solution and 0.1-15 percent of conductive carbon material, wherein the lead salt solution is prepared from a soluble lead salt and deionized water, and the mol concentration of the lead salt solution is 0.1-0.8M. The invention also discloses a preparation method of the lead / carbon composite for the storage battery. The lead / carbon composite is substantially a conductive carbon material modified by lead oxide. Lead has the characteristics of low resistivity, high plasticity and high hydrogen evolution overpotential. The characteristics of the lead ensure that the hydrogen evolution overpotential of the carbon material after modified by PbO in a lead-acid battery is remarkably increased; and meanwhile the charging current occupied by partial hydrogen evolution reaction in a charging process is reduced, and the charging efficiency is increased.

Owner:SHENZHEN CENT POWER TECH

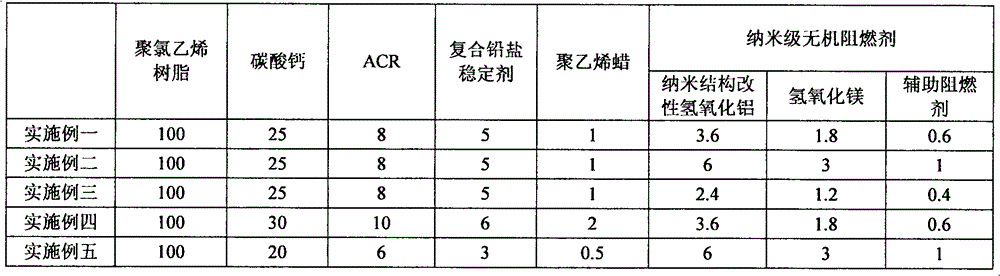

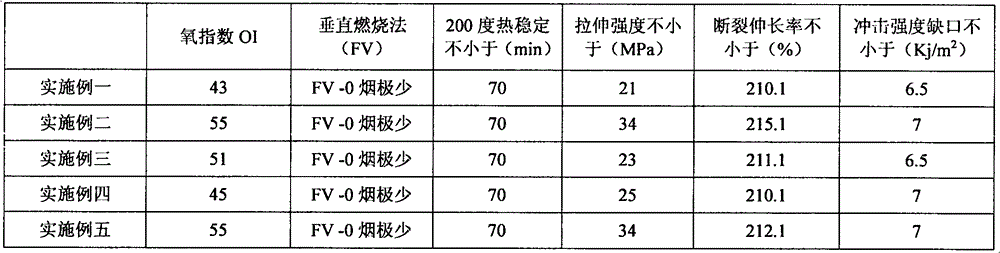

PVC (polyvinyl chloride) power pipeline material and preparation method thereof

ActiveCN102875932AImprove flame retardant performanceComply with safe use requirementsRigid pipesAging resistanceHeat resistance

The invention discloses PVC (polyvinyl chloride) power pipeline material. The PVC power pipeline material comprises, by weight, 100 parts of polyvinyl chloride resin 0.1-0.2mm in particle size, 20-30 parts of calcium carbonate 300-mesh to 700-mesh in particle size, 6-10 parts of impact modifier ACR, 3-6 parts of composite lead salt stabilizer, 0.5-2 parts of lubricant oxidized polyethylene wax, and 4-10 parts of nano-scale inorganic flame retardant. The PVC power pipeline material is high in flame retardancy with oxygen index up to more than 40. PVC power pipelines of the power pipeline material is high in rigidity, heat resistance and ageing resistance, low in manufacturing cost and simple in processing technique.

Owner:安徽安诺热能科技有限公司

Preparation method of environment-friendly type precious metal beneficiation agent

ActiveCN103937986AAvoid pollutionEfficient leachingProcess efficiency improvementLead saltSodium cyanide

The invention relates to a preparation method of a low-toxic environment-friendly type novel precious metal beneficiation agent. Raw materials of the low-toxic environment-friendly type novel precious metal beneficiation agent comprise a cyanate, sodium hydroxide, sodium sulfate, sodium ferrocyanide, a bromide, and a lead salt. The preparation method comprises following steps: sodium cyanate, sodium hydroxide, sodium sulfate, and sodium ferrocyanide are mixed at a certain ratio; an obtained mixture is delivered into a smelting pot which is heated to be slightly red, and is heated to 650 to 750 DEG C so as to obtain a fused material, temperature is maintained to be 750 DEG C for 30 to 50min of reaction, and then an obtained product is collected and cooled; the obtained product is smashed, the bromide and the lead salt are added for stirring, and the environment-friendly type precious metal beneficiation agent is obtained via combination. The environment-friendly type precious metal beneficiation agent can be widely used for precious metal beneficiation metallurgy of nonferrous metals ores, contains no hypertoxic compounds, is safe for human and animal, and is friendly to the environment. Compared with other metal beneficiation agents, the environment-friendly type precious metal beneficiation agent is excellent in effects, stable in performance, and low in production cost; the preparation method is simple; and environmental protection can be realized.

Owner:广西河池鑫银环保科技有限公司

PVC (Polyvinyl Chloride) stone-bumping resistant paint and preparation method thereof

The invention relates to PVC (Polyvinyl Chloride) stone-bumping resistant paint and a preparation method thereof. The PVC stone-bumping resistant paint is formed by mediating, reacting and finely rolling dioctyl phthalate, dibutyl phthalate, dioctyl sebacate, light calcium carbonate, heavy calcium carbonate, nano active calcium carbonate, zinc stearate, barium stearate, organic bentonite, polyamide resin, carbon black, titanium pigment and PVC resin. The low-temperature flexibility of the PVC stone-bumping resistant paint can be improved by compounding three plasticizers of the dioctyl phthalate, the dibutyl phthalate and the dioctyl sebacate; the thixotropic performance of the paint can be improved by combining the organic bentonite with the nano active calcium carbonate; the adhesive force and the high-temperature yellowing resistance of the paint can be enhanced by combining the polyamide resin with heat stabilizers of the zinc stearate and the barium stearate and the paint has no foaming, crack and falling after baked at 210DEG C, so that the coating effect of the automobile body can be improved and the service life of the automobile body can be prolonged. The PVC stone-bumping resistant paint has no lead salt heat stabilizers and avoids the damage to the environment and human body; and the produced PVC stone-bumping resistant paint has excellent performance and can carry out the multilayer anticorrosion protection of the body and the bottom of the automobile.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

Preparation method of composite oxide

InactiveCN101879439AHigh surface areaImprove catalytic performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickel saltMagnesium salt

The invention discloses a preparation method of a composite oxide. In the method, one or more of ammonium salt, magnesium salt, calcium salt, strontium salt, aluminum salt, lead salt, titanium salt, chromium salt, manganese salt, ferric salt, cobalt salt, nickel salt, copper salt, zinc salt, zirconium salt, silver salt, lanthanum salt and cerium salt are dissolved in water to form a solution A; and one or more of ammonia water, ammonium carbonate, sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, sodium silicate and sodium aluminate are dissolved in water to form a solution B. The solution A and the solution B are quickly mixed, stirred and ground after being cooled, and water is solidified quickly in the process of generating sediments so as to form a powder with ice and the sediments highly dispersed. The powder is aged, washed, dried and baked to obtain target material. In the preparation process, liquid-solid phase transformation is quick so as to ensure high dispersion of different components, and the synthetic material has the advantages of high specific surface, low bulk density, high catalytic performance and the like. The method has the characteristics of simple operation and low cost, and is generally suitable for synthesizing a variety of composite oxides.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

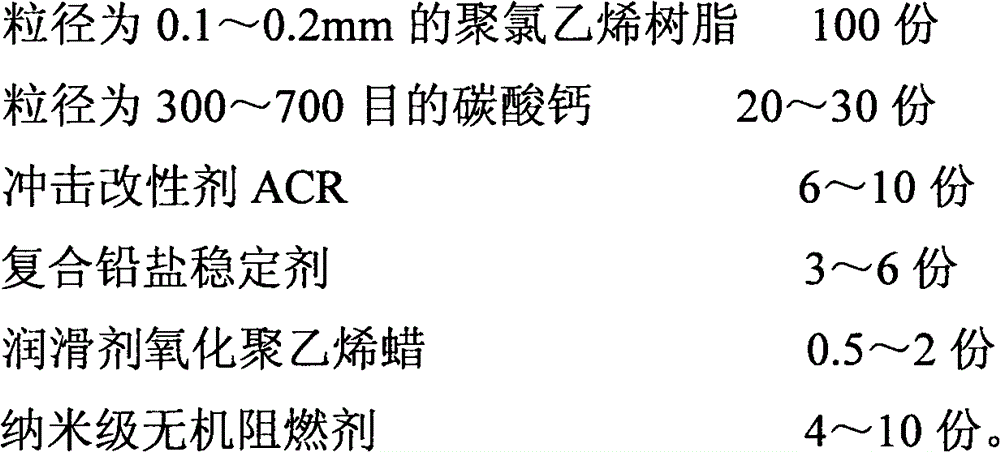

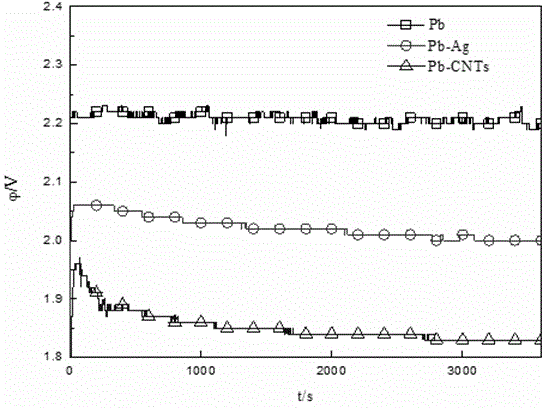

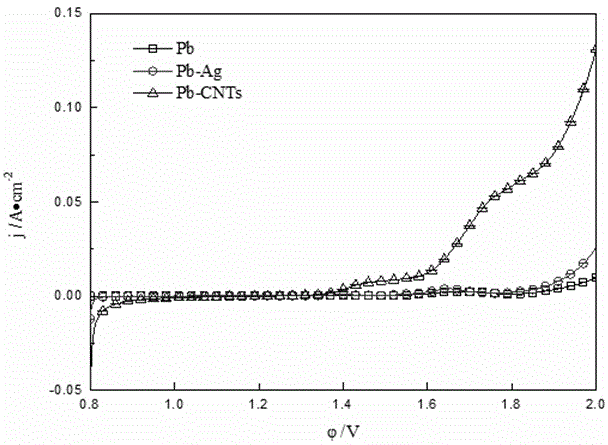

Preparation method for carbon nanotube and/or graphene reinforced lead based composite anode

Belonging to the technical field of new material preparation, the invention relates to a preparation method for a carbon nanotube and / or graphene reinforced lead based composite anode. The method includes: first, preparation of an electrolyte solution: mixing a soluble lead salt, supporting electrolyte, carbon nanotube and / or graphene, a dispersing agent and water evenly to obtain the electrolyte solution; a composite electrodeposition process: taking metal lead as the anode and adopting titanium as the cathode, controlling the electrolyte solution at a temperature of 20-80DEG C and the cathode current density at 200-500mA / cm<2>, and performing electrodeposition in the electrolyte solution so as to obtain carbon nanotube and / or graphene lead based composite powder; and preparation of the composite anode: subjecting the obtained carbon nanotube and / or graphene lead based composite powder to cold press molding at 20-50MPa, and performing sintering for 4h in a reducing atmosphere at 250DEG C, thus obtaining the composite anode. As the carbon nanotube and / or graphene have / has excellent mechanical and electrical properties, the prepared composite anode has improved mechanical properties and enhanced conductive ability.

