Preparation method for carbon nanotube and/or graphene reinforced lead based composite anode

A carbon nanotube and composite anode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of limited service life, high cost, insufficient mechanical properties, etc., and achieve the effect of small environmental impact, uniform dispersion and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

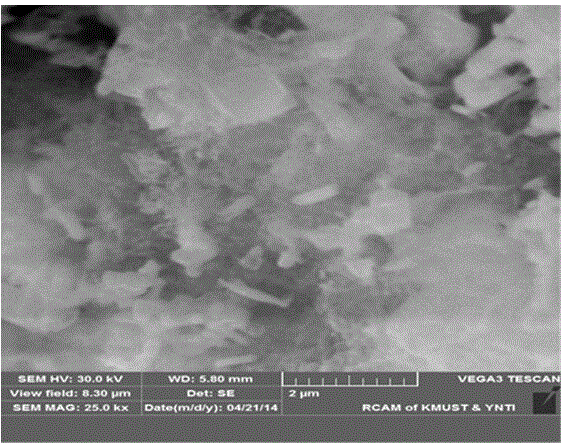

[0021] The carbon nanotube reinforced lead-based composite anode preparation method, its specific steps are as follows:

[0022] (1) Electrolyte preparation: First, mix soluble lead salt, supporting electrolyte, carbon nanotubes, dispersant and water to form an electrolyte solution. The concentration of soluble lead salt in the electrolyte is 0.01mol / L, and the soluble lead salt is Lead acetate, the concentration of supporting electrolyte is 3mol / L, the supporting electrolyte is acetic acid (1.5mol / L) and sodium acetate (1.5mol / L), the concentration of carbon nanotubes is 4g / L, and the carbon nanotubes are multi-walled carbon nanotubes , the dispersant concentration is 5g / L, the dispersant is polyvinylpyrrolidone, and the remainder is water;

[0023] (2) Composite electrodeposition process: take metallic lead as the anode and titanium as the cathode, control the electrolyte temperature at 30°C, and the cathode current density at 300mA / cm 2 Under these conditions, electrodepos...

Embodiment 2

[0027] The carbon nanotube reinforced lead-based composite anode preparation method, its specific steps are as follows:

[0028] (1) Electrolyte preparation: First, mix soluble lead salt, supporting electrolyte, carbon nanotubes, dispersant and water to form an electrolyte solution. The concentration of soluble lead salt in the electrolyte is 0.01mol / L, and the soluble lead salt is Lead fluorosilicate, the supporting electrolyte concentration is 1.5mol / L, the supporting electrolyte is sodium fluorosilicate, the carbon nanotube concentration is 0.5g / L, the carbon nanotubes are single-walled carbon nanotubes, and the dispersant concentration is 1g / L , the dispersant is sodium dodecylbenzenesulfonate, and the remainder is water;

[0029] (2) Composite electrodeposition process: metal lead is used as the anode, titanium is used as the cathode, the temperature of the electrolyte is controlled at 50°C, and the cathode current density is 400mA / cm 2 Under the above conditions, electrod...

Embodiment 3

[0032] The graphene reinforced lead-based composite anode preparation method, its specific steps are as follows:

[0033] (1) Prepare the electrolyte: first mix the soluble lead salt, supporting electrolyte, carbon nanotubes, dispersant and water to form an electrolyte, in which the concentration of the soluble lead salt in the electrolyte is 0.1mol / L, and the soluble lead salt is Lead nitrate, the concentration of the supporting electrolyte is 1.5mol / L, the supporting electrolyte is a mixture of boric acid and sodium borate with a mass ratio of 1:1, the concentration of graphene is 0.5g / L, the concentration of the dispersant is 8g / L, and the dispersant is mass 1:1 mixture of sodium dodecylbenzenesulfonate and gelatin, the rest is water;

[0034] (2) Composite electrodeposition process: take metallic lead as the anode and titanium as the cathode, control the electrolyte temperature at 80°C, and the cathode current density at 500mA / cm 2 Under the above conditions, electrodepos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com