Lead regeneration method for recovering lead paste from waste lead acid storage battery by wet method

A technology of waste lead-acid batteries and lead-acid batteries, which is applied in the field of regenerated lead in lead paste, can solve the problems of physical poisoning of operators, difficulty in industrialization of power consumption, and obstruction of industrialization, so as to achieve high lead recovery rate and avoid the loss of lead , The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

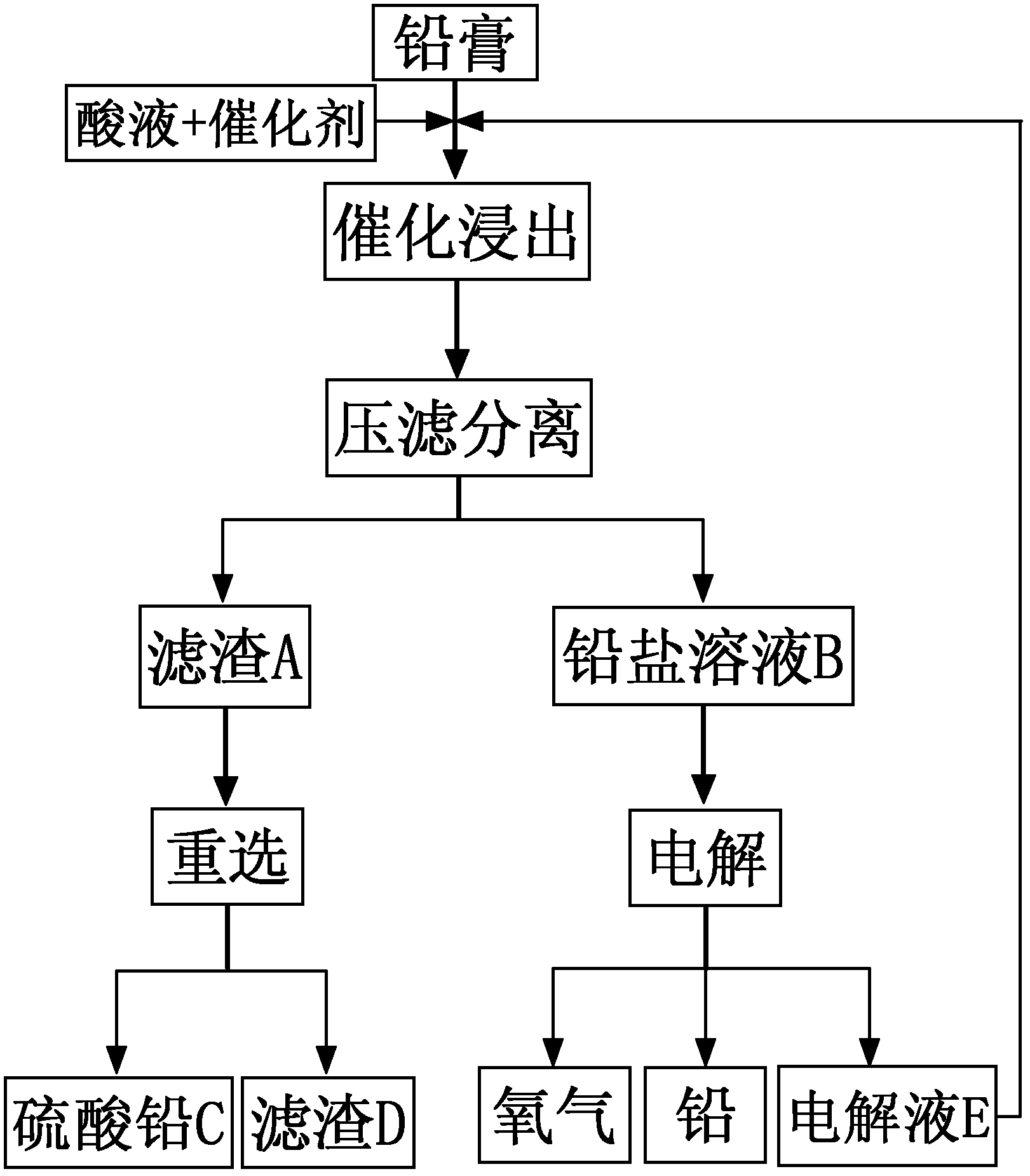

Method used

Image

Examples

Embodiment 1

[0049] Take the 12V, 10Ah lead-acid battery for ordinary electric vehicles retailed on the market, and the battery pack weighs 4.3 kg. The specific implementation process is as follows:

[0050] 1) The battery is conventionally crushed and separated to obtain lead paste, grids, waste sulfuric acid, separators and shells.

[0051] 2) Put 2 kg of lead paste into a 10L reactor containing 2.2mol / L of HClO 4 and 8g / L of chloroacetic acid, followed by constant temperature and stirring at 75°C for 2 hours. During this process, lead dioxide, lead powder, and lead oxide in the lead paste are gradually converted into lead perchlorate under the catalysis of chloroacetic acid. When the measured lead ion concentration reaches 1.5-1.6mol / L, the reaction is stopped, and the mother liquor in the reactor is transferred to a filter press for pressure filtration separation to obtain filter residue A and lead-containing solution B.

[0052] 4) The lead-containing solution B enters the electrol...

Embodiment 2

[0056] Take a common 12V, 45Ah car battery on the market, and the total weight of the battery pack is 13.5 kg. The specific recycling process is as follows:

[0057] 1) The lead paste obtained after the lead-acid battery is crushed and separated is used for standby.

[0058] 2) Prepare 45L acidity containing 2.5mol / L methanesulfonic acid and 3g / L chloroacetic acid, then add 8 kg of lead paste powder obtained in step 1, and then keep constant temperature and stir at 75°C for 6 hours. During this process, the lead dioxide of the original positive electrode and the lead powder of the original negative electrode in the lead paste are gradually converted into soluble lead methanesulfonate under the catalysis of chloroacetic acid, and the lead sulfate in the lead paste remains in the form of precipitation.

[0059] 3) Filtrate and separate the mother liquor in process 2 to obtain filter residue A and lead-containing solution B.

[0060] 4) Take 40L of filtrate and add 100g of bone...

Embodiment 3

[0064] Get 5 kilograms of ordinary waste lead-acid battery positive and negative plates and pulverize to obtain lead paste powder. The specific recovery process is as follows: 1) the waste lead oxide powder and 30L of 2.5mol / L HClO 4 Solution, while adding 150g of ammonium acetate as a catalyst, the reaction was stirred at 80°C. The lead analysis test shows that the concentration of lead ions tends to be stable after 3 hours of reaction. Press filtration is then carried out to obtain filter residue A and lead-containing solution B.

[0065] 2) Add 0.5g / L gelatin and 1.5g / L sodium lignosulfonate to the lead-containing solution B as electrodeposition additives to improve the cathode process. After static purification, the electrolyte enters the electrolytic cell and is electrolyzed at 55°C.

[0066] 3) Carry out electrolysis in the electrolyzer of embodiment 2, at first carry out the constant current electrolysis of the first stage, control current density is 200A / m 2 , The v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com