Owner:KUNMING HENDERA SCI & TECH

Method for improving machining thermal stability of chlorinated polyvinyl chloride resin

The invention discloses a manufacturing heat stability improving method of chlorinated polychloroethylene resin, which is characterized by the following: adding the composition of 3-5% Ca / Zn composite stabilizer and 2-5% hydrotalcite in the CPVC manufacturing course corresponding to 100% chlorinated polychloroethylene resin; replacing present organic tin system and composite lead salt system; possessing excellent static and dynamic heat stability without toxicity.

Owner:SHANGHAI CHLOR ALKALI CHEM

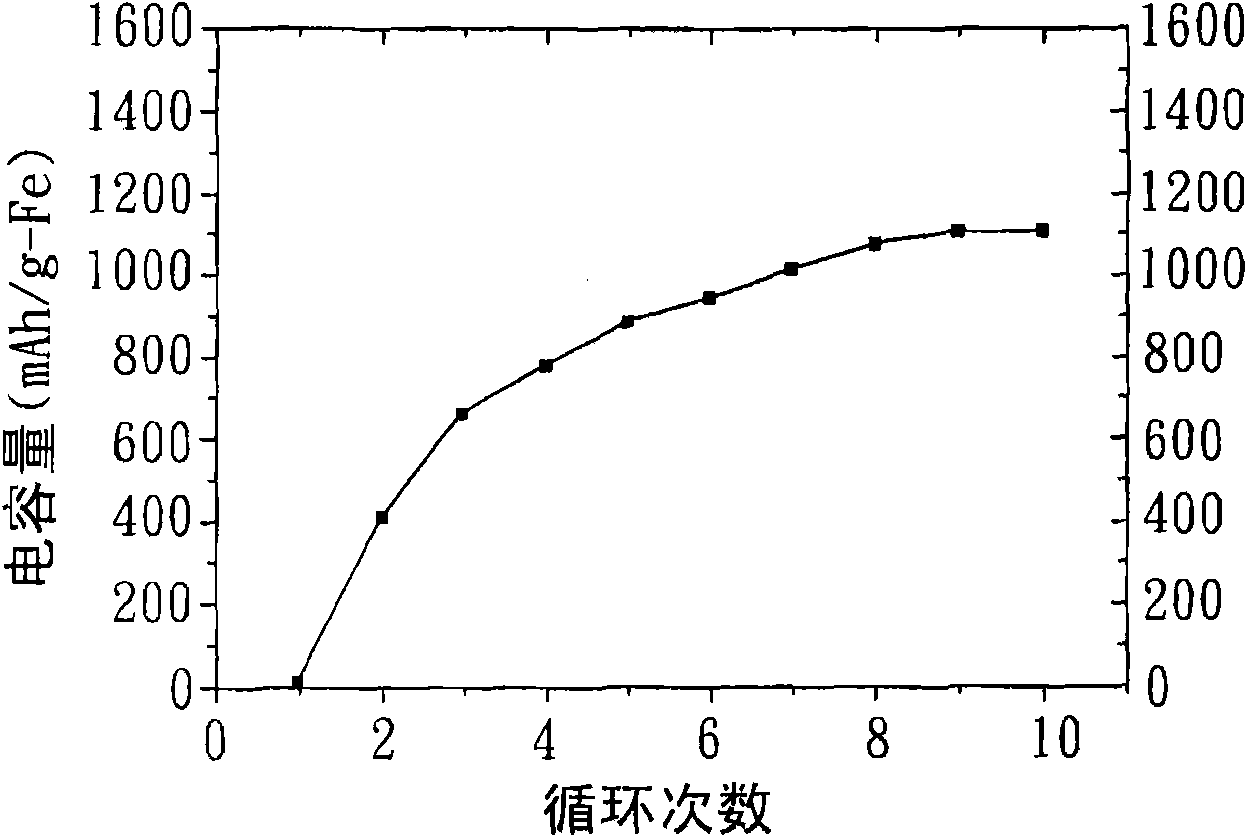

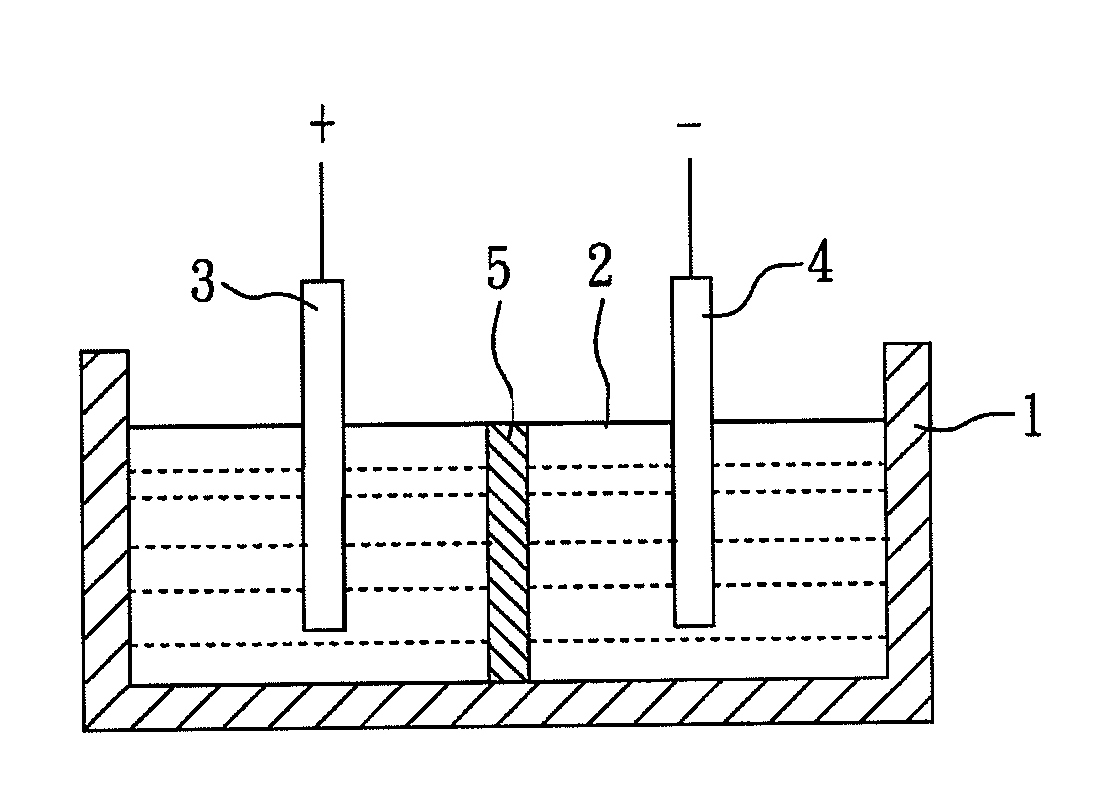

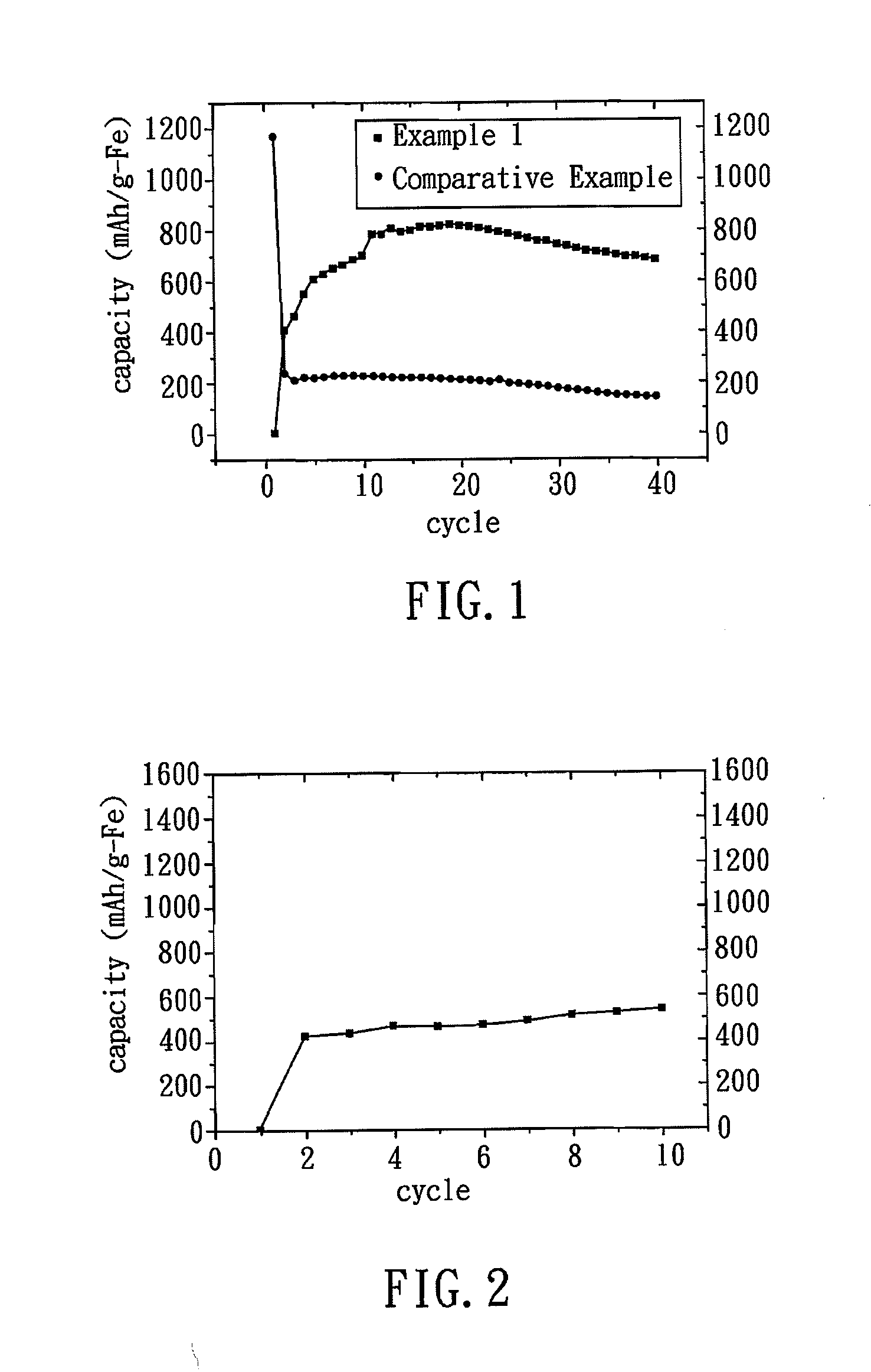

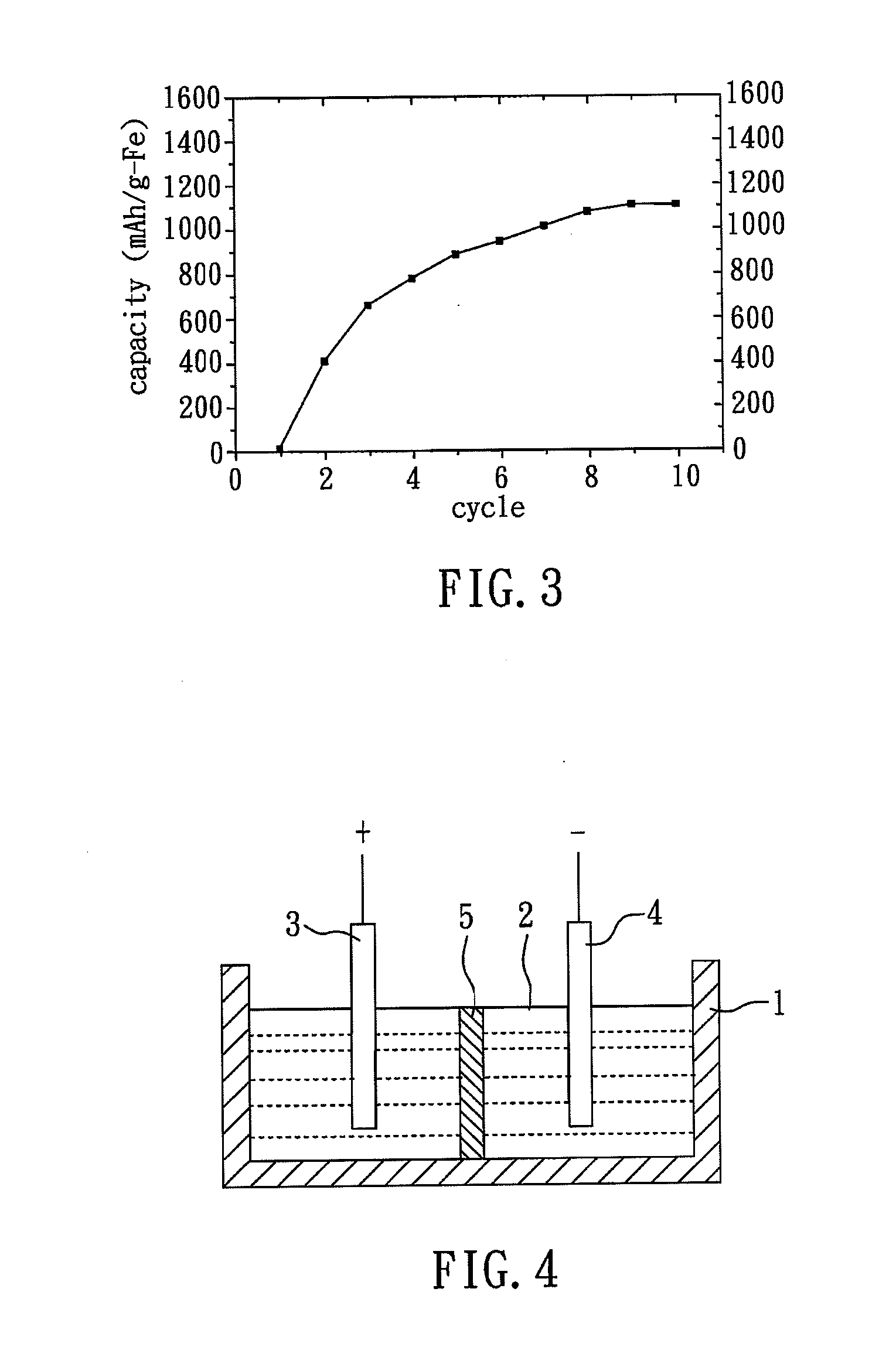

Cathode electrode composite material and preparation method thereof and electrochemical device applying same

InactiveCN102214822ASimple processReduce manufacturing costAlkaline accumulator electrodesNickel accumulatorsIndiumNickel salt

The invention discloses a cathode electrode composite material, which comprises a plurality of ferriferous oxide particles and a conductive aid which is selected from copper, cobalt, nickel, tin, antimony, bismuth, indium, silver, gold, lead, cadmium, carbon black, graphite, cupric salt, cobalt salt, nickel salt, tin salt, antimonic salt, bismuth salt, indium salt, silver salt, gold salt, lead salt, cadmium salt, cupric hydroxide, cobalt hydroxide, nickel hydroxide, tin hydroxide, stibine hydroxide, bismuth hydroxide, indium hydroxide, silver hydroxide, gold hydroxide, lead hydroxide, cadmium hydroxide and a group consisting of the combinations. When applied to an electrochemical device, the cathode electrode composite material can show high charging and discharging characteristics and high electric capacity. Moreover, the invention provides a preparation method of the cathode electrode composite material and an electrochemical device applying the same.

Owner:NATIONAL TSING HUA UNIVERSITY

Luminescent plastic products

InactiveCN101074307AHas a luminous effectSave energyLuminescent compositionsPolymer sciencePolyvinyl chloride

A luminescent plastic product and its production are disclosed. The plastic product consists of polyvinyl chloride resin 100 proportion, plasticizer 1-80 proportion, stabilizer 0.1-6 proportion, rare-earth long-acting fluorescent powder 0.5-6 proportion, and coupler 1-4 proportion. The plasticizer is made from dibutyl phthalate, dioctyl ester, non-toxic plasticizer or flame-retardant plasticizer or its combination; stabilizer is made from lead salt, metal soap, organic tin, composite stabilizer and ultraviolet absorbent or its combination; rare-earth long-acting fluorescent powder is strontium aluminate. The process is carried out by furnishing, forming, adding mixture into mono-screw extruder or bi-extruder, heating, extruding into products with various shapes by mould ram head, vacuum sizing, cooling by water, inspecting and packing. It can be used for household furniture, indoor and outdoor ornaments, door and window seal and road sign. It's economical and practical, has long life and better luminescent effect and saves resources.

Owner:谷广强

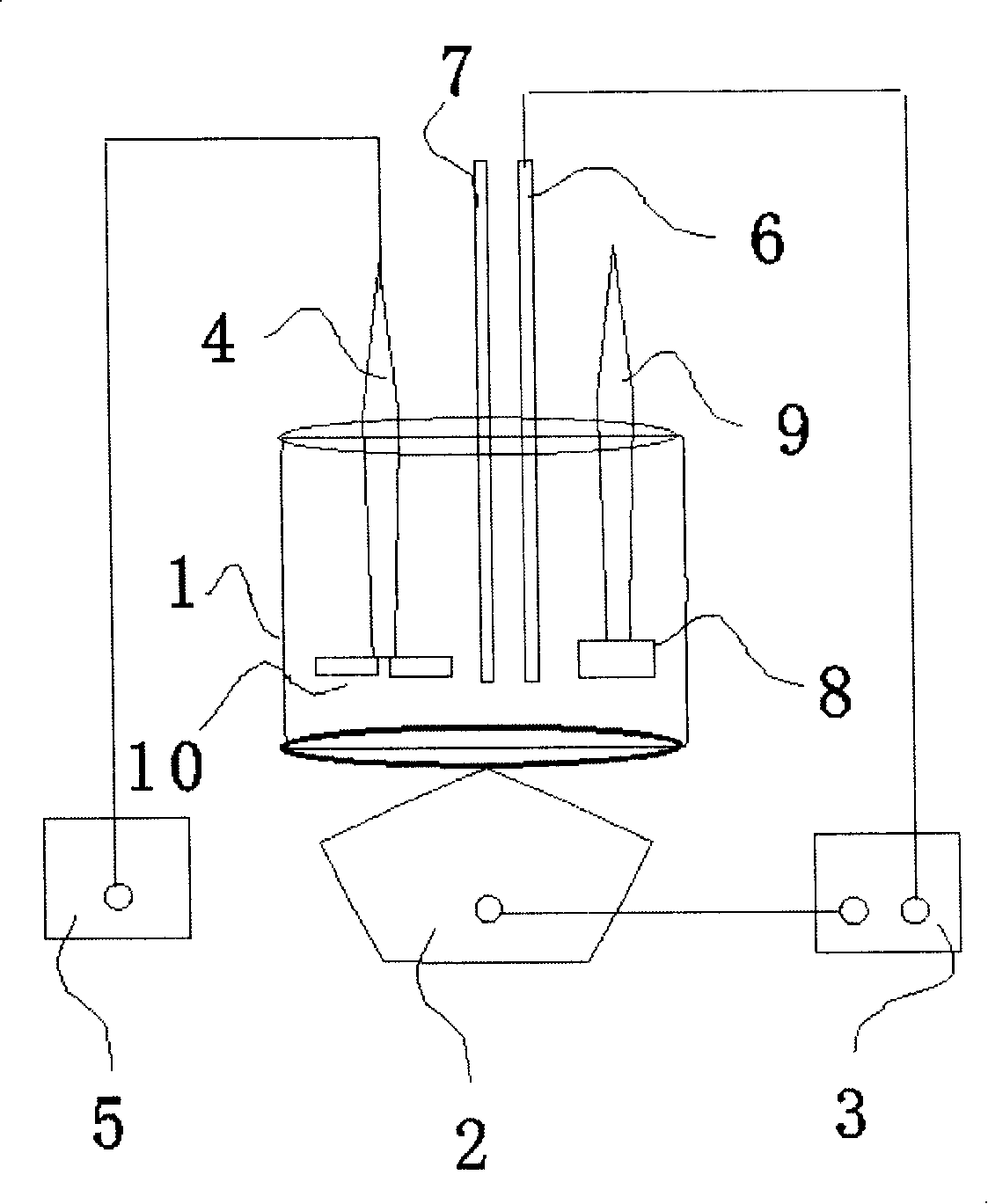

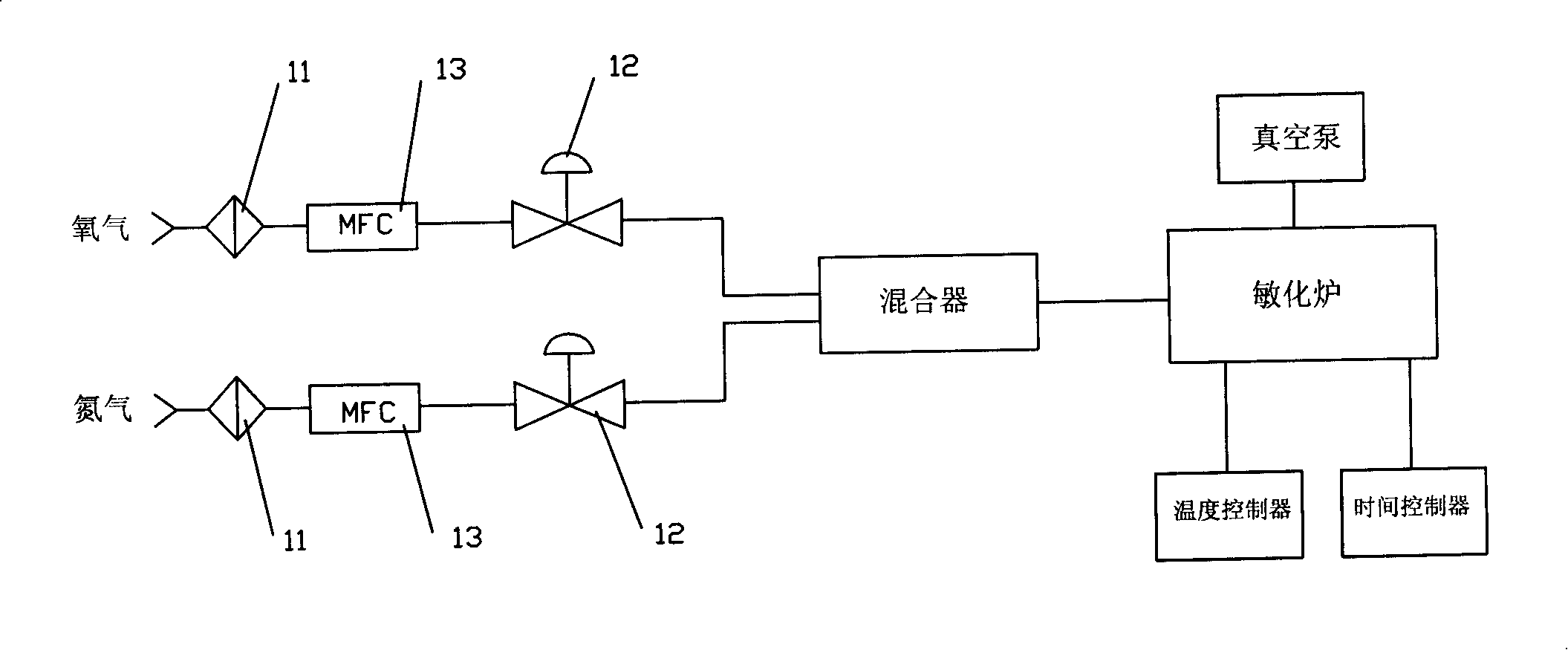

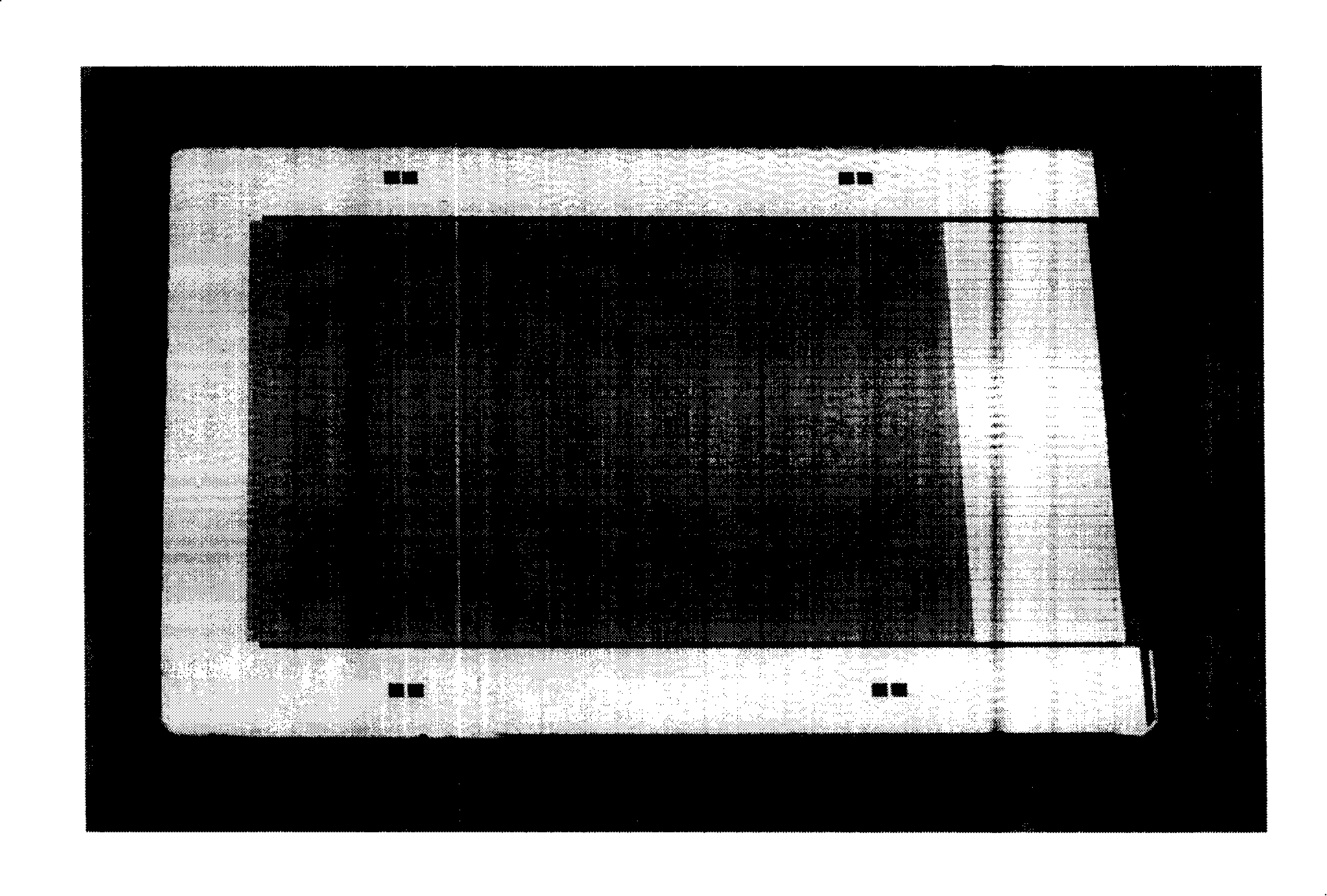

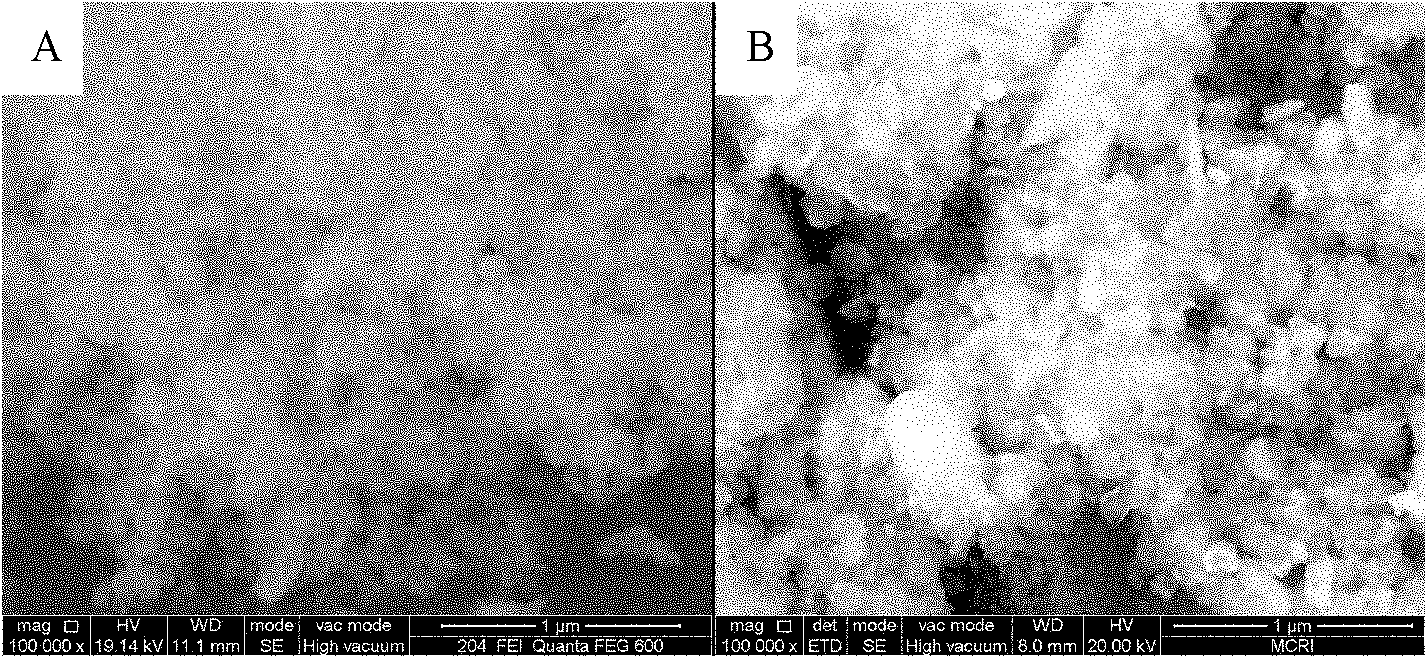

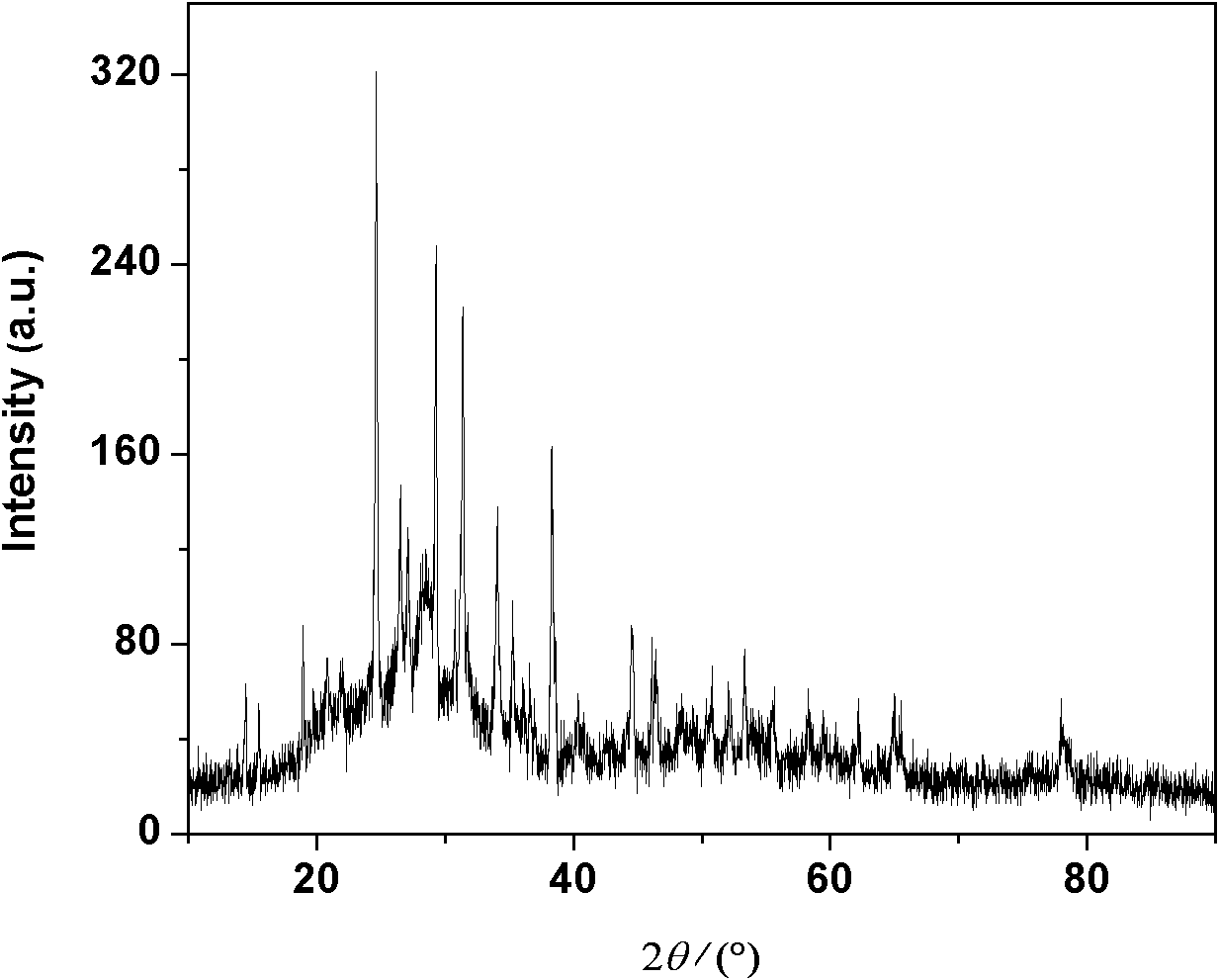

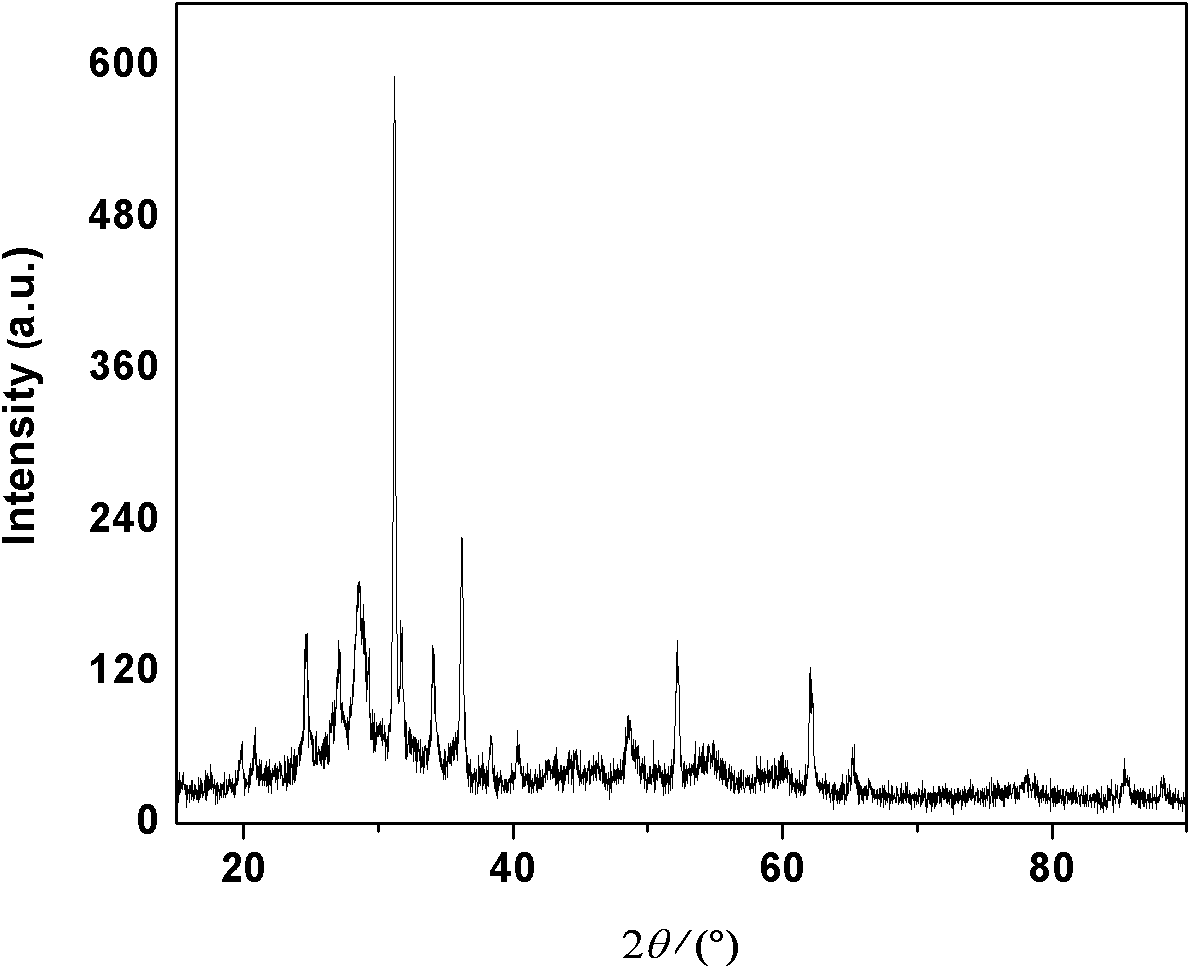

Method of making photosensitive lead salt thin film of infrared detector

InactiveCN101170149AImprove uniformityImprove surface uniformityFinal product manufactureSemiconductor devicesLead saltNitrogen

The invention relates to a method of preparing a photosensitive lead salt film of infrared detectors. Compared with the lead salt film prepared by the chemical deposition method, the invention comprises the steps of adopting a stirring method and supplements chemical mother liquid participating in reaction at right time in the preparation course and realizes the components spatial evenness of the prepared lead salt; adopting controllable large discharge gas mixture of nitrogen and oxygen to perform sensitizing treatment to the lead salt film and realizes the spatial evenness of the prepared lead salt film with photoelectrical response character. By practice test, the 25mm multiplies by 25mm PbS film prepared by the invention has the evenness of photoelectrical response more than 25 percent.

Owner:CHINA AIR TO AIR MISSILE INST

Ca/Zn compound heat stabilizer

InactiveCN101857682AProlong the discoloration timeImprove heat resistancePolyvinyl chlorideLead salt

Owner:CHONGQING UNIV

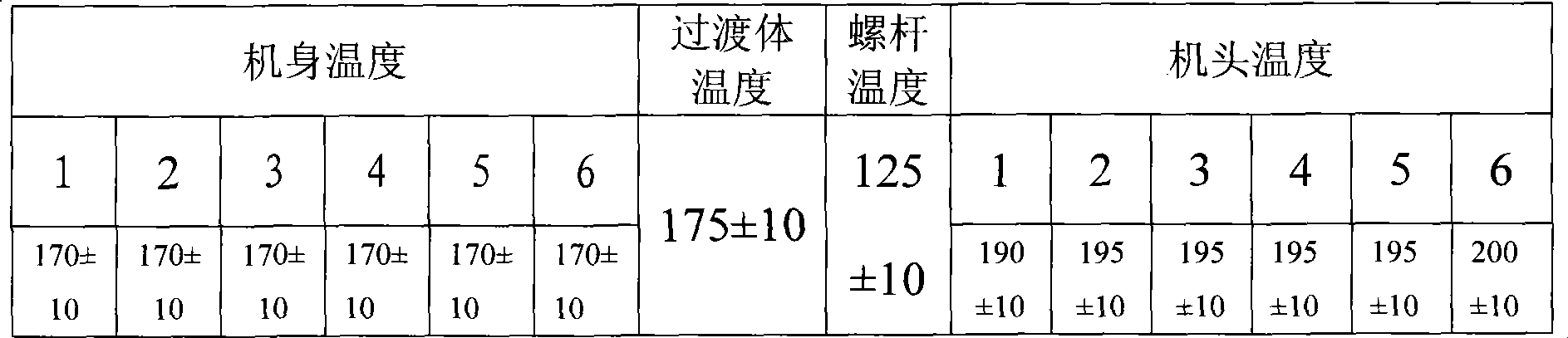

Chlorinated polyvinyl chloride double-wall corrugated pipe formulation and its production process

Disclosed are dispensation of perchlorinated polyvinyl chloride wave-shaped pipe and its productive technique, especially that for high volume cable and its productive technique. The dispensation (mass ratio) is: perchlorinated polyvinyl chloride resin(50-80), polyvinyl chloride resin (20-50), compound lead salt stabalizer (4.5-7.5), stearic acid (0.6-0.8), polyethylene(0.3), paraffin(0.3), calcium carbonate (4-10) and anti-impact ACR (6-8). Its productive technique is: mix the mixture for 10-13min, till the temperature reaches 120-135deg.c, cool it to be 45-55deg.c and feed the material, finally press and plasticize to form the product in 170-185deg.c. The invention produces the wave-shaped pipe whose hot deformative temperature is not lower than 93deg.c, with sentific dispensation and reasonable productive technique, which can solve the protective jacket problem existing in high volume cable underground.

Owner:杭州波达塑料科技股份有限公司

Preparation method of super-thermite Al/PbO nano-composite energetic material

The invention discloses a super-thermite Al / PbO nano-composite energetic material and a preparation method thereof. The super-thermite Al / PbO nano-composite energetic material consists of nano-grade aluminum powder and PbO, wherein the molar ratio of aluminum powder to PbO is (1:3)-(1:1), the grain diameter of aluminum powder is 20-100nm, and the grain diameter of obtained nano-composite energetic material is 50nm-150nm. The method comprises the following steps: respectively dissolving organic or inorganic lead salt and organic or inorganic base in alcoholic solution; dissolving completely, mixing the alcoholic solution of the lead salt and the base to generate lacte sol; and finally adding nano aluminum powder, completely mixing, filtering, washing and drying. The method has simple process, convenient operation and high safety performance and is easy to control, and the obtained nano-composite energetic material Al / PbO has excellent catalytic effect on the combustion of a double-base solid propellant when being taken as a combustion catalyst, thus significantly improving the burning speed of the propellant and reducing the pressure exponent.

Owner:XIAN MODERN CHEM RES INST

Soft PVC plastic for electric wire and cable

ActiveCN1931915ANo adverse effectsImprove thermal stabilityPlastic/resin/waxes insulatorsPlastic materialsLead salt

The PVC plastic material for electric wire and cable consists of PVC resin 100 weight portions, plasticizer 30-100 weight portions, magnesia 2-5 weight portions, zinc oxide 3-5 weight portions, stearic acid 2- 4 weight portions and filler 5-60 weight portions. The facile and cheap magnesia and zinc oxide as the heat stabilizer result in no toxicity, no bad smell, no harm to the operator, less environmental pollution, no degradation on the electric performance and secondary machining performance of the product. The PVC plastic material is superior to that with lead salt as stabilizer in that it has obviously raised heat stability and weather resistance.

Owner:WUXI JIANGNAN CABLE

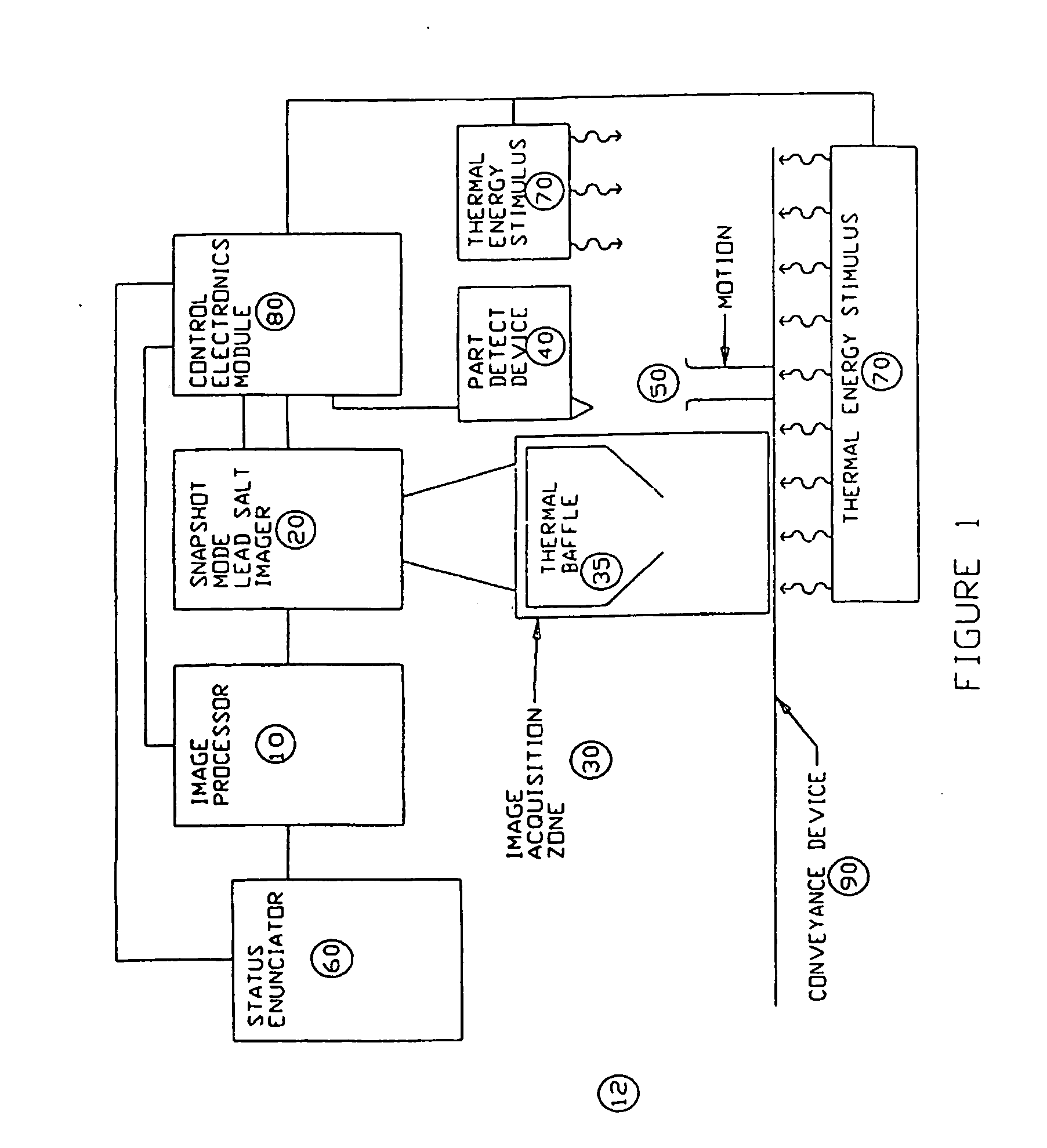

Apparatus and method for providing snapshot action thermal infrared imaging within automated process control article inspection applications

ActiveUS8097857B2Low-cost and on-line surfaceRobust structural integrity inspection capabilityTelevision system detailsRadiation pyrometryElectricityMachine vision

This application relates to an apparatus and method for providing snapshot action thermal infrared imaging within automated process control article inspection applications. More specifically, it pertains to the use of snapshot mode lead salt area-array imaging sensors (20) as the imaging front-end in high-speed machine vision inspection systems (12). the relatively low-cost, good measurement sensitivity at temperatures consistent with thereto-electric cooling means, and the ability to be operated in snap-shot mode enables lead salt-based image acquisition sensors (20) to be used in a variety of automated process control and article inspection applications.

Owner:PRESSCO TECH INC

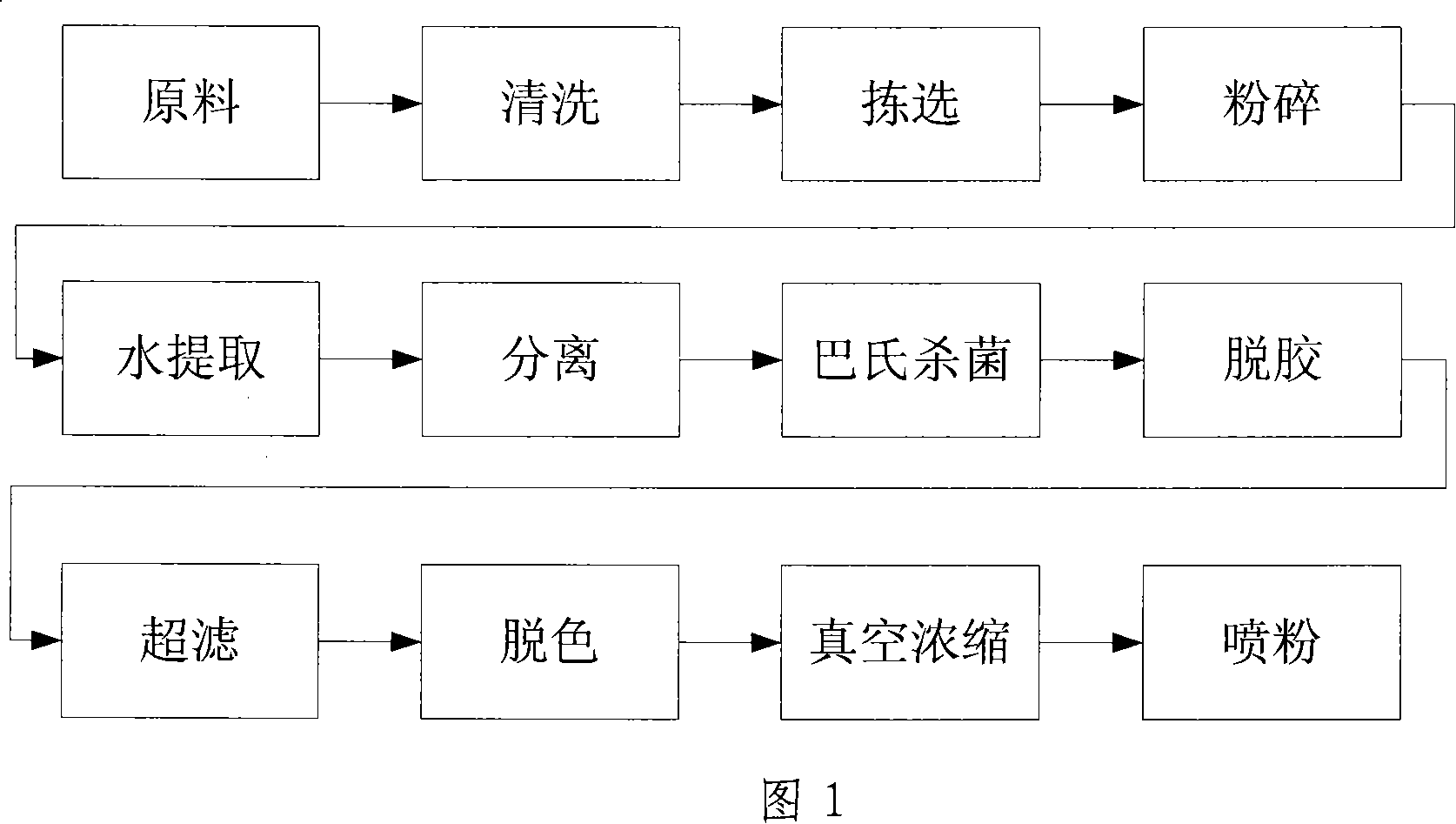

Method for extracting stachyose

InactiveCN101139370ASolving the problem of lead saltsIncrease profitOligosaccharidesPlant ingredientsProduction rateUltrafiltration

The present invention provides a method for stachyose hydrate extraction. Leaf bamboo shoot or Yintiao are cleaned, grinded and soaked, and then are Paste-pasteurized. The plant protein of the leaf bamboo shoot or Yintiao is coagulated. The fruit compound enzyme which is ten thousandth of the weight of the extraction is added into the extraction for degumming. After the degumming, the solution is filtered by 10000D ultrafiltration membrane, and then is bleached and concentrated in vacuum, and is dried into stachyose hydrate powders. The method solves the problem of the use of chemical reagents which generates lead salt residue. The method shortens the processing time. The production rate of the method is more than 90 percent and the purity is of 95 percent. Raw materials utilization in the method is high.

Owner:FENGXIAN WOPUSEN BIOLOGICAL TECH

Organotin leadless sectional materials

The invention relates to an organotin lead-free proximate matter which consists of the following matters (counted in weight portions): 100 portions of polyvinyl chloride, 1.3 to 1.5 portions of organotin stabilizing agents; 8 to 10 portions of titanium pigment, 8 to 10 portions of Haloflex, 1.3 to 1.5 portions of ACR processing modifiers; 2.0 to 29 portions of compound wax-hard calcium lubricating systems. After being counted according to a prescription, the matters are firstly processed into a mixture, and then the mixture is extruded to be the proximate matters by a double screw extruder. The proximate matter has the advantages of uniform and mild color, good impacting performance and high fillet intensity after a door and a window are assembled; besides, the output rate is high and completely accords with or exceeds the standard demands of GB / T8814-2004. The organotin stabilizing agent which is corresponding to the drinking water quality policy paper of the world health organization in particular completely abandons a lead salt stabilizing agent and thoroughly realizes free of lead.

Owner:XIAN GAOKE BUILDING MATERIALS TECH

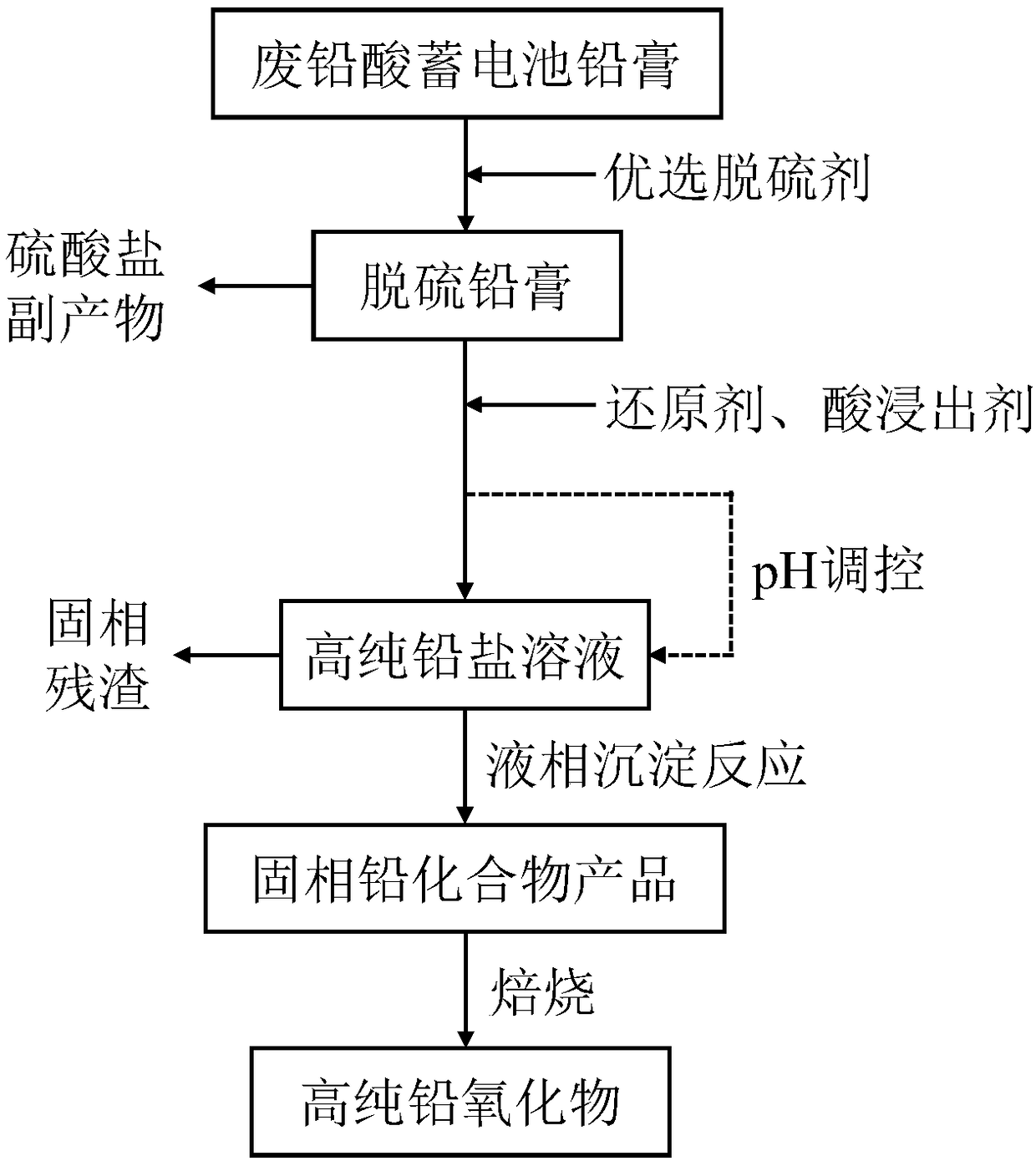

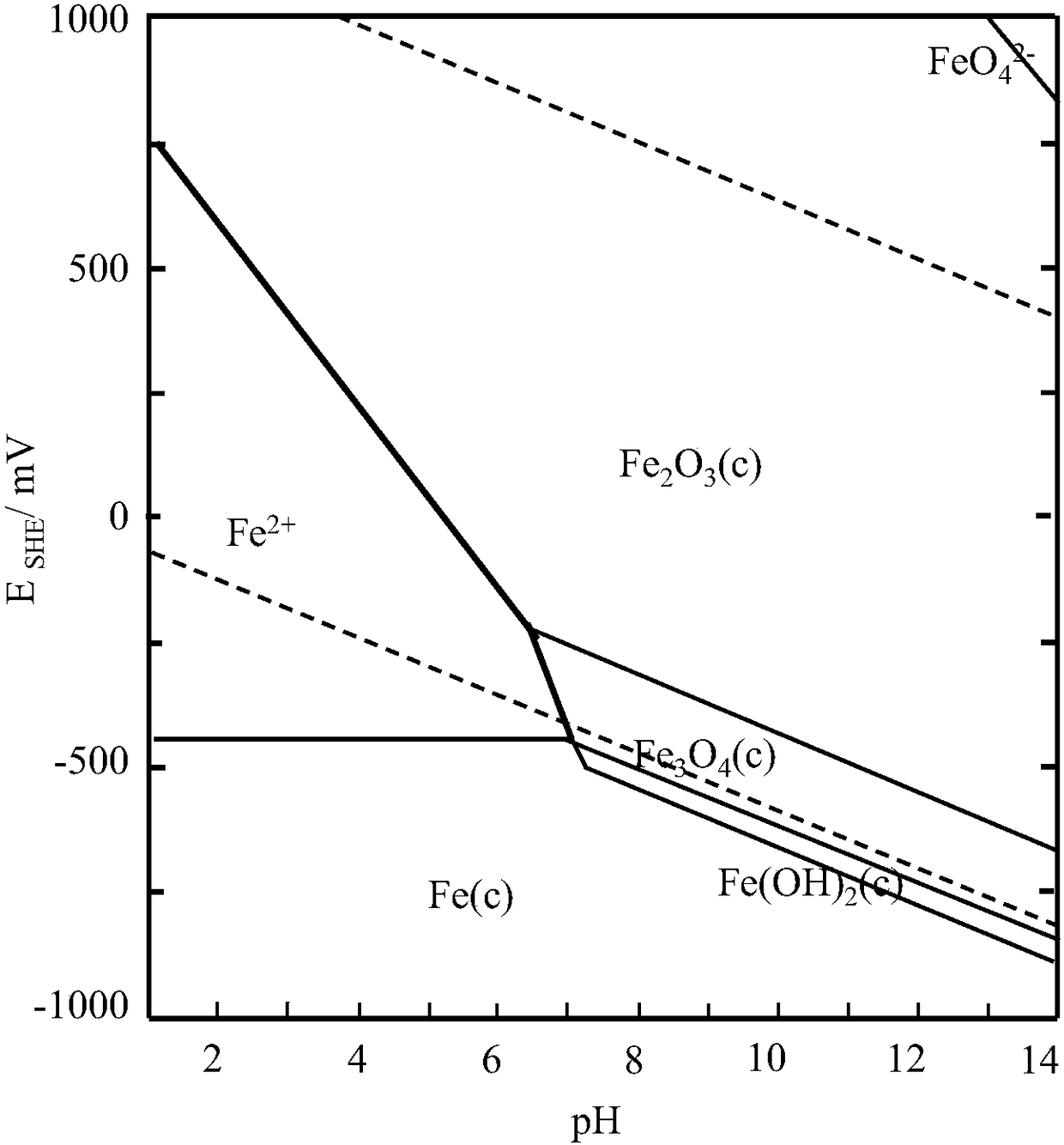

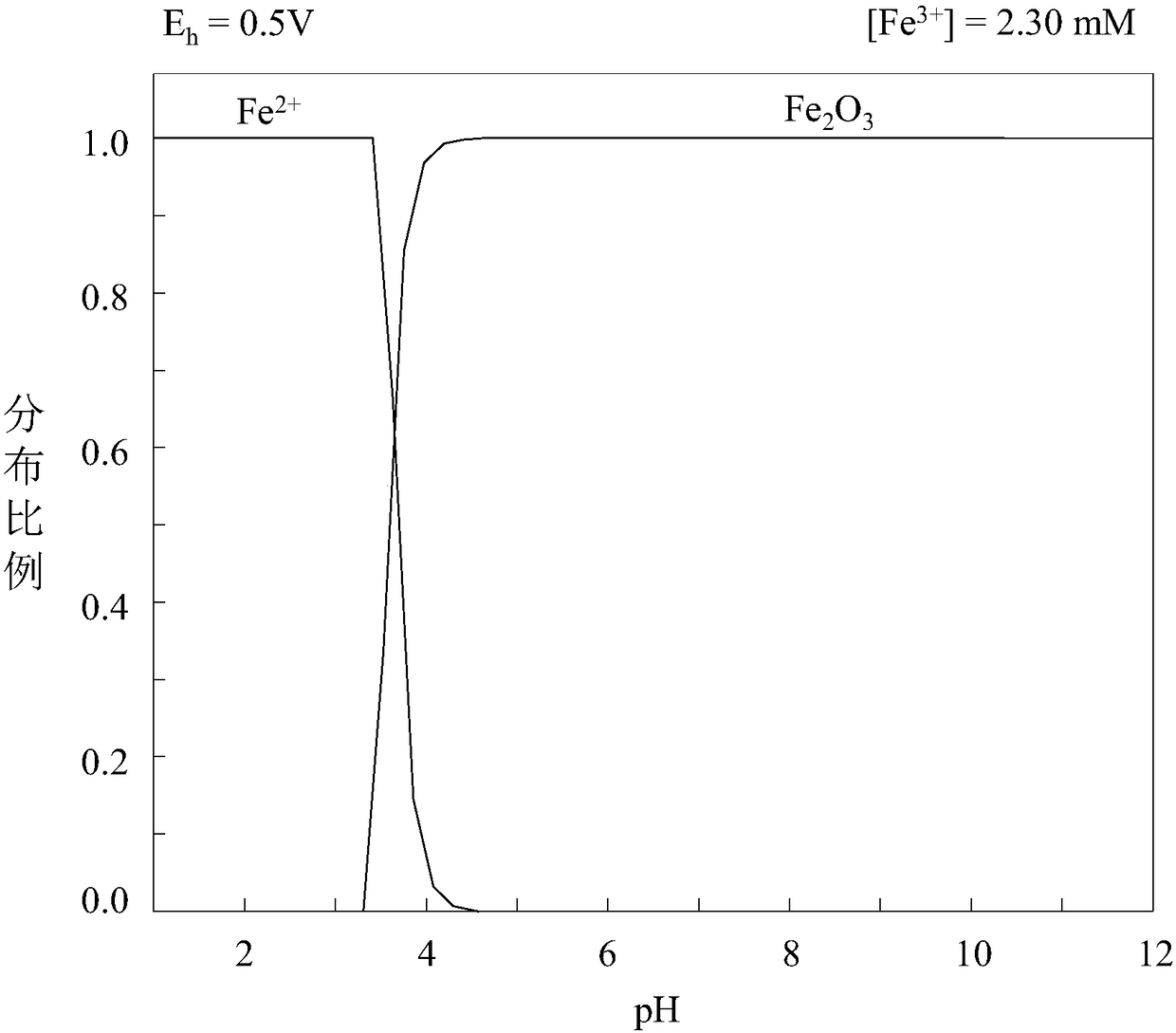

Method for preparing high-purity lead compound through wet recovery and impurity removal of waste lead plaster

The invention discloses a method for preparing a high-purity lead compound through wet recovery and impurity removal of waste lead plaster. The method comprises the following steps that 1, strong basecontaining Na and K elements is used as a basic desulfurizer for carrying out normal-temperature desulfuration on waste lead paster, the obtained desulfurated lead paster reacts with an acid leachingagent mixed with a hydrogen peroxide reducing agent, after reaction is finished, a lead salt solution is obtained by adjusting the pH value and carrying out filtration according to the variety of theacid leaching agent, or the lead salt solution is obtained through direct filtration; 2, the lead salt solution is subjected to liquid phase reaction conversion to prepare a solid phase lead compound, and lead oxide and other products can also be produced through follow-up roasting. By means of the whole process technological set of wet recovery and parameter conditions adopted by key technologysteps are improved and optimized, the high-purity lead compound (and high-purity lead oxide) can be prepared from waste lead paster through an acid leaching wet recovery method, and the problems thattwo impurity elements Ba and Fe are high in content and not likely to be removed are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

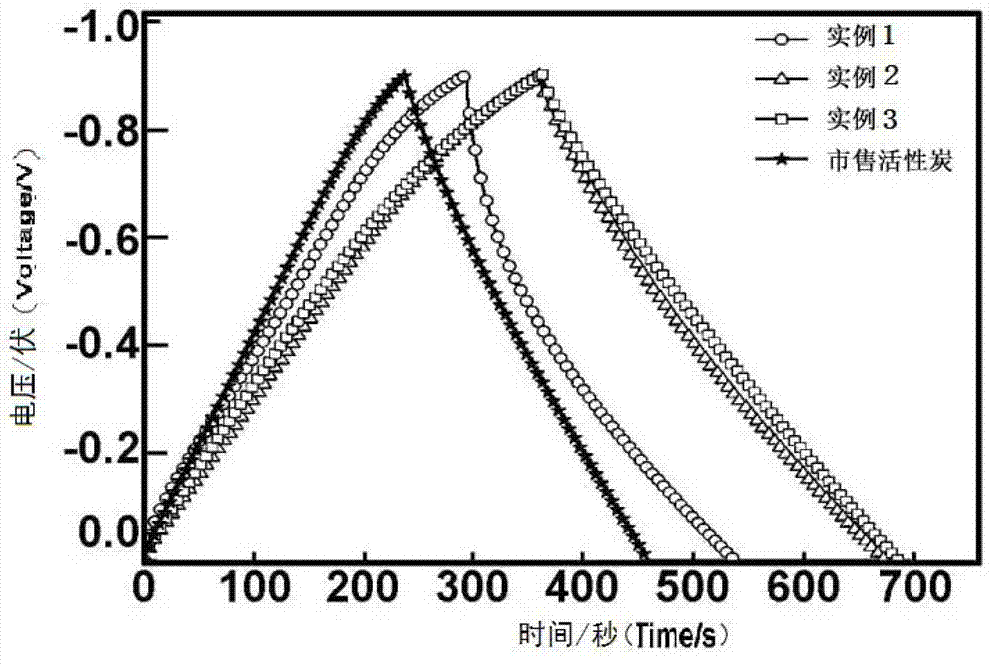

Preparation method for modified actived carbons

InactiveCN103043659ASimple preparation processShorten the production cycleCarbon compoundsCapacitanceActivated carbon

The invention discloses a preparation method for modified actived carbons. The modified active carbons are actived carbons modified by adopting hydrogen inhibitor; and the hydrogen inhibitor is lead oxide loaded on the surfaces of the actived carbons. The preparation process comprises the following steps: firstly, lead ions are absorbed by using the actived carbons; then the lead ions are deposited on the surfaces of the actived carbons by using alkali; and finally, lead hydrogen is decomposed to lead oxide through the heat treatment, and the lead oxide is loaded on the surfaces of the actived carbons; the actived carbons, lead salt and the alkali are chemically reacted through the ball milling method, and are treated at the high temperature under the protecting air environment to prepare the modified actived carbons. The method has the advantages of simple preparation technique, short production period, facilitation of industrial production, lower equipment investment, environmental friendliness and wide application, and can increase the specific capacitance of the active carbons.

Owner:HUNAN FENGRI ELECTRIC GROUP

Composite material for negative electrode, method for fabricating the same and electrochemical device using the same

ActiveUS20110236747A1Large capacityLarge scaleSilver accumulatorsNon-metal conductorsIndiumNickel salt

The present invention relates to a composite material for a negative electrode, including: a plurality of iron oxide particles; and a conductivity improver, which is selected form the group consisting of copper, cobalt, nickel, tin, antimony, bismuth, indium, silver, gold, lead, cadmium, carbon black, graphite, copper salt, cobalt salt, nickel salt, tin salt, antimony salt, bismuth salt, indium salt, silver salt, gold salt, lead salt, cadmium salt, copper hydroxide, cobalt hydroxide, nickel hydroxide, stannic hydroxide, antimony hydroxide, bismuth hydroxide, indium hydroxide, silver hydroxide, gold hydroxide, lead hydroxide, cadmium hydroxide and the combination thereof. In the case of applying the composite material for a negative electrode according to the present invention in an electrochemical device, the improved charge / discharge characteristics and high capacity can be achieved. In addition, the present invention further provides a method for fabricating the above-mentioned composite material for a negative electrode and an electrochemical device using the same.

Owner:NATIONAL TSING HUA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com